Patents

Literature

58results about How to "Protect against deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

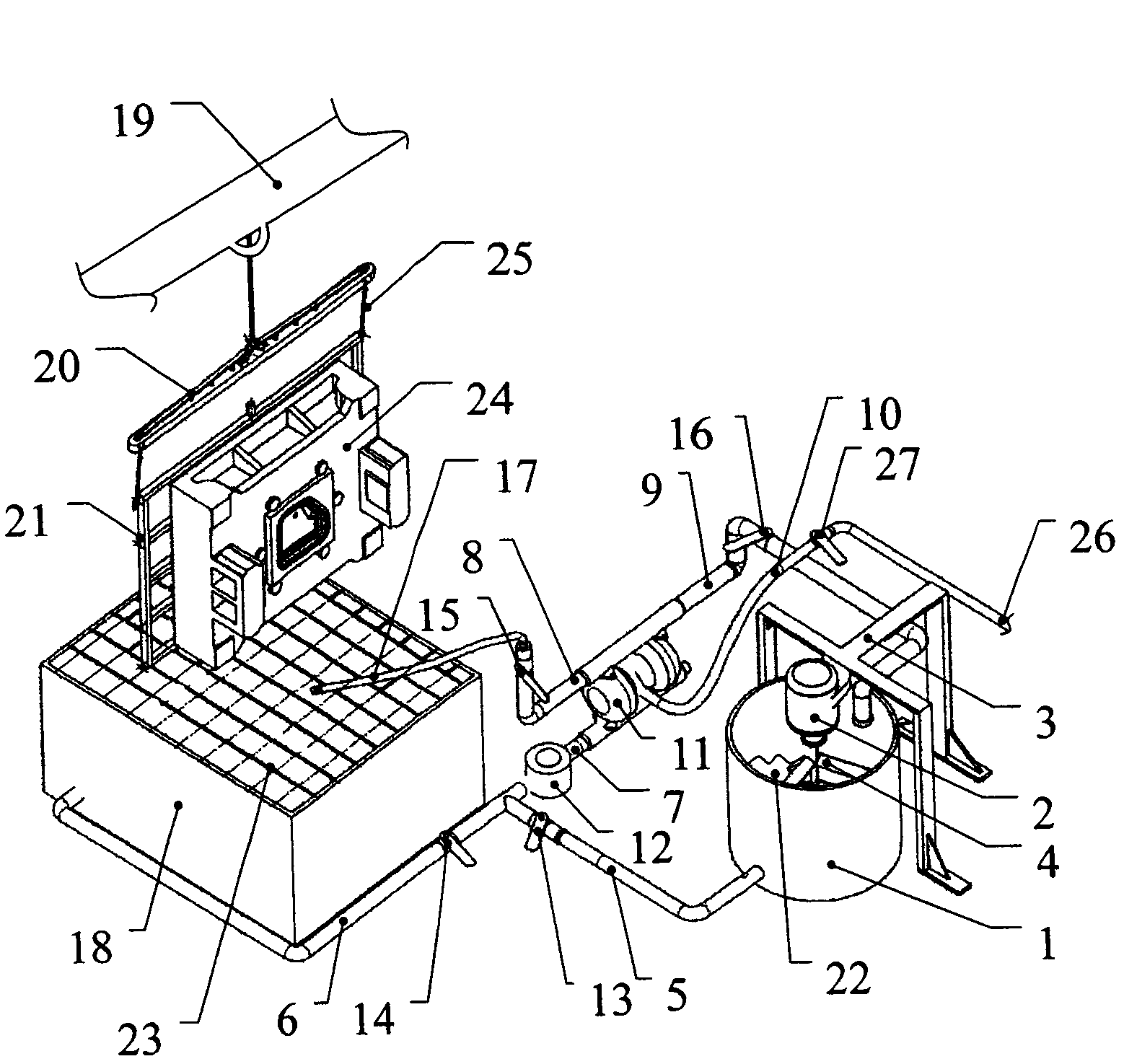

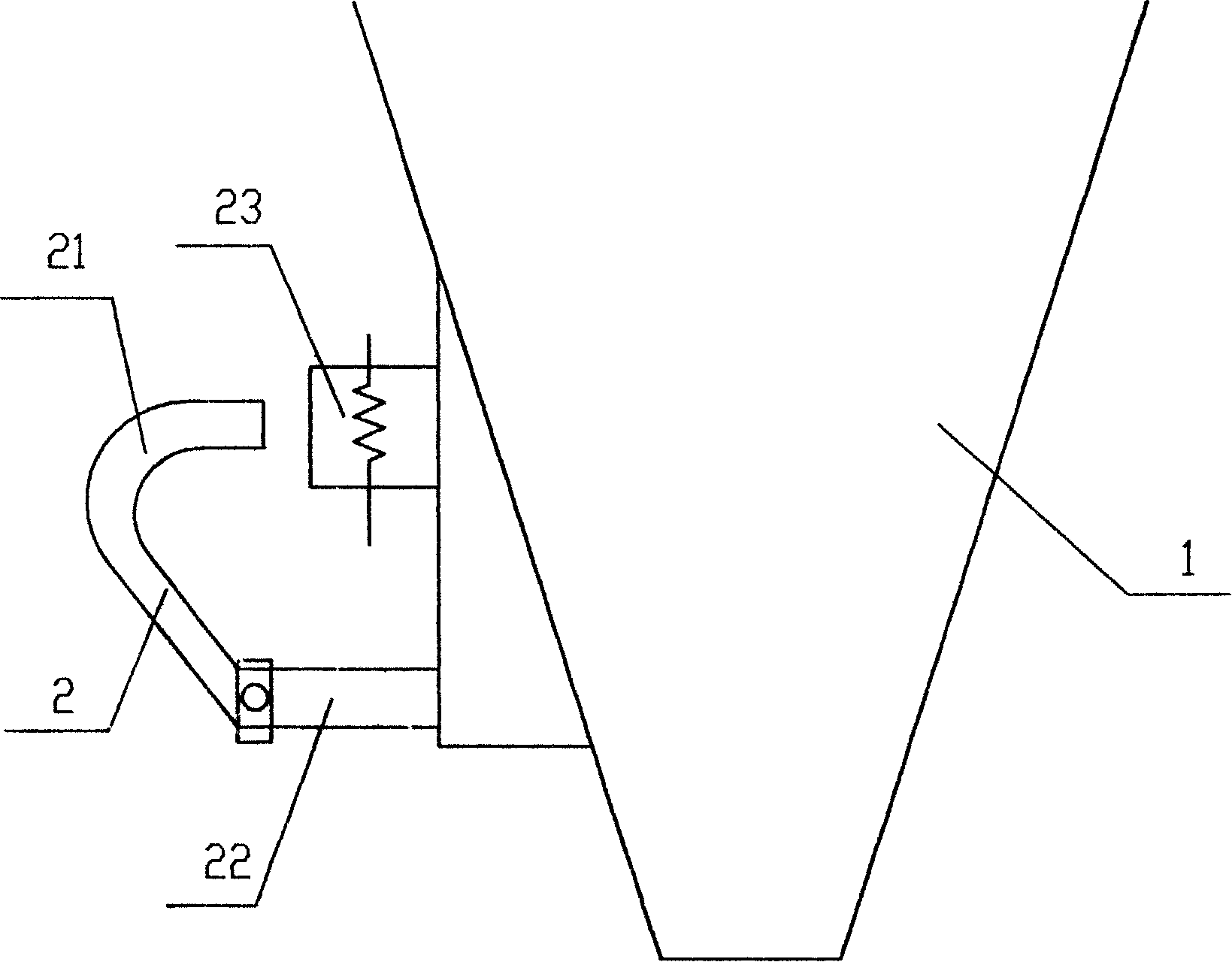

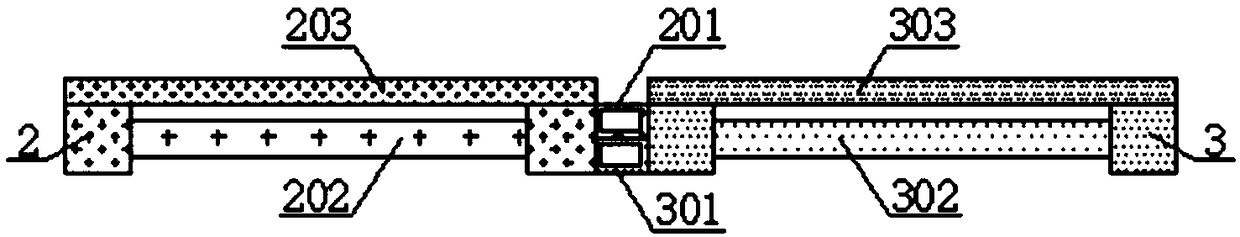

Evanescent mode coating spraying system

InactiveCN102641990AProtect against deformationAvoid damageMoulding toolsFoundry mouldsDiaphragm pumpImpeller

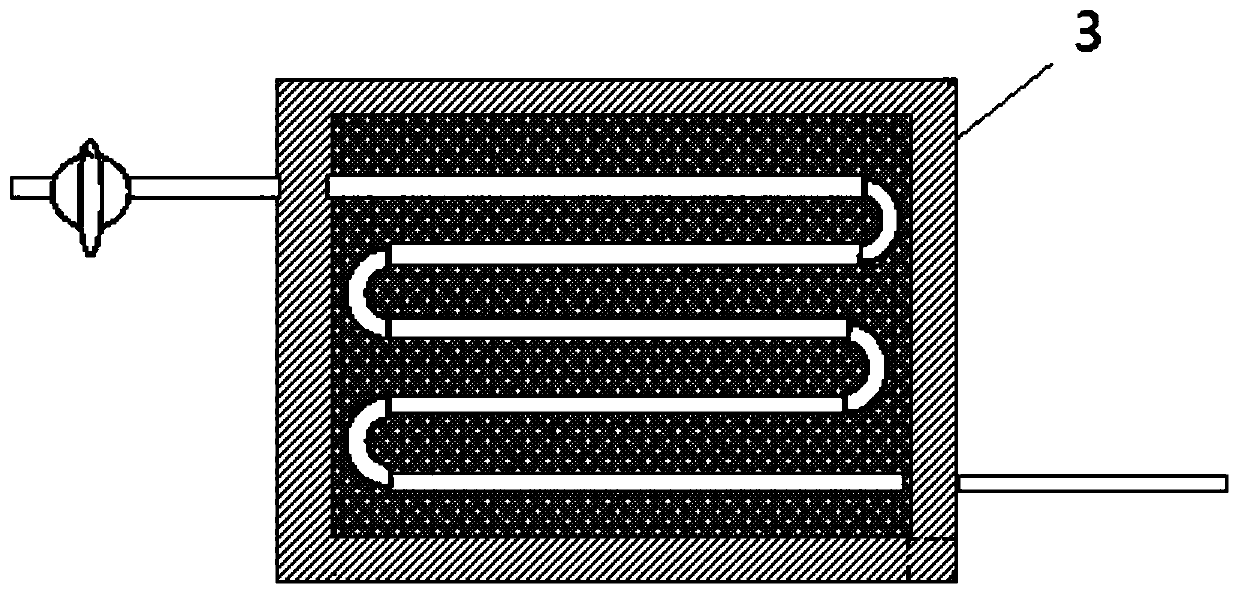

The invention discloses an evanescent mode coating spraying system which comprises a storage vat (1), a motor (2), a motor bracket (3), a stirring impeller (4), a feed delivery pipe (5), a return pipe (6), a connecting pipe (7), an output pipe (8), a feedback pipe (9), an air pipe (10), a pneumatic diaphragm pump (11), a magnetic filter (12), a first control valve (13), a second control valve (14), a third control valve (15), a fourth control valve (16), a spray pipe (17), a storage tank (18), a crown block (19), a lifting frame (20), a mounting rack (21), an evanescent mode coating (22), a mesh enclosure (23) and a fifth control valve (27). The evanescent mode coating spraying system has the advantages and effects that: during the evanescent mode coating process of the system, manpower and material resources as well as time are saved, the coating is uniformly coated, and cannot be limited by an evanescent mode structure, and deformation during the evanescent mode coating process is avoided.

Owner:枣庄市同捷汽车模具有限责任公司

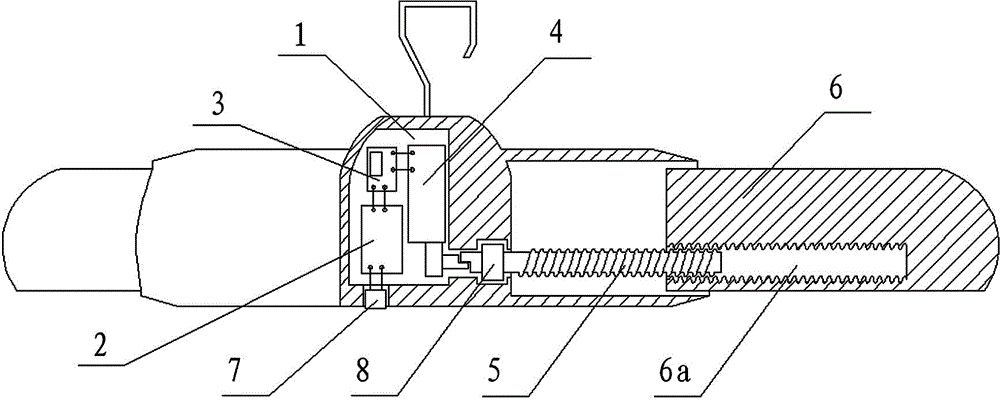

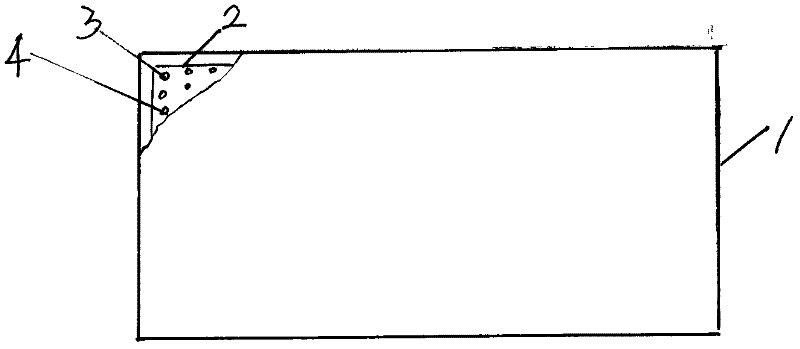

Size-adjustable clothes hanger

InactiveCN105768804AIngenious designDimensionally stableApparel holdersOther drying apparatusClothes hangerPurchase cost

The invention discloses a size-adjustable clothes hanger, which comprises a clothes hanger shell (1), wherein a movable block (6) is arranged on the side of the shell (1); the clothes hanger is characterized in that an inner threaded bushing port (6a) is arranged in the movable block (6); the bushing port (6a) is correspondingly bushed with a screw rod (5) which is connected to a rotating shaft of a motor (4); the motor (4) is connected to a motor steering module (3) by virtue of lead wires; and the input ends of the steering module (3) are connected to a storage battery (2) by virtue of lead wires. The size-adjustable clothes hanger disclosed by the invention is skillful in design; the size of the clothes hanger is adjusted as the movable block is driven to move by virtue of the screw rod, and on the basis of the self-locking principle of the screw rod, the adjusted size is kept stable and the clothes hanger is prevented from sliding, so that family members in different figures can hang out clothes conveniently, and expensive clothes can be protected from getting deformed; and moreover, the clothes hanger disclosed by the invention is reasonable and relatively simple in structure, enterprise's production cost and consumer's purchase cost are reduced, and the clothes hanger is quite suitable for popularization.

Owner:CHONGQING KUQI MODEL CO LTD

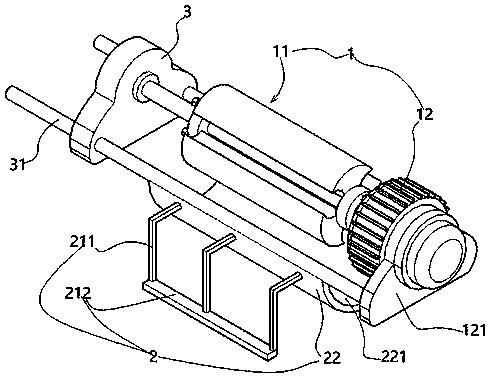

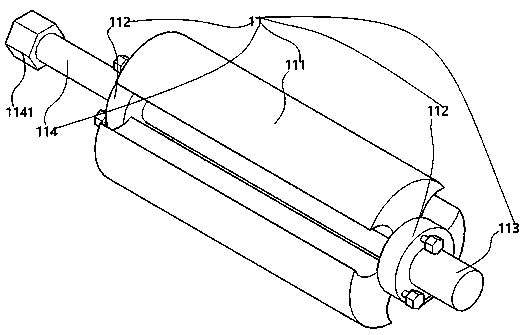

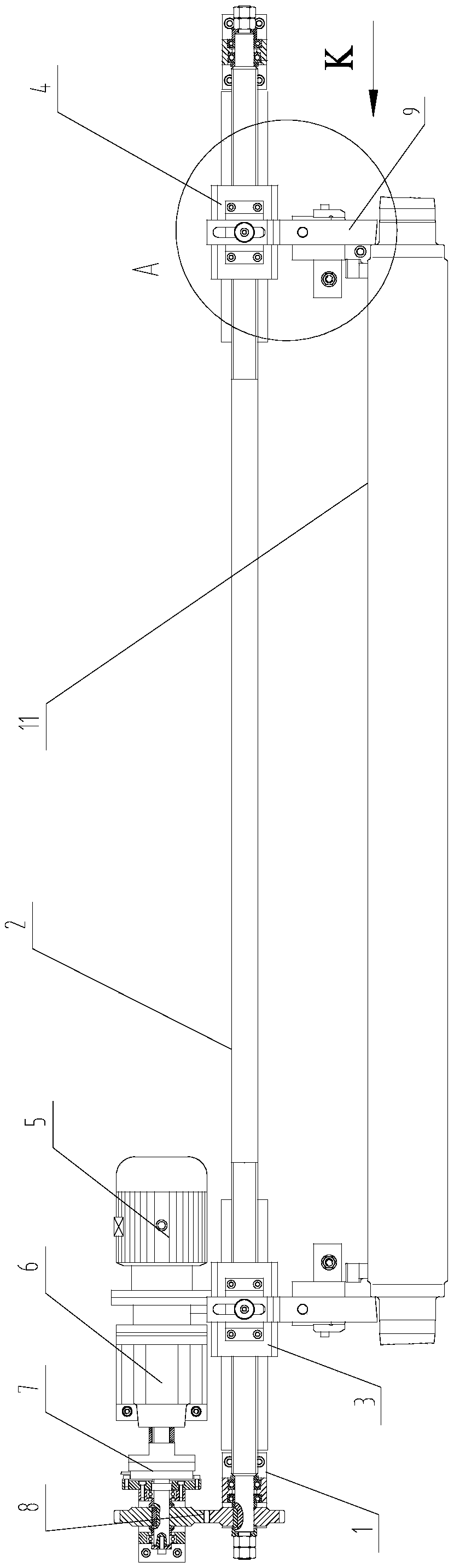

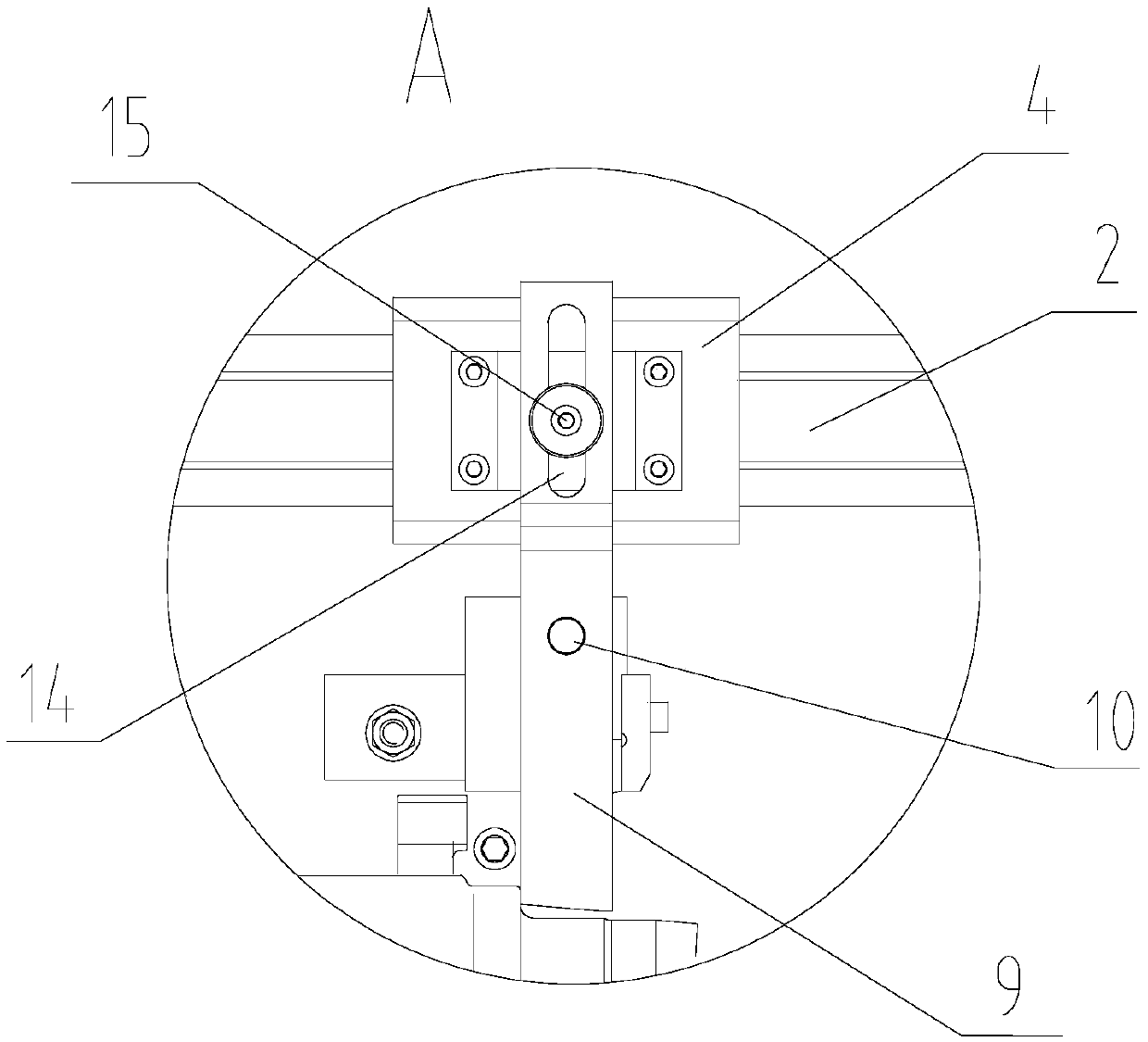

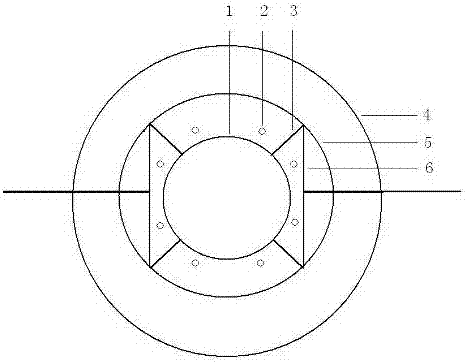

Novel grinding device for inner protrusion of steel pipeline

ActiveCN111055175AEasy to installAchieve grindingRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention discloses a novel grinding device for inner protrusion of a steel pipeline. The device comprises a protrusion grinding assembly, the protrusion grinding assembly comprises a plurality offan-shaped grinding rods distributed annularly, the left ends and the right ends of the multiple fan-shaped grinding rods are fixedly connected to mounting disc bodies, a shaft rod is fixedly arranged between the mounting disc bodies in a connection mode, the left end of the shaft rod penetrates through the mounting disc bodies, and the left end of the shaft rod is rotationally connected to a left end frame; the left end frame is detachably mounted on the shaft rod; the protrusion grinding assembly further comprises a driving motor; the driving motor is fixedly connected to a right end frame;the device further comprises a supporting assembly, and the supporting assembly is located under the fan-shaped grinding rod; and the supporting assembly comprises a corrugated supporting plate, thecorrugated supporting plate is provided with an arc-shaped recess, and supporting frames are fixedly connected to the front end and the rear end of the corrugated supporting plate. By means of the parts of the device, the inner side walls of steel pipes of different specifications and sizes are automatically ground, and the technical defects that the grinding efficiency is low and operation is unsafe when workers enter large steel pipes are overcome.

Owner:青岛豪德博尔实业有限公司

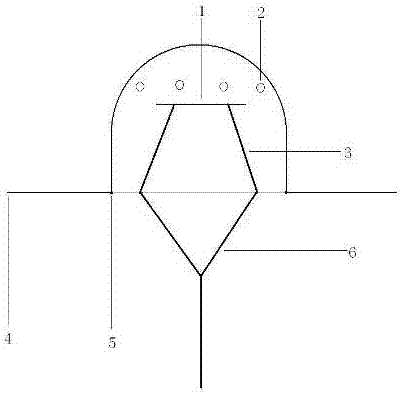

Fireproof door panel made of pearlite

The invention discloses a fireproof door panel made of pearlite. The fireproof door panel comprises the following components in percentage by weight: 65 to 75 percent of granulated expanded perlite, 15 to 25 percent of a powdered magnesium oxide, and 10 percent of a magnesium oxide solution. 10 to 20 grams of phosphoric acid is added into and mixed with each cubic meter of materials; and the mixture is uniformly stirred and molded according to the following method comprising the steps of: uniformly stirring the materials, putting the mixture into a die, and applying 30 to 40 tons of pressure by a pressing machine for 3 to 10 minutes to prepare a blank; heating the cold-pressed blank to reach temperature of between 80 and 100 DEG C, and applying 110 to 130 tons of pressure by the pressing machine for 20 to 40 minutes to prepare the door panel. The expanded perlite serving as a main ingredient is a natural substance, and is nontoxic and non-radioactive; and when the expanded perlite is combusted, the smoke toxicity AQ1 is more than or equal to 100.0, so that the safety is high. The prepared door panel has stable physical property and high fire resistance, and the heat value of the door panel is only 0.1 MJ / kg. The fireproof door panel is light and is favorable for protecting an assorted door from being deformed.

