Patents

Literature

167results about How to "Improve the combustion process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

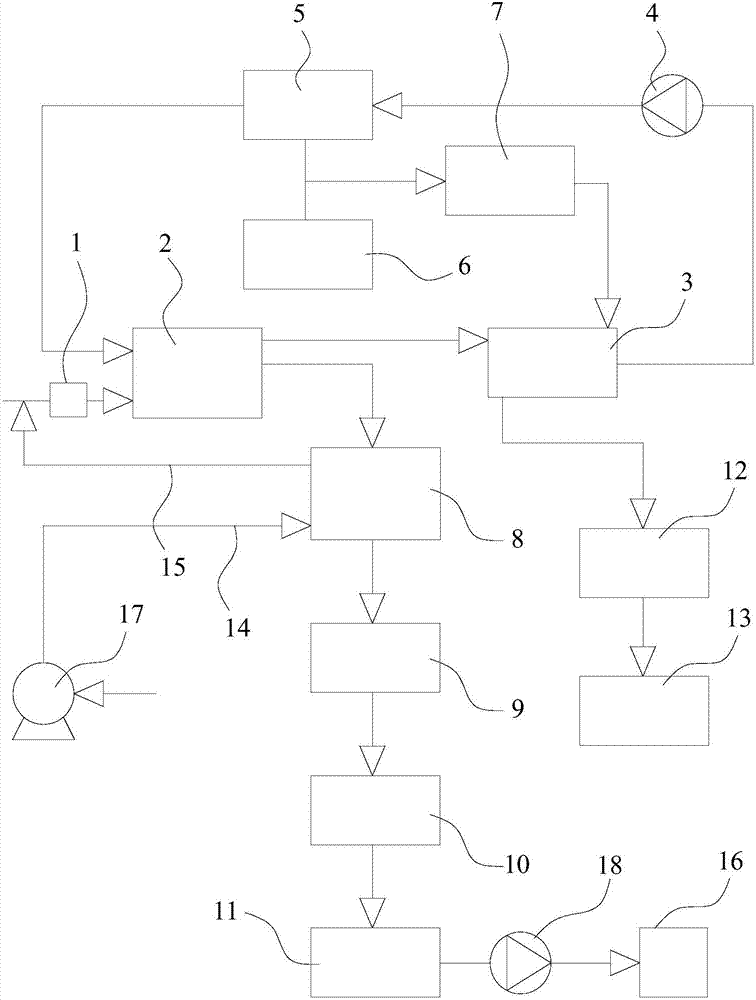

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Hydrogen-gasoline blended fuel rotary engine and control method

ActiveCN104234832AAir-fuel ratio A/F adjustmentEmission reductionInternal combustion piston enginesEngine controllersCombustionHydrogen

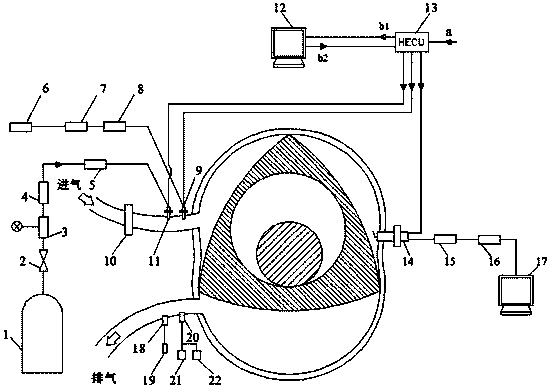

The invention relates to a hydrogen-gasoline blended fuel rotary engine and a control method, in particular to the hydrogen-gasoline blended fuel rotary engine and a control device, and belongs to the field of internal combustion engine control. The rotary engine main comprises an electronic control gasoline jetting system, an electronic control hydrogen jetting system, an ignition system and the like. The rotary engine has the advantages that existing electronic control jetting technologies of the internal combustion engine are applied to the rotary engine, and the fuel jetting and control under of the hydrogen-gasoline blended fuel rotary engine different working conditions are improved. In addition, due to the specific physical and chemical properties of hydrogen, the combustion of fuel can be improved, the oil consumption can be reduced, and meanwhile, the discharge of noxious substances can be reduced. The rotary engine and the control method have the advantages that the implementation manner is simple and feasible, the reliability and the stability are high, and the development prospects are good.

Owner:BEIJING UNIV OF TECH

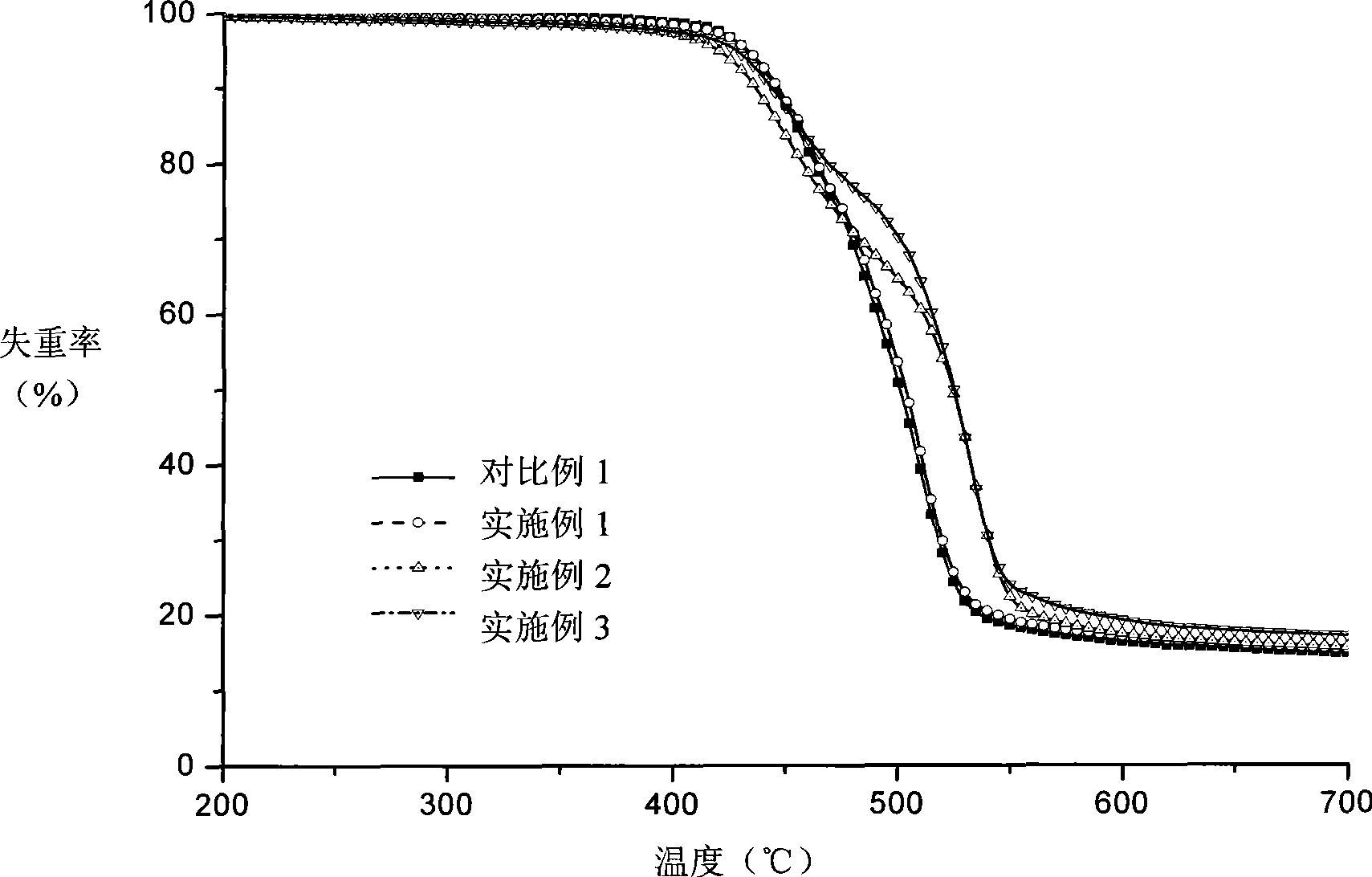

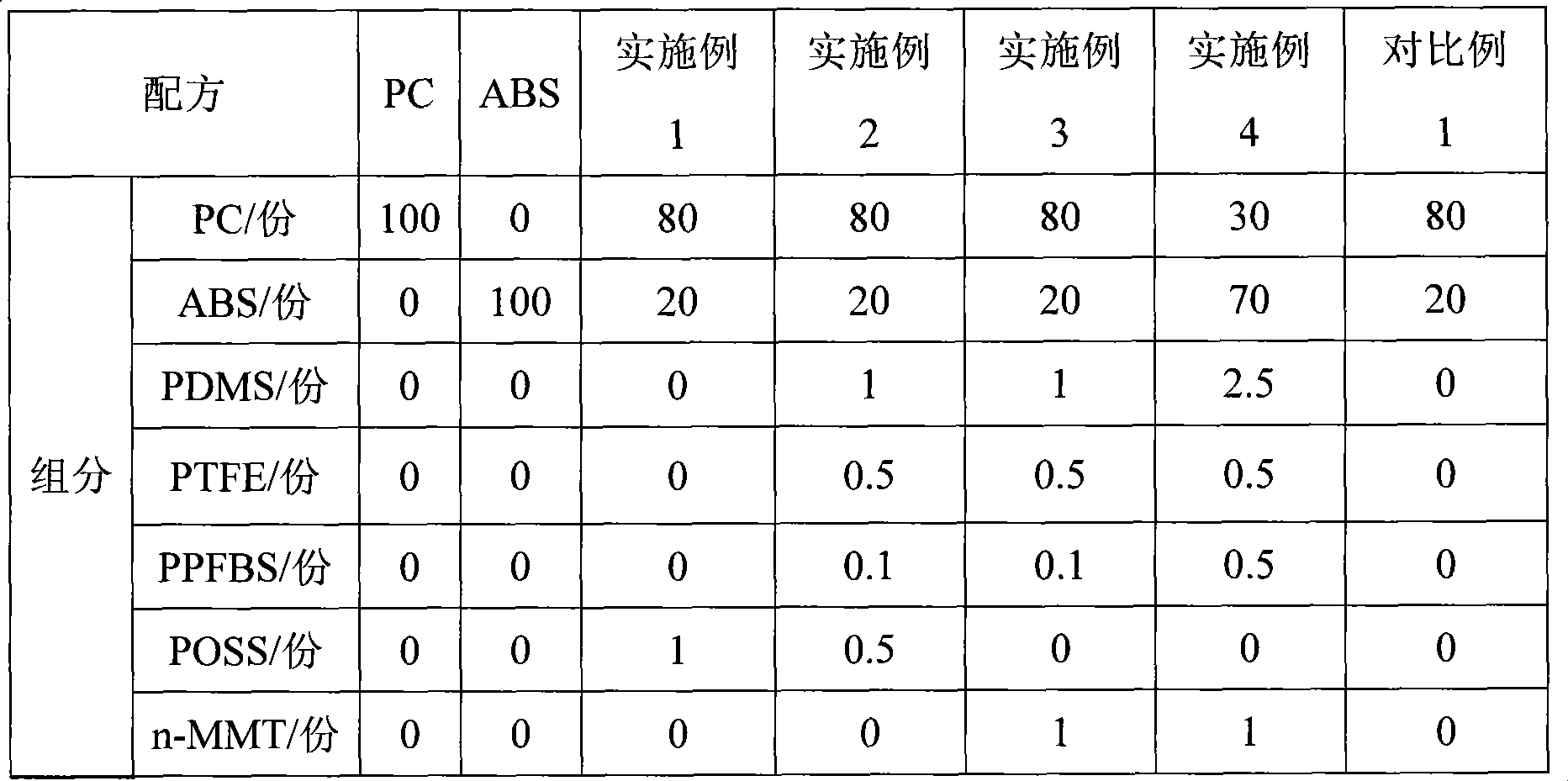

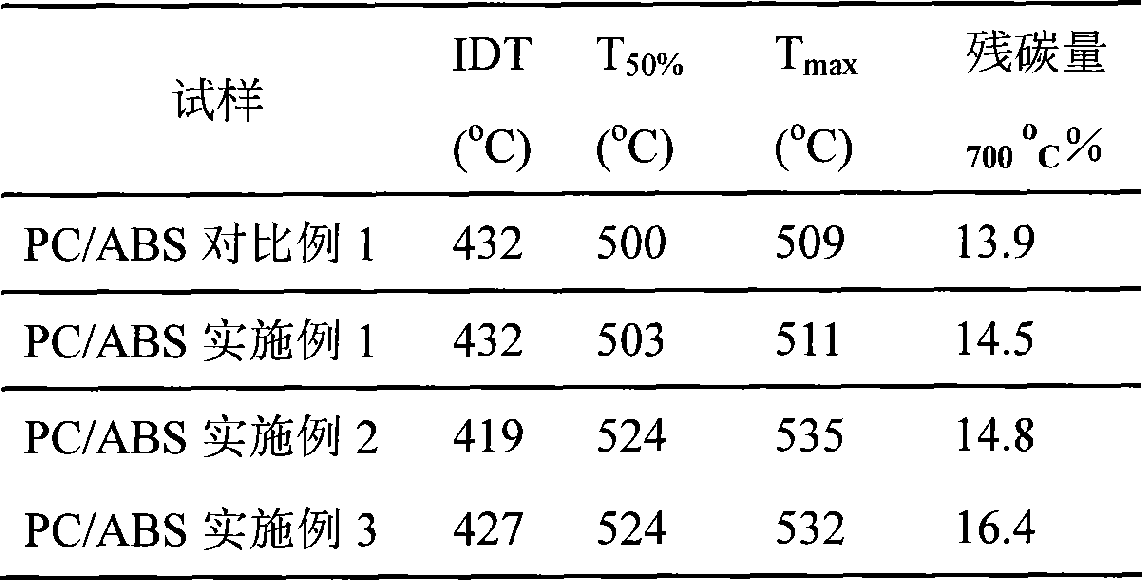

Preparation method of non-halogen flame-retarded makrolan/acrylonitrile-butadiene-styrene copolymer alloy

InactiveCN101445653AFacilitate cross-linkingIncrease the rate of charringPolytetrafluoroethyleneFire retardant

The invention discloses a preparation method of halogen-free flame-retarded makrolan / acrylonitrile-butadiene-styrene copolymer alloy. The following are all showed according to weight portions: the non-halogen flame-retarded makrolan / acrylonitrile-butadiene-styrene copolymer alloy is obtained by drying 20-99 portions of polycarbonate, 80-1 portions of ABS resin, 0.1-1 portion of Teflon, 0.01-4.5 portions of sulphonate series flame retardant, 0.01-5 portions of organic silicon series flame retardant and 0.01-5 portions of nano assistant under the temperature of 85 to 105 DEG C for 4 to 8 hours, then the mixture is uniformly mixed, and added in a double screw extruder, extruding is carried out under the temperature of 230 to 250 DEG C at a rotating speed of 200 to 240 r / min, then cooling, drying and cutting granules are carried out. The preparation method utilizes the complex formulation of the sulphonate series flame retardant, the organic silicon series flame retardant and the nano assistant, thus forming a synergism system co-acted on by a plurality of flame retardants; the alloy obtained is halogen free and the total adding amount of the flame retardants is less; in a vertical burning experiment, the alloy shows effects of self extinguishing, no fused drop and thick and having firm carbon layers and can reach a grade from UL94 V0 to V1. The preparation method has the characteristics that the flame-retarding efficiency is high, the mechanical property is good, and the method is also environmental friendly.

Owner:SHANGHAI JIAO TONG UNIV

Moxibustion column

InactiveCN102871837AImprove densification performanceImprove the effect of moxibustionDevices for heating/cooling reflex pointsCombustionNuclear chemistry

The invention belongs to the field of a medical appliance, relates to moxibustion, and provides a moxibustion column. The moxibustion column is mainly characterized in that purified moxa is used as a base stock, and proper absinthe oil and plant spice are added to the base stock, and pressurized and sliced into the moxibustion column. The moxibustion column has the advantages of improved moxibustion effect, good appropriate audibility and combustion persistence.

Owner:河南绿莹艾草制药有限公司

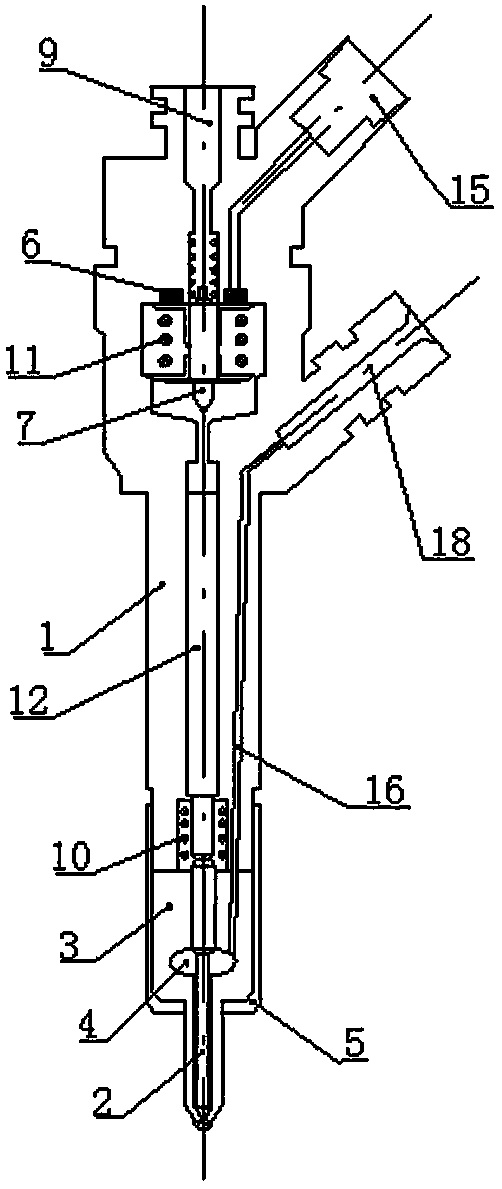

Double-oil-duct oil atomizer with controllable fuel oil temperature

InactiveCN103590947AEasy to controlGood fuel atomizationFuel injection apparatusMachines/enginesCombustionEconomic benefits

The invention relates to a double-oil-duct oil atomizer with a controllable fuel oil temperature. A main oil duct and a controlled oil duct are formed inside an oil atomizer body. Meanwhile, a fuel oil heating plug is arranged in front of an oil inlet of the controlled oil duct and used for heating fuel oil injected into the controlled oil duct, the main oil duct can continuously provide low-temperature fuel oil, the controlled oil duct provides set high-temperature fuel oil, and the high-temperature fuel oil and the low-temperature fuel oil are proportionally mixed in a fuel mixing cavity, so that the fuel oil is ejected according to different temperatures. Meanwhile, after the fuel oil heating plug is removed from the oil atomizer, the main fuel is distributed in the main oil duct, the auxiliary fuel is distributed in the controlled oil duct, so that mixing of the double fuel is achieved, and the double-oil-duct oil atomizer can be well adapted to the combustion mode of double fuel ejecting at the current stage. The fuel oil atomizing effect of a direction injection engine in a cylinder is optimized, combustion and emission quality of the engine is greatly promoted, and meanwhile quantitative mixing and ejecting combustion of the double fuel are achieved. The double-oil-duct oil atomizer is scientific and reasonable in design and has high social and economic benefits.

