Patents

Literature

113results about How to "Fire stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

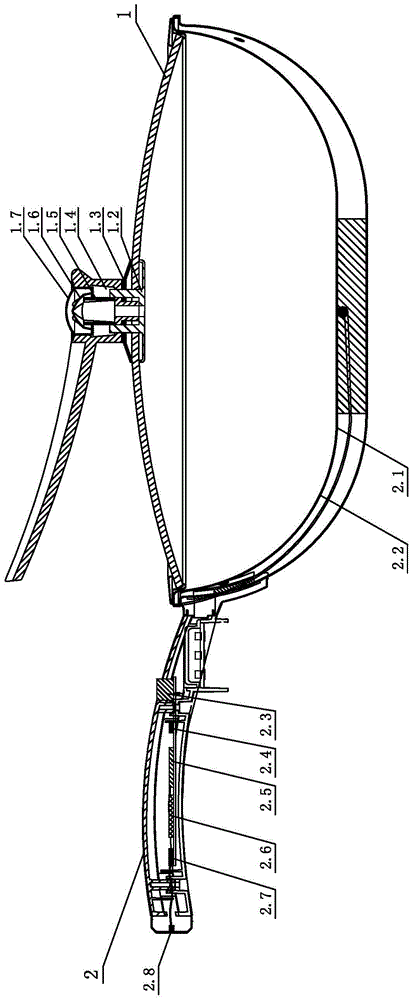

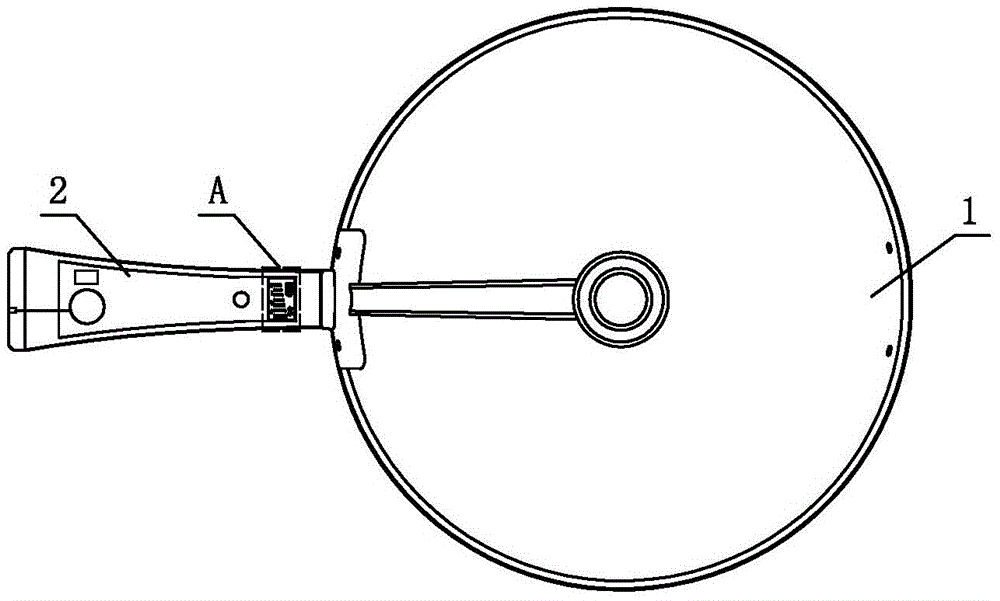

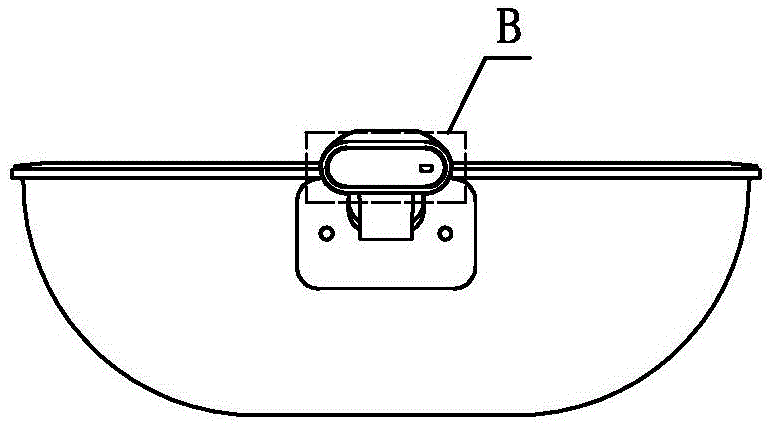

Intelligent cooker with fire prompting function

ActiveCN105640299AImprove cooking tasteAccurate control of temperature requirements AccurateWarming devicesControl roomEngineering

An intelligent cooker with a fire prompting function comprises a pot body and a pot cover. The pot body is connected with a handle. The handle is internally provided with a control chamber and a fire prompting device. The fire prompting device comprises a built-in chip processor, a display screen exposed out of the handle, and a thermocouple set arranged on the pot body. The chip processor is connected with the display screen and the thermocouple set. By the arrangement of the fire prompting device and the application of the chip processor, the temperature of the pot body is accurately controlled, the stability of cooking temperature is ensured, fire is more accurately controlled during cooking, and the cooked food taste is improved. The intelligent cooker has the advantages of being simple and reasonable in structure, convenient to operate, durable and visual.

Owner:李耀凯

Water coke slurry buring technology

A combustion technique for water-coke slurry features that a pre-combustion chamber with secondary tangential air inlet, a cyclone burner of primary air at one end of said pre-combustion chamber and a spray gun in the center of cyclone burner for atomizing the water-coke slurry are used. The outlet of said precombustion chamber is communicated to industrial furnace. The temp in the pre-combustion chamber is at least 950-1000 deg.C.

Owner:SOUTHEAST UNIV +1

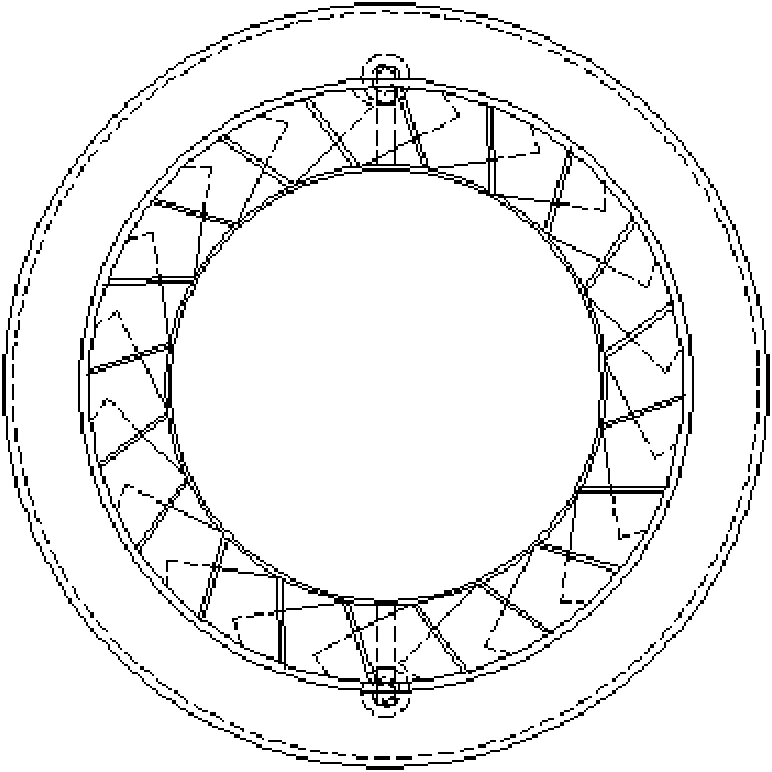

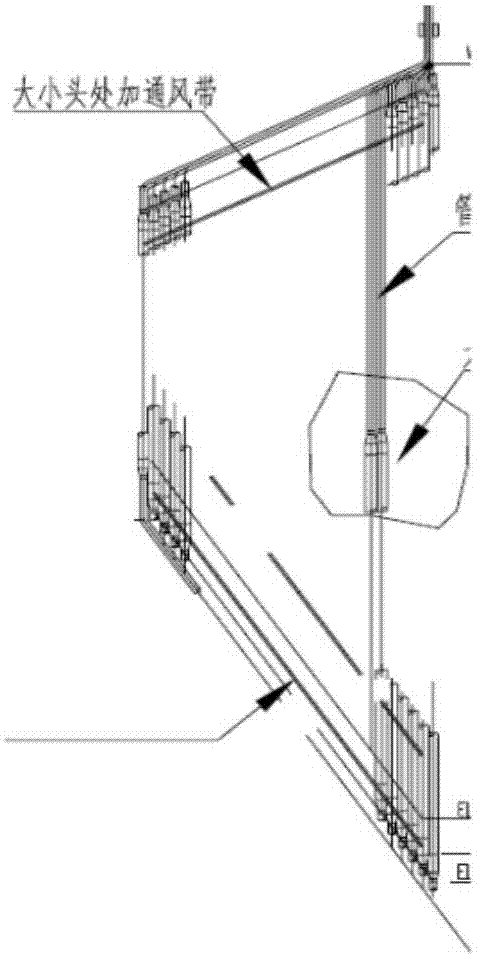

Three-layer secondary air low nitrogen oxide swirling burner

InactiveCN102434878AImprove circumferential unevennessConducive to stable combustionPulverulent fuel combustion burnersAir volumeCombustor

The invention discloses a three-layer secondary air low nitrogen oxide (NOx) swirling burner which comprises a central air pipe as well as a primary air pipe, an inner secondary air pipe, a middle secondary air pipe and an outer secondary air pipe which are concentrically arranged at the periphery of the central air pipe from inside to outside, wherein the air inlets of the inner secondary air pipe, the middle secondary air pipe and the outer secondary air pipe are provided with swirling adjusting mechanisms for generating straightly-flowing secondary air or secondary air with variable swirling intensity by virtue of the respective secondary air pipes; three independent air boxes are sleeved outside each secondary air pipe; and the air volume of each secondary air pipe can be adjusted by air box baffle plate adjusting mechanisms on the air boxes. By adopting the structure of the low NOx swirling burner, the partial grading burning effect of the burner is enhanced and the high temperature smoke reflow is increased, thus finally achieving the aim that the burner burns coals stably and reduces the NOx generated by burning. The three-layer secondary air low NOx swirling burner has a simple structure, is easy to manufacture and install, is high in industrial applicability, is applicable to various coals and guarantees the burning stability and the burning economy of a boiler.

Owner:HUAZHONG UNIV OF SCI & TECH

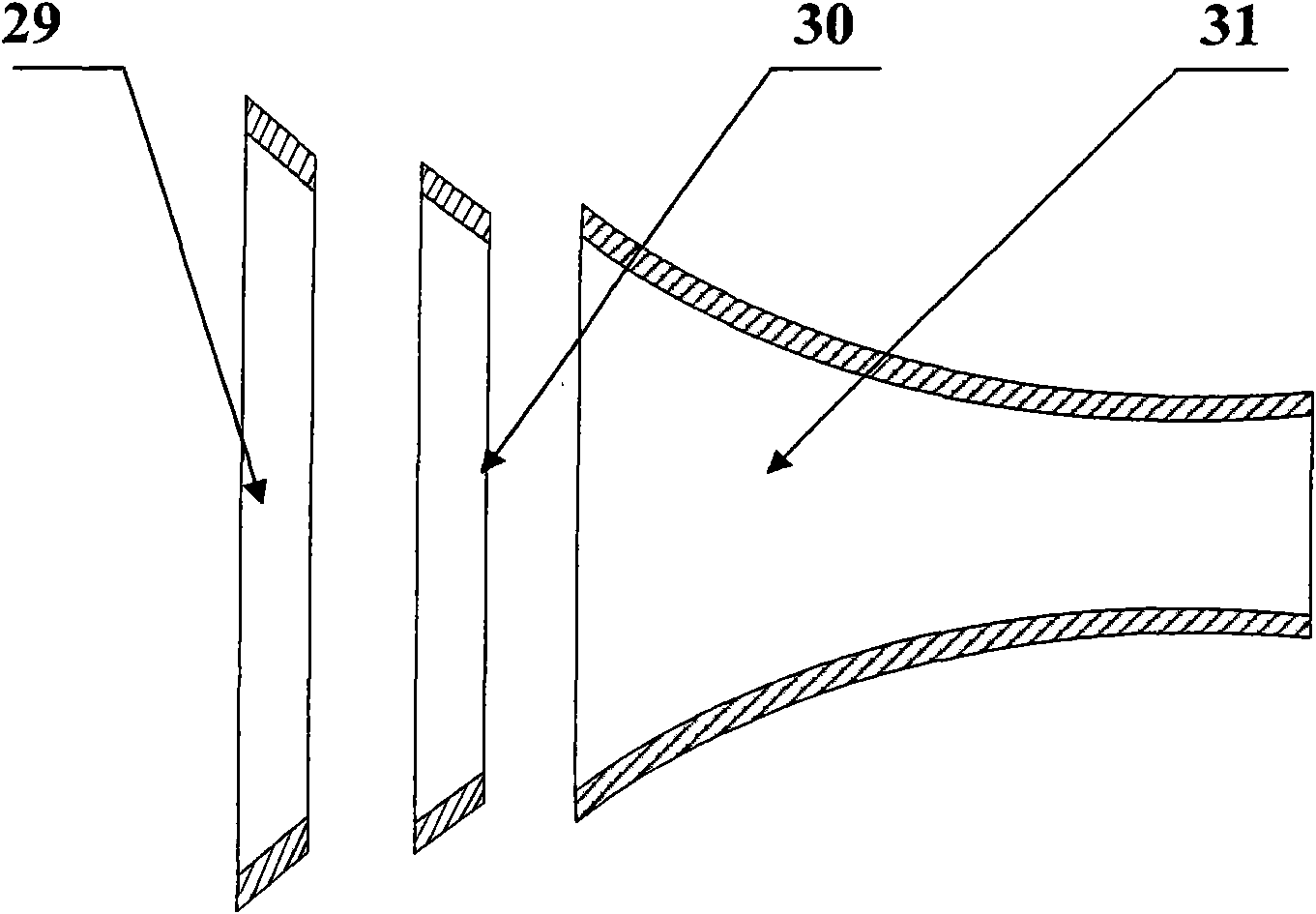

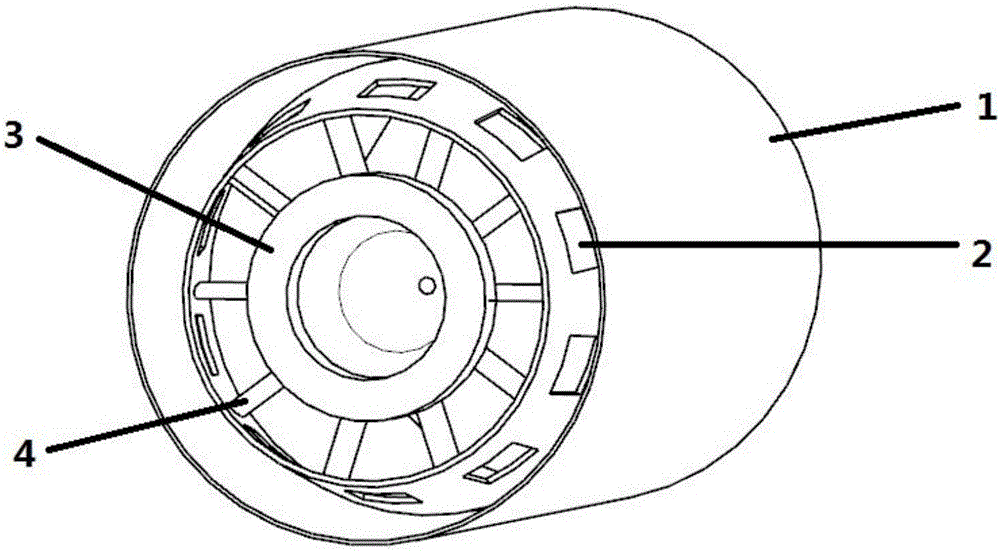

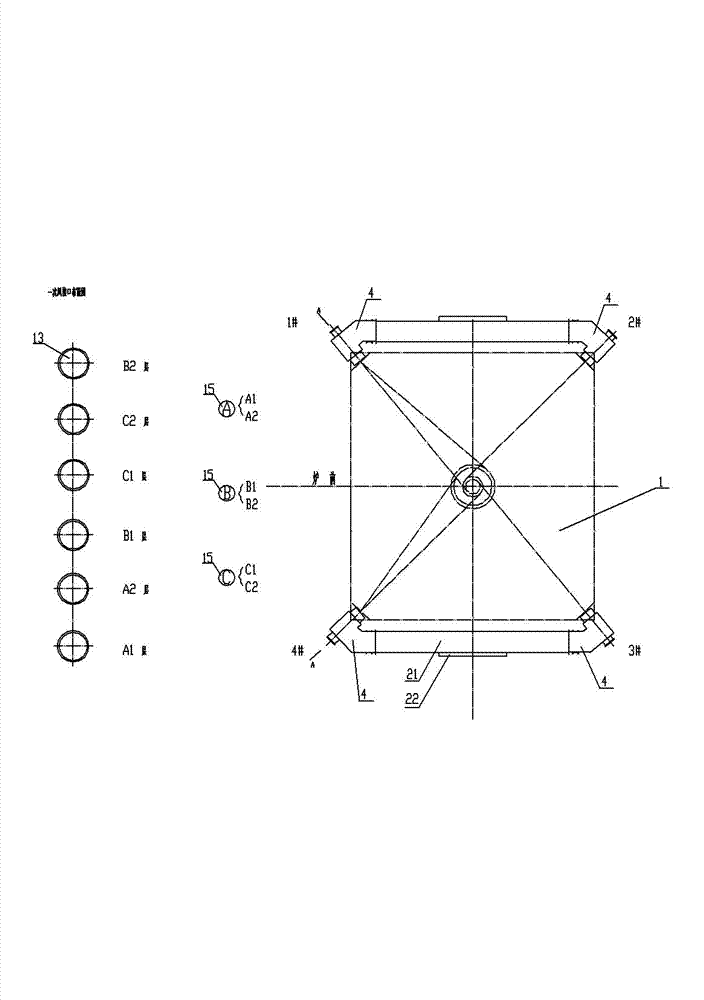

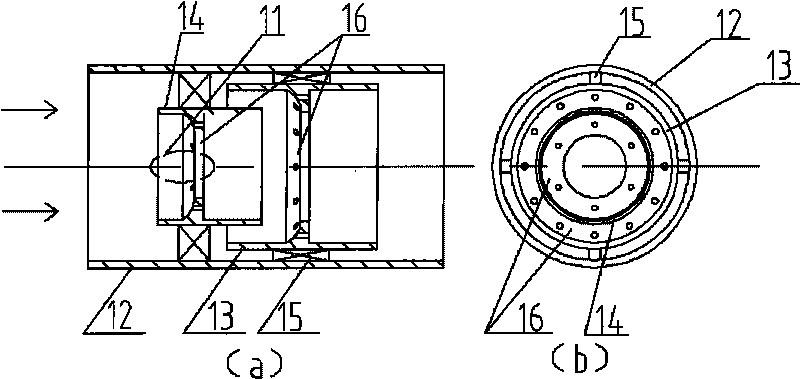

Composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner

ActiveCN102062396AFire stableExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCycloneConvex structure

The invention relates to a composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner which comprises a central wind passage, wherein a primary wind passage, an internal direct-flow secondary wind passage, an internal rotational-flow secondary wind passage and an external rotational-flow secondary wind passage are sequentially and concentrically arranged at the outer side of the central wind passage from inside to outside, a conical pulverized-coal concentrating device and a star-shaped pulverized-coal concentrating device are arranged in the primary wind passage, and a reversed V-shaped expanded opening and a zigzag axial and radial double concave-convex structured burning-stabilizing device are arranged at the outlet of the primary wind passage; and after primary wind passes through the pulverized-coal concentrating device, an intense standing-vortex burning-stabilizing firing area with obvious circumferential and radial pulverized-coal concentration distribution is formed at the outlet of the burner, and the burning conditions of high-temperature reflow smoke gas and oxygen-deficient rich fuel are generated. The burner has extremely strong firing-stabilizing performance and good coal adaptability and effectively reduces the concentration of nitrogen oxides.

Owner:XI AN JIAOTONG UNIV

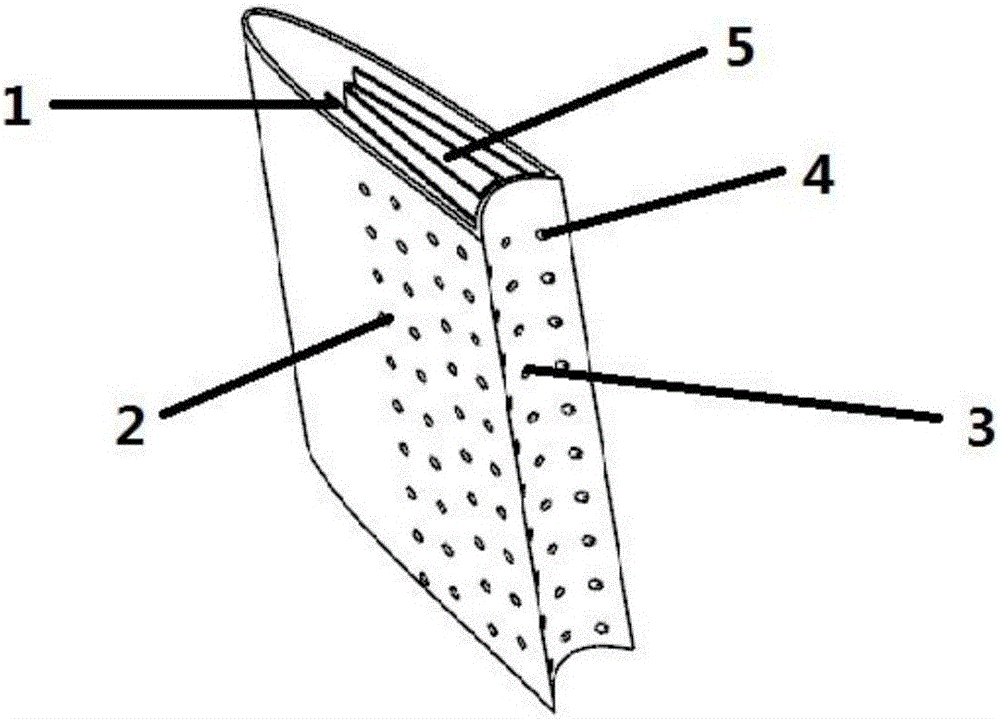

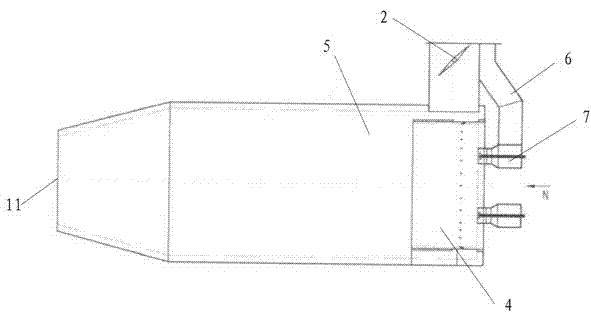

Afterburner with airflow channel designed in rectifying support plate

ActiveCN106678876AImprove mixing uniformityFire stableContinuous combustion chamberCombustion chamberEvaporation

The invention provides an afterburner with an airflow channel designed in a rectifying support plate, the oil and gas mixing degree can be effectively improved, the mixed gas staying time is prolonged, and the combustion efficiency is improved. Airflow from an inner duct and an outer duct is mixed among rectifying support plate flame stabilizers through a sliding baffle type rear duct ejector, airflow enters the support plate from small air inlet holes formed in the surfaces of the two sides of the rectifying support plate flame stabilizers and passes through the airflow channel formed by partition plates, the speed is reduced in the process, fuel oil in fuel oil channels is heated, then the fuel oil is sprayed out towards the center on the back through small air spraying holes formed in the surfaces of the tail flame stabilizers, the fuel oil enters fuel oil channels in the rectifying support plate flame stabilizers through oil supply pipelines, after being heated, the fuel oil is sprayed out through small oil spraying holes connected with the surfaces of the flame stabilizers, the fuel oil is disturbed through multiple strands of airflow, the fuel oil is further heated and mixed with the airflow, and combustion is conducted in a back low-speed backflow area. The fuel oil is good in heating, atomizing and evaporation effect and is disturbed by the airflow, the oil and gas mixing time is long in the low-speed area, accordingly the oil and gas mixing effect is good, and therefore the combustion efficiency can be improved. Meanwhile, ignition and stable combustion can be achieved under the condition of the small oil and gas ratio.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

