Novel grinding device for inner protrusion of steel pipeline

A new type of technology for steel pipes, which is applied in the field of new-type steel pipe inner protrusion grinding devices, and can solve problems such as inability to realize automatic grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

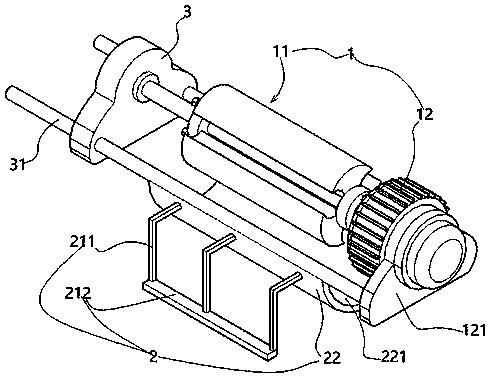

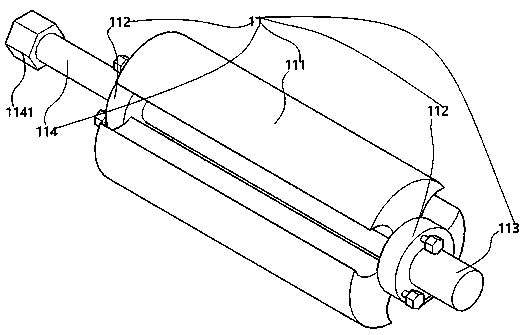

[0058] Such as Figure 1-3 As shown, a novel steel pipe internal protrusion grinding device includes a protrusion grinding assembly 1, and the protrusion grinding assembly 1 includes a grinding part 11, and the grinding part 11 includes 3 fan-shaped grinding rods 111 distributed in an annular array (according to the existing Grinding tool design, the surface of the fan-shaped grinding rod 111 has a rough rubbing structure, such as a grinding raised structure, which is convenient for grinding and smoothing the protrusions on the inner wall of the pipeline), and the length of the fan-shaped grinding rod 111 is 2.5m, so it can be applied to the length of the pipeline Sanding for large pipes up to 2.5m.

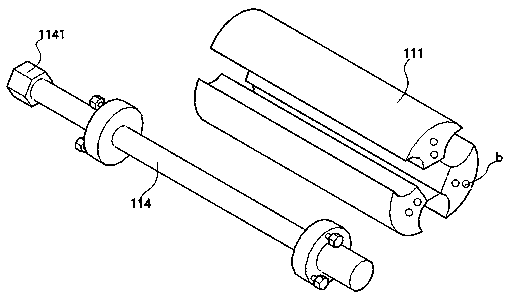

[0059] The left and right ends of the three fan-shaped grinding rods 111 are fixedly connected with mounting discs 112 , and shafts 114 are fixedly connected between the mounting discs 112 . Specifically, the left side wall and the right side wall corresponding to the fan-shaped...

Embodiment 2

[0078] Such as Figure 1-4 As shown, this embodiment is based on the structure disclosed in Embodiment 1, in order to realize that the left end frame 3 can be flexibly separated from the shaft 114 (to facilitate pushing the steel pipe to the fan-shaped grinding rod 111) and flexibly install the shaft 114 to the left end On the frame 3, it is convenient for the shaft rod 114 to be rotationally connected with the left end frame 3. Adopt the following structural design:

[0079] The left end of the shaft 114 is fixedly connected with a hexagonal clip 1141 (the left end of the shaft 114 passes through the mounting plate 112 on the left side and is connected to the mounting plate 112 in this position); the left end frame 3 is fixed A special-shaped bearing 32 matched with the hexagonal clip 1141 is connected. Wherein, the main structure of the special-shaped bearing 32 is the same as that of the existing rolling bearing, the difference is that the inner ring 322 of the special-sh...

Embodiment 3

[0089] Such as Figure 1-9 As shown, on the basis of Example 2, this embodiment adopts the following structural design in order to realize the technical defect that the steel pipe rolls due to friction during the grinding process:

[0090] The novel steel pipe internal protrusion grinding device also includes a locking device 4, and the locking device 4 is located directly above the fan-shaped grinding rod 111 . Cooperating with the corrugated support plate 22 by the locking device 4 prevents the steel pipe from rolling.

[0091] The concrete structure of locking device 4 is as follows:

[0092] The locking device 4 includes several arc-shaped rods 41 distributed at intervals on the left and right, and the bottoms of the several arc-shaped rods 41 are distributed with several extruded locking parts 44 in an arc-shaped distribution; the several arc-shaped rods 41 The front and rear ends of the front and rear ends are fixedly connected with end side plates 411 .

[0093] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com