Owner:ZHONGBEI UNIV

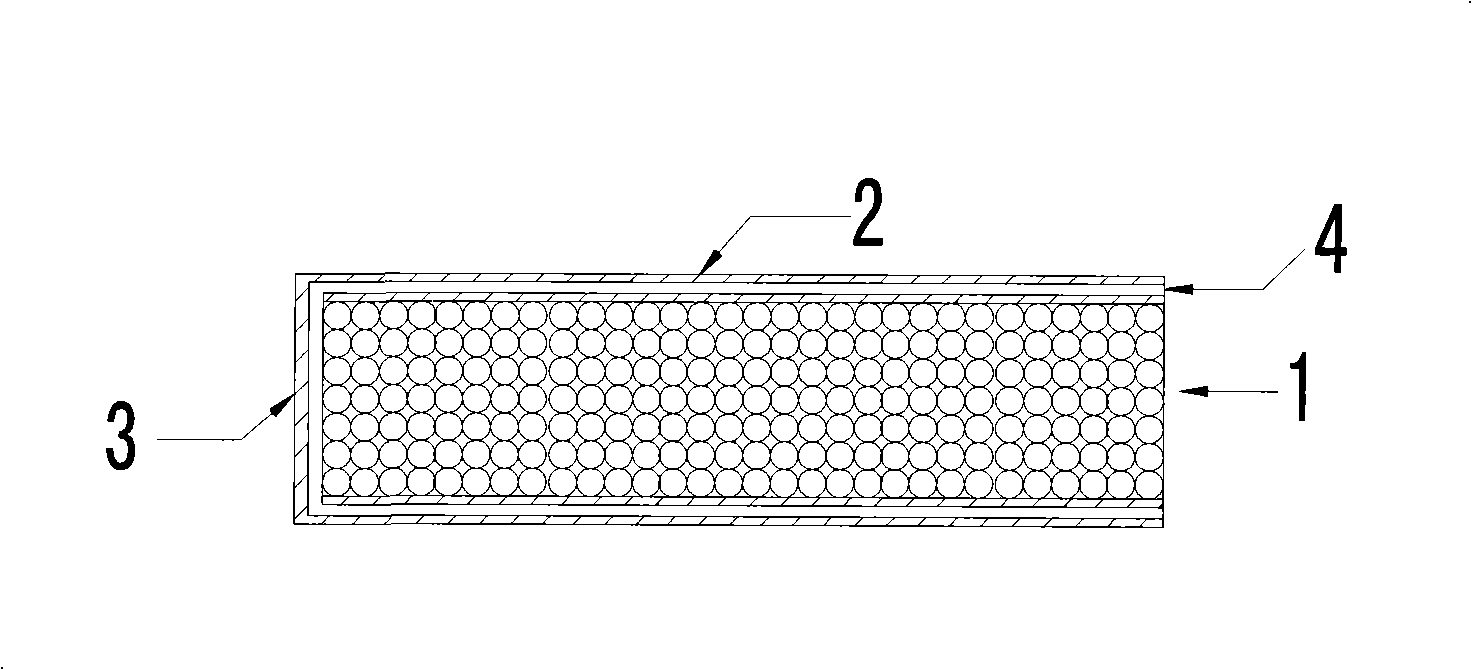

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

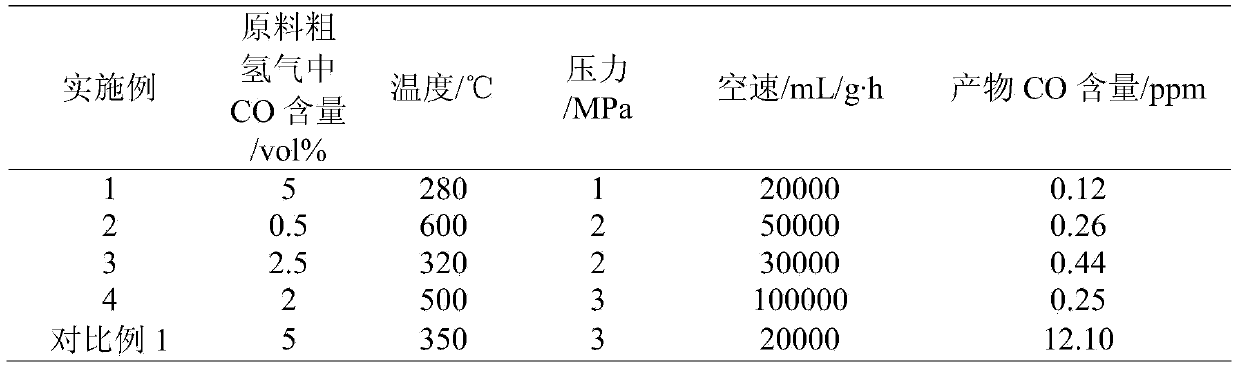

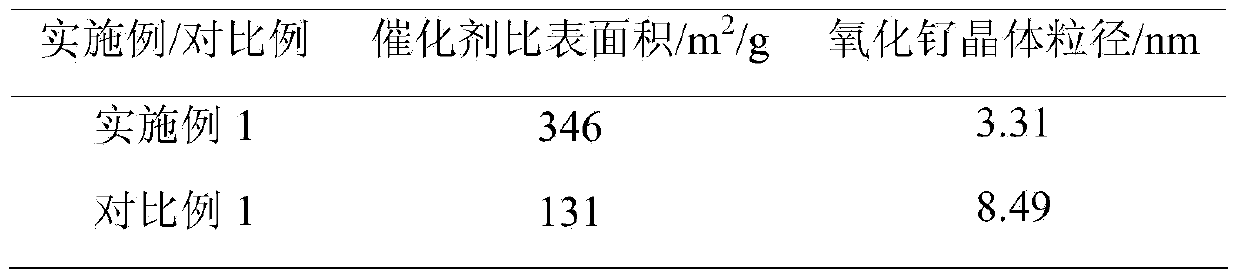

Precious metal methanation catalyst prepared by using solution combustion method and preparation method and applications thereof

