Patents

Literature

213results about "Gaseous fuel pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

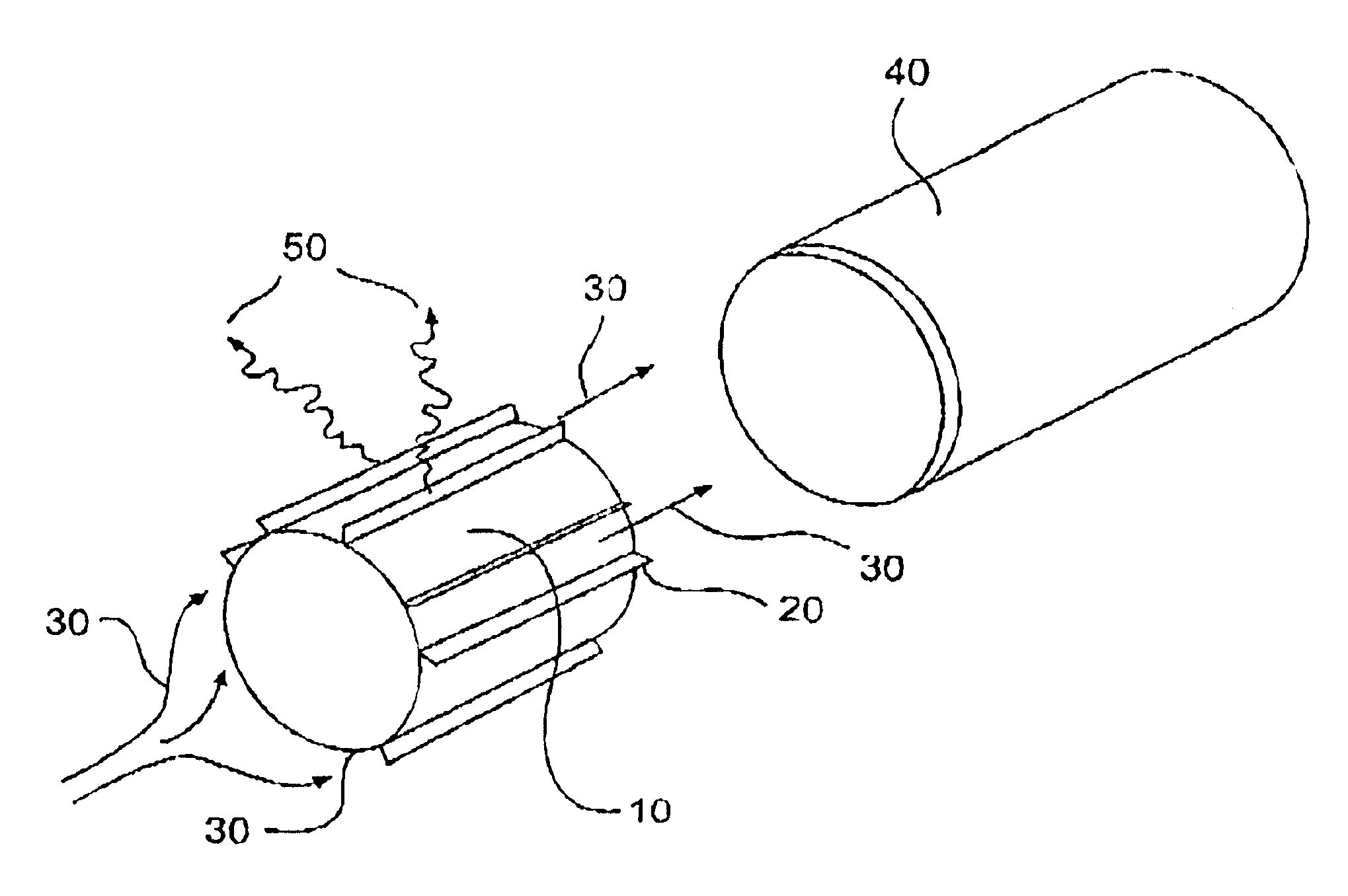

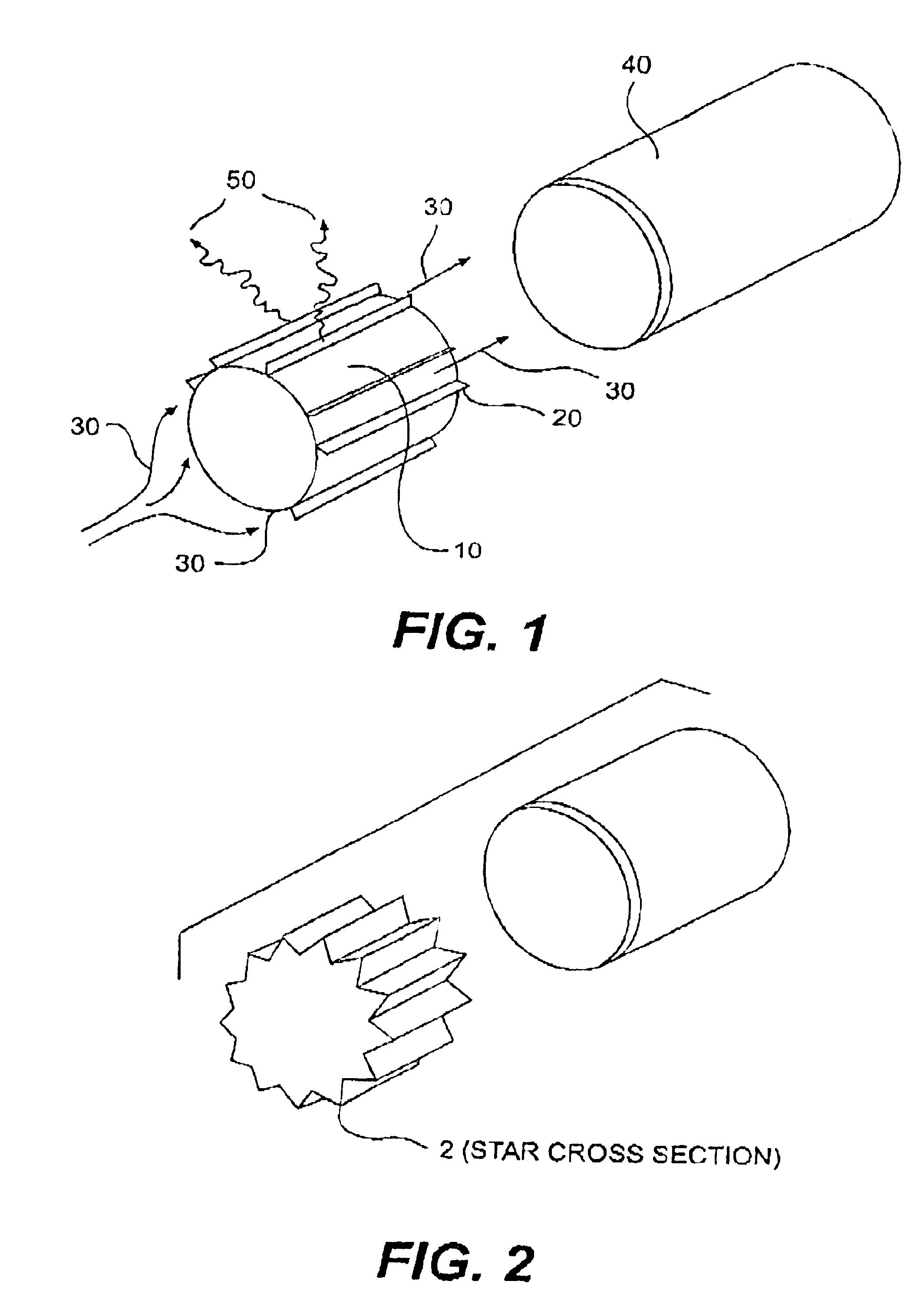

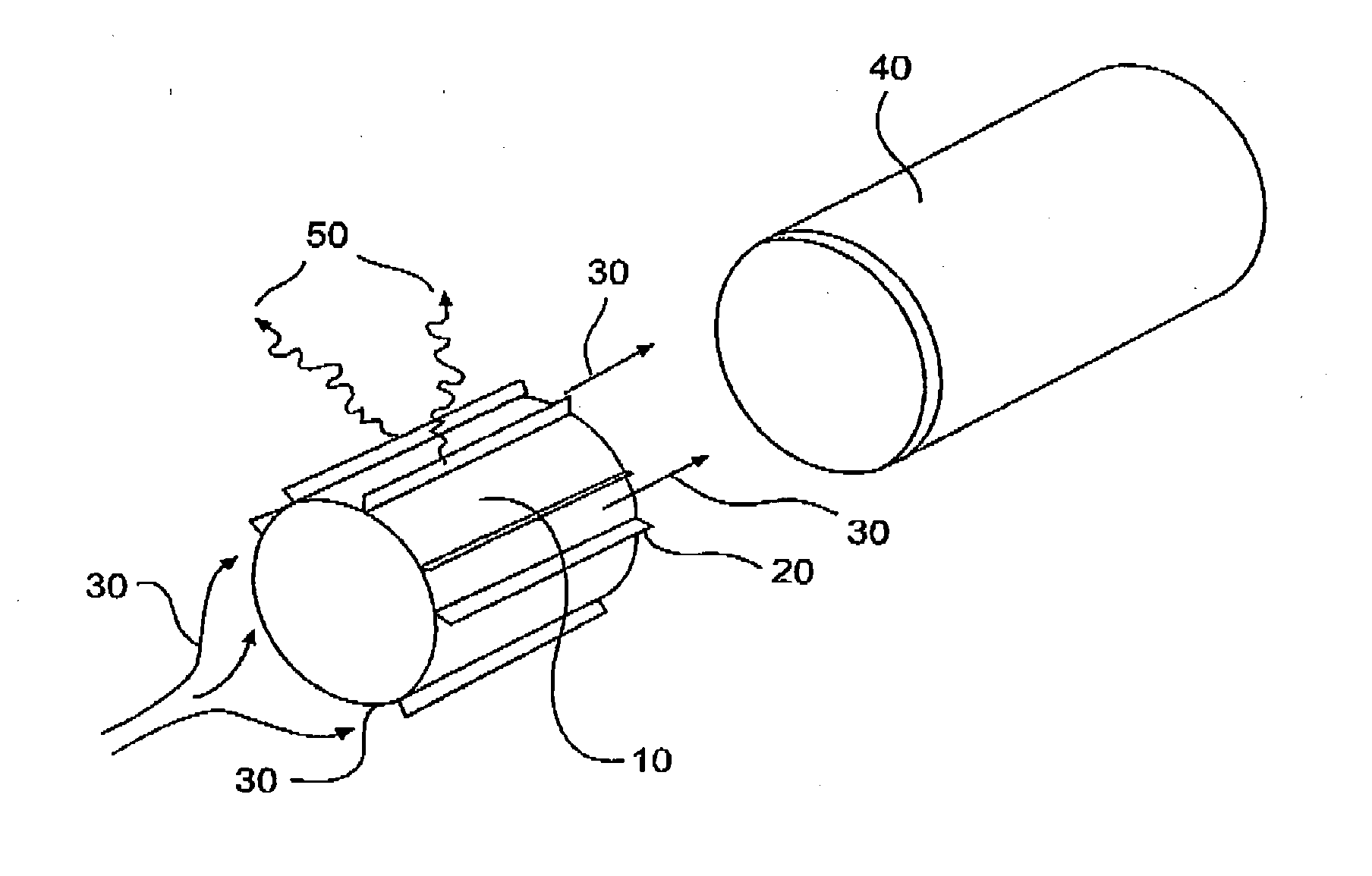

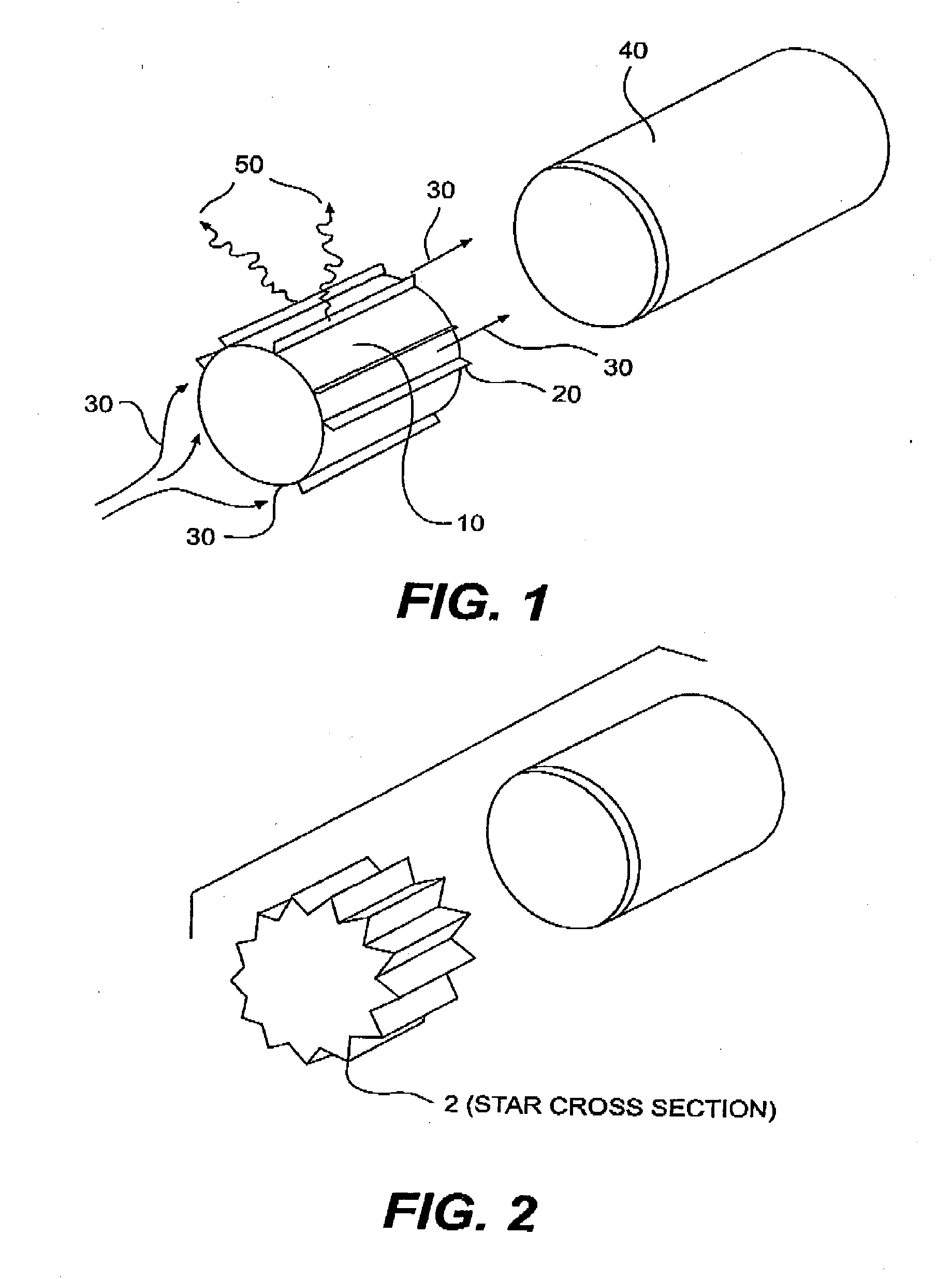

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

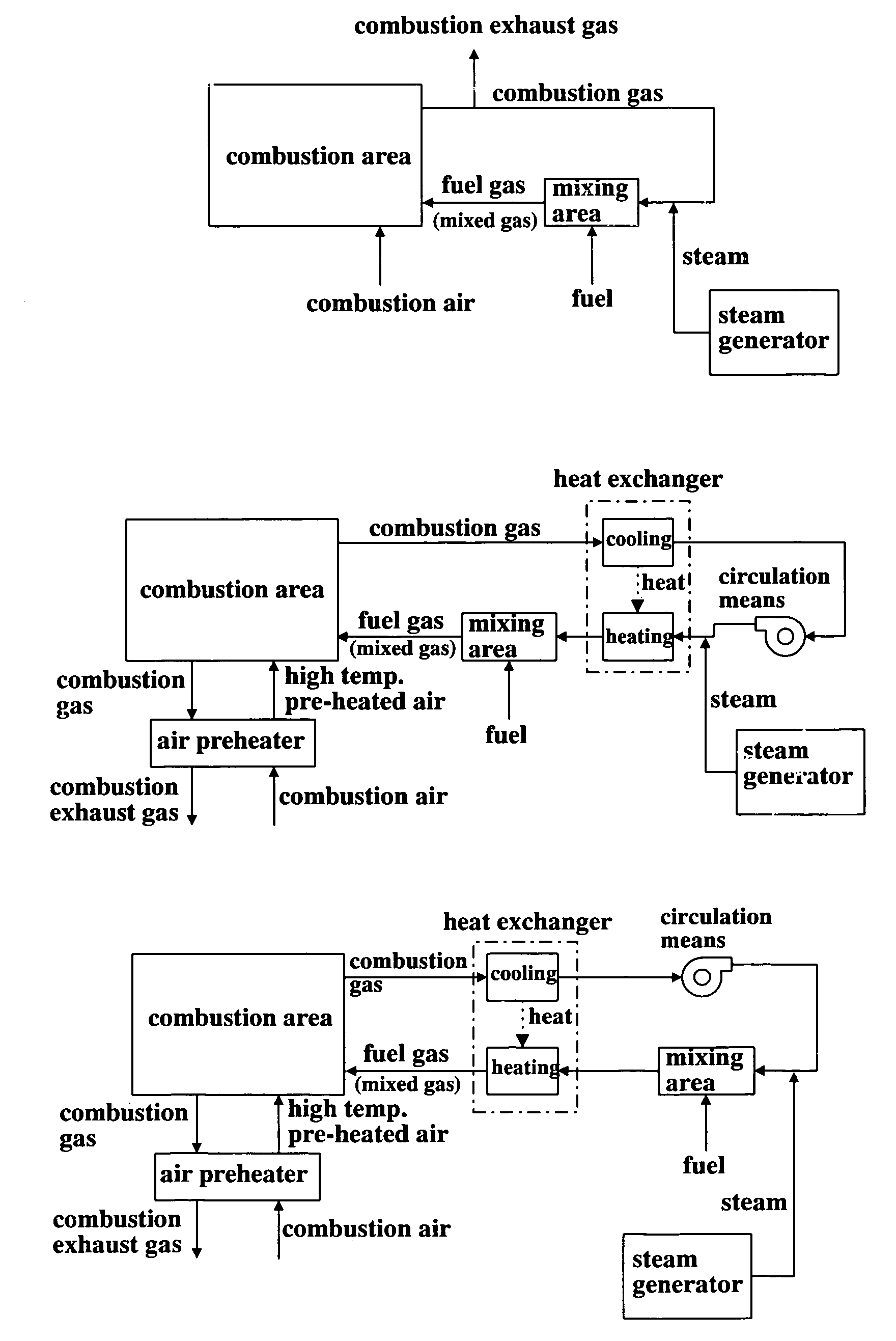

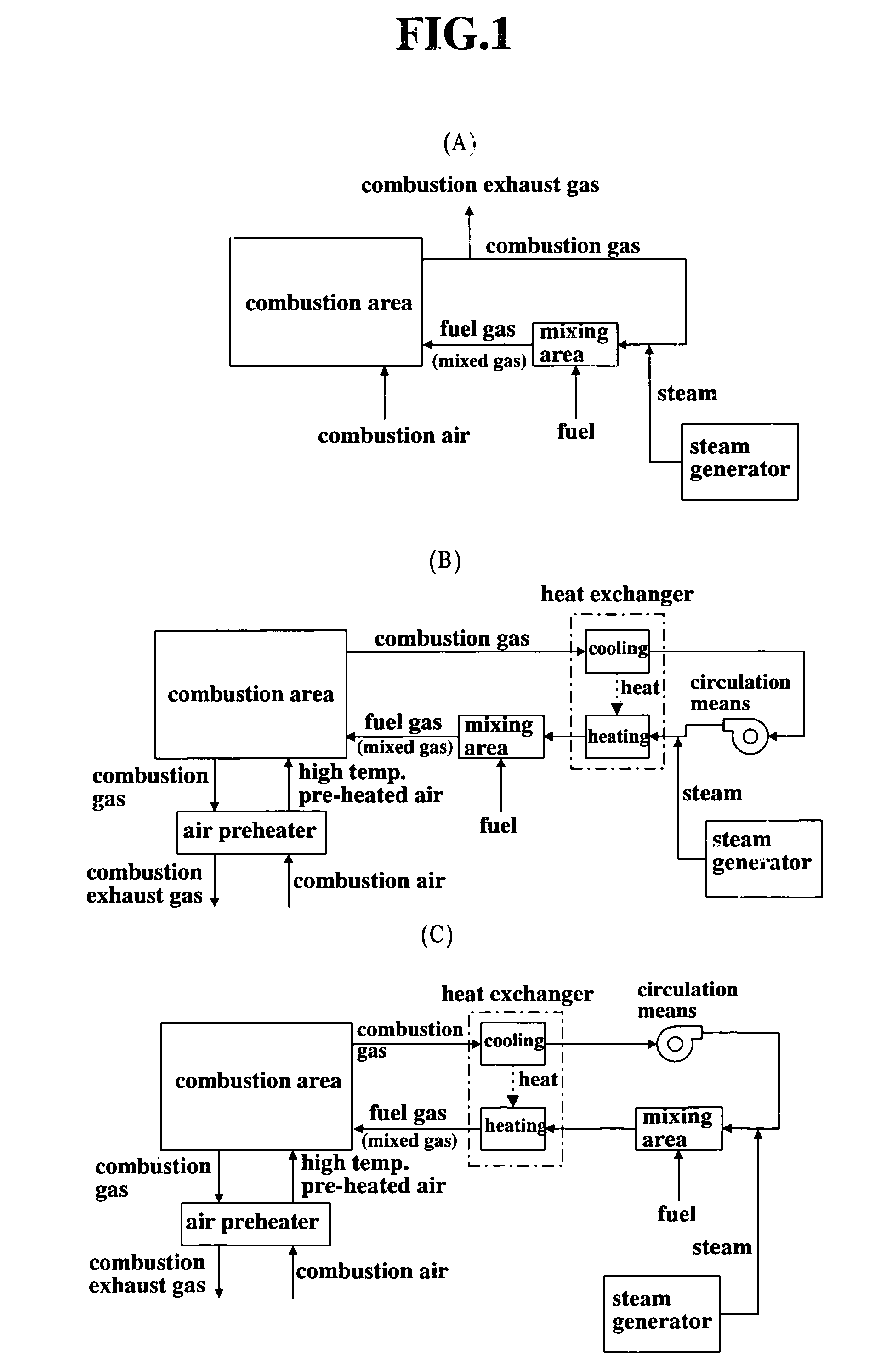

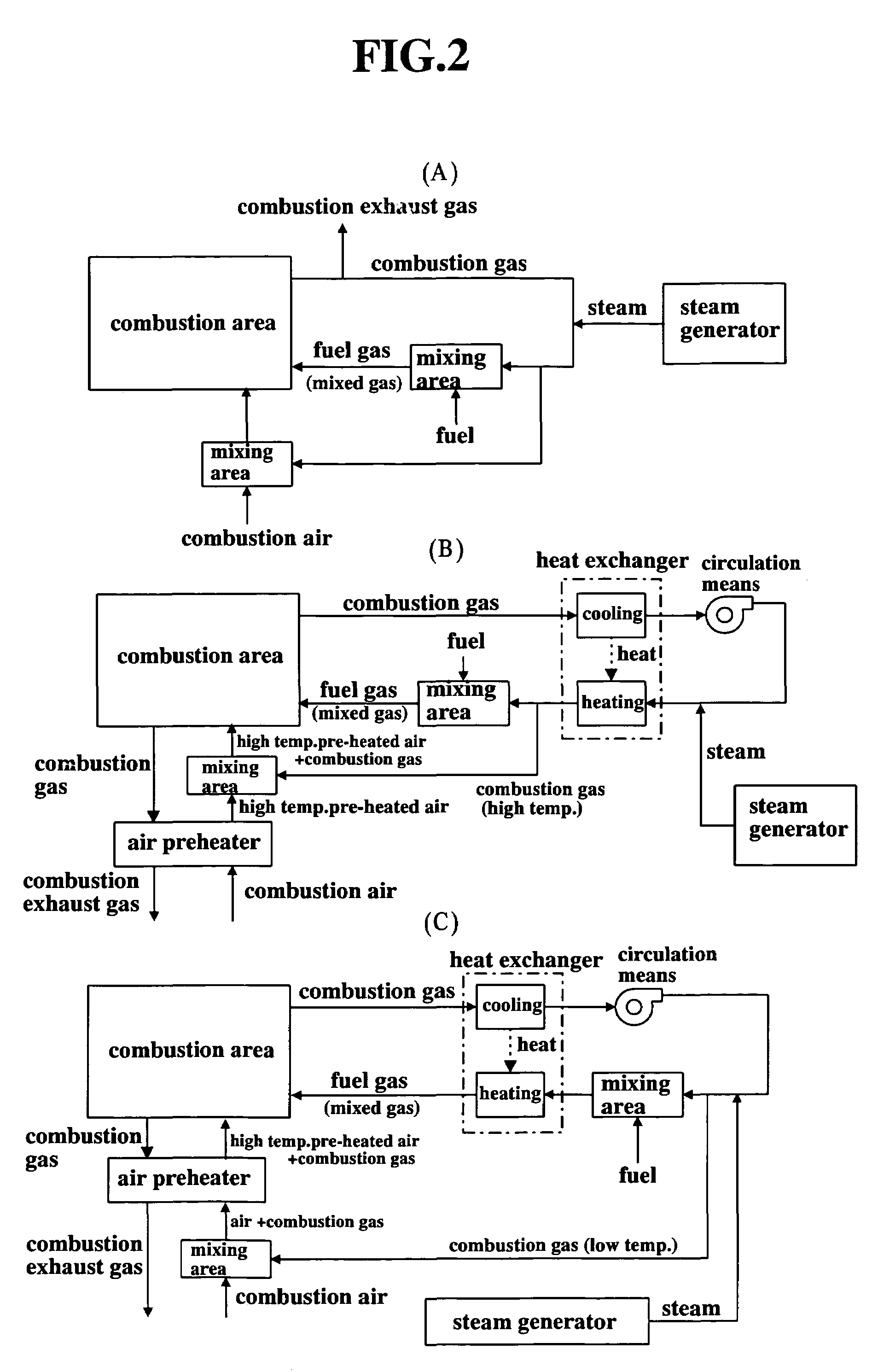

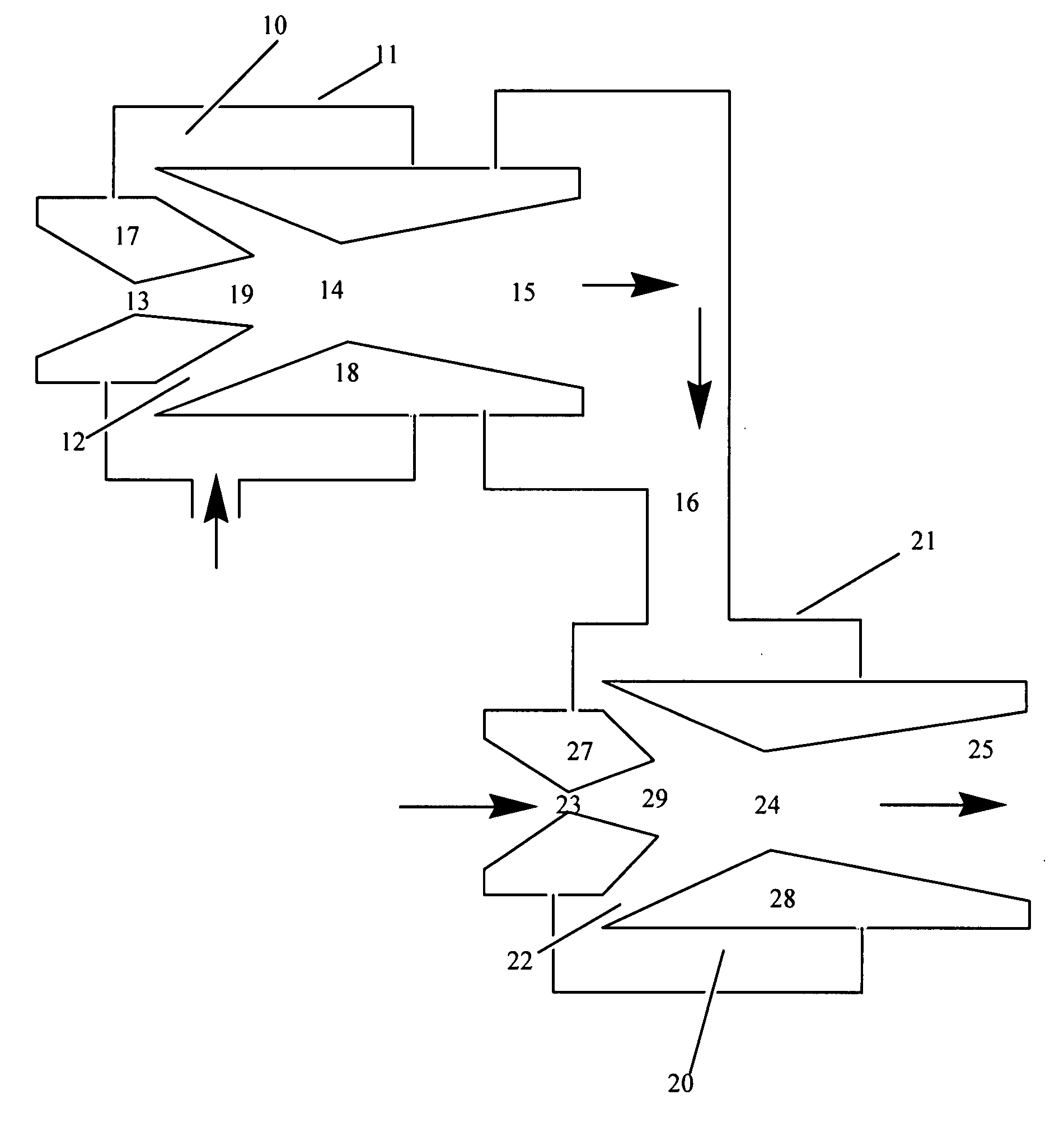

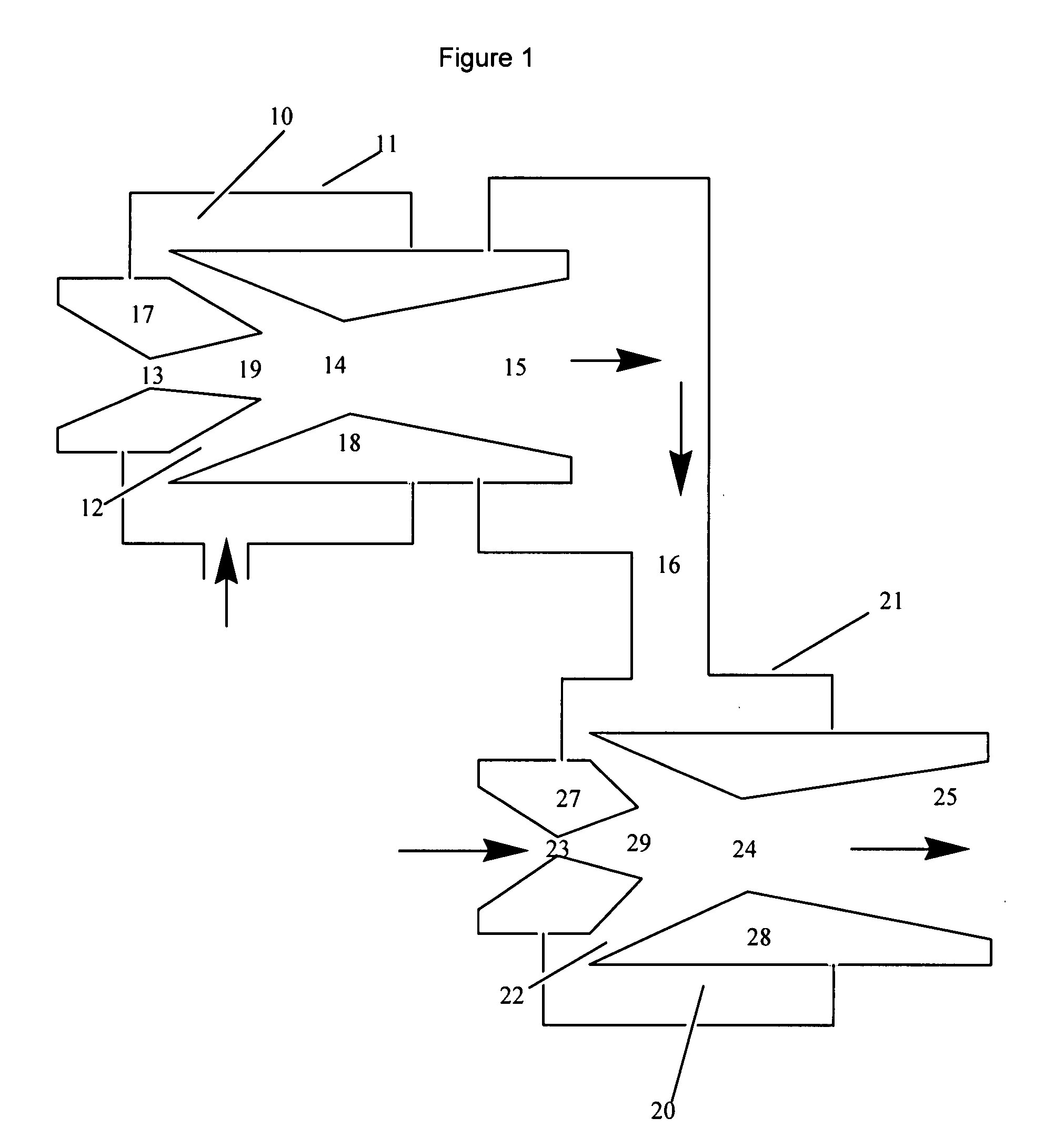

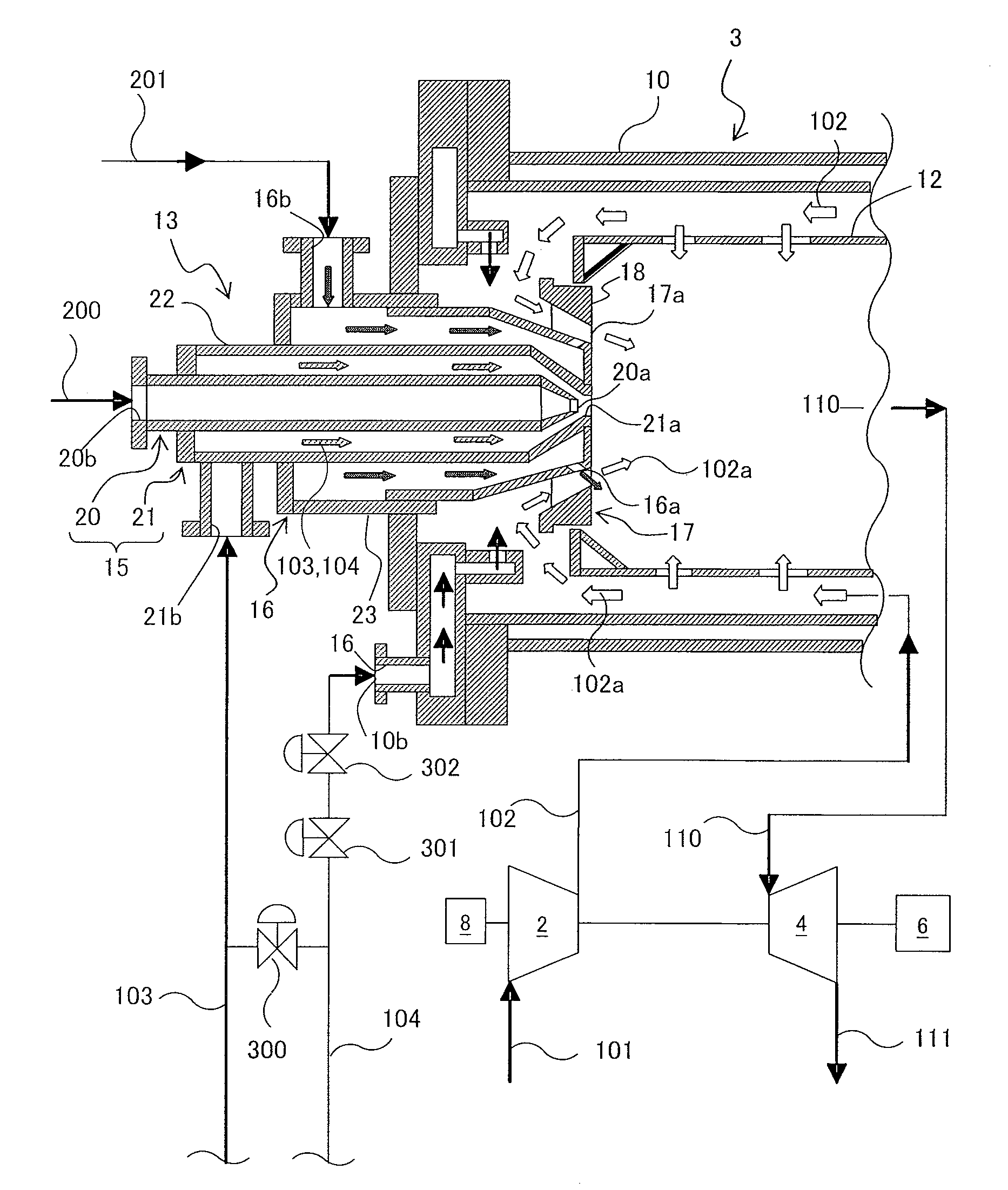

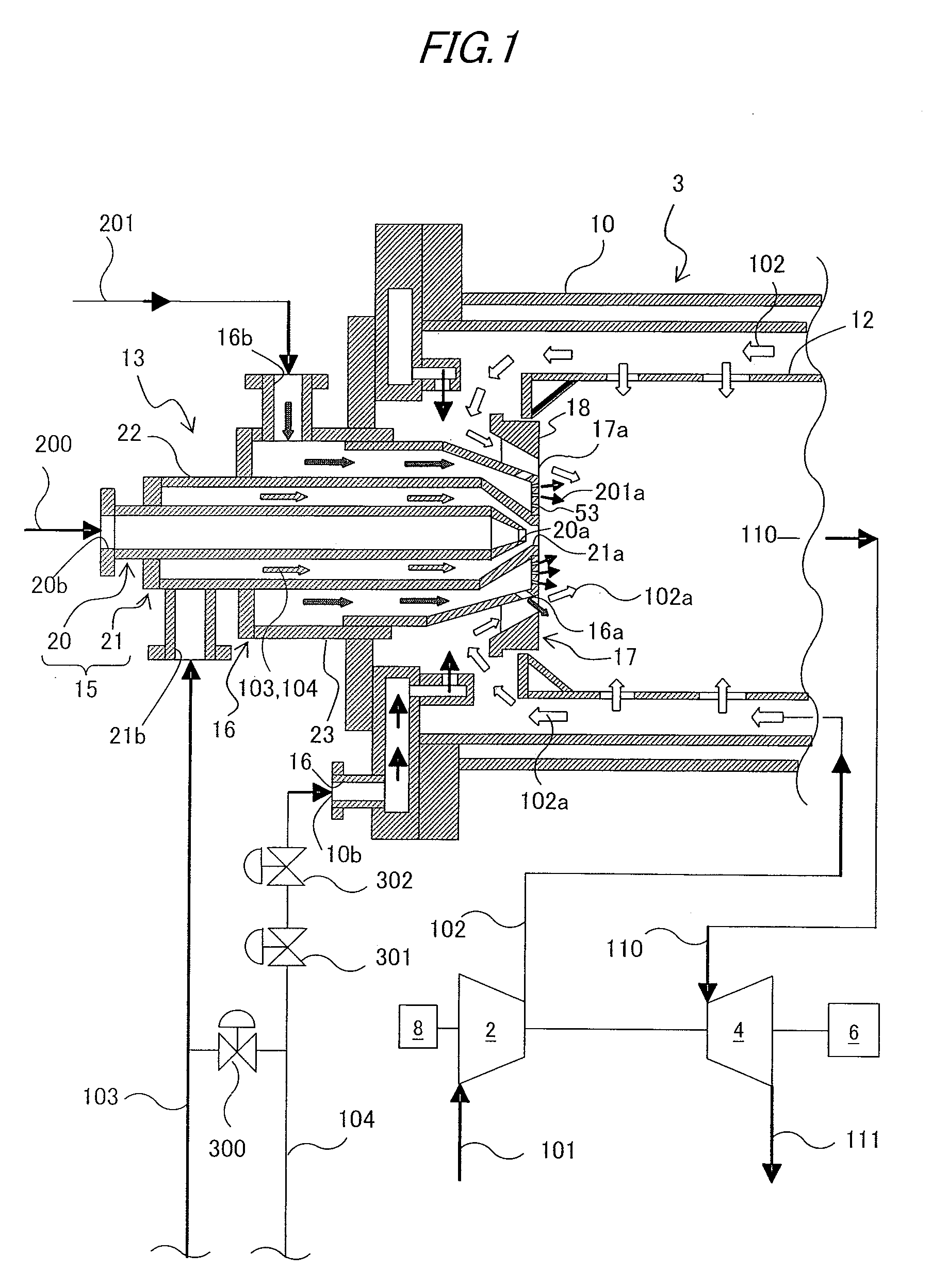

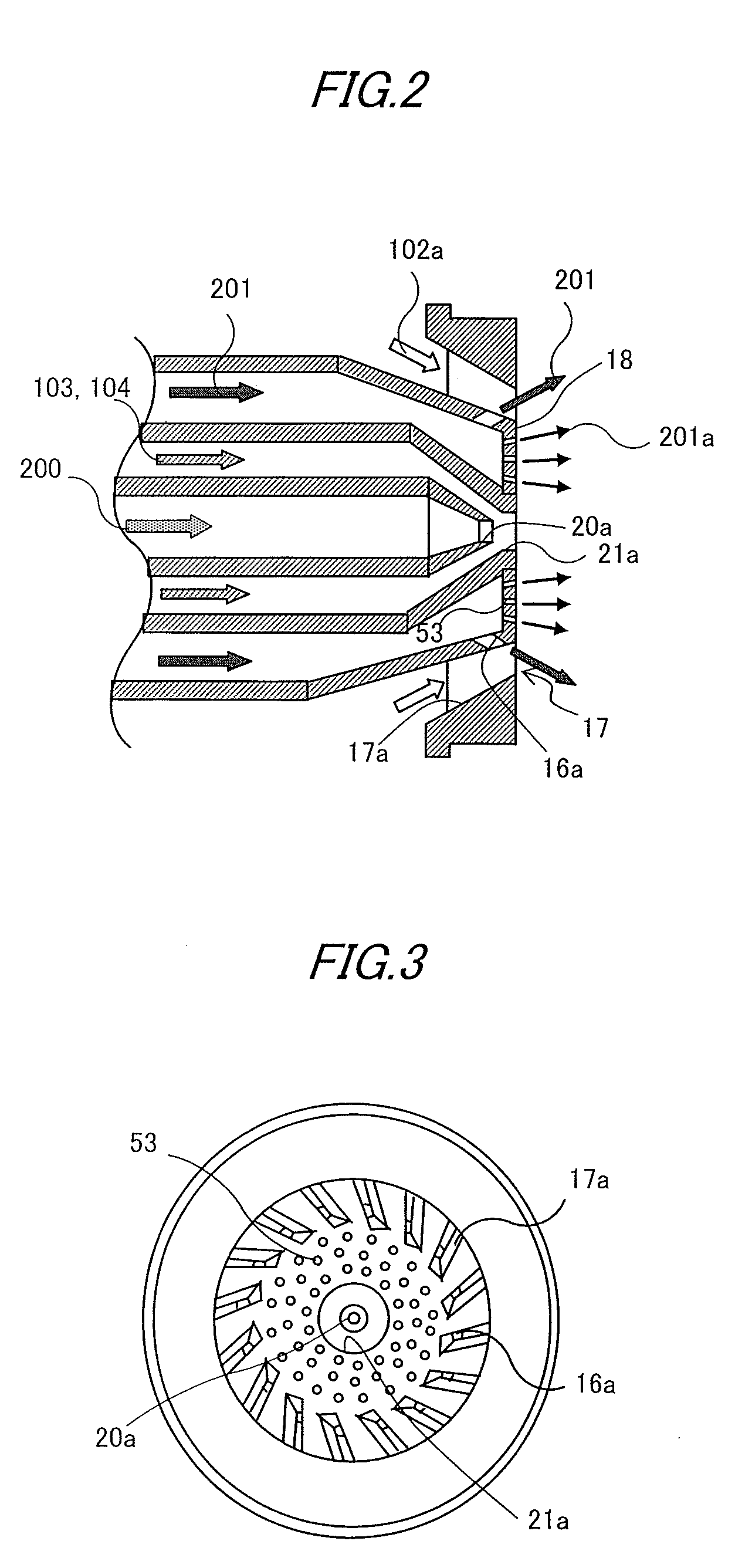

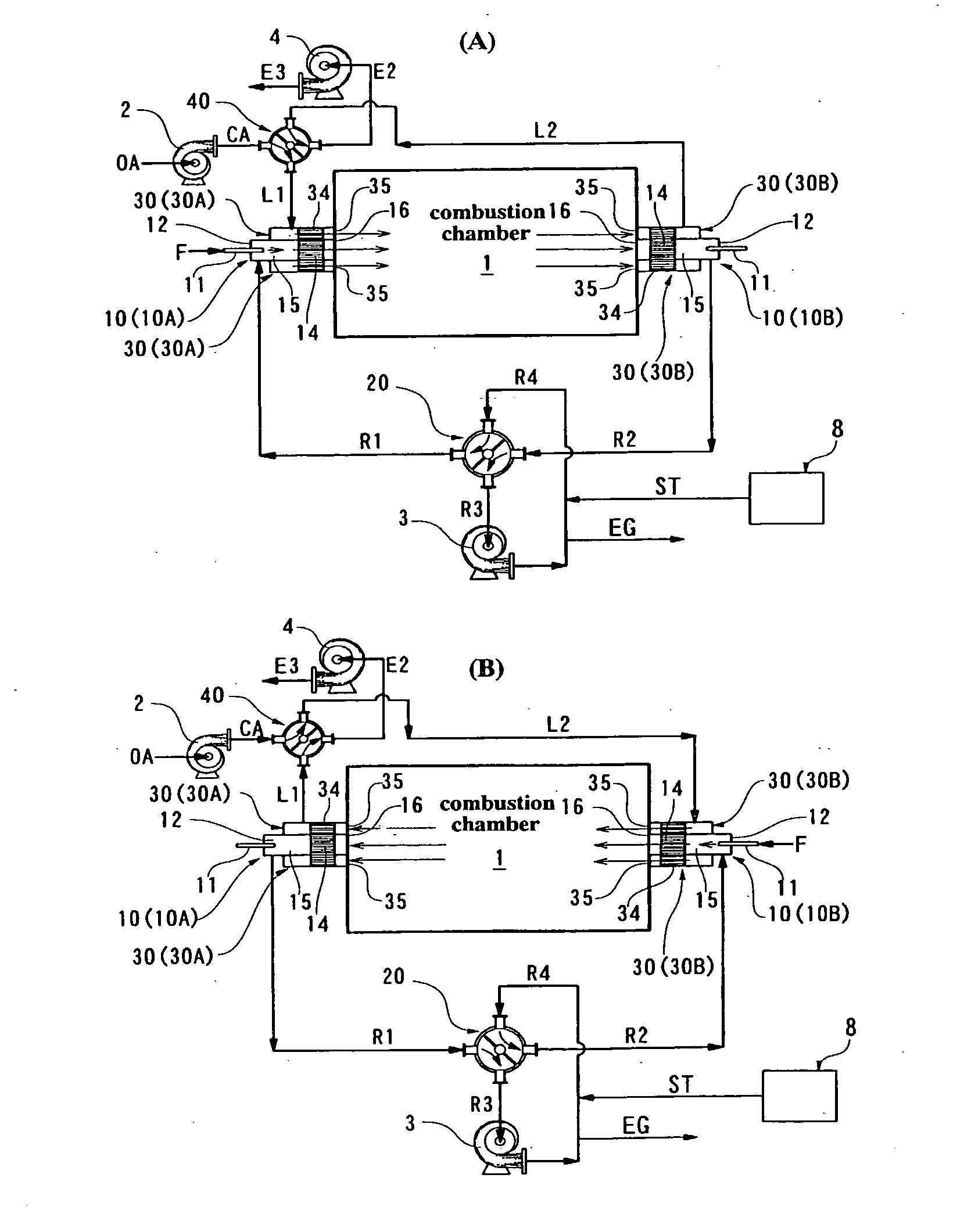

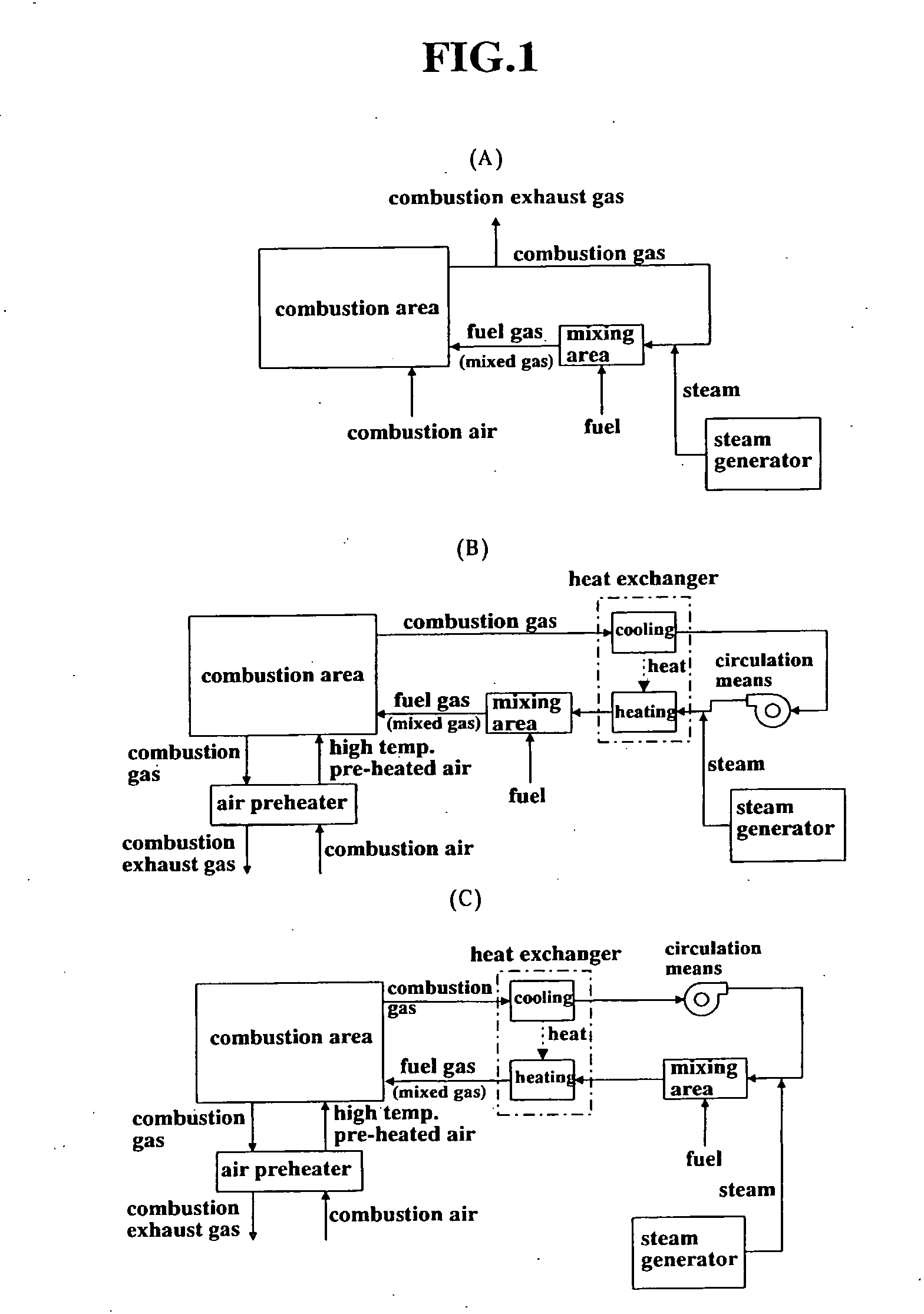

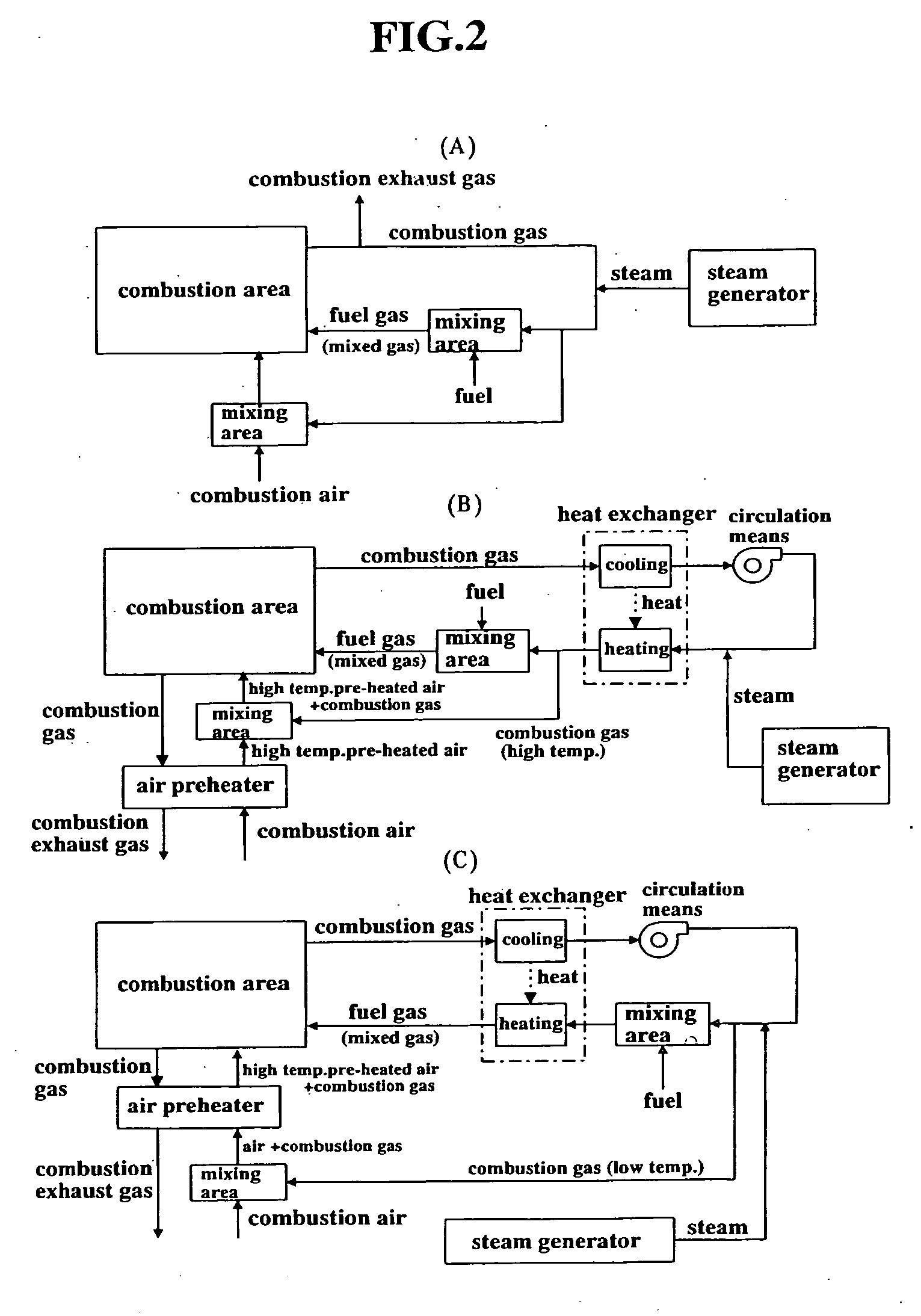

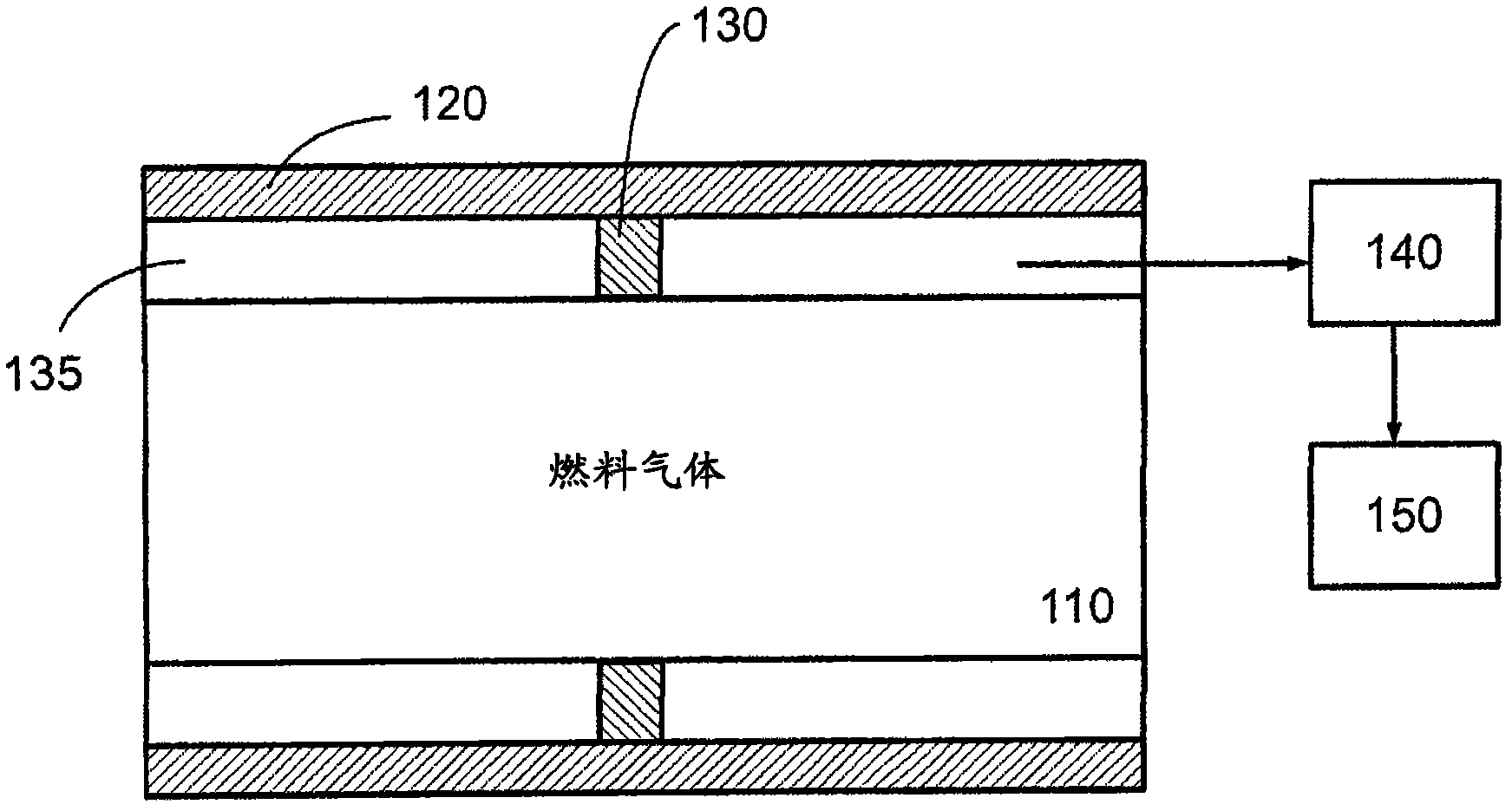

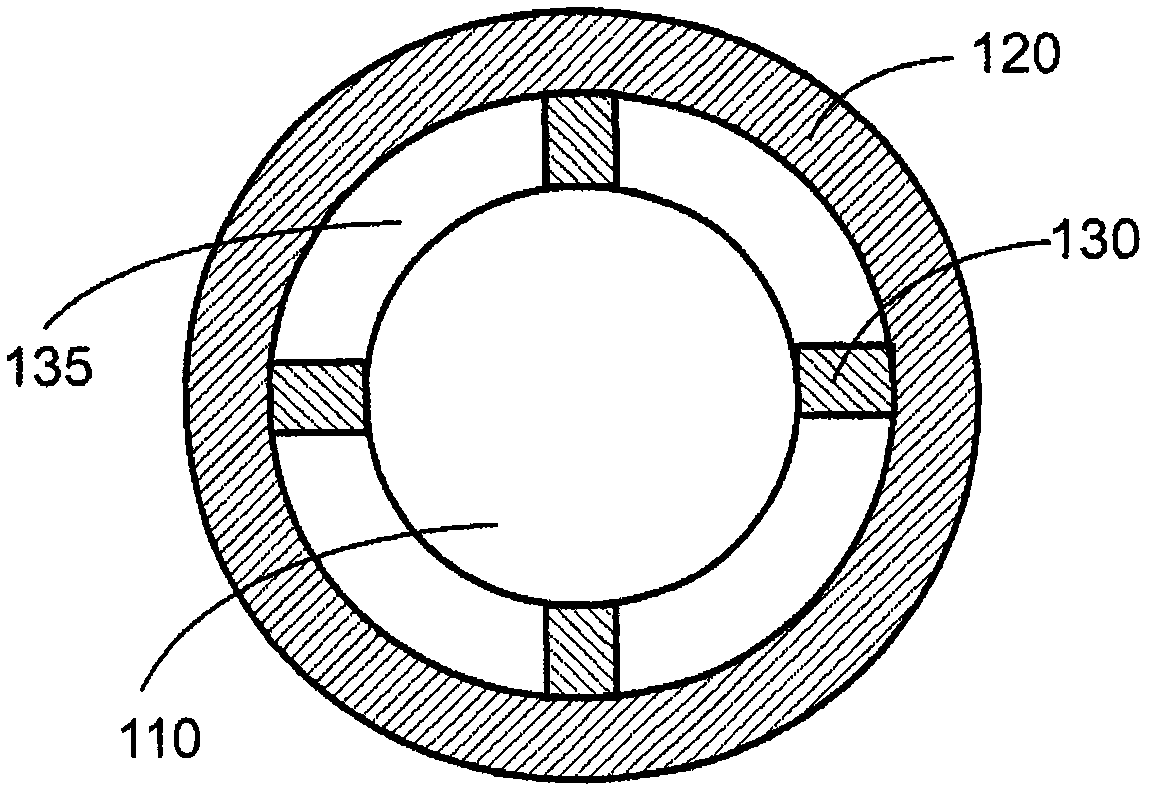

Device and method for feeding fuel

InactiveUS7104784B1Control of combustionReduced flexibilityGaseous fuel pretreatmentCombustion using multiple fuelsCombustion systemProduct gas

The present invention provides a fuel feeding apparatus and method for improving the controllability of mixing process and mixing ratio of fuel and combustion air, and a combustion system and method for effecting new combustion properties. The fuel feeding apparatus of the combustion system has fuel feeding means, combustion gas extraction means, steam supply means, mixing means and fuel gas introduction means. The combustion gas extraction means extracts combustion gas of a combustion area therefrom. The mixing means mixes the fuel of fuel feeding means with at least one of combustion gas extracted from the furnace and steam of a steam generator. The fuel gas introduction means introduces a mixed fluid of combustion gas, steam and fuel to the combustion area as a fuel gas, and allows the fuel gas to be mixed with the combustion air. A step of mixing the fuel with the combustion gas after extracted from the furnace and a step of mixing the fuel gas with the combustion air are stepwisely carried out, so that the controllability of mixing process and ratio of the air and fuel is improved. Such a control of fuel gas flow enables control of characteristics of flame and production of flame with new properties in the combustion area.

