Patents

Literature

31results about How to "High coating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

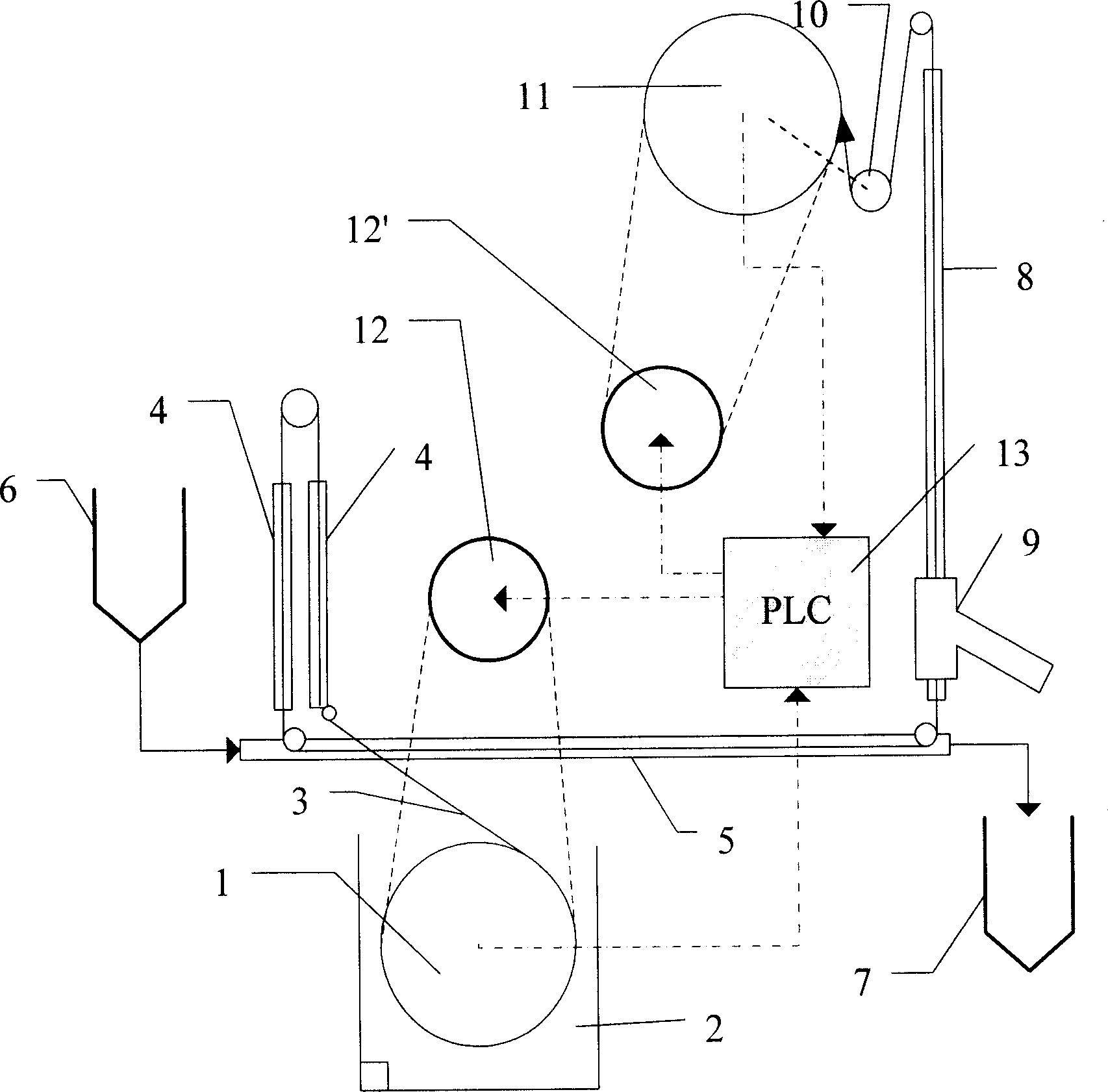

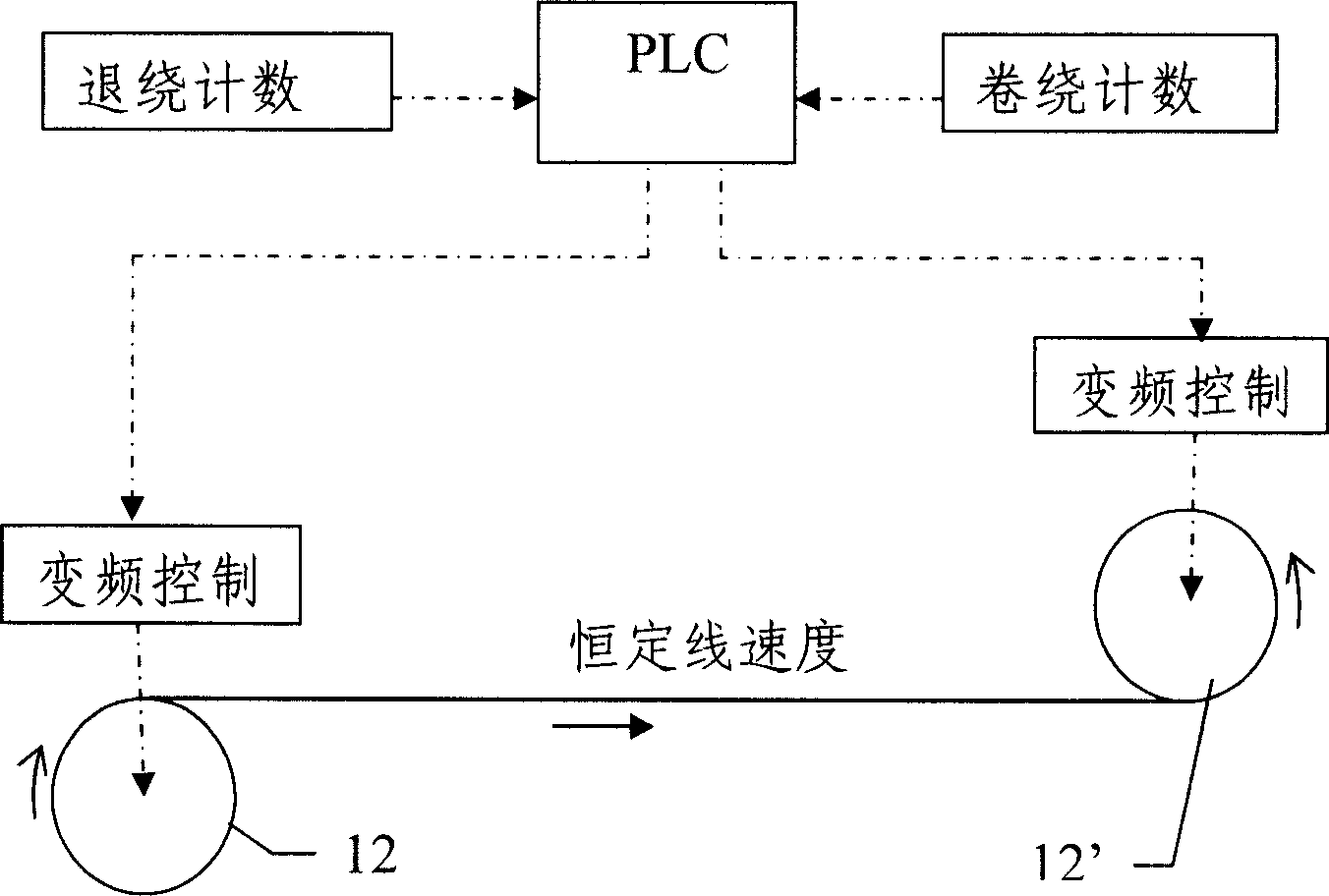

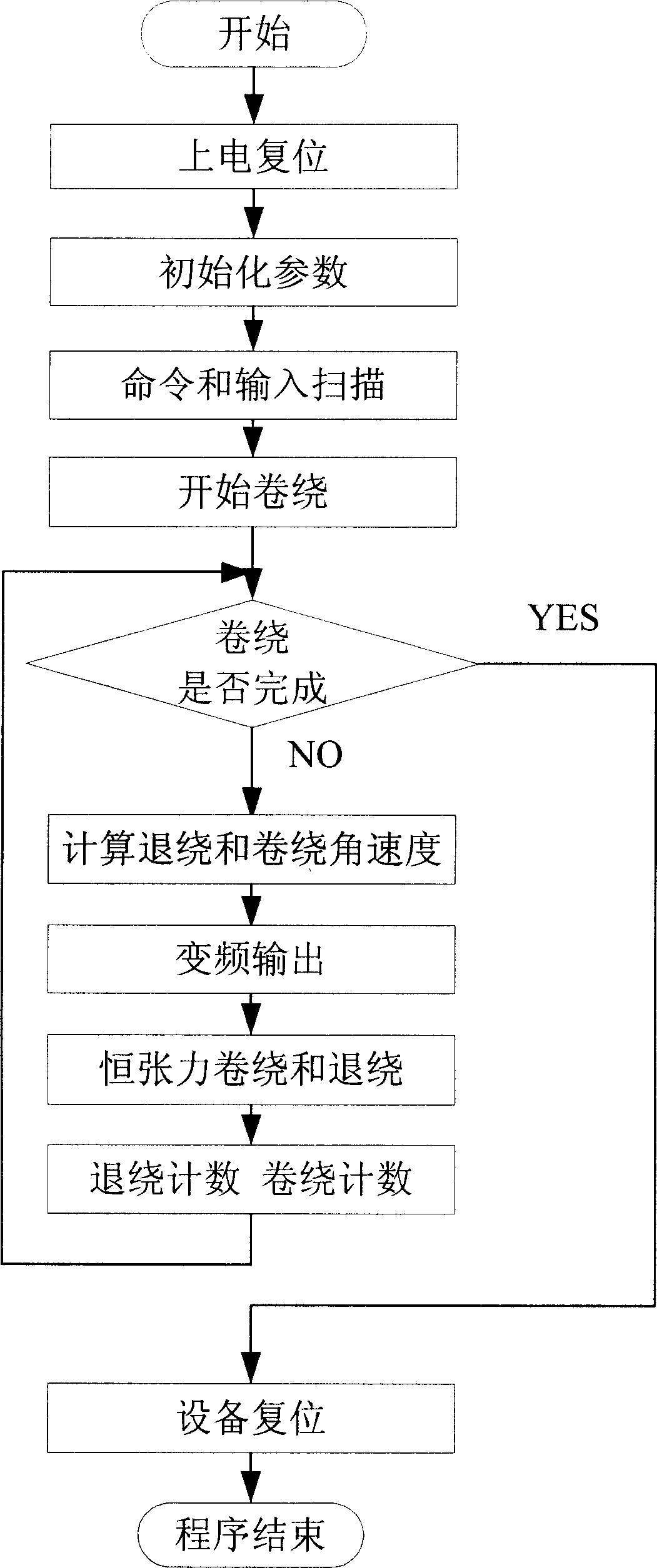

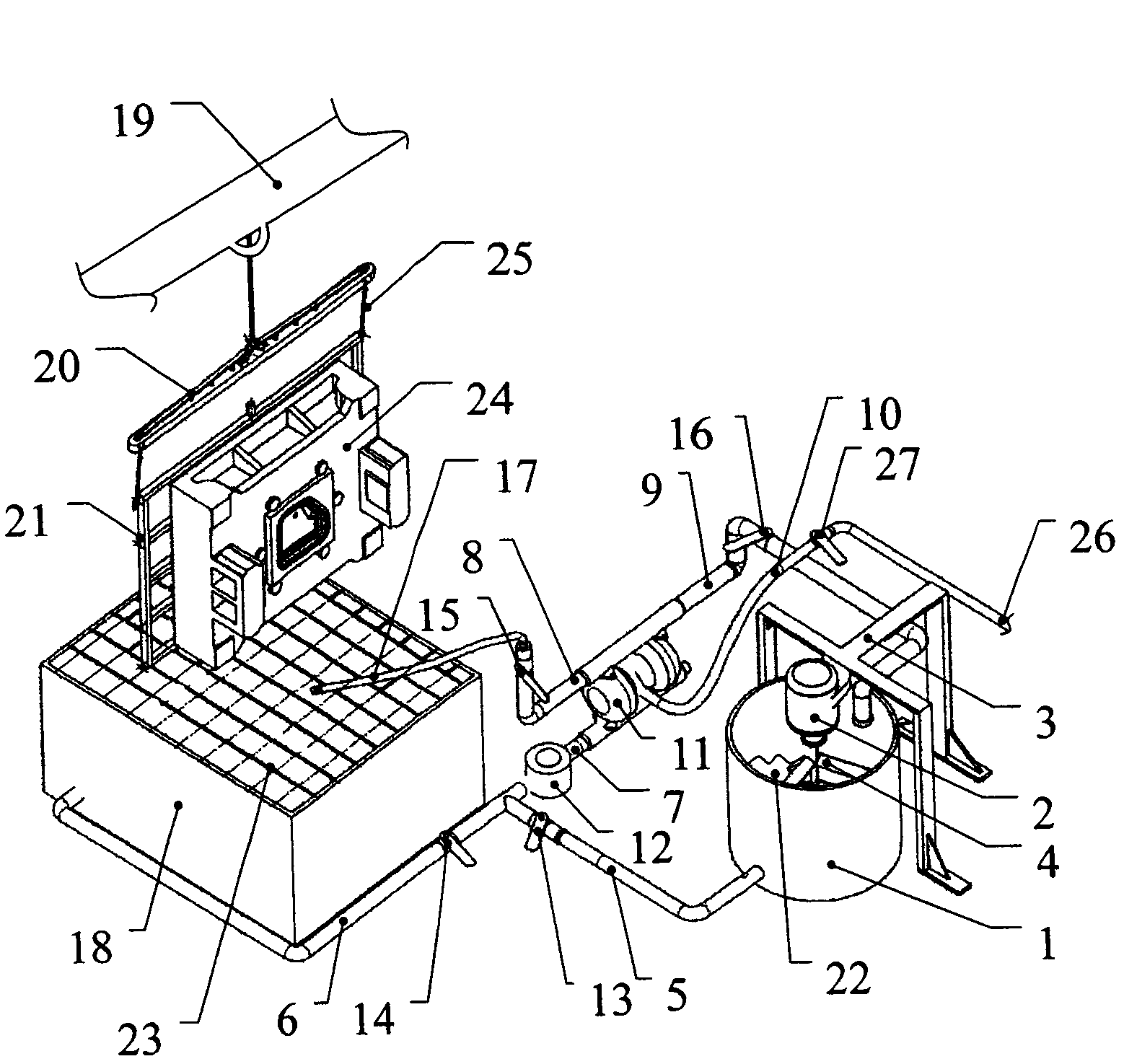

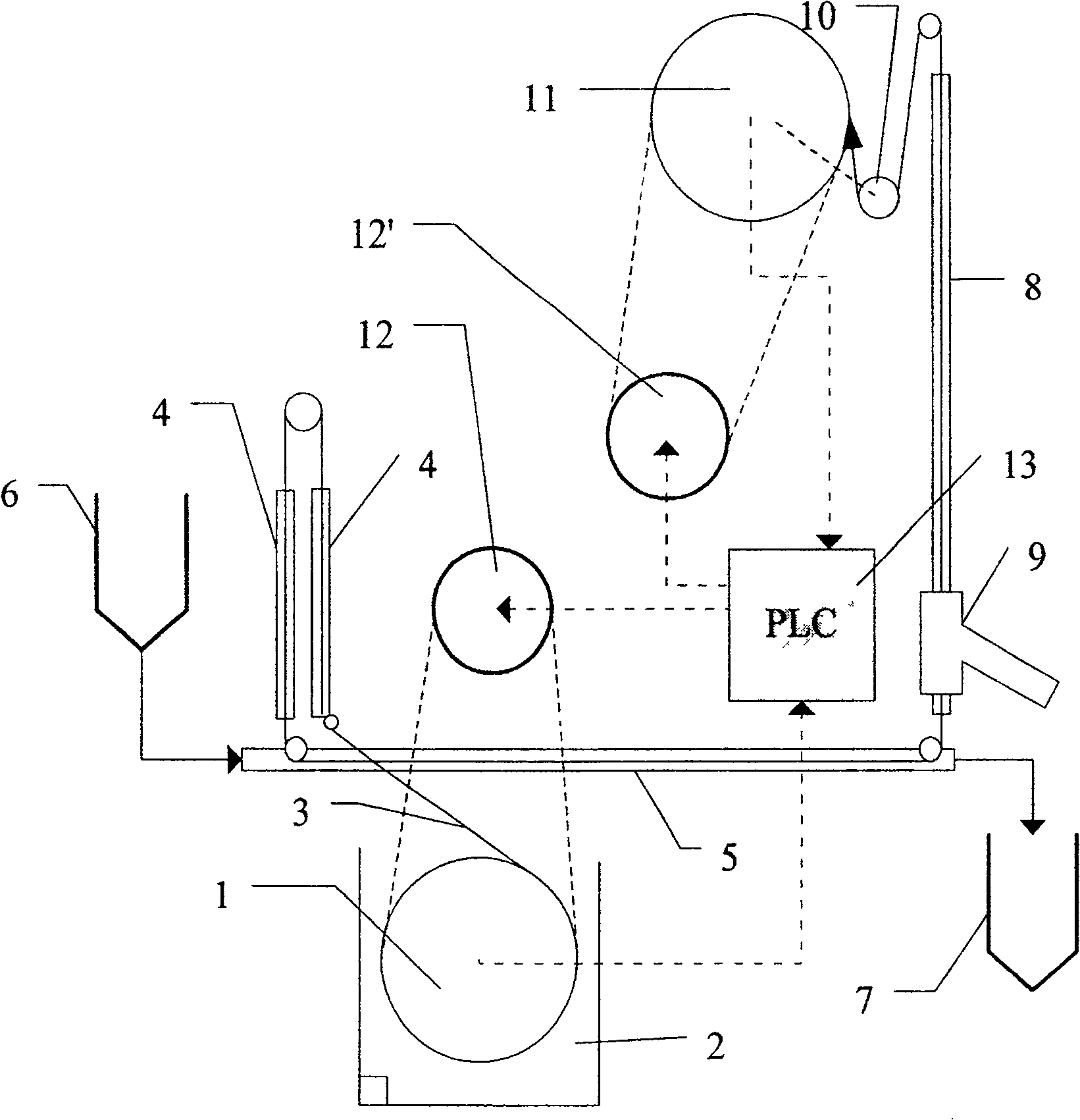

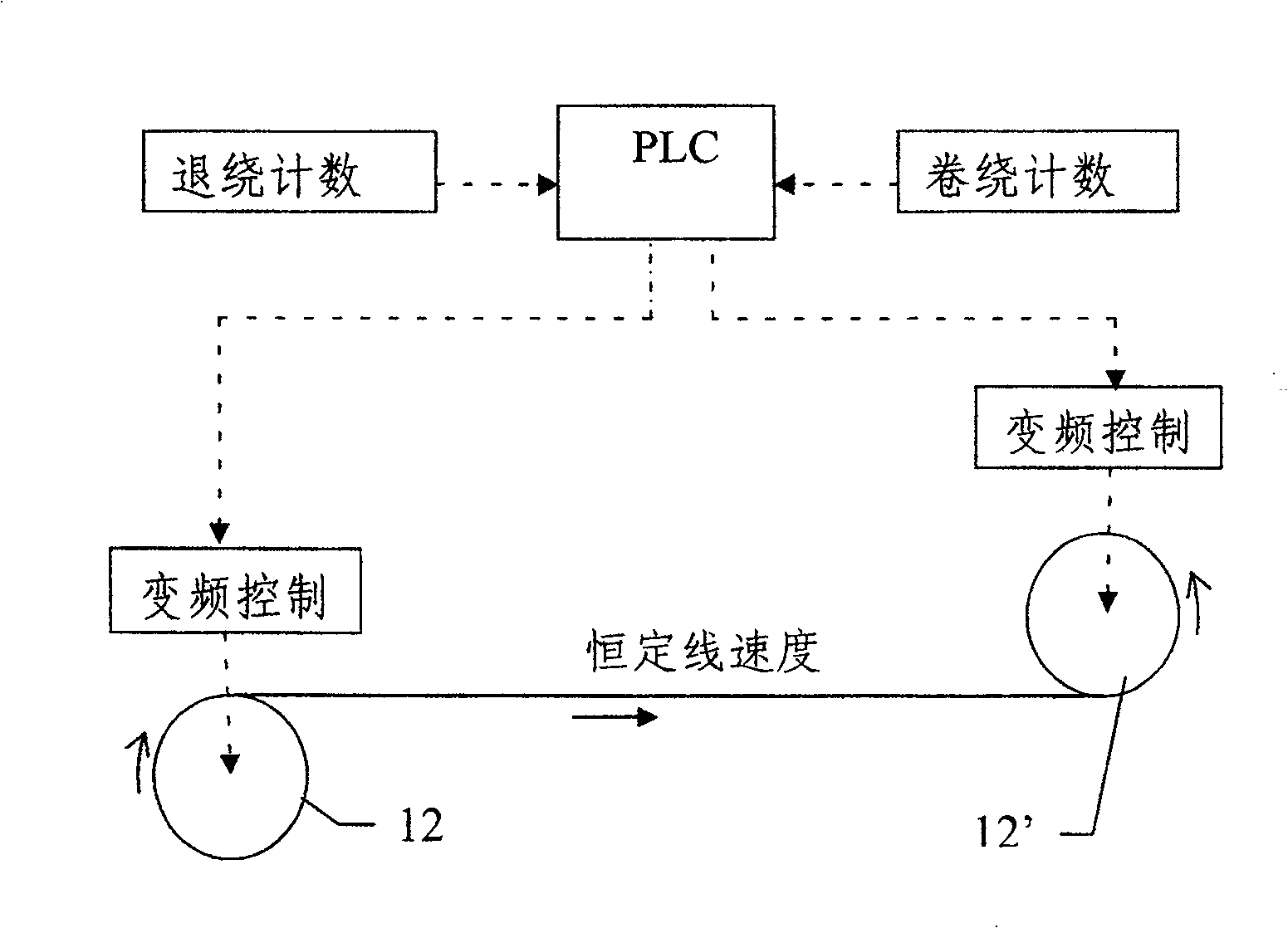

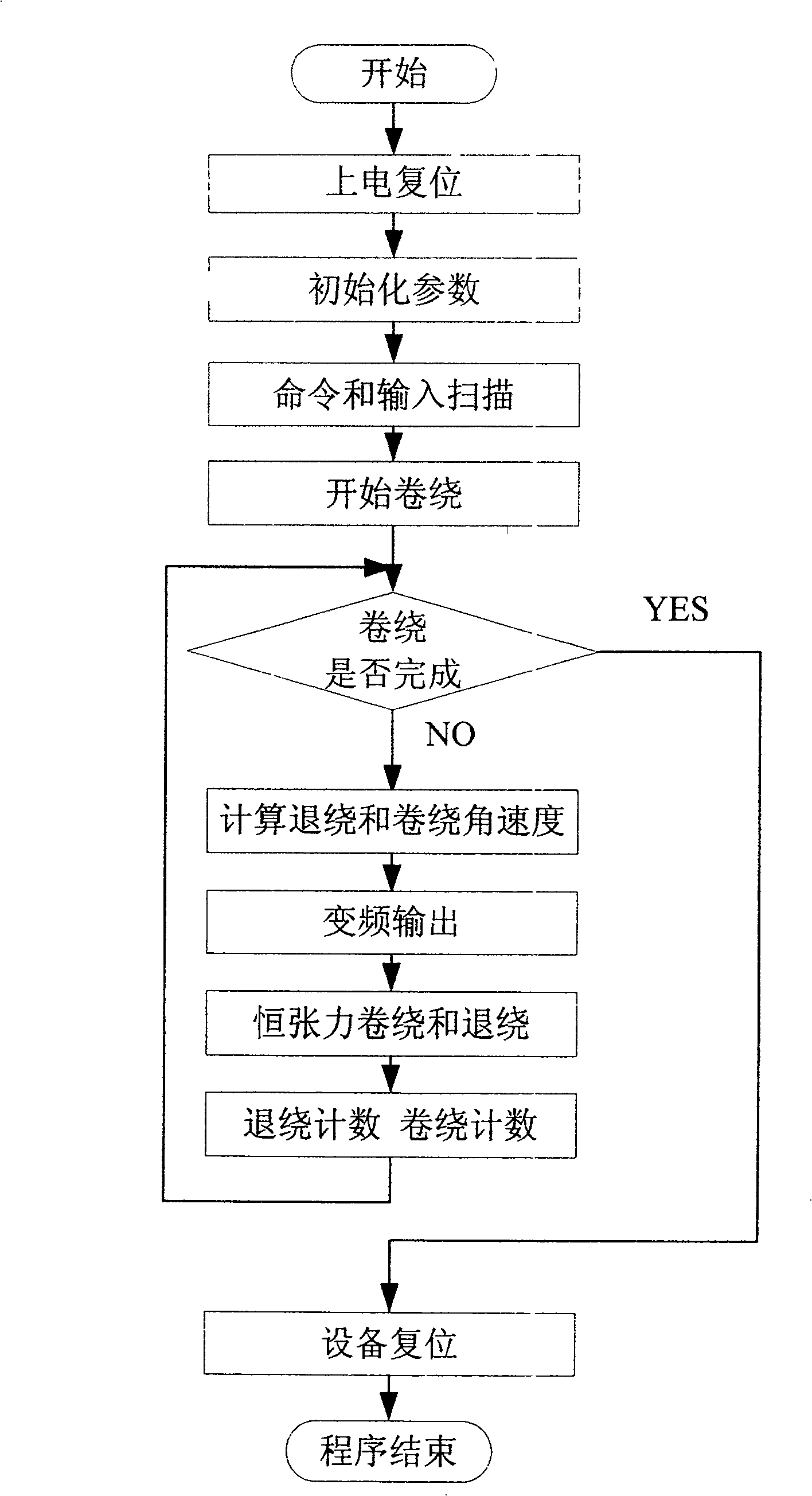

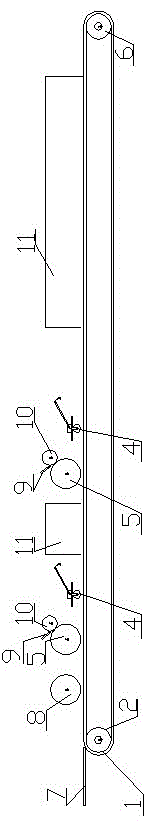

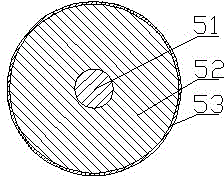

Hollow fiber composite membrane applicator, method for producing said hollow fiber composite membrane and product

The invention relates to a hollow fiber complex coating machine and the preparing method and product. Said coating machine comprises roller installed in water phase tank, front drying pipe, reacting pipe, back drying pipe, godet roller and pick-up roller all of which are sequentially connected with water tank; reacting pipe is installed horizontally and pipe jointed with organic phase replenishing device in the inlet, and pipe jointed with overflow device in the outlet; front drying pipe and back drying pipe are vertically installed; roller and pick-up roller are connected with PLC controller and two variable-frequency control generator connected to PLC controller respectively. The method can continuously produce hollow fiber complex film, which is characterized by even coating and stable quality.

