Patents

Literature

757results about "Fuel feeding arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid heating system

ActiveUS20100251973A1Facilitate control of fluid flowAvoid the needMechanical apparatusDomestic stoves or rangesEngineeringBiological activation

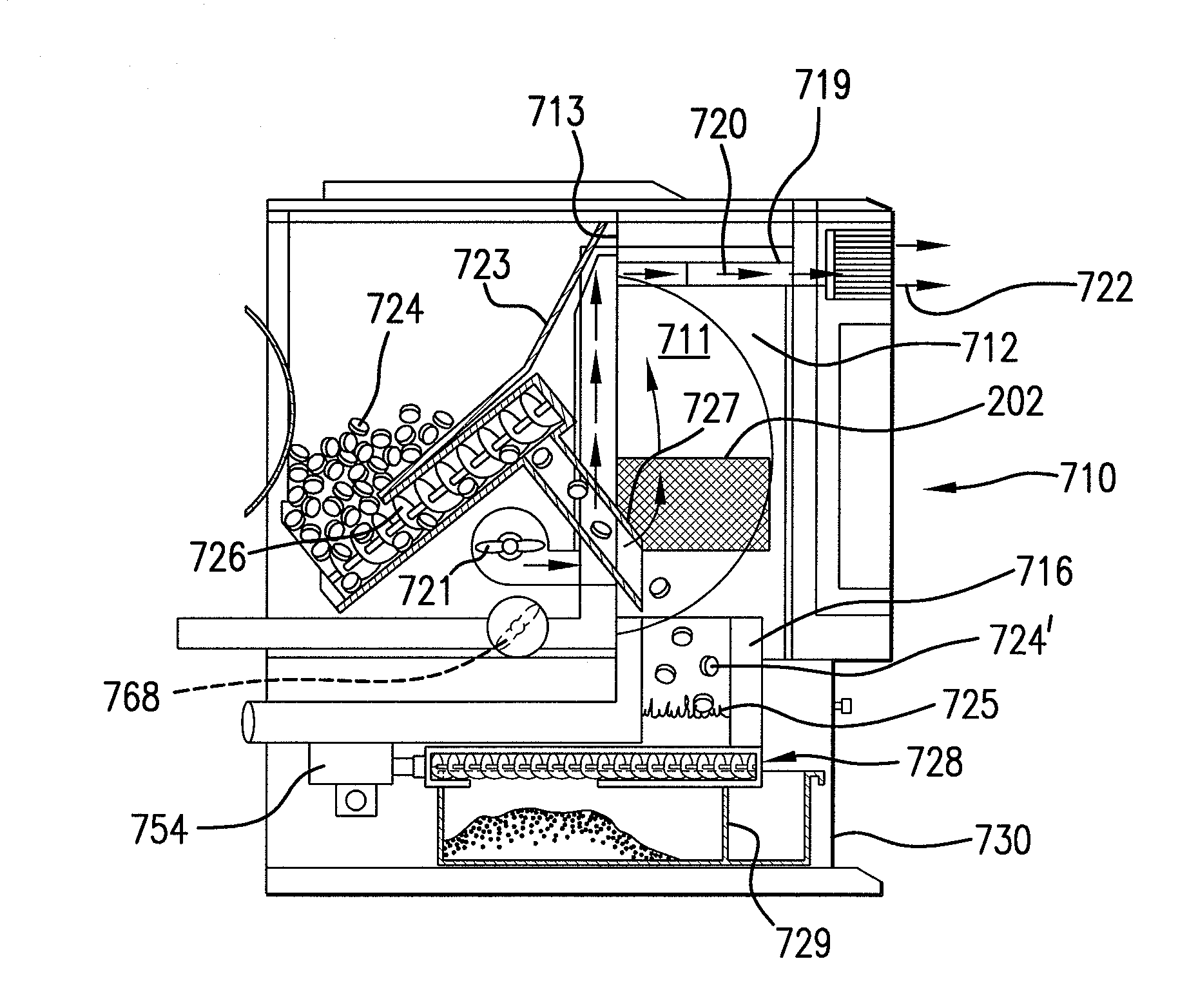

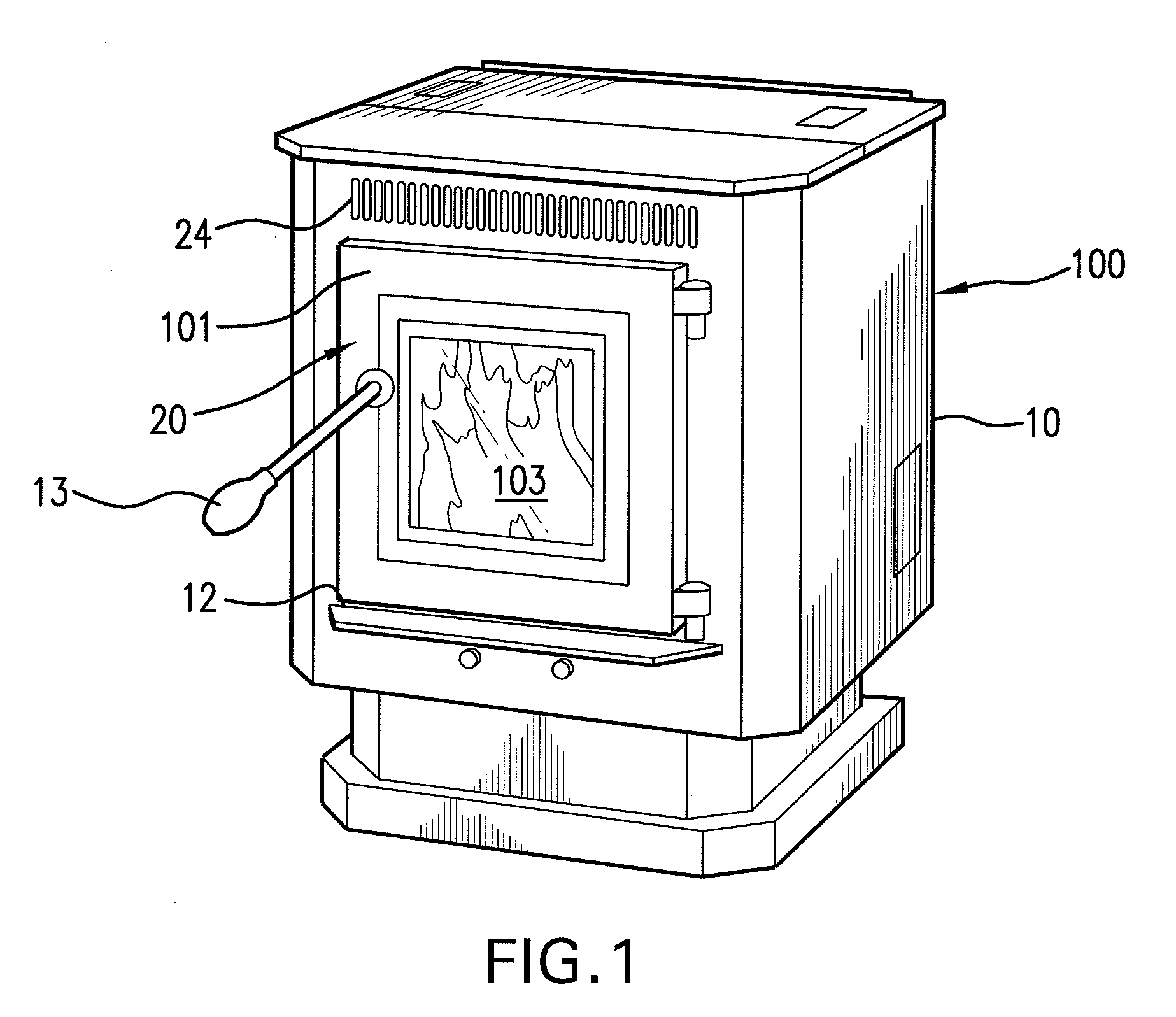

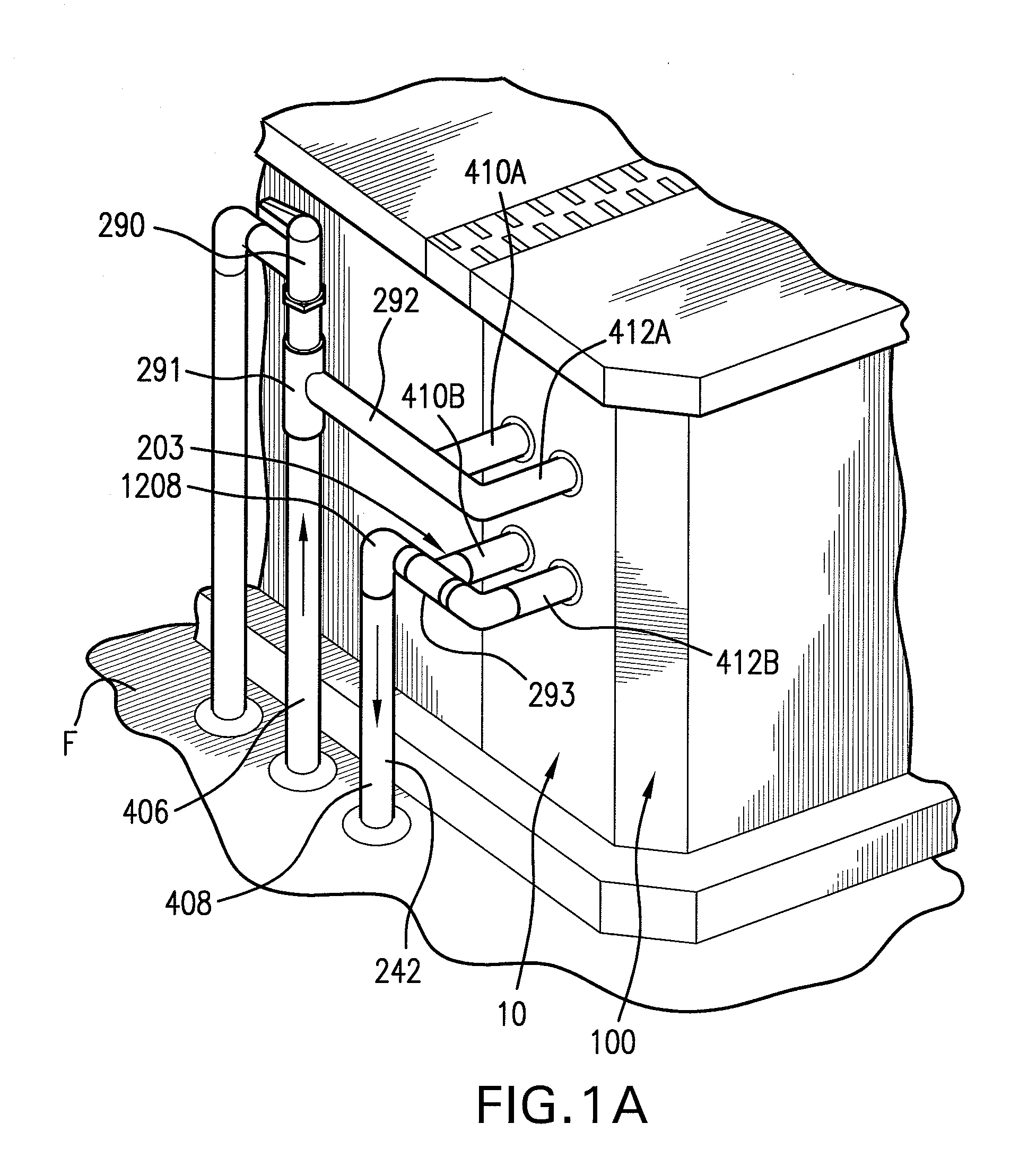

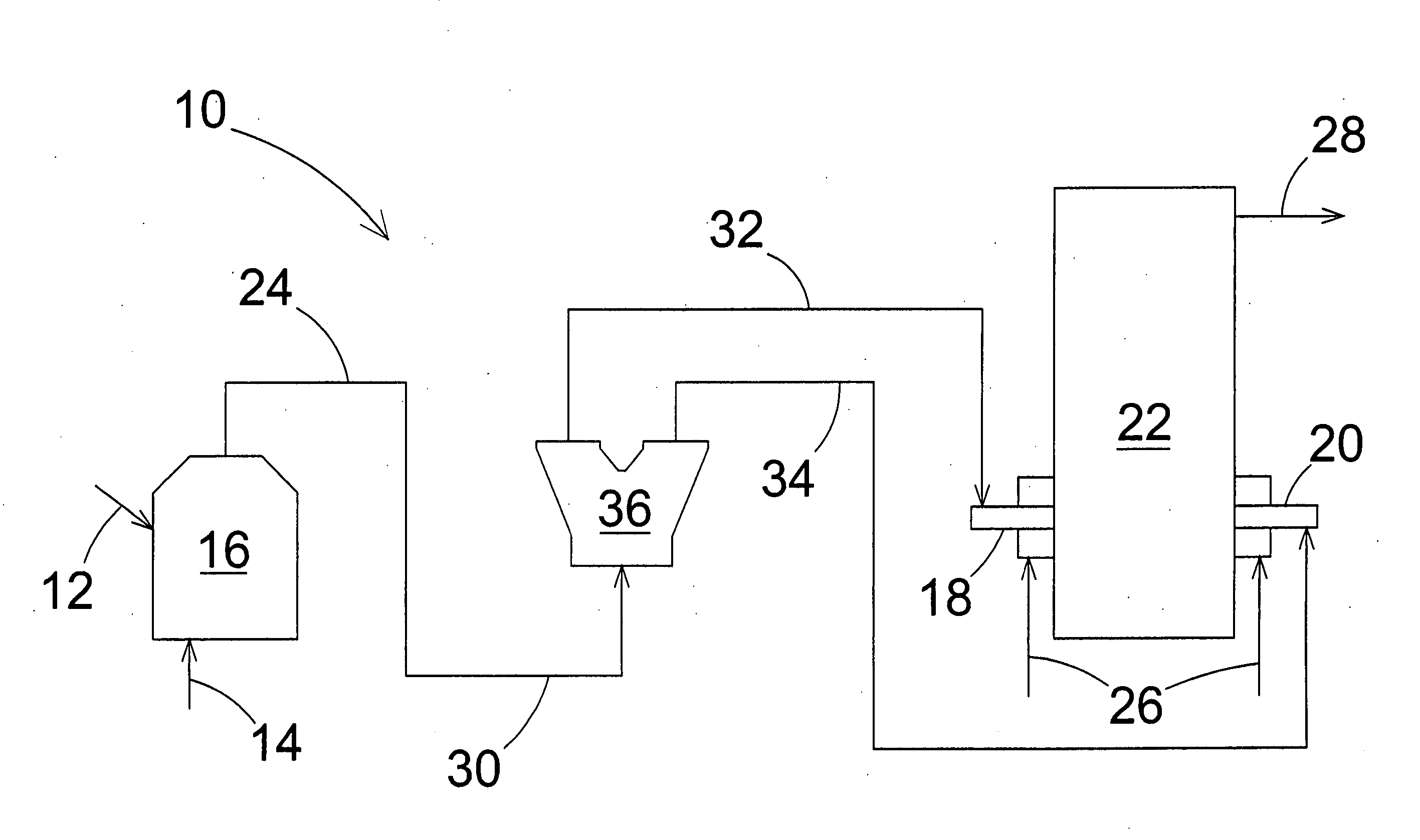

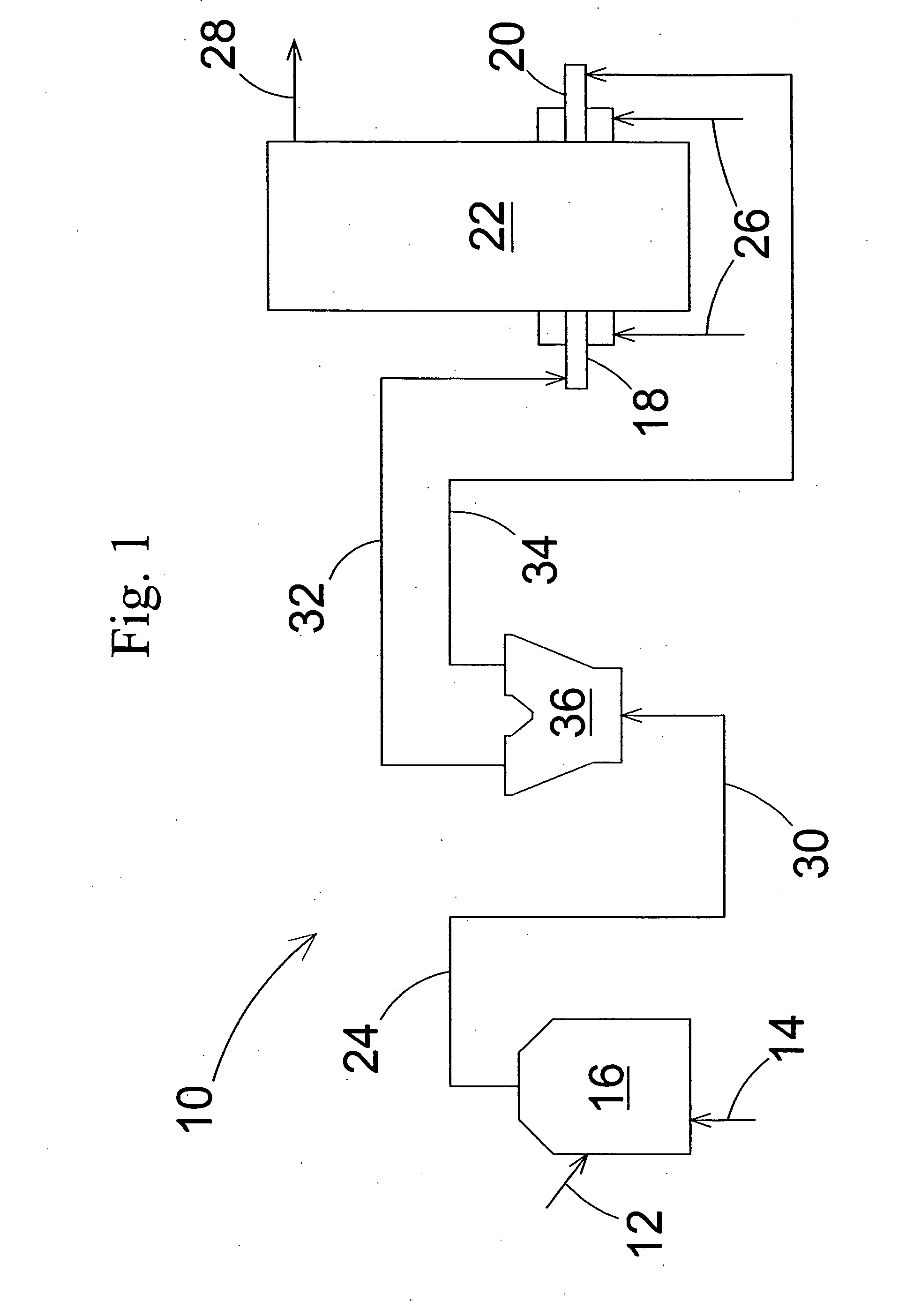

A fluid heat exchange system with a fluid flow circuit having a heat exchange fluid flow loop, a heat absorption component (as in a domestic hot water tank inclusive of small commercial use tanks as in tanks of 20 to 120 gallons), a heat exchanger and preferably also a pump. A controlled and automated fuel supply source based heater (as in a pellet stove) is in heat passage communication with the said heat exchanger. A control unit triggers activation of the pump upon fluid in the heat absorption component reaching or dropping below a preset temperature, and the fluid flow circuit is arranged such that, during times of non-activation of the pump, fluid is free to flow in a unidirectional flow within the fluid circuit based on thermodynamic temperature differentials alone. A retrofitting of a domestic hot water tank is also featured preferably making use of preexisting drain and safety vent porting for in-feed and out-feed porting in the exchange loop side. Also, the flow circuit preferably is free of check valves and steam accommodation equipment.

Owner:DONGO KENNETH A +1

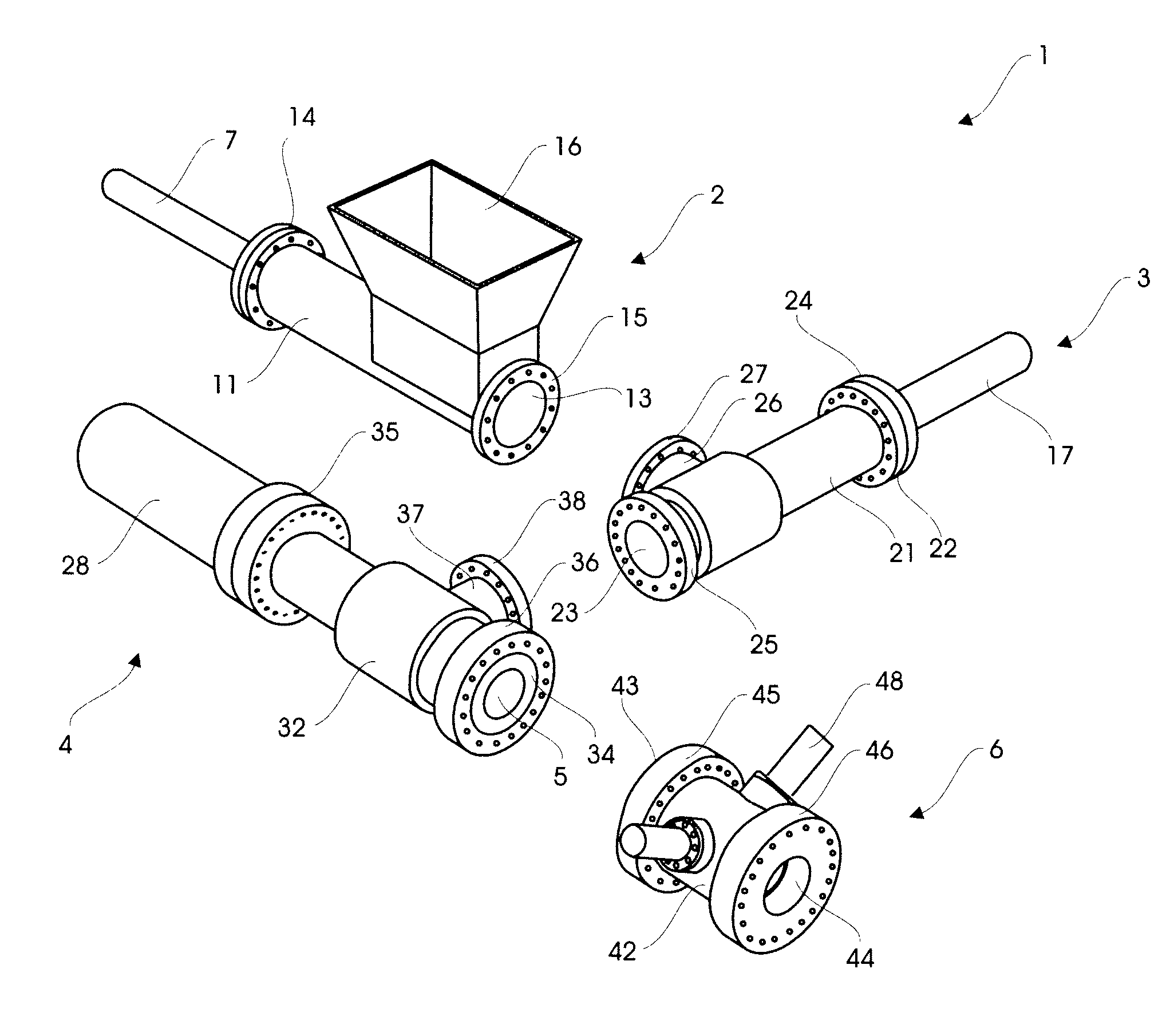

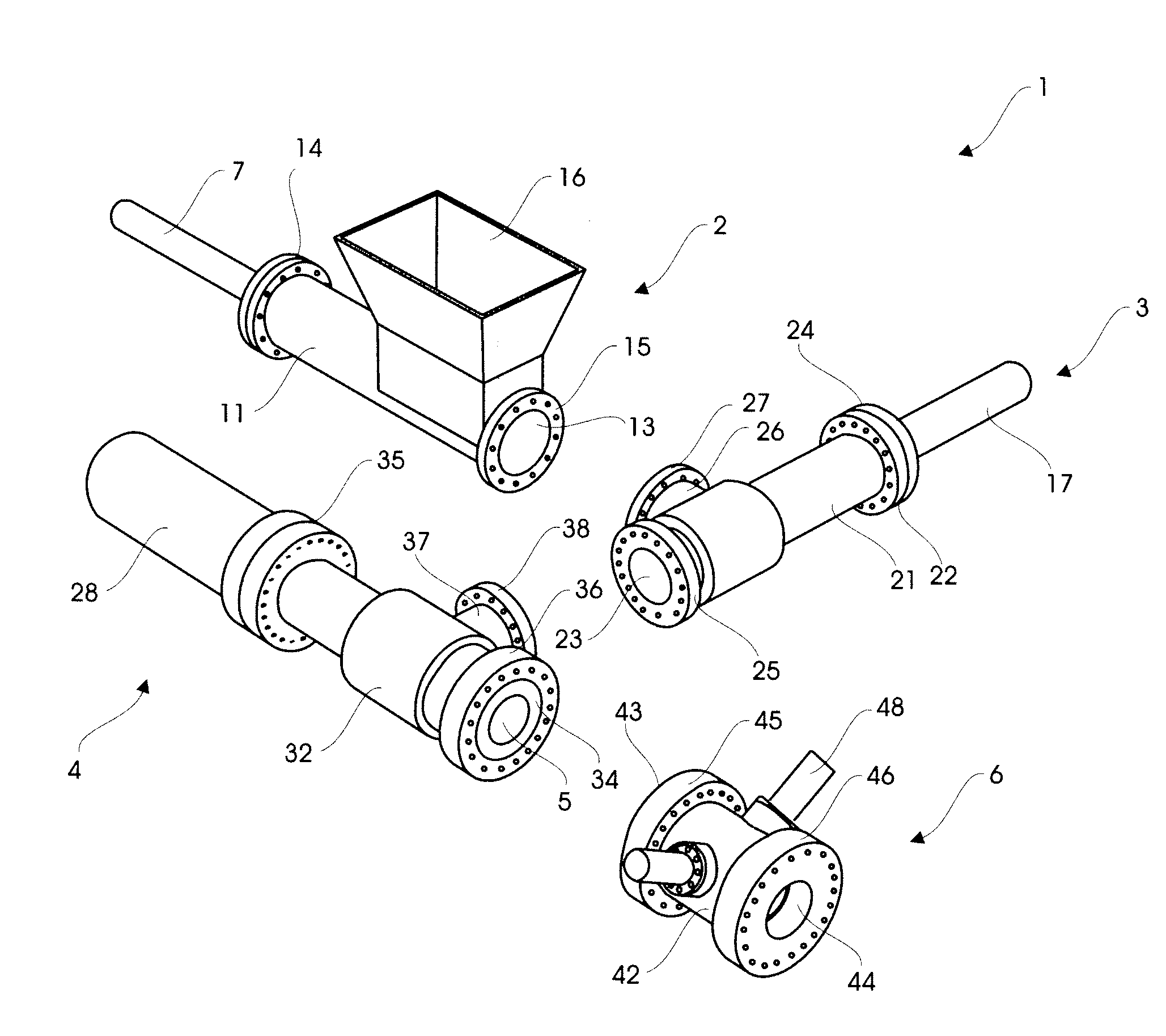

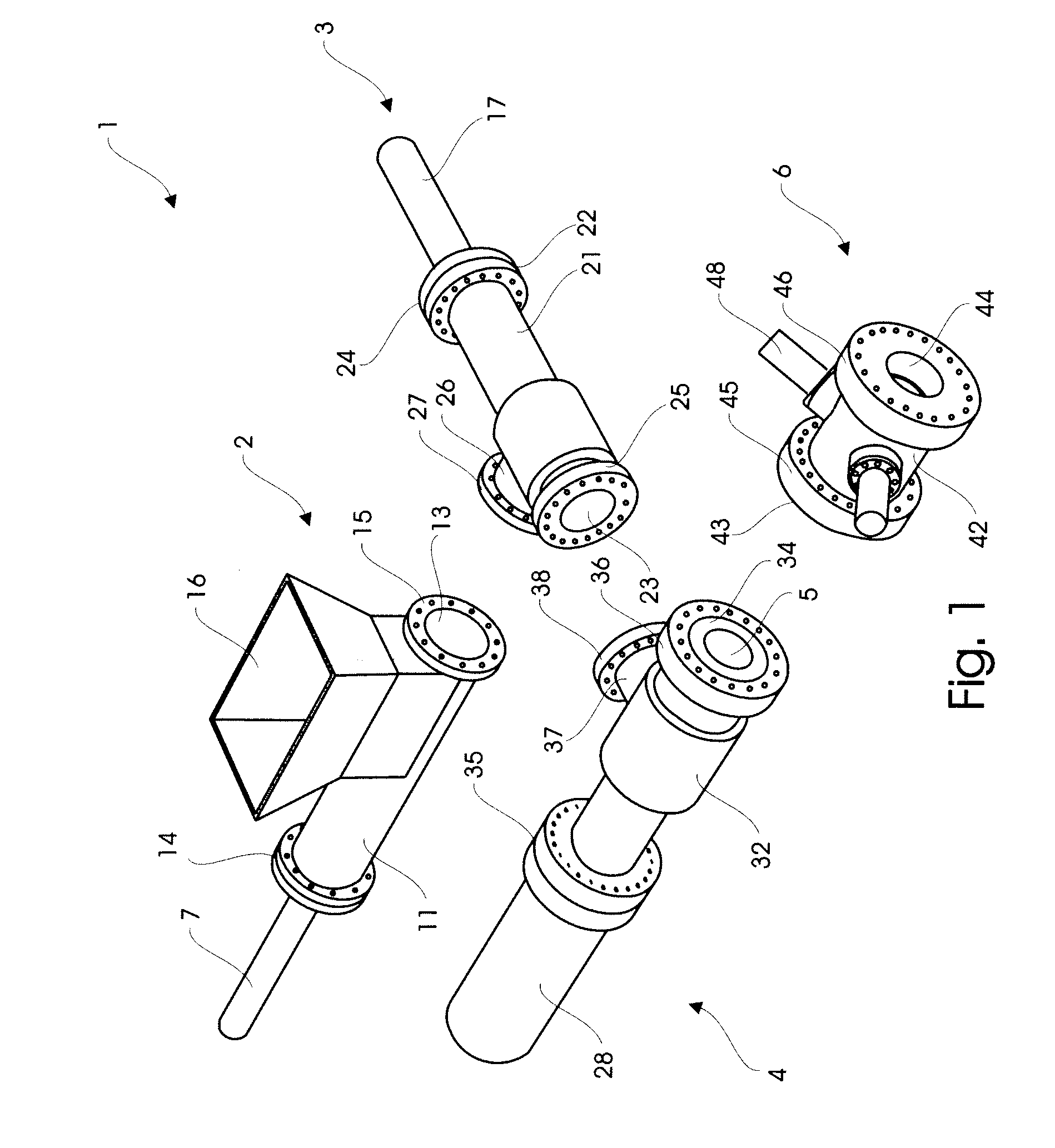

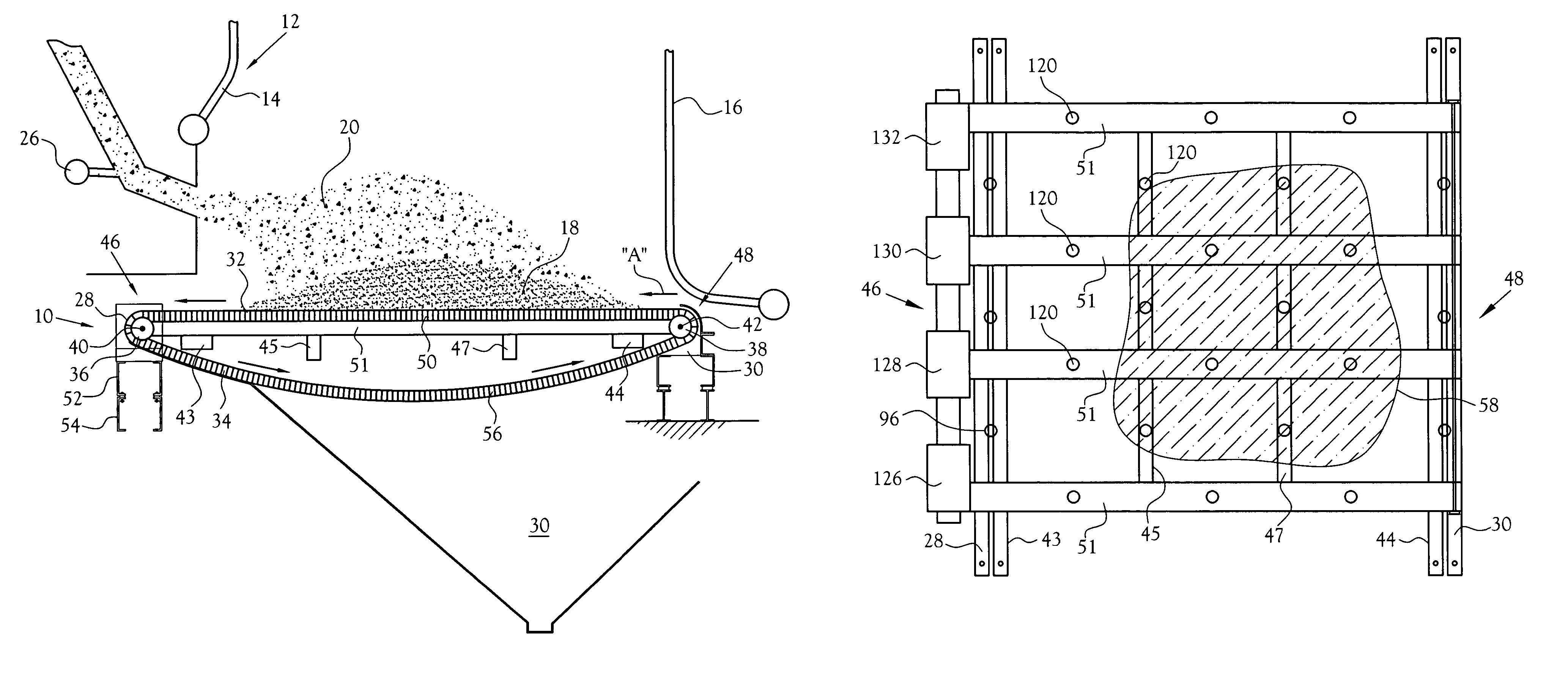

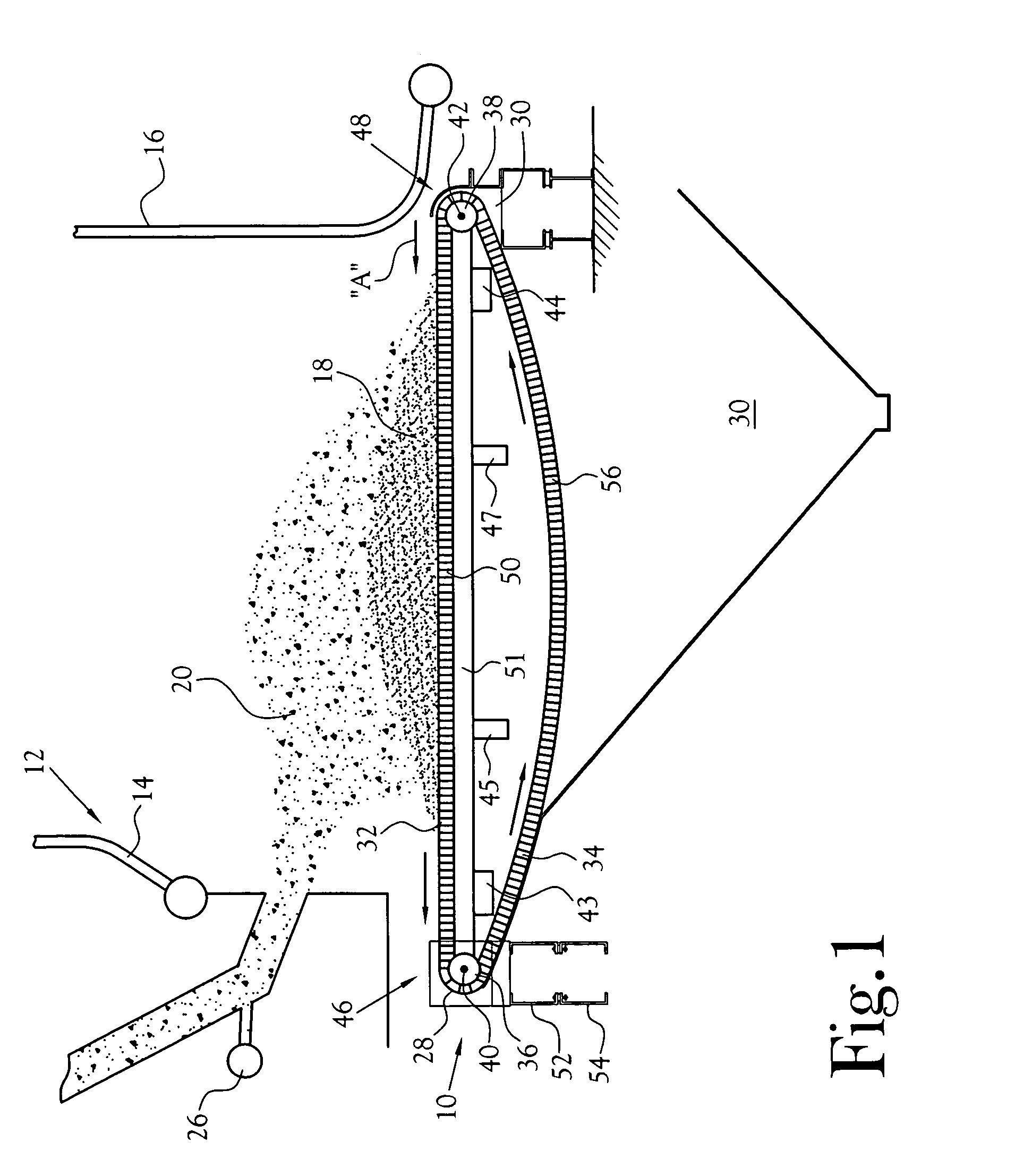

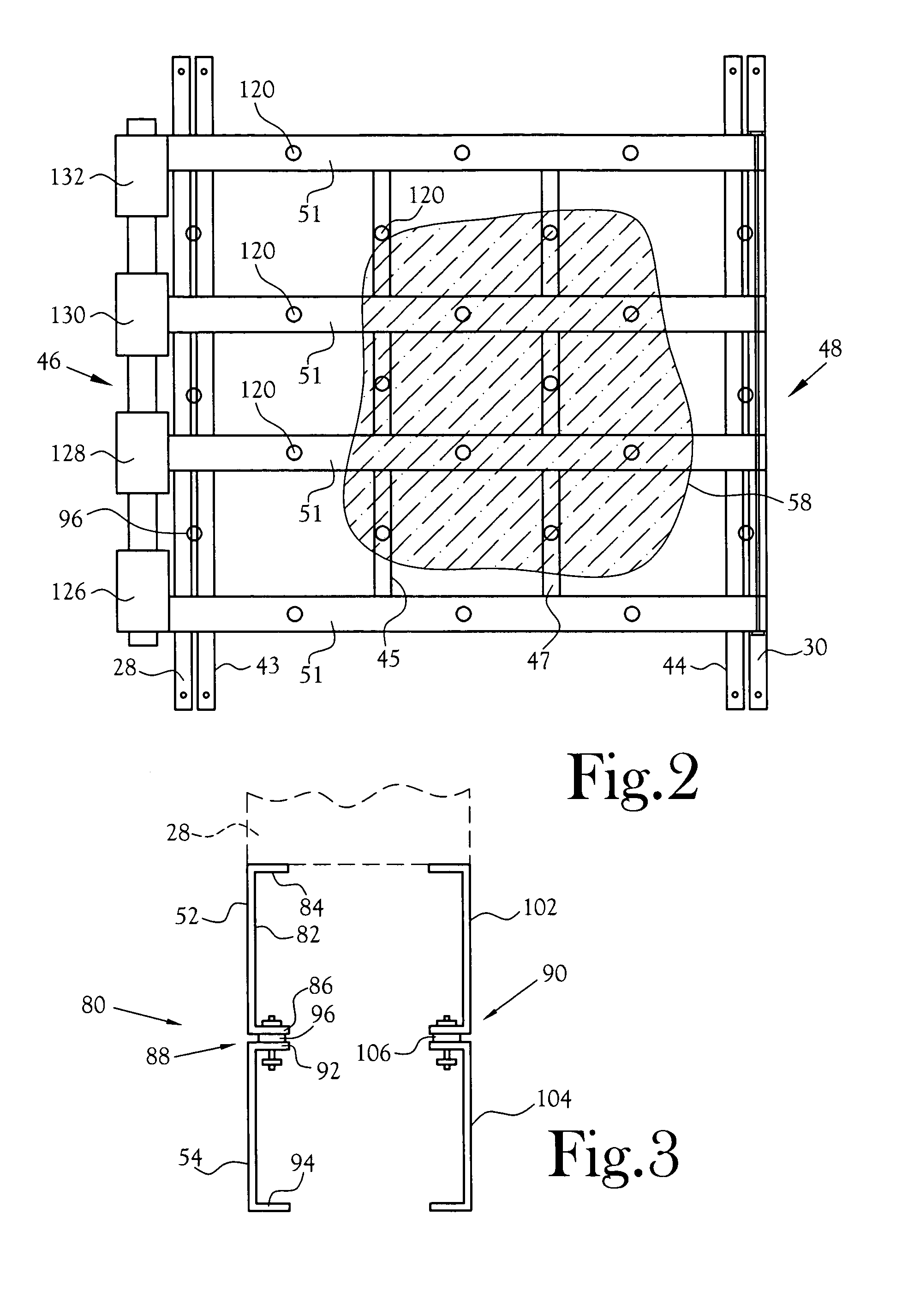

Feeding apparatus for creation of one or more plugs of compressible material for feeding into a gasifier or reactor

ActiveUS7964004B2Large in humidityDensity variationPressurized chemical processConveyorsCompressible materialCombustion chamber

Owner:TK ENERGI +1

Biomass pelletizing process

ActiveUS20100281767A1Impact soil qualityImpact water useFuel feeding arrangementsSolid fuel pretreatmentAgricultural residueEngineering

A process is provided using non-food or limited-feed agricultural residue and energy crops for energy production, such as ethanol or electricity generation. The agricultural plant material is harvested and baled. The bales are transported to the processing site for storage or immediate processing. The bale strings are first removed, and then the broken bales are shredded. The shredded plant material is then ground to a small size. The ground material is then pelletized to produce densified pellets of the agricultural plant material. The pellets are cooled and then stored or transported to an end user.

