Heater furnace to produce titanium sponge by combination method

A heating furnace and sponge titanium technology, which is applied in the field of heating furnaces for producing sponge titanium by the magnesium method, can solve problems such as unsatisfactory, and achieve the effects of reduced power consumption, strong heat dissipation, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

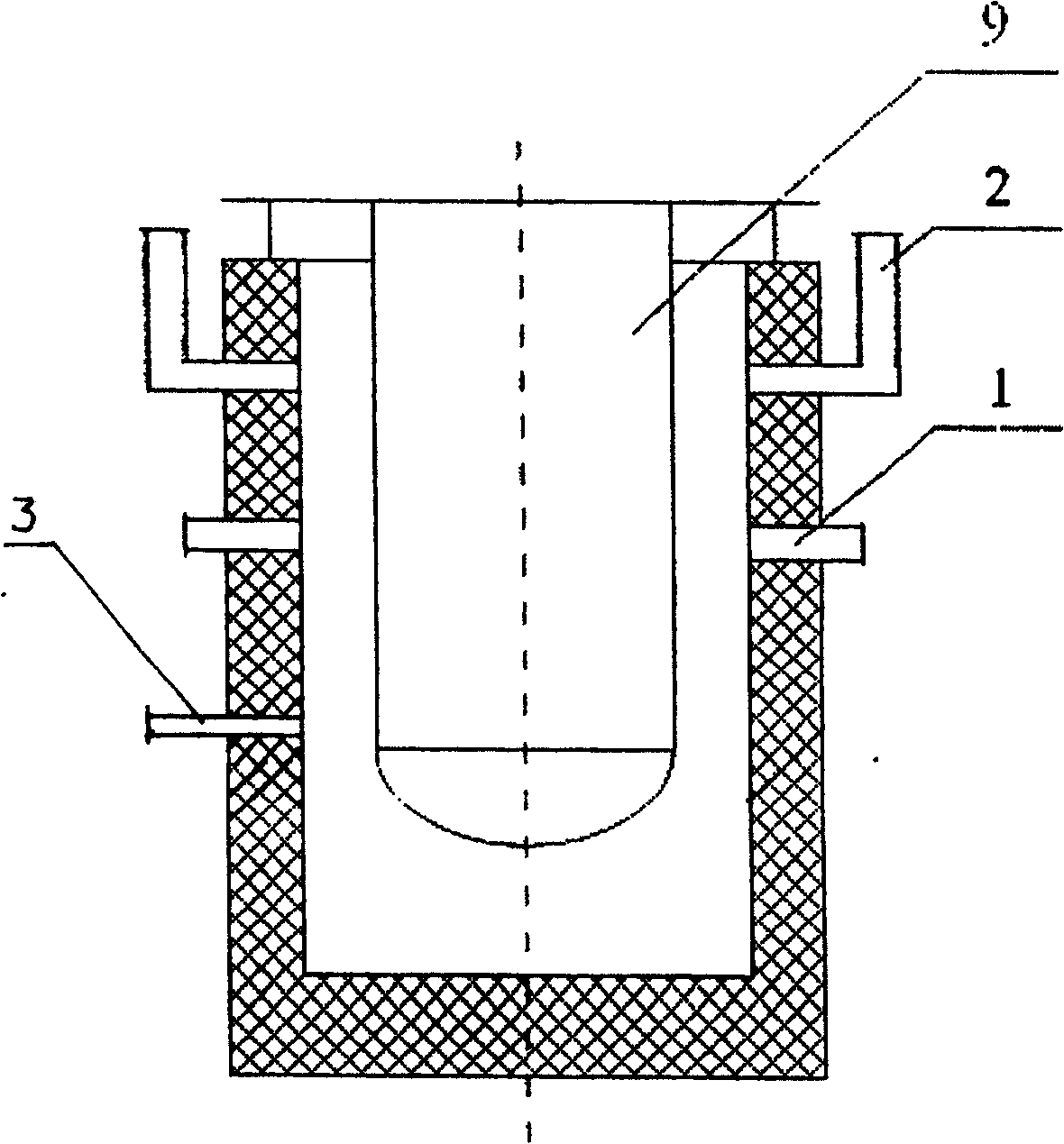

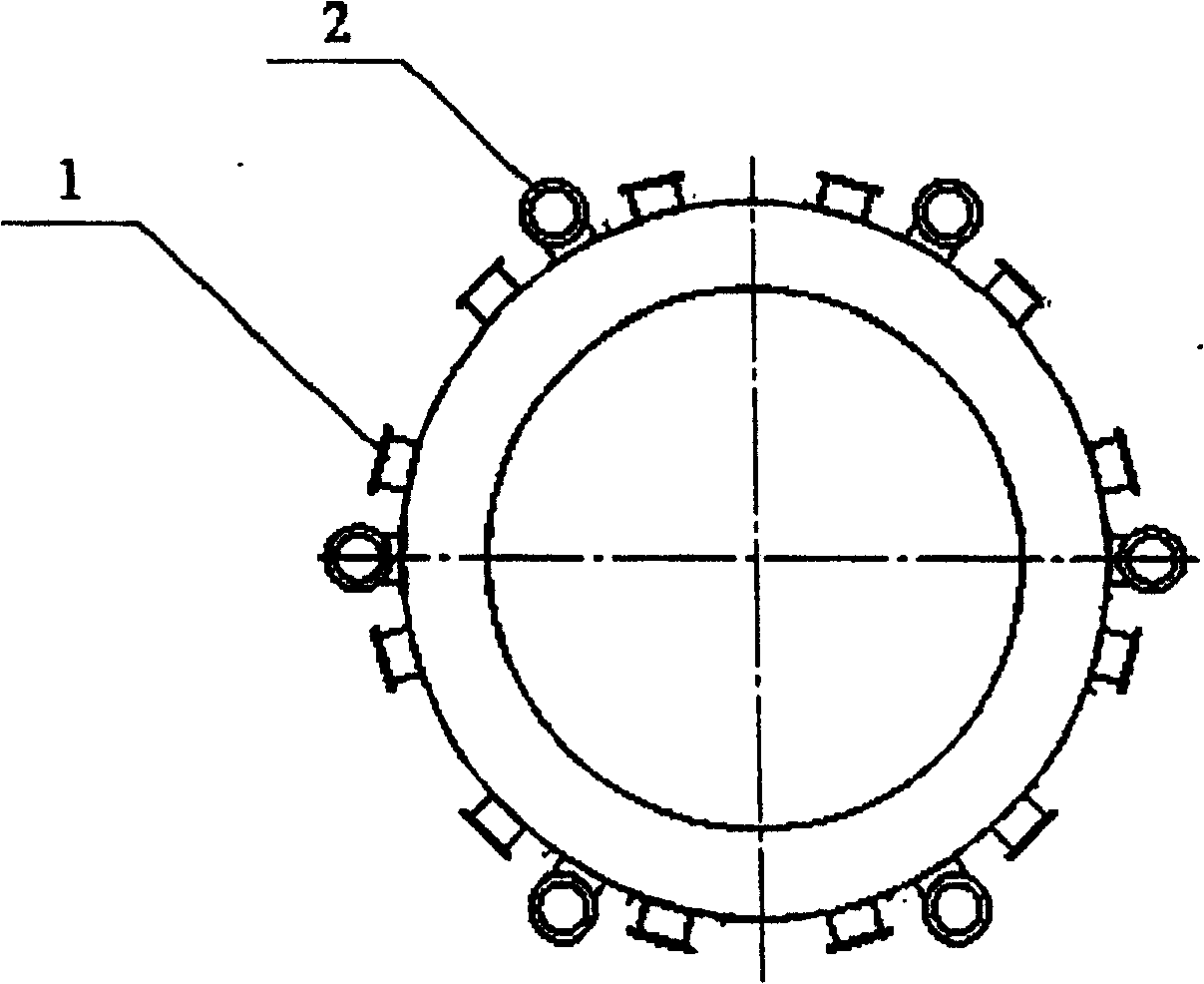

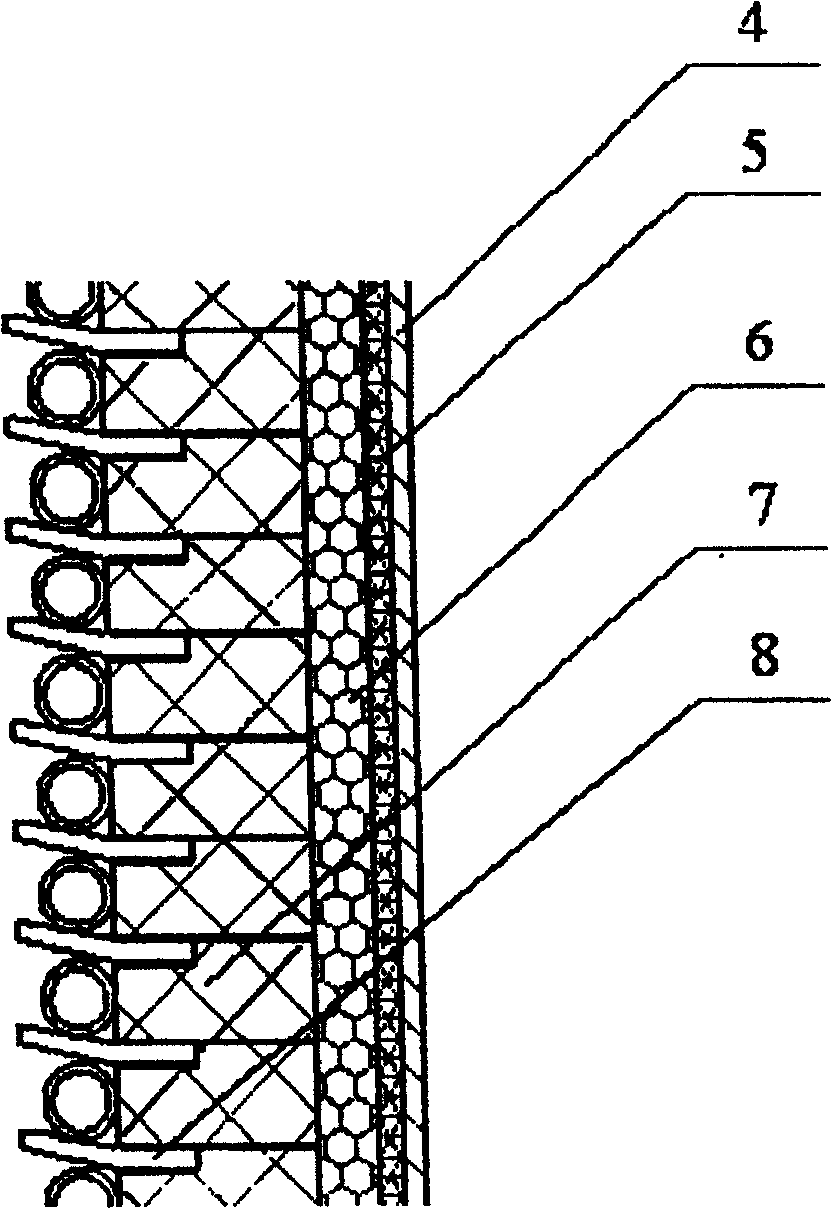

[0012] In a titanium sponge production plant, titanium sponge is produced by combined magnesium reduction distillation method. As attached picture 1, figure 2 As shown, the well-type electric heating furnace has a furnace bottom and a furnace wall. The well-type electric heating furnace is equipped with 12 air inlets 1 evenly distributed in the middle of the heating furnace wall, and 6 air exhaust outlets are evenly distributed on the upper part of the heating furnace wall. 2. The air outlet 2 has a length vertically upward after being released from the furnace, and the furnace wall of the heating furnace is also provided with an evacuation port 3; as shown in Figure 3, the furnace wall of the well-type electric heating furnace is the furnace shell 4 from the outside to the inside. , furnace lining and electric heating body, furnace lining is made up of refractory brick 7, insulation layer, heat insulation layer, and electric heating body is that resistance wire is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com