Owner:TIANJIN POLYTECHNIC UNIV

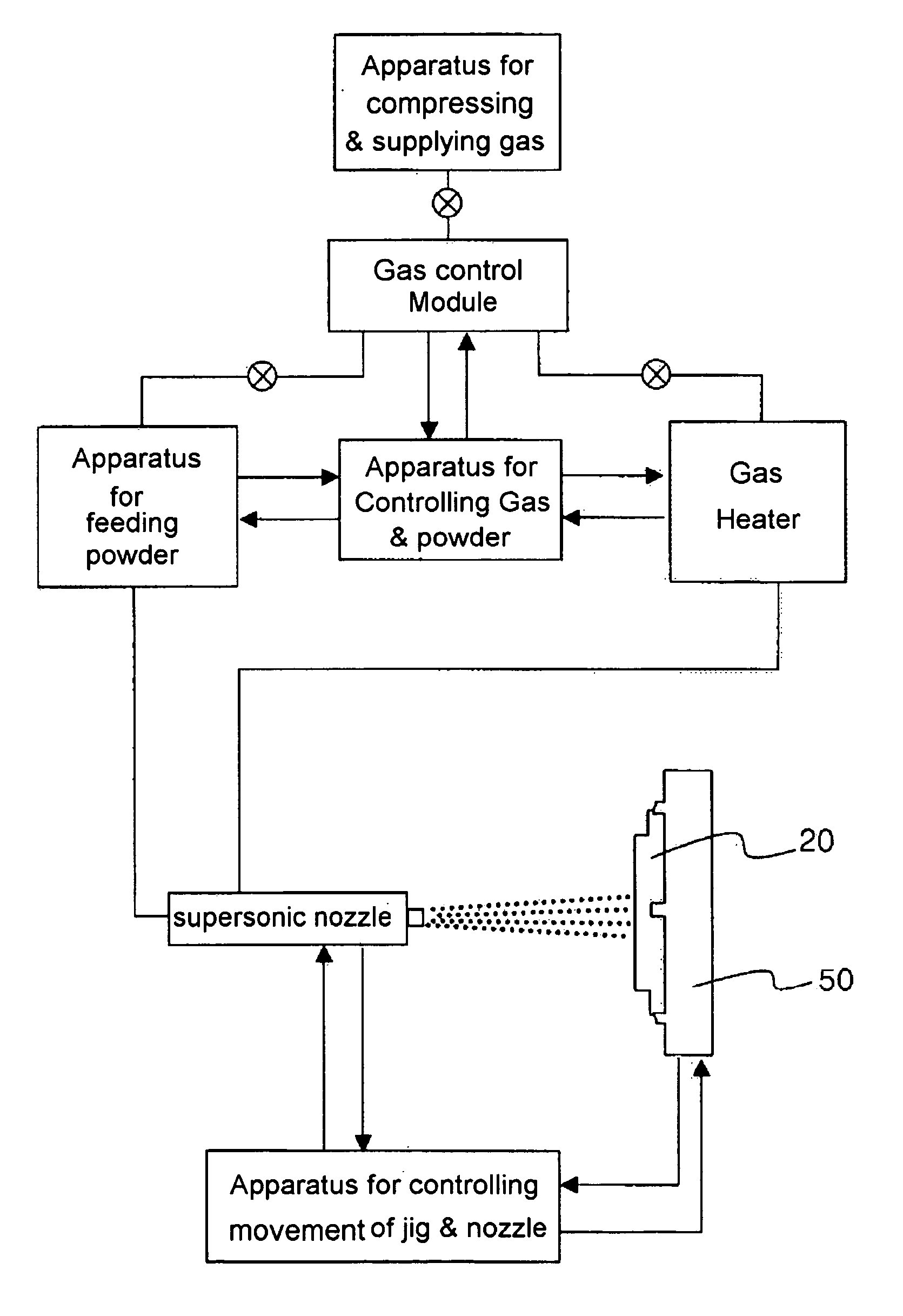

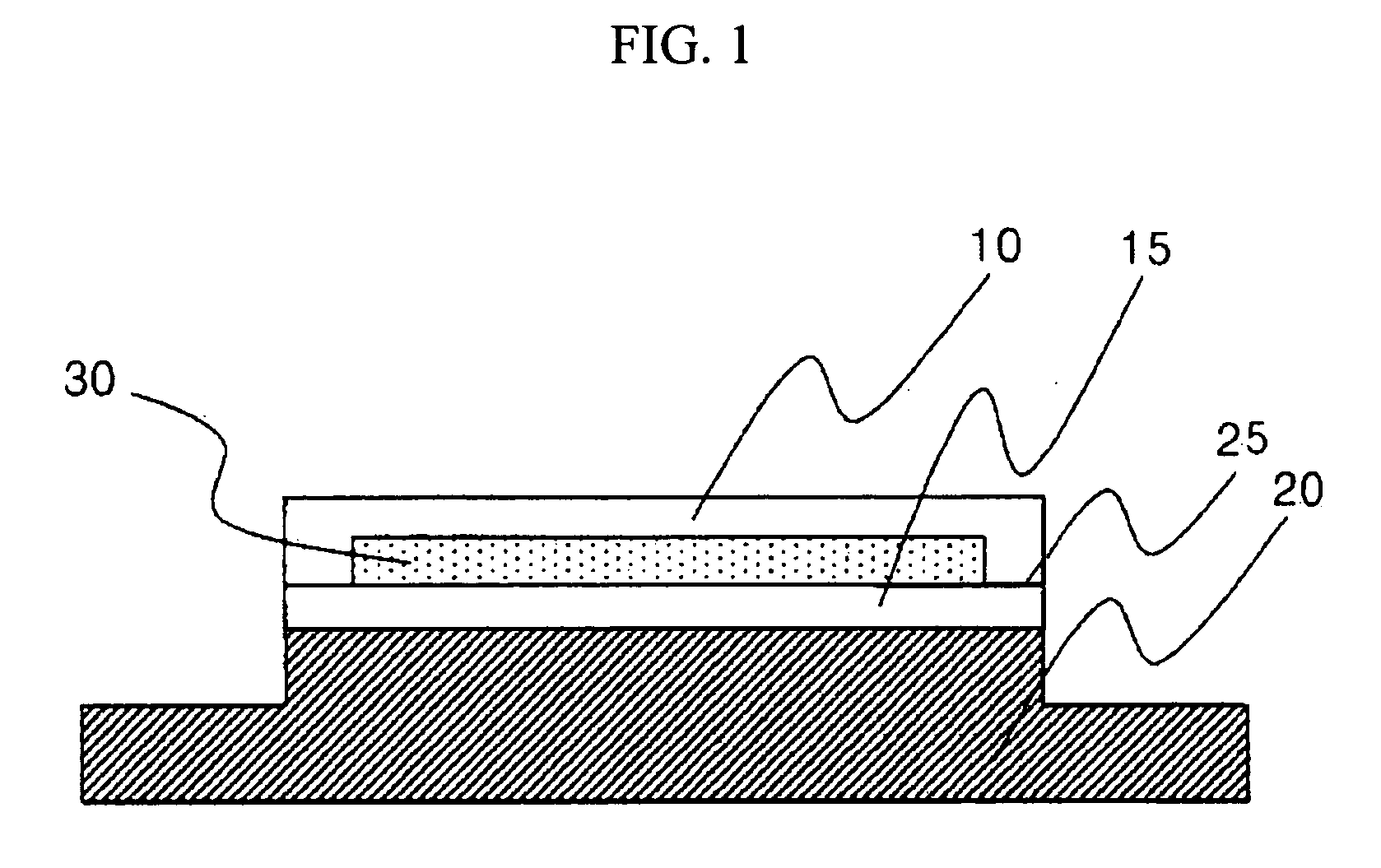

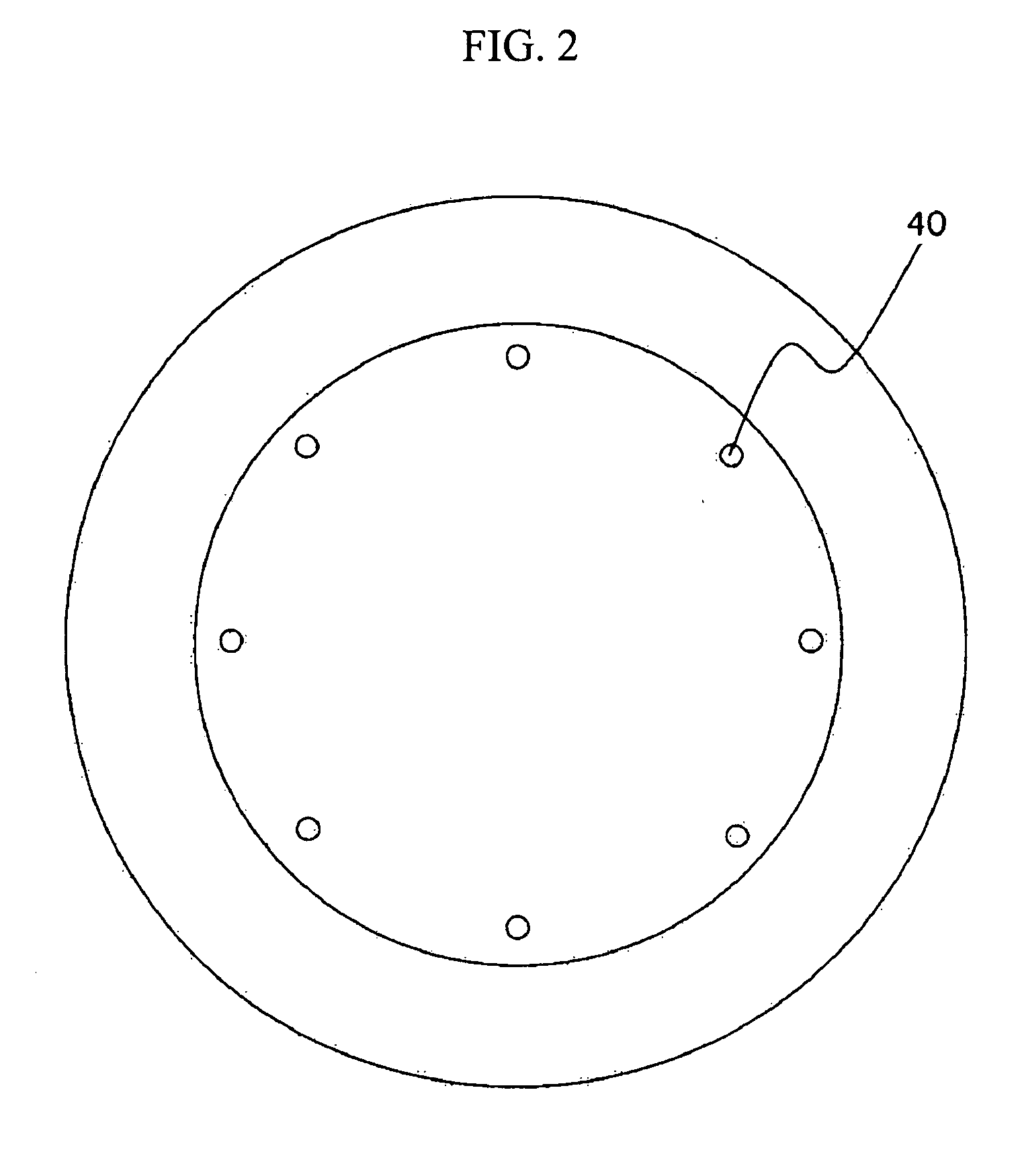

Electro-static chuck with non-sintered aln and a method of preparing the same

InactiveUS20070065678A1Excellent electrostatic propertyImprove thermal conductivityPretreated surfacesSemiconductor/solid-state device manufacturingBonding processNitride

The present invention relates to an electro-static chuck with non-sintered AlN and a method of preparing the same. Especially, the present invention relates to the electro-static chuck with non-sintered AlN which having coated aluminum nitride (AlN) layer as a dielectric one on the purpose of chucking the wafers in the process of wafers and a method of preparing the same. The electro-static chuck of the present invention has excellent dielectric characteristics, bonding strength and thermal conductivity by forming an AlN layer as a dielectric one without sintering process or bonding process with binders.

Owner:SNT CO LTD

Paper printing method for fibrous and leather materials

ActiveCN102597364AGood effectReduce drainage loadWater-repelling agents additionDuplicating/marking methodsFiberAdhesive

Disclosed is a paper printing method for fibrous and leather materials characterized by having: a step wherein printing paper is obtained by applying a mixed paste comprising a water-soluble synthetic binder, a natural adhesive, and an auxiliary agent to base paper, which is then dried to obtain paper for printing, onto which a dye ink is printed; a step wherein the printing paper is bonded to a fibrous or leather material and fixed using pressure / heat; and a step wherein the printing paper is removed after a dye fixing process is carried out while the printing paper is fixed to the fibrous or leather material. Further disclosed are the paper for printing and the printing paper used in the paper printing process, and the fibrous and leather materials characterized by being printed on in the paper printing process.

Owner:山本眩士

Coating device

InactiveCN101648175AFast coatingApply evenlyLiquid surface applicatorsCoatingsBiochemical engineeringCoating

The invention provides a coating device. The coating device comprises an operating platform, a carrier plate which can be slidably arranged on the operating platform, a support arm which is positionedat one side of the carrier plate and fixed on the operating platform, and a coating rod which is arranged on the support arm in a penetrating manner and can slide in relation to the support arm. Thesurface of the carrier plate is provided with a lens fixing area and the lower end of the support arm is just opposite to the lens fixing area. The coating device has the advantages of quick and evencoating after replacing traditional artificial coating, thus improving coating efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

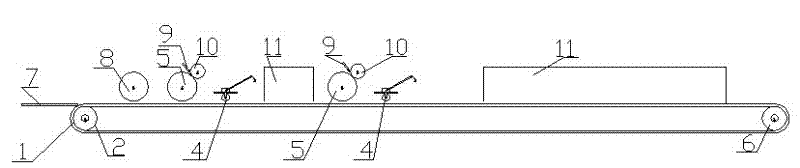

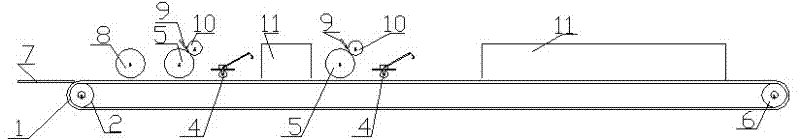

Production process and painting equipment of composite heat-insulation board

ActiveCN102518222AAvoid drippingImprove uniformityLiquid surface applicatorsHeat proofingInsulation layerAdhesive

The invention discloses a production process and painting equipment of a composite heat-insulation board. The production process of the composite heat-insulation board comprises the following steps of: (a) cutting a heat-insulation layer, and coating an adhesive on the upper surface of the heat-insulation layer; (b) preparing protective layer slurry, injecting to a mold, carrying out pressure filtration and molding; (c) laminating the heat-insulation layer and the protective layer; (d) maintaining; and (e) coating paint on the upper surface of the laminated protective layer obtained in the step (d) of the heat-insulation board and drying. The painting equipment comprises a conveyer belt for conveying the heat-insulation board, wherein a coating roller wheel which is in driving connection with a driving device is arranged above the front end of the conveyer belt, a gap, matched with the thickness of the heat-insulation board is formed between the coating roller wheel and the conveyer belt, a charging device for supplementing the paint is arranged above the coating roller wheel, the coating roll wheel comprises a roller wheel shaft at the center and an elastic roller body, and a silk screen is coated on the external surface of the roller body. According the invention, the working procedure is simple, the production efficiency is high, and the painting equipment has good coating effect and high coating efficiency.

Owner:郑州工大高新材料科技有限公司

Metal flexible cloth for metal surface modification and preparation method thereof

The invention relates to a special metal flexible cloth for the preparation of a coating with high temperature and corrosion resisting and a preparation method thereof. The metal flexible cloth can be used for the protection of mechanical parts in fields, i.e. a power station, petroleum, aviation, food, plastic, and the like. The metal powder cloth is prepared by adding a forming agent and a bonding agent into the mixed power of metals, i.e. WC-Co, Ni, Cr, and the like, and the cloth patch can be bonded on a metal base body by an organic bonding agent to form a thicker protective layer with abrasion resistance, high temperature resistance and corrosion resistances by being metallurgically combined with the metal base body in a penetration brazing way. The coating has good heat conductivity, corrosion resistances and impact resistance, and wrapped parts can recover the original mechanical property of base materials through heat processing, thereby, the costing can be suitable for the recovery of pieces with heterogeneous surfaces and especially suitable for the recovery of a curved surface, a folded surface, a helical surface, and the like. The invention an solve the problems of the high temperature corrosion and the abrasion of parts with serious abrasion and heat resistance in mechanical equipment and power station equipment, decreases the times of stopping production for overhauling and enhances the economic benefits.