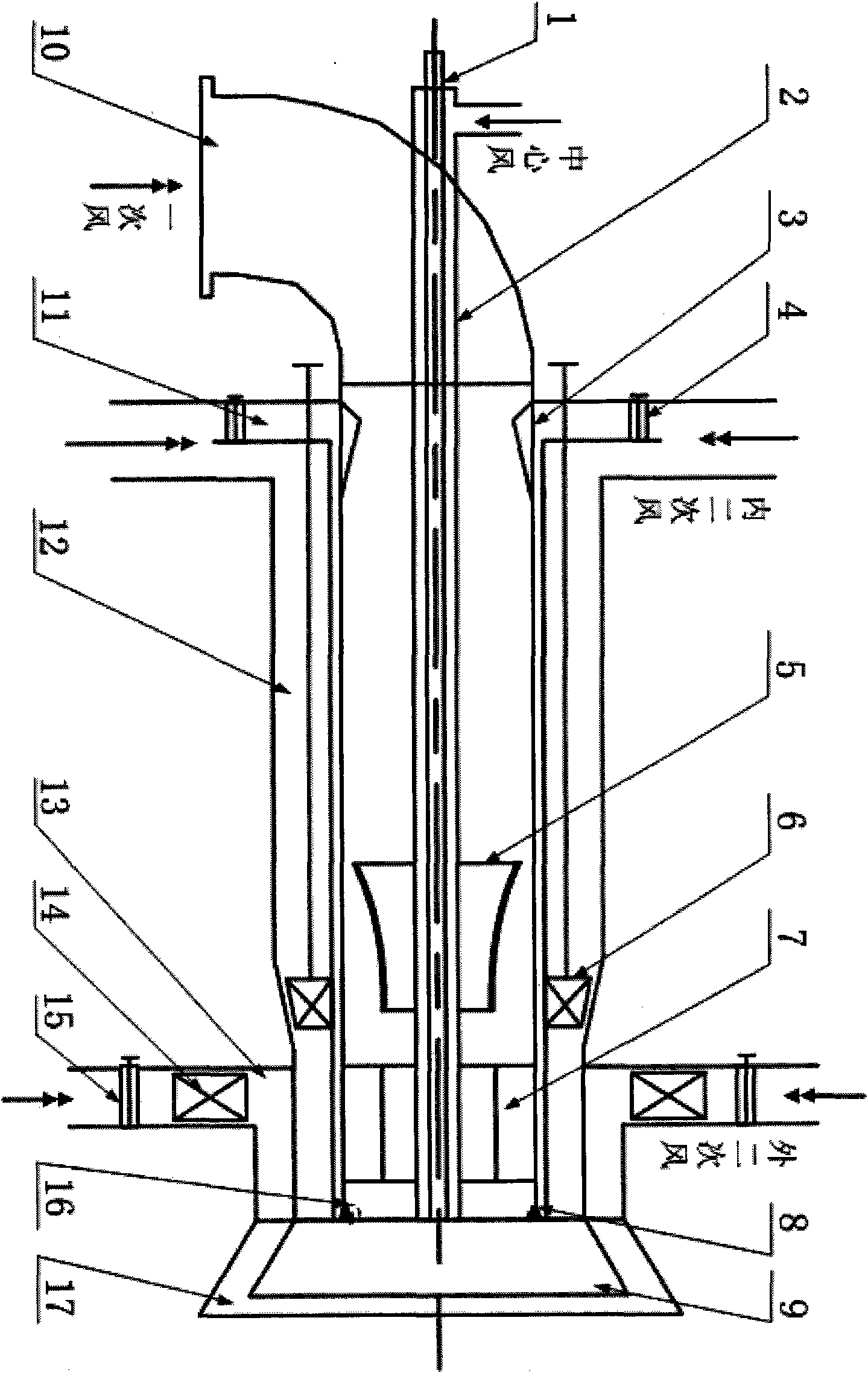

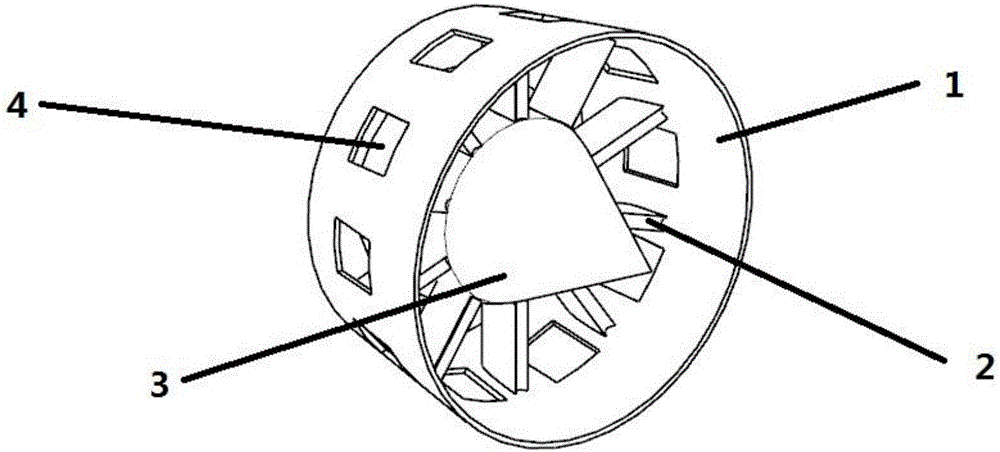

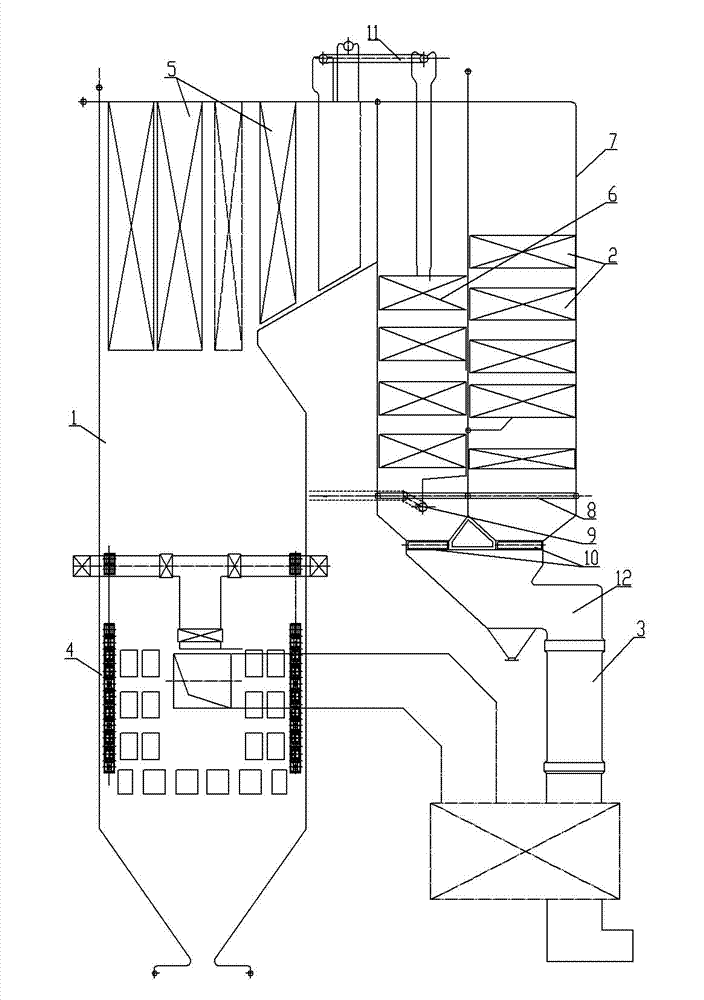

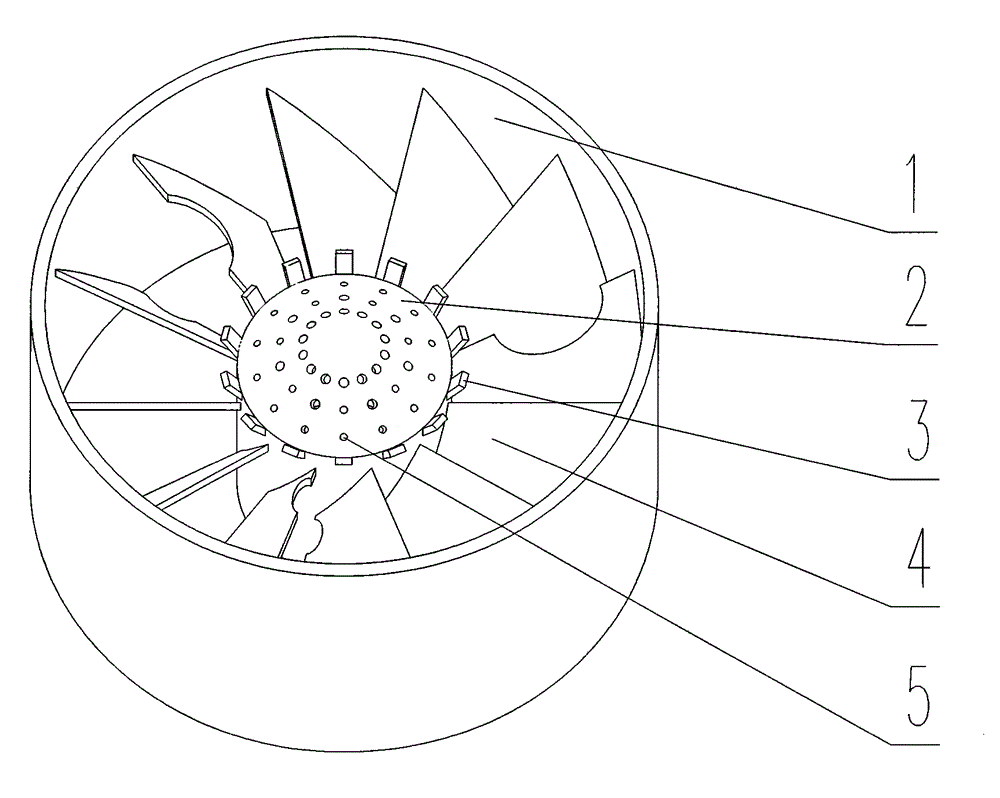

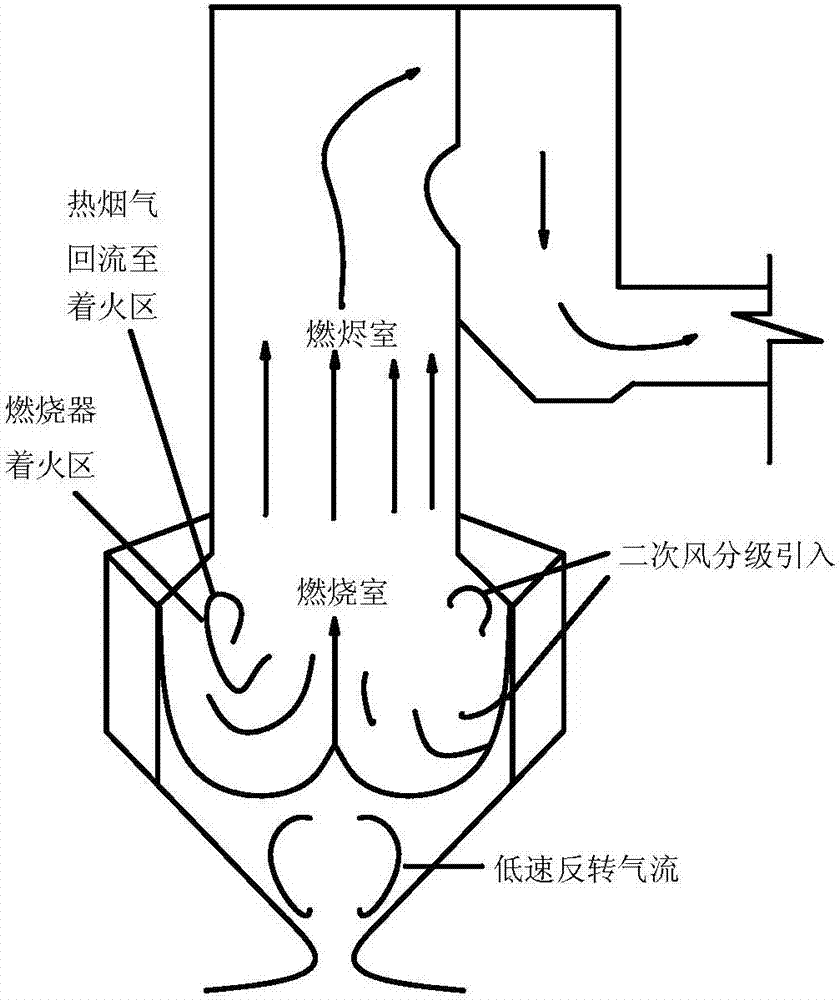

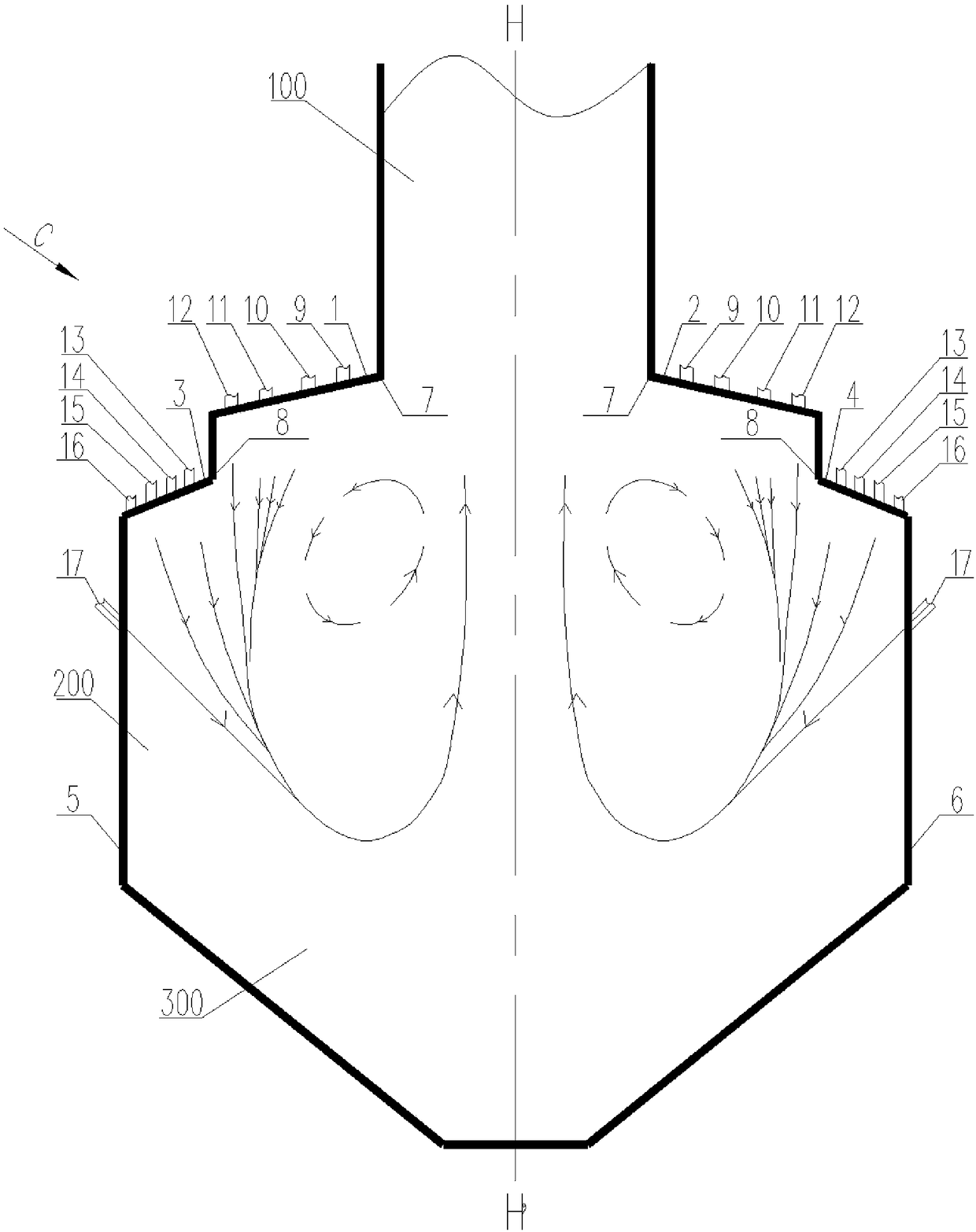

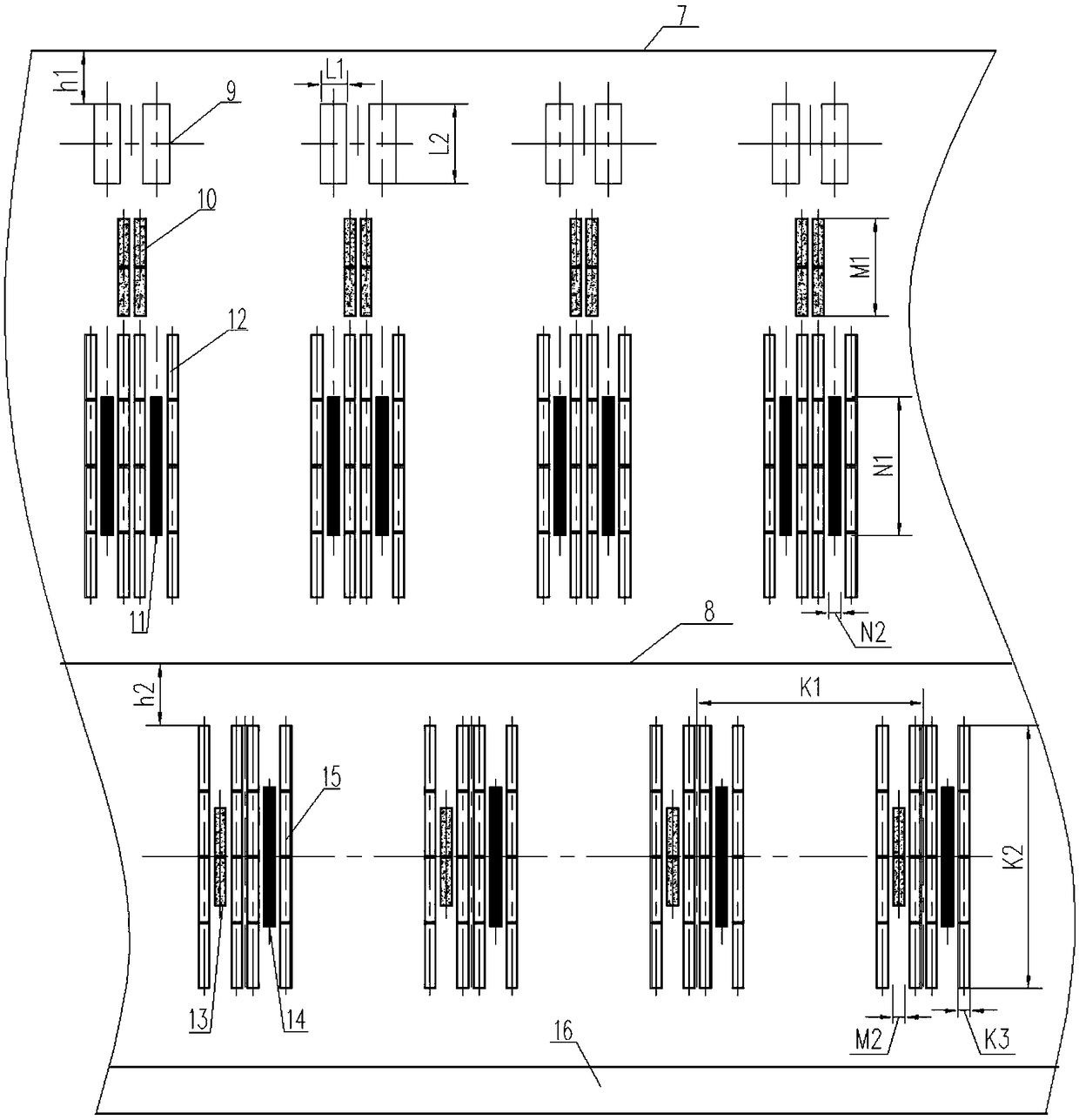

Center-feeding cyclone pulverized coal combustion device adopting pre-combustion chamber and double-layer jet flow to separate secondary air

InactiveCN107559818AReduce generationEmission reductionPulverulent fuel combustion burnersNon-combustible gases/liquids supplyCycloneHigh concentration

The invention discloses a center-feeding cyclone pulverized coal combustion device adopting a pre-combustion chamber and double-layer jet flow to separate secondary air, and relates to a pulverized coal combustion device, and the center-feeding cyclone pulverized coal combustion device solves the problems that an existing pulverized coal combustion device is high in NOx discharge amount, is poor in flame stability, is severe in slag-bonding and is poor in after-combustion. High-concentration pulverized coal gas flow is conveyed in a primary air tube; a cyclone pulverized coal combustor is arranged at the front end of the pre-combustion chamber; the cyclone pulverized coal combustor and the pre-combustion chamber are coaxially arranged, and each pipeline spray hole of the cyclone pulverizedcoal combustor is flush to the inner wall of the pre-combustion chamber; a plurality of separating secondary air spray holes are distributed at the outer side of the pre-combustion chamber in a double-layer annular mode; a circle on which the centers of each layer of separating secondary air spray holes are located is coaxial with the cyclone combustor; the two layers of separating secondary airspay holes are uniformly crossed with one another; each separating secondary air spray hole is flush to the inner wall of a furnace hearth; and included angles beta between the center lines of the separating secondary air spray holes and the axis of the air tube at each stage of the cyclone combustor are 0-60 degrees. The center-feeding cyclone pulverized coal combustion device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

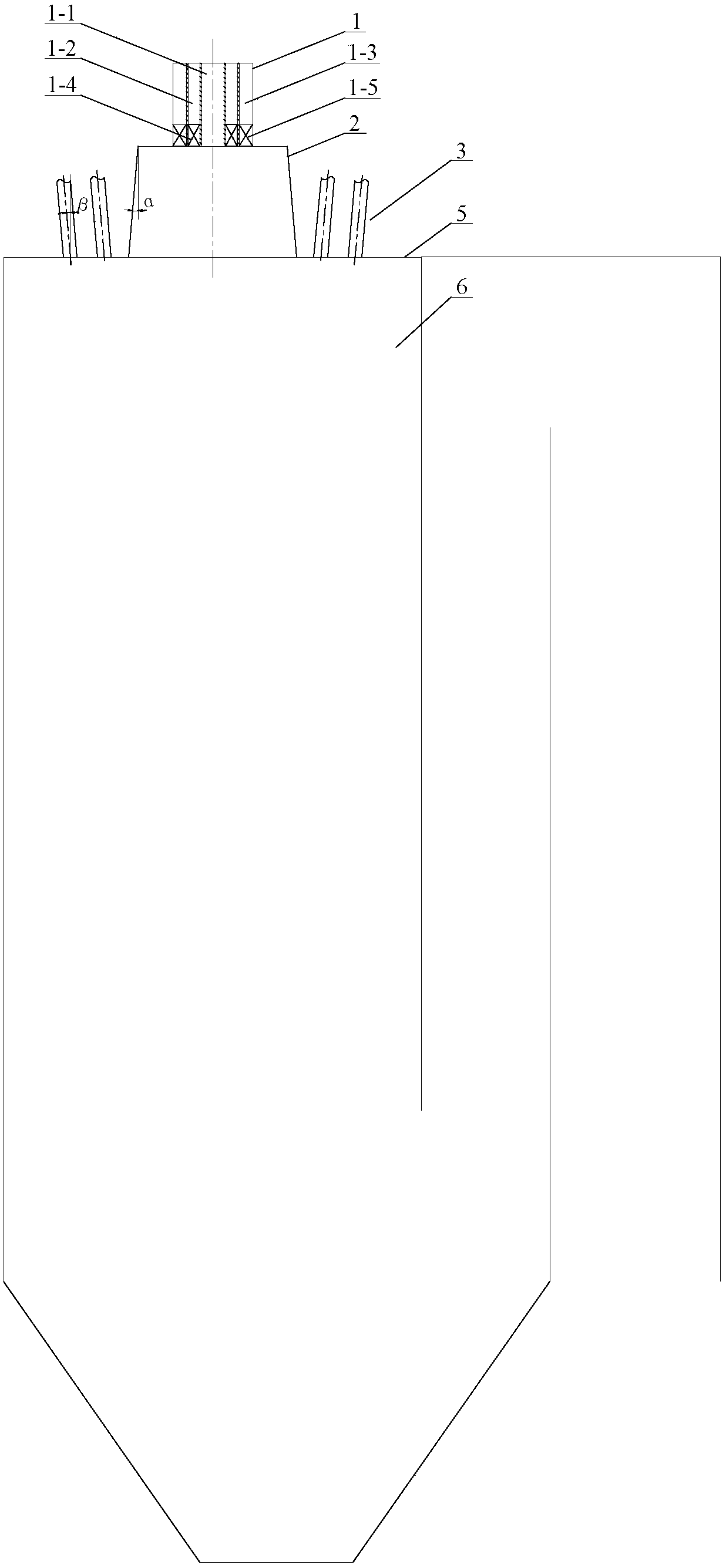

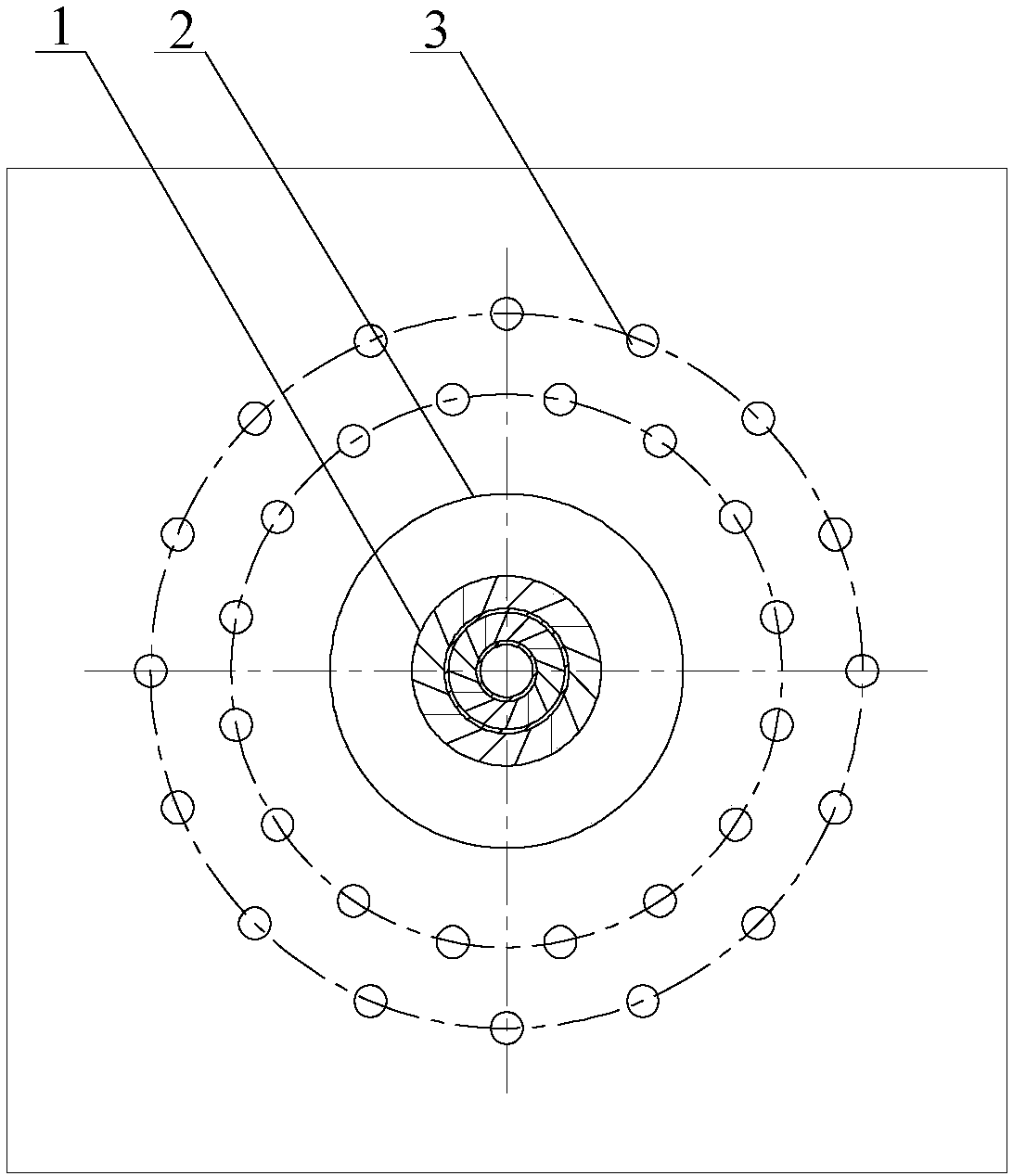

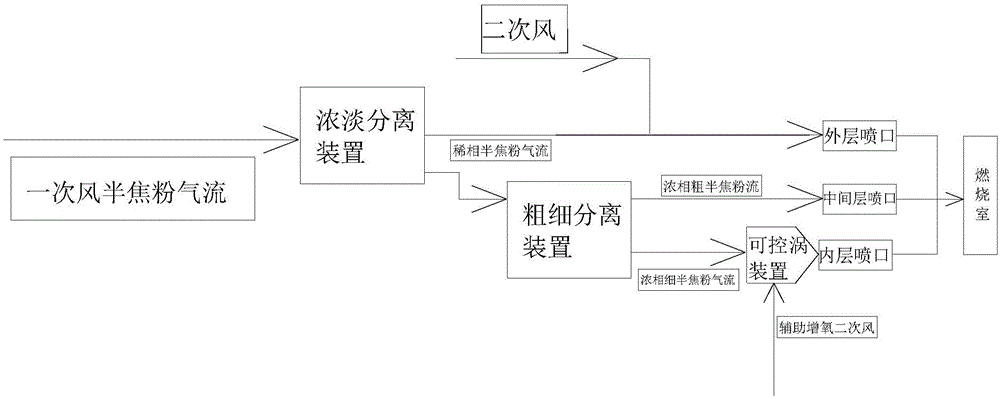

Method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies

InactiveCN106556007AFire stablePrevent high temperature corrosionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

