Cigarette paper containing astaxanthin

A technology of cigarette paper and astaxanthin, which is applied in the field of cigarette paper materials, can solve the problems of astaxanthin not yet available, and achieve the effects of improving smoking quality, convenient operation, and simple and easy process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

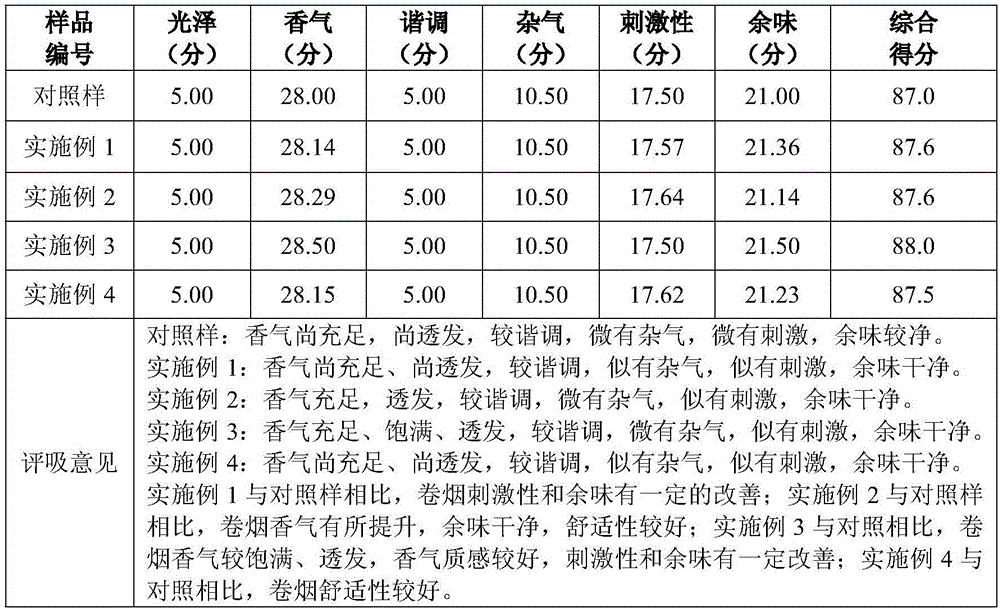

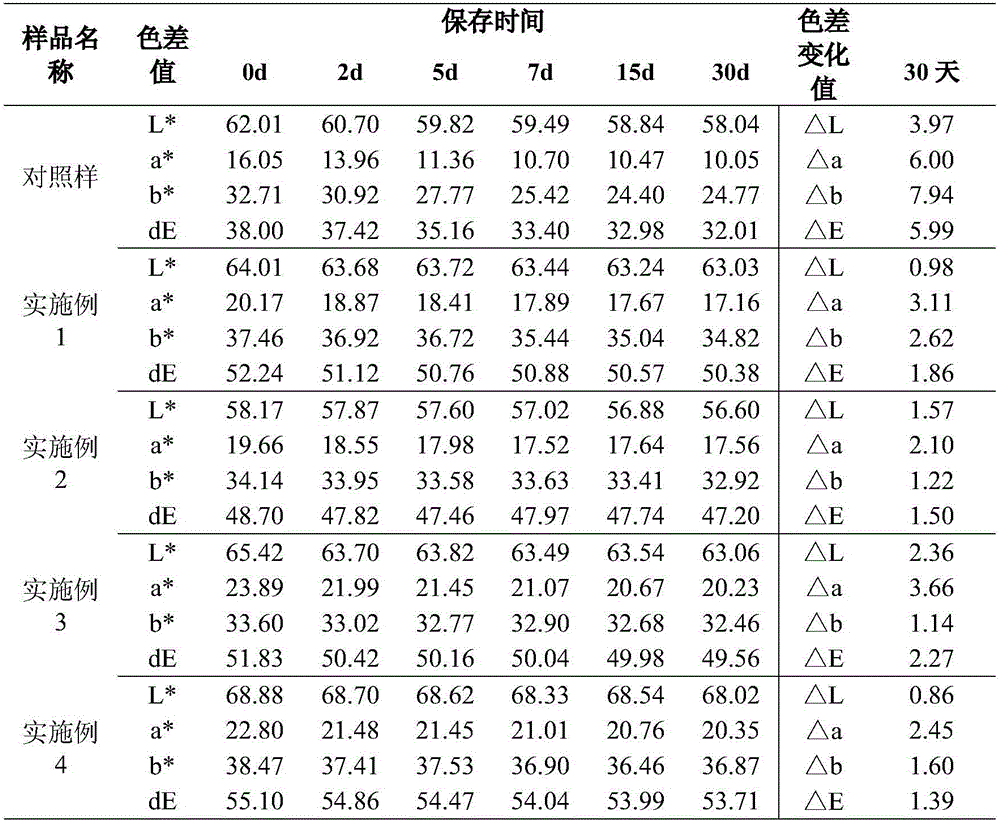

Examples

Embodiment 1

[0014] Weigh 700kg of wood pulp fiber and 350kg of calcium carbonate, and mix them uniformly in the pulp mixing tank to obtain papermaking pulp; weigh 15kg of potassium citrate and 10kg of sodium citrate and dissolve them in water to prepare a combustion aid solution; weigh After dissolving 15kg of natural astaxanthin into 40kg ethanol solution and diluting with water, add 50kg of tobacco extract, 5kg of shellac red, 4kg of curcumin, and 2kg of gardenia blue, and stir evenly to prepare a dyeing solution and then dye The solution is added into the combustion aid solution, fully stirred evenly, and the dyeing solution is prepared. The mass content of active ingredients in the natural astaxanthin is 5%. The cigarette paper base is produced from the papermaking slurry according to the prior art papermaking process, and the double-sided addition method is carried out by spraying at the adding place of the sizing section, and the mixed solution is added on the cigarette paper base. ...

Embodiment 2

[0016] Take by weighing 600kg of wood pulp fiber, 100kg of hemp pulp fiber, and 300kg of calcium carbonate, and mix uniformly in the pulp mixing tank to obtain papermaking slurry; take by weighing 25kg of potassium malate and 10kg of sodium citrate, add water and dissolve to prepare