Patents

Literature

180results about "Combustion pretreatment/prehandling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

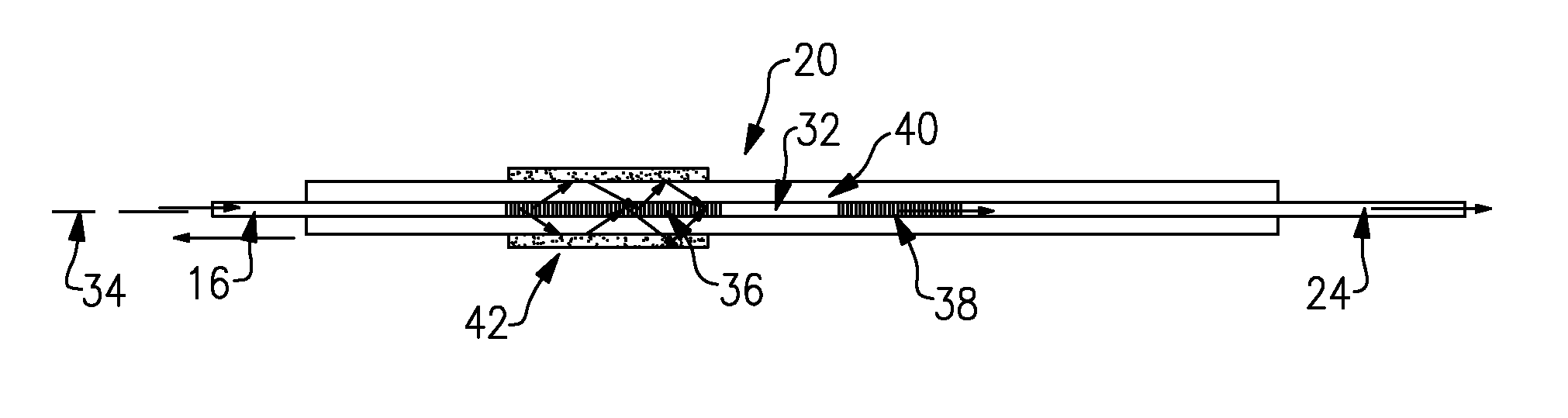

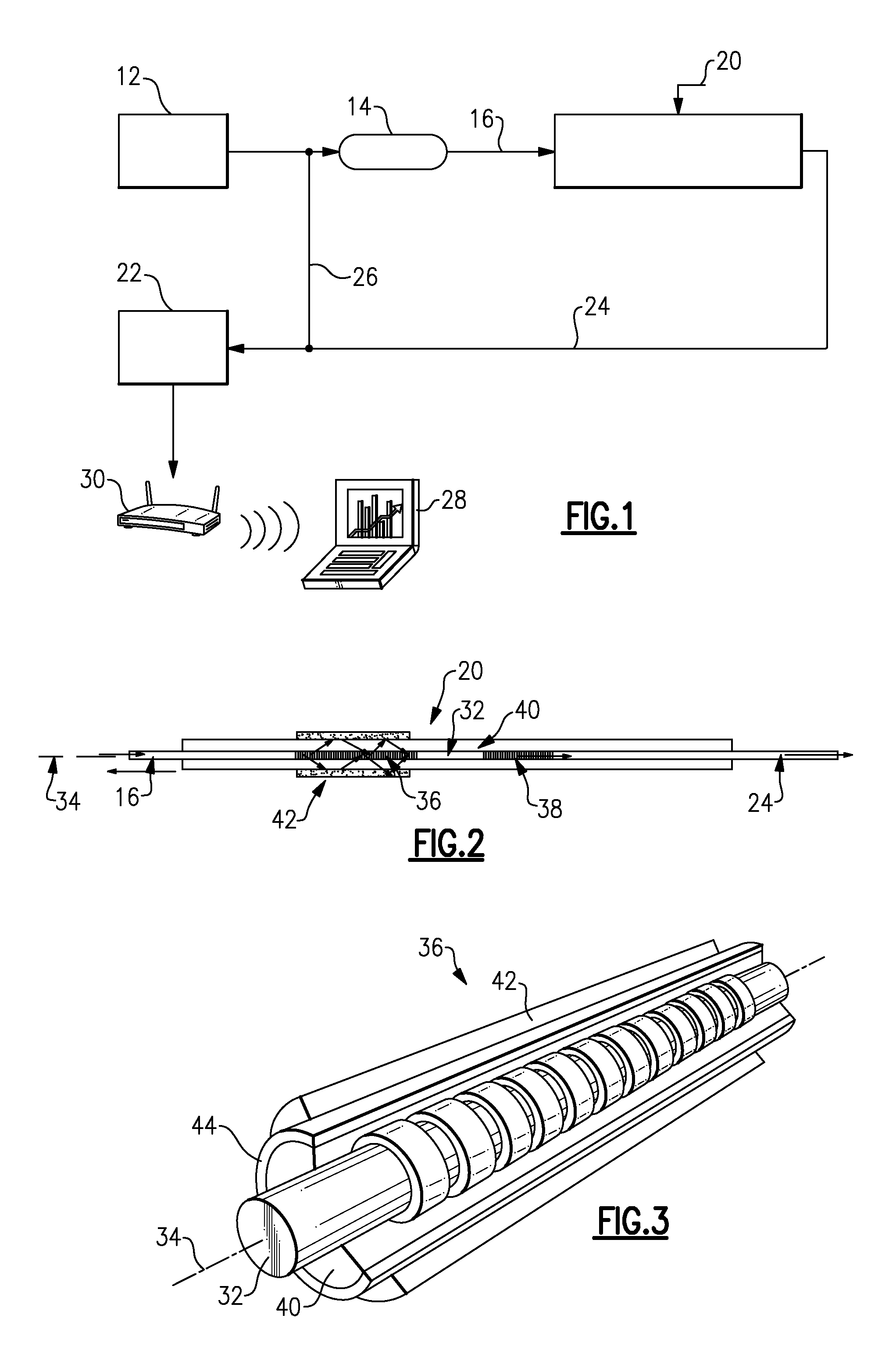

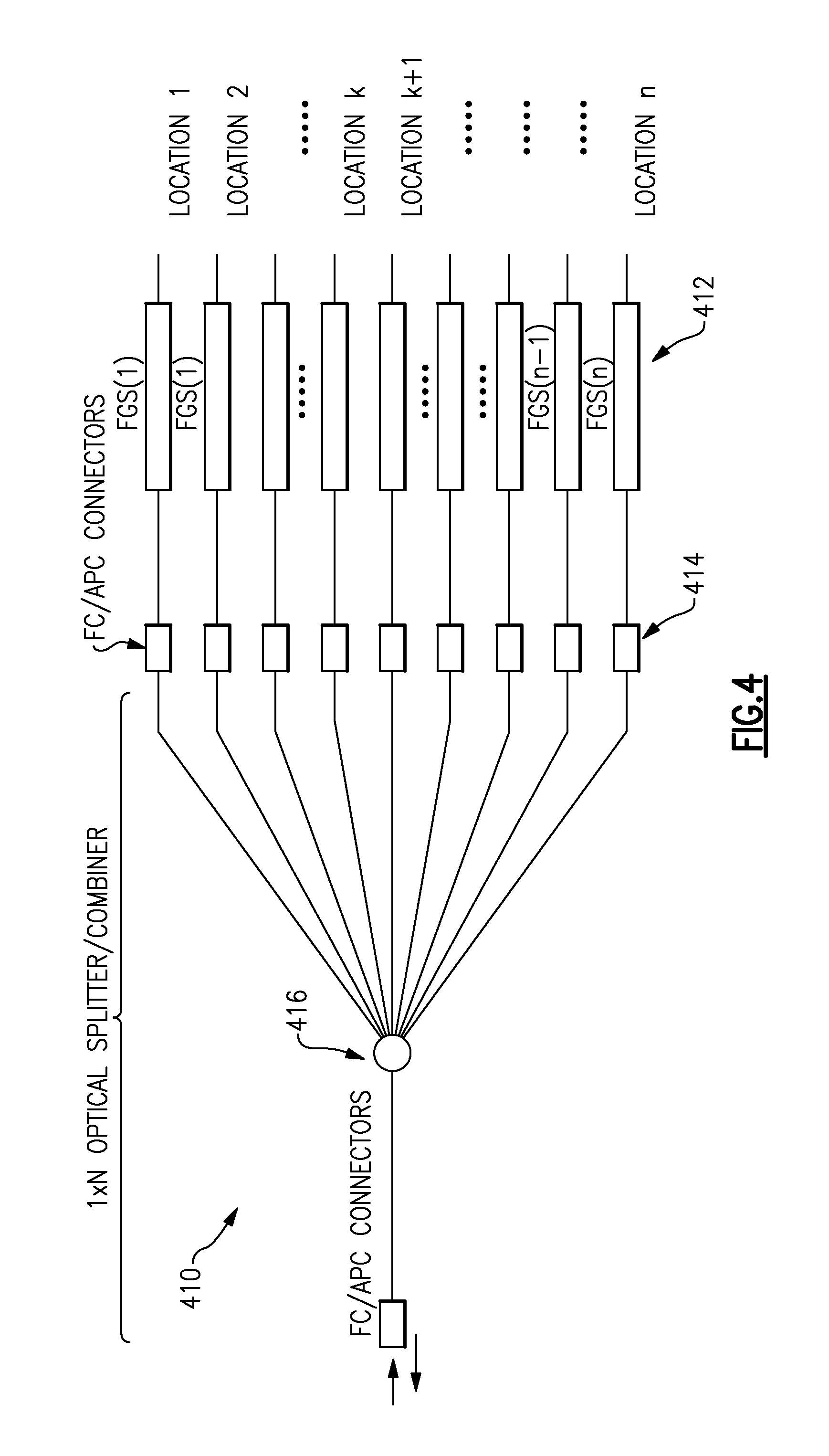

Sensing system with fiber gas sensor

A fiber gas sensor includes a fiber core with first and second refractive index periodic modulated grating structures having different amplitude modulation profiles positioned about the fiber core. A fiber cladding is positioned about the first and second refractive index periodic modulated grating structures. A sensing layer is positioned about the fiber cladding of one of the refractive index periodic modulated grating structures. The sensing layer includes a sensing material made of a Pd-based alloy, such as nano-PdOx, nano-Pd(x)Au(y)Ni(1-x-y) or nano-Pd / Au / WOx. The fiber gas sensor provides a measurement of localized, temperature-corrected gas concentration and composition from a combustion environment. A reflection-based or a transmission-based sensing system with an array of one or more fiber gas sensors is also described.

Owner:GENERAL ELECTRIC CO

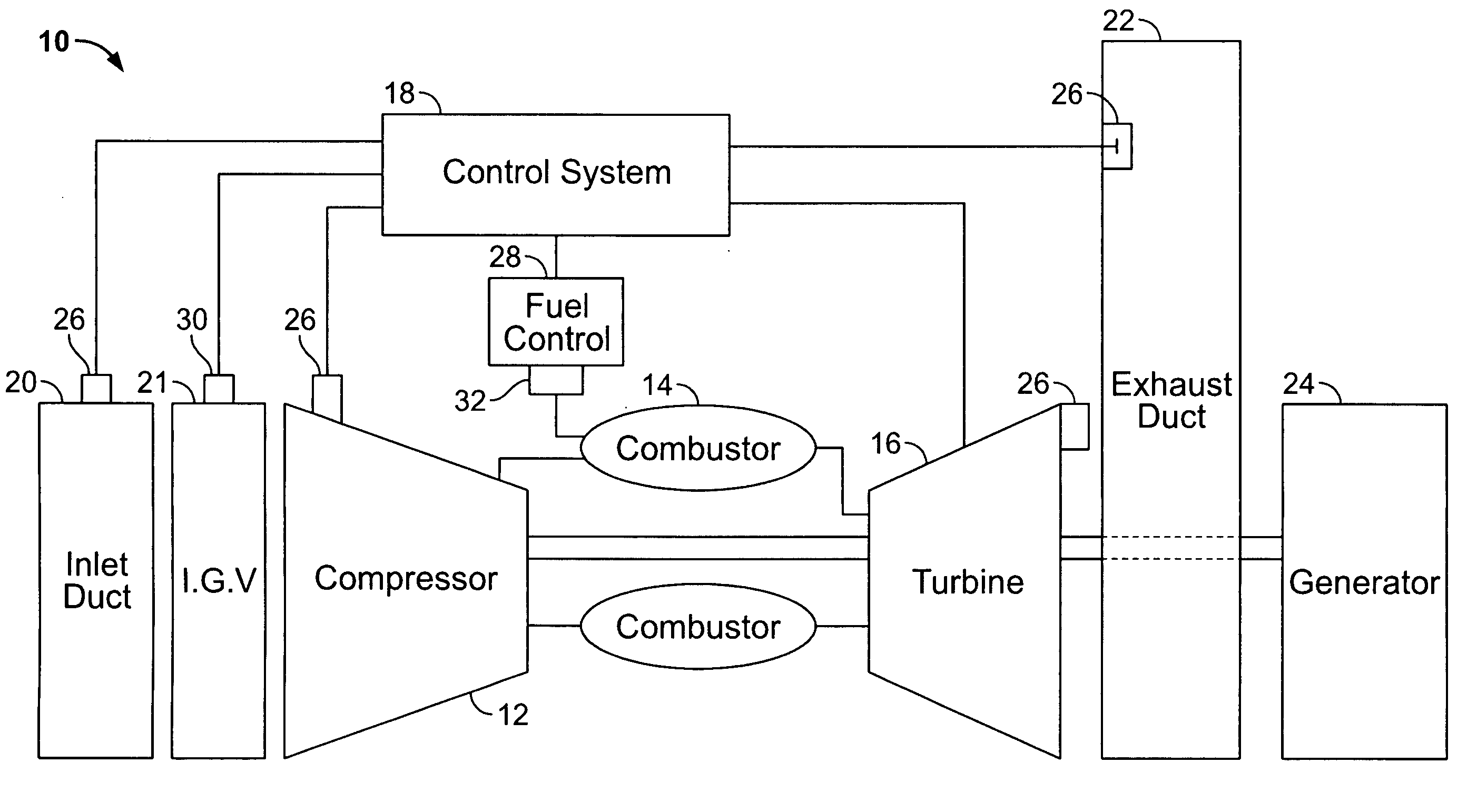

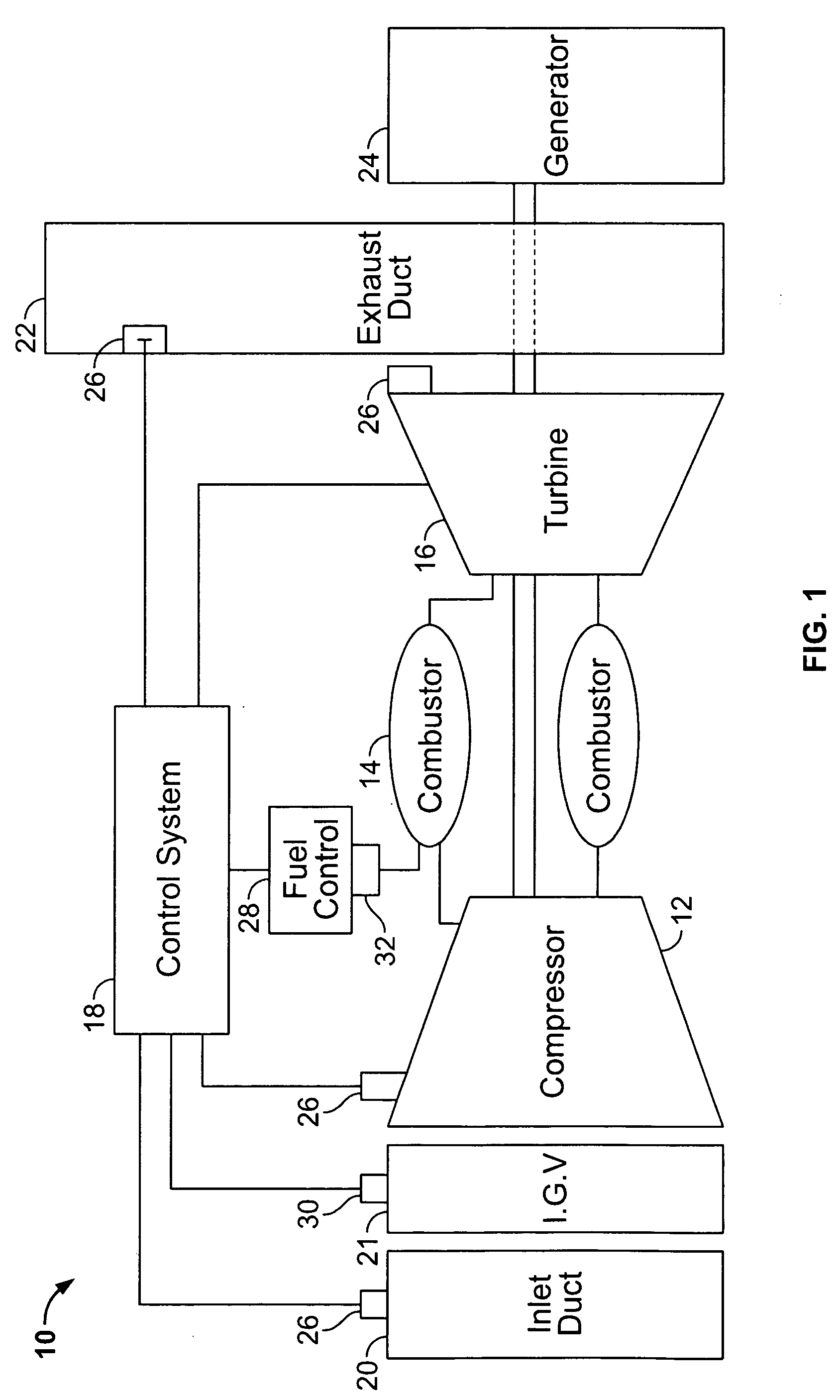

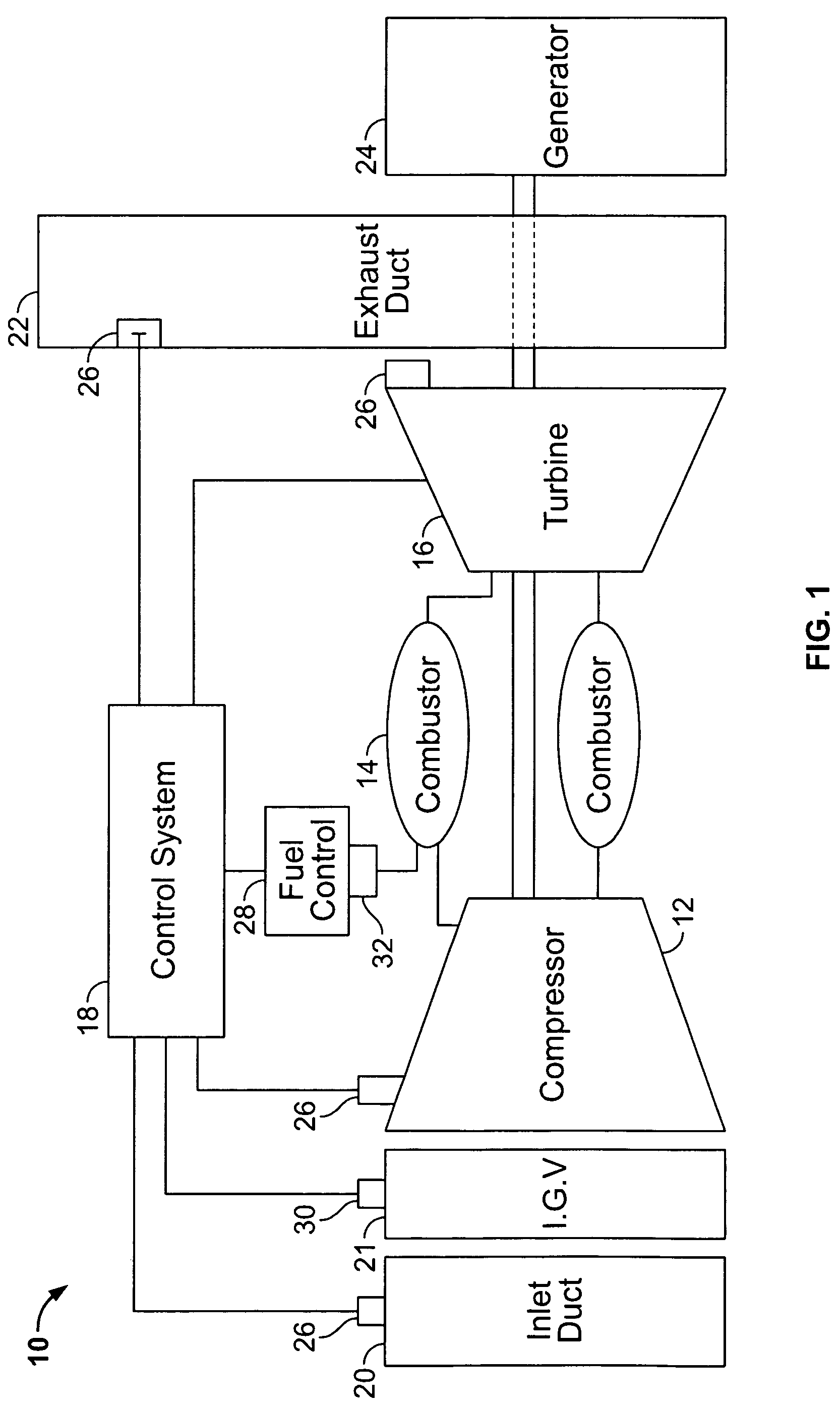

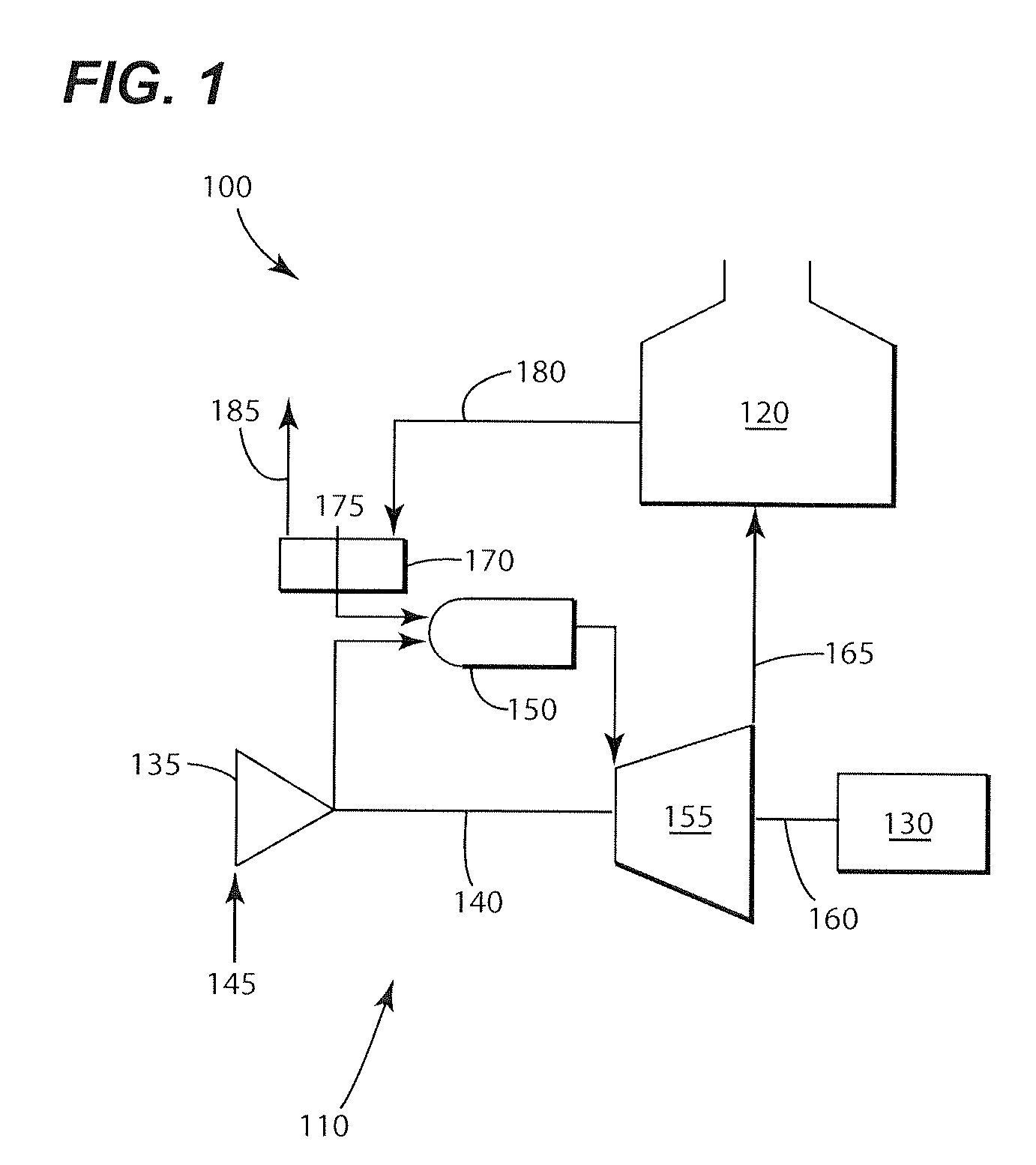

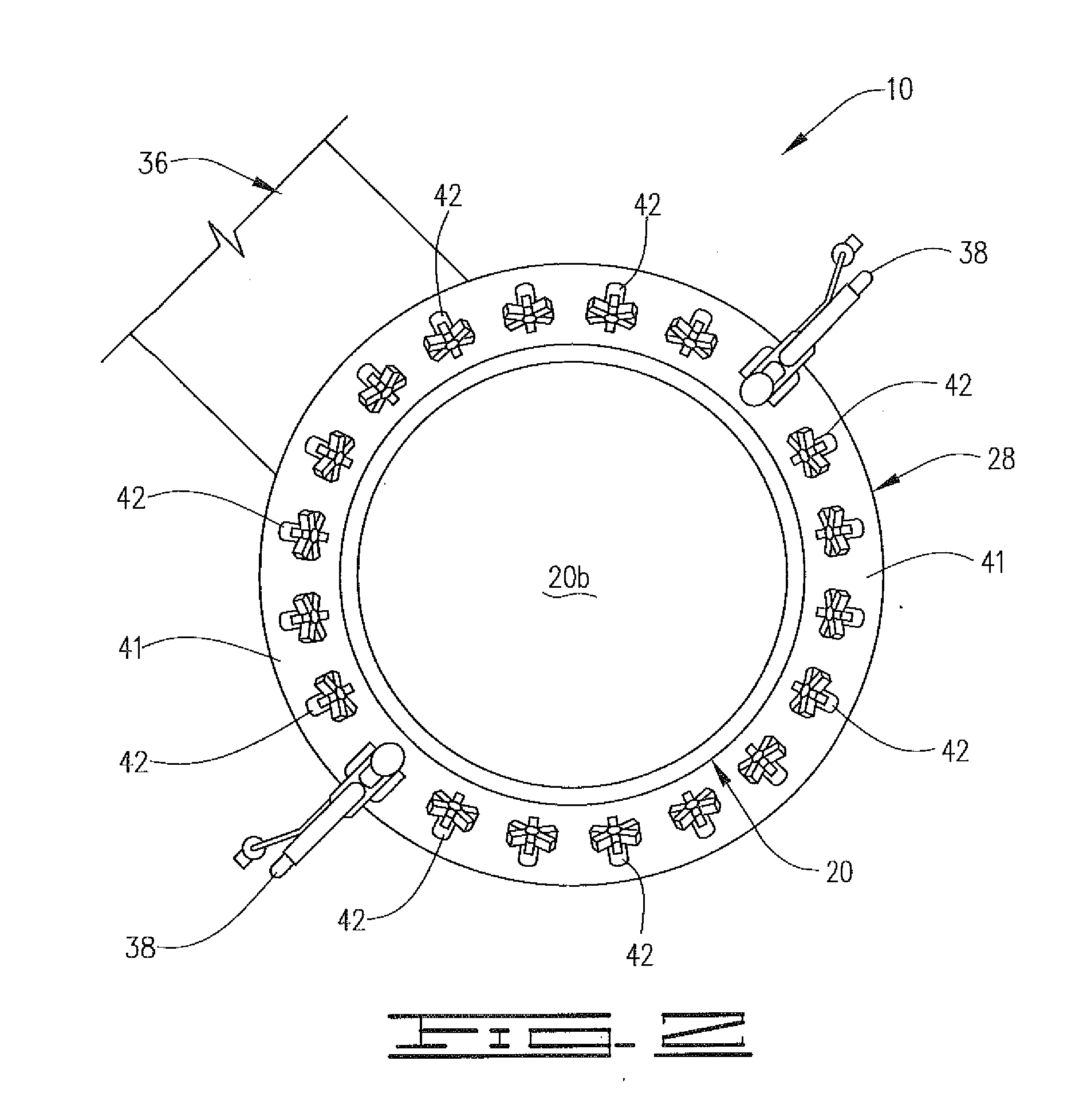

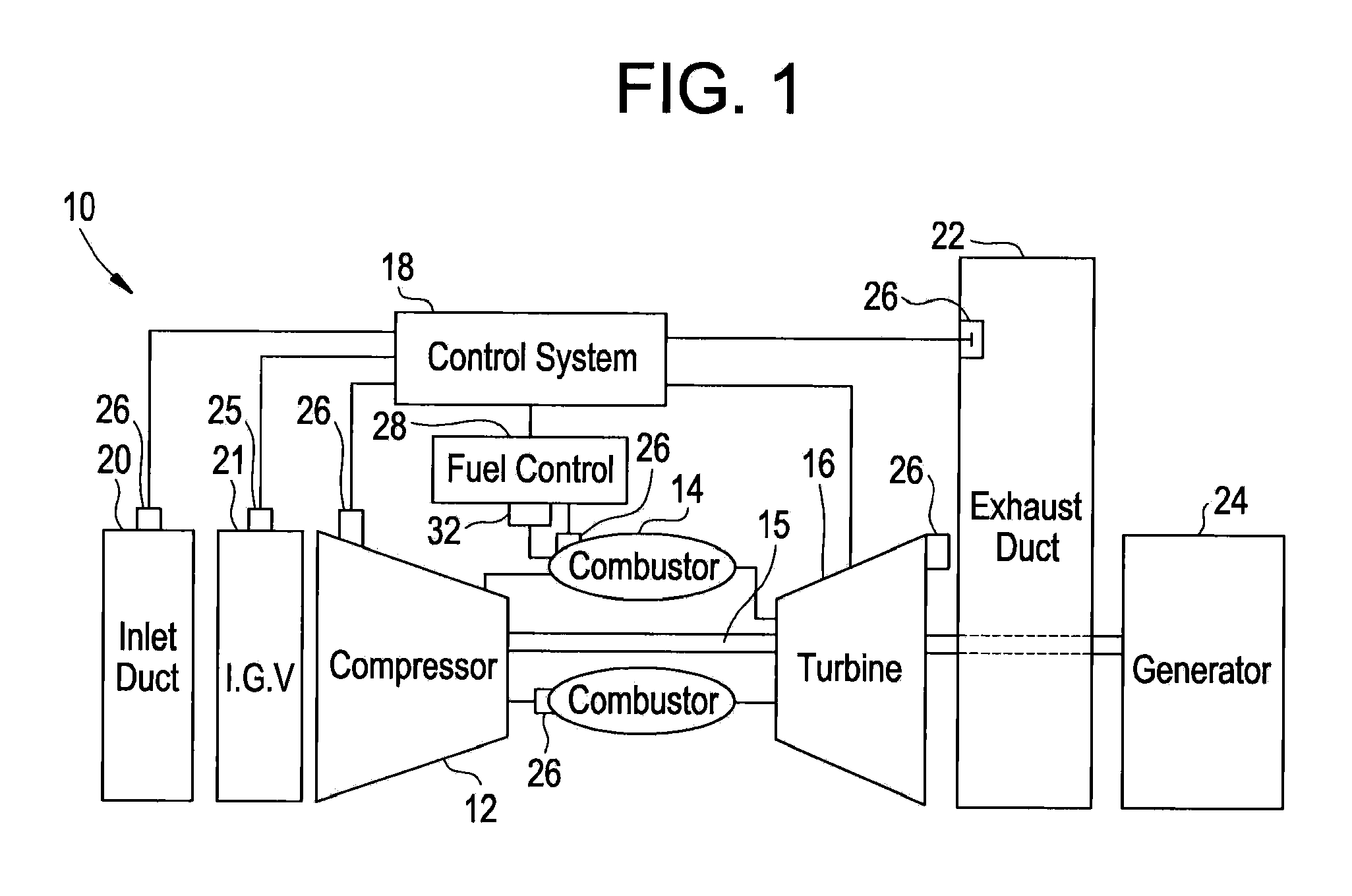

Methods and apparatus for operating gas turbine engine systems

ActiveUS20070113560A1Improve efficiencyContinuous combustion chamberTurbine/propulsion engine ignitionCombustorAutomatic control

Methods and systems for operating a gas turbine engine system include an electrical generator configured to provide electrical energy to a load, a gas turbine engine including at least one combustor that includes a plurality of fuel injection points configured to inject a fuel into the combustor at a plurality of different locations wherein the combustor configured to combust the fuel and the gas turbine engine is rotatably coupled to the generator through a shaft. The gas turbine engine system includes a control system including a plurality of sensors positioned about the gas turbine engine system and configured to measure at least one parameter associated with the sensor, a processor programmed to receive a signal indicative of a heating value of the fuel, and automatically control a fuel split between the fuel injection points on the combustor using the determined heating value.