A method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies is characterized in that low-rank coal primary air semi-coke powder flow carrying gasified semi-coke is subjected to concentrated-dilute separation to obtain concentrated-phase semi-coke powder flow and dilute-phase semi-coke powder flow; the concentrated-phase semi-coke powder flow is subjected to coarse-fine separation to obtain concentrated-phase coarse semi-coke powder flow and concentrated-phase fine semi-coke flow; the dilute-phase semi-coke powder flow and secondary air are mixed, and the mixture is guided into an outer-layer nozzle of a combustion chamber; and the concentrated-phase fine semi-coke powder flow and the concentrated-phase coarse semi-coke powder flow are guided into an inner-layer nozzle and an intermediate-layer nozzle of the combustion chamber respectively and then sprayed into the combustion chamber, a controlled vortex bluff body device and an auxiliary aeration secondary air nozzle are mounted in the inner-layer nozzle of the combustion chamber, and during ignition, the concentrated-phase fine semi-coke powder flow sprayed by the inner-layer nozzle of the combustion chamber is ignited at first. The method can effectively improve ignition, combustion and burn-out characteristics of gasified semi-coke, reduces pollutant discharge and can effectively prevent a furnace wall from slag-bonding and a water wall from high-temperature corrosion.

Owner:CHONGQING UNIV

AC Plasma Ejection Gun, the Method for Supplying Power to it and Pulverized Coal Burner

ActiveUS20100300335A1Small currentIncrease motivationPulverulent fuel combustion burnersSolid cathode detailsElectricityEngineering

An AC plasma ejection gun, the method for supplying power to the gun and a pulverized coal burner are provided. The ejection gun comprising: a power supply device, having a live wear and a null wear; an electric front electrode, inside of which a front chamber is set, a nozzle connected with said front chamber is set at the outlet of the front electrode, an air inlet pipe connected with said front chamber is set at the inlet of the front electrode, and the front electrode is connected with said null wire; an electric rear electrode, connected with the inlet of said front electrode by an insulated ring, there is a gap between the electric rear electrode and said front electrode, said rear electrode is connected with the live wire, a spinning air inlet ring is set at the outside of the gap between said front electrode and said rear electrode, compressed air from the air inlet pipe passes the spinning air inlet ring and enters into the front chamber; wherein, the arc between said front electrode and said rear electrode discharges, ionizing the compressed air into plasma in the gap between said front electrode and said rear electrode, and the plasma is ejected out of the nozzle from the front chamber. The ejection gun in present invention can work with small current and large power, so that the life of the plasma ejection gun is prolonged.

Owner:BEIJING GUNGYAO ELECTRICITY EQUIP CO LTD

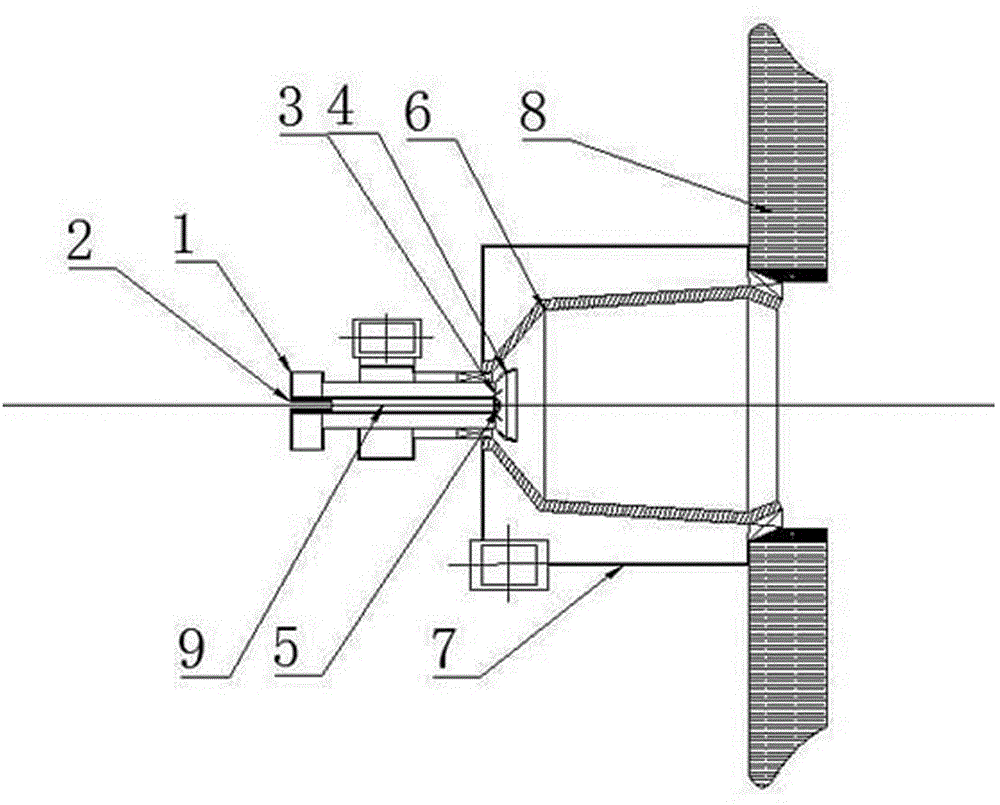

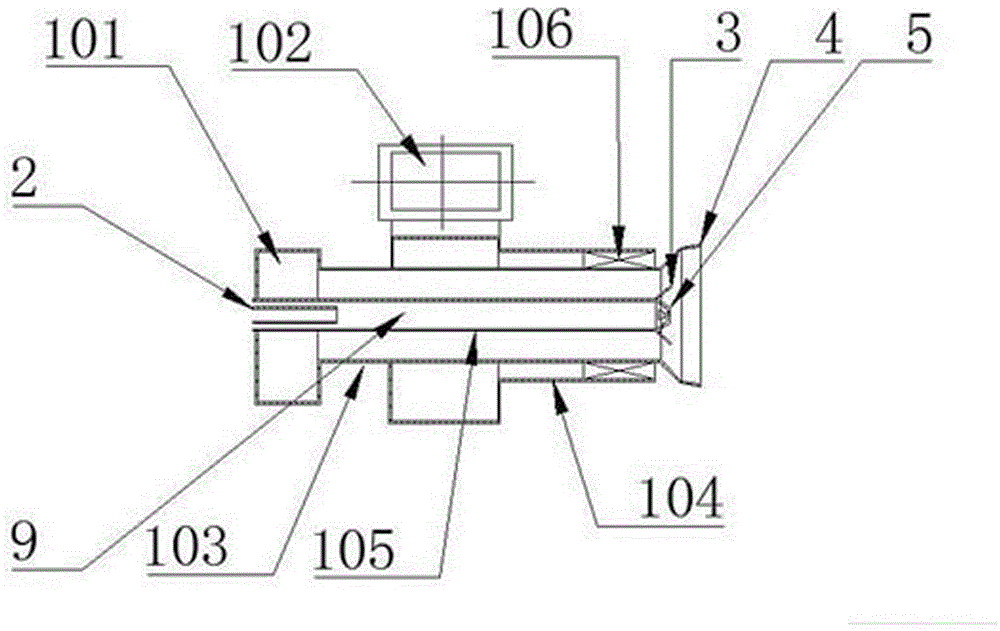

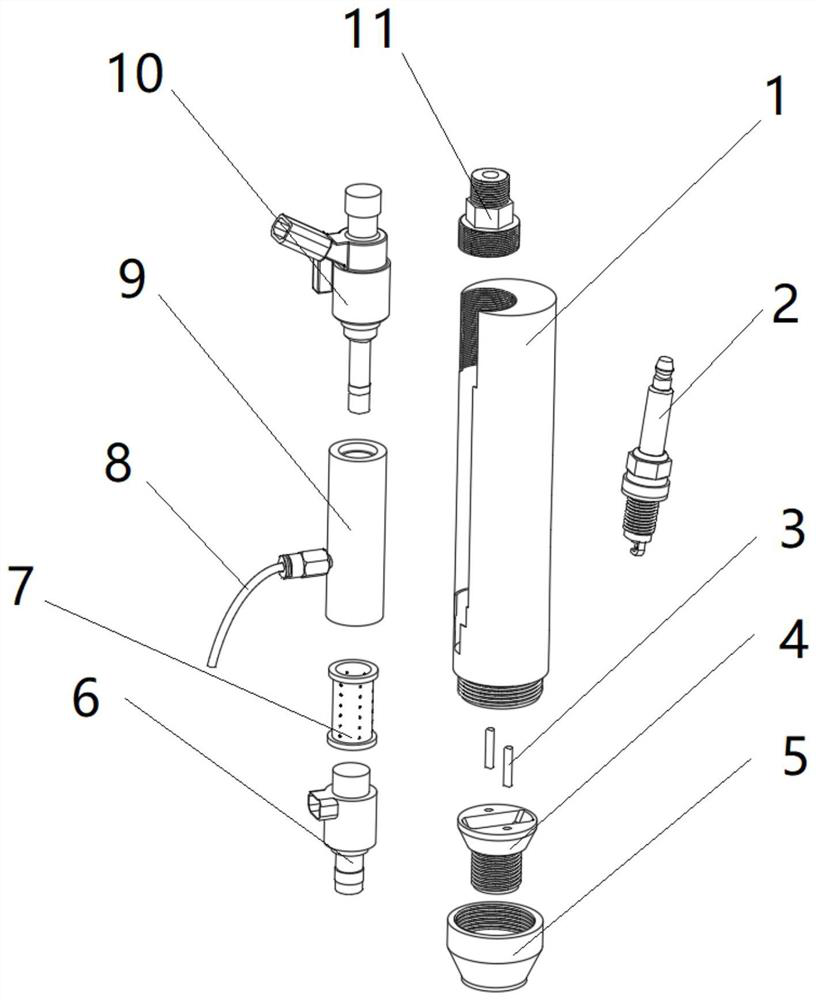

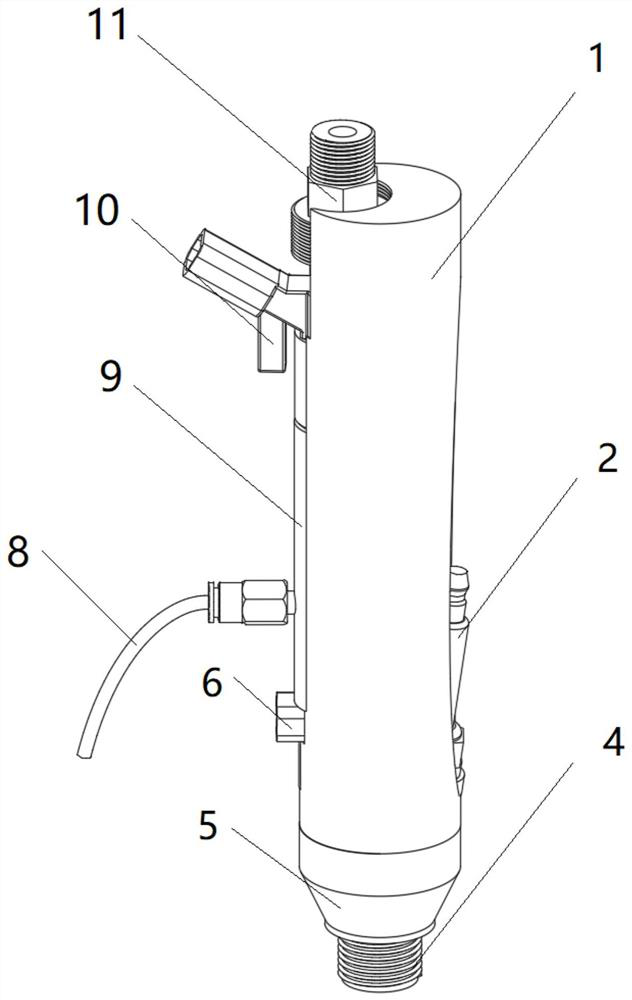

Dual-injection turbulent jet ignition pre-chamber device for spark ignition engine

