Hollow fiber composite membrane applicator, method for producing said hollow fiber composite membrane

A fiber compounding and manufacturing method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of coating on the outside of the hollow fiber base membrane, difficulty in accurately controlling the liquid content on the surface of the membrane, and the quality of the membrane. Difficult to guarantee and other problems, to achieve the effect of simple structure, low cost, uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

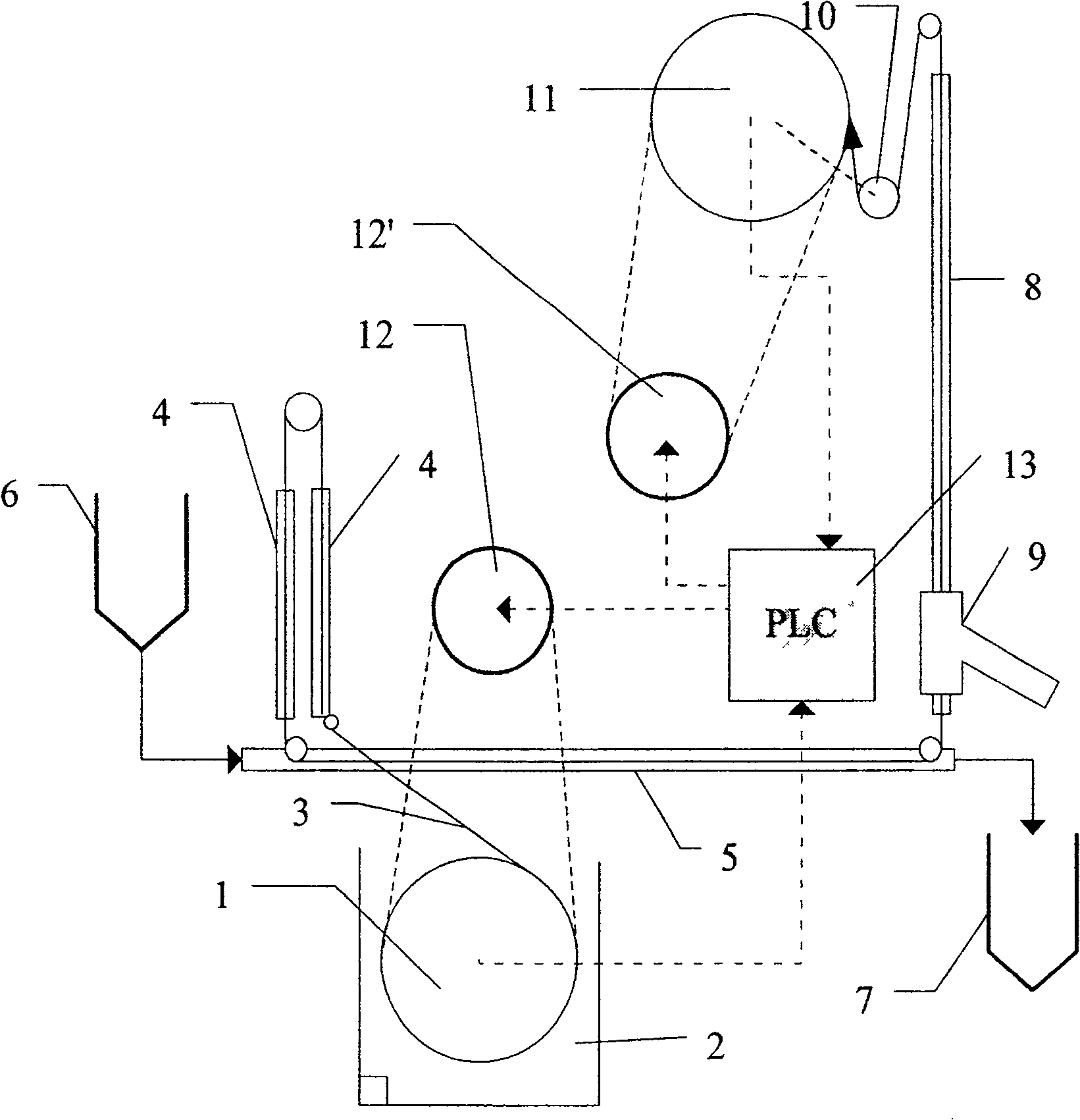

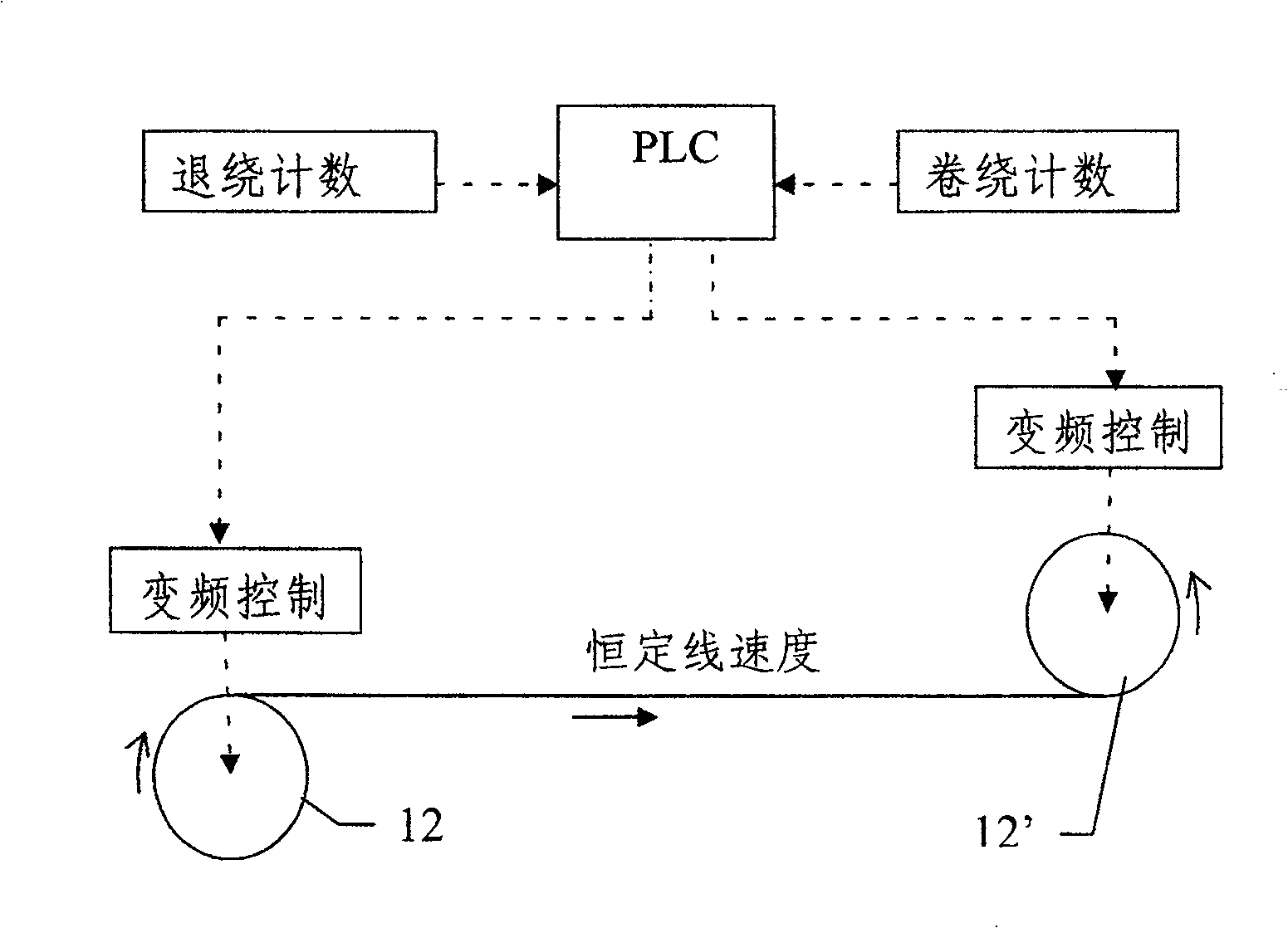

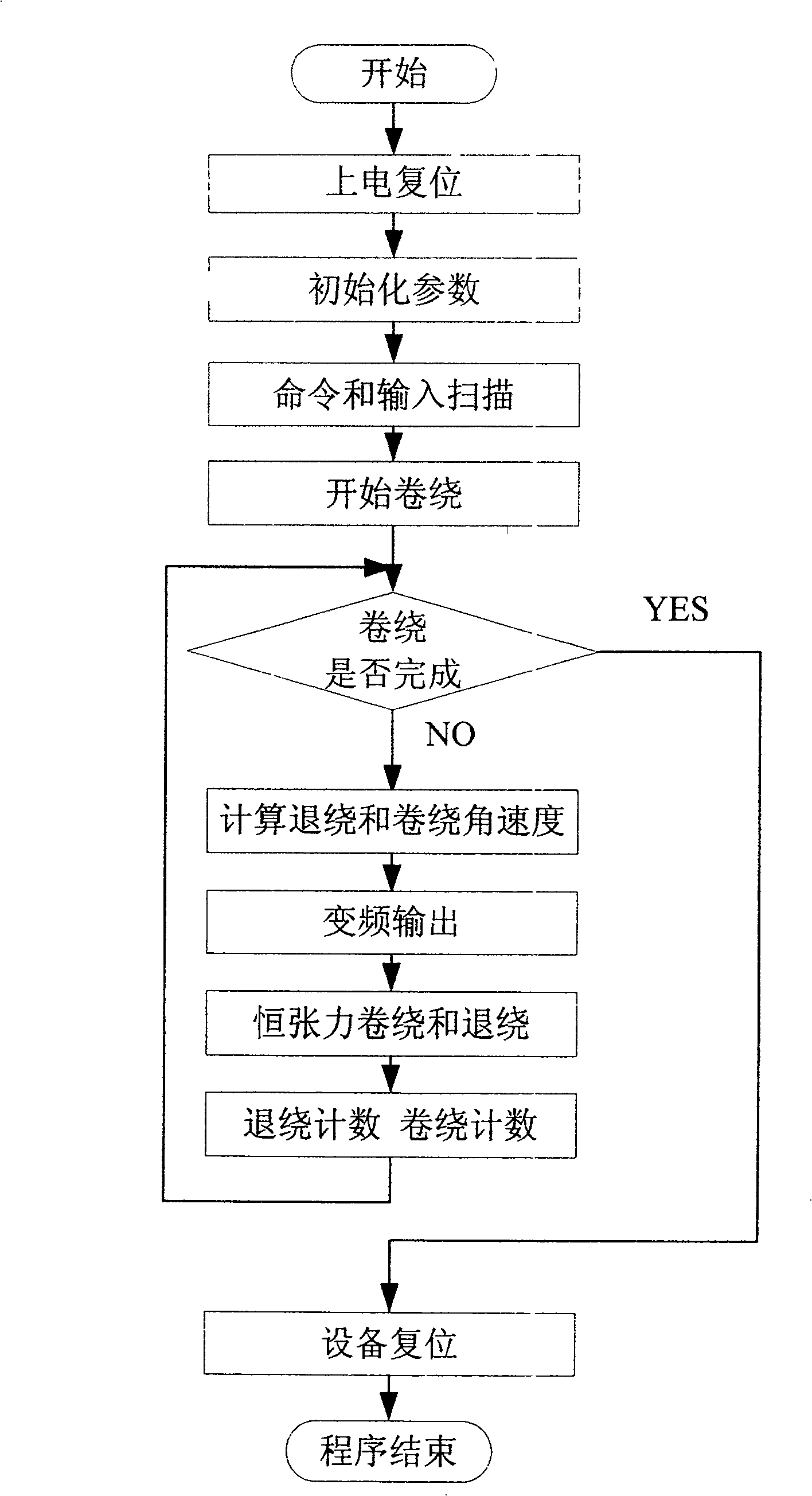

Embodiment 1

[0028] An embodiment of the inventive coating machine is designed as follows: the diameters of the wire feeding roller 1 and the wire receiving roller 11 are both 450mm, the height of the drying pipe 4 is 1.5M, the height of the drying pipe 8 is 