Image analysis method for spray freezing coating effect based on Image J

A technology of spray freezing and image analysis, which is applied in the field of image analysis, can solve the problems of not being able to guarantee the objective consistency of image processing, not being convincing enough, and errors, so as to ensure uniformity and standardization, avoid the influence of human factors, and achieve results precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

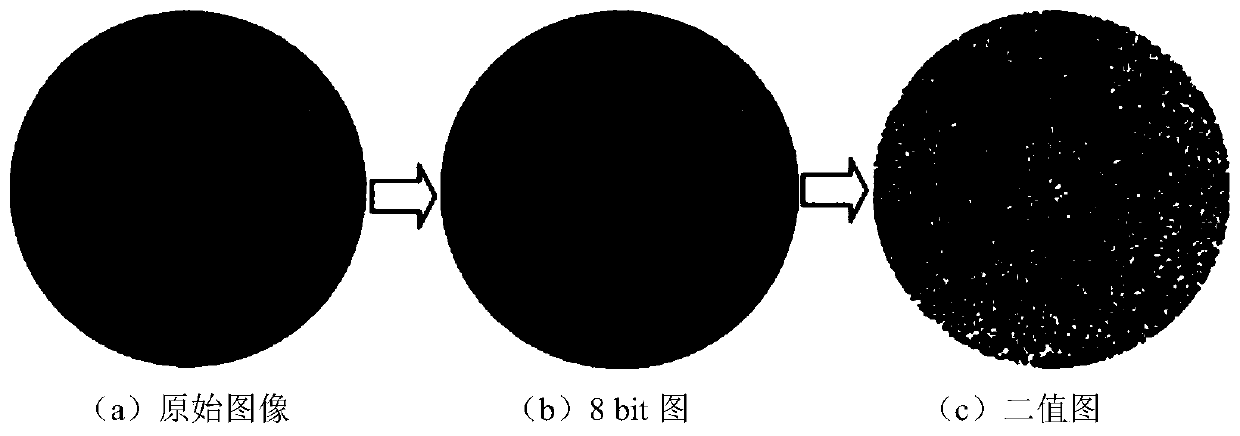

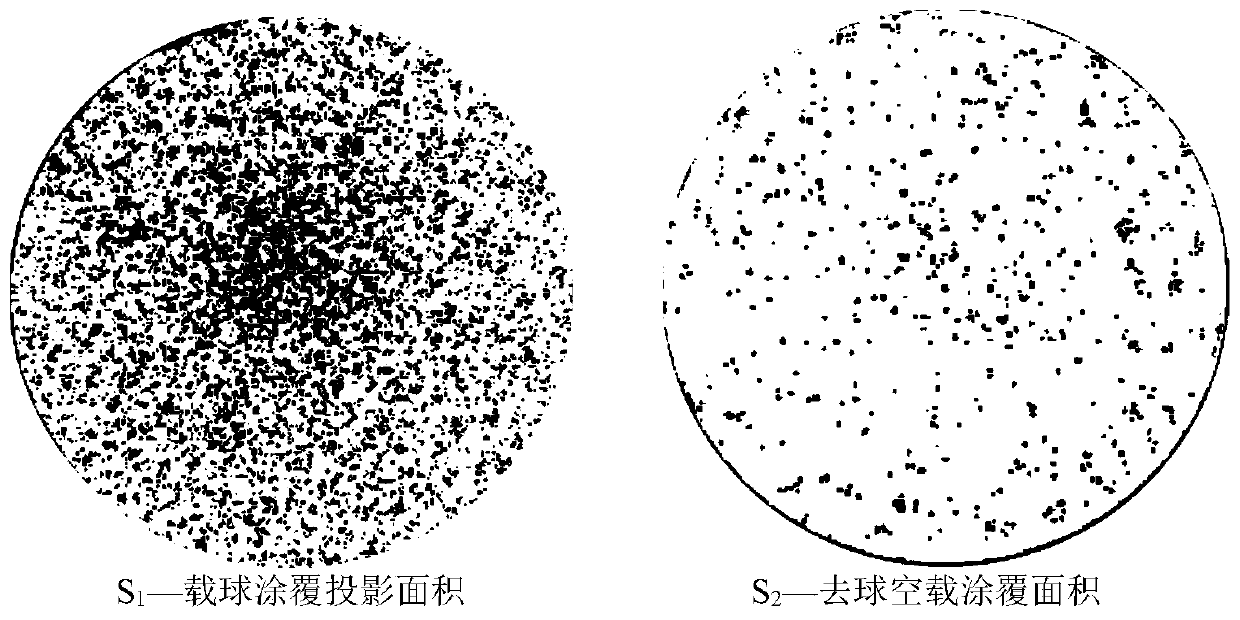

[0041] A kind of image analysis method of the spray freezing coating effect based on Image J, it may further comprise the steps:

