Diaphragm coating device

A technology for coating devices and diaphragms, which is applied to devices and coatings for coating liquid on surfaces, can solve the problems of high initial investment in coating equipment, narrow coating thickness control range, and difficult post-maintenance, etc., and achieve production costs. Low cost, easy maintenance and cleaning, and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

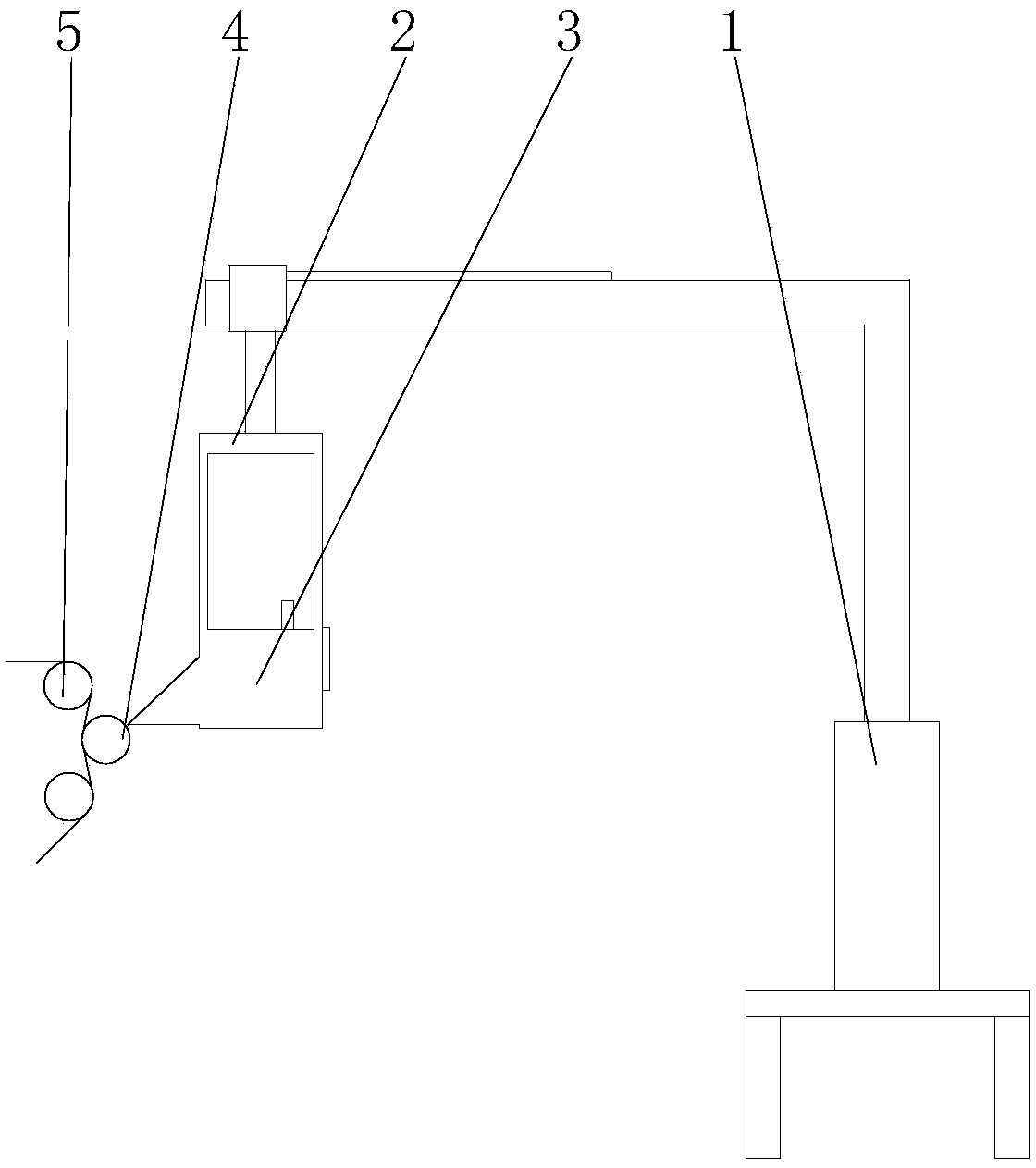

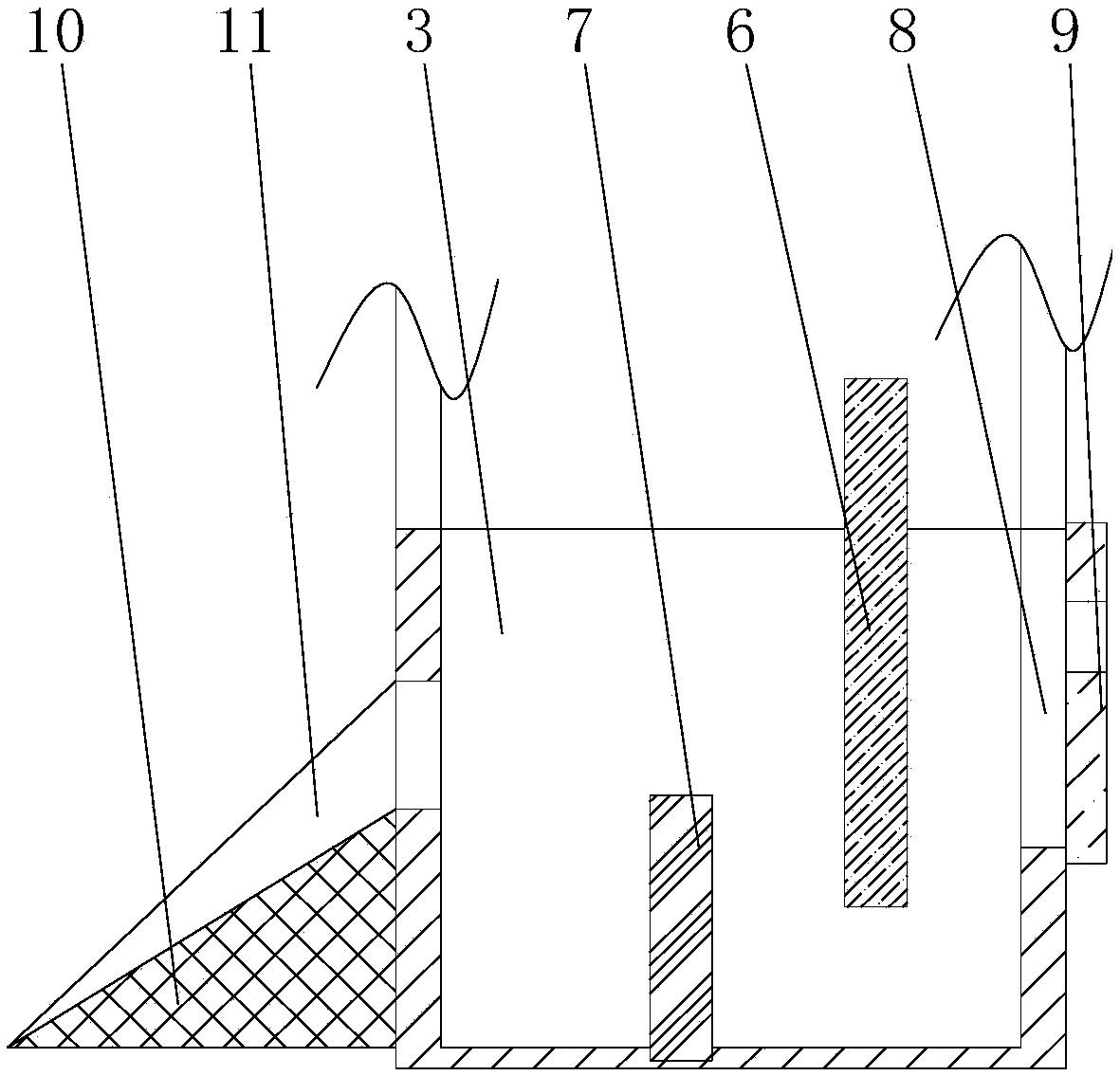

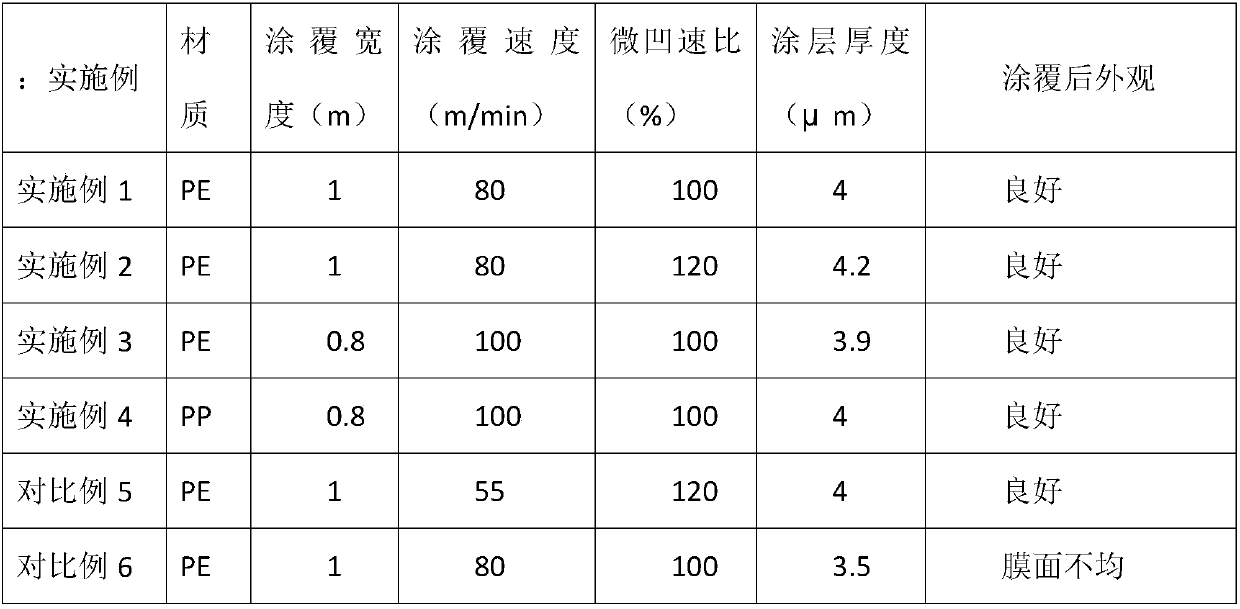

[0018] see Figure 1-2 , in an embodiment of the present invention, a diaphragm coating device includes a liquid storage tank 3 and an anilox roller 4 and a guide roller 5 arranged on the lower side of the liquid