Owner:GENERAL ELECTRIC CO

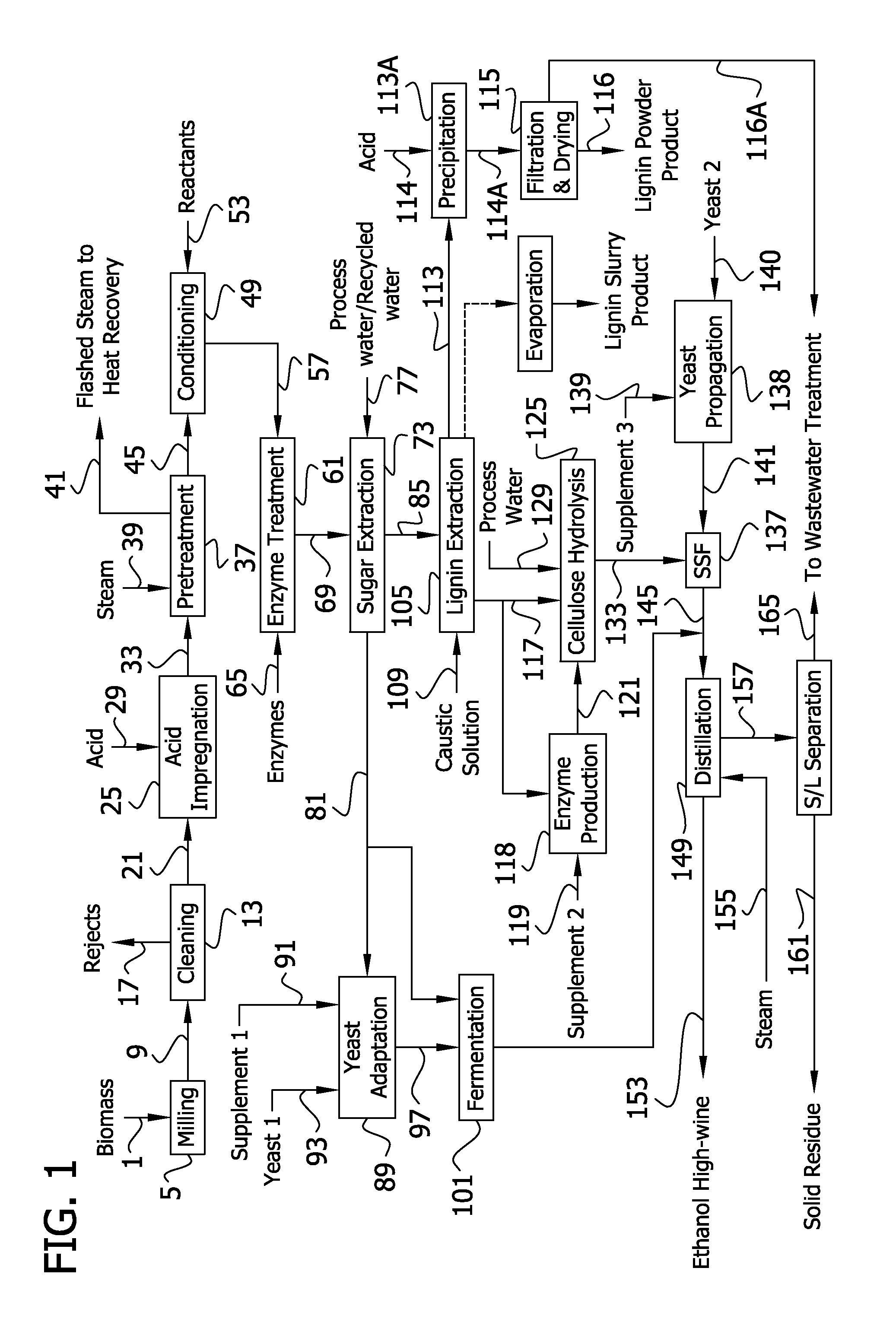

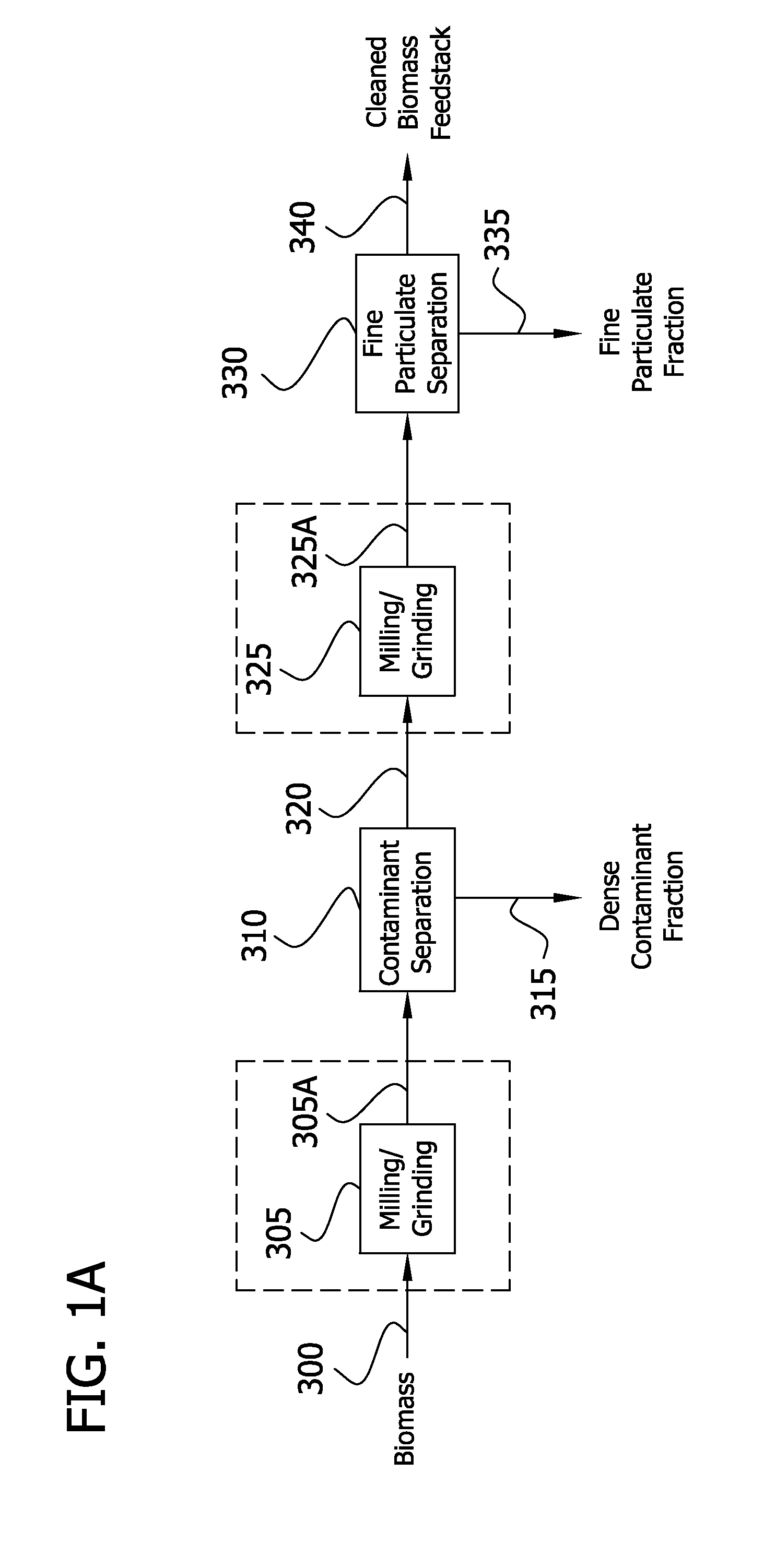

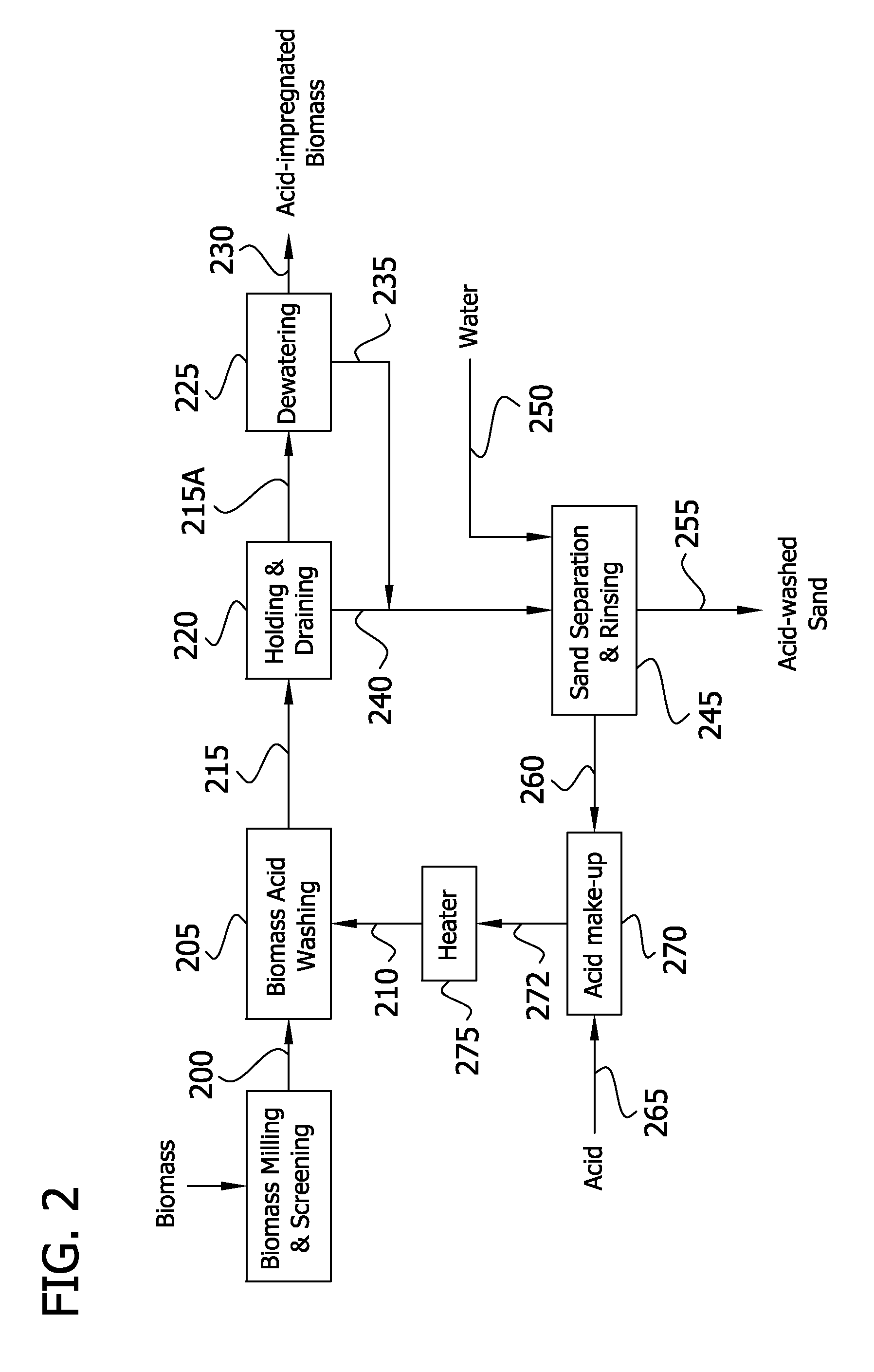

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

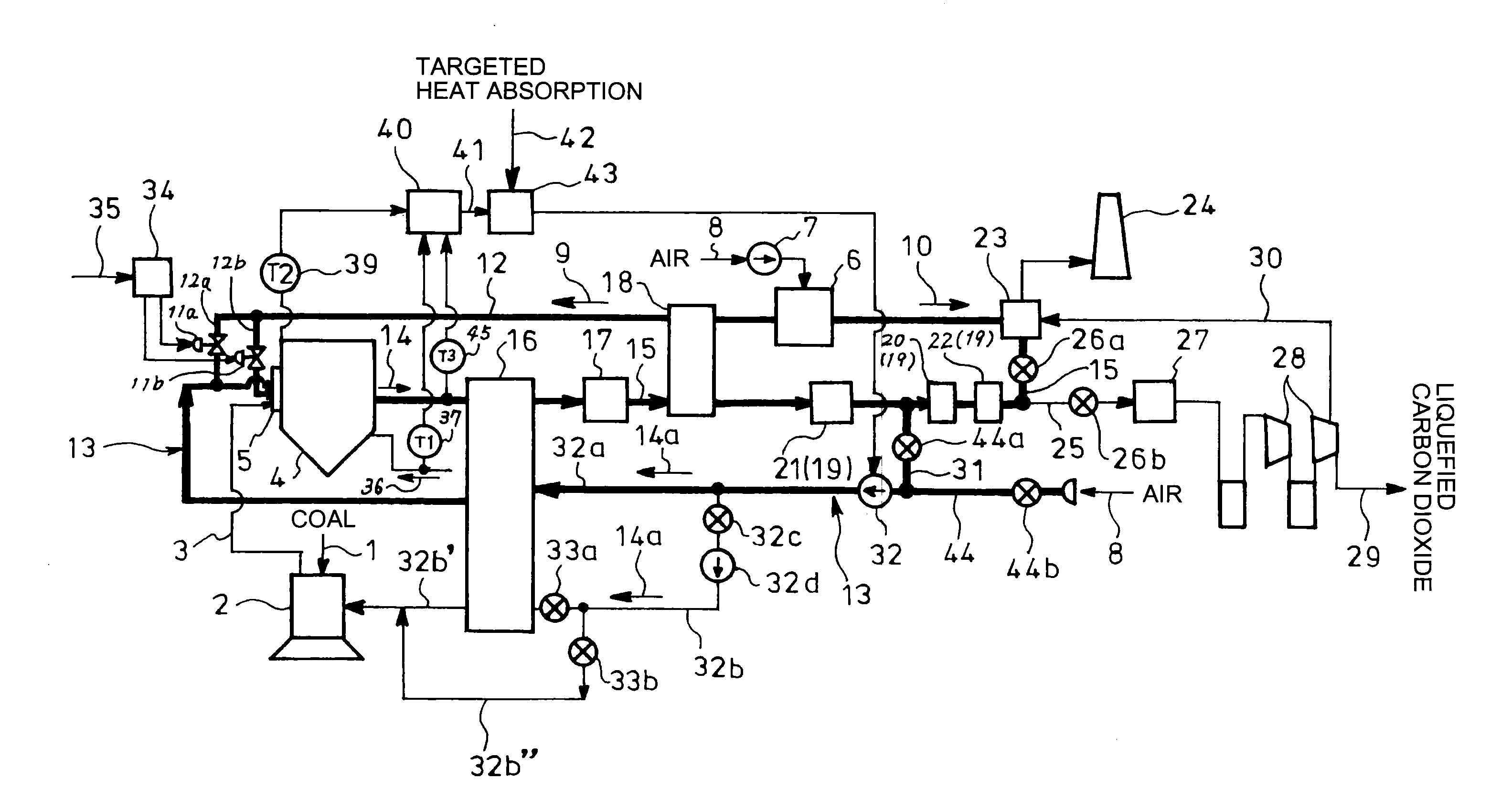

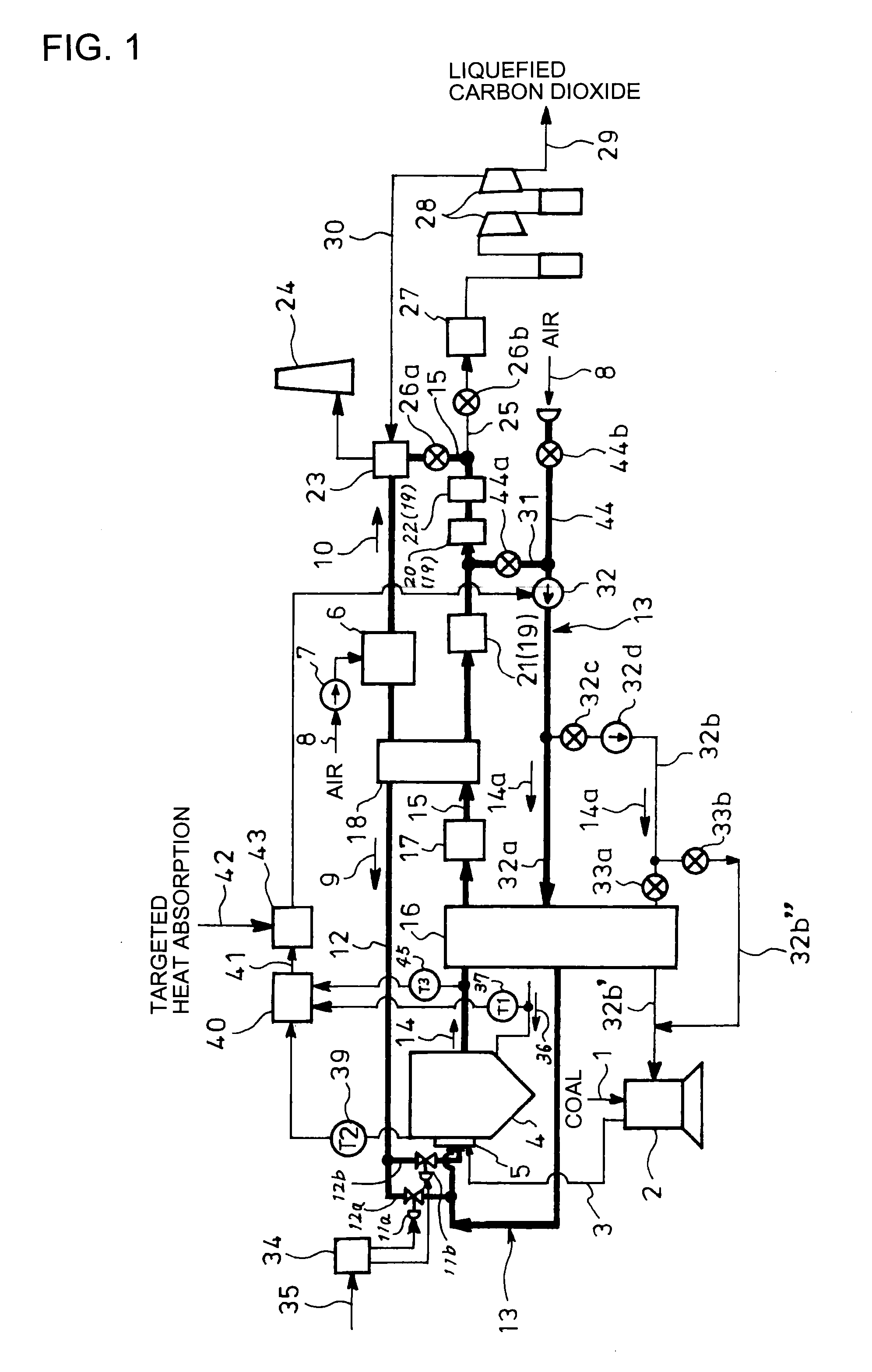

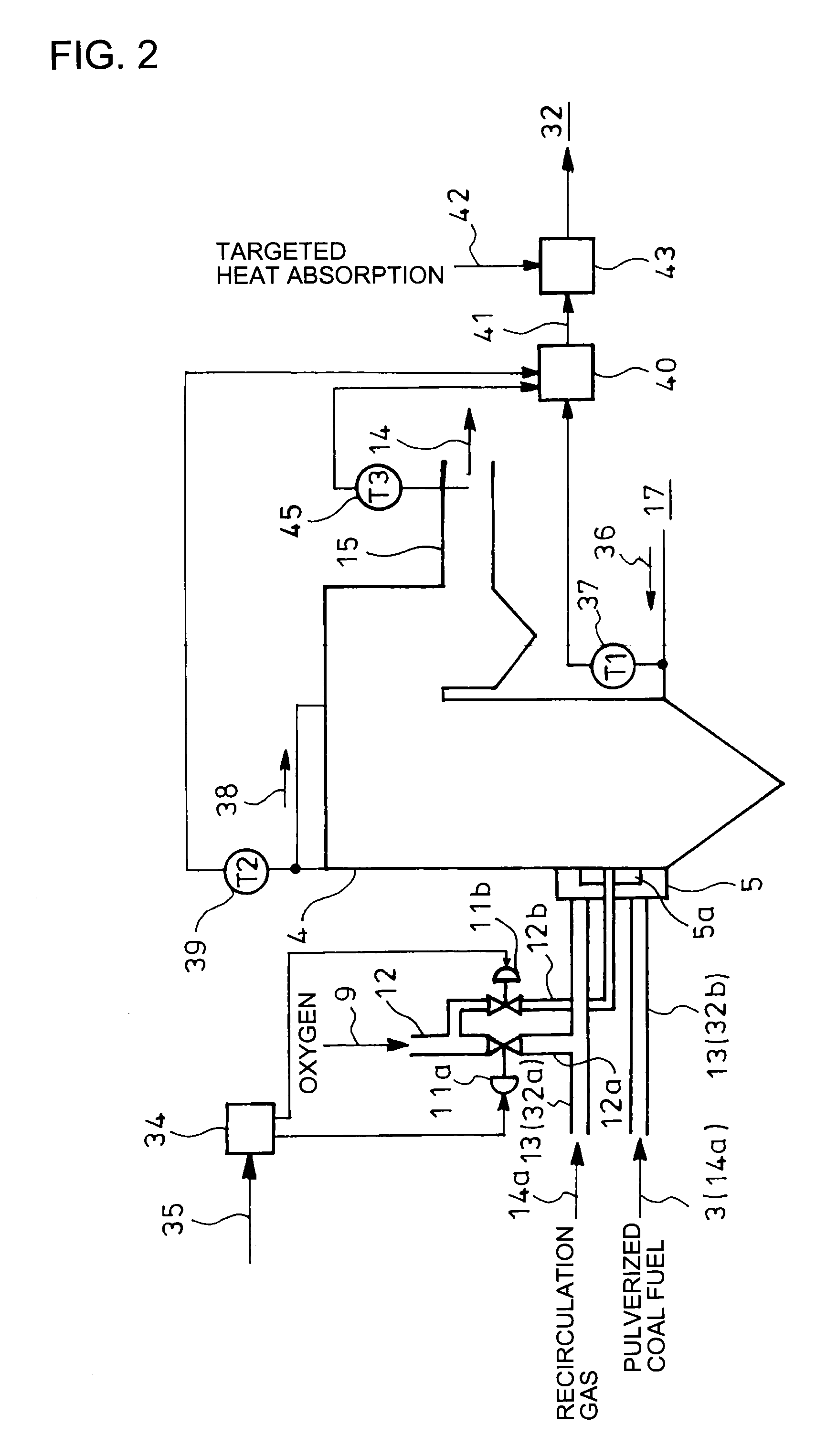

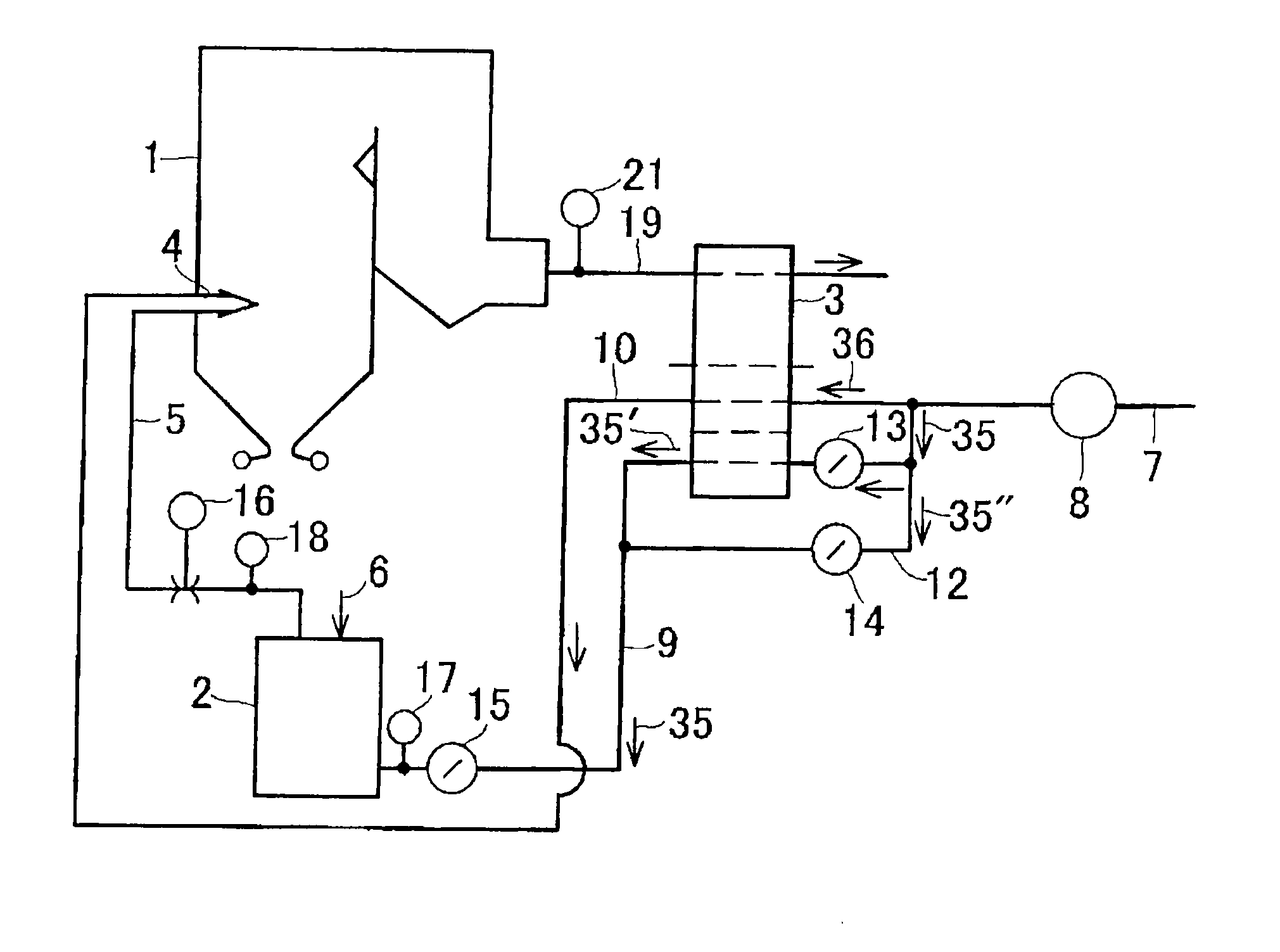

Method and apparatus for controlling combustion in oxygen fired boiler

ActiveUS20090272300A1Great advantageGood effectMechanical apparatusFluegas recirculationCombustionEngineering

Provided are a method and an apparatus for controlling combustion in an oxygen fired boiler which are easily applicable to an existing air fired boiler for easy and stable control of the combustion.Oxygen with a setting amount in accordance with a boiler load demand 35 is supplied to a boiler body 4. Heat absorption amount of the boiler is measured from inlet temperature of feedwater supplied to the boiler body 4 and outlet temperature of steam. Recirculation flow rate of combustion exhaust gas 14a is controlled such that heat absorption amount 41 of the boiler body 4 becomes equal to a targeted heat absorption amount 42 to thereby control oxygen concentration in all gas guided to the boiler body 4.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

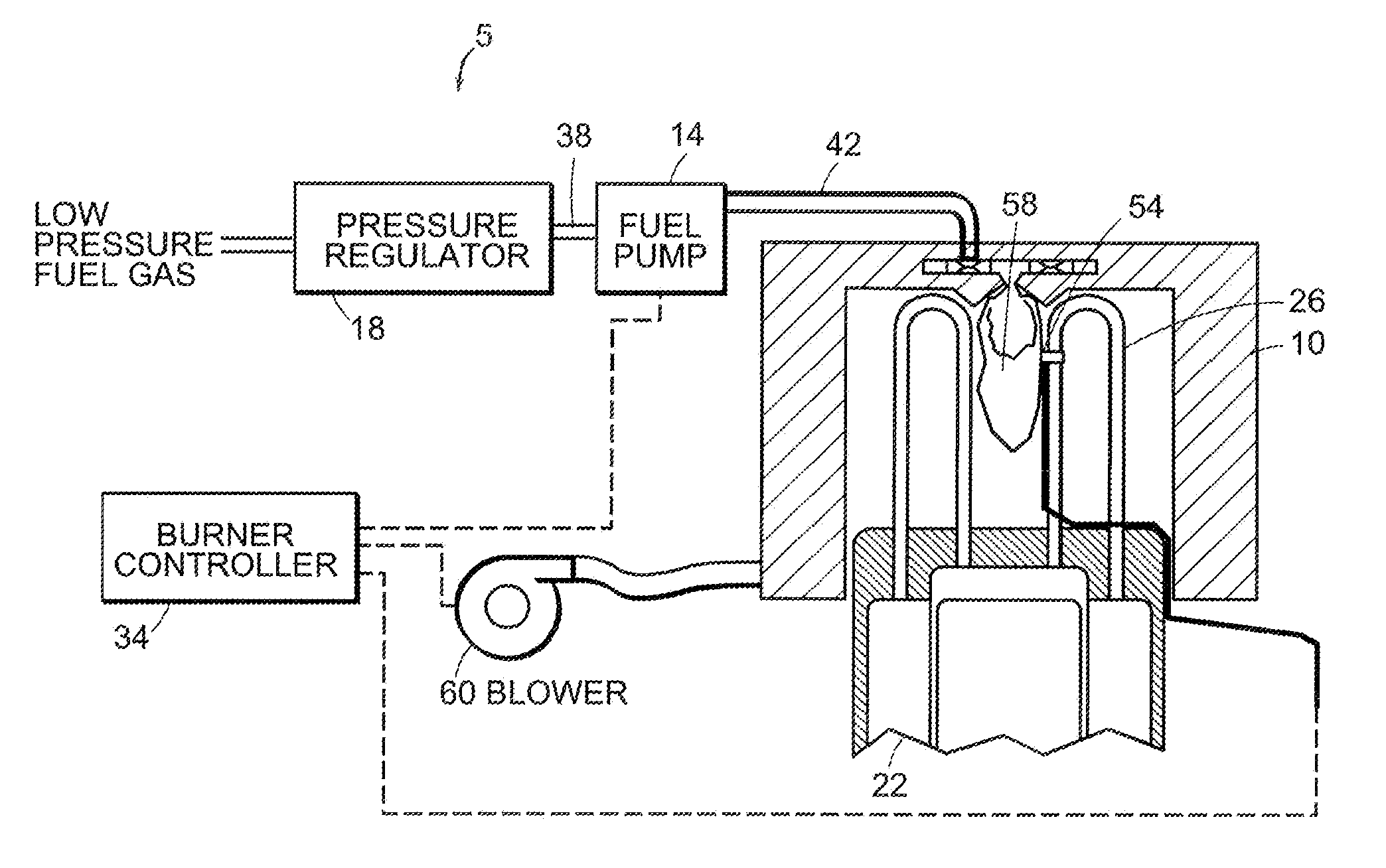

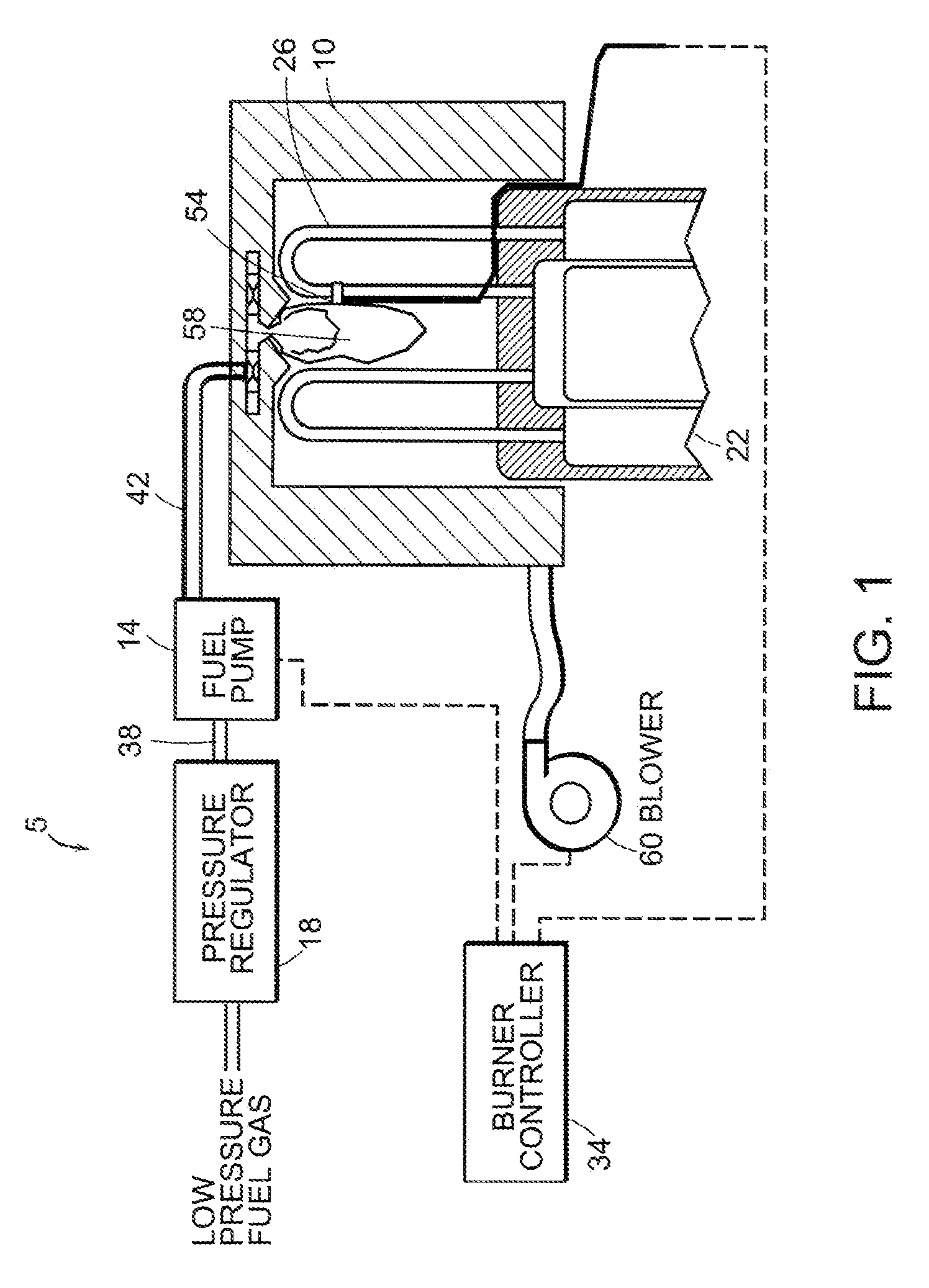

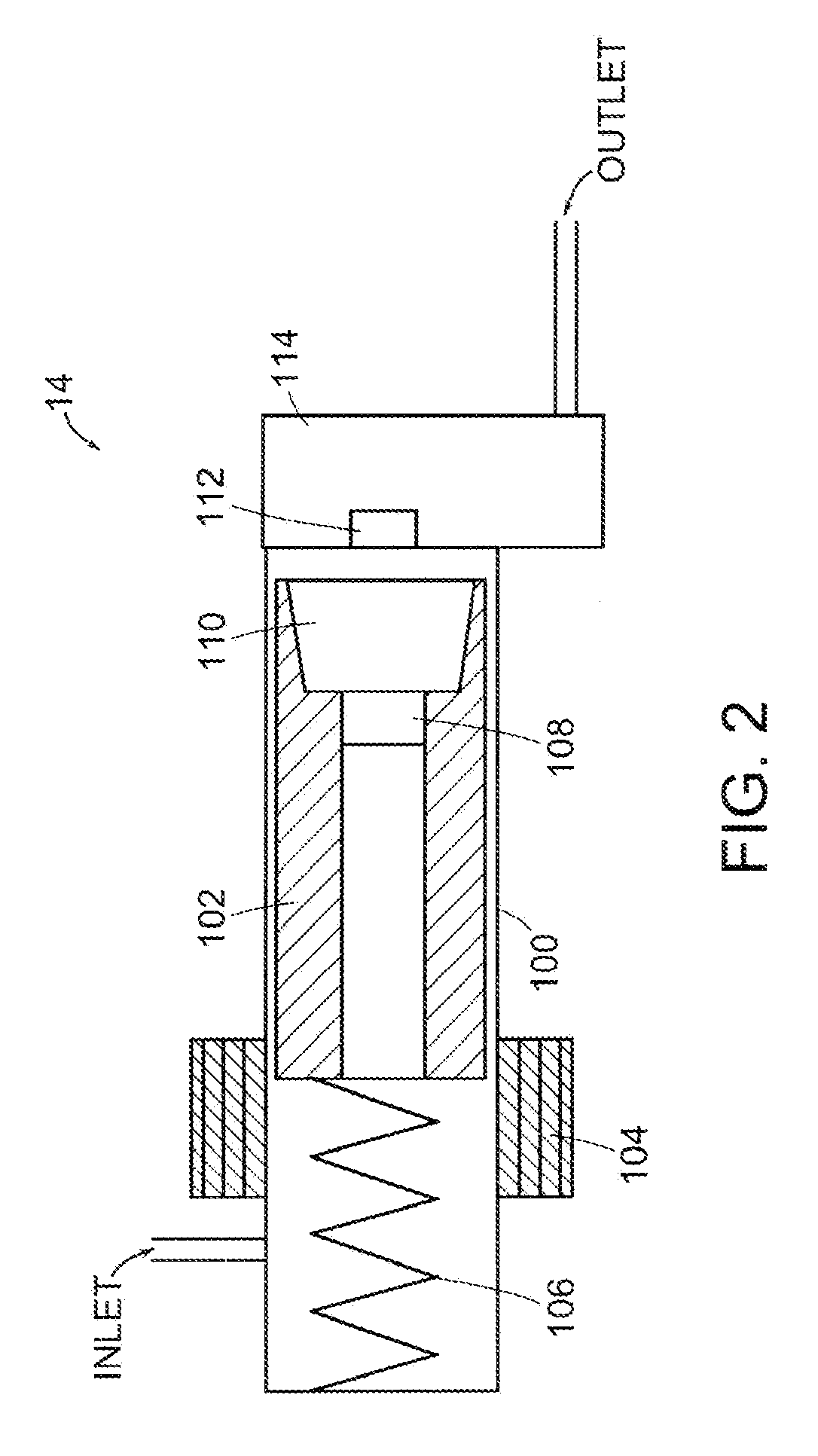

Metering fuel pump

InactiveUS7111460B2Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesDiaphragm pumpCombustion chamber

