Adhering technique of sole structure

A process method and structural technology, applied in the field of shoe sole component adhesion process, can solve the problems of manufacturers such as large processing cost, injury, and inability to recover, and achieve the effect of reducing costs, reducing material costs, and solving human and environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

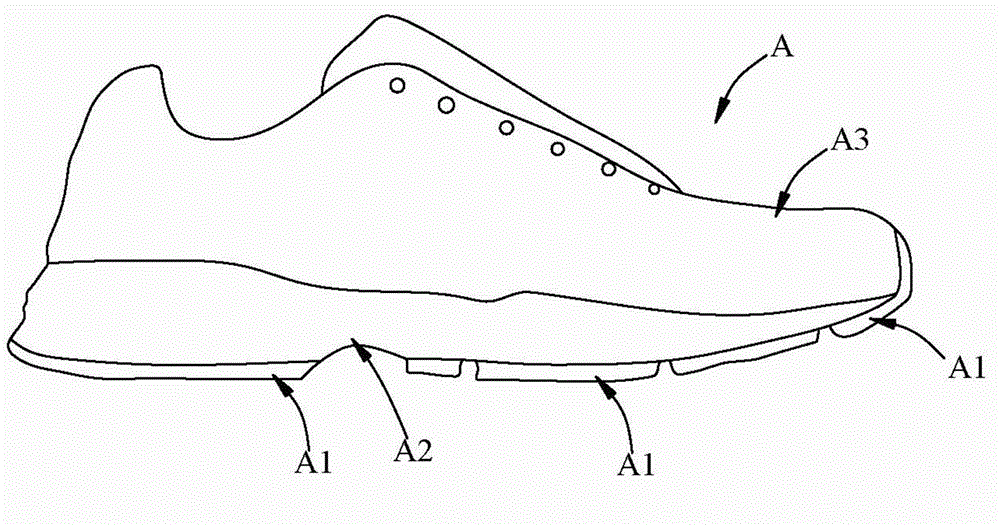

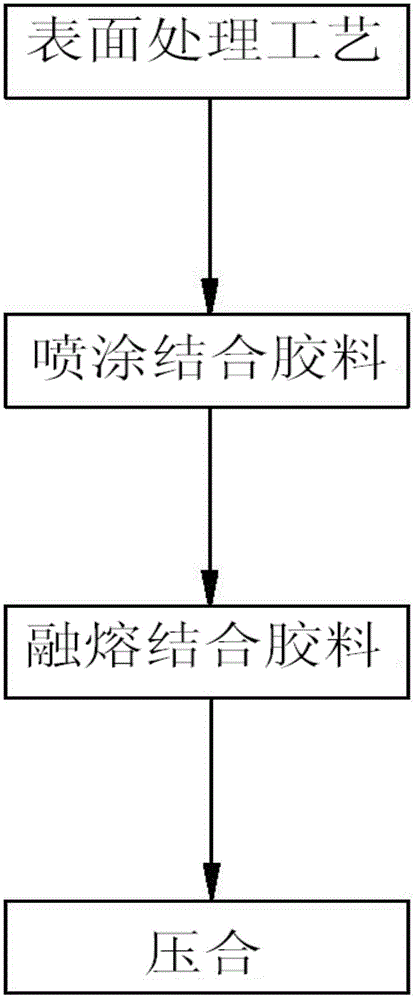

[0021] The present invention sole structure dry type adhesion process method, its steps comprise:

[0022] STEP 1. Surface treatment process: apply a surface treatment process to one of the combined surfaces of the outsole (OuterSole) and the midsole (Mid-sole) to be combined. The type of the surface treatment process is not limited, it can be a traditional wet surface treatment process or preferably a dry surface treatment process or a photoreactive surface treatment process. The purpose of the surface treatment process is to change the surface state of the bonding surface, make the bonding surface have more functional groups, roughen or increase the surface energy, etc., so that the bonding surface of the outsole and the midsole can be more tightly bonded combined.

[0023] The so-called traditional wet surface treatment process uses a solvent-based treatment agent, a water-based treatment agent or a solvent-free treatment agent to coat the joint surface, so that the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com