Owner:NFK HLDG

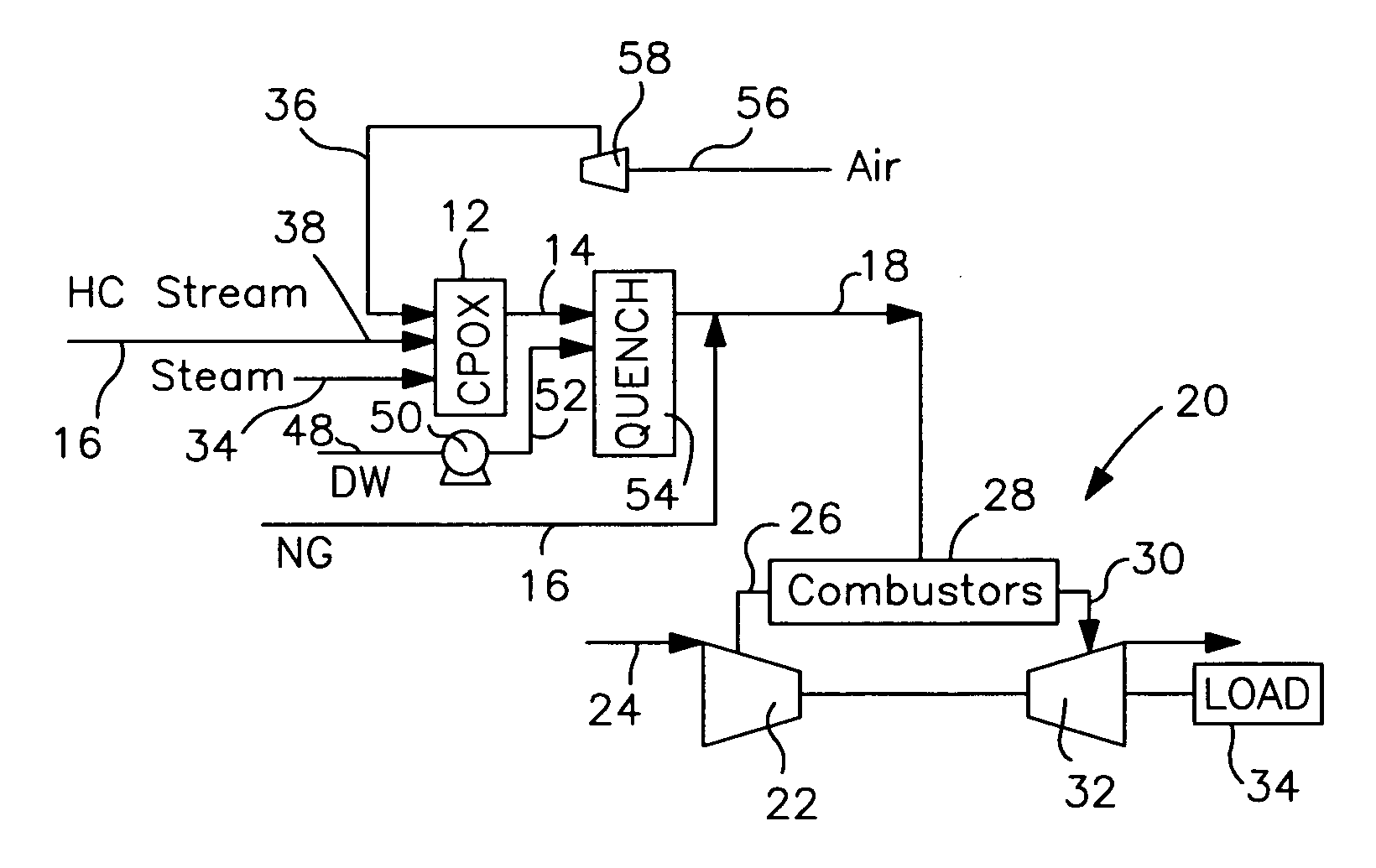

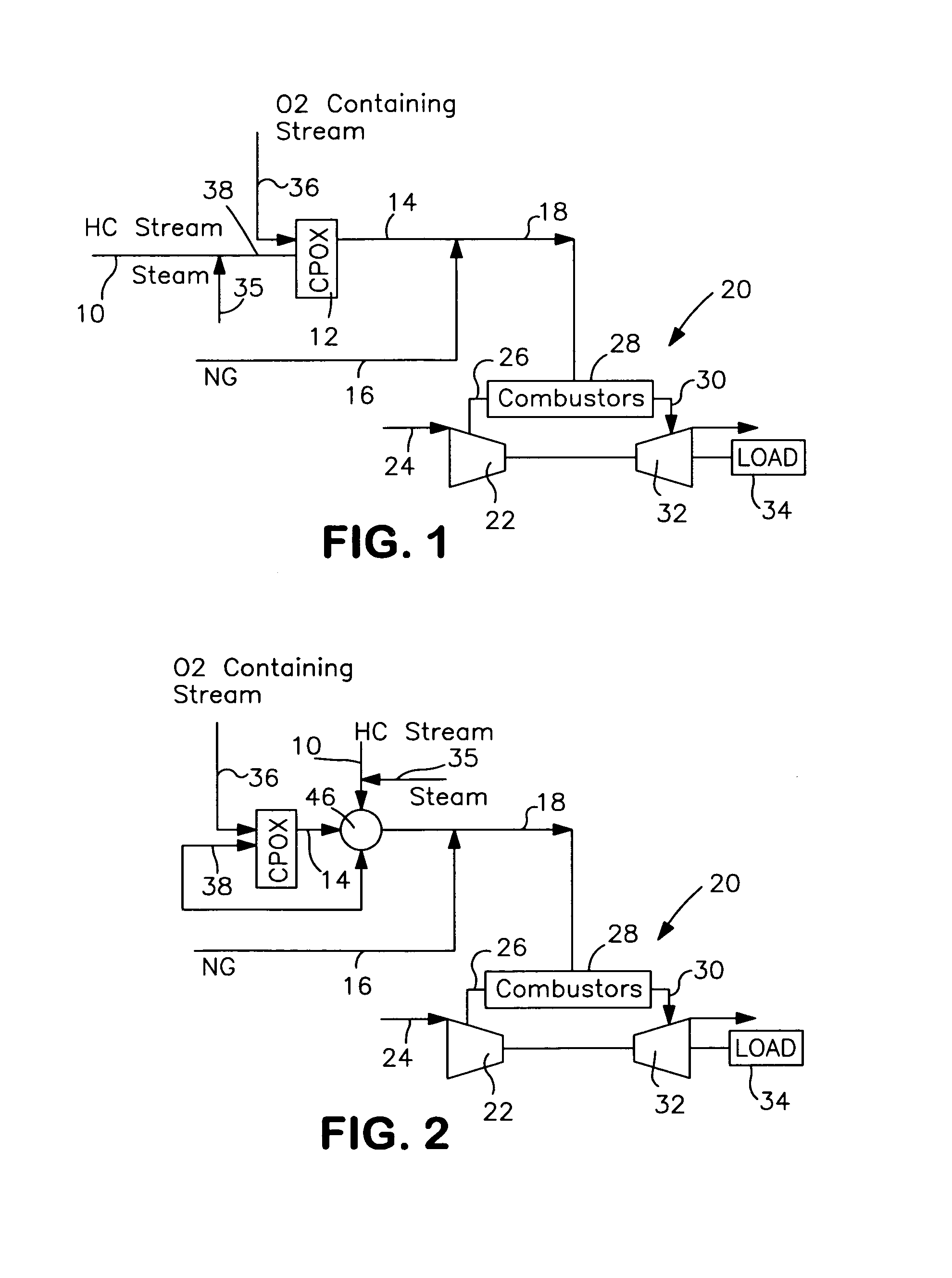

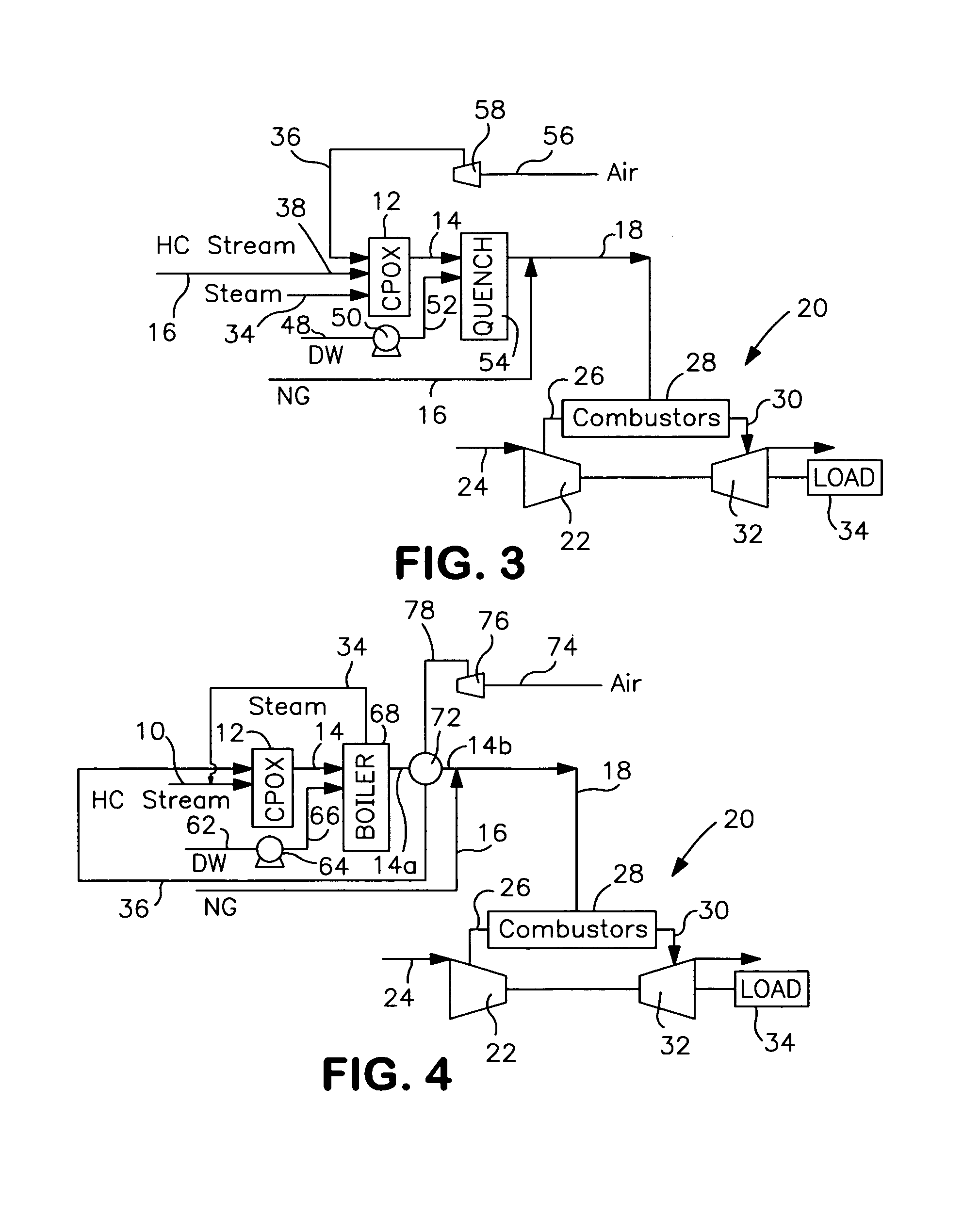

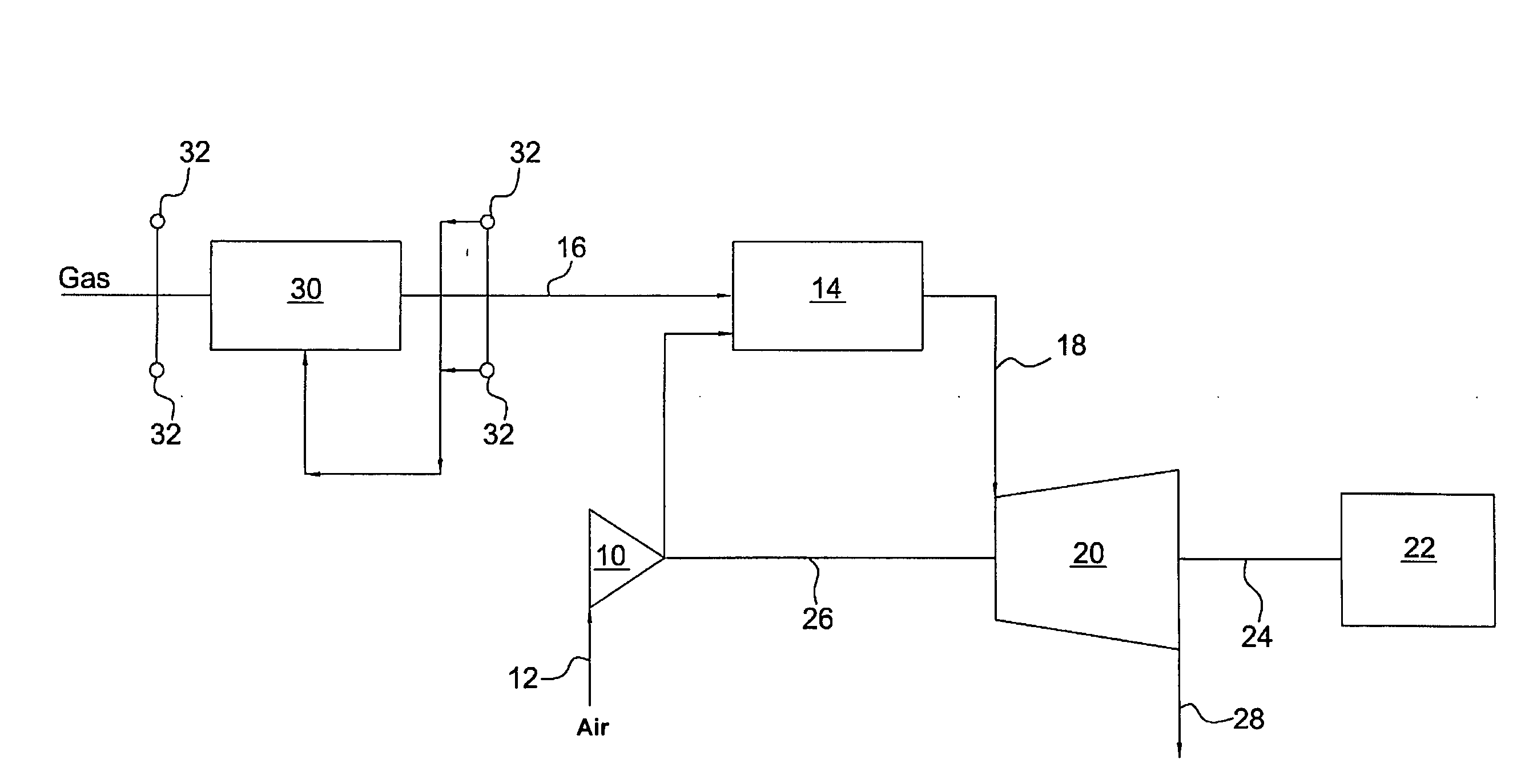

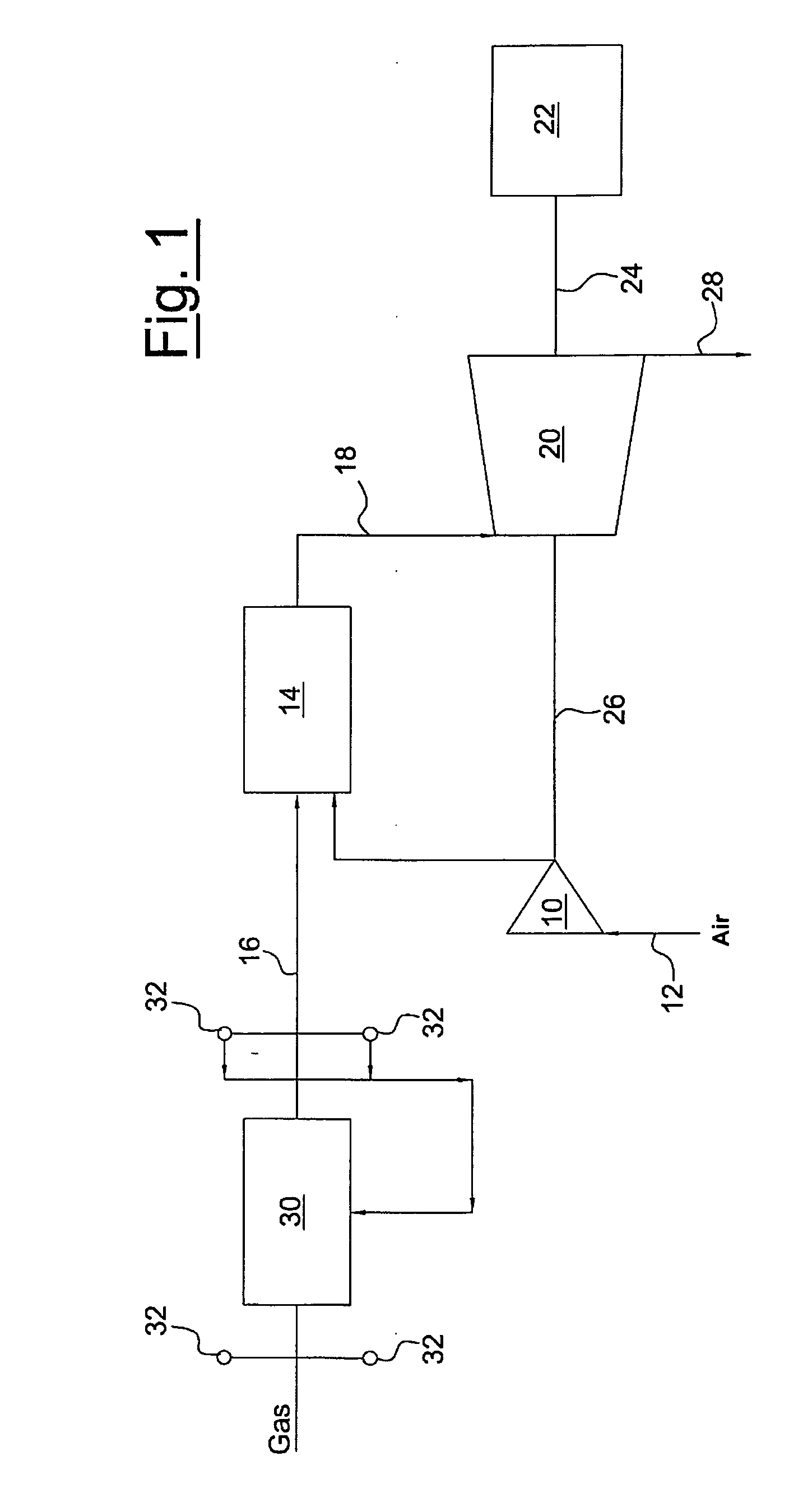

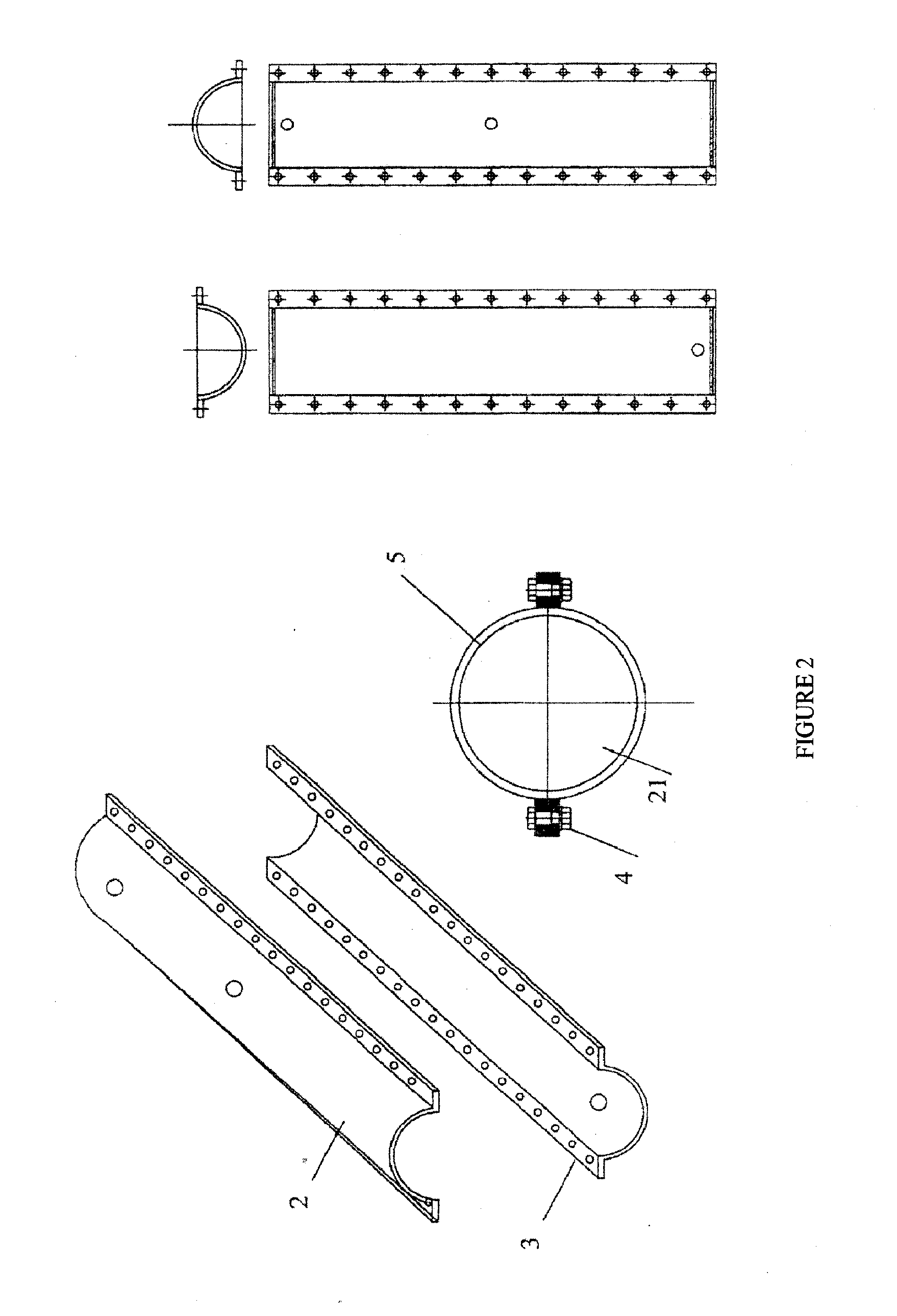

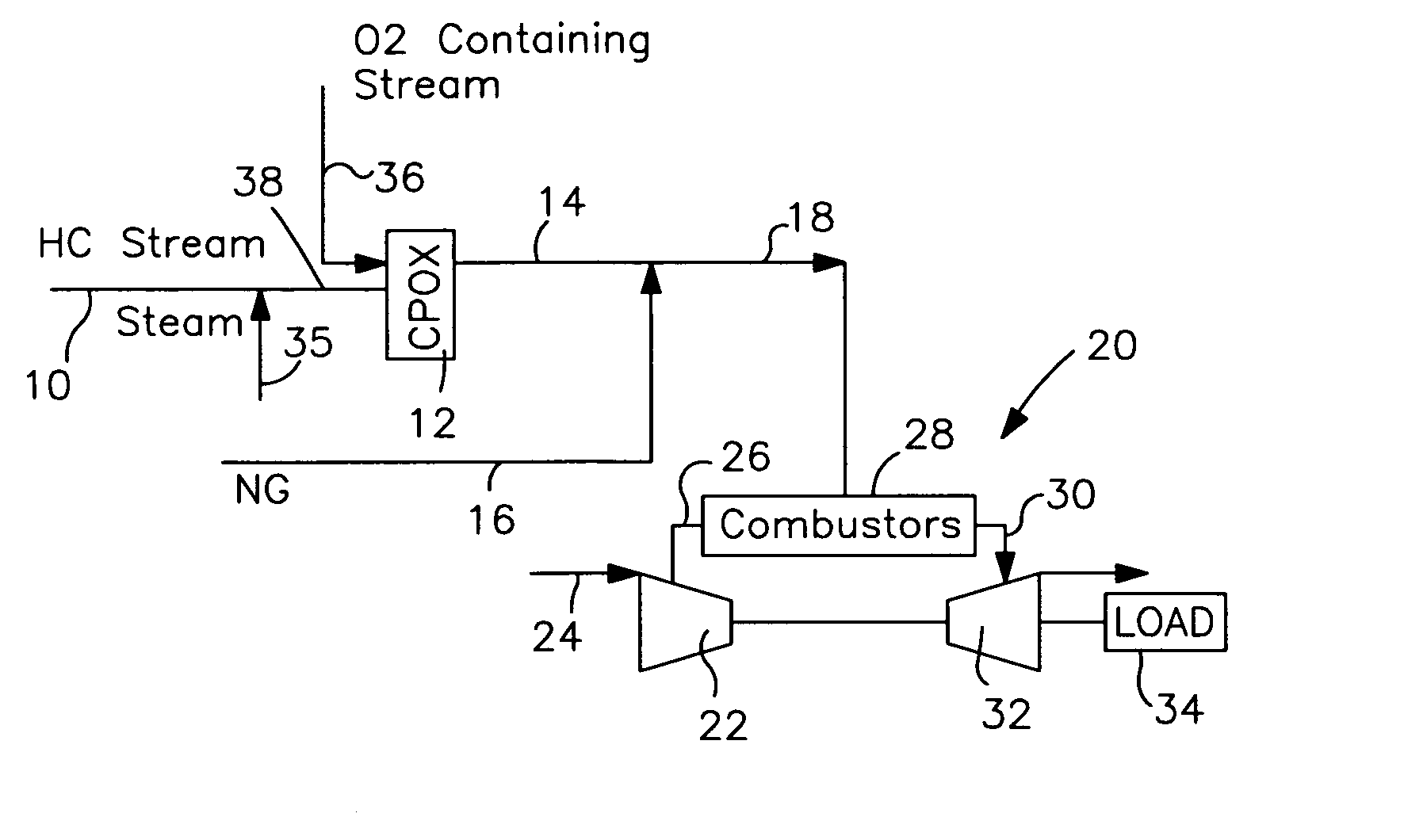

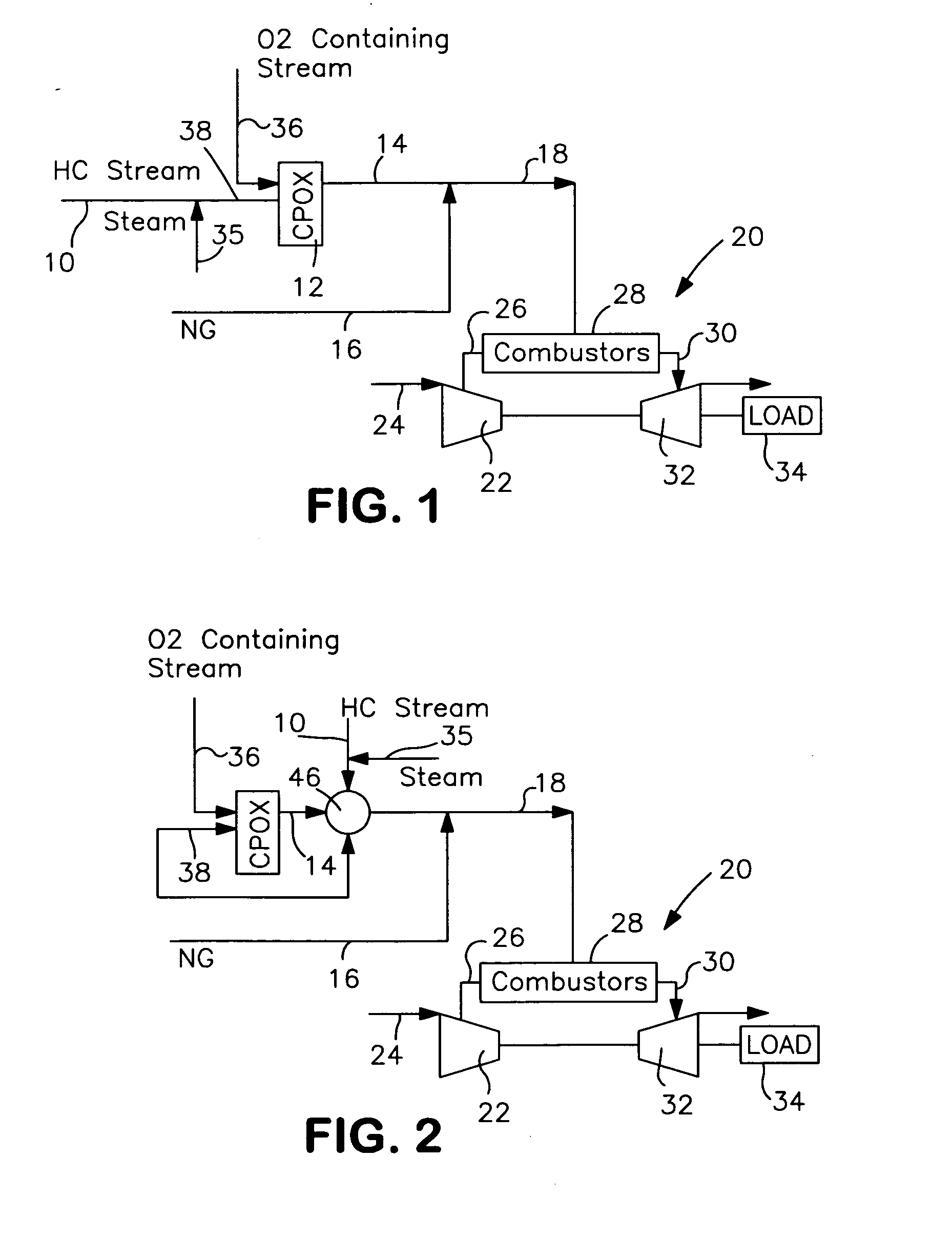

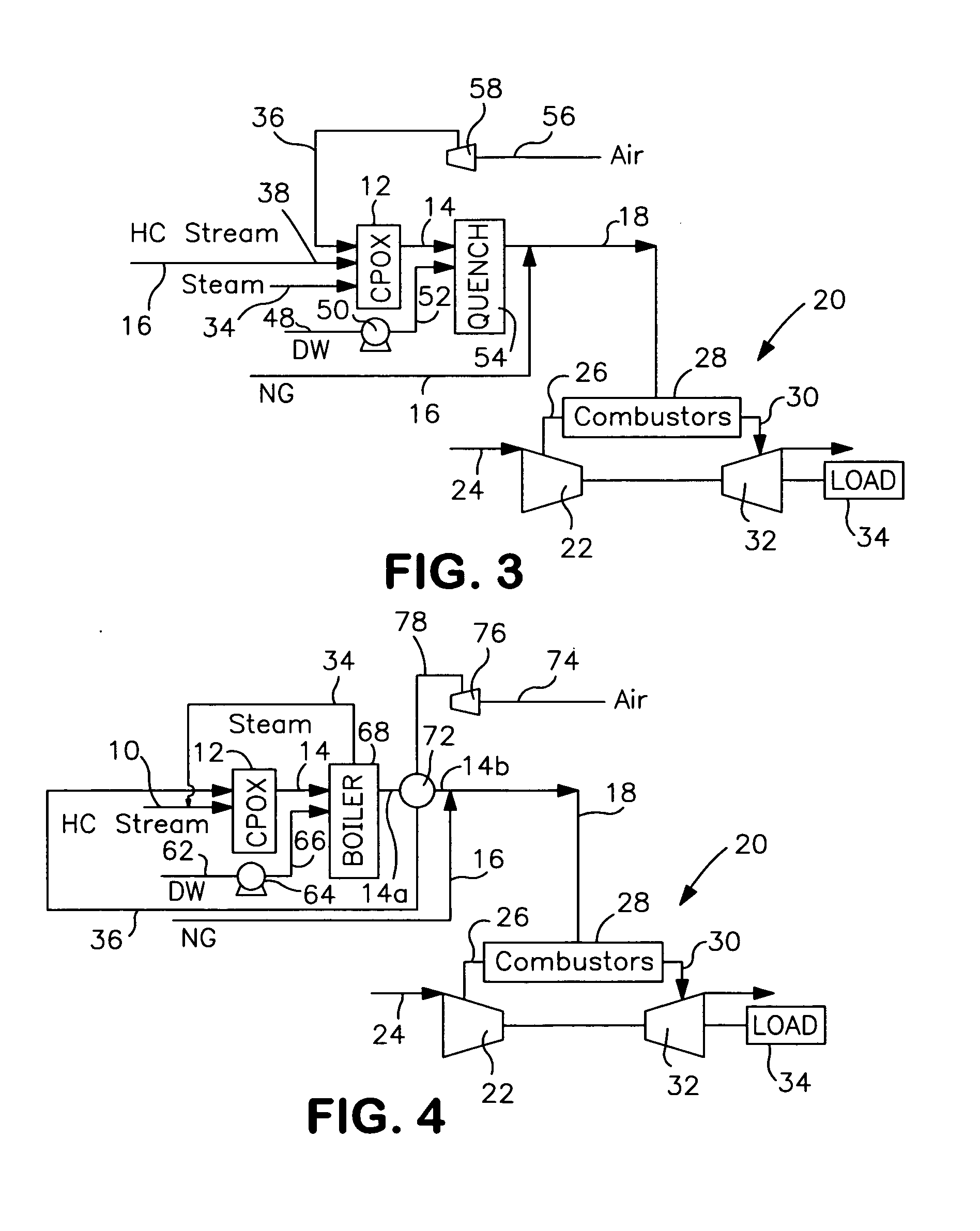

Gas turbine fuel preparation and introduction method

ActiveUS7395670B1Gaseous fuel feeder/distributionContinuous combustion chamberCombustorPartial oxidation

Method of preparing and introducing fuel into the combustors of a gas turbine in which a hydrocarbon containing feed, oxygen and steam are introduced into a catalytic partial oxidation reactor to produce a product stream. The hydrocarbon containing feed contains no less than about 15 percent by volume on a dry basis of hydrocarbons with at least two carbon atoms and / or at least about 3 percent by volume of olefins. The reactant mixture formed of the hydrocarbon containing feed, oxygen and steam has an oxygen to carbon ratio of between about 0.08 and about 0.25 and a water to carbon ratio of between about 0.05 to about 0.5. The hydrocarbon containing feed is introduced into the reactor alone or with a steam at a temperature no greater than 600° C. and the product stream is produced at a temperature of between about 600° C. and 860° C. and contains less than about 0.5 percent of olefins and less than 10 percent of hydrocarbons with two or more carbon atoms on a dry basis. After cooling the product stream the product stream is introduced into the combustors of the gas turbine to form part or all of the fuel required to support combustion.

Owner:PRAXAIR TECH INC

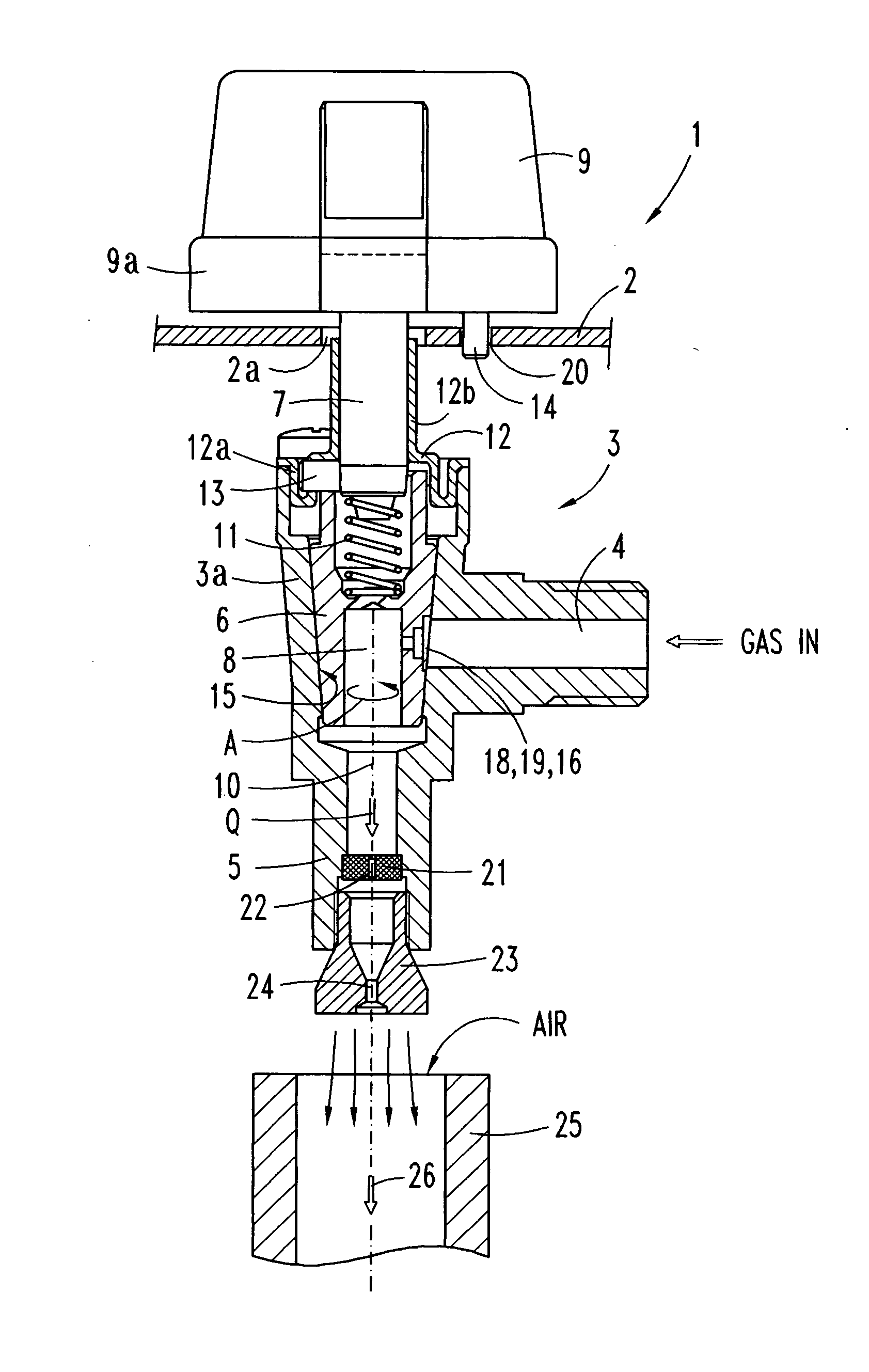

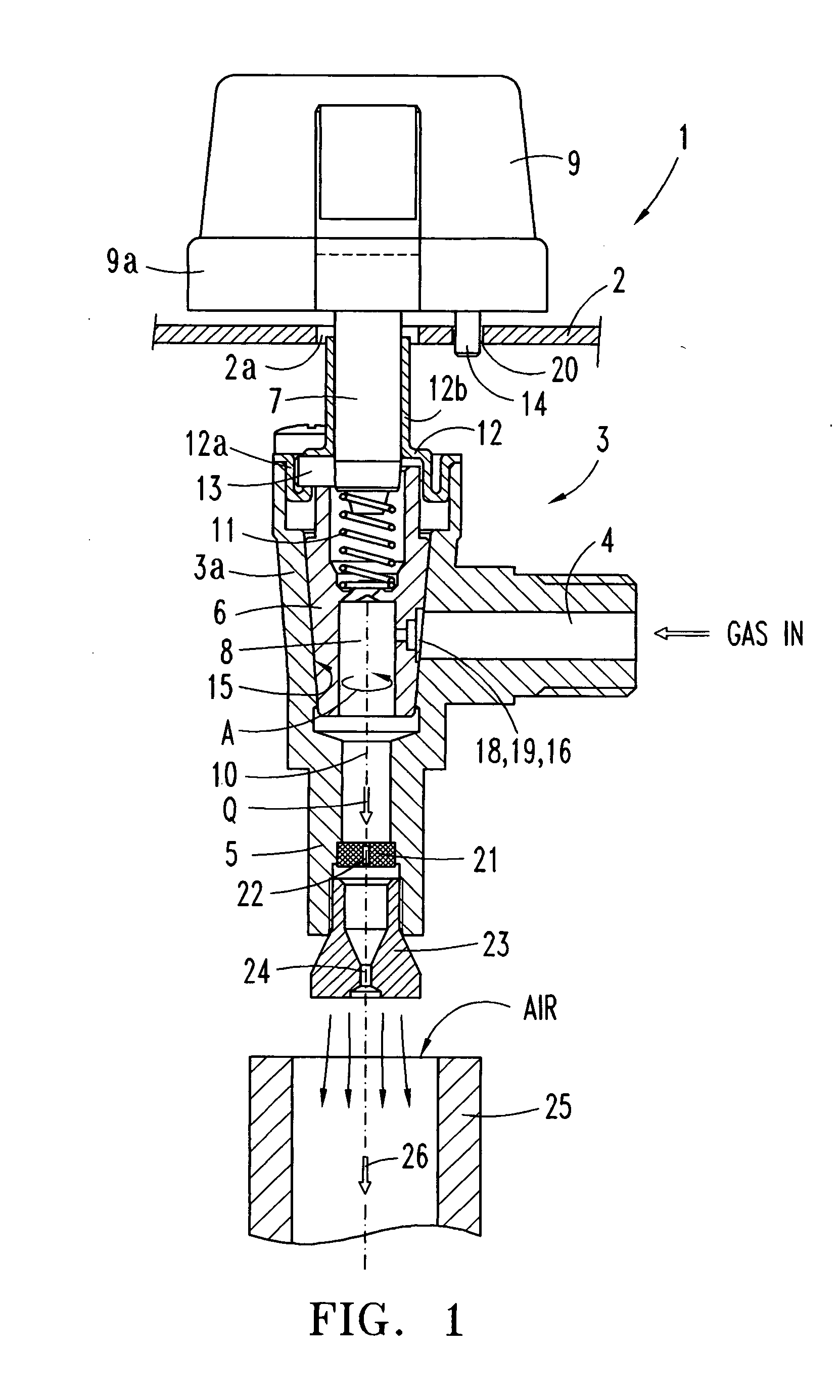

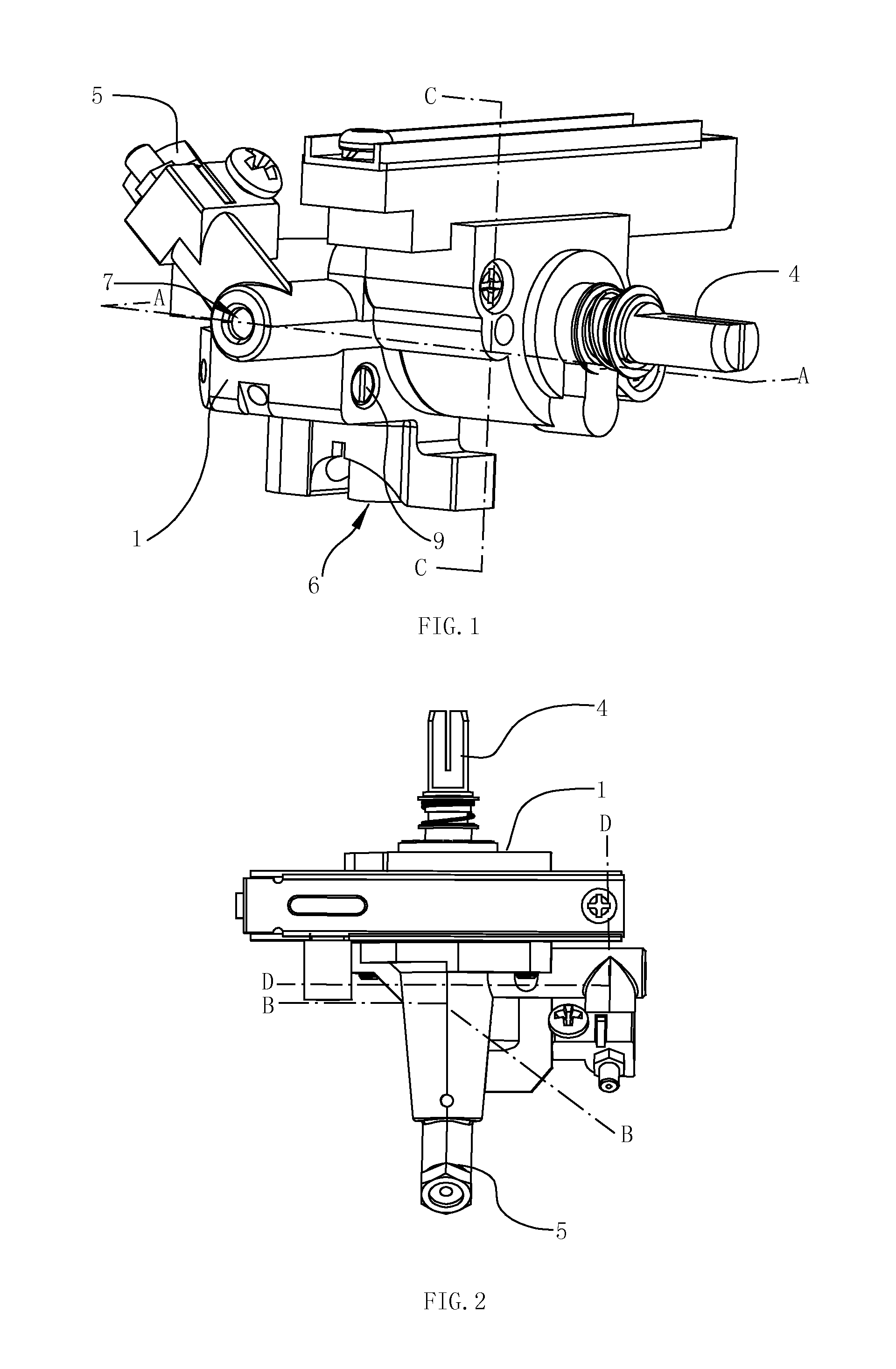

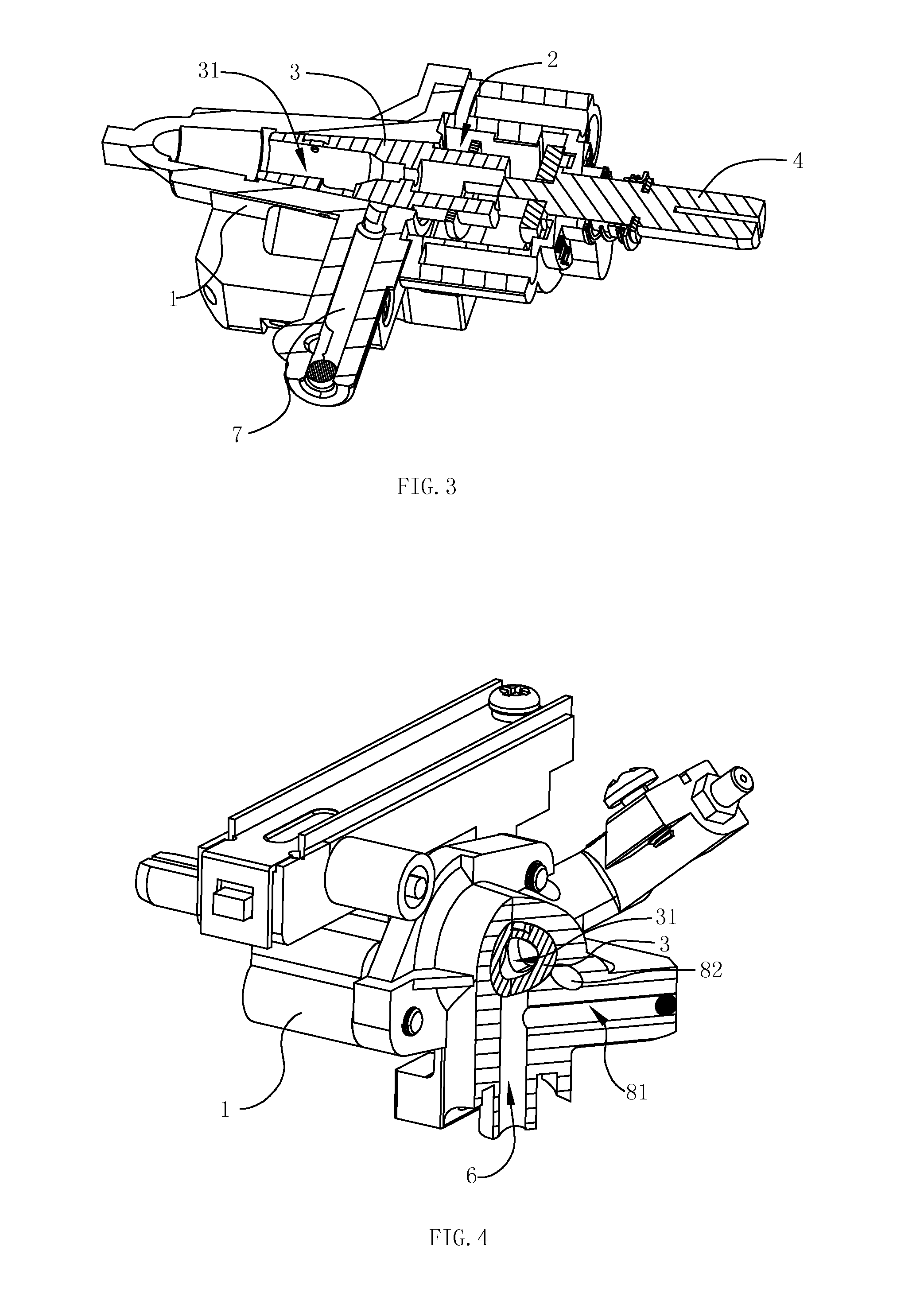

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS20050016507A1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

