Patents

Literature

455results about "Colorants/pigments addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whitened fluff pulp

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

Fibrous Structures Including an Active Agent and Having a Graphic Printed Thereon

The present disclosure relates to fibrous structures including active agents and having a graphic printed thereon. In some embodiments, a nonwoven web may include a fibrous structure comprising filaments. In turn, the filaments may include filament forming material, and an active agent releasable from the filaments when exposed to conditions of intended use. In addition, a graphic may be printed directly onto the fibrous structure.

Owner:THE PROCTER & GAMBLE COMPANY

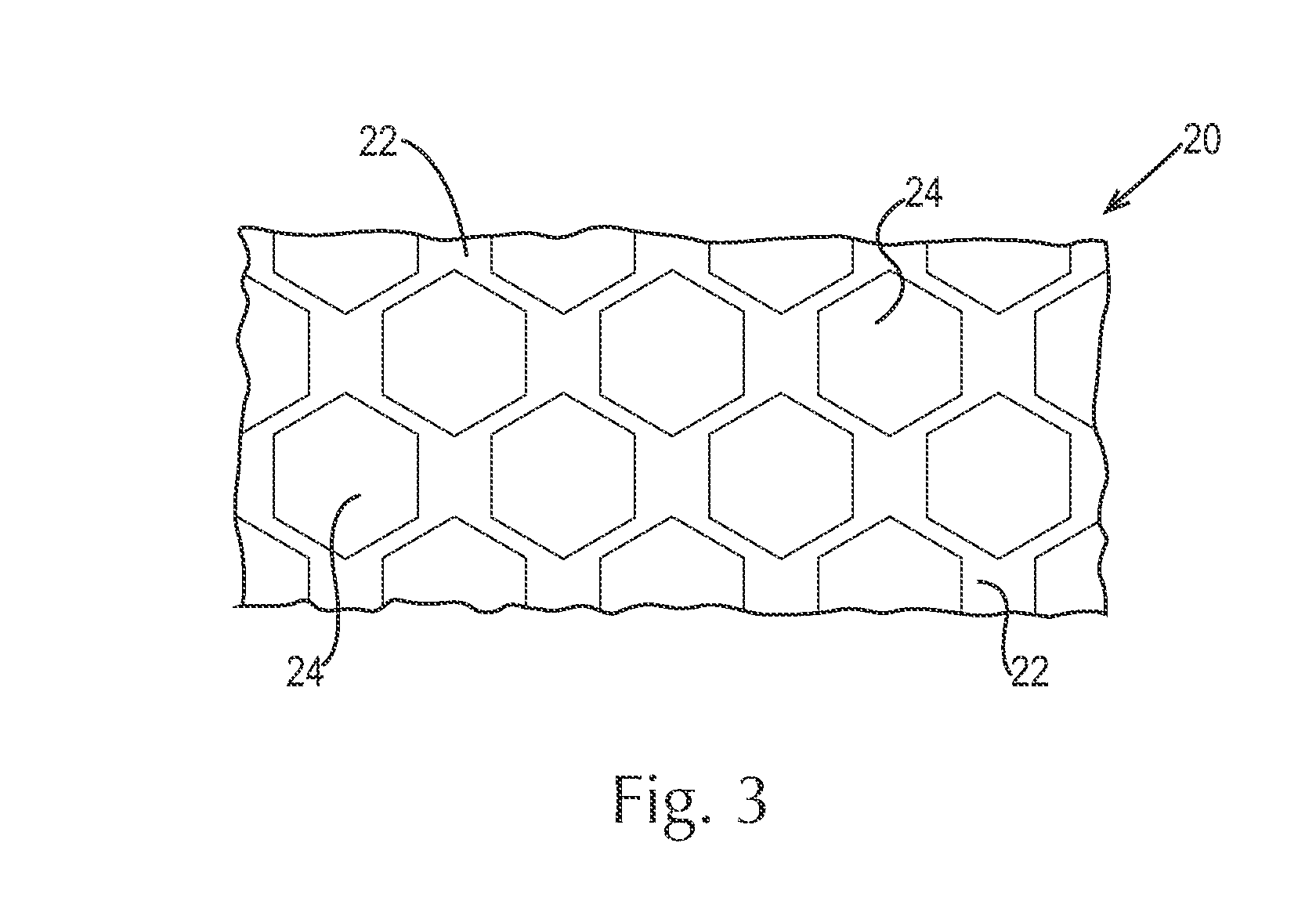

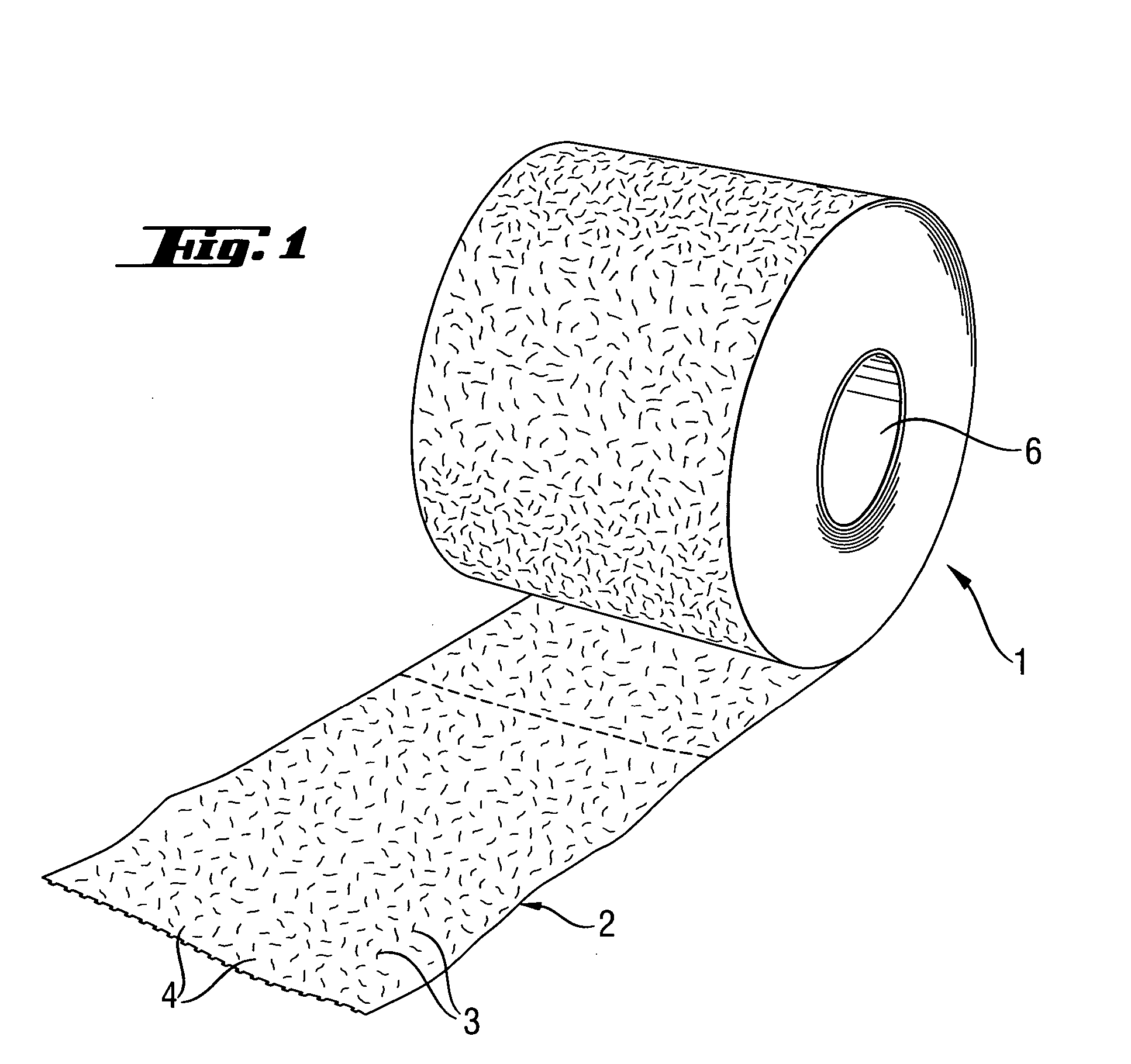

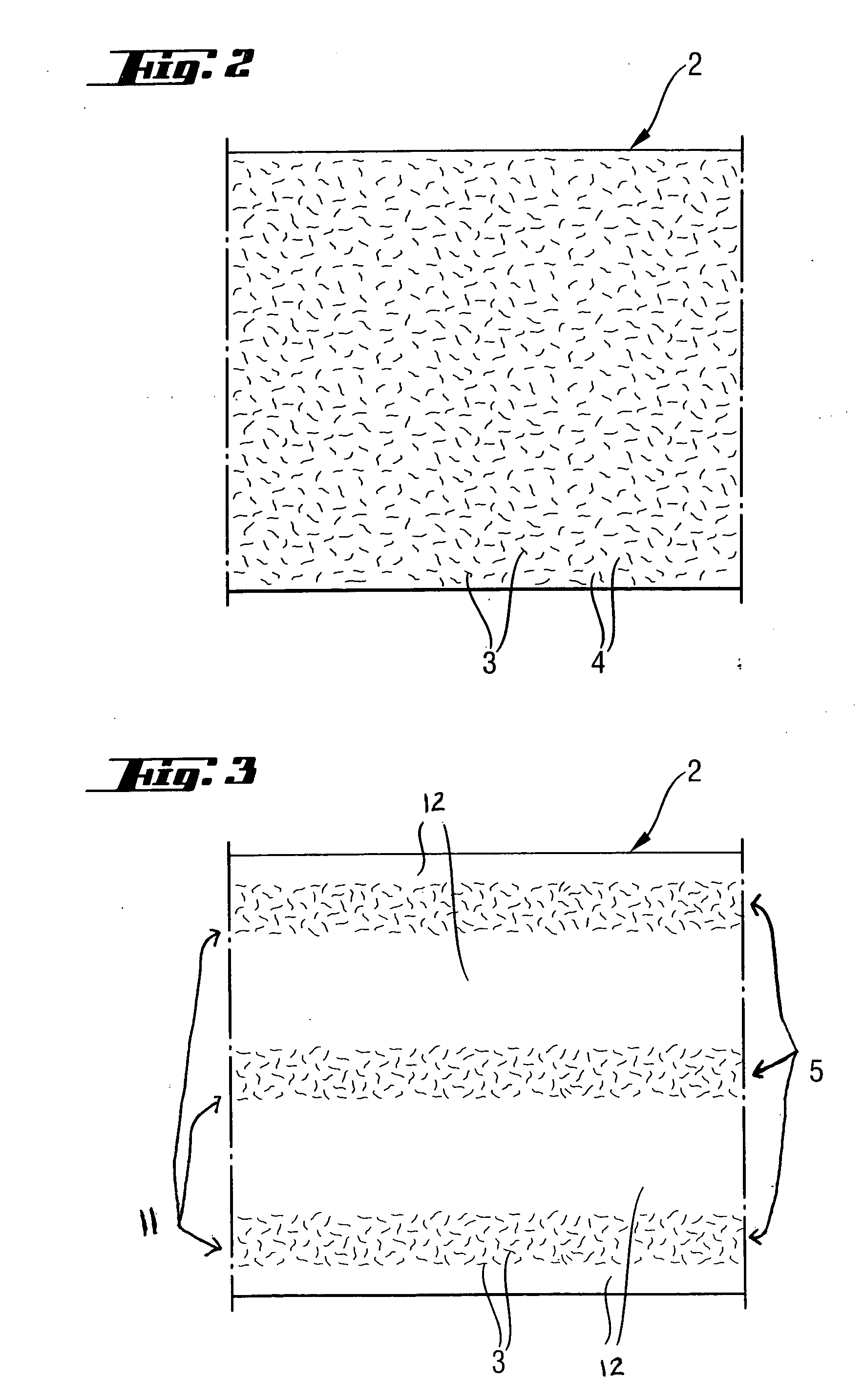

Hygiene or wiping product comprising at least one patterned ply and method for patterning the ply

InactiveUS20110027545A1Prevent precipitationLamination ancillary operationsDecorative surface effectsCellulose fiberEngineering

A hygiene or wiping product includes at least one ply of a fibrous web containing cellulose fibers and having a graphical pattern of at least first and second areas. The ply contains a coloring compound providing a coloration of the ply in the first area. The coloring compound is at least partly chemically destroyed in the second area so that the ply is less colored in the second area than in the first area. A method for producing such a ply includes the steps of providing a fibrous web containing a coloring compound, which provides a uniform coloration in at least a portion of the web, and applying a bleaching agent to a part of the colored portion of the web to at least partly decolor the web in the part generating a pattern of at least first colored and second less colored areas.

