Patents

Literature

31results about How to "Extended combustion range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

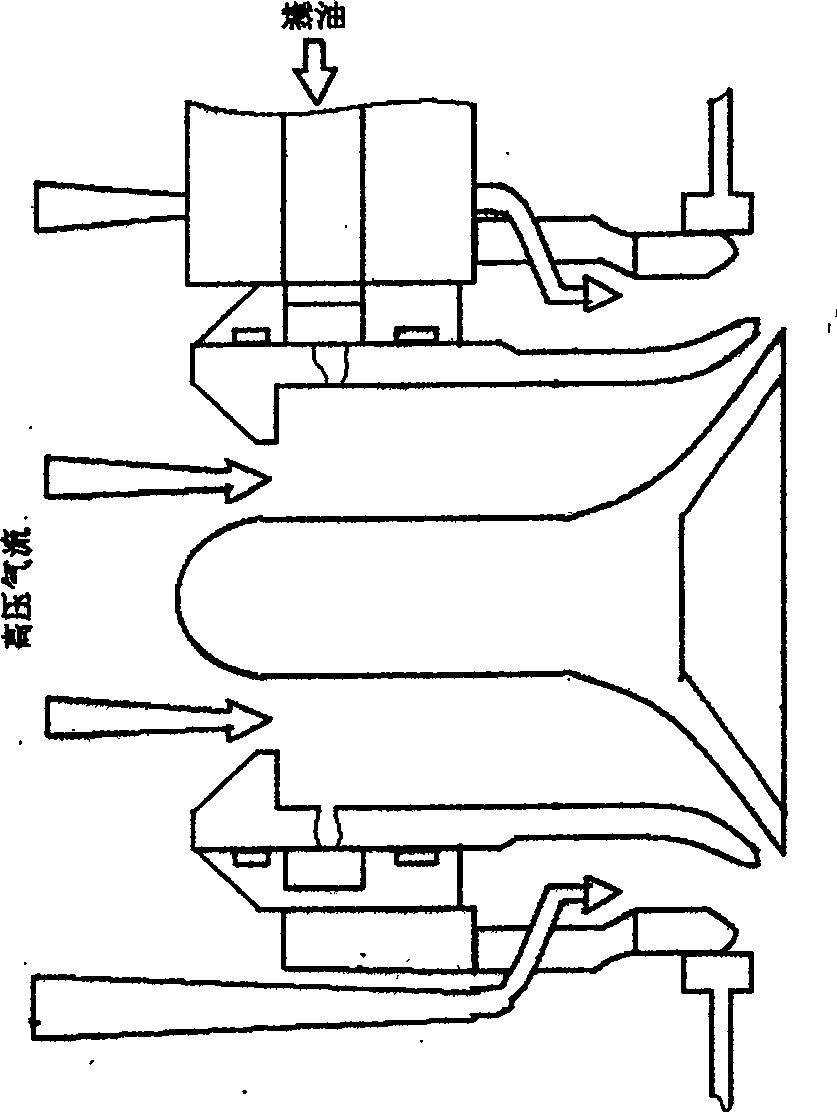

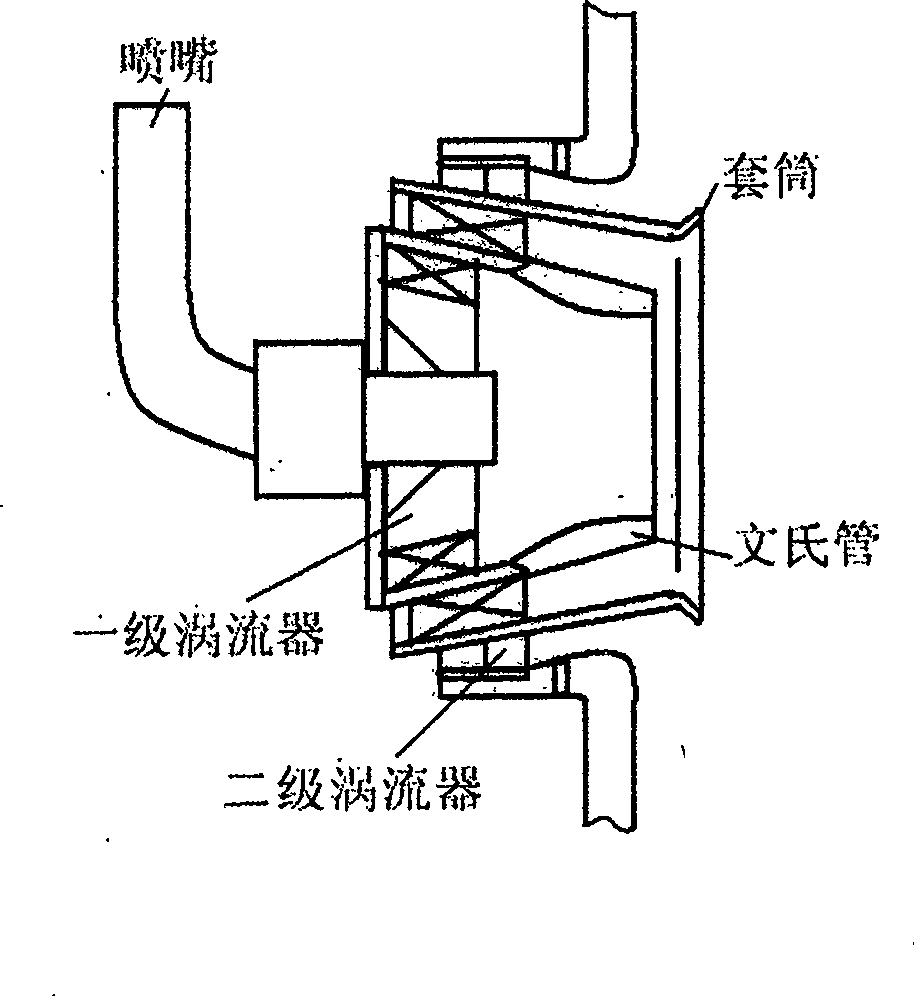

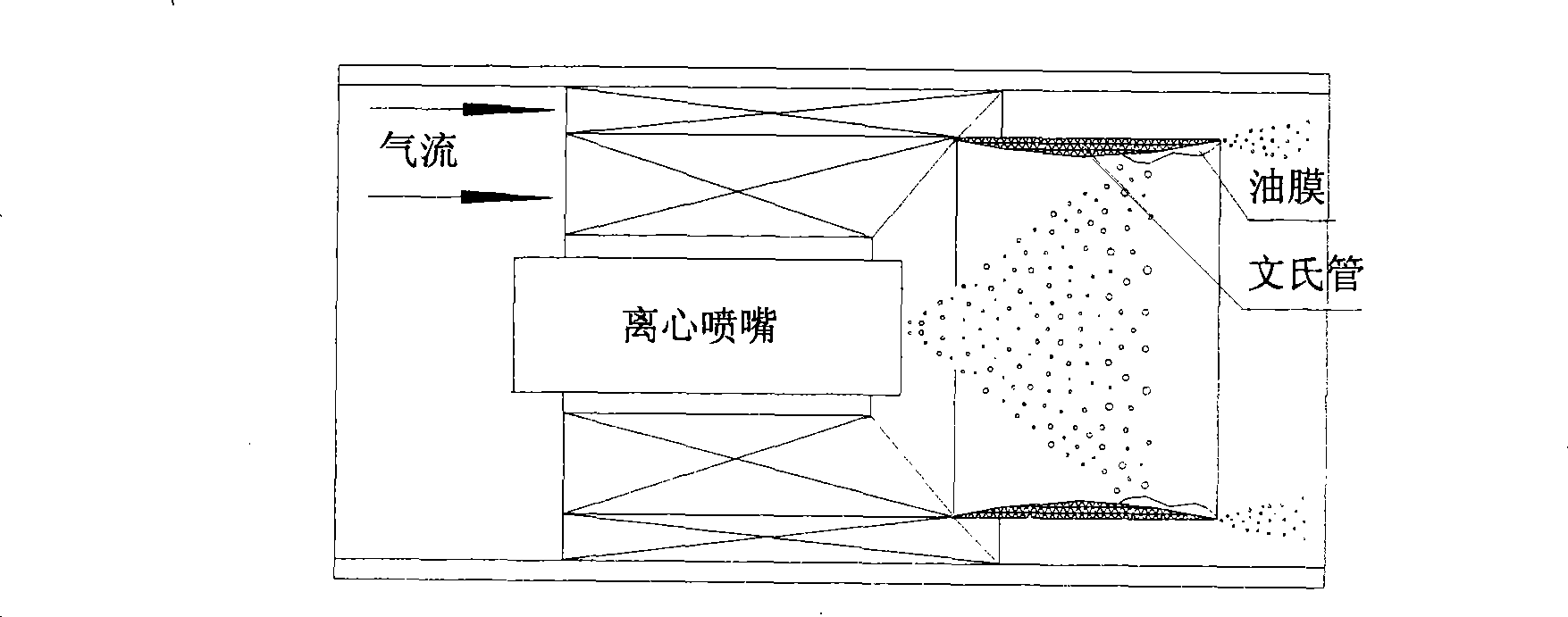

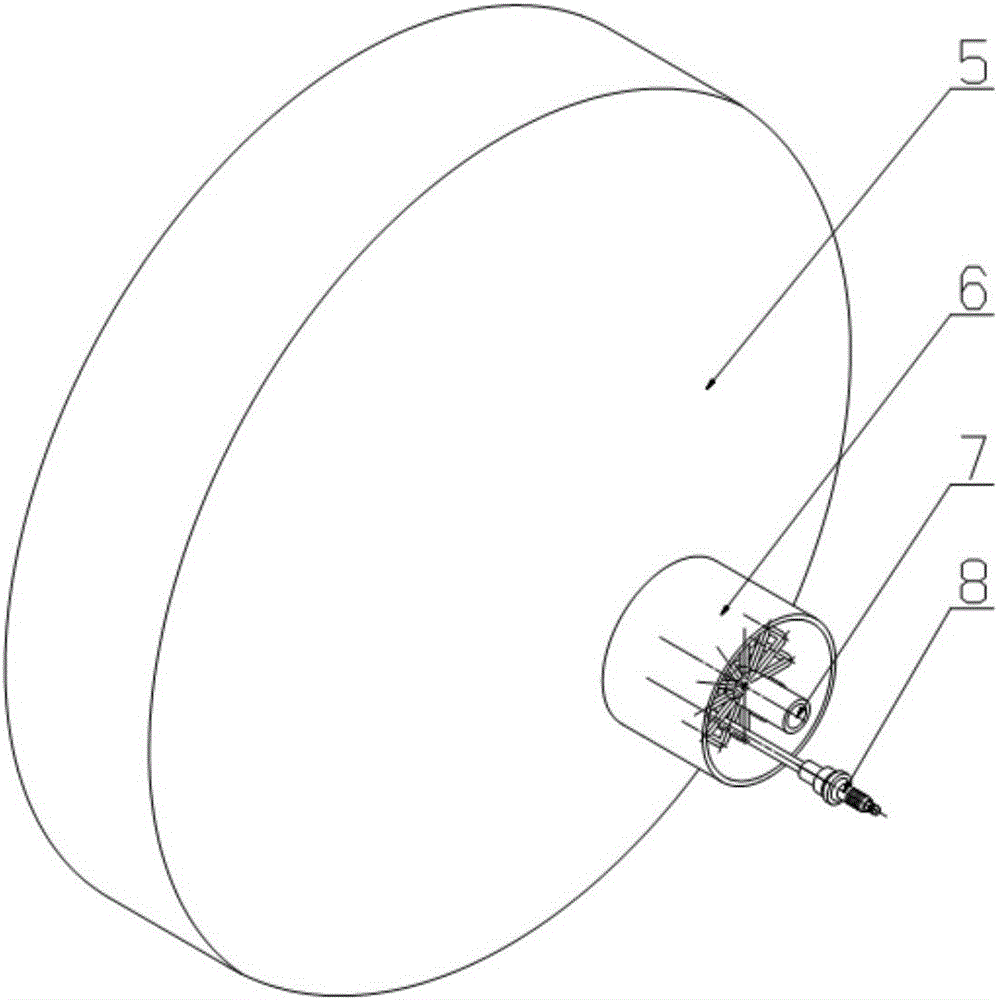

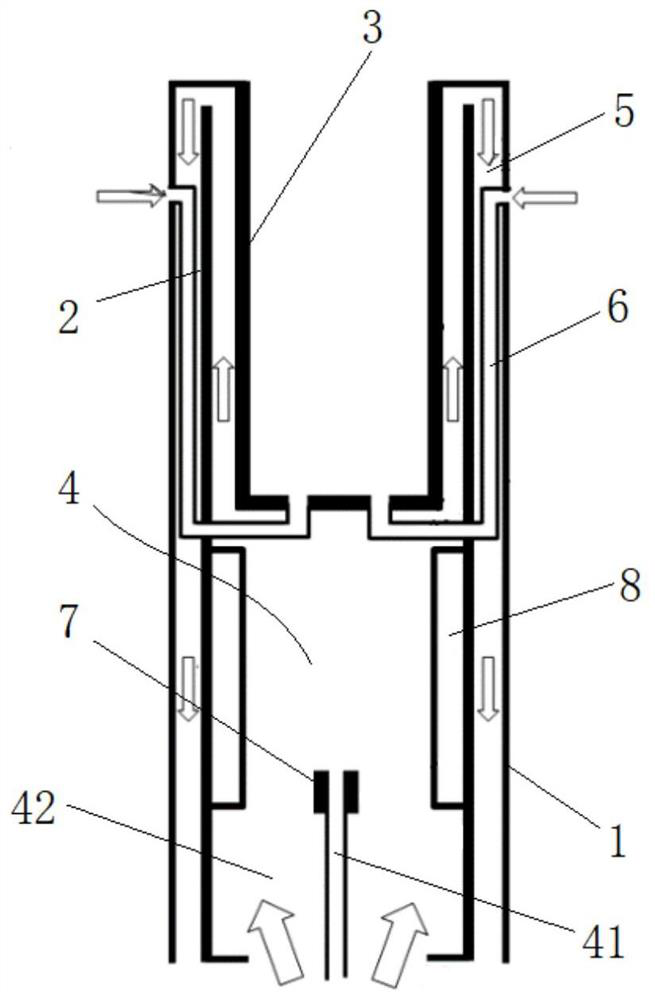

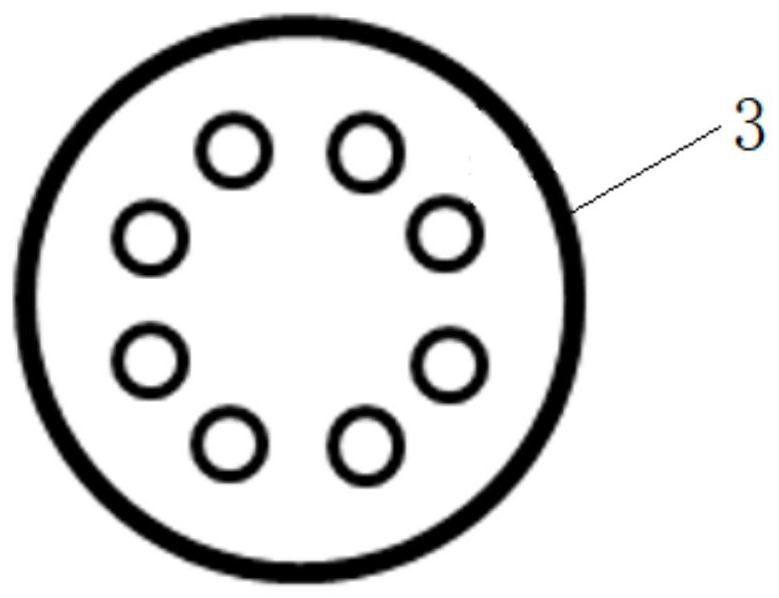

Gas turbine combined type fuel evaporating and atomizing combustion apparatus

InactiveCN101435585AIncrease the pre-mixed pre-evaporation processImprove atomization and evaporationContinuous combustion chamberAviationCyclone