a combustion aid solution; After dissolving 20kg of natural astaxanthin extracted from algae into 60kg of ethanol solution and diluting with water, add 50kg of tobacco extract, 10kg of beet red, 6kg of safflower yellow, and 4kg of cocoa shell color, and stir evenly to prepare a dyeing solution Then add the dyeing solution into the combustion aid solution, stir well and evenly, and prepare the dyeing solution. The mass content of active ingredients in the natural astaxanthin is 2%. The cigarette paper base is produced from the papermaking slurry according to the prior art papermaking process, and the double-sided addition method is carried out by spraying at the adding place of the sizing section, a...

Embodiment 3

[0018] Weigh 500kg of wood pulp fiber, 250kg of hemp pulp fiber, and 400kg of calcium carbonate, and mix them uniformly in the pulp mixing tank to obtain papermaking slurry; weigh 20kg of potassium tartrate or sodium tartrate, and add water to dissolve 20kg of sodium malate to prepare a combustion aid solution; Dissolve 50kg of natural astaxanthin extracted from algae into 100kg of ethanol solution and dilute with water, add 80kg of tobacco extract, 20kg of shellac red or gardenia red, 30kg of turmeric or gardenia yellow, and stir evenly. Prepare a dyeing solution, then add the dyeing solution into the combustion enhancer solution, stir well, and prepare a dyeing solution. The mass content of active ingredients in the natural astaxanthin is 8%. The cigarette paper base is produced from the papermaking slurry according to the prior art papermaking process, and the double-sided addition method is carried out by spraying at the adding place of the sizing section, and the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com