Patents

Literature

191results about How to "Convenient socket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

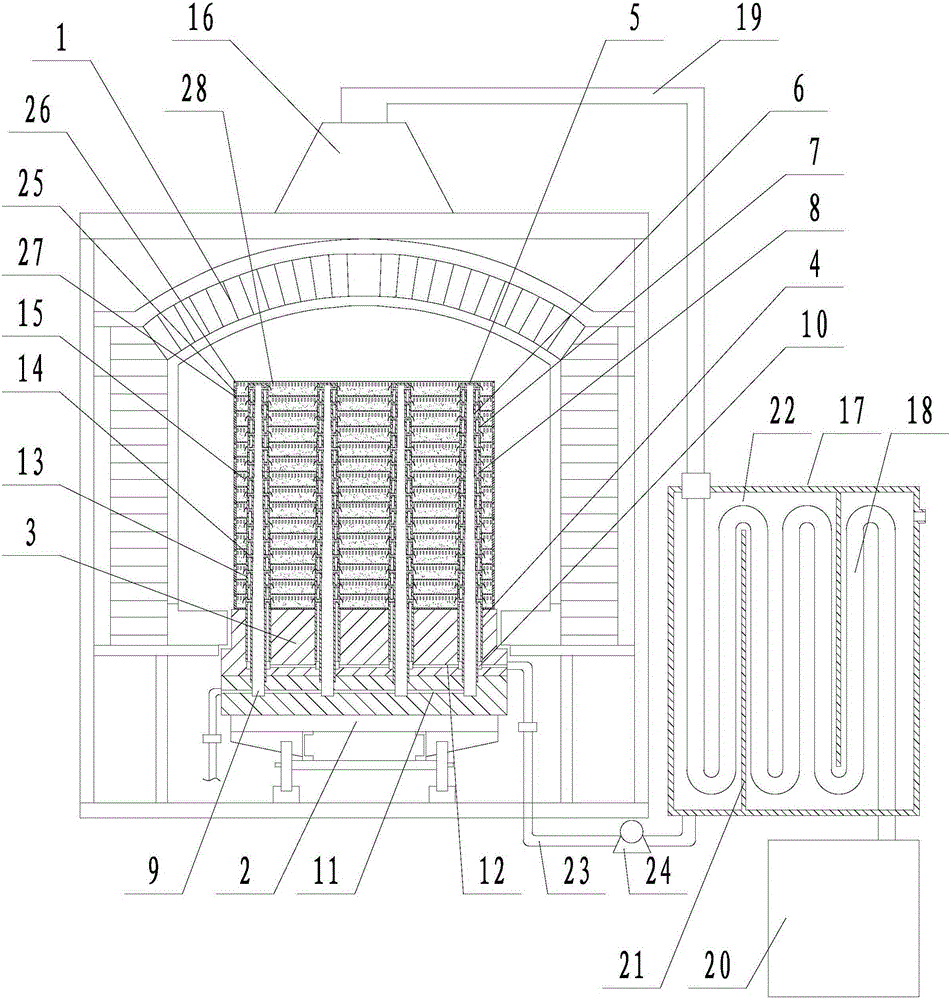

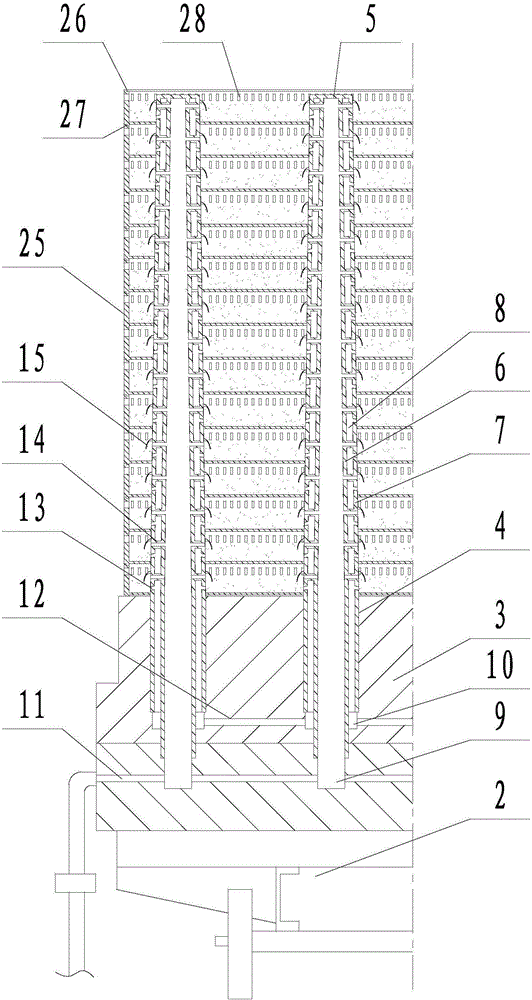

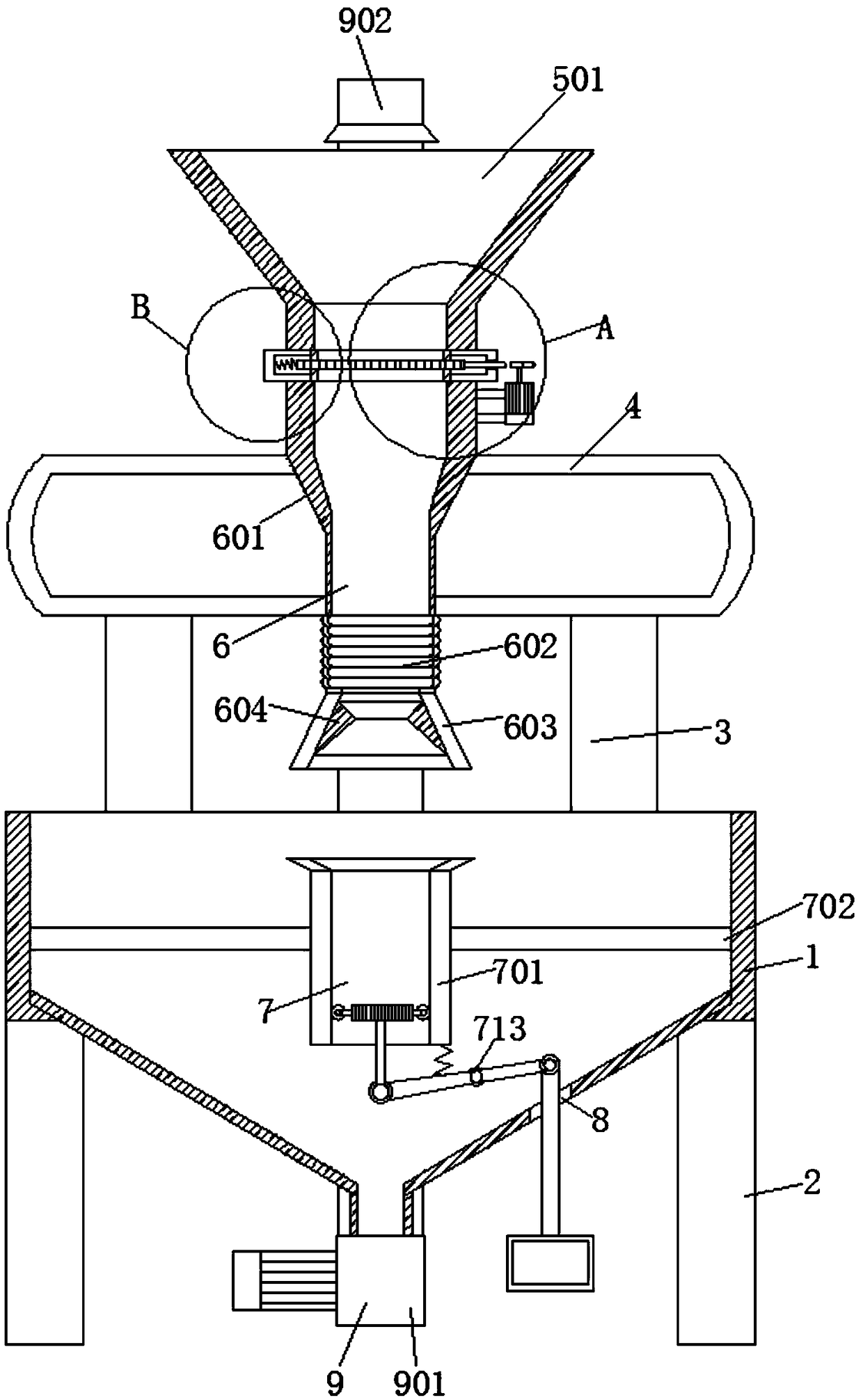

Production technology and device of high-quality calcium oxide

ActiveCN105217974AGuarantee the quality of calcium oxideEvenly heatedLime productionCalciteCalcination

The present invention discloses a production technology and device of high-quality calcium oxide, and is intended to address the deficiencies that the calcium oxide produced after calcination of the existing limestone can be easily mixed with ash, underfiring and overburning are common in the calcining process, and the calcium oxide has lower quality. The process is as below: 1, selecting calcite as the raw material, cleaning and draining; 2, crushing the calcite and sieving calcite particles in similar size for standby; 3, sending the calcite raw material into a shuttle kiln for calcining; 4, taking calcium oxide out of the kiln, cooling calcium oxide to about 400 DEG C, and milling the calcium oxide at a temperature more than 200 DEG C; 5, after milling, sending the calcium oxide immediately into a sealed dry container for cooling, cooling to around 50 DEG C, and packaging immediately, wherein the time interval between taking calcium oxide out of the kiln and packaging is 30 min.

Owner:建德市泰合新材料有限公司

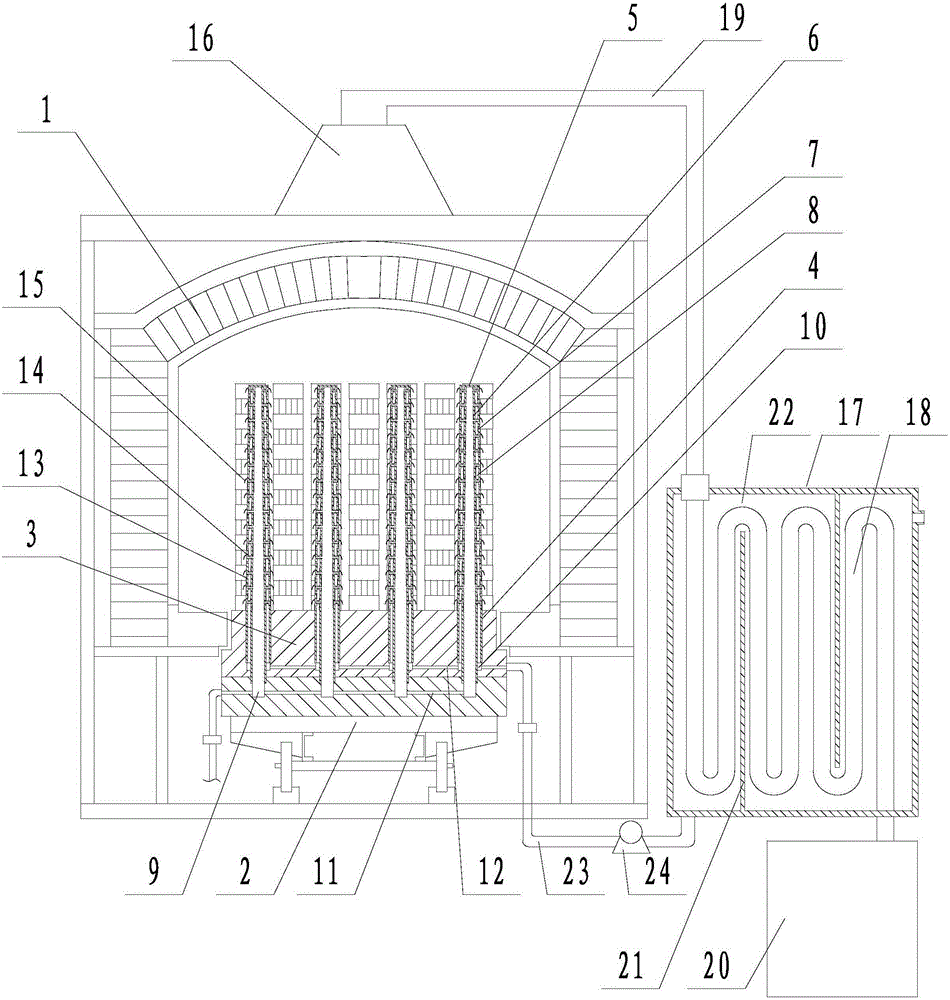

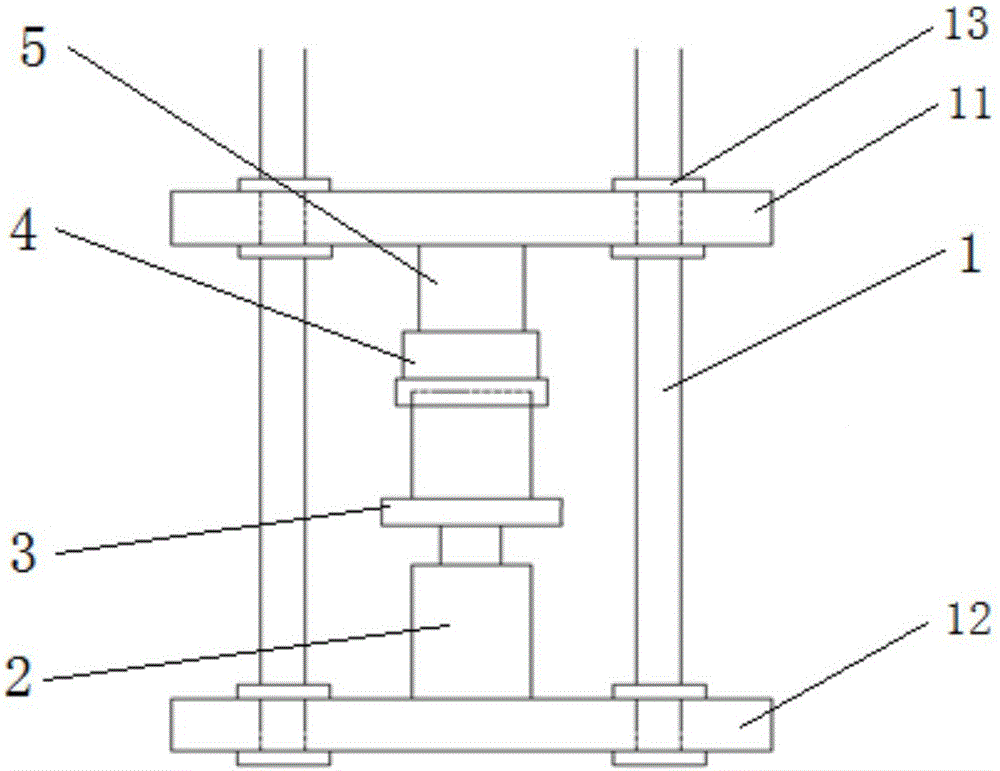

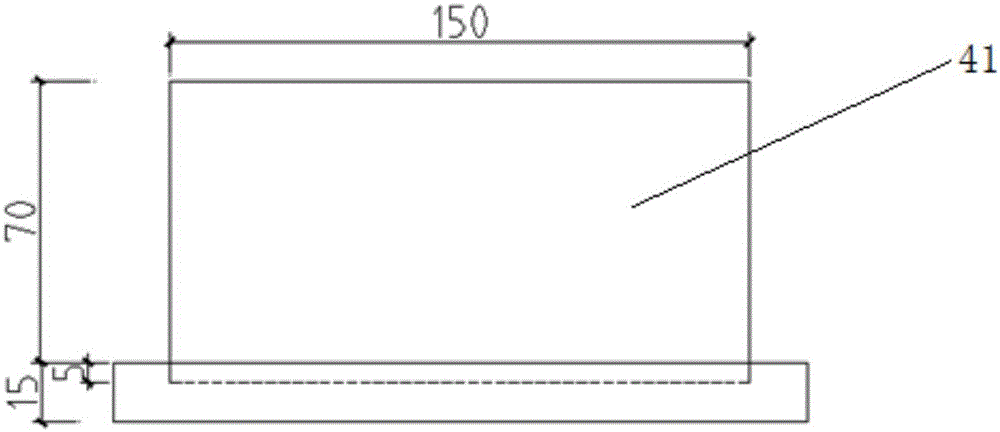

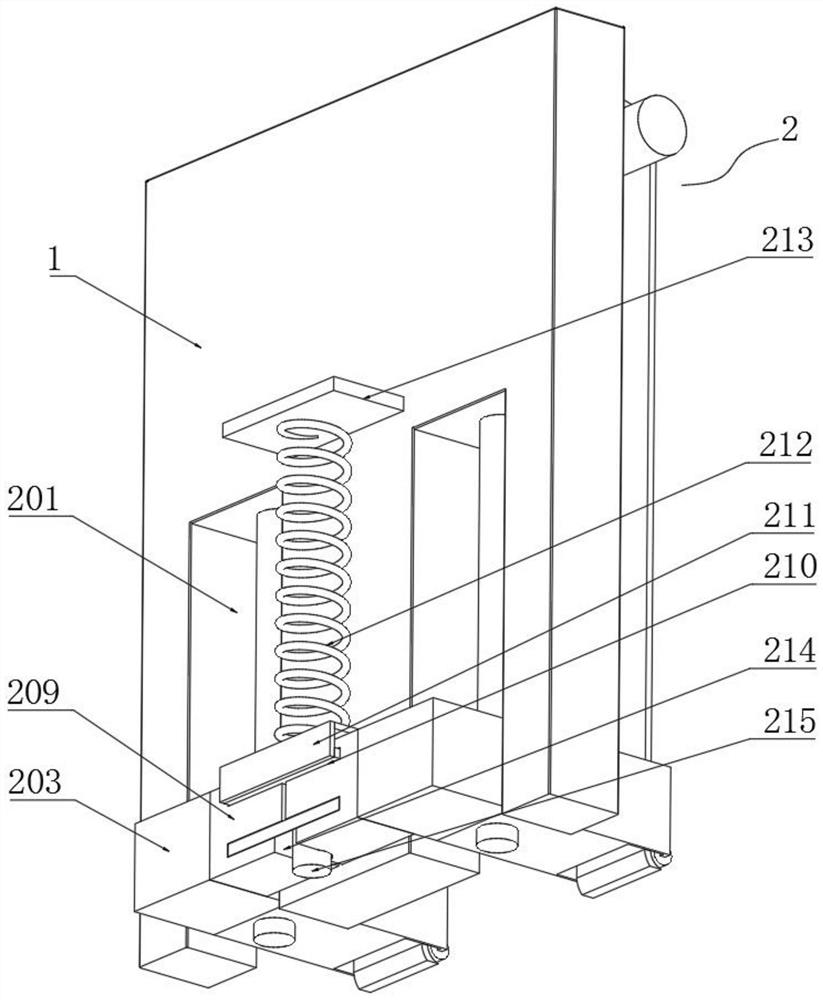

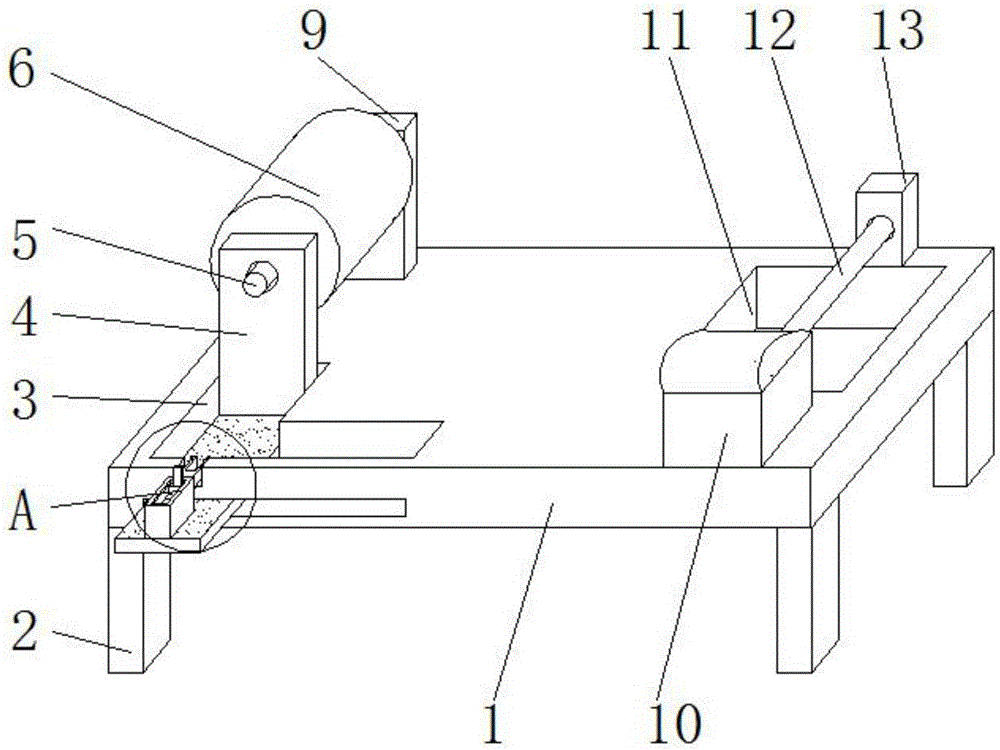

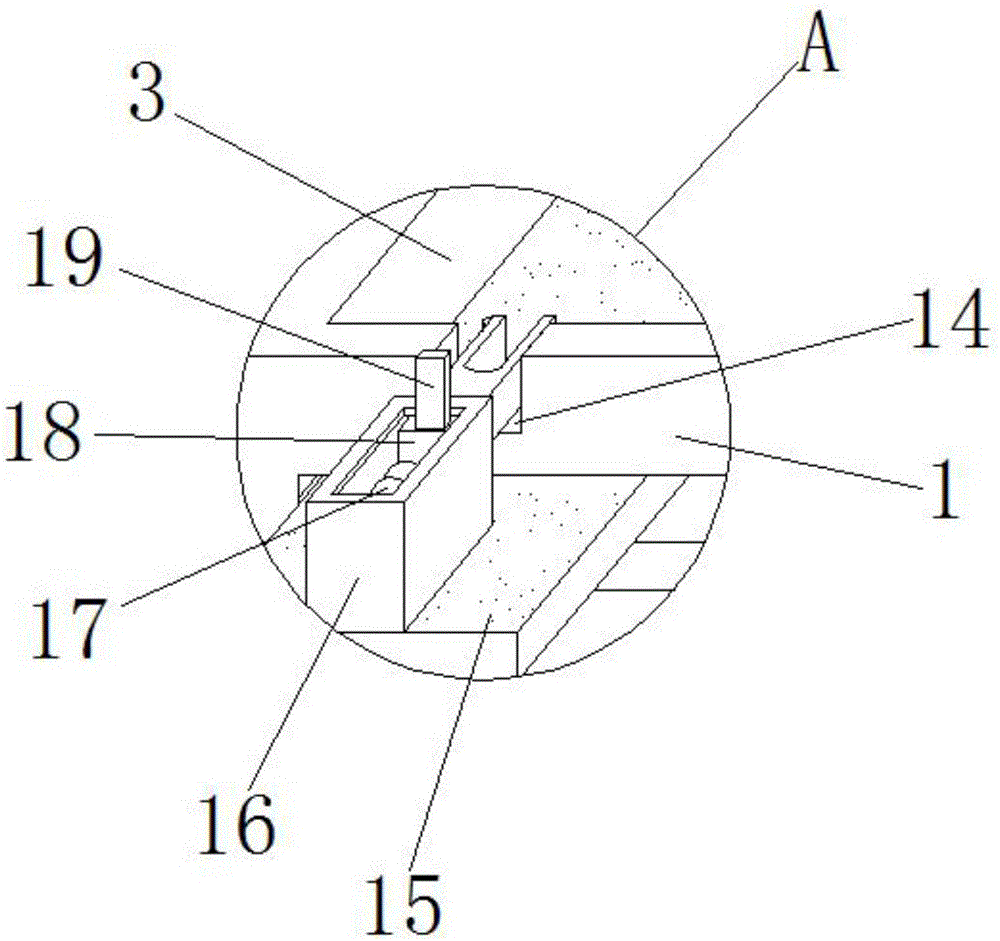

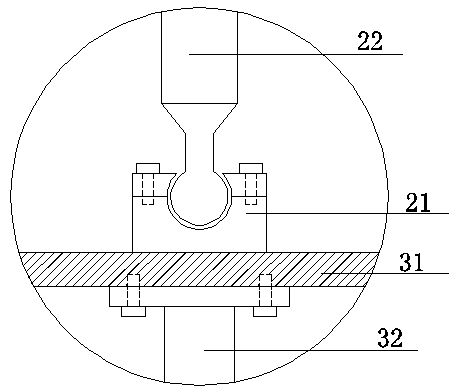

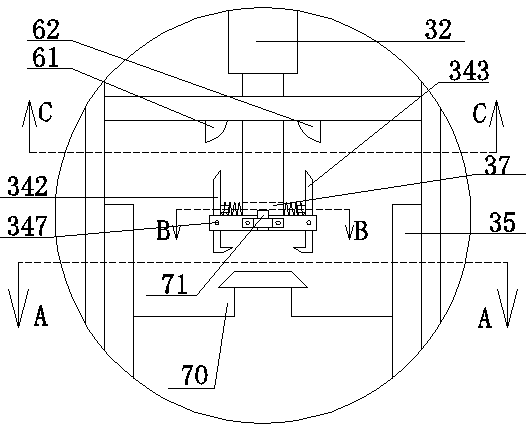

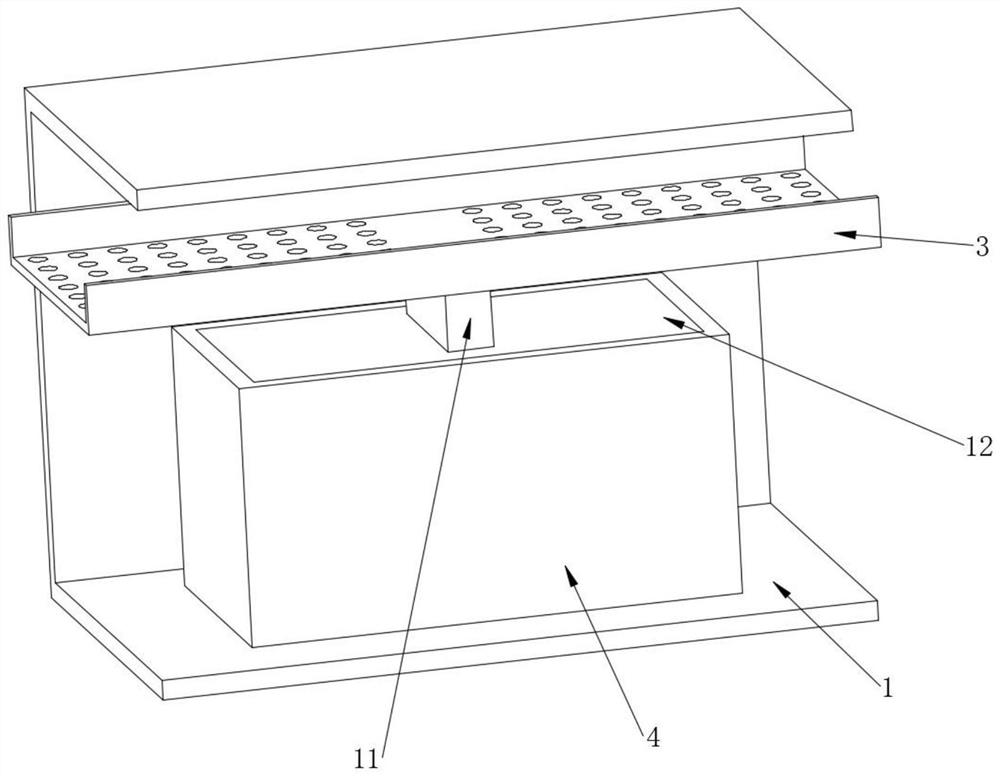

Sample preparation method and compaction device for immature soil base materials

ActiveCN105890961AStable compressive strengthGood densityPreparing sample for investigationDuctilityMaterials science

The invention discloses a sample preparation method and a compaction device for immature soil base materials. The method comprises the steps that the interior of a mold is coated with a lubricating oil layer, the immature soil base materials are put into the mold layer by layer, the immature soil base material layers in the mold are compacted through a jack every time one layer of immature soil base material is laid, and therefore a sample to be detected is obtained; the compaction speed of the jack is 0.5 mm / s, the compaction pressure of the jack is 18-19 K / N, and the compaction time of the jack is 3-5 min; the compaction device comprises a test bed, the test bed is sequentially provided with a first platform and a second platform in parallel in the horizontal direction from top to bottom, the second platform is coaxially provided with the jack, a gasket, the mold and a pressing column in sequence from bottom to top in the vertical direction, and the top end of the pressing column abuts against the first platform. Compared with a traditional hammer test, a press compaction test and a jack compaction test, the compressive strength of a test piece compacted by the jack is more stable than the compressive strength of a test piece compacted by the other two test methods, test piece overall deformation is good, and the test piece has good ductility when compacted.

