Patents

Literature

56 results about "Polymer interaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

If the interaction between the surface and the polymer is strong, the polymer adsorbs in a conformation that is flat and aligned with the surface. For example, this would be the case with polyquatenium-6 and hair at high pH, where the polymer and the hair surface would carry opposite ionic charges.

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS20070154704A1Strong adhesionIncreased durabilitySynthetic resin layered productsRecord information storageEpoxyPolymer science

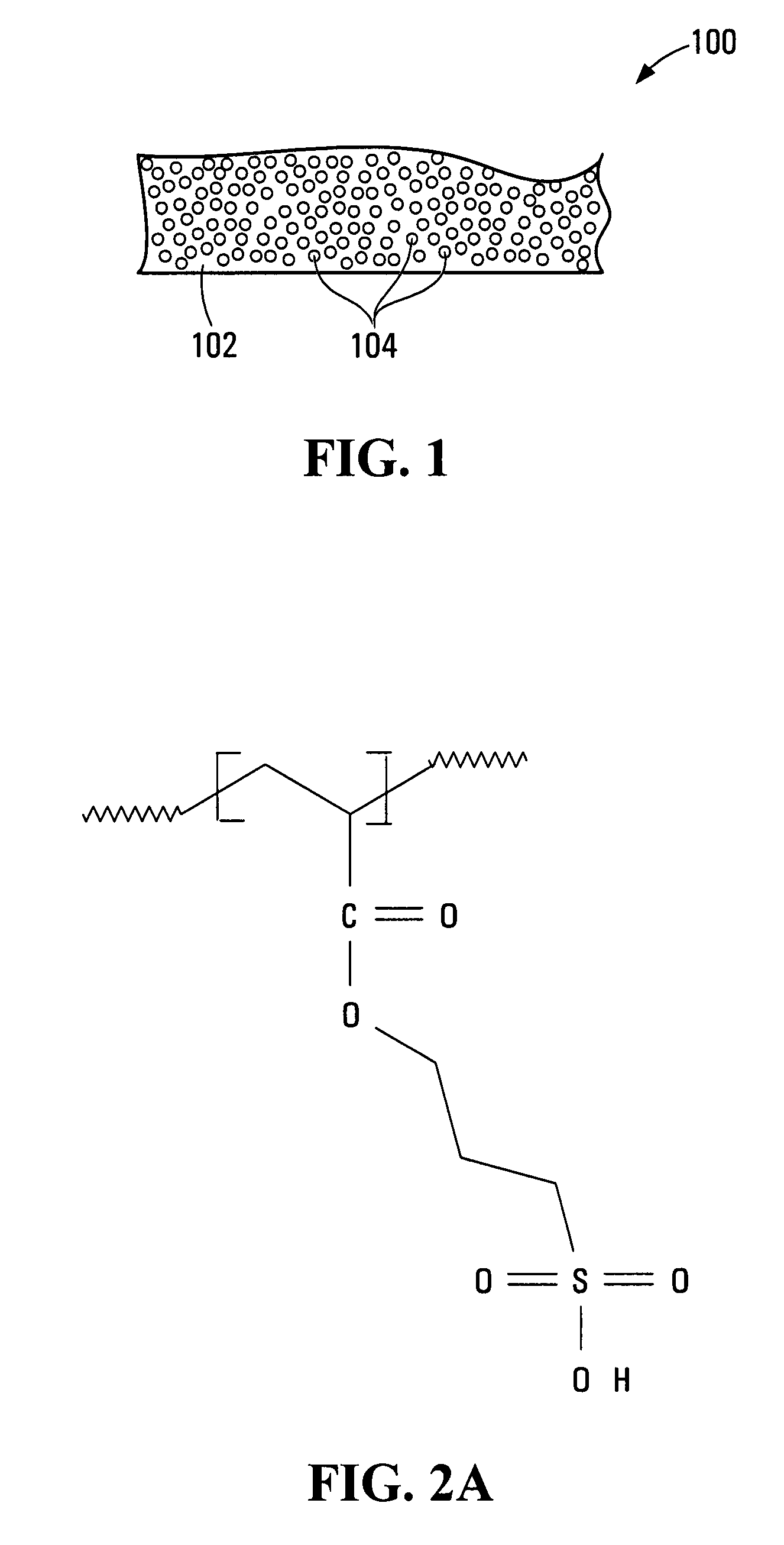

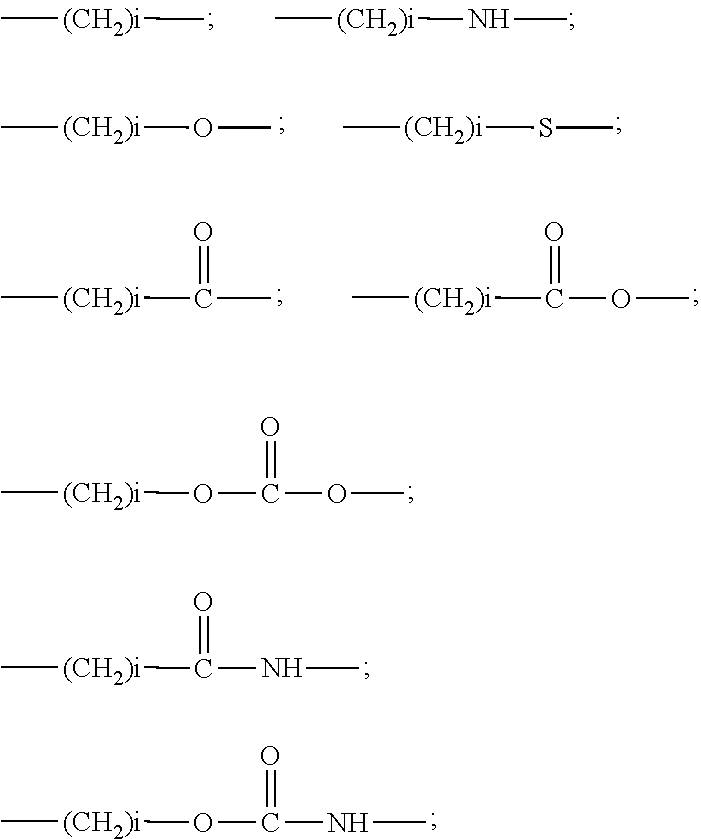

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

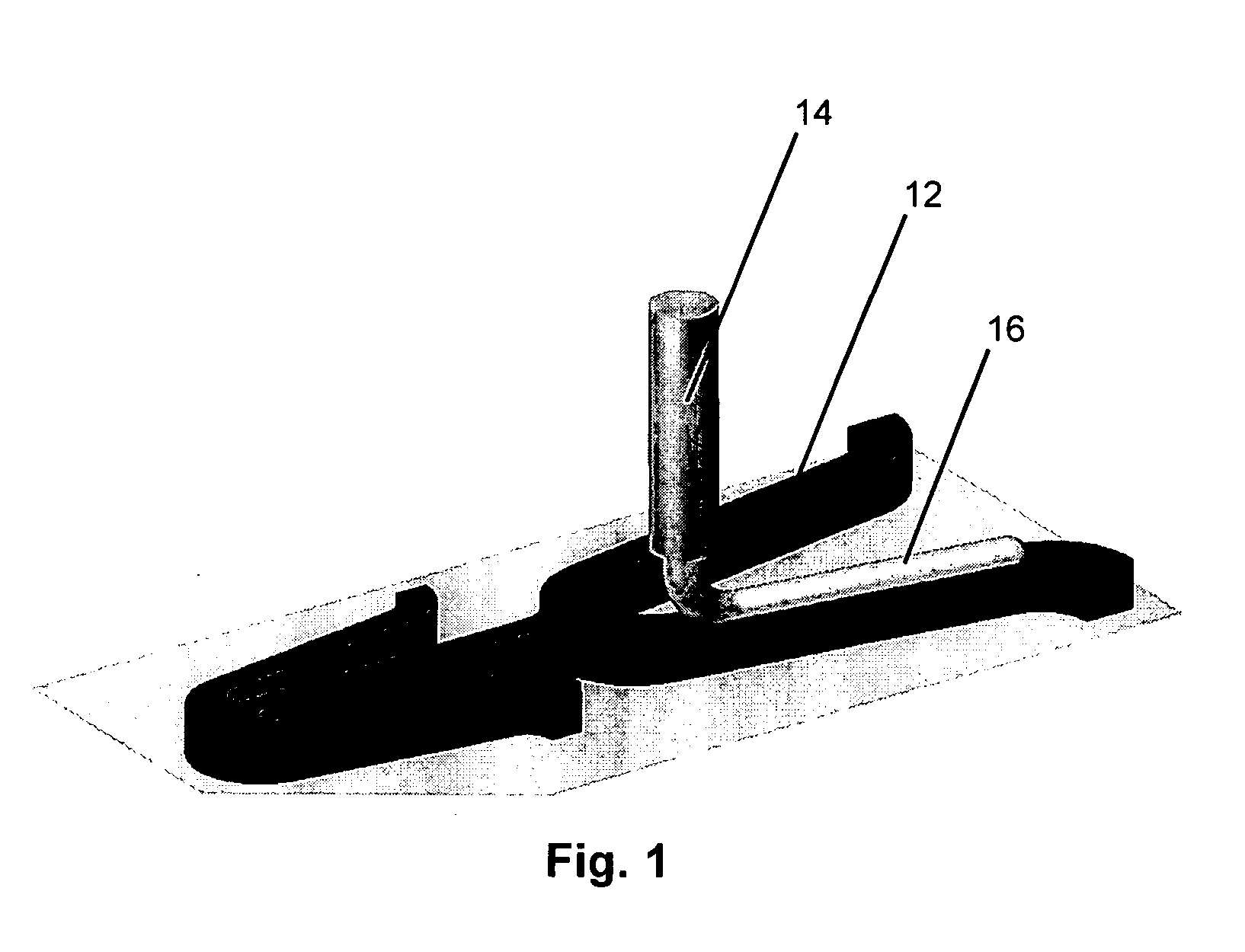

Processes for producing polymer coatings for release of therapeutic agent

InactiveUS6923996B2Minimizes poolingEffectively wettedImpression capsGlovesCross-linkTherapeutic effect

A method for furnishing a therapeutic-agent-containing medical device is provided. The method comprises: (a) providing a reactive layer comprising a cross-linking agent on a medical device surface; and (b) subsequently applying a polymer-containing layer, which comprises a polymer and a therapeutic agent, over the reactive layer. The cross-linking agent interacts with the polymer to form a cross-linked polymeric region that comprises the therapeutic agent. Examples of medical devices include implantable or insertable medical devices, for example, catheters, balloon, cerebral aneurysm filler coils, arterio-venous shunts and stents.