[0042] 1. Spray freezing coating process:

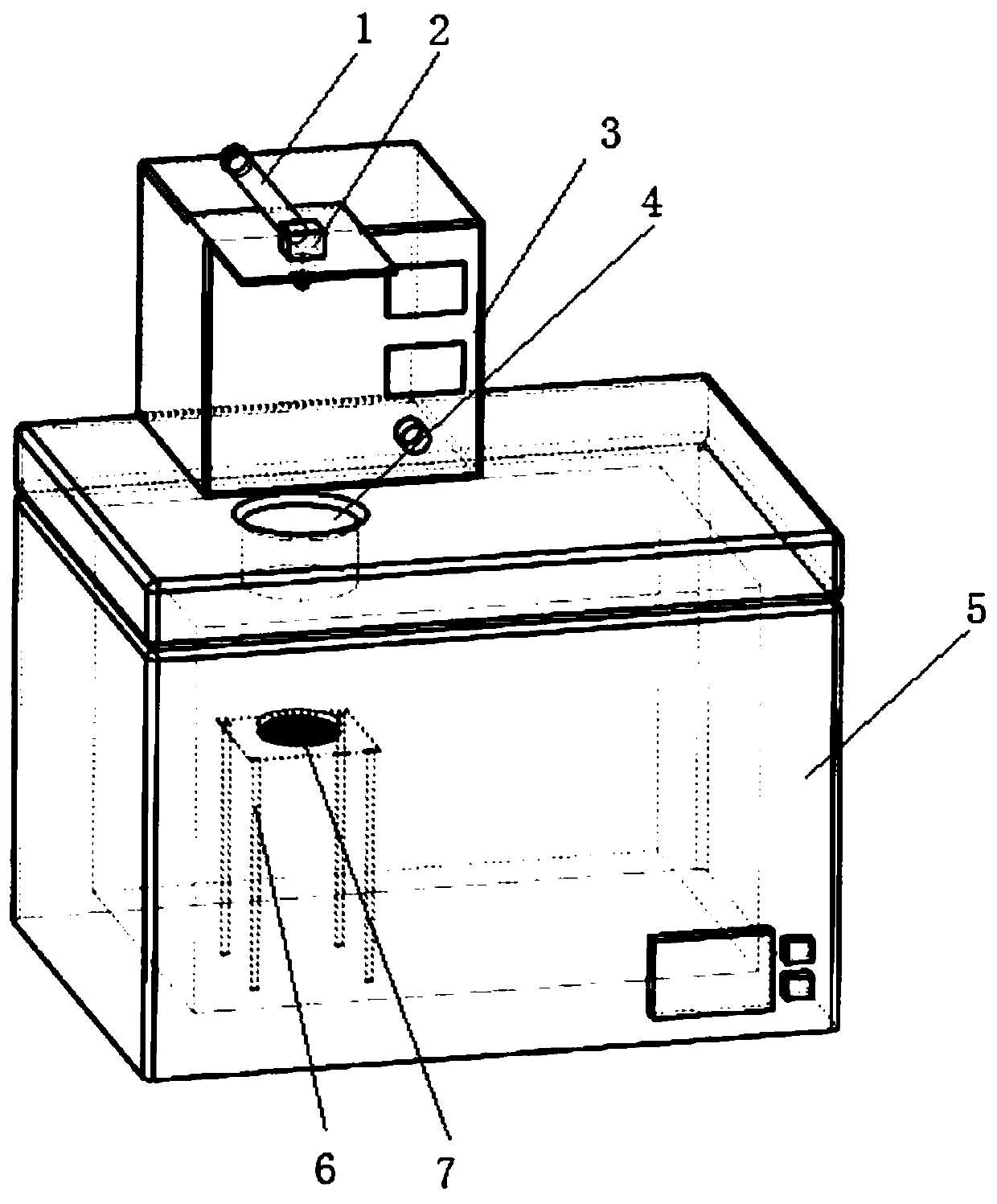

[0043] Spray freeze coating test device, such as figure 1 As shown, it includes: freezer 5, particle tray 7, tray frame 6, microcapsule granulator 3, a tray frame is placed inside the freezer, a particle tray is placed on the upper part of the tray frame, and an opening 4 is formed on the top surface of the freezer. Place the microcapsule granulator, the nozzle 2 of the microcapsule granulator corresponds to the position of the hole made on the top surface of the refrigerator, and the nozzle is connected to the syringe 1. The Haier special experiment freezer (DW-60W15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com