Owner:刘粉林

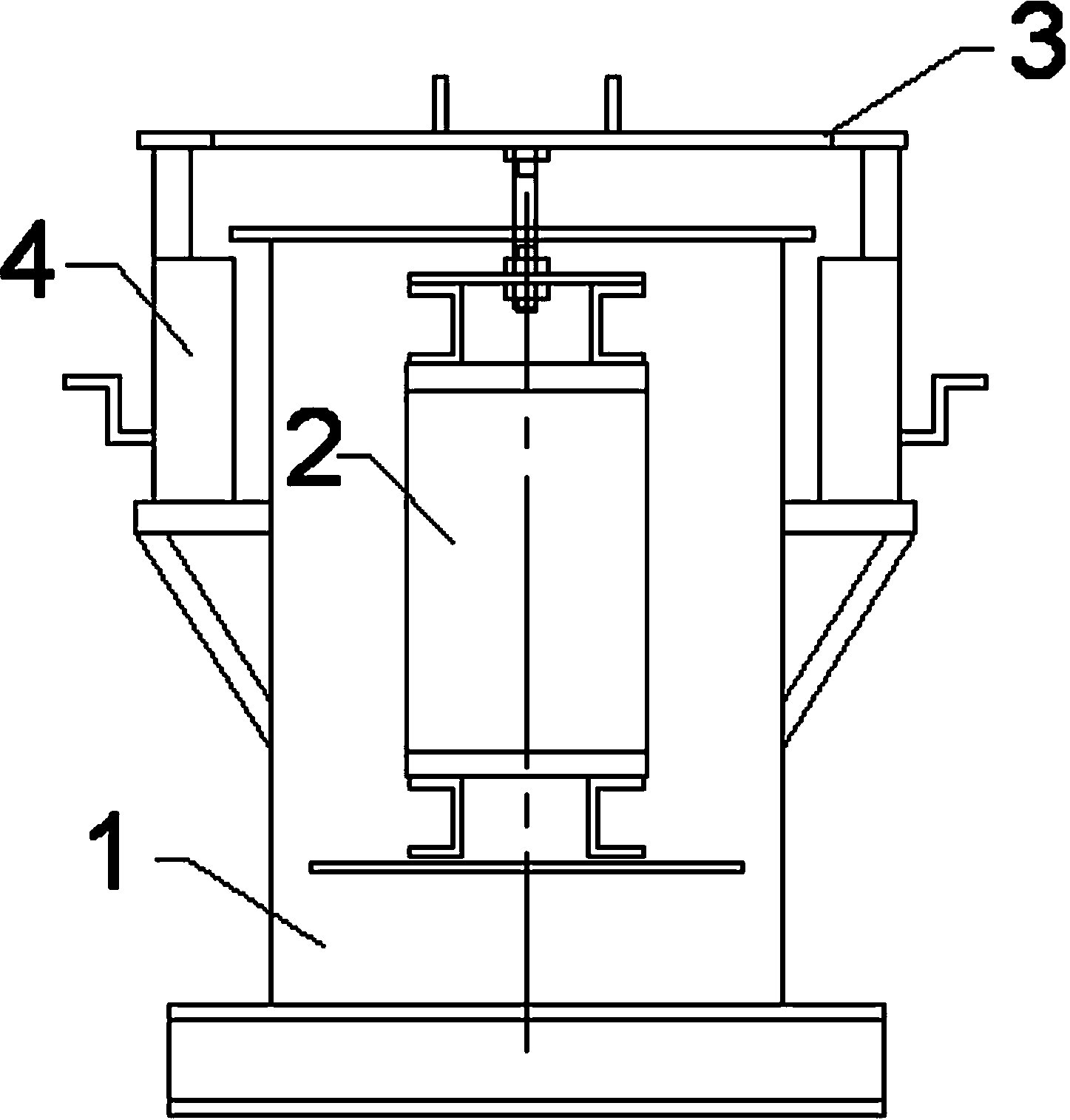

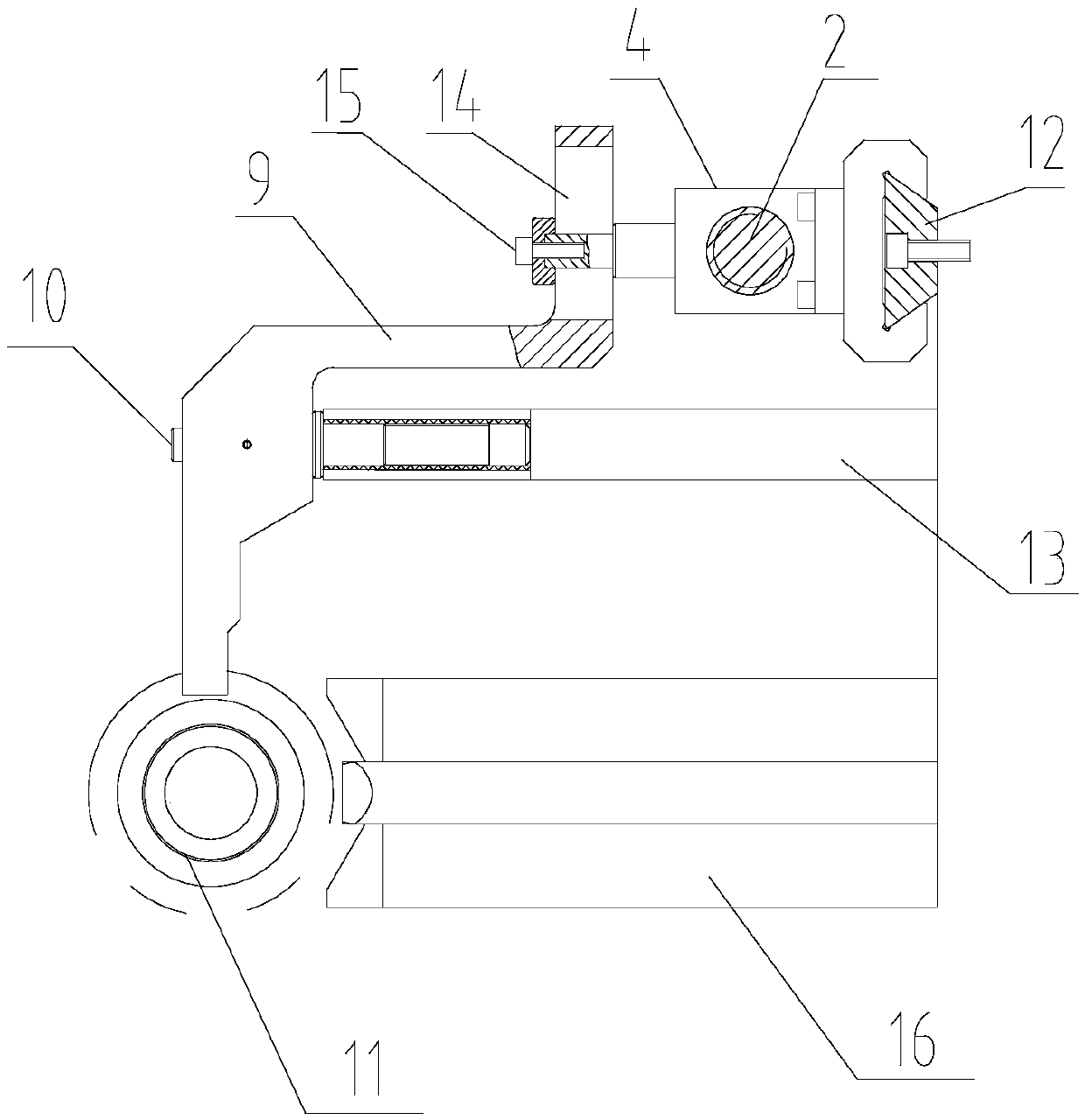

Full hydraulic furnace pounding machine

InactiveCN101408376AProtect against deformationProtection from damageMechanical apparatusCharge manipulationSupport plane

A full-hydraulic stoking machine comprises a conveying mechanism, a stoking mechanism and a rotary beam. Wheels are arranged under a seat; plinths are arranged on the lower parts of four angles of the seat; a wheel bracket at the back end of the seat is fixedly connected with a movable linkage-rod of a translation cylinder; an inner arm is movably connected with an outer arm in a matching way through the hydraulic manner to do telescopic movement; a stoking head is arranged at the front end of the inner arm and the back part of the outer arm is articulated with the movable linkage-rod of an amplitude cylinder; the rotary beam is arranged on the seat and rotationally connected with the seat through a central shaft. An L-shaped rotary support frame is respectively arranged at both the front end and the back end of the rotary beam; the bottom surface of the L-shaped rotary support frame is buckled with the lower surface of the arc side of the seat; and a tensile roller is arranged between the lower surface of the seat edge and the L-shaped rotary support frame. The design of the full-hydraulic stoking machine is scientific and reasonable; the structure is compact and tight; the materials can be saved; the manufacturing cost is low; the function is complete; the operation is easy; the efficiency is high; the manufacturing process is simple; the performance is stable; and the practicability is higher. The full-hydraulic stoking machine is applicable to the metallurgy industry.

Owner:单世纲

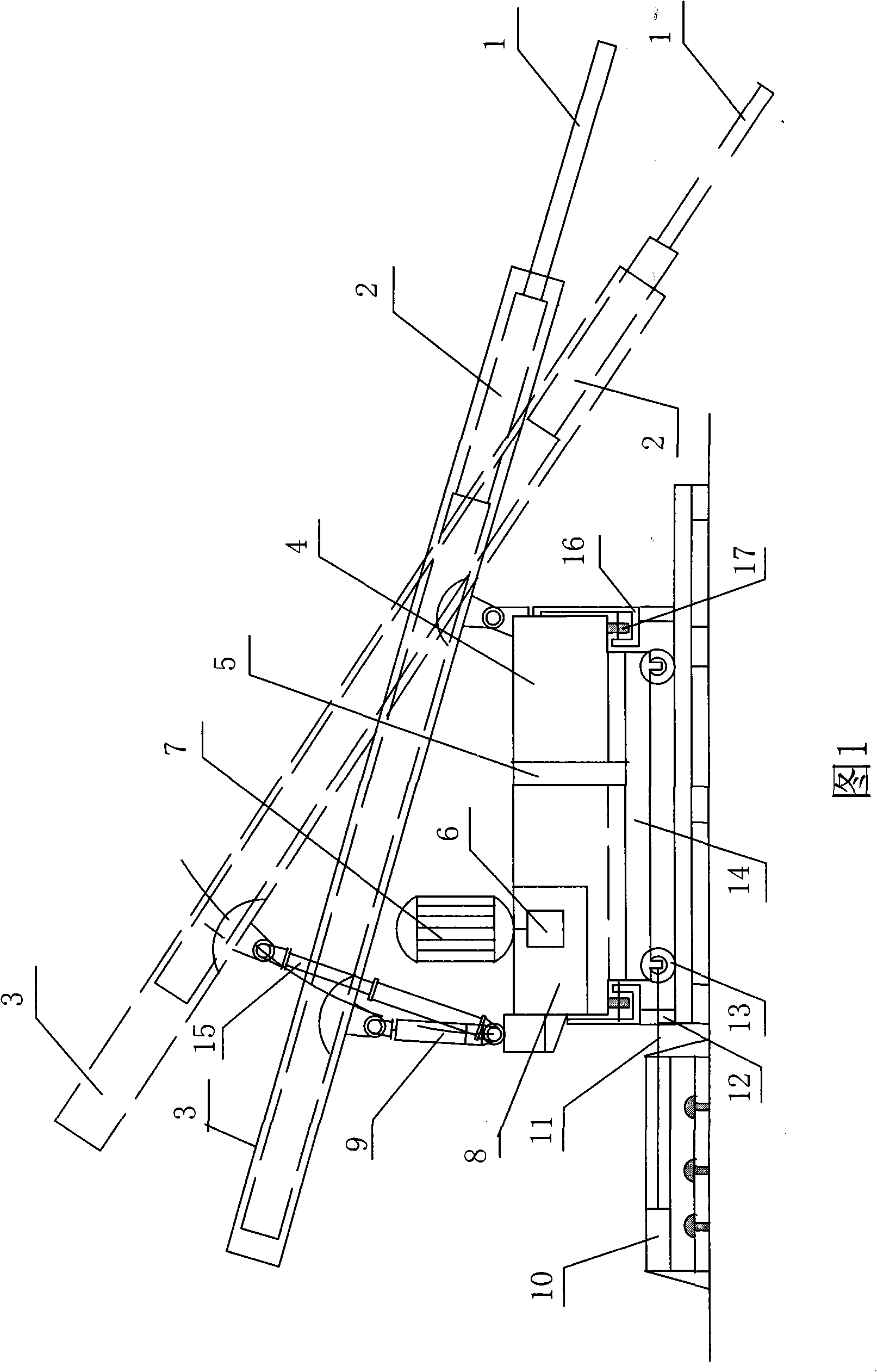

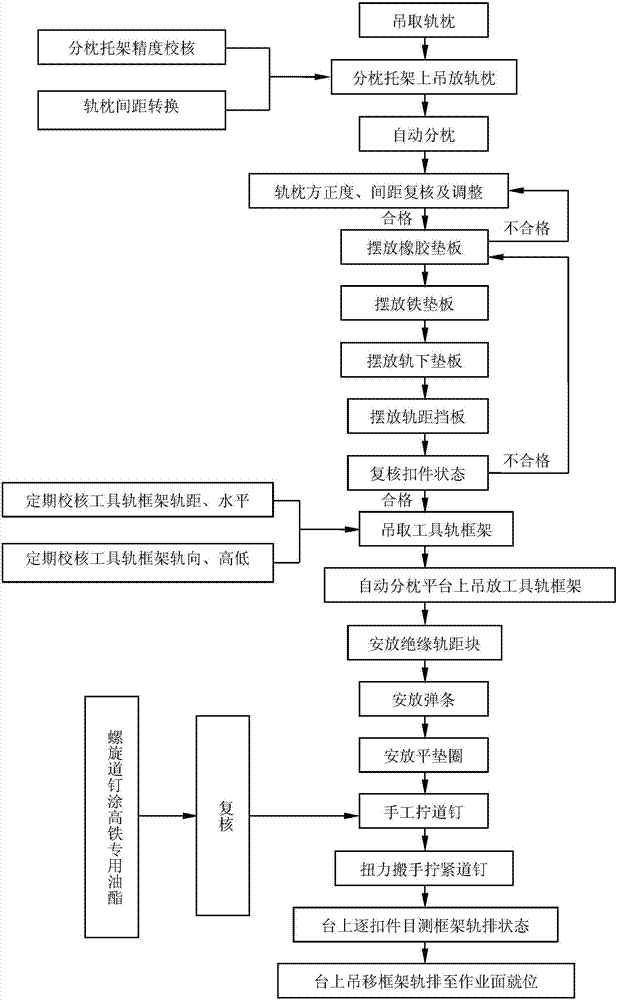

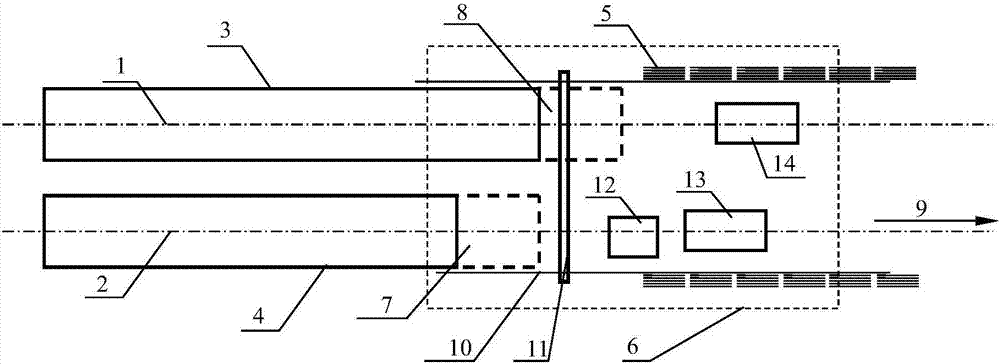

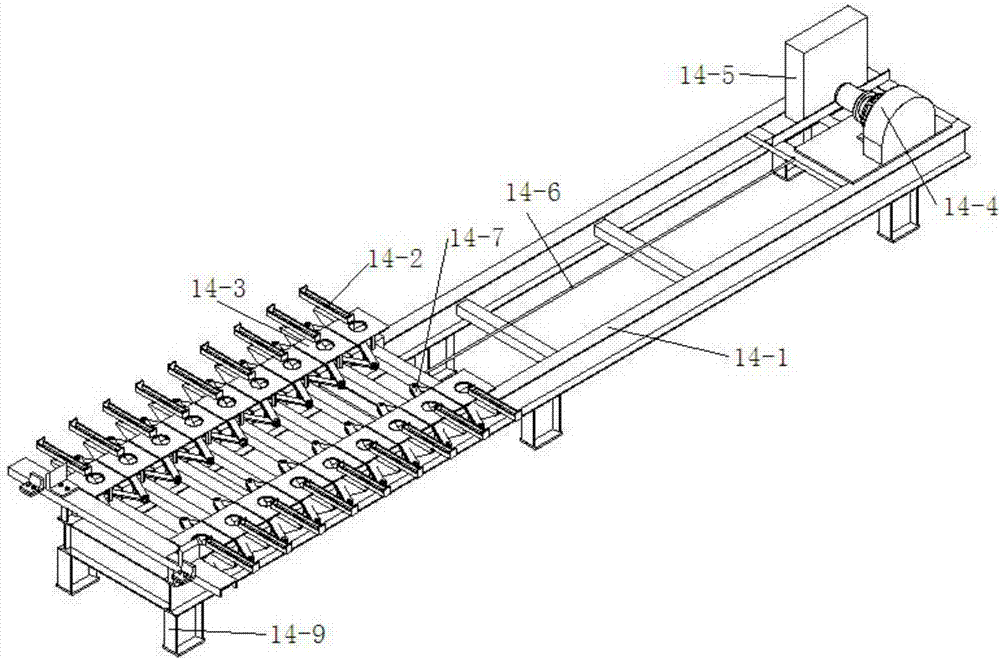

Double-block type framework rail section assembling device and method for ensuring geometrical state of rails

ActiveCN107165005AGauge up to standardMake sure the trackRailway track constructionStructural engineeringWasher

The invention discloses a double-block type framework rail section assembling device for ensuring a geometrical state of rails. The device comprises a cross-line gantry crane, a sleeper sling, an automatic sleeper splitting device and a tool rail framework sling, wherein the cross-line gantry crane is arranged on the two rails; the two rails are fixedly connected with the outsides of a left line poured ballastless rail bed and a right line poured ballastless rail bed; the sleeper sling is detachably connected to a lifting hook of the gantry crane and used for suspending a sleeper; the tool rail framework sling is detachably connected to the lifting hook of the gantry crane and used for suspending a tool rail framework; and the automatic sleeper splitting device is installed between the two rails, arranged in the lengthwise direction of the rails and used for automatically splitting multiple rows of sleepers. The double-block type framework rail section assembling device can ensure the effect that the rail distance does not exceed the standard, the sleepers are respaced, the distance between the sleepers meets the requirements, empty suspension of the sleepers is prevented, embedded sleeves are prevented from being damaged or blocked, fastening elastic rods and flat washers do not deform, and it is ensured that the high-speed rail structure can operate for 100 years or more stably.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

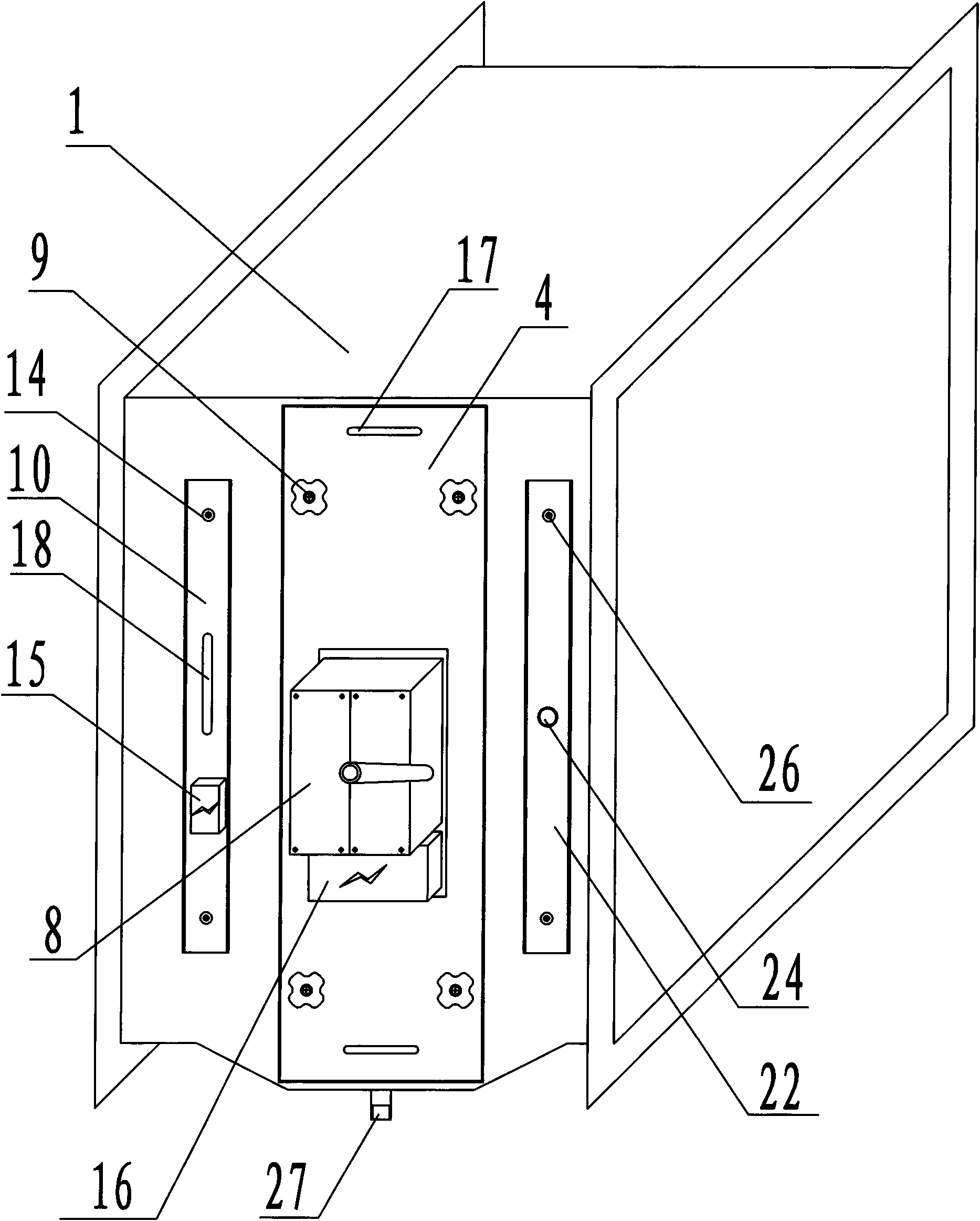

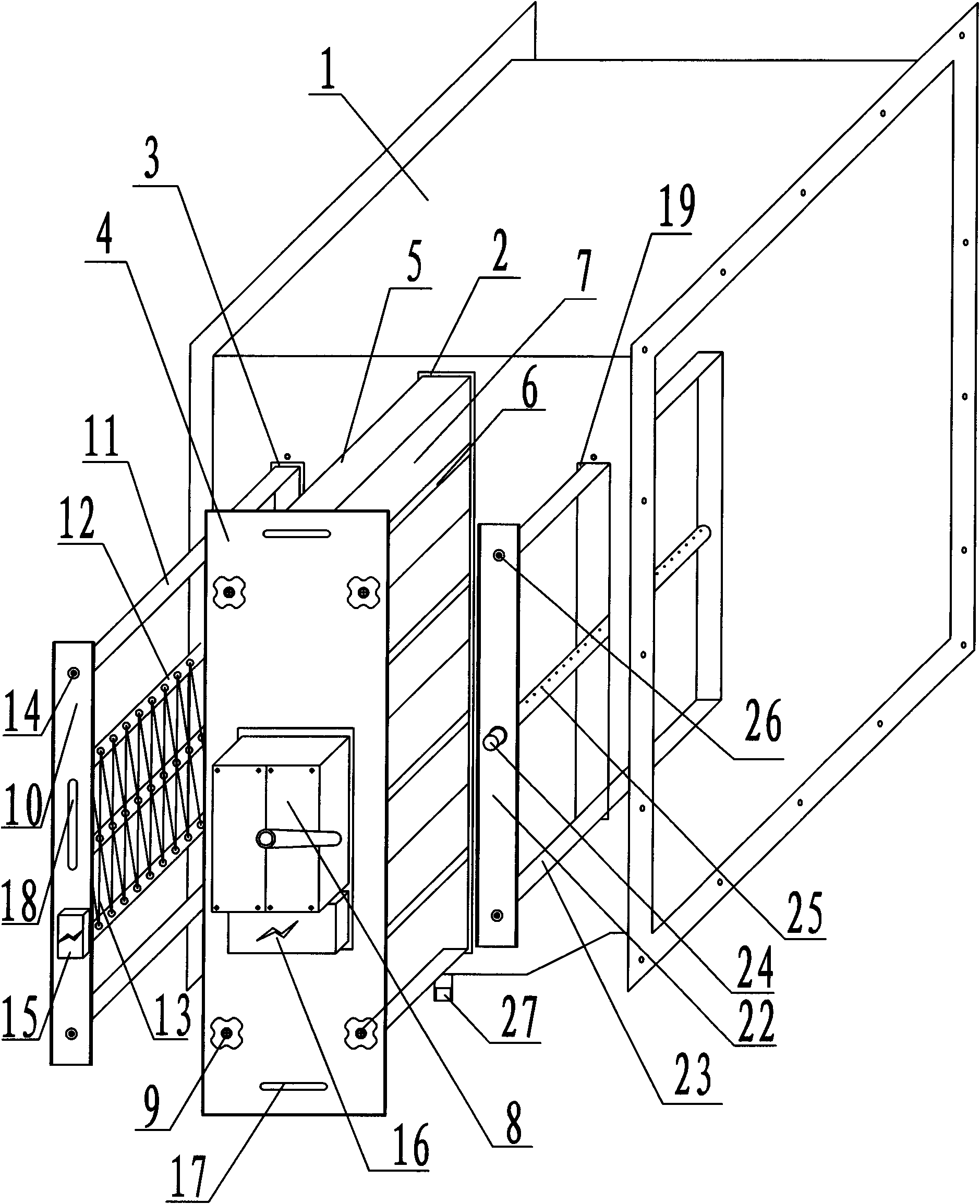

Fireproof valve for oil smoke pipeline of setting machine

ActiveCN101825193AEasy to disassembleEasy to installOperating means/releasing devices for valvesHeating/cooling textile fabricsEngineeringVALVE PORT

The invention discloses a fireproof valve for an oil smoke pipeline of a setting machine, which has convenient disassembly and assembly and can rapidly induct a fire alarm signal. The fireproof valve comprises a shell, and one side of the shell is provided with a track-type valve core mounting cavity, and the shell at both sides of the track-type valve core mounting cavity is respectively provided with a track-type fire alarm sensor mounting cavity and a track-type spray device mounting cavity; a valve core, a fire alarm sensor and a spray device are respectively arranged in the track-type valve core mounting cavity, the track-type fire alarm sensor mounting cavity and the track-type spray device mounting cavity. The invention has the advantages that the fireproof valve with the structure, which is used in the oil smoke pipeline of the setting machine, is easy to disassemble and install, and thereby, cleaning and maintaining the inside of the fireproof valve are convenient. Simultaneously, the fire alarm signal can be rapidly inducted, and then a channel between the oil smoke pipeline and the setting machine is cut off so as to prevent fire from spreading, prevent blades from deformation for a long time and prolong the service life of the fireproof valve.