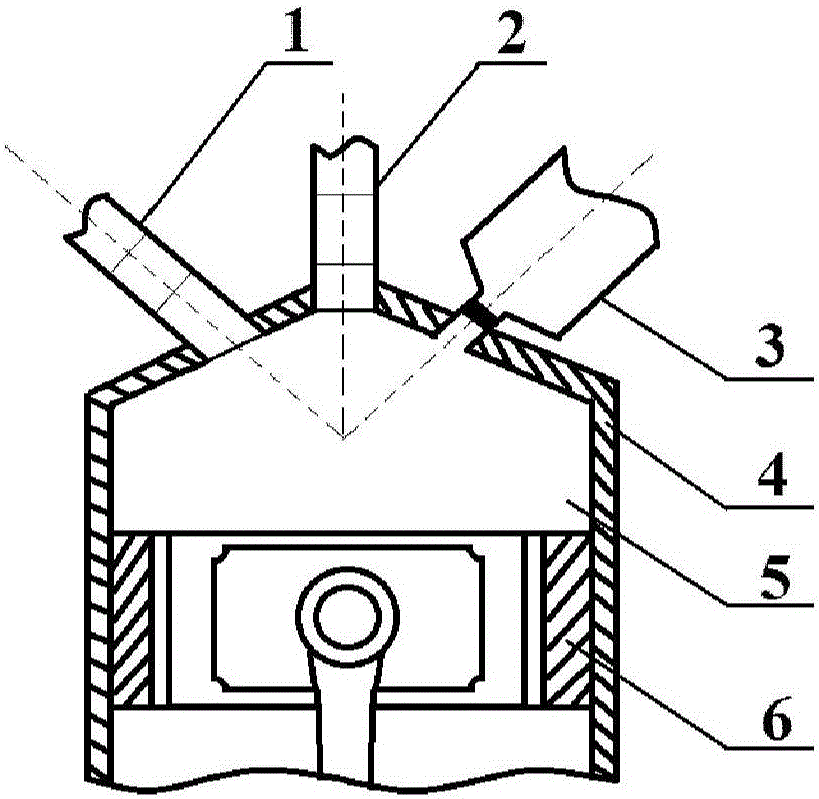

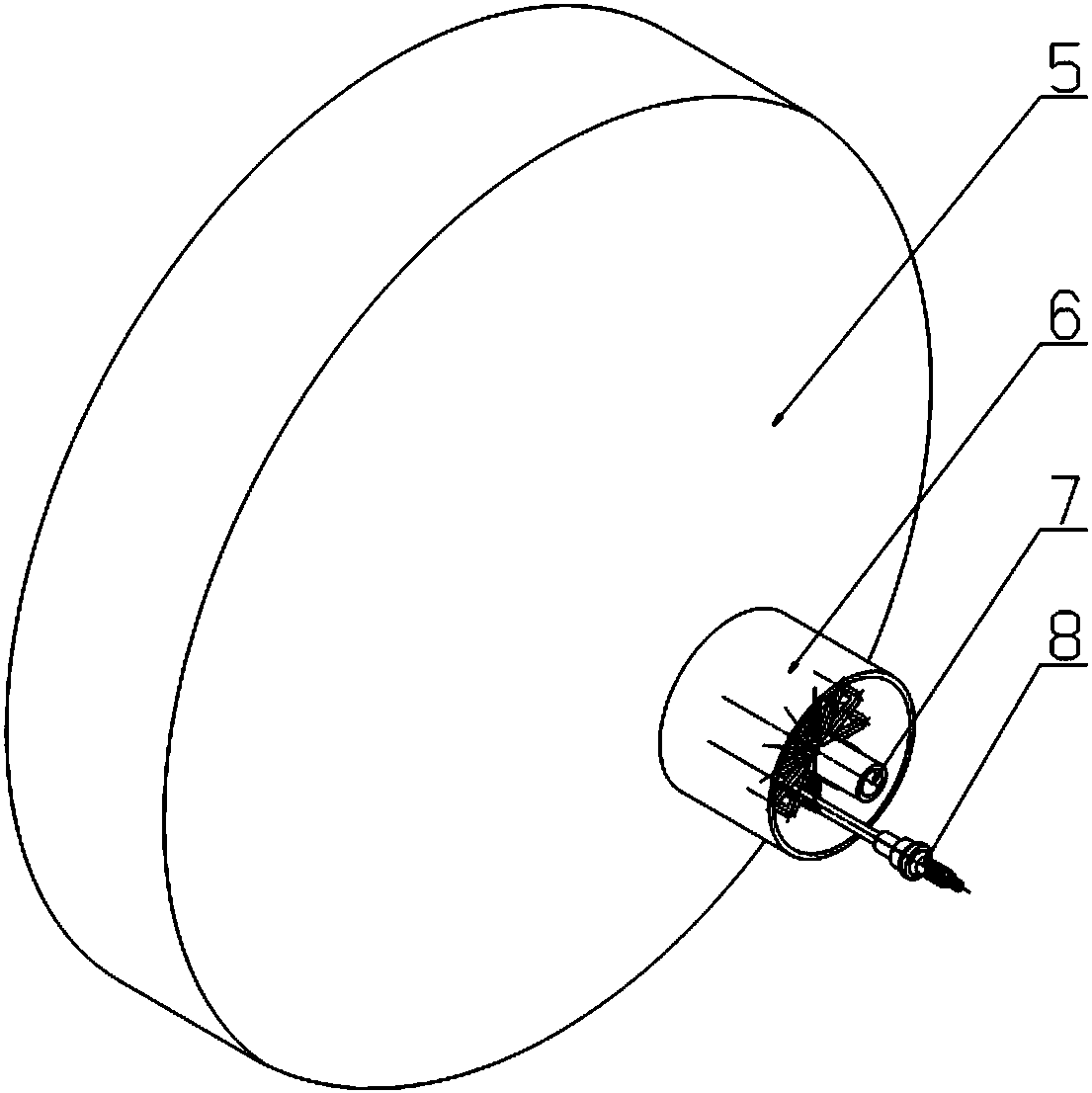

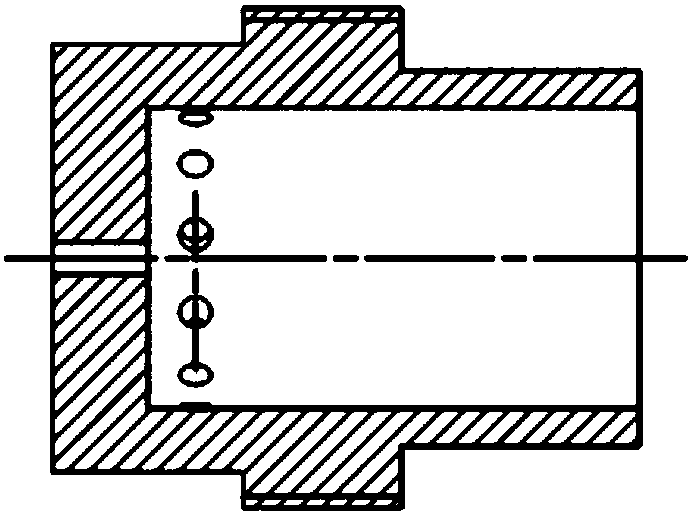

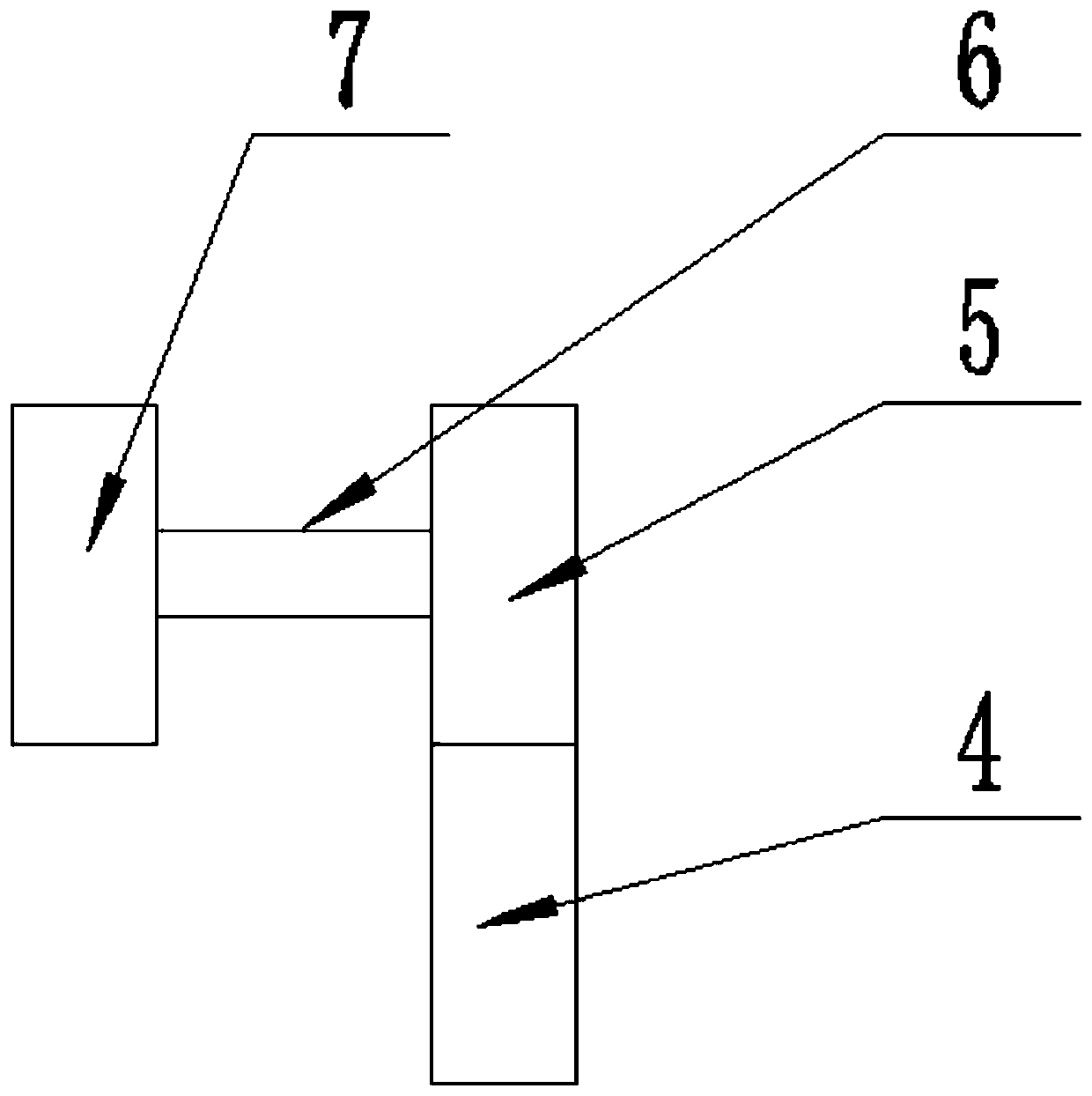

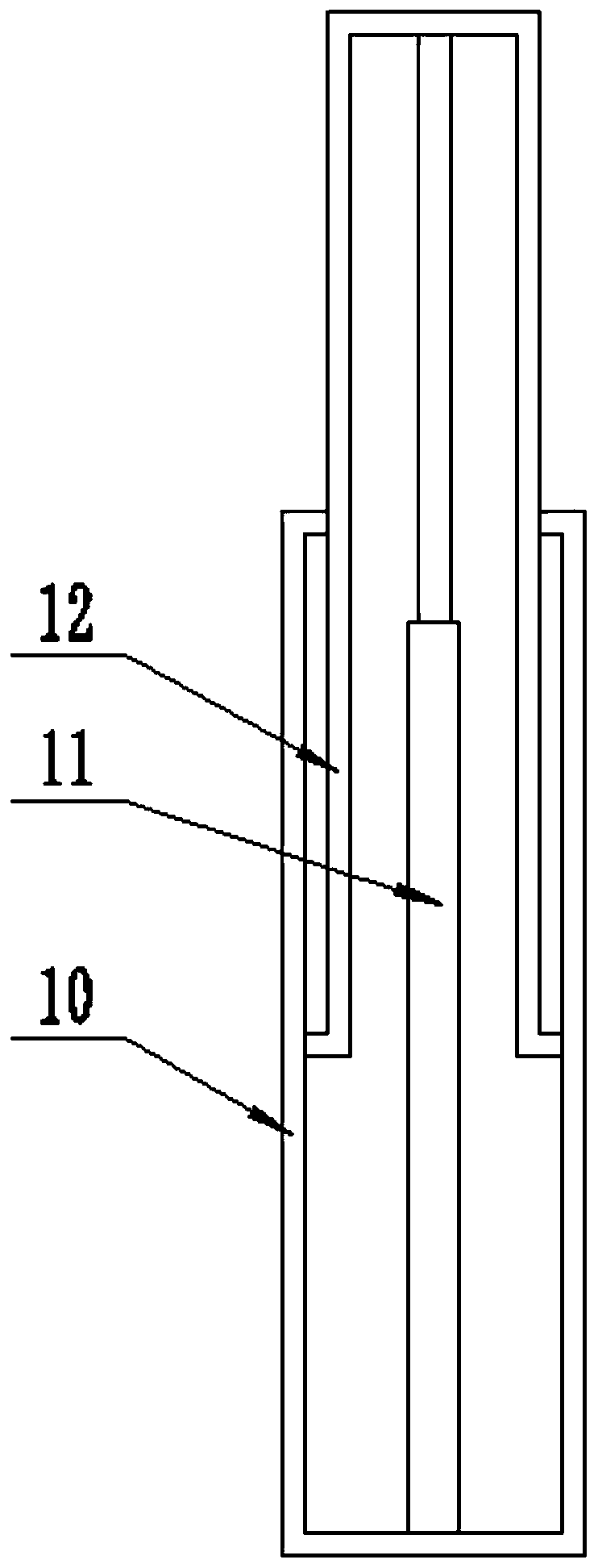

The invention provides a combined fuel oil atomizing, evaporating and combusting device for a gas turbine, relates to an air inlet device of the gas turbine, a fuel oil atomizing, evaporating and blending device, and core technology of organized combustion and stable flame, and belongs to the power field of an aeronautic power propulsion system and a ground gas turbine. A nozzle 1 is arranged at a central position of an inlet of a premixing chamber 2; an evaporator 3 is fixed in an inner cavity of the premixing chamber 2; double cyclones 4 are arranged at the inside of the outlet end of the premixing chamber 2 and connected hermetically; a centrifugal nozzle 5 is arranged at a central position of the double cyclones 4; a venturi 6 is welded at a transition position of an outlet of internal and external cyclones of the double cyclones 4; a sleeve 7 is hermetically welded with the outside of an outlet of the premixing chamber 2; and the head of a combustion chamber 8 is hermetically welded with the sleeve 7. Compared with the prior fuel oil combined nozzle, the device has the advantages of improving properties of fuel oil atomizing, evaporating and blending and evenness of oil-gas space distribution, improving combustion performance, shortening flame length and reducing discharge of pollutant, and is a comparatively ideal combined fuel oil atomizing and combusting device for a high-performance gas turbine.

