Patents

Literature

30results about How to "Improve fire conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

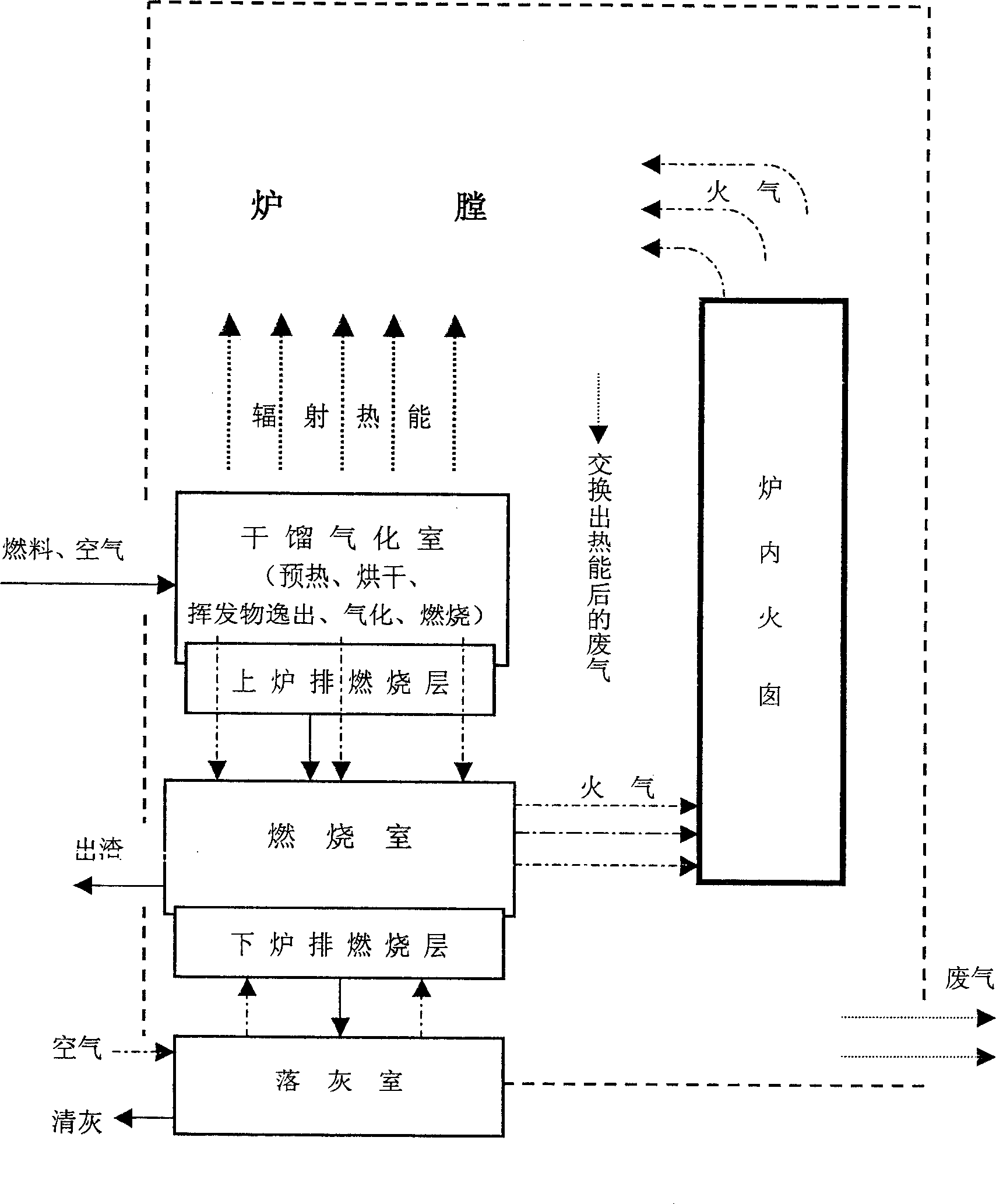

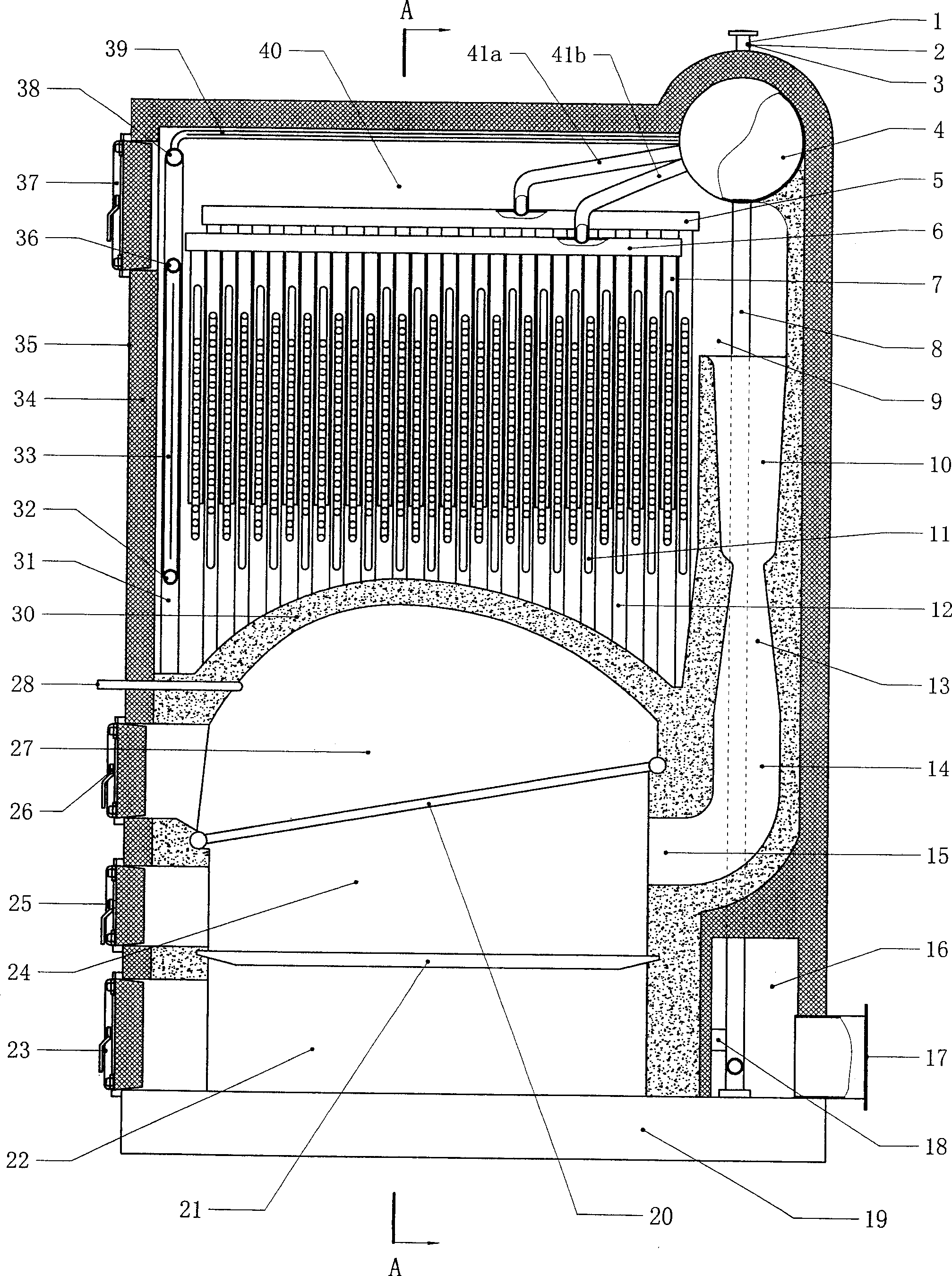

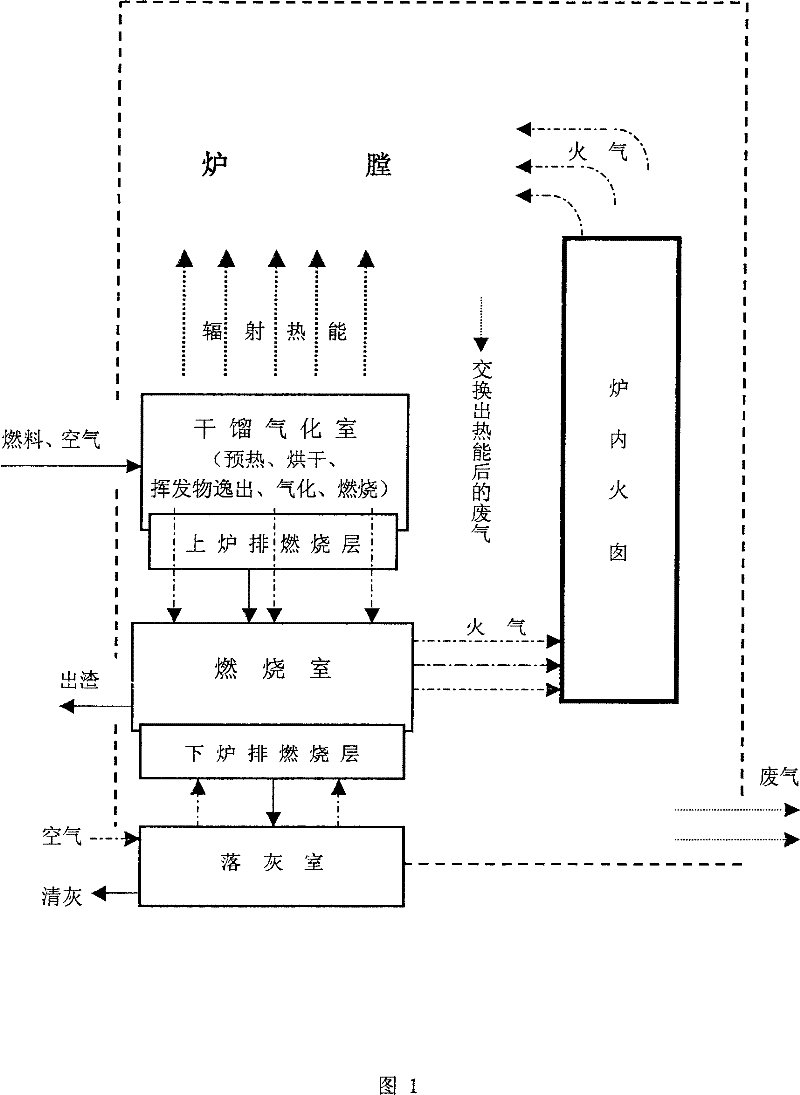

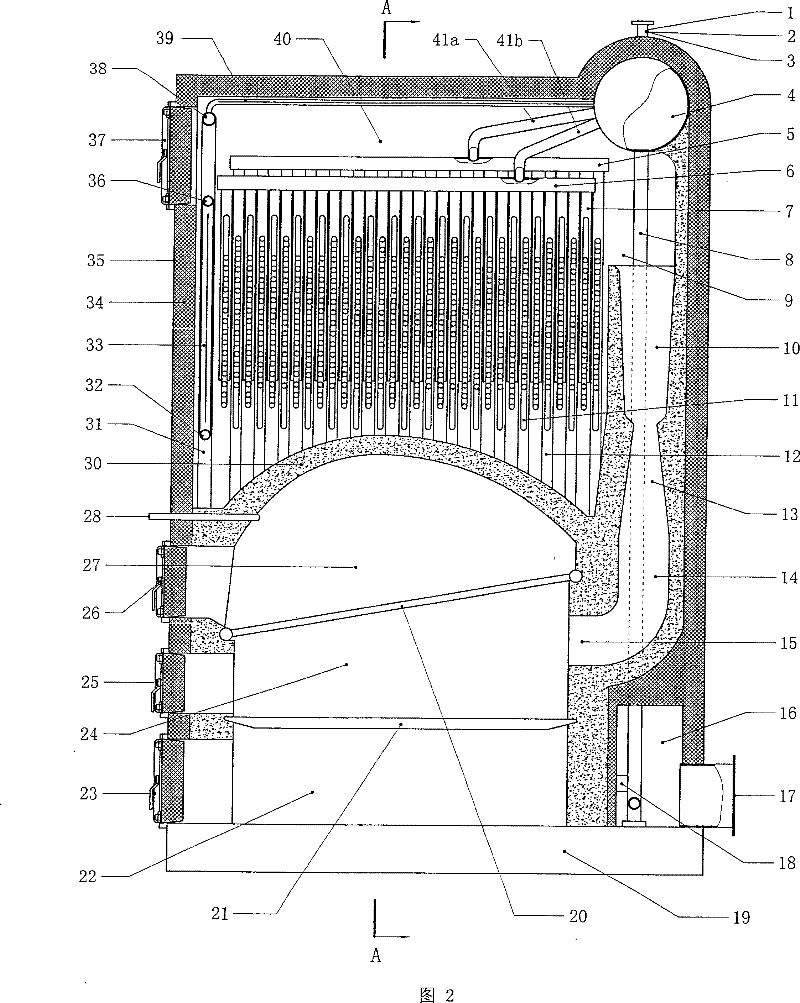

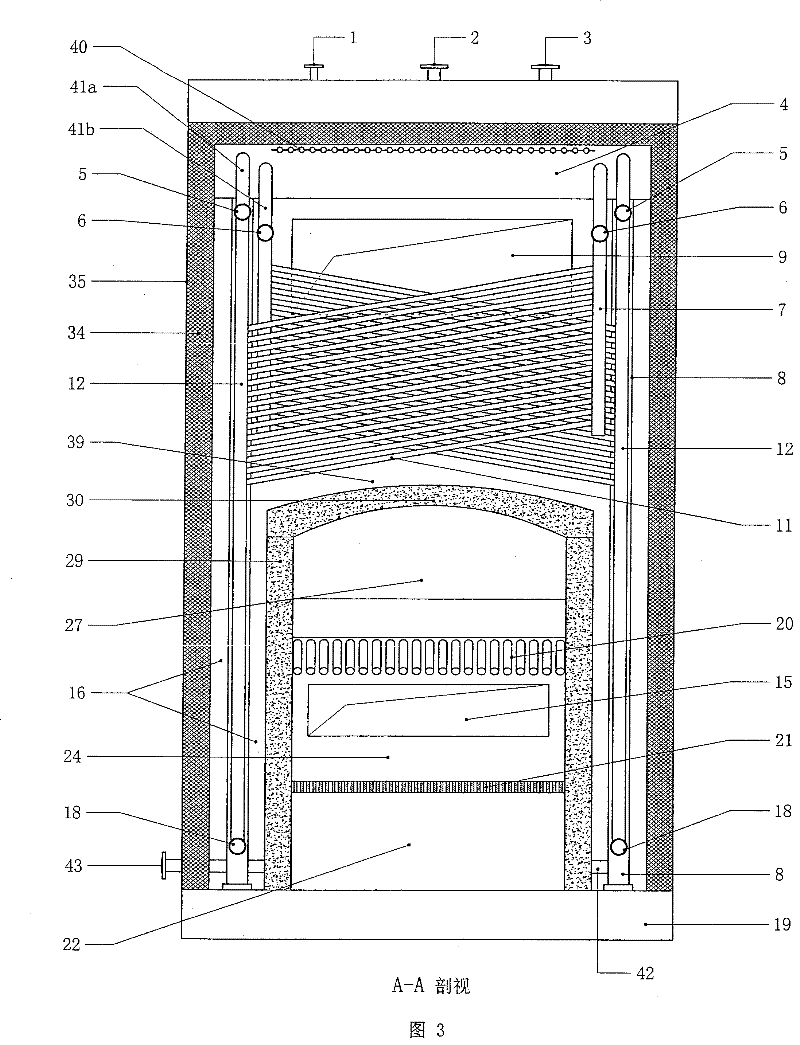

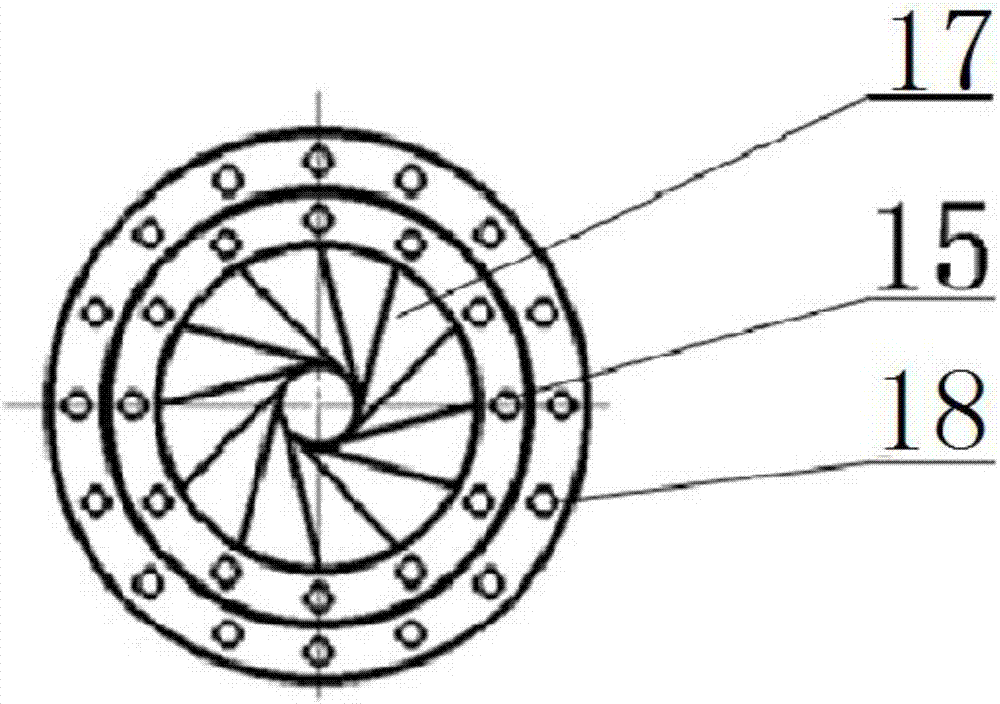

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490AAchieve clean combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

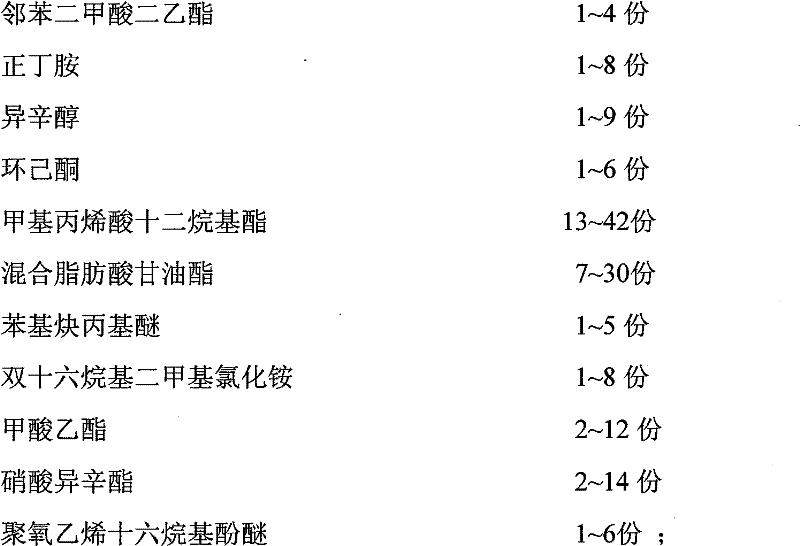

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234AGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel and inhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