Owner:SCA HYGIENE PROD AB

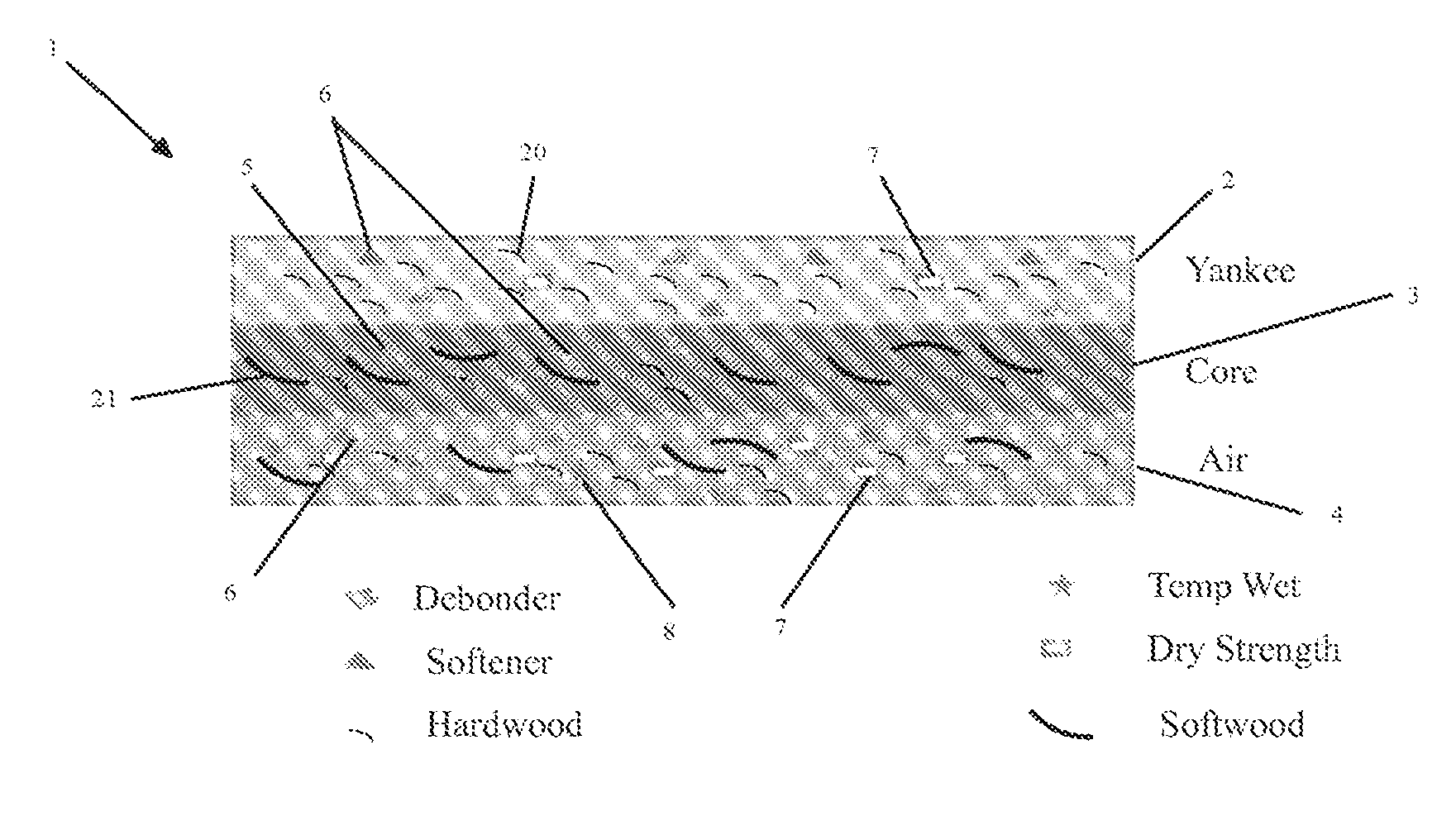

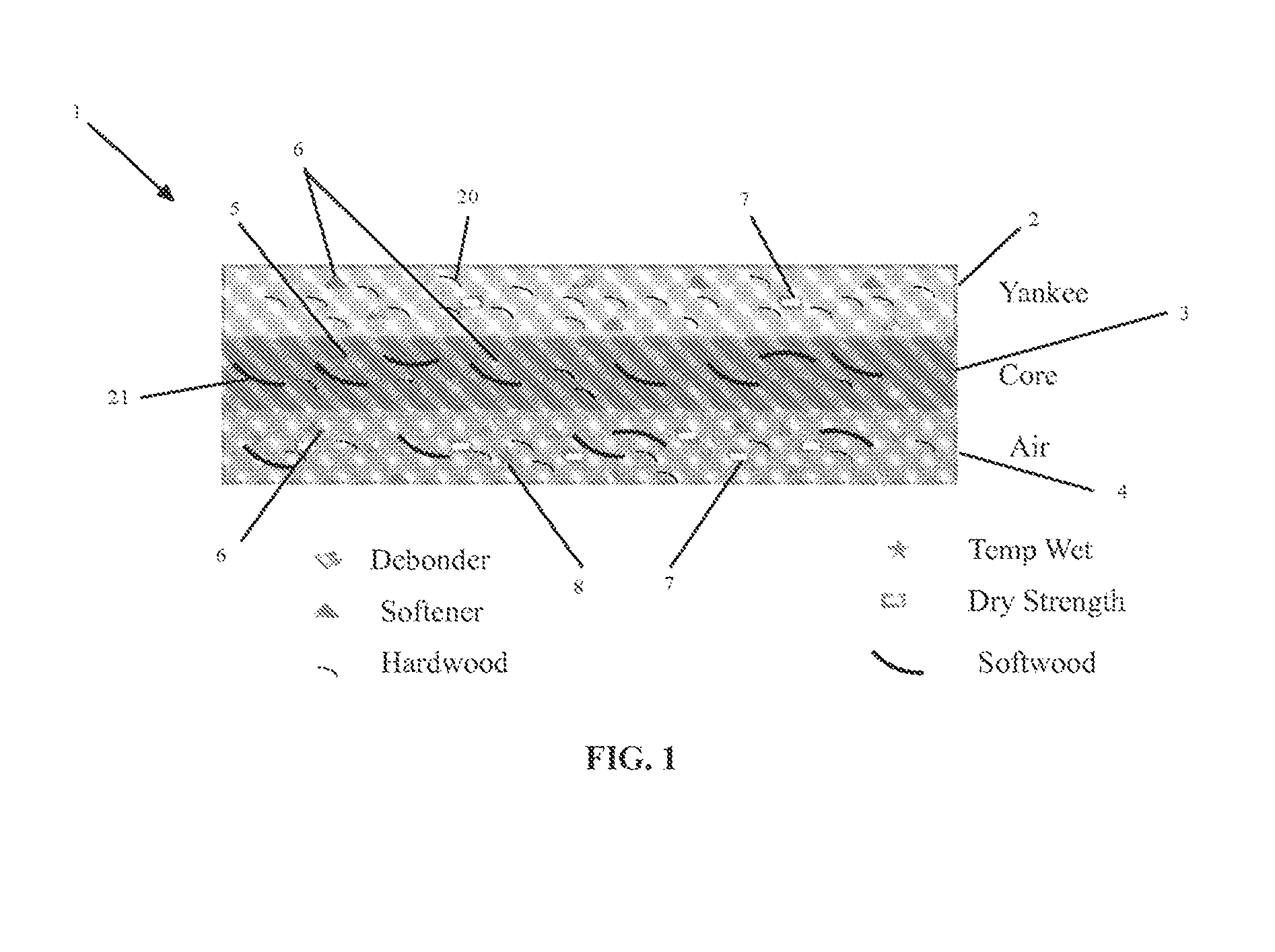

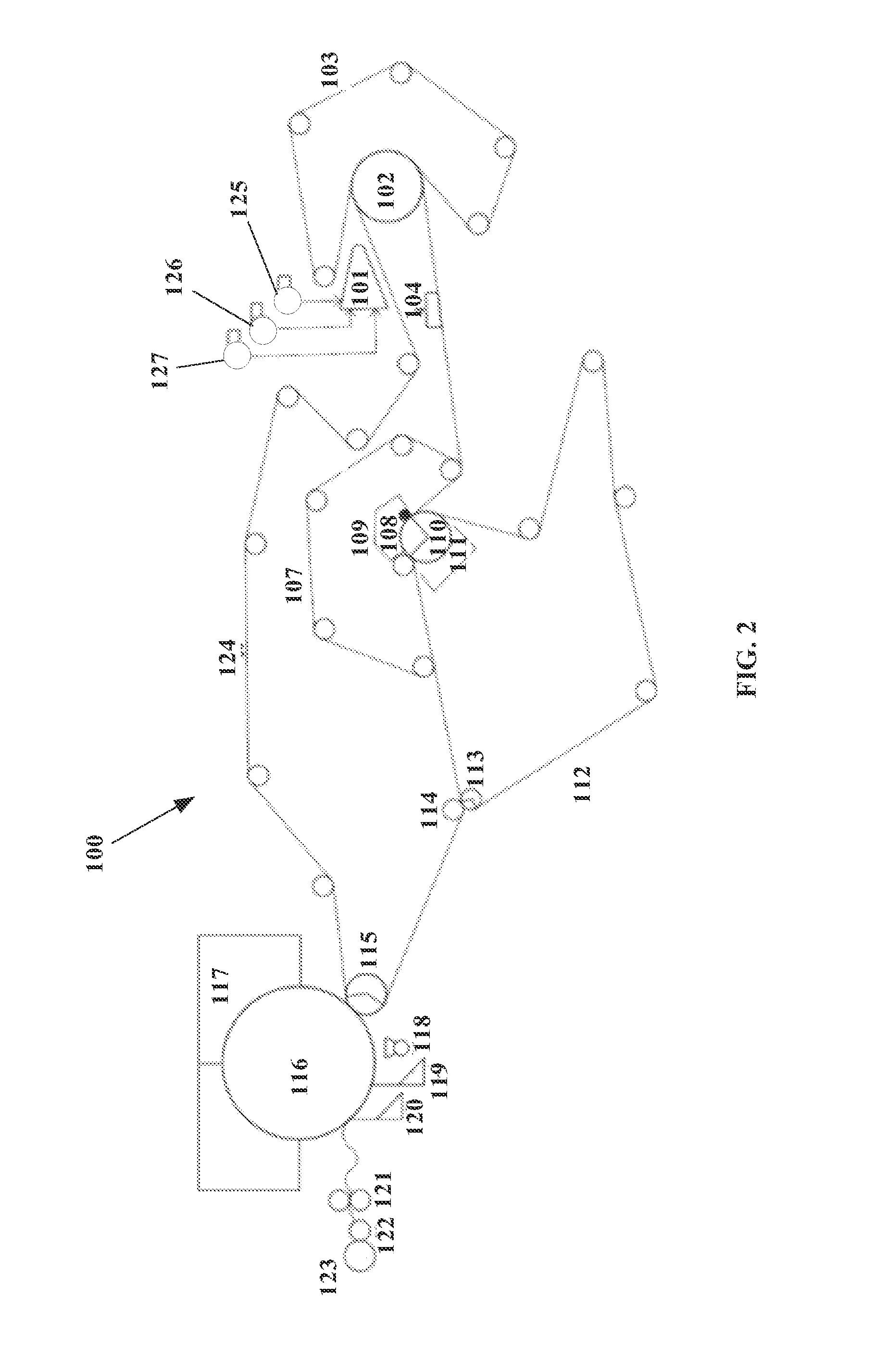

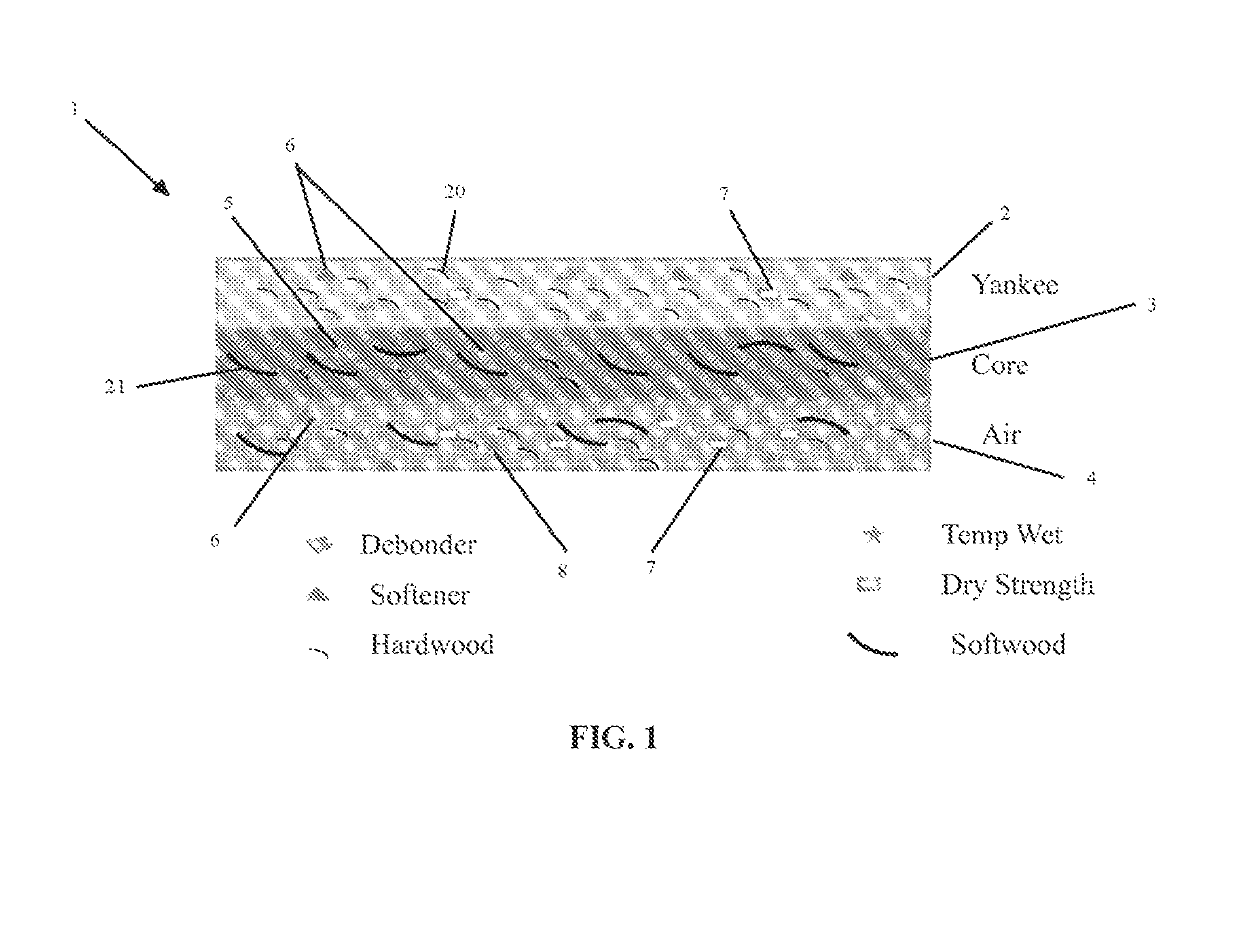

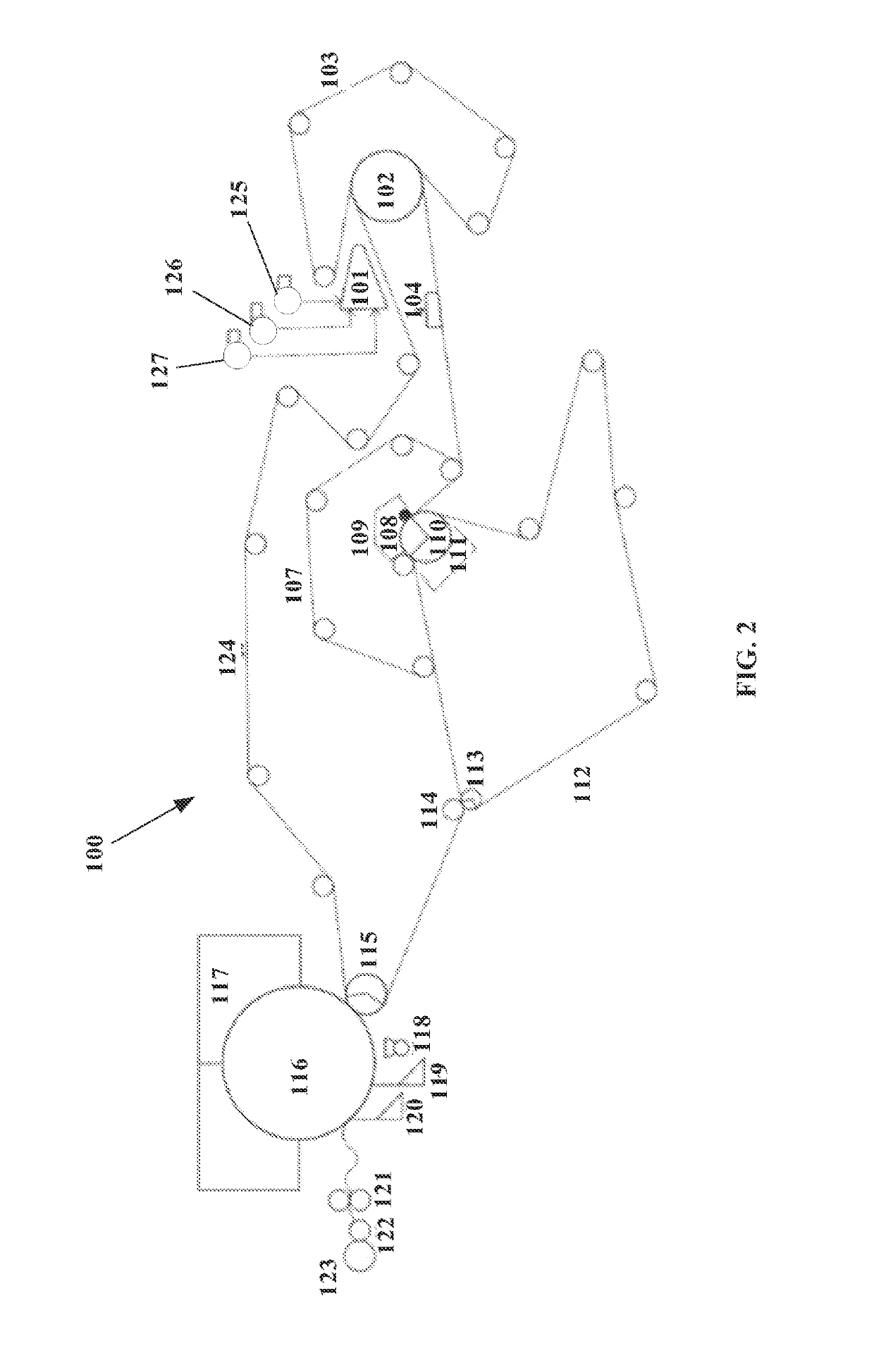

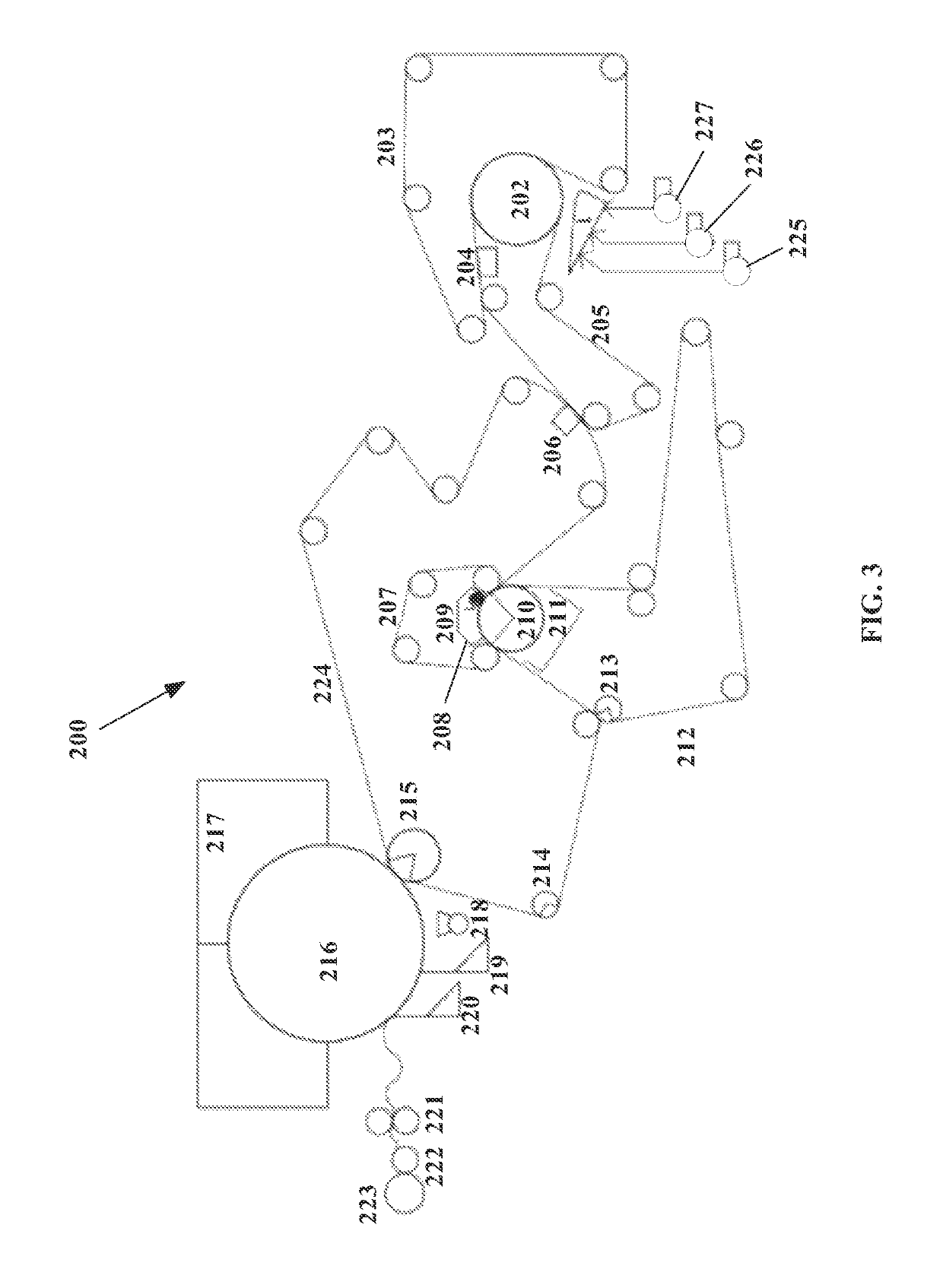

Soft tissue produced using a structured fabric and energy efficient pressing

ActiveUS20160145810A1Avoid disadvantagesLarge structureMechanical working/deformationPaper after-treatmentGram-forceEngineering

Owner:FIRST QUALITY TISSUE

Anti-microbial hand towel with time-delay chromatic transfer indicator and absorbency rate delay

ActiveUS20070237807A1Easy transferExtended absorption timeCosmetic preparationsBiocideMedicinePaper towel

A disposable paper towel with an anti-microbial lotion and is provided with a chromatic transfer indicator which undergoes a delayed, visually perceptible color change at a predetermined time after the towel is wetted. An anti-microbial lotion on the towel increases water absorbency times (WAR) to further promote lotion transfer to the skin and increase lotion transfer effectiveness.

