Patents

Literature

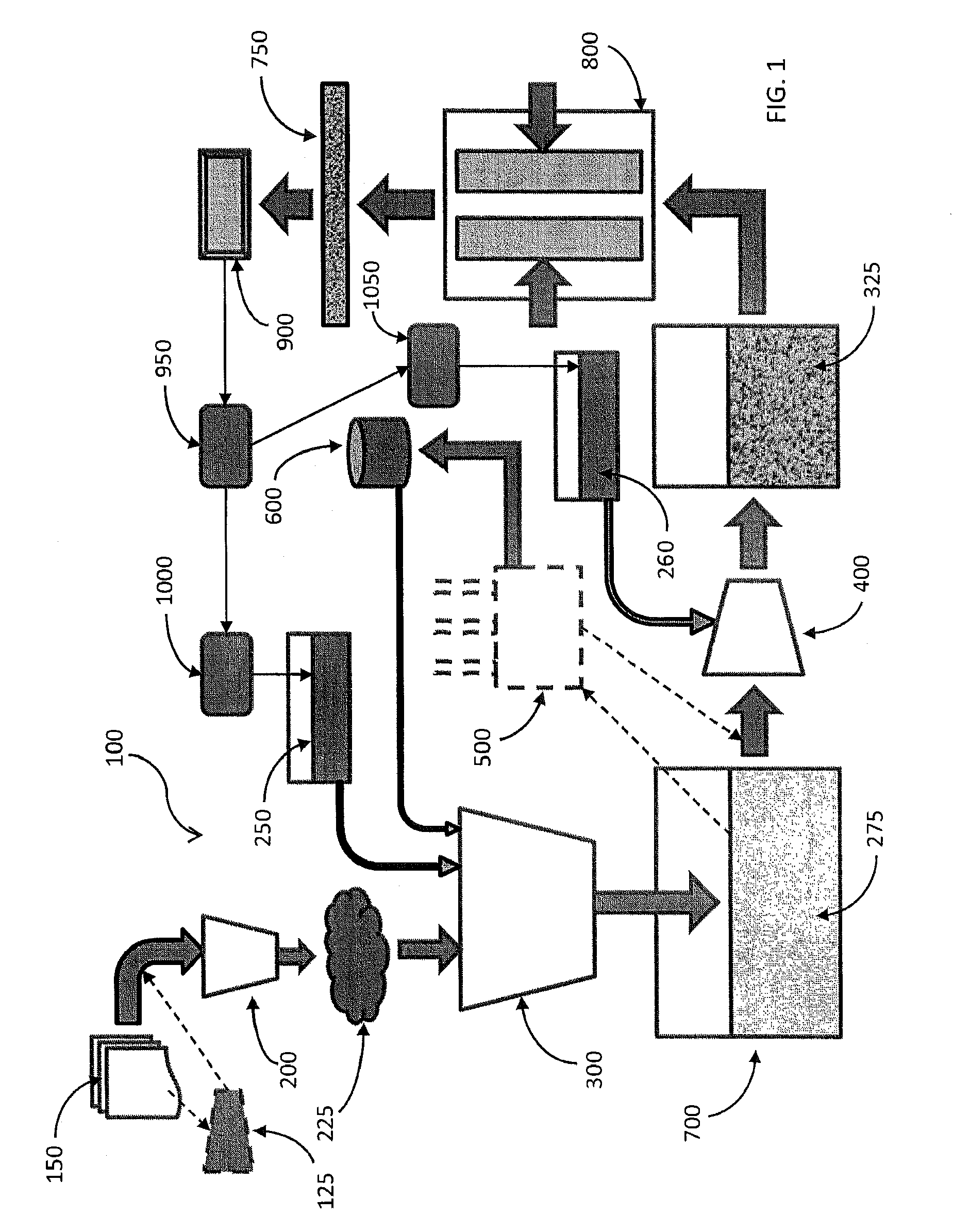

375results about "Dough homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

Thermoplastic molding process and apparatus

A system and method for forming an article from thermoplastic material and fiber. The method includes heating thermoplastic material to form a molten thermoplastic material for blending with the fiber. The molten thermoplastic material is blended with the fibers to form a molten composite material having a concentration of fiber by weight. The molten composite material may then be extruded through dynamic dies to deliver discrete controlled material that is gravitated onto a lower portion of a mold. The lower portion of the mold may be moved in space and time while receiving the flow of composite material to deposit a predetermined quantity of molten composite material thereon conforming to mold cavities of the lower and an upper portion of the mold. The upper portion of the mold may be pressed against the predetermined quantity of molten composite material and closing on the lower portion of the mold to form the article.

Owner:D&D MFG LLC

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

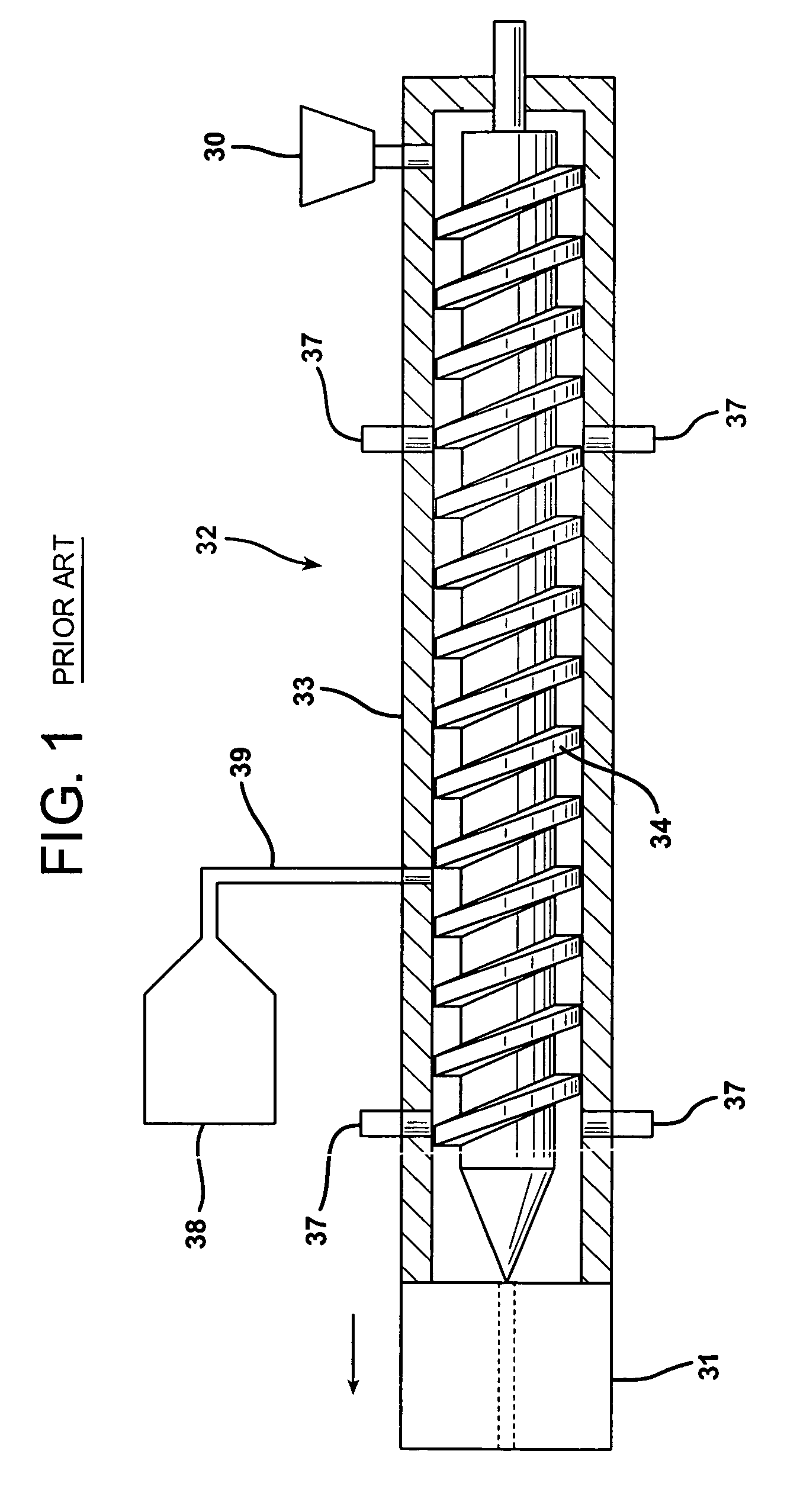

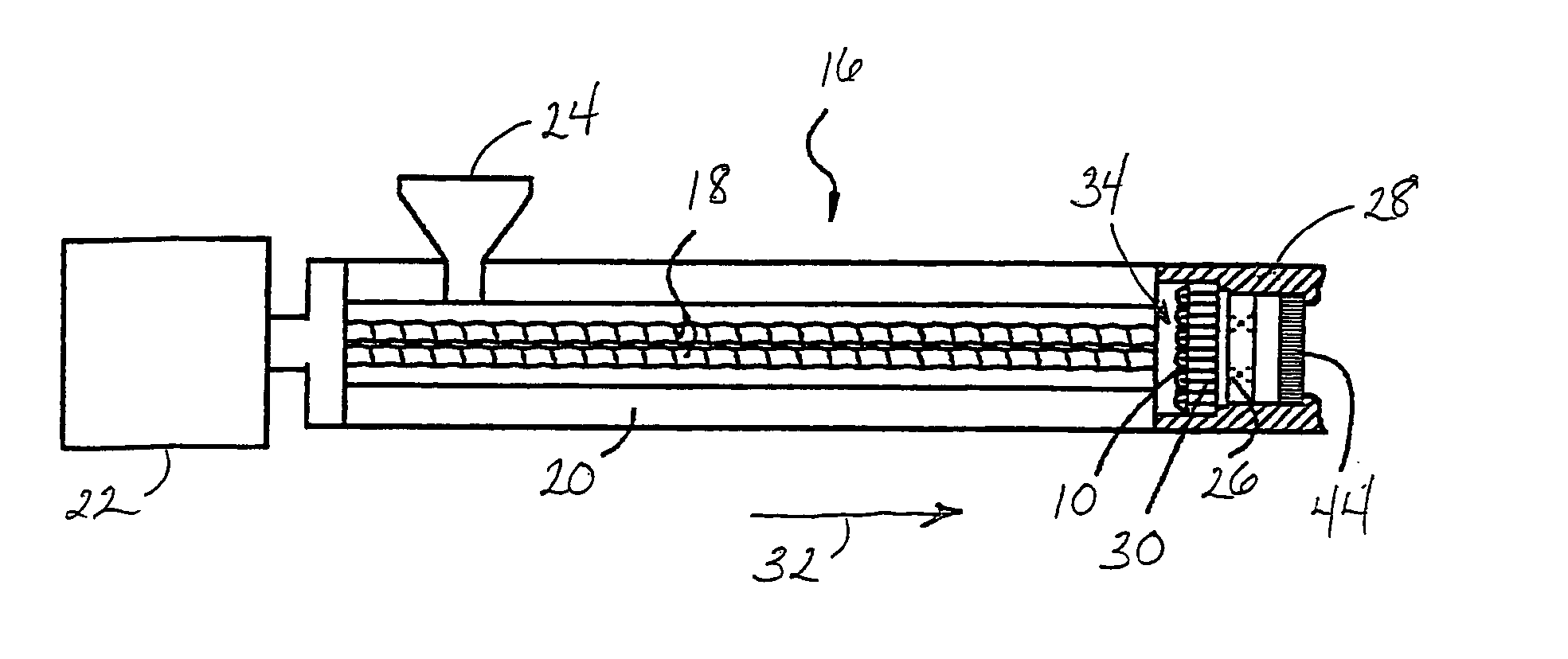

Wet use chopped strand glass as reinforcement in extruded products

InactiveUS20060103045A1Easy to operateImprove wind resistanceCovering/liningsDough homogenizationFiberGlass fiber

A method for incorporating wet use chopped strand glass (WUCS) in a screw extrusion process is provided. A polymeric resin is added to an extruder in a polymer feed zone and conveyed to a first compression zone where the resin is at least partially melted. The molten resin is conveyed to a high volume zone where WUCS fibers are added. In the high volume zone, the flights of the screw may have a greater pitch to facilitate the introduction of the WUCS into the extruder. The molten resin / fiber mixture is conveyed to a second compression zone where the resin and fibers are intimately compounded. Next, the molten resin / fiber mass is conveyed to a low pressure zone where moisture evaporated from the fibers is released through an opening. The resin / fiber mixture is then conveyed through a compression / die feed zone to further compound and mix the resin and fibers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Array of nozzles for extruding multiple cellulose fibers

An array of nozzles is disclosed for forming multiple cellulose fibers. Each nozzle has a longitudinal central axis and includes a tube with a cross-section having a diameter through which an aqueous solution of cellulose and a solvent can be extruded into a molten filament. A first opening is present which surrounds each of the tubes. The first opening has a cross-section with a diameter, and each of the first openings is capable of emitting a pressurized gas which surrounds one of the extruded molten filaments. At least three second openings are spaced away from each of the first openings. Each of the second openings is capable of emitting a pressurized gas stream essentially parallel to the longitudinal central axis of each of the nozzles, and each of the pressurized gas streams functions to shroud one of the extruded molten filaments.

Owner:REIFENHAUSER GMBH & CO

Injection molding screw

InactiveUS7172333B2Minimized pressure lossRotary stirring mixersFrozen sweetsEngineeringInjection molding machine

An injection molding screw for metal injection molding includes a first end, a second end, a longitudinal body with a first stage and a second stage extending axially along a length of the screw between the ends, a pressure retention device, and optionally, a screw tip. The pressure retention element minimizes loss of pressure in the second stage portion.

Owner:SOUTHCO +1

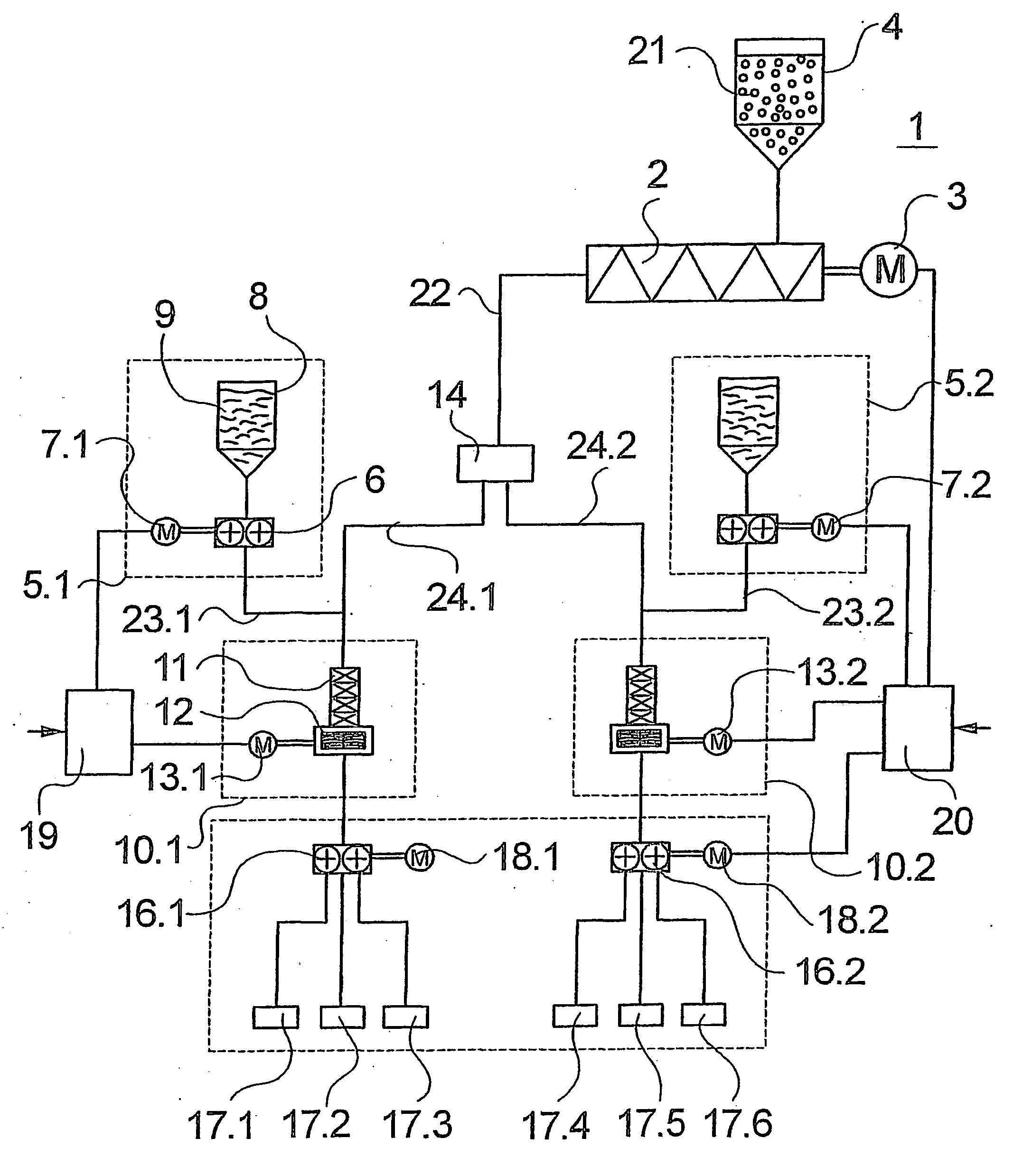

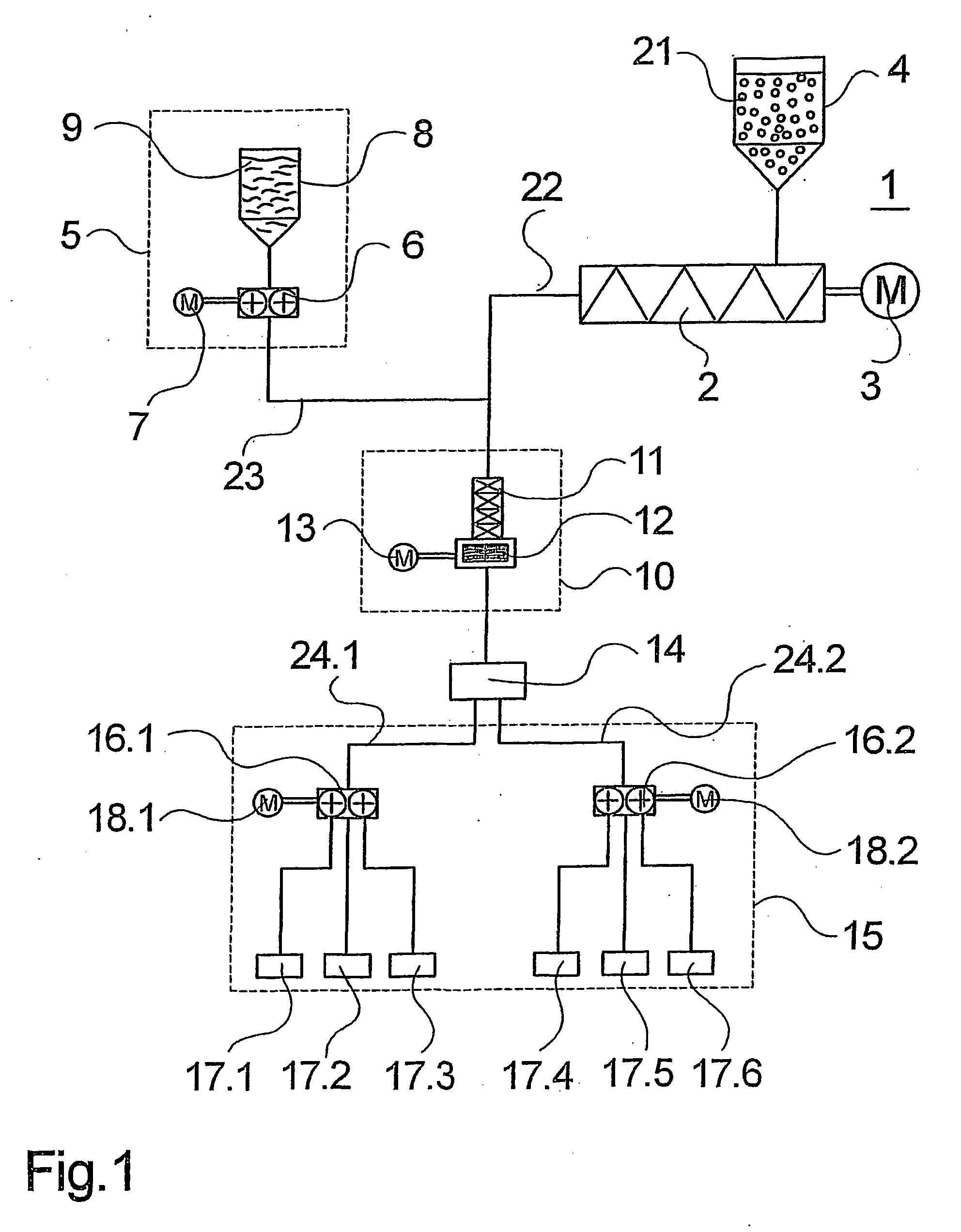

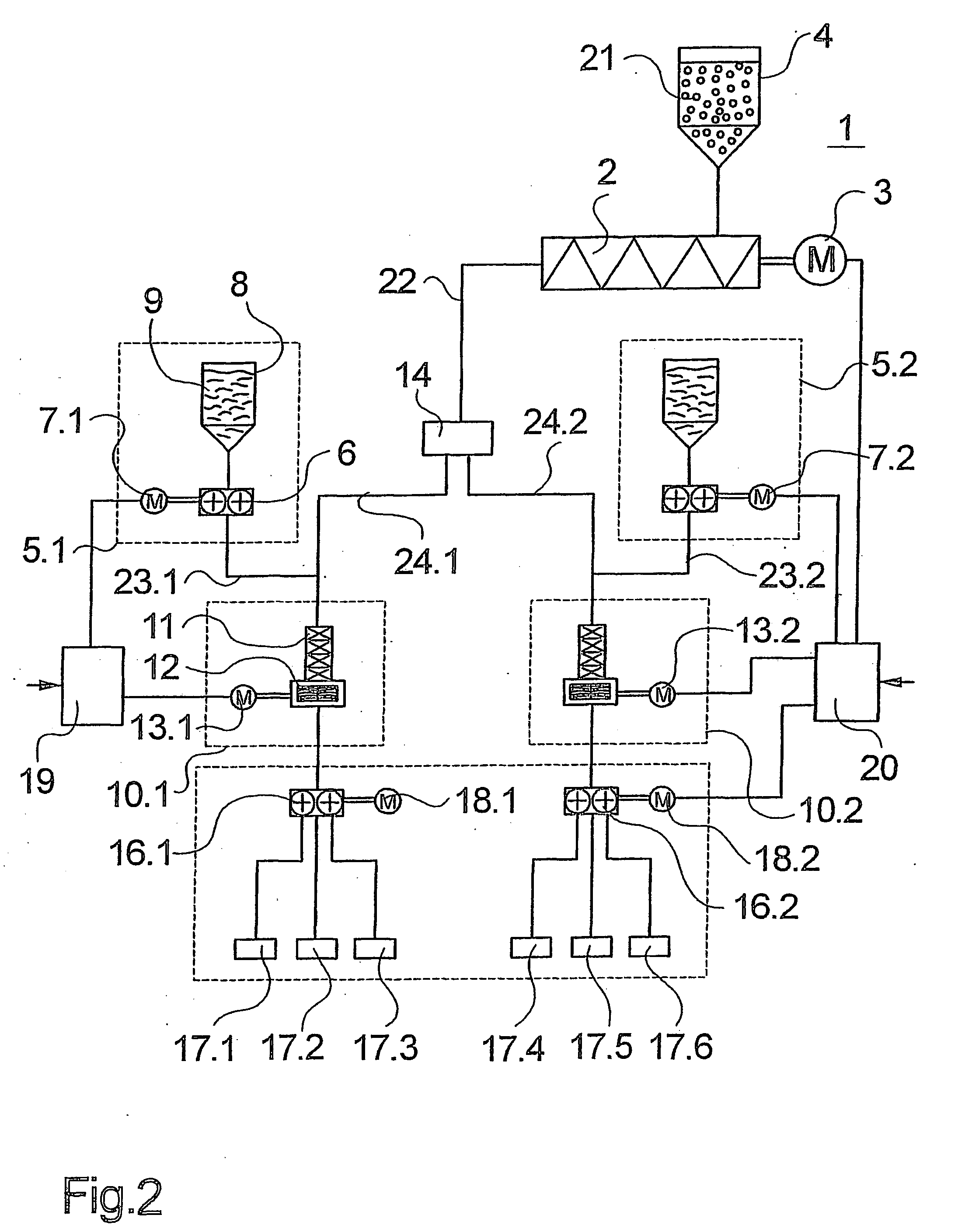

Apparatus and method for melt spinning dyed yarn filaments

InactiveUS20050263941A1Good flexibilityPolymer meltDough homogenizationSpinning head liquid feederYarnStatic mixer

An apparatus and a method for spinning dyed filaments from a dyed polymer melt, wherein an undyed polymer melt is produced by a melt producer. A liquid dye is added to the polymer melt by means of a dye metering device. To mix the liquid dye and dye the polymer melt, a mixing unit is provided. The dyed polymer is then spun to filaments by means of a spin unit. To obtain before the spinning step a uniform coloration of the polymer melt despite the short dwelling time of the liquid dye in the polymer melt, the liquid dye and the polymer melt are mixed in a plurality of successive mixing units which are formed by a mixer combination comprising at least one static mixer and at least one dynamic mixer.

Owner:SAURER GMBH & CO KG

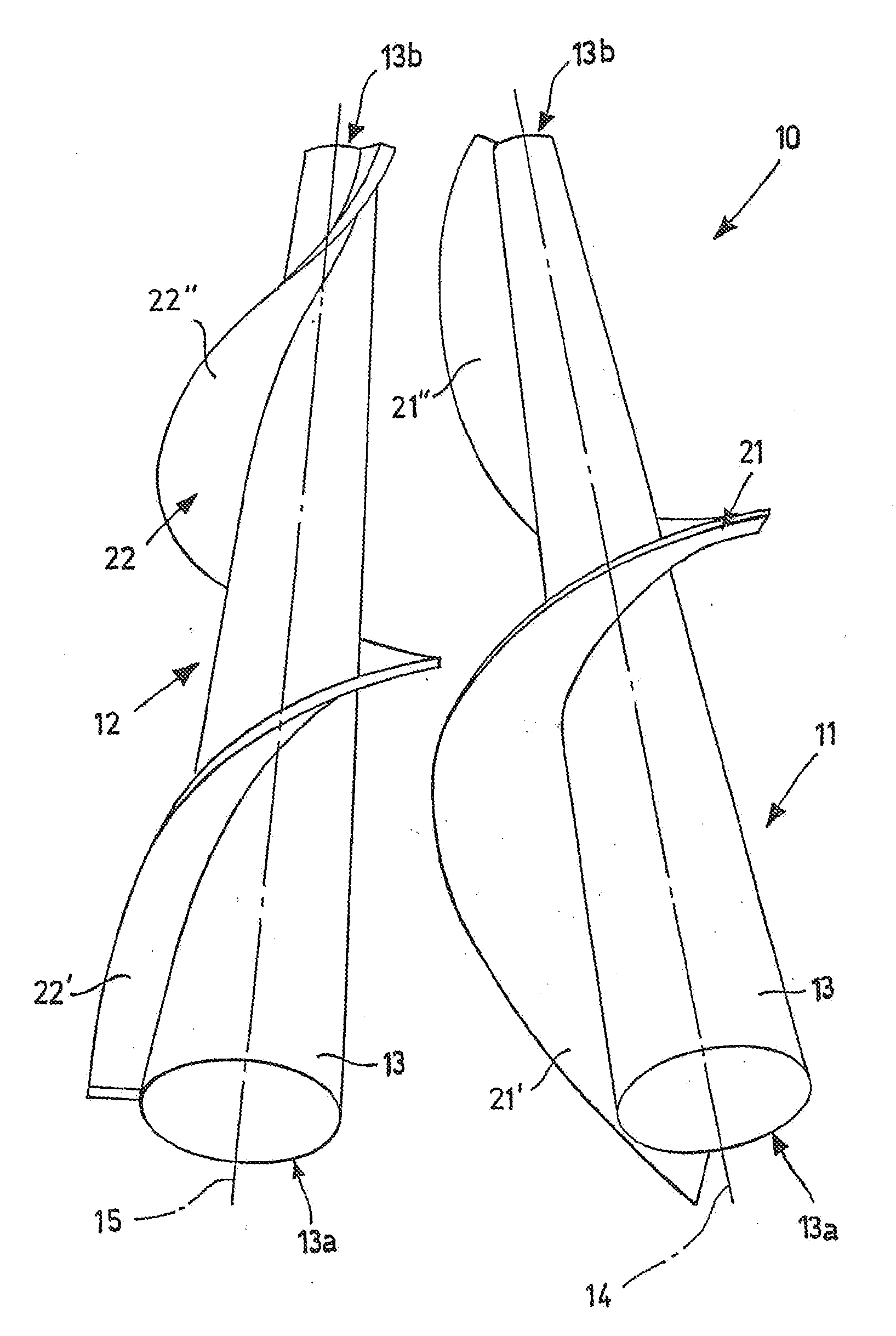

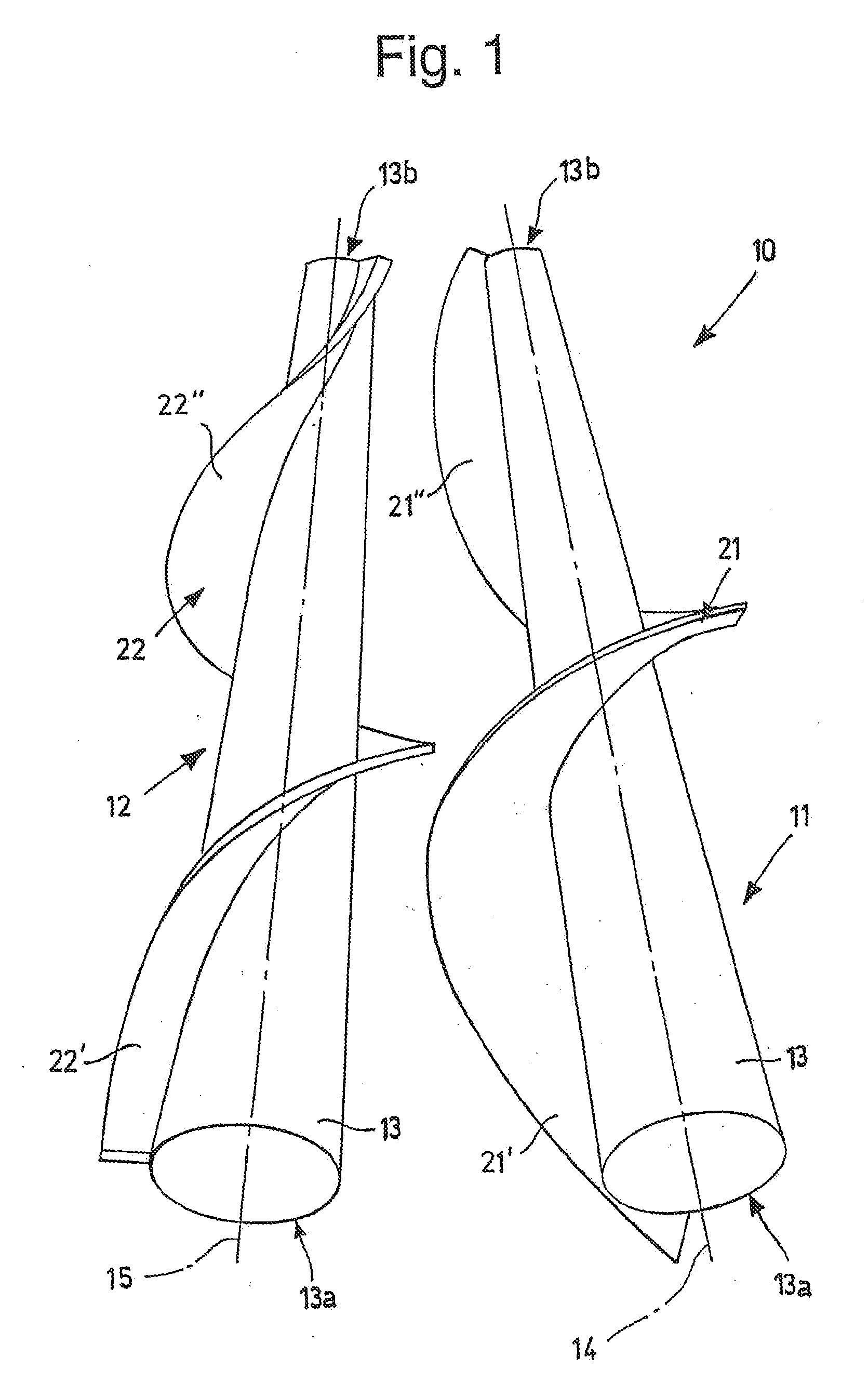

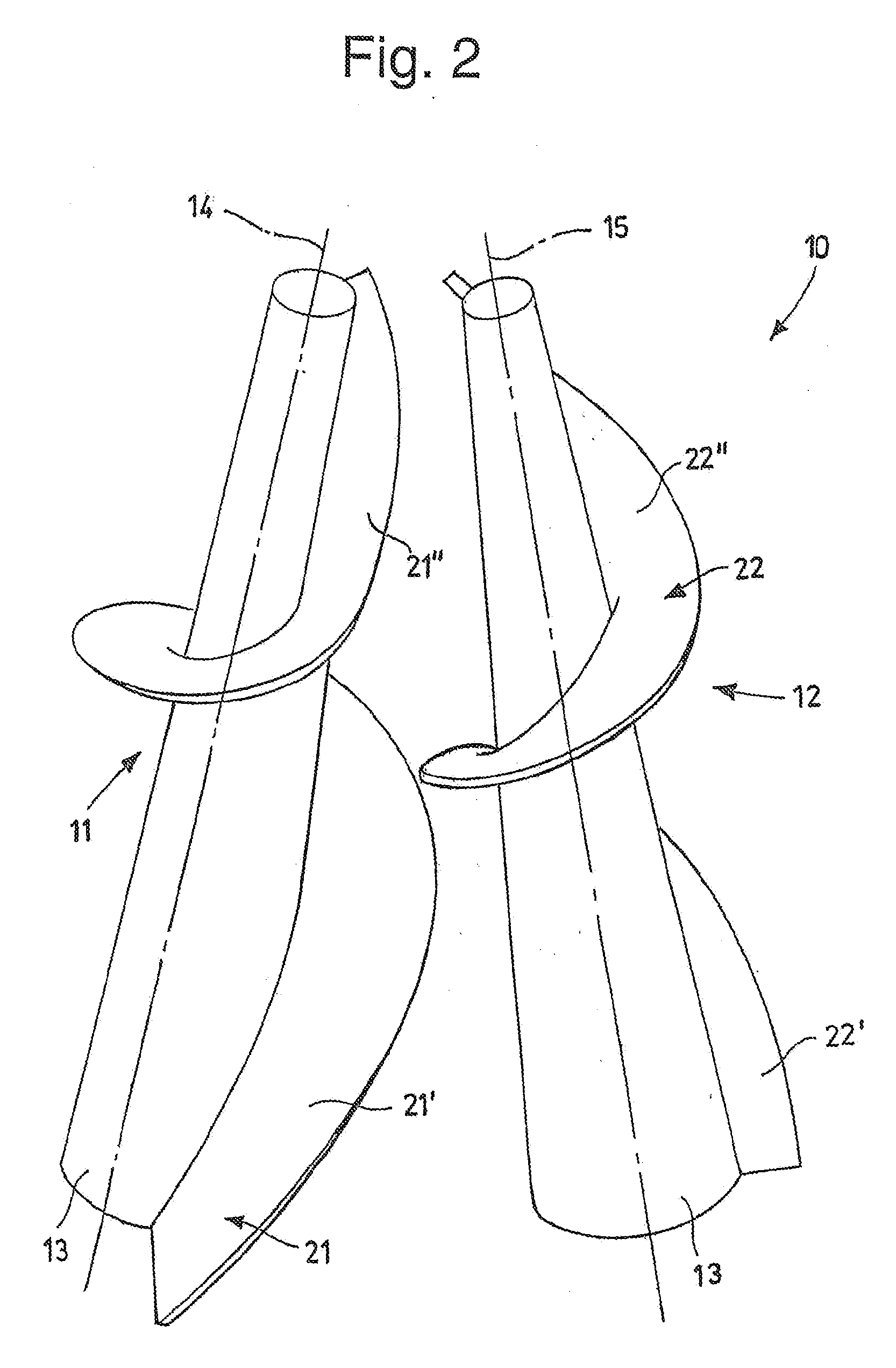

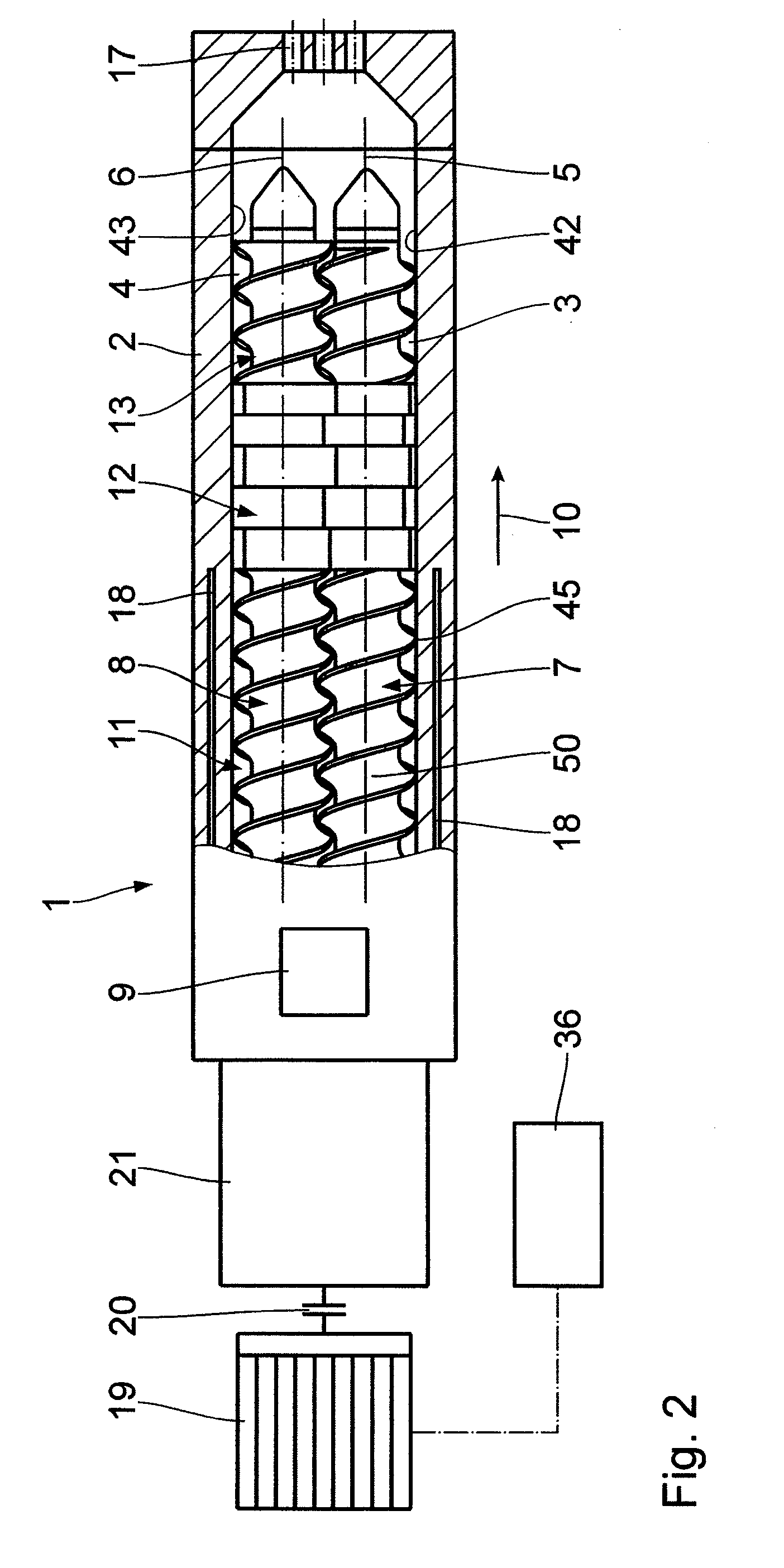

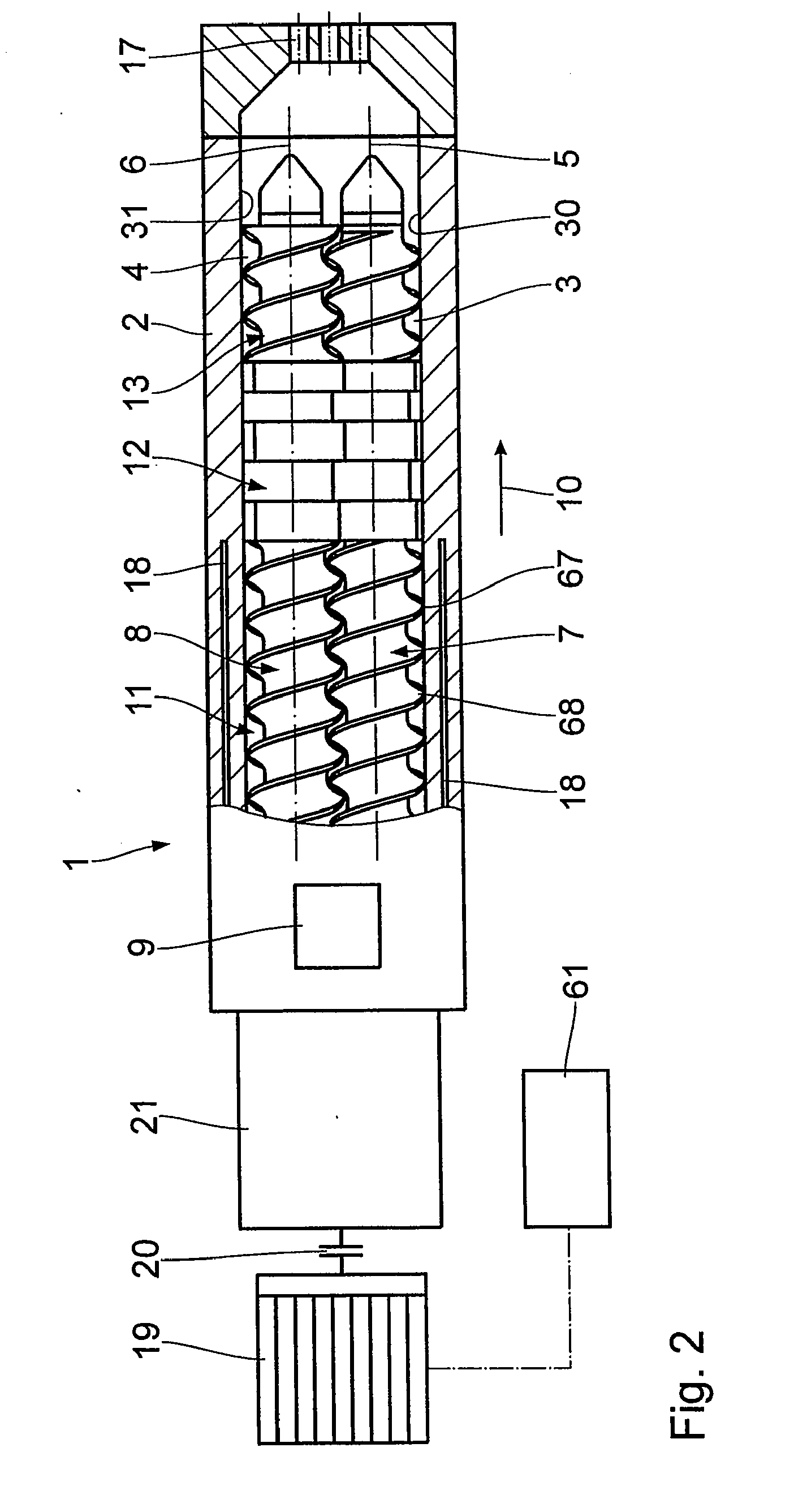

Extruder with twin converging screws for extruding plastomers, elastomers and viscous liquids in general

The invention relates to an extruder with two screws, a first screw and a second screw each comprising a threaded conical shaft having a first end with a bigger diameter and a second tapered end, said screws being arranged converging towards each other for the extrusion of plastomers, elastomers and viscous liquids in general. According to the invention, said first screw has a corresponding thread with a first portion which is diametrically larger than a corresponding first portion of the thread of the second screw.