Owner:PELLET TECH USA

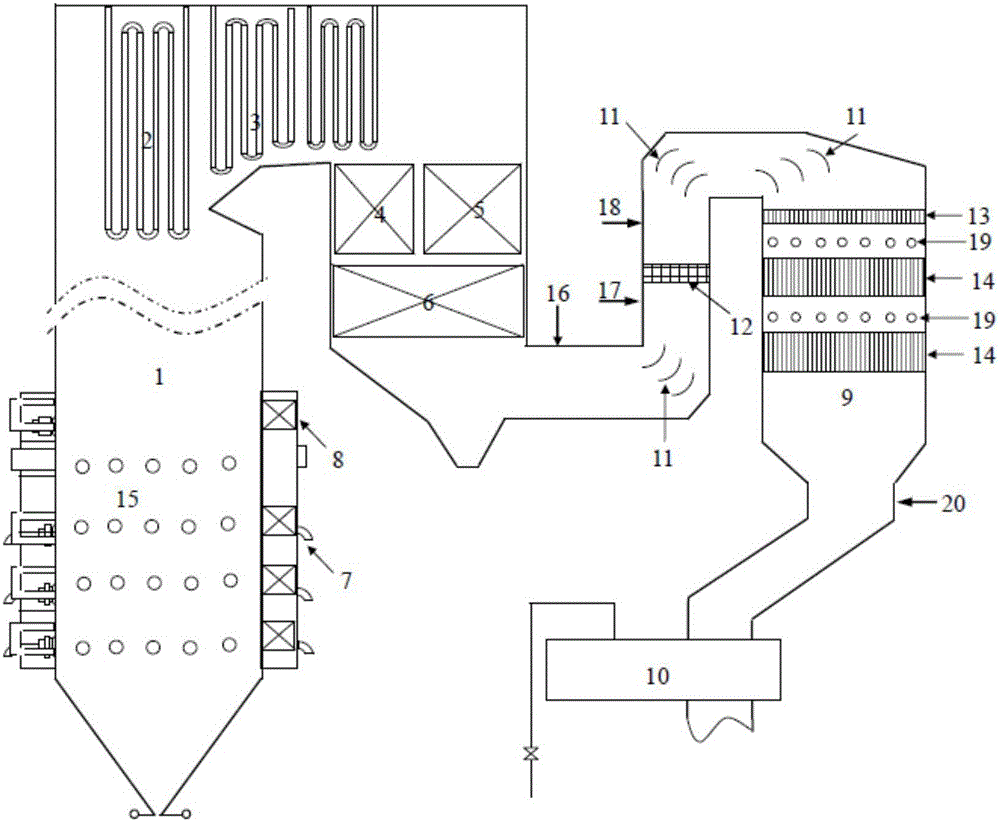

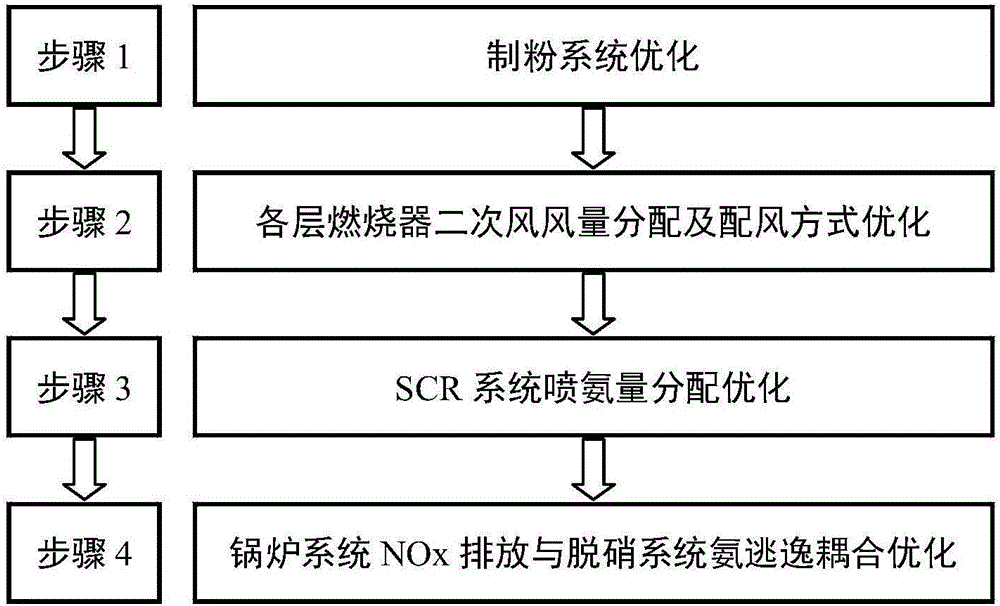

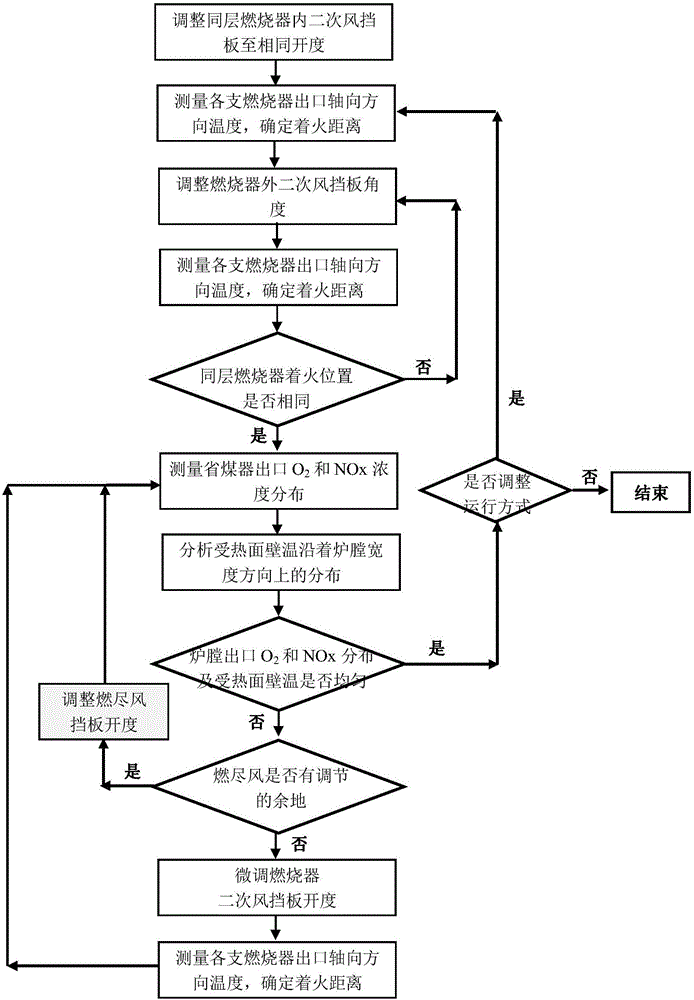

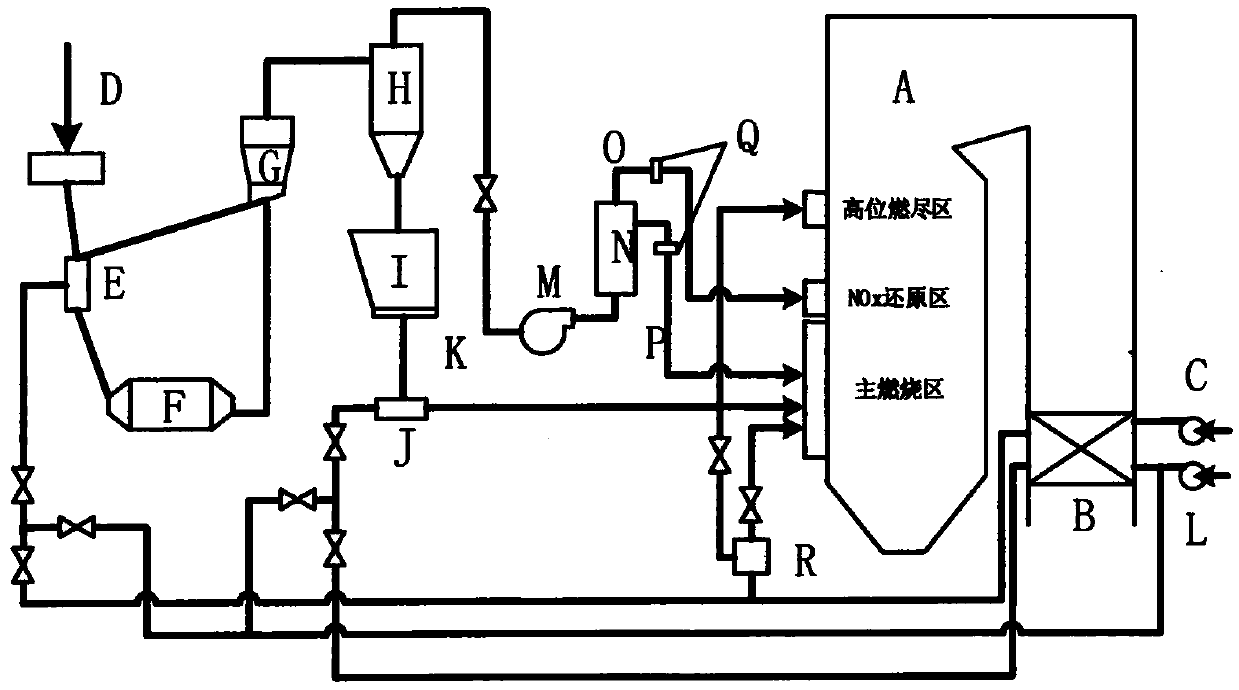

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

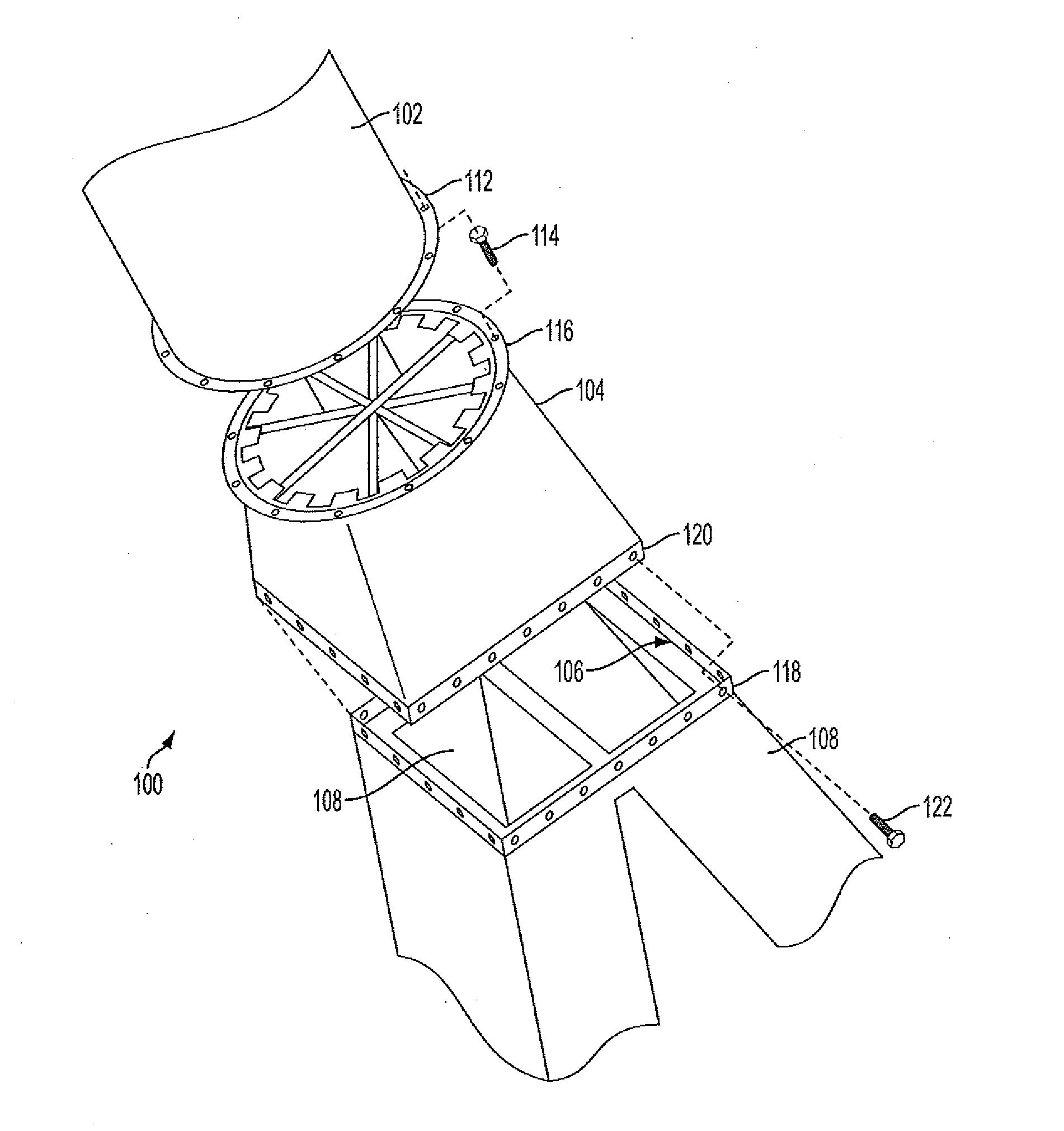

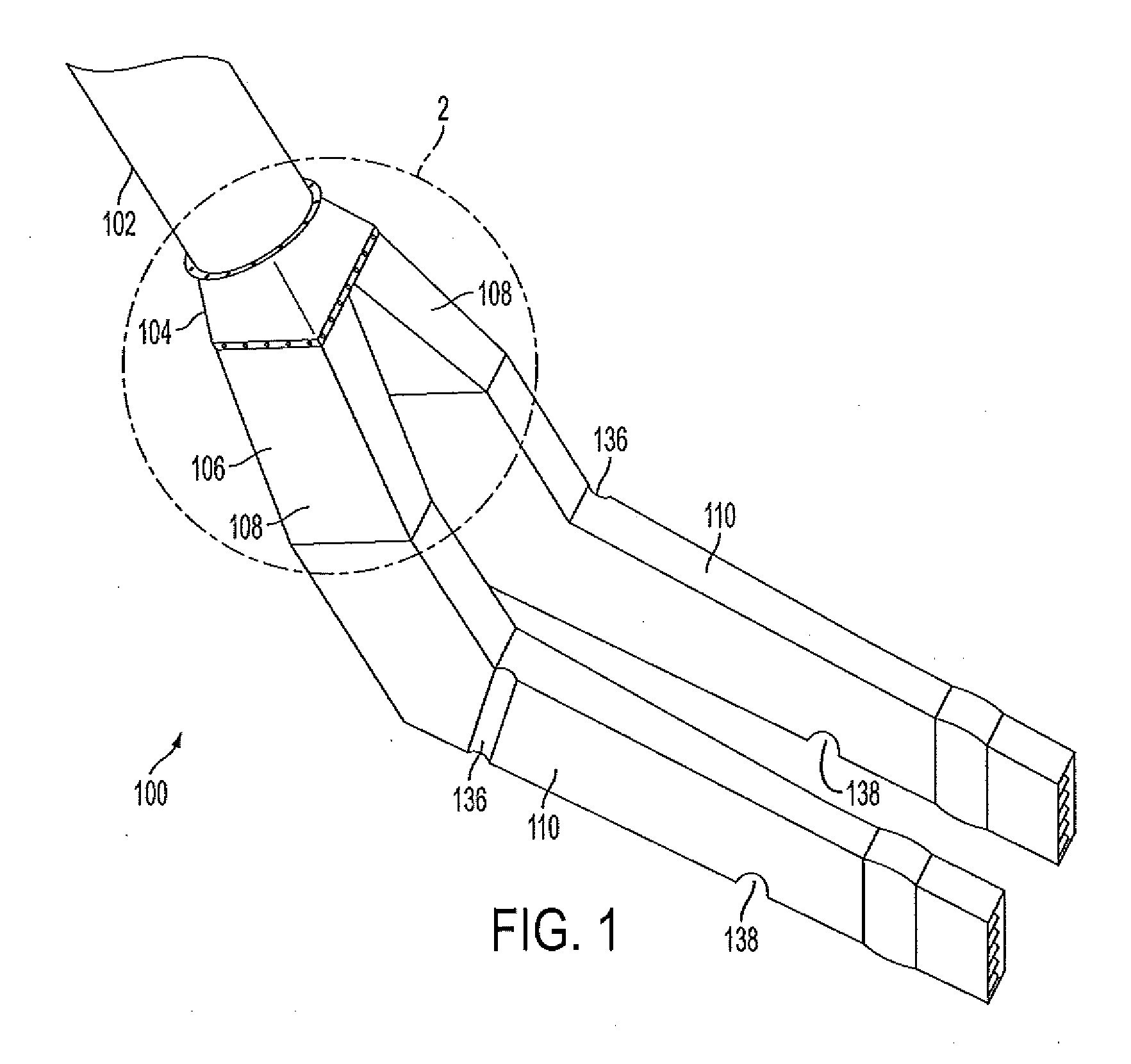

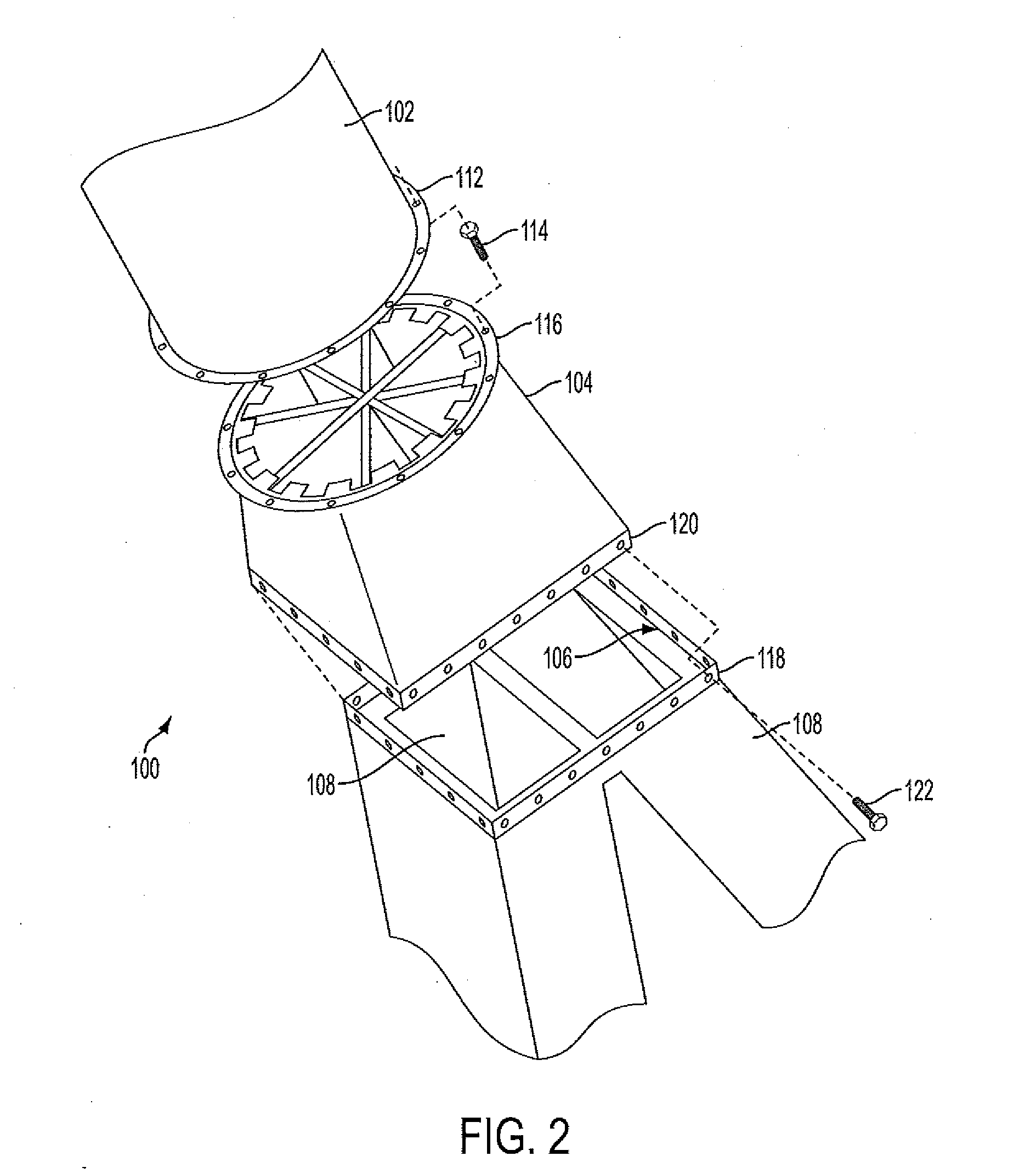

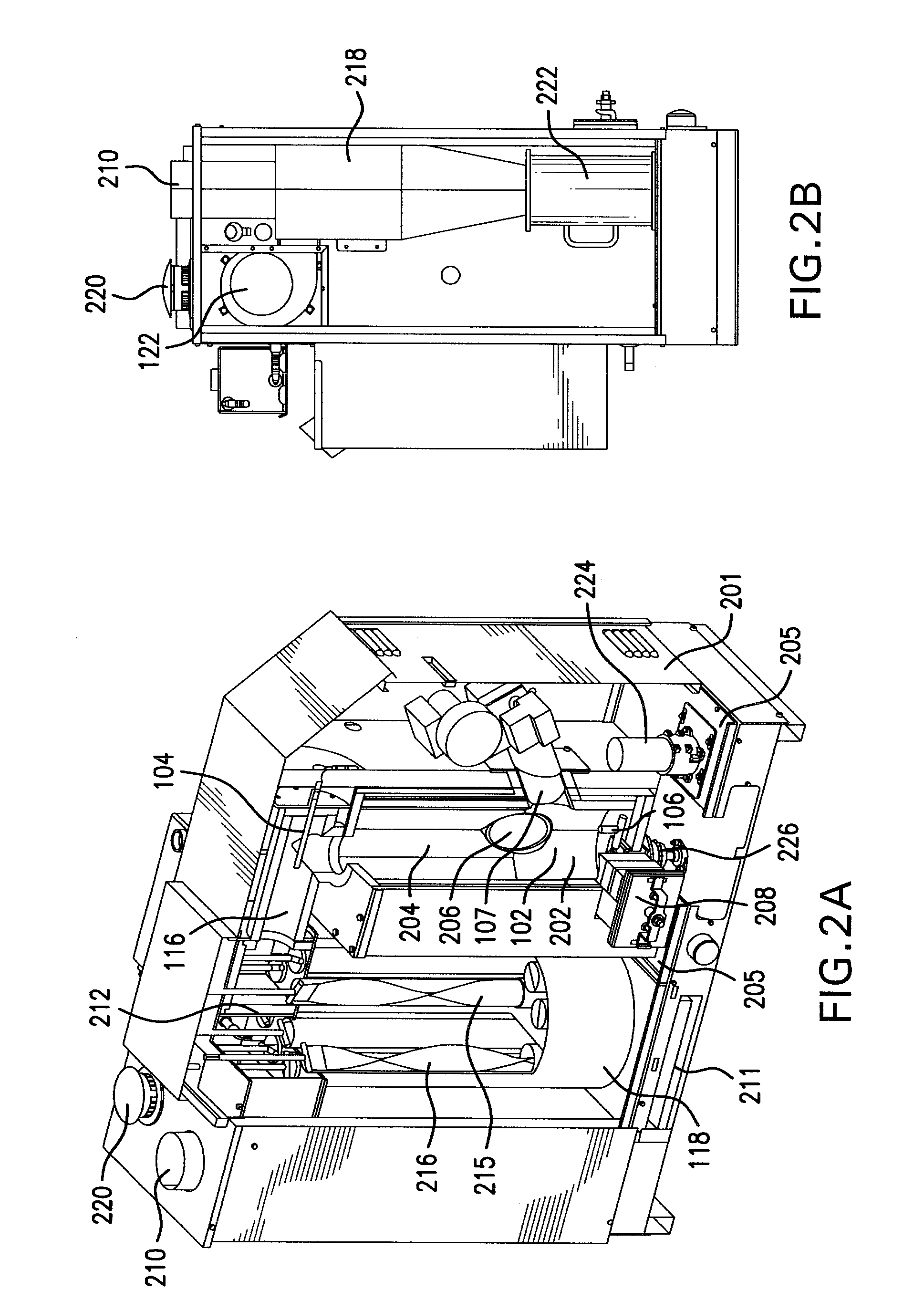

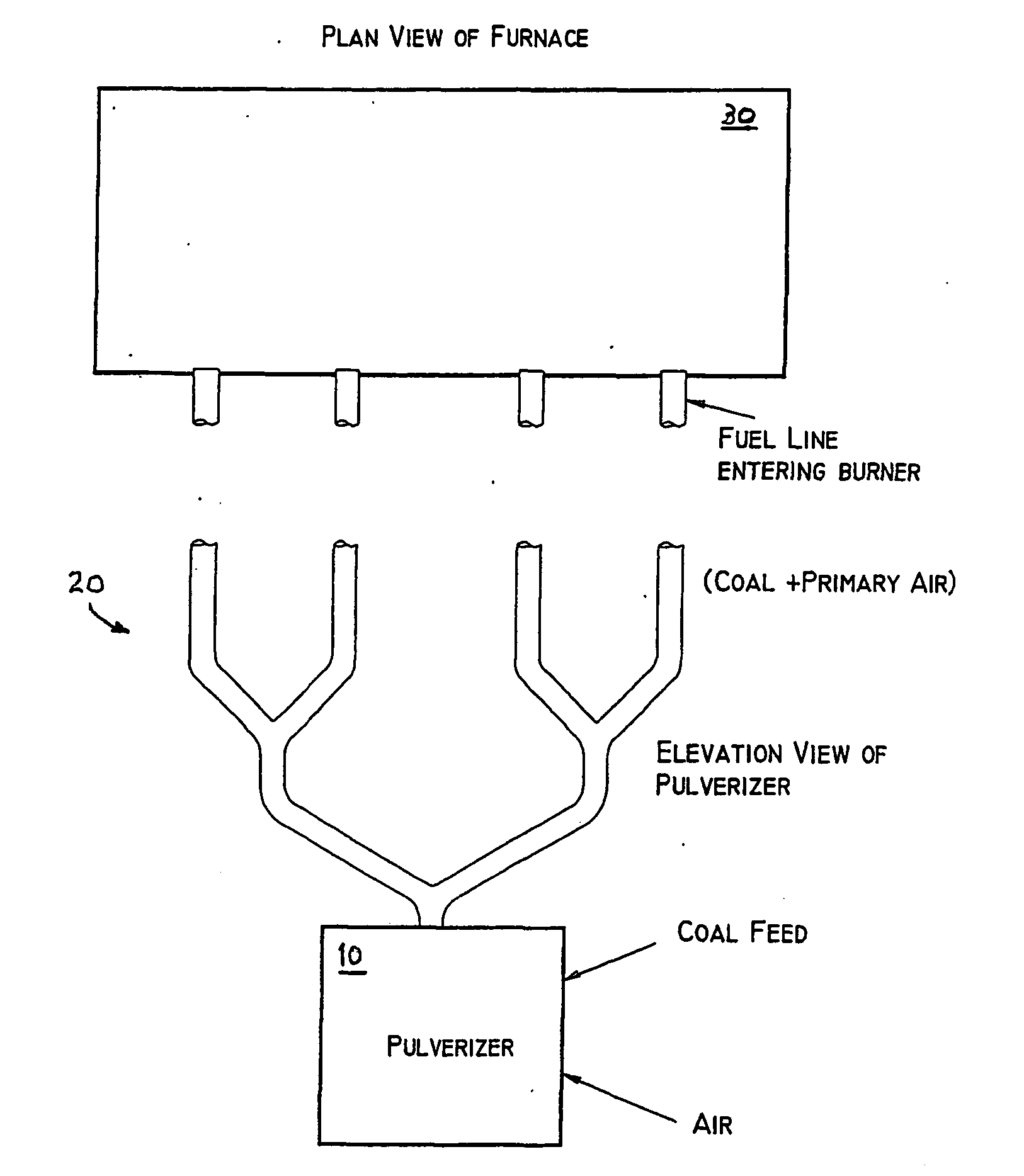

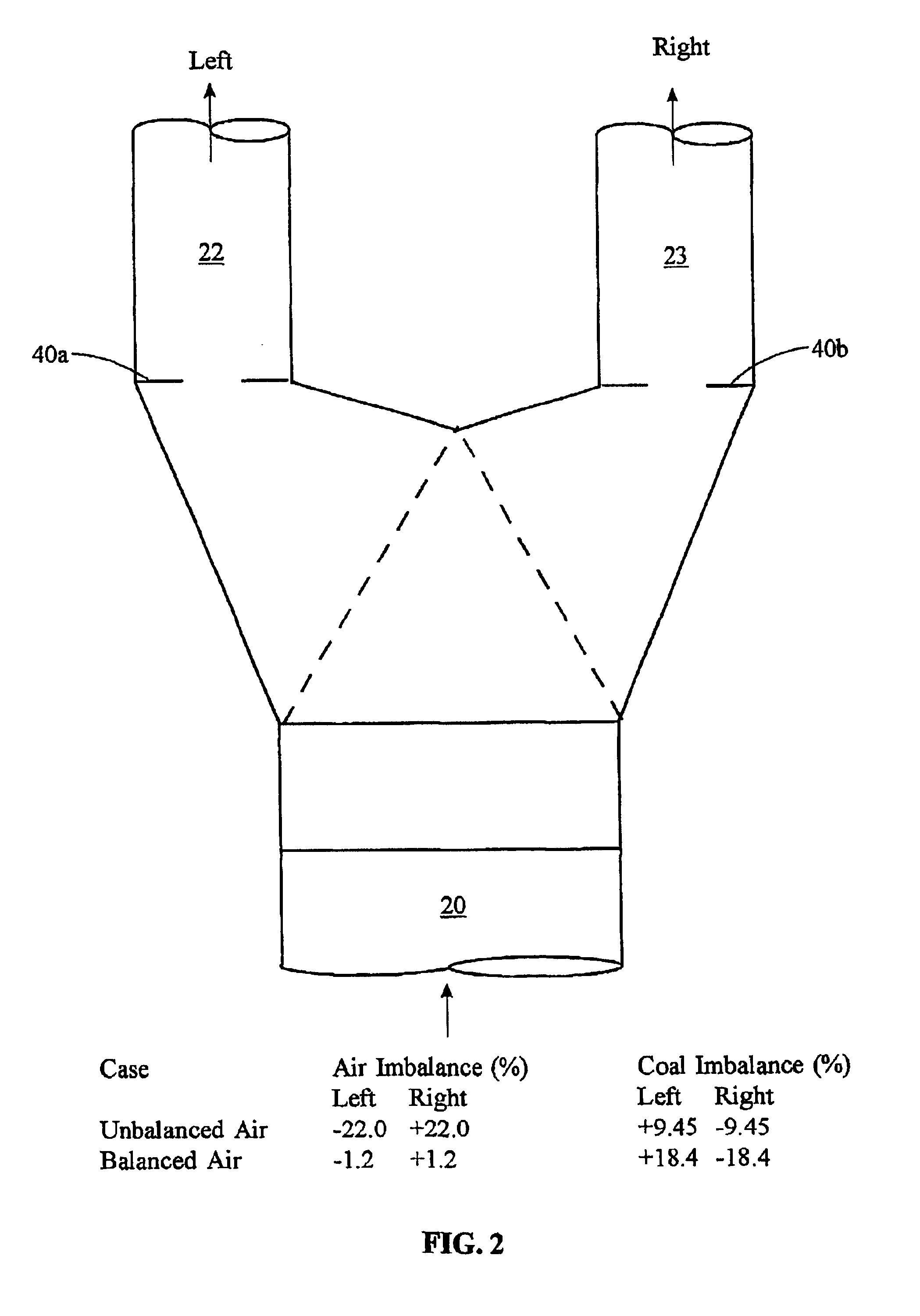

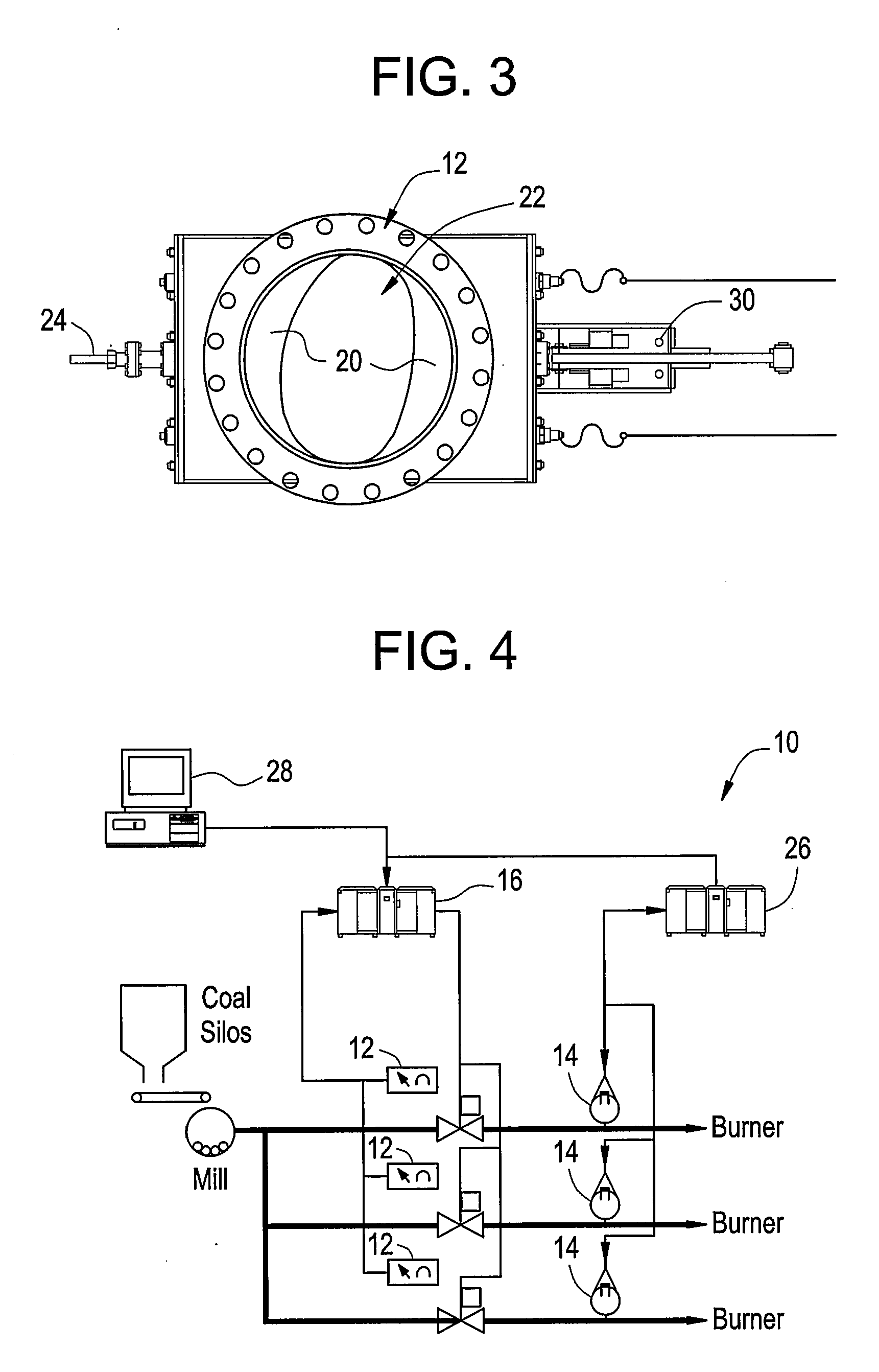

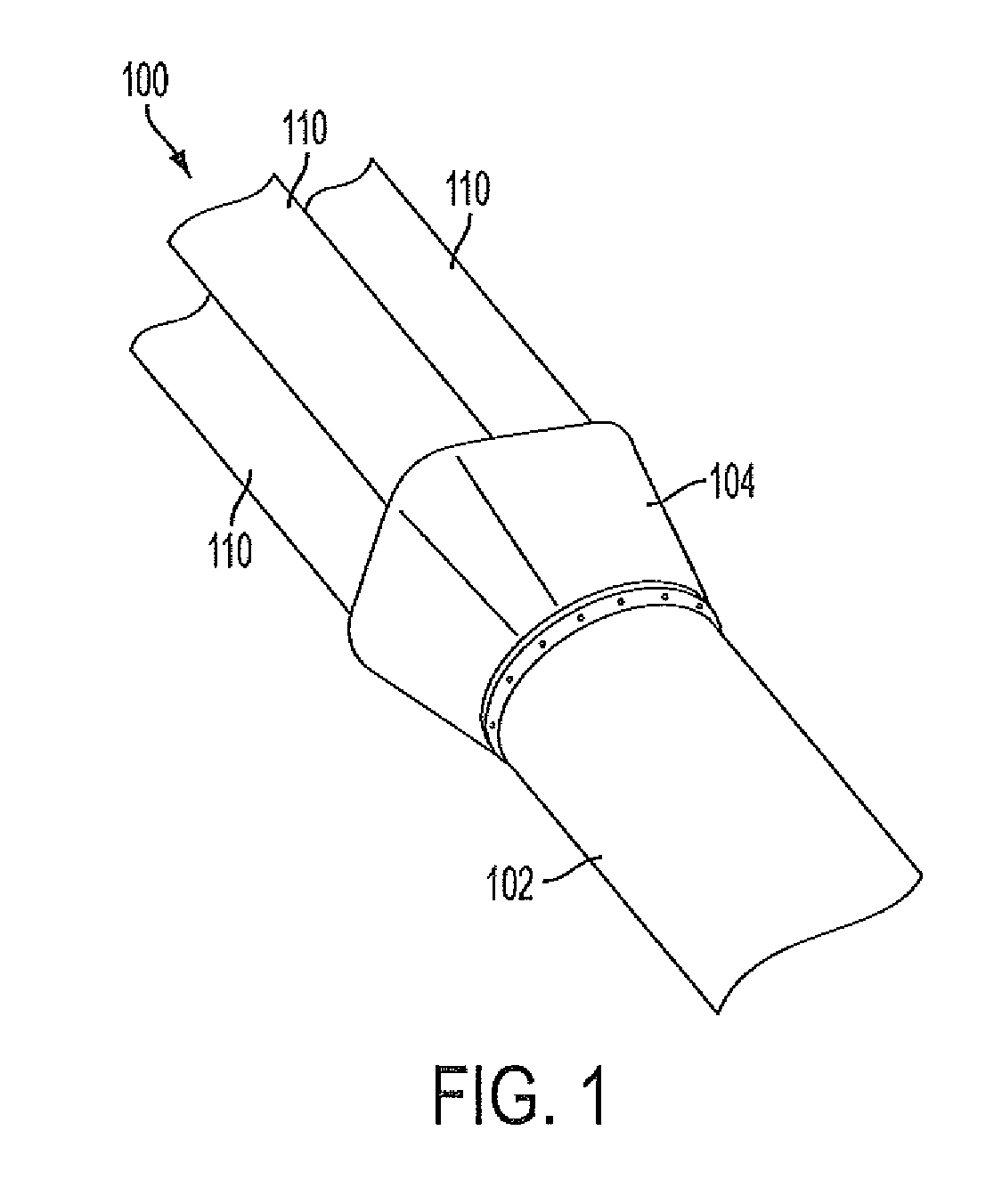

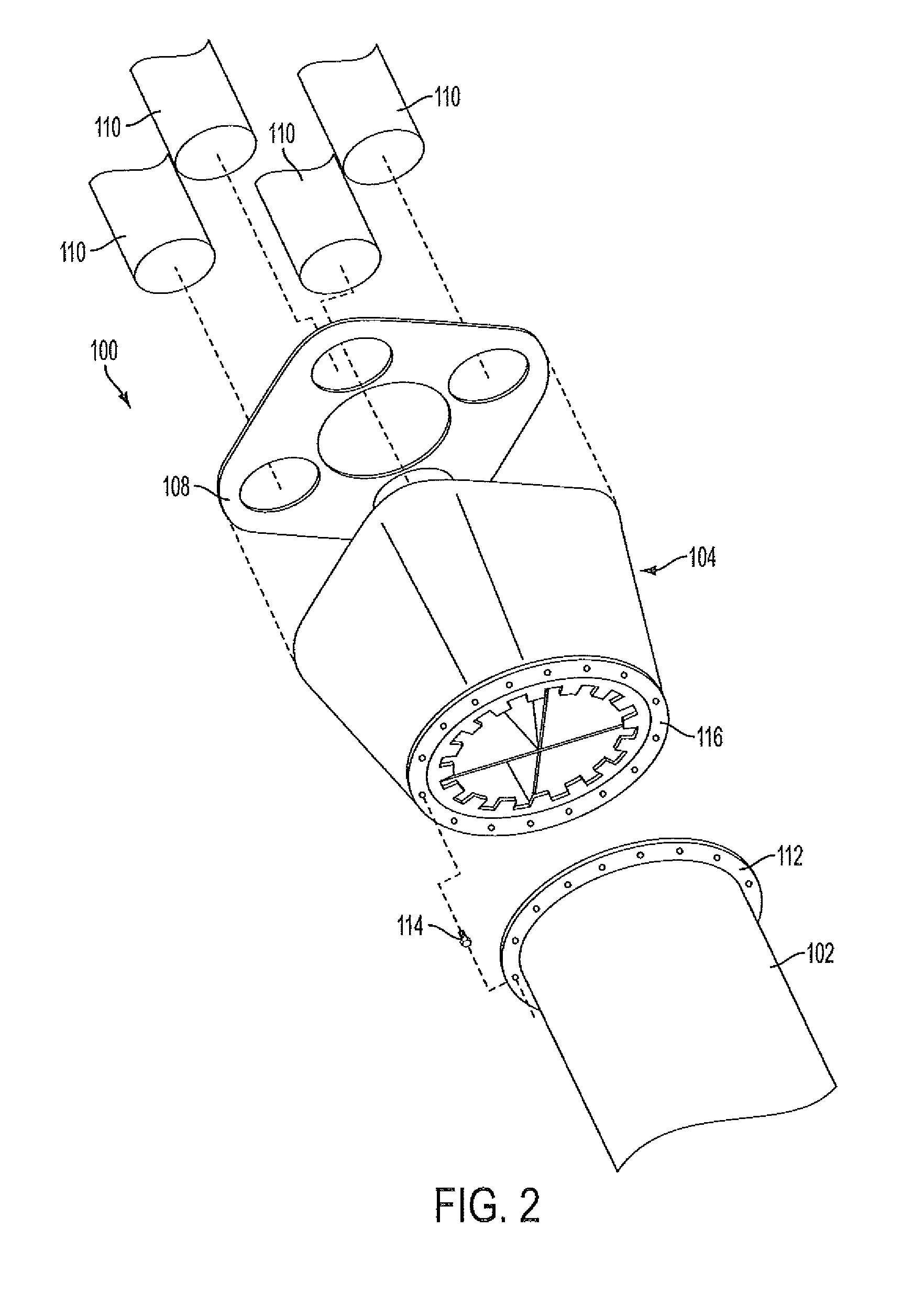

Coal flow balancing devices

InactiveUS20120186501A1Reduce unevennessImprove uniformityFuel feeding arrangementsBulk conveyorsParticle flowSolid particle

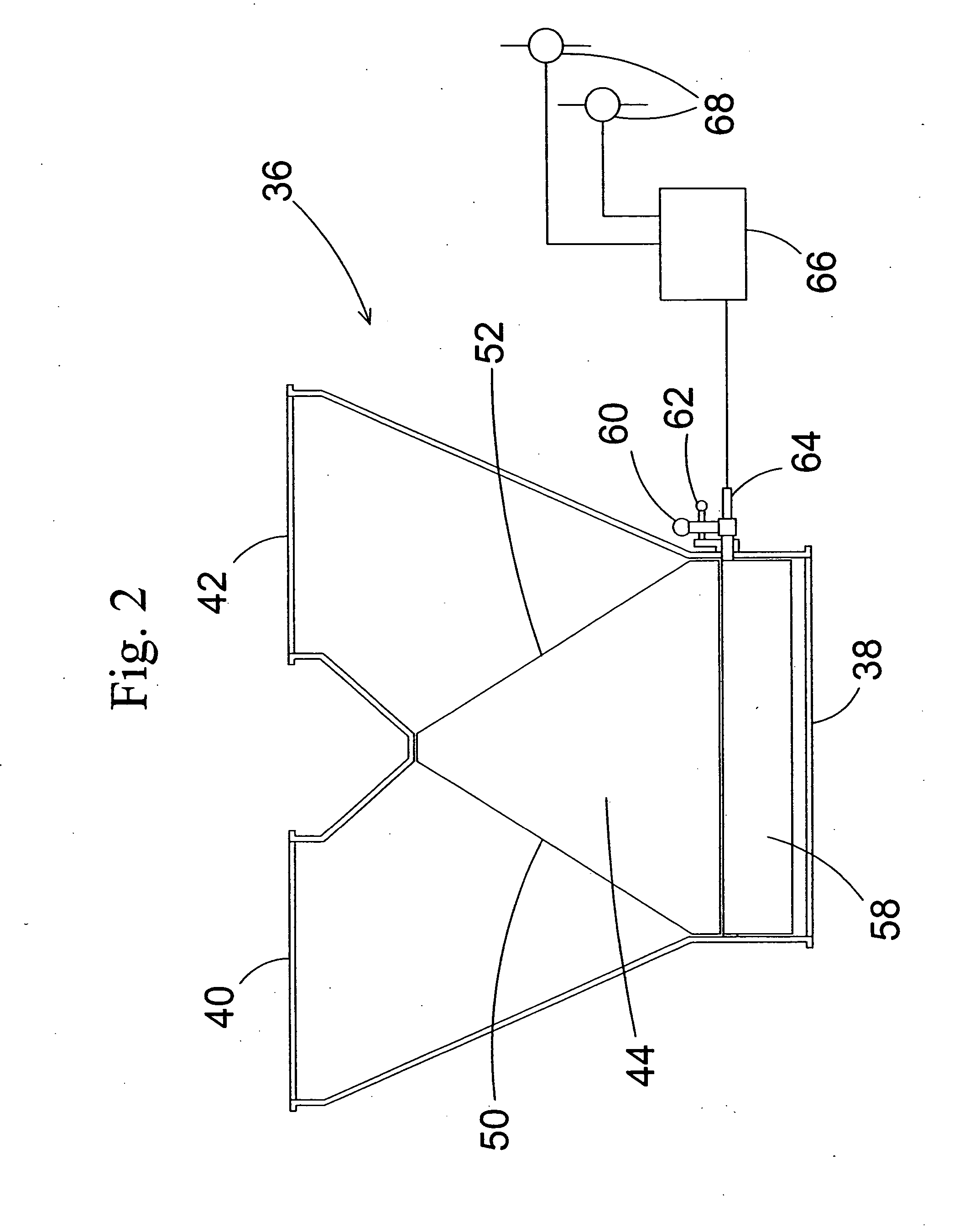

A flow splitter distributes solid particles flowing in a fluid, such as coal particles flowing in air, through a piping system. The flow splitter includes a divider housing having an inlet configured to connect to an upstream pipe and having an outlet configured to connect to a plurality of downstream pipes, e.g., by way of a divider head. A divider