Owner:PEKING UNIV

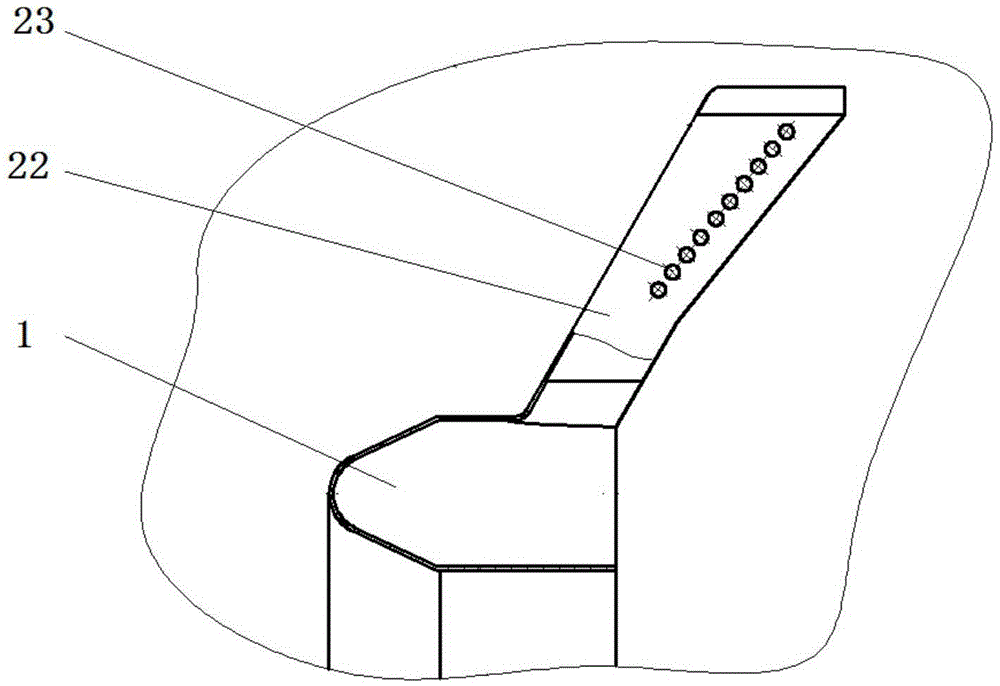

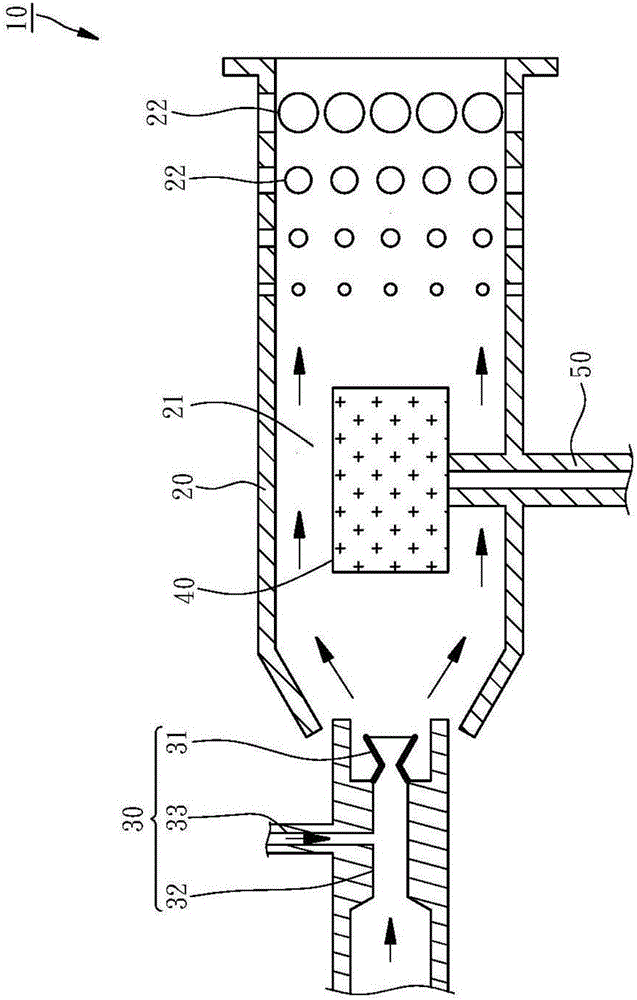

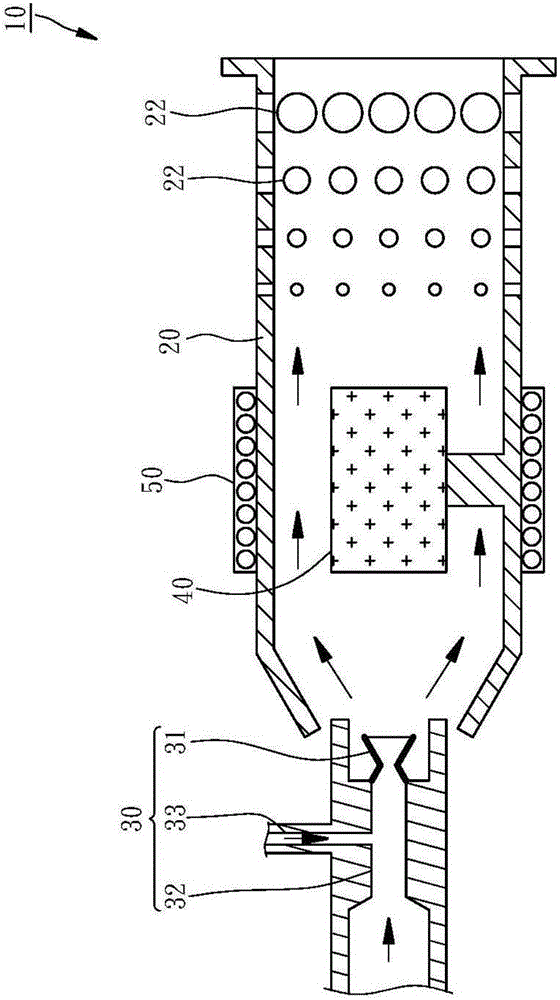

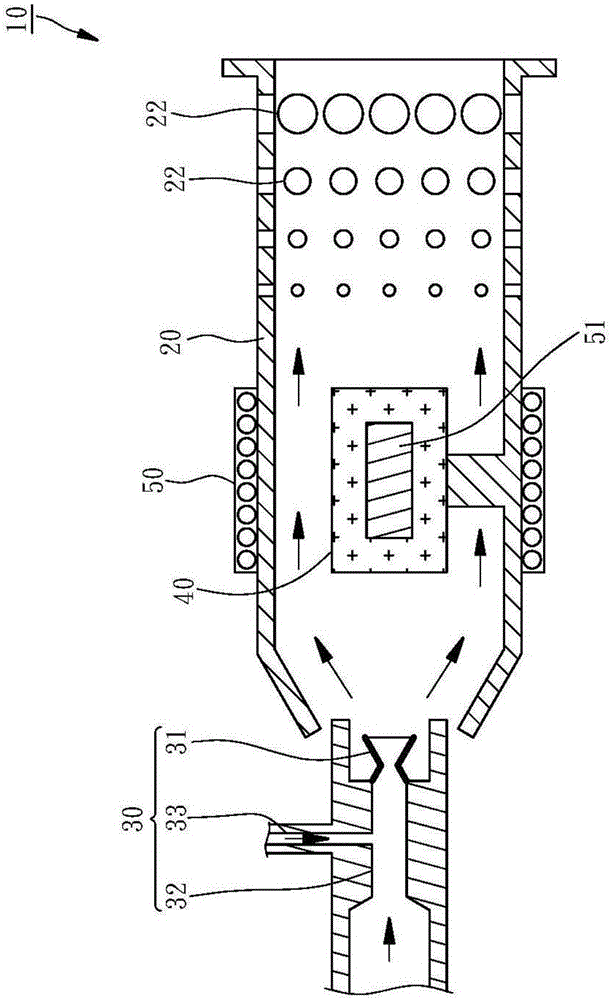

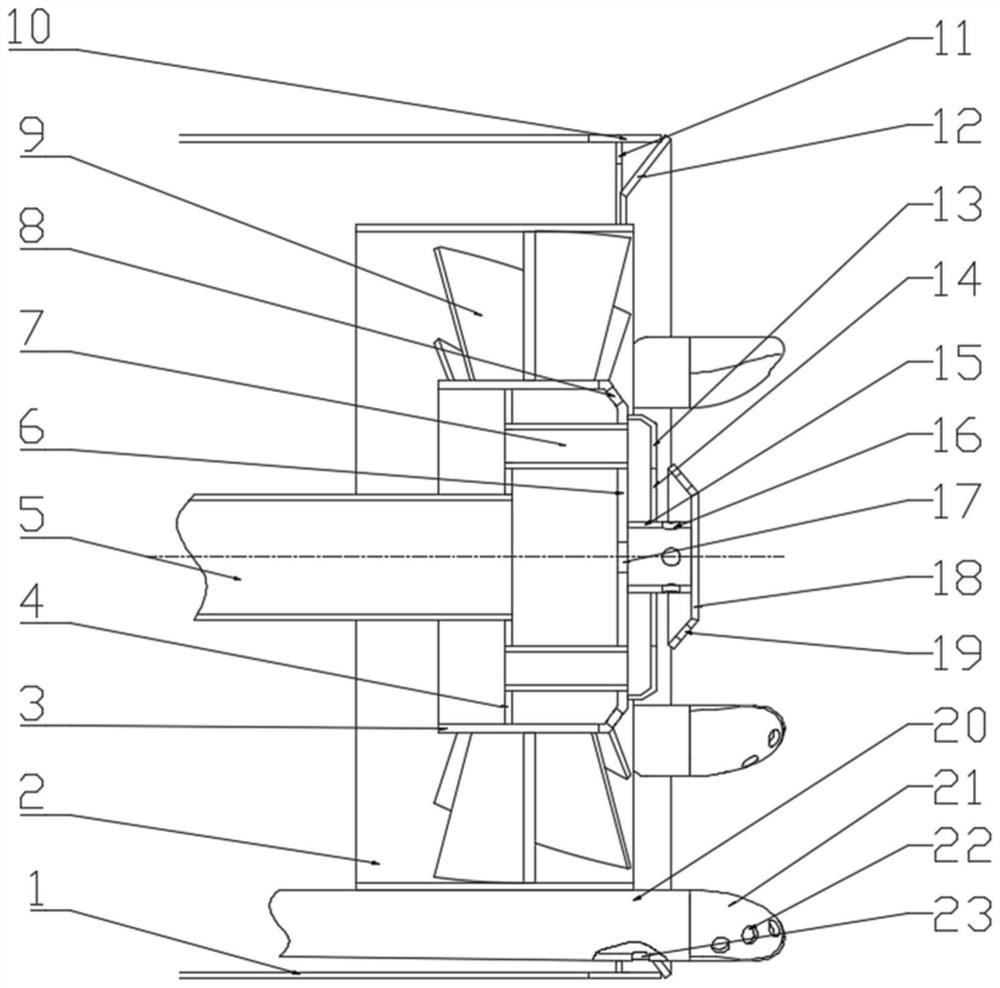

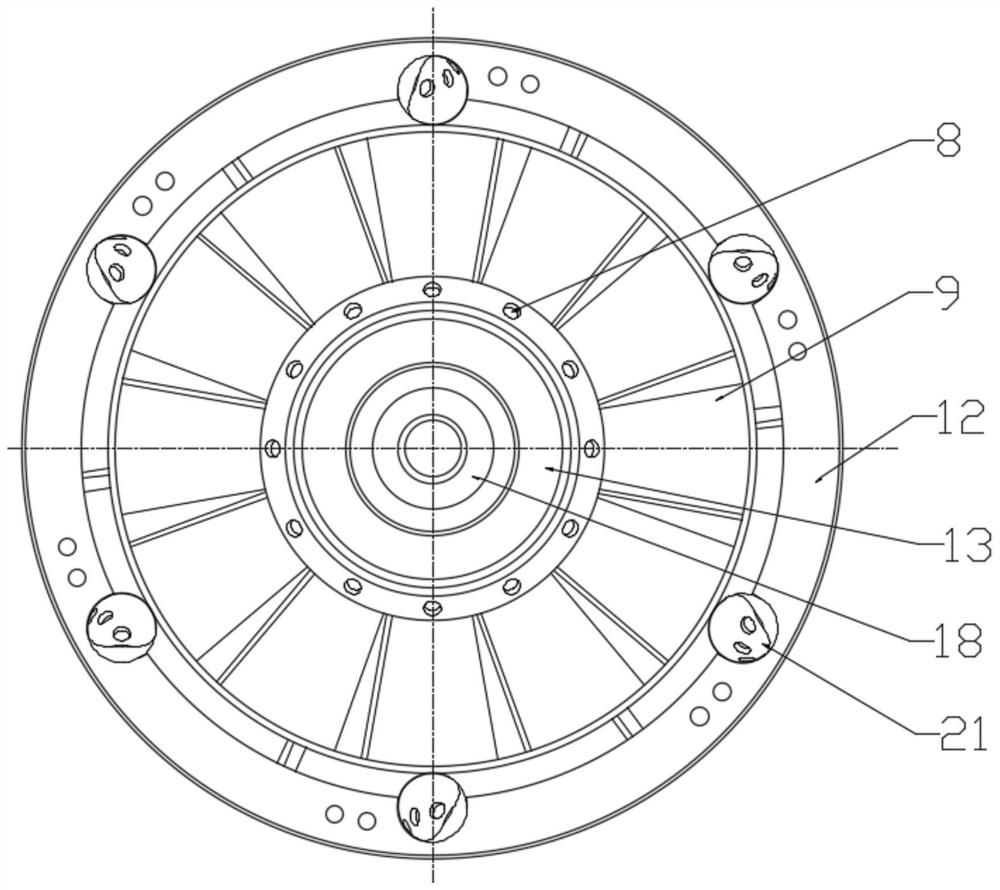

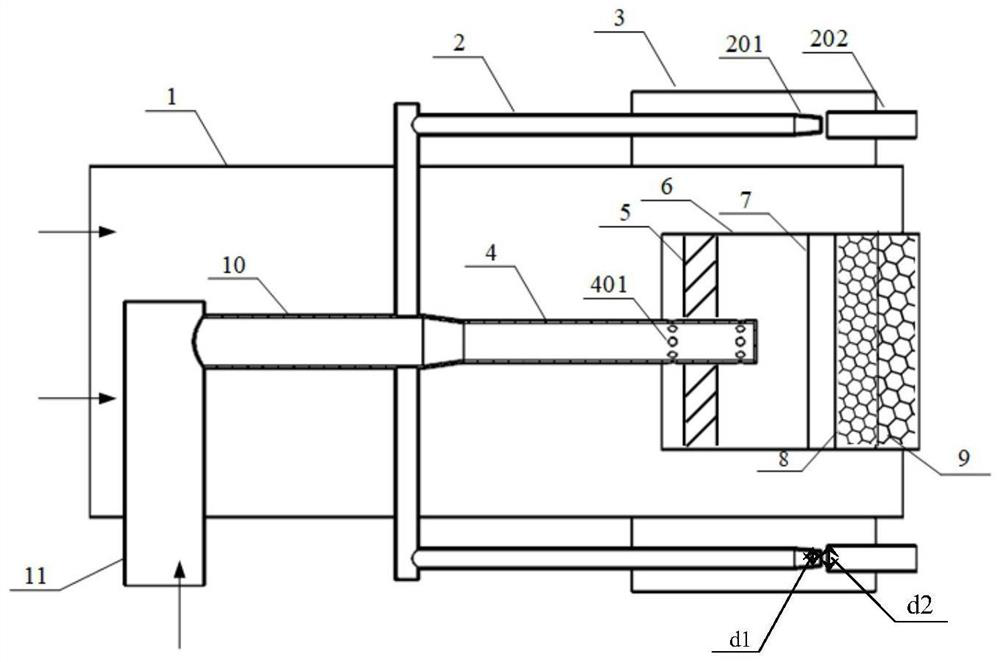

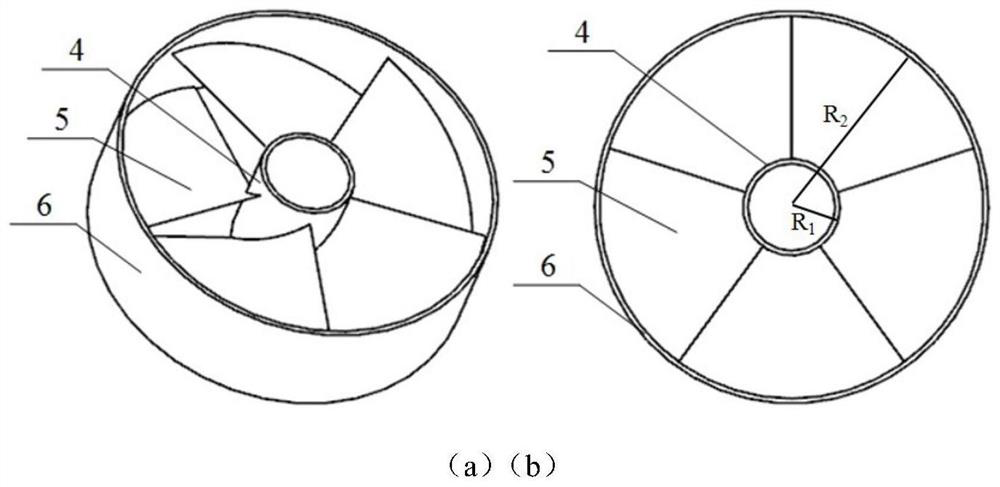

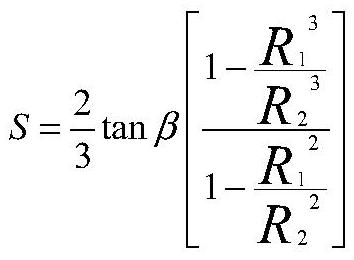

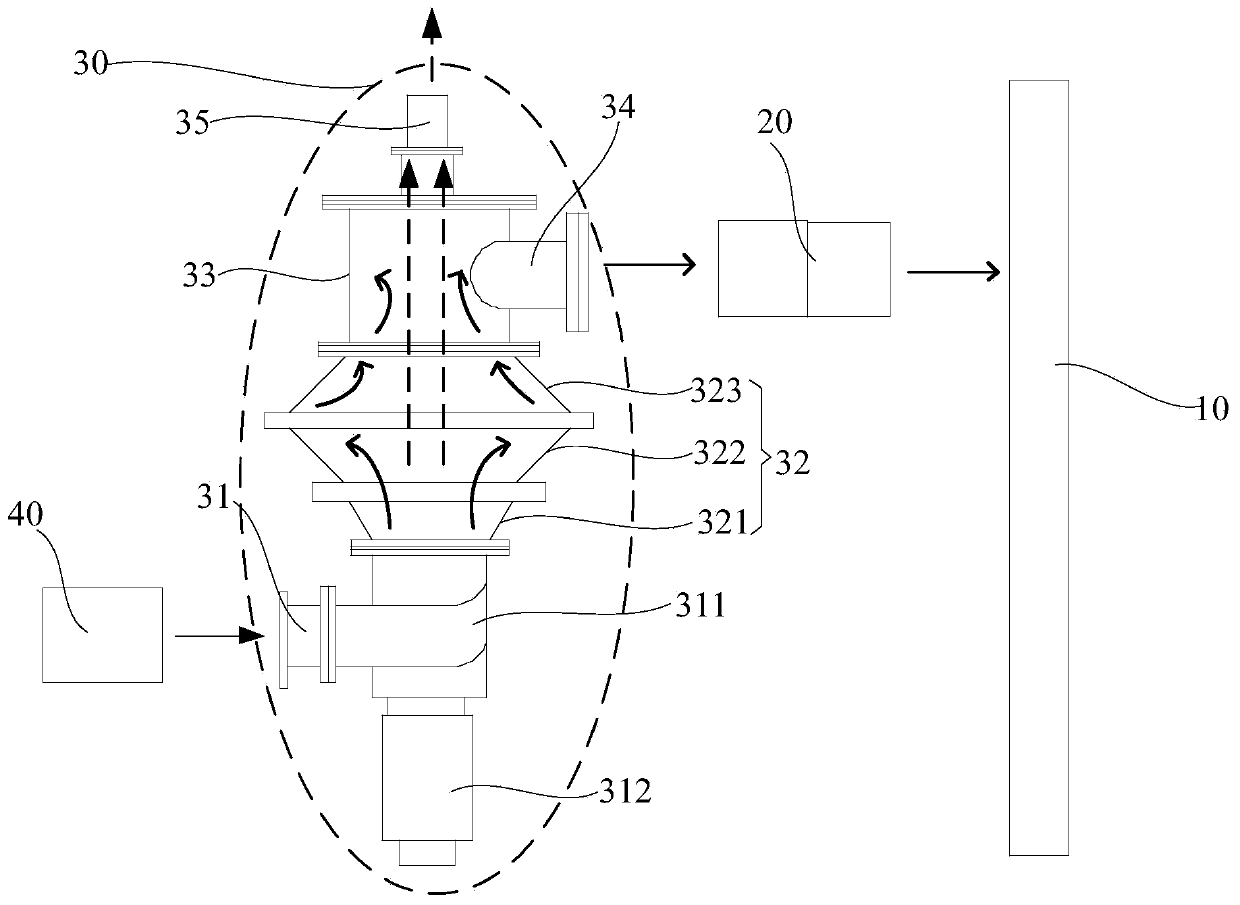

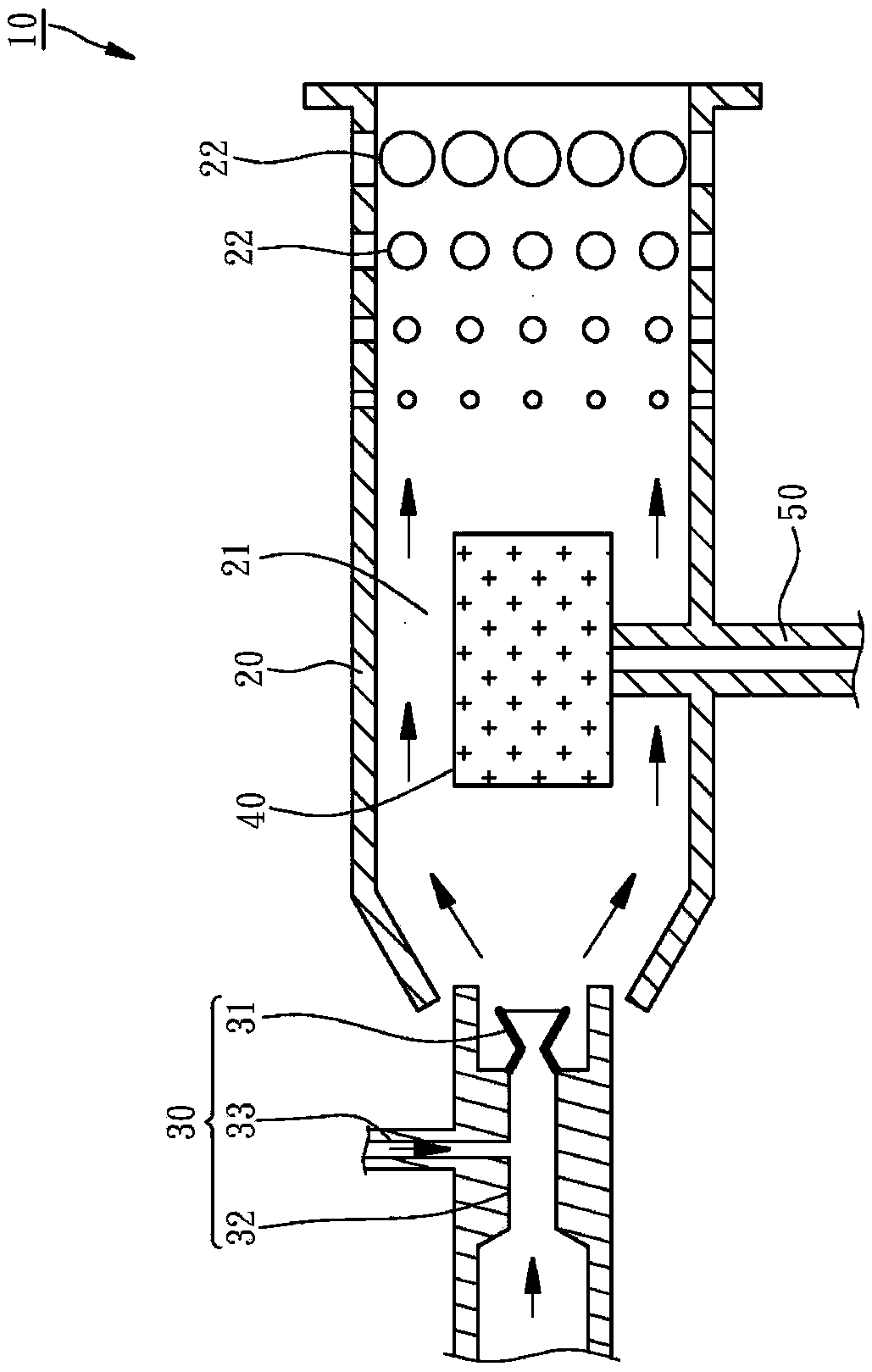

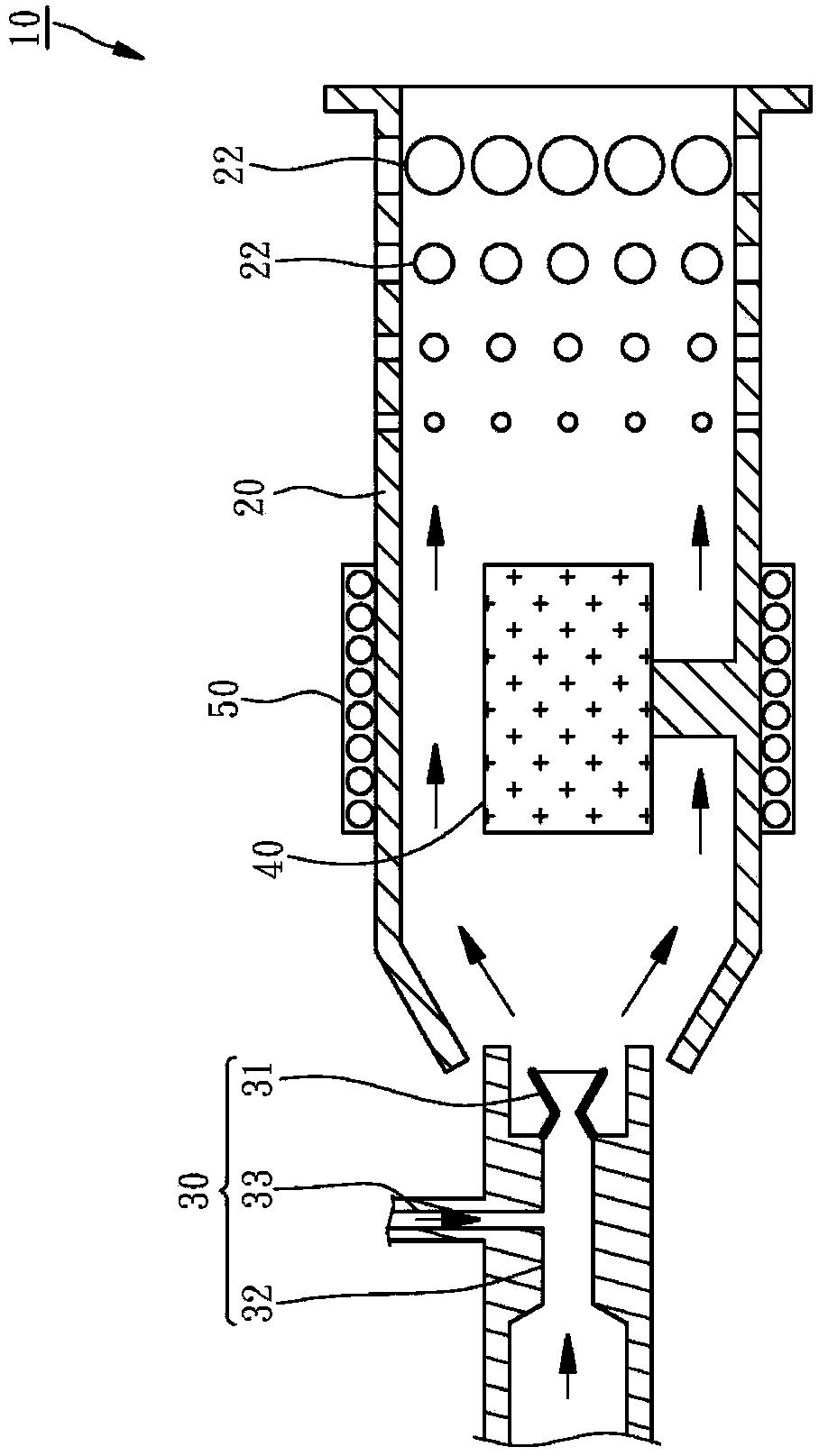

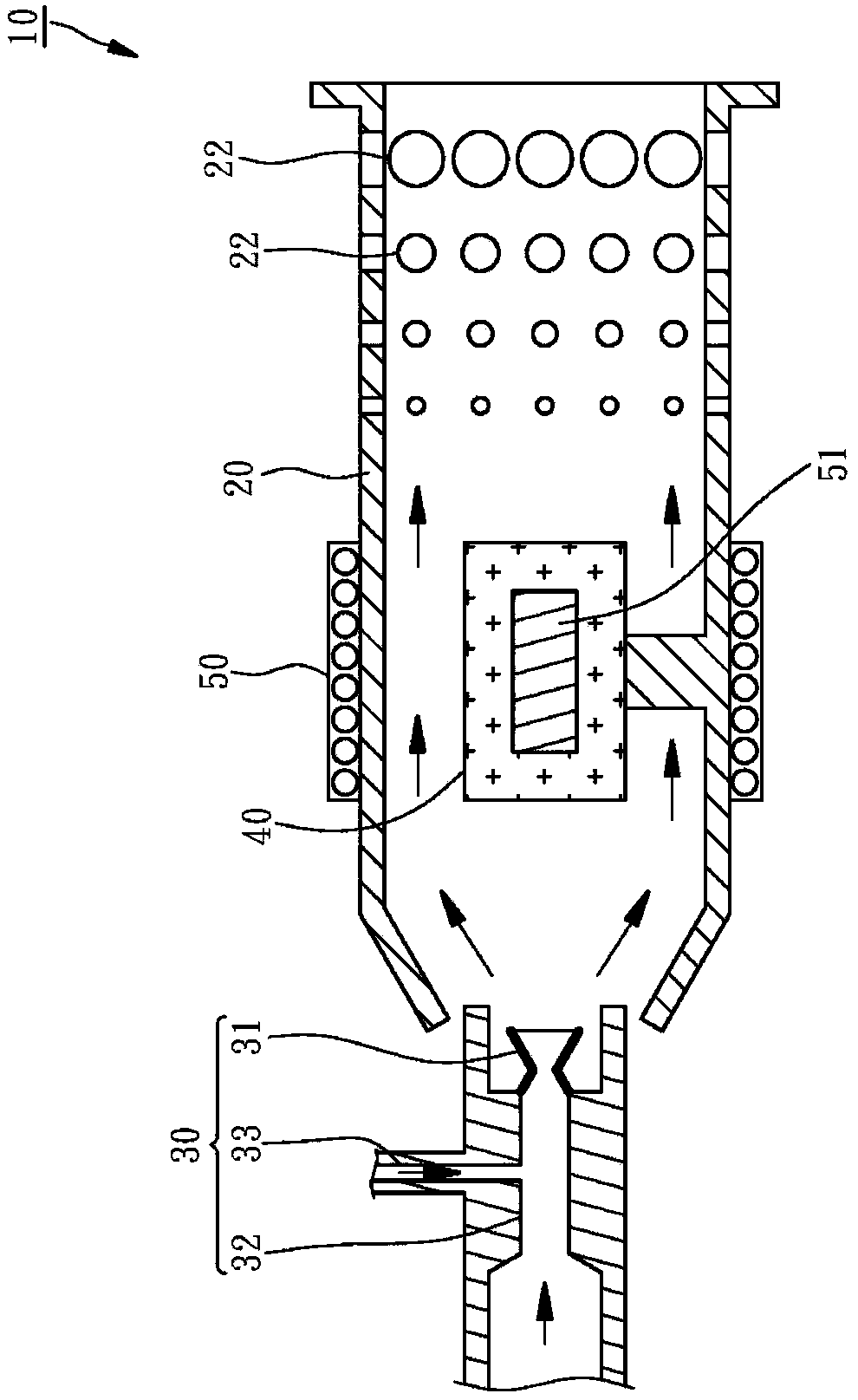

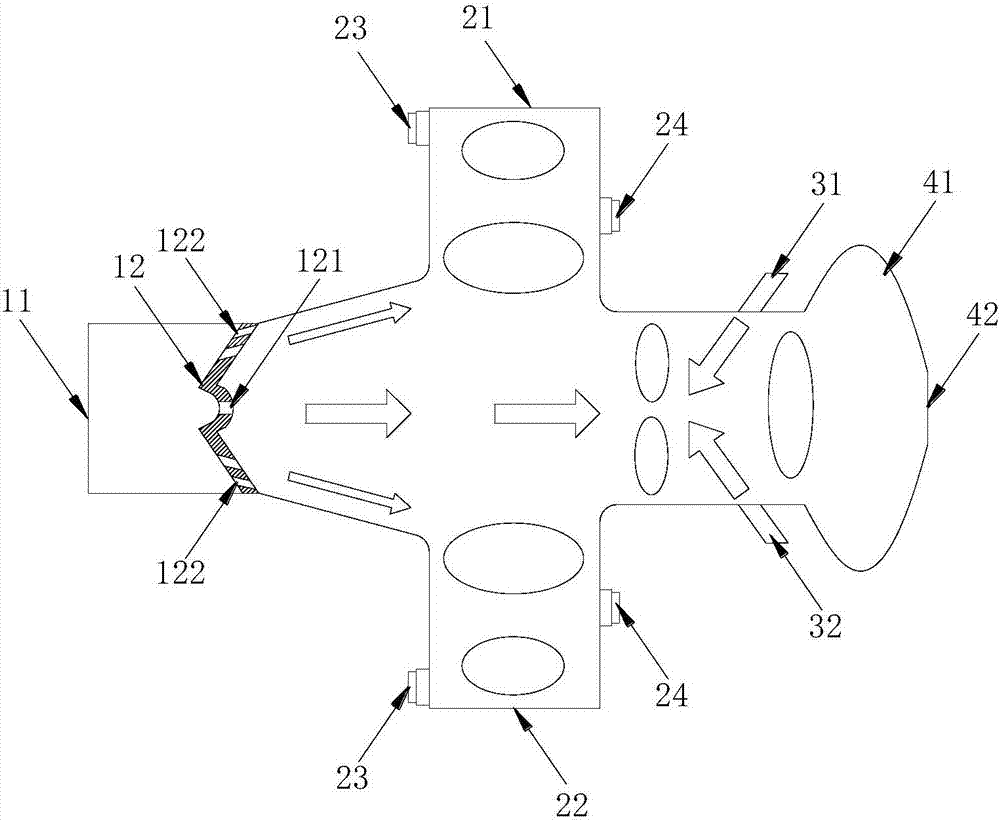

Premixing strong swirling flow flame diffusion burner

ActiveCN106090907AExtended combustion rangeIncrease the heating areaGaseous fuel burnerCombustion chamberCombustor

The invention discloses a premixing strong swirling flow flame diffusion burner. Center grading structure design is adopted. The premixing strong swirling flow flame diffusion burner comprises a combustion box, an air pipeline, a fuel pipeline, a swirler, a precombustion level air hole, a precombustion level nozzle and a main combustion level nozzle. The air pipeline is connected with an inlet of the combustion box through welding and is used for guiding air to pass through the swirling flow burner and enter a combustor for combustion. The fuel pipeline supplies gaseous fuel to the precombustion level nozzle and the main combustion level nozzle, wherein 25%-40% of the fuel enters the precombustion level nozzle and is then sprayed into the combustor to be mixed with precombustion level air directly entering the combustor through the precombustion level air hole for diffusive combustion. Through a premixing strong swirling flow flame diffusion structure adopted by the burner, the downstream combustion area can be enlarged well, the heating area is enlarged, thus a larger space range can be heated through the burner with a small area, meanwhile, the combustion efficiency is improved, and pollutant discharge is reduced.