Owner:BOSTON SCI SCIMED INC

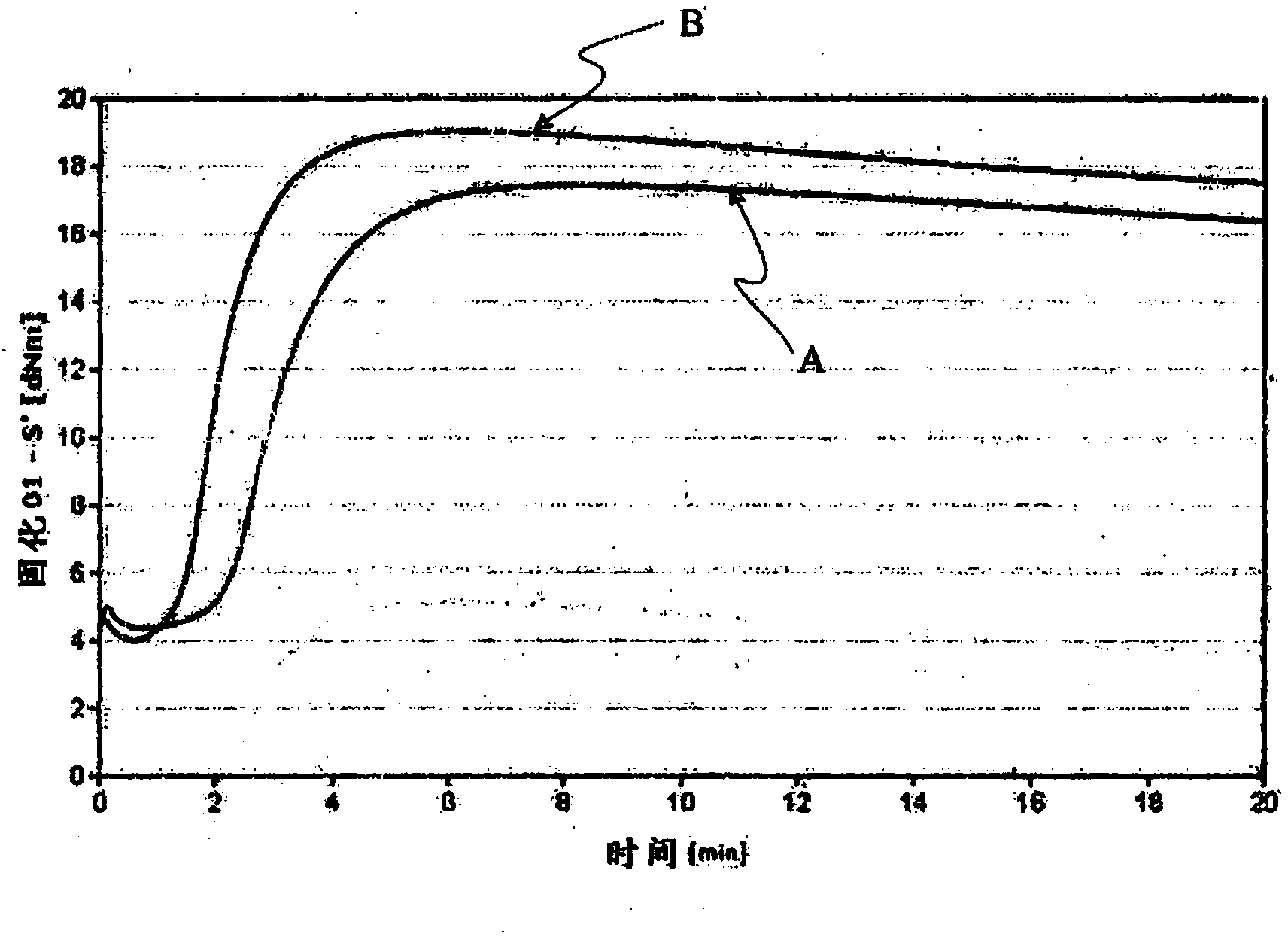

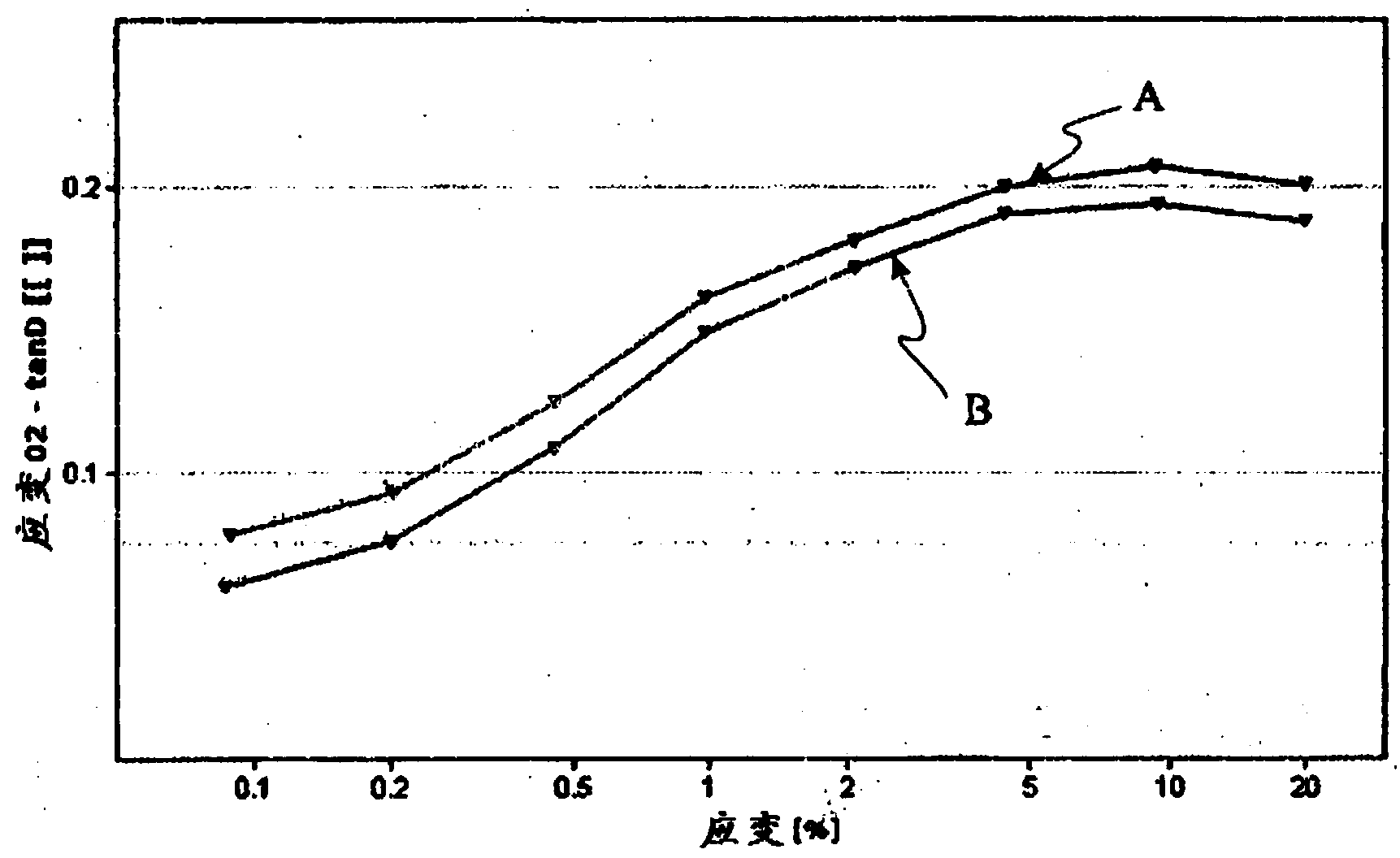

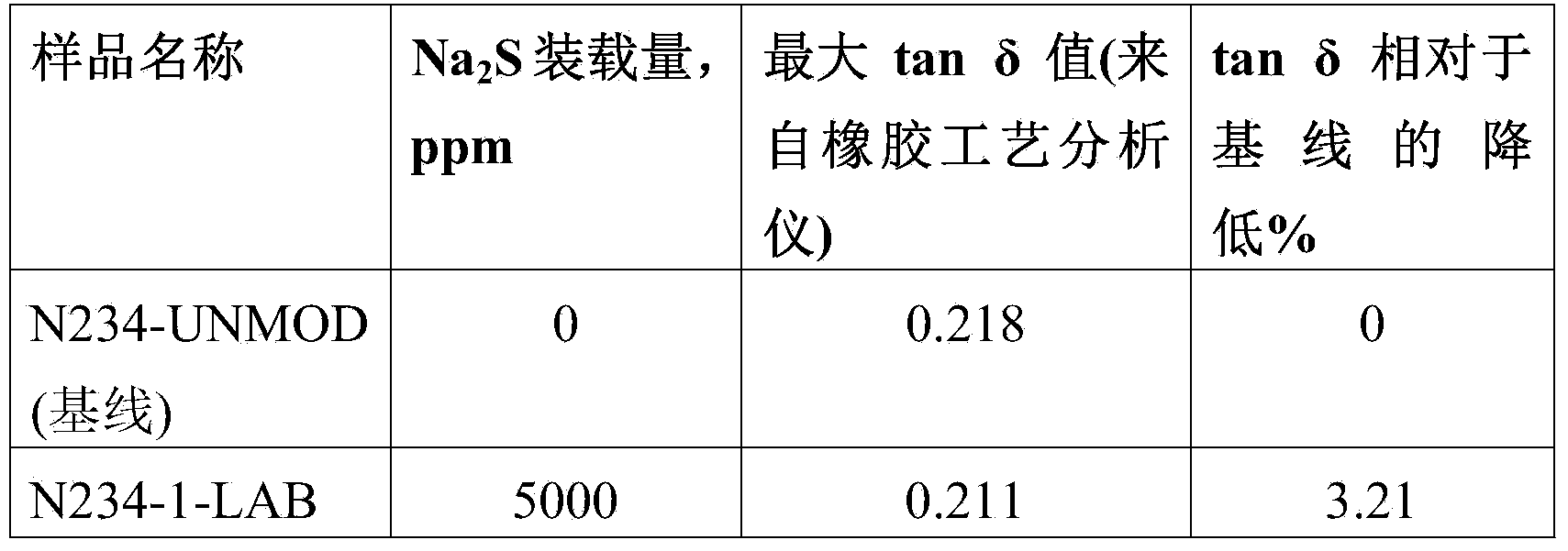

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

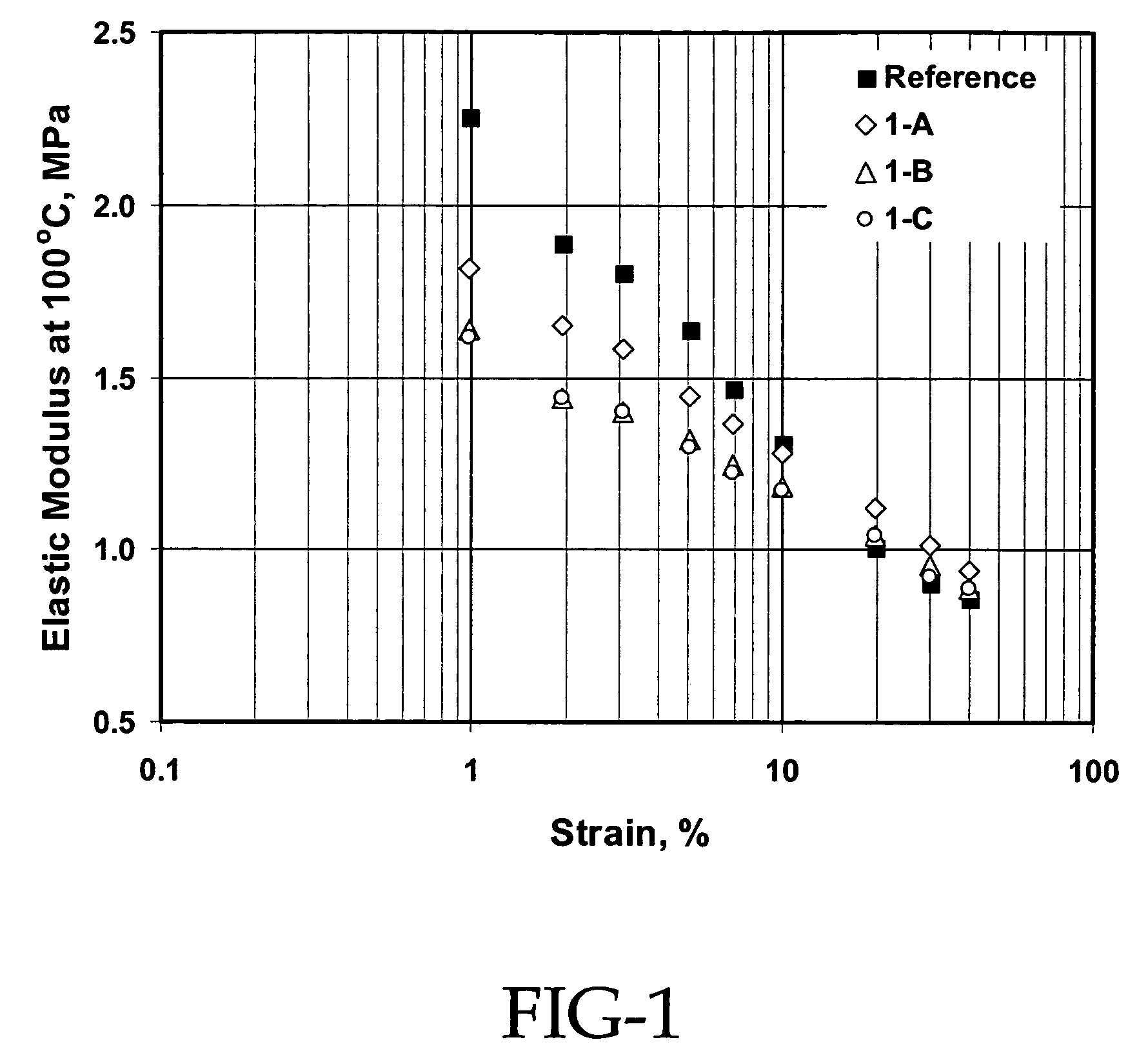

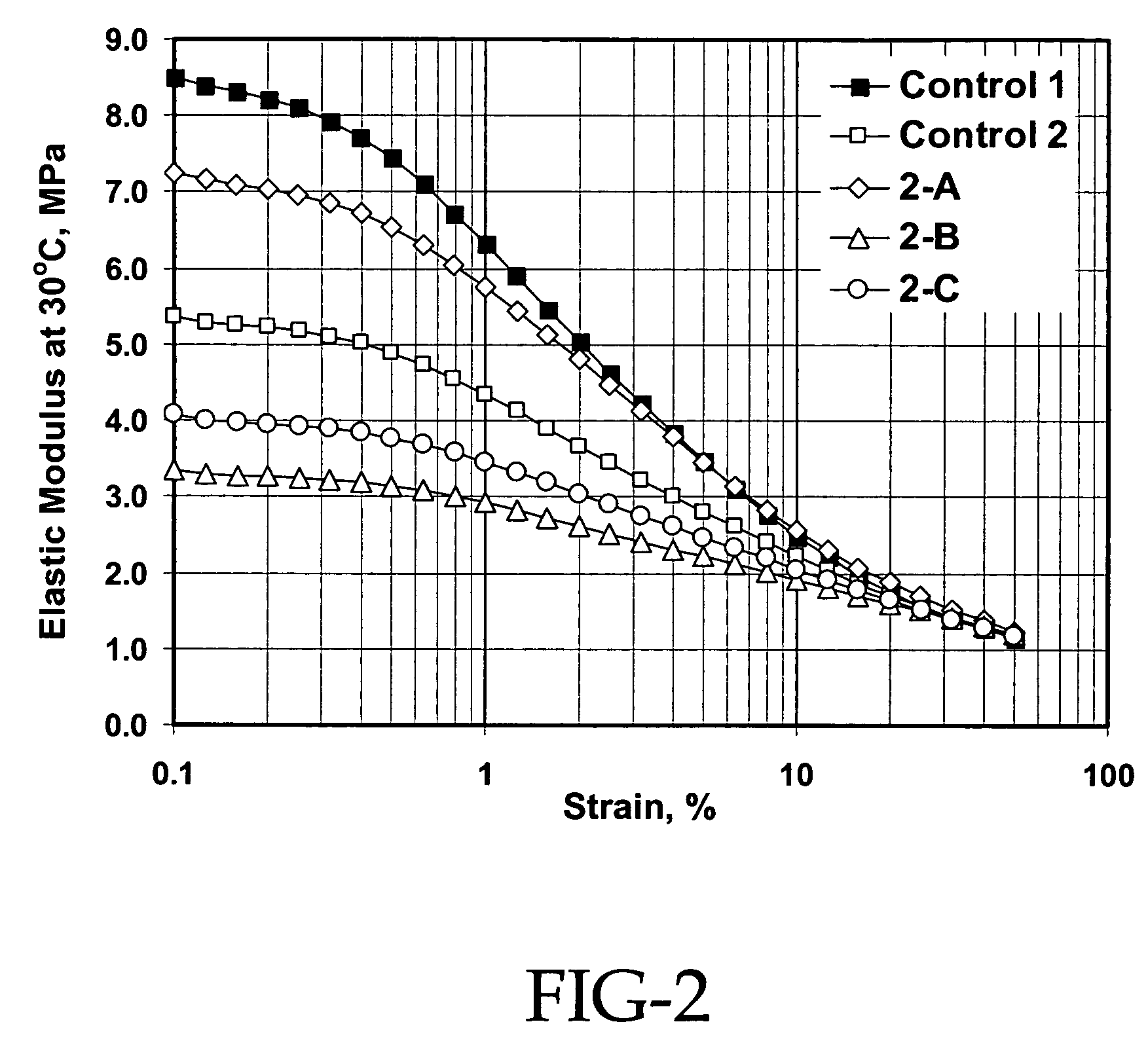

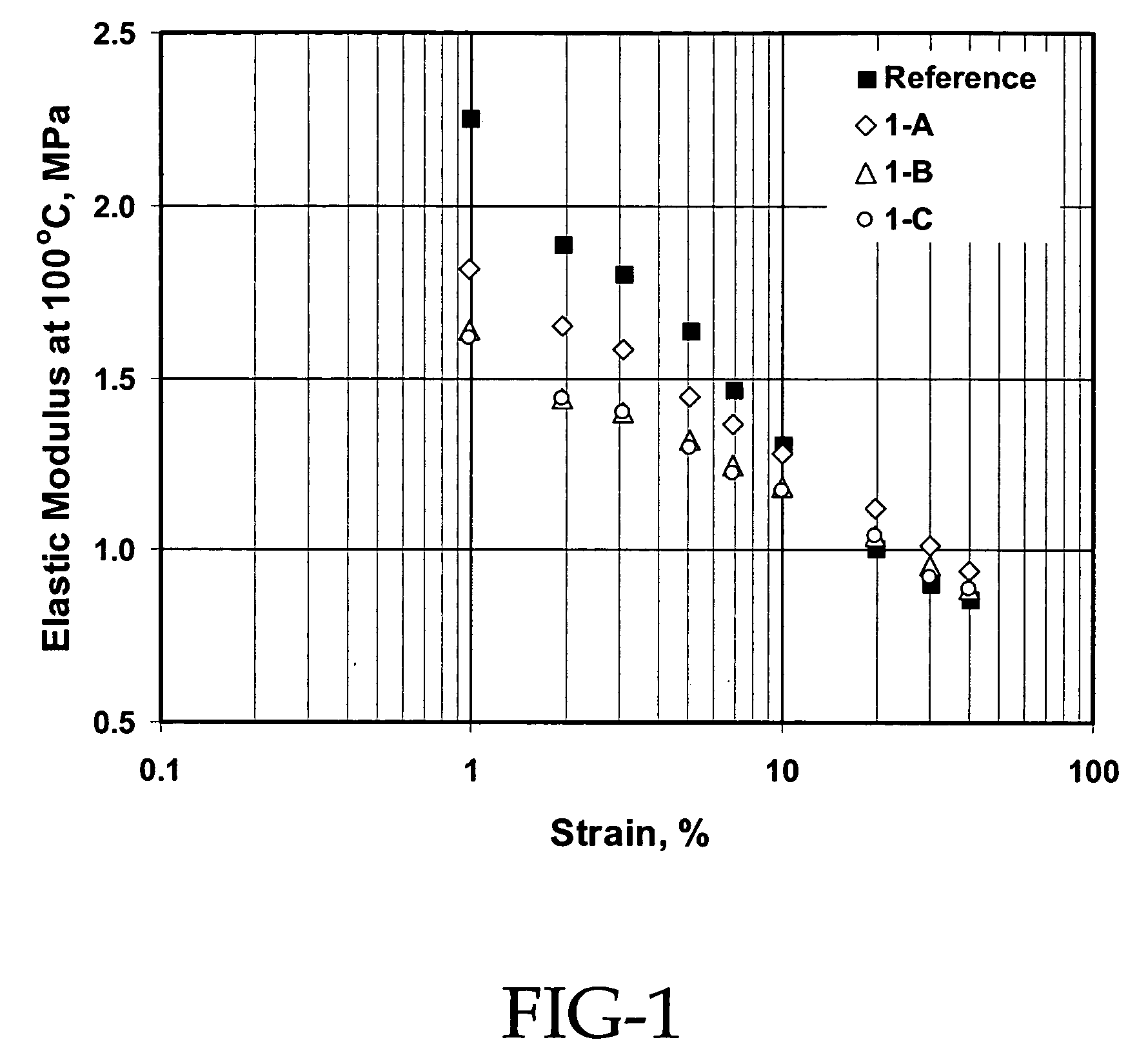

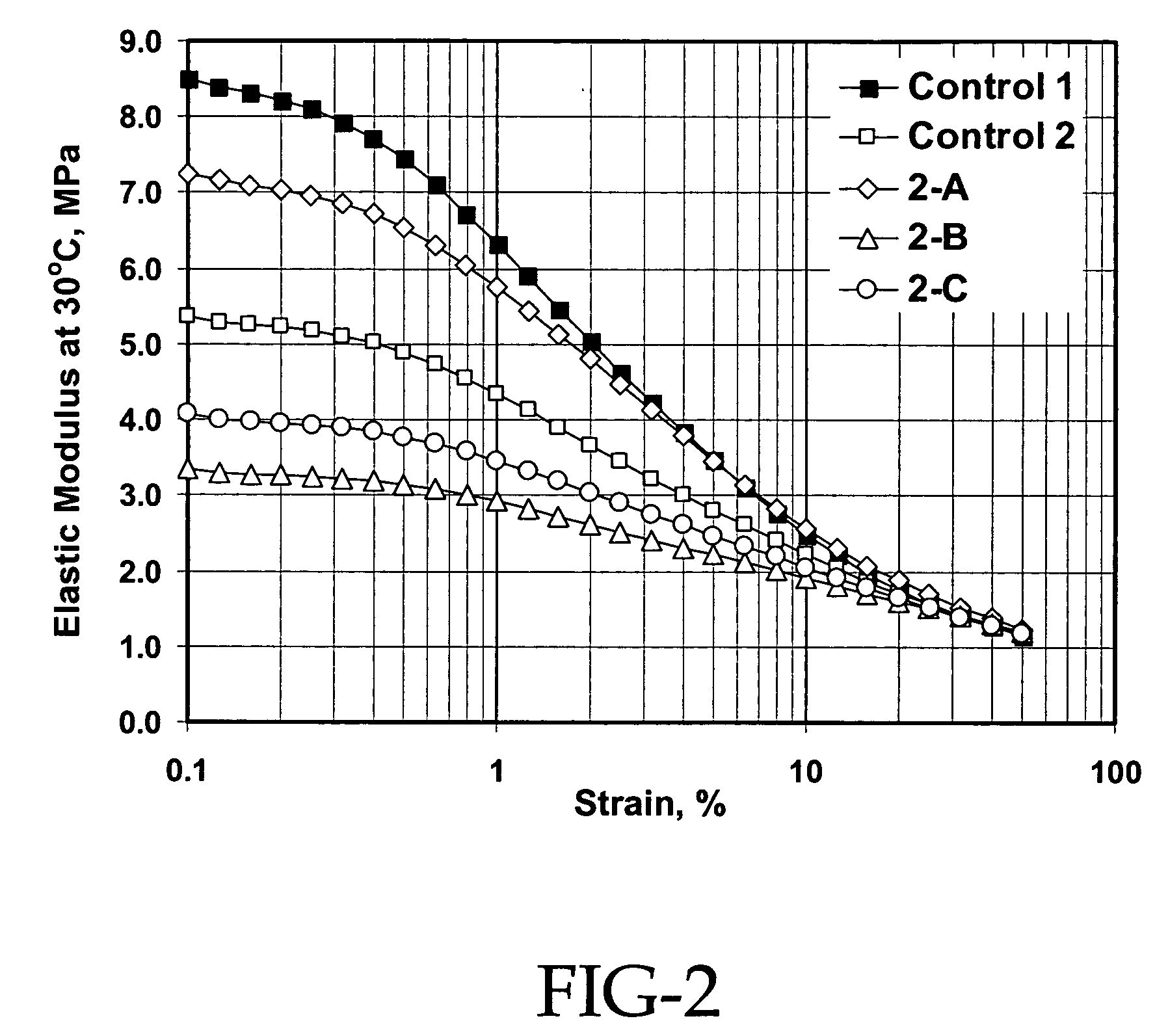

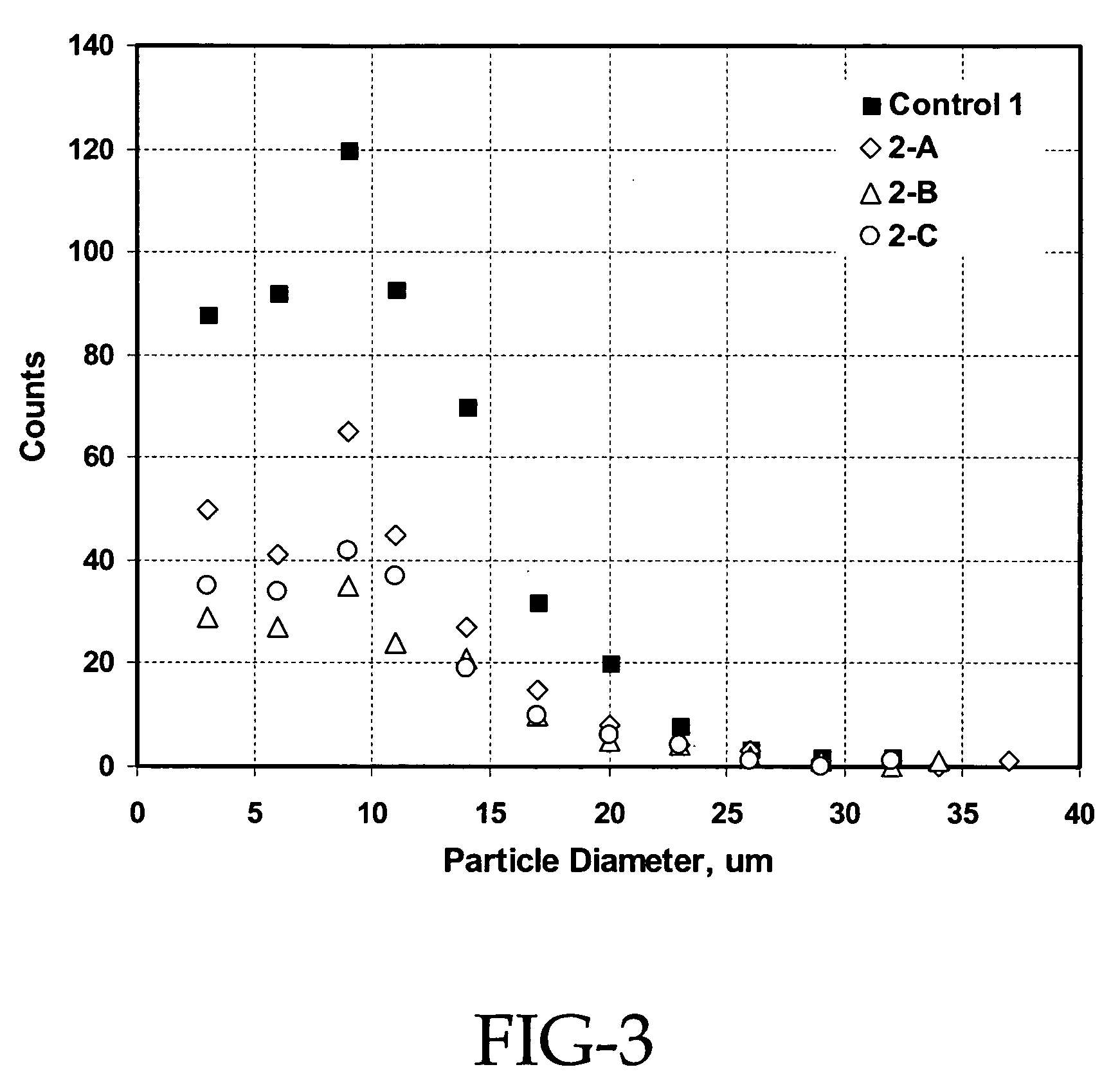

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS7553540B2Strong adhesionIncreased durabilityFilm/foil adhesivesSynthetic resin layered productsEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

Silicane coupling agent surface grafted modified clay as well as preparation method and use thereof

InactiveCN101254924AGood dispersionEnhanced Interfacial InteractionSilicon compoundsCouplingPolymer interaction

The invention relates to the clay surface modification, in particular to modified clay with silane coupling agent grafted surface, preparation method and application thereof. The grafting modification of the silane coupling agent with a grafting amount of 0.2-5*10<-3> mol / gram clay is performed in solvent by using reactive hydroxyl group on a clay sheet layer. The inventive modified clay, in which the silane coupling agent is grafted on the clay sheet layer via the covalent bond, has strong thermostability and realizes clay functionalization while improving the clay surface lipophilicity. As the inventive clay has high thermostability and enhanced interaction with polymer, it can be used for the preparation of polymer / clay nanometer composite material to improve the clay dispersibility in the polymeric matrix for stripping and dispersing, thereby improving the performance of the composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Silica containing rubber composition

InactiveUS20050209370A1Enhanced snow/ice tractionReduce rolling resistanceSpecial tyresOrganic dyesElastomerHydrocarbon solvents

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Fluoropolymer coating compositions containing adhesive polymers and substrate coating process

ActiveUS20070166469A1Strong adhesionIncreased durabilityPretreated surfacesSpecial surfacesEpoxyPolymer science

A liquid fluoropolymer coating composition and a process for using the composition to make fluoropolymer coated polymeric substrates. The liquid fluoropolymer composition comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer, solvent, and compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. In the process, the composition is applied to a polymeric substrate comprising functional groups on its surface that interact with said compatible adhesive polymer to promote bonding of said fluoropolymer coating to said substrate. The solvent is removed from the coating composition applied to the substrate to form a fluoropolymer coating on the substrate.