body is mounted within the divider housing. A plurality of divider vanes is included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow from the outlet to each of the downstream pipes.

Owner:BABCOCK POWER SERVICES

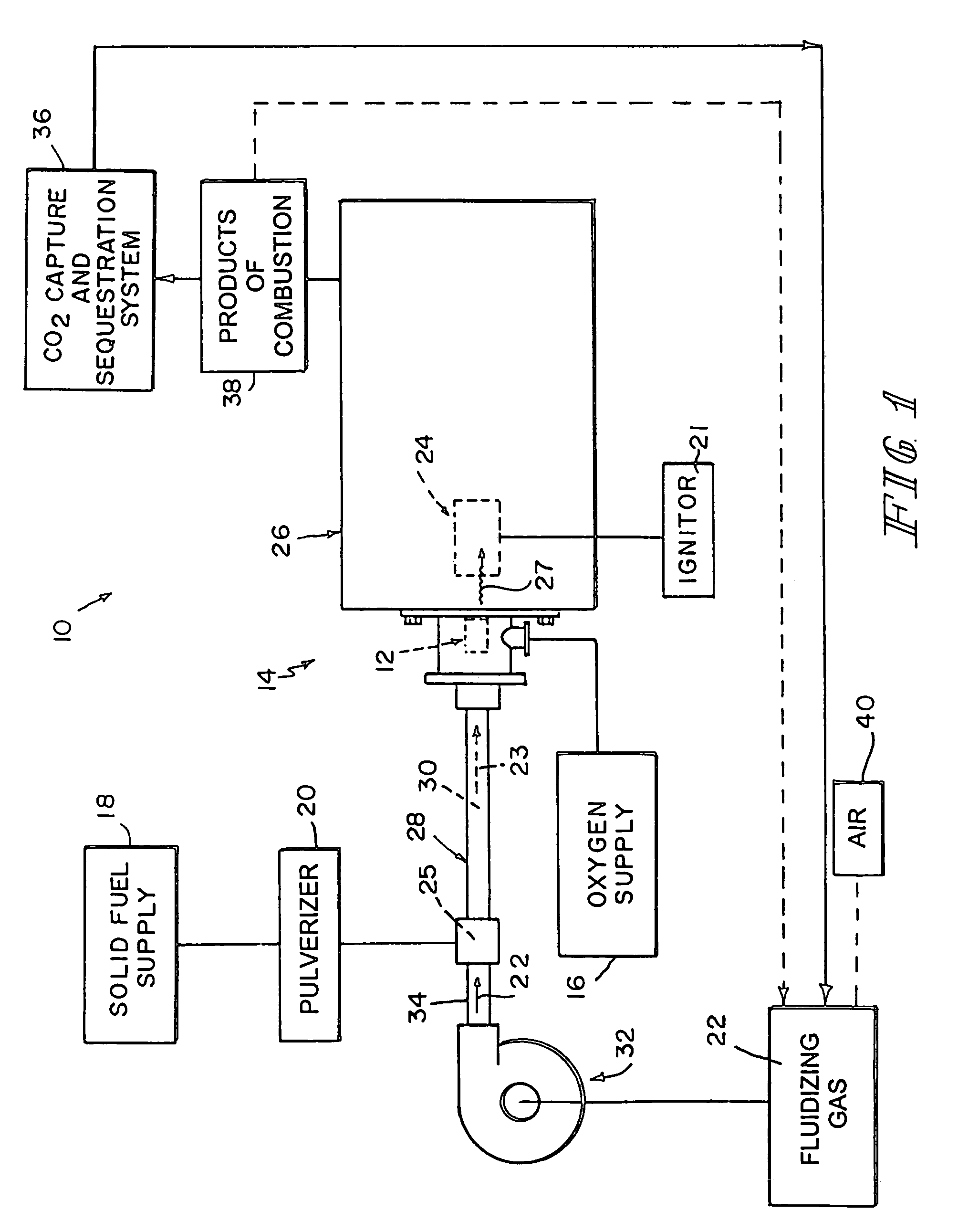

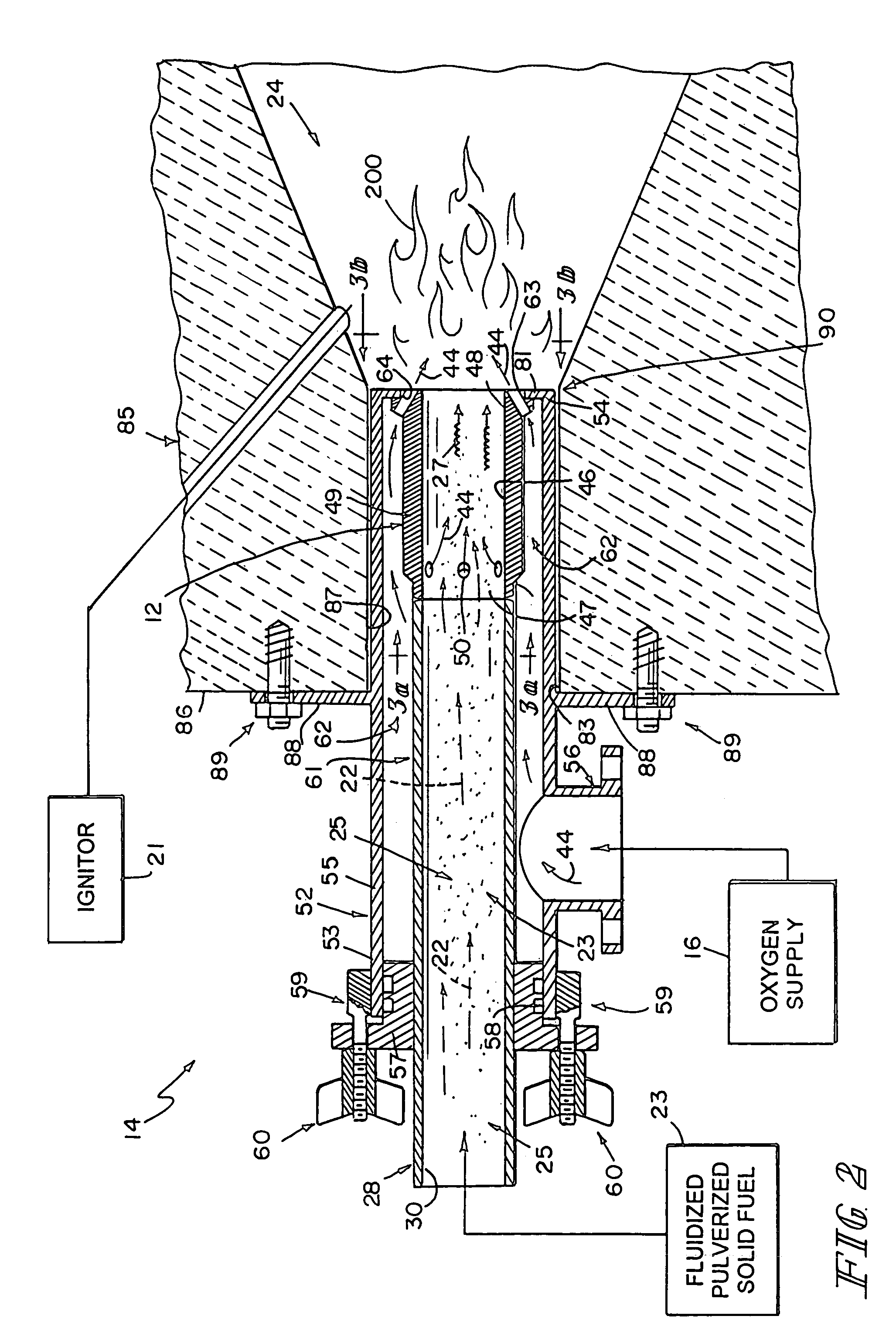

Apparatus for burning pulverized solid fuels with oxygen

InactiveUS7028622B2Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelDomestic stoves or rangesCombustorSolid fuel

A burner assembly combines oxygen and fuel to produce a flame. The burner assembly includes an oxygen supply tube adapted to receive a stream of oxygen and a fuel supply tube arranged to extend through the oxygen tube to convey a stream of fluidized, pulverized, solid fuel into a flame chamber. Oxygen flowing through the oxygen supply tube passes through oxygen-injection holes formed in the fuel supply tube and then mixes with fluidized, pulverized, solid fuel passing through the fuel supply tube to create an oxygen-fuel mixture in a downstream portion of the fuel supply tube. This mixture is discharged into the flame chamber and ignited in a flame chamber to produce a flame.