Owner:POMINI RUBBER & PLASTICS SRL

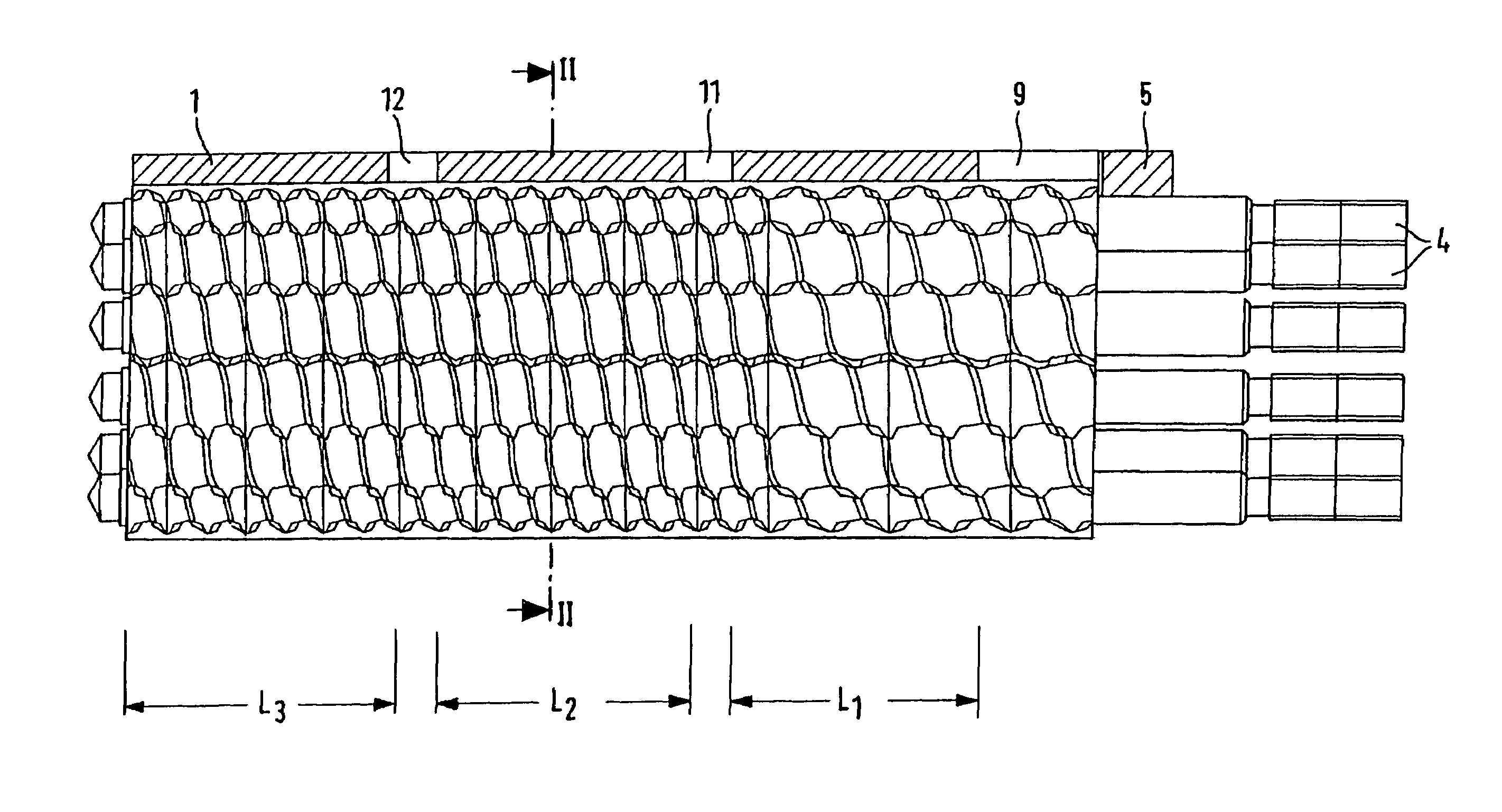

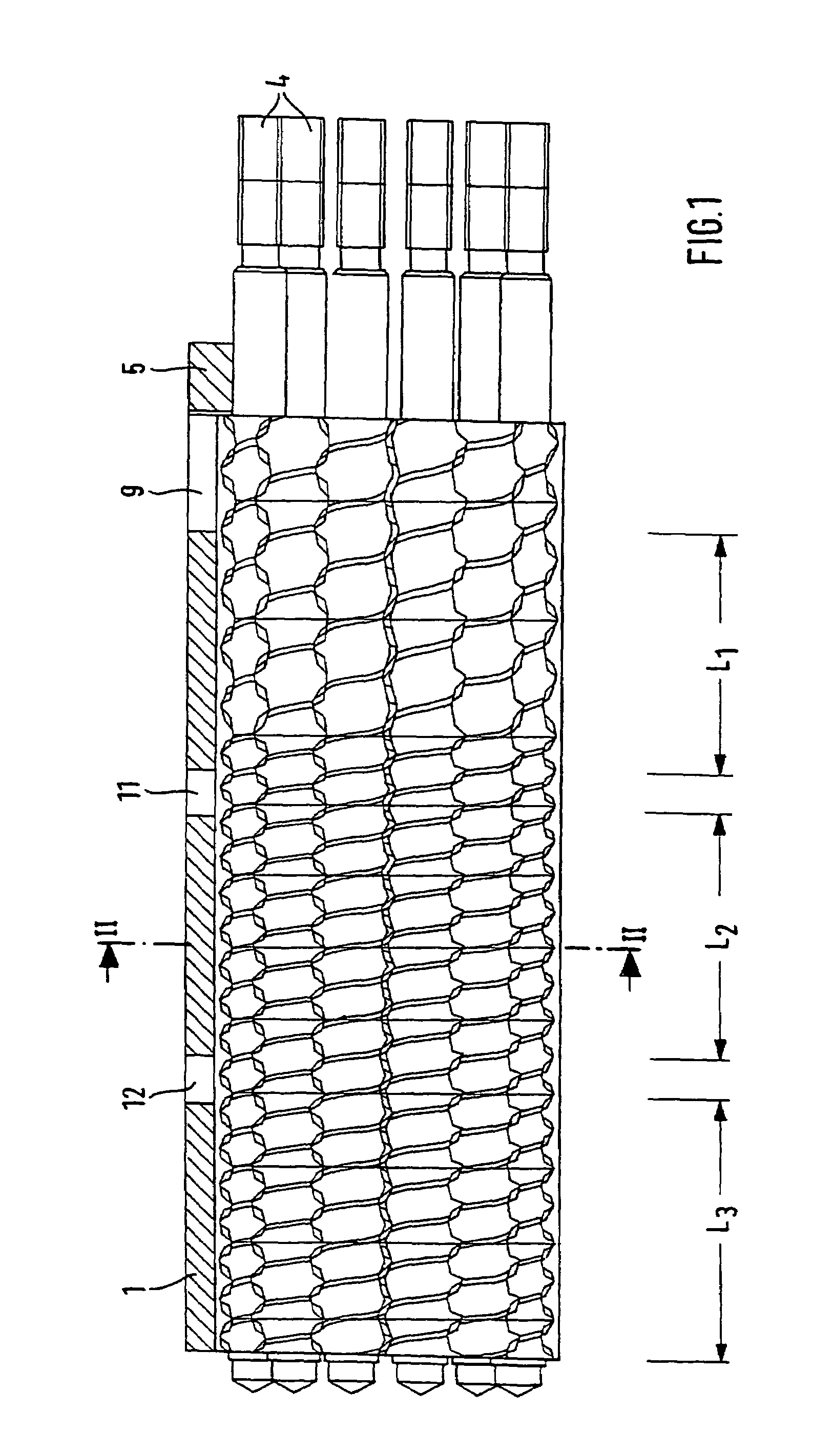

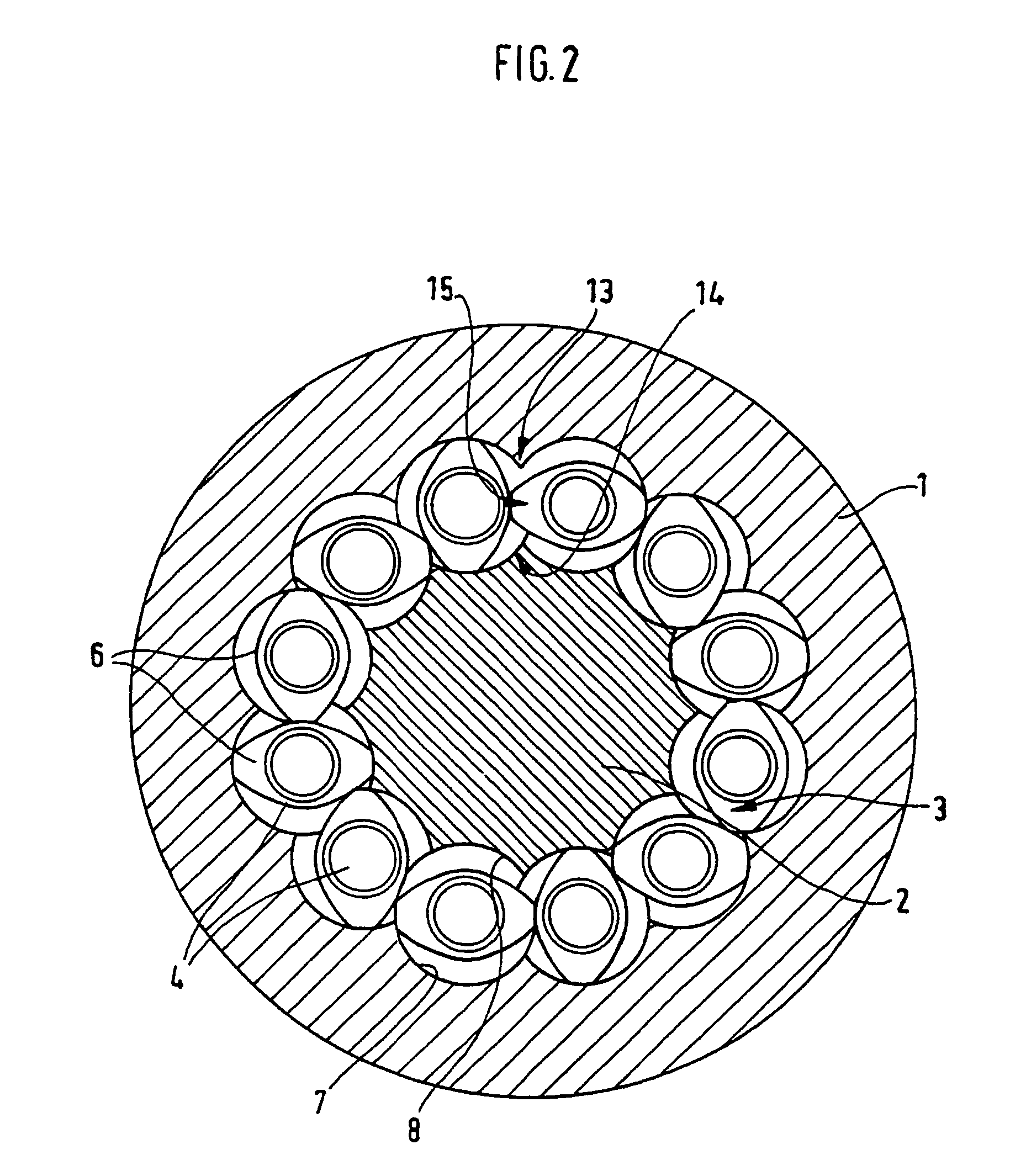

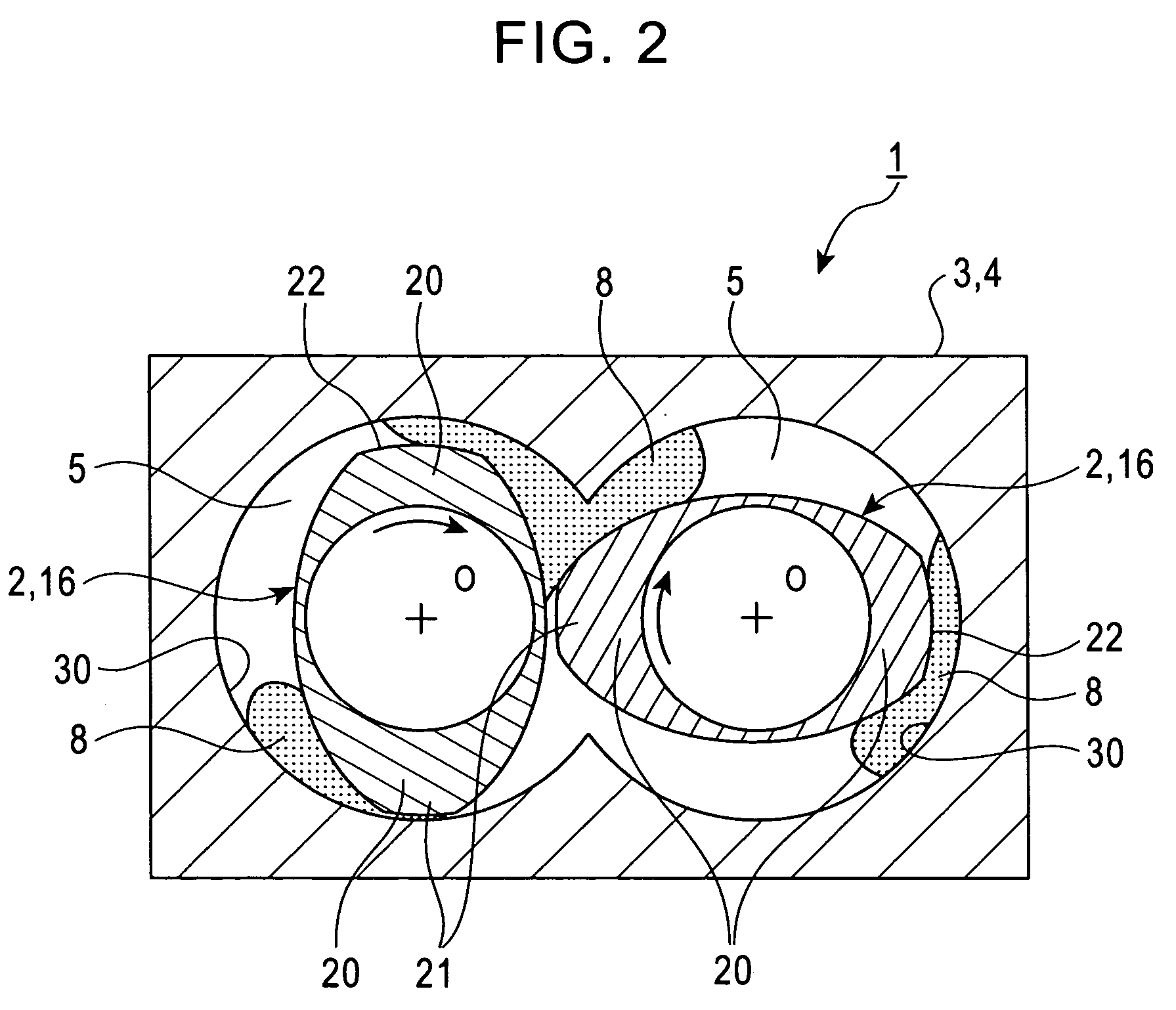

Homogenizing and/or dispersing device comprising endless screws

An apparatus for homogenizing and / or dispersing at least one viscous substance and at least one solid and / or at least one other substance of different viscosity includes in a space in a housing axis-parallel rotatable shafts disposed along a circle with equal central-angle distance and provided with tightly intermeshing screw elements. The shafts in the area outside the openings in the housing are provided with screw elements having a pitch (S) of at most three quarters of the outside screw diameter (D) over a length (L=L1+L2+L3) corresponding to at least ten times the outside diameter (D) of the screw elements.

Owner:BLACH VERWALTUNGS GMBH

Polymer processing systems including screws

Owner:TREXEL

Apparatus for preparing a gypsum wallboard core

A gypsum wallboard core, and methods and apparatus for making the same are disclosed. Methods of making a gypsum wallboard core include extruding a gypsum slurry containing water, gypsum, slip agents, water-reducing agents, surfactants and, optional additives, through a die and onto a substantially flat, smooth, moving surface. The die has provisions at its outer sides for the introduction of slip agents into the slurry, and provisions at its lateral outer edges for the introduction of a strength-enhancing agent. Once extruded onto the conveyor belt, the slurry is chemically-activated to set and form a hardened board core which then may be easily removed from the conveyor belt and dried.

Owner:GOLD BOND BUILDING PROD LLC

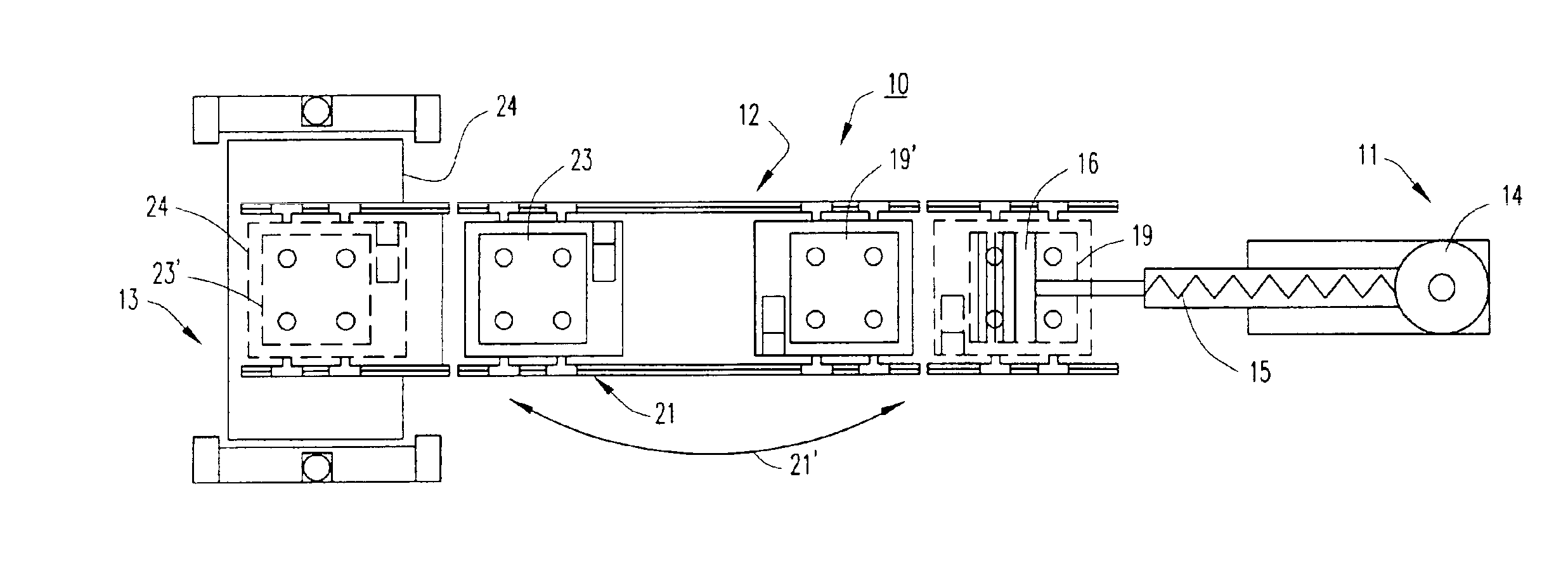

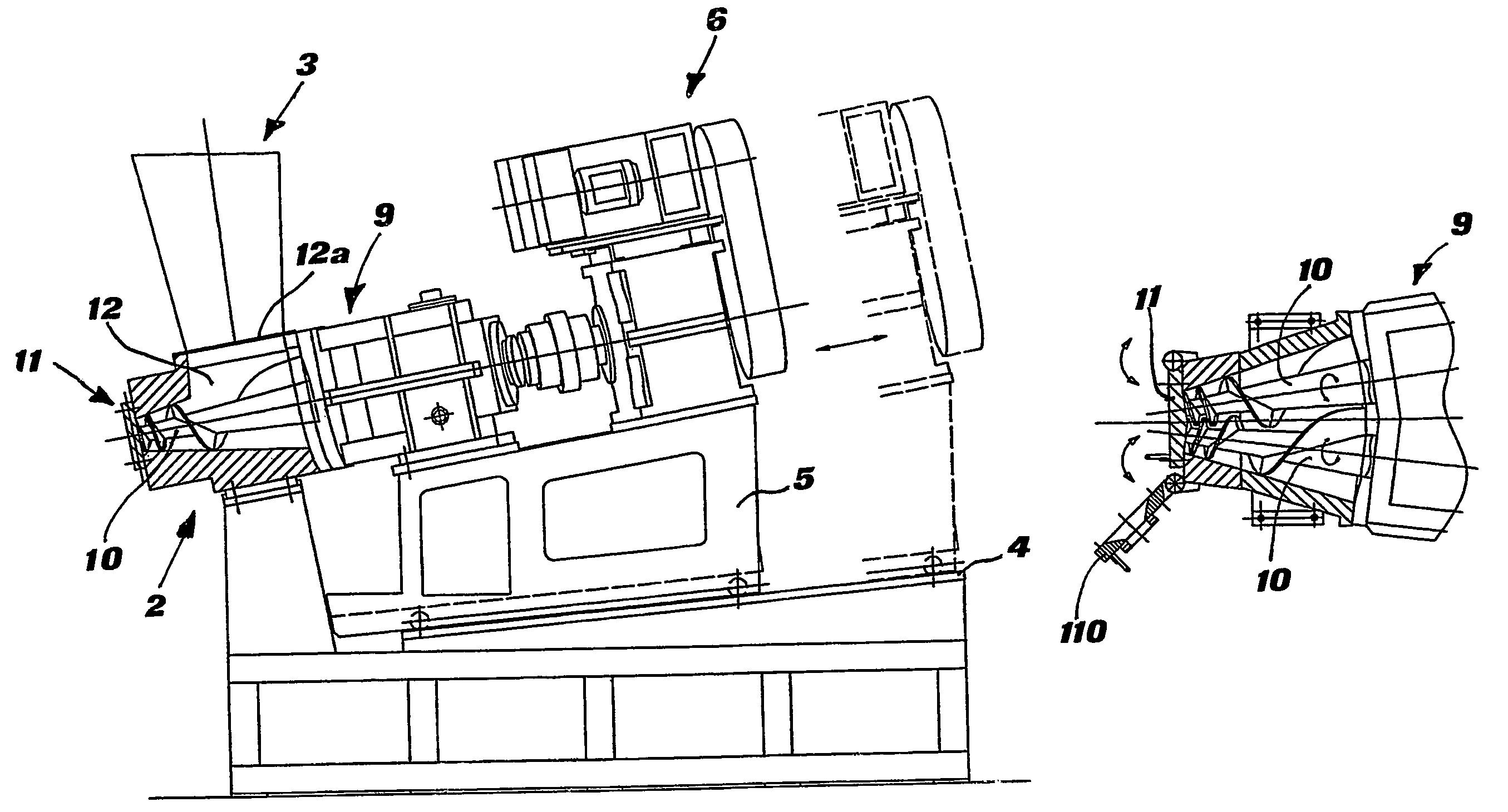

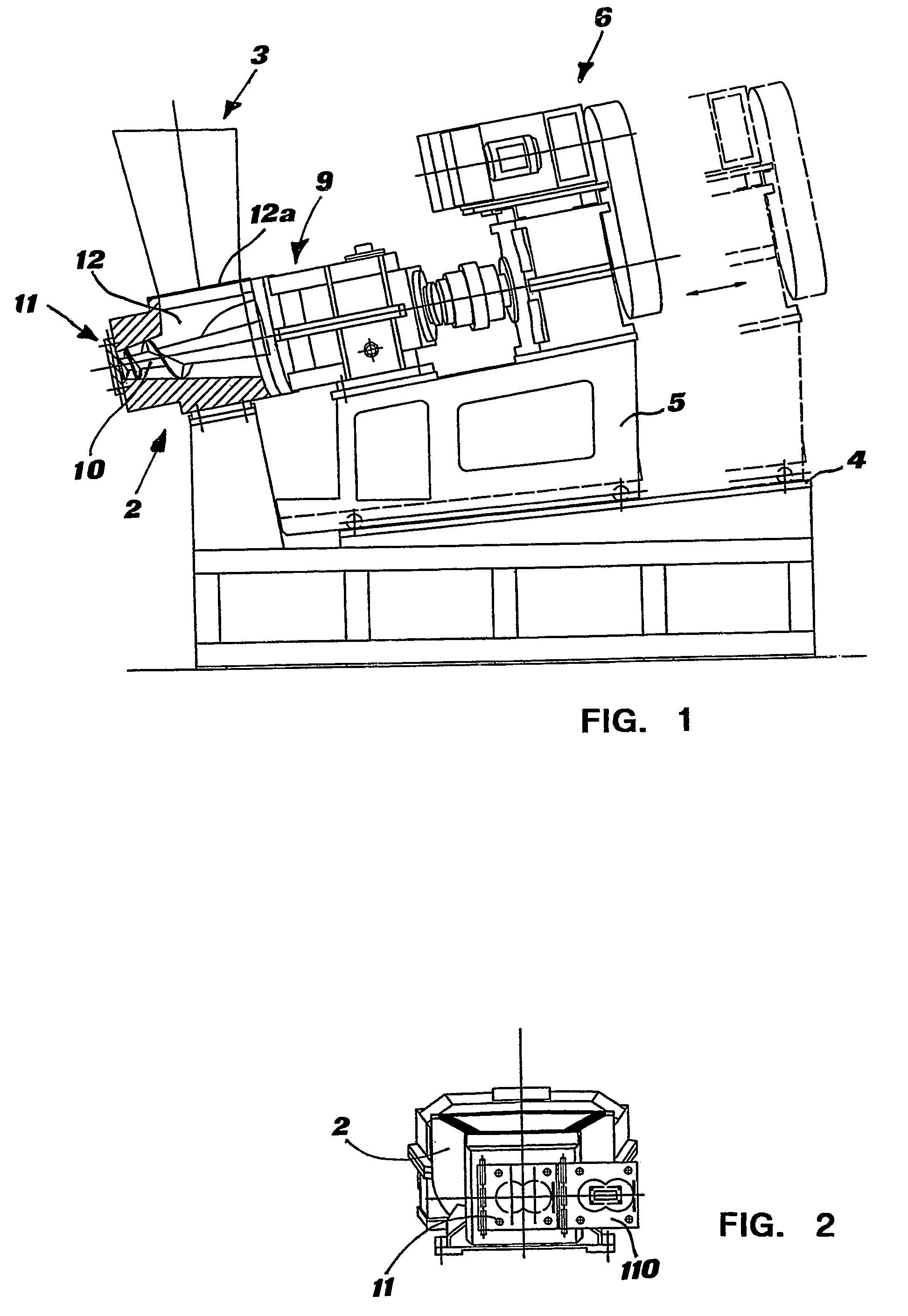

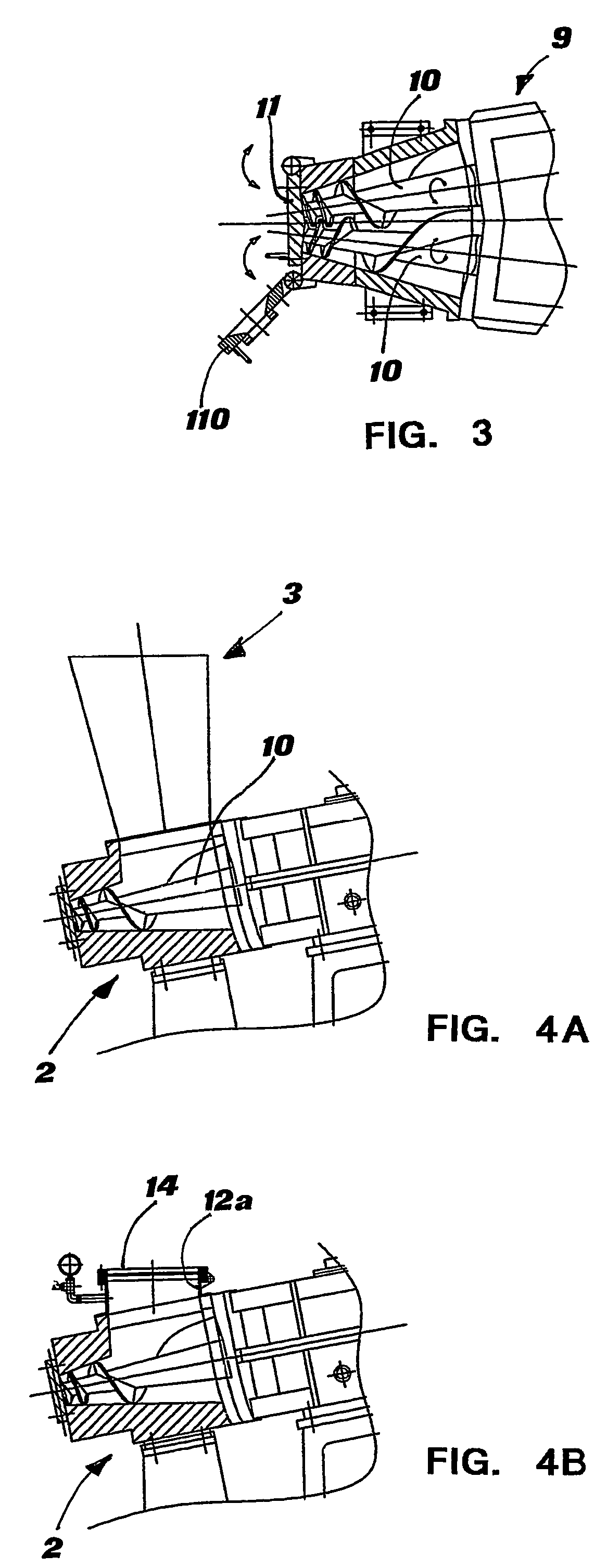

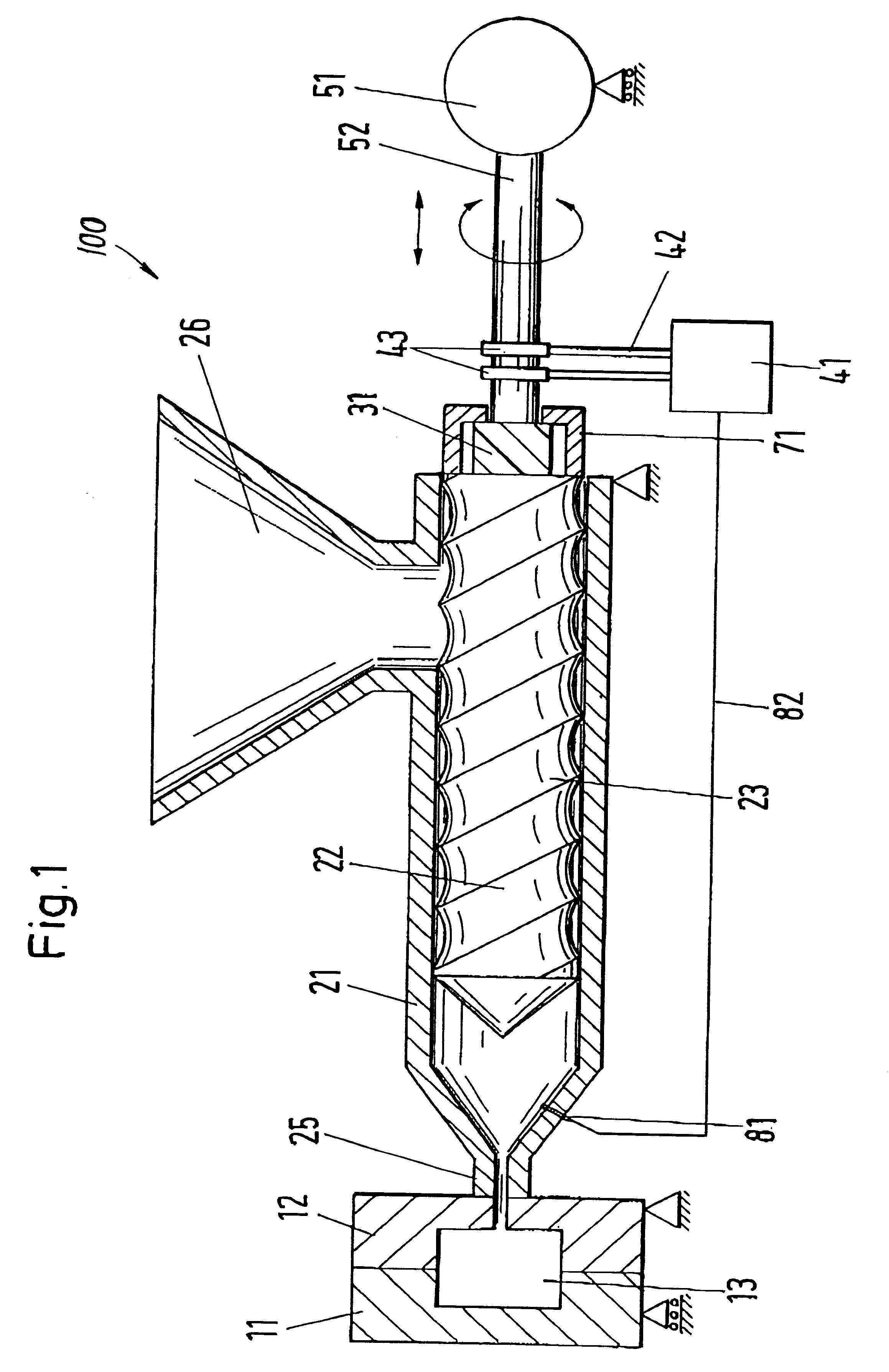

Machine for mixing and extruding rubber-based and silicone-based plastic materials and method therefor

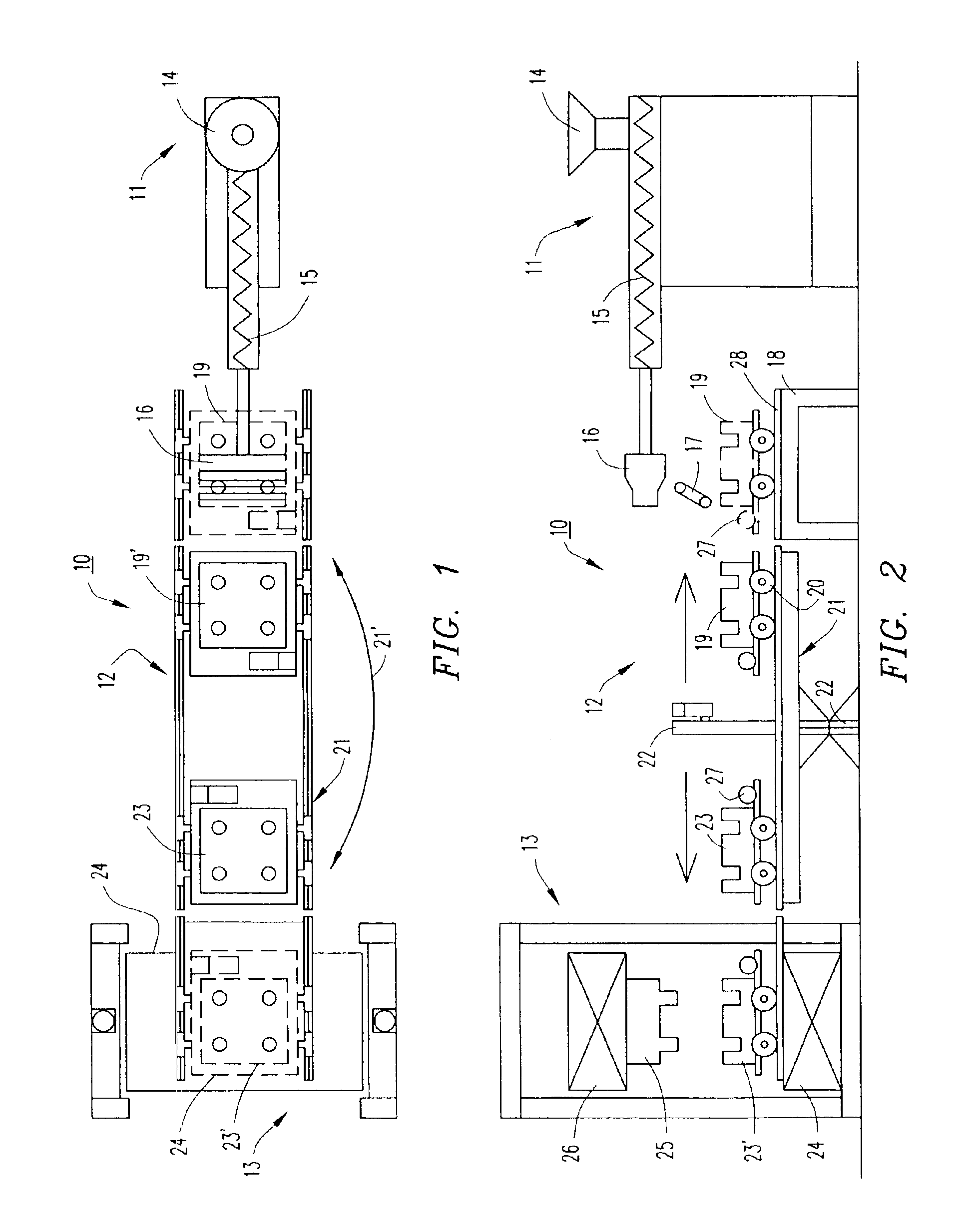

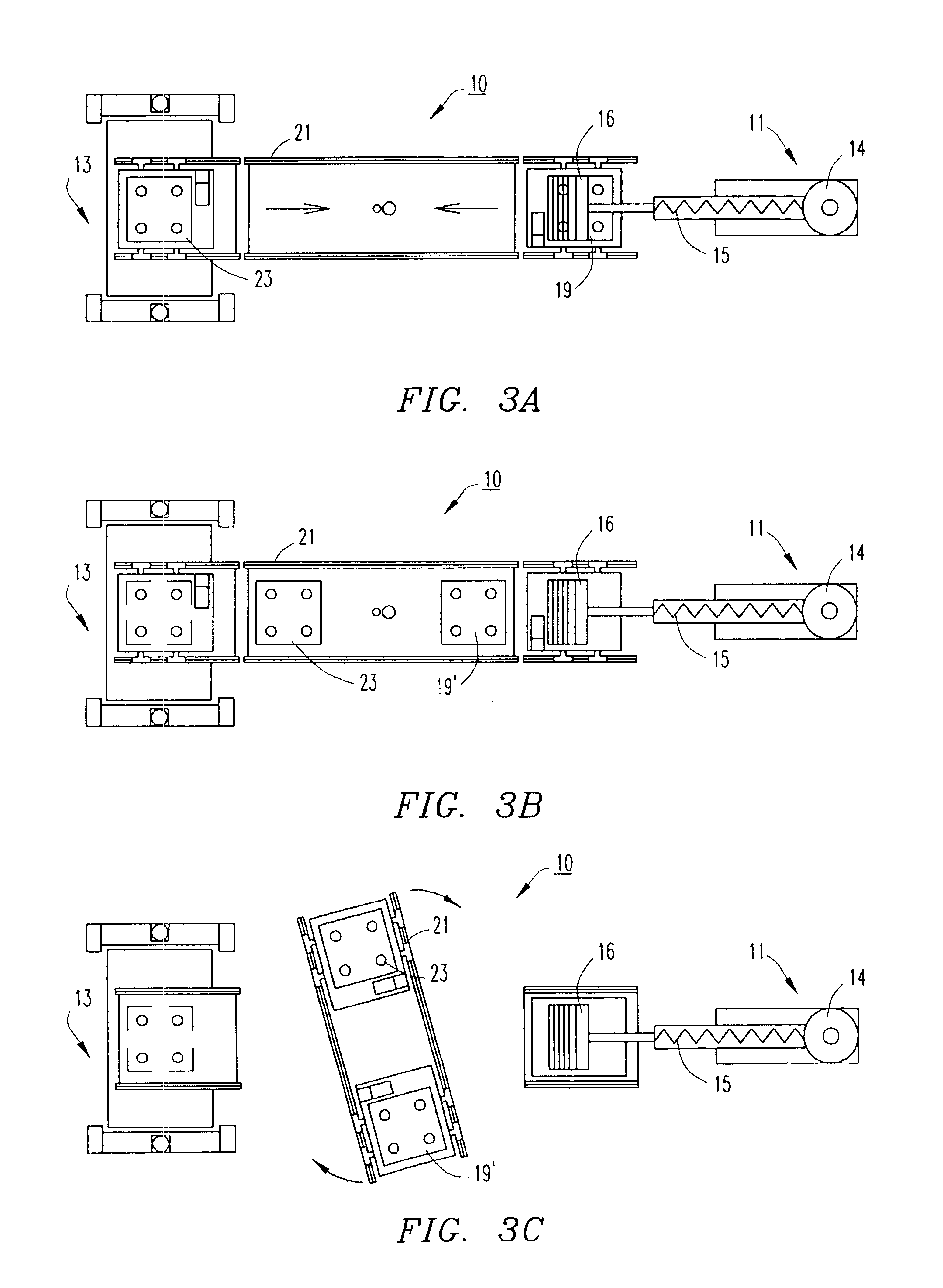

A machine for the mixing and extrusion of rubber-based and silicone-based plastic materials and method thereof is disclosed, comprising a dump extruder with conical converging twin screws (10) arranged in a batching chamber (12) in which the outlet of the dump extruder is temporarily closed by a removable blind flange (11), the batching chamber also acting as a compounding chamber.

