Patents

Literature

225results about How to "Low processing technology requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

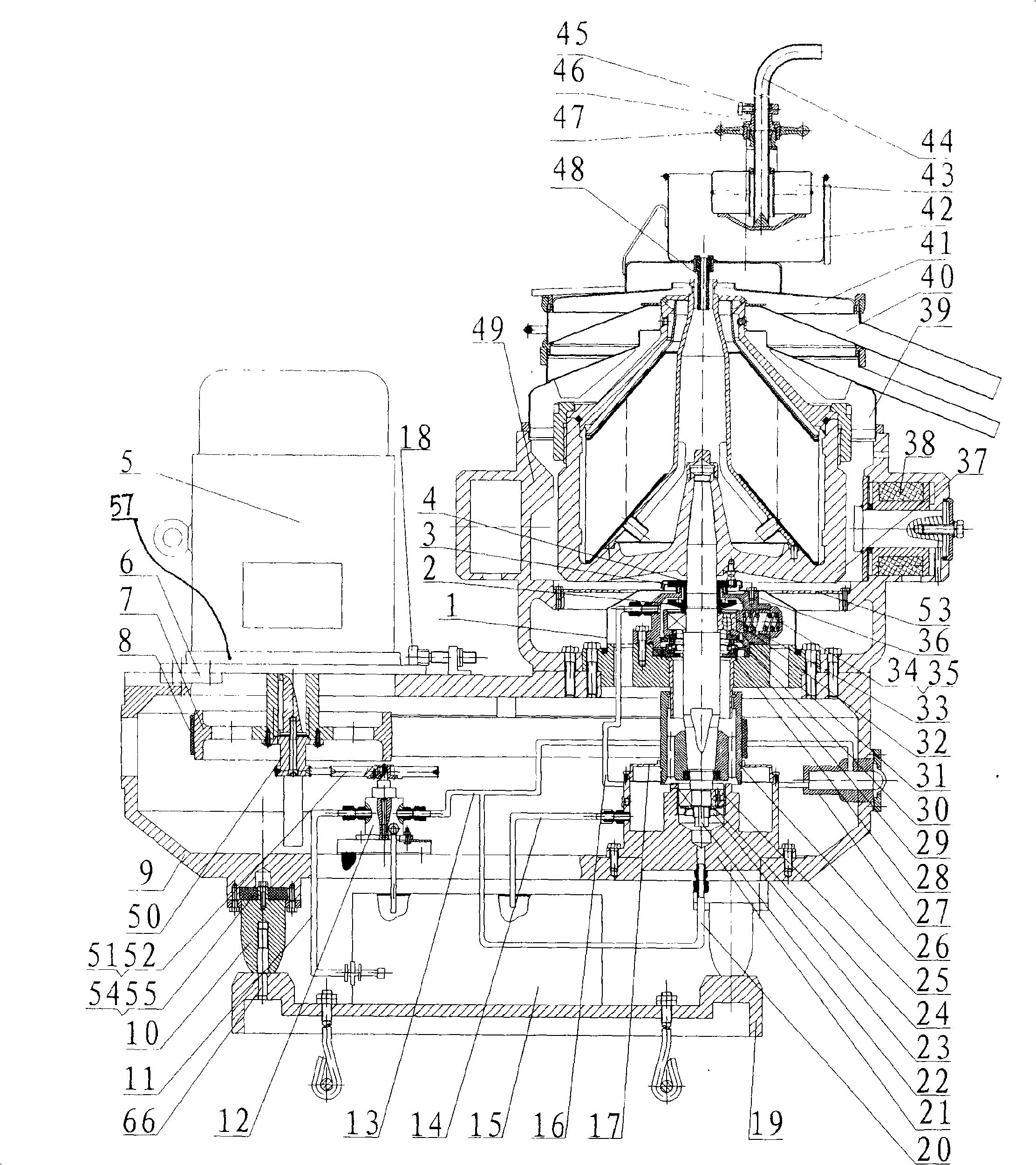

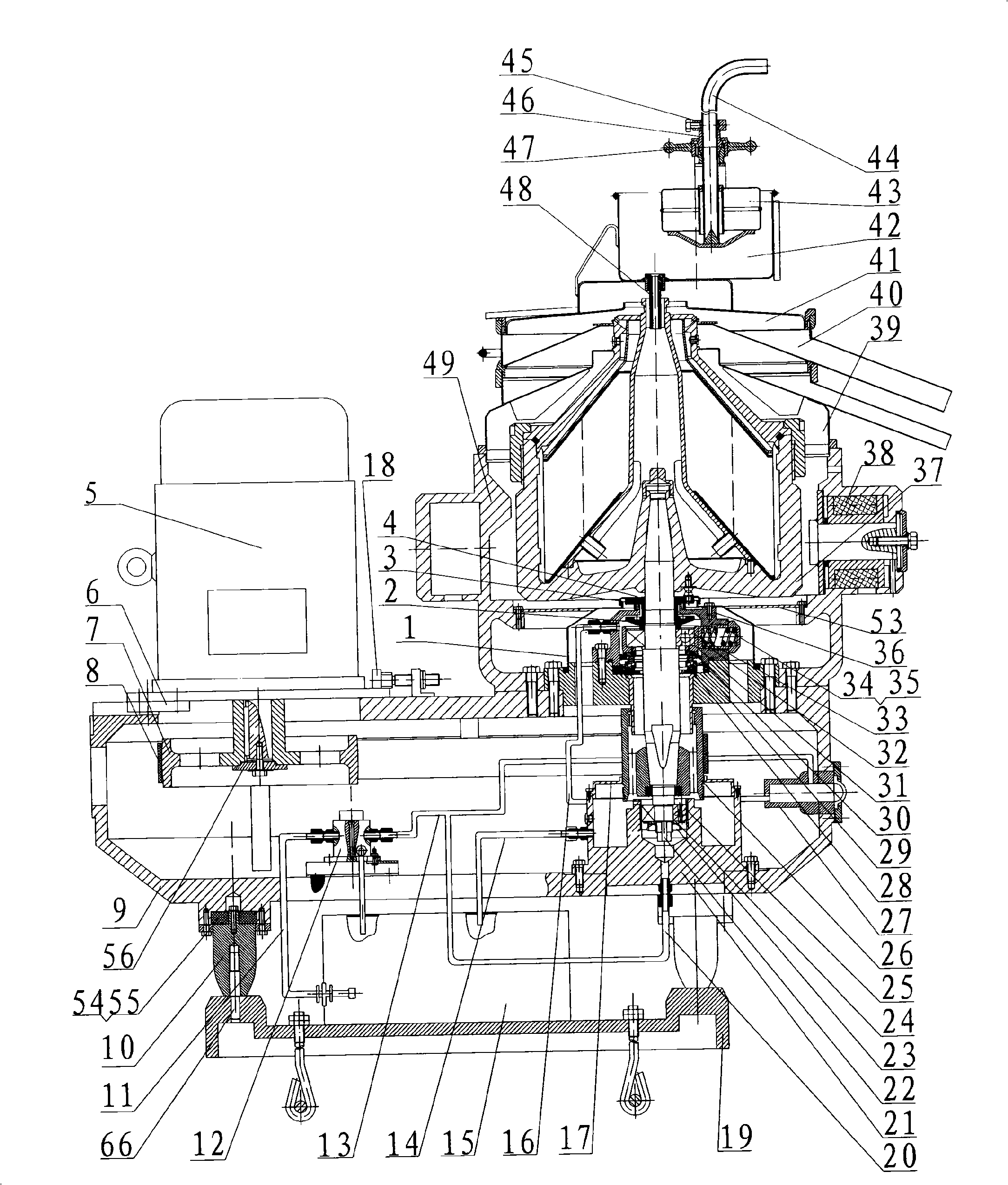

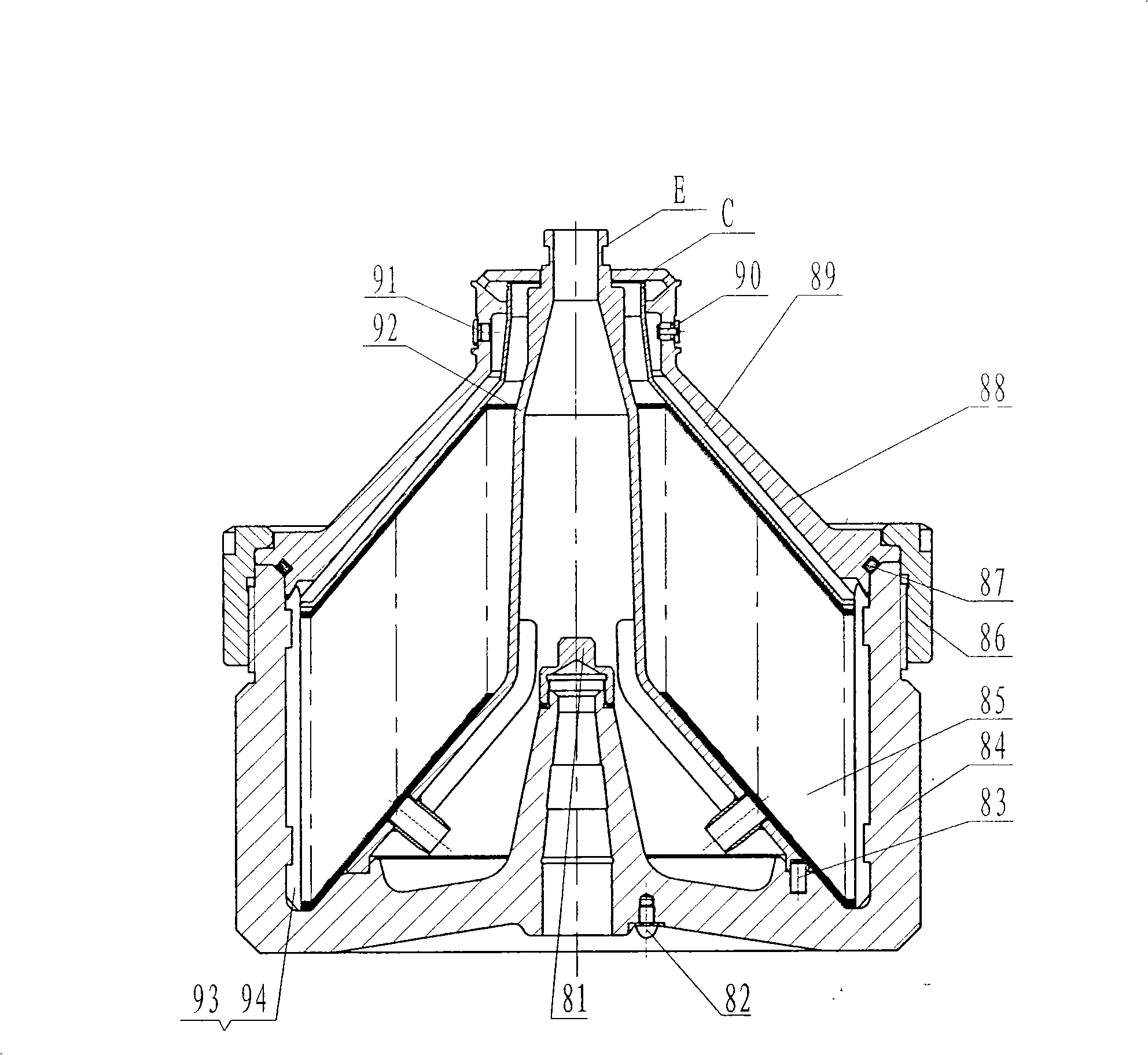

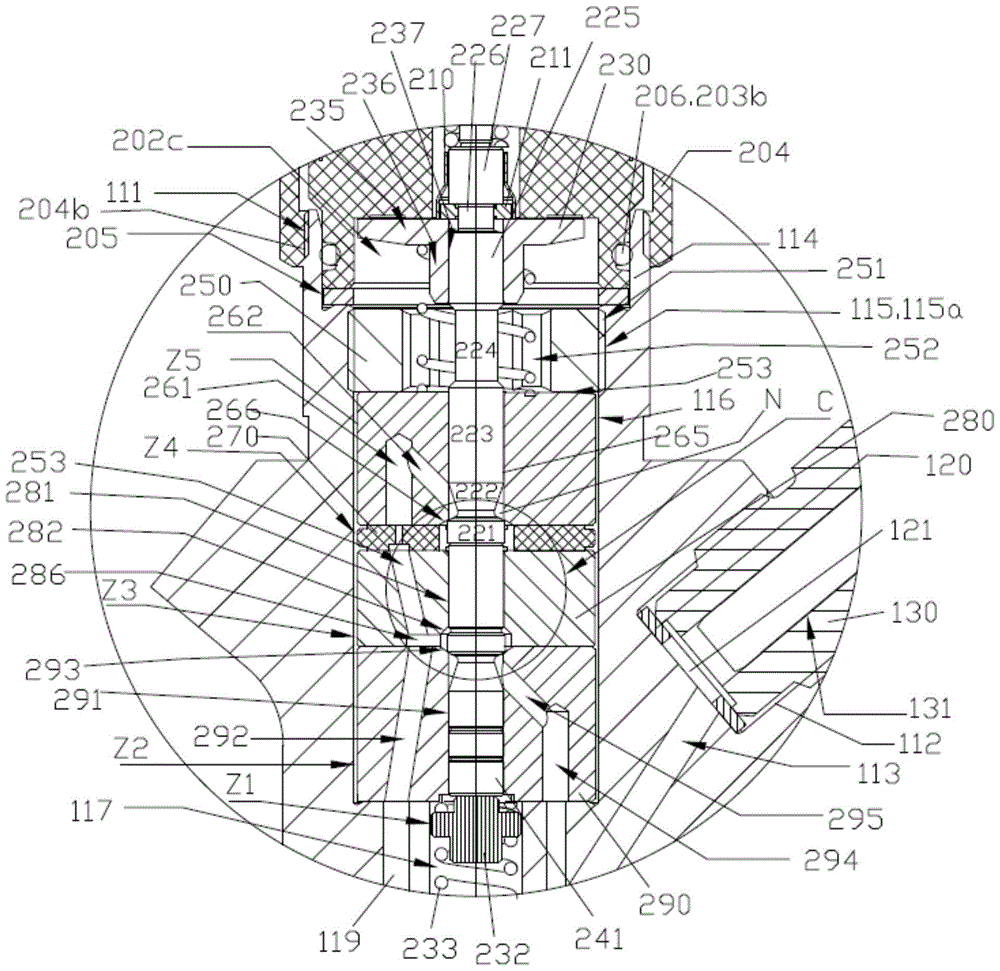

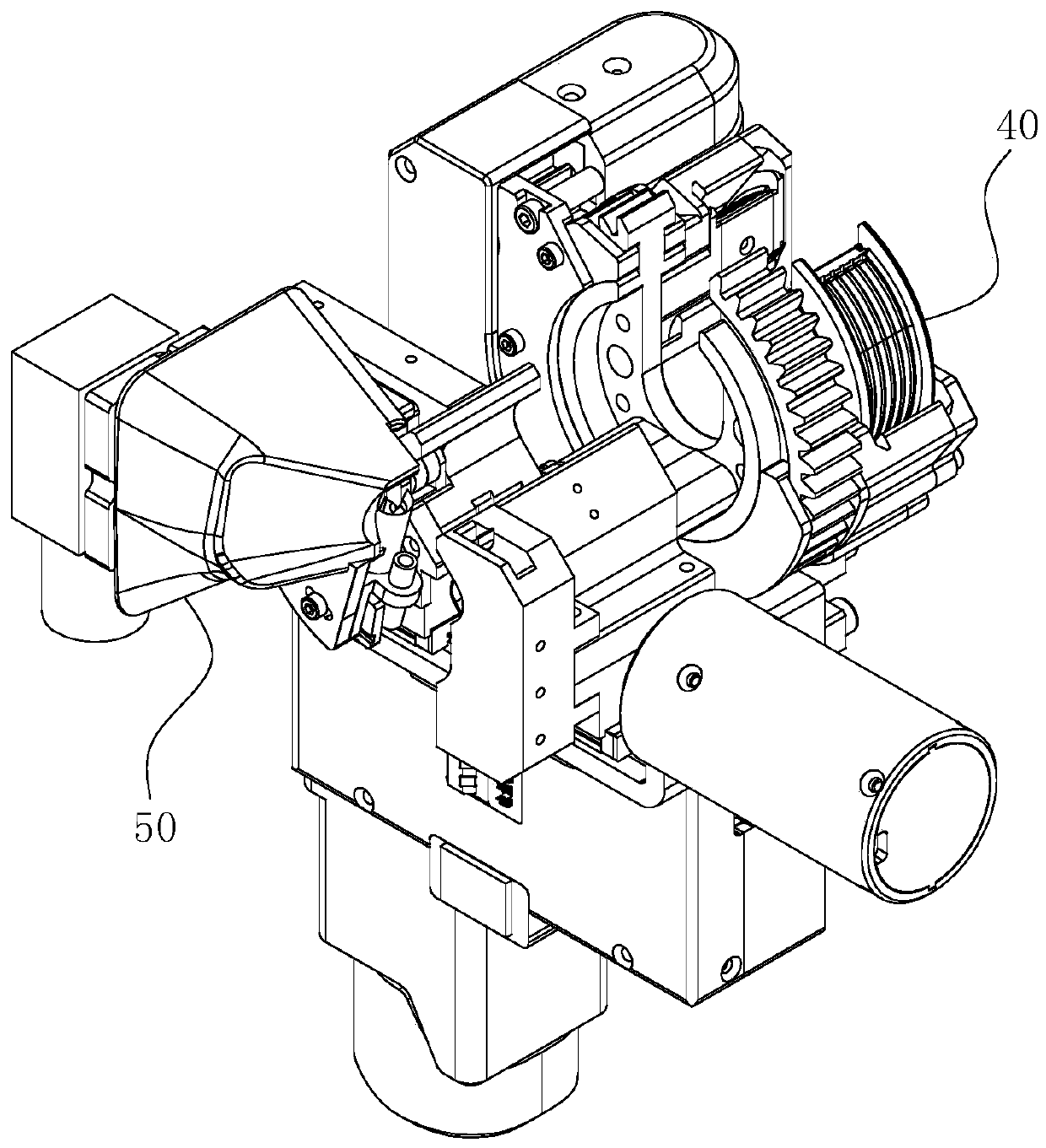

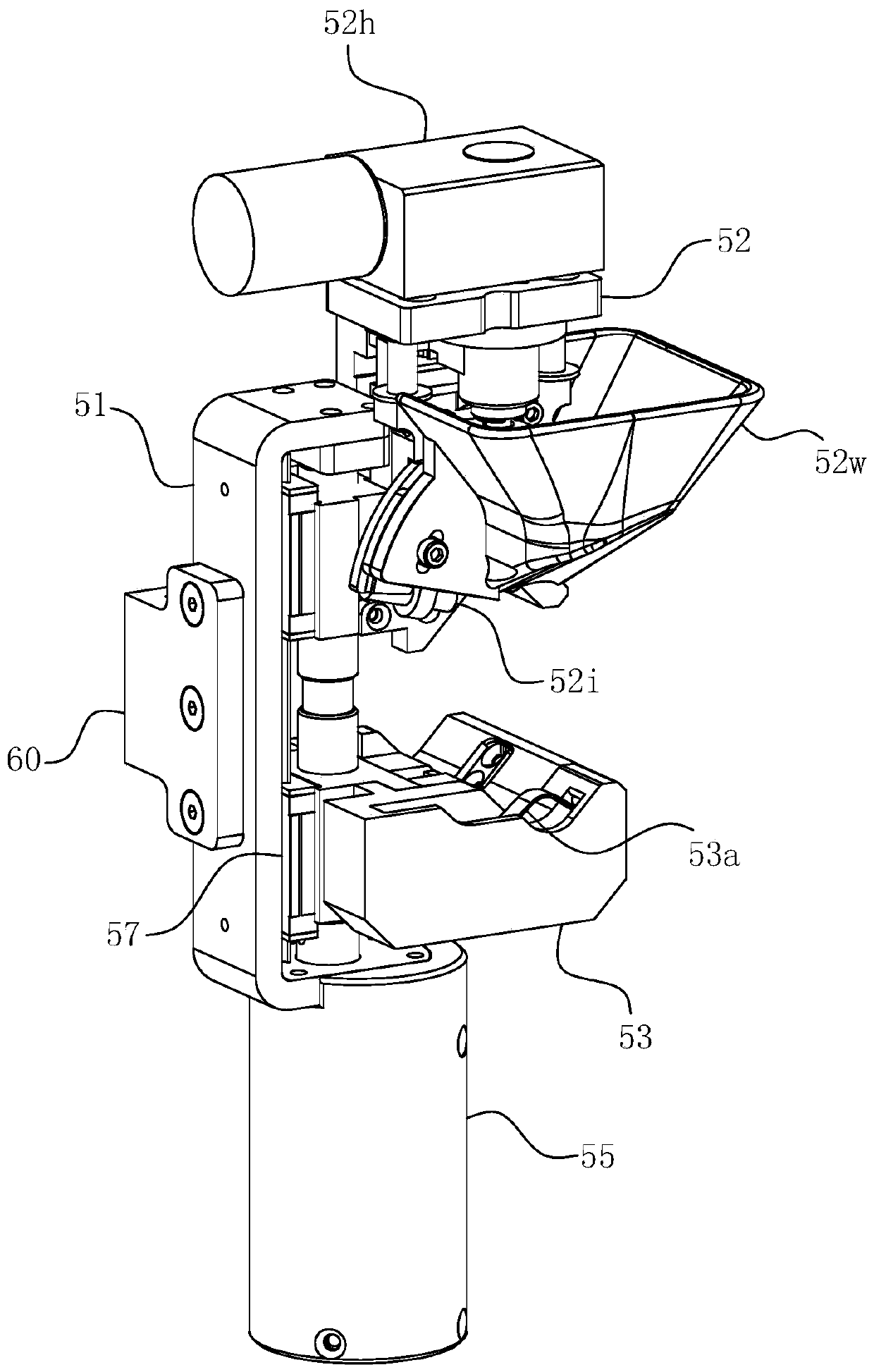

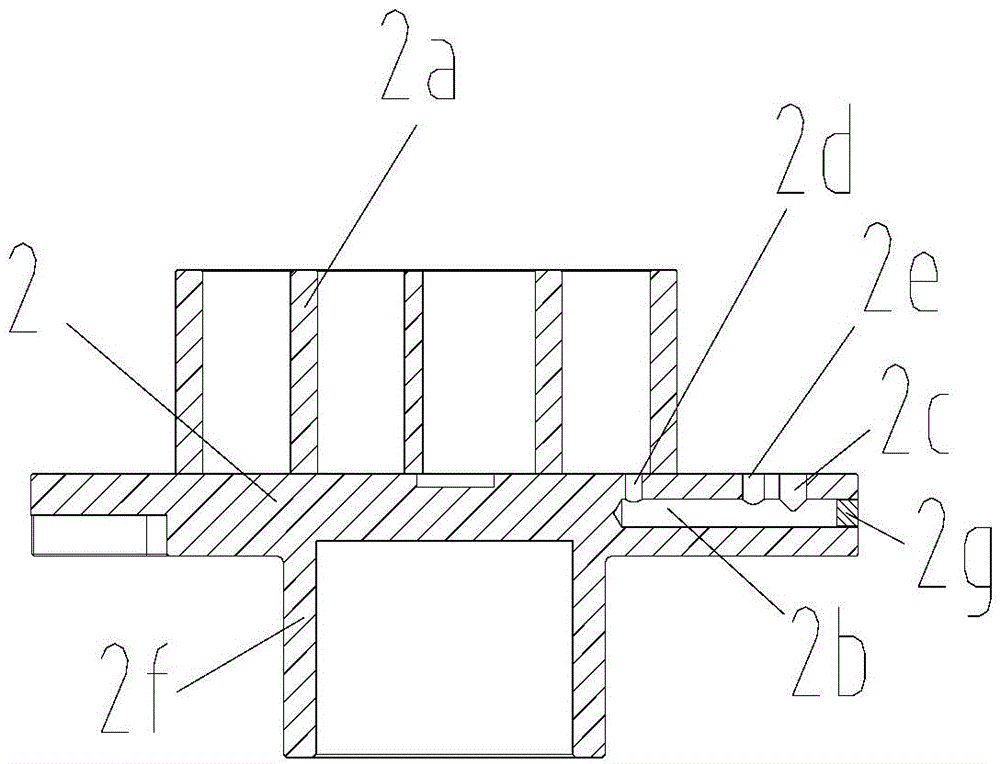

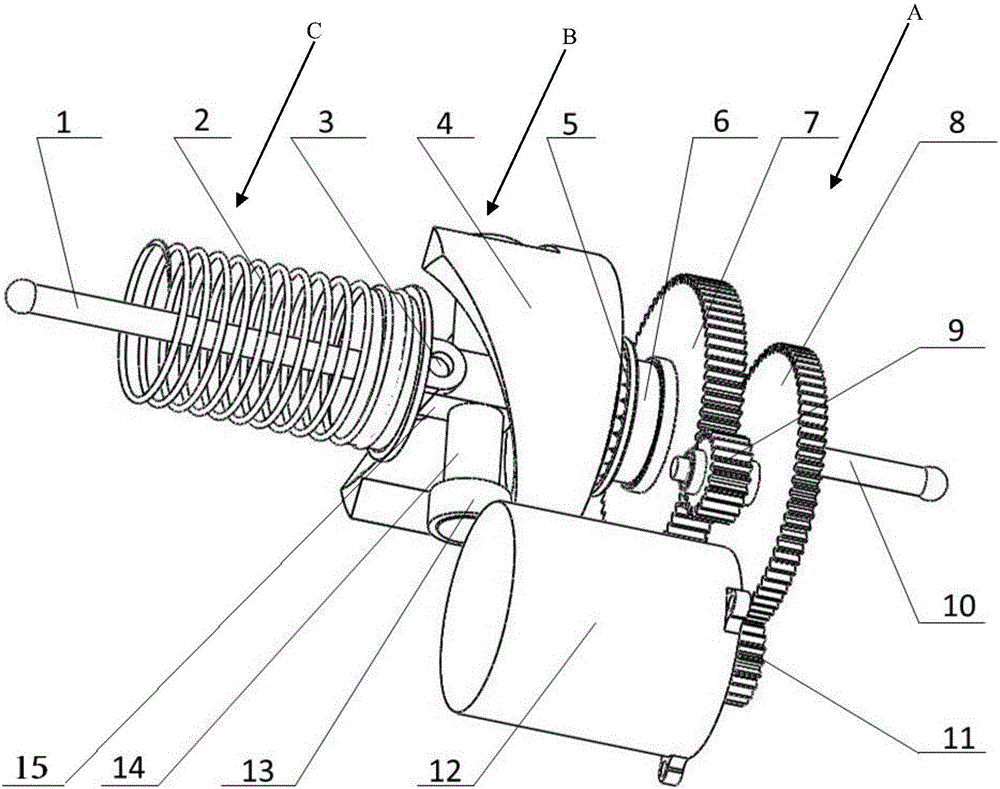

Flat belt driven dish type splitter

The present invention discloses a flat-belt driven disc separator, comprising a power part, a driving part, a lubrication system, a working part, a machine part and a control and assisting part. In addition to that the requirements of the function and performance of the separator is satisfied, the driving system is largely simplified, the driving path is brief, the quantity of driving components is largely reduced and the technical requirement of processing is lowered; regular replacement of expensive copper gear wheel, friction drum and other wearing parts is avoided, and as a result, the structure of the complete machine is simplified, the cost of production and use is reduced, the failure rate of the machine is lowered, and the technical performance of the complete machine is improved. The invention can be directly applied to condensing separation of natural rubber, and the invention can also be applied to separating other emulsions; the rotary-drum structure of the invention can overcome the disadvantages of the prior art; the continuous operation time is prolonged and the rotary-drum heating is alleviated; the strength, safety, reliability and maintenance technique are improved. The driving part and the lower machine body can form the driving of a manual slag-discharge separator, a gushing slag-discharge separator and a ring-valve slag-discharge separator and the lower machine body.