Owner:JIANGXI HENGDA HI TECH CO LTD

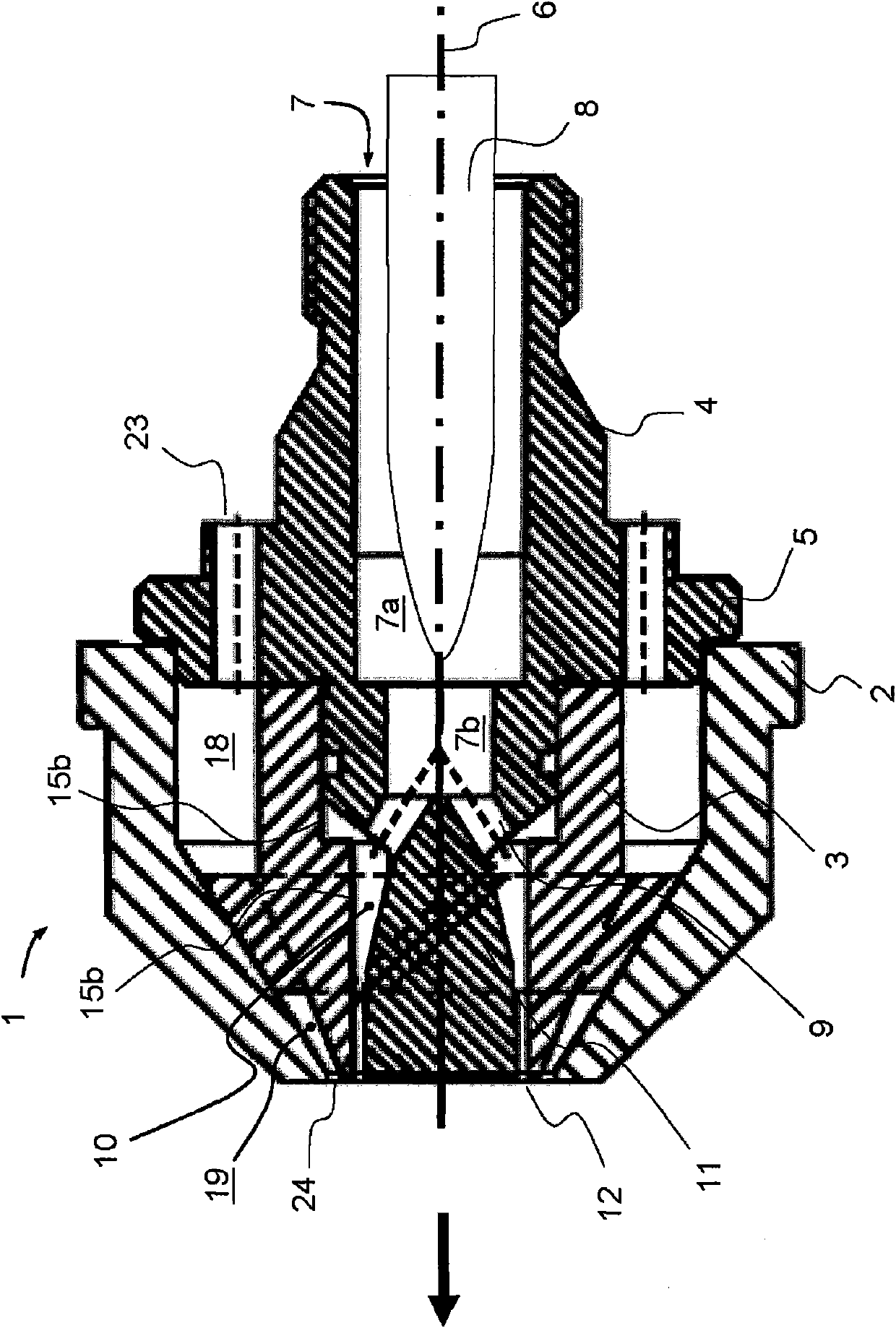

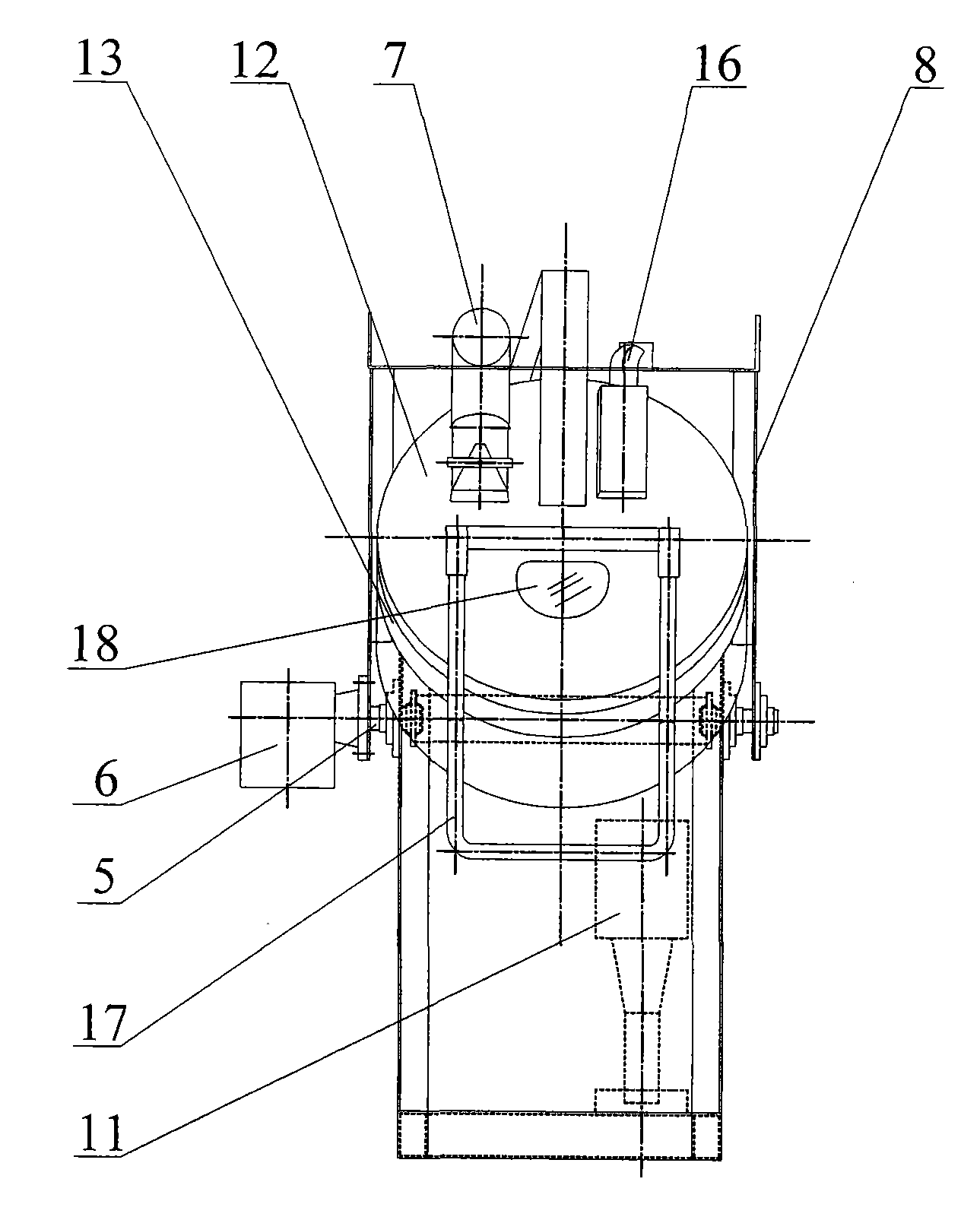

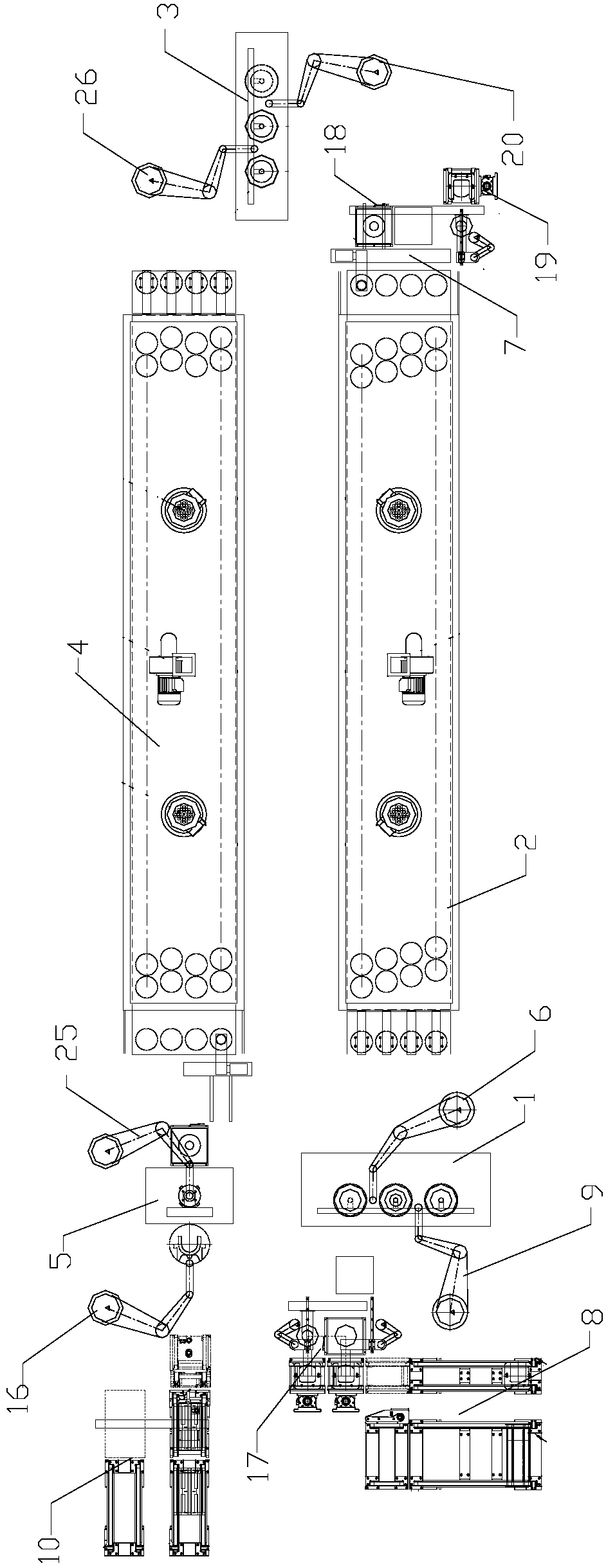

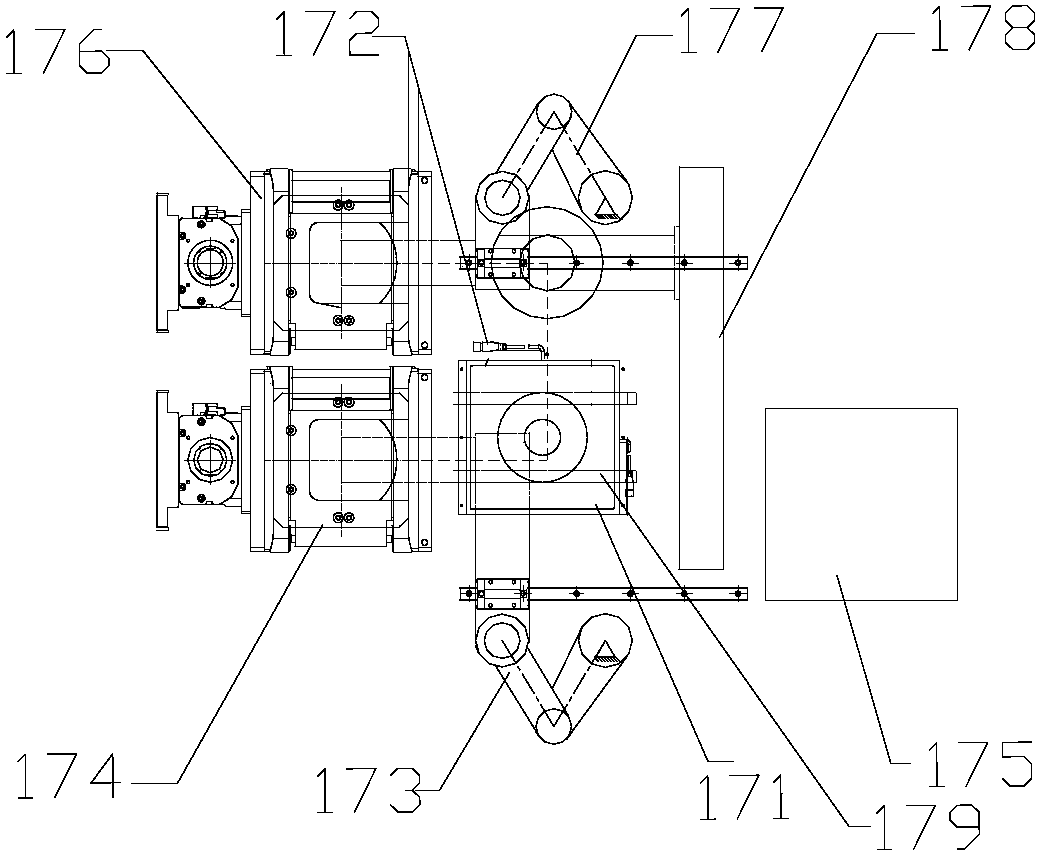

Evanescent mode coating spraying system

InactiveCN102641990AProtect against deformationAvoid damageMoulding toolsFoundry mouldsDiaphragm pumpImpeller

The invention discloses an evanescent mode coating spraying system which comprises a storage vat (1), a motor (2), a motor bracket (3), a stirring impeller (4), a feed delivery pipe (5), a return pipe (6), a connecting pipe (7), an output pipe (8), a feedback pipe (9), an air pipe (10), a pneumatic diaphragm pump (11), a magnetic filter (12), a first control valve (13), a second control valve (14), a third control valve (15), a fourth control valve (16), a spray pipe (17), a storage tank (18), a crown block (19), a lifting frame (20), a mounting rack (21), an evanescent mode coating (22), a mesh enclosure (23) and a fifth control valve (27). The evanescent mode coating spraying system has the advantages and effects that: during the evanescent mode coating process of the system, manpower and material resources as well as time are saved, the coating is uniformly coated, and cannot be limited by an evanescent mode structure, and deformation during the evanescent mode coating process is avoided.

Owner:枣庄市同捷汽车模具有限责任公司

Concave and convex hand feeling texture printing method with high simulation degree

InactiveCN109823071AHigh degree of simulationClose to the real pattern effectDuplicating/marking methodsPattern printingSurface layerHeight difference

The invention discloses a concave and convex hand feeling texture printing method with the high simulation degree. The method comprises following steps that A, a plan pattern with textures is generated on printing software; B, through digital printing equipment, multiple layers of UV ink are printed on the position, with the texture position, of the surface of the plane base material to be machined; C, through an ultraviolet lamp, the UV ink is cured to form a texture layer, and a height difference exists between the texture layer and the surface of the plane base material; D, through the digital printing equipment, the plane patterns are printed on the surface layer of the plane base material and the texture layer. According to the printing method, the surface of the made board has the concave and convex hand feeling, particular hand feeling and visual effects of true wood, stone, fabric and the like can be simulated on the plane base material, the plane pattern is directly printed onthe surface of the plane base material and the surface of the texture layer, the pattern effect and the hand feeling get close to the reality, and the simulation degree is high;

Owner:HOPE CERAMICS MACHINERY

Hollow fiber composite membrane applicator, method for producing said hollow fiber composite membrane

The invention relates to a hollow fiber complex coating machine and the preparing method and product. Said coating machine comprises roller installed in water phase tank, front drying pipe, reacting pipe, back drying pipe, godet roller and pick-up roller all of which are sequentially connected with water tank; reacting pipe is installed horizontally and pipe jointed with organic phase replenishing device in the inlet, and pipe jointed with overflow device in the outlet; front drying pipe and back drying pipe are vertically installed; roller and pick-up roller are connected with PLC controller and two variable-frequency control generator connected to PLC controller respectively. The method can continuously produce hollow fiber complex film, which is characterized by even coating and stable quality.

Owner:TIANJIN POLYTECHNIC UNIV

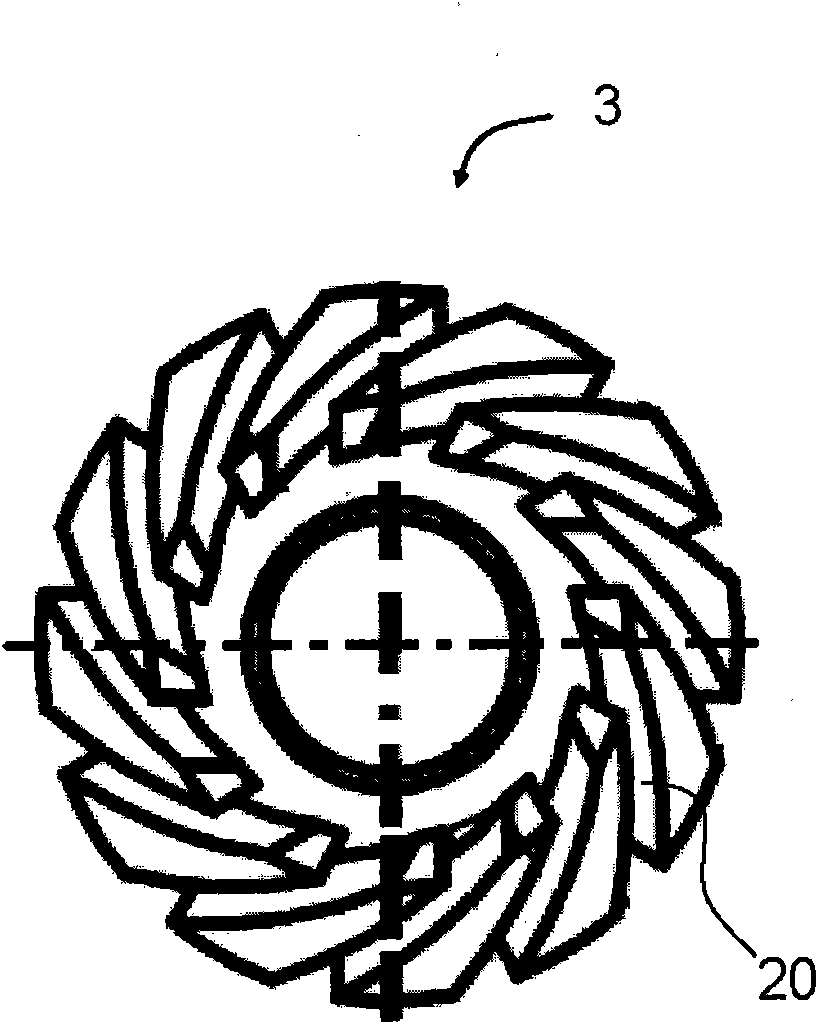

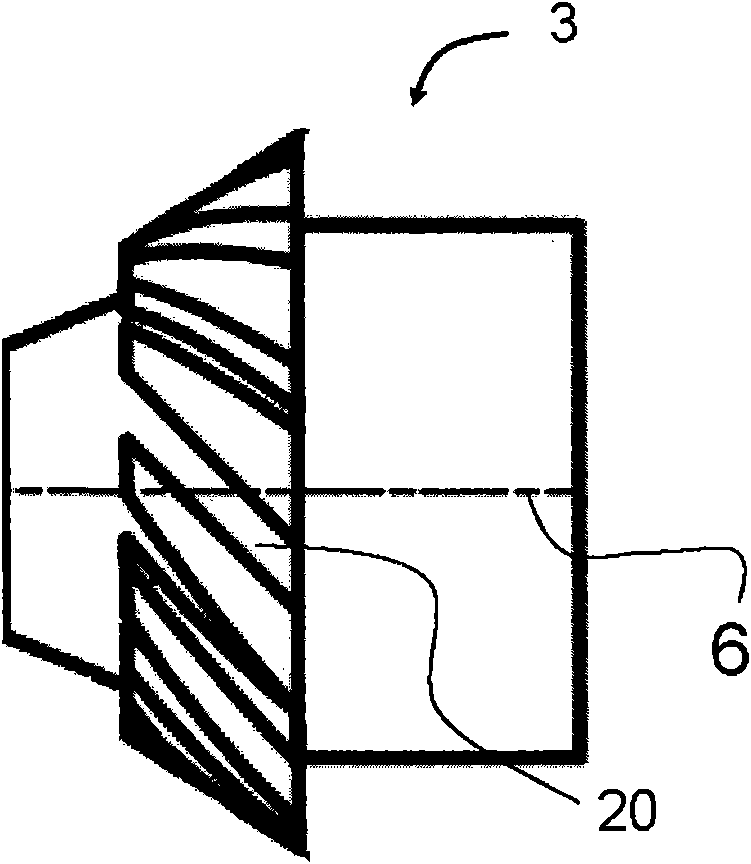

Device and method used for spraying liquid

InactiveCN102114441AHigh coating efficiencyEfficient sprayingLiquid spraying apparatusEngineeringWhirlwind

The invention relates to a method used for pneumatically spraying liquid especially such as colourant, enamel paint, paint, and the like and generating spray that is applied to an object, wherein the method is characterized in that a spraying device (1) is utilized. In the method, liquid basically departs from the spraying device (1) under zero pressure. Spraying air in the spraying device is formed through rotation at a first angle (14) relative to a longitudinal axis (6) of the spraying device and at a second angle (21) relative to an axes (22) perpendicular to the longitudinal axis (6) of the spraying device, so that spraying air can depart from the spraying device in a whirlwind manner. The first angle (14) ranges from 25 to 40 degrees, and the second angle (21) ranges from 35 to 55 degrees. Liquid is sprayed by spraying air after departing from the spraying device.