Owner:CHANGAN UNIV

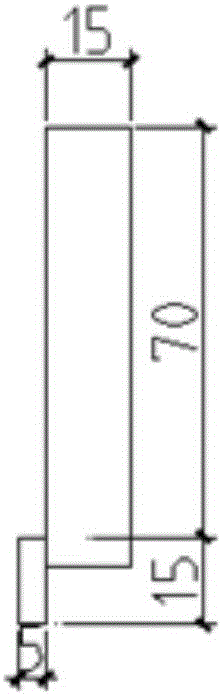

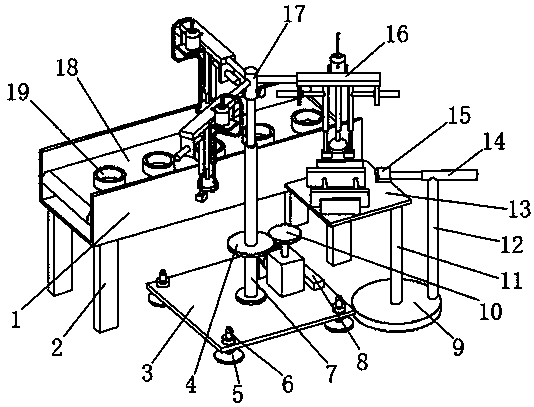

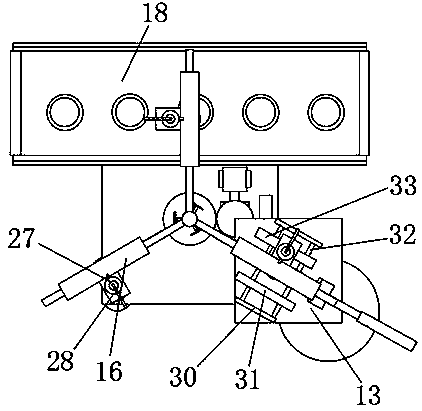

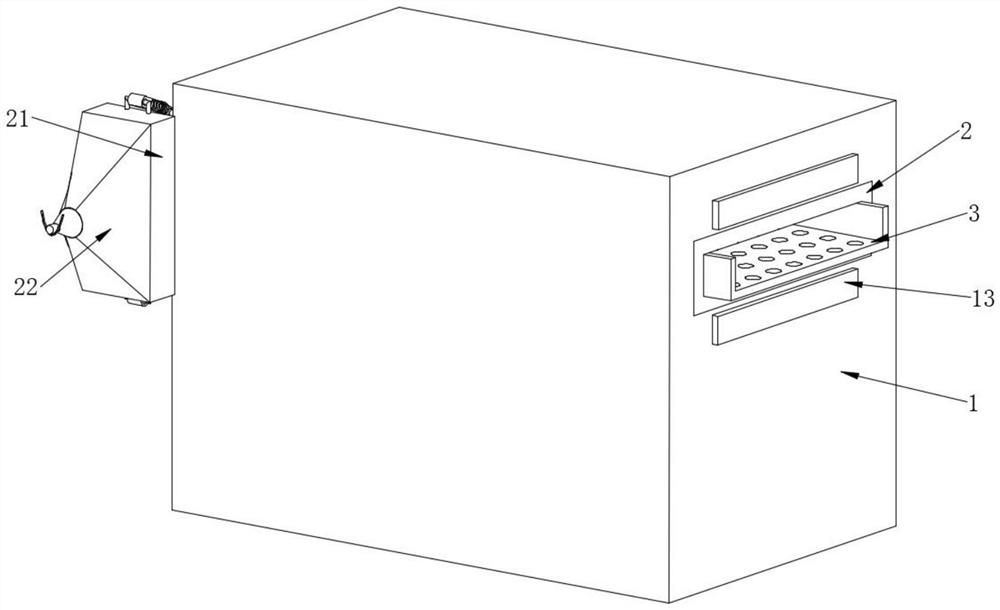

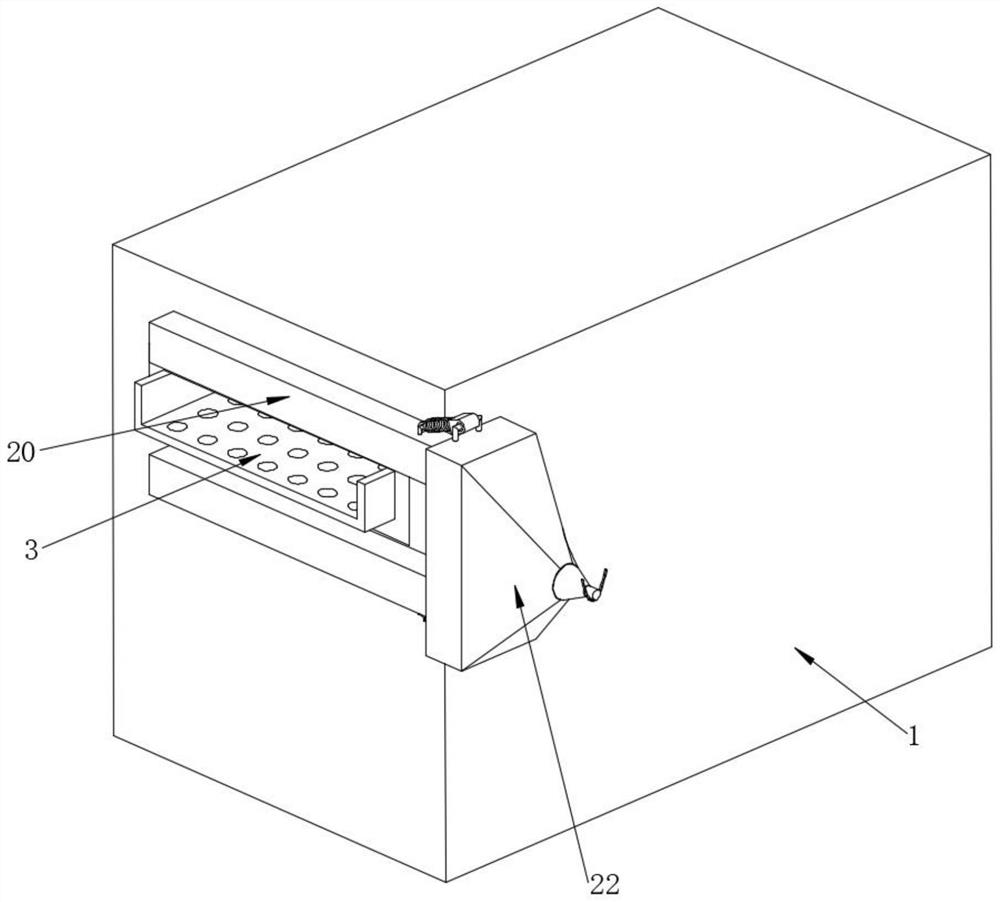

Semi-automatic pearl wool net sleeving device for fruits and vegetables

InactiveCN110053800ACompact structureEasy to operateMetal working apparatusPackaging fruits/vegetablesSemi automaticEngineering

The invention discloses a semi-automatic pearl wool net sleeving device for fruits and vegetables. The semi-automatic pearl wool net sleeving device for the fruits and vegetables comprises a base. According to the semi-automatic pearl wool net sleeving device for the fruits and vegetables, the structure is compact, operation is convenient, the occupation space is small in the using process, and the outer surfaces of the fruits and vegetables can be quickly and efficiently sleeved with pearl wool nets; fruit and vegetable positioning grooves are formed, therefore, the fruits and vegetables canbe clamped and fixed, and positioning in the fruit and vegetable sleeving process is convenient; a sleeve is arranged, and therefore lifting adjusting of U-shaped positioning plates is convenient; anair pump and an umbrella-shaped air bag are arranged, therefore, the pearl wool nets can be quickly opened, and sleeving connection of the pearl wool nets is convenient; a third electric telescopic rod is arranged, and therefore lifting adjusting of the umbrella-shaped air bag is convenient; electric fixtures are arranged, and therefore clamping and positioning of the pearl wool nets are convenient; the pearl wool nets can be automatically connected in a sleeving mode through fourth electric telescopic rods; upper-end openings of the pearl wool nets can be quickly opened through fifth electrictelescopic rods; and positioning studs are arranged, and therefore lifting adjusting of anti-skid blocks is convenient.

Owner:李占福

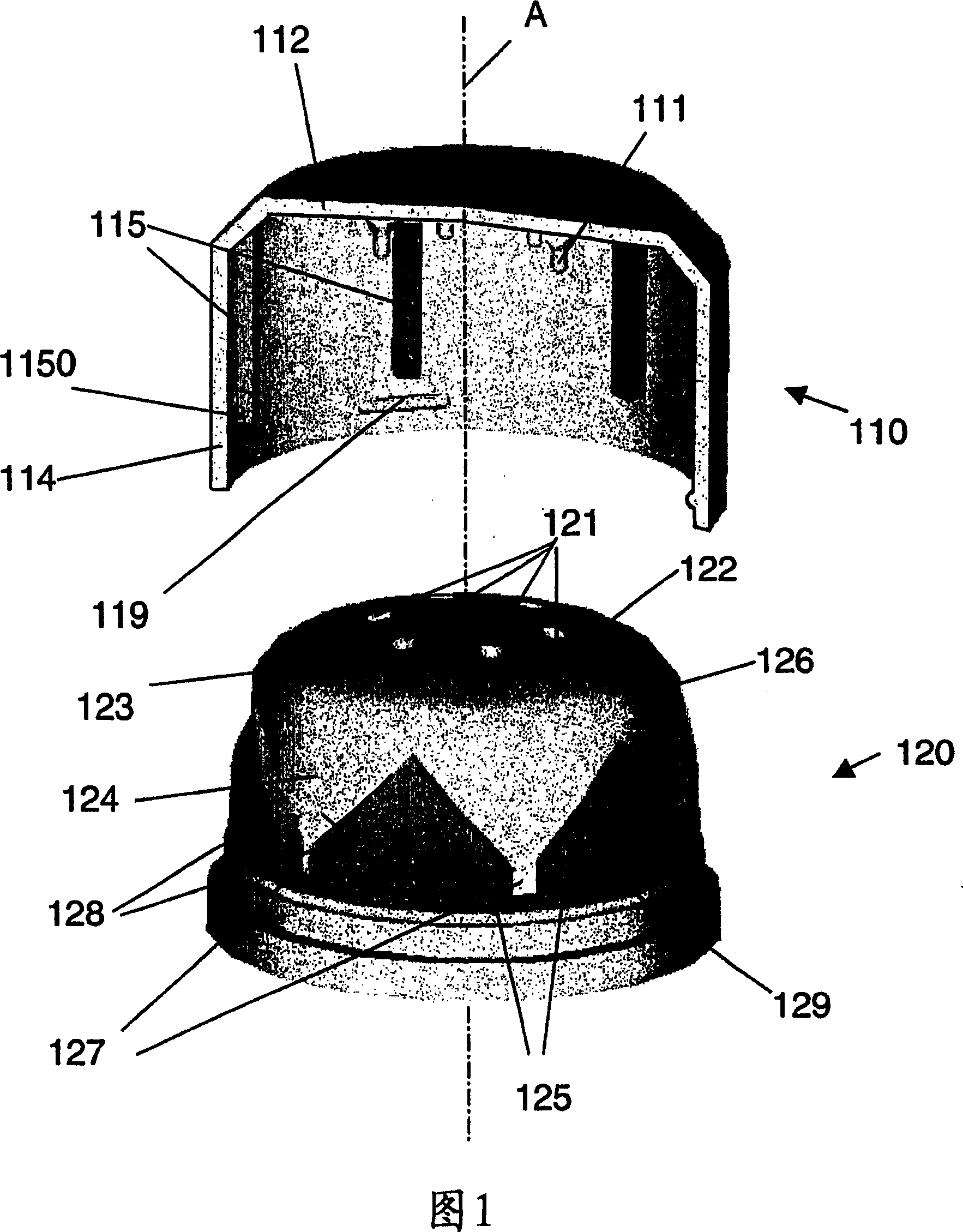

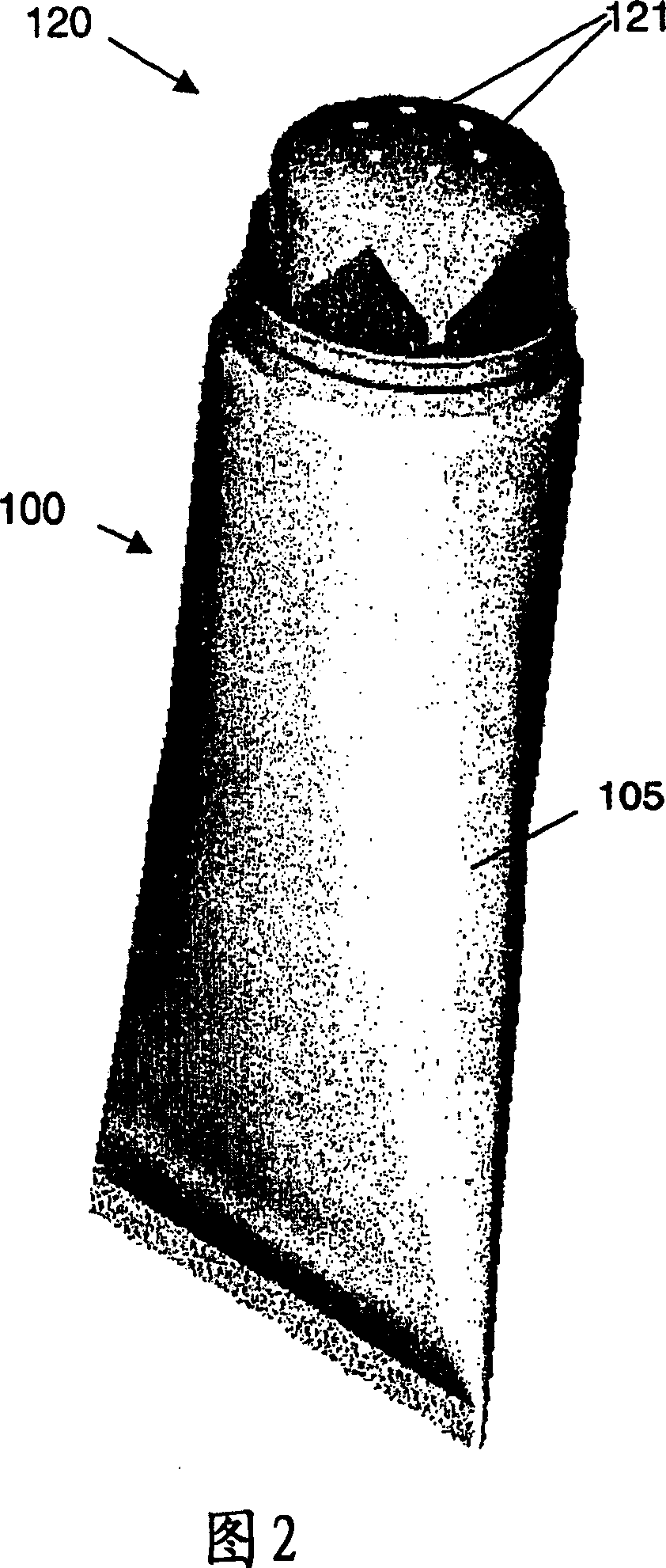

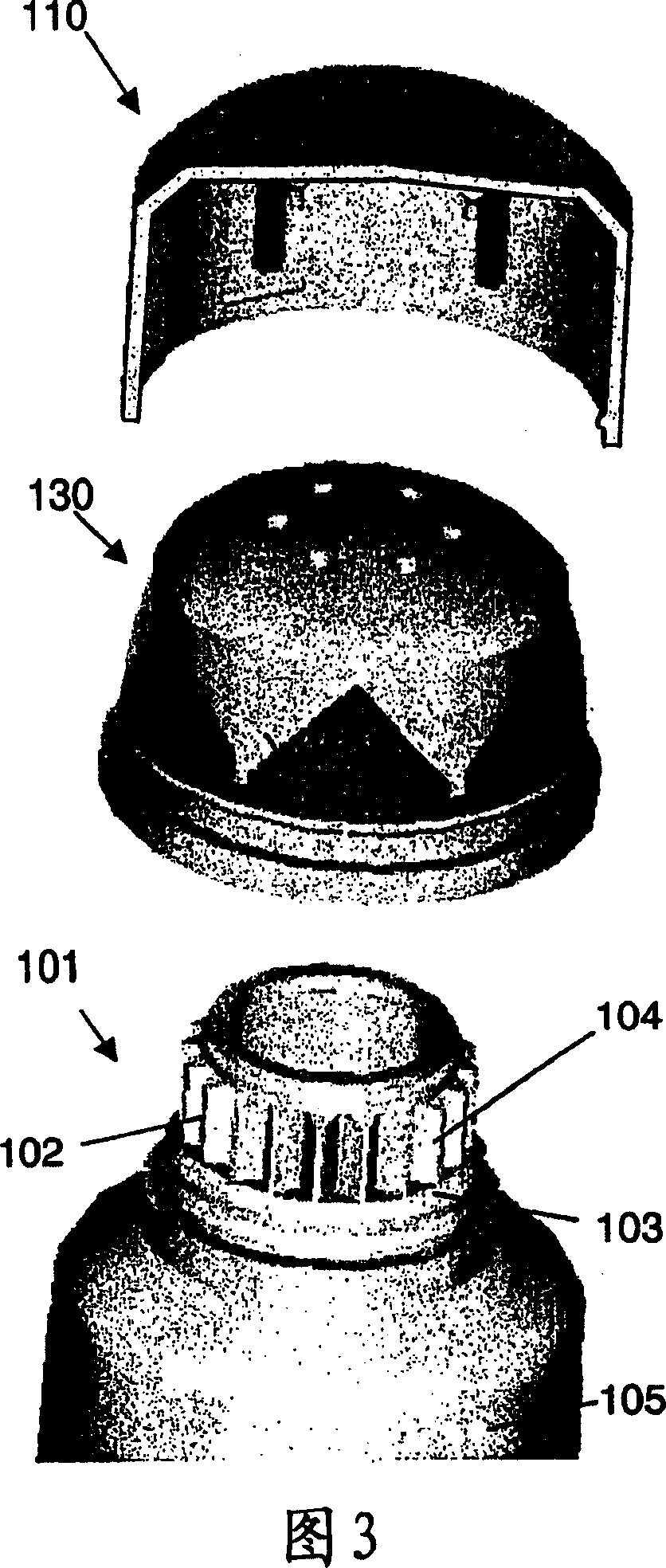

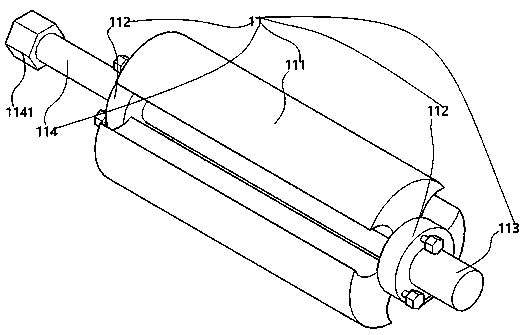

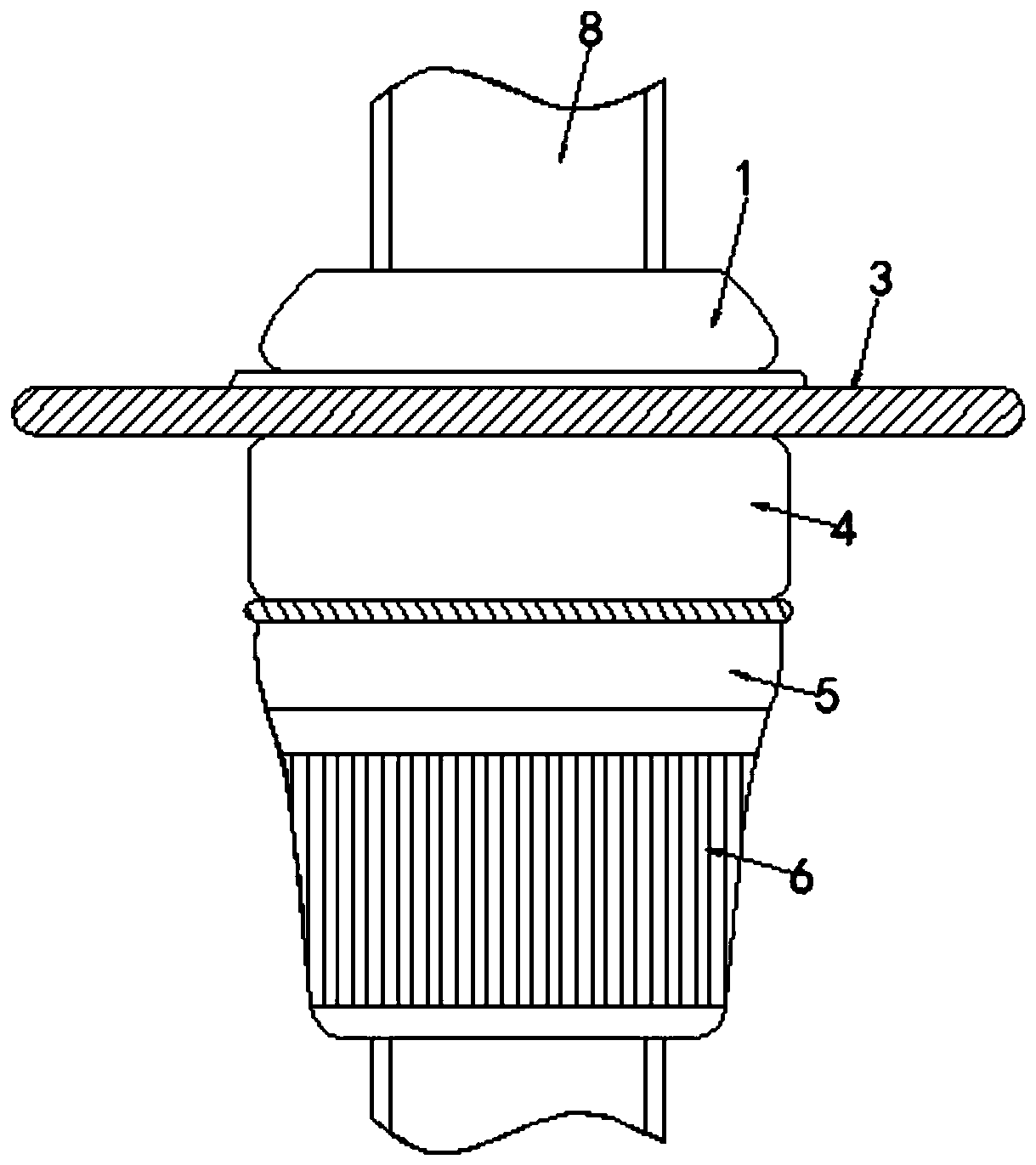

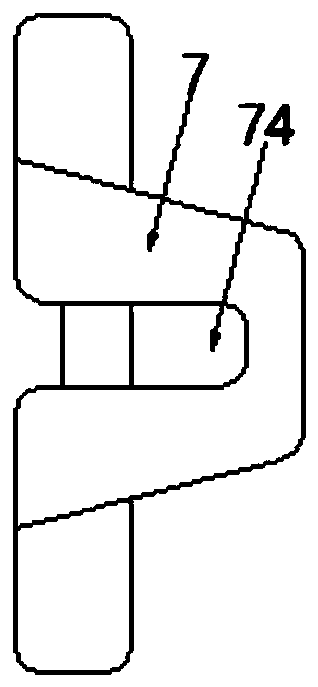

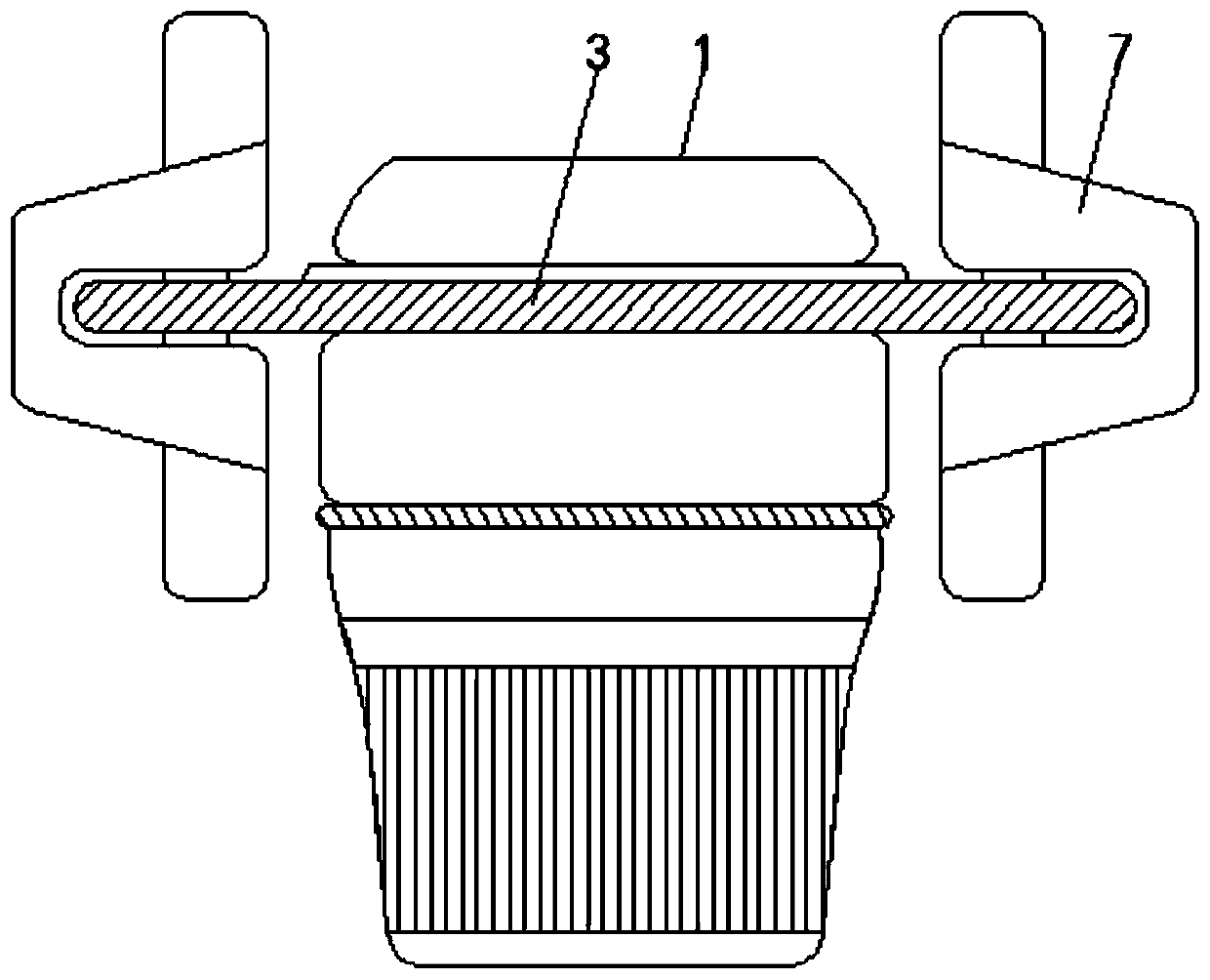

Dispenser for creamy products, comprising an axially sunk cap

InactiveCN1921784AConvenient socketPrevent further axial riseCapsClosure capsBiomedical engineeringAxial projection

The invention relates to a dispenser / applicator (100) comprising a recipient consisting of a body (105) and a distribution head (120) which is provided with at least one opening (121) and a cap (110) for blocking said distribution head by being axially sunk thereinto. According to the invention, a) the arrangement of the openings (121) is not revolutionally symmetrical to any other axis A parallel to the sinking direction, b) the cap comprises a bottom (112) provided with a single axial projection or a plurality of n axial projections (111) having a cross-section which is adapted to that of the openings in order to block the same, and c) said cap is provided with a first orientation means (115; 215 and 217) and said head is provided with a second orientation means (125 and 127; 225), the first and second orientation means co-operating during the axial sinking process in such a way as to orient by rotation and then axially displace the cap towards the head such that the axial projections extend up to the hole of said openings and block the same. In another embodiment of the inventive dispenser / applicator, the arrangement of the openings has an n order symmetry in relation to the axis A.