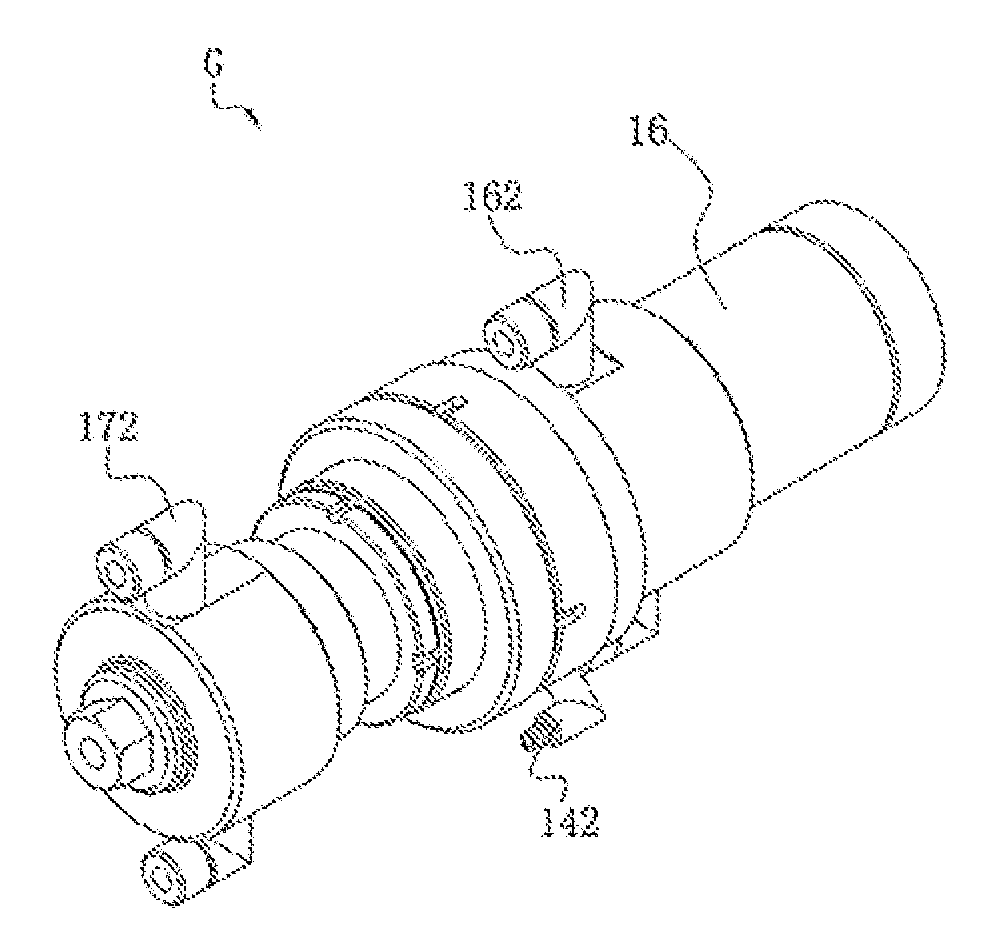

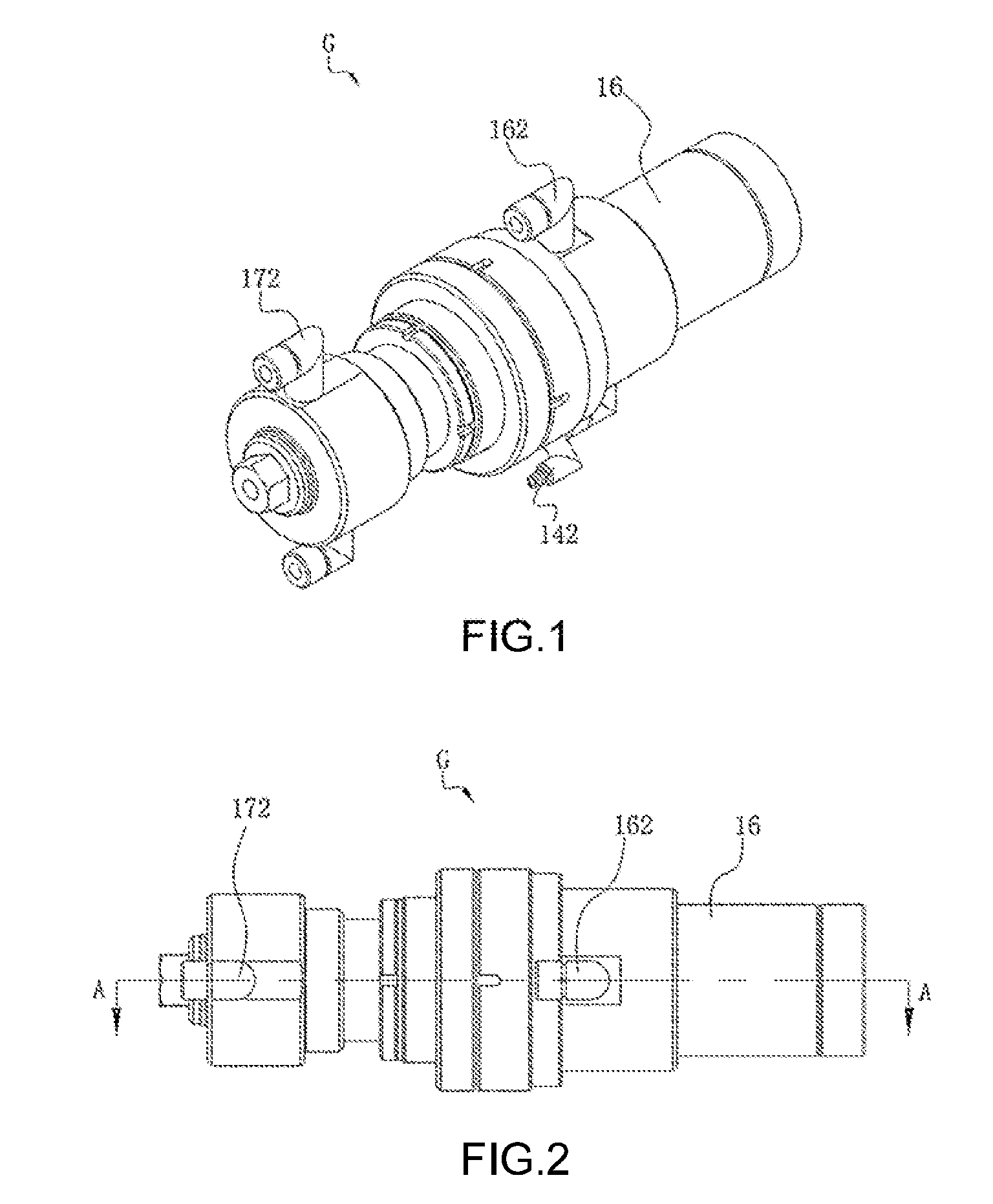

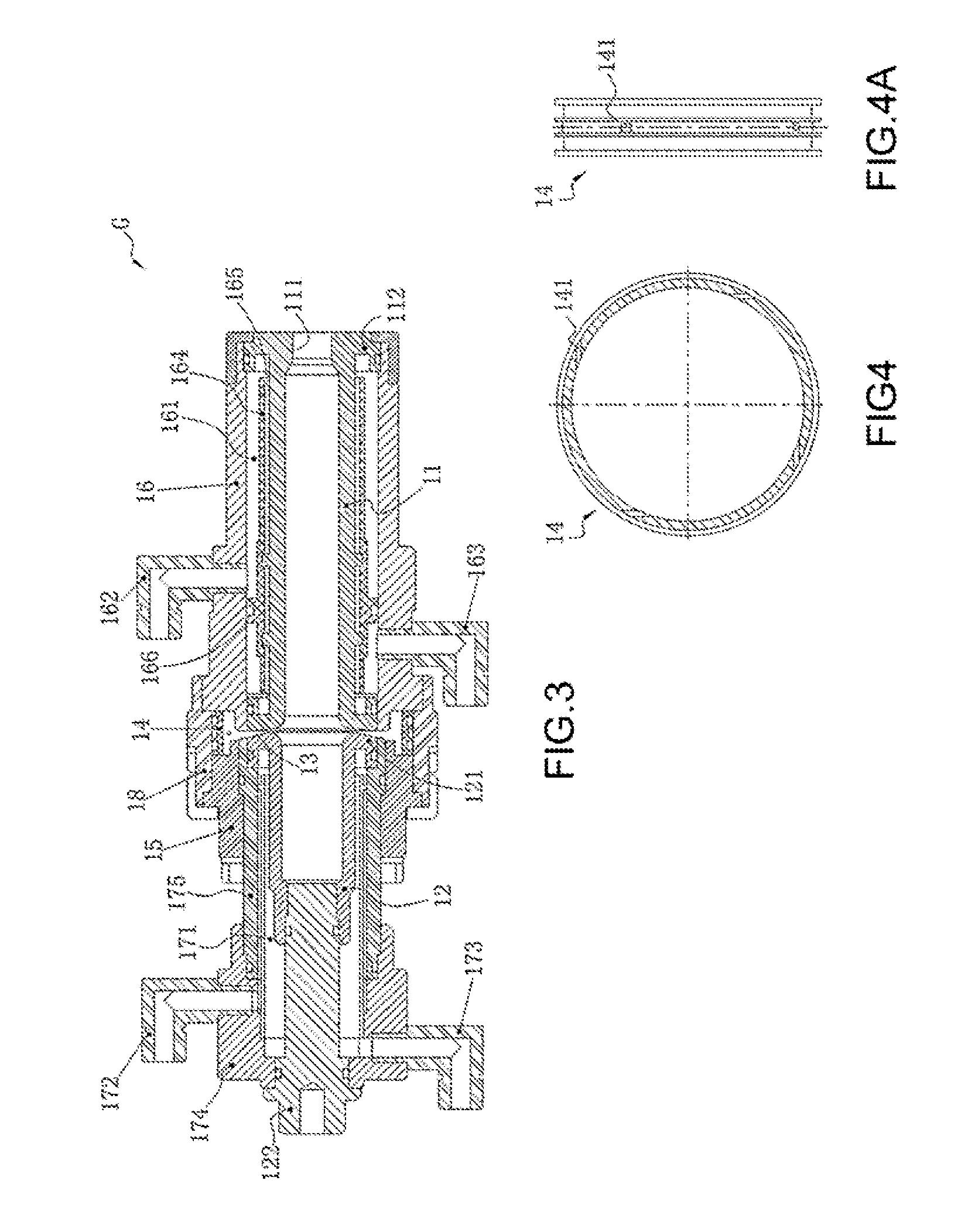

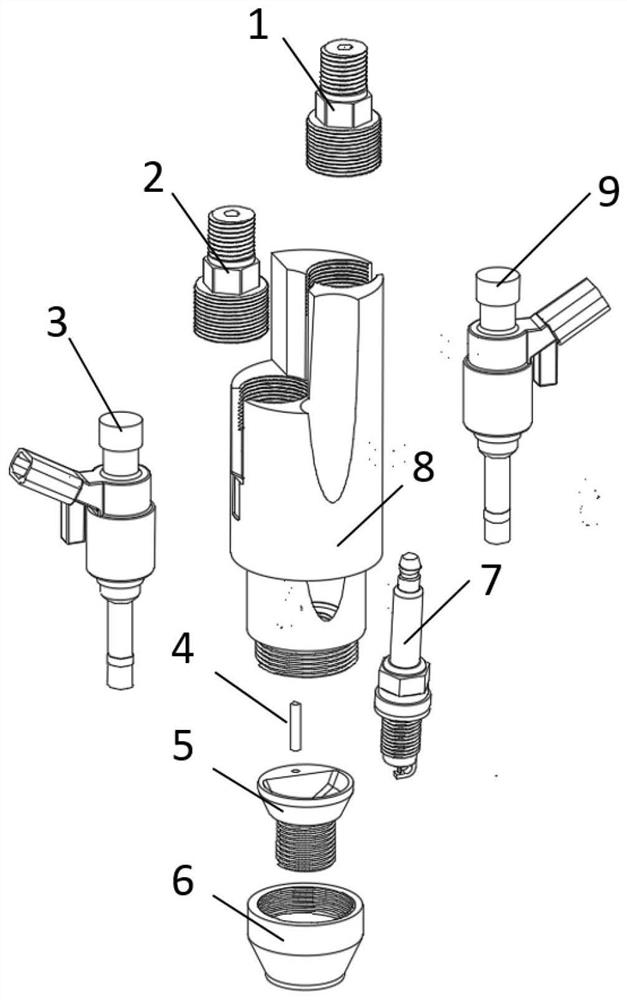

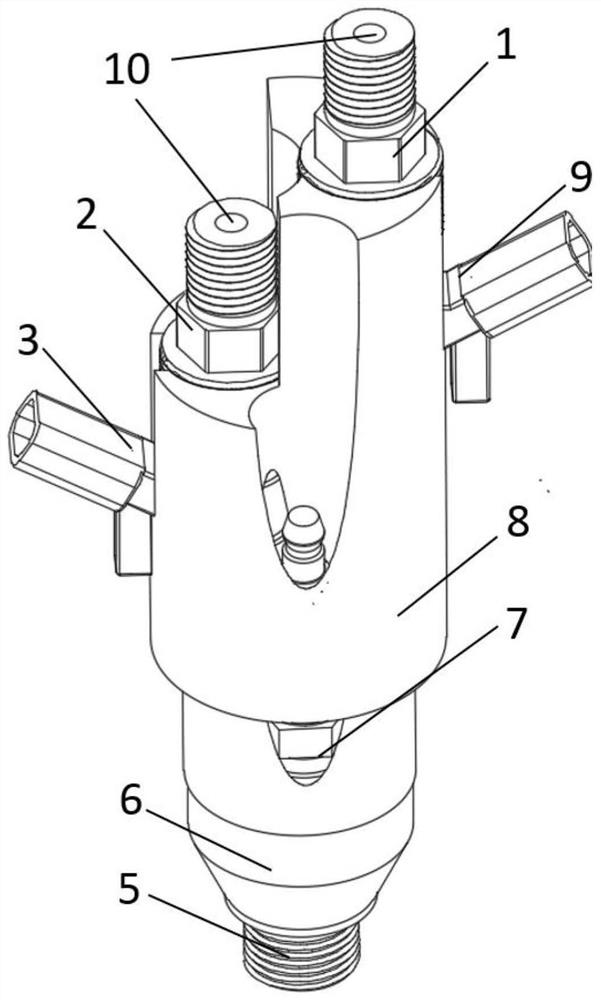

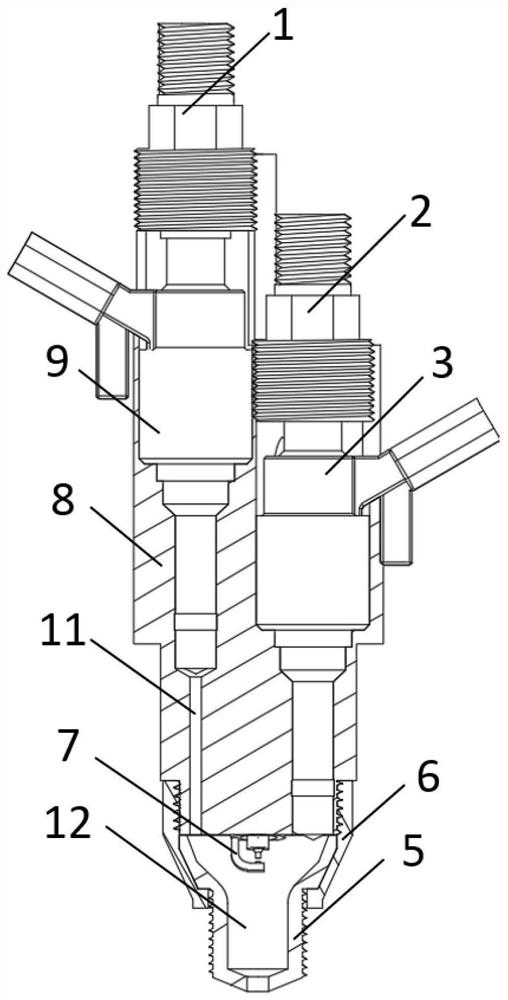

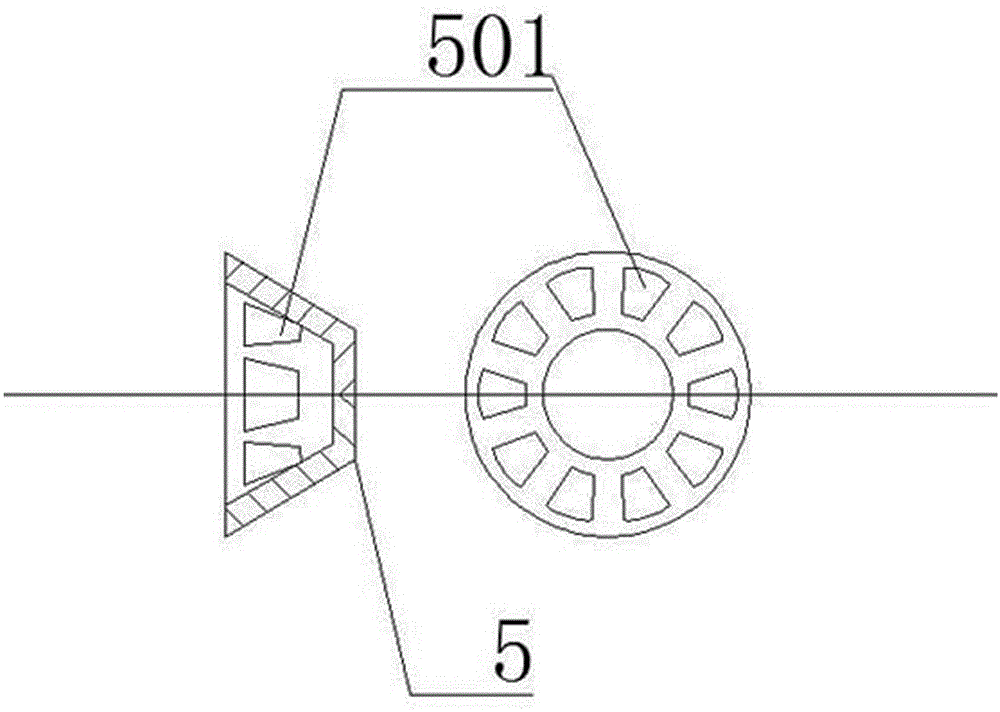

PendingCN112796870AFire stableImprove combustion efficiencyElectrical controlInternal combustion piston enginesPhysicsAutomotive engineering

The invention provides a dual-injection type turbulent jet ignition pre-combustion chamber device for a spark ignition engine. The dual-injection type turbulent jet ignition pre-combustion chamber device comprises two compression bolts, a fuel injector (3), a gas injector (9), a pre-combustion chamber upper cavity (8), a pre-combustion chamber nozzle (5), a pre-combustion chamber nozzle compression piece (6) and a spark plug (7). The spark plug (7), the fuel injector (3) and the gas injector (9) are fixed in the pre-combustion chamber upper cavity (8), and each of the fuel injector (3) and the gas injector (9) is fixed in the pre-combustion chamber upper cavity (8) through a compression bolt; each compression bolt is provided with a through hole (10), two ends of each compression bolt are provided with threads, one end of each compression bolt is connected with the pre-combustion chamber upper cavity (8) through the threads and used for fixing the gas injector (9) or the fuel injector (3), and the other end of each compression bolt is connected with a gas path or a fuel path; and the pre-combustion chamber nozzle (5) is pressed by the pre-combustion chamber nozzle compression piece (6) and is fixed to the lower end of the pre-combustion chamber upper cavity (8) to form a pre-combustion chamber inner cavity (12).

Owner:TIANJIN UNIV

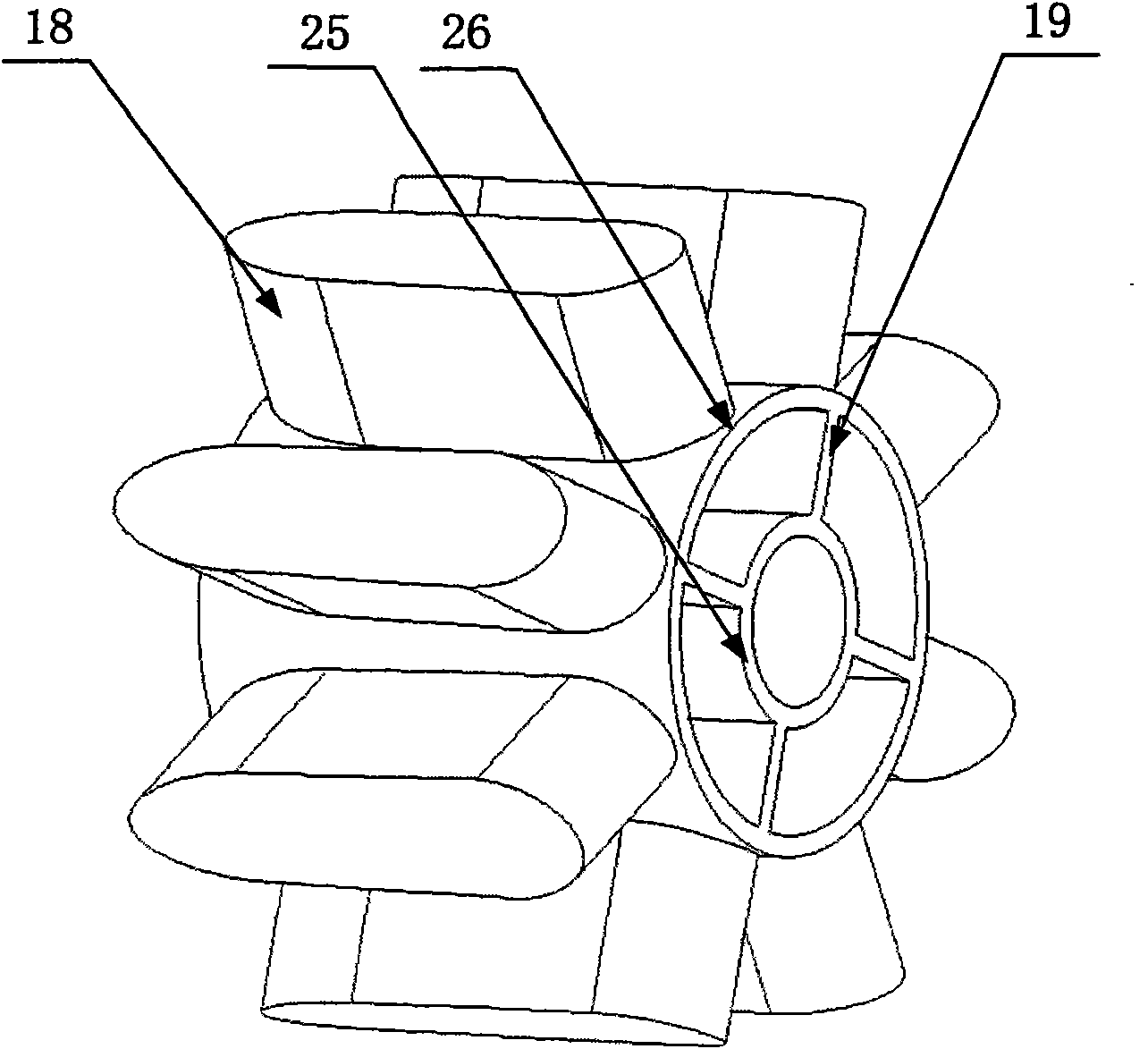

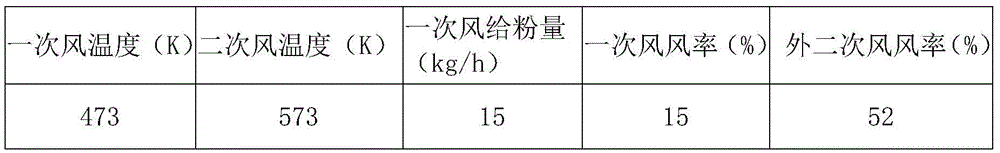

Two-stage-adjustable steam plasma swirl burner

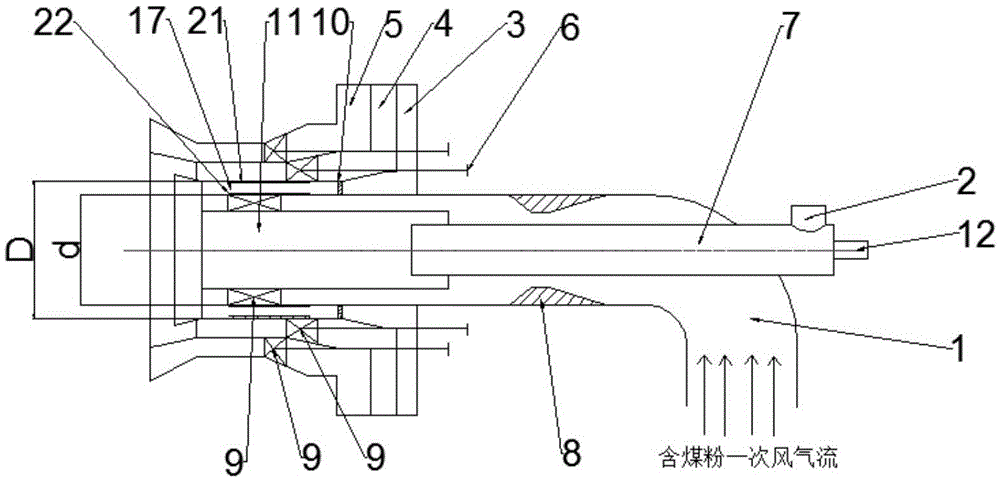

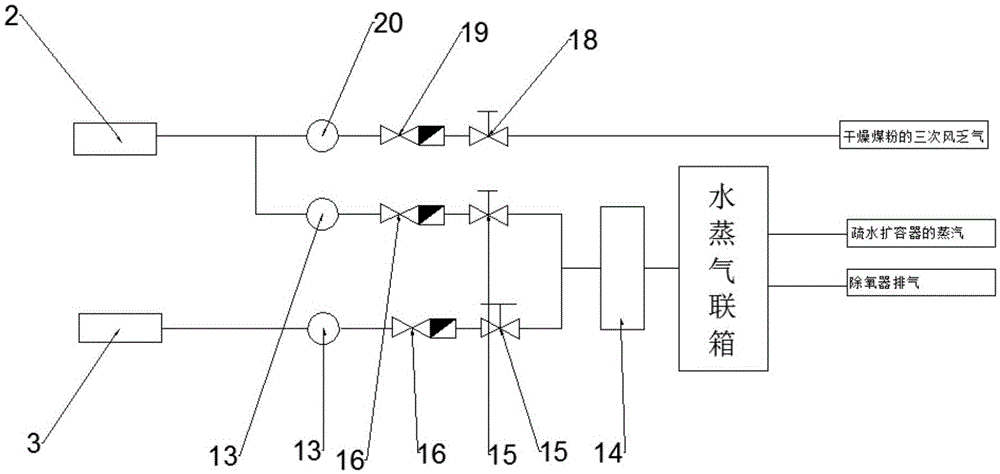

ActiveCN105674257AEasy to get materialsRational use of resourcesPulverulent fuel combustion burnersNon-combustible gases/liquids supplyCombustorPlasma generator

The invention discloses a two-stage-adjustable steam plasma swirl burner. The two-stage-adjustable steam plasma swirl burner comprises a first-stage plasma ignition device, a second-stage plasma adjuster and a steam supply system. The first-stage plasma ignition device comprises a primary air pipeline, an internal combustor, a rich-lean separator, a swirl generator, a first-stage steam inlet pipeline, a central air pipeline and a first-stage plasma generator. The second-stage plasma adjusting device comprises a second-stage steam inlet pipeline, a second-stage plasma generator, an internal secondary air inlet pipeline and an external secondary air inlet pipeline. The two-stage-adjustable steam plasma swirl burner solves the problems that combustion is hardly stable and the NOx pollutant emission is high, is especially suitable for meager coal, smoke-free coal and the coal which is difficult to ignite and generates a large amount of NOx pollutants and has the effects of being low in nitrogen and stable in combustion.

Owner:HUAZHONG UNIV OF SCI & TECH

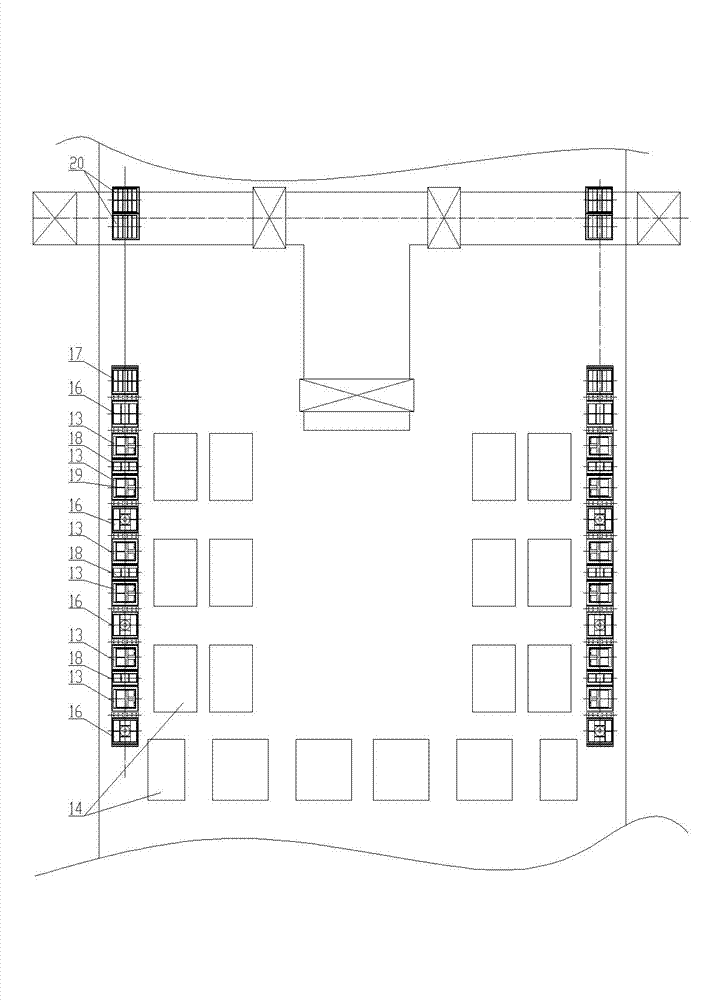

Pulverized coal boiler capable of subcritically combusting lean coal

ActiveCN103206699AImprove fullnessNot easy to deflectIndirect carbon-dioxide mitigationSteam boilersAir preheaterCombustor

The invention provides a pulverized coal boiler capable of subcritically combusting lean coal. The pulverized coal boiler comprises a hearth, superheaters, coal economizers and an air preheater. Combustors are arranged in the hearth. The pulverized coal boiler is characterized in that the superheaters include high-temperature superheaters and low-temperature superheaters, the high-temperature superheaters are arranged on the upper side of the hearth, a flue with a vertical shaft is communicated with the upper side of the hearth, two sides of the flue with the vertical shaft are separated from each other, the low-temperature superheaters and the coal economizers are respectively arranged on the two sides of the flue with the vertical shaft, a superheated steam inlet pipeline is arranged below the low-temperature superheaters, an emergency spray attemperator is mounted on the overheated steam inlet pipeline, the flue with the vertical shaft is provided with flue gas temperature regulating barriers which are respectively arranged below the low-temperature superheaters and the coal economizers, and the high-temperature superheaters and the low-temperature superheaters are respectively connected with trim spray attemperators. The pulverized coal boiler has the advantages that the lean coal with the Vdaf (volatile) equal to 14% can be sufficiently combusted in the boiler, so that energy is sufficiently utilized, and the pulverized coal boiler is energy-saving.

Owner:WUXI HUAGUANG BOILER

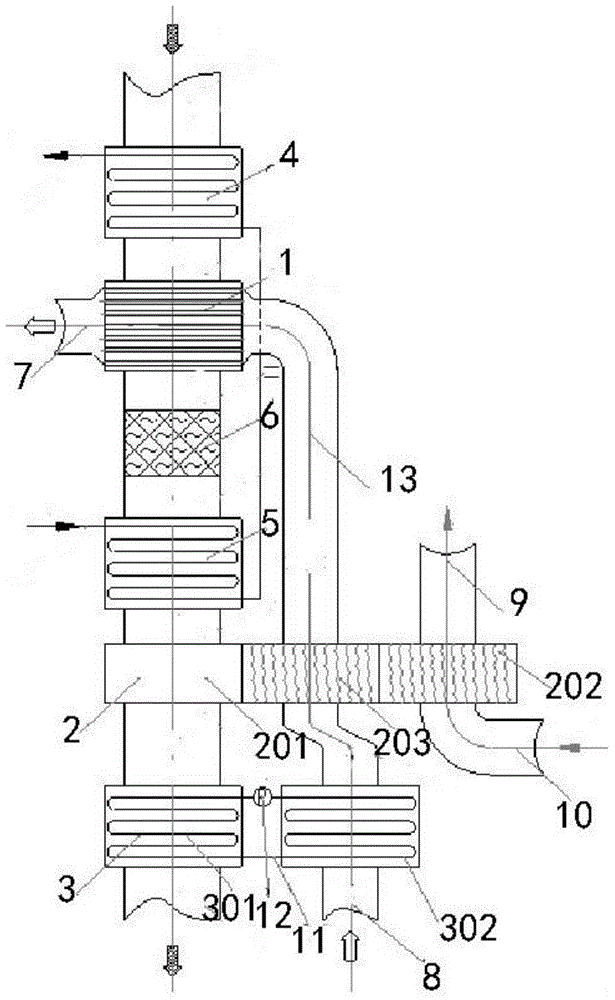

Boiler tail exhaust gas heat utilization system

ActiveCN104976635ALower the feverImproved stable fireCombustion processIndirect carbon-dioxide mitigationExhaust gasFlue

The invention discloses a boiler tail exhaust gas heat utilization system which comprises multiple stages of preheaters with the progressively-increasing and mixed temperatures and a coal economizer. The preheaters are communicated with the coal economizer through a flue. The boiler tail exhaust gas heat utilization system further comprises a secondary flue (13) penetrating through all the preheaters. Some heat of boiler tail exhaust gas is absorbed by the coal economizer, and the rest of the heat is totally used for heating primary air and secondary air entering a boiler, so that the boiler efficiency is improved by 0.5%-2%, and the coal consumption is lowered.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