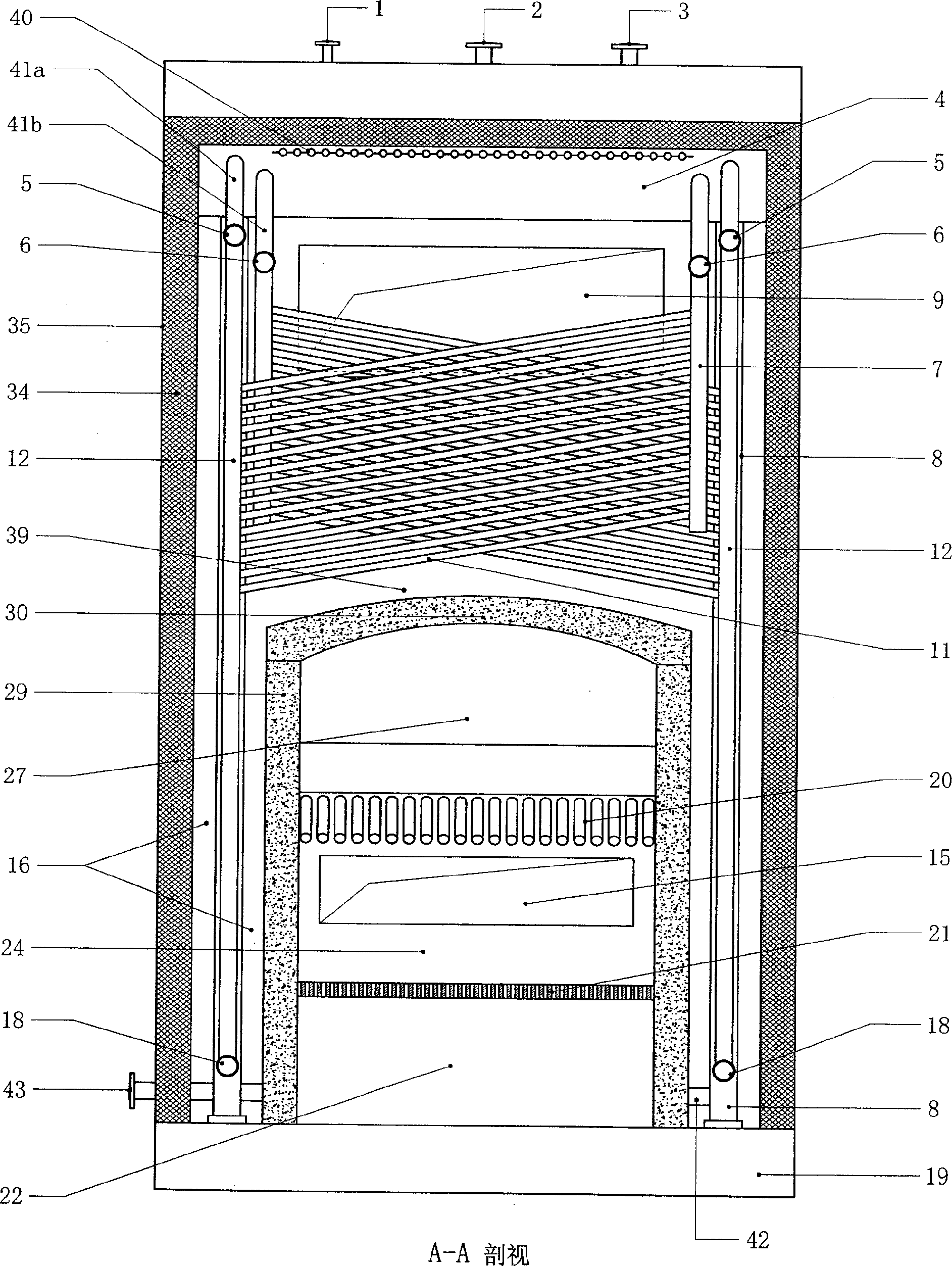

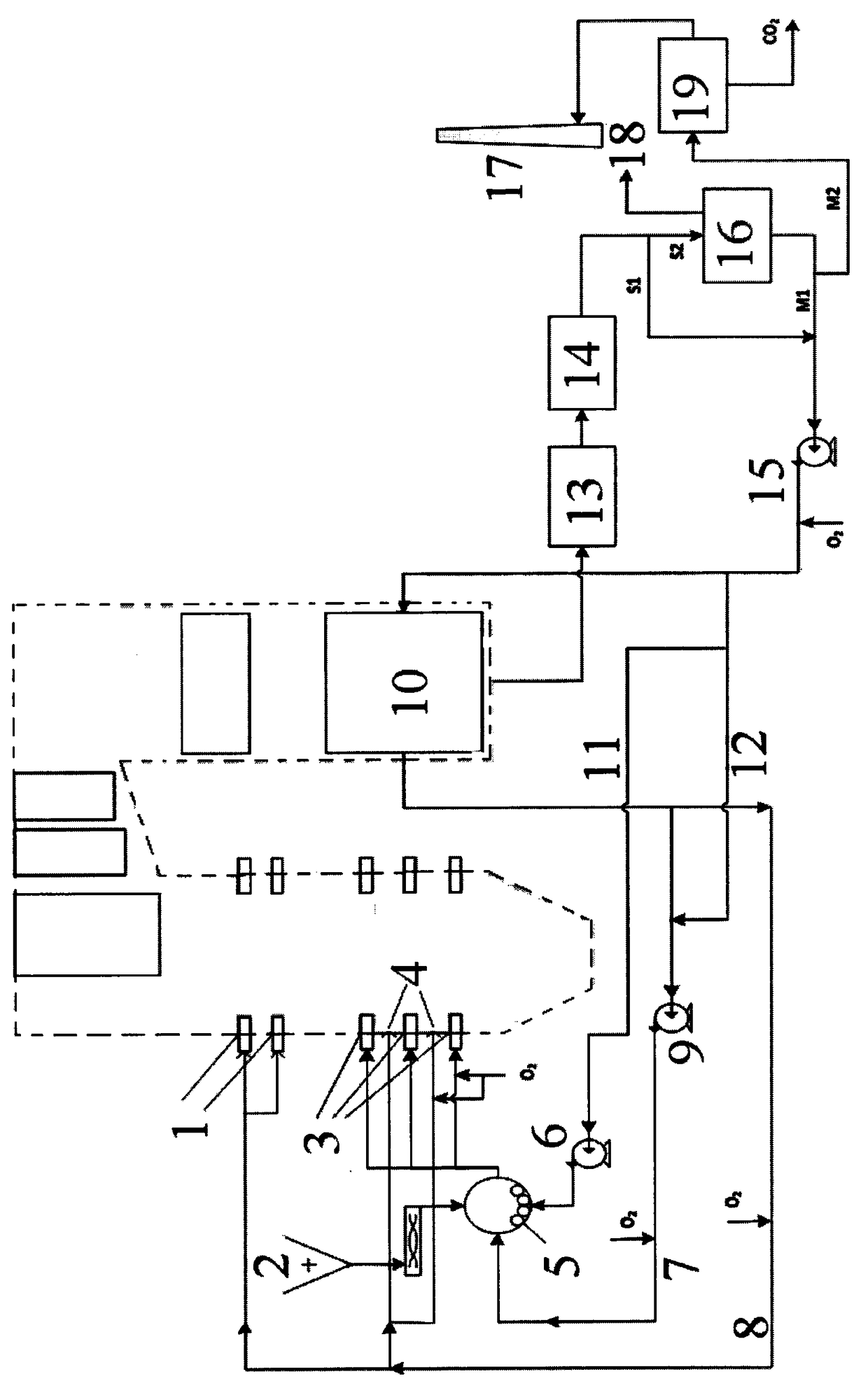

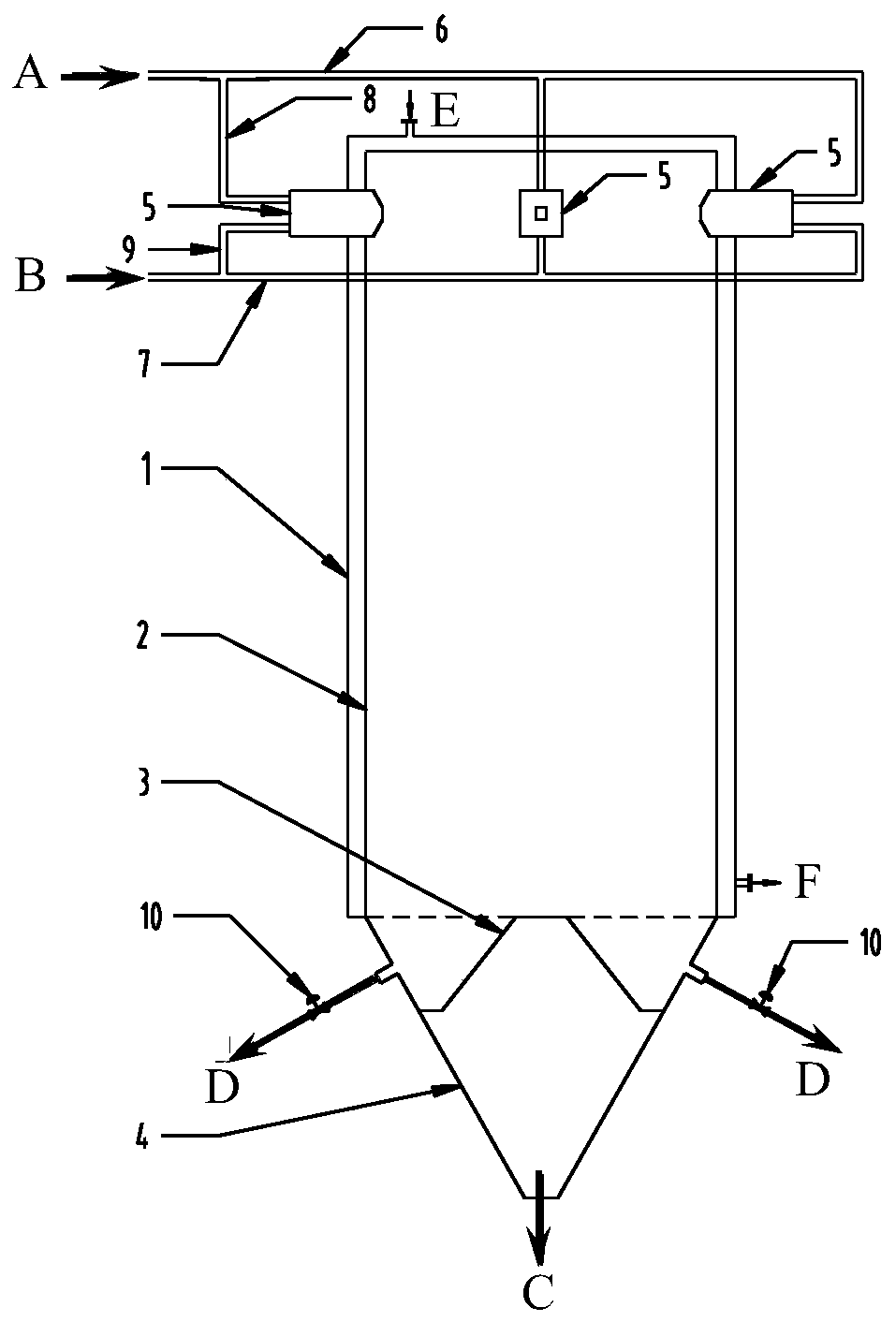

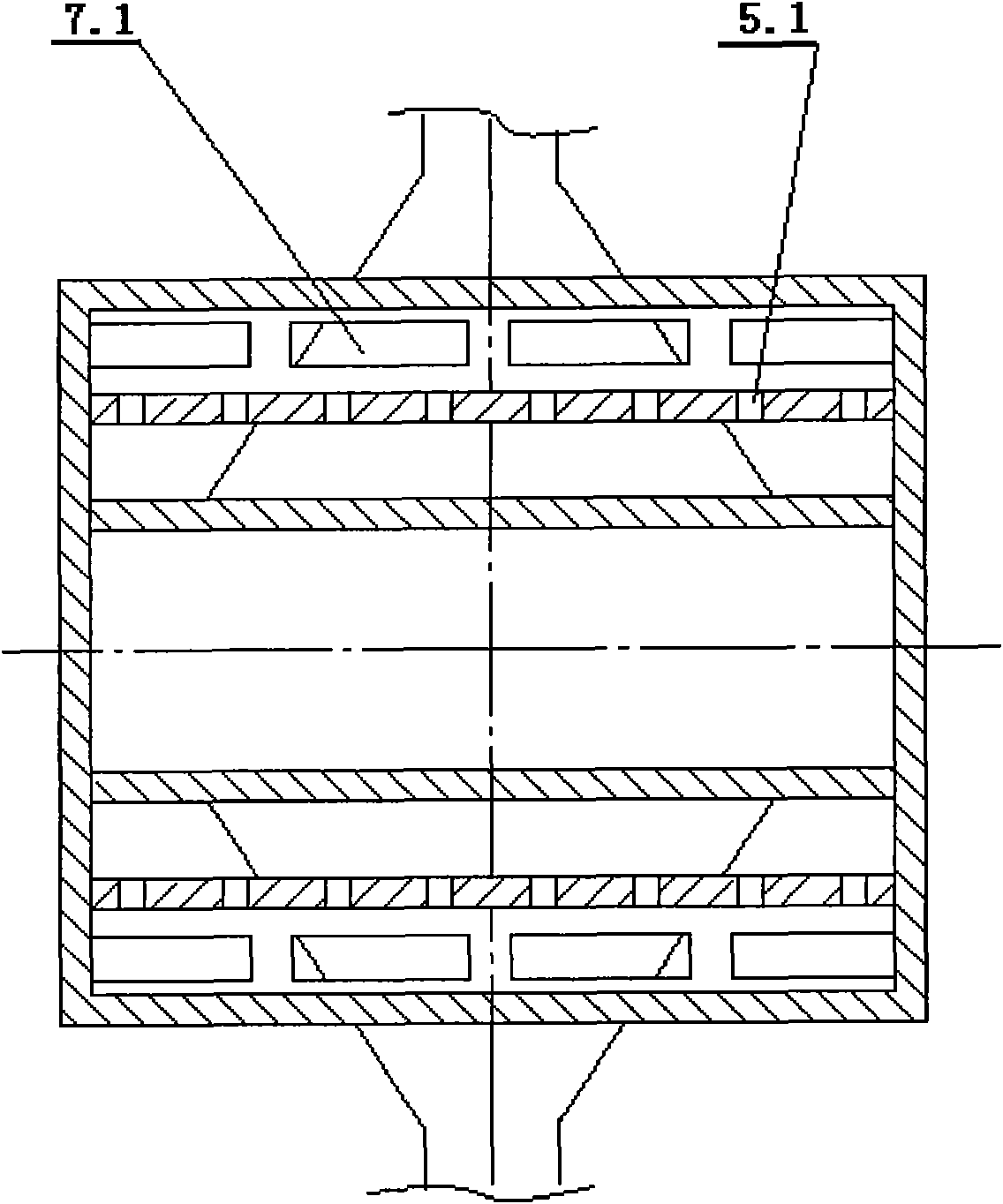

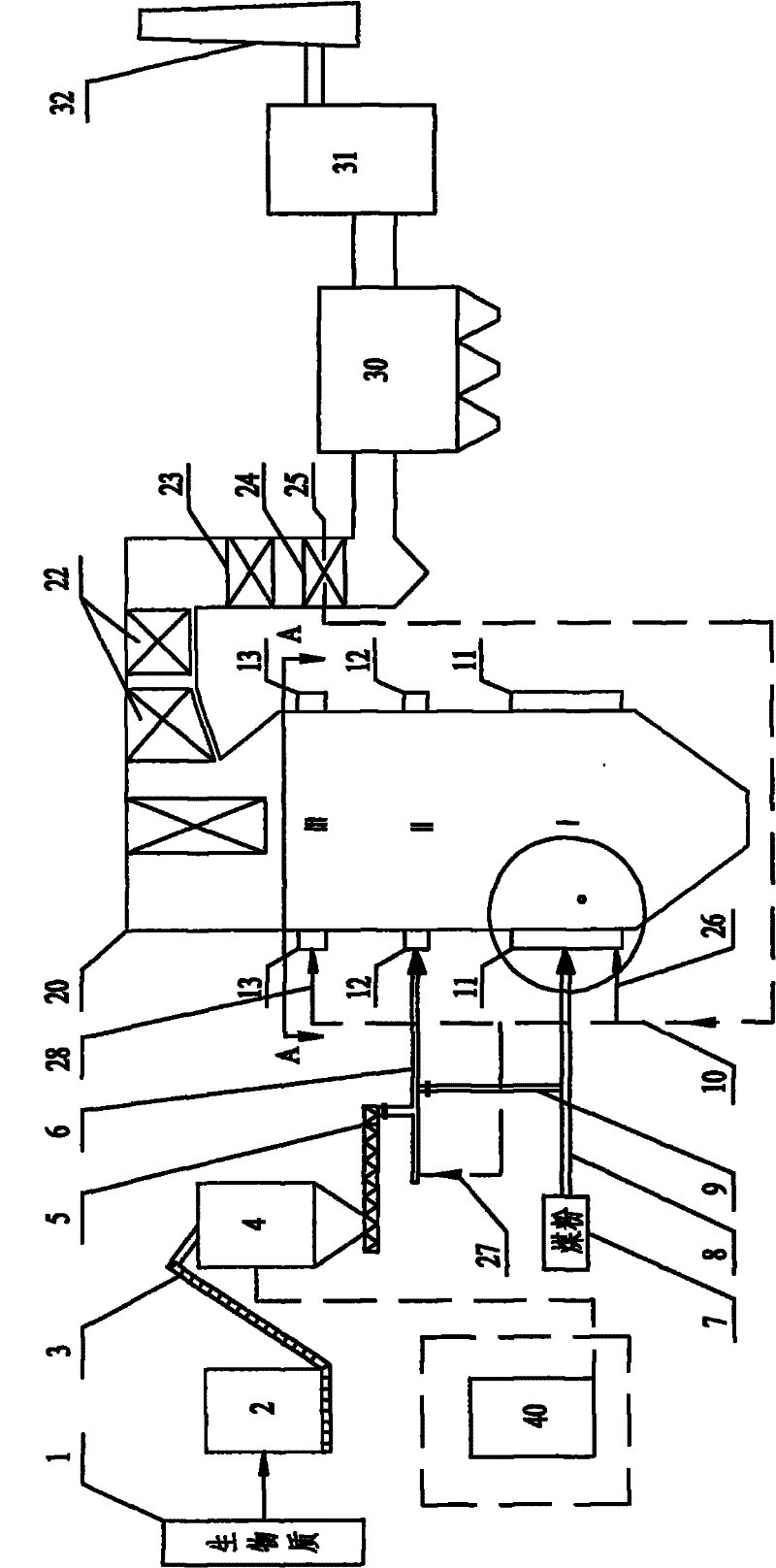

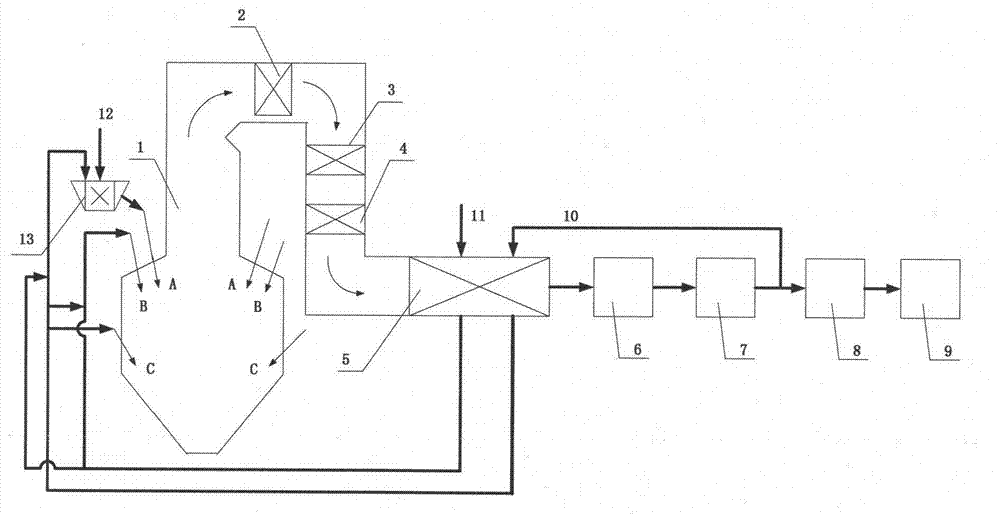

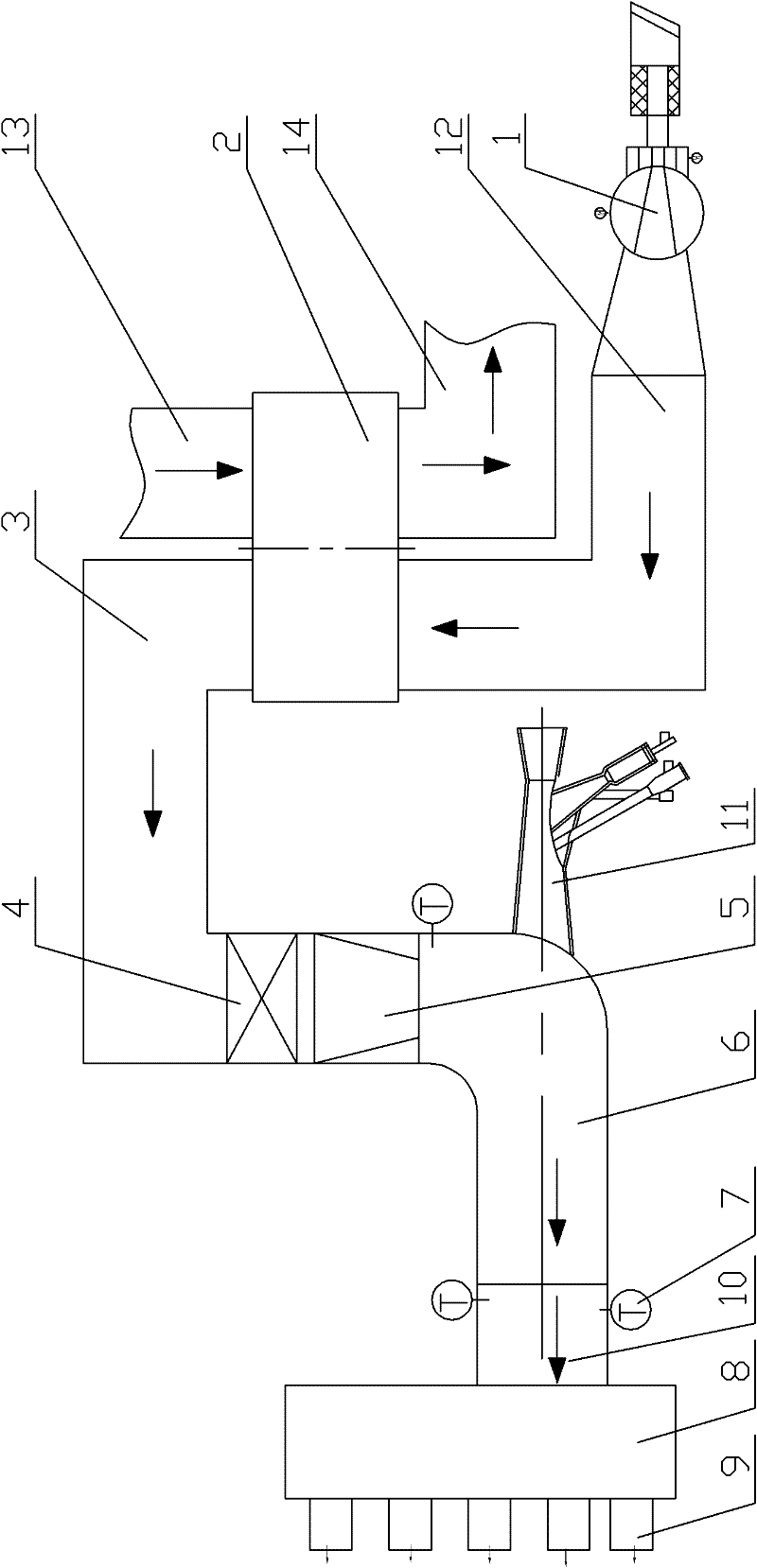

Oxygen-enriched combustion W-shaped flame boiler system and combustion process thereof

ActiveCN103017151AImprove fire conditionsIncreased radiant heat absorption areaIndirect carbon-dioxide mitigationCombustion apparatusSlagFlue

The invention provides an oxygen-enriched combustion W-shaped flame boiler system and a combustion process thereof. Flue gas discharged from a dewaterer is divided into two strands, wherein one strand of flue gas sequentially enters a desulfurization device and a CO2 recovery device and the other strand of flue gas enters a gas-gas heat exchanger and is heated by flue gas in a main flue; the flue gas in the main flue also heats O2 separated in the air when heating the recycled flue gas; the heated recycled flue gas is divided into three strands; O2 is divided into two strands; after the first strand of O2 is mixed with the first strand of recycled flue gas, the mixed gas enters a coal mill and enters a primary air pipeline; after the second strand of O2 is mixed with the second strand of recycled flue gas, the mixed gas enters a furnace arch secondary air pipeline; and the third strand of recycled flue gas enters a front and rear wall secondary air pipeline The system provided by the invention overcomes the defects in the prior art and greatly improves ignition conditions of a hearth; when the radiation and heat adsorption area of a lower hearth is effectively increased, slag-bonding possibility is greatly reduced; efficiency of the integral system is improved; steel consumption and manufacturing cost of a boiler are reduced; and zero emission of CO2 can also be realized.