Owner:江苏保丽洁环境科技股份有限公司

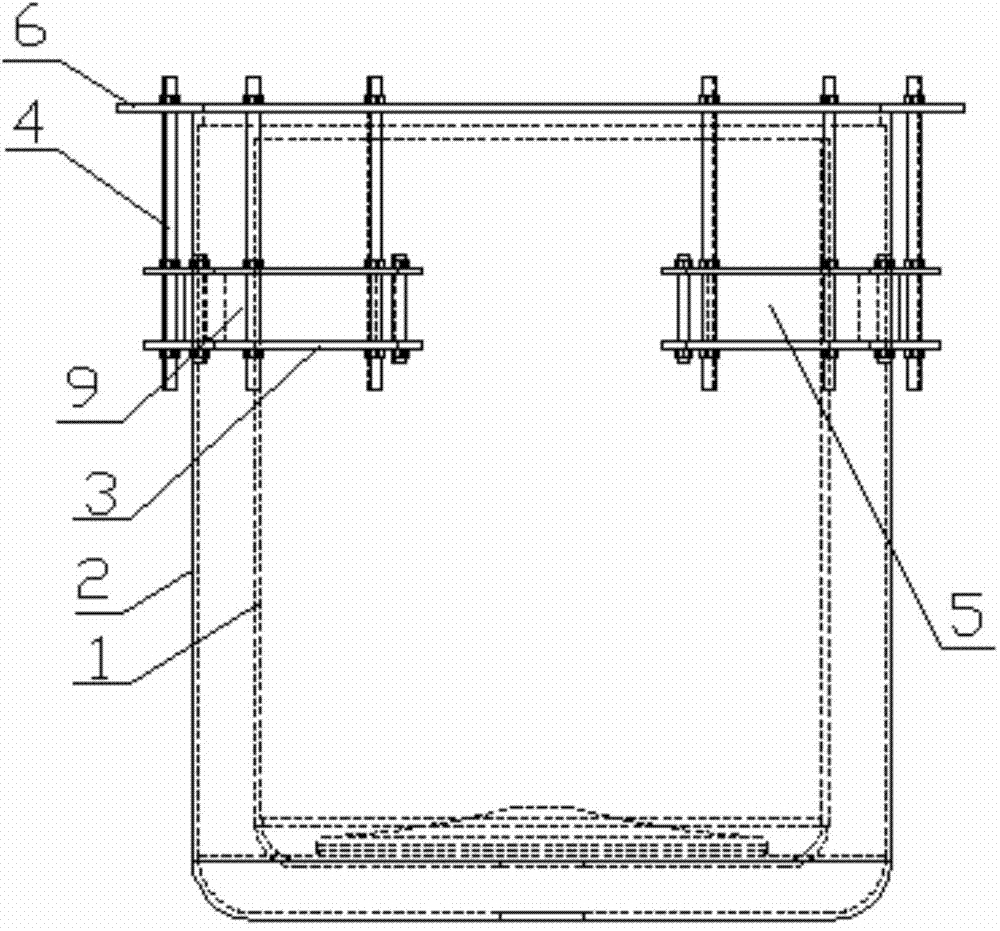

Oil immersed transformer with core lifting device

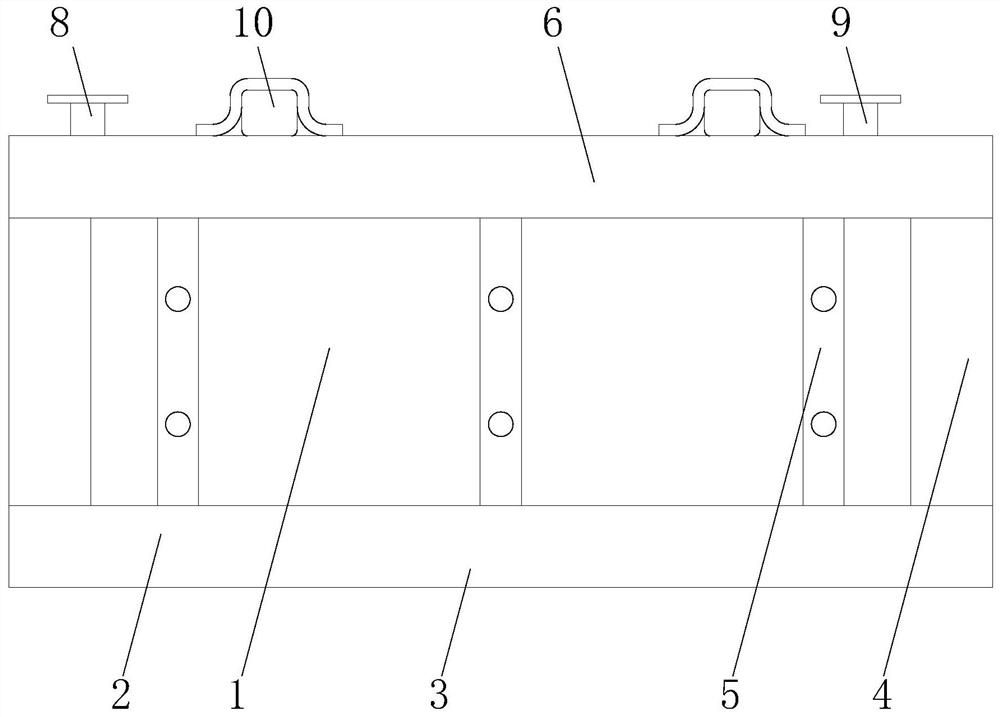

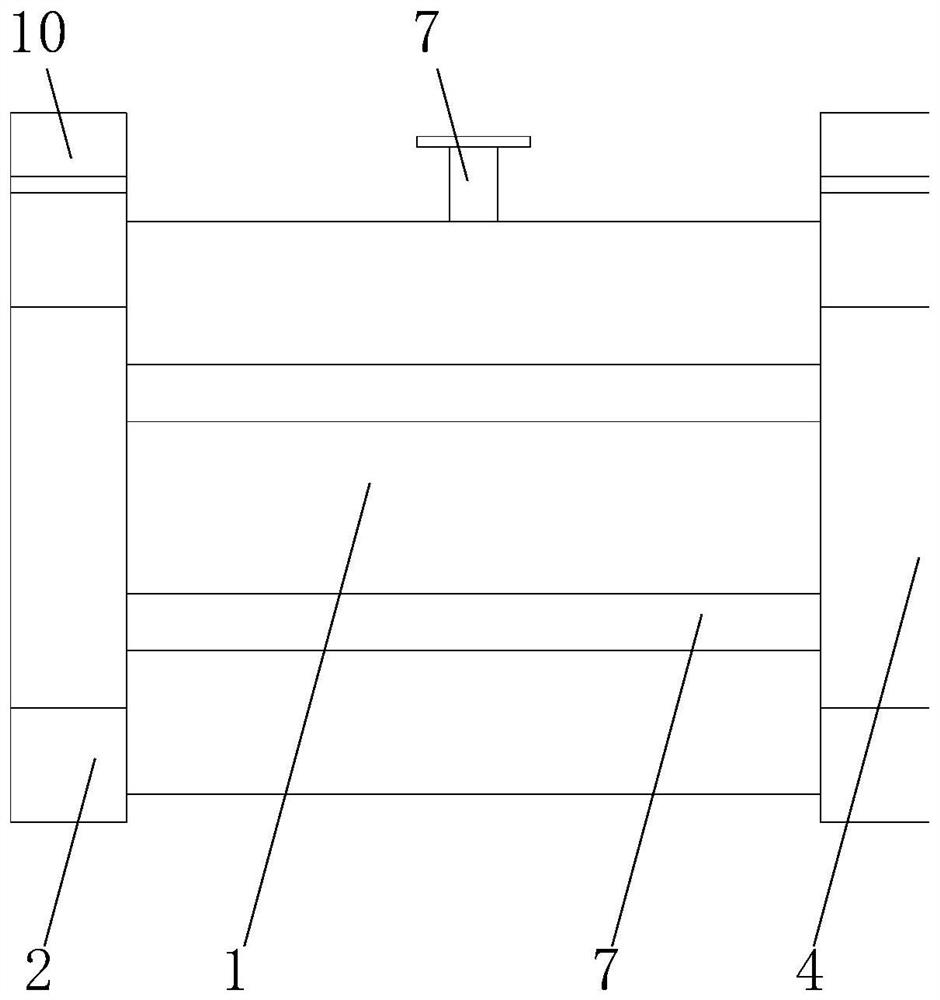

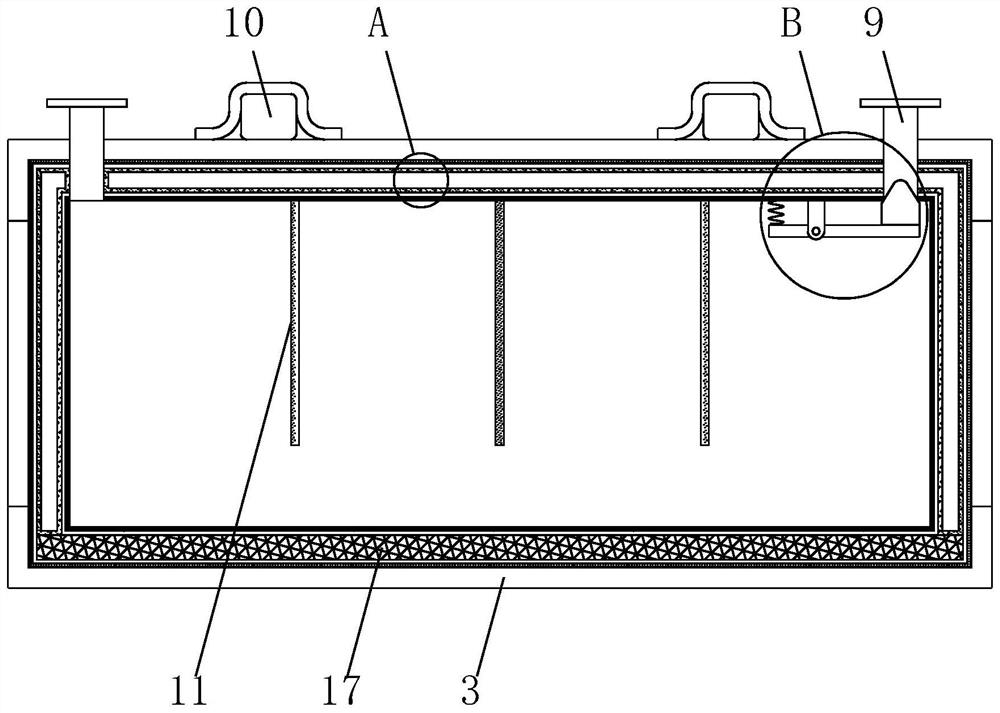

InactiveCN103928217AReduce maintenance costsLabor-saving operationTransformers/inductances coolingTransformer oilWaste management

The invention relates to an oil immersed transformer with a core lifting device. The oil immersed transformer comprises a transformer oil tank and a core and winding assembly. The core and winding assembly is arranged in the transformer oil tank. A tank cover is arranged on the top of the transformer oil tank. The two corresponding outer sides of the transformer oil tank are respectively connected with one or more jacks. The jacks are connected with the tank cover and can drive the tank cover to ascend to open the transformer oil tank or descend to package the transformer oil tank. According to the oil immersed transformer with the core lifting device, the structure that the jacks are arranged on the side edges of the transformer oil tank is adopted, and the jacks are used for supporting the tank cover and packaging the transformer oil tank, so that the requirement that the transformer oil tank is opened in a lifting mode when the core and winding assembly in the transformer oil tank needs to be overhauled is met; the oil immersed transformer with the core lifting device is simple and stable in structure, convenient and safe to operate, and capable of lifting the core and winding assembly in the transformer oil tank in real time, reducing the overhauling cost and improving the overhauling efficiency.

Owner:BORUI ELECTRIC

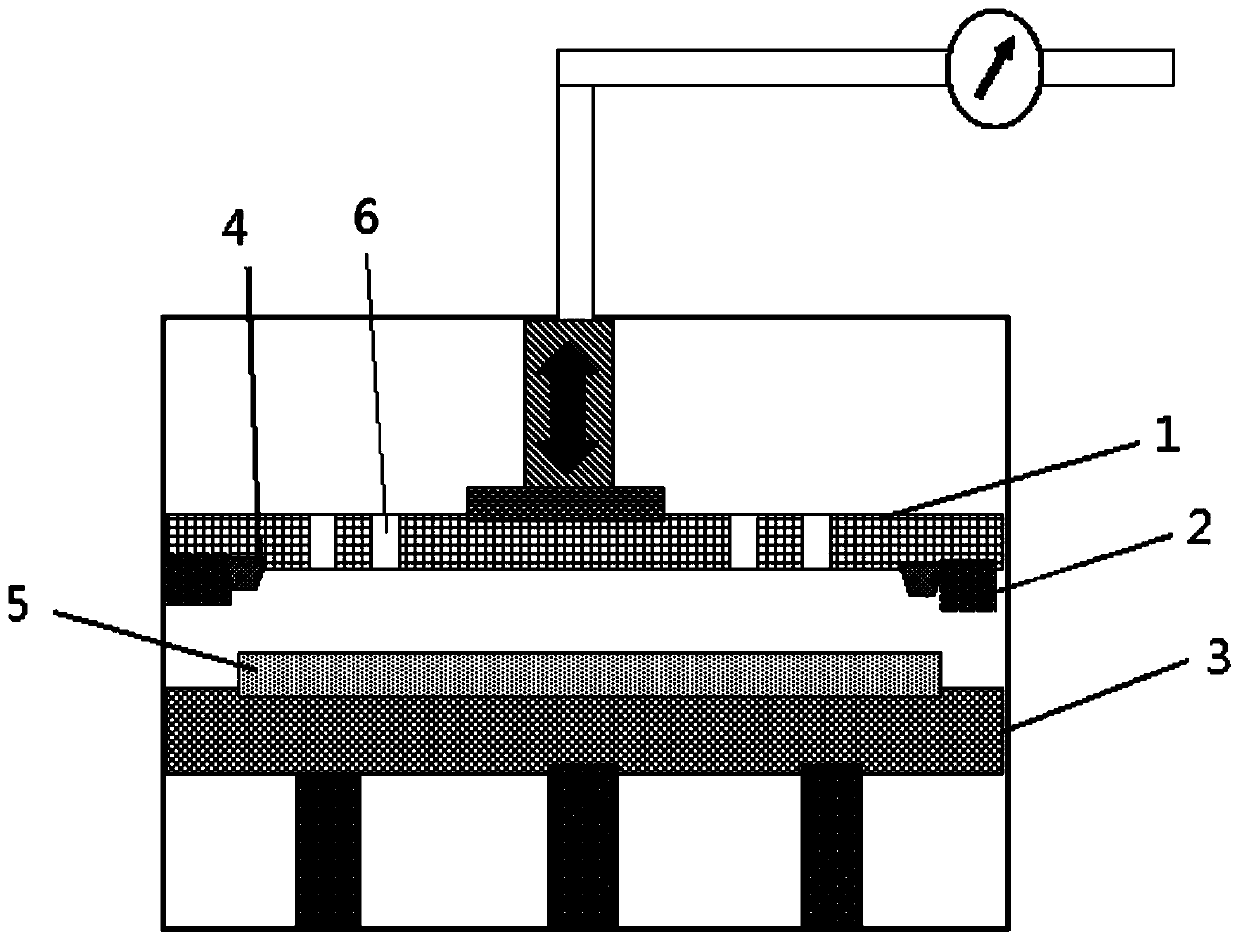

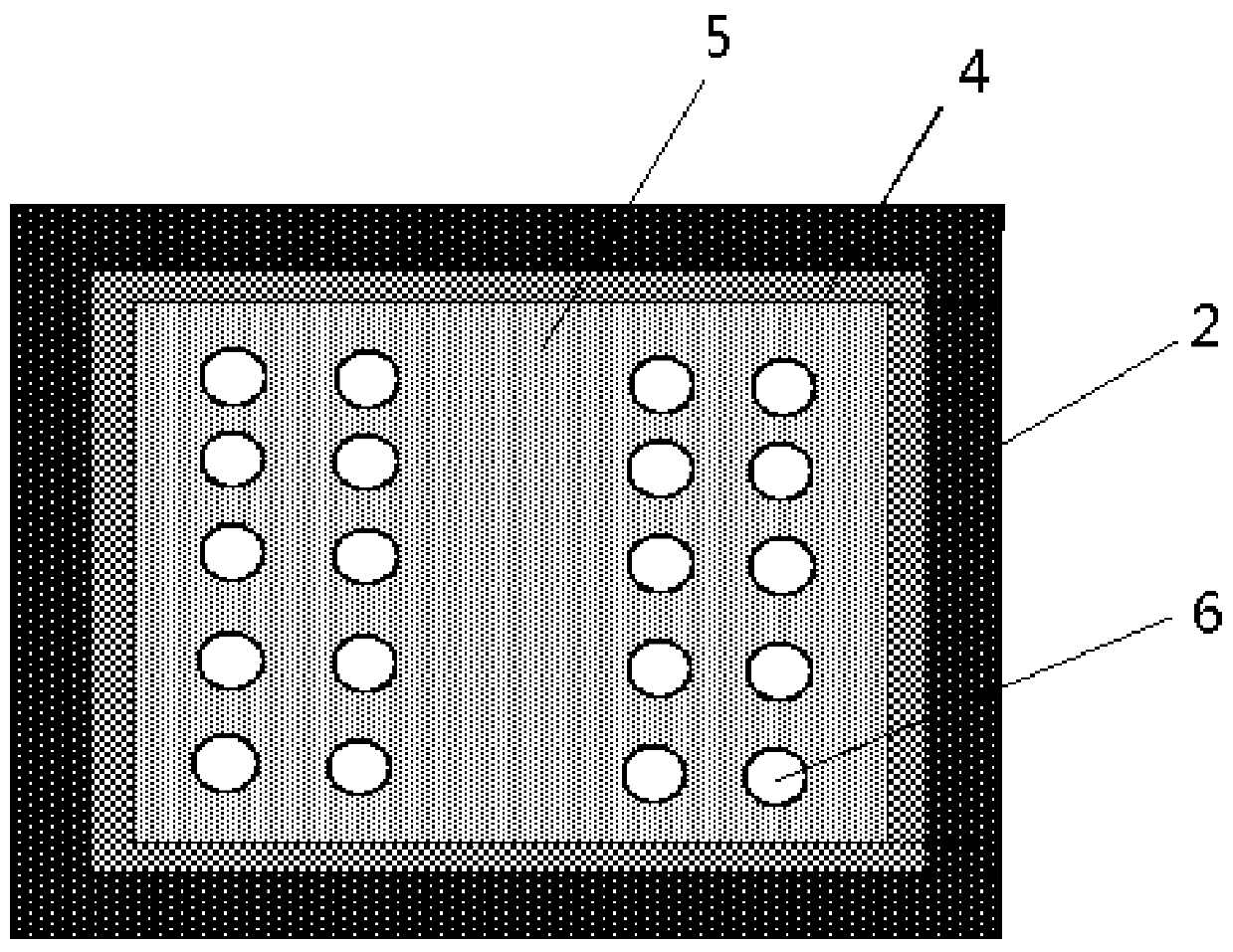

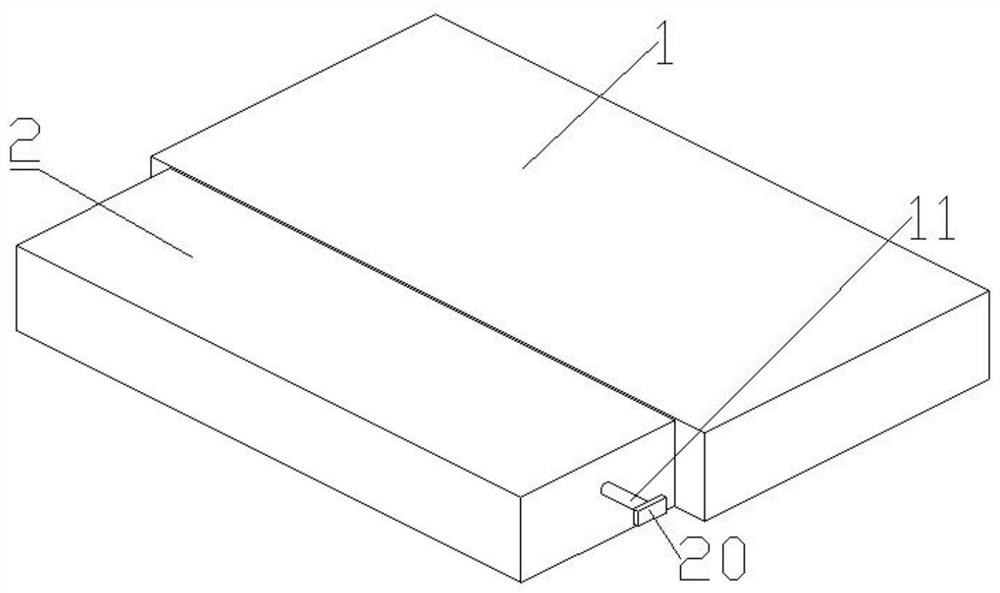

Semiconductor device for correcting warpage of plastic packaging panel and correction method

InactiveCN109801859AFirmly connectedThe first connection of the connection is convenientSemiconductor/solid-state device manufacturingPlastic packagingCorrection method

The invention relates to the technical field of advanced packaging technologies for integrated circuits, and specifically relates to a semiconductor device for correcting warpage of a plastic packaging panel containing an integrated circuit chip and a correction method. The semiconductor device comprises a load-bearing structure, a vacuum channel, a pressing structure and a heating structure, wherein the load-bearing structure is used for bearing a load-bearing area of the plastic packaging panel, and the load bearing area is set to be a plane; the vacuum channel is arranged on the load-bearing structure, communicated with the load-bearing area, and used for applying vacuum to a gap between the plastic packaging panel and the load-bearing area; the pressing structure is arranged above theload-bearing structure and moves back and forth in a direction perpendicular to the load-bearing area, the pressing structure is provided with a pressing end which is arranged corresponding to the plastic packaging panel and used for applying correction pressure to a part without a bare chip of the plastic packaging panel, and the contact surface between the pressing end and the plastic packagingpanel is a plane; and the heating structure is arranged on the load-bearing structure and / or pressing structure and used for heating the plastic packaging panel. The semiconductor device of the invention is not easy to damage the bare chip during correction and is good in correction effect.

Owner:NAT CENT FOR ADVANCED PACKAGING

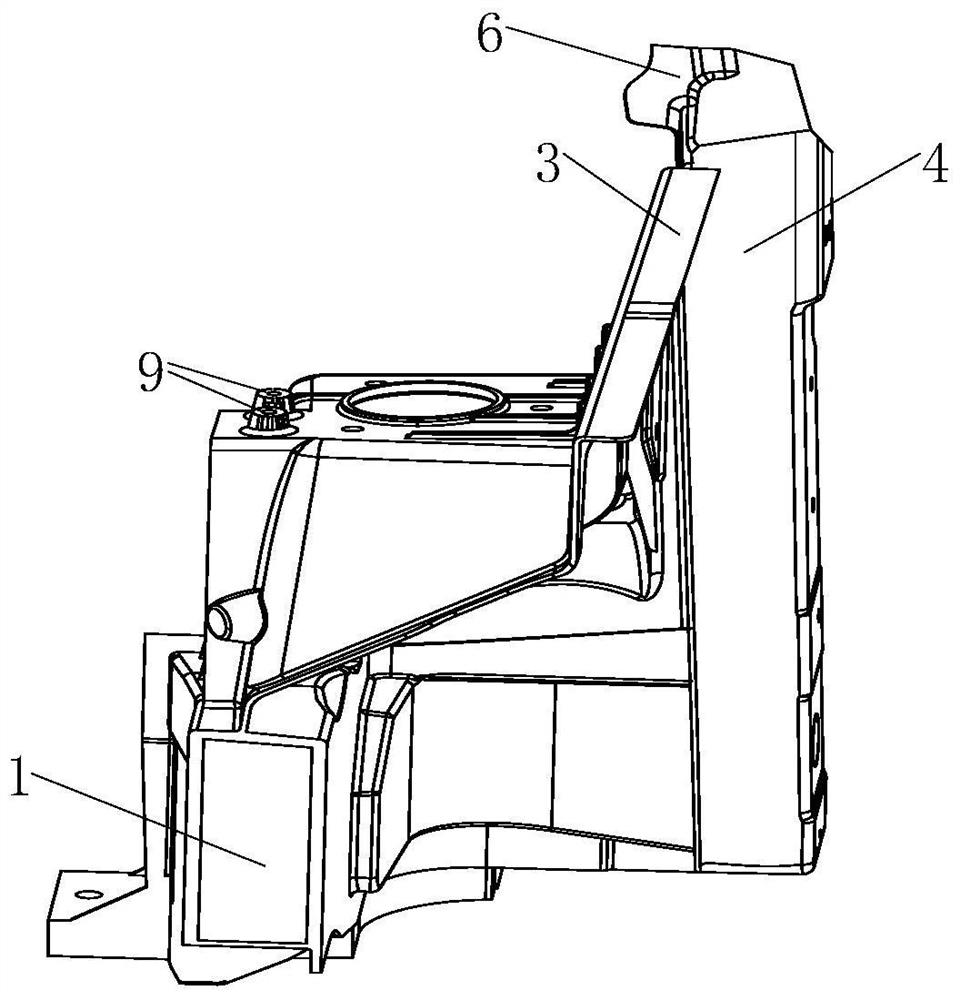

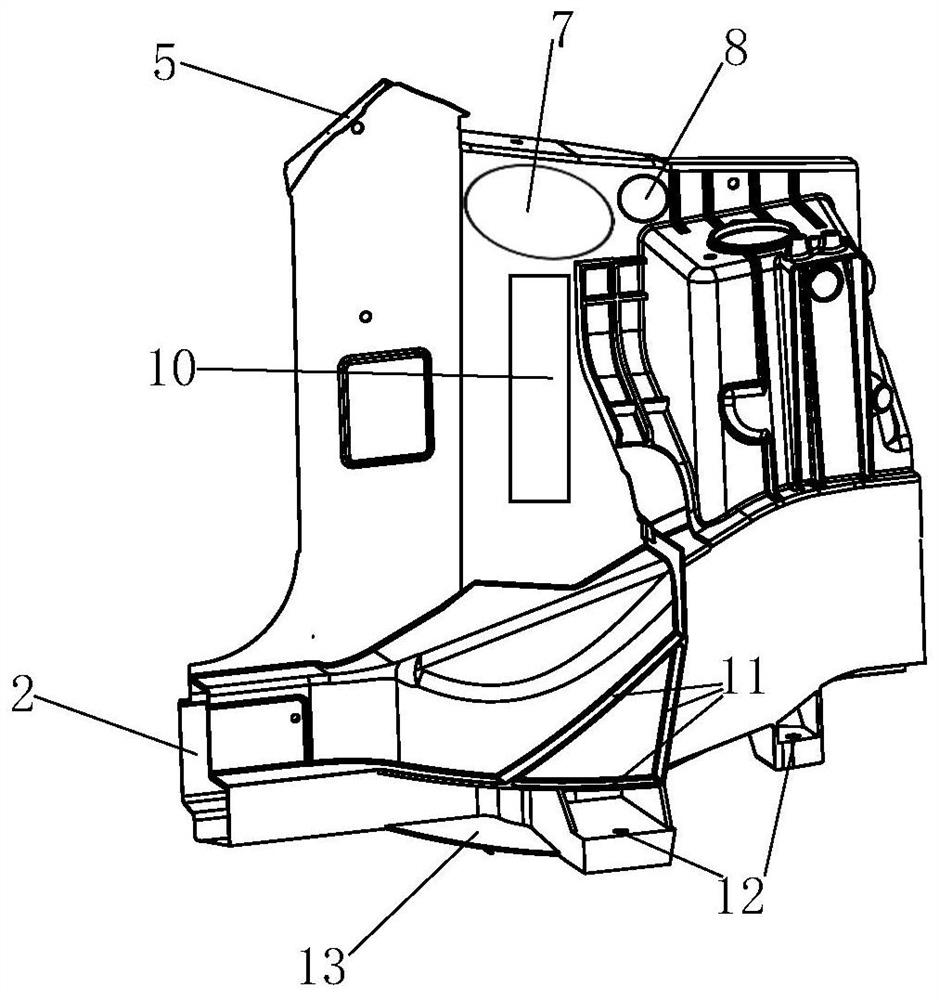

Leakage-proof automobile fuel tank

InactiveCN112193061AImprove the protective effectImprove securityUnderstructuresFuel supplyEnvironmental geologyAutomotive engineering

The invention relates to the technical field of automobile oil tanks, and discloses a leakage-proof automobile oil tank which comprises an oil tank body and a leakage-proof mechanism; the oil tank body comprises an oil suction port, an oil filling port, a partition plate, an oil tank outer shell, a buffer layer, an air bag, flame-retardant gas, an oil tank inner shell and oil suction fibers; the oil suction port is located on one side of the top of the oil tank body and the oil filling port is arranged on the other side of the top of the oil tank body, the partition plate is fixedly connectedto the top of the interior of the oil tank inner shell, the air bag is filled with the flame-retardant gas, the buffer layer wraps the air bag and is arranged between the oil tank outer shell and theoil tank inner shell, the oil absorption fibers are arranged at the bottom of the interior of the oil tank outer shell, and a protection mechanism is arranged outside the oil tank body. The protectionmechanism comprises a lower cross arm, a vertical rod, reinforcing ribs, an upper cross arm and a connecting rod, the bottom of the vertical rod and the lower cross arm are fixedly installed, and thetop of the vertical rod and the upper cross arm are fixedly installed. The invention solves the problems that an existing automobile fuel tank leaks easily and is poor in protection performance.