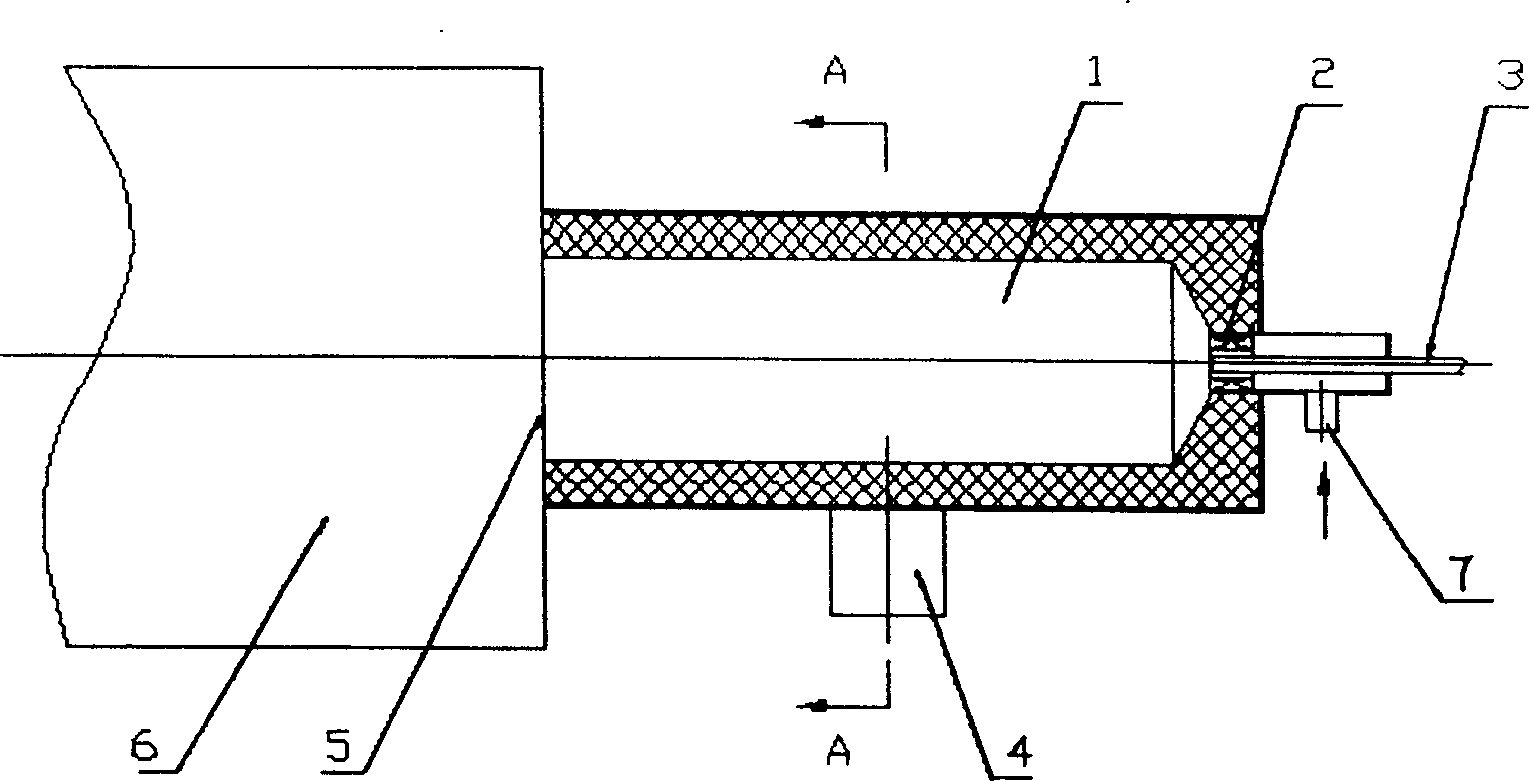

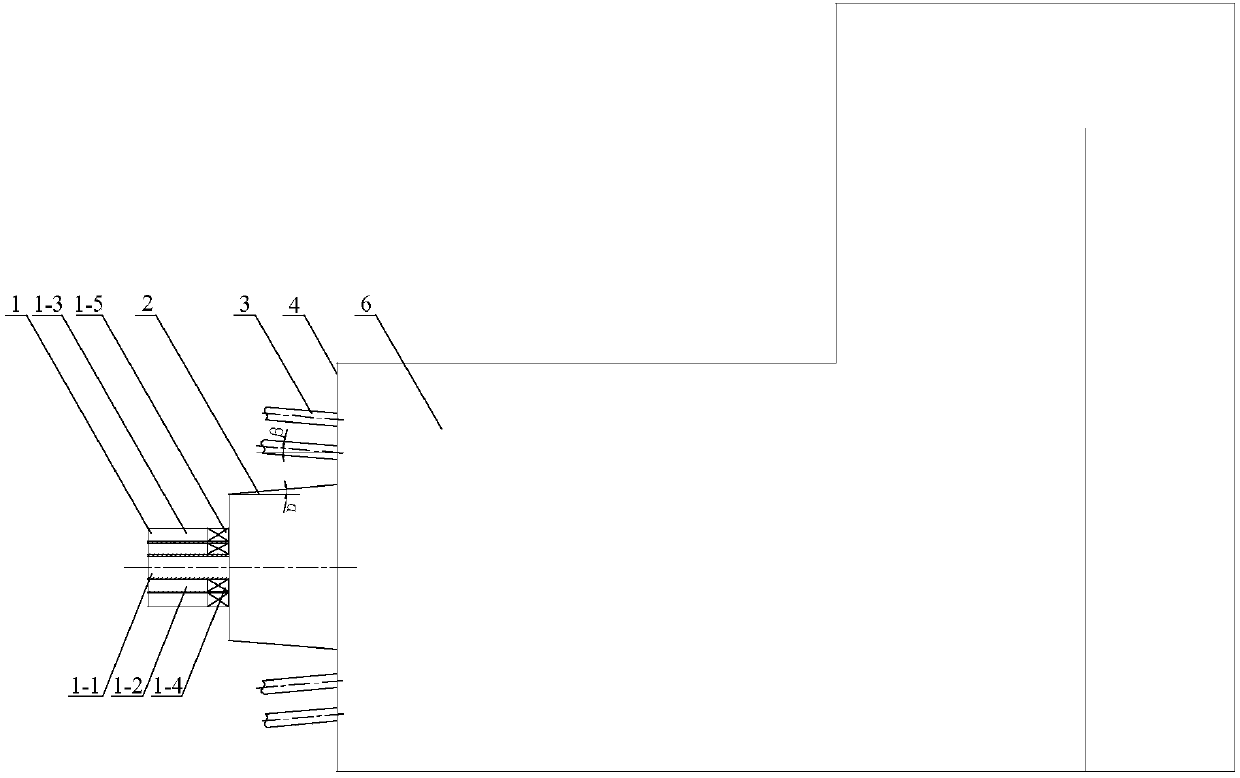

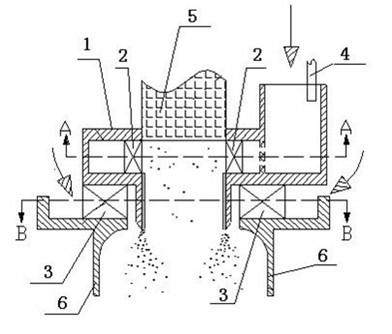

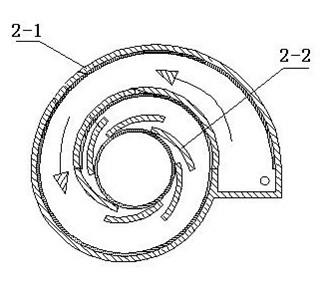

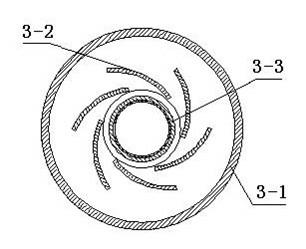

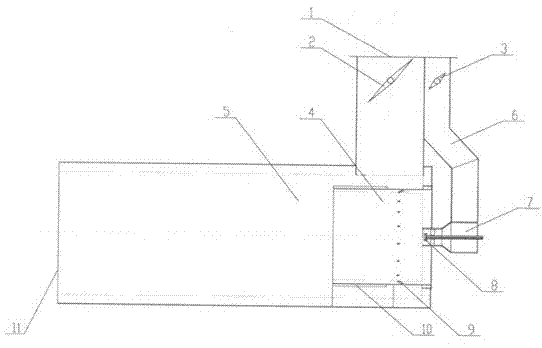

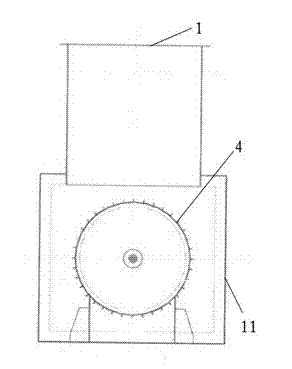

Small-size precombustion chamber for engine

InactiveCN102519056AReasonable structural designCompact structureContinuous combustion chamberFuel oilEngineering

The invention discloses a small-size precombustion chamber for an engine. The small-size precombustion chamber for the engine comprises a precombustion chamber body (1), wherein a primary cyclone (2), a secondary cyclone (3), an oil spray rod (4) and an ignition electric nozzle (5) are arranged in the precombustion chamber body (1), the ignition electric nozzle (5) is vertically arranged on the center line of the primary cyclone (1) and the secondary cyclone (2), the oil spray rod (4) is inserted into an oil inlet passage communicated with the primary cyclone (2), the primary cyclone (2) comprises a worm case (2-1) and a cyclone blade (2-2), the secondary cyclone (3) comprises a worm case (3-1), a cyclone blade (3-2) and a Venturi pipe (3-3), and the rotating directions of the cyclone blade (2-2) and the cyclone blade (3-2) are opposite. The small-size precombustion chamber for the engine provided by the invention has the advantages that a good fuel oil atomization and stable low-speed ignition region can be provided, the structure of the whole precombustion chamber is compact, the dimension is small, the successful ignition can be realized in a wide stream Mach number range, and the application range is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas-charcoal furnace for smoldering for foliage and case plant and powder offal

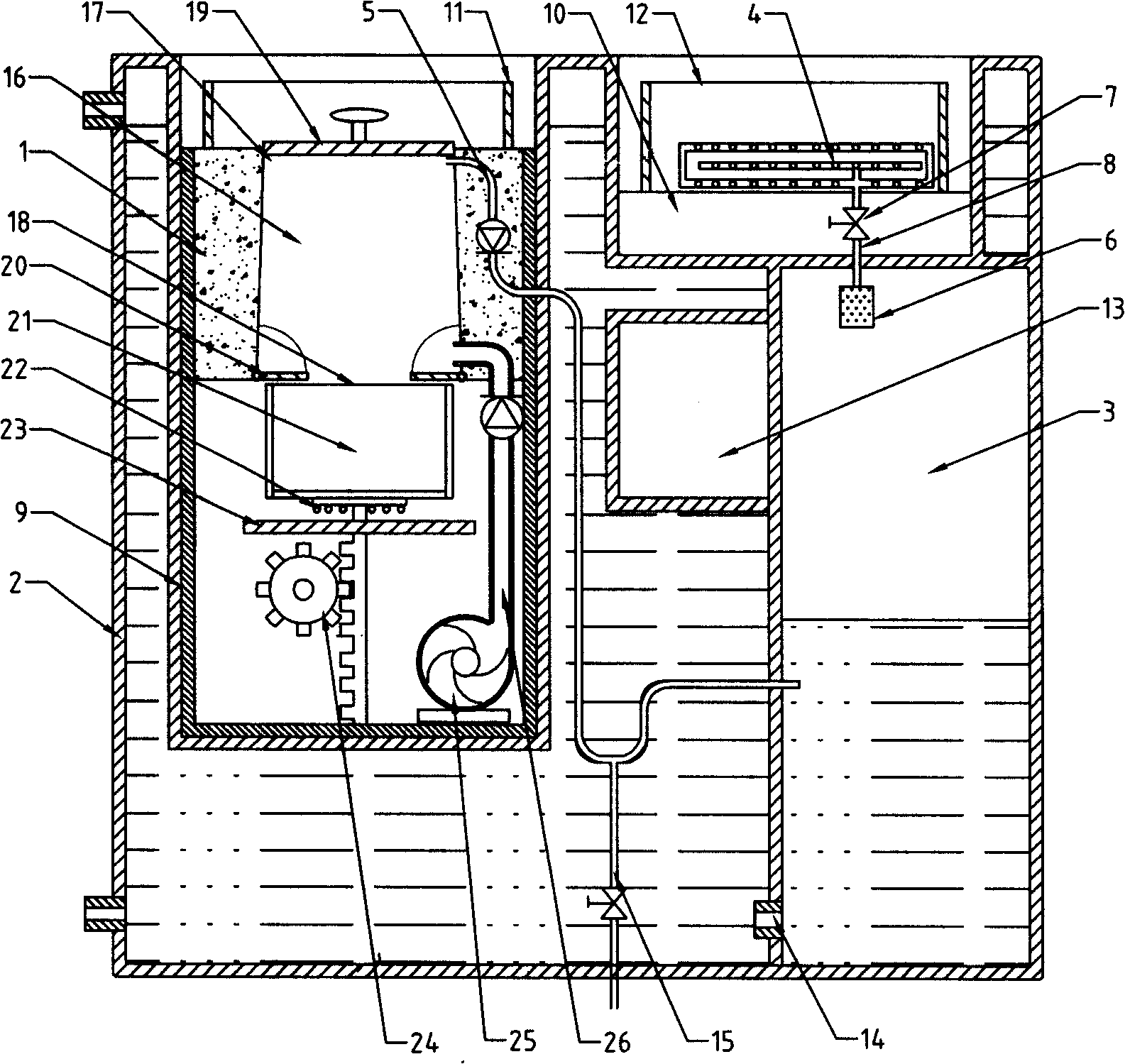

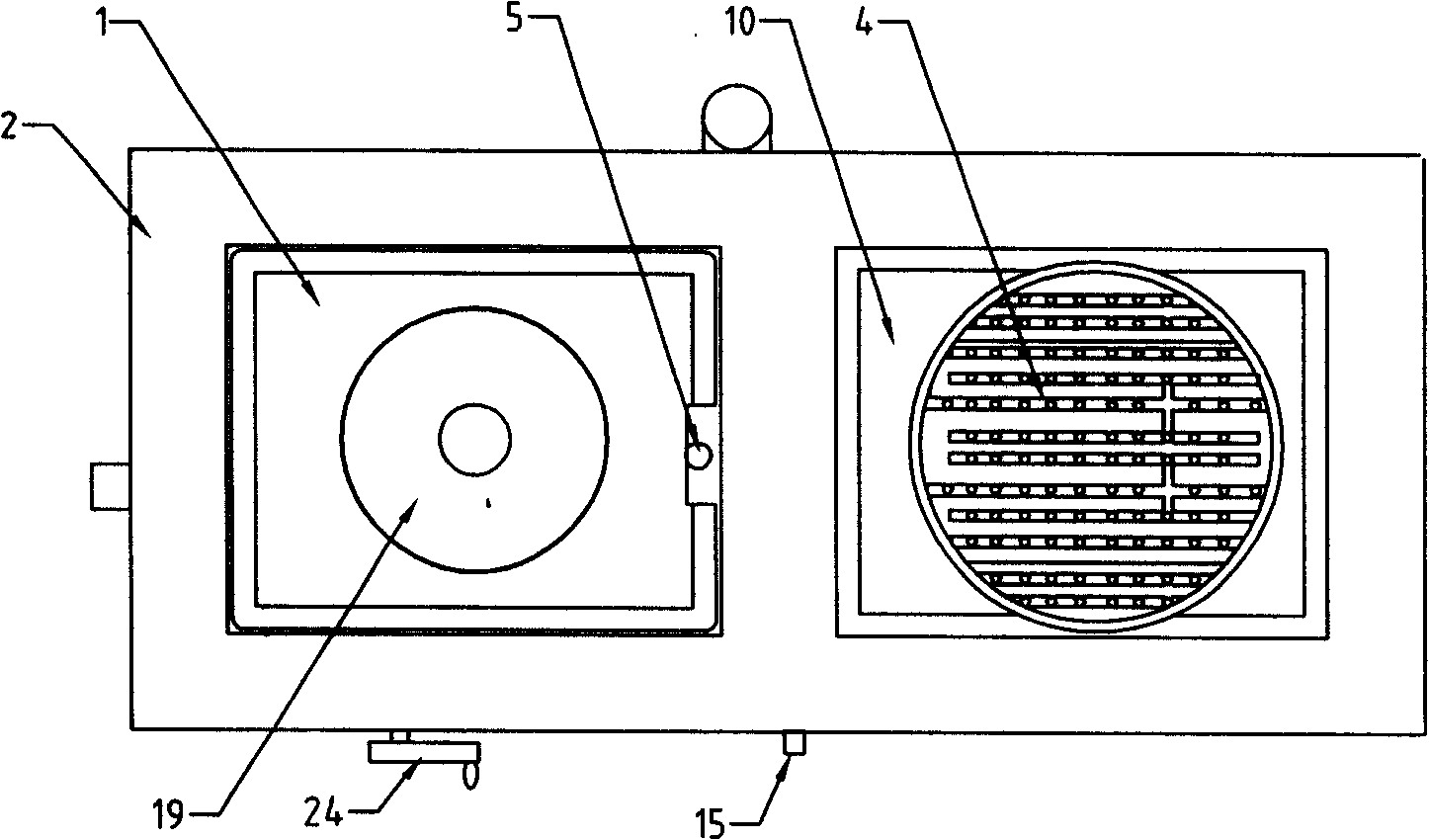

InactiveCN101358745AFire stableReasonable structureLighting and heating apparatusWater heating stoves/rangesEngineeringCoal

The present invention relates to a gas-charwood stove that can combust the leaves-hulls plants and the scattered leftovers, and belongs to the technical field of the stove, and is mainly composed of a gas-production charcoaling stove (1), a surplus-heat water tank (2), a water pressure gas box (3) and a fuel-gas stove (4), wherein, the top of the surplus water tank (2) is provided with two concave-downwards pits that are paralleled to each other, namely, a stove shell (9) and a stove terrace (10); the gas-production charcoaling stove (1) is arranged inside the stove shell (9), and the fuel-gas stove (4) is arranged on the stove terrace (10); the highest point of two wind-return heat-separation walls (11, 12) that are arranged above the two stoves is lower than the upper part of the surplus-heat water tank (2); the middle part of the surplus-heat water tank 92) is provided with a compulsory cooler (13); the bottom of the surplus-heat water tank (2) is provided with a water pipe (14) that is communicated with the lower end of the water pressure gas box (3). The gas-charwood stove of the present invention adopts the scattered coal and the biomass scattering materials such as the straws and leaves as the fuel, and is free to select the counter combustion and the positive combustion, so as to heat the water, produce the gas and to cook; at the same time, the gas-charwood stove can also realize multiple usages such as recycling of the artificial charcoal and coke.

Owner:曹邦文

Piezoelectric ceramic composition and piezoelectric ceramic electronic component

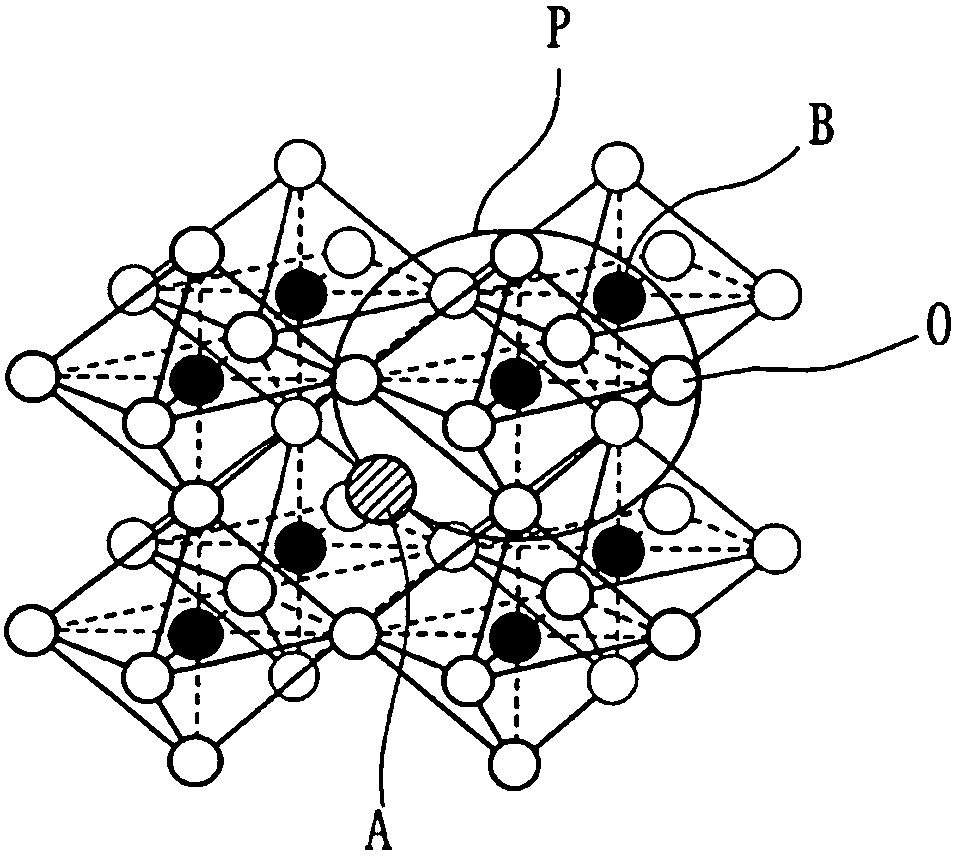

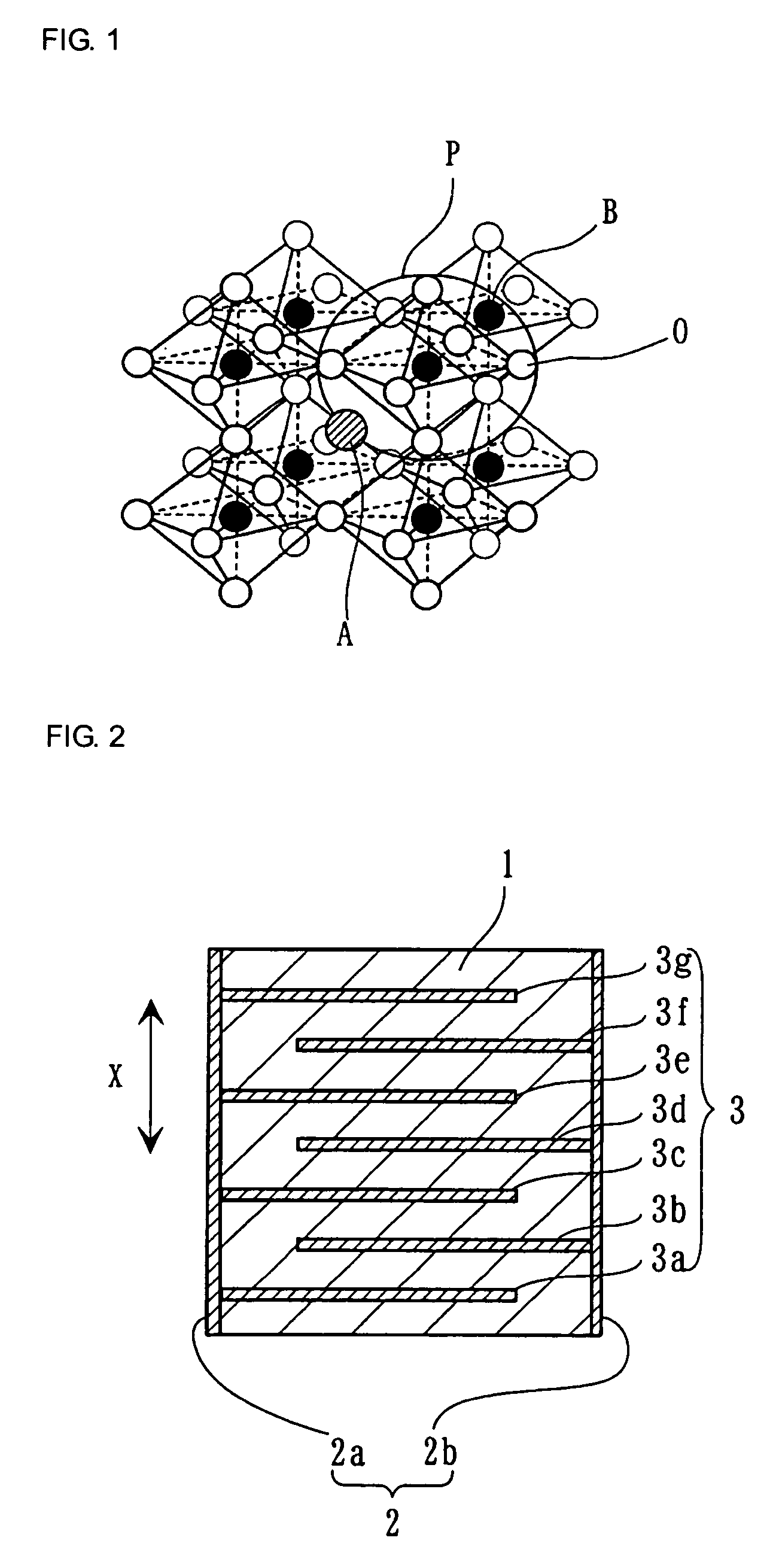

ActiveUS7754095B2Excellent piezoelectric propertiesConstant gainPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectronic componentHigh pressure

A main component has a general formula of {(1−x)(K1−a−bNaaLib)m(Nb1−c−dTacSbd)O3−x(M10.5Bi0.5)nM2O3} (wherein M1 is Ca, Sr or Ba, M2 is Ti, Zr or Sn, 0.005≦x≦0.5, 0≦a≦0.9, 0≦b≦0.3, 0≦a+b≦0.9, 0≦c≦0.5, 0≦d≦0.1, 0.9≦m≦1.1, and 0.9≦n≦1.1). At least one specific element selected from the group consisting of In, Sc, Y, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Yb and Lu is contained at as in sample numbers 46 to 48, 0.1 to 10 mol in total per 100 mols of the main component (preferably, 1.5 to 10 mol). This provides a piezoelectric ceramic composition and a piezoelectric ceramic electronic component that can have a desired high piezoelectric d constant in a consistent and highly efficient manner in both a very low electric field and a high electric field.

