Coating device

A coating device and coating technology, which is applied to the surface coating liquid device, coating, optics, etc., can solve the problems of coating failure, manual coating time-consuming and labor-intensive, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

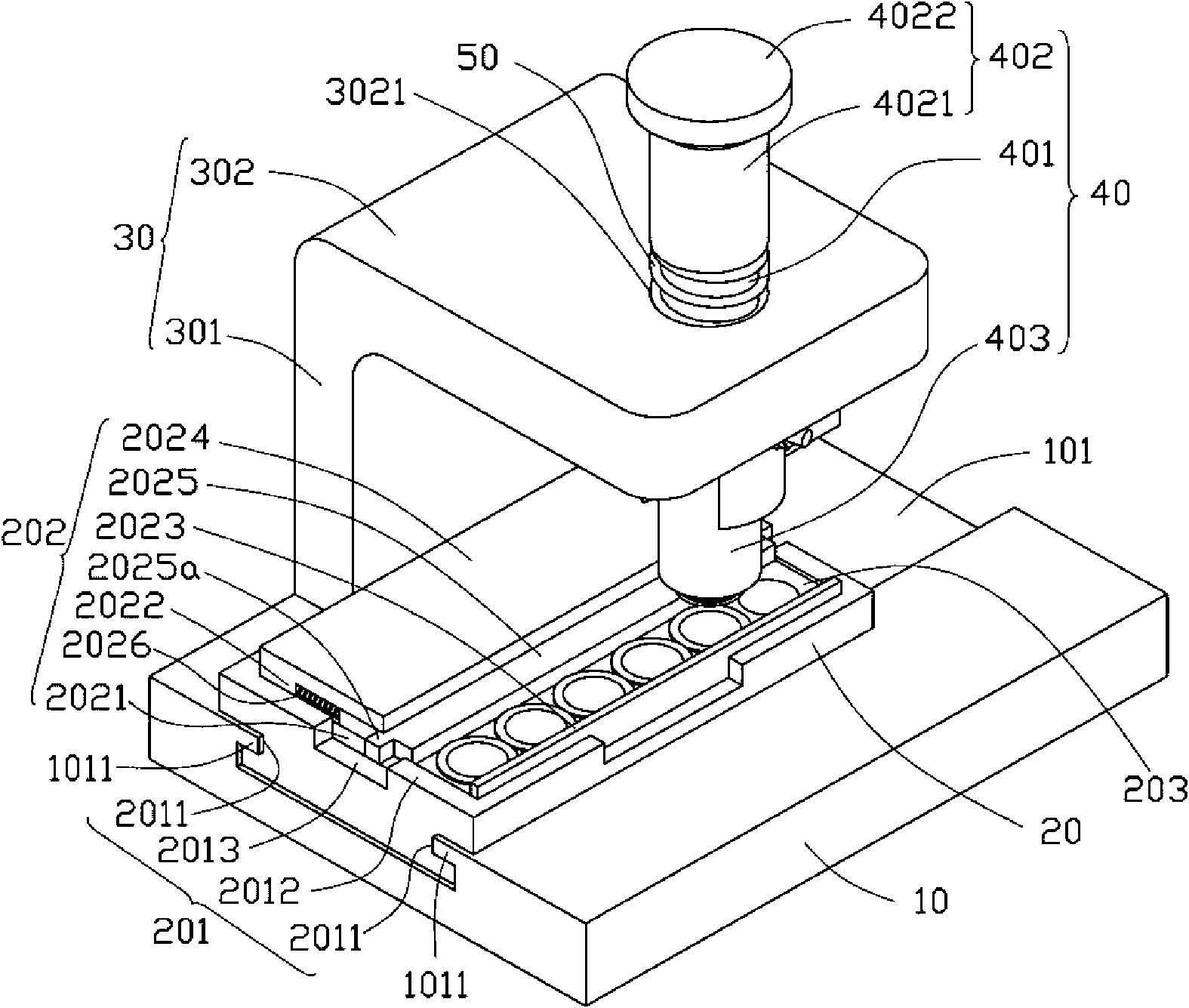

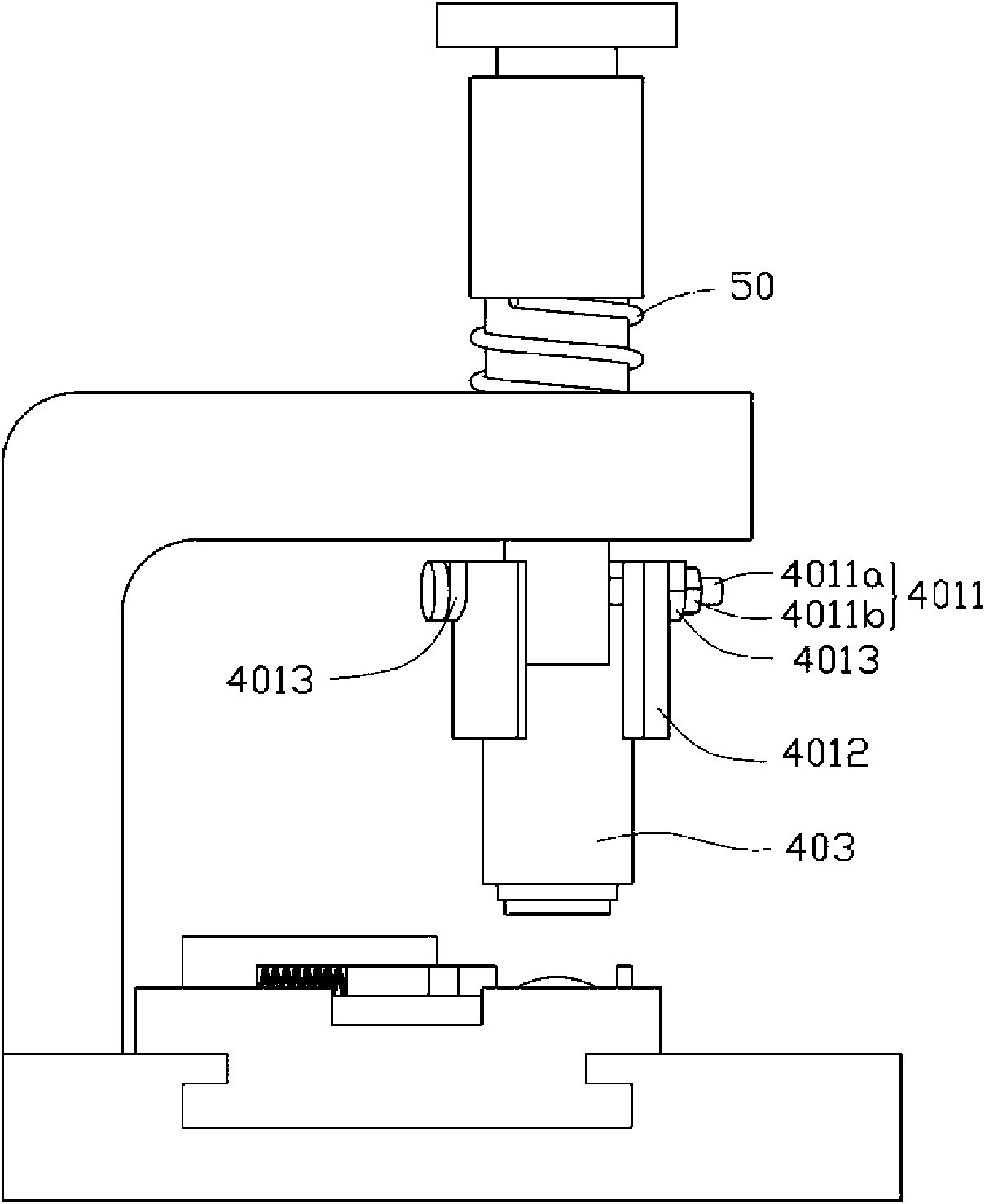

[0012] see figure 1 and figure 2 , the coating device provided by the present invention includes an operating platform 10, a carrier plate 20 slidably installed on the operating platform 10, a The support arm 30 and a coating rod 40 that passes through the support arm 30 and can slide relative to the support arm 30 , the surface of the carrier plate 20 is provided with a lens fixing area 203 , the bottom of the support arm 30 The end faces the lens fixing area 203 .

[0013] The operating platform 10 is provided with a groove 101 across its surface, and a sliding rail 1011 is extended from two opposite top ends of the sidewalls of the groove 101 .

[0014] The carrier board 20 includes a sliding portion 201 and a lens fixing portion 202 on the sliding portion 201 . Two opposite sliding grooves 2011 are provided on both sides of the bottom end of the sliding part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com