Owner:薛晓宁

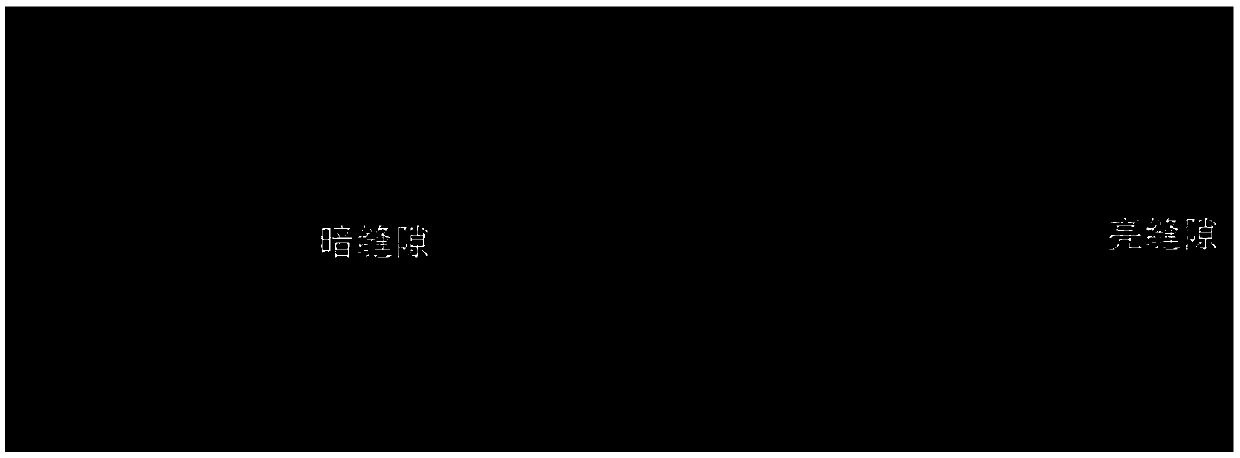

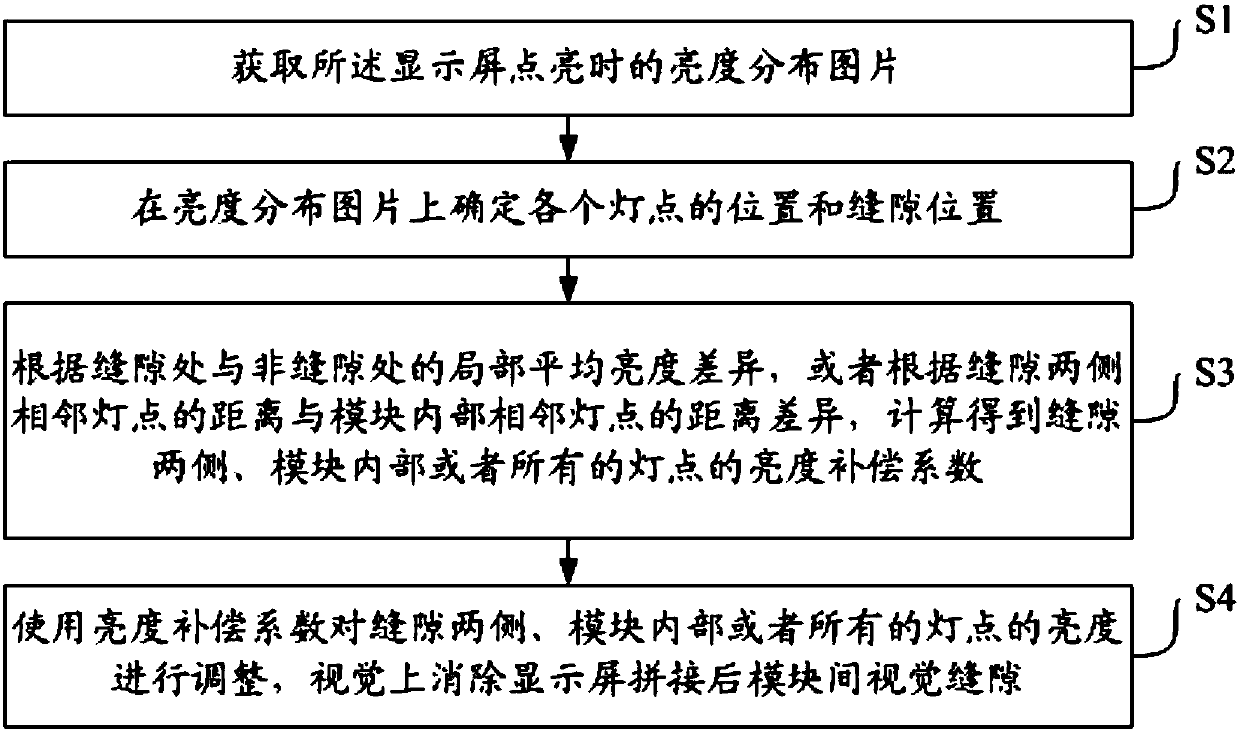

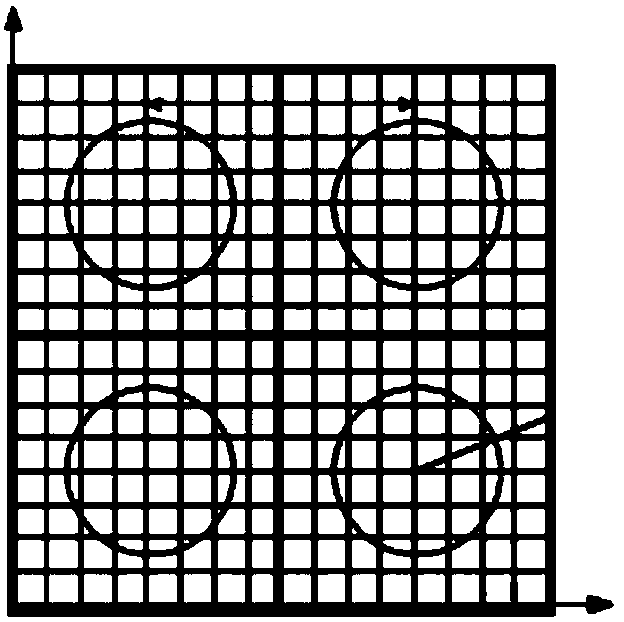

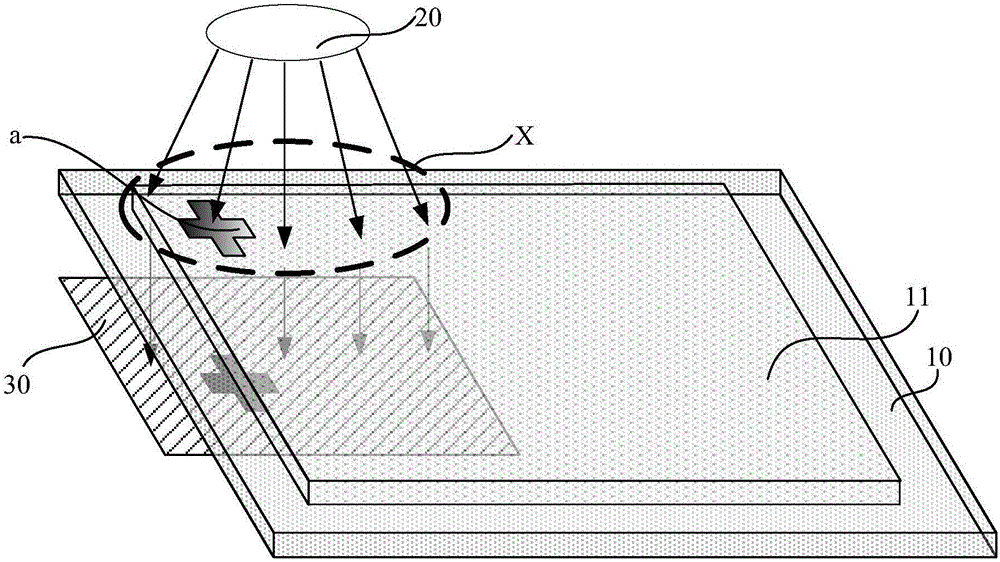

Method for removing visual gaps among modules after display screen is spliced and display method

ActiveCN107742511ALow processing technology requirementsLow machining accuracy requirementsCathode-ray tube indicatorsLocal averageComputer science

The invention discloses a method for removing visual gaps among modules after a display screen is spliced and a display method, and belongs to the field of display screens. The method comprises the steps of S1, obtaining a brightness distribution picture when the display screen is lightened; S2, determining the positions and gap positions of all light points on the brightness distribution picture;S3, calculating to obtain brightness compensation coefficients of the light points at the two sides of each gap and inside each module or all the light points according to the local average brightness difference of the gaps or the non-gaps, or according to the distance of adjacent light points at the two sides of each gap and the distance difference of adjacent light points inside each module; S4, using the brightness compensation coefficients to adjust the brightness of the light points at the two sides of each gap and inside each module or all the light points to visually remove the visualgaps among the modules after the display screen is spliced. Bright and dark lines in gaps among display units of the spliced display screen are visually removed, the visual effect is obviously improved, the achievement steps are simple, and the splicing and installation difficulty and installation cost are lowered.

Owner:颜色空间(北京)科技有限公司

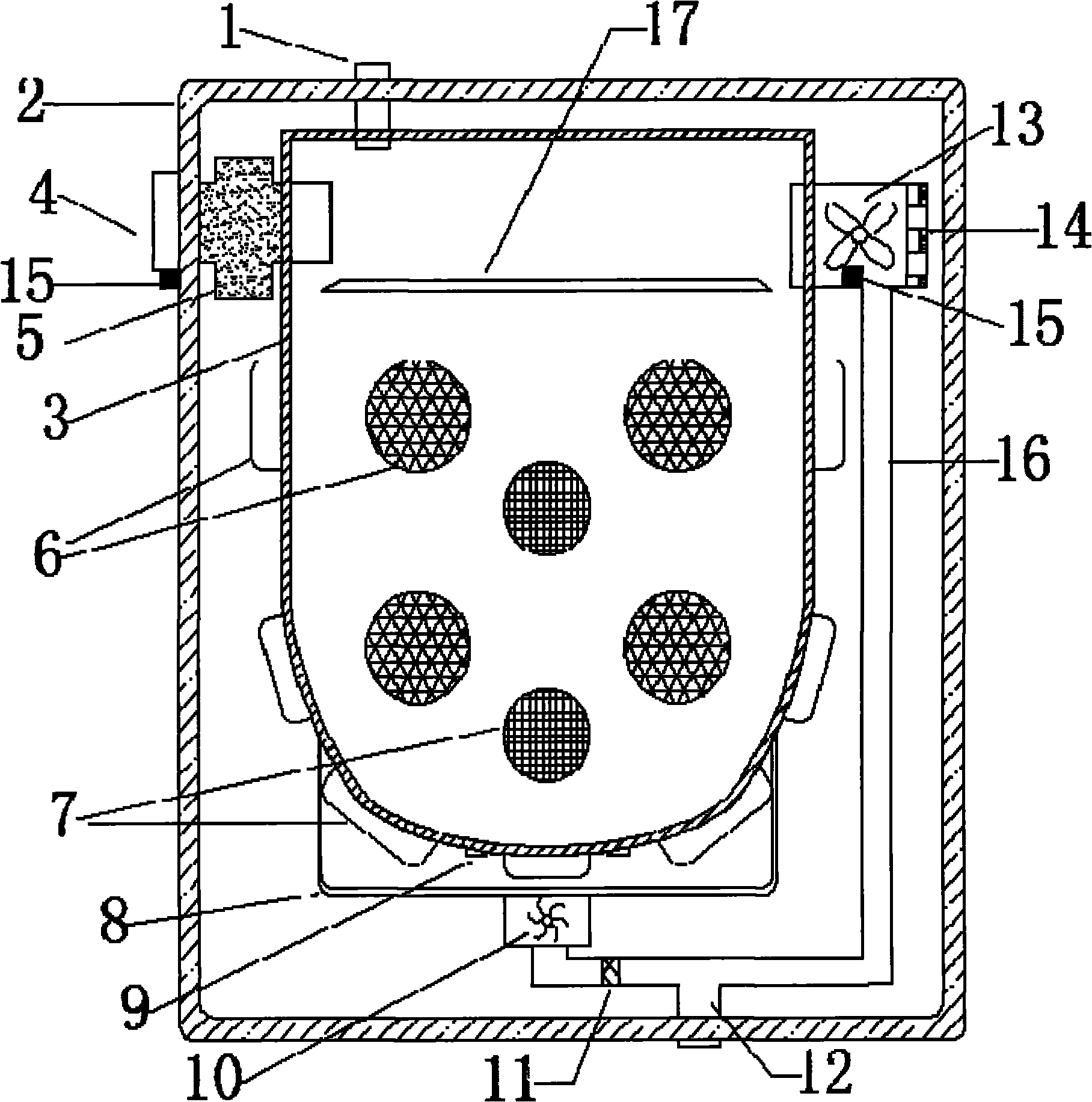

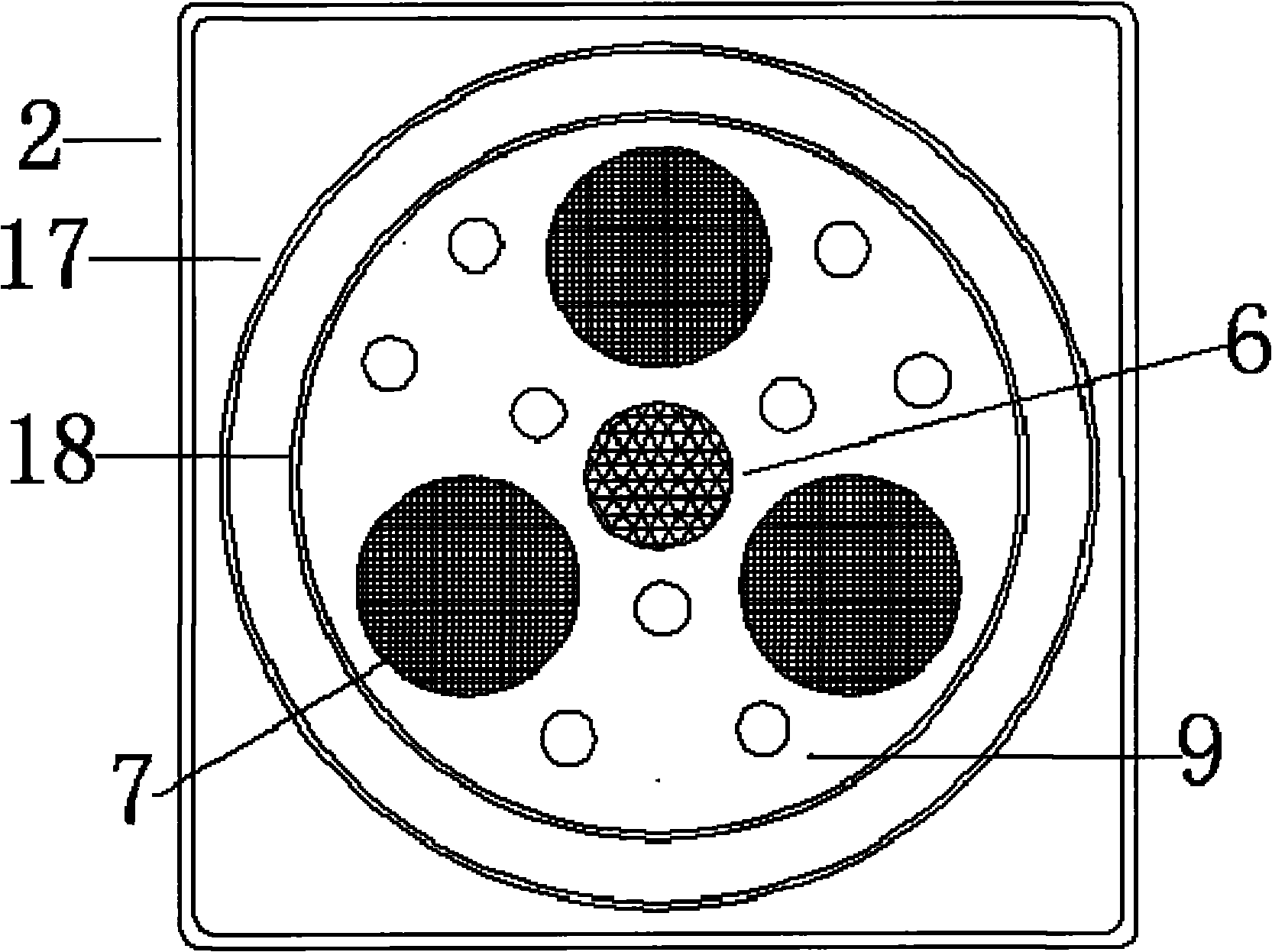

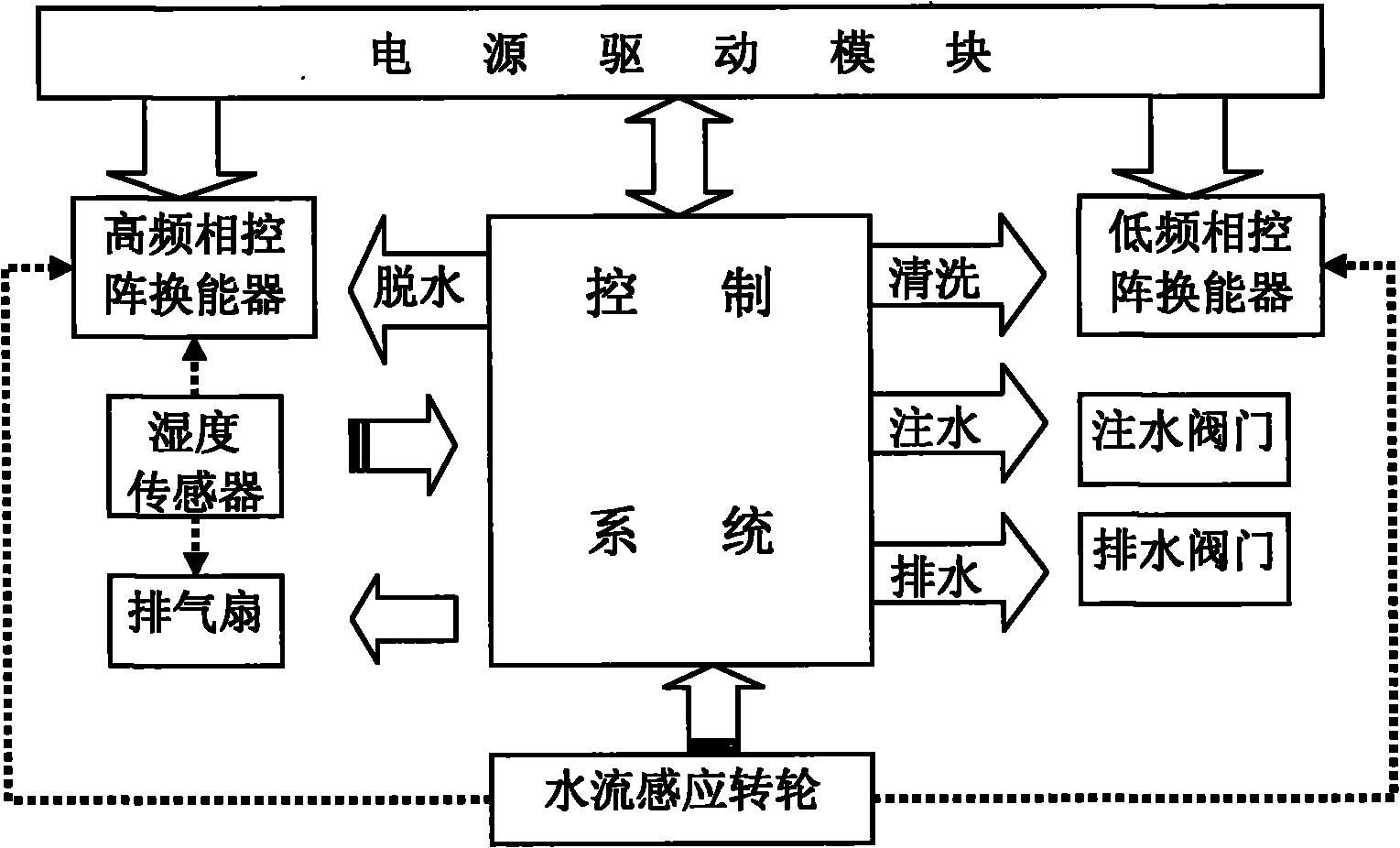

Multifrequency phased ultrasonic clothes cleaning and dehydration method and device

InactiveCN101962898AReduce wearImprove work efficiencyControl devices for washing apparatusVibration washing machinesCavitationEngineering

The invention discloses a multifrequency phased ultrasonic clothes cleaning and dehydration method and device, wherein the device comprises a clothes washing box, a circuit control system, a water inlet and drain device, a display control panel, ultrasonic phased-arrays and an air exchange device, wherein an acoustic wave baffle board is arranged in the clothes washing box, and floats on the liquid surface when working; the ultrasonic phased-arrays are uniformly distributed on the side wall and the bottom part of a barrel; the clothes washing box is provided with a water inlet device at the top part and a drain device at the bottom part; the ultrasonic phased-arrays comprise ultrasonic phased-arrays of different resonant frequencies. The invention finishes full ultrasonic clothes washing by using the method combining high and low frequency ultrasonic according to different characteristics of the cleaning and the dehydration processes in the washing process, that is to say, low frequency ultrasonic is used for cavitation cleaning, and the high frequency ultrasonic is used for atomization dehydration. The invention utilizes the method of scanning with ultrasonic beams so that the energy of the ultrasonic is more concentrative, the penetrating power is stronger, the washing and the dehydration effects are more uniform, and both the cleanness and the dehydration rate are improved.

Owner:SOUTH CHINA UNIV OF TECH

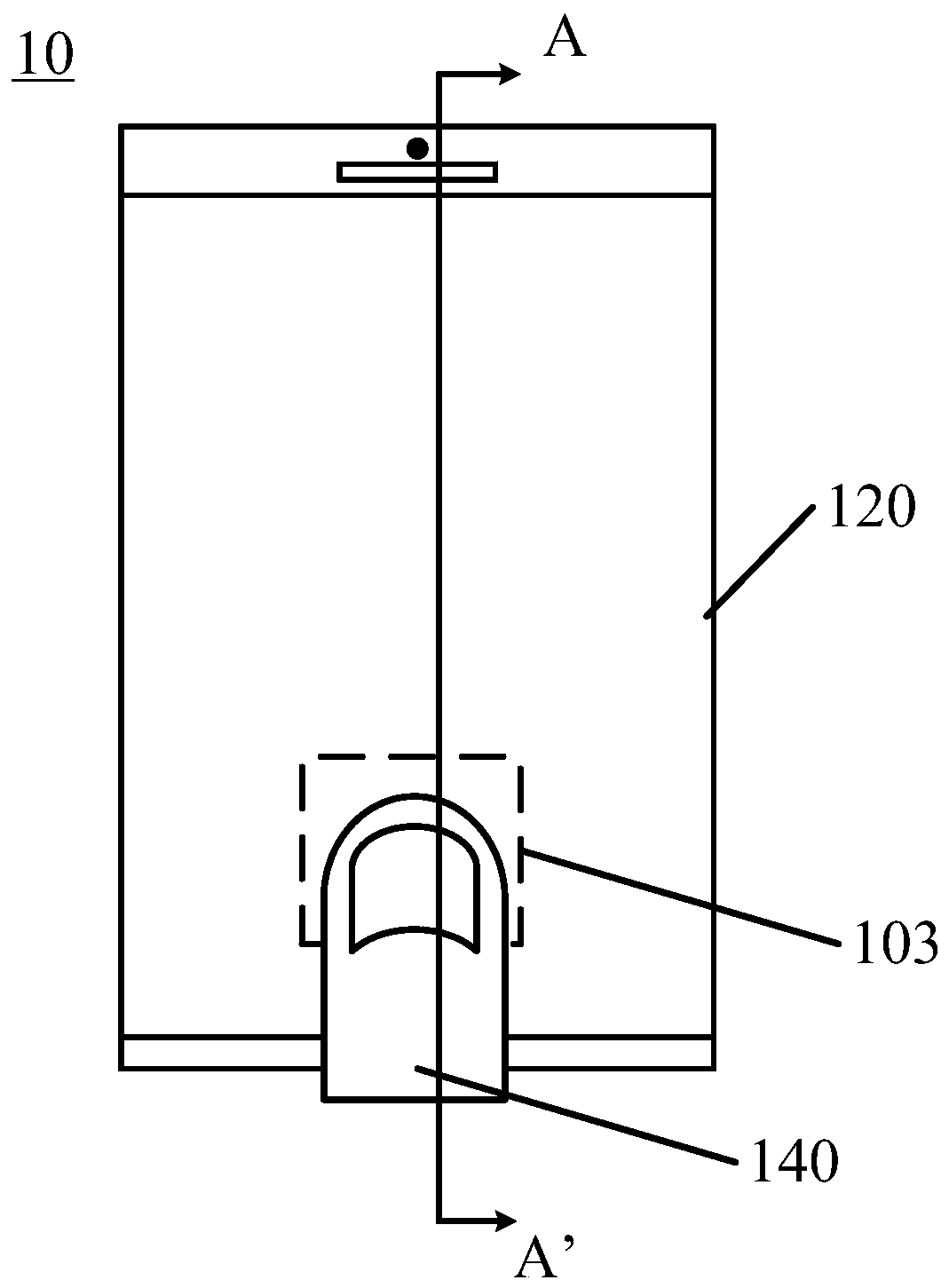

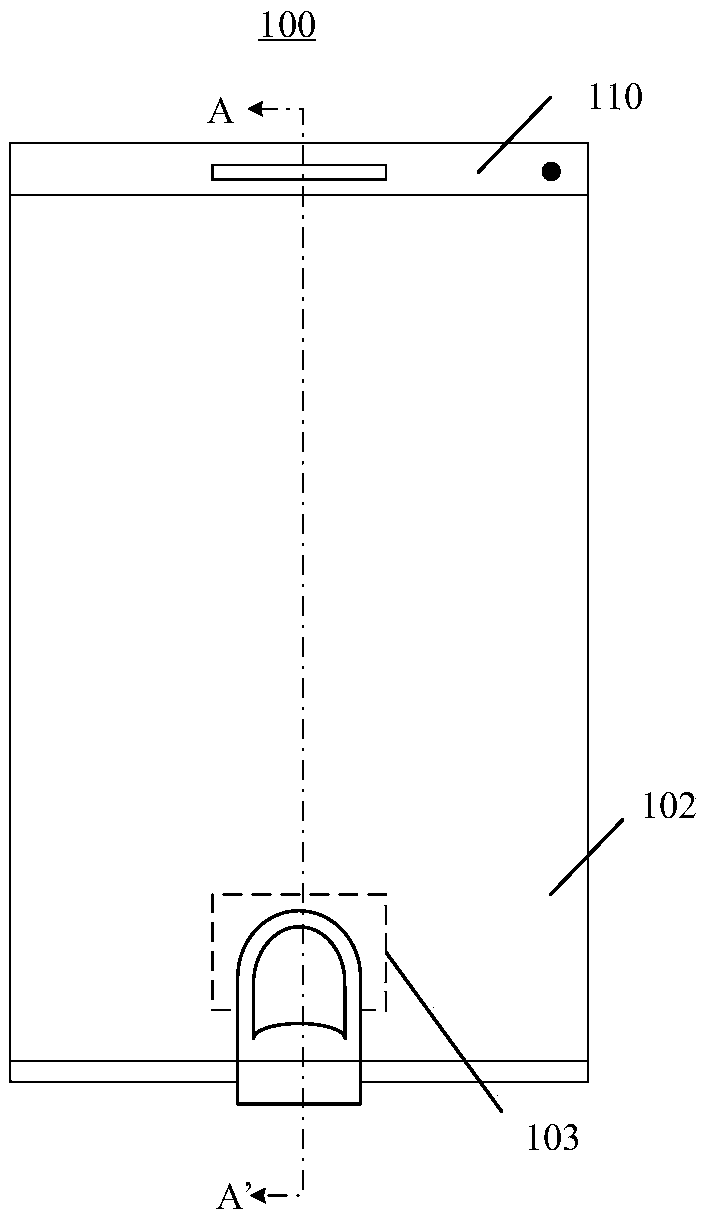

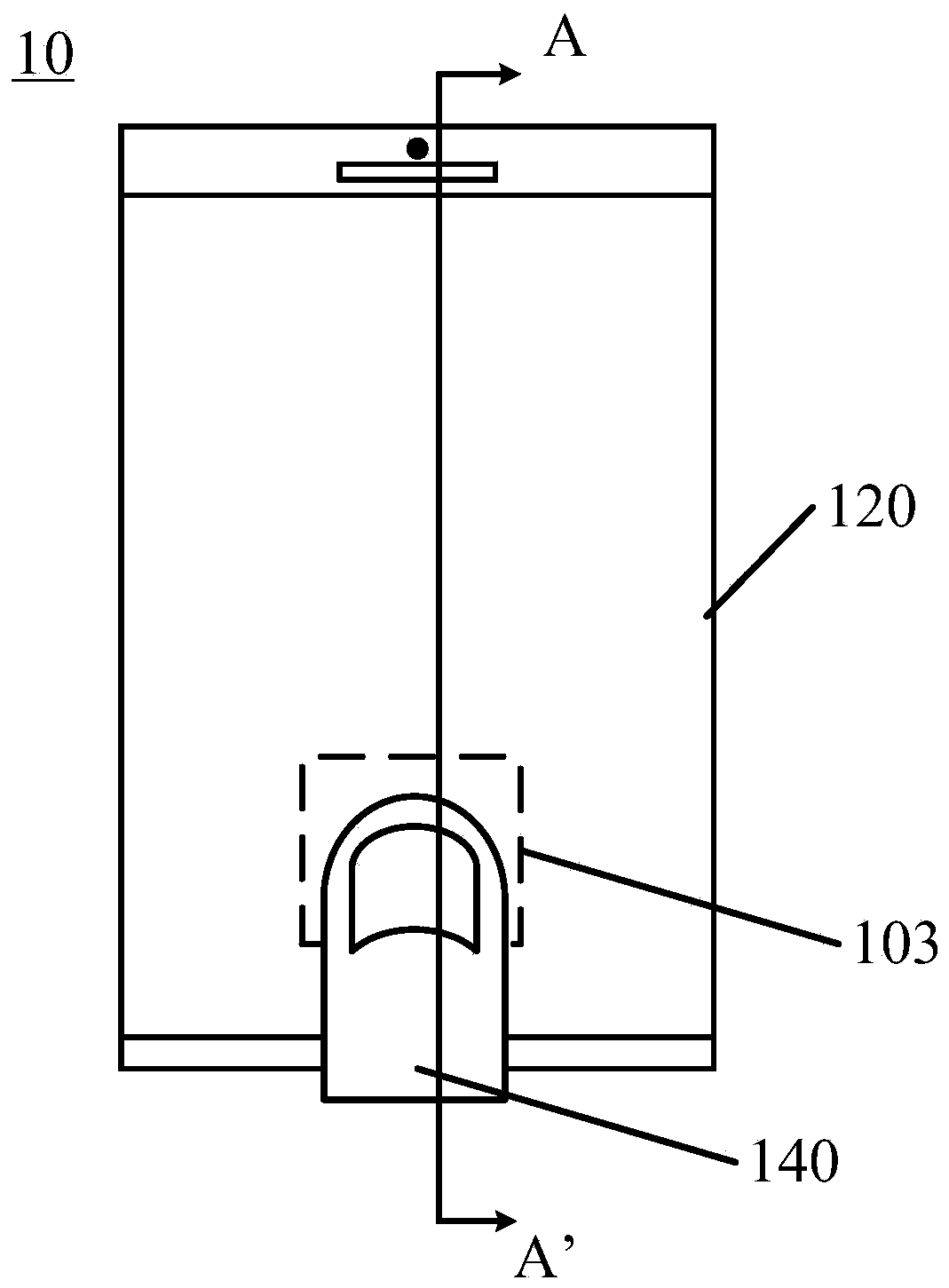

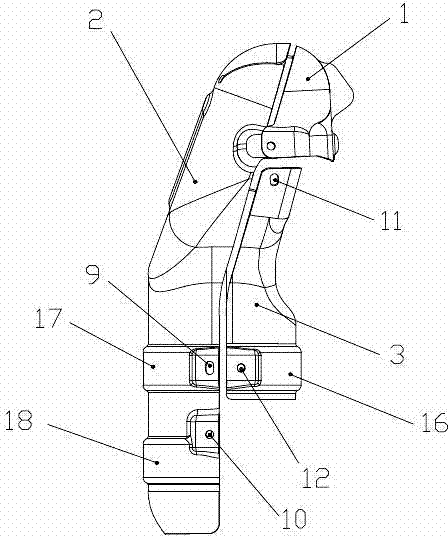

Fingerprint identification device and electronic device

ActiveCN109791611AEasy to implementLow processing technology requirementsPrint image acquisitionIdentification deviceFingerprint detection

The invention discloses a fingerprint identification device and an electronic device that has a display screen, wherein the fingerprint identification device comprises a support plate for connecting amiddle frame of the electronic device in a fixed way; at least one fingerprint sensor chip disposed at the The upper surface of the support plate and under the display screen through the support plate. The at least one fingerprint sensor chip is configured to receive a fingerprint detection signal returned by reflection or scattering by a human finger above the display screen, and the fingerprintdetection signal is used to detect fingerprint information of the finger.