Owner:GPCP IP HLDG LLC

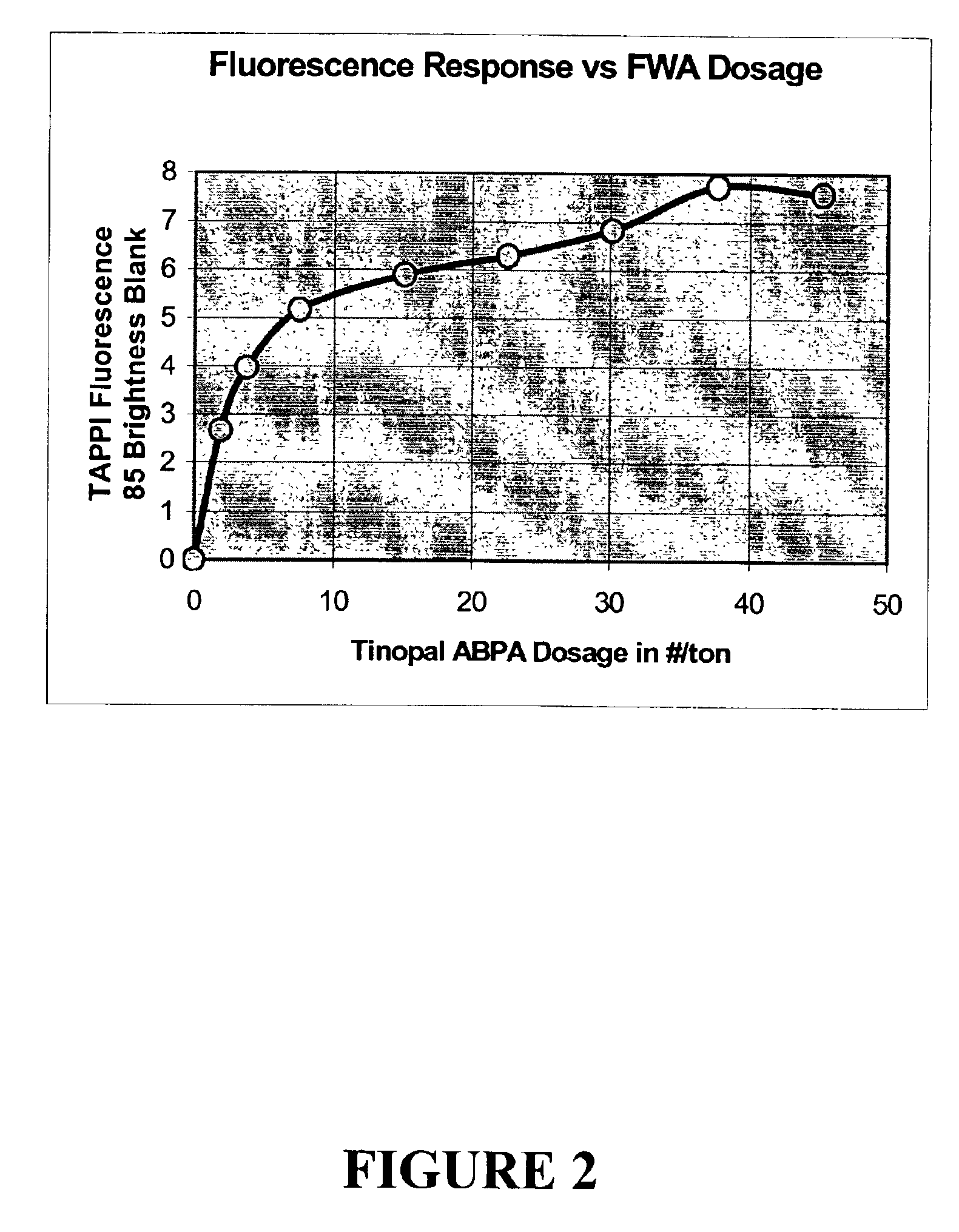

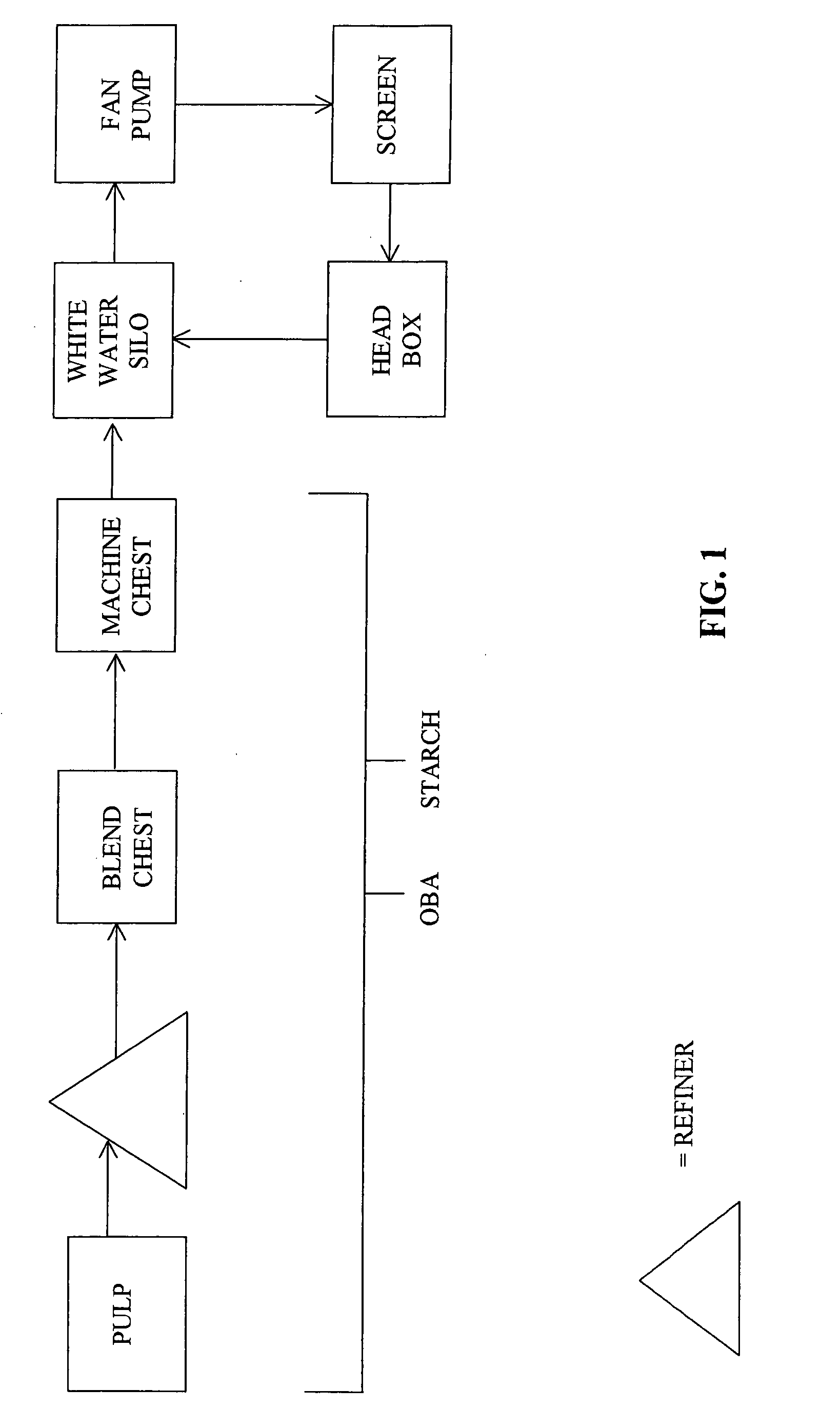

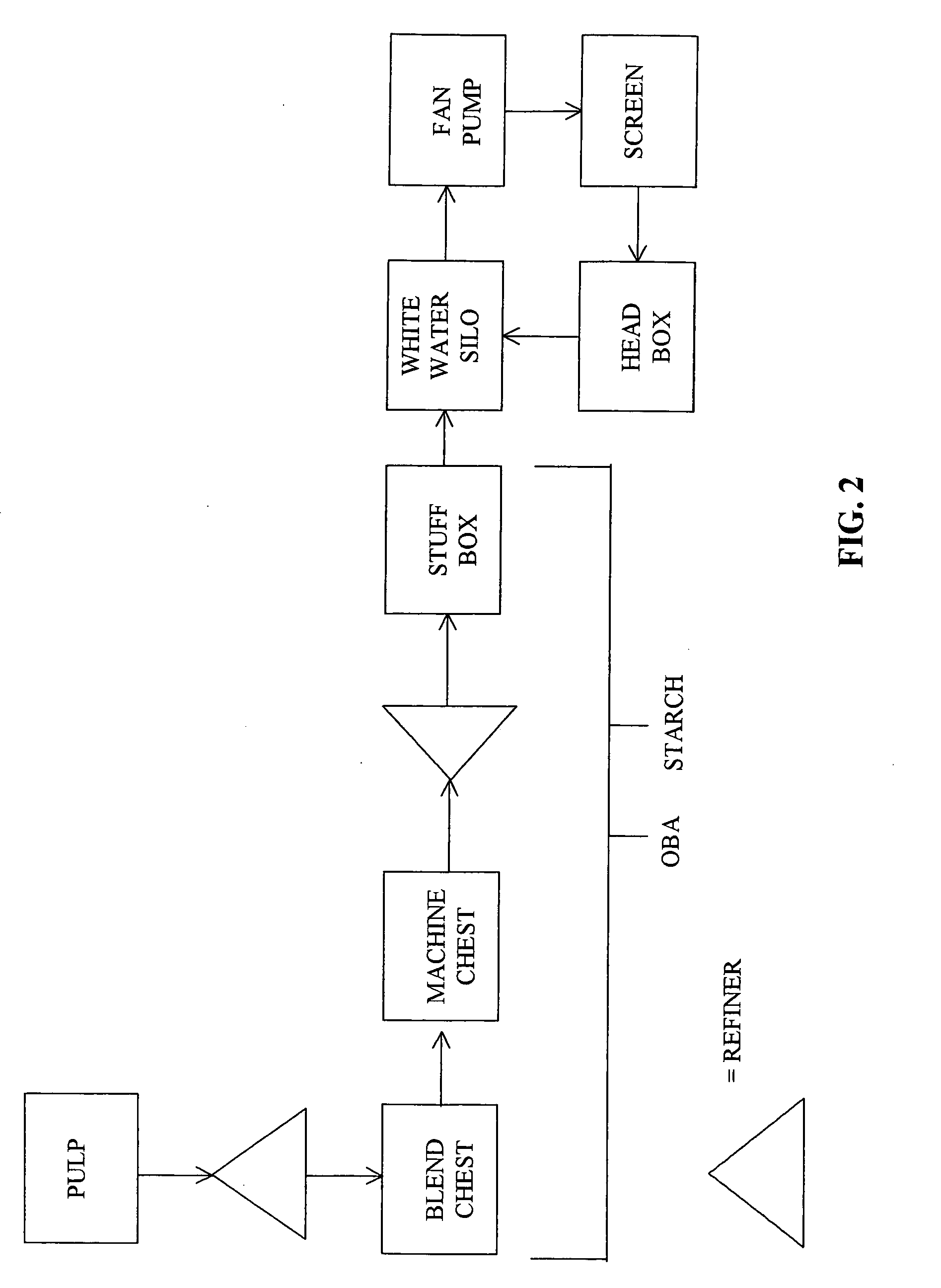

Papermaking processes using coagulants and optical brighteners

InactiveUS20070169903A1Reduce the amount requiredSatisfactory brightnessNatural cellulose pulp/paperSpecial paperPaperboardEngineering

A method of making paper or paperboard is described, which includes introducing at least one charged starch, preferably having a degree of substitution greater than 0.045, and at least one optical brightening agent to a papermaking pulp and then forming the pulp into paper or paperboard. The present invention further describes methods of improving optical brightener performance.

Owner:BUCKMAN LAB INT INC

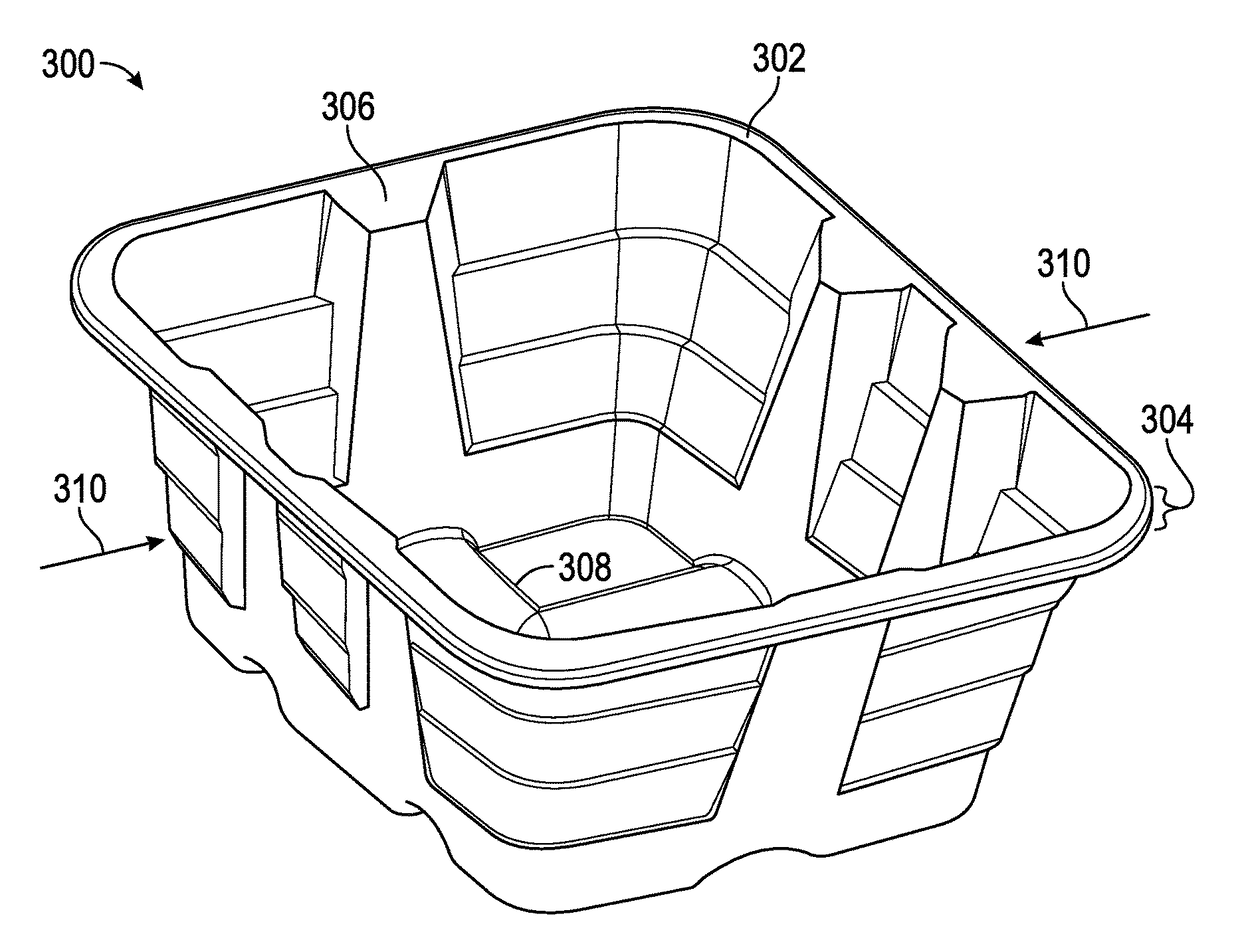

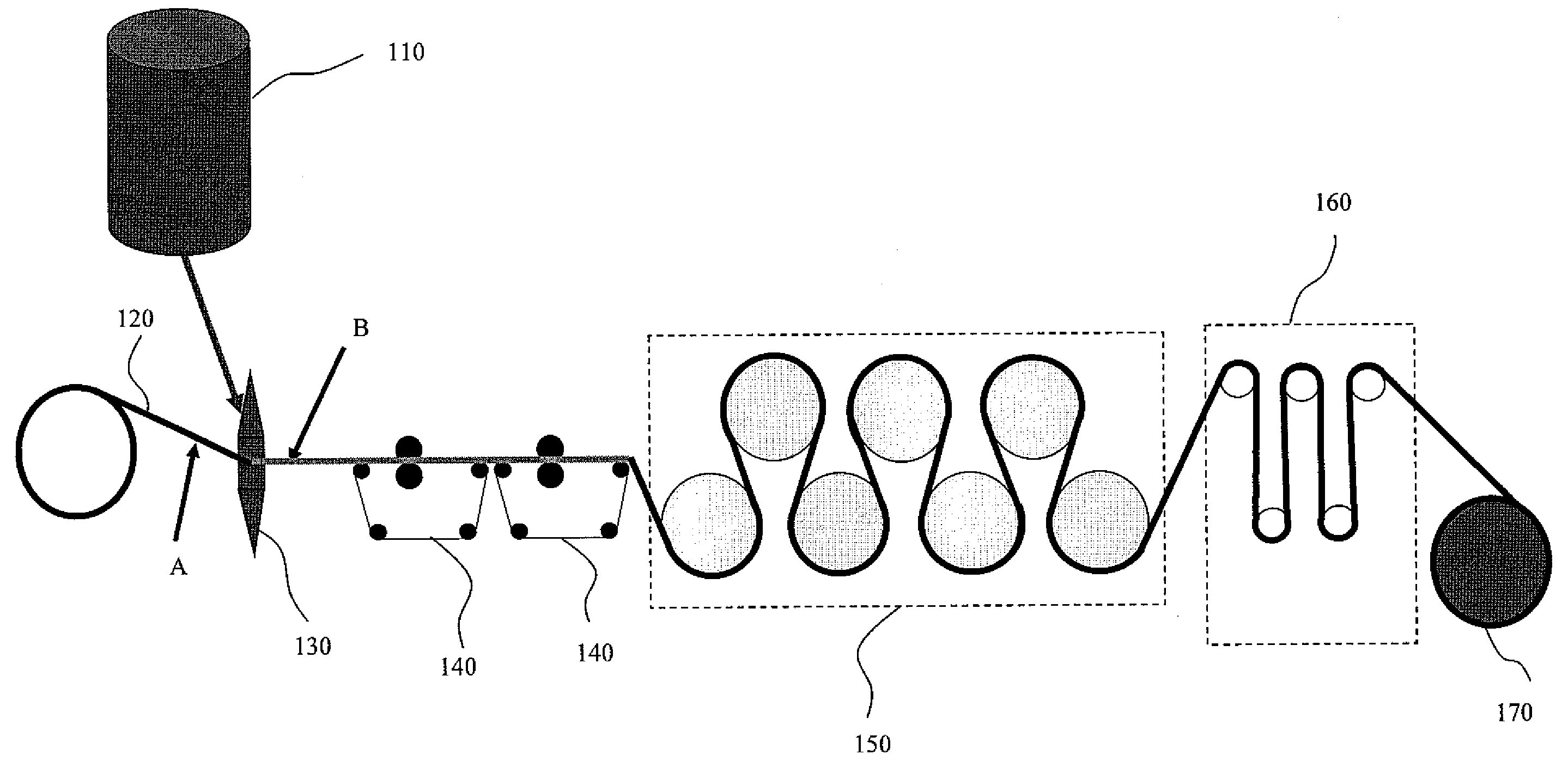

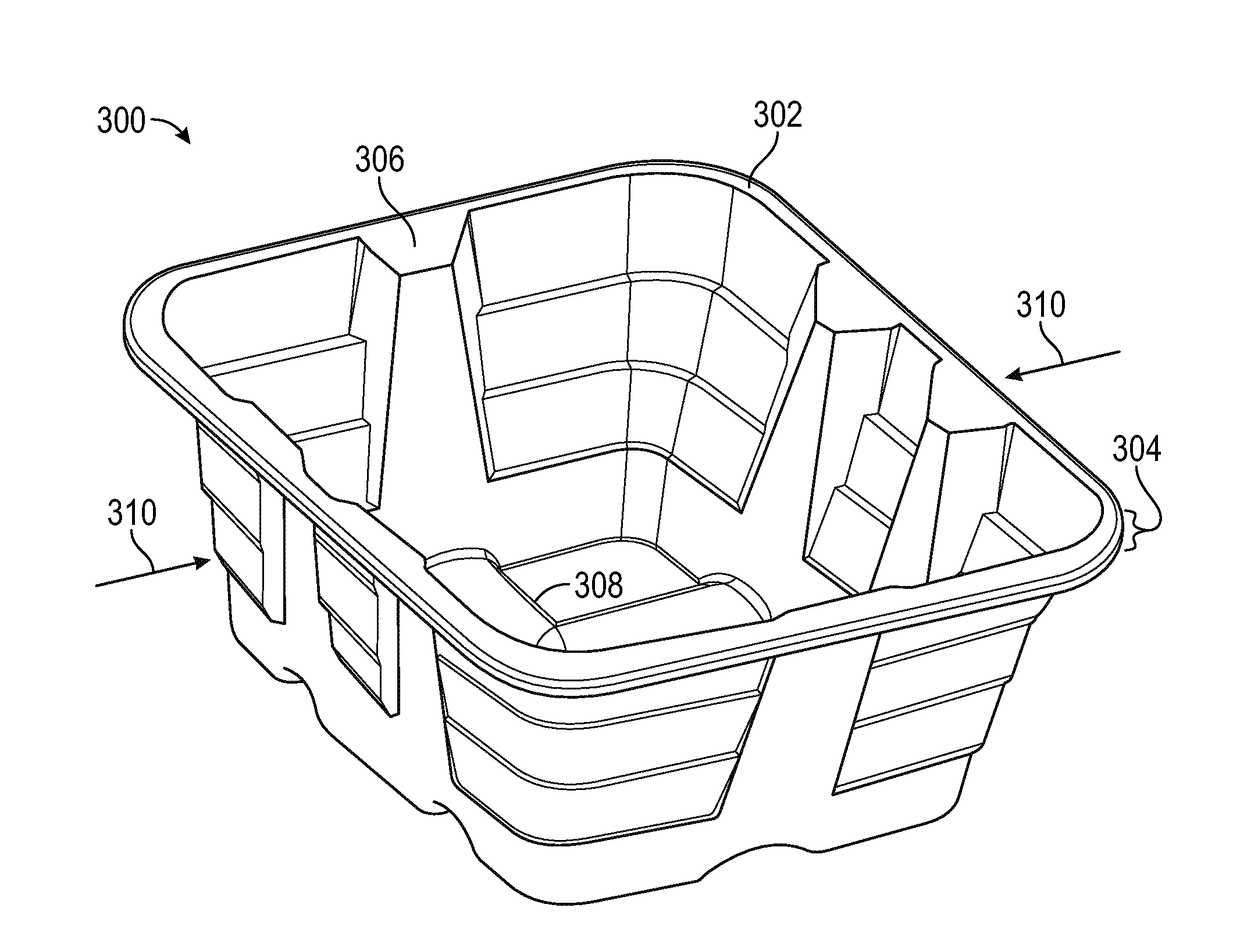

Method for manufacturing fiber-based produced containers

ActiveUS9856608B1Increase in sizeImprove structural rigidityWrappersWater-repelling agents additionFiberSlurry