InactiveCN103801290AImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

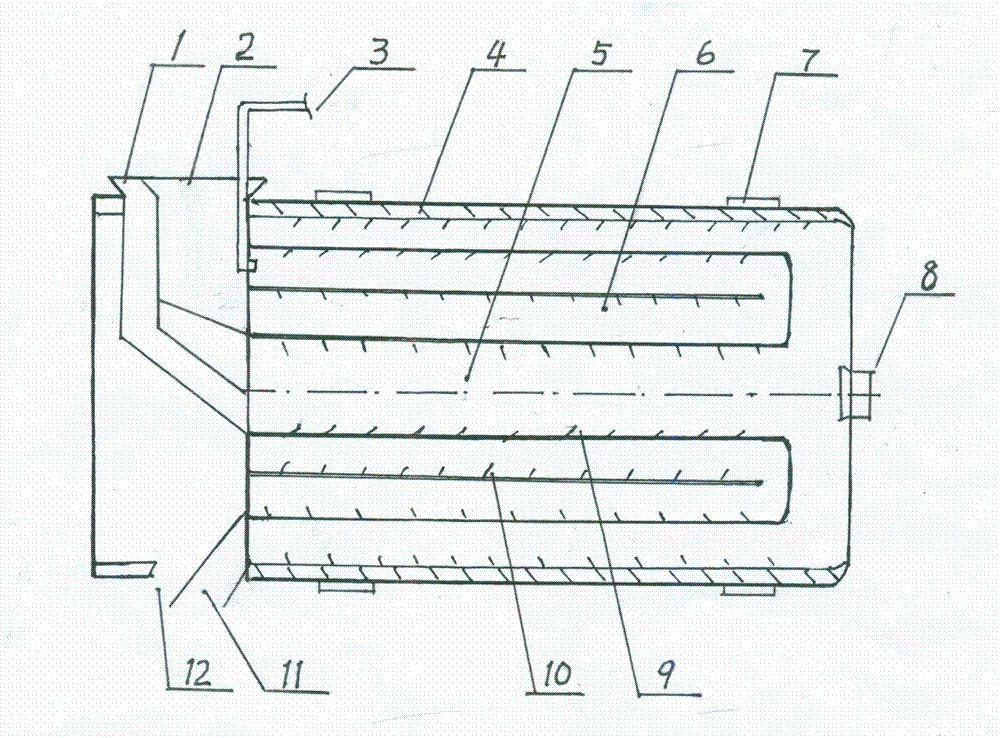

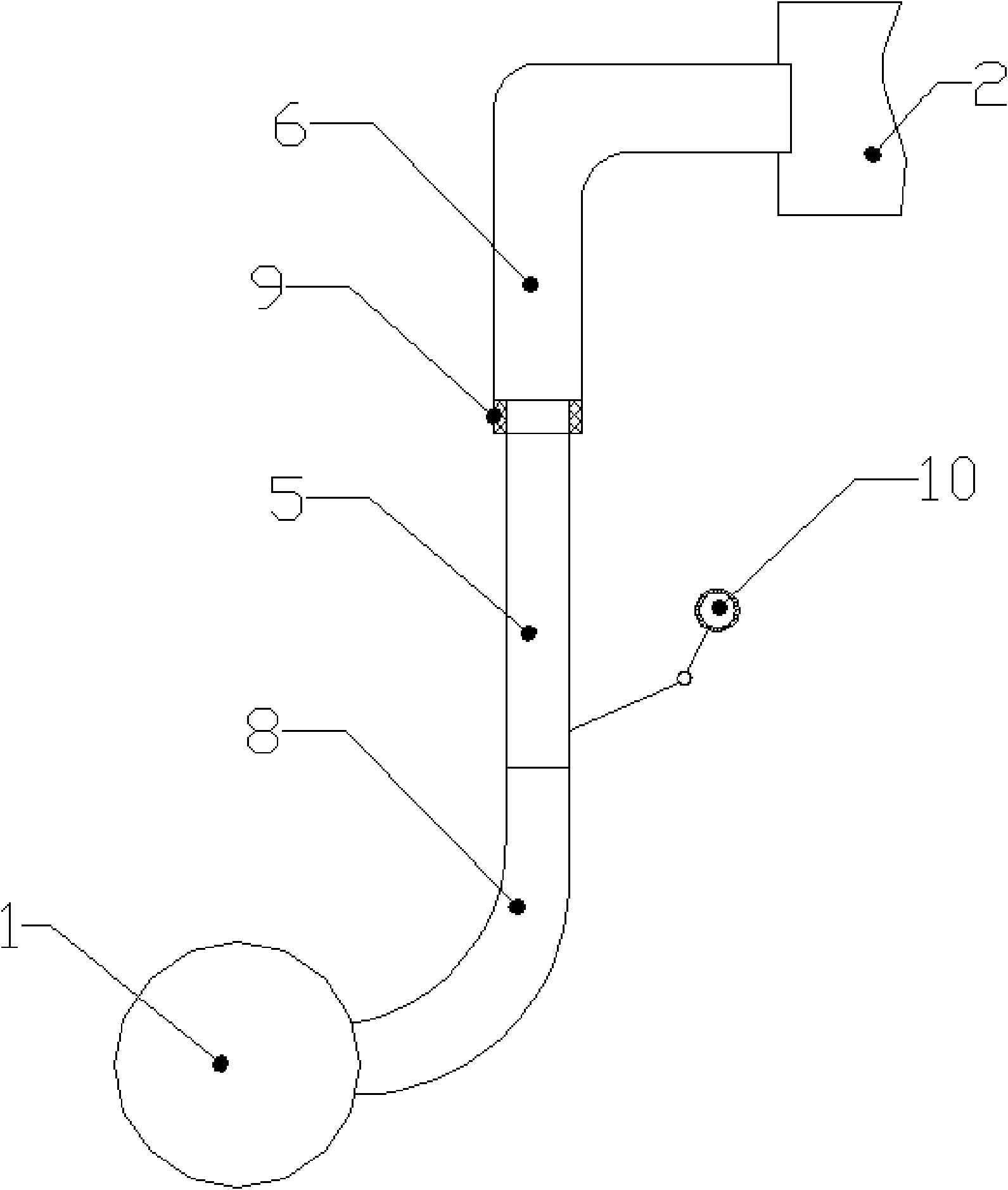

U-shaped internal-combustion rotating limekiln capable of recovering CO2

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Owner:赵光辉

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

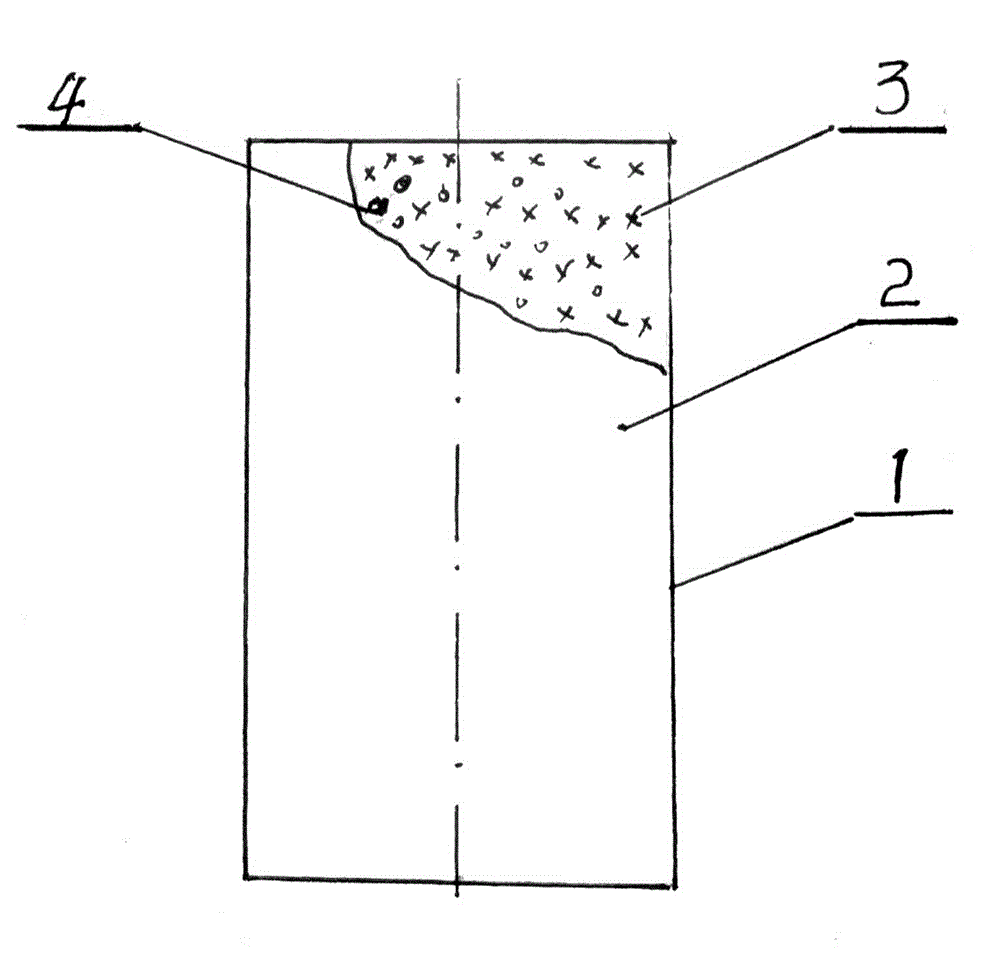

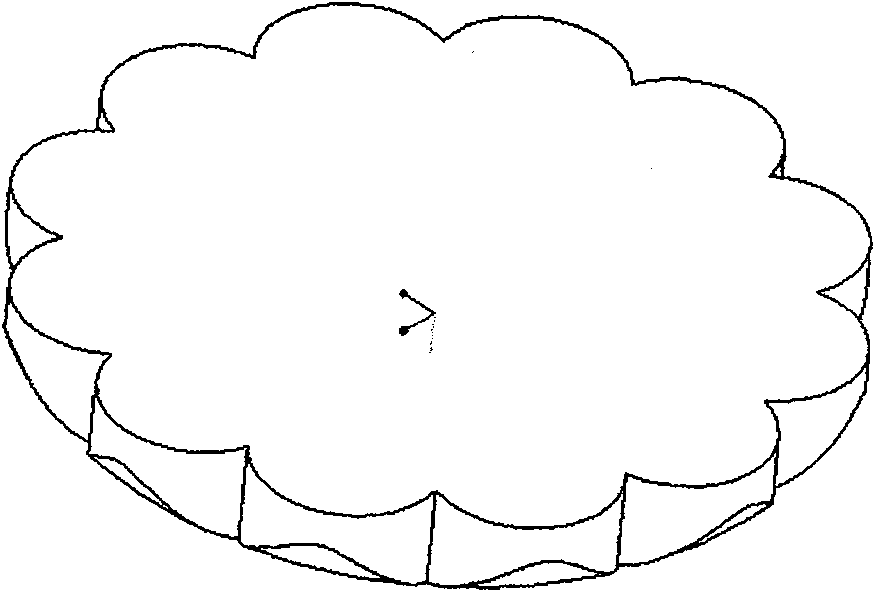

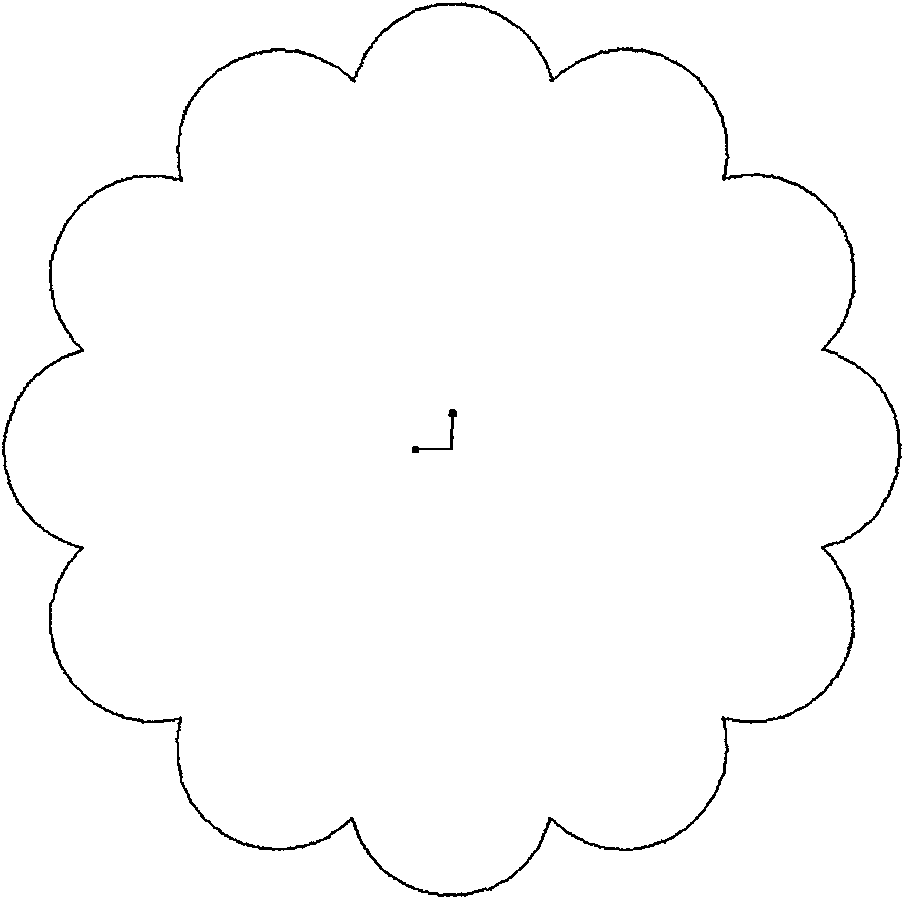

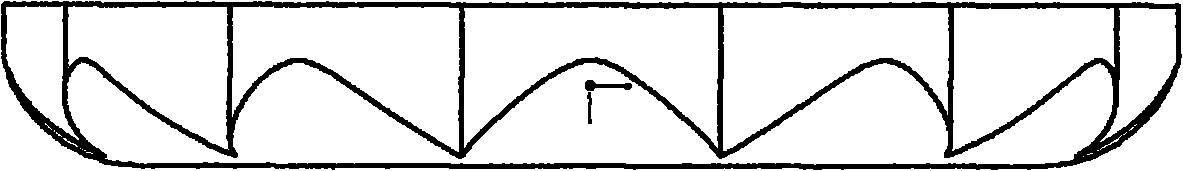

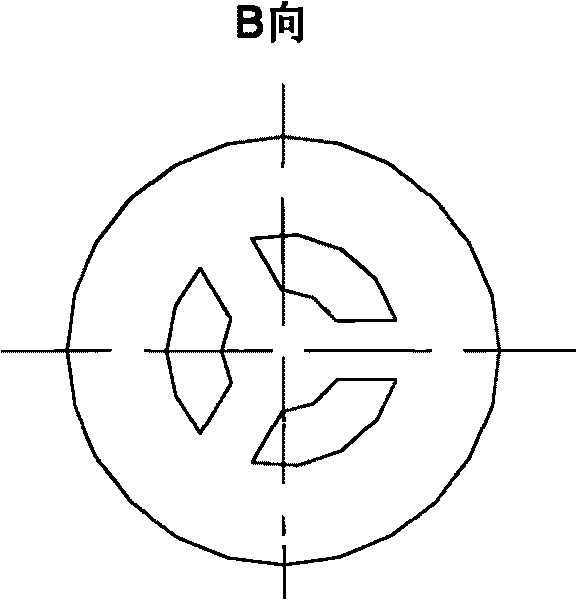

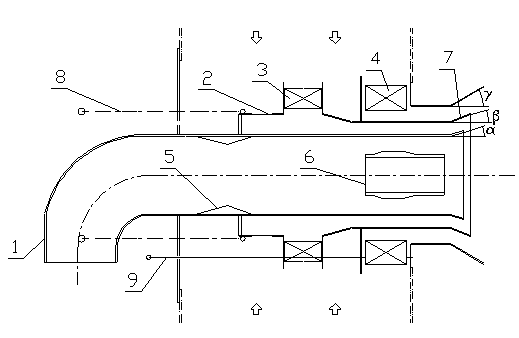

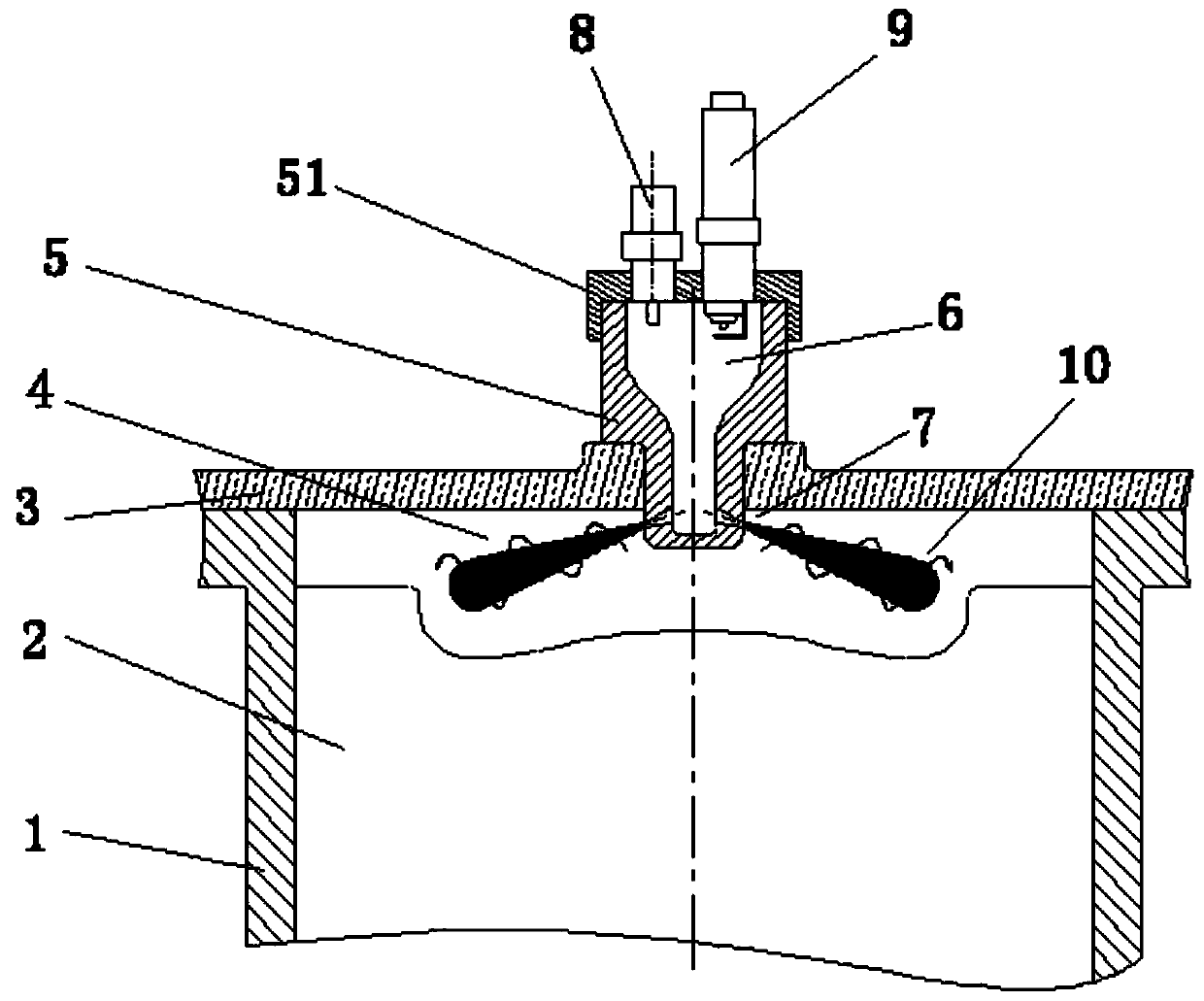

Lateral-swirl combustion chamber

InactiveCN101839166AEnhanced mixing processImprove the combustion processInternal combustion piston enginesCombustion chamberDiesel engine

The invention relates to a combustion chamber structure reconstructed on a basis of a common omega-shaped diesel engine combustion chamber. A top shunt model is processed and manufactured on the outer margin of an original omega-shaped combustion chamber without changing the matching relationship among the geometric size, the fuel injection included angle and the fuel injection characteristic of a fuel injector of the original reference omega-shaped combustion chamber. When fuel knocks the top shunt model in a right moment, the fuel turns into a lateral swirl to improve the far-end air utilization rate of the combustion chamber, expand a fuel distribution area of the combustion chamber in a radial direction and accelerate the mixing and the combusting of oil and air of the diesel engine so that the requirement for an intake swirl is relatively lowered. In the invention which is reconstructed on a basis of the original common omega-shaped combustion chamber, the top shunt model is easy and practical to process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

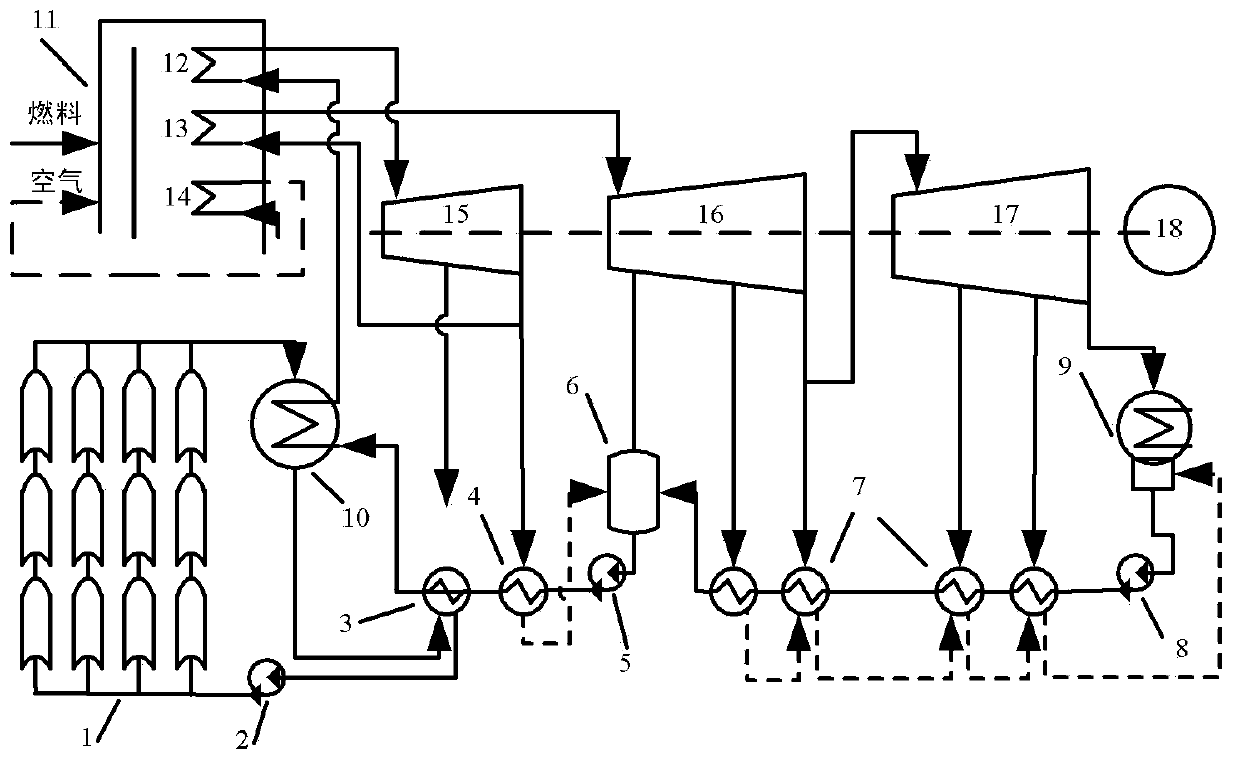

Power generation system capable of realizing complementation between solar energy and biomass energy

InactiveCN104179647AEfficient use ofReduce lossesFrom solar energyMachines/enginesAir preheaterThermal energy

The invention discloses a power generation system capable of realizing complementation between solar energy and biomass energy. The power generation system comprises a slot type solar heat collection sub-system, a biomass after-burning sub-system and a power generation sub-system, wherein the slot type solar heat collection sub-system comprises a solar heat collection field, an oil-water heat exchanger and a heat conduction oil pump, and is used for receiving and gathering solar radiation energy; supplied water is heated up to a certain temperature or is heated until becoming steam by the oil-water heat exchanger; waste heat of heat conduction oil is used for replacing part or all high-pressure cylinder extract air of a steam turbine for heating the low-temperature supplied water; the biomass after-burning sub-system comprises a biomass boiler, a superheater, a reheater and an air pre-heater, and is used for generating high-temperature flue gas and heating products at an outlet of the oil-water heat exchanger and steam at an outlet of a high-pressure cylinder into high-temperature and high-pressure steam; the power generation sub-system comprises the steam turbine and a generator set, and is used for converting received thermal energy into electric energy and outputting the electric energy. After the power generation system capable of realizing complementation between solar energy and biomass energy is adopted, the problem that a slot type solar single thermal power generation system is low in main steam parameter can be solved, the dosage of biomass is reduced, and the biomass resource collection, transportation and storage costs can be lowered.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

