Boiler and combustion control method

a combustion control and boiler technology, applied in the direction of combustion regulation, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of not being able to accurately control the air ratio, requiring complicated construction and control, and not being able to propose a boiler or a combustion control method capable of controlling both the air and the combustion ratio, etc., to achieve suppress the generation of nox in the exhaust gas, simple construction, and stable manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

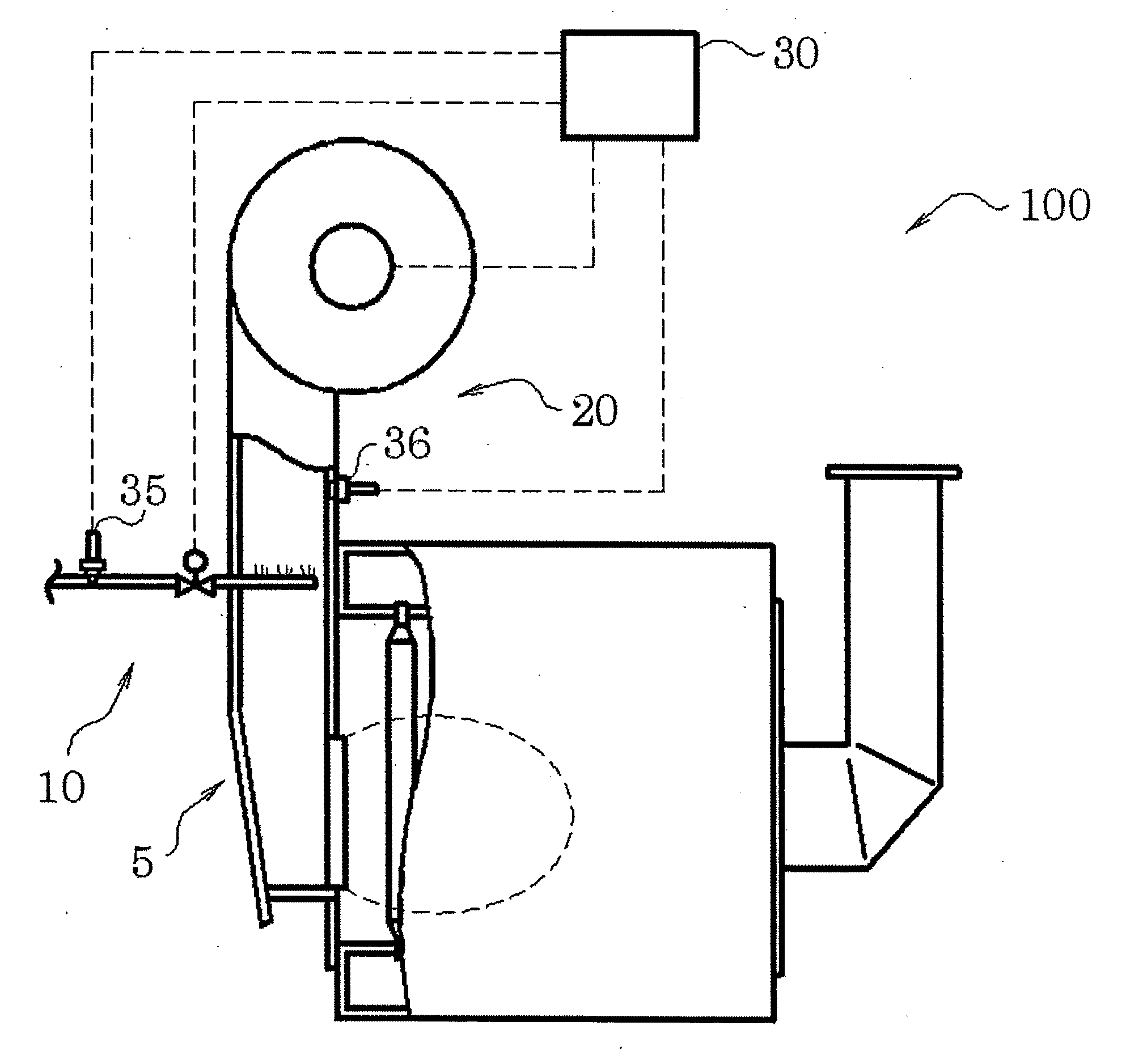

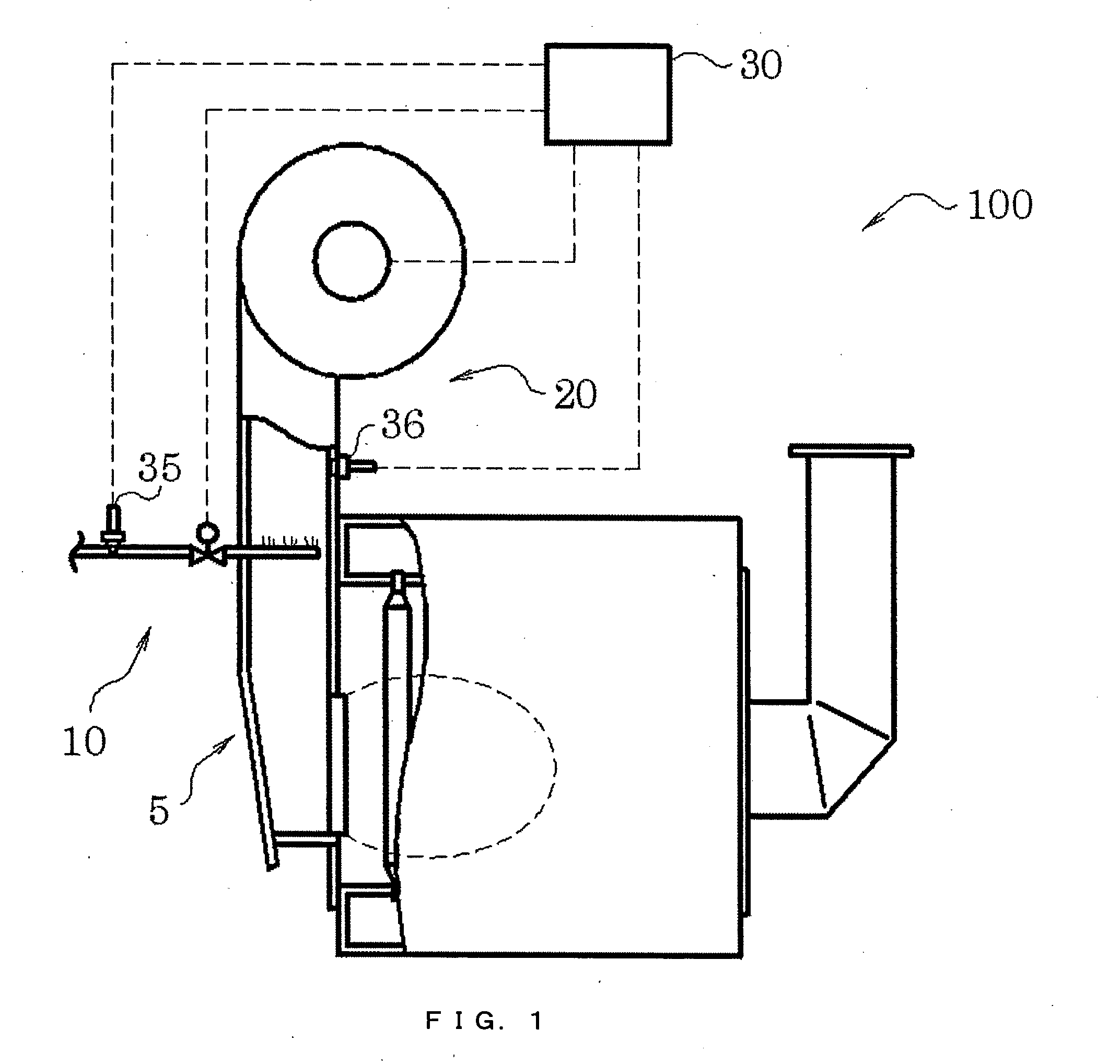

[0024]In the following, a boiler according to an embodiment of the present invention will be described with reference to the drawings. The boiler according to the present invention is provided with a control device for adjusting air quantity based on temperature changes of air and fuel. FIG. 1 is a schematic view of an embodiment thereof. As shown in FIG. 1, a boiler 100 has a burner 5, a fuel supply device 10 for supplying fuel to the burner 5, a blowing device 20 for supplying air to the burner 5, and a control device 30 for controlling the amount of fuel supplied to the burner 5 and the quantity of air supplied to the burner 5; further, the boiler 100 has a fuel temperature measuring device 35 for measuring the temperature of the fuel supplied to the burner 5 and transmitting a corresponding signal to the control device 30, and an air temperature measuring device 36 for measuring the temperature of the air supplied to the burner 5 and transmitting a corresponding signal to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com