Owner:SHANGHAI BOILER WORKS

Dehydrating combustion treating method for living refuse

InactiveCN1644986AHigh calorific valueImprove burnout rateIncinerator apparatusGrain treatmentsPretreatment methodCombustion

This invention is a dewatering burning treatment method of household garbage. Mechanical dewatering pretreatment method is adopted to replace the heat drying pretreatment method, household garage is broken up at first then efficient deep dewatering process is carried out by high speed centrifuge after removing water by filtering, the garbage dewatered is sent into the furnace to burning, the amount of the calorific power generated is increased by burning garbage through controlling the burning temperature and residence time of flue gas, the amount of generating dioxin is reduced too. The fluw gas generated by burning will be discharged after spray damp dry acid stripping and dsting. This invention can raise the burning temperature of garbage, and reduce the cost for flue gas treatment and environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

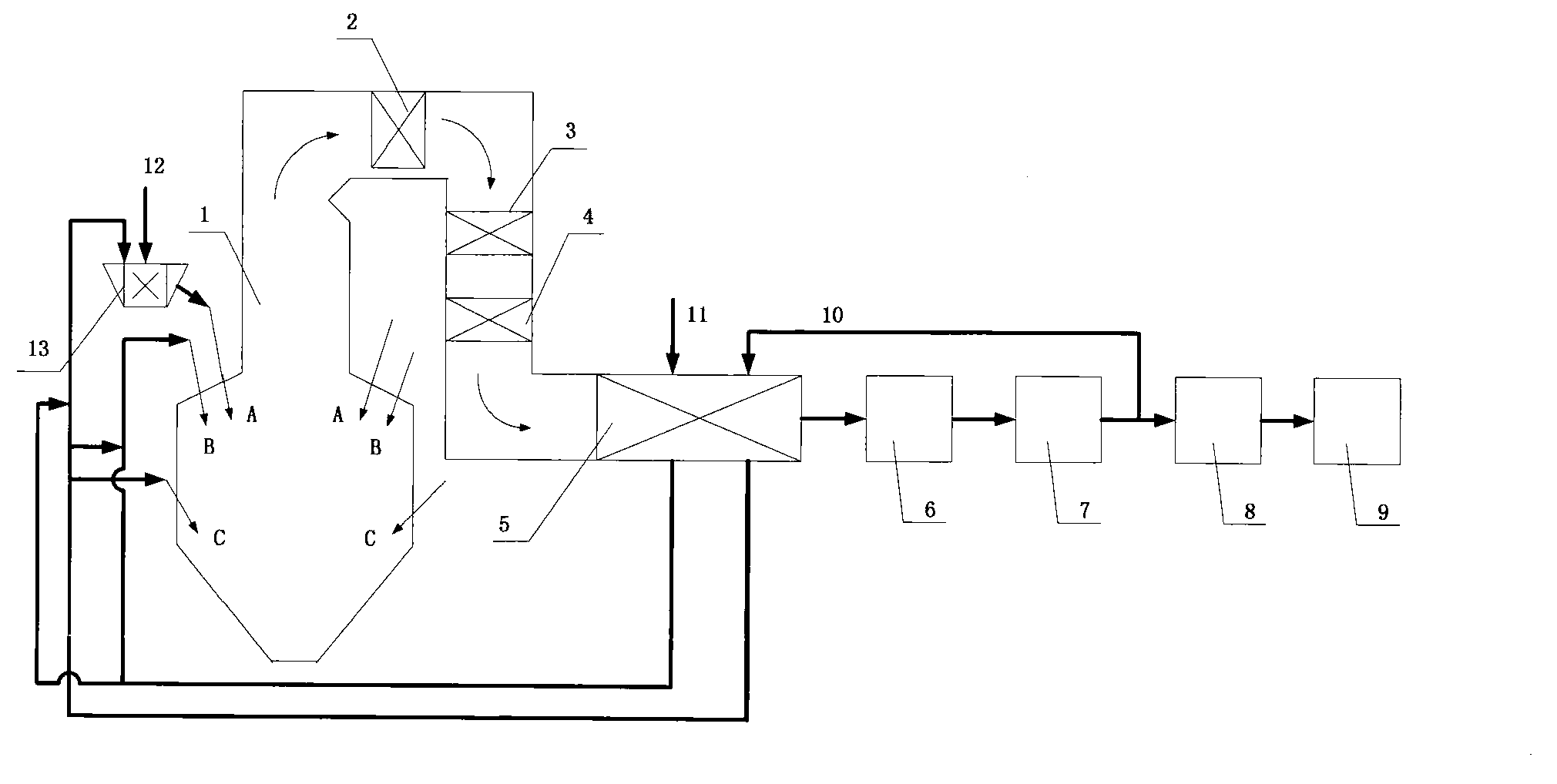

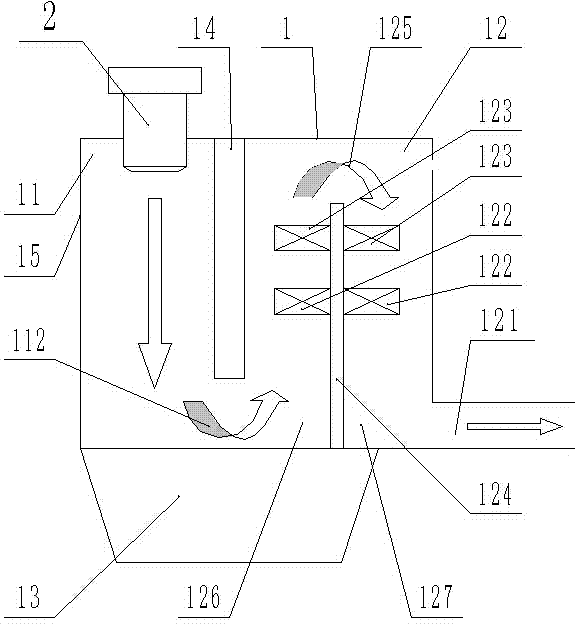

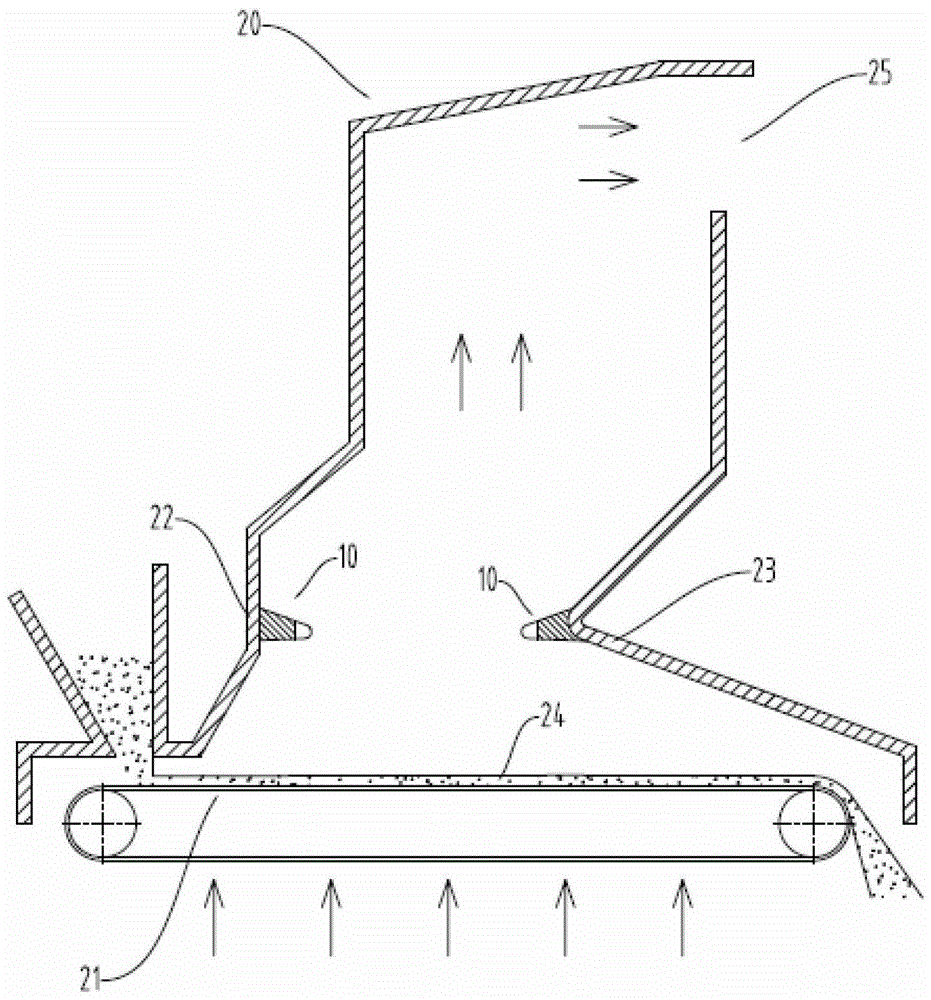

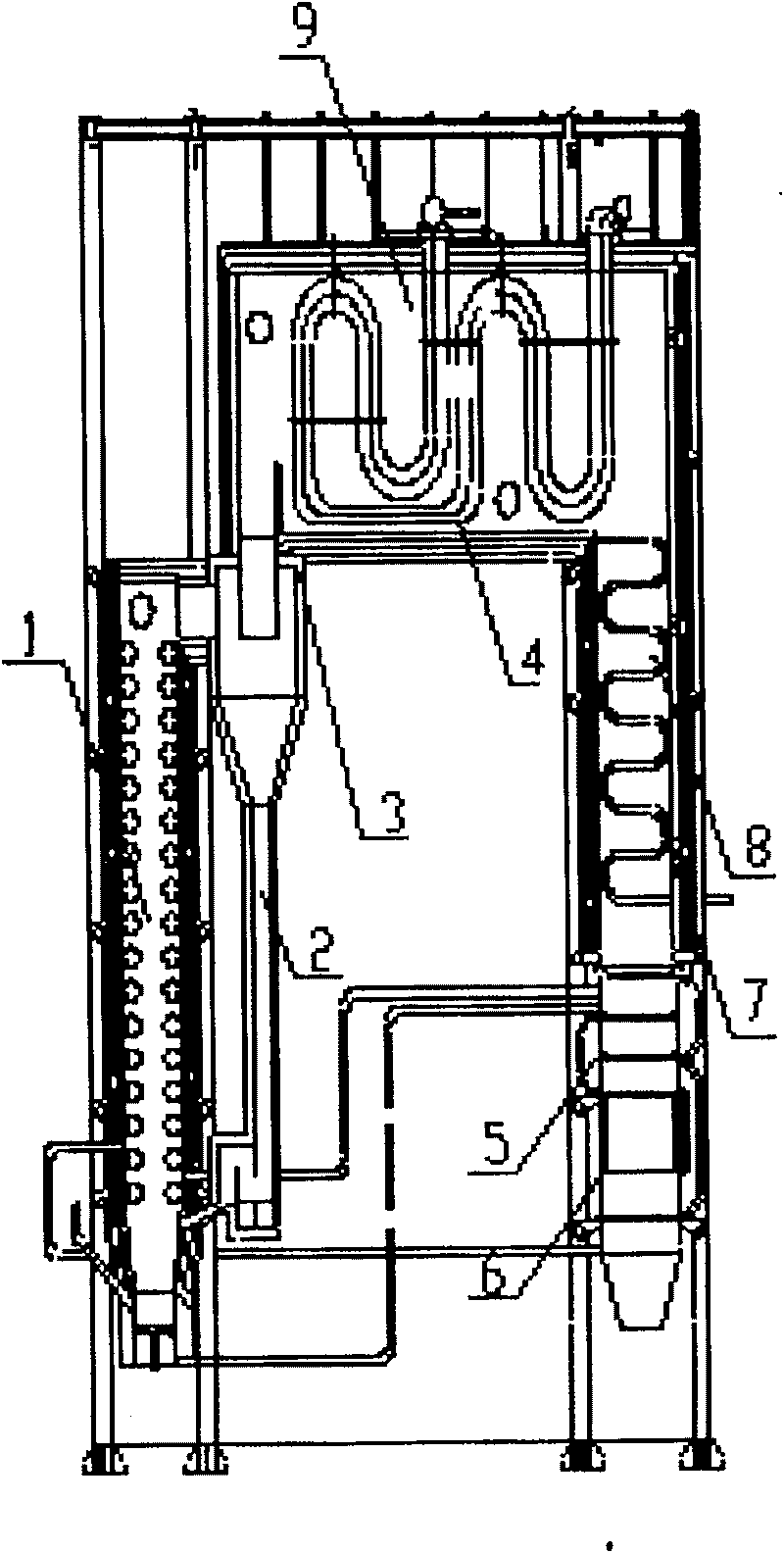

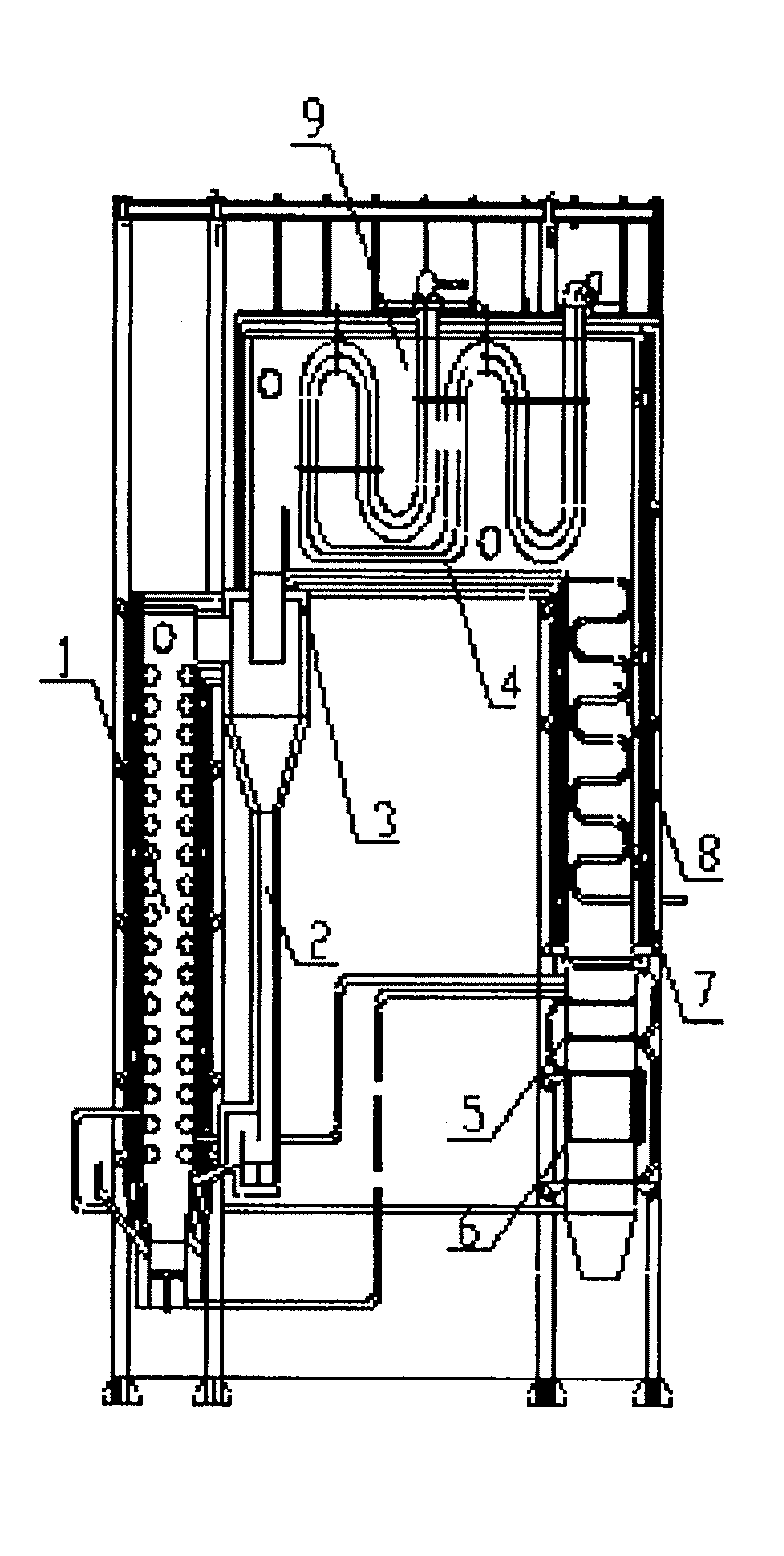

Boiler provided with dual-register pulverized coal burner on top

InactiveCN104121579AThorough heat exchangeReduce energy consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlueCoal

The invention discloses a boiler provided with a dual-register pulverized coal burner on the top, belonging to the technical field of boilers, and aiming at providing a U-shaped flame boiler which is provided with the dual-register pulverized coal burner on the top and is high in combustion efficiency. According to the technical scheme, the boiler provided with the dual-register pulverized coal burner on the top comprises a boiler body and an ash falling pit, wherein the ash falling pit is formed in the bottom of the boiler body, a membrane type water-cooling wall is arranged on the inner wall of the boiler body, a first partitioning wall is arranged on the top in the boiler body and is used for partitioning the boiler body into a combustion chamber and a waste gas chamber, the lower parts of the combustion chamber and the waste gas chamber are communicated with each other to form a first pair of flue channels, the dual-register pulverized coal burner is arranged at the top of the combustion chamber, a second partitioning wall is arranged at the bottom of the waste gas chamber and is used for partitioning the waste gas chamber into a left chamber and a right chamber, the upper parts of the left chamber and the right chamber are communicated with each other, and a flue discharging channel is arranged at the bottom of the side wall of the right chamber. The boiler is high in heat utilization rate and less in waste gas emission.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

Oxygen-enriched combustion boiler system with dehydration adjusting performance

InactiveCN108548173AEasy to adjustImprove adaptabilityDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustionFlue gas

The invention discloses an oxygen-enriched combustion boiler system with a dehydration adjusting performance. After flue gas that is discharged from a boiler body is processed by a dedusting device and a desulfurizing device, the flue gas is divided into two parts. One part is introduced into a dehydration device through a dehydration inlet flue, and the other part goes through a dehydration adjusting flue. The flue gas, which has been dehydrated by the dehydration device, is divided into two parts. One part is introduced into a CO2 processing apparatus after going through a post-dehydration smoke discharge flue, and the other part is mixed with the flue gas from the dehydration adjusting flue after going through a post-dehydration recirculation flue. The mixed flue gas is divided into three parts; one part is introduced into a gas preheater and heated, the second part is introduced into a temperature adjusting air channel, and the third part is introduced into a powder production facility after going through a sealed air channel and a sealed blower fan. The performance of the boiler system on adjusting the dehydration amount is greatly enhanced, and the performance of the boiler system on adapting to the fluctuation of coal quality or change of coal species under an oxygen-enriched combustion condition is obviously enhanced.