Owner:FOOTPRINT INT LLC

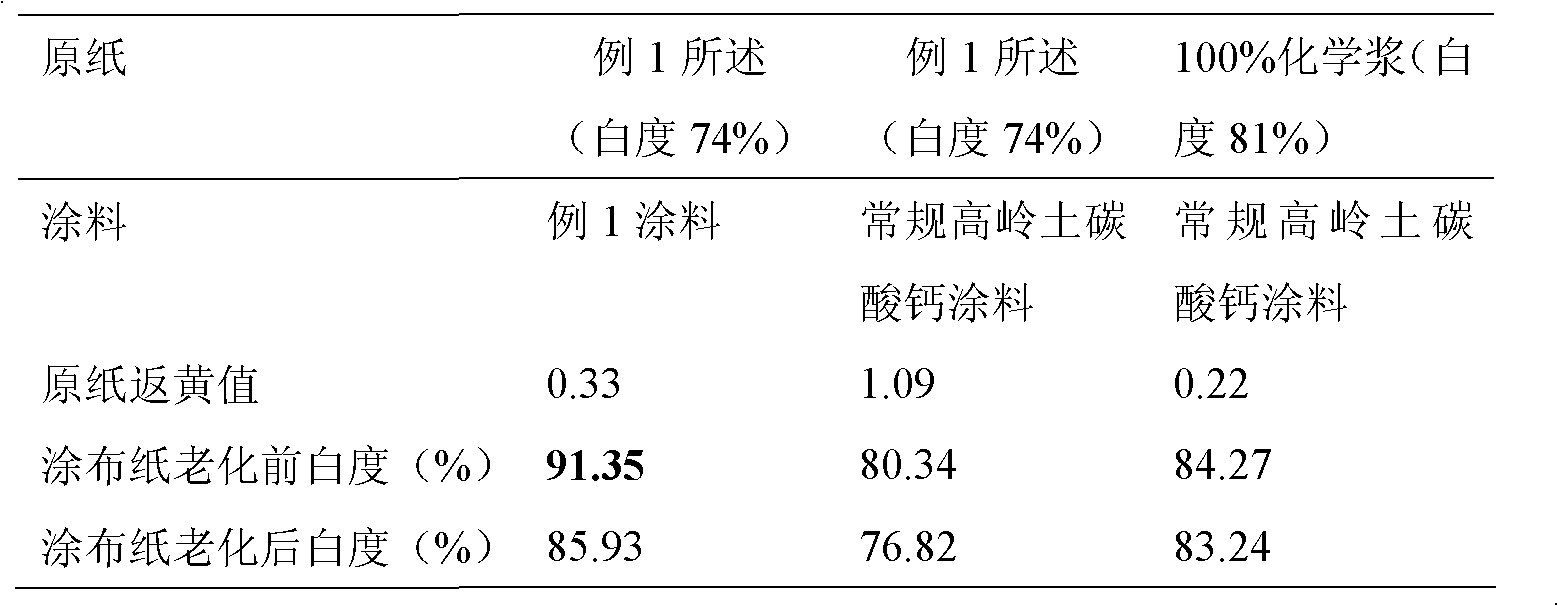

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

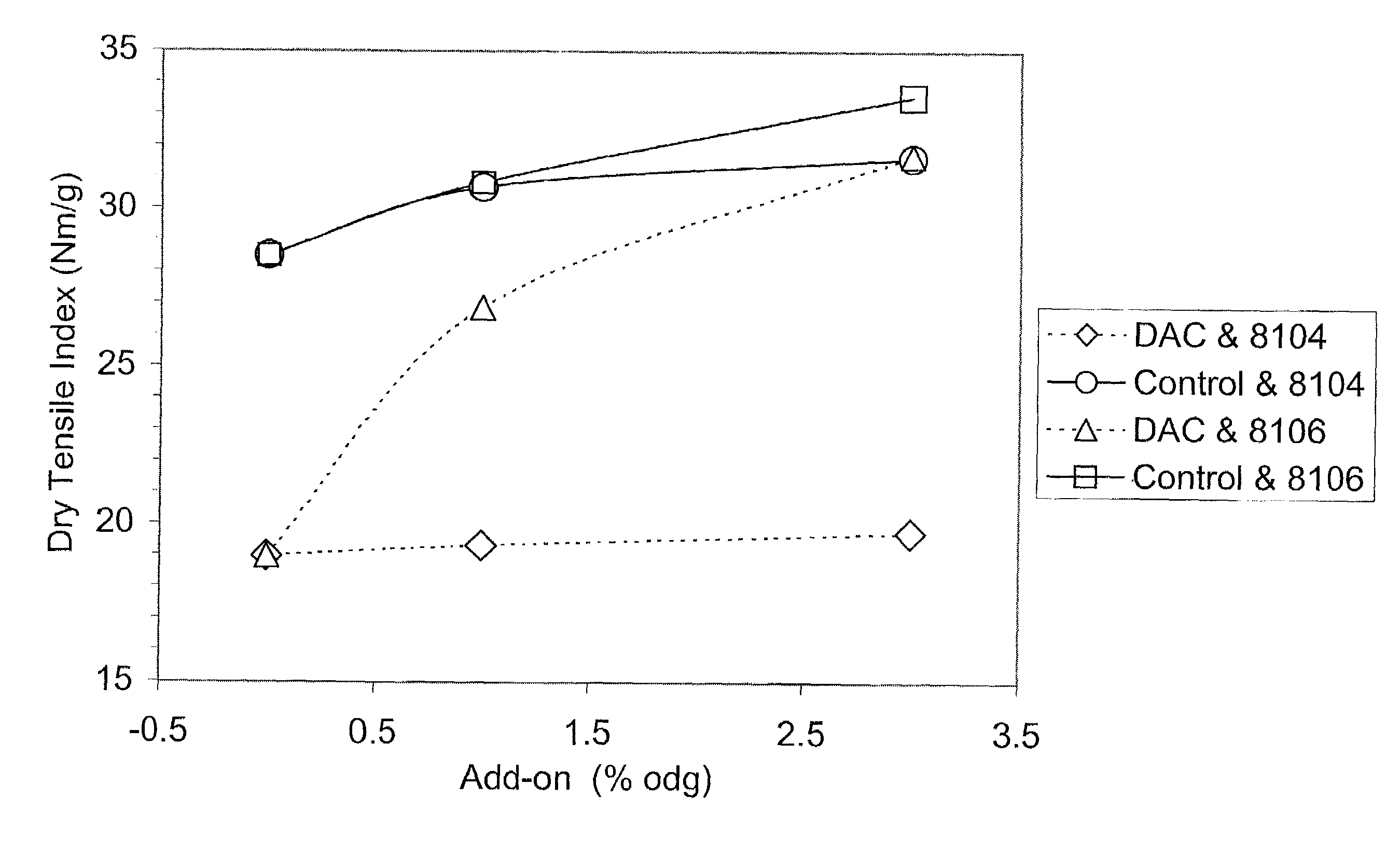

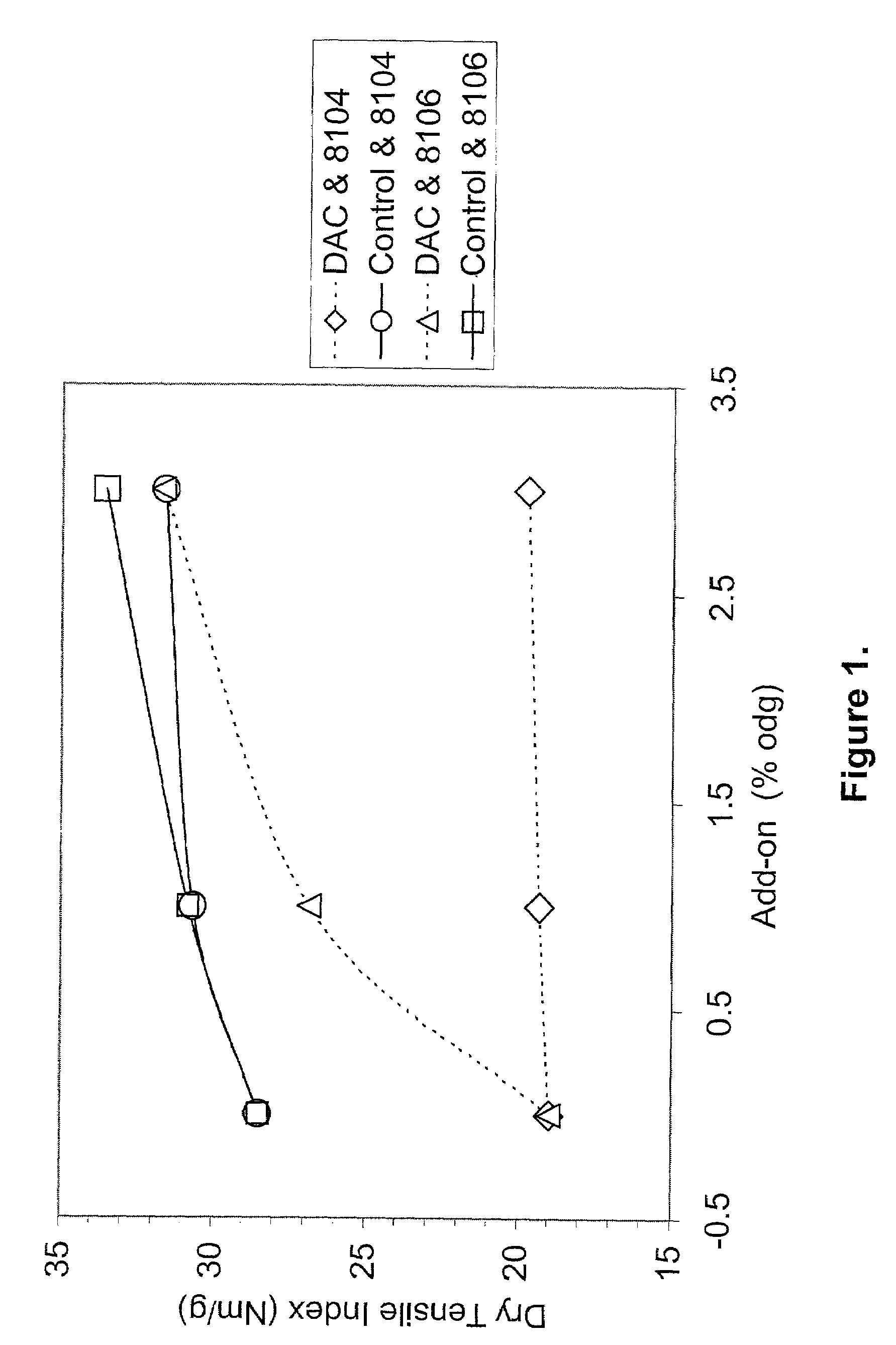

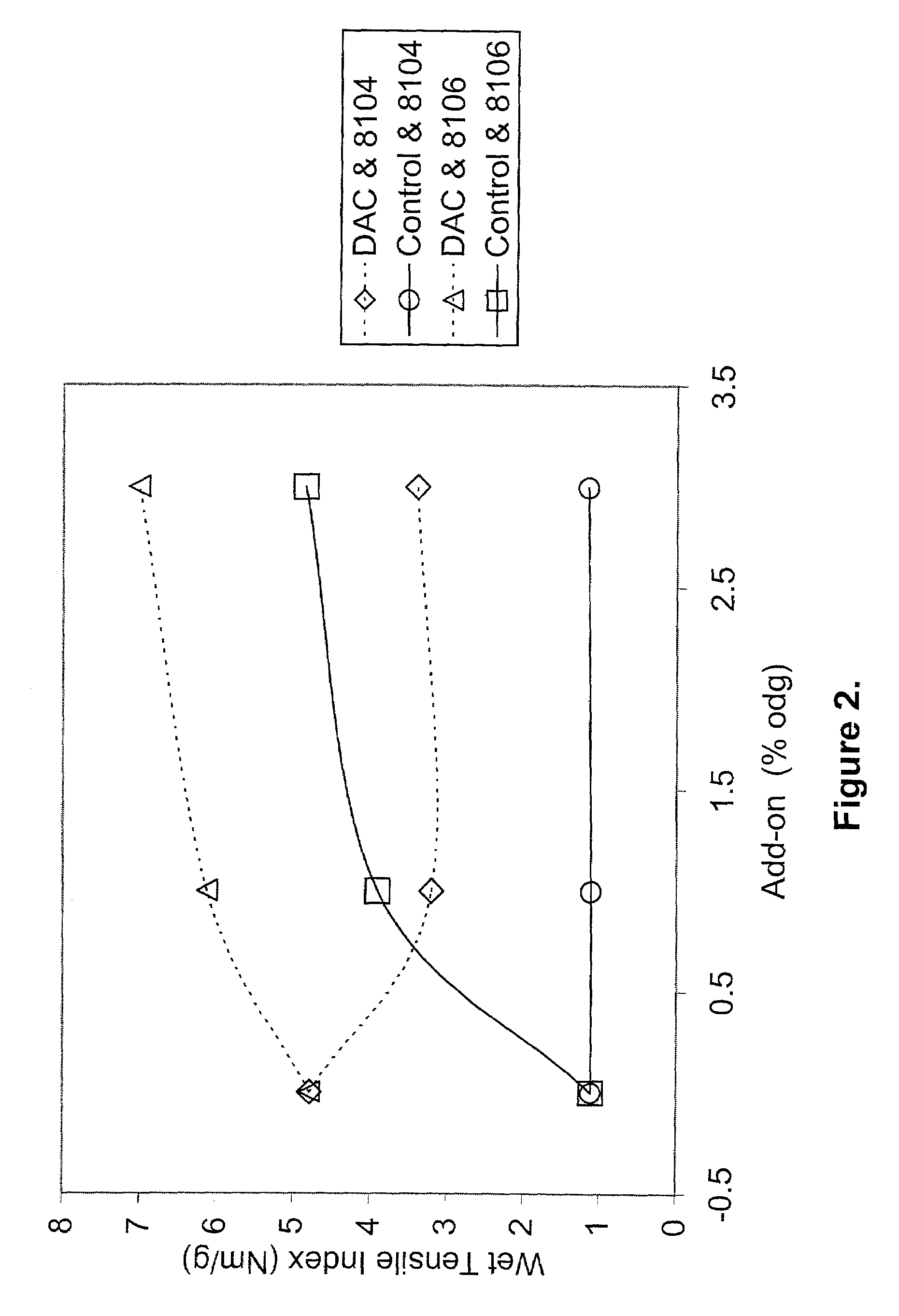

Polyvinylamine treatments to improve dyeing of cellulosic materials

InactiveUS7214633B2Improve wet strengthEasy to dyeDecorative surface effectsFibre treatmentCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Starch-chitosan compound, method for its manufacture and application

Starch-chitosan mixture (I) comprises water-soluble chitosan (0.1-50, preferably 0.5-20 wt.%), and optionally other additives such as inorganic- or organic pigments, aluminum oxide, barium sulfate, calcium carbonate, kaolin, titanium dioxide, talc, satin white, silicates and plastic pigments. An independent claim is included for the preparation of (I) comprising: mixing a water-soluble chitosan (50-99.9 wt.%) with starch (0.1-50, preferably 0.5-20 wt.%); preparing an aqueous solution of the mixture; treating the aqueous solution in a spray boiler; and drying the boiled product.

Owner:EMSLAND STARKE GMBH

Tissue product with silk fibers and method of making the same

InactiveUS20060108082A1Natural cellulose pulp/paperOrganic non-cellulose fibresMaterials scienceSilk fiber

A tissue product comprising a plurality of first fibers and a plurality of silk fibers and a method of making the tissue product wherein the silk fibers are a different color than the color of the first fibers, as assessed by the human naked eye.

Owner:THE PROCTER & GAMBLE COMPANY

Pulping process for environment-friendly kraft board paper

InactiveCN106245395ABright colorStrong water resistancePulp beating methodsPaper recyclingFiberEnvironmental resistance

The invention discloses a pulping process for environment-friendly kraft board paper. The pulping process includes the steps that 1, the United States waste paper, England waste paper and European waste paper are mixed uniformly by a certain ratio, wood pulp of a certain ratio is added into the waste paper mixed uniformly, repulping is carried out, and a certain amount of bio-enzyme is added into the repulping process; 2, high-concentration residue removal and screening are carried out on the pulp obtained in the step 1; 3, pulp obtained through screening in the step 2 enters a grading workshop section and is divided into long fiber pulp, middle fiber pulp and short fiber pulp; 4, the three kinds of pulp obtained through grading in the step 3 sequentially pass through respective medium and low concentration residue removal devices to be purified in a residue removal mode; 5, pulp can be obtained by carrying out concentration, heat dispersion and disk milling on the pulp obtained after residue removal. The environment-friendly kraft board paper which is bright in color, high in water resistance and light resistance and consistent in color is manufactured by improving the original pulping process and strictly controlling the beating degree, the temperature and the pH value of the pulp.