Owner:BEIHANG UNIV

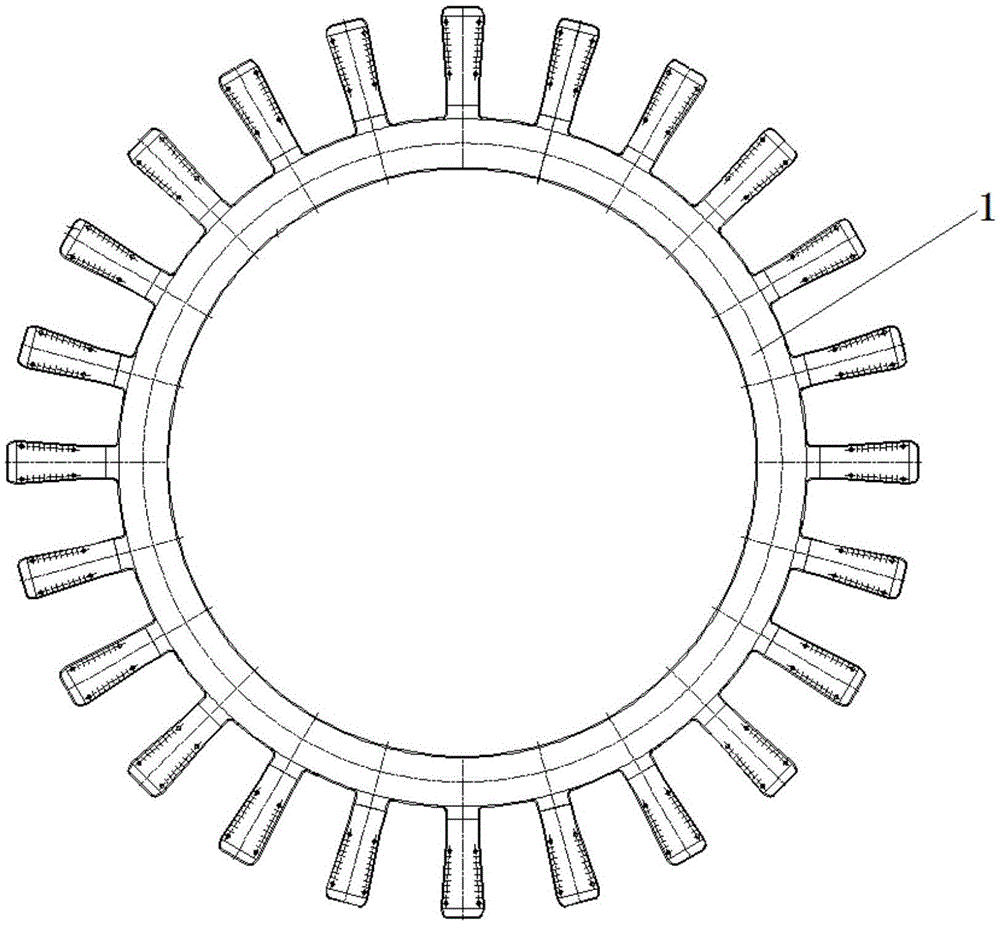

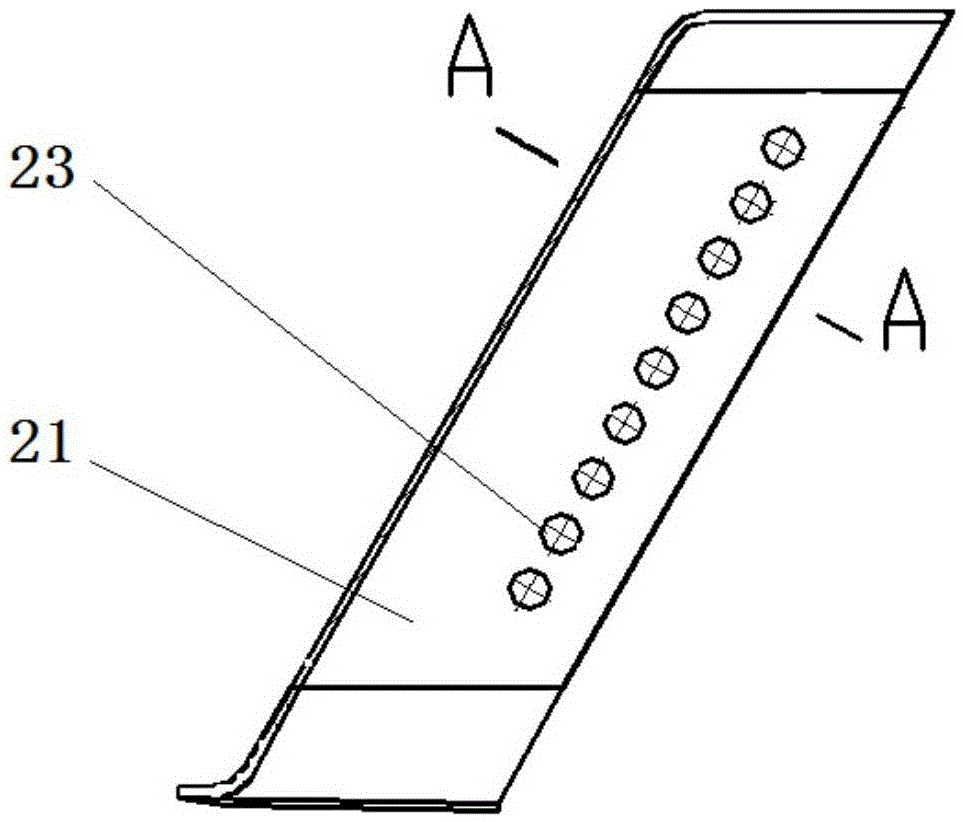

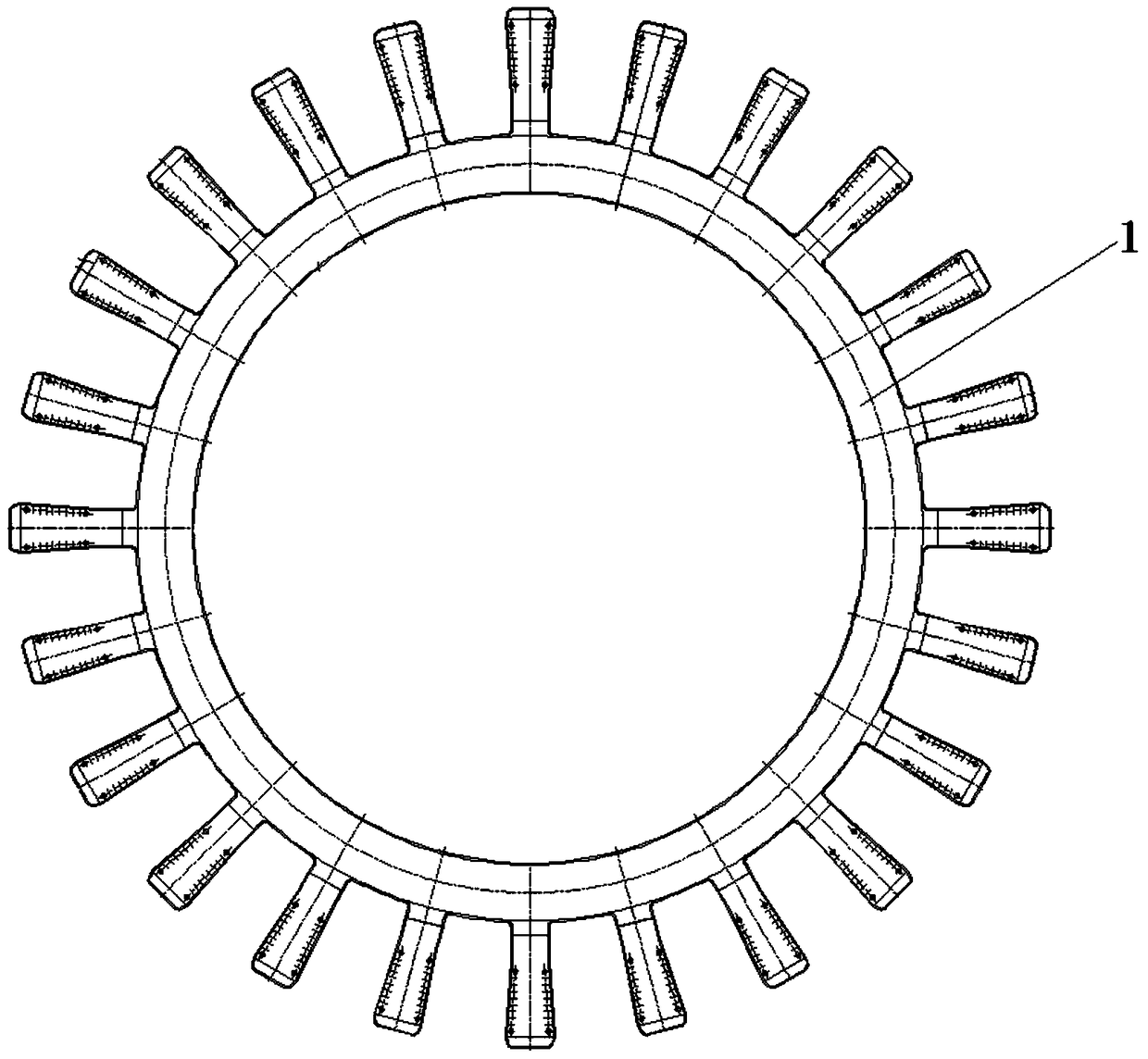

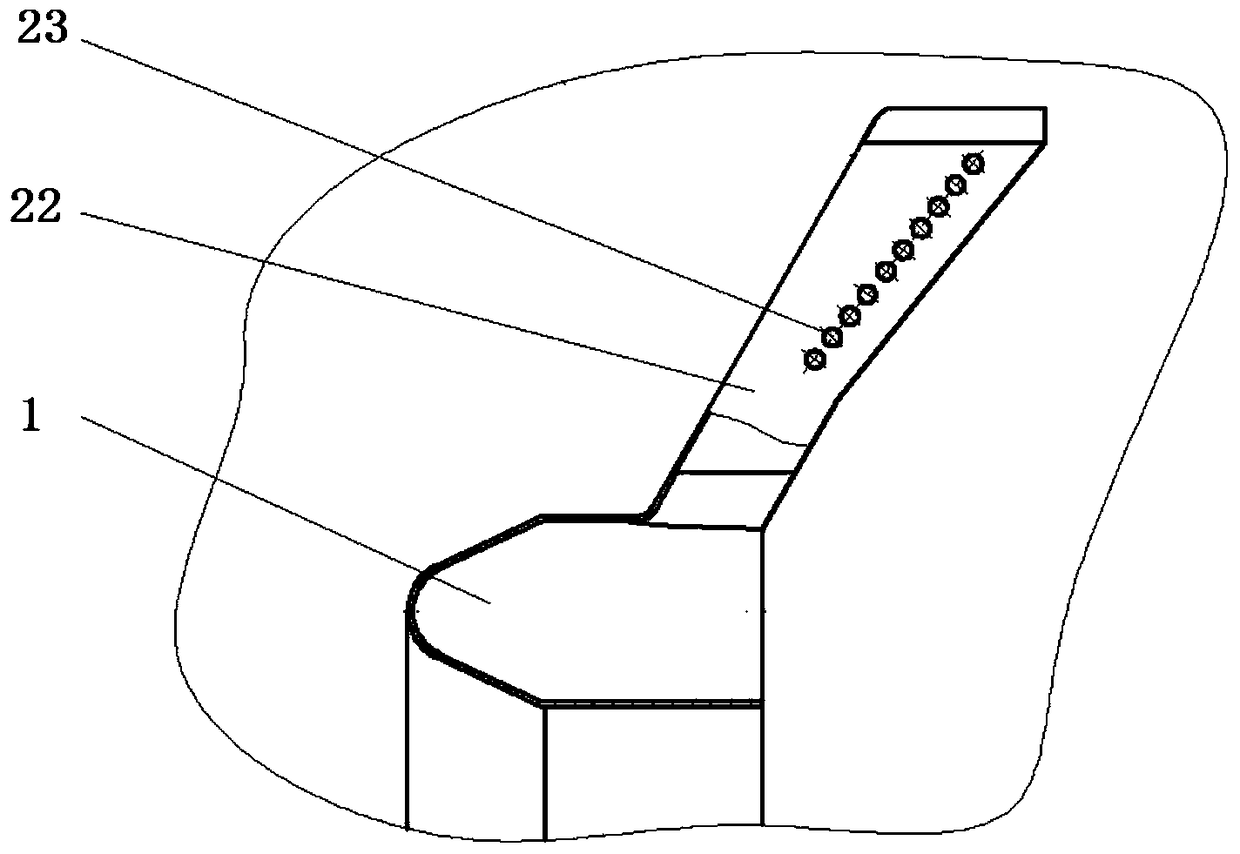

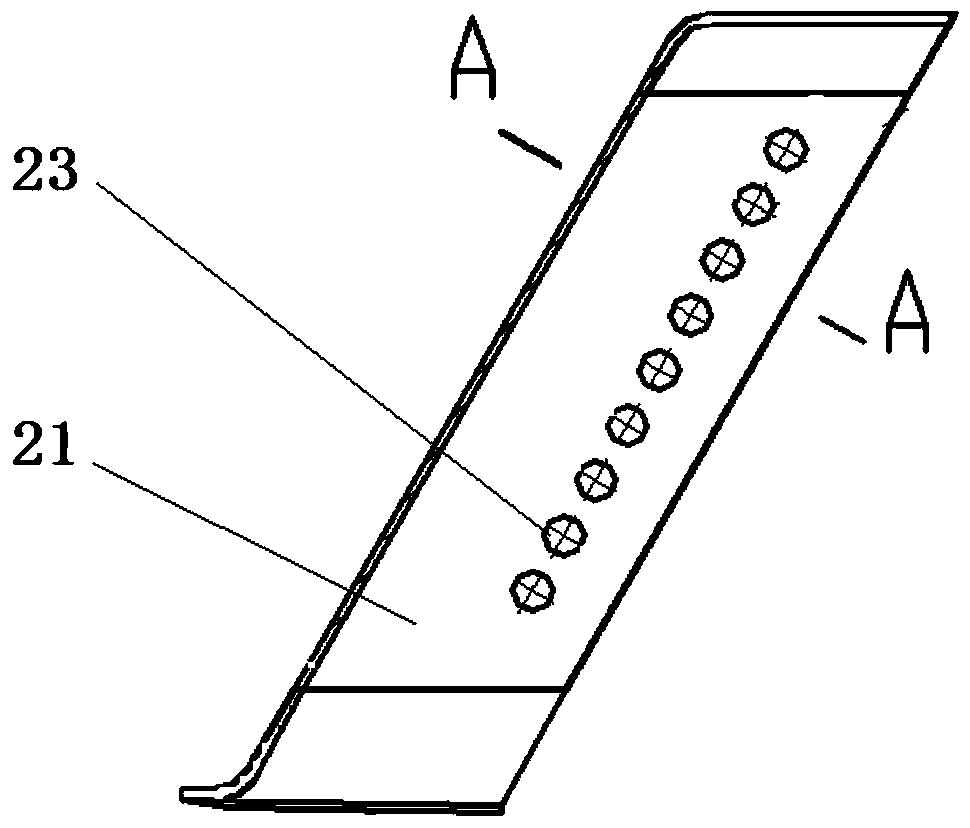

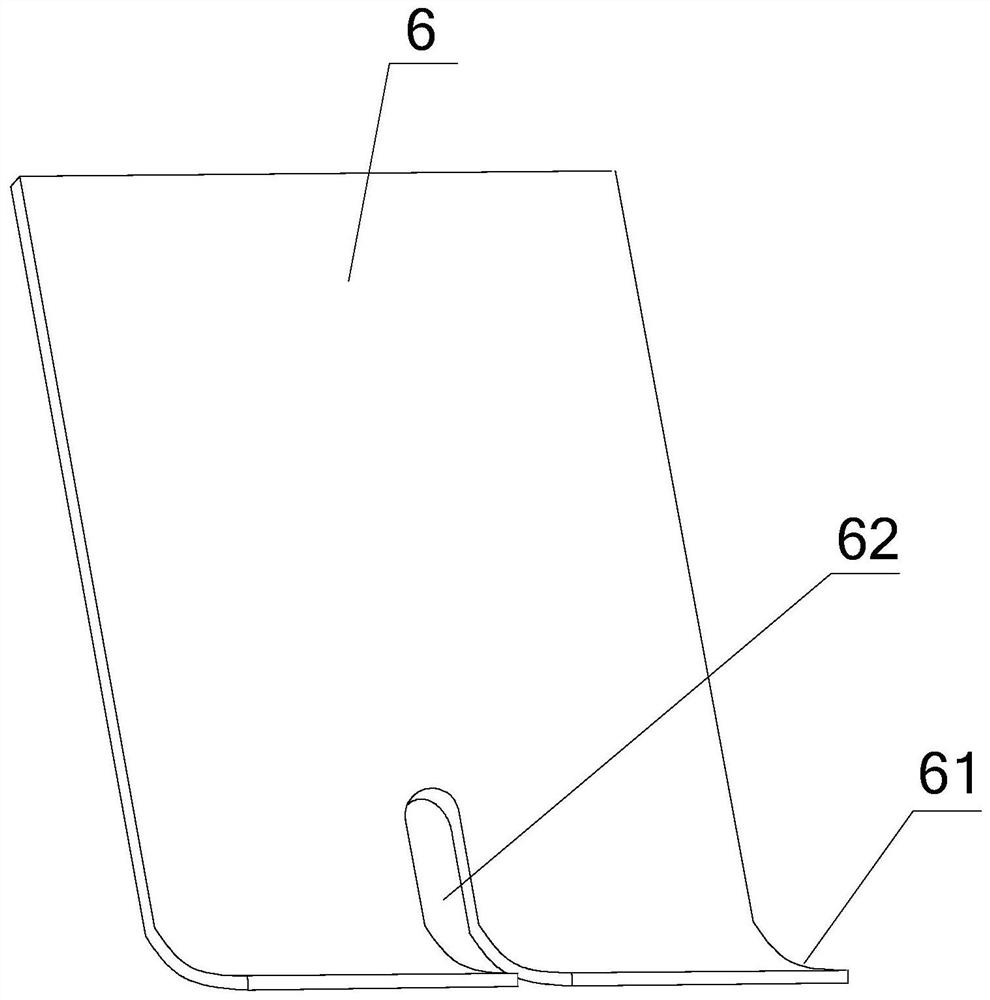

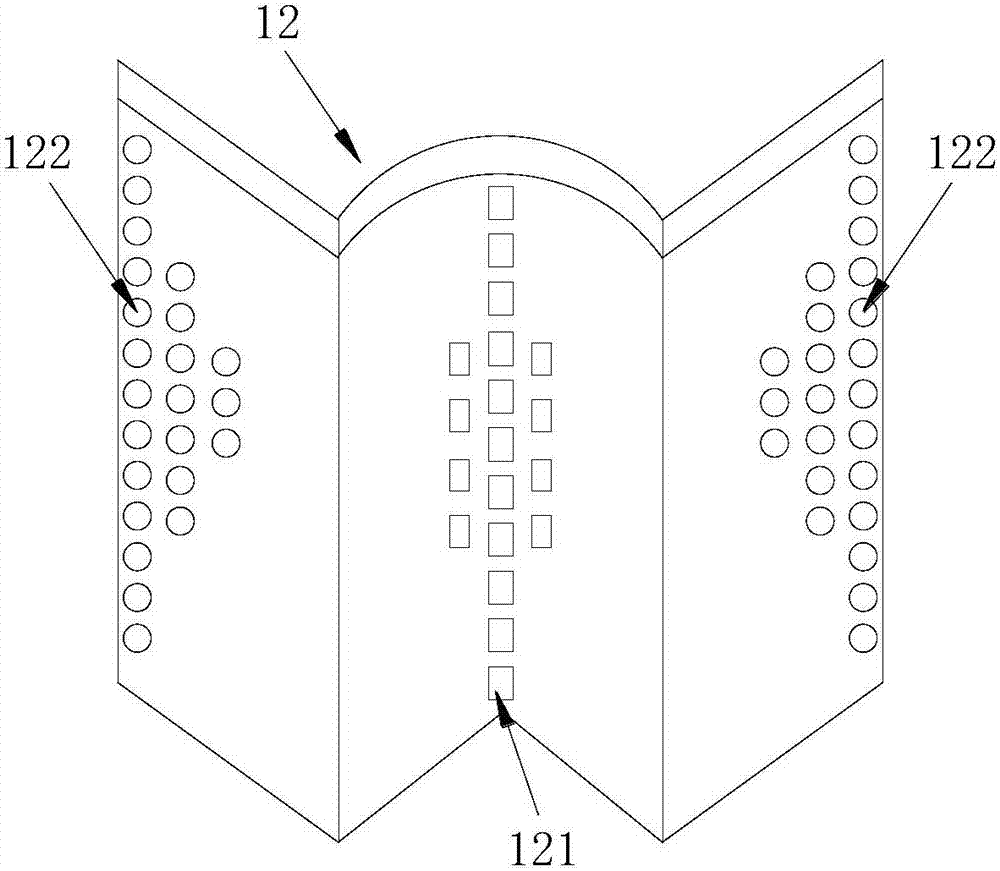

Flame stabilizer

ActiveCN105546578AWiden the boundary of lean flameoutImprove combustion efficiencyContinuous combustion chamberAviationLiquid state

The invention relates to an aviation gas turbine engine afterburner flame stabilization technology, in particular to a flame stabilizer which at least solves the problem that mixed gasoline gas in a recirculation zone of the conventional flame stabilizer is lean. The flame stabilizer is positioned in an outer duct of an afterburner, and is a radial flame stabilizer which extends outwards from an annular flame stabilizer at a junction of an inner duct and the outer duct; the flame stabilizer is provided with a first wall surface and a second wall surface that are symmetrically distributed; and a plurality of air suction holes are symmetrically formed in the first wall surface and the second wall surface. Low-pressure air in the recirculation zone can be used to suck liquid-state fuel oil nearby the wall surfaces of the flame stabilizer, and a lean oil flameout boundary of the flame stabilizer can be widened. In addition, a mass-energy exchange rate in the recirculation zone can be increased, the combustion efficiency of the flame stabilizer can be improved, and the stable combustion range can be widened.