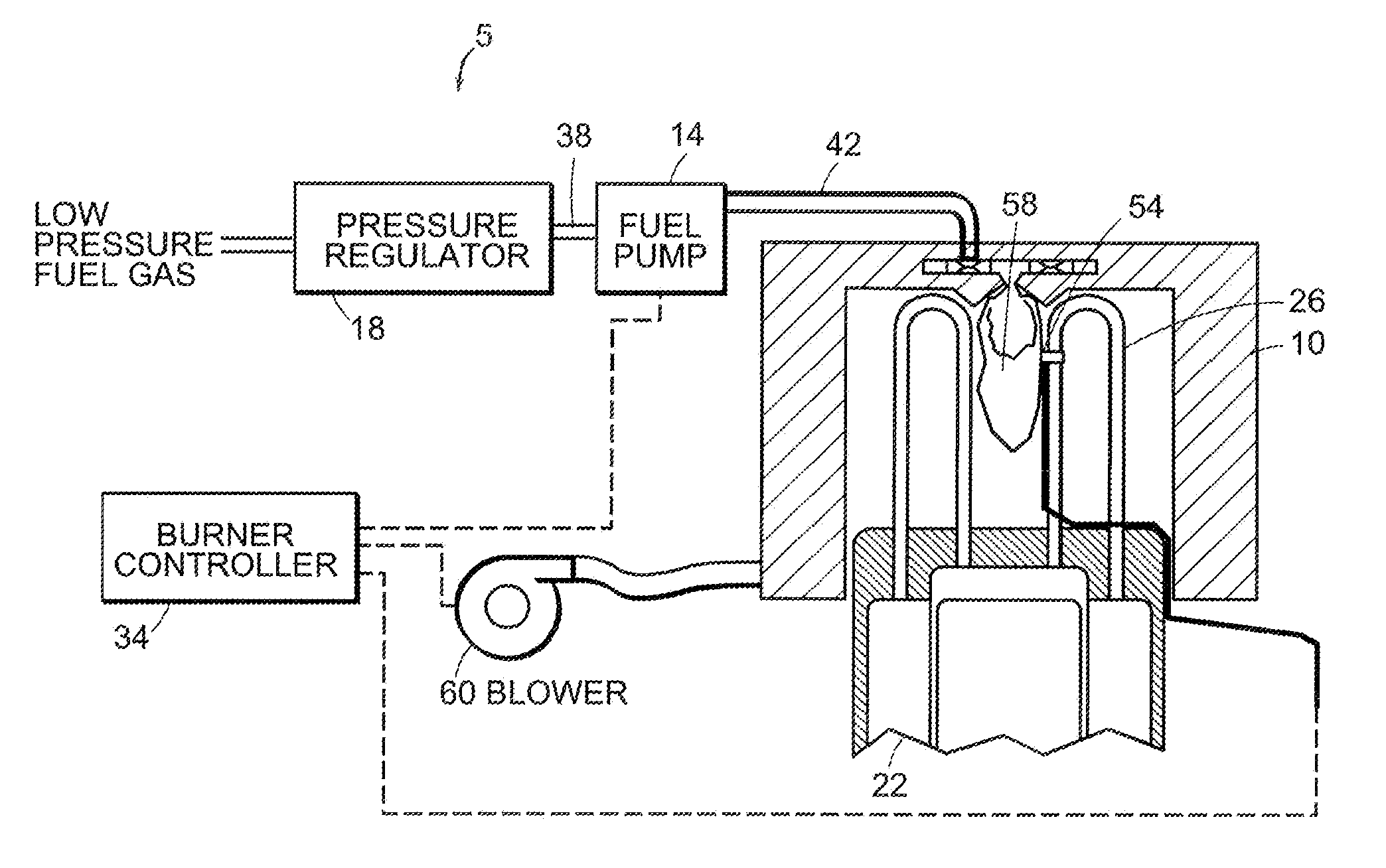

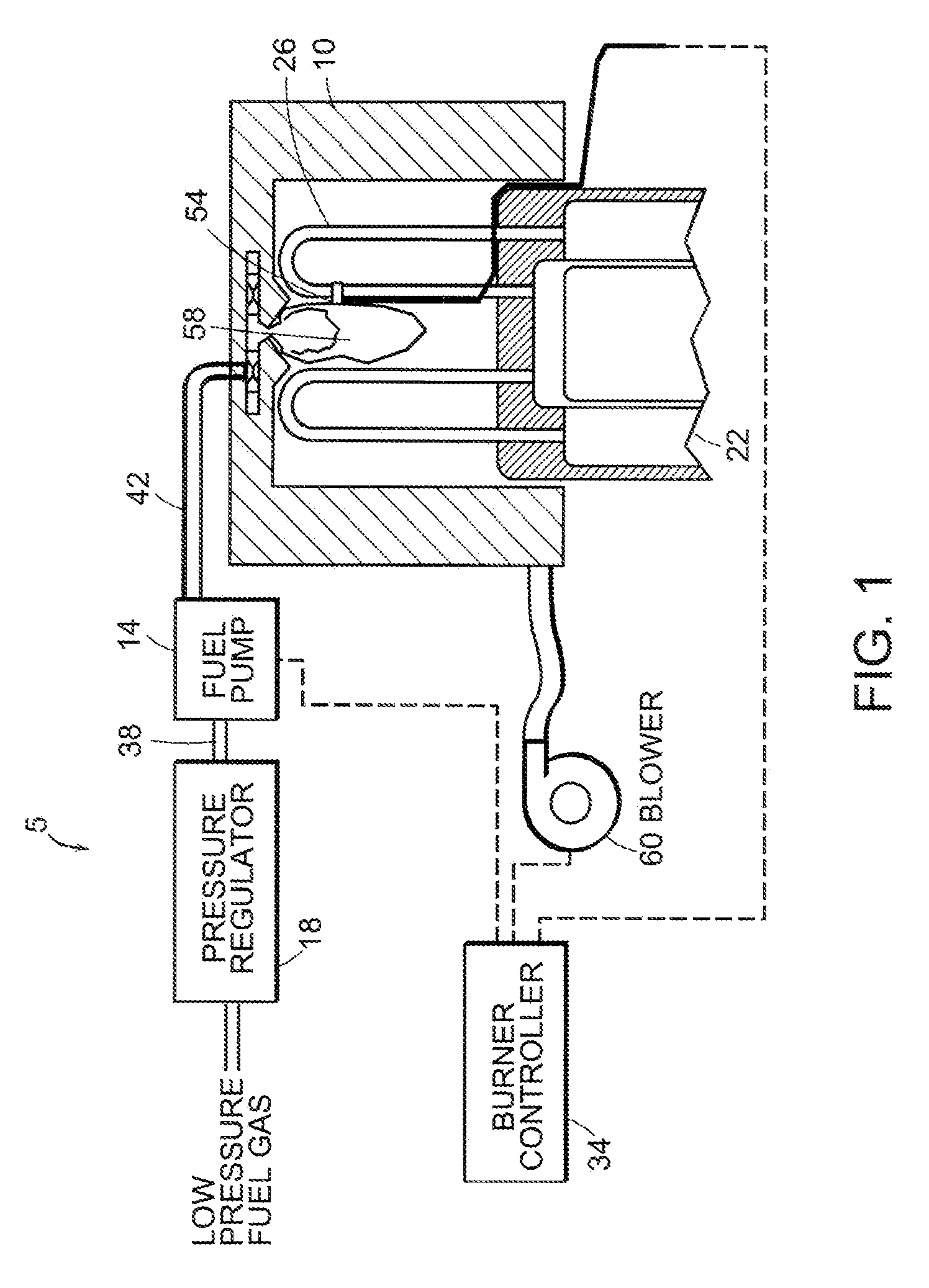

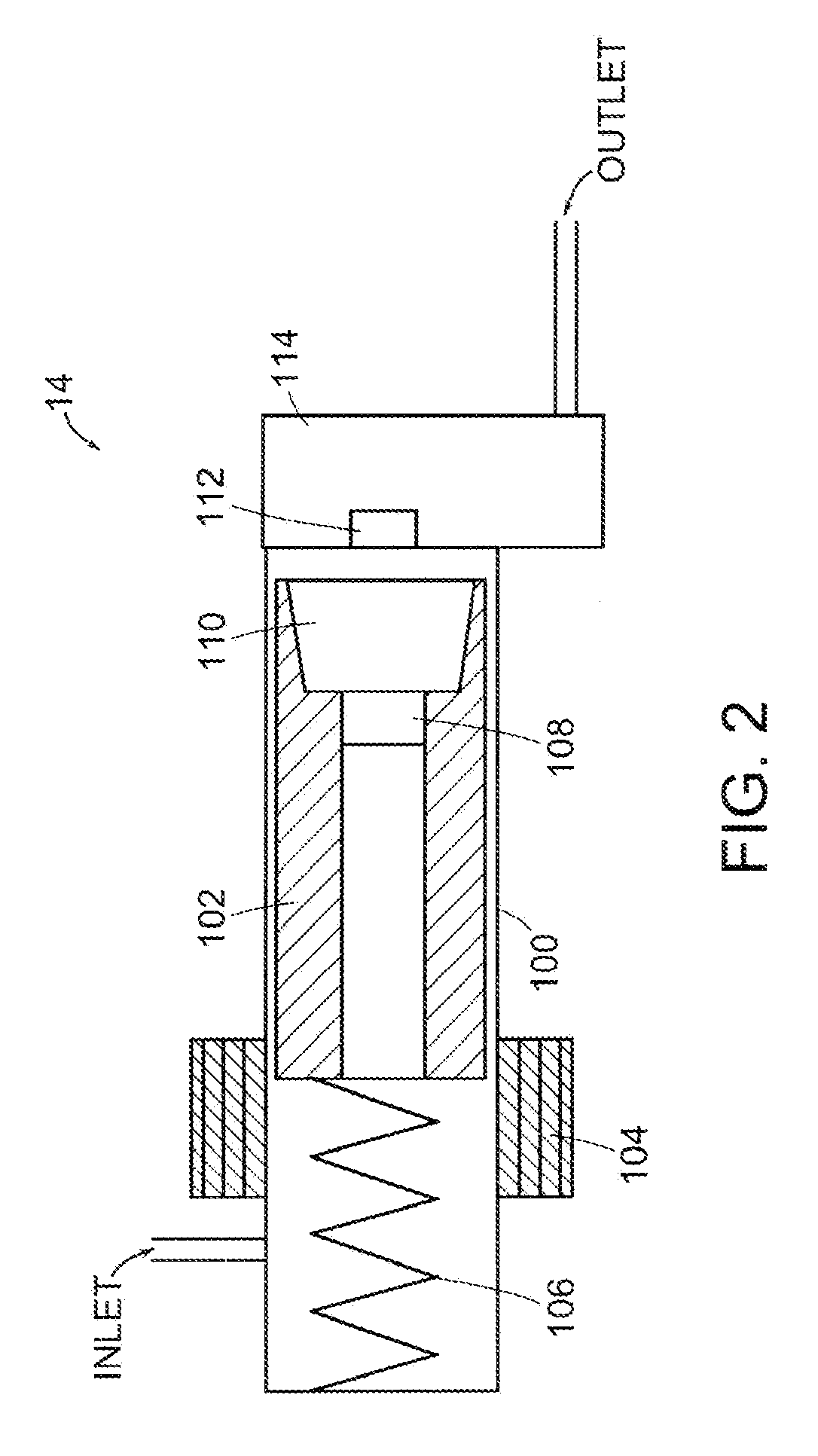

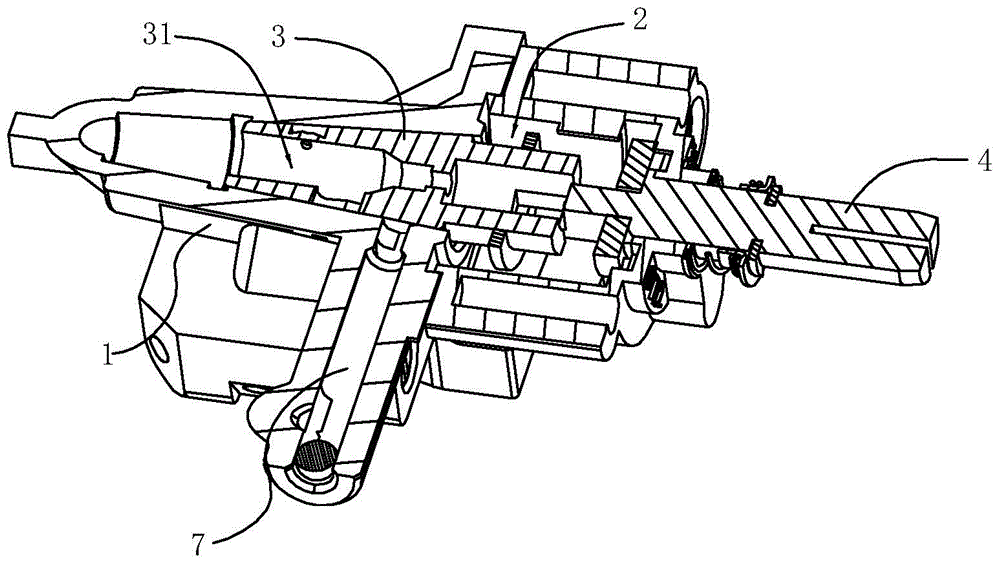

Metering fuel pump

InactiveUS7111460B2Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesDiaphragm pumpCombustion chamber

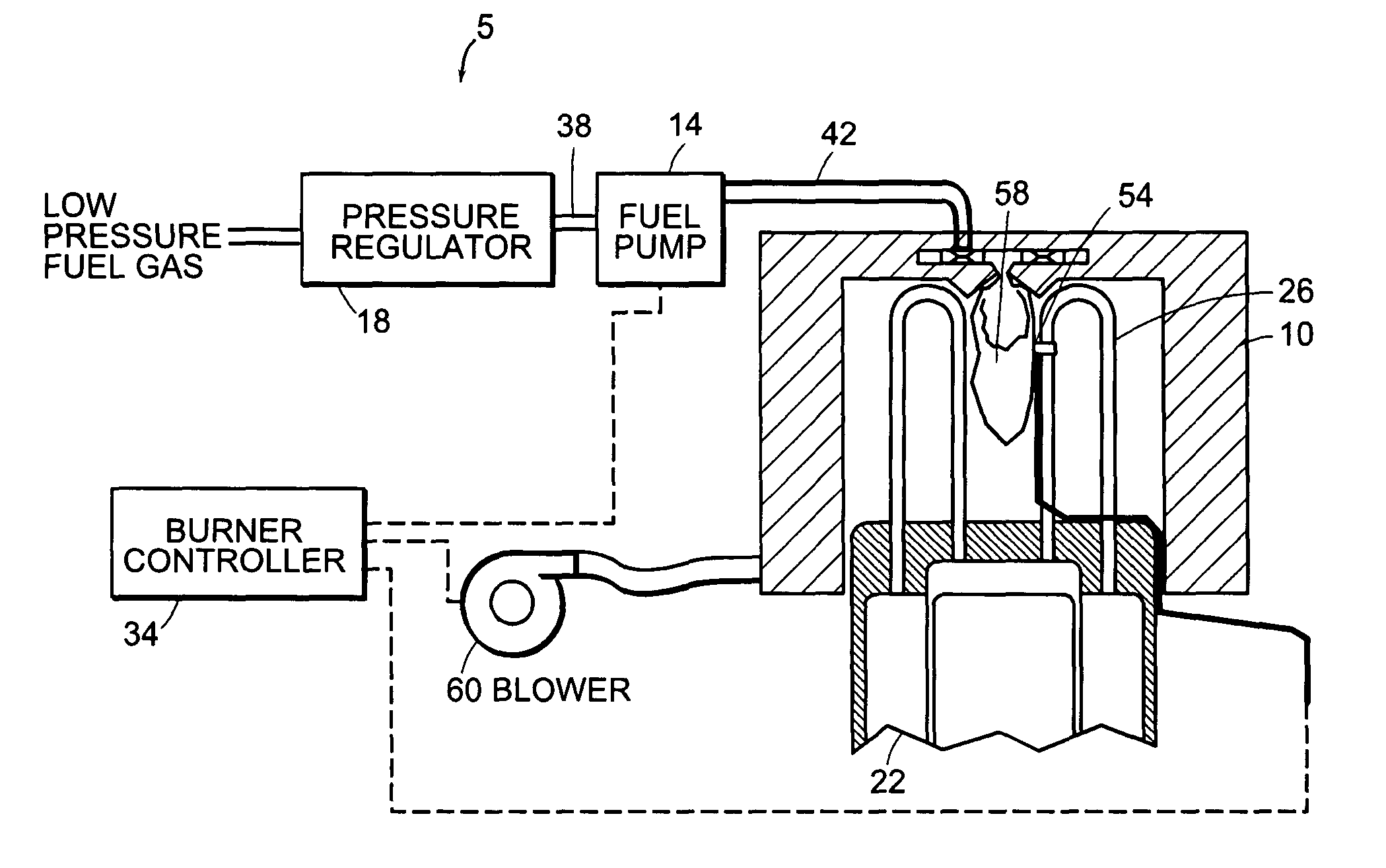

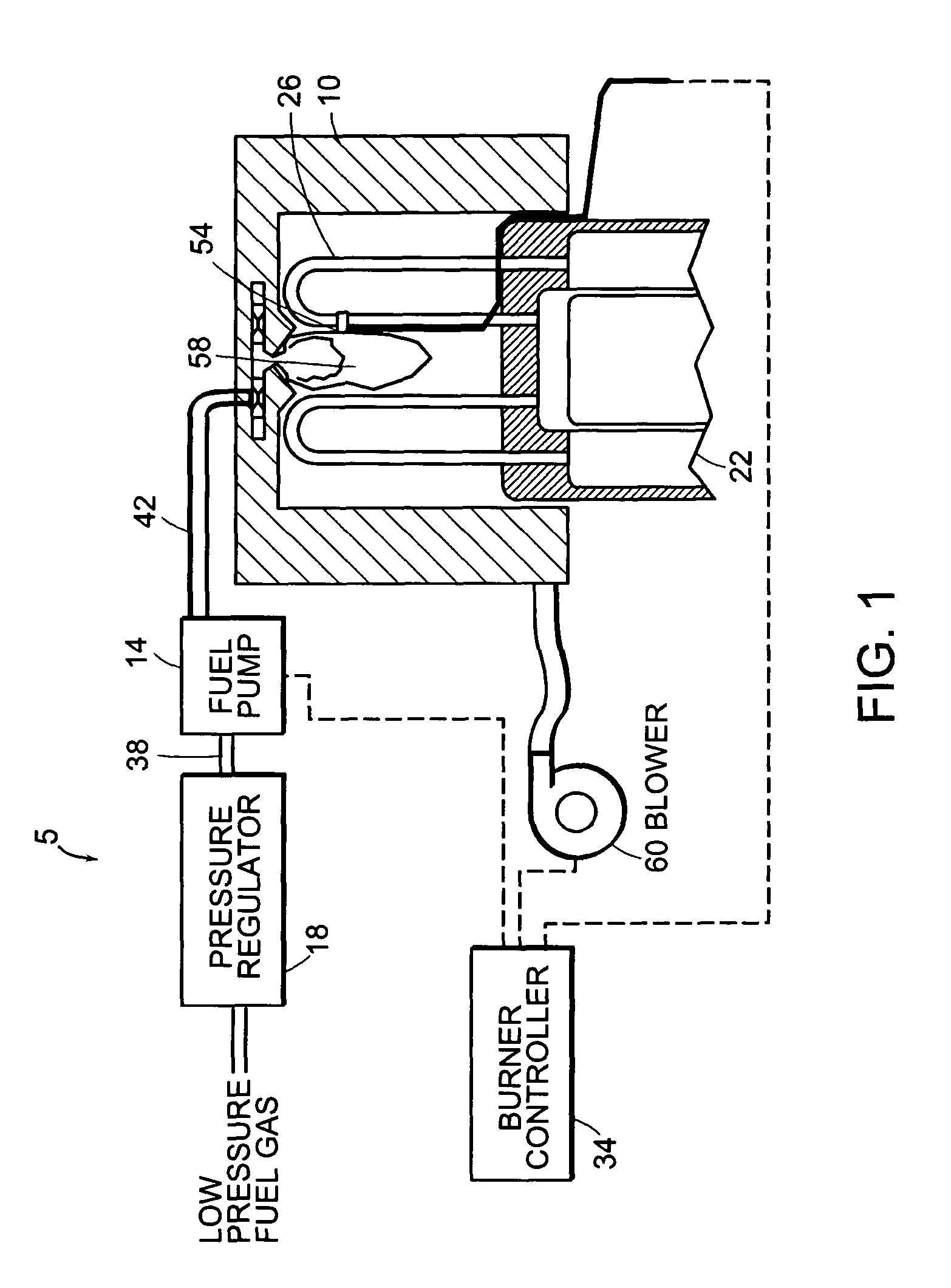

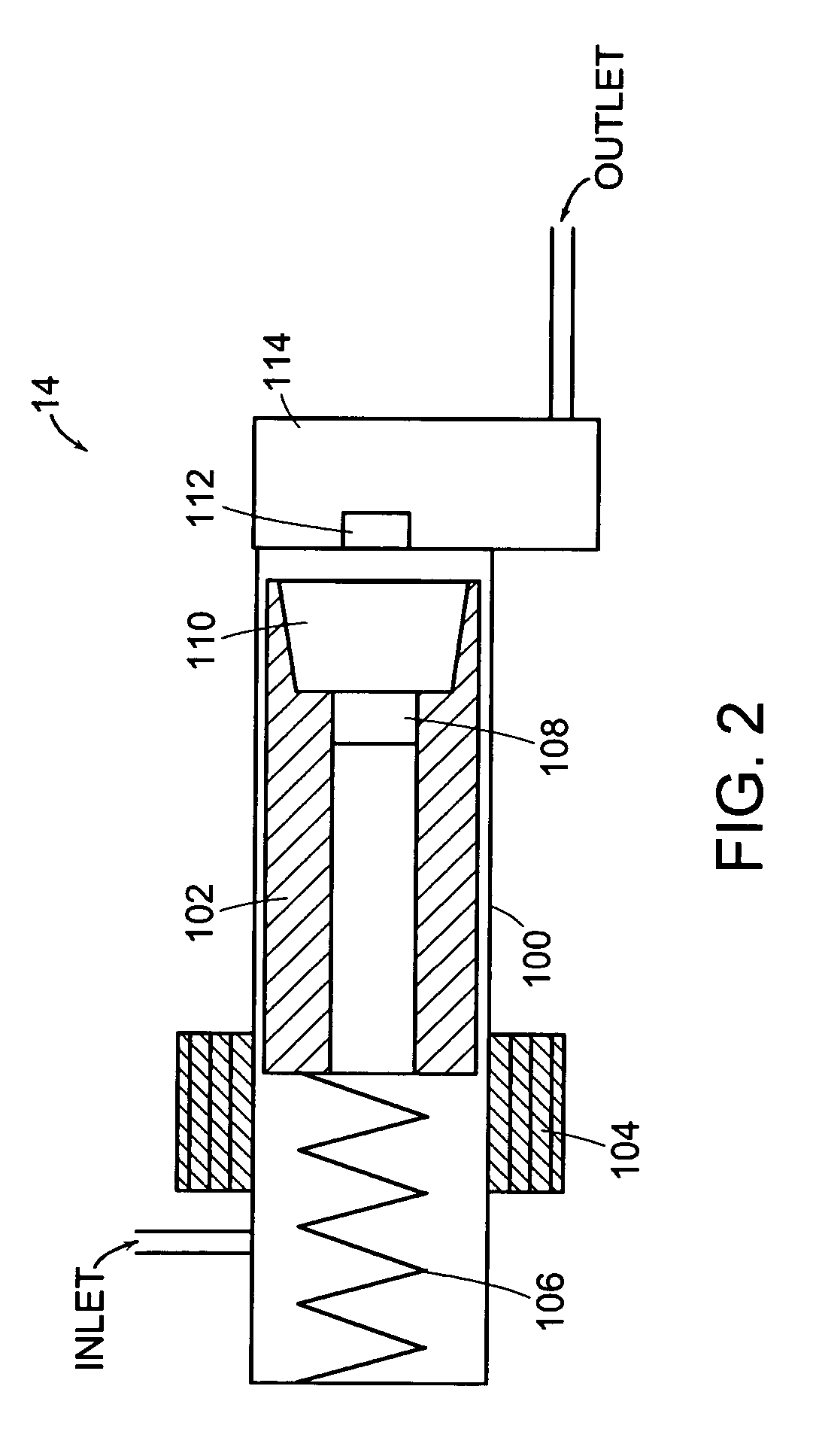

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

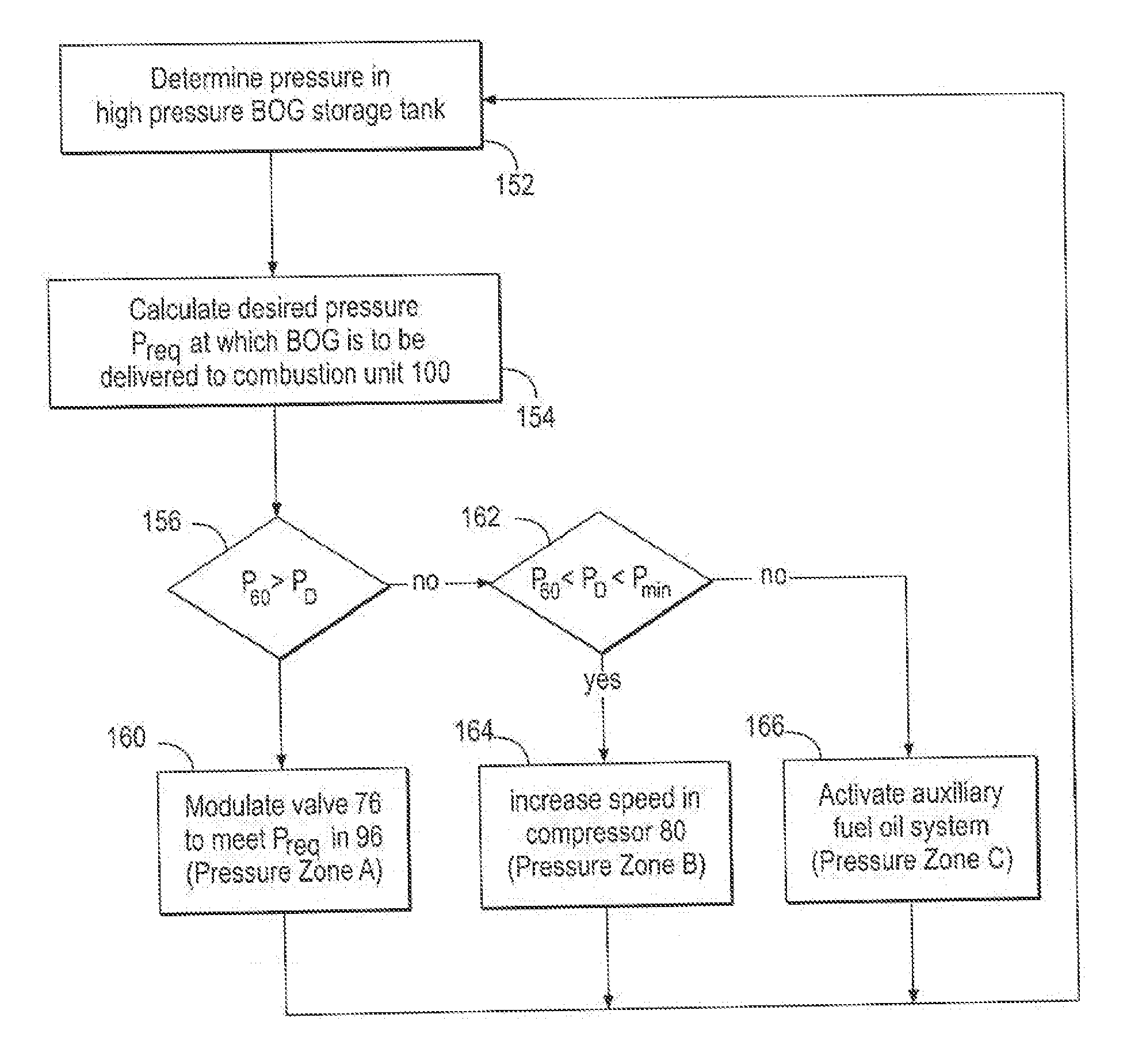

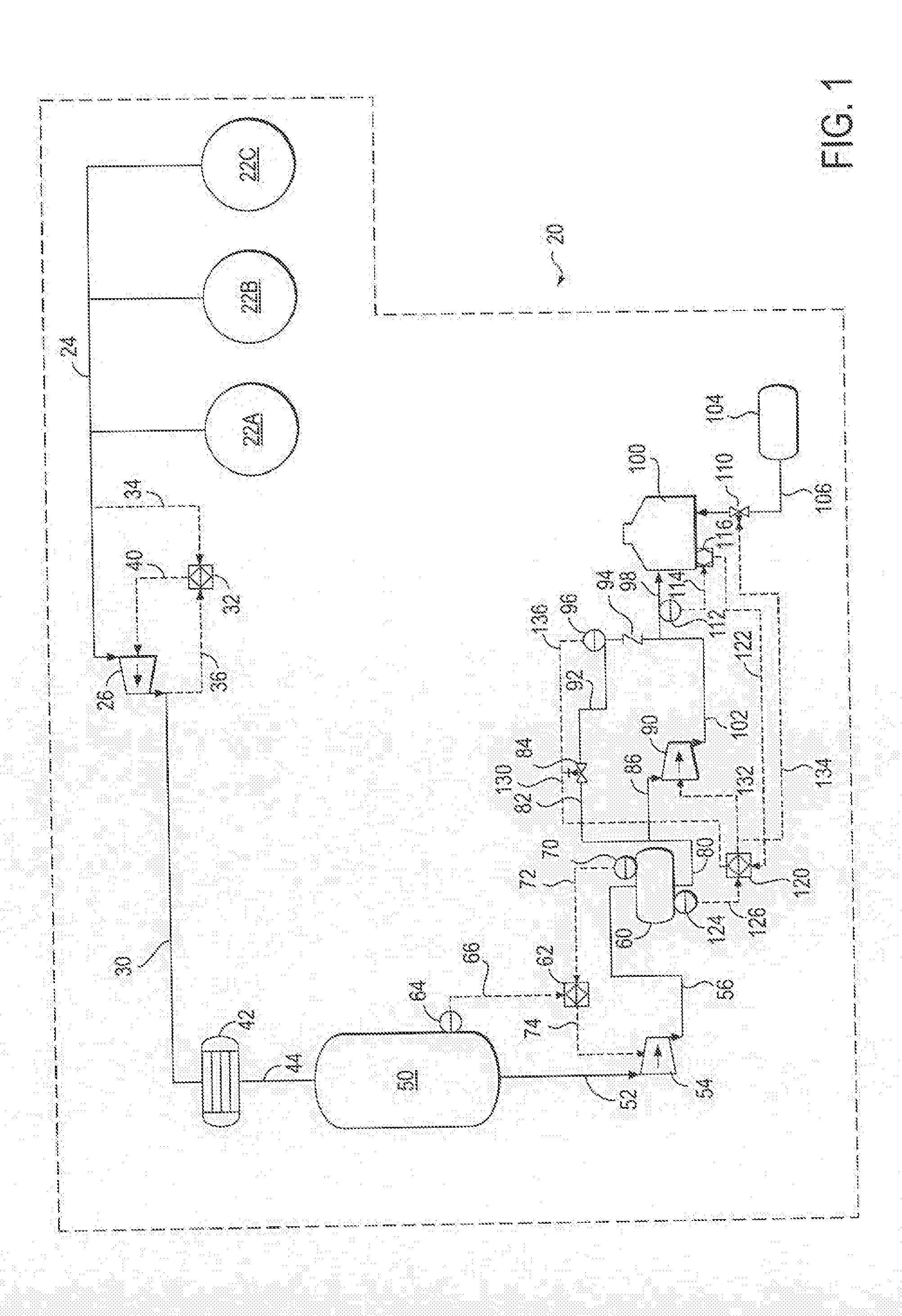

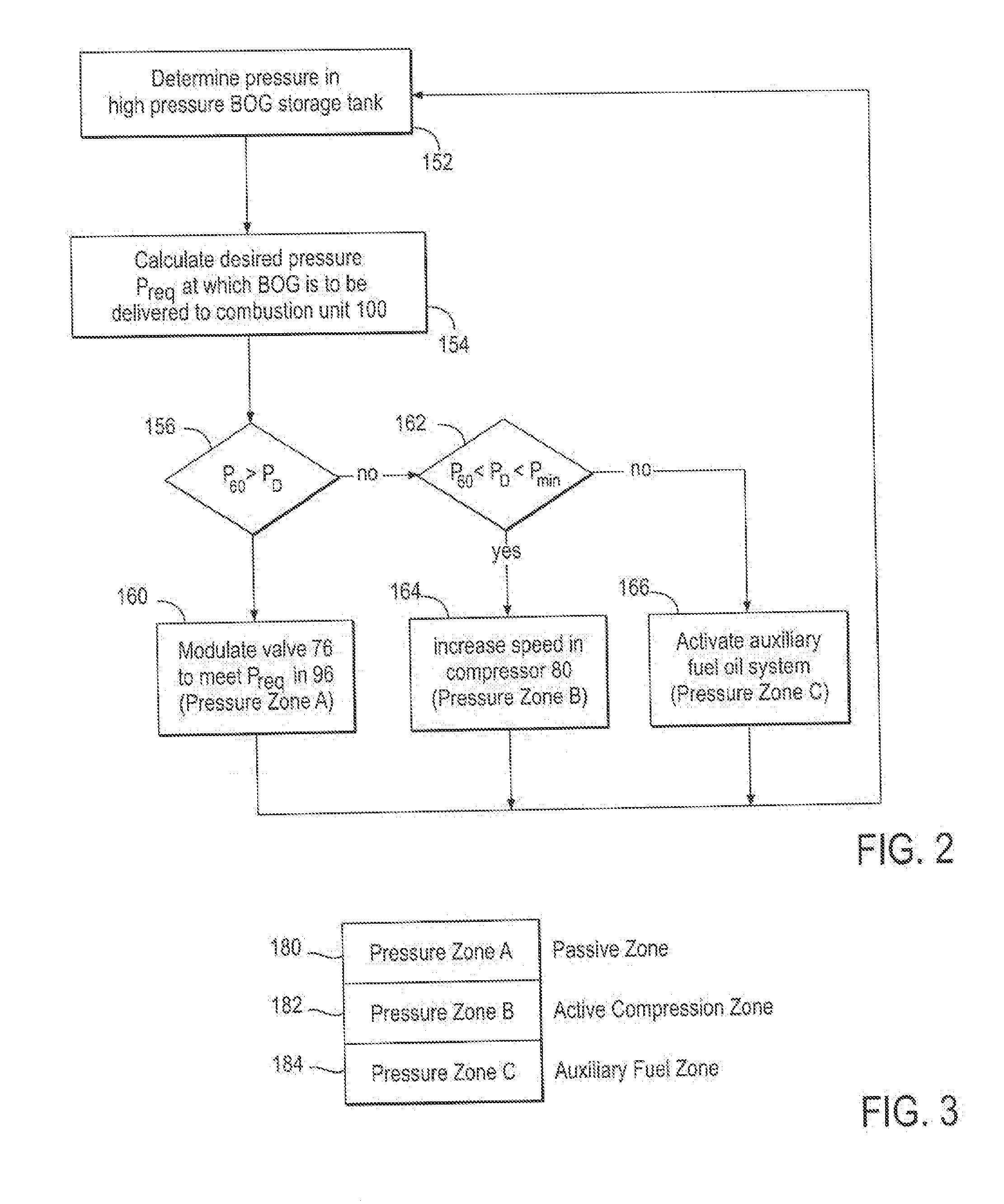

LNG transport vessel and method for storing and managing excess boil off gas thereon

InactiveUS20110302923A1Sufficient pressureReciprocating combination enginesFuel supply regulationCombustionHigh pressure

A liquefied natural gas (LNG) transport vessel for transporting liquefied natural gas (LNG) is disclosed which is capable of storing excess boil off gas BOG until needed for combustion in one or more combustion apparatus on the vessel. A method for managing the delivery of the BOG to the combustion apparatus is also described. The LNG vessel includes at least one insulated LNG storage tank which stores LNG. A first stage LNG receiver receives and stores BOG from the at least one LNG storage tank. A second stage or high pressure BOG storage tank receives compressed BOG from the receiver and stores the BOG as needed for combustion by one or more combustion apparatus of the vessel. A pressure regulator allows BOG gas to be delivered to the combustion apparatus if there is sufficient pressure in the high pressure storage tank to passively deliver the BOG at a predetermined delivery pressure. If the pressure in the high pressure BOG storage tank is insufficient to passively delivery the BOG to combustion apparatus, then a combustion apparatus compressor may be used to actively increase the pressure in BOG such that the BOG is delivered at the necessary delivery pressure. If there is still insufficient BOG in the high pressure BOG storage tank, then it may be necessary to supply supplemental auxiliary fuel to meet the needs of the combustion apparatus.