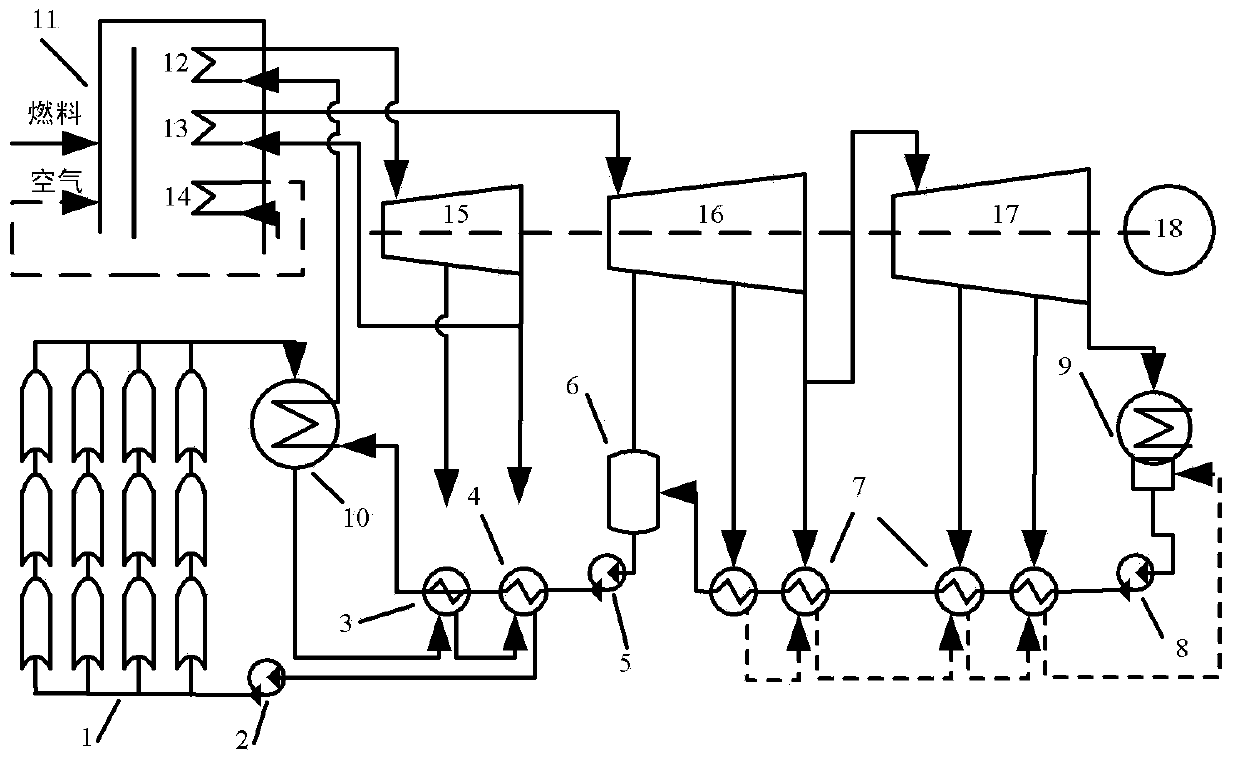

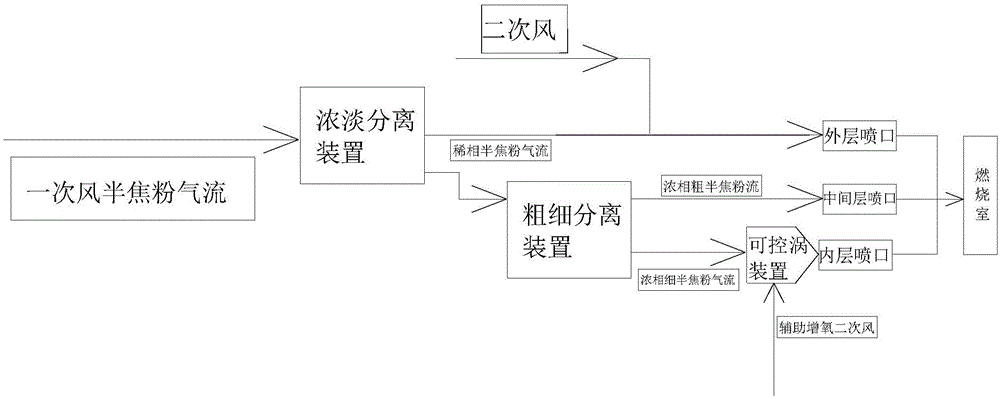

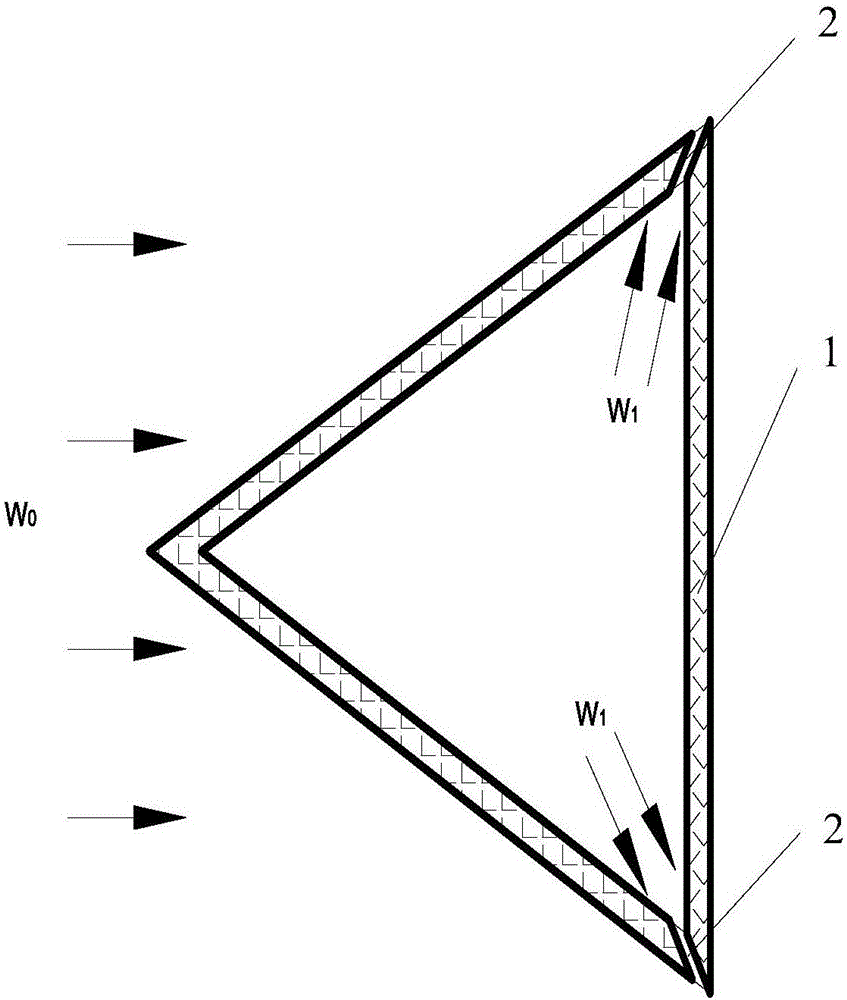

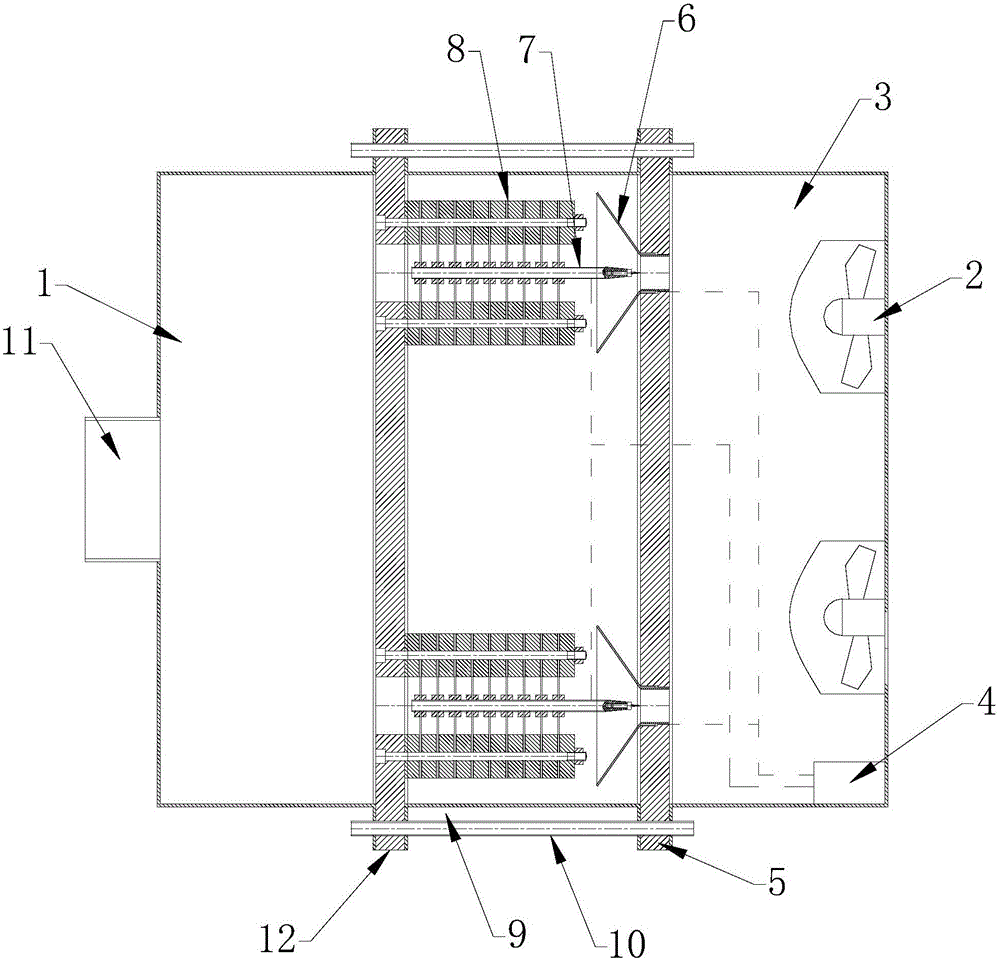

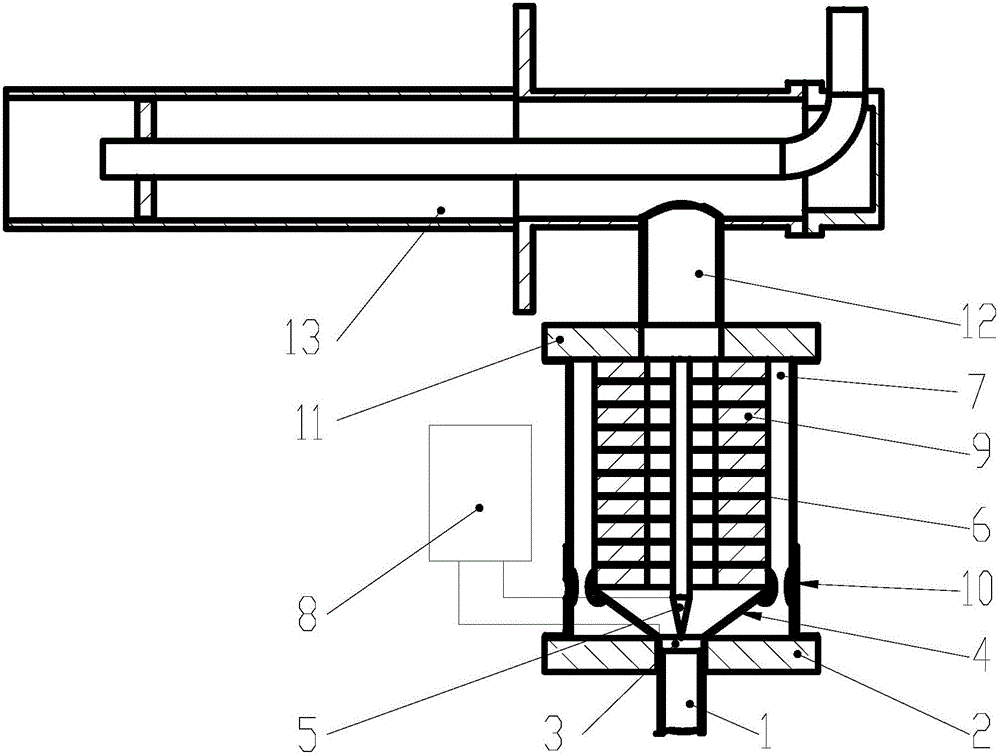

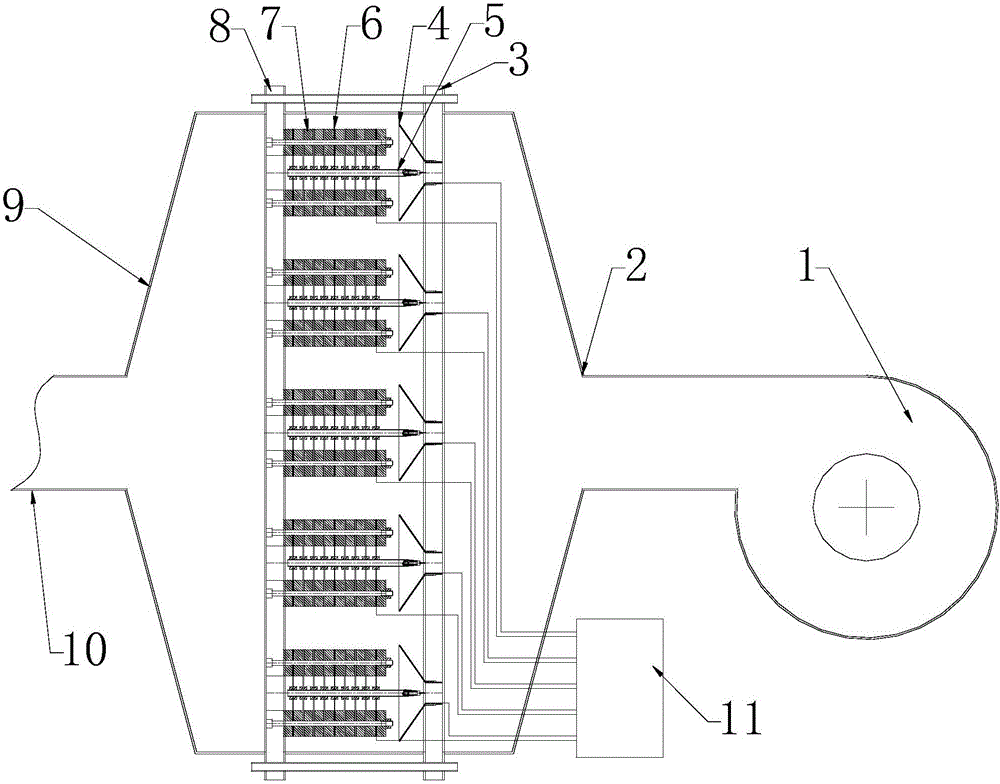

Method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies

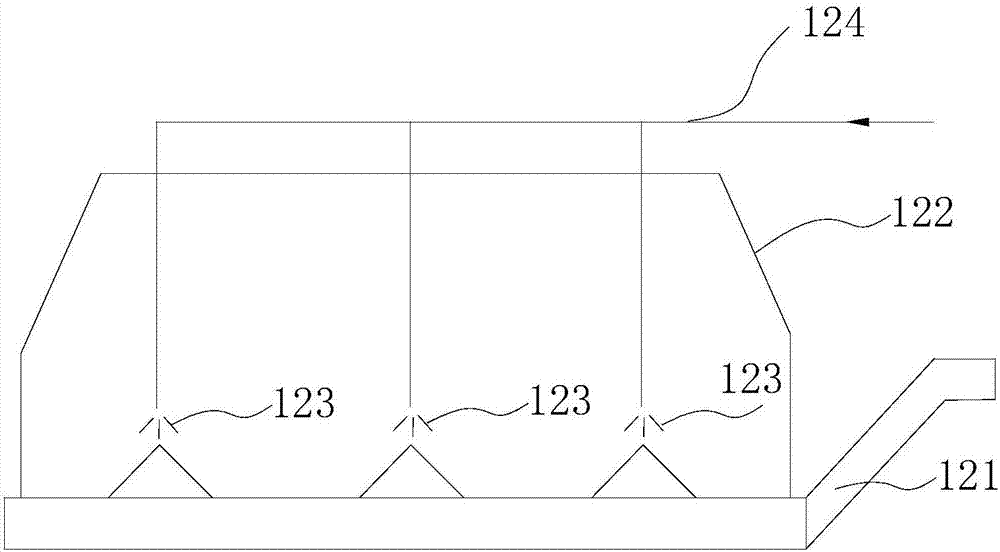

InactiveCN106556007AFire stablePrevent high temperature corrosionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

A method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies is characterized in that low-rank coal primary air semi-coke powder flow carrying gasified semi-coke is subjected to concentrated-dilute separation to obtain concentrated-phase semi-coke powder flow and dilute-phase semi-coke powder flow; the concentrated-phase semi-coke powder flow is subjected to coarse-fine separation to obtain concentrated-phase coarse semi-coke powder flow and concentrated-phase fine semi-coke flow; the dilute-phase semi-coke powder flow and secondary air are mixed, and the mixture is guided into an outer-layer nozzle of a combustion chamber; and the concentrated-phase fine semi-coke powder flow and the concentrated-phase coarse semi-coke powder flow are guided into an inner-layer nozzle and an intermediate-layer nozzle of the combustion chamber respectively and then sprayed into the combustion chamber, a controlled vortex bluff body device and an auxiliary aeration secondary air nozzle are mounted in the inner-layer nozzle of the combustion chamber, and during ignition, the concentrated-phase fine semi-coke powder flow sprayed by the inner-layer nozzle of the combustion chamber is ignited at first. The method can effectively improve ignition, combustion and burn-out characteristics of gasified semi-coke, reduces pollutant discharge and can effectively prevent a furnace wall from slag-bonding and a water wall from high-temperature corrosion.

Owner:CHONGQING UNIV

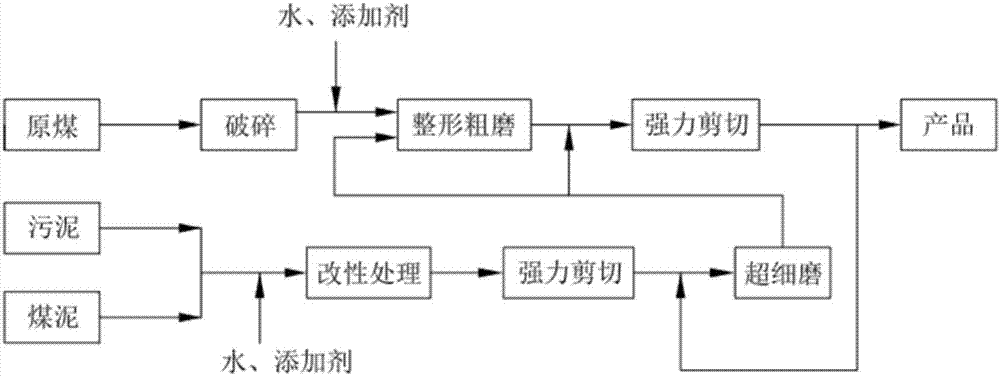

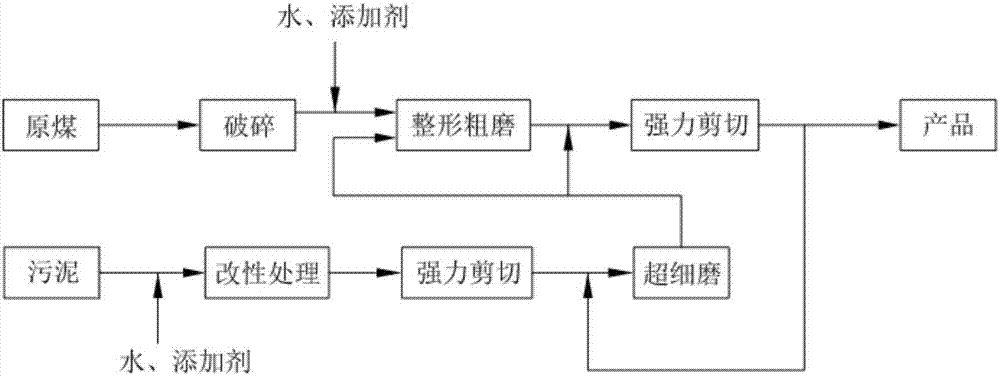

Method for preparing novel coal water slurry product from multiple materials

ActiveCN107267235AQuality improvementEfficient and clean utilizationLiquid carbonaceous fuelsCoal waterMulti material

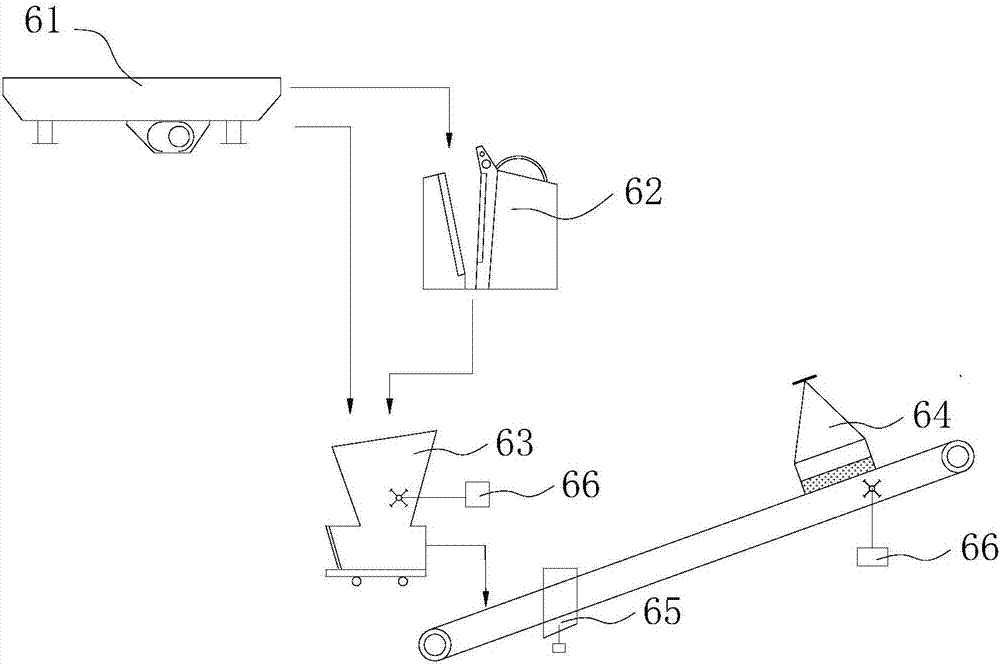

The invention provides a method for preparing a novel coal water slurry product from multiple materials. The method includes the following steps: (1) after raw coal is crushed, a material A is obtained; (2) after being modified together, sludge, optional coal slime, water and additive then undergo strong shear treatment, so that a material B is obtained; (3) the material B is ultrafinely ground, so that a material C is obtained; (4) the material A, part of the material C, water and additive are shaped and roughly ground, so that a material D is obtained; (5) after being mixed, the material D and the remaining material C undergo strong shear, and thereby the coal water slurry product is obtained. The grain size distribution of the multi-material coal water slurry prepared by the preparation method is reasonable, and the novel coal water slurry product has good stability, flowability and good atomizing effect, and is also applicable to the preparation of fuel and gasified coal water slurry; in addition, the preparation method is easy to implement, energy consumption is low, and the problem on how to utilize sludge and coal slime on a large scale can be reasonably solved.