Owner:AECC SHENYANG ENGINE RES INST

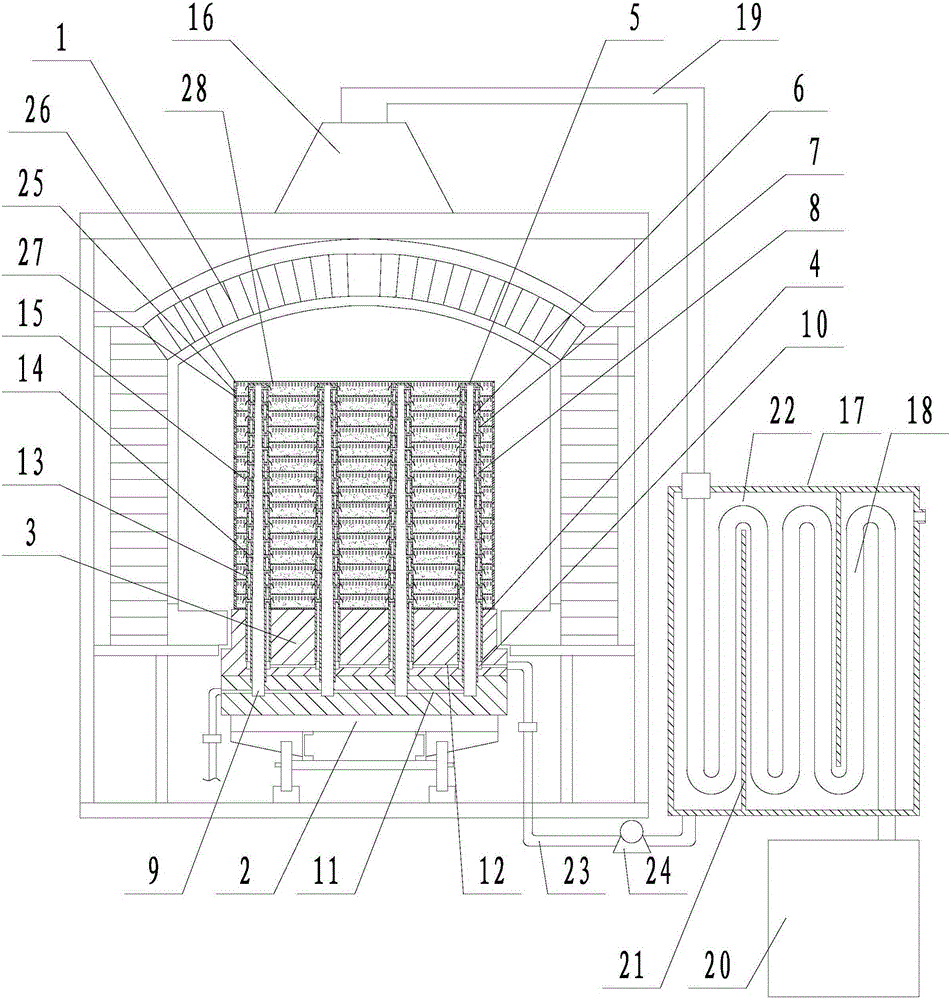

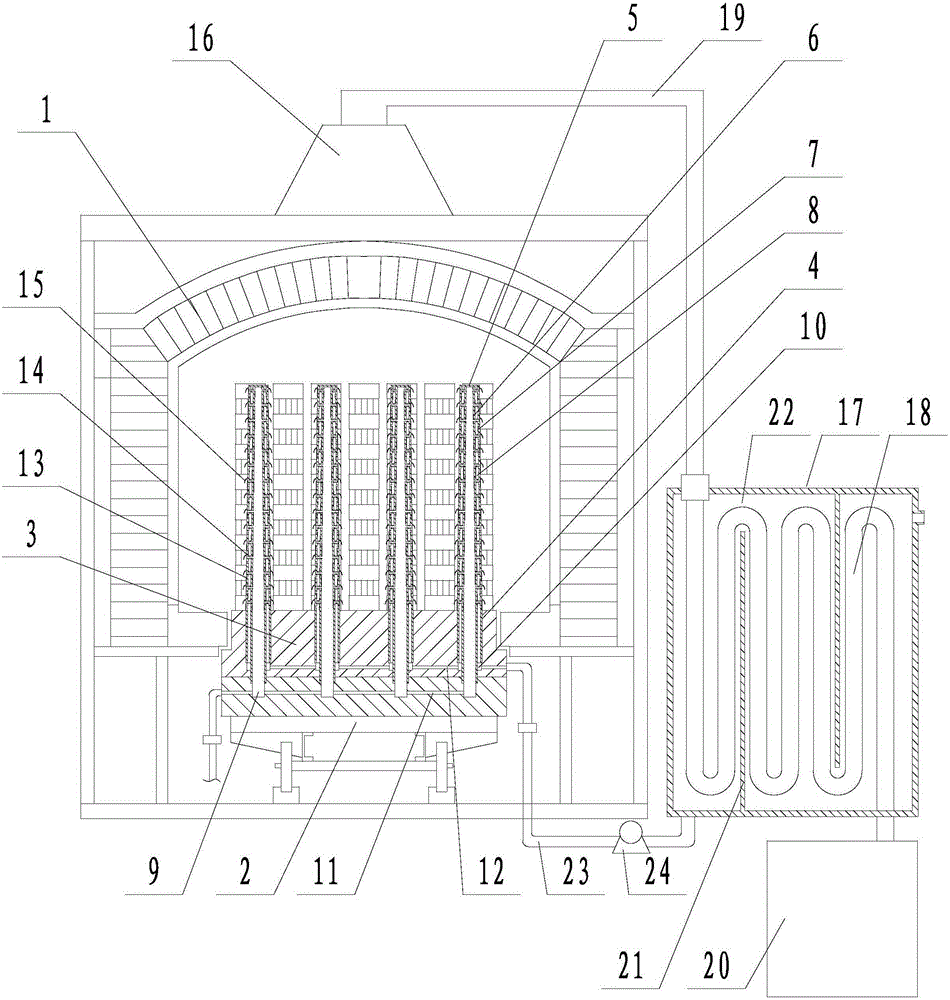

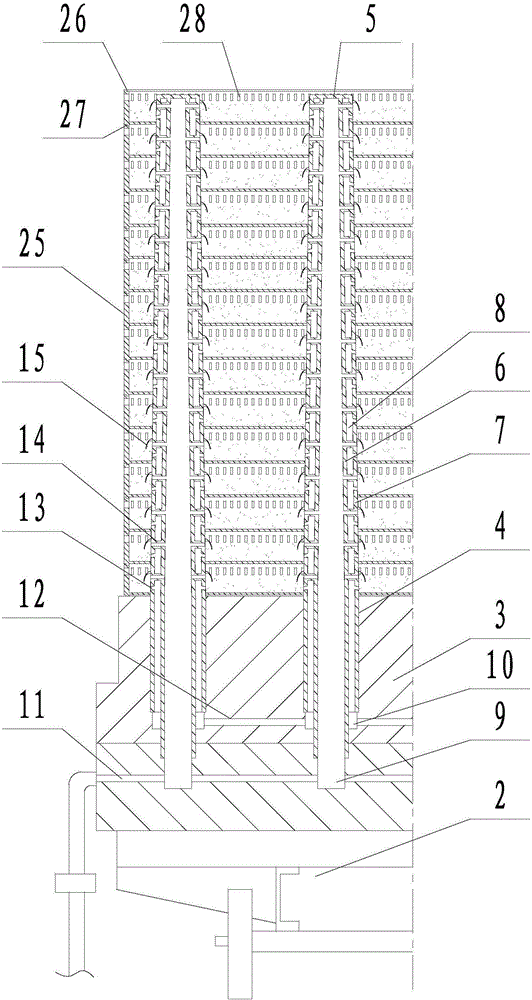

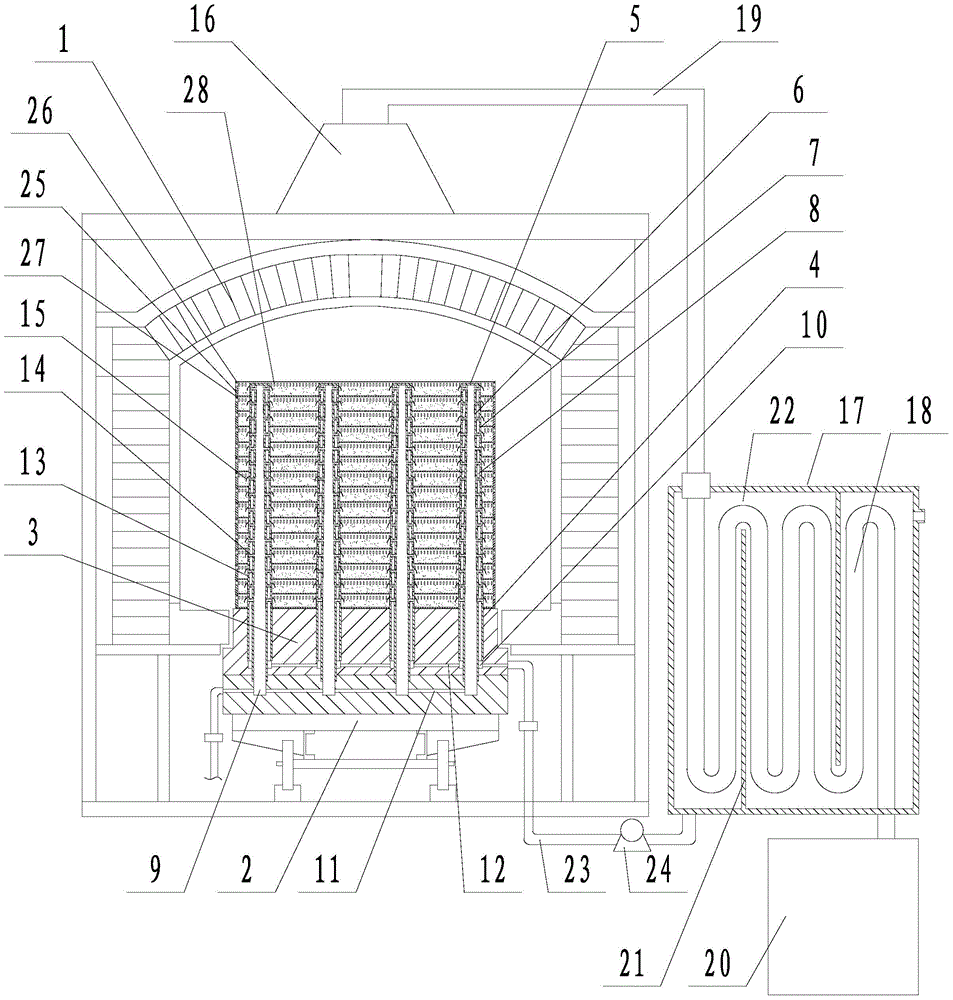

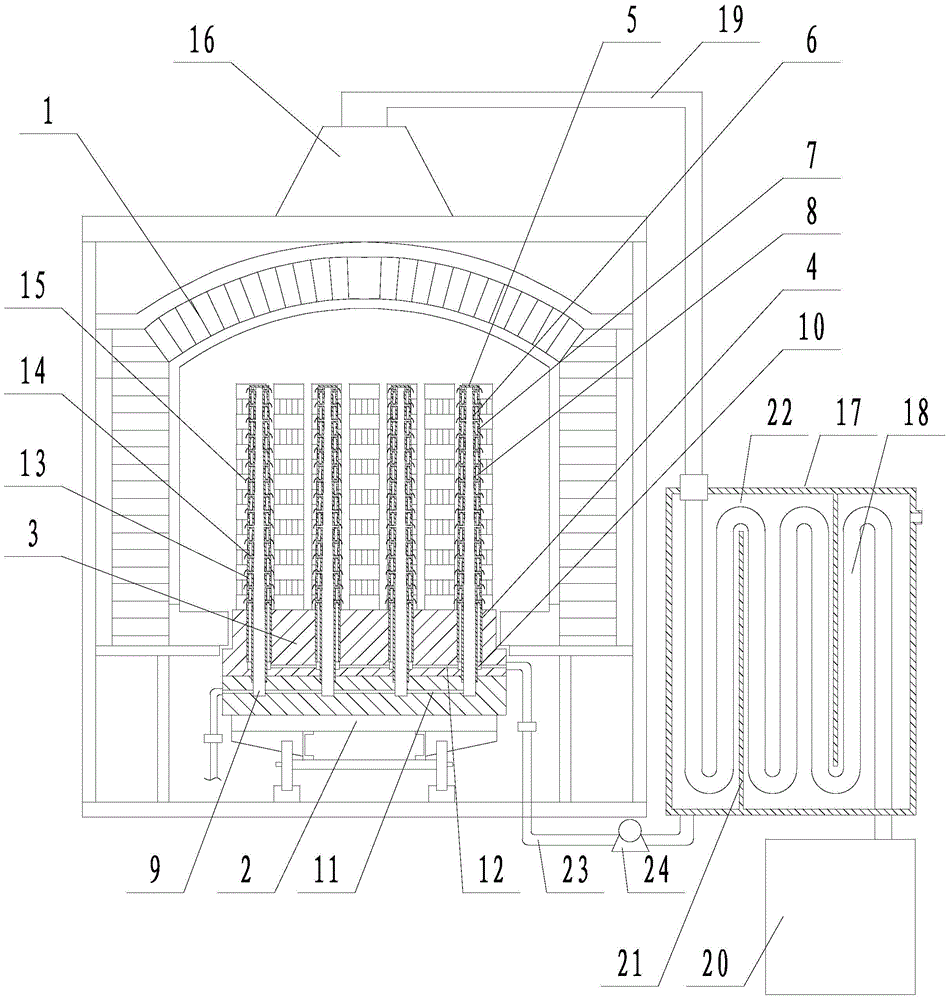

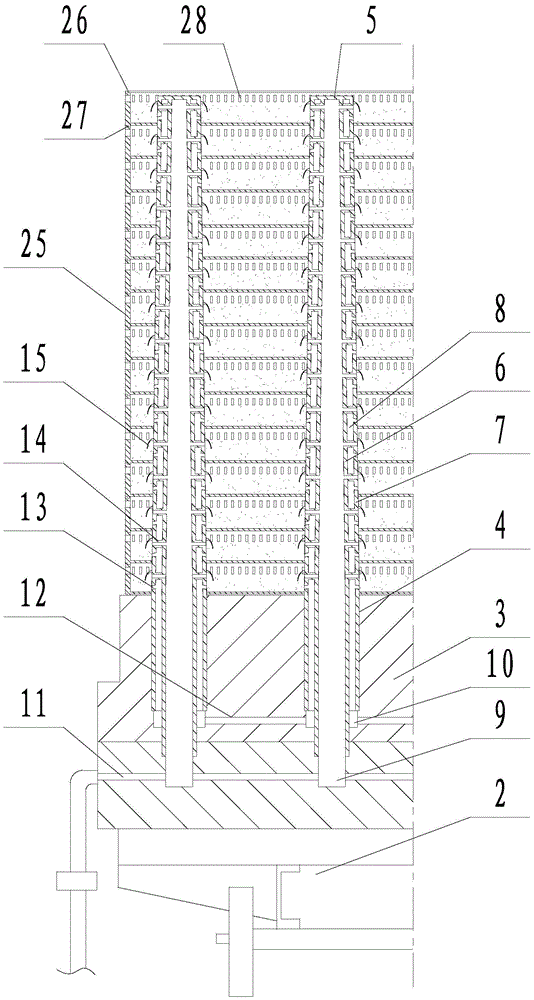

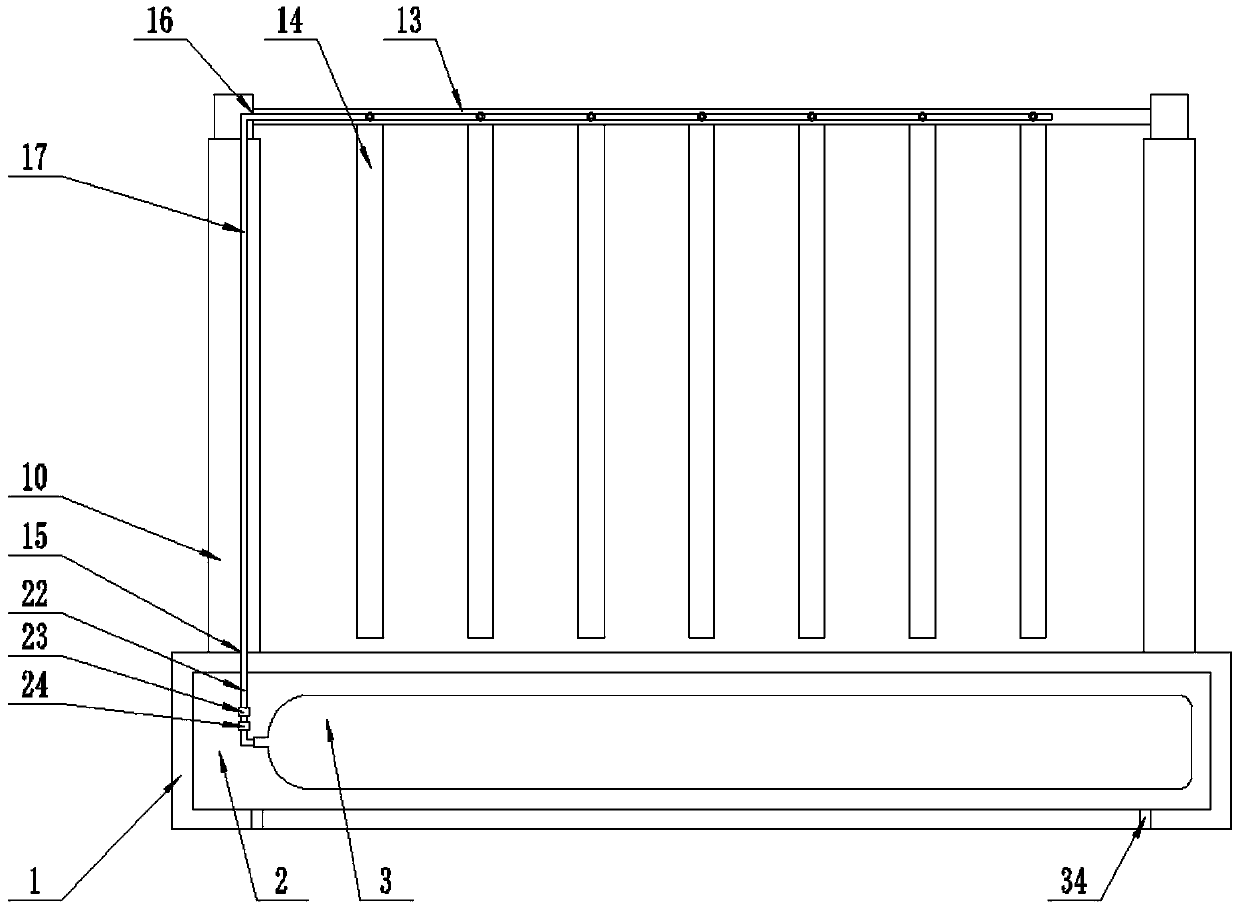

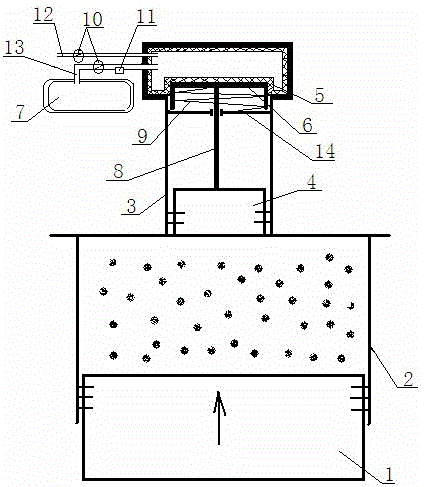

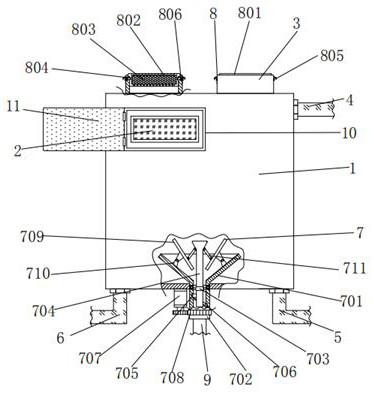

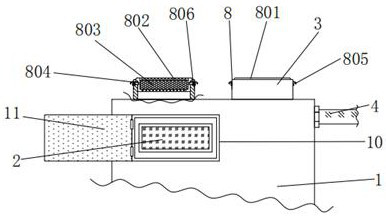

Production technology and device of high-quality calcium oxide

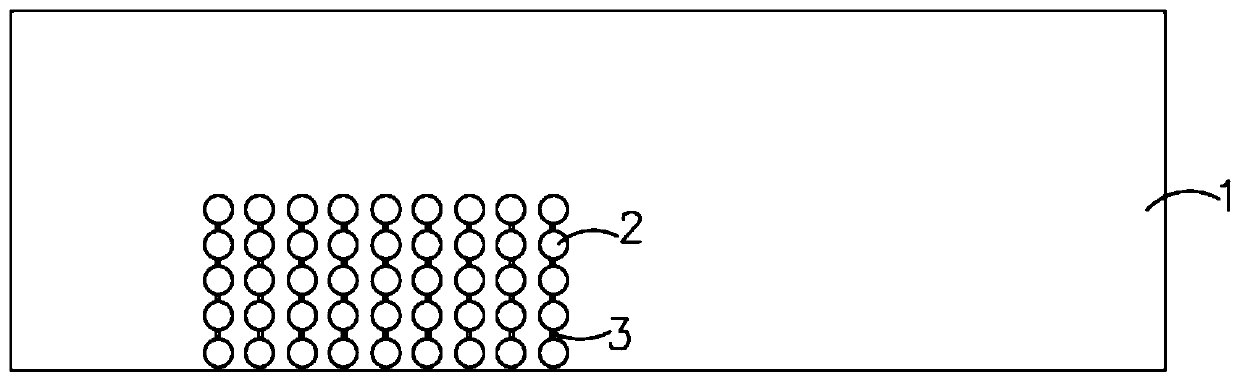

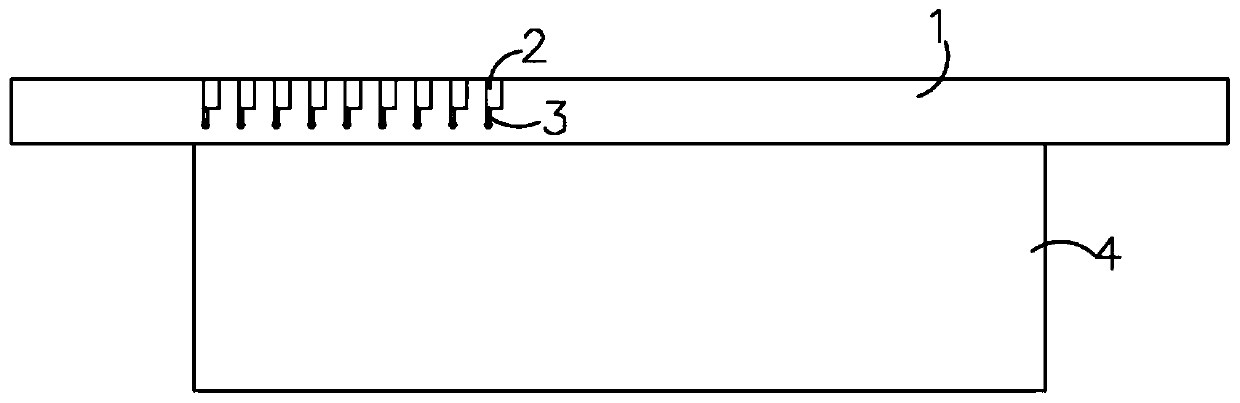

ActiveCN105217974AGuarantee the quality of calcium oxideEvenly heatedLime productionCalciteCalcination

The present invention discloses a production technology and device of high-quality calcium oxide, and is intended to address the deficiencies that the calcium oxide produced after calcination of the existing limestone can be easily mixed with ash, underfiring and overburning are common in the calcining process, and the calcium oxide has lower quality. The process is as below: 1, selecting calcite as the raw material, cleaning and draining; 2, crushing the calcite and sieving calcite particles in similar size for standby; 3, sending the calcite raw material into a shuttle kiln for calcining; 4, taking calcium oxide out of the kiln, cooling calcium oxide to about 400 DEG C, and milling the calcium oxide at a temperature more than 200 DEG C; 5, after milling, sending the calcium oxide immediately into a sealed dry container for cooling, cooling to around 50 DEG C, and packaging immediately, wherein the time interval between taking calcium oxide out of the kiln and packaging is 30 min.

Owner:建德市泰合新材料有限公司

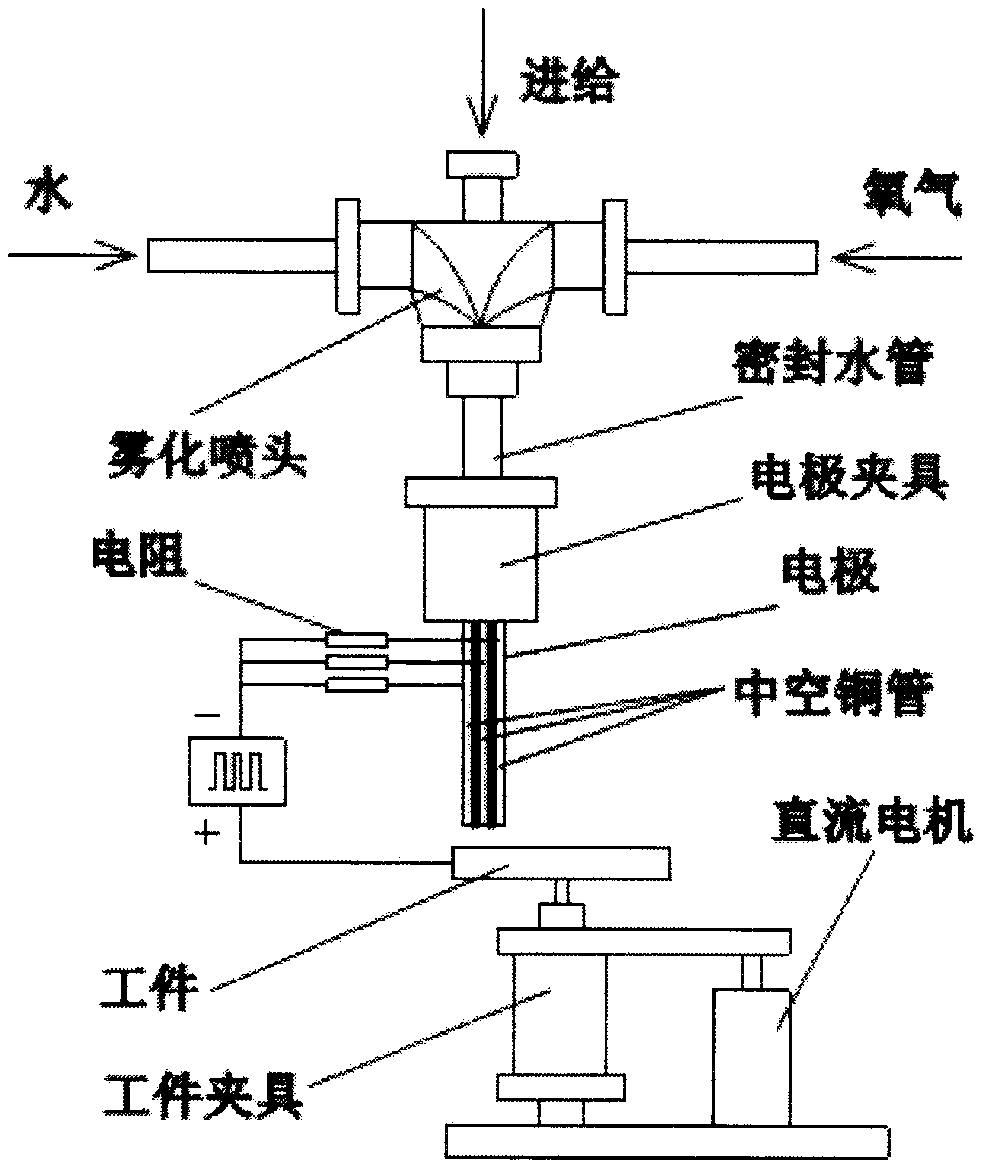

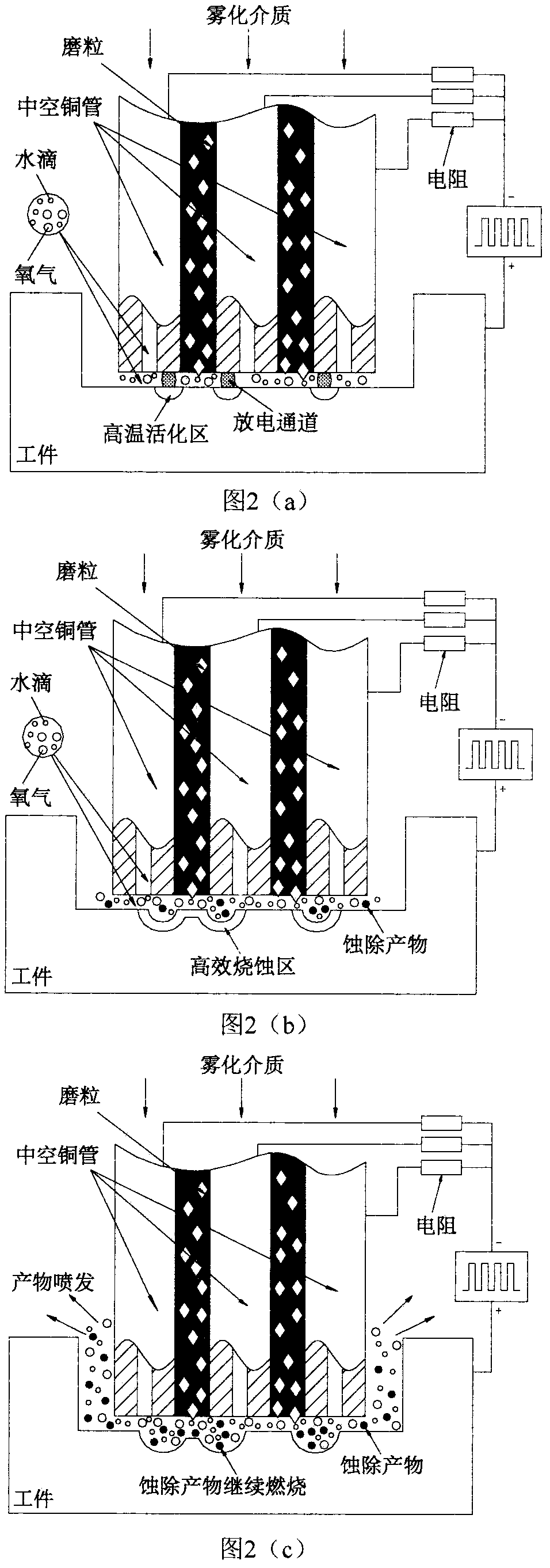

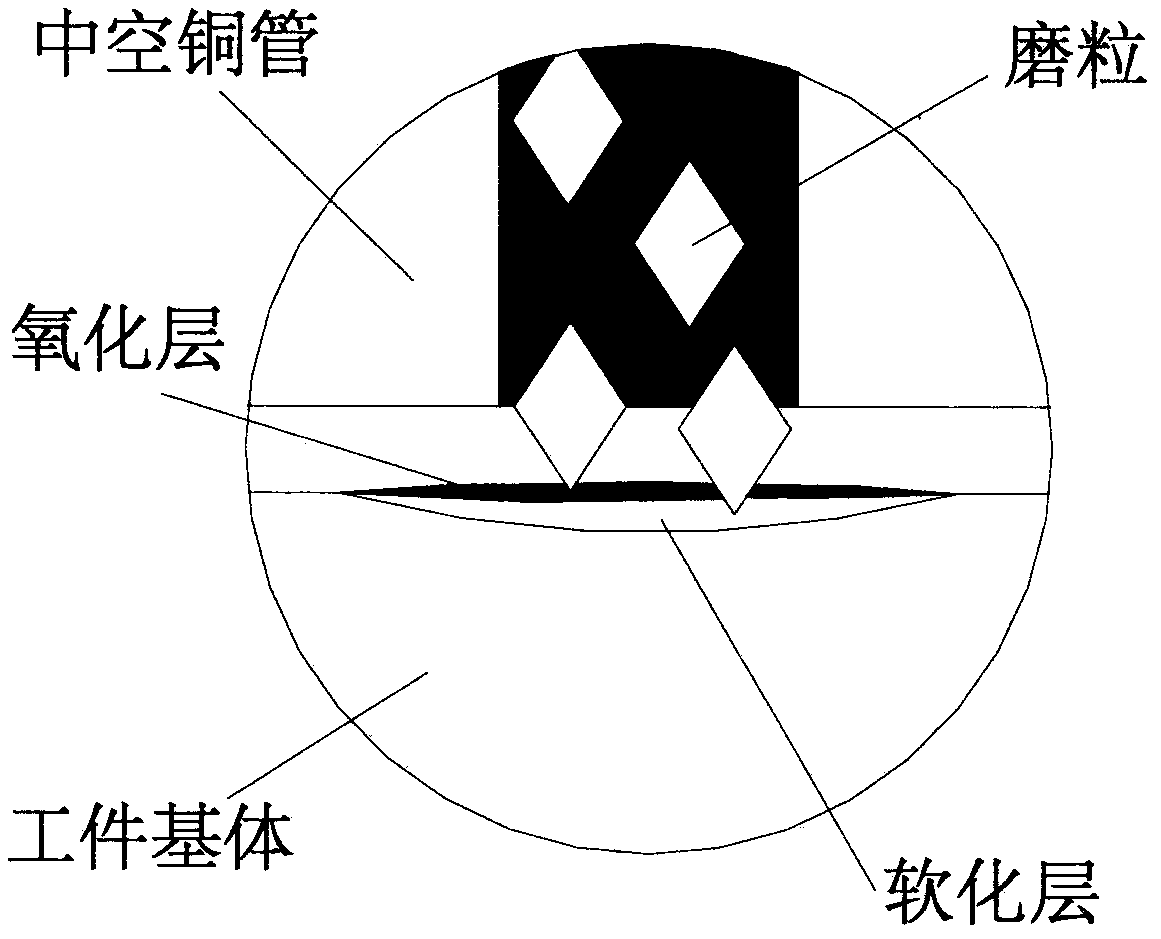

Multichannel discharging, atomizing, ablating and grinding compound processing method

ActiveCN109746533APromote ongoingImprove processing efficiencyElectricityElectrical resistance and conductance

The invention provides a multichannel discharging, atomizing, ablating and grinding compound processing method. The multichannel discharging, atomizing, ablating and grinding compound processing method is characterized in that multiple hollow copper pipe electrode bundles which are insulating from one another are made into the required shape, a resistor is connected into the electricity inlet endof each copper pipe electrode, and the copper pipe electrodes are connected with a pulse power supply as a whole to generate multichannel discharging; then, resin adhesive liquid mixed with abrasive particles is used and flows into gaps between the different copper pipe electrodes, and a multichannel discharging electrode, namely, a discrete electrode, with a grinding effect is obtained through solidification forming. Discharging, atomizing, ablating and grinding compound processing is conducted through the electrode, simultaneous multipoint discharging is achieved in the processing area, andtherefore discharging energy can be dispersed and multipoint induced ablating reaction is formed; the metal combustion range of the processing area is widened so that efficient corrosion removing canbe achieved; and secondly, by means of the abrasion effect of the abrasive particles in the electrode, oxide and softened layers on ablating processing surfaces are removed through abrasion, and new base bodies are exposed. By means of the multichannel discharging, atomizing, ablating and grinding compound processing method, the continuity of ablating processing, the utilization rate of valid pulses, the ablating efficiency and the surface quality can be improved, and the contradiction between the processing efficiency and the processing quality is resolved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