Owner:EIC GRP GMBH (DE)

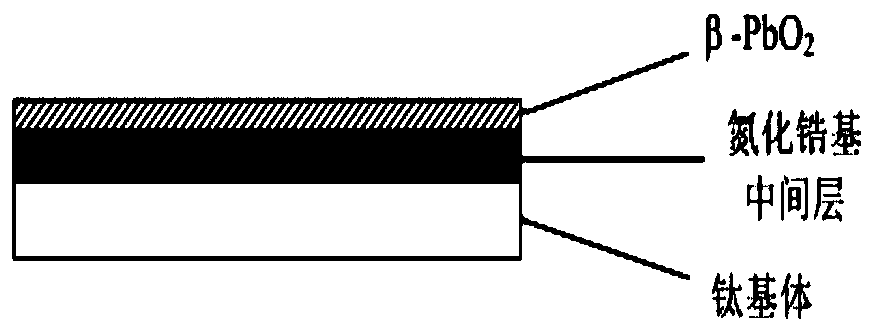

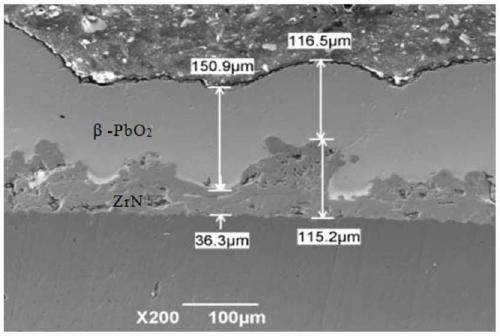

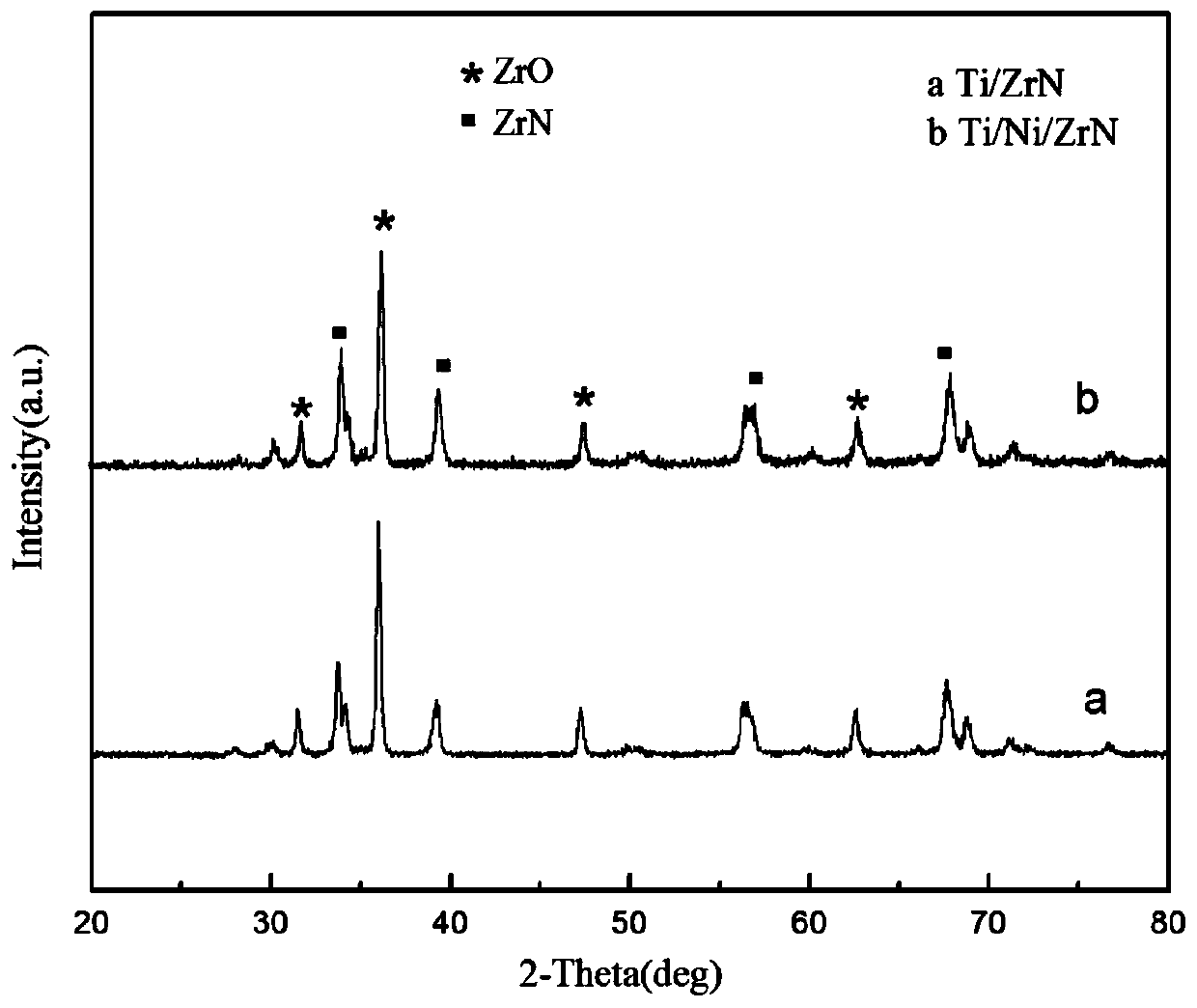

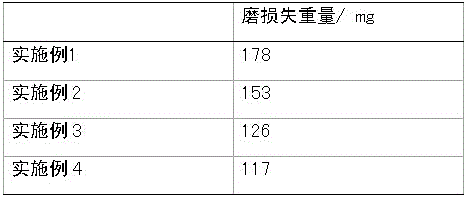

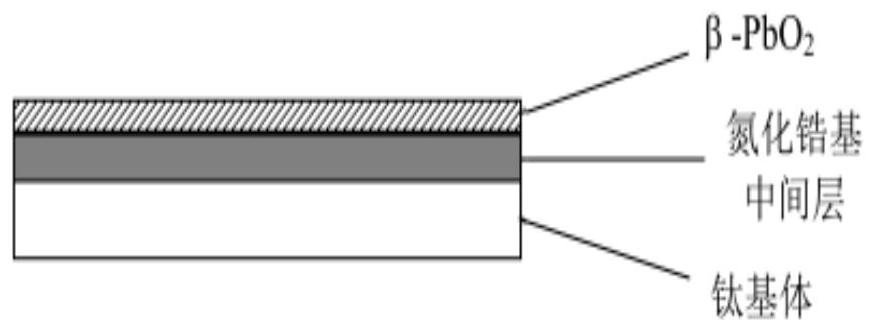

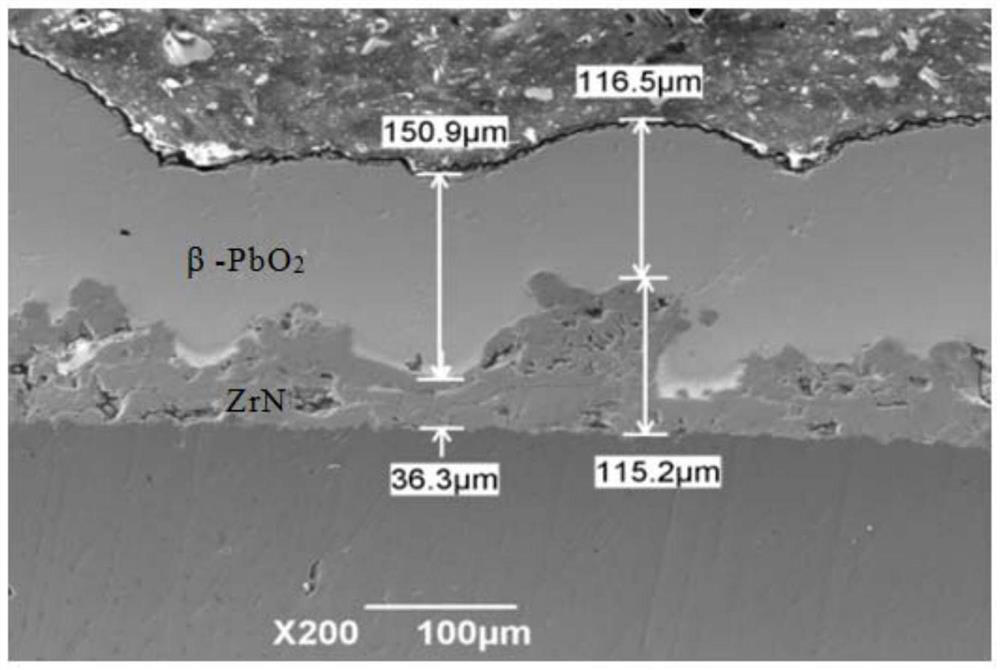

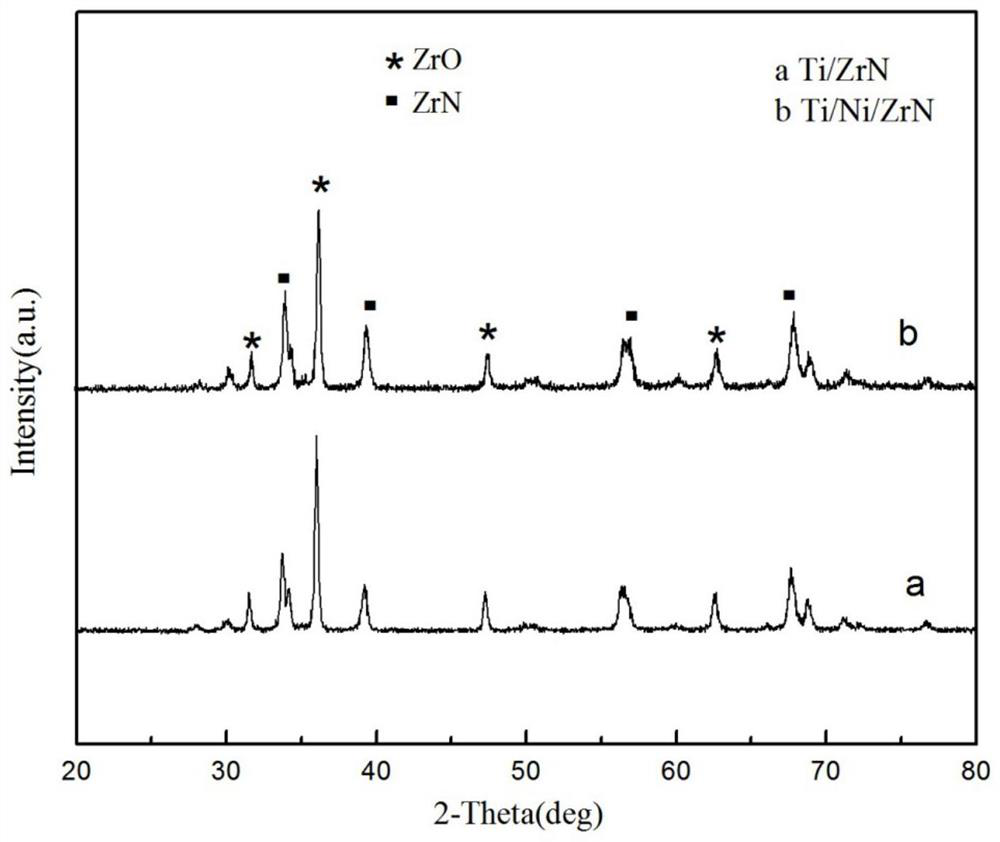

Electric arc thermal spraying preparing method for life prolonging and energy saving shape stabilizing PbO2 anode intermediate layer

ActiveCN109778100AEasy to operatePromote crystallizationMolten spray coatingAcid etchingThermal spraying

The invention discloses an electric arc thermal spraying preparing method for a life prolonging and energy saving shape stabilizing PbO2 anode intermediate layer. A conductive and corrosion-resistantzirconium-nitride-based intermediate layer is prepared on the surface of a titanium base material through electric arc thermal spraying, wherein the titanium base material is subjected to oil removaland acid etching pretreatment; then, anode electro-deposition of a beta-PbO2 active layer is conducted on the zirconium-nitride-based intermediate layer, and accordingly a long-service-life and low-energy-consumption Ti / ZrN / PbO2 coating anode is obtained. Excellent electrical conductivity and acid, alkali and salt corrosion resistance of the sprayed zirconium-nitride-based intermediate layer are brought into full play, good bonding strength is achieved between the sprayed zirconium-nitride-based intermediate layer and a titanium matrix, firm loading of the beta-PbO2 active layer can be achieved through the coarse sprayed surface; meanwhile, migration of corrosive media and active oxygen towards an anode substrate can be effectively resisted, screen protection and other functions are achieved, and the service life of an anode is obviously prolonged; and in addition, the intermediate layer has good electrical conductivity, the cell voltage of the electrochemical process is obviously reduced, and energy consumption is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

