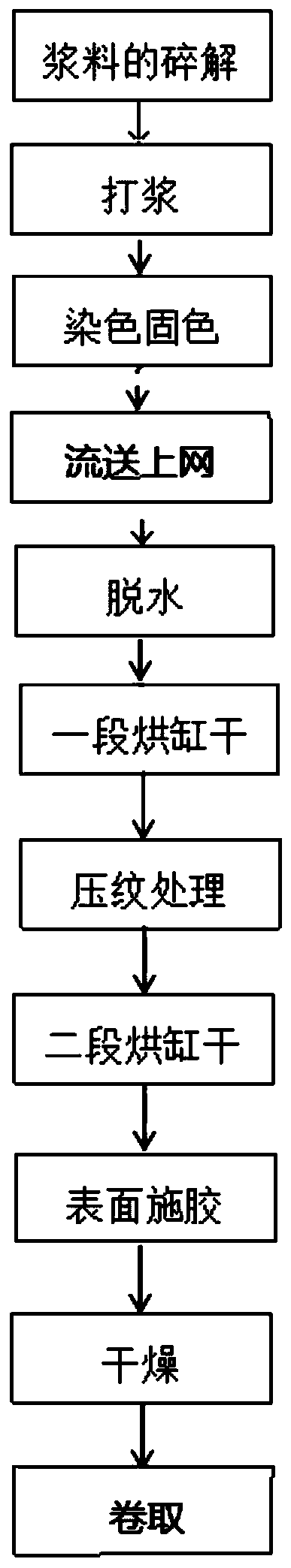

Production method of embossed double-color art paper

A production method and technology of art paper, applied in patterned paper, paper, papermaking, etc., can solve problems such as unnatural, hard and dull lines, and damage to the surface of paper sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