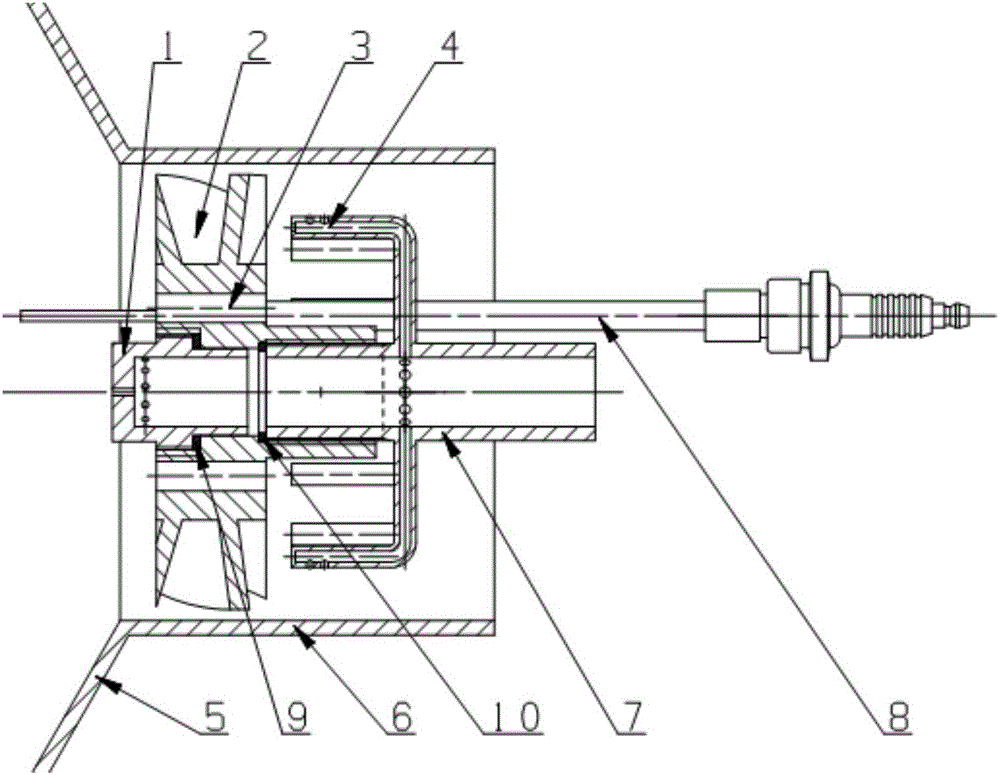

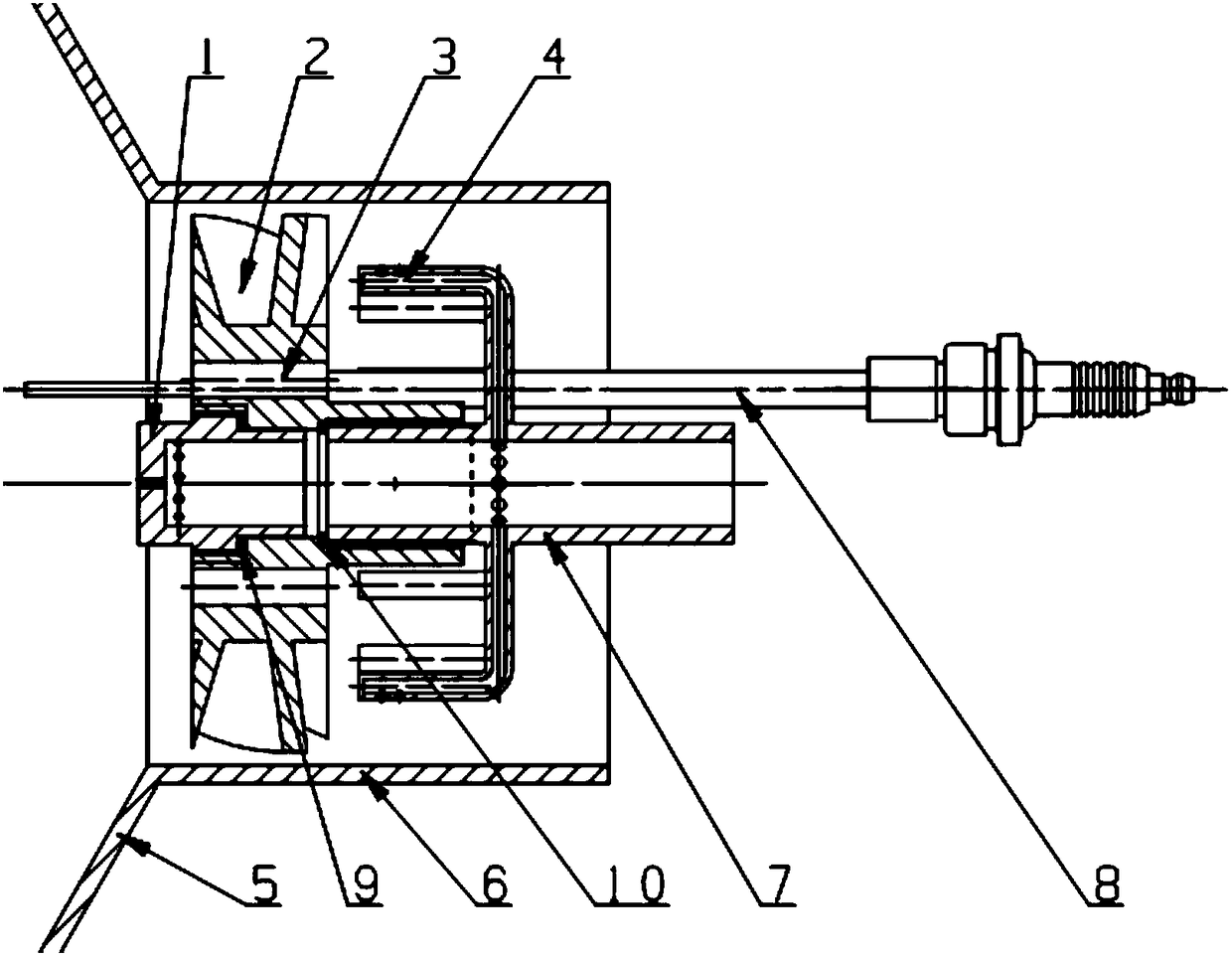

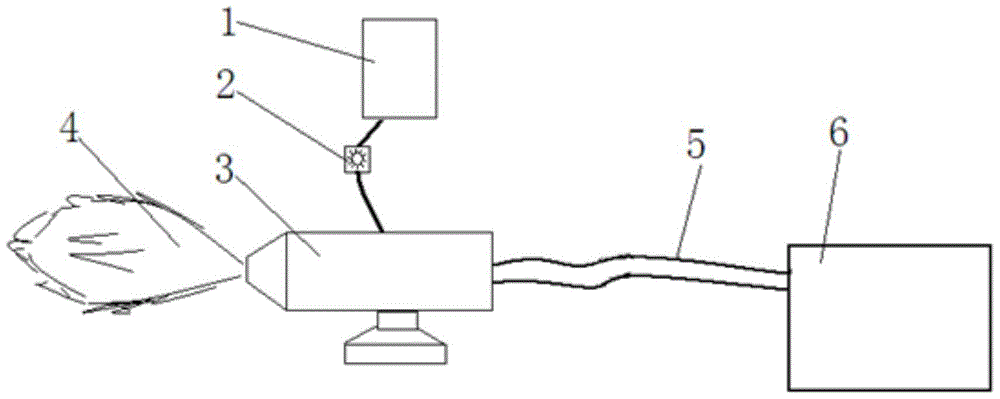

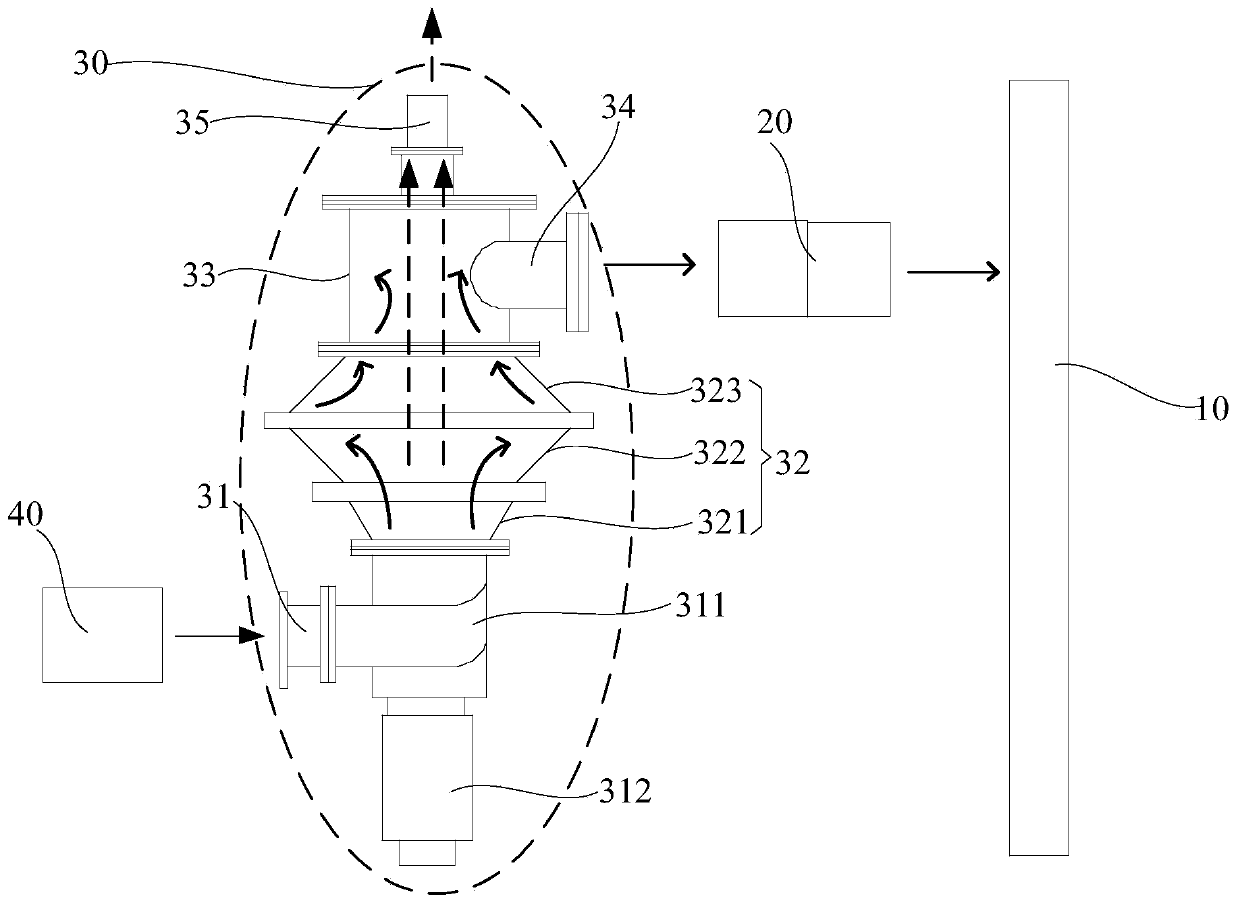

Device and method for ignition through dual-mode lasers in gas breakdown manner

ActiveCN105134453AIncreased ignition path/rangeFast ignitionMachines/enginesEngine ignitionPistonCombustion chamber

The invention provides a device and method for ignition by generating plasma sparks through continuous and pulsed dual-mode lasers in a gas breakdown manner. The device is mainly provided with a continuous laser transmitting end, a pulsed laser transmitting end, a fuel injection device, a cylinder cover, a combustion chamber, a piston and the like. The laser transmitting ends do not stretch into the combustion chamber. According to the device and method for ignition through the continuous and pulsed dual-mode lasers in the gas breakdown manner, the plasma sparks can always be reliably generated to ignite a fuel-air mixture in the combustion chamber; and the ignition path / range can be effectively increased, the ignition speed can be increased, the combustion area can be increased, combustion efficiency can be improved, and fuel can be saved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

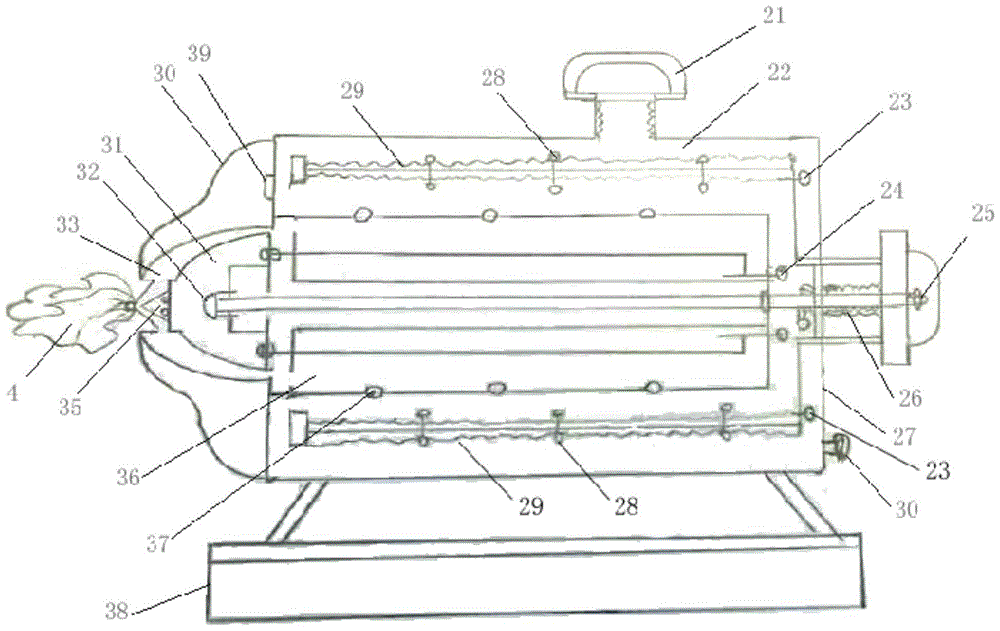

Combustion apparatus capable of controlling temperature of output heat source

InactiveCN106257138AMaximize combustion efficiencyCombustion efficiency, energy saving and environmental protectionBurnersTemperature resistanceHigh energy

The invention relates to a combustion apparatus capable of controlling the temperature of an output heat source. The combustion apparatus includes an igniter which is made from a high temperature resistance material having a high-energy density and is arranged in a first combustion chamber, a heating unit which is arranged outside the first combustion chamber and is used to heat the igniter to allow the temperature of a surface of the igniter to be higher than a fire point of an atomized fuel; a mixer which is arranged on the outer periphery of the first combustion chamber, has a second combustion chamber arranged on the outer periphery of a flame outlet of the first combustion chamber, and is used for supplying gas. Accordingly, the atomized fuel can contact the surface of the igniter in the first combustion chamber, and is ignited and combusts instantly, and then the atomized fuel enters the second combustion chamber, the vaporization of the fuel is completed, the combustion efficiency is maximized, and the temperature of the output heat source is adjusted through a gas supplying action of the mixer.

Owner:NAT CHIN YI UNIV TECH +1

Preparation of alcohol ether fuel

InactiveCN101440314AHigh calorific valueExtended combustion rangeLiquid carbonaceous fuelsAlcoholDistillation

The invention relates to a method for preparing an alcohol ether fuel, which belongs to the technical field of the method for preparing a fuel to replace gasoline. The technical problem to be solved is to provide the method for preparing the ethanol ether fuel which can replace the gasoline and improve the ignitability. The technical proposal for solving the technical problem comprises the following steps: preparing a mixed solution of methanol, ethanol and gasoline, performing oscillatory mixing, adding oil microbial ferment and methyl tert-butyl ether to the solution, adding grease doped with a latent solvent to the solution, hot mixing, and keeping stand, wherein the weight ratio of the methanol to the ethanol to the gasoline is (150 to 650) : (50 to 250): (50 to 450), an additive is added in the methanol, dimethyl ether and nitrobenzene are added in the ethanol, and carotene is added to the gasoline. The method is applied to preparing the alcohol ether fuel which can replace the petrol, has the advantages of increasing the heat productivity of the fuel, prolonging the combustion distillation range, optimizing the combustion of the fuel in an engine and improving the combustion performance that the combustion curve is close to that of the gasoline.

Owner:李新勇

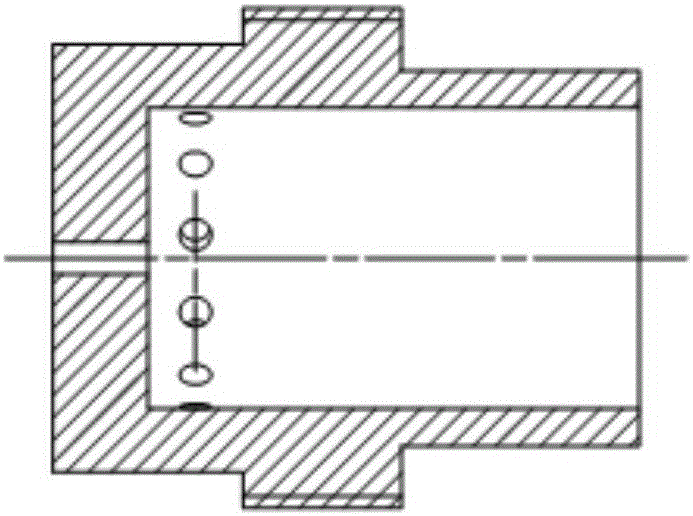

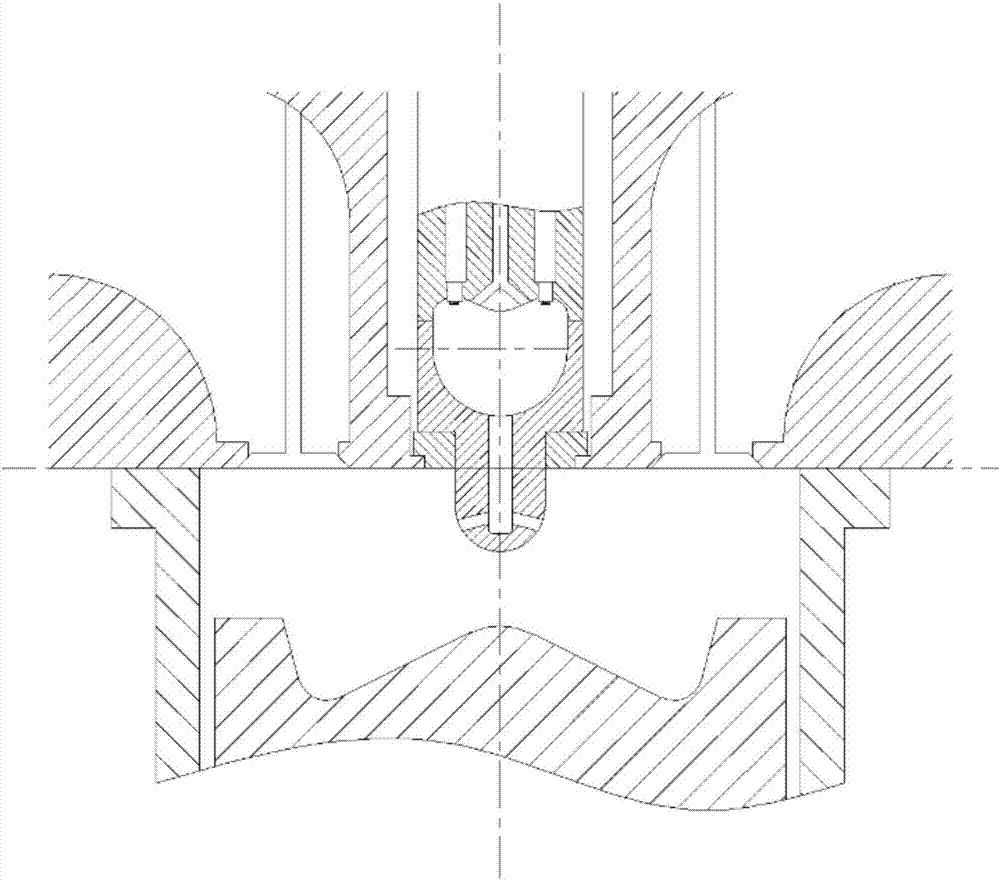

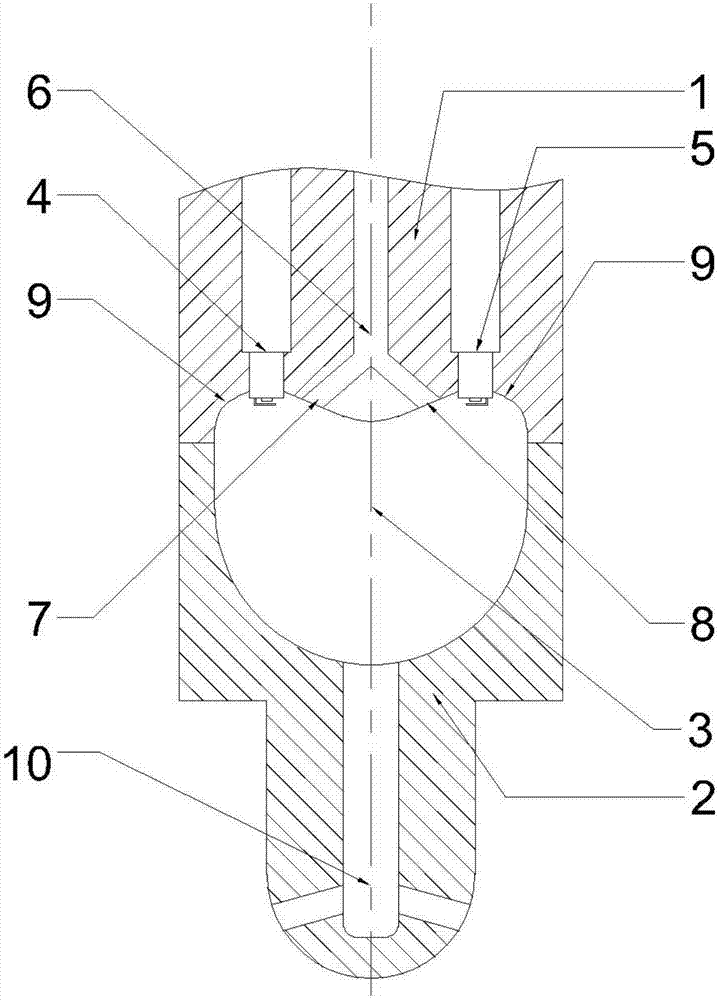

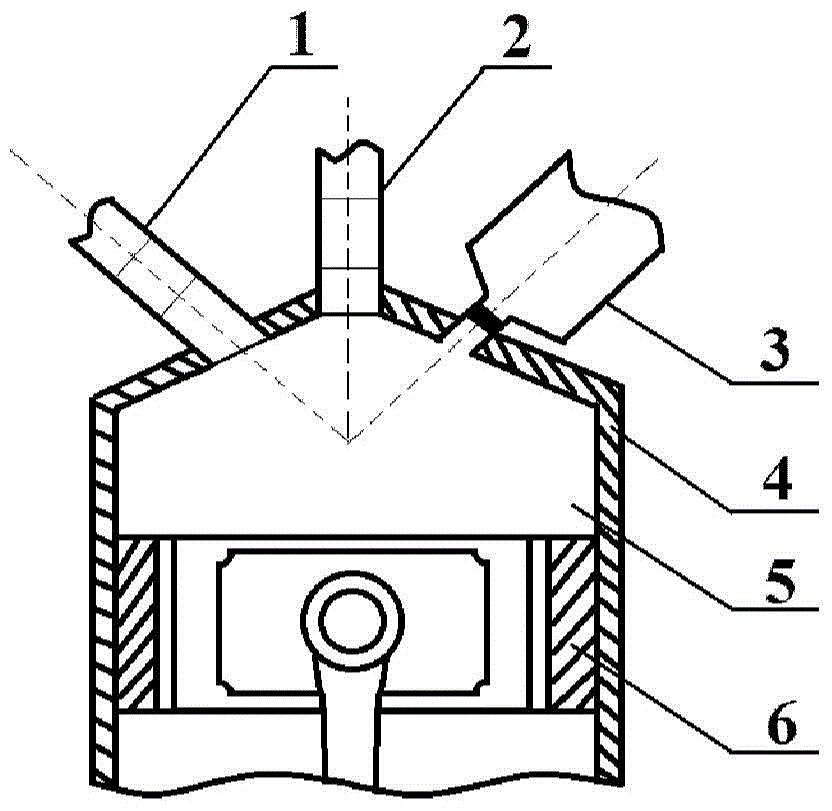

Precombustion chamber for marine large cylinder bore gas engine

InactiveCN107091145AEasy to igniteExtended combustion rangeInternal combustion piston enginesGaseous engine fuelsCombustion chamberNuclear engineering

The invention provides a precombustion chamber for a marine large cylinder bore gas engine. The precombustion chamber comprises a precombustion chamber upper part and a precombustion chamber lower part; a precombustion chamber cavity is formed between the precombustion chamber upper part and the precombustion chamber lower part; two spark plugs are arranged at the precombustion chamber upper part; a fuel gas injection channel and two fuel gas injection channel outlets are formed in the precombustion chamber upper part; a flame jetting channel is formed in the precombustion chamber lower part; and the upper part of the precombustion chamber cavity is in an inverted omega shape. The precombustion chamber has the biggest characteristics that aiming to a working mode of the large cylinder bore gas engine, double spark plugs are configured in the precombustion chamber; and meanwhile, in order to reasonably organize air flow movement in the precombustion chamber, the upper part of the precombustion chamber cavity is designed into the inverted omega shape, the ignition stability of mixed gas in the precombustion chamber is improved, and stable combustion of fuel in a main combustion chamber is promoted.

Owner:HARBIN ENG UNIV

Fuel gas decoupling combustor and using method thereof

The invention relates to a fuel gas decoupling combustor and a using method thereof. The fuel gas decoupling combustor adopts a partition staged combustion mode of central and peripheral oxygen deficit and central area lean combustion, diffusion type oxygen-deficient combustion with high combustion stabilizing capacity and low heat intensity is adopted in the central combustion area, reliable ignition and low-load stable combustion of the oxygen-deficient combustion area are ensured, the peripheral oxygen-deficient combustion area controls temperature distribution of a combustion chamber by accurately controlling partition mixing of fuel gas and air, the radiation heat transfer capacity is improved, and mixed burnout of the peripheral fuel gas and the main combustion area is promoted. In aword, the problem that the combustion temperature of a diffusion combustion mode is too high in the central stage is effectively solved by the fuel gas decoupling combustor and the using method thereof, the combustion chamber is more uniform in heat intensity, high in flame fullness, high in heat transfer capacity and long in smoke retention time, the combustion efficiency is guaranteed under thecondition of low fan power consumption, meanwhile, generation of thermal NOX is reduced, and decoupling combustion of the fuel gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A Premixed Strong Swirl Flame Diffusion Burner

ActiveCN106090907BExtended combustion rangeIncrease the heating areaGaseous fuel burnerCombustion chamberCombustor

The invention discloses a premixing strong swirling flow flame diffusion burner. Center grading structure design is adopted. The premixing strong swirling flow flame diffusion burner comprises a combustion box, an air pipeline, a fuel pipeline, a swirler, a precombustion level air hole, a precombustion level nozzle and a main combustion level nozzle. The air pipeline is connected with an inlet of the combustion box through welding and is used for guiding air to pass through the swirling flow burner and enter a combustor for combustion. The fuel pipeline supplies gaseous fuel to the precombustion level nozzle and the main combustion level nozzle, wherein 25%-40% of the fuel enters the precombustion level nozzle and is then sprayed into the combustor to be mixed with precombustion level air directly entering the combustor through the precombustion level air hole for diffusive combustion. Through a premixing strong swirling flow flame diffusion structure adopted by the burner, the downstream combustion area can be enlarged well, the heating area is enlarged, thus a larger space range can be heated through the burner with a small area, meanwhile, the combustion efficiency is improved, and pollutant discharge is reduced.

Owner:BEIHANG UNIV

Chemical experiment table capable of automatically extinguishing fire

ActiveCN110102358AExtended combustion rangePlay the role of collecting flammable liquidFire rescueLaboratory benches/tablesEngineeringLinkage concept

The invention discloses a chemical experiment table capable of automatically extinguishing fire, which comprises a table top. A base is fixedly connected below the table top, a plurality of storage grooves are formed in the table top, linkage mechanisms are arranged in the storage grooves, each linkage mechanism comprises an isolation block and a connecting shaft, the connecting shaft is fixedly connected at the bottom of the isolation block, and a copper plate is installed in the isolation block. A primary memory metal is fixedly connected to the inner wall of each storage groove, and two ends of the copper plate both abut against the primary memory metal. When a fire spreads to the insides of the storage grooves, secondary memory metals in the storage grooves are heated to stretch, the secondary memory metals abut against the U-shaped shafts when stretching, the isolating blocks are pulled into the storage grooves, air is isolated due to the fact that most combustion requires the participation of oxygen, namely the oxygen is isolated, the oxygen in the storage grooves is consumed completely, and the combusting flame is extinguished. Liquid collection and fire extinguishing are achieved.

Owner:南城县永昌教学设备发展有限公司

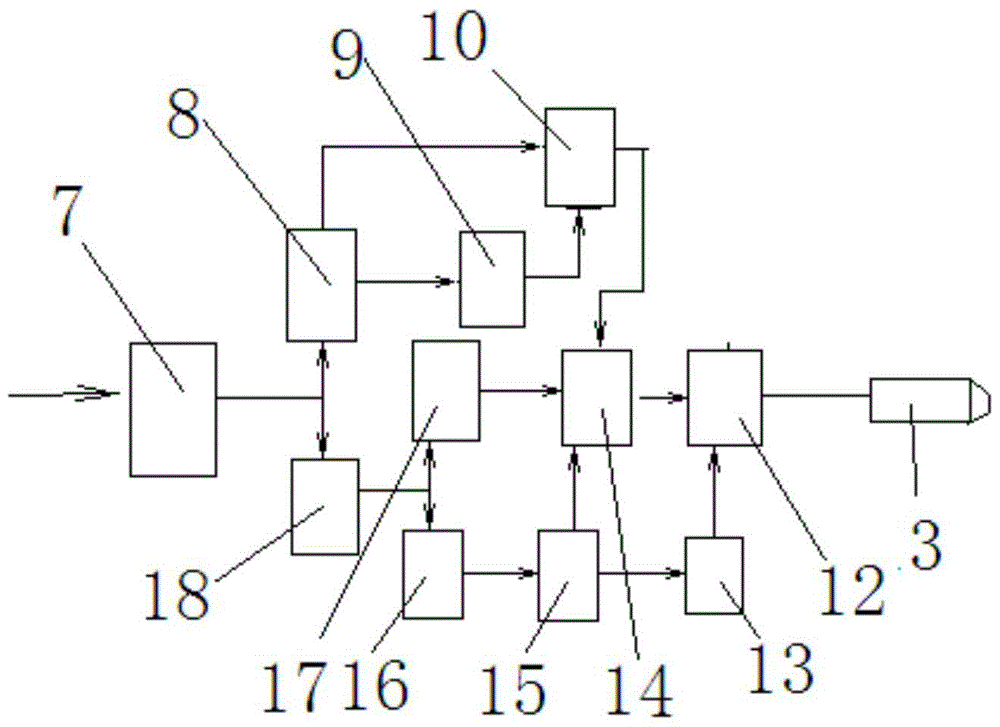

Double-heat-reflux partially-premixed low-nitrogen combustor and combustion method

PendingCN112113218AExtended combustion rangeAchieve low nitrogen combustionIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention discloses a double-heat-reflux partially-premixed low-nitrogen combustor and combustion method. The double-heat-reflux partially-premixed low-nitrogen combustor comprises a guide cylinder, a main fuel pipe and an on-duty fuel pipe; and an injection control baffle is arranged on the front portion of the main fuel pipe and arranged on the periphery of the main fuel pipe in a surrounding mode to form an injection area, an injection pipe is arranged at the front end of an outlet of the main fuel pipe, an outlet of the injection pipe extends out of the injection area, an on-duty fuelpremixing cavity is arranged on the front portion of the guide cylinder, a main air channel is formed between the premixing cavity and the guide cylinder, the front portion of the on-duty fuel pipe isprovided with a plurality of on-duty fuel nozzles and extends into the on-duty fuel premixing cavity, a swirl disc, a first porous medium unit and a second porous medium unit are arranged in the on-duty fuel premixing cavity from back to front, and the porosity of the first porous medium unit is smaller than that of the second porous medium unit. The combustor has the advantages of being good inadaptability and stable in combustion, the contradiction between great reduction of the oxygen content during low-NOx combustion and combustion stability is overcome, and low NOx emission can be achieved.