Owner:COLMEC

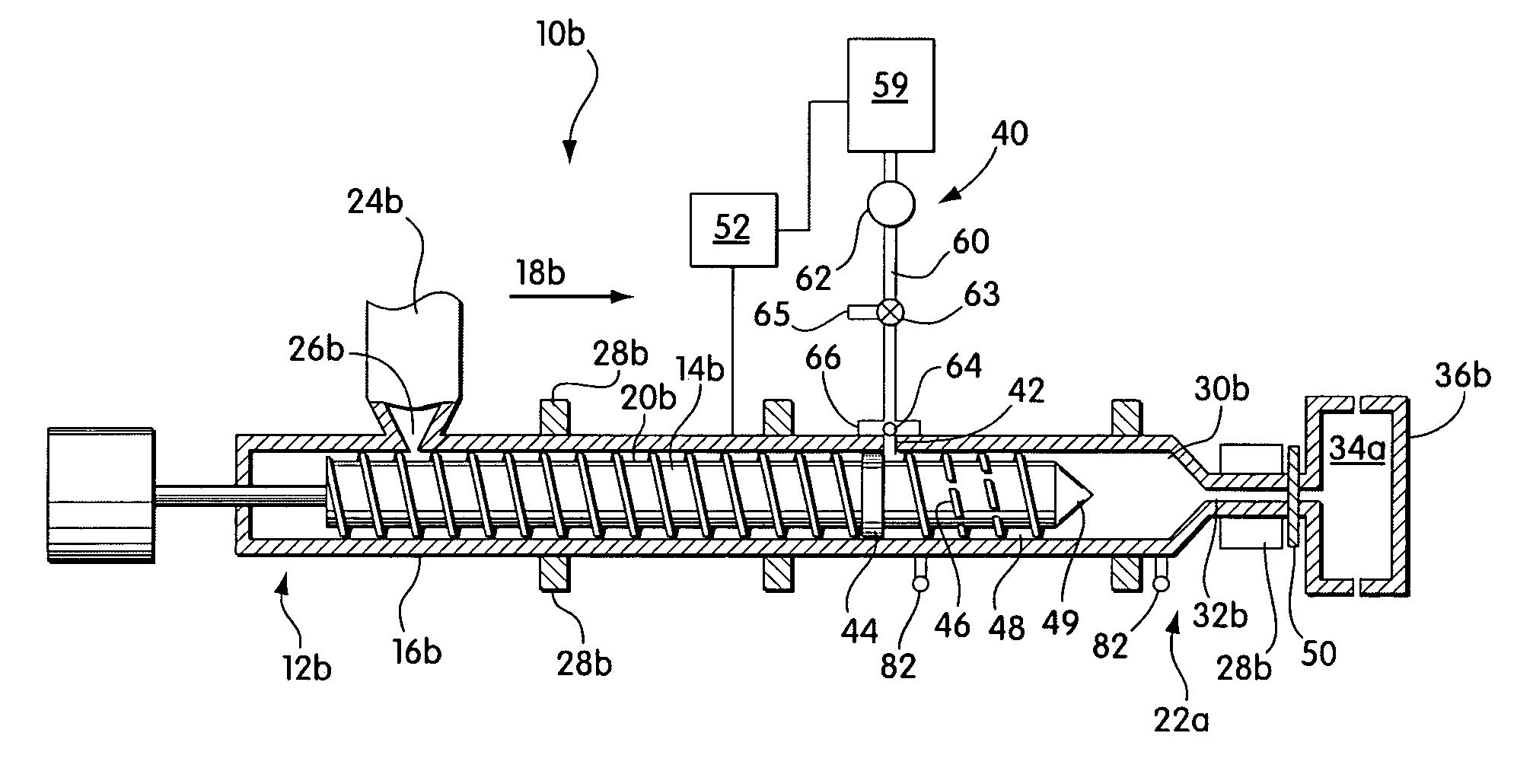

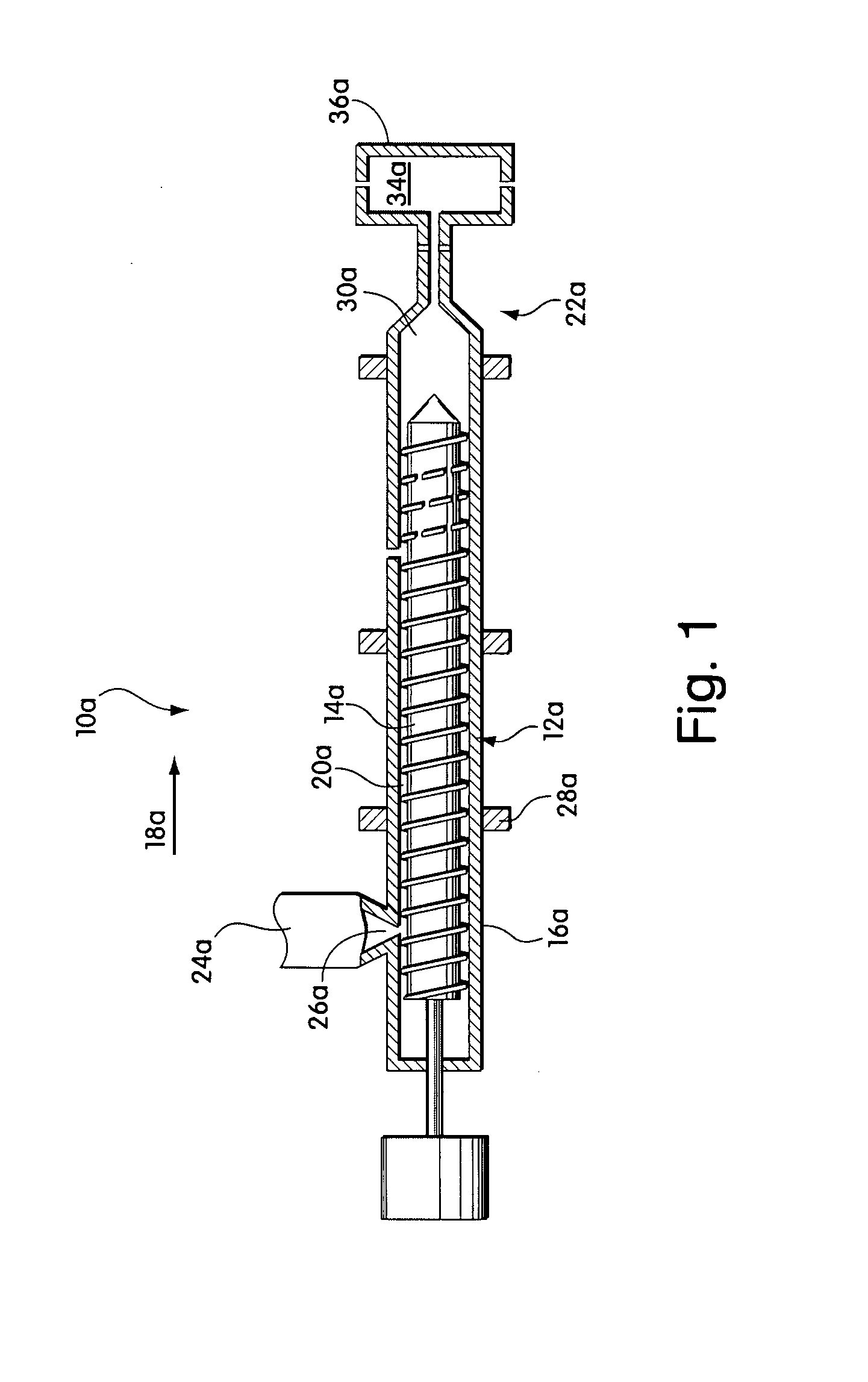

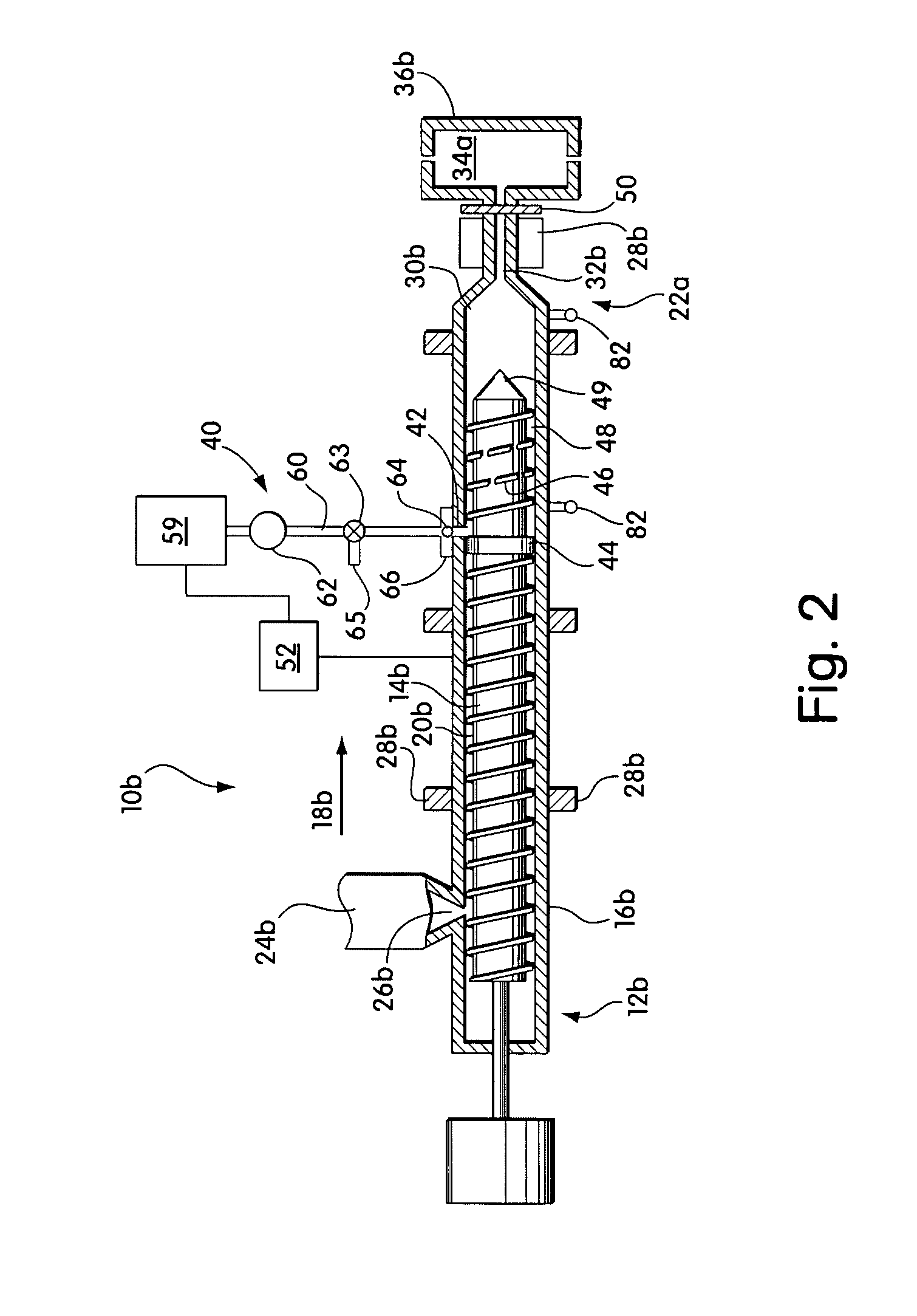

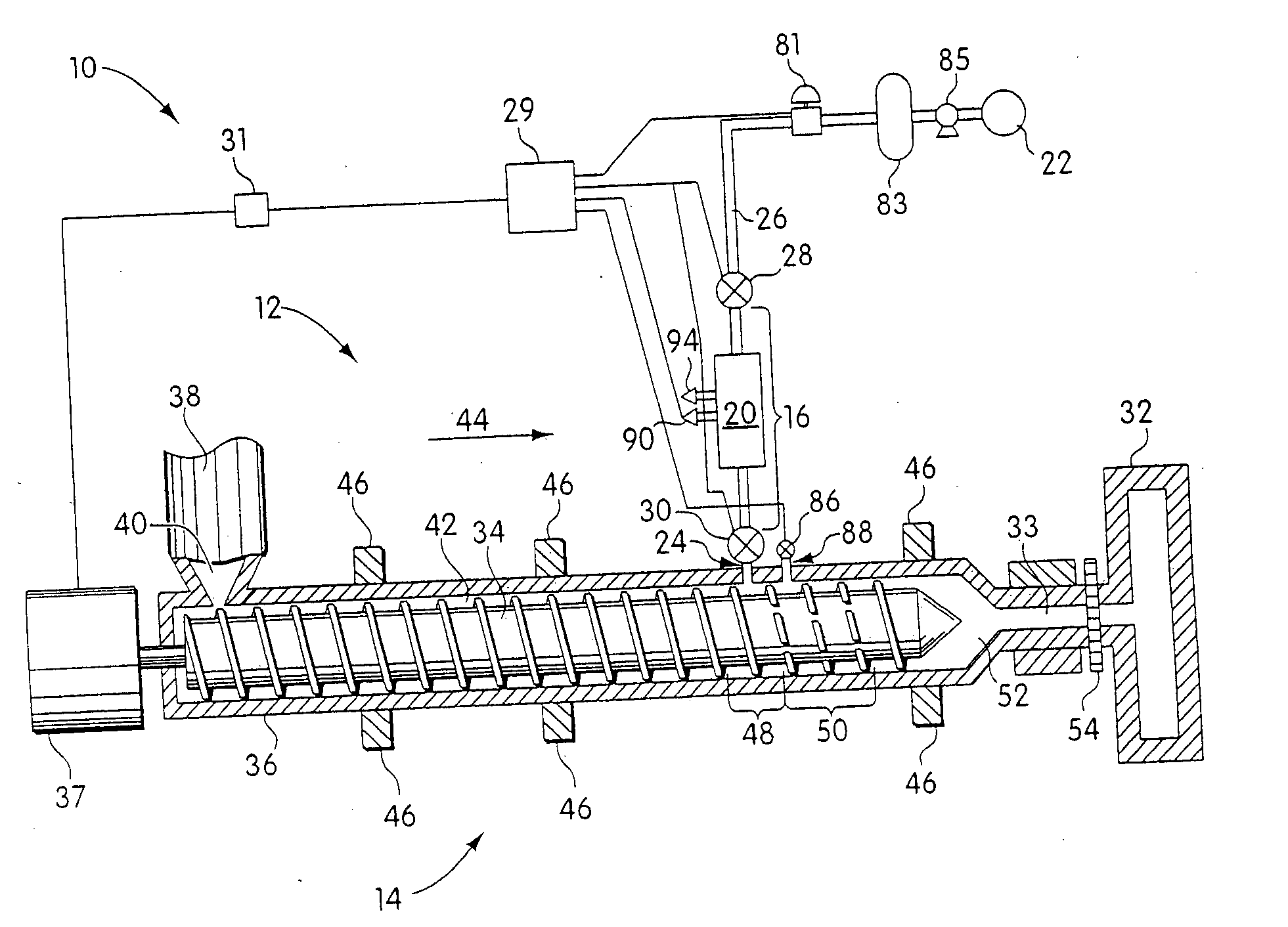

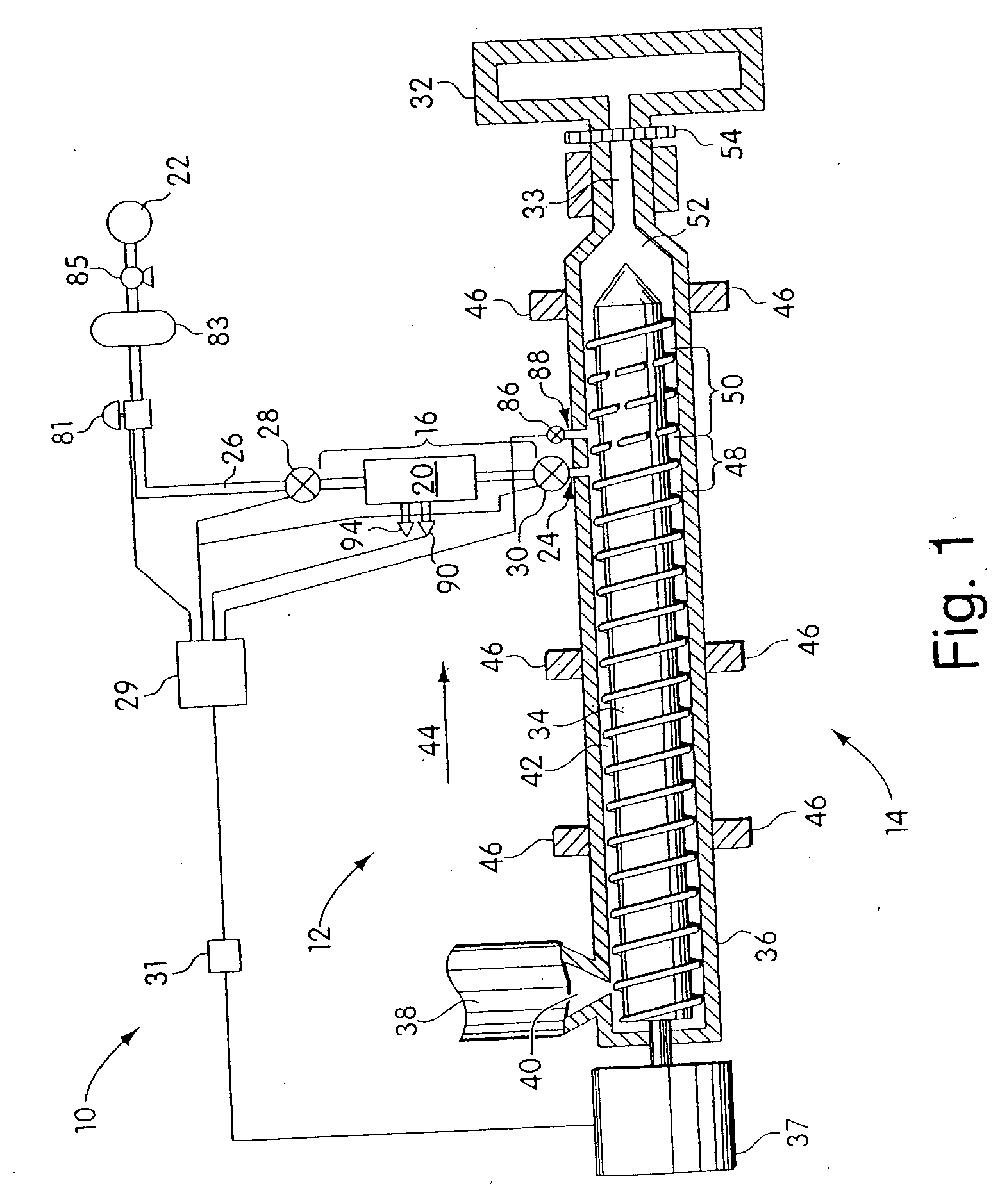

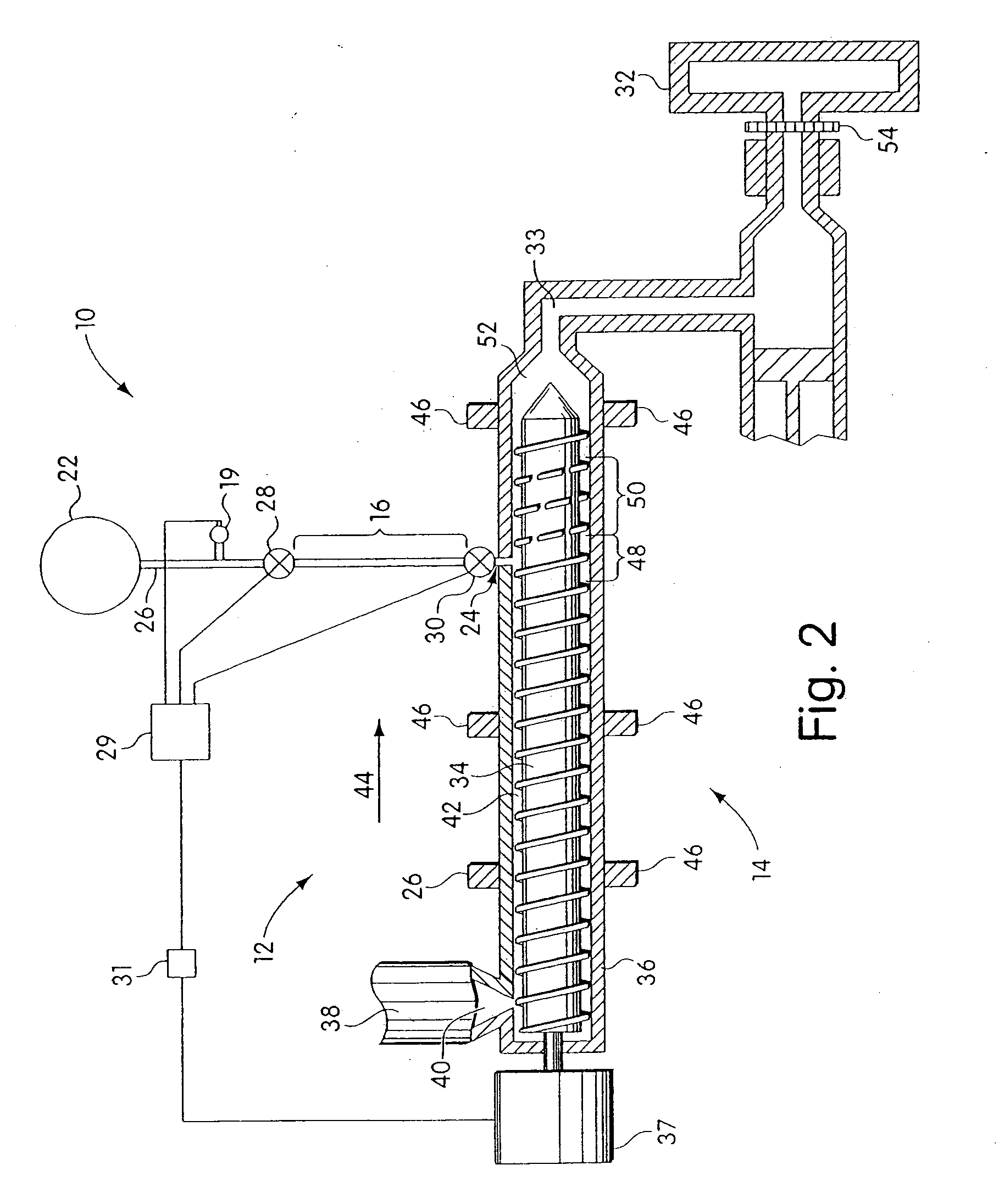

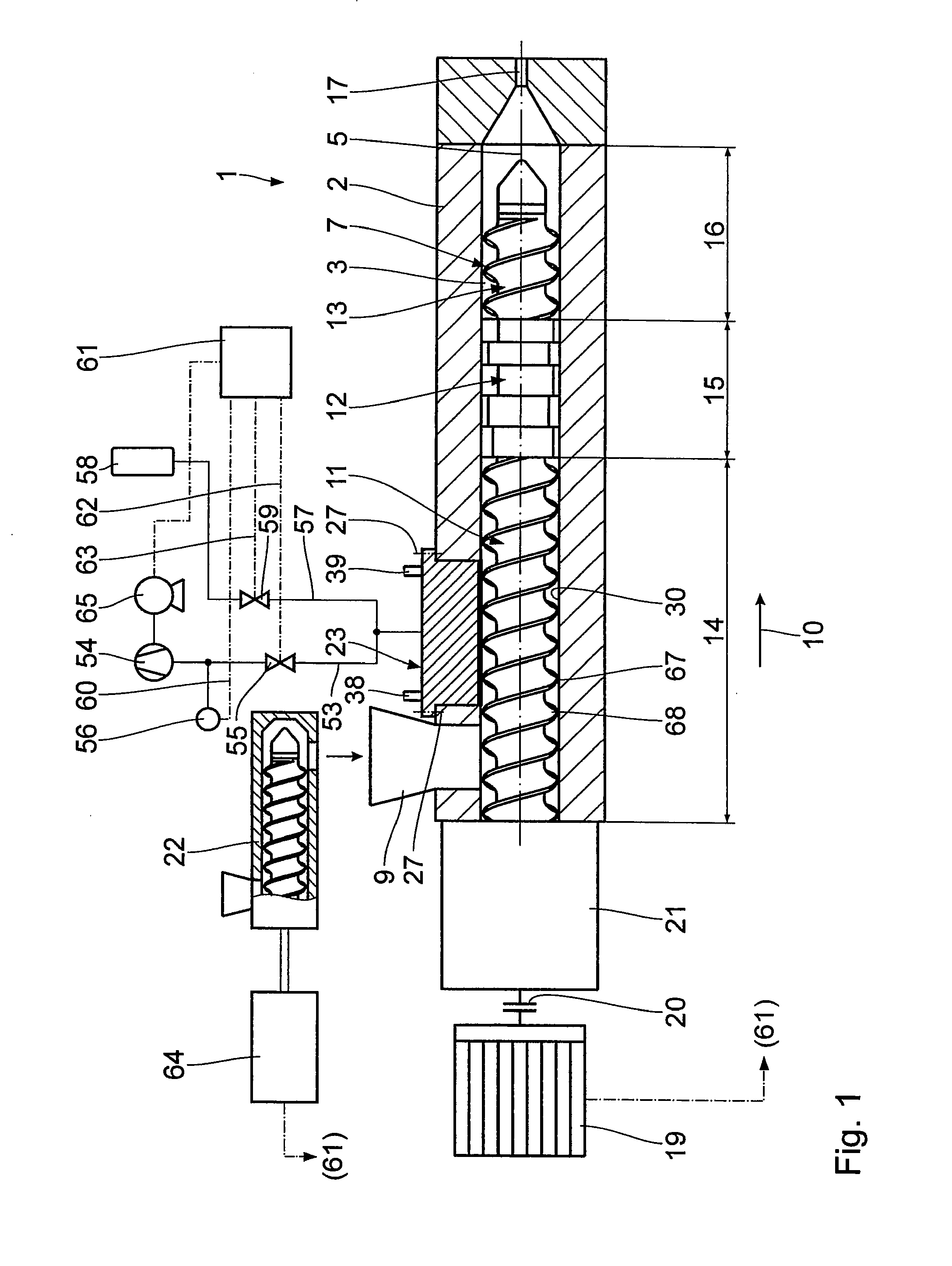

Blowing agent introduction systems and methods

The present invention provides blowing agent introduction systems and methods for introducing blowing agent into polymeric foam processing systems. The methods may involve introducing one or more doses of blowing agent into polymeric material in an extruder during a plastication period of a molding cycle. Prior to introduction, a dose is confined in an accumulator which, for example, has a volume defined between an inlet valve and an outlet valve. A control system may receive inputs related to system parameters (e.g., pressure of polymeric material in extruder, axial position of screw in barrel, whether screw is rotating, and the like) and based on the inputs coordinates operation of the valves to confine and introduce the blowing agent dose(s). The introduction systems may be used in discontinuous plasticating processes, such as injection molding and blow molding, and can be particularly useful in processes that use precise quantities of blowing agent.