Owner:DUPONT ELECTRONICS INC

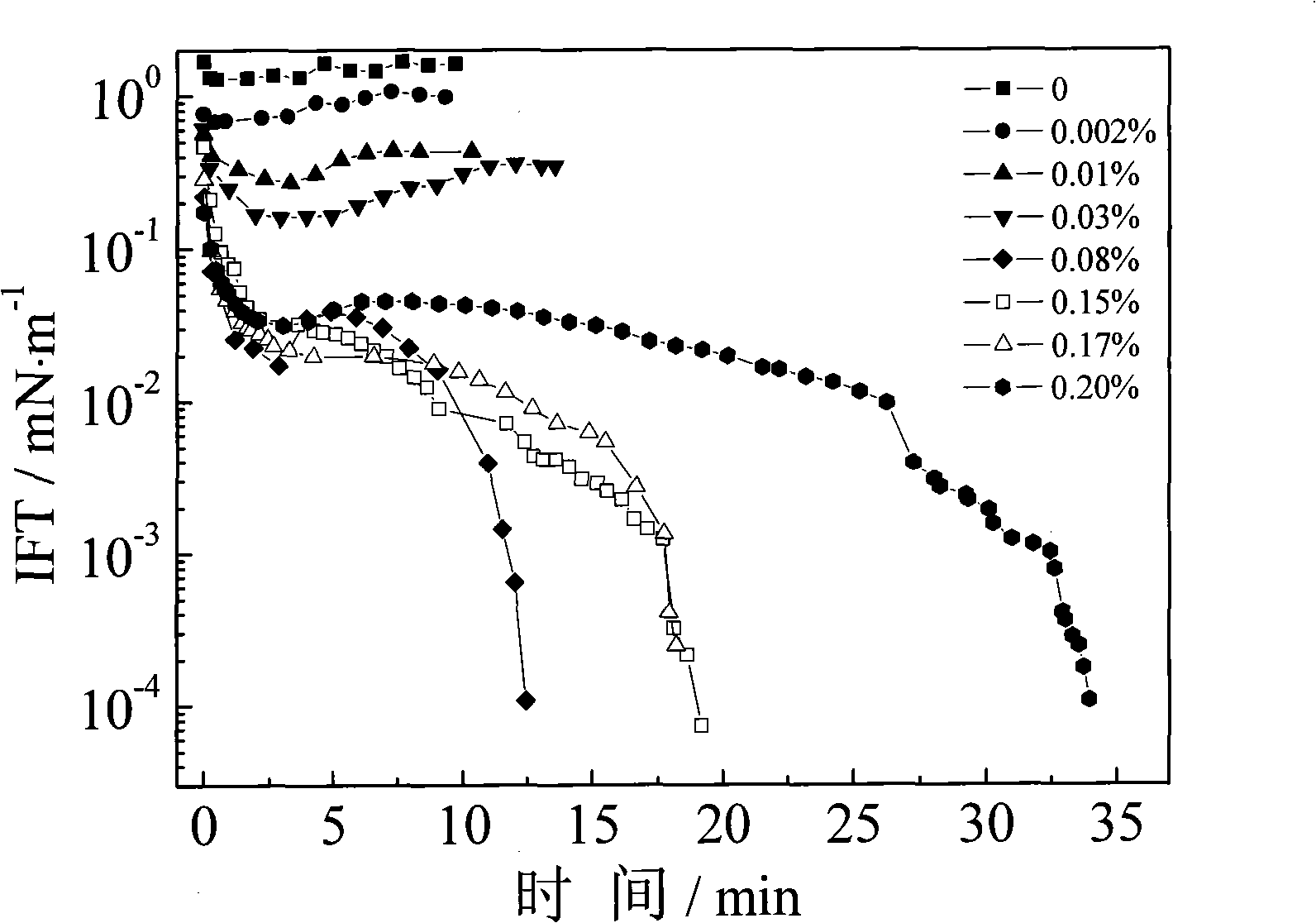

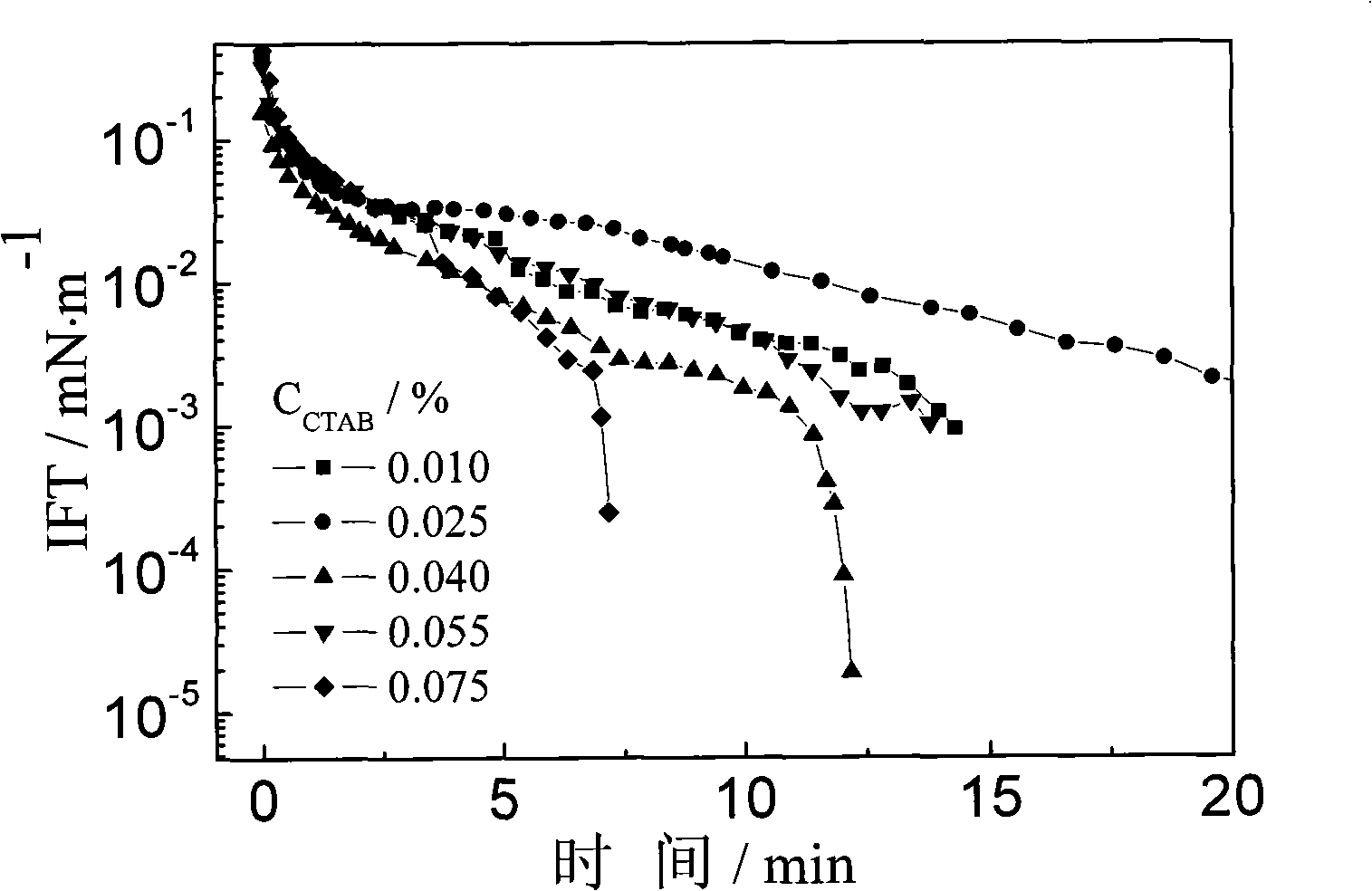

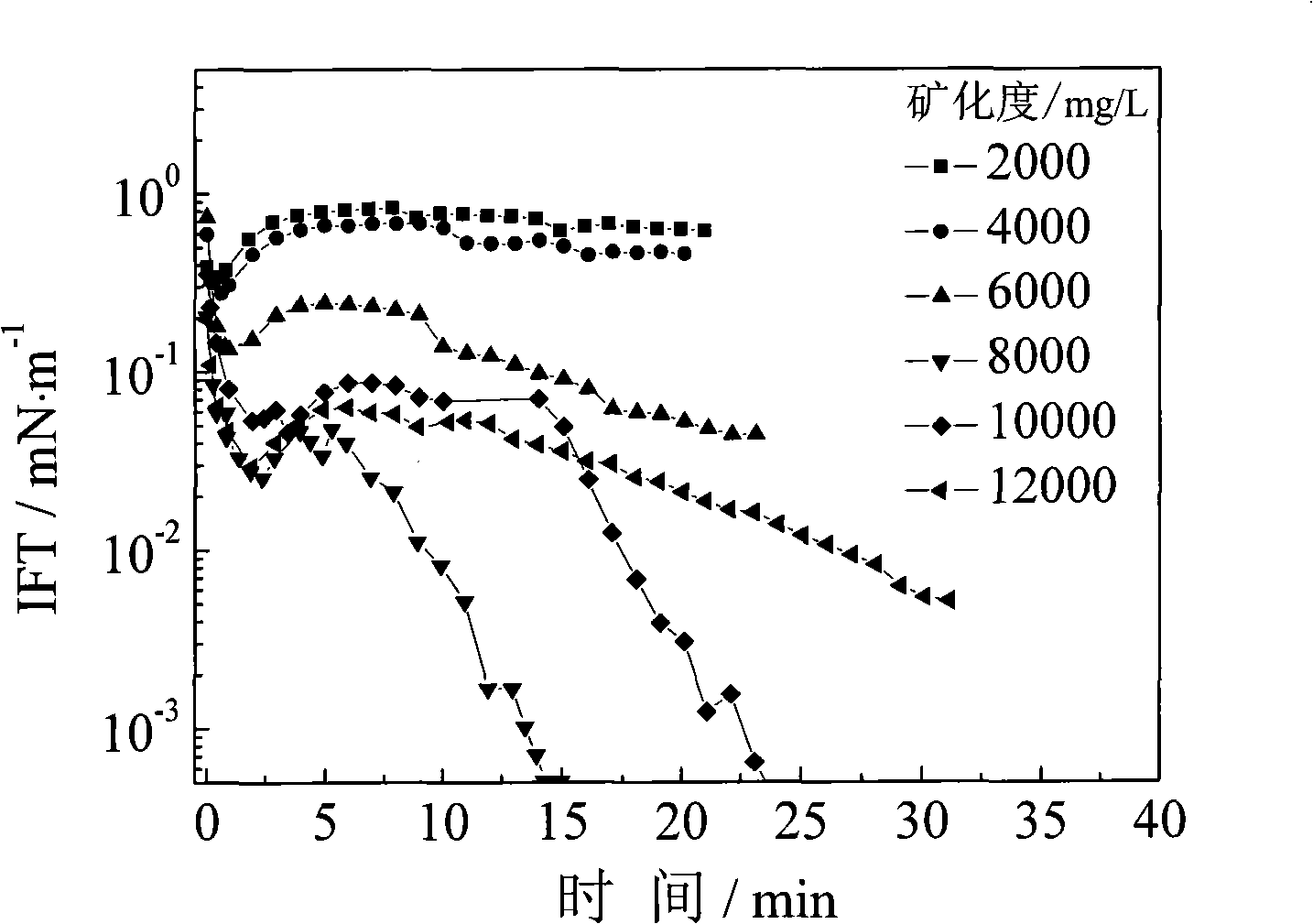

Oil displacement system for improving recovery factor after polyalcohol drive and preparation method thereof

InactiveCN101270279AEnhanced overall recoveryReduce dosageDrilling compositionPolymer interactionHigh activity

The invention relates to a flooding system used for improving the recovery factor after polymer flooding and a preparation method thereof, which belongs to the technical field of enhanced recovery of oil fields. A surfactant with unlike charges and a polymer react with each other to produce a high-activity compound; and the high-activity compound is mixed with a non-ionic surfactant to produce the novel flooding system. The novel flooding system solves the problems of the poor temperature resistance and the inorganic high valence cation resistance of the prior flooding system. The novel flooding system has the advantages of high viscocity, ultra-low interfacial tension, low feeding quantity and so on. The system has wide application prospects in oil fields to apply the technology for improving the oil recovery factor.

Owner:SHANDONG UNIV

Processes for producing polymer coatings for release of therapeutic agent

InactiveUS20040224080A1Manufacturing limitationMinimizing pooling and beadingImpression capsSurgeryCross-linkTherapeutic effect

A method for furnishing a therapeutic-agent-containing medical device is provided. The method comprises: (a) providing a reactive layer comprising a cross-linking agent on a medical device surface; and (b) subsequently applying a polymer-containing layer, which comprises a polymer and a therapeutic agent, over the reactive layer. The cross-linking agent interacts with the polymer to form a cross-linked polymeric region that comprises the therapeutic agent. Examples of medical devices include implantable or insertable medical devices, for example, catheters, balloon, cerebral aneurysm filler coils, arterio-venous shunts and stents.