Owner:SHANGHAI BOILER WORKS

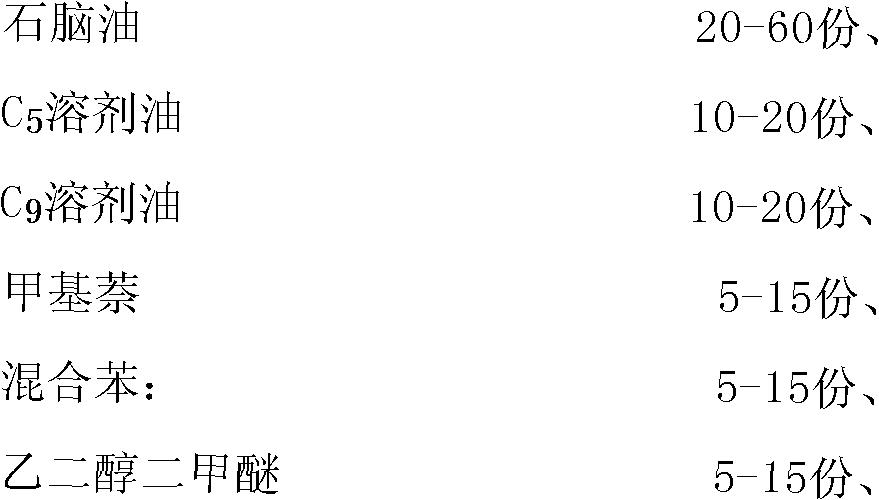

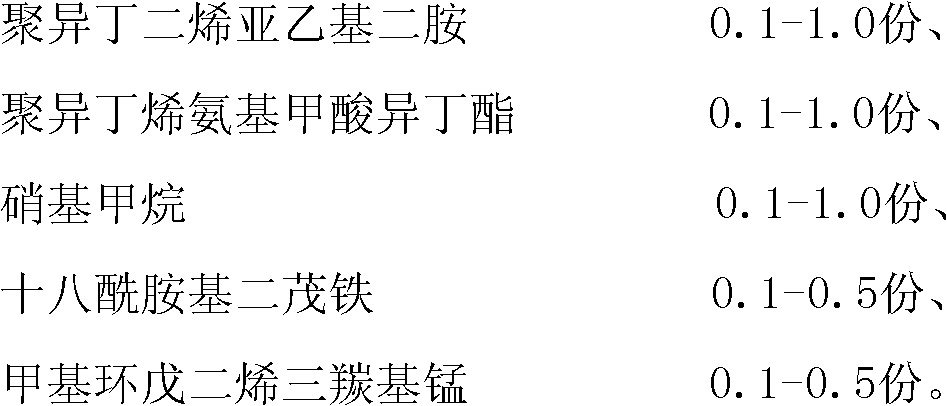

Formula and preparation method of clean gasoline

The invention belongs to the technical field of petrochemical fuel oil processing and especially relates to a formula and preparation method of clean gasoline using naphtha as one of raw materials. The preparation method is that naphtha is used as raw material and C5 solvent oil, C9 solvent oil, methylnaphthalene, mixed benzene and dimethoxyethane are added according to a ratio, thus the firing behavior, octane number and boiling range of naphtha can be improved and increased under synergy. The raw materials of the clean gasoline are simple, common and economical and the clean gasoline has cost benefit.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

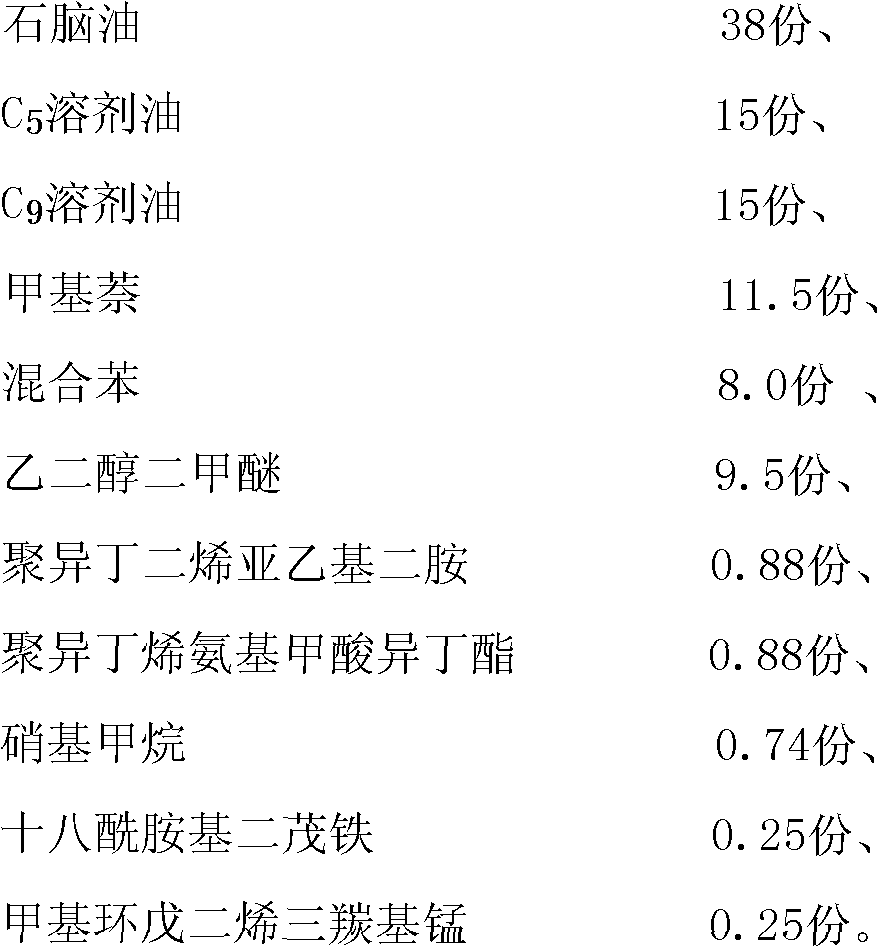

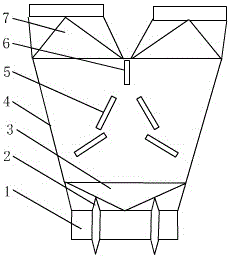

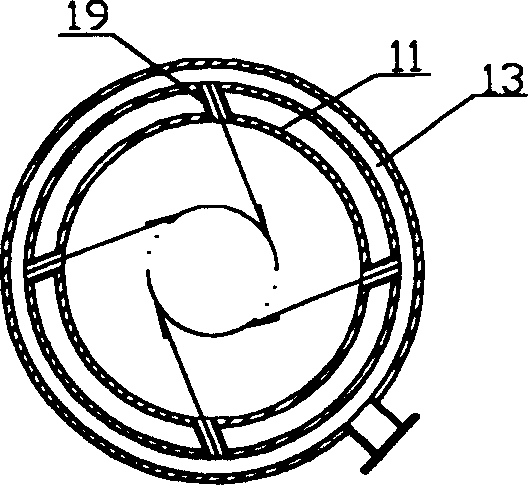

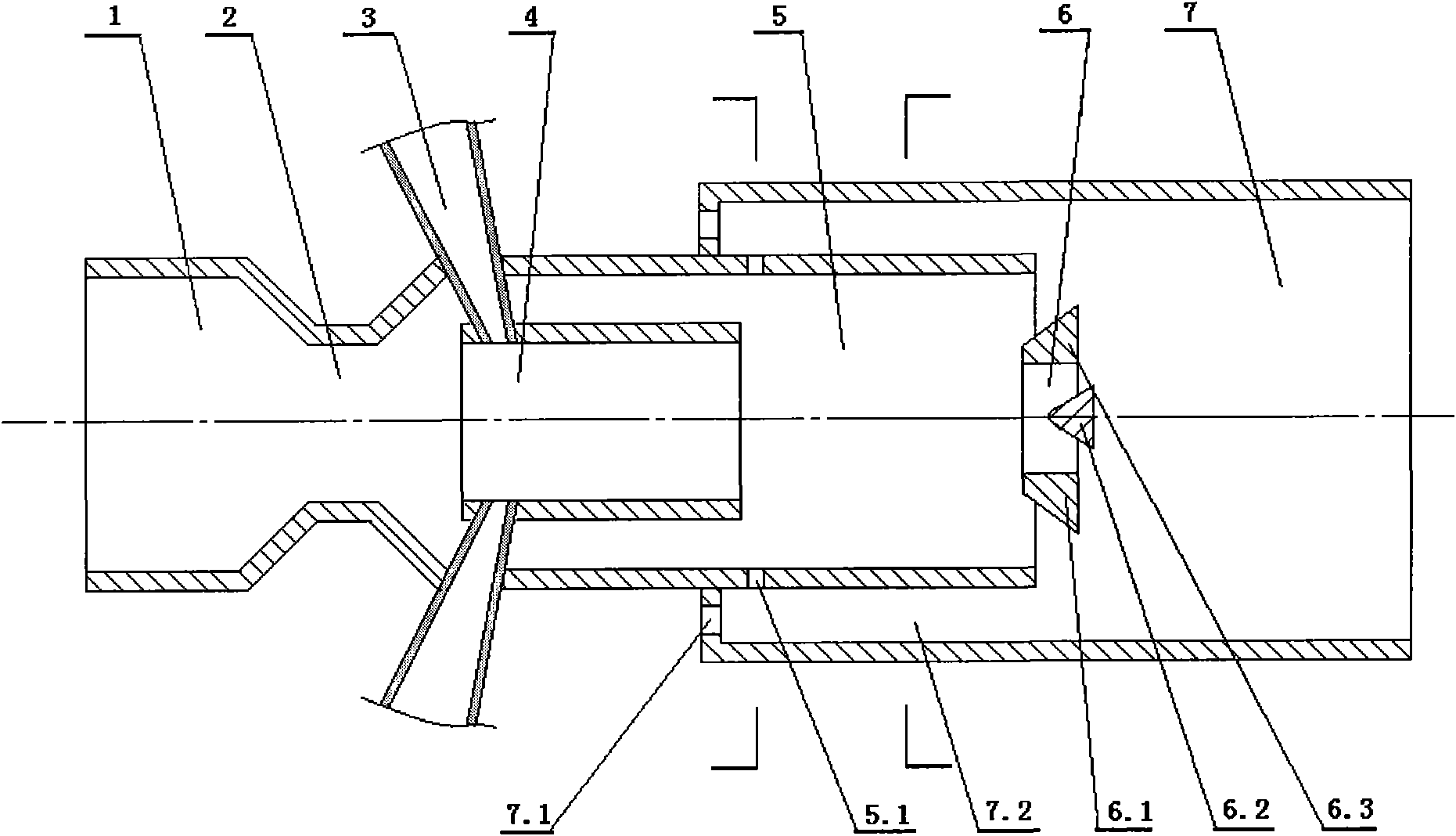

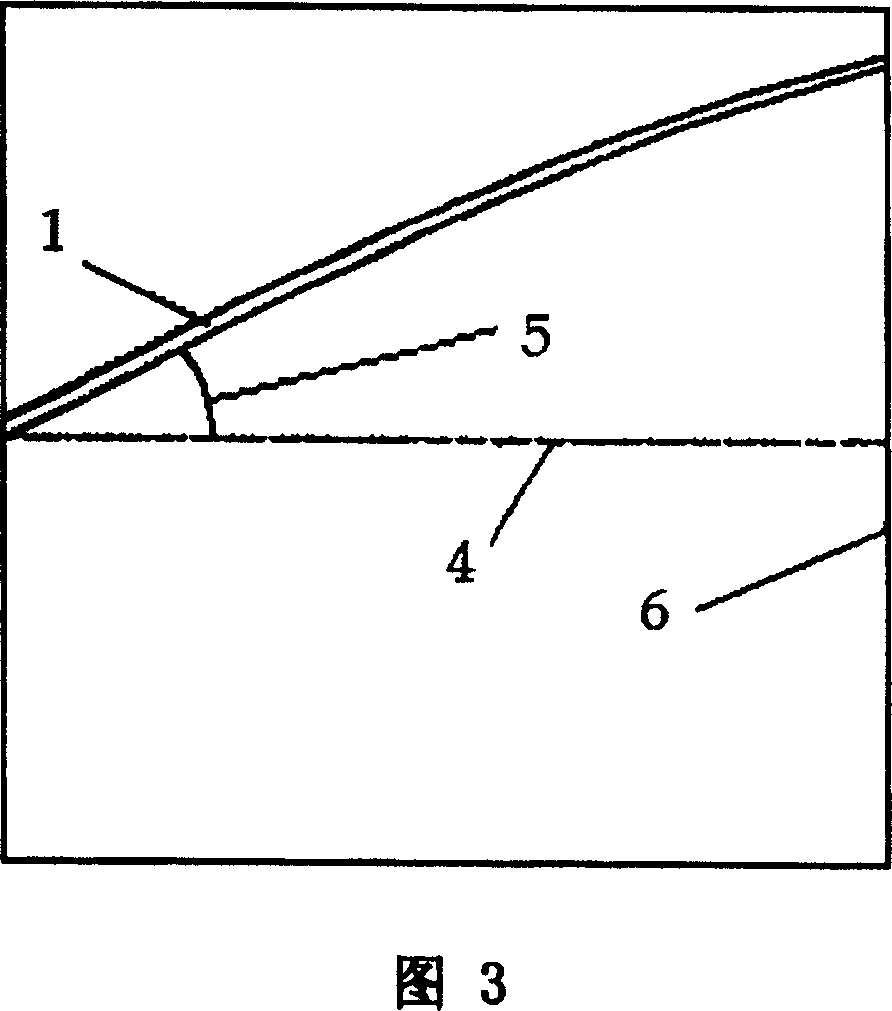

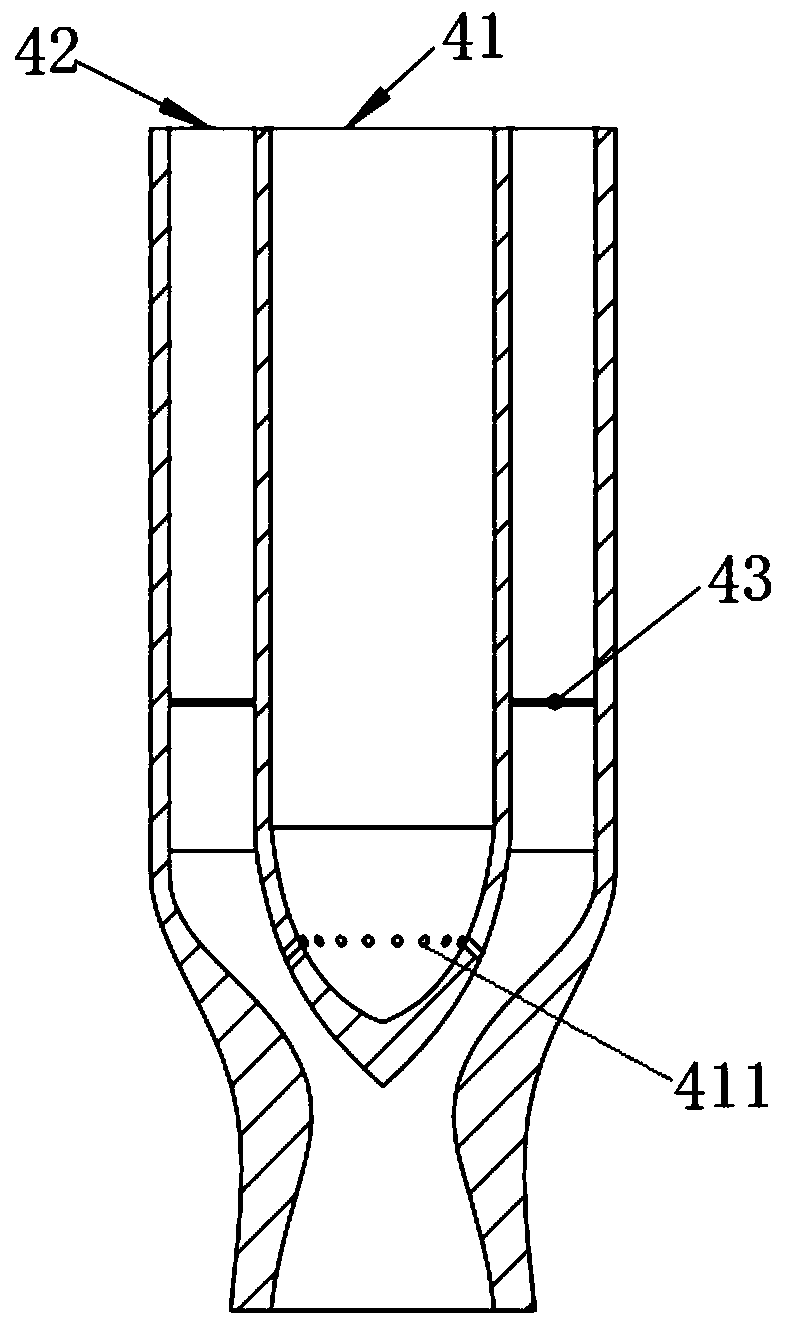

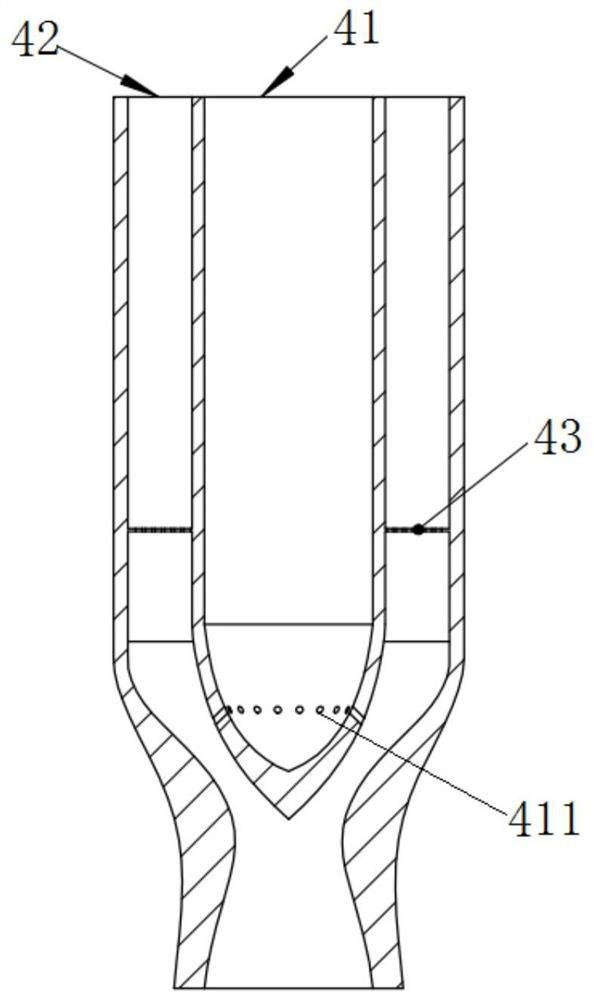

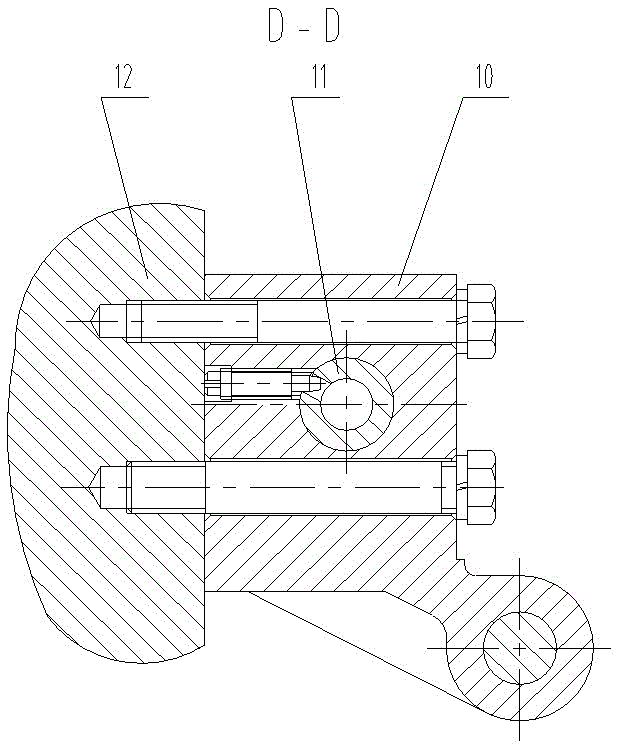

Little oil burner of double-sided ignition combination blunt body

InactiveCN101696801AHeating fastExtended stayPulverulent fuel combustion burnersCombustion chamberCoal dust

The invention discloses a little oil burner of a double-sided ignition combination blunt body. A primary air pipeline is communicated with a secondary coal dust combustion chamber through a section of coal dust concentrator formed by a tapered pipeline with a throat part formed through invagination, a primary coal dust combustion chamber is arranged in the secondary coal dust combustion chamber, and the secondary coal dust combustion chamber extends into a tertiary coal dust combustion chamber. The upper side surface and the lower side surface of the tertiary coal dust combustion chamber connected with the secondary coal dust combustion chamber are provided with a plurality of secondary air inlets in equal intervals, an upper oil combustion chamber and a lower oil combustion chamber are arranged on the primary coal dust combustion chamber after aslant penetrating through the secondary coal dust combustion chamber, a combination blunt body is arranged at the port of the secondary coal dust combustion chamber, and a plurality of through-flow holes are arranged on the upper surface and the lower surface of the second coal dust combustion chamber positioned in the tertiary coal dust combustion chamber. By adopting the top and bottom arrangement of two oil guns, coal dust entering into the primary coal dust combustion chamber are ignited in a double side way, which strengthens turbulent mass and heat exchange of coal dust current and oil flame to rapidly heat the coal dust and form a fire curtain, thereby prolonging the residence time of the coal dust and strengthening the ignition process.