Owner:ZHEJIANG HANGMO OUYI AUTOMOTIVE COMPONENTS

Obstruction preventing material feeder

InactiveCN101172536AProtect against deformationSave human effortLarge containersLoading/unloadingEngineering

The invention discloses an anti-clogging batch feeder, which comprises a baiting funnel of a batch feeder, and a shaker fixed on the outer wall of the baiting funnel of the batch feeder. When finding that the batch feeder dose not lay off, working personnel can only press a switch, the shaker can start to shake, and the materiel in the batch feeder can automatically drop down, therefore, the uninterrupted feeding is realized; the invention can save manpower, thereby preventing the batch feeder from deforming, and ensuring the normal operation of the device.

Owner:于波涛

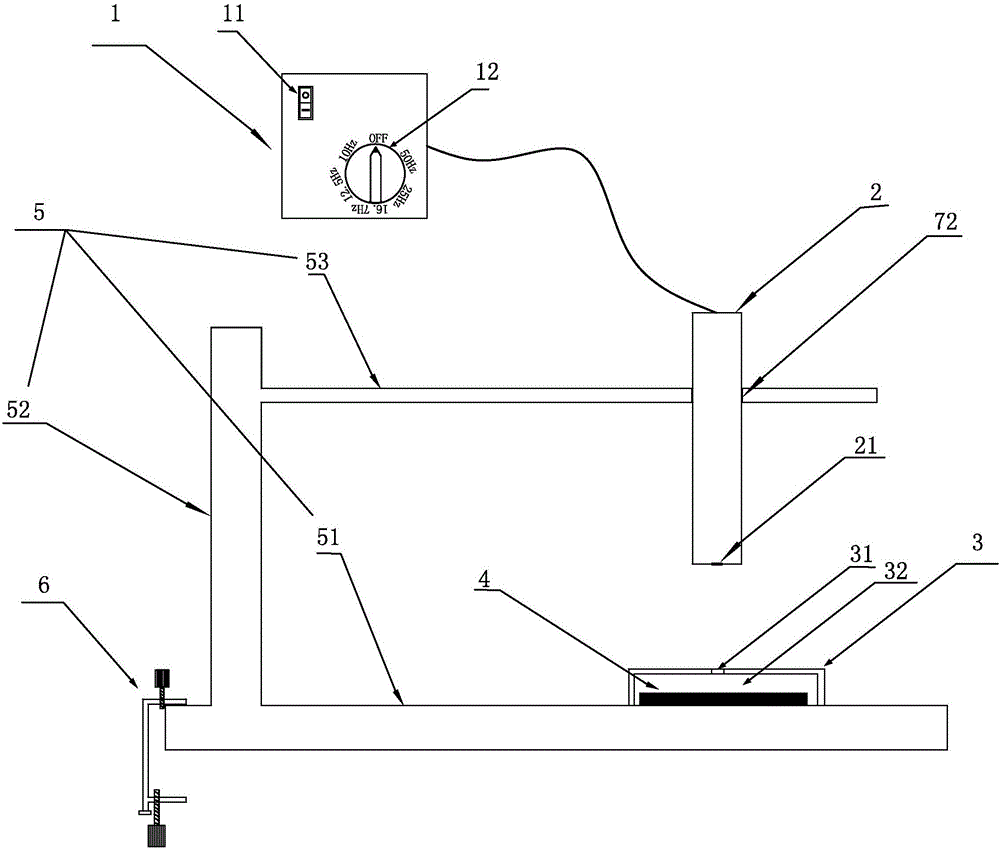

Frequency conversion laser motion recorder

InactiveCN106548689AAvoid obstructionHigh precisionEducational modelsFrequency conversionClassical mechanics

The invention discloses a frequency conversion laser motion recorder. The frequency conversion laser motion recorder comprises a pulse laser capable of frequency modulation, a photosensitive paper tape, a horizontal-U-shaped support frame and a fixation apparatus. According to different moving speeds of a detected moving object, the pulse emission period of the pulse laser can be adjusted to a proper size so that data acquisition and analysis are facilitated. The fixation apparatus fixes the horizontal-U-shaped support frame on a desktop or an experiment table surface such that unnecessary experiment errors caused by movement in an experiment are avoided.

Owner:刘子潇

Steel tube clamping device for machining

The invention discloses a steel tube clamping device for machining, and relates to the technical field of machining. The problems of complex operation and low working efficiency of an existing steel tube clamping device are mainly solved. The steel tube clamping device comprises at least two groups of clamping assemblies longitudinally installed on a machine frame, and the clamping assemblies comprise first gears, second gears, upper clamping tables and lower clamping tables; the steel tube clamping device further comprises a protective unit, the protective unit comprises a protective assemblyand an adjusting assembly for adjusting the position of the protective assembly, and the protective assembly comprises a second motor, a rotary shaft, a driving gear, a driven gear, a two-way screw,a movable plate, a connecting rod and an arc plate. The clamping assemblies are arranged, the operation is simple, convenient and fast, the clamping assemblies can adapt to steel tubes with differentdiameters, and the adaptability is high; and the protective unit is arranged to protect the steel tubes from deforming, the protective assembly can drive the steel tubes to rotate, and the machining is convenient.

Owner:瑞安市祥泽机械设备经营部

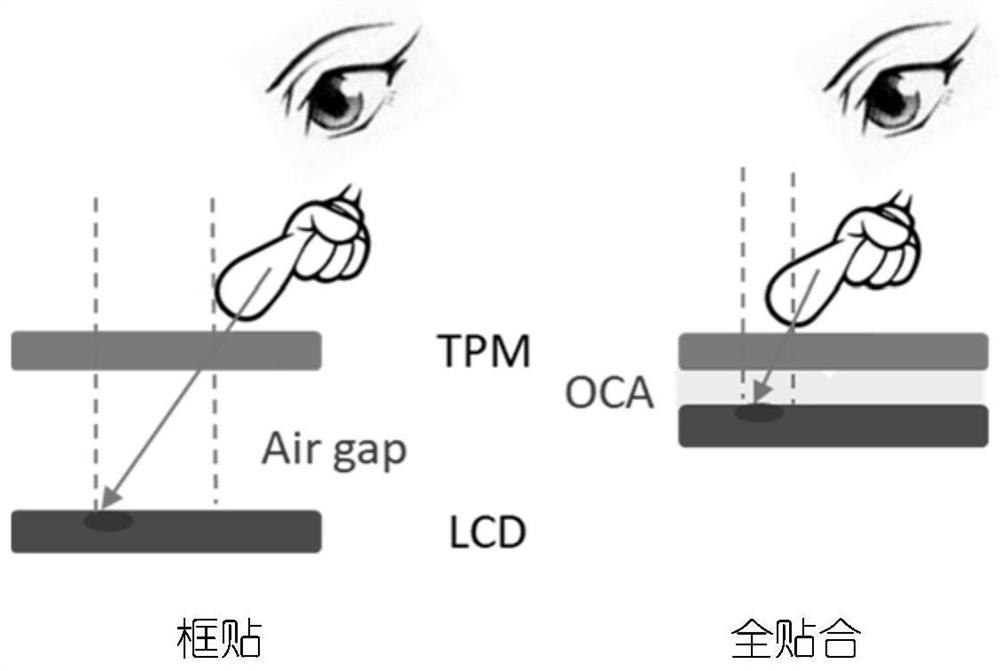

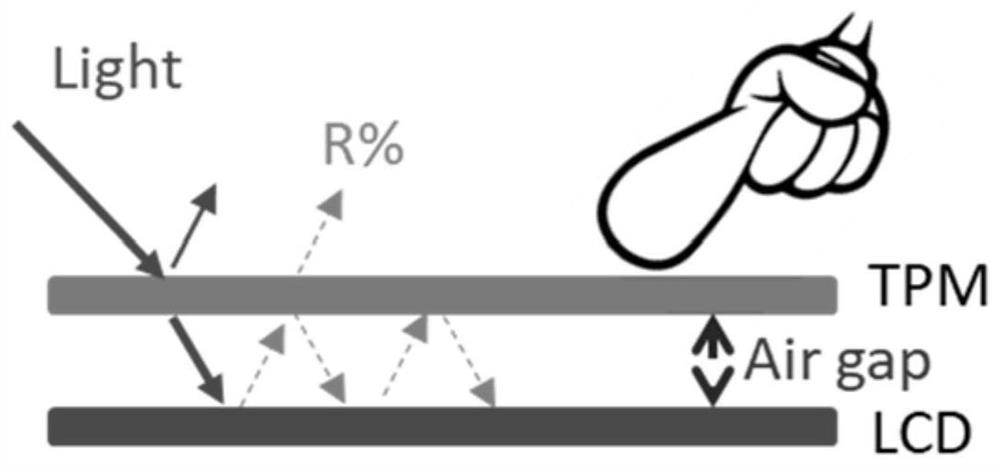

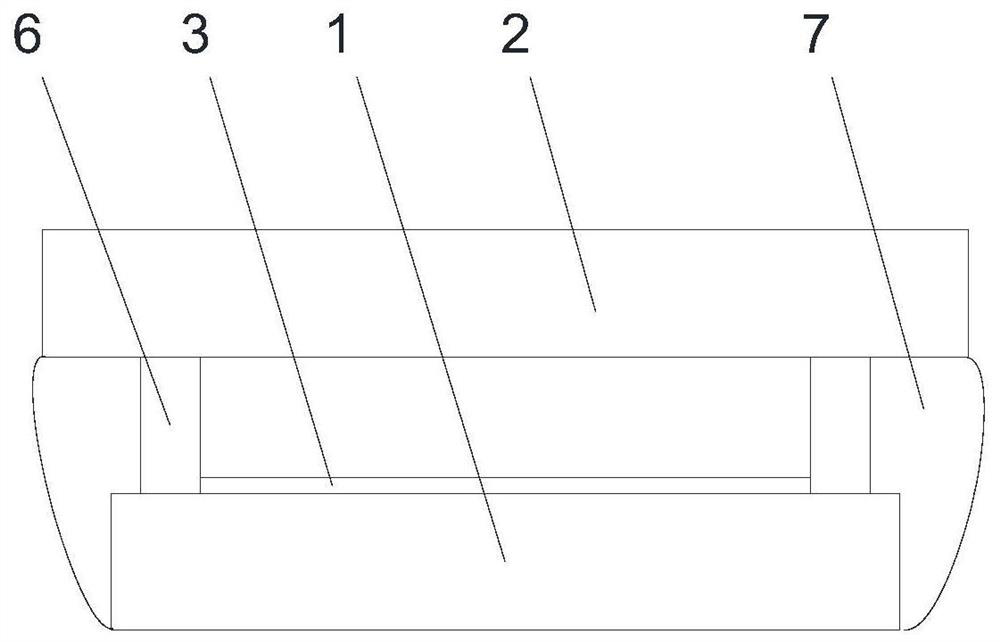

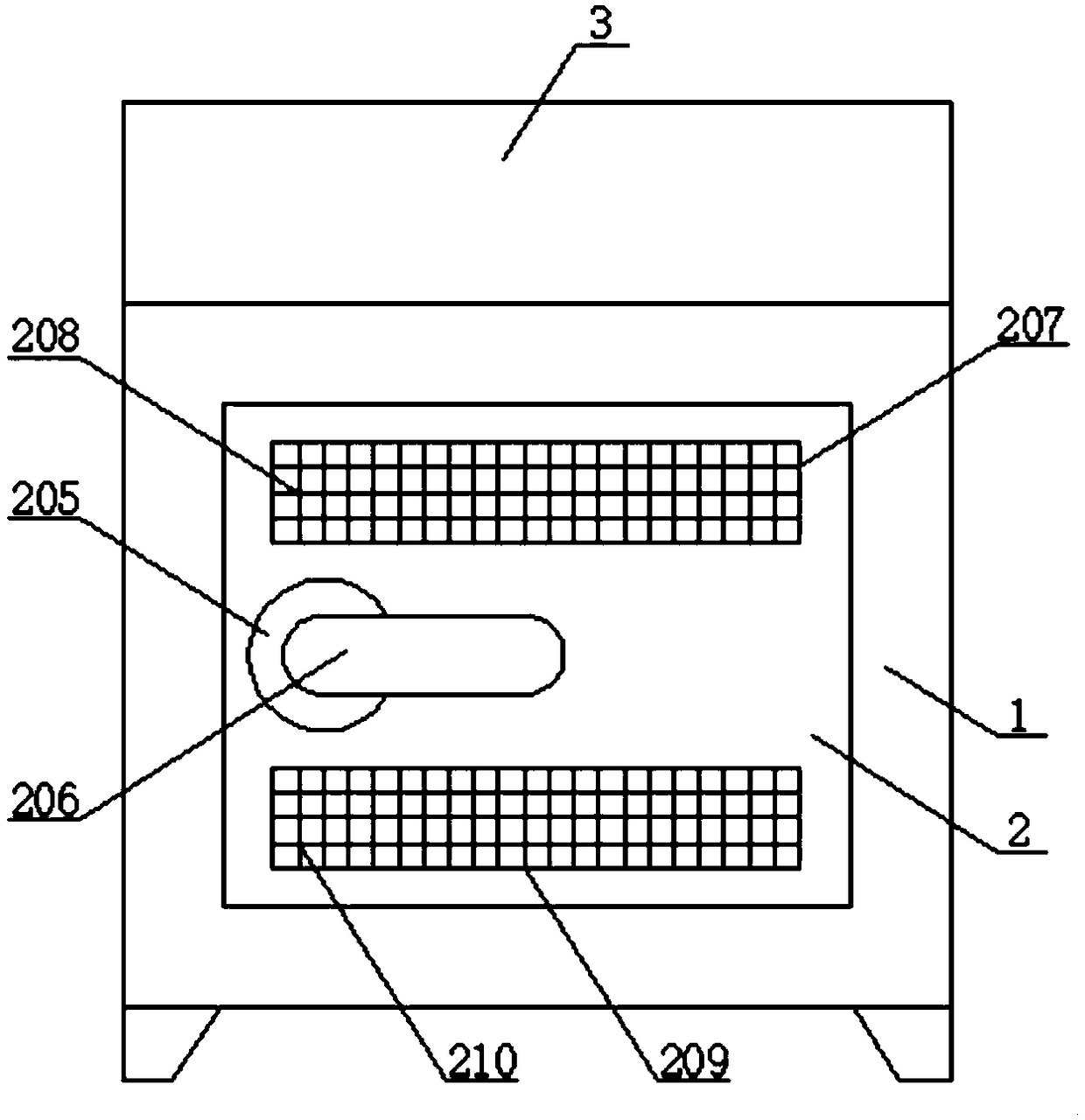

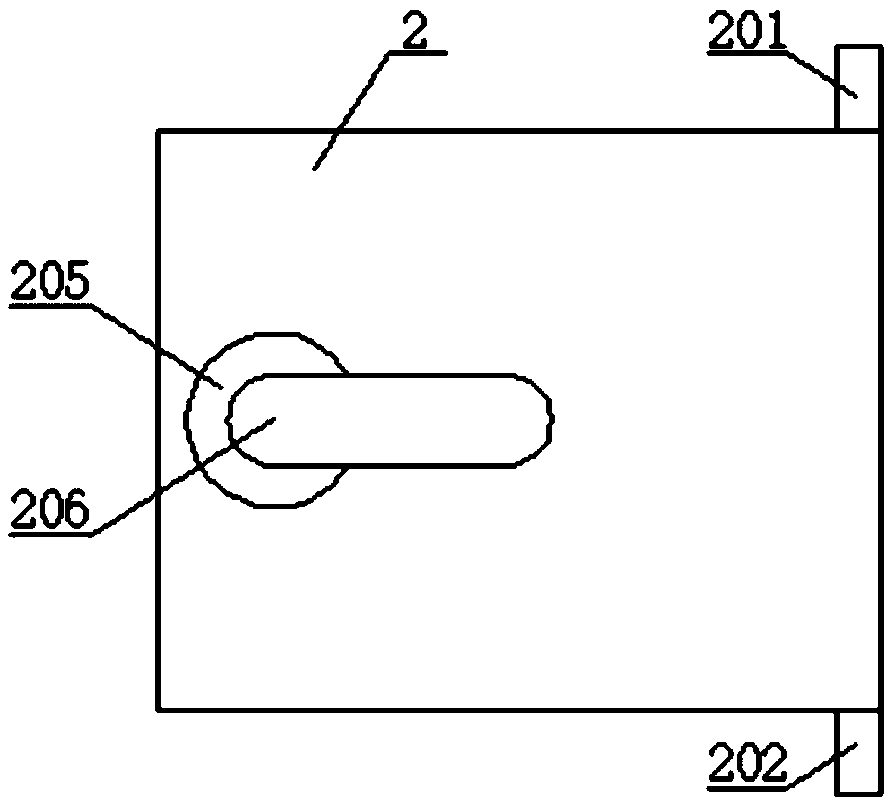

Touch control display

PendingCN112162663AProtect against deformationAvoid bouncingInput/output processes for data processingDisplay deviceEngineering

The invention discloses a touch control display. The touch control display comprises a display module, a touch control module and an optical unit, wherein the touch control module is connected with the display module in a frame pasting mode, a closed gap space is formed between the touch control module and the display module, the gap space is in a vacuum state, and the thickness of the gap space ranges from 0 mm to 3 mm; and the optical unit is arranged on at least one of the display module and the touch module and is adjacent to the gap space, the optical unit comprises an anti-reflection layer or an anti-glare layer or a combination of the anti-reflection layer and the anti-glare layer, the reflectivity of the anti-reflection layer is 0.3-3%, and the haze of the anti-glare layer is 4-60%. According to the touch control display, through adopting the optical technology and small fixing parts, the defects of optical visual effect can be effectively solved, the whole framework can be protected from deformation, and the existing frame pasting technology can achieve the full pasting effect.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

Drying device for effectively reducing drying cracks of humid honeycomb briquettes

InactiveCN108759399AAvoid wastingEasy to observeDrying chambers/containersDrying machines with non-progressive movementsElectric machineryHoneycomb

The invention relates to the technical field of drying, and discloses a drying device for effectively reducing drying cracks of humid honeycomb briquettes. The drying device comprises a drying box. Abox door is arranged on the front side wall of the drying box. A drying mechanism is arranged on an opening in the top end of the drying box. A drying box cavity is provided with a rotation disc, wherein first containing grooves are evenly distributed in the surface of the top side of the rotation disc. The center of the surface of the bottom side of the rotation disc is connected with the shaft end face of an output shaft of a motor located at the center of the bottom end face in the drying box cavity. First ventilation holes are evenly distributed over the center of the left side wall of thedrying box. Cavities of the first ventilation holes penetrating the left side wall of the box communicate with the drying box cavity. A first shielding net is arranged over the center of the left side face in the drying box cavity, and square holes are evenly distributed in the surfaces of the two sides of the first shielding net. The drying device solves the problem that due to existing humid honeycomb briquette drying equipment, the drying cracks are likely to be generated in the humid honeycomb briquette drying process.