Owner:CCTEG CLEAN ENERGY CO LTD

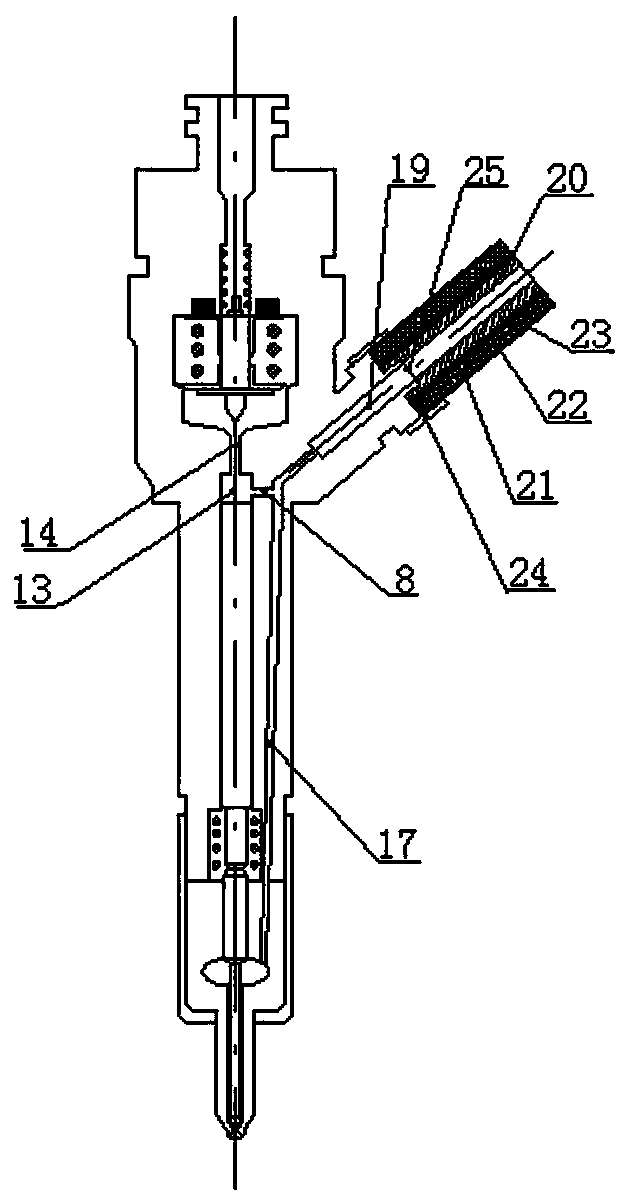

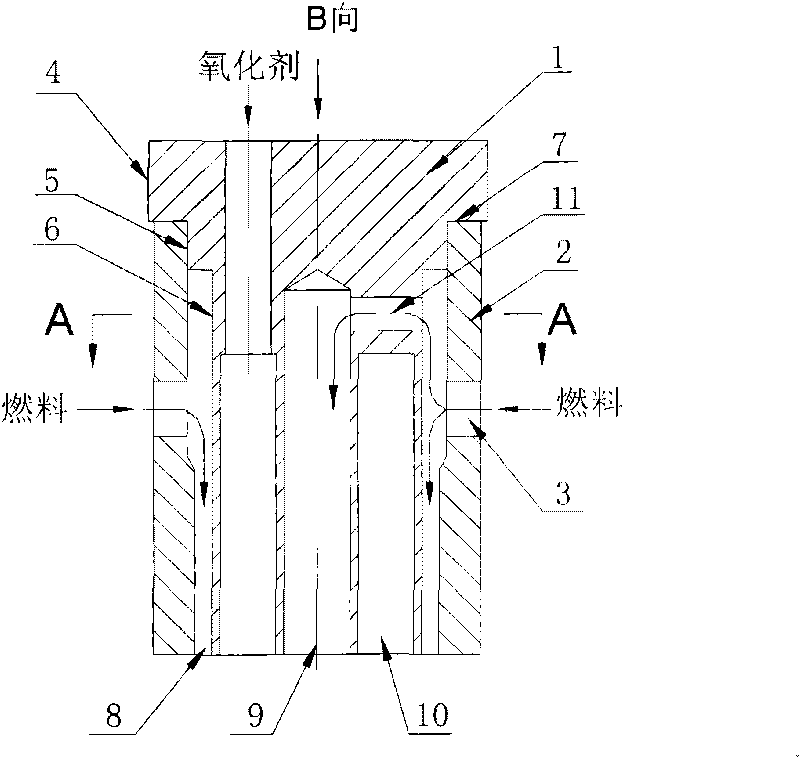

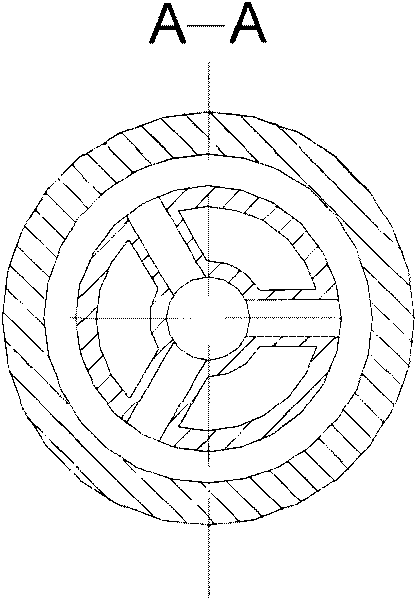

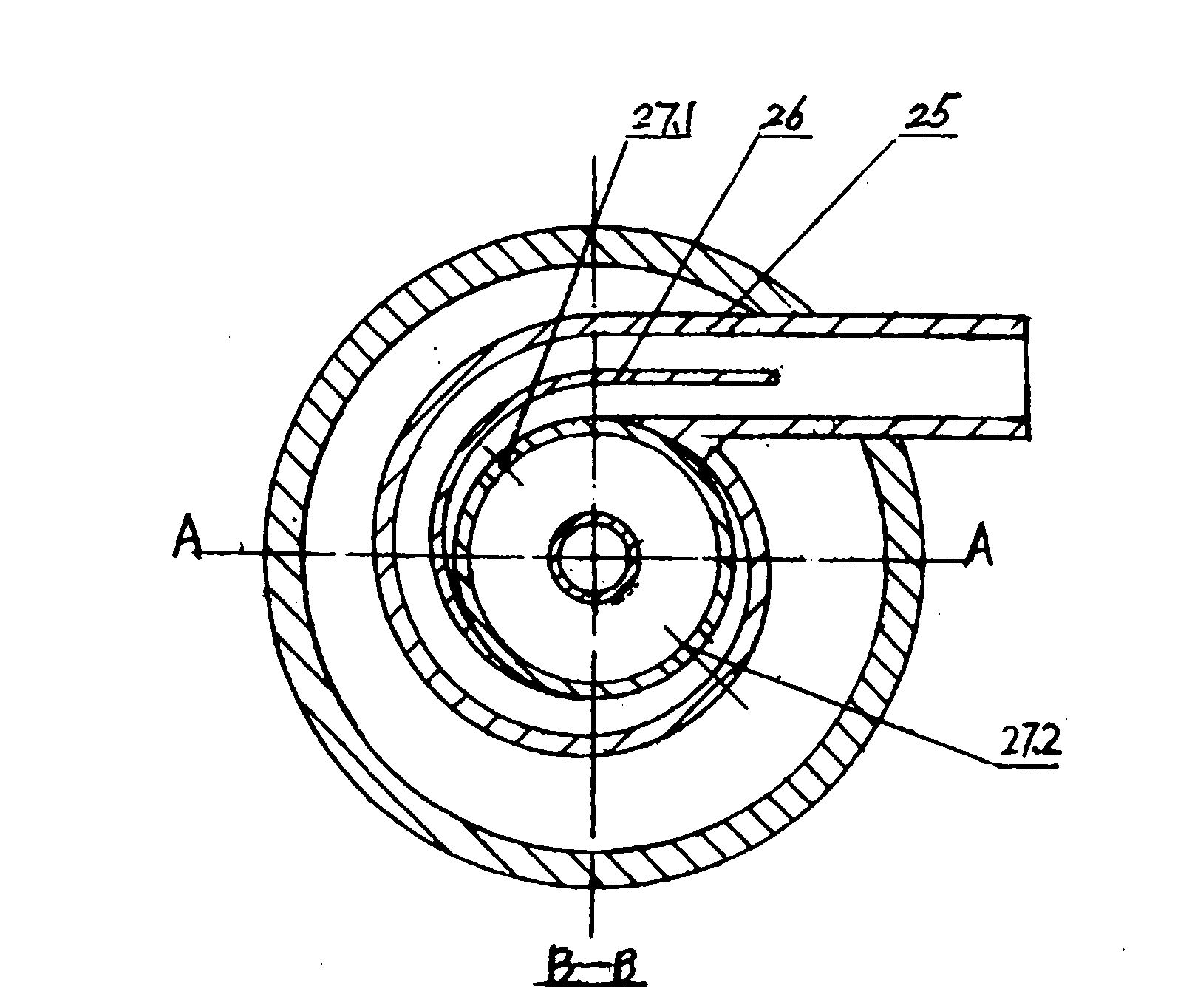

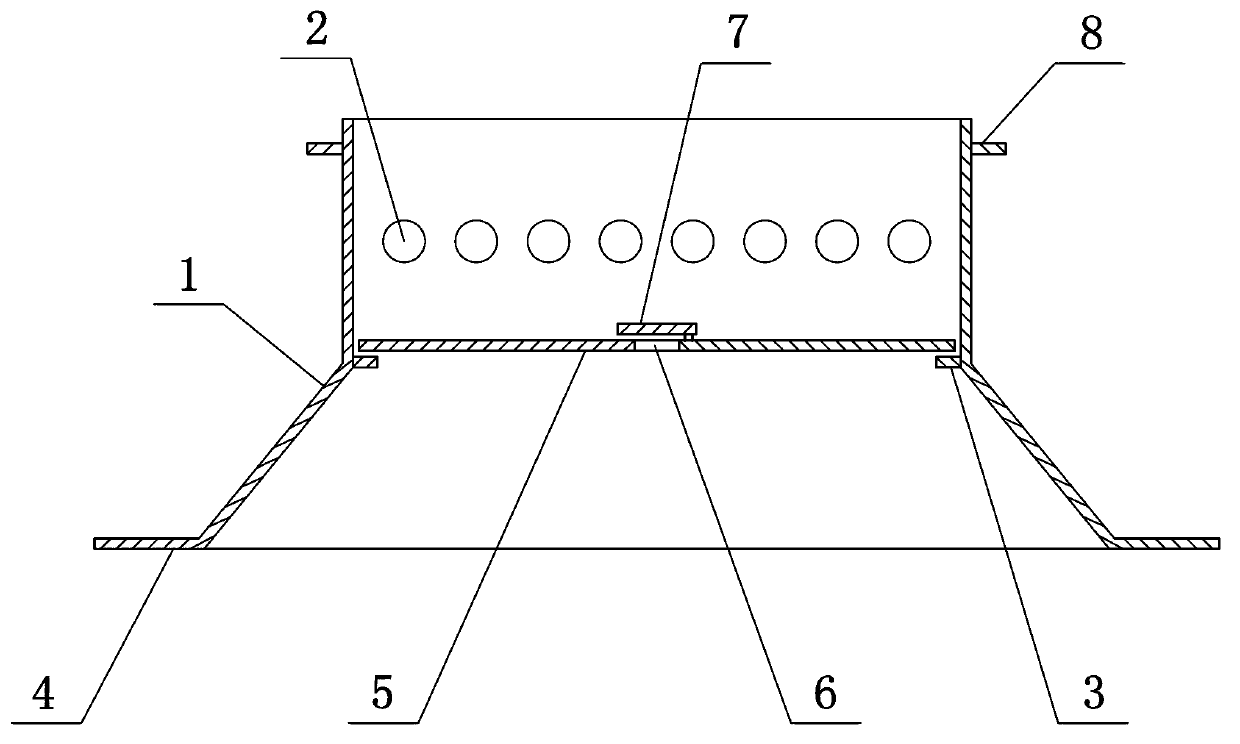

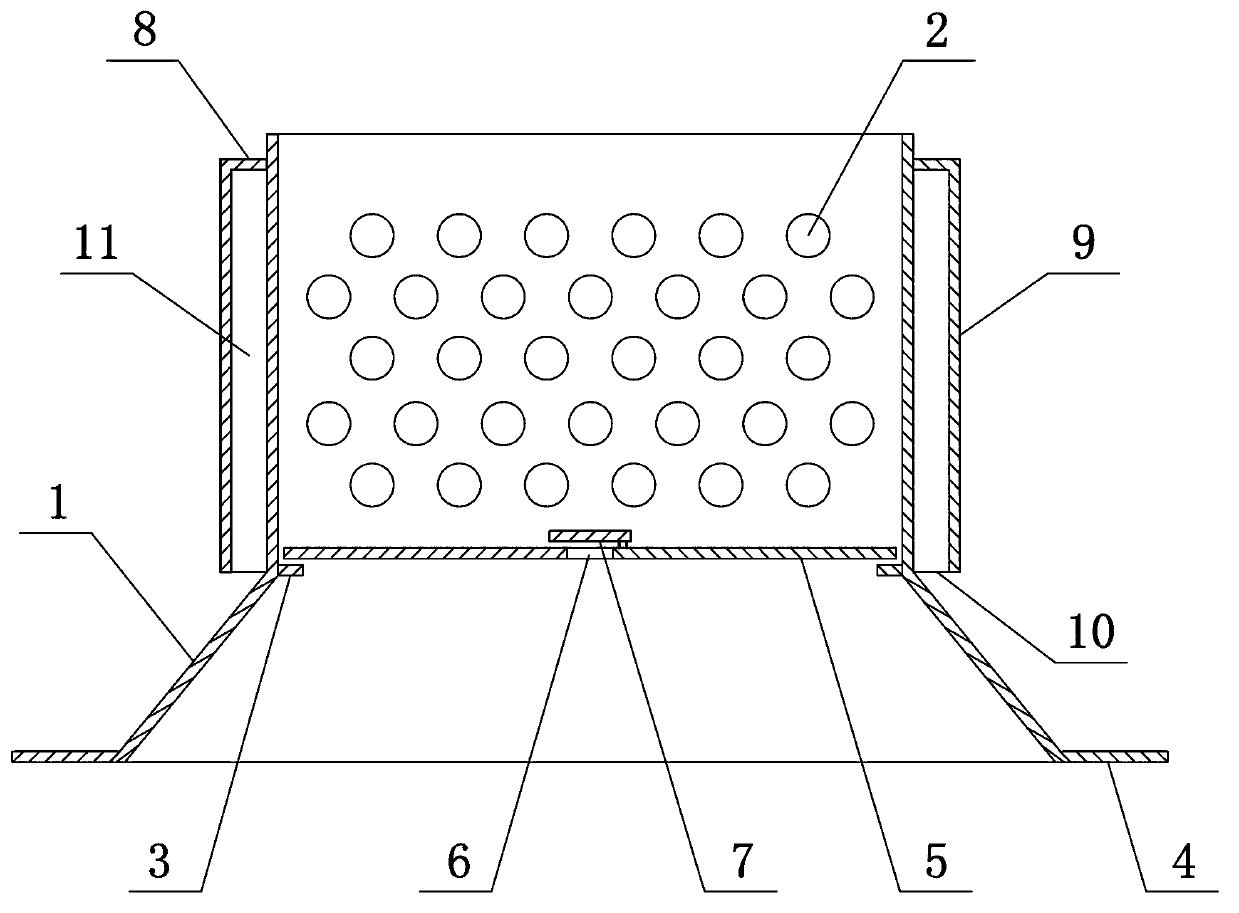

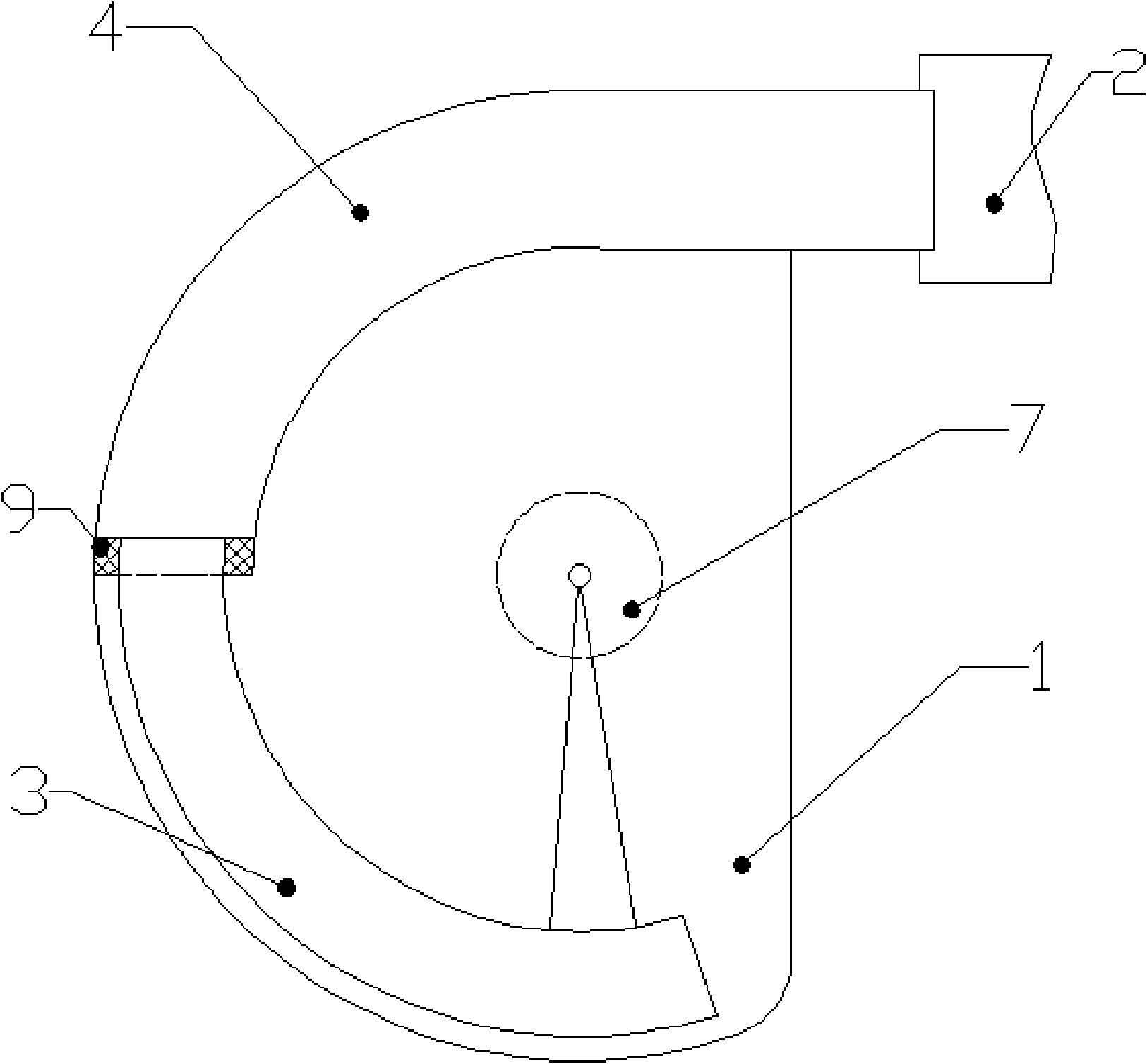

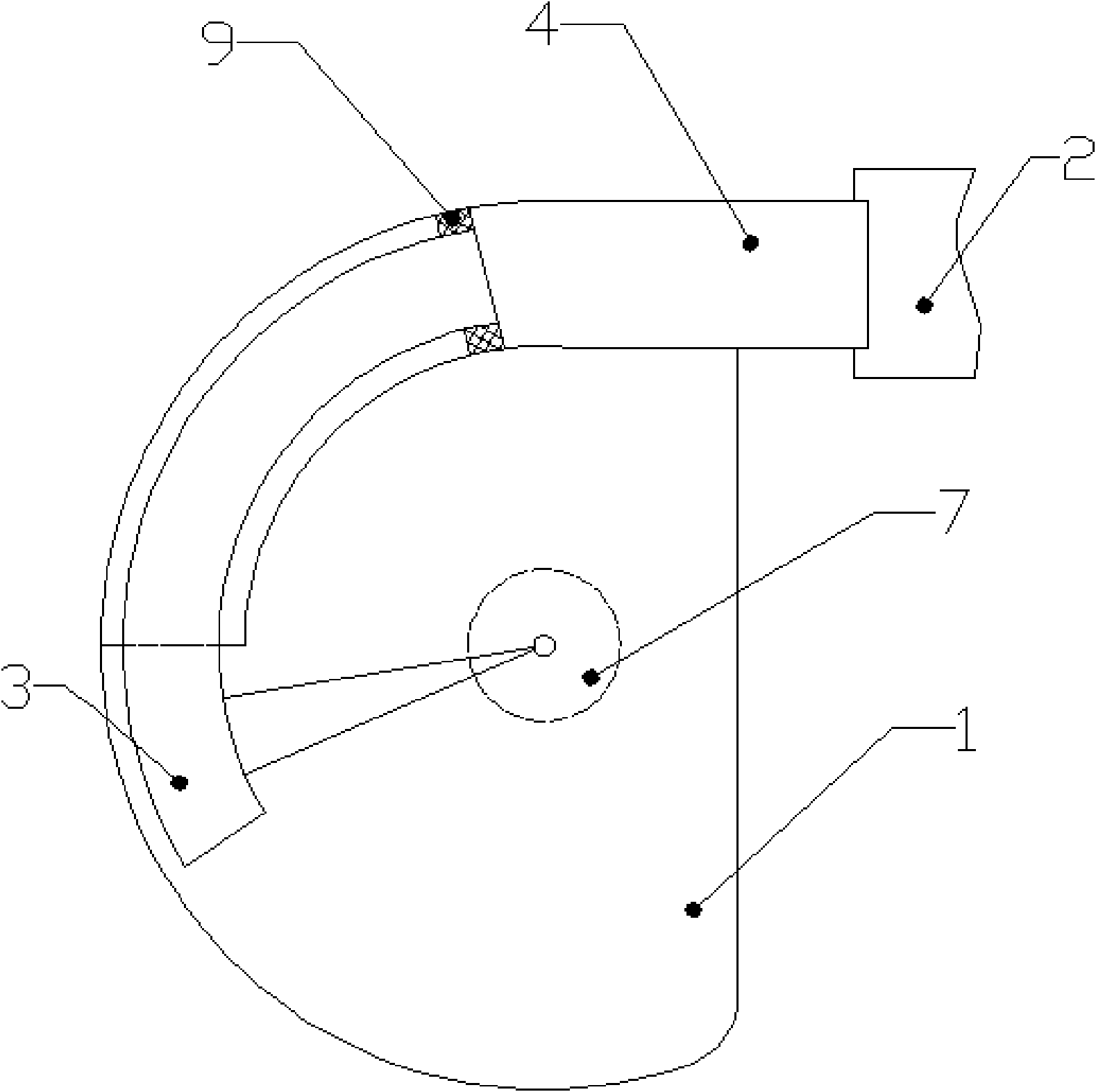

Dual concentric gas-gas nozzle

InactiveCN101737197AReduce the numberImprove the combustion processRocket engine plantsCombustion chamberEngineering

The invention relates to a dual concentric gas-gas nozzle, which ensures that a propellant forms a 'fuel-oxidant-fuel' distribution form in a motor combustor to increase contact area of the fuel and the oxidant so as to form an inner annular combustion surface and an outer annular combustion surface in the combustor. The nozzle comprises a nozzle main body (1) and a cylinder sleeve (2), wherein the side wall of the cylinder sleeve is provided with a plurality of through holes (3); the nozzle main body and the cylinder sleeve are connected into a whole; an annular cavity (8) is formed between the cylinder sleeve and the nozzle main body; a central spray orifice (9) and an annular spray orifice (10) are formed in the nozzle main body; the side of the nozzle main body is provided with a radial hole (11) to ensure that the central spray orifice (9) is communicated with the annular cavity (8); and the upper end face of the nozzle main body is provided with a fluid channel (12) communicated with the annular spray orifice (10). The dual concentric gas-gas nozzle can accelerate combustion process and shorten combustion length, can ensure that the propellant realizes high combustion efficiency under a working condition of large flow, and can greatly reduce the quantity of head nozzles so as to reduce structural complexity and manufacturing cost.

Owner:BEIHANG UNIV

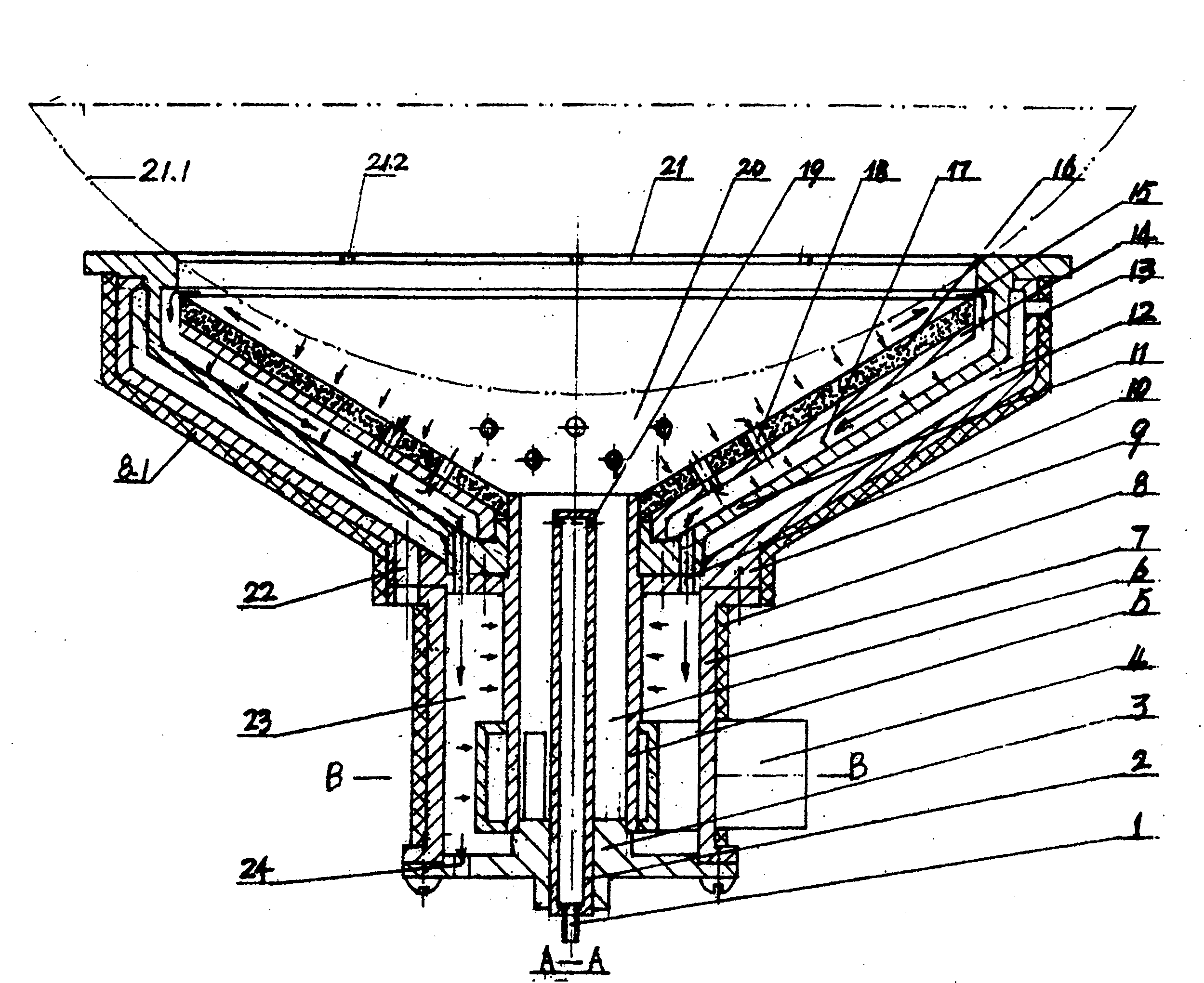

Spiral-flow type fishtail high-efficiency energy-saving burner

ActiveCN103629705AHeating up fastHeat up fastDomestic stoves or rangesStoves/ranges topsAir preheaterEngineering

The invention discloses a spiral-flow type fishtail high-efficiency energy-saving burner. The spiral-flow type fishtail high-efficiency energy-saving burner comprises a burner and a hearth. The burner comprises a spiral-flow type air register, a cylindrical channel, a return pipe, combustion gas holes and an air preheater. The hearth comprises a furnace ring and an expansion cover. The expansion cover is a hollow interlayer and comprises an inner expansion cover, a middle expansion cover and a flue gas chamber between the inner expansion cover and the middle expansion cover. An upper opening of the inner expansion cover and a lower opening of the furnace ring form an annular flue gas shunting opening and the annular flue gas shunting opening is communicated with the flue gas chamber, flue gas holes, the air preheater and a gas outlet hole. The outer wall of the middle expansion cover is provided with a hot water sleeve. The hot water sleeve is provided with a water inlet and a water outlet. A temperature-resistant heat-collection corrosion-resistant sleeve is arranged in the inner expansion cover and the lower periphery of the temperature-resistant heat-collection corrosion-resistant sleeve is provided with a flue gas backflow hole communicated with the flue gas chamber. When the spiral-flow type fishtail high-efficiency energy-saving burner burns, the flame in a fishtail shape radially burns closely to the surface of the inner expansion cover, a pan clings to the furnace ring and is closely heated and high-temperature flue gas goes through the flue gas chamber from the annular flue gas shunting opening and then enters into the air preheater to heat air so that the hearth has a high temperature, foods can be heated fast and work efficiency is high. The spiral-flow type fishtail high-efficiency energy-saving burner is environmentally friendly, saves energy, can supply hot water and can effectively improve a kitchen environment.