Owner:SHENZHEN GOODIX TECH CO LTD

Preparation method of few-layer MoS2 thin film

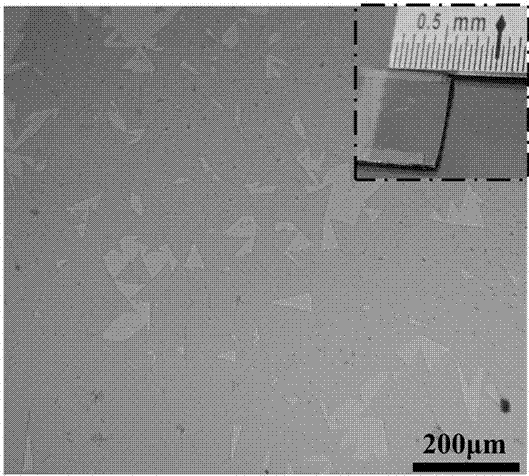

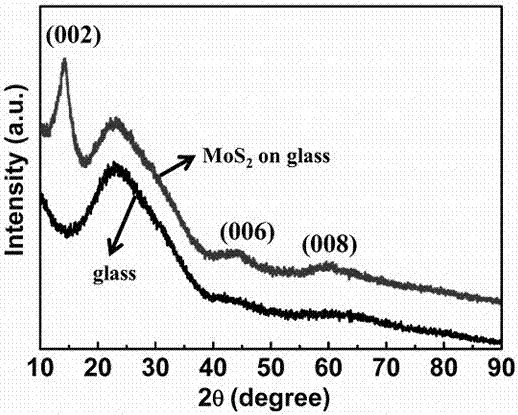

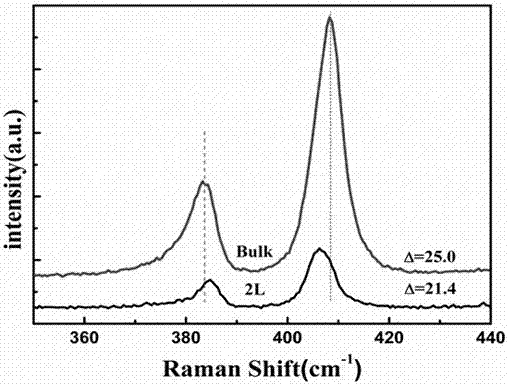

InactiveCN106929827AIncrease the areaLow processing technology requirementsChemical vapor deposition coatingVulcanizationTube furnace

The invention provides a preparation method of a few-layer MoS2 thin film. The preparation method adopts MoO3 powder and S powder as precursors and a two-temperature-zone tube furnace as equipment, and particularly comprises the following steps: (1) deposition of a MoO3 thin film: placing MoO3 powder at one end of a quartz boat, backing off a substrate, placing the substrate at the other end of a quartz boat, injecting an inert gas, and heating up MoO3 to obtain the MoO3 thin film on the substrate; and (2) placing the MoO3 prepared in the step (1) and S powder in two temperature zones of the two-temperature-zone tube furnace, injecting an inert gas, heating the MoO3 thin film and the S powder, and finishing vulcanization of the MoO3 thin film to obtain the MoS2 thin film. The obtained MoS2 is triangular, each triangular MoO3 is a monocrystal, and a plurality of triangles are mutually connected to form the MoS2 thin film. The MoS2 thin film with the few-layer structure has the area of about 0.7 cm*1 cm.

Owner:ZHENGZHOU UNIV

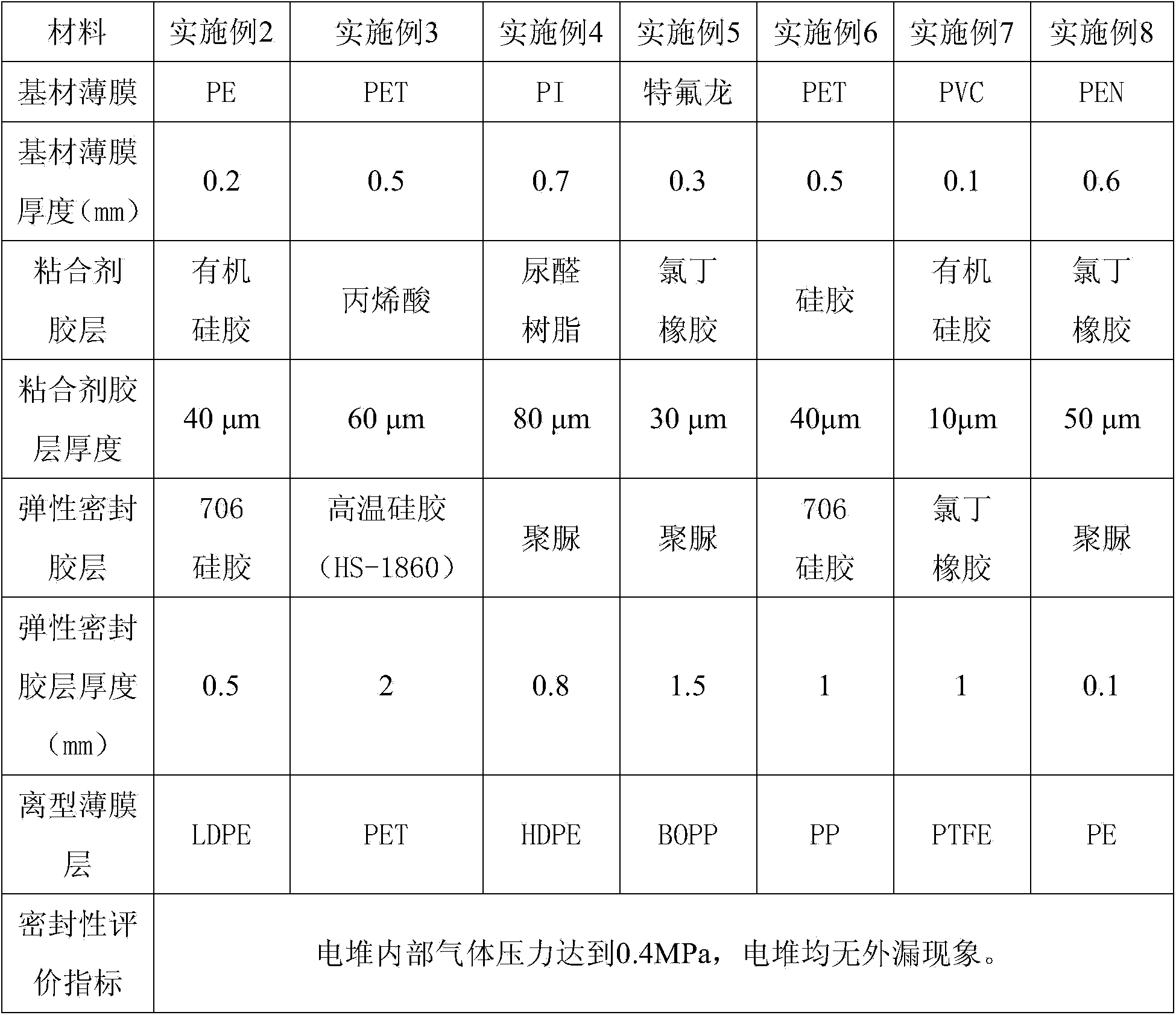

Fuel cell sealing material and preparation method thereof

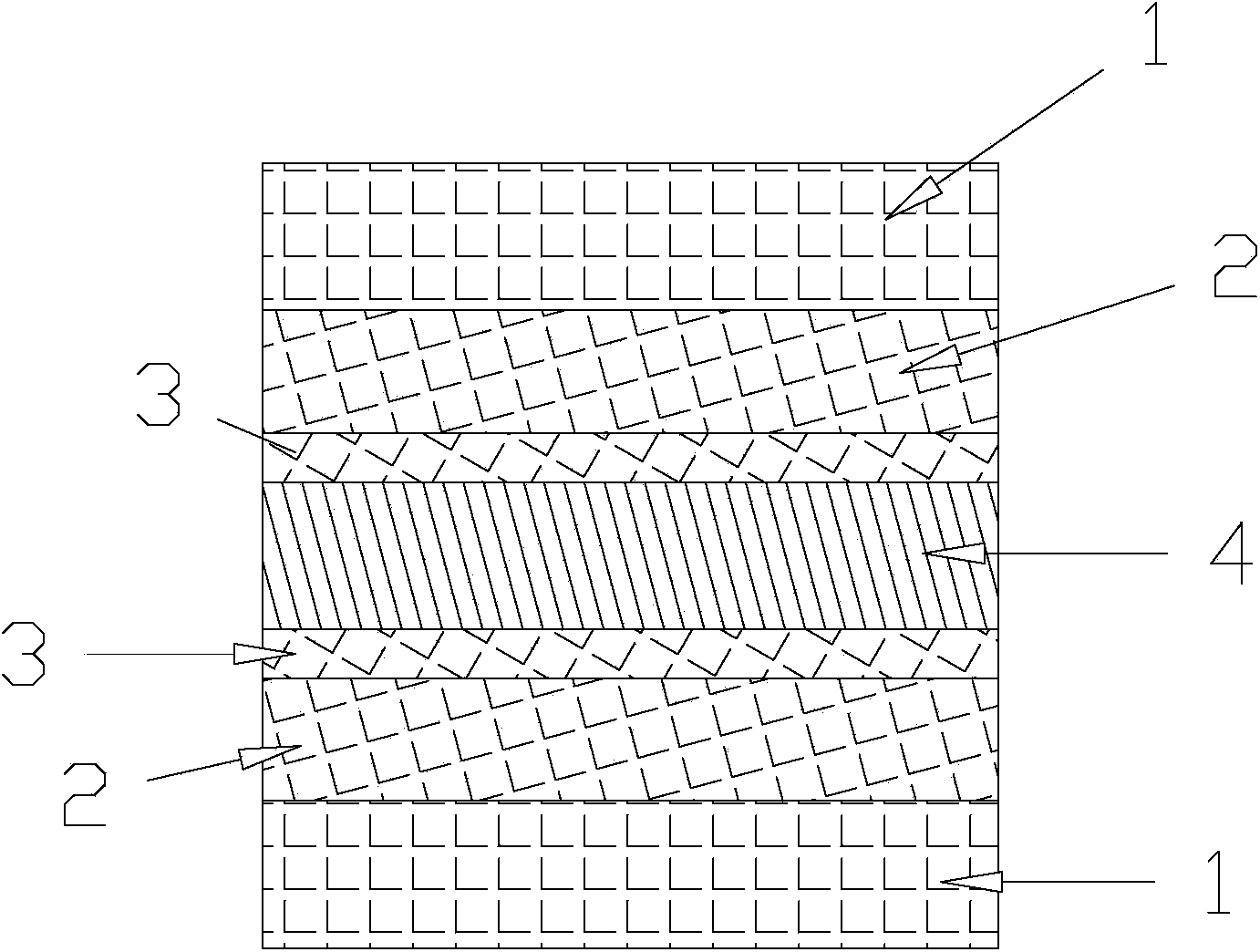

ActiveCN103779515AIncrease production capacityReduce usageSynthetic resin layered productsLaminationFuel cellsAdhesive glue

The invention discloses a fuel cell sealing material. The fuel cell sealing material comprises a release film layer and an adhesive glue layer, a substrate film and an elastic sealant layer, wherein the adhesive glue layer, the substrate film and the elastic sealant layer are arranged outwards in sequence on two sides of the release film layer. Through the fuel cell sealing material, inner sealing of membrane electrodes in fuel cell and external sealing between the membrane electrodes and bipolar plates are solved simultaneously; the raw material is saved; the fuel cell sealing material is good in adhesive performance under room temperature; the hot sealing is not required, so that the sealing processing time of the membrane electrodes is shortened; the production efficiency is improved; the inner sealing material and the external sealing material are integrated, so that the automatic production of electric piles of the fuel cells is facilitated; and the fuel cell sealing material is of great significance to the industrialization of the fuel cells.

Owner:江苏氢电新能源有限公司

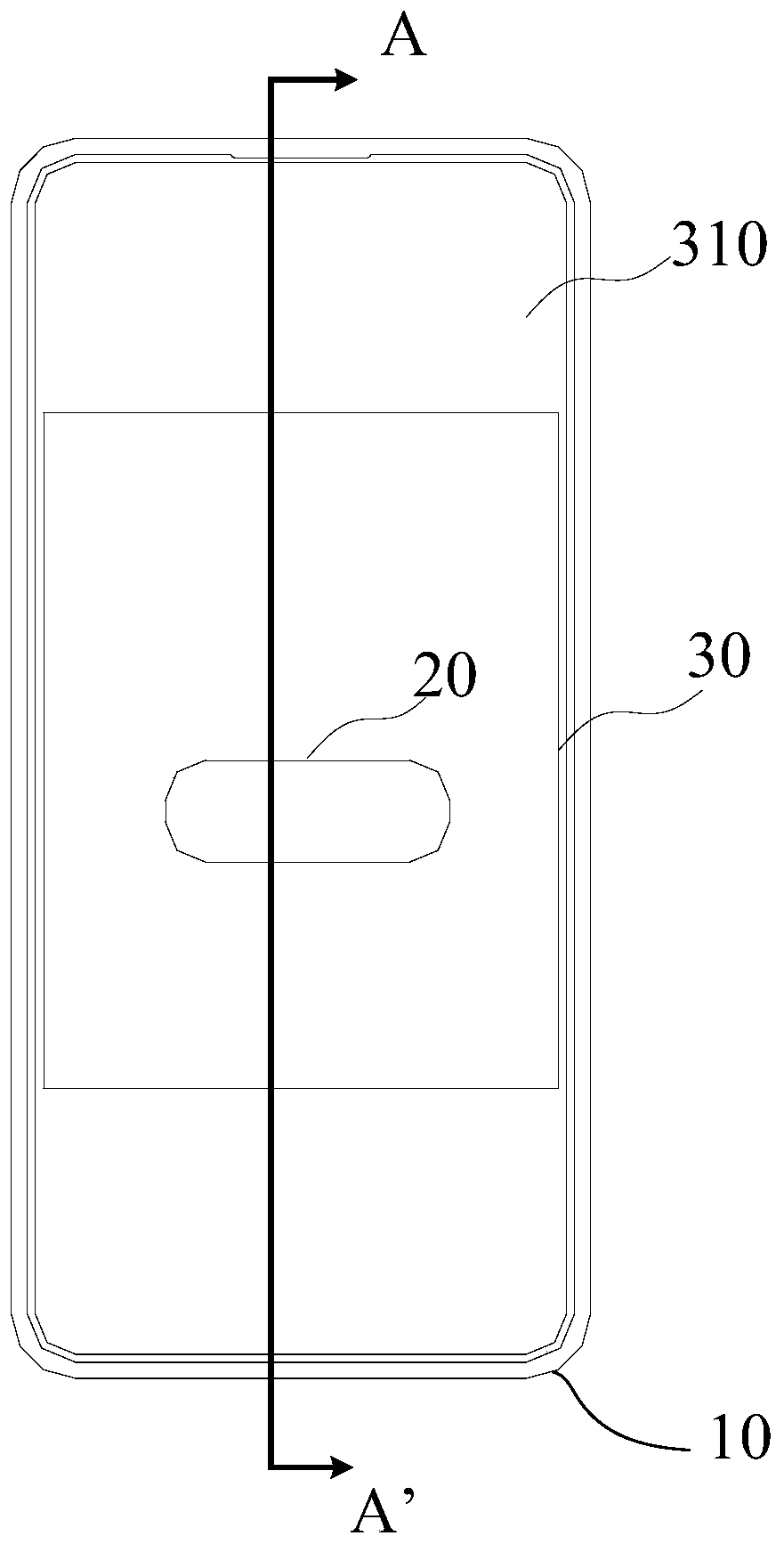

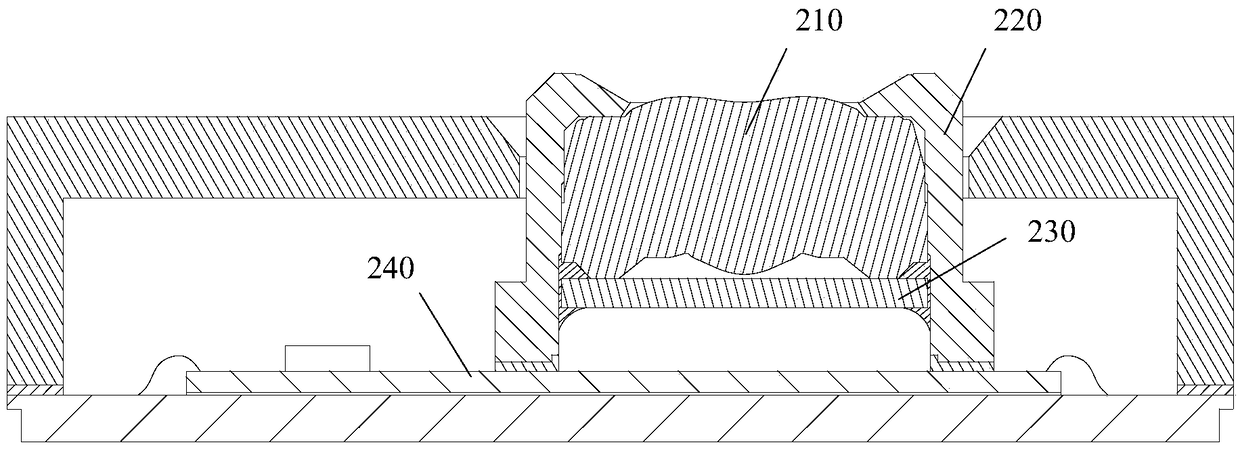

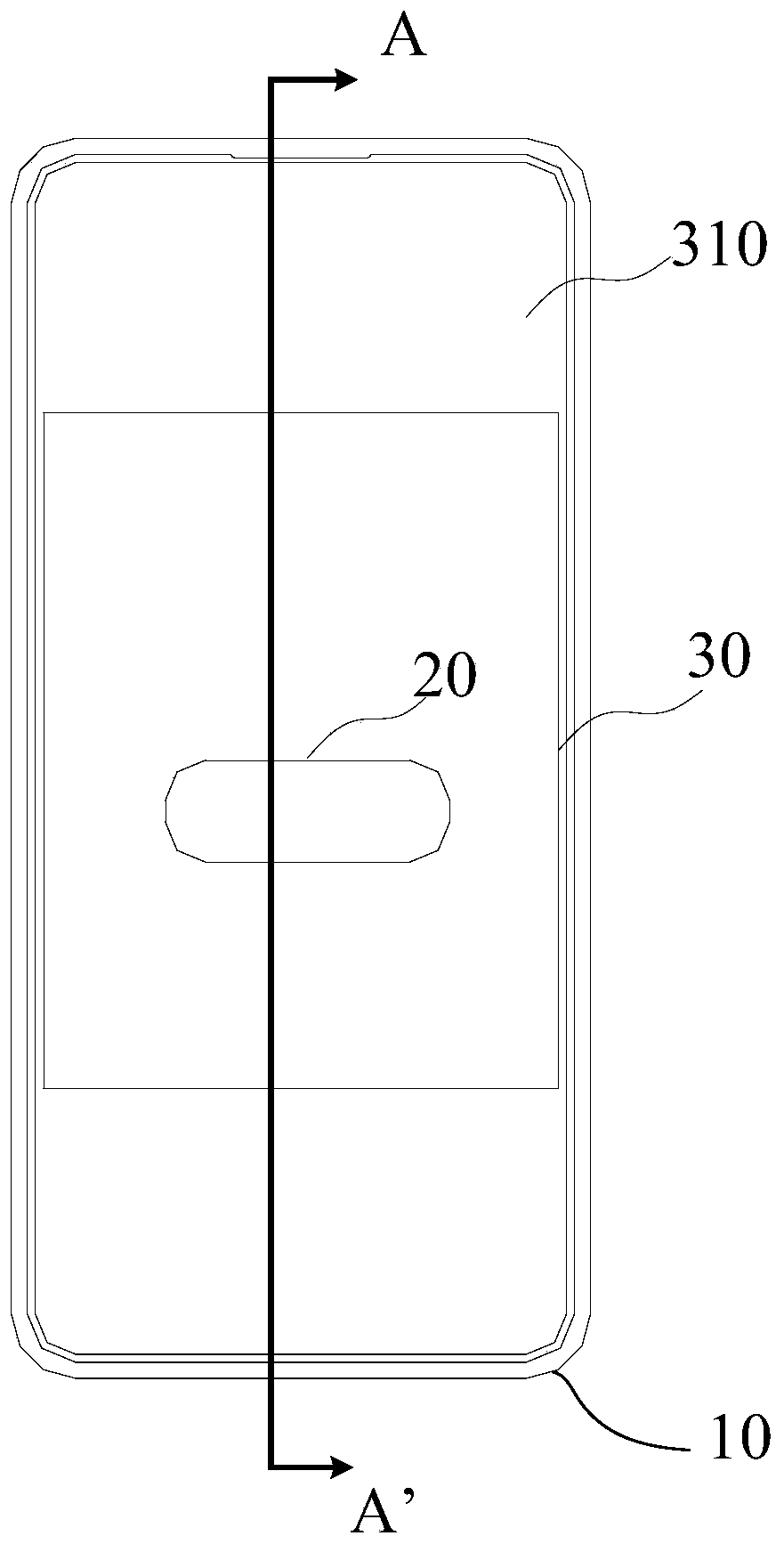

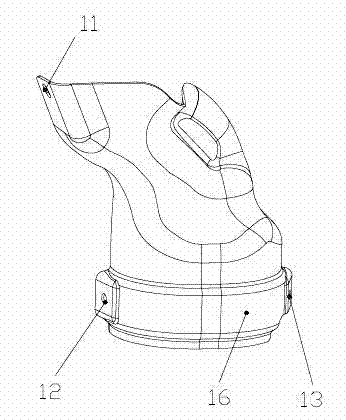

Under-screen biological identification device and electronic device

InactiveCN109496311ASolve batch yield problemsSolve the problem that the best focal length cannot be aligned preciselySolid-state devicesCharacter and pattern recognitionCamera lensIdentification device

The invention provides an under-screen biological identification and an electronic device. The under-screen biological identification device comprises: a lens which is disposed under a display screento receive an optical signal returned from the upper portion of the display screen via a human finger, a lens barrel, an optical filter, and a sensing chip wherein the optical signal is used to detectbiological identification information of the finger; the lens is fixed in the lens barrel; the optical filter is located under the lens; the sensing chip is disposed under the lens barrel, and is used for imaging based on an optical signal passing through the lens; and a distance between a photosensitive surface of the sensing chip and an imaging surface of the lens is greater than or equal to apreset value. The under-screen biological identification device and the electronic device provided by the embodiments of the present application can improve the efficiency of under-screen biological identification recognition.

Owner:SHENZHEN GOODIX TECH CO LTD

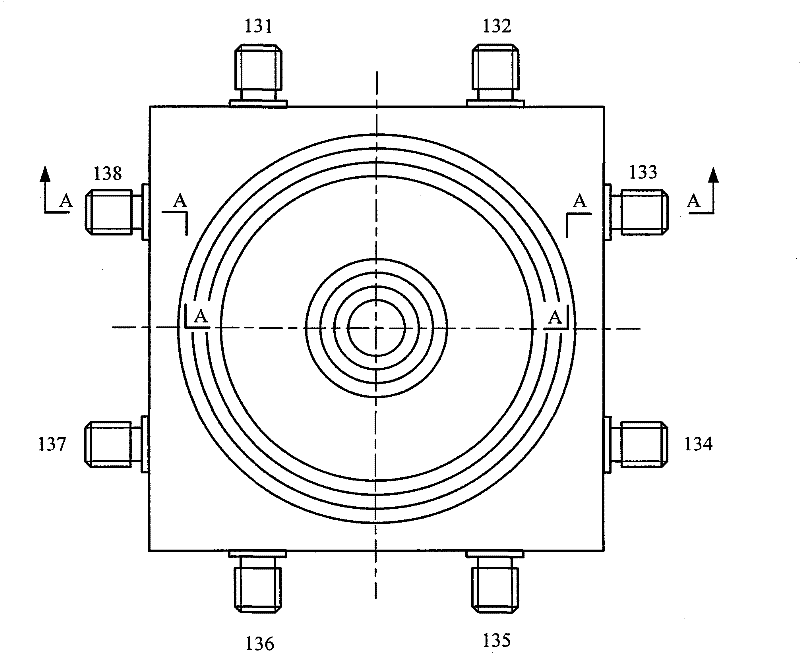

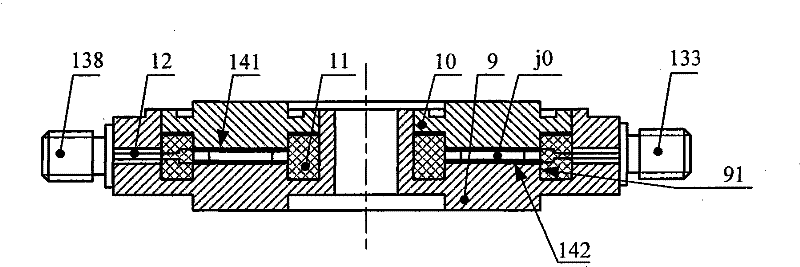

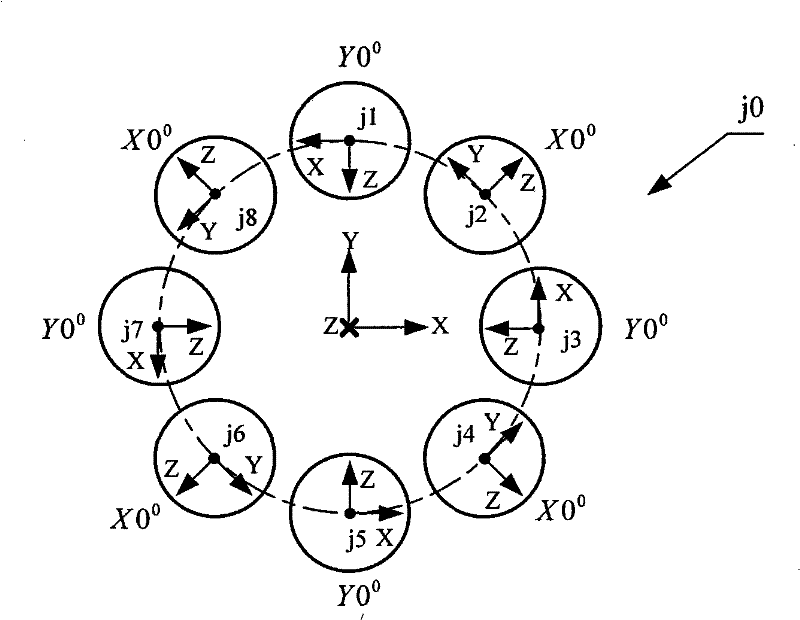

Piezoelectric type six-dimensional force sensor

InactiveCN101750173ASimple structureLow processing technology requirementsForce measurement using piezo-electric devicesCouplingMiniaturization

The invention relates to a piezoelectric type six-dimensional force sensor which comprises a base, a force and moment measurement meter, a cover, a signal lead and an insulated filling material, wherein the base is internally provided with a subpanel and a socket, and the force and moment measurement meter is clamped by an upper insulated plate electrode and a lower insulated plate electrode and is installed on the subpanel in the base. In the invention, the force and moment measurement meter is formed only by eight quartz wafers, and the eight quartz wafers are respectively four cut quartz wafers with Y0 degrees and four cut quartz wafers with X0 degrees. The information of three-dimensional force and three-dimensional moment to be measured can be obtained by carrying out additive operation and / or subtractive operation after the output signals of the eight quartz wafers are collected. Except for the advantages that the invention still can keep dimensionless coupling and does not need decoupling operation, the invention also has the advantages of simple structure and requirement reduction of a processing process because the quartz wafers used by the invention are greatly reduced, so that the invention is especially suitable for the processing of an MEMS process and realizes the miniaturization of the piezoelectric type six-dimensional force sensor.