Owner:CHINA JILIANG UNIV

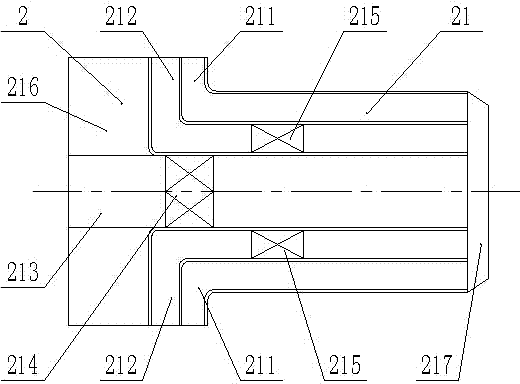

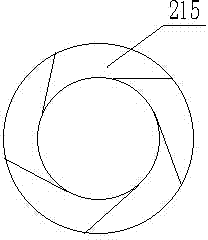

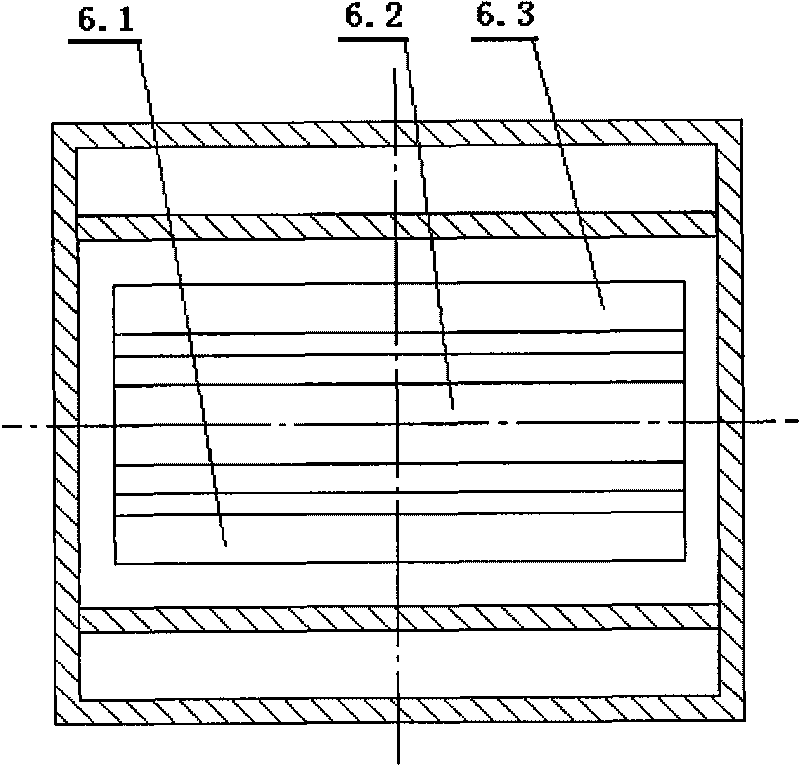

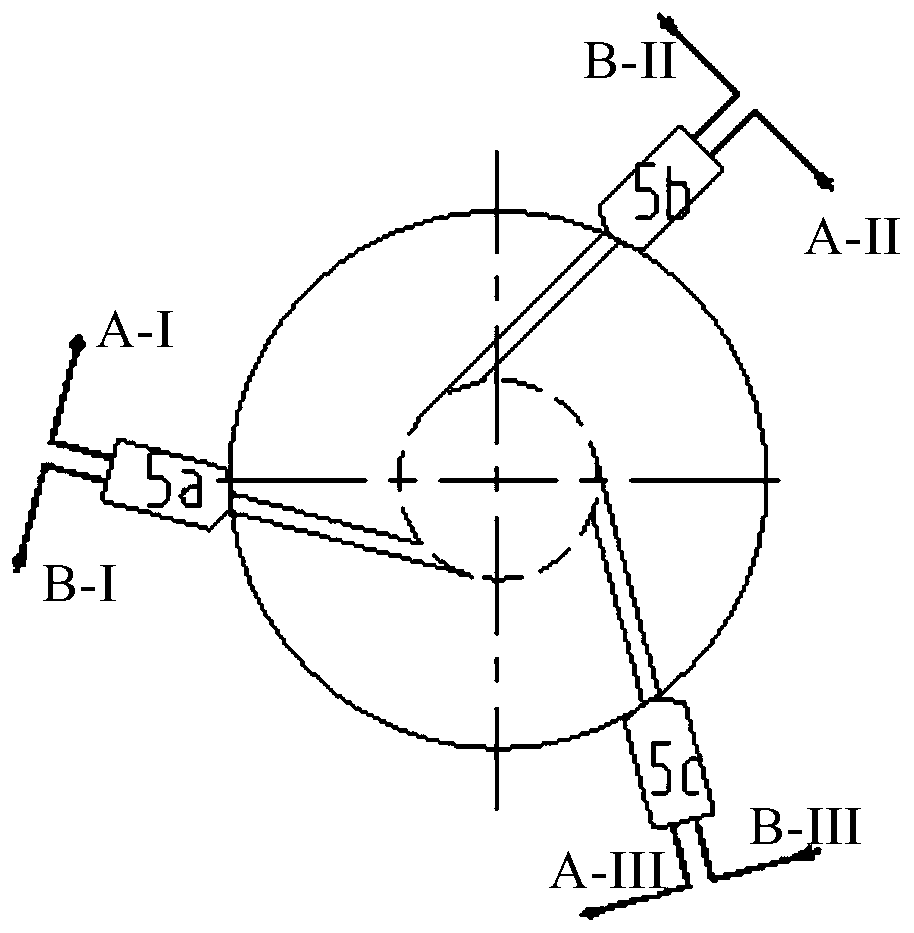

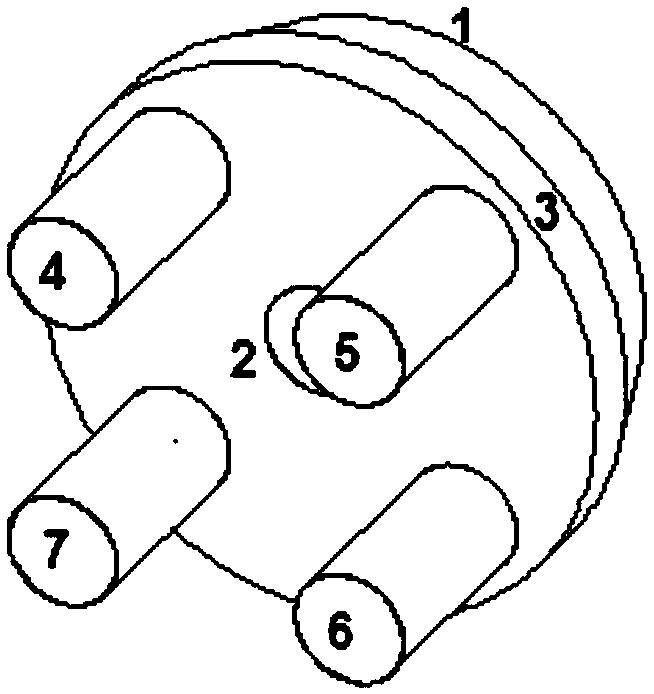

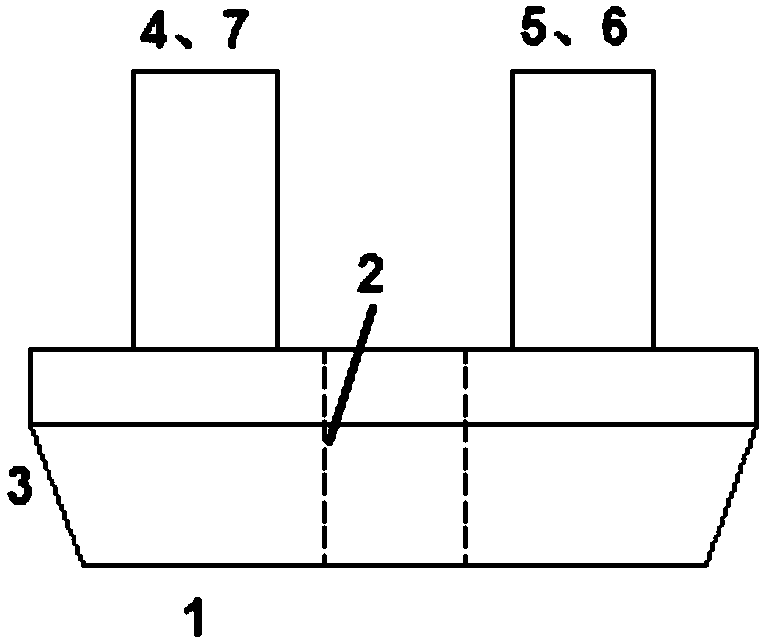

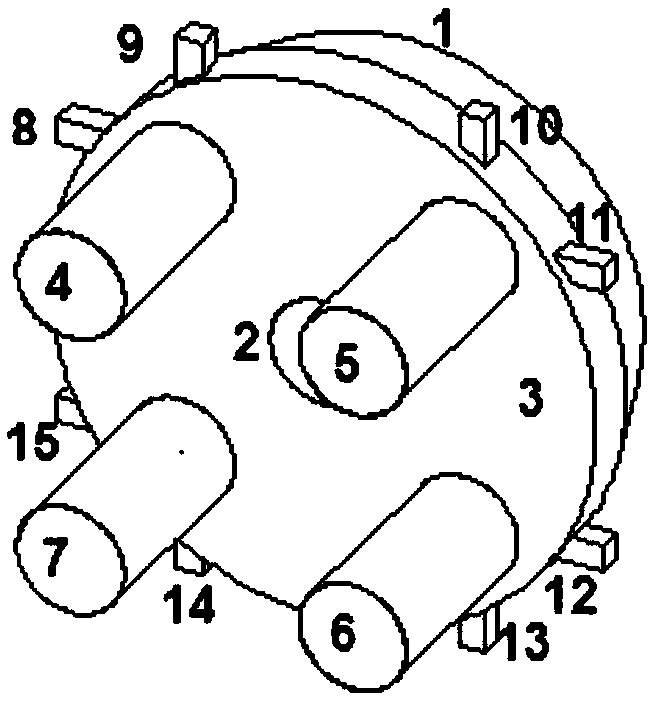

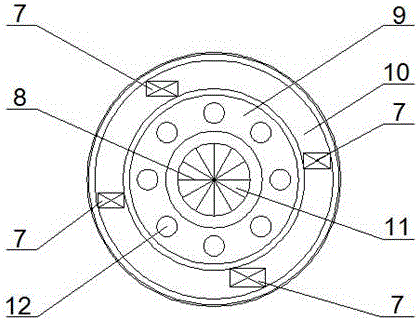

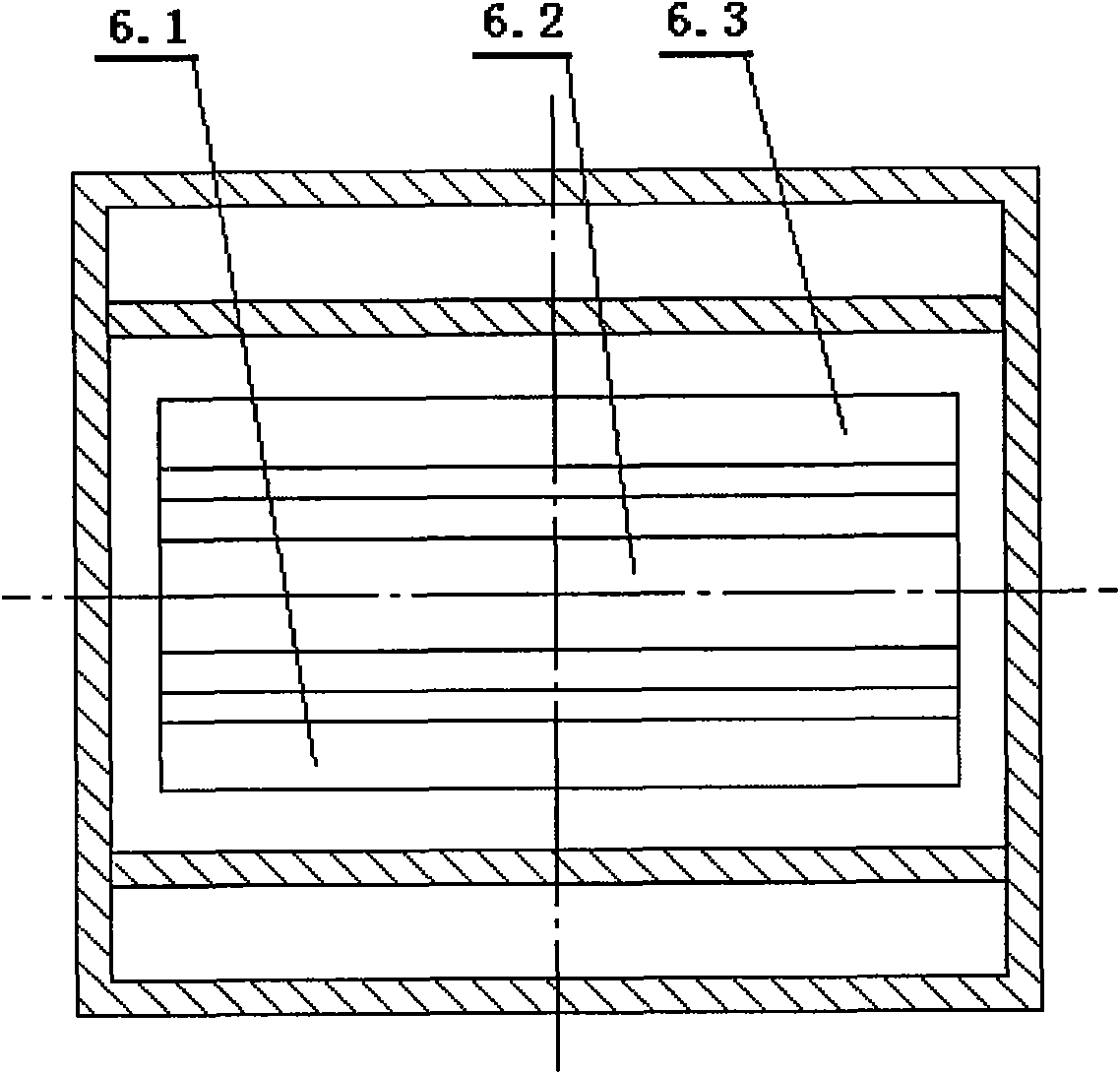

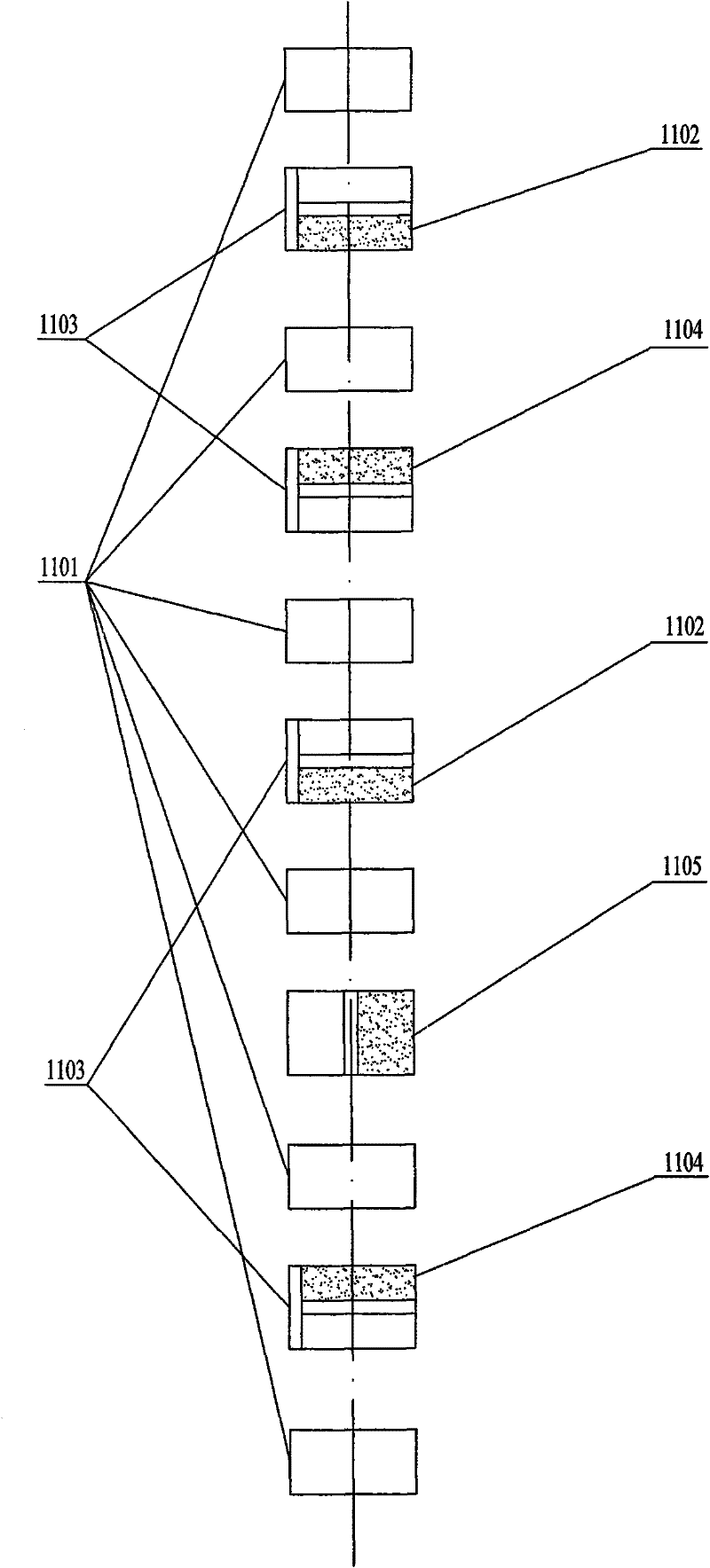

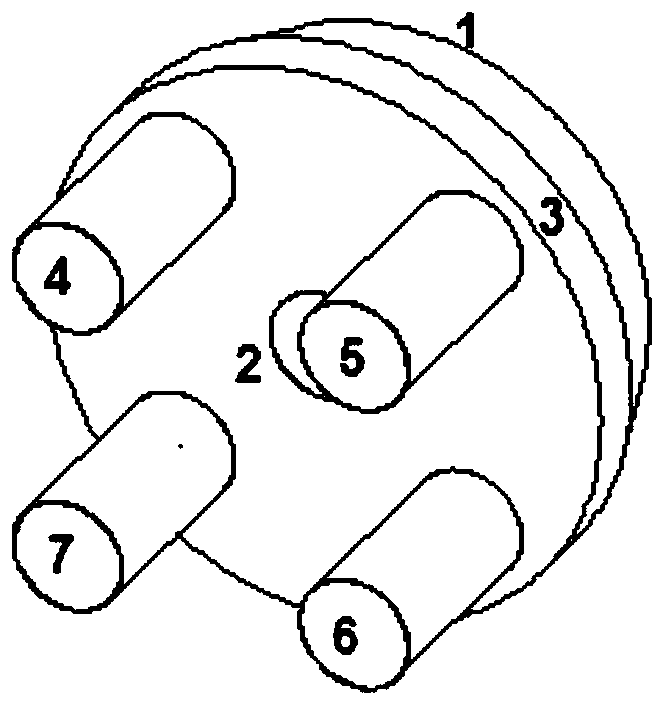

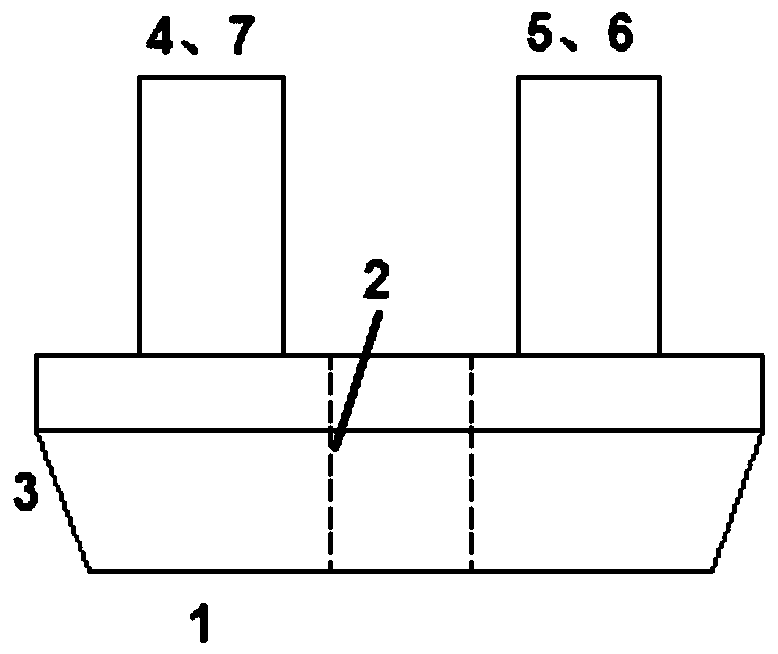

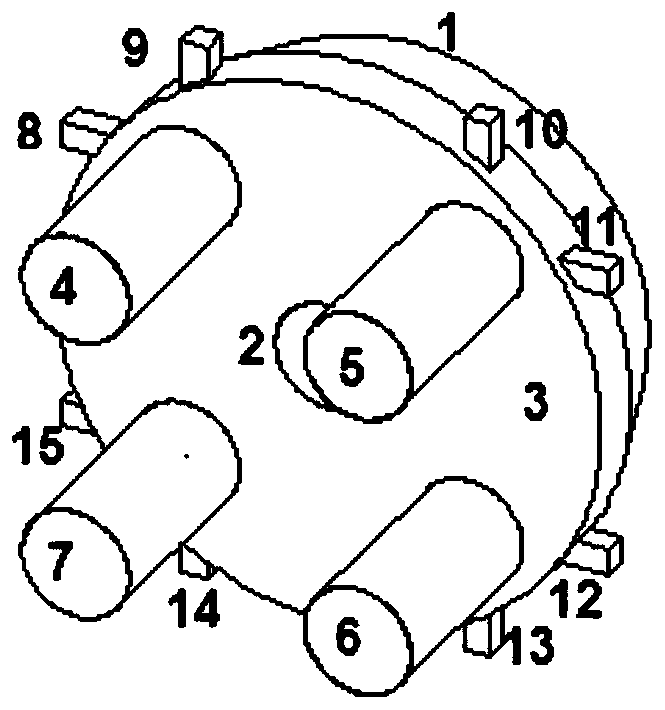

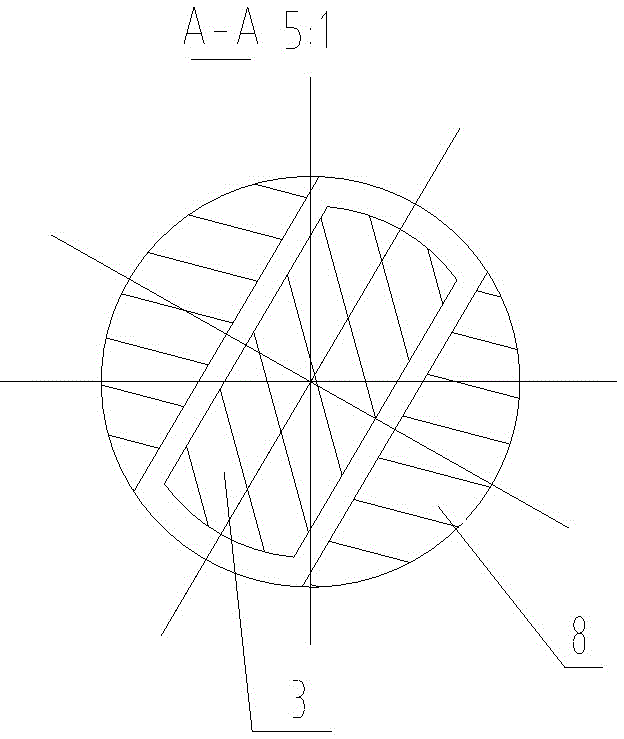

Pulverized coal distributor allowing double angles to be adjusted

ActiveCN106090981AEvenly distributedImprove fire conditionsFuel feeding arrangementsLump/pulverulent fuel feeder/distributionCombustorWear resistant

The invention provides a pulverized coal distributor allowing double angles to be adjusted. A pulverized coal inlet is formed in the lower part of a middle casing; two spindly baffles are arranged in the pulverized coal inlet; a diffusion tube section is arranged in the lower part of the middle casing, and two symmetric pulverized coal outlets are formed in the upper part of the middle casing; a middle partition board is arranged between two pipelines of the pulverized coal outlets; louvers are mounted in a cavity of the middle casing. Wear-resistant ceramic is attached to inner walls of the pulverized coal inlet, the diffusion tube section, the middle casing and the pulverized coal outlets, and the louvers and the middle partition board are overall made of wear-resistant ceramic through firing. Pulverized coal and air at the outlets are uniformly distributed by adjusting the louvers, the middle partition board and the spindly baffles in the pulverized coal distributor, the ignition condition of a burner is good, burning in a boiler is stable, and the safety and the economical performance of the unit are improved. Besides, the pulverized coal distributor allowing double angles to be adjusted is simple to adjust, wear-resistant, free from leaking, long in service life and suitable for being mounted in narrow space.