Owner:ALCAN PACKAGING BEAUTY SERVICES

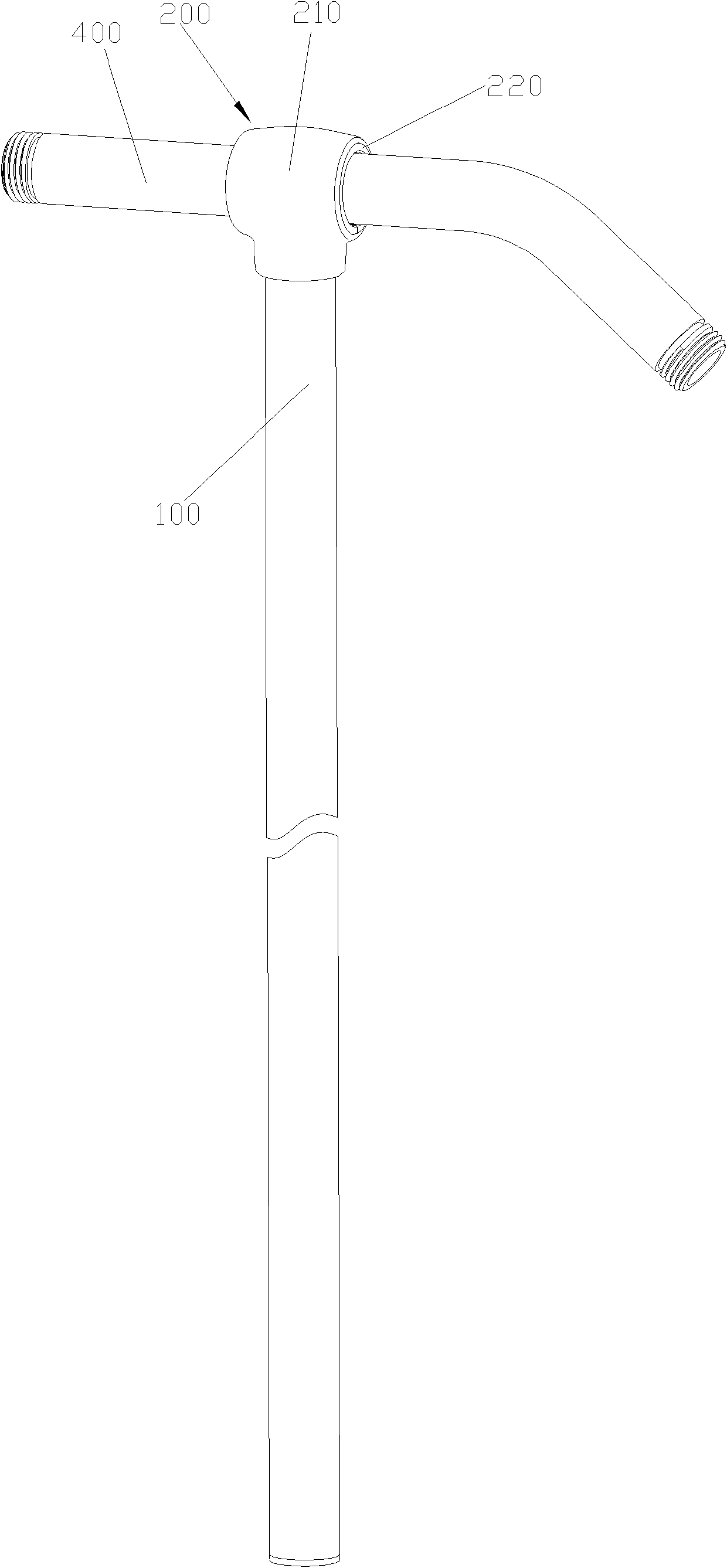

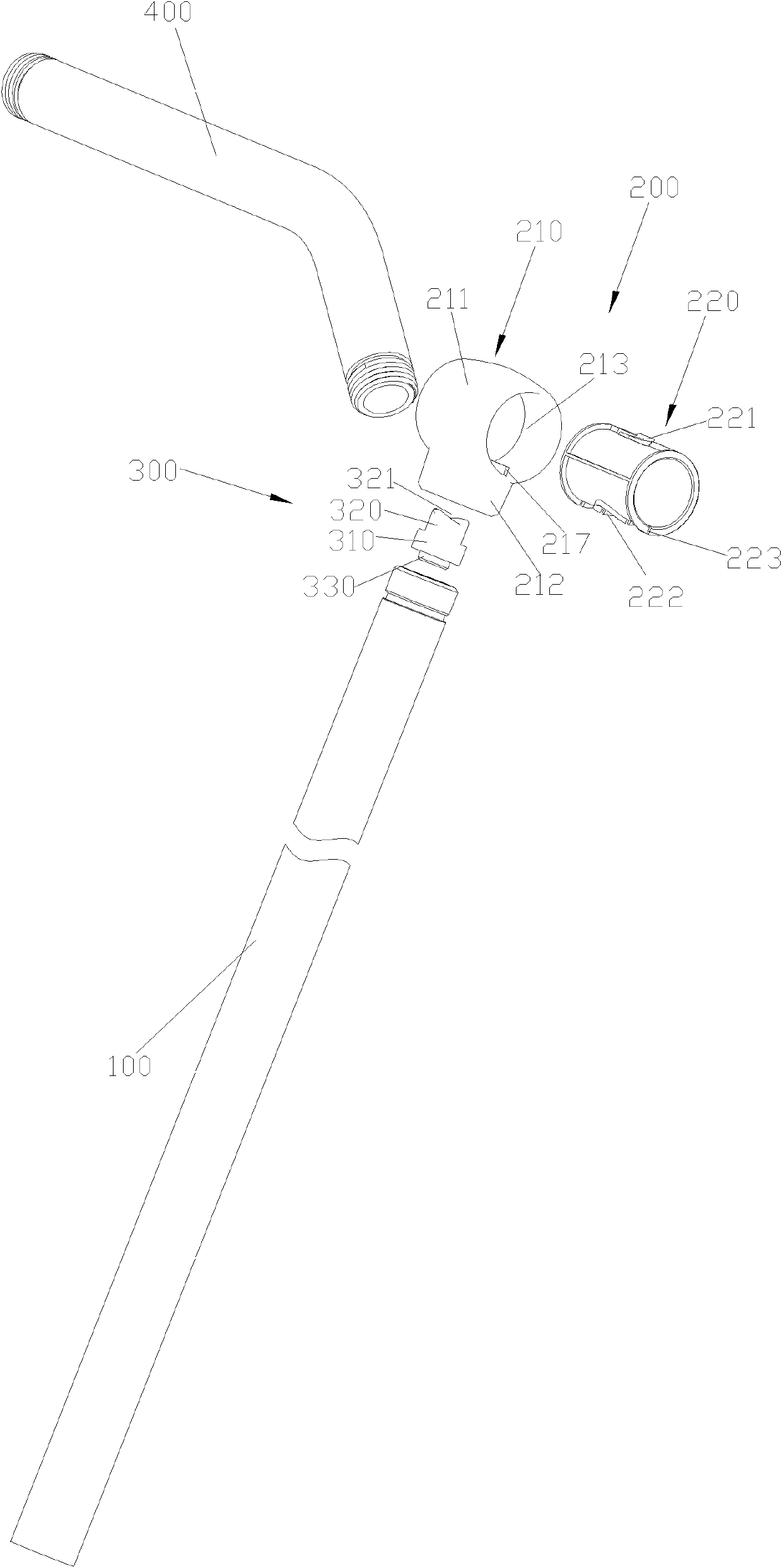

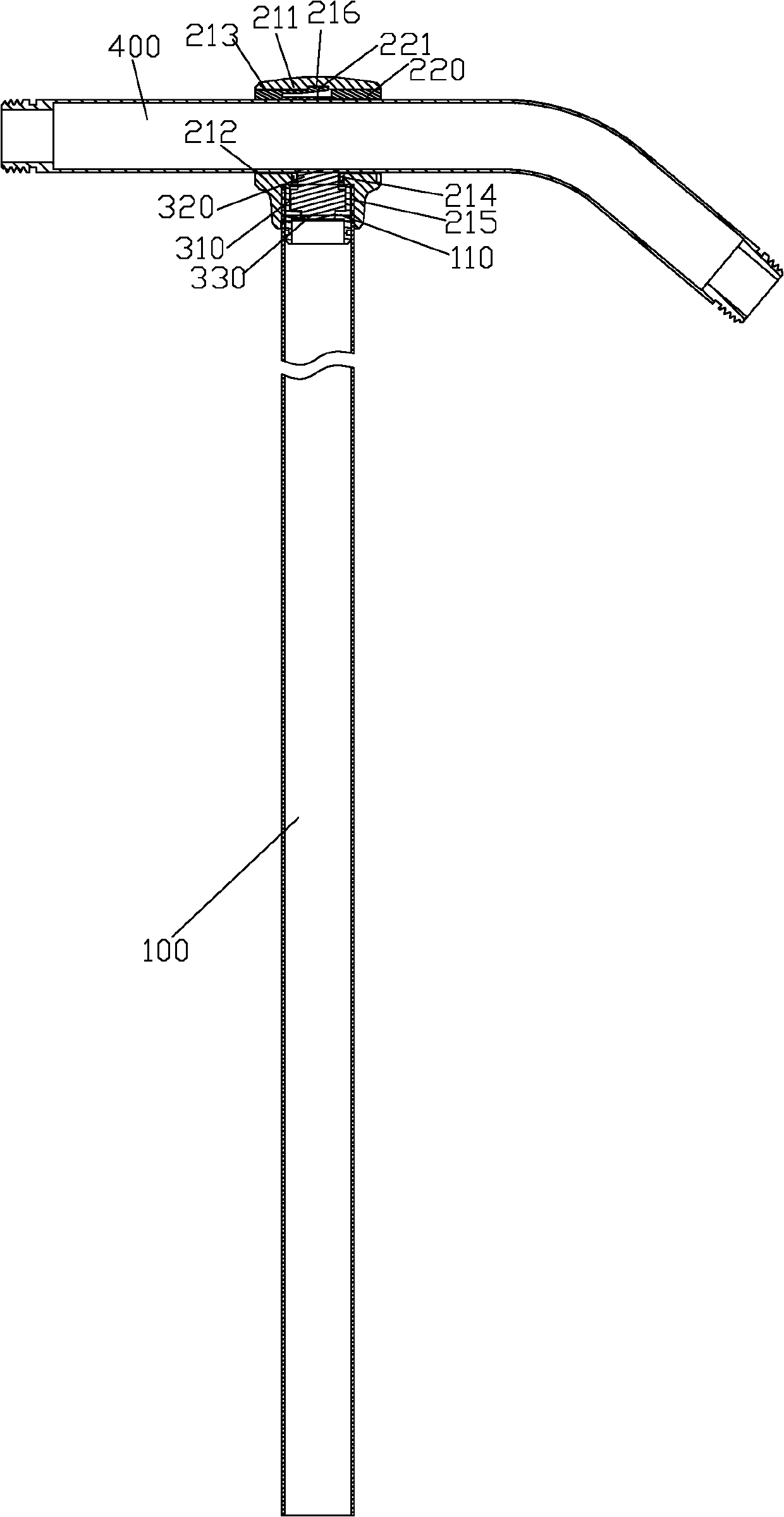

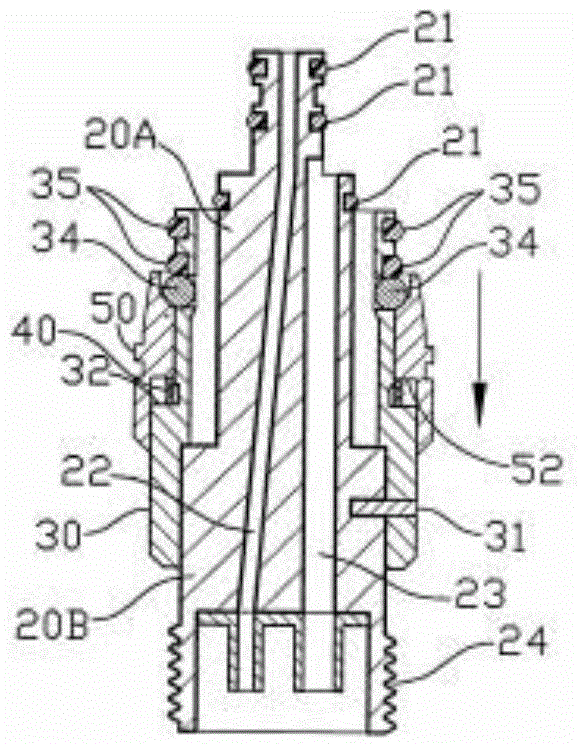

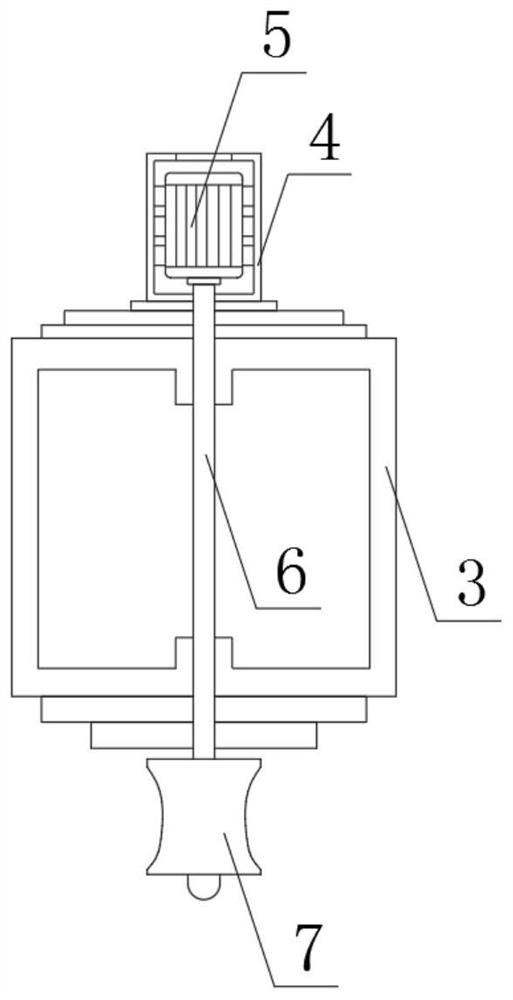

Lifting rod component

InactiveCN102003442AControl the degree of compressionControl lockSpraying apparatusDomestic plumbingEngineering

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

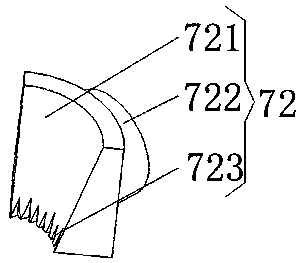

Novel grinding device for inner protrusion of steel pipeline

ActiveCN111055175AEasy to installAchieve grindingRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention discloses a novel grinding device for inner protrusion of a steel pipeline. The device comprises a protrusion grinding assembly, the protrusion grinding assembly comprises a plurality offan-shaped grinding rods distributed annularly, the left ends and the right ends of the multiple fan-shaped grinding rods are fixedly connected to mounting disc bodies, a shaft rod is fixedly arranged between the mounting disc bodies in a connection mode, the left end of the shaft rod penetrates through the mounting disc bodies, and the left end of the shaft rod is rotationally connected to a left end frame; the left end frame is detachably mounted on the shaft rod; the protrusion grinding assembly further comprises a driving motor; the driving motor is fixedly connected to a right end frame;the device further comprises a supporting assembly, and the supporting assembly is located under the fan-shaped grinding rod; and the supporting assembly comprises a corrugated supporting plate, thecorrugated supporting plate is provided with an arc-shaped recess, and supporting frames are fixedly connected to the front end and the rear end of the corrugated supporting plate. By means of the parts of the device, the inner side walls of steel pipes of different specifications and sizes are automatically ground, and the technical defects that the grinding efficiency is low and operation is unsafe when workers enter large steel pipes are overcome.

Owner:青岛豪德博尔实业有限公司

Protective training device for muscle training in sports classroom

The invention discloses a protective training device for muscle training in a sports classroom, one end of a support frame is provided with an adjusting mechanism, and the adjusting mechanism comprises a sliding groove, a guide rod, a connecting block, a connecting belt, a mounting block, a rotating rod, a guide hole, an auxiliary rotating shaft, a support block, a clamping groove, a clamping plate, an extension spring, an embedded plate, an embedded groove, a support rod and a bearing frame; according to the structure, the adjusting mechanism is arranged, the connecting block is conveniently driven to move through the connecting belt, the extension spring is conveniently installed through the cooperation of the clamping groove and the clamping plate, when an exerciser is a beginner, the exerciser is assisted to do pull-up through the action of the extension spring, muscle strain caused by forced upward stretching is avoided, in addition, through the cooperation of the clamping groove and the support rod, the bearing frame can be conveniently installed, and therefore by placing a heavy object in the bearing frame, the exerciser can add the proper weight according to the situation of the exerciser, and the exercise effect is improved.

Owner:JILIN INST OF PHYSICAL EDUCATION

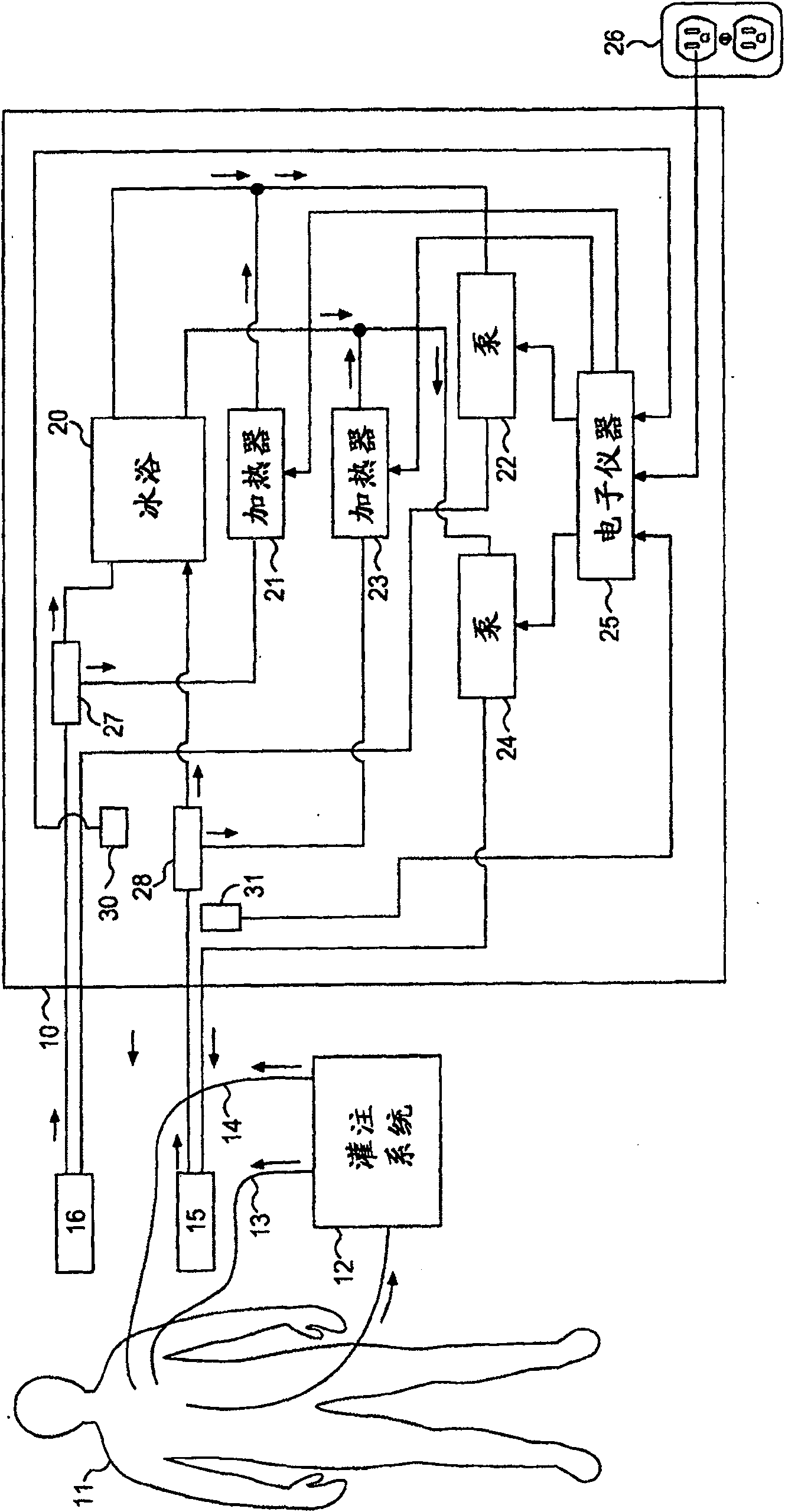

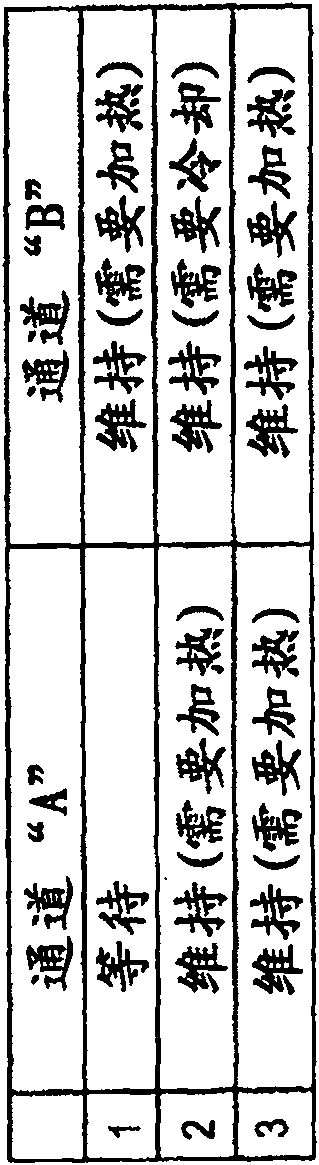

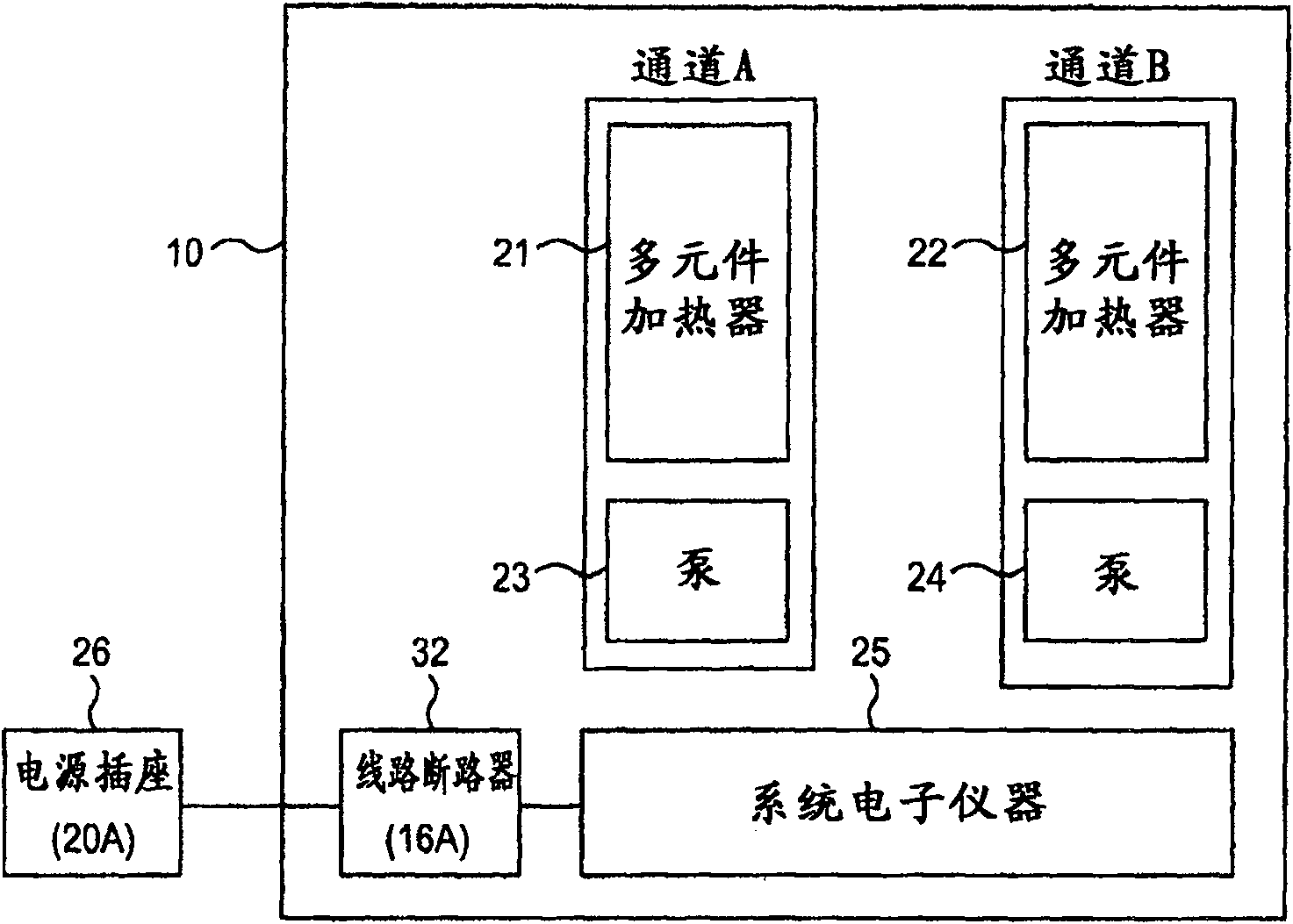

Dual heating device and method

InactiveCN100558416CTemperature controlConvenient socketOther blood circulation devicesMedical devicesEngineeringPower limits

A dual channel fluid temperature control device that controls the temperature of cardiac fluid during surgery by using power from a convenient electrical outlet with a power limit. The first pump receives the first heat exchange fluid for selectively pumping the first heat exchange fluid within the first circulation channel. The second pump receives the second heat exchange fluid for selectively pumping the second heat exchange fluid within the second circulation channel. The first heater unit includes a first plurality of independently activatable heating elements, each of which has its own power consumption. The second heater unit includes a second plurality of independently activatable heating elements, each of which has its own power consumption. The controller selectively activates the first and second pumps and the first and second plurality of heating elements to selectively heat or cool the first and second heat exchange fluids such that power to all activated pumps and heating elements is drawn Stay within power limits.