Owner:CHEVROU USA INC

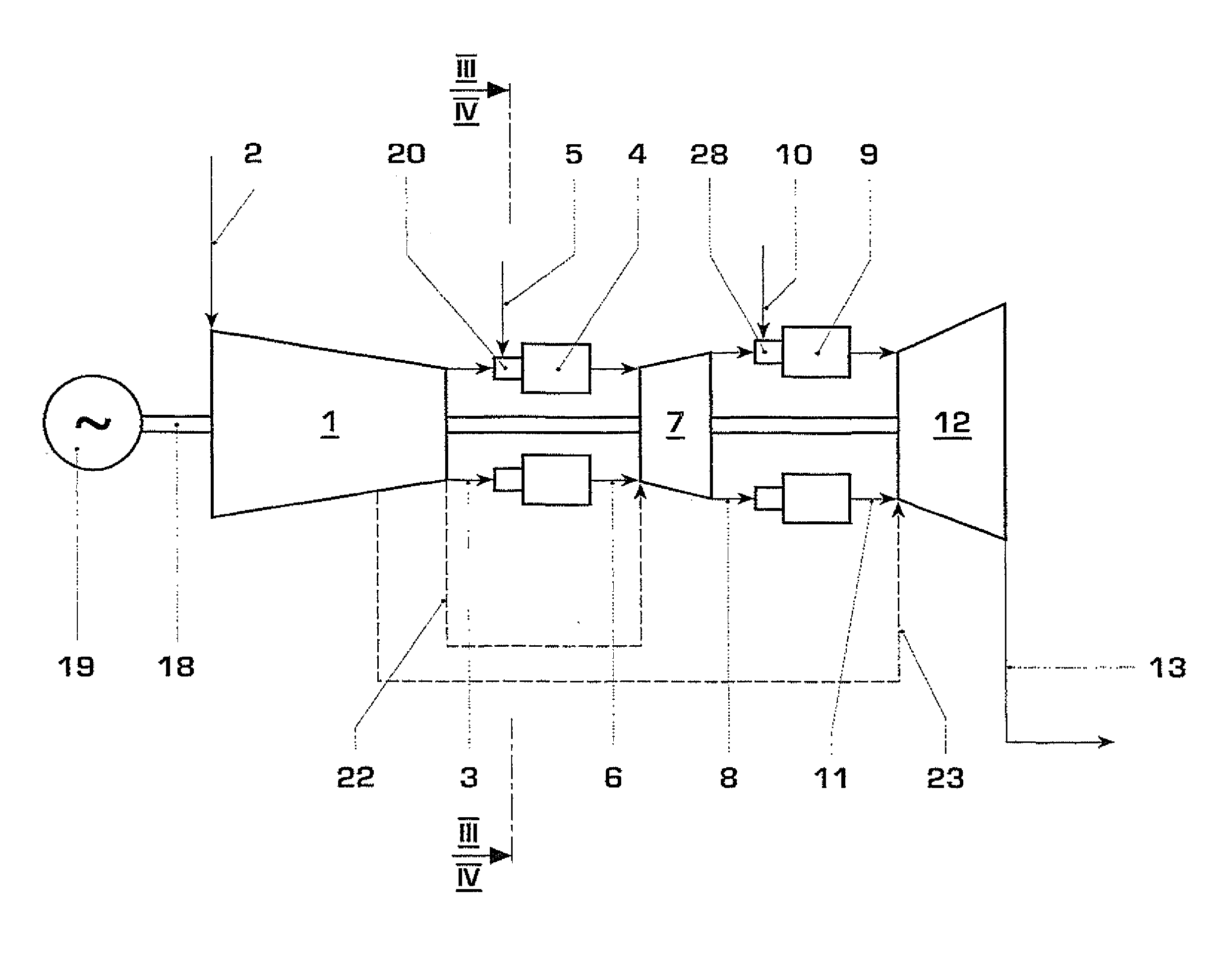

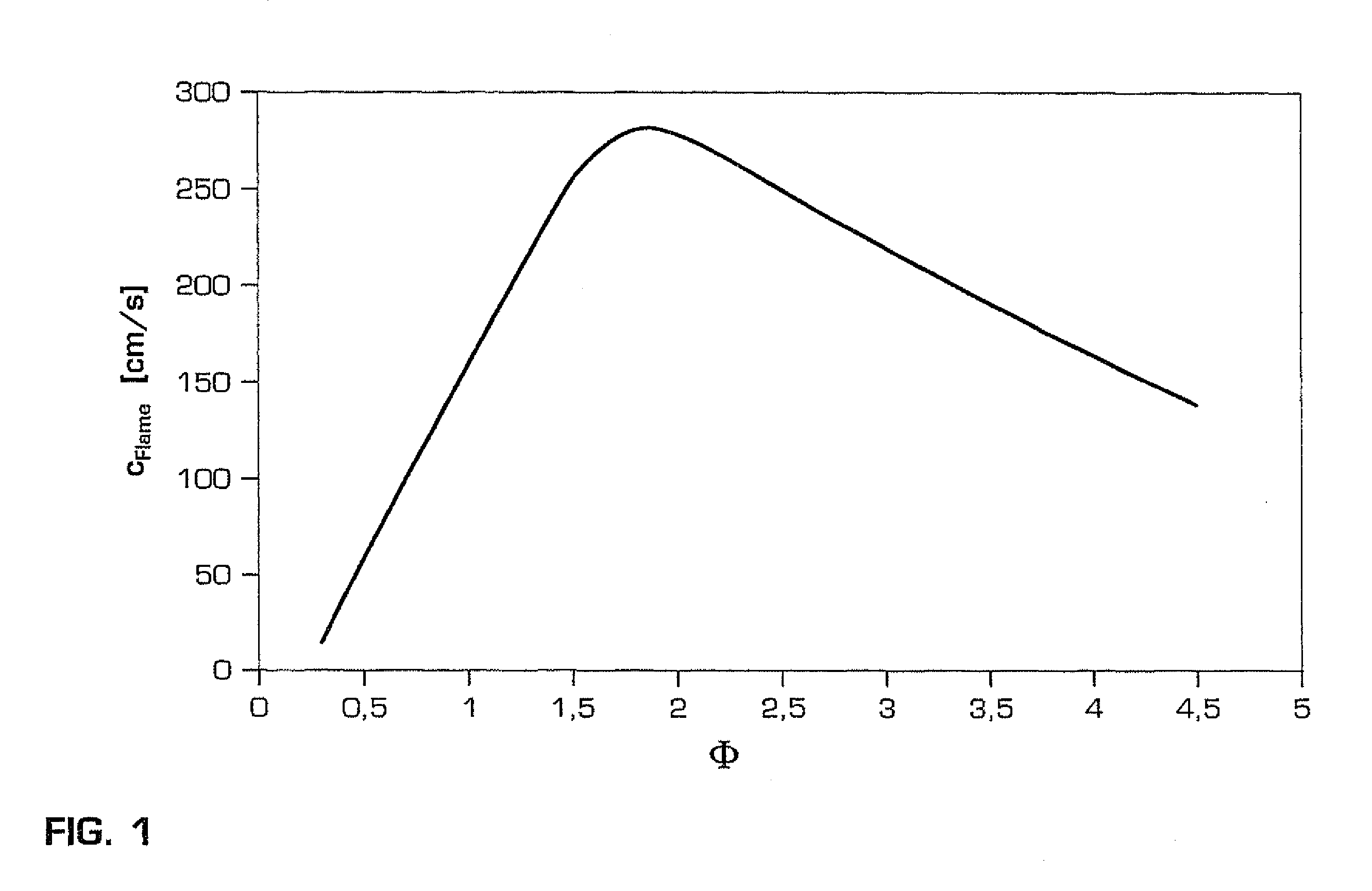

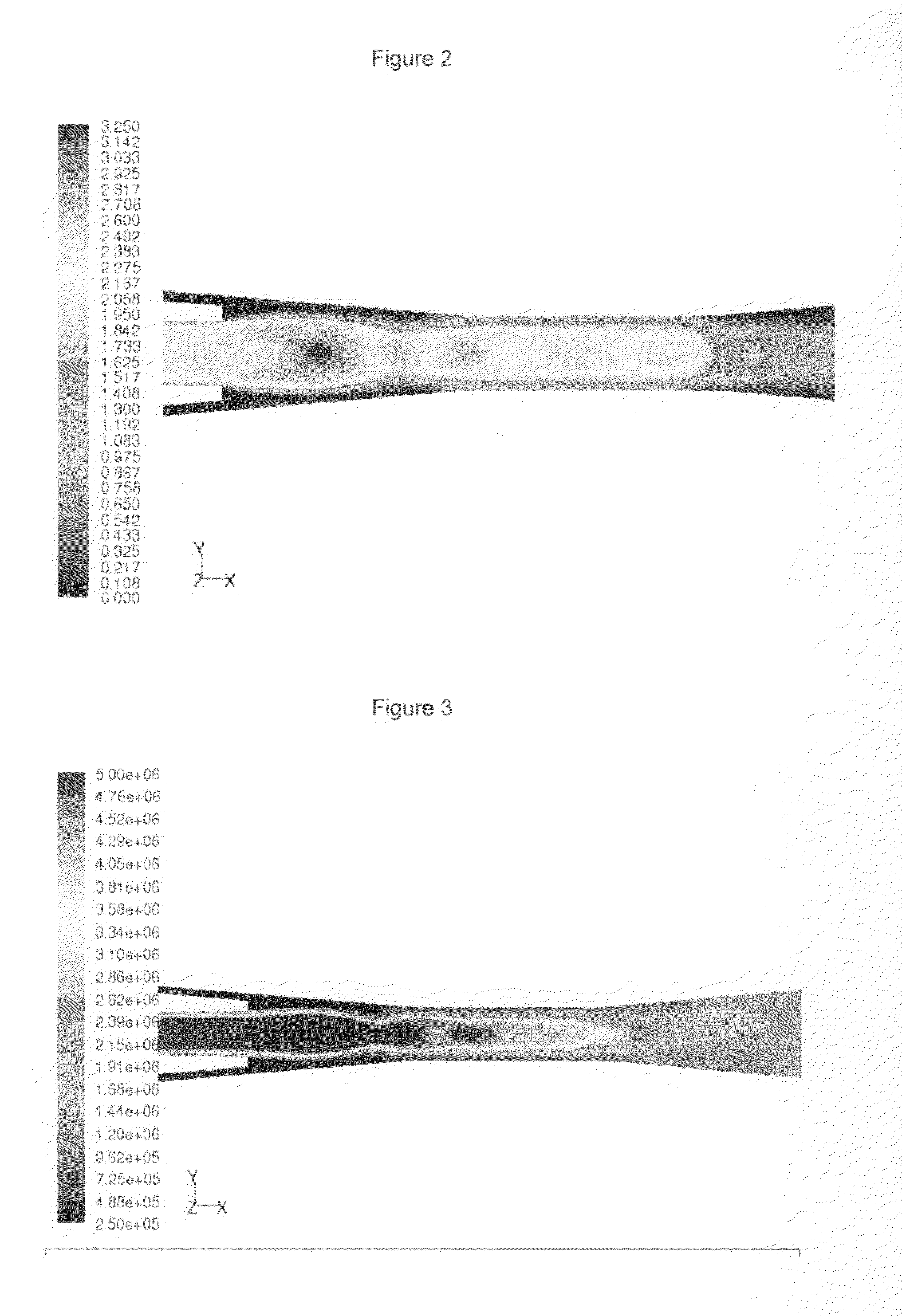

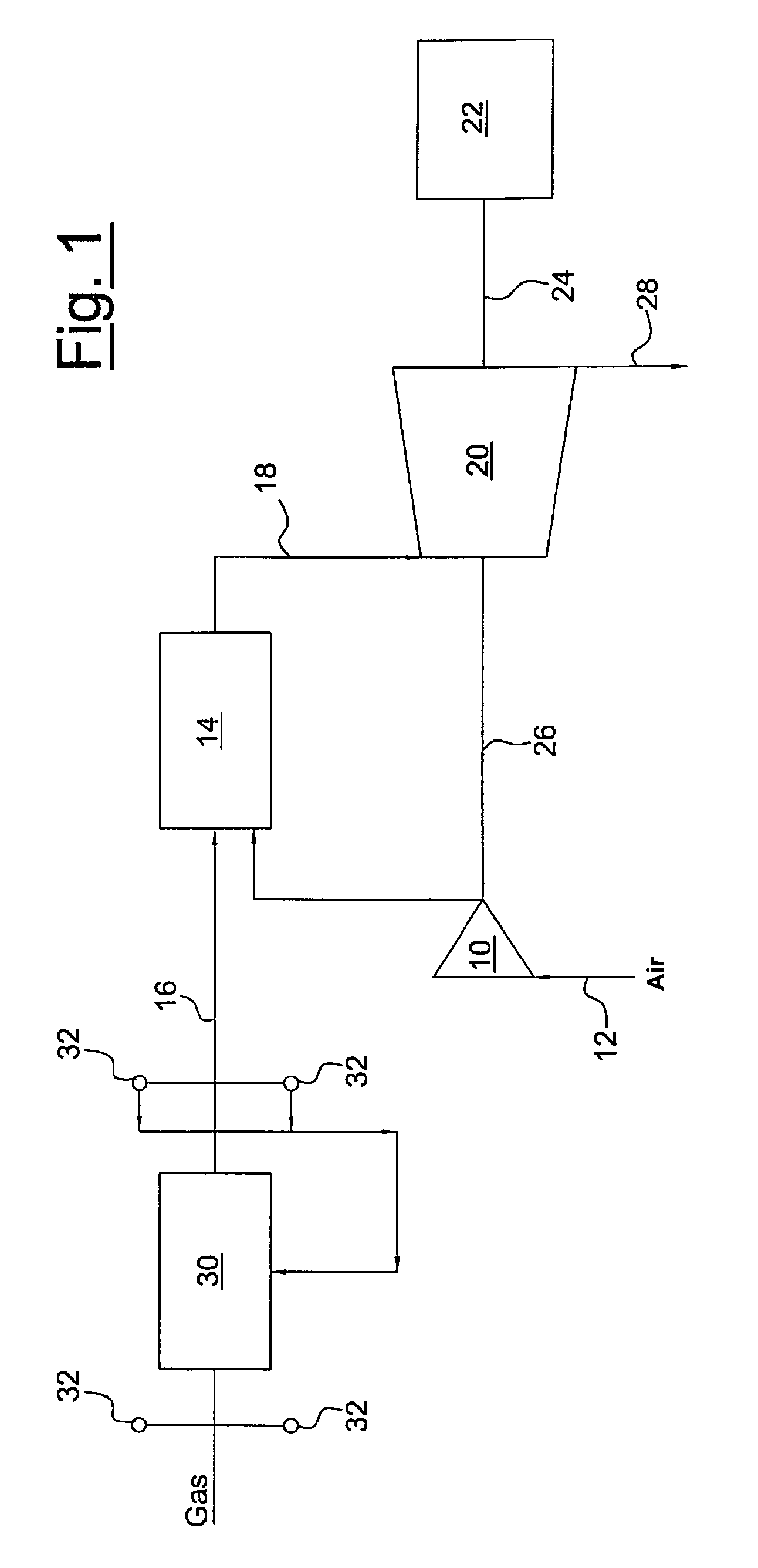

Gas turbine with water injection

ActiveUS20100146984A1Reduce burnShorten speedContinuous combustion chamberGaseous fuel feeder/distributionHydrogenCombustor

Reliable, low-NOx-emission operation of a gas turbine plant with hydrogen-rich fuel gas, and a gas turbine plant with a device for water injection into hydrogen-rich fuels in a gas turbine, involves suitable water injection (21), a water-fuel gas mist, i.e., a fuel gas in which fine water droplets are suspended, is created in the fuel gas feed line (15). This mist is introduced into the burners (20) of the gas turbine. As a result of the water-fuel gas mist, four effects are combined for ignition delay and reduction of the flame velocity of hydrogen-rich fuel gas. When using a water-fuel gas mist, the water, in a directed manner, reaches the region in the burner (20) in which it directly has the greatest possible effect upon the flame or the flame velocity.

Owner:ANSALDO ENERGIA SWITZERLAND AG

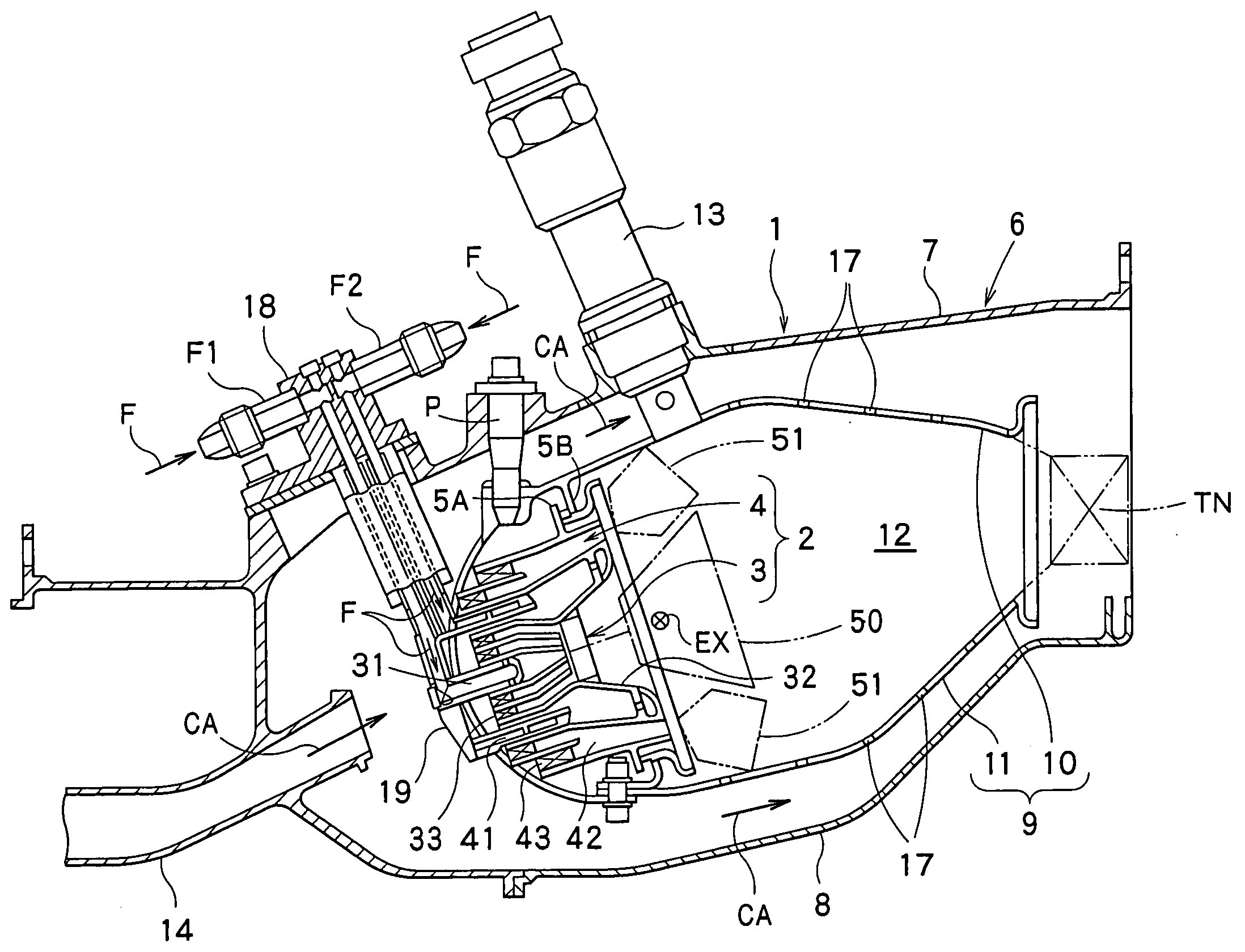

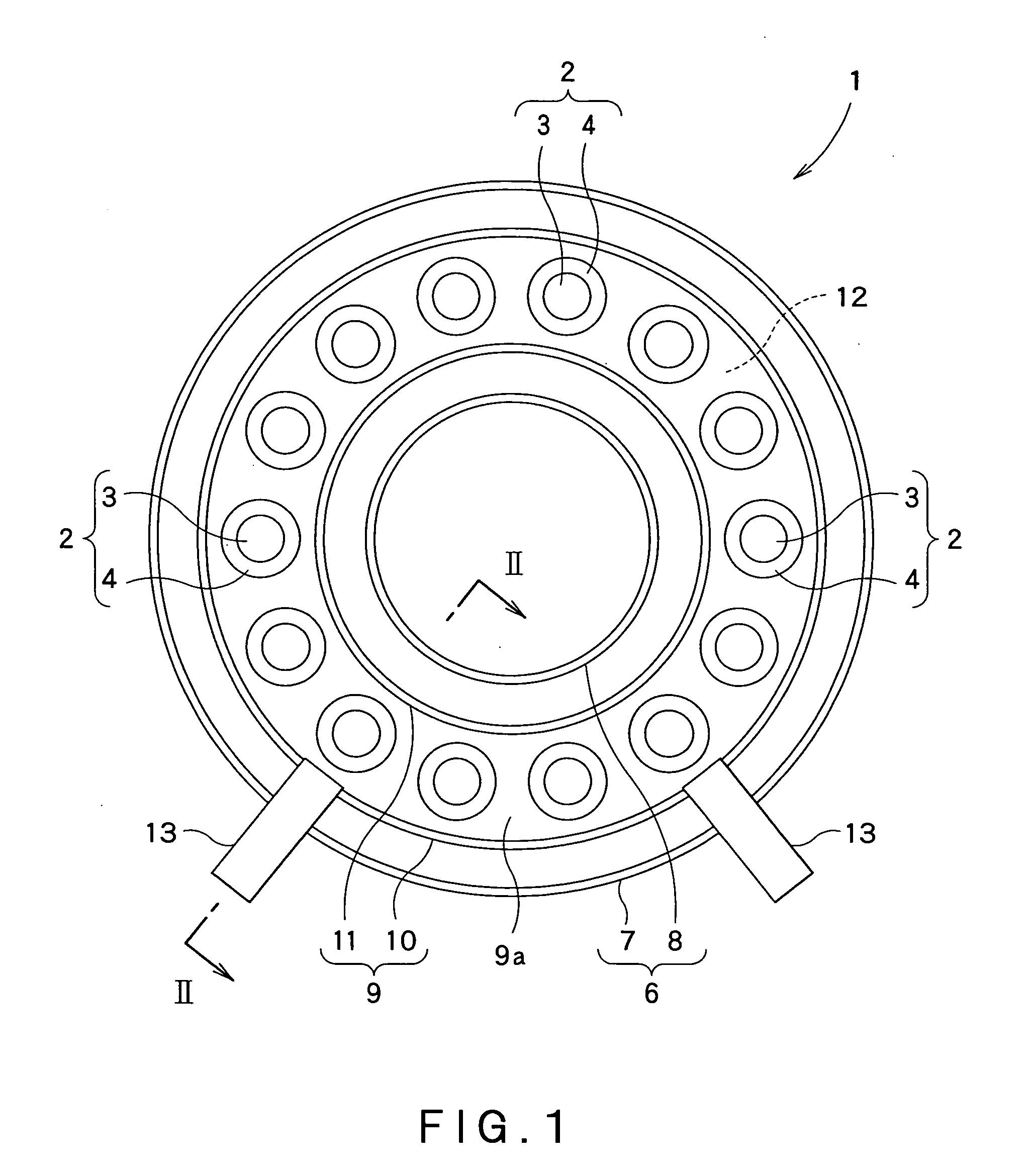

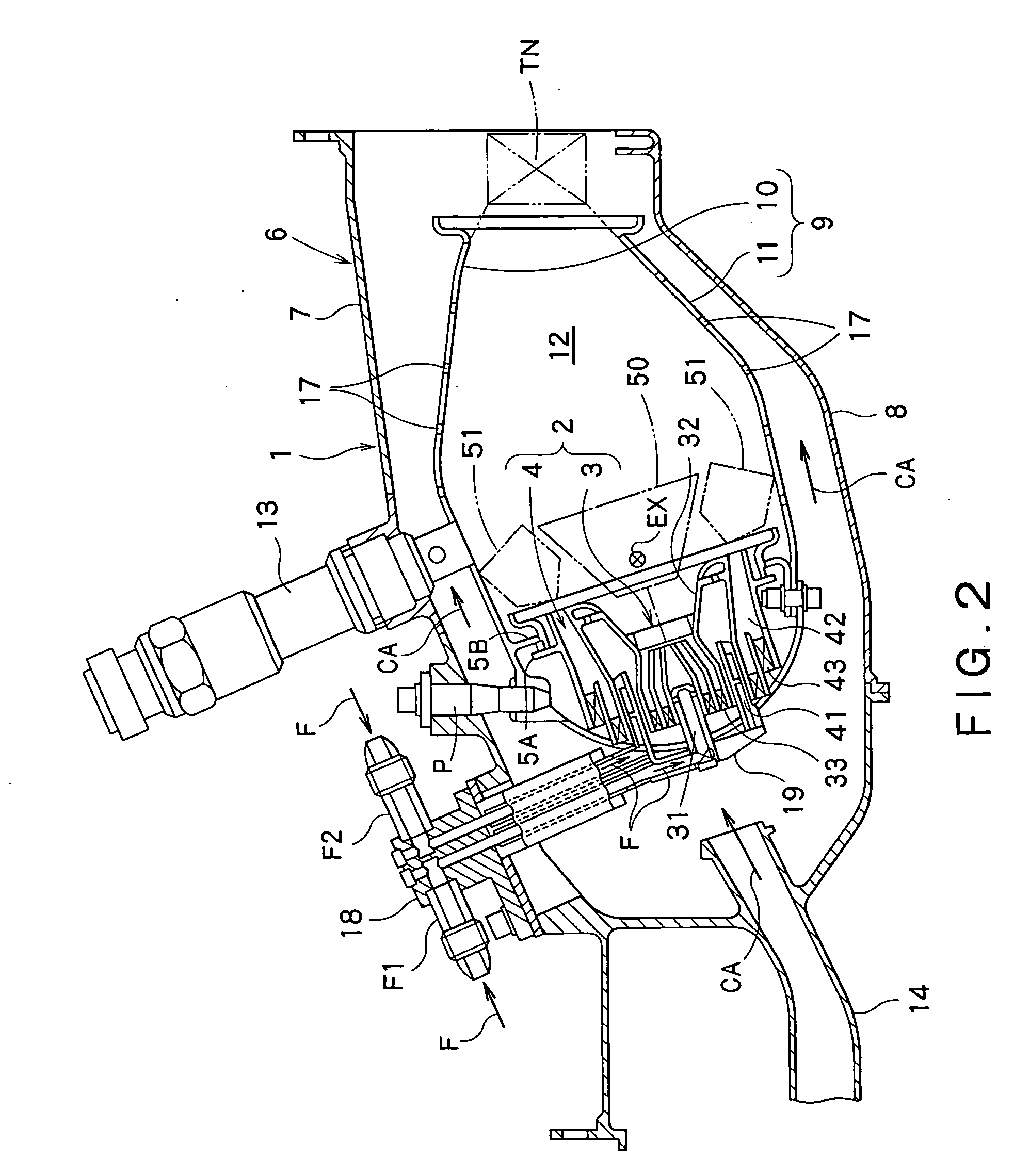

Burner, gas turbine combustor, burner cooling method, and burner modifying method

InactiveUS20130019584A1Improve reliabilityLower flame temperatureContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberInjection port

In a burner for injecting mixed gas fuel containing at least one of hydrogen and carbon monoxide into a combustion chamber of a gas turbine combustor, the burner includes a fuel nozzle for startup from which liquid fuel is injected into the combustion chamber, and a mixed fuel nozzle disposed around the fuel nozzle for injecting the mixed gas fuel. An air swirler is disposed at a downstream end of the mixed fuel nozzle and has a plurality of flow passages from which compressed air is injected into the combustion chamber, and the mixed fuel nozzle has injection ports disposed in the inner peripheral side of the flow passages of the air swirler. Cooling holes formed in the nozzle surface and positioned to face the combustion chamber introduce a part of the mixed gas fuel injected from the mixed fuel nozzle into the combustion chamber.

Owner:HITACHI LTD

Combustor of a gas turbine engine

ActiveUS20080245074A1Simple structureLow costBurnersLiquid fuel feeder/distributionCombustorDistributor

The present combustor of gas turbine engine includes: a fuel injection unit including a fuel spray part to spray a fuel so that a diffusion combustion region is formed in a combustion chamber, and a pre-mixture supply part to supply a pre-mixture of a fuel and an air so that a pre-mixture combustion region is formed in the combustion chamber; and a fuel supply unit to supply the fuel to the fuel spray part and pre-mixture supply part. The fuel supply unit includes: a pilot fuel passage and a main fuel passage to supply the fuel to the fuel spray part and the pre-mixture supply part, respectively; an assembled fuel passage to supply the fuel to the pilot and main fuel passages; and a fuel distributor disposed at a branch point where the assembled fuel passage is connected to both the pilot and main fuel passages. The fuel distributor is configured to automatically control amounts of the fuel to be distributed to the pilot fuel passage and to the main fuel passage in accordance with the fuel pressure.

Owner:KAWASAKI HEAVY IND LTD

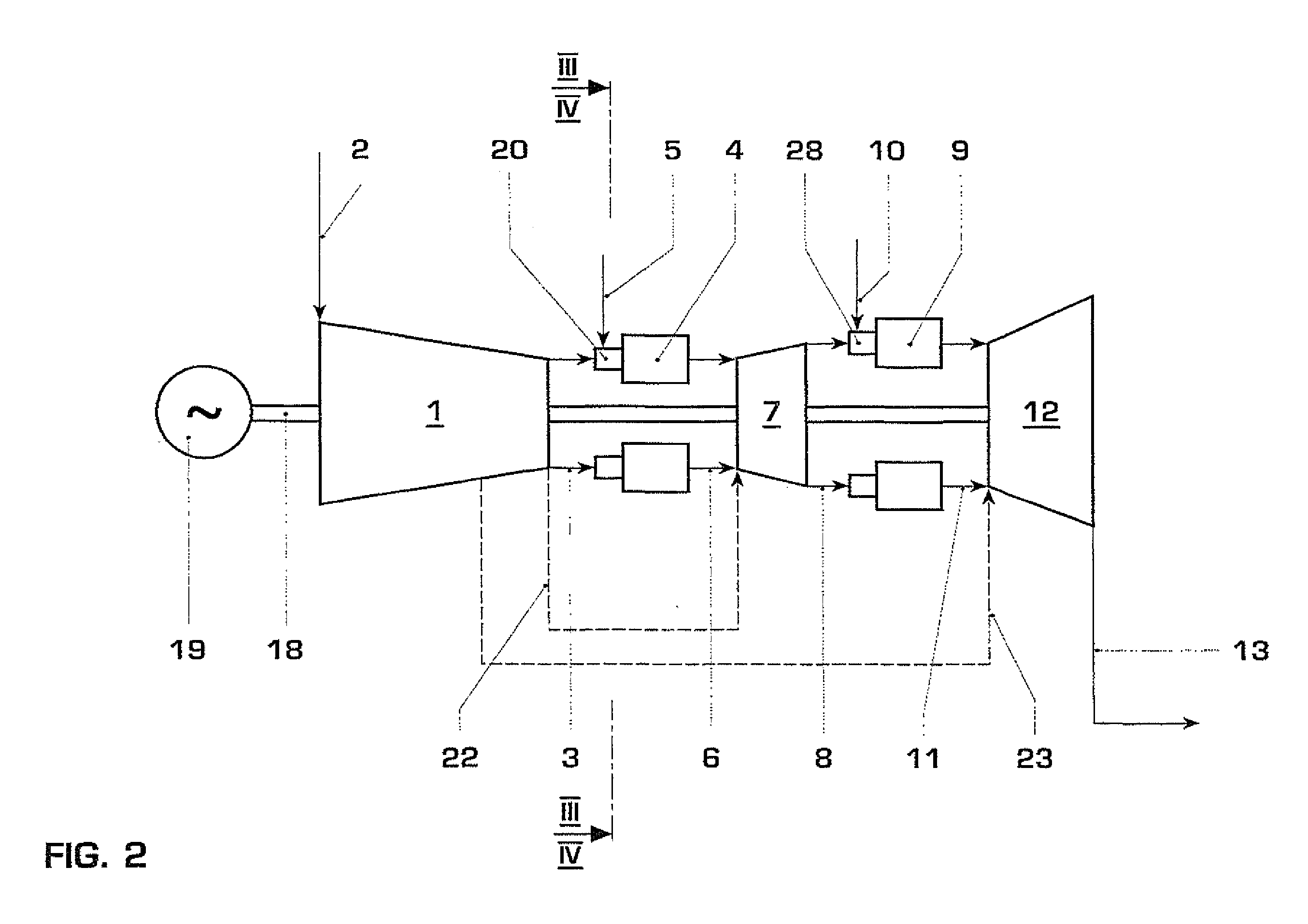

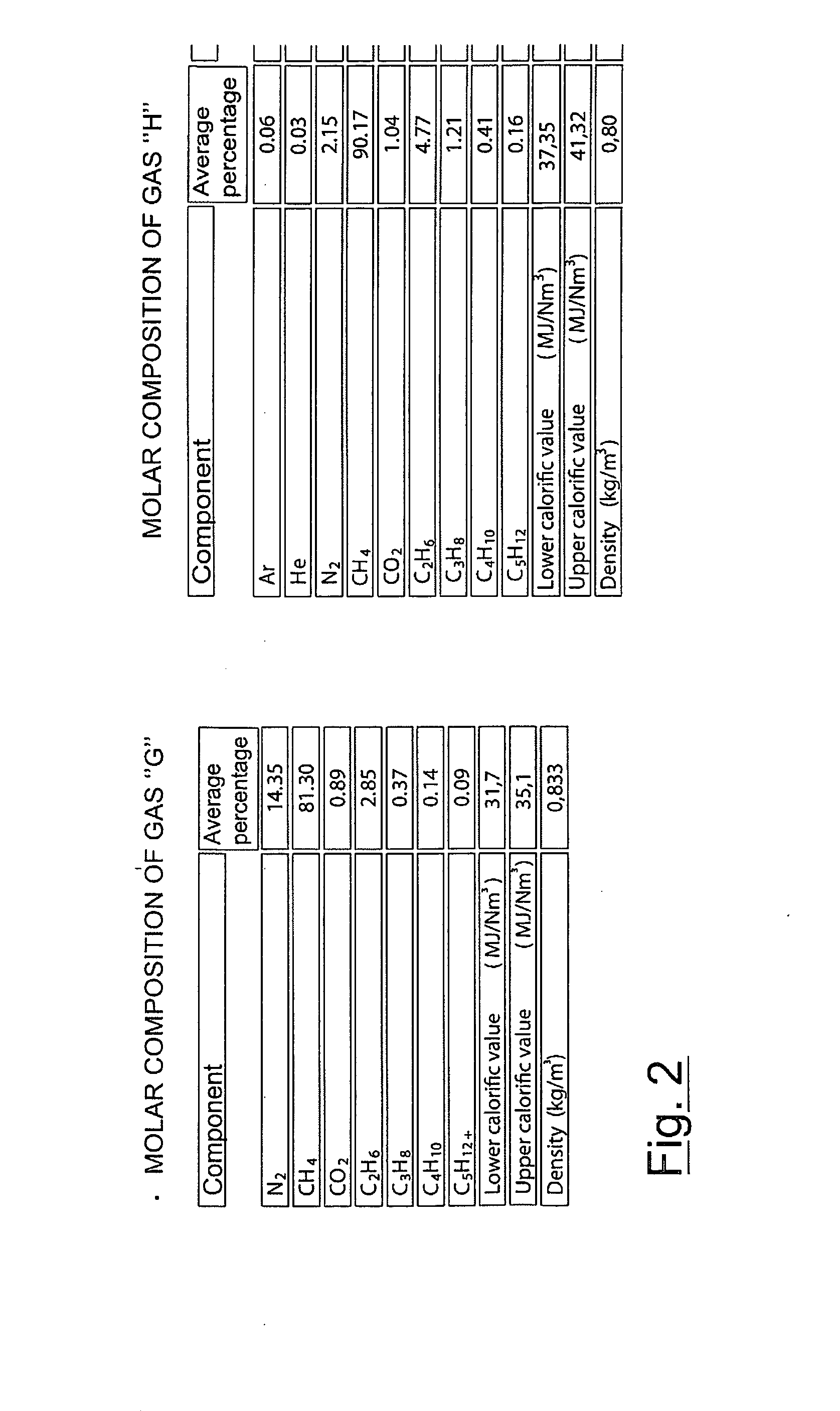

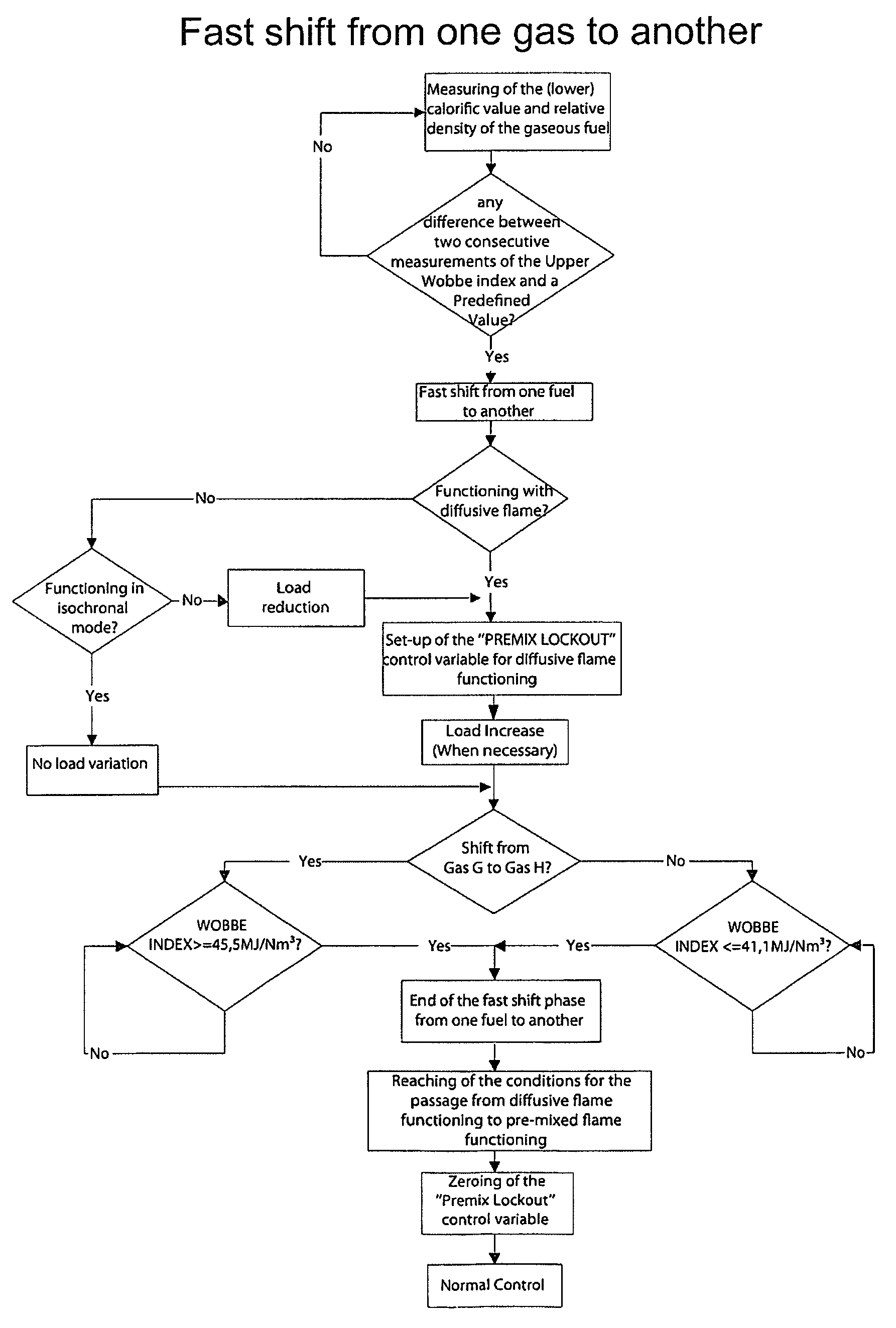

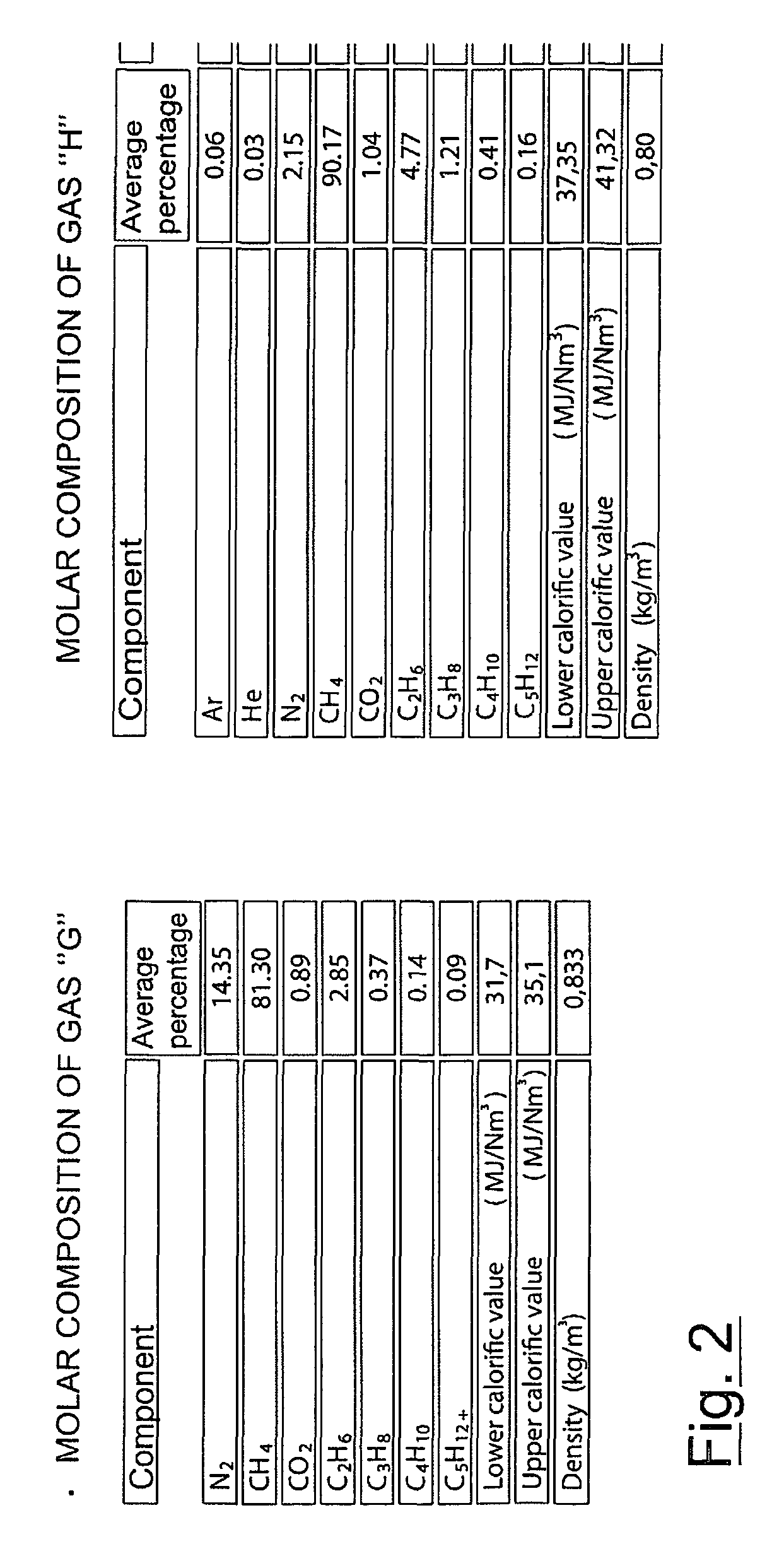

Method and apparatus for controlling the combustion in a gas turbine

InactiveUS20080289339A1Efficient solutionPrecise functionFuel supply regulationGaseous fuel pretreatmentCombustionProcess engineering

A method and apparatus are described for controlling the combustion in a gas turbine. The method includes measuring, by means of one or two calorimeters, the temperature, calorific value and relative density of a gaseous fuel in order to determine the Wobbe index, comparing the Wobbe index value measured with a predefined Wobbe index value for the gaseous fuel and regulating the temperature of the gaseous fuel by means of at least one heat exchanger in order to reach the predefined Wobbe index value. The method may also include using a second gaseous fuel, having a different Wobbe index from the gaseous fuel, or a fuel obtained by mixing the gaseous fuel and the second gaseous fuel, according to arbitrary proportions and variable with time.