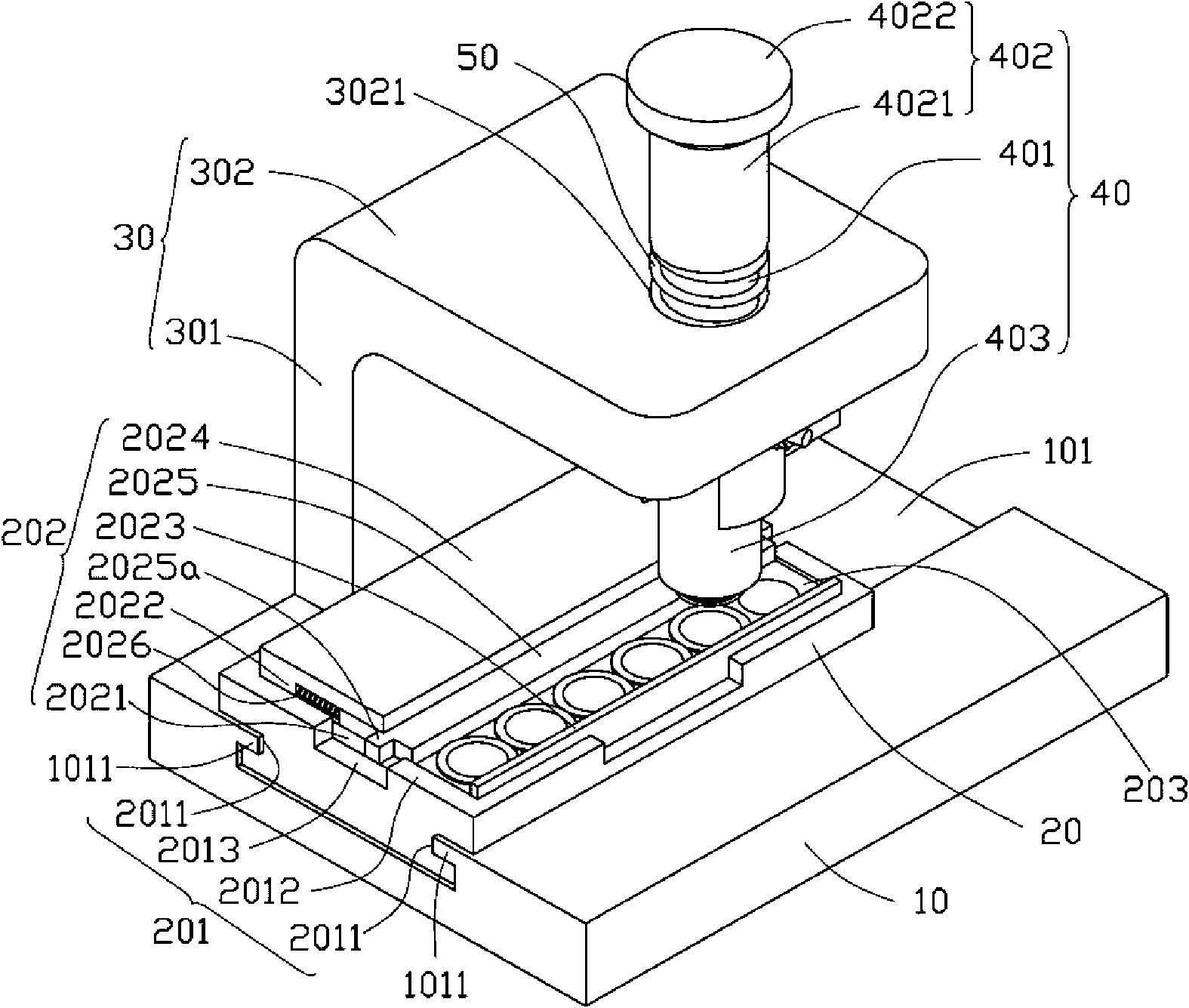

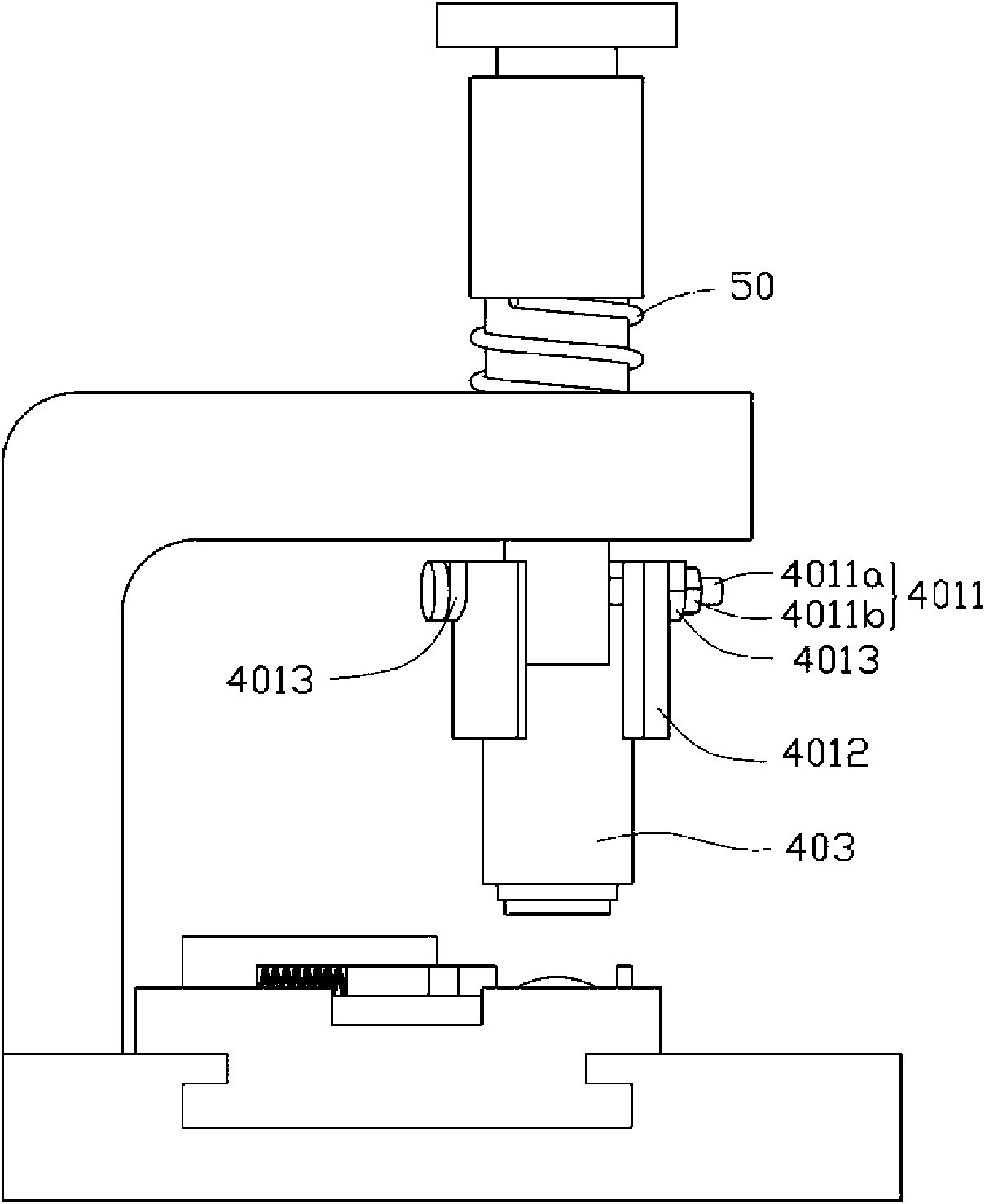

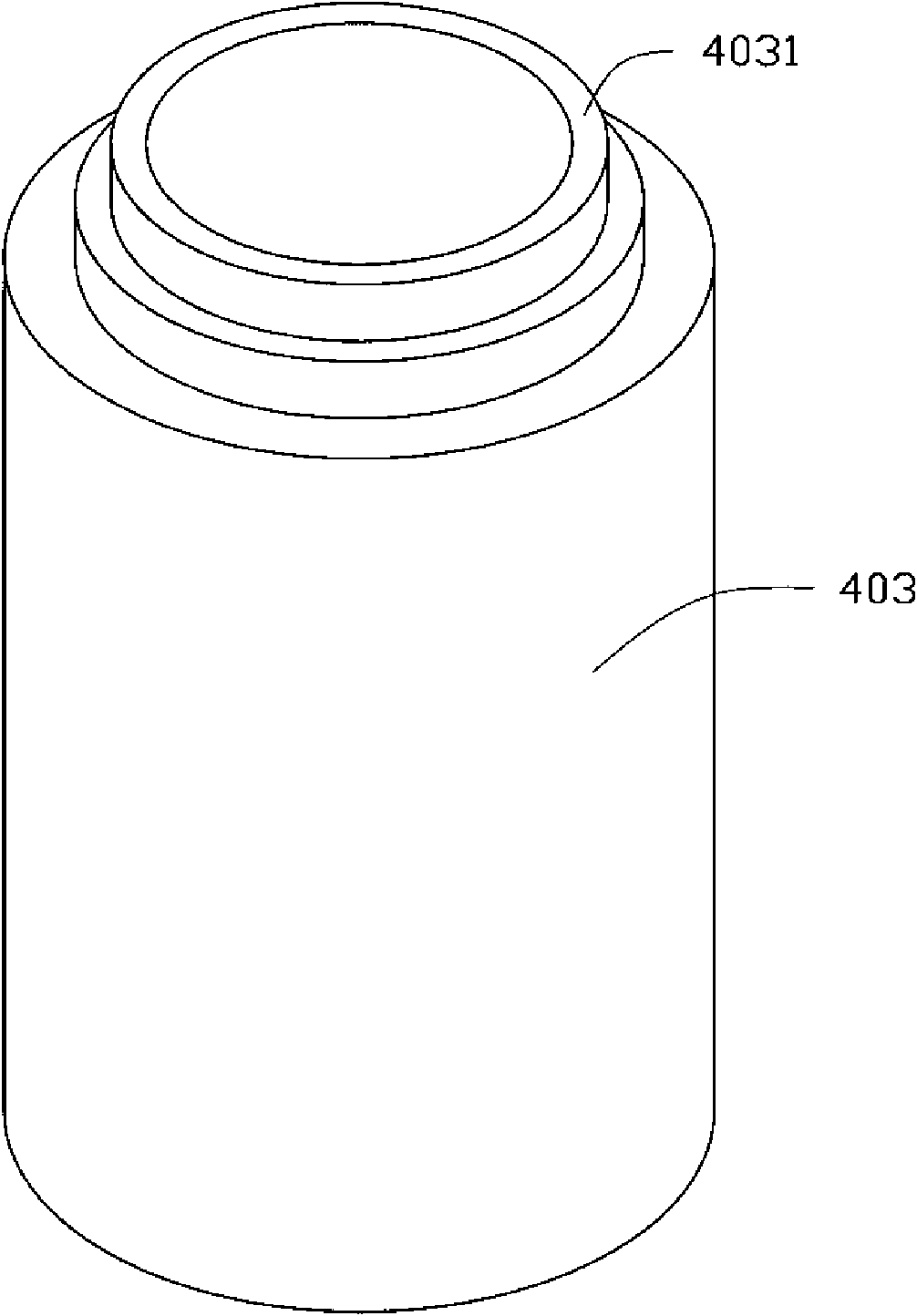

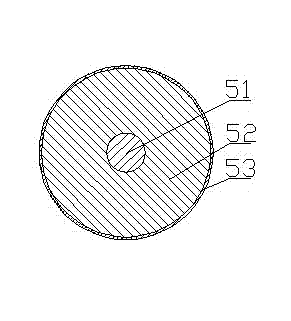

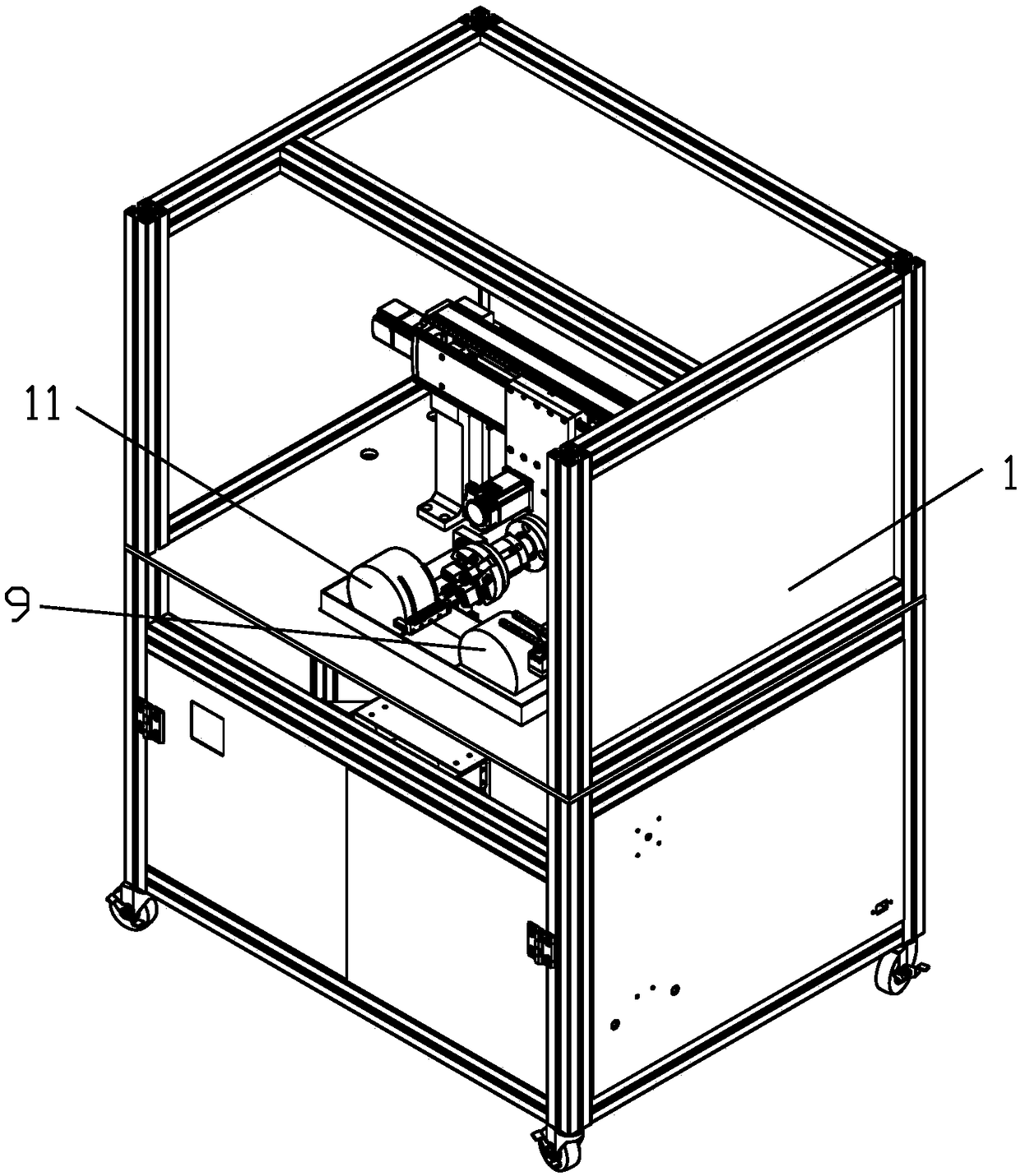

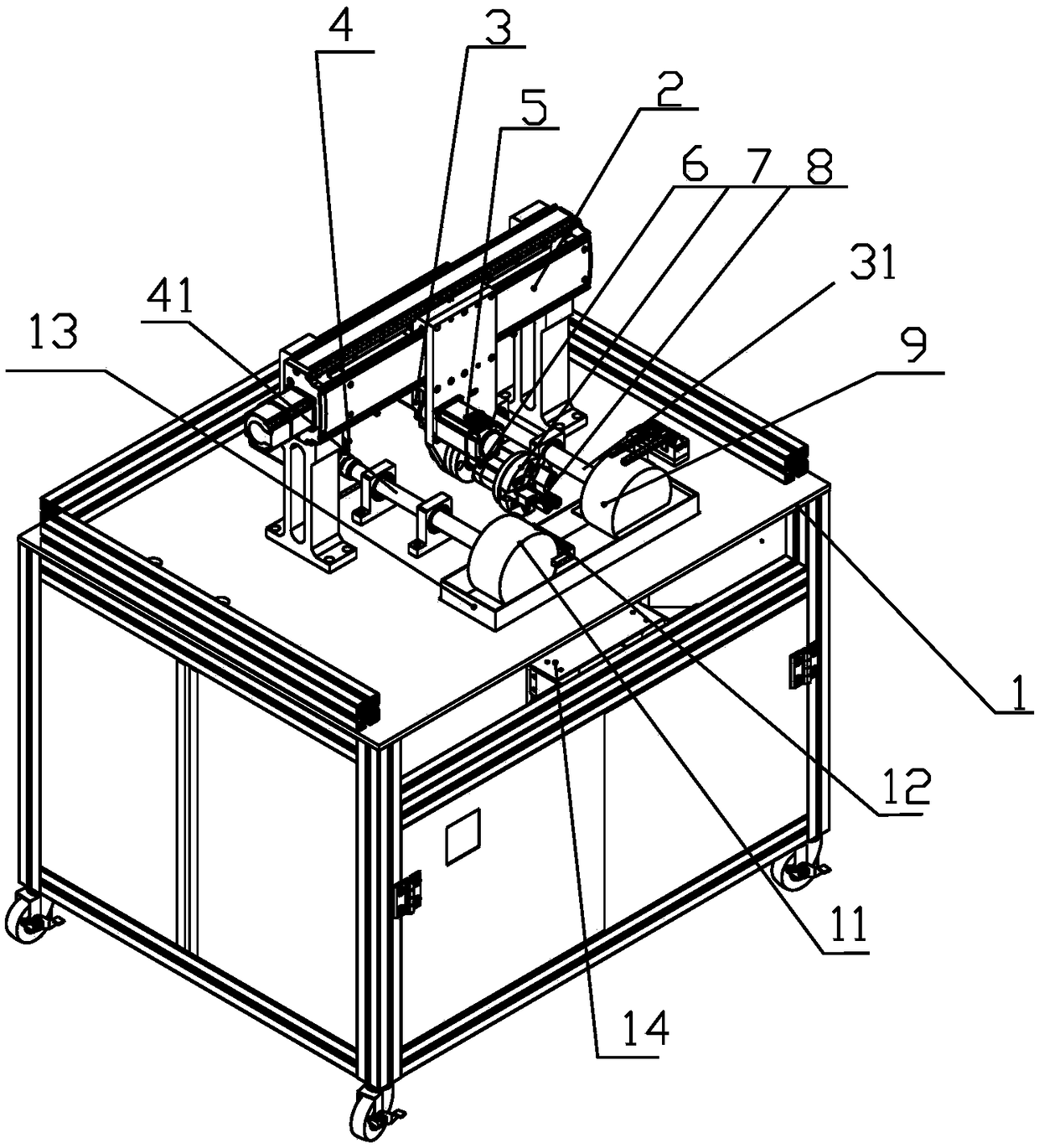

Motor rotor lamination gluing machine and method

PendingCN108097518AApply evenlyHigh coating efficiencyLiquid surface applicatorsManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses a motor rotor lamination gluing machine and method. The motor rotor lamination gluing machine comprises a glue groove device, a rotor lamination clamping-rotating device, a gluing device, a glue scraping device and a rotor lamination moving device. The glue groove device comprises a glue groove which is provided with a glue containing cavity capable of being injected with glue, and the glue groove is at least provided with a gluing and glue scraping station. The rotor lamination clamping-rotating device is used for loading and unloading motor rotor laminations and can drive the motor rotor laminations mounted on the rotor lamination clamping-rotating device to rotate. The gluing device comprises gluing wheels and gluing wheel rotating driving mechanisms which are connected with the gluing wheels so as to drive the gluing wheels to rotate. According to the motor rotor lamination gluing machine and method, coating on the motor rotor laminations is even, and the coating efficiency is improved; the problem that in the current industry, flying dust and discharging, comprising factors which can cause damage to the occupational health of operators, are generated inthe coating process adopting 3M epoxy powder is solved; and zero discharging and efficient automated production are achieved.

Owner:江苏三禾新能源科技有限公司

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838BHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyAviation

Owner:JIANGXI HENGDA HI TECH CO LTD

Activated molybdenum-manganese slurry used in ceramic metallization and preparing method thereof

The invention provides activated molybdenum-manganese slurry used in ceramic metallization and a preparing method thereof. The slurry comprises, by mass percentage, 0.5% of added herring oil, and 0.1% of soybean lecithin, so that degree of finish of a prepared ceramic metallization printed layer can be raised from 85% to 95% or above, and the sealing strength of the metallization is raised from a range (larger than or equal to 70 MPa) to a range (larger than or equal to 100 MPa). The provided preparing method is simple in technology and easy to operate; meanwhile, the complexity of the preparing procedures is reduced, the preparing method has good repeatability, and thus the preparing method is suitable for industrial production.

Owner:康文涛

A production process of automobile door and window frame

ActiveCN107138645BExtended service lifeHarm reductionFouling preventionMetal-working apparatusCar doorExtrusion

The invention discloses a car door and window frame production process, and relates to the field of cars. A car door and window frame is manufactured through the steps of window frame strip extrusion, window frame strip combination, car door assembling, electrophoretic painting, stopping opening gluing, drying, stopping opening paint repairing, sealing strip installing and the like. According to the car door and window frame production process, a blank is pressed into a die cavity in a certain shape to form window frame strips in different models, then the window frame strips are combined to form car window frames in different shapes, the production process is simple, large production equipment is not needed, the application scope is wide, and the product quality is even.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Fluorine-containing polymer powder and method for production thereof and coated article

InactiveUS7094838B2High coating efficiencyMaintain good propertiesCoatingsPolymer scienceHeat resistance

A stabilized fluorine-containing polymer powder having an average particle size of 5 to 100 μm is prepared by contacting a fluorine-containing polymer powder, which is prepared by milling the fluorine-containing polymer and removing fine particles, fibrous particles and coarse particles by classification, with a fluorinating agent so that the total number of unstable terminal groups is decreased to 7 to 50 per 106 carbon atoms. This a fluorine-containing polymer powder achieved a high coating efficiency in an electrostatic coating method and provides a film having good properties such as heat resistance, non-tackiness, low frictional property, chemical resistance, etc.