Owner:JIANGSU LEE & MAN PAPER MFG

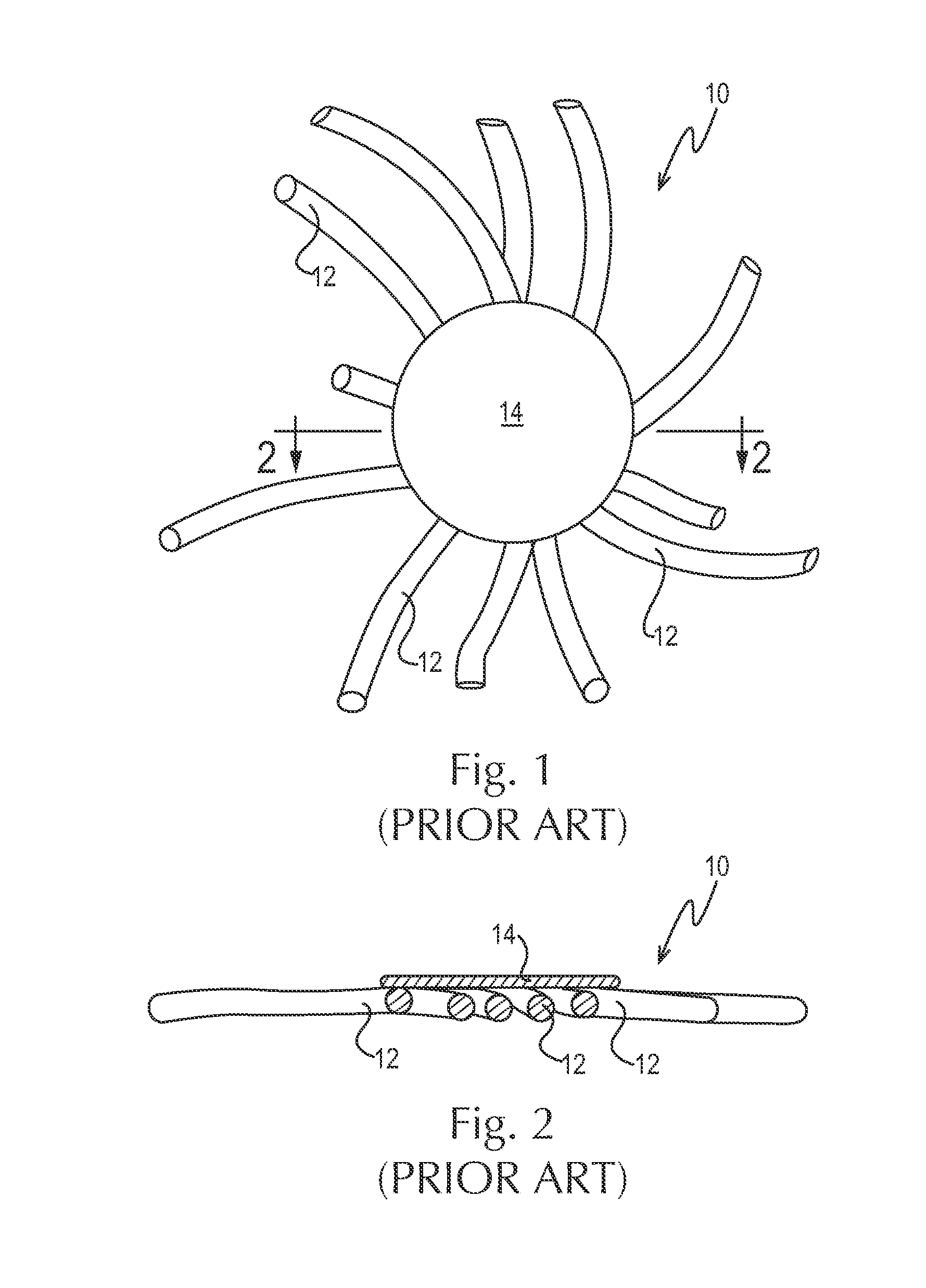

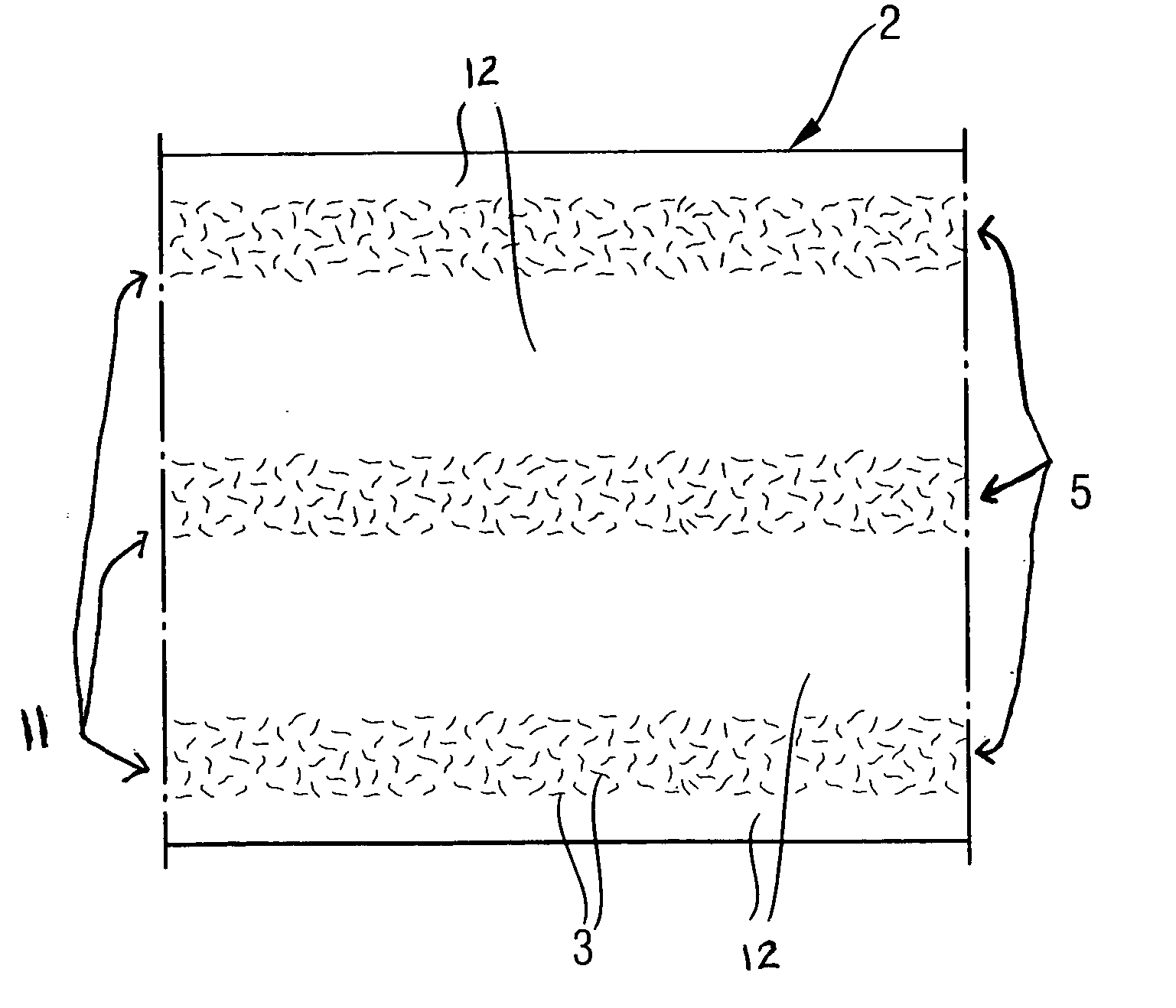

Dyed cellulose comminution sheet, dyed nonwoven material, and processes for their production

InactiveUS20100311296A1Natural cellulose pulp/paperSpecial paperCellulose fiberVolumetric Mass Density

The present invention relates to a process for the dyeing of cellulosic fibers in the form of a comminution sheet to produce a dyed cellulose pulp comminution sheet with high moisture content. The dyed cellulose comminution sheet contains (a) a cellulose pulp comminution sheet having a cellulose content of from about 60 weight percent to about 99.9 weight percent cellulose based on the total weight of solids in the cellulose pulp comminution sheet, and a density of from about 0.3 g / cm3 to about 0.95 g / cm3; (b) a moisture content of from about 25 weight percent to about 55 weight percent, based on the total weight of the dyed cellulose comminution sheet, wherein the moisture content does not exceed bleed point of the comminution sheet; and (c) a dye.

Owner:GEORGIA PACIFIC NONWOVENS LLC

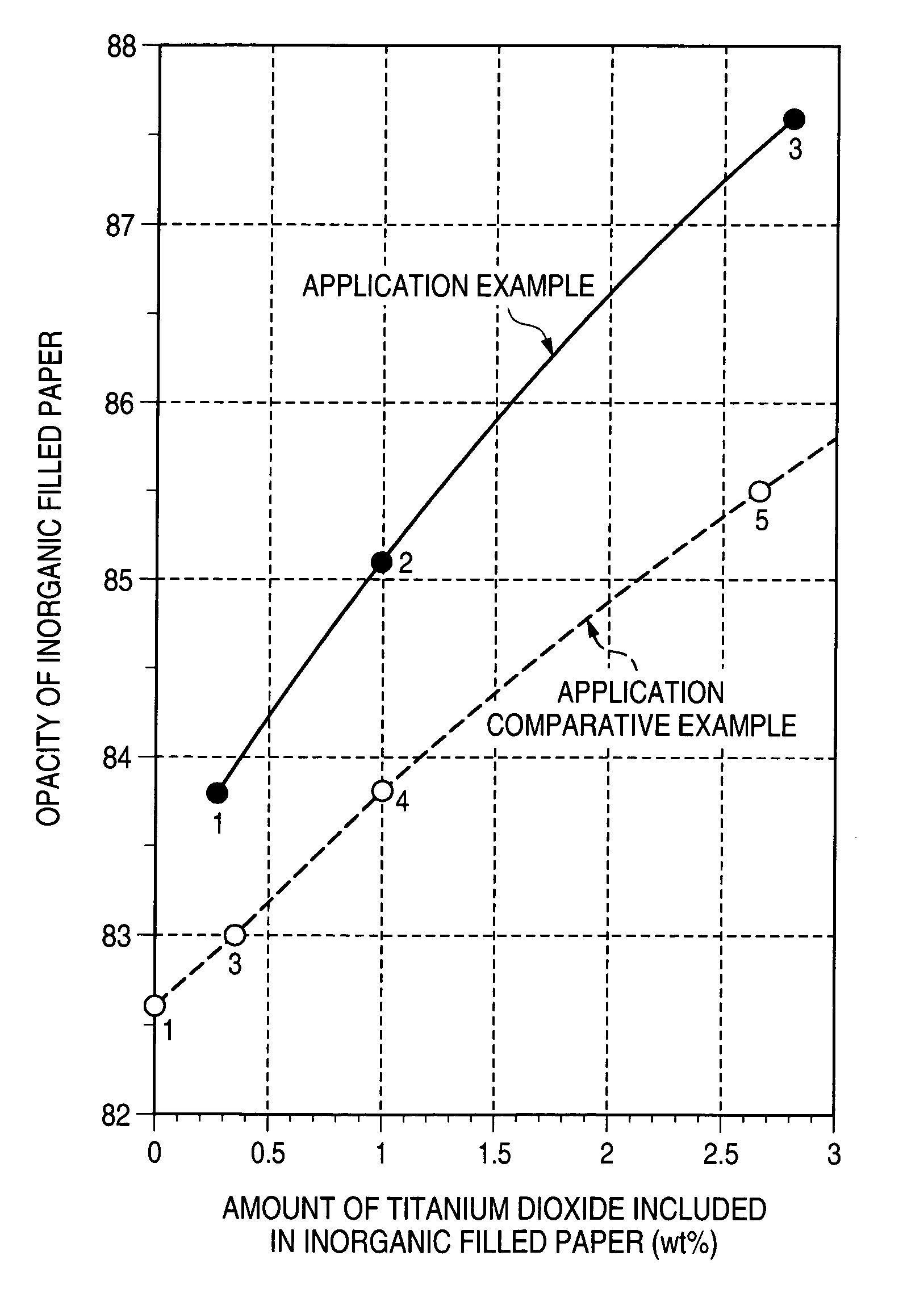

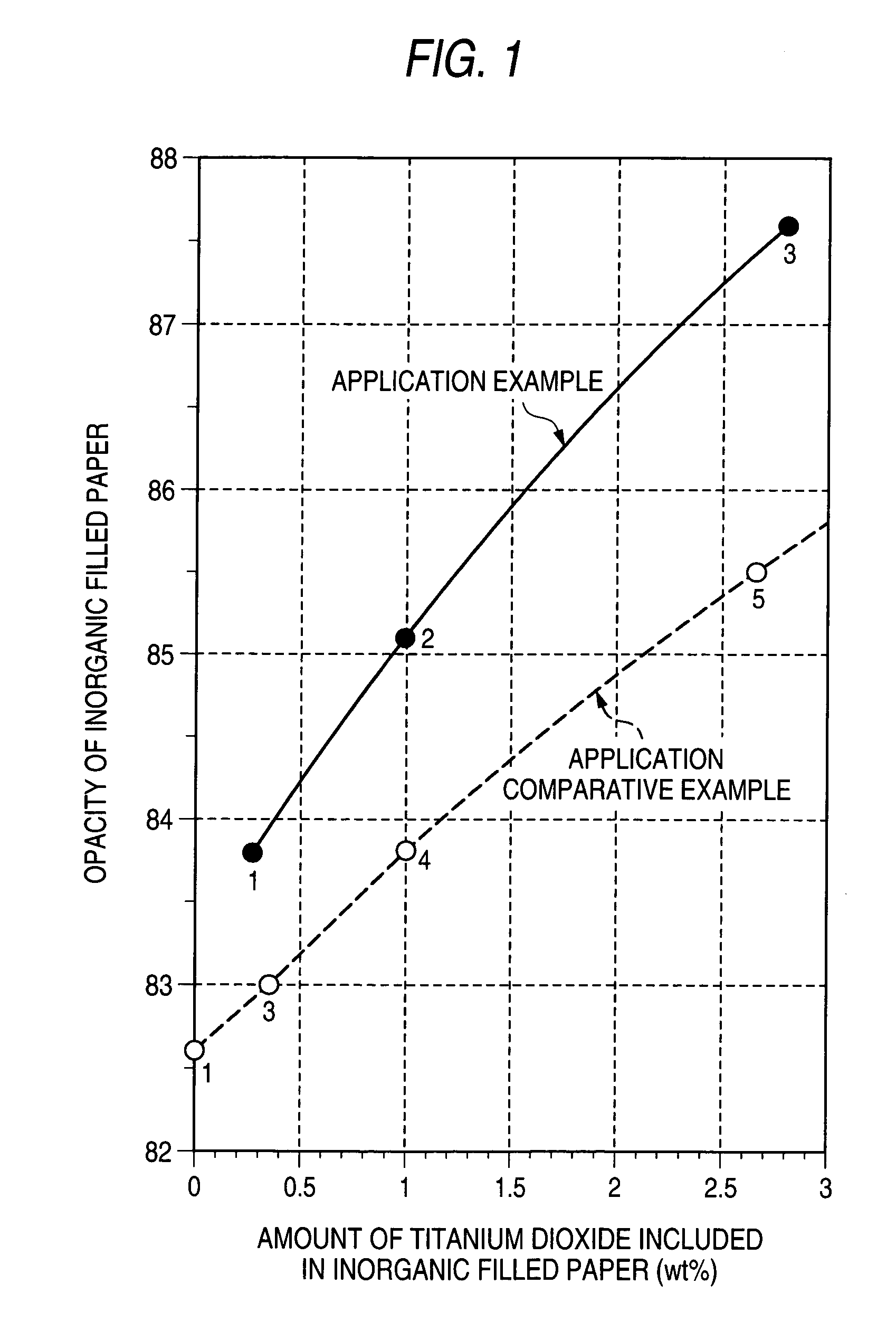

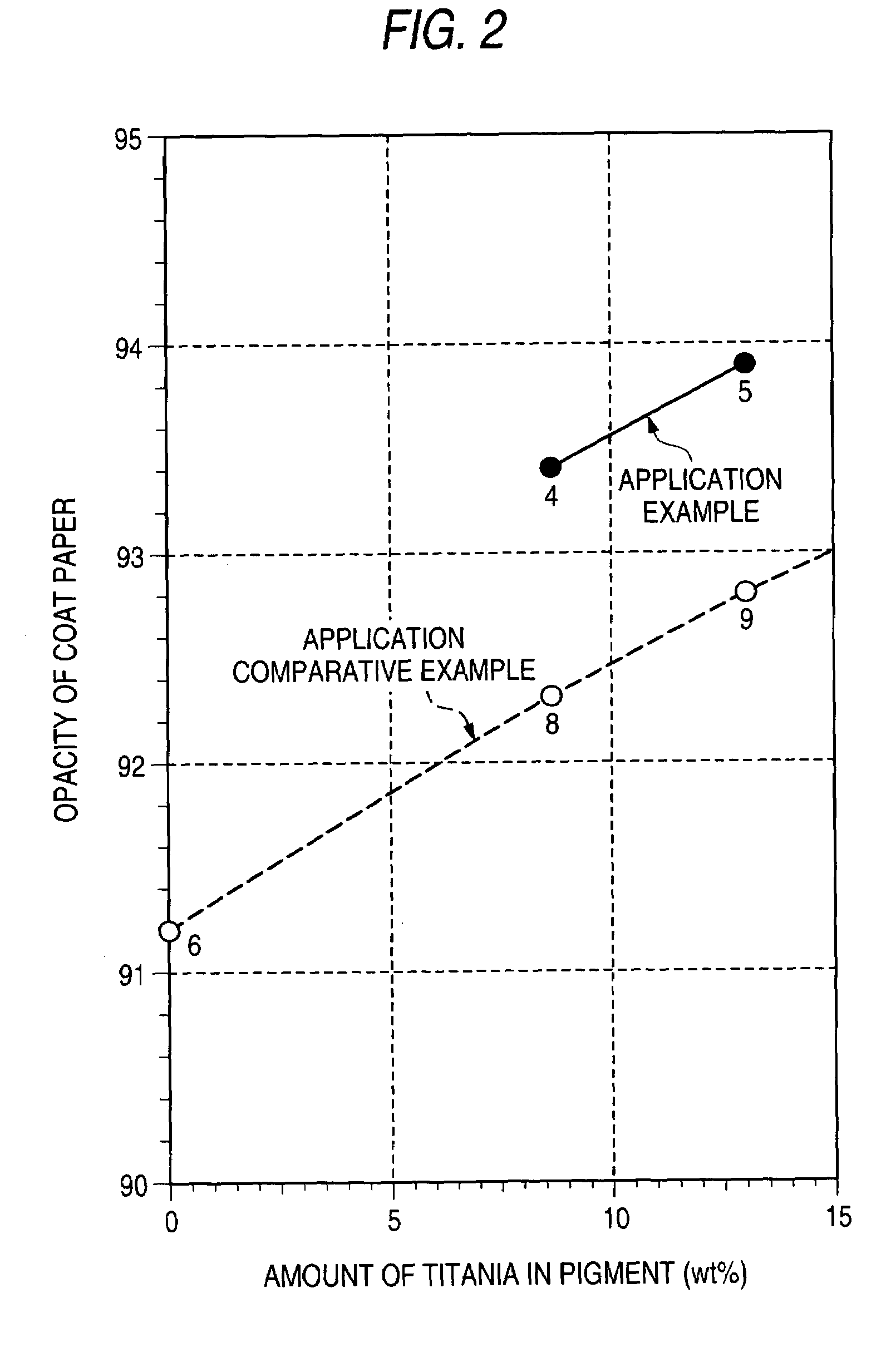

Titanium dioxide-calcium carbonate composite particles

InactiveUS6991677B2Efficient realization of opacity-enhancing effectLow yield ratioCalcium/strontium/barium carbonatesNatural cellulose pulp/paperCalcium hydroxideShell molding

Titanium dioxide-calcium carbonate composite particles capable of realizing characteristic properties inherent in titanium dioxide such as a high opacity, a process for producing the same, and a complex composition or complex incorporated with the same are provided. The composite particles were prepared by adding titanium dioxide particles having an average particle diameter of 0.1 to 0.5 μm in a carbonation step, typically a step of introducing a gaseous mixture of carbon dioxide and air into a calcium hydroxide slurry with stirring, to conduct a carbonation, and continuing the reaction till pH of the slurry becomes 7 by continuous introduction of the gaseous mixture. Moreover, by incorporating the formed composite particles, complexes such as coatings and paints for paper making or composite materials such as paper, plastic molded materials, and rubber molded materials are produced.

