Oil displacement system for improving recovery factor after polyalcohol drive and preparation method thereof

A polymer and recovery technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large dosage, poor resistance to inorganic high-valent cations, etc., and achieve low cost, ultra-low interfacial tension, and improved The effect of recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

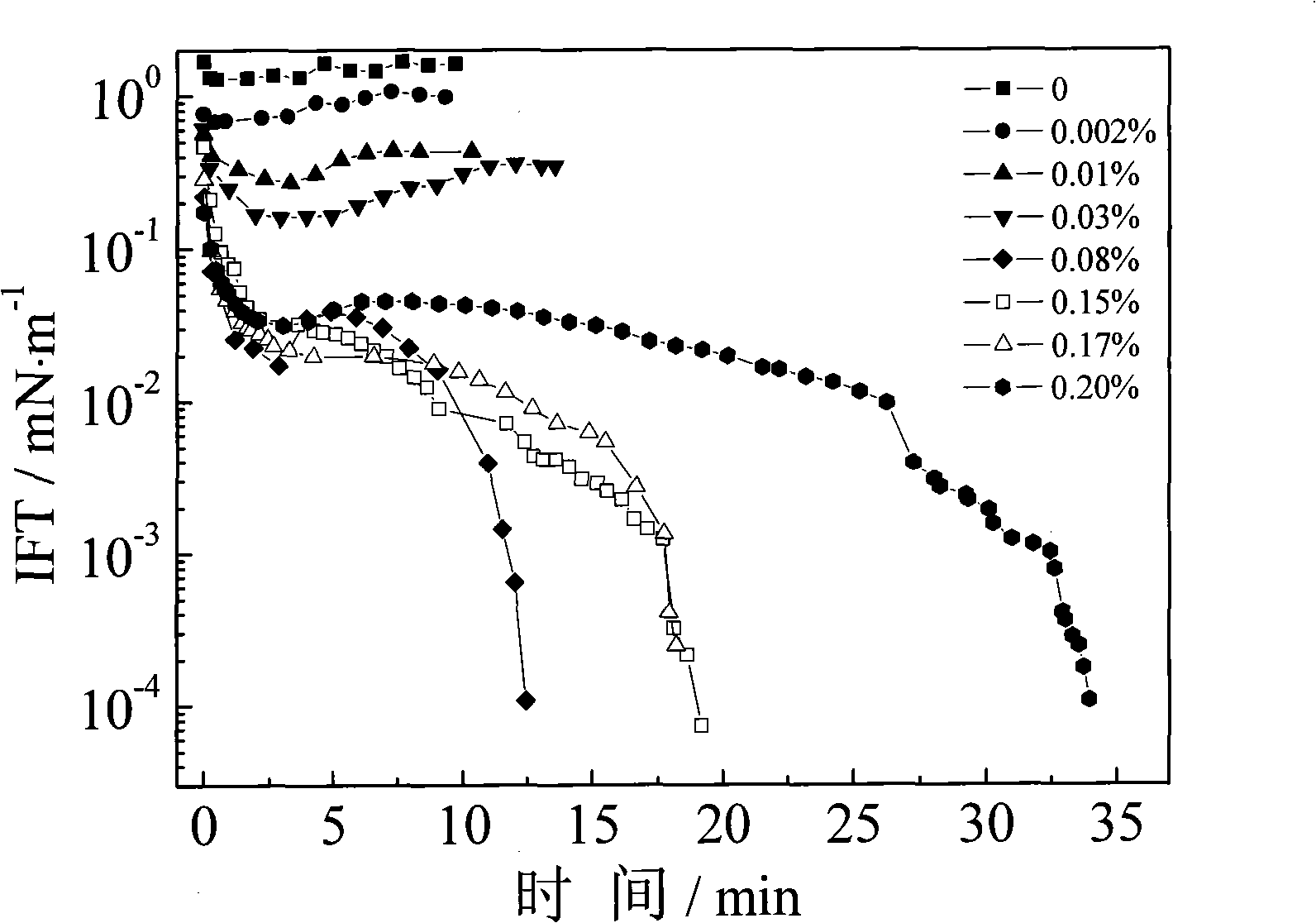

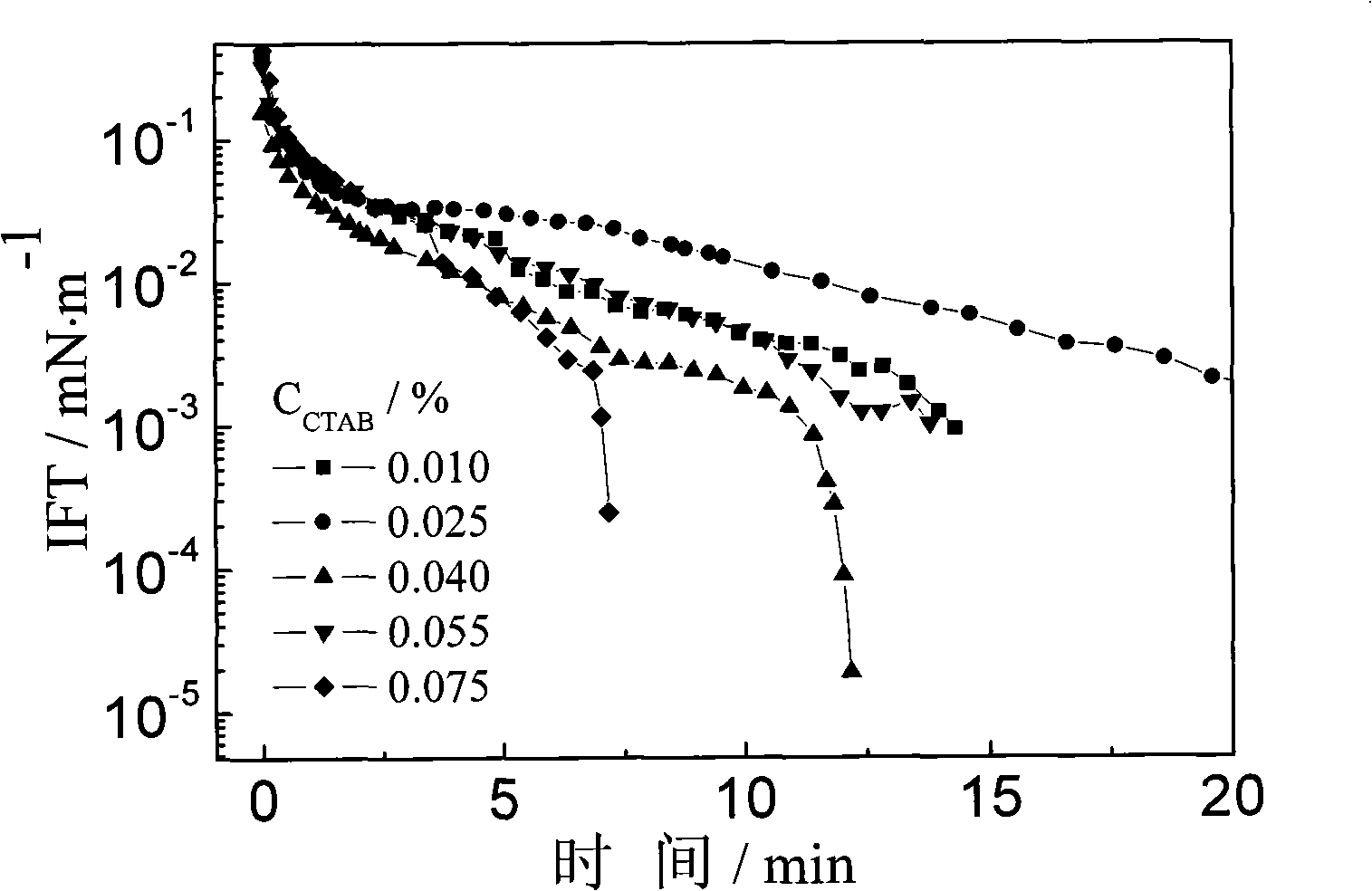

[0039] Example 1: Oil displacement system for enhanced oil recovery after polymer flooding

[0040] Raw materials: 17.0g of hydrolyzed polyacrylamide, 7.5g of isooctylphenol polyoxyethylene ether (Triton X-100), 2.5g of cetyltrimethylammonium bromide, 46.3g of sodium chloride, 1.52g of calcium chloride g, magnesium chloride 2.18g, purified water 9923g.

[0041] Add the above raw materials into a mixer with a stirring device, and stir at room temperature for 1-2 hours.

[0042] At a temperature of 70°C and a shear rate of 7s -1 The measured viscosity of the system was 13.2mPa·s, and the lowest interfacial tension was 2.8×10 -3 mN·m -1 ; After being adsorbed three times by quartz sand and formation sand (the mass ratio of adsorbent to adsorbate is 1:3), the viscosities of the system are 29.6 and 15.8 mPa s, respectively, and the lowest interfacial tension is 4.8×10 -3 mN·m -1 , 3.0×10 -3 mN·m -1 .