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

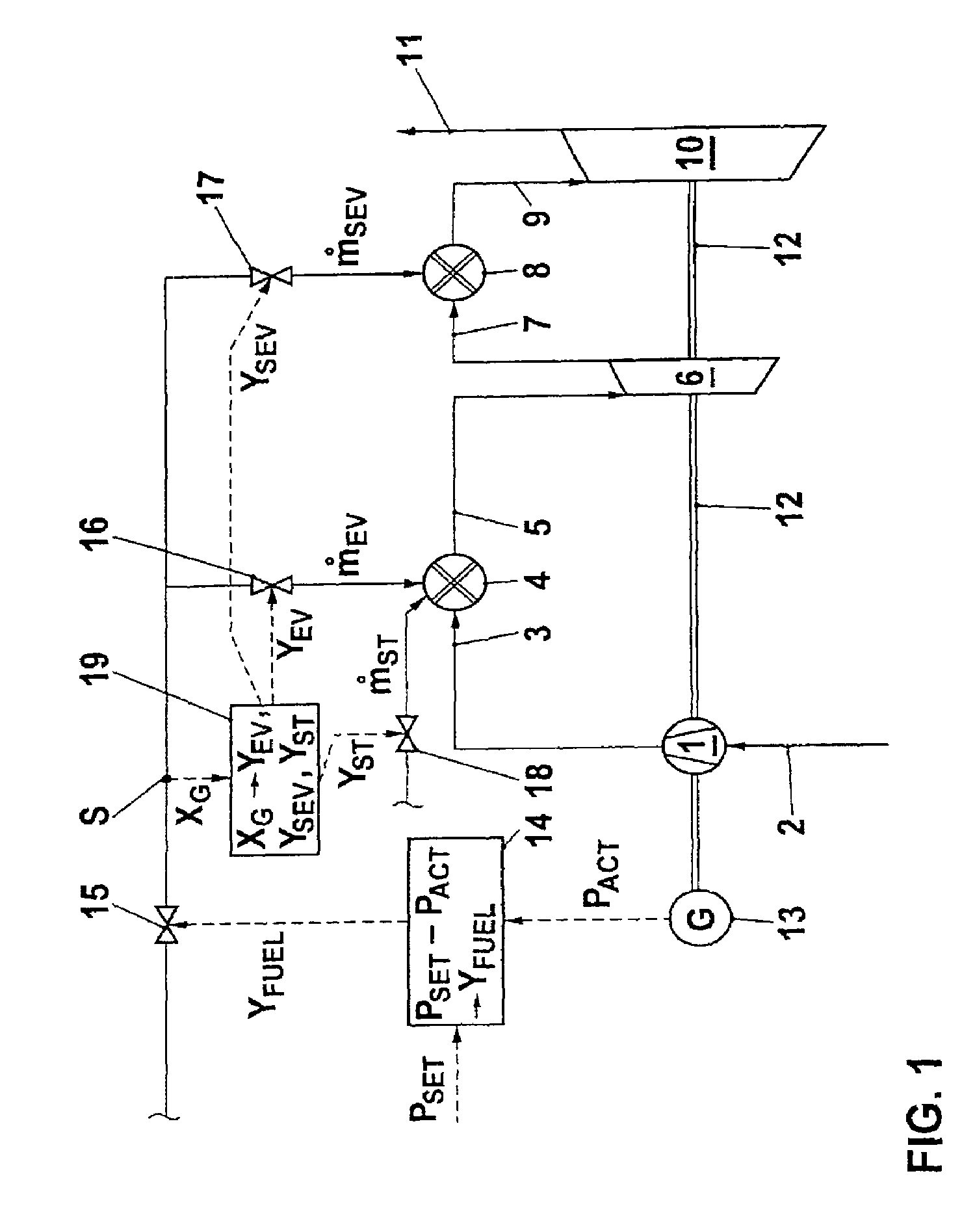

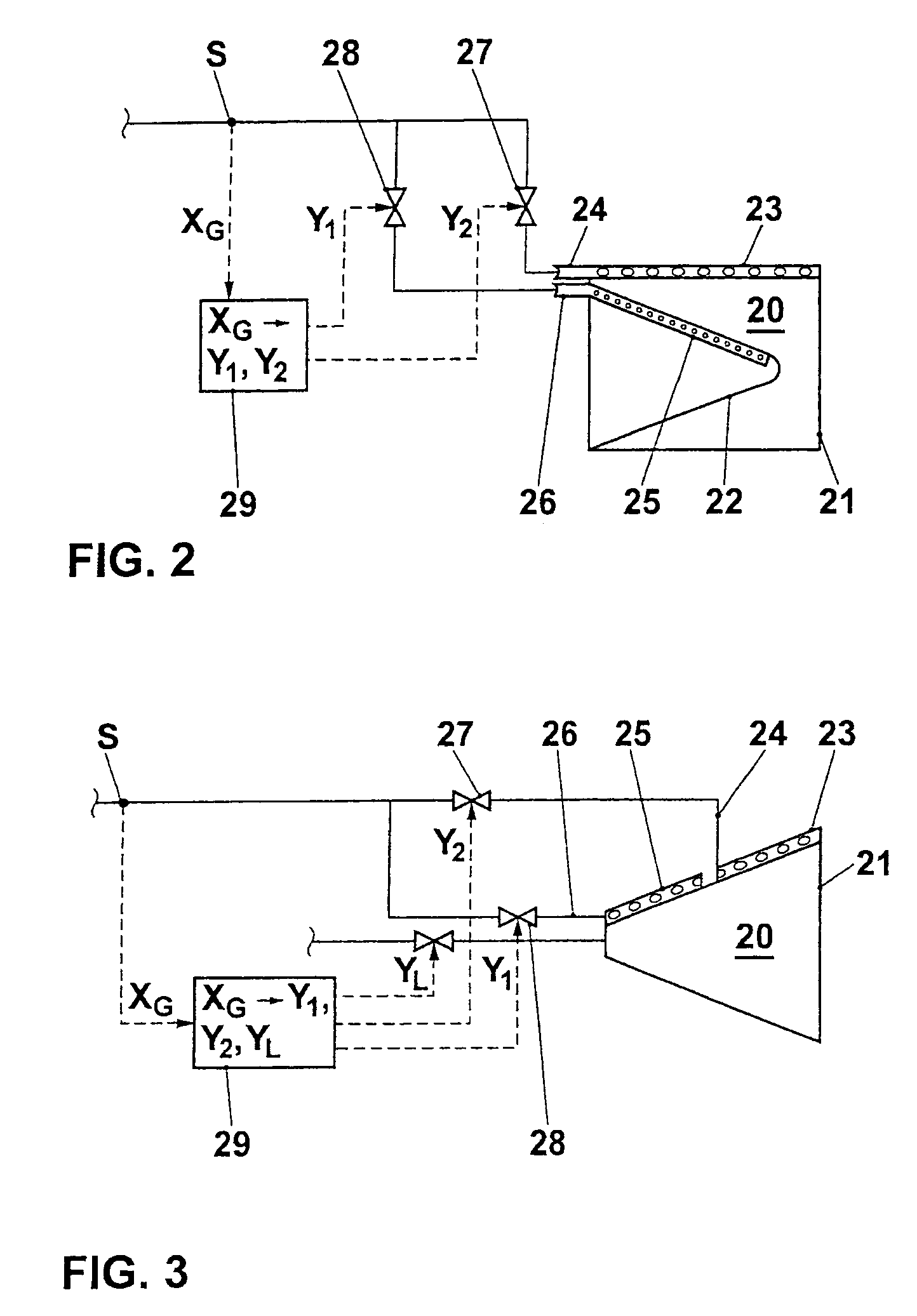

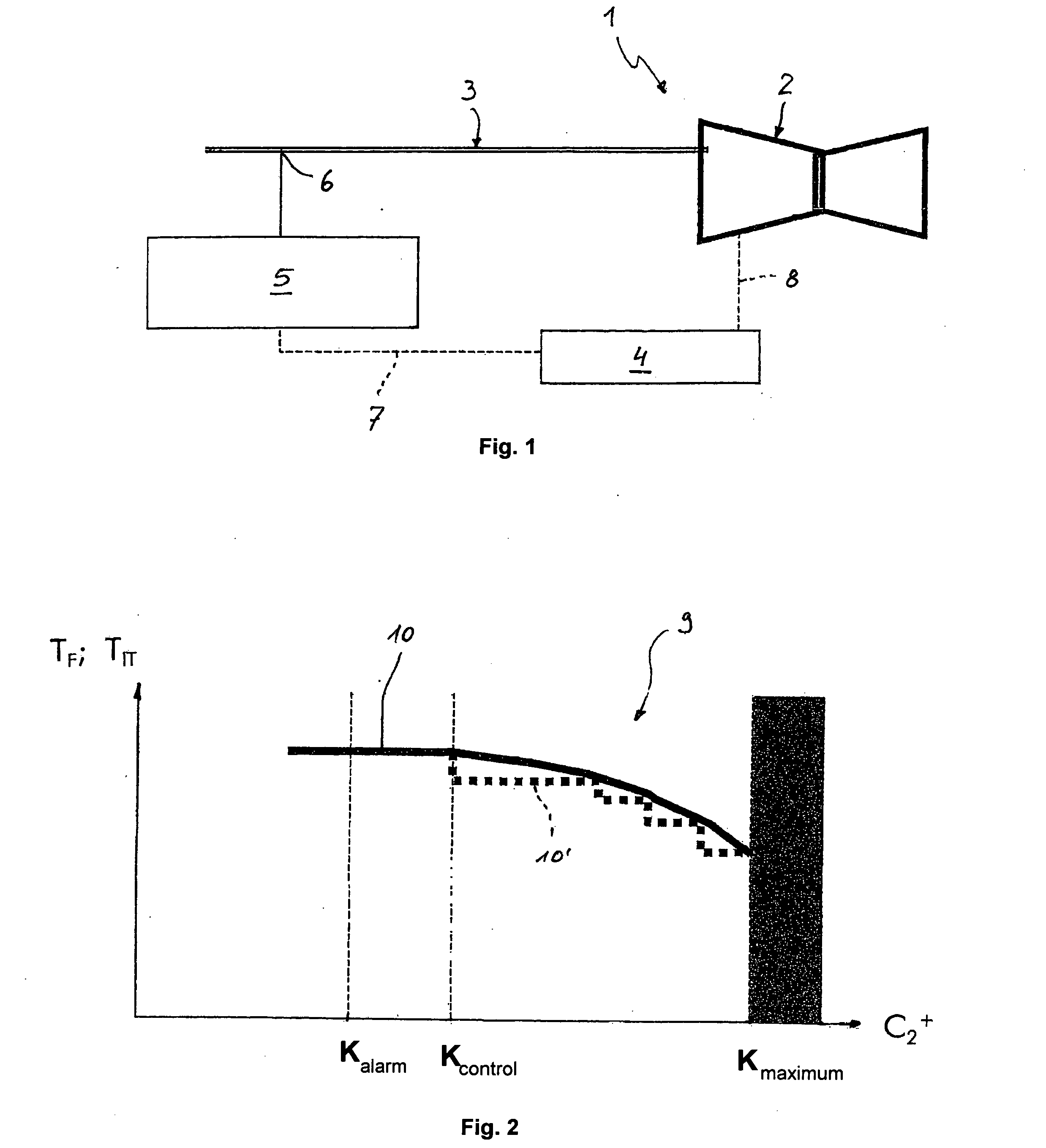

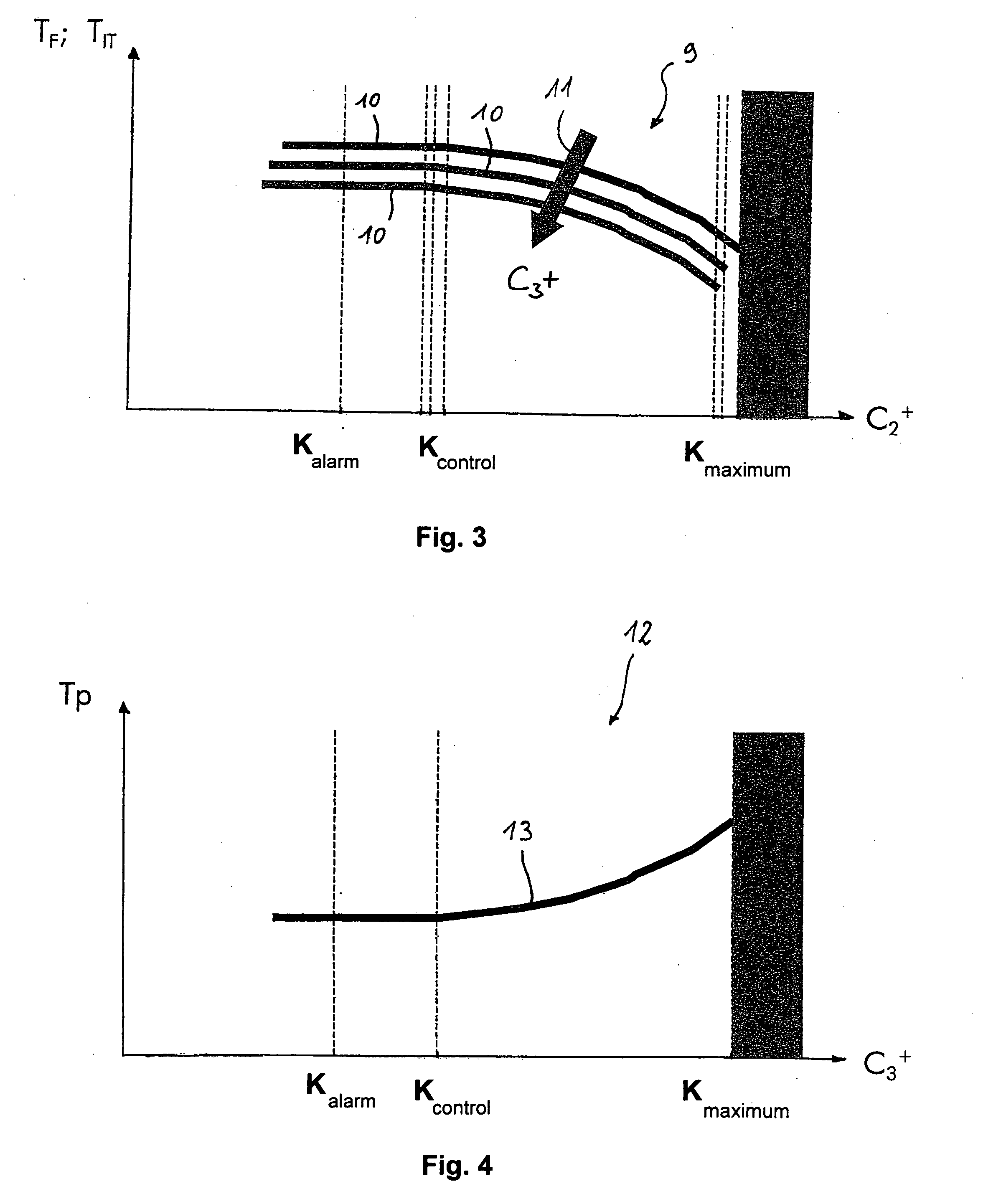

Method for operating a turbine group

InactiveUS7216486B2Quick measurementCross-sensitivity between the spectral regions is lowContinuous combustion chamberTurbine/propulsion engine ignitionAlkaneCombustion chamber

Owner:ANSALDO ENERGIA IP UK LTD

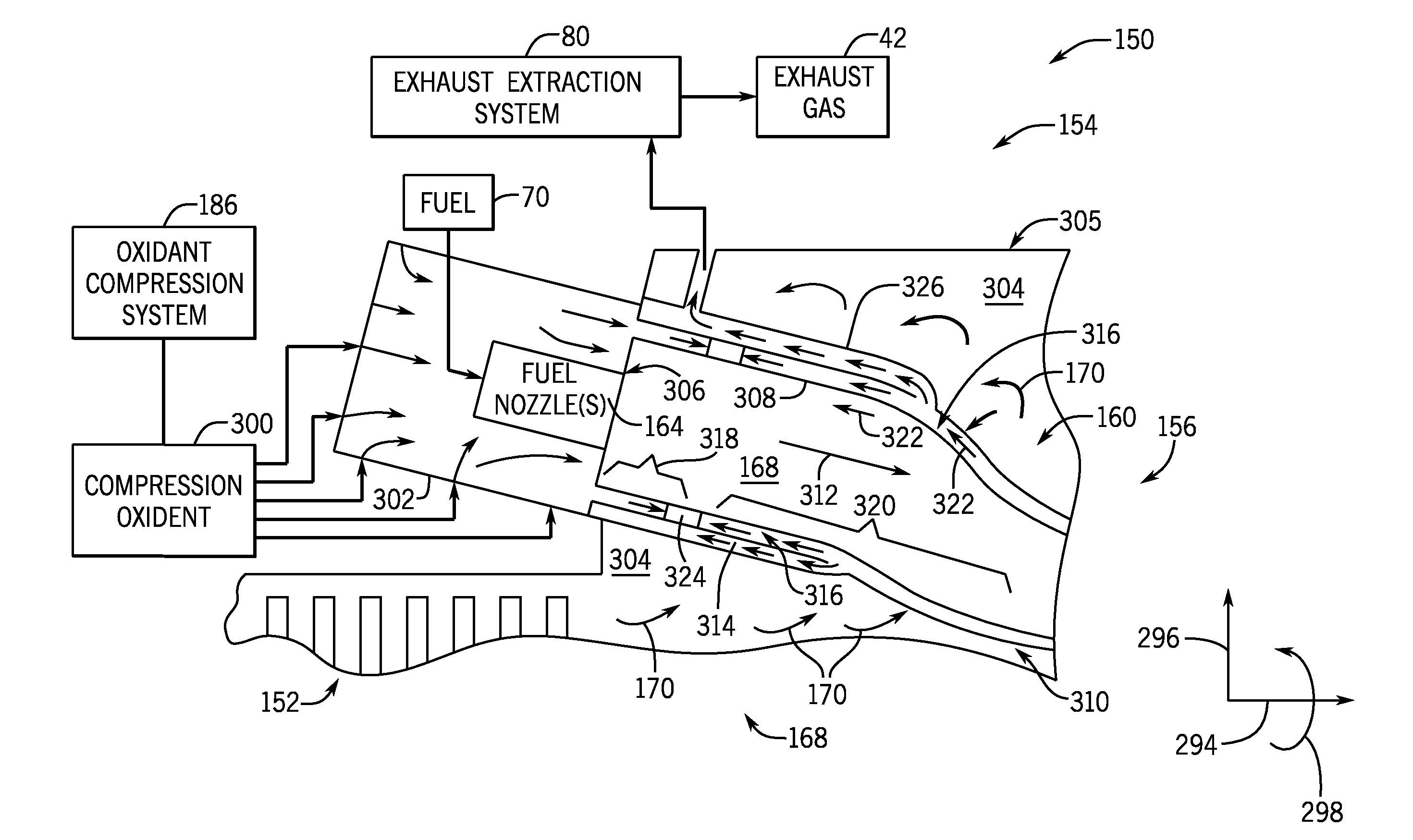

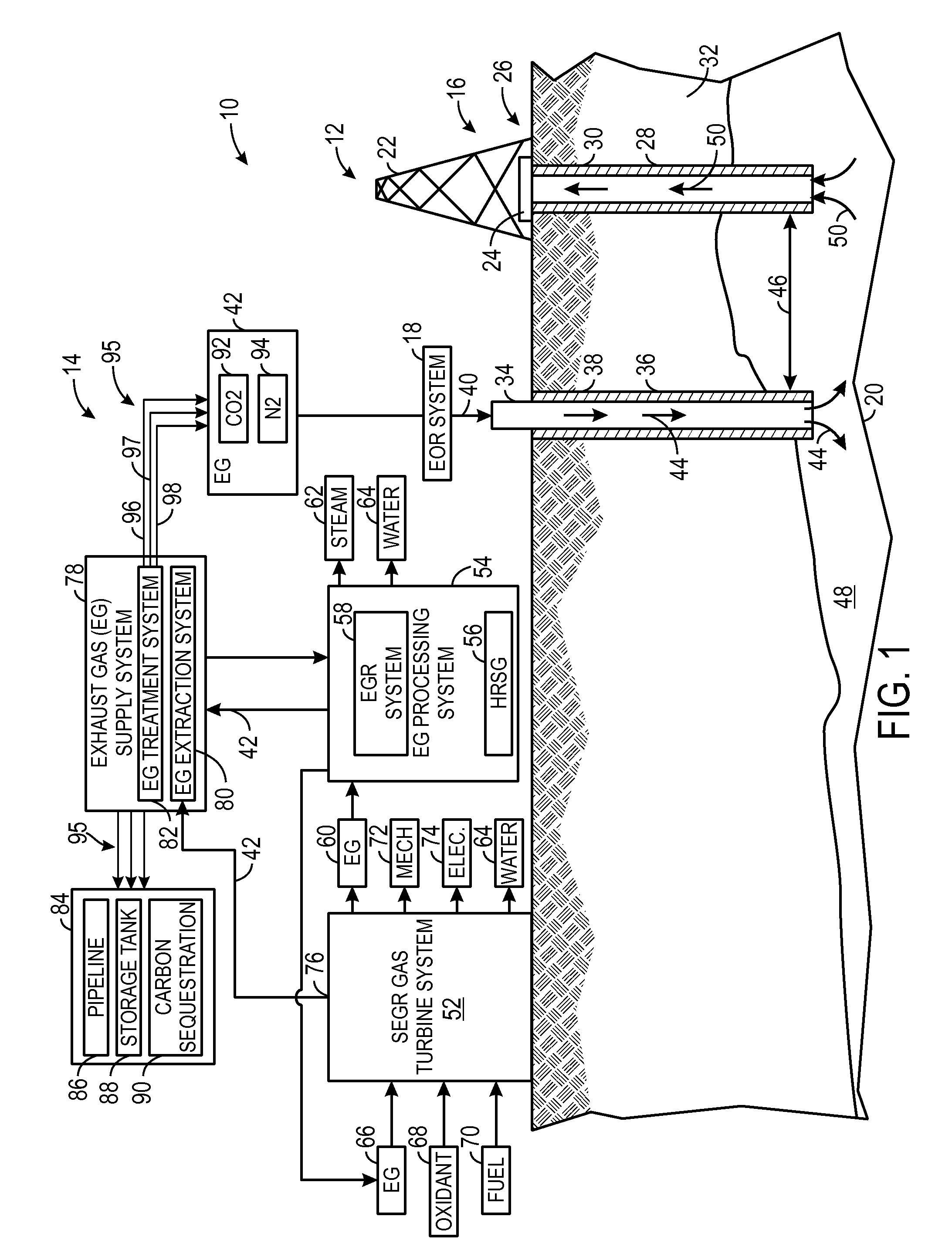

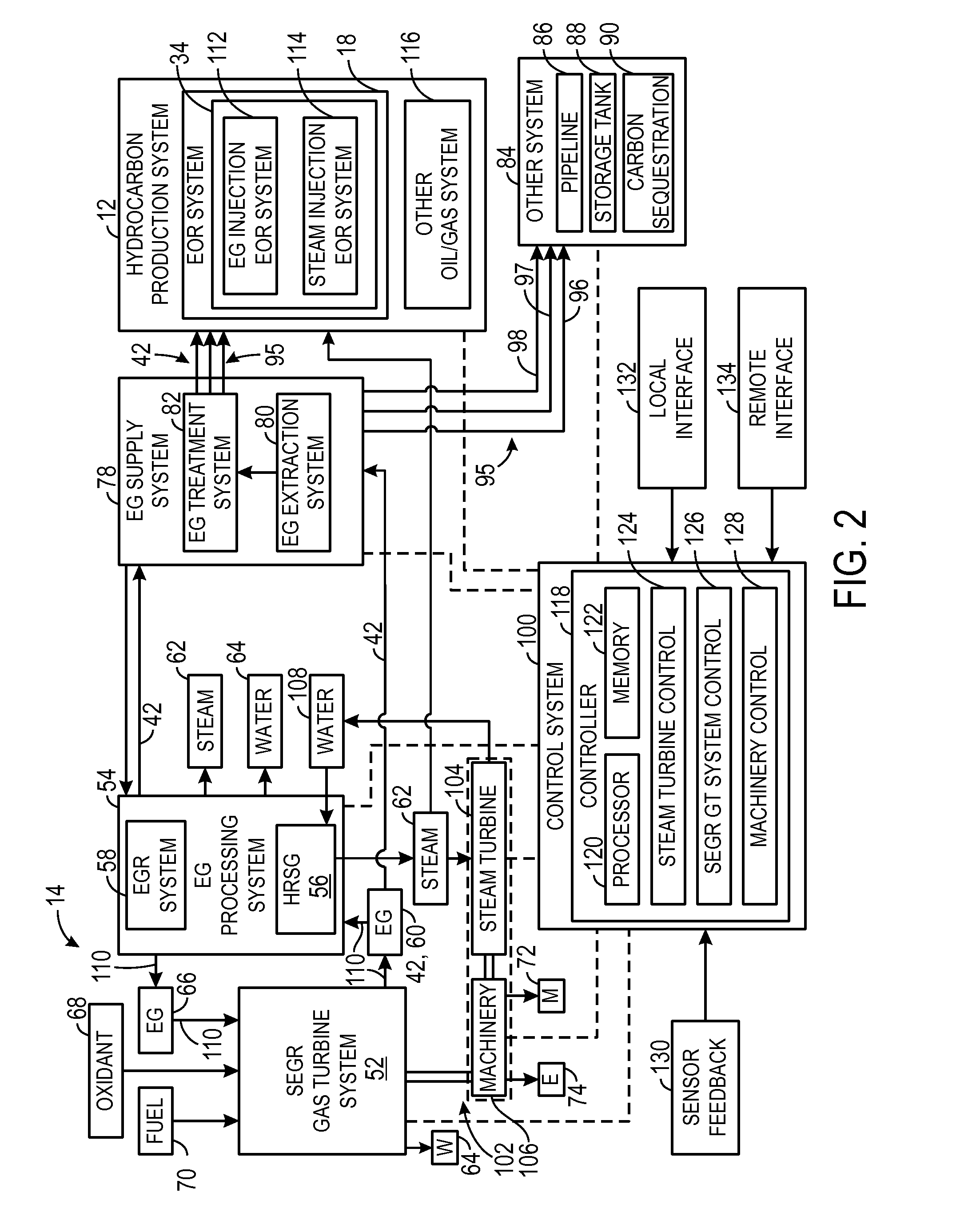

System and method of controlling combustion and emissions in gas turbine engine with exhaust gas recirculation

In one embodiment, a system includes a turbine combustor having a combustor liner disposed about a combustion chamber, a head end upstream of the combustion chamber relative to a downstream direction of a flow of combustion gases through the combustion chamber, a flow sleeve disposed at an offset about the combustor liner to define a passage, and a barrier within the passage. The head end is configured to direct an oxidant flow and a first fuel flow toward the combustion chamber. The passage is configured to direct a gas flow toward the head end and to direct a portion of the oxidant flow toward a turbine end of the turbine combustor. The gas flow includes a substantially inert gas. The barrier is configured to block the portion of the oxidant flow toward the turbine end and to block the gas flow toward the head end within the passage.

Owner:GENERAL ELECTRIC CO +1

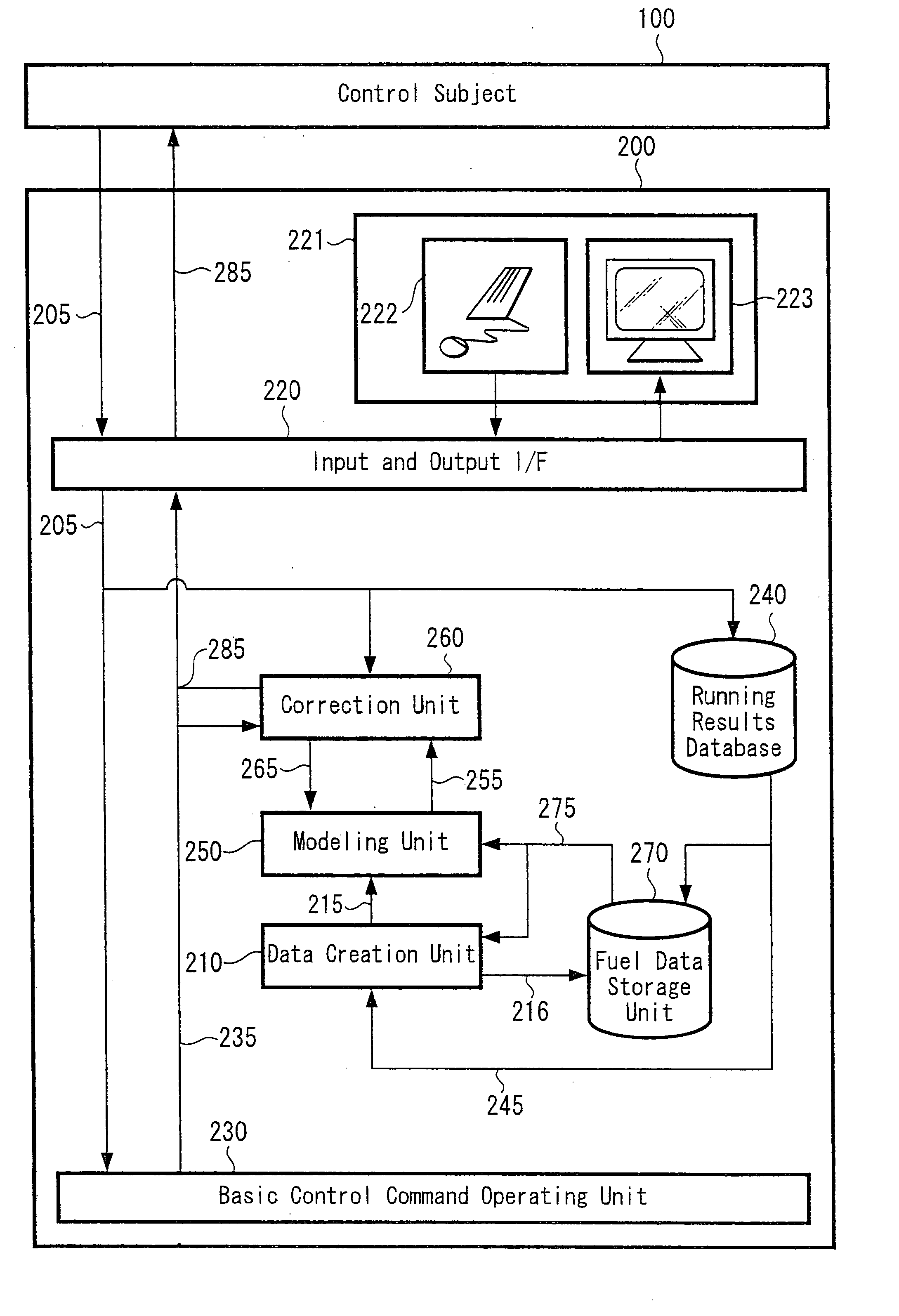

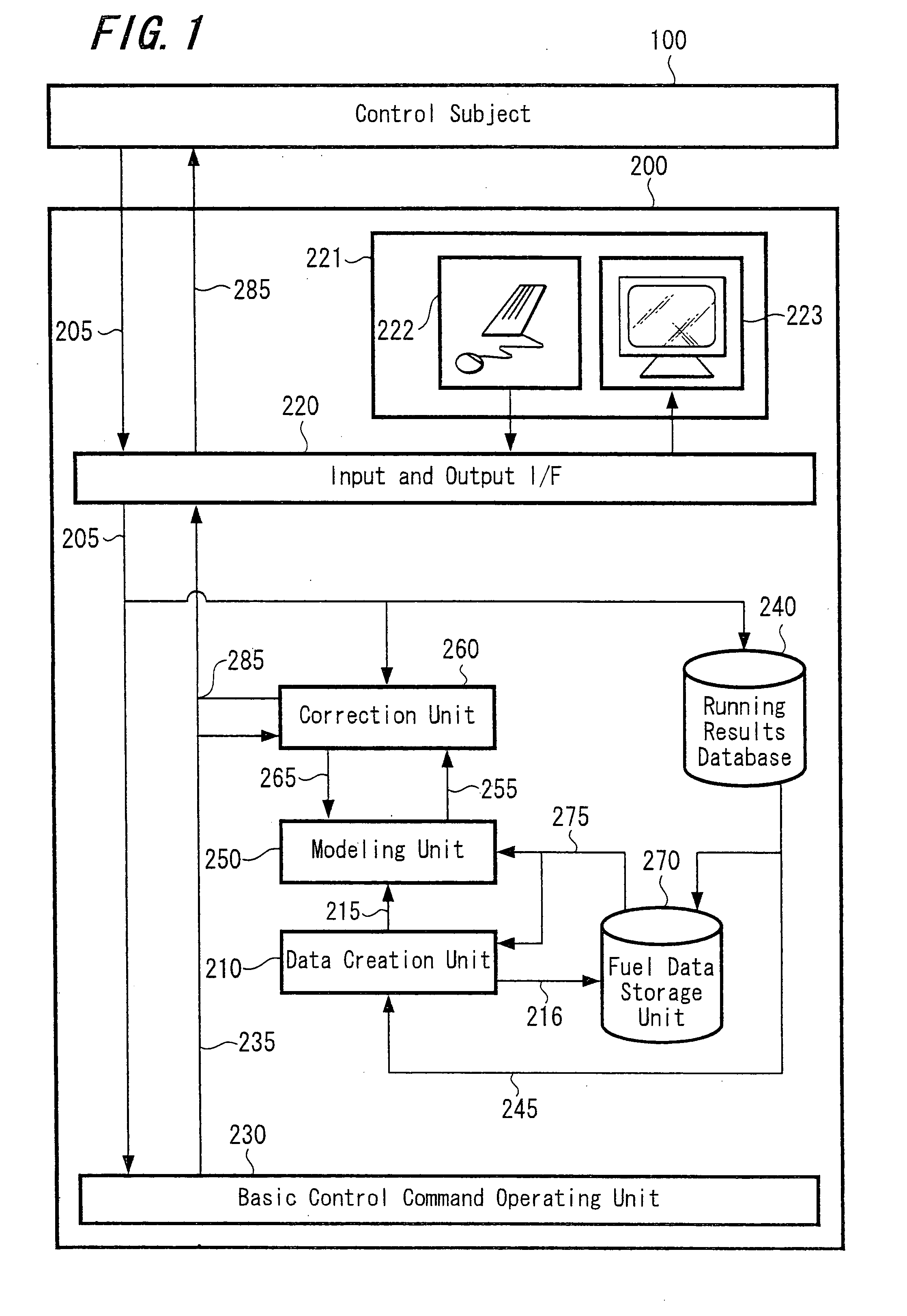

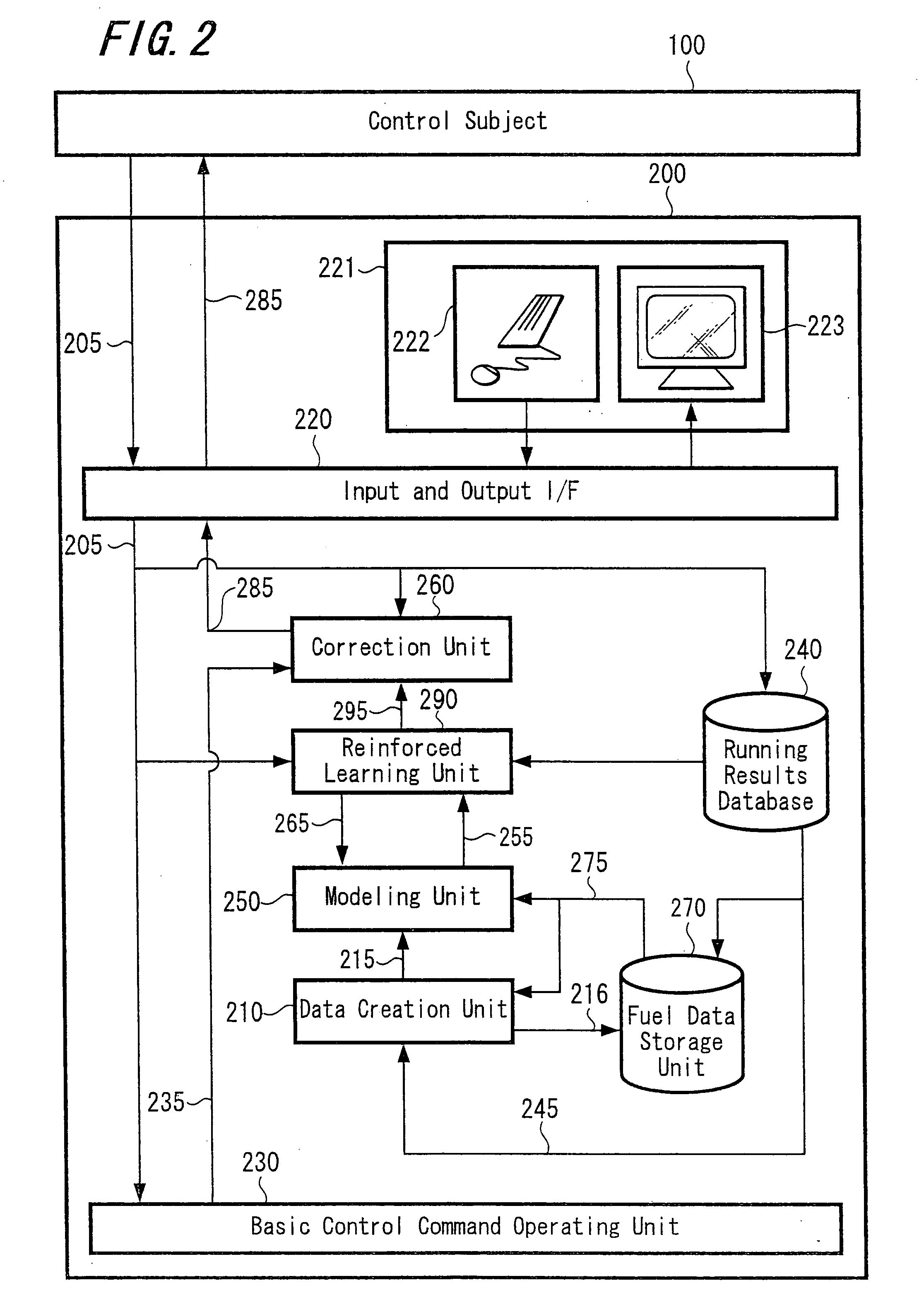

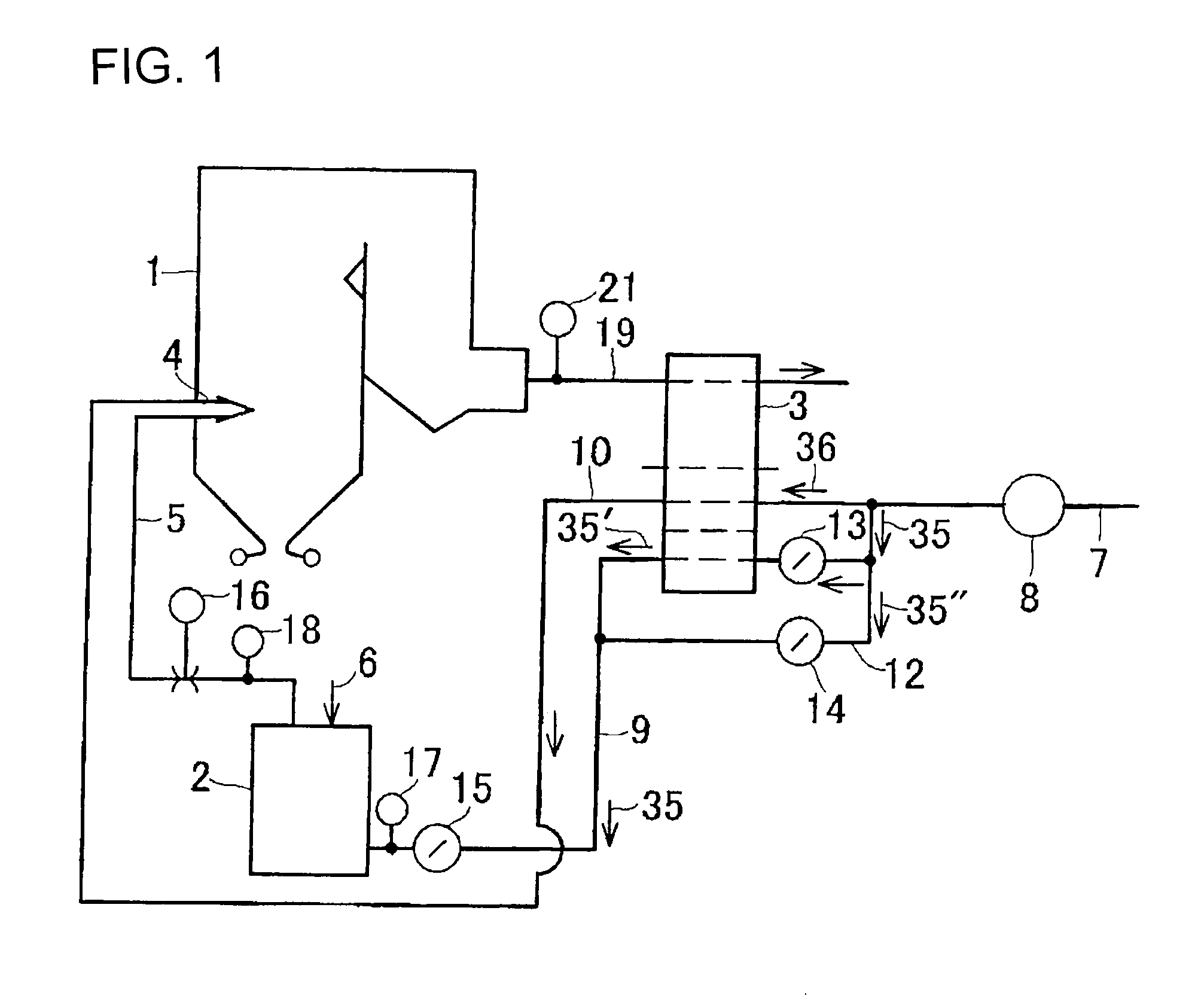

Control system for control subject having combustion unit and control system for plant having boiler

ActiveUS20070234781A1Reduce the amount requiredEasy to controlAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansControl subjectsCombustion

A control system includes a basic control command operating unit, a fuel data storage unit, a running results database for storing past running results values of a control subject, a data creating unit configured to calculate a distance between data of the past running results values and the data sets and determining data set in which a distance between data becomes minimum, a modeling unit configured to model a relationship between operation parameters of a combustion apparatus and components in combustion gas of the combustion apparatus by using the data set determined by the data creating unit and a correcting unit for calculating combustion apparatus operation parameters with which components having a better condition than that of the components in a current gas are provided by using a model of the modeling unit and correcting operation command values of the basic control command operating unit by calculated operation parameters.