Owner:NUOVO PIGNONE SPA

Metering Fuel Pump

InactiveUS20070028612A1Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesCombustion chamberEngineering

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

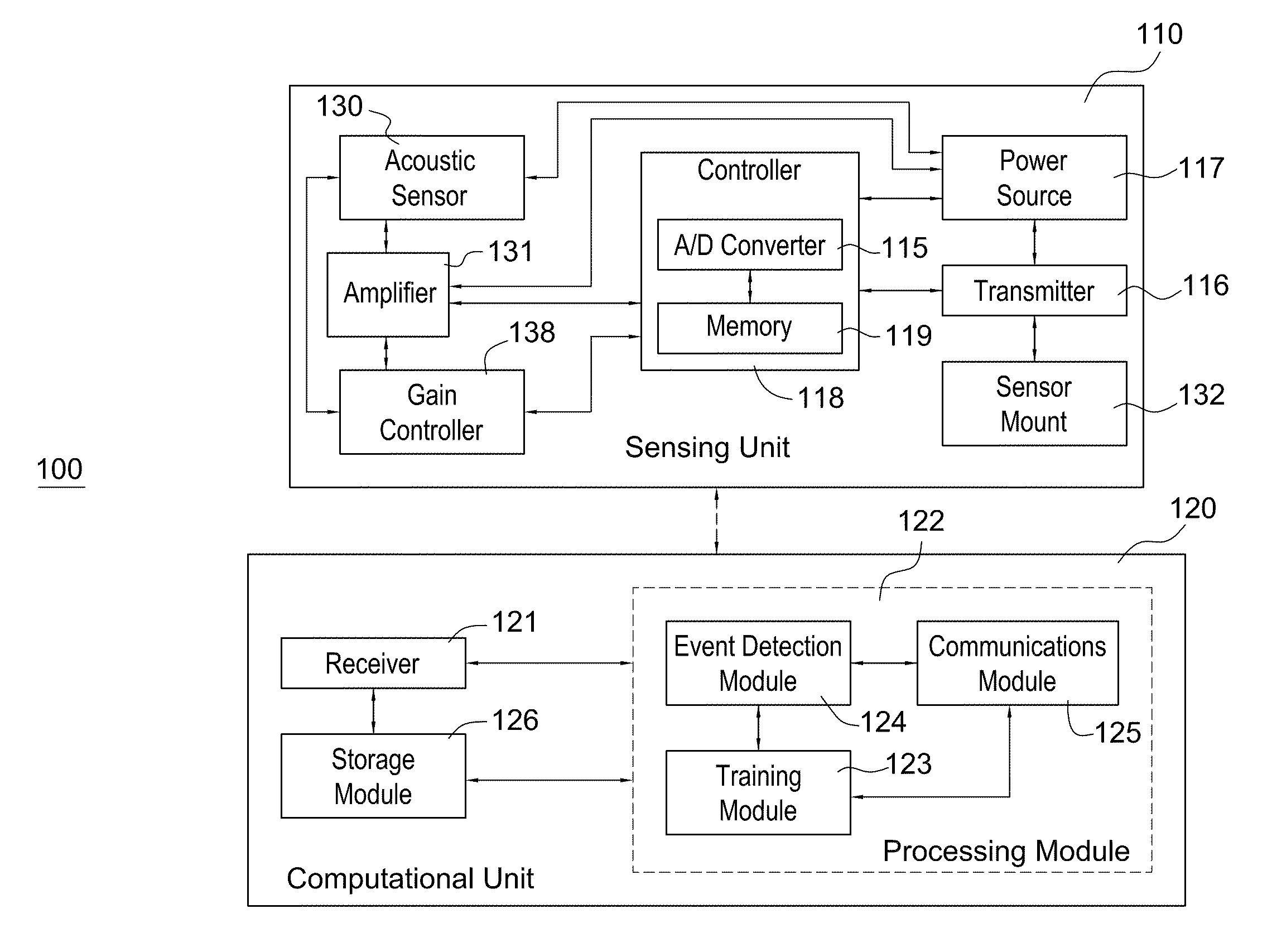

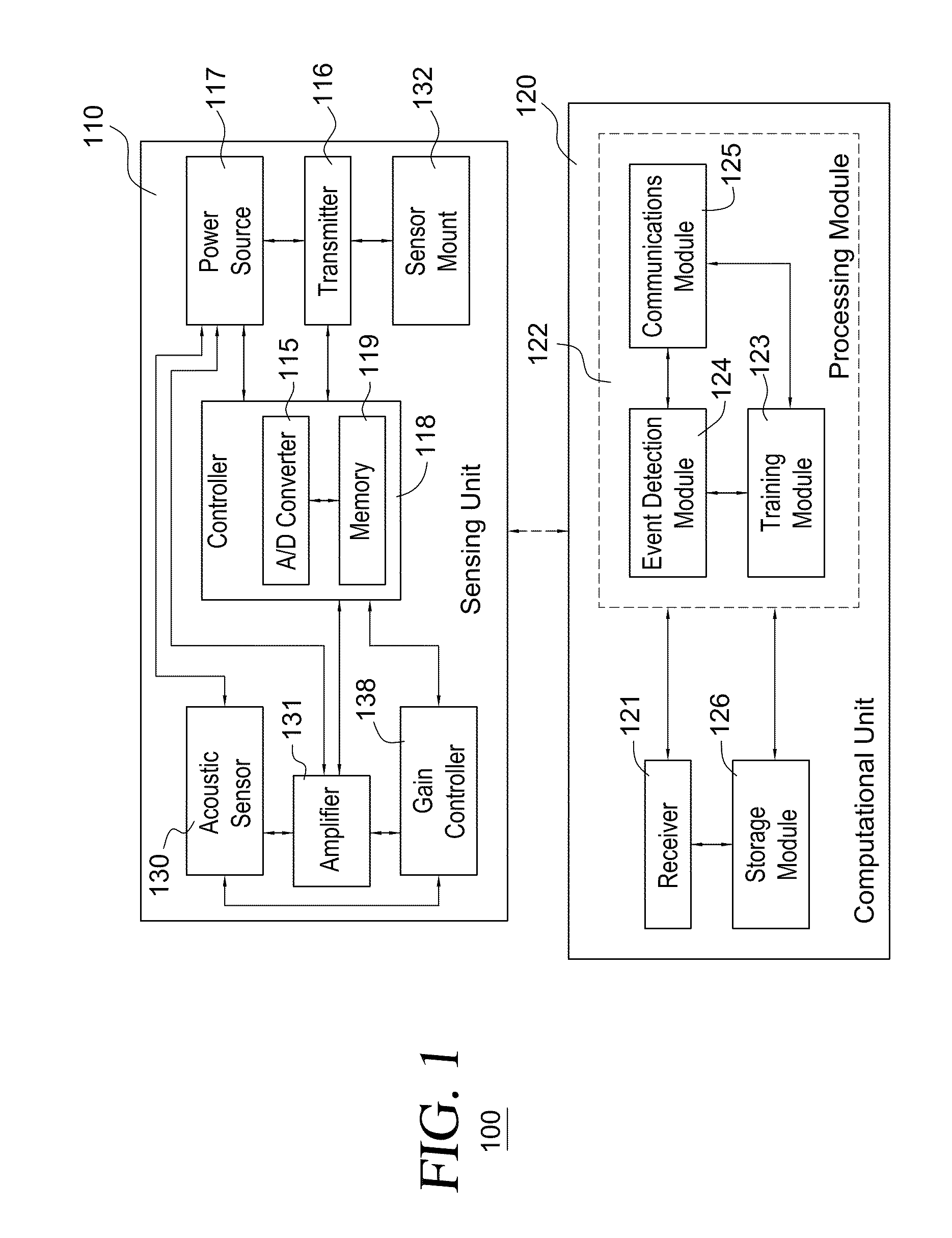

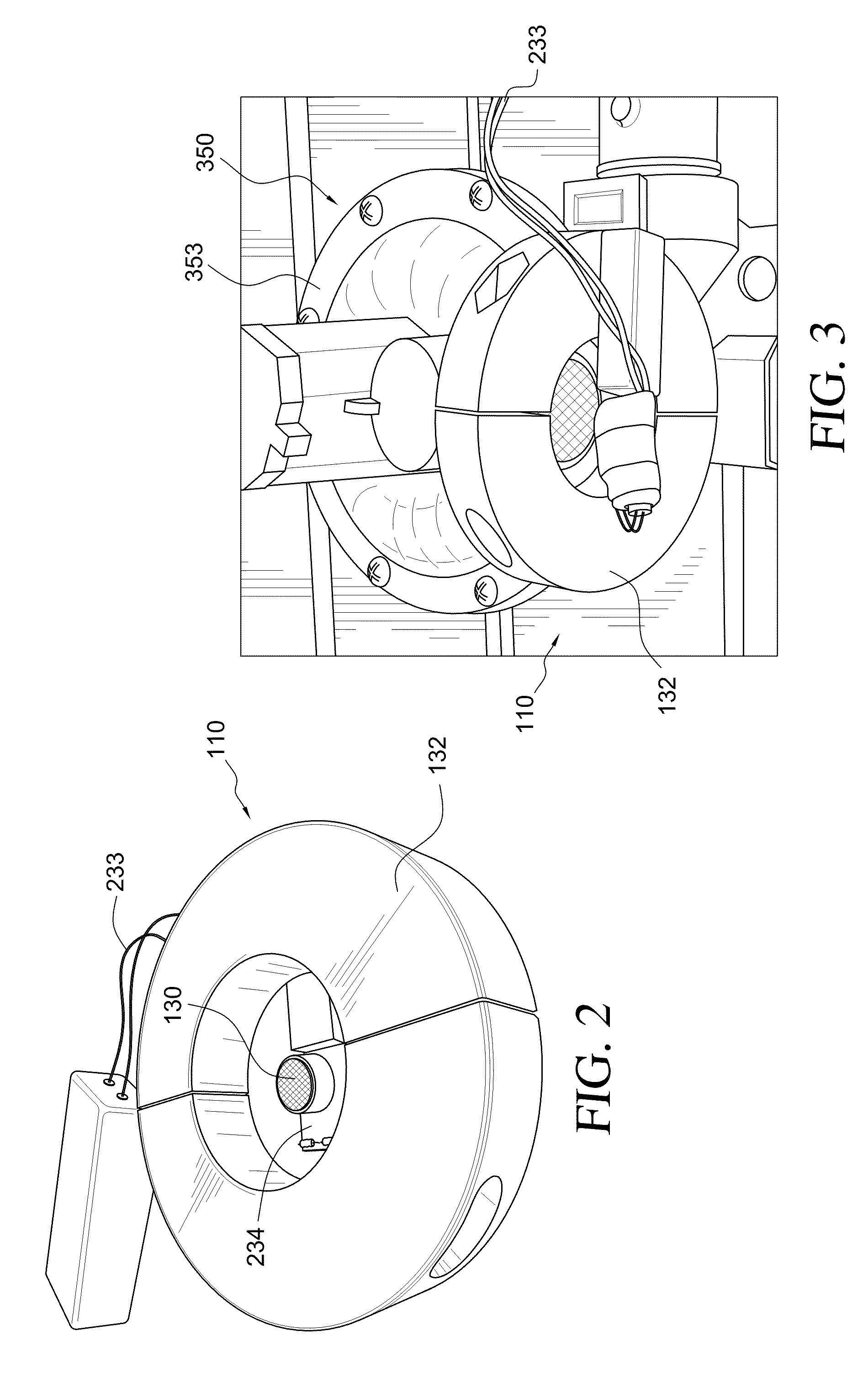

Apparatus Configured to Detect Gas Usage, Method of Providing Same, and Method of Detecting Gas Usage

In some embodiments, an apparatus can be configured to detect gas usage. The apparatus can include: (a) a processing module configured to run on a computational unit; and (b) a sensing unit configured to be coupled to a gas regulator, the sensing unit having: (1) at least one acoustic sensor configured to detect two or more acoustic signals produced by the gas regulator and convert the two or more acoustic signals into one or more first data signals; and (2) a transmitter electrically coupled to the at least one acoustic sensor and configured to transmit the one or more first data signals to the computational unit. The processing module is configured to use the one or more first data signals to determine the gas usage. Other embodiments are disclosed.

Owner:BELKIN INT

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS20070257235A1Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

Device and method for feeding fuel

InactiveUS20060263731A1Control of combustionReduced flexibilityGaseous fuel pretreatmentCombustion using multiple fuelsCombustion systemControllability

The present invention provides a fuel feeding apparatus and method for improving the controllability of mixing process and mixing ratio of fuel and combustion air, and a combustion system and method for effecting new combustion properties. The fuel feeding apparatus of the combustion system has fuel feeding means, combustion gas extraction means, steam supply means, mixing means and fuel gas introduction means. The combustion gas extraction means extracts combustion gas of a combustion area therefrom. The mixing means mixes the fuel of fuel feeding means with at least one of combustion gas extracted from the furnace and steam of a steam generator. The fuel gas introduction means introduces a mixed fluid of combustion gas, steam and fuel to the combustion area as a fuel gas, and allows the fuel gas to be mixed with the combustion air. A step of mixing the fuel with the combustion gas after extracted from the furnace and a step of mixing the fuel gas with the combustion air are stepwisely carried out, so that the controllability of mixing process and ratio of the air and fuel is improved. Such a control of fuel gas flow enables control of characteristics of flame and production of flame with new properties in the combustion area.

Owner:NFK HLDG

Method and apparatus for controlling the combustion in a gas turbine

InactiveUS7730726B2Efficient solutionPrecise functionFuel supply regulationGaseous fuel pretreatmentCombustionEngineering

Owner:NUOVO PIGNONE SPA

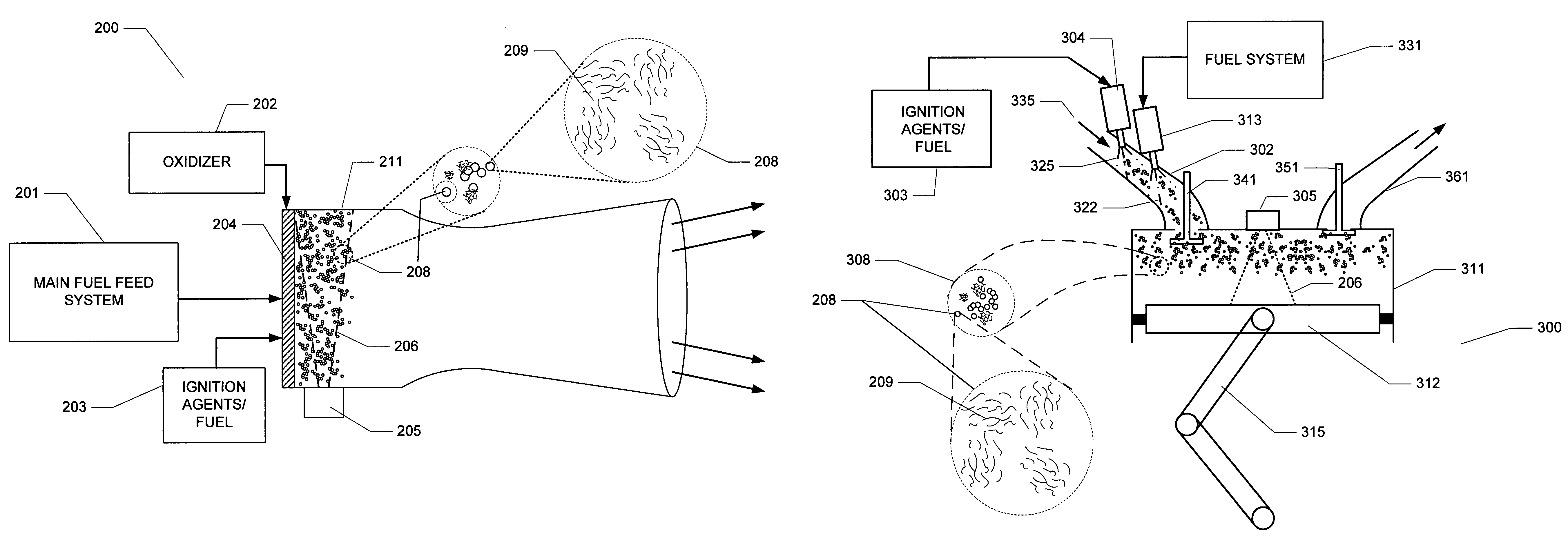

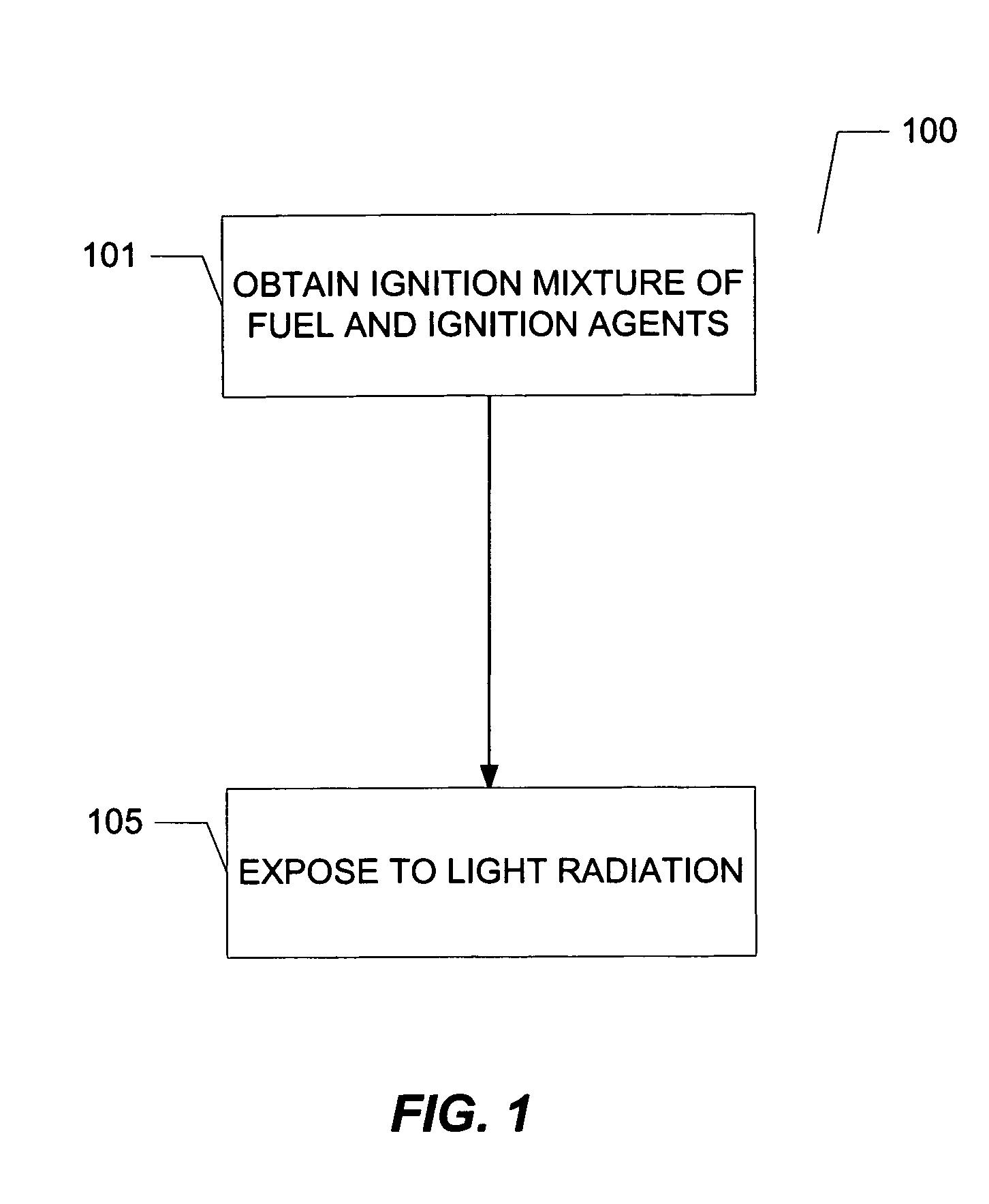

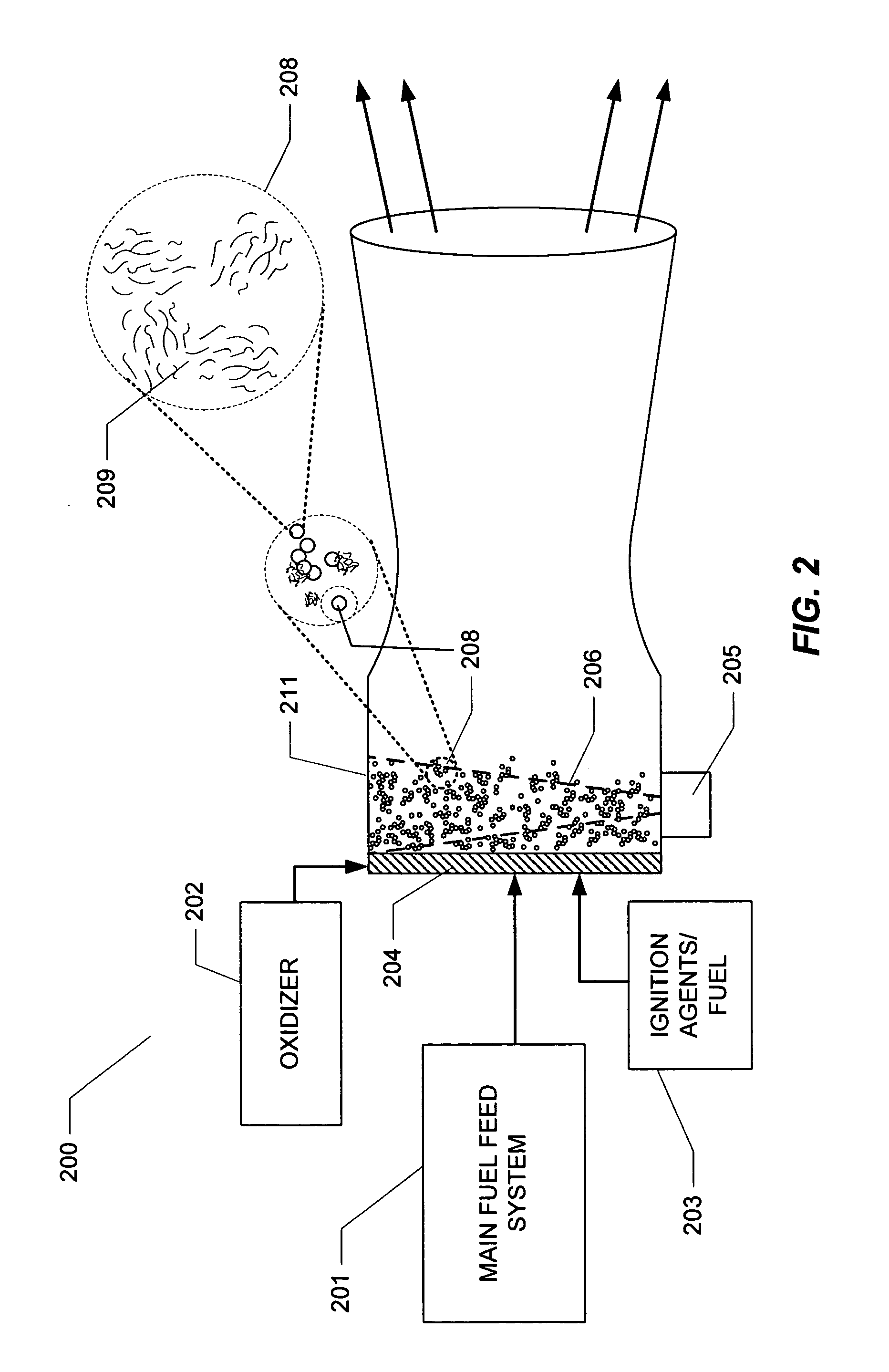

Method for distributed ignition of fuels by light sources

A method for distributed ignition is disclosed wherein a combustion fuel and an ignition mixture are combined where the ignition mixture comprises ignition agents and fuel and where ignition agents can be nano-metallic particles in combination with single-walled carbon nano-tubes (SWCNTs). The combination of ignition mixture and combustion fuel in the presence of oxygen are exposed to light causing heating of the ignition agents and combustion of the fuel within which the ignition agents are interspersed. A system for igniting fuels using the method is also disclosed.

Owner:ERC

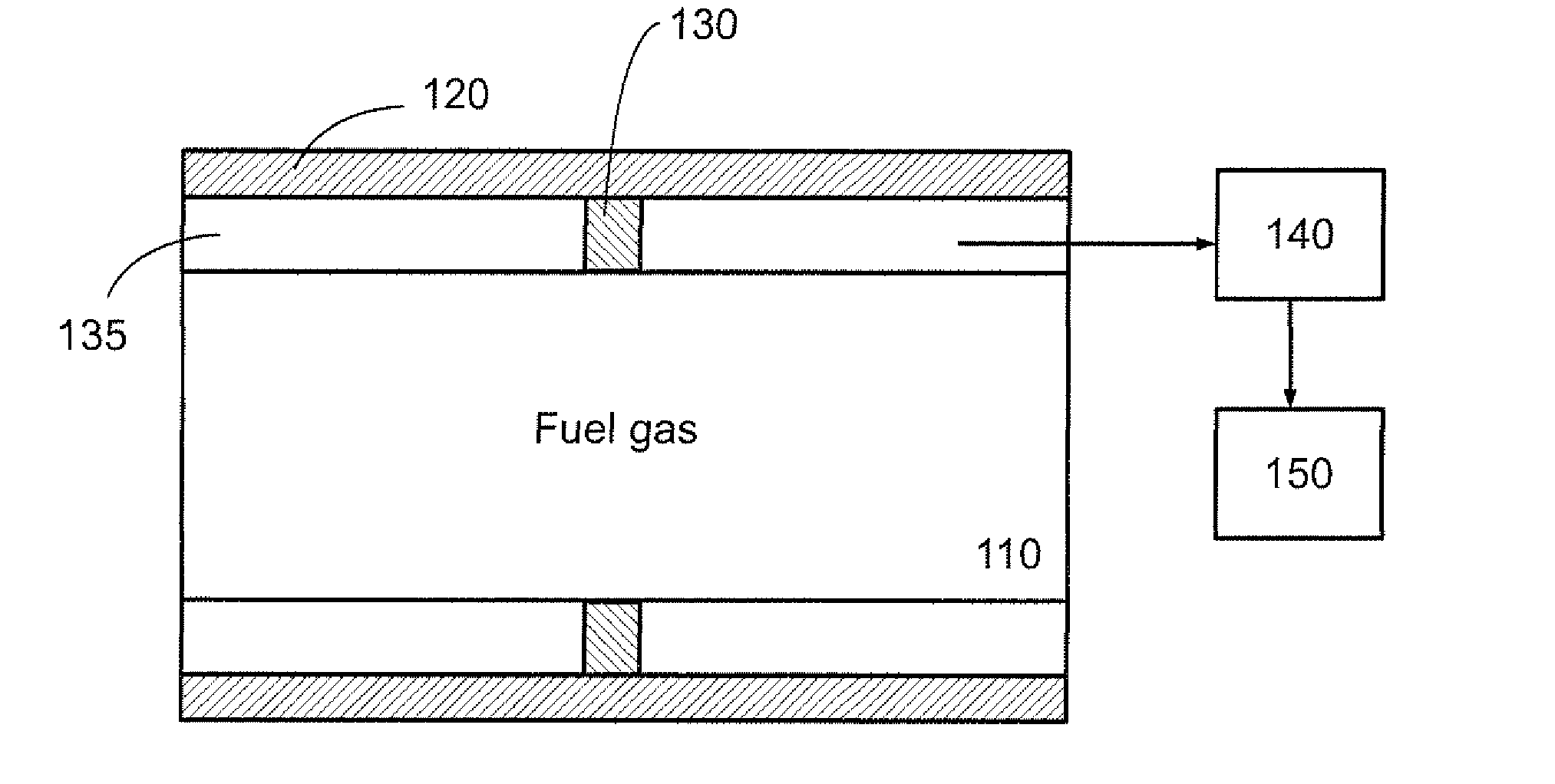

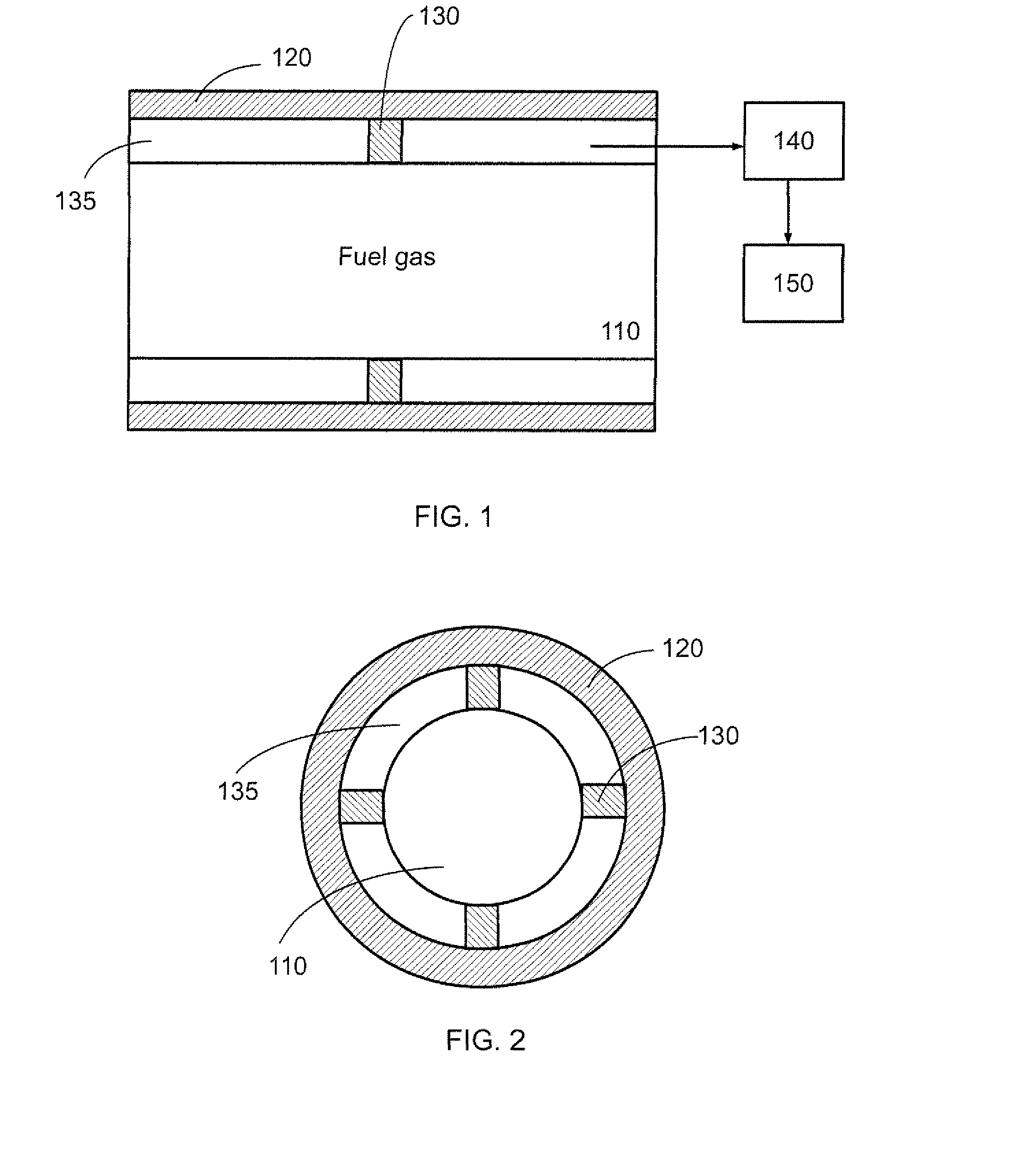

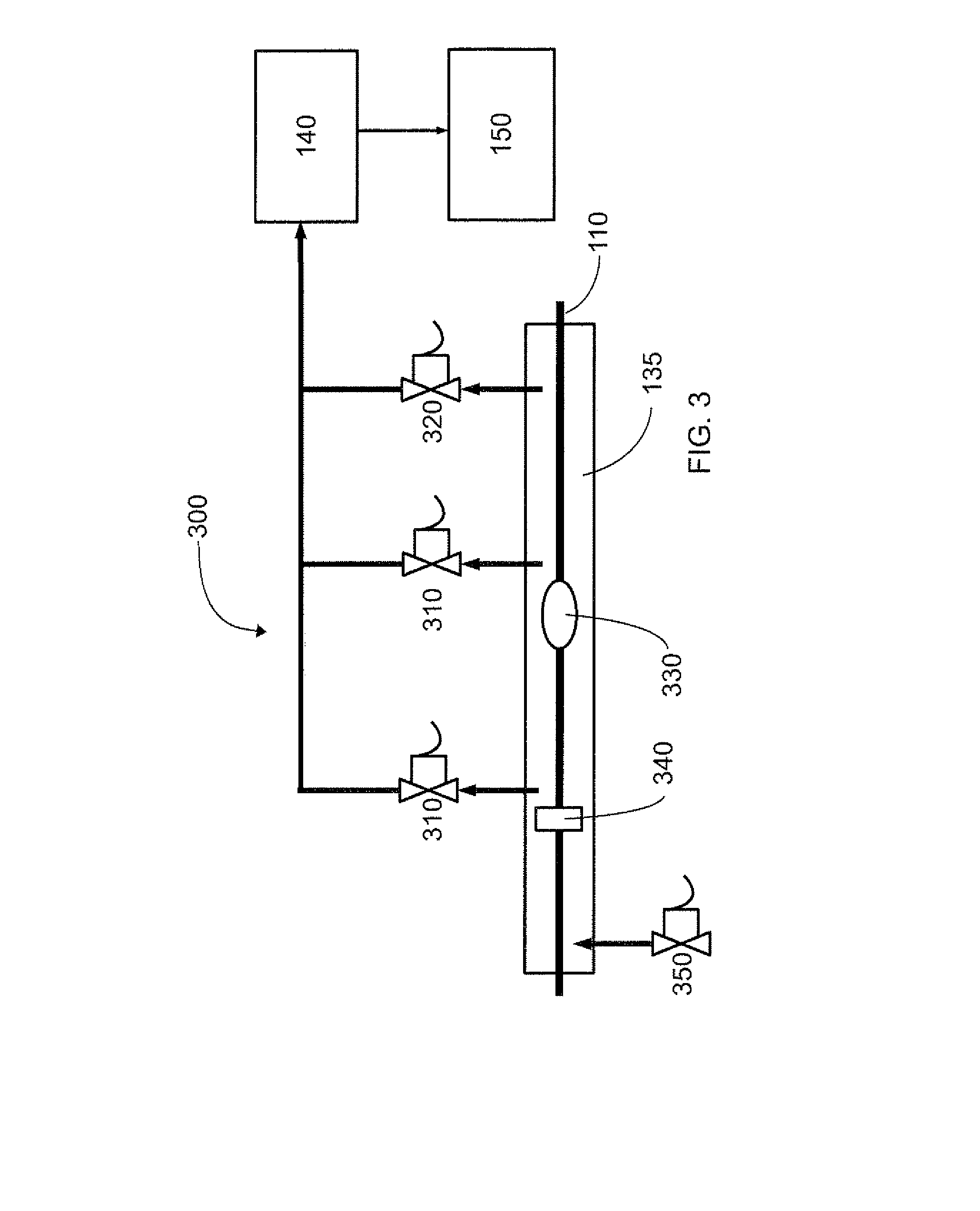

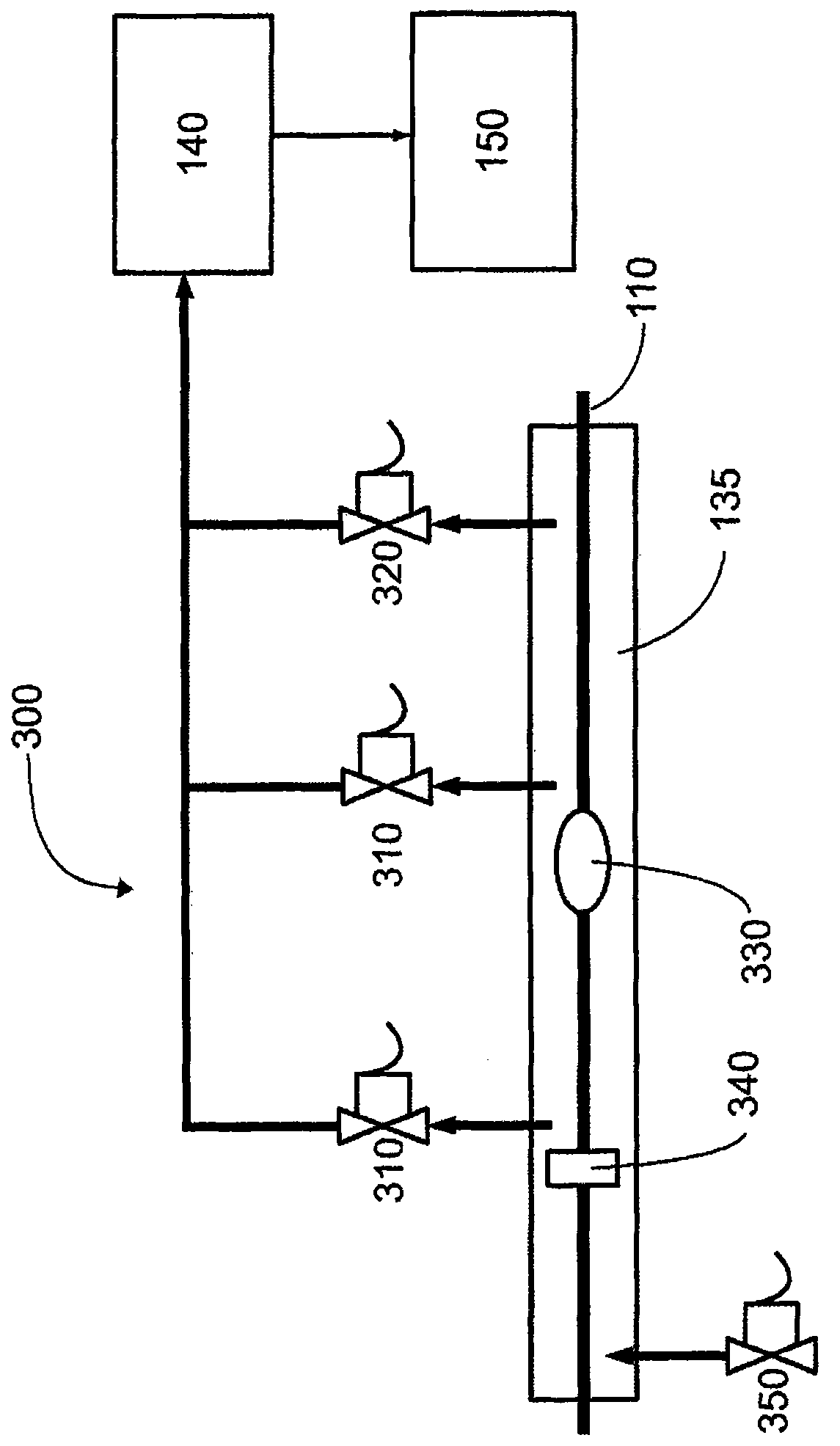

Method and system to detect and measure piping fuel leak

InactiveUS20120048000A1Detection of leakageTurbine/propulsion fuel supply systemsMeasurement of fluid loss/gain rateCombustorHydrocotyle bowlesioides

The described method and system utilize continuous and / or periodic measurement of the fuel pipes to detect leakage of fuel. In general, the piping is enclosed in an air-tight containment cover so that a passage is formed between the piping and containment cover. Measurements can be conducted, using known hydrocarbon and other combustible gases industrial analyzers, and leak detectors. Pressure drop within the passage can be compensated by controlling of air inlet flow into the passage, coordinated with the analyzer pumping rate. Temperature and motion of a gas sample can be controlled by heating the inlet air. The system can includes the controlling valves for the leak source localization. The described method and system can be used to analyze and control fuel leak for late lean injection system for combustor of a turbine.