Owner:TSINGHUA UNIV

Tail gas treatment device for treating process exhaust gas of LED MOCVD equipment

InactiveCN105276592AExtended combustion rangeBurn safely and thoroughlyIncinerator apparatusCombustion chamberExhaust fumes

A tail gas treatment device for treating process exhaust gas of LED MOCVD equipment comprises a combustion chamber for combusting exhaust gas and a heating tape for packaging the combustion chamber. The combustion chamber comprises an outer chamber and an inner chamber which are annularly nested together. The outer chamber and the inner chamber which are nested together have a common top end cap. The end cap locks the outer chamber and the inner chamber together through screws and a sealing pad. The outer wall of the outer chamber is provided with two surrounding type heating tape. The heating tape packages the whole outer chamber. The tail gas treatment device sufficiently utilizes combustion heat and realizes relatively small amount of consumed electric energy. The tail gas treatment device has advantages of high safety, thorough combustion and no waste water through combusting the waste gases of H2 and NH3, energy-saving and environment-friendly performance, low cost, long maintenance period, simple structure and easy mounting.

Owner:SHANGHAI XIEWEI PRECISION MACHINERY

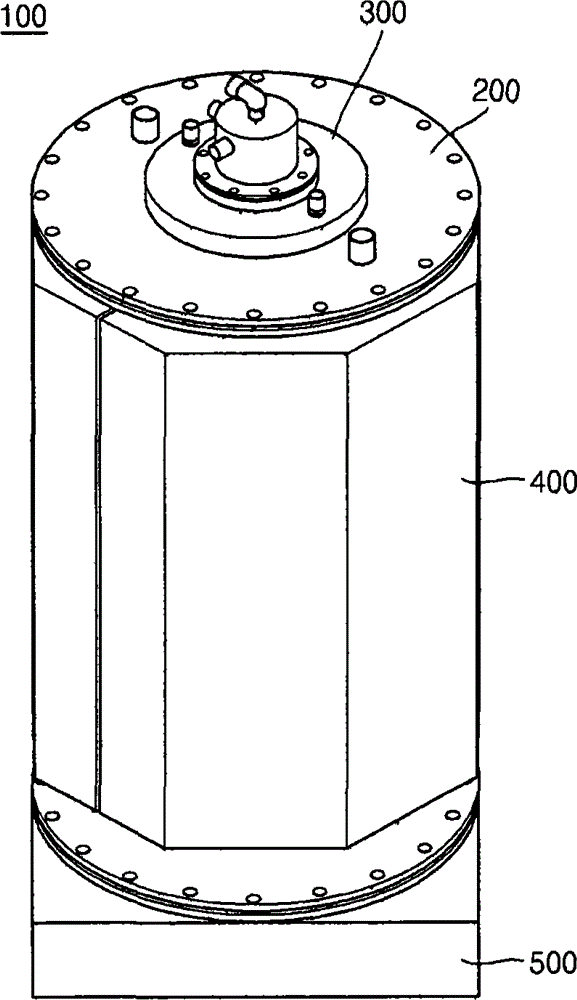

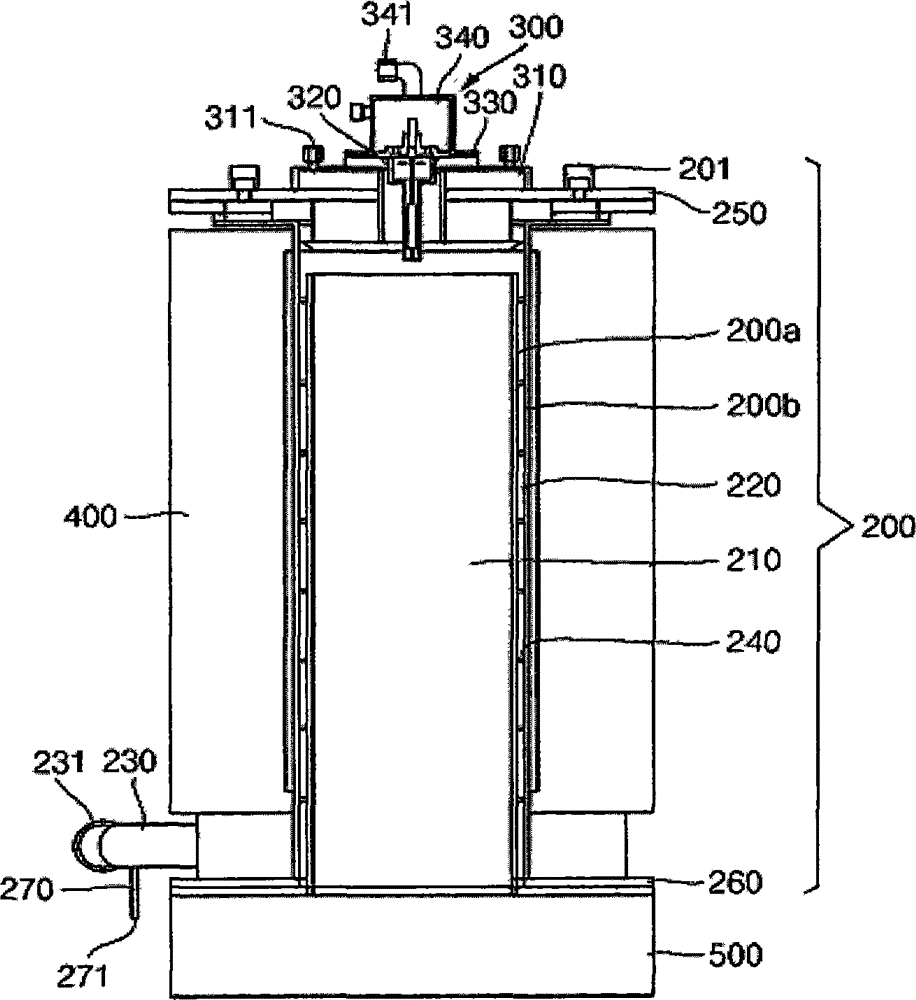

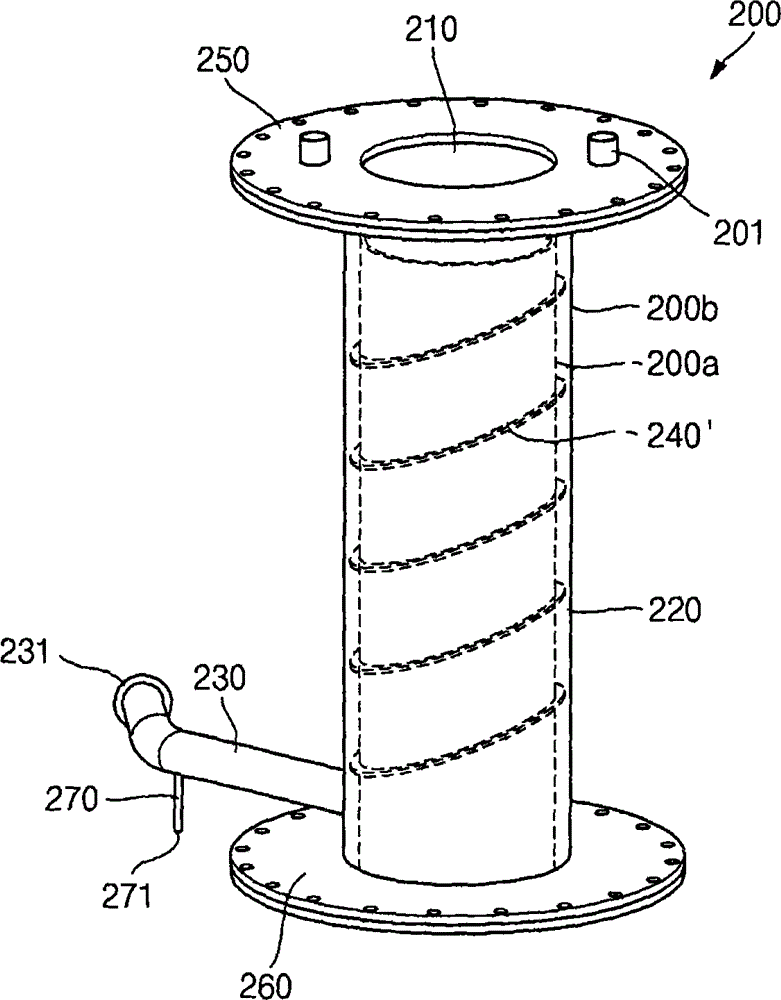

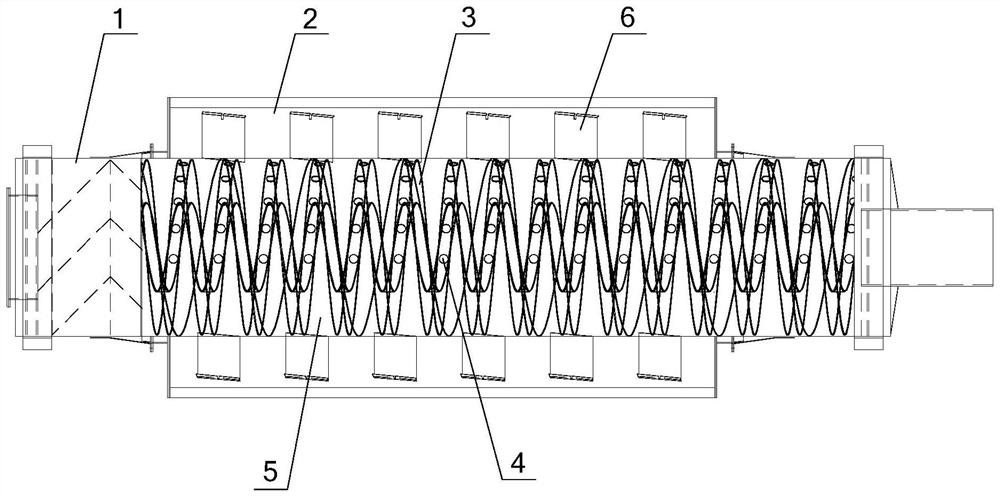

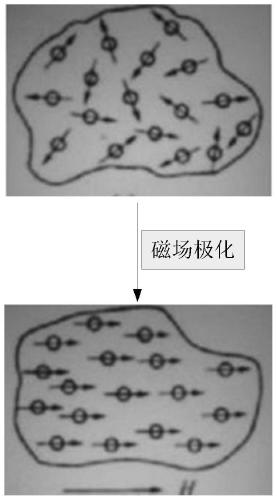

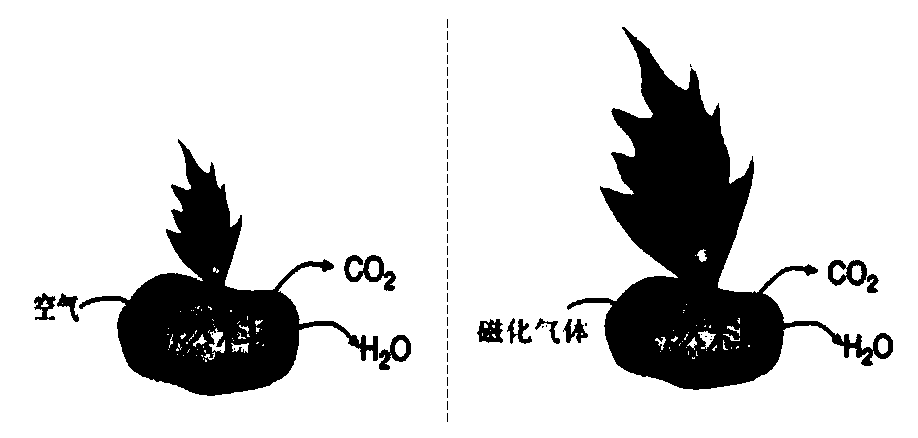

Oxygen gathering device surrounded by magnetic field, kiln combustion system and oxygen gathering combustion method surrounded by magnetic field

ActiveCN110015641BIncrease oxygen contentImprove combustion efficiencyFurnace componentsGaseous fuel burnerEngineeringCarbon dioxide content

The invention relates to a magnetic field-surrounding oxygen-collecting device, a furnace kiln combustion system containing the magnetic field-surrounding oxygen-collecting device and a magnetic field-surrounding oxygen-collecting combustion method. The magnetic field-surrounding oxygen-collecting device comprises a gas inlet pipe section, a vortex pipe section, an oxygen collecting pipe section,a nitrogen-oxide separation pipe section and an oxygen discharge pipe section which are connected in sequence; and the oxygen collecting pipe section is composed of a shell, cylindrical magnets and amagnetic conductive metal blanket, a plurality of cylindrical magnets are arranged at intervals around the inner wall of the shell to form a magnetic field ring, and the magnetic conductive metal blanket is arranged on the side of the magnetic field ring to form magnetic field surrounding. The magnetic field-surrounding oxygen-collecting device and the magnetic field-surrounding oxygen-collectingcombustion method provided by the invention can improve an oxygen content of a combustion-supporting gas flow, have low energy consumption, and can improve combustion efficiency, save fuel, reduce carbon dioxide content and significantly improve thermal efficiency, thereby facilitating promotion.

Owner:WUHAN FUSHIDA ENERGY TECH CO LTD

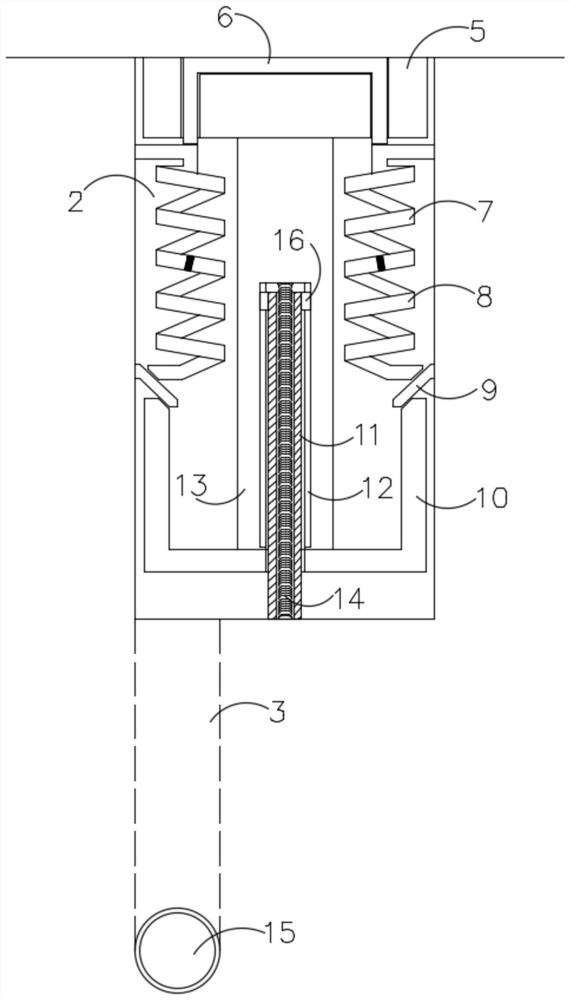

a combustion device

ActiveCN105444164BExtended combustion rangeHigh flame temperatureIncandescent ignitionCombustion apparatusHydrogenCombustion

The invention discloses a combustion device. The combustion device comprises a plasma arc spray nozzle 3, a plasma generator 6 and a water atomization supply device, wherein a water mist output port of the water atomization supply device is located at a spray port of the plasma arc spray nozzle 3, and the plasma generator 6 is communicated with the plasma arc spray nozzle 3 through a pipeline 5; and the water atomization supply device comprises a water vapour supply device and / or a water pressure atomization device and / or an ultrasonic water atomization device. According to the invention, water is pyrolysed into hydrogen and oxygen under a high temperature of the plasma arc spray nozzle, and ignited through a high-temperature plasma arc to provide a heat source for the outside, and the heat source has a large combustion range and a high flame temperature, and is convenient to move and capable of being fixedly used, thus a new application is developed for plasma equipment.

Owner:XINJIANG 830009

Ignition device and method using dual-mode laser gas breakdown mode

ActiveCN105134453BLow output power requirementHigh beam qualityMachines/enginesEngine ignitionCombustion chamberDual mode

The invention provides a device and method for ignition by generating plasma sparks through continuous and pulsed dual-mode lasers in a gas breakdown manner. The device is mainly provided with a continuous laser transmitting end, a pulsed laser transmitting end, a fuel injection device, a cylinder cover, a combustion chamber, a piston and the like. The laser transmitting ends do not stretch into the combustion chamber. According to the device and method for ignition through the continuous and pulsed dual-mode lasers in the gas breakdown manner, the plasma sparks can always be reliably generated to ignite a fuel-air mixture in the combustion chamber; and the ignition path / range can be effectively increased, the ignition speed can be increased, the combustion area can be increased, combustion efficiency can be improved, and fuel can be saved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

High-quality calcium oxide production process and equipment

The present invention discloses a production technology and device of high-quality calcium oxide, and is intended to address the deficiencies that the calcium oxide produced after calcination of the existing limestone can be easily mixed with ash, underfiring and overburning are common in the calcining process, and the calcium oxide has lower quality. The process is as below: 1, selecting calcite as the raw material, cleaning and draining; 2, crushing the calcite and sieving calcite particles in similar size for standby; 3, sending the calcite raw material into a shuttle kiln for calcining; 4, taking calcium oxide out of the kiln, cooling calcium oxide to about 400 DEG C, and milling the calcium oxide at a temperature more than 200 DEG C; 5, after milling, sending the calcium oxide immediately into a sealed dry container for cooling, cooling to around 50 DEG C, and packaging immediately, wherein the time interval between taking calcium oxide out of the kiln and packaging is 30 min.

Owner:建德市泰合新材料有限公司

Fireproof protection type transformer fence device for transformer

The invention discloses a fireproof protection type transformer fence device for a transformer. The fireproof protection type transformer fence device for the transformer comprises a base. The base isfixedly installed on the ground. A carbon dioxide storage device is arranged in the base. A fire fighting fence device is arranged on the upper side of the base. A waterproof controller box is arranged outside the base. A controller is arranged inside the waterproof controller box. The signal receiving end of the controller is electrically connected with a gas pressure sensor. The power output end of the controller is electrically connected with a cover plate drive device, an electric telescopic rod and an electromagnetic valve. The fireproof protection type transformer fence device for the transformer has the beneficial effects that the structure is simple and the practicability is high.

Owner:JIAXING NIYA OPTOELECTRONICS CO LTD

A dual-piston internal combustion engine

ActiveCN103953437BMeet the control needs of different working conditionsImprove cycle thermal efficiencyInternal combustion piston enginesCombustionSolenoid valve

The invention discloses a double-piston internal combustion engine which comprises a piston (1), an air cylinder (2) and an air cylinder cover (3), wherein the air cylinder cover (3) is arranged at the upper end of the air cylinder (2); a connecting rod is connected to the lower end of the piston (1); the connecting rod and a crankshaft are connected to form a piston crank connecting rod mechanism. The double-piston internal combustion engine further comprises a pressure sensor (11), a pressure strain piston (4), an air bag (5) and a stress piston (6); the pressure strain piston (4), the air bag (5) and the stress piston (6) are arranged in the air cylinder cover (3); one end of the stress piston (6) is supported against the lower part of the air bag (5); the other end of the stress piston (6) is connected with the pressure strain piston (4) through a connecting rod (8); a pressure relief pipe (12) and a pressurizing pipe (13) are respectively connected onto the air bag (5); normally-closed solenoid valves (10) are respectively arranged on the pressure relief pipe (12) and the pressurizing pipe (13). According to the double-piston internal combustion engine, the control over the combustion state and characteristics of the internal combustion engine is realized.

Owner:孙大林

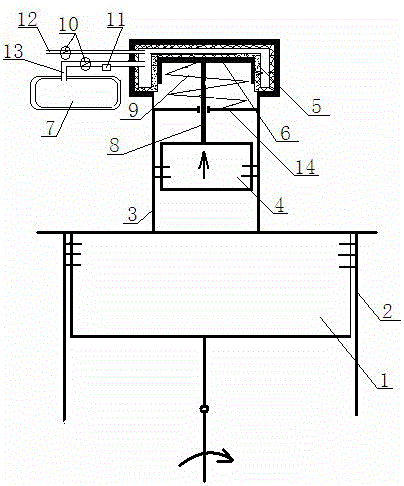

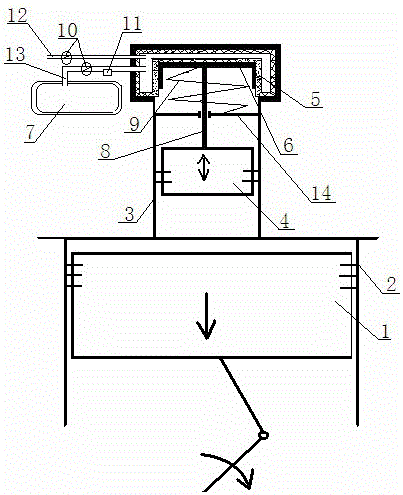

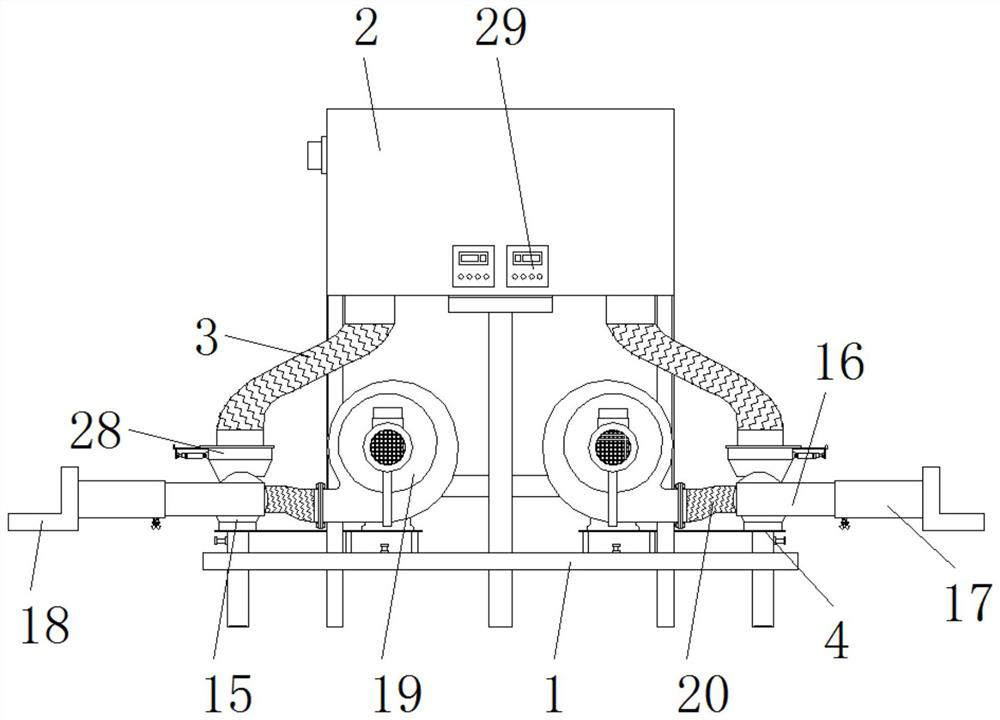

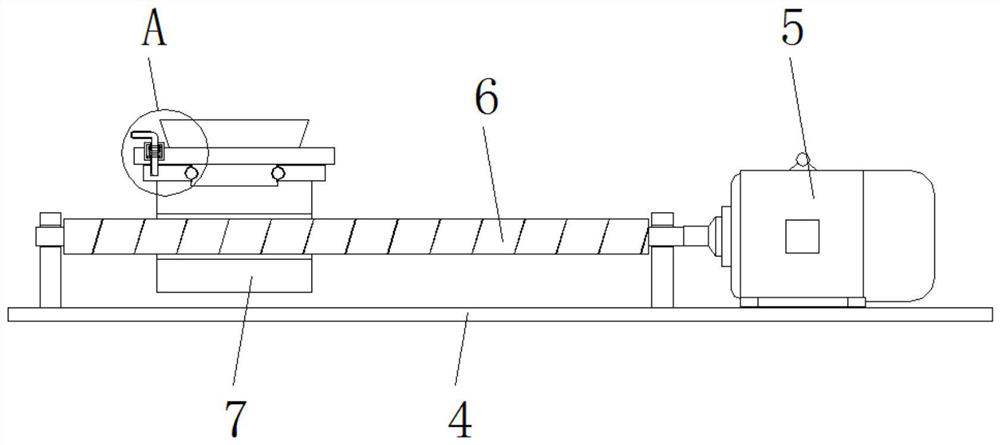

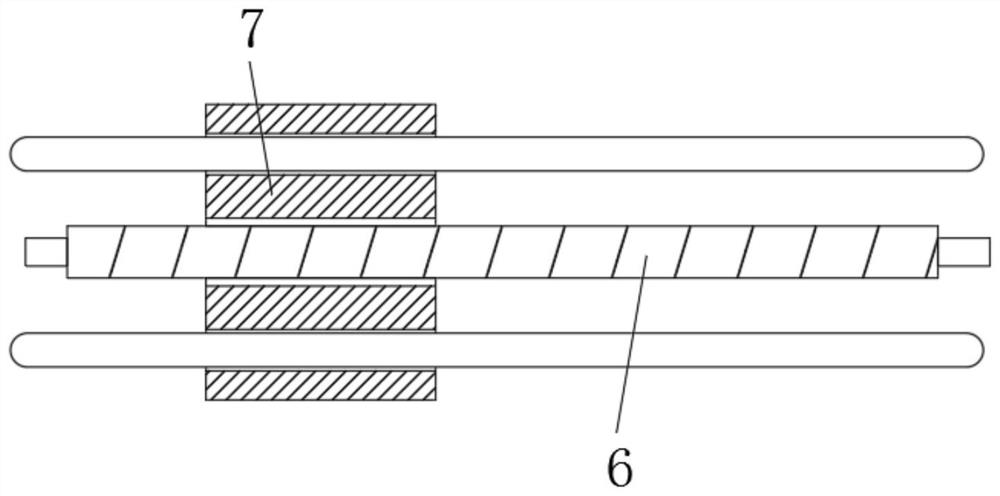

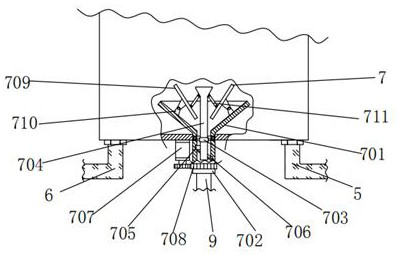

A feed assembly for a pellet burner that is easy to adjust

ActiveCN111623358BReduce workloadEasy to adjustIncinerator apparatusClassical mechanicsStructural engineering

The invention discloses an easy-to-adjust particle burner feeding assembly, which includes a base, a feeding bin is arranged directly above the base, and first hoses are symmetrically connected to both ends of the bottom of the feeding bin, and the top of the base Mounting plates are arranged symmetrically at both ends of the mounting plate, and a servo motor is installed at one end of the top of the mounting plate. The present invention is equipped with mounting plate, servo motor, lead screw shaft, lead screw slider, feeding bin, discharge pipe and sliding limit rod, and the servo motor drives the lead screw slider to move left and right on the outside of the lead screw shaft. The sliding limit rod is used to limit the sliding track to adjust the overall lateral position of the feeding structure, adjust the positional relationship with it, and then lock the locking bolt to facilitate the adjustment of the lateral position according to the needs, which improves the device's stability. applicability.