Owner:NITTETABU MINING CORP

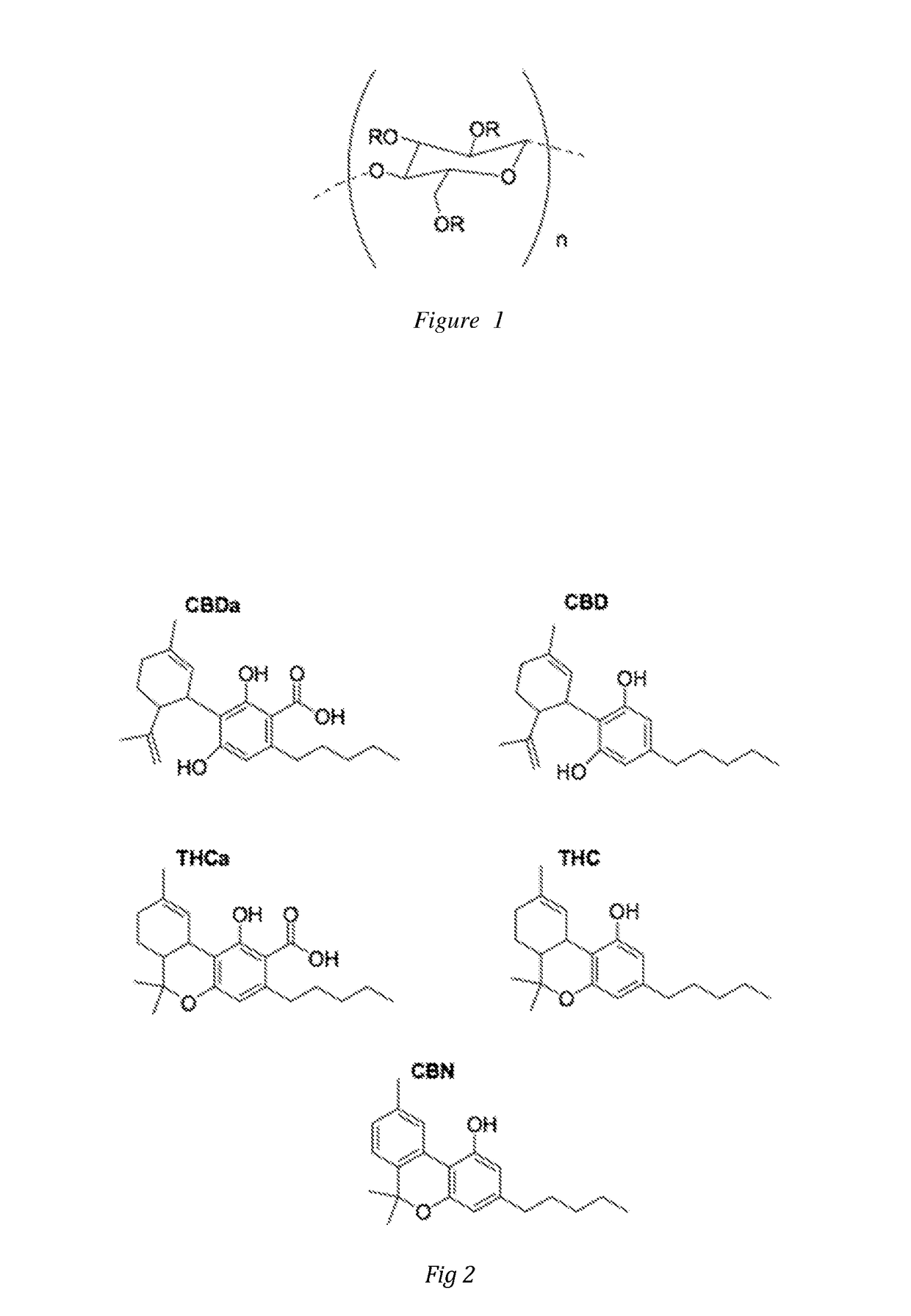

Cannabinoid Containing Cannabis Extract Infused into Rolling Paper

ActiveUS20180360103A1Good dispersionEvenly dispersedWater-repelling agents additionCigar manufactureCannabisRolling paper

A rolling paper is formed according to a modified conventional paper-making process. The end product is infused with cannabinoids from an oil extract from the cannabis plant. Since paper-making is highly water intensive and the cannabinoid containing cannabis extract is an oil that is ordinarily immiscible in the water, an emulsifier is used to allow the cannabinoids to evenly disperse in the making of the paper. The addition of the cannabinoids and the emulsifier is done prior to the drying of the paper. Preferably, the emulsifier and cannabinoids are added during the sizing step of the paper-making. Preferably the emulsifier is a starch-like carbohydrate, a modified starch, more preferably hydroxy-propyl-methyl-cellulose. The cannabinoid containing cannabis extract can be added at the pulping, web-forming step and / or preferably at the sizing step of paper-making.

Owner:DIGITAL RARITY LLC

Thickeners for paper dye compositions

InactiveUS6858255B2Readily apparentNatural cellulose pulp/paperSpecial paperEthylene HomopolymersPhotochemistry

The present invention is a thickened dye composition and method of applying same to a paper web that produces colored or patterned paper having good bleed resistance. The dye composition of the invention includes a binder; a dye; a thickener selected from the group consising of polyvinylpyrrlidone homopolymers, polyvinylpyrrolidone copolymers, and mixtures thereof; and water. The present invention also includes colored or patterned papers prepared using this conposition.

Owner:BASF CORP

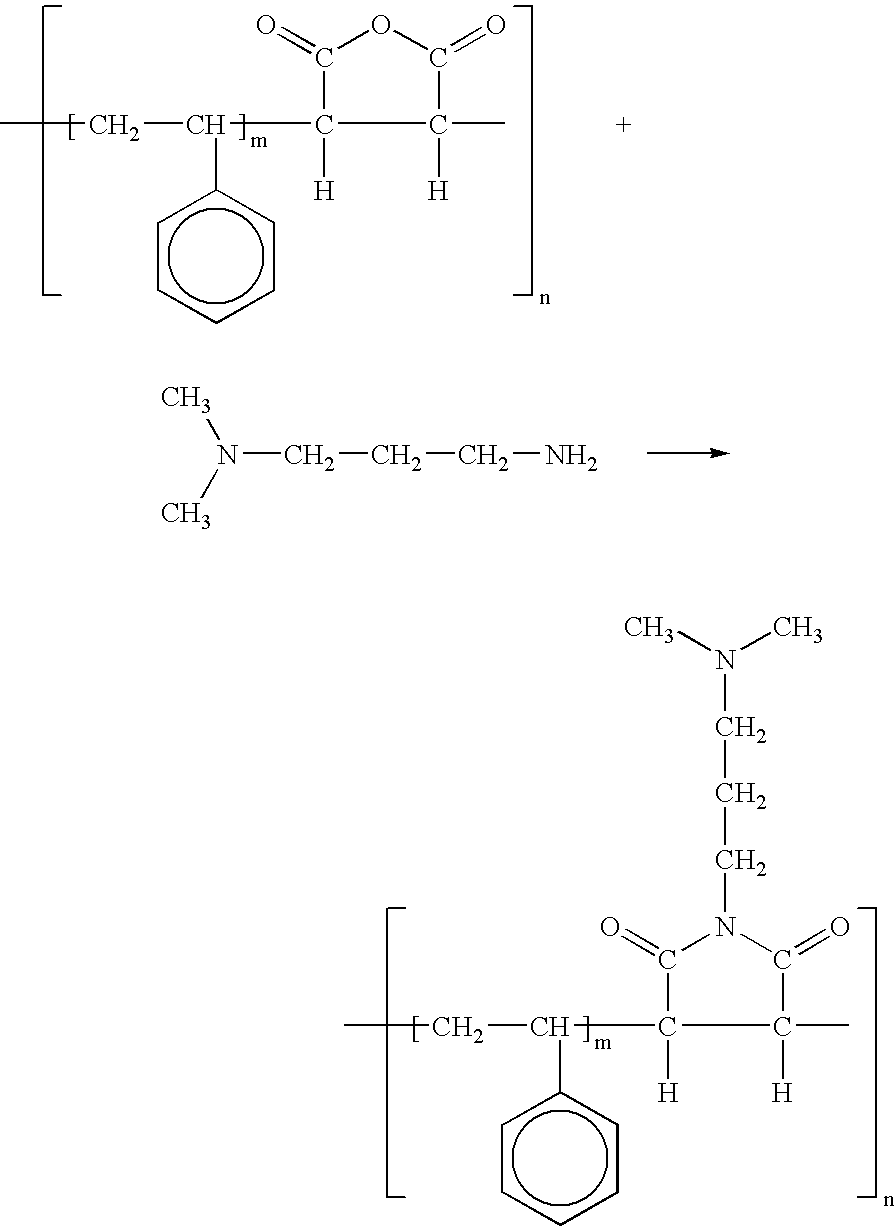

Method for coloring cellulosic materials using cationic pigment dispersion

A method of coloring a cellulosic material which includes a) dispersing pulped cellulosic material into water; and b) coloring the pulped cellulosic material by adding a cationic dispersion to the water, where the dispersion includes: (i) at least one pigment; (ii) water; and (iii) at least one quaternary salt of a styrene maleimide imide resin in an amount effective to disperse the pigment. The cationic dispersion may be prepared by (i) mixing, at 500 to 10,000 rpm, at least one pigment; water; and either (a) at least one a quaternary salt of a styrene maleimide imide resin or (b) at least one styrene maleimide imide resin in combination with at least one weak acid, thereby forming a dispersion premix; (ii) milling the dispersion premix in a mixer filled with ceramic, metal or glass beads for a period of time sufficient to reduce pigment agglomerates to primary particles, thereby forming a nonstandardized dispersion; and (iii) standardizing the dispersion against a color standard by adding water. The resulting cationic dispersion can be used to color cellulosic materials such as cotton and paper.

Owner:SUN CHEM CORP

Needle bush fiber paper yarn and preparation method for same and application

ActiveCN106222828APromote degradationImprove protectionNatural cellulose pulp/paperWater-repelling agents additionYarnFiber

The invention relates to a needle bush fiber yarn and a preparation method for the same and application. The paper yarn is mainly made of main material and auxiliary material according to weighty by parts. The main material comprises 100 parts of needle bush slurry; the auxiliary material is formed by 0.04 to 0.06 parts of softener, 0.06 to 0.08 parts of water-repellent agent and microscale of dyeing agent. The paper yarn preparation step is formed by first, preparing slurry, in which needle bush is pulped with water, second, adding auxiliary material and evenly stirring, third, making paper, in which making paper slurry into thin weaving paper with weight of 11 to 22g, fourth, slitting the paper into paper strips with 2 to 4mm width, and fifth spinning, in which twisting the elongated paper strip into 21 to 32 paper yarns. The paper yarn can be applied to paper-made socks, underwears, knitting shirts, paper towel, paper shoes and paper caps and great ventilation and water absorption can be achieved; sweat can be absorbed and bacteria can be resisted and odor can be eliminated; and the needle bush fiber paper yarn can be recovered, thereby causing no pollution to the environment.

Owner:太仓兴鑫纸业有限公司

Nano color paste dispersant for paper as well as preparation method and application of nano color paste dispersant

ActiveCN107200807AGood dispersionEasy to fix colorPaper/cardboardColorants/pigments additionHydrophilic monomerFiber

The invention discloses a nano color paste dispersant for paper as well as a preparation method and application of the nano color paste dispersant. The nano color paste dispersant for the paper is prepared by the following steps: uniformly mixing water and an emulsifier; then, regulating a pH (Potential of Hydrogen) value to be 8 to 9 to obtain emulsified liquid; then adding a hydrophobic monomer and a hydrophilic monomer and emulsifying to form a uniform state; after raising the temperature, adding an initiator water solution and reacting; then adding a stabilizer to obtain a dispersant. The dispersant disclosed by the invention has a good dispersion effect, and color powder is easy to disperse, so that the color powder is more stable; the color of color paste containing the dispersant is easy to fix, and the color paste is easily combined with fibers in a papermaking process and is firmly attached. The color paper obtained by the color paste provided by the invention has extremely strong anti-sunlight fastness reaching grade 6, and the color is bright and lasting.

Owner:FENGKAI JIACHENG PAPER CO LTD

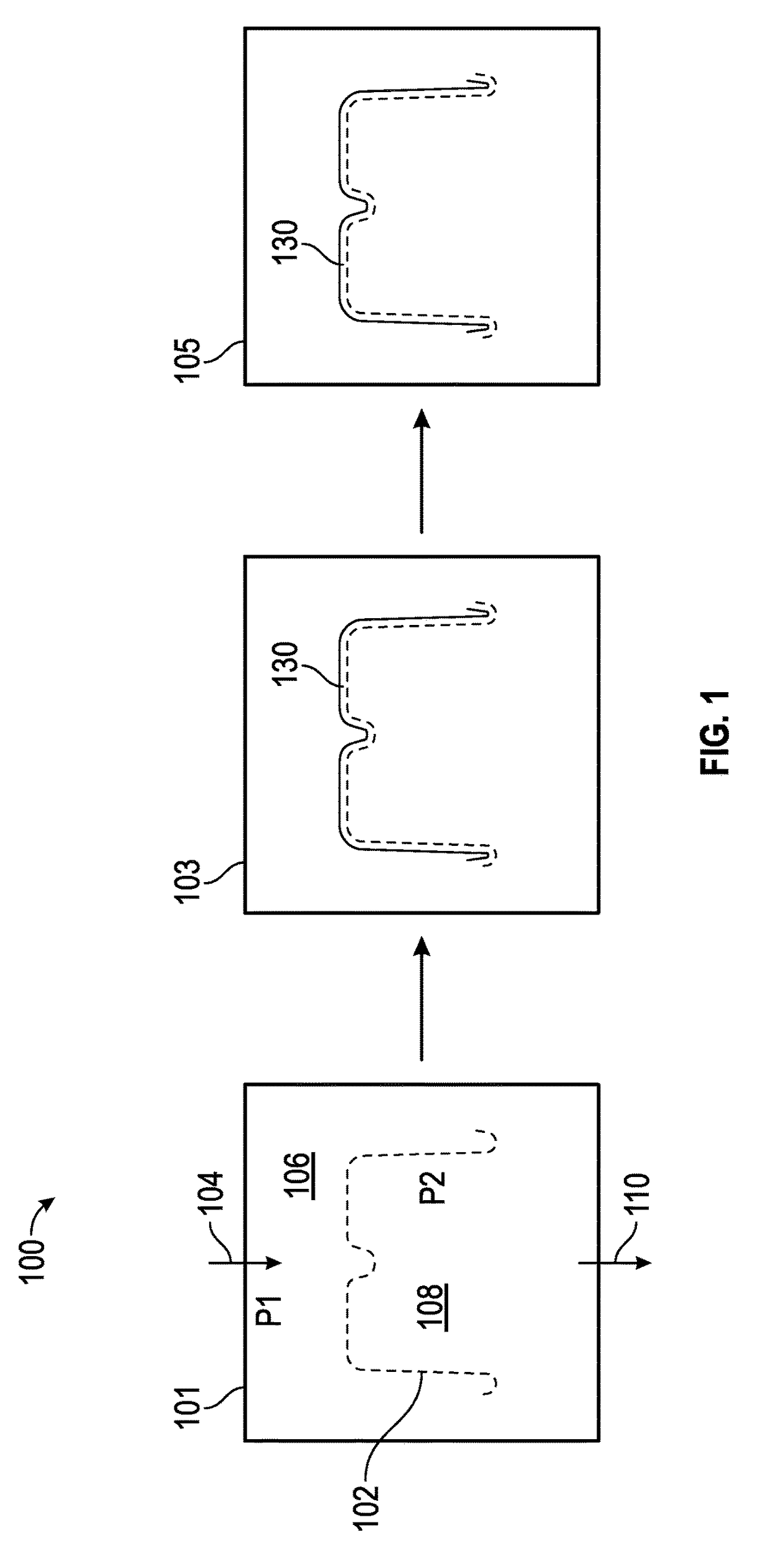

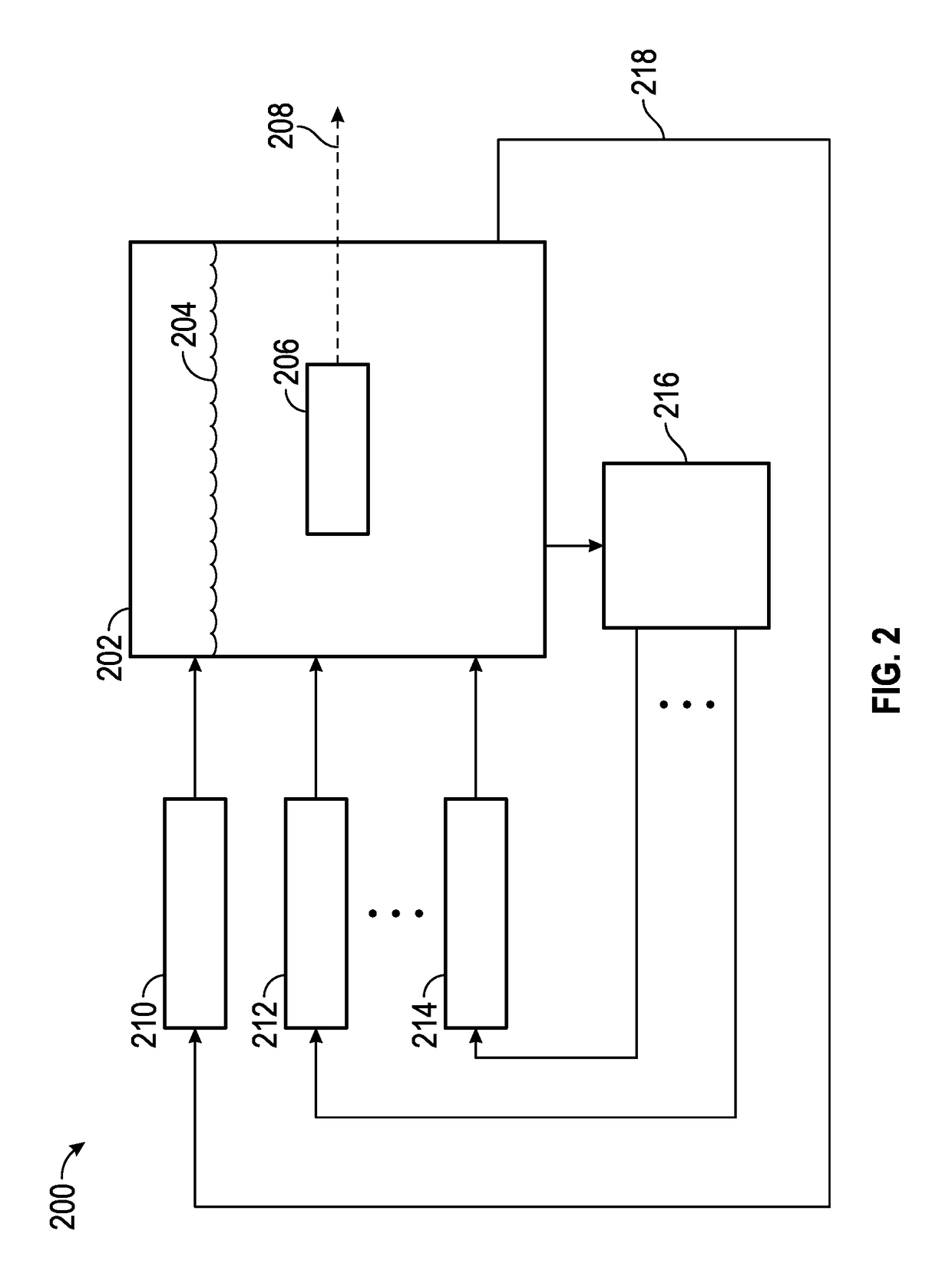

Methods and Apparatus For Manufacturing Fiber-Based Produce Containers

InactiveUS20180030658A1Increase in sizeImprove structural rigidityWrappersWater-repelling agents additionFiberSlurry