Owner:TREXEL

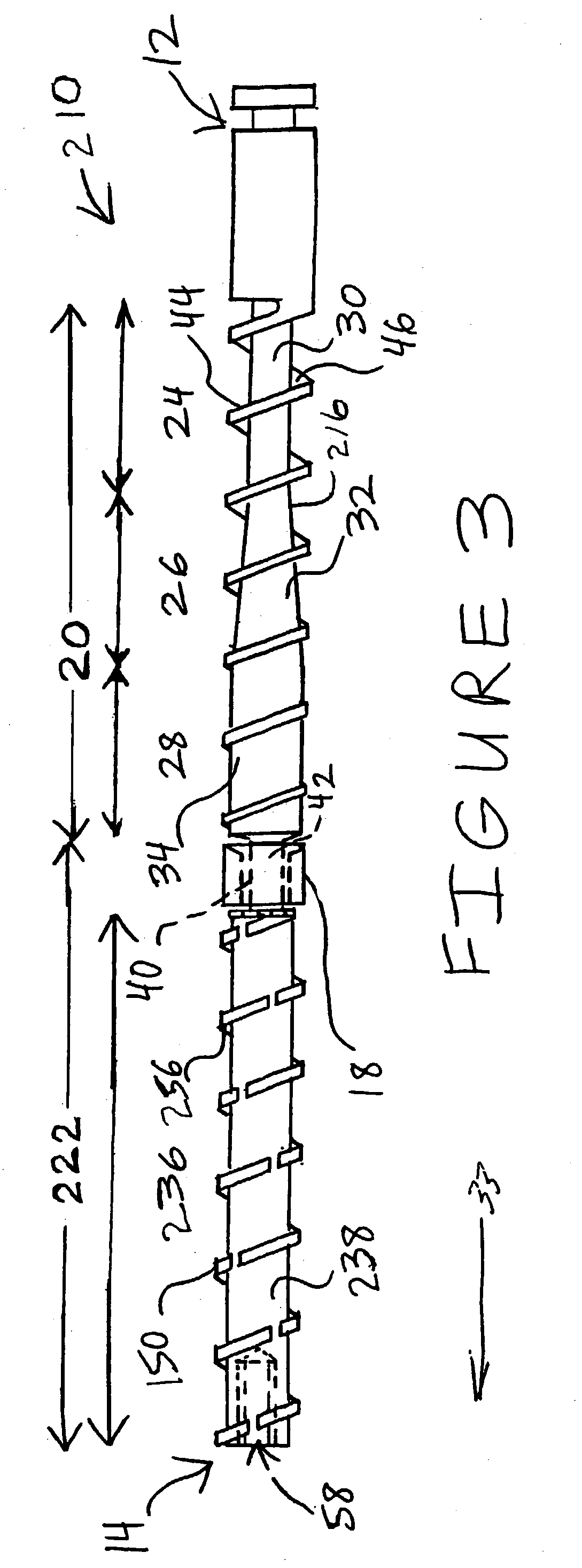

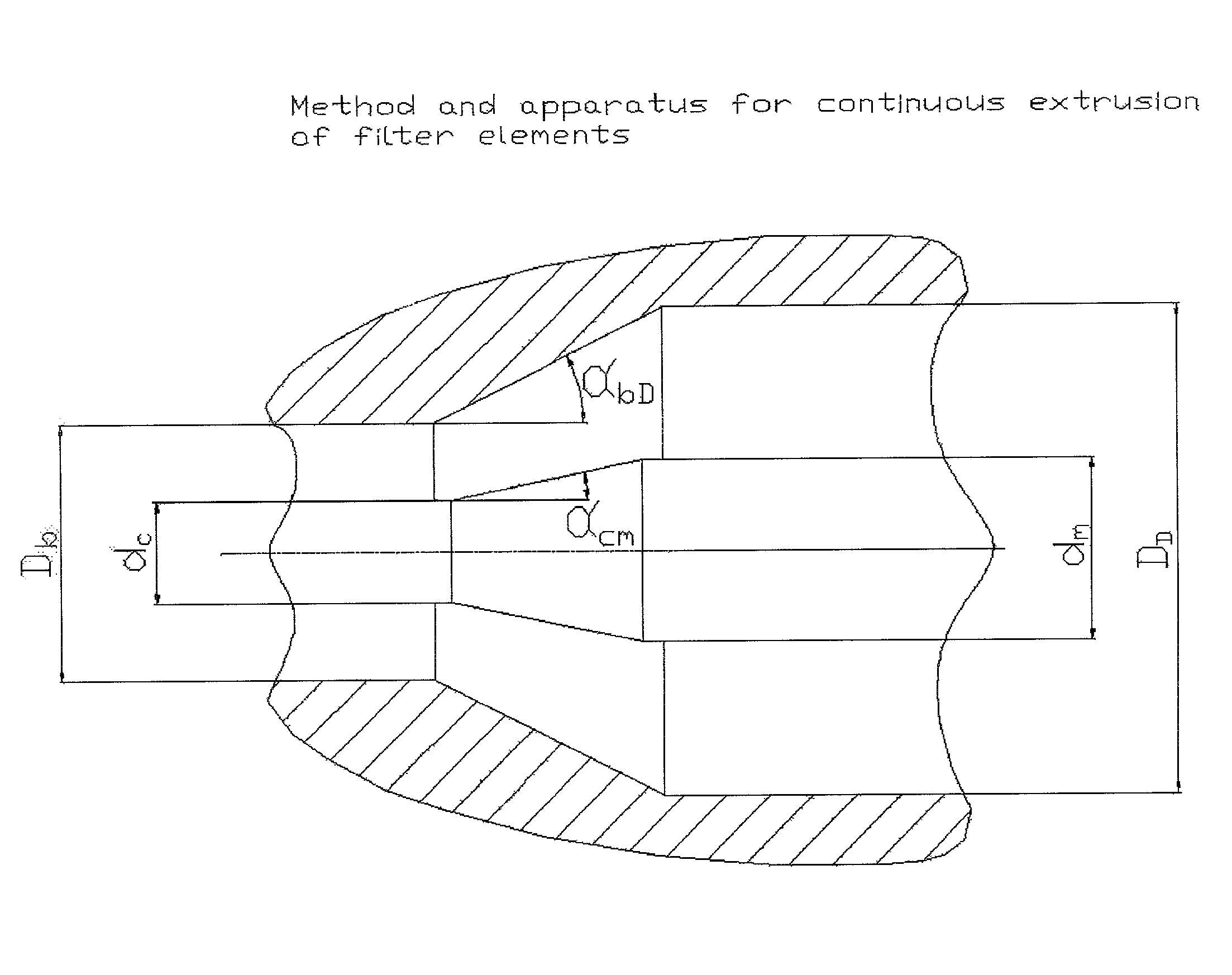

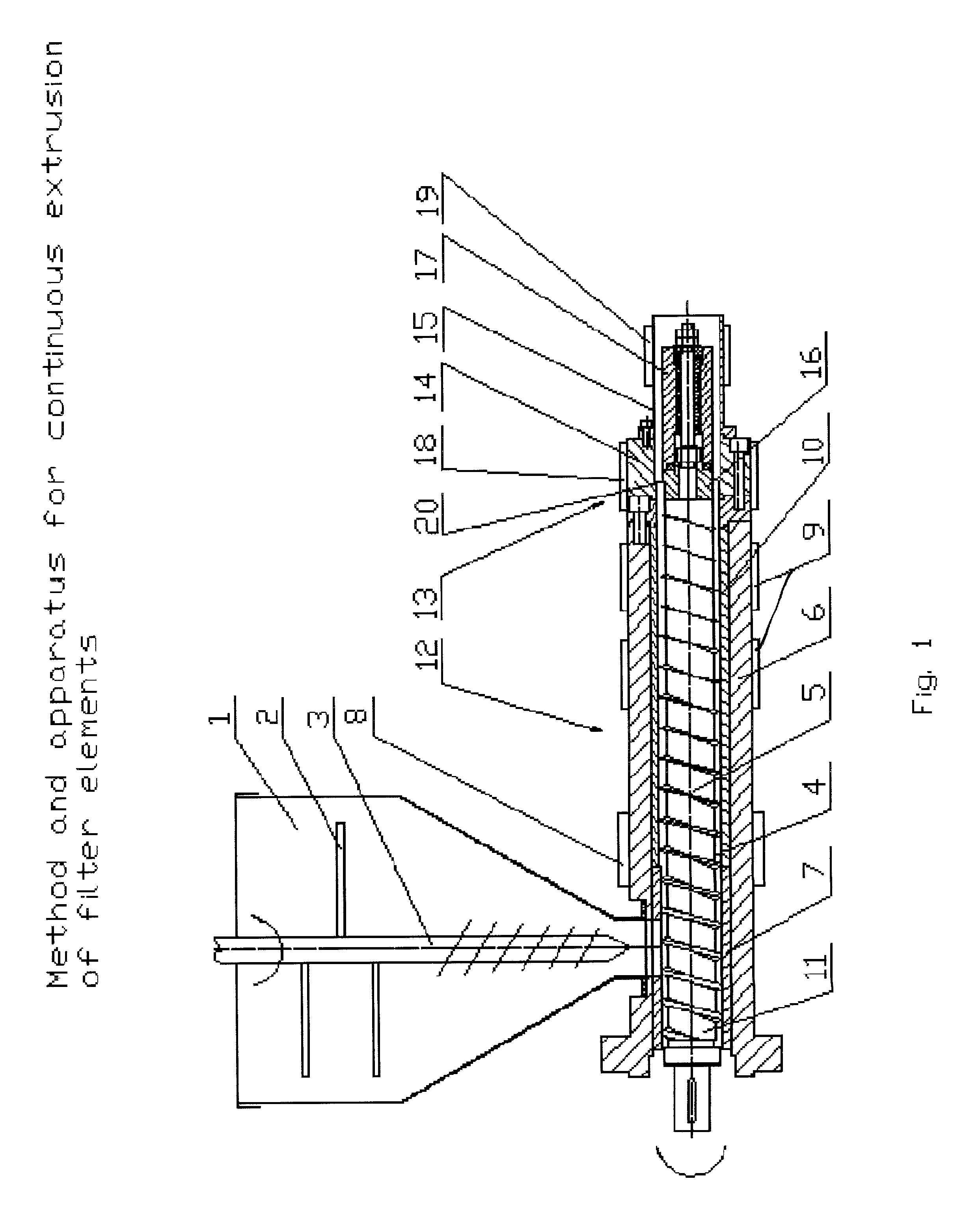

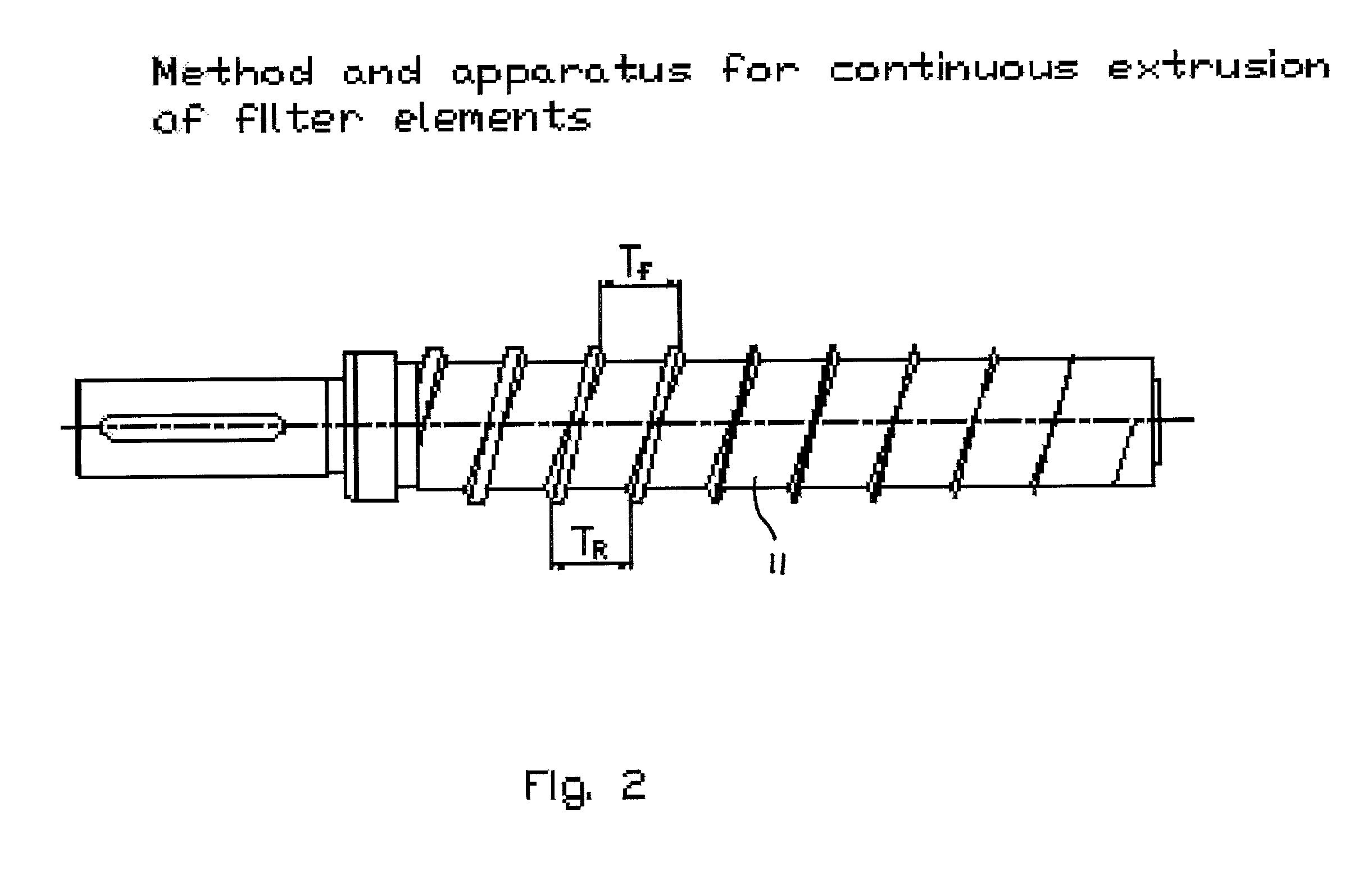

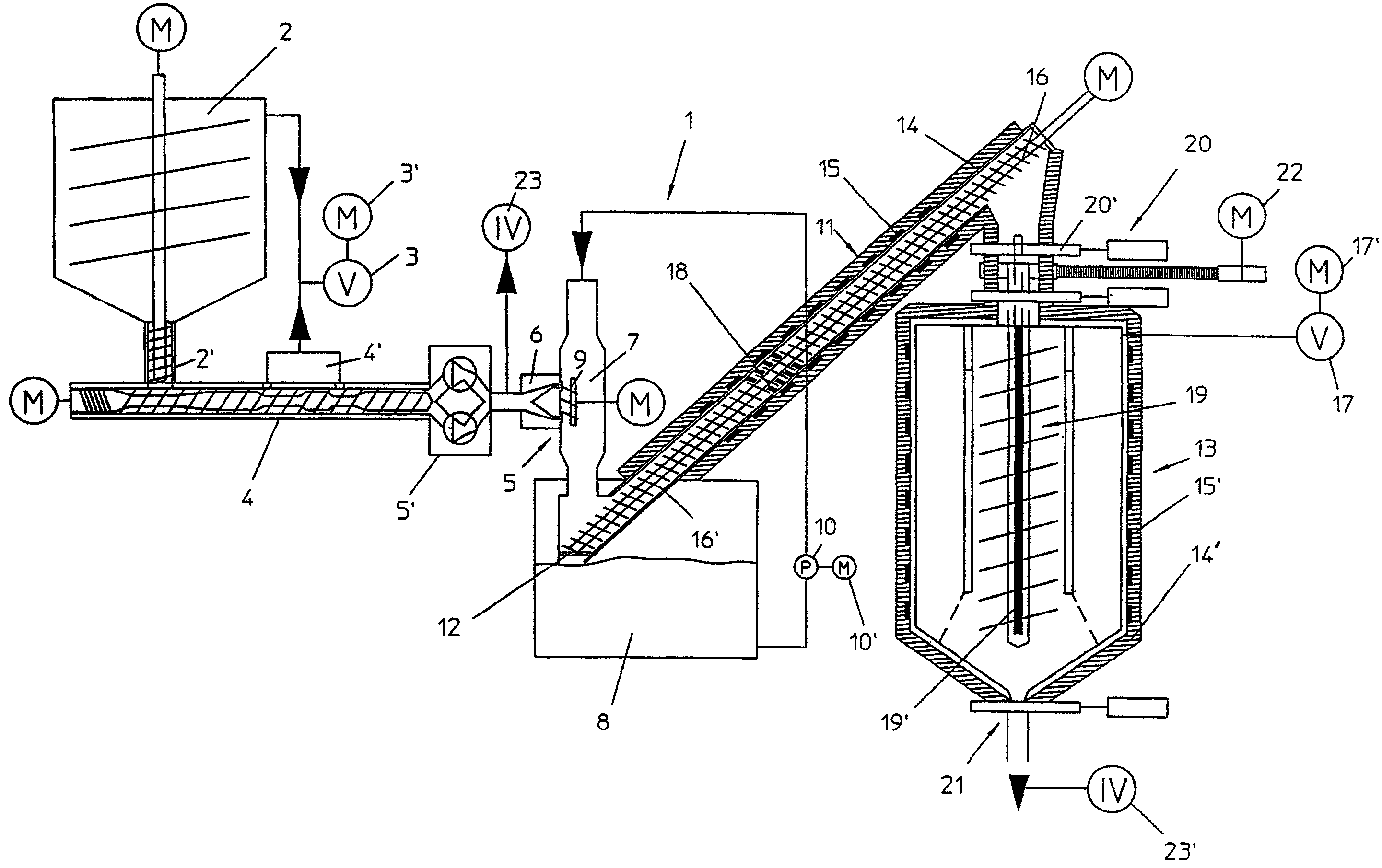

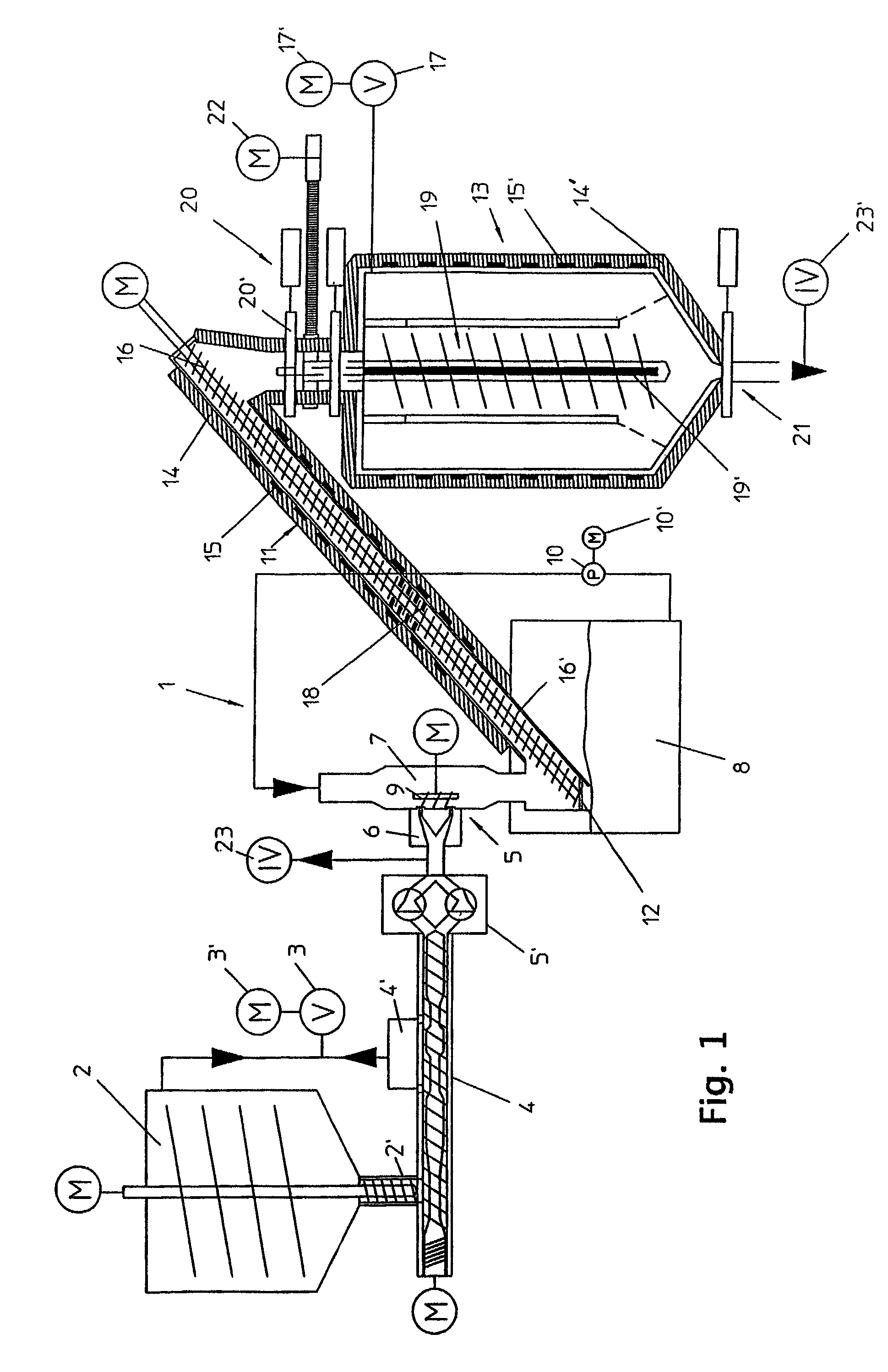

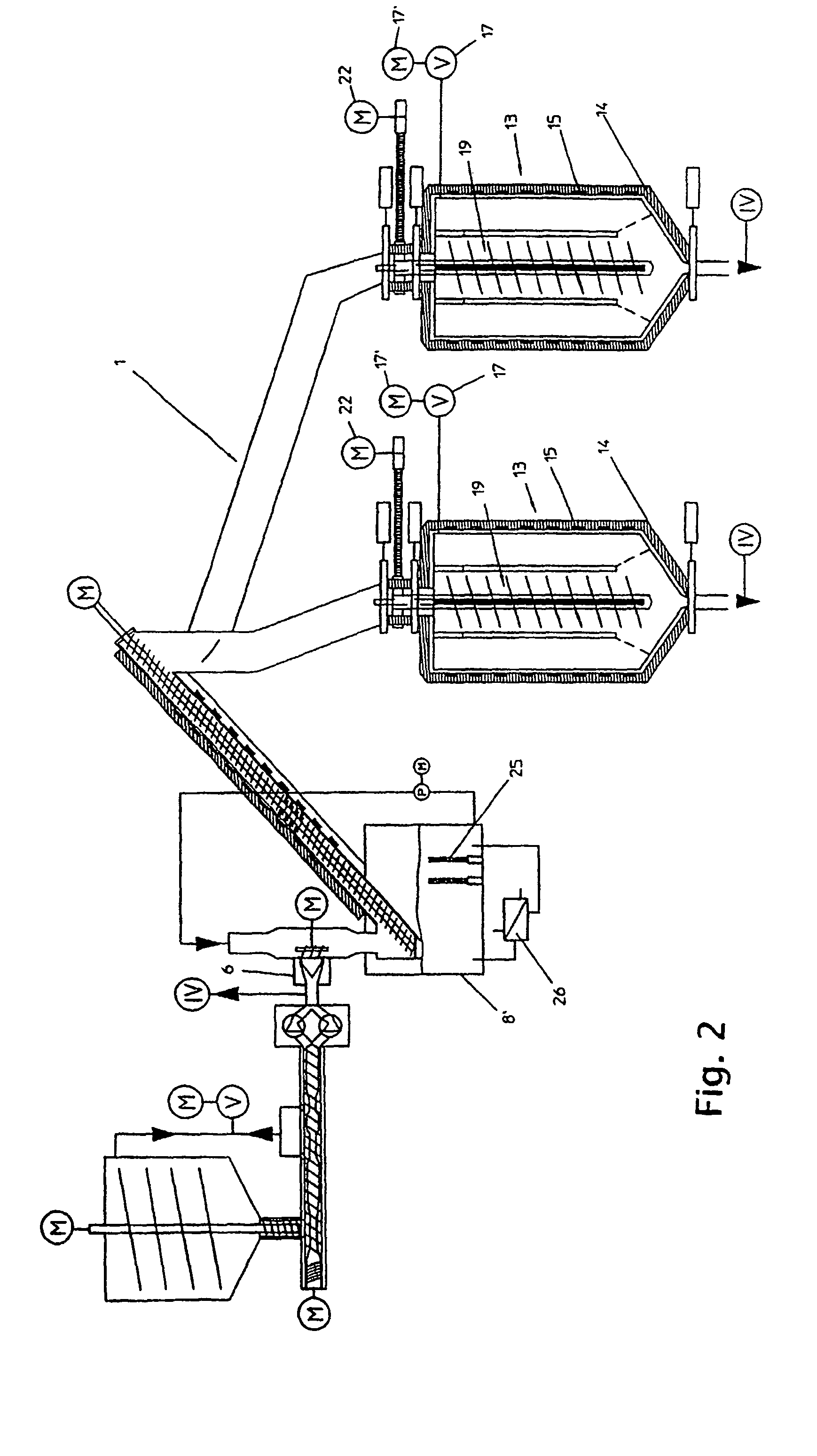

Method and apparatus for continuous extrusion of filter elements

InactiveUS20020062740A1Flight height is reducedHigh densityFrozen sweetsConfectioneryActivated carbonFiber

A method and apparatus for making filter elements in which a mixture of activated carbon granules and fibers are processed with meltable polymer fibers to form a porous element. The density of the porous structure increases in a direction from the periphery thereof to its center. Also, the article formed by the method using the apparatus.

Owner:BRUKOV NIKOLAY V +1

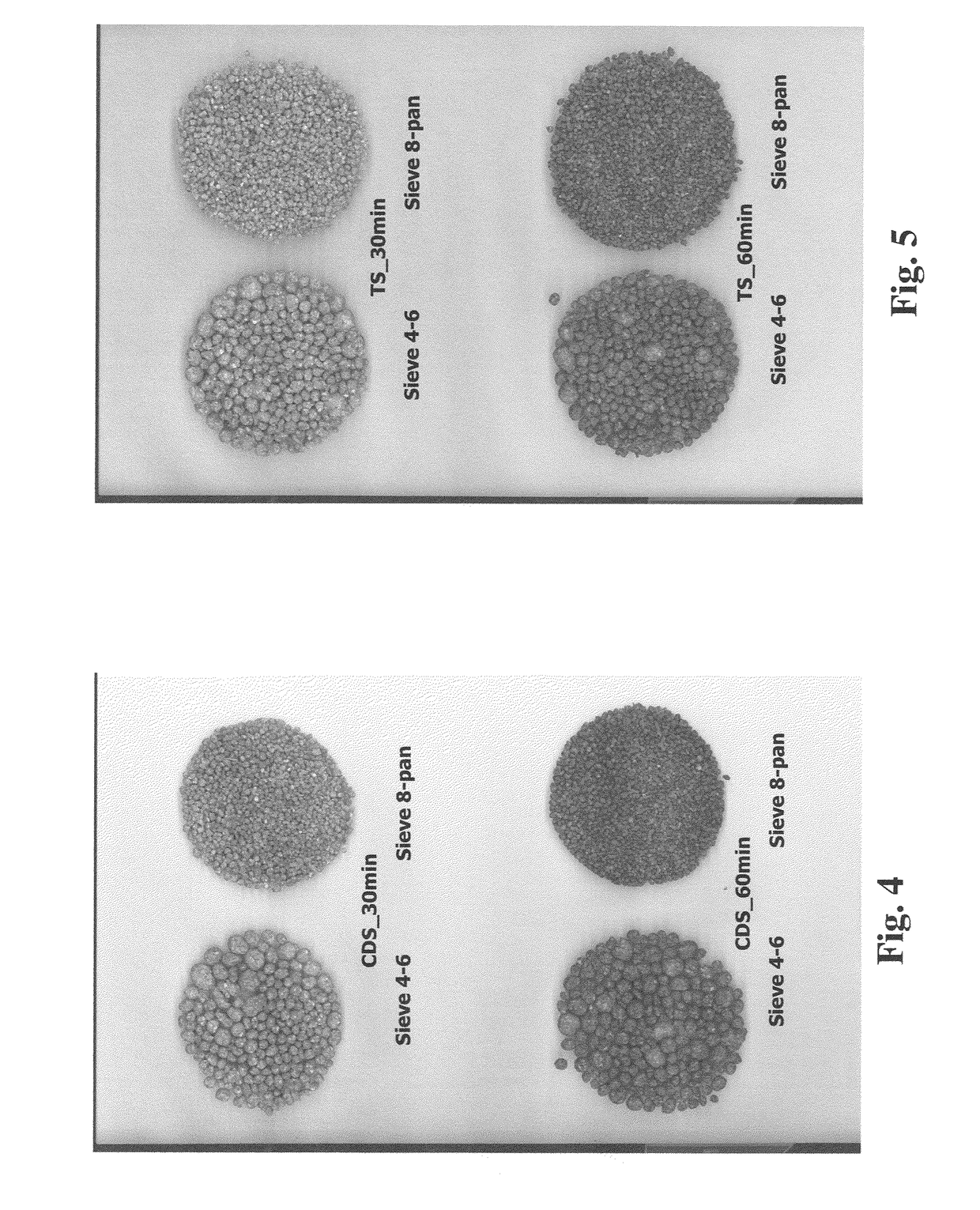

Method and apparatus for increasing an intrinsic viscosity of polyester

A method of increasing the intrinsic viscosity of polyester by means of solid state polymerization, wherein a polyester plastics melt is granulated and after granulation is conveyed into a thermal treatment container (13) for thermal treatment therein, the granules being produced slightly below their melting temperature and being fed into the thermal treatment container (13) immediately after granulation so as to utilize the residual heat in the granules, as well as an arrangement for increasing the intrinsic viscosity of polyester by means of solid state polymerization with a granulating and a thermal treatment unit, with an unheated, thermally insulated container (13) or a container (13) having wall heating means (15) being provided as the thermal treatment unit, which is directly connected to the granulating unit via a conveying device (11, 36, 37).

Owner:FELLINGER MARKUS

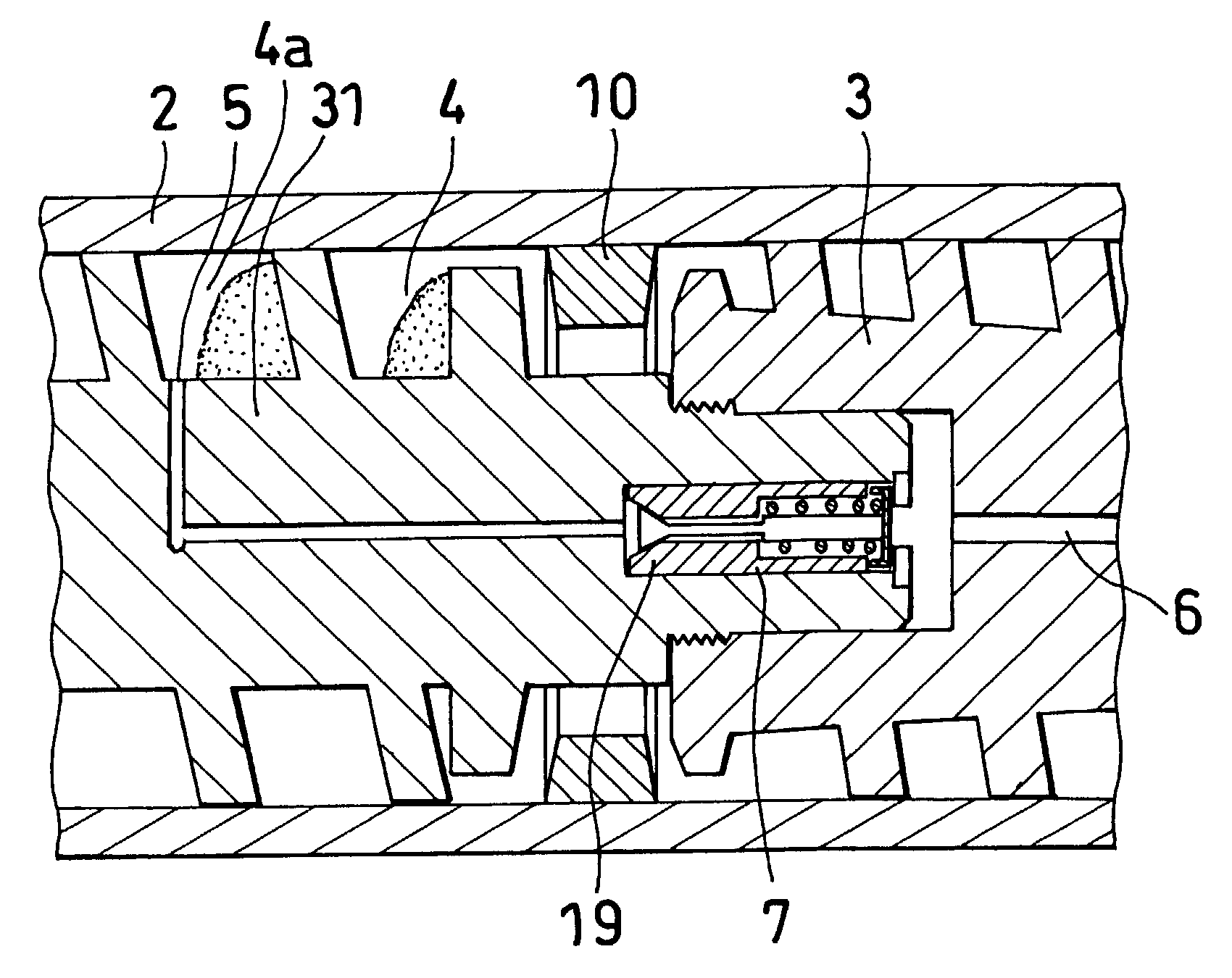

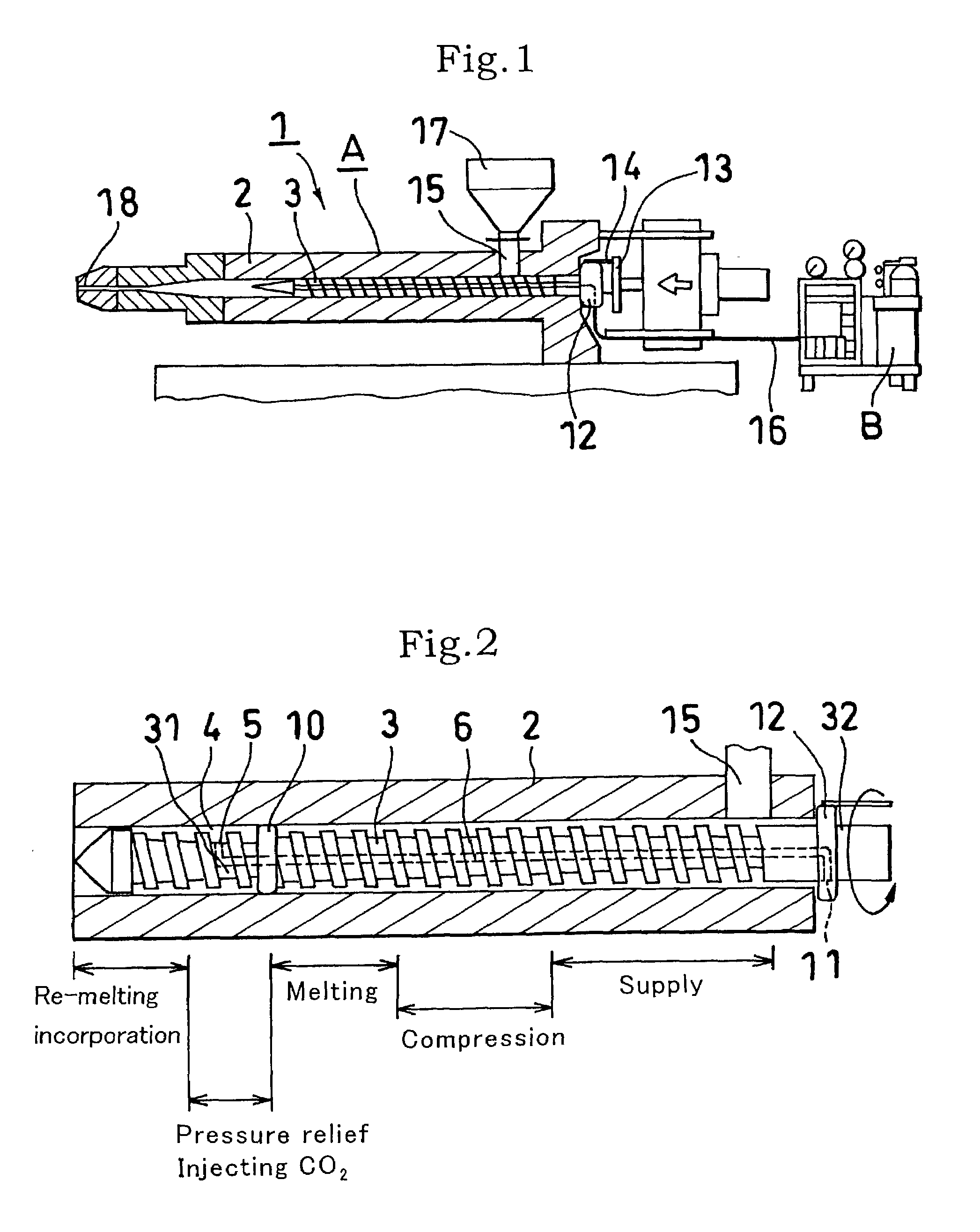

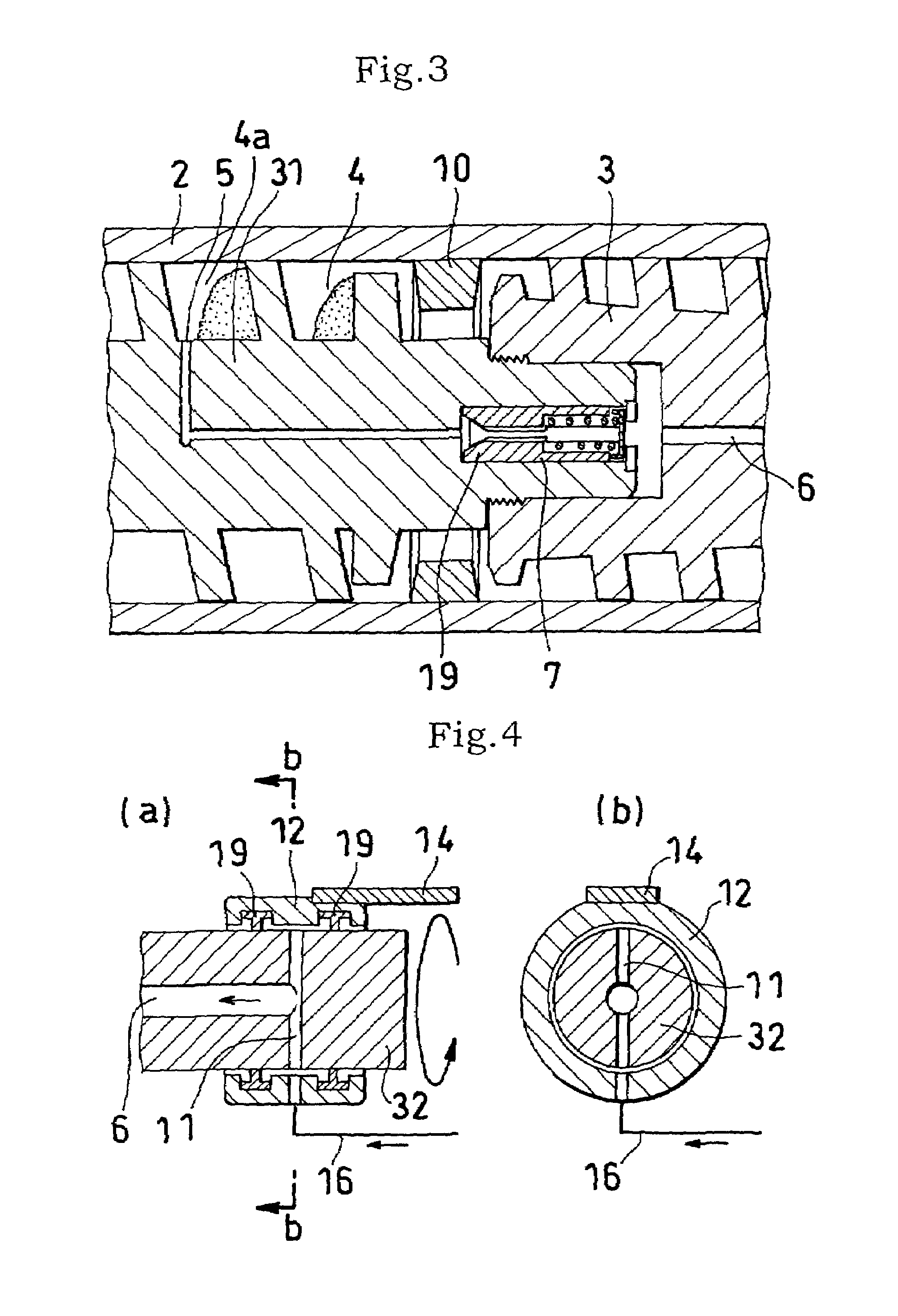

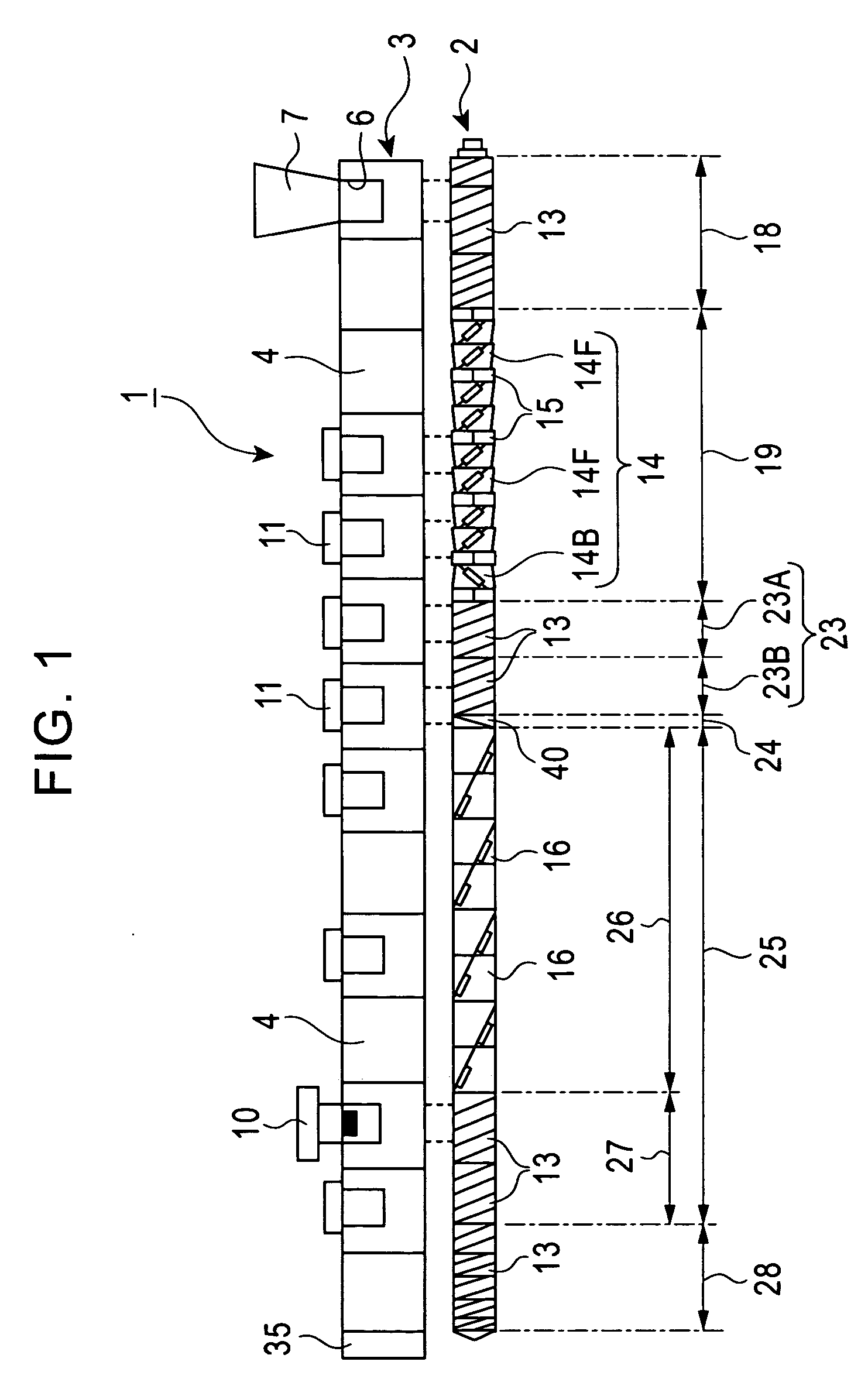

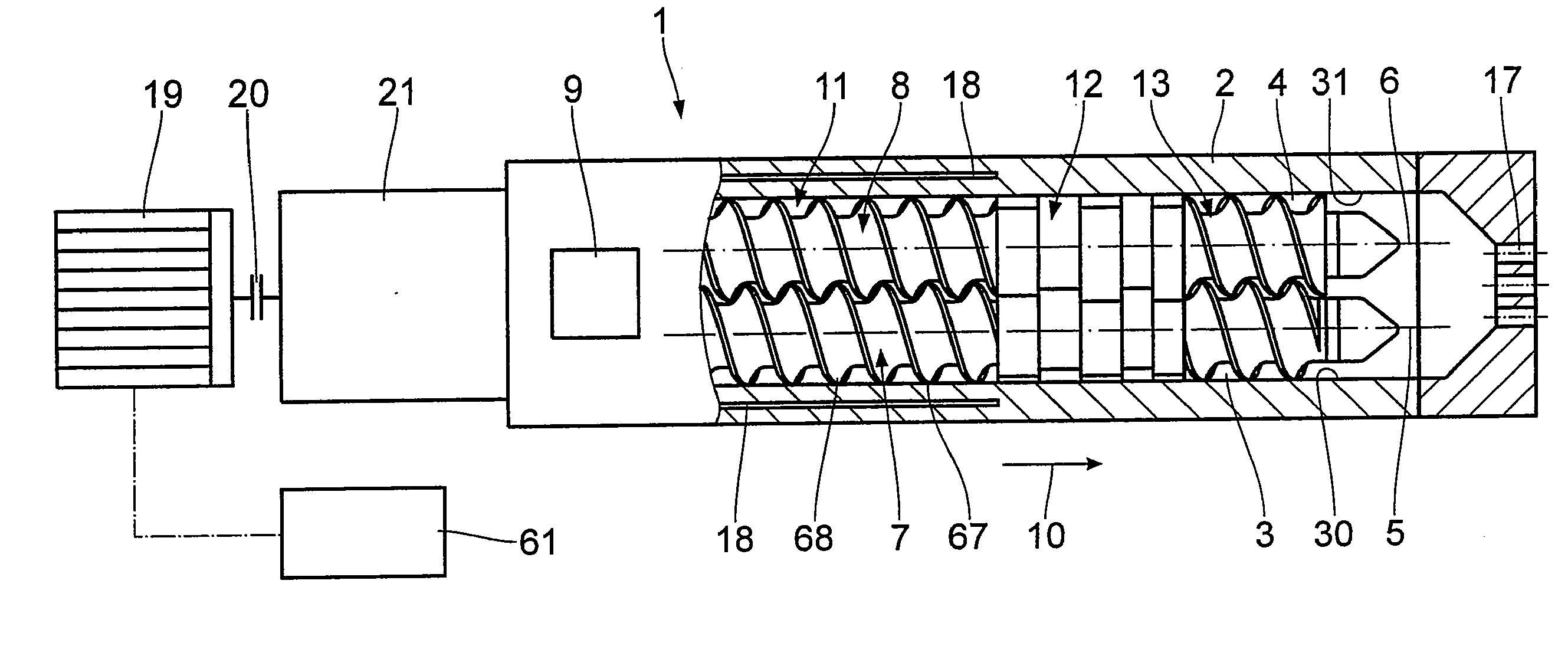

Injection molding process and injection molding apparatus for thermoplastic resin molded articles

InactiveUS6949208B1Efficient meltingIncrease pitchRotary stirring mixersFrozen sweetsFoaming agentReactive gas

Owner:SEKISUI CHEM CO LTD

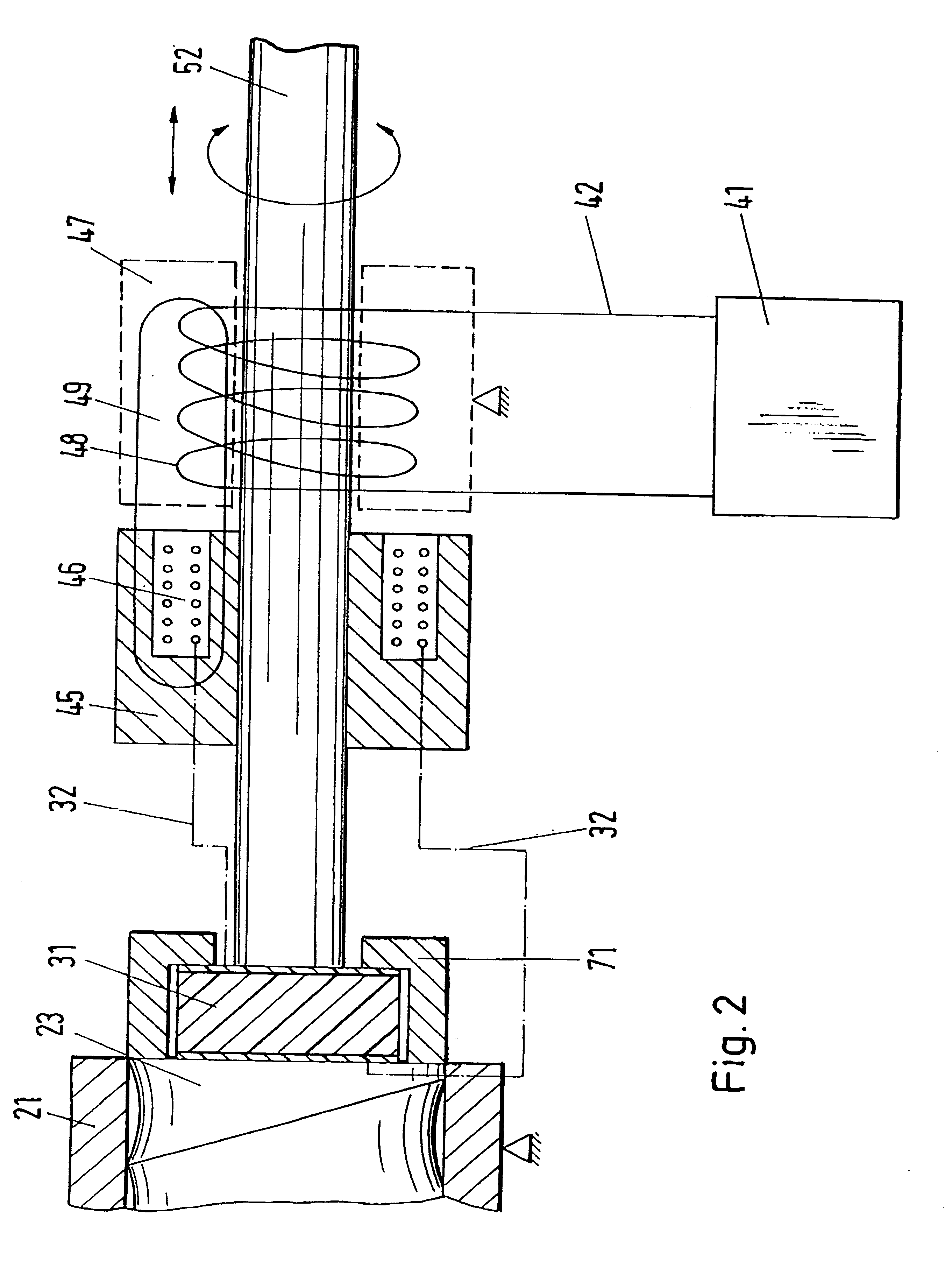

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

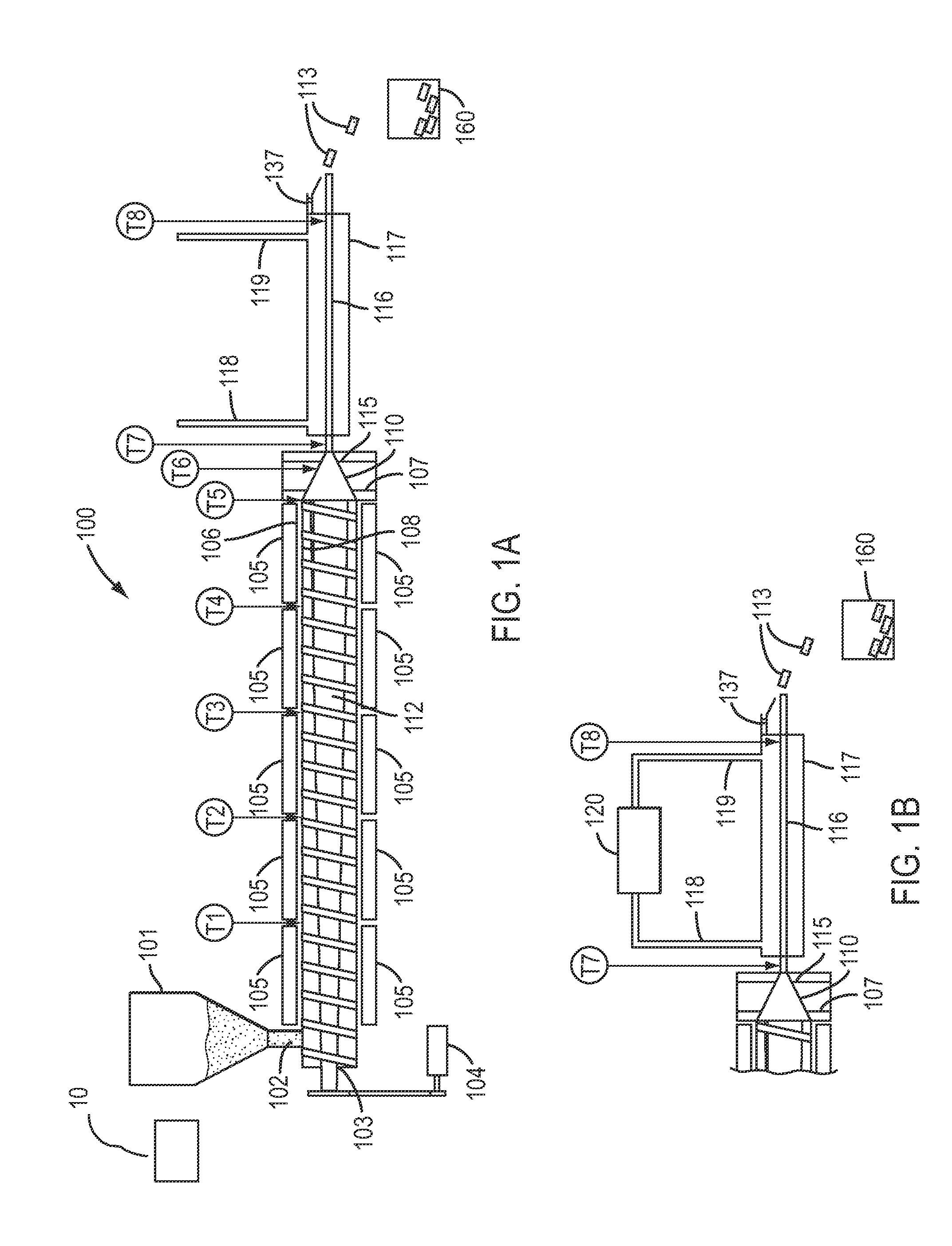

Distiller grain pellet production devices

ActiveUS8287268B1Increased durabilityCompact and efficient formFeeding-stuffMouldsHigh densityMetallurgy

A device for producing a high density compact livestock feed from a loose granular material according to various embodiment can include a source for supplying a loose granular material to be treated. A series of successive treatment zones comprises a heating zone, a compression zone, and a cooling zone. The heating zone comprises at least one heater and at least one screw compression dryer configured to receive the loose granular material to be treated for drying. Rotation of the screw transfers the treated material to the compression zone. The compression zone comprises a compression chamber for compacting the treated material to form a high density compact body. The treated material is pressed through the compression chamber while a two-dimensional cross-section compression is applied to the treated material. The cooling zone comprises a cooling unit for cooling the high density compact body received from the compression zone.