Embodiment 2

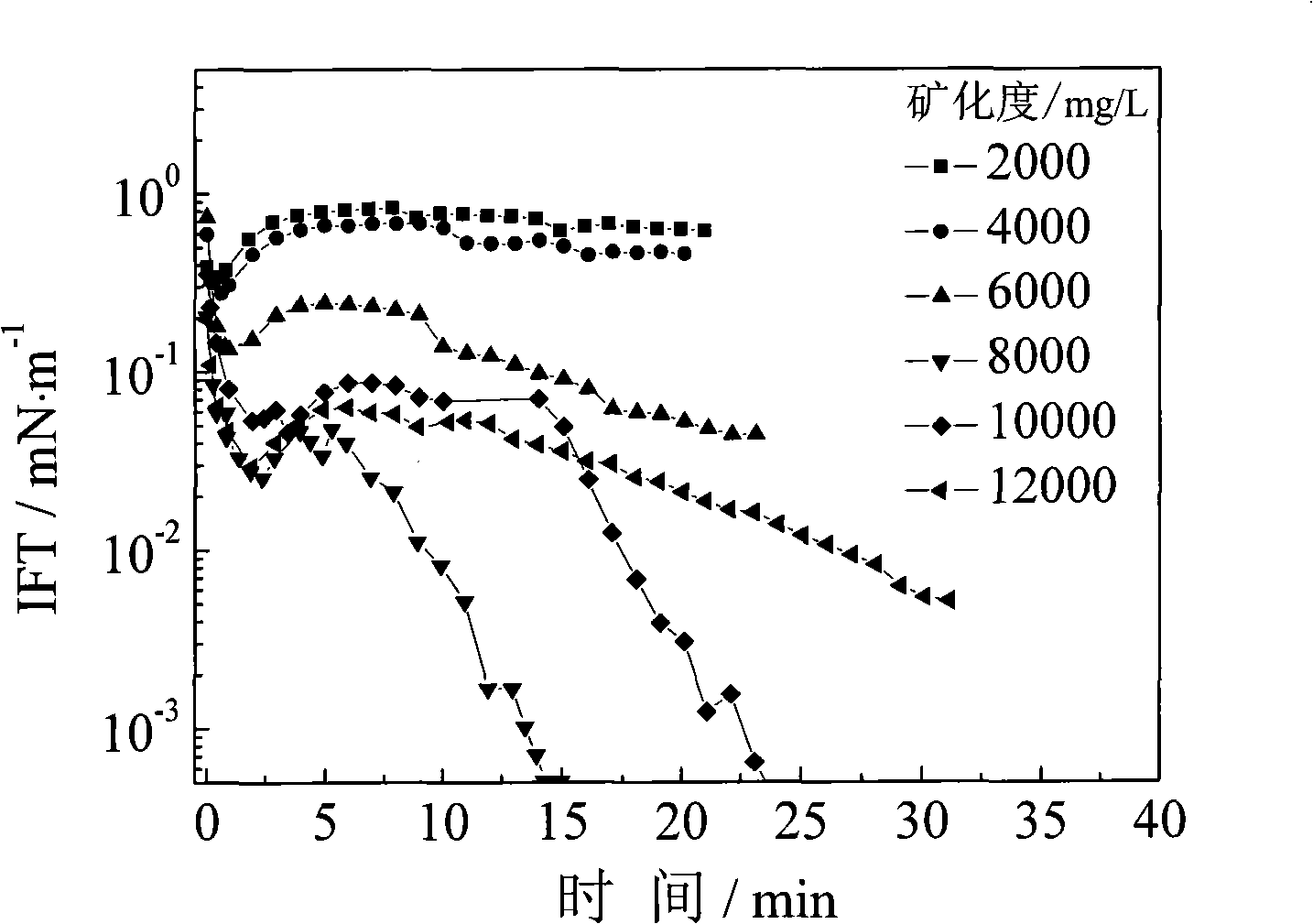

[0043] Example 2: Oil displacement system for enhanced oil recovery after polymer flooding

[0044] Raw materials: 17.0g of hydrolyzed polyacrylamide, 7.5g of isooctylphenol polyoxyethylene ether (Triton X-100), 2.5g of cetyltrimethylammonium bromide, and 9973g of formation water from Gudao Oil Production Plant of Shengli Oilfield.

[0045] Add the above raw materials into a mixer with a stirring device, and stir at room temperature for 1-2 hours.

[0046] At a temperature of 70°C and a shear rate of 7s -1 The measured viscosity of the system was 16.5mPa·s, and the lowest interfacial tension was 4.6×10 -3 mN / m; after being adsorbed three times by quartz sand and formation sand (the mass ratio of adsorbent to adsorbate is 1:3), the viscosities of the system are 48.1 and 25.3 mPa s, respectively, and the lowest interfacial tension is 8.3×10 -3 mN·m -1 , 6.4×10 -4 mN·m -1 .

Embodiment 3

[0047] Example 3: Oil displacement system for enhanced oil recovery after polymer flooding

[0048] Raw materials: 17.0g of hydrolyzed polyacrylamide, 3.0g of xanthan gum, 7.5g of polyethylene glycol octylphenyl ether (OP-6), 2.5g of cetyltrimethylammonium bromide, 46.3g of sodium chloride , calcium chloride 1.52g, magnesium chloride 2.18g, purified water 9920g.

[0049] Add the above raw materials into a mixer with a stirring device, and stir at room temperature for 1-2 hours.

[0050] At a temperature of 70°C and a shear rate of 7s -1 The measured viscosity of the system was 12.7mPa·s and the lowest interfacial tension was 1.3×10 -3 mN·m -1 ; After being adsorbed three times by quartz sand and formation sand (the mass ratio of adsorbent to adsorbate is 1:3), the viscosities of the system are 31.4 and 19.0 mPa s, respectively, and the lowest interfacial tension is 1.2×10 -3 mN·m -1 , 3.2×10 -3 mN·m -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Minimum interfacial tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com