Owner:BOSTON SCI SCIMED INC

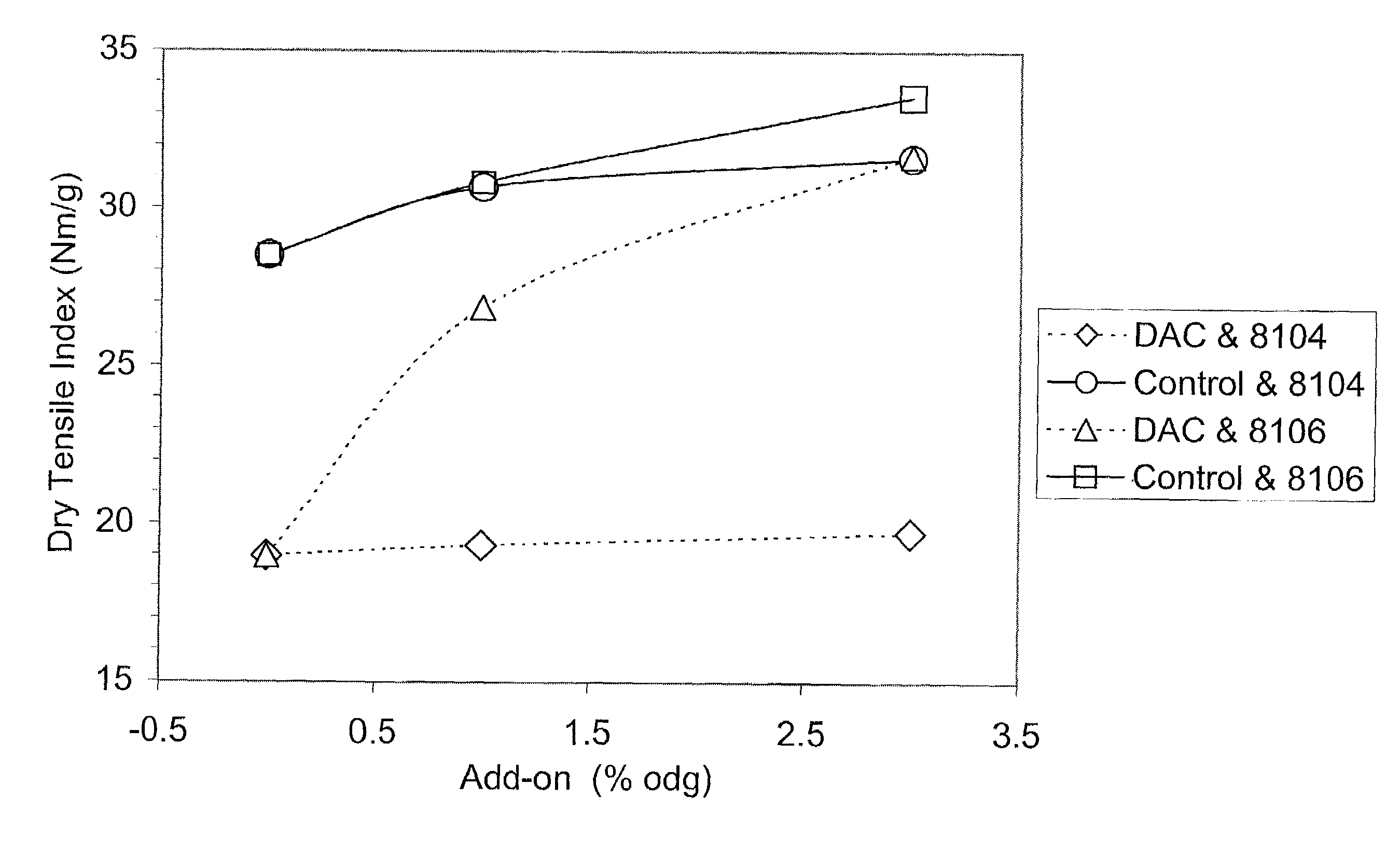

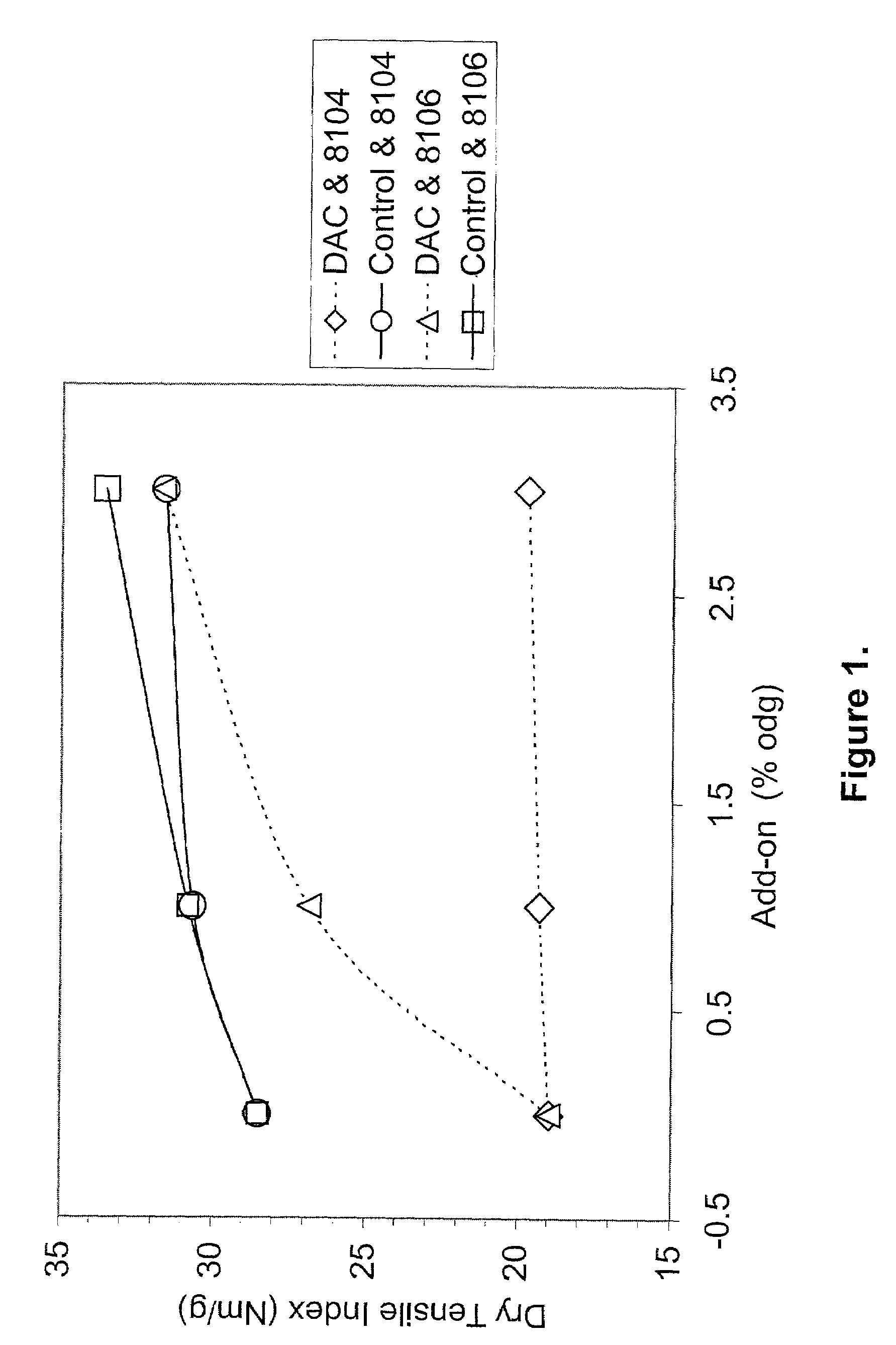

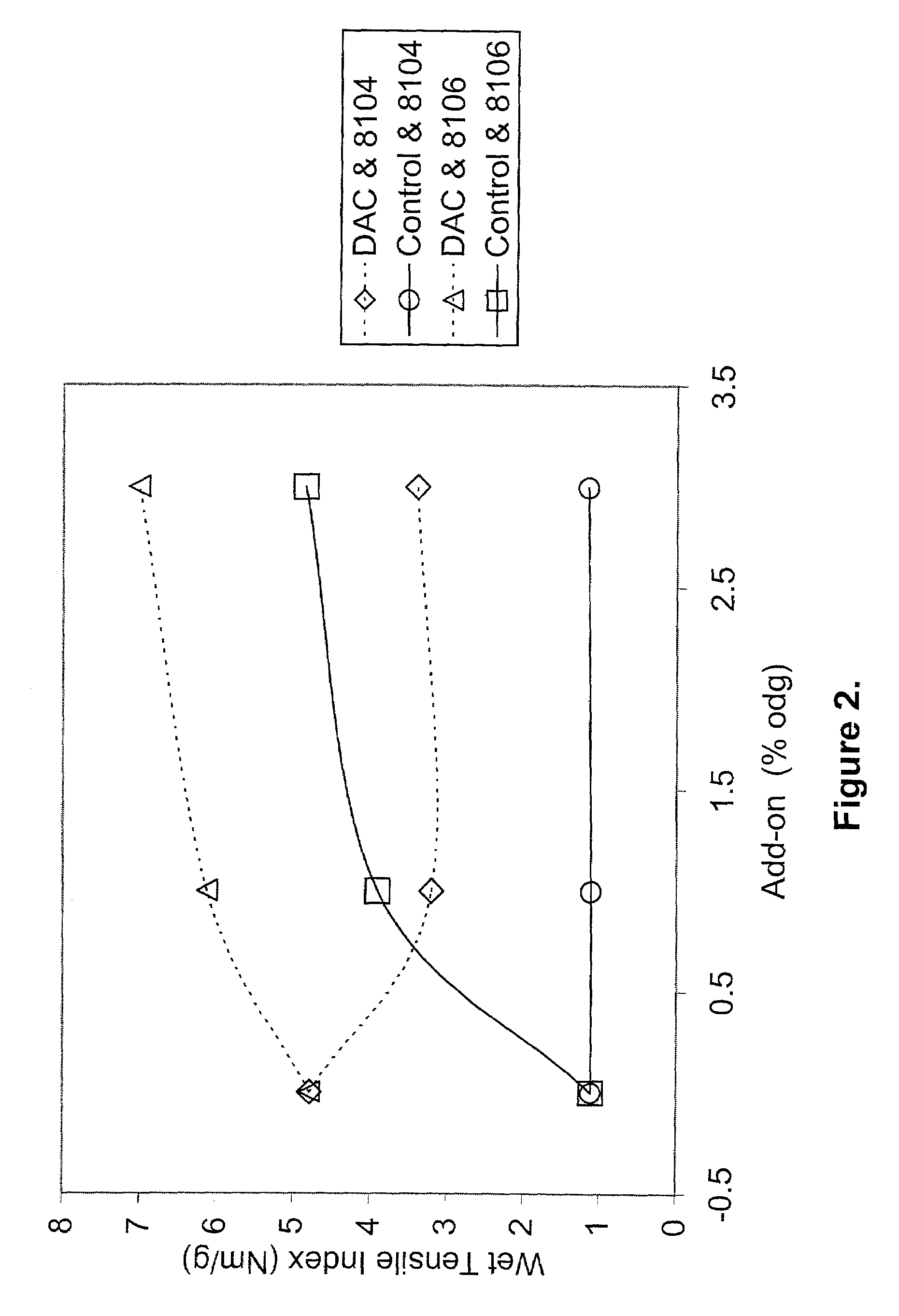

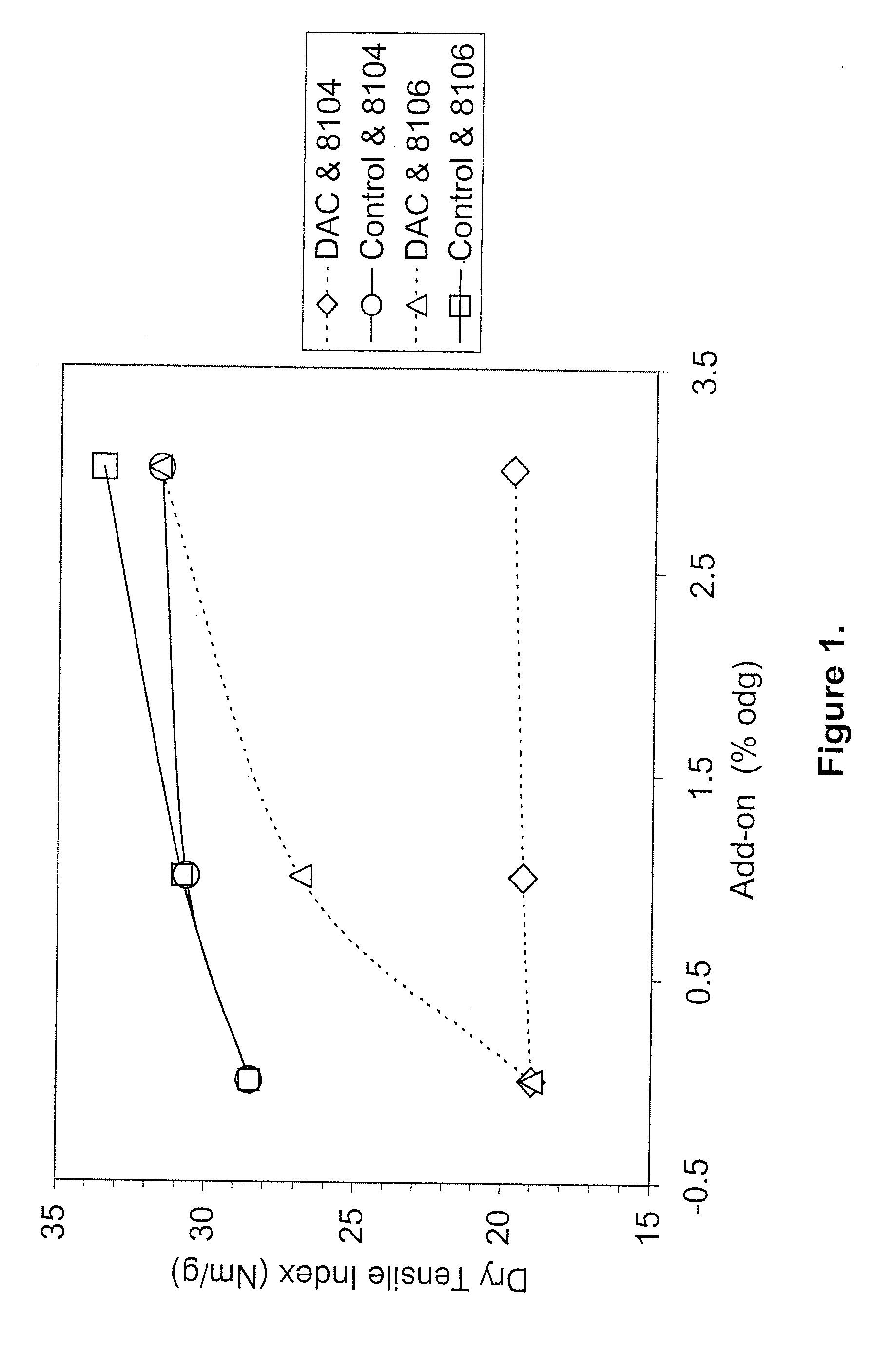

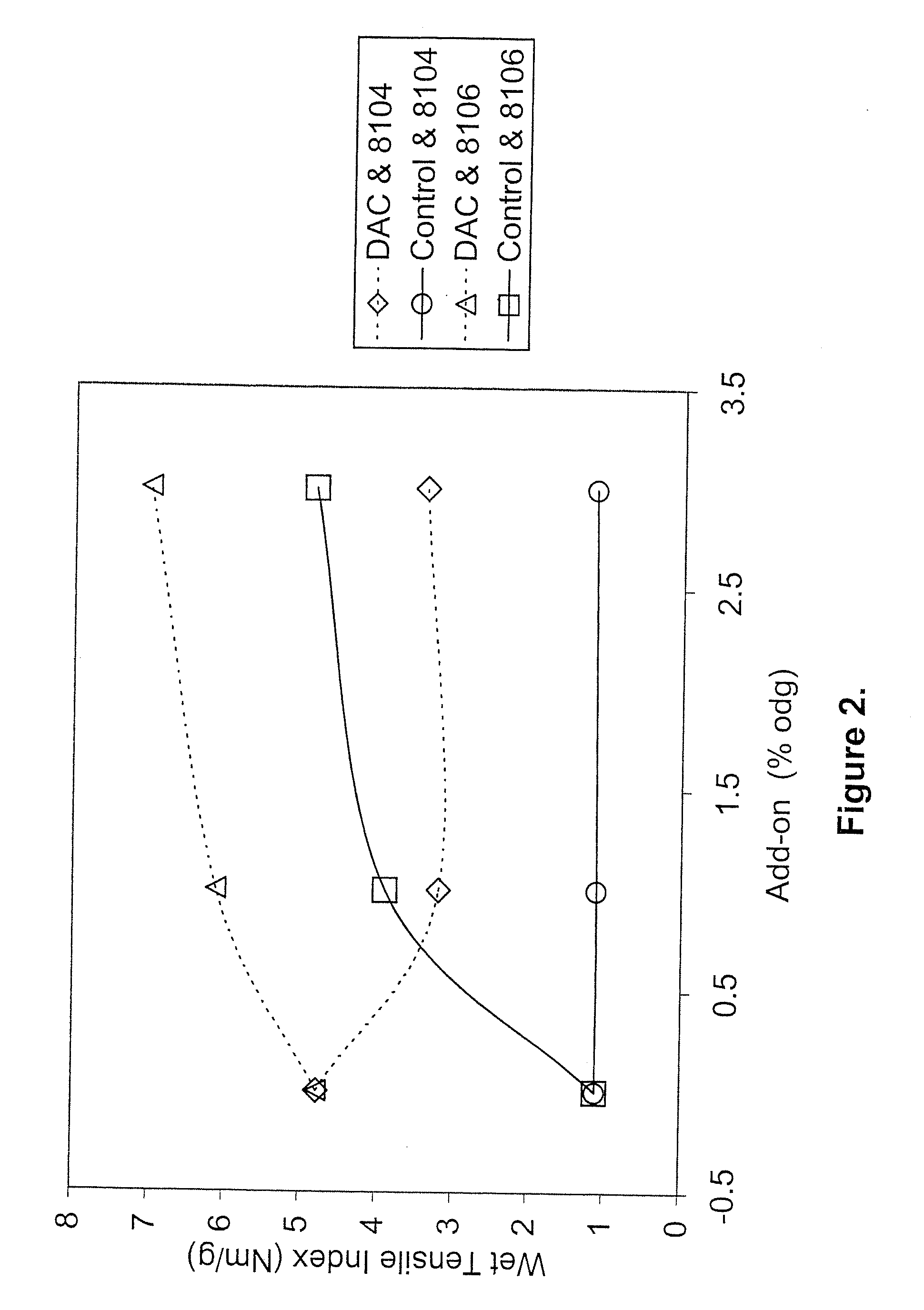

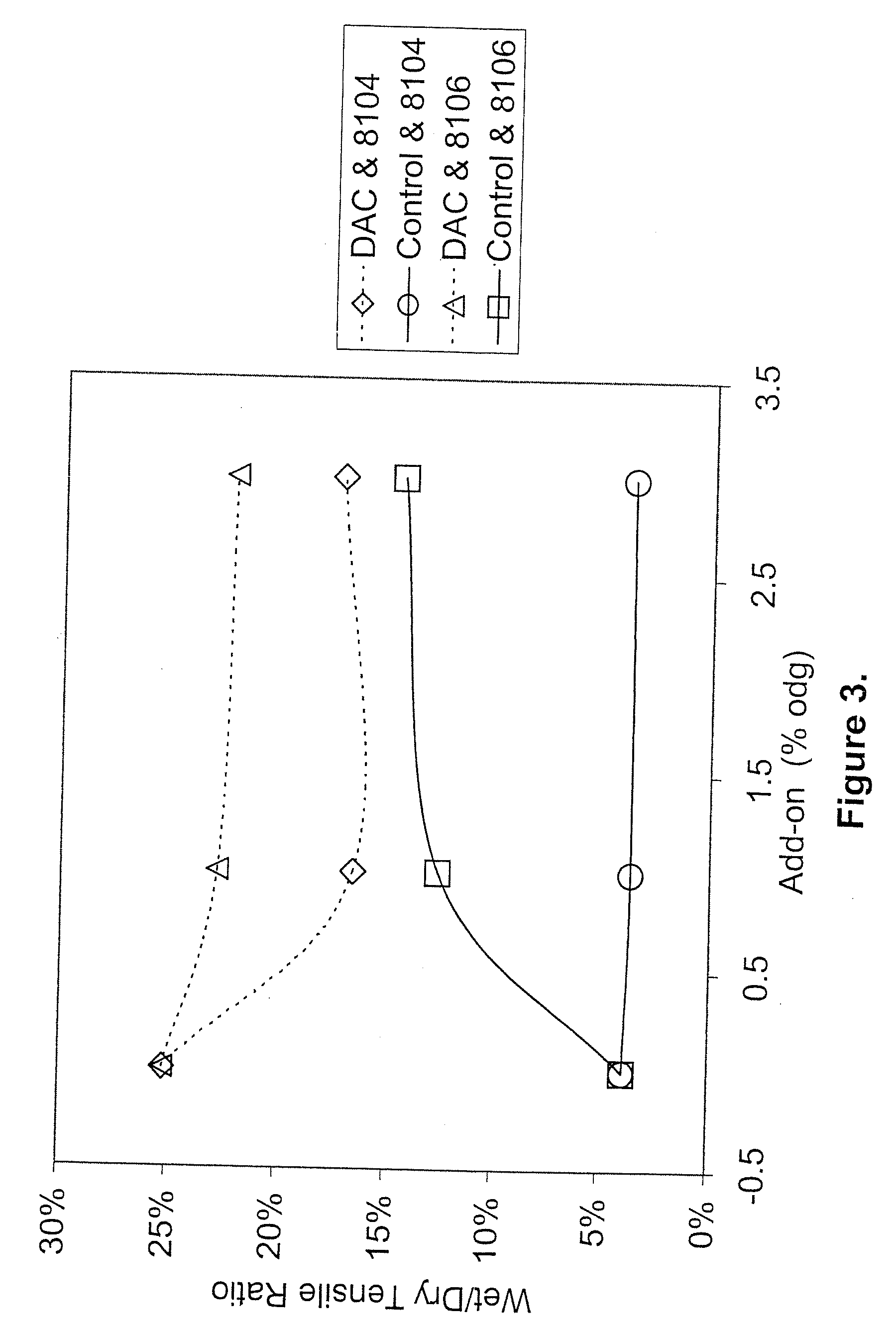

Polyvinylamine treatments to improve dyeing of cellulosic materials

InactiveUS7214633B2Improve wet strengthEasy to dyeDecorative surface effectsFibre treatmentCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

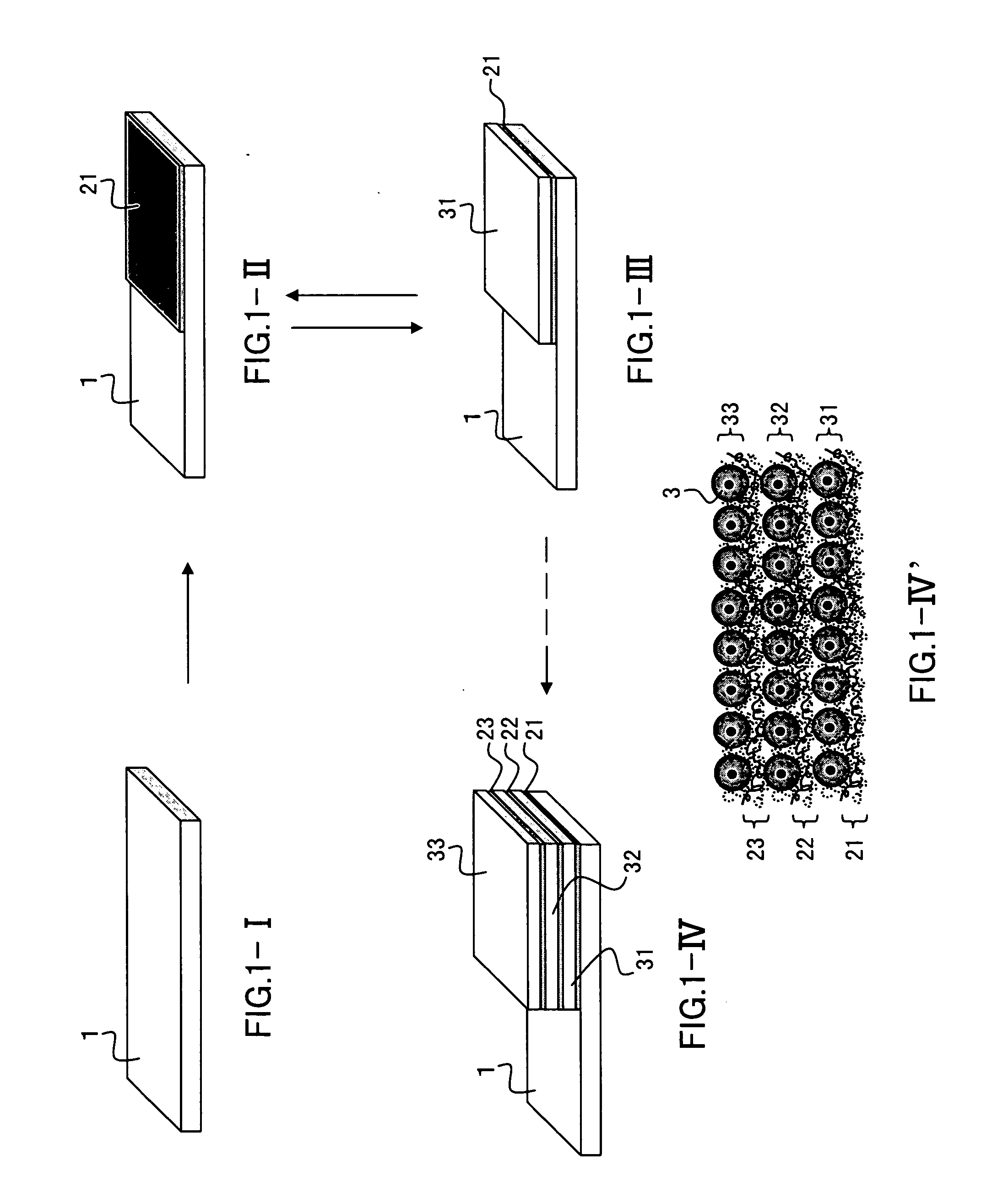

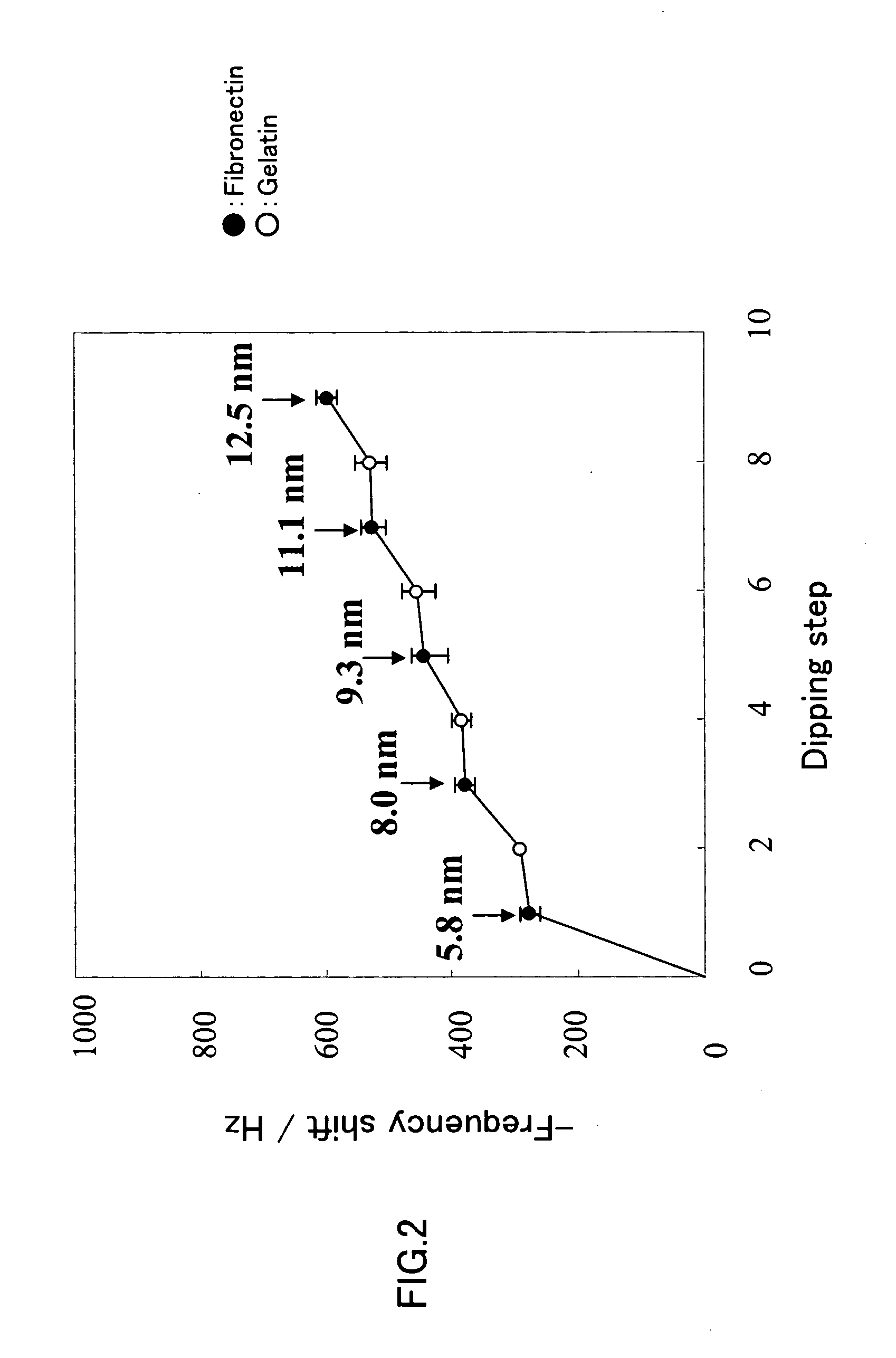

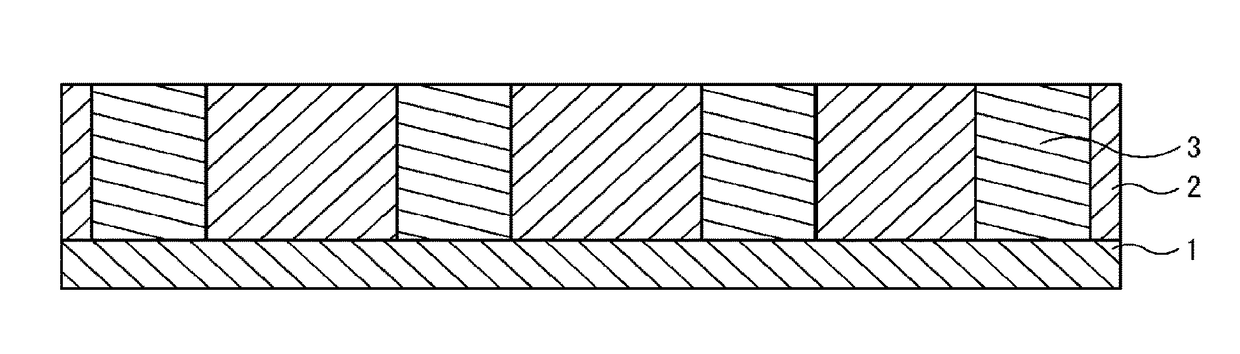

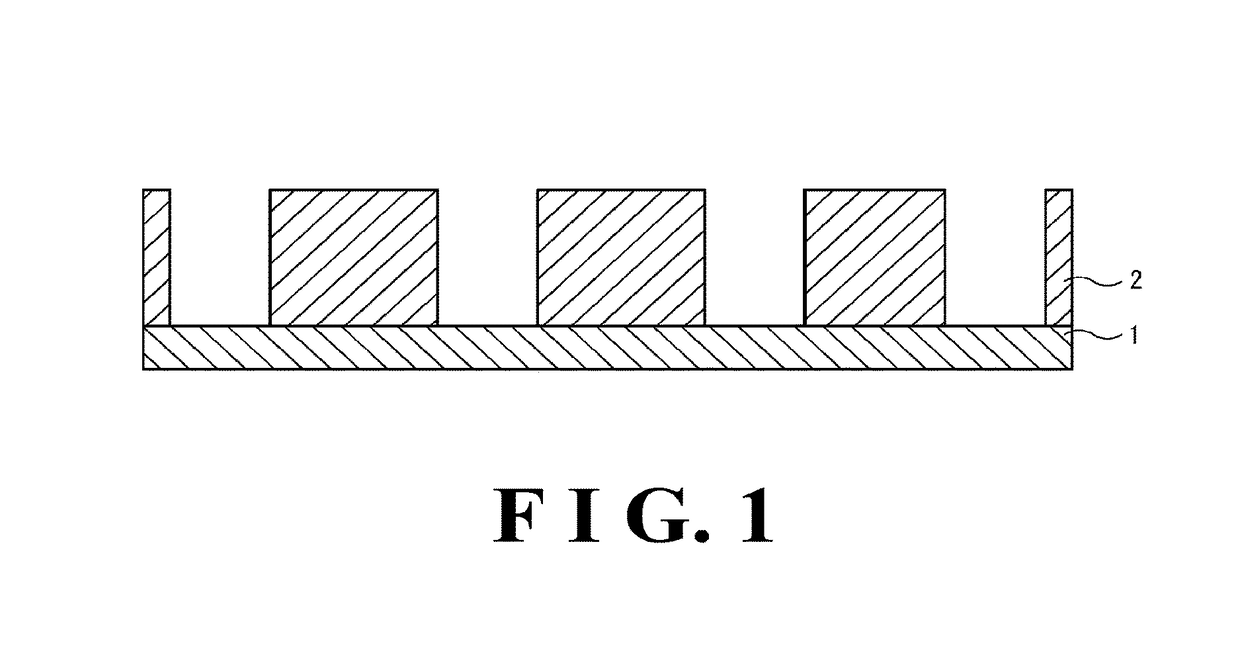

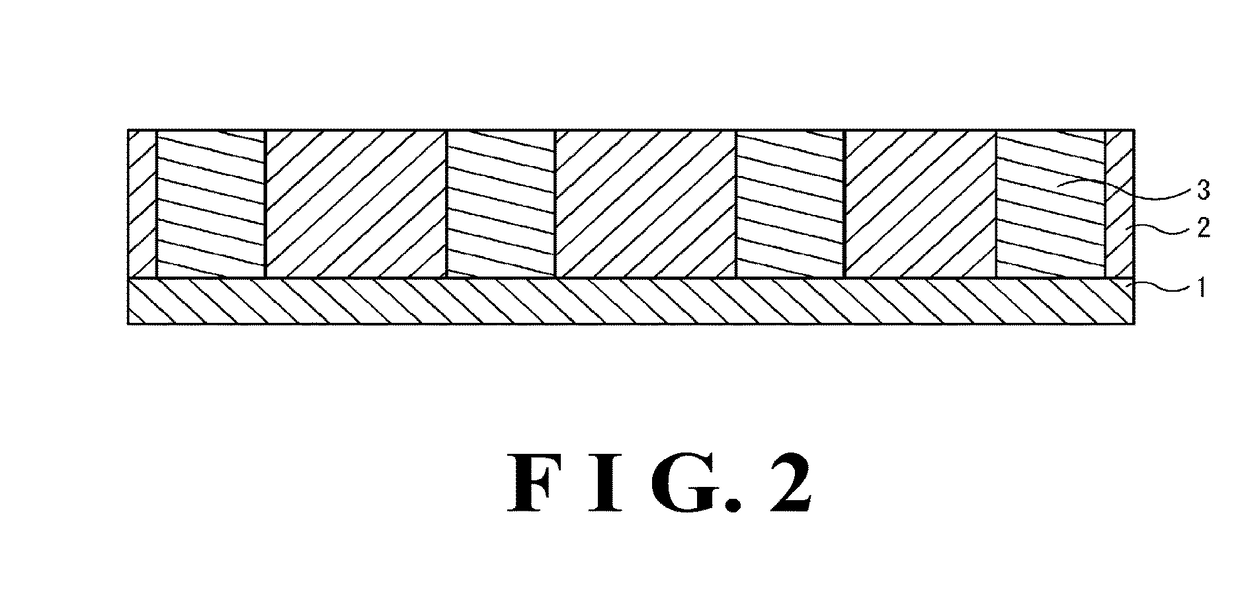

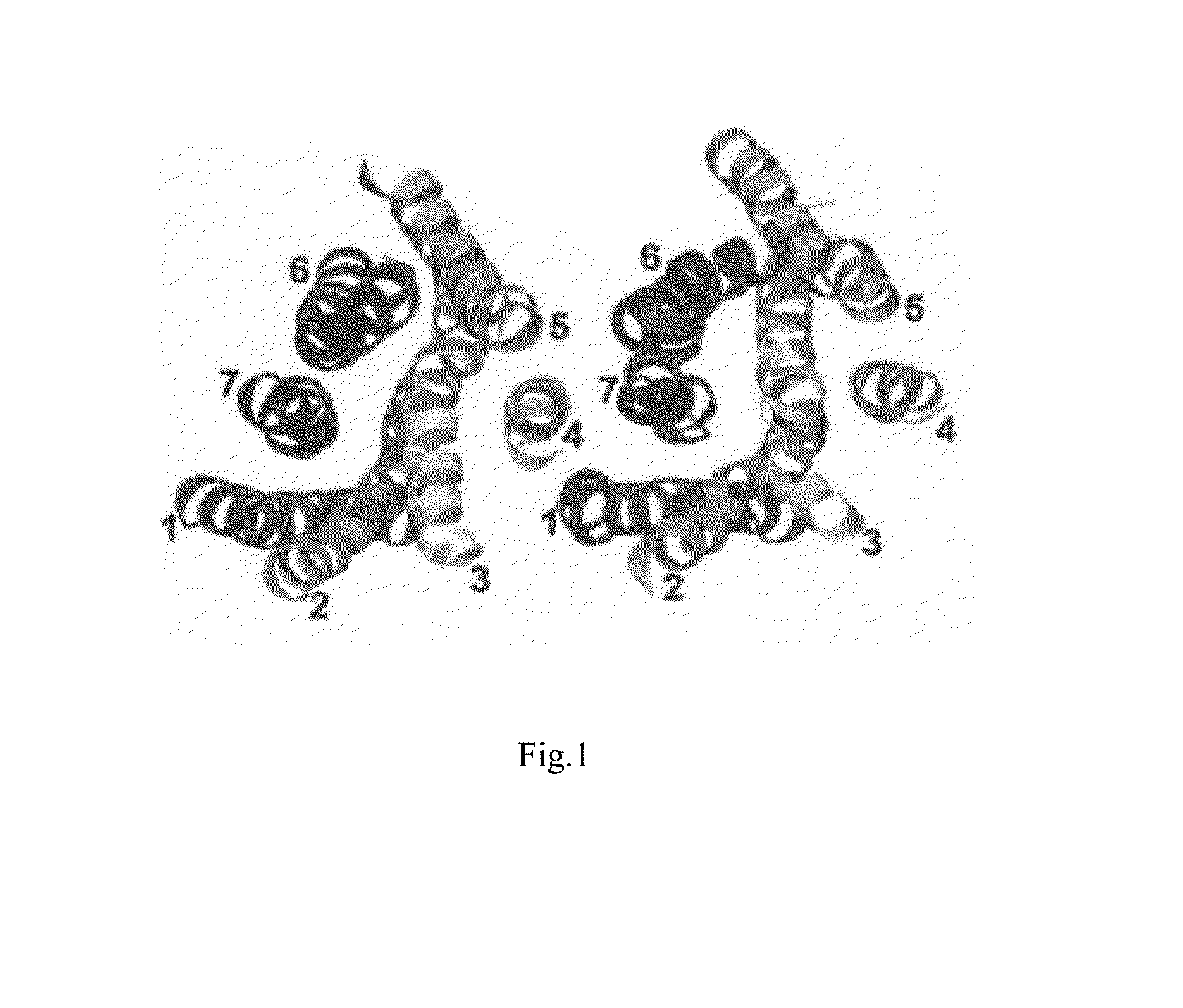

Method of producing three-dimensional tissue and method of producing extracellular matrix used in the same

