Fuel gas valve

A gas valve and valve core technology, applied in multi-port valves, valve devices, valve details, etc., can solve problems such as misoperation, achieve the effects of convenient and simple adjustment, reduce misoperation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

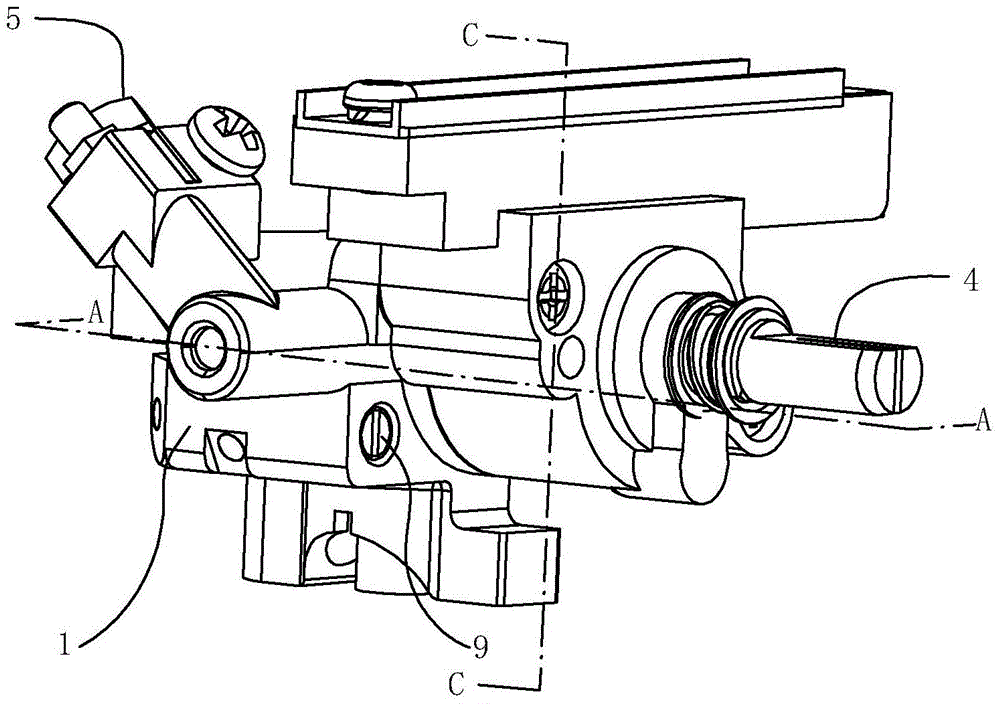

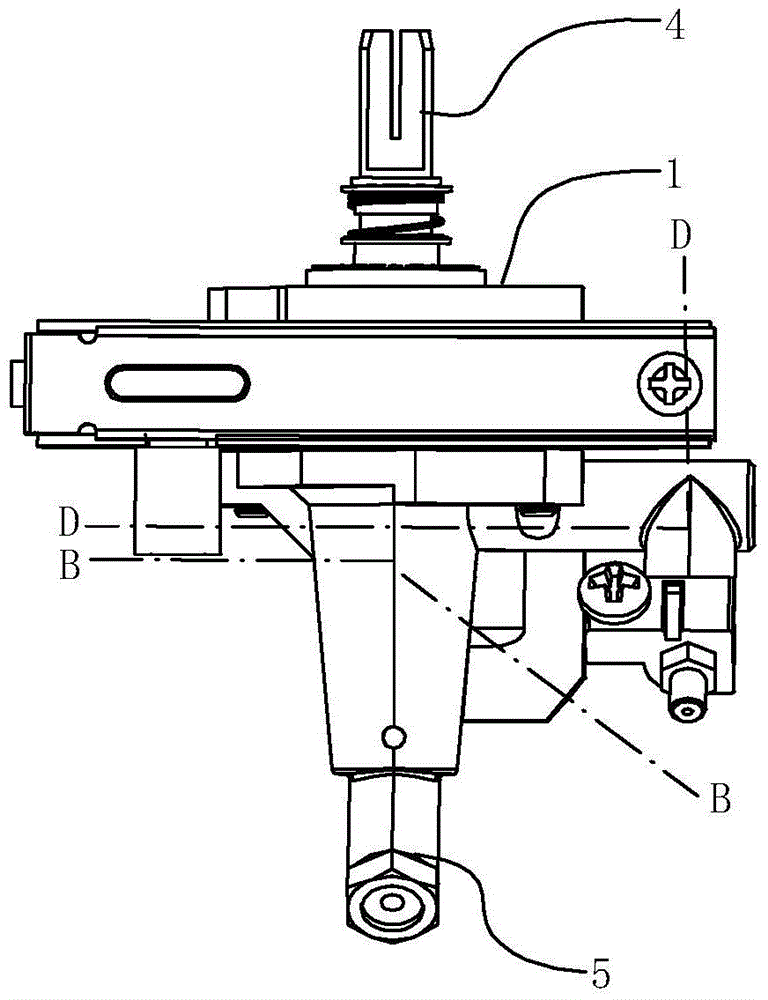

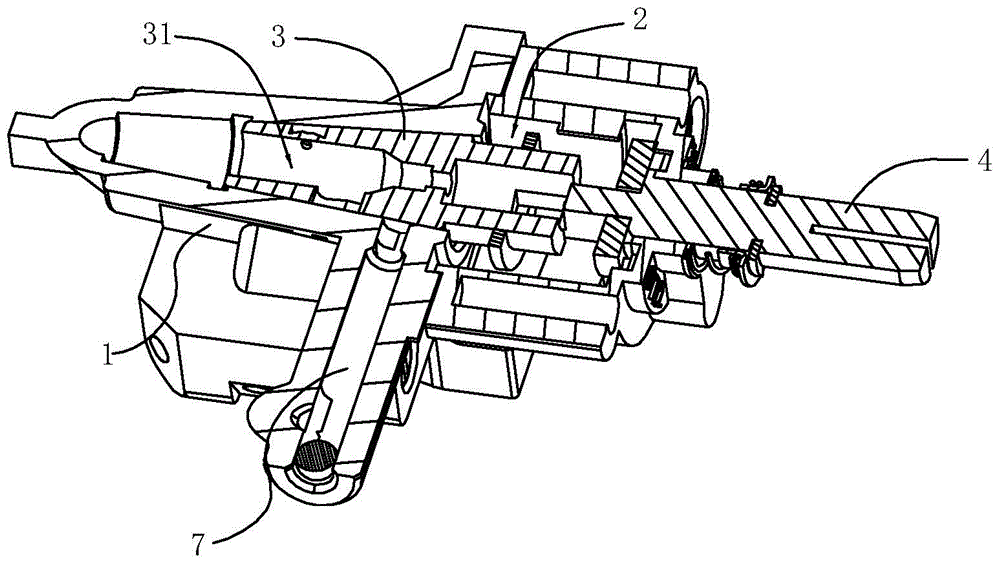

[0031] Such as Figure 1-6 As shown, the gas valve of the embodiment of the present invention includes a valve body 1, a cavity 2 located in the valve body 1, and a valve core 3 located in the cavity 2, the valve core 3 is closely matched with the cavity 2, and the valve The core 3 can rotate around its own axial direction in the cavity 2 . The valve core 3 is provided with a ventilation cavity 31 extending along its axial direction, and one end of the valve body 1 is provided with a rotating shaft 4, and the end of the rotating shaft 4 is inserted into the cavity 2 of the valve body 1 and cooperates with the valve core 3 , to drive the valve core 3 to rotate, the other end of the valve body 1 is provided with a nozzle 5 , and the nozzle 5 communicates with the vent chamber 31 in the valve core 3 .

[0032] One side of the valve body 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com