Owner:JOHNSON RAYMOND T +1

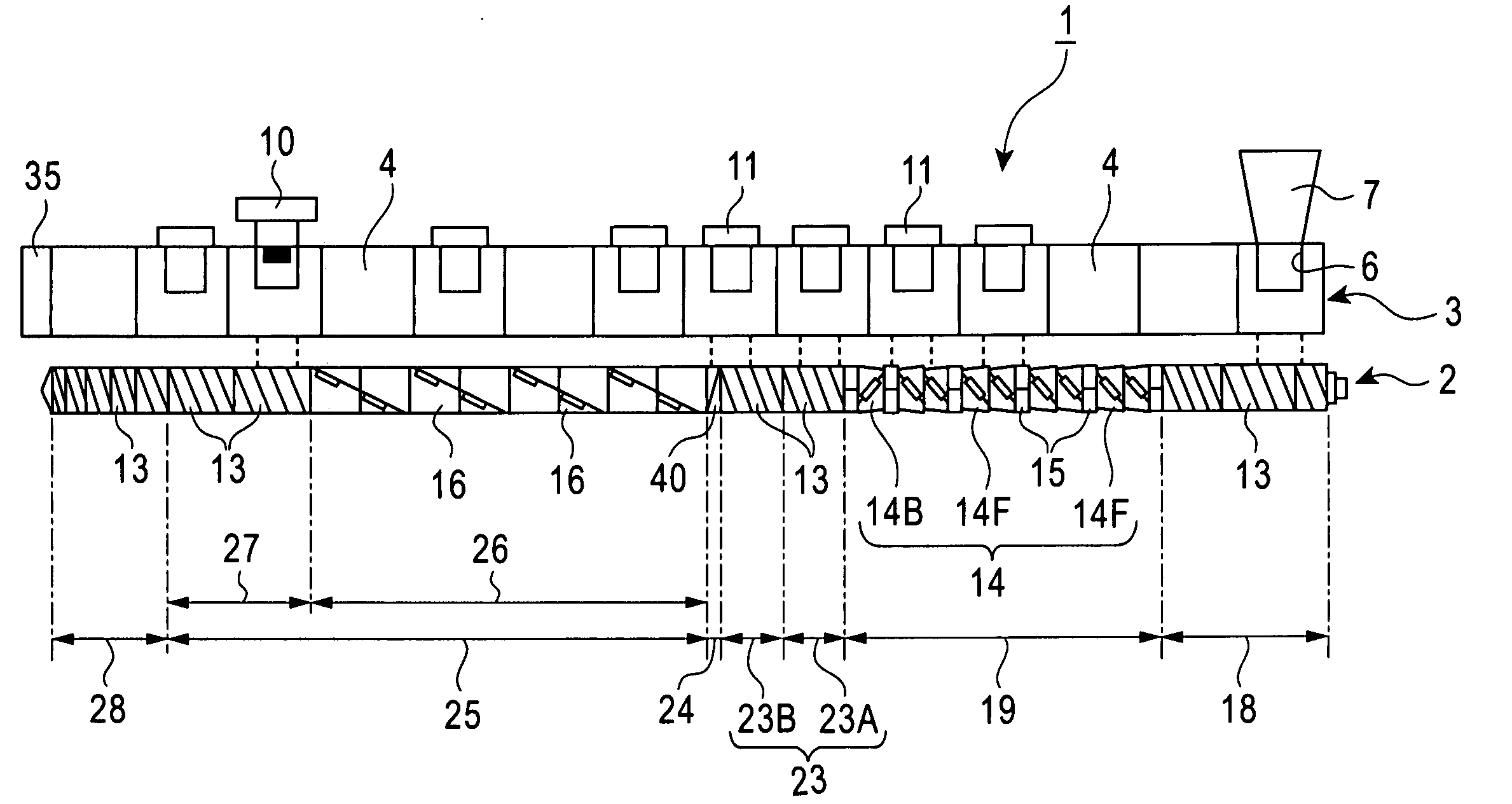

Extruder

ActiveUS20060003042A1Efficient devolatilization operationDough homogenizationFrozen sweetsEngineeringAir tightness

An extruder includes a barrel and a kneading screw extending through the barrel in a rotatable fashion. The kneading screw is provided with a devolatilization portion. The devolatilization portion includes a kneading flight that is twisted in a direction for transferring a material downstream. The kneading flight kneads the material while transferring the material downstream and separates a volatile component from the material. Impregnation sections, which allow the kneading chamber to be impregnated with the material, are respectively disposed adjacent to an upstream side and a downstream side of the devolatilization portion so that the air-tightness of the devolatilization portion of the extruder is maintained. Accordingly, an efficient devolatilization operation of the material is achieved.

Owner:KOBE STEEL LTD

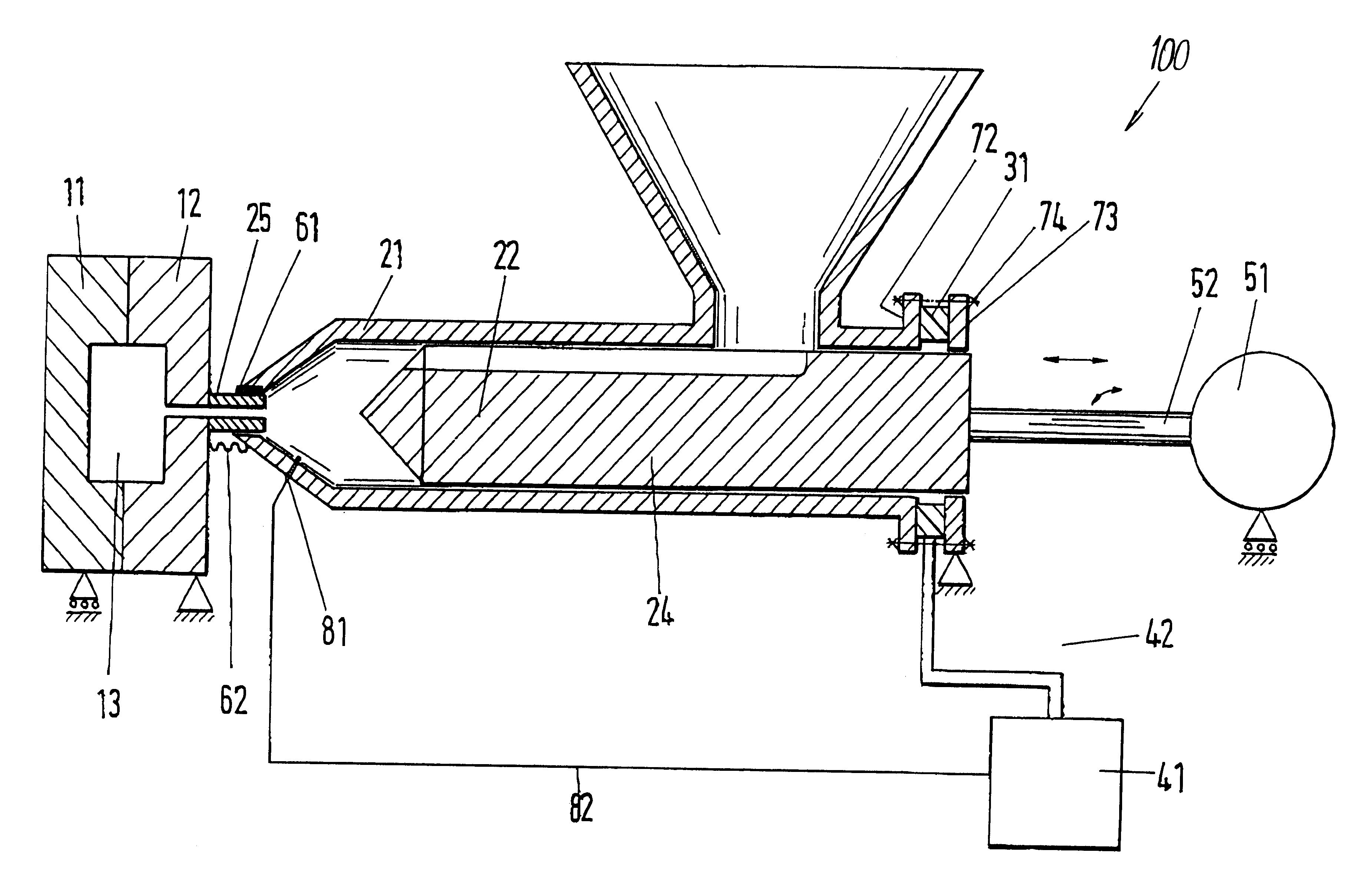

Process and apparatus for the production of filled thermoplastic polymers

ActiveUS7842221B2Low costNot expensiveRotary stirring mixersFrozen sweetsFilling materialsThermosetting polymer

To produce filled thermoplastic polymers starting from a waste thermoplastic base material, the base thermoplastic material is fed into a container (1) provided with a device for mixing and stirring (2,3) in which the base thermoplastic material is softened, the required filler is fed into said device and stirring is continued to thoroughly blend filler and softened material, subsequently collecting the softened and filled material from said container and subjecting it to an extrusion or other densification step.

Owner:MAGMA

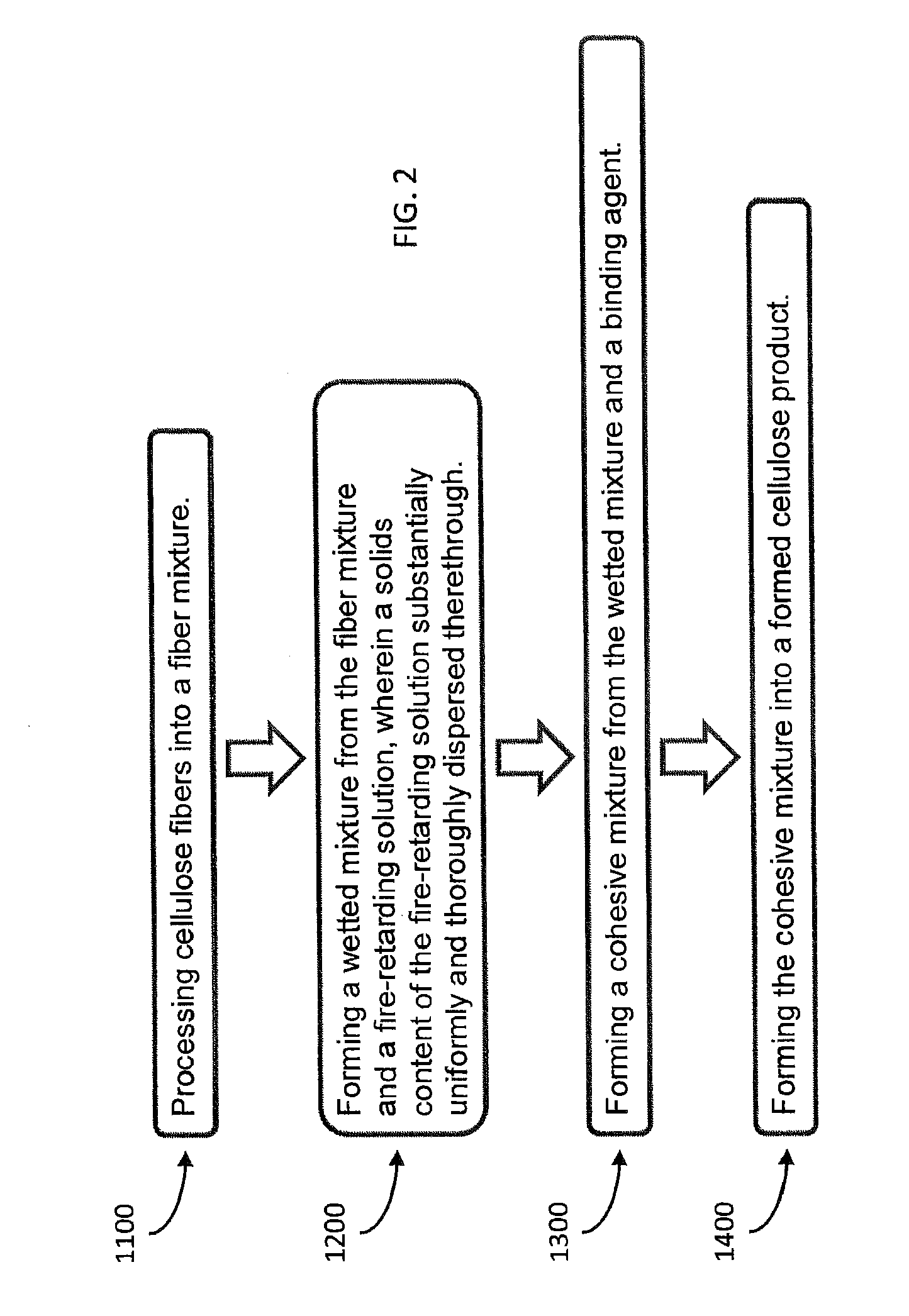

Method for forming a fire resistant cellulose product

A method is provided for forming a fire resistant cellulose material. Such a method comprises processing cellulose fibers into a fiber mixture, and then forming a wetted mixture from the fiber mixture and a fire-retarding solution, wherein the wetted mixture has a solids content of the fire-retarding solution substantially uniformly and thoroughly dispersed therethrough. In some aspects, a cohesive mixture may be formed from the wetted mixture and a binding agent, and the cohesive mixture then formed into a formed cellulose product. An associated apparatus is also provided.

Owner:BLH TECH

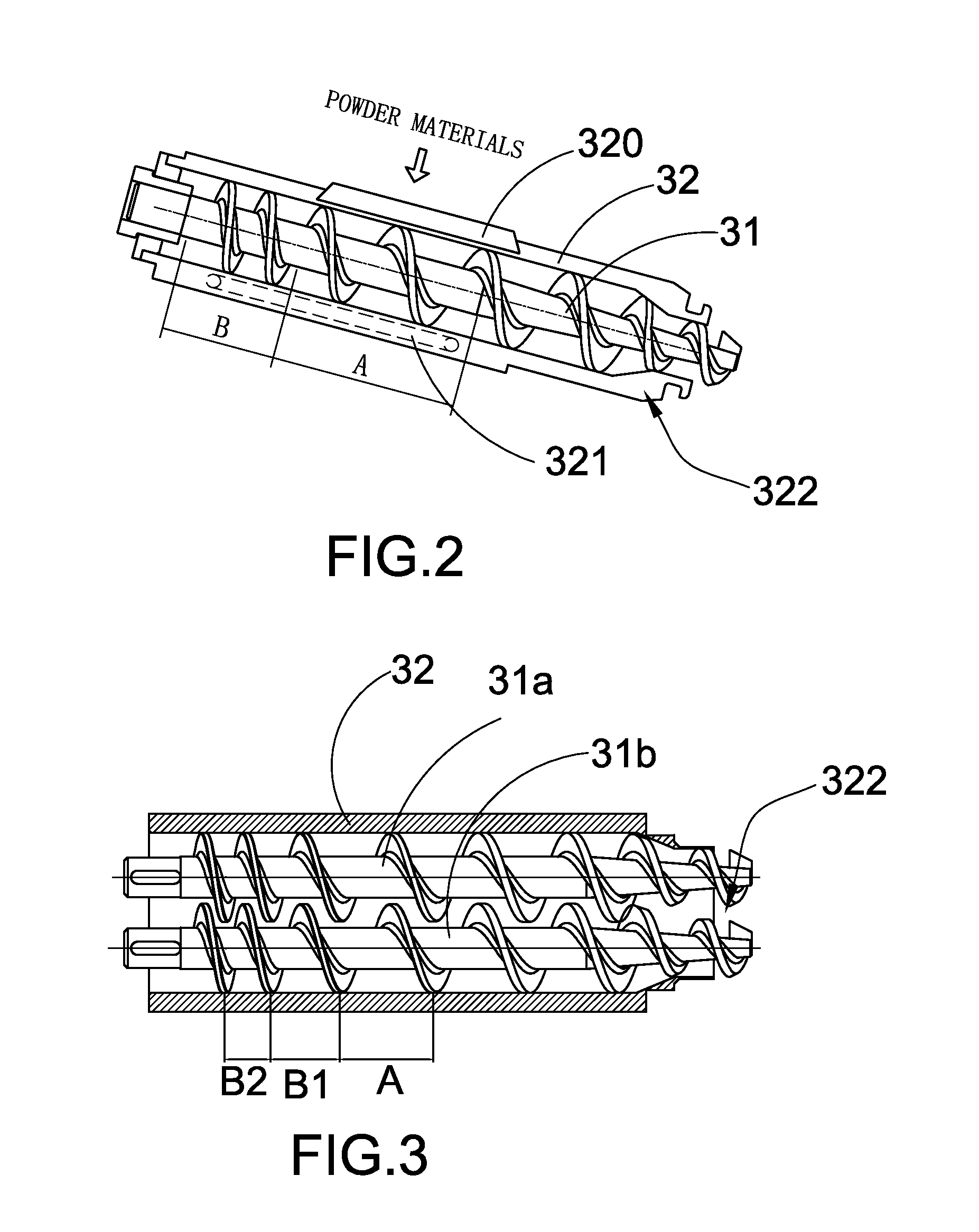

Extruder

ActiveUS20080248152A1Improve throughputDough homogenizationFrozen sweetsPartial fillingMechanical engineering

An extruder with a housing comprising parallel, partially inter-engaging bores and screws disposed therein is used when applying a method of feeding powdery bulk materials into such an extruder. A solid transport of powdery bulk material takes place in an inlet zone disposed downstream of a feed opening wherein said inlet zone is partially filled. The inlet zone is provided with at least one gas-permeable wall portion wherein a layer of bulk material is created on said wall portion, thereby preventing bulk material from passing through.

