Anti-fake fiber and anti-fake paper containing the false proof fibre

An anti-counterfeiting fiber and anti-counterfeiting paper technology, applied in the field of anti-counterfeiting paper, can solve the problems of contaminating the paper surface, printing thin lines, and printing colored thin lines that are easy to imitate, etc., and achieves the effect of convenient identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

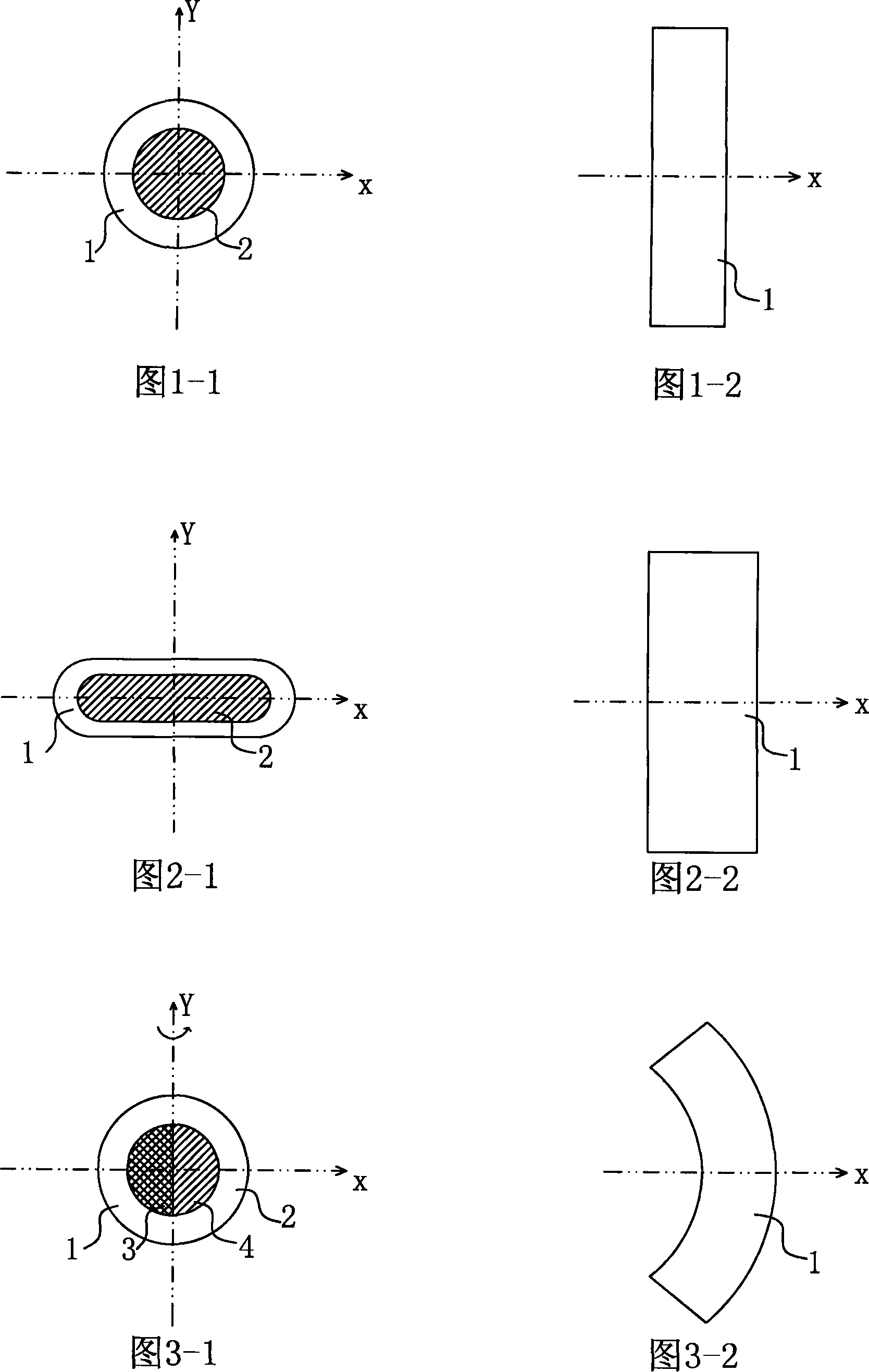

Embodiment 1

[0039] Example 1: The cross-sectional shape of the anti-counterfeiting fiber shown in Figure 1-1 and Figure 1-2 is circular, the outer layer material 1 and the inner layer material 2 are concentric structures, and the outer layer material 1 is color A, such as containing titanium The organic material of white powder, the inner layer material 2 is color B, the color B and color A have obvious visual difference, and the color B is transparent, for example, the inner layer material 2 is a transparent red organic material, the thickness of the outer layer material 1 is the same as that of titanium The concentration of the white powder can just cover the red color of the inner layer material 2 to ensure that the fiber is copied into the white pulp layer, and when the fiber is observed in the paper under the condition of reflected light (sunlight), it is white or the same or similar to the color of the paper surface Excessive coverage will affect the color of the inner layer material...

