Modifying transport air to control NOX

a technology of transport air and nox, which is applied in the direction of emission prevention, combustion types, lighting and heating apparatus, etc., can solve the problems of limit on the production of emissions such as nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

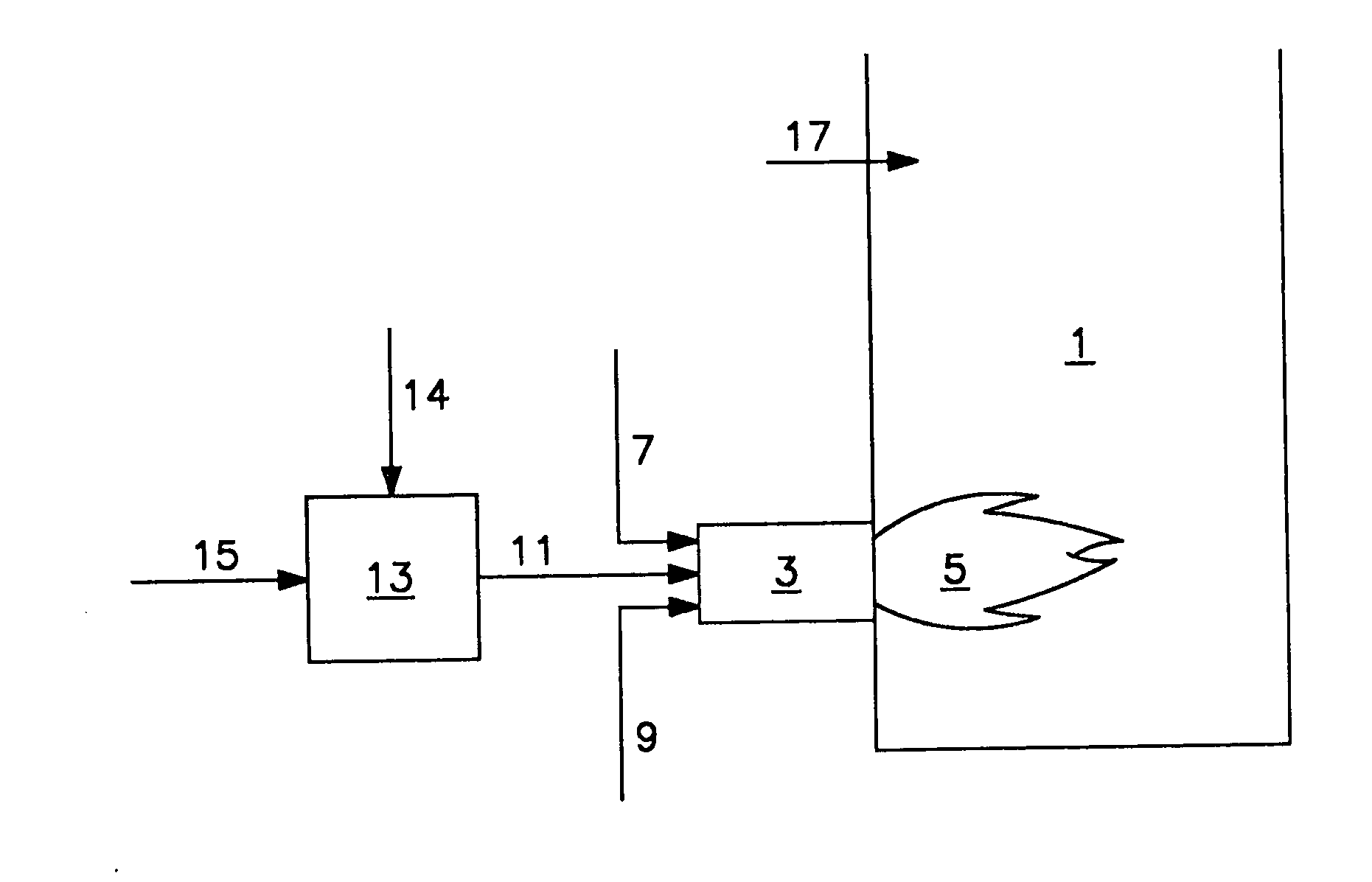

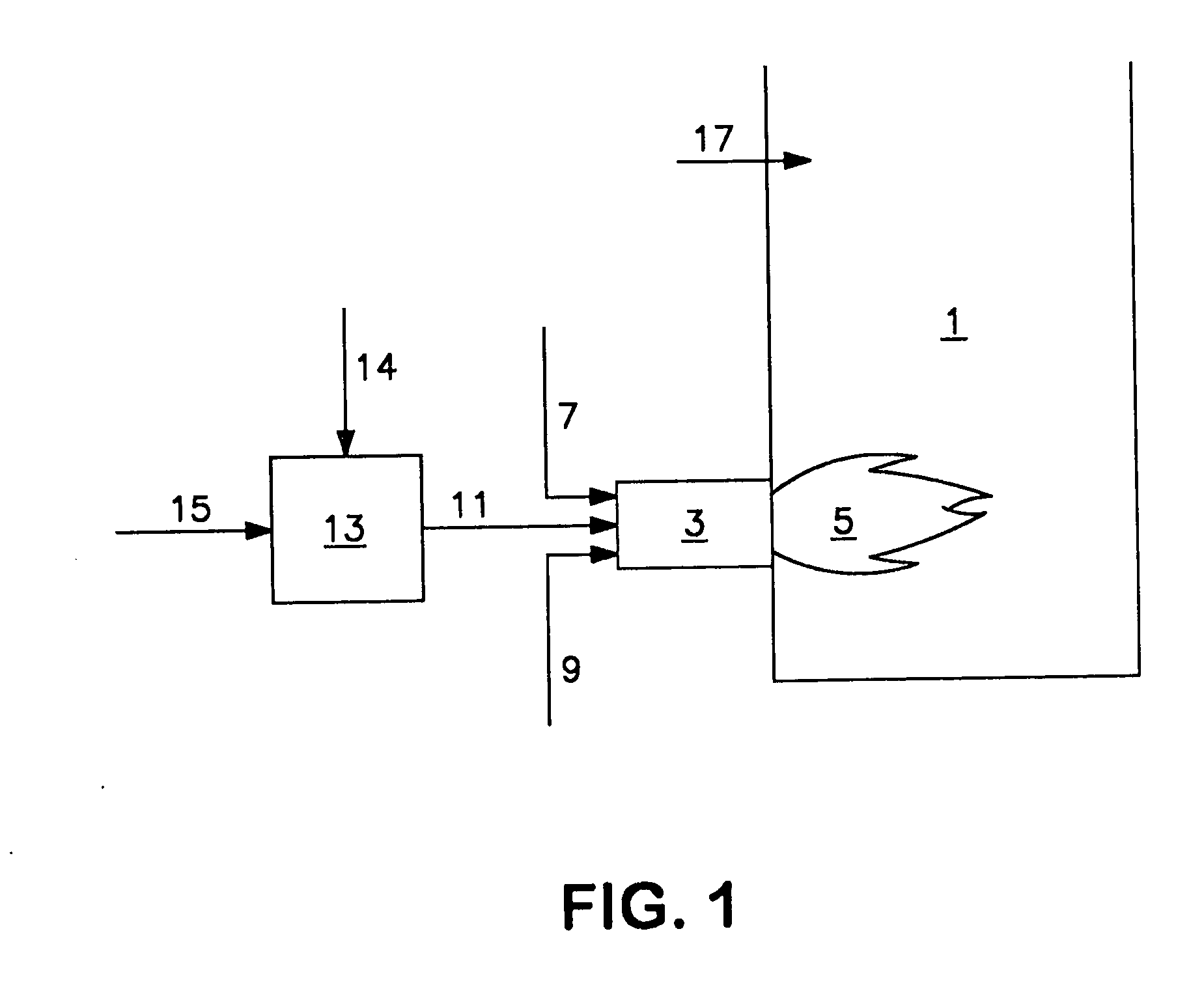

Image

Examples

example 1

[0046]In this example, a bituminous coal is assumed to be pulverized in a conventional pulverizer and combined with air at a mass ratio of transport air to fuel (TaF) of 1.8. The coal is assumed to have a moisture content of 8.5 wt. %. The moisture in the coal is reduced to 2.7 wt. % by combining it with air at a temperature of 500° F. in the pulverizer. The resulting stream of air and pulverized coal leaves the pulverizer at a temperature of 180° F.

[0047]If the same coal is then assumed to have an initial moisture content of 15 wt. %, then to reach the same final moisture content of 2.7 wt. % the amount of air at 500° F. fed to the pulverizer and combined with the fuel must be increased so that the TaF ratio of air to fuel increases to 2.0. This increase in the amount of air and, thus, the amount of oxygen being fed to the burner would be expected to cause an increase in the production of NOx upon combustion of this fuel.

[0048]In accordance with this invention, adding preheated nit...

example 2

[0049]This example shows the effect of switching from a bituminous coal to a subbituminous coal, having a lower specific energy value. The increased moisture content as well as the lower specific energy content of the subbituminous coal requires that a higher amount of coal be pulverized and fed to the burner to achieve the same rate of energy production in the combustion chamber. If this increased flow rate of fuel to the combustion chamber is achieved without increasing the TaF ratio, then much more oxygen will be fed into the combustion chamber because of the increased air flow, leading to increased production of NOx. If instead it is assumed that the same degree of moisture removal is achieved, even then the TaF must increase again leading to production of increased amounts of NOx. The calculations presented in Table 2 again illustrate that adding nitrogen to the transport air, rather than increasing the amount of transport air, would be expected to produce less NOx.

TABLE 2Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com