Owner:COPERION

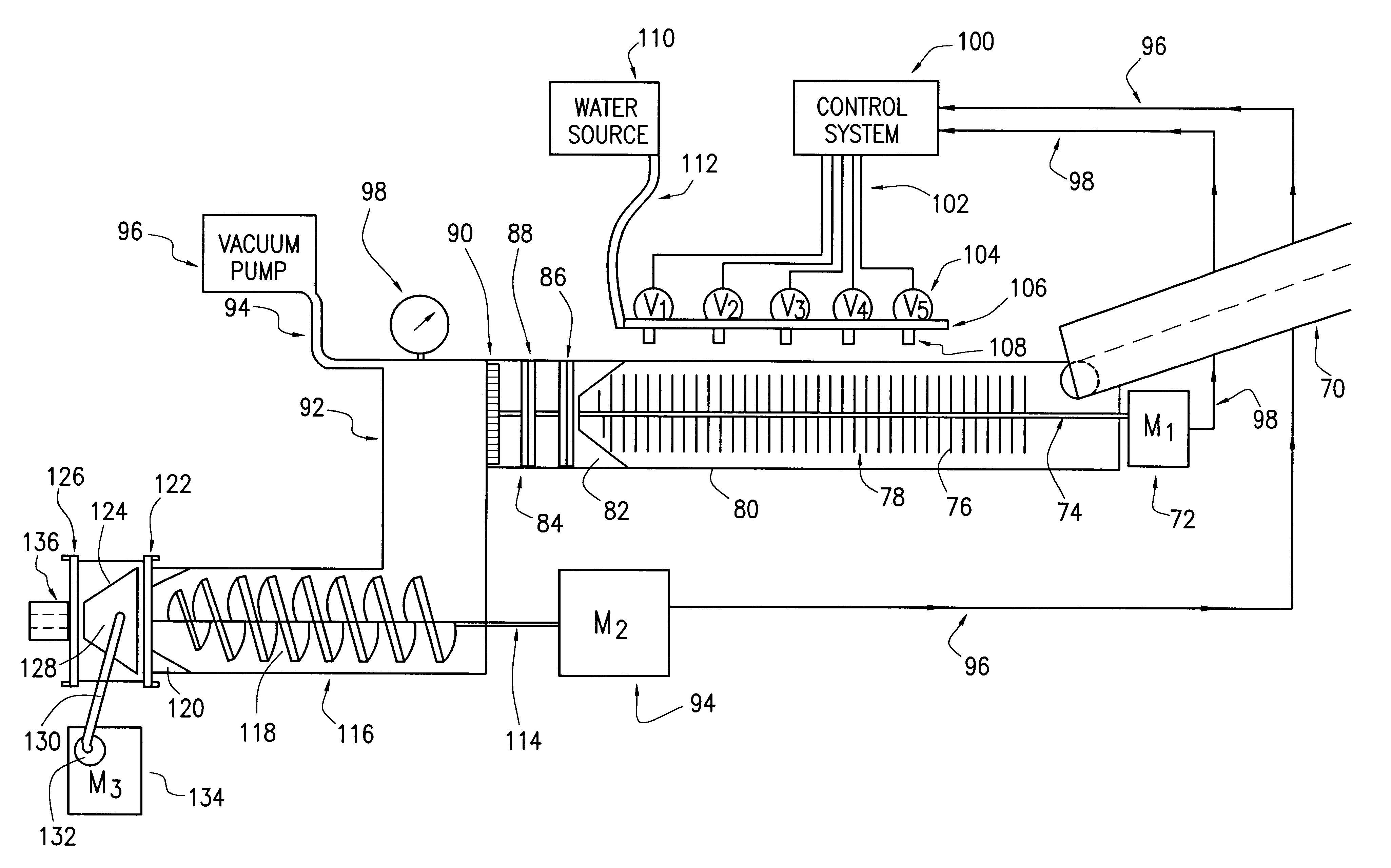

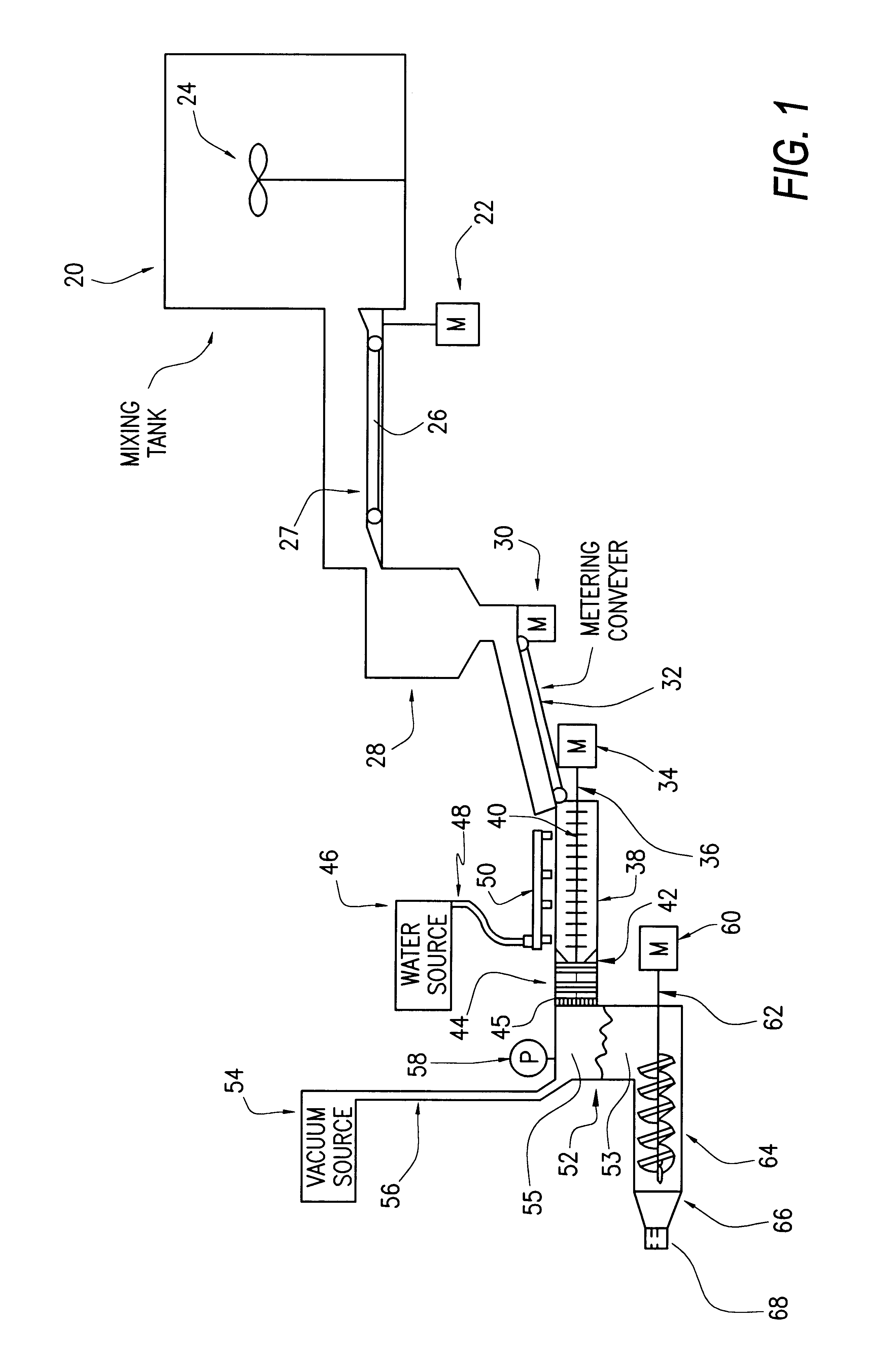

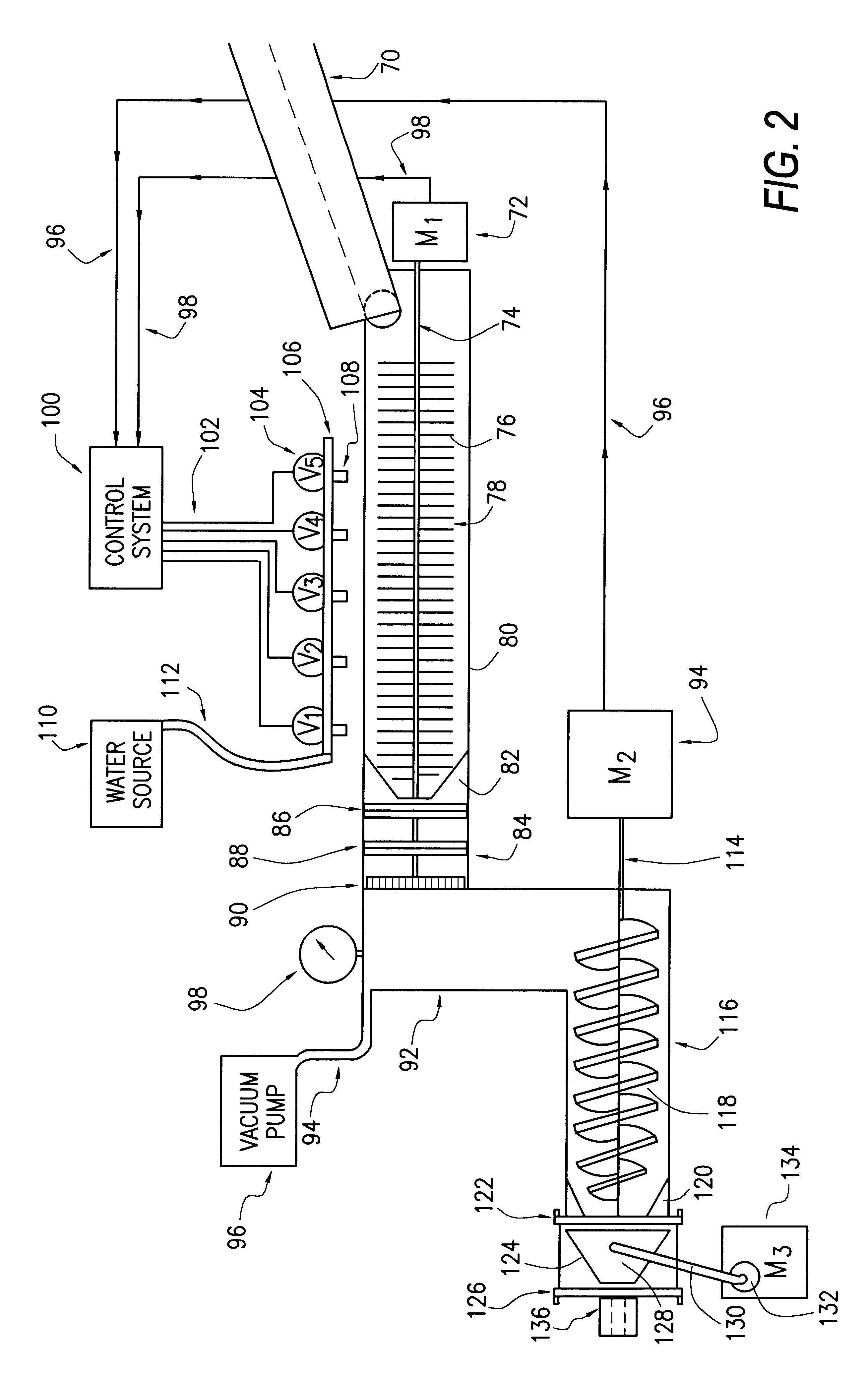

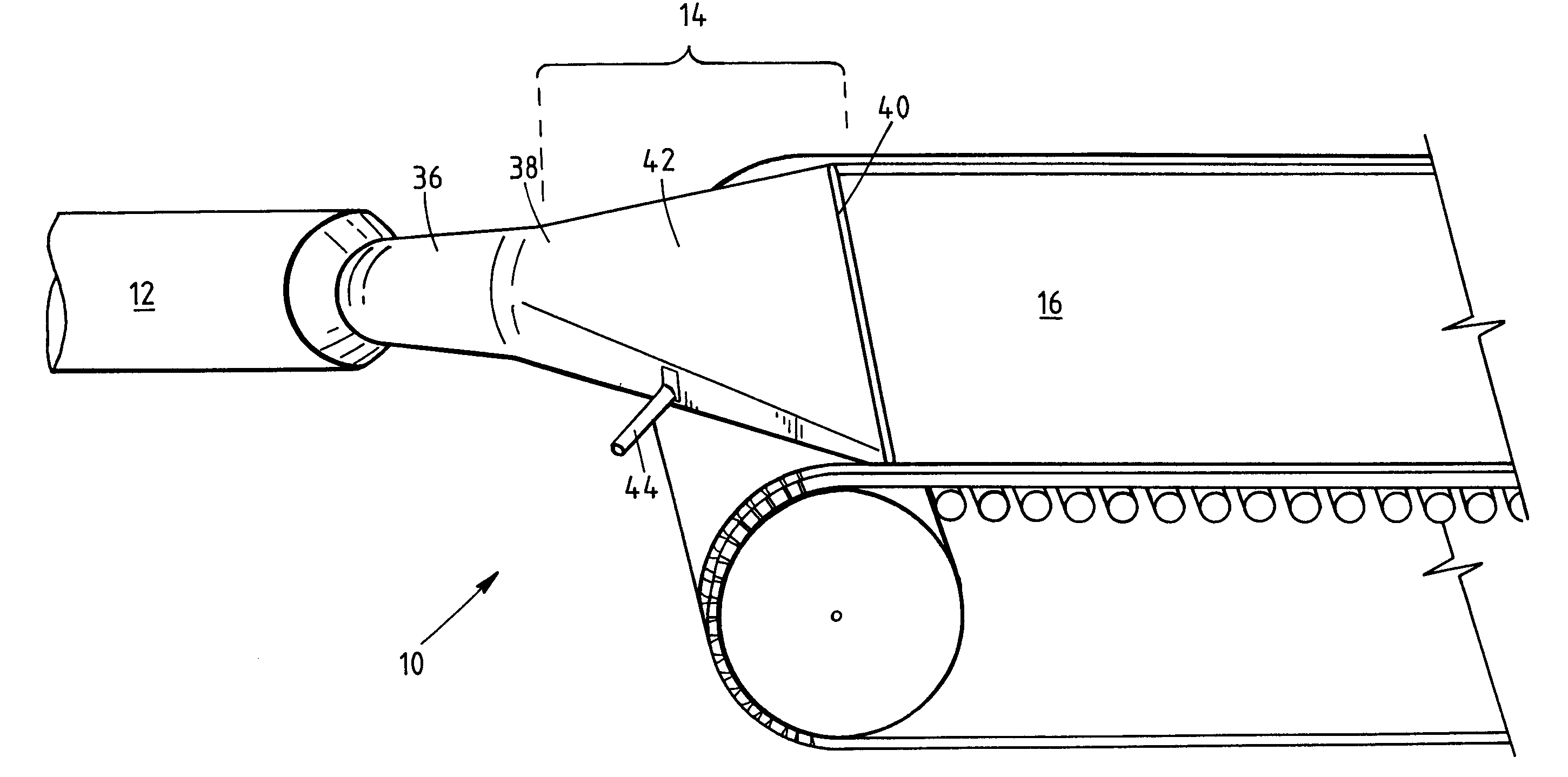

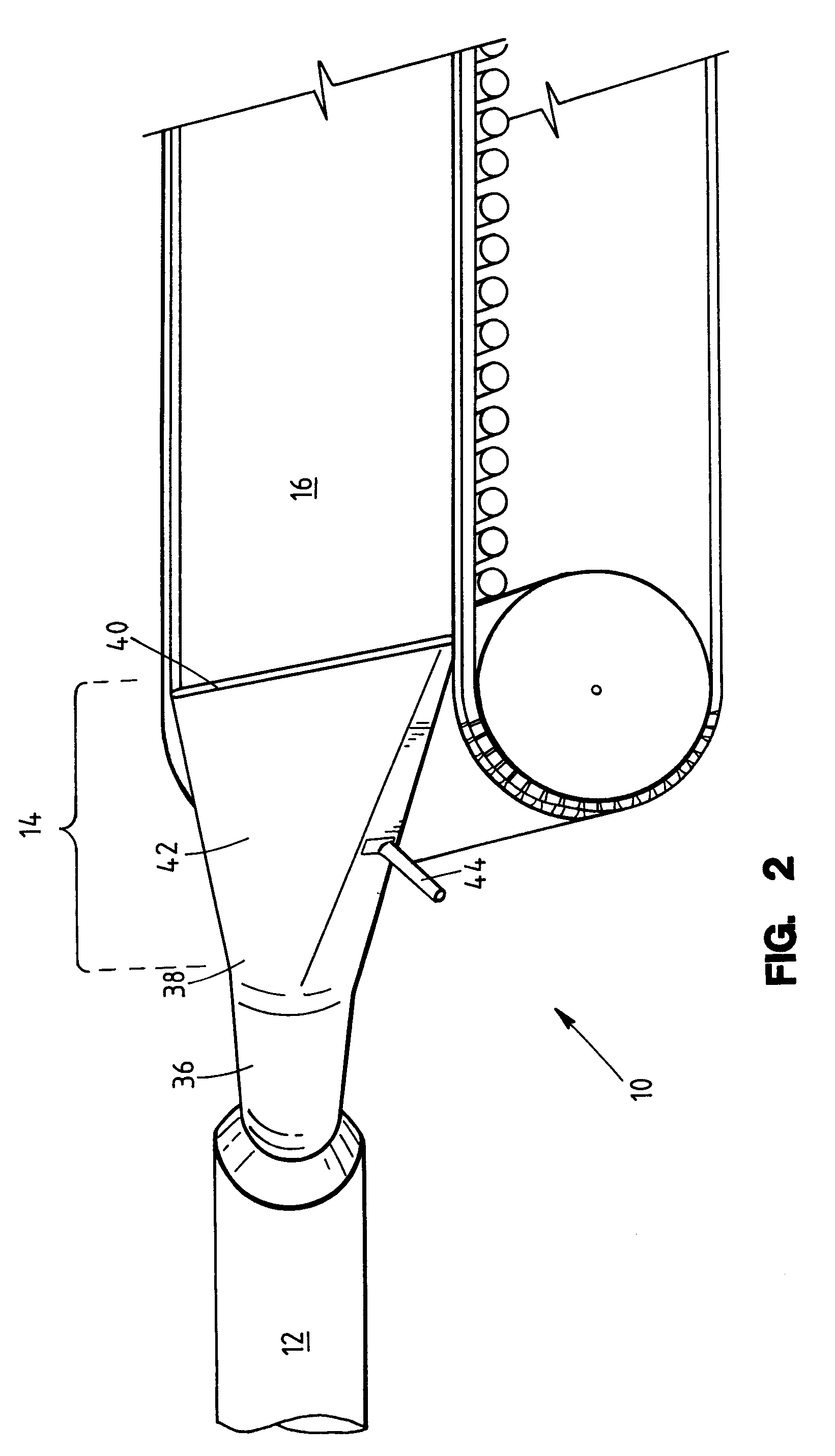

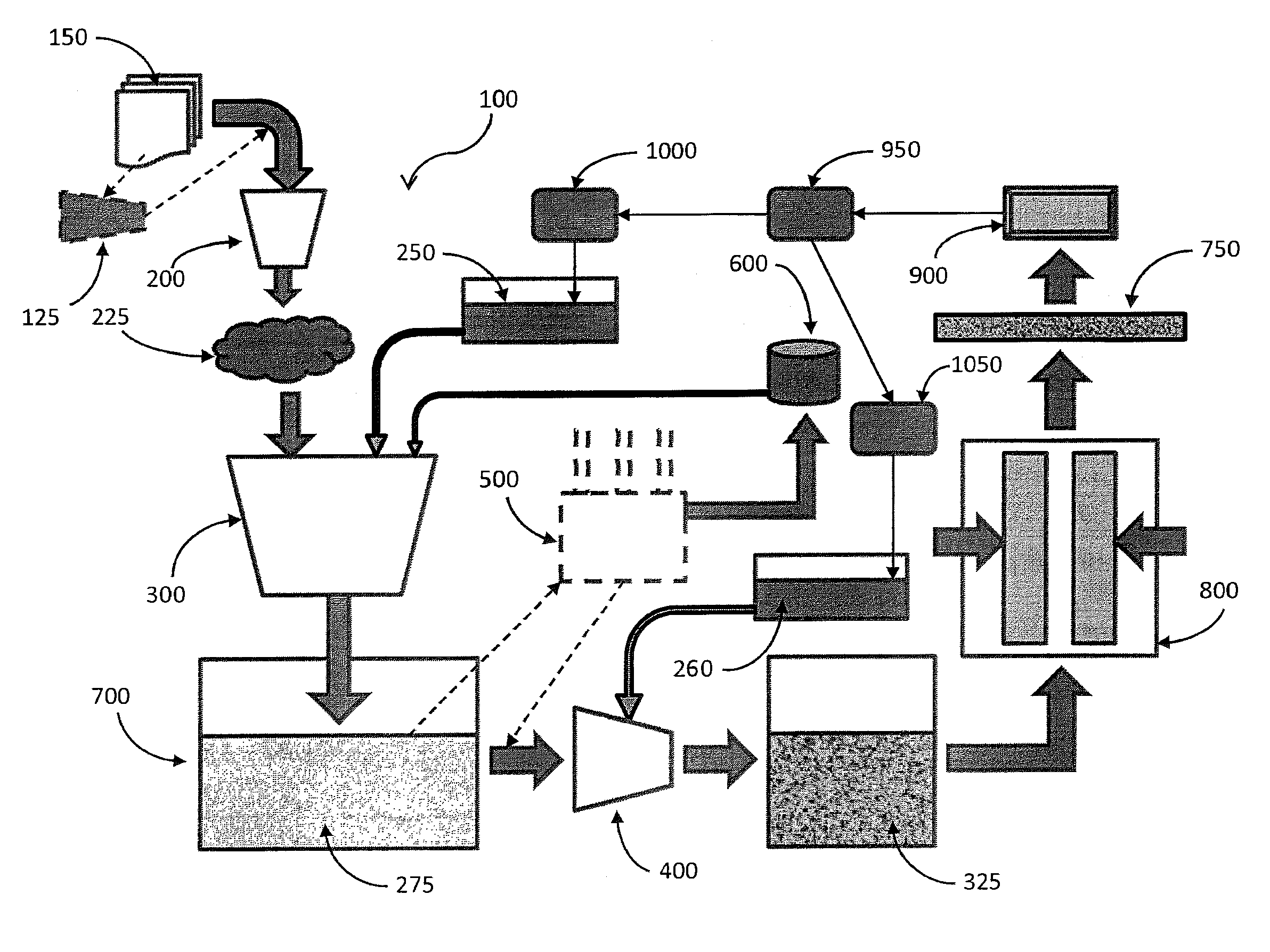

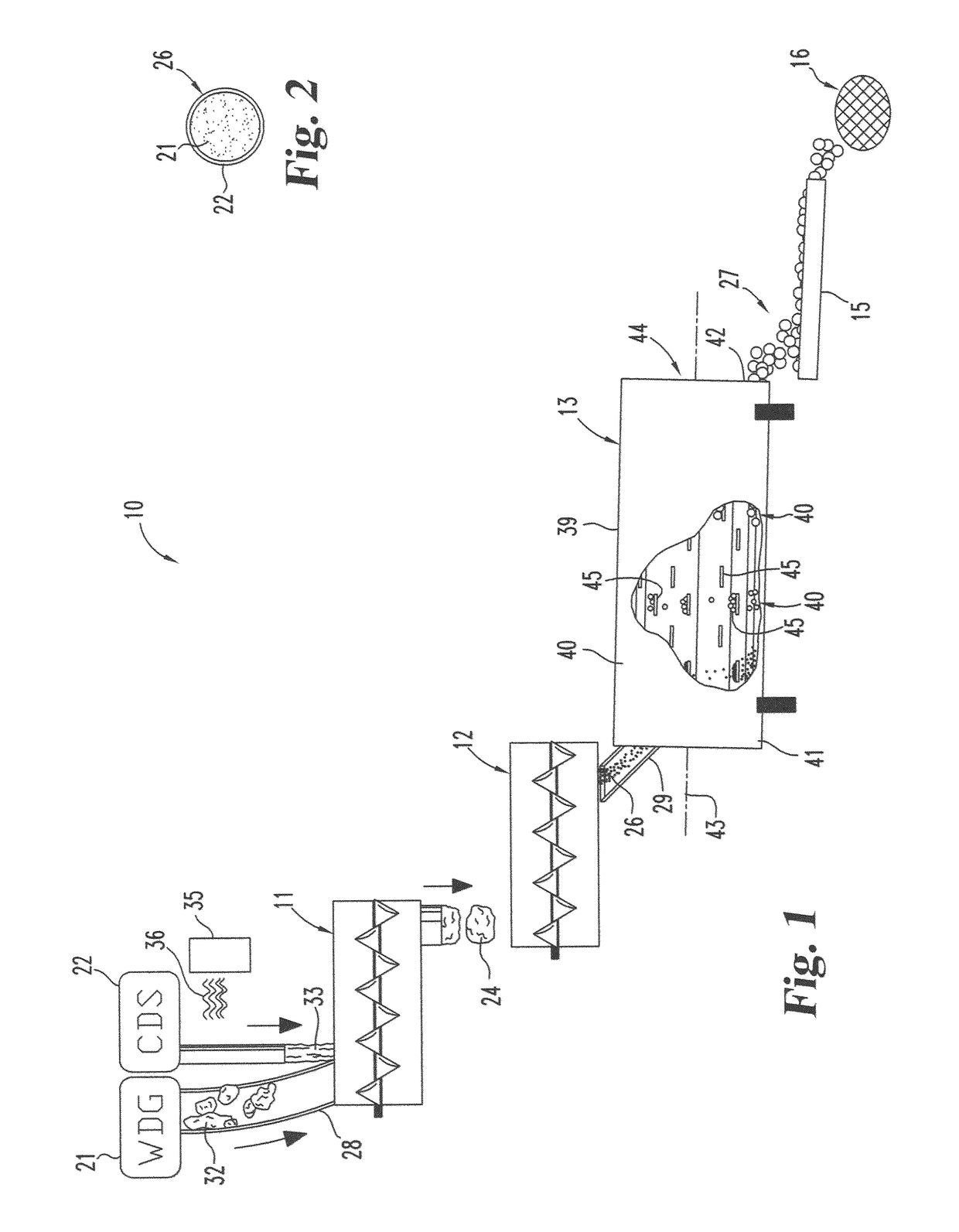

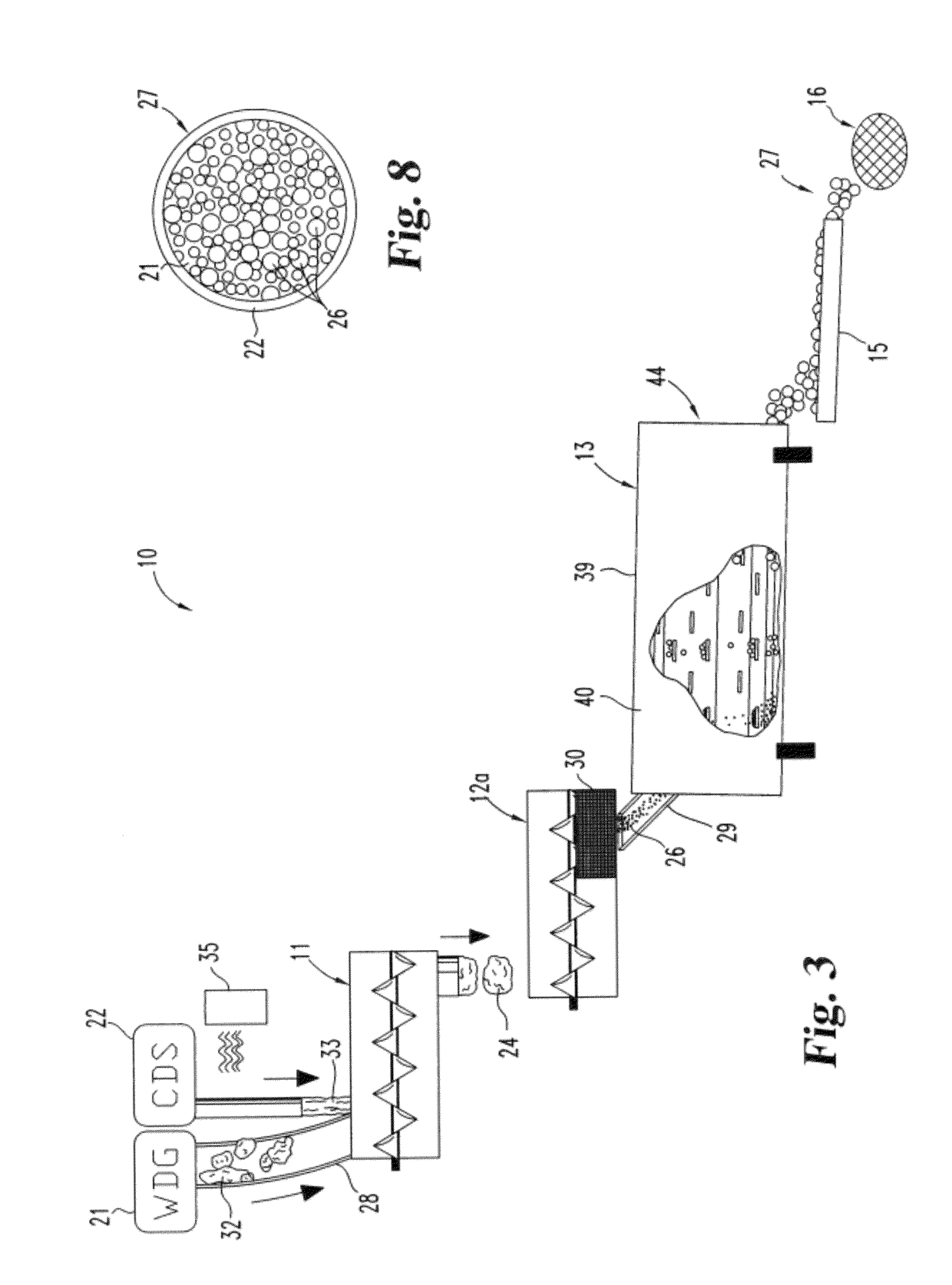

Method and apparatus for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a cavity for receiving a coproduct of a wet biomass process and a binder and being operable to premix the coproduct and binder to produce a substantially homogeneous DDGS mixture; a high shear mixer having a receptacle for receiving the DDGS mixture and being operable to shear mix the mixture and produce very small DDGS particles; and, an agglomerator having an interior chamber sized and configured to receive and transform the DDGS particles into substantially spherical DDGS pellets.

Owner:PURDUE RES FOUND INC

Apparatus and method for controlled pelletization processing

An apparatus and process maintain control of the temperature of low-melting compounds, high melt flow polymers, and thermally sensitive materials for the pelletization of such materials. The addition of a cooling extruder, and a second melt cooler if desired, in advance of the die plate provides for regulation of the thermal, shear, and rheological characteristics of narrow melting-range materials and polymeric mixtures, formulations, dispersions or solutions. The apparatus and process can then be highly regulated to produce consistent, uniform pellets of low moisture content for these otherwise difficult materials to pelletize.

Owner:GALA INDUSTRIES INC

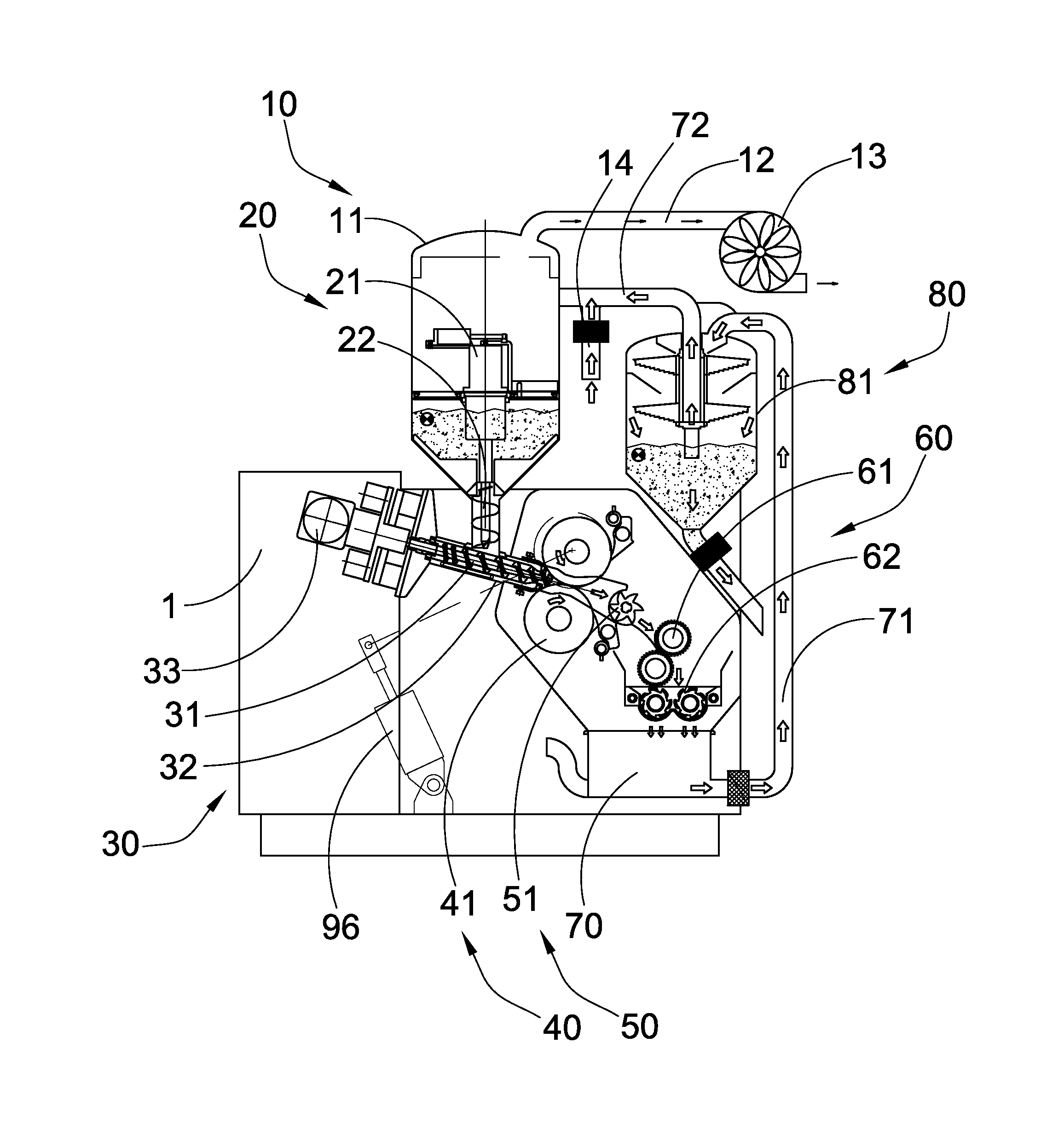

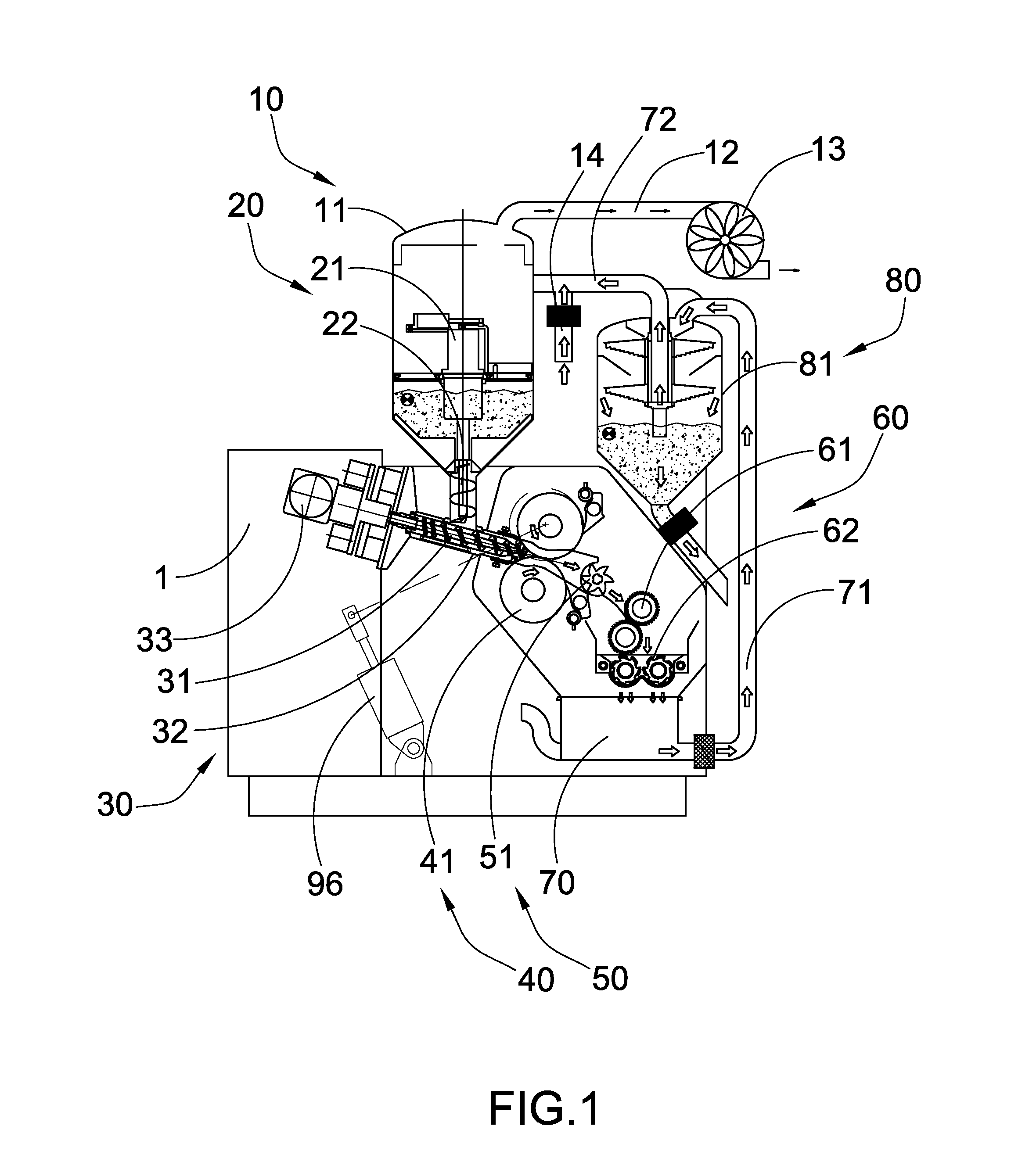

Dry Granulator

ActiveUS20150239152A1Compact structureImprove sealingDough homogenizationFrozen sweetsHardnessMaterials science

A dry granulator includes a feeding mechanism applied to suck powder materials into the material tanks; a vertical feeding mechanism to deliver the power materials to a bottom outlet of the material tank; a pressing mechanism to compress the powder materials into powder sheets with qualified hardness and thickness; an oblique feeding mechanism to deliver the powder materials to from the vertical feeding mechanism to the pressing mechanism; a crushing mechanism to crush the powder sheets into crushed powder sheets; a granulating mechanism to granulate the crushed powder sheet into finished particles products, so as to deliver to a collection storage; a sieving mechanism to separate the finished particle products with fine powders; a pressing wheel regulator applied to adjust an axial position of the lower and the upper pressing wheel; and a floating sealing device applied to provide a reliable sealing effect for the feeding mechanism.

Owner:ZHEJIANG FUTURE MACHINERY

Method and apparatus for extruding a ceramic material

A method is provided for manufacturing a thin-walled honeycomb ceramic substrate by extruding a plasticized ceramic batch material through a filter screen having wedge shaped filter wires to remove foreign particulate and agglomerated batch material. The filter wires are supported by a set of support wires attached substantially perpendicular to the filter wires. The support wires are may also be advantageously wedge shaped. The filter screen of the present invention may have a wear resistant layer at the surface of the screen, typically a boride or a nitride. The wear resistant coating may also be a nickel-based coating.

Owner:CORNING INC

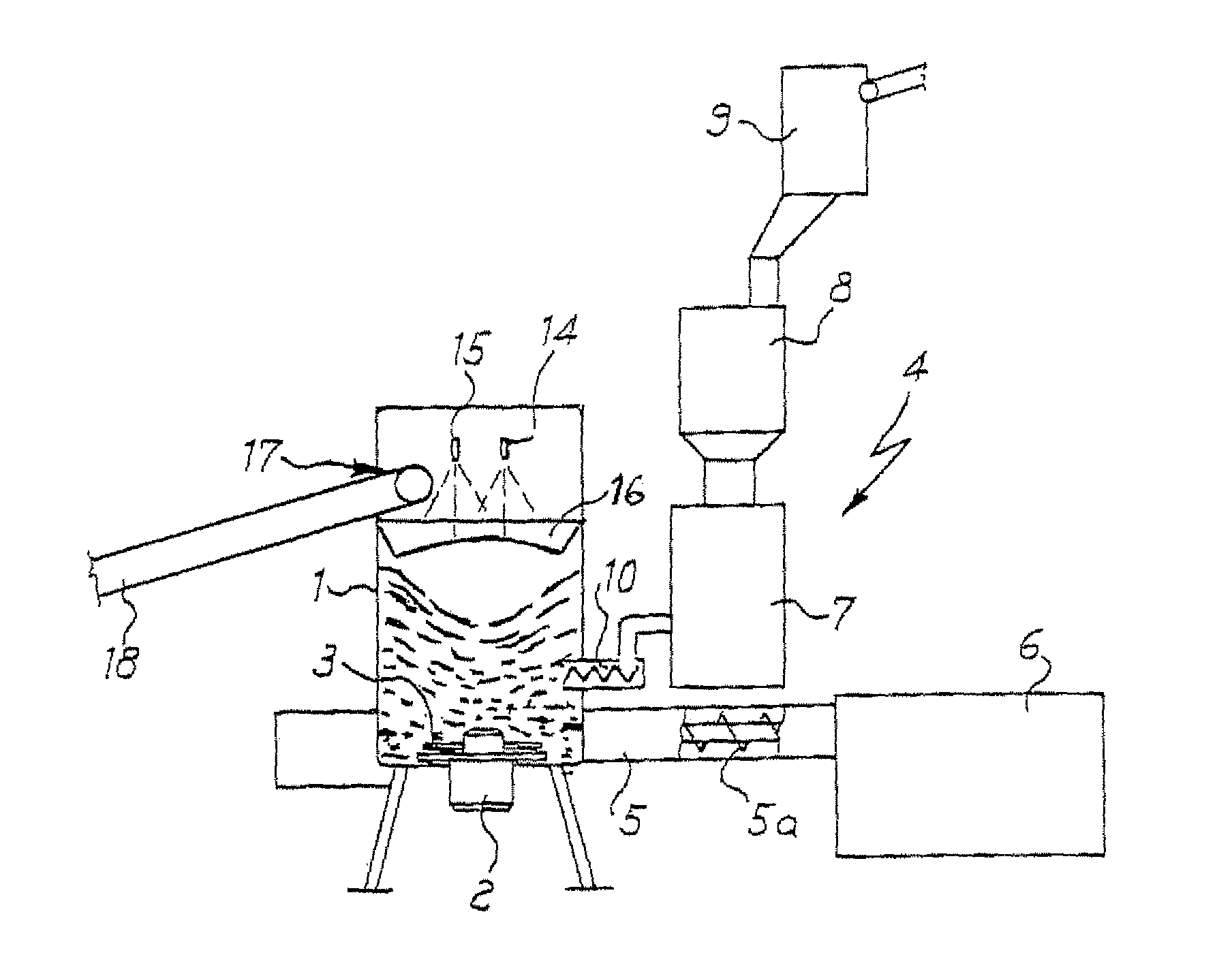

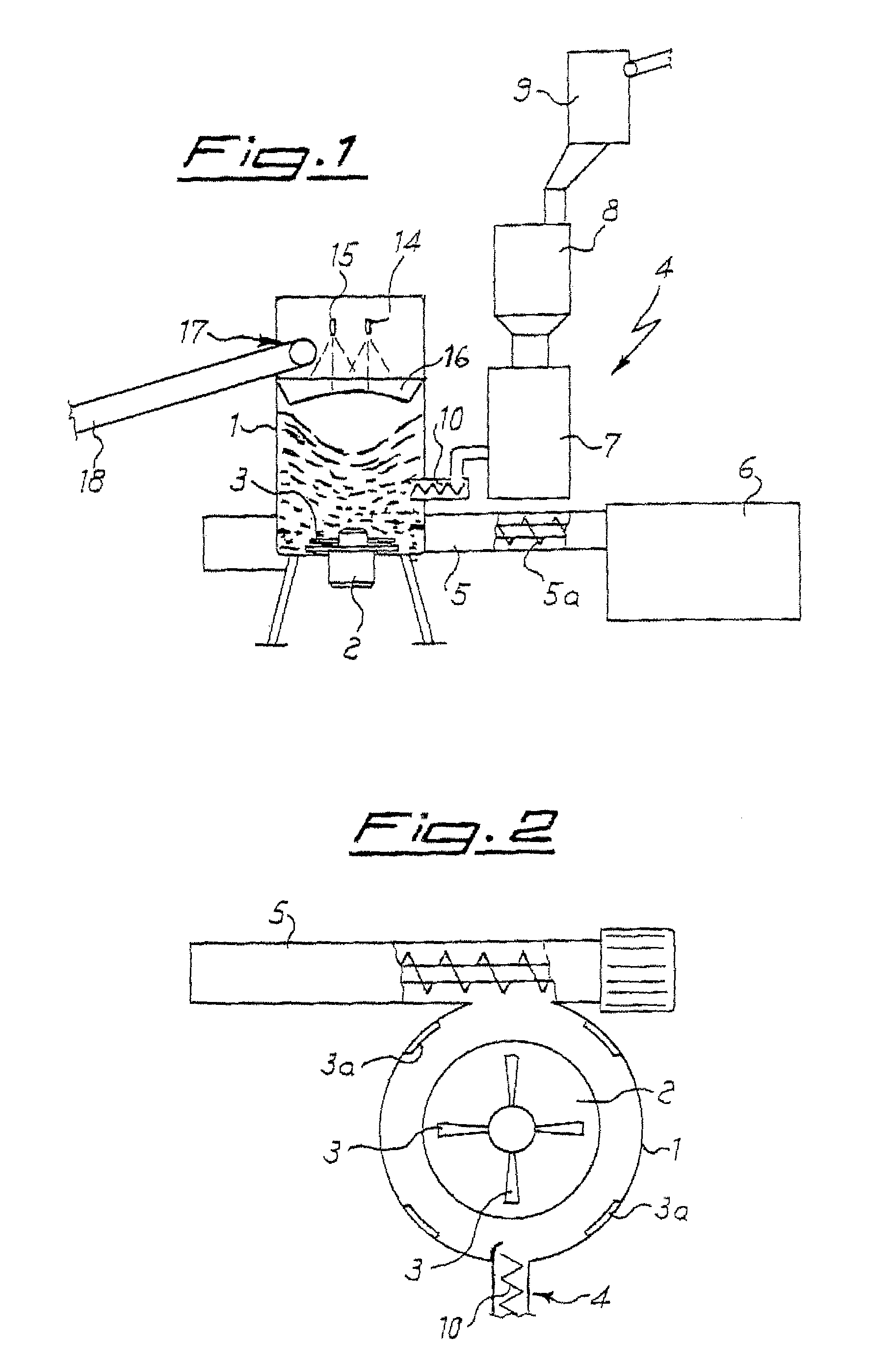

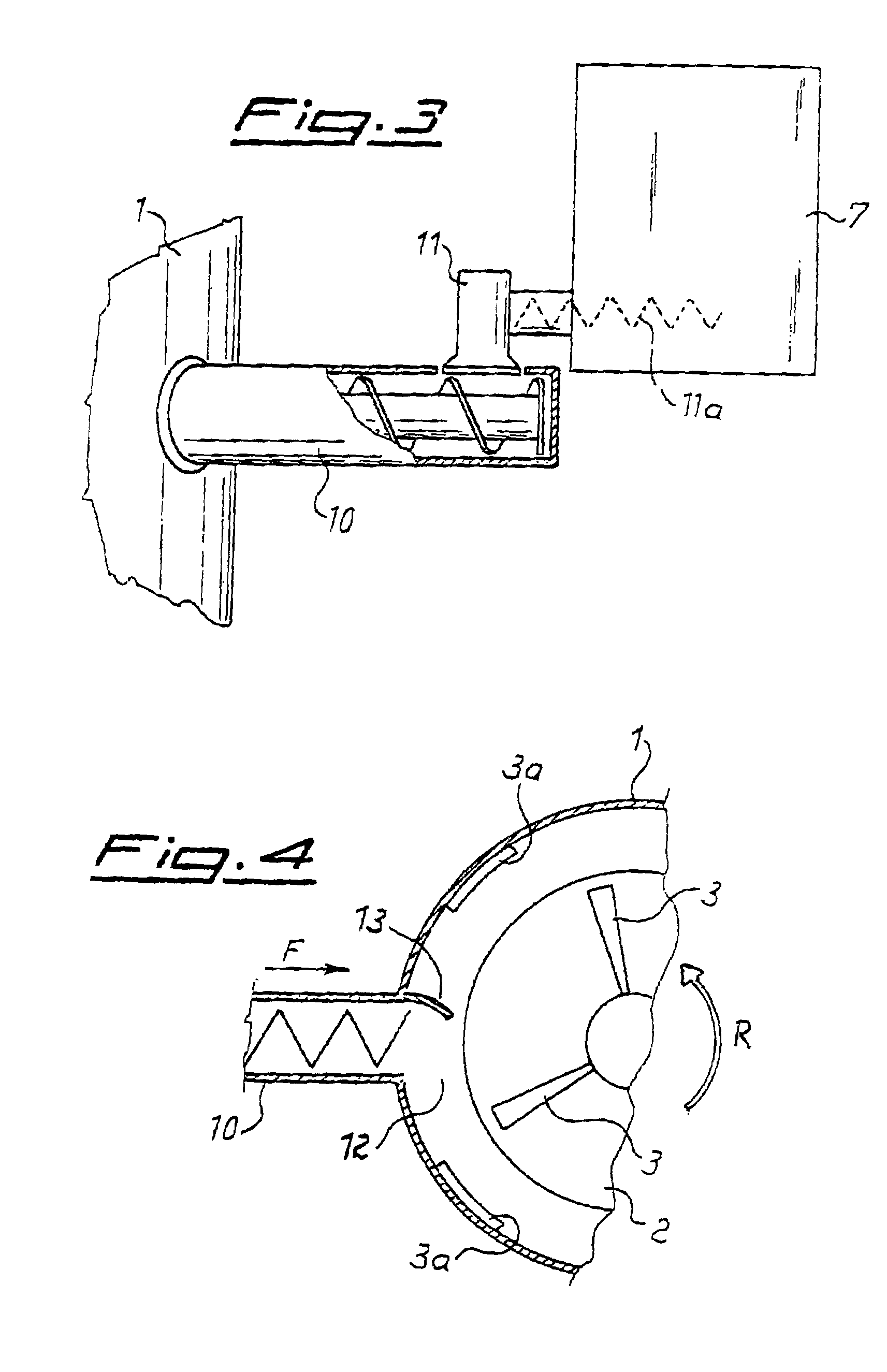

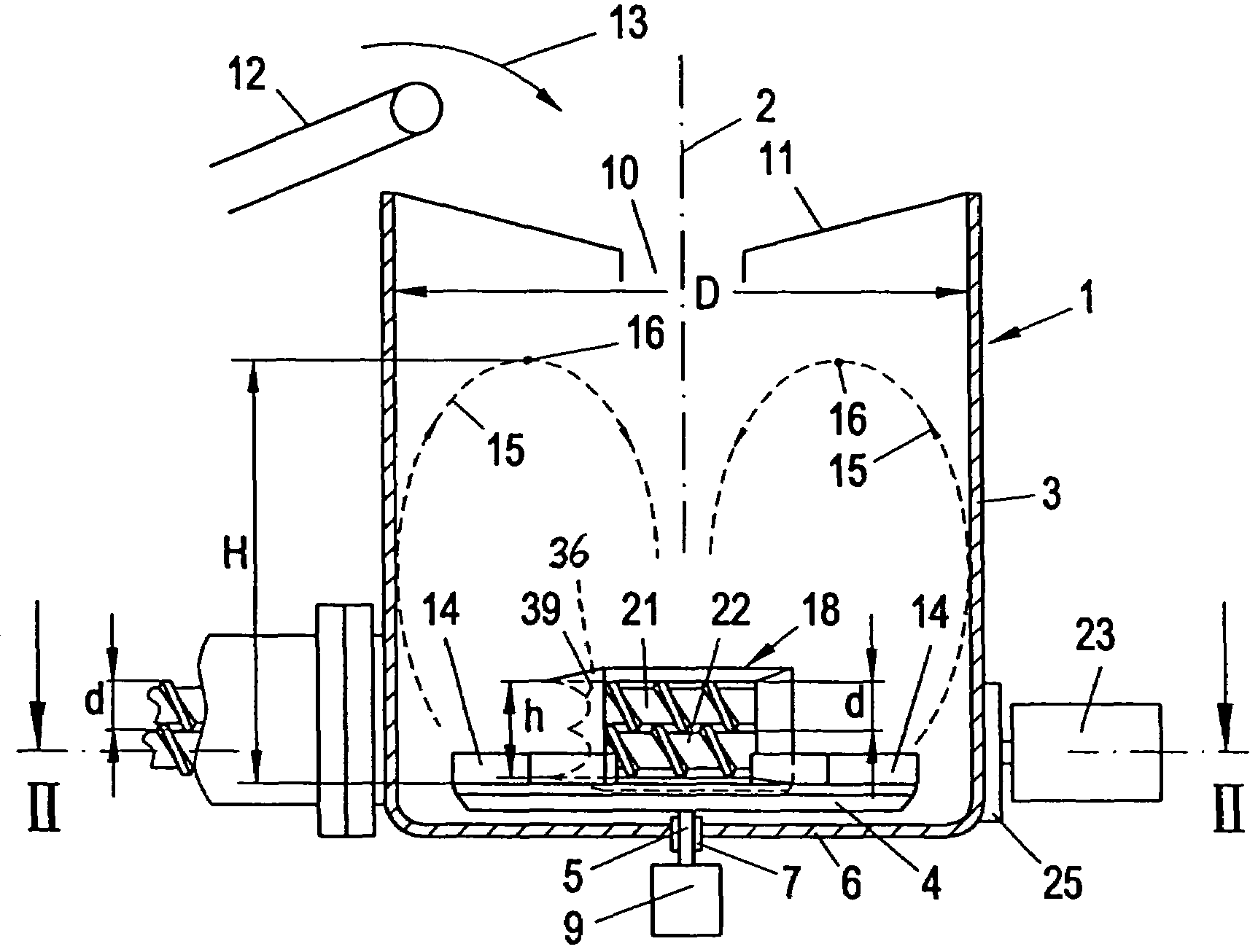

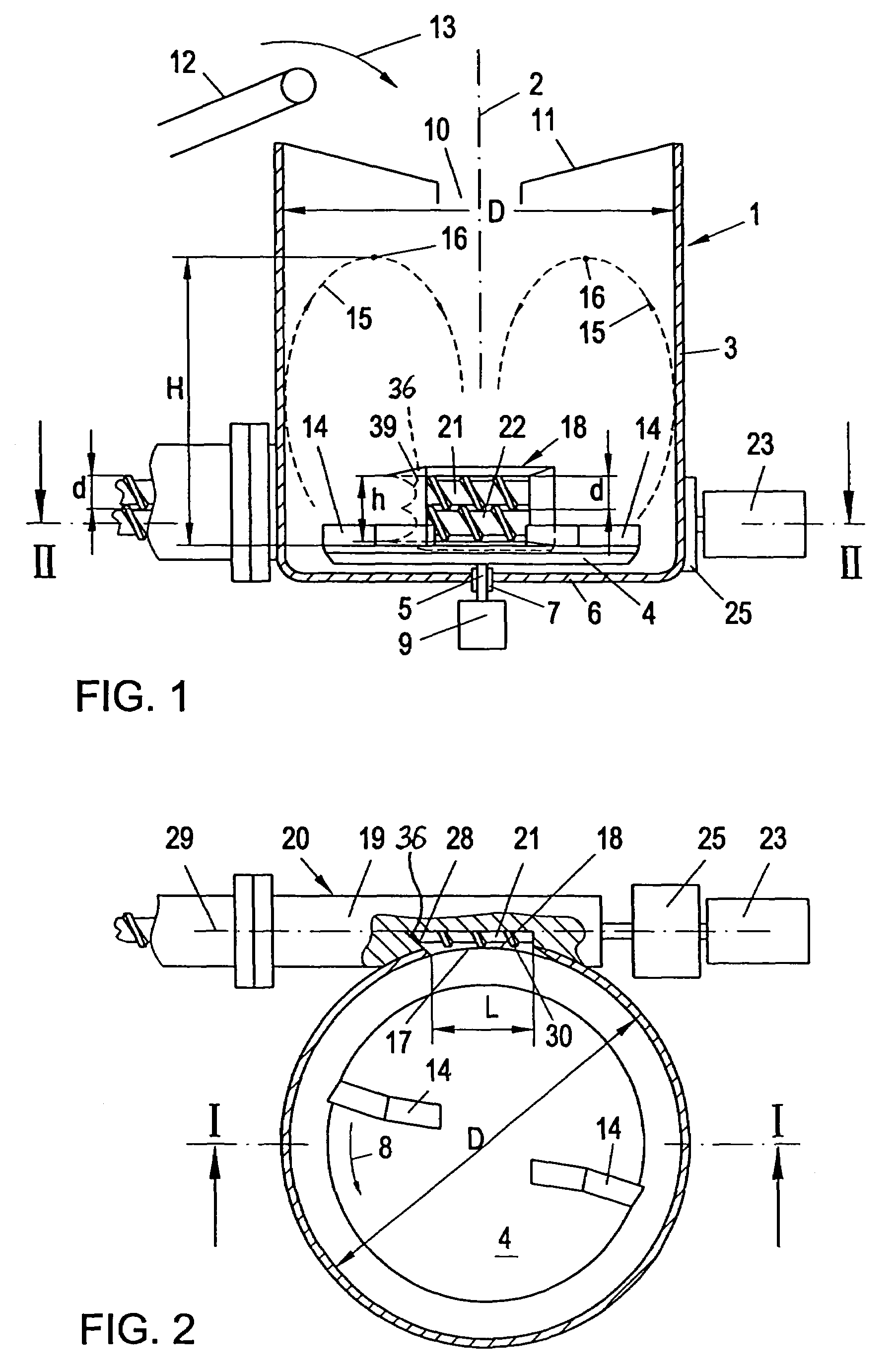

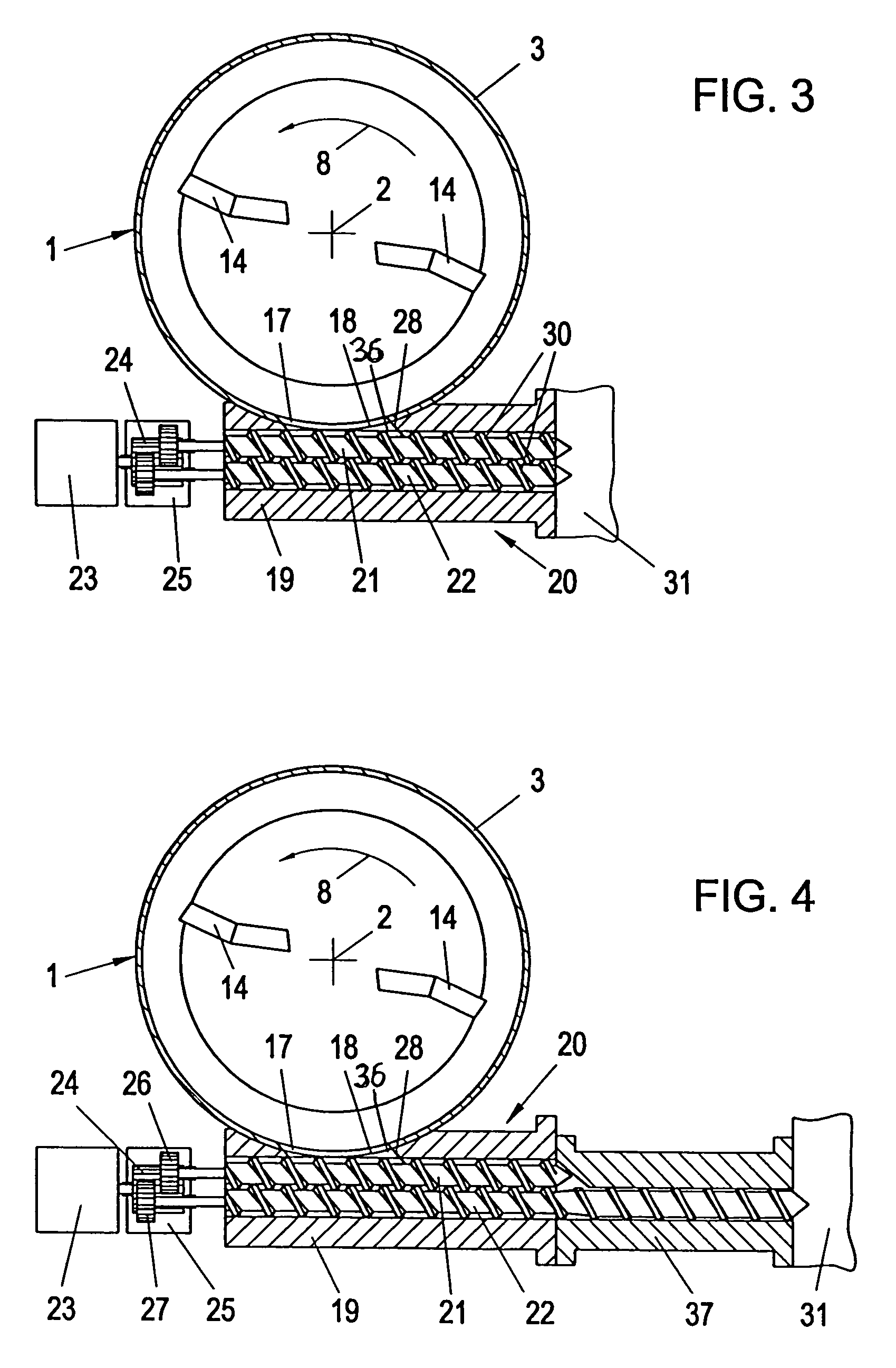

Device for preparation of plastic materials for recycling purposes

ActiveUS7309224B2Starting torqueUniform outputRotary stirring mixersFrozen sweetsPlastic materialsEngineering

A device for the preparation of plastics material for recycling purposes has a container (1) with an upper inlet opening (10) for the material. In the container (1), at least one tool (14) rotates about the vertical container axis. This tool feeds the treated material through an outlet opening (17) which is arranged at the bottom of the container (1) and to which the housing (19) of at least one screw (21, 22) is connected. That side wall (28) of the feed opening (18) at which the tool (14) discharges defines a widening (36) extending continuously towards the screw axis. This widening (36) extends over part of the circumference of the screw turns (30) so that the screw-side edge of this widening (36) forms an uninterrupted shearing edge (39) co-operating with the screw turns (30).