ActiveUS20070207540A1Easy to carryExcellent reproducibility and efficiencyNanotechCell culture supports/coatingCell-Extracellular MatrixCell layer

The present invention provides a novel method of producing a three-dimensional tissue by which cell lamination can be carried out easily. According to the method, a three-dimensional tissue in which cell layers are laminated with an extracellular matrix intervening between each pair of the adjacent cell layers is produced by: (A) forming a cell layer on a substrate; (B) bringing the cell layer formed on the substrate into contact with a solution containing a first substance and a solution containing a second substance alternately, thus forming, on the cell layer, an extracellular matrix in which the first substance and the second substance are laminated alternately; and (C) culturing a cell on the extracellular matrix to form a further cell layer. In the present invention, a combination of the first substance and the second substance is (a) a combination of a protein or polymer having an RGD sequence and a protein or polymer that interacts with the protein or polymer having the RGD sequence or (b) a combination of a protein or polymer that is positively charged and a protein or polymer that is negatively charged.

Owner:OSAKA UNIV

Processes for producing polymer coatings for release of therapeutic agent

InactiveUS20050158359A1Effectively wettedMinimizing pooling and beadingImpression capsSurgeryVenous shuntCross linker

A method for furnishing a therapeutic-agent-containing medical device is provided. The method comprises: (a) providing a reactive layer comprising a cross-linking agent on a medical device surface; and (b) subsequently applying a polymer-containing layer, which comprises a polymer and a therapeutic agent, over the reactive layer. The cross-linking agent interacts with the polymer to form a cross-linked polymeric region that comprises the therapeutic agent. Examples of medical devices include implantable or insertable medical devices, for example, catheters, balloon, cerebral aneurysm filler coils, arterio-venous shunts and stents.

Owner:BOSTON SCI SCIMED INC

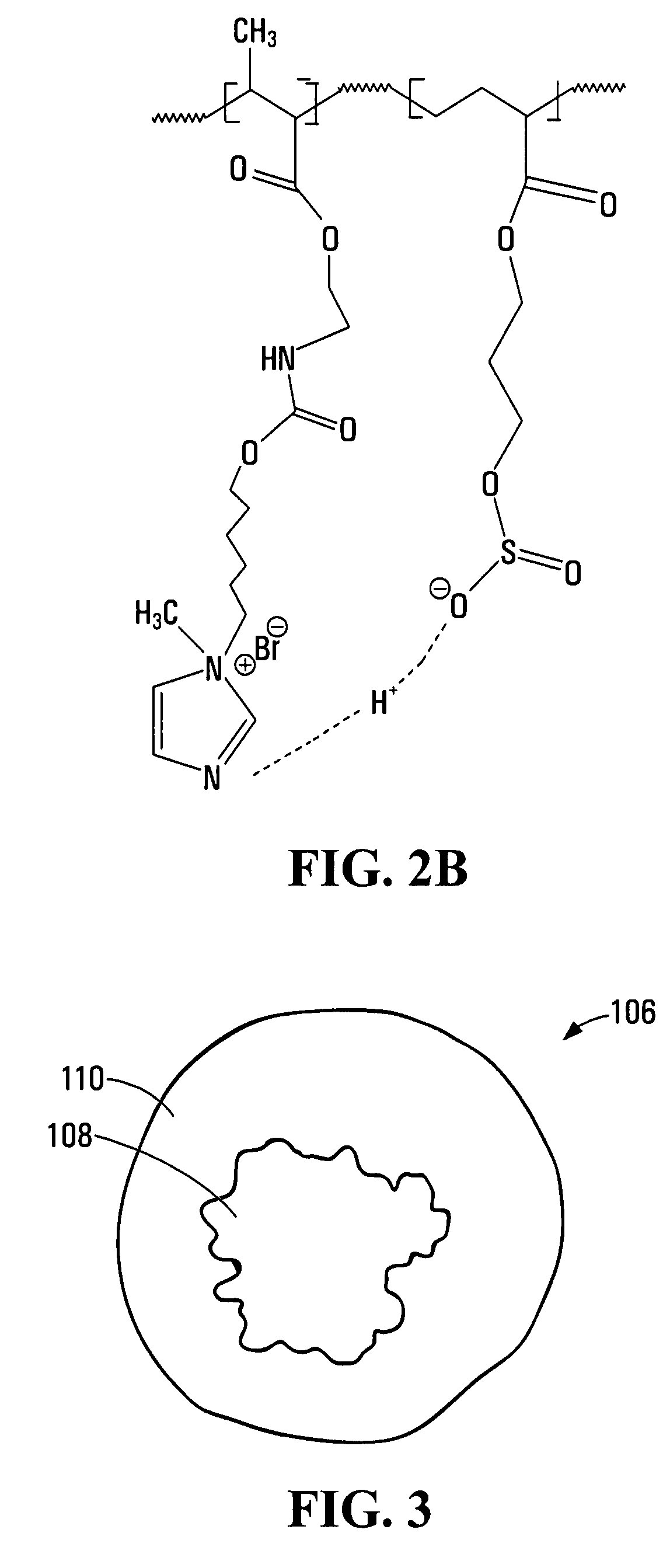

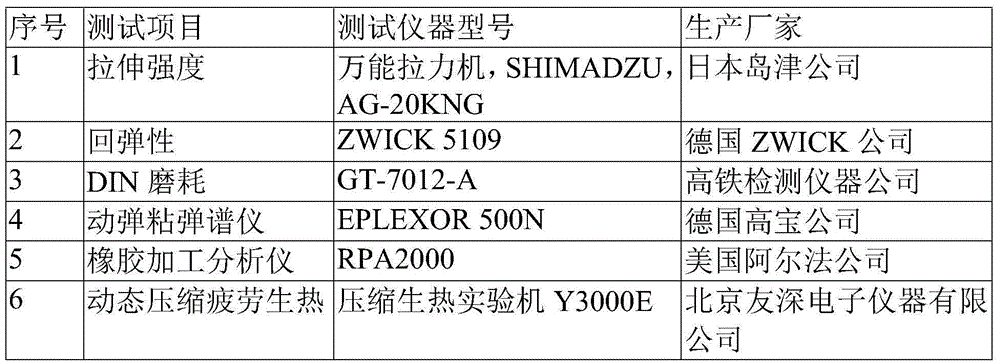

Proton-exchange composite containing nanoparticles having outer oligomeric ionomer, and methods of forming

ActiveUS20080233451A1Evenly distributedSolid electrolytesCation exchanger materialsParticulatesSilica particle

A proton-exchange composite includes a polymer matrix formed from a proton-exchange polymer and ionomer particles distributed therein. The polymer has side chains with ionic groups. The particles have an average particle size of less than 20 nm and include an oligomeric ionomer that interacts with the polymer and attracts the ionic groups on its side chains. The composite may be formed by a method in which an initiator is bonded to silica particulates. The initiator is used to initiate polymerization of a precursor monomer to form a salt form of the oligomeric ionomer bonded to the silica particulates, which is then reacted with an acid to produce the oligomeric ionomer, thus forming the ionomer particles. The ionomer particles are dispersed in a solution containing a solvent and the polymer dissolved therein. The solvent is removed. The residue is cured to form the composite.

Owner:AGENCY FOR SCI TECH & RES

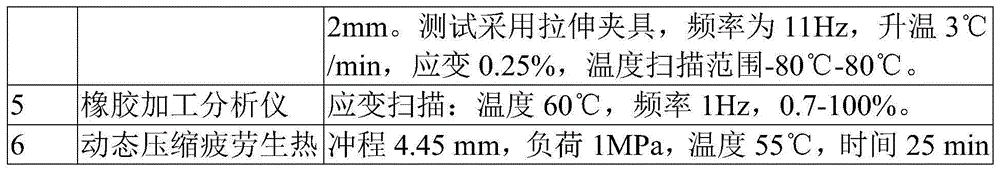

Rubber composition and preparation method thereof, and vulcanized rubber

The present invention discloses a rubber composition and a preparation method thereof, and a vulcanized rubber. The rubber composition preparation method comprises: (1) carrying out first mixing on solution polymerized styrene-butadiene rubber, white carbon black, a surface modifier and an optional cis-polybutadiene rubber to prepare white carbon black rubber master batch; (2) carrying out second mixing on the white carbon black rubber master batch, an activator, an anti-aging agent, a softening agent and an optional carbon black to prepare a second-stage rubber master batch; and (3) carrying out third mixing on the second-stage rubber master batch, an accelerator and a vulcanizing agent to obtain the final mixed rubber. According to the present invention, in the processing process, the effect of the surface modifier can be well provided, the complete interaction between the white carbon black and the polymer can be easily achieved, the strength of the vulcanized rubber prepared through the vulcanization can be improved, the heat generation of the vulcanized rubber can be reduced, and the wet skid resistance of the vulcanized rubber can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

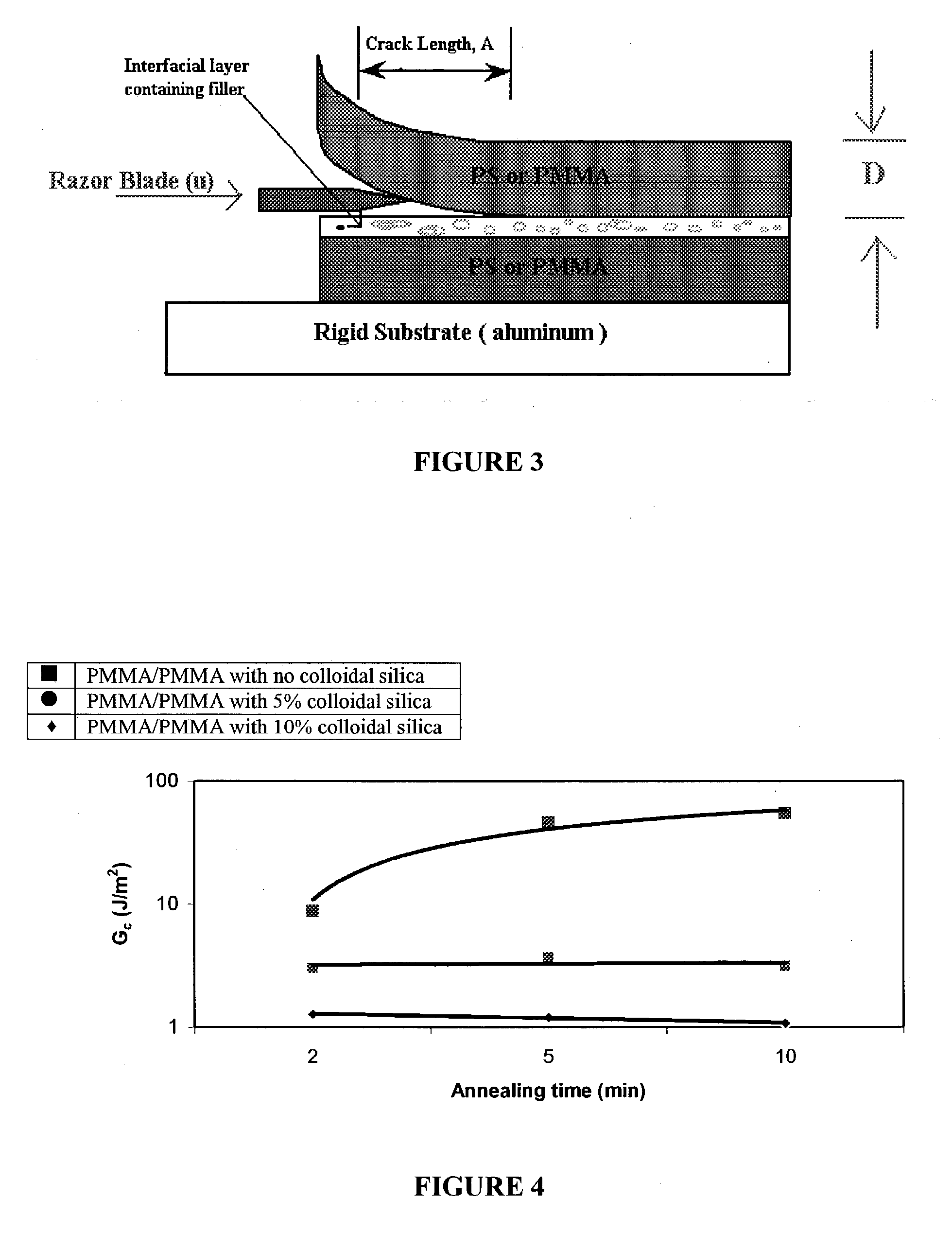

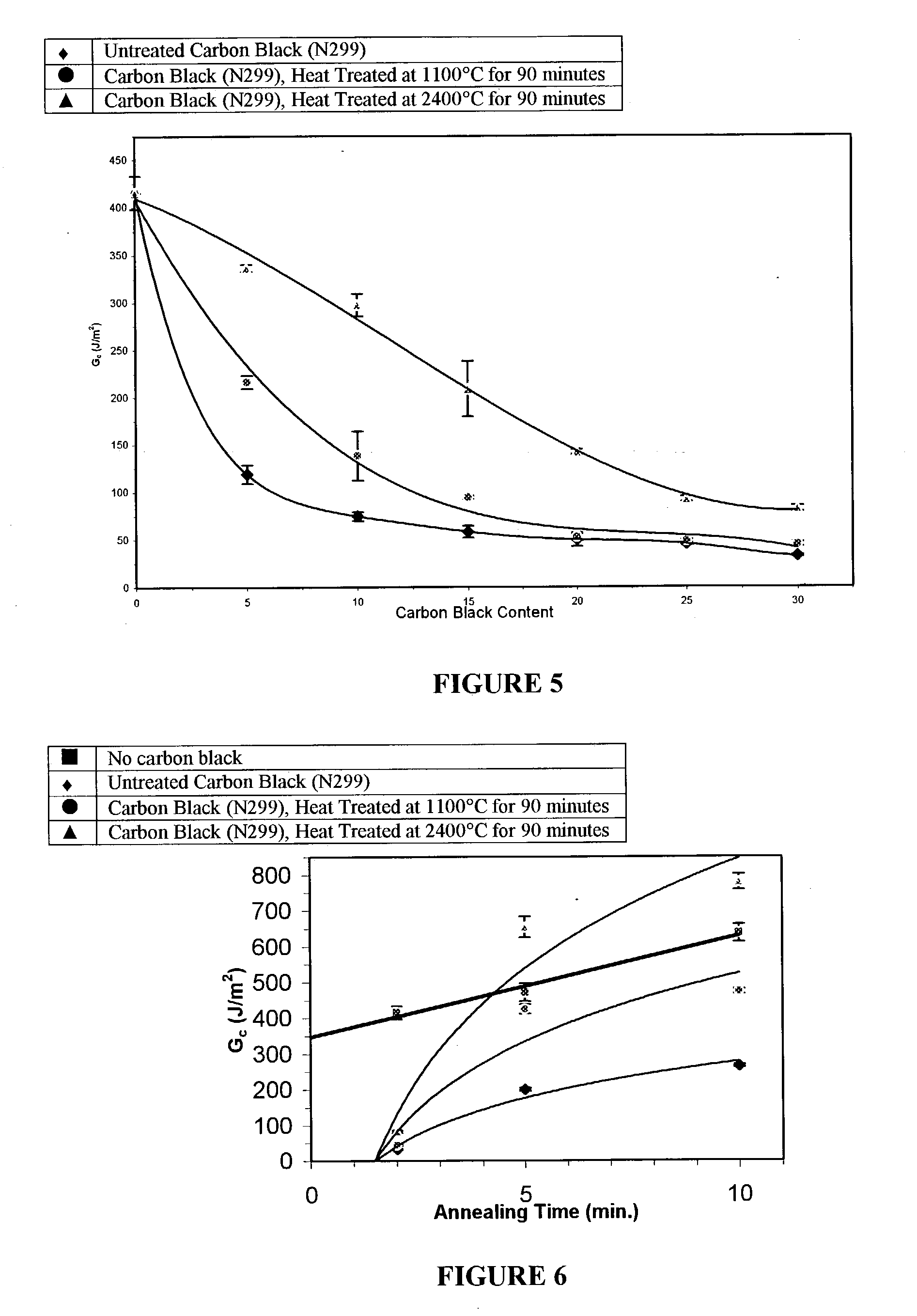

Method for enhancing polymer adhesion using filler particle mix and compositions made using the method

InactiveUS20030176562A1Synthetic resin layered productsCellulosic plastic layered productsColloidal silicaPolystyrene

A method of making and polymer compositions with enhanced adhesion that include a rubbery or glassy polymer, about 0.1 to 30% by weight of carbon black filler and from about 0.1 to 5% by weight of carbon filler. Preferred polymers are polybutadiene, brominated isobutylene methylstyrene, polystyrene or polymethylmethacrylate and preferred carbon fillers are colloidal silica, pure graphite particles and a carbon black filler heat treated to an extent sufficient to reduce interaction with the polymer.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

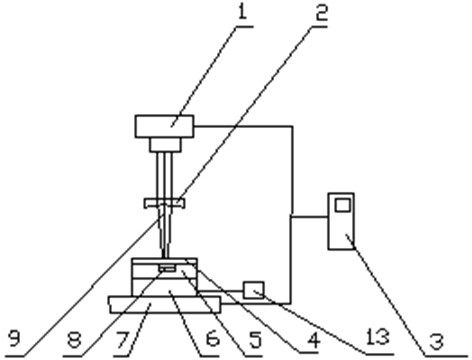

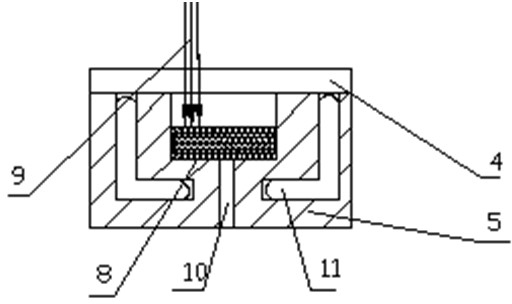

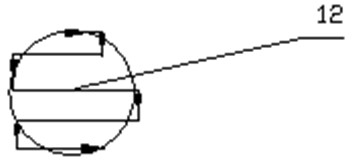

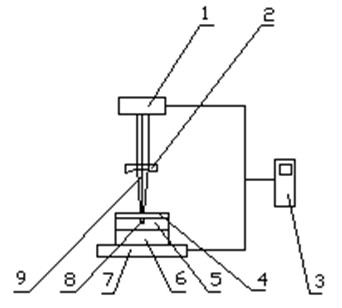

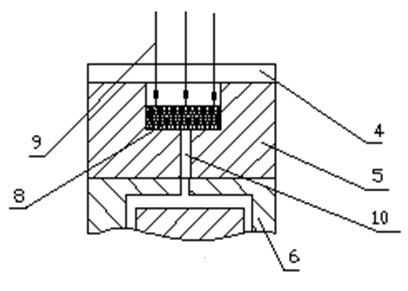

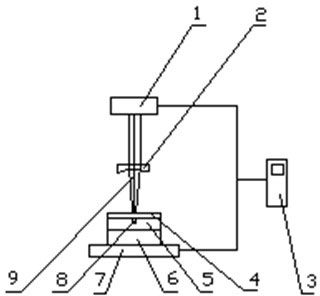

A plastic plasticizing method and device based on co2 laser

The invention discloses a plastic plasticizing method and device based on a CO2 laser, and relates to the field of laser plasticizing molding processing. The invention is based on the photothermal effect of the interaction between the laser and the polymer. For the light energy generated by the CO2 laser, most plastics almost completely absorb it. Through precise control of laser parameters: wavelength, spot size, energy, and irradiation method, the temperature rise range of laser irradiated plastics is controlled, and the plastic solid is heated and plasticized by laser to realize the polymer from glass state to high elastic state to viscous flow state. The plasticizing process, and finally complete the polymer molding process. The invention has the advantages of short plastic melting time, uniform plasticization and good plasticization stability, overcomes the problems of low plasticization efficiency and uneven plasticization in the traditional plasticization process, is suitable for plastic micro-molding processing, and has high application value.