Owner:CHONGQING UNIV

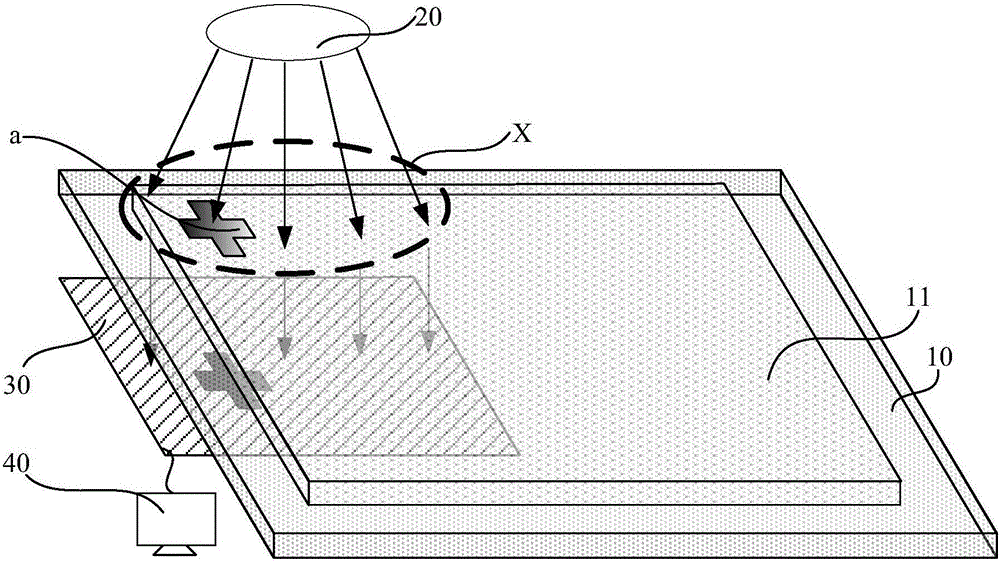

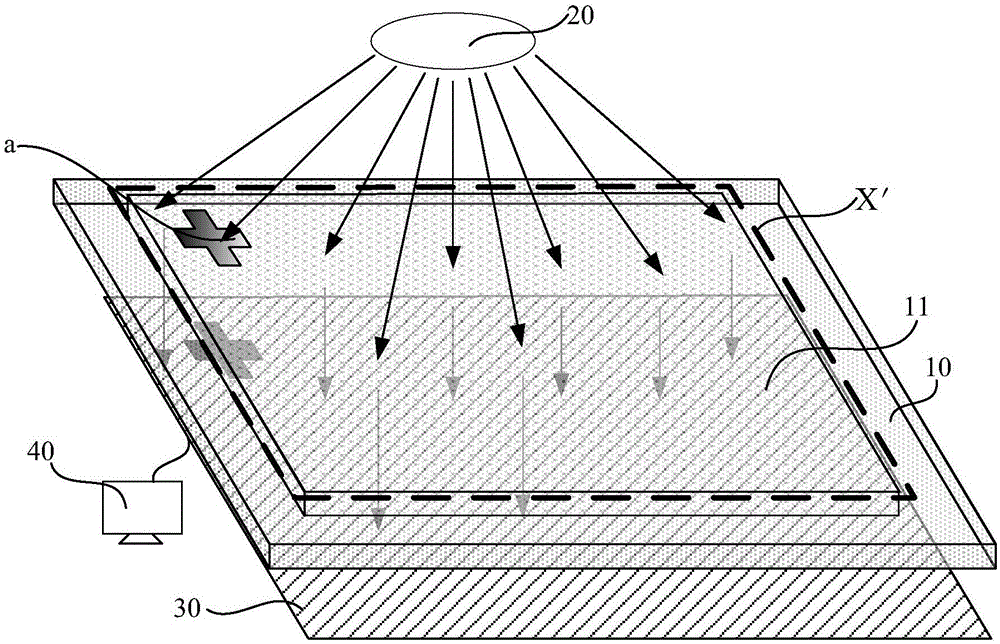

Substrate processing equipment and alignment control method of to-be-processed substrate

InactiveCN106711074AImprove stabilityLow processing technology requirementsSemiconductor/solid-state device manufacturingNon-linear opticsImage sensorEngineering

The embodiment of the invention provides substrate processing equipment and an alignment control method of a to-be-processed substrate, and relates to the semiconductor technical field. When the substrate processing equipment positions the to-be-processed substrate in the prior art, the alignment result may be inaccurate because alignment marks are poor in reflective performance; the substrate processing equipment can solve said problems, and comprises the following units: a carrier deck used for bearing the to-be-processed substrate, wherein the to-be-processed substrate has alignment marks made of shading material; a light source arranged on one side of the carrier deck; an image sensor arranged on the other side of the carrier deck, wherein the light source is used for sending lights to the to-be-processed substrate; the light reaches the image sensor through the to-be-processed substrate, the image sensor can collect the image containing the alignment marks; the irradiation zone of the light source at least covers the outer edges of the alignment marks.

Owner:BOE TECH GRP CO LTD +1

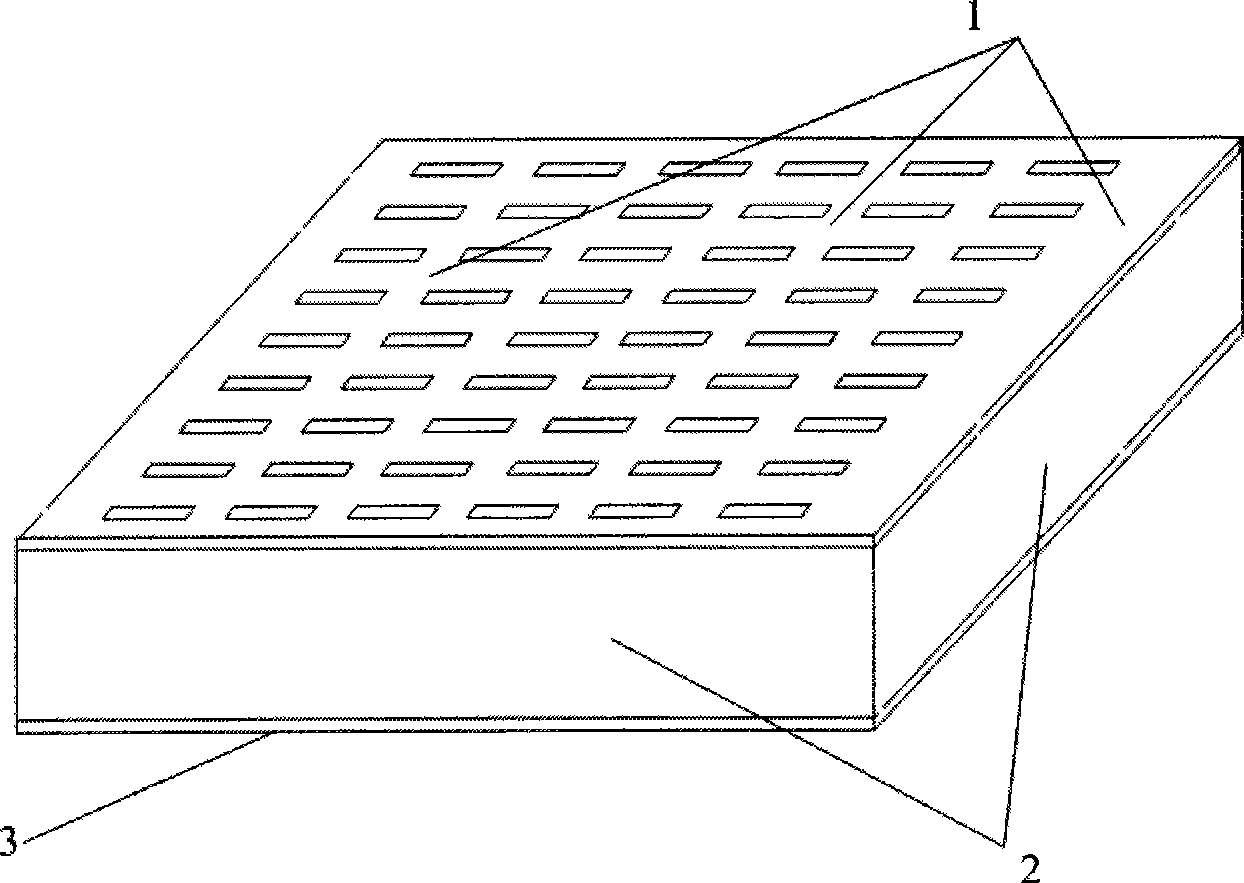

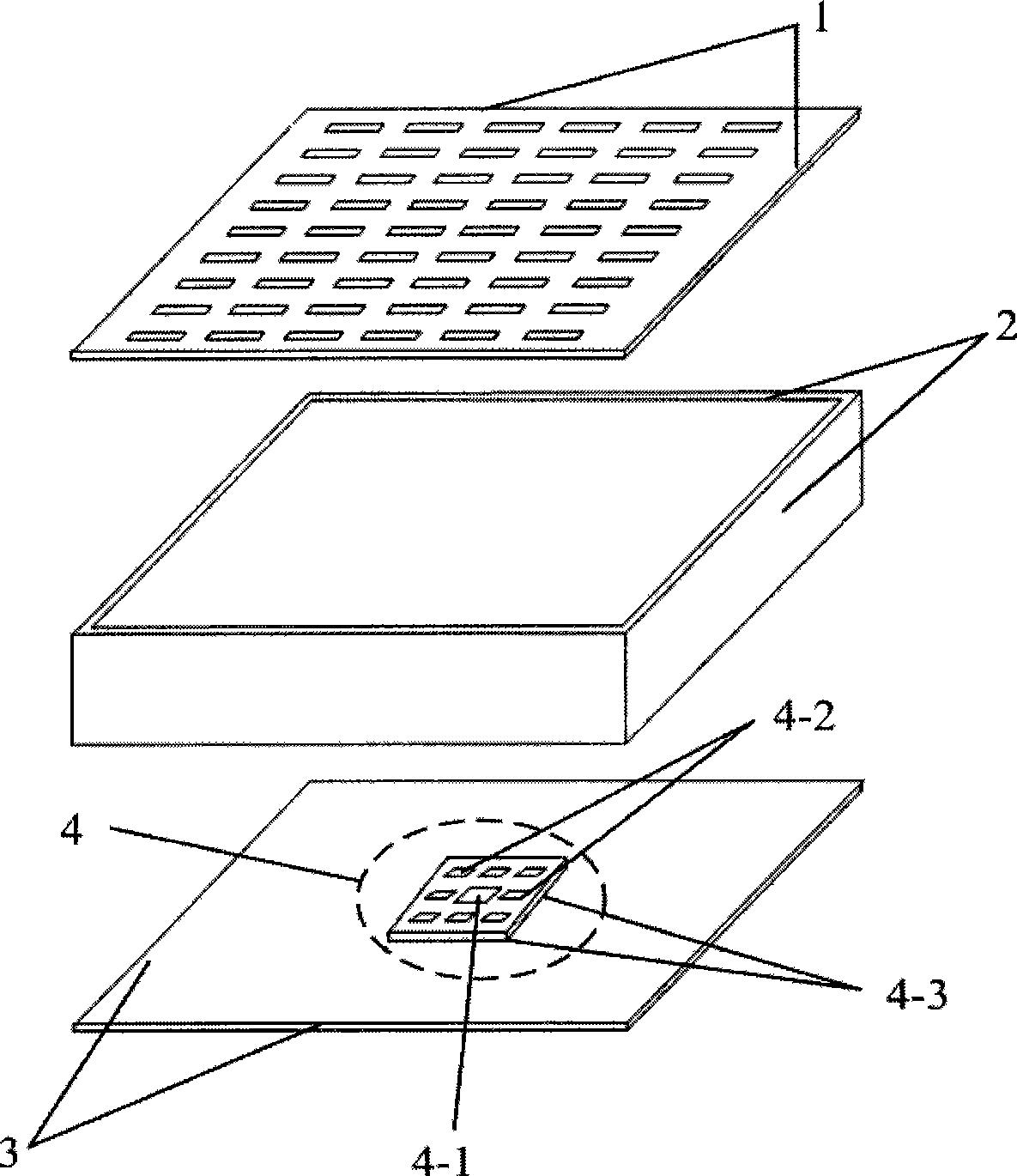

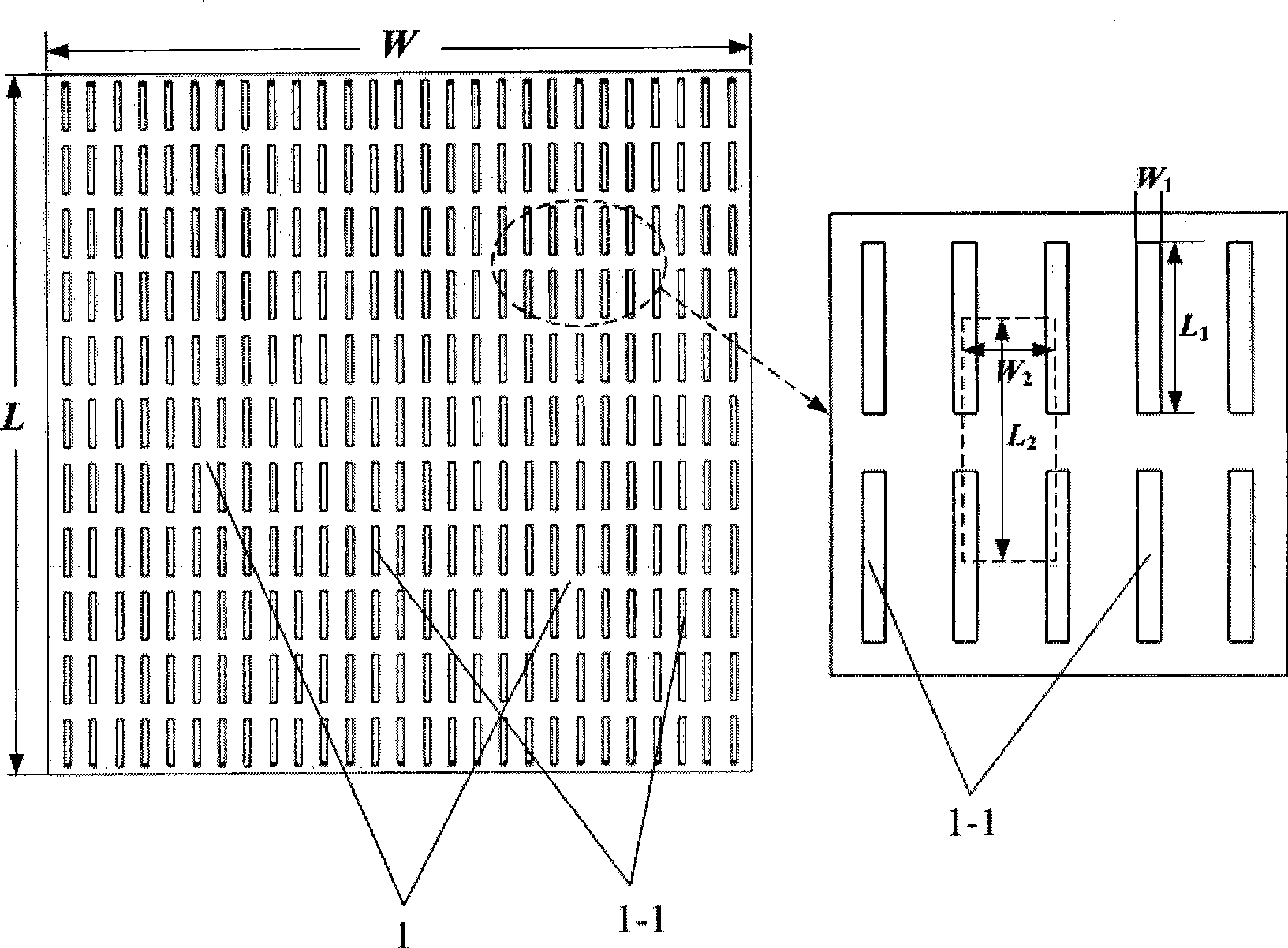

High-gain low-profile null feed array antenna

A high-gain low-profile null feed array antenna comprises a metal cover plate, a metal side plate, a metal bottom plate and a feed source. The metal cover plate locates at the upper part, the metal bottom plate locates at the lower part and the metal side plate locates at the middle part; the metal cover plate, the metal bottom plate and the metal side plate are connected with each other to form a cavity in which the feed source is arranged; the metal cover plate is a metal flat plate which is provided with a group of gap units arranged periodically; the feed source comprises a feeding patch located in the middle of the housing and a group of passive parasitized patches around; the feeding patch and the parasitized patch are printed on the upper surface of a same dielectric substrate; the lower surface of the dielectric substrate is attached on the upper surface of the metal bottom plate; and the feeding patch is activated by a cable through a radio frequency coaxial joint. The antenna has the advantages of simple feeding, high gain of more than 20dBi, high caliber efficiency of more than 60 percent and low cost.

Owner:SOUTHEAST UNIV

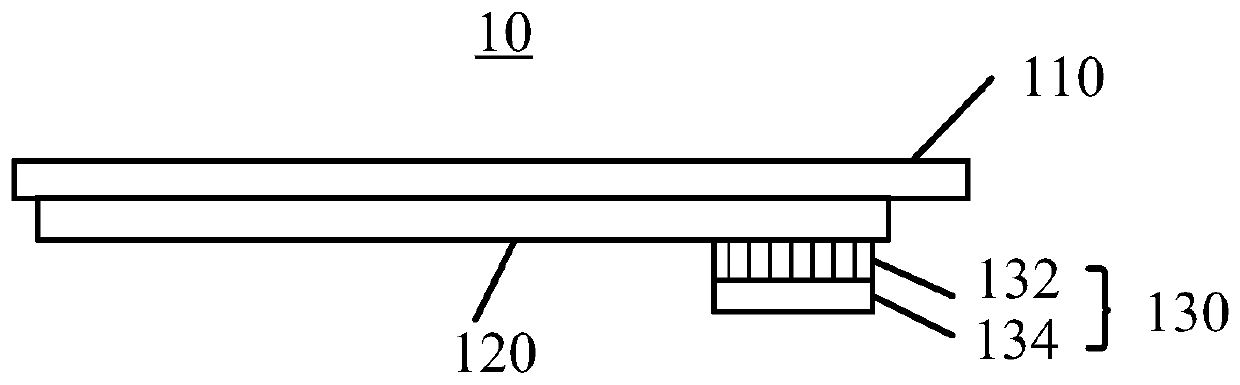

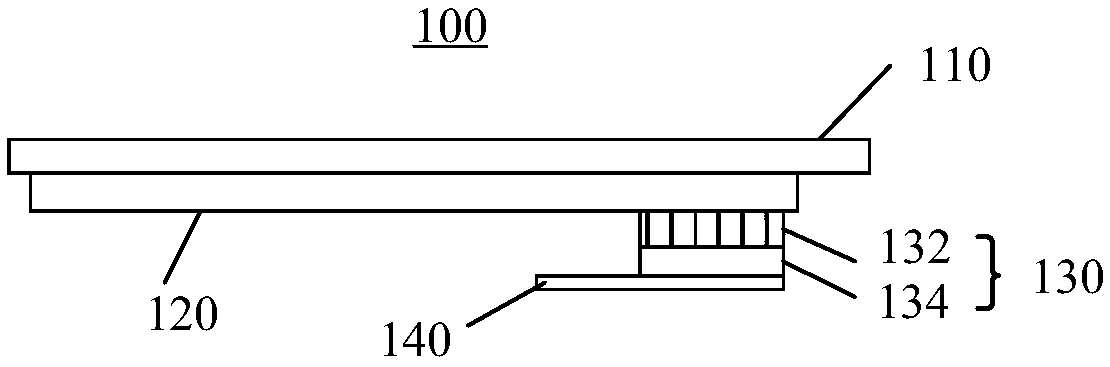

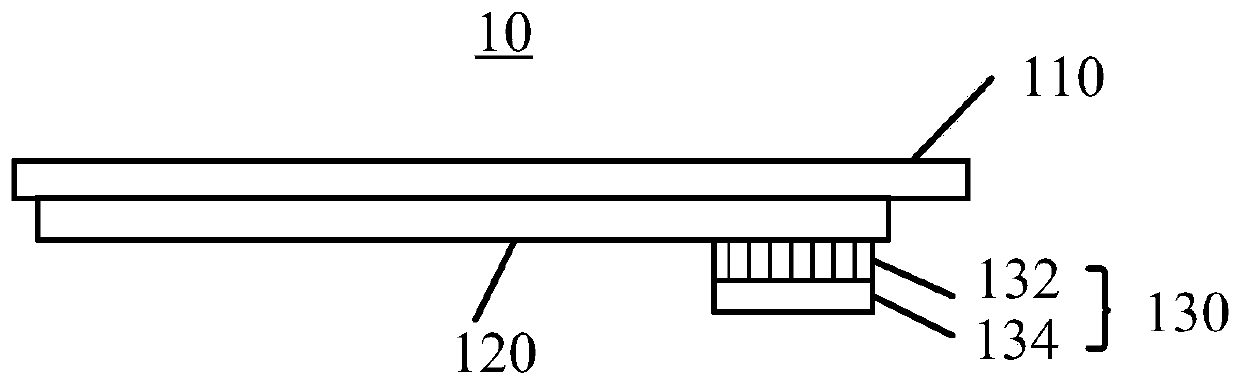

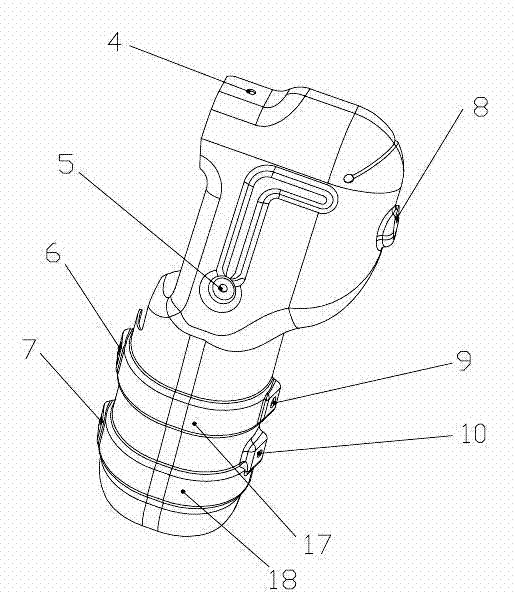

Fingerprint identification device and electronic device

ActiveCN109844765AEasy to implementLow processing technology requirementsCharacter and pattern recognitionIdentification deviceFingerprint detection

The invention discloses a fingerprint identification device and an electronic device. The fingerprint identification device is applied to an electronic device with a display screen. The fingerprint identification device comprises a support plate, wherein the edge of the support plate is provided with a clamp structure that cocks upwards, and the clamp structure is installed into the slot of the middle frame of an electronic device; and at least one fingerprint sensor chip, which is arranged on the support plate and is arranged under a display screen through the support plate. At least one fingerprint sensor chip is used to receive fingerprint detection signals, which are returned by a finger above the display screen through reflecting or scattering; and the fingerprint detection signals are used to detect the fingerprint information.

Owner:SHENZHEN GOODIX TECH CO LTD

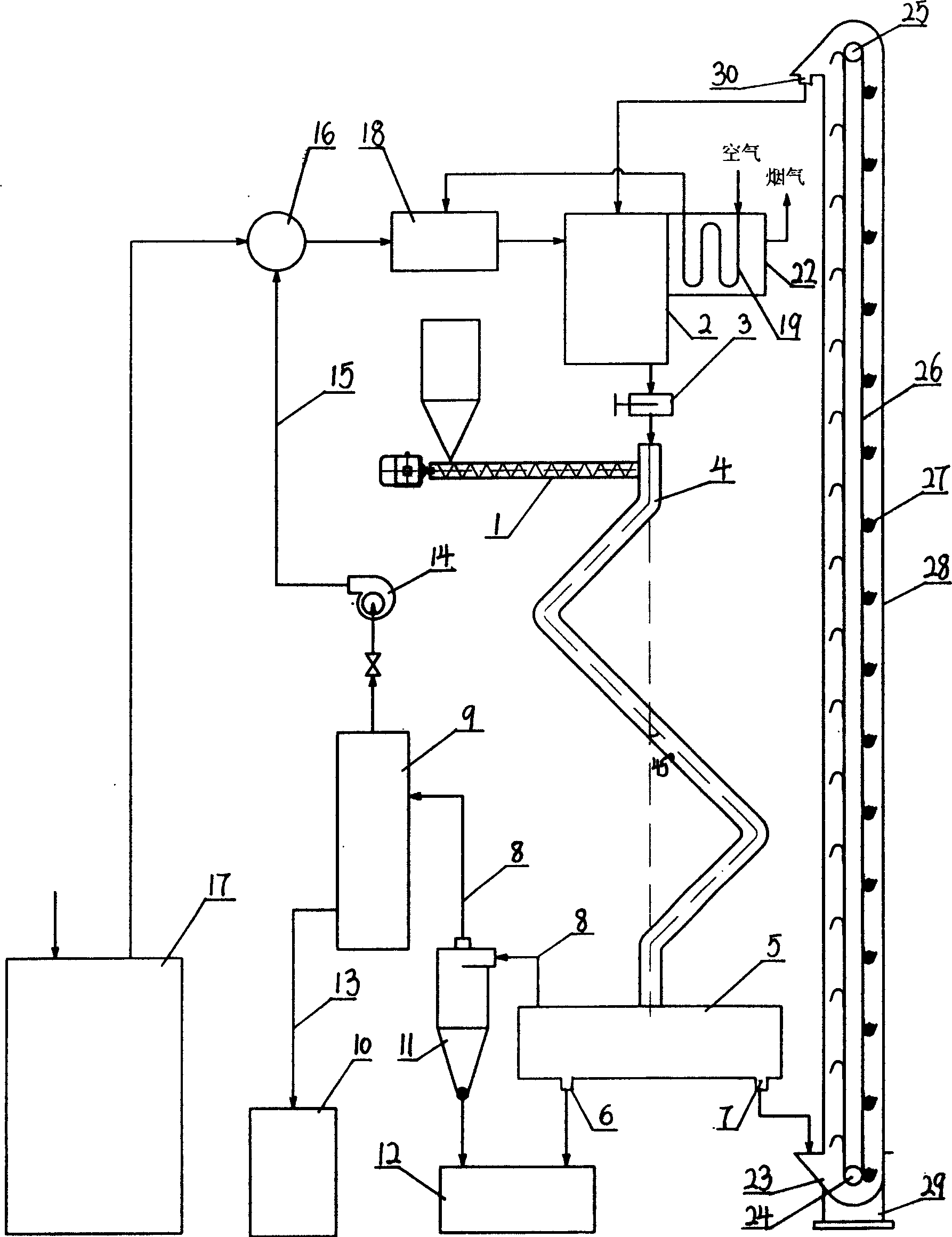

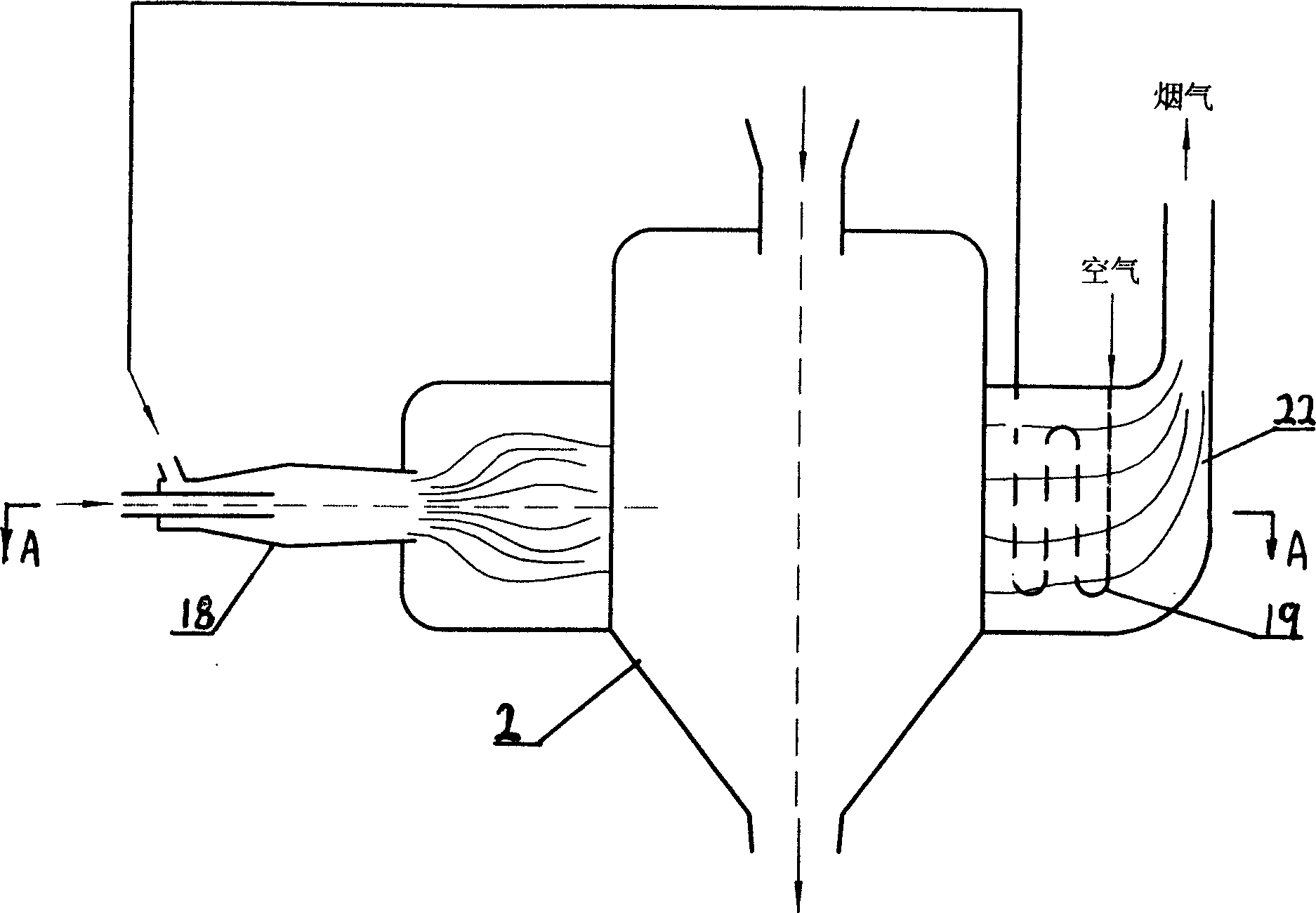

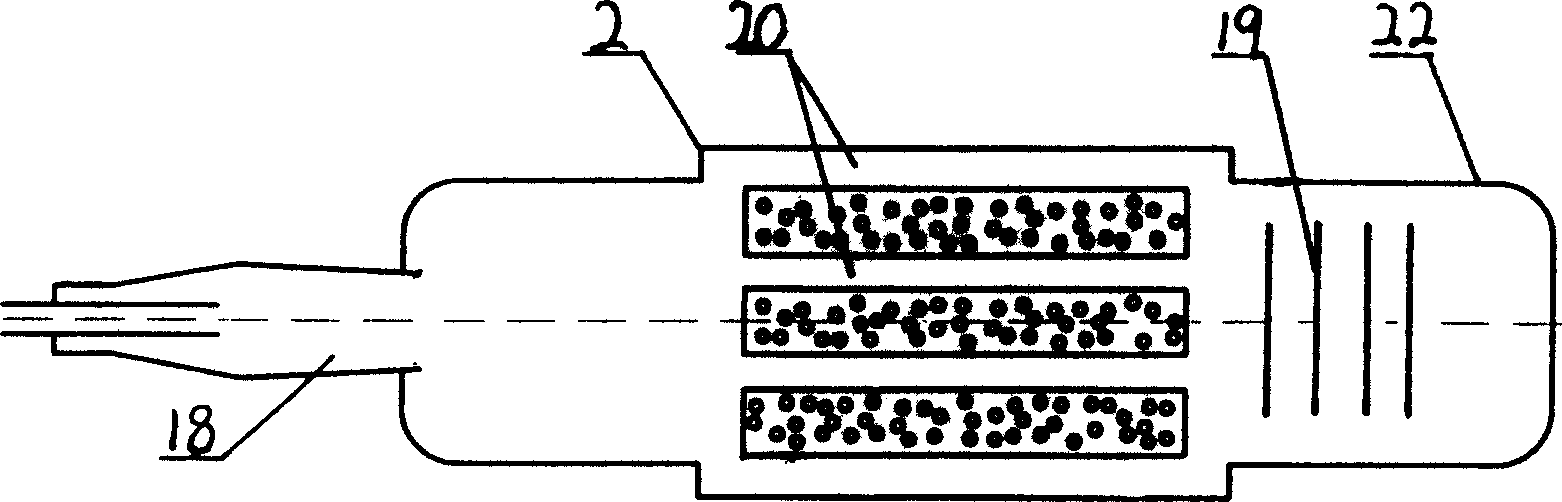

Biomass pyrolysis liquefying systems

InactiveCN1490380ALow costTake advantage ofLiquid hydrocarbon mixture productionHeat carrierResidual biomass

A biomass cracking and liquefying system is disclosed. The Z-shaped reaction pipe has a top end connected respectively with the feeder of biomass and the heat carrier outlet of the heat carrier heater, and a bottom end connected to the separator whose top end is connected to cooling unit and whose bottom end has residual biomass outlet and heat carrier outlet. The input of gas mixer is connected respectively to the gas outlet of biomass gasifier and the thermocomposed gas outlet of cooling unit, and its output is connected to gas burner communicated to the heater of heat carrier. It features that the combustible gas generated in gasifying and liquefying biomass is used as the energy source for thermodecomposing and liquefying, so having low cost.