Owner:HITACHI LTD

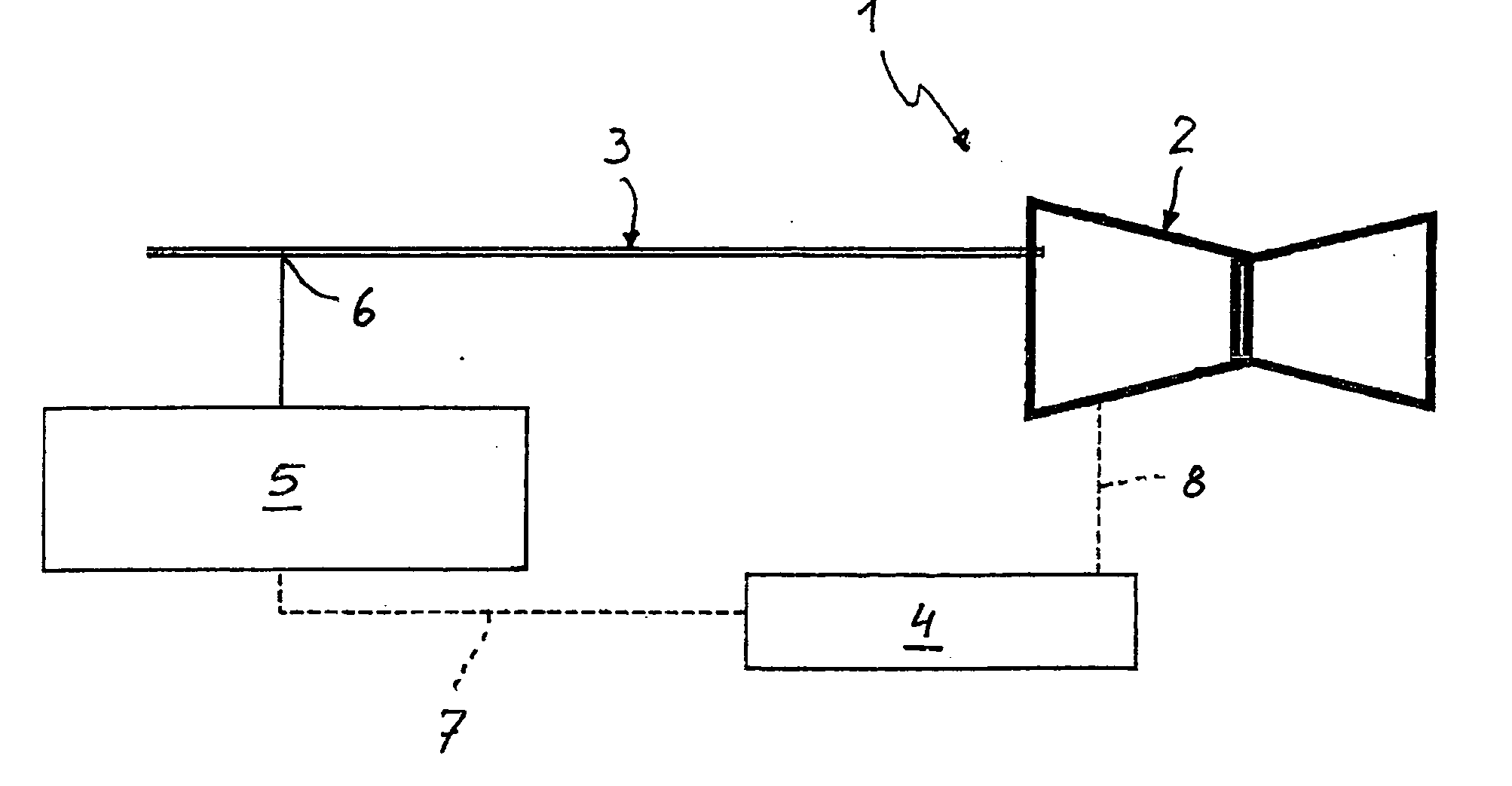

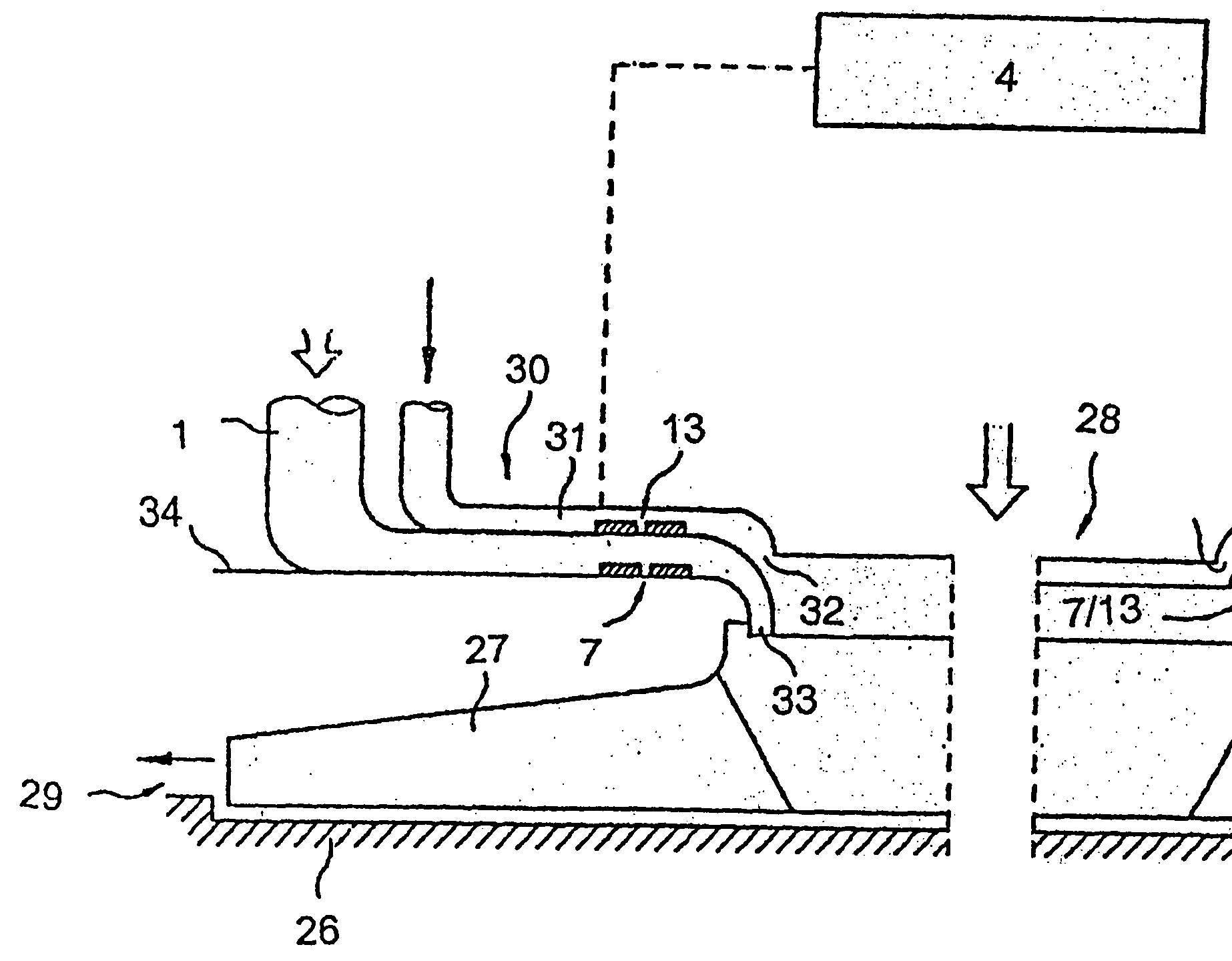

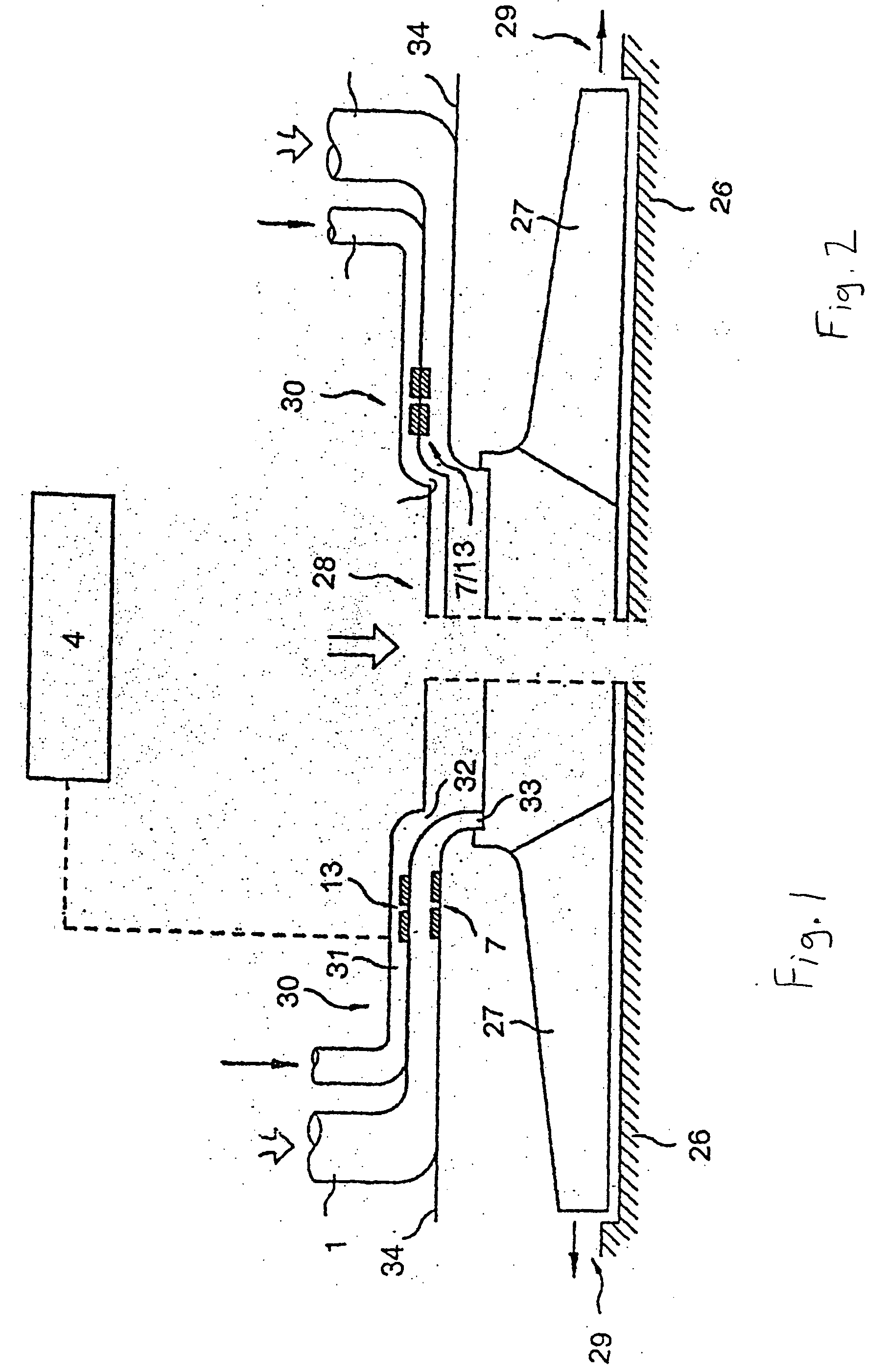

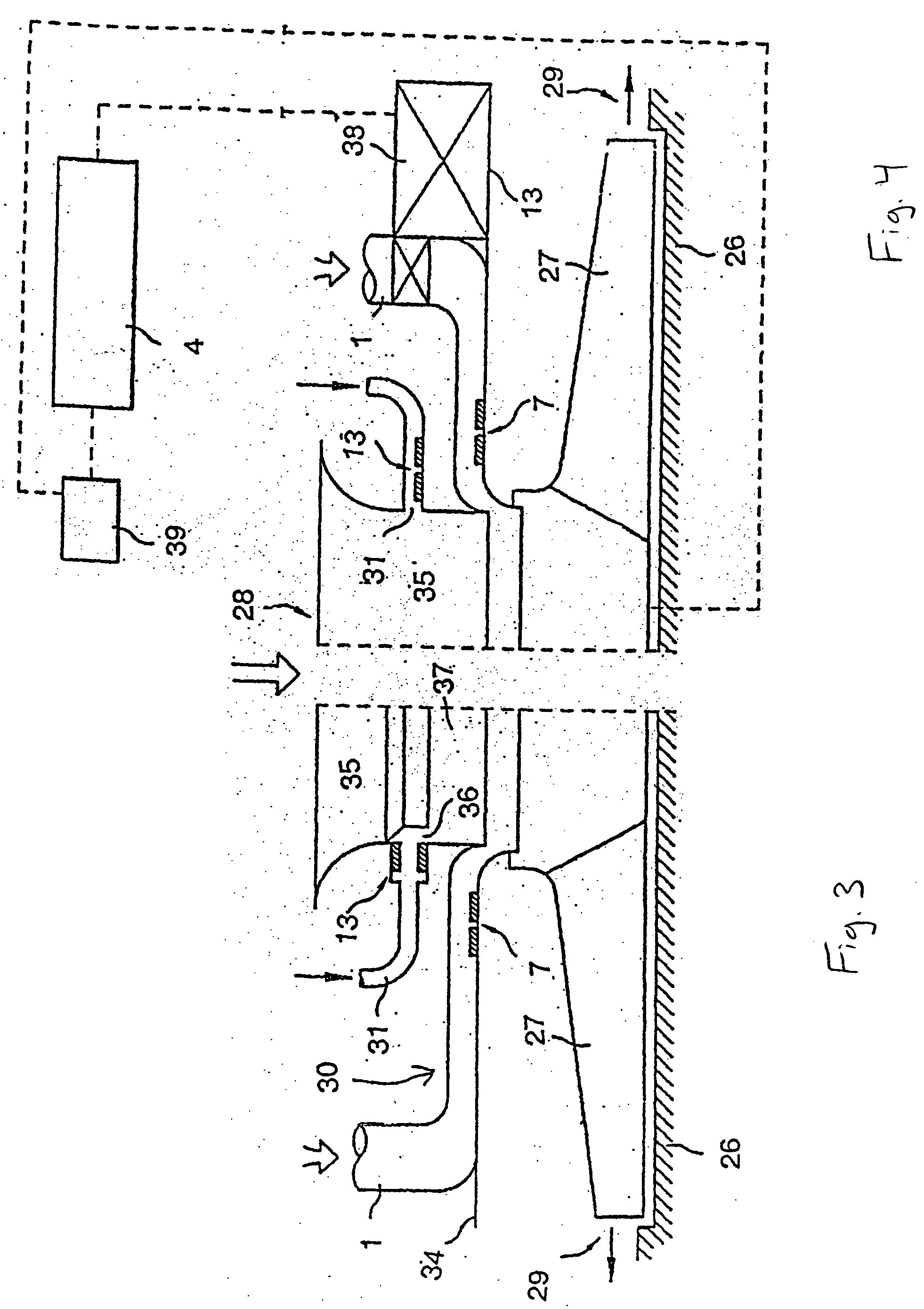

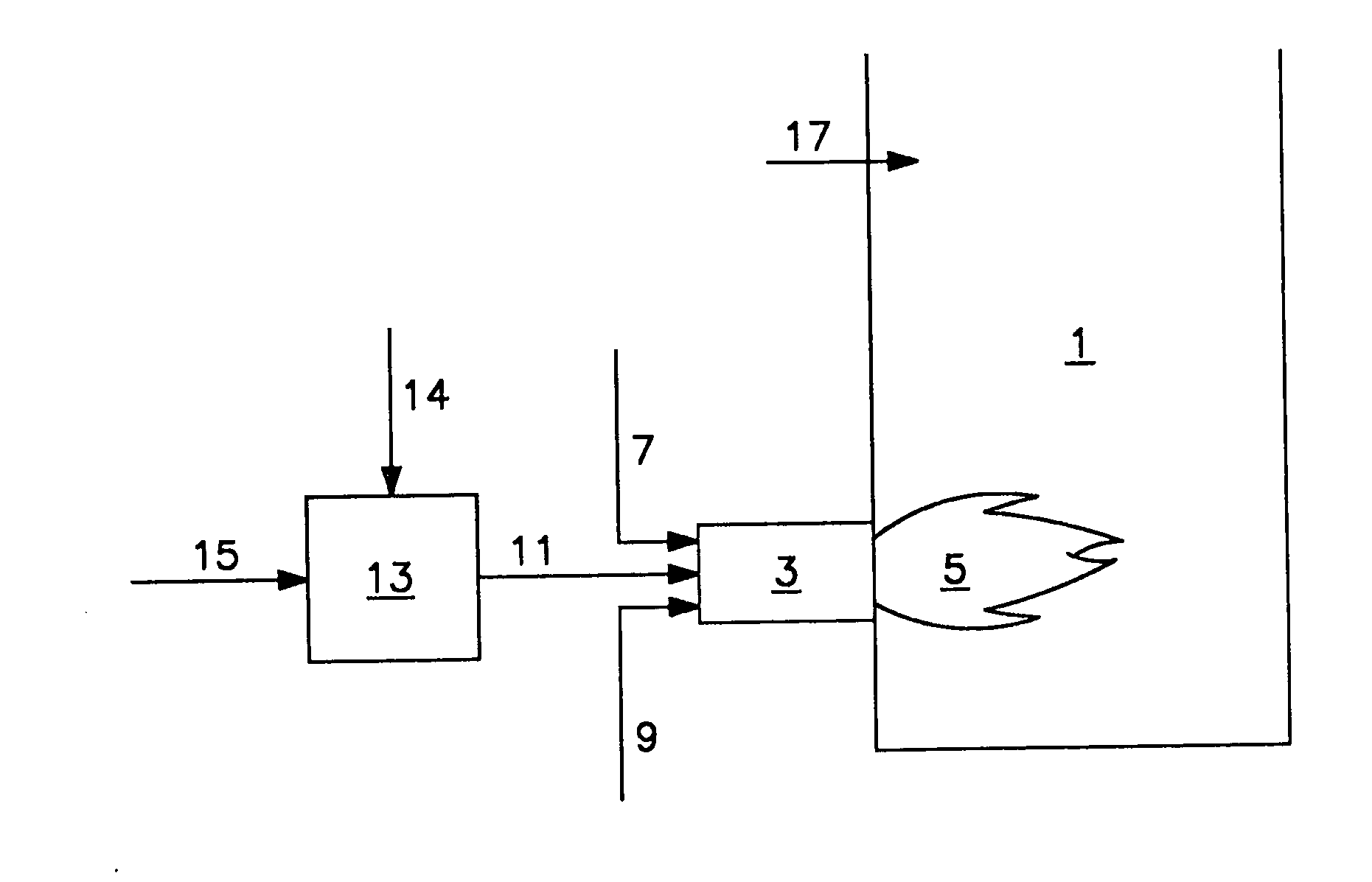

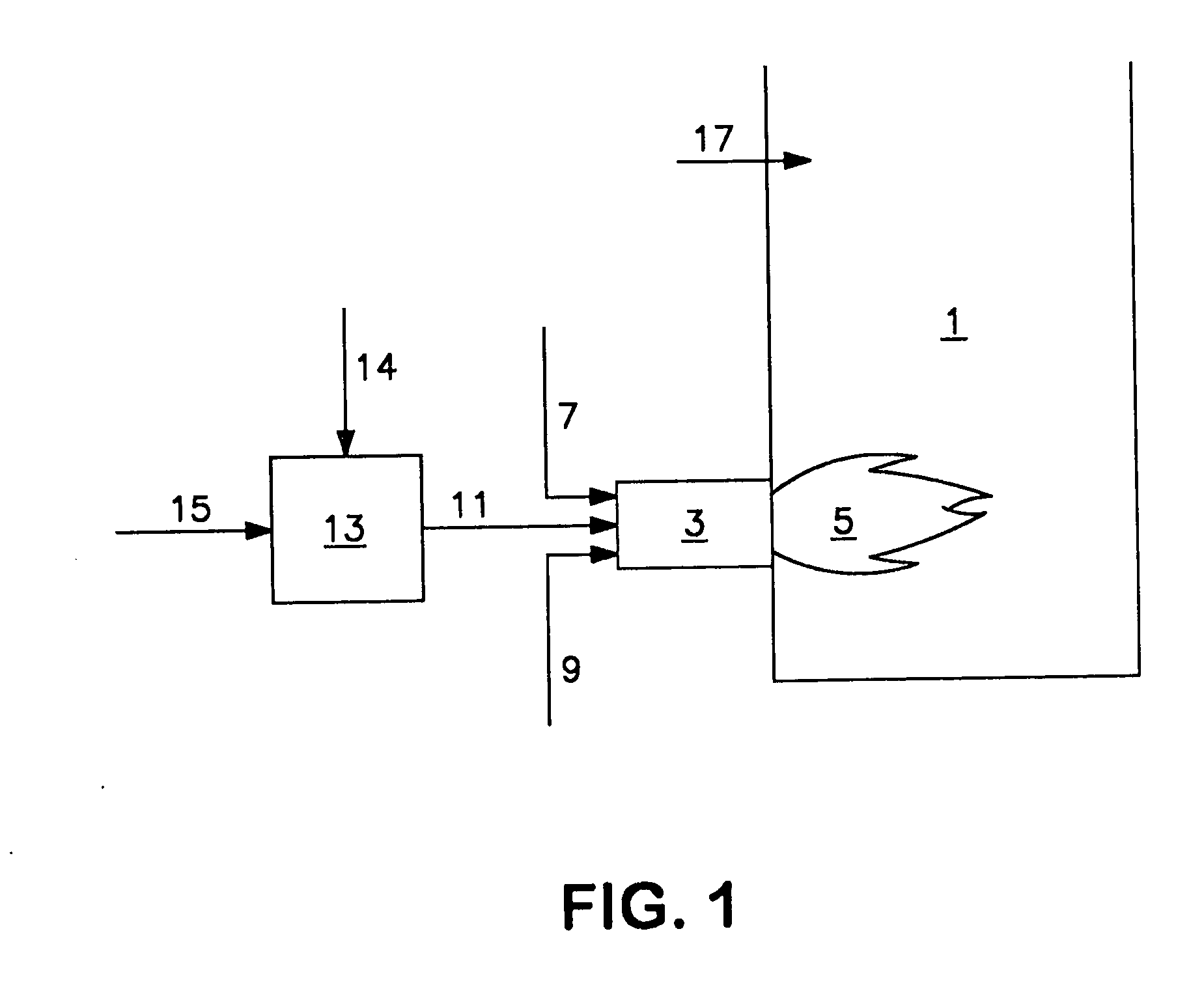

Blower for combustion air

InactiveUS7223094B2Work lessContinuous suctionFuel supply regulationAir supply regulationImpellerCombustion

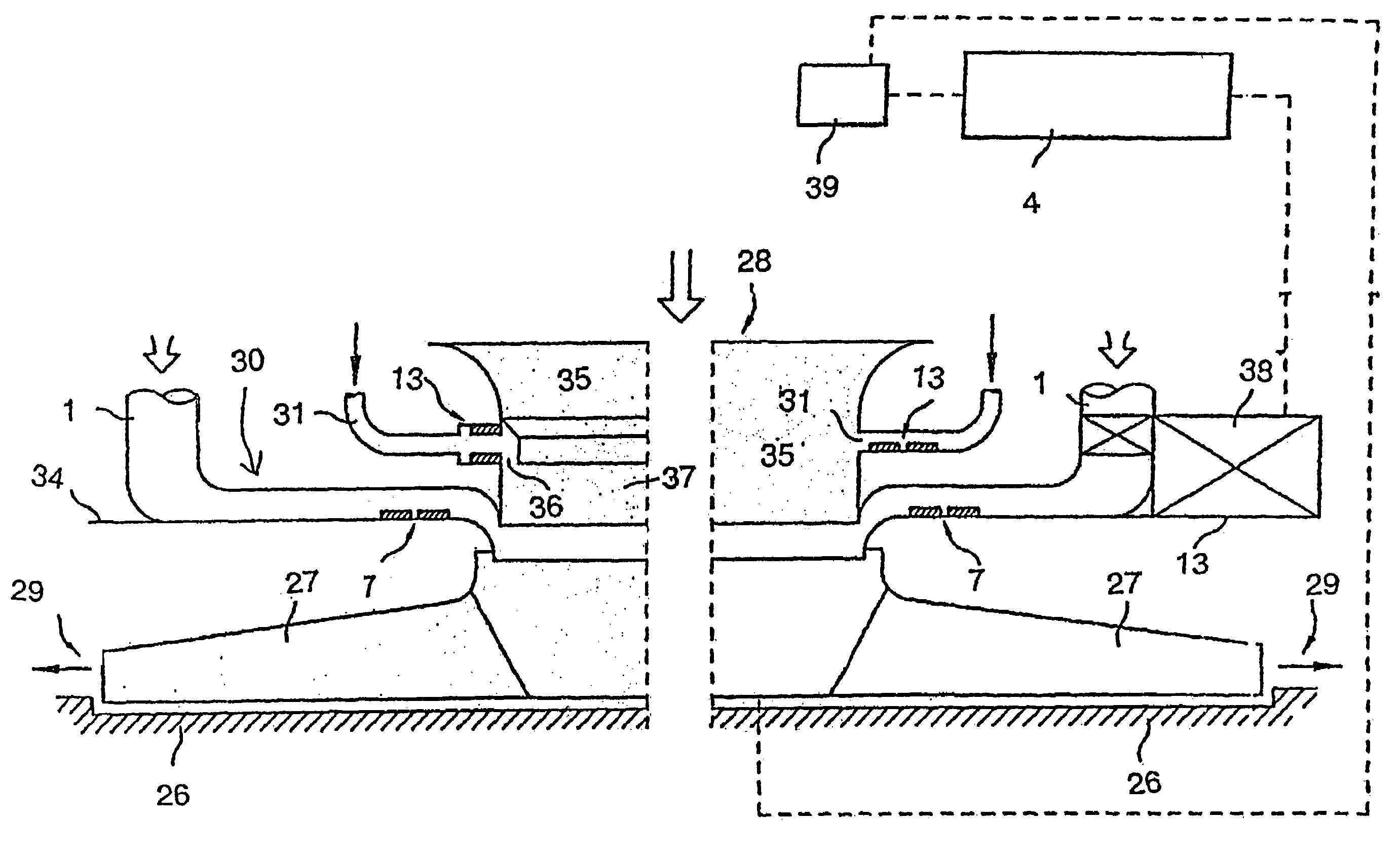

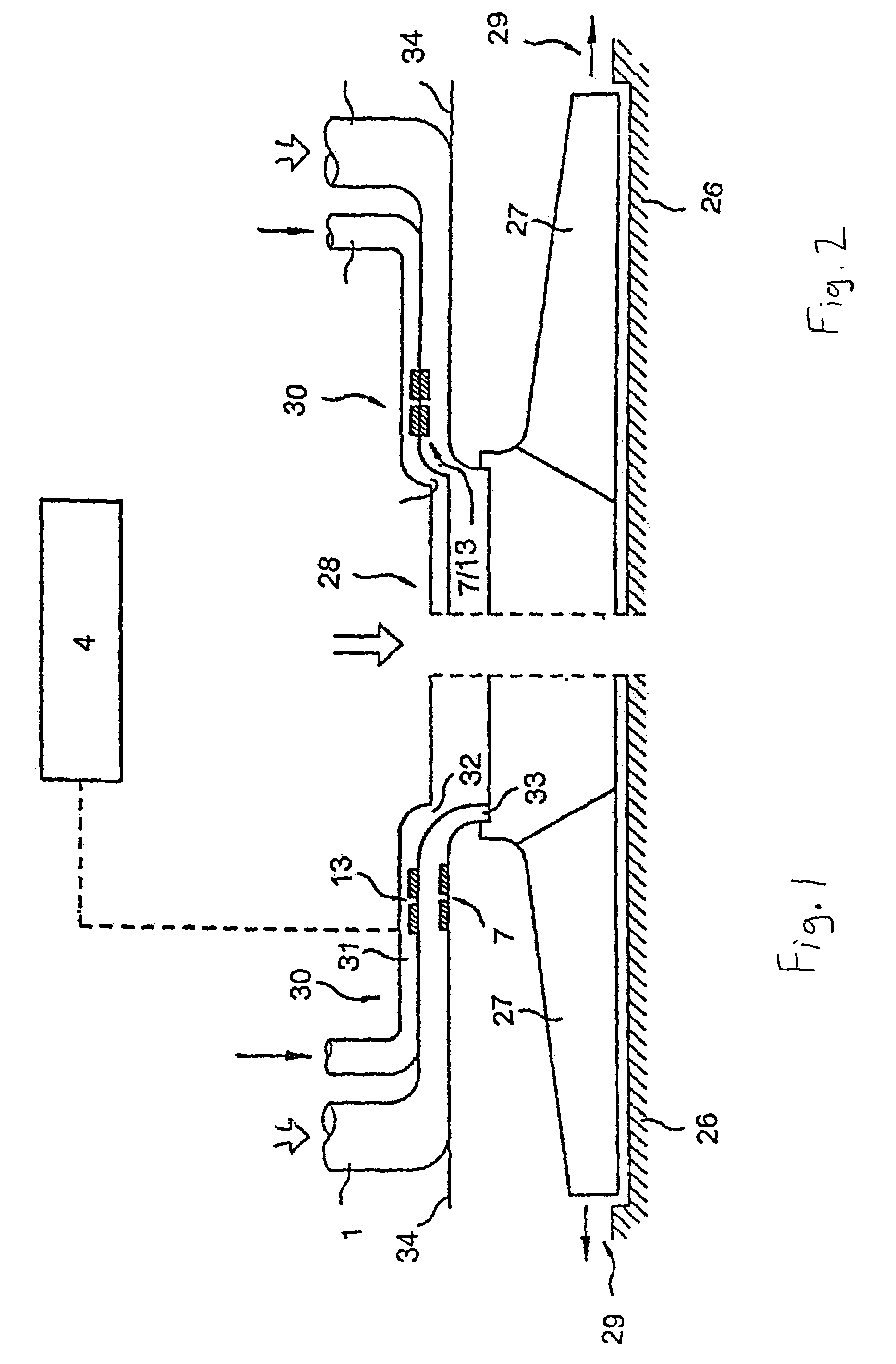

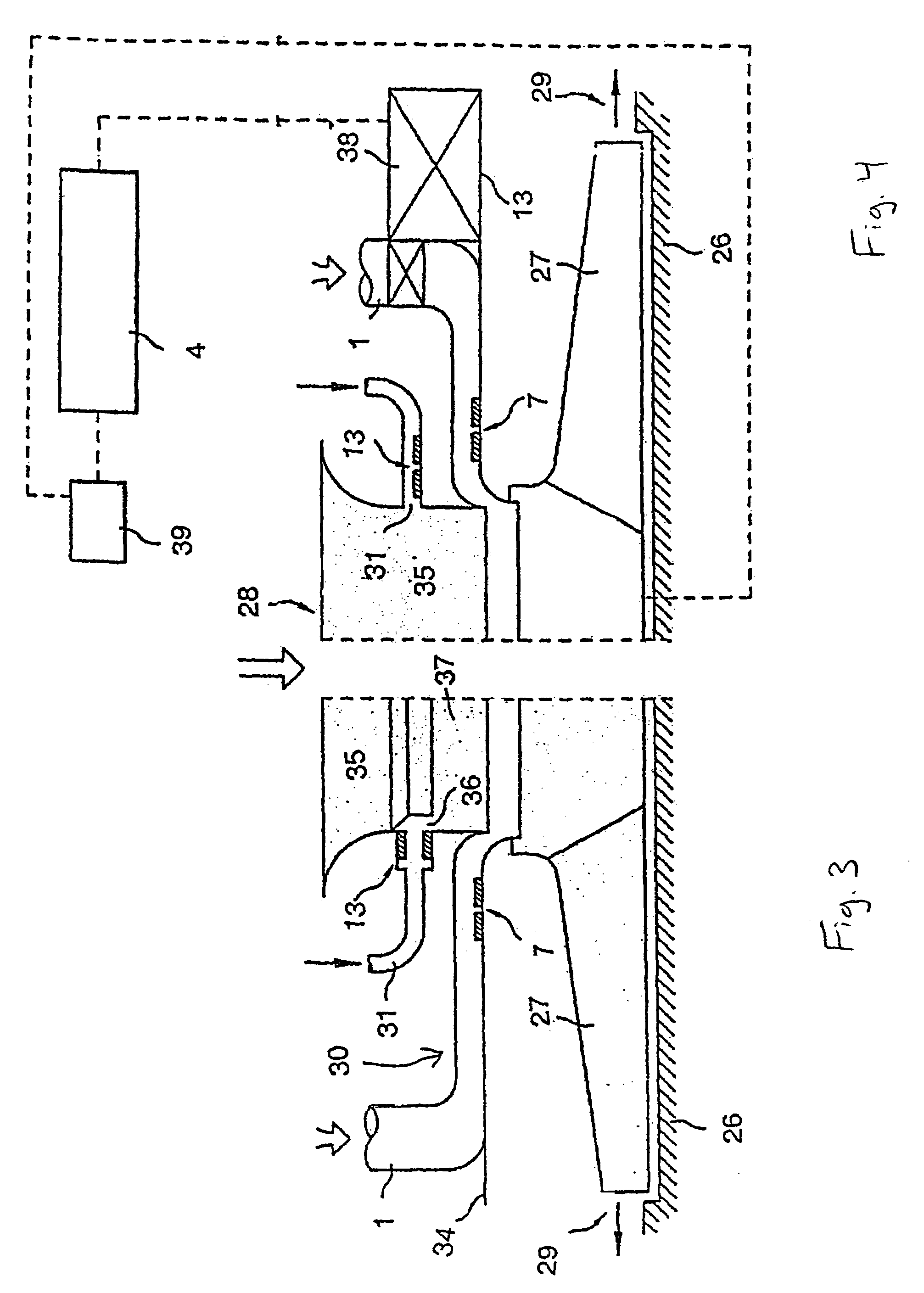

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

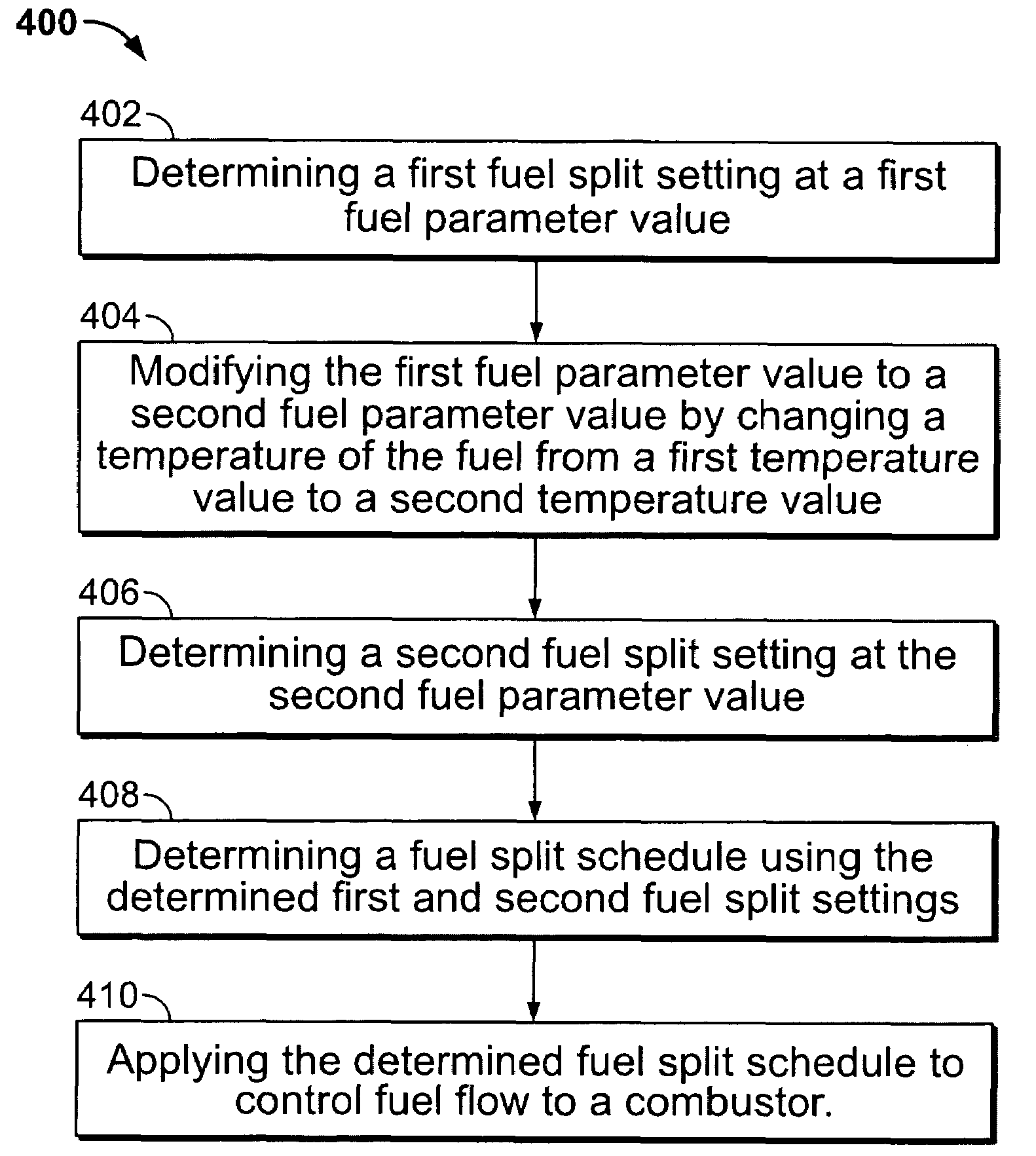

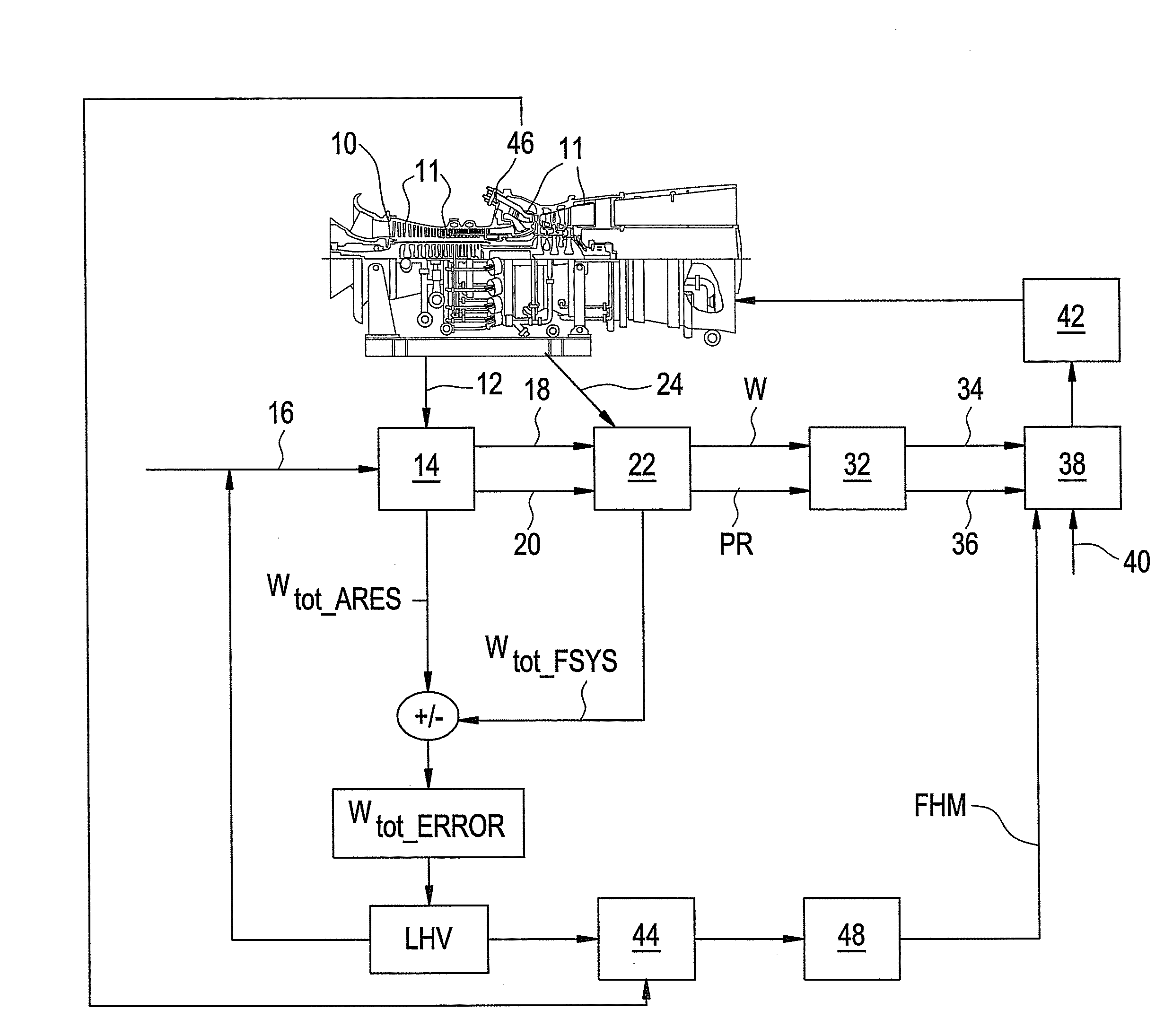

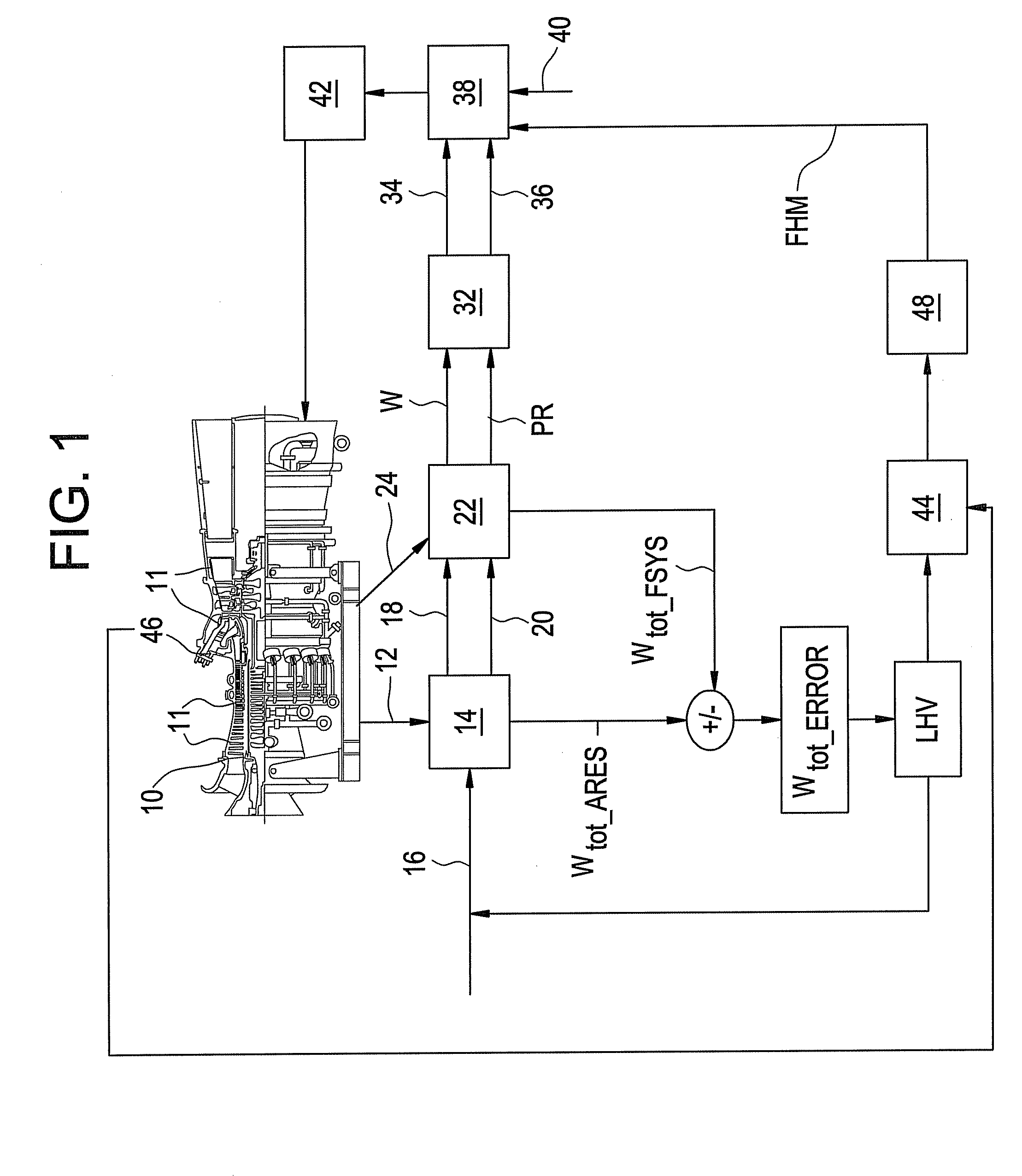

Method for operating gas turbine engine systems

ActiveUS7565805B2Improve efficiencyContinuous combustion chamberTurbine/propulsion engine ignitionCombustorAutomatic control

Methods and systems for operating a gas turbine engine system include an electrical generator configured to provide electrical energy to a load, a gas turbine engine including at least one combustor that includes a plurality of fuel injection points configured to inject a fuel into the combustor at a plurality of different locations wherein the combustor configured to combust the fuel and the gas turbine engine is rotatably coupled to the generator through a shaft. The gas turbine engine system includes a control system including a plurality of sensors positioned about the gas turbine engine system and configured to measure at least one parameter associated with the sensor, a processor programmed to receive a signal indicative of a heating value of the fuel, and automatically control a fuel split between the fuel injection points on the combustor using the determined heating value.