Owner:JIANGSU UNIV

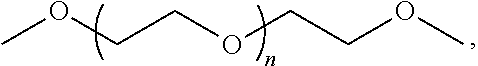

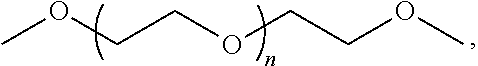

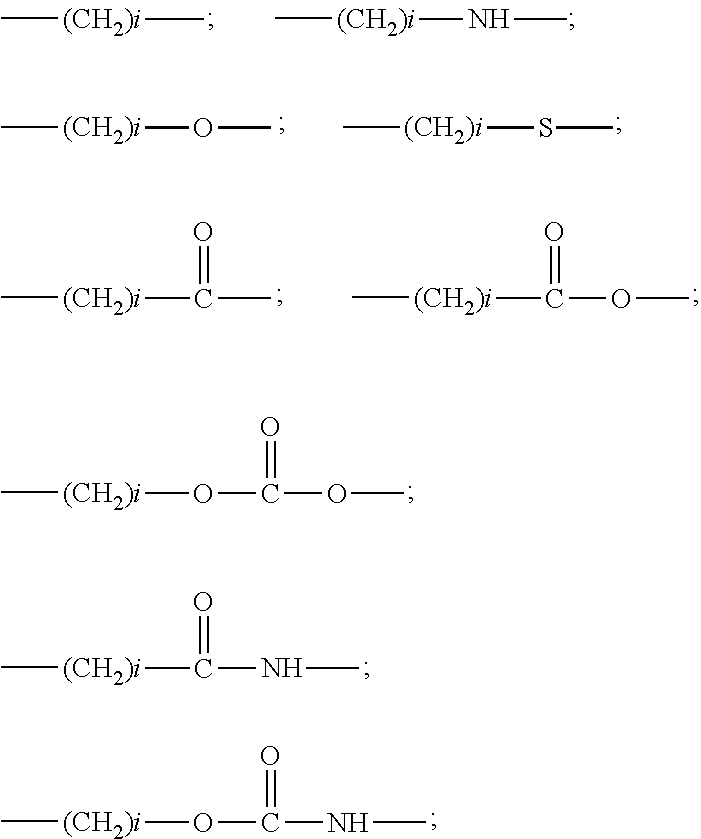

Low molecular weight polyethylene glycol drug conjugates having improved drug biological activity

ActiveUS9789198B2Comprehensive performance is smallReduce penetrationEther/acetal active ingredientsPharmaceutical non-active ingredientsPolyethylene glycolBlood brain barrier penetration

Provided are polyethylene glycol drug conjugates of general formula (I), (II) or (III) and pharmaceutical compositions and a use thereof. The conjugates are formed by combining low molecular weight polyethylene glycol with 2-4 drug molecules. The conjugates can interact with receptor dimers or polymers, thereby improving the in vivo distribution of the drug, changing the oil and water distribution coefficient, enhancing the pharmacological activity, reducing the blood-brain barrier permeability of the drug, and improving the bioavailability of the drug.

Owner:JENKEM TECH CO LTD TIANJIN

Polyvinylamine Treatments to Improve Dyeing of Cellulosic Materials

InactiveUS20070199165A1Improve wet strengthMaterial is facilitatedFibre treatmentPaper/cardboardCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

An improved process for the production of carbon black

Owner:ADITYA BIRLA NUVO

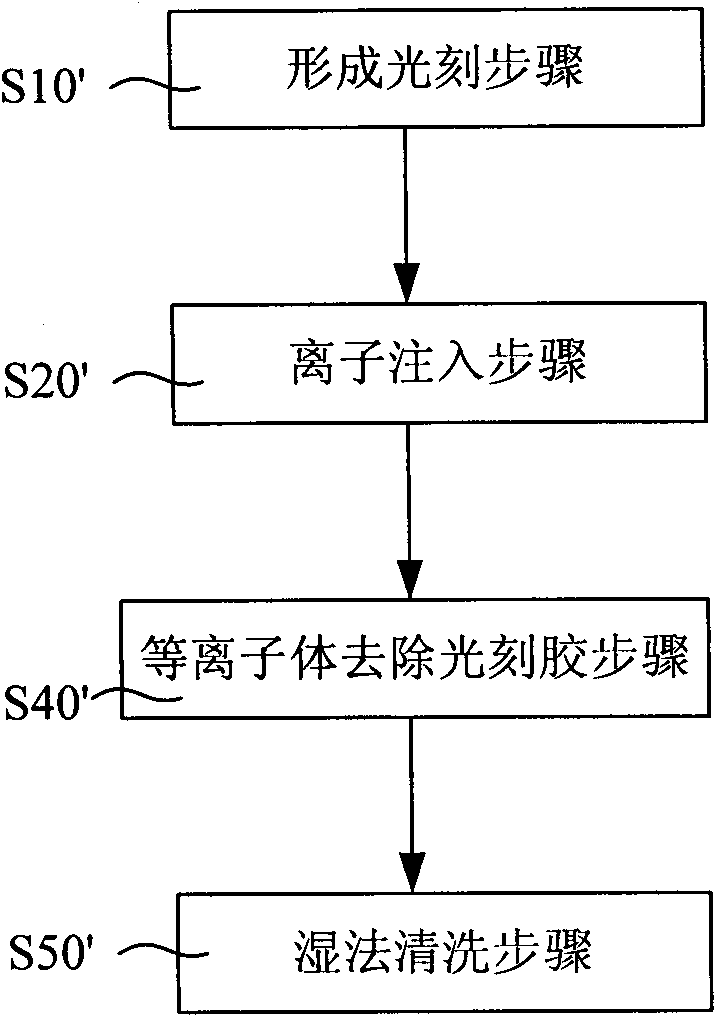

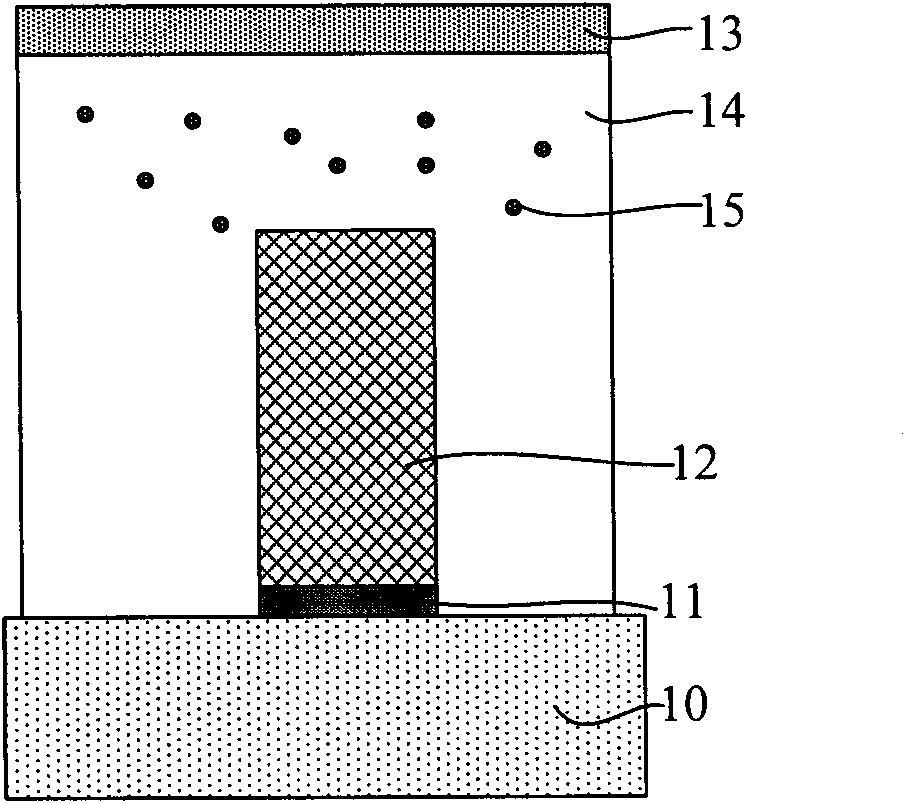

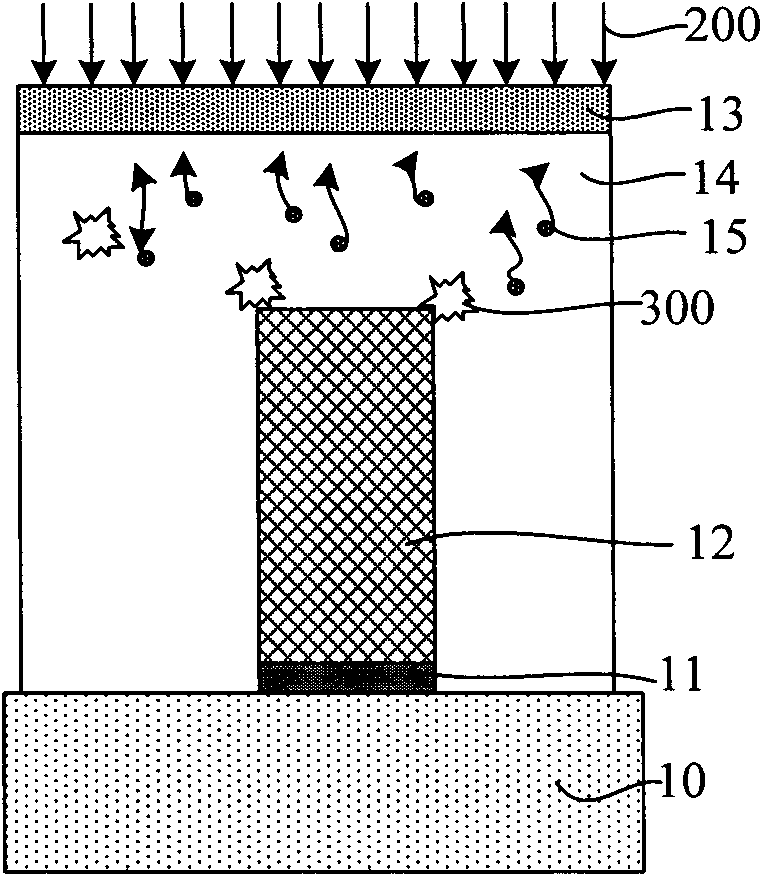

Method for preventing grid electrode from damage in ion implantation process

ActiveCN102376552AAvoid explosionQuality improvementSemiconductor/solid-state device manufacturingPhotosensitive material processingCooking & bakingSurface layer

The invention provides a method for preventing a grid electrode from damage in an ion implantation process. The ion implantation process comprises a photoresist forming step, an ion implantation step and a plasma photoresist removal step. A surface treatment step is also comprised between the ion implantation step and the plasma photoresist removal step. The surface treatment step comprises a washing step, a baking step and a cooling step. In the method for preventing the grid electrode from the damage in the ion implantation process, the surface treatment step is added between the ion implantation step and the plasma photoresist removal step so as to remove a hard surface layer formed on the surface of a photoresist and a polymer formed in the photoresist in the ion implantation step, and further, the phenomenon that a plasma and the polymer act with each other to explode in the plasma photoresist removal step is avoided, thereby, the condition that the grid electrode is damaged is avoided, and the quality of a device is improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Method and device for plasticizing plastics based on Nd: YAG solid state laser

The invention discloses a method and a device for plasticizing plastics based on a Nd: YAG solid state laser, relates to the laser micro-molding field, and is suitable for plasticizing, molding and processing micro-scale plasticized micro-plastics, such as miniature gears, connectors, chips and the like. According to the invention, the heat effect caused by interacting of a laser energy field and a polymer can be used, the plastic is irradiated under the laser with high energy density to absorb light energy, a rapid temperature rising is realized to reach the fusing temperature so that the micro-molding processing can be completed. The device of the invention comprises an Nd: YAG laser, a laser beam regulator, a restraint layer, a plasticizing cylinder, a molding die, a work bench and a controller. The method of the invention is used for plasticizing or molding plastics, and has the characteristics of high plasticizing efficiency of plastics, good quality, energy saving, environmental protection, simple and easy operation and good processing flexibility, and can realize the plastic micro-molding processing with high efficiency and environmental protection.

Owner:JIANGSU UNIV

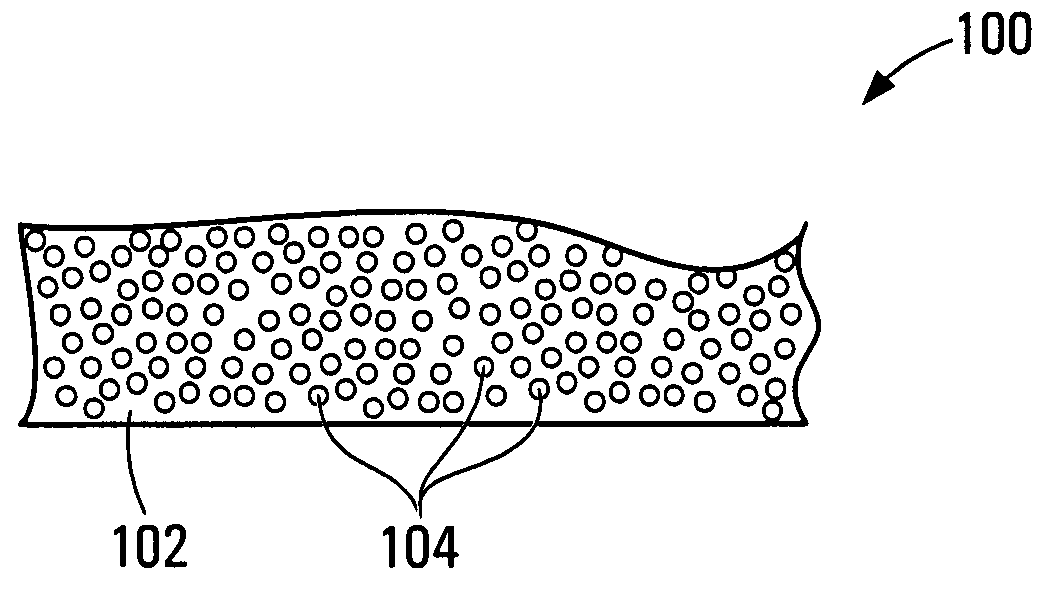

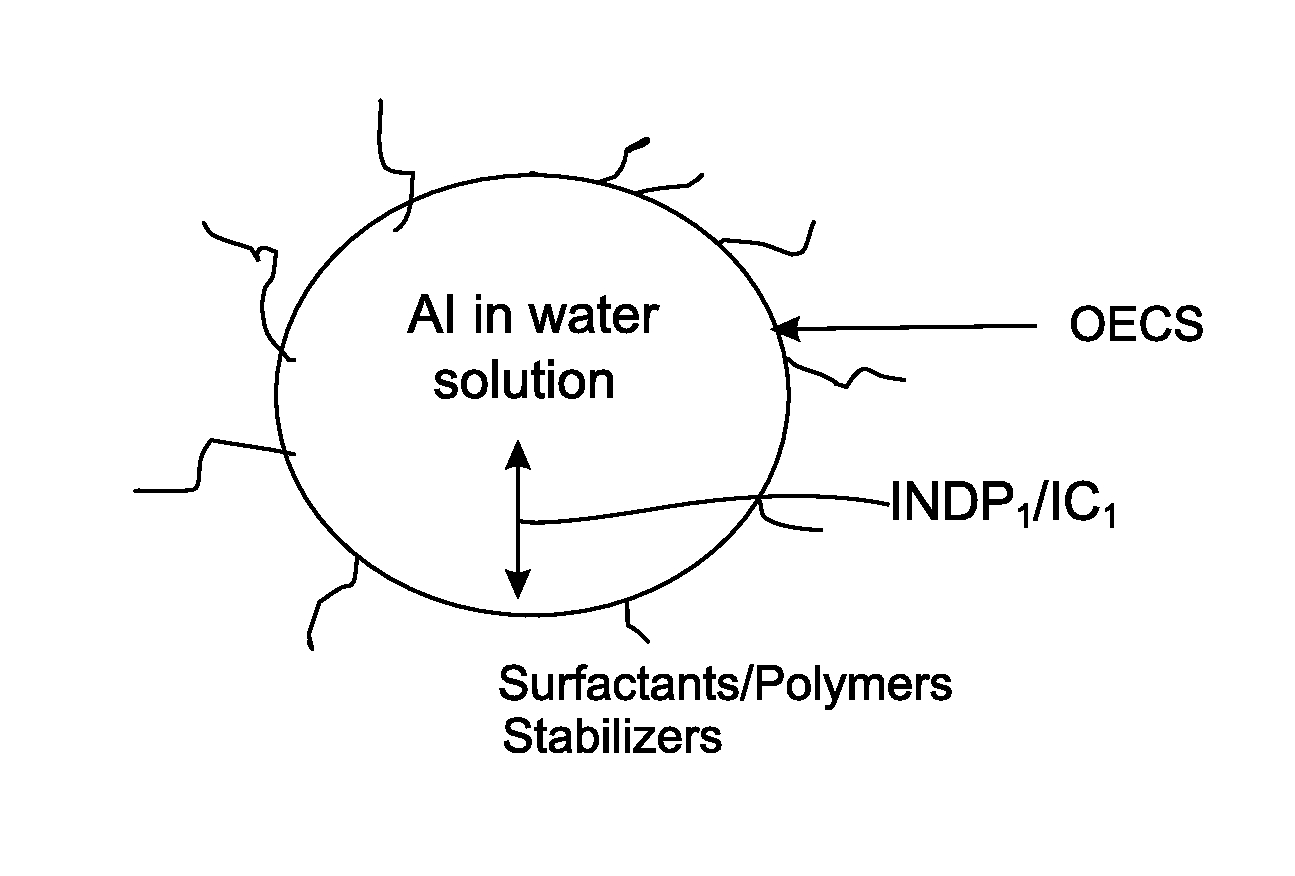

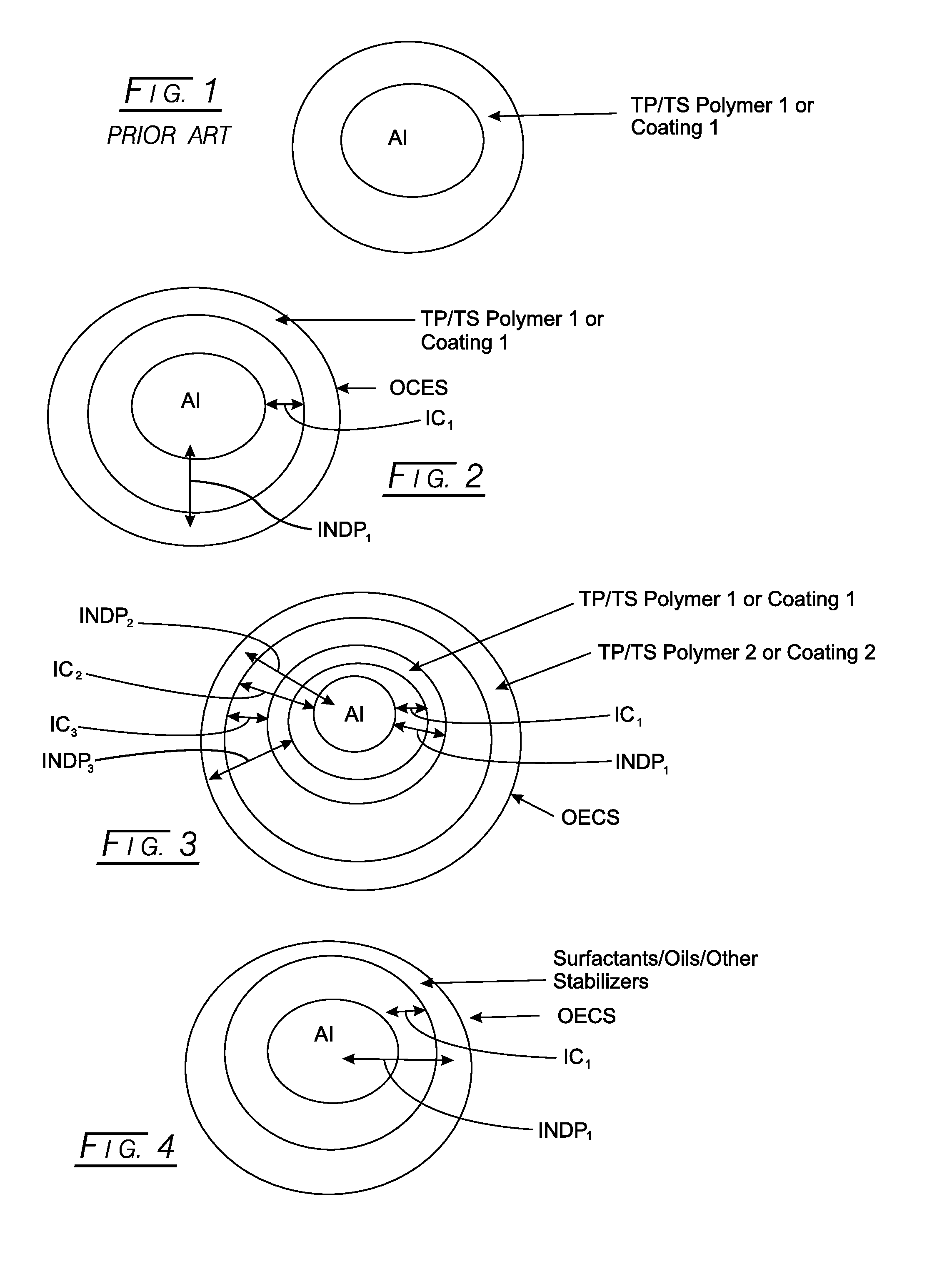

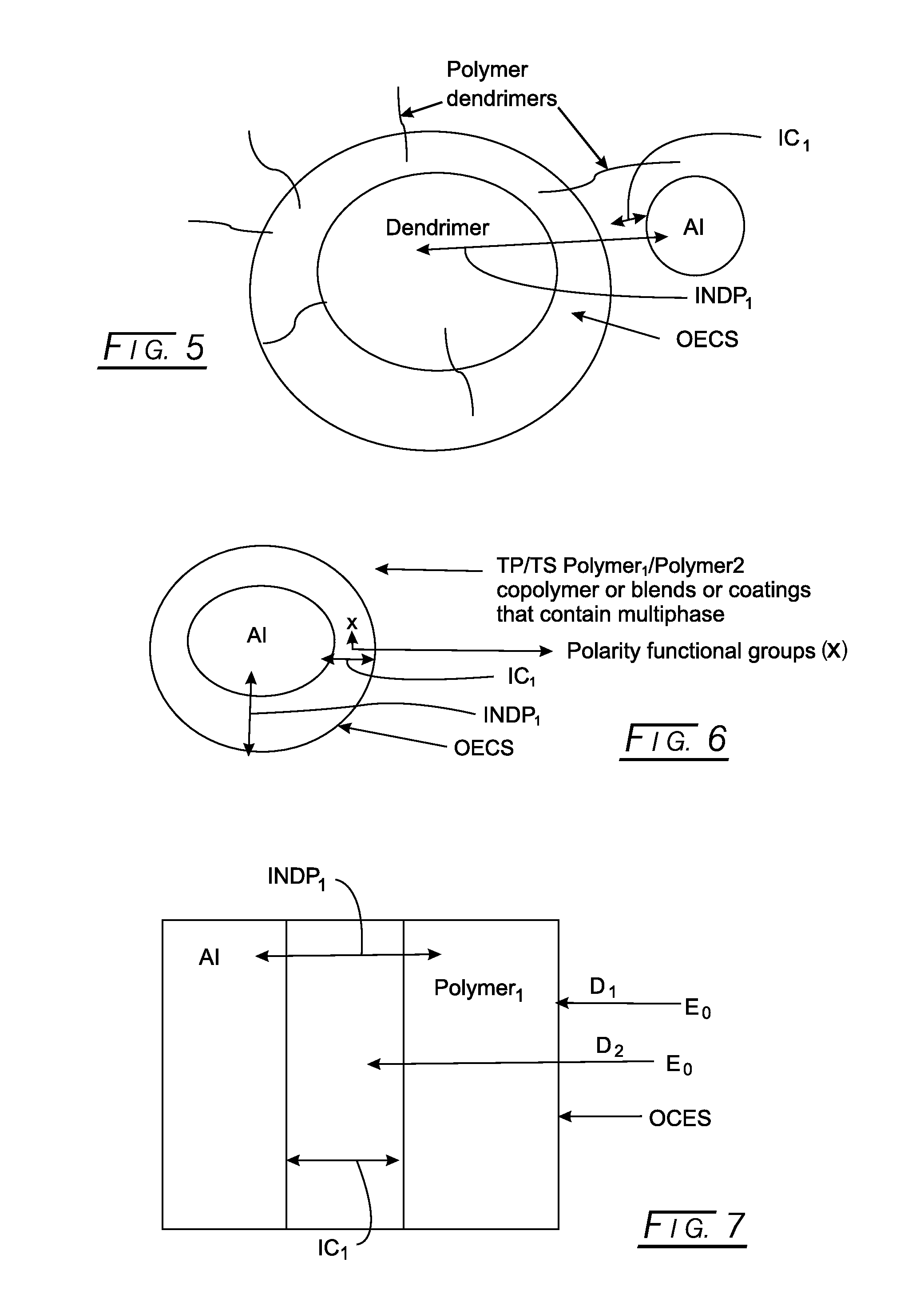

Self-Assembling Polymer Particle Release System

Self-assembly is defined as the ability of an active ingredient (AI), when mixed with a polymer or polymers (solid or liquid state), to form either a complex or a strong attraction with the polymer / polymers, which influences the controlled release of the total system. This AI-polymer interaction or strong attraction can form in the solid state or in solution. The AI-polymer interaction also can form when applied to a filter paper, soil, seeds, or plant vegetation substrates, where the AI and polymer self-assembles into an AI-polymer-substrate matrix or complex that influences how the AI releases from the complex or matrix in a controlled manner.