Owner:MAXON

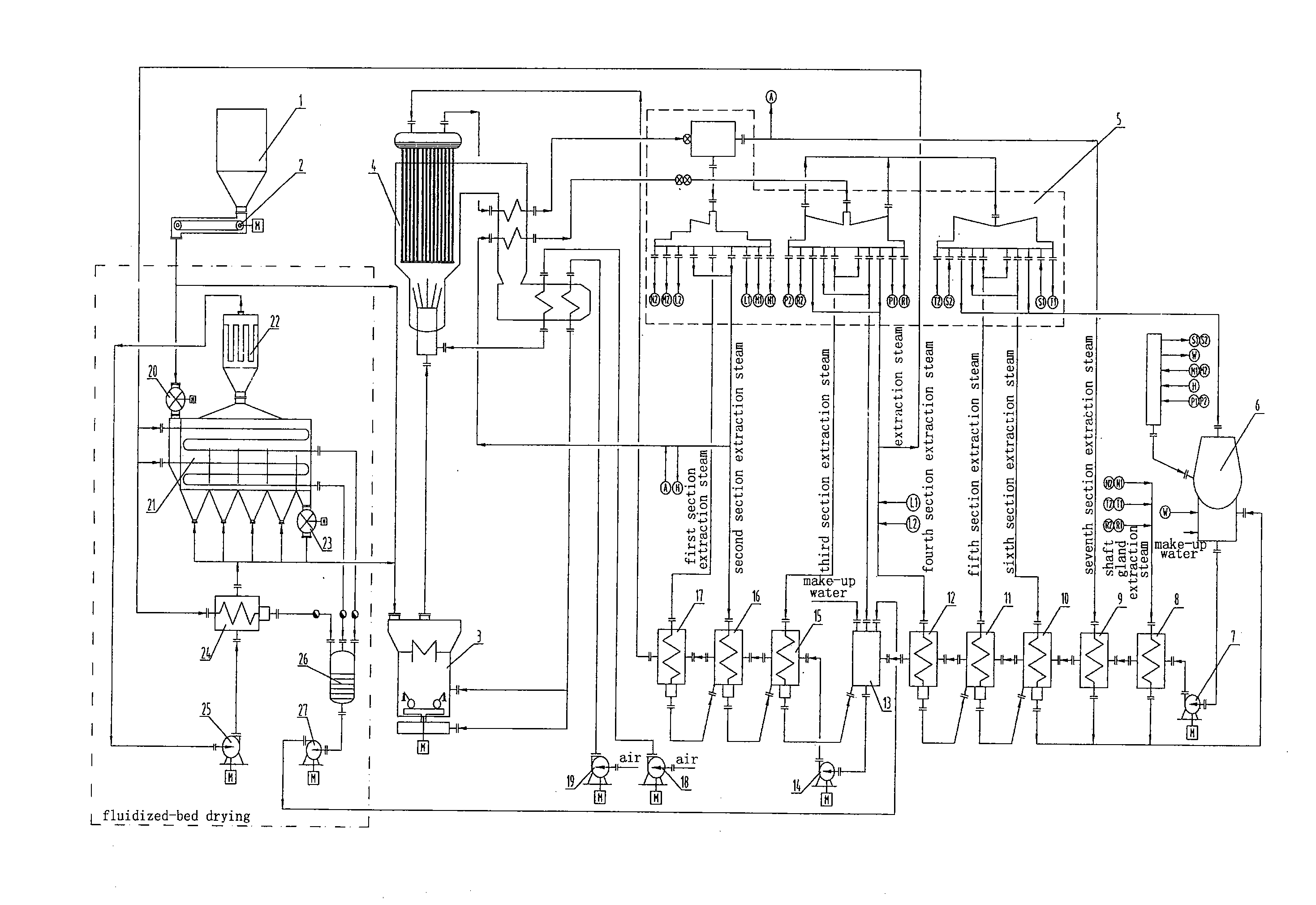

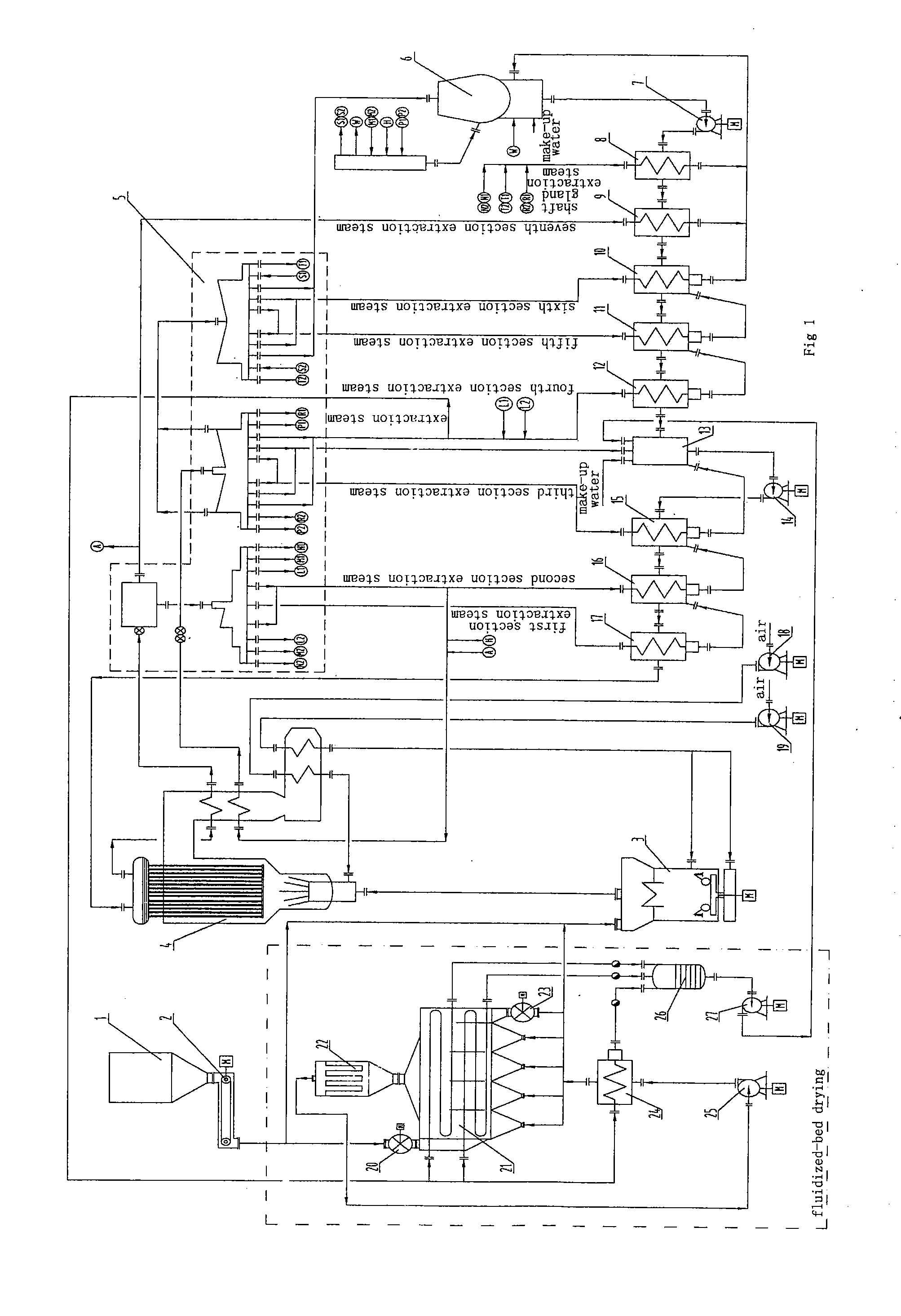

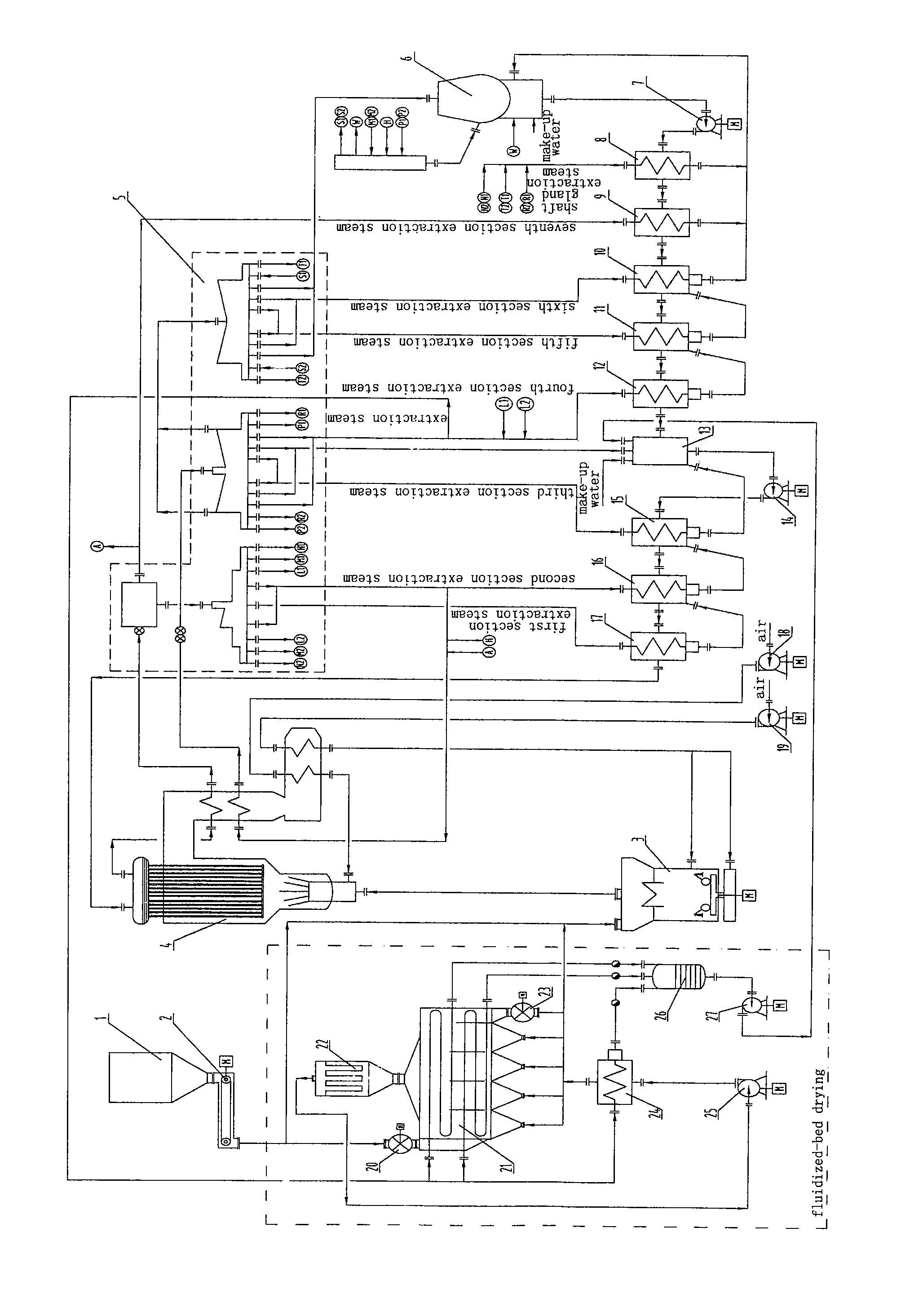

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

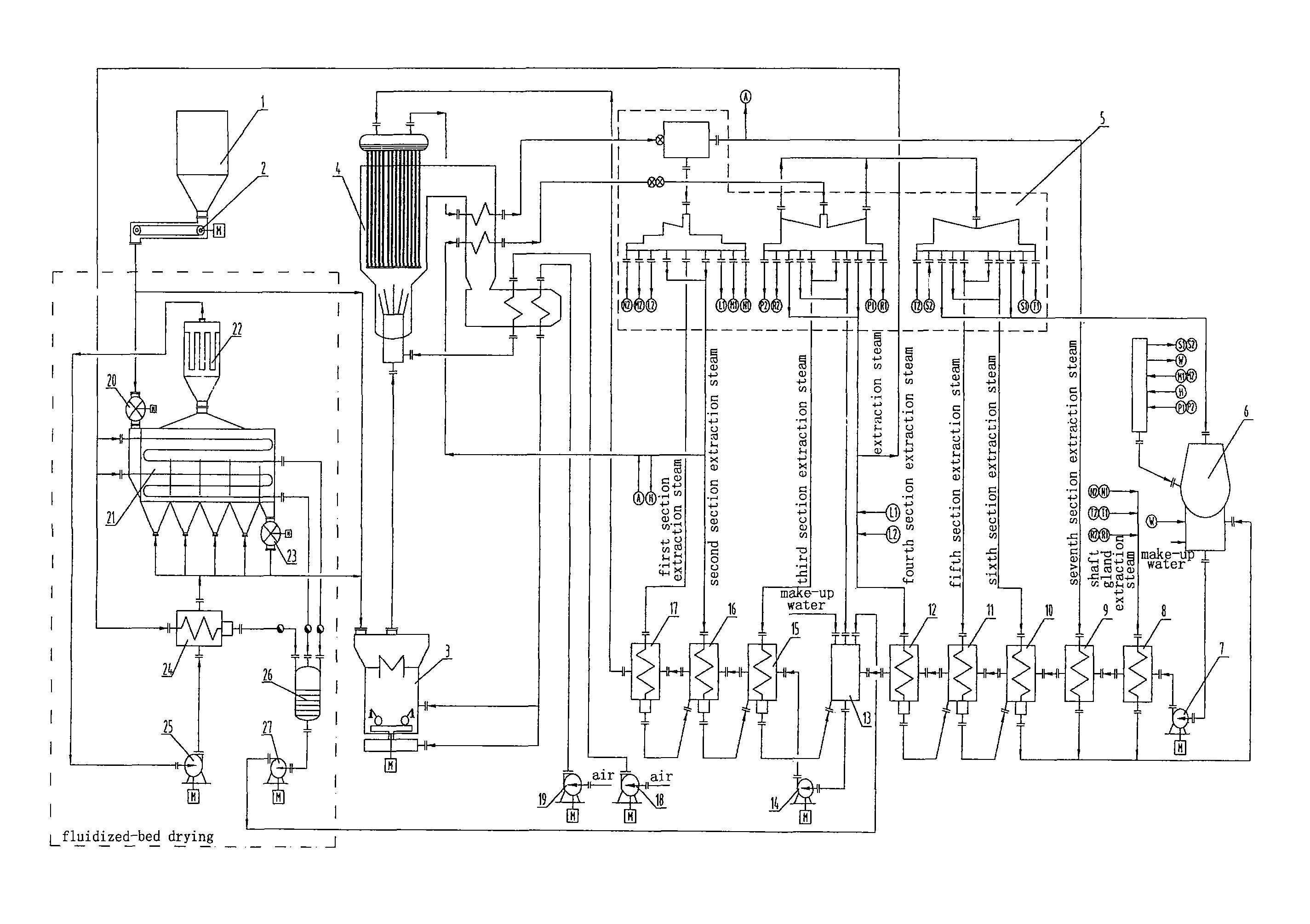

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

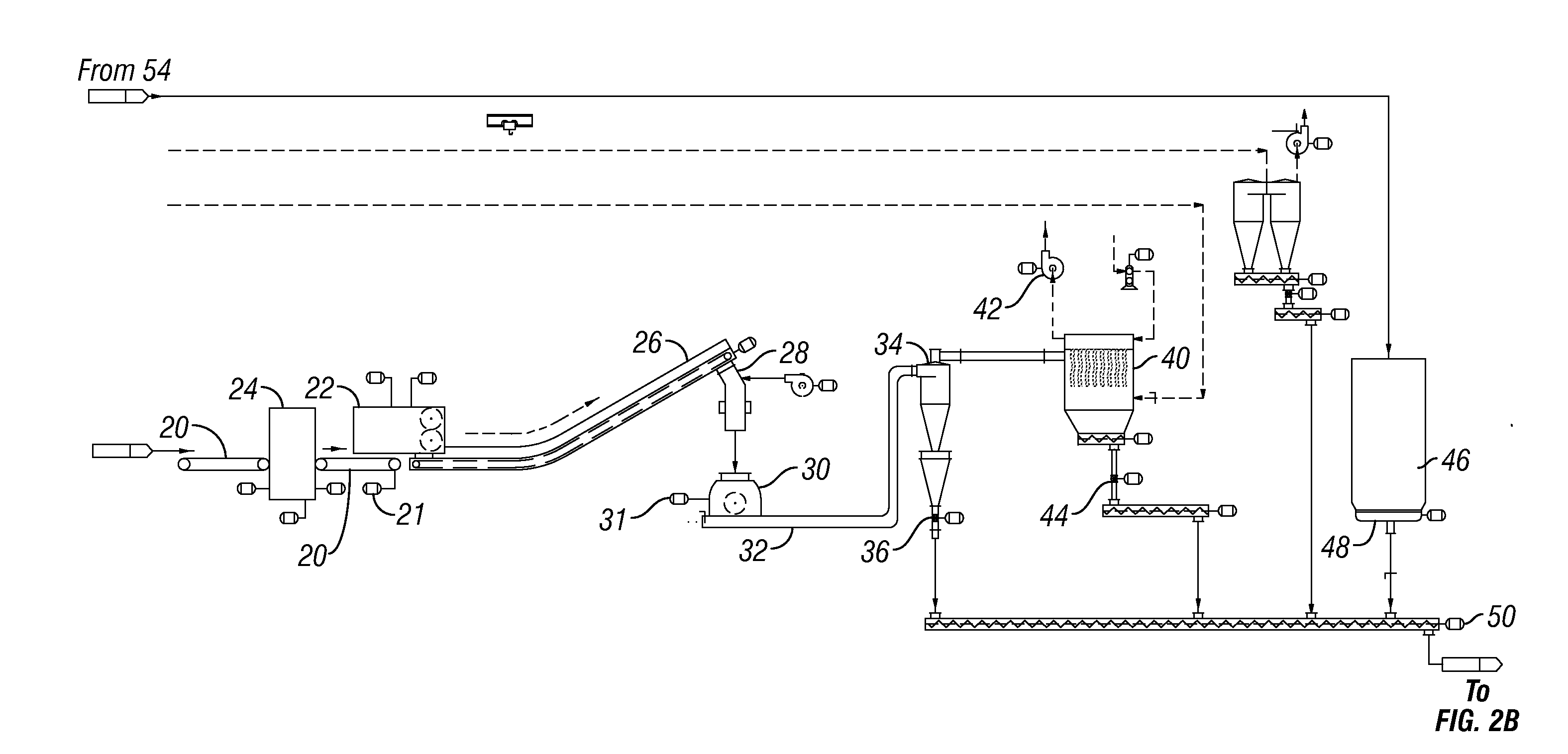

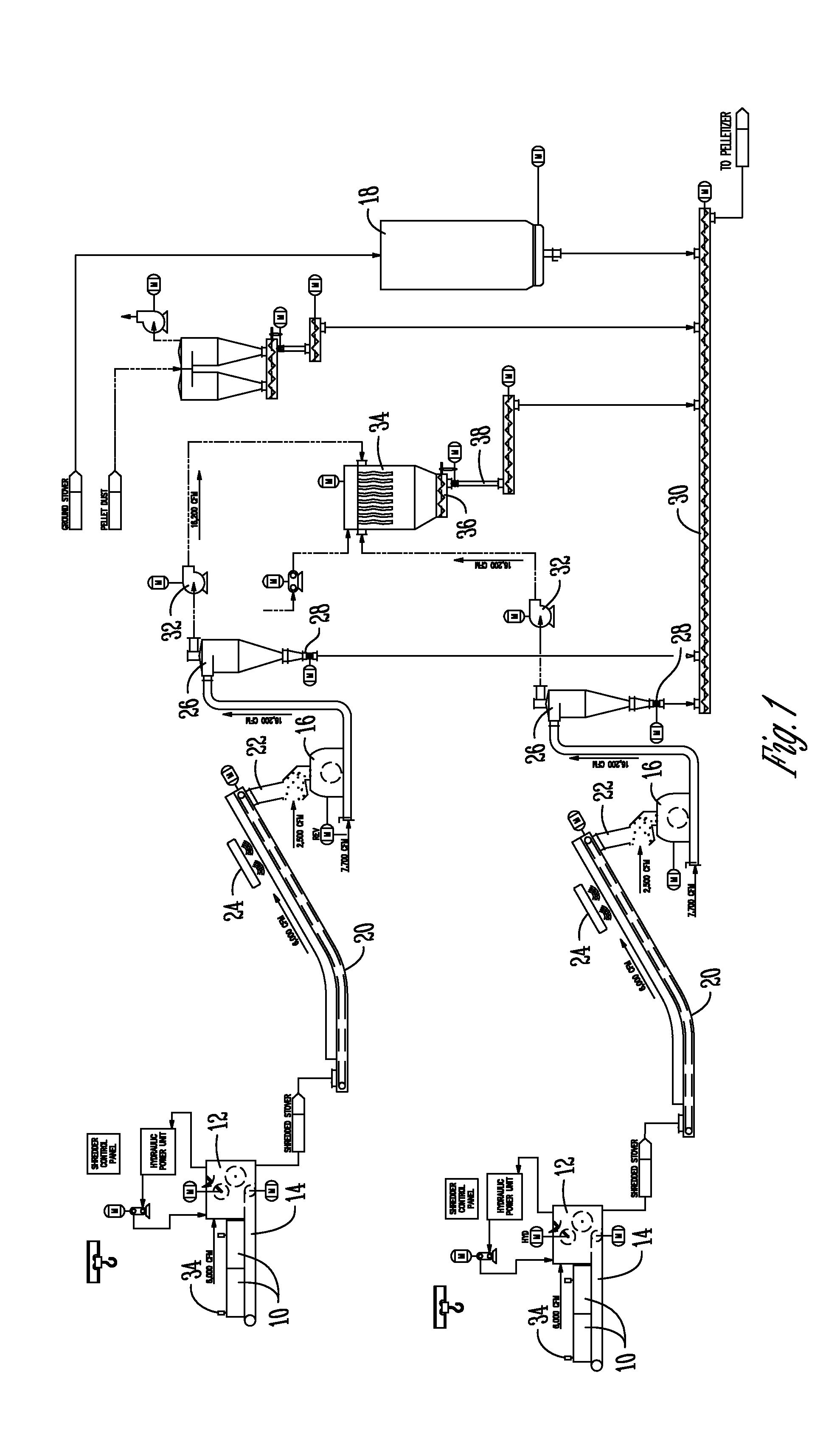

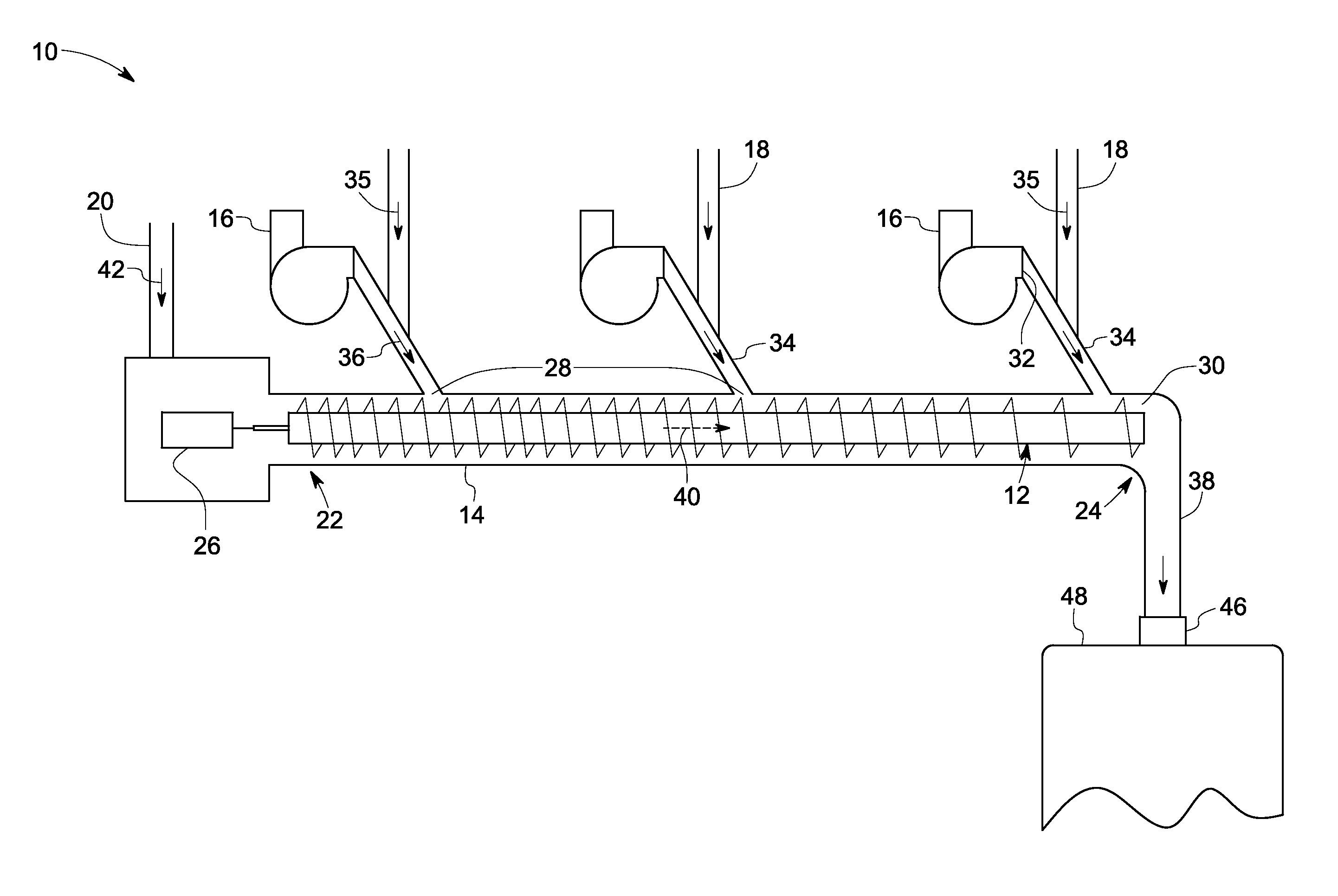

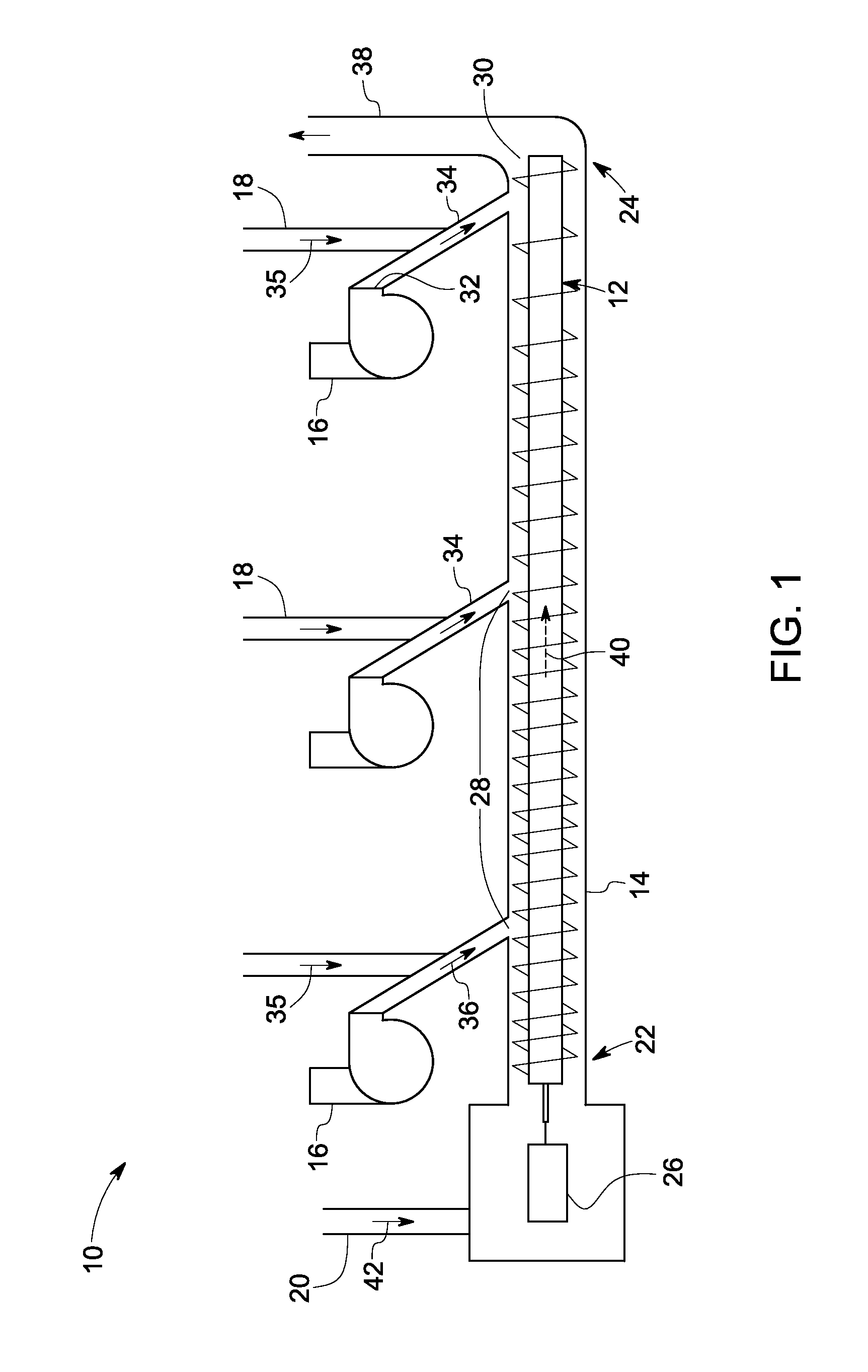

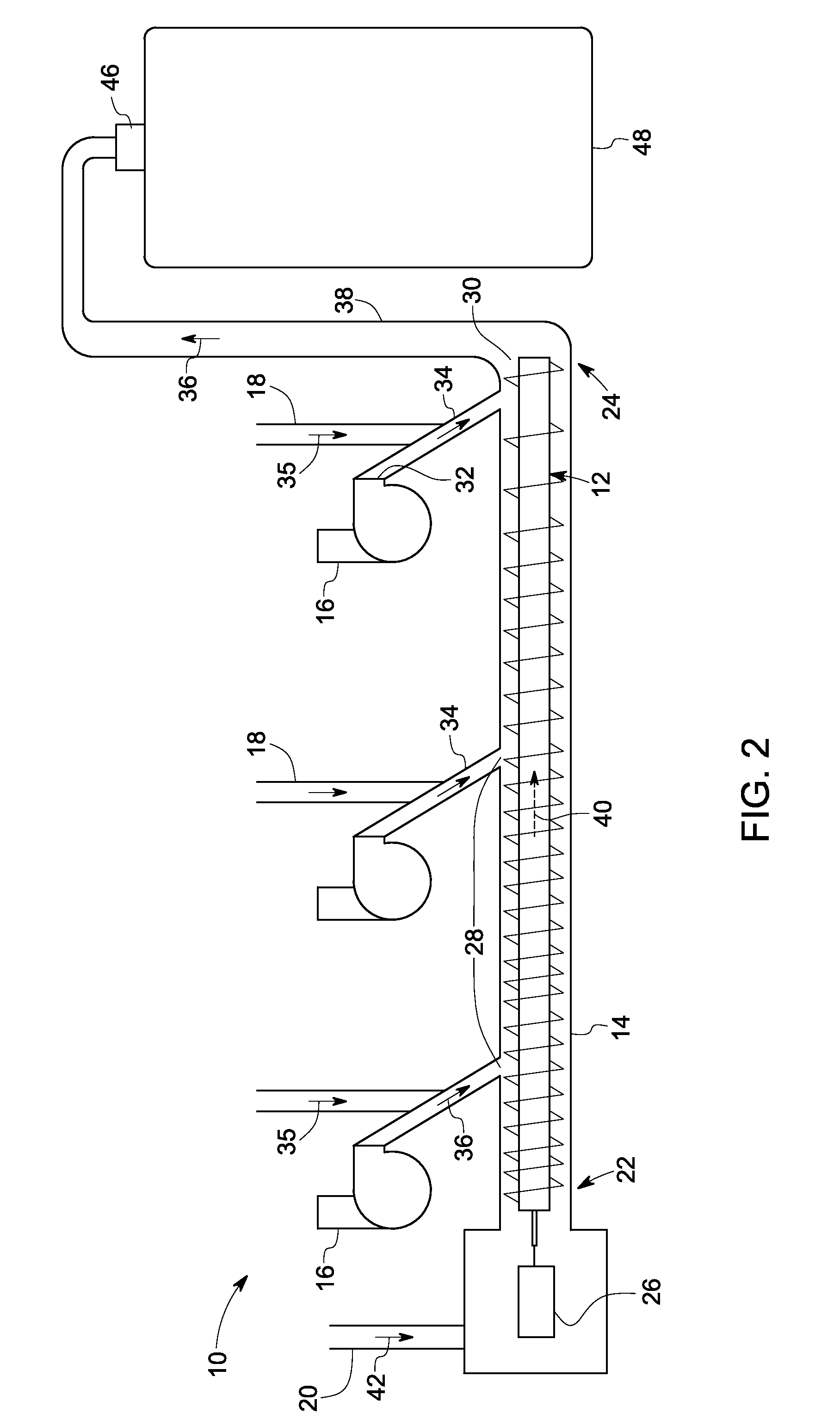

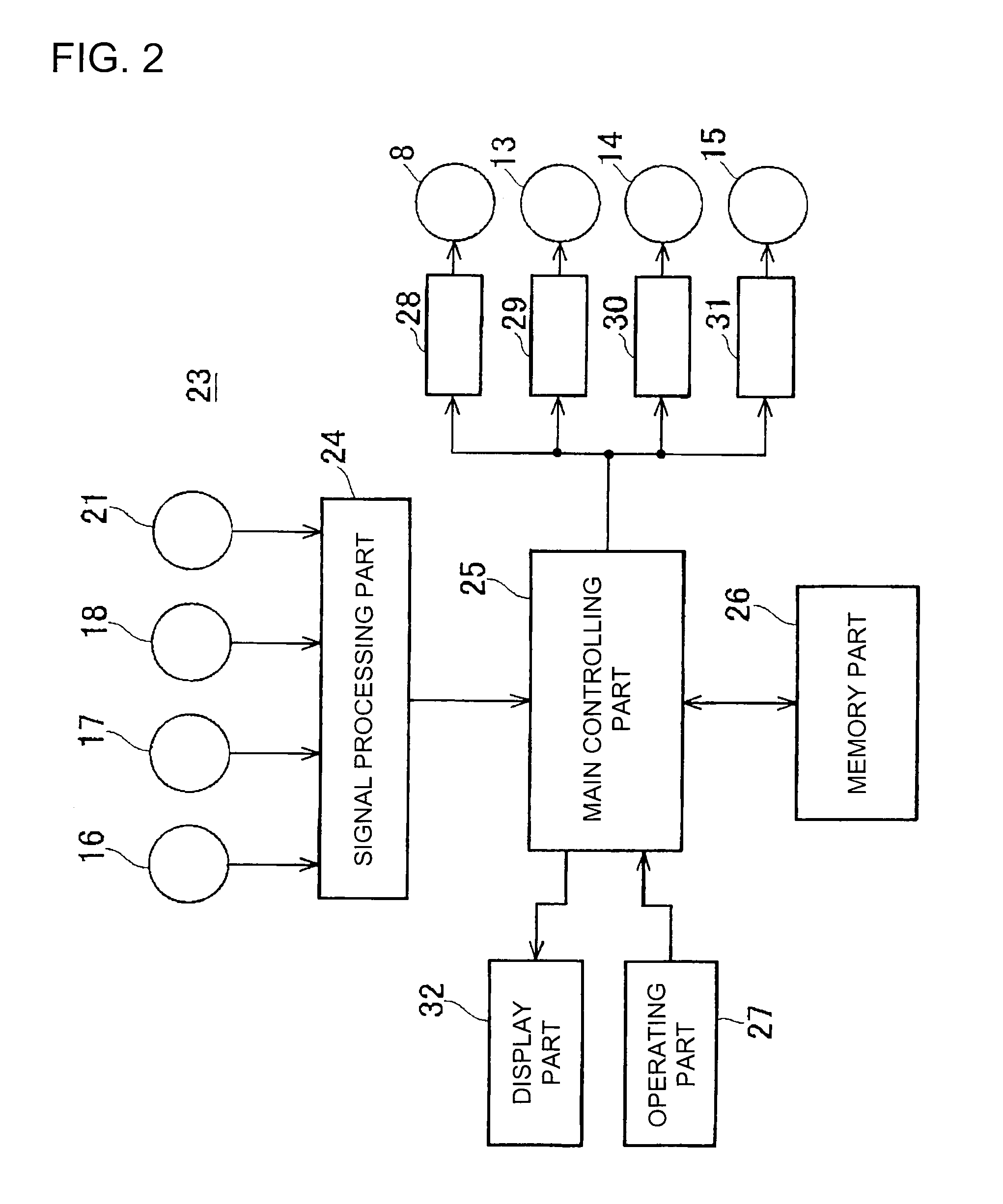

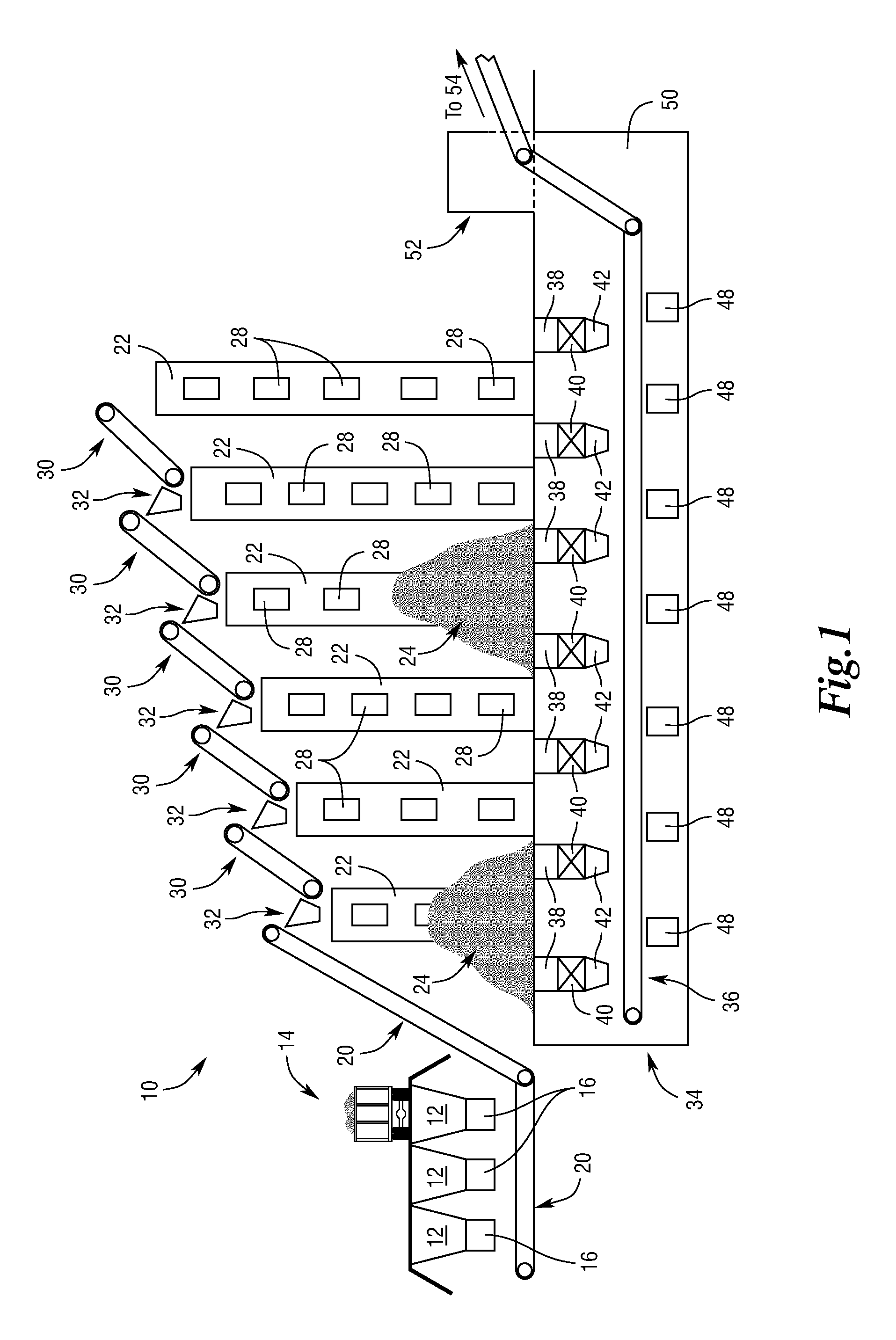

System for shredding and grinding biomass

InactiveUS20140014748A1Efficiently economically shred grindRapid and economic and sustainable developmentFuel feeding arrangementsSolid fuel pretreatmentAgricultural residuePulp and paper industry

A method and system for processing biomass material from harvest to pelletizing includes a continuous shredding stage and grinding stage to reduce the size of the material. A fan pulls air through the shredder and the grinder to assist the movement of the biomass material through the shredder and the grinder. Due to the light weight of the biomass material, the material is transported between the shredding and grinding stages mechanically and pneumatically by a combination auger with air assist. The biomass material may include agricultural residues, such as corn stover. The process and equipment eliminates or minimizes damage to the carbohydrates in the biomass so as to maintain pre-grinding cellulose and hemi-cellulose levels.

Owner:PELLET TECH USA

Solid fuel transporting system for a gasifier

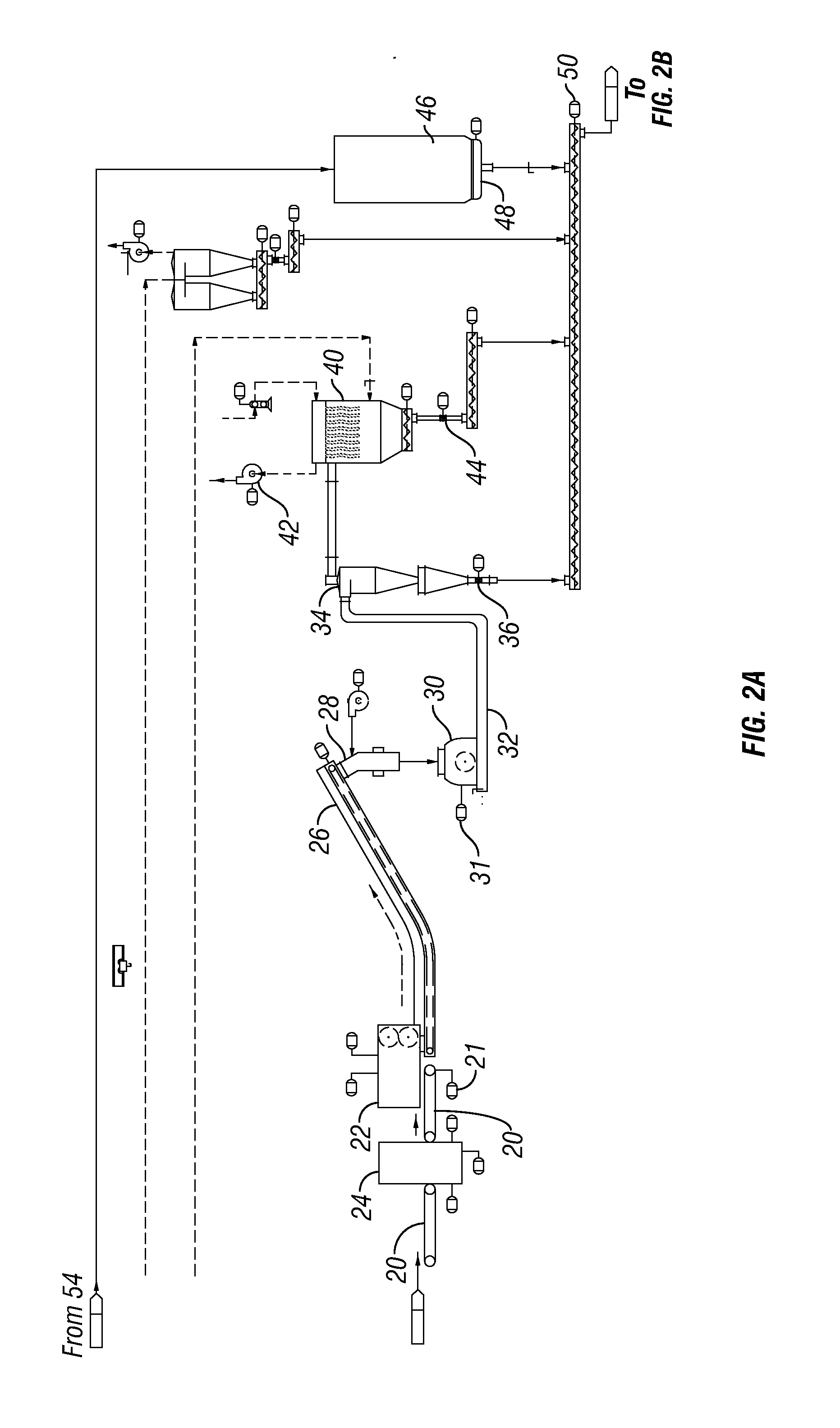

A system for use in a gasification system comprises an increasing pitch screw feeder and a high-pressure vessel disposed about said increasing pitch screw feeder. The high-pressure vessel comprises an inlet for connection to an outlet of a solid pump and a conveyance gas line and an outlet through which solid fuel delivered from the solid pump is transported to a gasifier. The outlet is downstream of the solid pump and the conveyance gas line.