Owner:GE INFRASTRUCTURE TECH INT LLC

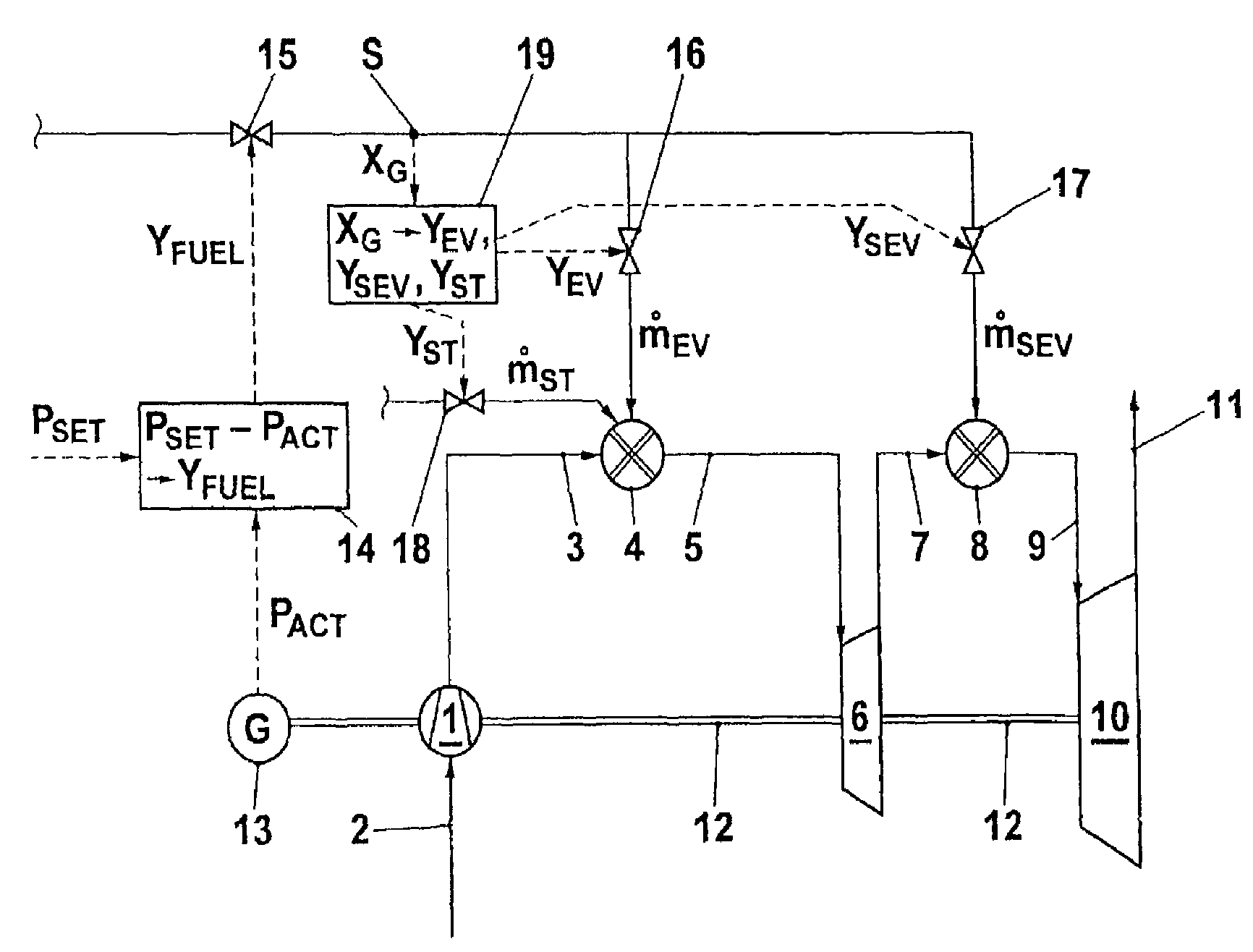

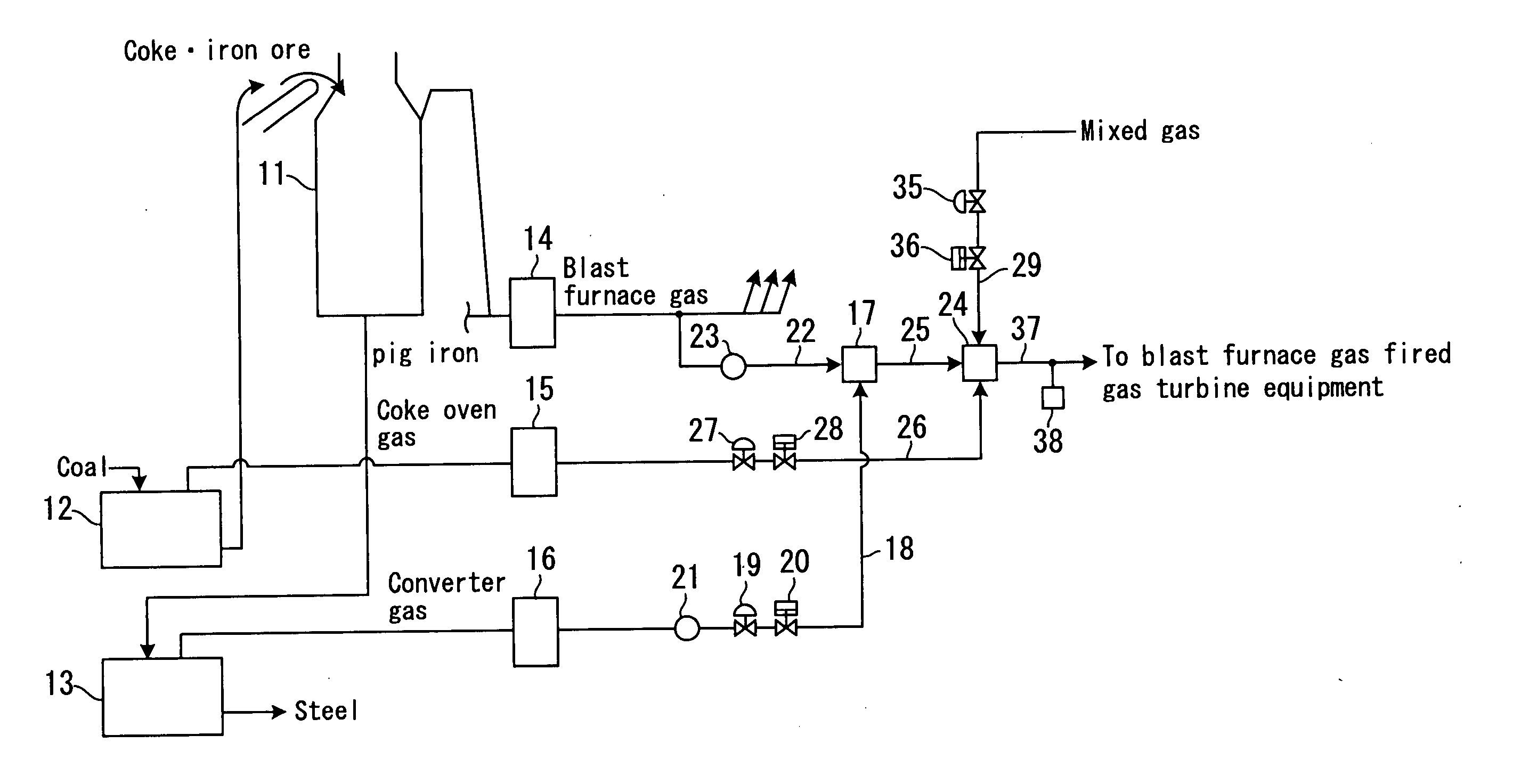

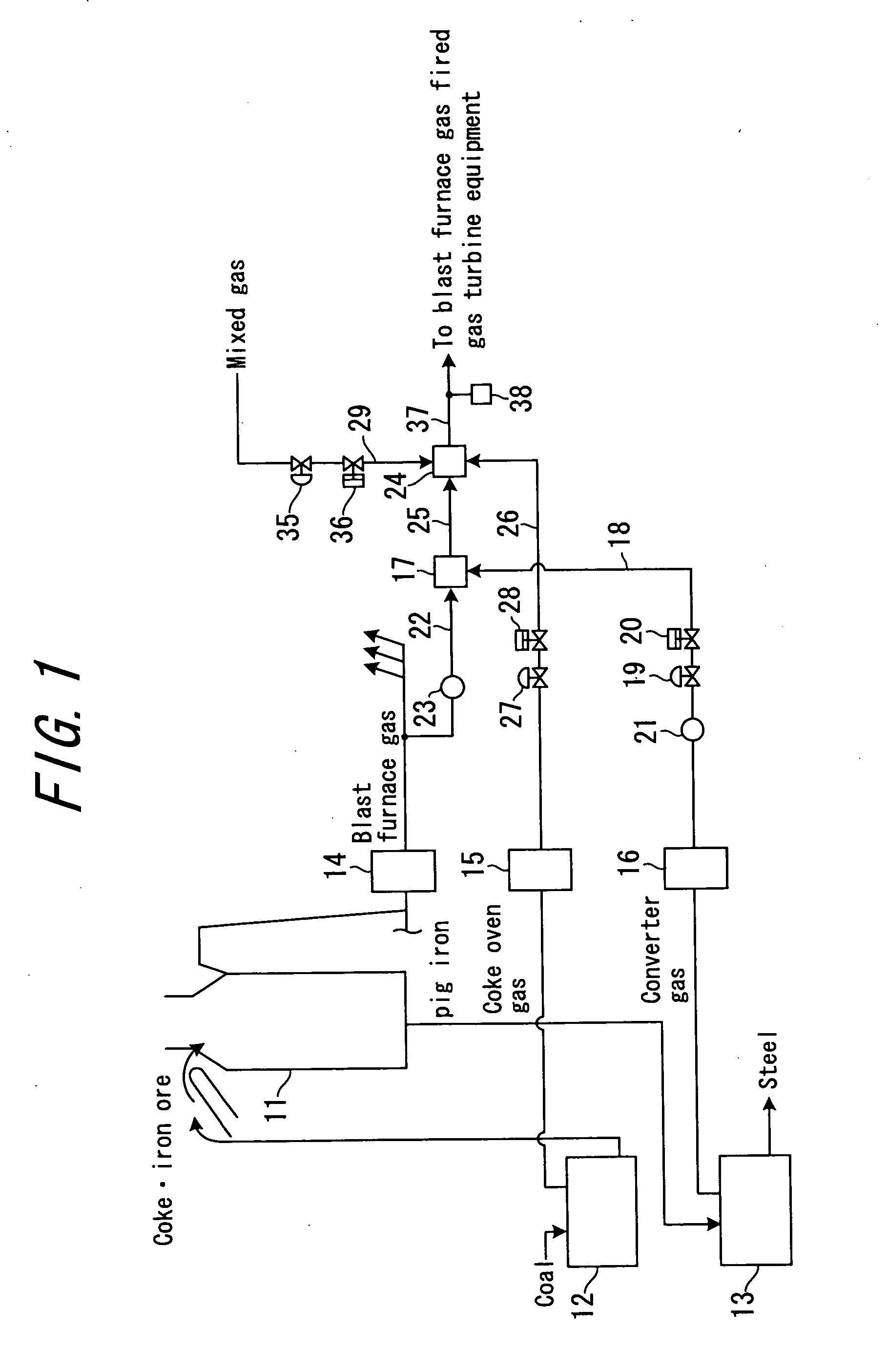

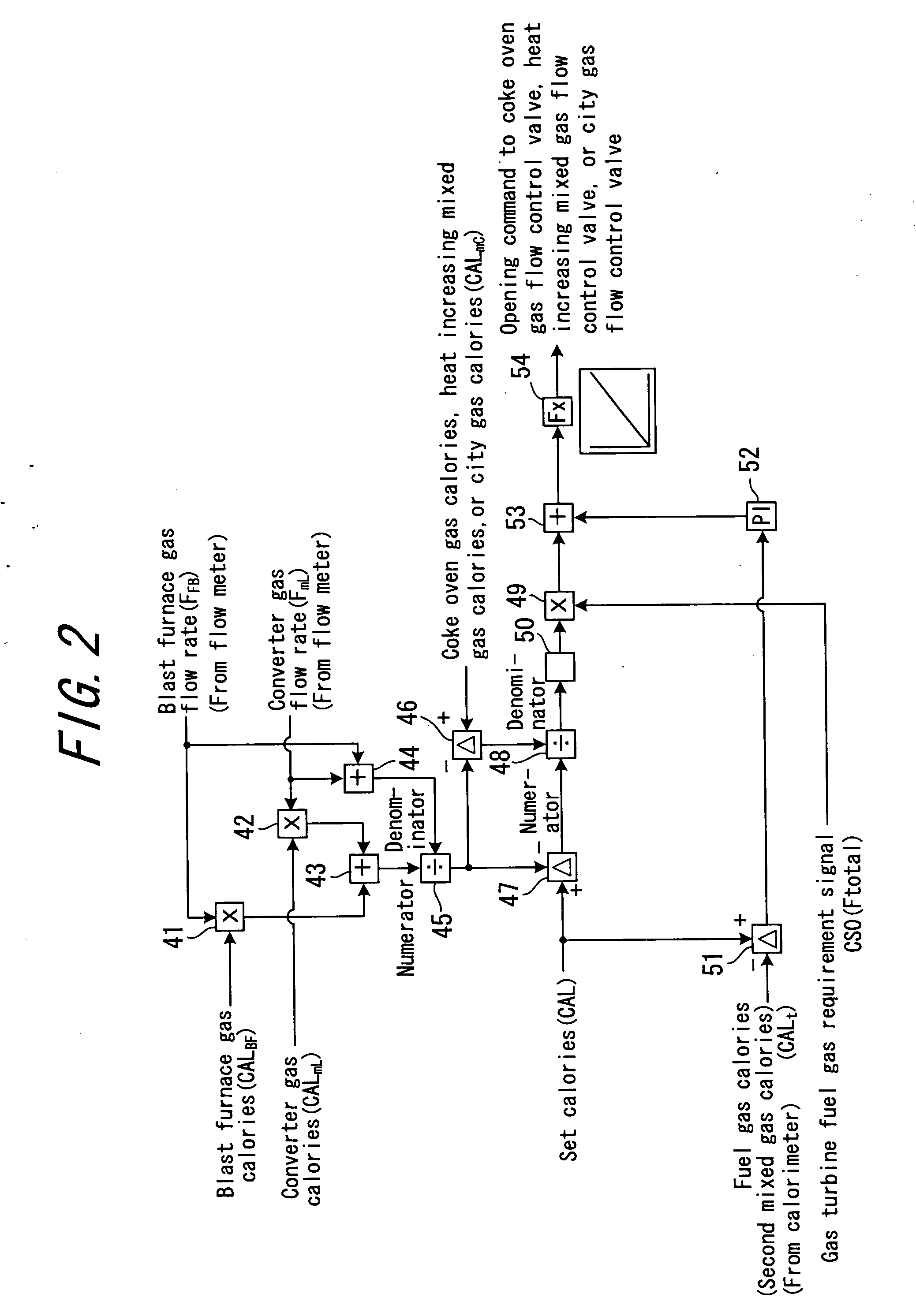

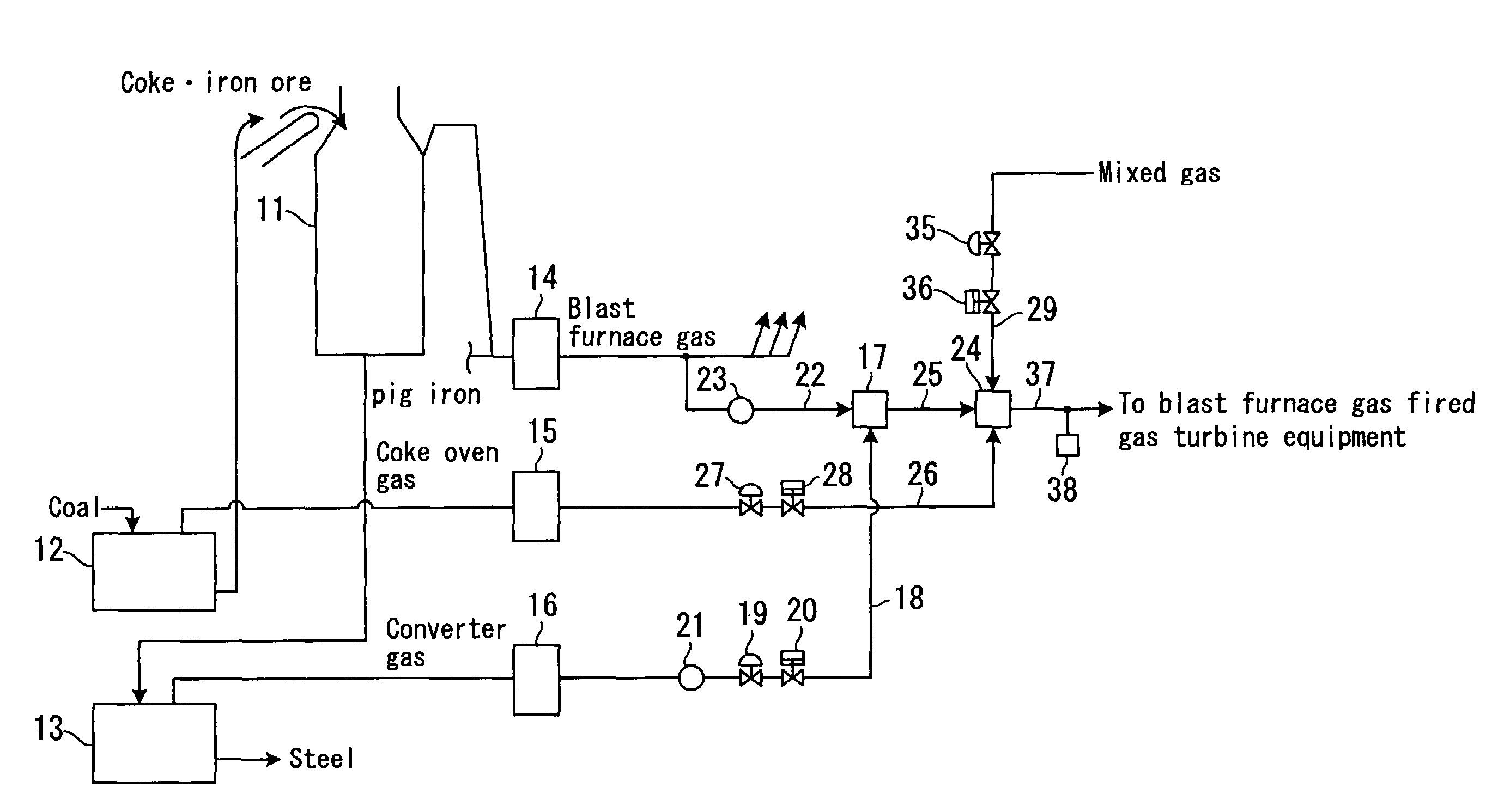

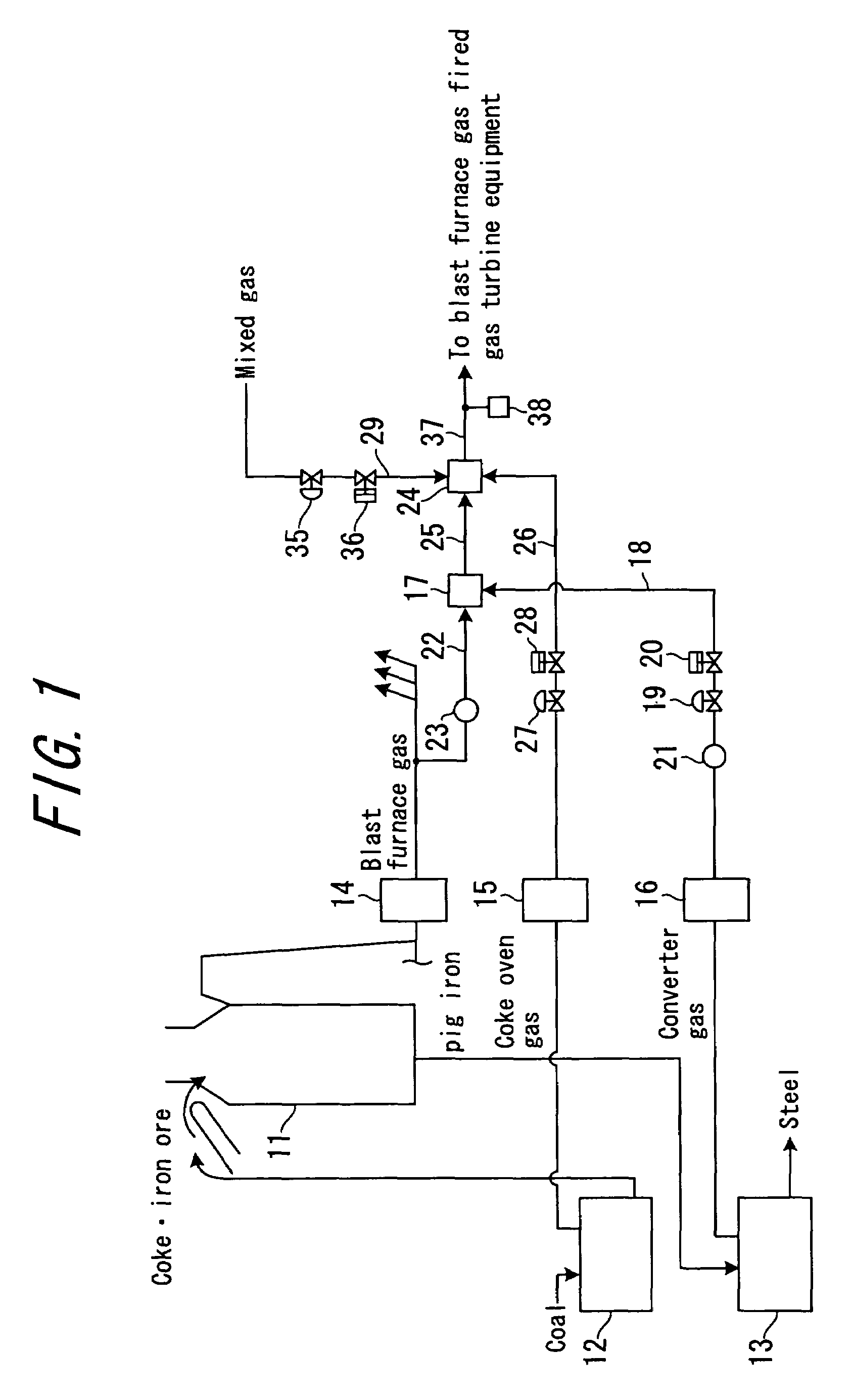

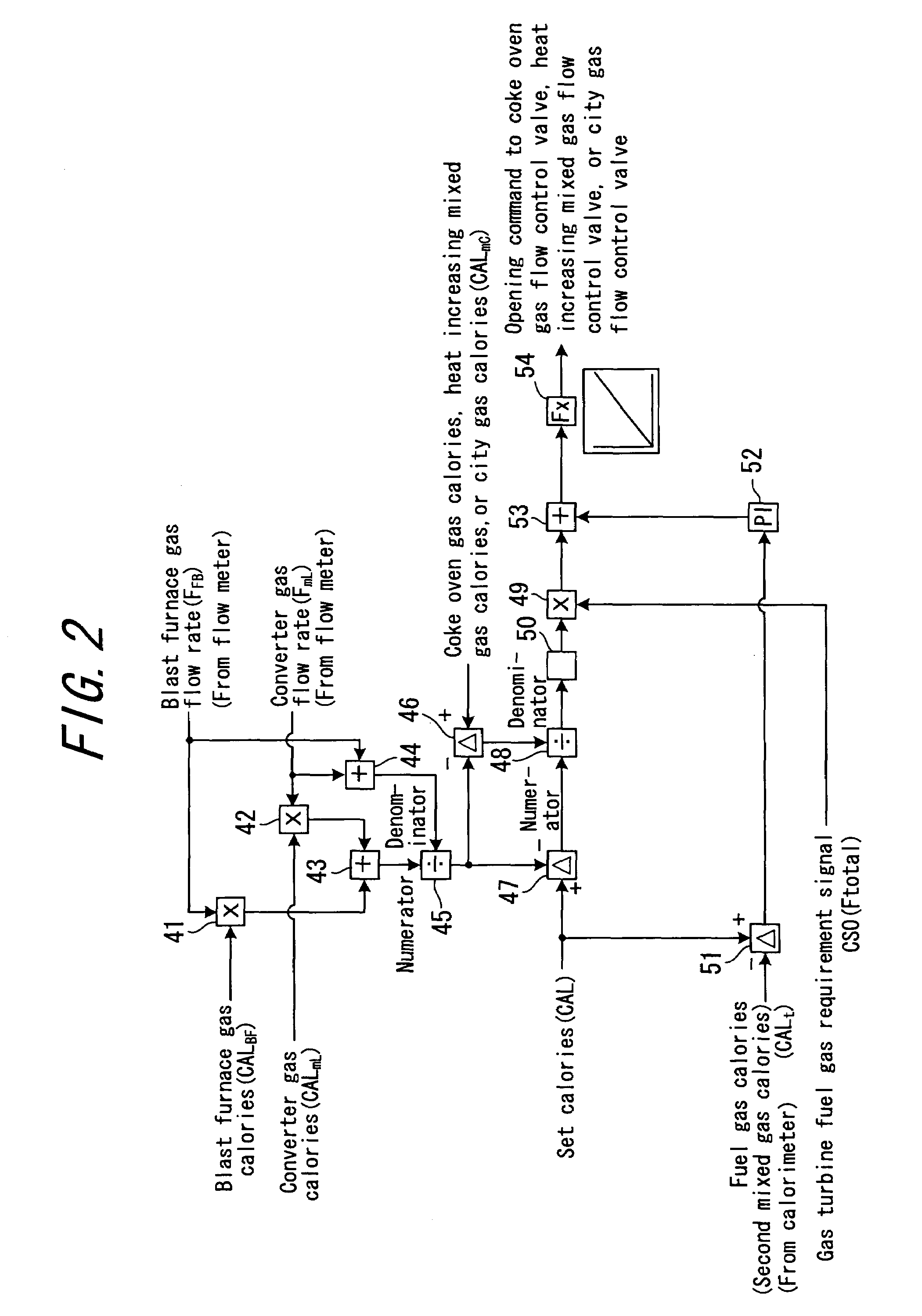

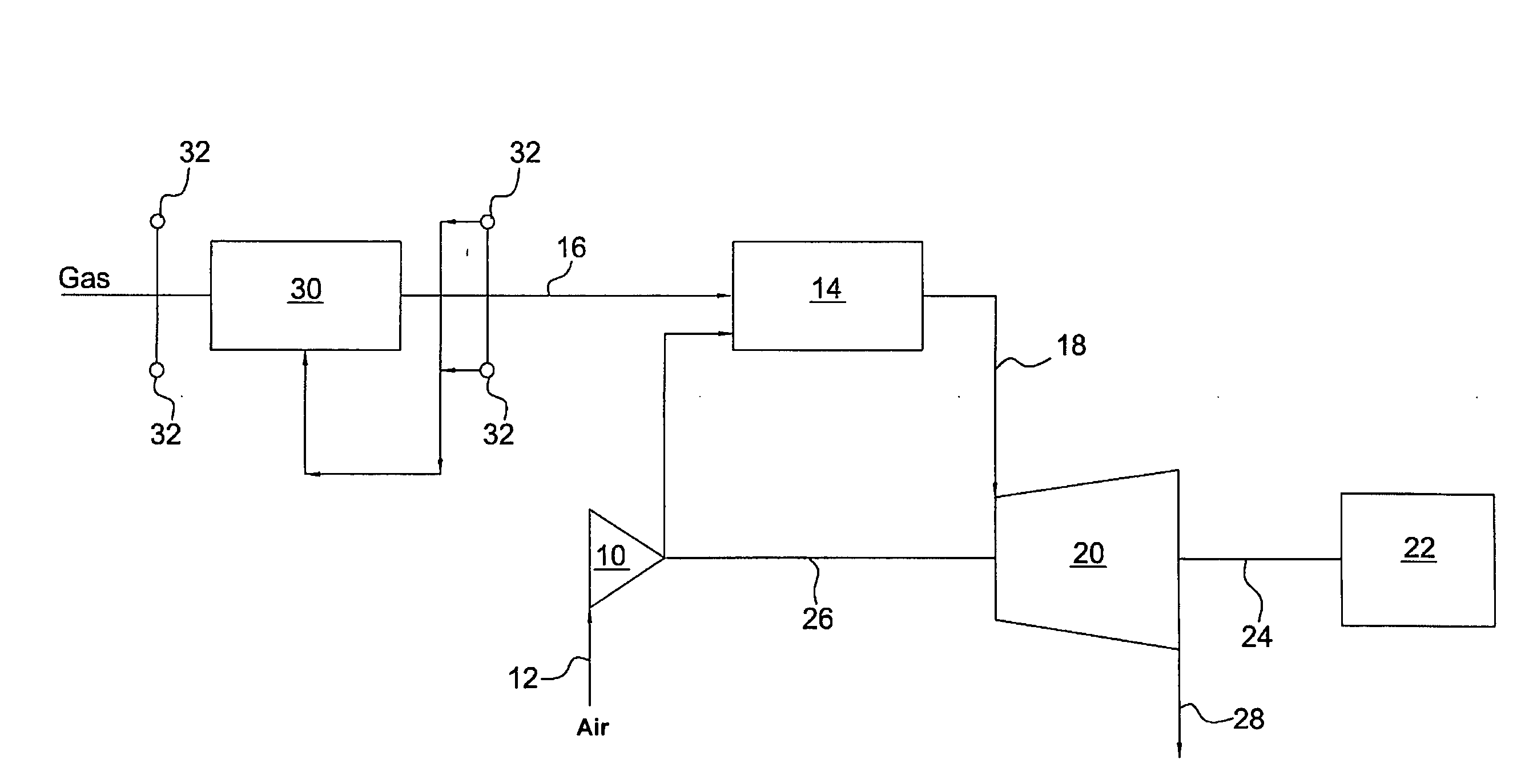

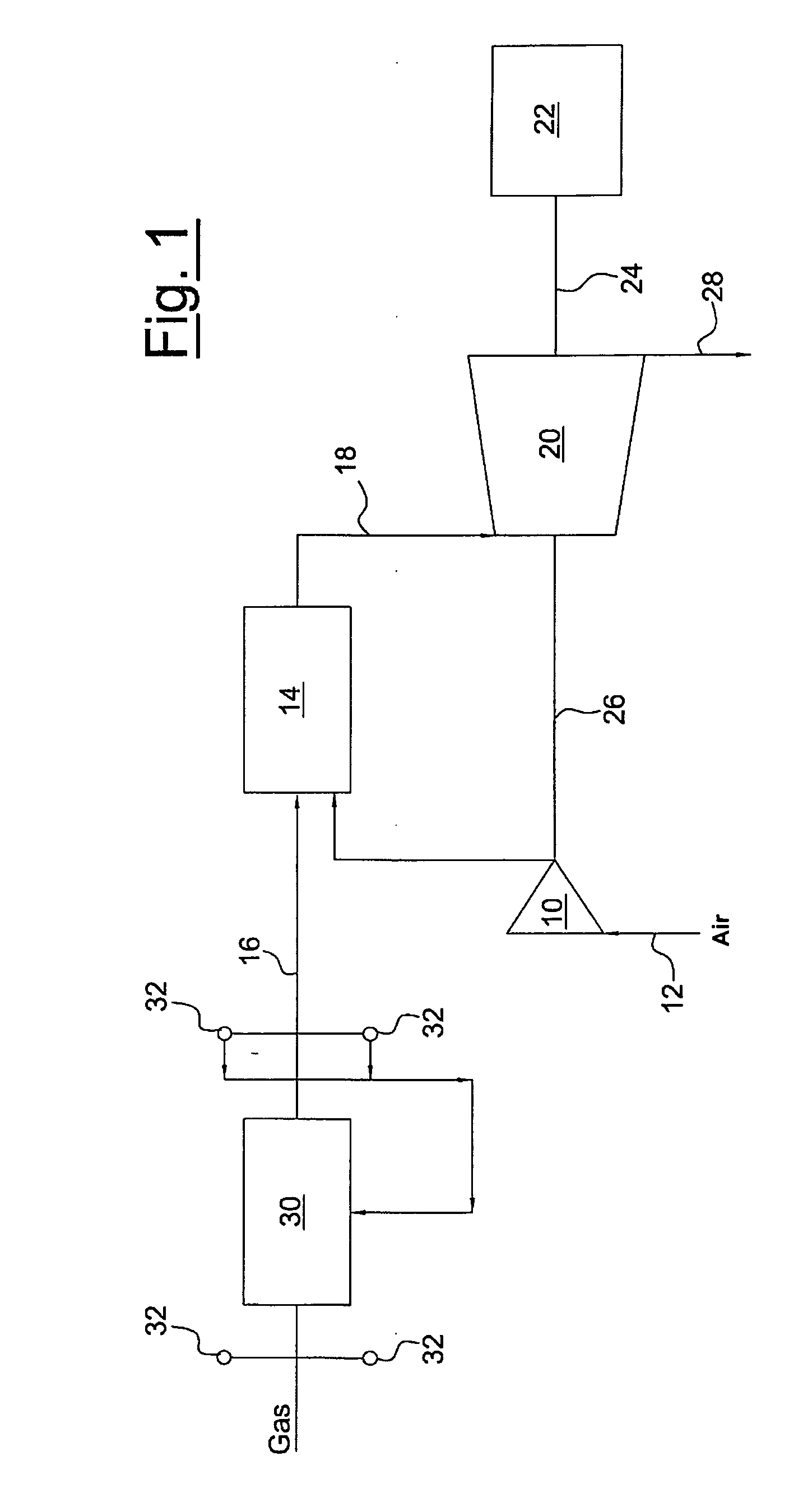

Fuel gas calorie control method and device

ActiveUS20060234171A1Excessive mixingEasy to controlBurnersGas modification by gas mixingMixed flowEngineering

