Temperature-sensitive color-changing paint dyeing technology of textile fabrics

A heat-sensitive color-changing and paint dyeing technology, which is applied in the field of heat-sensitive color-changing paint dyeing technology, can solve the problems of poor bonding or crosslinking, short service life, etc., and achieve the effects of sensitive residence time, low processing difficulty, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

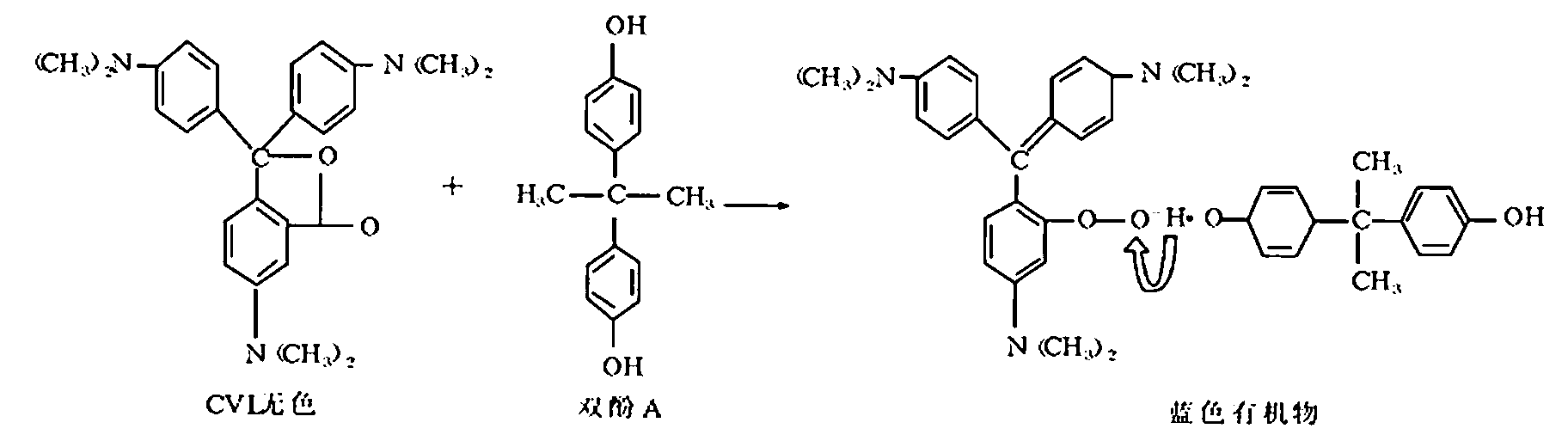

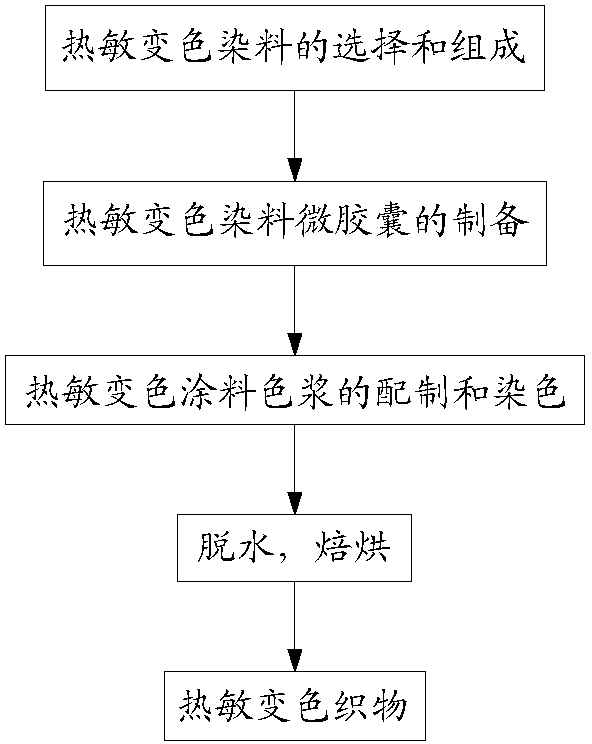

[0064] Such as image 3 Shown is a flow chart of the present invention.

[0065] Thermochromic dyeing of fabrics

[0066] Fabric: fabric blank (fabric after annealing, boiling and bleaching treatment) specifications: cotton plain cloth, 32x32 / 68x68.

[0067] Preparation of thermosensitive color-changing dye microcapsules:

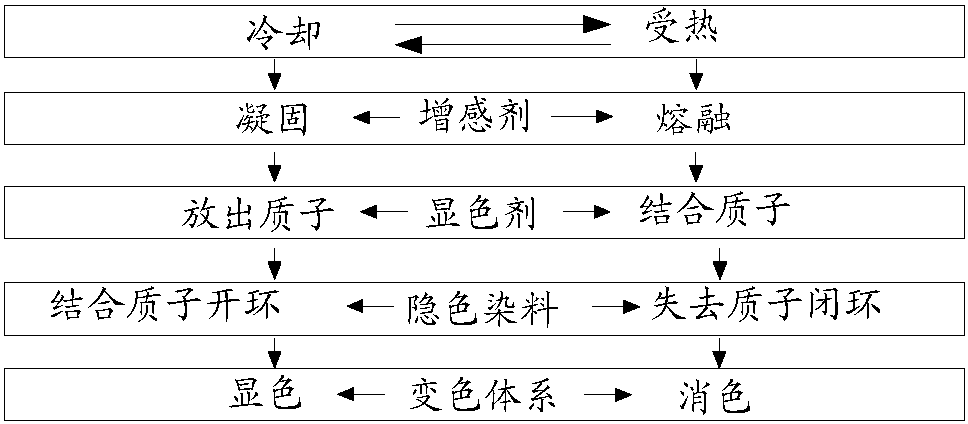

[0068] Thermochromic dye (leuco dye, developer and sensitizer) composition:

[0069] Leuco dye / developer / sensitizer: Crystal Violet Lactone (CVL) / Stearic Acid / Myristyl Alcohol: 1 / 2 / 30.

[0070] (1) Preparation of heat-sensitive color-changing dye: Weigh 50 g crystal violet lactone, 100 g stearic acid and 1500 tetradecyl alcohol in a mass ratio of 1 / 2 / 30 into a container with a stirrer, heat up with a water bath Temperature is about 80°C, stirring and reacting for 30-60 minutes, and the heat-sensitive color-changing core material is obtained.

[0071] (2) Preparation of microcapsules:

[0072] Accurately weigh 55g of chitosan (wall material A) and full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com