Owner:AIR PROD & CHEM INC

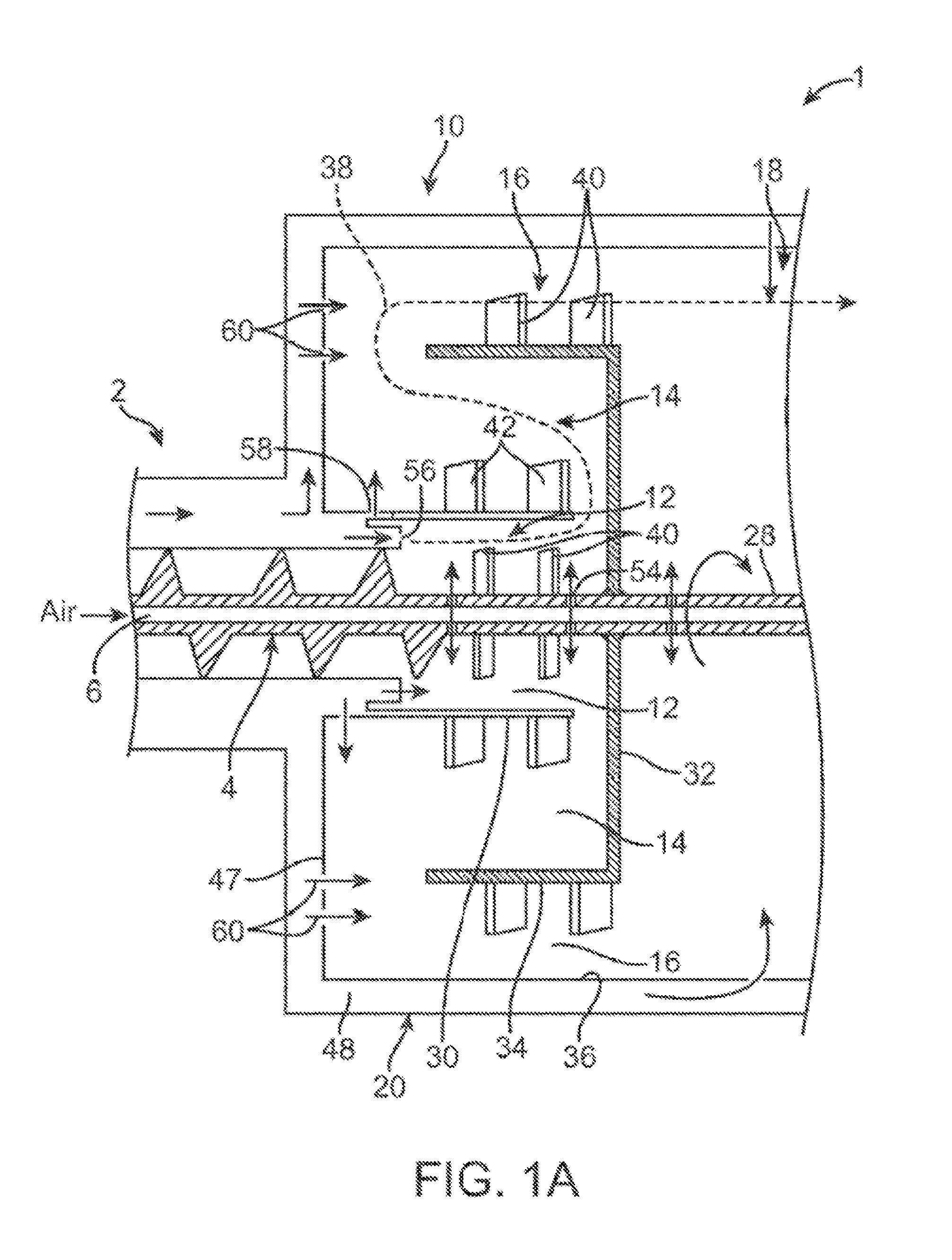

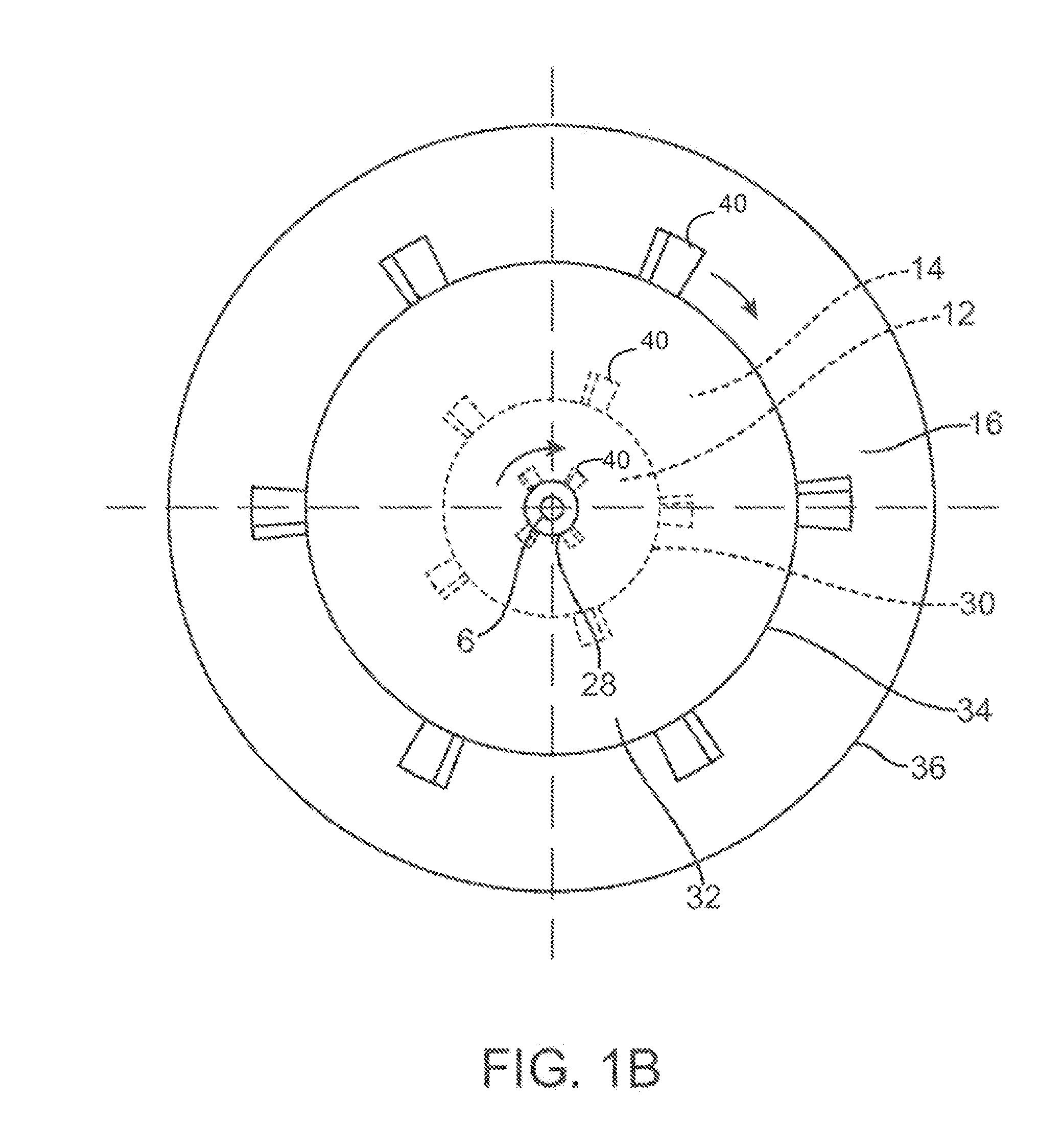

Non-catalytic biomass fuel burner and method

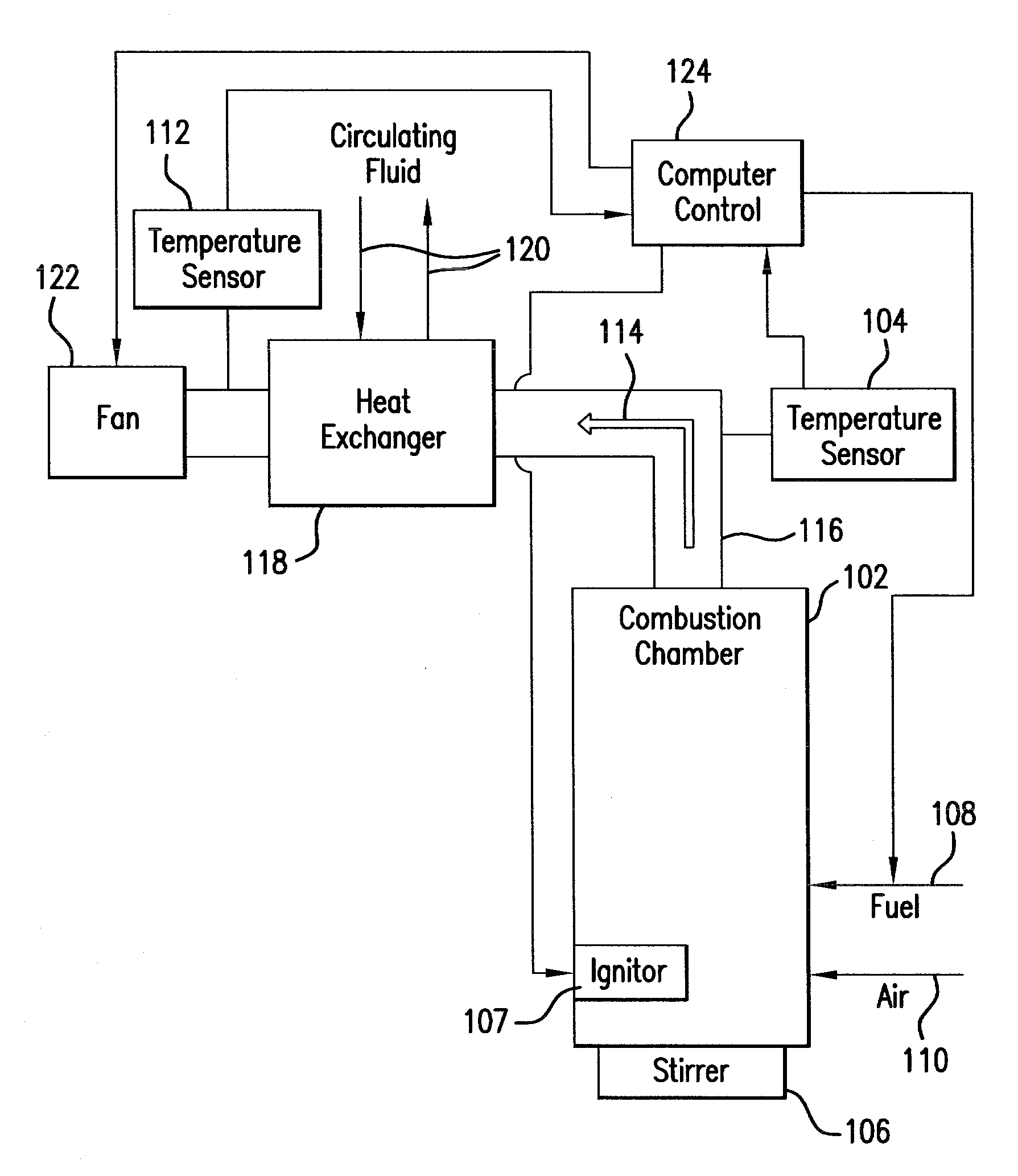

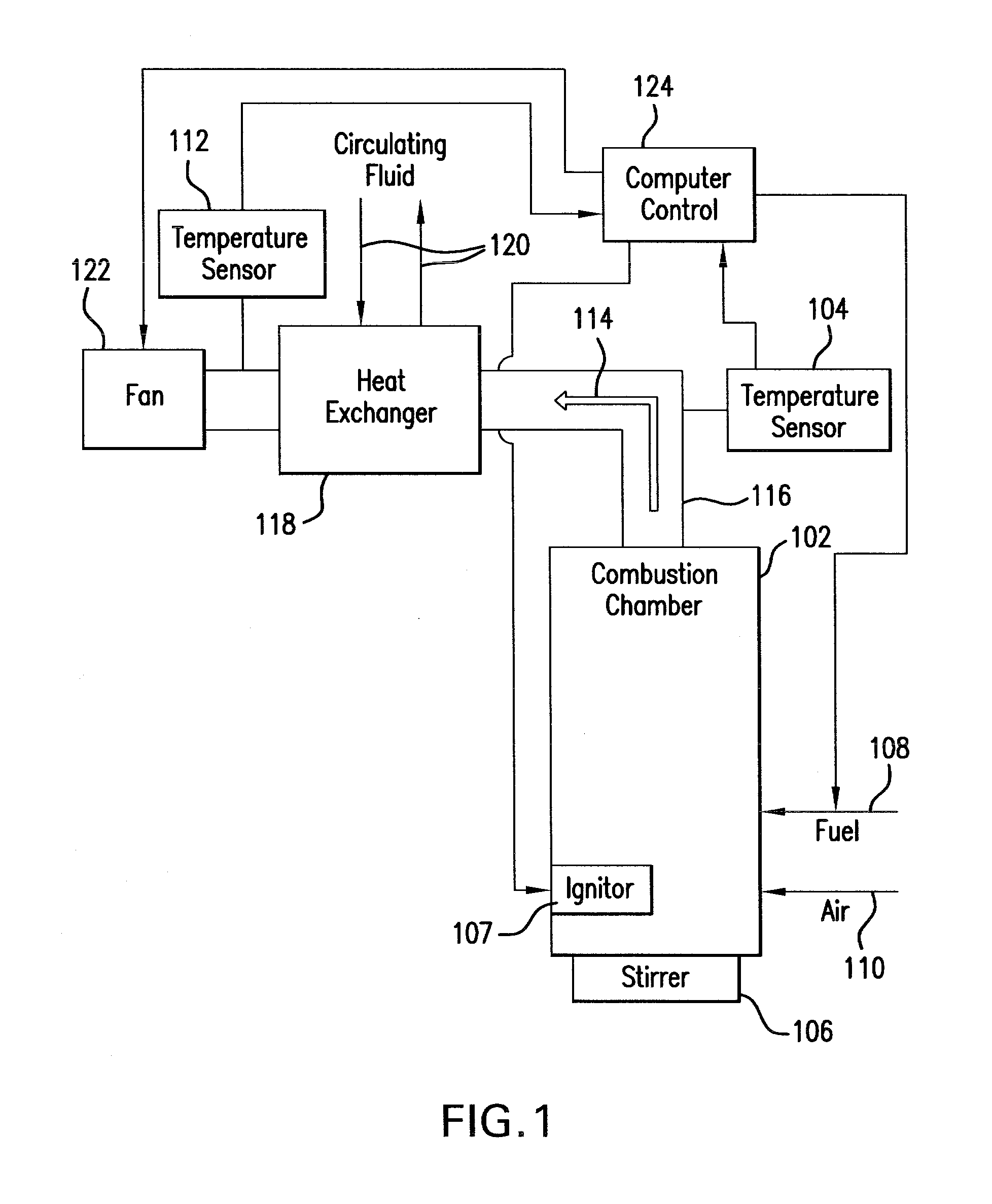

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

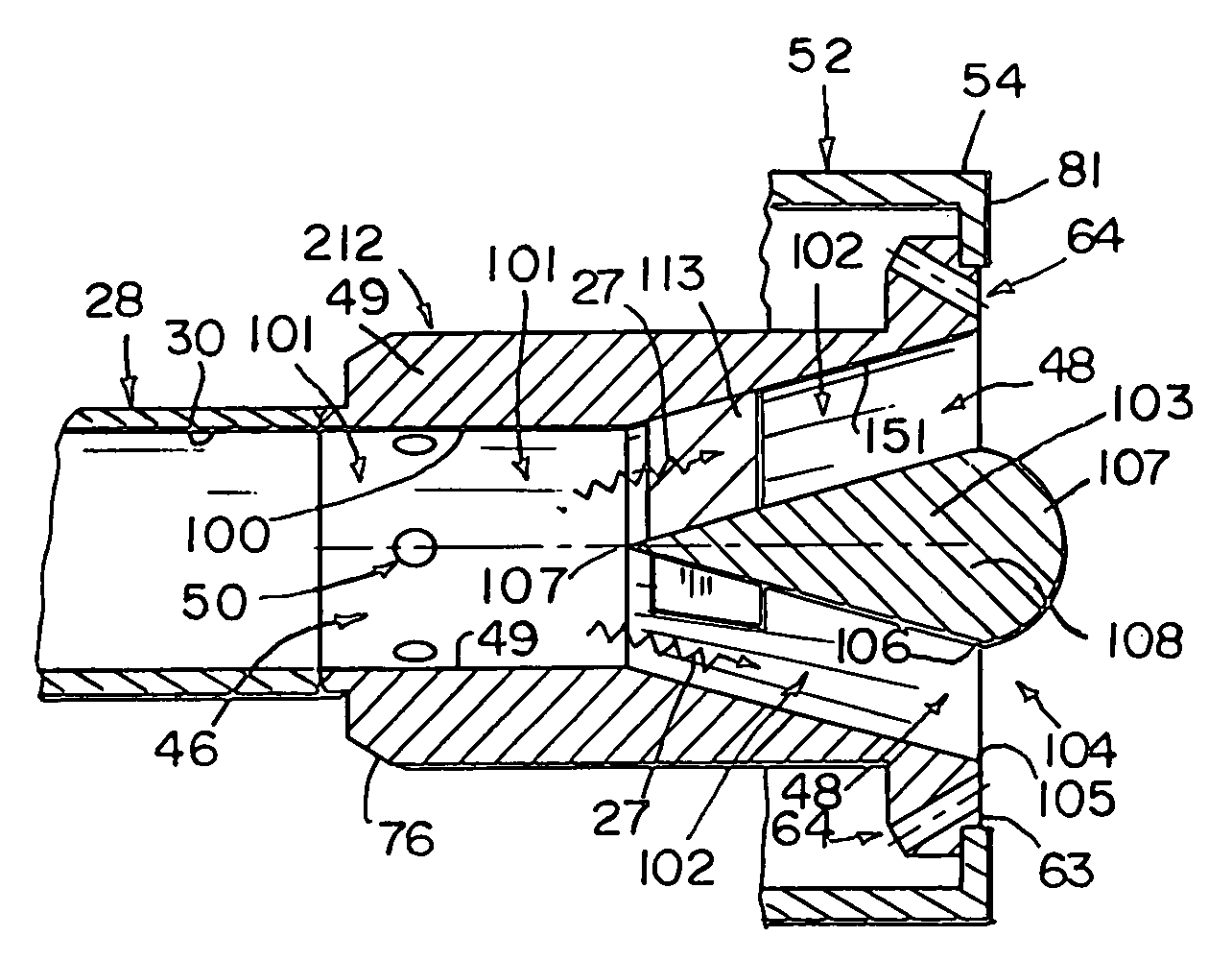

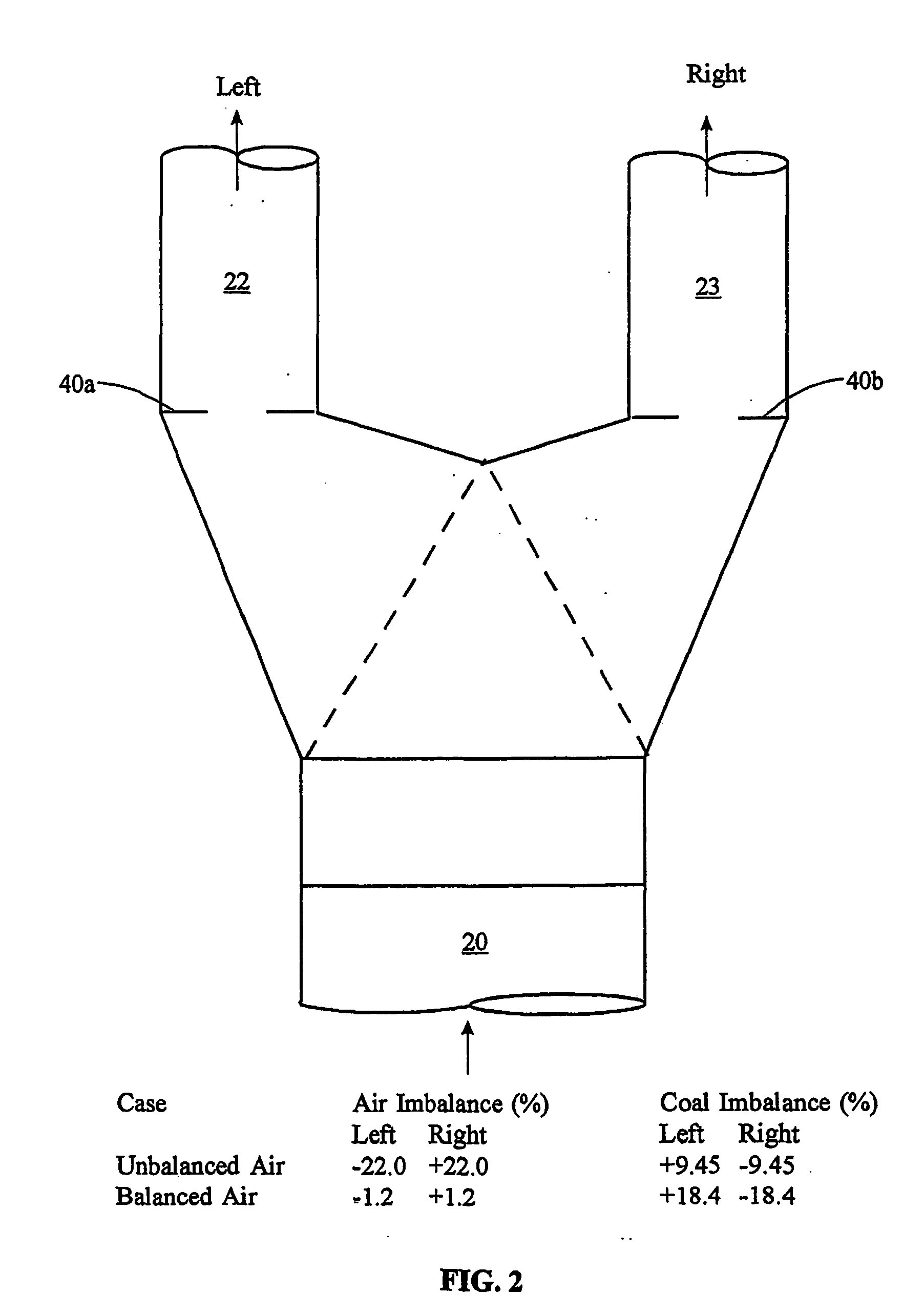

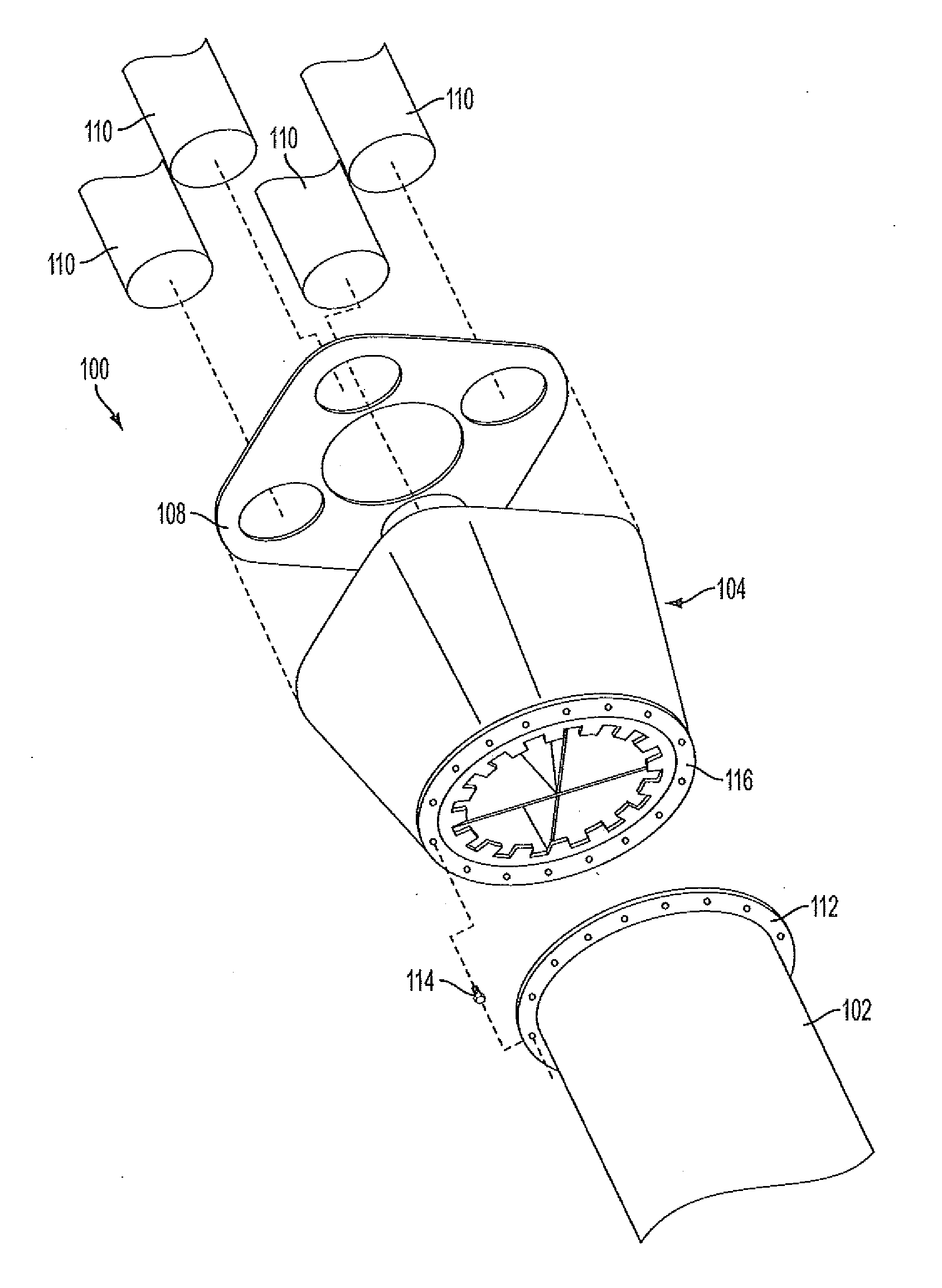

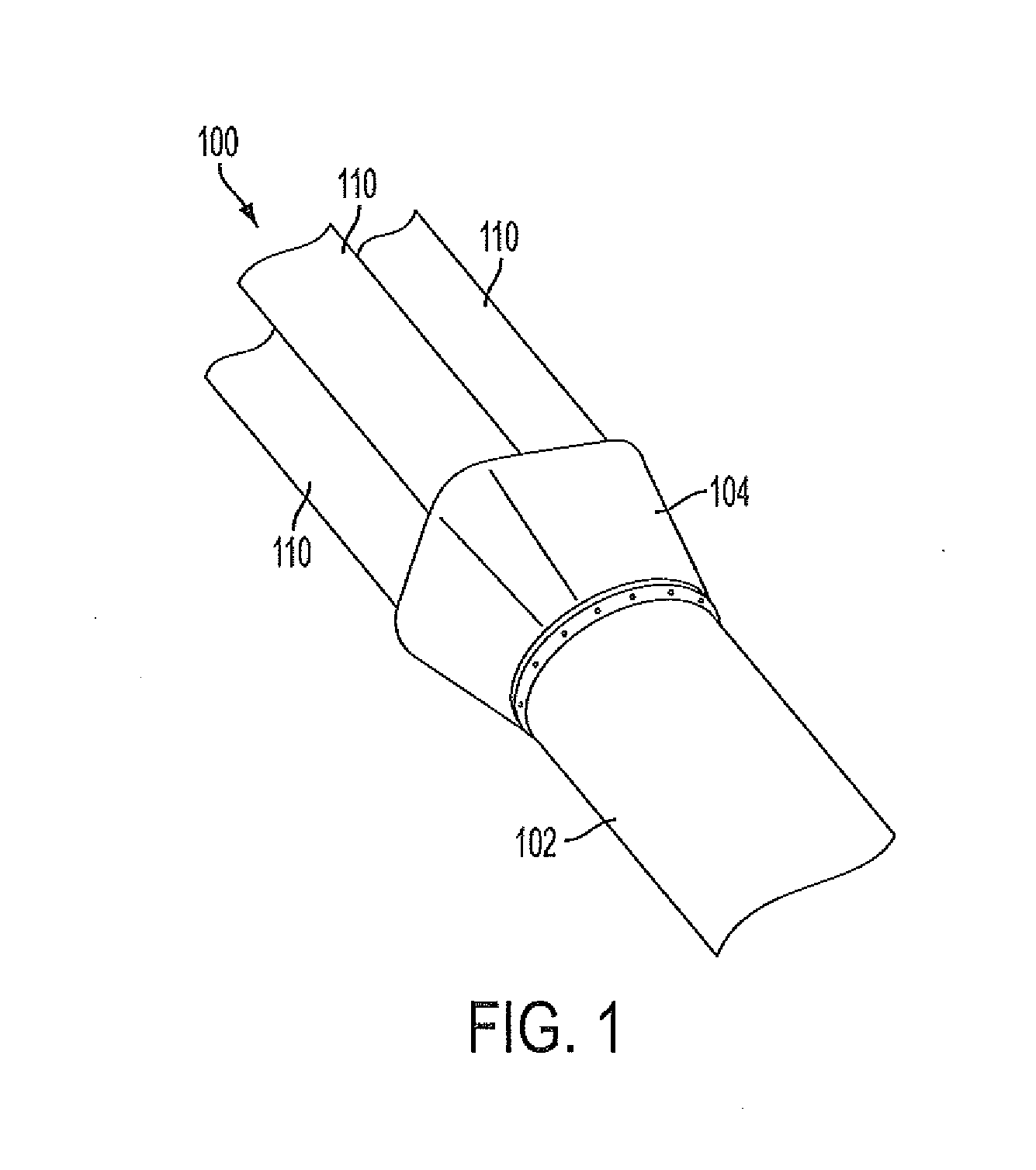

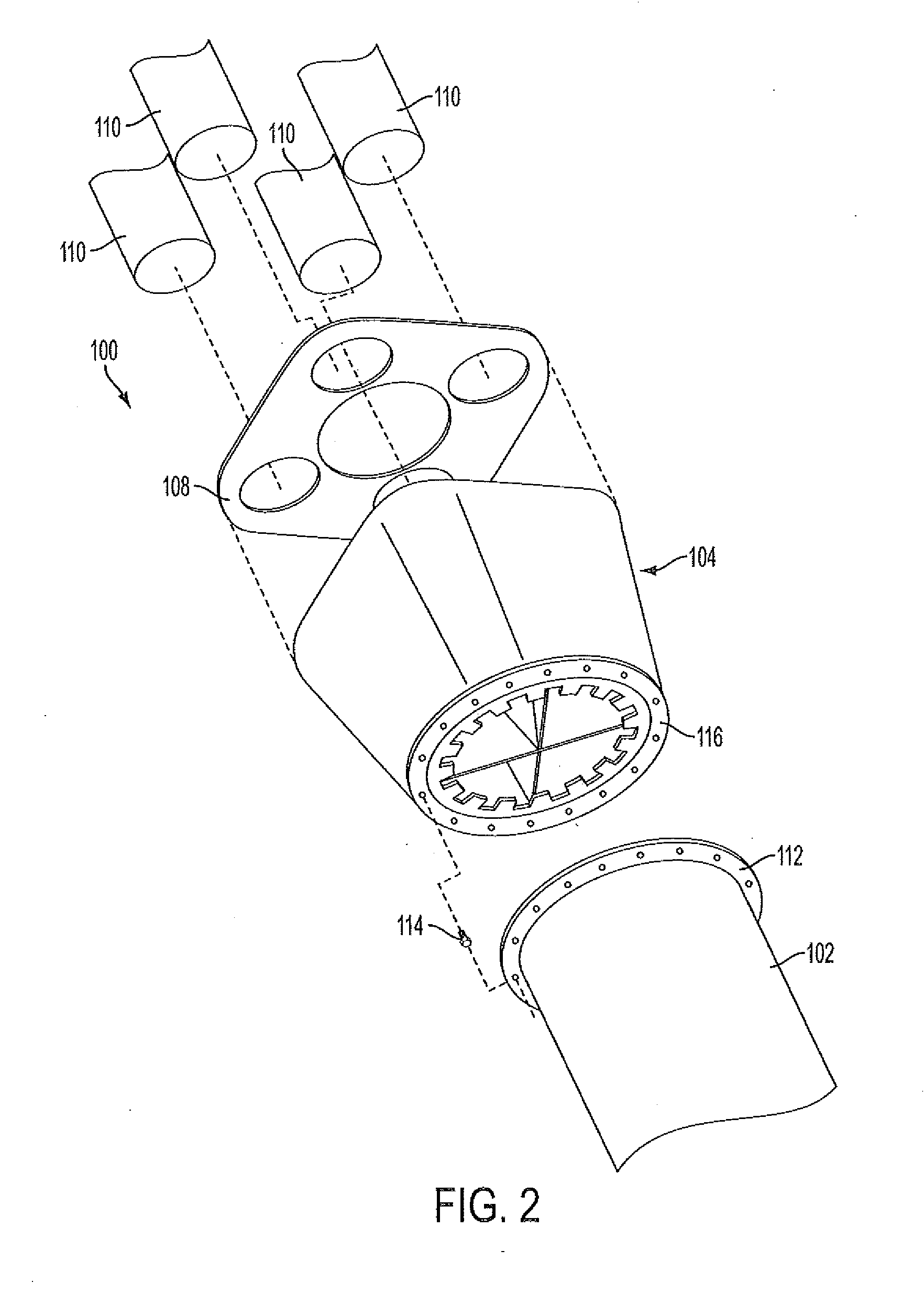

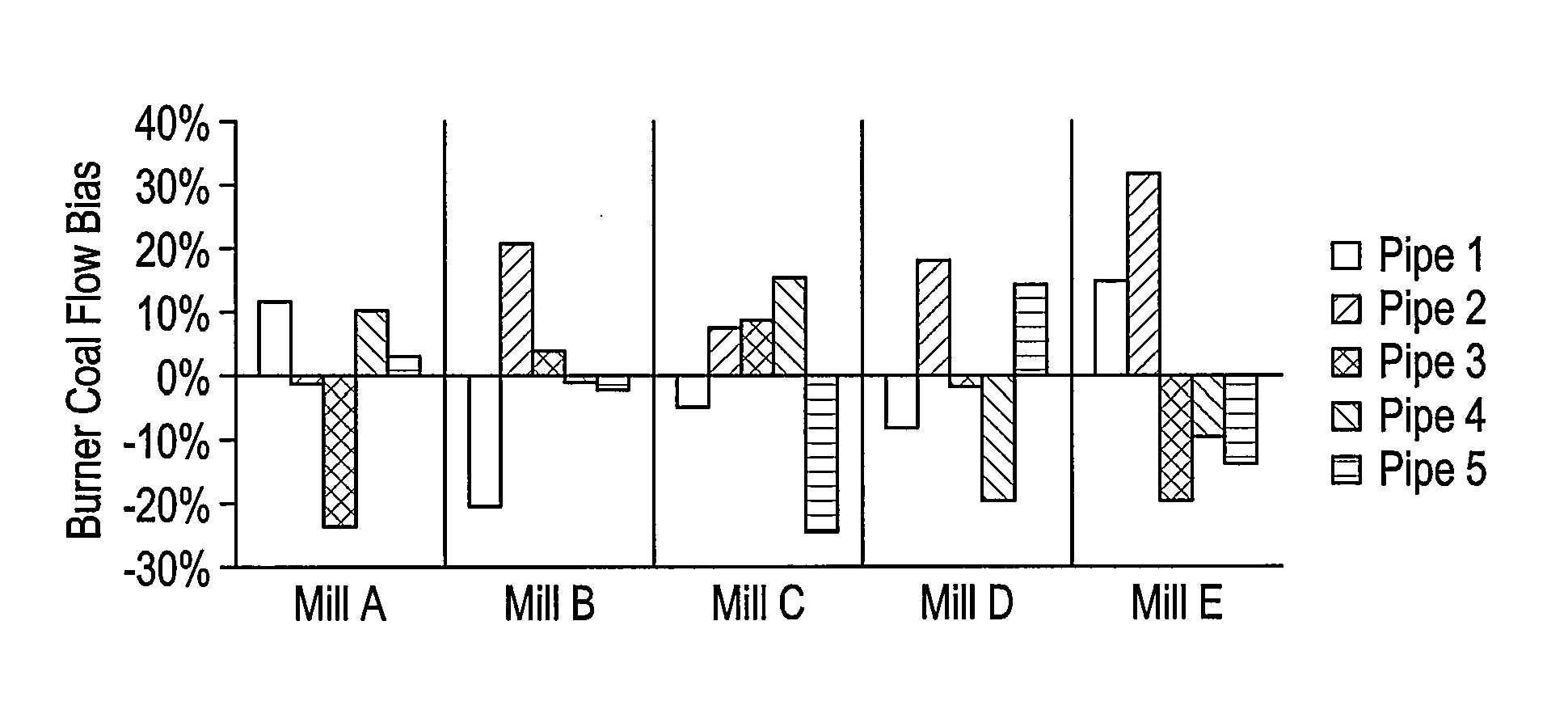

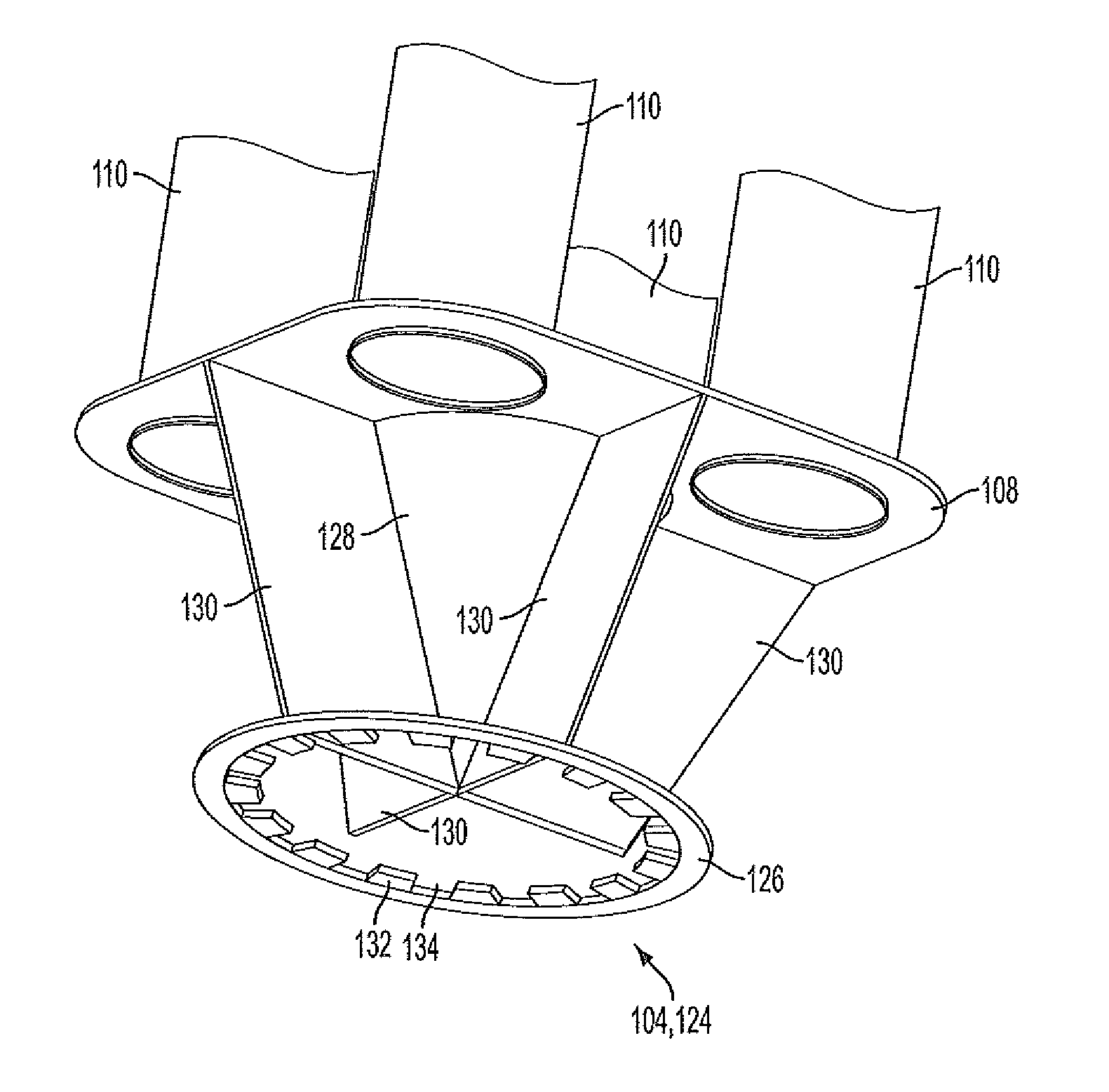

Adjustable air foils for balancing pulverized coal flow at a coal pipe splitter junction

InactiveUS20050042043A1Coal flow imbalanceIncreasing and decreasing flowFuel feeding arrangementsDamper arrangementPollutant emissionsCoal

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of wake inducing airfoils (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each wake-inducing airfoil has a cross-section defined by a width W that varies along its length H for creating upstream turbulence, and a particle wake that preferentially diverts the coal flow to one of the outlet pipes at the splitter junction without affecting primary air flow. For example, each wake inducing airfoil may comprise a rounded convex edge leading to straight tapered sides. The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers. In addition, conventional fixed or variable orifices may be used in combination with the wake inducing airfoils for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air, resulting in closely balanced coal flow, reduced pollutant emissions and improved combustion efficiency.

Owner:LEVY EDWARD KENNETH +3

Coal flow splitters and distributor devices

A flow splitter for distributing solid particles flowing in a fluid through a piping system includes a divider housing. The divider housing has an inlet configured to connect to an upstream pipe and has a plurality of outlets, each outlet being configured to connect to a respective downstream pipe. A divider body is mounted within the divider housing. A plurality of divider vanes are included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow to each outlet.

Owner:BABCOCK POWER SERVICES

Adjustable flow control elements for balancing pulverized coal flow at coal pipe splitter junctions

InactiveUS6789488B2Lower Level RequirementsImprove combustion efficiencyFuel feeding arrangementsPulverulent fuel combustion burnersCombined usePollutant emissions

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of flow control elements (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each flow control element preferably comprises a rounded convex edge leading to straight tapered sides (FIG. 9). The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers (FIG. 9). In addition, conventional fixed or variable orifices may be used in combination with the flow control elements for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air. The combination of the riffler assembly and the coal flow control elements (60) results in closely balanced coal flow. Balanced coal flow is imperative to the optimization of the operation of pulverized coal boiler systems (i.e. reduced pollutant emissions, improved combustion efficiency).

