Coal burning boiler apparatus

a boiler and coal technology, applied in lighting and heating apparatus, solid fuel pretreatment, combustion types, etc., can solve problems such as inability to ignite and burn coal, and achieve the effects of reducing running costs, excellent effects and advantages, and reducing running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

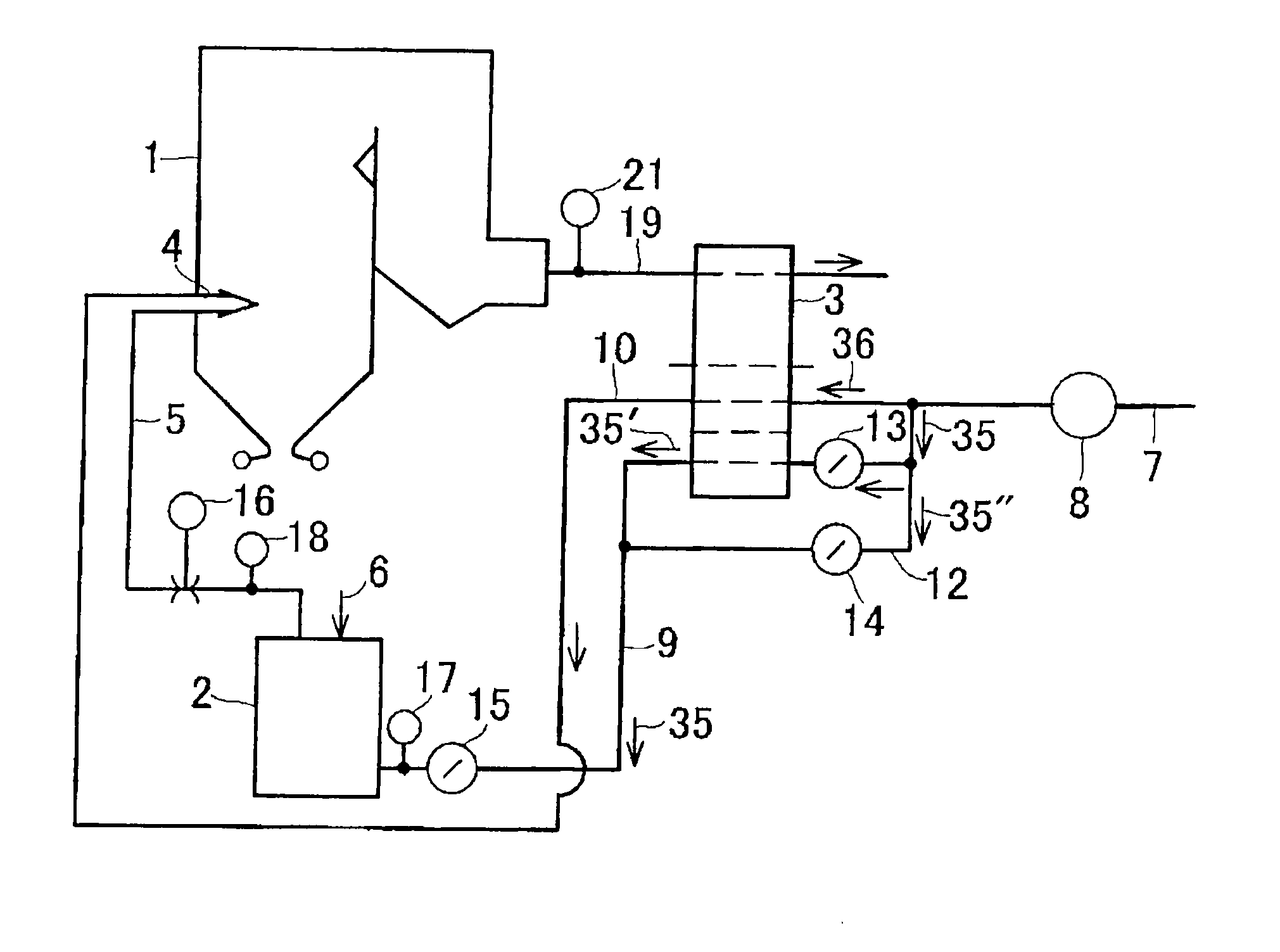

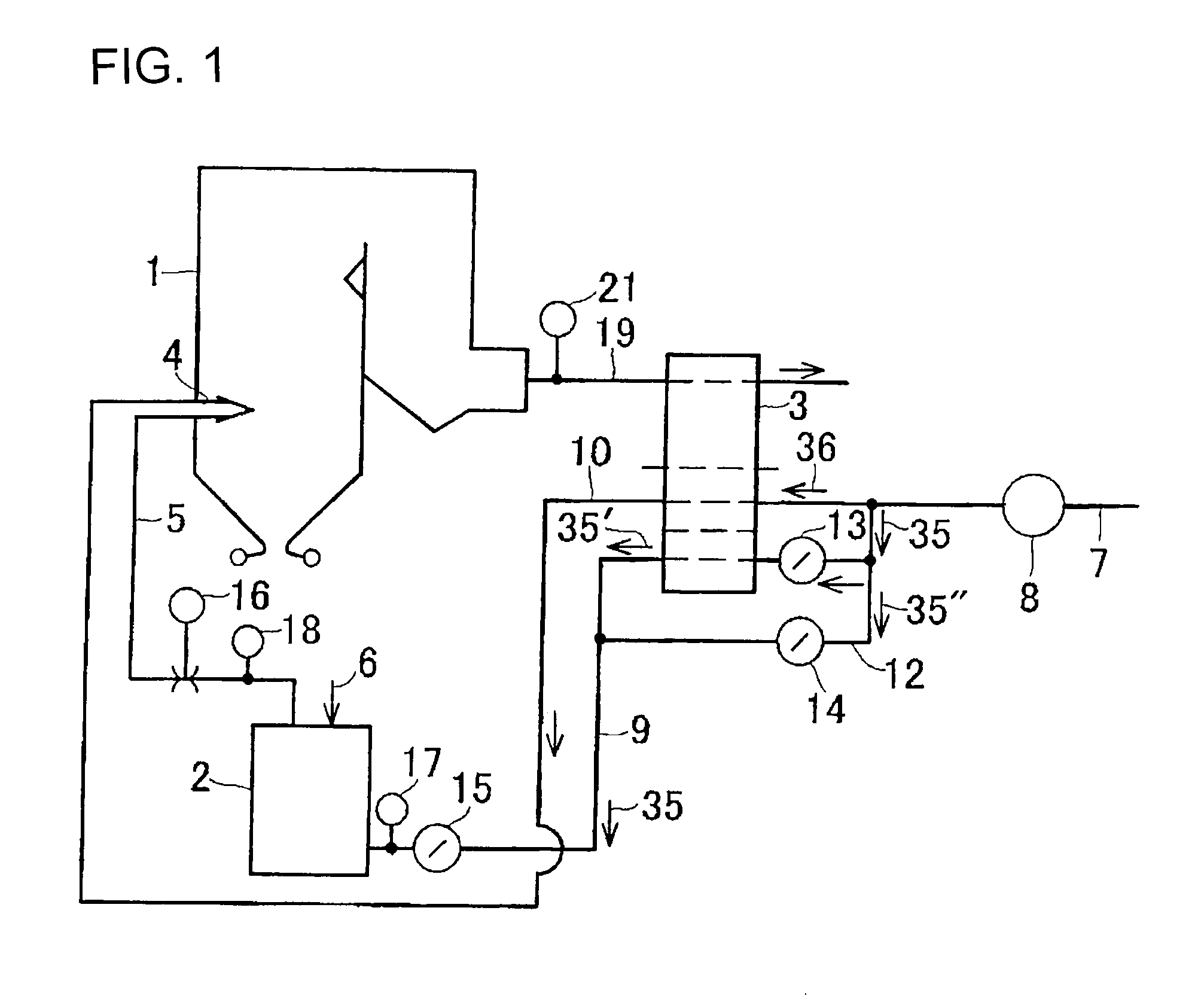

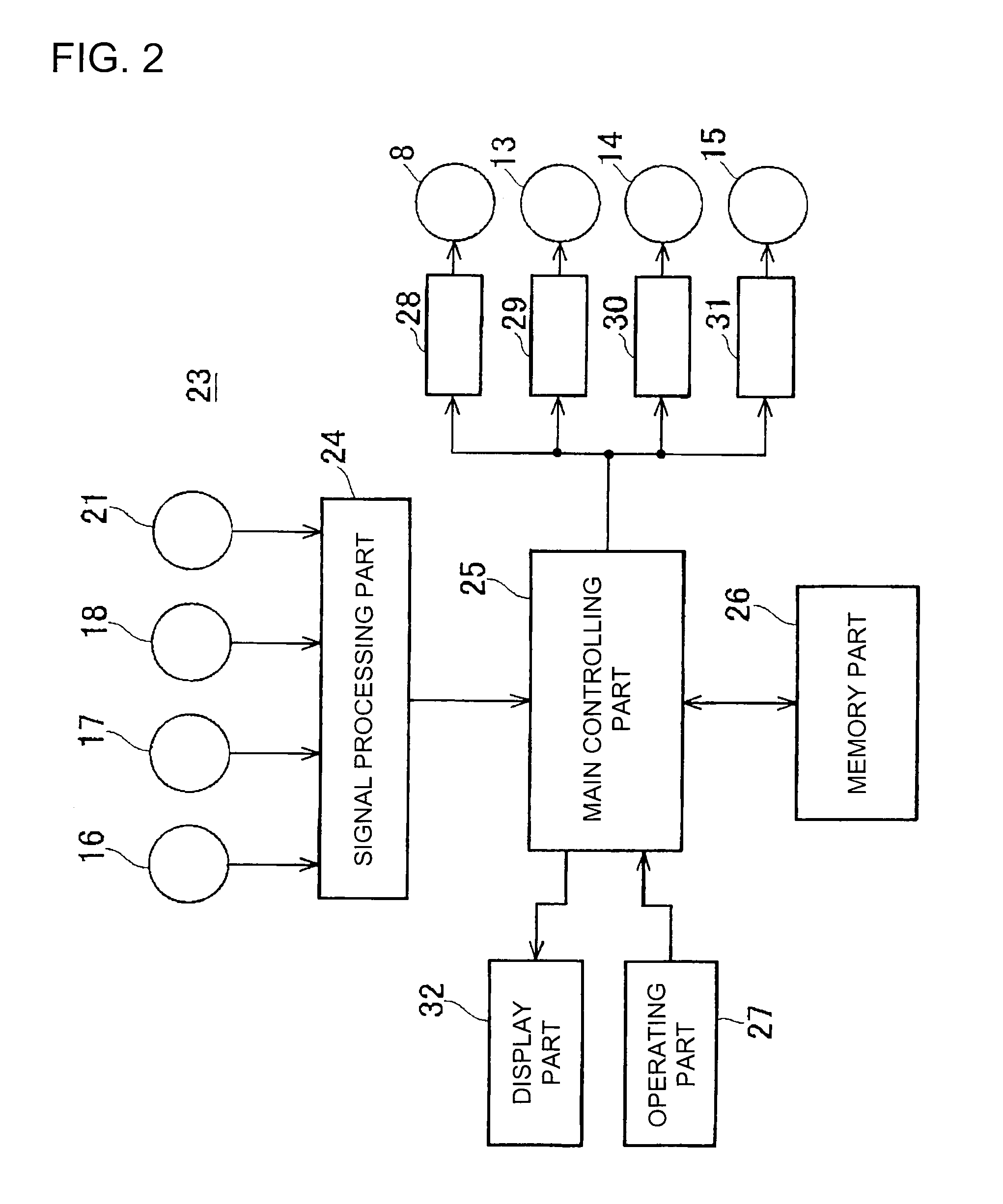

[0037]An embodiment of the invention will be described in conjunction with the drawings.

[0038]First of all, the embodiment of a coal burning boiler apparatus according to the invention will be described with reference to FIG. 1.

[0039]In FIG. 1, reference numeral 1 denotes a coal burning boiler in a coal burning boiler apparatus, for example, for power generation or industrial purpose; 2, a coal pulverizer (mill) for pulverizing massive coal 6 into fine powder; and 3, an air preheater 3 for heating combustion air through exhaust heat.

[0040]Arranged on a wall of the coal burning boiler 1 are a required number of pulverized coal burners 4 connected via a pulverized coal feed pipe 5 to the coal pulverizer 2 which is supplied with the massive coal 6.

[0041]Combustion air to be fed to the coal burning boiler 1 is sucked from an air aspirator pipe 7 by a forced draft fan 8. The pipe is branched at a discharge side of the forced draft fan 8 into primary and secondary air feed pipes 9 and 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com