Owner:GENERAL ELECTRIC CO

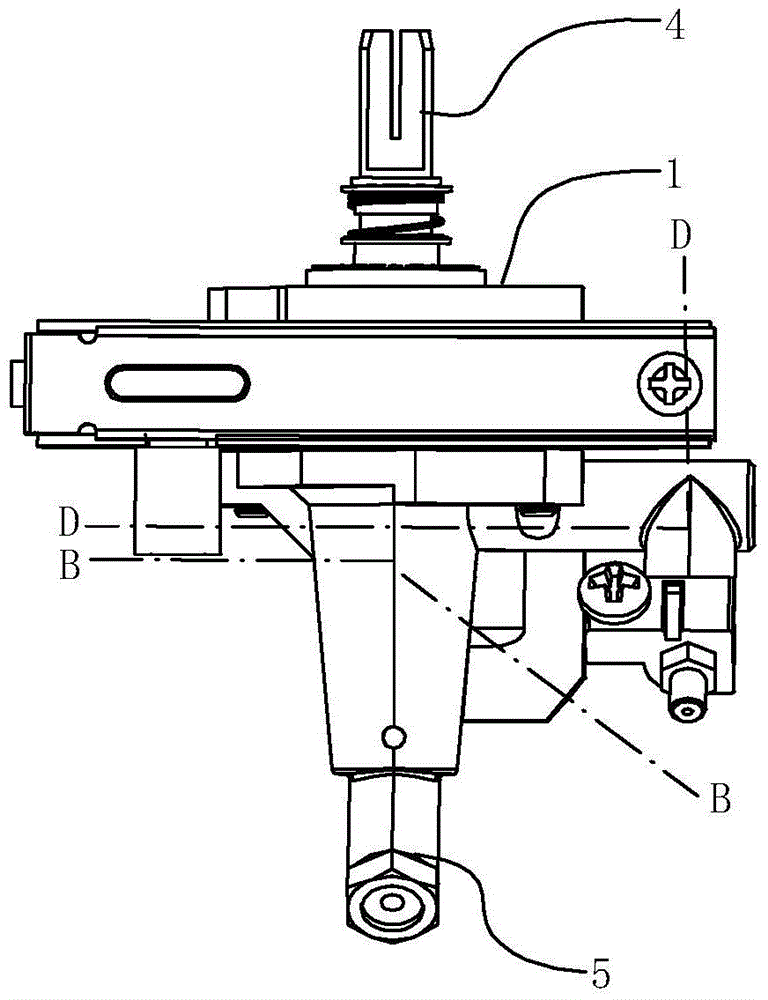

Gas valve

ActiveUS9410701B1Reduce operating errorsEasy to manufacturePlug valvesFuel supply regulationStreamflowBiomedical engineering

A gas valve includes a valve body and a valve core; the valve core has a center hole and an inlet hole defined in the peripheral surface of the valve core and capable of aligning with the inlet of the valve body and in communication with the center hole of the valve core; an auxiliary inlet with two ends is defined in the valve body linking the inlet with the chamber of the valve body; an auxiliary inlet hole is defined in the peripheral surface of the valve core and capable of aligning with the auxiliary inlet, the auxiliary inlet hole is in communication with the center hole of the valve core, and the auxiliary inlet hole is defined away from the inlet hole. The gas valve with the separated inlet hole and auxiliary inlet hole can reduce the operational error during the adjustment of the gas flow rate.

Owner:NINGBO CHAOYANG HOUSEHOLD GAS STOVES

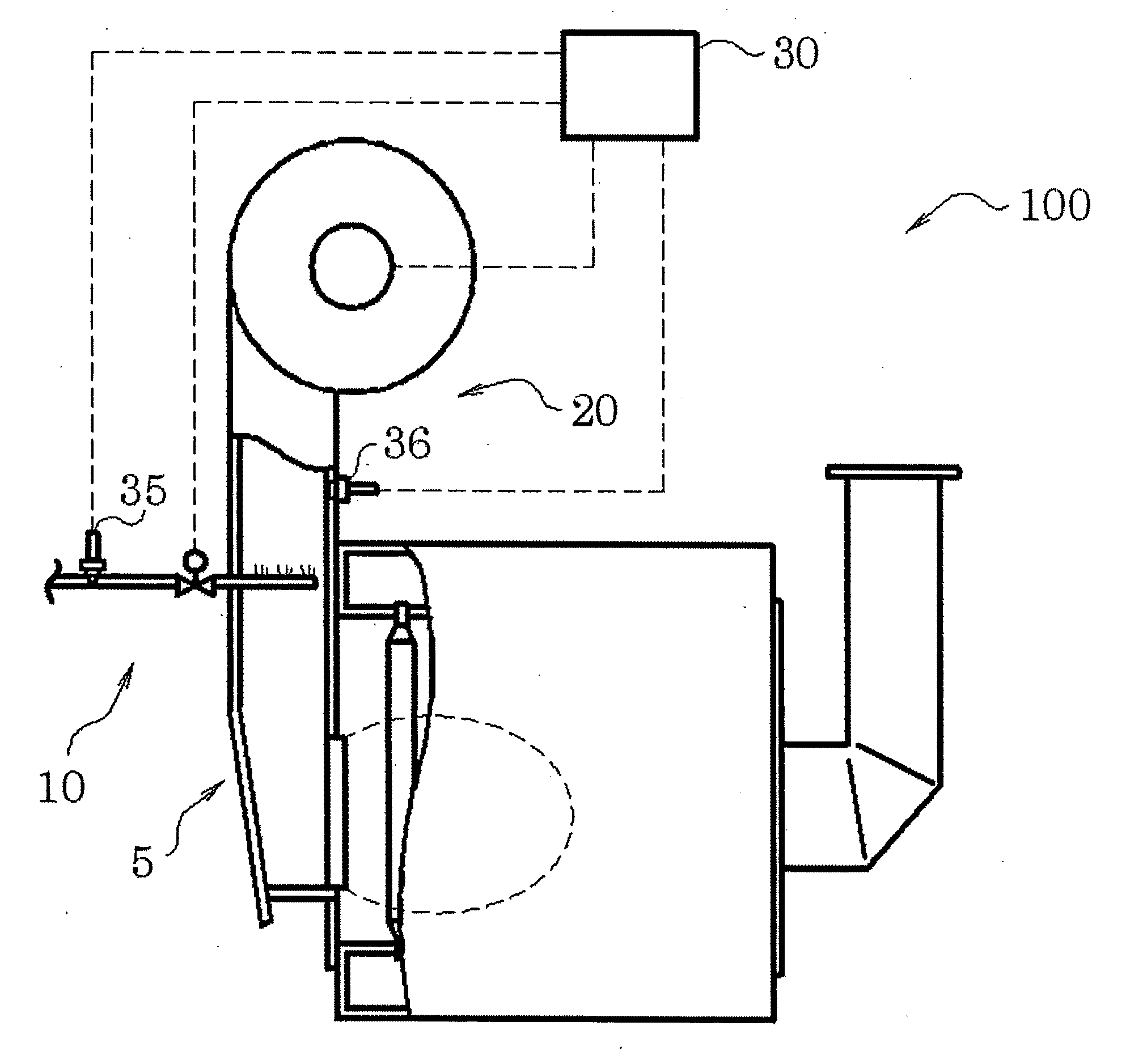

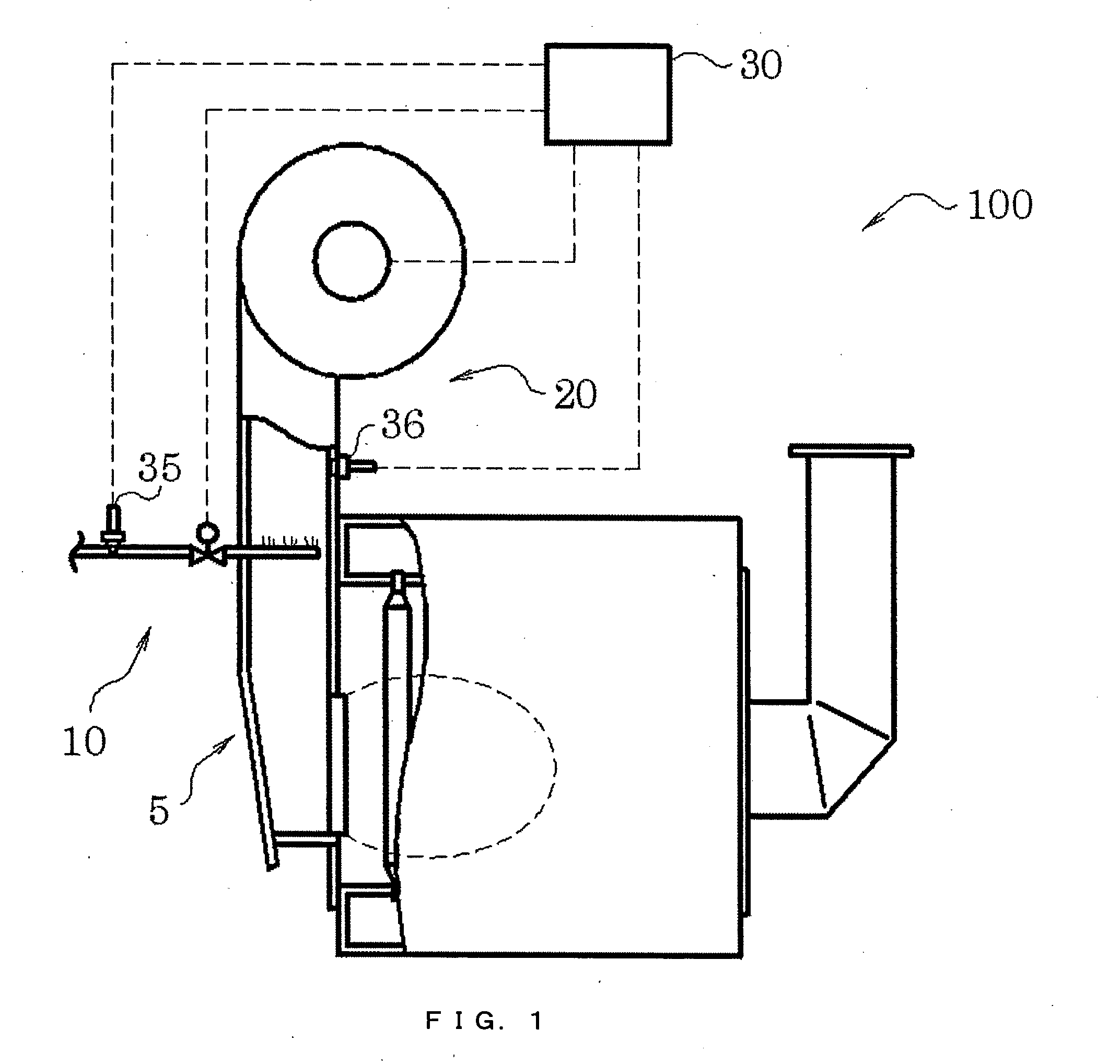

Boiler and combustion control method

InactiveUS20080057451A1Easy constructionWay stableFuel supply regulationMechanical apparatusCombustorFuel supply

Provided is a boiler (100) including: a burner (5); a fuel supply unit (10) for supplying fuel to the burner (5); a blowing unit (20) for supplying air to the burner (5); and a control unit (30) for adjusting an amount of fuel to be supplied to the burner (5) and a quantity of air to be supplied to the burner (5), in which the control unit (30) has a reference amount computing portion for calculating a reference fuel amount and a reference air quantity to be supplied to the burner (5) with respect to a required load, an air quantity computing portion that corrects the reference air quantity based on a temperature of the air to be supplied to the burner (5) and a temperature of the fuel to be supplied to the burner (5) and calculates the corrected air quantity as a supply air quantity, and a control portion that controls combustion at the burner based on the reference fuel amount and the supply air quantity.

Owner:MIURA COMPANY LIMITED

Gas flowrate control device for gas burner

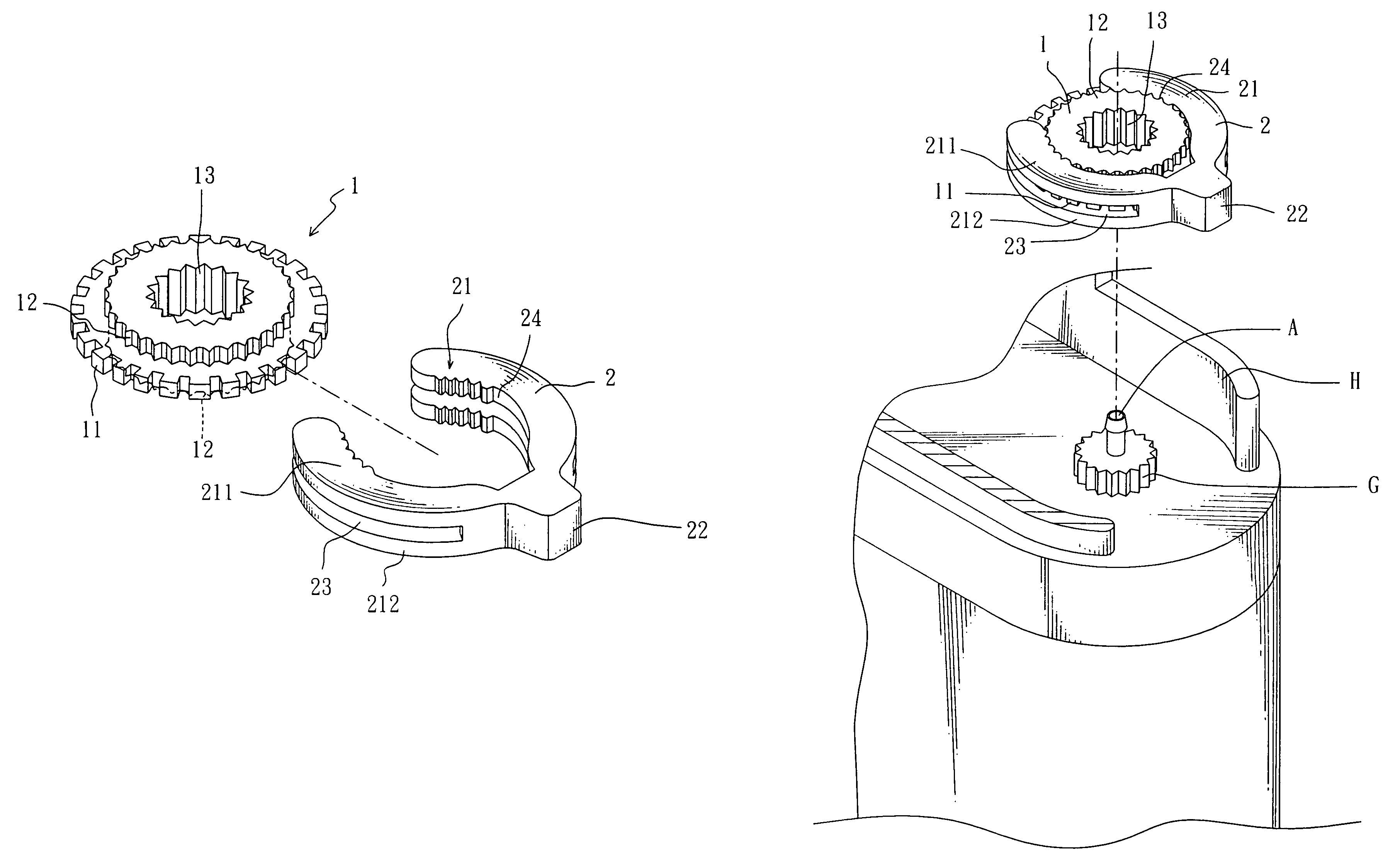

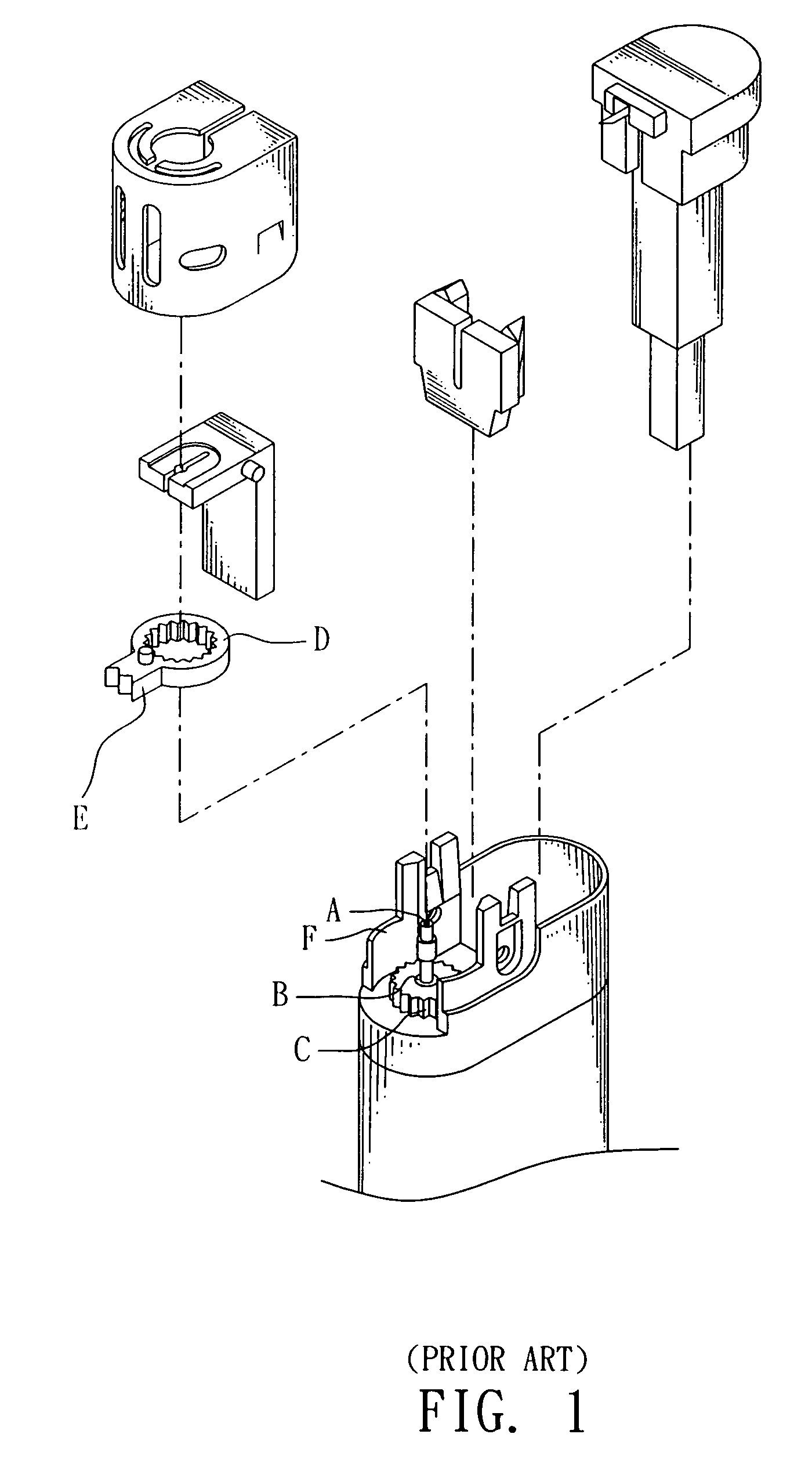

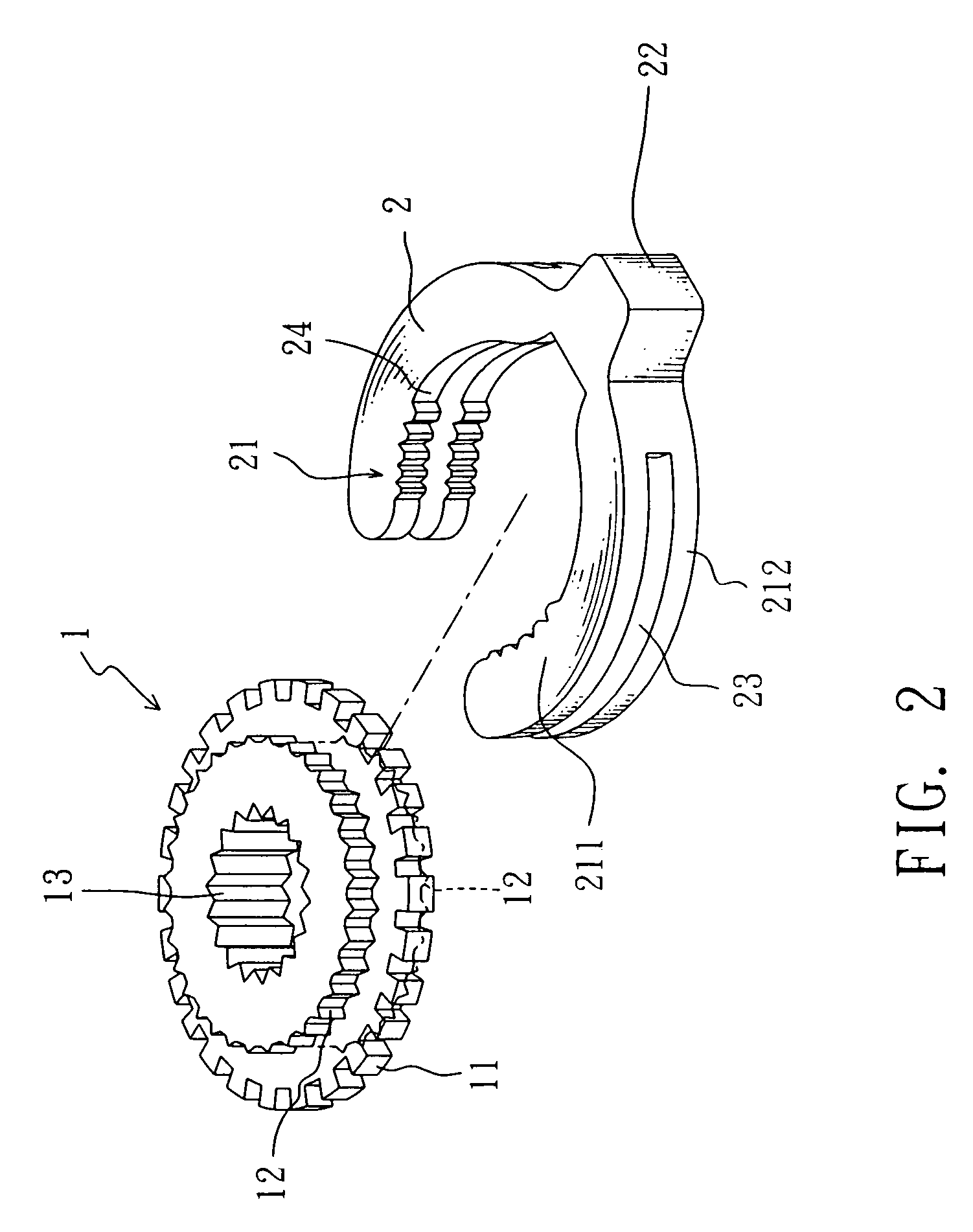

A gas flowrate control device for turning the flame adjustment wheel of a gas burner is disclosed to include a control wheel, which has an internal gear meshed with the flame adjustment wheel of the gas burner, a big gear surrounding the internal gear, and two small gears respectively formed integral with two sides of the big gear and surrounding the internal gear, and a handle, which has a grip and two arched clamping arms symmetrically extending from the grip and clamped on the control wheel, each arched clamping arm having two toothed arm positions respectively meshed with the two small gears of the control wheel and a crevice defined between the two arm portions for accommodating the big gear.

Owner:TSAI CHIN LIN

Method and system to detect and measure piping fuel leak

InactiveCN102435399ALeak delayDetection of fluid at leakage pointTurbine/propulsion fuel supply systemsCombustorCombustible gas

Owner:GENERAL ELECTRIC CO

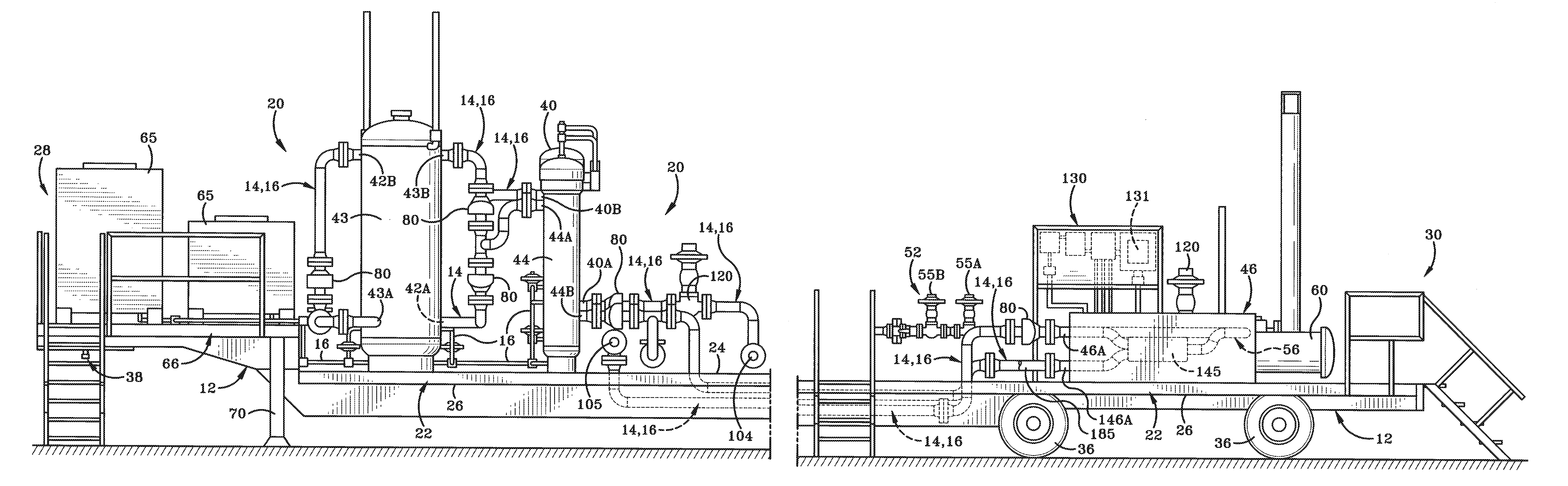

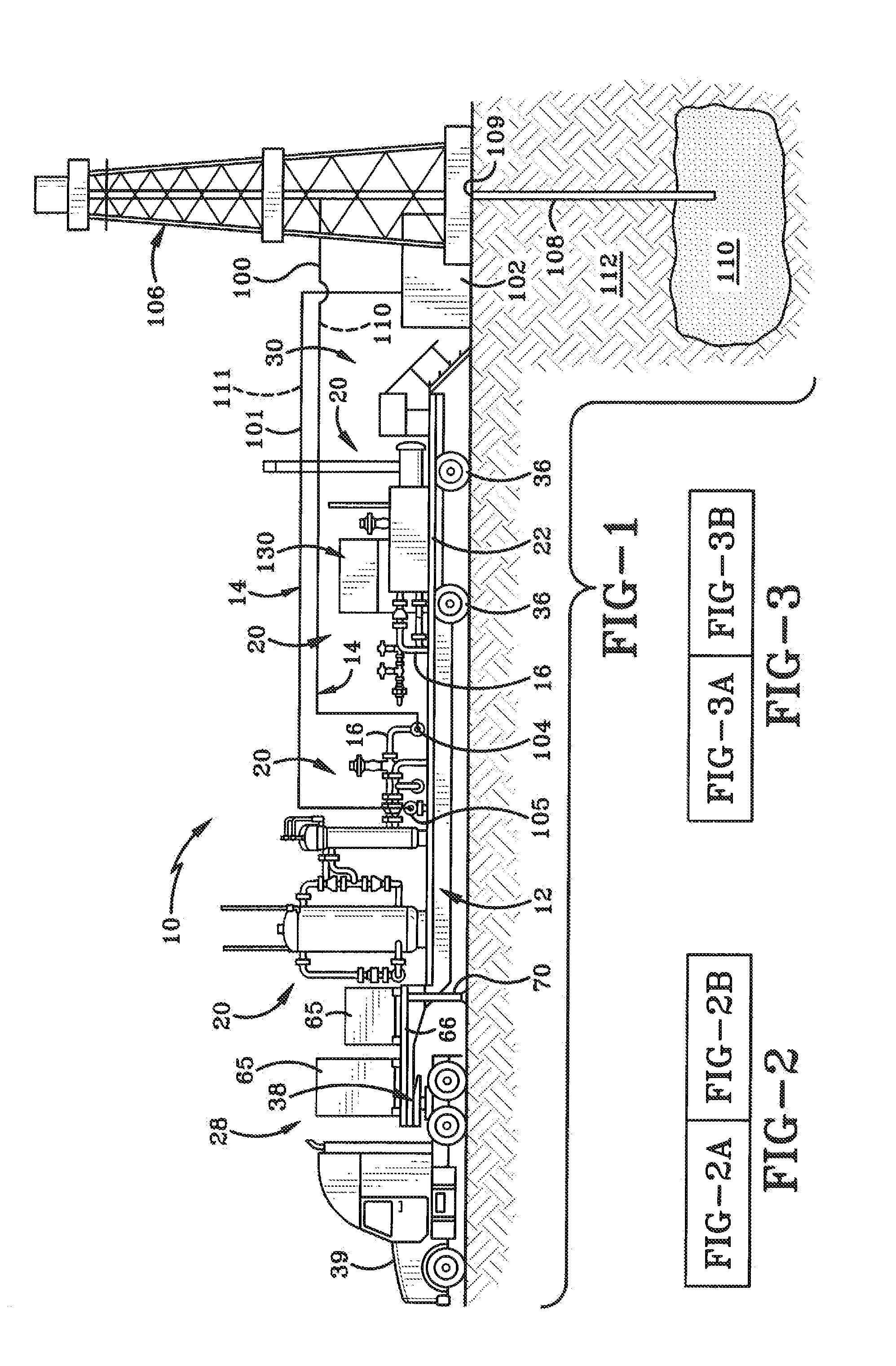

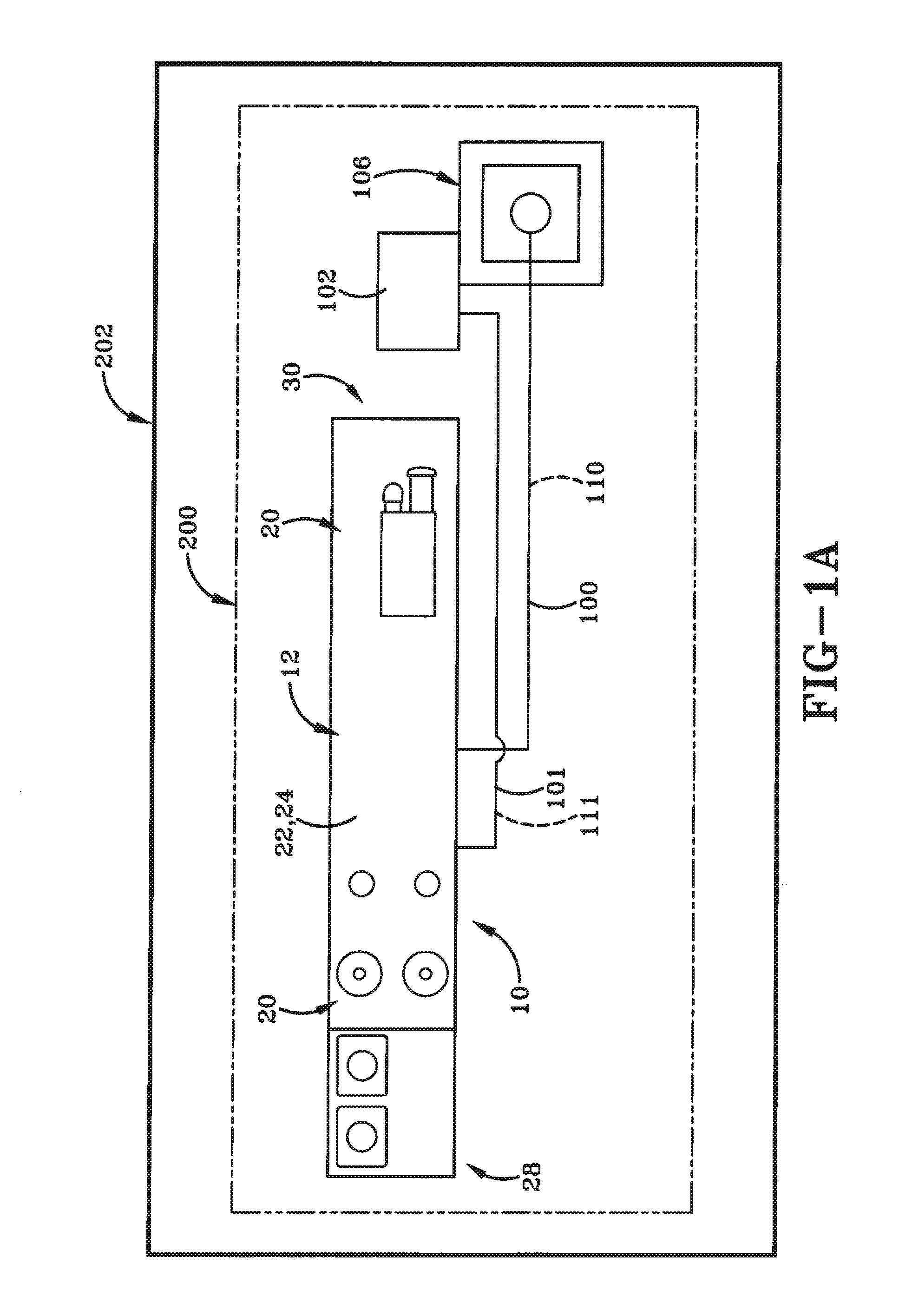

Method for operating a gas processing system

InactiveUS20150267871A1Gaseous fuel feeder/distributionInternal combustion piston enginesProcess engineeringHandling system

A method of operating a gas processing system is provided. Namely, the gas processing system is mounted atop a mobile facility for processing raw fossil fuel adjacent the well site where they were extracted from the ground. The method moves a fossil fuel along a pathway through the mobile gas processing system. Fuel events, such as, pressure, temperature, or flow rate are sensed by sensors along the pathway. A signal generator generates a signal containing information of the fuel event and sends the signal wirelessly to a remote access device where the signal is interpreted. Then, an element of the processing system, such as a valve, is actuated in response to the signal.

