Oxygen-enriched combustion W-shaped flame boiler system and combustion process thereof

An oxygen-enriched combustion and flame technology, applied in the field of boiler combustion, can solve problems such as failure to consider collection, emission reduction, and insufficient research, and achieve the effects of improving ignition conditions, increasing efficiency, and reducing steel consumption and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

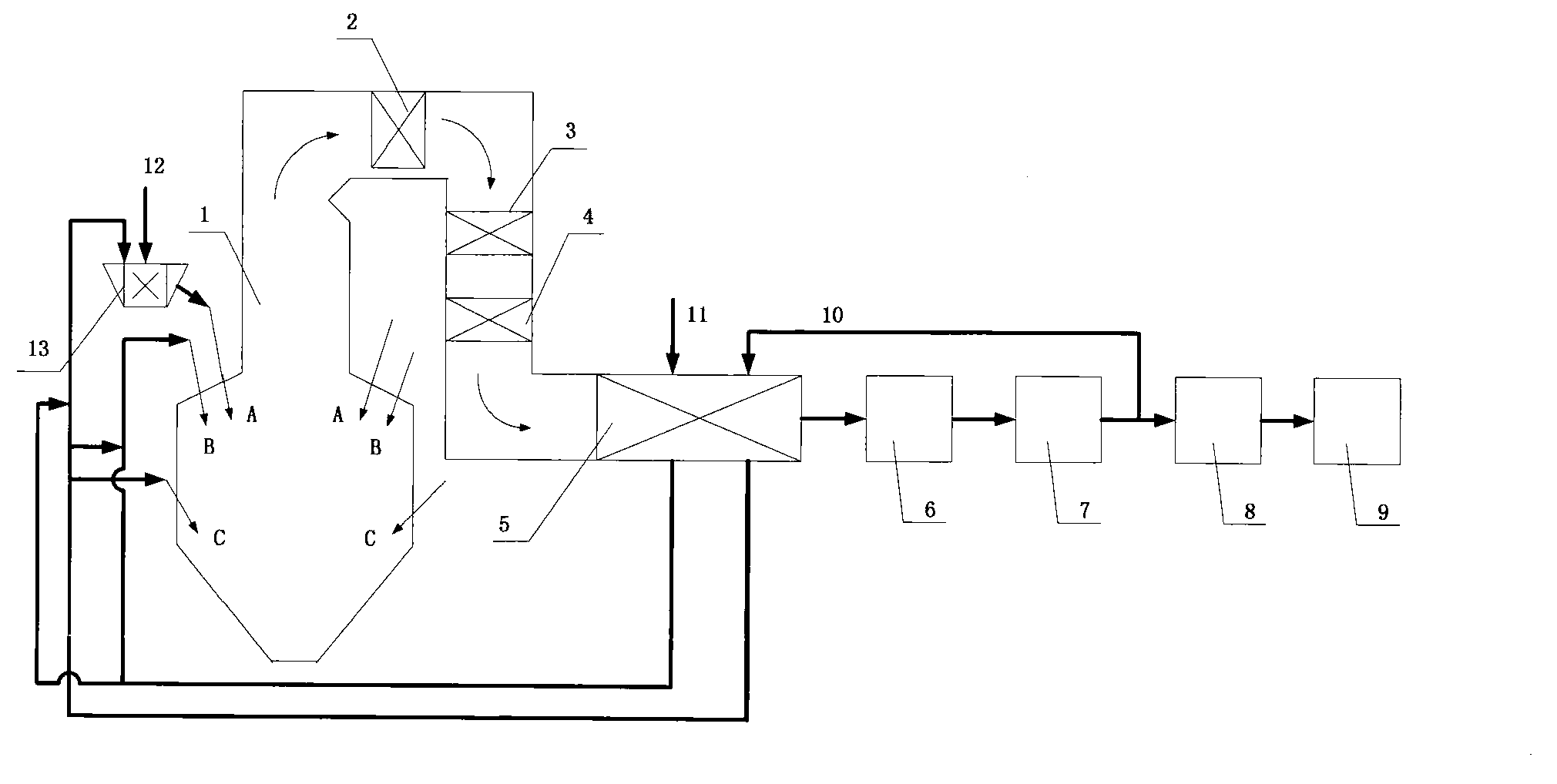

[0025] figure 1 It is a schematic diagram of an oxygen-enriched combustion W flame boiler system provided by the present invention. The described oxygen-enriched combustion W flame boiler system includes a W flame furnace 1, a superheater 2 is located in the top flue, and reheating furnaces are sequentially arranged in the tail flue. 3, economizer 4 and gas-gas heat exchanger 5; one end of water removal device 7 is connected to the main flue outlet of gas-gas heat exchanger 5 through dust collector 6, and the other end of water removal device 7 is connected to one end of desulfurization device 8, The other end of the water removal device 7 is connected to the input end of the recirculation flue gas of the gas-gas heat exchanger 5 through the recirculation flue gas channel; the CO 2 The recovery unit 9 is connected to the other end of the desulfurization unit 8;

[0026] Gas-gas heat exchanger 5 is also equipped with an O 2 Input side, gas-gas heat exchanger 5O 2 The export ...

Embodiment 2

[0031] The difference with embodiment 1 is:

[0032] A small amount of hygienic combustion belts are laid on the lower furnace water wall of the oxy-fuel combustion W flame boiler system.

[0033] In the combustion process of the oxygen-enriched combustion W flame boiler system, the O in the primary air 2 The volume share is 65%, and O in the furnace arch secondary air 2 The volume share is 40%, and the secondary air on the front and rear walls is recirculated flue gas; the O entering the furnace 2 The volume ratio of the recycled flue gas (the volume ratio under the standard state) is 1:1.7.

[0034] Other parts are all identical with embodiment 1.

Embodiment 3

[0036] The difference with embodiment 1 is:

[0037] A small amount of hygienic combustion belts are laid on the lower furnace water wall of the oxy-fuel combustion W flame boiler system.

[0038] In the combustion process of the oxygen-enriched combustion W flame boiler system, the O in the primary air 2 The volume share is 80%, O in the furnace arch secondary air 2 The volume share is 60%, and the secondary air on the front and rear walls is recirculated flue gas; the O entering the furnace 2 The volume ratio of the recycled flue gas (the volume ratio under the standard state) is 1:1.5.

[0039] Other parts are all identical with embodiment 1.

[0040] The oxygen-enriched combustion W flame boiler system provided by the present invention combines the oxygen-enriched combustion technology with the W flame boiler, almost no NOx gas is generated during the combustion process, and lower-cost desulfurization, denitrification and CO 2 Capture, and achieve zero emissions.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com