Novel common rail injector

A common rail fuel injector and fuel injector technology, which is applied in the directions of machines/engines, fuel injection devices, engine components, etc., can solve the problem of short-term connection between the oil inlet channel and the oil return channel, reduce the fuel injection efficiency, and increase the oil return amount. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

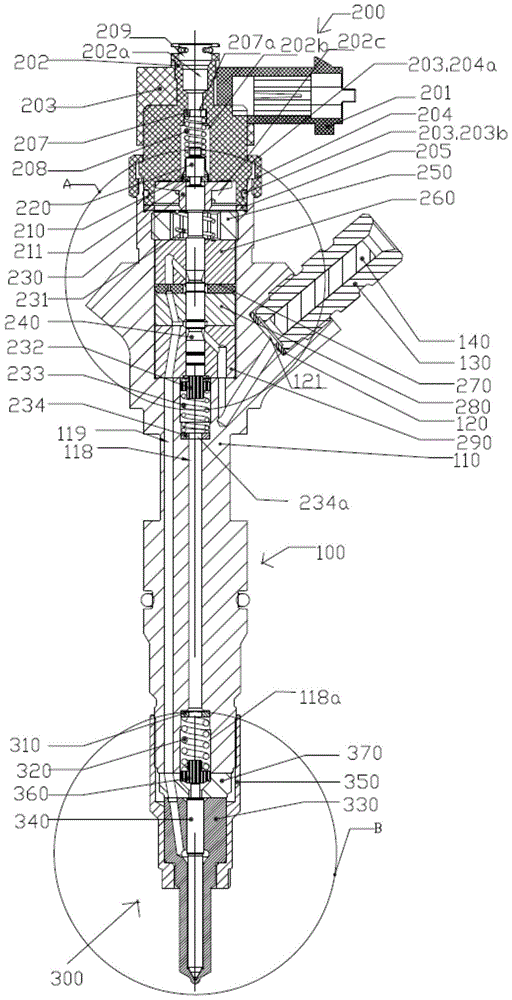

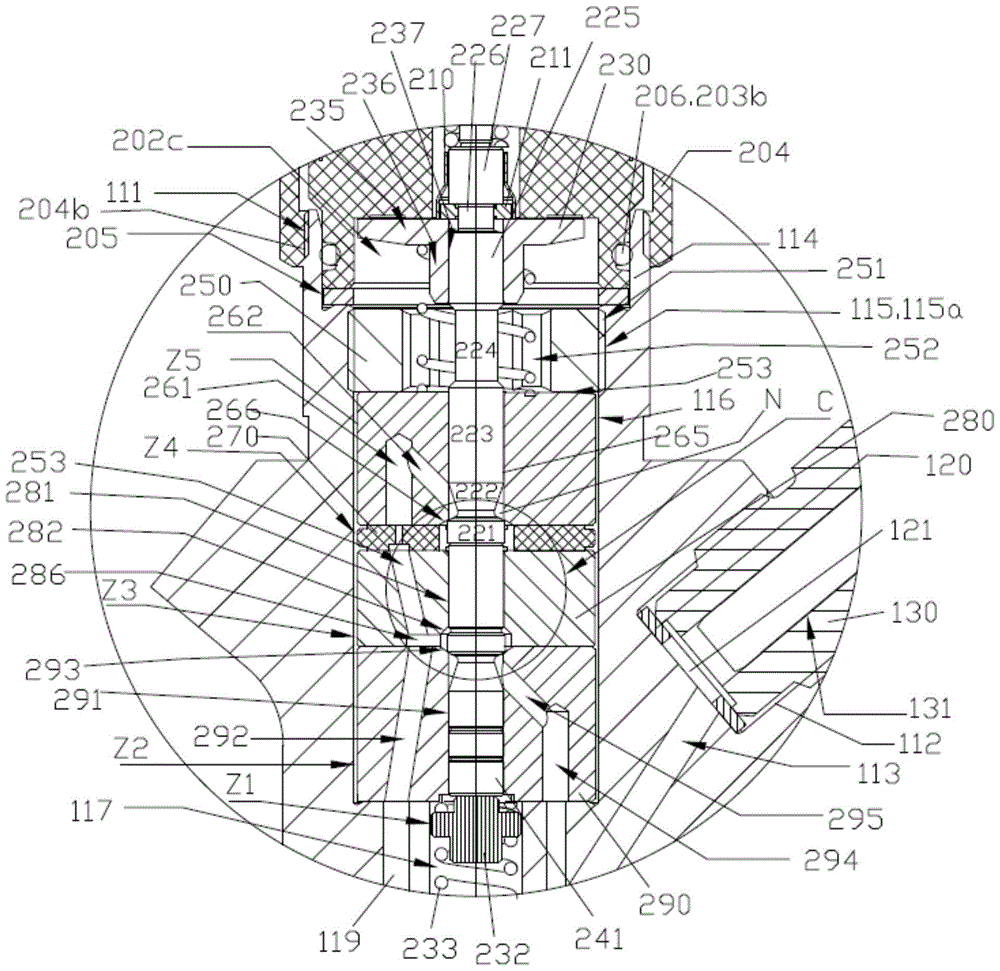

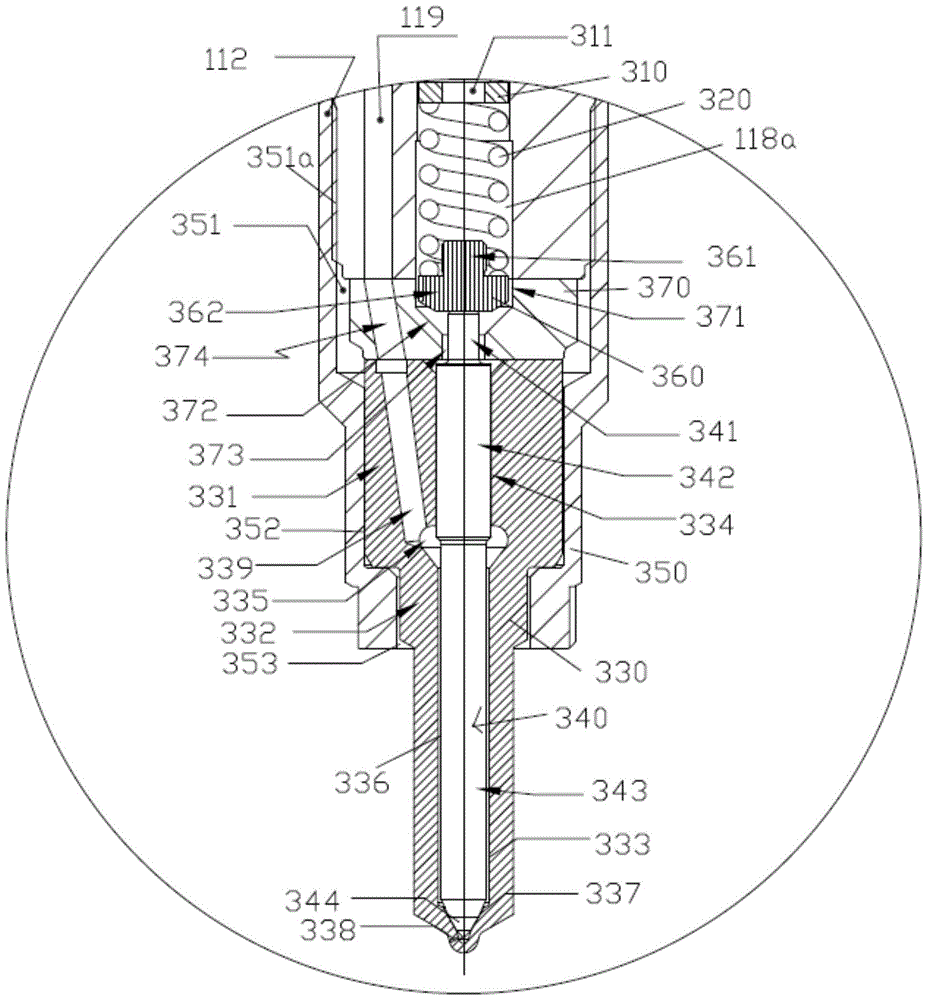

[0069] see Figure 1 to Figure 14 , the new common rail injector shown in the figure includes injector body part 100 , electromagnet part 200 and fuel injector part 300 .

[0070] The fuel injector body part 100 includes a fuel injector body 110 , an oil inlet pipe connector sealing gasket 120 , an oil inlet pipe connector 130 and a slit filter element 140 .

[0071] The upper end of the injector body 110 is provided with an upper external thread 111, and the lower end is provided with a lower external thread 112; an oil inlet pipe joint installation hole 112, a first oil inlet passage 113, Mounting holes for solenoid valve components.

[0072] The mounting holes of the solenoid valve components are divided into the upper hole 114 for installing the solenoid valve components coaxially arranged from top to bottom and communicated in sequence with the inner diameter decreasing successively, the middle hole 115 for installing the first solenoid valve component, and the middle ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com