A clamping tool for automatic processing of flat parts

A technology for clamping tooling and parts, applied in the field of automated processing, can solve problems such as inability to automatically turn over, and achieve the effect of protecting from deformation and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

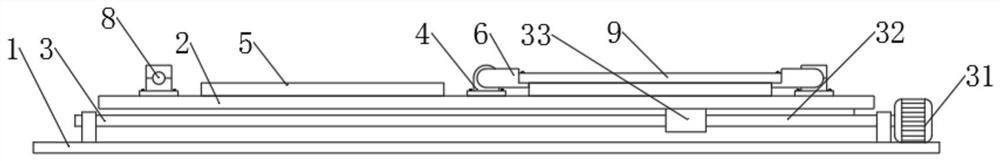

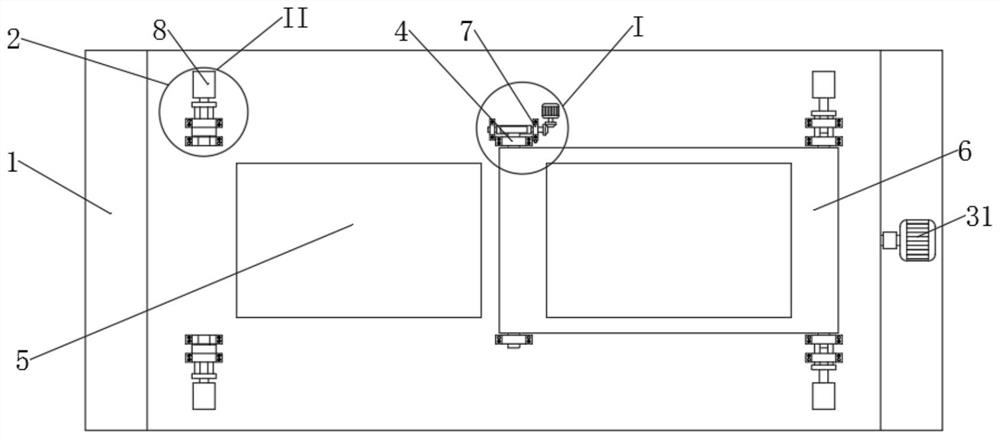

[0024] Depend on Figure 1 ~ Figure 4 As shown, a clamping tool for automatic processing of flat parts, including a base 1, the base 1 is equipped with a moving base 2 capable of moving on the base 1 through the driving unit 3 of the moving base, and the moving base 2 is provided with an overturning support seat 4. A clamping plate 6 for clamping the workpiece 9 is hinged on the turning support base 4, and the clamping plate 6 is connected with a turning unit 7 for driving the clamping plate 6 to turn over. Press the pressing unit 8 of the clamping plate 6, and the moving base 2 is also provided with a support unit 5 for preventing the deformation of the workpiece 9 during processing, and the supporting unit 5 is detachably installed on the moving base 2 superior;

[0025] The base 1 is a flat plate, and the base 1 is provided with a mounting hole for being installed on a plate processing device;

[0026] The mobile seat 2 is a flat plate, and the mobile seat drive unit 3 in...

Embodiment 2

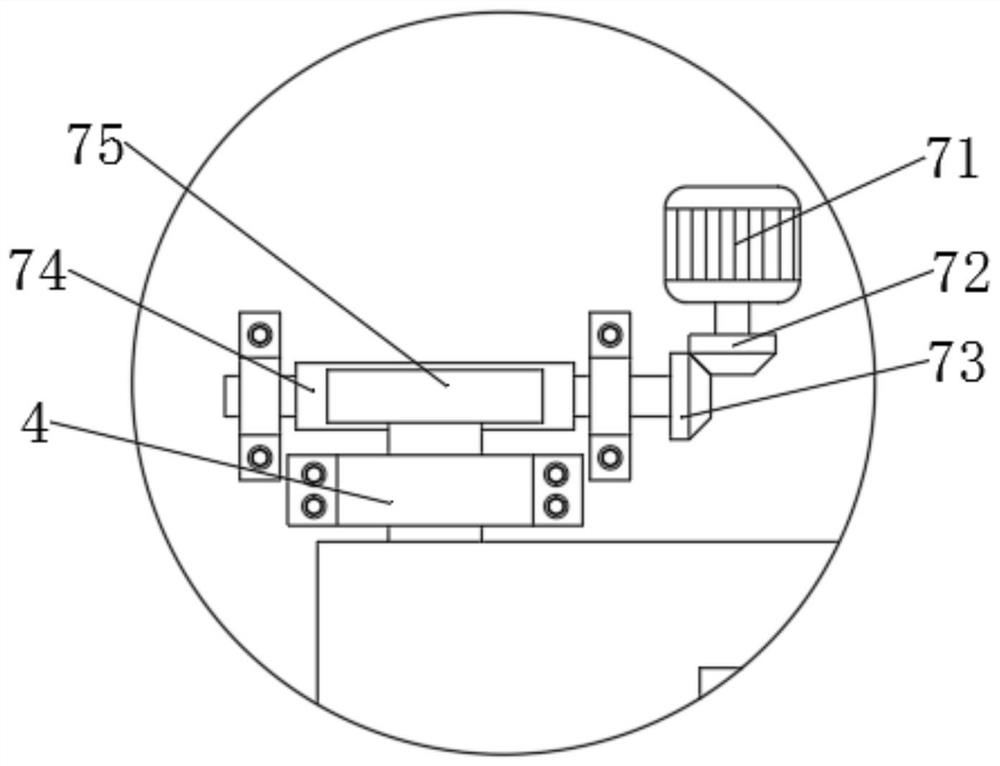

[0035] Depend on Figure 1 ~ Figure 4As shown, a clamping tool for automatic processing of flat parts, including a base 1, the base 1 is equipped with a moving base 2 capable of moving on the base 1 through the driving unit 3 of the moving base, and the moving base 2 is provided with an overturning support seat 4. A clamping plate 6 for clamping the workpiece 9 is hinged on the turning support base 4, and the clamping plate 6 is connected with a turning unit 7 for driving the clamping plate 6 to turn over. Press the pressing unit 8 of the clamping plate 6, and the moving base 2 is also provided with a support unit 5 for preventing the deformation of the workpiece 9 during processing, and the supporting unit 5 is detachably installed on the moving base 2 superior;

[0036] Preferably, in this embodiment, the first motor 71 and the worm 74 are connected through the first bevel gear 72 and the second bevel gear 73, the first bevel gear 72 is fixed on the output shaft of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com