Owner:党玉滨

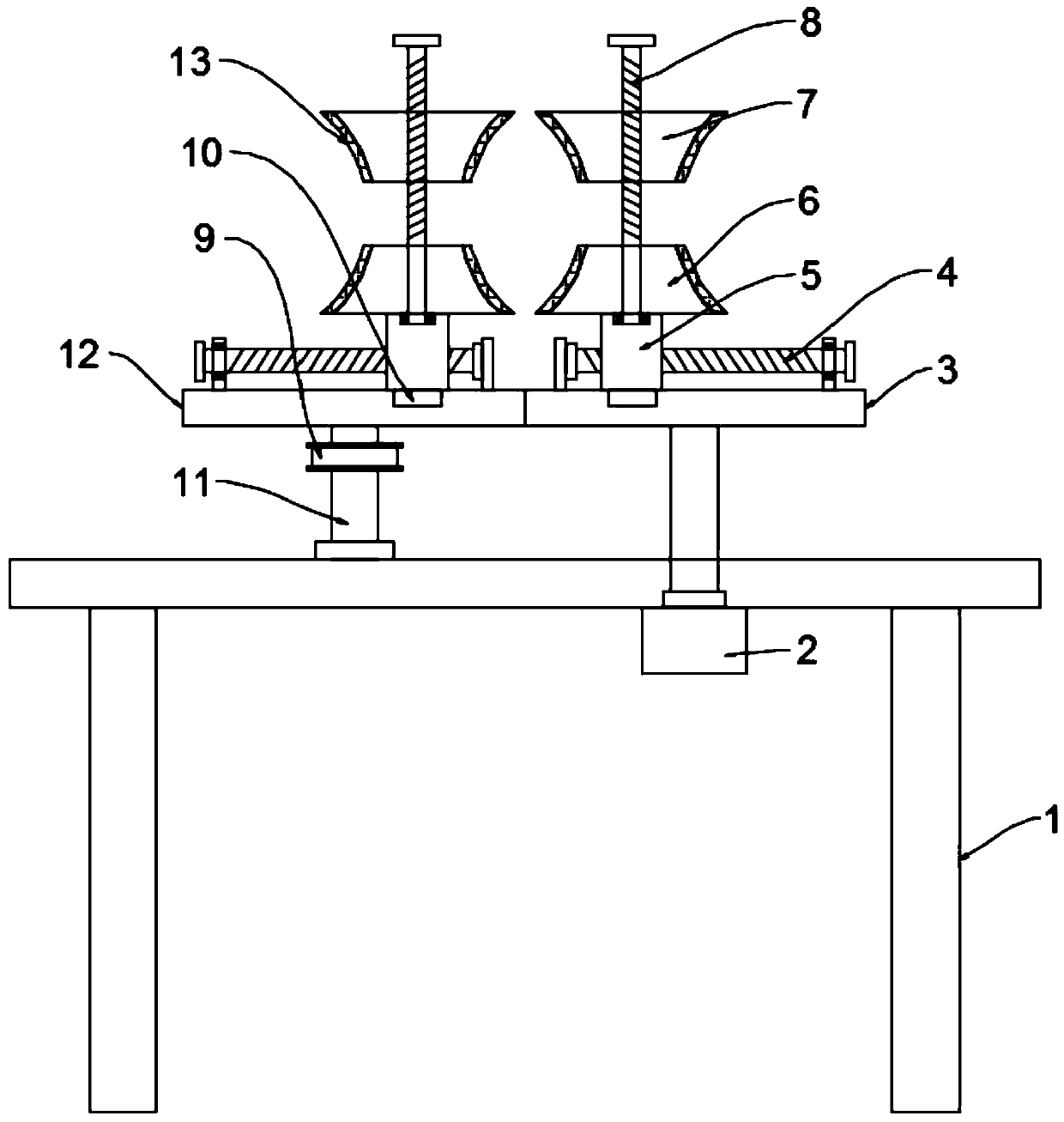

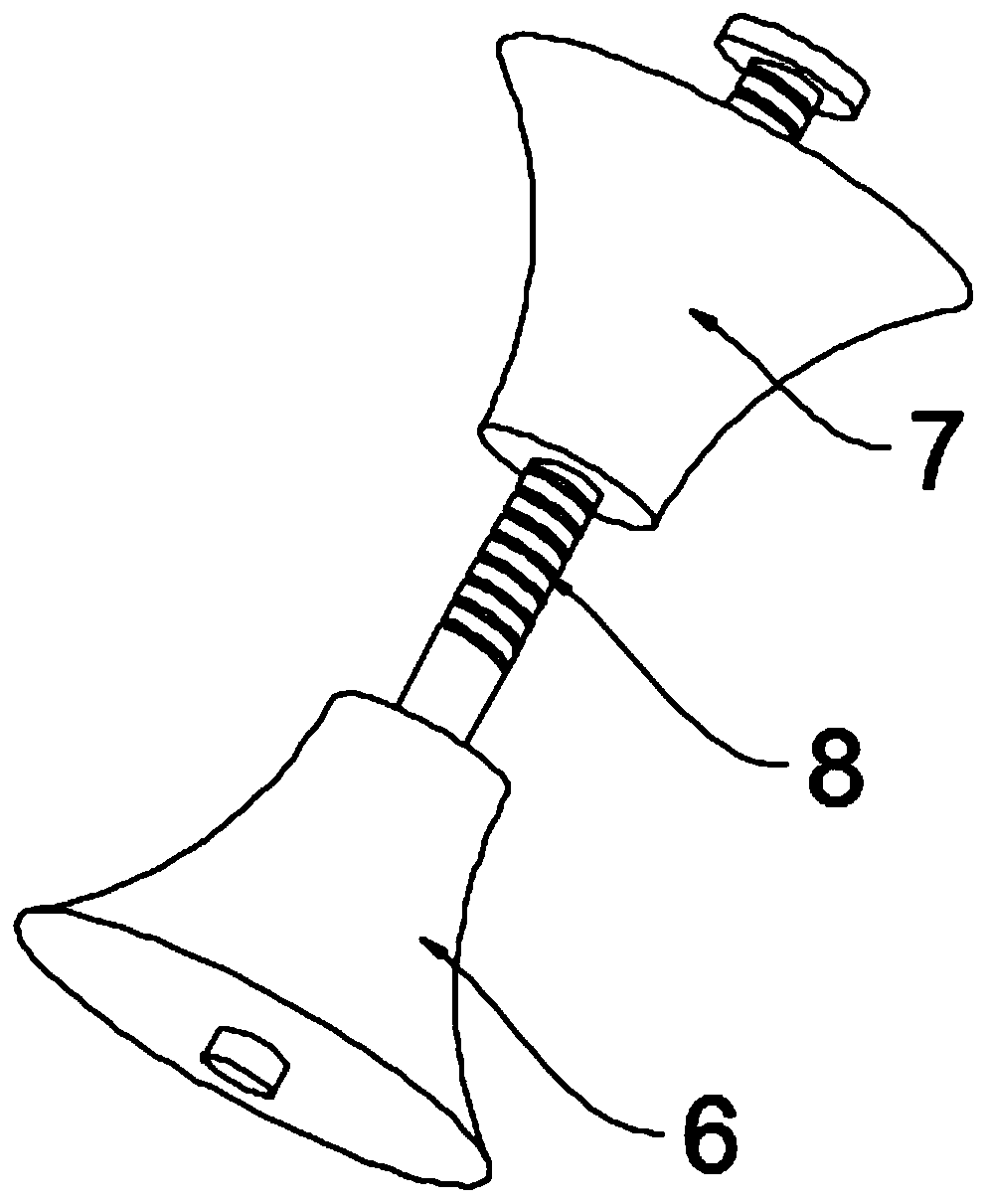

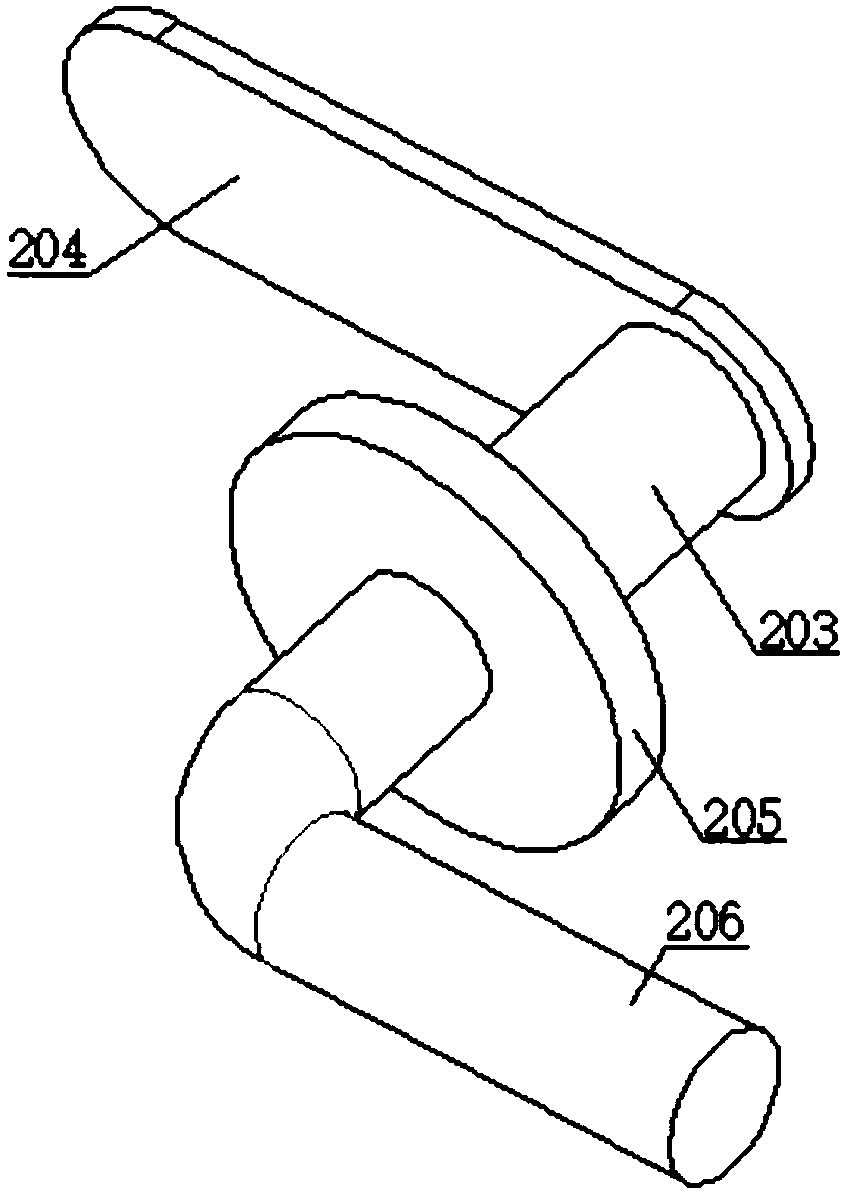

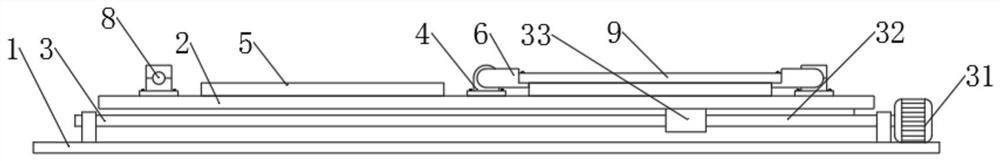

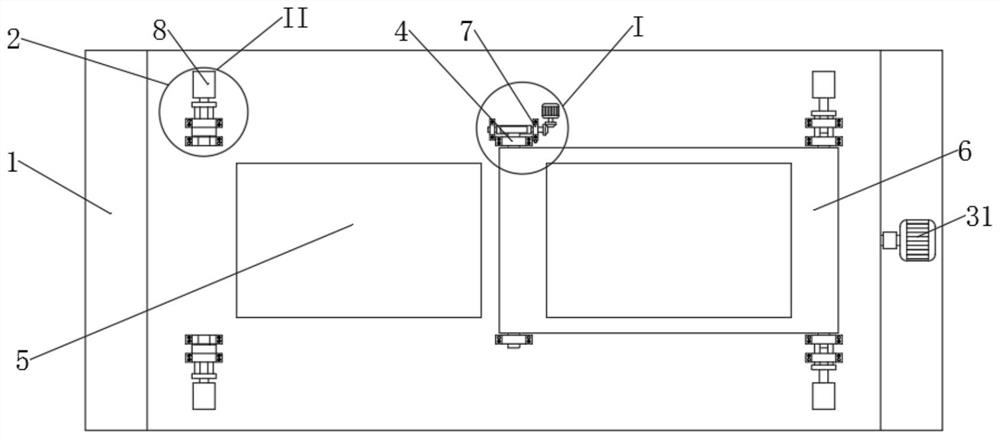

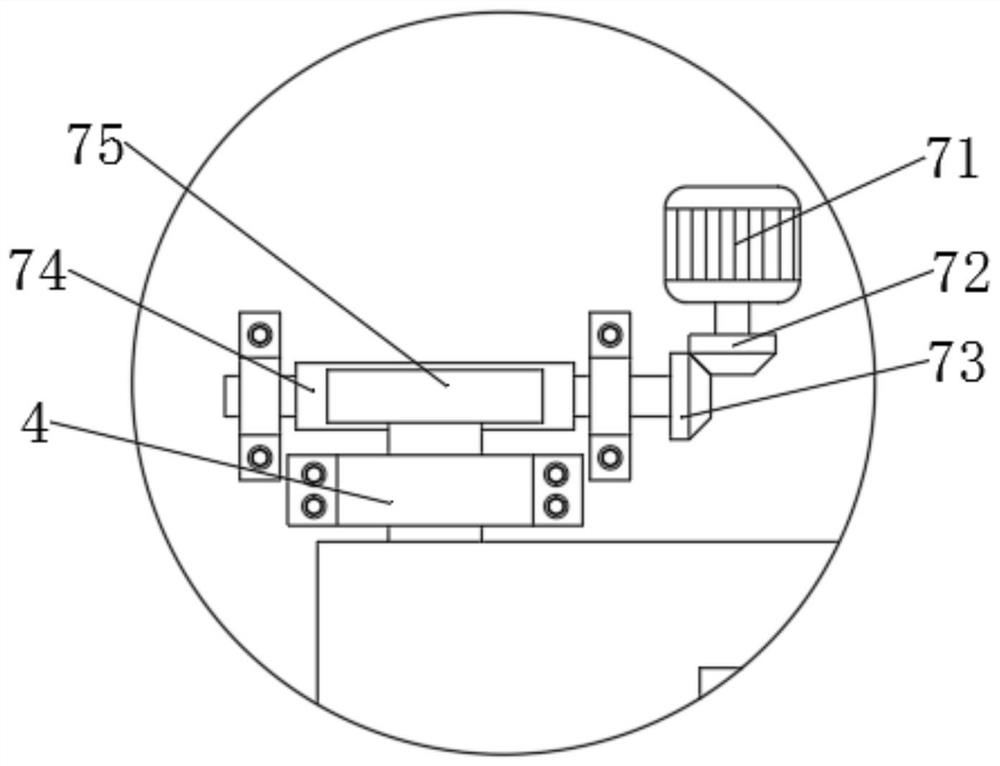

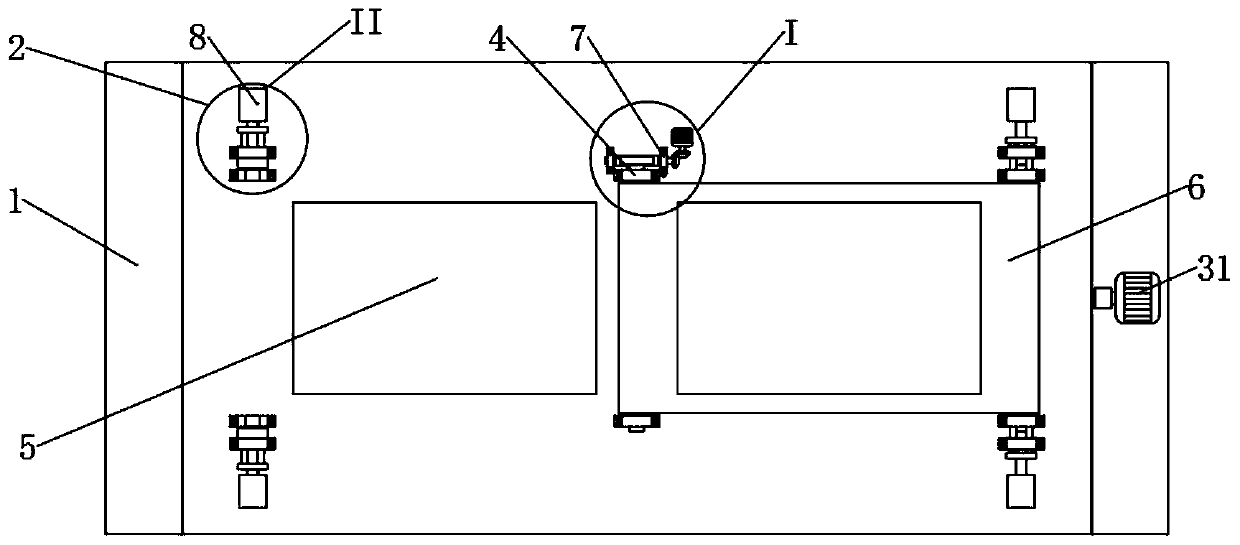

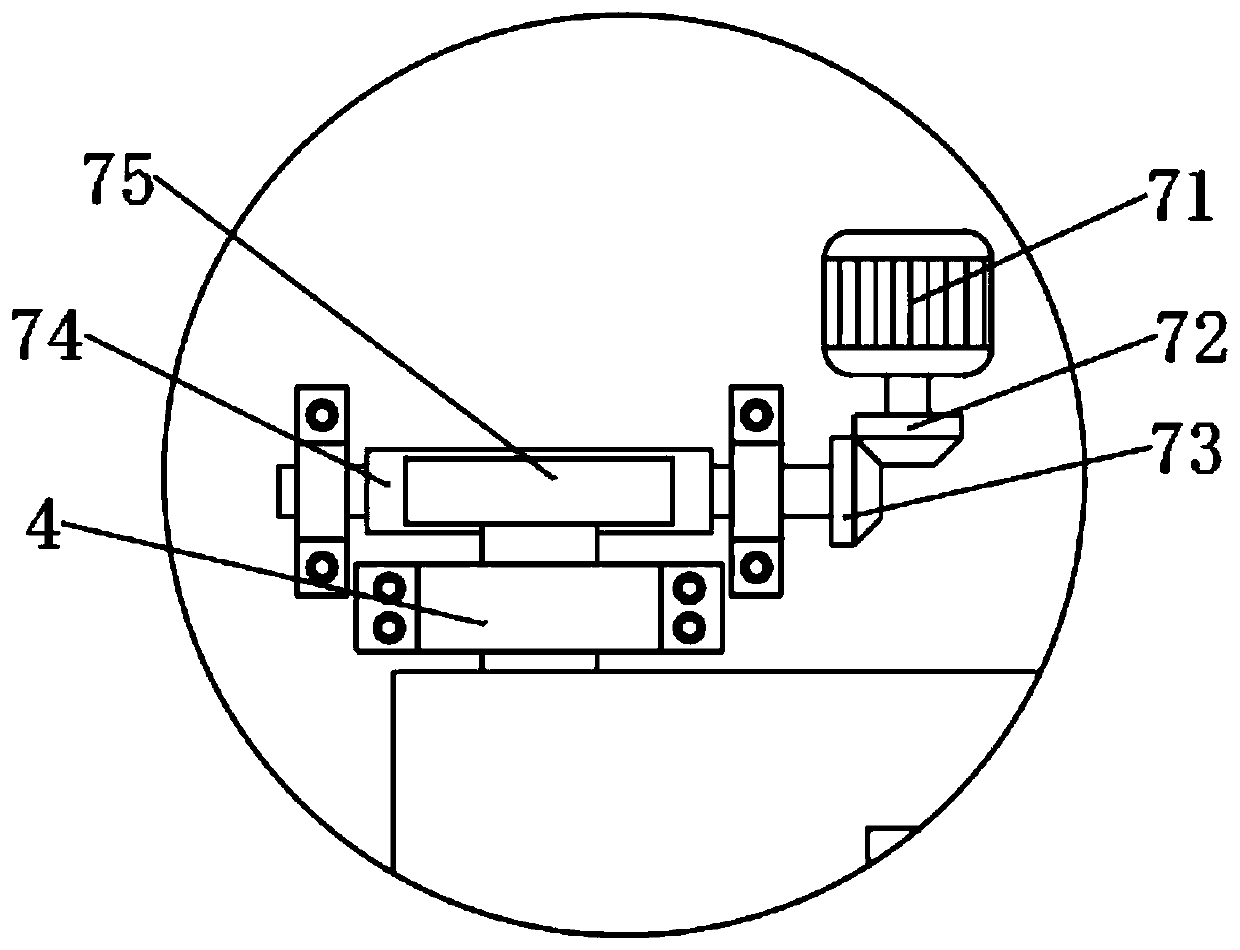

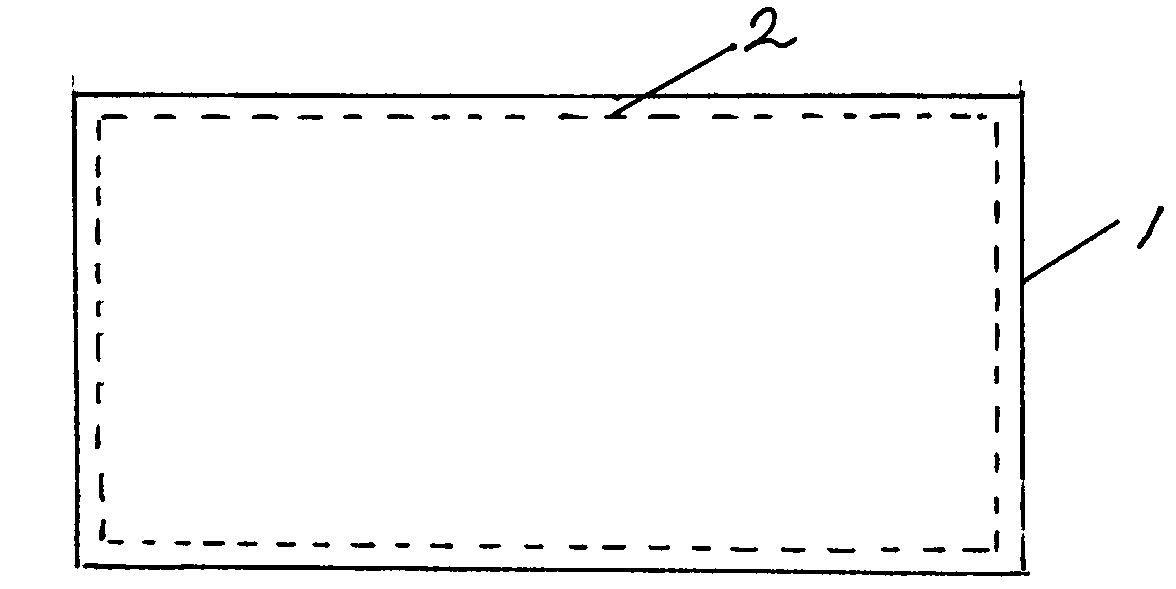

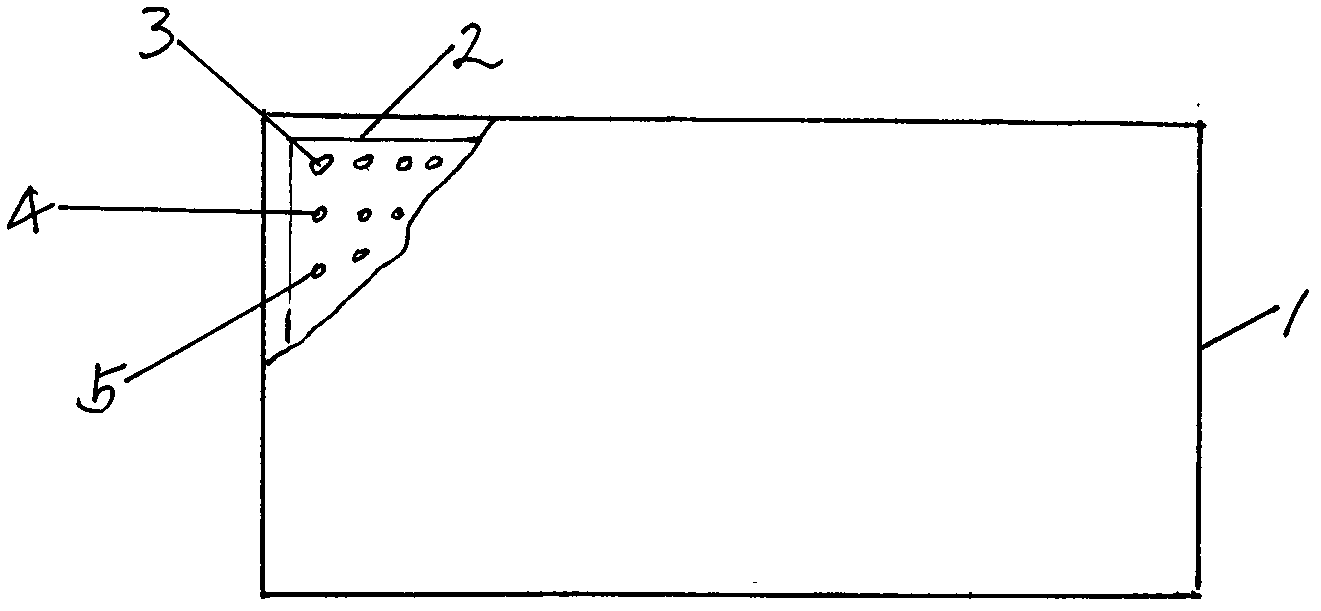

A clamping tool for automatic processing of flat parts

ActiveCN111390616BImprove processing efficiencyProtect against deformationMetal working apparatusPositioning apparatusEngineeringAutomatic processing

The invention discloses a clamping tool for automatic processing of flat parts, relates to the field of automatic processing, and solves the problem in the prior art that the flat parts cannot be turned over automatically when processing flat parts. The drive unit of the mobile seat is equipped with a mobile seat that can move on the base. The mobile seat is provided with an overturning support seat. A clamping plate for clamping the workpiece is hinged on the overturning support seat. Turning unit, the two ends of the moving seat are also equipped with a pressing unit for supporting and pressing the clamping plate, and the moving seat is also equipped with a supporting unit for preventing the deformation of the workpiece during processing. The supporting unit is detachable The method is installed on the moving seat; the invention can improve the processing efficiency of flat workpieces, and at the same time, can protect flat workpieces from deformation during processing.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

