Gas-charcoal furnace for smoldering for foliage and case plant and powder offal

A technology of leftovers and shells, which is applied in the field of stoves to achieve the effects of improving utilization, stabilizing firepower, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

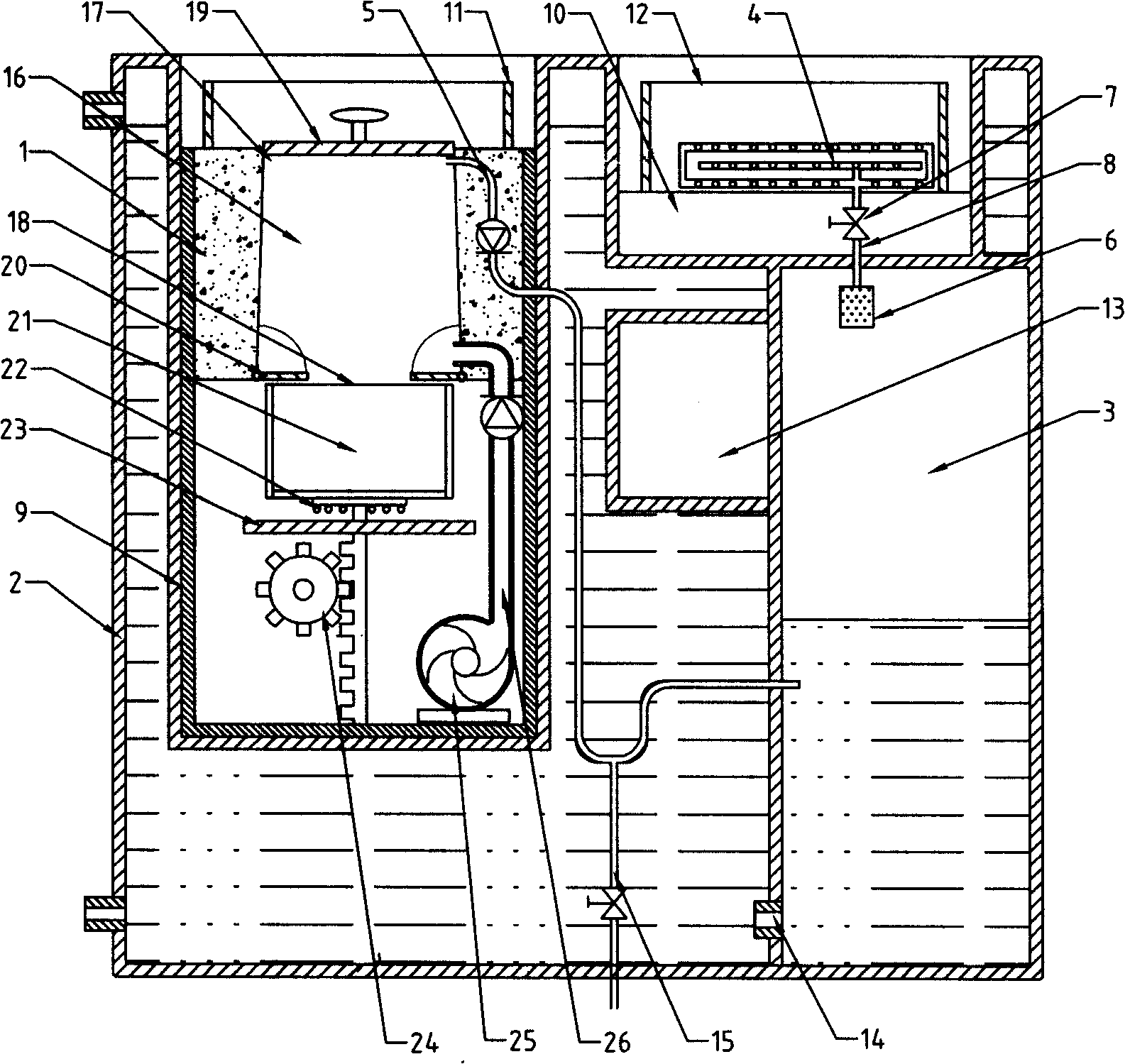

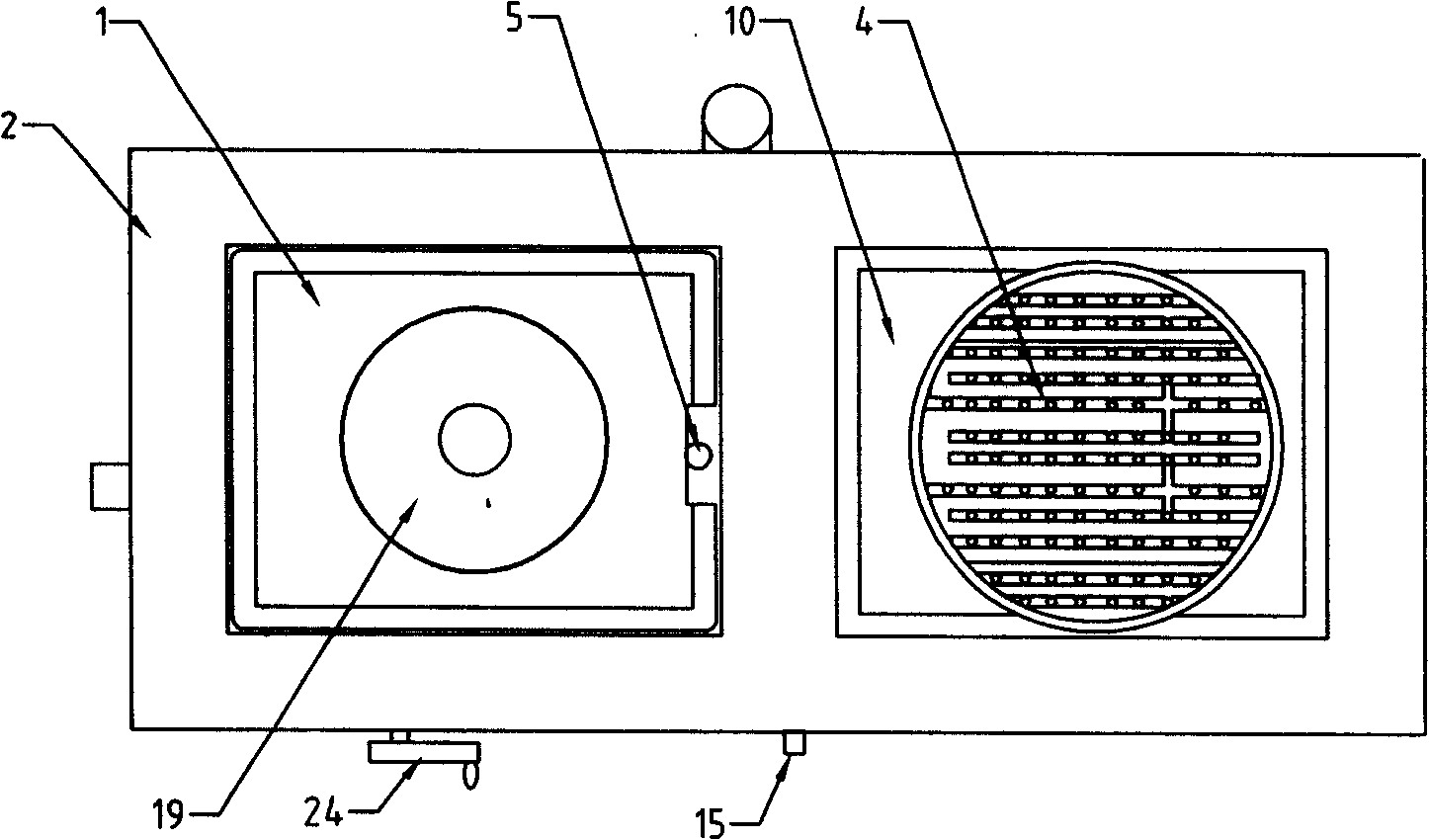

[0011] Such as figure 1 , 2 As shown, a gas-charcoal furnace capable of smoldering leaf shell plants and loose leftovers is mainly composed of a gas-producing charcoal furnace 1, a waste water tank 2, a hydraulic gas tank 3 and a gas furnace 4. The gas-producing charcoal furnace 1 Connect the hydraulic air tank 3 through the air pipe 5 with a check valve, and the tar discharge pipe 15 is connected to the lowest part of the air pipe 5 with a check valve; the top of the hydraulic air tank 3 has a water filter 6 and an air valve 7 The gas outlet pipe 8 is connected to the gas furnace 4; the top of the waste water tank 2 has two sunken pits side by side, which are the furnace shell 9 and the furnace platform 10; the gas-making charcoal furnace 1 is placed in the furnace shell 9, and the gas furnace 4 is placed in On the hearth 10, and the top of the two furnaces are equipped with a return air insulation wall 11 and a return air insulation wall 12. The highest points of the two re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com