1.5M, and the length of the stainless steel reaction pipe 5 is 1.5M. Around the rise angle of 6 degrees. A contact counter is used to record the number of unwinding layers and the number of winding layers. Frequency conversion motors 12 and 12' use YST12A, inverters use INVERTER's CVF-72, and PLC controller 13 uses Siemens ST-200CN.

Embodiment 2

[0030] Another embodiment of the invention coating machine is designed as follows: the diameter of the wire feeding roller 1 and the wire receiving roller 11 is 1000mm, the height of the drying pipe 4 is 1M, the height of the drying pipe 8 is 2M, the length of the stainless steel reaction pipe 5 is 2.5M, and the winding The rise angle is 6 degrees. A contact counter is used to record the number of unwinding layers and the number of winding layers. Frequency conversion motors 12 and 12' use YST12A, inverters use INVERTER's CVF-72, and PLC controller 13 uses Siemens ST-200CN.

Embodiment 3

[0032] Use embodiment 1 device, water phase concentration is the piperazine aqueous solution of 2% (weight ratio), and water phase immersion time is 40 minutes; The concentration of the n-hexane solution of TMC is 0.5%, polysulfone hollow fiber base membrane stays in reaction tube The time is 30 seconds (the operating line speed of the device in Example 1 is 3m / min), and a uniformly coated nanofiltration hollow fiber composite membrane can be prepared. The air temperature of the front drying pipe 4 is 65°C, and the air volume is 1m 3 / min; the air temperature of the post-drying pipe 8 is 75°C, and the air volume is 0.6m 3 / min.

[0033] Experiments have shown that the hollow fiber nanofiltration composite membrane of gained is under 0.4MPa, to the MgSO of 2g / L. 4 The rejection rate can reach 96.8%, and the flux can reach 20.0L / m 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com