Owner:PRIDE OF THE HILLS MFG

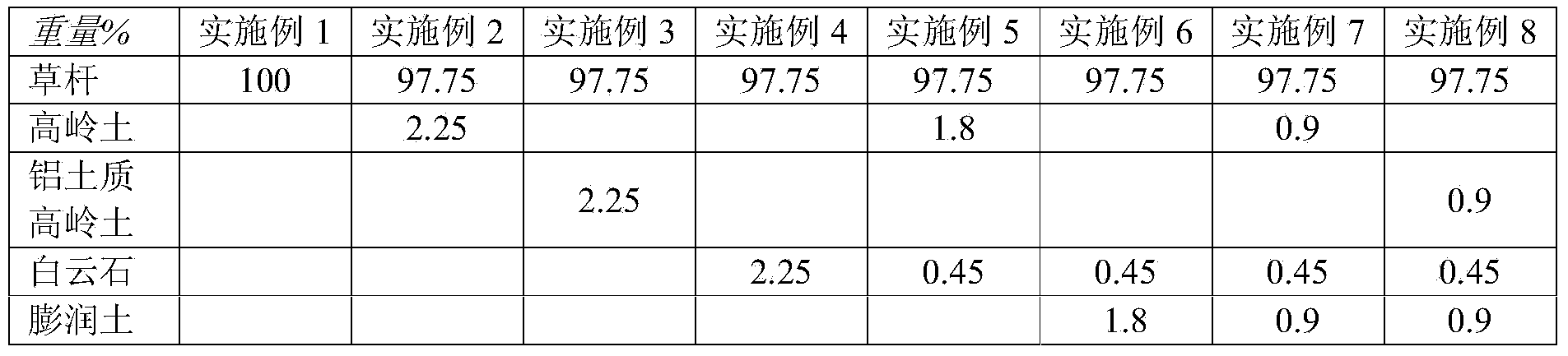

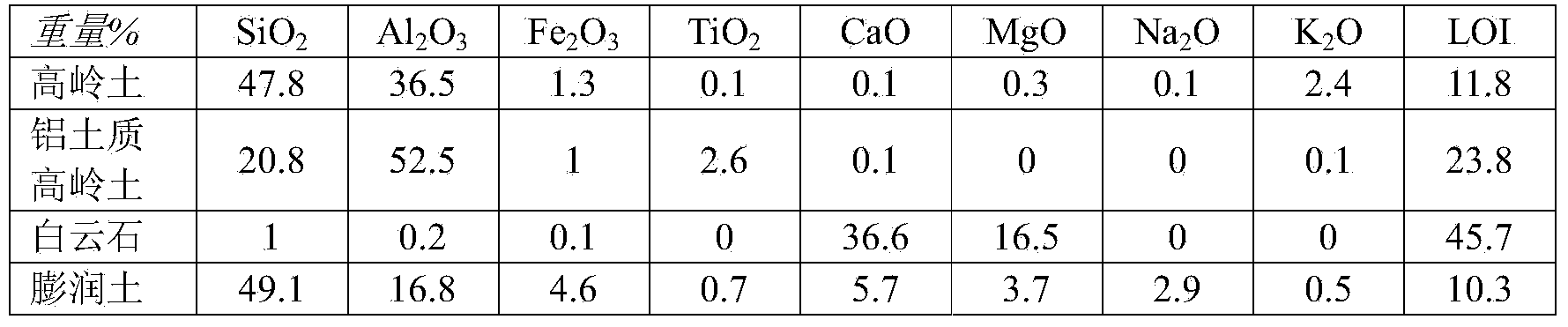

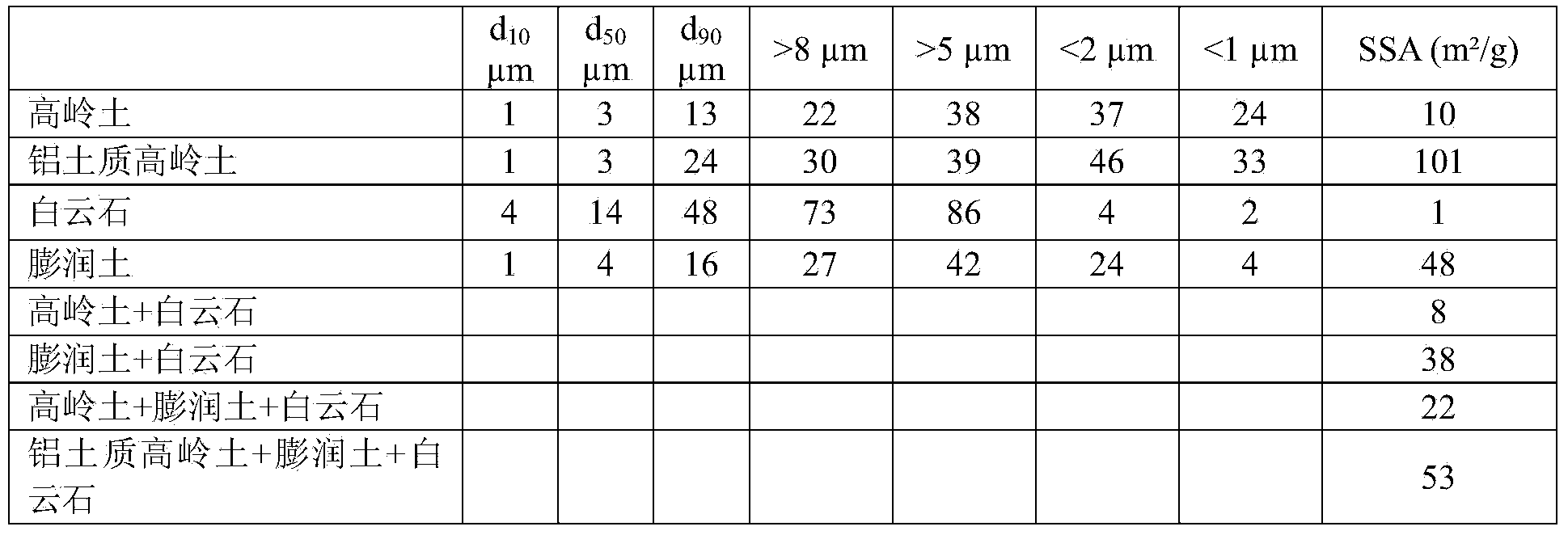

Mineral additive blend compositions and methods for operating combustors for avoiding problems such as agglomeration, deposition, corrosion and reducing emissions

Mineral additive blend compositions and a method for operating a furnace are provided in order to avoid combustion problems such as agglomeration, deposition, corrosion and reducing emissions. A method for operating a furnace, such as a fluidized bed reactor, pulverized-fuel combustor, grate combustor includes introducing fuel and a mineral additive blend comprising a clay and a functional mineral into the furnace. The method further includes heating at least a portion of the inorganic compound-containing material and clay, such that at least a portion of the clay is at least partially calcined and the at least partially calcined clay and functional mineral adsorbs at least a portion of the inorganic volatile compounds present in the furnace and react with the ash produced during fuel combustion increasing its refractoriness. The method further includes removing at least a portion of the at least partially calcined clay and adsorbed inorganic compounds from the furnace.

Owner:KENTUCKY TENNESSEE CLAY

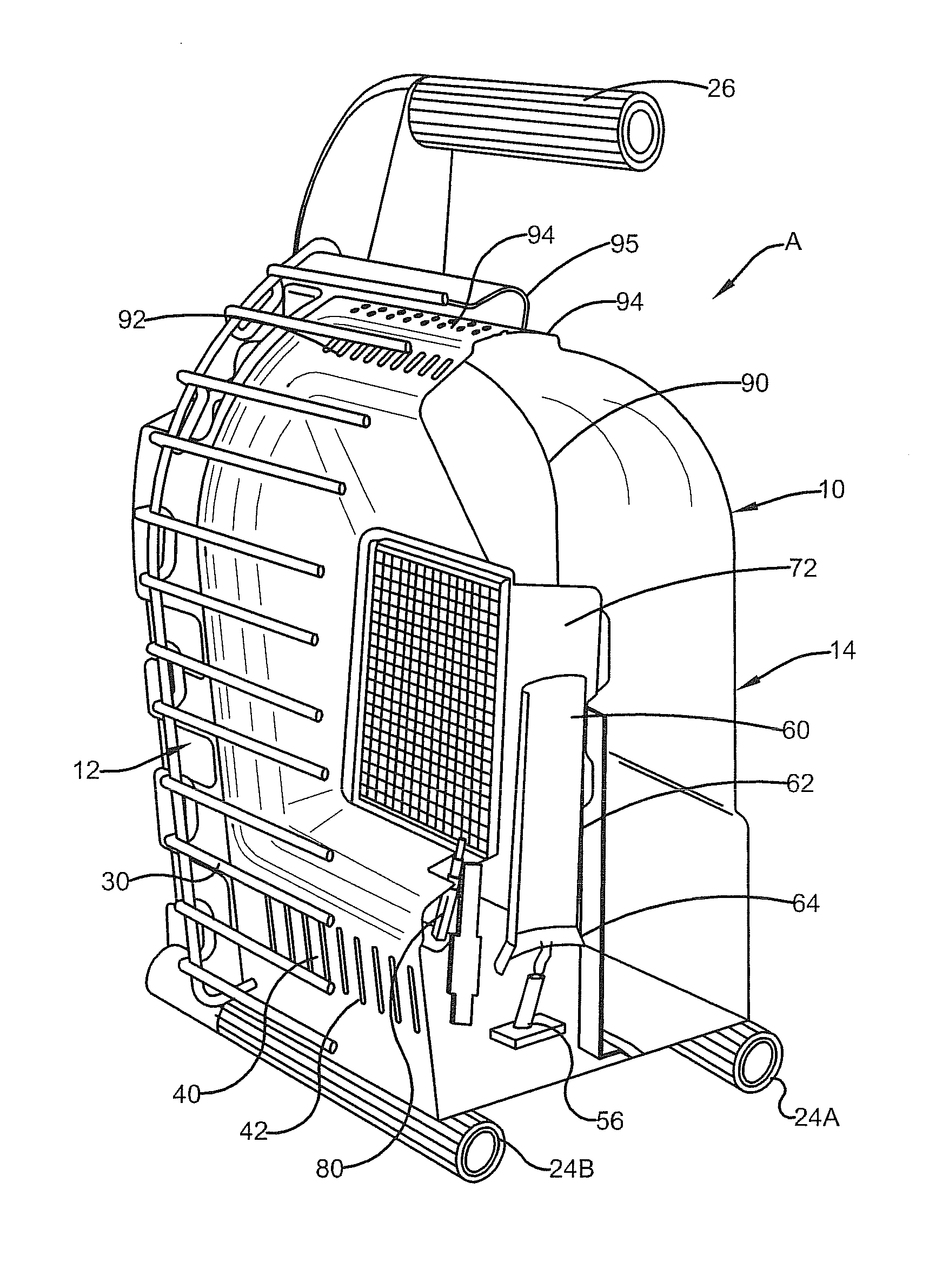

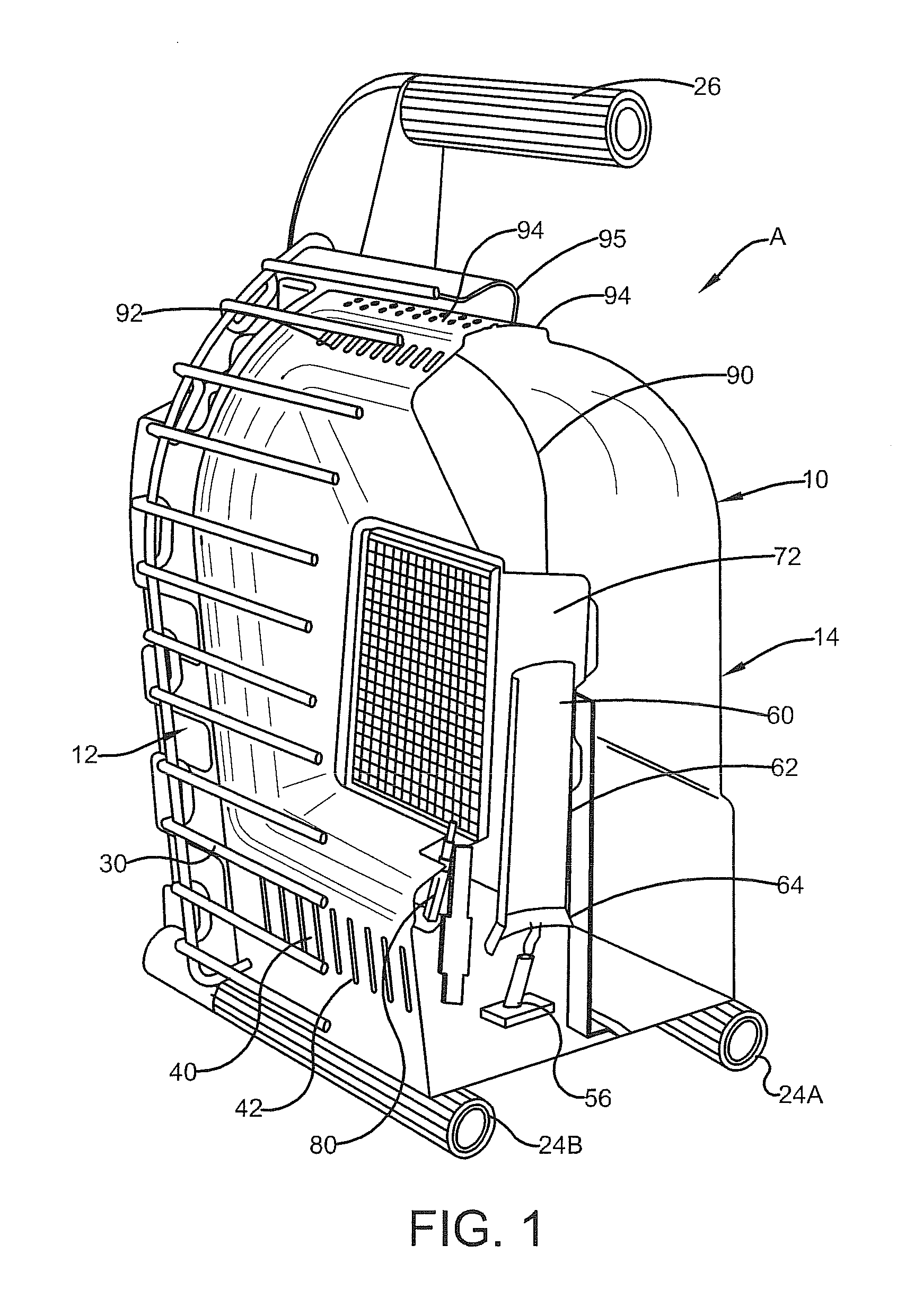

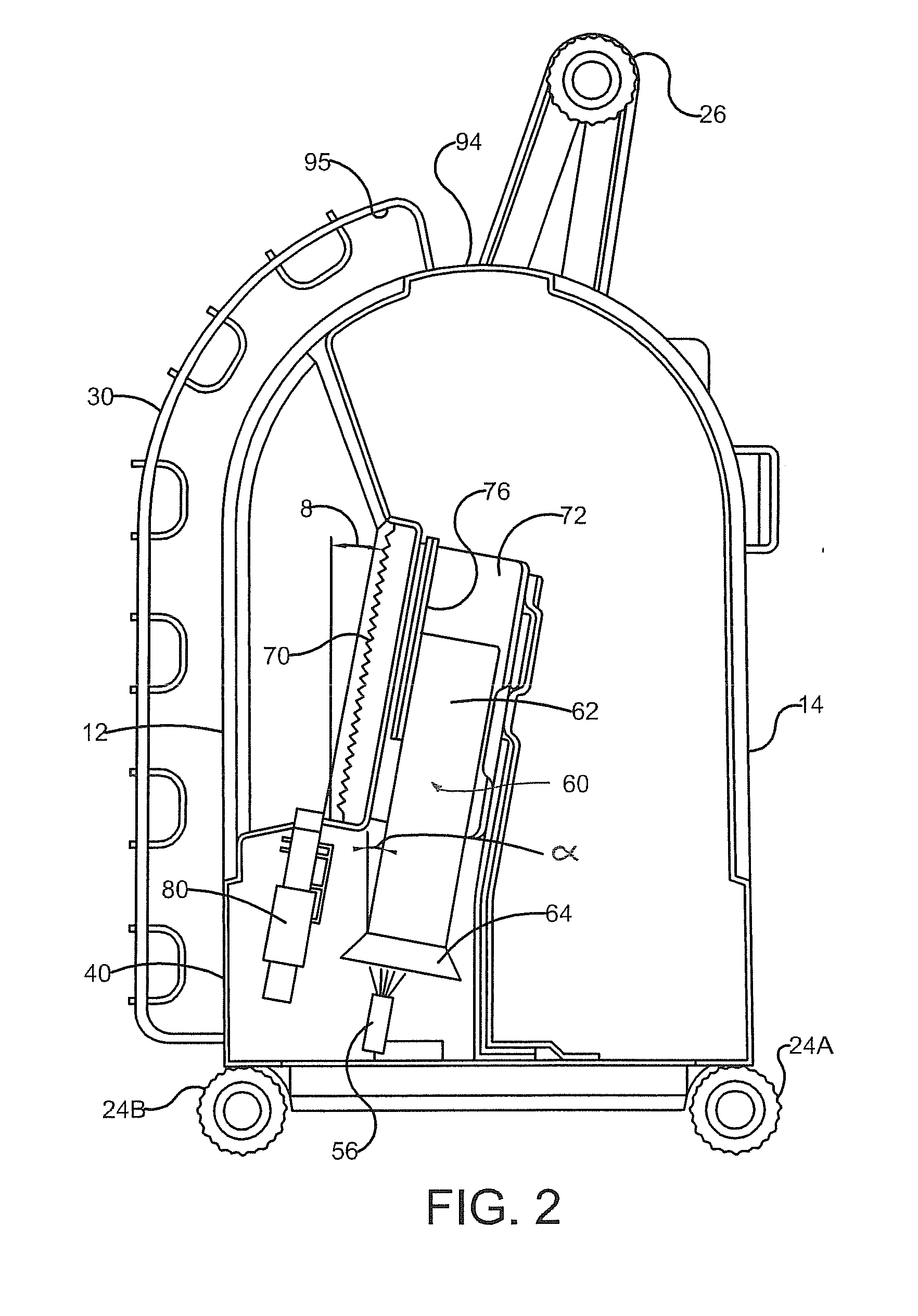

Gas-Fired Portable Unvented Infrared Heater

InactiveUS20120180784A1Easy to installRelieve supply pressureDomestic stoves or rangesBurner control devicesRadiant heaterCombustor

A portable radiant heater supplied by an associated fuel source comprises a housing having a handle for transporting the heater. A plenum in the housing receives fuel from the associated fuel source and mixes the fuel with air. A burner assembly includes a radiant surface that communicates with the plenum. A regulator limits the pressure of the associated propane source to approximately eleven inches water column, and an oxygen depletion system associated with the burner assembly automatically shuts off the heater at a predetermined oxygen content. A tank fitting with a position that can be adjusted relative to the regulator facilitates the installation of the associated fuel source to the heater.

Owner:ENERCO GROUP

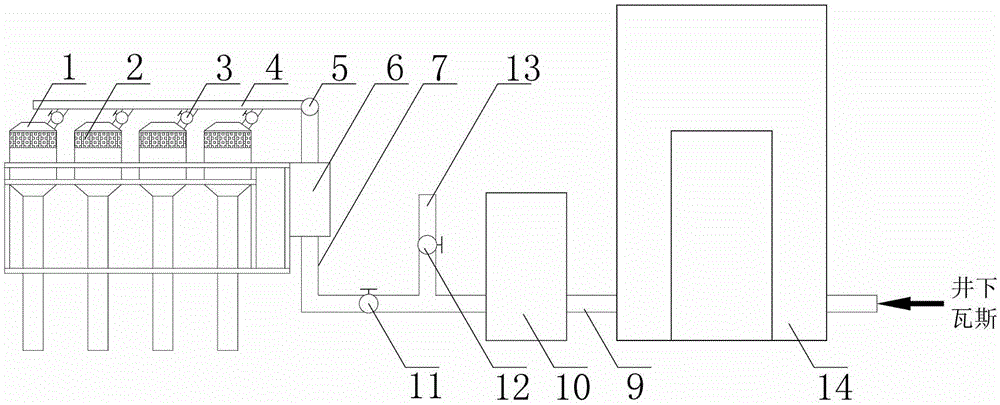

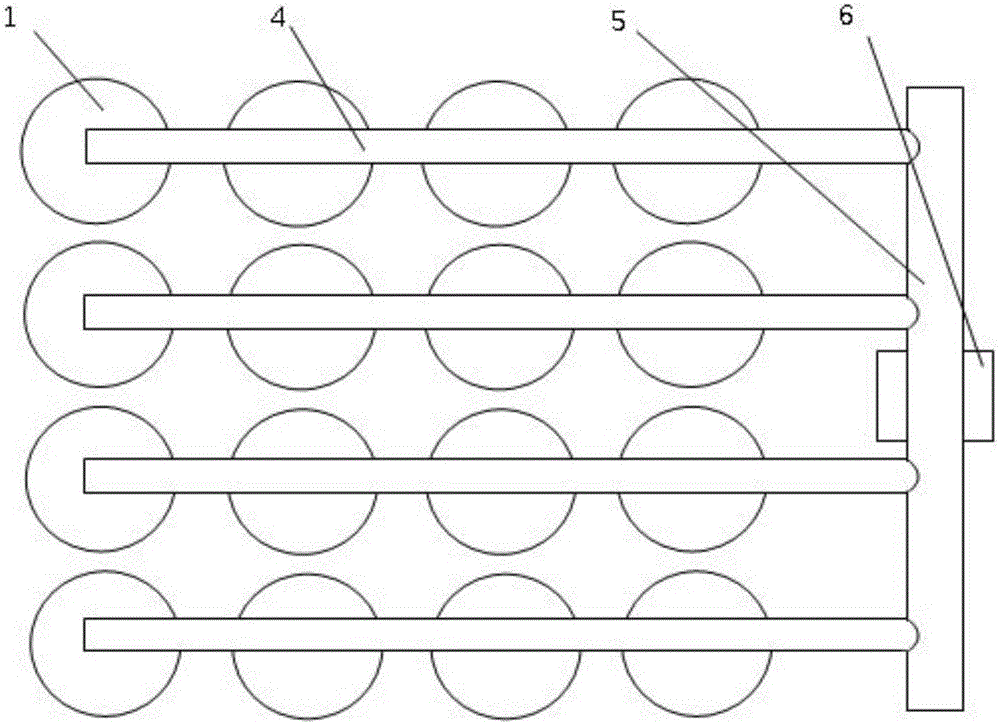

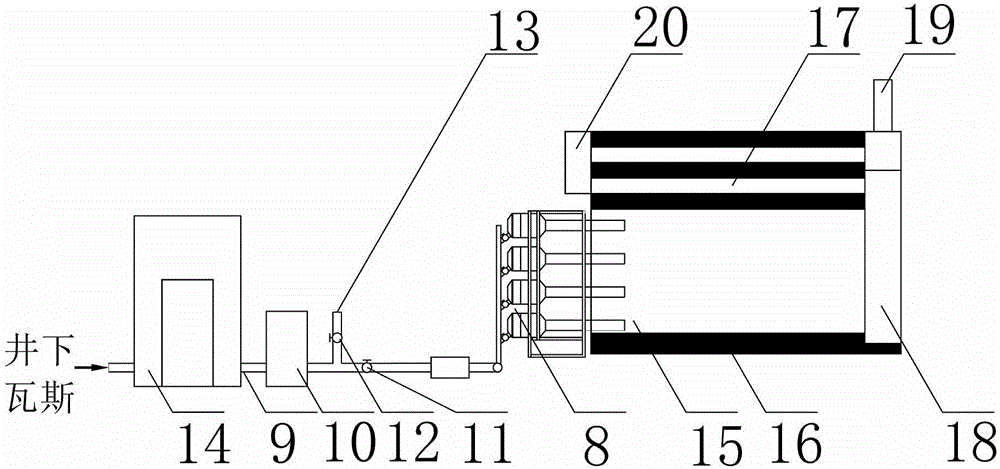

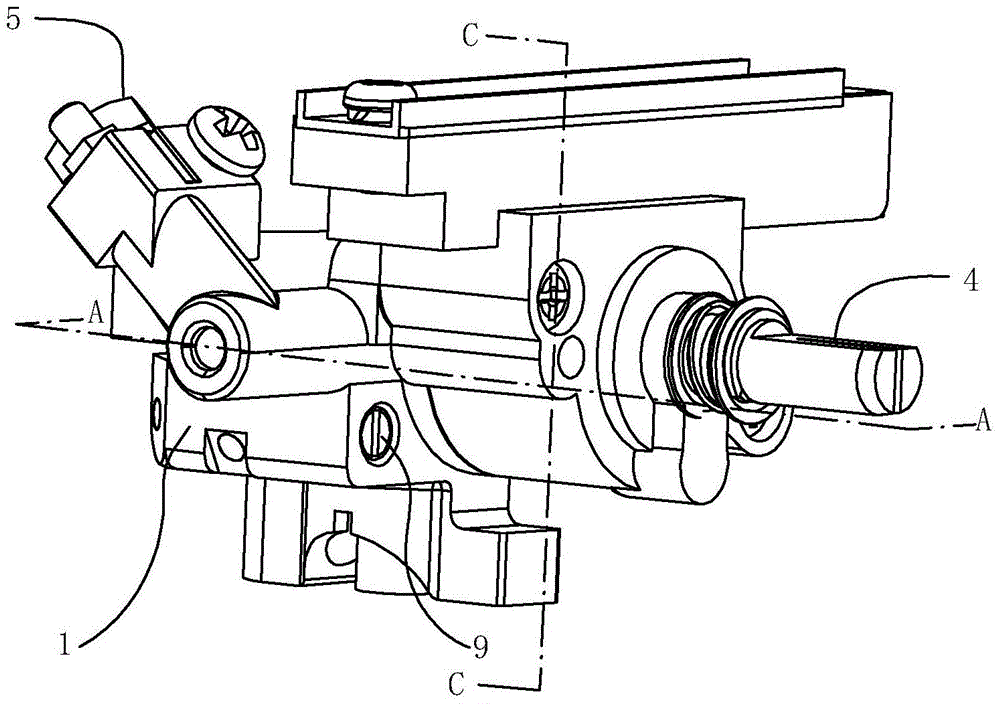

High-power array low-concentration gas pulse combustion method and device

ActiveCN107525066AReduced use rangeCompact structureGaseous fuel feeder/distributionPulsating combustionCombustionDetonation

The invention belongs to the technical field of gas combustion, and relates to a high-power array low-concentration gas pulse combustion method and a device. 2-16 pulse combustion units with porous medium chambers and damping adjusting valves are arranged to form an independent subarray in an array manner; all units in the subarray share one intake branch pipe; each subarray is connected with a distribution mother pipe through the intake branch pipe to form an array system; and the distribution mother pipe is connected with a supply main pipe with a combustion controller. The porous medium chambers can effectively prevent detonation or explosion; and the damping adjusting valves guarantee balanced intake flows among all the pulse combustion units in the array system. The low-concentration gas utilization range can be narrowed by above 5%, so that the problems of difficult ignition and explosion in the low-concentration gas pulse combustion process are solved, and the stable combustion is guaranteed; and as the number of the pulse combustion units is flexibly combined, the total power of the device can be changed, and low-concentration gas is used more reasonably according to the gas extracting conditions.

Owner:CHINA UNIV OF MINING & TECH +1

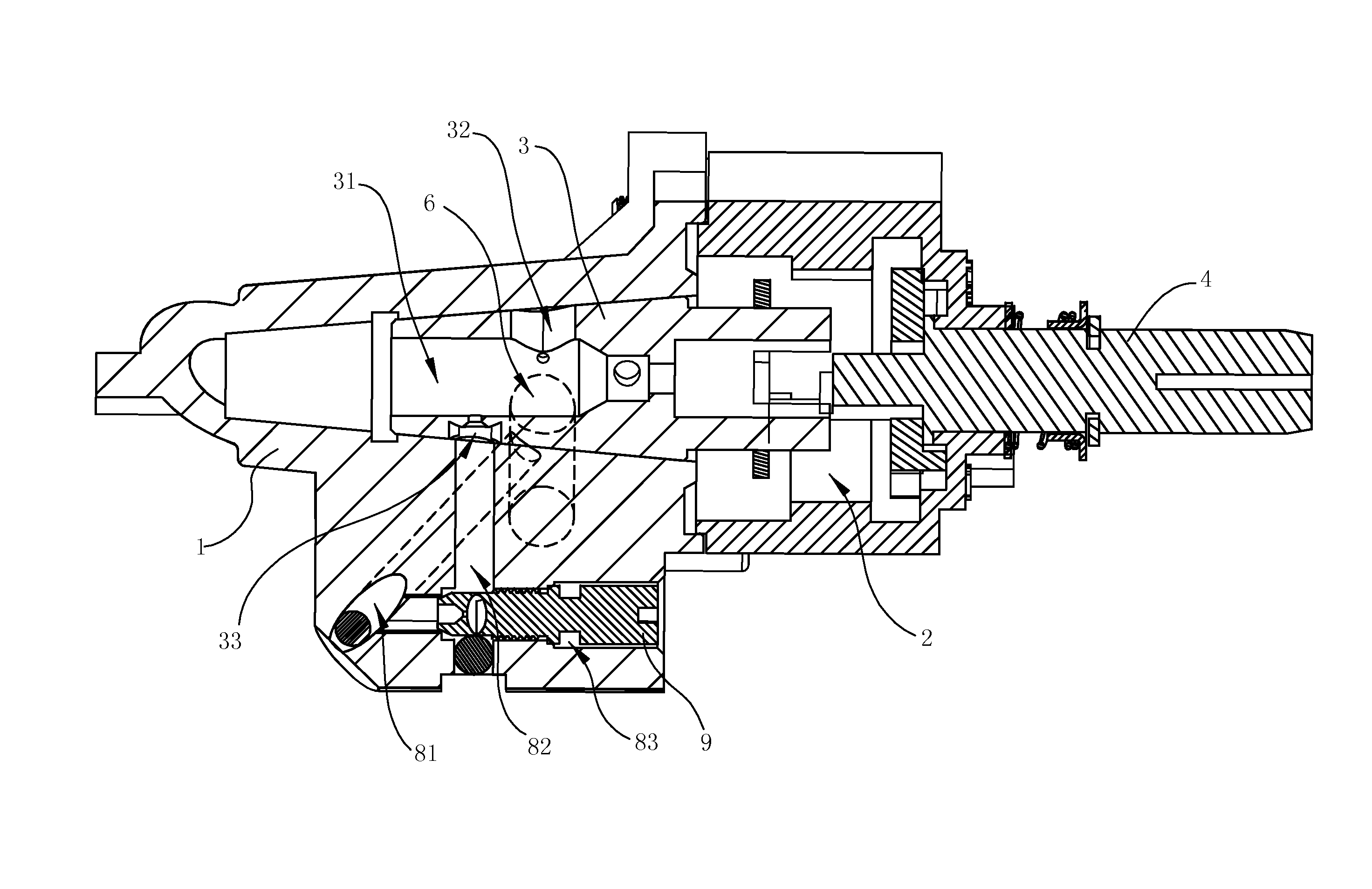

Fuel gas valve

ActiveCN104791509ALow processing technology requirementsEasy to processFuel supply regulationPlug valvesEngineeringMechanical engineering

The invention provides a fuel gas valve comprising a valve body, a valve element and an auxiliary gas intake channel. A gas cavity is formed in the valve element. The side wall, matched with a gas intake channel of the valve body, of the valve element is provided with gas intake holes. The gas intake holes are communicated with the gas cavity in the valve element. The auxiliary intake channel is arranged in the valve body. One end of the auxiliary gas intake channel is communicated with the gas intake channel. The other end of the auxiliary gas intake channel is communicated with the cavity of the valve body. The side wall of the valve element is provided with auxiliary gas intake holes matched with the auxiliary gas intake channel in position. The auxiliary gas intake holes are communicated with the gas cavity in the valve element. The auxiliary gas intake holes and the gas intake holes are staggered in the axial direction and the circumferential direction of the valve element. The fuel gas valve can adjust the flow of fuel gas in a pipeline, so that the fuel gas valve is suitable for different gas sources. The fuel gas valve is provided with the gas intake holes and the auxiliary intake holes separated from the gas intake holes, so that when the flow of the fuel gas is adjusted, the possibility of misoperation is reduced, and the flow of the fuel gas is more convenient and easier to adjust.

Owner:NINGBO CHAOYANG HOUSEHOLD GAS STOVES

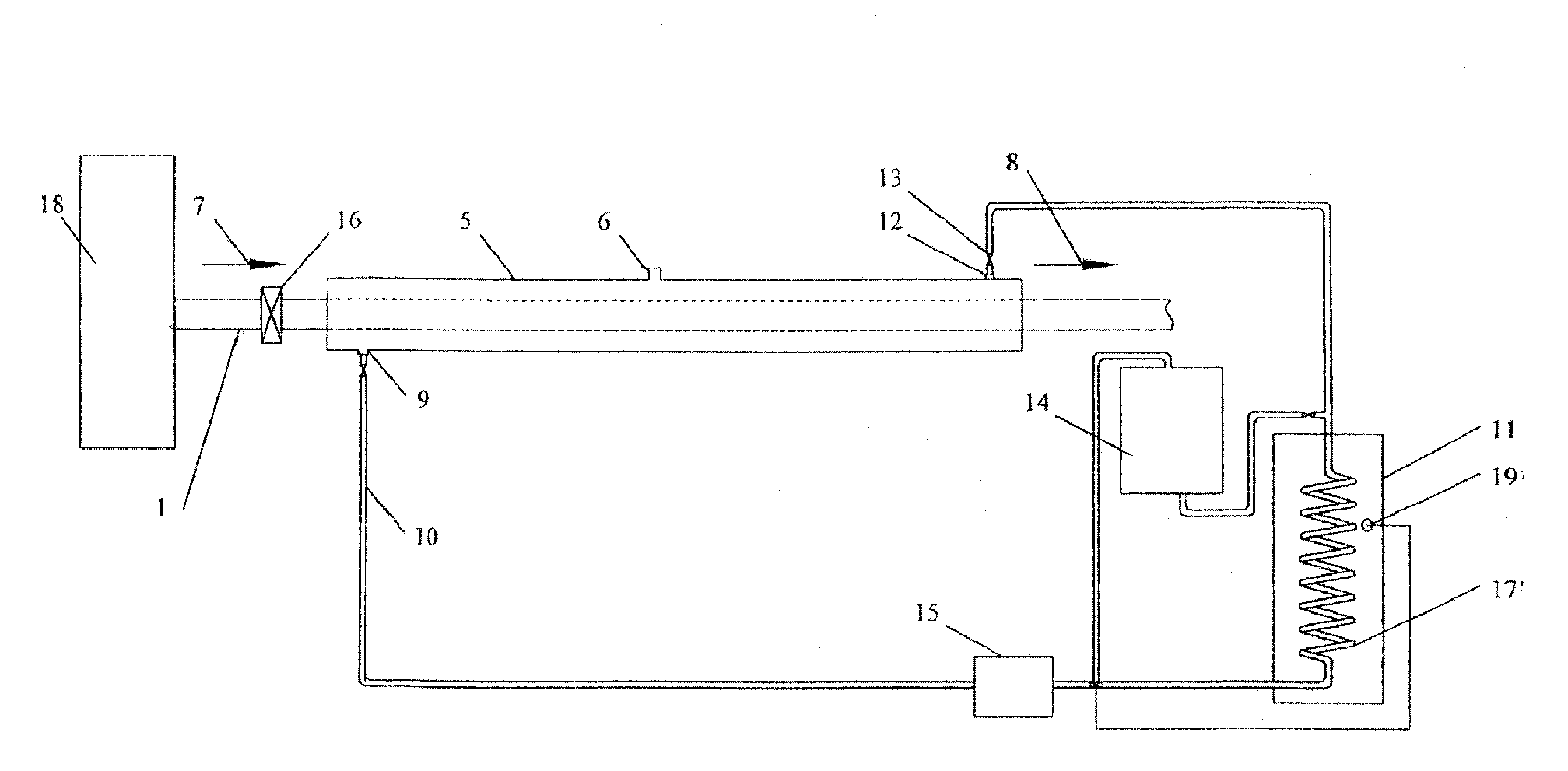

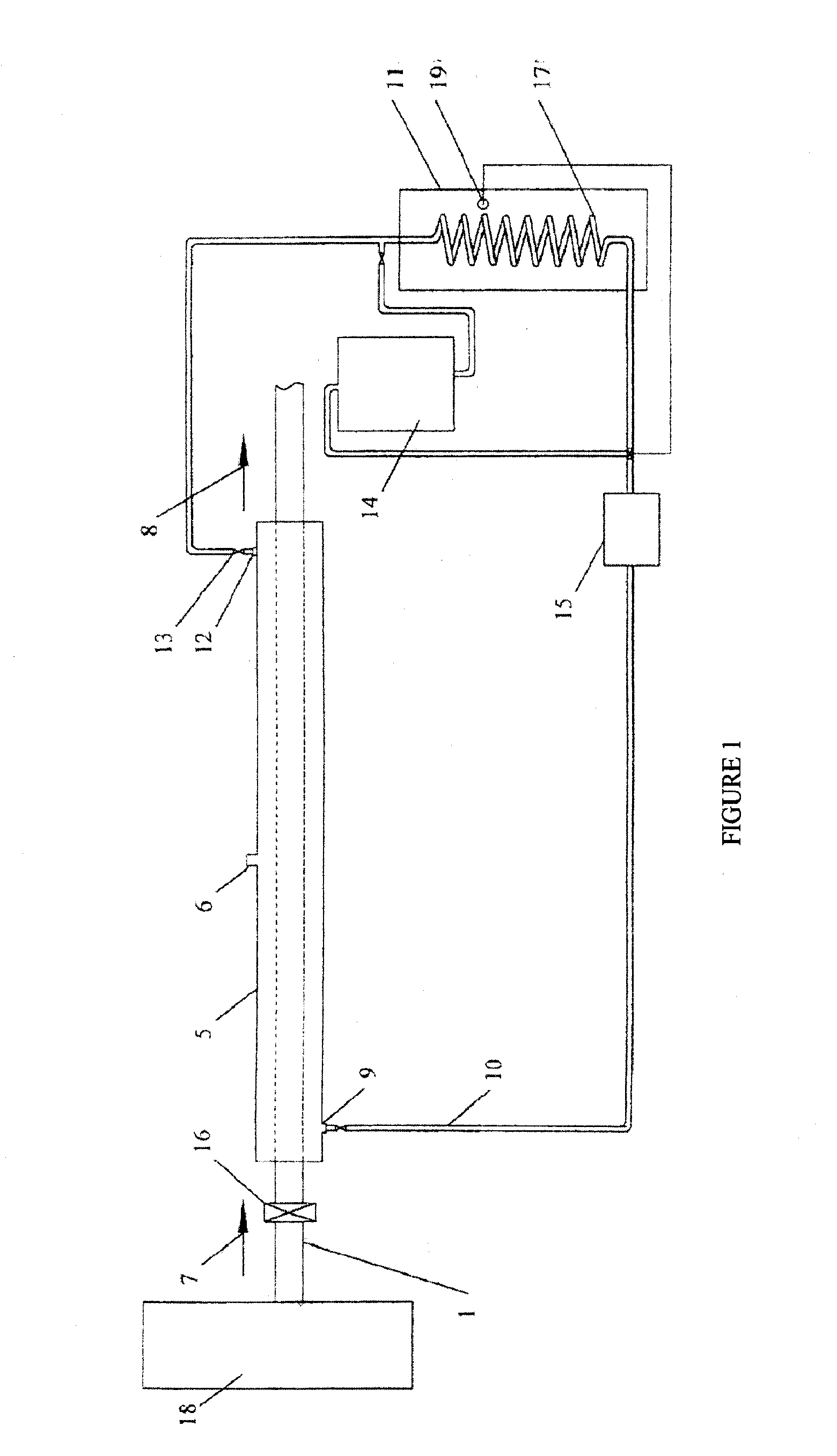

Fuel preheating system

InactiveUS20100167221A1Save fuelImprove fuel efficiencyBurnersLiquid fuel feeder/distributionCombustion chamberEngineering

The present invention provides fuel saving systems. Fuel consumption can be reduced by 5% to 40% or more by pre-combustion heating the fuels. The heat exhaust of a combustion chamber can be used to heat a heat transfer fluid, which exchanges heat with the incoming fuel stream.

Owner:YENBU MAKINE SANAYI & TICARET A S

Gas turbine fuel preparation and introduction method

ActiveUS20080168774A1Gaseous fuel feeder/distributionContinuous combustion chamberPartial oxidationCombustor

Method of preparing and introducing fuel into the combustors of a gas turbine in which a hydrocarbon containing feed, oxygen and steam are introduced into a catalytic partial oxidation reactor to produce a product stream. The hydrocarbon containing feed contains no less than about 15 percent by volume on a dry basis of hydrocarbons with at least two carbon atoms and / or at least about 3 percent by volume of olefins. The reactant mixture formed of the hydrocarbon containing feed, oxygen and steam has an oxygen to carbon ratio of between about 0.08 and about 0.25 and a water to carbon ratio of between about 0.05 to about 0.5. The hydrocarbon containing feed is introduced into the reactor alone or with a steam at a temperature no greater than 600° C. and the product stream is produced at a temperature of between about 600° C. and 860° C. and contains less than about 0.5 percent of olefins and less than 10 percent of hydrocarbons with two or more carbon atoms on a dry basis. After cooling the product stream the product stream is introduced into the combustors of the gas turbine to form part or all of the fuel required to support combustion.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com