Owner:DAIKIN IND LTD

Metalized slurry of power battery sealing connector and preparation method of metalized slurry

InactiveCN110120275AWell mixedFully brokenNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveActive agent

The invention discloses metalized slurry of a power battery sealing connector and a preparation method of the metalized slurry. The metalized slurry comprises a metalized raw material and an organic adhesive, and the mass ratio of the metalized raw material to the organic adhesive is 8-9 : 1-2. The metalized raw material comprises a metal oxide active agent, and the metal oxide active agent comprises the following components in percentage by mass: 10-15% of aluminum oxide powder, 8-15% of silicon dioxide, 1-2% of titanium dioxide and 1-2% of tantalum pentoxide. The organic adhesive comprises ethyl cellulose, terpene alcohol, organic silicon defoamer and an organic silicon flatting agent, and the mass ratio of the ethyl cellulose to the terpene alcohol to the organic silicon defoamer to theorganic silicon flatting agent is 10-15 : 1000-1199 : 3 : 5. The roughness of the metalized surface of the sintered battery sealing connector is reduced to be less than or equal to 1.0 [mu]m, and themetalized sealing strength is improved to be more than or equal to 120Mpa.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

Metal flexible cloth for metal surface modification and preparation method thereof

Owner:JIANGXI HENGDA HI TECH CO LTD

Paper printing method for fibrous and leather materials

ActiveCN102597364BGood effectReduce drainage loadWater-repelling agents additionDuplicating/marking methodsFiberAdhesive

Owner:山本眩士

Production process and painting equipment of composite heat-insulation board

ActiveCN102518222BHigh strengthImprove volume stabilityLiquid surface applicatorsHeat proofingAdhesive cementInsulation layer

The invention discloses a production process and painting equipment of a composite heat-insulation board. The production process of the composite heat-insulation board comprises the following steps of: (a) cutting a heat-insulation layer, and coating an adhesive on the upper surface of the heat-insulation layer; (b) preparing protective layer slurry, injecting to a mold, carrying out pressure filtration and molding; (c) laminating the heat-insulation layer and the protective layer; (d) maintaining; and (e) coating paint on the upper surface of the laminated protective layer obtained in the step (d) of the heat-insulation board and drying. The painting equipment comprises a conveyer belt for conveying the heat-insulation board, wherein a coating roller wheel which is in driving connection with a driving device is arranged above the front end of the conveyer belt, a gap, matched with the thickness of the heat-insulation board is formed between the coating roller wheel and the conveyer belt, a charging device for supplementing the paint is arranged above the coating roller wheel, the coating roll wheel comprises a roller wheel shaft at the center and an elastic roller body, and a silk screen is coated on the external surface of the roller body. According the invention, the working procedure is simple, the production efficiency is high, and the painting equipment has good coating effect and high coating efficiency.

Owner:郑州工大高新材料科技有限公司

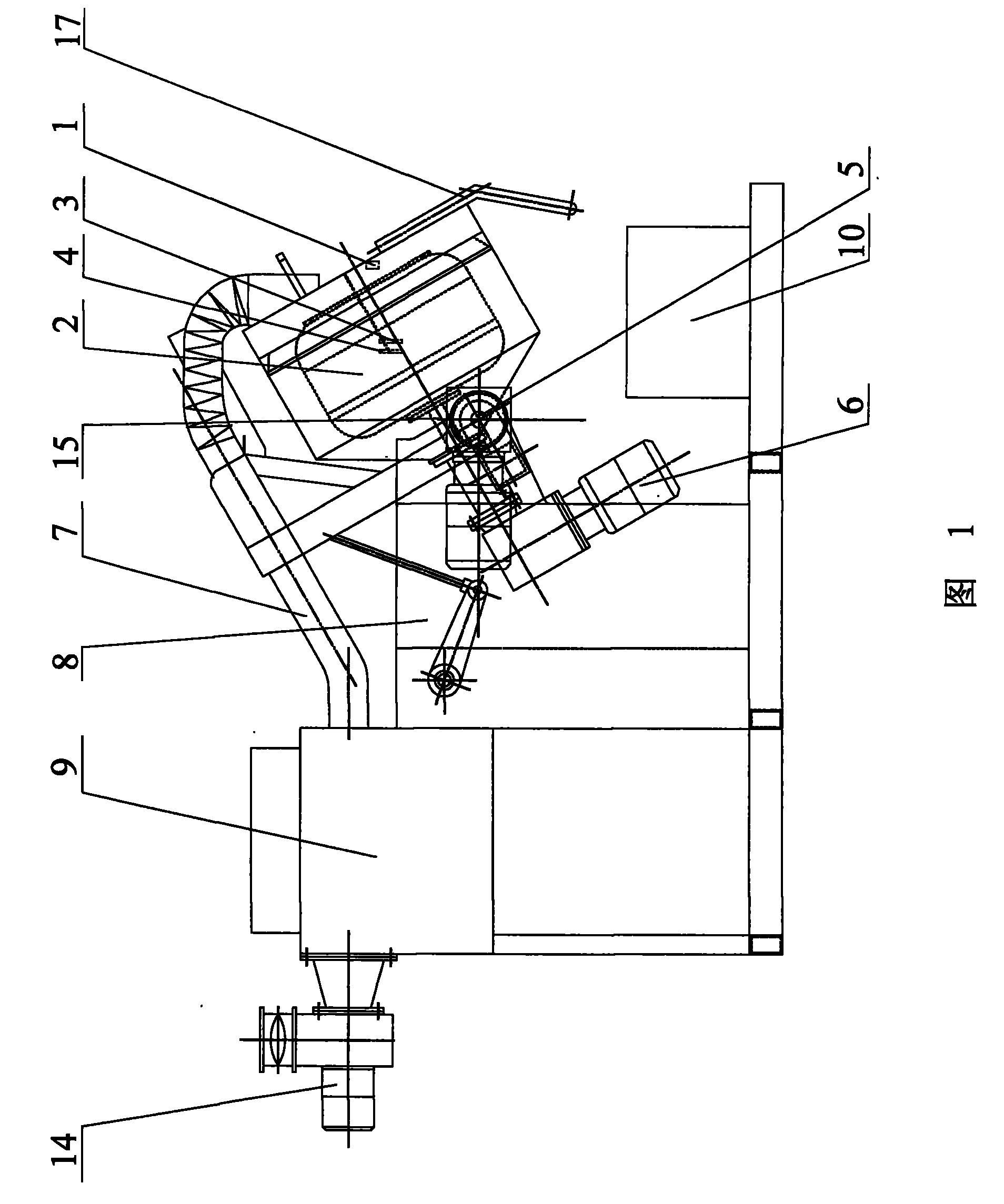

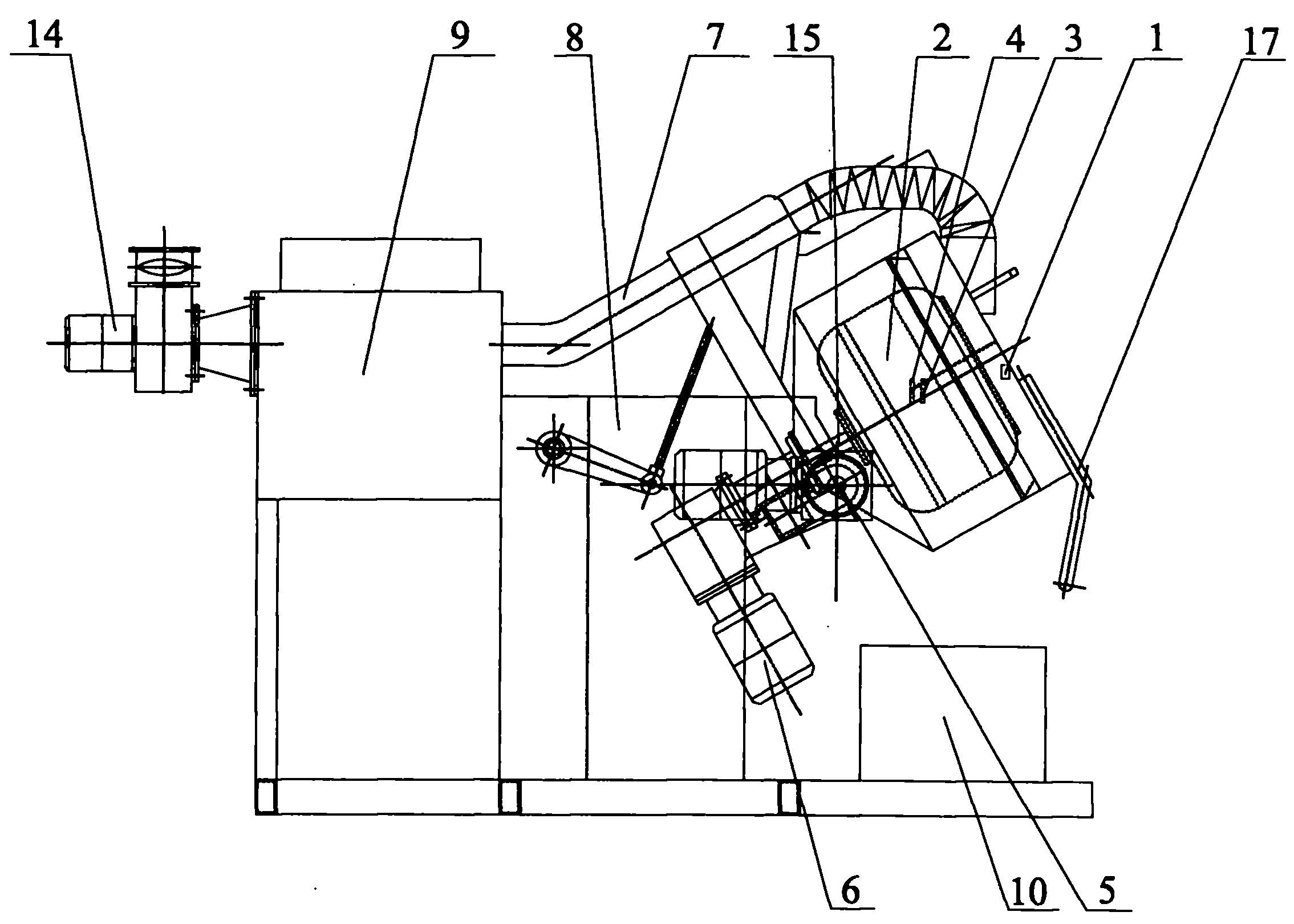

Automatically vibrating glue-spraying machine

ActiveCN101406866BHigh coating efficiencyImprove applicabilityPretreated surfacesCoatingsAdhesiveFiltration

The invention relates to an automatic swinging glue sprayer used during rubber metal piece producing process. A heat exchanger is fixed on a frame; the inlet end of the heat exchanger is connected with a draught fan, while the outlet end of the heat exchanger is connected with a hot air heating tube; a mount seat of a swinging roller used for holding a workpiece is hinged on the frame through a pin roll; a rotating shaft is rotationally connected in the mount pad seat; one end of the rotating shaft is fixedly connected with the swinging roller, while the other end of the rotating shaft is connected with an output shaft of a speed reducer of a drive motor; the outlet end of the hot air heating tube extends into the swinging roller; the swinging roller is provided with an automatic sprayingpistol; a discharging port of the swinging roller is hinged with an airtight cover; the discharging port of the swinging roller is fixed with a gland strip matched with the airtight cover; and the swinging roller or the airtight cover of the swinging roller is provided with an aspiration pipeline of an adsorption filtration device. When the automatic swinging glue sprayer operates, bonding adhesive has high coating efficiency and good coating effect, and can effectively prevent toxic gas in the bonding adhesive from leaking.

Owner:WUXI HUANENG SURFACE TREATMENT

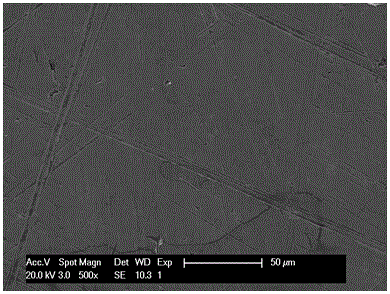

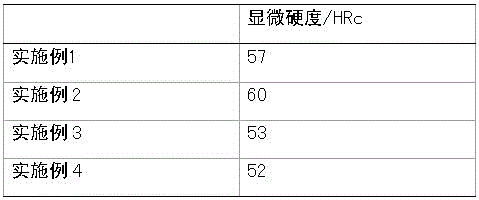

A preparation method of tungsten carbide anti-corrosion and wear-resistant composite coating

InactiveCN104178762BAvoid reunionSimple processSoldering apparatusWelding/soldering/cutting articlesPhysical chemistrySlurry

The invention discloses a method for preparing a tungsten carbide anti-corrosion and wear-resistant composite coating, that is, first spraying a slurry containing tungsten carbide particles, an anticoagulant, a nickel-based solder and a water-based epoxy adhesive on a metal substrate, and naturally Dry to obtain a metal substrate sprayed with coating materials, and then in a vacuum brazing furnace, control the temperature rise rate to 20°C / min, rise from room temperature to 350°C for 20 minutes, and then continue to rise at a rate of 20°C / min Sinter at 1050-1200°C for 30 minutes, then control the cooling rate to 20°C / min for cooling, and cool down to 500°C with nitrogen until room temperature, that is, a layer of tungsten carbide with a thickness of 0.5-3mm is formed on the surface of the metal substrate Anti-corrosion and wear-resistant composite coating. The coating has a compact structure, high bonding strength with the metal substrate, has the ability to resist impact, wear and corrosion, and has a service life of up to 36‑42 months.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Static even-color painting method

InactiveCN102059208BReduce defective rateReduce manufacturing costLiquid surface applicatorsCoatingsOrganic solventEngineering

Owner:DONGGUAN GUANHUI HARDWARE

A life-prolonging, energy-saving and shape-stable PBO 2 Preparation method of arc thermal spraying for anode intermediate layer

ActiveCN109778100BEasy to operatePromote crystallizationMolten spray coatingAcid etchingThermal spraying

The invention discloses a life-prolonging, energy-saving and shape-stable PbO 2 The arc thermal spraying preparation method of the anode intermediate layer is to prepare a conductive and corrosion-resistant zirconium nitride-based intermediate layer by using arc thermal spraying on the surface of the titanium substrate that has been pretreated by degreasing and acid etching, and then coat the zirconium nitride-based Anodic electrodeposition of β-PbO on the interlayer 2 Active layer for long life, low energy consumption Ti / ZrN-based interlayer / β‑PbO 2 Structural Coating Anodes. The invention takes full advantage of the excellent electrical conductivity of the sprayed zirconium nitride-based intermediate layer, acid, alkali, and salt corrosion resistance, not only has good bonding strength with the titanium substrate, and the rough sprayed surface can firmly load β-PbO 2 The active layer can effectively prevent the migration of corrosive media and active oxygen to the anode substrate, and play a role in barrier protection, which significantly prolongs the service life of the anode. In addition, the good conductivity of the middle layer makes the cell voltage of the electrochemical process significantly Reduced energy consumption.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

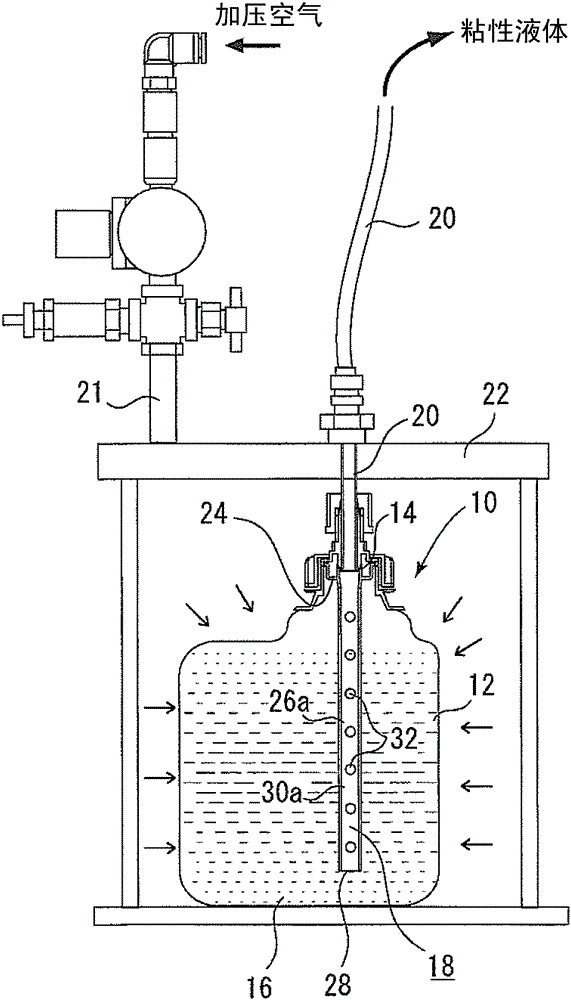

Plastic container, elongated flow path member and coating device

ActiveCN102641828BEfficient spraying by pressingEfficient pressing and ejectionLiquid surface applicatorsClosure capsViscous liquidMechanical engineering

Owner:CEMEDAINE CO LTD

Fluorine-containing polymer powder, method for producing the same and coated article

InactiveUS20060247385A1High coating efficiencyMaintain good propertiesCoatingsPolymer scienceHeat resistance