Owner:TERUMO CARDIOVASCULAR SYST CORP

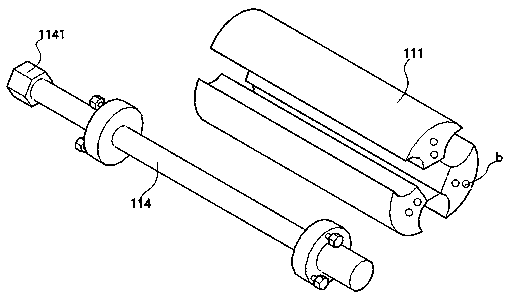

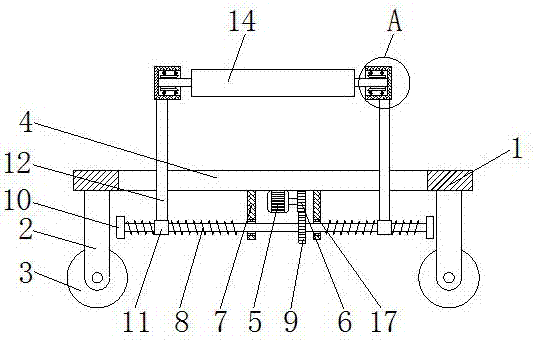

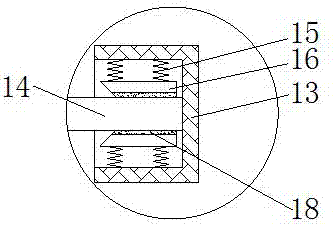

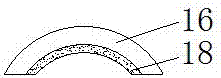

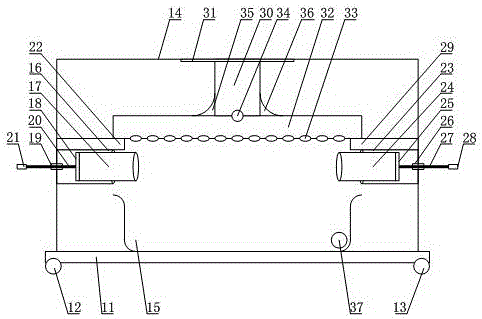

Reeling frame capable of storing cloth rolls of different lengths

InactiveCN107499984AConvenient socketEasy to disassembleWebs handlingArchitectural engineeringIdler-wheel

The invention discloses a material rack capable of placing cloth rolls of different lengths, which comprises a bottom plate, brackets are fixedly connected to both sides of the bottom of the bottom plate, rollers are movably connected to the bottom of the bracket through a rotating shaft, and the surface of the bottom plate is provided with There is a long hole, the bottom of the base plate is fixedly connected with a motor, the shaft of the motor is provided with a first gear, the bottom of the base plate and both sides of the motor are fixedly connected with vertical plates, between the two vertical plates And a threaded rod is arranged below the motor, both ends of the threaded rod pass through the riser and extend to the outside of the riser, the surface of the threaded rod and a second gear is sleeved between the two risers. The invention can make the threaded sleeve move laterally, and the threaded sleeve drives the vertical bar and the casing to move laterally, so that the disassembly and replacement of the cloth roll can be facilitated, and at the same time, the cloth roll with different lengths can be clamped, which improves the applicability of the coil rack and makes it more convenient. It is convenient for users to use.

Owner:SUZHOU FABAI TEXTILE CO LTD

Plastic spraying and film covering device for lamp post of street lamp

InactiveCN105921322AConvenient socketEasy laminationSpraying apparatusEngineeringMechanical engineering

The invention discloses a plastic spraying and film covering device for a lamp post of a street lamp. The plastic spraying and film covering device comprises a bottom plate, wherein a film covering rack is arranged on the bottom plate; a recycling tank is arranged at the inner bottom of the film covering rack; the film covering rack is provided with a fixed pipe; a regulating pipe is arranged in the fixed pipe in a sleeving manner; a guide pipe is arranged between the fixed pipe and the film covering rack; a regulating post is arranged in the guide pipe in a sleeving manner; the guide pipe is in threaded connection with the regulating post; the outer end of the regulating post is a free end, and the inner end of the regulating post is connected to the regulating pipe; a liquid spraying machine is arranged on the inner top of the film covering rack; a liquid spraying shell is arranged at the lower part of the liquid spraying machine; a plurality of liquid spraying holes are arranged in the lower part of the liquid spraying shell; a control pump is arranged between the lower end of the liquid spraying machine and the liquid spraying shell; and the liquid spraying shell is arranged above the recycling tank. The plastic spraying and film covering device has the beneficial effects that the liquid spraying shell can be conveniently supported through a fixed plate; and the liquid spraying machine can spray pasty polyvinyl chloride resin liquid onto the outer surface of the lamp post of the street lamp through the liquid spraying holes in the liquid spraying shell, thereby facilitating the film covering treatment on the surface of the lamp post of the street lamp.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

Scaffold inclination early-warning device based on dielectric constant change principle

The invention discloses a scaffold inclination early-warning device based on a dielectric constant change principle, and relates to the technical field of engineering early-warning equipment. The scaffold inclination early-warning device comprises an upper positioning ring, a through hole is formed in the middle of the upper positioning ring, a flange mechanism is movably connected to the bottom of the upper positioning ring, and a shell is movably connected to the bottom of the flange mechanism, a lower positioning ring is movably connected to the bottom of the shell, an anti-skid sleeve is movably connected to the outer side of the lower positioning ring, and four hinge mechanisms are movably connected to the outer side of the flange mechanism. According to the scaffold inclination early-warning device based on the dielectric constant change principle, whether a scaffold steel pipe inclines or not is detected through the variable quantity of the dielectric constant, an early warningsignal is sent out in time when the scaffold steel pipe inclines, and on-site constructors can be reminded to evacuate in time at the early stage of an accident; the problem that the optimal escape time is missed due to the fact that the scaffold cannot be reminded in time in the initial stage of deviation is avoided, and the safety coefficient of the working environment of constructors is increased.

Owner:梁志权

Semi-automatic filling equipment for lotus roots filled with glutinous rice

The invention provides semi-automatic filling equipment for lotus roots filled with glutinous rice and relates to the food processing field. The semi-automatic filling equipment for lotus roots filledwith glutinous rice comprises a filling bin, support legs are fixedly connected with the bottom of the filling bin, the back of the filling bin is fixedly connected with a support pillar, a fixing plate is connected with one end, away from the filling bin, of the support pillar, a feeding device is arranged above the fixing plate, and a conveying device is connected onto the feeding device. According to the semi-automatic filling equipment for lotus roots filled with glutinous rice, a discharging motor is arranged on the feeding device, the discharging motor rotates to drive a stirring blockto rotate, a bounce spring is arranged on a discharging plate, the stirring block rotates to stir a stirring rod and the discharging plate to circularly move left and right, rice grains can be smoothly leaked from leaking holes of the discharging plate through circular bilateral movement and uniformly discharged from the discharging plate, filling of lotus root sections is facilitated, and the condition that a lot of rice grains are stacked at a loop ring is prevented.

Owner:江西艾斯欧匹精密智造科技有限公司

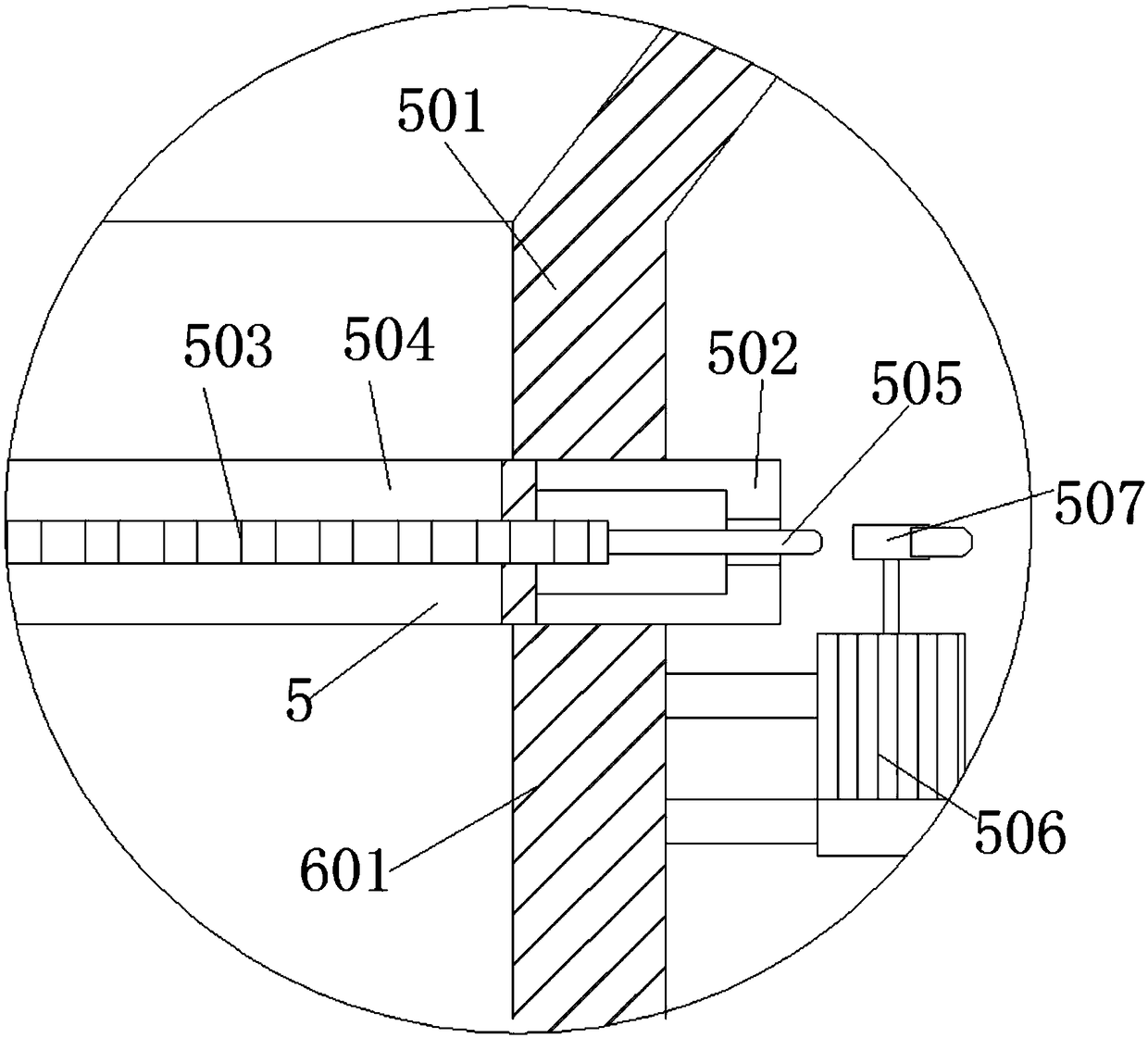

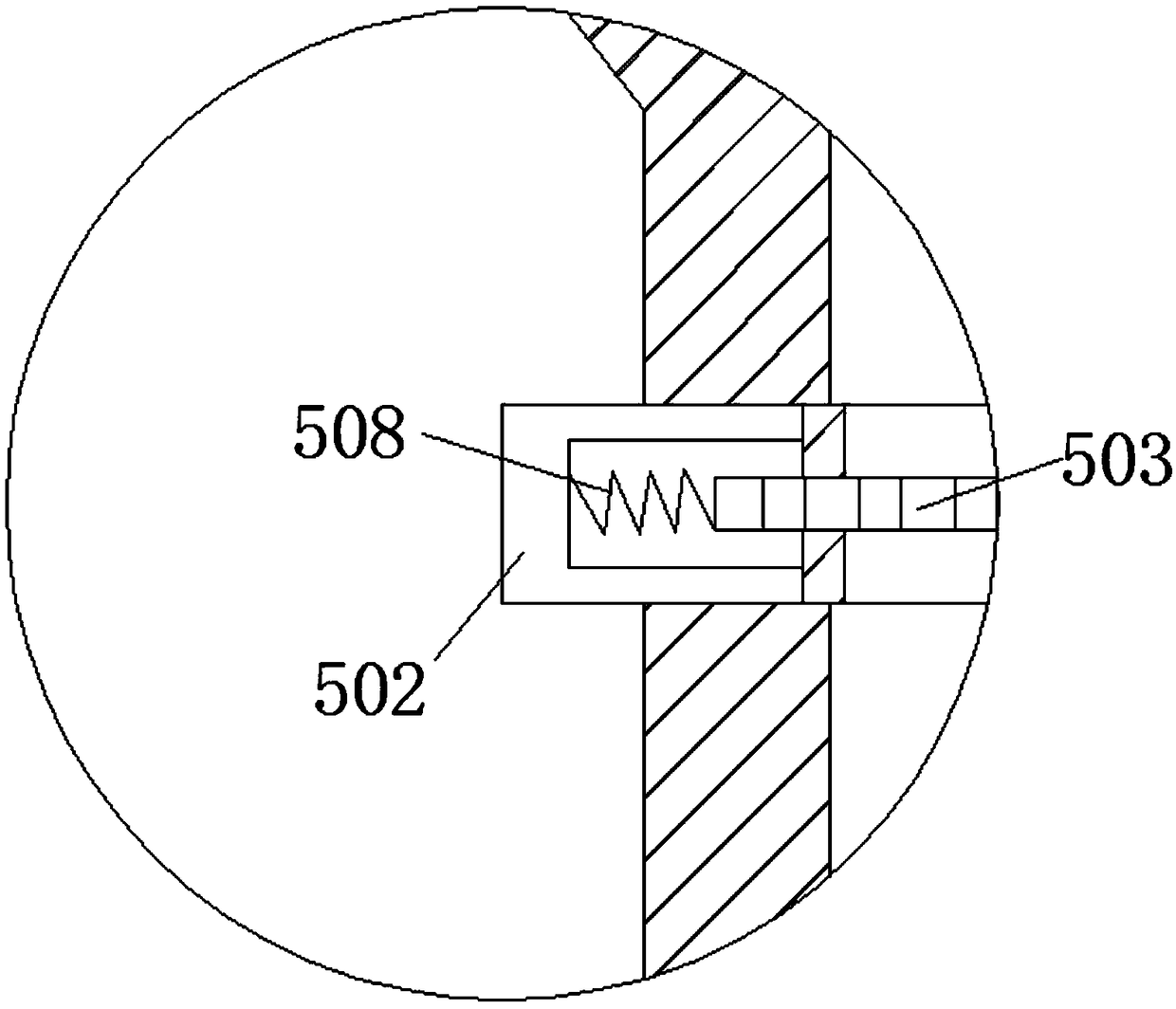

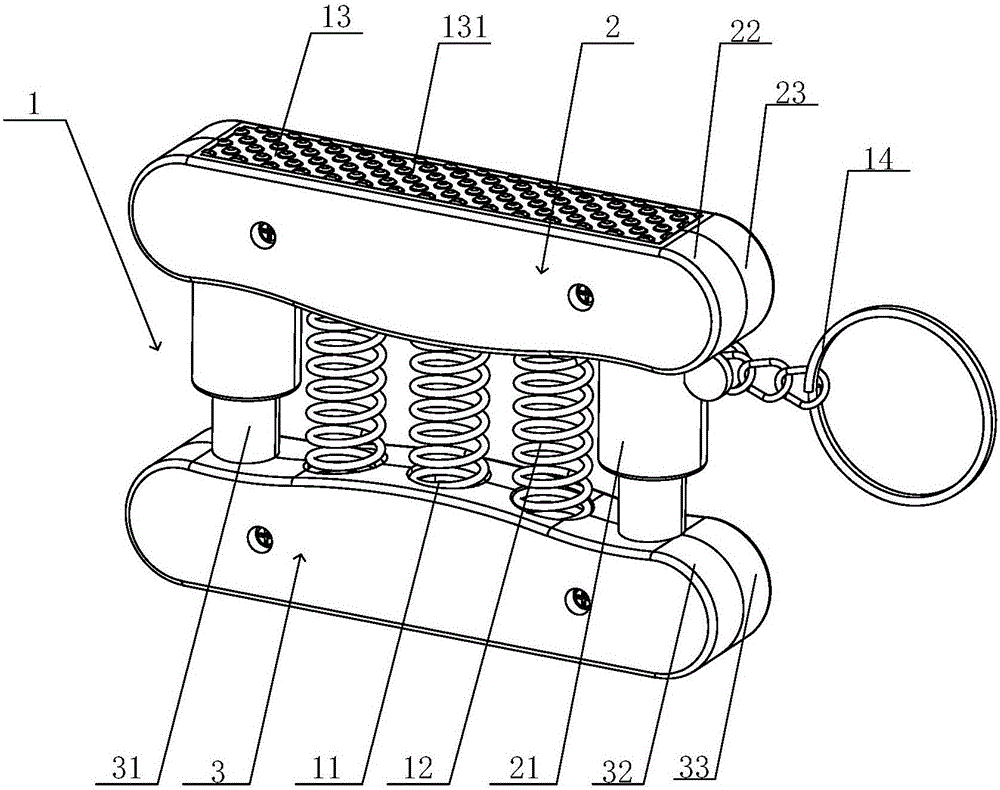

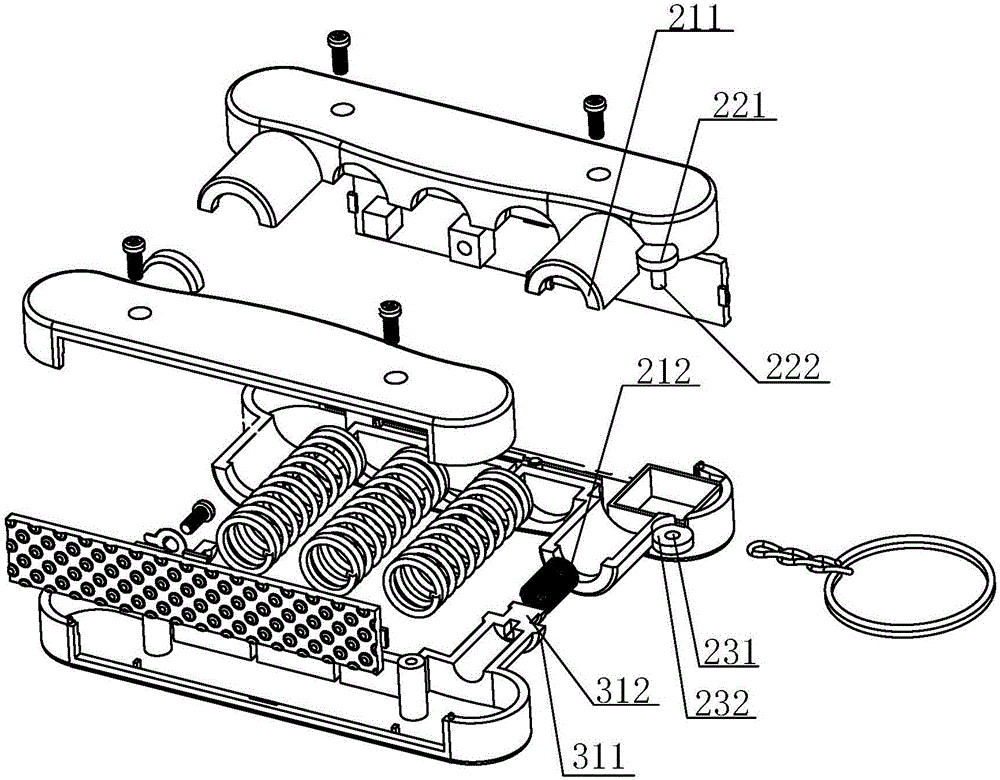

Hand grip

ActiveCN105999615AEffective protectionConvenient socketMuscle exercising devicesEngineeringGrip strength

The invention discloses a hand grip which comprises a shell. The shell comprises a first gripping part and a second gripping part which can move relatively, first sleeves are arranged on the first gripping part, second sleeves are arranged on the second gripping part, the second sleeves are arranged in the first sleeves, each first sleeve is internally provided with a first elastic part, and replacement of the first elastic parts is convenient through matching of the first sleeves and the second sleeves. Grip strength needed by the hand grip can be changed by replacing the first elastic parts with different elastic forces and increasing the number of the first elastic parts, the hand grip has a better application range, the hand grip can adapt to different users for use, and therefore the muscles can be better exercised.

Owner:深圳市汲众科技开发有限公司

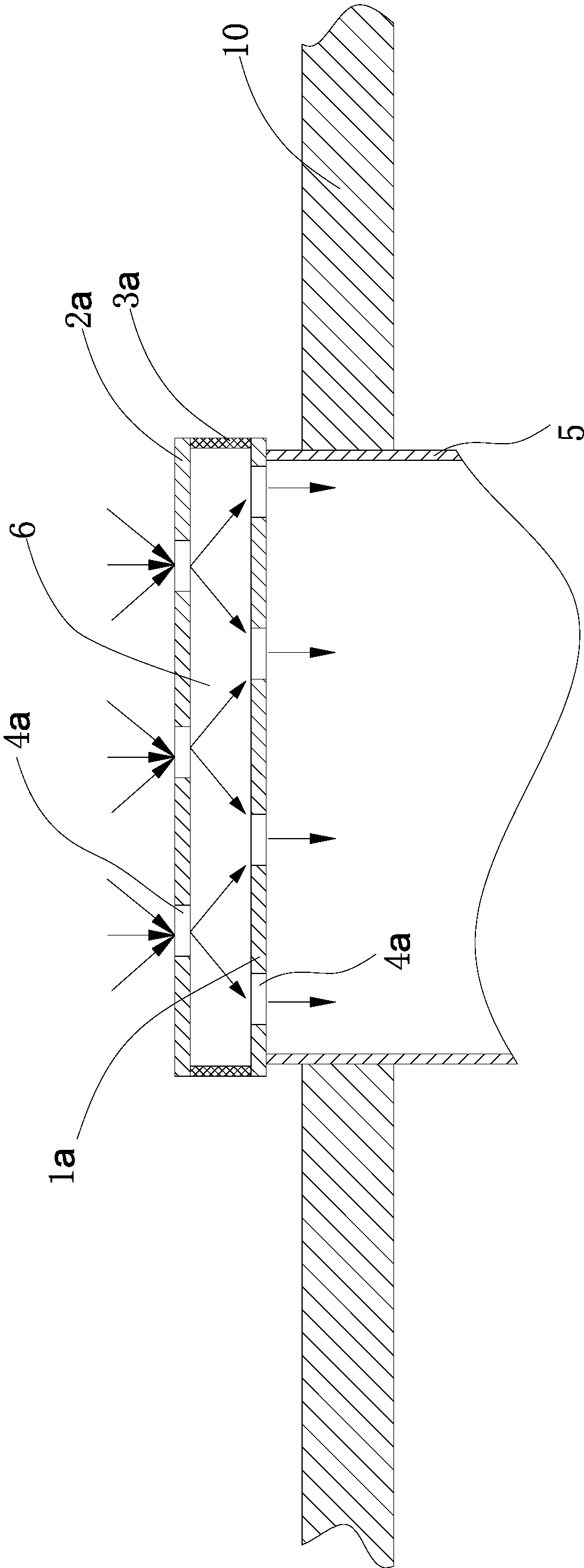

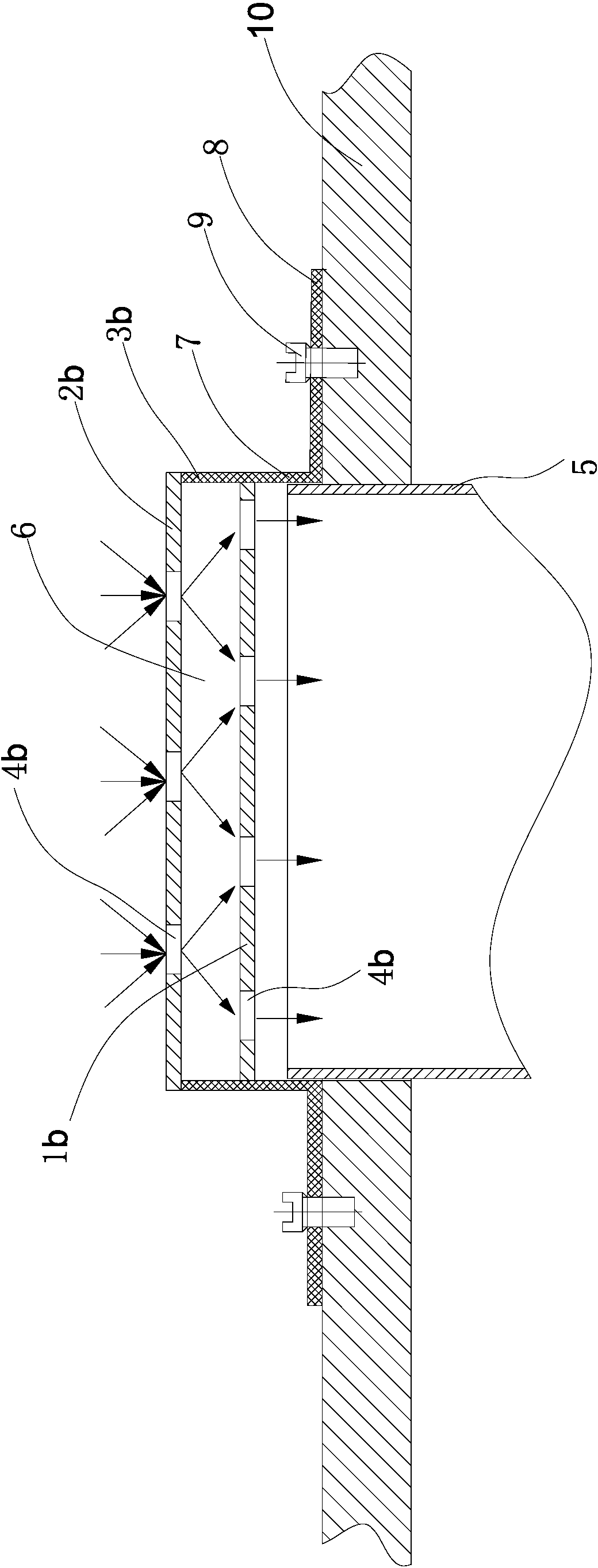

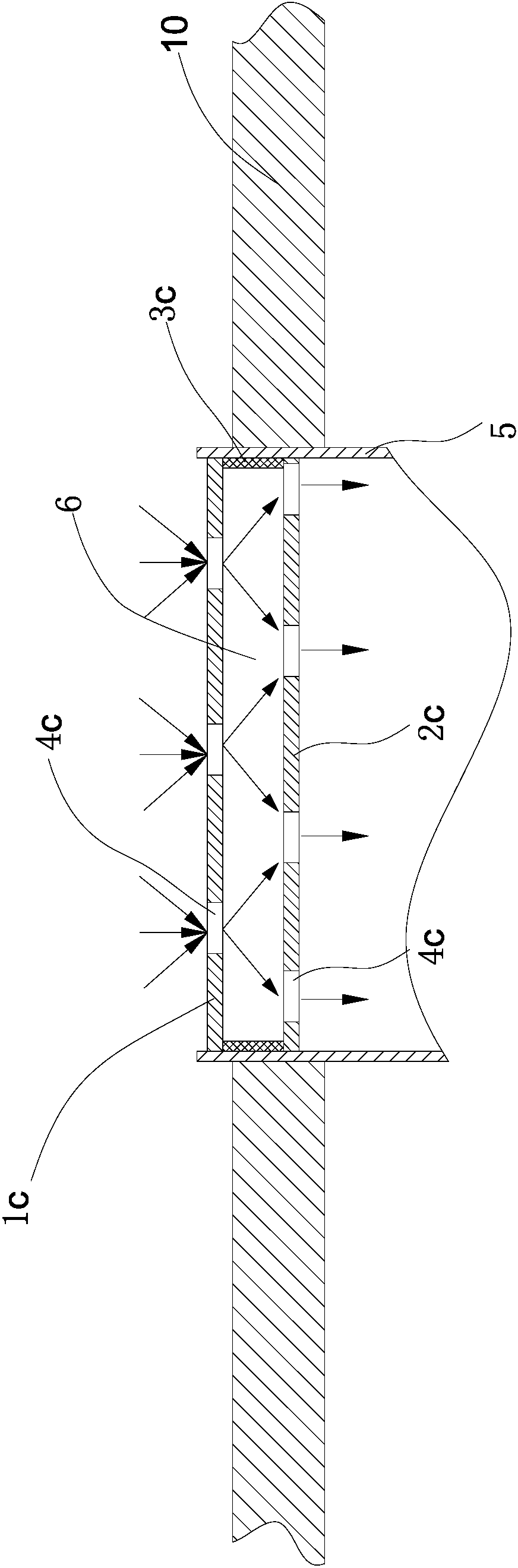

Buffering and filtering device for air exhaust port of vacuum pump

InactiveCN103062062AReduce forcePrevent flying intoRotary/oscillating piston pump componentsLiquid fuel engine componentsForeign matterEngineering

The invention relate to a buffering and filtering device for an air exhaust port of a vacuum pump. The device comprises a closed cavity which is formed by a first baffle, a second baffle and side walls, wherein the side walls are fixedly connected with the edges of the first and second baffles; the air exhaust port of the vacuum pump is completely occluded by the first baffle; air exhaust holes for communicating the cavity with the outside are respectively formed in the first baffle and the second baffle; and the air exhaust holes of the first baffle and the second baffle are staggered in the axial direction of the air exhaust port. The device disclosed by the invention has the advantages that the flow of sucked air can be reduced during the operation of the vacuum pump, so that the force of air motion on objects in a vacuum chamber can be reduced, and the damage of dust and foreign matters to rotary vanes of the vacuum pump is alleviated.

