Controllable expanded plugging agent

A technology of plugging agent and content, which is applied in the field of expansion plugging agent, which can solve the problems that the strength and temperature resistance of water-absorbing resin cannot meet the plugging requirements, the plugging material does not have expansibility, and affects the performance of drilling fluid, etc., so as to improve the leakage Formation, reduced processing time and cost, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: The preparation method of controllable expansion plugging agent KP.

[0024] First put 120g of water into the reaction tank, slowly add 7g of acrylic acid (AA) and 21g of acrylamide (AM) while stirring; after completely dissolving, slowly add 30% NaOH solution of neutralizer dropwise to adjust the pH value of the solution to 9-11; then slowly add ultra-fine CaCO33g, cross-linking agent NMBA0.05g, initiator Na2SO3 and (NH4)2S2O80.6g, after the addition is completed, stir and react at a constant temperature of 50°C in a water bath for 50-150min; after the reaction is completed , to obtain an elastic gel, which is cut and dried, and the sample is set aside; then 40g of paraffin is heated to a liquid state, and the above sample is added to the liquid paraffin, and the emulsifier Span 80 5g is slowly added, and the stirring is continued for 30-45 Minutes until the sample is uniformly dispersed in liquid paraffin; then dried and crushed at 70°C to obtain the contro...

example 2

[0025] Example 2: KP The effect in drilling fluid (experimental results are shown in Table 2).

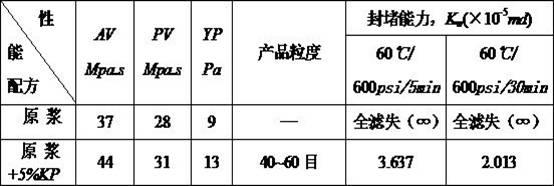

[0026] Table 2 KP Drilling Fluid Properties

[0027]

[0028] Note: 1. The original slurry is 6% Anqiu secondary soil slurry. 2. The plugging capacity is measured by sand packing method, the condition is 600Psi.

[0029] From the results in Table 2, it can be seen that MFA-2 Adding as expanded particles into the original slurry can effectively seal the filling layer. If the original slurry is completely filtered off, the permeability of clear water is ∞, while adding 5% KP After the product, the penetration rate is very low, visible, KP With strong plugging ability, it can effectively and quickly achieve the purpose of plugging, and because KP has good expansibility, as time goes on, the permeability continues to decrease, and the plugging ability is stabilized. Therefore, KP has good plugging performance and can be widely used in drilling operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com