Owner:北京中电联众电力技术集团有限公司 +2

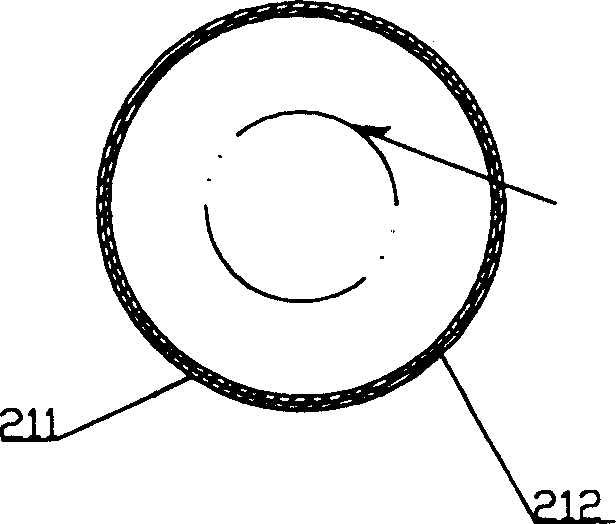

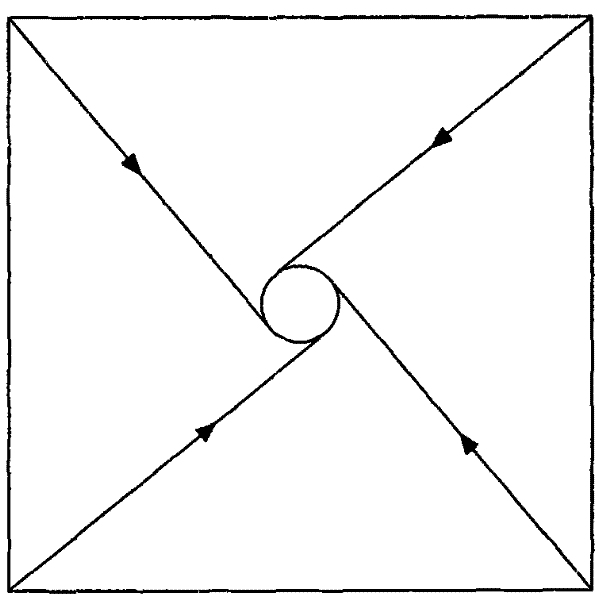

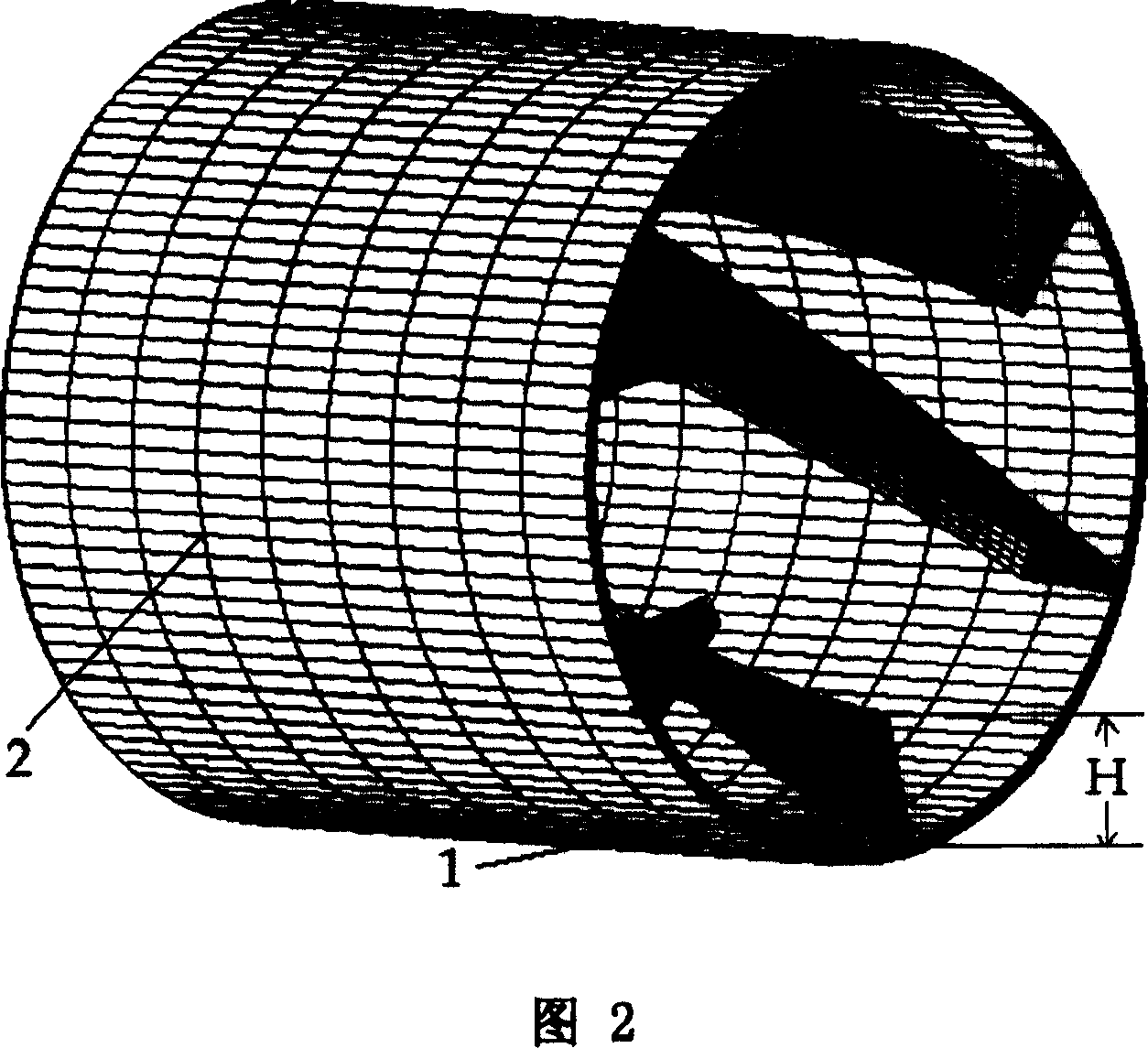

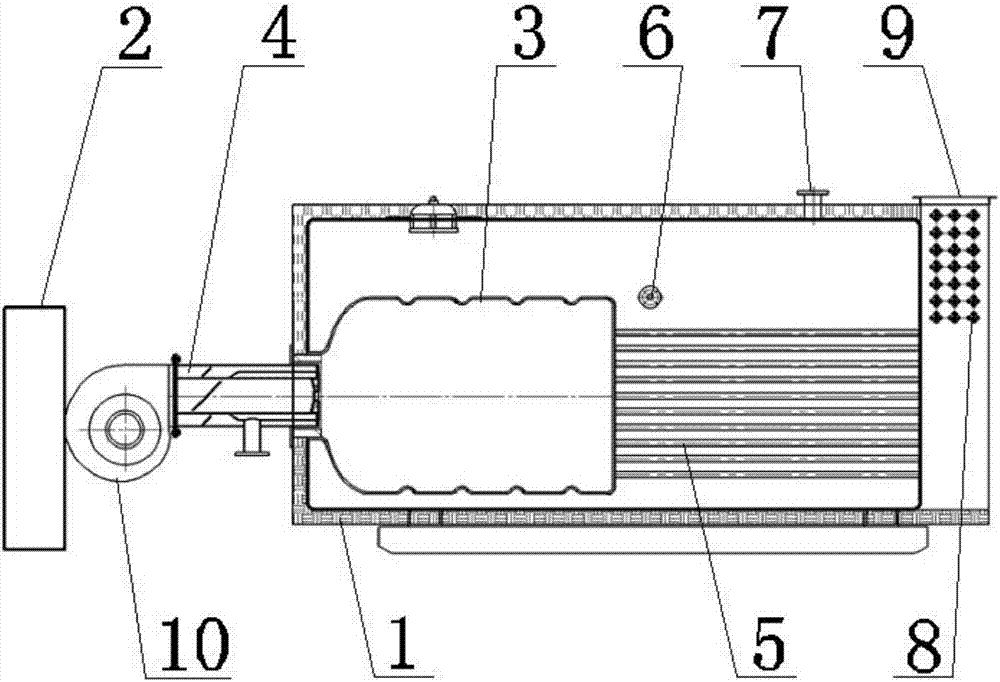

Spiral-flow type supercritical hydrothermal combustion device and method

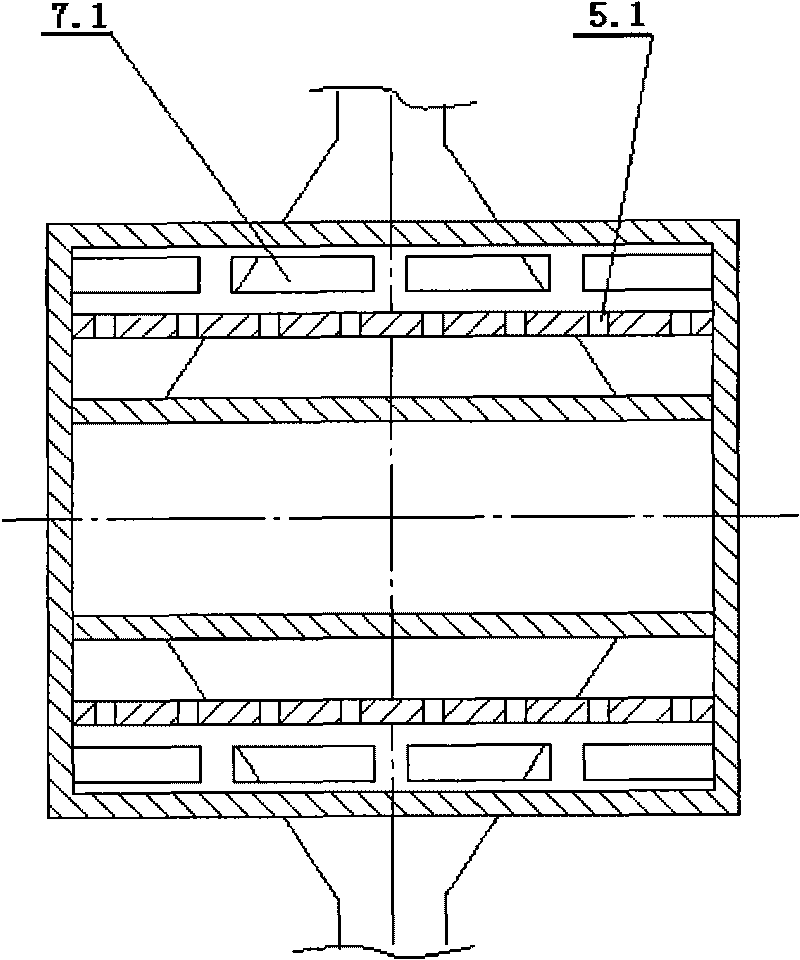

PendingCN111237743AImprove fire conditionsFire stableCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionSlag

The invention discloses a spiral-flow type supercritical hydrothermal combustion device and method. The device comprises a plurality of hydrothermal flame generators which are uniformly distributed atthe upper part of a device main body in the circumferential direction, and each hydrothermal flame generator is provided with a high-pressure organic slurry input branch pipe and a high-pressure oxidant input branch pipe; the geometric axis of an output port of each hydrothermal flame generator is externally tangent to an imaginary circle of a core combustion area in the device, a burnout slag slurry gathering cone is arranged on the lower part of the device main body and connected with a supercritical thermal fluid guide cone on the lower part of the burnout slag slurry gathering cone, a plurality of burnout slag slurry outlets D are formed in the upper part of the side face of the burnout slag slurry gathering cone, and a supercritical thermal fluid outlet C is formed in the bottom of the supercritical thermal fluid guide cone. According to the invention, rapid ignition, efficient clean combustion and effective separation of slag flow after burnout of solid-phase or solid-containingfuels such as fossil fuels (such as coal) and urban / industrial sludge are realized, and the method is an advanced combustion technology for promoting efficient and pollution-free conversion of chemical energy into heat energy.

Owner:XI AN JIAOTONG UNIV

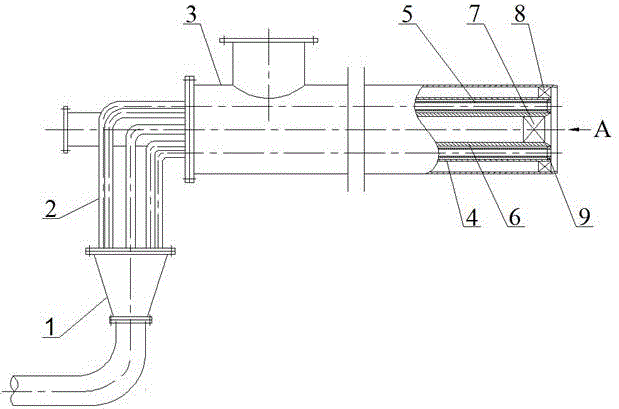

Online adjusting system for jet distribution of pulverized coal

ActiveCN108679639AImprove fire conditionsImprove securityFuel supply regulationLump/pulverulent fuel feeder/distributionEngineeringDistributor

The invention discloses an online adjusting system for jet-stream distribution of pulverized coal, comprising: a pulverized coal distributor distributing pulverized coal at an outlet of a splitter ofa coal pulverizer into branch pipes connected in parallel; a pulverized coal concentration online-measuring device performing real-time online measurement of pulverized coal concentration in the branch pipes; a stream-jetting device including a jet nozzle and a pneumatic pump, the stream-jetting device jetting high-speed stream into the pulverized coal distributor from the jet nozzle according toan online measurement of pulverized coal concentration in the branch pipes, and thereby improves pulverized coal distribution in the branch pipes, and improves a phenomenon of uneven distribution of pulverized coal among burners in the same layer.

Owner:NANJING UNIV OF SCI & TECH

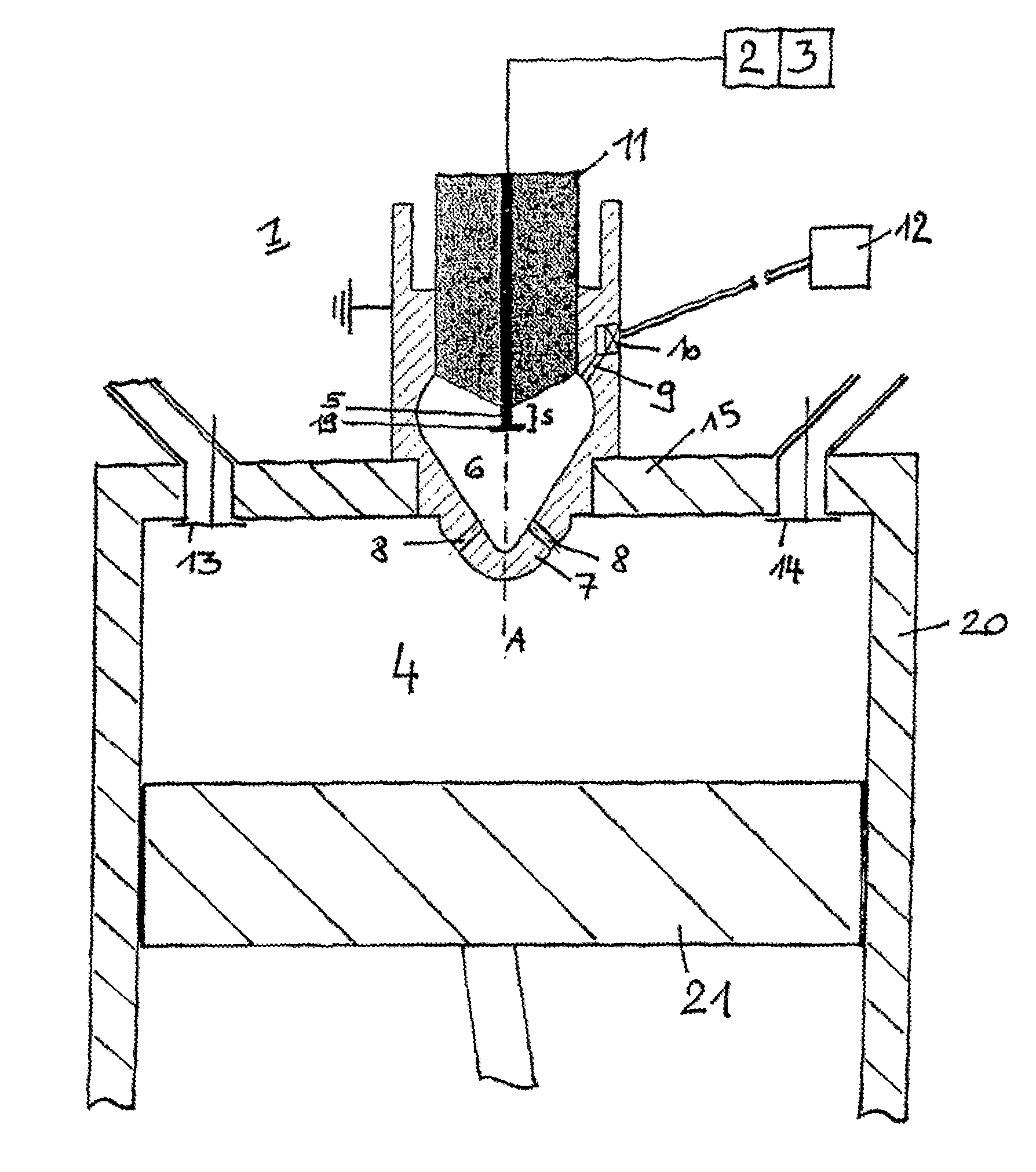

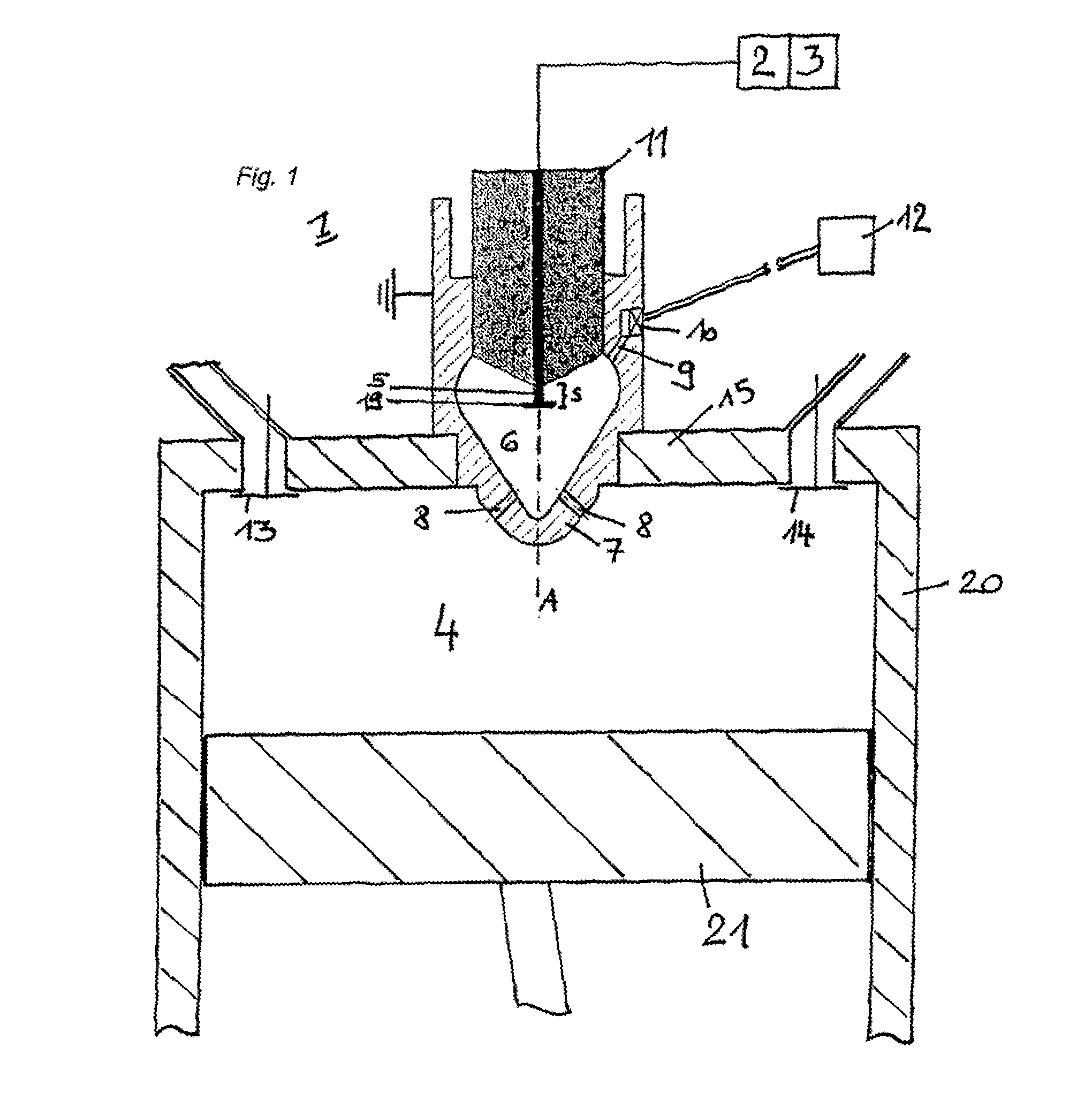

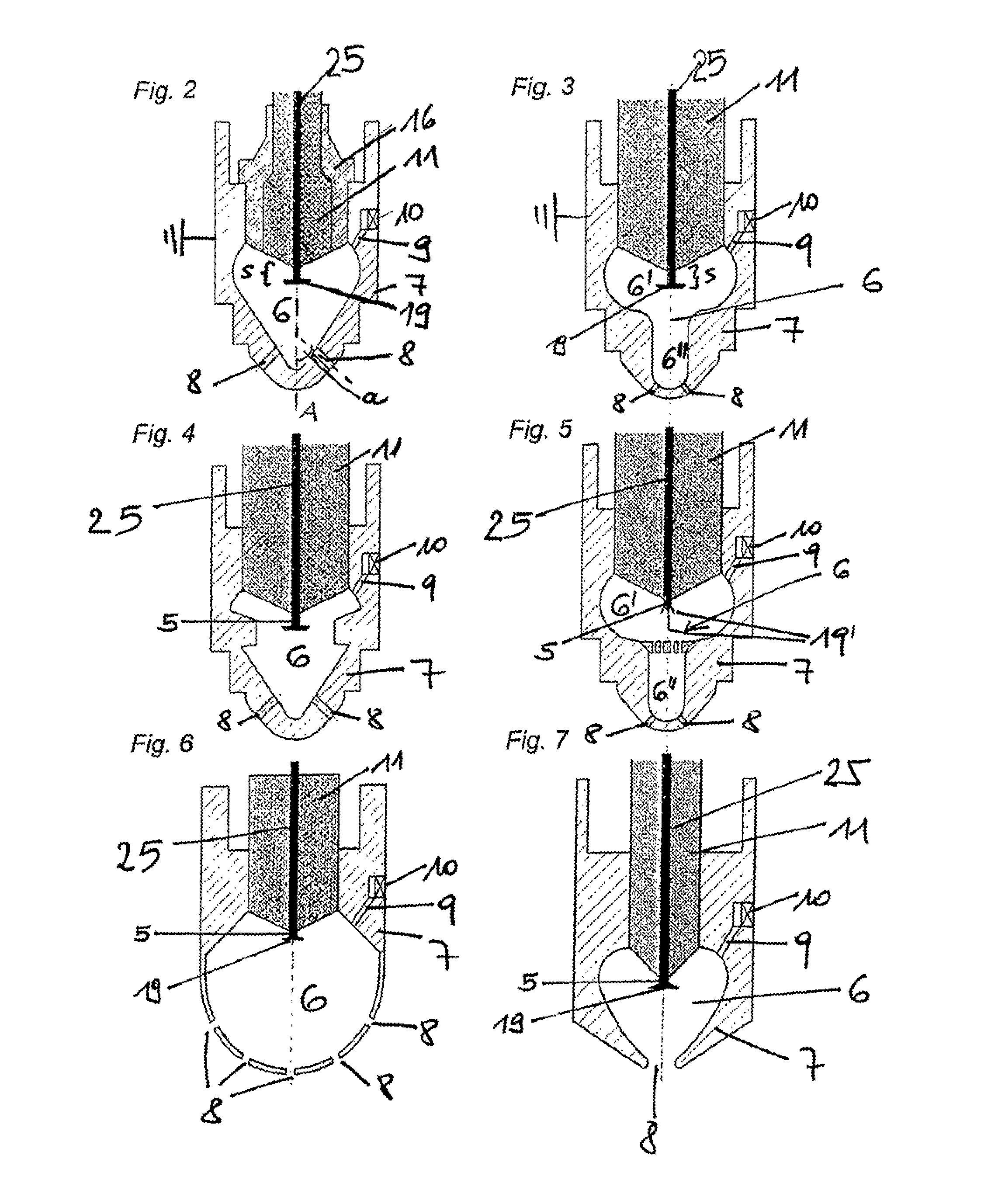

Device for igniting a fuel/air mixture

ActiveUS8191530B2Not easy to damageLower energy requirementsSparking plugsInternal combustion piston enginesCombustion chamberCorona discharge