Owner:ANHUI BENGBU HUAYI CONDUCTIVE FILM GLASS

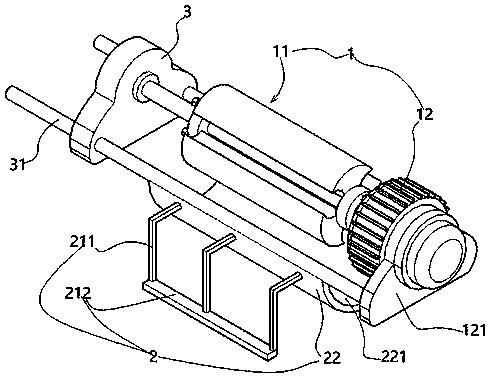

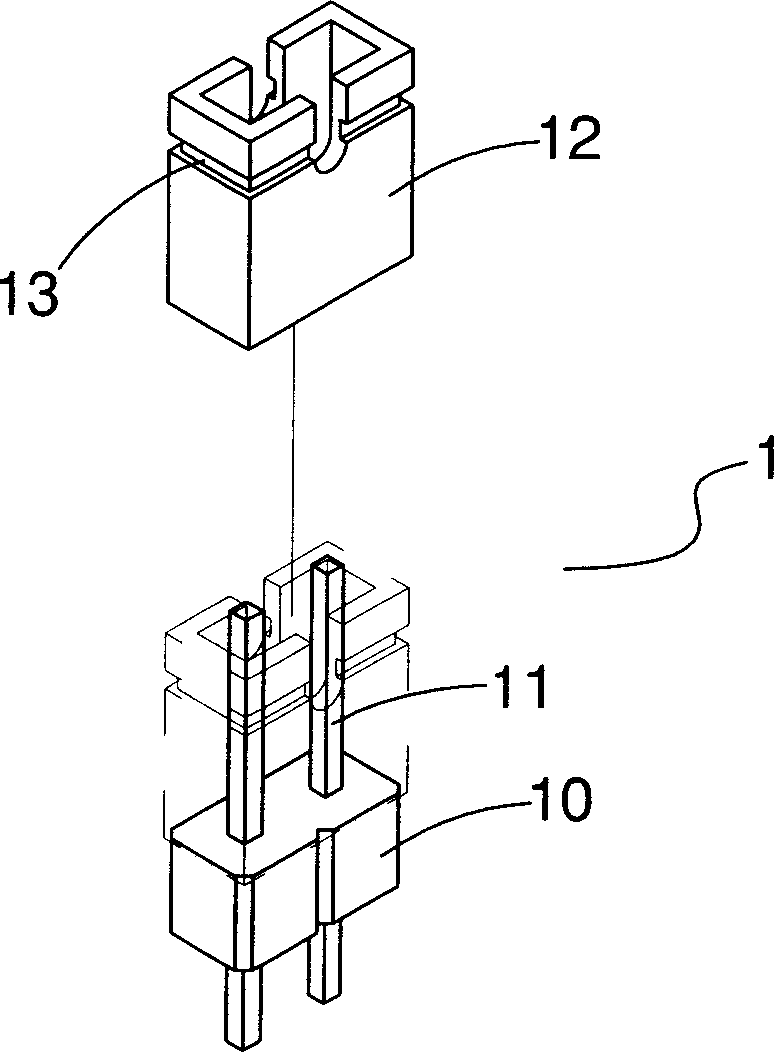

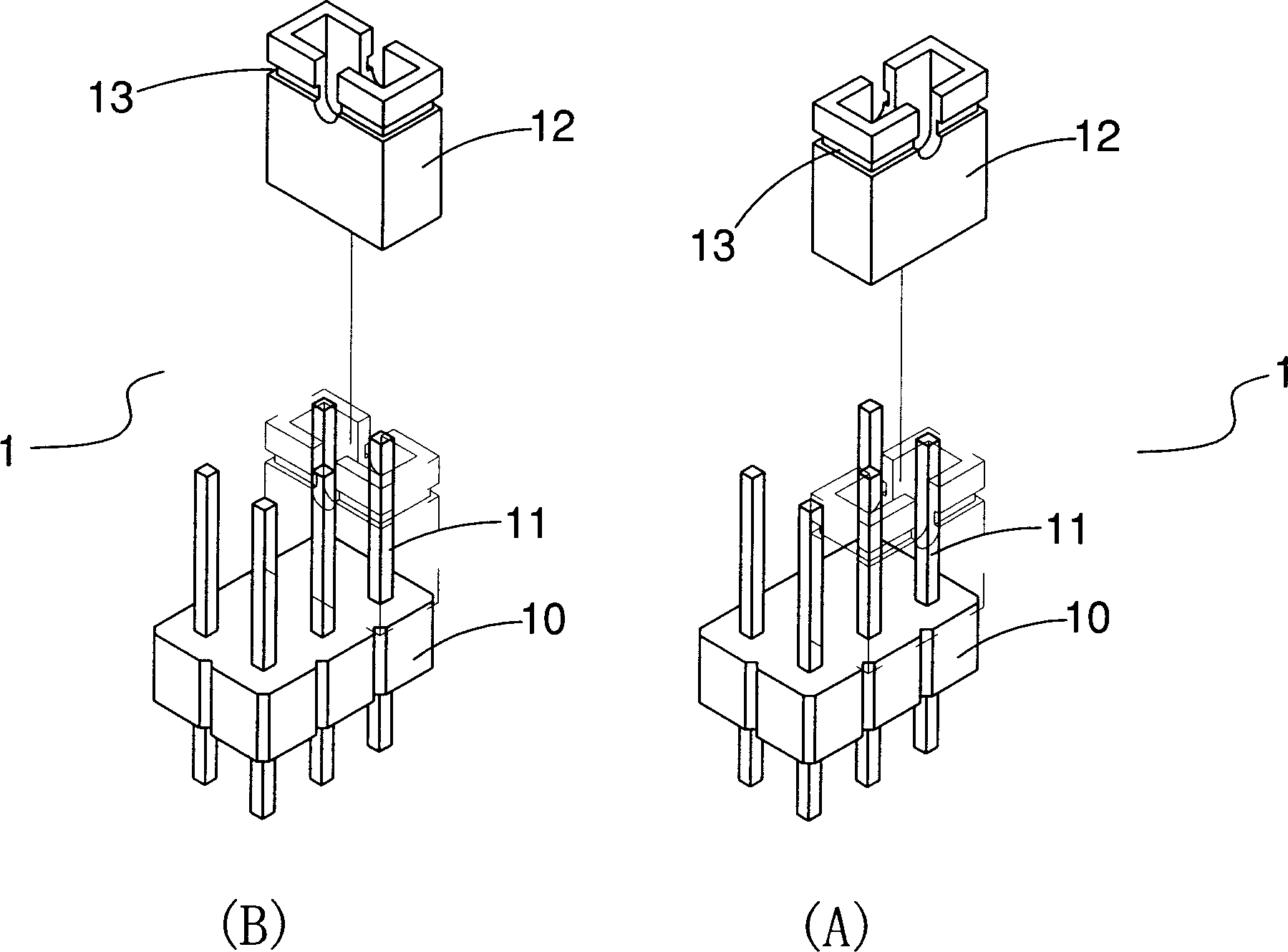

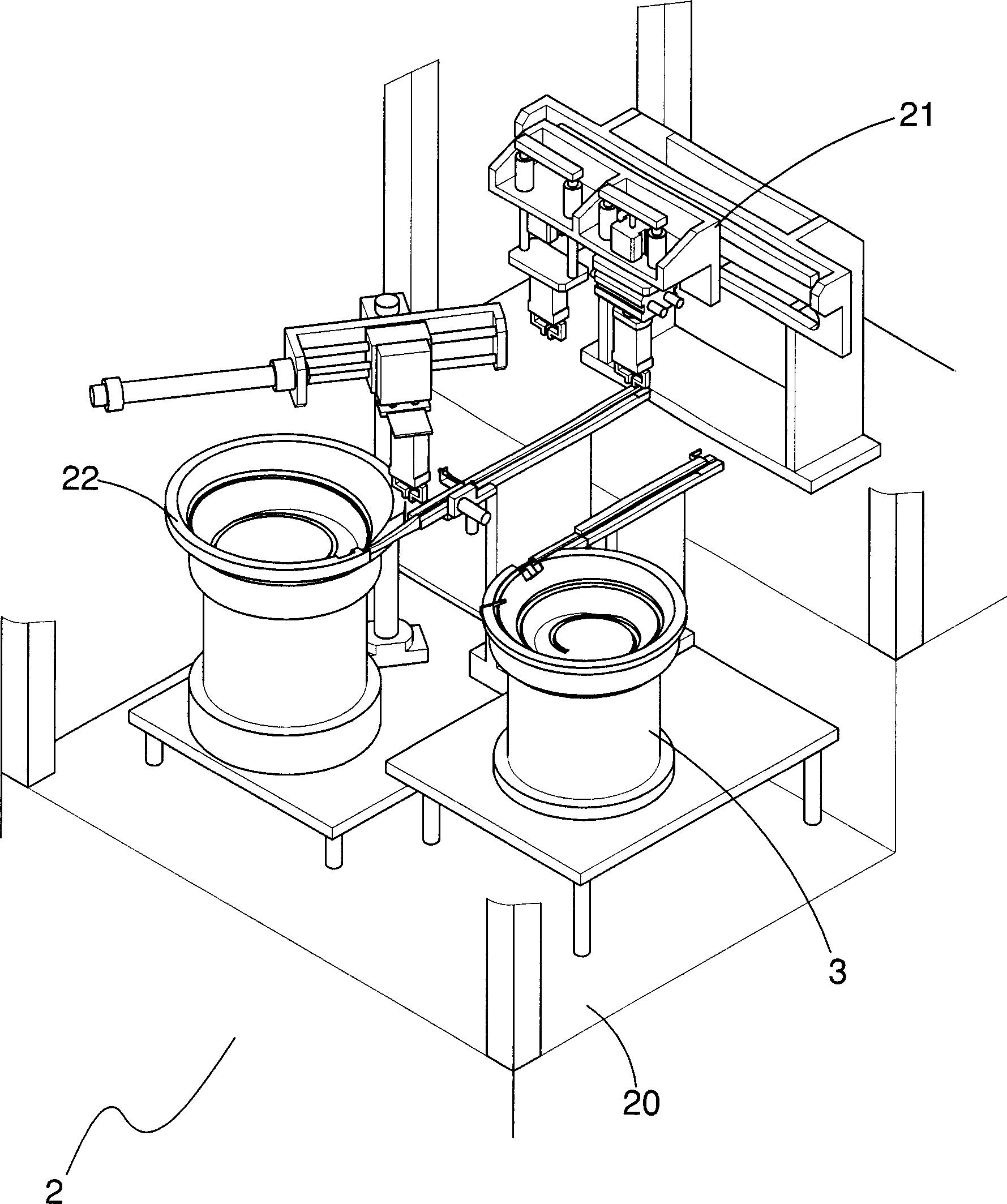

Jumper feeding device

InactiveCN1802085AConvenient socketSave human resourcesElectrical componentsEngineeringMechanical engineering

Present invention discloses a jumper cap feeder for turning jumper cap to right assembling direction. It contains feed disk including batch bin for holding jumper cap to form cone surface wall with an outlet, a spiral guided groove, feed disk making jumper cap being delivered to said outlet along spiral guided groove, a screen portion connected with outlet of spiral groove, including a incline extended to said batch bin, a leading rib on incline surface for leading jumper cap having right assembling direction to opposite side, and a guideway connected with feed disk, including a leading-in end, a leading-out end and a guided groove from leading-in end to leading-out end, leading-in end connected with screen portion. Said jumper cap feeder can save a lot of time and manpower with high work efficiency.

Owner:GIGA BYTE TECH CO LTD

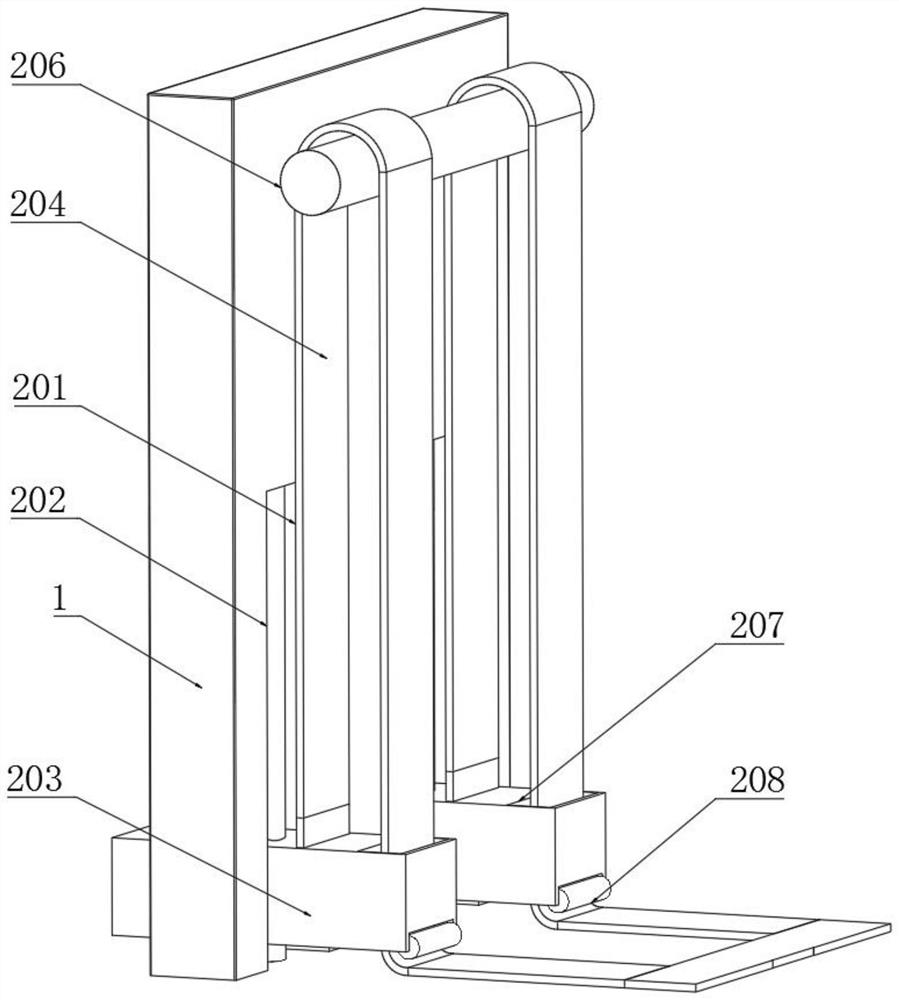

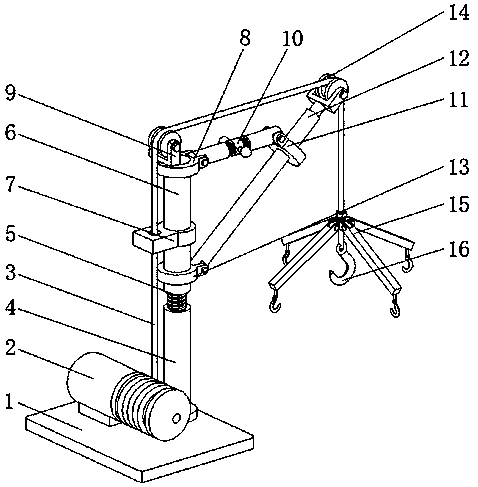

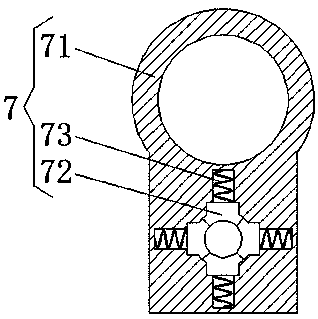

Lifting device for indoor decoration

The invention relates to the technical field of decoration equipment, and discloses a lifting device for indoor decoration. The lifting device comprises a mounting bottom plate and a lifting motor fixedly mounted at the top of the mounting bottom plate; a pull rope is wound on an output shaft of the lifting motor; a fixed bottom column positioned on one side of the lifting motor is fixedly mountedat the top of the mounting bottom plate; a stud is fixedly mounted at the top of the fixed bottom column; the exterior of stud is in threaded connection with an adjusting column; and the adjusting column is fixedly sleeved with a self-locking device. According to the lifting device for the indoor decoration, through mutual cooperation of a fixing plate, a clamping block device and springs, the lifting device is not affected when goods are stably lifted, and once the pull rope at the lifting motor is disengaged or disconnected, the springs generate a push force on the clamping block device andlimiting thorns lock the pull rope to prevent the pull rope from continuing to slide, so that the goods are prevented from falling rapidly, and the personal safety of operators and properties are protected from being lost.

Owner:杭州富阳飞尚装饰工程有限公司

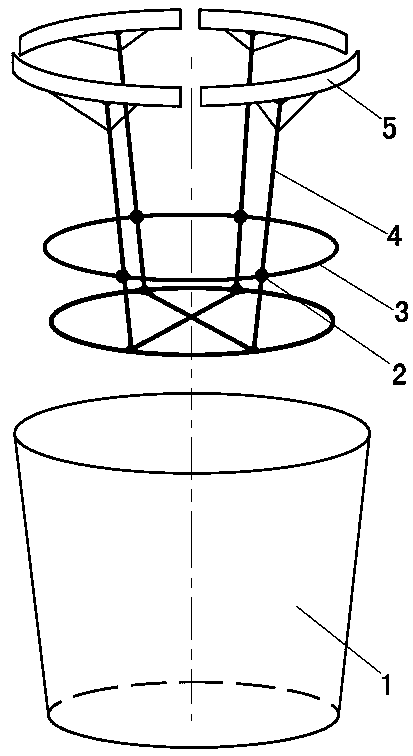

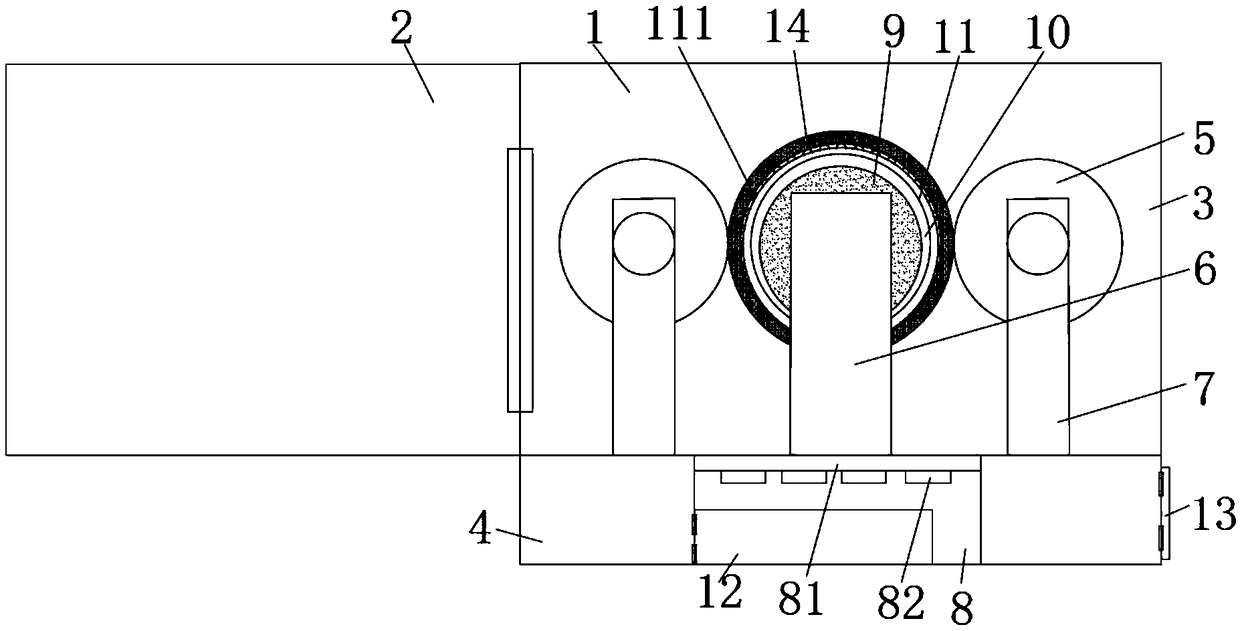

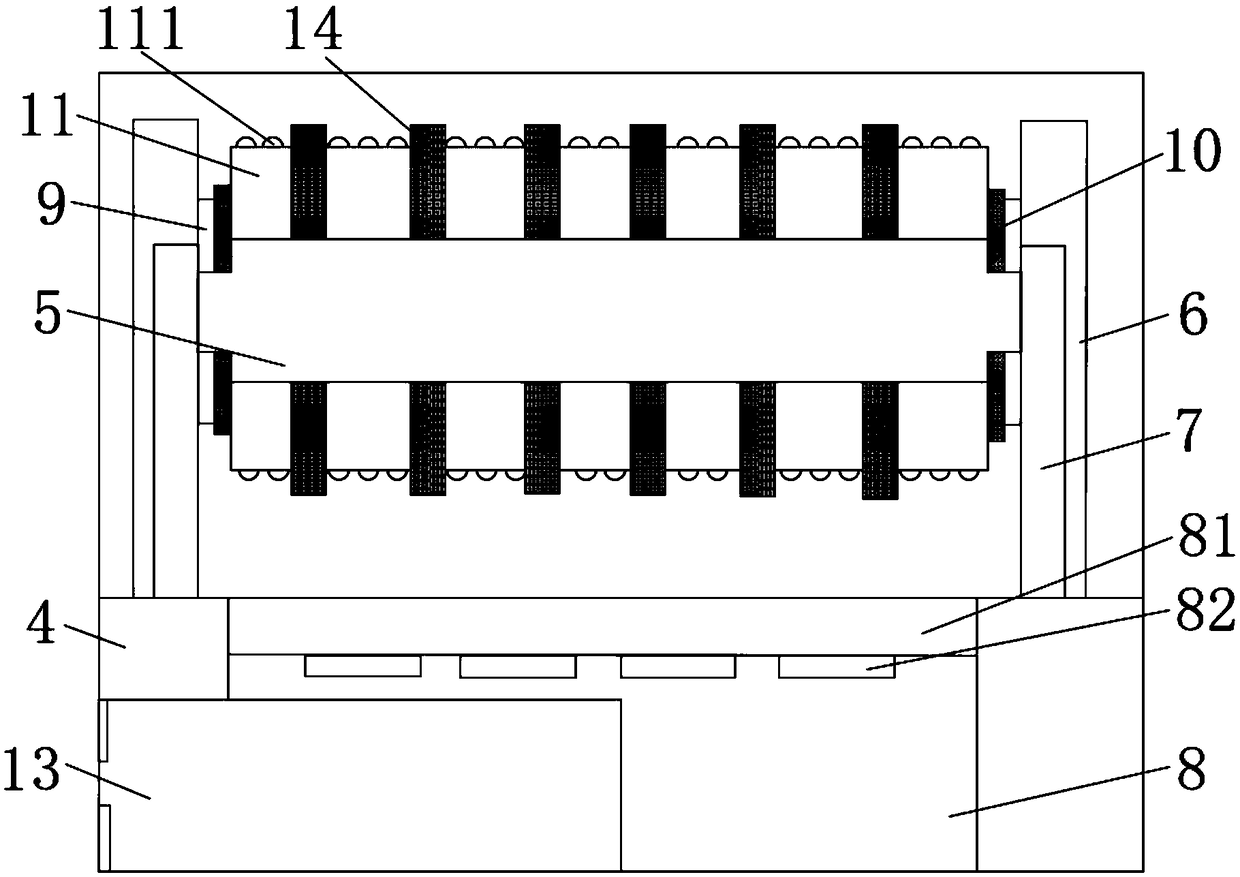

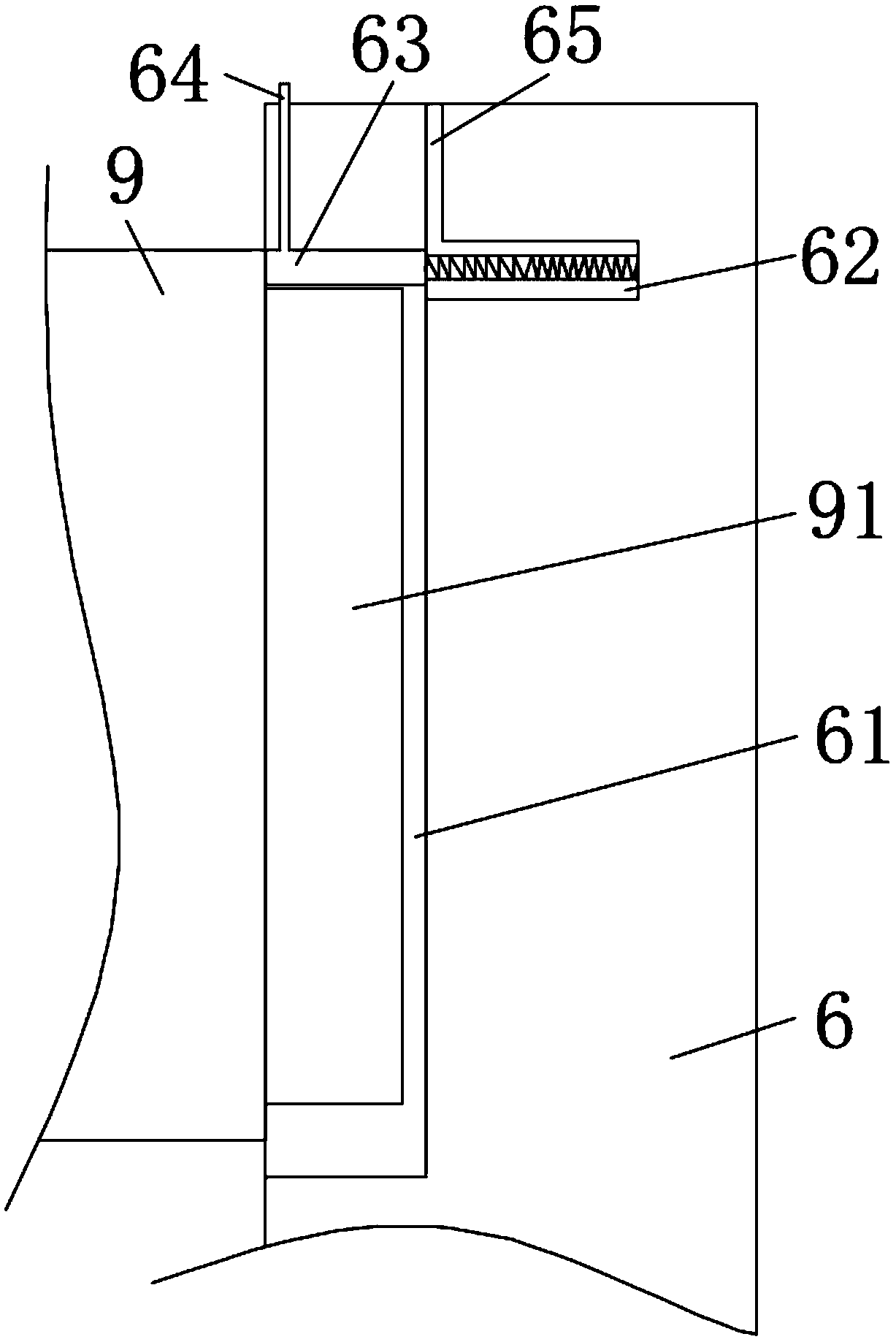

Dustbin

The invention relates to a dustbin, which comprises a dustbin body. The dustbin is characterized in that the interior of the dustbin body is provided with an inner bracket, the inner bracket consists of a plurality of elastic vertical rods and a plurality of transverse press strips, the elastic vertical rods are fixedly connected with the bottom end of the inner bracket, the transverse press strips are respectively and fixedly arranged at the upper ends of the elastic vertical rods, the shape of each transverse press strip corresponds to the shape of the inner cavity of the dustbin body, and the transverse press strips are attached on the inner wall of the dustbin body. The dustbin has the beneficial effects that after a large plastic bag coats all the transverse press strips, the excessive part of the plastic bag is extruded into the dustbin through elastic force, a small plastic bag only coats one part of transverse press strips, and an opening or a lift handle of the plastic bag can also be pressed into the dustbin, so a plurality of plastic bags different in sizes can coat the dustbin; the plastic bags can more stably coat the dustbin, so the falling of the plastic bags loaded with garbage is avoided; by adopting the inner bracket structure, the plastic bag cannot be exposed out of the dustbin, so the appearance is attractive.