Owner:MURATA MFG CO LTD

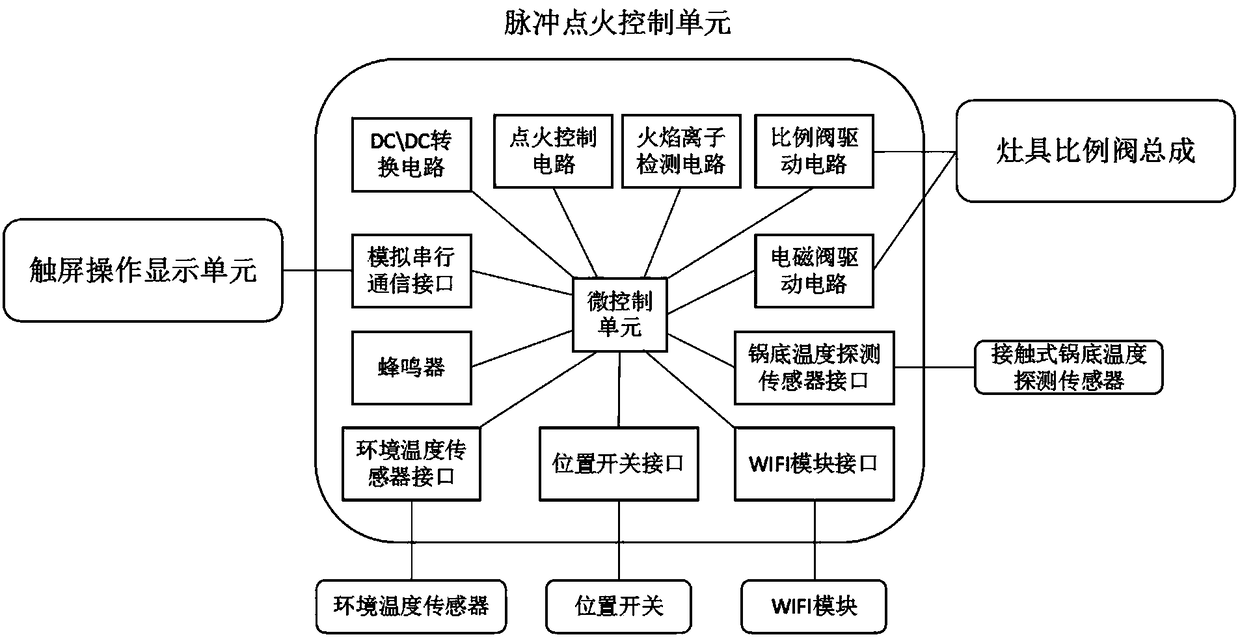

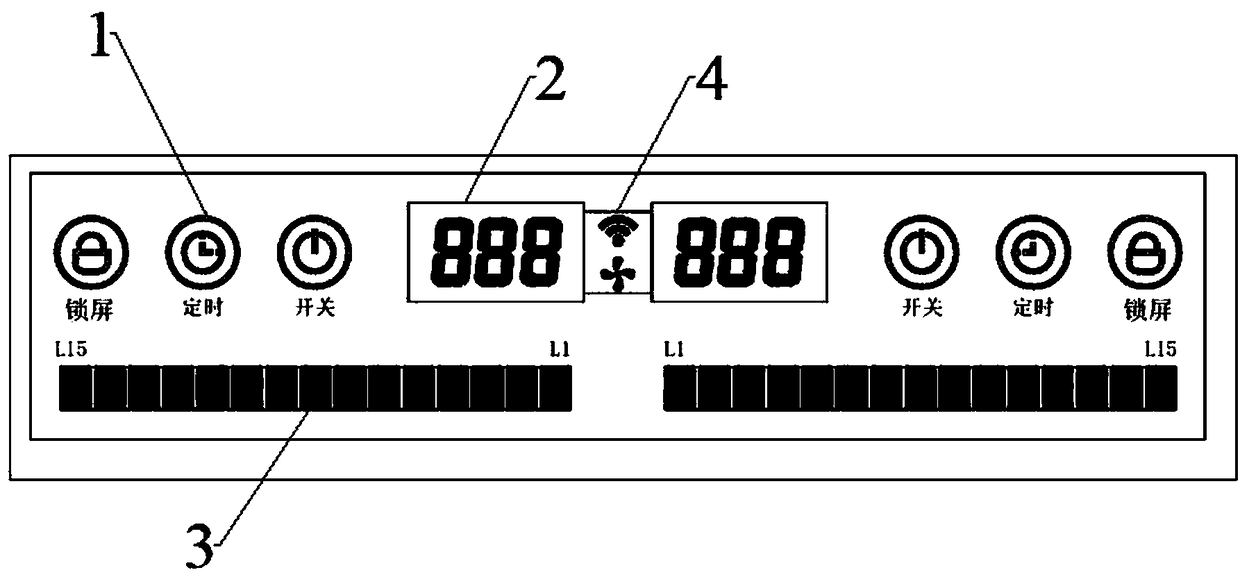

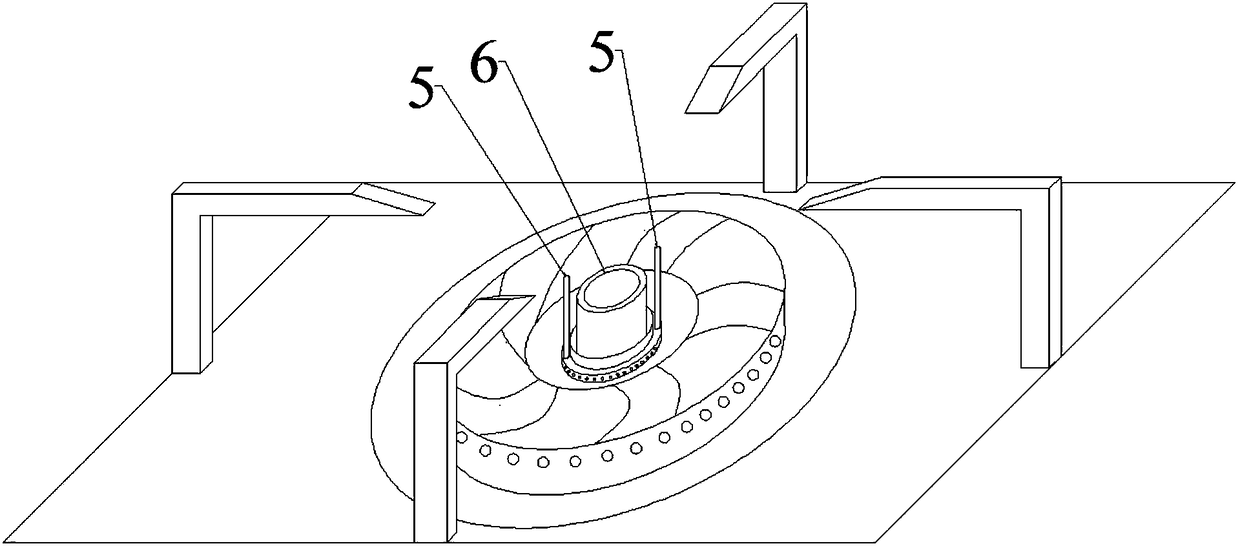

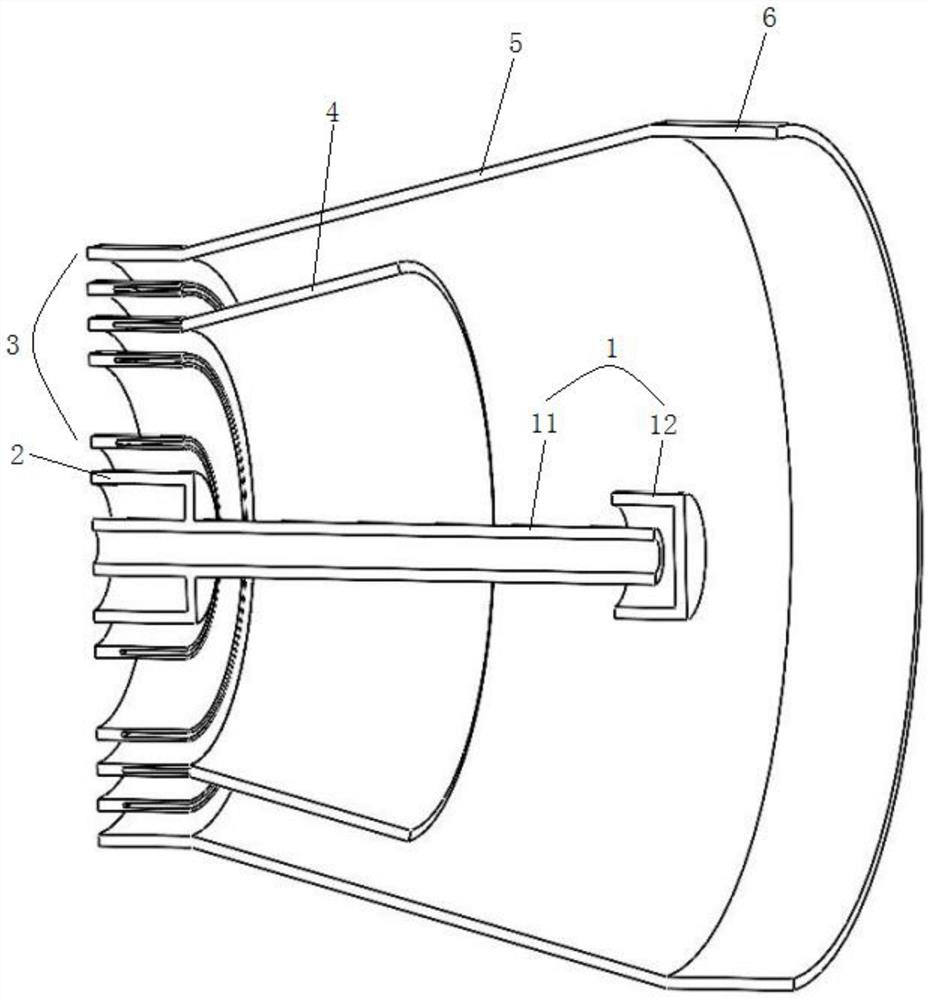

Intelligent control type cooker control system, and control method and application thereof

ActiveCN108266758AEasy to controlRealize the effect of stepless regulationDomestic stoves or rangesLighting and heating apparatusAutomatic controlControl system

The invention discloses an intelligent control type cooker control system, and a control method and an application thereof. The intelligent control type cooker control system comprises a touch screenoperation display unit, a cooker proportional valve assembly, and a pulse ignition control unit for connecting the cooker proportional valve assembly with the touch screen operation display unit, wherein the touch screen operation display unit comprises a plurality of slider buttons, and a plurality of strip-shaped display lights arranged on the bottom surfaces of the slider buttons and connectedwith the slider buttons, and the plurality of slider buttons are connected with the pulse ignition control unit, and are provided with a plurality of gear positions; and the cooker proportioning valveassembly is a stepless adjustment type cooker proportioning valve assembly. The intensity and the timing of fire are automatically controlled in an intelligent control manner, so the heating matchingproperty is good; and when the intelligent control type cooker control system is applied to cooking, the cooking process is automatically and accurately controlled by a cooker to realize the standardization of the cooking, so the dependence on professional chefs is solved, and the standardization of cooking processing is kept.

Owner:广东百威电子有限公司

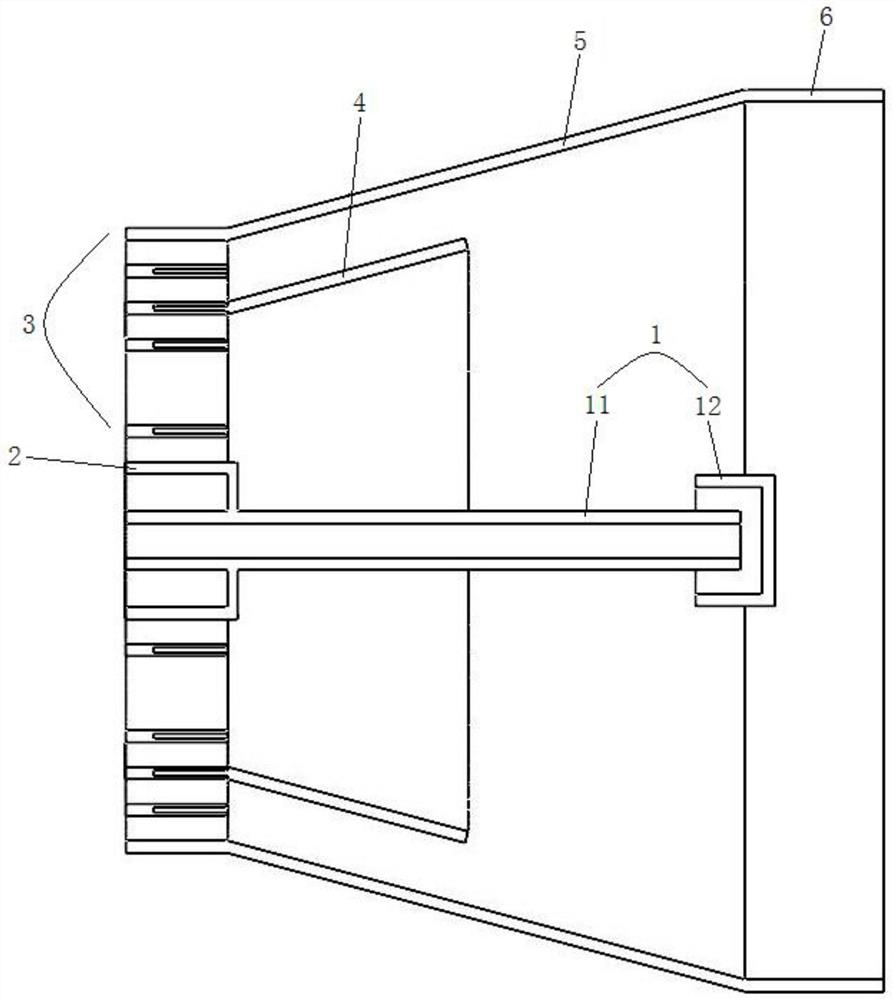

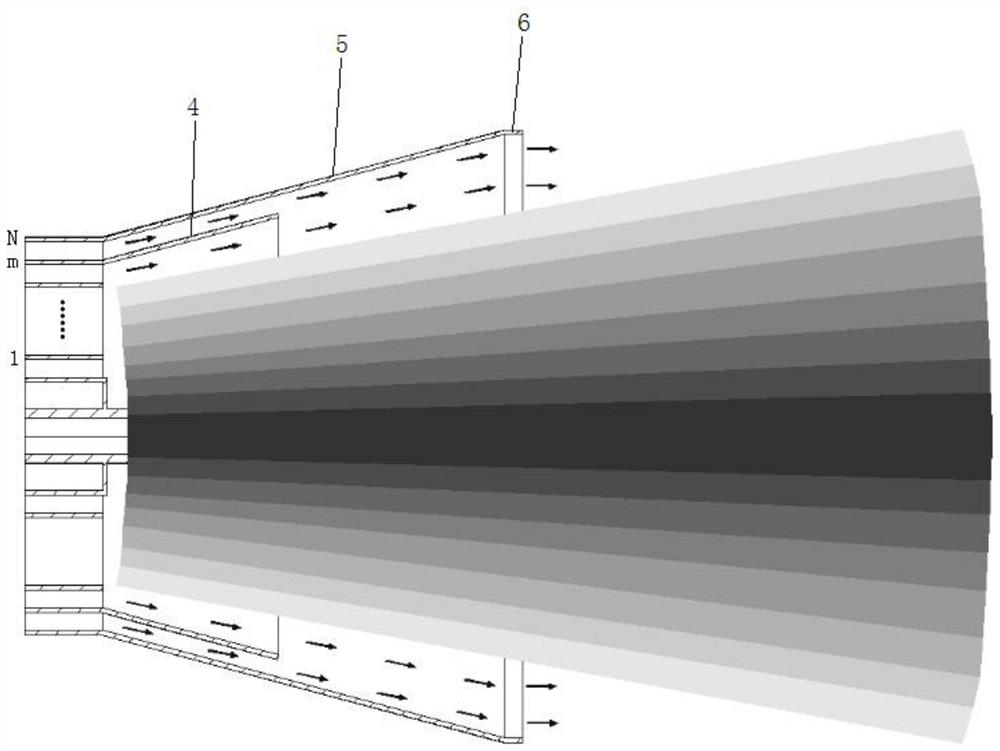

Multi-channel reverse injection type swirl single cone combustor and use method thereof

PendingCN111895400AIncrease mixing rateFire stablePulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a multi-channel reverse injection type swirl single cone combustor and a use method thereof. The combustor comprises a pulverized coal supply mechanism, a transition channel,a multi-stage air distribution assembly, diversion plates, a stable combustion cavity and a rectifying cavity; the multi-stage air distribution assembly comprises N air ducts, the N air duct is connected with the stable combustion cavity and the rectifying cavity in sequence to form a combustor body, the pulverized coal supply mechanism penetrates through the inner part of the combustor body,and the transition channel sleeves the pulverized coal supply mechanism; except for the N air duct, the other air ducts are of double-layer hollow structures, and one end of at least one diversionplate is inserted into the corresponding air duct; at least one direct current channel is formed between each diversion plate and the stable combustion cavity, flaring is formed in the other end of each diversion plate, and the angle of the flaring is the same as the angle of the stable combustion cavity. The combustor adopts the design of the multi-stage air distribution assembly, air is dividedinto N strands to enter the combustor body, and the turbulence intensity at the airflow boundary is strong, so that the air and powder mixing rate is strengthened, pulverized coal ignites stably, andhigh-efficiency and low-nitrogen combustion of the pulverized coal can also be guaranteed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Double-volute swirl type pulverized coal burner provided with natural gas spray pipe and pre-burning chamber

ActiveCN104613466AIncrease volatile contentFire in timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a double-volute swirl type pulverized coal burner provided with a natural gas spray pipe and a pre-burning chamber. The burner mainly comprises a double-volute burner, the natural gas spray pipe, a natural gas-air nozzle, a central air pipe flaring, a primary air pipe flaring, the pre-burning chamber and a rear secondary air duct. Combustion of low-volatile coal is supported in a natural gas feeding manner, and the natural gas can increase coal dust volatiles through phase conversion at the preliminary stage of pulverized coal combustion through reasonable structure design; a good air dynamic field is organized through structure design and reasonable air distribution, so that the low-volatile pulverized coal can be timely ignited, stably burned and efficiently burnt out. The double-volute swirl type pulverized coal burner is simple in structure, convenient to modify, capable of efficiently burning the low-volatile pulverized coal and particularly suitable for structure transformation of a small industrial boiler burner, and can be widely applied to the low-volatile pulverized coal burnt on an industrial boiler.

Owner:JIMEI UNIV

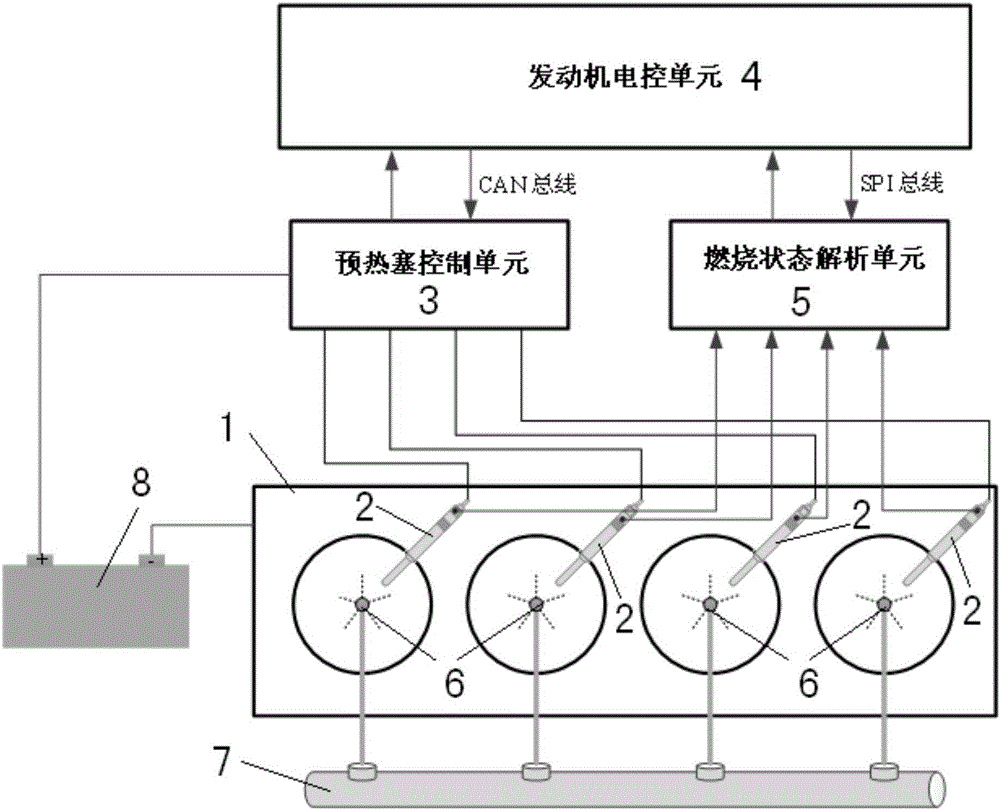

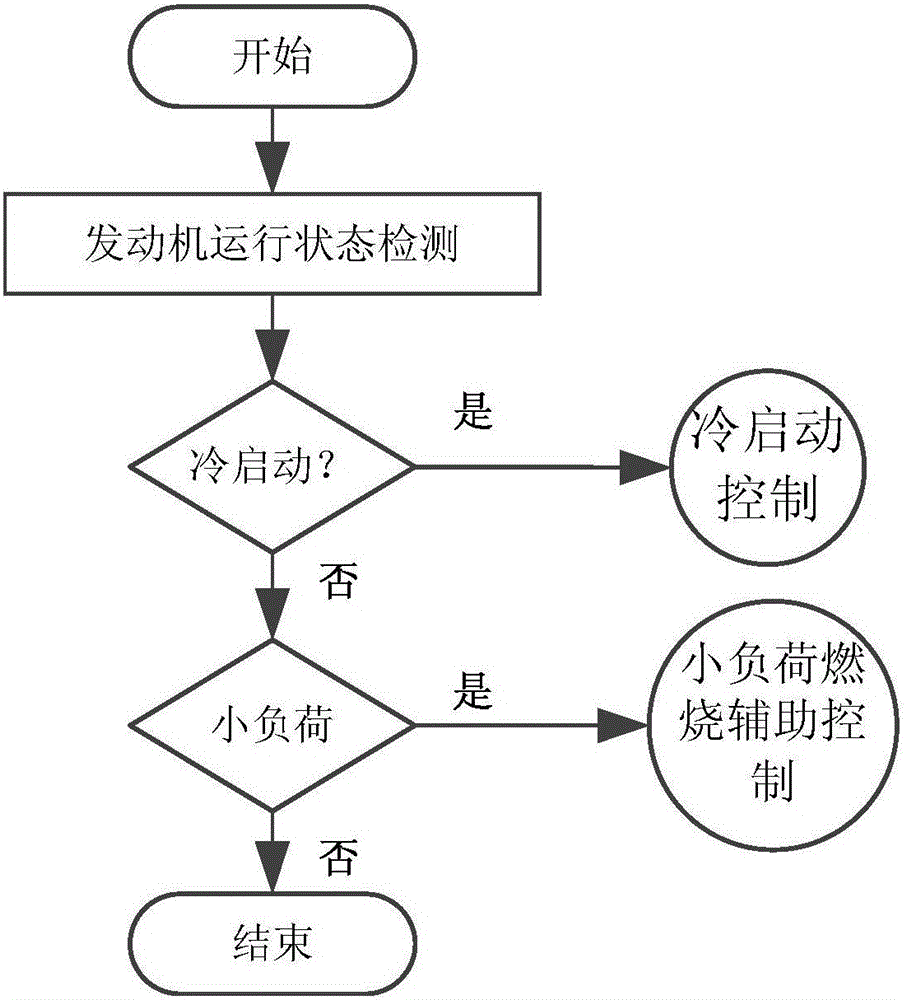

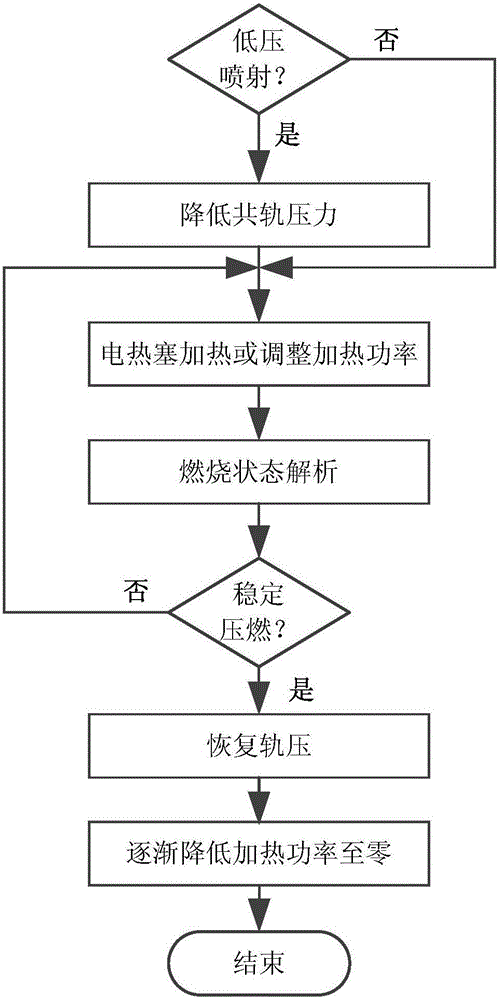

Cold-start and small-load combustion control system and method for low-temperature combustion engine

InactiveCN105863864AStable ignition and combustionFire stableElectrical controlMachines/enginesInlet temperatureIntake pressure

The invention relates to a cold-start and small-load combustion control system and method for a low-temperature combustion engine. The cold-start and small-load combustion control method for the low-temperature combustion engine comprises the steps that a control system which comprises cylinder pressure detection glow plugs, oil nozzles, common rail systems, batteries, engine electric-control units, glow plug control units and combustion state analysis units which are arranged in four air cylinders of an internal combustion engine correspondingly is arranged; the operating state information of the engine is detected, and the operating state information includes the temperature of the engine, the temperature of cooling liquid, the air inlet temperature, the air inlet pressure, the rotating speed of the engine, the torque of the engine, the torque required by a driver and the environment temperature and pressure; whether the engine is in a cold-start state or not currently is judged, and cold-start control is conducted if it is judged that the engine is in a cold-start state; the next step is executed if the engine is not in the cold-start state; whether the engine is under a small load working condition or not is judged, and small-load combustion assisting control is conducted if the engine is under the small load working condition; and otherwise, heating through the glow plugs and intervention of a low-pressure spraying method are not needed. The cold-start and small-load combustion control system and method for the low-temperature combustion engine can be widely applied to various electric-control diesel engines and electric-control gasoline engines.