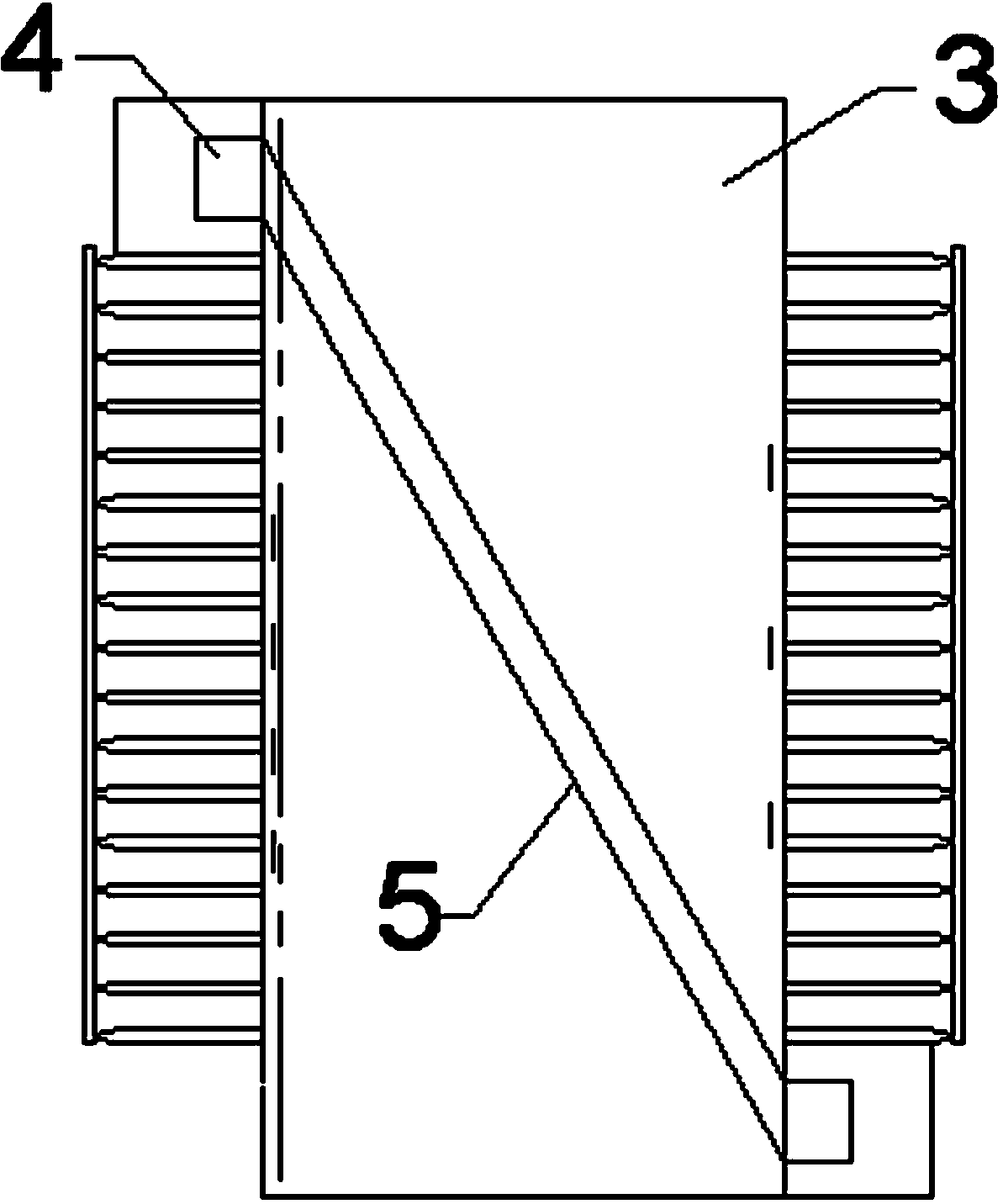

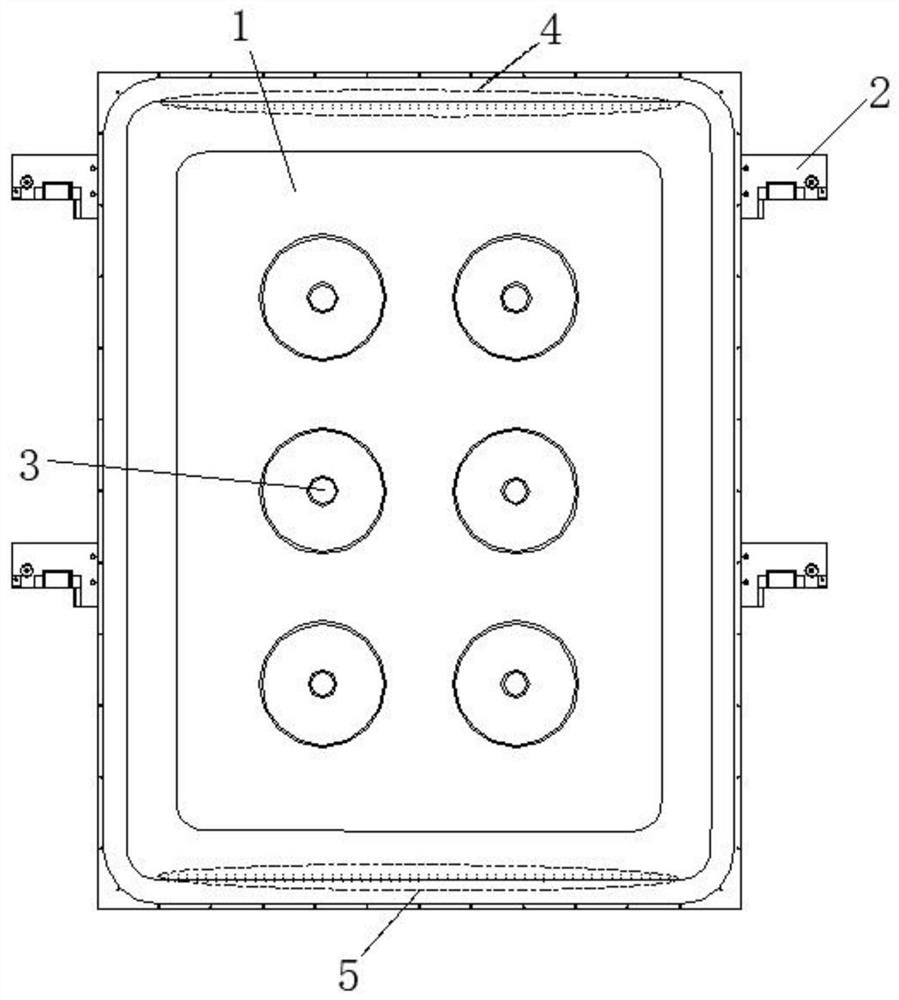

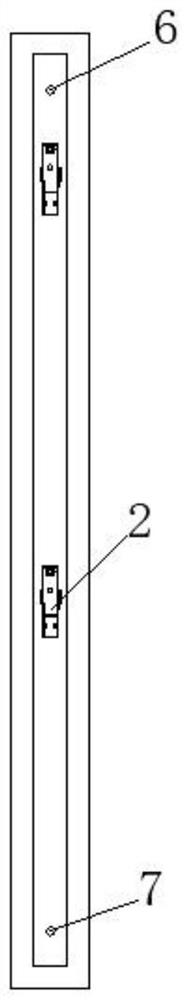

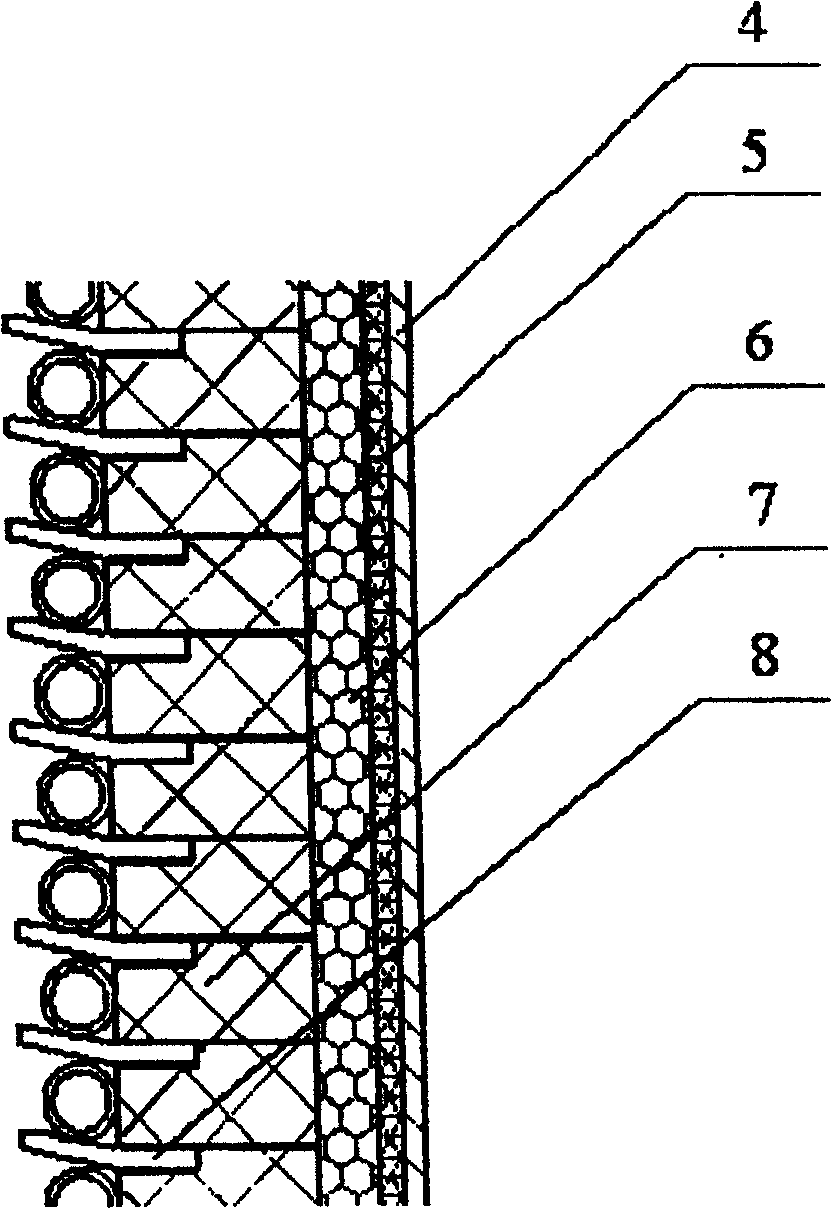

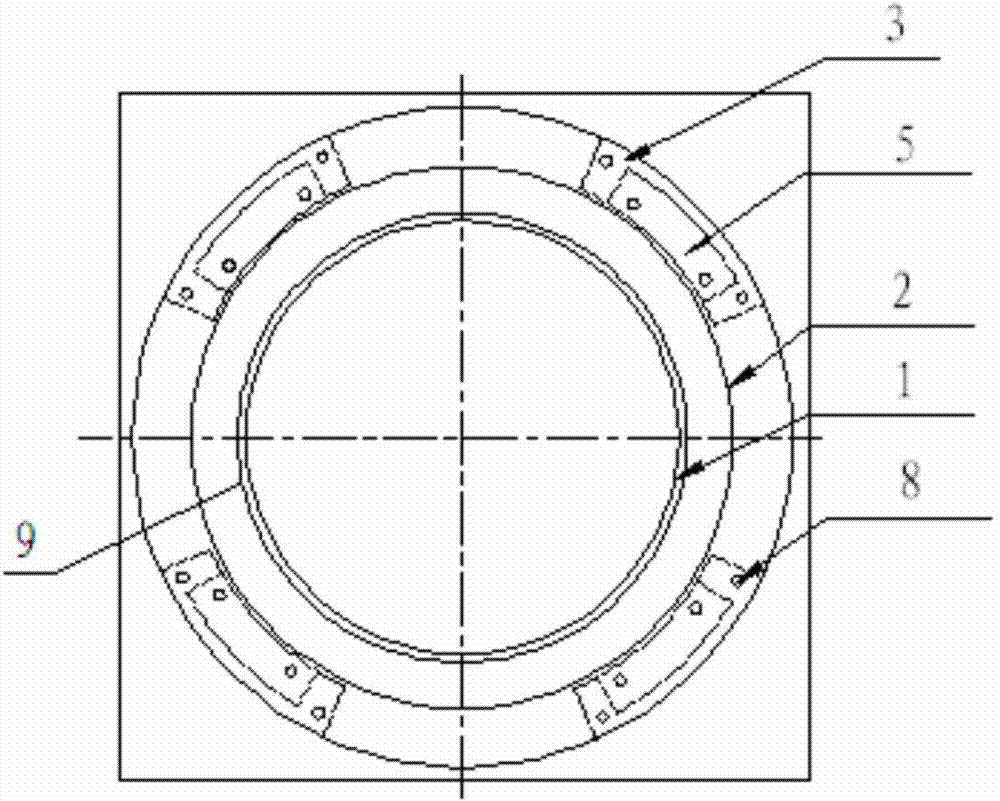

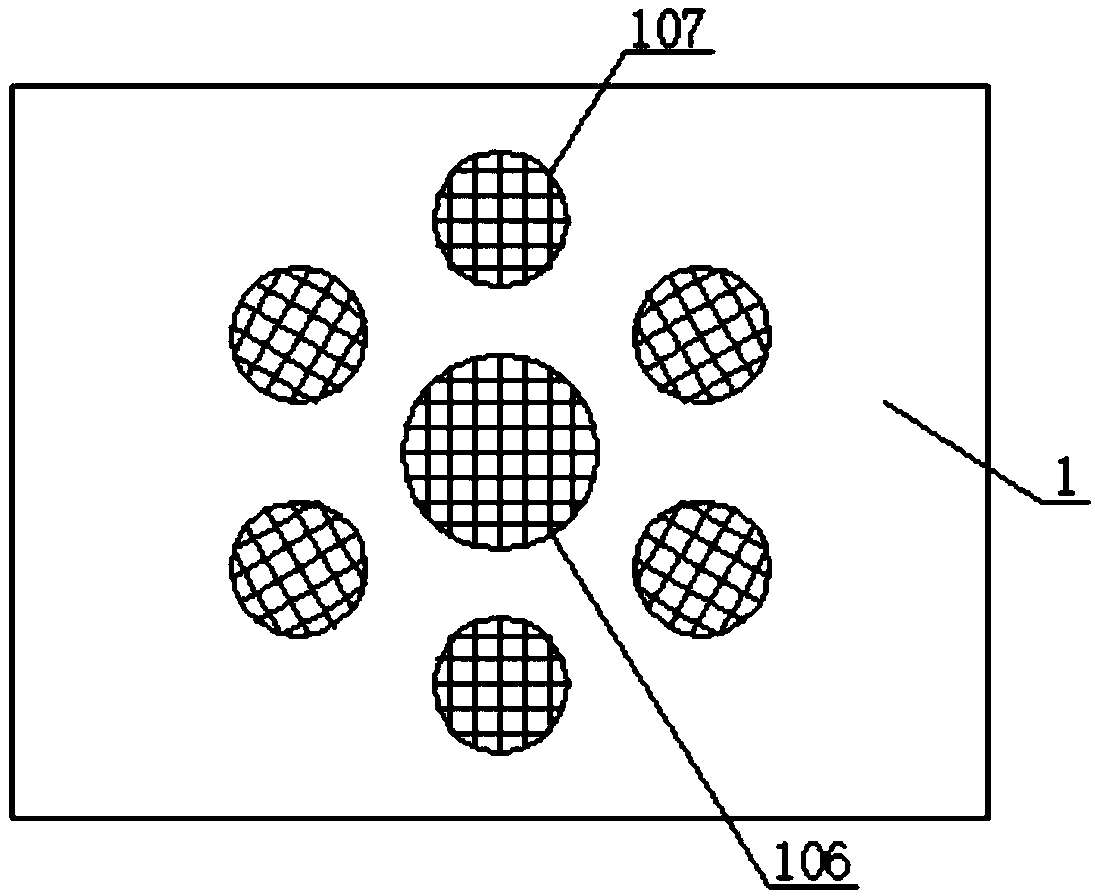

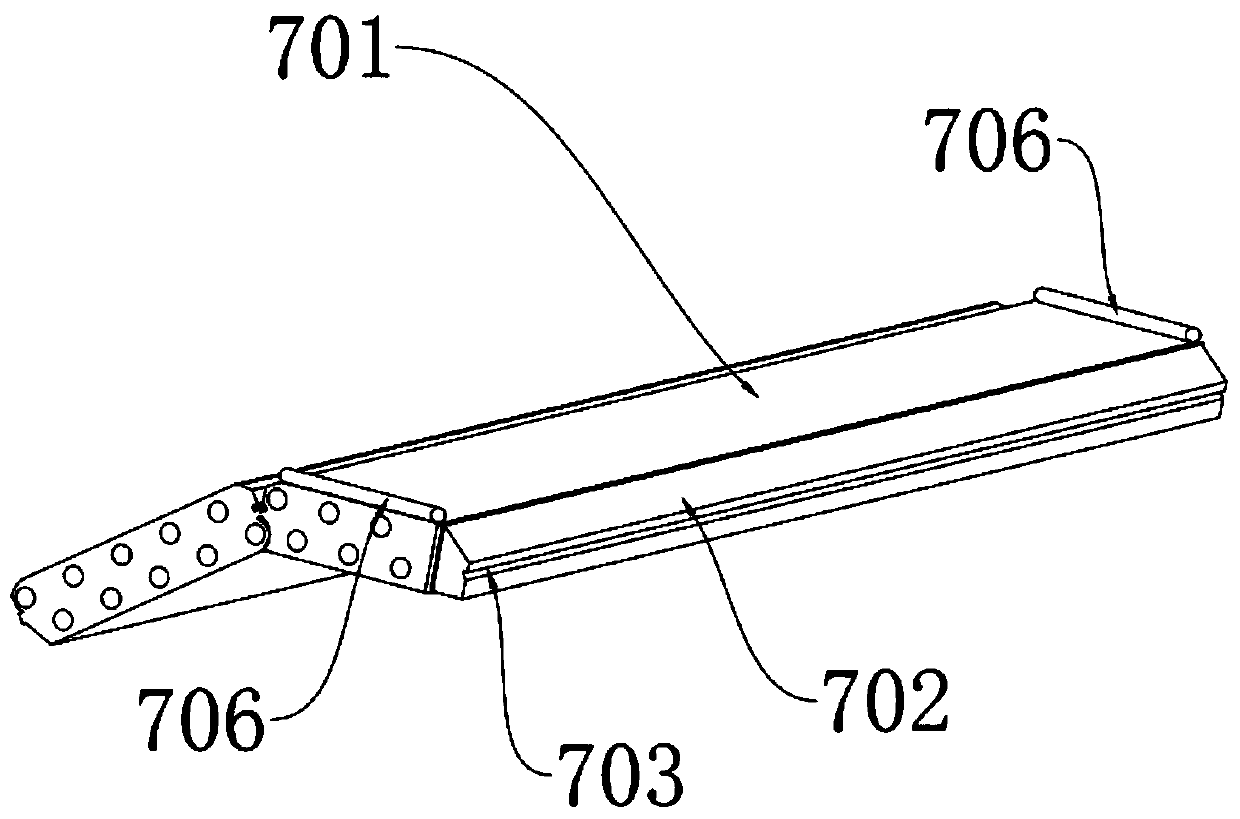

Intelligent in-phase separator membrane plates

InactiveCN112675583AProtect against deformationStable supportFiltration separationUltra high pressureEngineering

The invention discloses intelligent in-phase separator membrane plates, and relates to the technical field of separators. Each membrane plate comprises a membrane plate main body, two handrails are arranged on the two sides of the membrane plate main body, and a plurality of supporting points are arranged in the membrane plate main body; and an air blowing hole is formed in the upper side of the diaphragm plate main body, and a high-pressure water inlet and outlet hole is formed in the lower side of the diaphragm plate main body. Corrosion-resistant high-quality aluminum materials are adopted for the ultrahigh-pressure membrane plates; compared with the pressure borne common PP materials, the pressure borne by the ultrahigh-pressure membrane plates is high, high-pressure water is injected into the high-pressure water inlet and outlet in the lower end of each membrane plate to conduct deep extrusion dehydration of 10 MPa, six supporting points are designed on the front surfaces and the rear surfaces of the membrane plates respectively, effective supporting can be achieved under the pressure of the whole filter plates and the membrane plates, the membrane plates are protected from being deformed under ultra-high pressure, and unique structure design is achieved; and compared with a high-pressure filter plate / membrane plate on the market at present, the membrane plate has the advantages of high strength, corrosion resistance, no deformation and capability of bearing pressure of 10 MPa or even higher.

Owner:国合机械装备制造江苏有限公司 +1

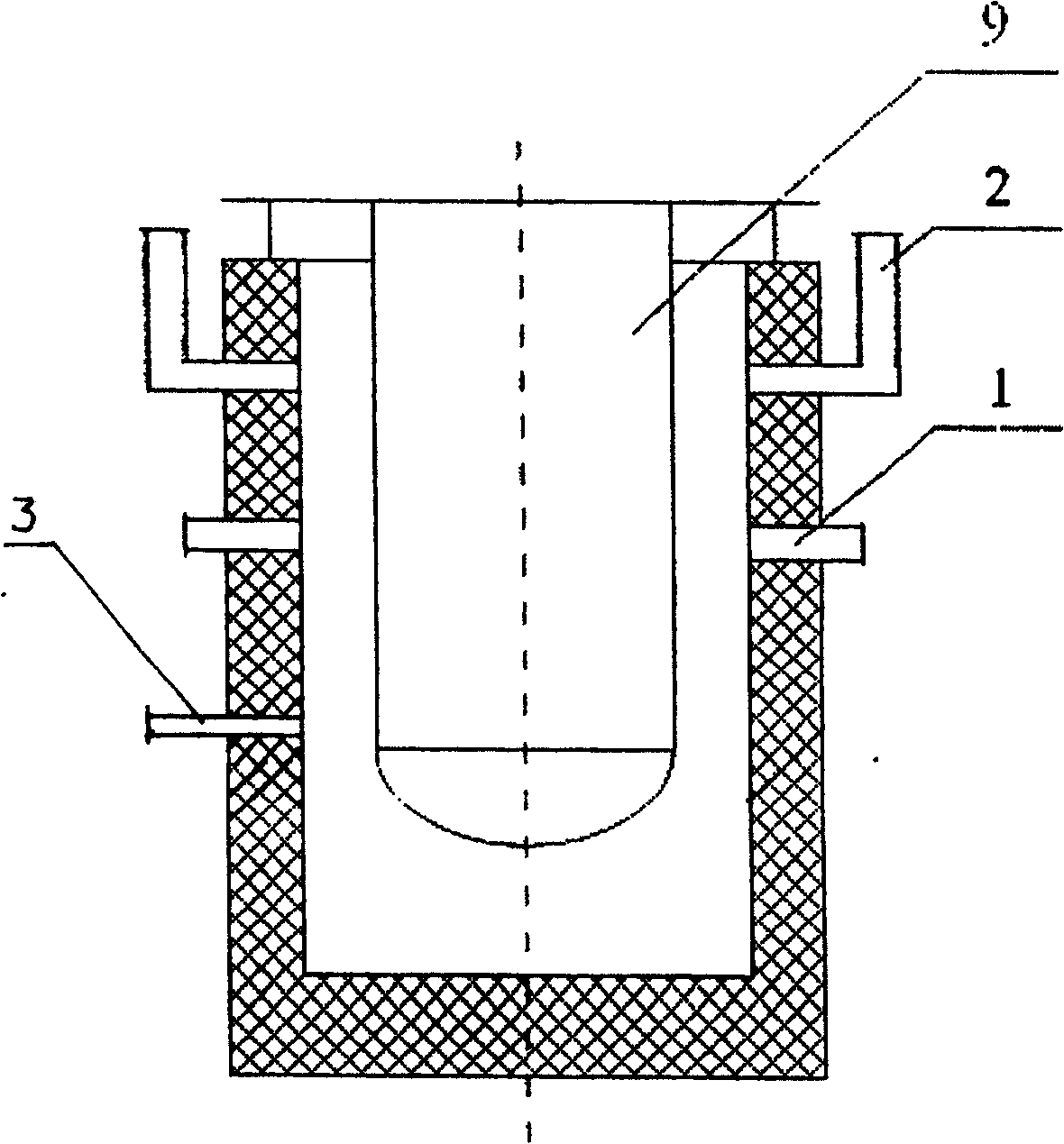

Heater furnace to produce titanium sponge by combination method

InactiveCN100436613CImprove cooling effectImprove insulation effectVertical furnacesElectrical resistance and conductanceFire brick

Owner:ZUNYI TITANIUM

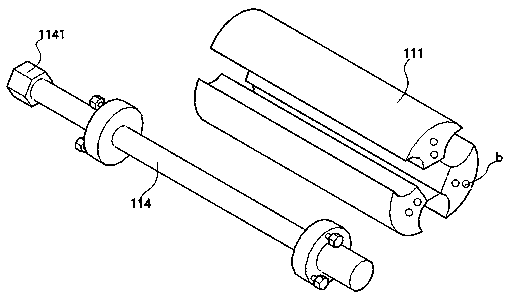

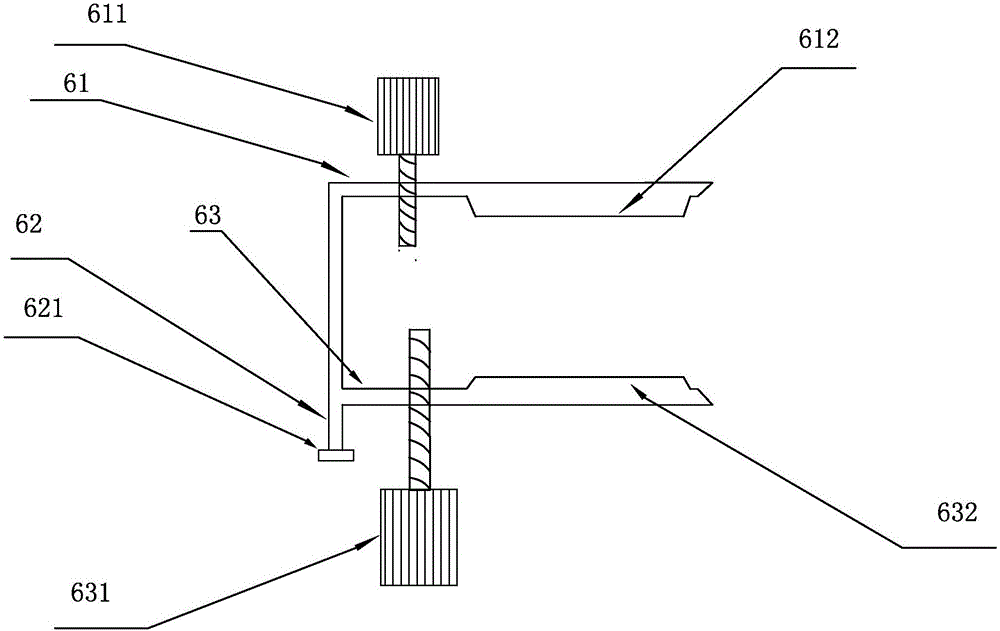

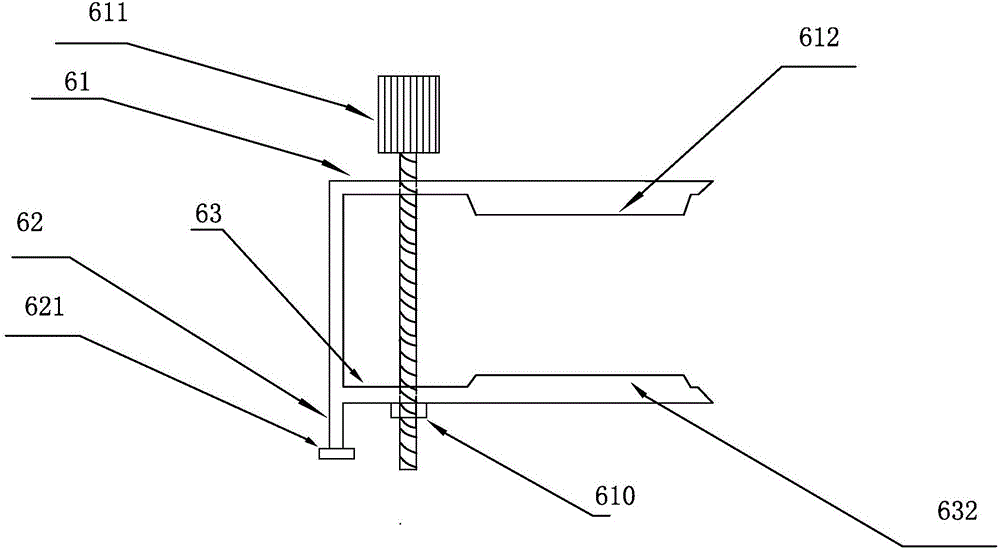

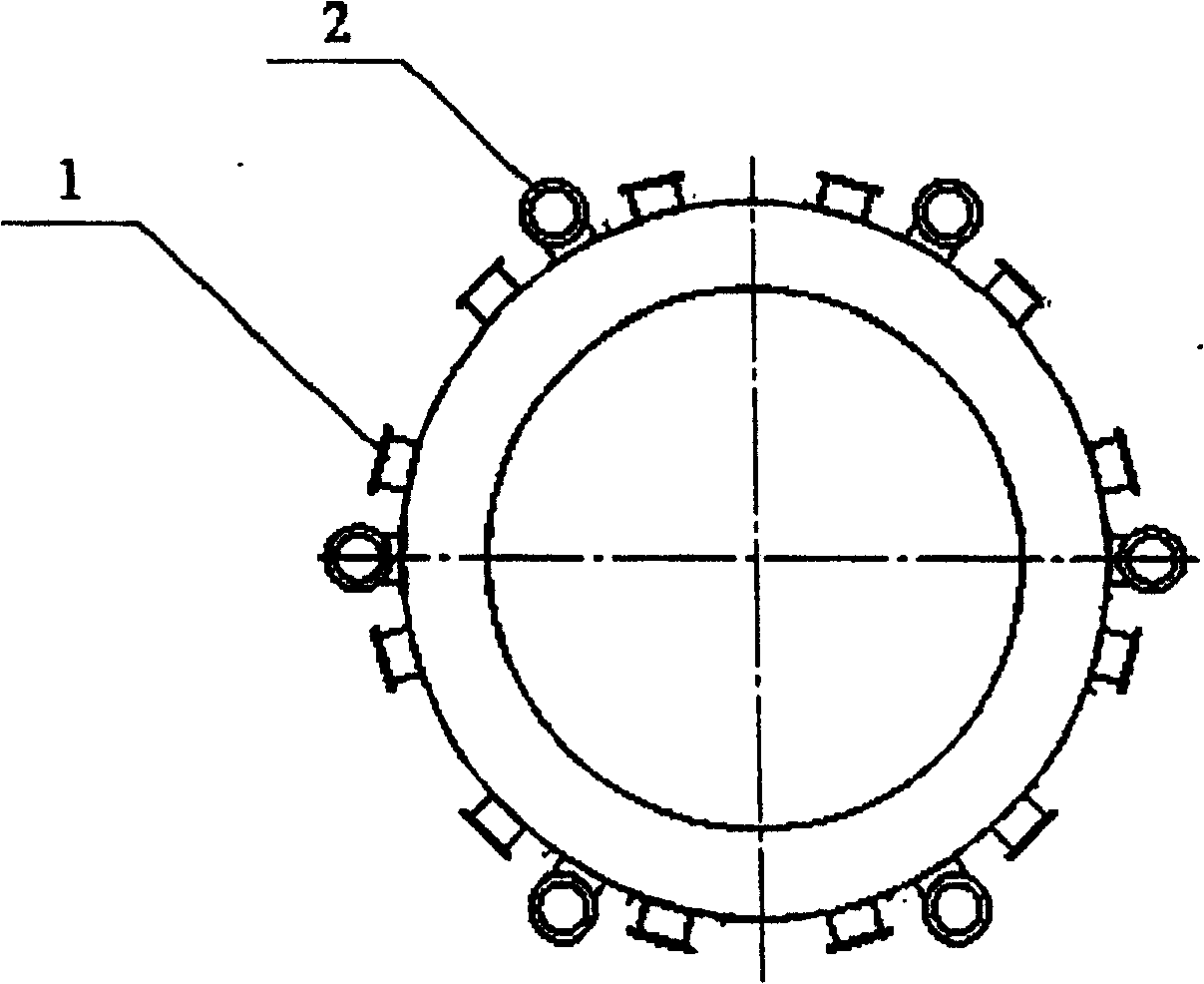

Axial centering device of axle tube type parts

InactiveCN105499653AAxially centered and stableCentered and stableDrilling/boring measurement devicesTurning machine accessoriesReduction driveReducer

The invention discloses an axial centering device of axle tube type parts. The axial centering device comprises a rack, wherein the rack is rotatably provided with a forward-reversed screw rod; a left outer thread section is arranged at the left end of the forward-reversed screw rod and a right outer thread section is arranged at the right end of the forward-reversed screw rod; screwing directions of the left outer thread section and the right outer thread section are opposite; and the outer sides of the left outer thread section and the right outer thread section are in threaded connection with a left side block and a right slide block respectively; the forward-reversed screw rod is driven to rotate by a driving mechanism; the driving mechanism comprises a motor, a speed reducer and a clutch, which are connected in sequence; the speed reducer and the clutch are driven by the motor so that the forward-reversed screw rod is driven to rotate; the upper ends of the left slide block and the right slide block are connected with swinging arms, which extend frontwards, respectively; a vertical rotary shaft is arranged under the middle part of each swinging arm and the upper end of the rotary shaft penetrates through the middle part of the swinging arm; and the swinging arms can rotate along the rotary shafts and the front ends part of the swinging arms are used for pushing the end parts of the axle tube type parts. The axial centering device of the axle tube type parts has the advantages that the synchronism of the two swinging arms is high and the axial centering of the axle tube type parts is stable.