Owner:EREMA ENG RECYCLING MASCH & ANLAGEN GMBH

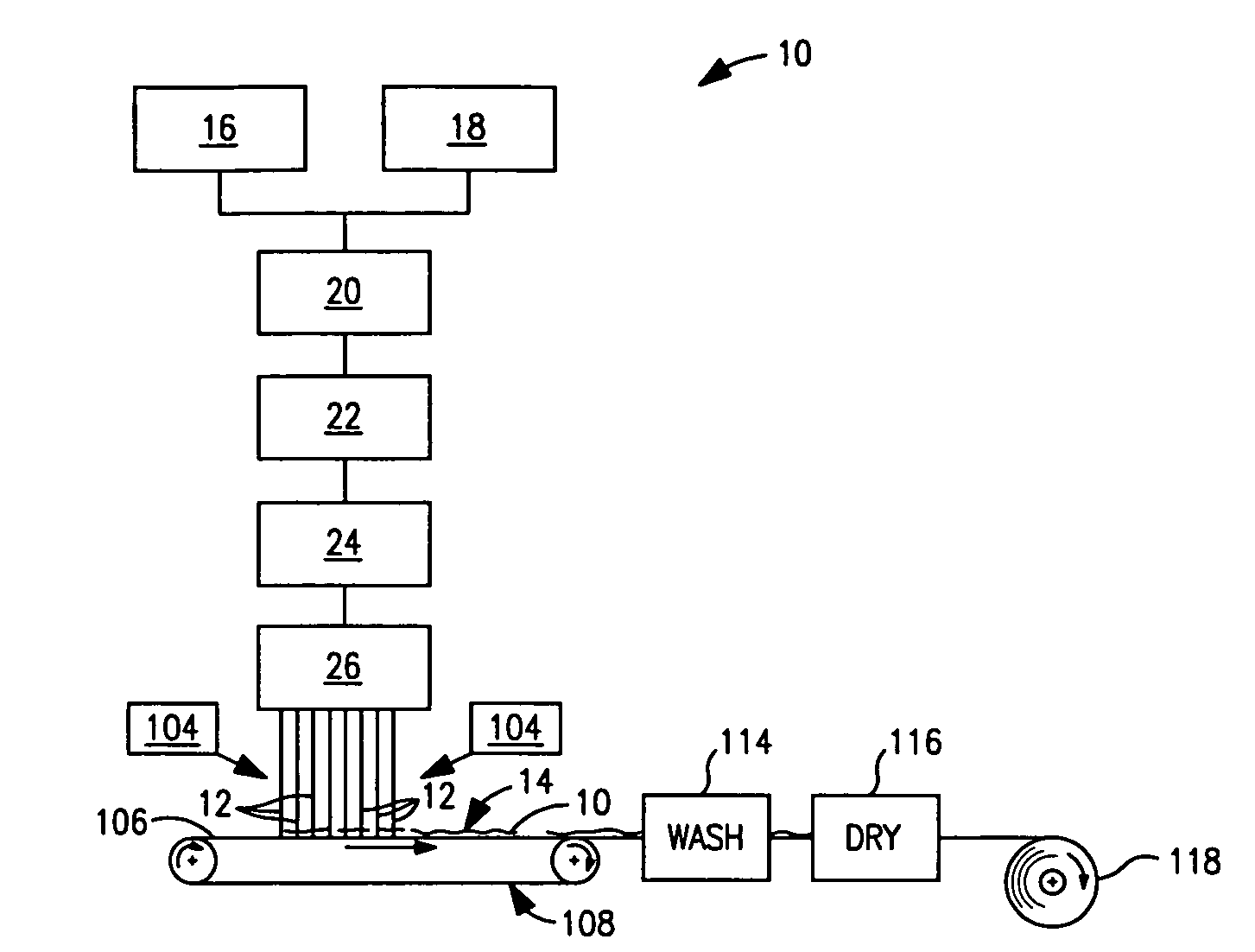

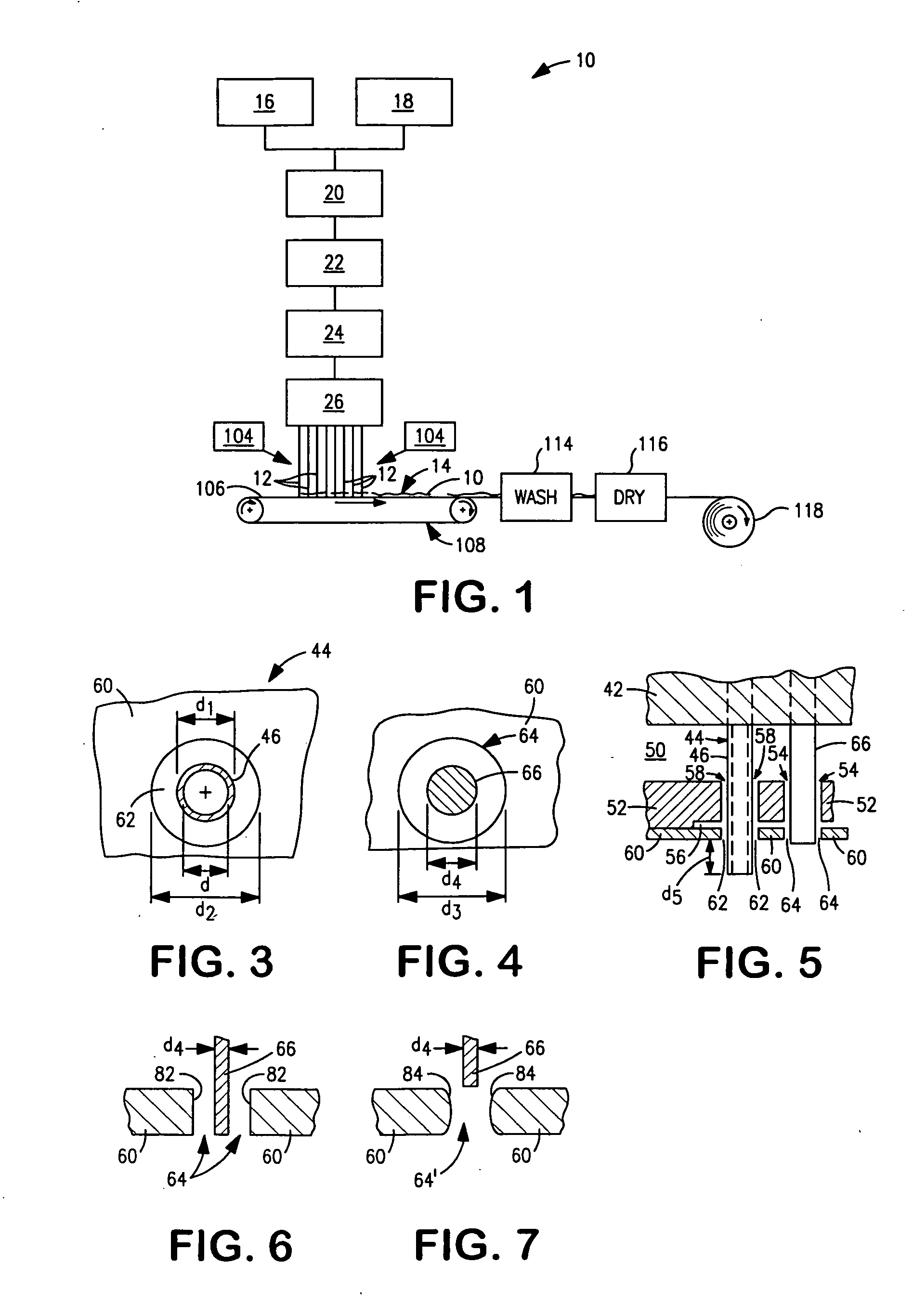

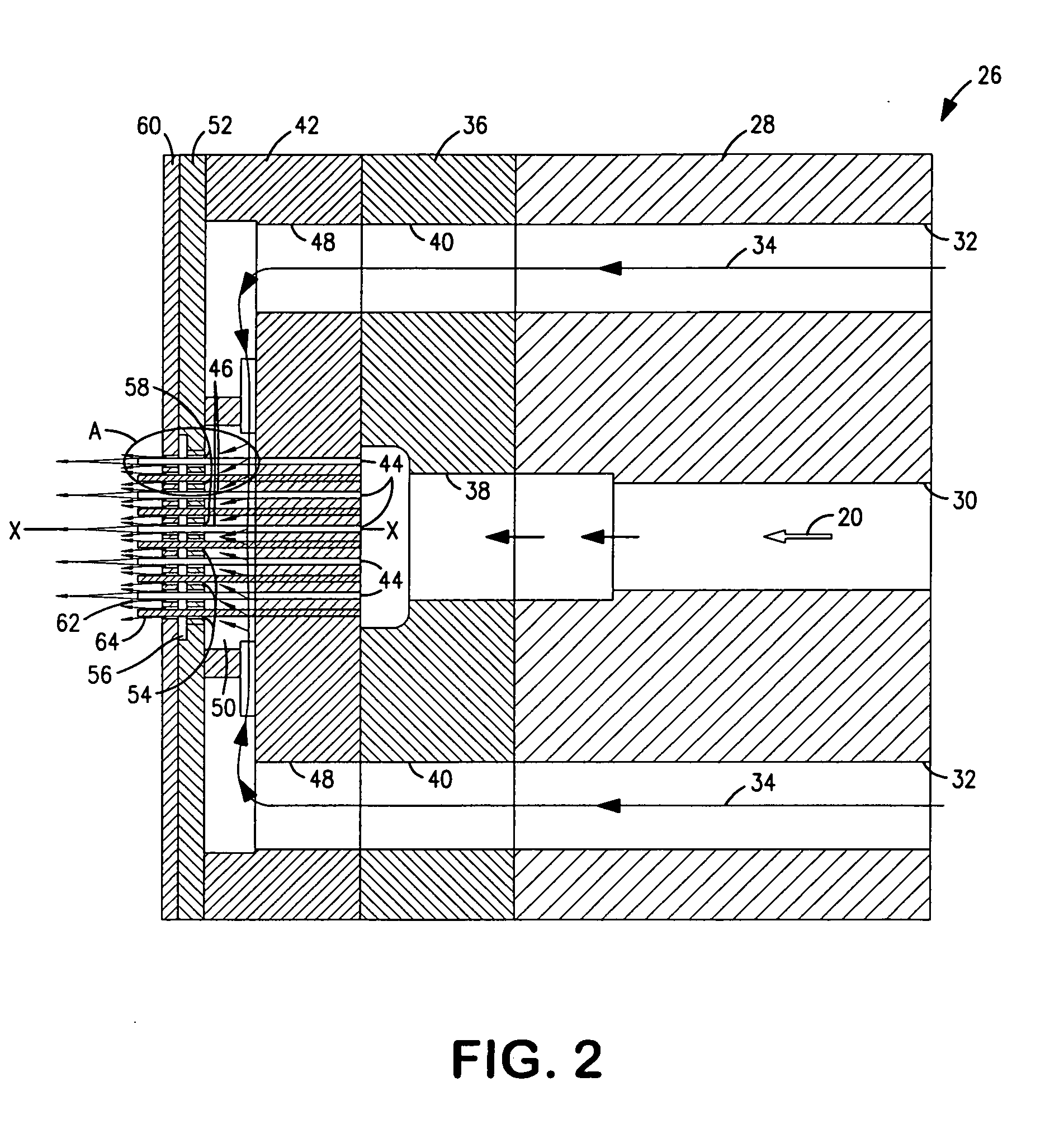

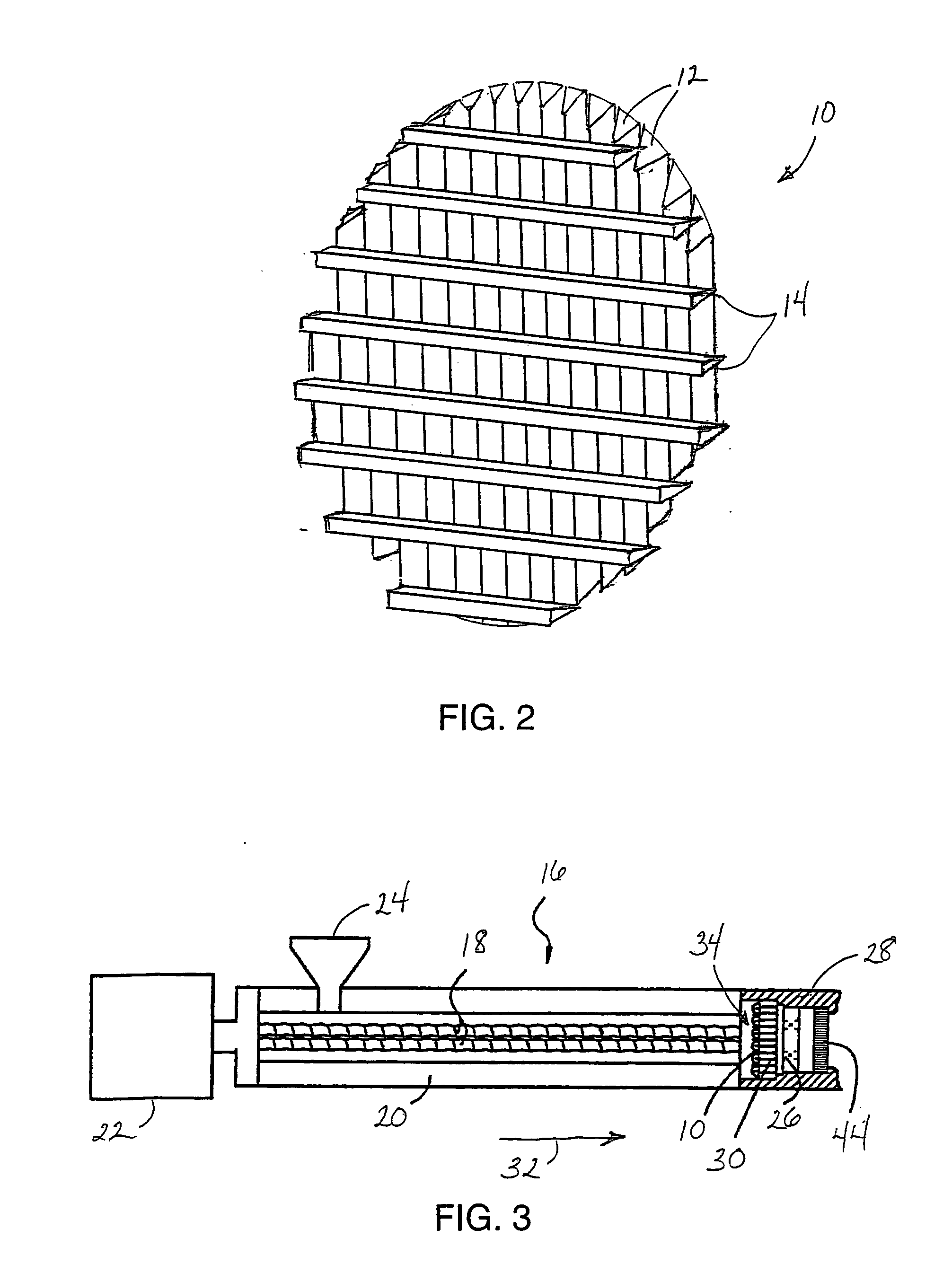

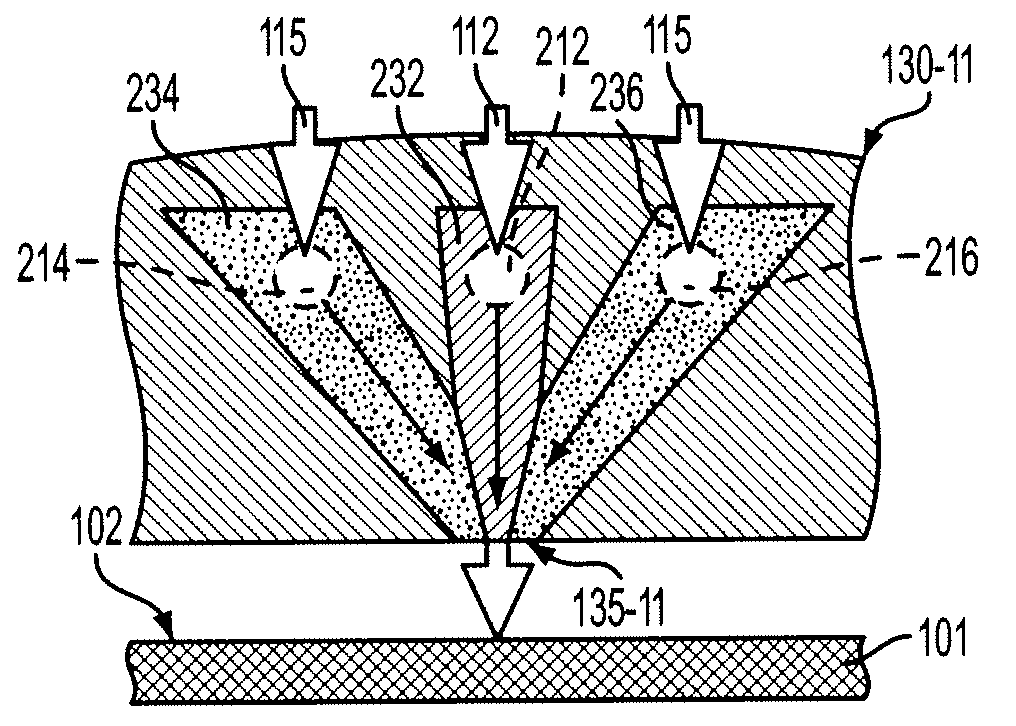

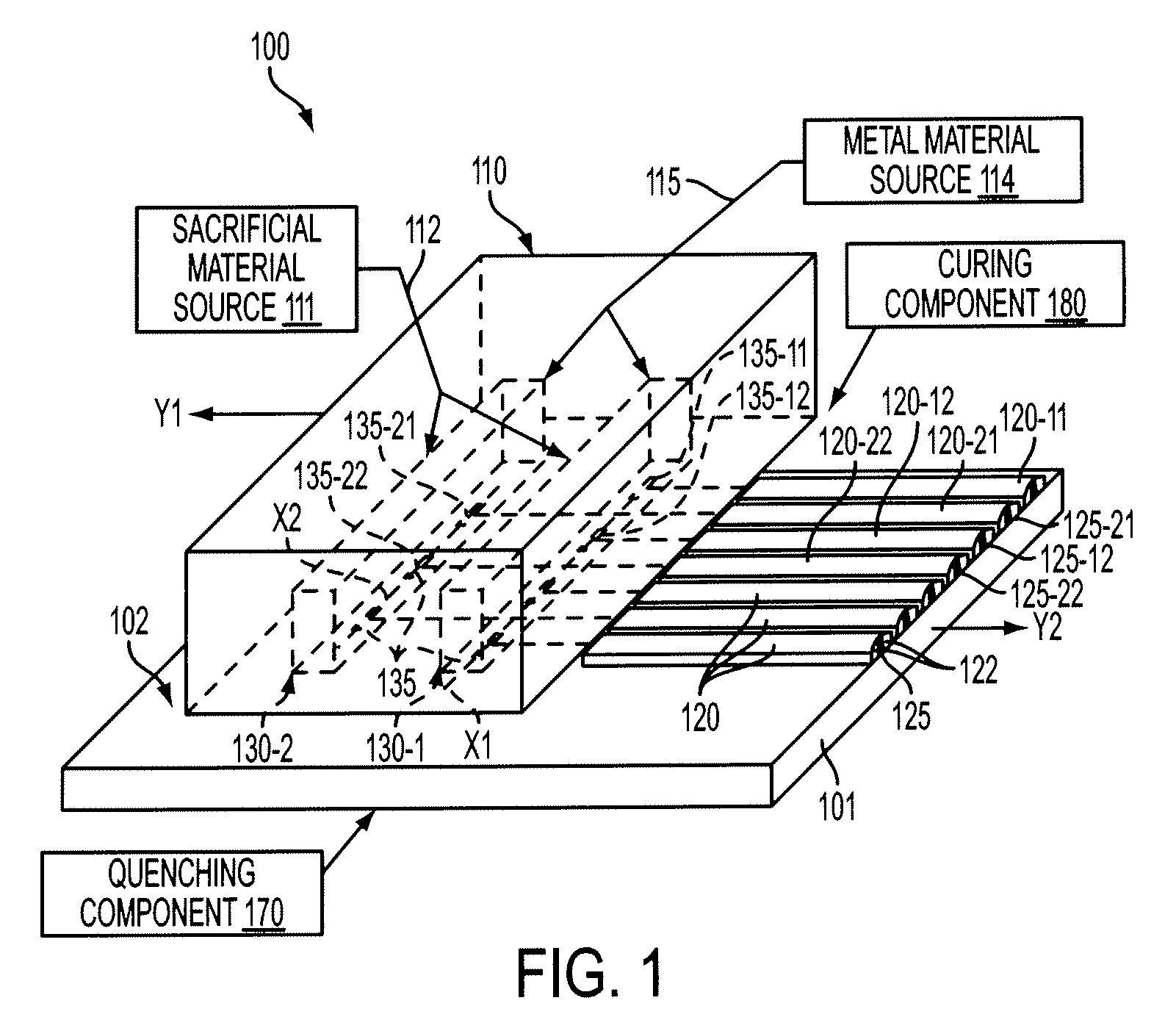

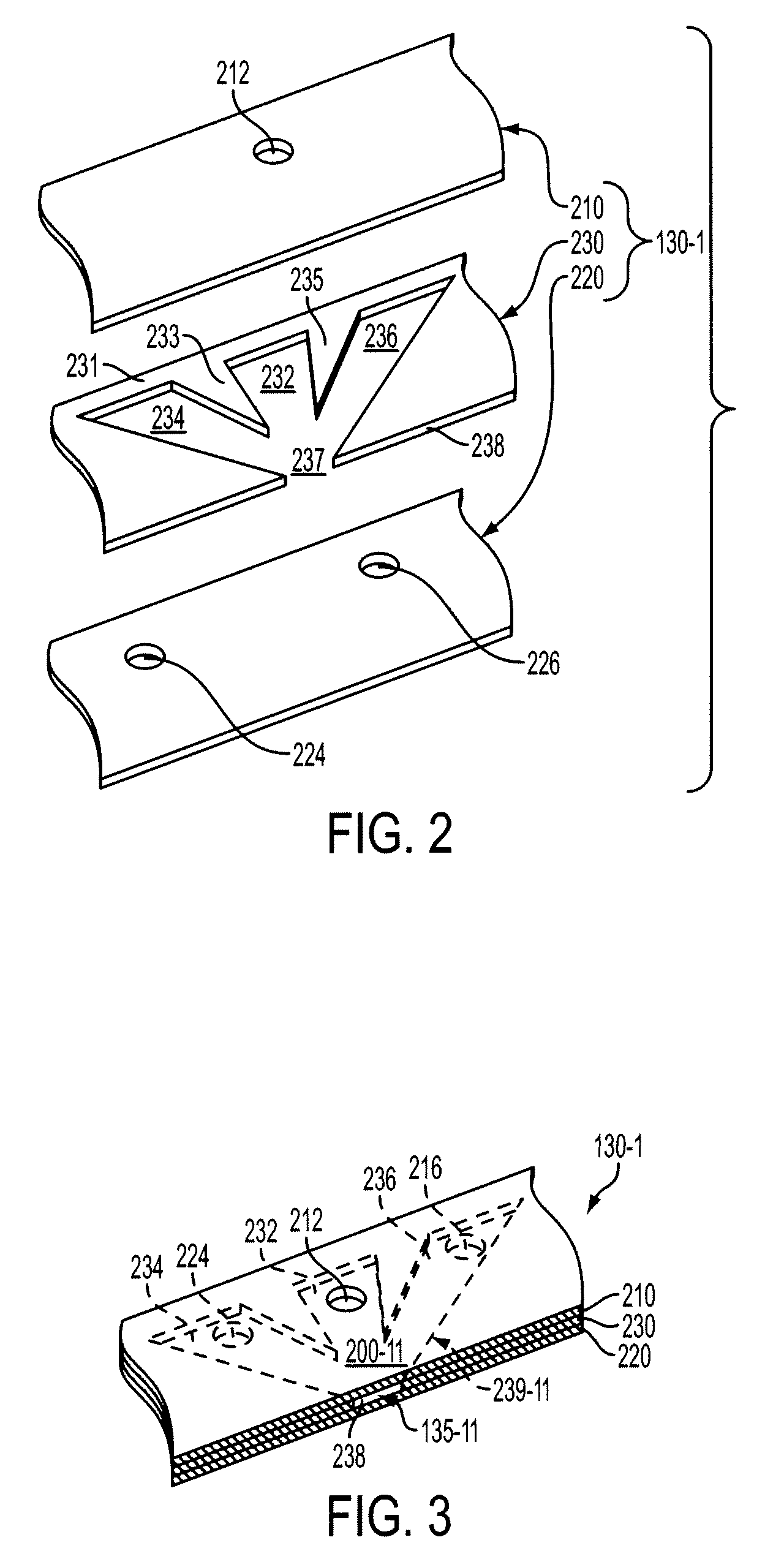

Closely Spaced, High-Aspect Extruded Gridlines

ActiveUS20080102558A1Wide spaceHigh aspect ratioTube/lamp screens manufactureLiquid surface applicatorsEngineeringCo extrusion

Closely spaced, high aspect-ratio gridline structures are formed on the surface of a substrate using two or more co-extrusion heads that co-extrude gridline material and sacrificial material such that the deposited gridline material is compressed between opposing portions of the sacrificial material. The co-extrusion heads include three-channel cavity structures that converge to a relatively small outlet orifice that dispenses the gridline material with relatively fine features and a relatively high aspect ratio. The outlet orifices of the co-extrusion heads are disposed in a staggered arrangement such that gridlines extruded from the first co-extrusion head are disposed between two gridlines extruded from the second co-extrusion head. Photovoltaic cells are produced with metal gridlines formed in this manner.