Owner:TSINGHUA UNIV

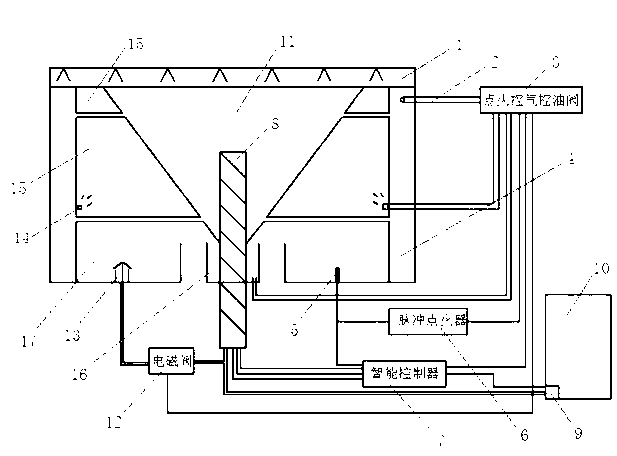

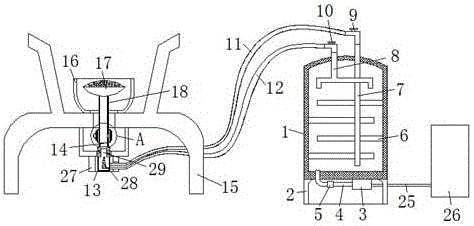

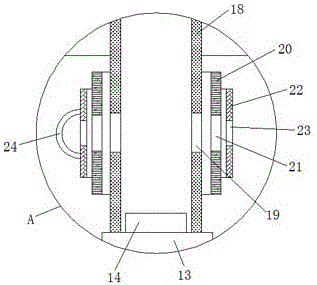

Intelligent gasification furnace and control method thereof

InactiveCN103343987AWith automatic oil controlSave fuelDomestic stoves or rangesLighting and heating apparatusSolenoid valveFuel tank

The invention relates to an intelligent gasification furnace and a control method thereof. The intelligent gasification furnace comprises a combustion net, a fuel pipe, an ignition air control and material control valve, a gasification chamber, an ignition sensor, a fuel pump, a fuel tank, another gasification chamber, a solenoid valve, an oil nozzle, an annular air injection port, a combustion port, a preheating chamber, a pulse igniter, an intelligent controller, a sensor and an air injection groove. The intelligent gasification furnace solves the problems that an existing intelligent gasification furnace valve is low in work efficiency, firepower is not stable, fuel cannot be combusted fully, gas escapes easily, and air content of mixed gas is non-uniform. According to the intelligent gasification furnace, oil is controlled automatically, the fuel is saved, the structure is simple, the firepower is stable and safe, the gasification speed is high, gas is mixed uniformly, and operation is convenient. The operation method is the same as that of an existing cooking range commonly used. The intelligent gasification furnace protects environment and is economical, and liquefied gas can be replaced.

Owner:唐川盛

Air duct ignition burner

The invention discloses an air duct ignition burner, which belongs to the field of ignition devices. The air duct ignition burner of the present invention includes an inlet air duct and an outlet air duct, the inlet air duct and the outlet air duct (11) are connected to each other, and both are connected to the hot primary air duct, and the outlet air duct is provided with an inner A pre-chamber, at least one oil burner is arranged in the inner pre-chamber. The air duct ignition burner of the present invention has a simple structure and is easy to operate, and it has stable combustion during operation; the burning loss of the ignition air duct and the burner itself is small, and it can also be used as a non-combustion device for a preheating boiler; the structure is stable Reliable, not easy to be damaged by spontaneous combustion, long service life, and conducive to popularization.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

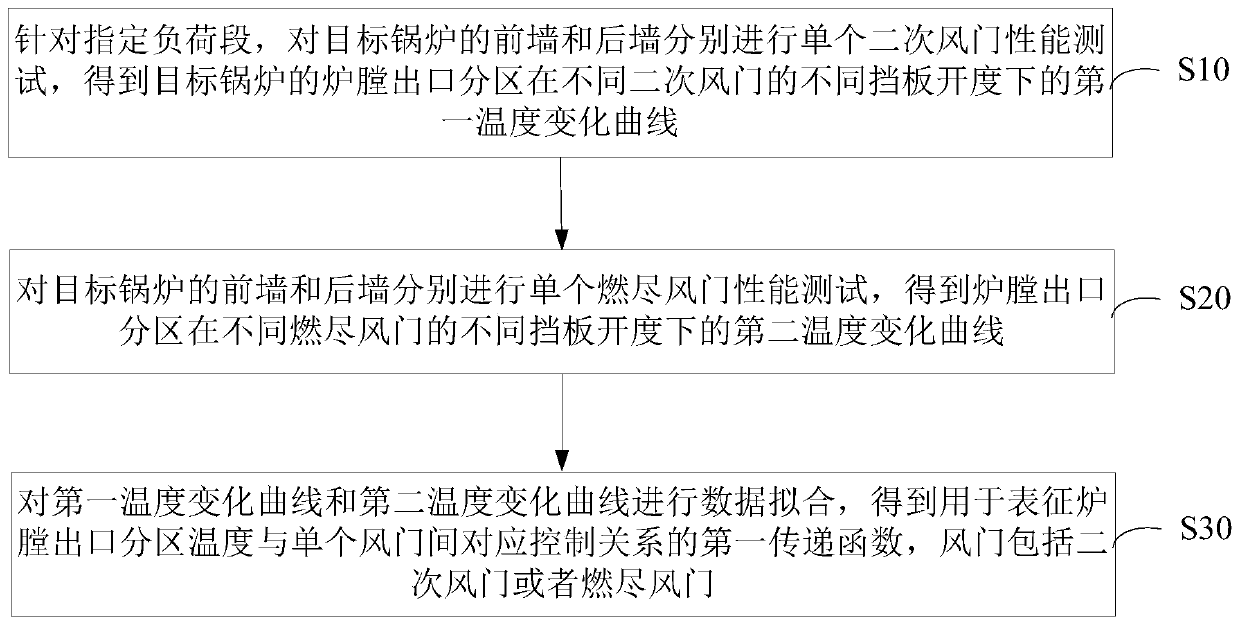

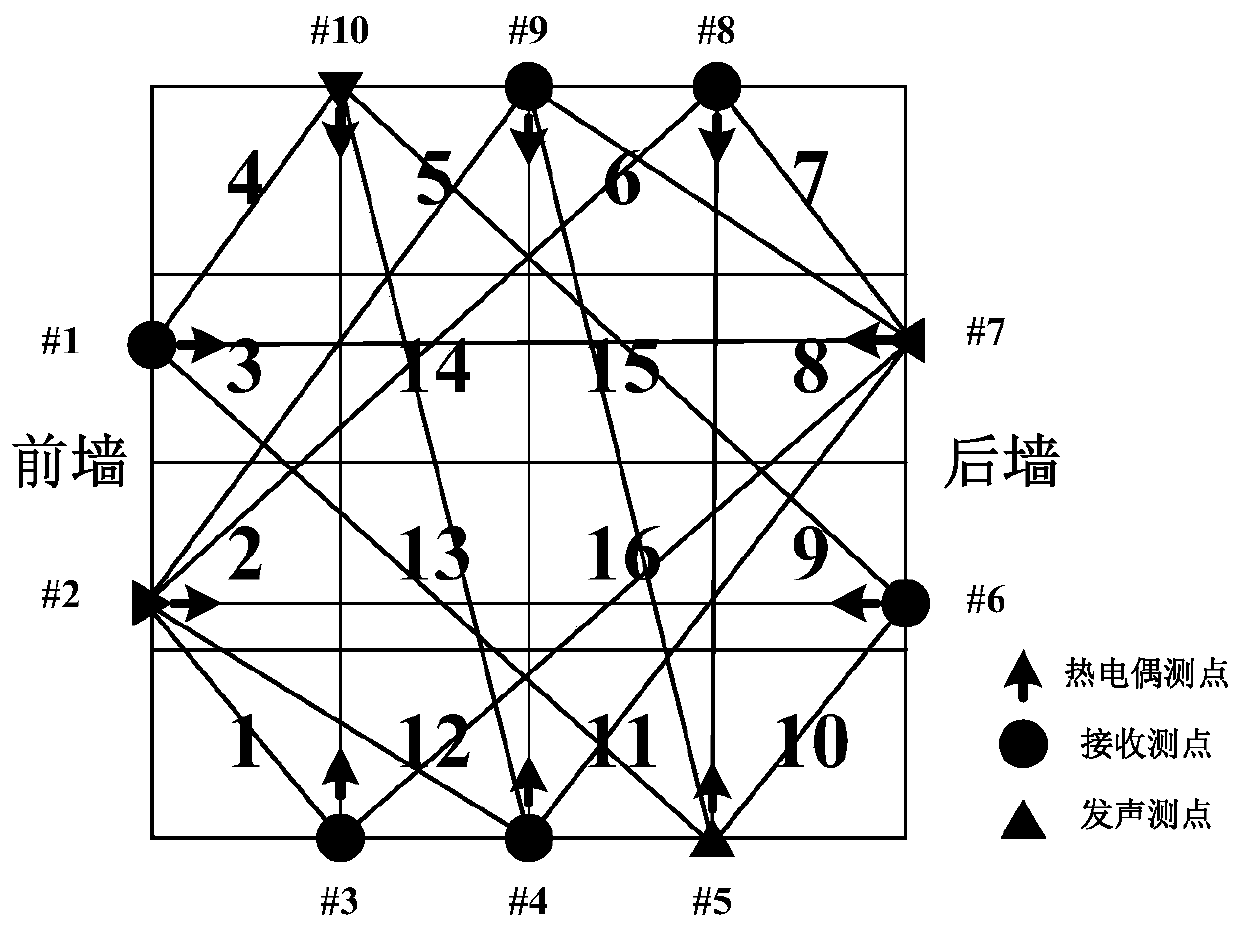

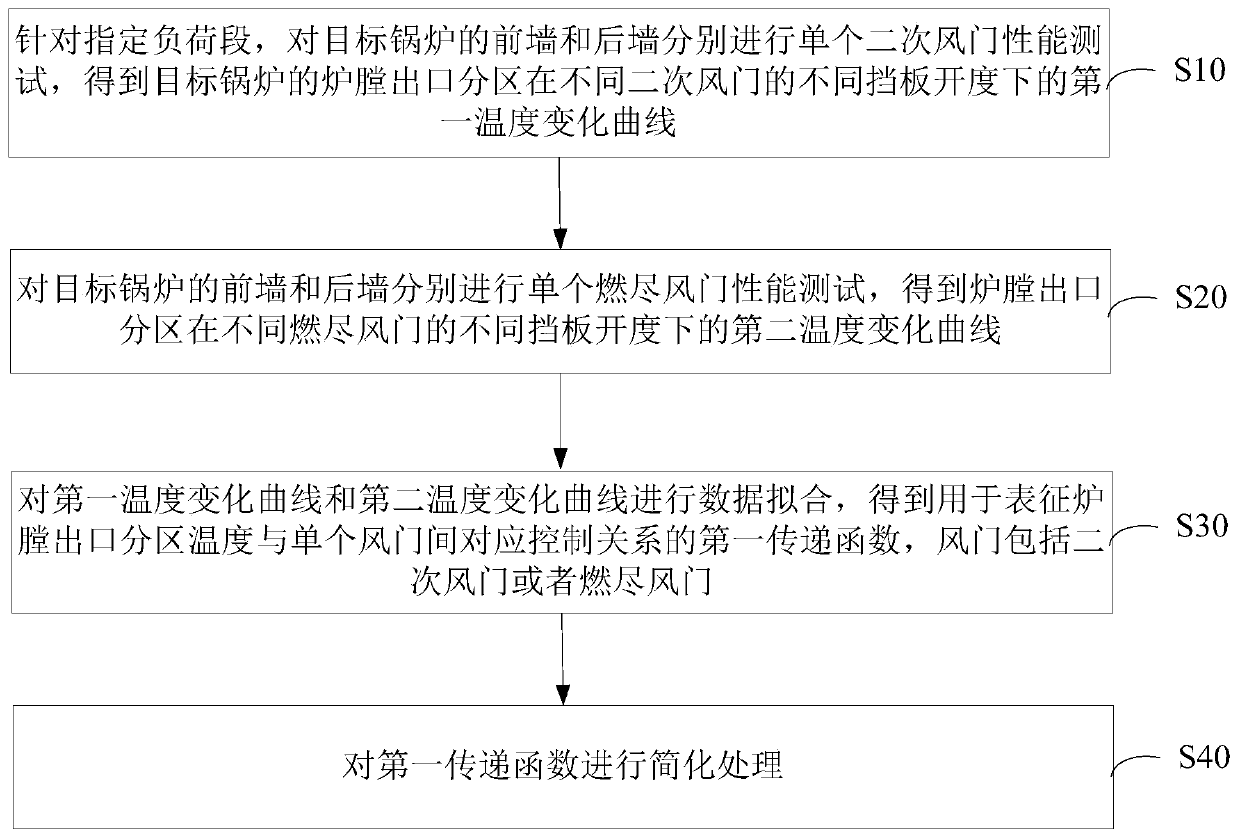

Method and device for determining control relationship between temperature of hearth outlet partition of boiler and air doors

ActiveCN110006024AGuaranteed uptimeBurn completelyAir supply regulationBoiler controlHearthEngineering

The invention provides a method and device for determining a control relationship between temperature of a hearth outlet partition of a boiler and air doors. The method comprises the steps that for adesignated load section, single secondary air door performance testing is carried out on a front wall and a rear wall of a target boiler to obtain a first temperature change curve of the hearth outletpartition of the target boiler under different baffle opening degrees of different secondary air doors, single burn-out air door performance testing is carried out on the front wall and the rear wallof the target boiler to obtain a second temperature change curve of the hearth outlet partition under different baffle opening degrees of different burn-out air doors, and data fitting is carried outon the first temperature change curve and the second temperature change curve to obtain a first transfer function for representing the corresponding control relationship between the temperature of the hearth outlet partition and the single air door. The air doors comprise the secondary air doors or the burnt-out air doors.

Owner:GUODIAN SCI & TECH RES INST

Zigzag gas burner

InactiveCN104421939AAdaptableIgnition and stable combustionBurner safety arrangementsGaseous fuel burnerGas burnerFuel gas

The invention discloses a zigzag gas burner. A tapered gas nozzle is formed in the center of the inside of a jet. Air distribution blades are circumferentially formed between the jet and the tapered gas nozzle. Zigzag flame stabilizing bodies are arranged on the circumference of the taped gas nozzle. Gas spraying holes are formed in the tapered gas nozzle. Gas enters from the tapered gas nozzle and is sprayed out through the gas spraying holes. Gas distributed air enters a circular channel between the jet and the tapered gas nozzle and generates rotational-flow distributed air by the aid of the air distribution blades with angles. At the front end of the jet, the gas and the rotational-flow distributed air are intensely mixed and then meet an igniting device to fire. The zigzag gas burner is effective in preventing the flame from lifting, returning and extinguishing.

Owner:SHAANXI SHENGHUIYUAN INFORMATION SCI & TECH

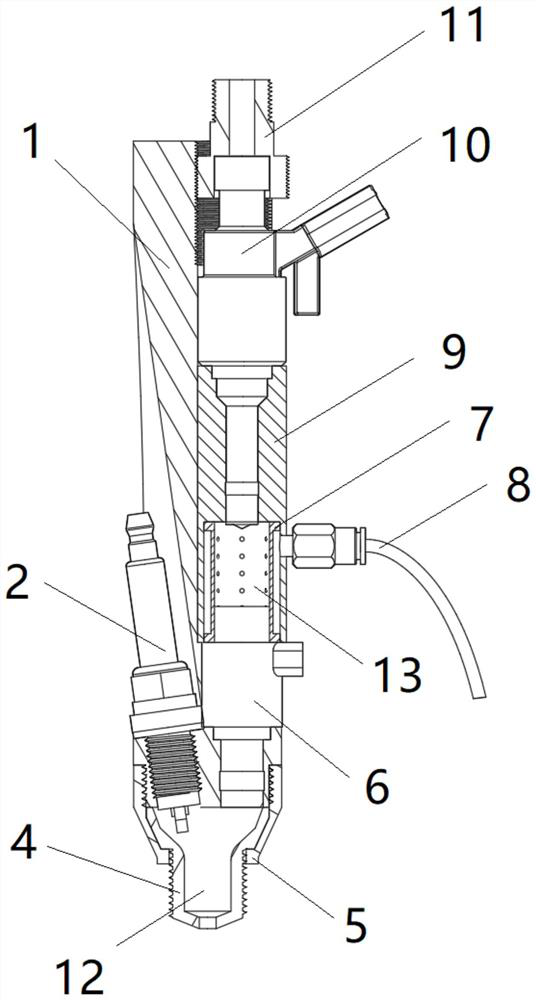

Air-assisted jet flow flame ignition device and ignition method thereof

ActiveCN112814778AFire stableHigh viscosityElectrical controlInternal combustion piston enginesCombustion chamberEngineering

The invention provides an air-assisted jet flow flame ignition device which comprises a shell (1), a fuel oil-air premixing unit and a pre-combustion chamber. The device is characterized in that the fuel oil-air premixing unit comprises an oil injector (10), an air injection valve (6), a premixing sleeve (9), a premixing sleeve inner core (7) and an oil injector fastening bolt (11), and the premixing sleeve inner core (7) arranged in the premixing sleeve (9), and an oil injector fastening bolt, wherein the inner wall surface of the premixing sleeve (9) and the outer wall surface of the premixing sleeve inner core (7) form a premixing sleeve inner cavity (14), the inner wall surface of the premixing sleeve inner core (7), the lower end surface of a nozzle of the oil injector (10) and the upper end surface of an air inlet of the air injection valve (6) form a premixing cavity (13), the premixing cavity (13) communicates with the premixing sleeve inner cavity (14) through a through hole in the sidewall of the premixing sleeve inner core (7), and a pre-combustion chamber nozzle (4) is fixedly connected to the lower part of the shell (1) through a positioning pin.

Owner:TIANJIN UNIV

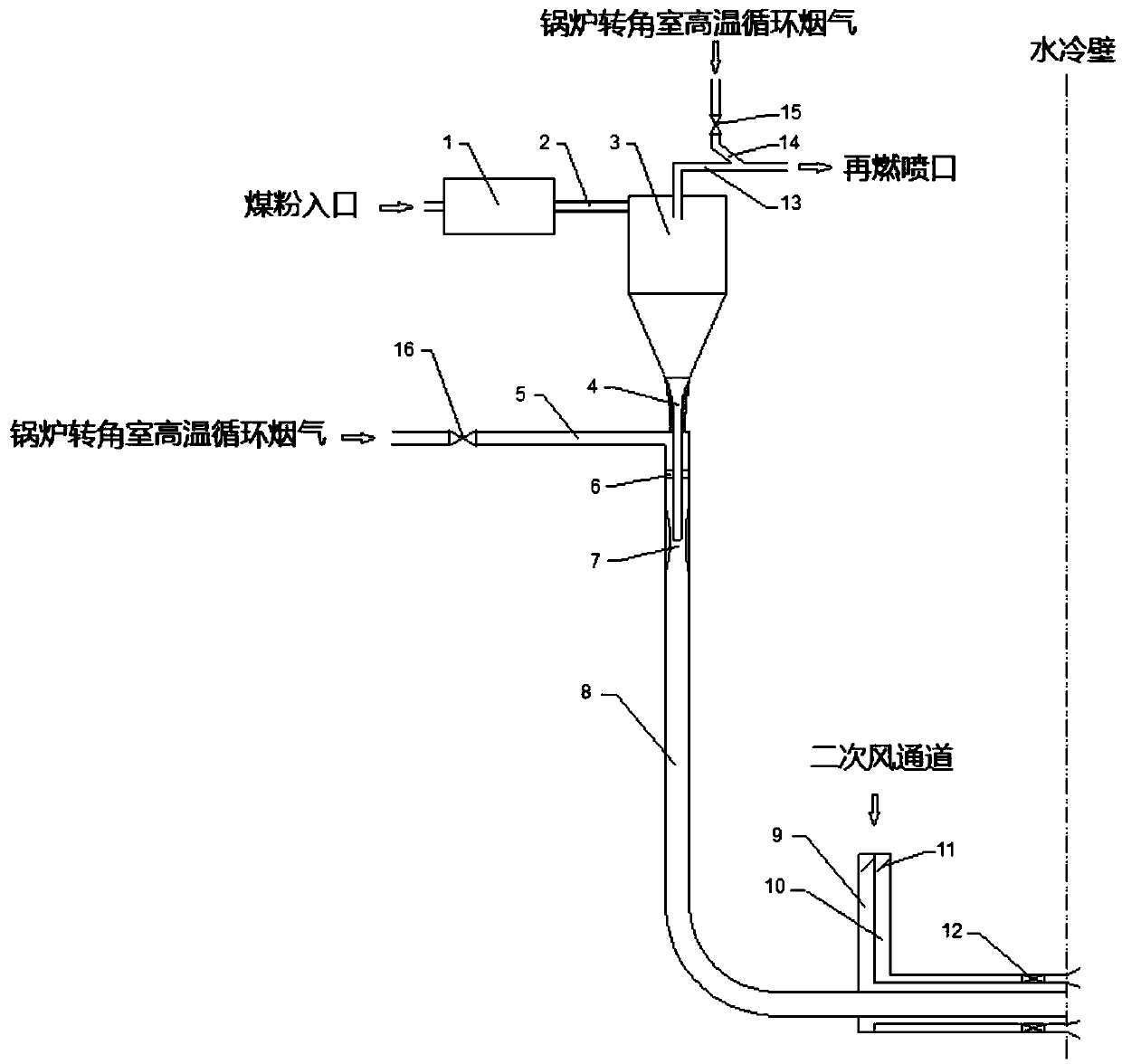

Pulverized coal pre-pyrolyzation decoupling combustion device

ActiveCN109539245AHigh reactivityEfficient combustionNon-combustible gases/liquids supplyDraught inductionProcess engineeringCoal

The invention discloses a pulverized coal pre-pyrolyzation decoupling combustion device comprising a pyrolysis chamber, a cyclone separator, an ejector device and a particle burning device; the pyrolysis chamber is provided with a raw material inlet and a product outlet; the cyclone separator is provided with a product inlet, a volatile component outlet and a particle outlet; the product inlet ofthe cyclone separator communicates with the product outlet of the pyrolysis chamber through a pyrolysis product transport passage; a reburning fuel pipe is arranged at the volatile component outlet ofthe cyclone separator; a discharging pipe is arranged at the particle outlet of the cyclone separator; the reburning fuel pipe is used for being led into a hearth; the discharging pipe communicates with a particle combustion device through the ejector device; ejector gas flow is led into the ejector device; a particle combustion device comprises an air duct; and the air duct is led into the hearth. The pulverized coal pre-pyrolyzation decoupling combustion device is based on the decoupling idea, is suitable for pulverized coal decoupling combustion, can achieve the higher pulverized coal combustion rate, is relatively good in combustion stability, and can effectively suppress NOx generation.

Owner:XI AN JIAOTONG UNIV

W-shaped flame boiler grading combustion method

InactiveCN107355802AIncrease burnoutReduce generationSolid fuel pretreatmentStaged combustionFlue gasSlag

The invention relates to a W-shaped flame boiler grading combustion method. Free-burning coal reacts with oxygen to form first grade combustion; the free-burning coal is formed by bituminous coal or a mixture between the bituminous coal and meager coal; and high-temperature flue gas atmosphere formed in the first stage ignites anthracite wrapped up with the high-temperature flue gas and second grade combustion is formed. A method for determining an optimal mixture ratio of a mixture ratio of the bituminous coal and the anthracite and a mixture ratio of the bituminous coal, the meager coal and the anthracite comprises steps of pre-deciding a boiler combustion strategy according to coal quality elements and an industrial analysis result, and comparing and analyzing boiler work conditions when different combustion strategies are employed to achieve an optimal boiler grading combustion coal type ratio, and an coal mill coal powder injection way. A combustion coal and the anthracite mixture ratio is determined during the boiler grading combustion process, so second combustion burn-off rate can be effectively improved; and secondary flying ash and large slag carbon content can be reduced.

Owner:中国大唐集团科学技术研究总院有限公司

Outdoor portable pneumatic atomizing furnace

ActiveCN106594812AAvoid cleaningNo maintenanceDomestic stoves or rangesLiquid heating fuelCombustionGasoline

The invention discloses an outdoor portable pneumatic atomizing furnace which comprises an oil storage bottle. A support is installed at the bottom end of the oil storage bottle. The bottom end of the oil storage bottle is fixedly connected with a pneumatic device. The gas outlet end of the pneumatic device communicates with one end of a gas guide pipe. A one-way valve is arranged on the gas guide pipe. The end, away from the pneumatic device, of the gas guide pipe is connected in the oil storage bottle in an inserted manner. Atomizing plates are installed in the oil storage bottle. Aerodynamics, physics and the combustion science are integrated in the outdoor portable pneumatic atomizing furnace, high efficiency and oil conservation are achieved, the value of each drop of oil is utilized, energy conversion is direct and thorough, and therefore resources are saved; and in addition, the outdoor portable pneumatic atomizing furnace has the beneficial effects that the size is small, firepower is fierce, oil consumption is low, maintenance, cleaning and preheating are omitted, carbon deposition is avoided, blockage does not exist, the firepower is consistent and stable, carrying is convenient, operation is simple, safety and high efficiency are achieved, and the effect of a gas furnace can be achieved through combustion in the gasoline furnace, and great convenience is brought to people loving travel.

