An improved process for the production of carbon black

A carbon black and process technology, applied in fibrous fillers, rolling resistance optimization, road transportation emission reduction, etc., can solve low hysteresis, complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

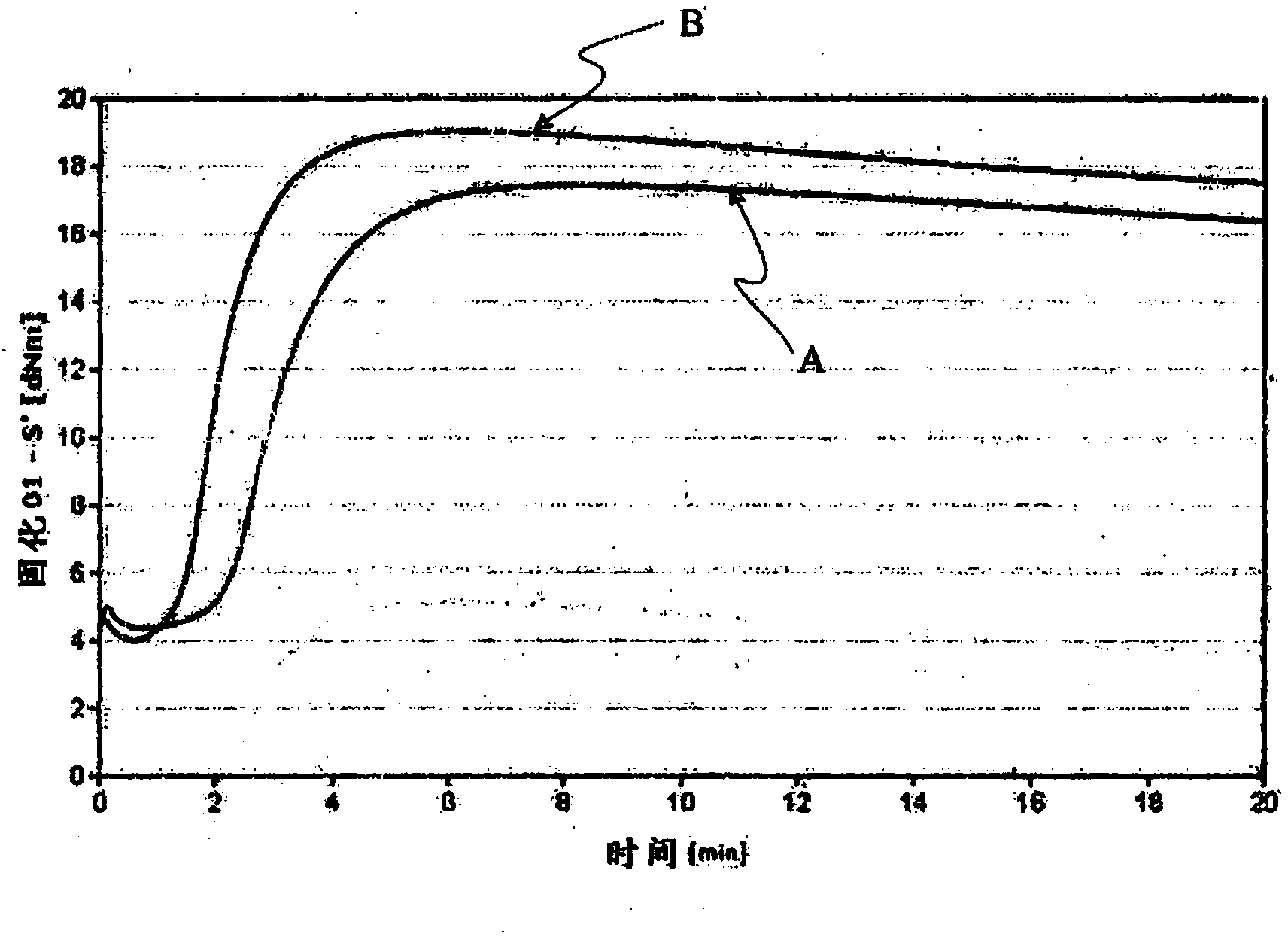

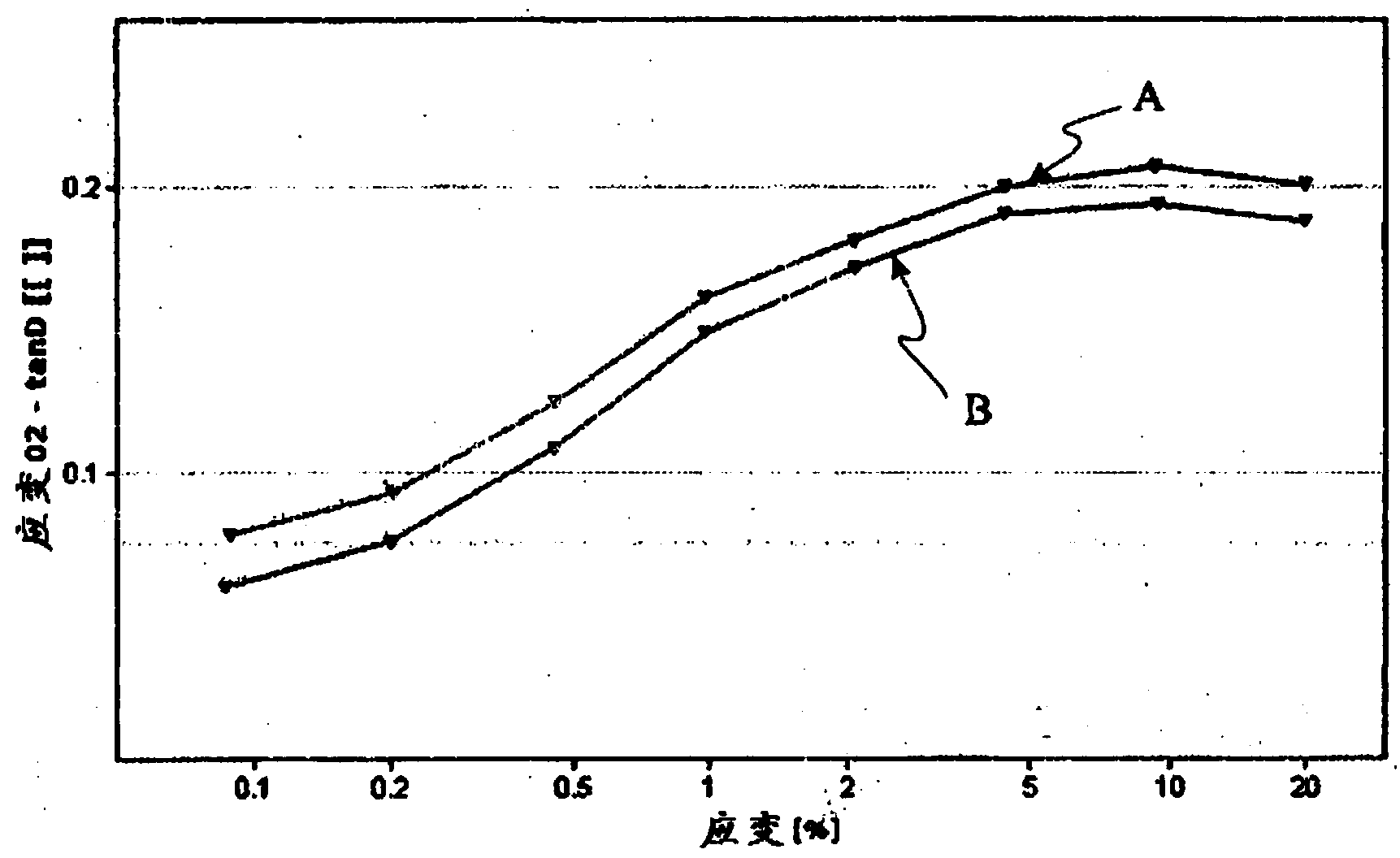

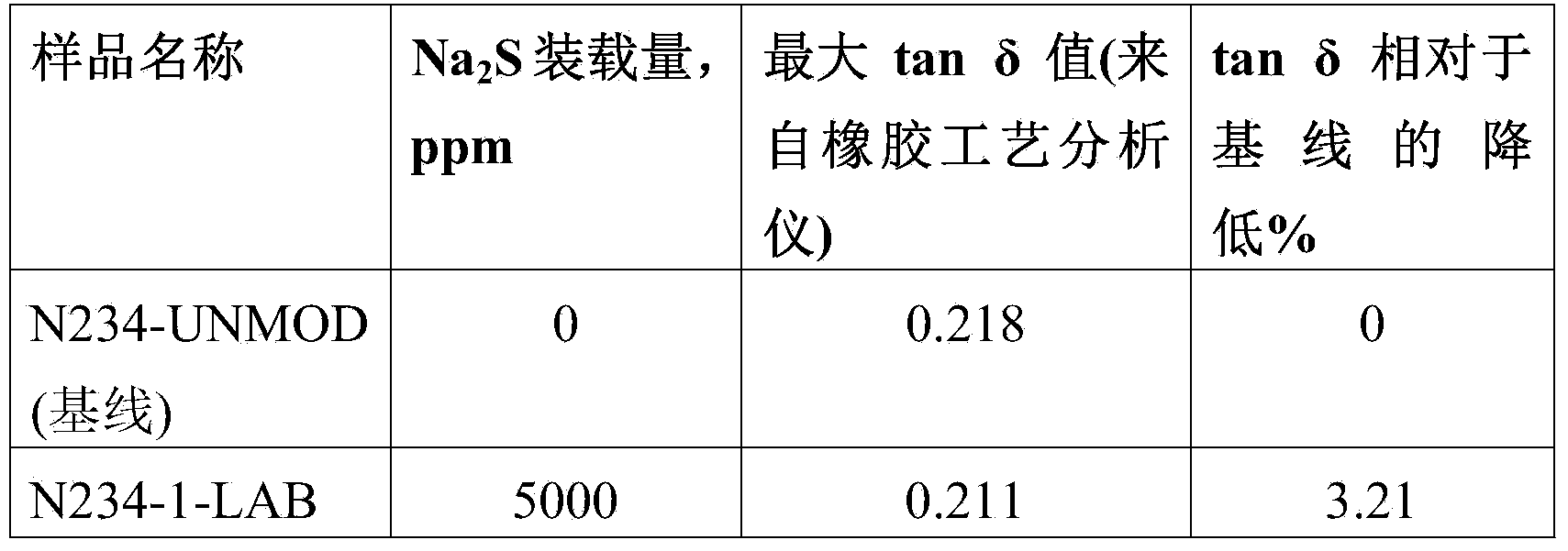

[0030] 500 g of ungranulated carbon black (grade N234) was placed in a tray and washed with 2.5 g Na 2 A solution of S in water (500 mL) was sprayed evenly and all surfaces of the carbon black were slowly exposed to the solution. The carbon black was flipped several times over a 2 hour period to promote good coverage. The obtained modified carbon black was