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

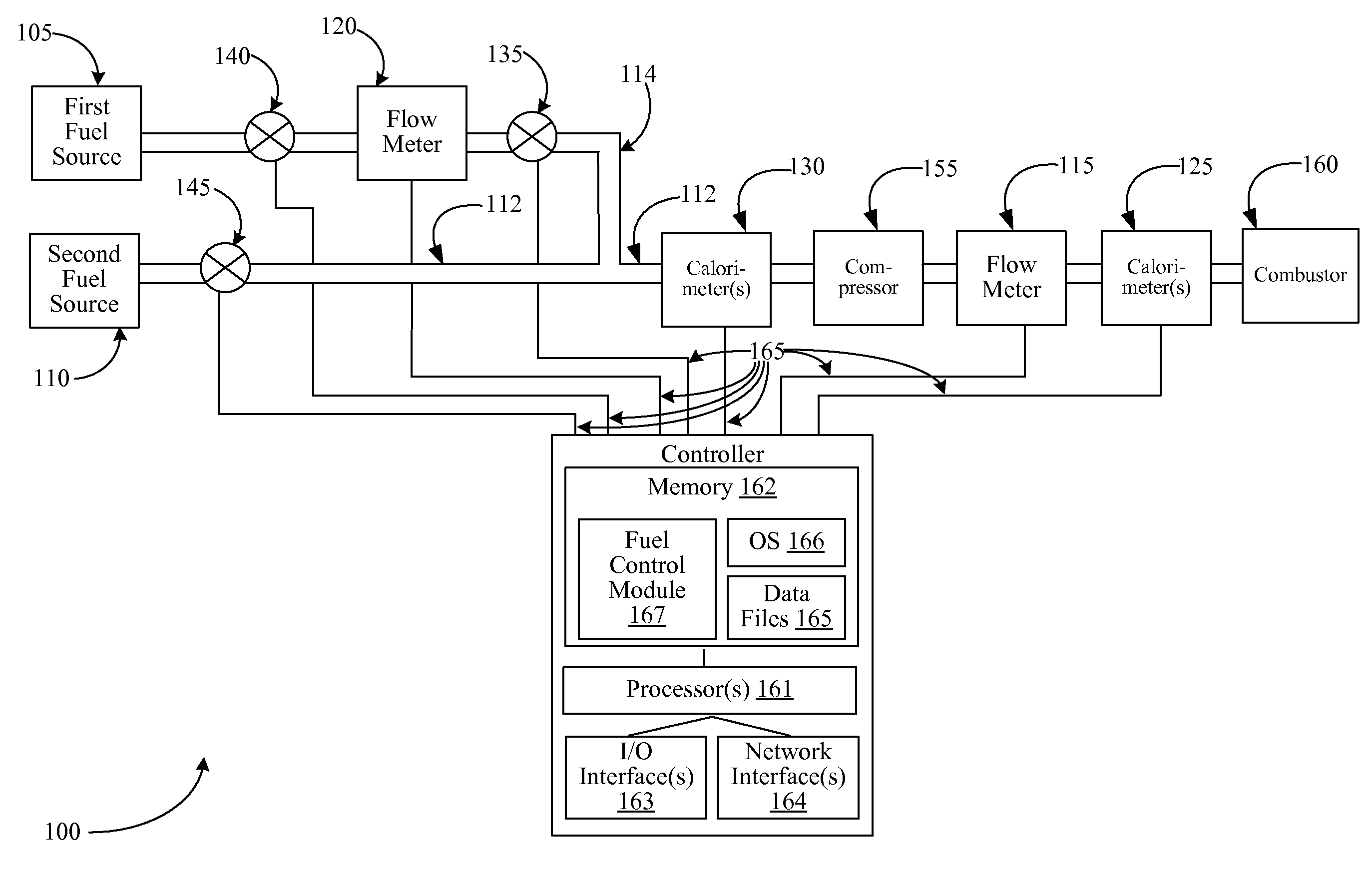

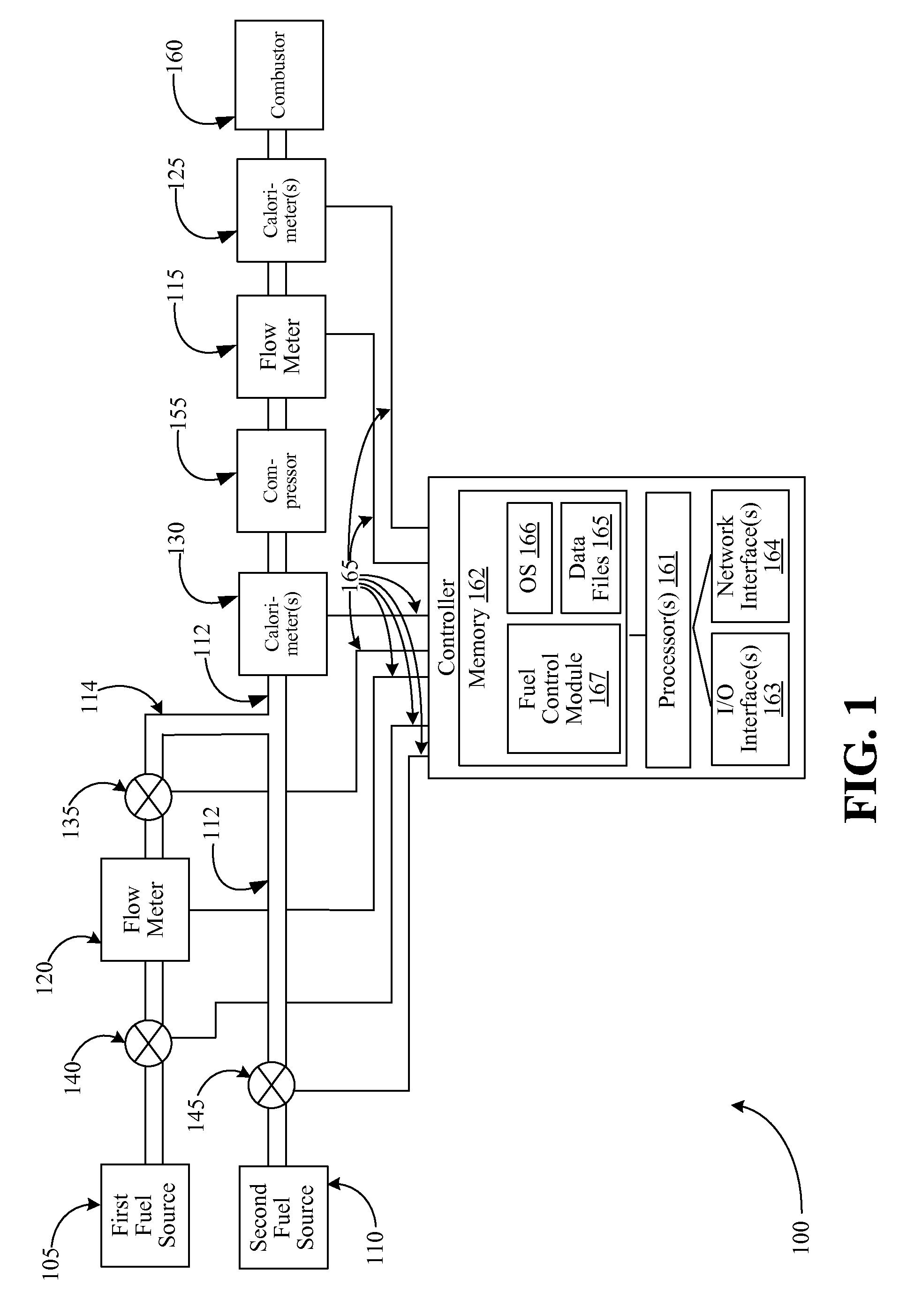

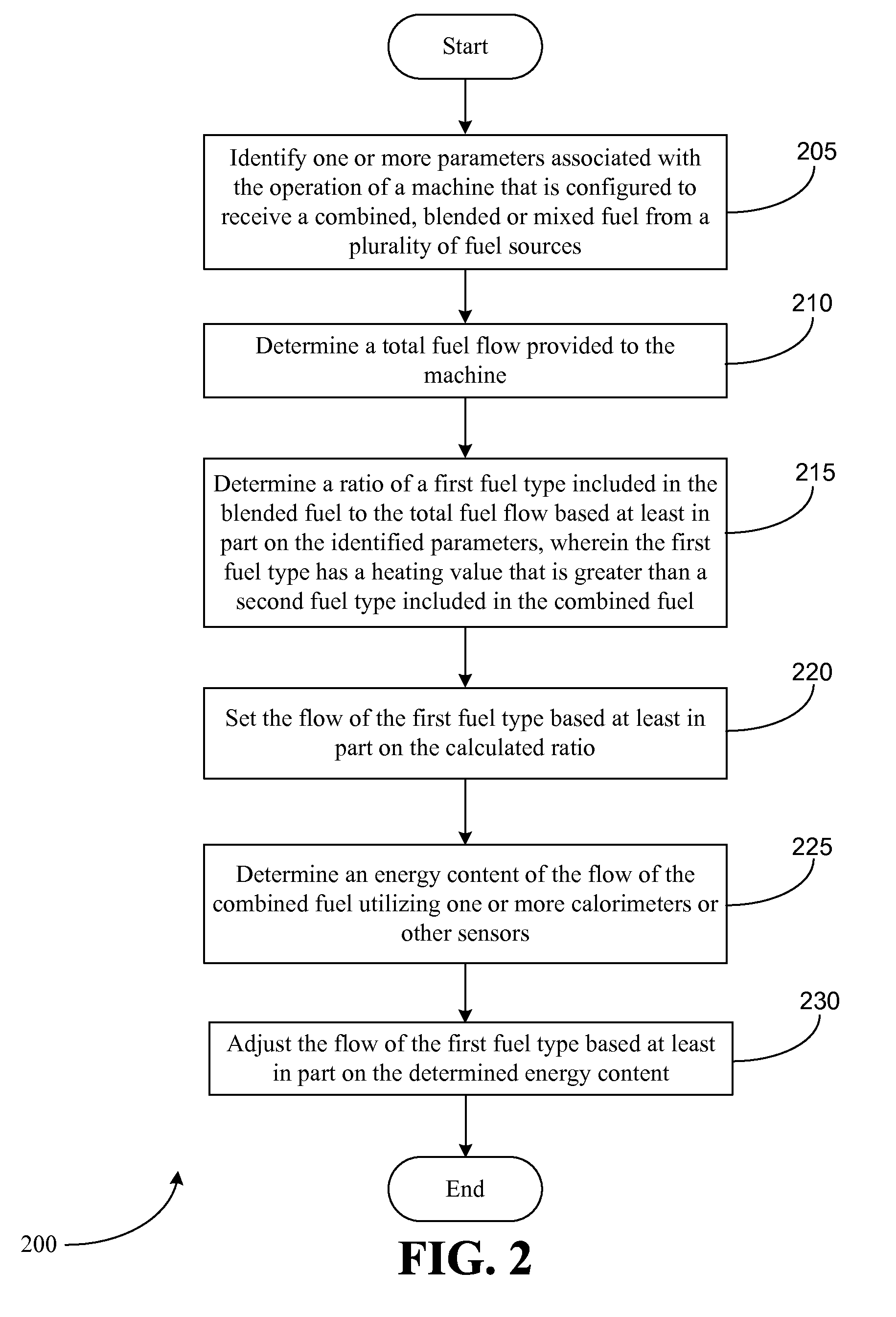

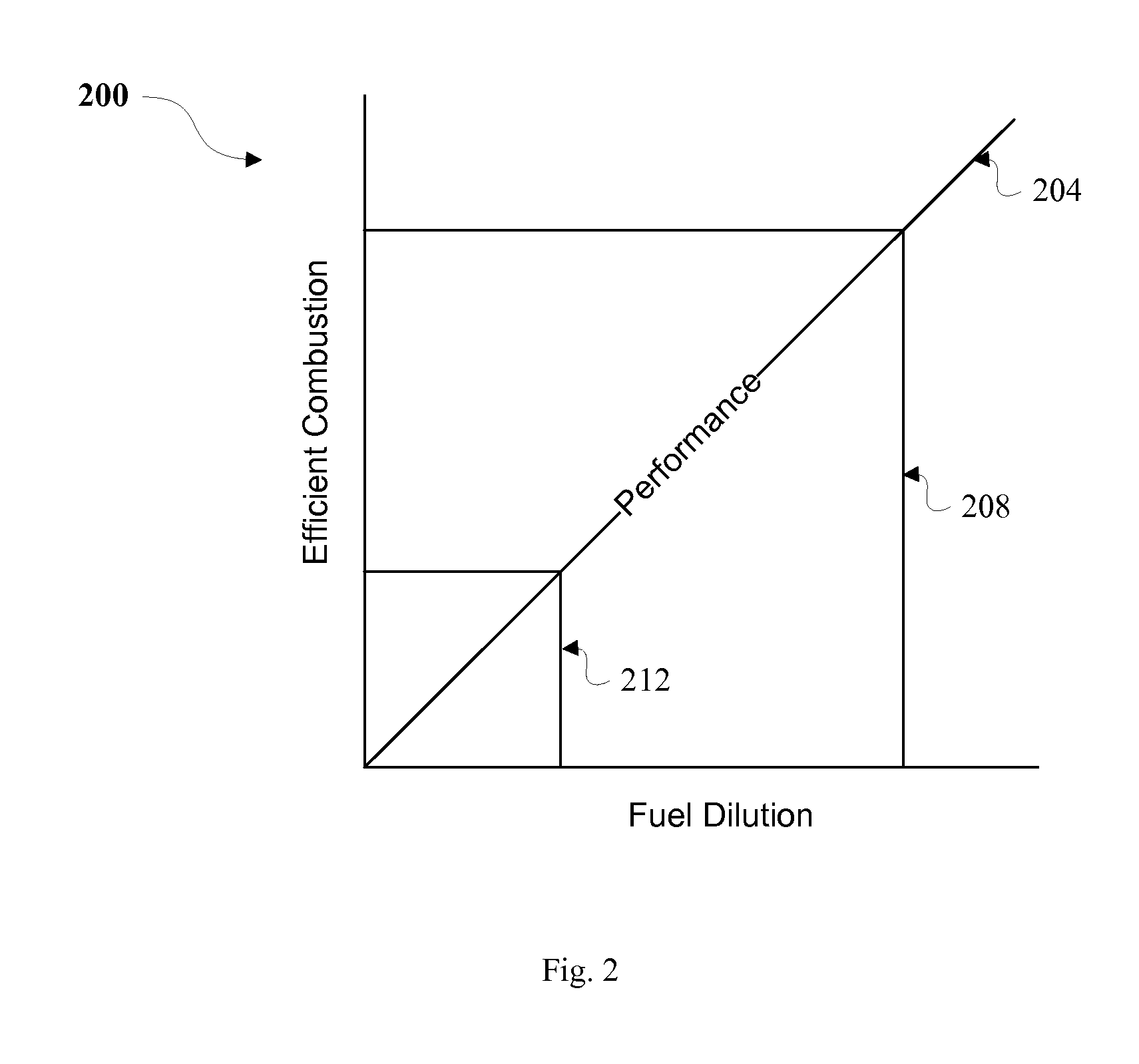

Systems and methods for controlling fuel mixing

InactiveUS20110126545A1Fuel supply regulationContinuous combustion chamberFuel typeAutomotive engineering

Systems and methods for controlling fuel mixing are provided. One or more parameters associated with the operation of a machine configured to receive a combined fuel may be identified. A fuel flow of the combined fuel that is provided to the machine may be determined. Based at least in part on the identified parameters, a ratio of a first fuel type included in the combined fuel to the determined fuel flow may be determined. The first fuel type may have a heating value that is greater than a second fuel type included in the combined fuel. A flow of the first fuel type may be set based at least in part on the ratio. Subsequent to setting the flow of the first fuel type, an energy content of the fuel flow of the combined fuel may be determined, and the flow of the first fuel type may be adjusted based at least in part on the determined energy content.

Owner:GENERAL ELECTRIC CO

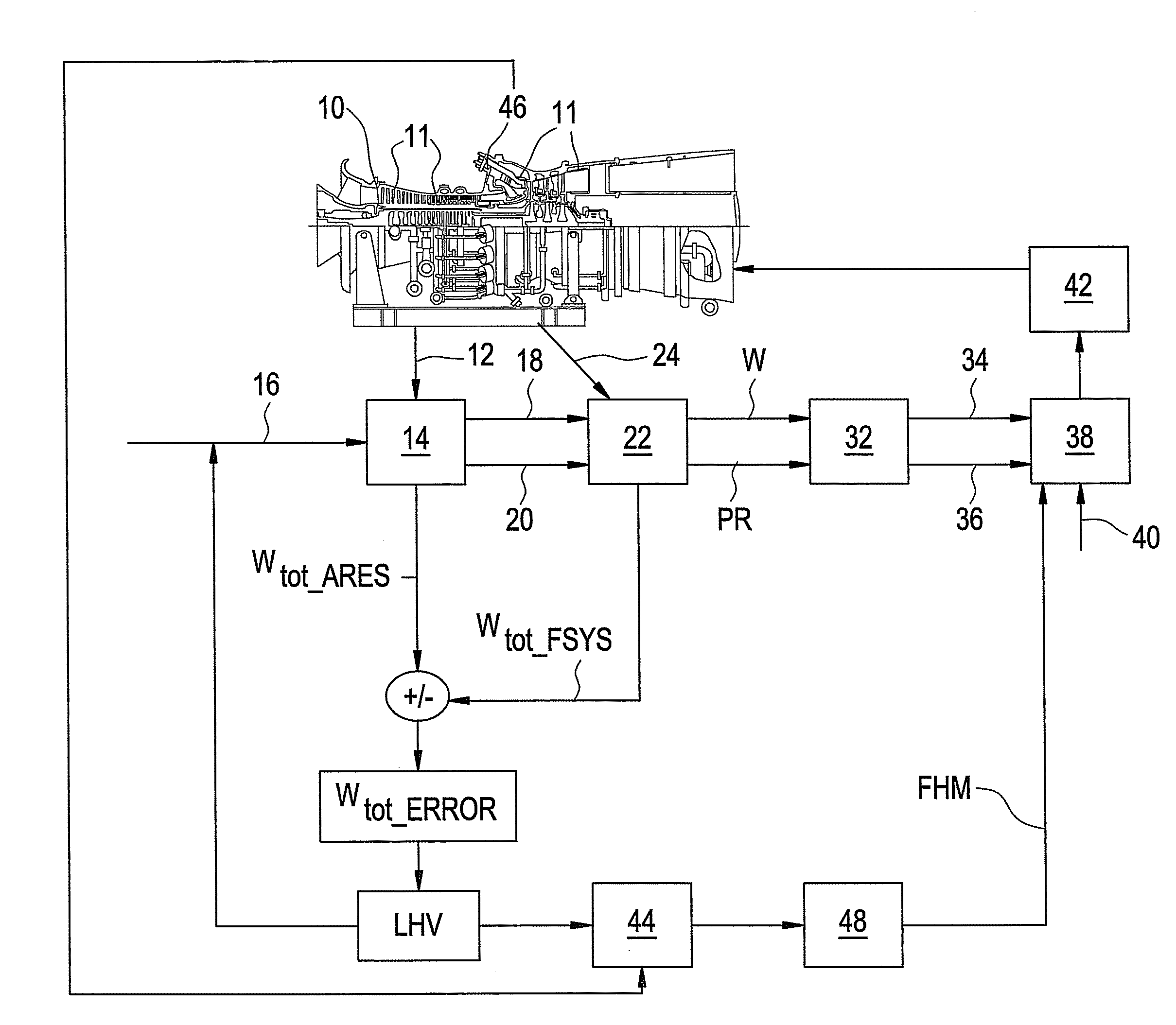

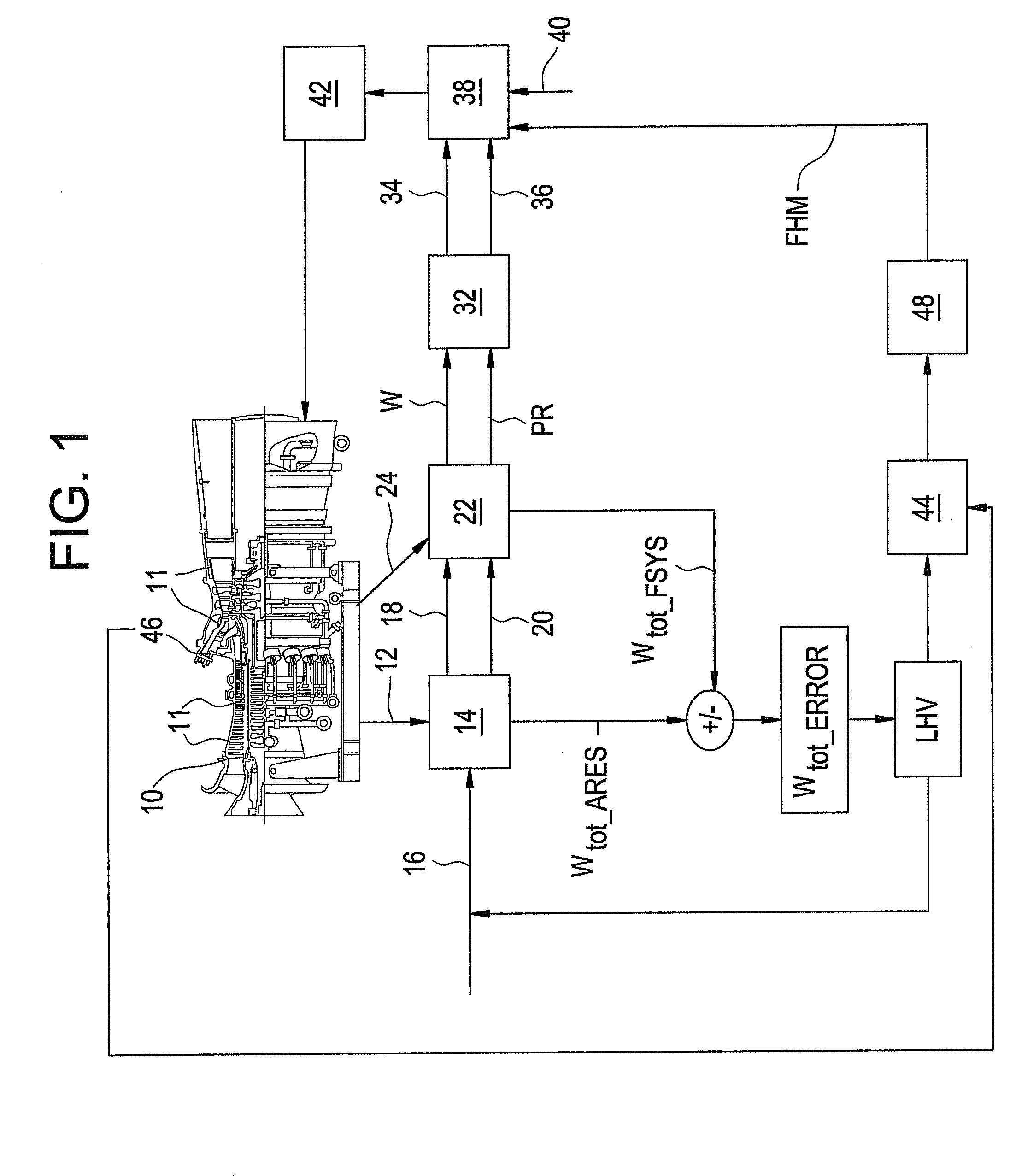

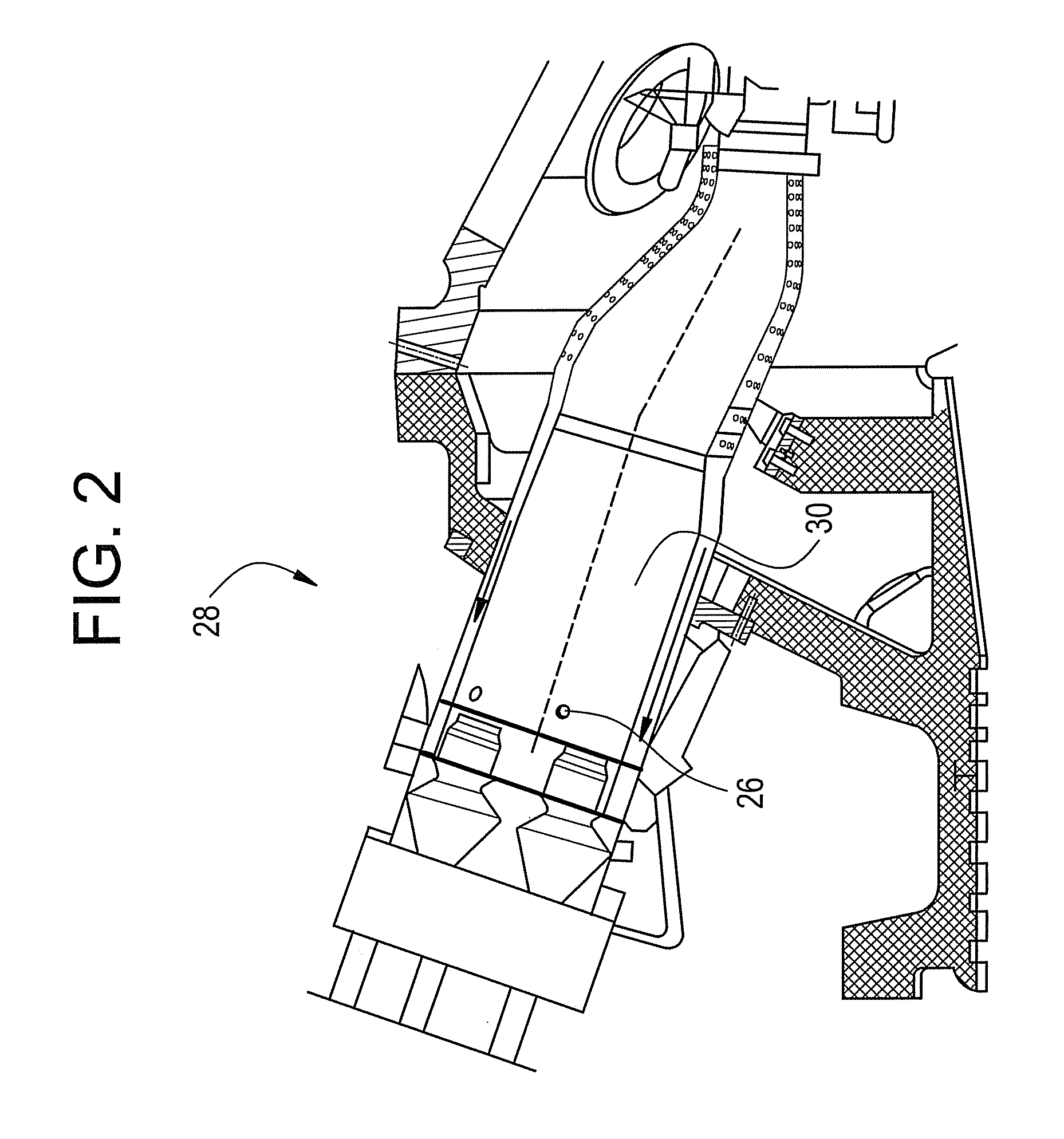

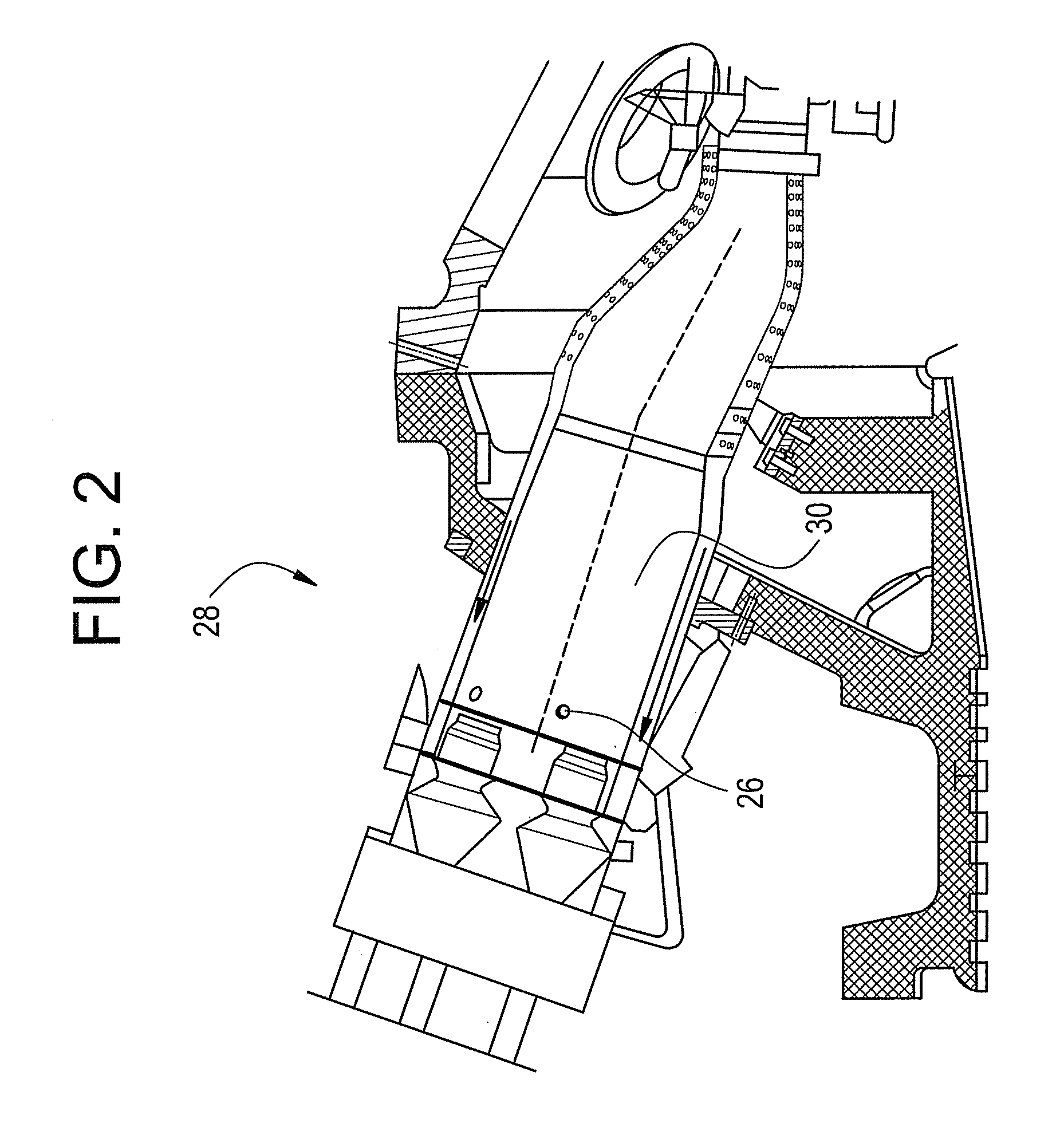

Method and system to determine composition of fuel entering combustor

Disclosed is a method and system for determining composition of a fuel entering a combustor. The method includes determining a temperature of the fuel entering the combustor, calculating a first estimated total fuel flow utilizing fuel properties and fuel nozzle effective area (Ae), and calculating a second estimated total fuel flow utilizing an aero-thermal cycle model analysis. The first estimated total fuel flow is compared to the second estimated total fuel flow and a lower heating value of the fuel is determined from a difference between the first estimated total fuel flow and the second estimated total fuel flow. A method and system for controlling a gas turbine includes calculating effects of the fuel composition on performance of the gas turbine and comparing one or more performance parameters to one or more parameter limits. One or more machine controls of the gas turbine are changed based on the results of the comparison.

Owner:GE INFRASTRUCTURE TECH INT LLC

On-line monitoring method and device for a fossil fuel converter apparatus

InactiveUS20070184556A1Sound scientific basisSatisfies of ash contentFuel supply regulationSolid fuelsMaterial balanceEnergy balanced

An online monitoring method and device for a fossil fuel converter apparatus. The method monitors fuel compositions in real time by measuring operating data of the converter apparatus and comprises the following steps: determining reactant compositions and number of variables thereof; determining fuel compositions and number of variables thereof; determining compositions of incomplete products and number of variables thereof; determining relationship between the fuel compositions and calorific value; establishing an equation set involving the fuel compositions, the reactant compositions and the resultants compositions, according to energy balance relationship and material balance relationship in the combustion process; providing given conditions for independent relationships concerning variables in the above equation set; measuring boiler operating data and assigning the variables in the above equation set; and finding the solution to the equation set and obtaining real-time monitoring data of the converter apparatus.

Owner:WANG ZHEN

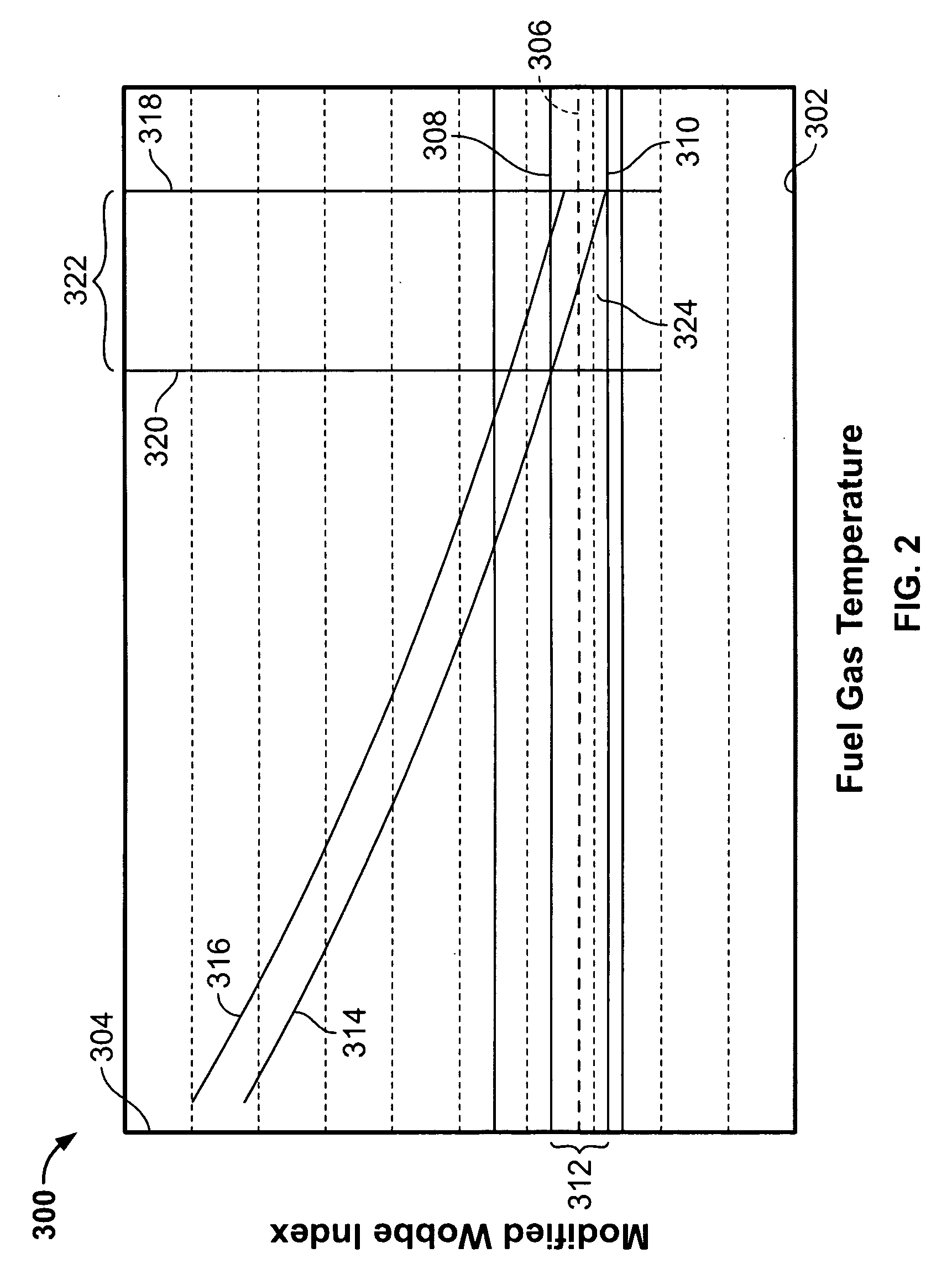

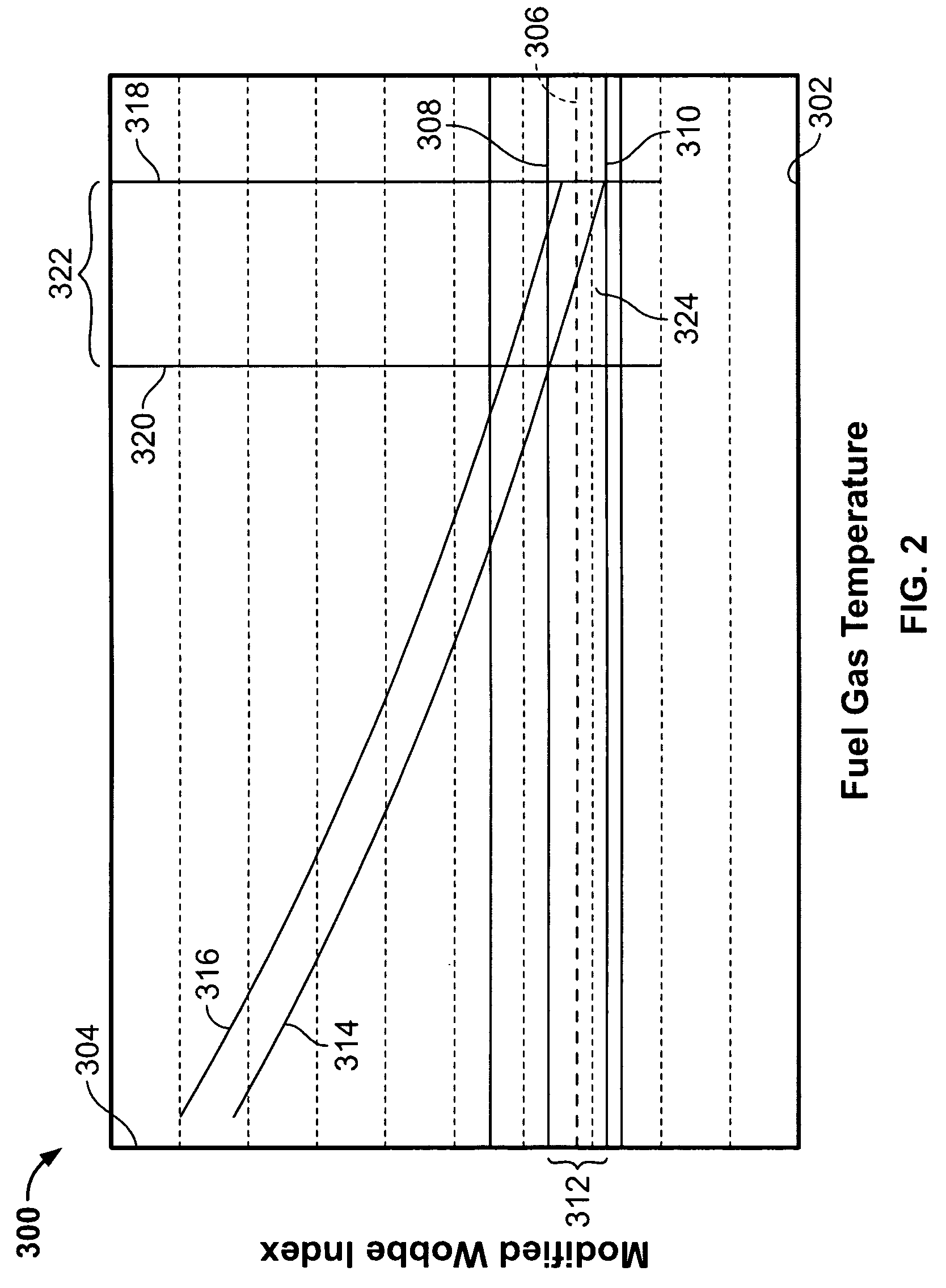

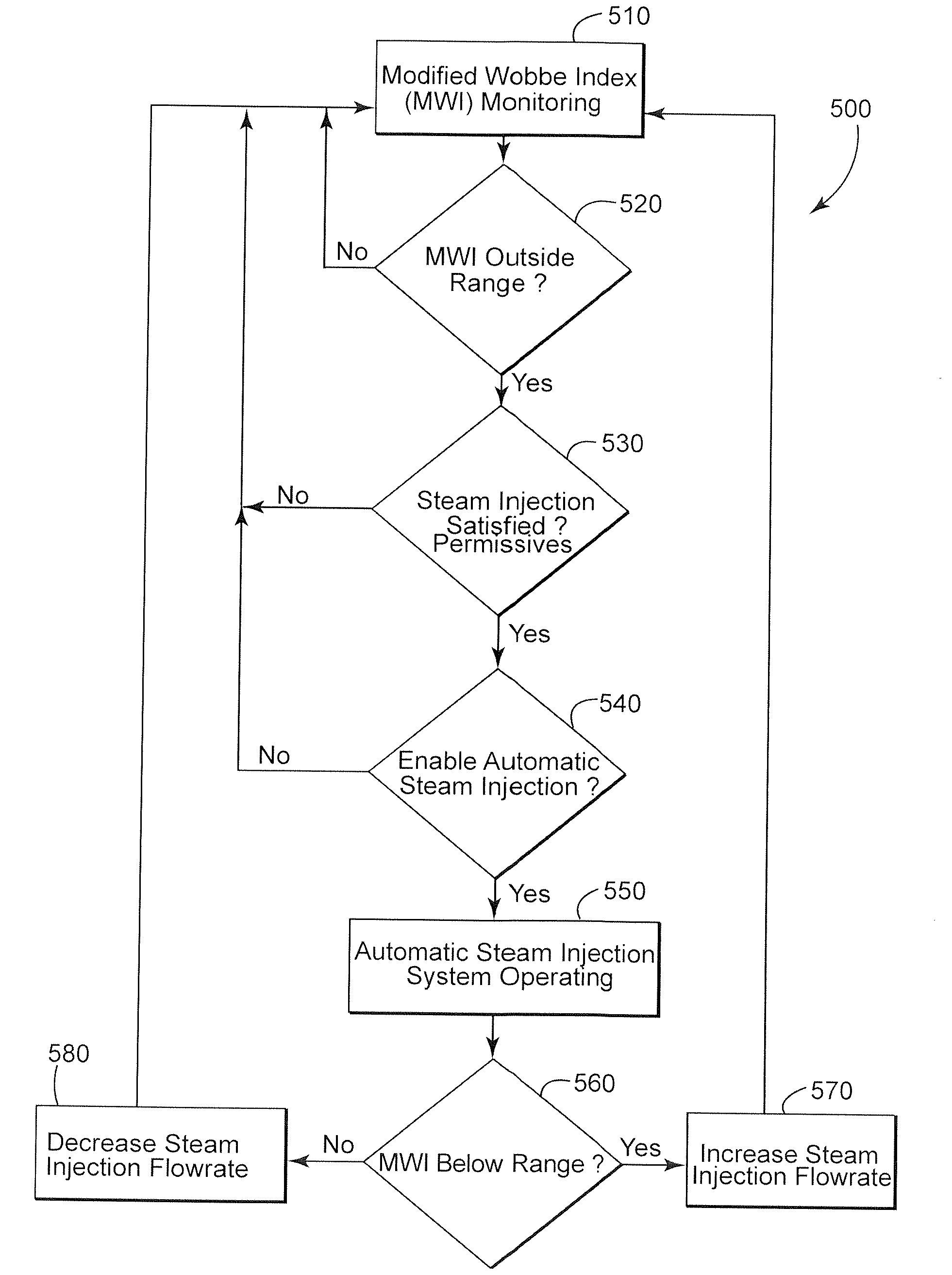

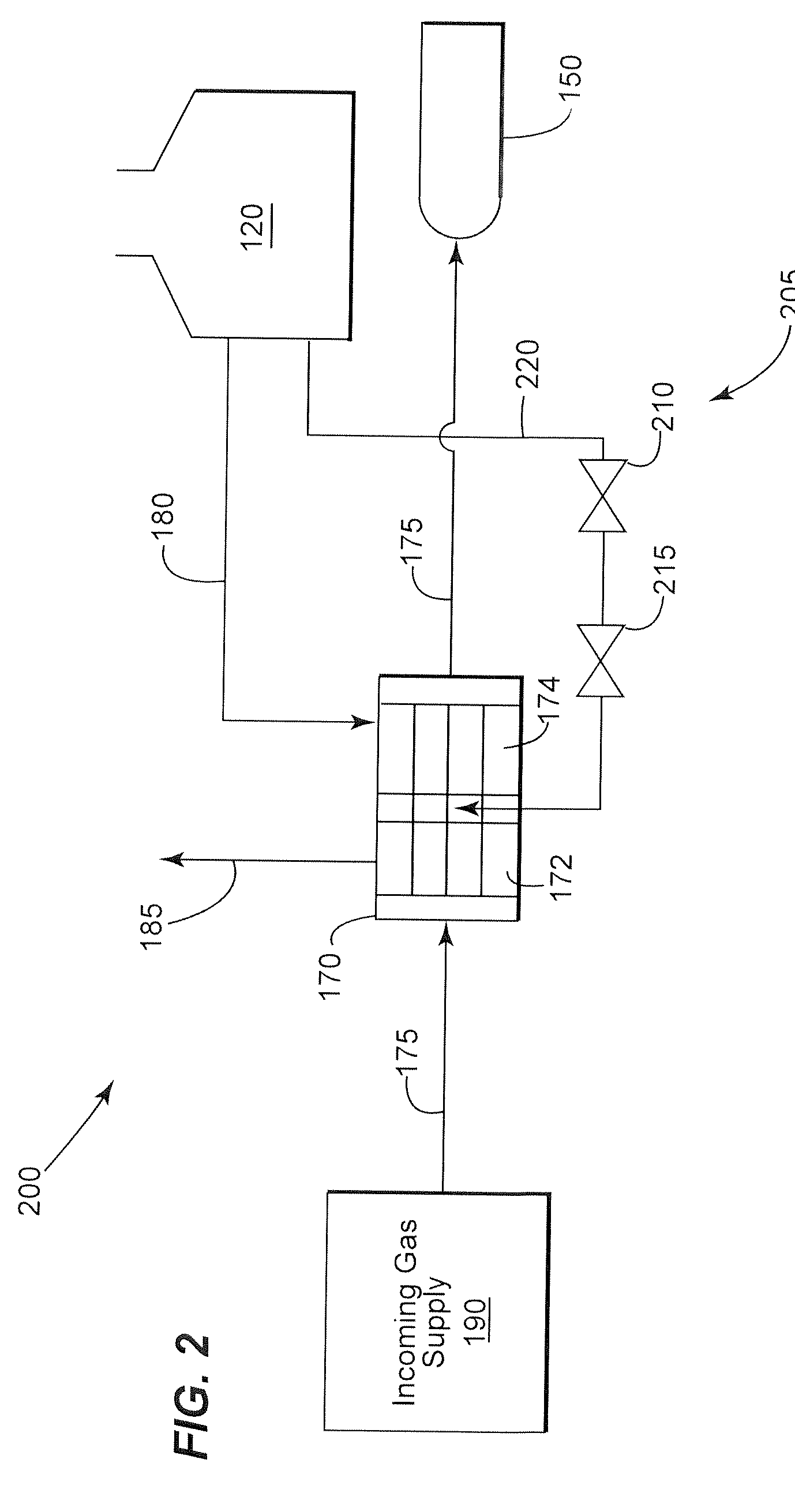

Method and system for modulating the modified wobbe index of a fuel

A method and system for modulating the Modified Wobbe Index (MWI) of a fuel is provided. A variety of industrial components, which may require a gas fuel, such as but not limiting of, a heavy-duty gas turbine; an aero-derivative gas turbine; or a boiler may utilize the method and system. The method and system may provide an industrial component comprising at least one steam injection system, wherein the at least one steam injection system injects steam into at least one fuel supply line upstream of a combustion system to modulate the MWI of at least one fuel. The method and system may also determine whether the MWI of the at least one fuel is outside of a predetermined range; and utilize the at least one steam injection system to automatically inject the steam at a flowrate for adjusting the MWI of the at least one fuel.