Owner:雷海平

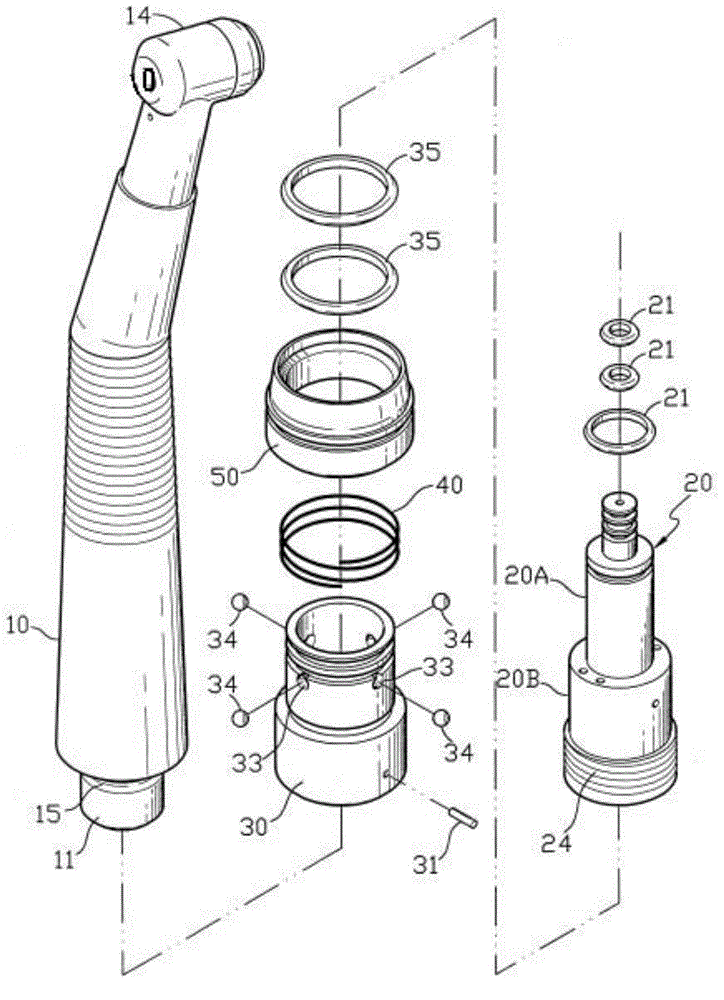

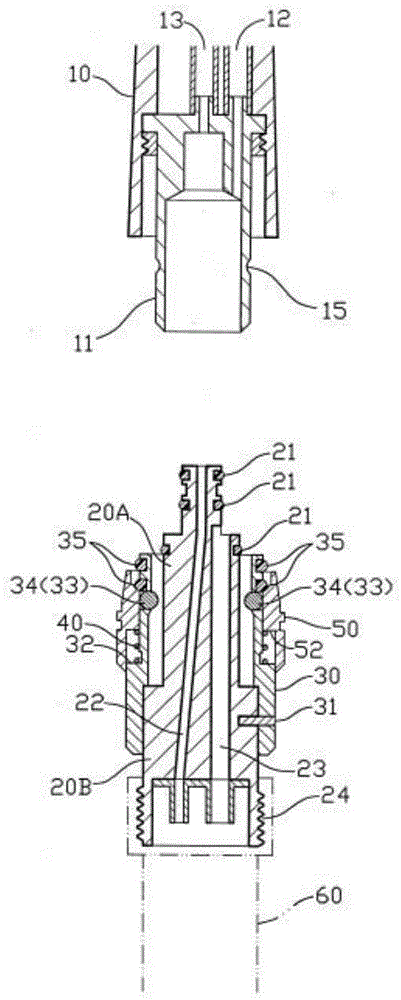

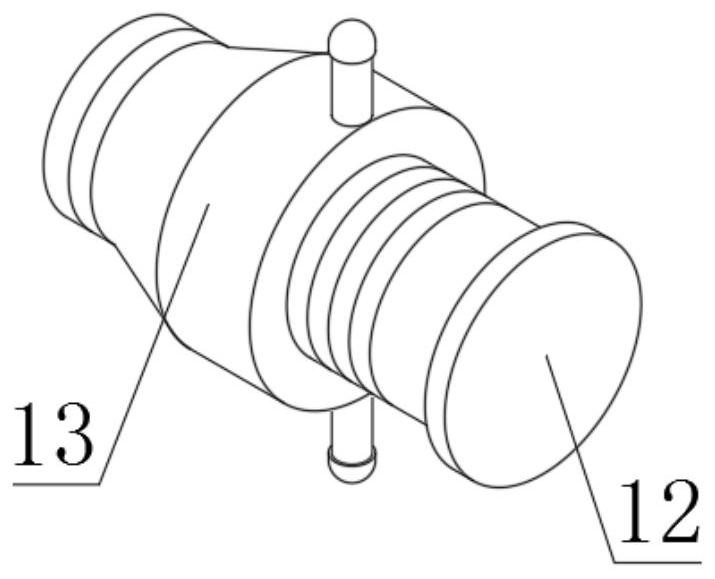

Fast-plugging tooth washing machine

InactiveCN104586521ASocketing is quick and easyQuick assemblyTooth rinsingEngineeringMechanical engineering

A fast-plugging tooth washing machine includes: a machine body, wherein the top of the machine body is provided with a tooth washing head, and the tooth washing head is provided with an ejection opening; the rear end of the machine body is provided with a jointing element, and a two-segment trepan bore is arranged in the jointing element; a plugging element, wherein the plugging element is a stepped hollow circular tube, and the front end of the plugging element is provided with a two-segment plugging joint cooperatively embedded into the trepan bore; an outer sleeve, wherein the outer sleeve is arranged outside the plugging element, and has a hollow tubular shape; a brake sleeve having a hollow tubular shape and sleeved in the periphery of the upper half step of the outer sleeve; and a spring sleeved between the outer sleeve and the brake sleeve in order to provide elastic force of the brake sleeve. The fast-plugging tooth washing machine realizes fast and convenient jointing, so the machine body can be rapidly assembled; and the machine realizes stable clamping, so the unexpected disengaging of the machine body is avoided.

Owner:CHENGDU YINGTAI SCI & TECH

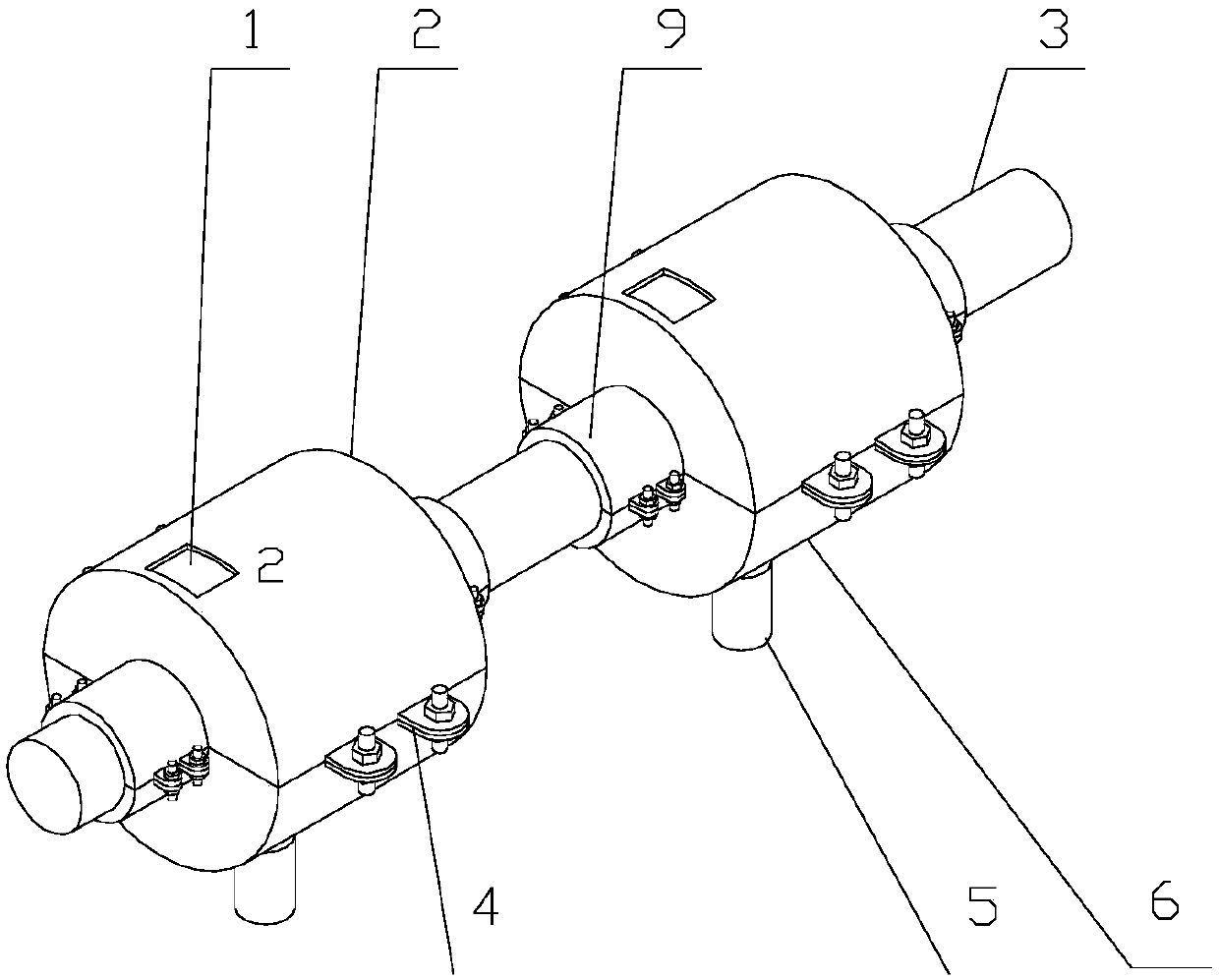

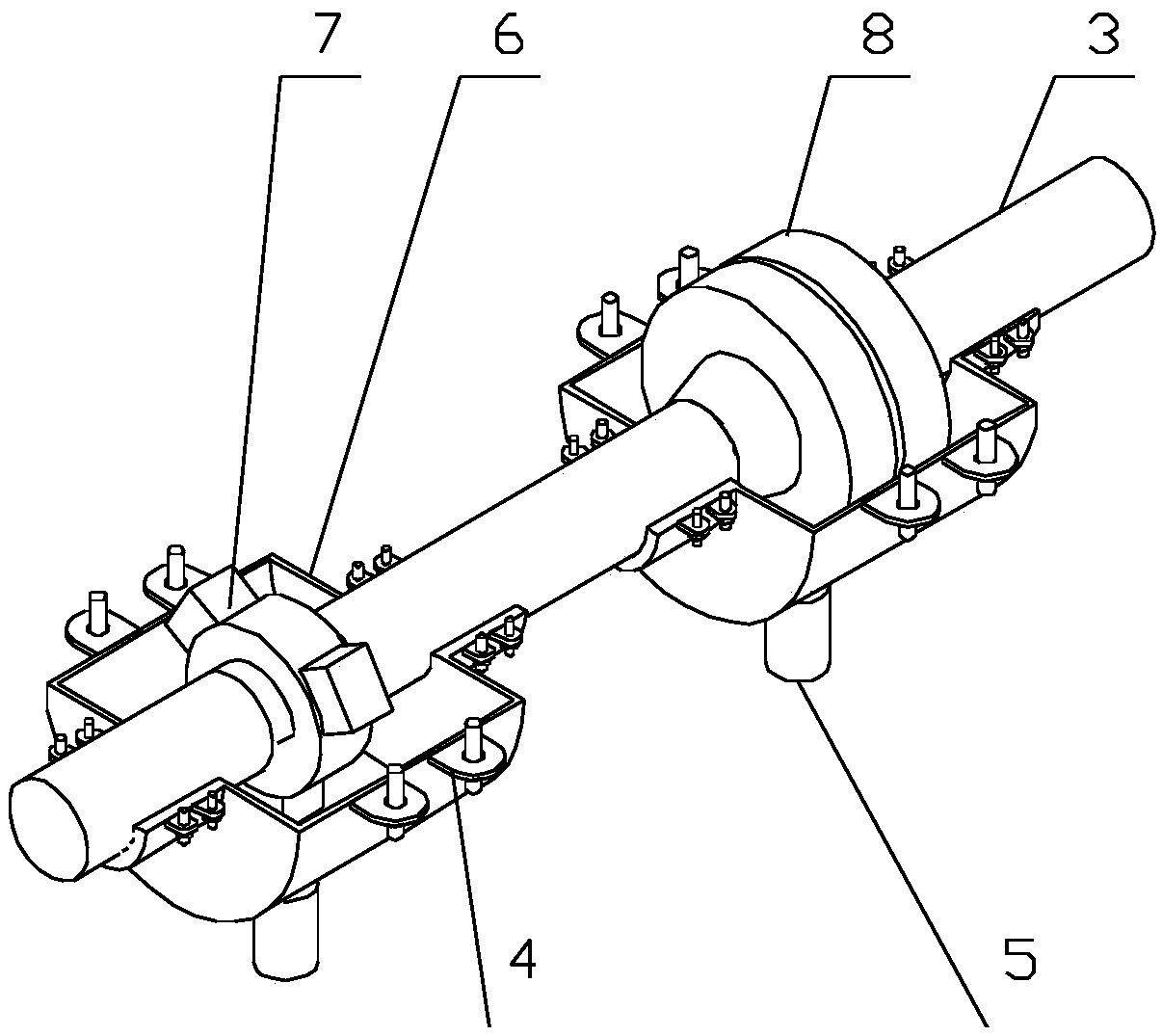

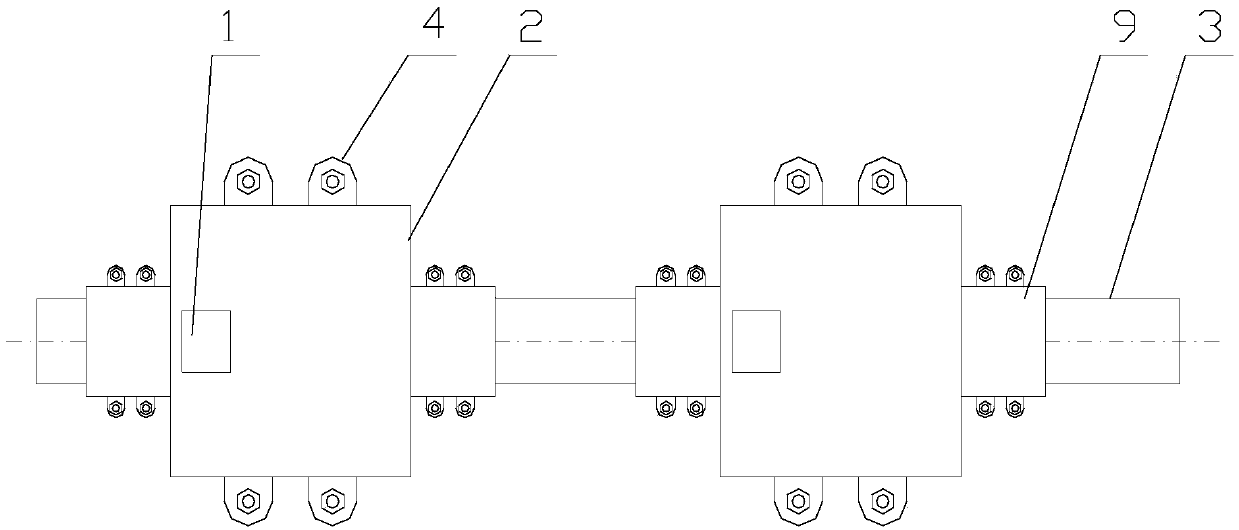

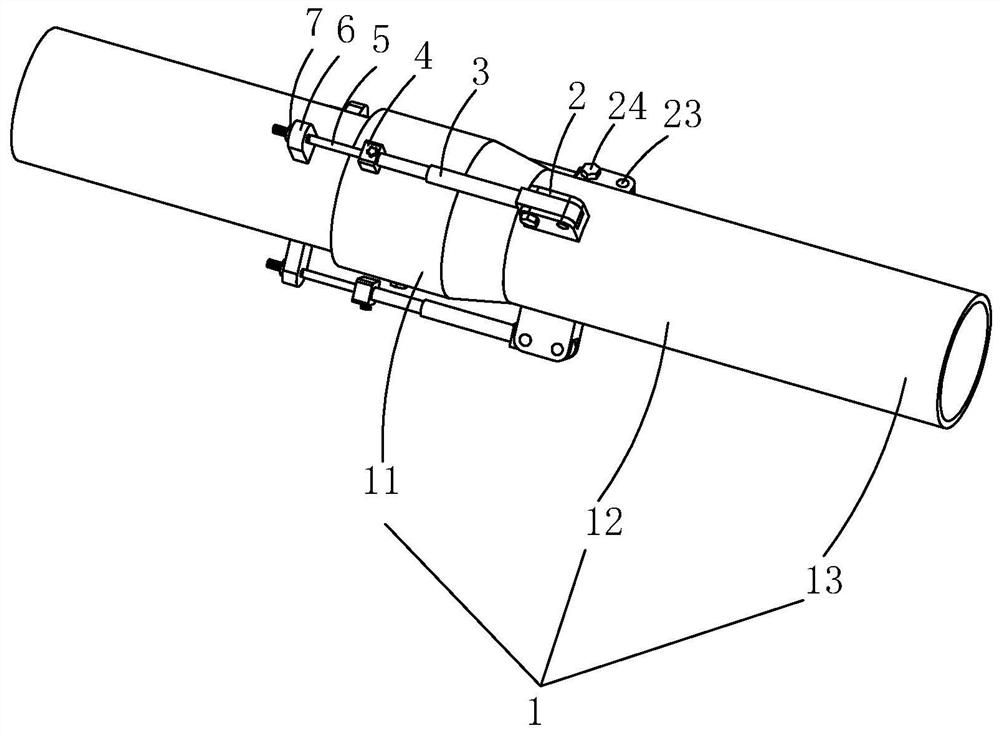

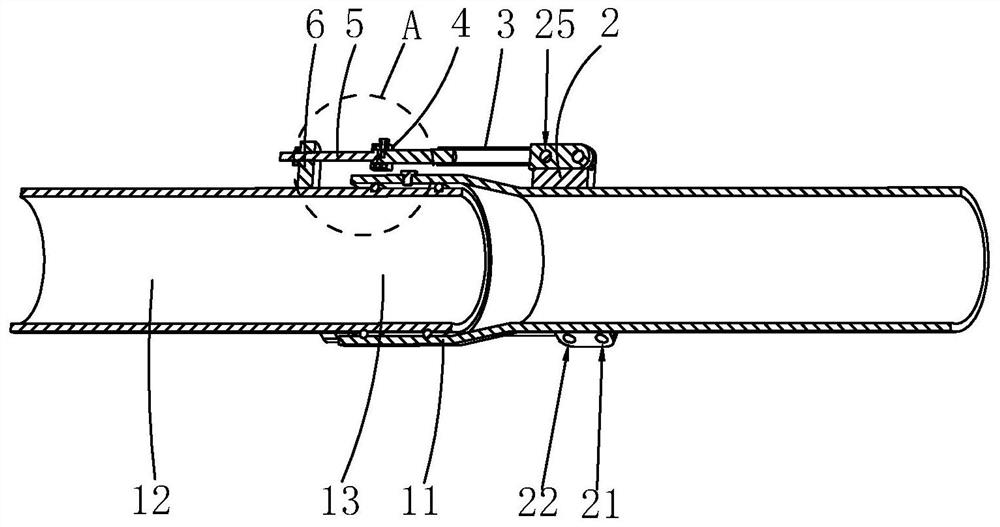

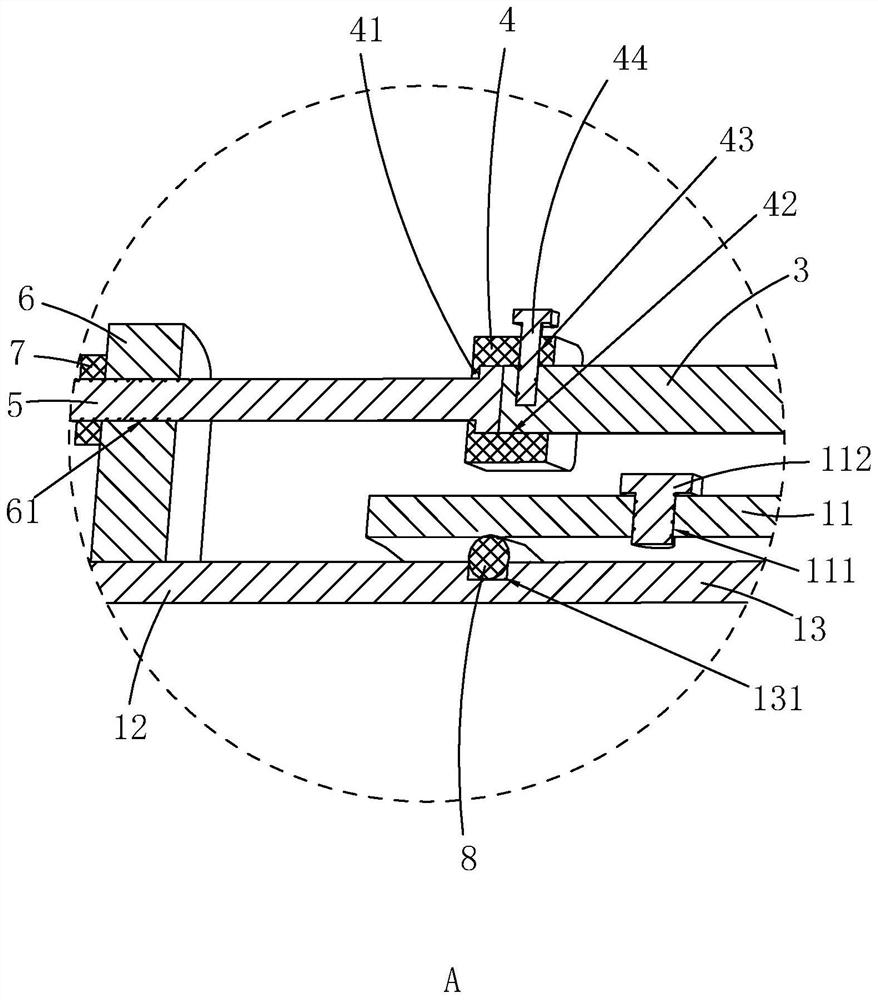

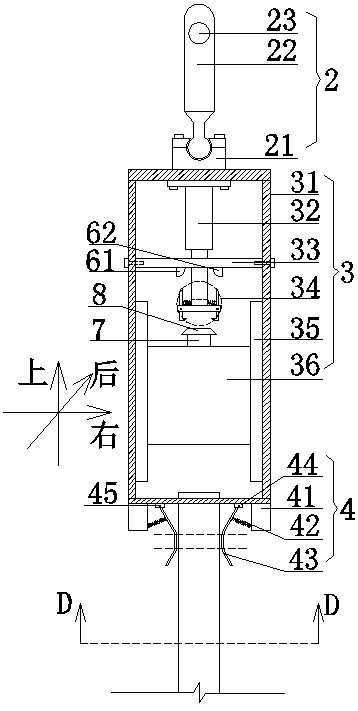

Special protection device for flange and union

PendingCN109681721AAvoid damageSimple structureFlanged jointsPipe protection against damage/wearEngineeringHigh pressure

The invention discloses a special protection device for a flange and a union. The device comprises a protection shell, the protection shell comprises a shell body and a shell cover, the shell body andthe shell cover are detachably connected in a butt mode to form a cylindrical body, a containing cavity for containing the flange or the union is arranged in the cylindrical body, the two ends of thecylindrical body are provided with pipe port portions in sleeved connection with a pipeline, the upper portion of the shell cover is provided with an overflow port, the lower portion of the shell body is provided with a liquid guide port, and the liquid guide port is connected with a liquid storage pipe. The special protection device is simple in structure, multifunctional, good in economical efficiency, high in practicality, capable of being used and popularized to high pressure pipeline projects which apply flange and union connection in offshore and onshore petroleum drilling machines, workover rigs and the like.