Owner:SHANDONG UNIV OF TECH

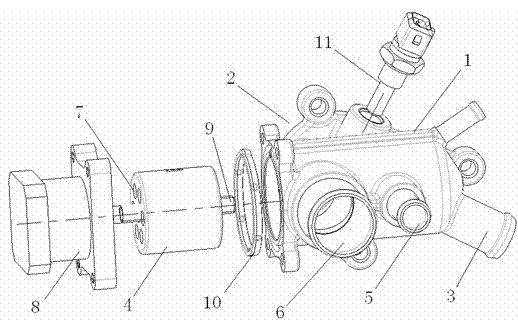

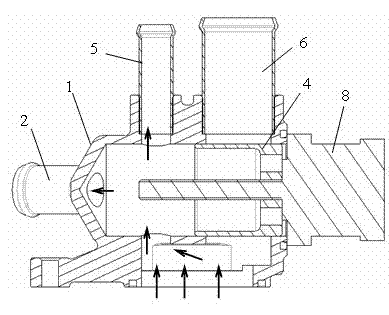

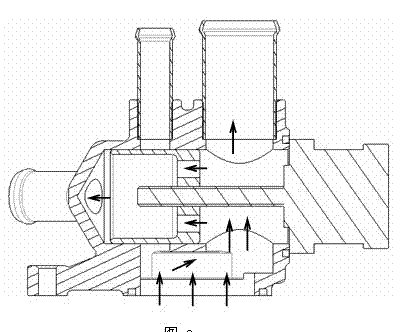

Automobile engine thermostat and thermoregulation method thereof

ActiveCN102877926ASimple structureVersatileCoolant flow controlMachines/enginesEngineeringThermostat

The invention aims to provide an automobile engine thermostat low in cost, easy to produce and accurate to control, and a thermoregulation method thereof. The automobile engine thermostat comprises a casing. The bottom of the casing is provided with a water inlet. The automobile engine thermostat is characterized in that one end of the casing is provided with an auxiliary water outlet, the other end of the casing, which is opposite to the auxiliary water outlet, is provided with a piston valve capable of moving in the casing, the top of the casing is provided with a small circulation water outlet and a large circulation water outlet sequentially along a movement direction of the piston valve, a valve block of the piston valve is provided with an axial through hole, and the piston valve is connected with an end drive structure of the casing. The automobile engine thermostat is simple in structure and multifunctional, the parts of the automobile engine thermostat can all be machined by common machining methods, machining technical requirements and cost are low, thermoregulation process is achieved by a motor, and precision control can be guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

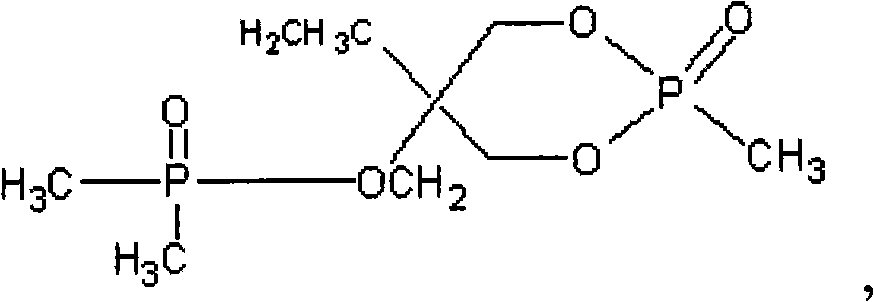

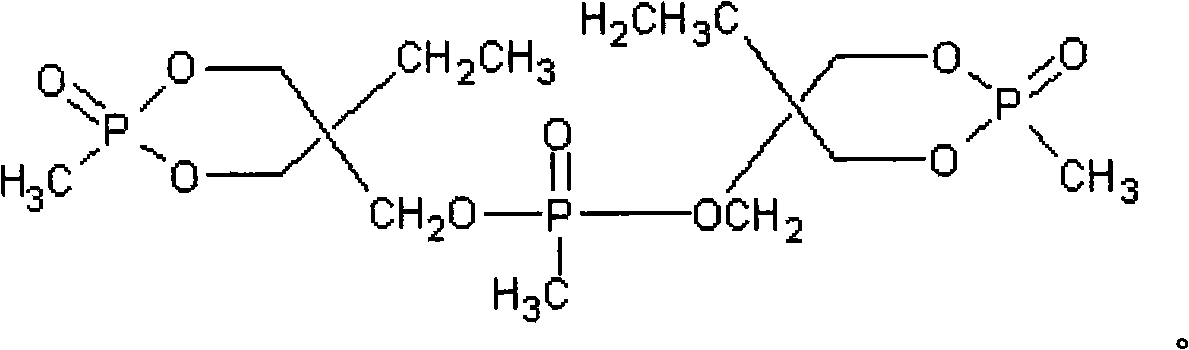

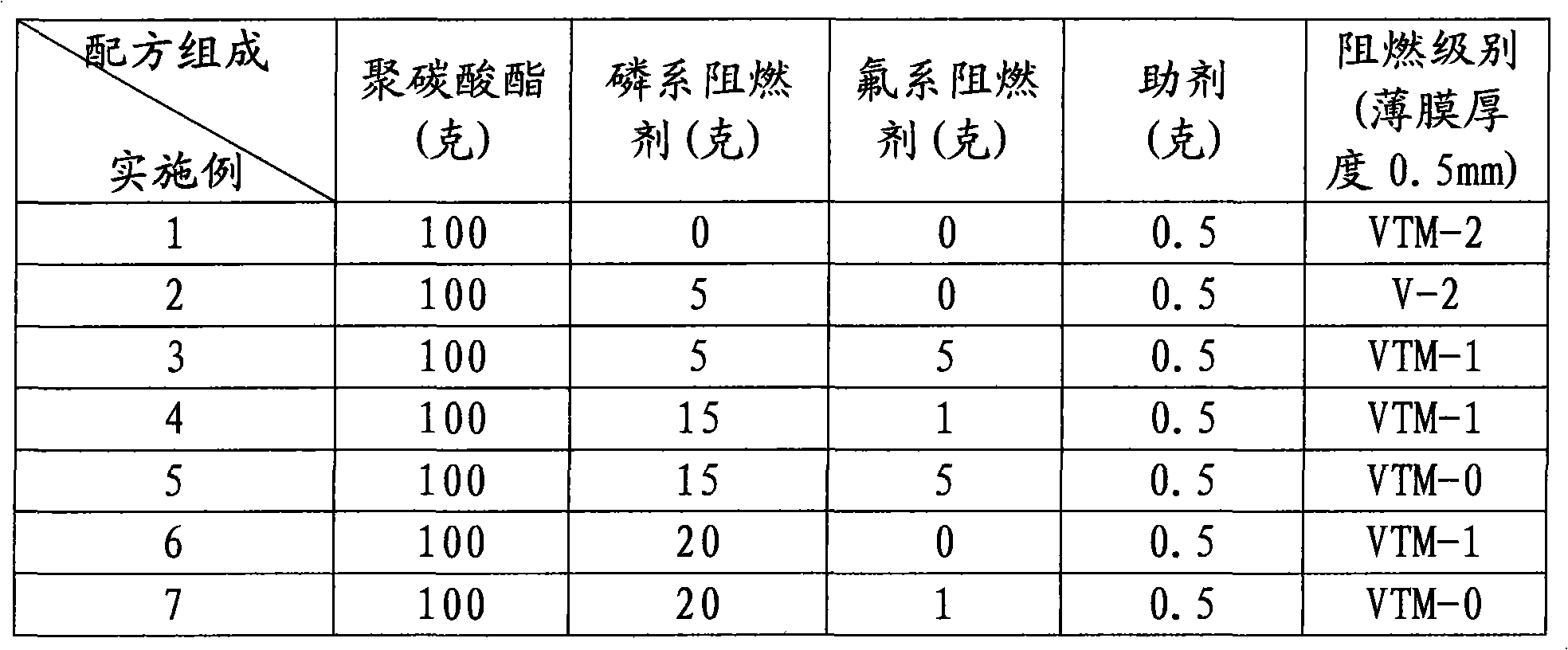

High-efficiency phosphorus flame retardant panlite, preparation method and film thereof

The invention relates to high-efficiency phosphorus flame retardant panlite, a preparation method and a film thereof. The panlite comprises the following components: makrolon, a phosphorus flame retardant, a fluorine flame retardant and an auxiliary agent, wherein the content of the phosphorus flame retardant accounts for 5-30 percent of the weight of the makrolon, the content of the fluorine flame retardan accounts for 0.1-10 percent of the weight of the makrolon, and the content of the auxiliary agent accounts for 0.1-10 percent of the weight of the makrolon. The film prepared from the high-efficiency phosphorus flame retardant panlite has good flame retardance and good shock resistance and also reduces the toxicity compared with an ordinary halogen flame retardant makrolon material whenexposed at high temperature; meanwhile, an addition agent containing chlorine or bromine is not used by the film. When the contents of the added phosphorus flame retardant and the fluorine flame retardant reach a certain quantity, the flame retardance of the film confirms to the standard of a UL94-VTM0 grade.

Owner:苏州奥美材料科技有限公司

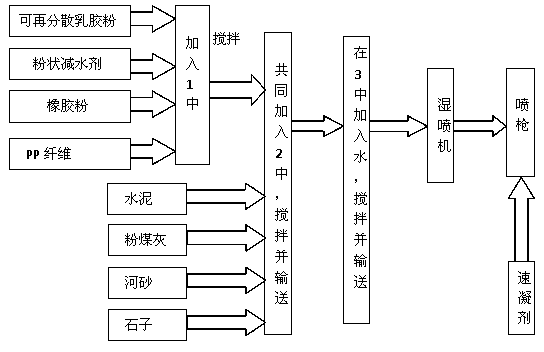

Ejection type ductile PP fiber strengthened cement base composite material and preparation method thereof

The invention relates to an ejection type ductile fiber strengthened cement base composite material and a preparation method thereof, and belongs to the technical field of construction material. The composite material formula comprises the following raw materials in parts by weight: 19 to 36 parts of cement, 1.9 to 5.7 parts of rubber powder, 11 to 40 parts of fly ash, 12 to 35 parts of river sand, 10 to 30 parts of stone, 7 to 18 parts of water, 1 to 2.2 parts of accelerator, 0.1 to 0.8 part of powder water reducer, 1 to 1.8 parts of redispersible latex powder, and 0.8 to 2 parts of PP fiber. The ejection type ductile PP fiber strengthened cement base composite material is prepared through following steps: primary stirring, secondary stirring, and final set. The invention provides a fiber strengthened cement base composited material, which has the advantages of low cost, simple processing, low requirements on processing technology and operation environment, and stable mechanical properties, and a preparation method thereof.

Owner:JIANGNAN UNIV

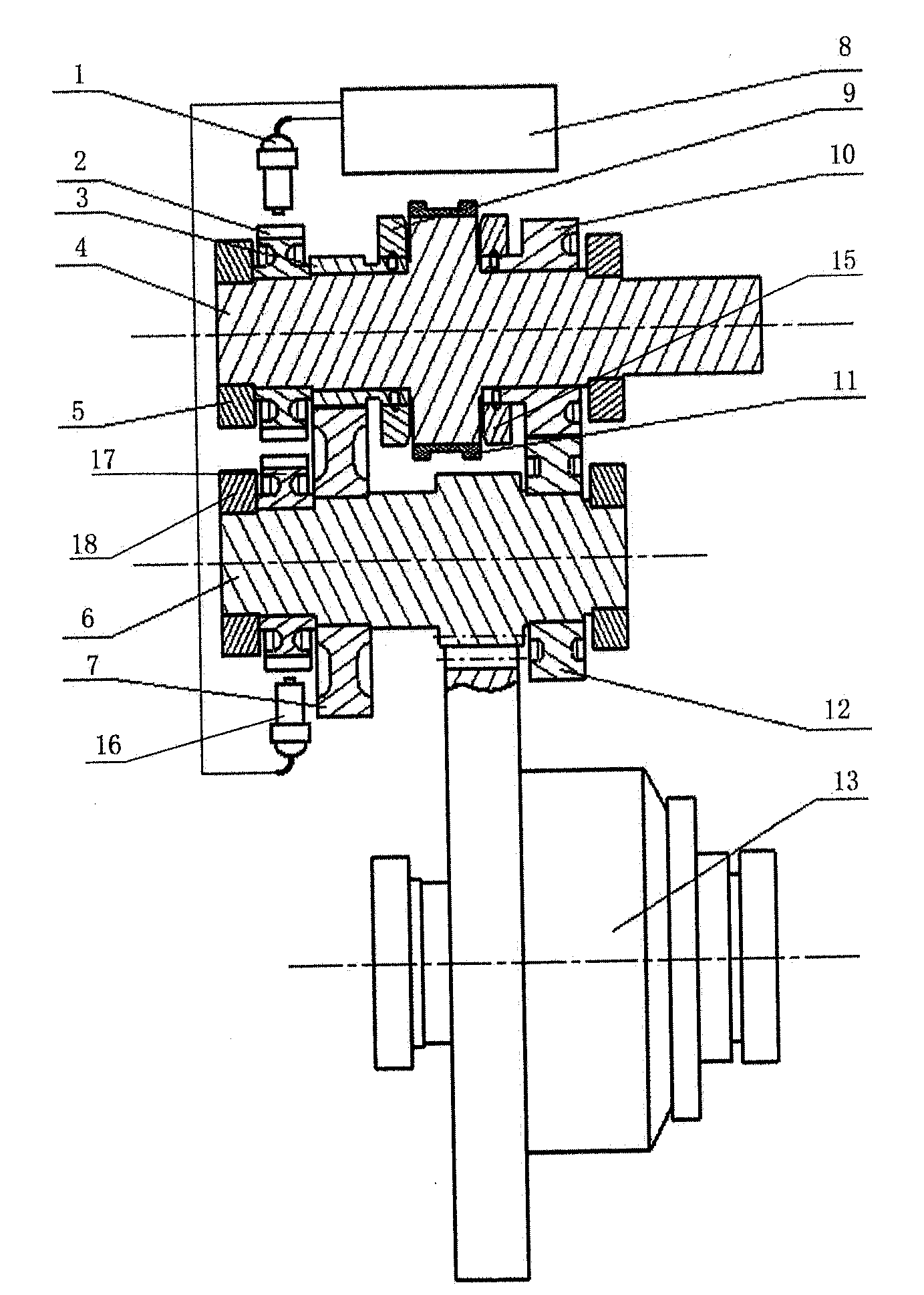

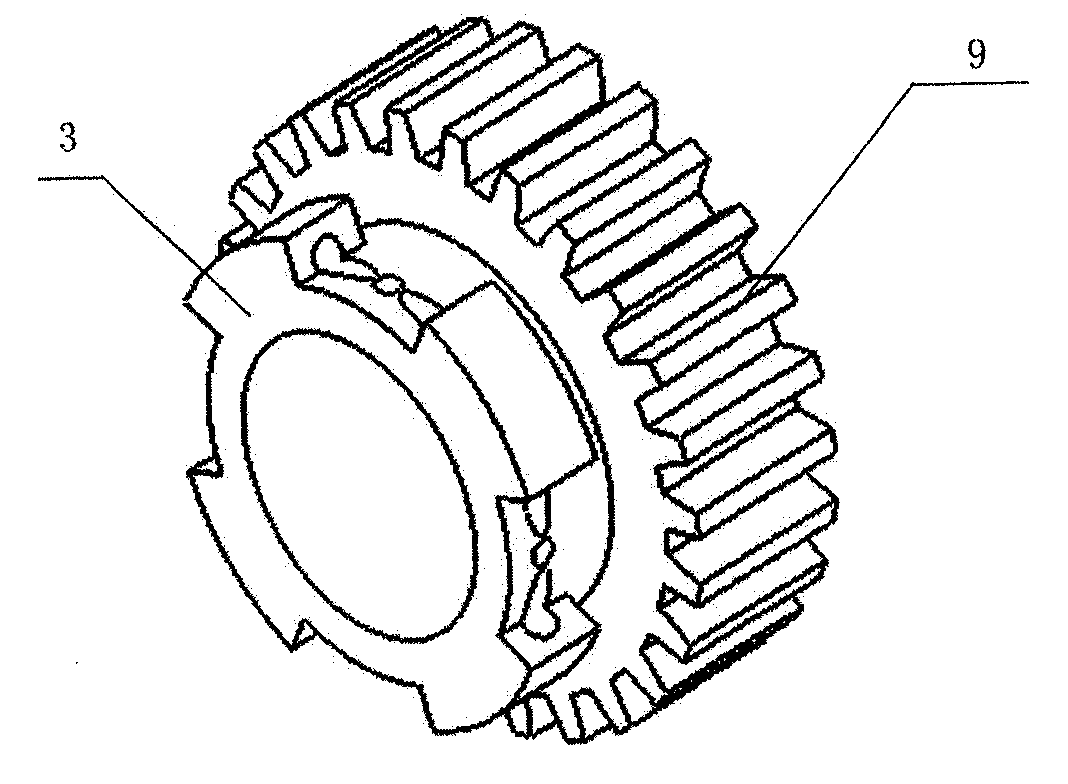

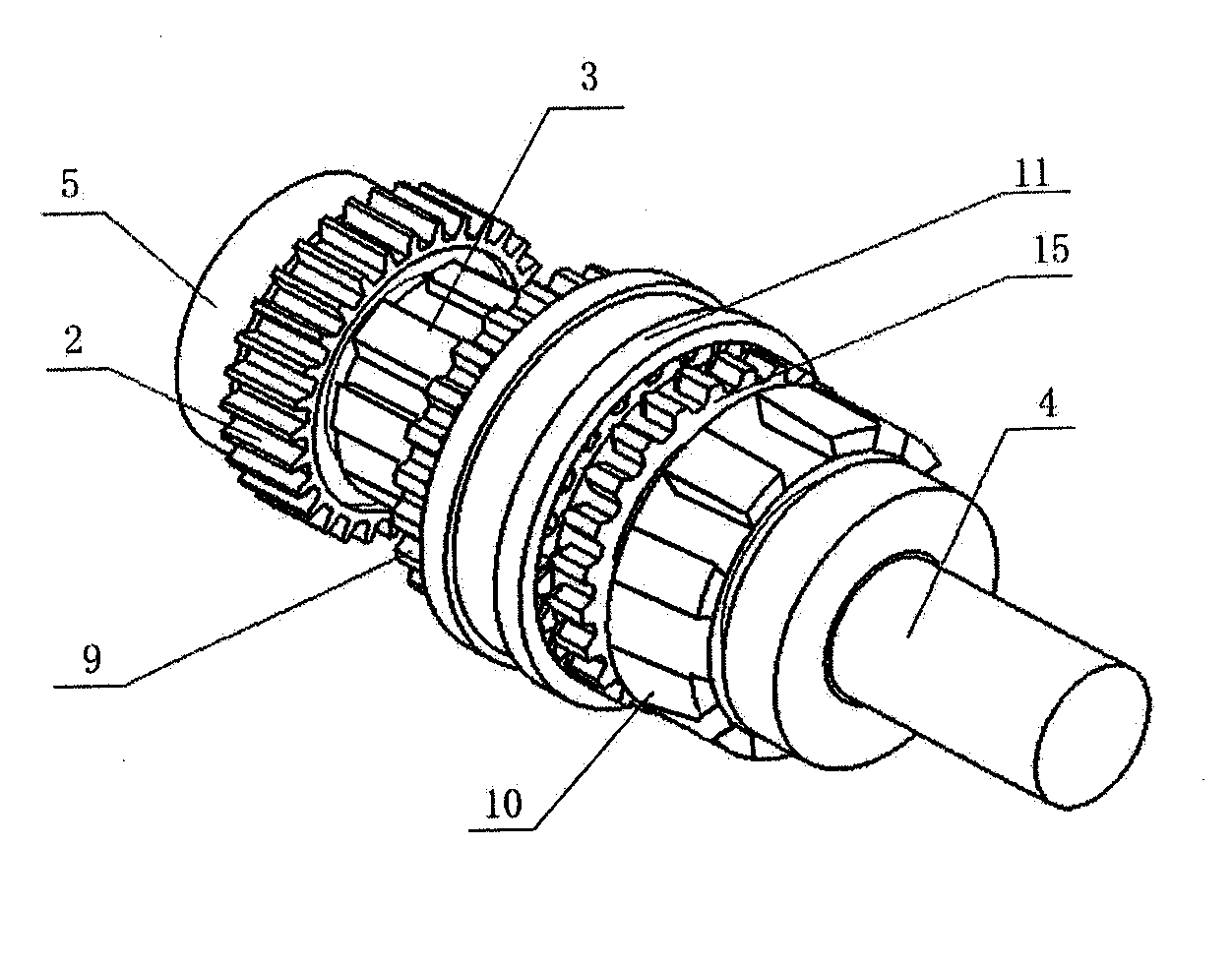

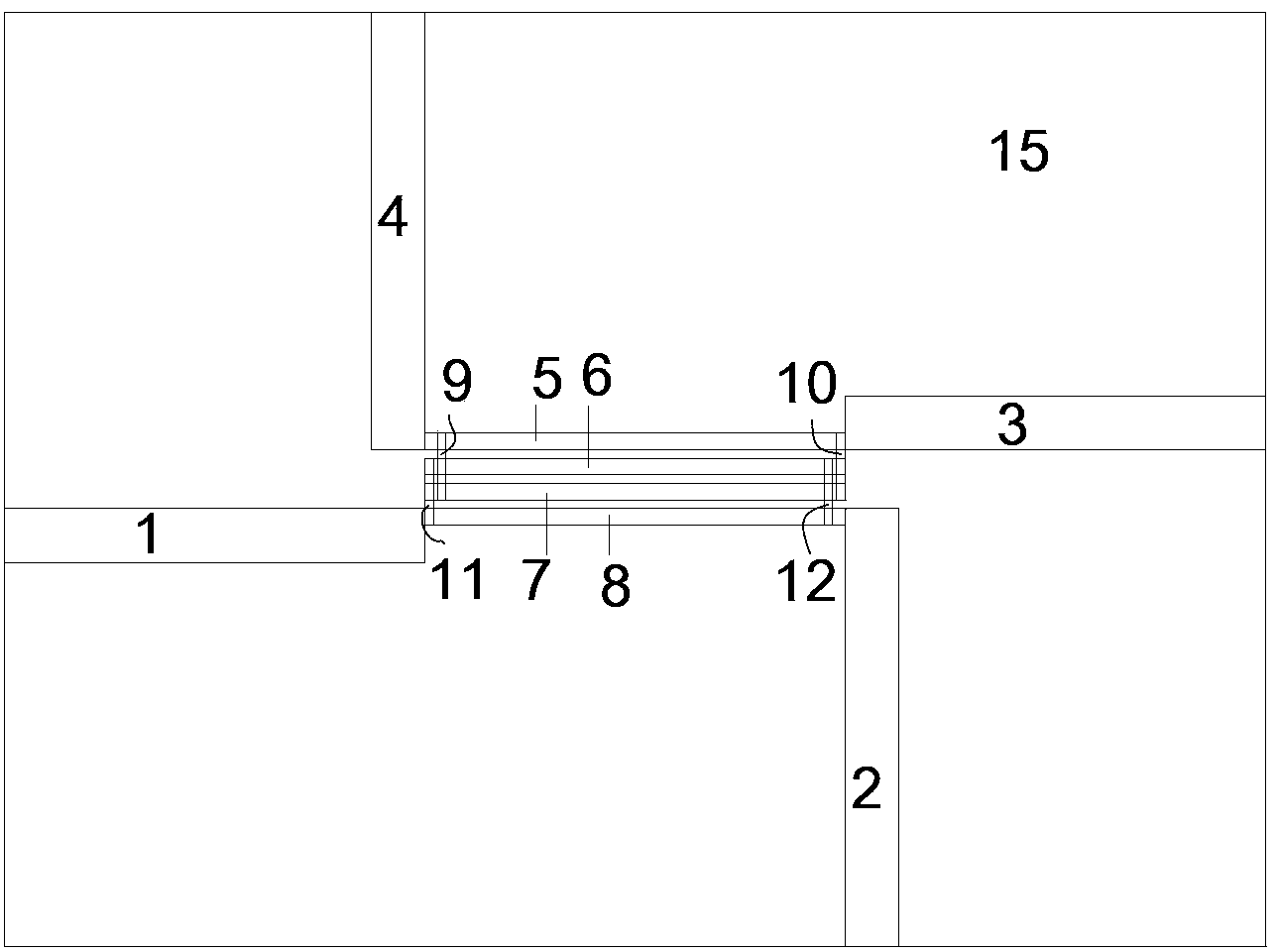

Two-stage automatic gear shift transmission device

InactiveCN101782132AExtended service lifeEasy accessToothed gearingsGearing controlDrive wheelDrive shaft

The invention discloses a two-stage automatic gear shift transmission device. A driving wheel I (3) of a first gear transmission device is engaged with a driven wheel I (7) of the first gear transmission device, and a driving wheel II (10) of a second gear transmission device is engaged with a driven wheel II (12) of the second gear transmission device. The driving wheel I (3) and the driving wheel II (10) are connected with a driving shaft (4) in a sliding way. The driving wheel I (3) and the driving wheel II (10) rotate in circumferential direction along the driving shaft (4). The driven wheel I (7) and the driven wheel II (12) are fixed on a driven shaft (6) and rotate synchronously with the driven shaft (6). The driven shaft (6) is connected with a differential (13) in a gearing way. A gear shift synchronizer is arranged between the driving wheel I (3) and the driving wheel II (10). A gear shift control device is connected to the gear shift synchronizer. The invention can optimally match with electric power output characteristics, reduce the intermediate loss and improve the driving comfort.