Owner:GENERAL ELECTRIC CO

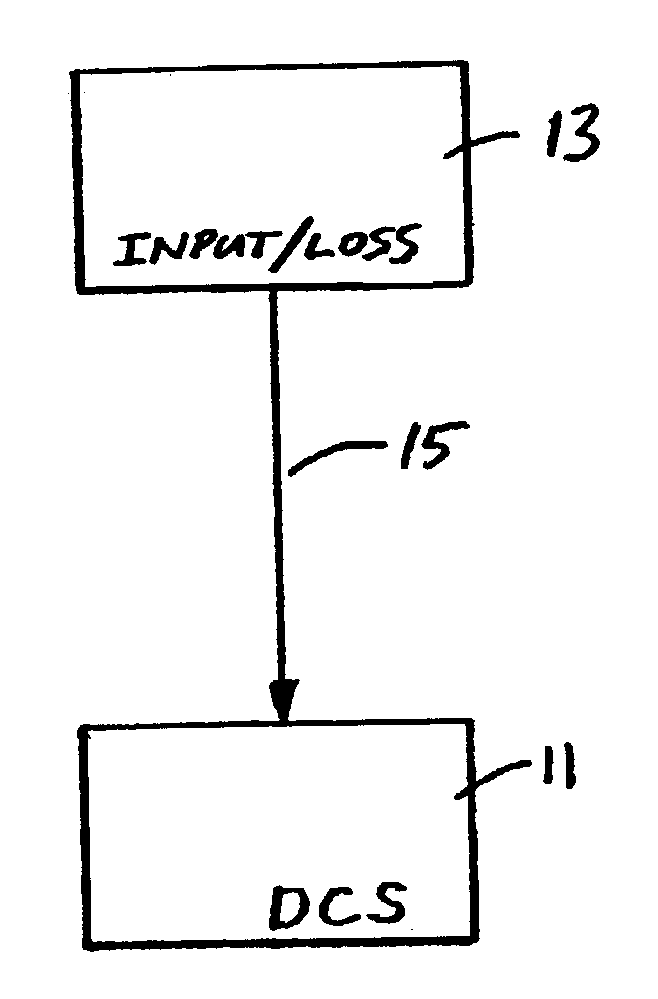

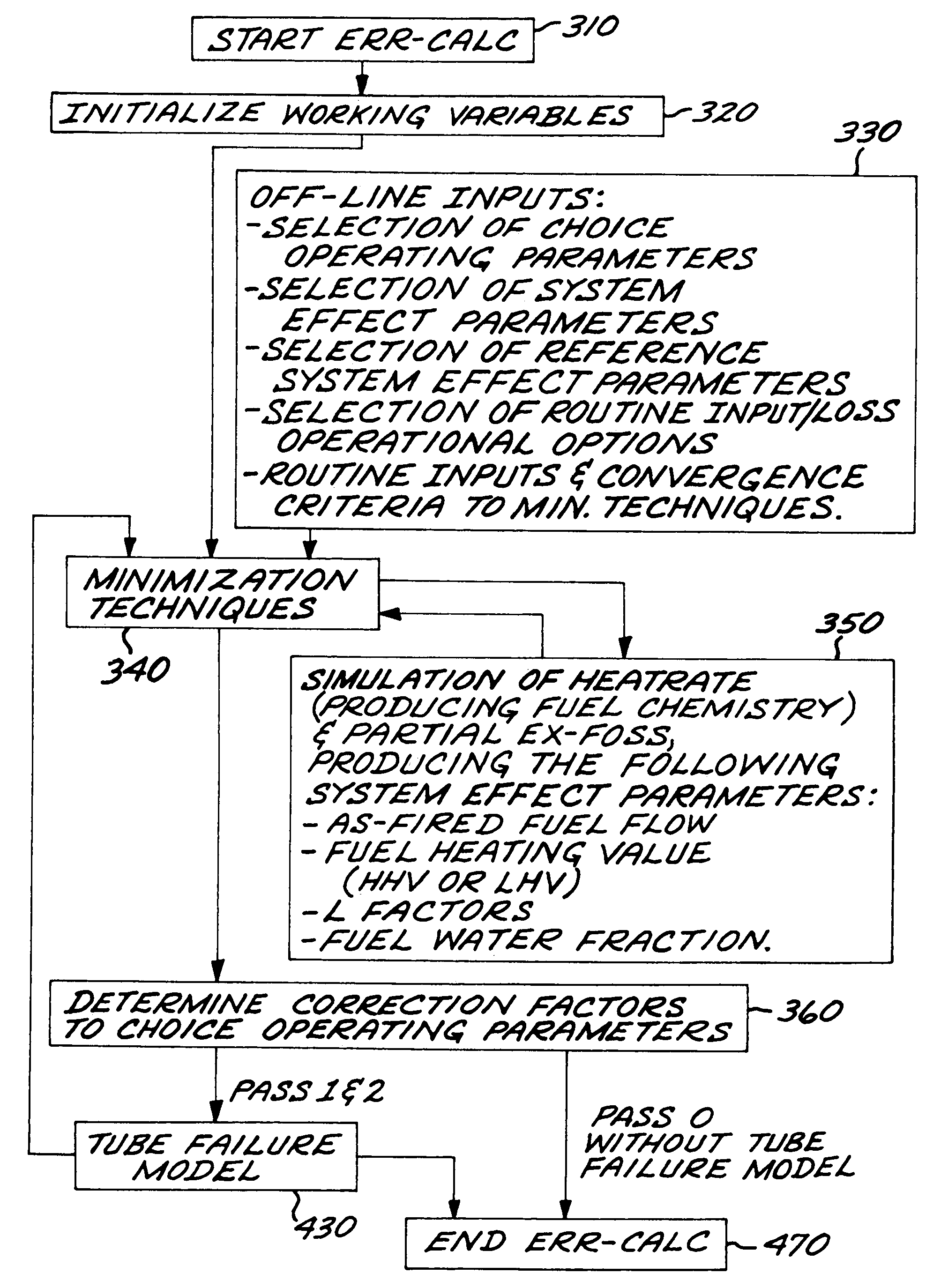

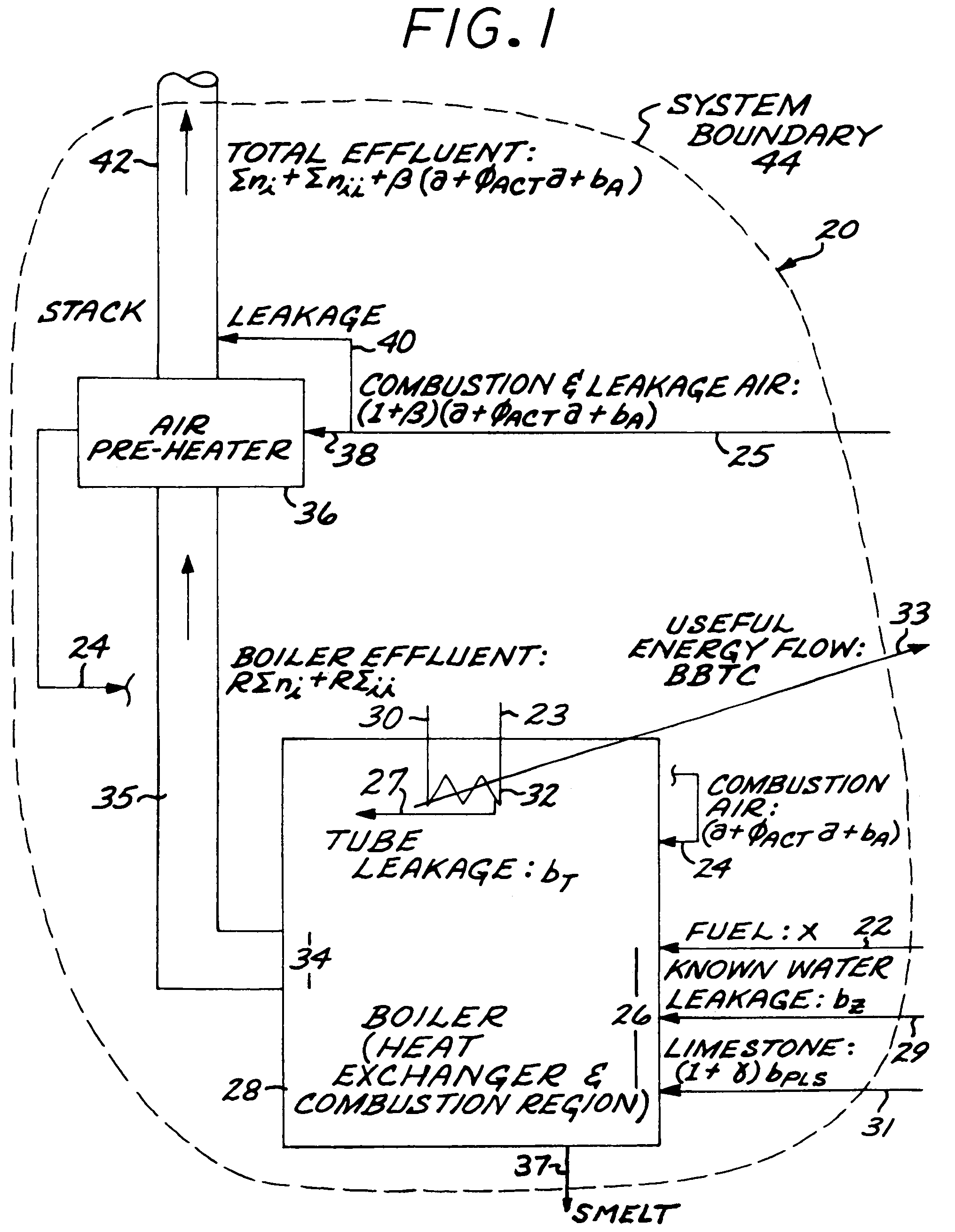

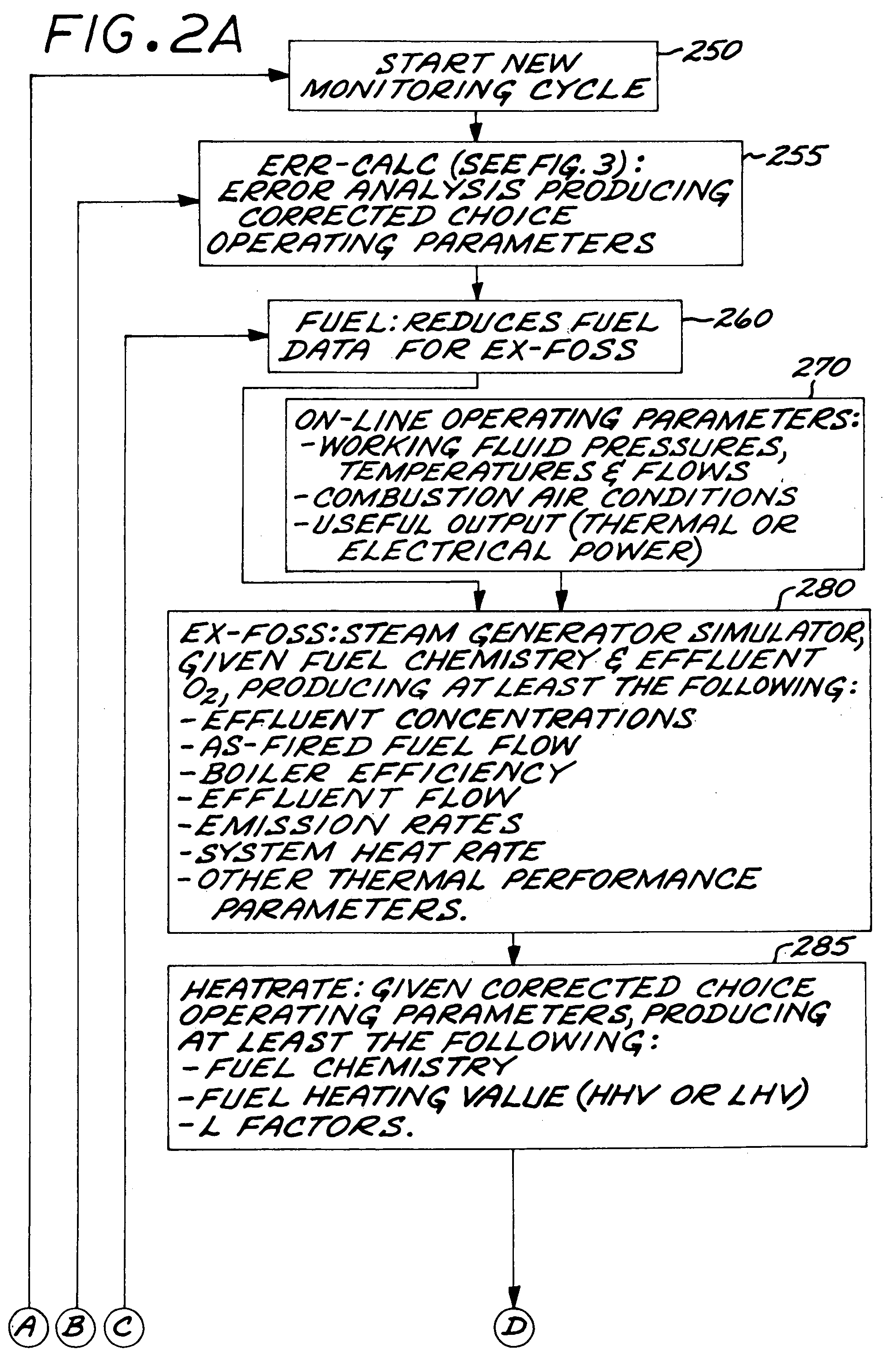

Method for improving the control of power plants when using input/loss performance monitoring

InactiveUS6868368B1Easy to controlImprove consistencyFuel supply regulationDigital computer detailsPower stationControl system

This invention relates to a fossil-fired thermal system such as a power plant or steam generator, and, more particularly, to a method for improving the control of a power plant or steam generator through use of computed output obtained from any of the Input / Loss methods. Typically such computed output may consist of As-Fired fuel flow, fuel heating value, fuel Firing Correction, and other similar terms which might effect the operating control system of a power plant or steam generator.

Owner:EXERGETIC SYST

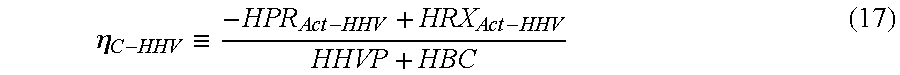

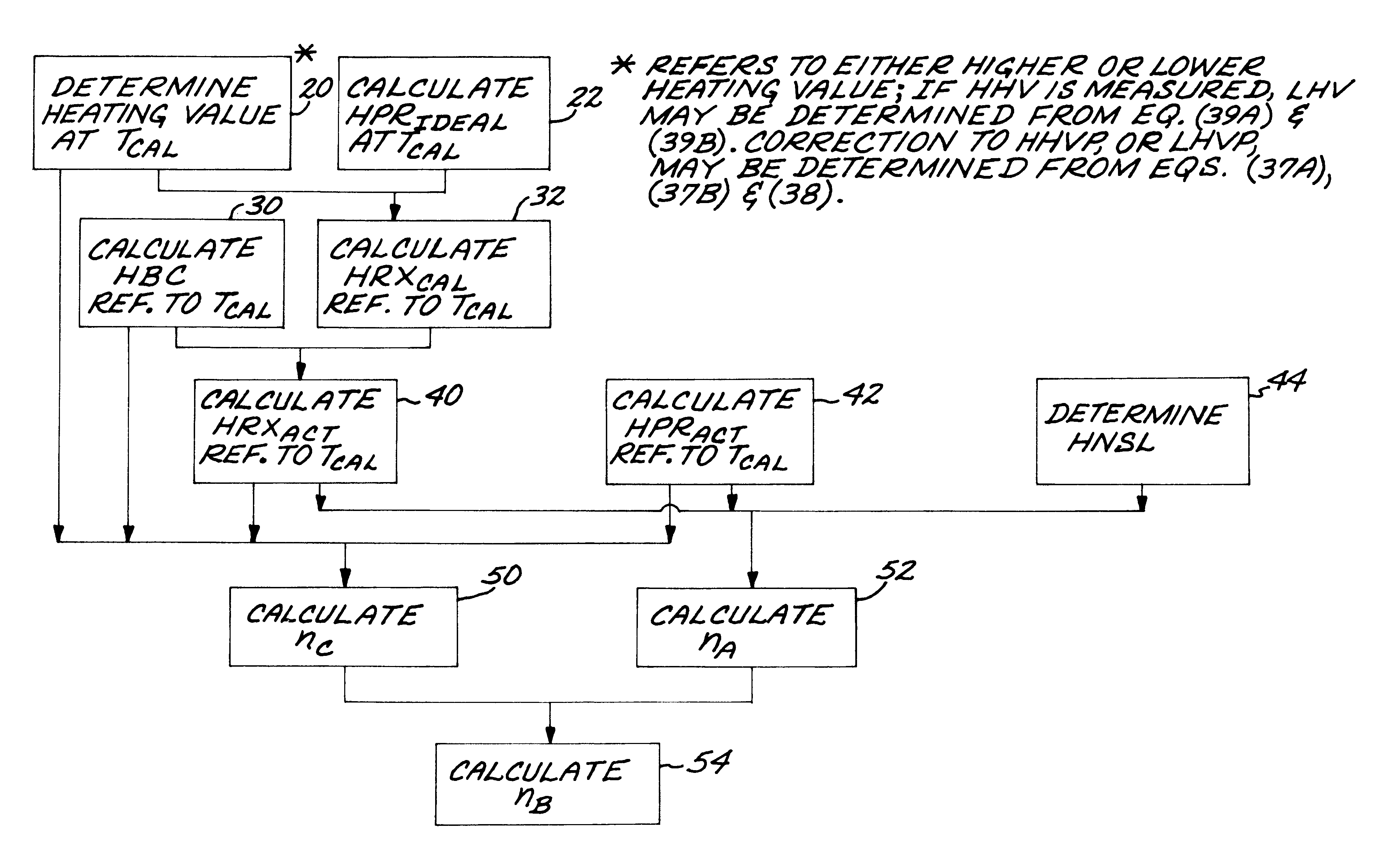

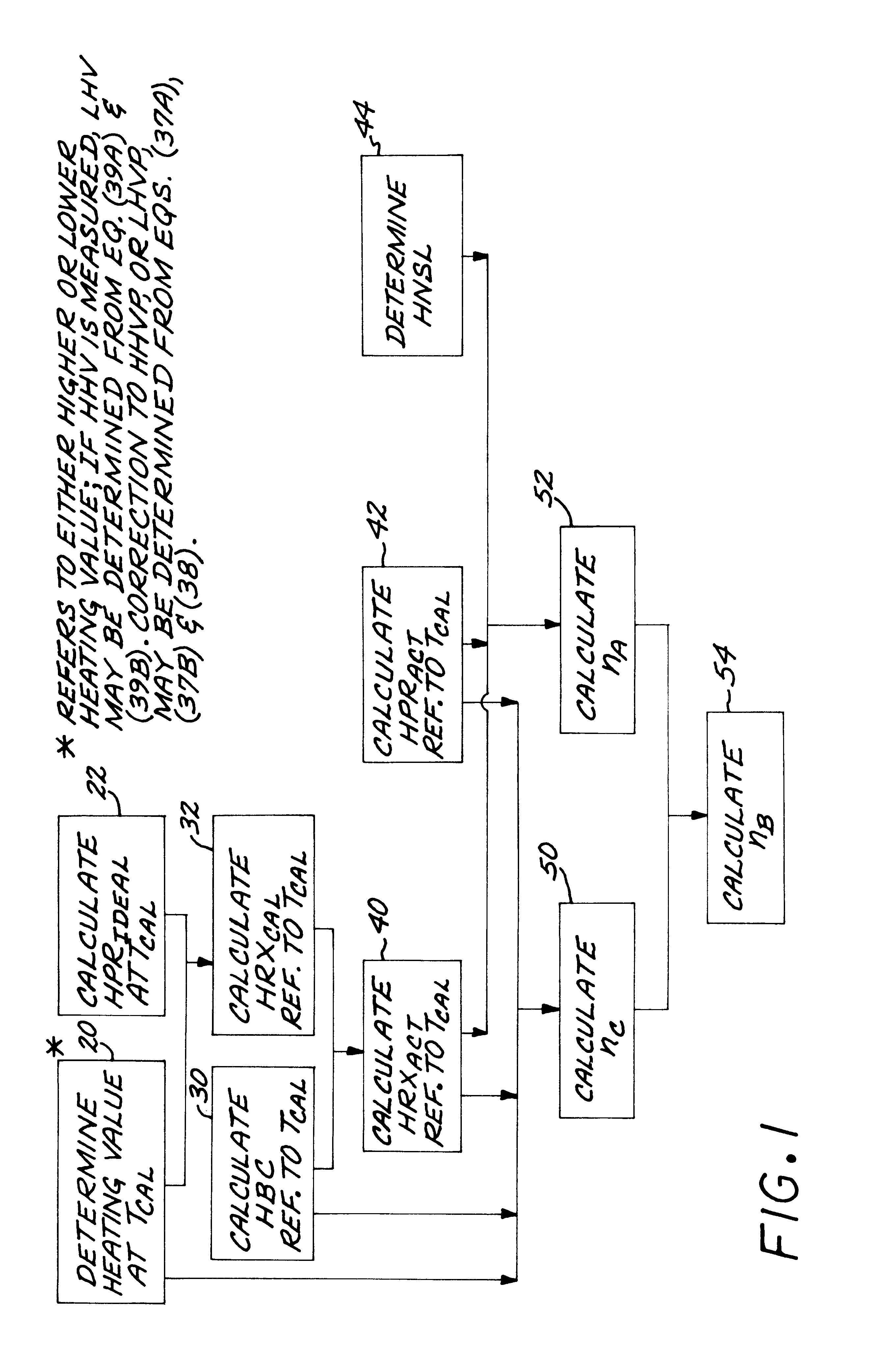

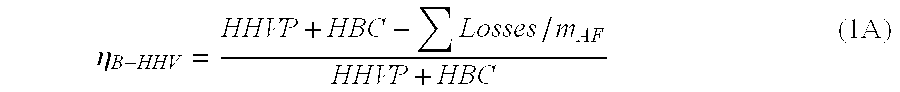

Input/loss method for determining boiler efficiency of a fossil-fired system

InactiveUS6584429B1Consistently appliedSampled-variable control systemsFuel supply regulationEngineeringBoiler efficiency

The operation of a fossil-fueled thermal system is quantified by obtaining an unusually accurate boiler efficiency. Such a boiler efficiency is dependent on the calorimetric temperature at which the fuel's heating value is determined. This dependency affects the major thermodynamic terms comprising boiler efficiency.

Owner:EXERGETIC SYST

Method for operating a gas turbine

InactiveUS20060174630A1Increased pollutant emissionShorter ignition delay timeTurbine/propulsion engine ignitionTurbine/propulsion engine startersPower stationProcess engineering

A method for operating a gas turbine (2), in particular in a power plant, includes operating the gas turbine (2) with natural gas. In order to adapt the gas turbine operation to different natural gas qualities, a concentration of C2+ is measured in the natural gas during gas turbine (2) operation. The gas turbine (2) then is operated based on the current concentration of C2+.

Owner:ANSALDO ENERGIA IP UK LTD

Fuel gas calorie control method and device

ActiveUS7396228B2Calorie controlEasy to controlBurnersTurbine/propulsion fuel supply systemsMixed flowProduct gas

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

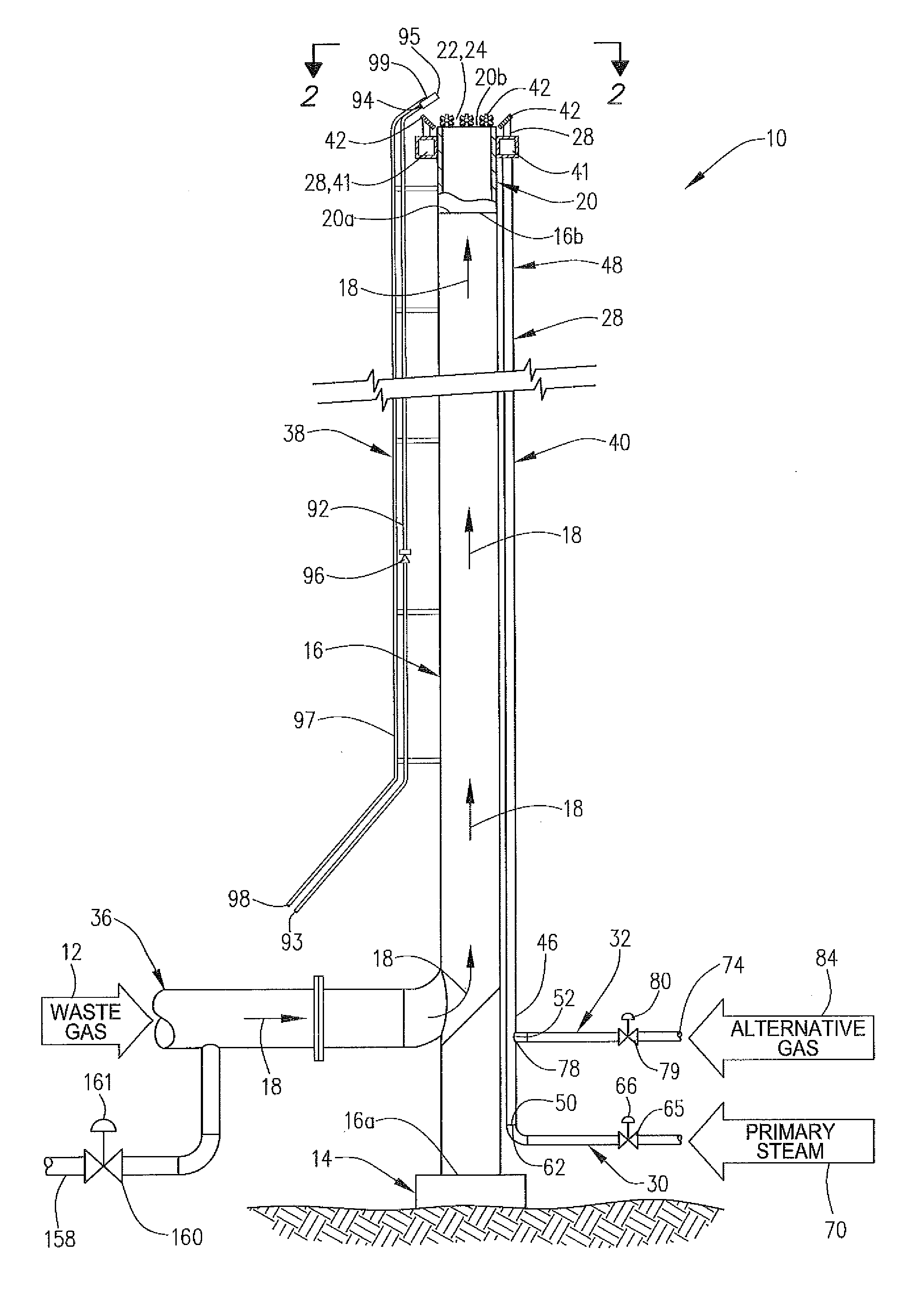

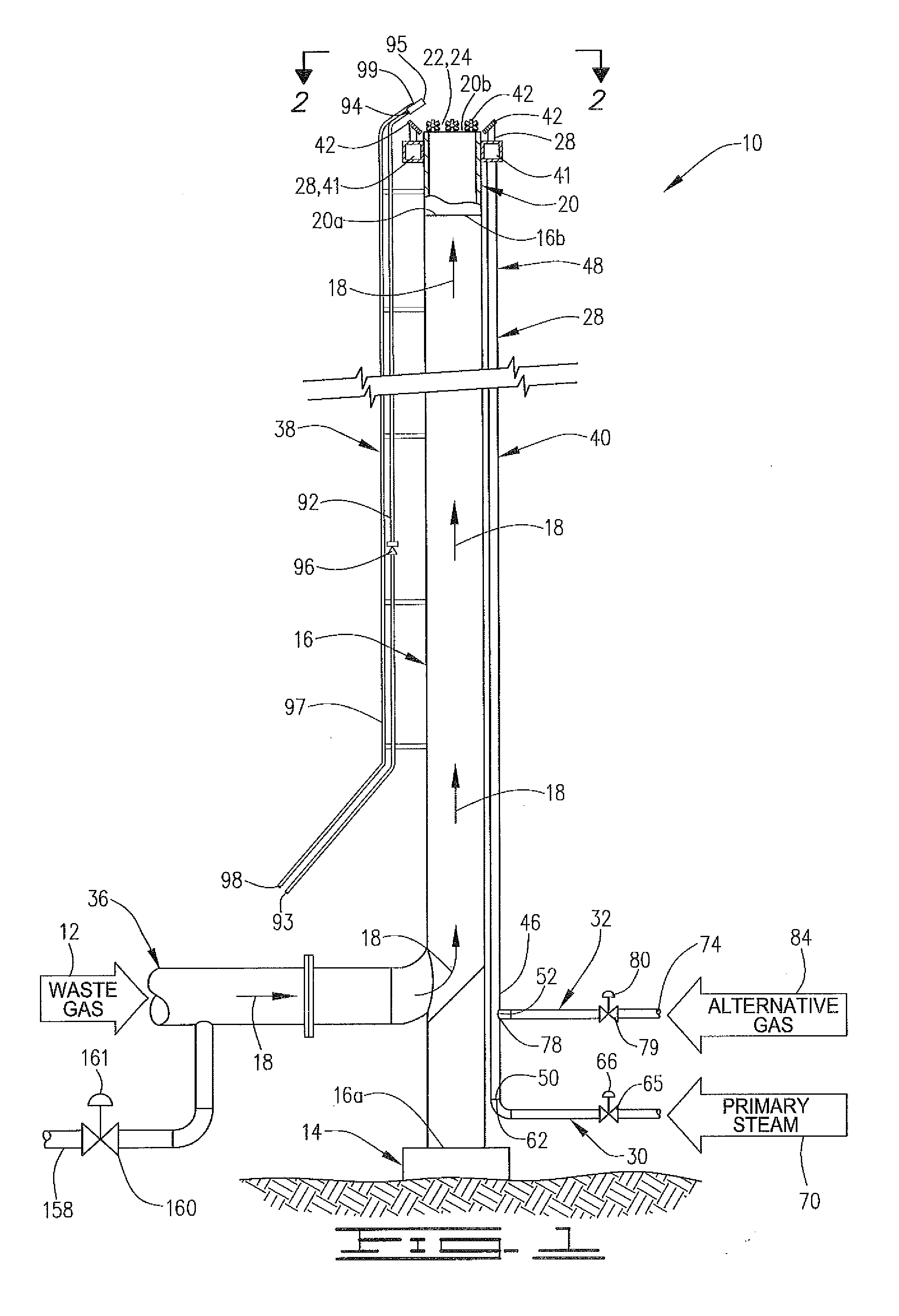

Hybrid flare apparatus and method

A method of operating a flare assembly is provided. If it is determined that the injection of primary steam into the combustion zone is necessary to achieve smokeless operation, primary steam is injected through a steam injector assembly into the combustion zone. If it is determined that steam is not necessary, an alternative gas is discharged though the steam injector assembly into the combustion zone. In one embodiment, the alternative gas is heated. In another embodiment, if it is determined that steam is necessary, a maximum allowable flow rate of steam is calculated, and the flow rate of steam is modulated to achieve smokeless operation and avoid a flow rate of steam in excess of the maximum allowable flow rate of steam. A flare assembly is also provided.

Owner:JOHN ZINK CO LLC

Blower for combustion air

InactiveUS20050255418A1Improve combustion conditionsContinuous suctionPump componentsMachines using electric/magnetic effectsImpellerCombustion

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

Method and system to determine composition of fuel entering combustor

Disclosed is a method and system for determining composition of a fuel entering a combustor. The method includes determining a temperature of the fuel entering the combustor, calculating a first estimated total fuel flow utilizing fuel properties and fuel nozzle effective area (Ae), and calculating a second estimated total fuel flow utilizing an aero-thermal cycle model analysis. The first estimated total fuel flow is compared to the second estimated total fuel flow and a lower heating value of the fuel is determined from a difference between the first estimated total fuel flow and the second estimated total fuel flow. A method and system for controlling a gas turbine includes calculating effects of the fuel composition on performance of the gas turbine and comparing one or more performance parameters to one or more parameter limits. One or more machine controls of the gas turbine are changed based on the results of the comparison.

Owner:GENERAL ELECTRIC CO

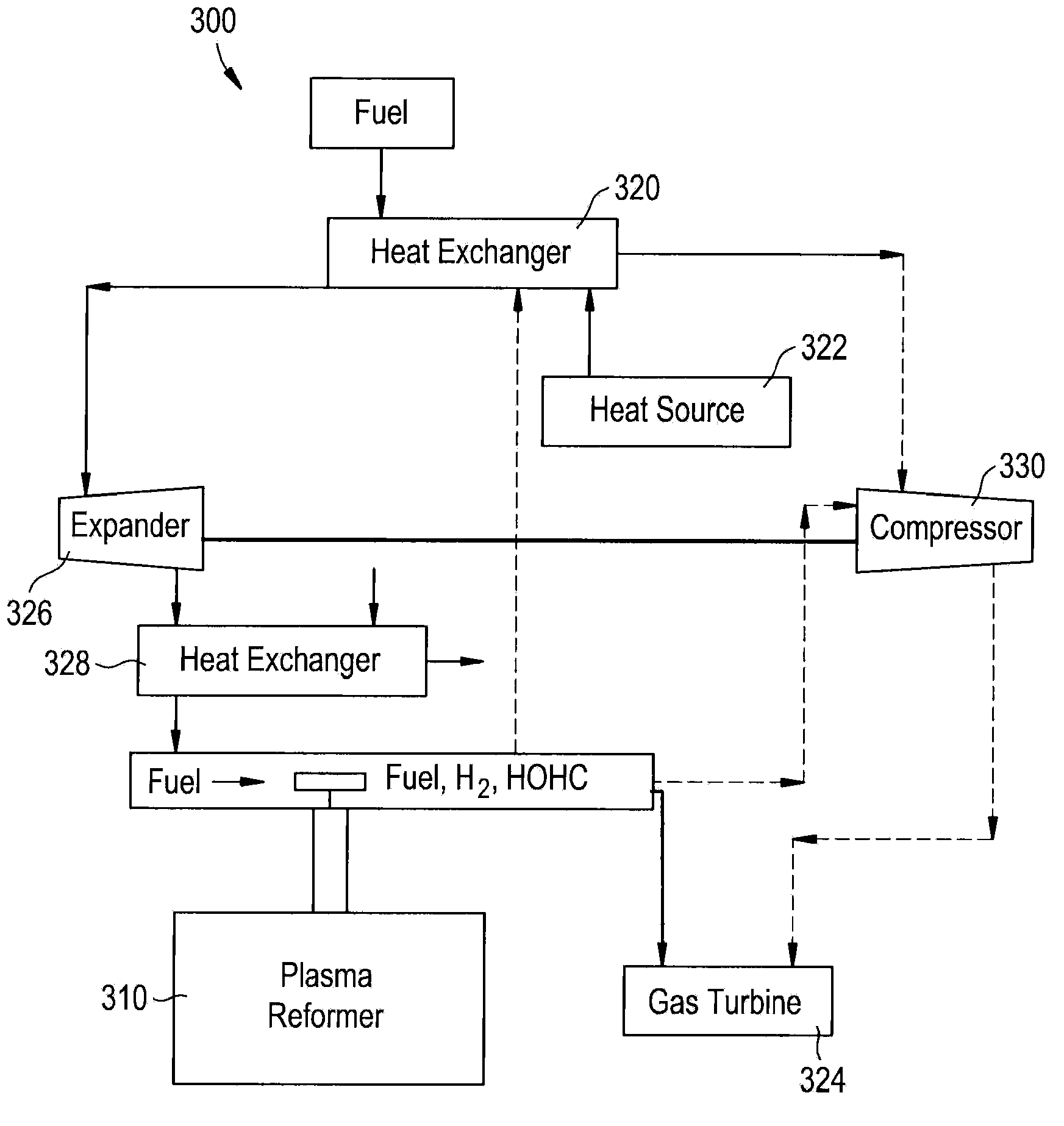

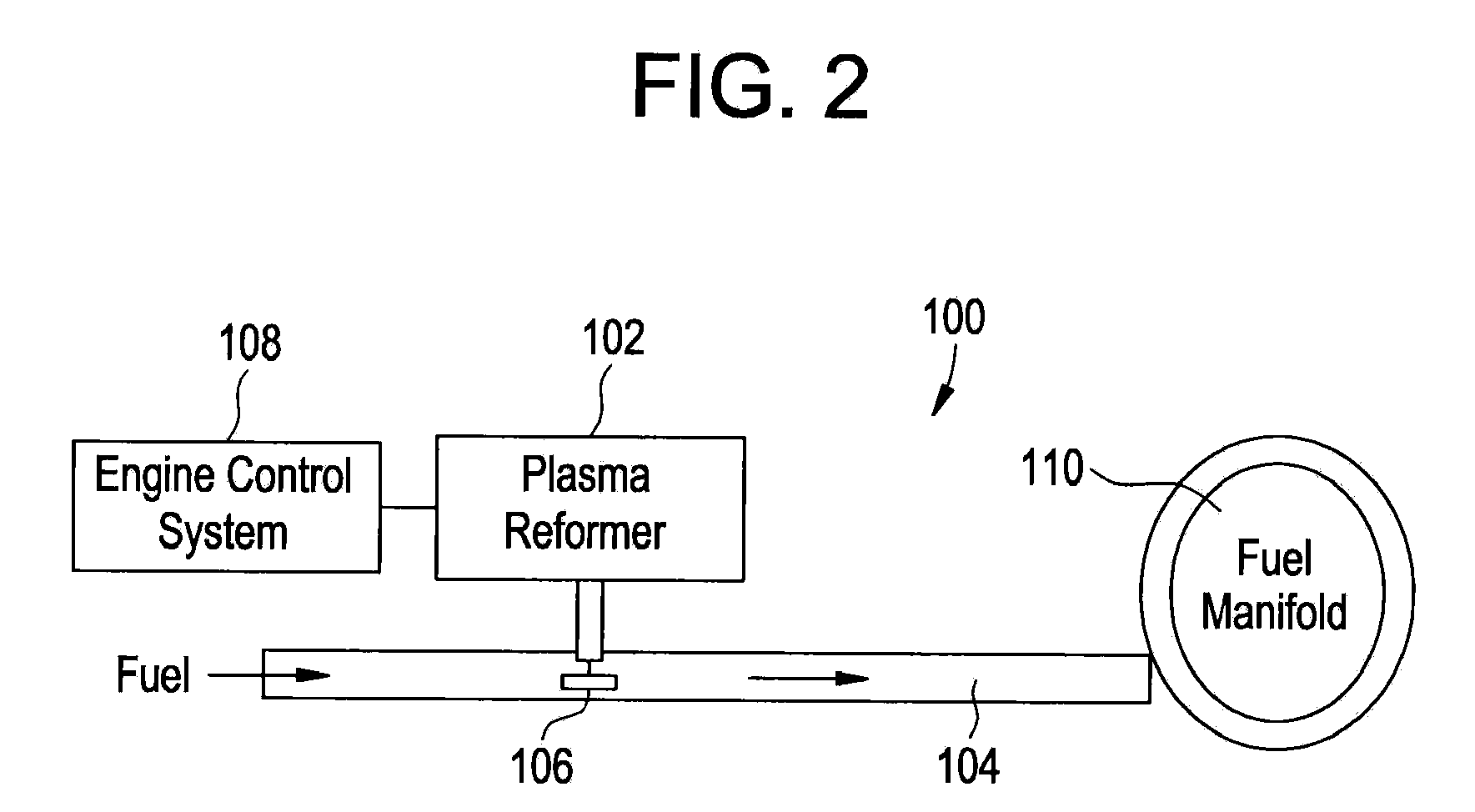

Gas Turbine Combustion System With In-Line Fuel Reforming And Methods Of Use Thereof

InactiveUS20100300110A1Liquid fuel feeder/distributionFuel supply regulationCombustion systemActive feedback

A process for providing a fuel supplied to one or more combustors in a gas turbine engine system, comprising: reforming a fraction of the fuel in one or more fuel circuits of the gas turbine combustion system with a plasma reformer system to form at least one of hydrogen and higher order hydrocarbons to be supplied to the one or more combustors with a remaining fraction of the fuel; and controlling at least one of power and fuel flow to the plasma reformer system with an active feedback control system.