Owner:LEVY EDWARD KENNETH +2

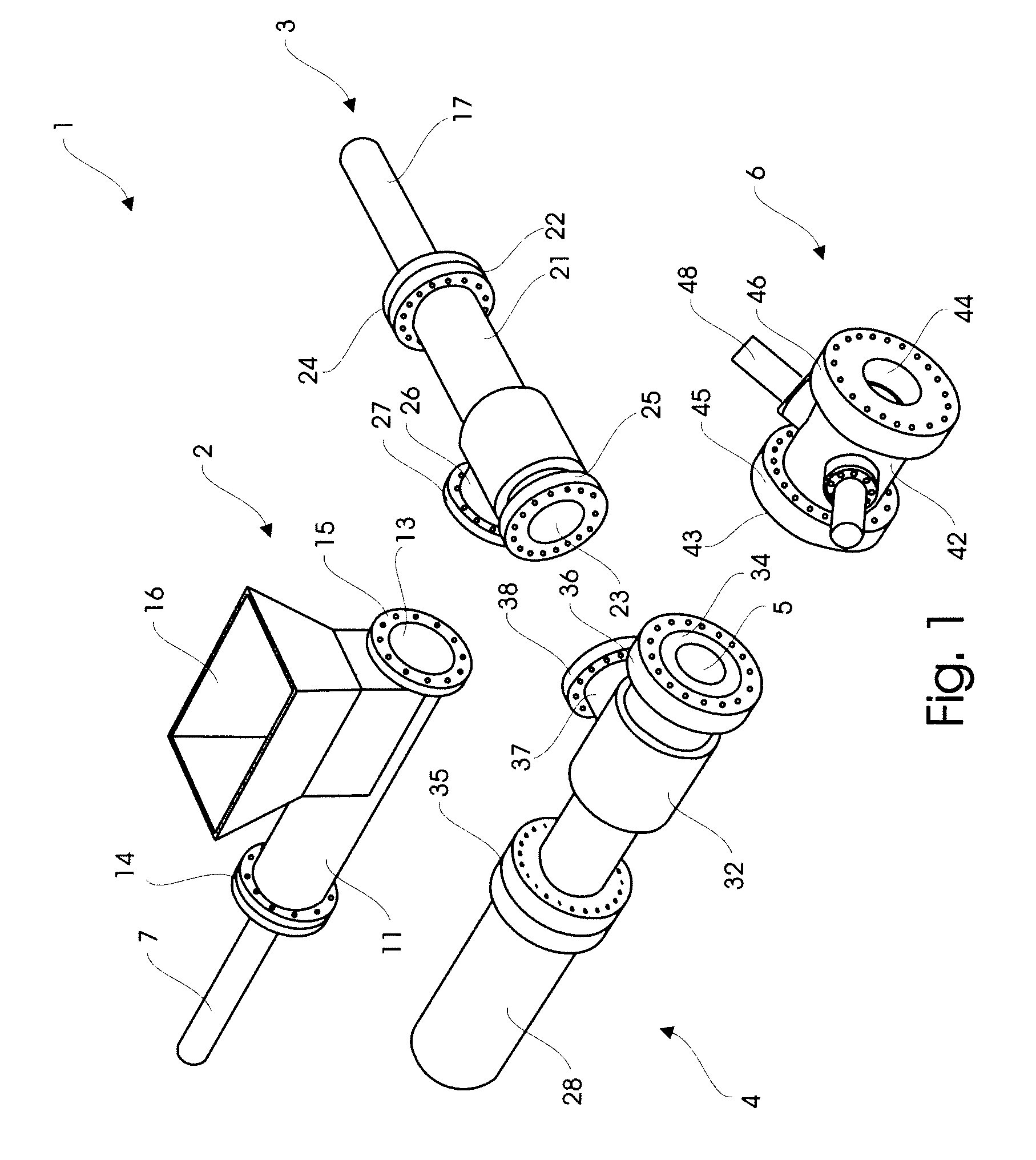

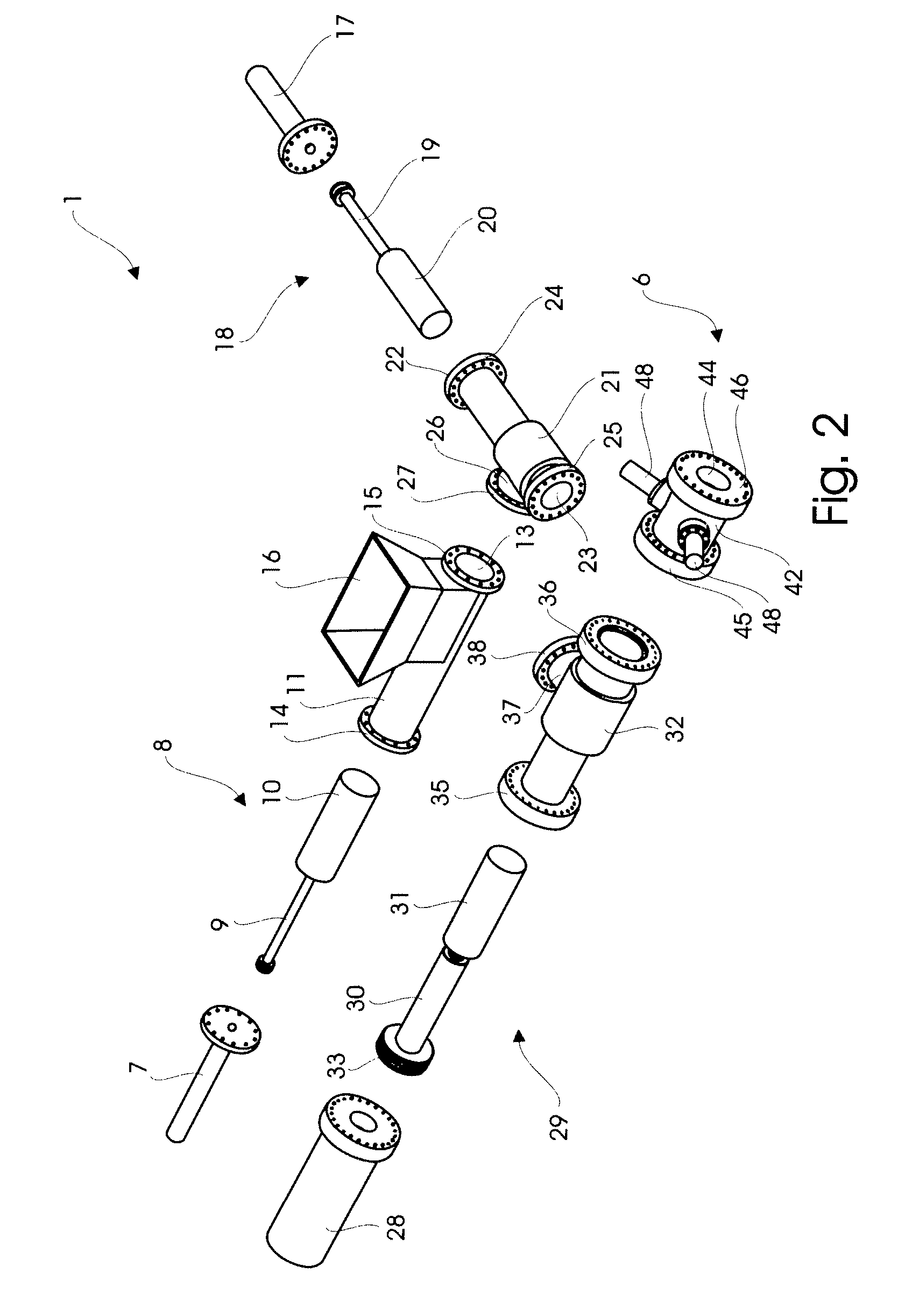

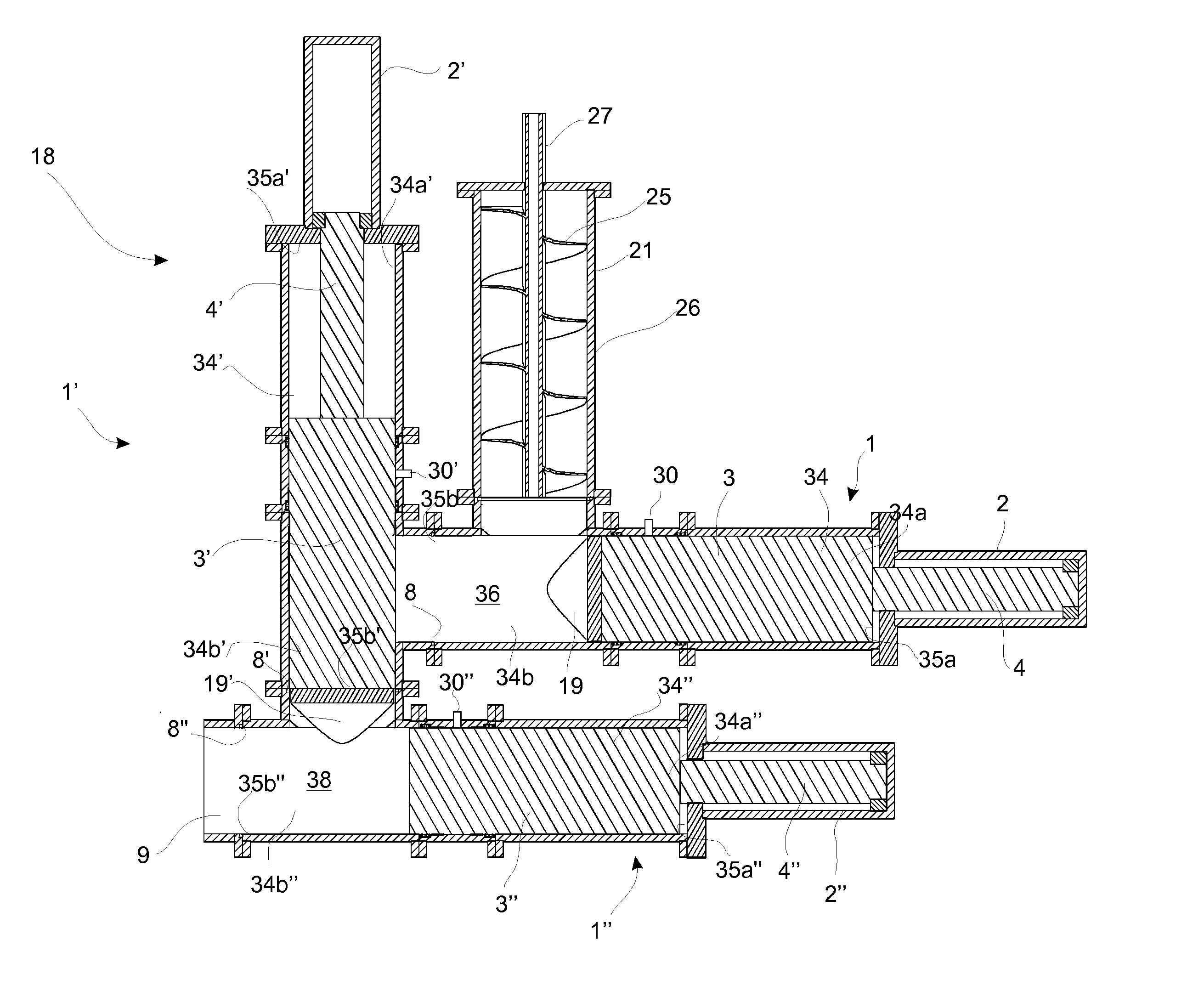

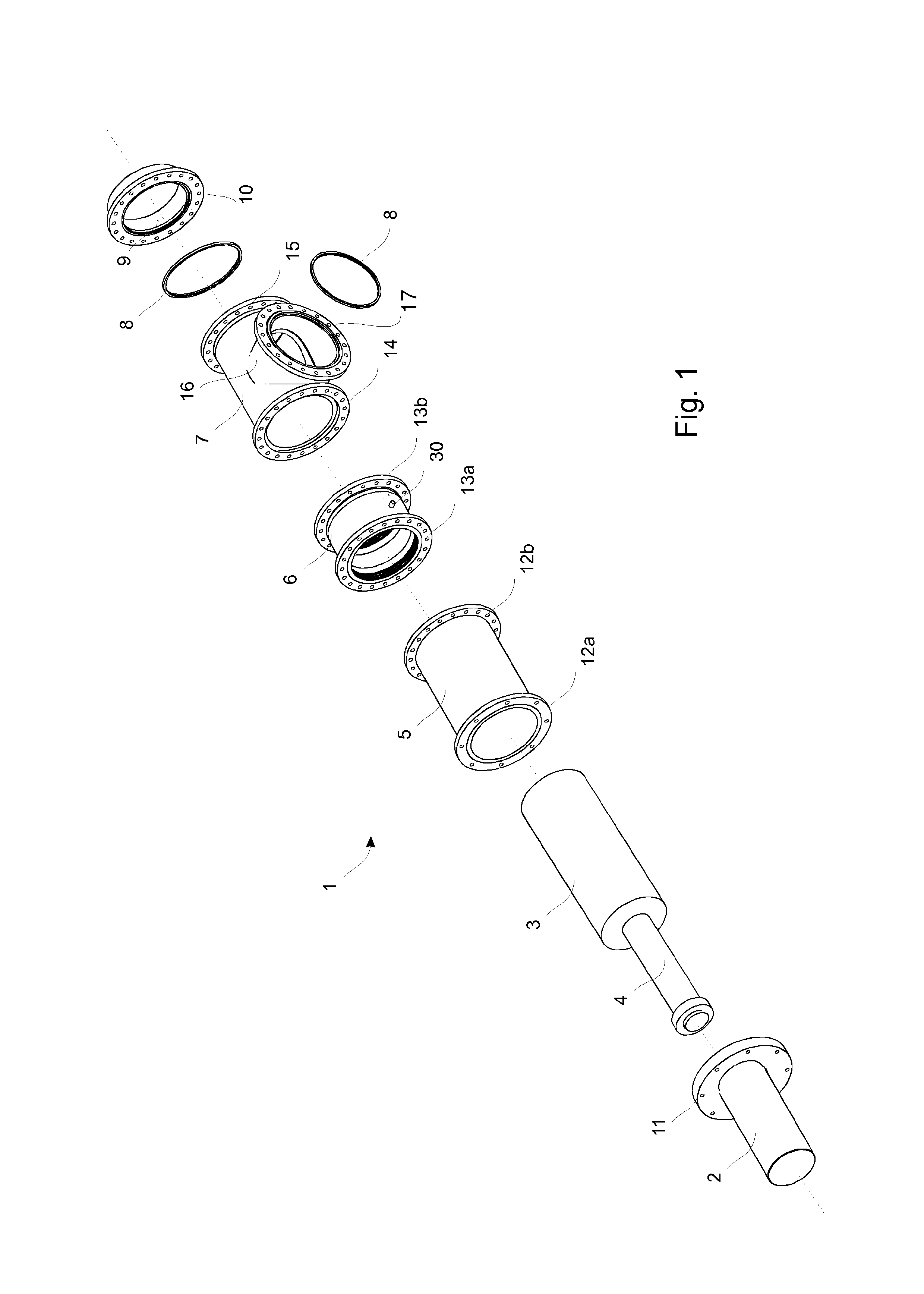

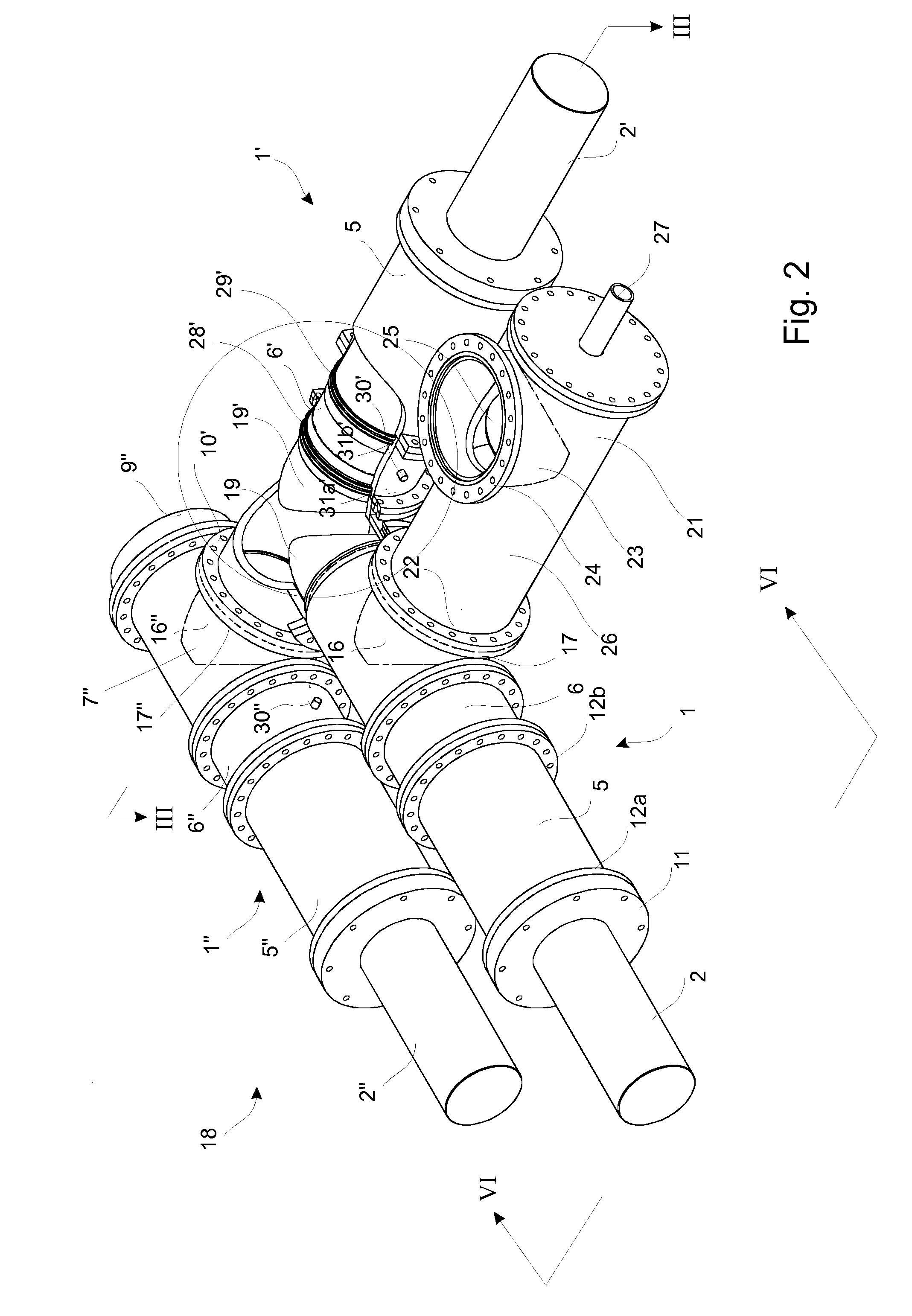

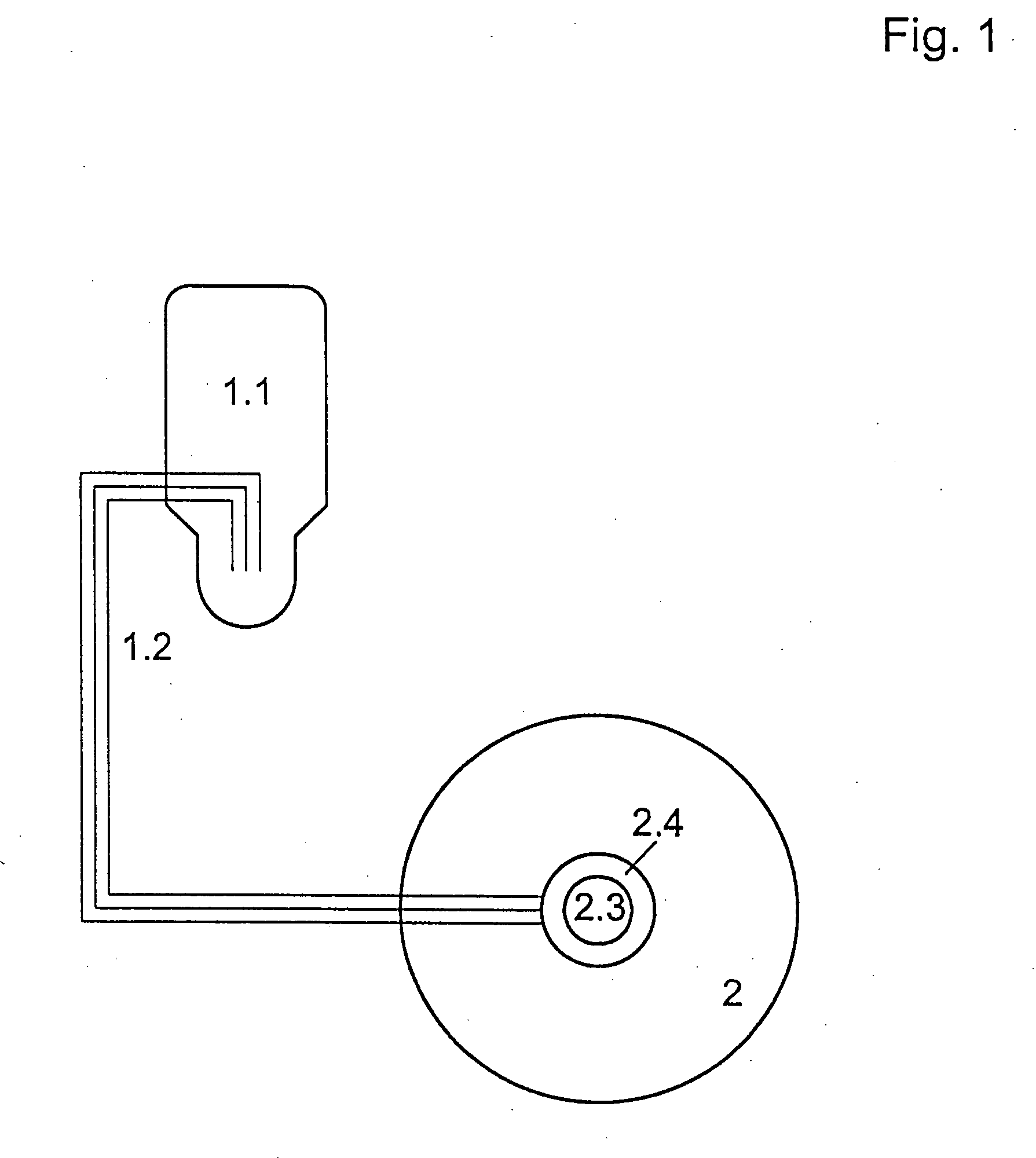

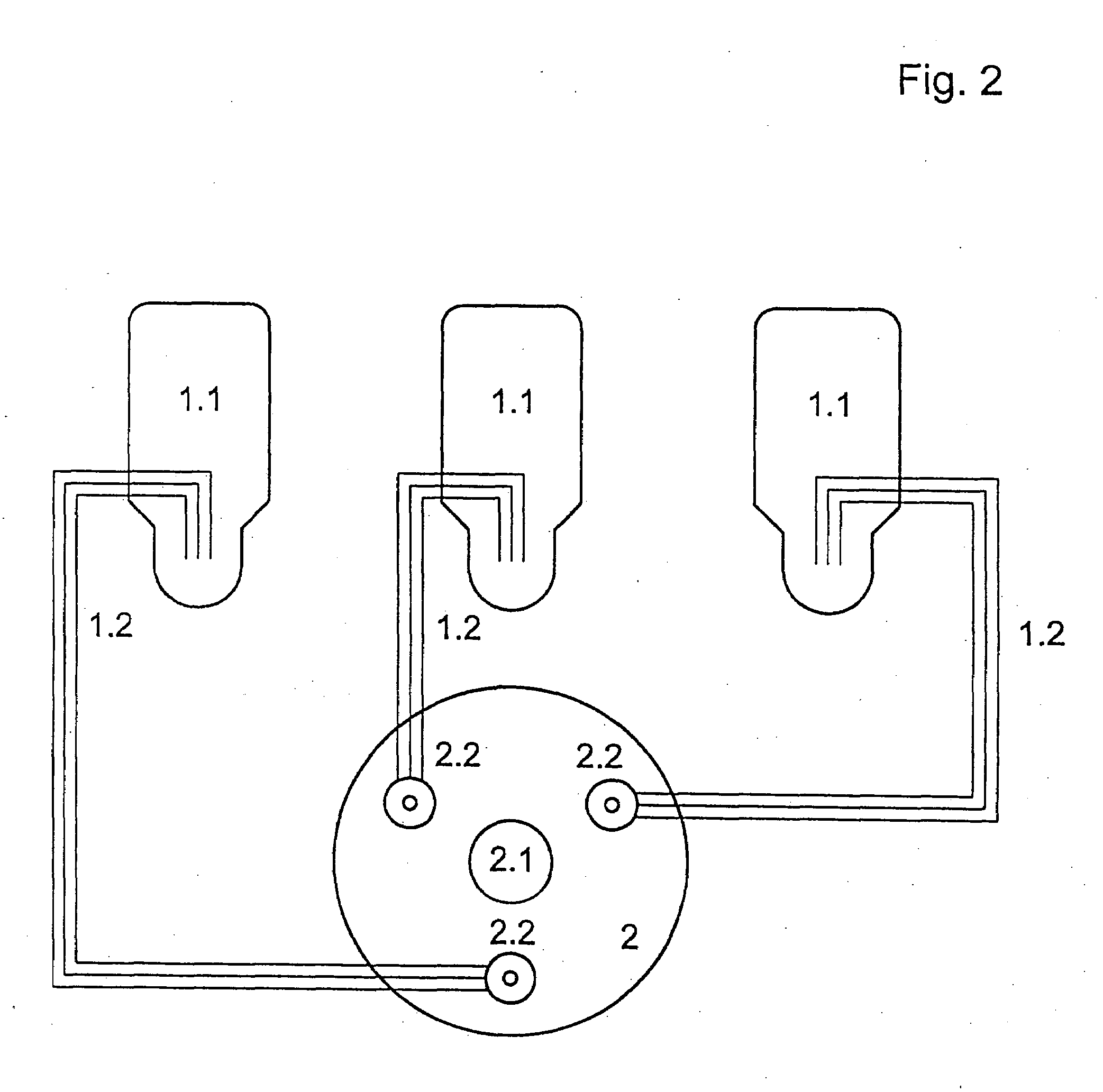

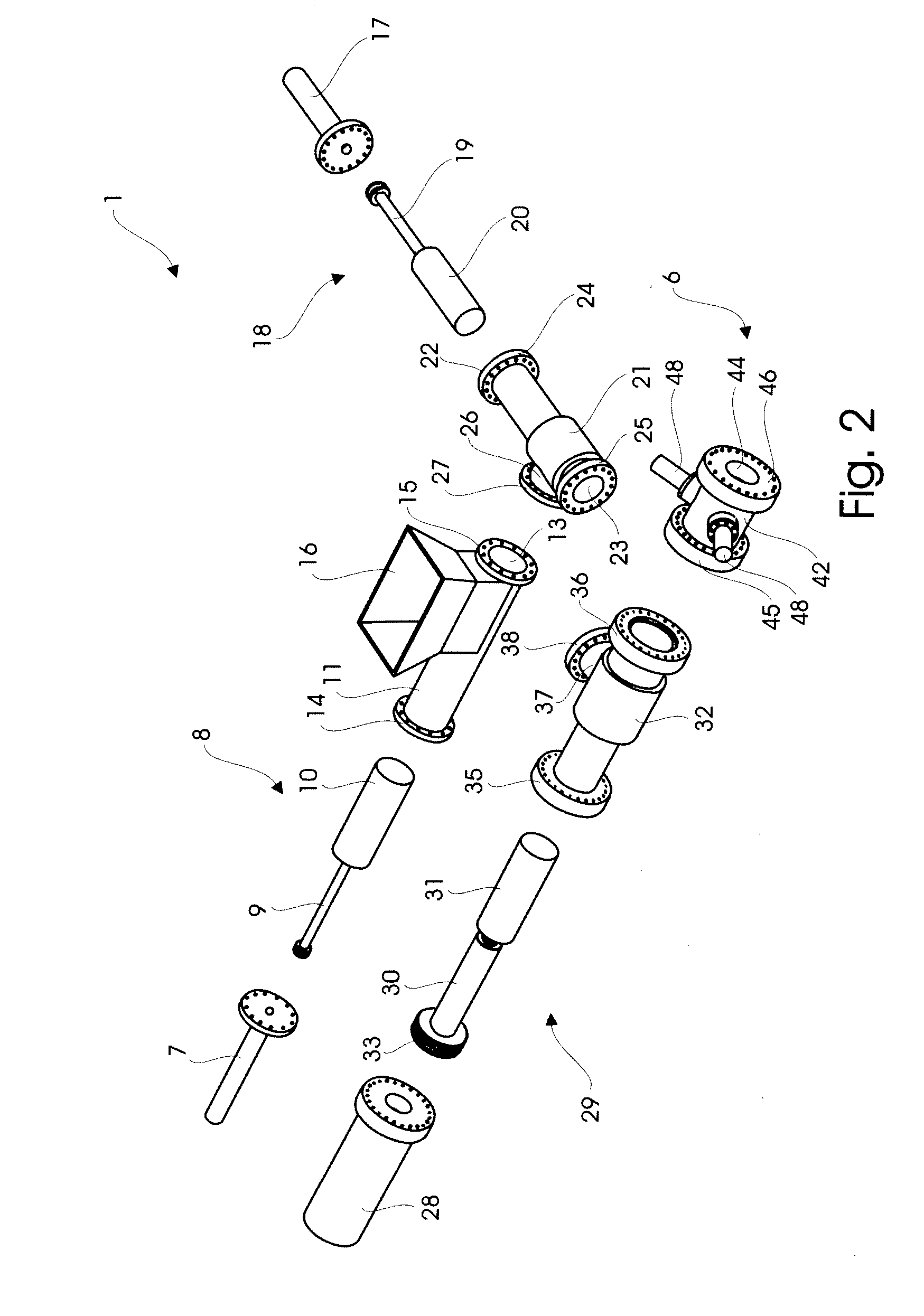

Piston member, an apparatus comprising the piston member, and methods and use of the piston member and the apparatus

ActiveUS8721299B2Easy to operateEasy maintenancePressurized chemical processFuel feeding arrangementsReciprocating motionEngineering

A piston member that includes a piston rod provided with a piston serves for reciprocating inside a cylinder barrel, the piston dividing the cylinder barrel chamber into a proximal cylinder barrel chamber having a proximal capped end opposite the piston and a distal cylinder barrel chamber having a distal cylinder barrel end opposite the piston. The piston member has at least one sealing ring or seat arranged inside the distal cylinder barrel chamber at the distal cylinder barrel end. Preferably three consecutive piston members are arranged to operate in a series in an apparatus for transporting coal powder to a gasifier. The movement of the pistons inside the cylinder barrels is controlled in relation to each other to transport apportioned batches of coal powder to a high pressure reactor.

Owner:THERMOCHEM RECOVERY INT

Method for starting high-performance entrained flow gasification reactors with combination burner and multiple burner array

ActiveUS20080000404A1Reduce needNeed can be heatedFuel feeding arrangementsGasification processes detailsCombustorCombustible gas

A method for starting high-performance entrained flow gasification reactors with a combination burner or a plurality of pulverized fuel burners, and an ignition and pilot burner. The ignition and pilot burner is ignited, substoichiometrically with fuel gas and a gasifier containing free oxygen. The reactor is brought to the pressure intended and a flow of a fuel gas is supplied with a partial flow of the gasification agent at a substoichiometric ratio through the fuel lines leading to the fuel burner and ignited by the flame of the ignition and pilot burner with a partial flow of the gasification agent. Next, the pulverized fuel is supplied together with a further oxygen-containing gasifying agent through the supply lines to the pulverized fuel burner and is ignited by the flame of the ignition and pilot burner and by the fuel gas flames of the combustible gas generated at the pulverized fuel burner.

Owner:MANFRED SCHINGNITZ +1

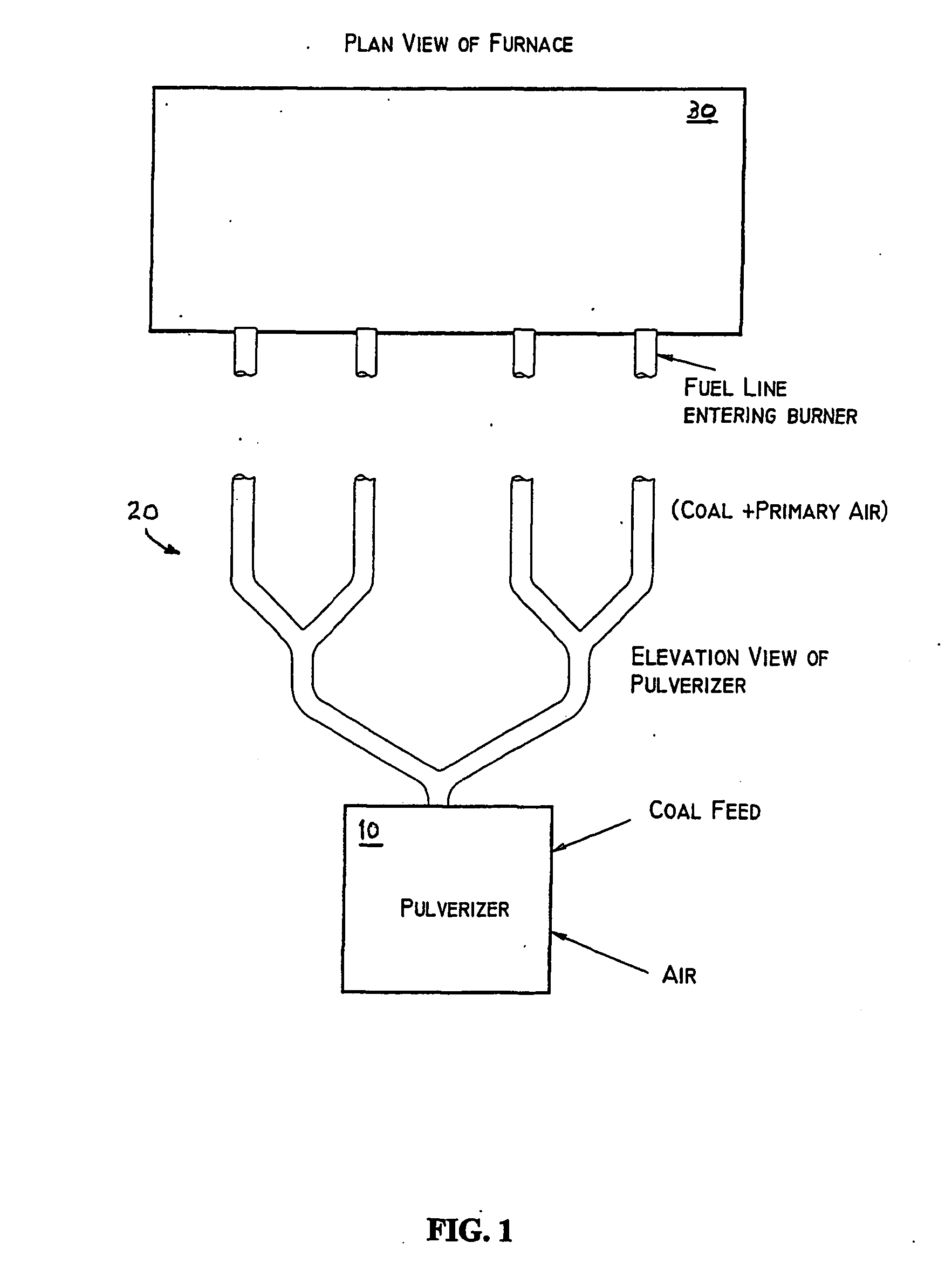

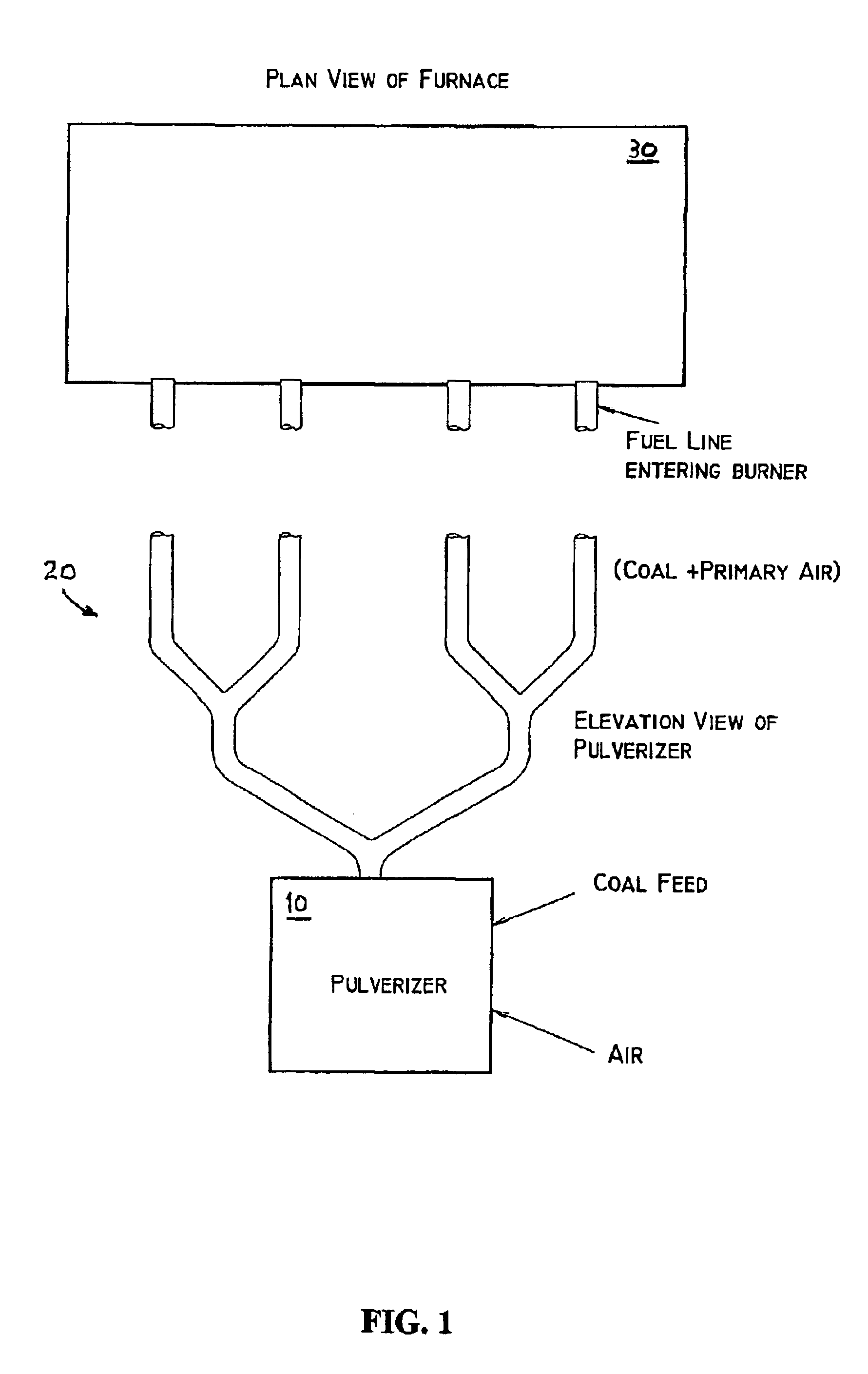

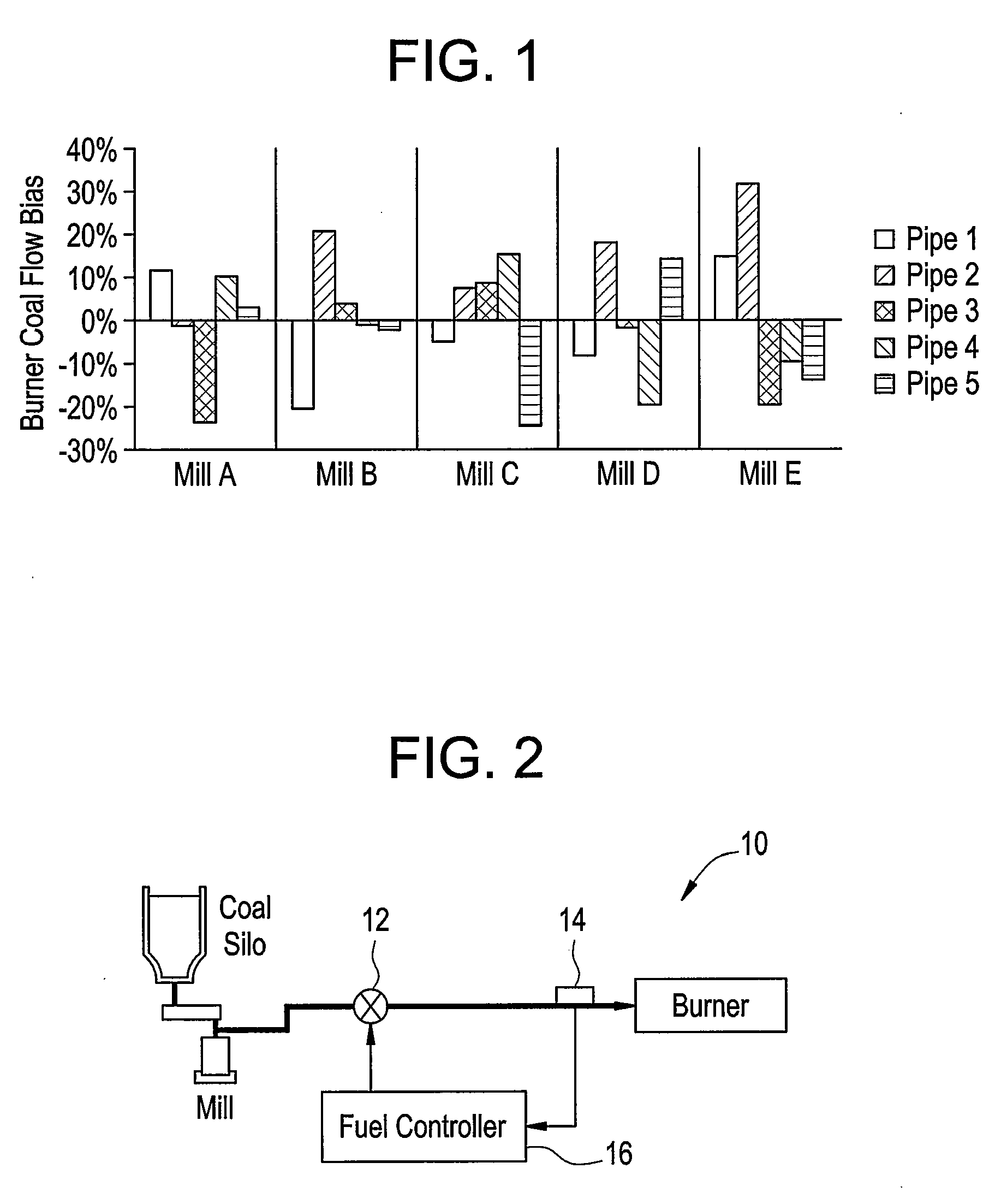

Method and System for controlling coal flow

A system for controlling coal flow in a coal-fired boiler including: a coal flow damper in operable communication with a burner pipe; a coal flow sensor in operable communication with the burner pipe which generates a coal flow signal; and a fuel trim controller in operable communication with the coal flow damper, the fuel trim controller controlling the coal flow damper responsive to the coal flow signal.

Owner:GENERAL ELECTRIC CO

Coal flow splitters and distributor devices

A flow splitter for distributing solid particles flowing in a fluid through a piping system includes a divider housing. The divider housing has an inlet configured to connect to an upstream pipe and has a plurality of outlets, each outlet being configured to connect to a respective downstream pipe. A divider body is mounted within the divider housing. A plurality of divider vanes are included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow to each outlet.

Owner:BABCOCK POWER SERVICES

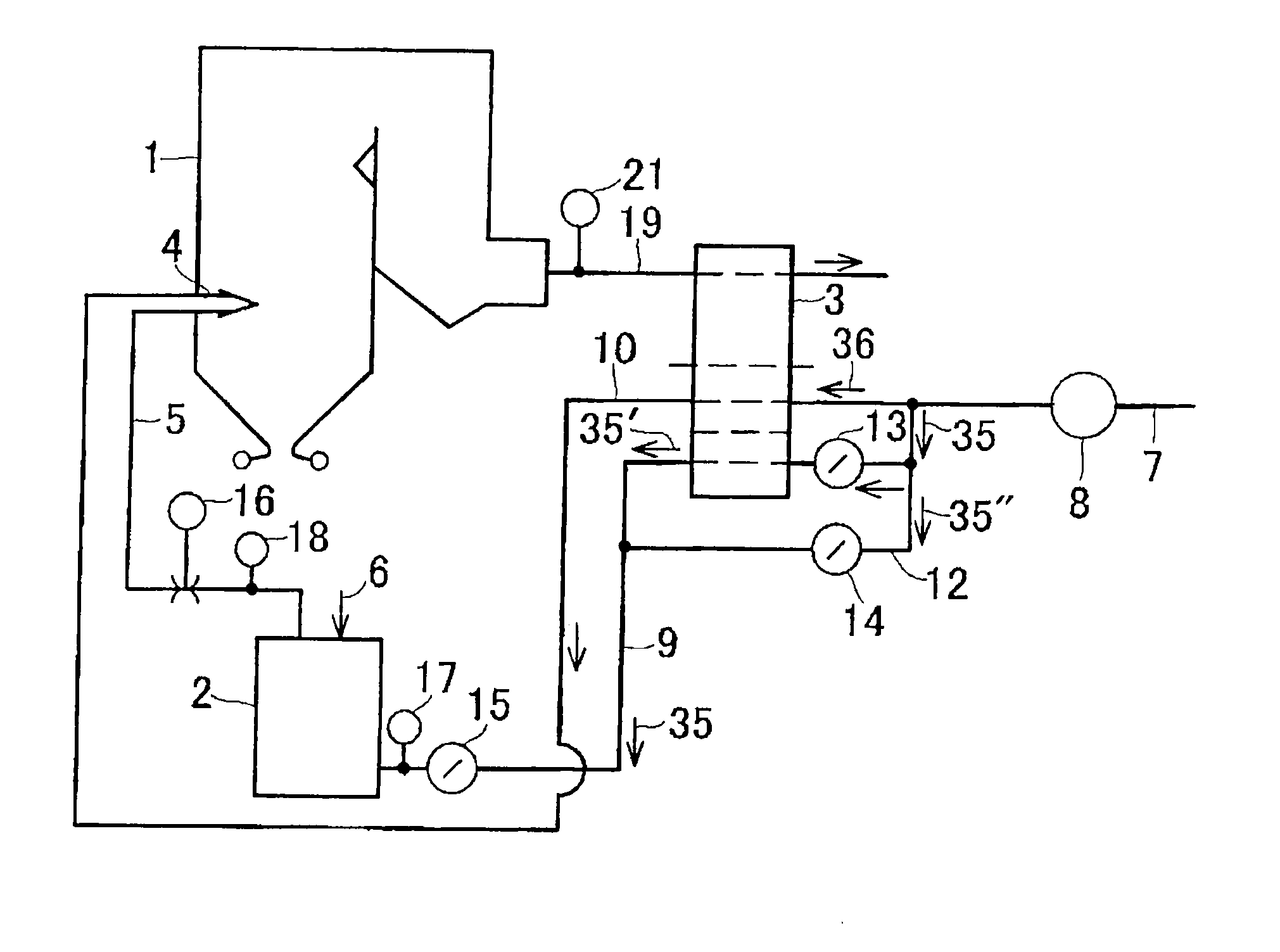

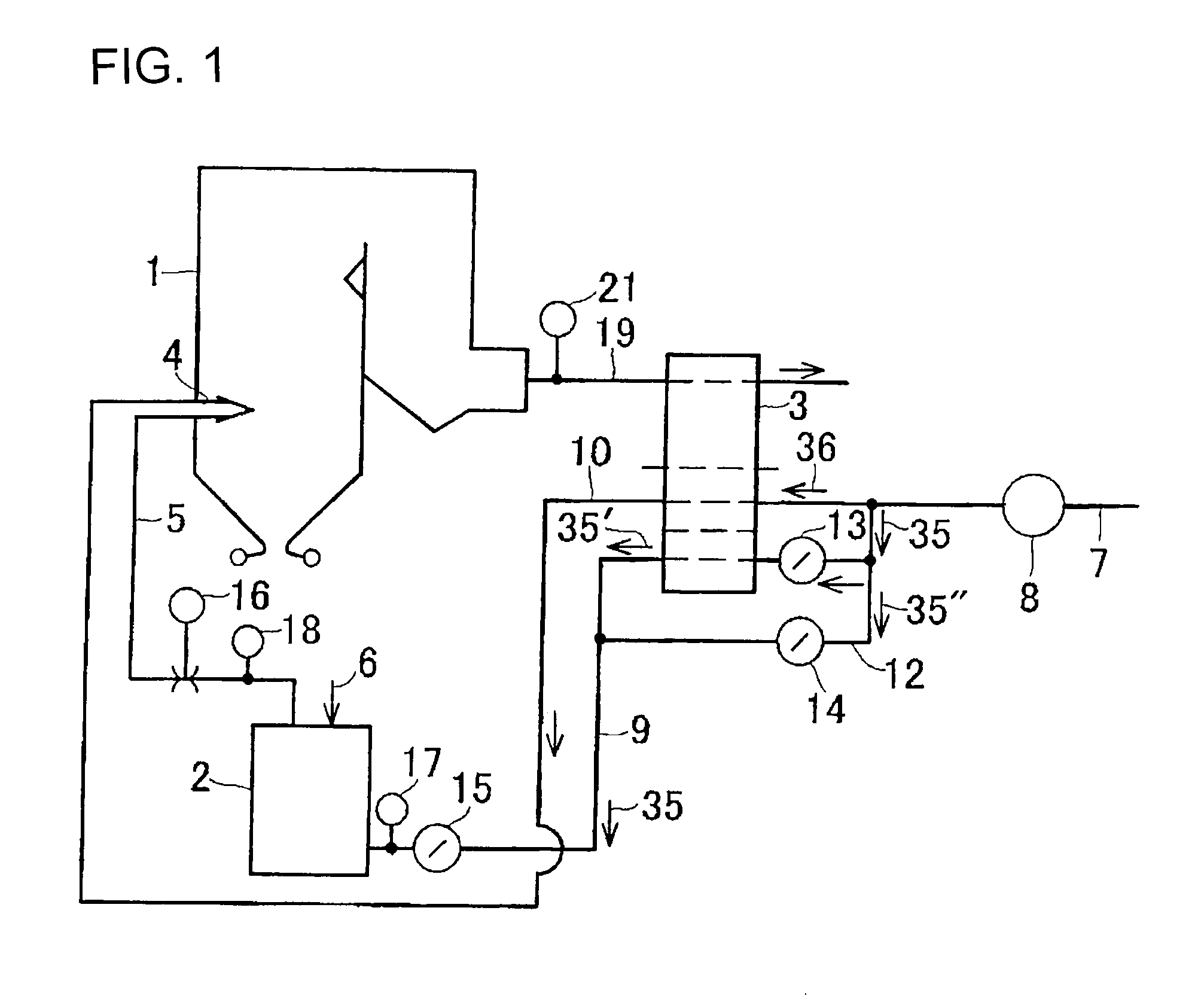

Coal burning boiler apparatus

InactiveUS20090308292A1Low running costGreat advantageAir supply regulationFuel feeding arrangementsCombustionEngineering

In a coal burning boiler apparatus, temperature of the pulverized coal to be fed to the boiler can be set depending on the property of the combustion coal, so that stable ignition and combustion can be made regardless of the property of the combustion coal fed.Provided are a coal burning boiler 1, a coal pulverizer 2 for pulverizing massive coal 6 into fine powder, a temperature sensor 18 for detecting temperature of the primary air 35 for entraining the pulverized coal to the coal burning boiler, regulators 9, 12, 13 and 14 for regulating the temperature of the primary air and a controller for controlling the primary air temperature regulators on the basis of detected result of the temperature sensor so as to make the primary air have a given temperature.