Owner:TAIZHOU KEMEIDA AUTO TECH DEV

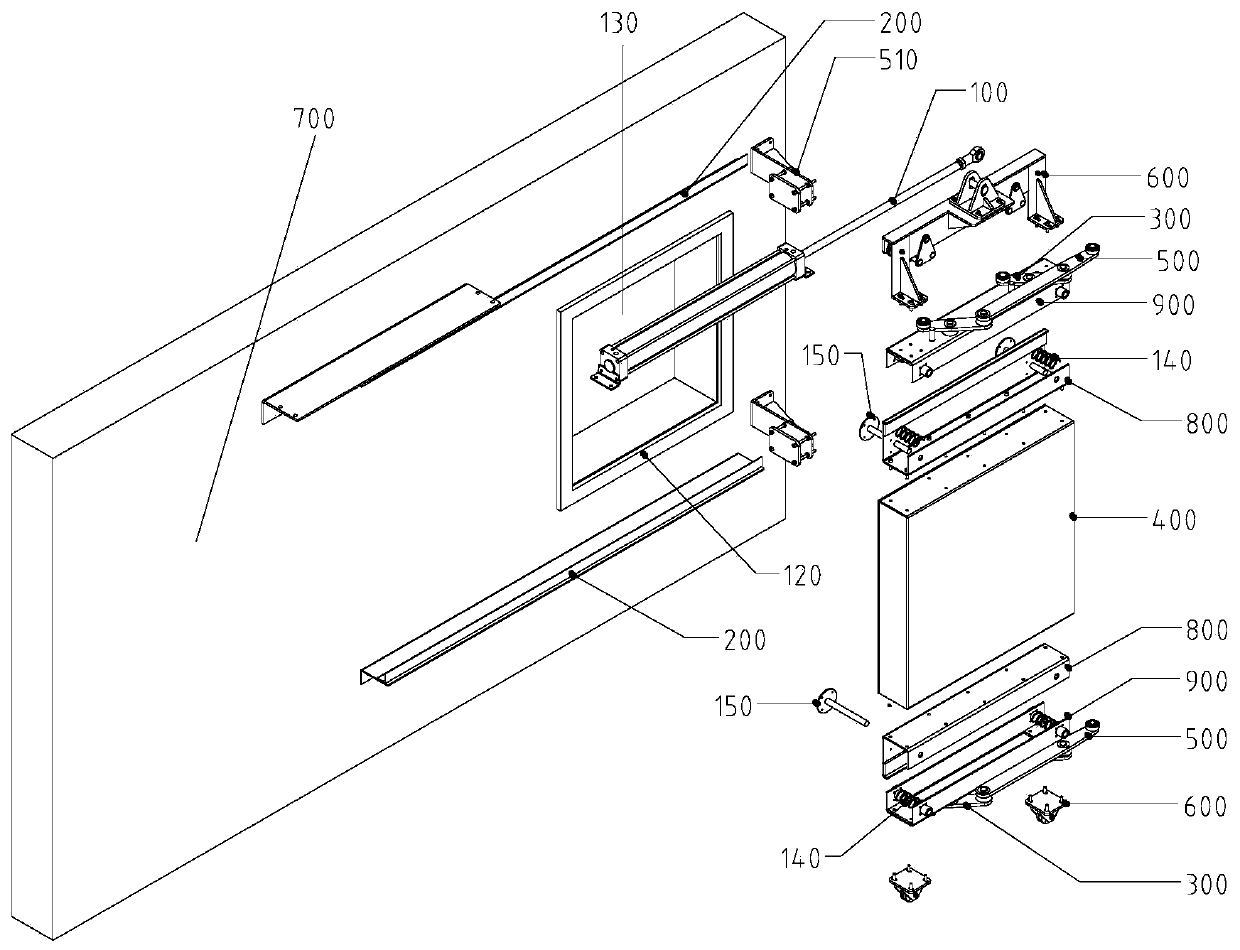

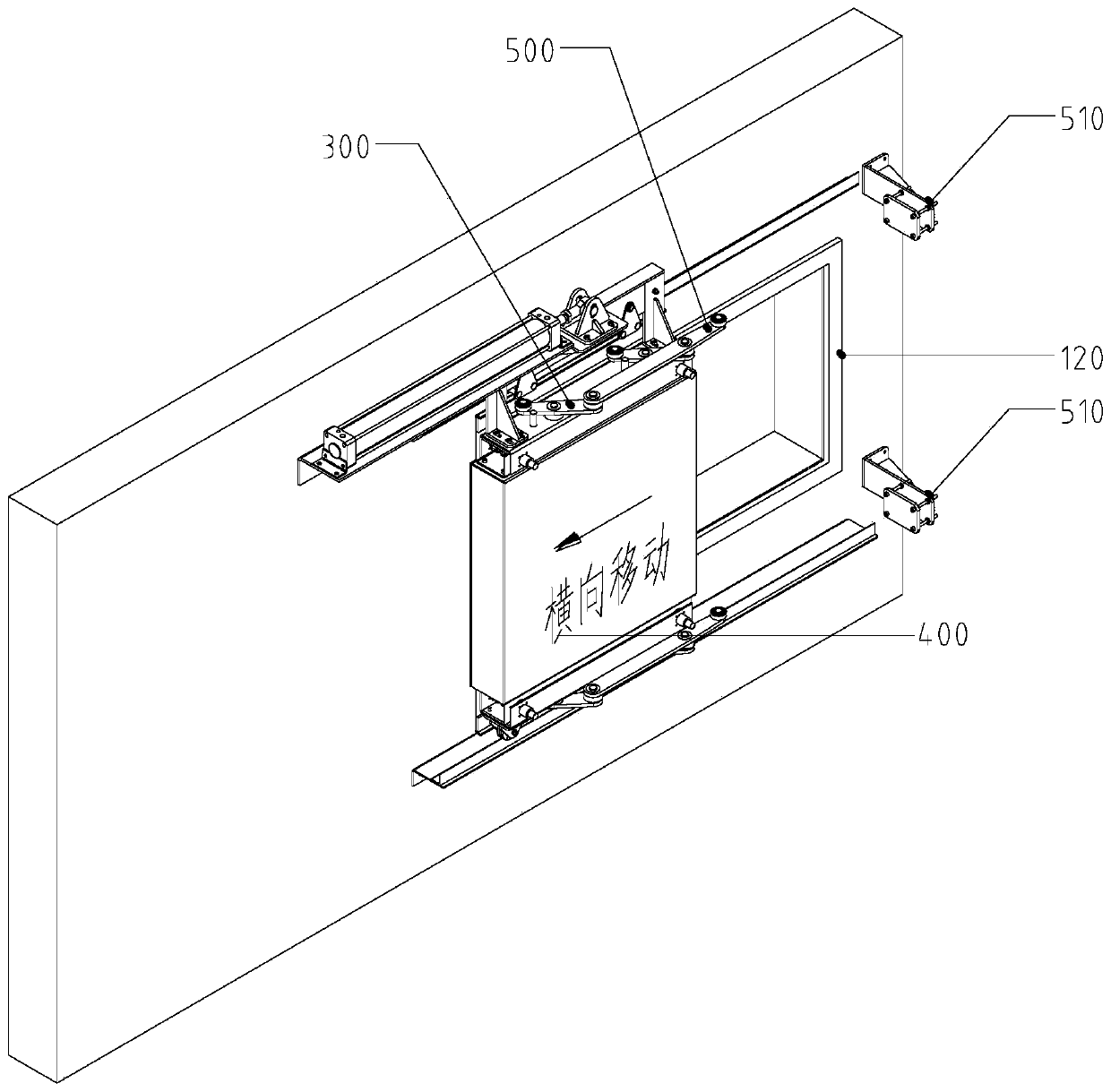

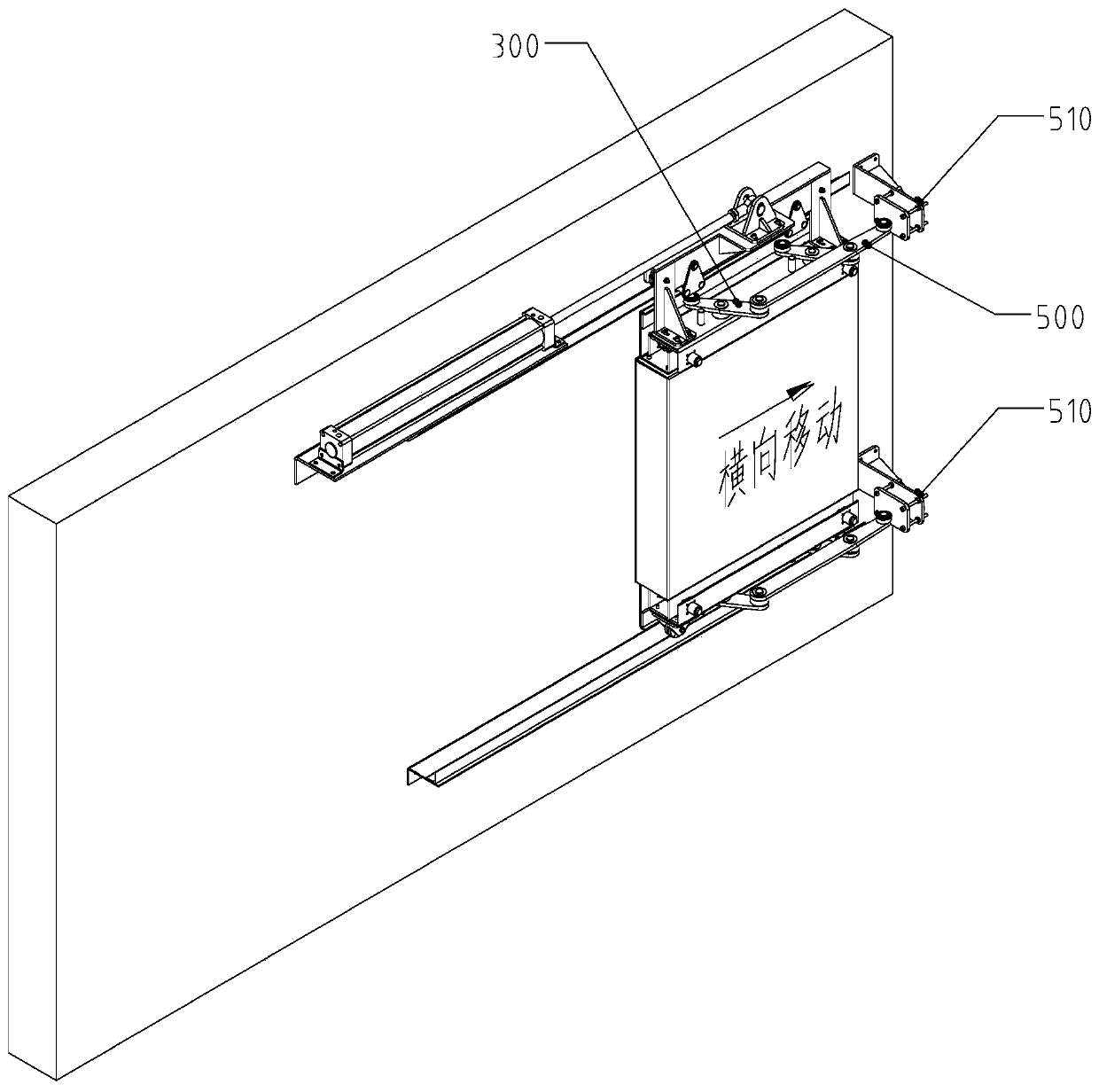

Mechanical press-bar type translation door sealing structure

PendingCN110067481AAchieve sealingAvoid the problem of degraded noise canceling effectNoise insulation doors/windowsPower-operated mechanismElastic componentReciprocating motion

The invention discloses a mechanical press-bar type translation door sealing structure. The mechanical press-bar type translation door sealing structure includes a door plate, two connecting rod assemblies, two guide rails, two limiting blocks and a plurality of sets of elastic assemblies, wherein sliding groove assemblies are horizontally mounted at the top and bottom of the door plate, each connecting rod assembly is rotatably arranged on one sliding groove assembly, and a guide wheel assembly is horizontally mounted on each connecting rod assembly; the two guide rails are horizontally mounted on a wall body, and the two guide rails is fitted with the two guide wheel assemblies respectively in a sliding mode; each limiting block is provided with a sliding groove assembly correspondinglyand arranged at the tail end of each guide rail; and each set of elastic assembly is embedded in one sliding groove assembly, after elastic deformation of the elastic component due to driving, the sliding groove assemblies is generated longitudinal reciprocating motion through elastic force, when a door is opened, the elastic assemblies are in extend states, when the door is closed, the elastic assemblies are in compressed states, the problem that the noise reduction effect is decreased due to frequent movement of the translation door is avoided, and the noise reduction effect, sealing and durability of the translation door are improved.

Owner:中山三和五金声控有限公司

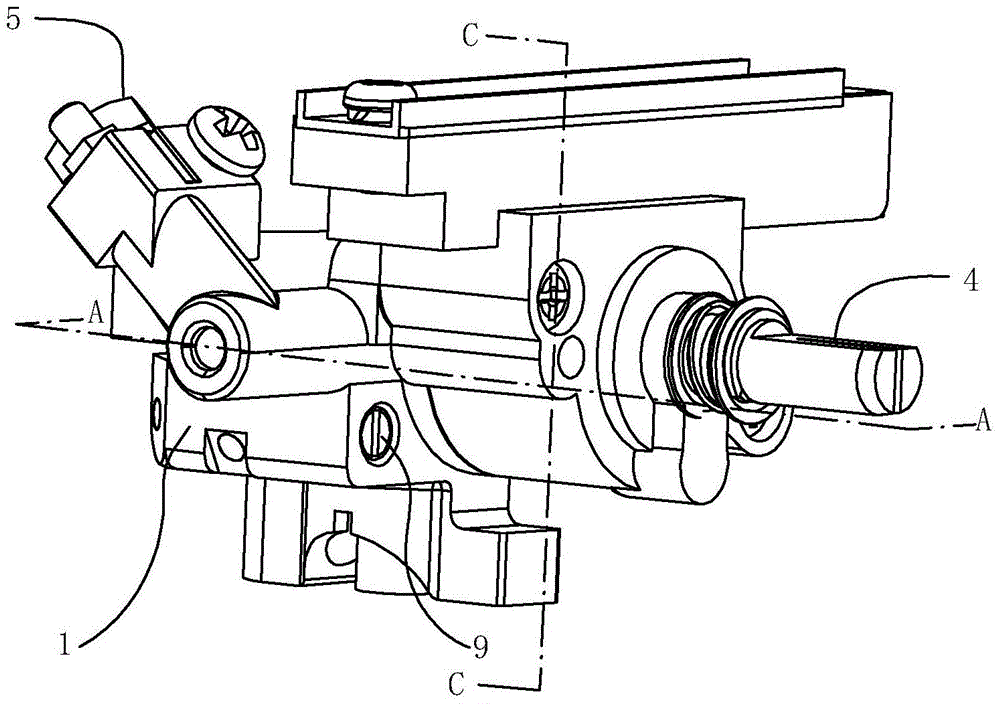

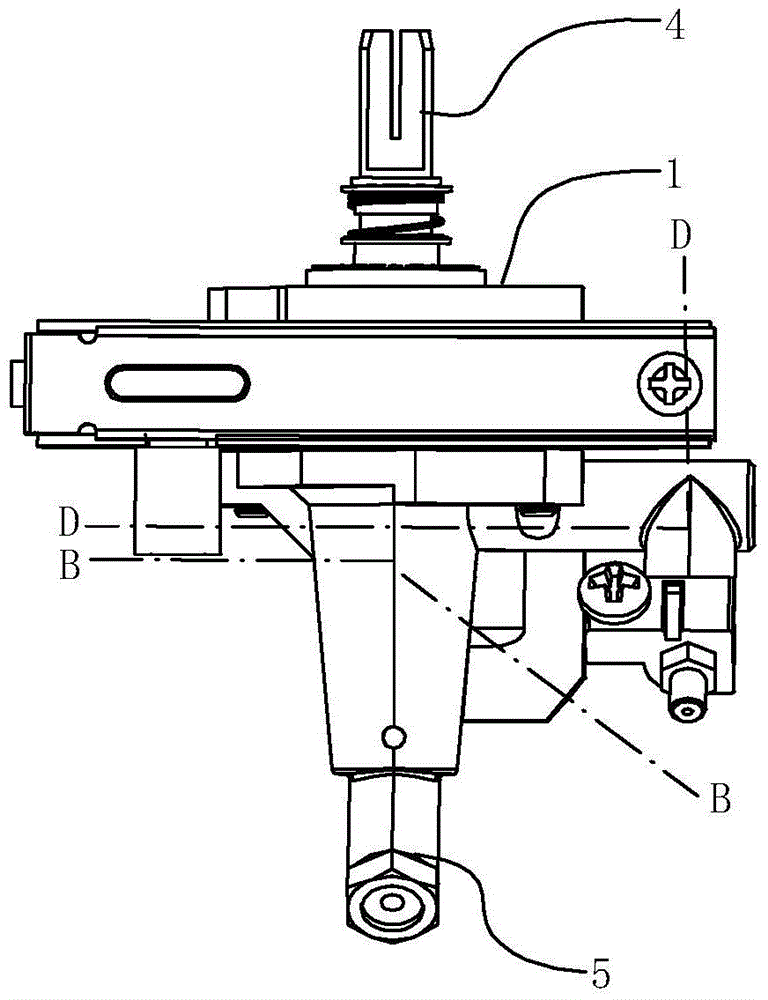

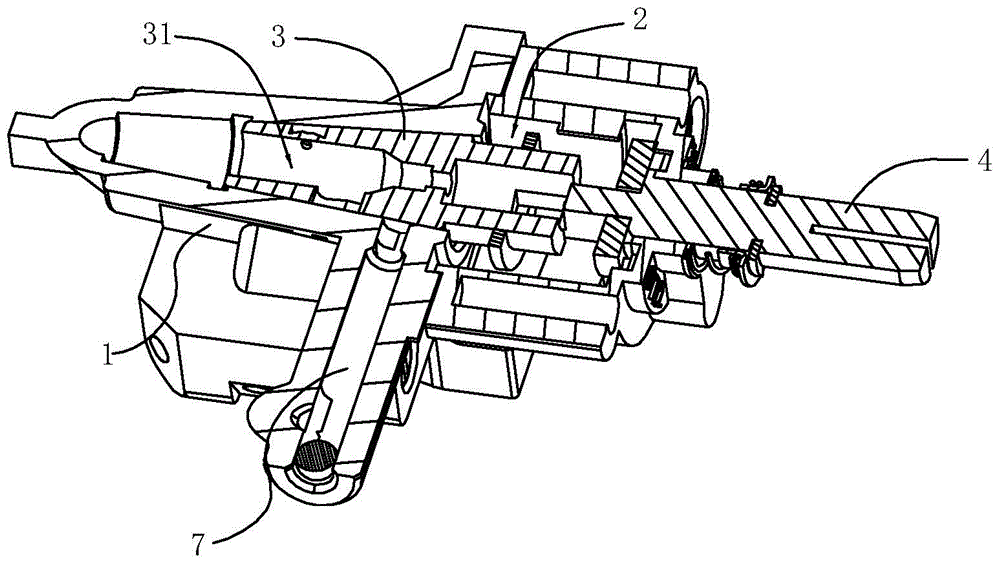

Fuel gas valve

ActiveCN104791509ALow processing technology requirementsEasy to processFuel supply regulationPlug valvesEngineeringMechanical engineering

The invention provides a fuel gas valve comprising a valve body, a valve element and an auxiliary gas intake channel. A gas cavity is formed in the valve element. The side wall, matched with a gas intake channel of the valve body, of the valve element is provided with gas intake holes. The gas intake holes are communicated with the gas cavity in the valve element. The auxiliary intake channel is arranged in the valve body. One end of the auxiliary gas intake channel is communicated with the gas intake channel. The other end of the auxiliary gas intake channel is communicated with the cavity of the valve body. The side wall of the valve element is provided with auxiliary gas intake holes matched with the auxiliary gas intake channel in position. The auxiliary gas intake holes are communicated with the gas cavity in the valve element. The auxiliary gas intake holes and the gas intake holes are staggered in the axial direction and the circumferential direction of the valve element. The fuel gas valve can adjust the flow of fuel gas in a pipeline, so that the fuel gas valve is suitable for different gas sources. The fuel gas valve is provided with the gas intake holes and the auxiliary intake holes separated from the gas intake holes, so that when the flow of the fuel gas is adjusted, the possibility of misoperation is reduced, and the flow of the fuel gas is more convenient and easier to adjust.

Owner:NINGBO CHAOYANG HOUSEHOLD GAS STOVES

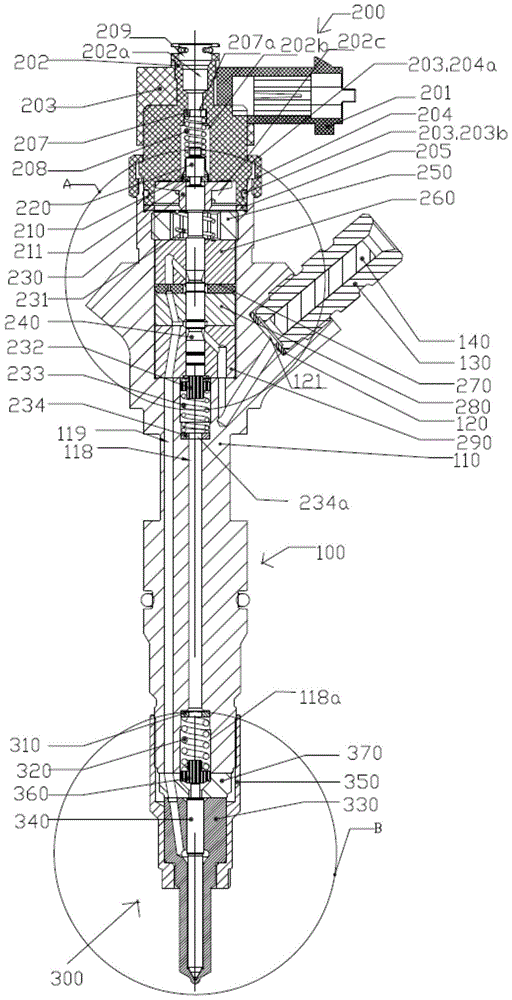

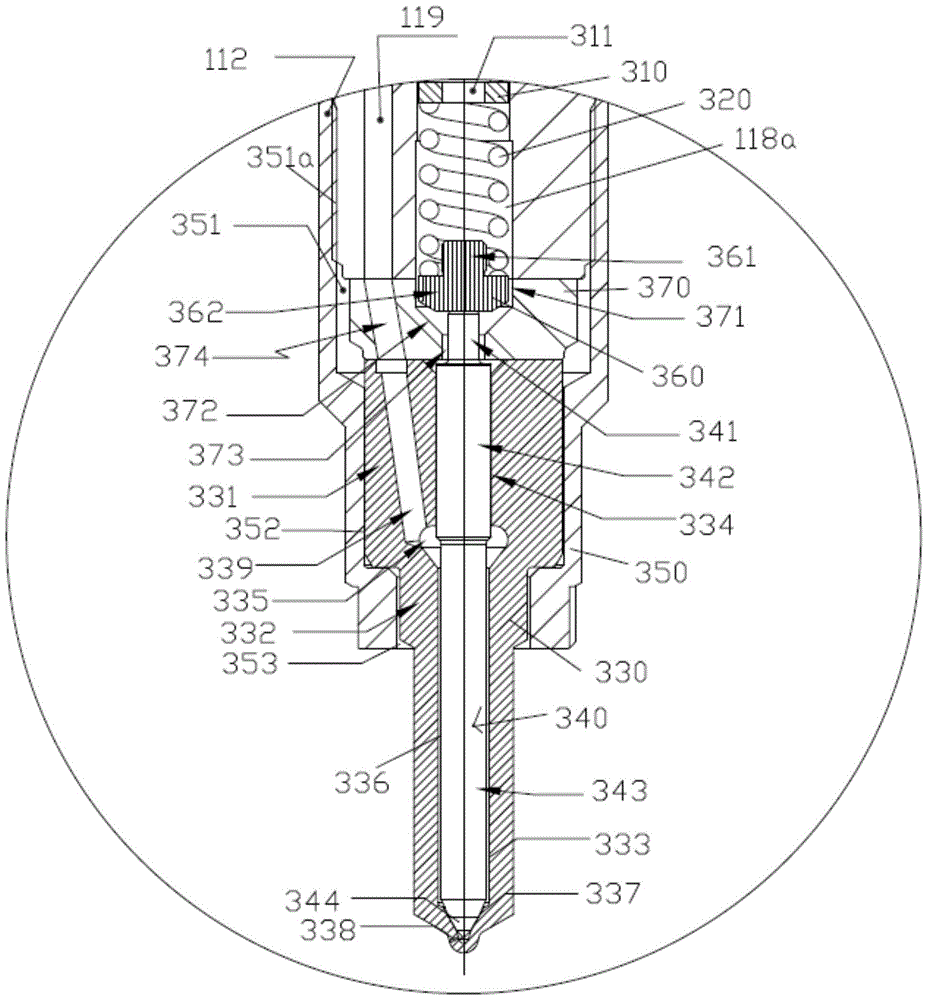

Novel common rail injector

ActiveCN105822475AReduce processing difficultyReduce processing costsFuel injection apparatusMachines/enginesEngineeringElectromagnetic valve

The invention discloses a novel common rail injector. The novel common rail injector comprises an injector part, an electromagnetic valve part and an injection nozzle part. The electromagnetic valve part and the injection nozzle part are installed at the upper end and the lower end of the injector part correspondingly. The mode combining the two-position three-way electromagnetic valve control part with the injection nozzle part with adjustable starting pressure is adopted, the structure is simple, and the injection initial point and injection amount can be flexibly controlled. A control valve element and an armature lever are of a fuel pressure self-balancing structure, the injection starting response speed can be remarkably increased, and the drive current of an electromagnet can be lowered, so that the service life of the electromagnet is effectively prolonged, and the reliability of the electromagnet is effectively improved. Return oil throttling holes are formed in an adjusting shim, return oil can be effectively controlled, and the return oil amount is reduced. Return oil grooves are formed between valve bodies, and the leakproofness can be remarkably improved. Pressure control chamber structures, oil outlet throttling hole control ball valves and control piston matching part pairs of traditional common rail injectors are omitted, the parts are easy to manufacture, the manufacturing difficulty is low, and the process cost is low.

Owner:NANYUE FUEL INJECTION SYST CO LTD

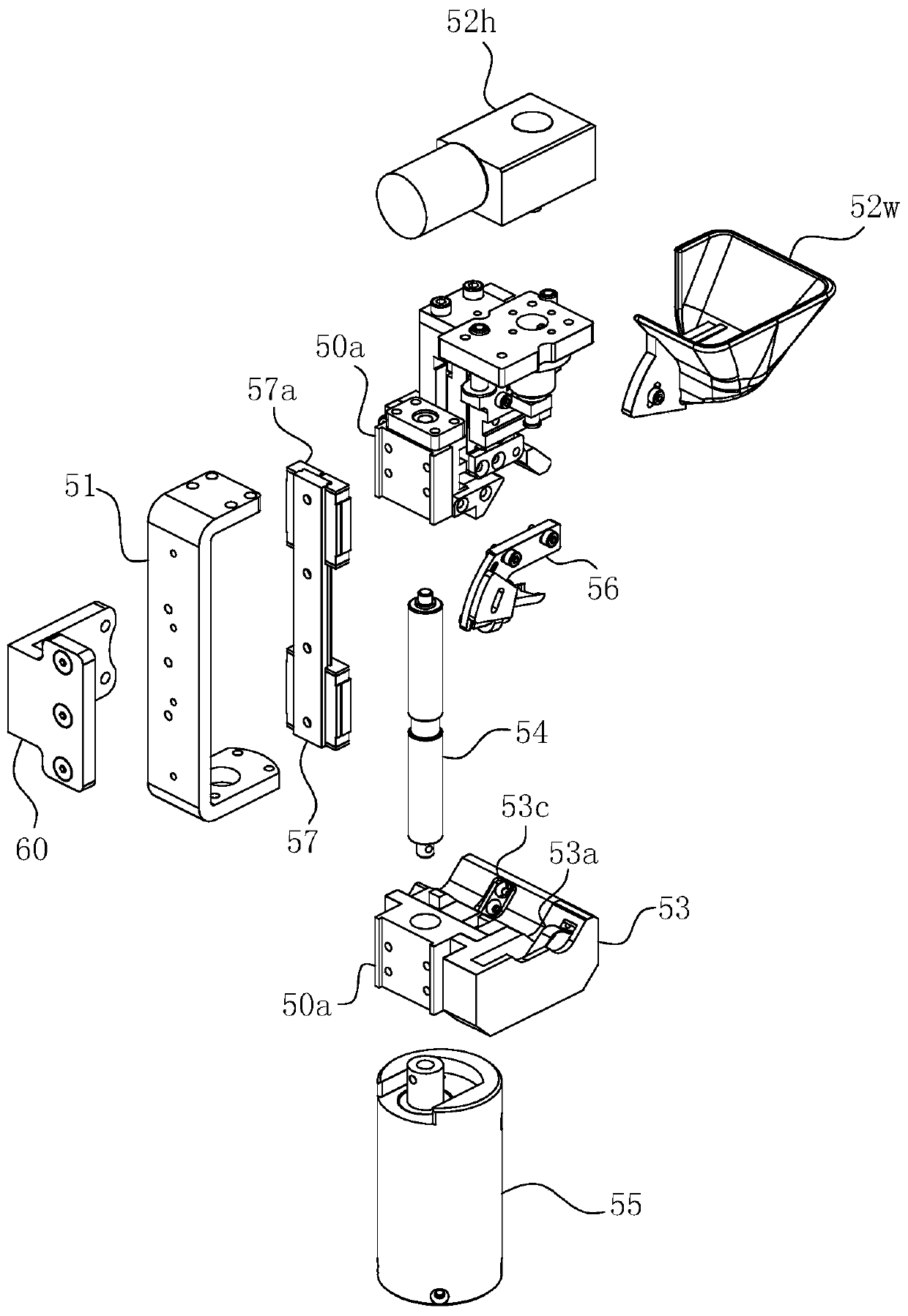

Automatic stripper

PendingCN110676767ALow rotational resistanceImprove convenienceApparatus for removing/armouring cablesElectric machineryEngineering

The invention belongs to the technical field of cable stripping, and particularly relates to an automatic stripper. The automatic stripper comprises a stripping clamp and a driving unit, wherein the stripping clamp comprises a rack, an upper clamp base and a lower clamp base; threaded holes are vertically formed in the upper clamp base and the lower clamp base in a penetrating mode, and vertical approaching and separating actions of the upper clamp base and the lower clamp base are achieved through rotating actions of two-way lead screws after the two-way lead screws are in threaded fit with threaded holes and opening and closing driving motors located at the ends of the two-way lead screws; the upper clamp base comprises a zero position reference sliding plate, a cutter depth adjusting sliding block, a pressing plate, a cutter depth adjusting threaded base, an elastic compression damping piece, a cutter depth adjusting bolt, a rotating sleeve, a cutter depth adjusting motor and a wirecore detection sensor. Thus, the purposes of self-adaptive adjustment of the feed amount of the cutter and adaptive opening adjustment of the stripping clamp can be flexibly realized, so that the stripping reliability and the stripping efficiency of the cable are greatly improved.