Owner:刘文

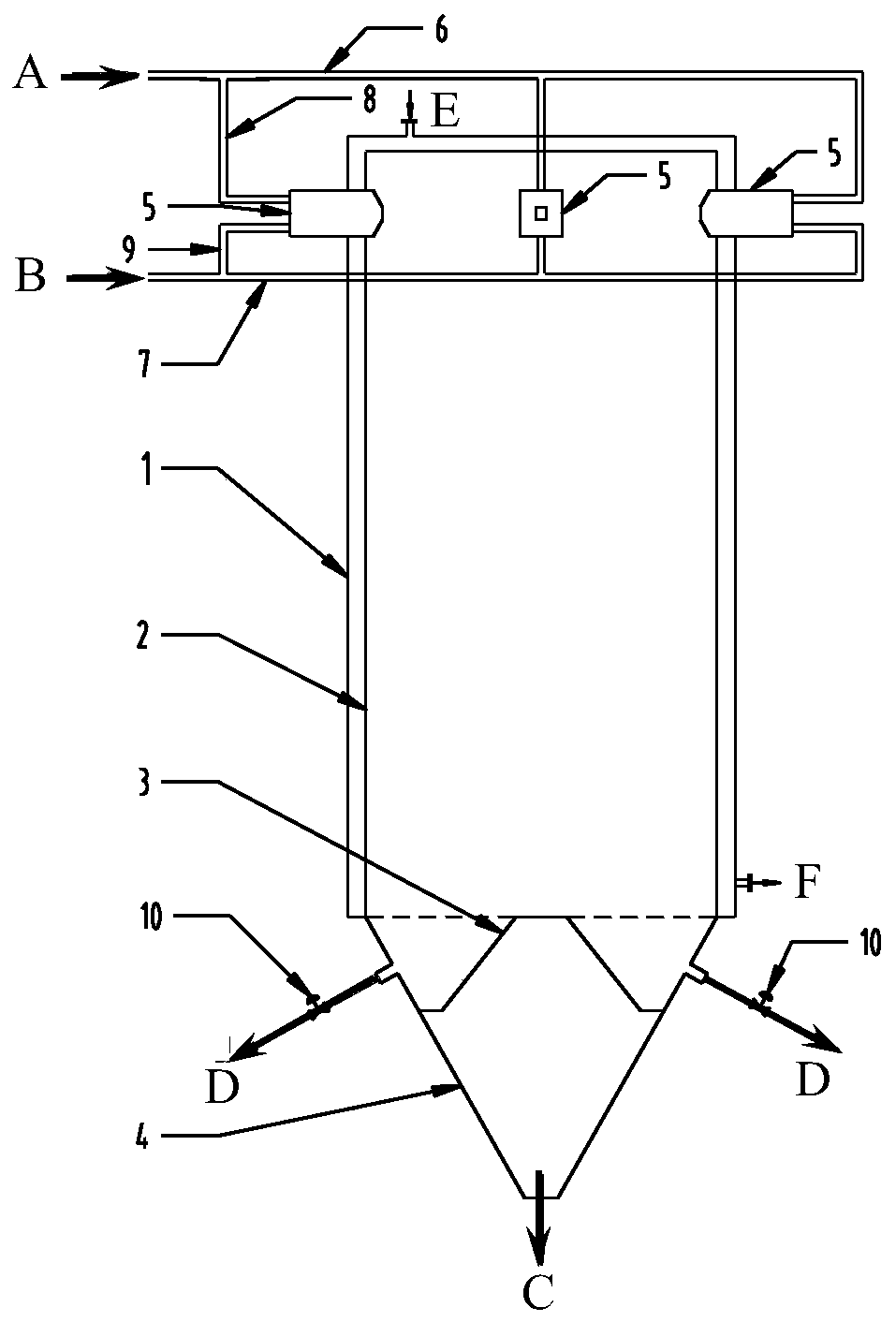

Spiral-flow type supercritical hydrothermal combustion device and method

PendingCN111237743AImprove fire conditionsFire stableCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionSlag

The invention discloses a spiral-flow type supercritical hydrothermal combustion device and method. The device comprises a plurality of hydrothermal flame generators which are uniformly distributed atthe upper part of a device main body in the circumferential direction, and each hydrothermal flame generator is provided with a high-pressure organic slurry input branch pipe and a high-pressure oxidant input branch pipe; the geometric axis of an output port of each hydrothermal flame generator is externally tangent to an imaginary circle of a core combustion area in the device, a burnout slag slurry gathering cone is arranged on the lower part of the device main body and connected with a supercritical thermal fluid guide cone on the lower part of the burnout slag slurry gathering cone, a plurality of burnout slag slurry outlets D are formed in the upper part of the side face of the burnout slag slurry gathering cone, and a supercritical thermal fluid outlet C is formed in the bottom of the supercritical thermal fluid guide cone. According to the invention, rapid ignition, efficient clean combustion and effective separation of slag flow after burnout of solid-phase or solid-containingfuels such as fossil fuels (such as coal) and urban / industrial sludge are realized, and the method is an advanced combustion technology for promoting efficient and pollution-free conversion of chemical energy into heat energy.

Owner:XI AN JIAOTONG UNIV

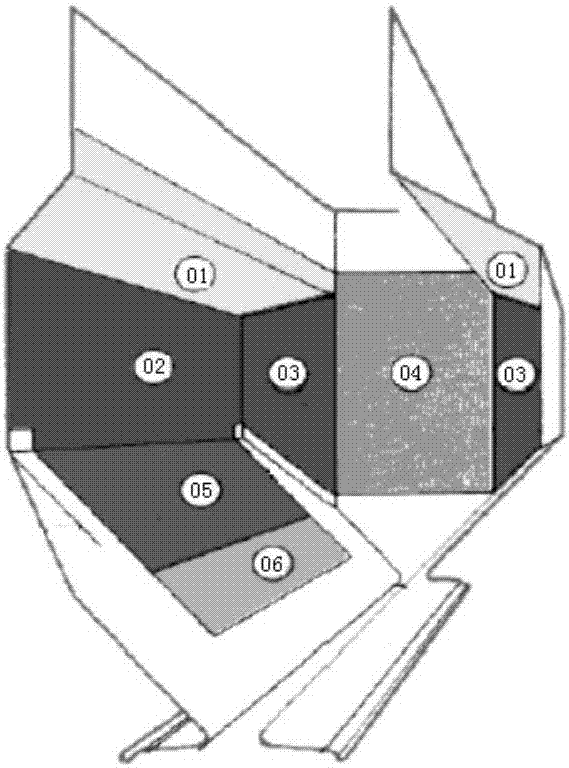

Four-arch W flame two-stage dense and thin combustion device

PendingCN108758613APromote refluxWay of increaseCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to the technical field of W flame staged combustion, in particular to a four-arch W flame two-stage dense and thin combustion device. A hearth of the device comprises an upper furnace body, a lower furnace body and a cold ash bucket, wherein the lower furnace body consists of a front upper furnace arch, a rear upper furnace arch, a front lower furnace arch, a rear lower furnace arch, a front wall and a rear wall bag. The four-arch W flame two-stage dense and thin combustion device has the beneficial effects that the ignition is stable, the space between the two sides of the jet flow of the two-stage combustor becomes large, the gas supplementing condition is good, the backflow of high-temperature flue gas is facilitated, the combustion is stable, and the heat load distribution is uniform; secondary air, dense coal powder and thin coal powder are subjected to layered injection and staged combustion after entering the hearth, so that the partial-stage concentrated community in the hearth is formed, and the air flow of the pulverized coal is reduced, the two-stage "thin-dense-dense and thin mixing" layered arrangement mode of coal power airflow is achieved, the mode of the single-layer combustor is further enhanced; and the high-efficiency low-NOx double-stage combustor and the air staged combustion technology are combined, so that the fuel reburning efficiency is improved and the emission of NOx is reduced.

Owner:CHINA SINOGY ELECTRIC ENG

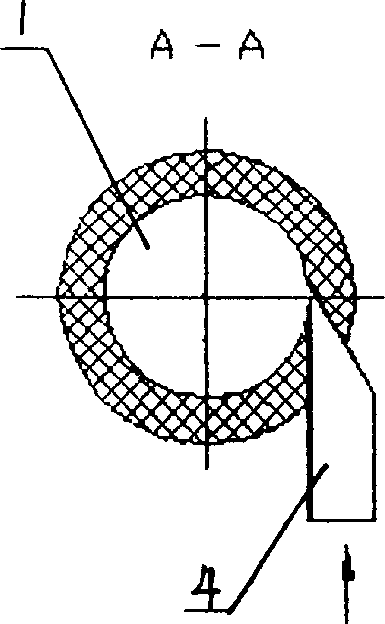

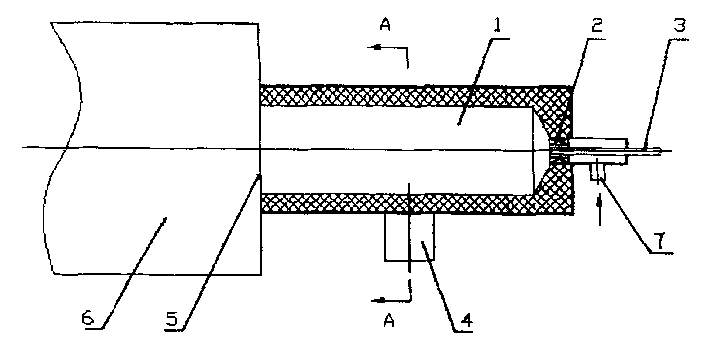

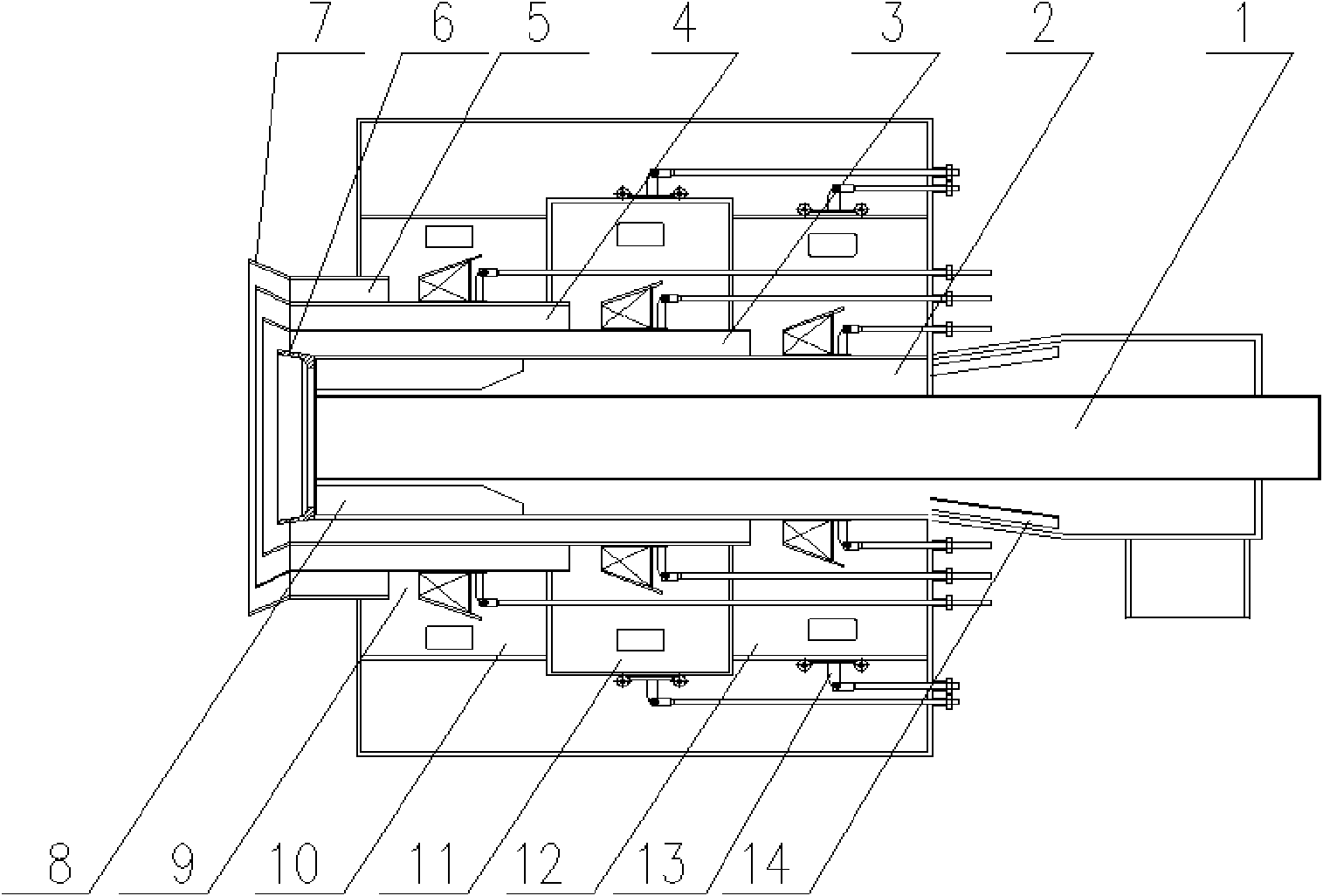

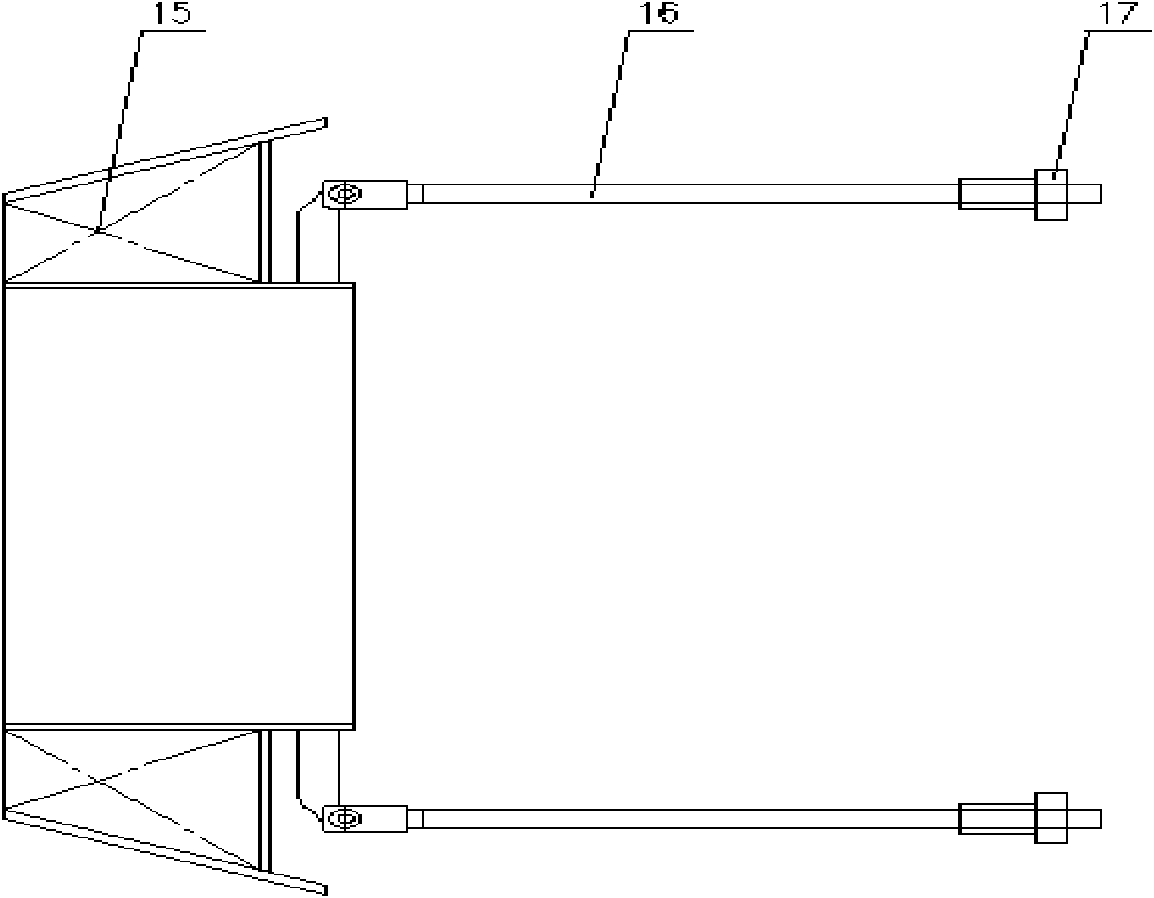

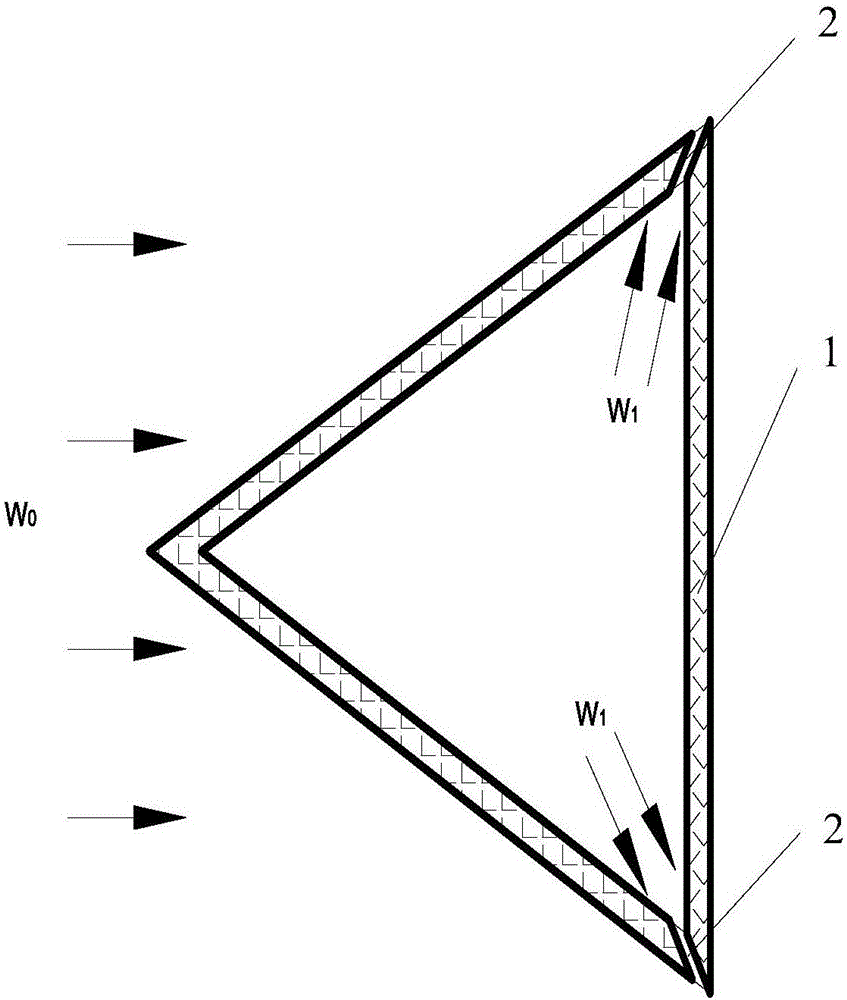

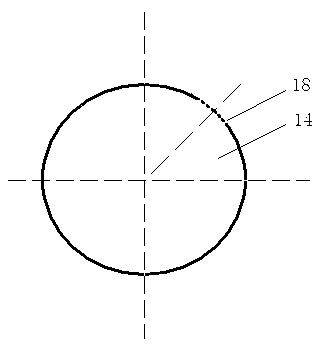

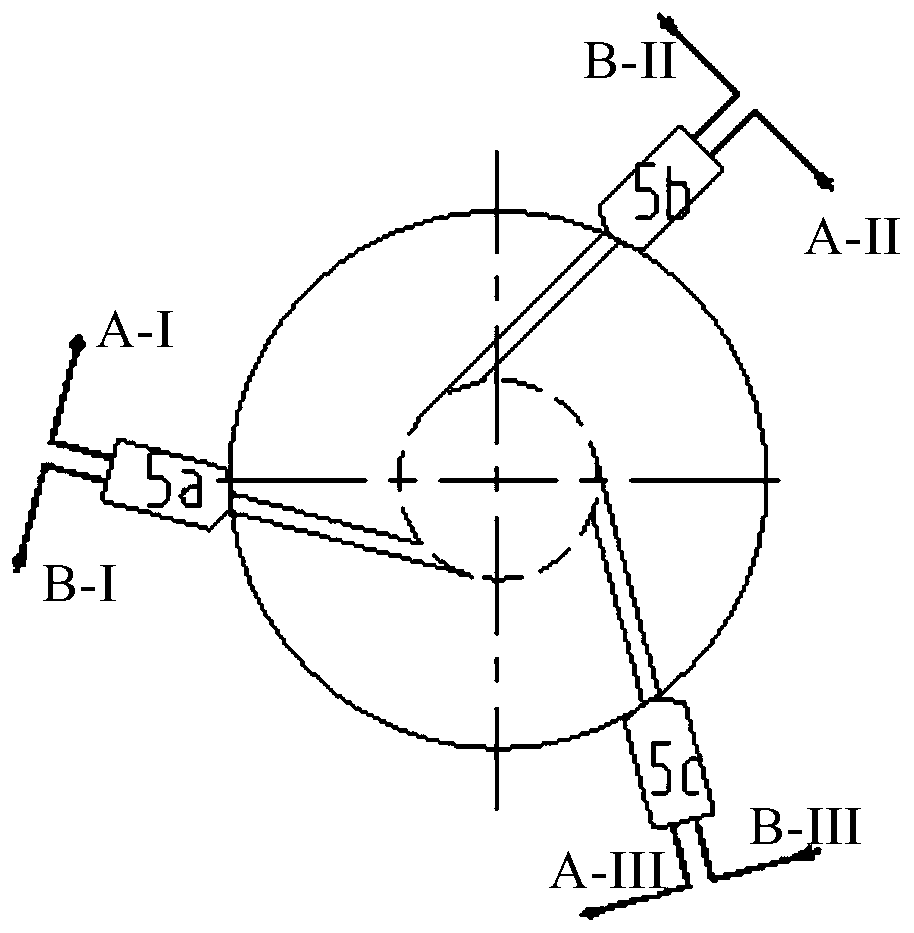

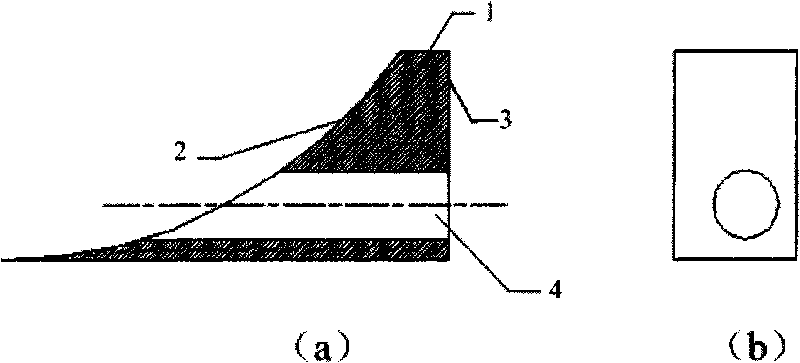

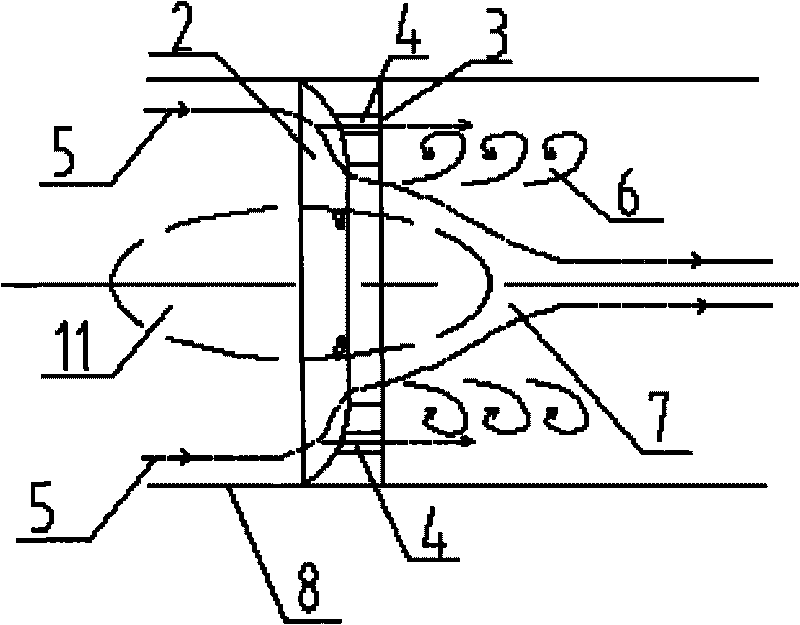

Pulverized coal concentrator and pulverized coal burner applying same

ActiveCN101761924AFlexible size adjustmentReduce resistancePulverulent fuel combustion burnersSolid fuelEngineering

The invention discloses a pulverized coal concentrator used for realizing concentration and dilution separation of solid fuel, which comprises a main body (1) with a spacial geometrical structure; the main body comprises a windward side (2) and a leeward side (3); and at least one deflector hole (4) is formed between the windward side (2) and the leeward side (3) of the main body (1). Because a principle of concentration impact guided separation is applied, the resistance is obviously reduced, and the size of the pulverized coal concentrator is conveniently adjusted flexibly in a certain specification range. The invention also discloses a pulverized coal burner applying the pulverized coal concentrator.

Owner:YANTAI LONGYUAN POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com