Composite decarbonizing solution for gathering carbon dioxide in mixed gas

A carbon dioxide and mixed gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high regeneration energy consumption, low decarbonization capacity of decarbonization solution, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

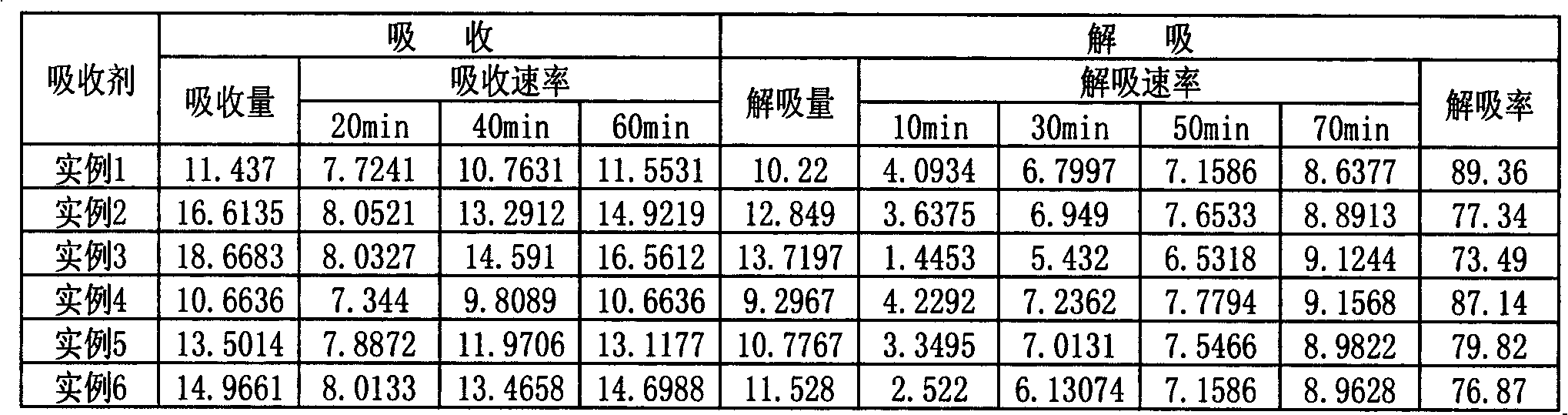

[0016] 200g wherein the total amine mass content is 20% MEA, 10% water and NMP mixed solution is packed in the reactor that is equipped with constant temperature oil bath stirrer of 500ml as absorbent, at temperature is 40 degrees Celsius conditions, with 0.02436 m 3 / h flow rate into the CO with a pressure of 0.2MPa and a concentration of 98% 2 , Continuous measurement is carried out with a wet anti-corrosion flowmeter, from which the absorption rate, absorption capacity and absorption load of carbon dioxide are calculated. After the solution reaches saturation, the oil bath temperature is set to 140 degrees Celsius for desorption, and its complete desorption amount and desorption rate are measured. The results are shown in the attached table (carbon dioxide absorption and desorption effect investigation table).

Embodiment 2

[0018] 200g of MEA in which the total amine mass content is 30%, 10% water and NMP mixed solution are packed into a 500ml reactor equipped with a constant temperature oil bath stirrer as an absorbent, the temperature is 40°C, and the temperature is 40°C, with 0.02436M 3 / h flow rate into the CO with a pressure of 0.2MPa and a concentration of 98% 2 , Continuous measurement is carried out with a wet anti-corrosion flowmeter, from which the absorption rate, absorption capacity and absorption load of carbon dioxide are calculated. After the solution reaches saturation, set the temperature of the oil bath to 140°C for desorption, and measure the complete desorption amount and desorption rate. The results are shown in the attached table.

Embodiment 3

[0020] 200g of which the total amine mass content is 40% MEA, 10% water and NMP mixed solution is packed into a 500ml reactor equipped with a constant temperature oil bath stirrer as an absorbent, the temperature is 40°C, and the temperature is 40°C, with 0.02436M 3 / h flow rate into the CO with a pressure of 0.2MPa and a concentration of 98% 2 , Continuous measurement is carried out with a wet anti-corrosion flowmeter, from which the absorption rate, absorption capacity and absorption load of carbon dioxide are calculated. After the solution reaches saturation, set the temperature of the oil bath to 140°C for desorption, and measure the complete desorption amount and desorption rate. The results are shown in the attached table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com