Owner:BATTELLE MEMORIAL INST

Adhesives and methods of applying the same

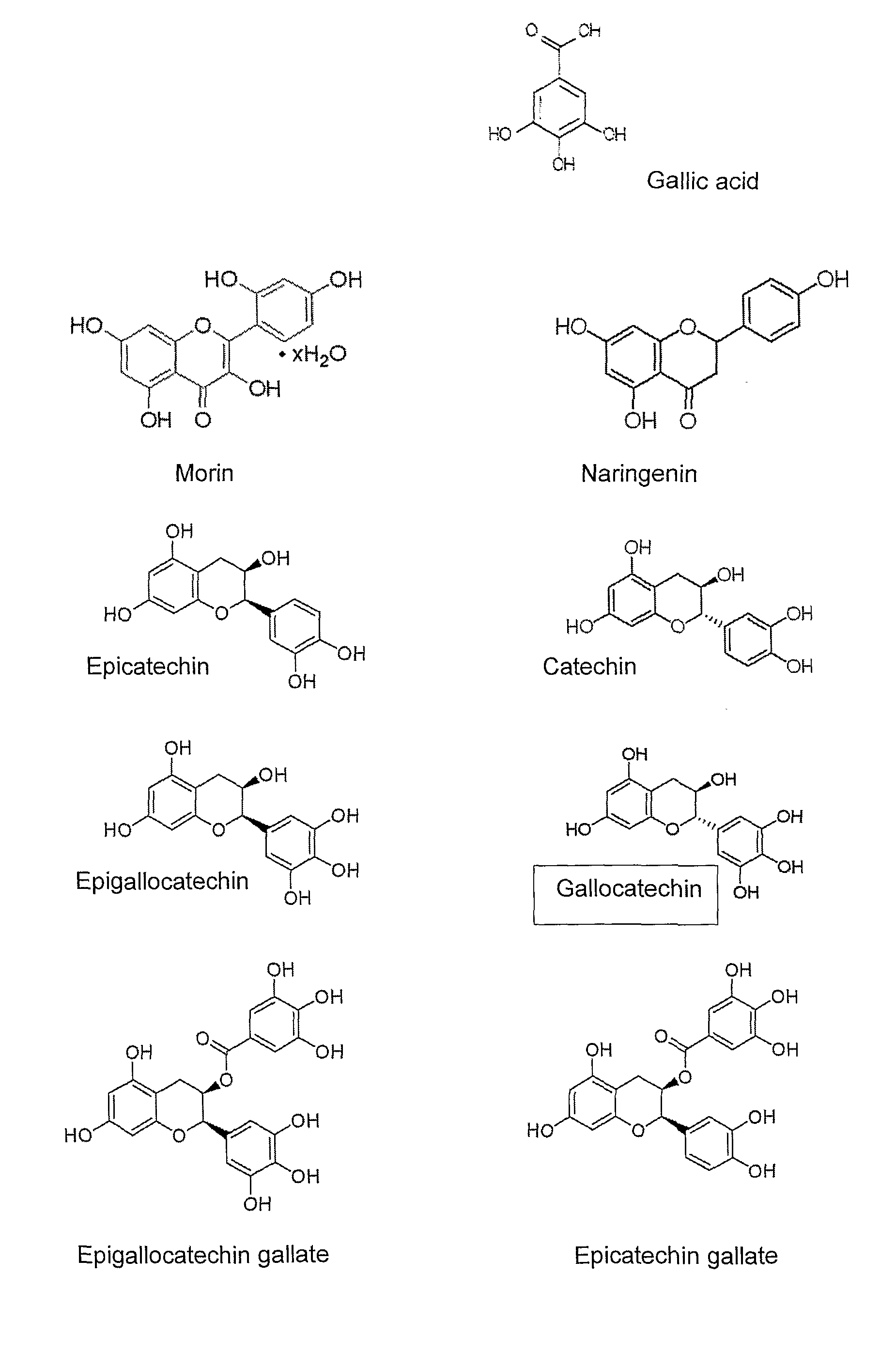

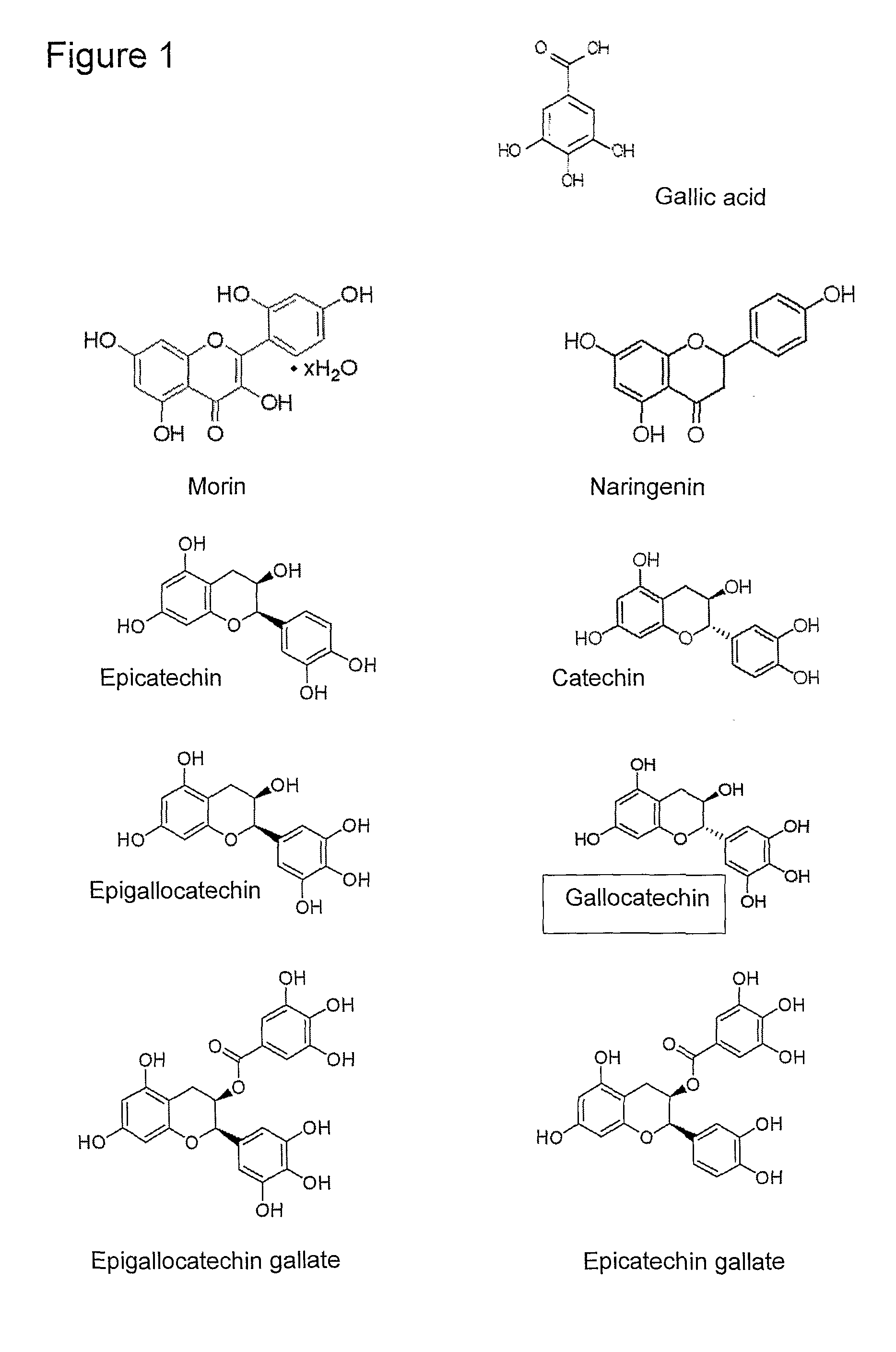

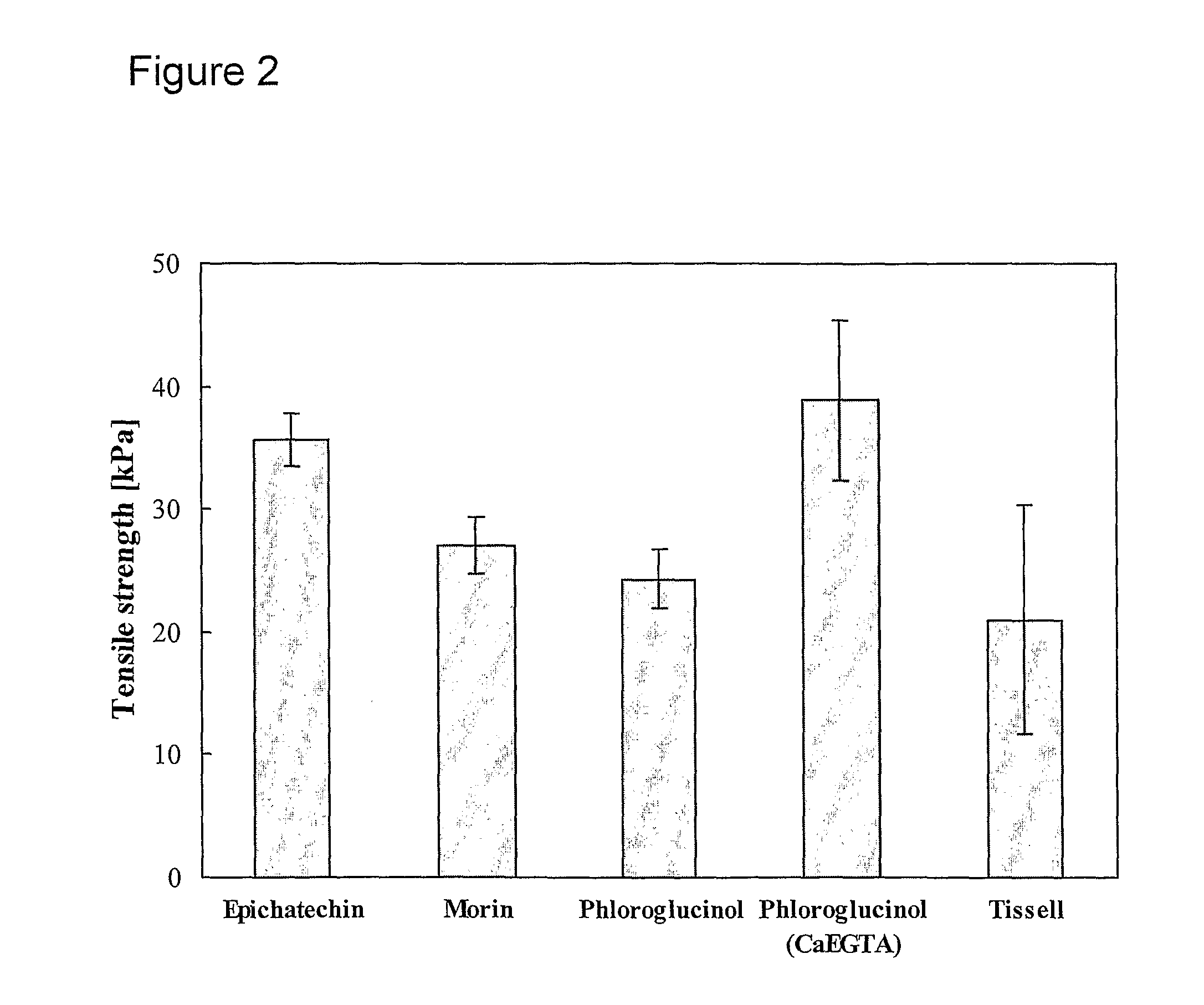

A composition including pre-gel including at least one phenol-based compound, excluding phloroglucinol and derivatives, at least one water miscible polymer, at least one cross linking agent capable of interacting with the polymer. The polymer is selected from one or more natural and / or synthetic carbohydrate, and salt of an anionic polysaccharide.

Owner:TECHNION RES & DEV FOUND LTD

Fluoropolymer coating compositions containing adhesive polymers and substrate coating process

ActiveUS20100247789A1Strong adhesionIncreased durabilityPretreated surfacesCoatingsEpoxyPolymer science

A liquid fluoropolymer coating composition and a process for using the composition to make fluoropolymer coated polymeric substrates. The liquid fluoropolymer composition comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer, solvent, and compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. In the process, the composition is applied to a polymeric substrate comprising functional groups on its surface that interact with said compatible adhesive polymer to promote bonding of said fluoropolymer coating to said substrate. The solvent is removed from the coating composition applied to the substrate to form a fluoropolymer coating on the substrate.

Owner:DUPONT ELECTRONICS INC

Pattern-forming method and composition

ActiveUS20170351174A1Shrinking superior in directional uniformitySuitable for useSemiconductor/solid-state device manufacturingPhotosensitive material processingResistPolymer interaction

A pattern-forming method includes forming a base pattern including a first polymer on a front face side. A composition is applied on at least a lateral face of the base pattern. The composition includes at least one polymer that is capable of interacting with the first polymer. The composition is heated such that a portion of the at least one polymer interacts with the first polymer and that a coating film is formed on the lateral face of the base pattern. Another portion of the at least one polymer not having interacted with the first polymer is removed to form a resist pattern. The base pattern in a planar view has a shape with a long axis and a short axis, and a ratio of lengths of the long axis to the short axis is no less than 1.5 and no greater than 10.