Owner:HEFEI PRESSURE MACHINERY

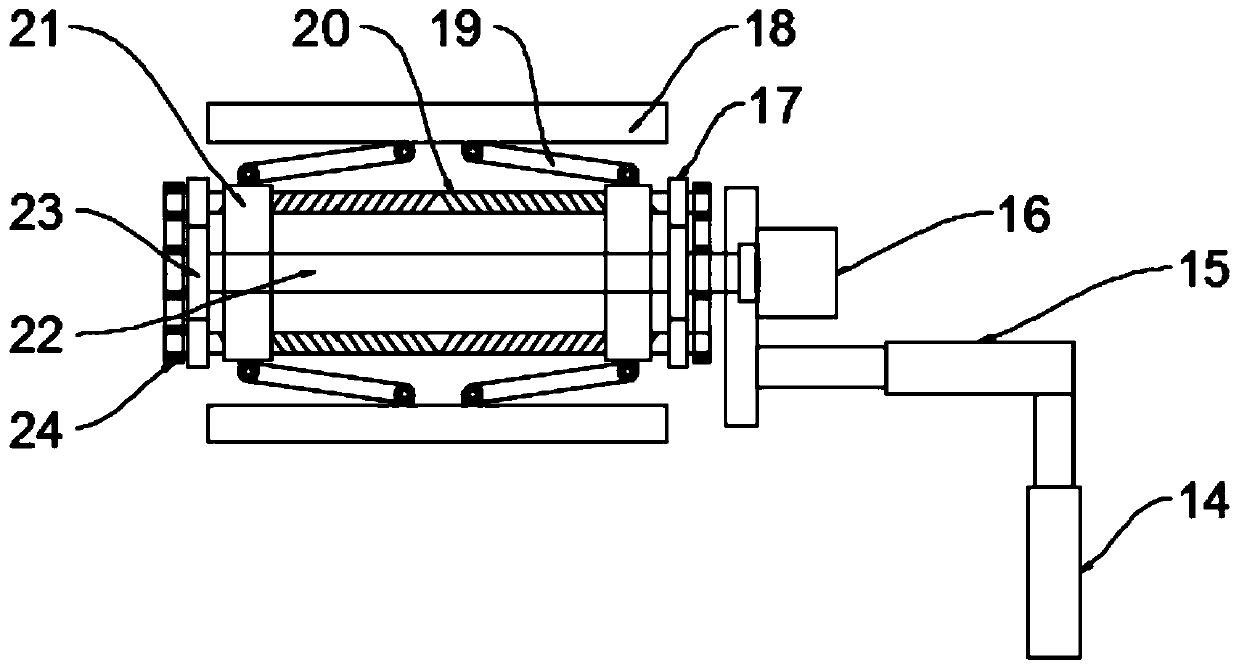

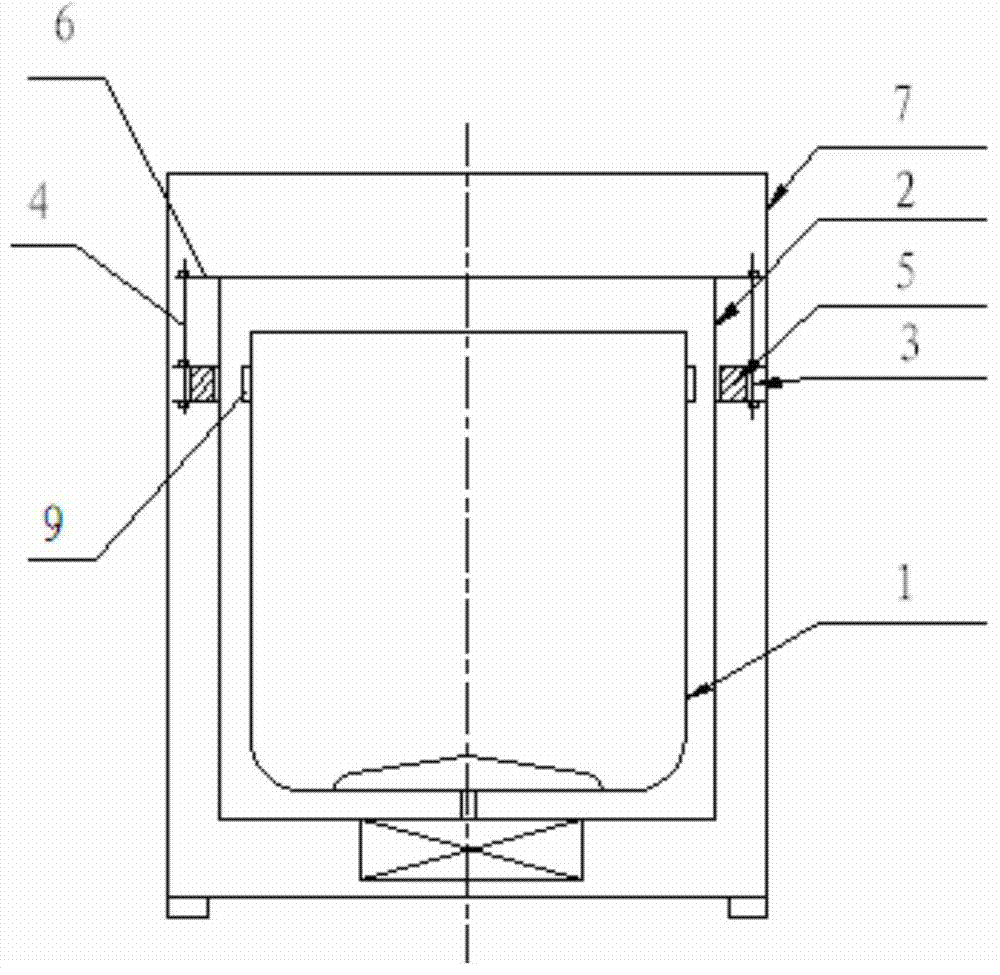

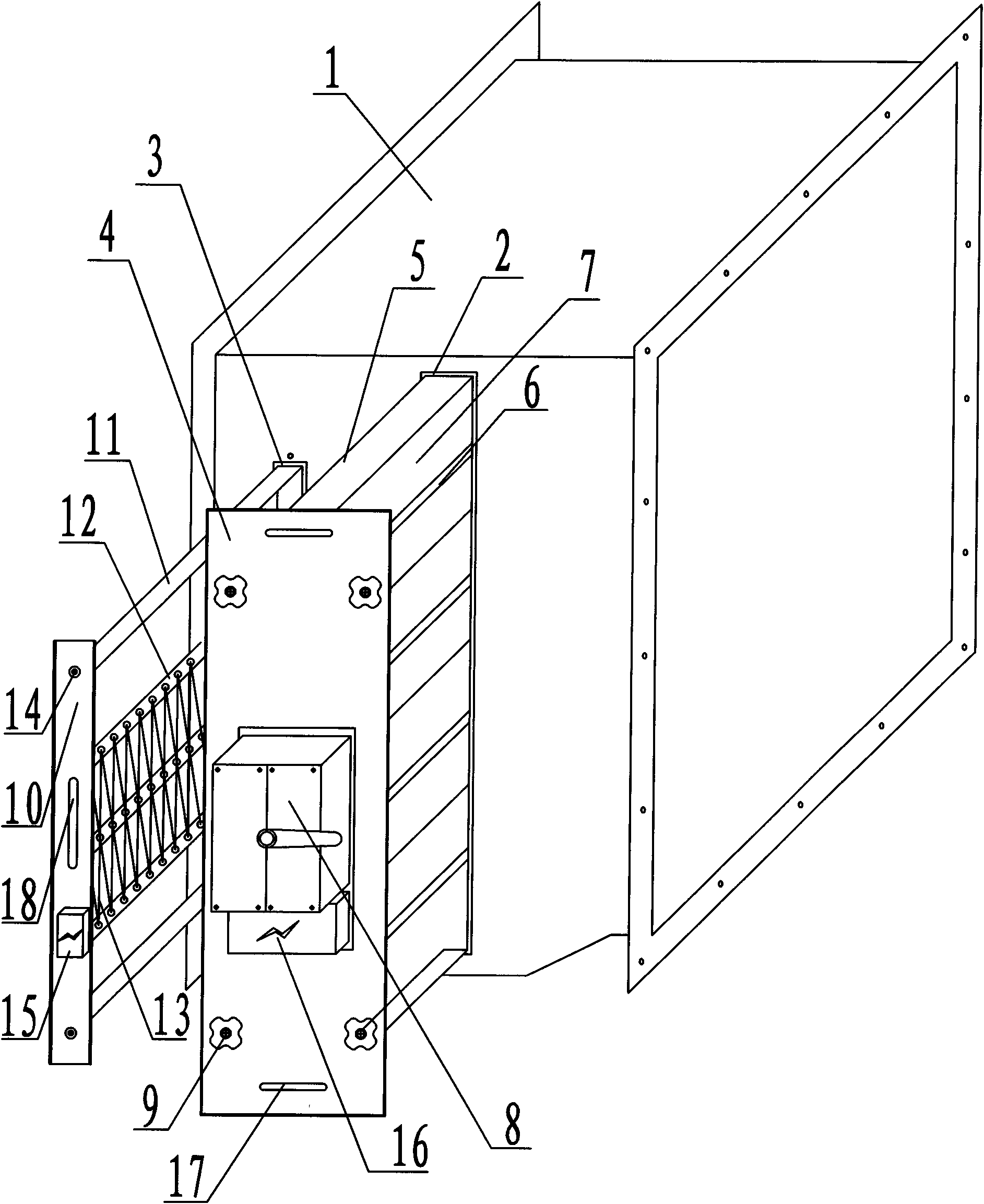

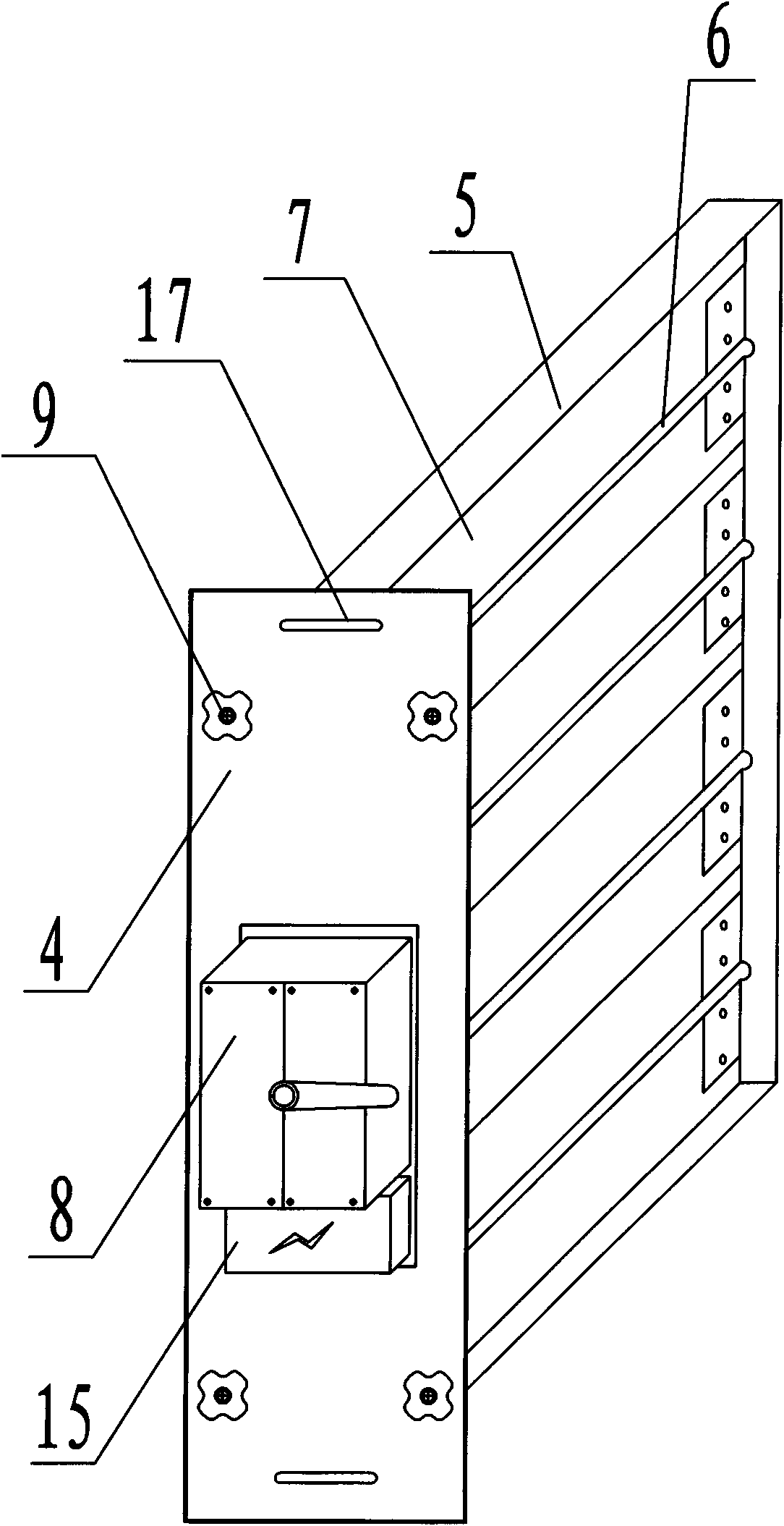

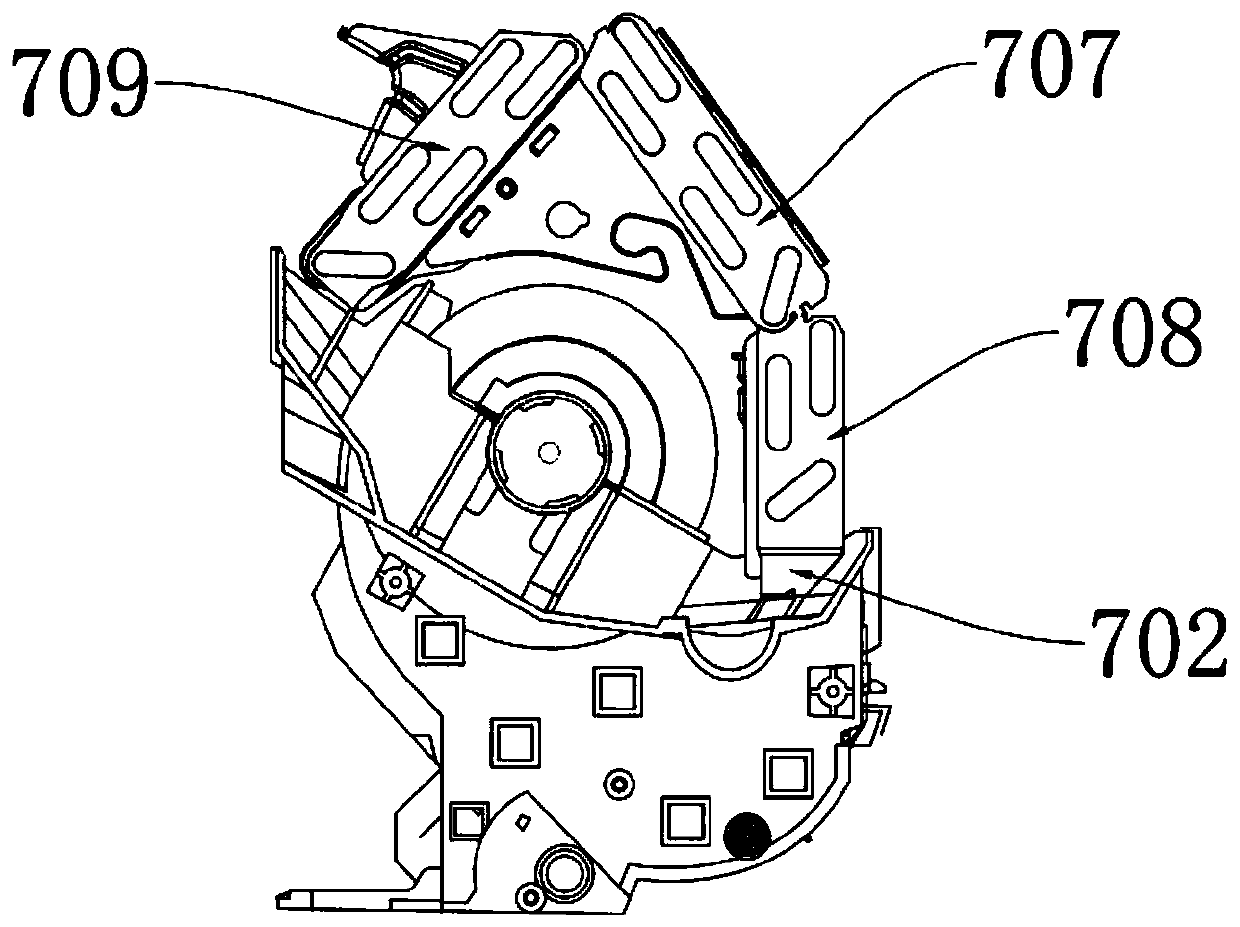

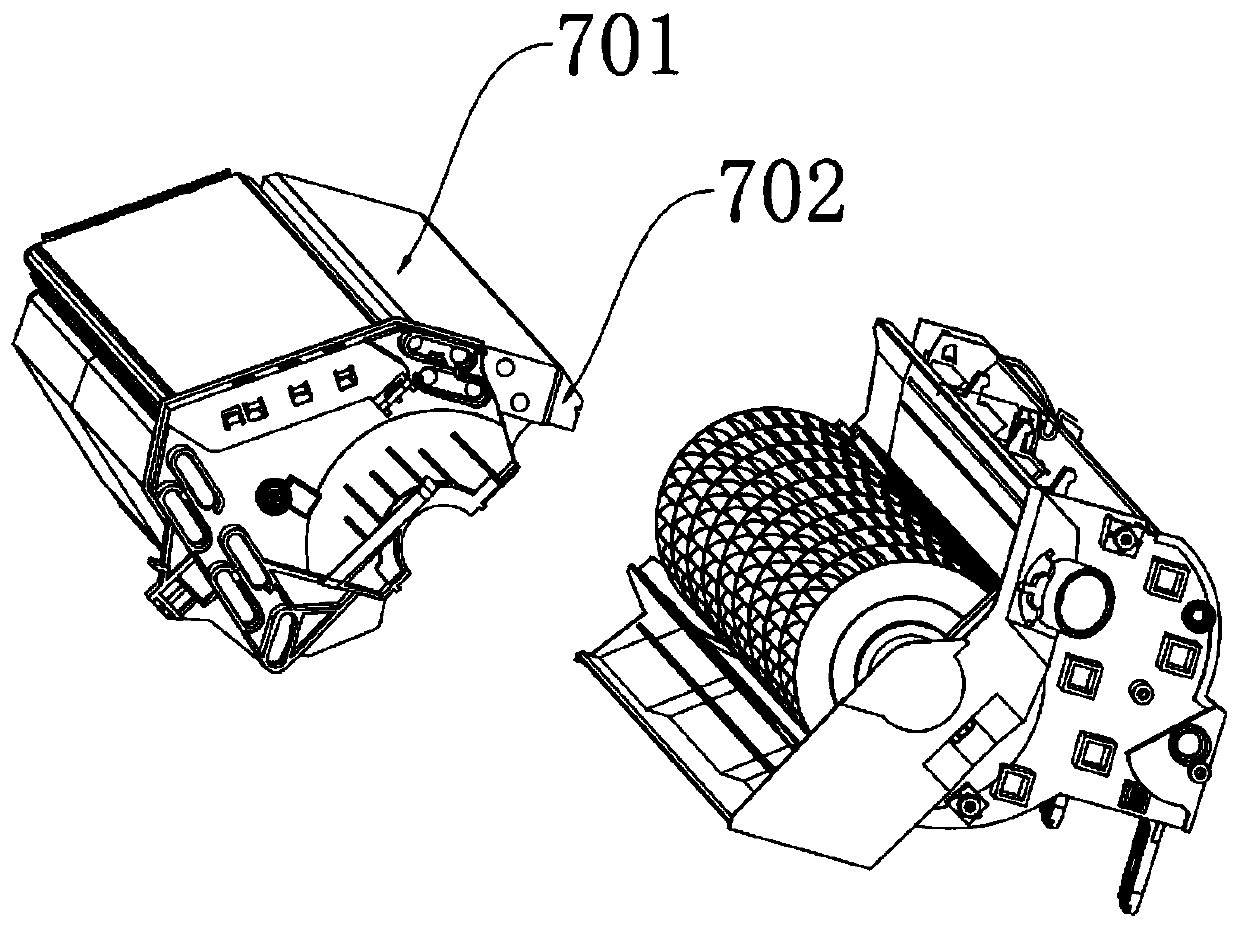

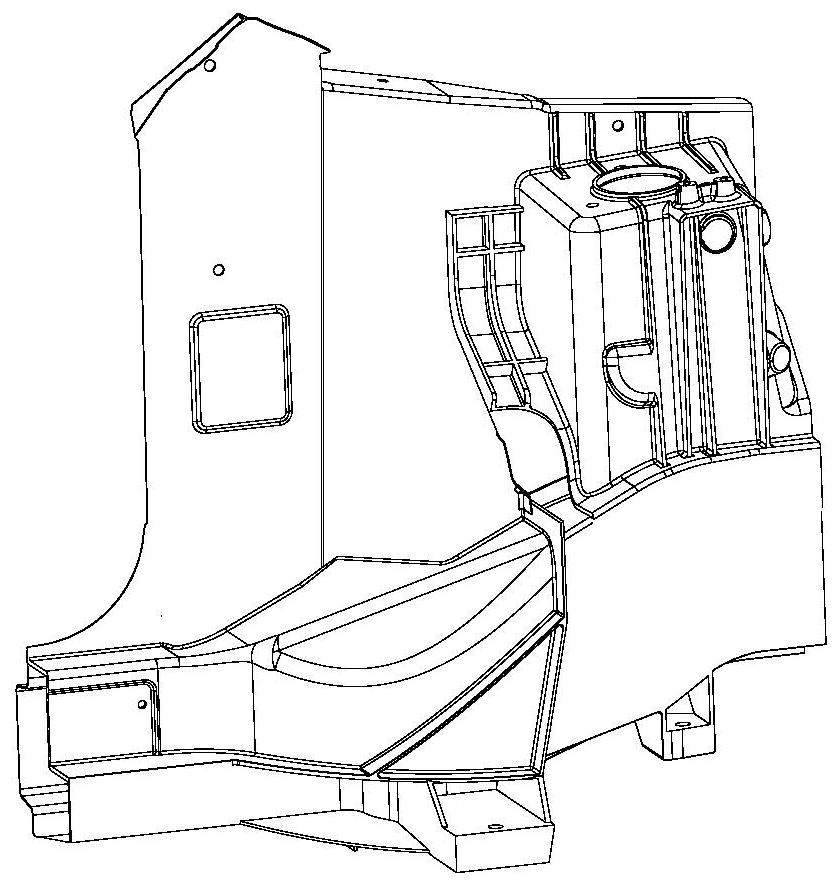

Washing machine motor fixing device and washing machine

ActiveCN104746301AProtect against deformationGuaranteed clearanceOther washing machinesTextiles and paperElectric machineryEngineering

The invention provides a washing machine motor fixing device. The washing machine motor fixing device comprises an arc-shaped motor fixing support and a connection rod, wherein the arc-shaped motor fixing support is in an arc shape, one end of the connection rod is connected with the arc-shaped motor fixing support, the other end of the connection rod is connected with the top of an outer barrel, the arc-shaped motor fixing support is located on the outer side of the outer barrel, and an arc-shaped motor is fixed on the arc-shaped motor fixing support. The washing machine motor fixing device hangs the arc-shaped motor fixing support on the outer barrel through the connection rod, and the arc-shaped motor fixing support provides a support function and prevents the outer barrel from deformation generated due to the fact that the outer barrel is impacted by an inner barrel. Furthermore, The arc-shaped motor fixing support is a fixing support of the arc-shaped motor, the arc-shaped motor is installed on the arc-shaped motor fixing support, the arc-shaped motor moves along with movements of the outer barrel, an interval between the inner barrel and the arc-shaped motor is guaranteed, and therefore stability of electromagnetic induction between the arc-shaped motor installed on the outer barrel and a sensing device installed in the inner barrel is guaranteed. The invention furthermore provides a washing machine. The washing machine is provided with the motor fixing device which can prevent the outer barrel from deforming when the inner barrel impacts the outer barrel.