The invention relates to a device for igniting a fuel / air mixture in the combustion chamber of an internal combustion engine. The device includes an electrode which is connected to a voltage source and extends into a precombustion chamber, and the precombustion chamber is separated at least in some regions from the combustion chamber by a wall. A control device or a regulating device is provided which controls the voltage supply to the electrode such that a corona discharge is carried out in the precombustion chamber. The wall has at least one opening for exchanging fluids between the combustion chamber and precombustion chamber, and a fluid inlet opens into the precombustion chamber.

Owner:GE JENBACHER

Vertical layer combustion refuse incinerating device

InactiveCN1824998AEnsure complete combustionDecompose fullyIncinerator apparatusCombustion chamberEngineering

There is disclosed a vertical layer combustion refuse incineration device, which comprises a vertical layer combustion furnace, two combustion chambers and a rotary driver. The incineration device is adapted for middle-sized and small cities, especially adapted for the house refuse incineration and treatment of the small cities.

Owner:江苏天楹赛特环保能源集团有限公司

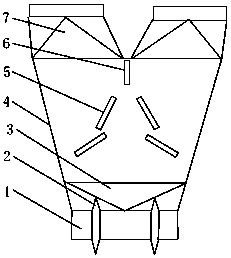

Combustor for efficiently and stably combusting anthracite coal in decomposition furnace

InactiveCN105864758AReduce the dosage ratioCalcination heat consumption reducedPulverulent fuel combustion burnersAutomatic controlCombustor

The invention relates to a combustor for efficiently and stably combusting anthracite coal in a decomposition furnace. The combustor consists of a center air passage, a clean air passage and an annular space, wherein the annular space is formed between the center air passage and the clean air passage; a plurality of coal air passages are uniformly distributed inside the annular space; a rotational porous annular partition is arranged at the outlet of the annular space; the outlet end of the center air passage and the outlet end of the clean air passage are each provided with a rotational flow generating device; the outlet of the center air passage adopts an external expansion design; the outlet of the clean air passage adopts an internal shrinkage design. The combustor disclosed by the invention is unique in structure and capable of making coal powder be completely coated and preheated by high-temperature tertiary air; meanwhile, clearances exist among a plurality of coal powder beams, so the contact area between high-temperature gas and the coal powder is greatly increased, the preheating speed of coal powder flow is remarkably increased, the anthracite coal is enabled to reach the ignition temperature after entering a high-oxygen-concentration region, the combustion efficiency is improved, and the amount of consumed coal is reduced; the amount of fed coal is automatically controlled, and the porous annular partition is rotationally regulated, so the rigidity of coal air is stabilized, the thermal load in a hearth is also effectively regulated, the combustion stability is guaranteed, the temperature in the decomposition furnace is uniformly distributed, and emission of NOx is reduced.

Owner:XIANGTAN UNIV

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490BSolve the problem of air pollutionPollution realizedSolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

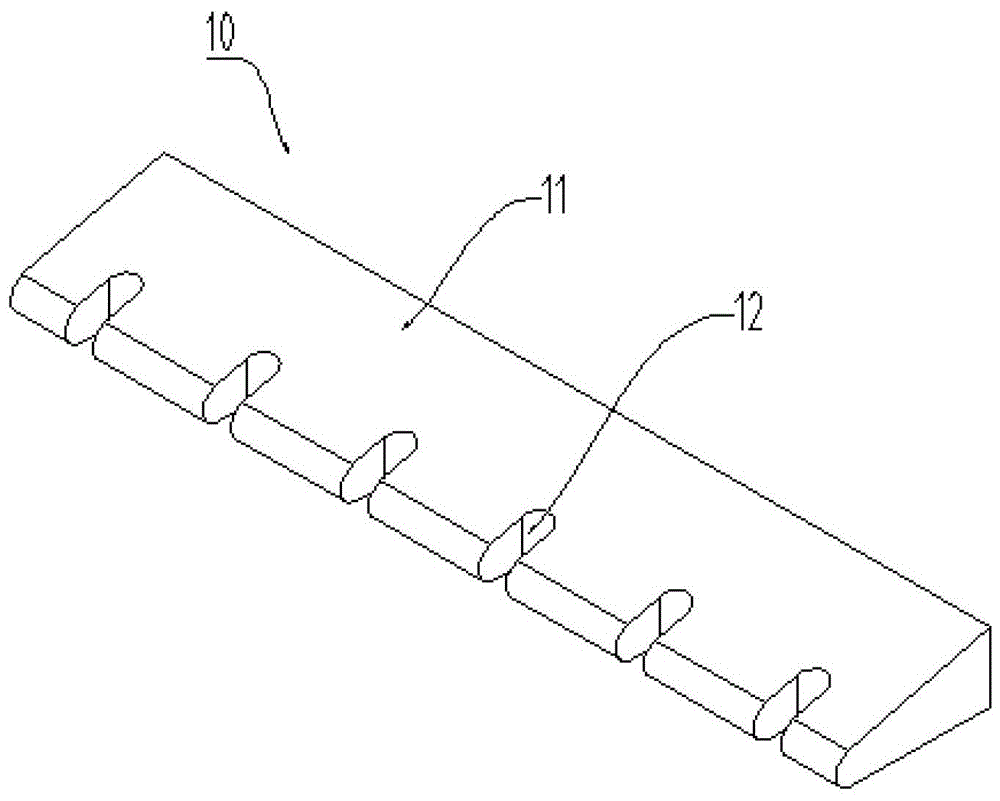

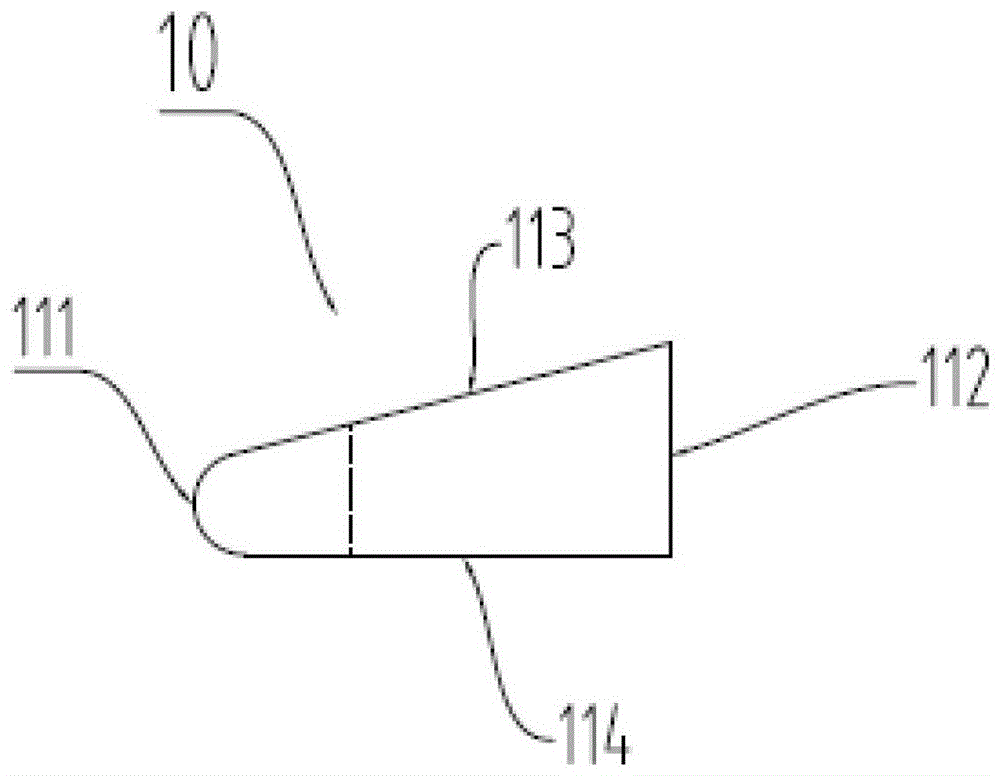

Small Wave Flame Disturbance Extended Combustion Device

InactiveCN103032870BIncrease disturbanceIncrease temperatureSolid fuel combustionCombustion apparatusFlue gasEngineering

The invention provides a small-wave flame disturbance extension combustion device, which comprises a main body and at least two grooves, wherein the main body is a hexahedron; the hexahedron comprises an upper surface, a lower surface, a front surface, a back surface and two side faces; the side faces are fixedly connected with the side wall of a chain furnace; the back surface is fixedly connected with the front arch surface or the back arch surface of the chain furnace; and the front end of the main body passes from the upper surface to the lower surface, so that the grooves are formed. Due to the adoption of the small-wave flame disturbance extension combustion device provided by the invention, the disturbance of flue gas is enhanced remarkably, the combustion of combustible matters in the flue gas is enhanced, the temperature of the flue gas is raised, thermal radiation on a coal bed is enhanced, the coal bed firing condition of the chain furnace can be improved remarkably, and the adaptability of the chain furnace to coal quality is enhanced. The small-wave flame disturbance extension combustion device is suitable for boiler design and technical reconstruction of the conventional boiler.

Owner:北京中煤神州节能环保技术开发有限公司

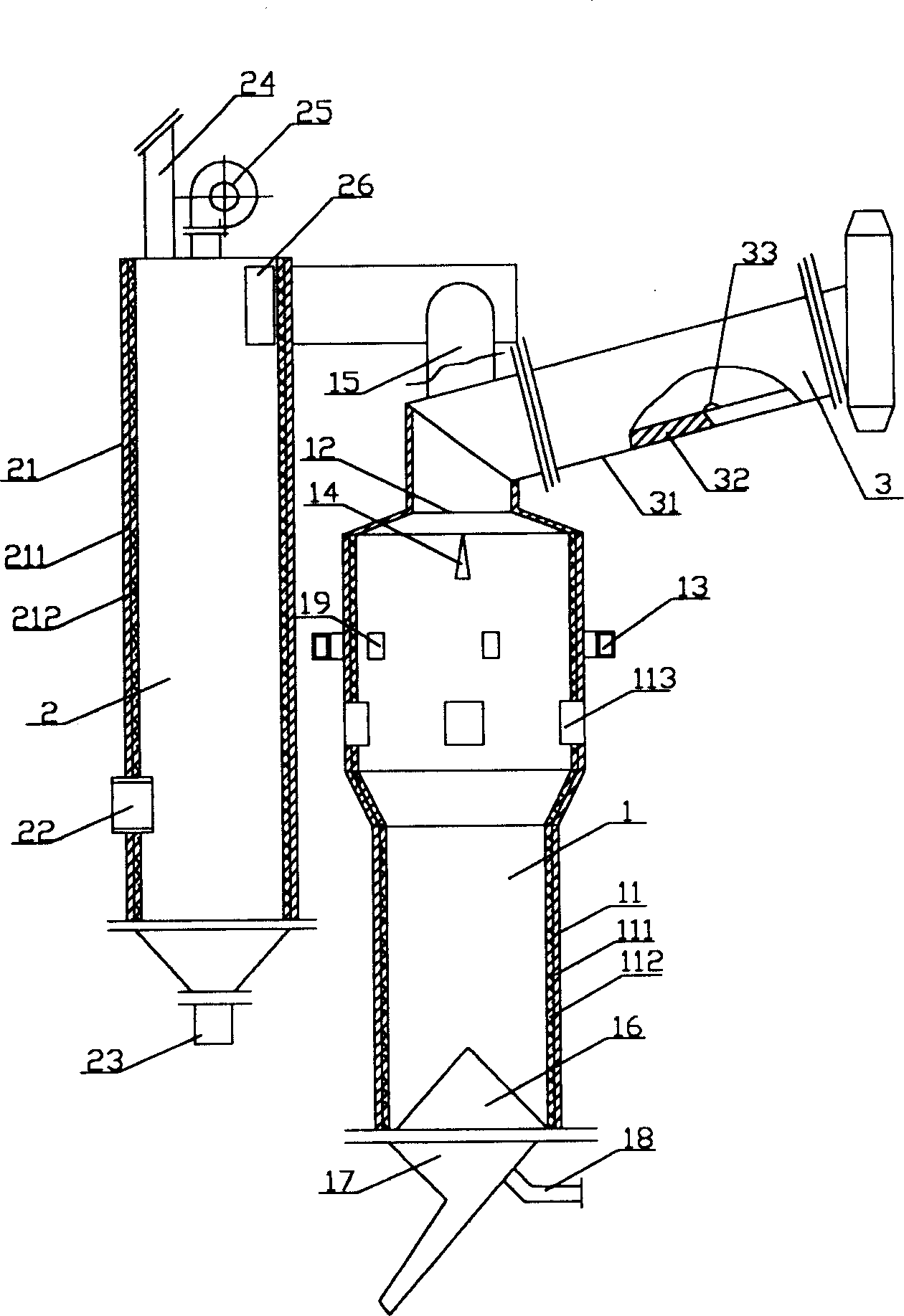

Circulating fluidized bed type high temperature hot blast stove system

InactiveCN1877195BFast fluidized stateGuaranteed to loop multiple timesFluidized bed combustionAir heatersAir preheaterFluidized bed

The invention relates to a cycle fluid bed high-temperature hot wind furnace, which comprises a hearth, a separator, a wind distributor, a material feeder, a high-low temperature exchanger and an airpreheat device. The invention is characterized in that: the hearth uses direct-current boiler type; the ascending tube uses three parallel tubes, to increase the heated area, avoid high-temperature smoke brushing the wall, and prolong the service life of wall; and guiding tail smoke into the secondary wind, to circulate the smoke and adjust the smoke temperature, strengthen the heat transmission and realize quick load adjustment; the air preheat device has a torsion plate as the turbolator to strengthen the heat transmission; and uses interlayer heater to confirm the clearness of hot wind; andcalculating each part, to select steel according to the temperature to reduce the consumption and refractory steel and reduce cost, based on confirmed strength.

Owner:XI AN JIAOTONG UNIV

Little oil burner of double-sided ignition combination blunt body

InactiveCN101696801BHeating fastExtended stayPulverulent fuel combustion burnersCombustion chamberResidence time

The invention discloses a little oil burner of a double-sided ignition combination blunt body. A primary air pipeline is communicated with a secondary coal dust combustion chamber through a section of coal dust concentrator formed by a tapered pipeline with a throat part formed through invagination, a primary coal dust combustion chamber is arranged in the secondary coal dust combustion chamber, and the secondary coal dust combustion chamber extends into a tertiary coal dust combustion chamber. The upper side surface and the lower side surface of the tertiary coal dust combustion chamber connected with the secondary coal dust combustion chamber are provided with a plurality of secondary air inlets in equal intervals, an upper oil combustion chamber and a lower oil combustion chamber are arranged on the primary coal dust combustion chamber after aslant penetrating through the secondary coal dust combustion chamber, a combination blunt body is arranged at the port of the secondary coal dust combustion chamber, and a plurality of through-flow holes are arranged on the upper surface and the lower surface of the second coal dust combustion chamber positioned in the tertiary coal dust combustion chamber. By adopting the top and bottom arrangement of two oil guns, coal dust entering into the primary coal dust combustion chamber are ignited in a double side way, which strengthens turbulent mass and heat exchange of coal dust current and oil flame to rapidly heat the coal dust and form a fire curtain, thereby prolonging the residence time of the coal dust and strengthening the ignition process.

Owner:CHINA JILIANG UNIV

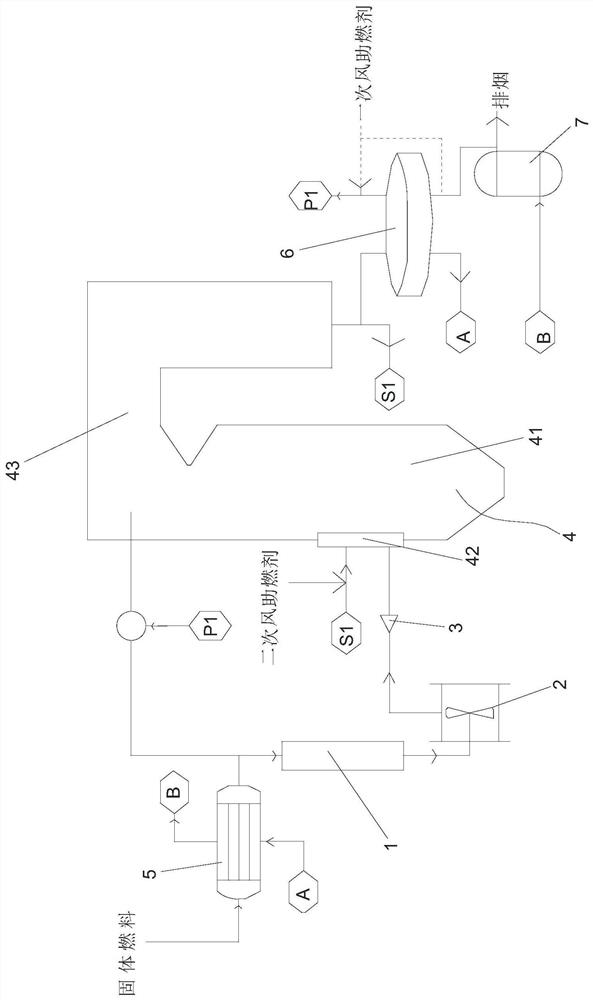

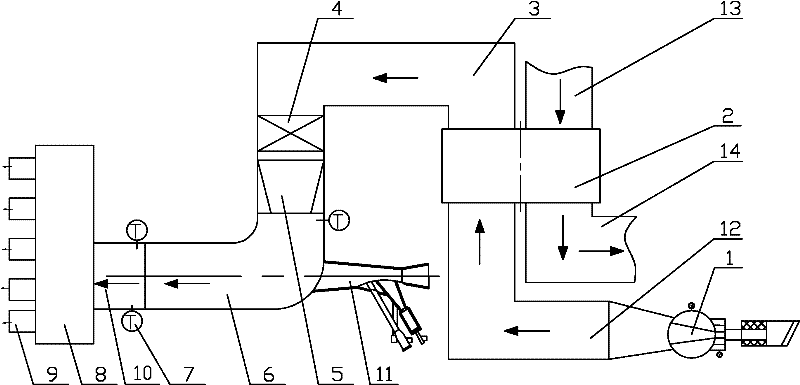

Oxygen-enriched combustion boiler system for multistage drying of lignite

ActiveCN111810940AMore evaporationGuaranteed uptimeFuel feeding arrangementsSolid fuel pretreatmentBrown coalThermodynamics

The invention relates to an oxygen-enriched combustion boiler system for multistage drying of lignite. The oxygen-enriched combustion boiler system comprises a front dryer, a drying pipe, a coal mill,a pulverized coal distributor, a boiler, a gas preheater and a desulfurization and dehydration device which are sequentially connected in series. Compared with the prior art, according to the oxygen-enriched combustion boiler system, under the condition that normal, safe and continuous operation of the system is guaranteed, the recycling smoke is fully utilized for pre-drying lignite, and part ofwater in fuel is discharged out of the system before combustion, so that the fuel combustion efficiency is improved, the boiler smoke exhaust heat loss is reduced, the boiler heating area is remarkably reduced, the steel consumption and the manufacturing cost of the boiler are reduced, and thus the whole system has higher technical economy. In the system, the concentration of CO2 in the discharged smoke can be greatly improved by applying the oxygen-enriched combustion technology, and the recovery cost and difficulty of CO2 are greatly simplified.