Owner:湖北满天星节能环保科技有限公司

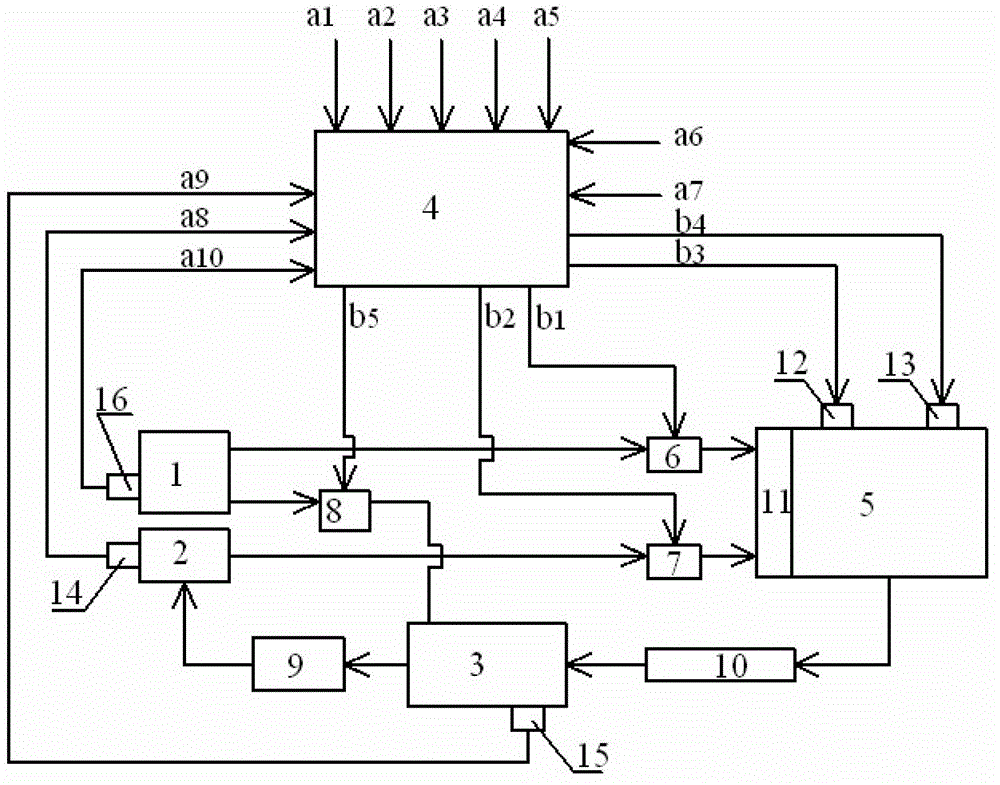

Control method for power system of dimethyl ether/hydrogen internal combustion engine

ActiveCN102748143AImprove the combustion processImprove emission effectNon-fuel substance addition to fuelInternal combustion piston enginesAlternative fuelsControl signal

The invention provides a power system of a dimethyl ether / hydrogen internal combustion engine and a control method for the power system of the dimethyl ether / hydrogen internal combustion engine, belonging to the fields of energy saving and the use of alternative fuels of the internal combustion engine. The power system comprises a dimethyl ether gas supply device and a hydrogen gas supply device, wherein dimethyl ether is reformed to produce hydrogen by the waste heat of the tail gas. The power system also comprises a dimethyl ether tank and a hydrogen tank, a tail gas waste heat reforming device, a blended fuel control unit and a dimethyl ether reformer controller, and input signals such as a crank angle signal, a cooling water temperature signal, a gas inlet temperature and pressure signal, and output signals such as a dimethyl ether jetting signal and a hydrogen jetting signal, an igniting module signal, an idle speed motor control signal, and a tail gas waste heat reforming device control signal. According to the invention, the discharging performance and the combustion performance of a spark ignition engine can be improved and increased due to dimethyl ether and hydrogen, and hydrogen is produced by reforming dimethyl ether, so that the use cost can be reduced, and the compensation of hydrogen can be realized. The device is simple in design structure, easy to install, and lower in cost, and the system is further good in adaptability and expansibility, wide in market prospect, and better in economic benefit.

Owner:BEIJING UNIV OF TECH

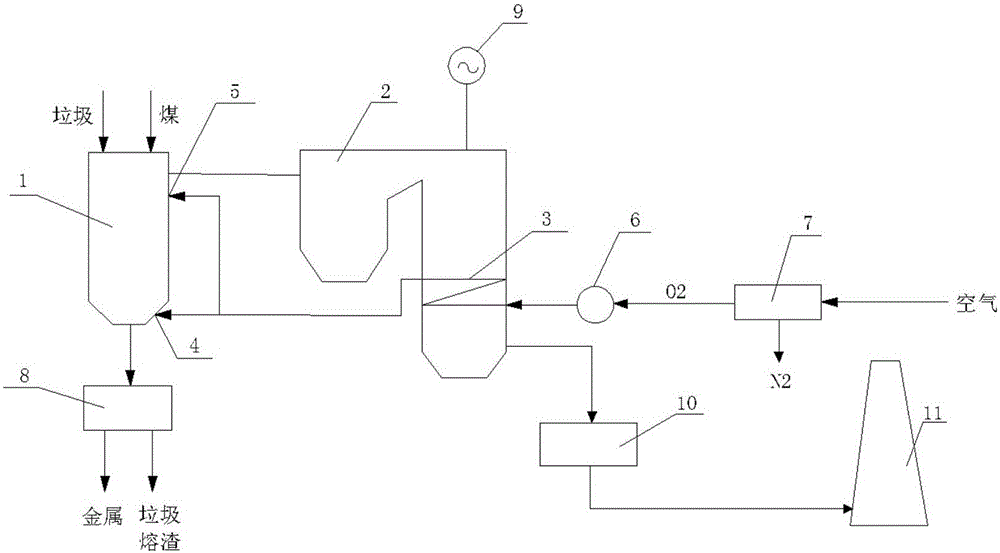

Device and method for heating and melting rubbish under oxygen-rich condition

InactiveCN105864782ALow ignition temperatureReduce usageIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterCombustion

The invention discloses a device and method for heating and melting rubbish under the oxygen-rich condition. The device comprises a rubbish melting furnace. The rubbish melting furnace is connected with an oxygen supply system. The bottom of the rubbish melting furnace is connected with a cooling device. The oxygen supply system comprises an air separation device, an air feeder and an air preheater which are connected sequentially. A first air blowing opening is formed in the upper portion of the rubbish melting furnace. A second air blowing opening is formed in the bottom of the rubbish melting furnace. Both the first air blowing opening and the second air blowing opening communicate with the air preheater. The oxygen supply system supplies separated oxygen-rich gas to the rubbish melting furnace, and the oxygen-rich gas is used as an oxidizing agent for melting the rubbish. The beneficial effects of the oxygen-rich combustion and melting treatment are used, combustion heat of fuel is used, fly ash of the rubbish is molten at the high temperature, stable glassy state slag is formed after cooling, organic components of Dioxin and the like are destroyed, and most of heavy metals are solidified in the glassy state slag.

Owner:SHANDONG UNIV

Oxygen-rich negative ion energy-saving filter

InactiveCN106321297APromote combustionStable combustionInternal combustion piston enginesCombustion-air/fuel-air treatmentEvaporationElectron

The invention relates to an oxygen-rich negative ion energy-saving filter. Air is ionized by means of high-frequency pulsed electric fields, the air is separated to form positive ions and negative ions, and electrons are separated to form free electrons. The positive electric fields and the negative electric fields are used for separating the positive ions and the negative ions in an attracting mode, and meanwhile, the positive electric fields are combined through a high-intensity permanent magnet, and a magnetic field and electric field twin-stage effect is generated. When the positive electric fields attract the negative ions, the magnetic field attracts oxygen in the air and the free electrons generating a spinning magnetic field after being separated to be gathered, so that oxygen-rich negative ion air flow is formed and used for combustion supporting, energy conservation and emission reduction of engines. Combustion is promoted, the efficiency is improved, and fuel is saved by 3-10%; combustion and evaporation are accelerated, and the burnout rate is increased; combustion is diffused, and the engines are stable in combustion; carbon deposition is reduced, and the service life of the engines is prolonged; polluted exhaust gas and emission are reduced; and an ordinary combustion-supporting air-preheating separation link is omitted, and heat loss is reduced.

Owner:ZIBO S & N MAGNET MFG

Intensive-classification low-NOx pulverized coal burner

ActiveCN103759259AIncrease swirl intensityIncrease combustionPulverulent fuel combustion burnersCombustion apparatusSlagNitric oxide

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

Magnetic electrode small-particle-size hydroxide ion generator

The invention relates to a magnetic electrode small-particle-size hydroxide ion generator. The magnetic electrode small-particle-size hydroxide ion generator comprises a raw material air supply channel, a cathode insulation fixation plate, a tunnel cylinder and an anode insulation fixation plate, wherein the cathode insulation fixation plate, the tunnel cylinder and the anode insulation fixation plate form a sealing cavity, the raw material air supply channel passes through the cathode insulation fixation plate and communicates with a cathode selection network inside the tunnel cylinder through a cathode conductive ring, the other end of the cathode selection network is connected with one end of an anode selection network, the other end of the anode selection network is fixed on the anode insulation fixation plate, an anode discharge needle is also fixed on the anode insulation fixation plate, the anode discharge needle is connected with a pulse high-frequency discharger, and the top portion of the tunnel cylinder is provided with a hydroxide ion air channel. Small-particle-size air negative ions prepared by use of the generator are widely applied, and since a prepared gas contains numerous negative hydrogen, oxygen ions and free electrons and is segmented and magnetized into small particle sizes, the magnetic electrode small-particle-size hydroxide ion generator can be widely applied to a health care industry, a medical industry and industrial combustion and machine combustion industries.

Owner:ZIBO S & N MAGNET MFG

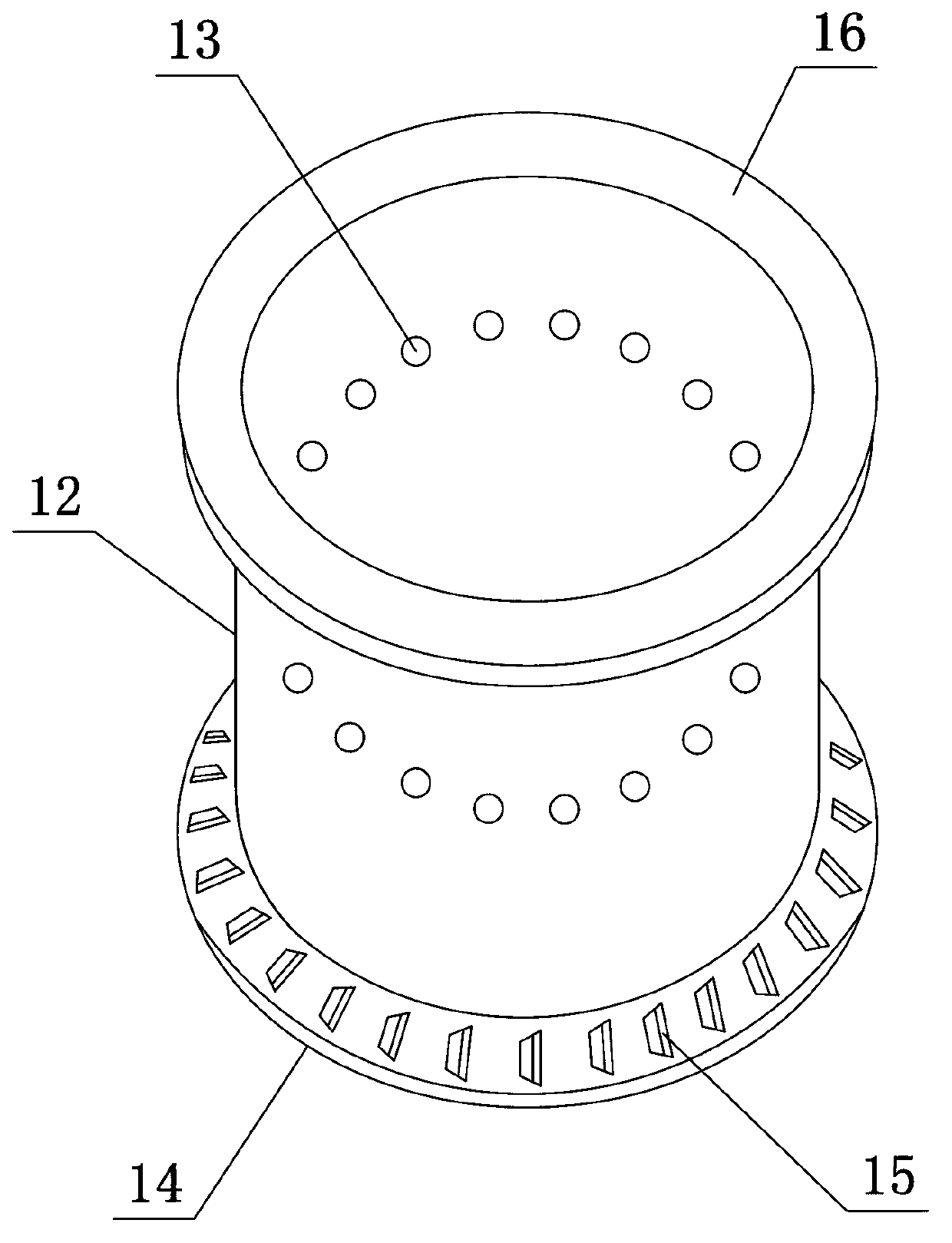

Gasification combustor of solid fuel cooking range

ActiveCN103123109ABurn fullyEasy to igniteSolid fuel combustionCombustion apparatusCombustorSolid fuel

The invention provides a gasification combustor of a solid fuel cooking range which comprises a first core body and a movable whirlwind combustion-supporting device. A plurality of air-in and gasification combustion-supporting holes are arranged on the first core body, a fire-sealing cover baffle plate is arranged on the inner wall of the first core body, and when an air blower is used for compulsorily supporting air for combustion supporting, the movable whirlwind combustion-supporting device is arranged on the fire-sealing cover baffle plate in the first core body. The movable whirlwind combustion-supporting device comprises a second core body, a top wall and a bottom wall, wherein the top wall is arranged on the upper portion of the second core body, and the bottom wall is arranged on the lower portion of the second core body. A plurality of second air-in and gasification combustion-supporting holes are arranged on the periphery of the second core body, and the bottom wall of the second core body is provided with a plurality of third air-in and gasification combustion-supporting holes which are coincident in slant directions. A cold furnace is easy to fire up and fast to inflame; flame rotates for combustion; and heat power is strong. The gasification combustor saves energy and is environment-friendly; and when fire is sealed, the movable whirlwind combustion-supporting holes are taken out, and the movable fire-sealing cover is arranged on the fire-sealing cover baffle plate to seal the fire. The gasification combustor is applicable to a boiler or a hot blast stove with solid fuel combusted, and use of combustion equipment with any structure such as the cooking range in a matched mode.

Owner:陕西华能恒大科技有限公司 +1

Rotary jet combustion system of ignition chamber type engine

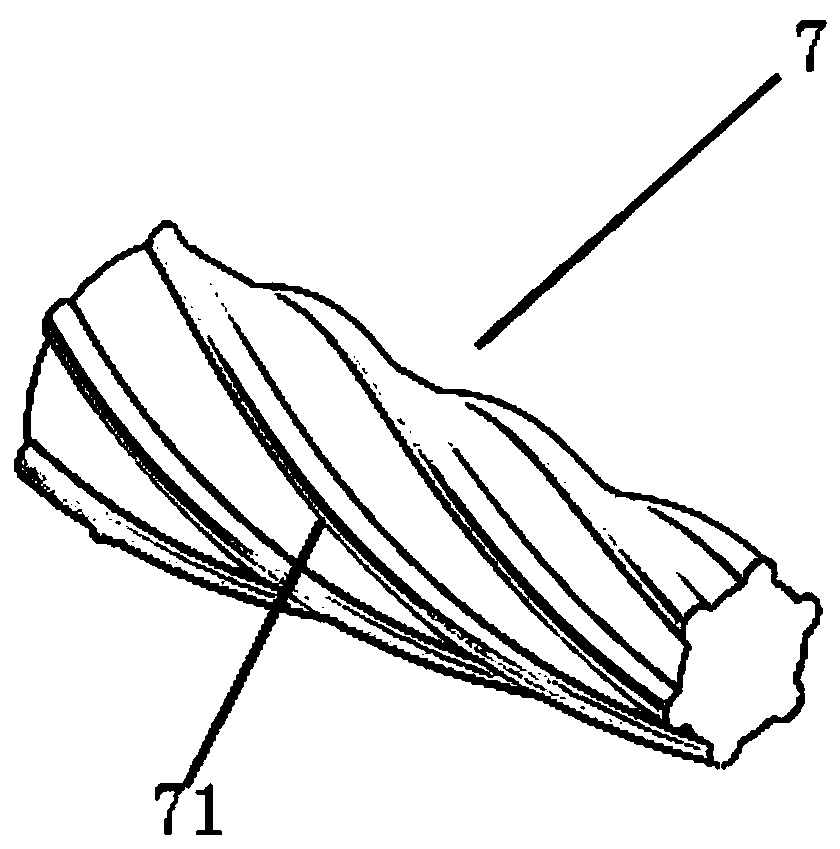

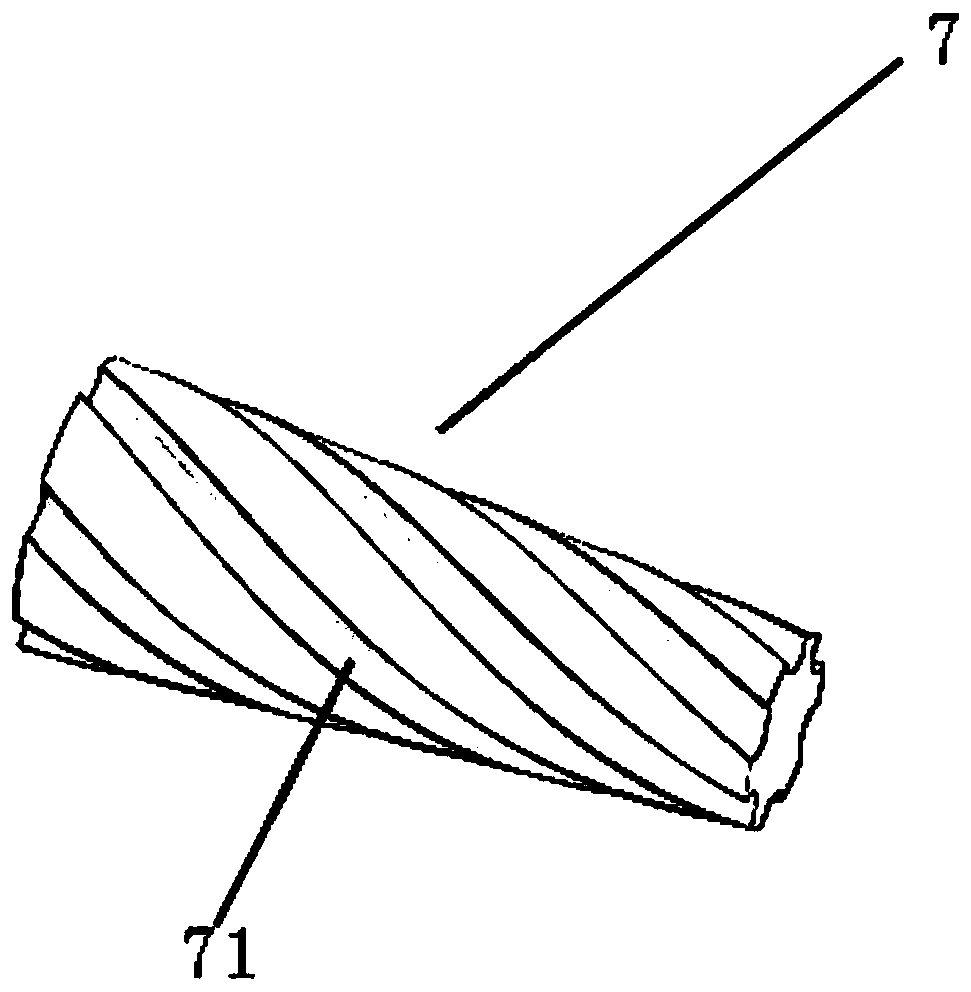

PendingCN110173341APromote formationSpeed up flame spreadInternal combustion piston enginesGaseous engine fuelsCombustion systemCombustion chamber

The invention discloses a rotary jet combustion system of an ignition chamber type engine. The system comprises an air cylinder, a piston and a cylinder cover. A space encircled by the air cylinder, the piston and the cylinder cover forms a main combustion chamber, at least one ignition chambers are mounted on the cylinder cover, each ignition chamber is composed of a shell and an inner cavity ina shell cover, an ignition device and a fuel supply device are mounted on the shell cover, the ignition chambers communicate to the main combustion chamber through a plurality of channels, and an engine working medium flows between the ignition chambers and the main combustion chamber of the engine by means of the channels. The channels are of cone-shaped structures, and the cross sections of thecone-shaped structures are gradually reduced from the ignition chamber ends to the main combustion chamber end; and a plurality of spiral grooves are formed in the inner wall of at least one cone-shaped channel. The rotary jet combustion system aims to further improve the turbulence intensity of a turbulent flame jet in a working process of the ignition chamber type engine, so that the in-cylindercombustion and the engine performance are improved.