Embodiment 2

[0042] Embodiment 2: The cross-sectional shape of the anti-counterfeiting fiber described in Fig. 2-1 and Fig. 2-2 is flat, the cross-sectional shape of the inner layer material 2 is flat strip shape, and the outer layer material 1 and the inner layer material 2 are coaxial structures , other material characteristics are the same as those of the above-mentioned embodiment 1.

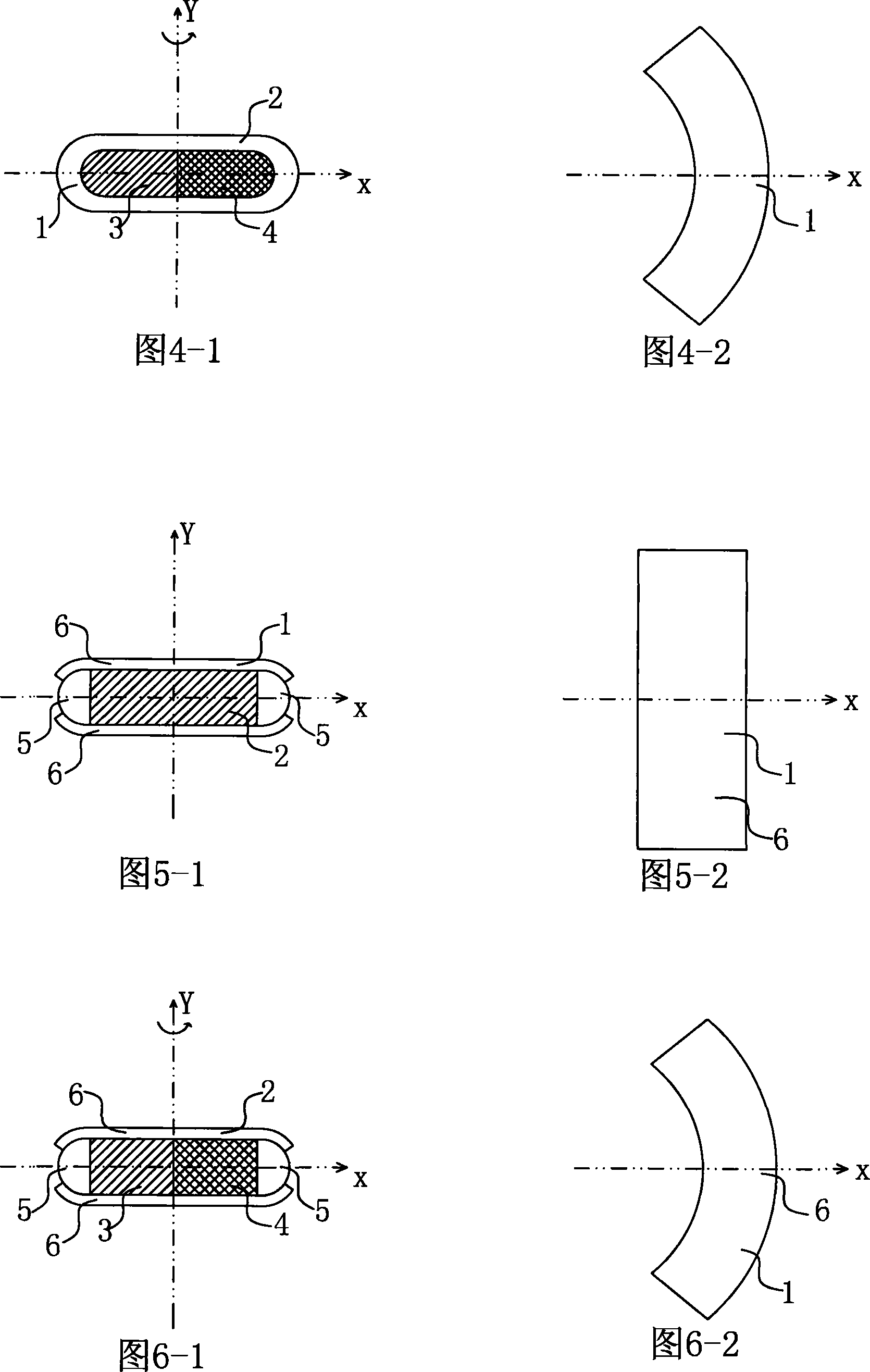

Embodiment 3

[0043] Embodiment 3: The cross-sectional shape of the anti-counterfeiting fiber shown in Fig. 3-1 and Fig. 3-2 is circular, and the cross-sectional shape of the inner layer material 2 is a circle composed of a semicircle first part 3 and a semicircle second part 4 juxtaposed , the semicircular first part 3 and the semicircular second part 4 have the same color and have different thermal shrinkage rates, which can ensure that the fibers are easy to bend, and other material characteristics are the same as in the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com