Owner:SOLARWORLD IND GMBH

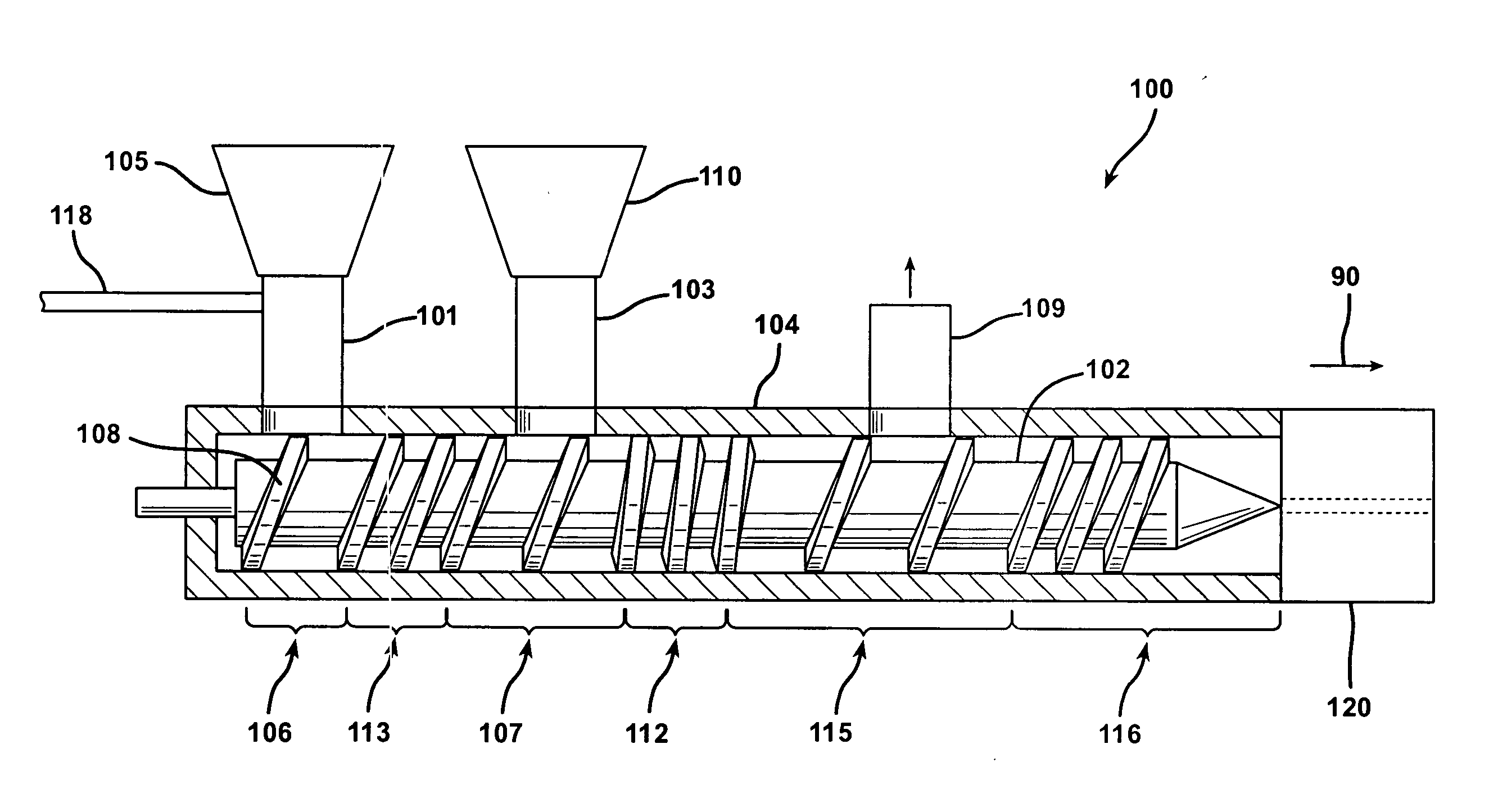

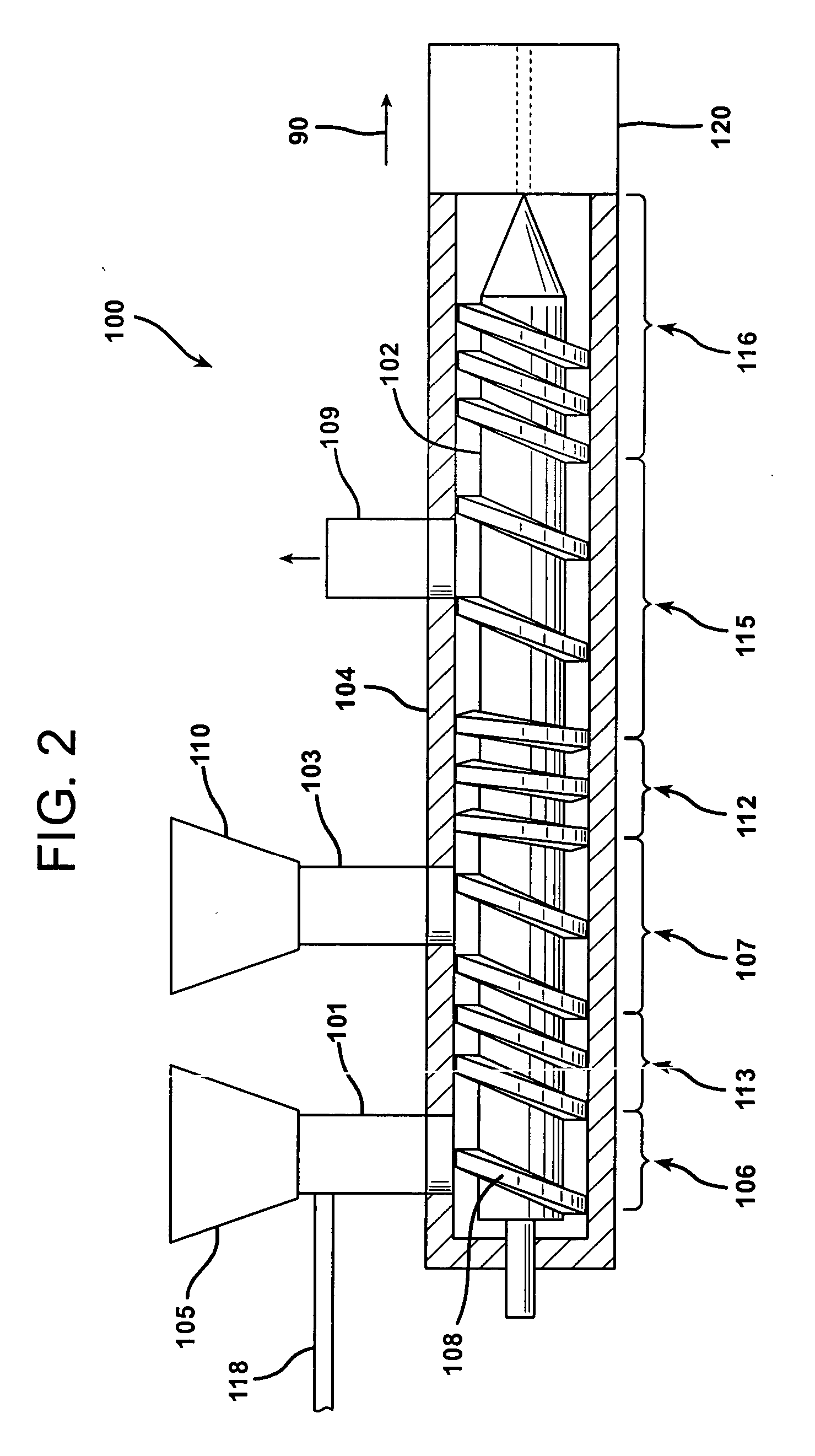

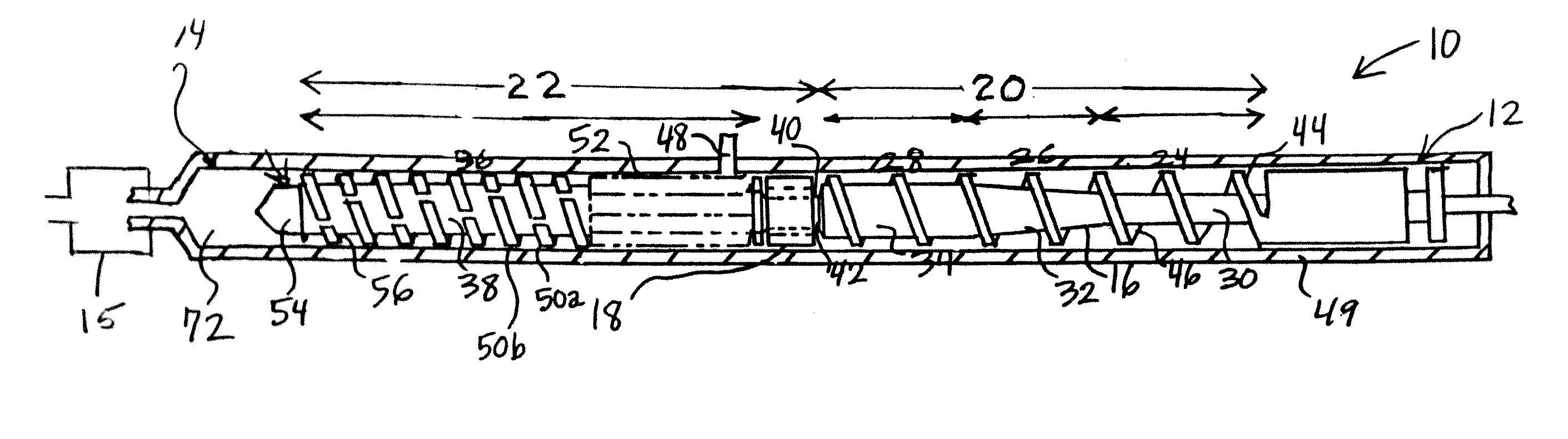

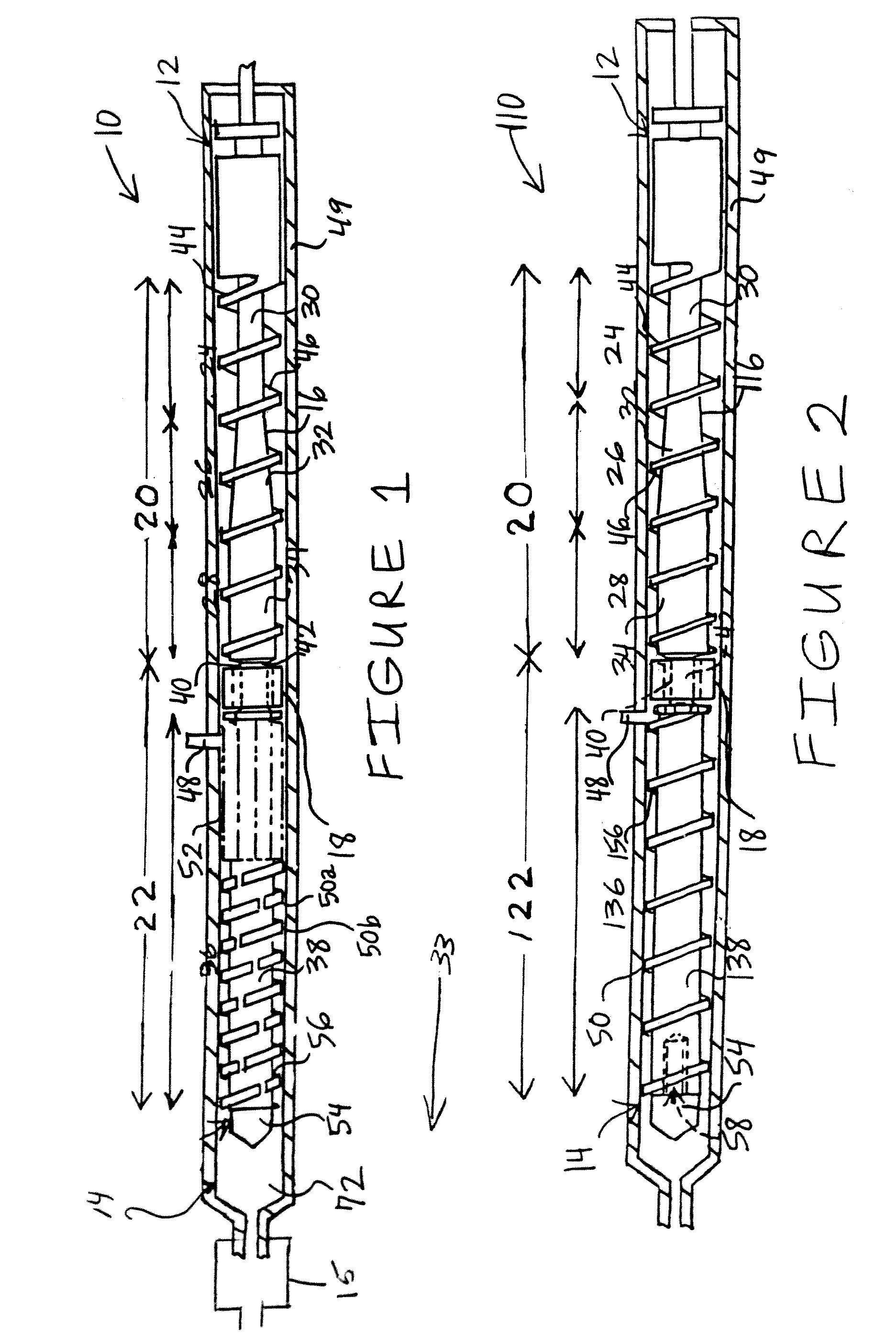

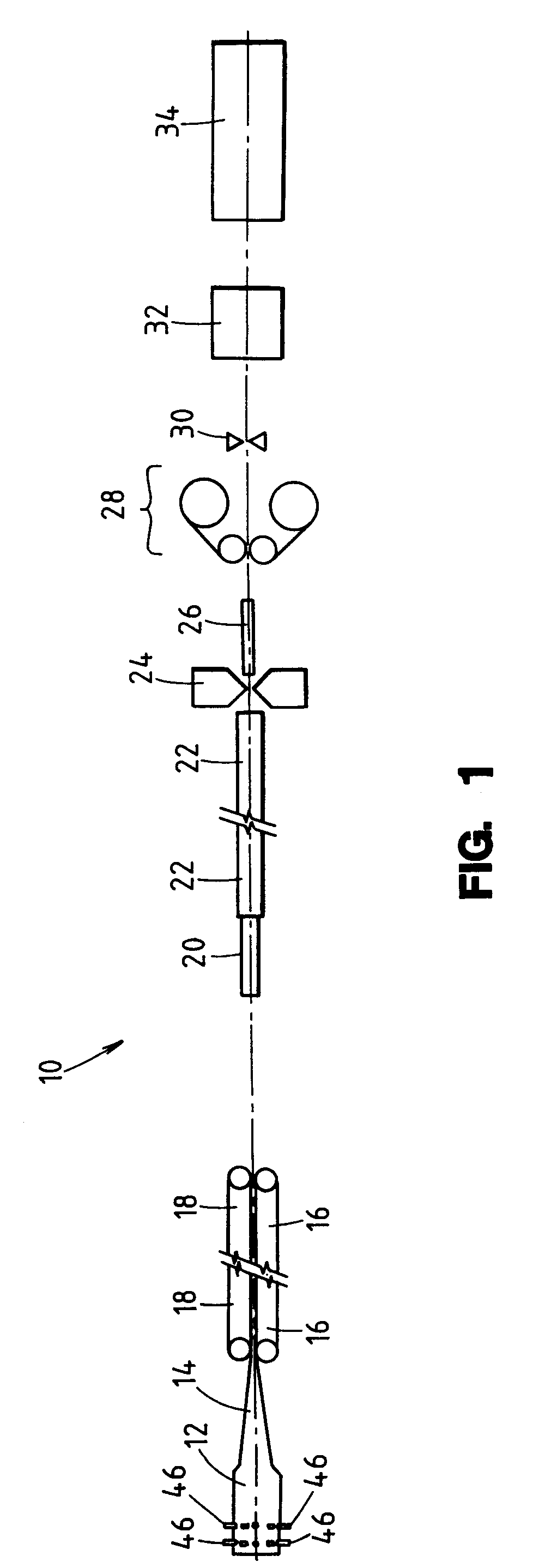

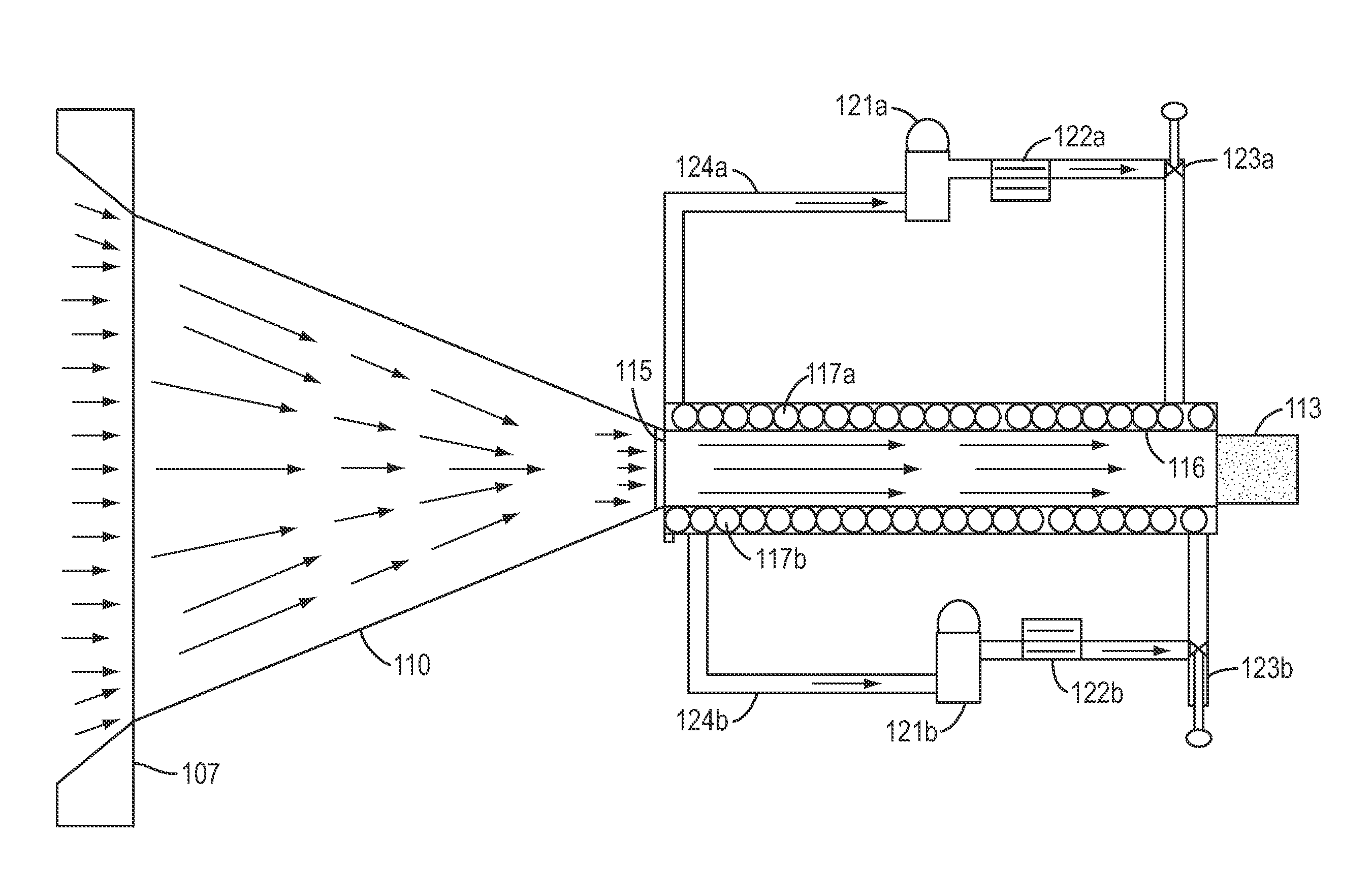

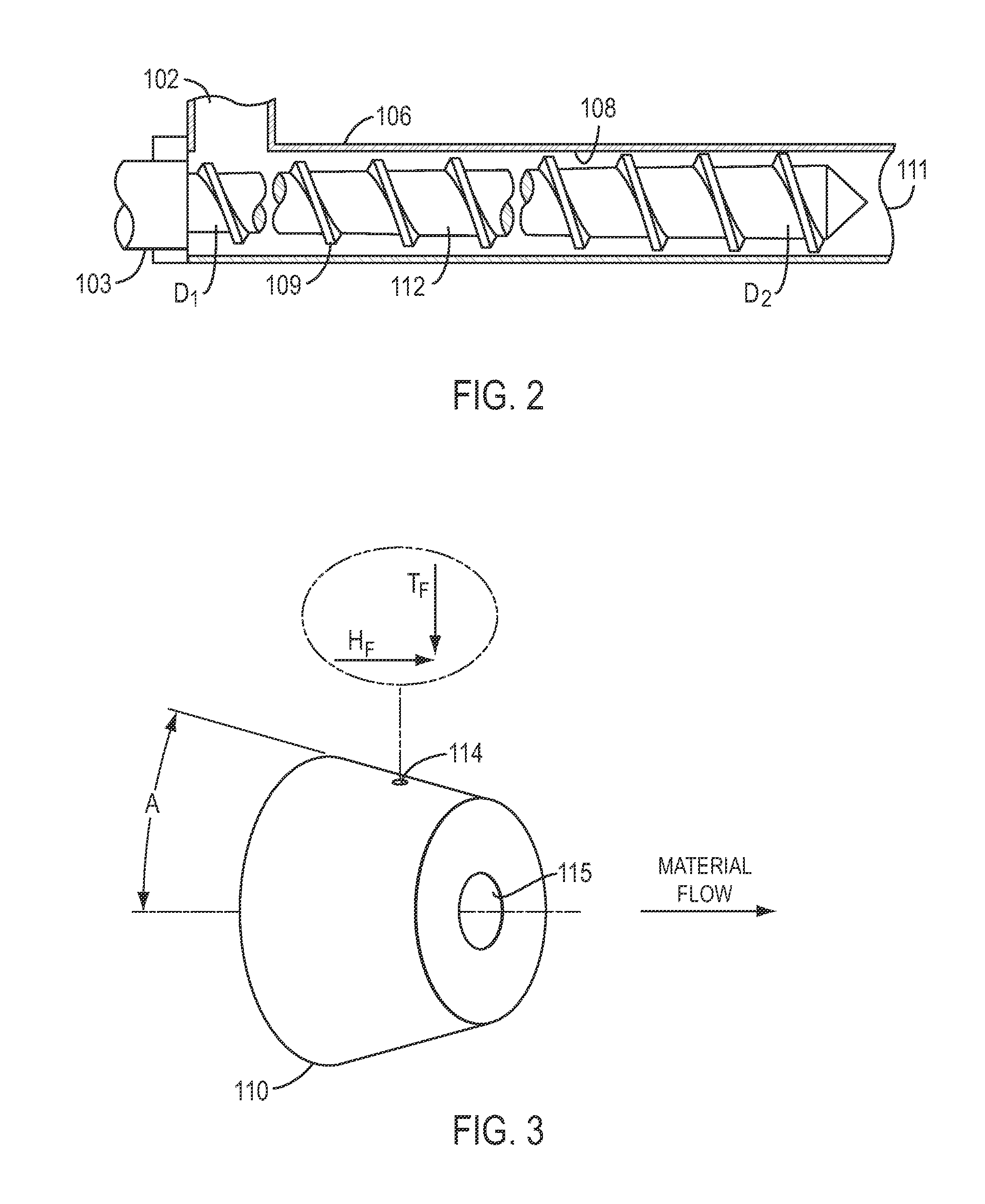

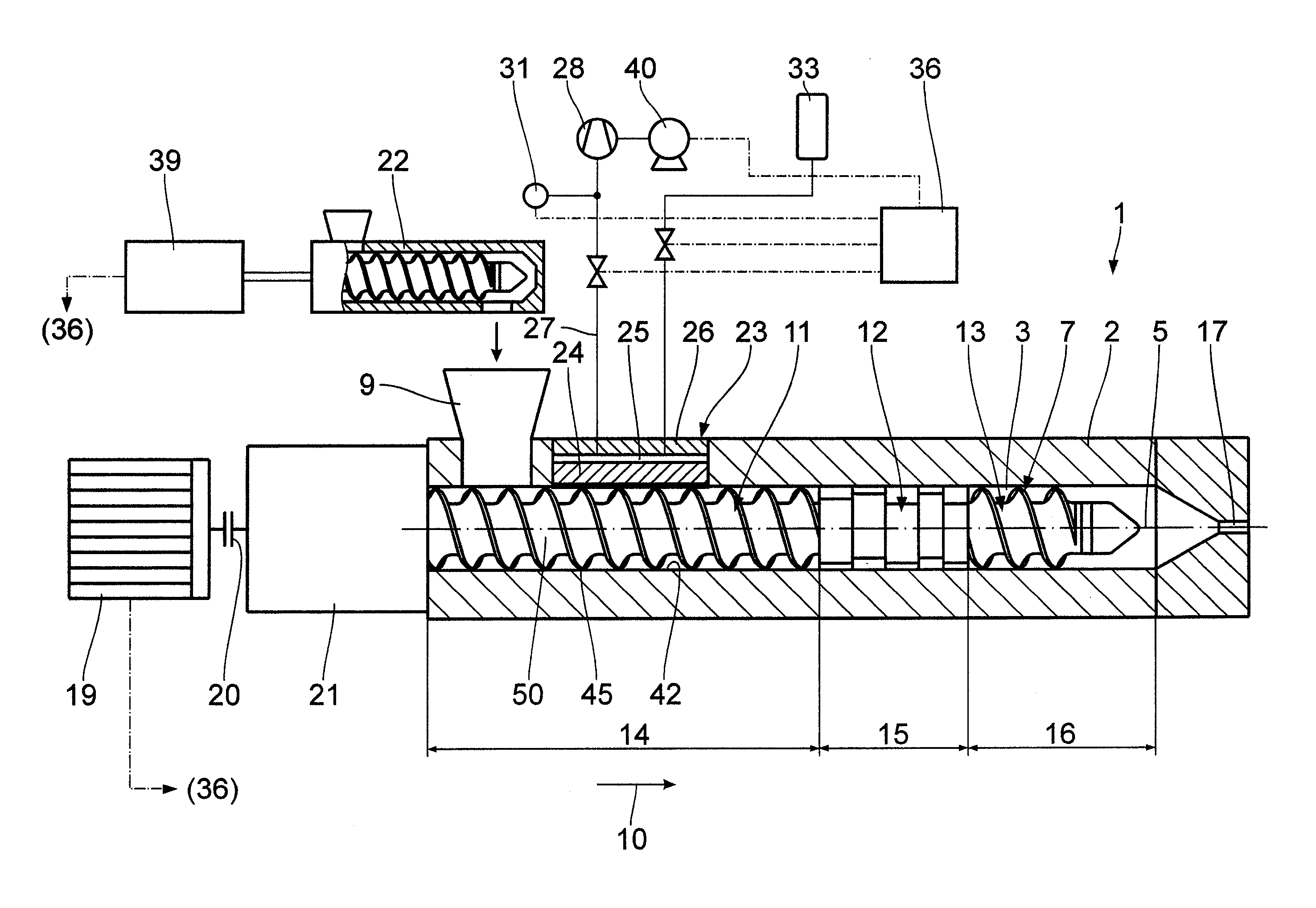

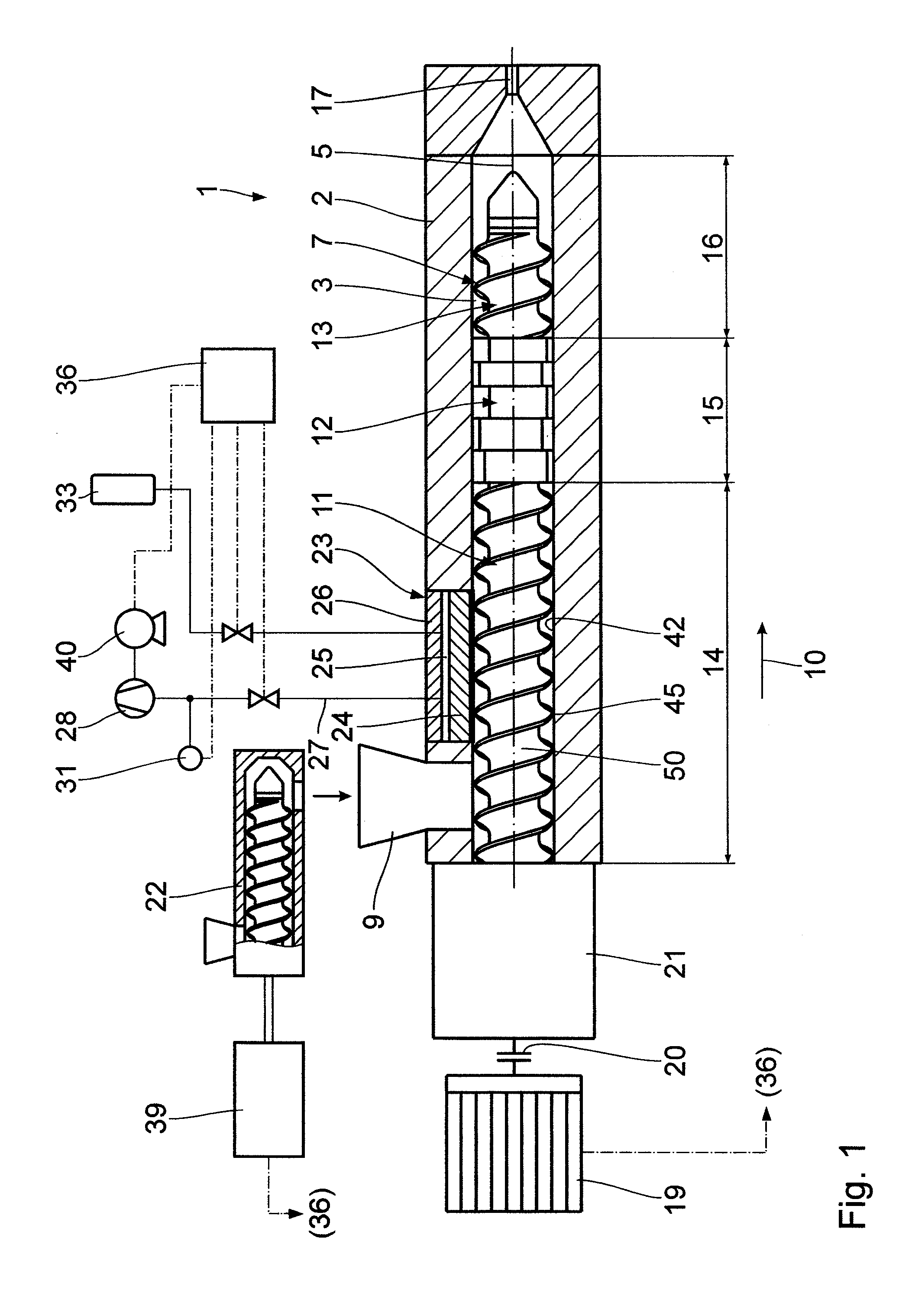

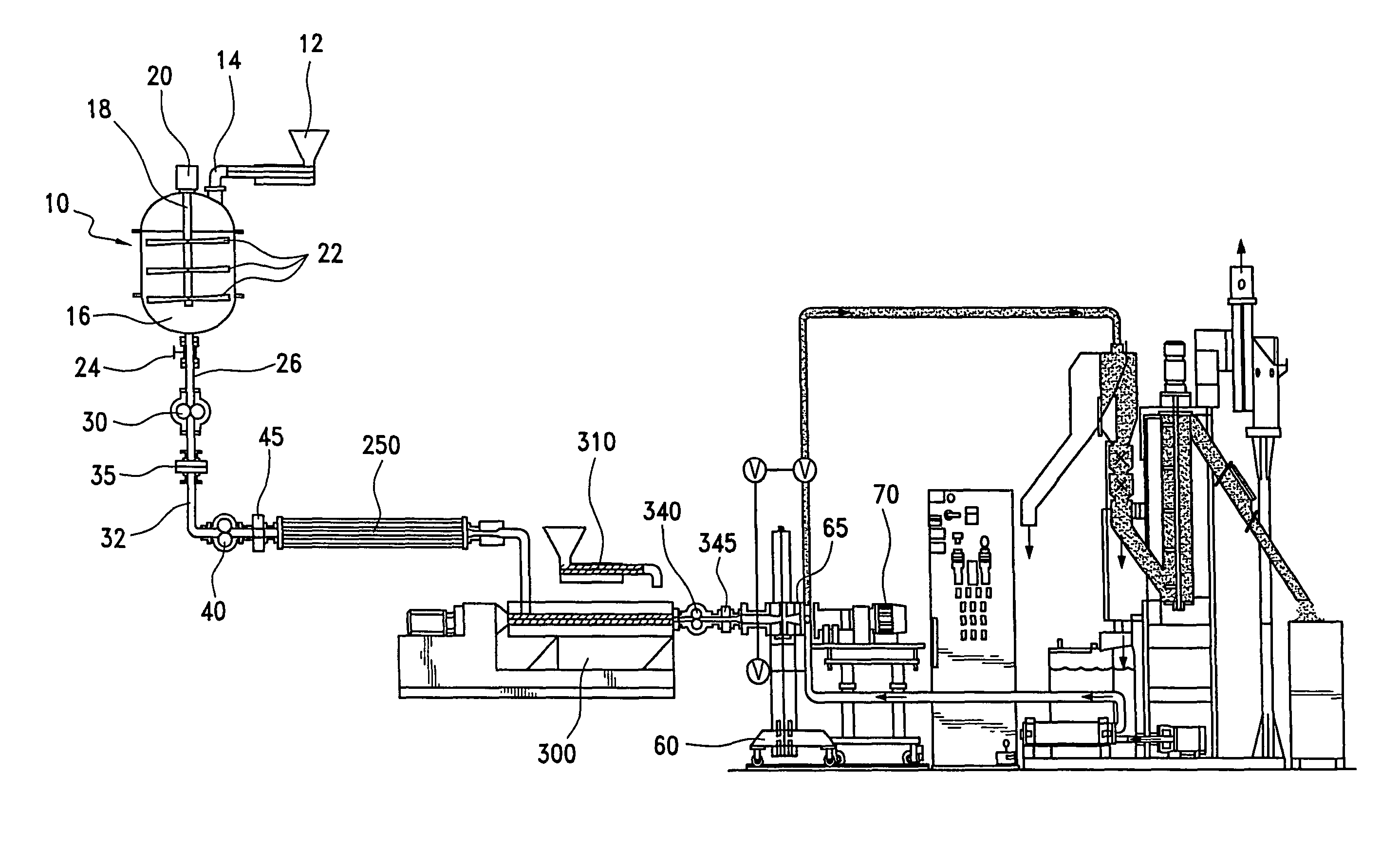

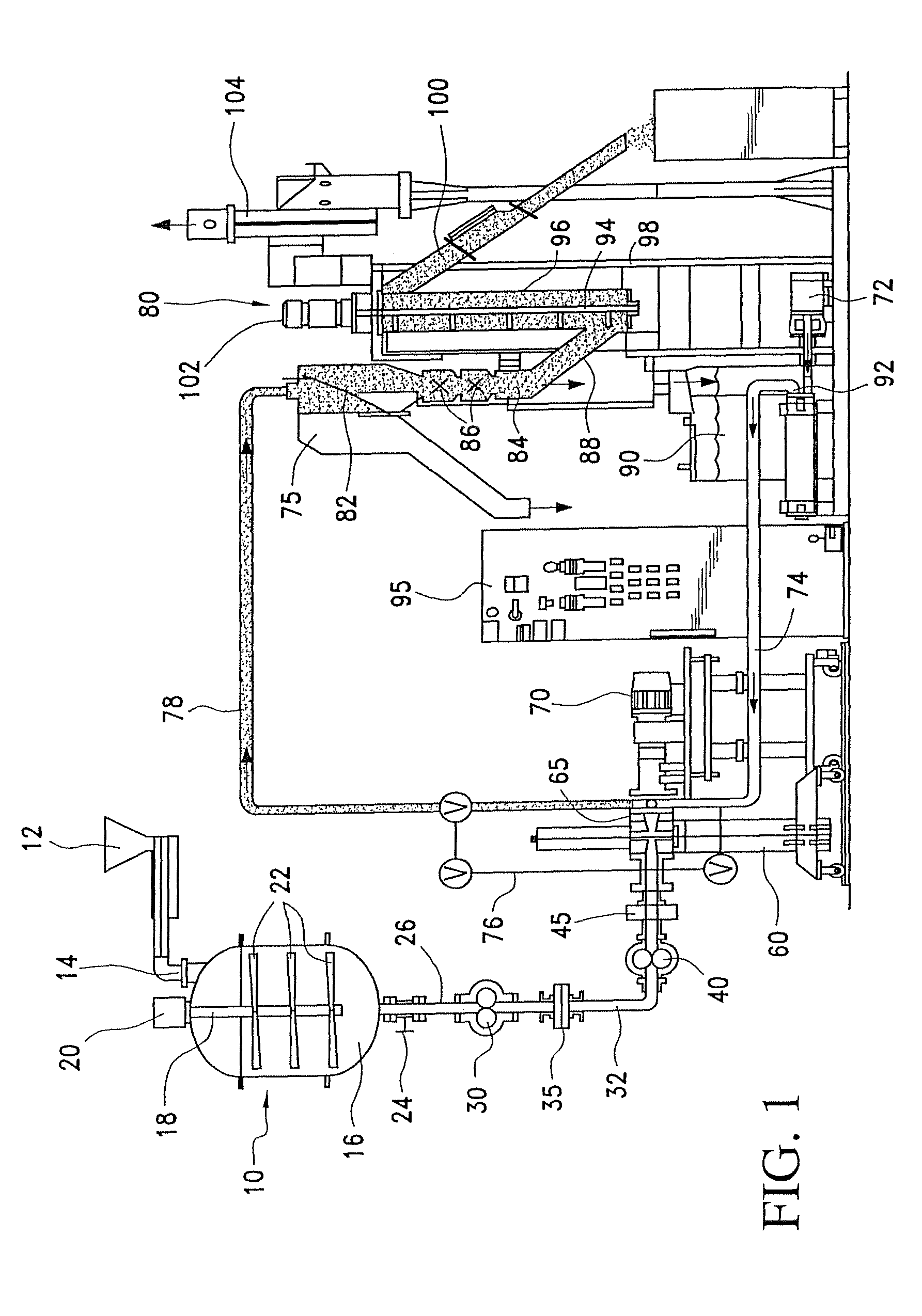

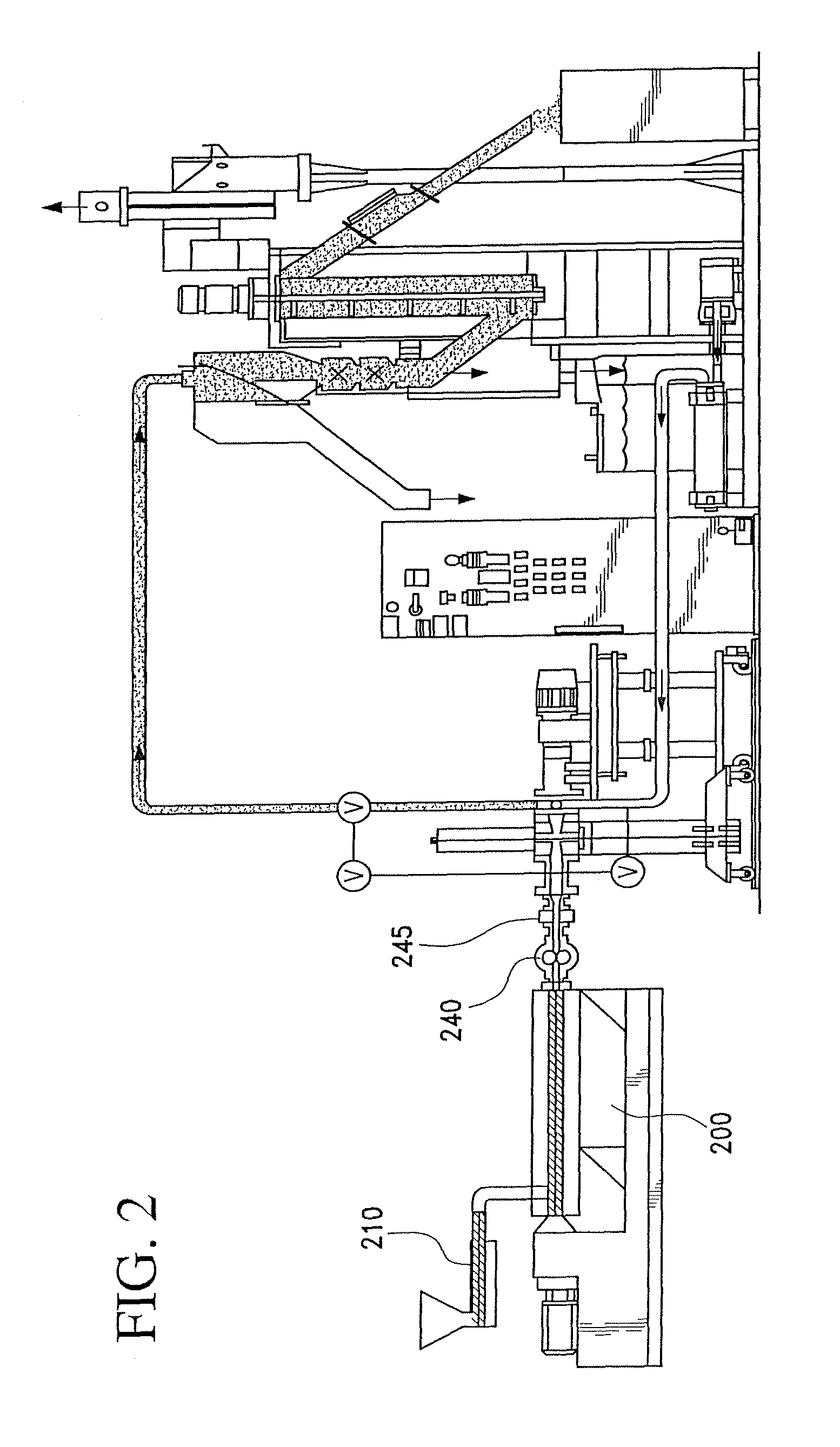

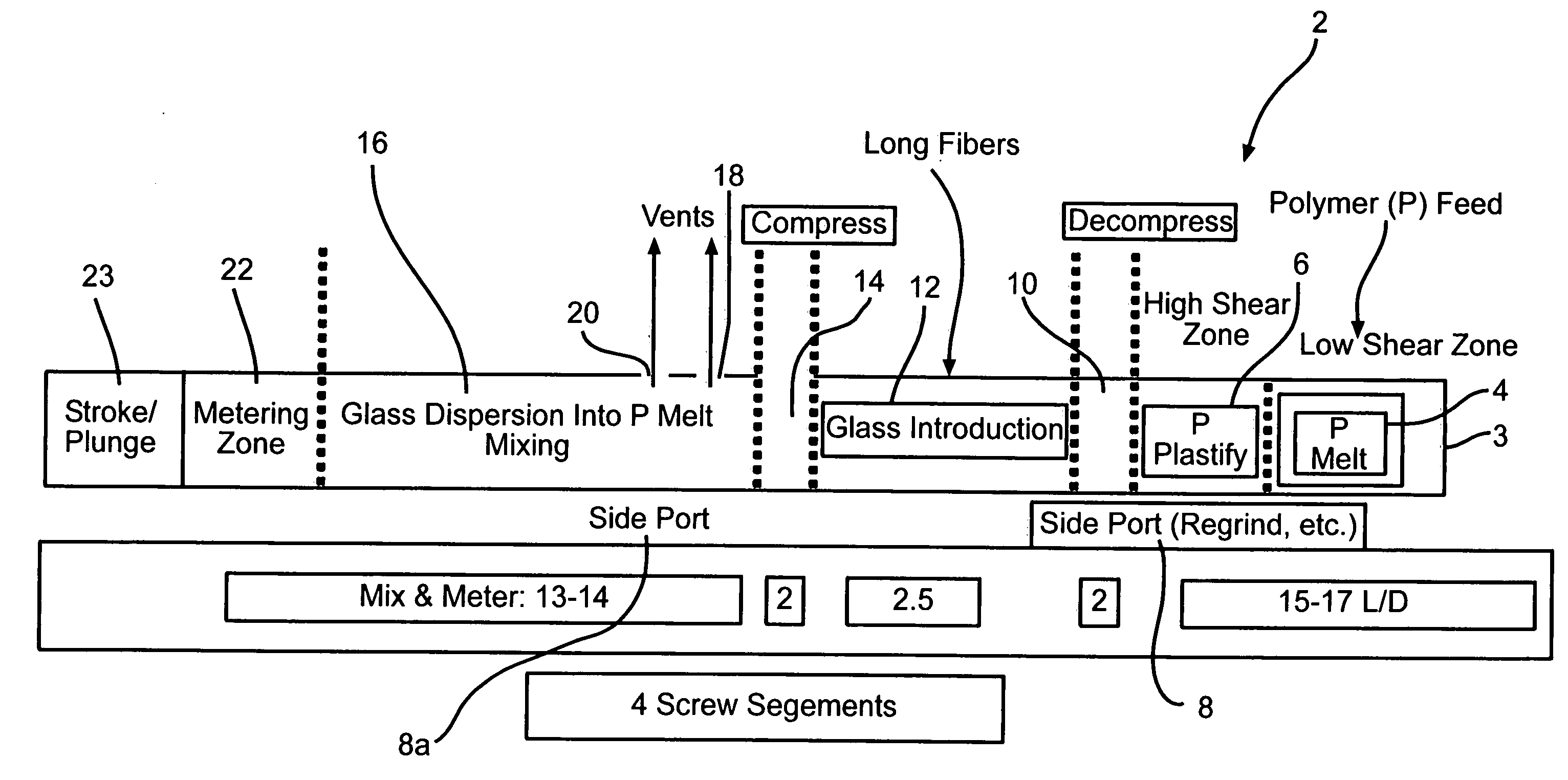

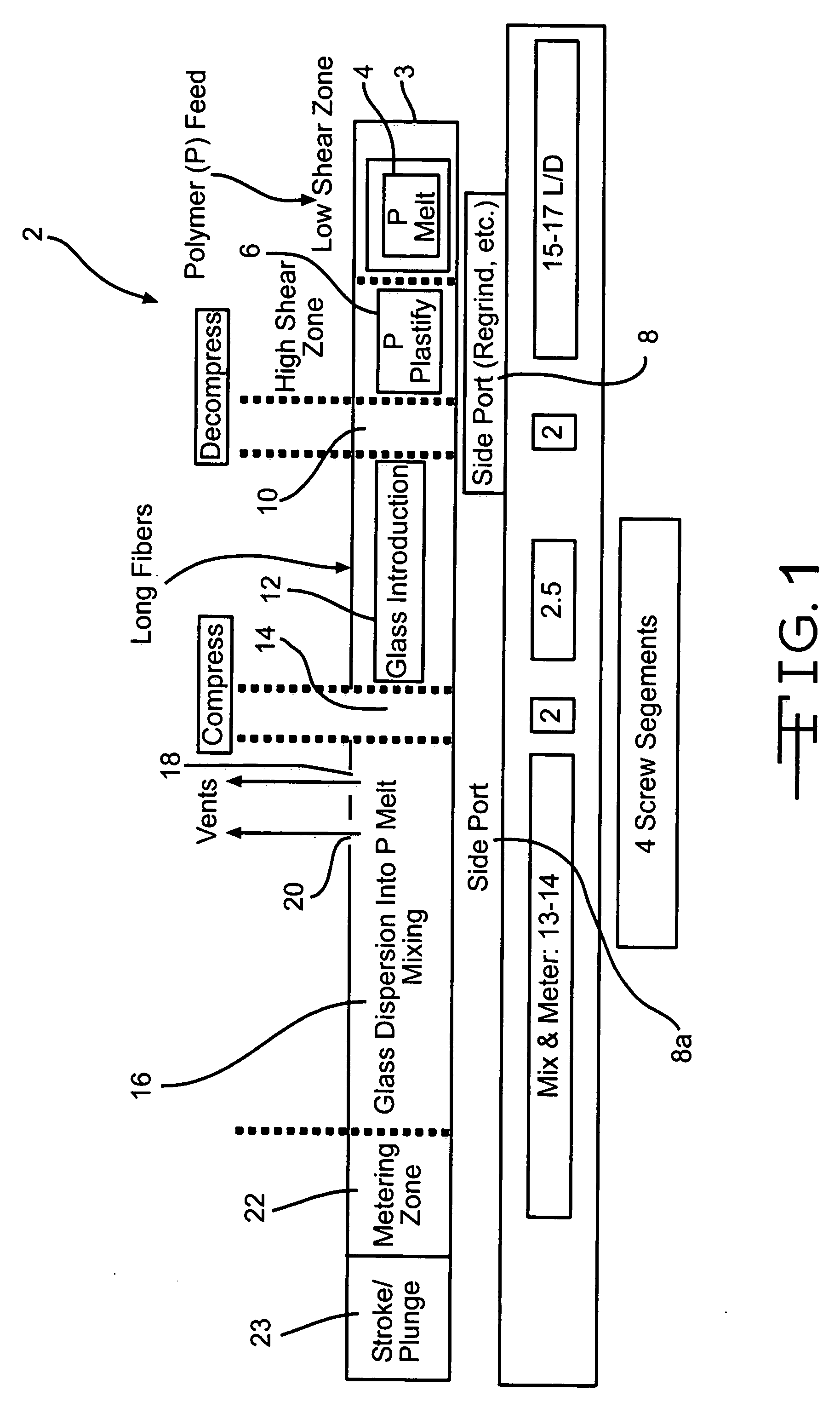

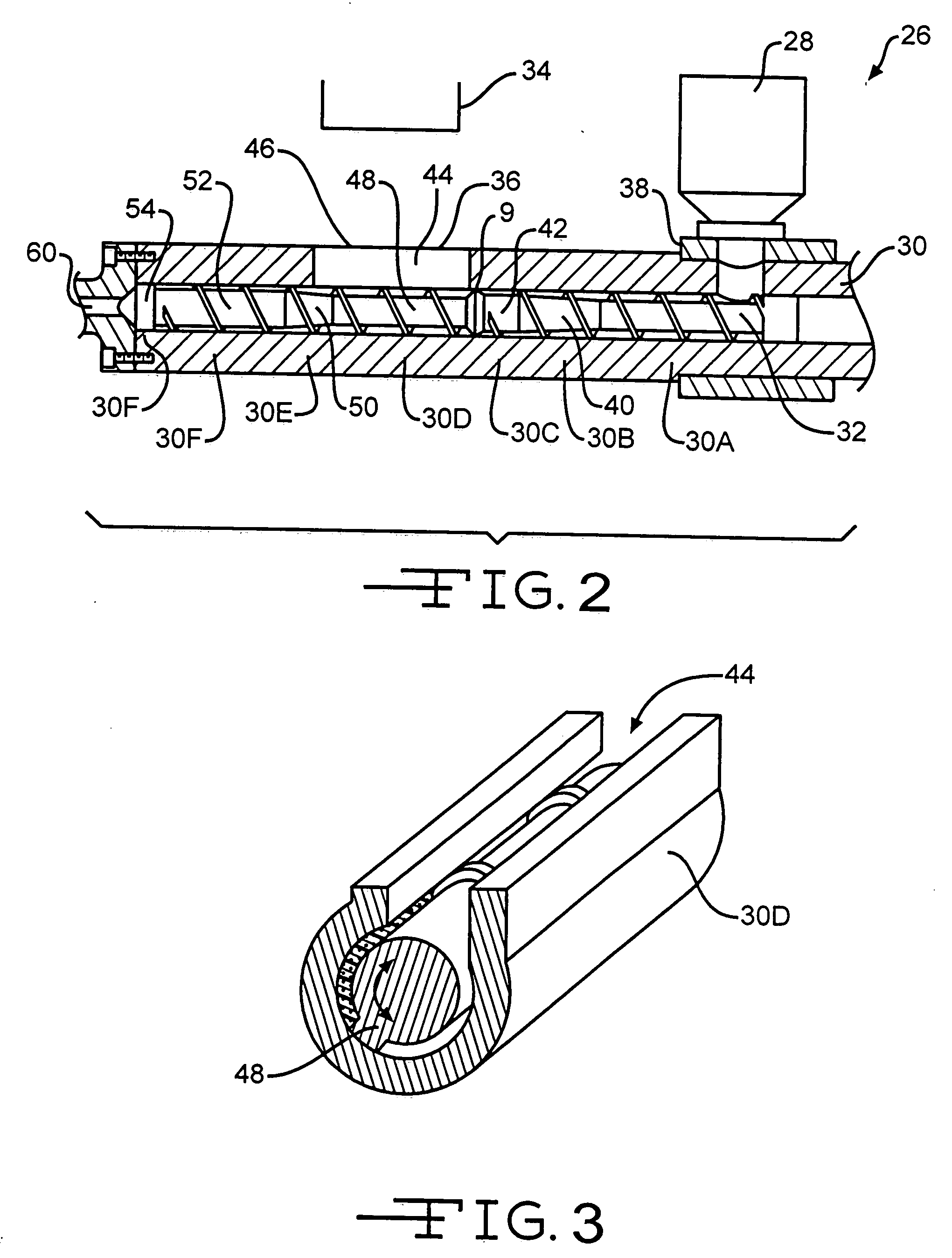

Methods and systems for making long fiber reinforced products and resultant products

InactiveUS20070007685A1Low costGood fiber dispersionDough homogenizationLayered productsProduct systemLow density

Systems and methods are disclosed for making a moldable polymer mixture containing long reinforcing fibers that suffered no significant damage during plastication. The system and method produces a mixture in which the long fibers are longer and have encountered less damage than moldable mixtures made in previous plasticators. The plasticator system has a single screw, but with multiple zones for treating the materials differently. The long fibers, wet or dry, are fed into a downstream zone, distributed over a large port in a low density concentration, and heated and dispersed with low shear to separate the long fibers and surround them with polymer for protection before subjecting them to medium to high shear to finalize the dispersion of the long fibers.

Owner:GLEICH KLAUS FRIEDRICH +3

Screw machine

ActiveUS20100202243A1Eliminate cloggingRaise the possibilityRotary stirring mixersFrozen sweetsEngineeringMechanical engineering

A screw machine for treating at least partially powdery bulk material has a housing with at least one housing bore and a screw arranged in the housing bore. A vacuum housing portion is provided, which is formed as a vacuum housing insert, which is releasably attached in the housing, in which a metal nonwoven is exchangeably held as a gas-permeable wall portion on a base body.

Owner:COPERION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com