Oil immersed transformer with core lifting device

A technology of oil-immersed transformers and transformers, applied in the field of transformers, can solve the problems of inability to be equipped with lifting devices in time, difficulty in maintenance, high cost, etc., and achieve the effects of improving maintenance efficiency, improving safety performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

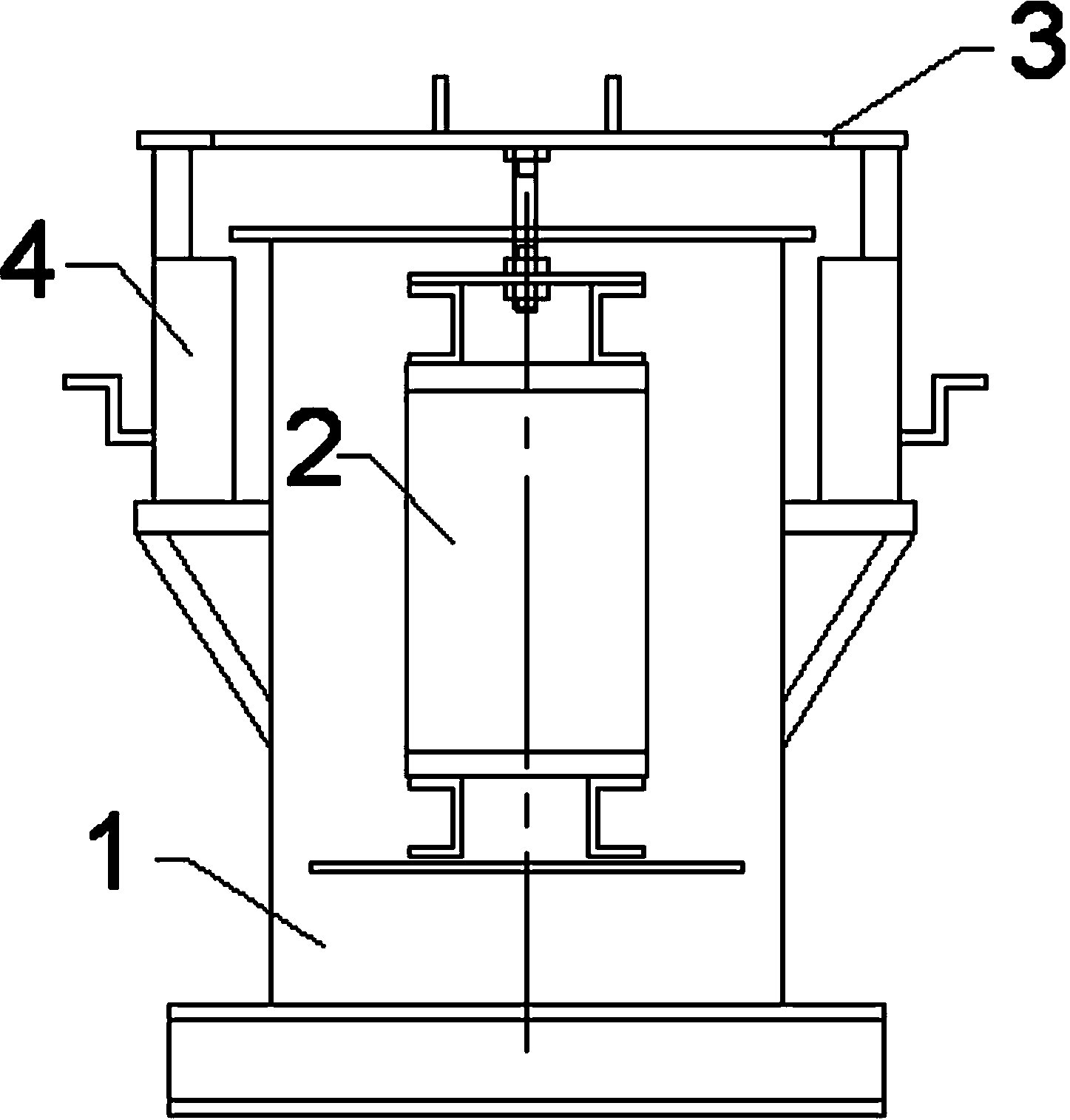

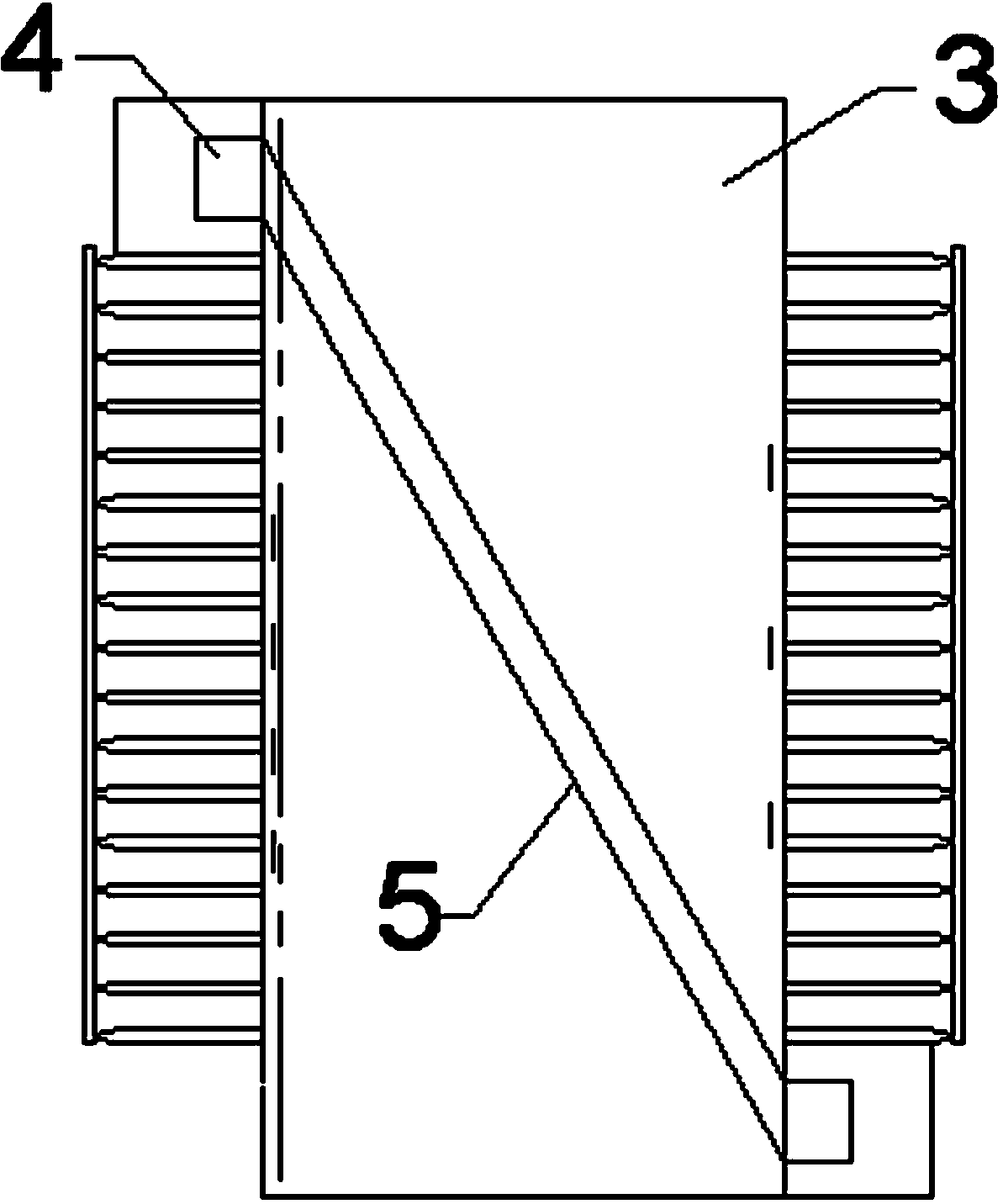

[0017] figure 1 , 2 As shown, an oil-immersed transformer with its own hanging core device includes a transformer oil tank 1 , a transformer body 2 , a tank cover 3 , a jack 4 and reinforcing ribs 5 . The transformer body 2 is arranged in the transformer oil tank 1, and the top of the transformer oil tank 1 is provided with a tank cover 3, and more than one jack 4 is respectively connected to two corresponding outer sides of the transformer oil tank 1, and the jack 3 is vertically connected to the tank cover 3 to drive the tank cover to be vertical In the lifting state, the connection point between the two corresponding jacks 4 on the outside of the transformer oil tank 1 and the box cover 3 is center-symmetrical on the box cover 3, and the box cover 3 is provided with reinforcing ribs 5, and the extension line of the reinforcing ribs 5 passes through the two correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com