Steel tube clamping device for machining

A clamping device and machining technology, applied in the field of machining, can solve the problems of troublesome operation, limited size of the curved plate, low work efficiency, etc., and achieve the effects of convenient machining, strong adaptability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

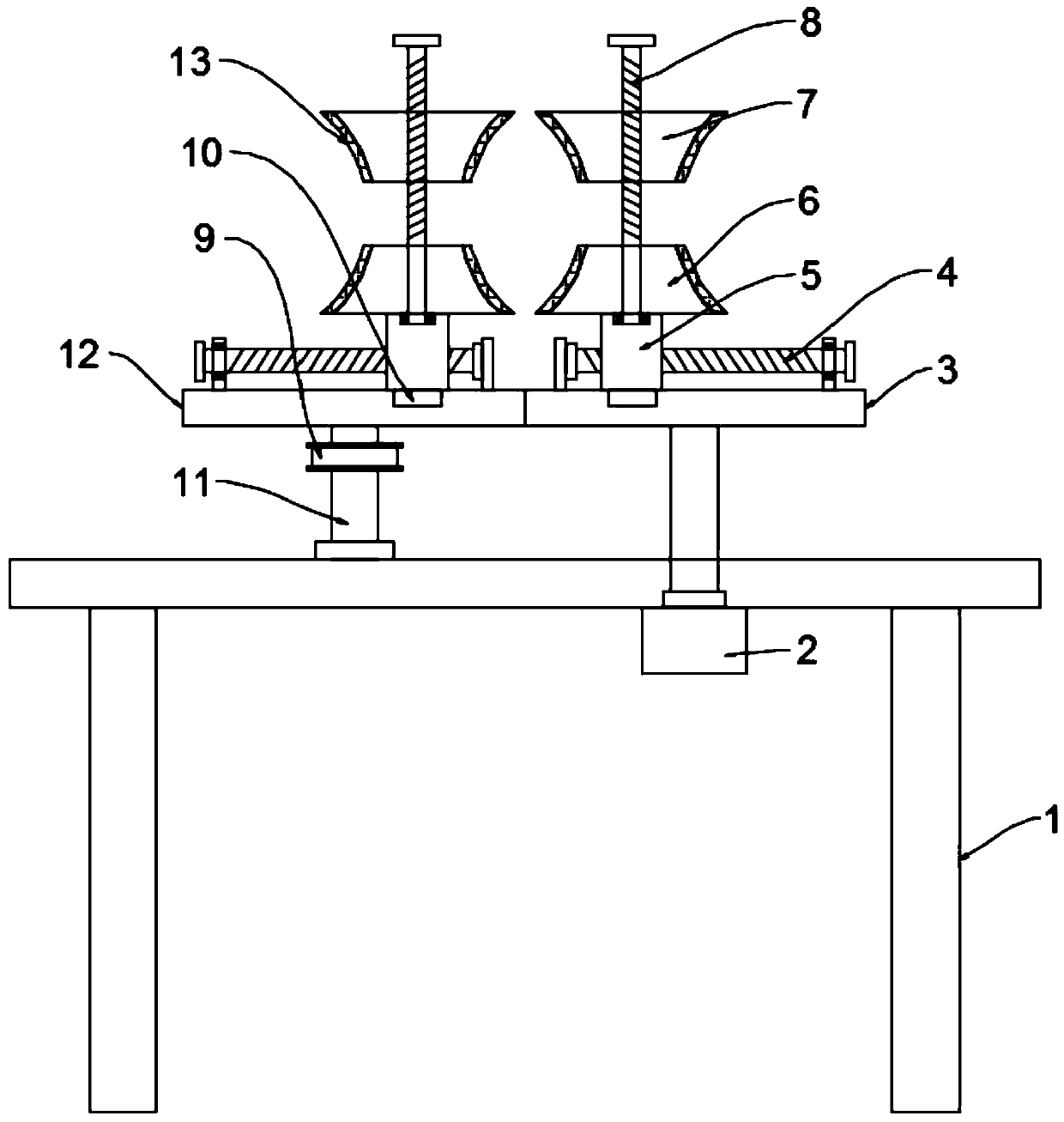

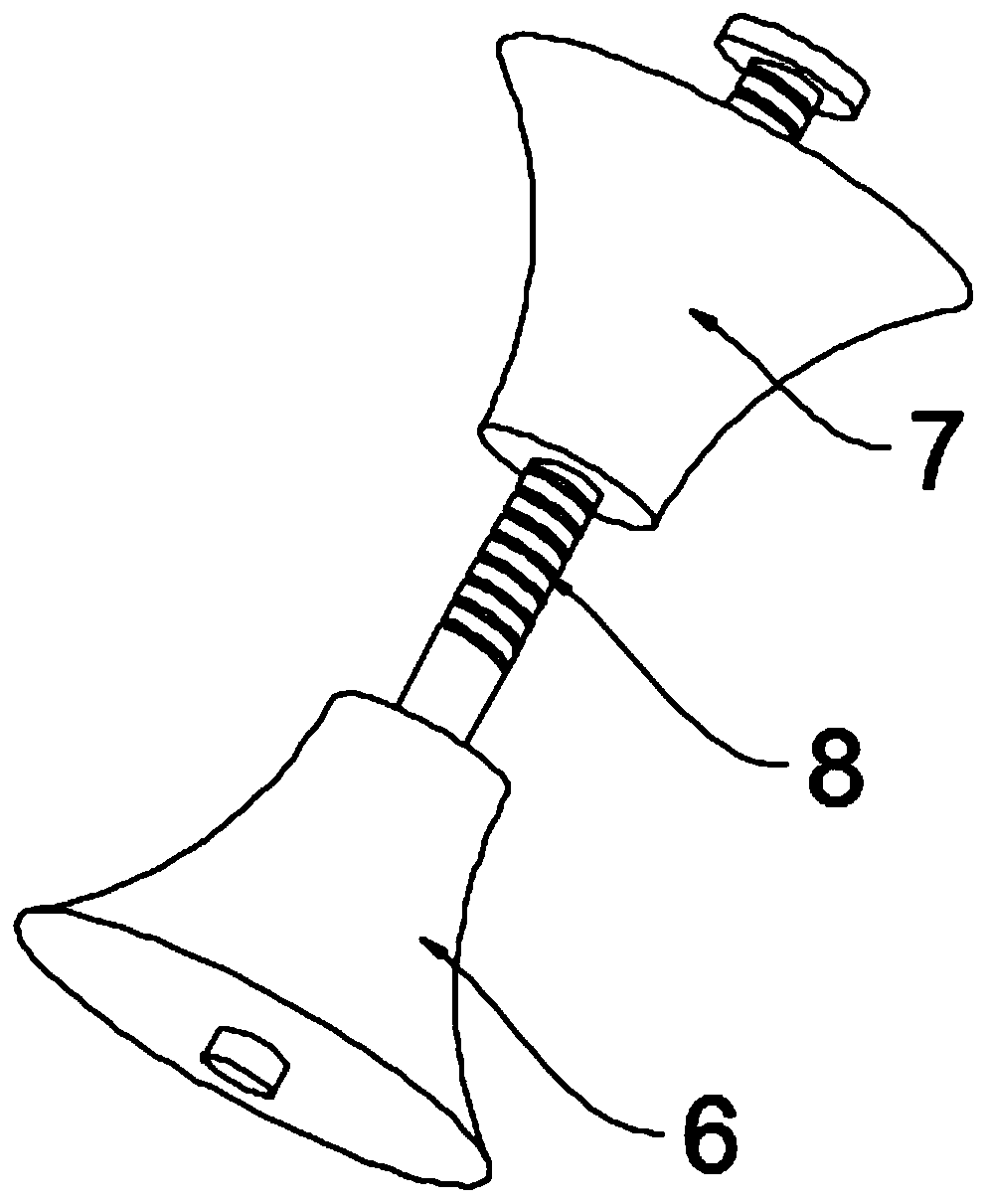

[0023] see Figure 1~2 , in an embodiment of the present invention, a steel pipe clamping device for mechanical processing includes at least two sets of clamping assemblies longitudinally installed on the frame 1, and the clamping assemblies include a first gear 3, a second gear 12, an upper The clamping platform 7 and the lower clamping platform 6, the first gear 3 and the second gear 12 