Owner:HEFEI CAS LANRUI TECH CO LTD +2

Supercharger engine hot end heat insulating shield assembly

ActiveCN103206289ASimple shape and structureEasy to installExhaust apparatusSilencing apparatusEngineeringMechanical engineering

The invention discloses a supercharger engine hot end heat insulating shield assembly which comprises an exhaust manifold heat insulating shield, a supercharger heat insulating shield and a three-way catalyst heat insulating shield. Both the supercharger heat insulating shield and the three-way catalyst heat insulating shield are in a layered structure, upper layers and lower layers of the two are hot-dipping aluminum plates, and middle layers of the two are ceramic fiber paper plates. The three-way catalyst heat insulating shield is formed by an upper three-way catalyst shield and a lower three-way catalyst shield, wherein the upper portion of the upper three-way catalyst shield is mounted on the left side of a supercharger, the lower portion of the lower three-way catalyst shield is mounted on the left side of a three-way catalyst, and the lower three-way catalyst shield is mounted on the right side of the three-way catalyst. The supercharger heat insulating shield is arranged above the three-way catalyst heat insulating shield, mounted on the right side of the supercharger and connected with the upper portion of the three-way catalyst shield via two mounting points. By the supercharger engine hot end heat insulating shield assembly, the supercharger and the three-way catalyst are integrally subjected to heat insulation, noise reduction and protection, strength can be guaranteed and modal requirements can be met, processing and manufacturing are enabled to be easy, and the mounting is enabled to be convenient.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

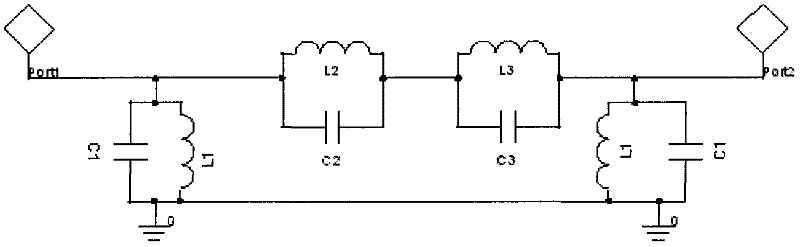

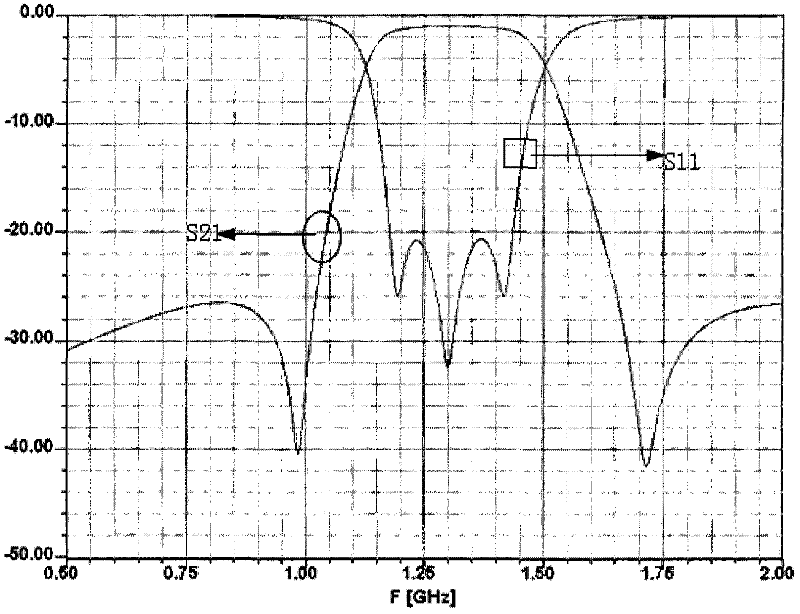

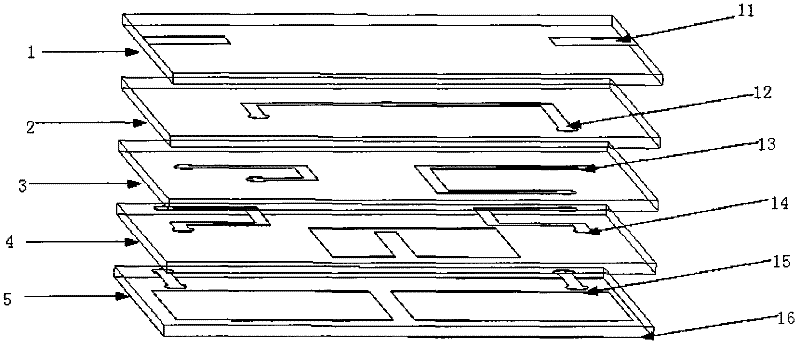

L frequency band LTCC band pass filter

ActiveCN102394325ACompact structureReduce parameter sensitivityMultiple-port networksWaveguide type devicesBand-pass filterInductor

An L frequency band LTCC band pass filter comprises five layers of medium substrates and six layers of metal layers. A bottom layer is a grounding metal layer. A top layer is an input output layer. Over-travel high impedance strip lines of the second and the third layers form an inductor L2 and an inductor L3 which are connected to the input output layer of the first layer through metal through holes of the third layer. Metal discs of a fourth layer and a fifth layer form a capacitor C2 and a capacitor C3. And the capacitor C2 and the capacitor C3 are connected to the inductors of the second and the third layers through the metal through holes of the second layer so as to form a series connection relation. The metal disc of the fifth layer and the grounding metal layer form a capacitor C1. Simultaneously, two stages of high impedance lines of the fourth and the fifth layers are connected with each other through the metal through holes so as to form an inductor L1 and are connected to ground so as to form a grounded inductor. By using the filter, parameter sensitivity of the filter can be reduced; a requirement to a processing technology can be reduced and a finished products rate can be effectively increased.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

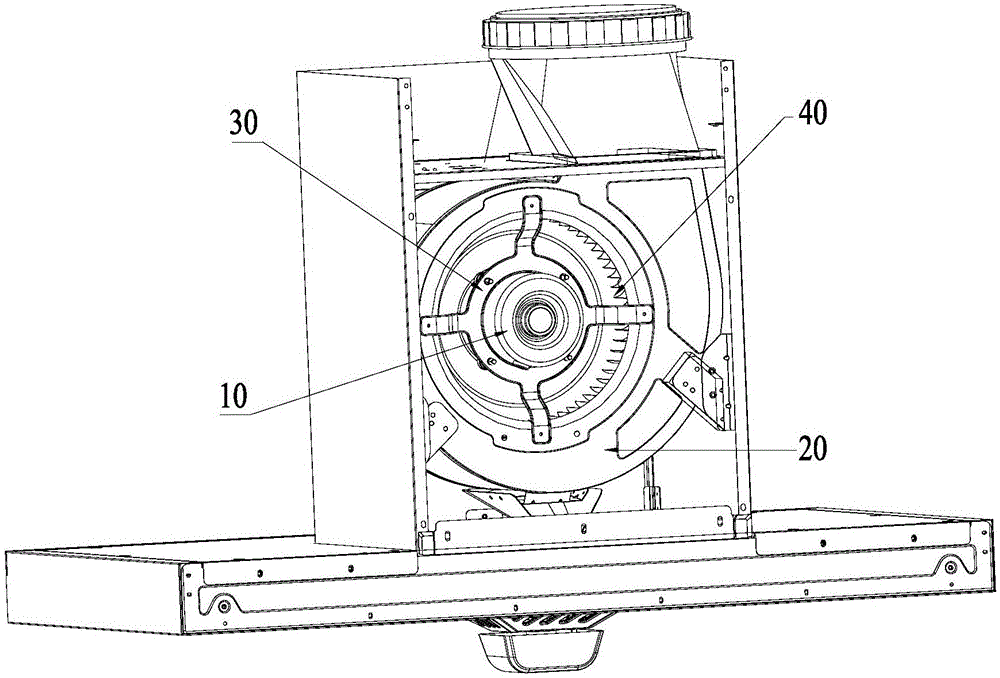

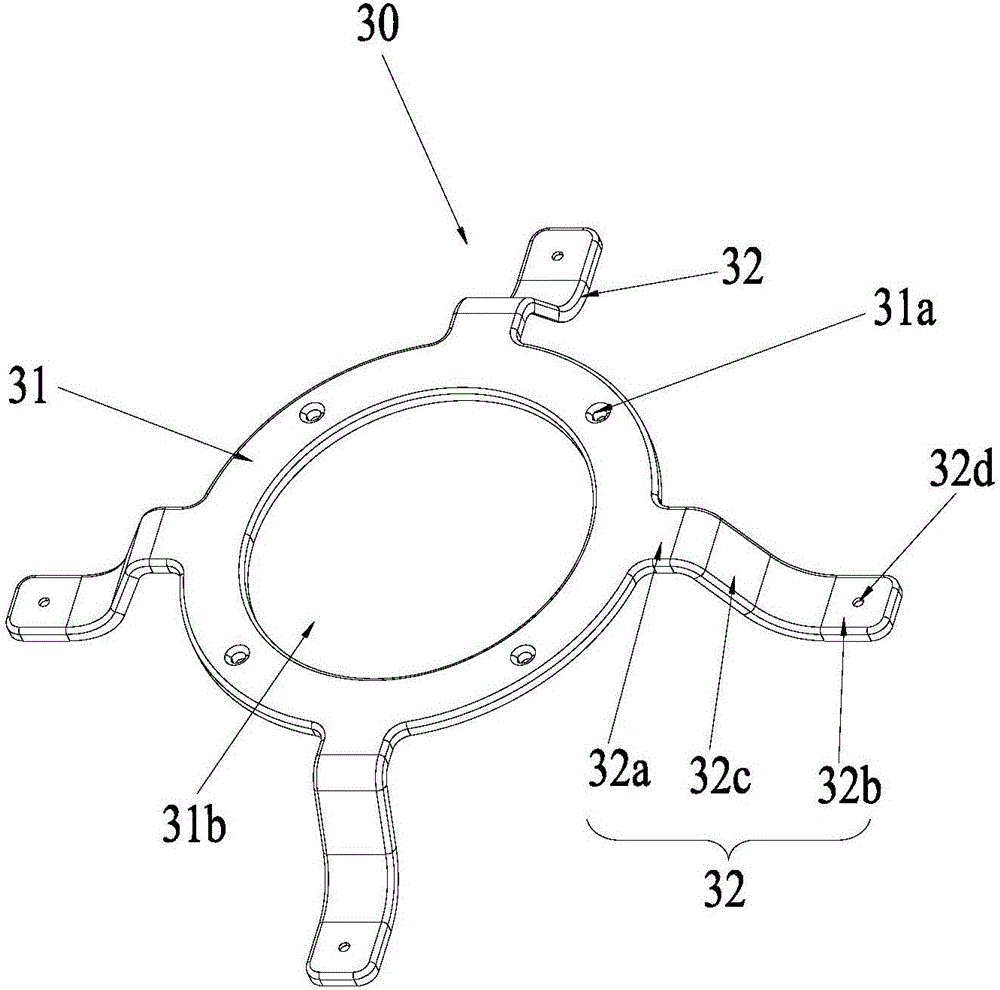

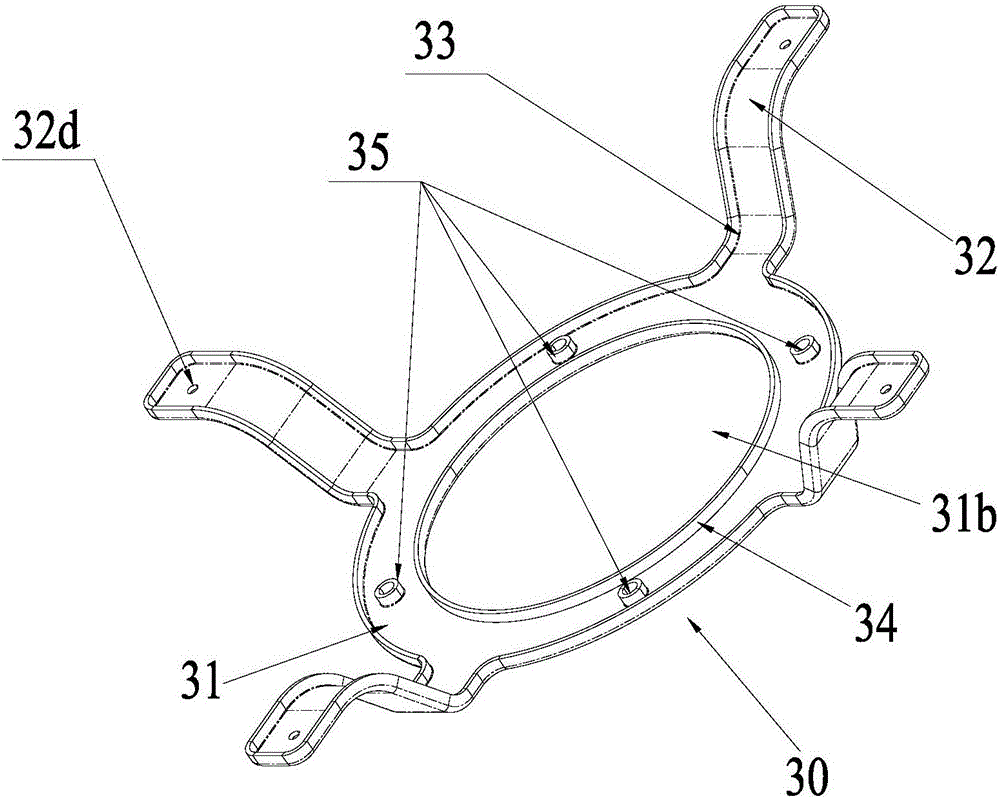

Mounting structure of range hood motor and range hood

InactiveCN106439971AAvoid deformationReduce eddy currentDomestic stoves or rangesLighting and heating apparatusImpellerControl theory

The invention relates to the field of range hoods, and discloses a mounting structure of a range hood motor and a range hood. The mounting structure of the range hood motor comprises the motor (10), a fan volute (20) and a motor bracket (30), wherein the motor is fixed to the motor bracket; the motor bracket comprises a mounting body (31) and a plurality of supporting feet (32) fixed to the fan volute; and the plurality of supporting feet integrally extend out of the mounting body and are uniformly distributed on the mounting body. According to the mounting structure of the range hood motor provided by the invention, the motor bracket is integrally formed, so that the structure is simple, the cost is relatively low, the requirement of the processing technology is low, and the assembly is simple during mass production; the integrally formed structure is adopted, so that the plurality of supporting feet are stressed at the same time and are not liable to deform, and vibration noise caused by nonuniform stress can be reduced; and besides, the supporting feet are uniformly distributed on the mounting body, so that vortex generated by airflow when entering an impeller from a back plate of the fan volute can be effectively reduced, and the flowing noise is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

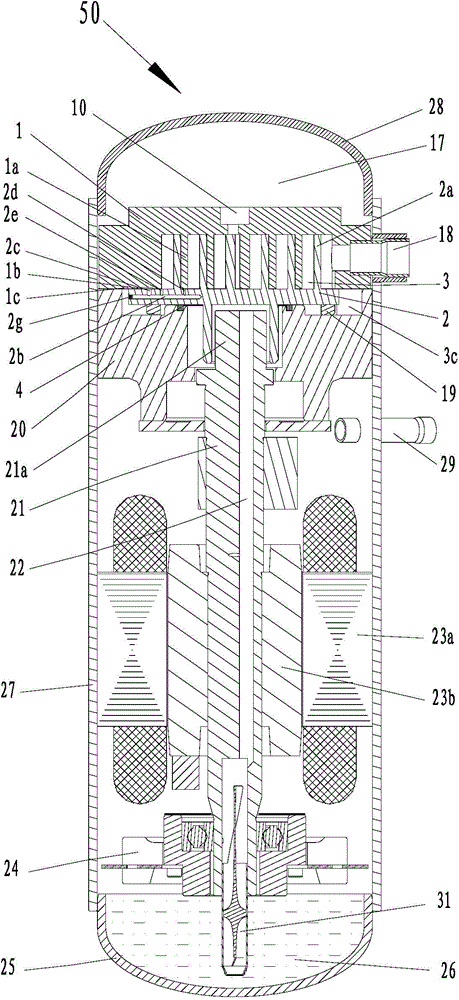

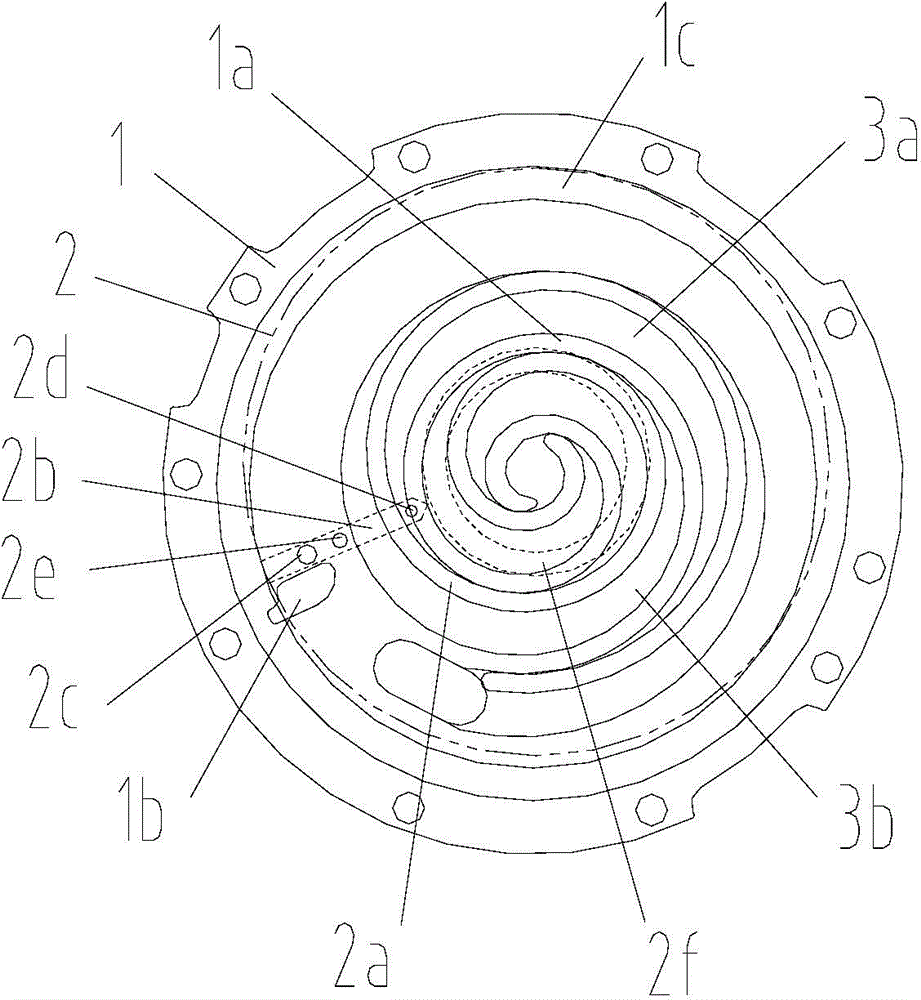

Scroll compressor and air conditioner

ActiveCN105822546AReduce performanceSimple structural designSealing arrangement for pumpsRotary piston pumpsNon symmetricEngineering

The invention provides a scroll compressor and an air conditioner. The profile structure of a static scroll is more than the 180-degree non-symmetric profile structure of an orbiting scroll; the orbiting scroll is provided with a back pressure chamber; scroll wraps of the static scroll and the orbiting scroll form an interior wiring side compression chamber and an external wiring side compression chamber, and a suction cavity is formed between the static scroll and the orbiting scroll; a first groove and a second groove communicated with the back-pressure chamber are formed in the static scroll; a medium-pressure pathway is arranged on the radial direction of the orbiting scroll, and a first communicating hole and a second communicating hole are formed in the axial direction of the orbiting scroll and are communicated with the medium-pressure pathway; the first communicating hole is used for intermittently communicating the first groove, and the second communicating hole is used for intermittently communicating the internal wiring side compression chamber; the back-pressure chamber is intermittently communicated with the internal wiring side compression chamber and the external wiring side compression chamber, or the oil supply system of the compressor is intermittently communicated with a suction cavity; and the internal wiring side compression chamber and the external wiring side compression chamber are never communicated with each other, so that sufficient oil supply can be guaranteed under different working conditions.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

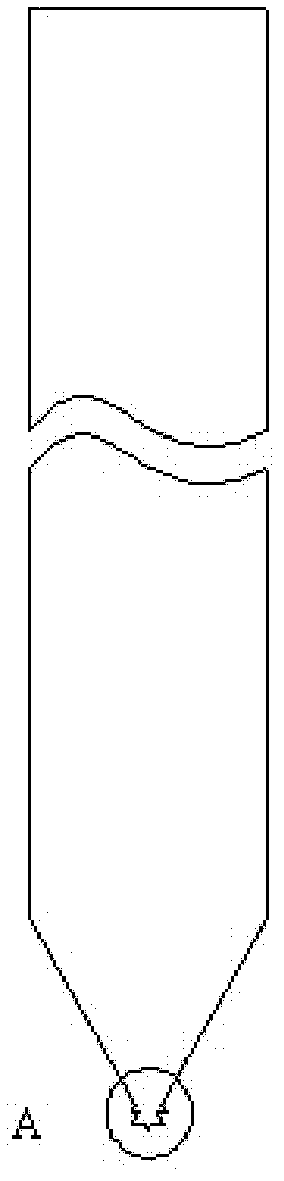

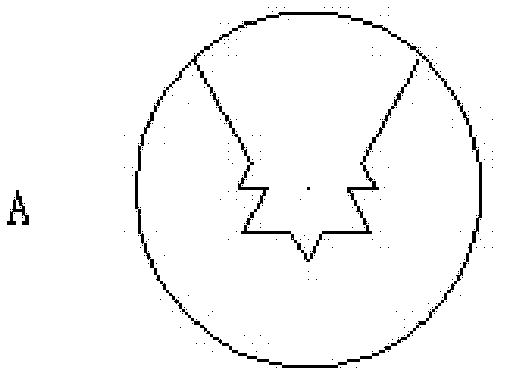

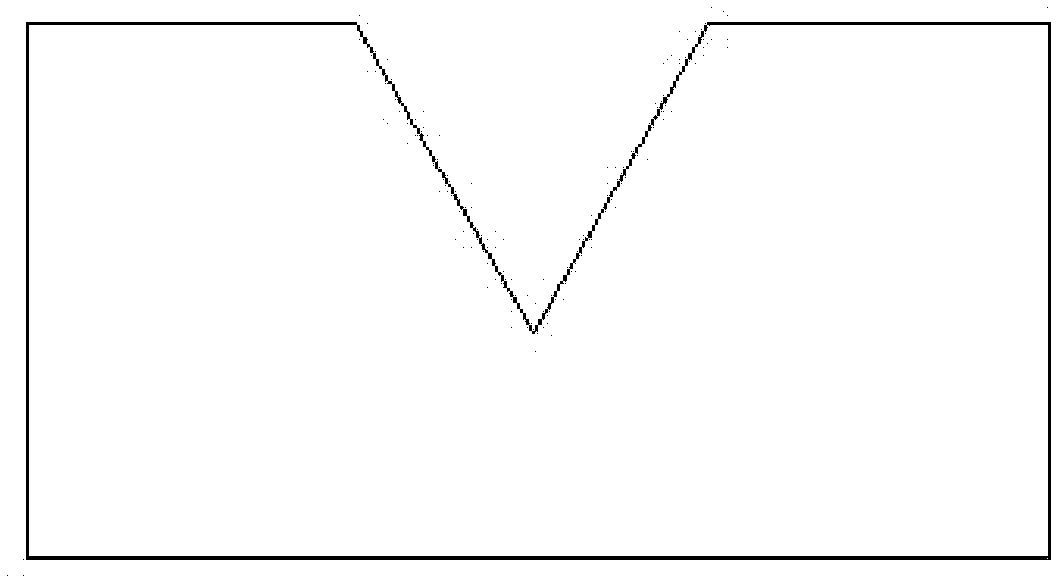

Microchannel heat exchange plate with V-shaped fractal structures and preparation method of microchannel heat exchange plate

ActiveCN102519292AIncrease the number of vaporization coresEnhanced vaporization processLaminated elementsBoiling processPlough

The invention discloses a microchannel heat exchange plate with V-shaped fractal structures and a preparation method of the microchannel heat exchange plate. A microchannel is processed on a single surface of a heat exchange plate, three stages of V-shaped fractal structures are arranged on the microchannel, and two second-stage V-shaped microchannels are respectively uniformly distributed on two side walls of a first-stage V-shaped microchannel. Two third-stage V-shaped microchannels are respectively uniformly distributed on two side walls of each second-stage V-shaped microchannel. A plate to be processed is flattened by a planer tool, and then is subject to plough cutting by the aid of a multistage composite fractal plough cutter, by the aid of movement of a planer worktable and a toolrest, and the pitches and the depths of the fractal microchannels are controlled, so that the microchannel with the V-shaped fractal structures is formed. The heat exchange plate has large specific surface area, nucleus of boiling can be greatly increased, vaporization in an evaporation boiling process is realized advantageously, so that the heat exchange plate has excellent boiling strengthening heat exchange ability, processing efficiency is greatly enhanced, processing technology is simple, and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

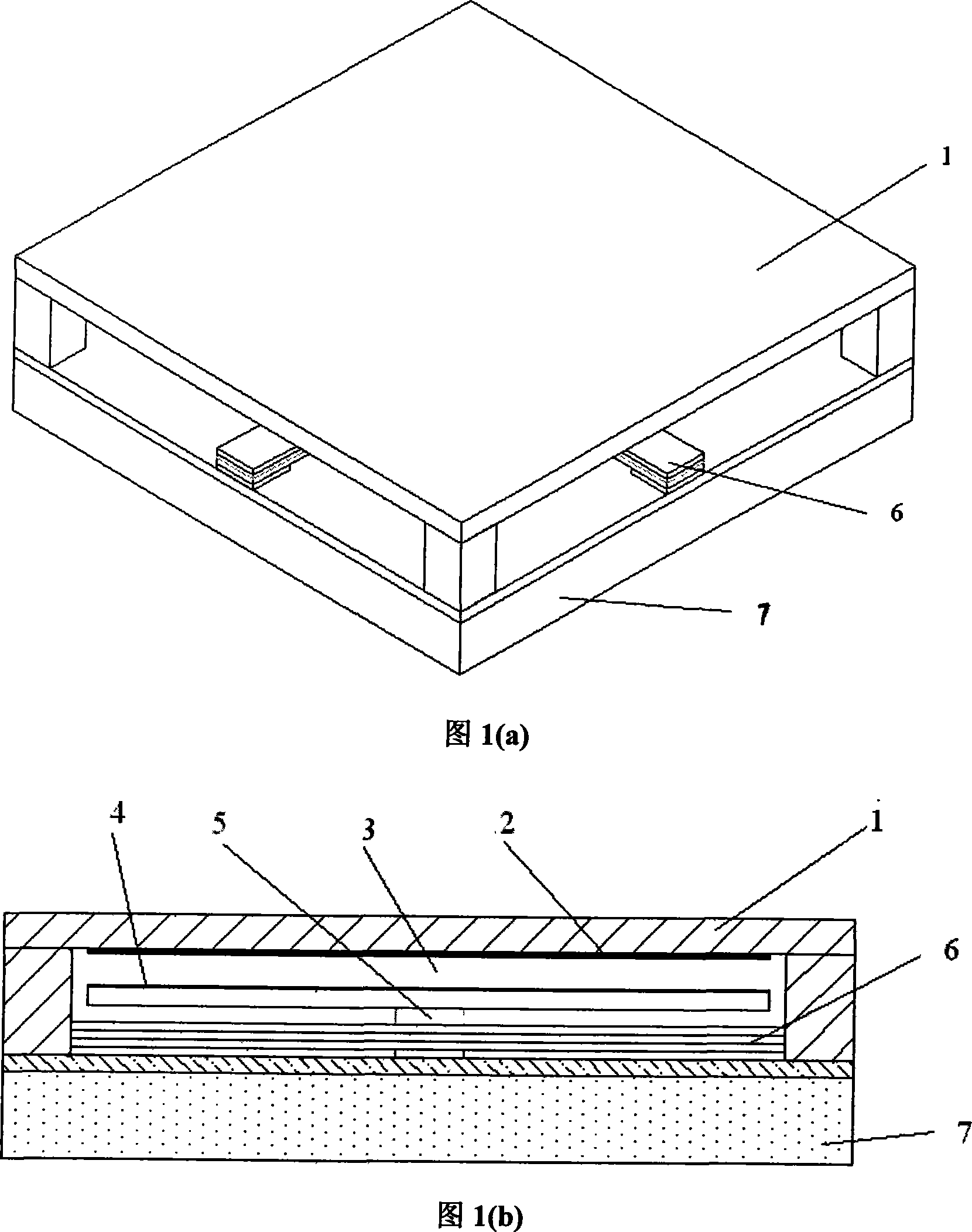

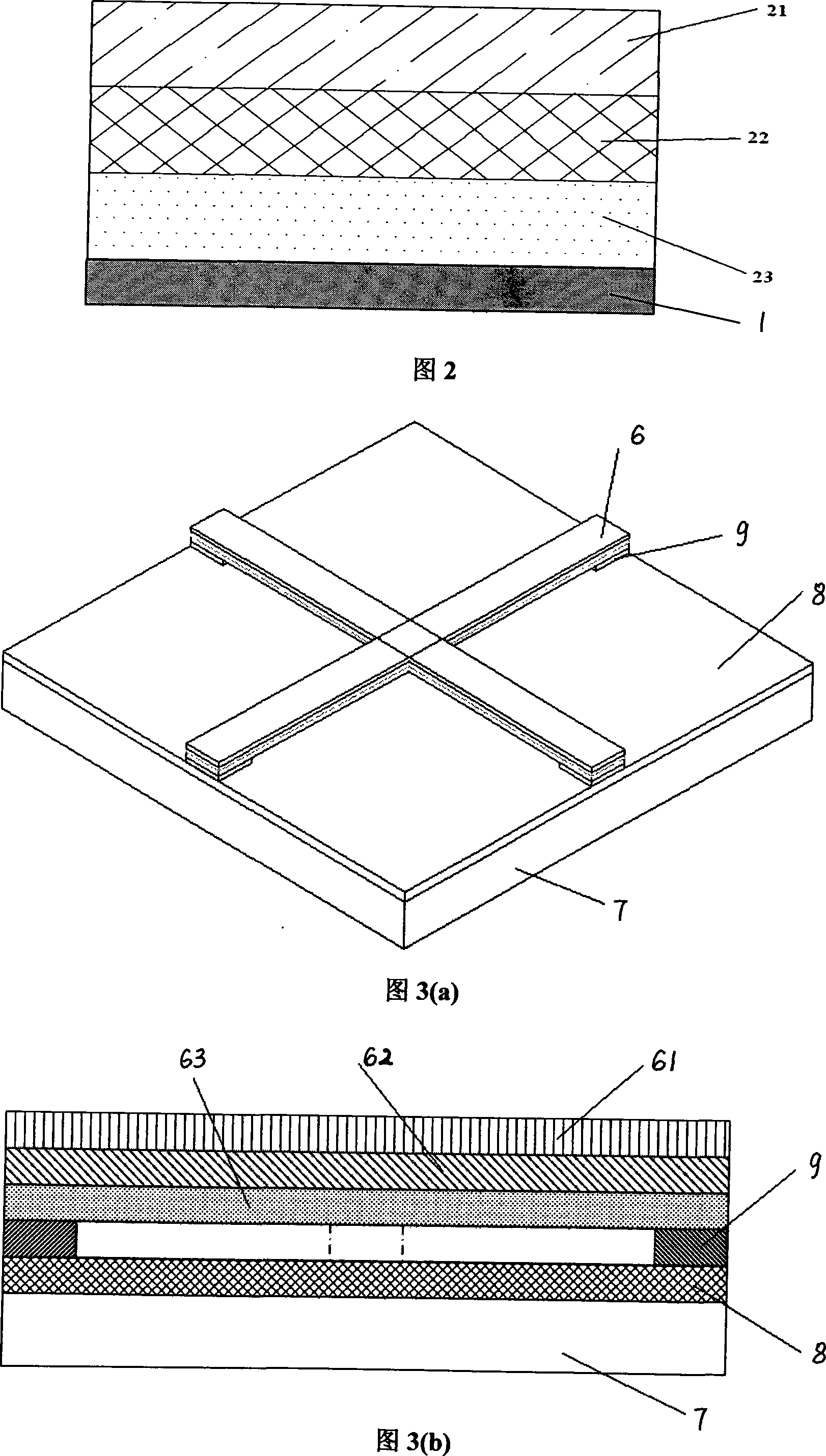

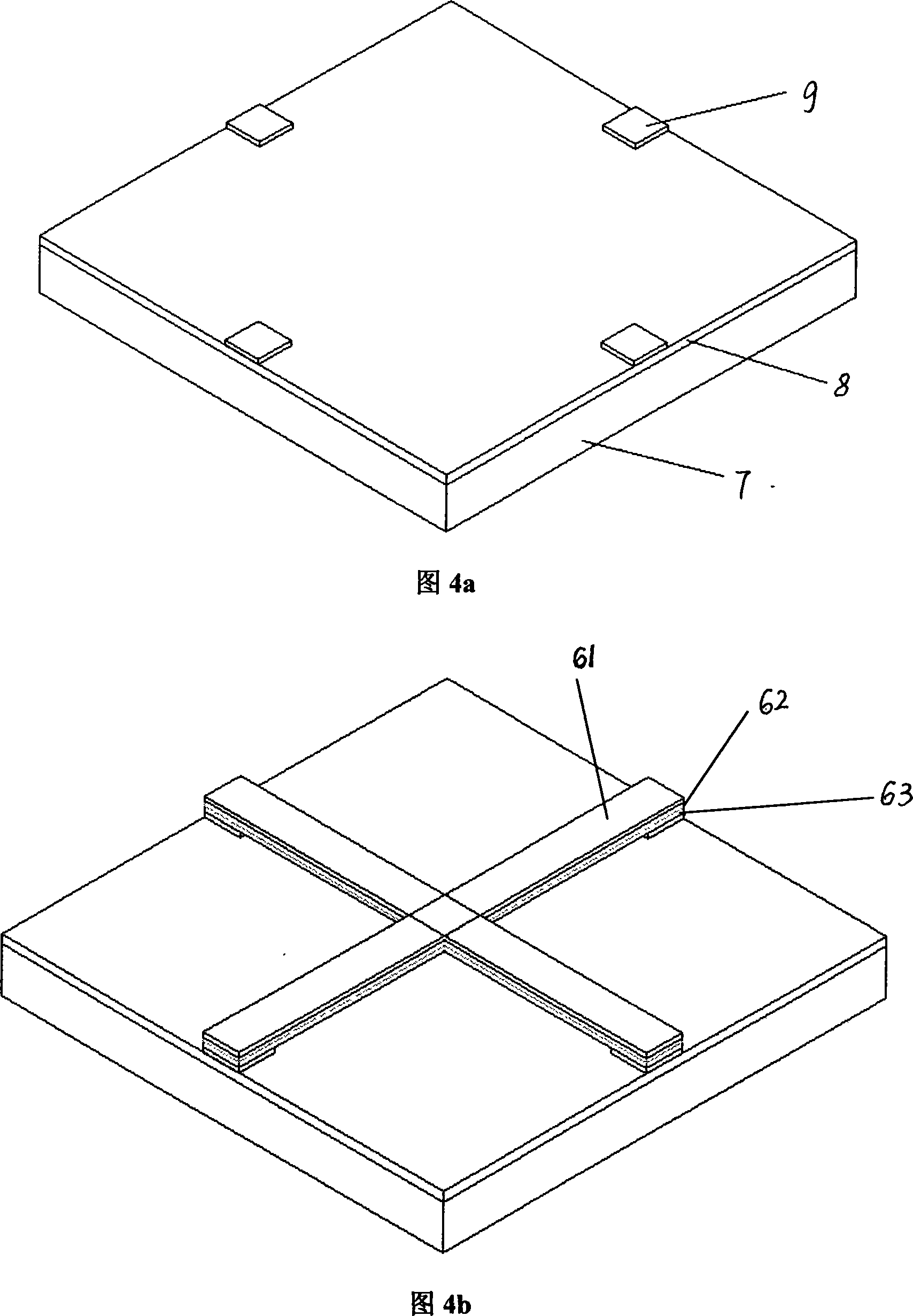

Electrothermic driven Fabry-perot light modulator

InactiveCN101162341AAvoid complex structuresLow processing technology requirementsNon-linear opticsThermal expansionElectric drive