Owner:CNOOC ENERGY TECH & SERVICES +1

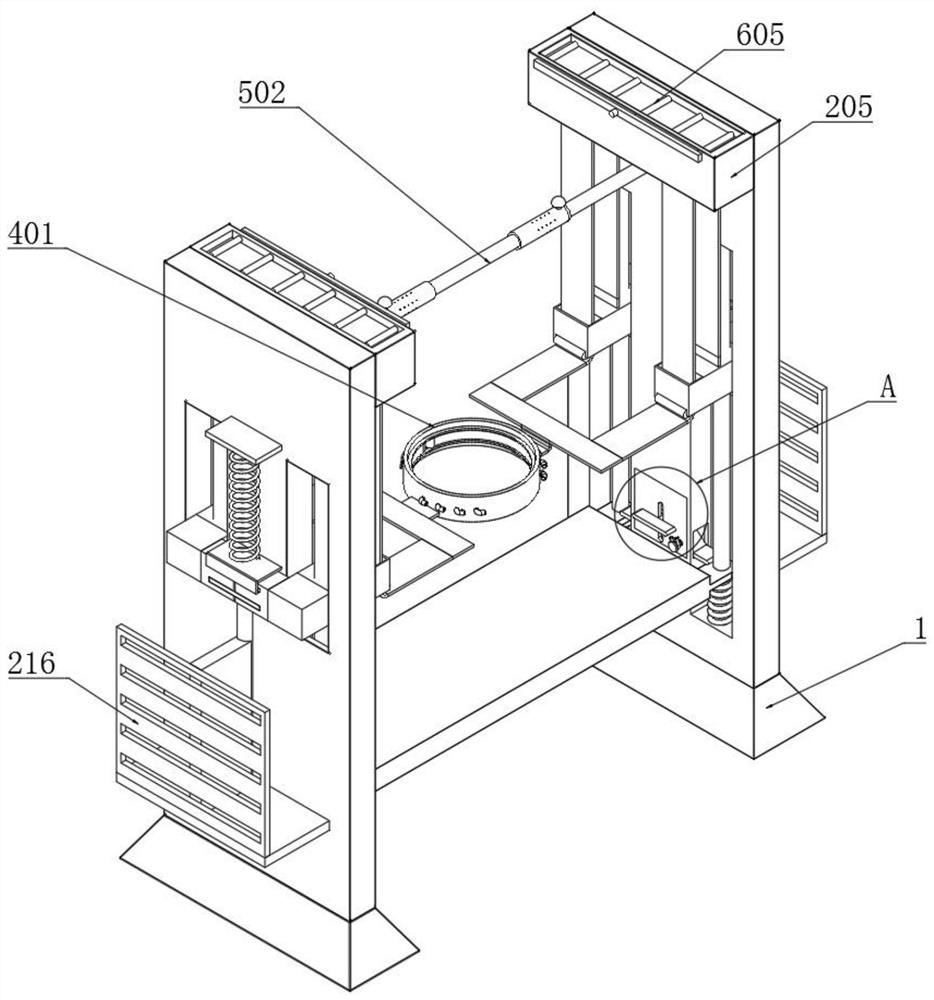

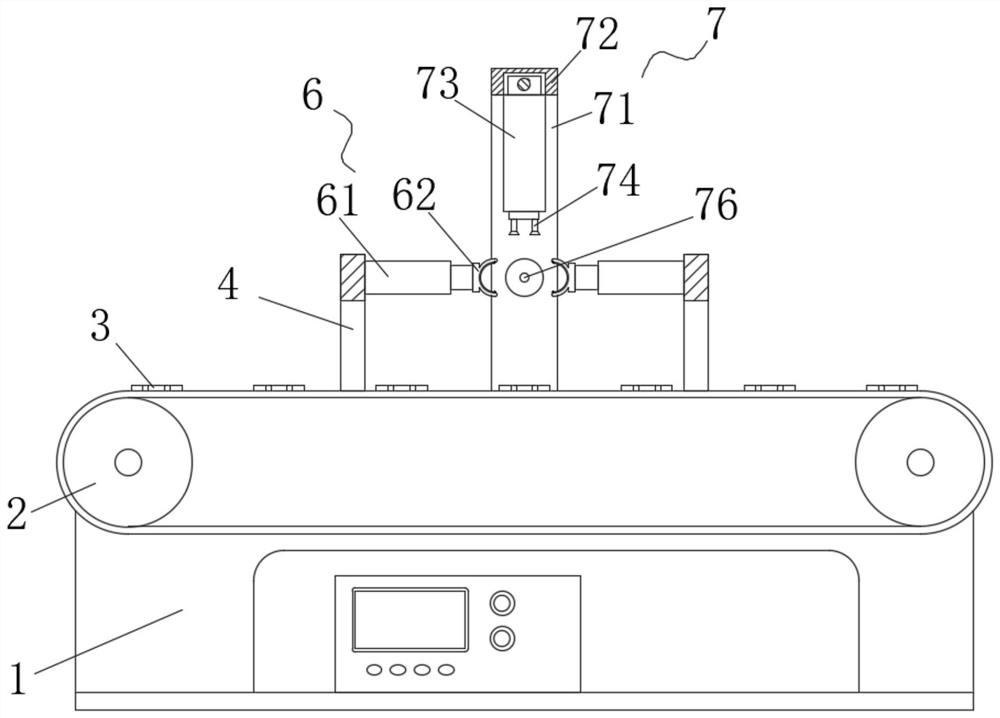

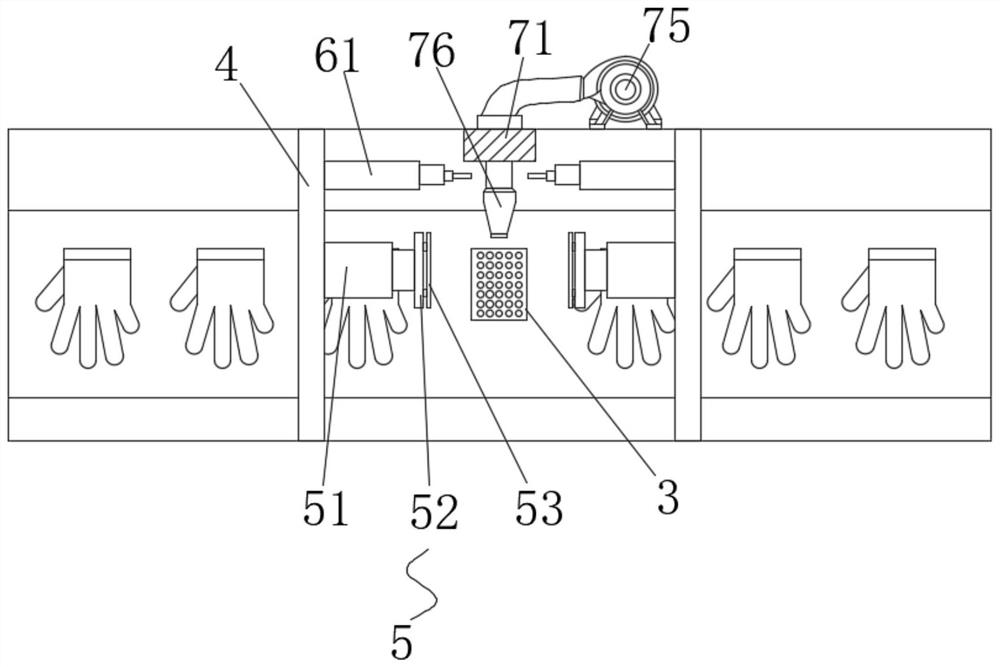

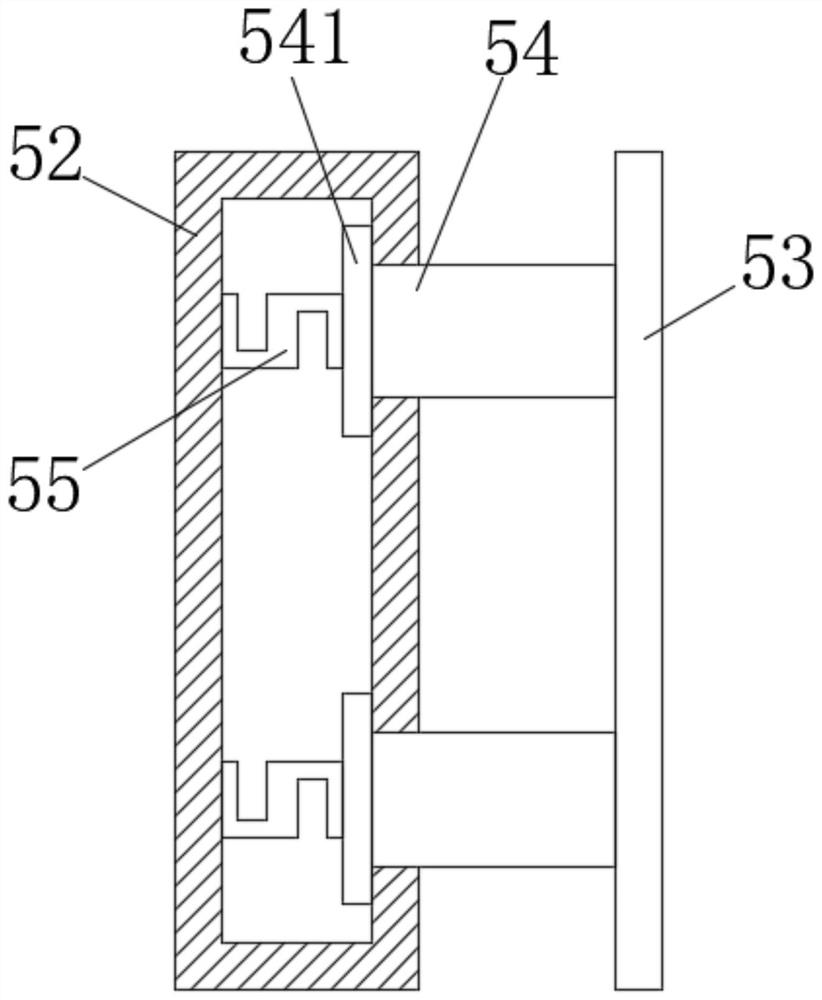

Medical sterile glove detection equipment for operation

PendingCN114061868ASolve pollutionImprove detection efficiencyMeasurement of fluid loss/gain rateWork holdersElectrical and Electronics engineeringMechanical engineering

The invention discloses medical sterile glove detection equipment for operation which comprises a machine body, a conveying line is arranged above the machine body, a suit inflation assembly is arranged on the surface of the machine body and located on one side of the conveying line, and then bridge frames are symmetrically arranged on the surface of the machine body and located above the conveying line. The two bridge frames are provided with sealing assemblies and detection assemblies respectively, each pair of sealing assemblies and each pair of detection assemblies are oppositely arranged, and whether gas in the sterile gloves leaks or not is obtained by measuring the pressure change value within a time period. If the difference value of the detection values of the pressure detectors in the same time period exceeds a preset change value threshold value, the sterile gloves are unqualified products, and if the difference value of the detection values of the pressure detectors in the same time period does not exceed the preset change value threshold value, the sterile gloves are qualified products.

Owner:安徽和佳医疗用品科技有限公司

Automatic steel tube straightening machine

InactiveCN112355087AEasy to straightenEasy to slideMetal-working feeding devicesMetal working apparatusSteel tubeElectric machinery

The invention discloses an automatic steel tube straightening machine which comprises a table plate and table legs, wherein the table legs are fixedly connected to the lower surface of the table plate, a supporting frame is fixedly connected to one side of the upper surface of the table plate, a motor box is fixedly connected to the upper surface of the supporting frame, and a motor is arranged inthe motor box; the output end of the motor is movably connected to a rotary shaft, and the surface of the rotary shaft is fixedly connected to a straightening roller. According to the automatic steeltube straightening machine disclosed by the invention, through cooperative arrangement of the motor, the rotary shaft and the straightening roller, the rotary shaft and the straightening roller can be driven to rotate by starting the motor; and through cooperative arrangement of the table plate, a slide slot, a slide table, a first supporting plate and a second supporting plate, the slide table,the first supporting plate and the second supporting plate can slide conveniently, and thus, the device focuses on straightening the slightly bent part of the steel tube; and the slightly bent part ofthe steel tube is in contact with the rotary straightening roller by pushing the slide table, so that the steel tube is straightened.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

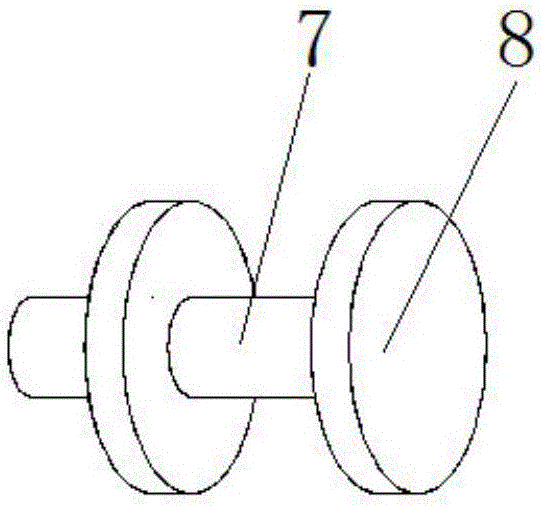

Steel strip winding machine with muff-coupling limiting function

The invention discloses a steel strip winding machine with a muff-coupling limiting function. The steel strip winding machine comprises a base. An L-shaped movable groove is formed in the left front end of the upper surface of the base. A movable plate is arranged in an inner cavity of the L-shaped movable groove. The rear end of the upper surface of the movable plate is fixedly connected with the bottom of a fixed plate. One end of a first supporting shaft penetrates through the top of the front side of the fixed plate. The other end of the first supporting shaft is fixedly connected with the axis of the front side of a sleeve. The left rear end of the upper surface of the base is fixedly connected with the bottom of a fixing device. According to the steel strip winding machine with the muff-coupling limiting function, the movable plate is pulled and moved to the other end in the inner cavity of the L-shaped movable groove; the sleeve is sleeved with a steel strip; the movable plate is moved to the original position, so that the first supporting shaft is sleeved with a through hole in the fixed plate, the movement range of the steel strip can be limited in the process of winding and pulling the steel strip after the steel strip is arranged on the sleeve in a sleeved mode, and the situation that the steel strip breaks away from the sleeve due to strong tensile force of a reel to the steel strip in the winding process when the steel strip is pulled through the reel cannot occur.

Owner:江苏中康金属材料有限公司

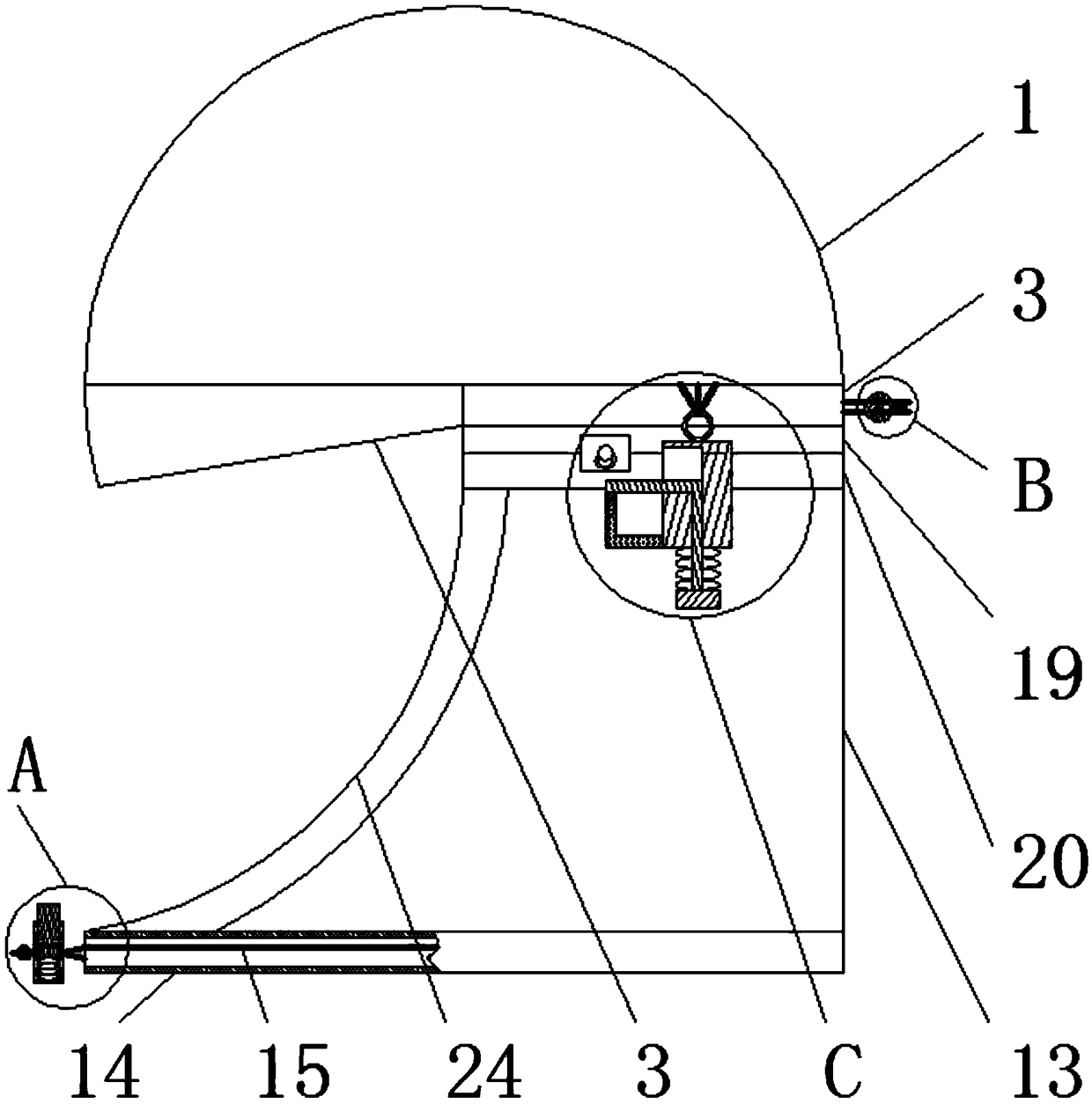

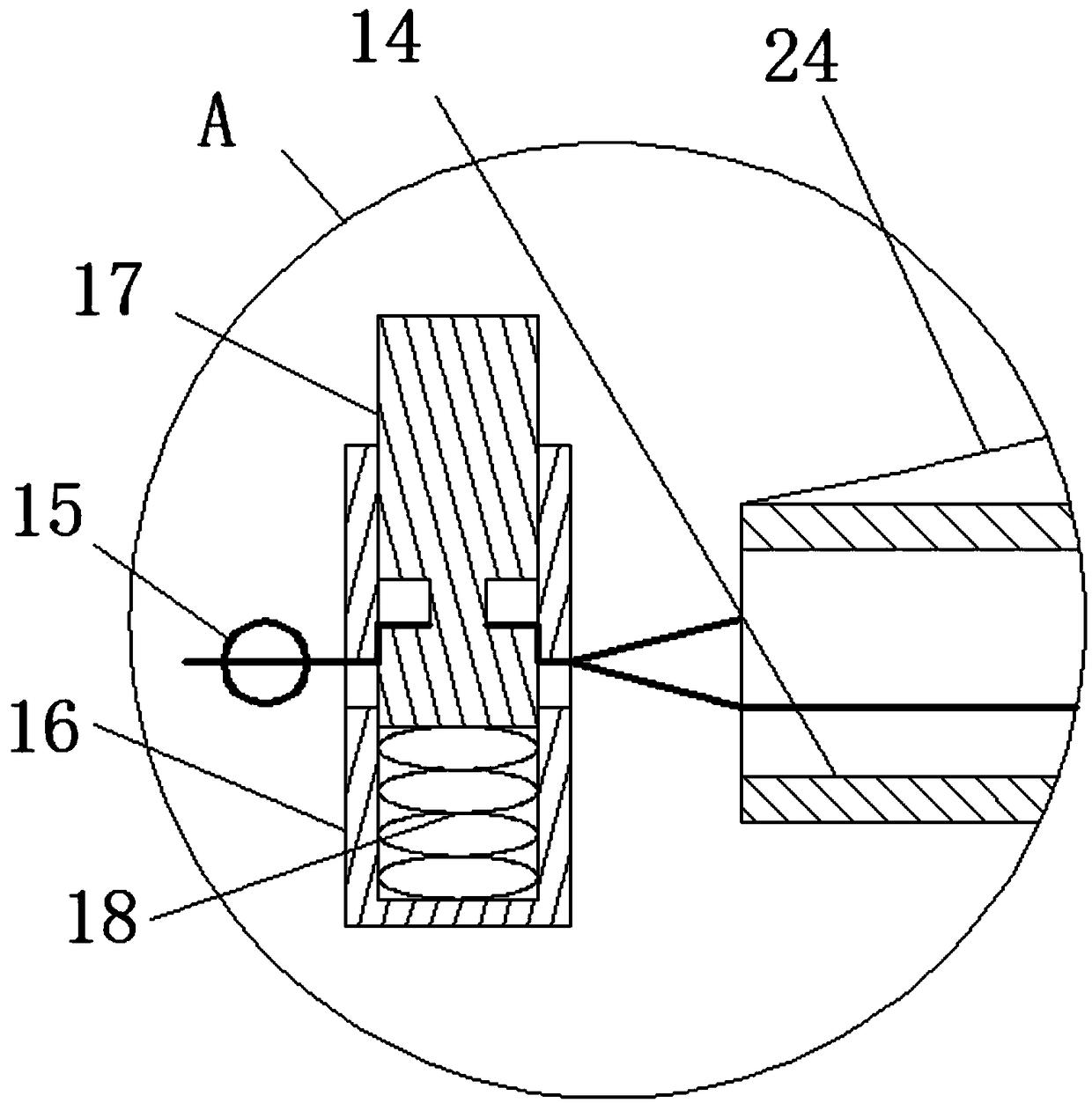

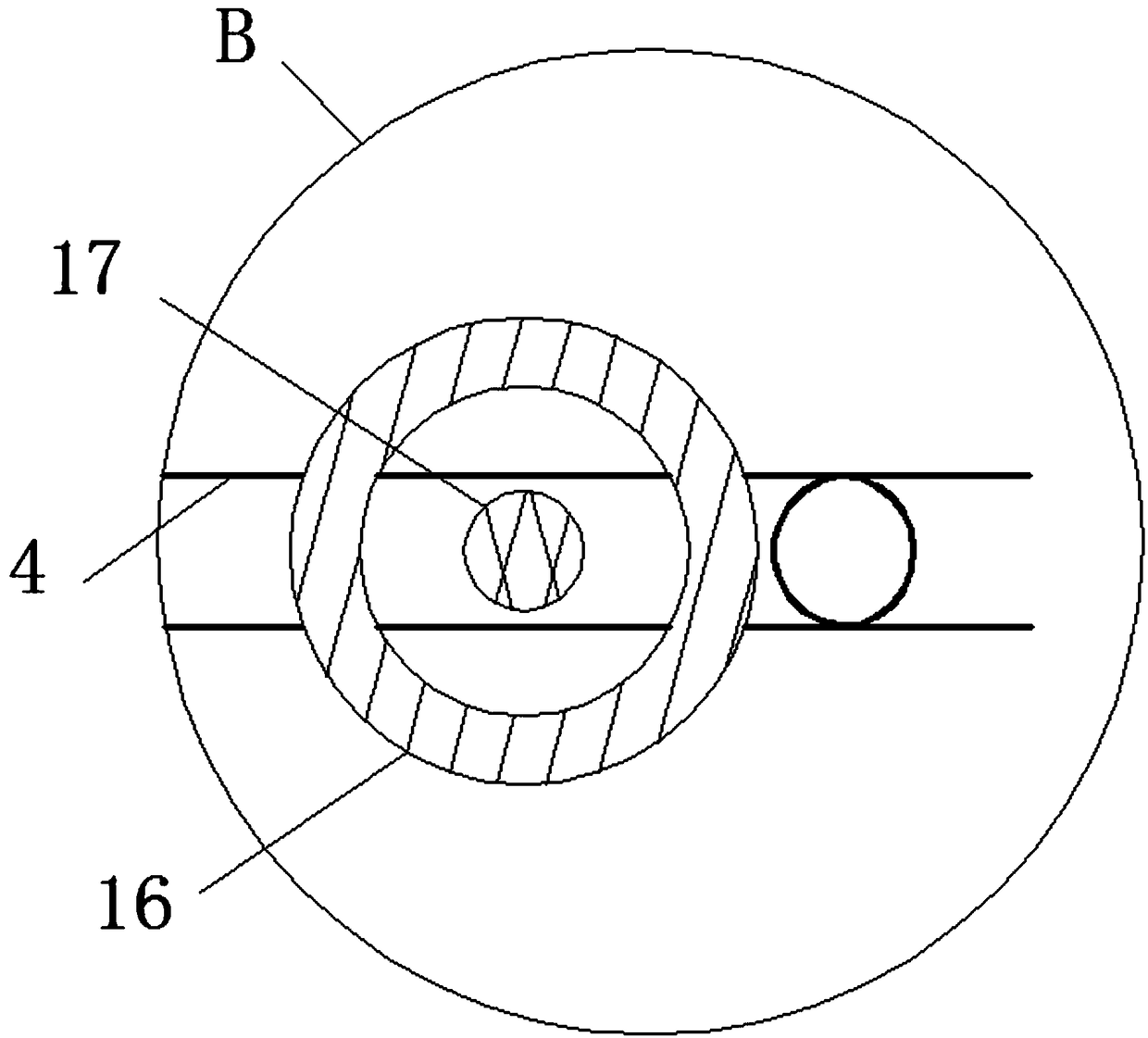

Automatic sweat-absorbing medical cap

ActiveCN109463833APrevent fallingAvoid affecting the effect of surgeryHatsHeadwear capsEngineeringHead shape

Owner:SICHUAN SUINING KANGDA HEALTH MATERIALS CO LTD

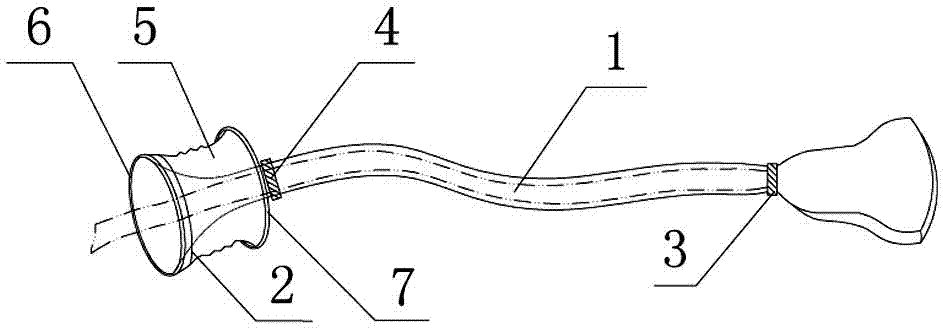

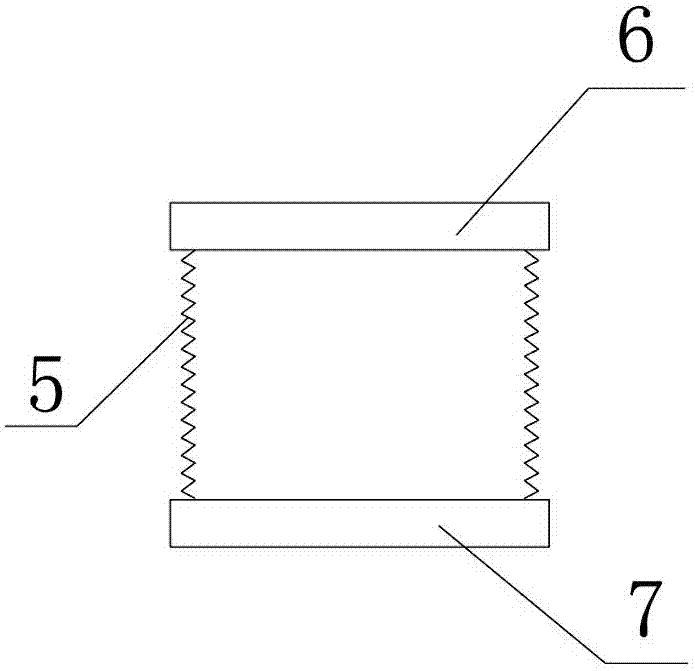

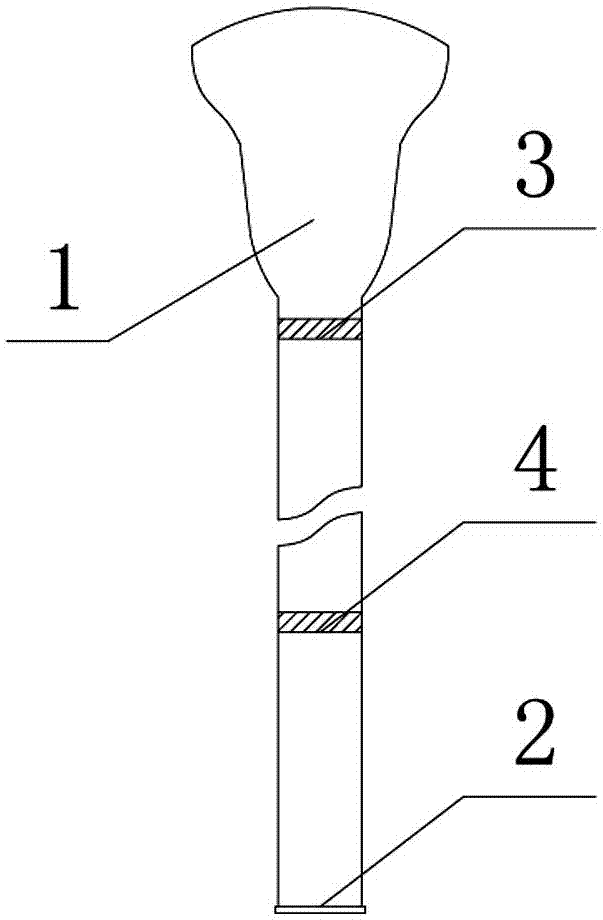

Disposable closed ultrasonic probe sleeve

ActiveCN106955163ASimple structureEasy to useUltrasonic/sonic/infrasonic diagnosticsSurgical furnitureFastenerRubber ring

The invention discloses a disposable closed ultrasonic probe sleeve. The disposable closed ultrasonic probe sleeve comprises a film sleeve coating an ultrasonic probe and an ultrasonic probe data line, wherein the front end of the film sleeve is matched with the ultrasonic probe in outer shape; an elastic rubber ring is arranged at the tail end of the film sleeve; a first tightening component and a second tightening component are distantly arranged on the surface of the film sleeve; the first tightening component is positioned at a junction of the ultrasonic probe and the ultrasonic probe data line; a telescopic tube sleeve sleeves the film sleeve; an upper supporting ring and a lower supporting ring are arranged at the two ends of the telescopic tube sleeve respectively; the elastic rubber ring is outwardly folded and is fixed to the upper supporting ring; the second tightening component is clamped below the lower supporting ring. The disposable closed ultrasonic probe sleeve is simple in structure, convenient to use, economical and practical.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