Owner:JIANGSU UNIV +1

Smokeless carbon block capable of quick ignition and its prdoucing method

InactiveCN1492029ABurning speedReduce consumptionSolid fuelsWaste based fuelCorn starchCarboxymethyl cellulose

The smokeless carbon block capable of being ignited quickly consists of charcoal powder 86-92 wt%, carboxymethyl cellulose 8-12 wt% and corn starch 1-2 wt%. The production process includes compounding material, mixing with adding water and stirring, extruding to form sheet, cutting to shape, and drying to form finished product. The smokeless carbon block features the open flame combustion and low oxygen combustion, may be ignited with one match, and may be used in cooking furnace, handwarmer, etc.

Owner:CHENGDU SPRINGHEAD HOUSEHOLD HEALTH

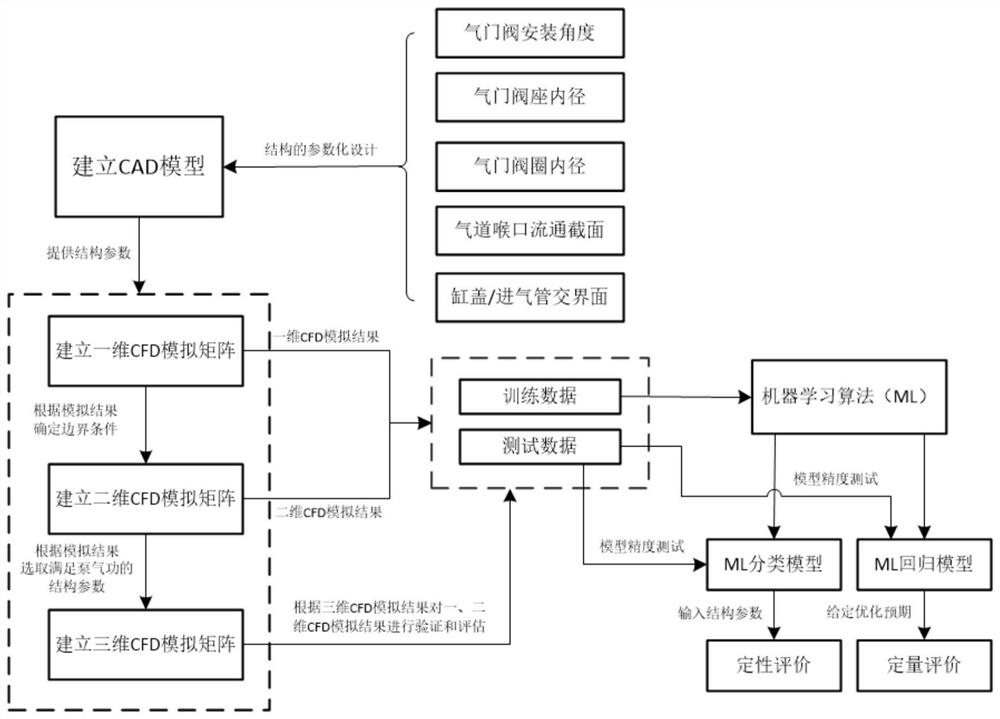

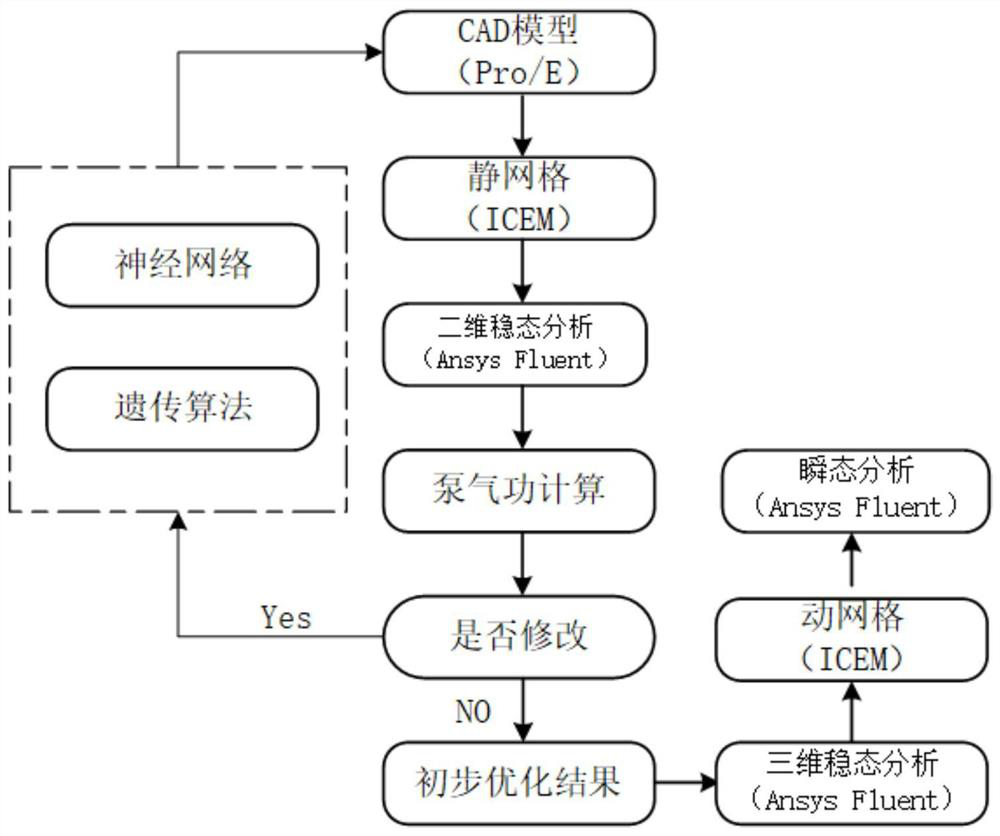

High-supercharged engine air passage structure optimization design method based on data driving

PendingCN112417769ASave time and costImprove the combustion processDesign optimisation/simulationSpecial data processing applicationsAirway structureSimulation

The invention discloses a high-supercharged engine air passage structure optimization design method based on data driving. The method comprises steps that parameterization design is conducted on an air valve installation angle in an air passage, the inner diameter of an air valve seat, the inner diameter of an air valve seat ring, an air passage throat flow section and a cylinder cover / air inlet pipe interface, and a CAD model is established; a one-dimensional, two-dimensional and three-dimensional CFD simulation matrix is established based on the parameters; based on a simulation result of the CFD simulation matrix, an ML machine learning algorithm is carried out to complete establishment of a model ML classification model and an ML regression model; and the ML classification model and the ML regression model carry out qualitative and quantitative evaluation on the airway structure optimization level respectively. According to the intelligent model established by adopting the method,the flowing performance of the air passage is predicted based on data driving, and the optimal design of the air passage structure can be optimally or optimally performed.

Owner:JIANGSU UNIV OF SCI & TECH

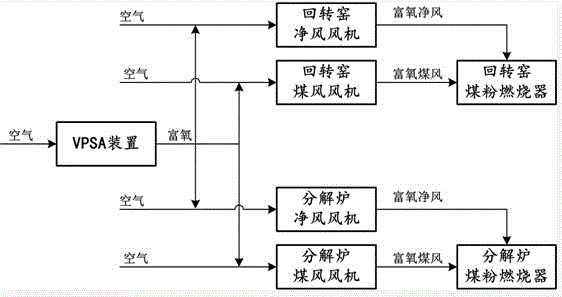

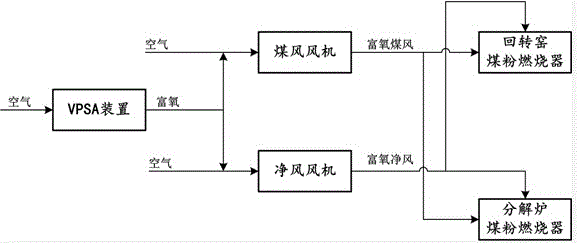

Rich oxygen supply process for dry-method cement rotary-kiln production

ActiveCN102913939ASimple equipmentLess investmentIndirect carbon-dioxide mitigationClinker productionDecompositionVacuum pressure

The invention relates to the technical field of a dry-method cement production process and provides a rich oxygen supply process adapted to a dry-method cement rotary-kiln production procedure. The rich oxygen supply process comprises the steps that an oxygen-enriched gas obtained after performing VPSA (Vacuum Pressure Swing Adsorption) treatment on air is sucked by a rotary kiln as well as a coal wind fan and a net wind fan of a decomposition furnace, is used as oxygen-enriched coal wind and oxygen-enriched net wind and is transferred to the rotary kiln and each multi-duct powdered coal burner of the decomposition furnace. According to the rich oxygen supply process for dry-method cement rotary-kiln production, the oxygen supply procedure meets oxygen-enriched combustion-supporting requirements of dry-method rotary-kiln cement clinker burning, does not need to change any existing cement production equipment, and has the characteristics of low equipment investment, low operational energy consumption and obvious energy-saving benefit.

Owner:李东林 +1

Engine intake manifold

InactiveCN101555846AImprove powerImprove the combustion processCombustion-air/fuel-air treatmentMachines/enginesEngineeringCombustion process

The invention discloses an engine intake manifold with adjustable length, which is characterized by being capable of improving the dynamic property of a car engine. The engine intake manifold comprises a manifold body; the inlet end of the manifold body is connected with an intake cavity and the outlet end thereof is connected with the intake port of an engine cylinder cover; and the length of the manifold body can be adjusted. By the adjustable length of manifold body, the engine can achieve the matching of the intake amount with the engine speed by changing the length of the manifold body at any speed, thereby improving the dynamic property of the engine at any speed; and the adjustment of the manifold body length can also lead the intake speed to change correspondingly, thereby improving the combustion process and the fuel economical efficiency to some extent, and accordingly reducing the emission of waste gases, and the engine intake manifold is especially suitable for the promotion and use on a car engine.

Owner:张成兴

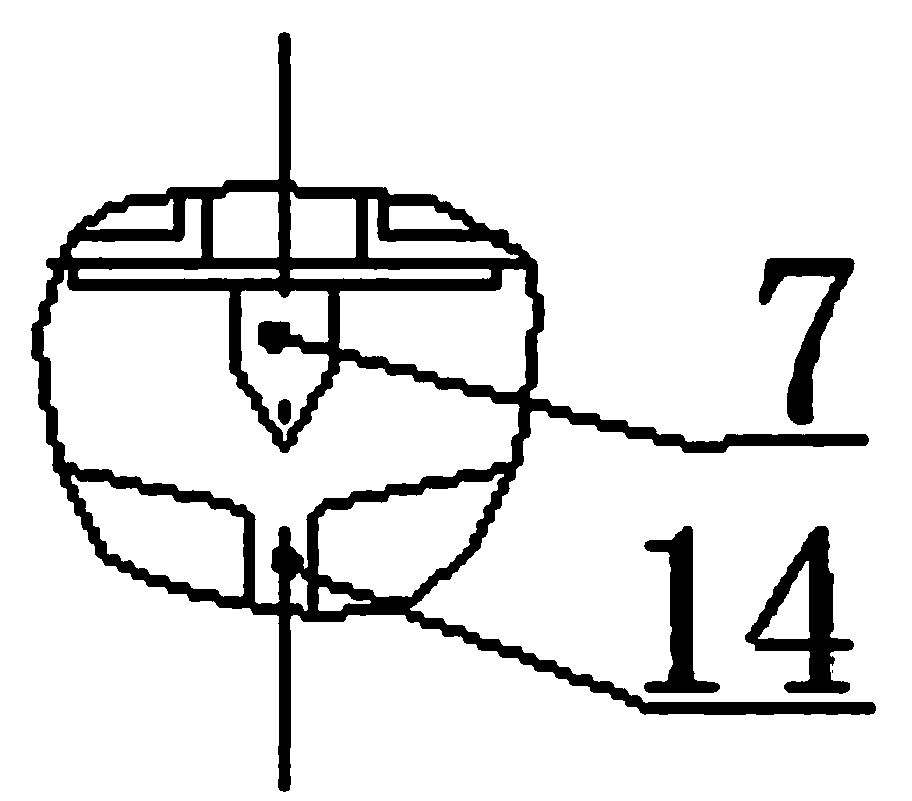

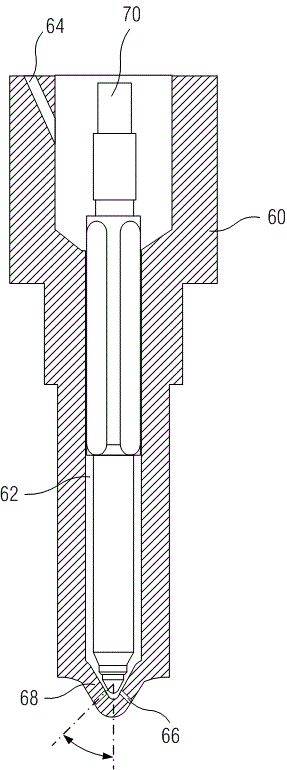

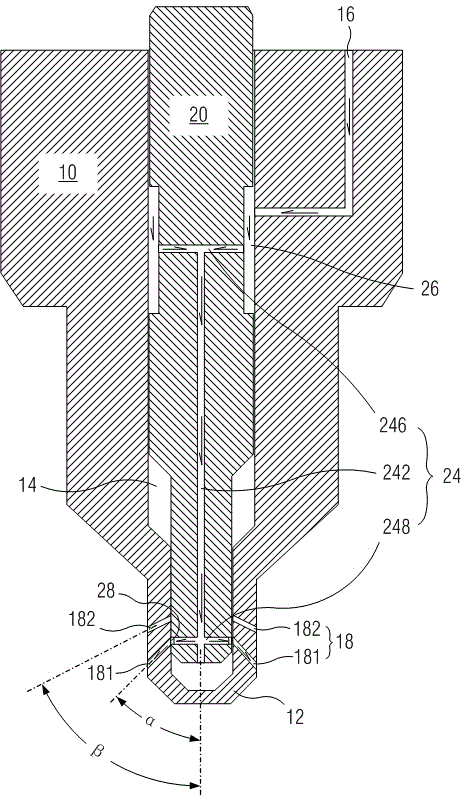

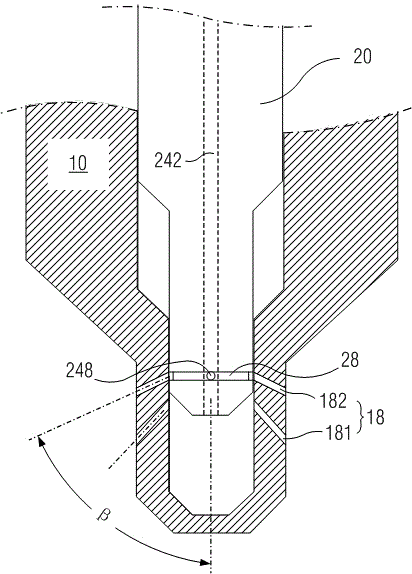

Needle valve component for fuel injection device

ActiveCN103982350ASimple structureEasy to processFuel injection apparatusMachines/enginesInlet channelReciprocating motion

The invention discloses a needle valve component for a fuel injection device. The needle valve component comprises a valve body (10) and a needle valve (20). The valve body is provided with a valve body end (12), a valve hole (14), an oil inlet channel (16) and an oil injection hole (18). The oil injection hole comprises a first group of oil injection holes (181) and a second group of oil injection holes (182), wherein the first jet angles of the first group of oil injection holes are smaller than the second jet angles of the second group of oil injection holes, and the communicating positions of the first group of oil injection holes and the valve hole are closer to the valve body end than the communicating positions of the second group of oil injection holes and the valve hole. The needle valve can reciprocate in the valve hole and comprises an oil inlet ring groove (26), an oil outlet ring groove (28) and an oil supply channel (24) for communicating the oil inlet ring groove and a first oil outlet ring groove. The first oil outlet ring groove is respectively communicated with the first group of oil injection holes and the second group of oil injection holes, the fuel oil is sprayed at different jet angles so as to adapt to oil-gas mixing under different loads, the oil consumption and discharge under the different conditions are both considered, and the needle valve component has the advantages of simple structure and convenience for processing.