Owner:DAIKIN IND LTD

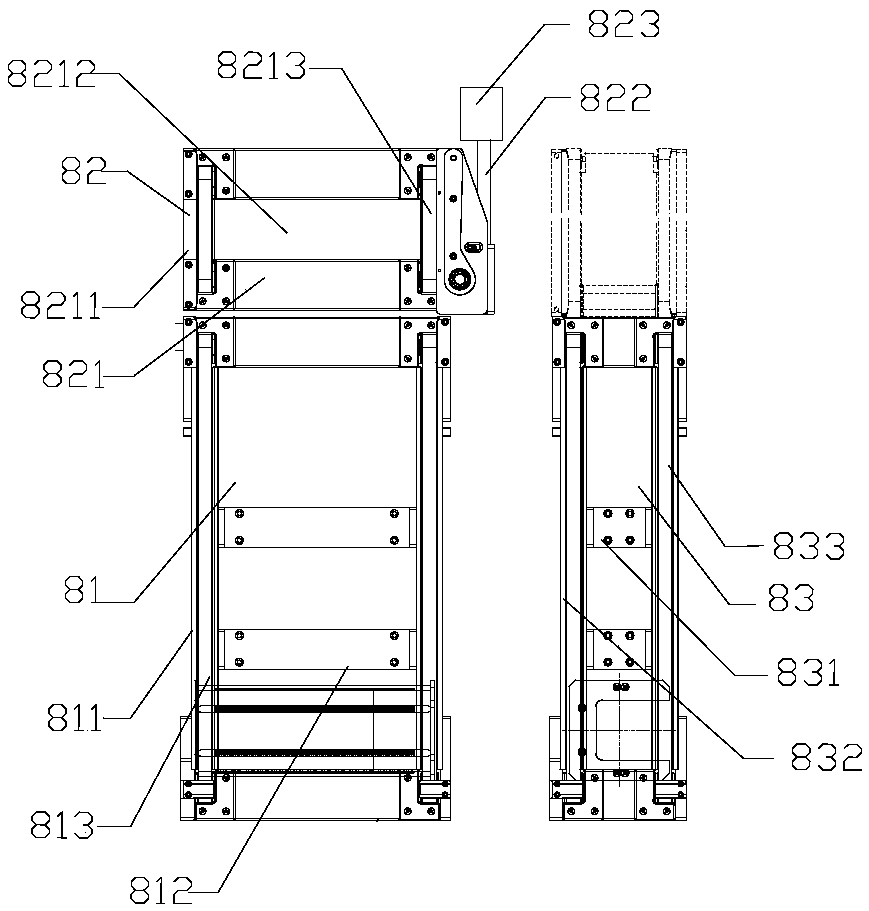

Silicon wafer automatic coating source production line

ActiveCN109560006AHigh degree of automationHigh coating efficiencySemiconductor/solid-state device manufacturingFinal product manufactureFailure rateProduction line

The invention provides a silicon wafer automatic coating source production line. The silicon wafer automatic coating source production line comprises a boron coating device, a first drying furnace, aphosphorus coating device, a second drying furnace and a powder spraying unit, first transfer manipulators are arranged between the boron coating device and the first drying furnace, between the firstdrying furnace and the phosphorus coating device, between the phosphorus coating device and the second drying furnace and between the second drying furnace and the powder spraying unit, and one end of the downstream of the first drying furnace is provided with a silicon wafer turnover mechanism. The silicon wafer automatic coating source production line is high in automatic degree, multiple processes of the silicon wafer coating sources are automatically performed with no need for equipping with a lot of special manual operation, the failure rate is low, the coating efficiency is high, the coating is uniform, and the product qualification rate is high.

Owner:TIANJIN HUANXIN TECH DEV

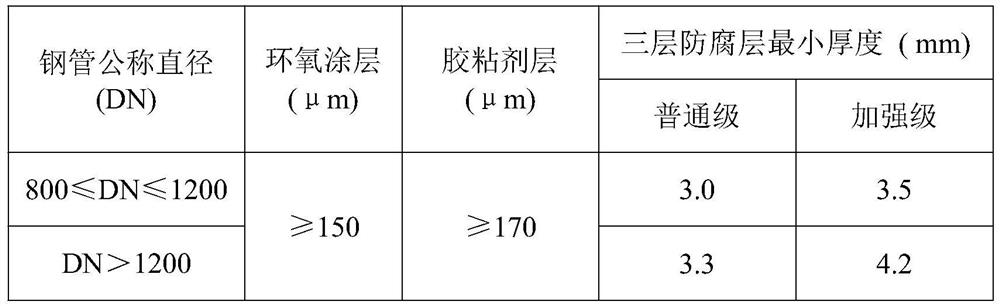

Three-layer-PE corrosion control method for steel outer protective pipe

The invention provides a three-layer-PE corrosion control method for a steel outer protective pipe. The method comprises the following steps that S1, the outer surface of the steel outer protective pipe is cleaned; S2, temperature control treatment is conducted on the outer surface of the steel outer protective pipe; S3, rust removal treatment is conducted on the outer surface of the steel outer protective pipe; S4, the outer wall of the steel outer protective pipe is sequentially coated with an epoxy powder coating, an adhesive layer and an outer anti-corrosion layer from inside to outside; S5, after three anti-corrosion layers of the steel outer protective pipe are coated, the three anti-corrosion layers at the end of the pipe are removed; and S6, process evaluation test and quality inspection are conducted on the three anti-corrosion layers. According to the three-layer-PE corrosion control method for the steel outer protective pipe, the steel outer protective pipe of each specification is coated with three corresponding anti-corrosion layers, a medium-frequency heating temperature control treatment mode is adopted for heating, the coating efficiency is improved, and an anti-corrosion pipe has the advantages of being smooth in surface, free of dark bubbles, pits, wrinkles and cracks, uniform in color, free of warped edges of the anti-corrosion pipe end and the like.

Owner:中投(天津)智能管道股份有限公司

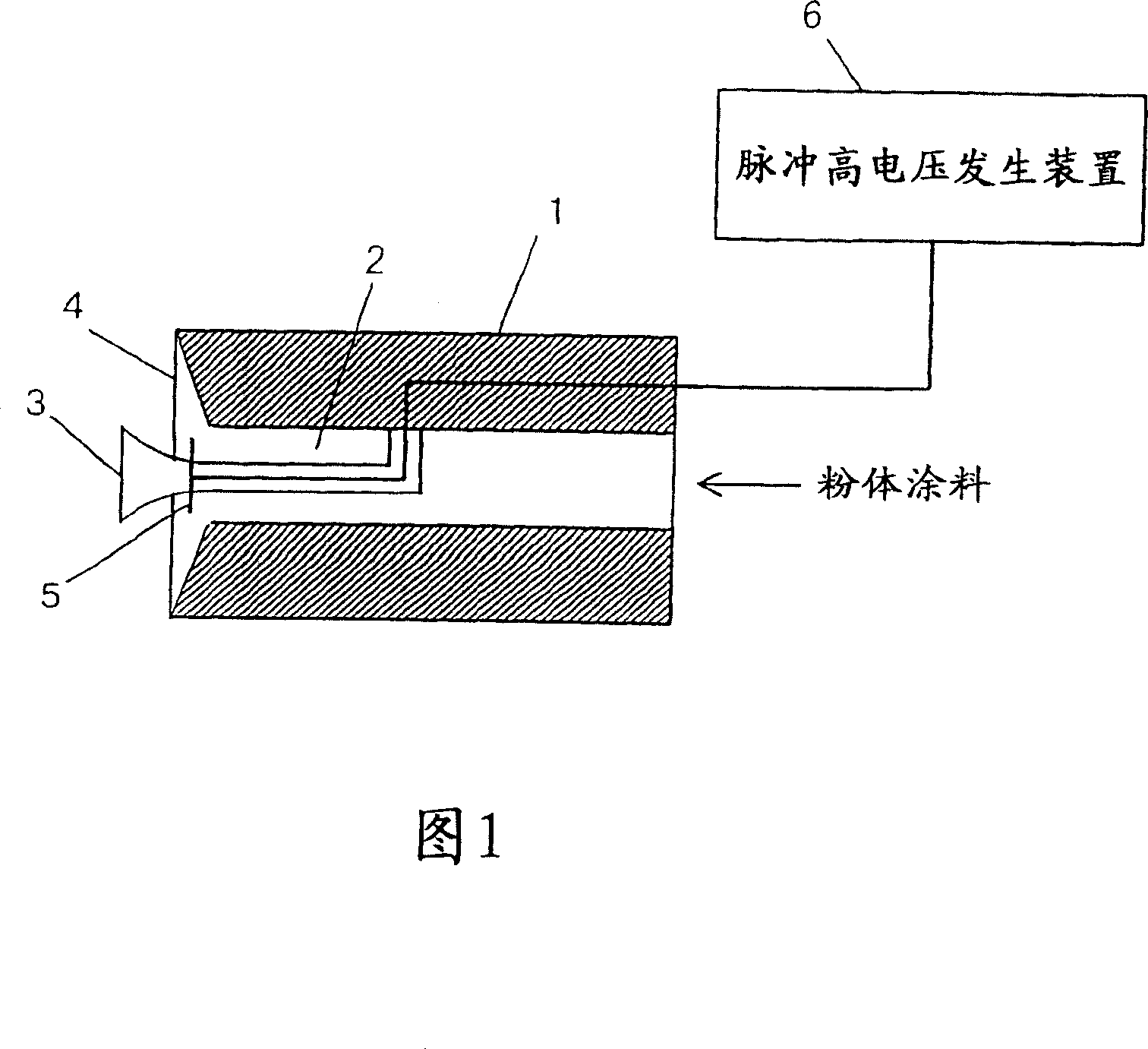

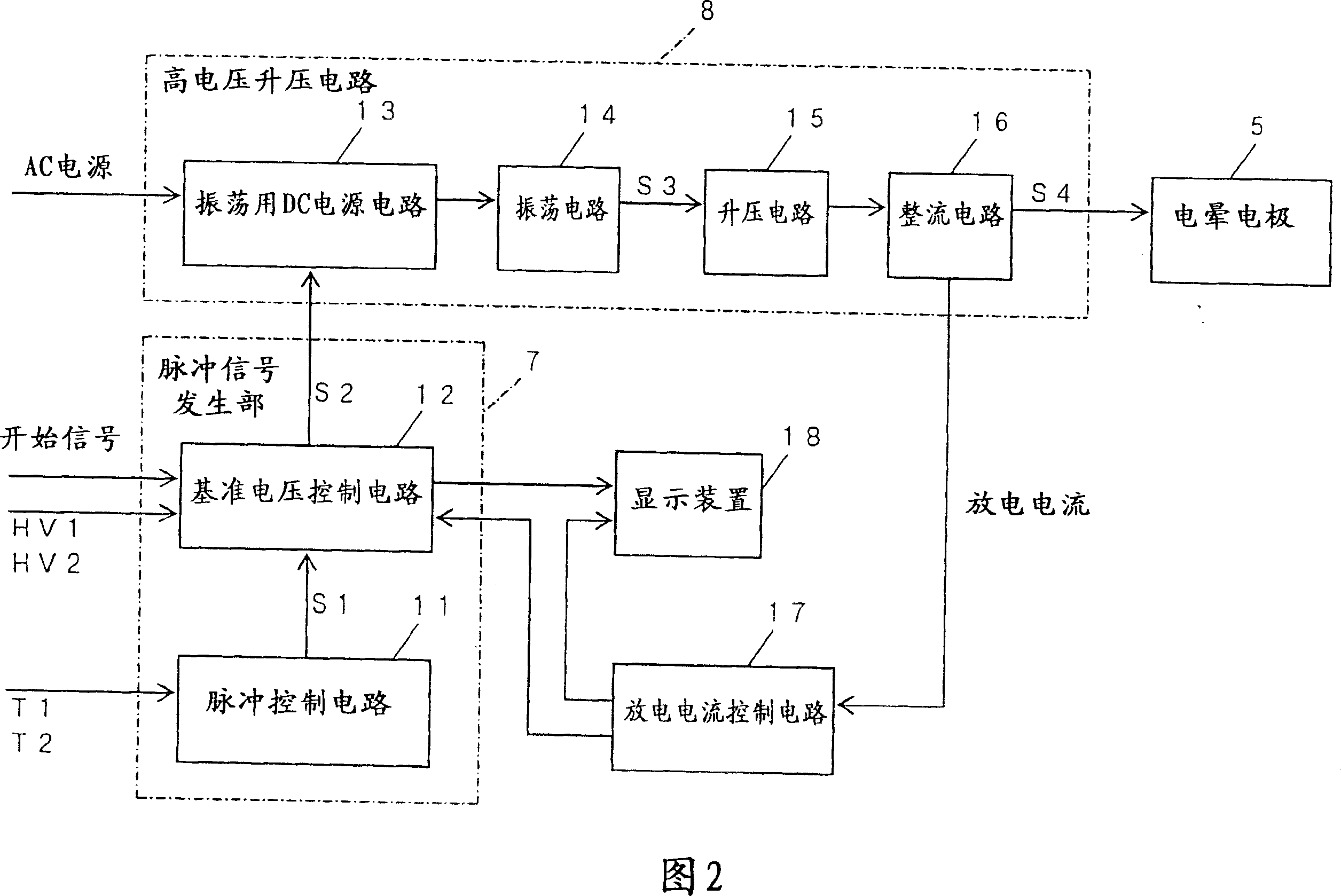

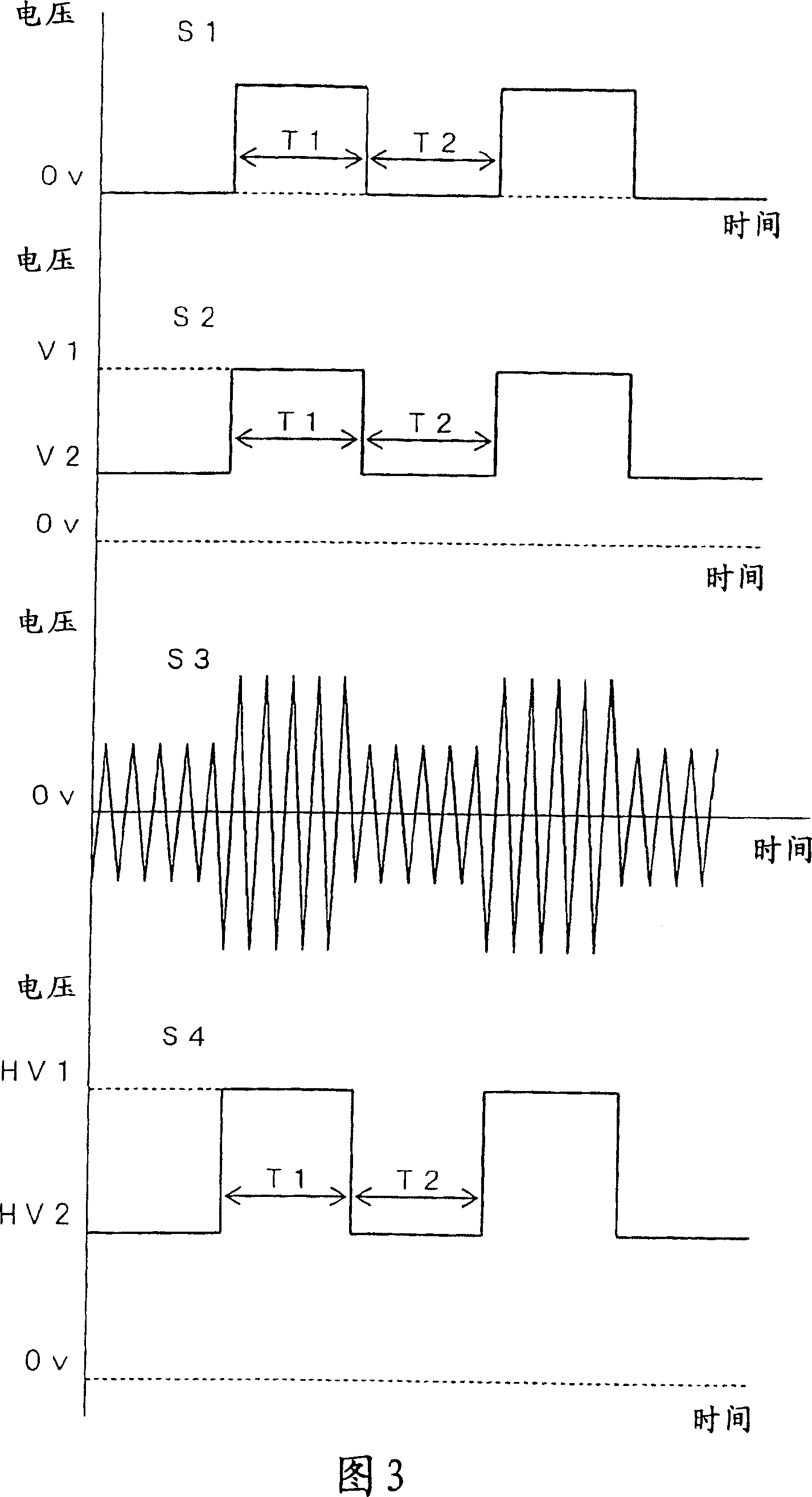

Powder coating device and method

InactiveCN1326626CHigh coating efficiencyImprove qualityLiquid spraying plantsSpraying power supplyLow voltageCorona discharge

A powder coating device, wherein a low-voltage pulse signal (S2) generated in a pulse signal generation circuit (7) is boosted to a high voltage in a high voltage application circuit (8) to be applied to a corona electrode (5). This enable corona discharging to be generated intermittently toward an object from the corona electrode (5), powder paint jetted forward from the nozzle opening of a gun body to be charged by negative ions produced by corona discharging, and then charged powder paint to be sent toward the object for coating on the surface of the object.

Owner:PARKER ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com