An electric heat drive type amber optical modulator for display, the structure at least comprises an electric heat drive part, a movable lower reflector or an upper reflector. The electric heat drive part is a multilayer beam made of two materials with greatly different coefficients of thermal expansion. The initial position between the upper reflector and the lower reflector is K x Lambda / 2 (Lambda represents an incident wavelength and K represents an integer.), and when the reflected light intensity of the incident light is zero after being transmitted by the modulator, the modulator is in a dark state. When an energizing current passes through the electric drive part, the two materials respectively have thermal expansions due to the thermal resistance effect, and a stress which is produced due to the different coefficients enables the electric heat drive part to deform, thereby driving the lower reflector to move upwardly. Accordingly the distance between the two reflectors becomes (2K-1) x lambda / 4, the light intensity after reflection through the modulator reaches a maximal value, and the modulator is in a light state. When the current disappears, the electric heat drive part restores to an original state, the distance between the two reflectors also restores to an original state, and the modulator is in the dark state, too. The modulator realizes the display function based on the principle.

Owner:CHONGQING UNIV

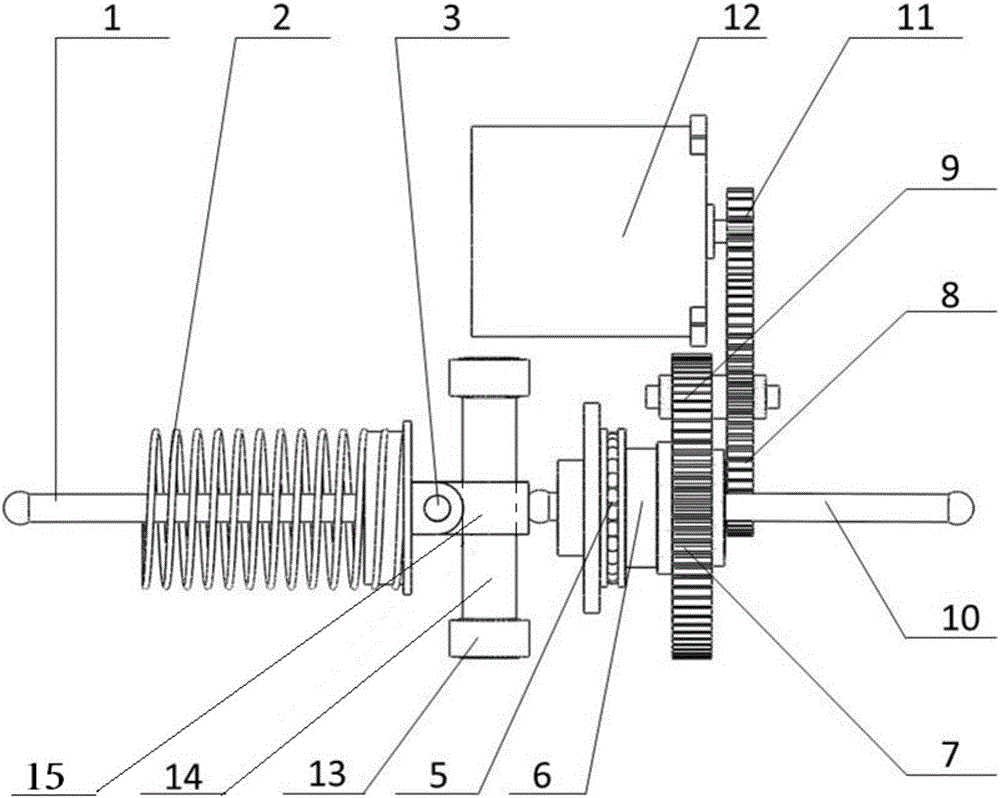

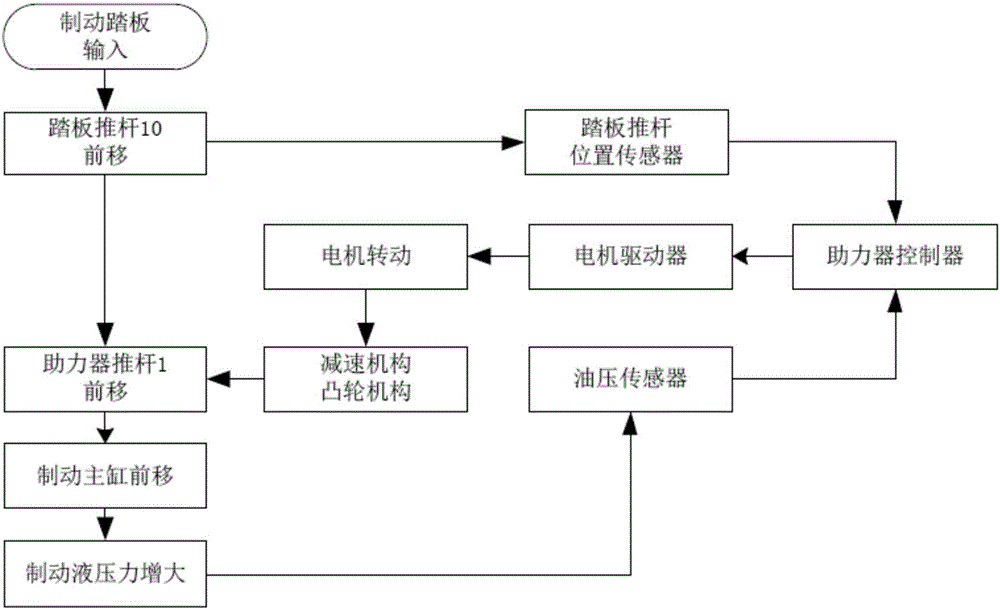

Electric brake booster

ActiveCN106740792ALow costWeak slowing downBraking action transmissionFoot actuated initiationsManufacturing technologyRolling resistance

The invention provides an electric brake booster which comprises a pedal push rod, a motor, a speed reduction mechanism, a cam mechanism and a booster body. The first end of the pedal push rod is connected with a brake pedal. The second end of the pedal push rod is connected with the first end of the speed reduction mechanism. The second end of the speed reduction mechanism is connected with the first end of the cam mechanism. The second end of the cam mechanism is connected with the booster body. The motor is connected with the third end of the speed reduction mechanism. Rotation motion of the speed reduction mechanism is converted into rectilinear motion through the cam mechanism; due to the fact that rolling friction exists inside the cam mechanism, transmission is stable; meanwhile, the installation cost is low, installation is easy, the requirement for the processing technology and the manufacturing technology is low, and the enterprise manufacturing cost is reduced.

Owner:SAIC GENERAL MOTORS +1

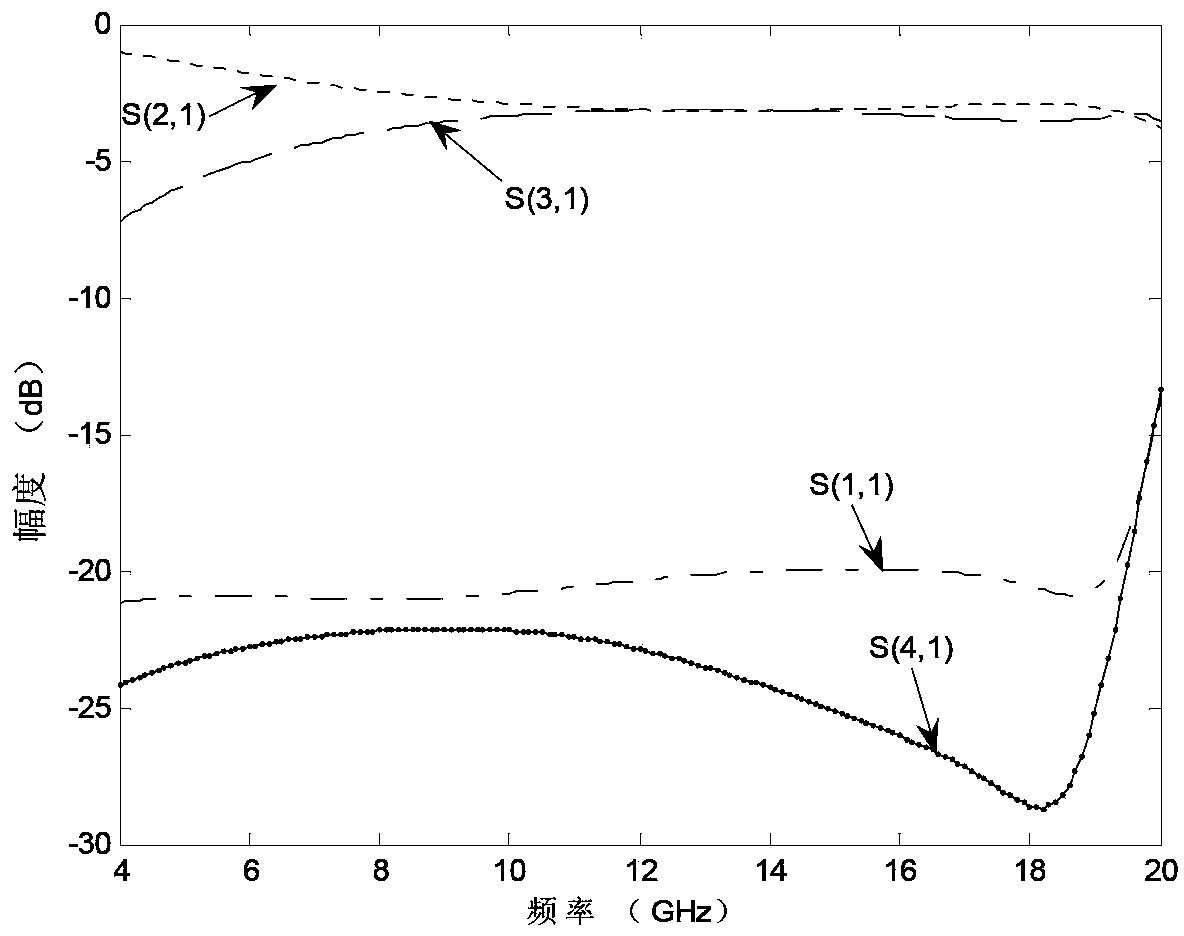

Defected ground structure interdigital coupler

InactiveCN103414003AImprove isolationImprove working bandwidthCoupling devicesIsolation effectCurrent distribution

The invention provides a defected ground structure interdigital coupler. Wire jumping bridging is adopted in the coupler to achieve four-wire interdigital coupling, accordingly, the large bandwidth is obtained, meanwhile, a DGS at the position of a ground plate of an interdigital coupling structure is introduced, current distribution of the interdigital coupling structure is changed, strong coupling of the coupler is guaranteed, the good isolation effect is achieved at the same time, and the work bandwidth of the coupler can be effectively increased. Meanwhile, the defected ground structure interdigital coupler is small in size and simple in structure, can be easily integrated with other parts, and reduces requirements for the processing process.

Owner:NANJING UNIV OF POSTS & TELECOMM

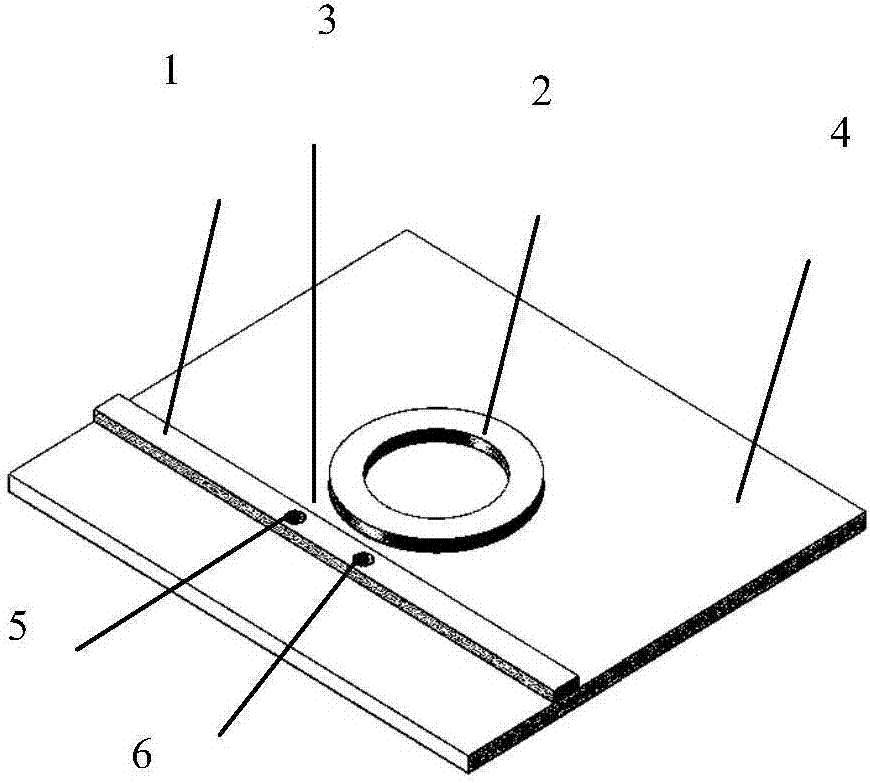

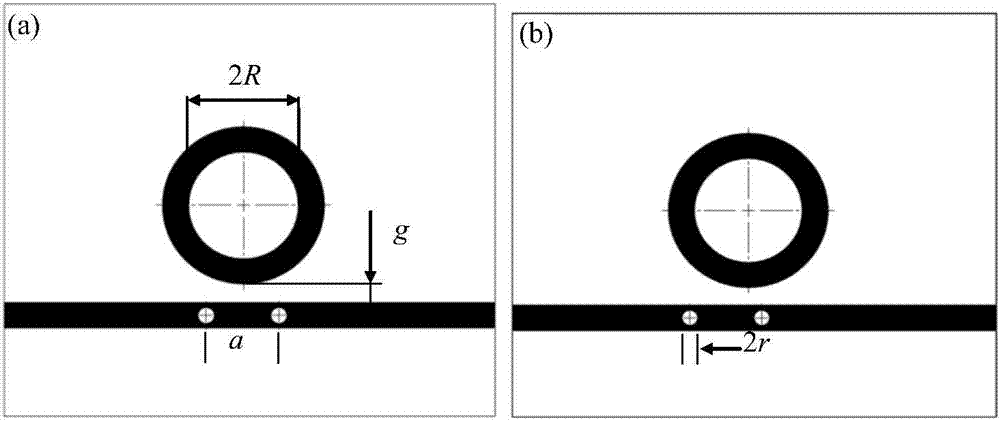

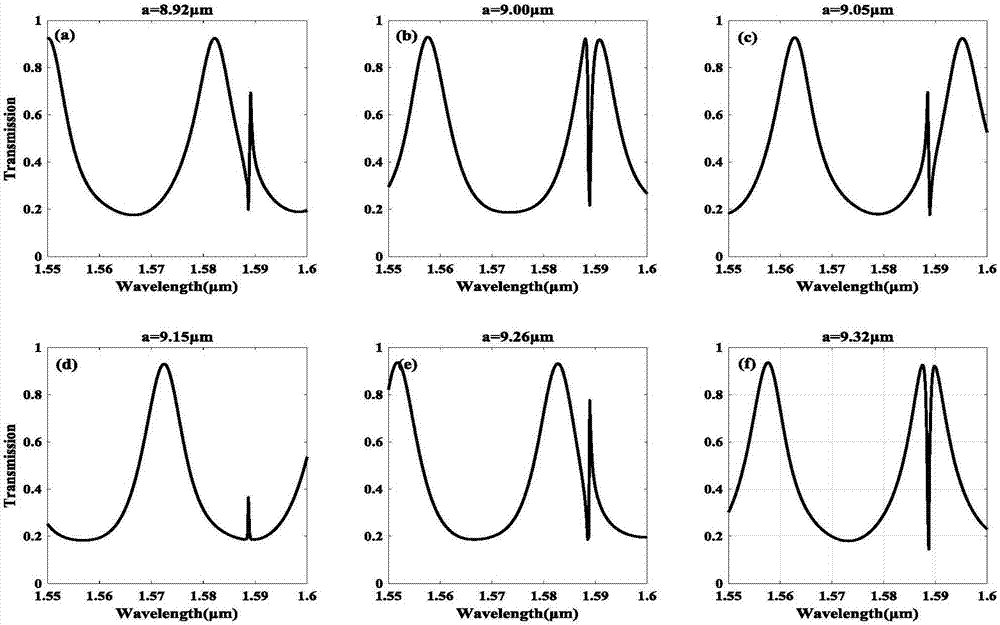

Compact photon structure capable of realizing various resonance line types based on micro ring cavity

InactiveCN106980155AAchieving a resonant line shapeLow processing technology requirementsCoupling light guidesCouplingResonance line

The invention relates to a compact photon structure capable of realizing various resonance line types based on a micro ring cavity. The compact photon structure comprises a straight waveguide (1), a micro ring cavity (2) and a substrate (4), and is characterized in that the straight waveguide (1) and a micro ring cavity (2) are located on the substrate (4), and a gap is reserved between the straight waveguide (1) and the micro ring cavity (2); the straight waveguide (1) is provided with two air holes; and the straight waveguide (1) and the micro ring cavity (2) are equal in thickness d and width w, and the straight waveguide (1) and the micro ring cavity mutually adopt lateral coupling. The beneficial effects comprise that the photon structure is compact, not only can realize various resonance line types at a specific resonant wavelength of a transmission spectrum of a waveguide-micro ring cavity coupling structure, but also has the characteristic at multiple resonant wavelengths in a wide band range, and can meet the demand of realizing various applications by using the single micro ring cavity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

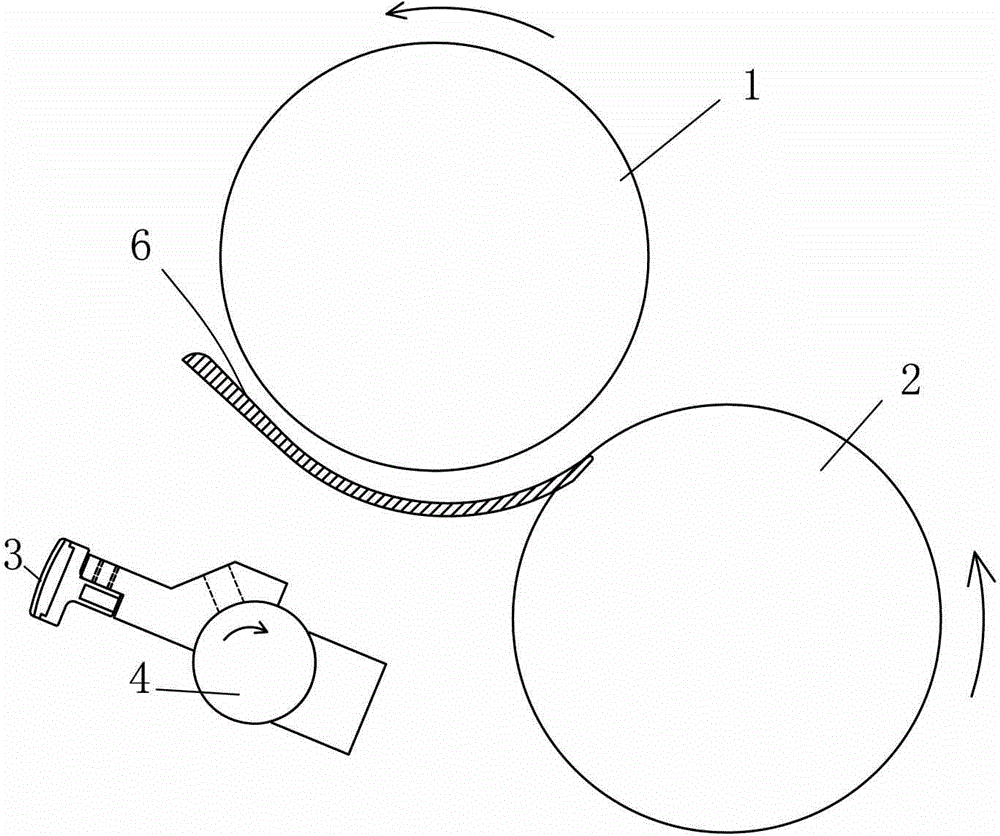

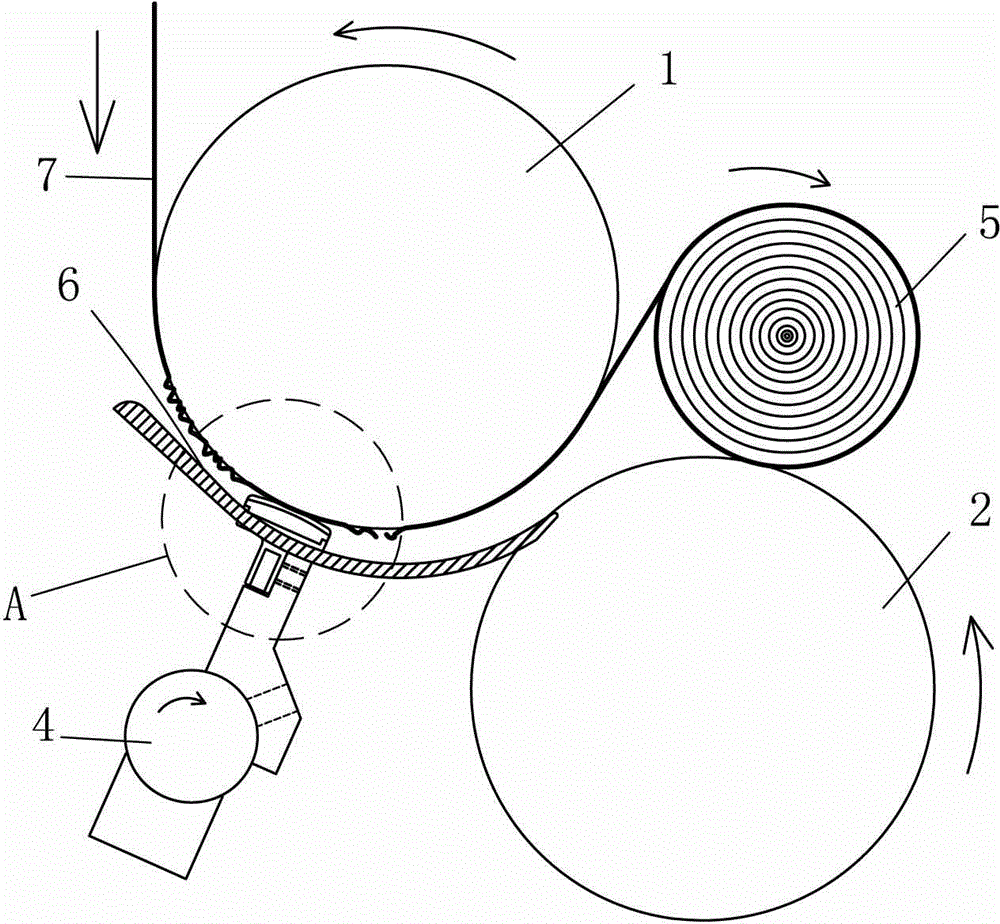

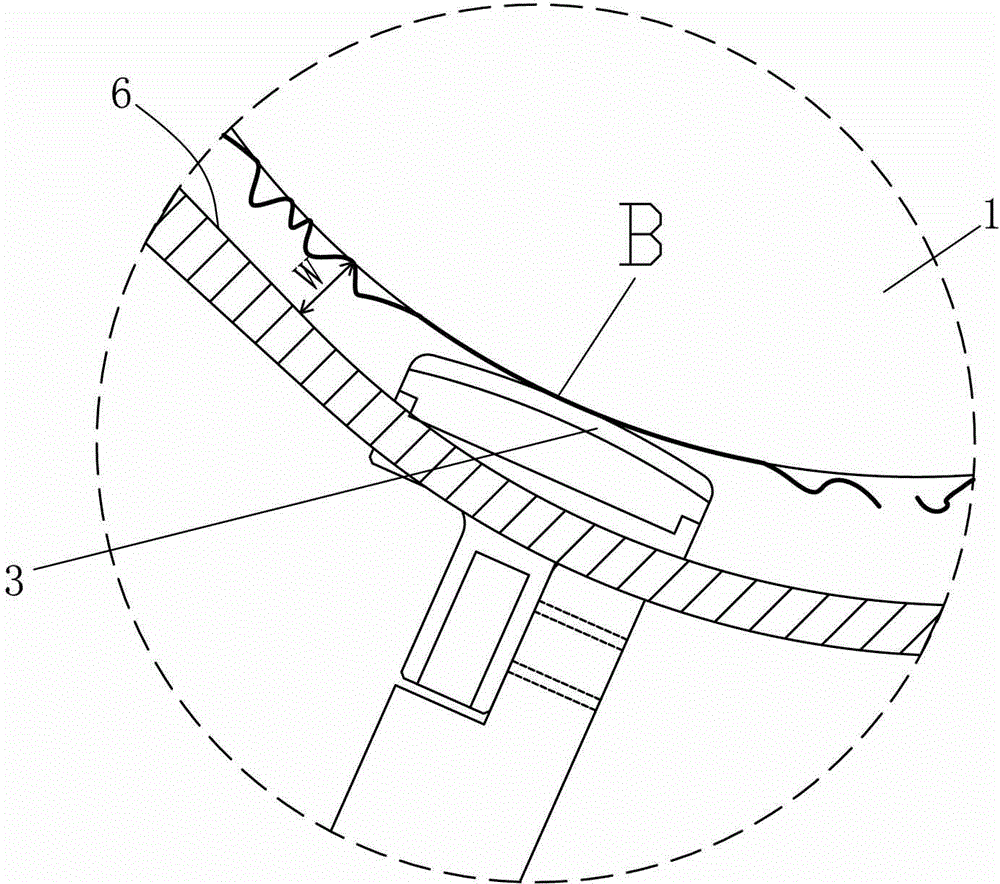

Coreless paper roll rewinder with reliable winding and winding method

The invention discloses a coreless paper roll rewinder with reliable winding; a press piece used for cutting paper is arranged below a rewind upper roller; a winding guide surface close to the roller surface of the rewind upper roller is arranged below the rewind upper roller; the minimum gap between the winding guide surface and the roller surface of the rewind upper roller is not bigger than 10mm, and the gap is arranged on upstream of a press position of the press piece on the paper; the invention also discloses a coreless paper roll rewinder winding method: in beginning, the press piece and the minimum gap are matched to start winding of the paper; the coreless paper roll rewinder is reliable in winding, and the winding process needs not to strictly control a spin angle of the rewind upper roller, thus reducing technical process requirements, and reducing machine debug difficulty.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com