Owner:FOOTPRINT INT LLC

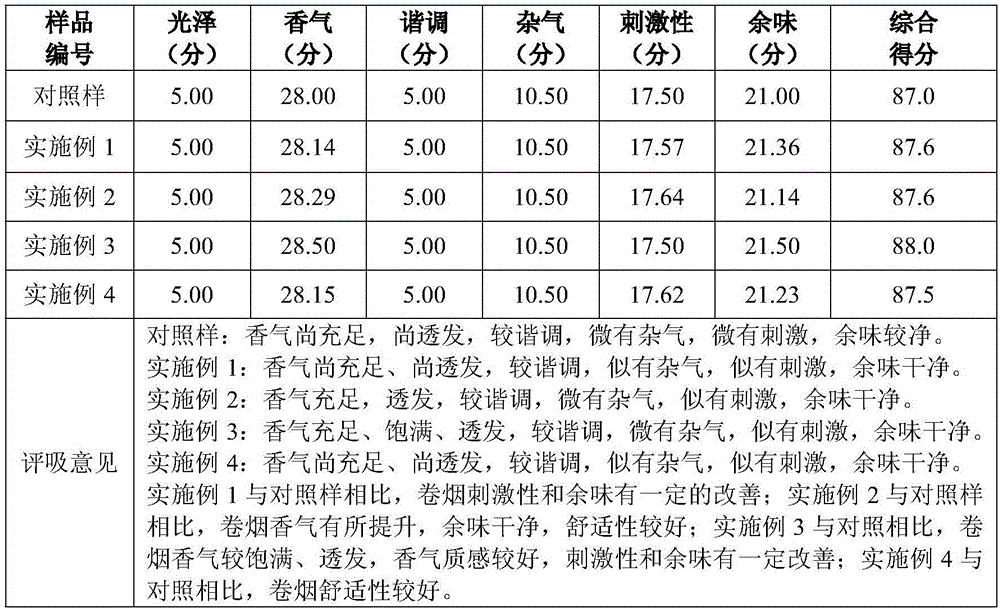

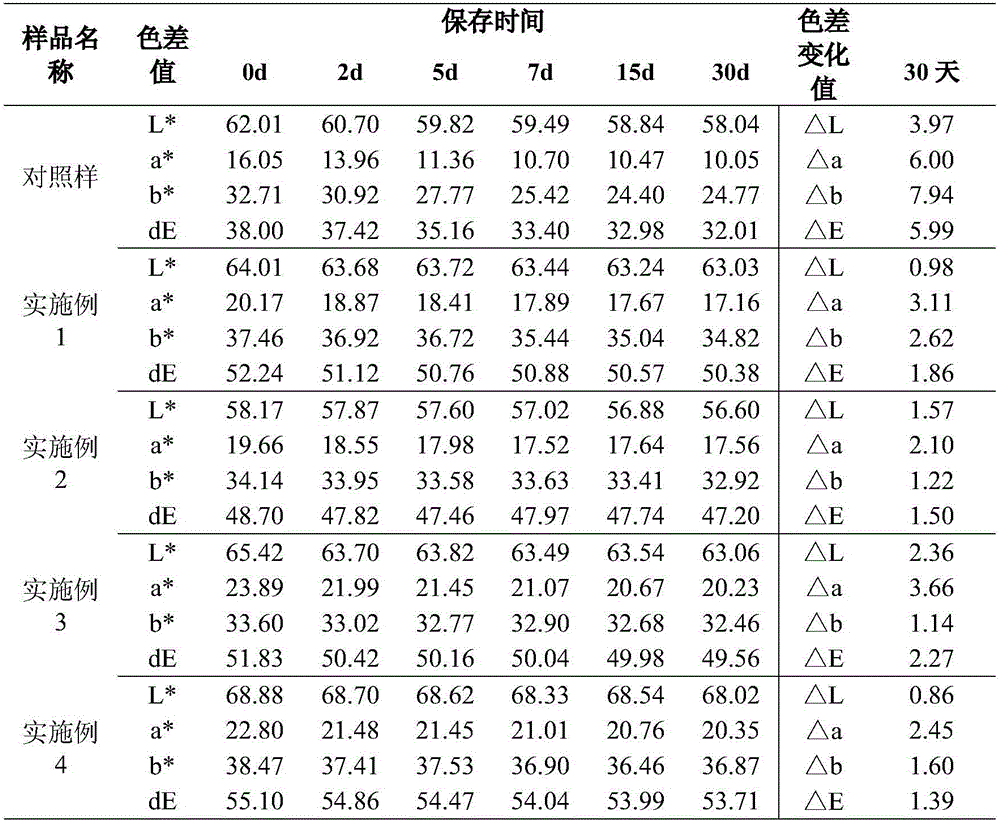

Cigarette paper containing astaxanthin

ActiveCN105755892AImprove securityImprove antioxidant capacityCigar manufactureNon-macromolecular organic additionFiberAstaxanthin

A cigarette paper containing astaxanthin comprises, by weight, 50-70 parts of fiber, 25-40 parts of a calcium carbonate filler, 0.5-8 parts of a combustion improver, 1-5 parts of astaxanthin, 0.5-8 parts of a tobacco extract, 0.1-5 parts of a natural pigment, 2-10 parts of ethanol and the balance of water. A method is as below: evenly mixing fiber and calcium carbonate filler in a slurry pond to obtain a papermaking slurry; dissolving the combustion improver in water to prepare a combustion improver solution; dissolving astaxanthin in ethanol solution and adding water for dilution; adding the tobacco extract and natural pigment, and stirring evenly to prepare a dye solution; then adding the dye solution into the combustion improver solution, and stirring uniformly to obtain a mixed solution; producing the papermaking slurry into a cigarette paper base; and adding the mixed solution onto the cigarette paper base in a sizing segment. The invention confers a unique appearance to the cigarette paper, enriches and harmonizes the incense of cigarettes, and enhances the cigarette smoking quality and safety.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

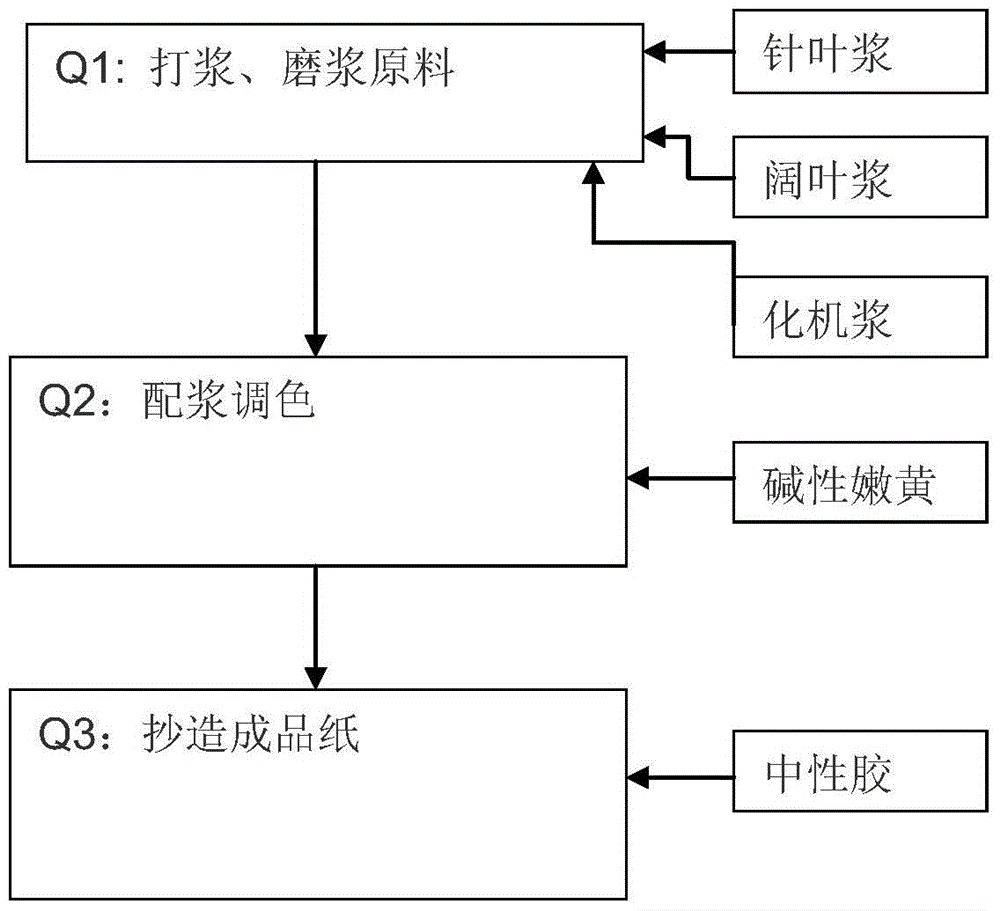

Production method of high-bulk myopia-prevention paper

InactiveCN107447587AIncrease bulkHigh opacitySpecial paperWater-repelling agents additionPulp treatmentPaper production

The invention relates to the technical field of paper production, in particular to a production method of high-bulk myopia-prevention paper. The method comprises the following steps of S1, pulp treatment: respectively treating bleaching needlebush pulp, bleaching chemical reed pulp and poplar chemithermomechanical pulp through a double-disc mill so that the process requirements are met, wherein the bulk of the poplar chemithermomechanical pulp is greater than 3.5cm<3> / g; S2, dyeing: feeding the treated pulp into a pulp mixing pool; firstly, adding the poplar chemithermomechanical pulp; then, adding dyeing agents for direct yellowing; then, adding chemical reed pulp; finally adding needlebush pulp; uniformly mixing all pulp through stirring; S3, paper making by a paper making machine; S4 paper forming through dewatering and drying. The production method of the high-bulk myopia-prevention exercise book paper provided by the invention has the advantages that the paper obtained through production has high bulk; the color of the paper is maize-yellow, the nontransparency is high; the two-side printing and writing can be performed; the paper is used as the paper for exercise books for primary and secondary school students; the obvious myopia-prevention effect can be achieved.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

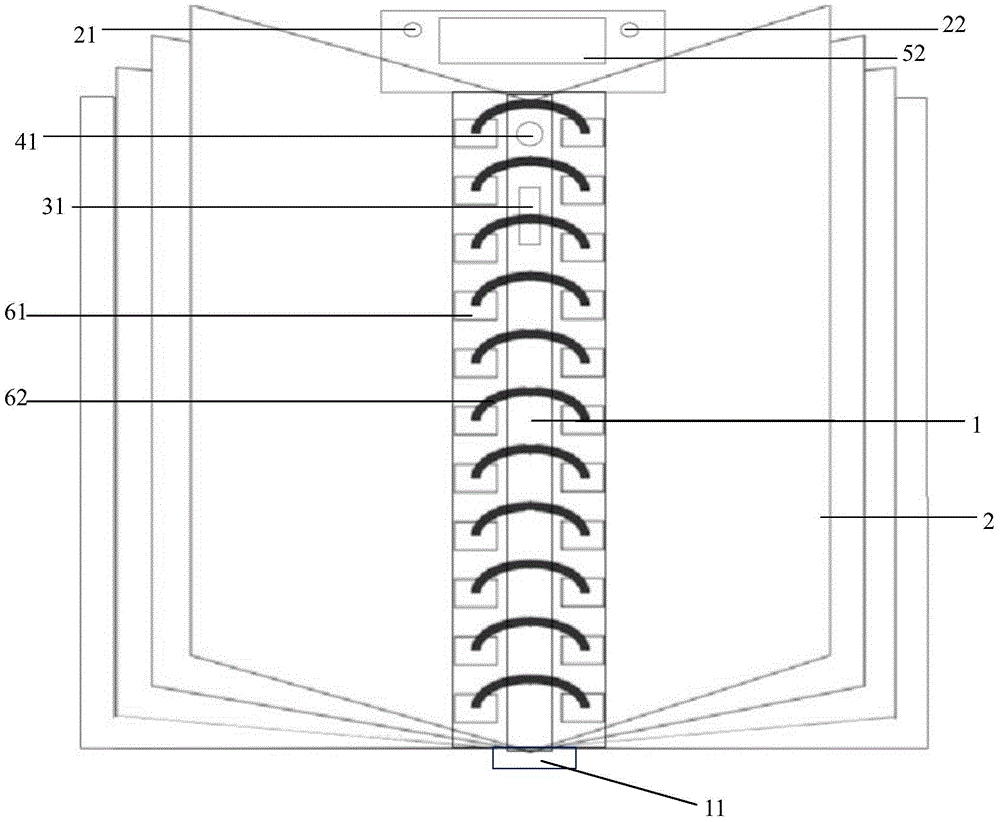

Novel exercise book capable of preventing myopia

InactiveCN105714595AImprove smoothnessFine paperBook keepingPaper/cardboardEconomic benefitsEngineering

The invention discloses a novel exercise book capable of preventing myopia. The novel exercise book comprises a book rod and paper. The novel exercise book has the advantages that the apparent brightness of the paper is 51-59% and the paper can reflect colored light with the wavelength of 500-550 nanometers and absorb blue and purple light harmful to the eyes, so that sufficient contrast is formed between the brightness of the paper and the chroma of images printed on the paper, an optimal visual environment is formed, and myopia can be prevented when the exercise book is used for studying and doing exercises; a display lamp flickers red light when a sensor senses excessive closeness; the novel exercise book is simple in structure, easy to operate, low in cost, promising in application prospect, capable of saving manpower and material resources and increasing economic benefits, and the like.

Owner:LUOYANG DEXIN PRINTING CO LTD

Mechanical-pulp-resistant thermo-sensitive paper

InactiveCN106120430ASolve the problem of poor thermal printingImprove stabilityDefoamers additionSpecial paperHigh humidityPulp and paper industry

The invention discloses mechanical-pulp-resistant thermo-sensitive paper. The mechanical-pulp-resistant thermo-sensitive paper is composed of a body paper layer, a base coating and a face coating. The body paper layer is body paper containing a mechanical pulp component. The body paper layer is sequentially coated with the base coating and the face coating. The mechanical-pulp-resistant thermo-sensitive paper solves the problems that body paper of traditional thermo-sensitive paper is thermo-sensitive paper containing mechanical pulp, and after the thermo-sensitive paper is stored for a long time under the high-temperature and high-humidity condition, thermo-sensitive printing is bad.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