Owner:安徽三九农业装备科技股份有限公司

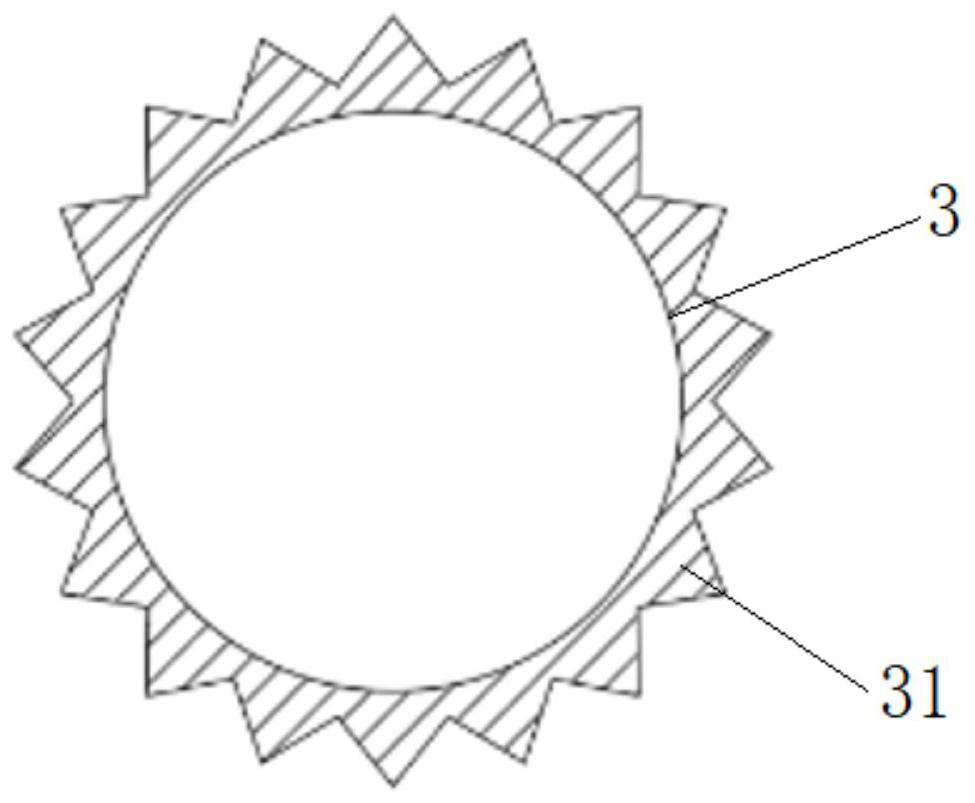

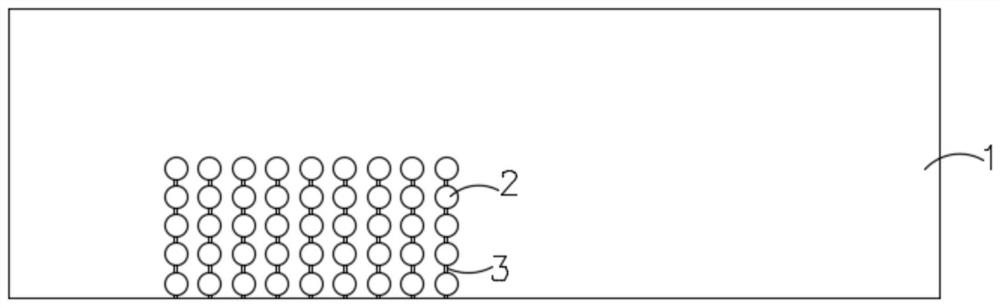

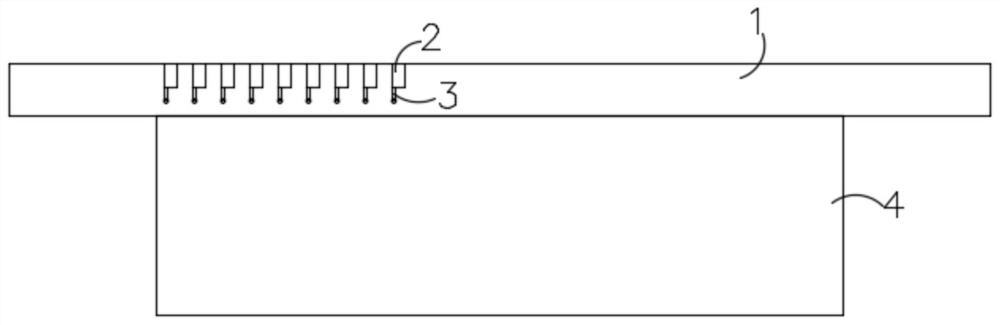

Fuel-saving gas steam engine

InactiveCN112393216ADiffusion fastBurn fullyGaseous fuel feeder/distributionDispersed particle filtrationActivated carbonFlue gas

The invention discloses a fuel-saving gas steam engine which comprises a liquid crystal time controller. A diffusion assembly is arranged at the top of a gas inlet pipe. According to the fuel-saving gas steam engine, through meshing connection of gears, clearance fit between sliding blocks and sliding grooves and clearance fit between branch pipes and lantern rings, gas can be annularly and rapidly diffused to the periphery in cooperation with the branch pipes, gas combustion is more sufficient, the combustion range is enlarged, heating is more uniform, the working efficiency is improved, andenergy consumption is reduced; a round shell can be quickly mounted in a smoke outlet through clamping connection of a clamping pin and a clamping rod, and then the smoke can be filtered and purifiedthrough a filter screen and activated carbon, so that environmental pollution is avoided, and the safety of workers is guaranteed; and the filter net at the upper portion is in threaded connection with the round shell, so that the filter net at the upper portion and the round shell are detachable, the activated carbon is convenient to replace, and the continuity and stability of flue gas filtration and purification are improved.

Owner:肖虎来

Combustion device with controllable output heat source temperature

InactiveCN106257138BIncrease energy densityComplete vaporizationBurnersCombustion chamberHigh energy

Owner:NAT CHIN YI UNIV TECH +1

a flame stabilizer

ActiveCN105546578BWiden the boundary of lean flameoutImprove combustion efficiencyContinuous combustion chamberCombustion chamberLiquid state

The invention relates to an aviation gas turbine engine afterburner flame stabilization technology, in particular to a flame stabilizer which at least solves the problem that mixed gasoline gas in a recirculation zone of the conventional flame stabilizer is lean. The flame stabilizer is positioned in an outer duct of an afterburner, and is a radial flame stabilizer which extends outwards from an annular flame stabilizer at a junction of an inner duct and the outer duct; the flame stabilizer is provided with a first wall surface and a second wall surface that are symmetrically distributed; and a plurality of air suction holes are symmetrically formed in the first wall surface and the second wall surface. Low-pressure air in the recirculation zone can be used to suck liquid-state fuel oil nearby the wall surfaces of the flame stabilizer, and a lean oil flameout boundary of the flame stabilizer can be widened. In addition, a mass-energy exchange rate in the recirculation zone can be increased, the combustion efficiency of the flame stabilizer can be improved, and the stable combustion range can be widened.

Owner:AECC SHENYANG ENGINE RES INST

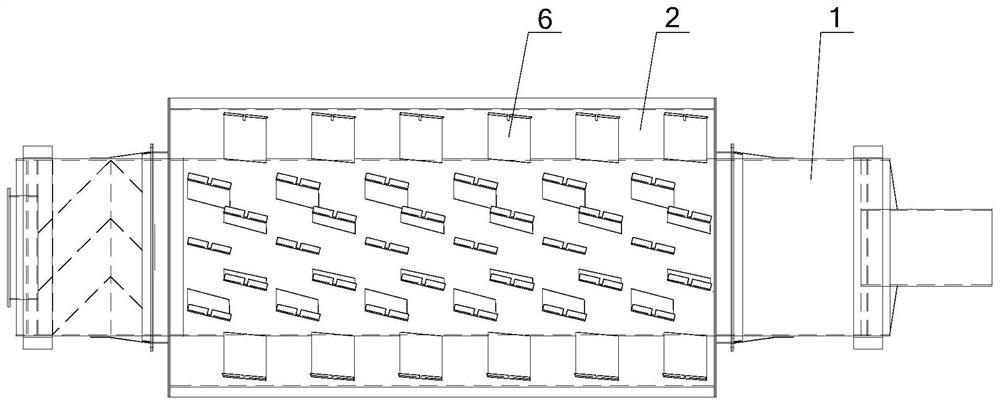

External heating rotary equipment

The invention discloses external heating rotary equipment. The external heating rotary equipment comprises a roller and a combustion cylinder, wherein the combustion cylinder is arranged on the periphery of the roller in a sealed and sleeving manner, and the roller rotates relative to the fixedly-arranged combustion cylinder. The external heating rotary equipment is characterized by further comprising lifting plates which are arranged on the outer wall of the roller and located in the combustion cylinder. In the rotating process of the roller, the lifting plates rotate along with the roller and lift up energy substances accumulated at the bottom of the combustion cylinder, so that the energy substances are diffused and combusted in the combustion cylinder, the combustion speed is improved,the combustion range is enlarged, the energy substances are sufficiently combusted, energy consumption is reduced, generated heat can meet the heating requirement, and the combustion efficiency of the energy substances is improved.

Owner:ZHAOYUAN HUICHAO NEW ENERGY TECH CO LTD

Magnetic field-surrounding oxygen-collecting device, furnace kiln combustion system and magnetic field-surrounding oxygen-collecting combustion method

ActiveCN110015641AIncrease oxygen contentReduce energy consumptionFurnace componentsGaseous fuel burnerMagnetEngineering

The invention relates to a magnetic field-surrounding oxygen-collecting device, a furnace kiln combustion system containing the magnetic field-surrounding oxygen-collecting device and a magnetic field-surrounding oxygen-collecting combustion method. The magnetic field-surrounding oxygen-collecting device comprises a gas inlet pipe section, a vortex pipe section, an oxygen collecting pipe section,a nitrogen-oxide separation pipe section and an oxygen discharge pipe section which are connected in sequence; and the oxygen collecting pipe section is composed of a shell, cylindrical magnets and amagnetic conductive metal blanket, a plurality of cylindrical magnets are arranged at intervals around the inner wall of the shell to form a magnetic field ring, and the magnetic conductive metal blanket is arranged on the side of the magnetic field ring to form magnetic field surrounding. The magnetic field-surrounding oxygen-collecting device and the magnetic field-surrounding oxygen-collectingcombustion method provided by the invention can improve an oxygen content of a combustion-supporting gas flow, have low energy consumption, and can improve combustion efficiency, save fuel, reduce carbon dioxide content and significantly improve thermal efficiency, thereby facilitating promotion.

Owner:WUHAN FUSHIDA ENERGY TECH CO LTD

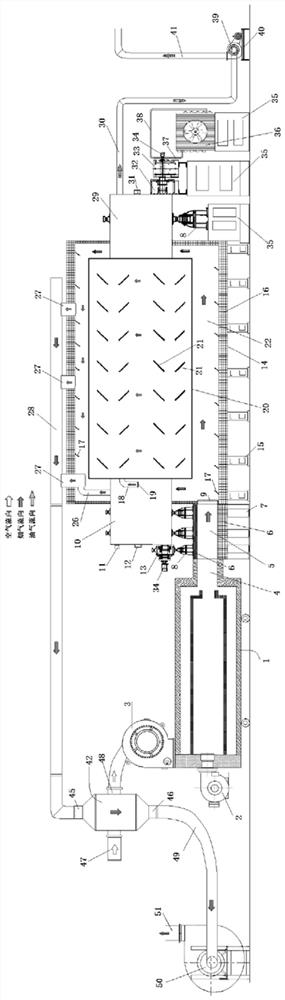

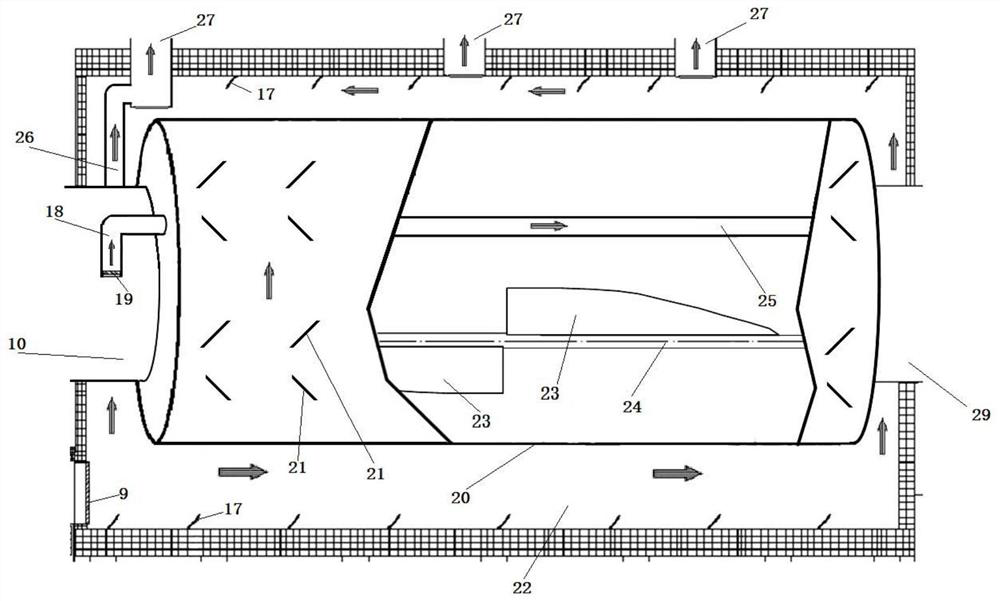

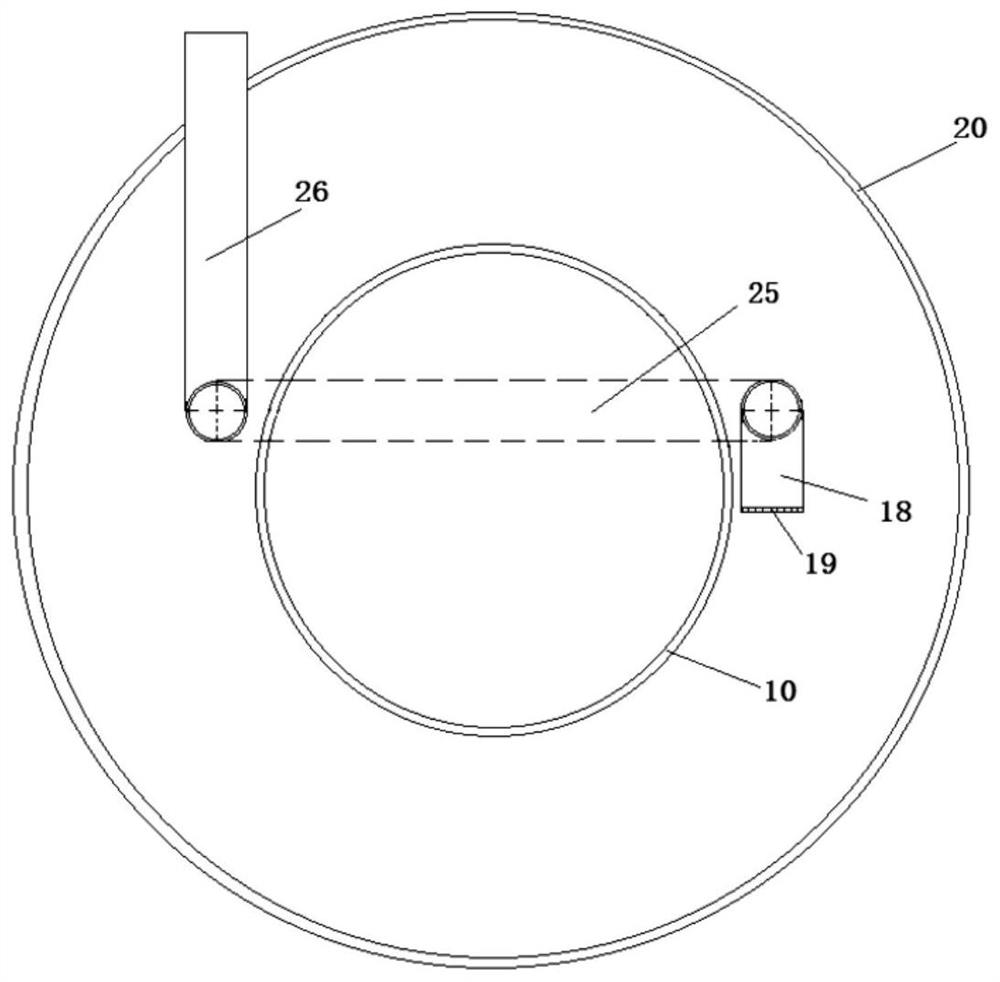

Energy-saving thermal cracking reaction kettle for treating organic solid wastes

PendingCN112708429AImprove utilization efficiencyIncrease the heat exchange areaIndirect and direct heating destructive distillationSpecial form destructive distillationFlue gasEnvironmental engineering

The invention discloses an energy-saving thermal cracking reaction kettle for treating organic solid wastes. The reaction kettle comprises a reaction kettle outer barrel (14) and a reaction kettle inner barrel (20), at least one group of U-shaped pipe components are arranged on the reaction kettle inner barrel (20), and each U-shaped pipe component comprises a U-shaped pipe (25) arranged at the upper part of an inner cavity of the reaction kettle inner barrel (20); and two opening ends of each U-shaped pipe (25) are respectively connected with the tail end of a smoke inlet pipe (18) of the corresponding U-shaped pipe component and the starting end of a smoke outlet pipe (26) of the corresponding U-shaped pipe component, an opening of the starting end of each smoke inlet pipe (18) faces the flowing direction of high-temperature smoke, and the tail end of each smoke outlet pipe (26) of the U-shaped pipe component communicates with a hot air channel smoke outlet (27). According to the thermal cracking reaction kettle disclosed by the invention, part of high-temperature flue gas is used for directly heating materials in the kettle body through the U-shaped pipe components, so that the heat exchange area is increased, and the energy utilization efficiency is improved.

Owner:胡进 +1

A dual-cavity flame-stabilized combustion device based on air-staged reverse jet technology

InactiveCN105972639BImprove the combustion processImprove stabilityContinuous combustion chamberCombustion chamberEngineering

Owner:CHONGQING UNIV

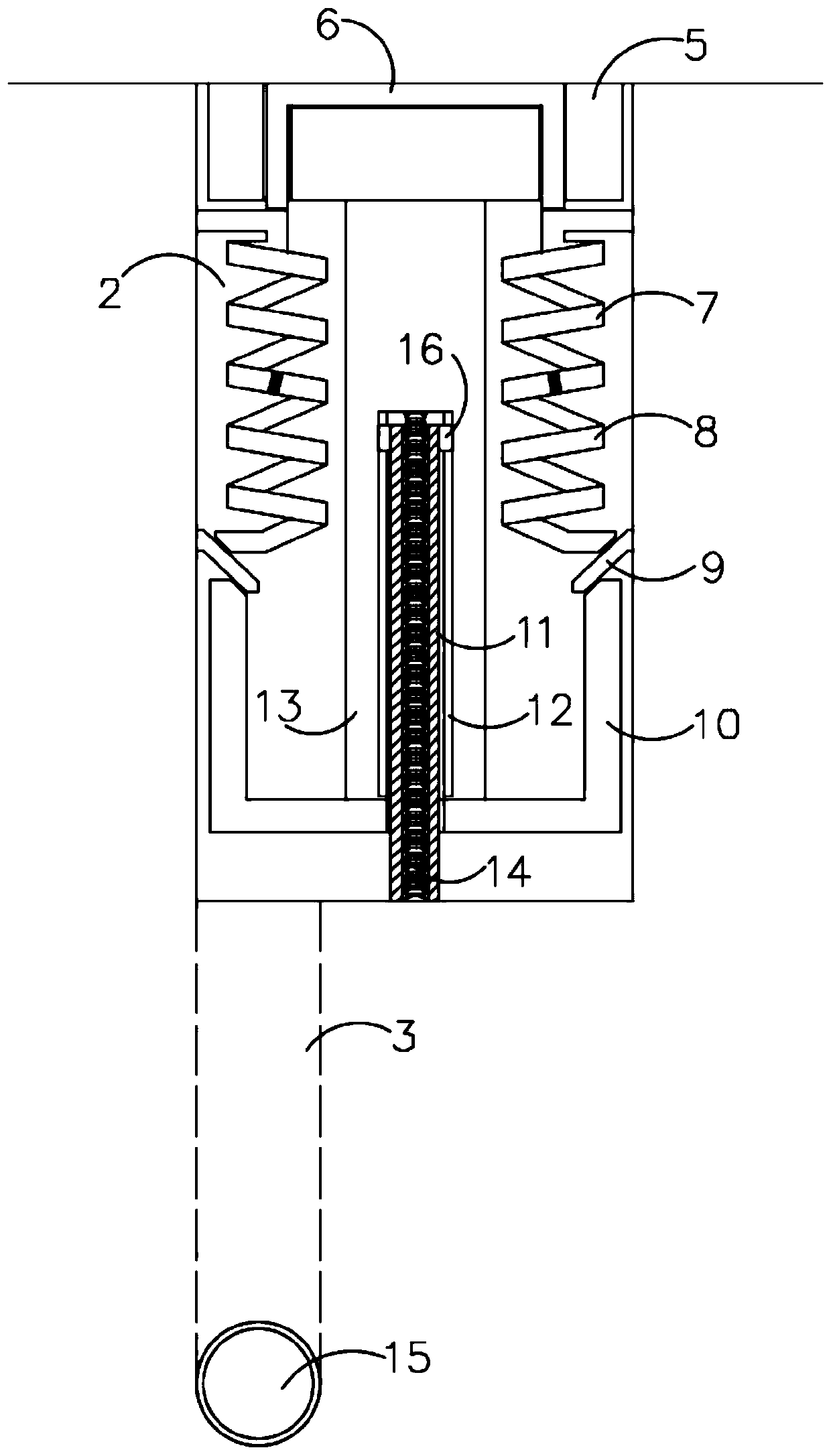

Heating device for heat-not-burn cigarette

The invention discloses a heating device for heat-not-burn cigarette. The device comprises a shell, wherein a cylinder body with openings at two ends is arranged in the shell, and a gap is arranged between the outer wall of the cylinder body and the inner wall of the shell; a cigarette accommodating part which is arranged in the shell and is used for accommodating a heating non-combustible cigarette; wherein the top end of the cigarette accommodating part is open and the bottom end is closed; a combustion chamber which is arranged in the cylinder body and is used for heating the heating non-combustion cigarette through the cigarette accommodating part; wherein the combustion chamber comprises a fuel channel used for providing fuel and a combustion air channel used for providing combustionair, the first end of the fuel channel and the bottom end of the cigarette containing part are arranged in a spaced mode, the second end of the fuel channel is communicated with the outside, and the combustion air channel is communicated with the outside; and a smoke exhaust channel which is arranged in the gap and used for exhausting tail gas generated after the fuel is combusted; wherein the first end of the smoke exhaust channel communicates with the interior of the cylinder body, and the second end of the smoke exhaust channel communicates with the outside. Long-time stable heating can beachieved, and the heat exchange efficiency is high.

Owner:HUBEI CHINA TOBACCO IND

A chemical experiment table that can automatically extinguish fire

ActiveCN110102358BPlay the role of collecting flammable liquidExtended combustion rangeFire rescueLaboratory benches/tablesCombustionAutomatic fire suppression

The invention discloses a chemical experiment table capable of automatically extinguishing fire, which comprises a table top, a base is fixedly connected to the bottom of the table top, a plurality of storage tanks are opened on the table top, and a linkage mechanism is arranged in the storage tanks. The linkage mechanism includes an insulating block and a connecting shaft, the connecting shaft is fixedly connected to the bottom of the insulating block, a copper plate is installed in the insulating block, a primary memory metal is fixedly connected to the inner wall of the storage tank, and the two ends of the copper plate All offset with the first-level memory metal. In the present invention, when the combustion spreads to the inside of the storage tank, the secondary memory metal inside the storage tank is heated and stretched, and when the secondary memory metal stretches, it presses against the U-shaped shaft and pulls the insulating block into the storage tank. All combustion requires the participation of oxygen, and if the air is isolated, that is, oxygen is isolated, and the oxygen in the storage tank is exhausted, the burning flame will be extinguished, so as to realize the collection of liquid and the extinguishment of the fire.

Owner:江西永昌环保实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com