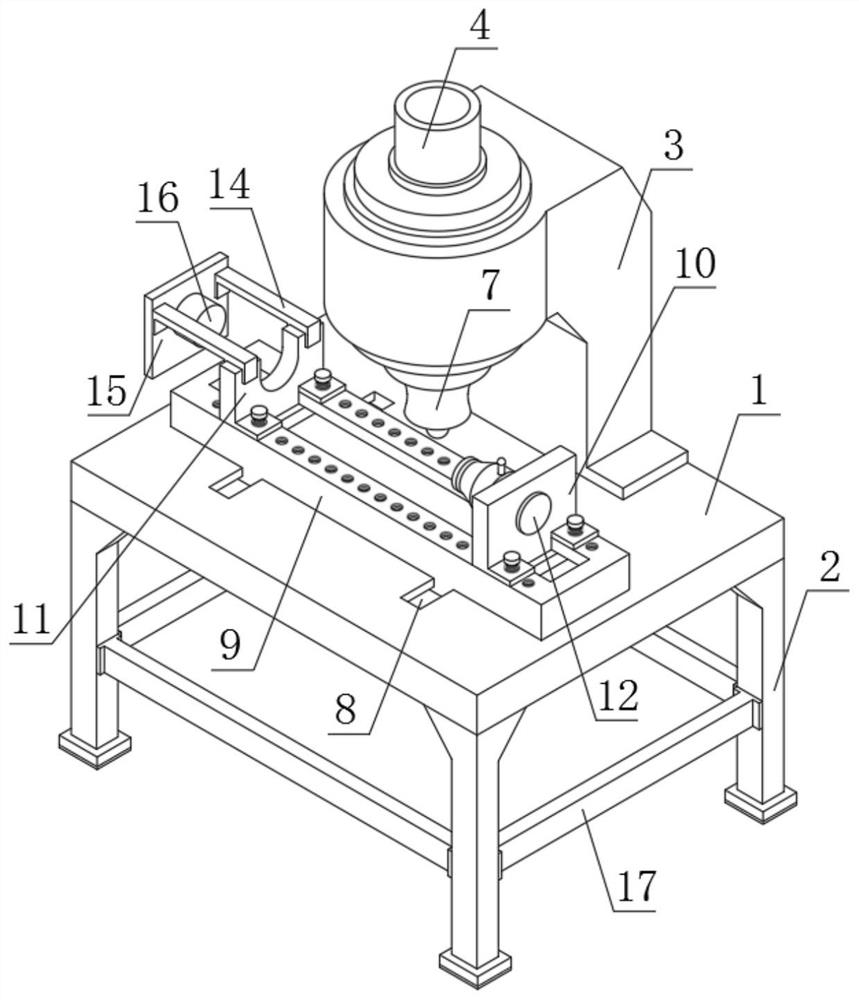

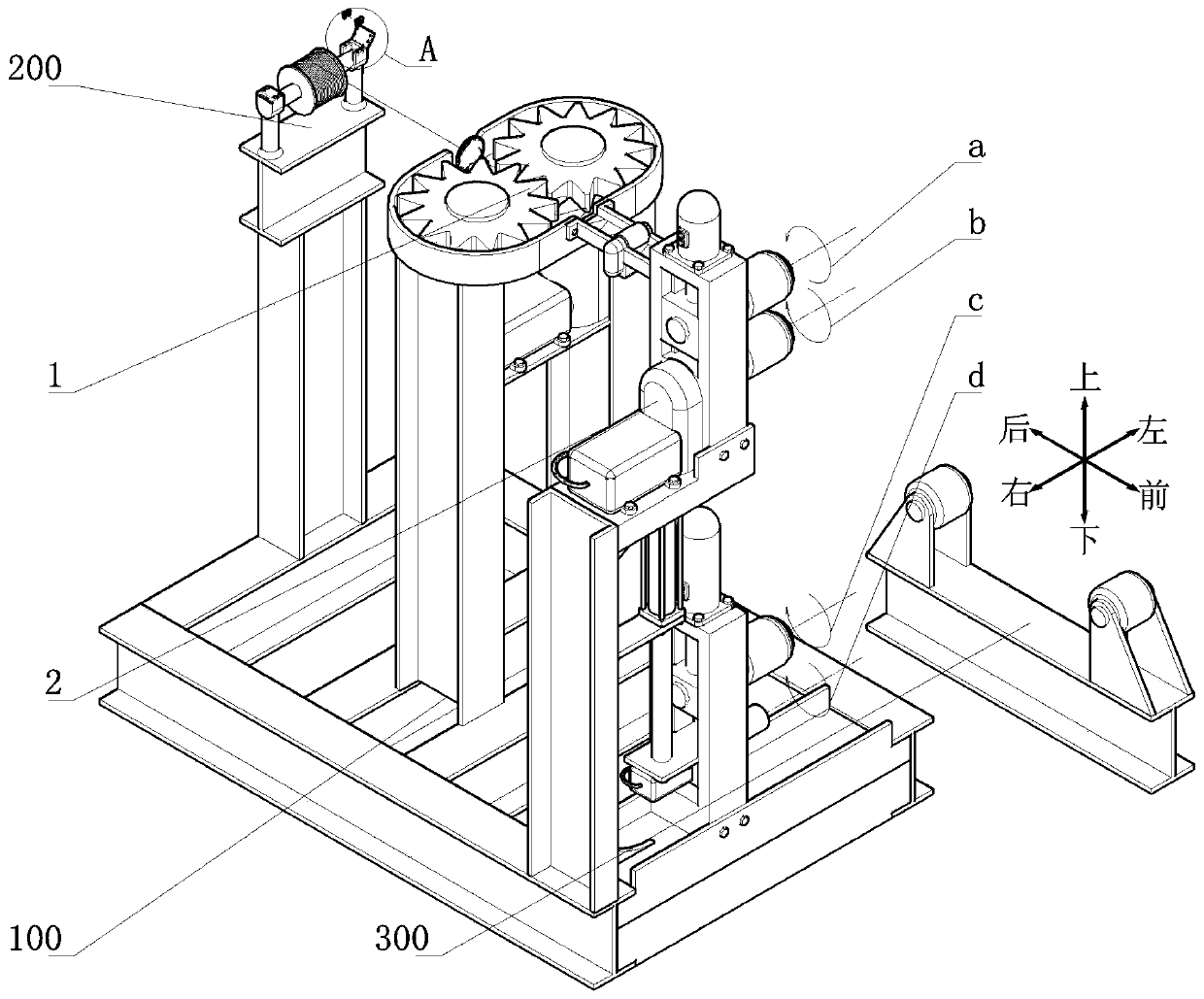

A wiring device for butt welding of ultra-high molecular weight polyethylene straight pipe and its working method

The invention relates to a wiring device for butt welding of ultra-high molecular weight polyethylene straight pipes and its working method, comprising a support base including a cross arm, a feeding device, a support roller and a control device; The second support vertical beam; the first support vertical beam is equipped with a shaping device, the shaping device includes a protective groove, a tooth surface pressing wheel, a first motor, a lead wire device, a wire feeding chute, a pressing wheel, and a heating component; the second The second support vertical beam is equipped with a cutting device including a disc pressing mechanism and a grinding mechanism. The disc pressing mechanism includes an upper slideway, a first slider, an upper pressing roller, an upper hydraulic cylinder, a second motor for the supporting roller, and a reduction box. The grinding mechanism includes a glide path, a first lower slider, a lower pressure roller, a lower hydraulic cylinder, a second lower slider, a grinding head, a third motor, and a stroke electric cylinder. The invention relates to a wiring device for butt welding of ultra-high molecular weight polyethylene straight pipes and a working method thereof, which automatically arranges regular electric heating wires to improve wiring efficiency, and the electric heating wires are reliably fixed on the outer wall of the straight pipe.

Owner:SHANDONG XIANHE POLYMER MATERIALS +1

Ultrasonic medical auxiliary detection equipment

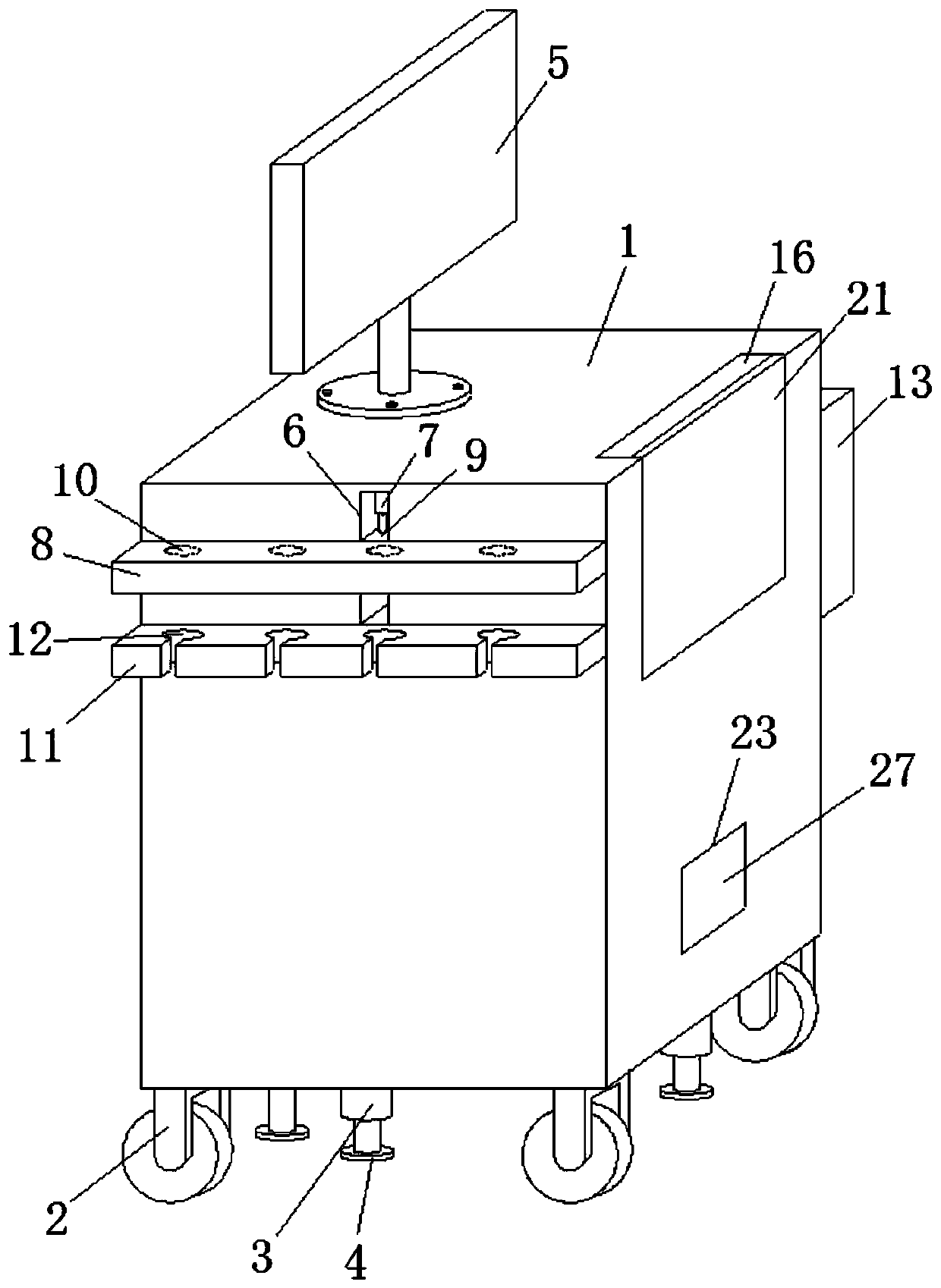

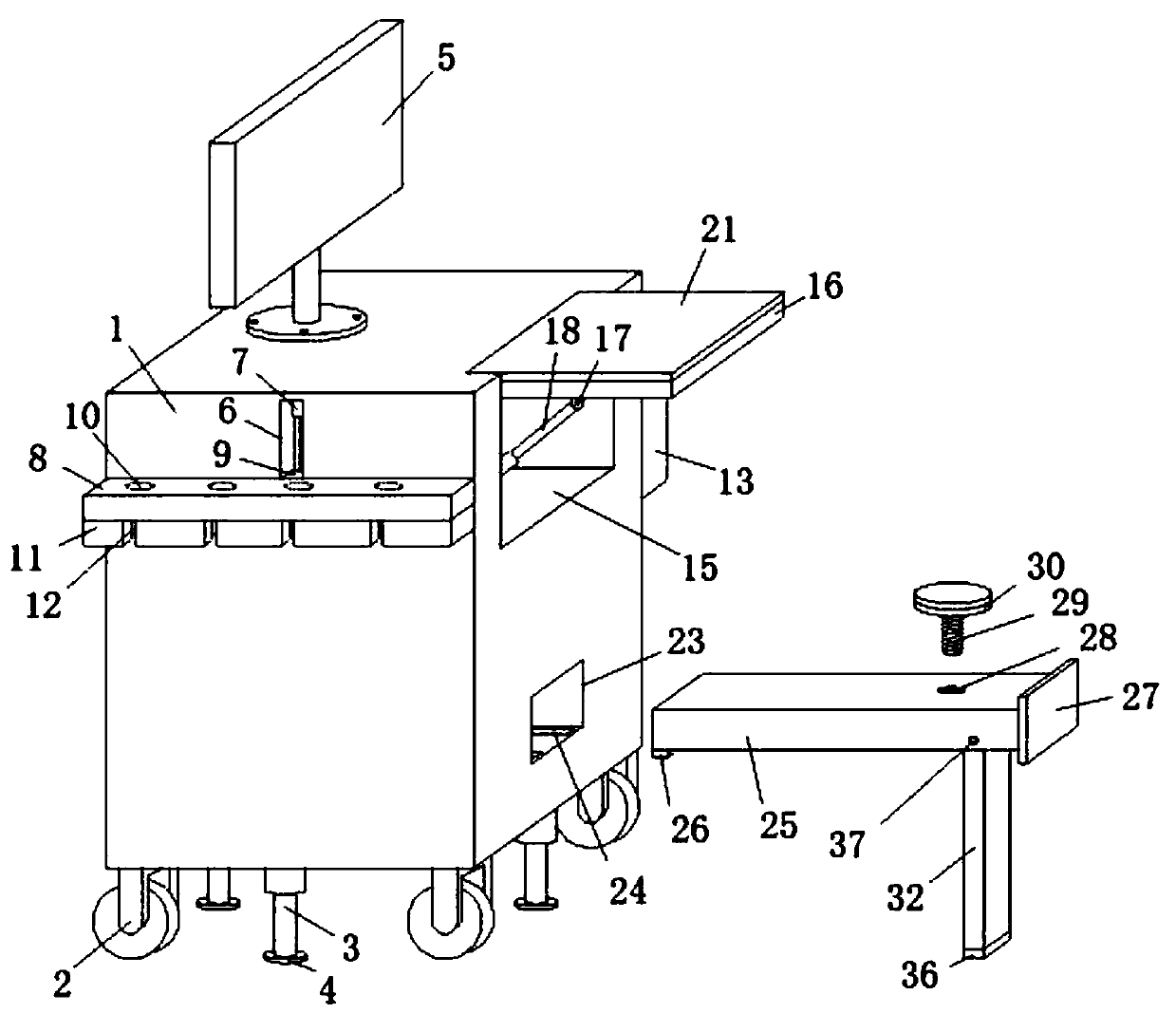

InactiveCN111035409AImprove protectionEasy to storeUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsHydraulic cylinderEngineering

The invention discloses ultrasonic medical auxiliary detection equipment. The equipment comprises a detection table, symmetrically-distributed universal wheels are fixedly installed on the periphery of the bottom of the detection table, hydraulic cylinders are fixedly installed on the periphery of the bottom of the detection table, a supporting disc is fixedly mounted at the bottom end of the hydraulic cylinder, the hydraulic cylinders are located on the inner sides of the universal wheels, and he left sideT of the top of the detection table is in threaded connection with a computer through screws. In the present invention, the universal wheels are fixedly installed on the periphery of the bottom of the detection table, so that the position of the detection table can be conveniently changed through the universal wheels and manpower is reduced, the hydraulic cylinders are fixedly installed around the bottom of the detection table, so that the hydraulic cylinders can drive the supportingdisc to move downwards conveniently and the supporting disc is supported on the ground, the universal wheels can be separated from the ground, so that the detection table is placed more stably, and afirst electric push rod is fixedly installed at the bottom end of the interior of the cavity, so that the first electric push rod drives a guide block to move downwards conveniently.

Polishing device for loudspeaker plastic side pressing production processing

PendingCN108772763AImprove grinding effectPrevent splashGrinding carriagesGrinding machinesEngineeringLoudspeaker

The invention discloses a polishing device for loudspeaker plastic side pressing production processing, and relates to the technical field of loudspeaker plastic side pressing production processing. The polishing device for loudspeaker plastic side pressing production processing comprises a polishing device body, wherein the polishing device body comprises a dust board, a polishing tank, a workingtable, polishing wheels, a first support rod, a second support rod, a dust collecting chamber, a fixed rod, a rotary shaft and a fixed wheel; and one end of the dust board is movably connected with one end of the polishing tank through a hinge. According to the polishing device for loudspeaker plastic side pressing production processing, on one hand, the two polishing wheels can be used for polishing pieces to be polished on the fixed wheel at the same time, so that a polishing effect of the polishing device body is better; on the other hand, the multiple polishing pieces to be polished can be arranged on the fixed wheel, so that the polishing device body can be used for polishing multiple polishing pieces at a time, and the working efficiency is improved; secondly, the dust collecting chamber can be used for collecting dust produced by polishing, so that the pollution on the ambient air is prevented; and in addition, the dust board can prevent the dust from splashing during polishing.

Owner:安吉县力顺电声配件厂

Hydraulic traction installation and construction method for double-rubber-ring socket and spigot type large-diameter pipelines

InactiveCN112145796AImprove securityReduce accidentsPipe laying and repairJoints with sealing surfacesRubber ringArchitectural engineering

The invention relates to the technical field of pipeline engineering, in particular to a hydraulic traction installation and construction method for double-rubber-ring socket and spigot type large-diameter pipelines. The method comprises the following installation and construction steps that S1, construction preparation is conducted; S2, the pipelines are hoisted into a trench; S3, spigot rubber rings are mounted; S4, pipeline traction is conducted, specifically, S41, a traction device is installed, S42, pipeline joints are aligned, and S43, pipeline traction is conducted; and S5, a connectorair tightness test is conducted. According to the hydraulic traction installation and construction method for the double-rubber-ring socket and spigot type large-diameter pipelines, the socket end andthe spigot end can be aligned and evenly stressed, so that the socket and spigot type connection of the two pipelines is facilitated, the pipeline installation efficiency is improved, and meanwhile the possibility that the spigot rubber rings are deformed greatly in the pipeline installation process is reduced.

Owner:鸿川建筑产业集团有限公司

Foundation pile high-strain hammering system

PendingCN111188371AIncrease impactLower the altitudeFoundation testingBulkheads/pilesArchitectural engineeringExcavator

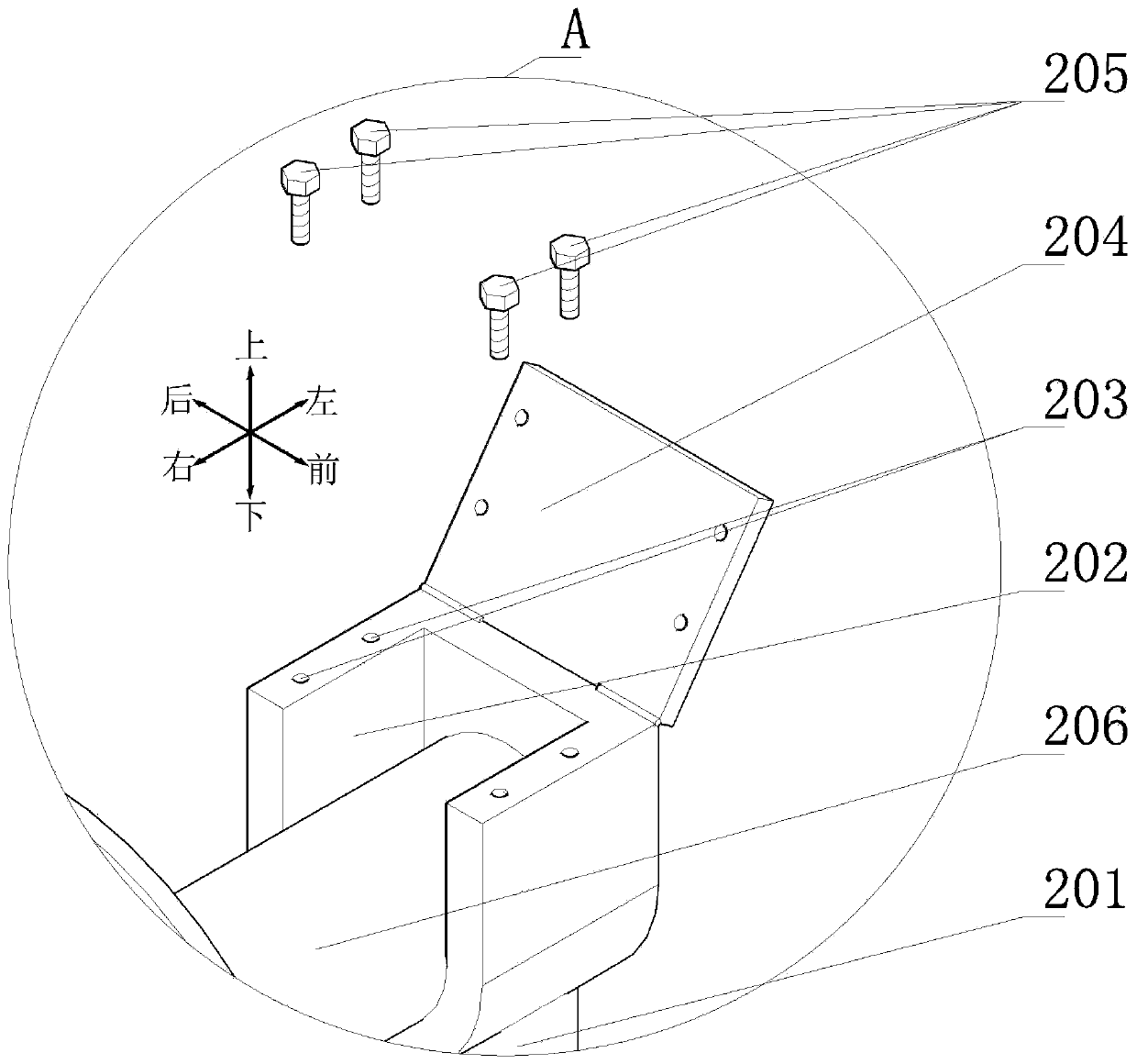

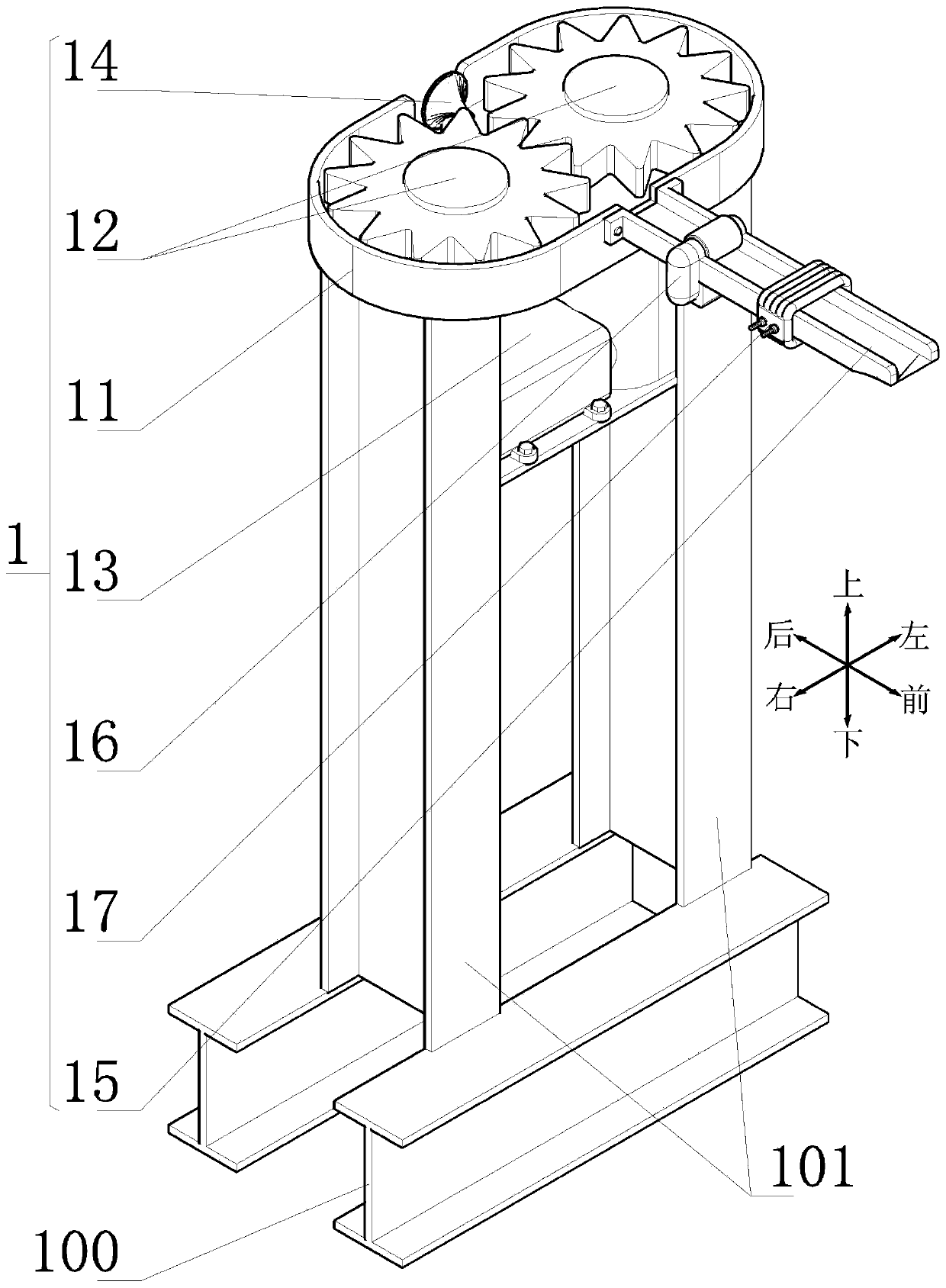

The invention discloses a foundation pile high-strain hammering system. The foundation pile high-strain hammering system comprises an excavator, a connecting mechanism, a hammering device and a limiting mechanism, wherein the end of the front arm of the excavator does not provide a bucket, the top of the hammering device is hinged to the end of the front arm of the excavator through the connectingmechanism, the bottom of the hammering device is connected with a pile body through the limiting mechanism, the connecting mechanism is composed of a connecting base, a connecting rod and a pin, theconnecting base is welded to an outer shell at the top of the hammering device, one end of the connecting rod is hinged to the connecting base, and the other end of the connecting rod is vertically and rotatably connected to the end of the front arm of the excavator through a pin A. By means of the structure, the hammer device is directly hinged to the end of the front arm of the excavator, so that the hammering device is stable in connection, the problem of slipping accidents is not prone to happening, and the safety is high; meanwhile, the hammering device and a foundation pile end head arebutted in real time through the limiting mechanism, the installation is simple, and the operation efficiency is greatly improved.

Owner:淮安市建筑工程质量检测中心有限公司

Wheat dedusting and filtering device

InactiveCN111992493AEasy to move up and downEasy to reinforceSievingGas current separationRubber ringAgricultural engineering

The invention relates to the technical field of agricultural product processing equipment and discloses a wheat dedusting and filtering device which comprises a dedusting box; first rubber rings are fixedly connected with the upper parts of the two sides of the dedusting box in a sleeving manner; sieve meshes are fixedly connected with the cavities of the first rubber rings in a sleeving manner; afan is fixedly mounted on one side of the dedusting box; a bottom box is fixedly mounted at the bottom of the cavity of the dedusting box; and support plates are fixedly mounted on the two sides of the bottom of the cavity of the bottom box. According to the wheat dedusting and filtering device, a motor operates to drive a rotary shaft to rotate, so that a rotary plate on the rotary shaft is driven to rotate, the rotary plate is in contact with one side and bottom of the cavity of a movable frame, the sieve meshes on the support plates are driven to move up and down, left and right, and wheatgrains are driven to move in the cavities of the sieve meshes and are raised; and a hanging rod operates to separate wheat grains from dust, and the wheat grains are enabled to move to the right sides of the sieve meshes from the left sides of the sieve meshes.

Owner:高福华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com