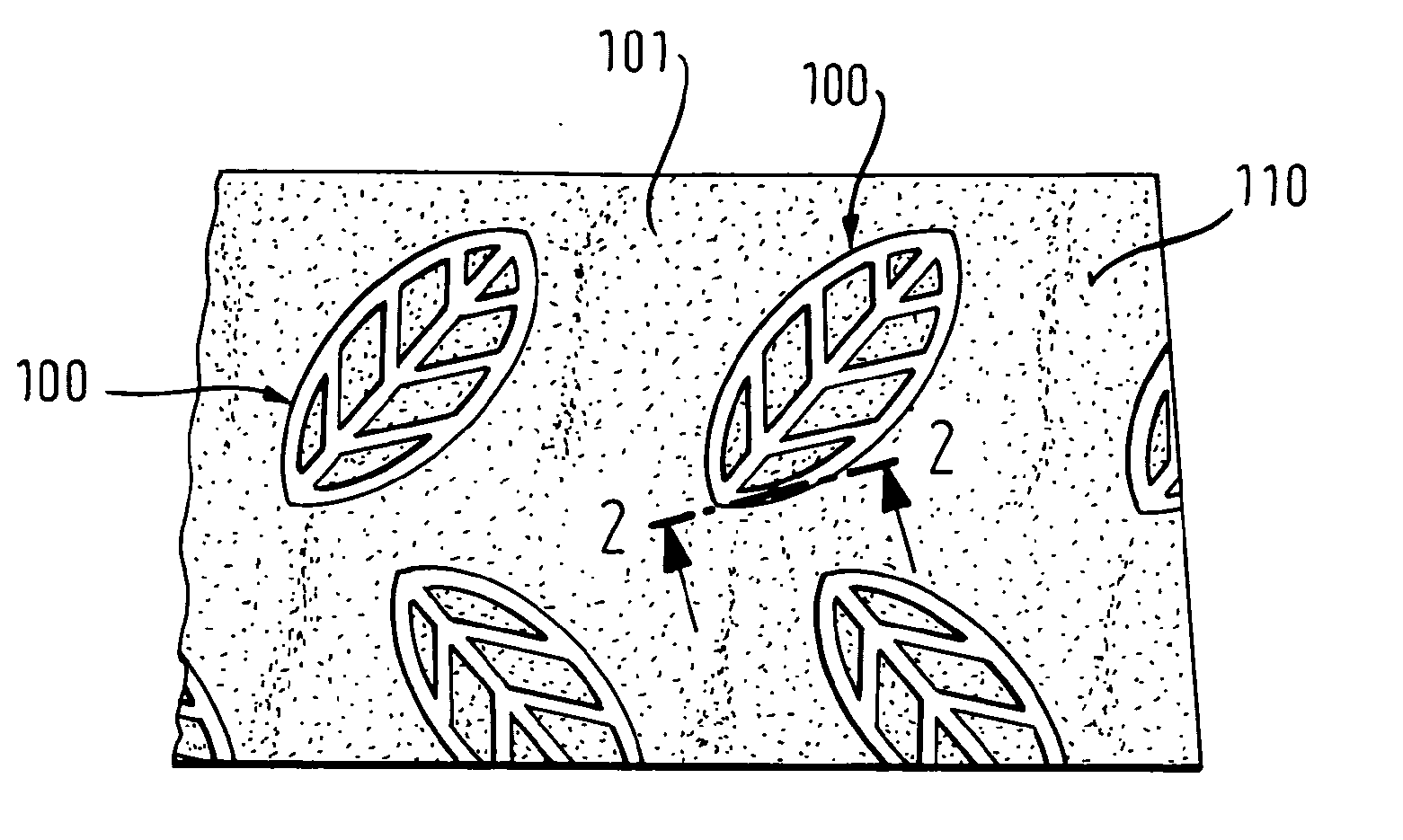

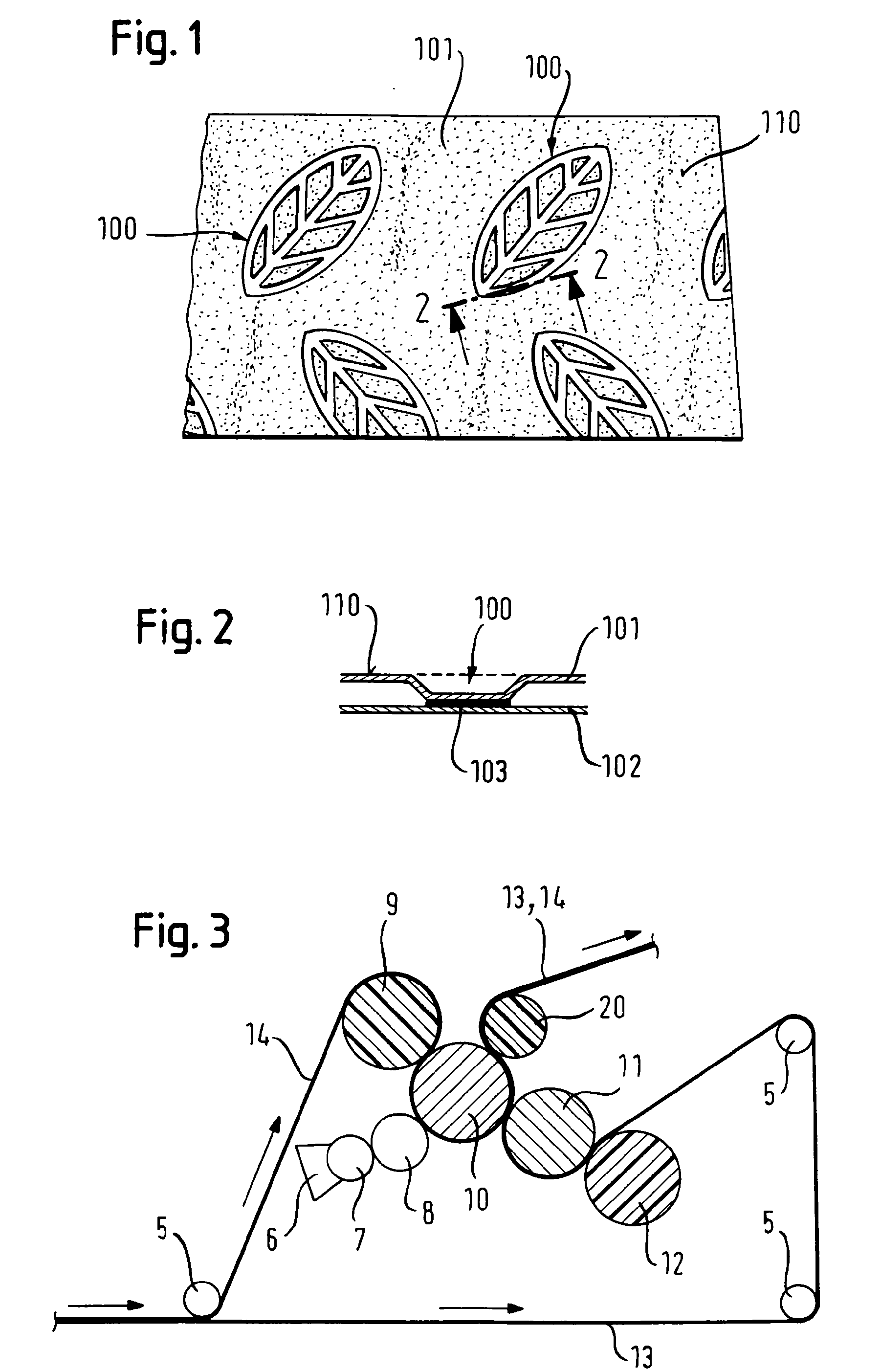

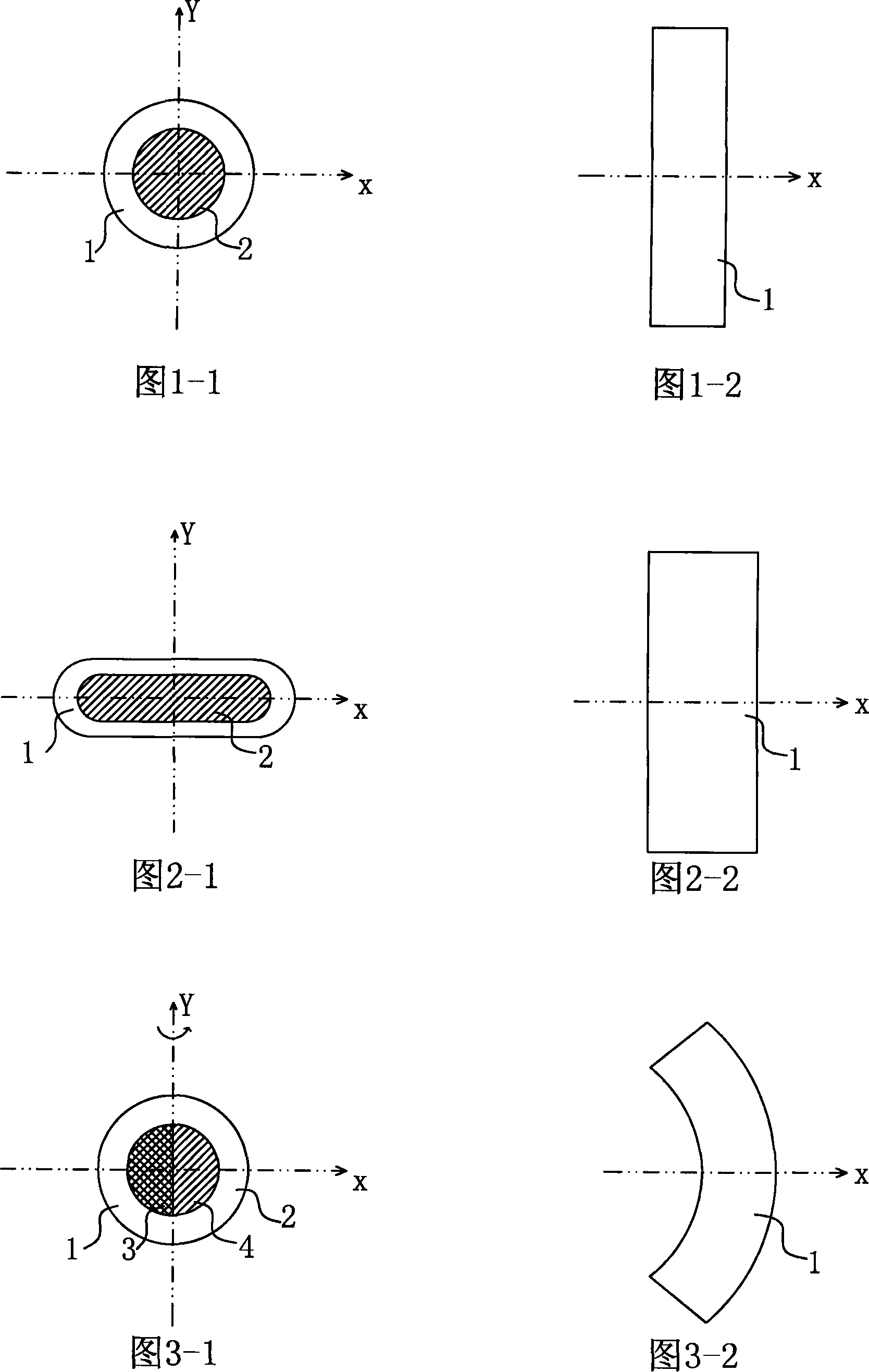

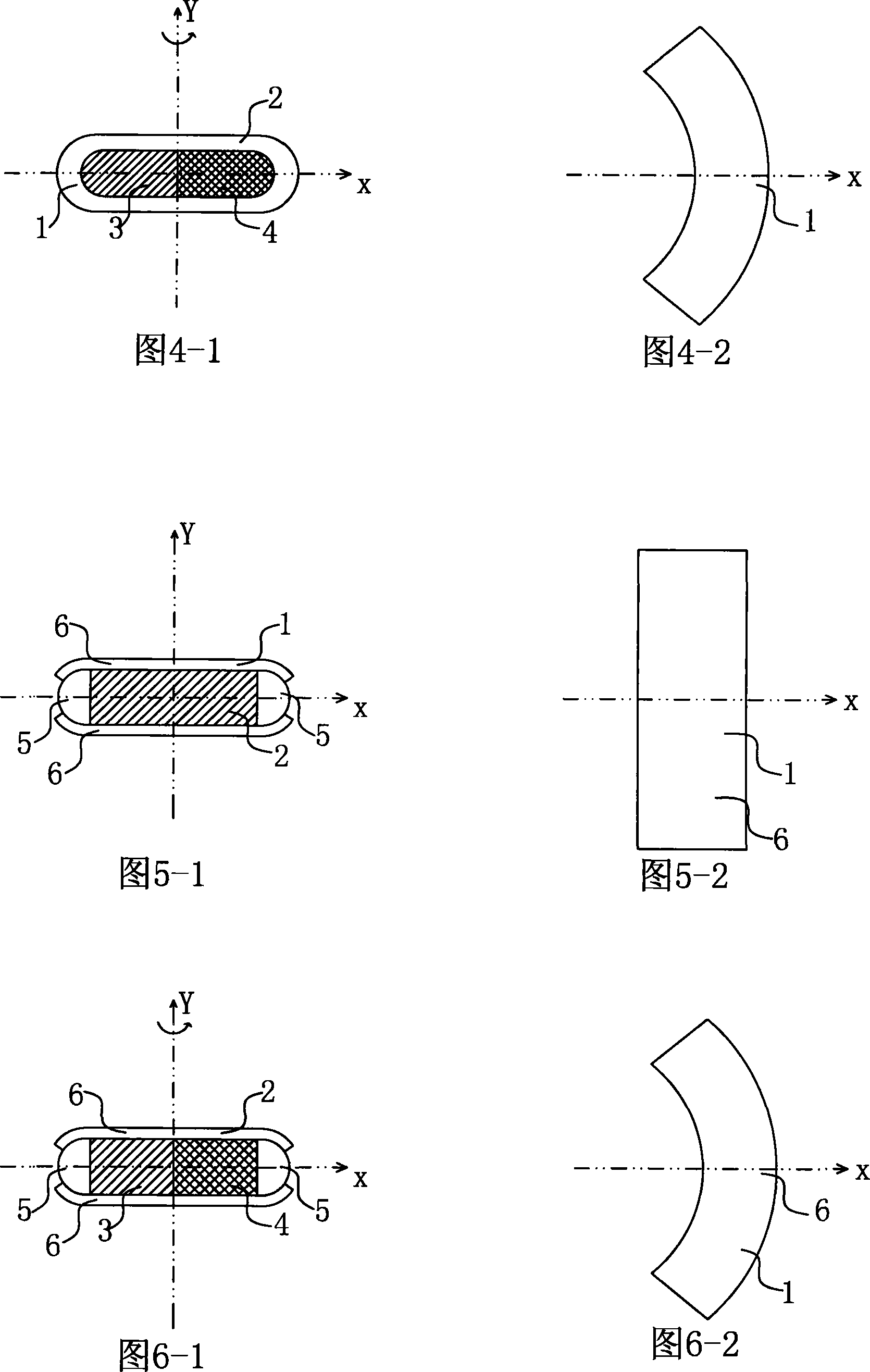

Anti-fake fiber and anti-fake paper containing the false proof fibre

InactiveCN101220571AEasy to identifyFilament/thread formingColorants/pigments additionFiberMaterials science

The invention relates to an anti-falsification fiber and an anti-falsification paper with the anti-falsification fiber, and the anti-falsification fiber which is formed by at least outer material (1) and internal material (2) through composition, and the internal material (2) is coated by the outer material (1); the invention is characterized in that: the color of the outer material (1) is color A, and the color of the internal material (2) is color B; an obvious vision difference exists between the color A and the color B, and an obvious vision difference also exists between the color of the reflected light observation of the anti-falsification fiber arranged in a pulp layer and the color of the penetration observation of the anti-falsification fiber after the anti-falsification fiber entering the paper pulp layer. The invention has the advantages of eliminating the passing-off of the printing technology efficiently, and avoiding the pollution on the paper surface in the reflected light observation.

Owner:孙显林

Preparation process and application of green environment-friendly paper

ActiveCN107012740APromote absorptionSo as not to damageSpecial paperBook keepingGreen environmentWastewater

The invention discloses a preparation process and application of green environment-friendly paper, belonging to the field of environment-friendly papermaking technology. According to the invention, a Chinese ink coloring apparatus is employed for uniformly coating the surface of a semi-dried paper web with a color coating in a full-web Chinese ink coloring manner; since the paper web has moisture, the paper web well absorbs Chinese ink during coloring, and a uniform color coating can be formed; thus, green environment-friendly myopia-preventing homework books, exercise books and examination paper of students prepared from produced paper through printing protect the eyesight of students from damage in use of the books and examination paper. A paper machine is employed for drying, compacting and synchronous dye fixation, so the coating on the surface of the paper is fully fused with the paper and is free of peeling. The whole process flow is integrated with a papermaking procedure, the semi-dried paper web is directly subjected to full-web Chinese ink coloring and then to further drying, and the papermaking procedure is integrated with the drying part of a coloring procedure, so drying time is reduced, energy needed in drying is saved, and high efficiency and energy conservation are realized. Produced wastewater is simple in composition and easy to treat.

Owner:四川北彩印务有限公司

Paper improver

InactiveUS7547376B2Increase distanceImprove adsorption capacityNatural cellulose pulp/paperSpecial paperPolymer scienceOptical property

The invention provides a paper quality improver for papermaking that allows improvement in the bulky value and the optical properties such as brightness and opacity as well as in the paper strength of a sheet obtained by papermaking a pulp material. The paper quality improver for papermaking is a paper quality improver for papermaking containing a copolymer (A) having a constituent unit derived from at least one nonionic monomer having a solubility parameter of 20.5 (MPa)1 / 2 or less and a constituent unit derived from at least one anionic or cationic monomer and a surfactant (B) at a certain ratio, the quality improver providing at least one paper quality improving effect of: (i) standard improved bulky value: 0.02 g / cm or more; (ii) standard improved opacity: 1.0 point or more; and (iii) standard improved brightness: 0.5 point or more.

Owner:KAO CORP

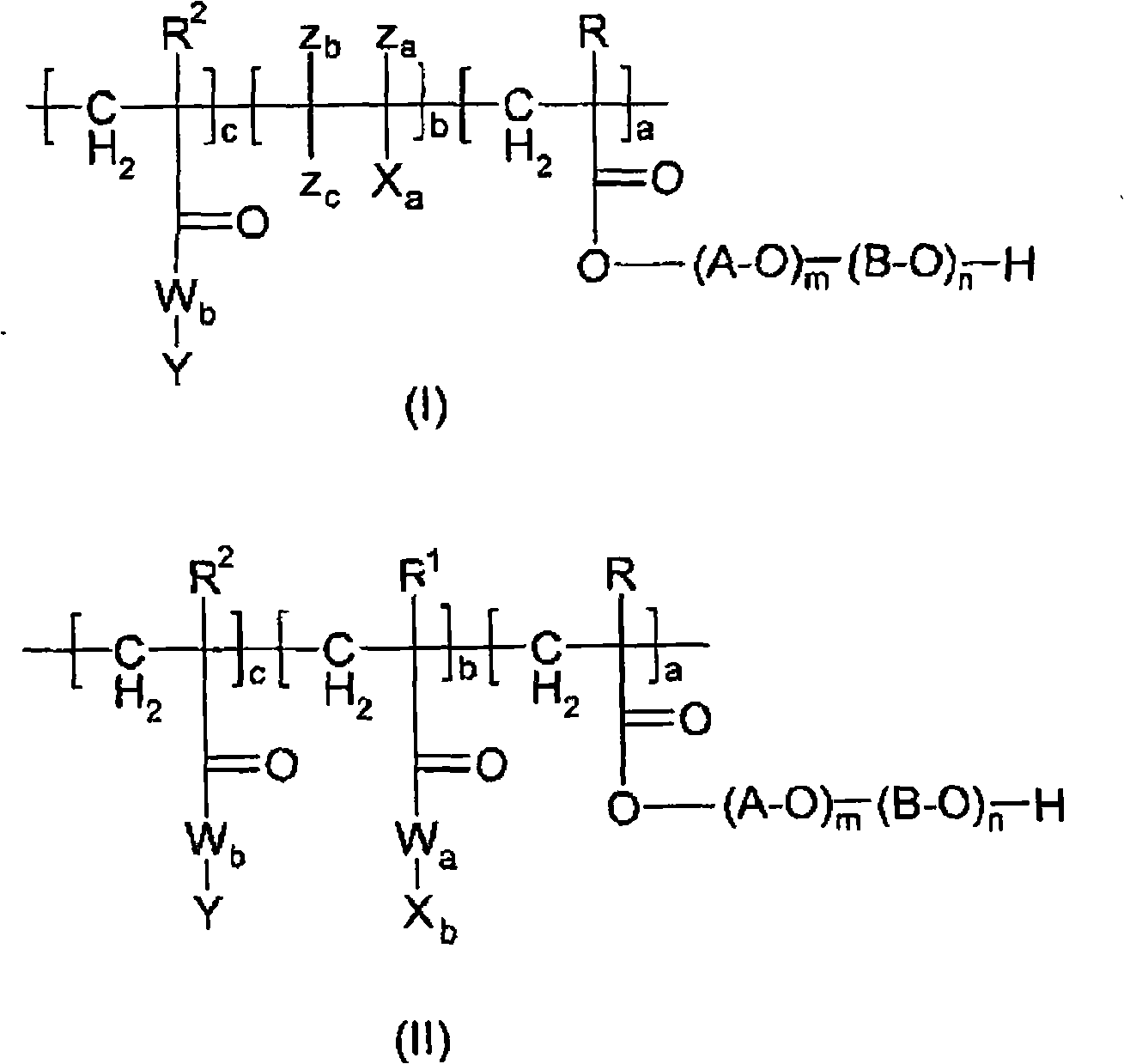

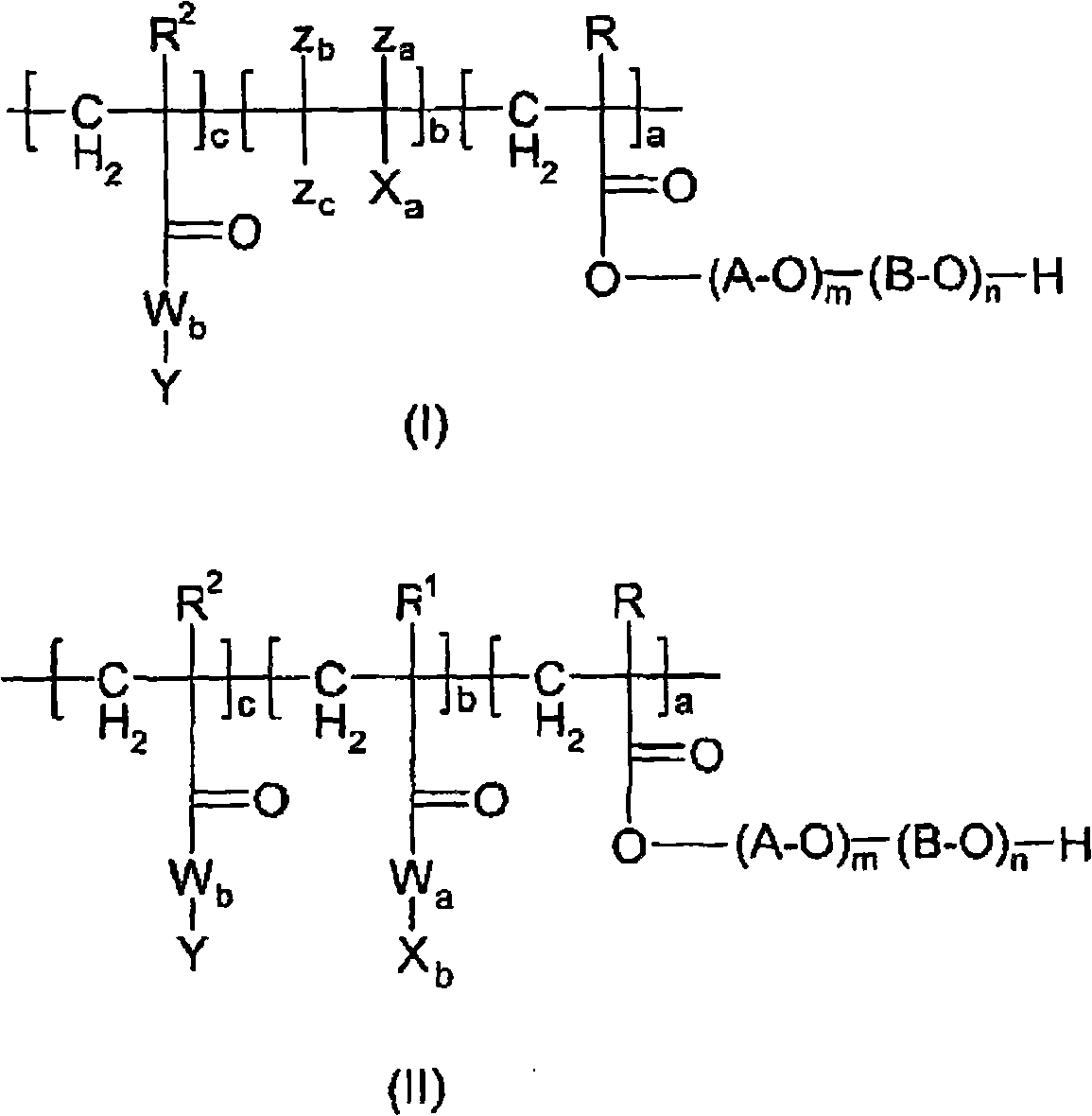

Aqueous pigment preparations

The invention relates to aqueous pigment preparations containing (A) at least one organic and / or inorganic pigment, (B) a dispersant of formula (I) or (II), or mixtures of the dispersants of formulas (I) and (II), (C) optionally wetting agents, (D) optionally other surfactants and / or dispersants, (E) optionally one or more organic solvents or one or more hydrotropic substances, (F) optionally other additives used conventionally for the production of aqueous pigment dispersions and (G) water.

Owner:CLARIANT INT LTD

Soft tissue produced using a structured fabric and energy efficient pressing

ActiveUS10273635B2Avoid disadvantagesLarge structureSurfactants additionReinforcing agents additionGram-forceEngineering

Owner:FIRST QUALITY TISSUE

Process for treating cellulose fibres in order to produce a composition comprising microfibrillated cellulose and a composition produced according to the process

InactiveUS20160060815A1Runnability of equipmentIncrease shear ratePulp properties modificationLuminescent/fluorescent substance additionCellulose fiberSlurry

The invention relates to a process for treating cellulose fibres which process comprises the steps of providing a slurry comprising cellulose fibers, adding anionic polyacrylamide (A-PAM) with high molar mass to the slurry in a first step and subjecting the slurry comprising fibers and A-PAM to a mechanical treatment in a second step thereby forming a composition comprising microfibrillated cellulose. The invention further relates to a composition produced according to the process.

Owner:STORA ENSO OYJ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com