Owner:JSR CORPORATIOON

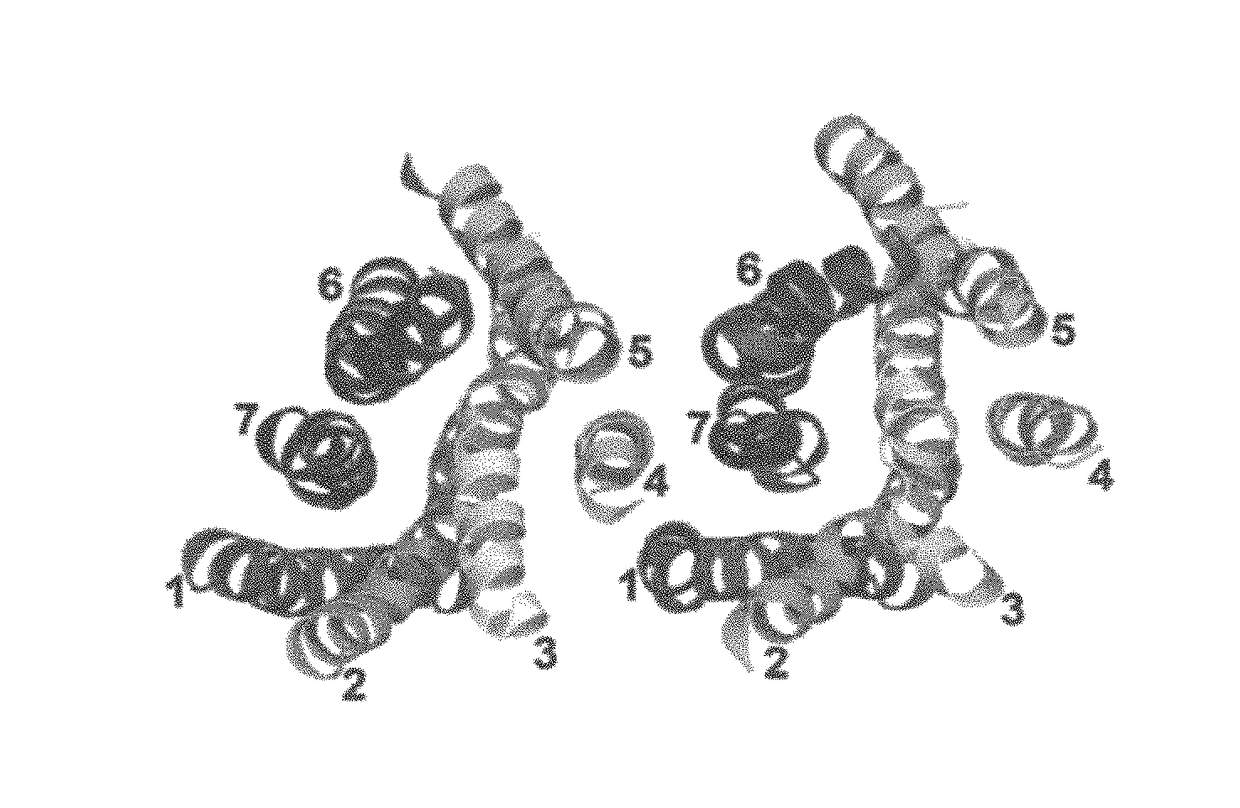

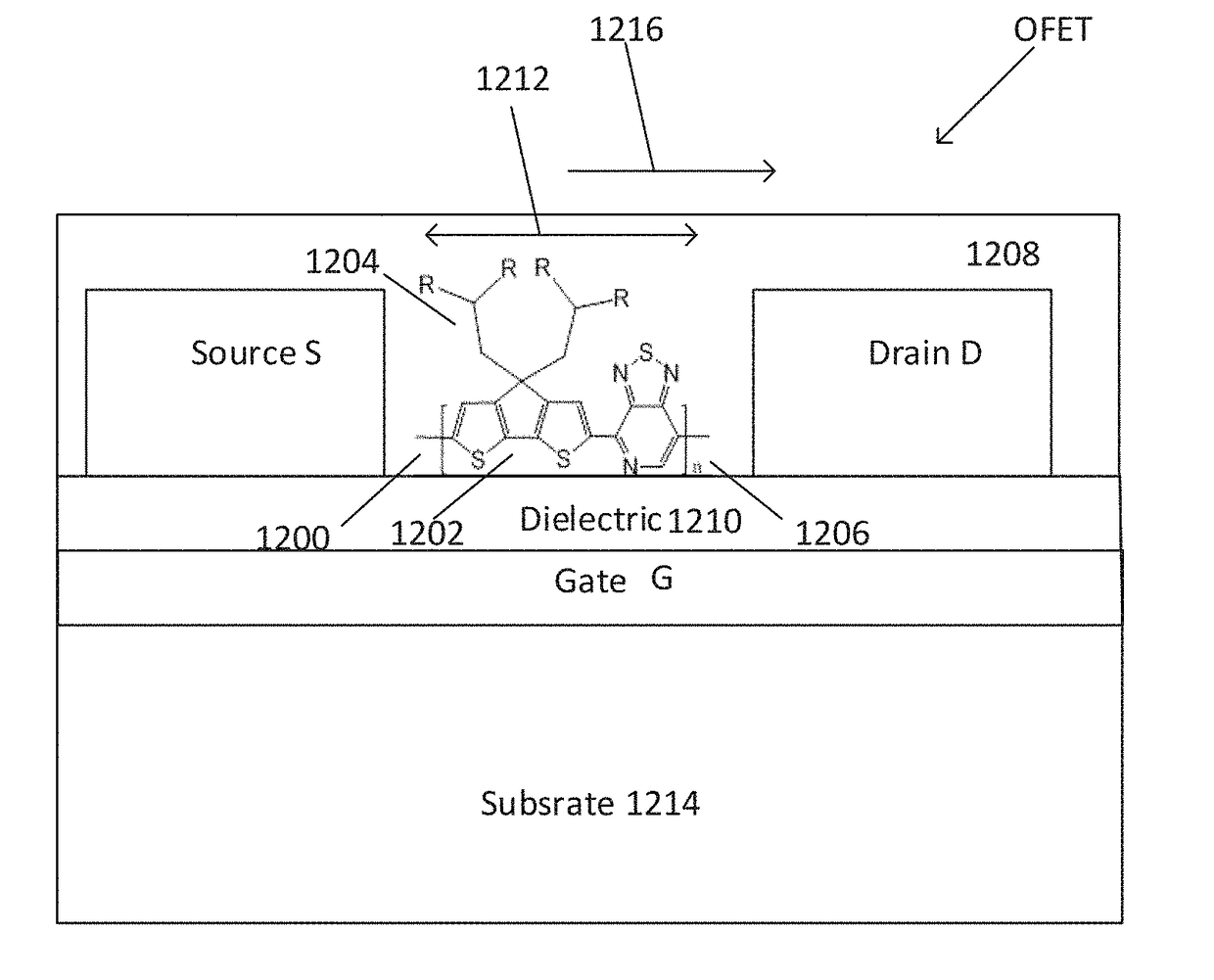

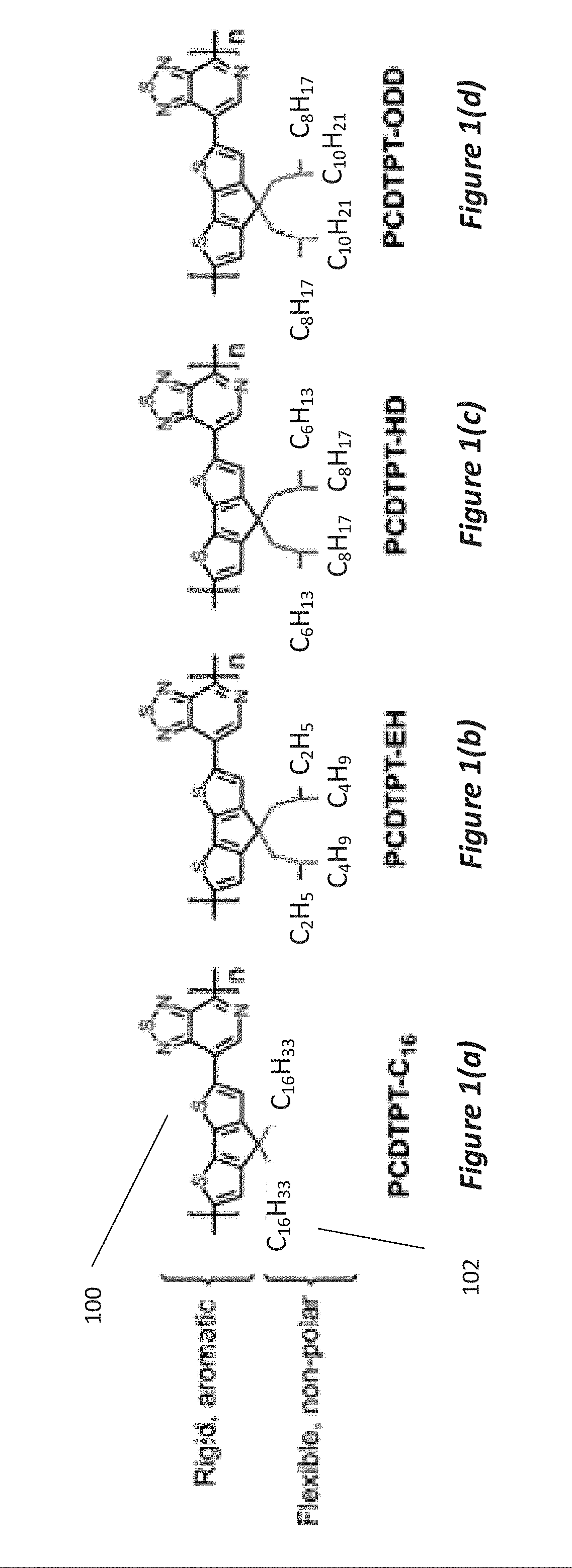

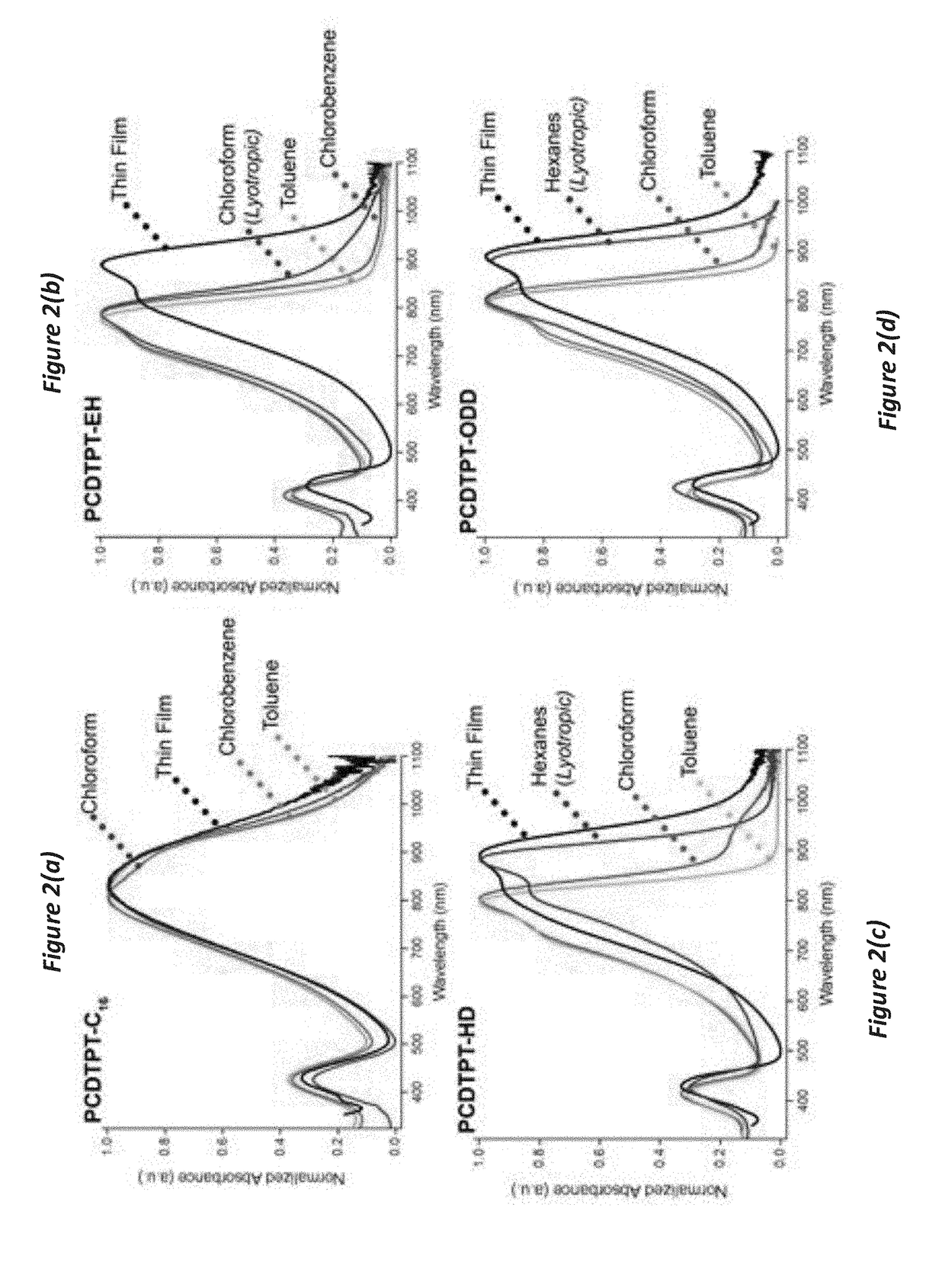

Formation and structure of lyotropic liquid crystalline mesophases in donor-acceptor semiconducting polymers

ActiveUS20180033971A1Improve efficiencyIncrease distanceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid crystallineSide chain

Design of side chains yielding highly amphiphilic conjugated polymers is proven to be an effective and general method to access lyotropic liquid crystalline mesophases, allowing greater control over crystalline morphology and improving transistor performance. The general strategy enables variations in structure and interactions that impact alignment and use of liquid crystalline alignment methods. Specifically, solvent-polymer interactions are harnessed to facilitate the formation of high quality polymer crystals in solution. Crystallinity developed in solution is then transferred to the solid state, and thin films of donor-acceptor copolymers cast from lyotropic solutions exhibit improved crystalline order in both the alkyl and π-stacking directions. Due to this improved crystallinity, transistors with active layers cast from lyotropic solutions exhibit a significant improvement in carrier mobility compared to those cast from isotropic solution. One or more embodiments of the present invention achieve a maximum carrier mobility of 0.61 cm2V−1s−1.

Owner:RGT UNIV OF CALIFORNIA

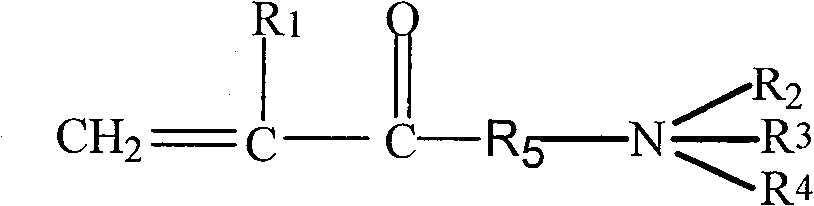

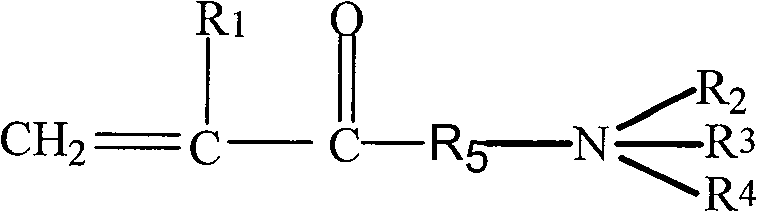

Method of preparing cationic polyacrylamide paper making intensifier

InactiveCN100570055CReduce viscosityImprove uniformityReinforcing agents additionPaper/cardboardFiberSolubility

The preparation method of the cationic polyacrylamide paper-making strengthening agent comprises firstly mixing the acrylamide monomer and polyethylene oxide, and then adding water, cationic monomer and water-soluble initiator to carry out polymerization reaction. Since the present invention dissolves the copolymer of acrylamide monomer and cationic monomer in the polyethylene oxide solution, the system undergoes phase separation through the interaction between the polymer and the dispersion medium, thereby increasing the molecular weight and solid content of the polymer and reducing the viscosity of the system. At the same time, polyacrylamide copolymer also has good solubility and can be quickly dissolved in water. Polyethylene oxide also has a good dispersion effect on paper-making fibers. Adding polyoxyethylene can improve the uniformity of paper production, and polyacrylamide copolymer Together, they can improve the strength of fiber paper.

Owner:SHAANXI UNIV OF SCI & TECH

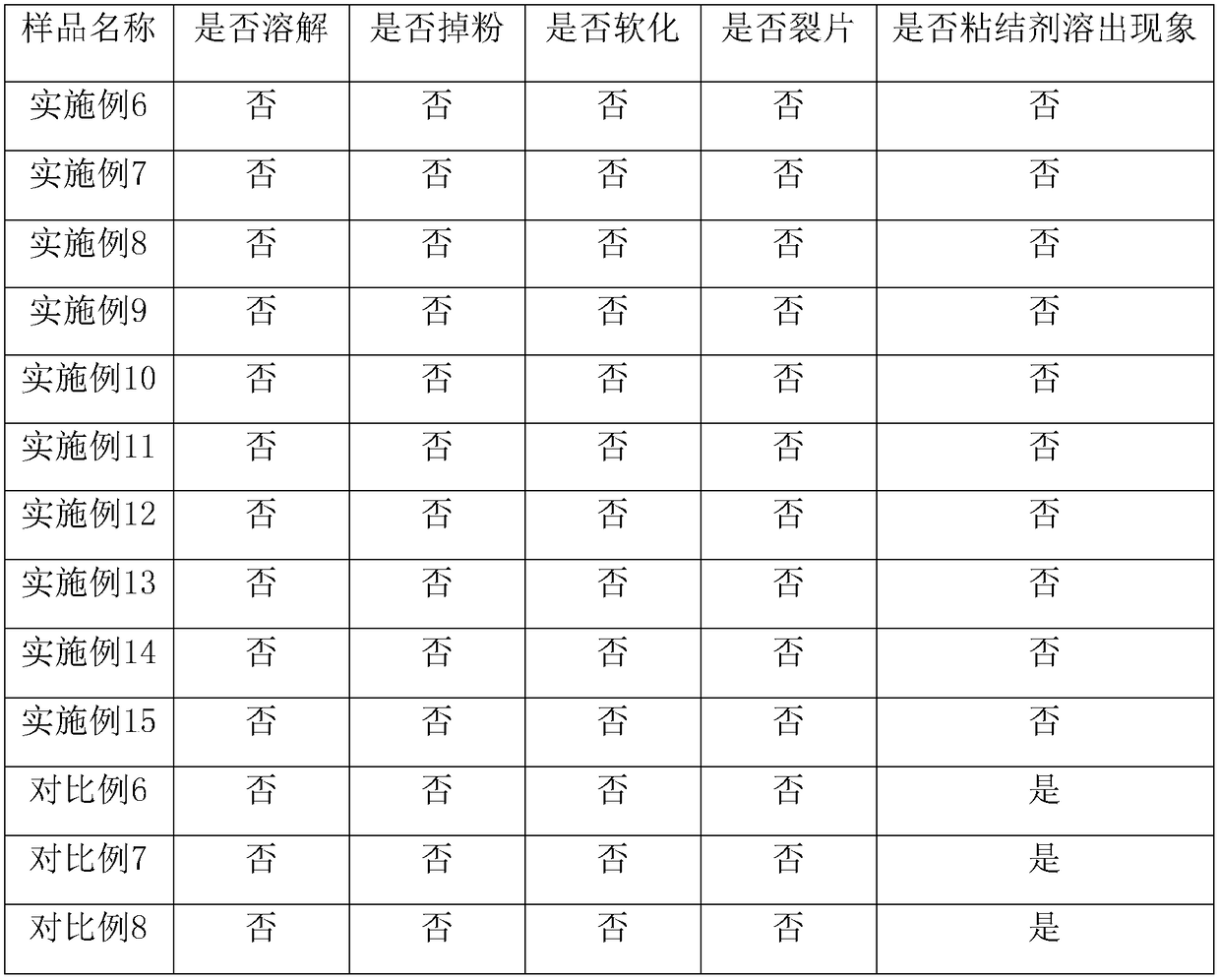

Battery thick pole plate and water-based composite binding agent

ActiveCN108878886AImprove mechanical stabilityIncrease capacityActive material electrodesState of artWater based

The invention belongs to the technical field of batteries, and particularly relates to a water-based composite binding agent for a battery thick pole plate. The water-based composite binding agent atleast comprises the following constituents based on parts by weight: 5-8 parts of vinyl fluoride polymer, 0.5-1 part of crosslinking water absorption polymer and 20-40 parts of water, wherein the vinyl fluoride polymer and the crosslinking water absorption polymer form a polymer network twisted in a staggered way. Compared with the prior art, the water-based composite binding agent has the advantages that the molecule chain of the crosslinking water absorption polymer is of a net-shaped structure, the macromolecular chain and the macromolecular net-shaped structure act with each other by a mutual effect of the vinyl fluoride polymer and the crosslinking water absorption polymer, the polymer network which is twisted in the staggered way is formed, and the phenomenon that the binding agent is dissolved out even if the binding agent is placed in an electrolyte for a long time is prevented.

Owner:赵明星

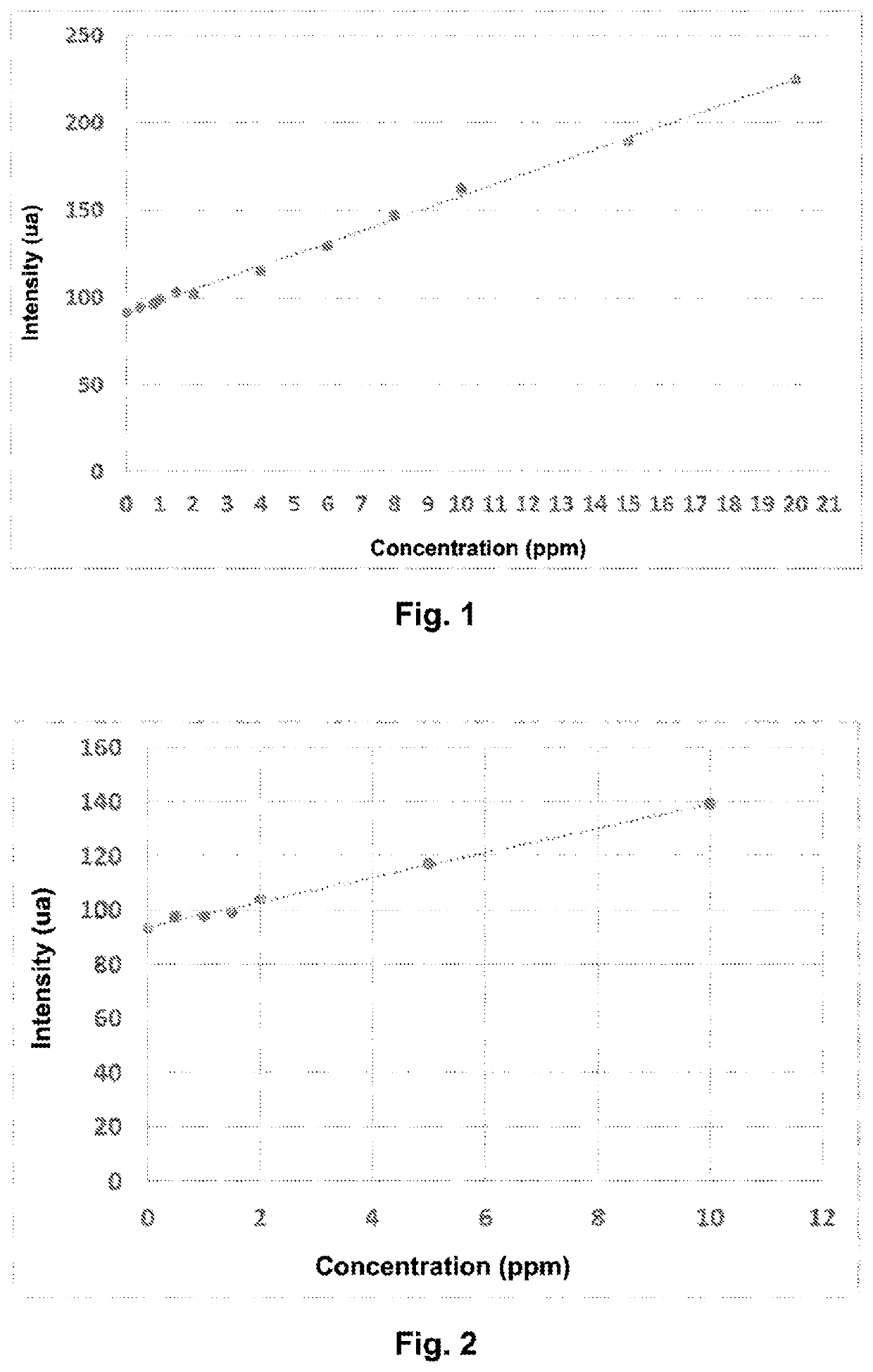

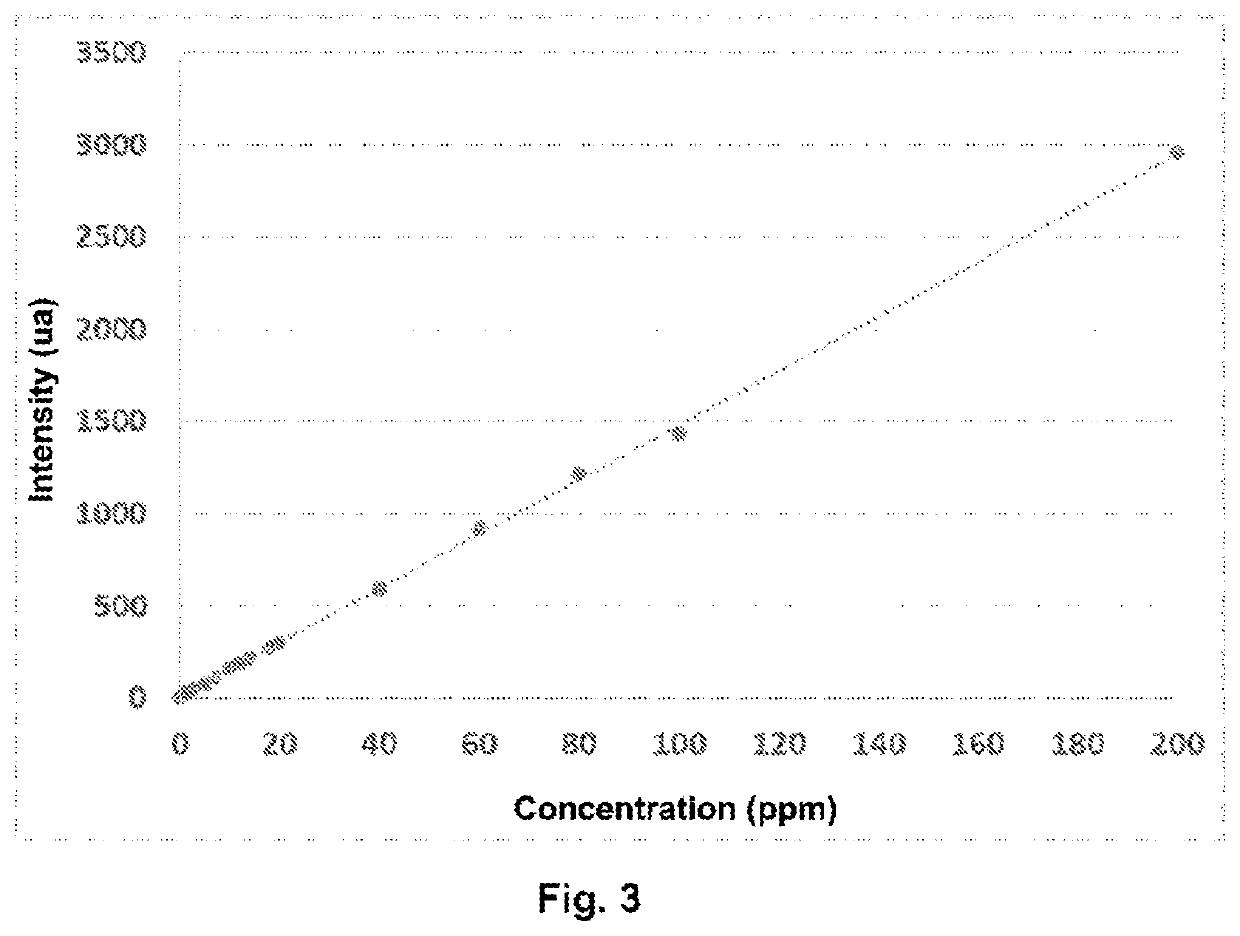

Method for assaying cationic polymers by time-resolved photoluminescence

ActiveUS20200132602A1Minimize background noiseControlled friction forceTesting waterFluorescence/phosphorescencePhotoluminescenceLanthanide

The present invention concerns a method for determining the concentration of cationic polymers present in a sample, according to the following steps: —bringing the cationic polymer or polymers present in the sample into contact with, and enabling the interaction thereof with, a developer solution comprising lanthanide (III) ions and at least one bonding agent, and —exciting the sample at an excitation wavelength λexc and detecting, by time resolved photoluminescence, a signal originating from the lanthanide (III) ions having interacted with the at least one bonding agent having previously interacted with the cationic polymer or polymers, at an emission wavelength λem, and —determining the cationic polymer concentration of the sample by using the signal detected at the emission wavelength λem, the sample originating from water originating from municipal or industrial water or sludge treatment processes.

Owner:S P C M SA

Low molecular weight polyethylene glycol drug conjugates having improved drug biological activity

ActiveUS20160082117A1Reducing blood-brain barrier permeabilityMaintaining and improving drug activityBiocideOrganic chemistryPolyethylene glycolBlood brain barrier penetration

Provided are polyethylene glycol drug conjugates of general formula (I), (II) or (III) and pharmaceutical compositions and a use thereof. The conjugates are formed by combining low molecular weight polyethylene glycol with 2-4 drug molecules. The conjugates can interact with receptor dimers or polymers, thereby improving the in vivo distribution of the drug, changing the oil and water distribution coefficient, enhancing the pharmacological activity, reducing the blood-brain barrier permeability of the drug, and improving the bioavailability of the drug.

Owner:JENKEM TECH CO LTD TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com