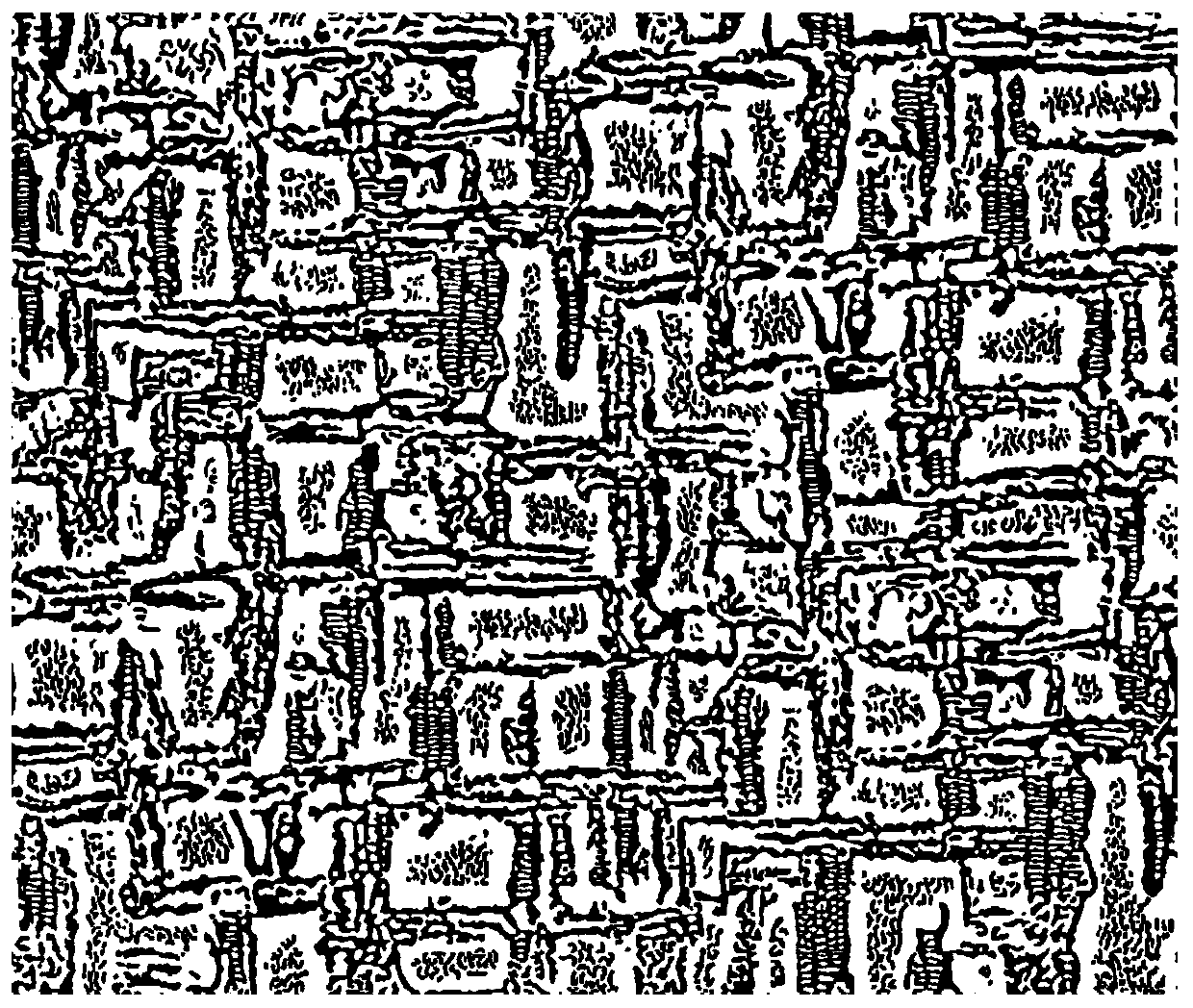

[0080] This embodiment provides a light yellow two-color ancient pottery pattern paper, the production method of the light yellow two-color ancient pottery pattern paper includes the following steps:

[0081] (a) Disintegration of pulp: placing pulp boards of softwood pulp and hardwood pulp in a pulper for disintegration;

[0082] (b) beating: the softwood pulp that accounts for 35% of the total pulp ratio and the hardwood pulp that accounts for 65% of the total pulp ratio are mixed and beaten to obtain a pulp that has a degree of knocking of 35 ° SR;

[0083] (c) Dyeing and color fixation: first mix the pulp with the dye for 30 minutes for dyeing, then add 0.1% of the total dry fiber content and mix for 5 minutes to fix the color, and finally add 0.8% of the total dry fiber content Mix PAE wet strength agent for 5 minutes;

[0084]The dye is a mixture of black G accounting for 0.062% of the total dry fiber content, scarlet 4BS accounting for 0.083% of the total dry fiber con...

Embodiment 2

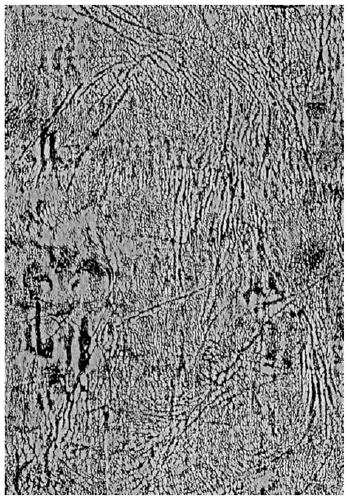

[0095] This embodiment provides a brown two-color textured paper, the production method of the brown two-color textured paper includes the following steps:

[0096] (a) Disintegration of pulp: placing pulp boards of softwood pulp and hardwood pulp in a pulper for disintegration;

[0097] (b) beating: the softwood pulp that accounts for 30% of the total pulp ratio and the hardwood pulp that accounts for 70% of the total pulp ratio are mixed and beaten to obtain a pulp that has a degree of knocking of 35 ° SR; the mass ratio is 1 : 1 waste paper pulp and bagasse pulp are mixed and beaten to obtain the pulp 2 that the degree of beating is 38 ° SR;

[0098] (c) Dyeing and color fixation: mix pulp 1 with dyestuff for 30 minutes for dyeing, then add 1.5% color fixing agent accounting for the total dry fiber content and mix for 5 minutes for color fixing, and finally add 0.8% color fixing agent accounting for the total dry fiber content PAE wet strength agent was mixed for 5 minutes...

Embodiment 3

[0111] This embodiment provides a kind of red two-color simple pattern paper, the production method of described red two-color simple pattern paper comprises the following steps:

[0112] (a) Disintegration of pulp: placing pulp boards of softwood pulp and hardwood pulp in a pulper for disintegration;

[0113] (b) beating: the softwood pulp that accounts for 40% of the total pulp volume and the hardwood pulp that accounts for 60% of the total pulp volume are mixed and beaten to obtain a pulp that has a beating degree of 32°SR;

[0114] (c) Dyeing and color fixing: firstly mix the pulp with the dye for 30 minutes for dyeing, then add 2.0% of the total dry fiber content and mix for 5 minutes to fix the color, and finally add 1.0% of the total dry fiber content PAE wet strength agent;

[0115] The dye is: a mixture of scarlet 4BS accounting for 1.25% of the total dry fiber content, blue BRL accounting for 0.25% of the total dry fiber content and yellow DY-PG accounting for 0.22%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com