Owner:IHI CORP

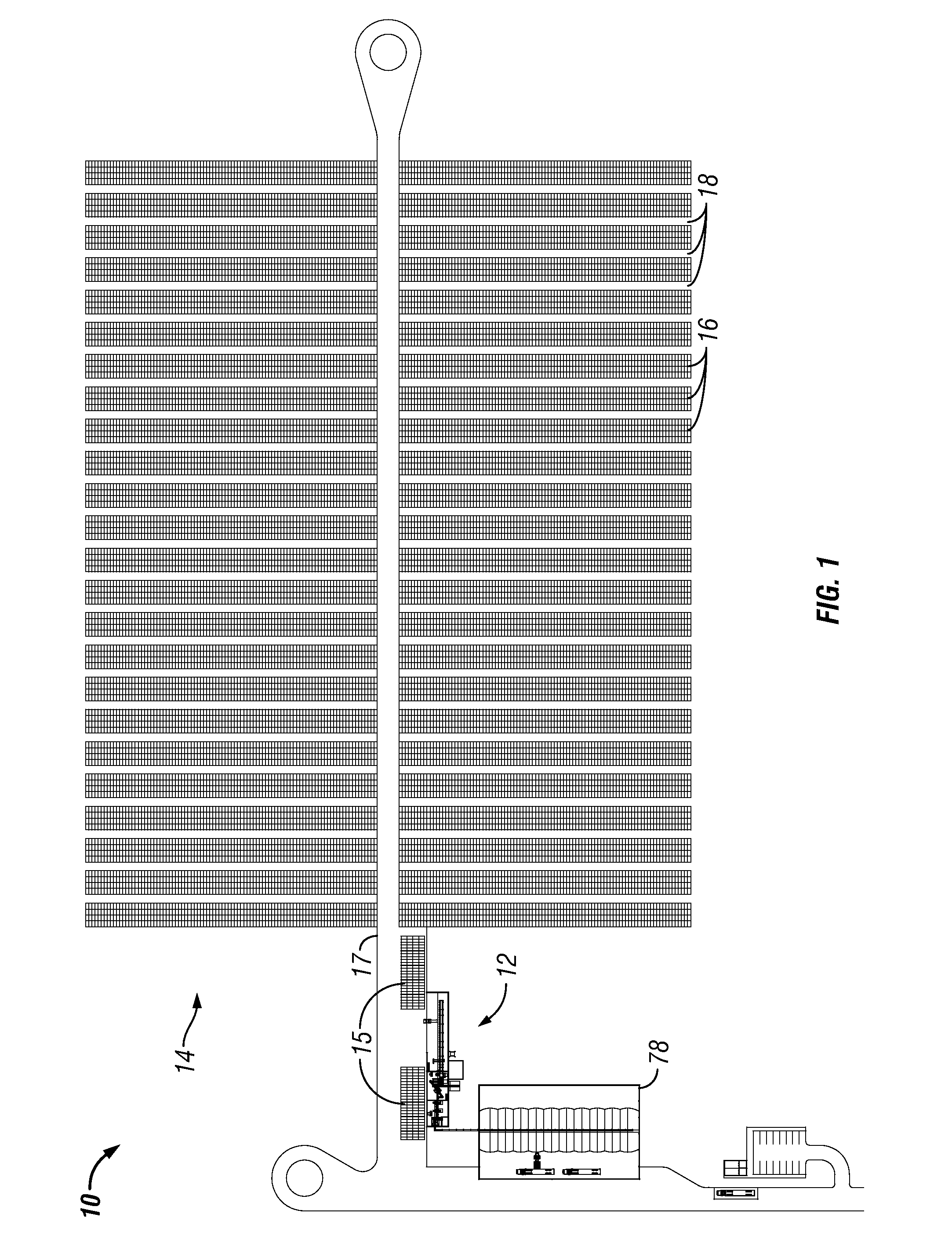

Automated system for sorting and blending coal

InactiveUS20130312321A1Improve efficiencyEliminate certain types of wasteFuel feeding arrangementsTransportation and packagingEngineeringProcess engineering

A method and apparatus for automatically sorting and blending coal and other fuel stocks through a computer-controlled process in order to achieve a specified blend of materials. By sorting fuel stocks with different characteristics into different stacking points, an operator can then automatically combine and uniformly blend these sorted fuel stocks to create a variety of blended materials with different properties tailored to the specific needs of the operator or end user. The computer-controlled nature of the process allows for precise blending in an automated and more efficient and reproducible fashion.

Owner:GENERAL TRADE

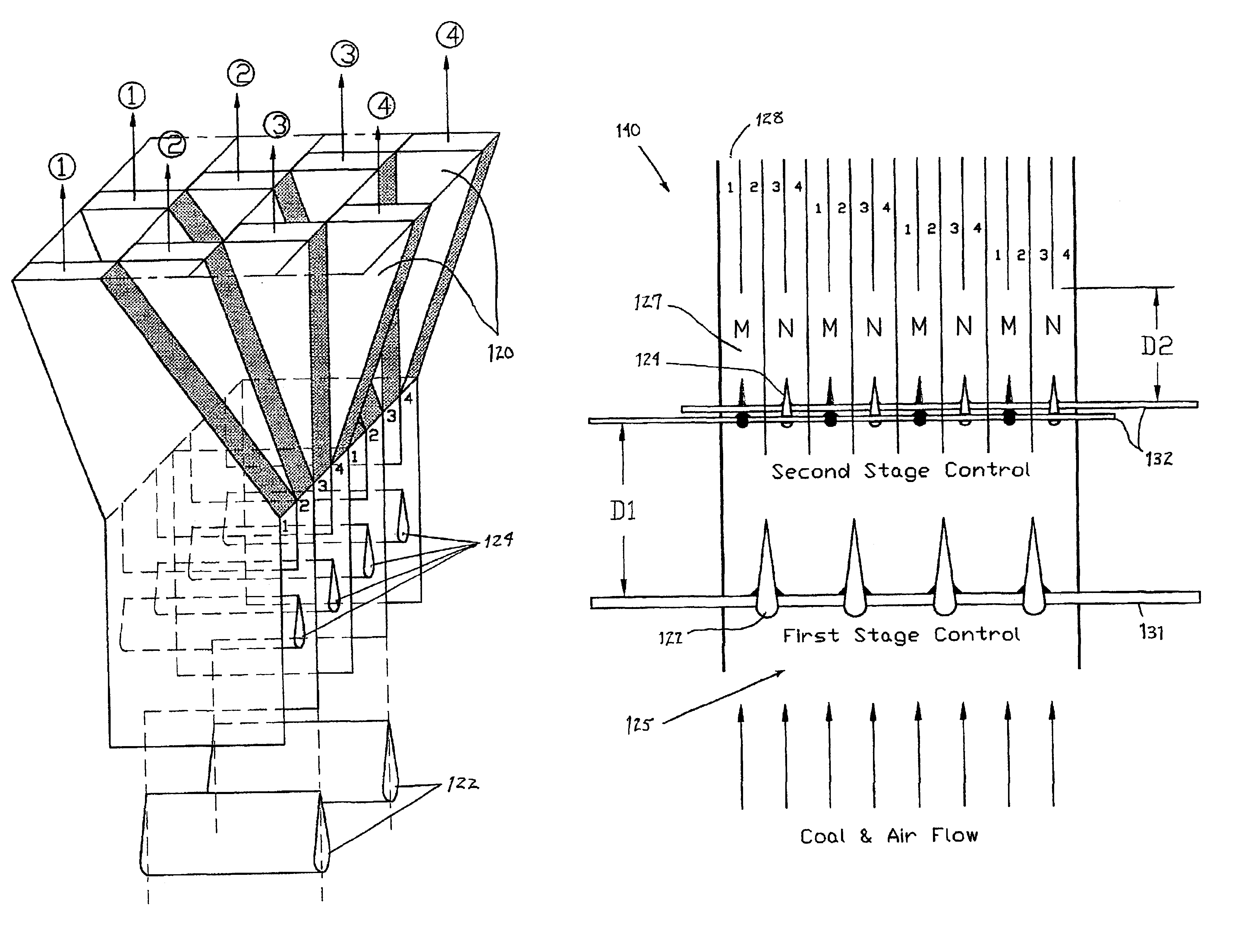

On-line adjustable coal flow distributing device

InactiveUS20070095260A1The method is simple and reliableEffective controlFuel feeding arrangementsSolid fuel combustionCombustorProcess engineering

A method of and an apparatus for operating a pulverized coal-fired boiler system, which includes at least one coal pulverizer in flow connection with at least two burners disposed on a boiler enclosure by a coal feed system having a coal pipe junction with a riffle enclosure including a plurality of parallel partition walls forming multiple flow channels from an upstream coal pipe to each of at least two downstream coal pipes and a plurality of individually pivotable vanes upstream of the plurality of partition walls, and controlling the distribution of coal between the downstream pipes by pivoting at least one of the vanes. Preferably a coal flow rate is monitored in the downstream coal pipes and at least one of the vanes is pivoted in response to a measured distribution of the coal flow rate.

Owner:FOSTER WHEELER ENERGY CORP

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS8661821B2Remarkable effectEasy to operateDrying solid materials with heatFuel feeding arrangementsFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

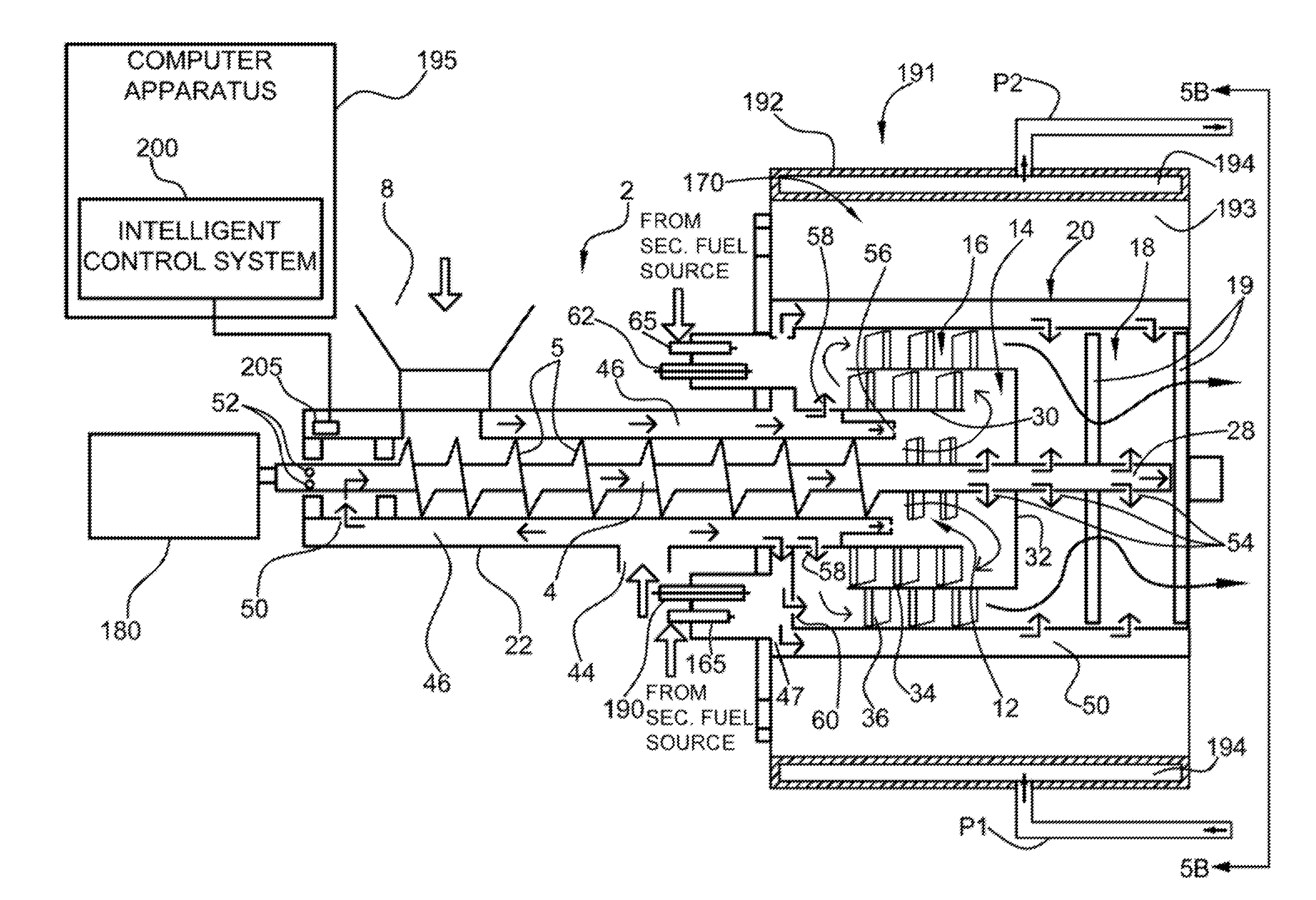

Burner system for waste plastic fuel

InactiveUS20120318180A1Minimized in sizeImprove heating efficiencyFuel supply regulationFuel feeding arrangementsThermal energyCombustion chamber

The present invention provides a burner system which uses waste fuels, especially waste plastic fuels. Burner size is minimized by having multiple combustion chambers concentrically located around a rotating screw conveyor. Heat efficiency is improved by having air passages disposed around the combustion chambers, thus preheating air for the combustion prior to its delivery to the combustion chambers, while simultaneously thermally insulating the combustion chambers against the environment. Waste fuel is transported from a fuel hopper to the combustion chambers by a rotating screw conveyor having the spiraling auger blades. Speed of screw conveyor rotation controls the consumption of waste fuel and, thus, the amount of thermal energy generated in the burner. The burner system includes an intelligent control system for controlling operation of the burner system, so that the burner system performs at optimum efficiency, safely and with minimum operator intervention.

Owner:BANG WILLIAM HUNKYUN +1

Adjustable division plate for classifier coal flow control

ActiveUS20150056024A1Optimize allocationPrevention of reverse air flowFuel feeding arrangementsSolid fuel pretreatmentEngineeringSolid particle

A solid particle distribution controller includes a plurality of division plates proximate a division between an upstream solid particle conveyance pipe and a plurality of downstream pipes. The solid particle distribution controller also includes a plurality of extension plates. Each of the extension plates is movably mounted proximate to a respective division plate for movement in an upstream and downstream direction with respect to the division plate. The plurality of extension plates are configured and adapted for motion in the upstream and downstream direction independent of one another to extend upstream of the division plates as needed to improve solid particle distribution among the downstream pipes.

Owner:BABCOCK POWER SERVICES

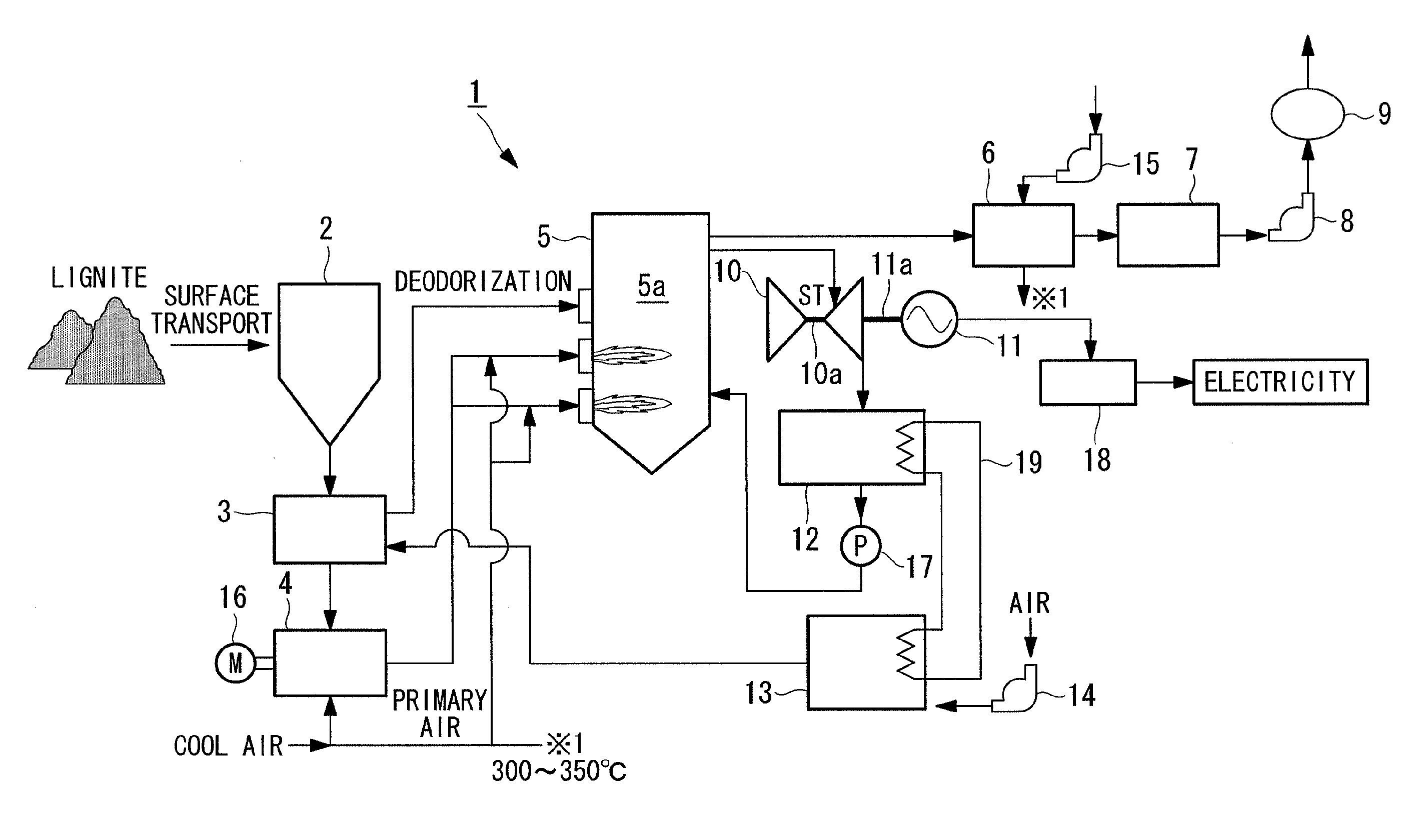

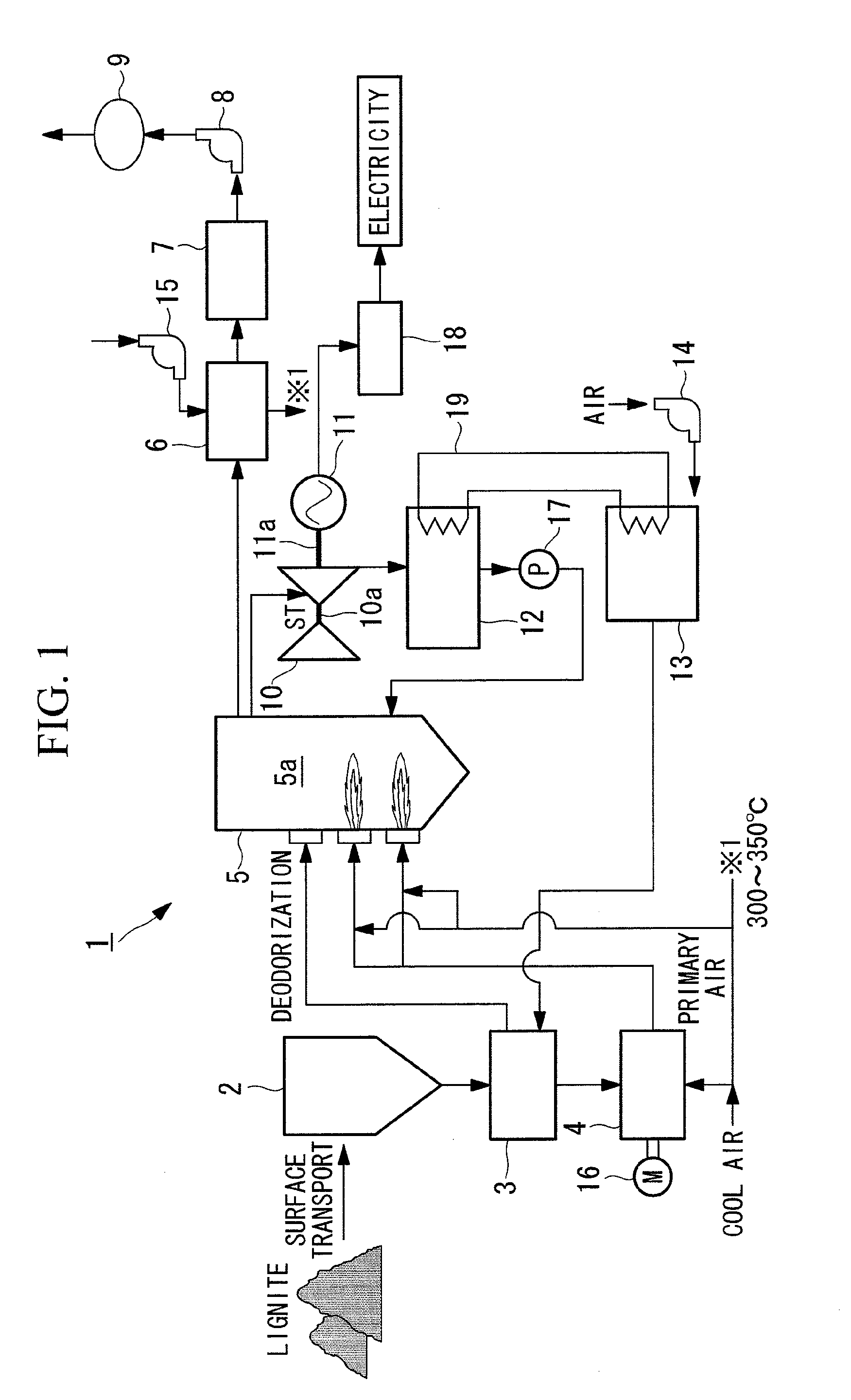

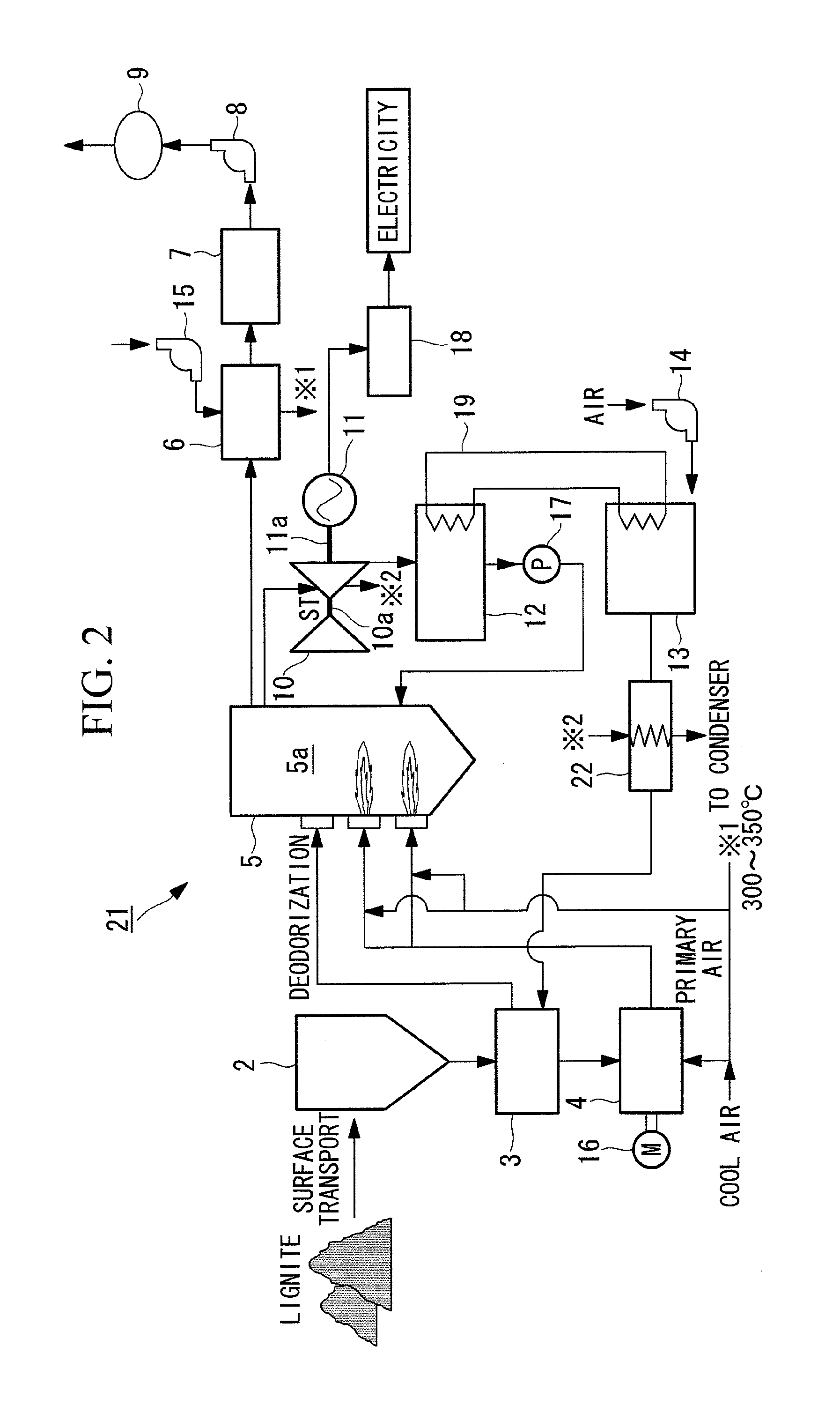

Thermal power plant using low-grade coal as fuel

InactiveUS20120006025A1Improve thermal efficiencyReduce heatFuel feeding arrangementsSolid fuel pretreatmentPulverizerCoal

A thermal power plant that uses low-grade coal as fuel and allows for increased thermal efficiency of the entire plant is provided. The thermal power plant includes a drying device (3) that dries the low-grade coal to be supplied to a lignite mill (coal pulverizer) (4), and a drying-gas heater (13) that heats air to be supplied to the drying device (3) so as to be used for drying the low-grade coal. A condenser (12) and the drying-gas heater (13) are connected with each other via a heat exchanger (19), and exhaust heat from the condenser (12) is used as a heat source for heating the air.

Owner:KYUSHU ELECTRIC POWER CO INC +1

Feeding apparatus for creation of one or more plugs of compressible material for feeding into a gasifier or reactor

ActiveUS20090130003A1Large in humidityLess-prone to congestPressurized chemical processConveyorsCompressible materialCombustion chamber

An energy efficient, very flexible and safe feeding apparatus serves for creation of one or more plugs of compressible material for feeding into a gasifier, reactor or other combustion chamber. This apparatus includes a piston feeder with at least three pistons for pre-compressing and delivering compressible material towards a mouthpiece serving as a non-return valve and having an exit end facing a braking device with a friction member for regulating the final degree of compression of the material, and an opposing inlet end for at least partly compressed material. The inner diameter of at least an inlet section extending from the inlet end of the mouthpiece increases towards the first end, so that an angle between the inner wall of at least the inlet section and the longitudinal axis of the mouthpiece is larger than 0° but less than or equal to 3°.

Owner:TK ENERGI +1

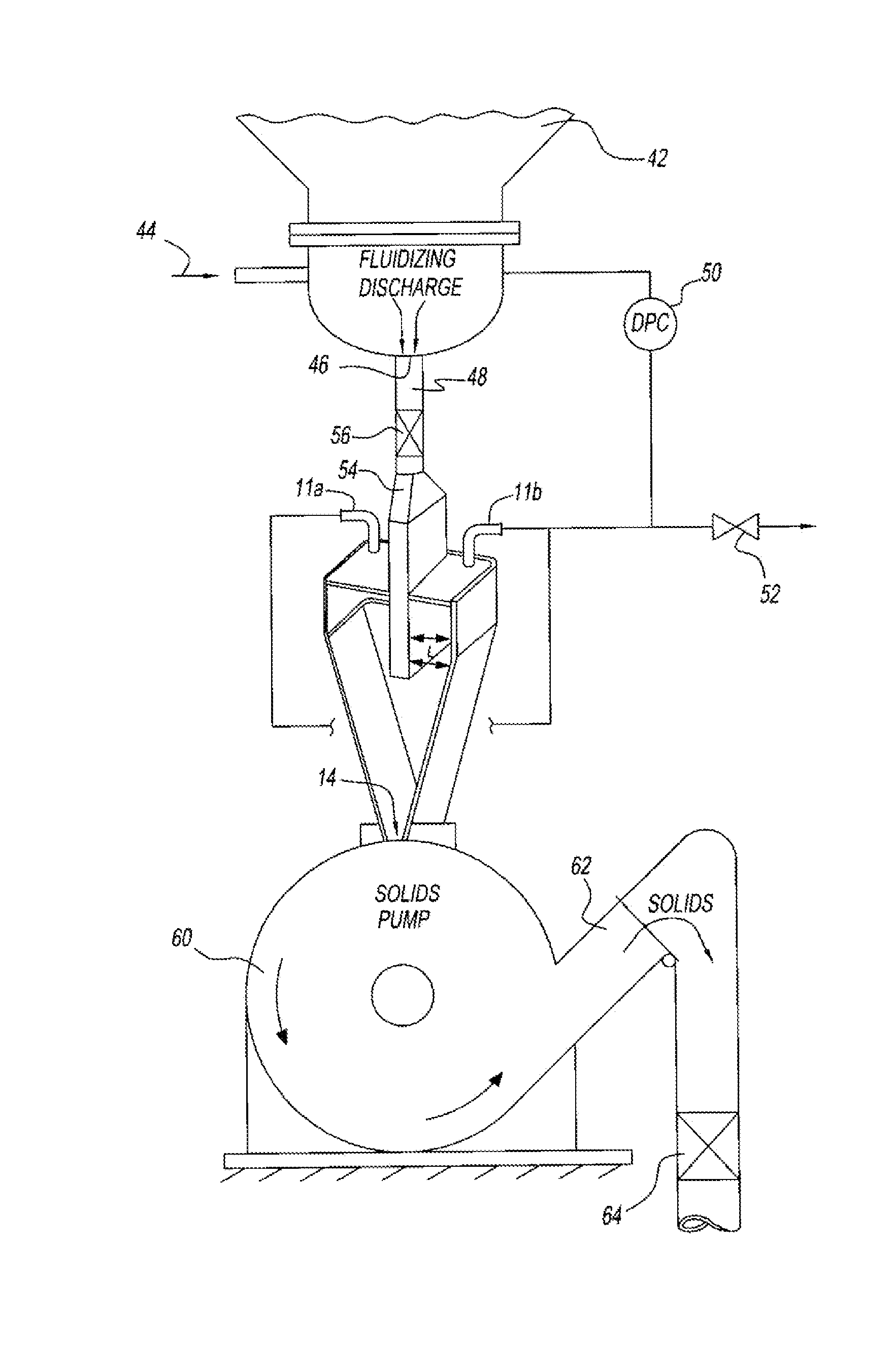

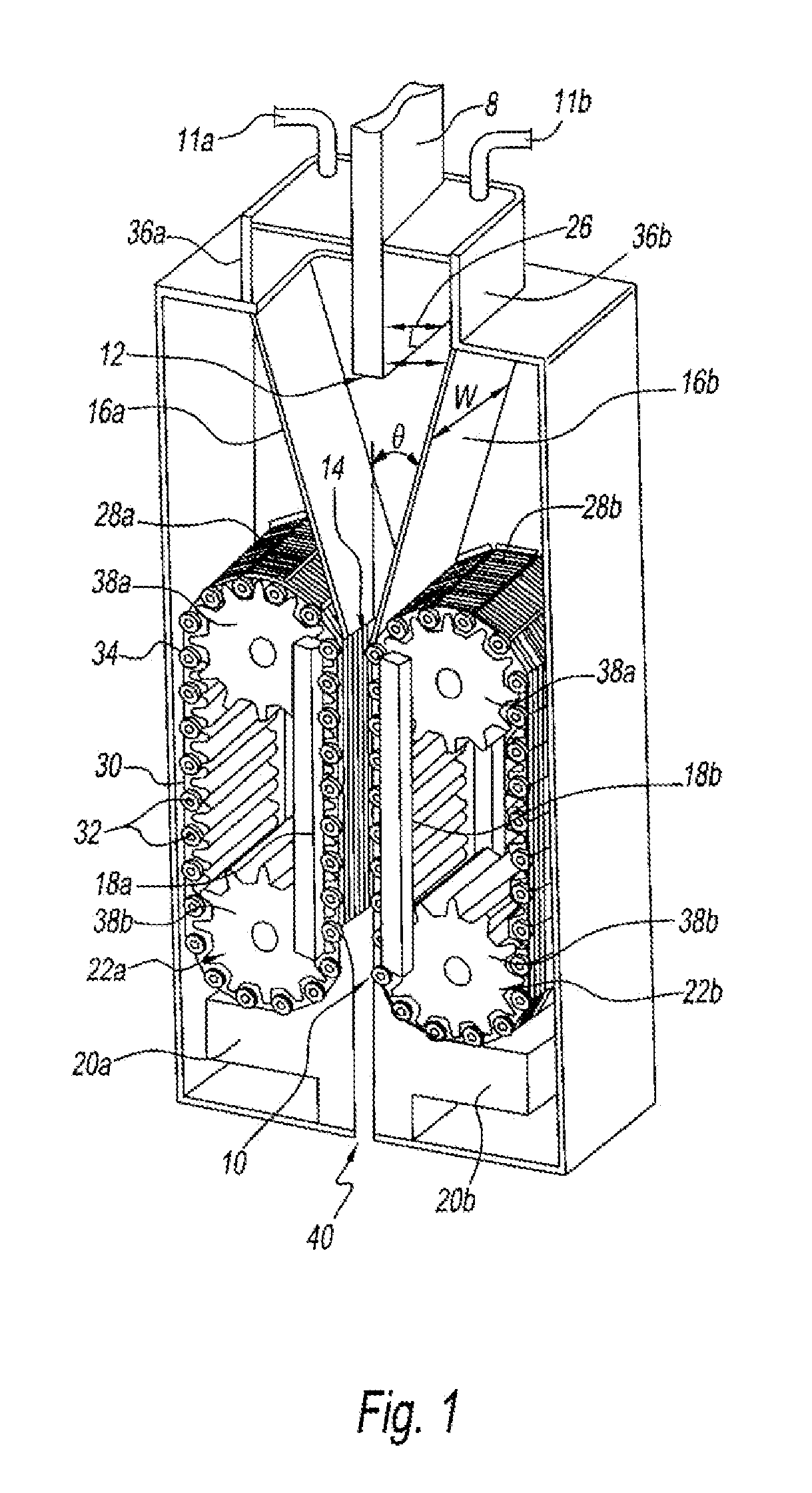

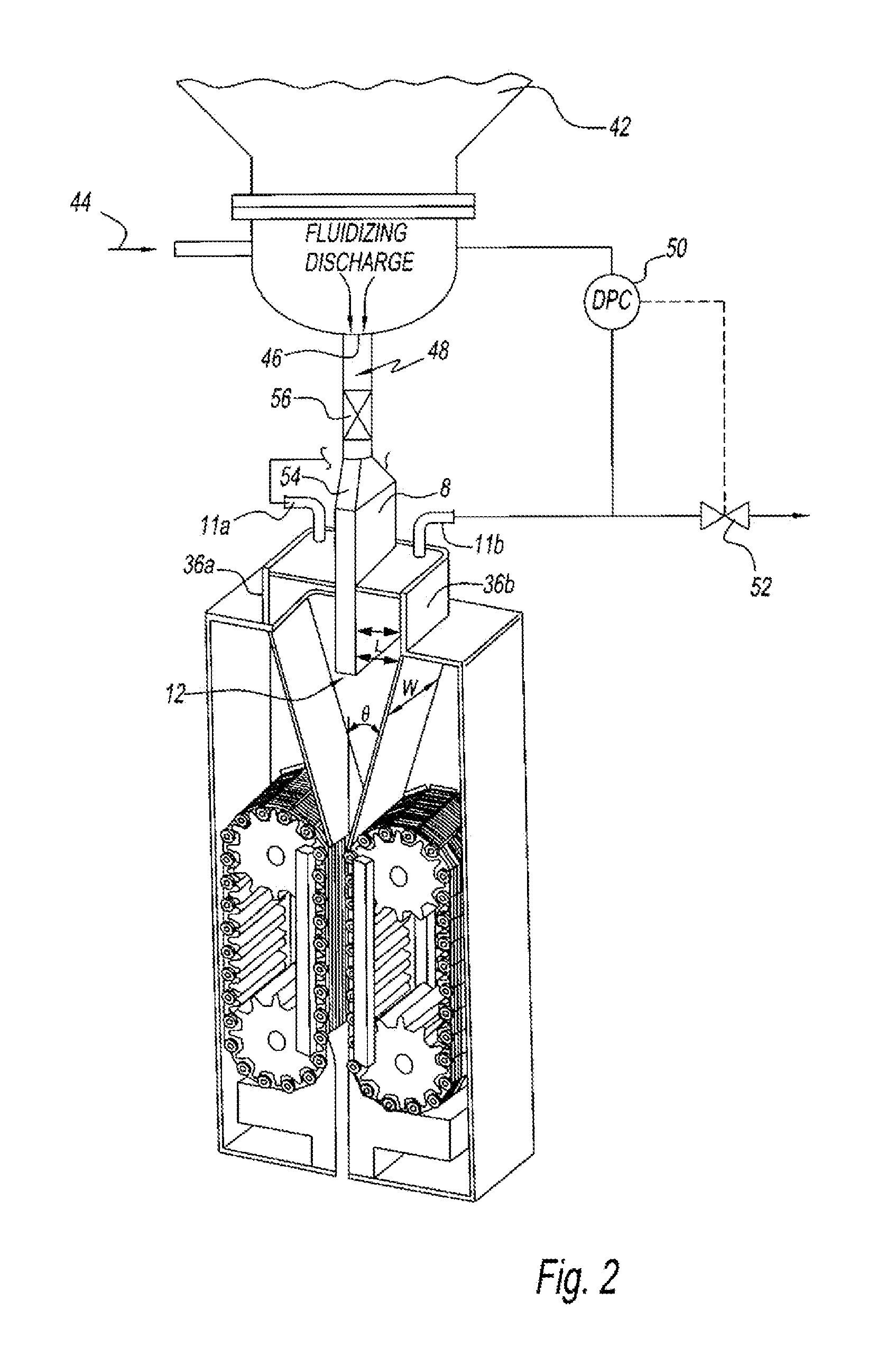

Passive solids supply system and method for supplying solids

A solids supply system having a solids deaeration zone and a solids pump zone, and a method for supplying the solids e.g., pulverized dry coal, to an application, e.g., gasification process. The solids deaeration zone includes a container having a passageway defined by one or more sloped walls. The solids deaeration zone is operable to deaerate and convey the solids to the solids pump zone. In the solids deaeration zone, the solids become sufficiently compacted prior to and upon entry into the solids pump zone to be effectively conveyed through the solids pump zone.