Owner:GENERAL ELECTRIC CO

Method and apparatus for controlling the combustion in a gas turbine

InactiveUS20080289339A1Efficient solutionPrecise functionFuel supply regulationGaseous fuel pretreatmentCombustionProcess engineering

A method and apparatus are described for controlling the combustion in a gas turbine. The method includes measuring, by means of one or two calorimeters, the temperature, calorific value and relative density of a gaseous fuel in order to determine the Wobbe index, comparing the Wobbe index value measured with a predefined Wobbe index value for the gaseous fuel and regulating the temperature of the gaseous fuel by means of at least one heat exchanger in order to reach the predefined Wobbe index value. The method may also include using a second gaseous fuel, having a different Wobbe index from the gaseous fuel, or a fuel obtained by mixing the gaseous fuel and the second gaseous fuel, according to arbitrary proportions and variable with time.

Owner:NUOVO PIGNONE SPA

Method for detecting heat exchanger tube failures and their location when using input/loss performance monitoring of a recovery boiler

InactiveUS7039555B2Improve abilitiesReduce outage timeCombustion pretreatment/prehandlingCombustion measurementsRepair timeBlack liquor

This invention relates to a recovery boiler as used by the pulp and paper industry burning black liquor, and, more particularly, to a method for rapid detection of tube failures and the location of the affect heat exchanger within the recovery boiler, without need for direct instrumentation, thereby preventing more serious equipment damage, preventing boiler explosion, preventing injury to operators and minimizing repair time on the affected heat exchanger. This method is applicable to Input / Loss methods of monitoring recovery boilers.

Owner:EXERGETIC SYST

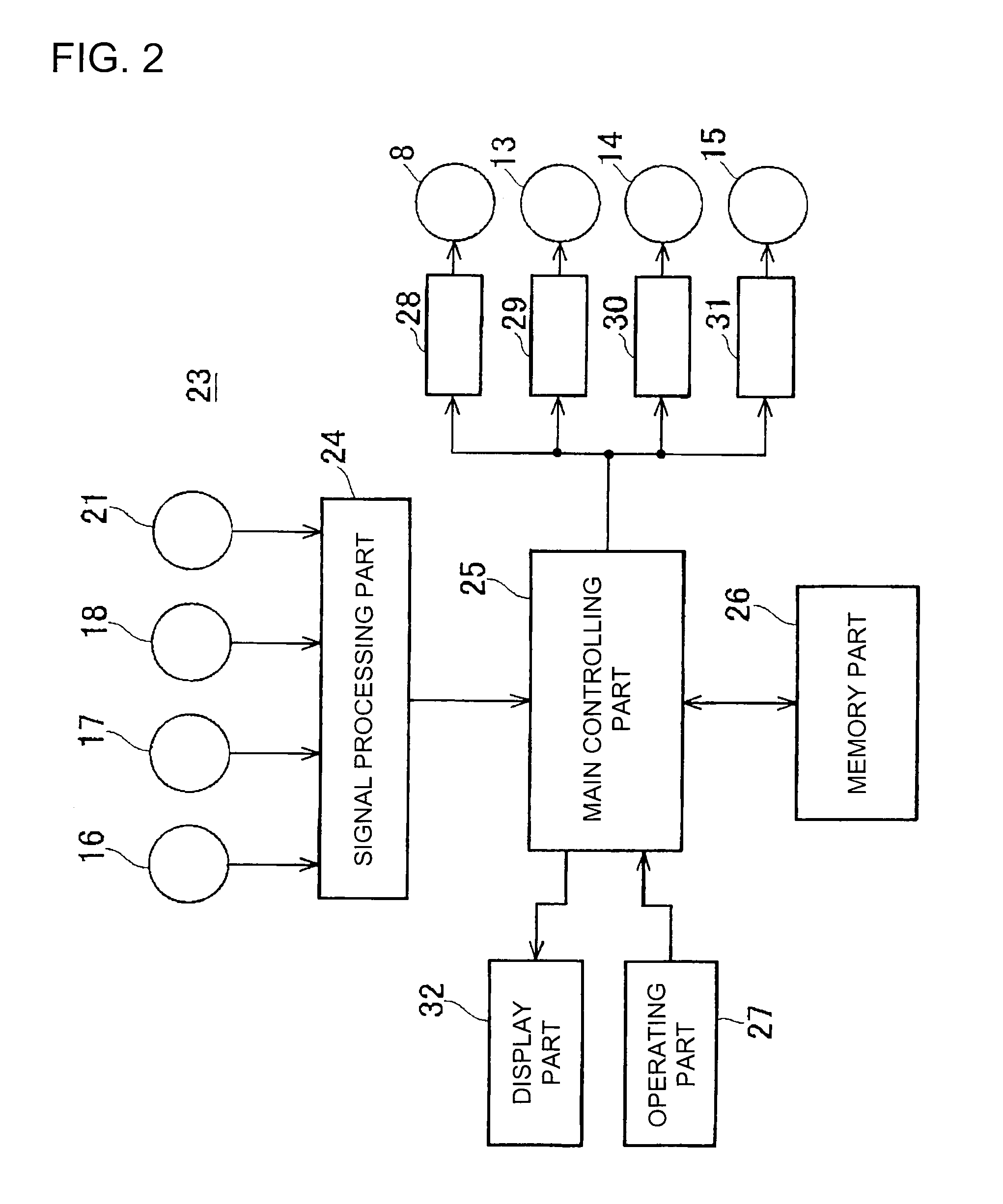

Coal burning boiler apparatus

InactiveUS20090308292A1Low running costGreat advantageAir supply regulationFuel feeding arrangementsCombustionEngineering

In a coal burning boiler apparatus, temperature of the pulverized coal to be fed to the boiler can be set depending on the property of the combustion coal, so that stable ignition and combustion can be made regardless of the property of the combustion coal fed.Provided are a coal burning boiler 1, a coal pulverizer 2 for pulverizing massive coal 6 into fine powder, a temperature sensor 18 for detecting temperature of the primary air 35 for entraining the pulverized coal to the coal burning boiler, regulators 9, 12, 13 and 14 for regulating the temperature of the primary air and a controller for controlling the primary air temperature regulators on the basis of detected result of the temperature sensor so as to make the primary air have a given temperature.

Owner:IHI CORP

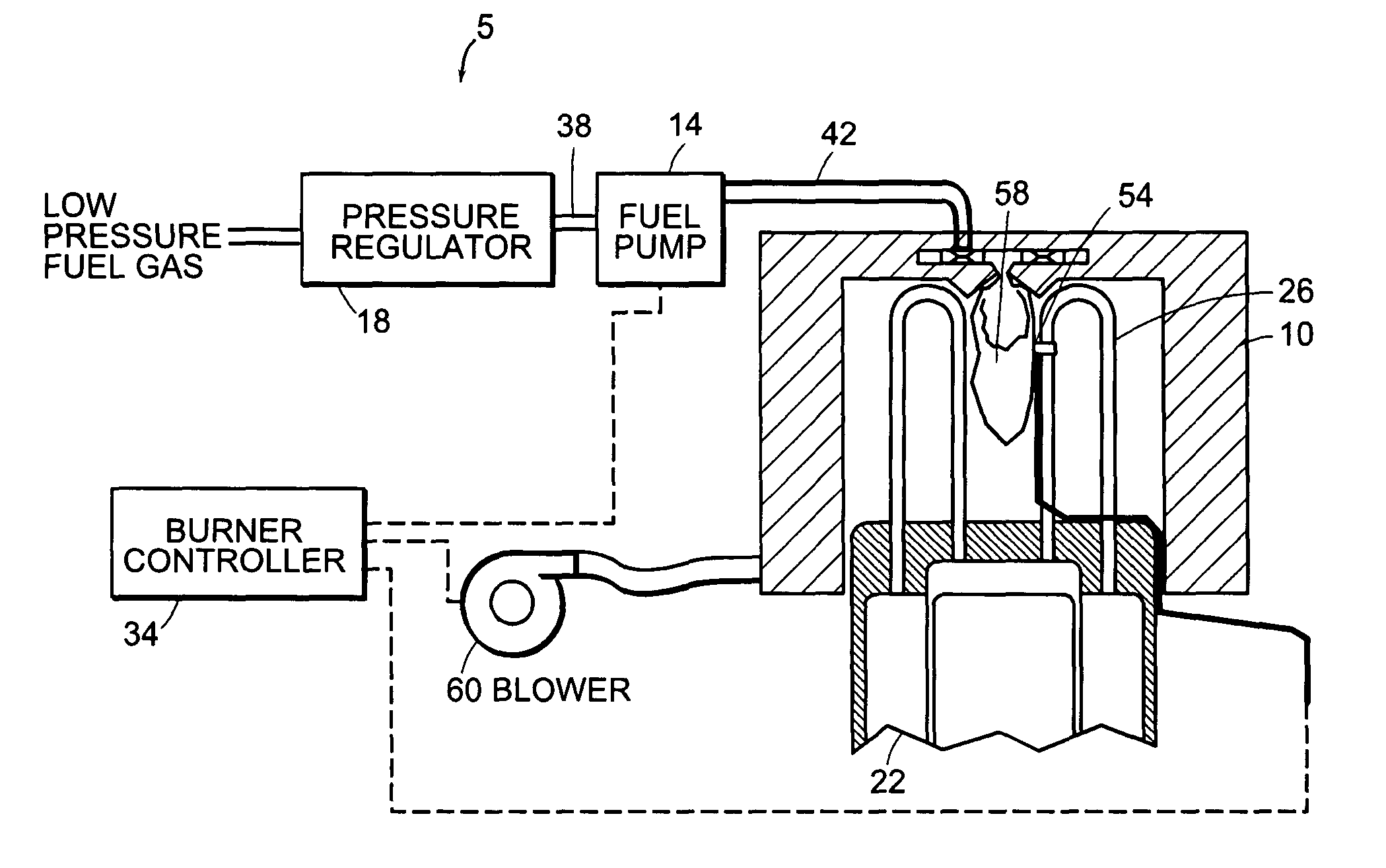

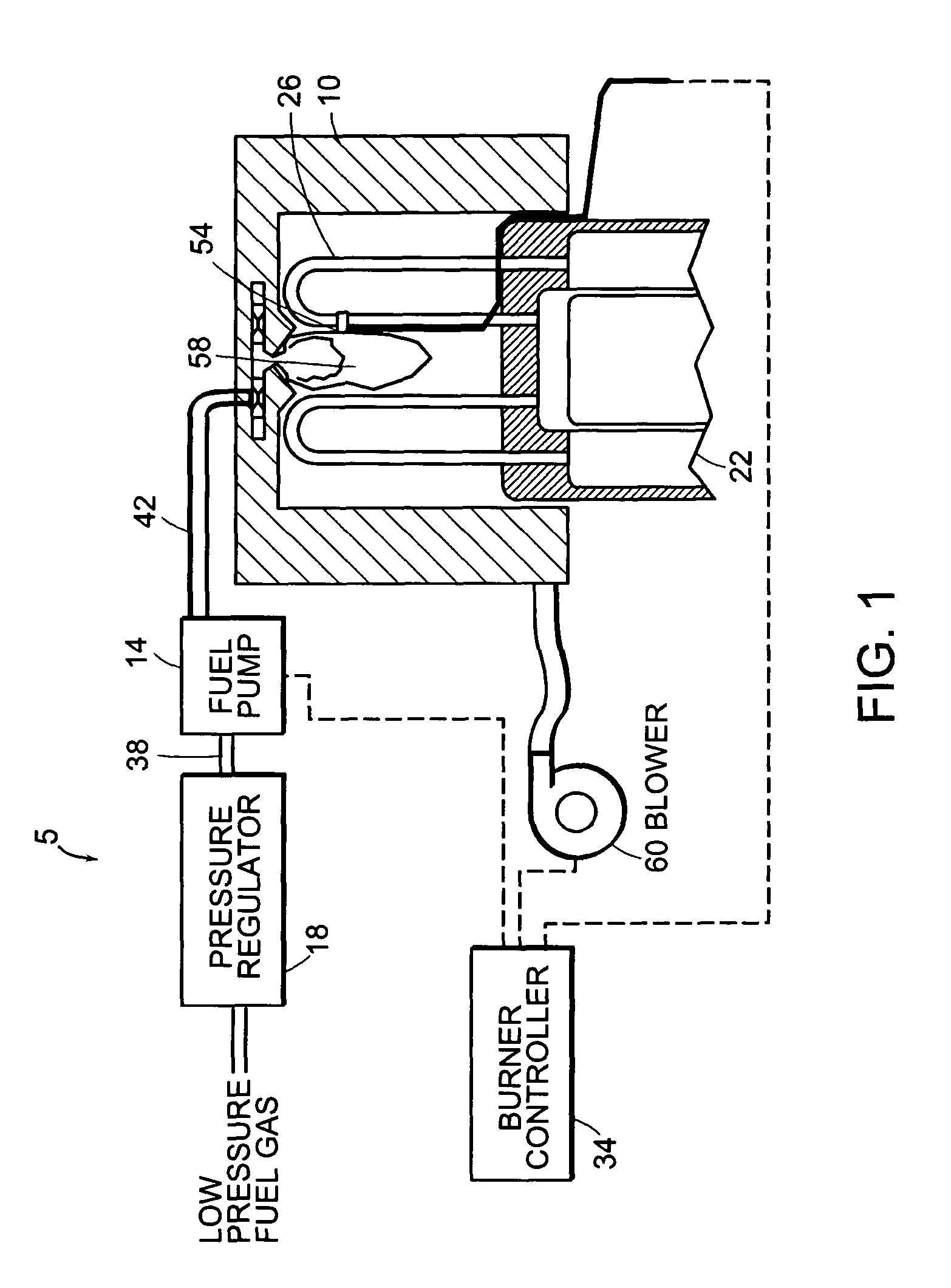

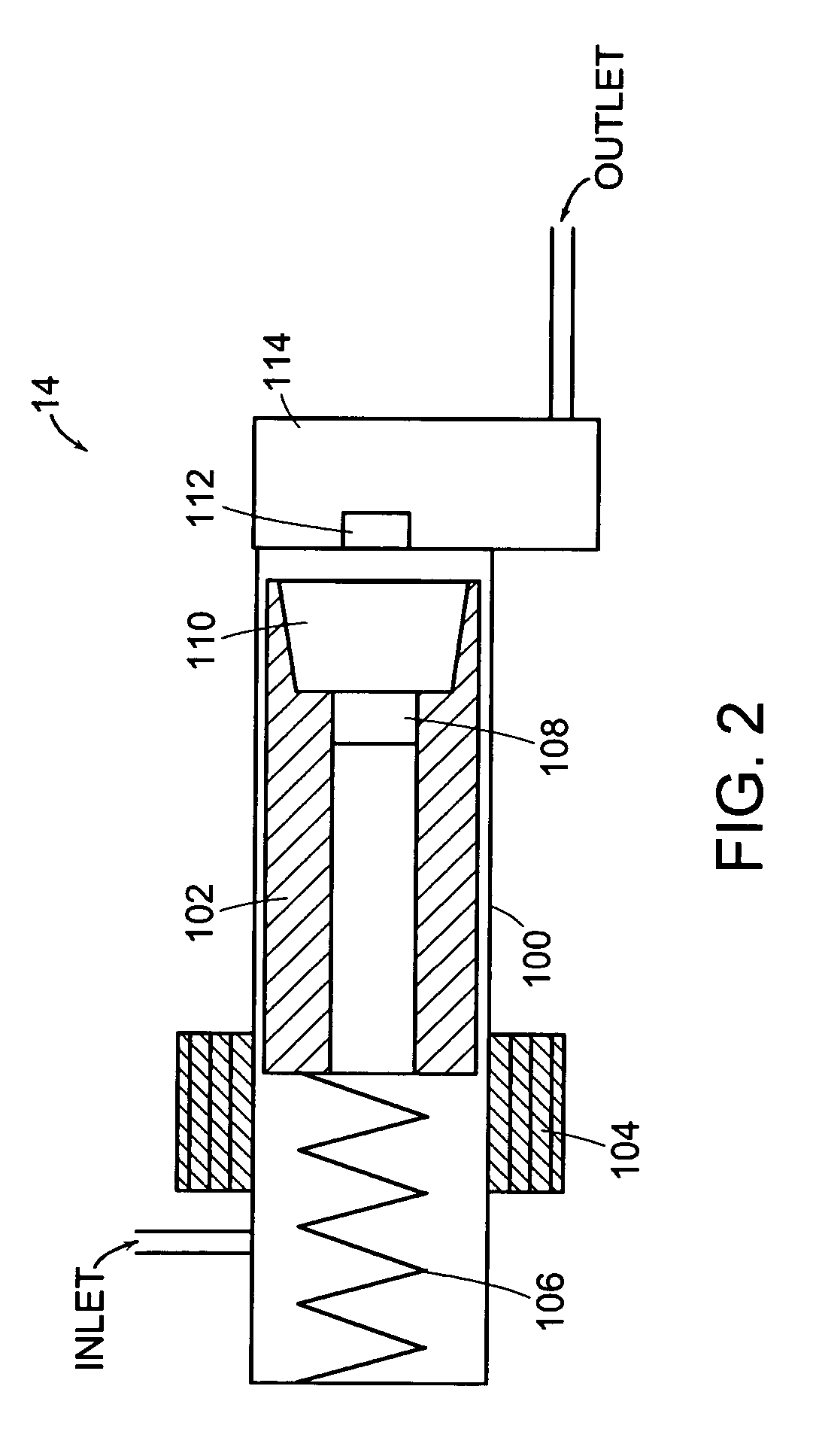

Metering Fuel Pump

InactiveUS20070028612A1Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesCombustion chamberEngineering

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

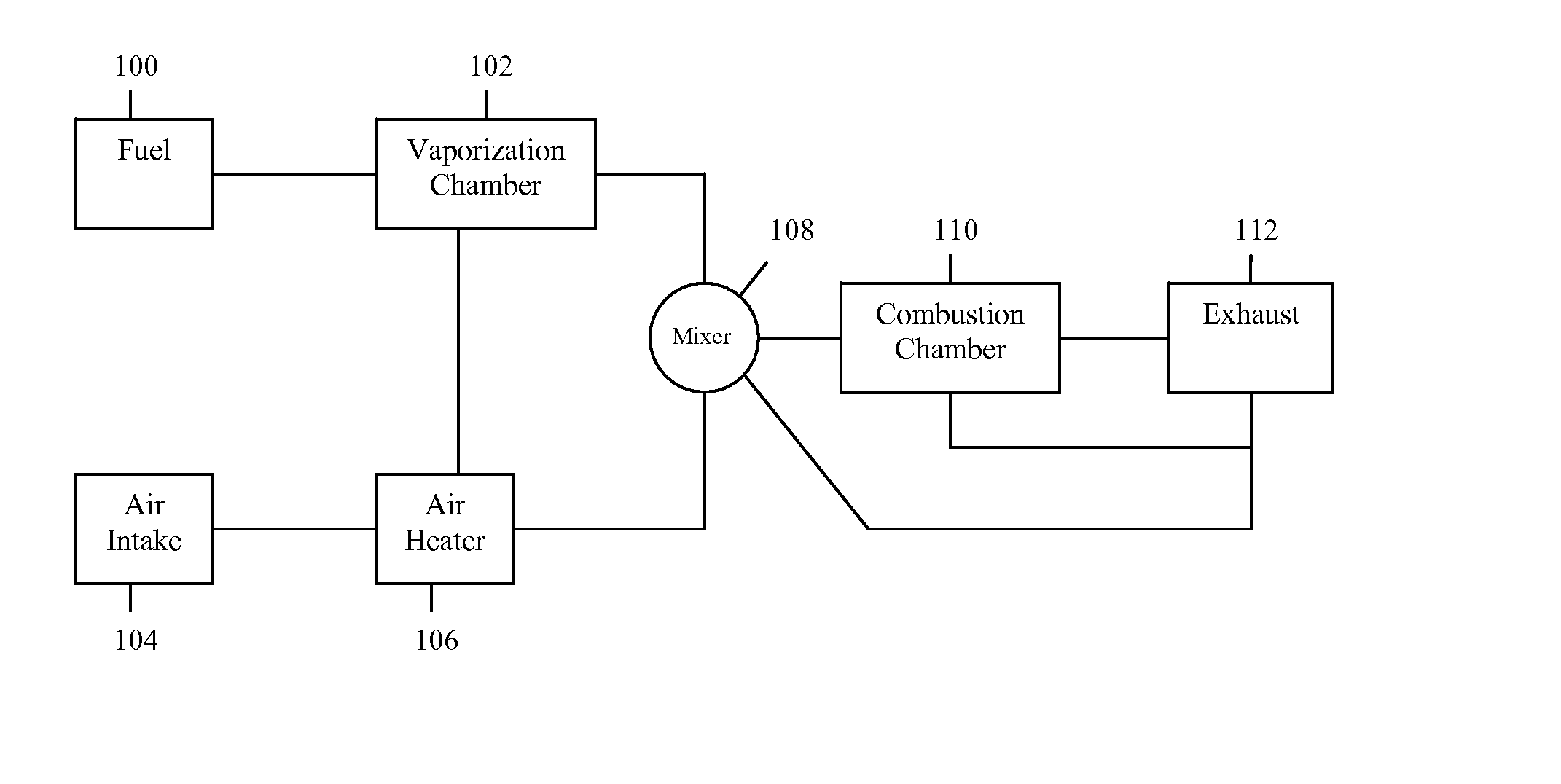

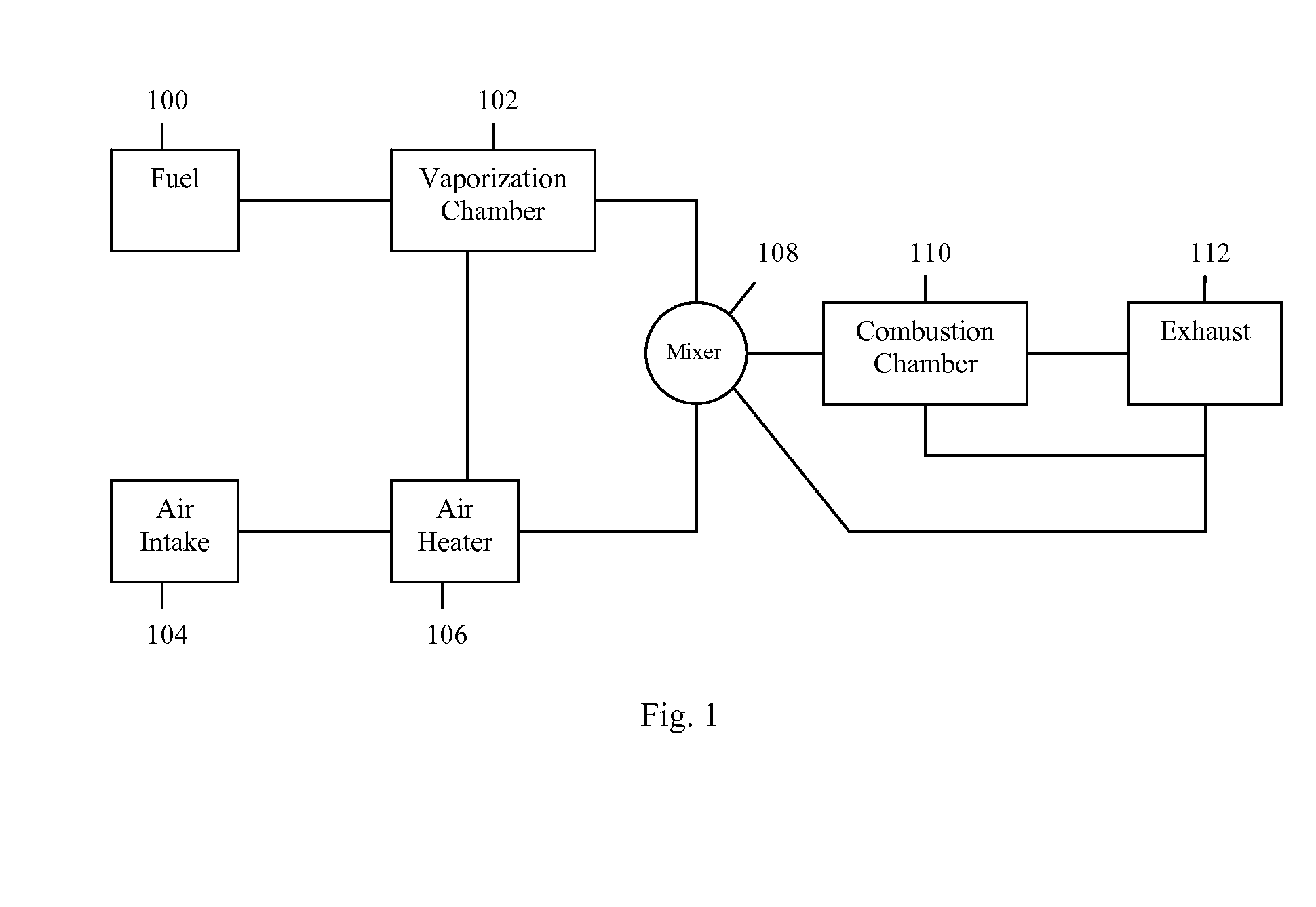

Fuel utilization

InactiveUS20080032245A1Less timeEfficient workBurnersLiquid fuel feeder/distributionFuel efficiencyEngineering

Embodiments of the present invention provide a fuel supply system for combustion engines, whereby the temperatures of an oxidizer and fuel may be increased so that the temperatures approach but do not achieve an auto-ignition temperature for the fuel charge. The fuel charge may result in substantial improvements in fuel efficiency.

Owner:VAPOR FUEL TECH

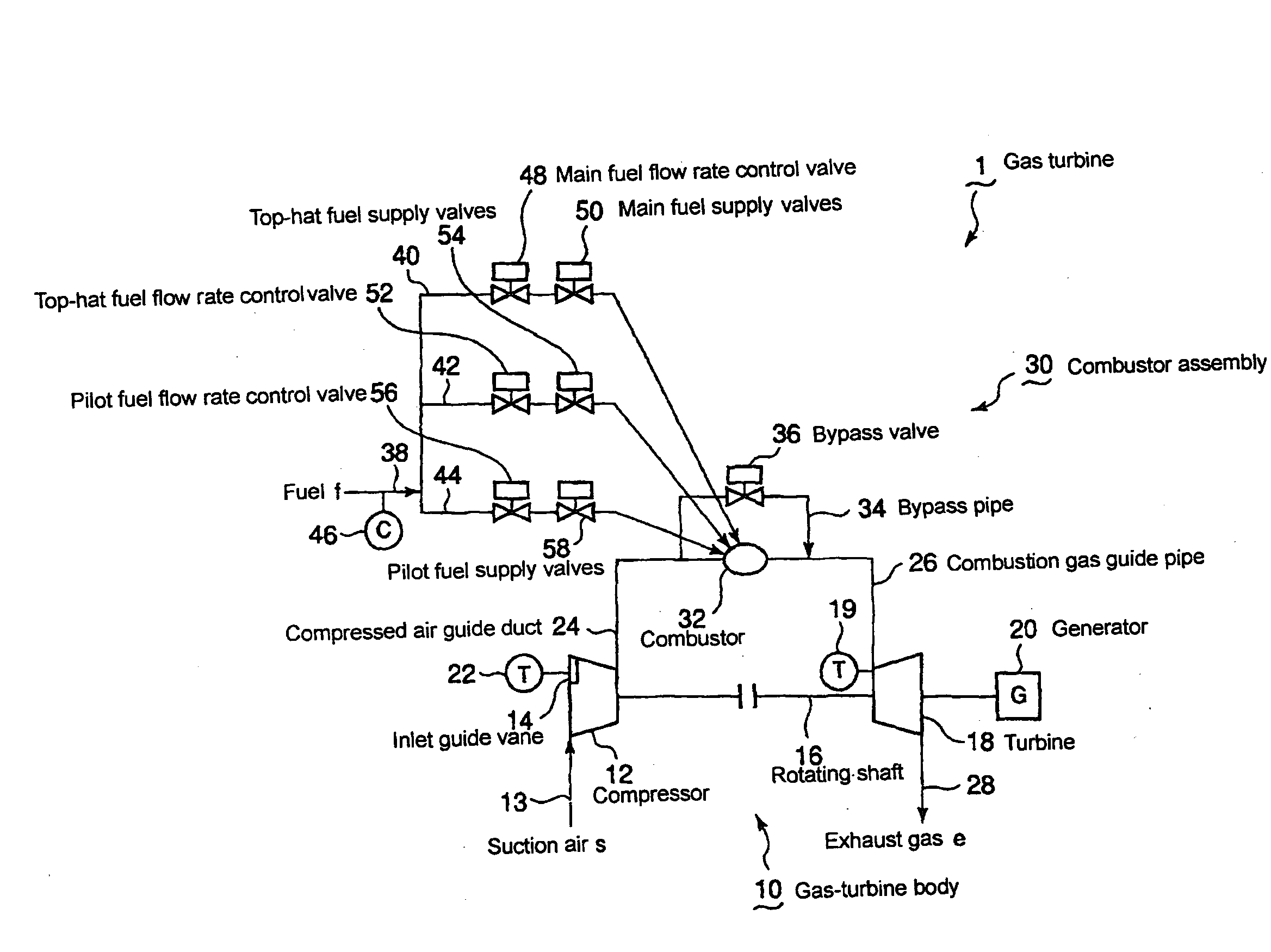

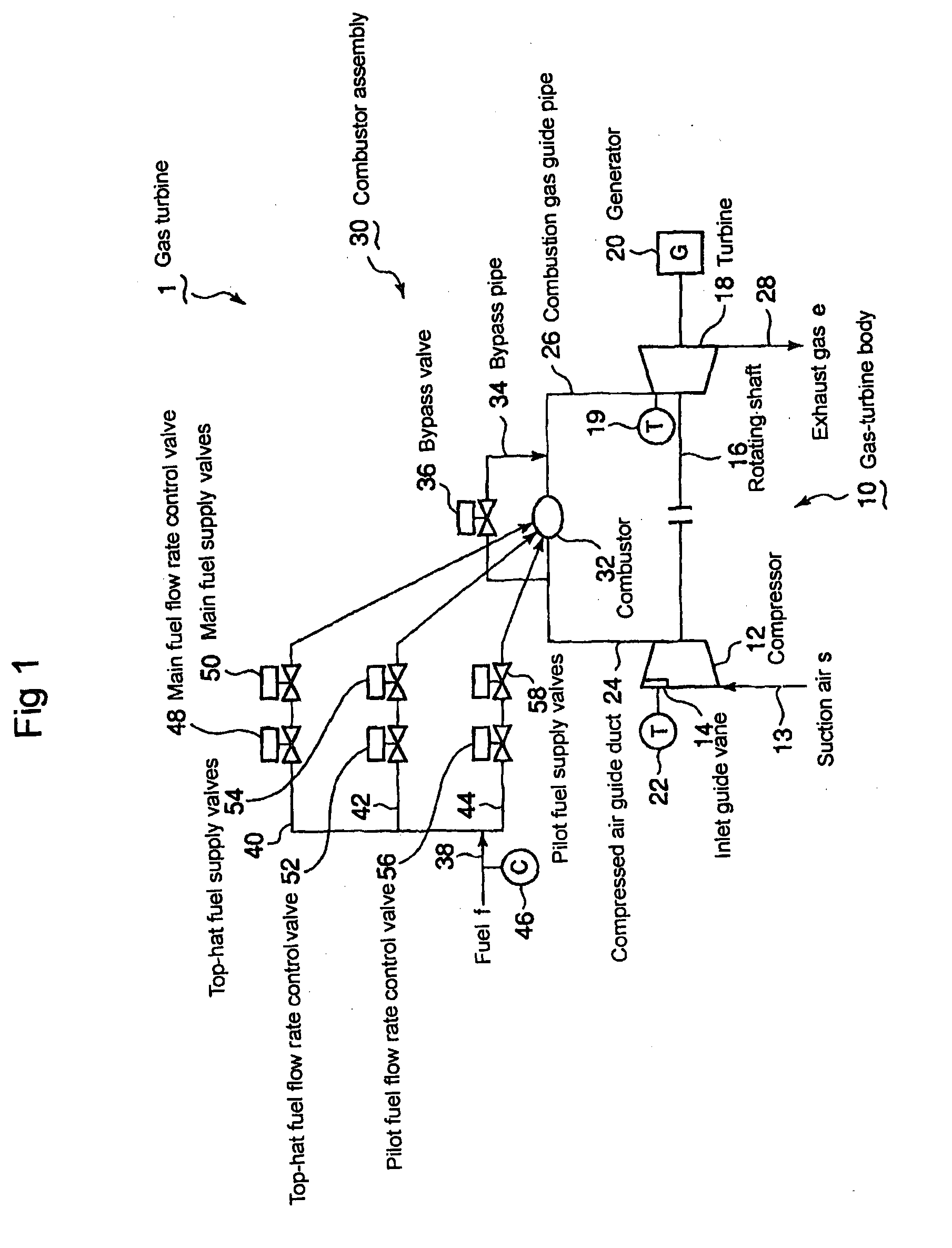

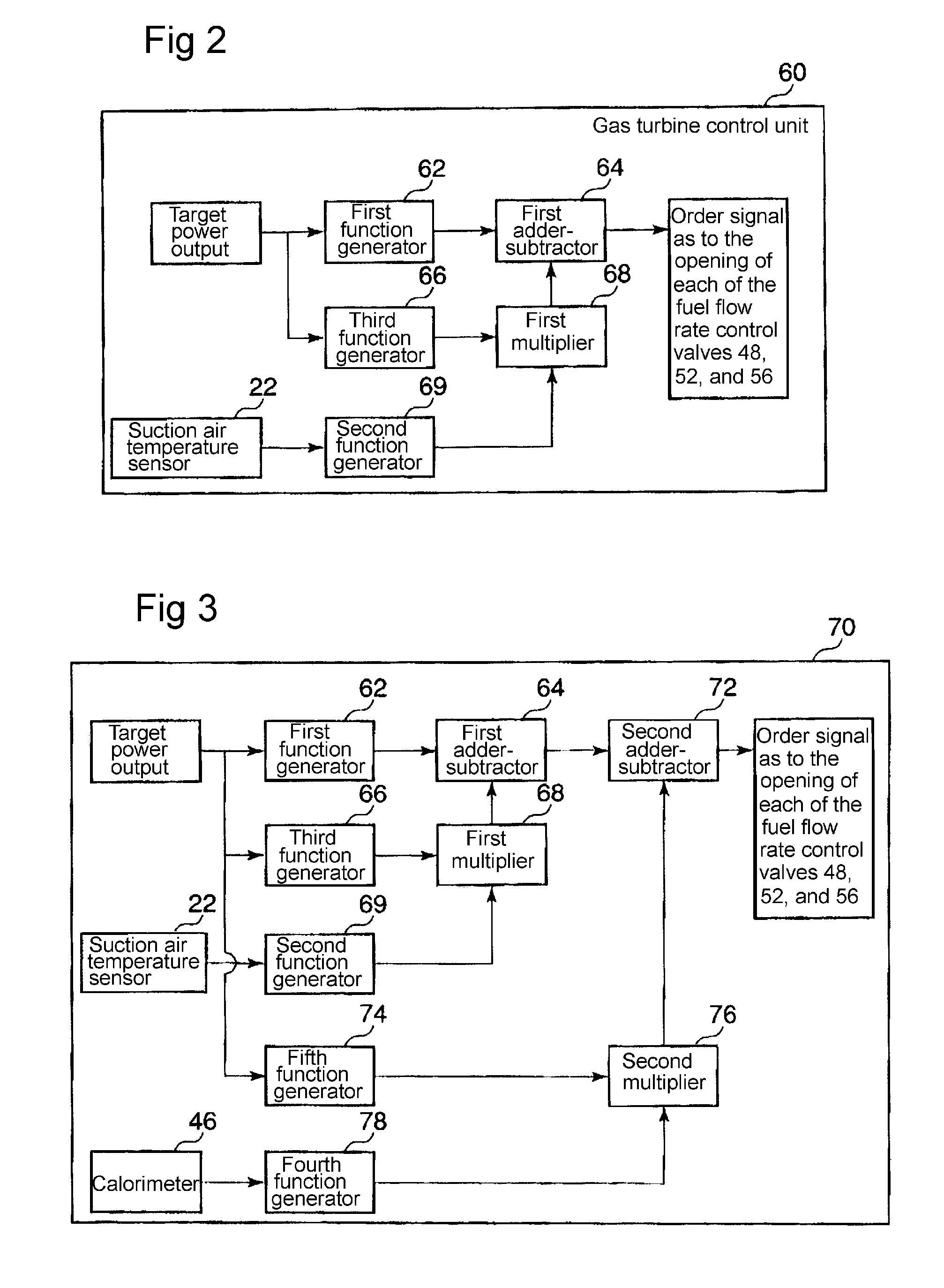

Gas turbine control device

ActiveUS20110056180A1Improve combustion stabilityAvoid vibrationFuel supply regulationContinuous combustion chamberCombustorEngineering

Occurrence of combustion vibration is prevented in a gas turbine plant by enhancing the degree of freedom in setting an airflow rate or a fuel flow rate in correspondence with a target load thereby enhancing combustion stability. A gas turbine controller comprises a first function generator (62) for setting the flow rate of fuel or air being supplied to a combustor (32) in correspondence with a target load, an suction air temperature sensor (22) for detecting intake temperature at the inlet of a compressor, a second function generator (69) for setting a correction amount of a set value of fuel flow rate or air flow rate based on the value detected by the suction air temperature sensor (22), a third function generator (66) for setting a modification amount of the correction amount while taking account of the target load, a first multiplier (68); for operating a modified correction amount from a correction amount set by the second function generator and a modification amount set by the third function generator, and a second multiplier (64) for calculating the flow rate of fuel or air being supplied to a combustor by adding the modified correction amount to the set value of fuel flow rate or air flow rate set by the first function generator.

Owner:MITSUBISHI POWER LTD

Modifying transport air to control NOX

InactiveUS20100275825A1Reduce the amount of solutionFuel supply regulationEmission preventionCombustion systemTransport medium

Using oxygen-lean gas as the transport medium in which pulverized fuel solids are conveyed to the burner of a combustion system permits combustion at levels of combustion rate and NOx production under circumstances under which those levels would not be attainable if the transport medium were air.

Owner:PRAXAIR TECH INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com