Owner:TONGJI UNIV

Method for jointly controlling emission of NOx by utilizing multi-stage bias combustion and fuel reburning

ActiveCN101569829BAdvantages of enhanced controlWide adaptabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlagEngineering

The invention belongs to the technical field of pulverized coal combustion, and discloses a method for jointly controlling the emission of NOx by utilizing multi-stage bias combustion and fuel reburning. The method comprises the steps: arranging a multi-stage bias burner containing 2 to 6 layers of bias burners in a multi-stage bias combustion area, sending 75 to 85 percent of fuel into the multi-stage bias combustion area, and generating flue gas containing the NOx during the combustion; spraying mixed reburning fuel of 15 to 25 percent of coal and biomass fuel into a mixed reburning area, forming a reburning reduction area, precipitating CHi and NHi active groups by the mixed reburning fuel in reducing atmosphere, and reacting the CHi and NHi active groups with the NOx generated in the multi-stage bias combustion area to be reduced into N2; and spraying the air into a burnout area, and completely combusting combustible substances which are not completely combusted. The method can efficiently control the emission of the NOx, ensure that the removal efficiency of the NOx is more than 80 percent, realize the combustion of high pulverized coal concentration, improve the performance of ignition and steady combustion, improve the adaptability of coal types, effectively prevent the slag bonding of water-cooled walls, and achieve the aims of improving boiler efficiency, saving energy and reducing consumption.

Owner:黄震

Main burner equipment with outer rotational flow and inner direct flow

ActiveCN1308617CIncrease swirl intensityEnhanced entrainmentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention is the outer cyclone inner direct flow main combustor device and belongs to the combustor device of boiler. The purpose of the invention is to produce the backflow area and the stable combustion. One device of the invention is to evenly arrange the delivery blades between the primary air diverting tube and the delivery tube, and the inside diameter of the delivery tube is as 0.5-0.7 times as the diameter of the primary air diverting tube. The other device is to evenly arrange the delivery blades in the inner chamber of the primary air diverting tube, and the axial height of the delivery blades is as 0.1-0.5 time as the semi-diameter of the primary air diverting tube. The invention through changing the opposite angles, the number, the length and the height of the delivery blades and the lengths and the section of the delivery tube to change the intensity and the size of the cyclone amount to adapt the characteristics of different fuels and ensure the stability and economy of the boiler combustion. The invention has simple structure and convenient equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Oxygen-enriched combustion W-shaped flame boiler system and combustion process thereof

ActiveCN103017151BReduce recirculation fan powerLow powerIndirect carbon-dioxide mitigationCombustion apparatusSlagFlue gas

The invention provides an oxygen-enriched combustion W-shaped flame boiler system and a combustion process thereof. Flue gas discharged from a dewaterer is divided into two strands, wherein one strand of flue gas sequentially enters a desulfurization device and a CO2 recovery device and the other strand of flue gas enters a gas-gas heat exchanger and is heated by flue gas in a main flue; the flue gas in the main flue also heats O2 separated in the air when heating the recycled flue gas; the heated recycled flue gas is divided into three strands; O2 is divided into two strands; after the first strand of O2 is mixed with the first strand of recycled flue gas, the mixed gas enters a coal mill and enters a primary air pipeline; after the second strand of O2 is mixed with the second strand of recycled flue gas, the mixed gas enters a furnace arch secondary air pipeline; and the third strand of recycled flue gas enters a front and rear wall secondary air pipeline The system provided by the invention overcomes the defects in the prior art and greatly improves ignition conditions of a hearth; when the radiation and heat adsorption area of a lower hearth is effectively increased, slag-bonding possibility is greatly reduced; efficiency of the integral system is improved; steel consumption and manufacturing cost of a boiler are reduced; and zero emission of CO2 can also be realized.

Owner:SHANGHAI BOILER WORKS

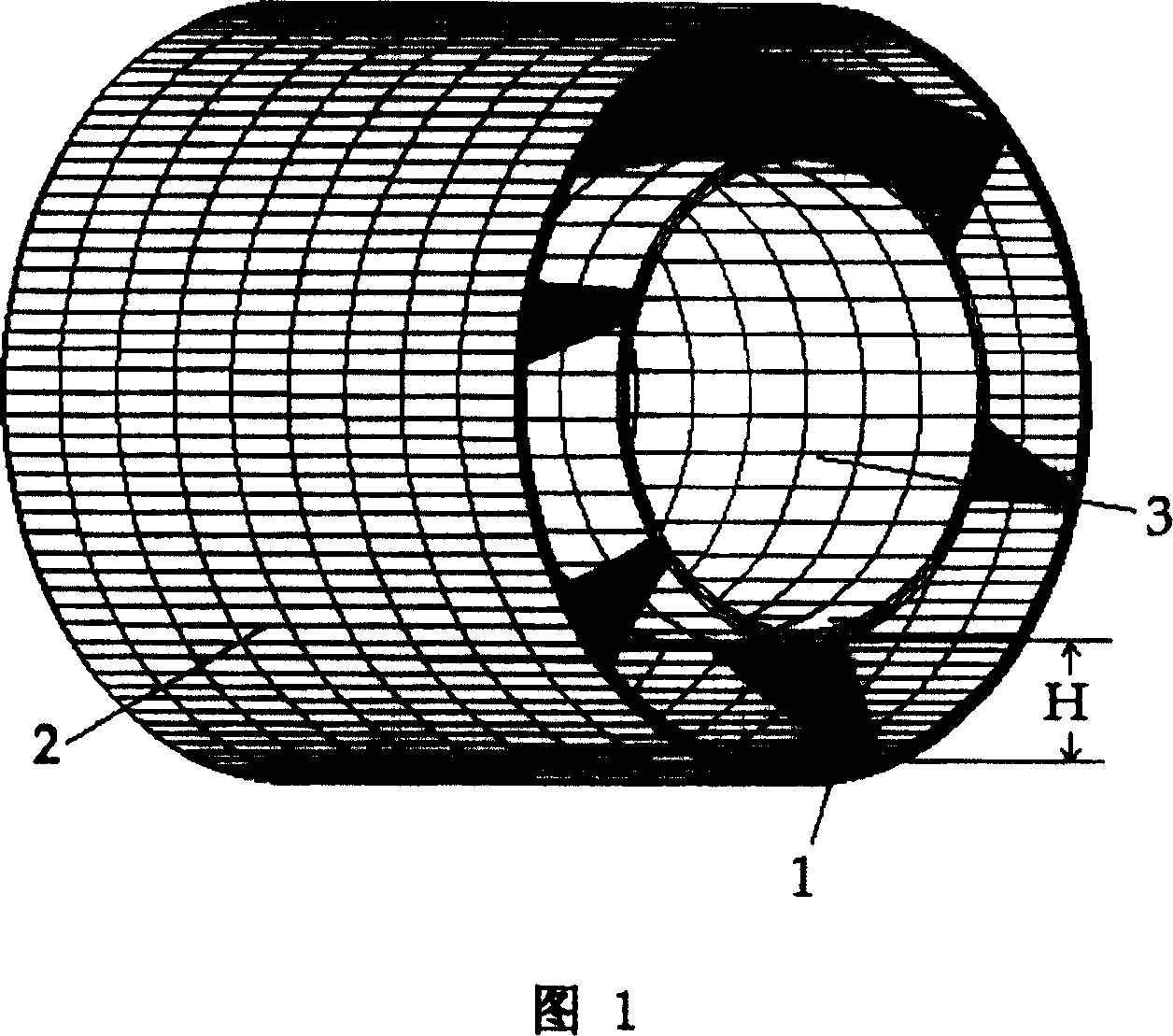

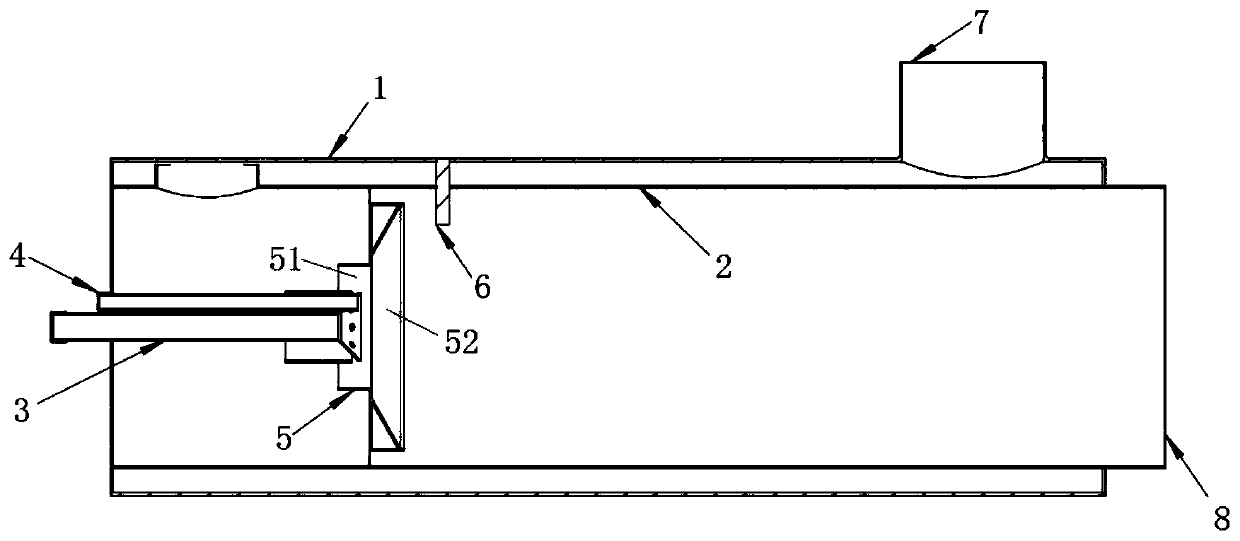

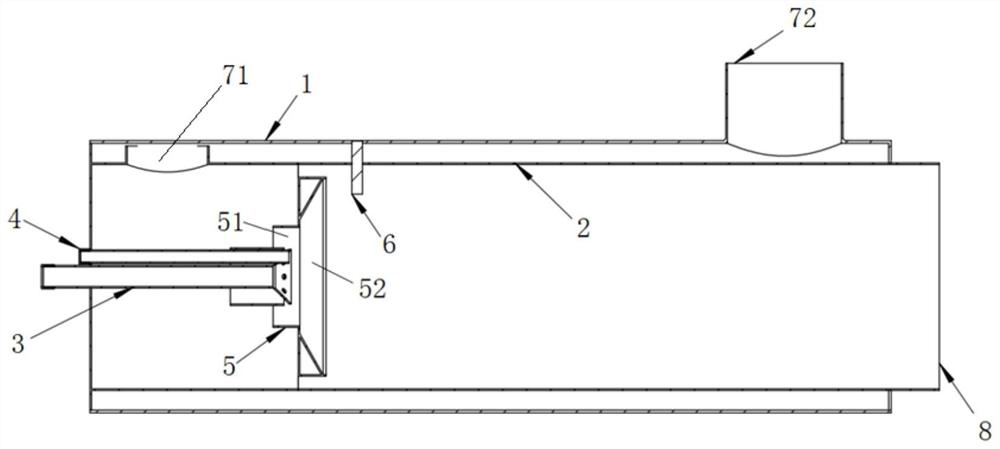

Duct burner for diesel engine

ActiveCN110953580AImprove fuel ignition conditionsGuarantee normal combustionBurnersExhaust apparatusExhaust gasFlue gas

The invention provides a duct burner for a diesel engine. The outer cylinder wall of the burner is arranged on the outer part of the inner cylinder wall of the burner in a nesting mode, the end of theinner cylinder wall is sealed and provided with an ignition gun and an oil gun, the other end of the inner cylinder wall of the burner is opened as a flue gas outlet, and flue gas inlets are formed in the inner cylinder wall of the burner and the outer cylinder wall of the burner; a firing stabilizer is arranged in the inner cylinder wall of the burner and located on the rear side of the oil gun,and a fire detection device is arranged on the rear part of a nozzle of the firing stabilizer. According to the duct burner, the fuel ignition conditions are improved by preheating air, and when theduct burner is operated at low power and low oxygen content, the normal combustion of the small-flow fuel is ensured; because of the two-stage atomization mode, the particle diameter of the fuel is smaller, the distribution is more uniform, and the combustion is better under the low-power and low-oxygen environment; by adjusting the relative position of inner and outer casings of the oil gun, thefuel flow can be adjusted auxiliarily, and the exhaust gas temperature is facilitated to be more accurately controlled; and the fuel and an atomizing medium can be fully accelerated by a two-stage spray pipe structure of the head of the oil gun, the atomization effect is enhanced, and thus the fuel is better ignited and burned.

Owner:SHANGHAI POWER EQUIP RES INST

A jet-type pulverized coal distribution online adjustment system

ActiveCN108679639BImprove fire conditionsImprove securityFuel supply regulationLump/pulverulent fuel feeder/distributionThermodynamicsJet flow

Owner:NANJING UNIV OF SCI & TECH

System for increasing pulverizing and drying output force during doped lignitous coal burning of burning bituminous coal boiler

ActiveCN102155842BImprove combustion efficiencyIncrease contentDrying gas arrangementsAir preheaterBrown coal

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

A double adjustable pulverized coal distributor

ActiveCN106090981BEvenly distributedImprove fire conditionsFuel feeding arrangementsLump/pulverulent fuel feeder/distributionCombustorWear resistant

The invention provides a pulverized coal distributor allowing double angles to be adjusted. A pulverized coal inlet is formed in the lower part of a middle casing; two spindly baffles are arranged in the pulverized coal inlet; a diffusion tube section is arranged in the lower part of the middle casing, and two symmetric pulverized coal outlets are formed in the upper part of the middle casing; a middle partition board is arranged between two pipelines of the pulverized coal outlets; louvers are mounted in a cavity of the middle casing. Wear-resistant ceramic is attached to inner walls of the pulverized coal inlet, the diffusion tube section, the middle casing and the pulverized coal outlets, and the louvers and the middle partition board are overall made of wear-resistant ceramic through firing. Pulverized coal and air at the outlets are uniformly distributed by adjusting the louvers, the middle partition board and the spindly baffles in the pulverized coal distributor, the ignition condition of a burner is good, burning in a boiler is stable, and the safety and the economical performance of the unit are improved. Besides, the pulverized coal distributor allowing double angles to be adjusted is simple to adjust, wear-resistant, free from leaking, long in service life and suitable for being mounted in narrow space.

Owner:北京中电联众电力技术集团有限公司 +2

A post-combustion burner for diesel engine

ActiveCN110953580BImprove fire conditionsGuaranteed normal combustionBurnersExhaust apparatusCombustorFlue gas

The invention provides a post-combustion burner for diesel engines. The outer cylinder wall of the burner is nested and arranged outside the inner cylinder wall of the burner. One end of the inner cylinder wall of the burner is sealed and an ignition gun and an oil gun are arranged. The inner cylinder of the burner The other end of the wall is opened as the flue gas outlet, and there are flue gas inlets on the inner cylinder wall of the burner and the side wall of the outer cylinder wall of the burner; Set behind the nozzle of the burner. The invention improves fuel ignition conditions by preheating air, and ensures the normal combustion of fuel with a small flow rate during low-power and low-oxygen operation; the two-stage atomization method makes fuel particles smaller in diameter and more evenly distributed Combustion is better in an oxygen environment; by adjusting the relative position of the inner and outer sleeves of the oil gun, the fuel flow can be adjusted to facilitate more precise control of the exhaust temperature; the two-stage nozzle structure at the head of the oil gun can fully accelerate the fuel and atomization medium, and strengthen The atomization effect makes the fuel burn better.

Owner:SHANGHAI POWER EQUIP RES INST

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234BGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel andinhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

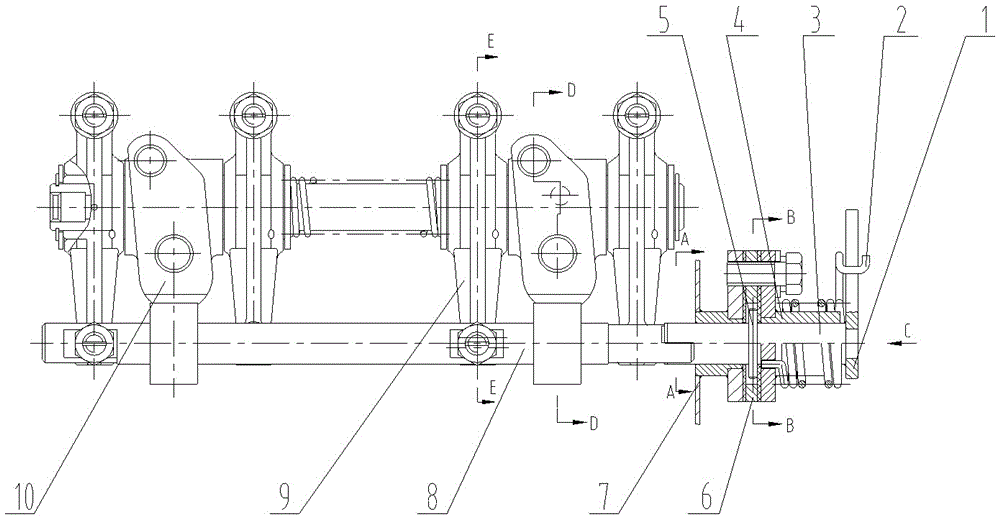

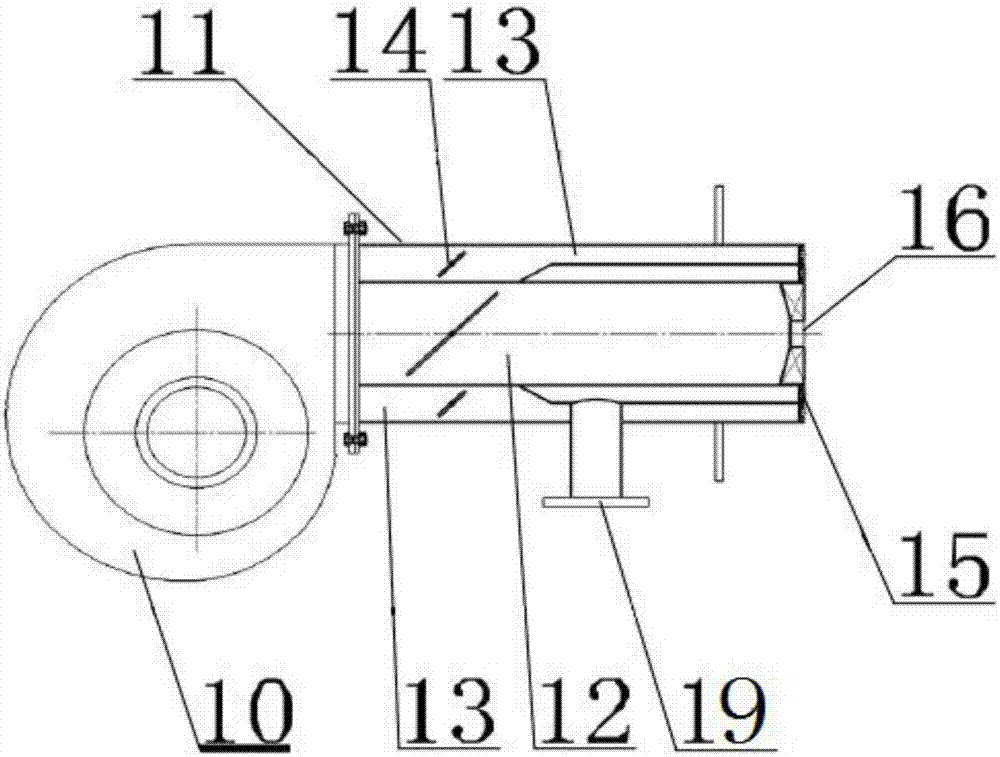

A two -cylinder diesel engine auxiliary starting decompression device

ActiveCN104131855BSimple structureReduce resistanceValve arrangementsCylinder headsLong armCylinder head

The invention relates to an auxiliary starting decompression device for a two-cylinder diesel engine. Wait. The valve rocker arm support is fixedly connected to the cylinder head by bolts, the valve rocker arm shaft is fixed in the shaft hole of the valve rocker arm support through the support top screw, and the valve rocker arm support lug through hole is sleeved on the decompression shaft superior. Both threaded holes on the decompression shaft are provided with decompression adjustment screws respectively corresponding to the longitudinal positions of the first and third valve rocker arms, and are locked by nuts. The end of the decompression adjustment screw is correspondingly abutted against the rear end of the long arm spherical contact of the first and third valve rocker arms. The flat groove at the end of the decompression shaft is keyed to the rear end of the decompression shaft. The present invention is simple in structure, only needs to add the decompression control device on the cylinder head cover, add a decompression shaft and decompression adjustment screw on the rocker arm part.

Owner:ANHUI QUANCHAI ENGINE

Single-return-stroke WNS-structure boiler

InactiveCN107228351AAvoid contactBurn out preventionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The present invention relates to the technical field of combustion and thermal energy conversion equipment, in particular to a single-return WNS structure boiler, including: a control cabinet, a burner, a pot shell, a corrugated furnace, a smoke pipe group, a water inlet, a hot water or steam outlet, and an economizer And the flue gas outlet, the water inlet, the hot water or steam outlet and the flue gas outlet are arranged on the surface of the pot shell. The burner, corrugated hearth and smoke pipe group are coaxially connected in sequence; the gas inlet is connected to the gas nozzle through the delivery pipe; a burner is arranged around the burner, and the burner is arranged at the other end of the installation pipe. The corrugated furnace and the smoke pipe group are installed in the pot shell to form a single-return structure; there is a flue gas outlet at the top of the tail of the pot shell, and an economizer is arranged between the flue gas outlet and the smoke pipe group. The invention saves the flue gas diverting parts, and adopts a single-return structure. The economizer is installed in the pot shell, and the structure is more compact, which is convenient for installation and transportation; efficiency, saving electricity.

Owner:陈黎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com