storage tank 3. The liquid storage tank 3 passes through the liquid storage tank hanger 2 and The support column 1 is fixed, the liquid storage tank 3 is arranged at the lower end of the liquid storage tank hanger 2, the liquid storage tank hanger 2 and the support seat 1 are slidably connected through guide rails, and the support seat 1 is provided with a hydraulic lifting rod, and the liquid storage tank 3 communicate with the slurry tank through the diaphragm pump and the pipeline, the liquid storage tank 3 is provided with a first stabilizing plate 6 and a second stabilizing plate 7, the first stabilizing plate 6 is fixedly connected with the liquid storage tank 3 and the second The bottom of the first stabilizing plate 6 is 1-5cm away from the bottom of the liqui...

Embodiment 2

[0022] Utilize the device of the present invention to carry out experiment and device structure is the same as embodiment 1.

[0023] The coating width of the diaphragm is 1m, the speed ratio of dimples is 120%, the material is PE, and the coating speed is 80m / min. The performance of the diaphragm after coating is as follows;

Embodiment 3

[0025] Utilize the device of the present invention to carry out experiment and device structure is the same as embodiment 1.

[0026] This time, the diaphragm coating width is 0.8m, the dimple speed ratio is 100%, the material is PE, and the coating speed is 100m / min. The performance of the diaphragm after coating is as follows;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com