heated in an oven at 800° C. for 8 hours under a reducing atmosphere, and turned over 4-5 times every 2 hours. Rubber compounds were prepared and tested using the dry modified carbon black (designation: N234-1-LAB). The properties of this compound were compared with those of a rubber compound prepared using unmodified carbon black N234 (designation: N234-UNMOD).

[0031] Preparation of Rubber Compounds

[0032] The compositions of the rubber compounds tested are provided below.

[0033] Element

Quantity, percentage (pph)

Natural Rubber (RSS4 Level)

75

Butadiene rubber (1220 grade)

25...

Embodiment 2

[0040] by adding Na 2 A 2% solution of S in water (previously prepared) was added to the granulator at an appropriate flow rate, and 100 ppm of sodium sulfide (Na 2 S) added to the granulation step of the manufacturing process. The treated carbon black was then dried in a rotary dryer according to common industrial processes. Samples of treated, granulated, dried carbon black were collected and compounded with rubber for testing (mark: N234-2-IND).

[0041] Preparation of Rubber Compounds

[0042] The compositions of the rubber compounds tested are provided below.

[0043] Element

Quantity, percentage (pph)

Natural Rubber (RSS4 Level)

75

Butadiene rubber (1220 grade)

25

Carbon black (N234 grade)

50

Zinc oxide

4

stearic acid

2

Antioxidant (6PPD)

1.5

sulfur

1

Accelerator (CBS)

1

[0044] These ingredients were mixed with a two-roll mill (friction ratio: 1:1.4) for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com