are installed on the frame 1 through the installation shaft 11 and the bearing rotation respectively, the first gear 3 meshes with the second gear 12, and the The upper surfaces of the first gear 3 and the second gear 12 are all rotatably equipped with first threaded rods 4. In this embodiment, both sides of the upper surfaces of the first gear 3 and the second gear 12 are fixed with fixed plates. The rod 4 is rotationally connected with the fixed plate through a bearing, and a first handle is fixed at one end of the first threaded rod 4. In this embodiment, the first handle is preferably fix...

Embodiment 2

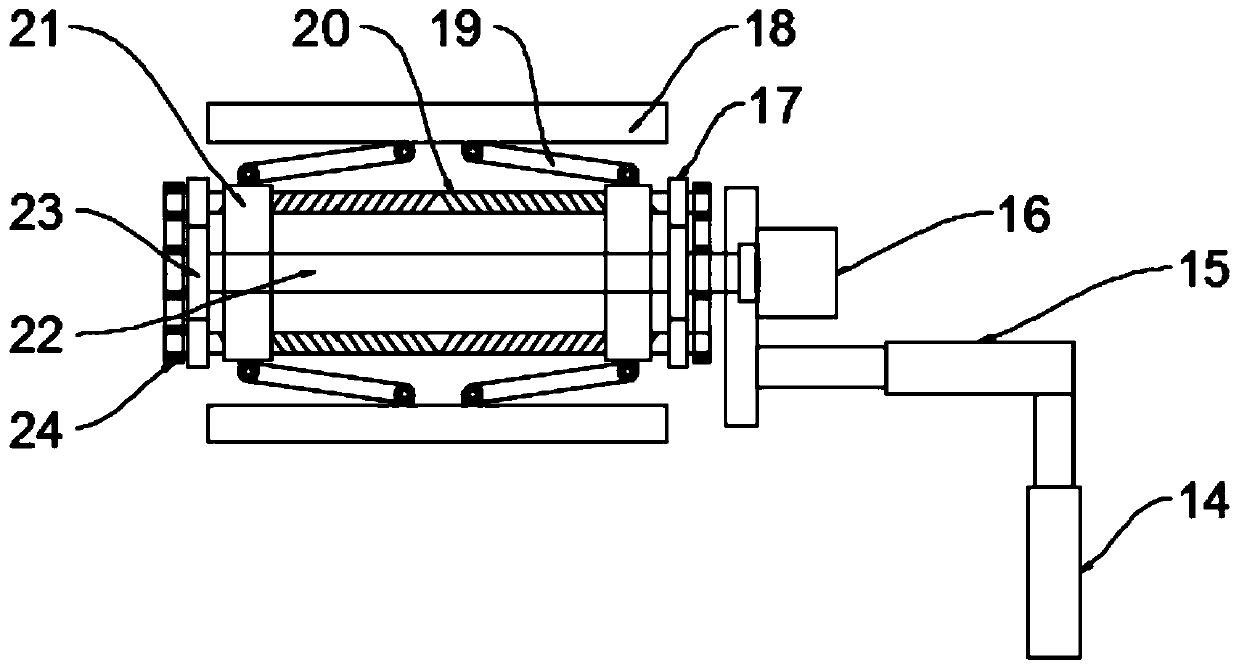

[0025] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that due to the different thickness of the pipe wall of the steel pipe, when the pipe wall of the steel pipe is relatively thin, the deformation of the steel pipe may be caused during clamping, thus, a protection unit is also included , the protection unit includes a protection assembly and an adjustment assembly for adjusting the position of the protection assembly, the adjustment assembly includes a first electric push rod 14 and a second electric push rod 15, the first electric push rod 14 is fixedly installed on the frame, the second Two electric push rods 15 are fixed on the telescopic rod top of the first electric push rod 14, and the protection assembly includes a second motor 16, a rotating shaft 22, a driving gear 23, a driven gear 17, a two-way screw rod 20, a movable plate 21, and a connecting rod 19 and arc-shaped plate 18, the second motor 16 is fixedly mounted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com