Owner:EXXON RES & ENG CO

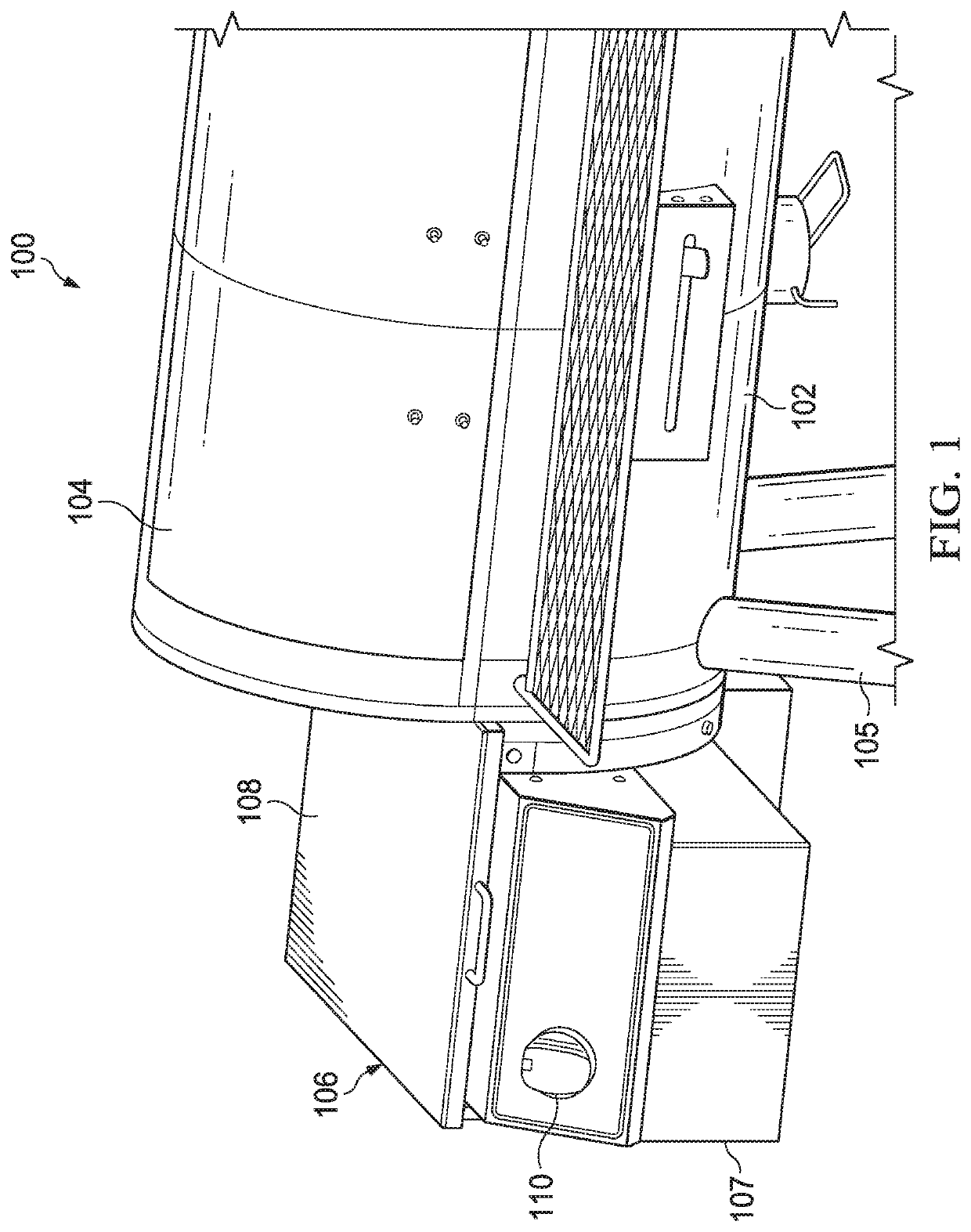

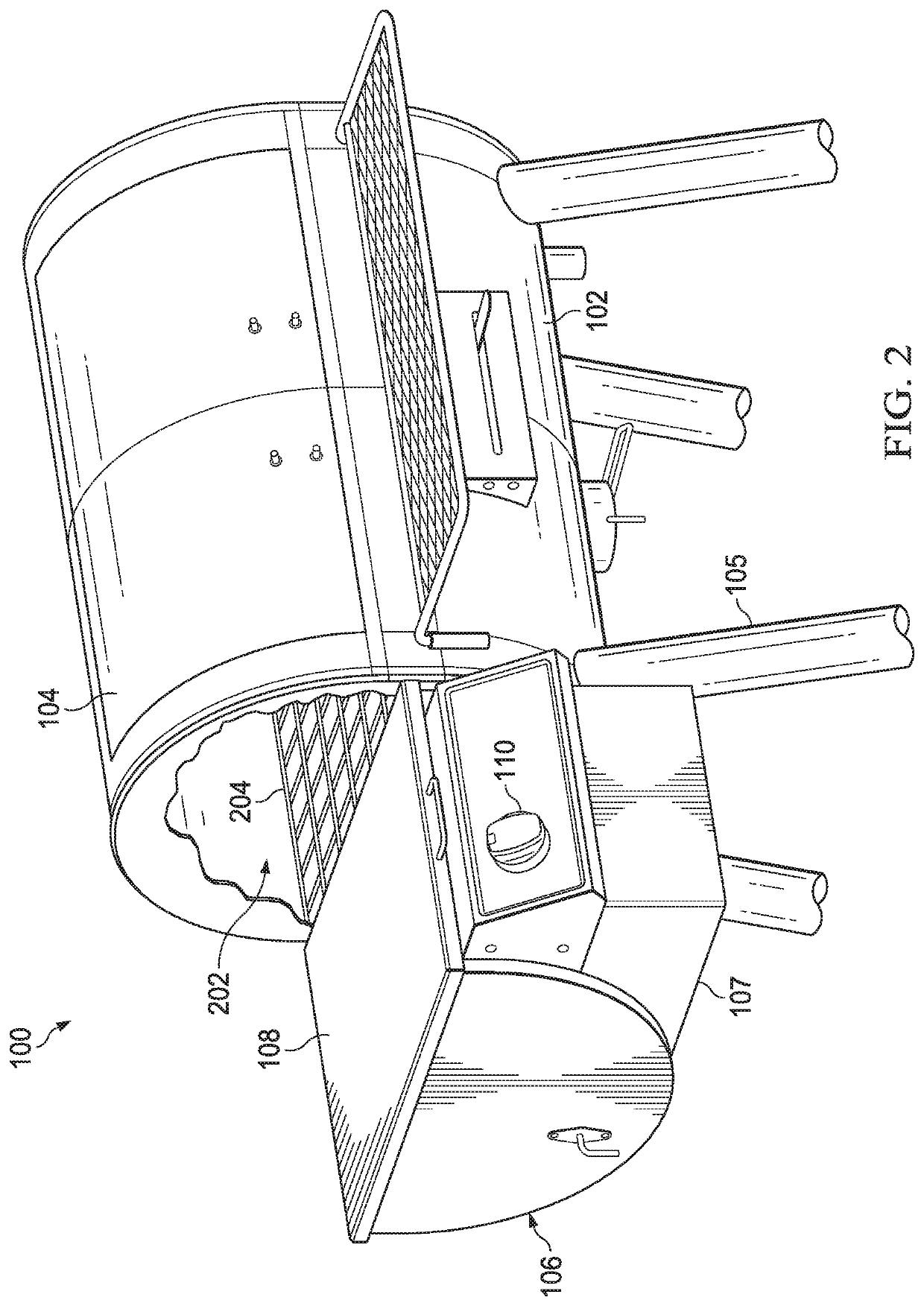

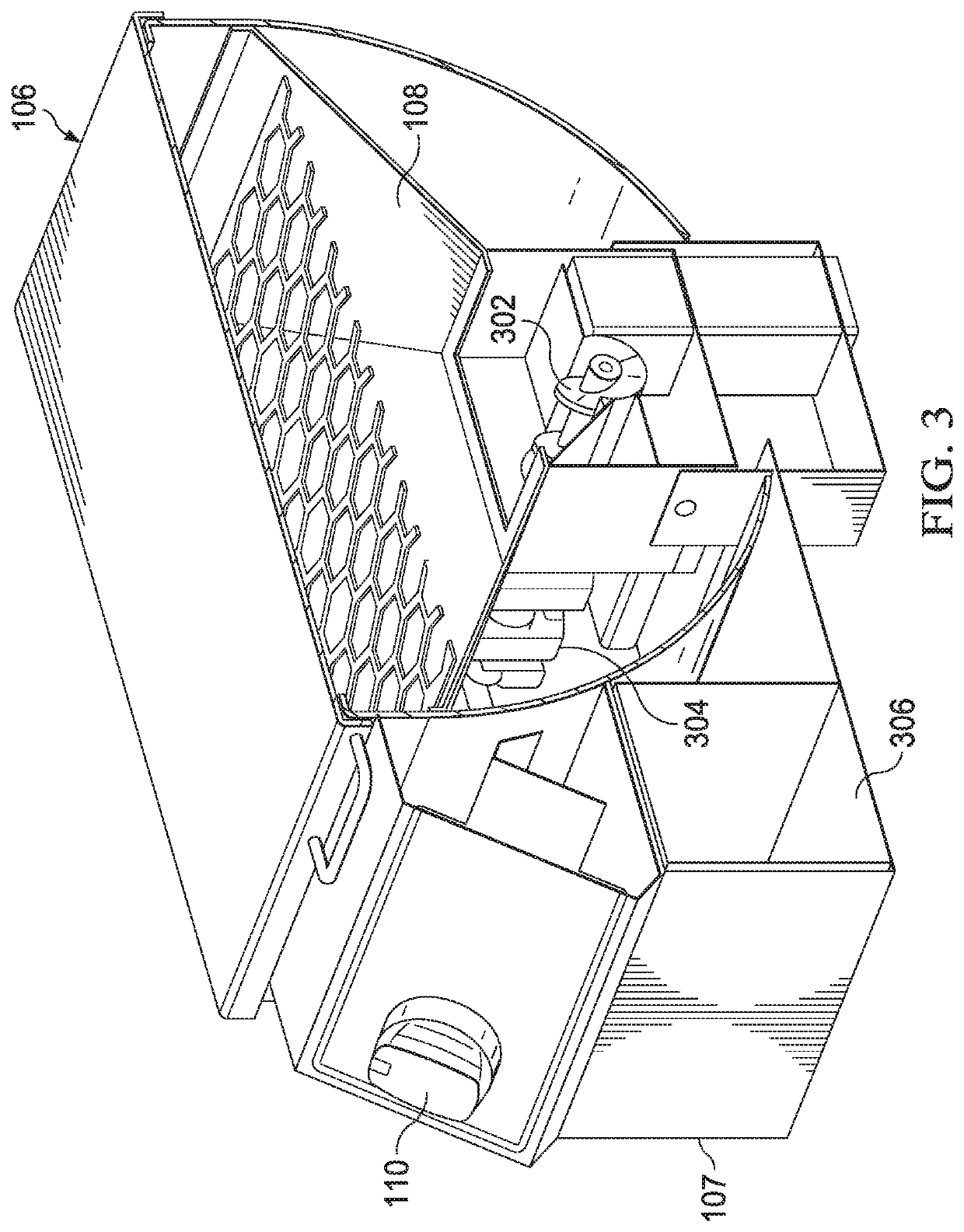

Battery enabled pellet grill

A system includes a cooking chamber defining a space for food to be cooked, a firepot inside the cooking chamber that is configured to utilize pelletized fuel to provide heat or smoke within the cooking chamber for cooking the food, and a fuel hopper defining a storage space for the pelletized fuel before delivery to the firepot. A battery powered auger interposes the fuel hopper and the firepot and is configured to selectively convey the pelletized fuel from the fuel hopper to the firepot for combustion. A rechargeable battery selectively provides power to the auger.

Owner:W C BRADLEY CO

Monitoring of fuel on a grate fired boiler

Owner:INT PAPER CO

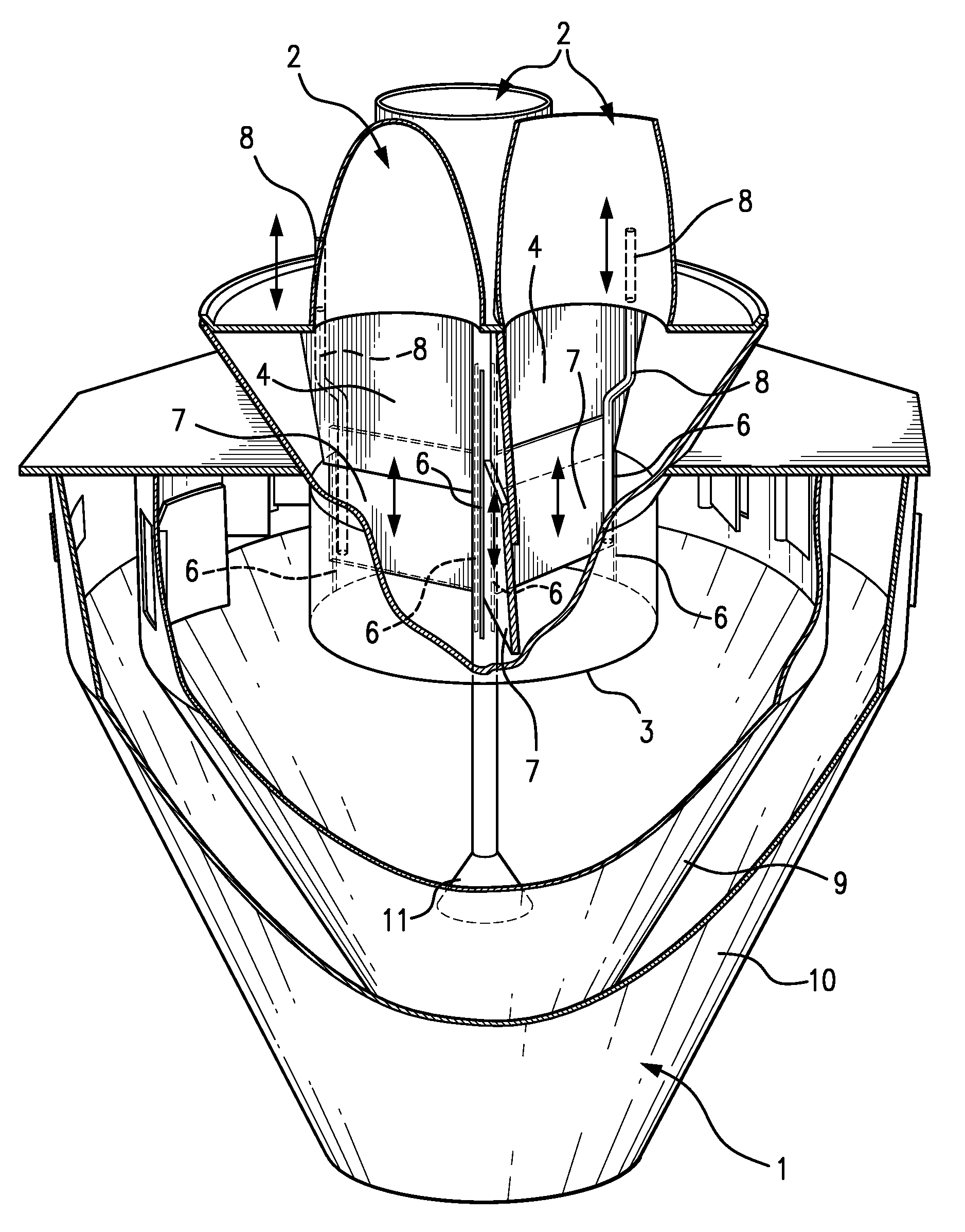

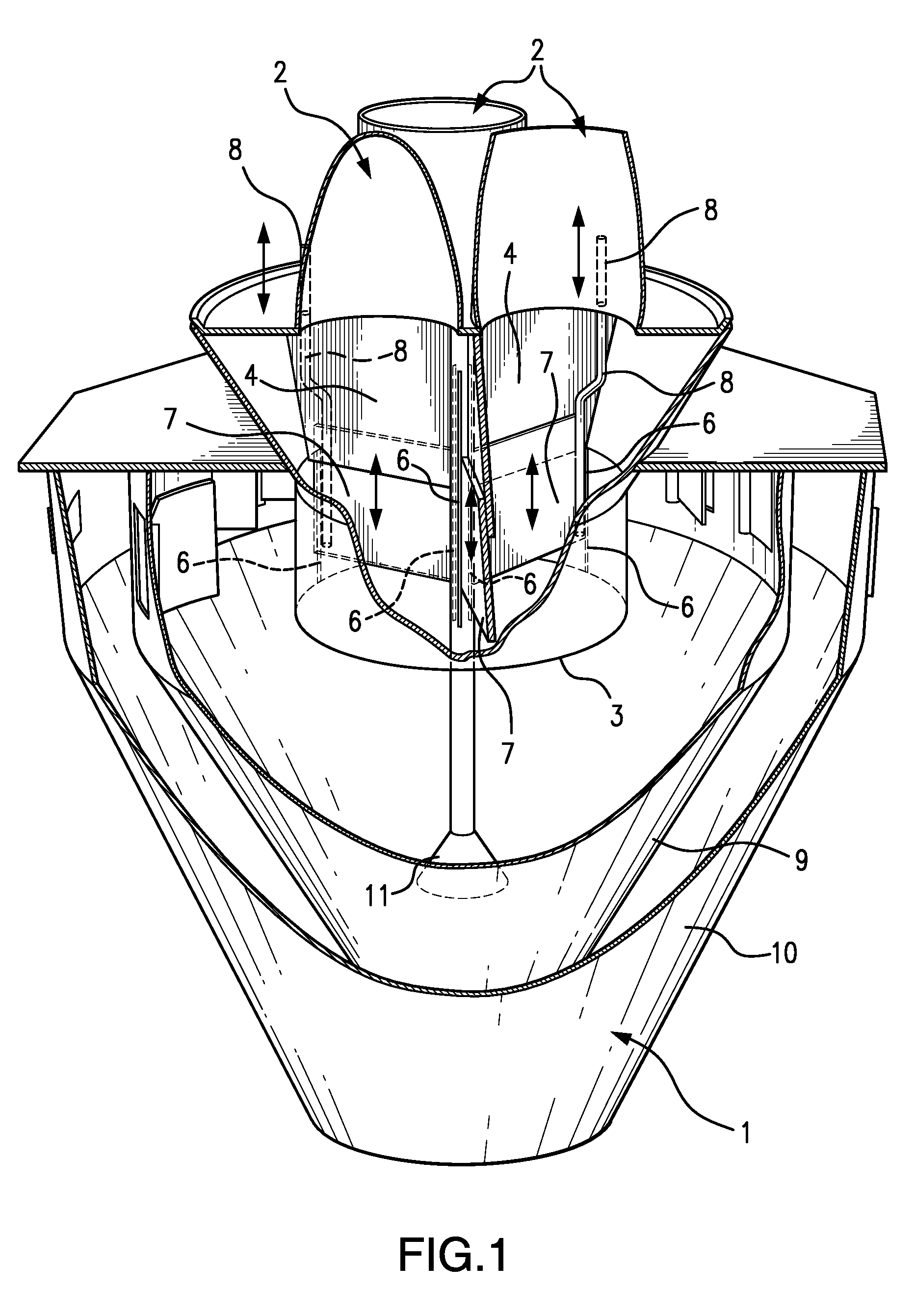

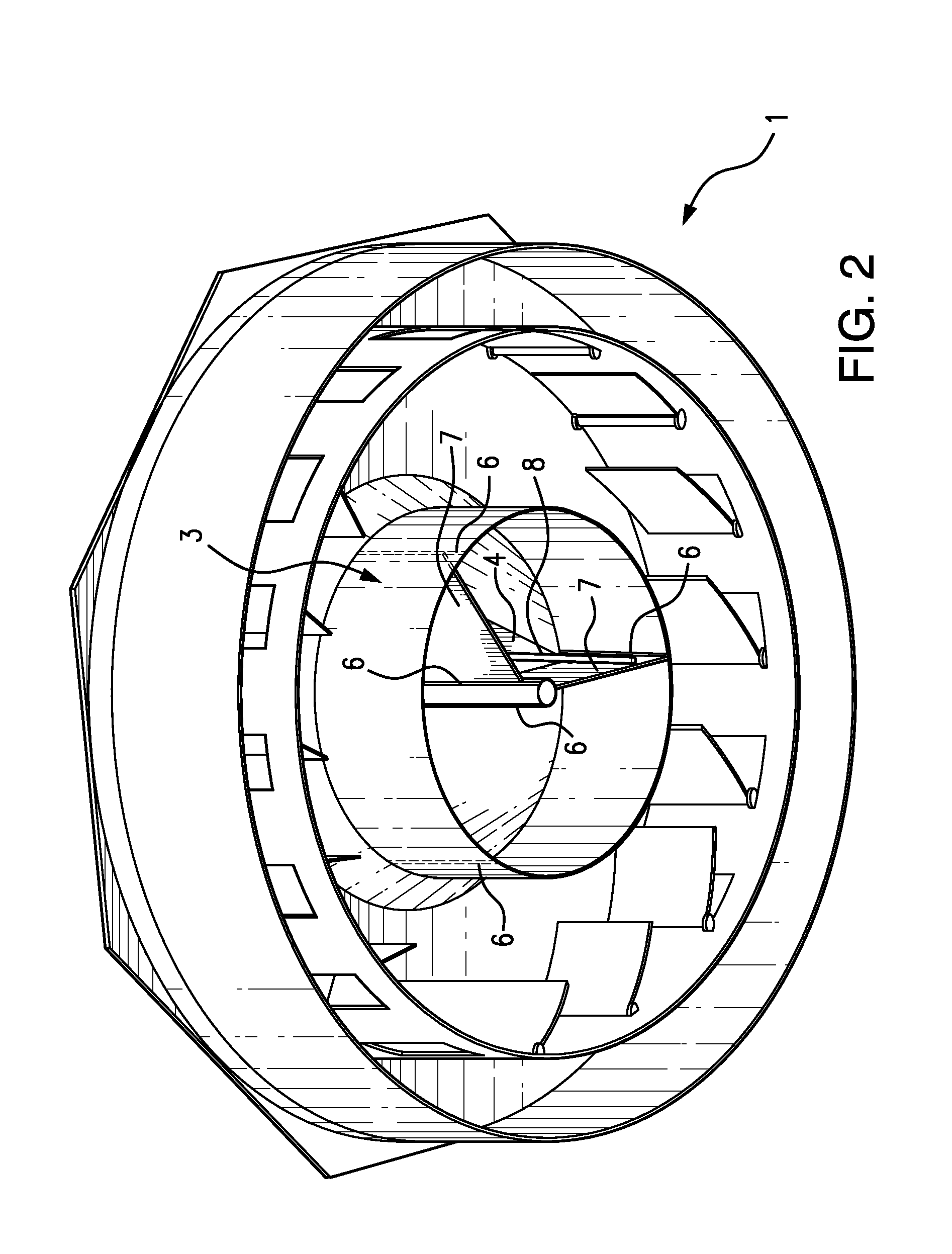

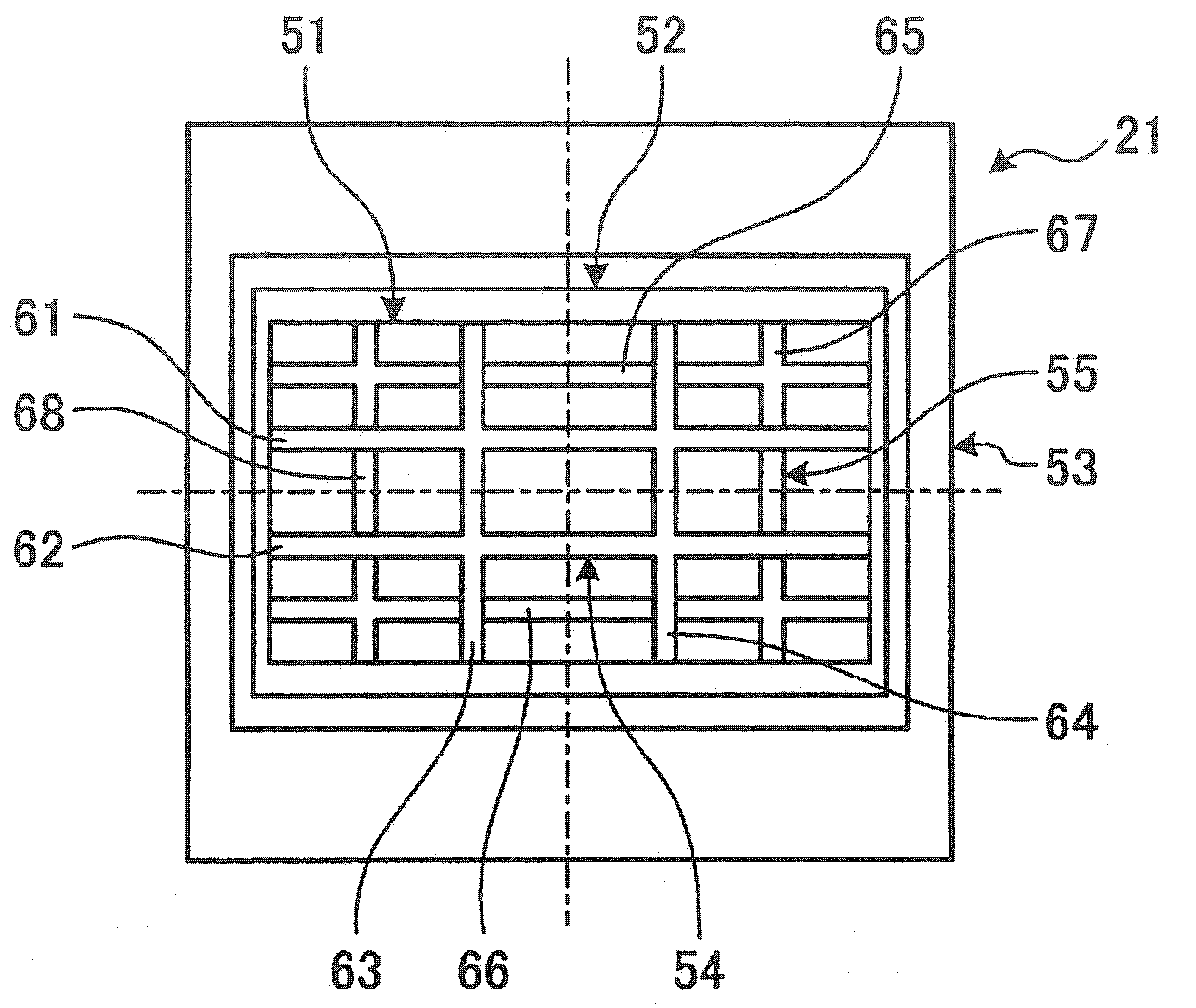

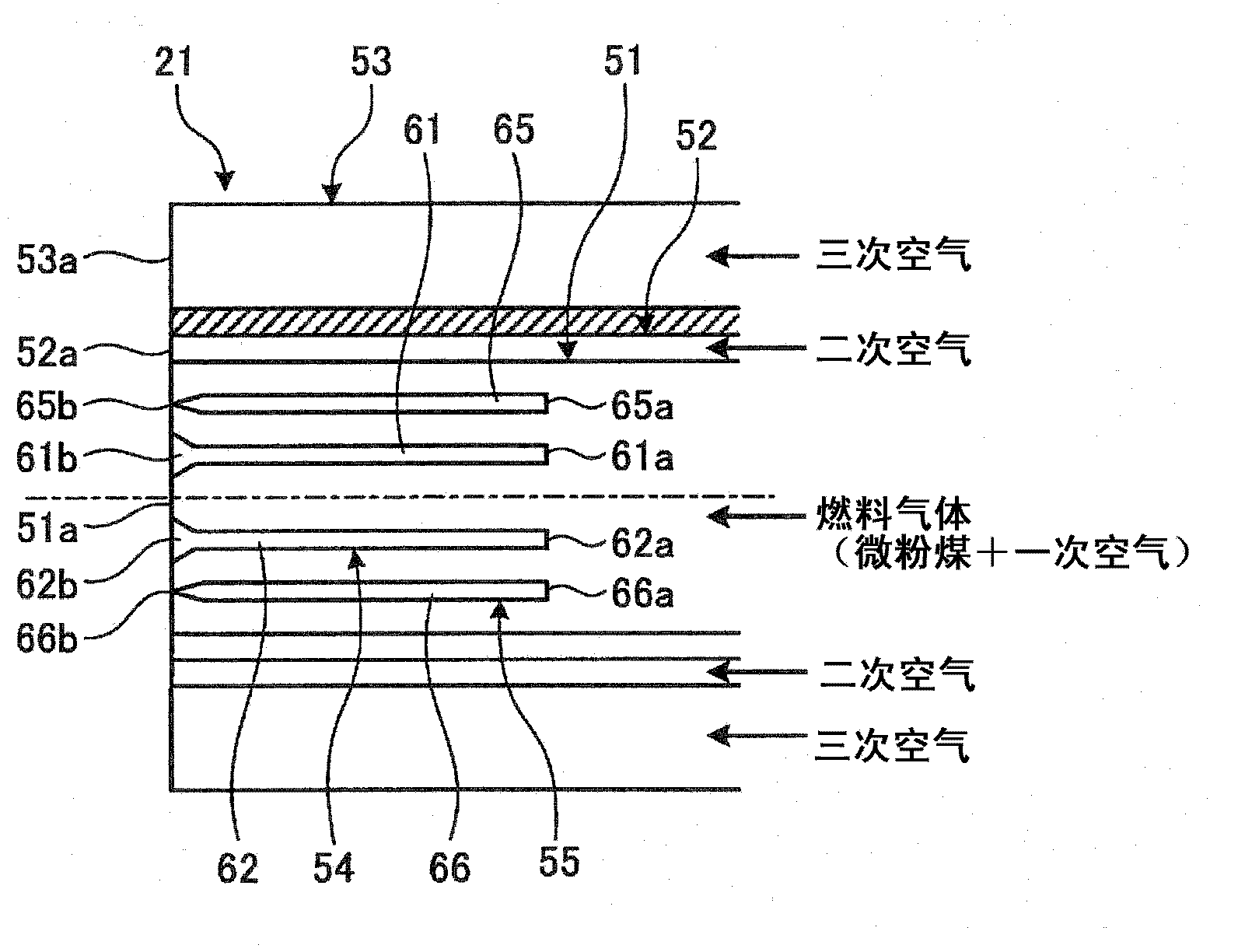

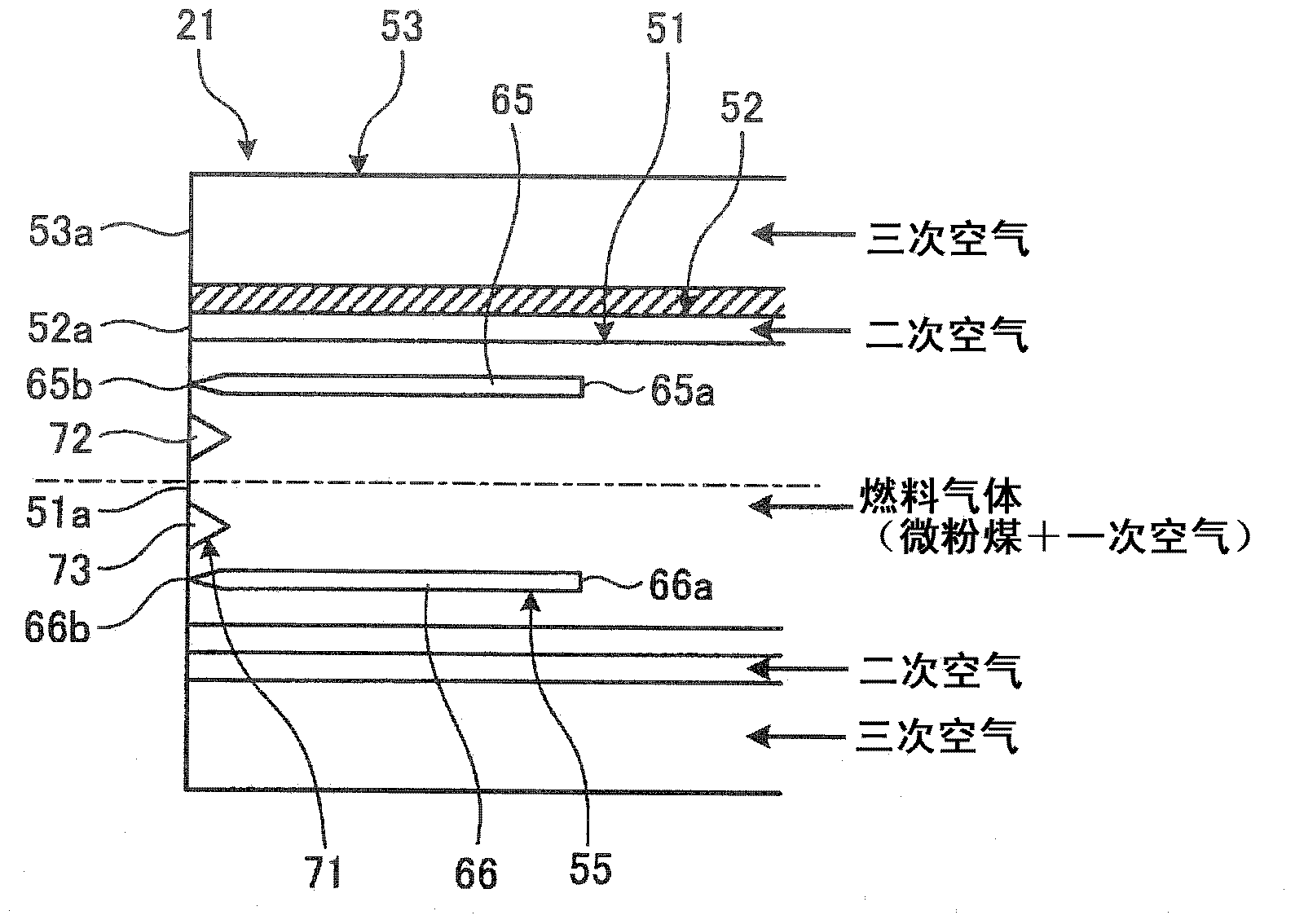

Combustion burner, solid-fuel-combustion burner, solid-fuel-combustion boiler, boiler, and method for operating the boiler

ActiveCN103443543AProper circulationAppropriate circulationBurner safety arrangementsAir supply regulationCombustorSolid fuel

The invention provides a combustion burner, a solid-fuel-combustion burner, a solid-fuel-combustion boiler, a boiler, and a method for operating the boiler. The combustion burner is provided with a fuel nozzle (51) through which a fuel gas mixing pulverized coal and primary air can be blown in, and a secondary air nozzle (52) through which secondary air can be blown in from the exterior of the fuel nozzle (51). A flame stabilizer (54) is disposed toward the axial center at a front end of the fuel nozzle (51), and a rectification member (55) is disposed between an inner wall surface of the fuel nozzle (51) and the flame stabilizer (54), thereby achieving an optimal flow of the fuel gas that is a mixture of solid fuel and air.

Owner:MITSUBISHI HEAVY IND LTD

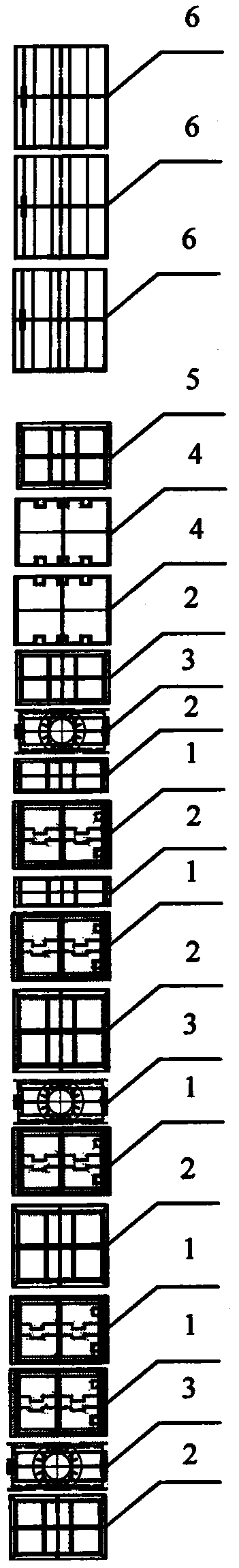

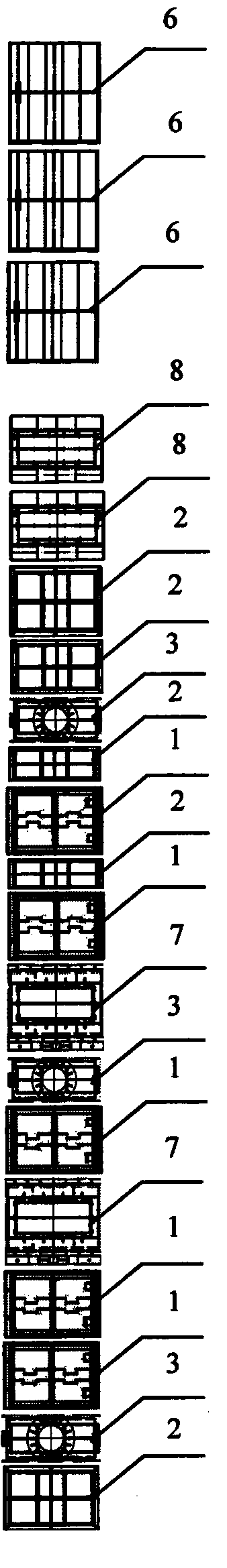

System and method for reducing boiler NOx emission by tertiary air concentrated-diluted separation

ActiveCN105509085AImprove reducibilityEmission reductionFuel feeding arrangementsSolid fuel pretreatmentEngineeringLower upper

The invention provides a system for reducing boiler NOx emission by tertiary air concentrated-diluted separation. An outlet of a tertiary air powder exhaust fan is connected with a coal powder concentrated-diluted separator; a separation blade for adjusting a separation quantity of concentrated-diluted coal powder is arranged on an inlet section of the coal powder concentrated-diluted separator, and a concentrated coal powder pipe and a diluted coal powder pipe are arranged on an outlet section; the concentrated coal powder pipe is connected with at least one layer of hearth main combustion area middle lower nozzles; and the diluted coal powder pipe is connected with at least one layer of hearth main combustion area upper nozzles. The invention further provides a method for reducing boiler NOx emission by tertiary air concentrated-diluted separation; tertiary air containing thin coal powder is separated as concentrated and diluted two parts of coal powder air currents; and the concentrated and diluted two parts of coal powder air currents are respectively sprayed into the middle lower part and the upper part of a hearth main combustion area. The concentrated coal powder current replaces one part of secondary air to form an oxygen debt environment in the main combustion area so as to enhance the reducibility of the main combustion area; the diluted coal powder current is quickly burnt to consume oxygen so as to enhance the reducibility of NOx in a boiler; and the secondary air quantity reduced in the main combustion area is replenished to high-level burnt air so as to guarantee the burn-off rate of the coal powder in the boiler.

Owner:SHANGHAI BOILER WORKS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com