Owner:HAIER GROUP TECHN R&D CENT +1

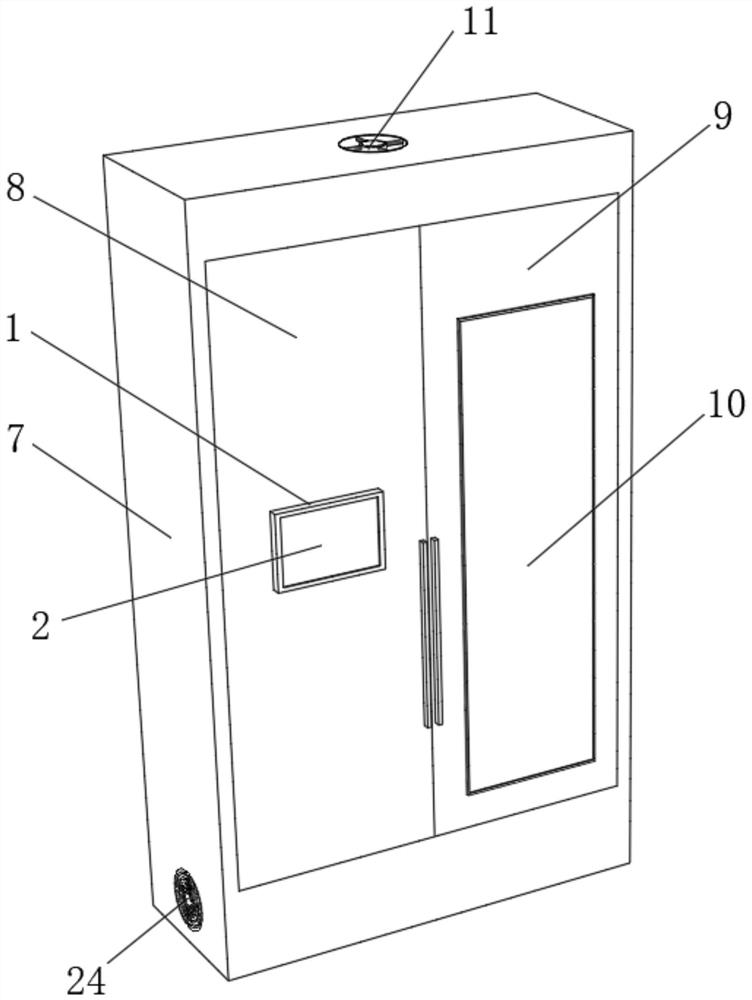

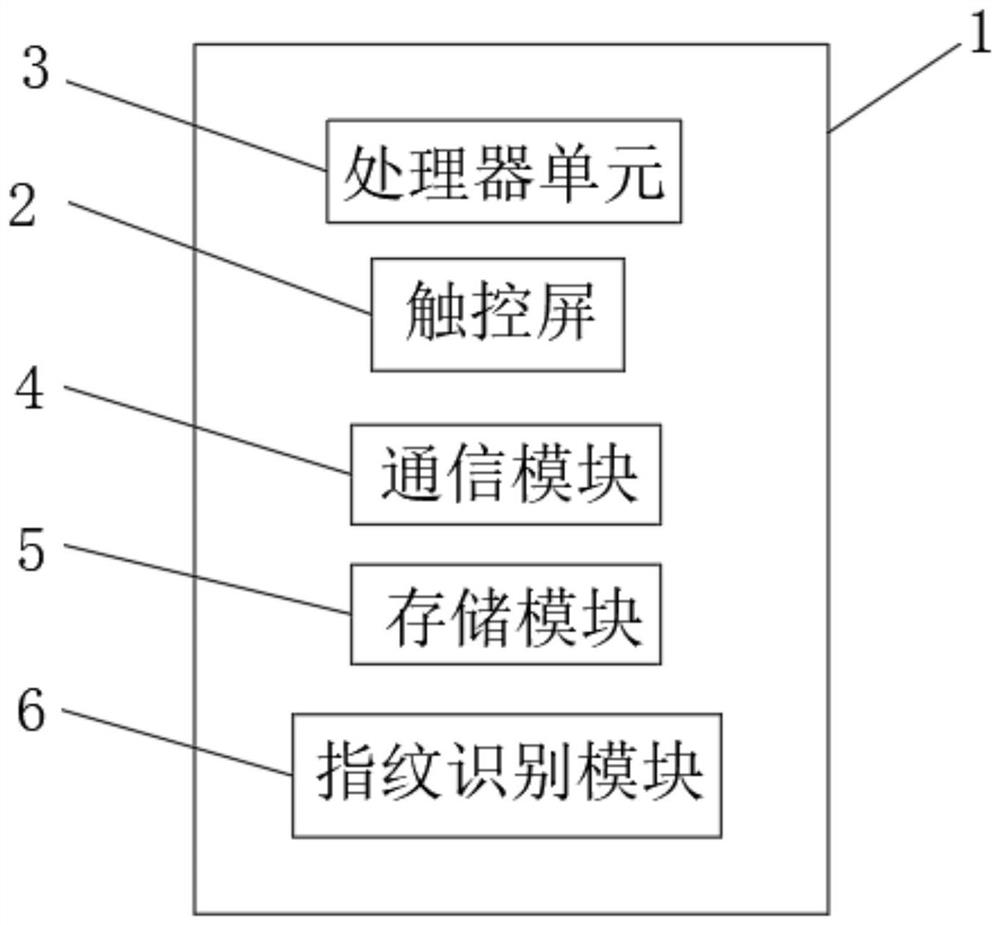

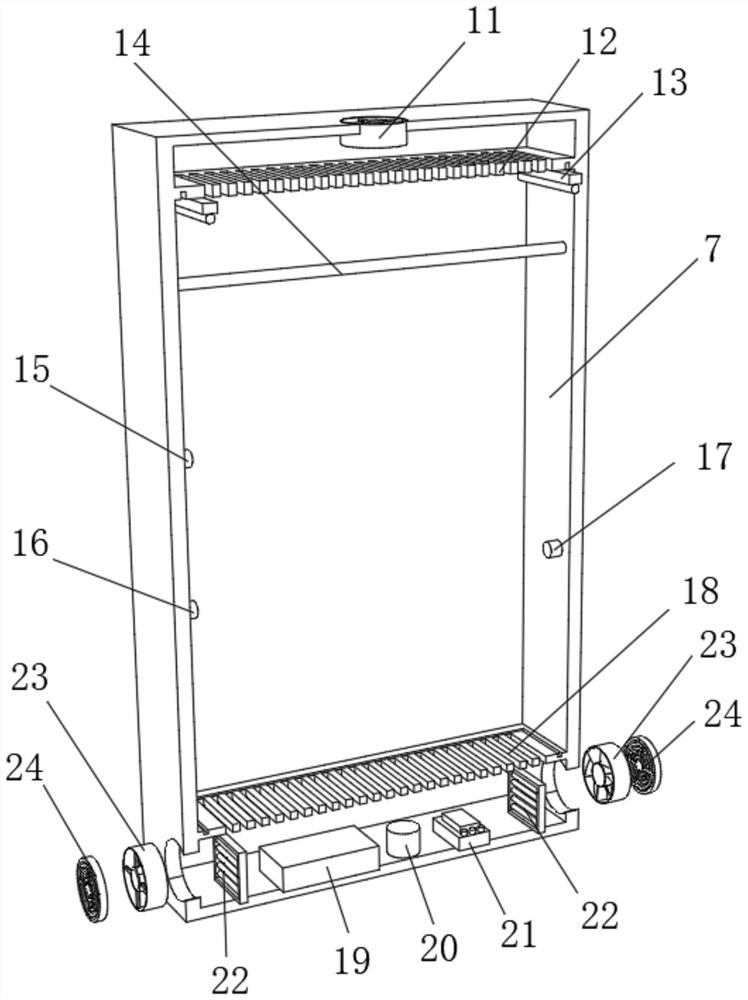

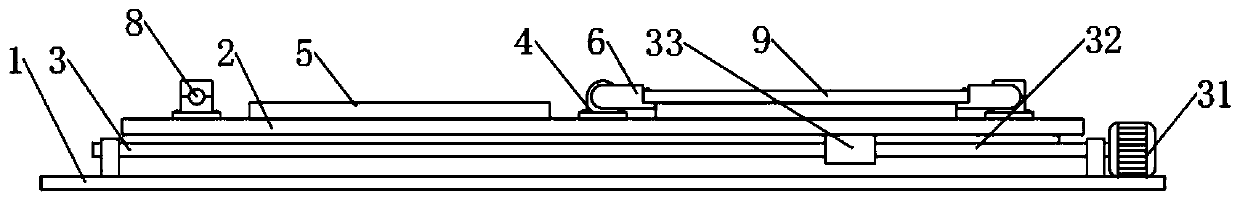

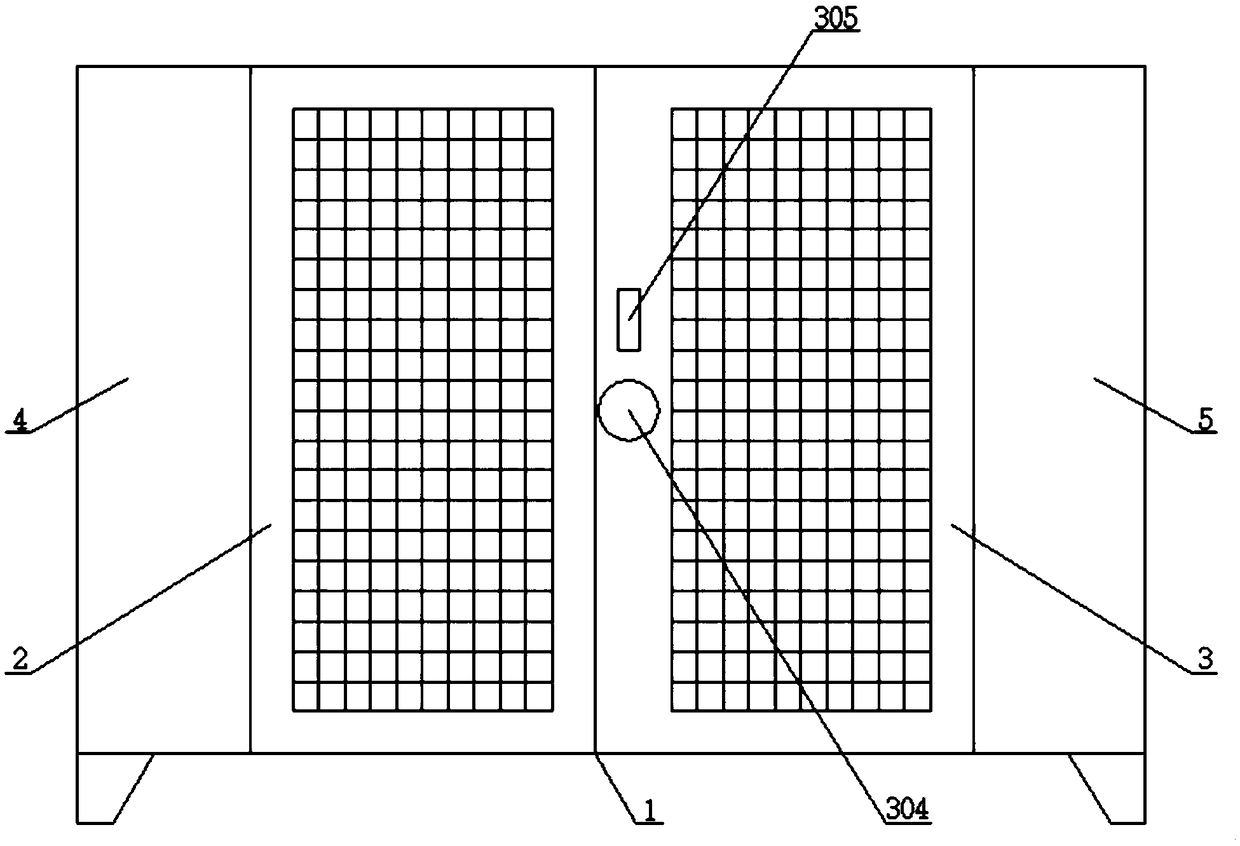

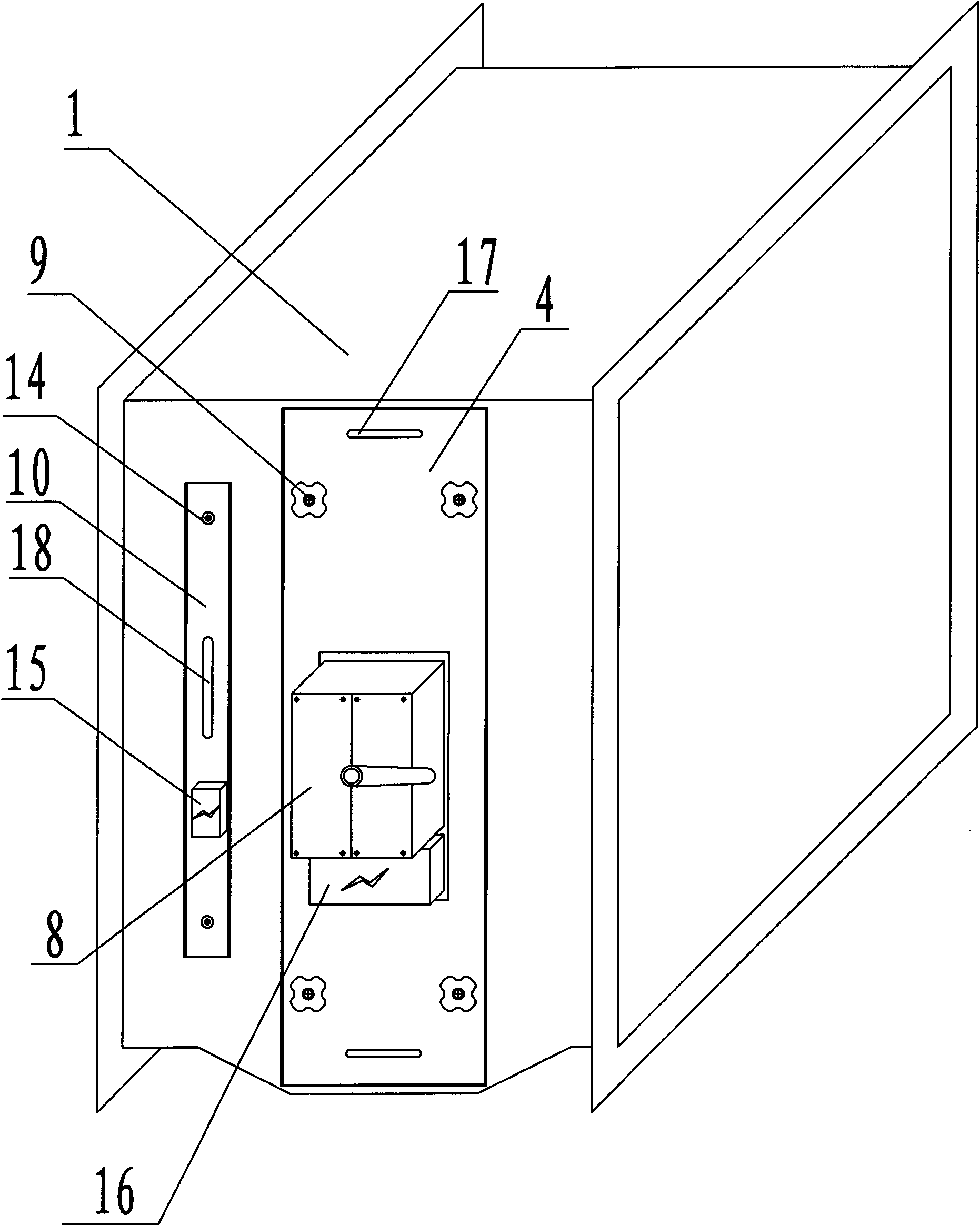

Intelligent optimal wardrobe

InactiveCN114027630AInvasion of privacyFeel the upper body effectWardrobesPump componentsUser privacyMobile payment

The invention provides an intelligent optimal wardrobe, and relates to the field of smart home. The intelligent optimal wardrobe comprises a tablet host and a wardrobe body. The tablet host is used for online clothes selection and purchase and controlling electronic equipment carried by the wardrobe body. The wardrobe body is used for storing clothes, a circuit breaker is fixedly connected to the right side of the inner wall of the bottom end of the wardrobe body, a first wardrobe door is rotatably connected to the left side of the front end of the wardrobe body, and the front end of the first cabinet door is fixedly connected with the tablet host. Through the figure data bound with the fingerprint information, the purpose of intelligently pushing clothes meeting the requirement can be achieved, and meanwhile, other people are prevented from invading the privacy of a user and stealing properties through a mobile payment service. A clothes picture selected by the user can be projected on a screen through the projection technology of fitting equipment, so that the user can feel the effect of the clothes more truly. The optimization ability of the intelligent optimal wardrobe is improved, and the purpose of intelligent optimal shopping is achieved.

Owner:赵刚

Clamping tool for automatically processing plate parts

ActiveCN111390616AImprove processing efficiencyProtect against deformationPositioning apparatusMetal working apparatusAutomatic processingPhysics

The invention discloses a clamping tool for automatically processing plate parts, relates to the field of automatic processing and solves the problem that in the prior art, the plate parts which are processed cannot overturn automatically. The technical key point of the clamping tool is as follows: the clamping tool comprises a base, wherein the base is provided with a mobile seat capable of moving on the base through a mobile seat driving unit, an overturning supporting seat is arranged on the mobile seat, a clamping plate for clamping a workpiece is hinged to the overturning supporting seat,the clamping plate is connected to an overturning unit for driving the clamping plate to overturn, compressing units for supporting and compressing the clamping plate are further arranged at two endsof the mobile seat, a supporting unit for preventing deformation of the workpiece in processing is further arranged in a position, below the workpiece, of the mobile seat, and the supporting unit ismounted on the mobile seat detachably. The clamping tool can improve the processing efficiency of the plate workpieces and can prevent the plate workpieces from deforming in a processing course.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

Sanitary health-care pillow for infant

InactiveCN102247082AProtect against deformationPromoting health carePillowsPediatricsBamboo charcoal

The invention relates to a sanitary health-care pillow for an infant, which is filled with round and homogeneous crataegus pinnatifida seed grains, round and homogeneous vegetable grains, air purifying bamboo charcoal grains. The pillow has the sanitary and health-care functions of keeping the head of the infant dry, cool and sanitary, preventing the head of the infant from deforming, promoting the growth of the head of the infant and ensuring that the head shape of the infant looks good.

Owner:王福起

Infant health-care pillow

The invention relates to an infant health-care pillow. The pillow is filled with round and uniform plant particles and bamboo charcoal for purifying air. The pillow has the health-care functions of being capable of protecting the head of an infant from deforming and promoting the head development and the attractive headform of the infant; meanwhile, the pillow plays a health-care role in ventilating and purifying air.

Owner:王福起

Formaldehyde scavenging agent for furniture

InactiveCN105729599AProtect against deformationDispersed particle separationWood treatment detailsMethyl celluloseEthylamine

The invention discloses a furniture formaldehyde scavenger, which comprises the following material components in parts by weight: 50-80 parts of wood vinegar, 3-15 parts of sodium hydroxycellulose, 3-10 parts of ethylglumine, 5-20 parts of imidazolone, pure water 50-80. It can form a film on the surface of furniture, which can not only remove slowly released formaldehyde, but also protect the furniture board from deformation.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

Drying equipment for drying ceramic green bodies

InactiveCN108955108AIncrease temperatureFast rotationDrying chambers/containersDrying solid materialsLocking mechanismEngineering

The invention relates to the technical field of drying and discloses drying equipment for drying ceramic green bodies. The drying equipment comprises a drying box body. A first box door and a second box door are formed in the front side wall of the drying box body. The left side of the first box door and the right side of the second box door are hinged to the drying box body through hinges correspondingly. The right side face of the first box door and the left side face of the second box door are provided with a first locking mechanism and a second locking mechanism correspondingly, wherein the first locking mechanism and the second locking mechanism are locked to each other. The top end of the drying box body is provided with heat dissipation holes, wherein the heat dissipation holes sequentially penetrate the top end face of the drying box body and an aluminum plate, and a shielding net with square through holes is mounted in the center of a cavity of each heat dissipation hole. A cavity of the drying box body is internally provided with drying grooves. A first drying mechanism and a second drying mechanism are mounted at the left side and the right side of the drying box body correspondingly, wherein the first drying mechanism and the second drying mechanism are symmetrical with each other. By means of the drying equipment, the problems that existing ceramic green body drying equipment is low in drying efficiency and poor in drying uniformity are solved.

Owner:郜耿光

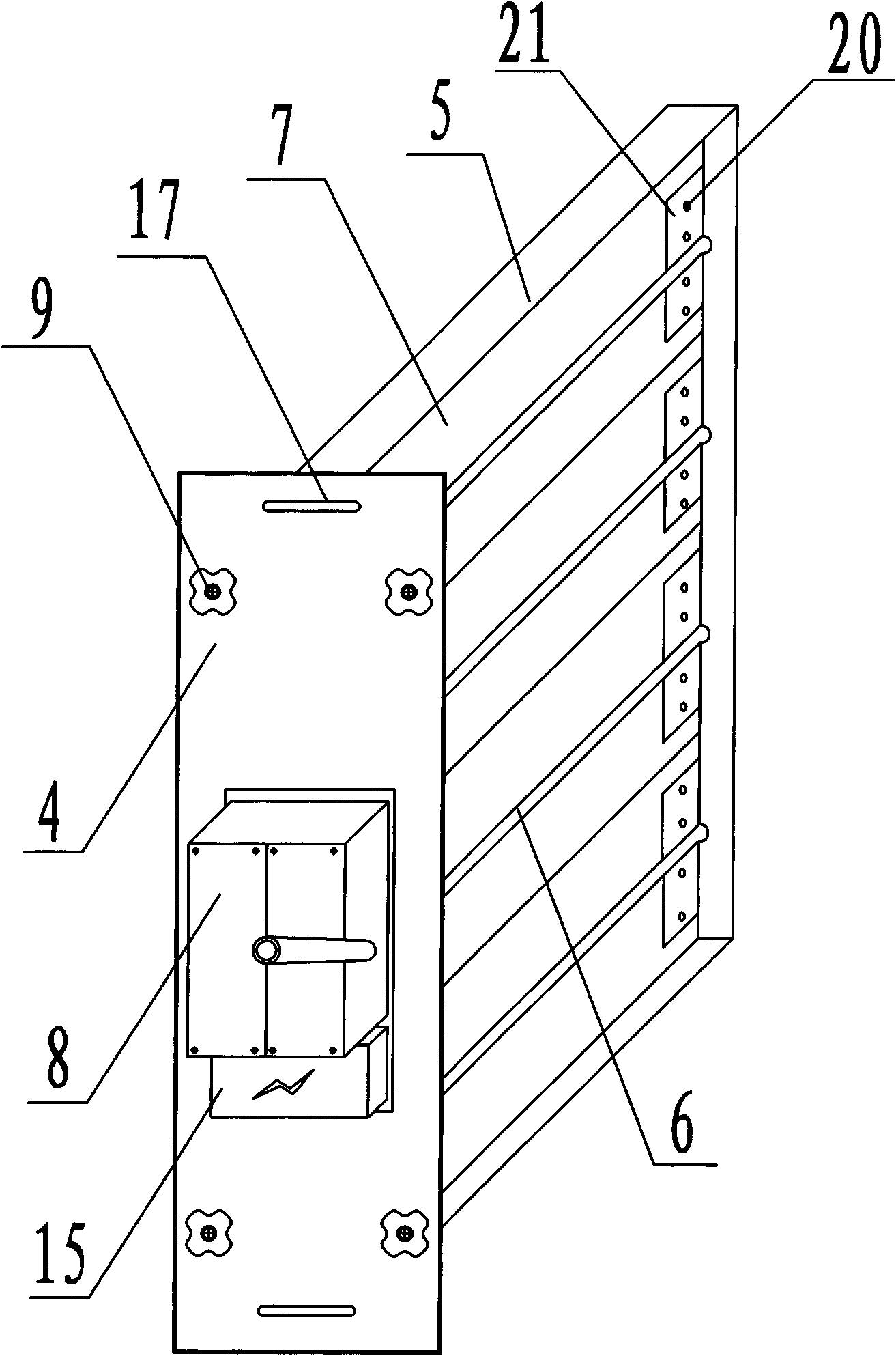

Fireproof valve for oil smoke pipeline of setting machine

ActiveCN101825192AEasy to disassembleEasy to installOperating means/releasing devices for valvesHeating/cooling textile fabricsEngineeringVALVE PORT

The invention discloses a fireproof valve for an oil smoke pipeline of a setting machine, which has convenient disassembly and assembly and can rapidly induct a fire alarm signal. The fireproof valve comprises a shell, and one side of the shell is respectively provided with a track-type valve core mounting cavity and a track-type fire alarm sensor mounting cavity; a valve core and a fire alarm sensor are respectively arranged in the track-type valve core mounting cavity and the track-type fire alarm sensor mounting cavity. The invention has the advantages that the fireproof valve with the structure, which is used in the oil smoke pipeline of the setting machine, is easy to disassemble and install, and thereby, cleaning and maintaining the inside of the fireproof valve are convenient. Simultaneously, the fire alarm signal can be rapidly inducted, and then a channel between the oil smoke pipeline and the setting machine is cut off so as to prevent fire from spreading, prevent blades from deformation for a long time and prolong the service life of the fireproof valve.

Owner:江苏保丽洁环境科技股份有限公司

Anti-collision structure and air conditioner

PendingCN110057140AGuaranteed heat transfer performanceIncrease cooling areaEvaporators/condensersSpace heating and ventilation detailsEvaporatorEngineering

The invention provides an anti-collision structure and an air conditioner. The anti-collision structure is applied to an evaporator and comprises a protecting plate, and the protecting plate is arranged at the bottom of the evaporator; and the air conditioner comprises the anti-collision structure. The anti-collision structure is arranged on the evaporator and can protect fins on the evaporator from deformation caused by external force influence, so that heat exchange performance of the evaporator is guaranteed.

Owner:NINGBO AUX ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com