Owner:JIANGSU UNIV +1

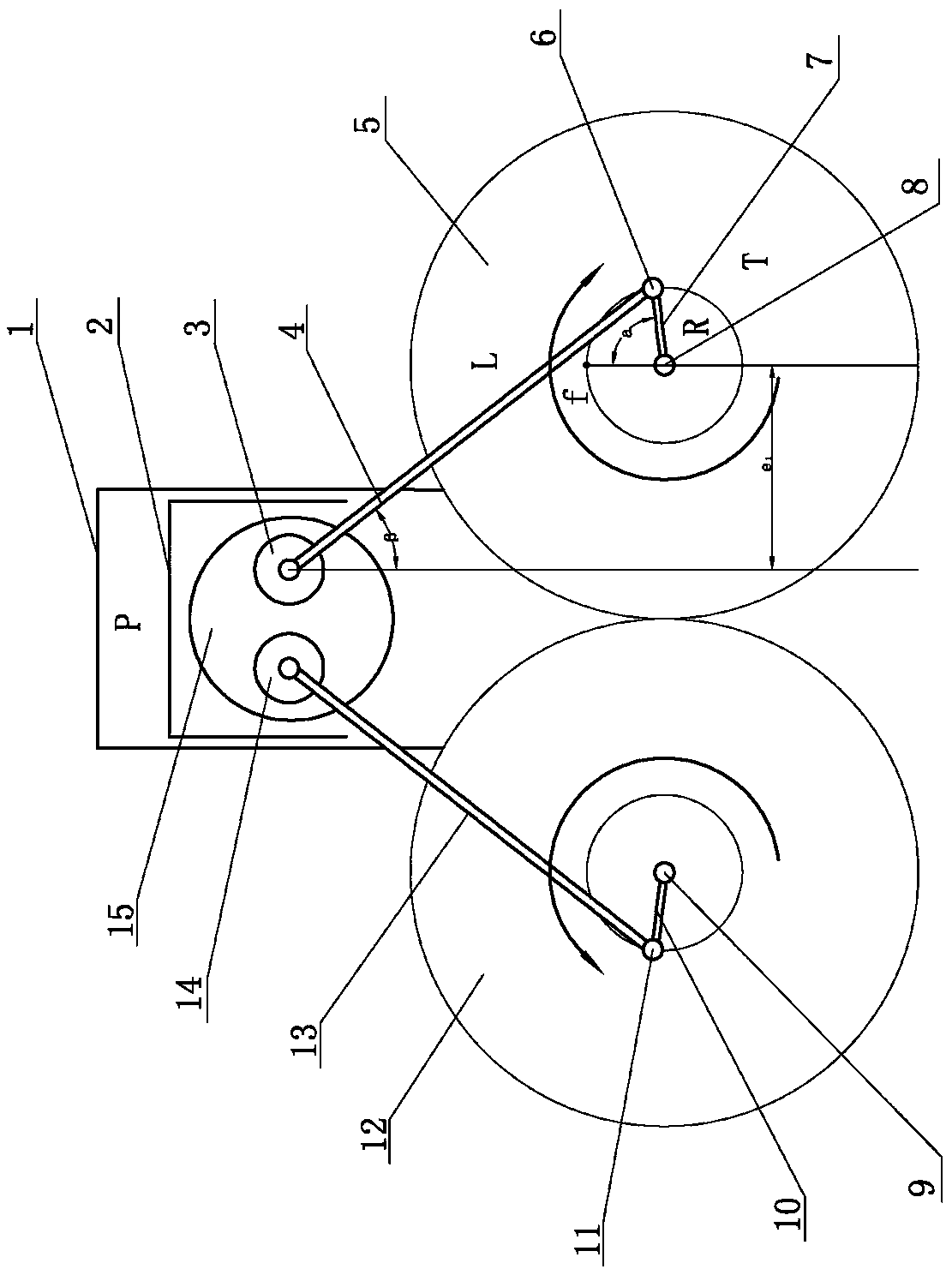

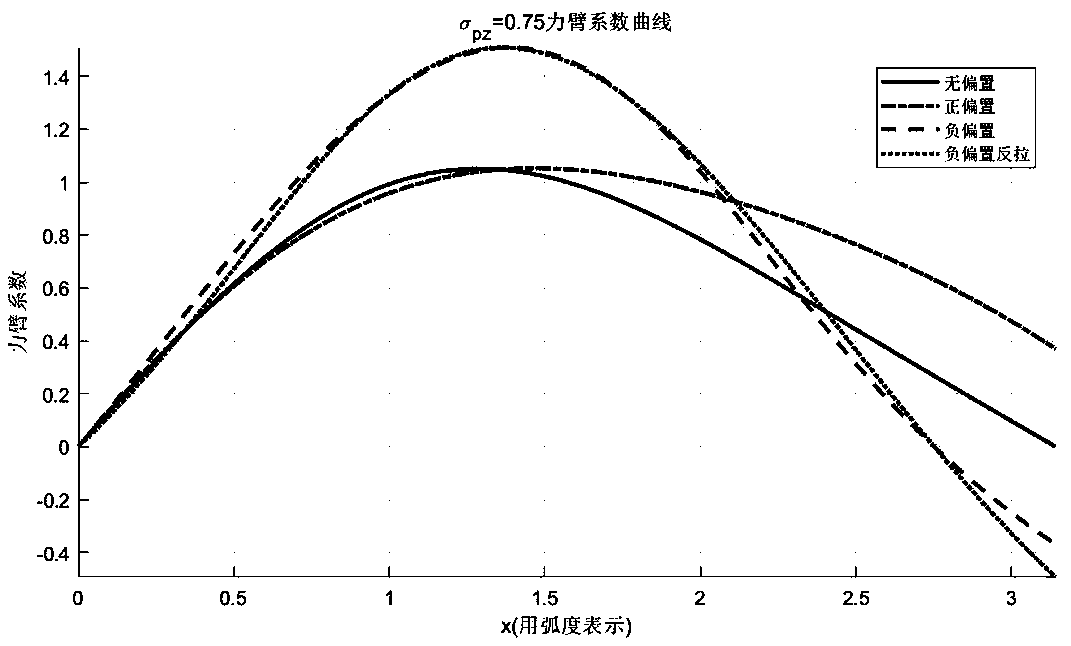

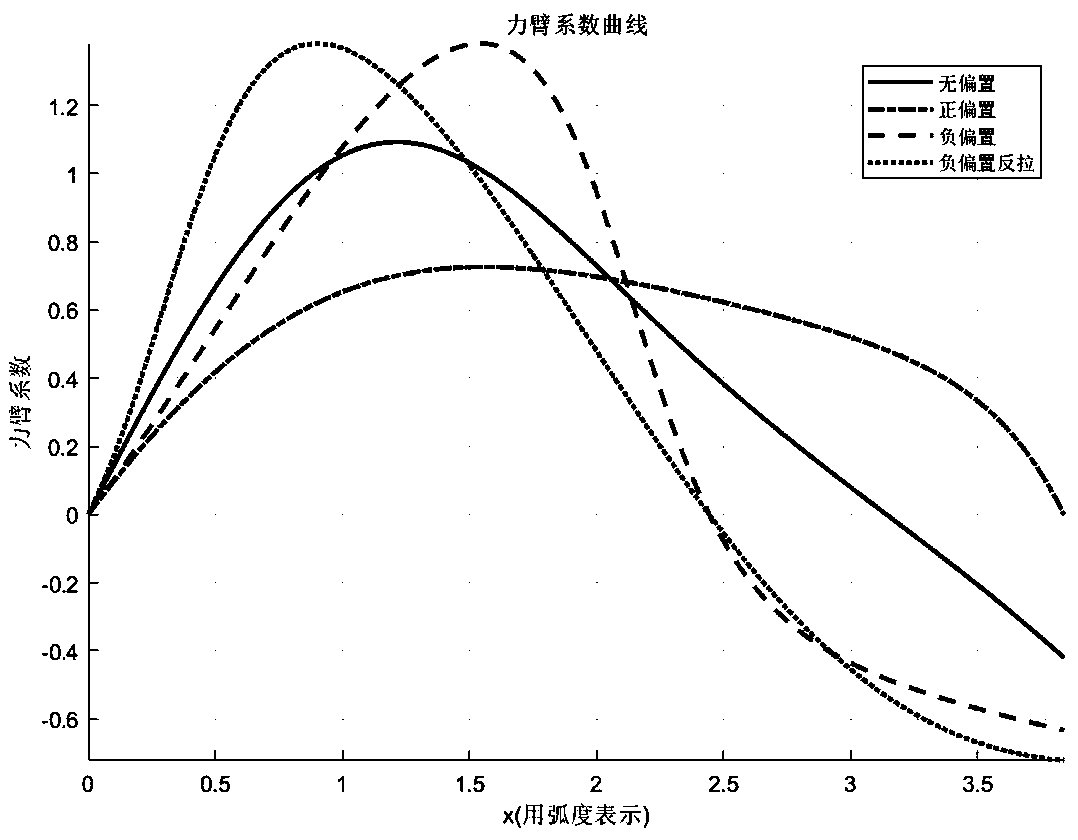

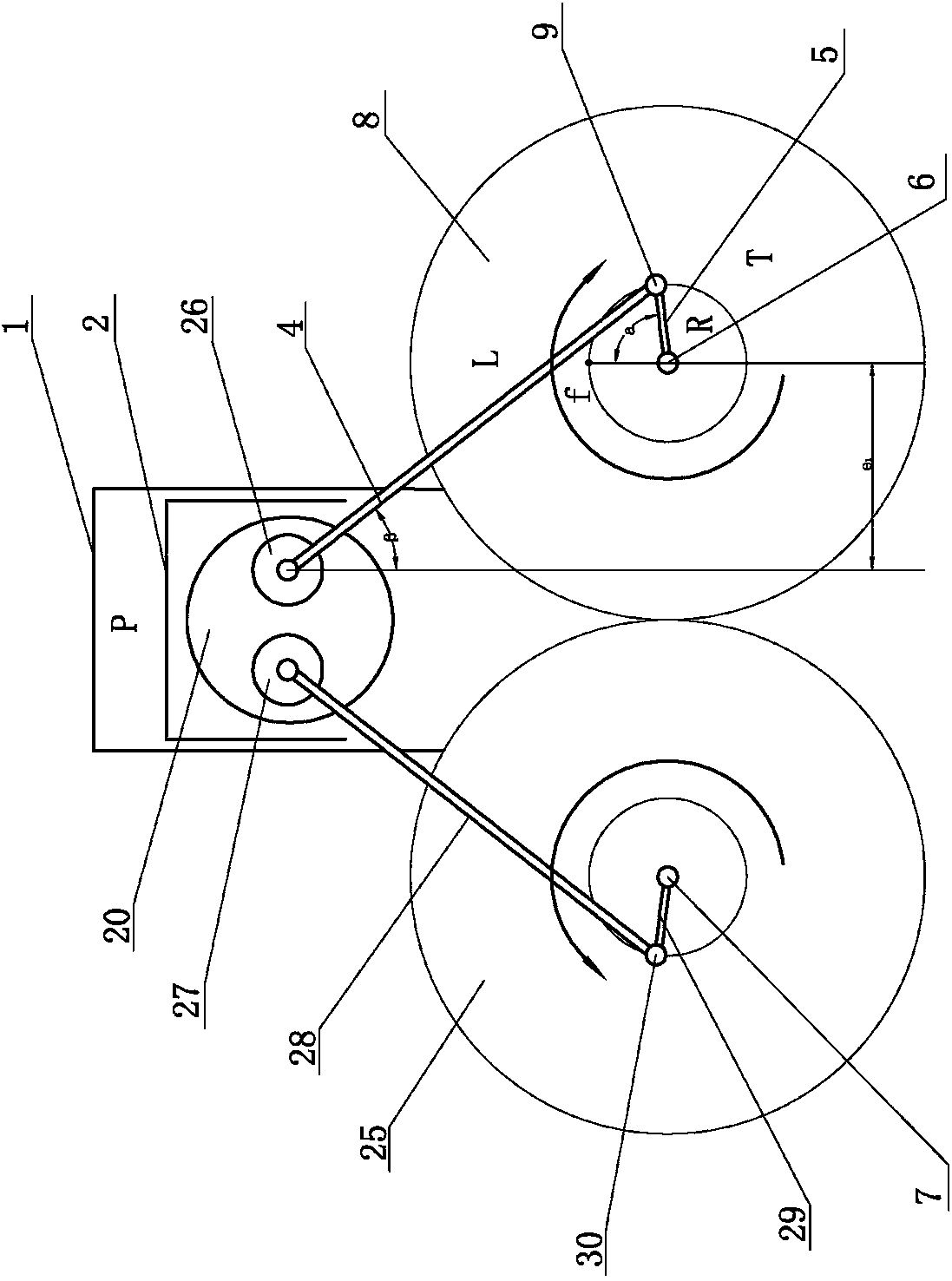

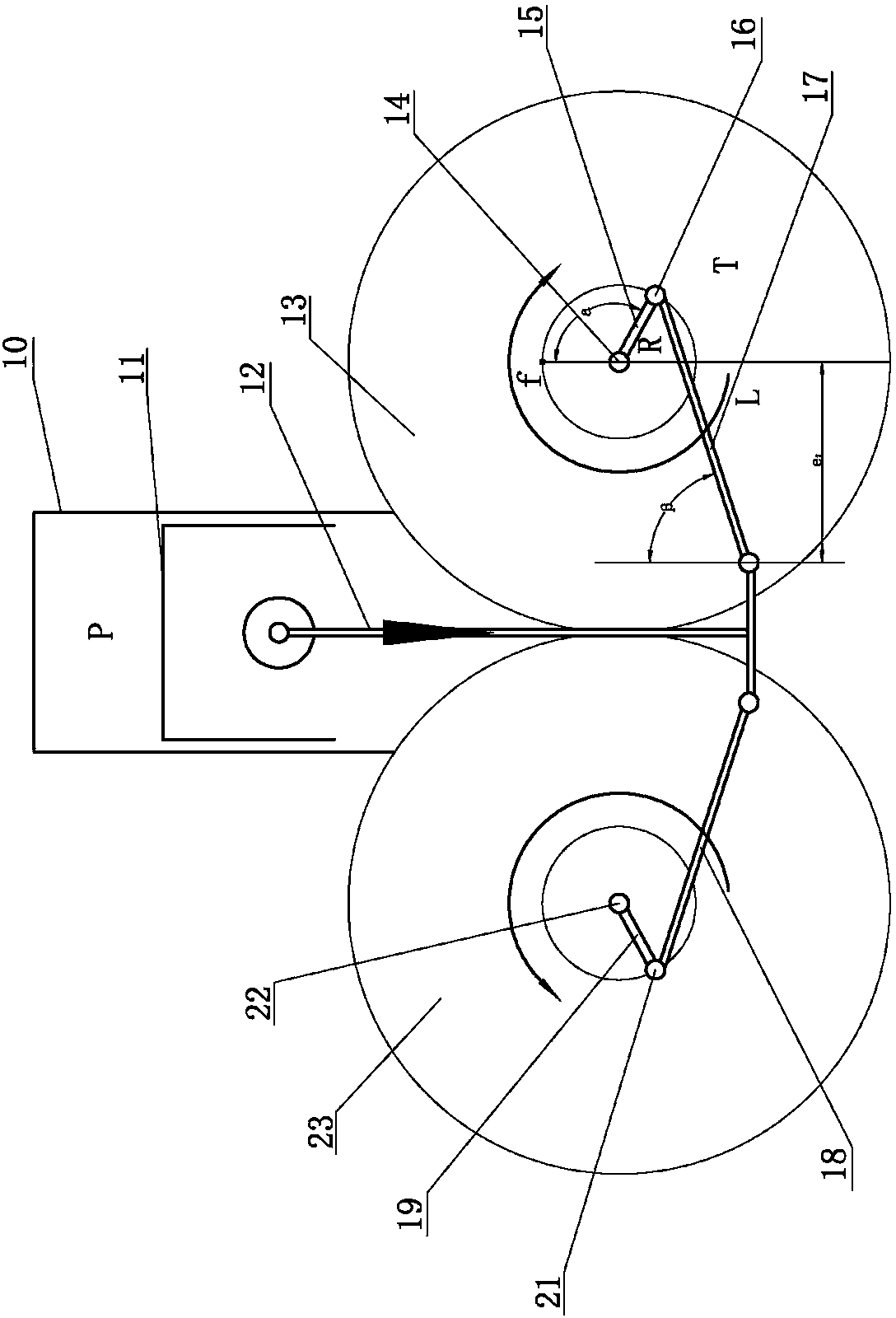

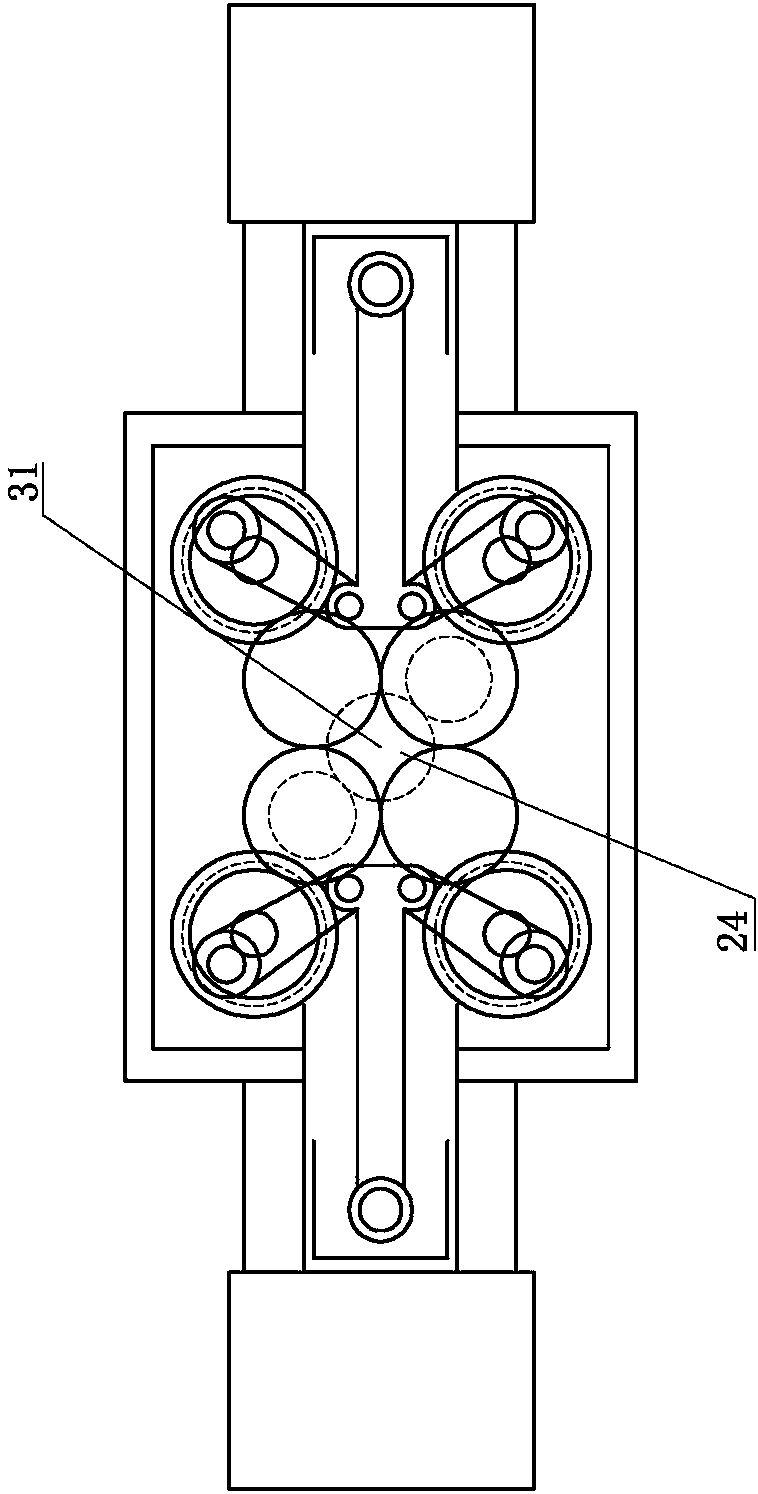

Method for improving effective thermal efficiency of engine and power transmission mechanism prepared through same

The invention discloses a method for improving effective thermal efficiency of an engine and a power transmission mechanism prepared through the method. An eccentric distance is set between each crankshaft axis in the power transmission mechanism of the engine and the connection end axis between a piston rod and a corresponding crank connecting rod or between each crankshaft axis and the connection end axis between the pin shaft center on each piston and the corresponding crank connection rod. The power transmission mechanism is large in power increase amplitude, oil consumption is saved, andexhaust contaminant is low; power is high, and the torque is large; the working stroke is accelerated, combustion and increase of the compression ratio are facilitated, and the heat loss is reduced; the number of parts is small, and the production cost is low; the length of the connection rods can be reduced, and the overall mechanism is compact; when crankshafts rotate in a negative offset manner, lubricating oil splashed through the crankshafts can face pistons all the time, a piston cylinder body is good in lubrication, heat dissipation of engine oil to the pistons is high, the work intensity of the engine is large, the service life is long, and the like.

Owner:张佰力

Integrated magnetic and electric pole selection hydroxide ion magnetic flow combustion-supporting system

ActiveCN106168382AEmission reductionOmit preheatingAir supply regulationIndirect carbon-dioxide mitigationParticulatesEvaporation

The invention relates to an integrated magnetic and electric pole selection hydroxide ion magnetic flow combustion-supporting system. The system comprises a raw material wind air-supply blower, a front pressure equalizing air distribution box and a hydroxide ion magnetic flow collection storage, the raw material wind air-supply blower is connected with an inlet of the front pressure equalizing air distribution box, a negative electrode electrical insulating board and a positive electrode electrical insulating board are arranged between the front pressure equalizing air distribution box and the hydroxide ion magnetic flow collection storage, a negative pole discharge pole selection network is fixed on the negative electrode electrical insulating board, a pulse high frequency spray point and a positive pole discharge pole selection network are fixed on the positive pole discharge pole selection network, and the hydroxide ion magnetic flow collection storage is provided with a hydroxide ion magnetic flow delivery outlet. According to the integrated magnetic and electric pole selection hydroxide ion magnetic flow combustion-supporting system, combustion is promoted, the efficiency is improved, and fuel is saved; combustion and evaporation are accelerated, and the burn-off rate is increased; heat loss is reduced, and heat conduction is improved; flue gas and particulate matter emission are reduced; ordinary combustion-supporting air preheating and cracking links are omitted, and the head loss is reduced.

Owner:ZIBO S & N MAGNET MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com