Patents

Literature

762results about "Elemental selenium/tellurium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of a composition made of mineral nutrients and optionally acetogenic and/or butyrogenic bacteria in order to avoid or reduce the formation of gas in the large intestine of a mammal and the resulting abdominal problems

InactiveUS20100247489A1Raise countSufficient supplyHeavy metal active ingredientsBiocideAcetic acidMammal

The present invention relates to a composition comprising one or more minerals selected from the group consisting of selenium, molybdenum or tungsten, which is carried out galenically or chemically in a way that the mineral or minerals are released completely or in part, just before, during or shortly after arrival at the large intestine, and their use in the manufacture of a medicament for administering to a mammal for the prevention or reduction of gas formation in the colon thus conditioned abdominal complaints, particularly bloatings, meteorism or abdominal cramps. Furthermore, the invention relates to a procedure for the isolation of acetogenic and butyrogenic bacterial strains that are suitable for therapeutic purposes outlined above.

Owner:SAUR BROSCH ROLAND

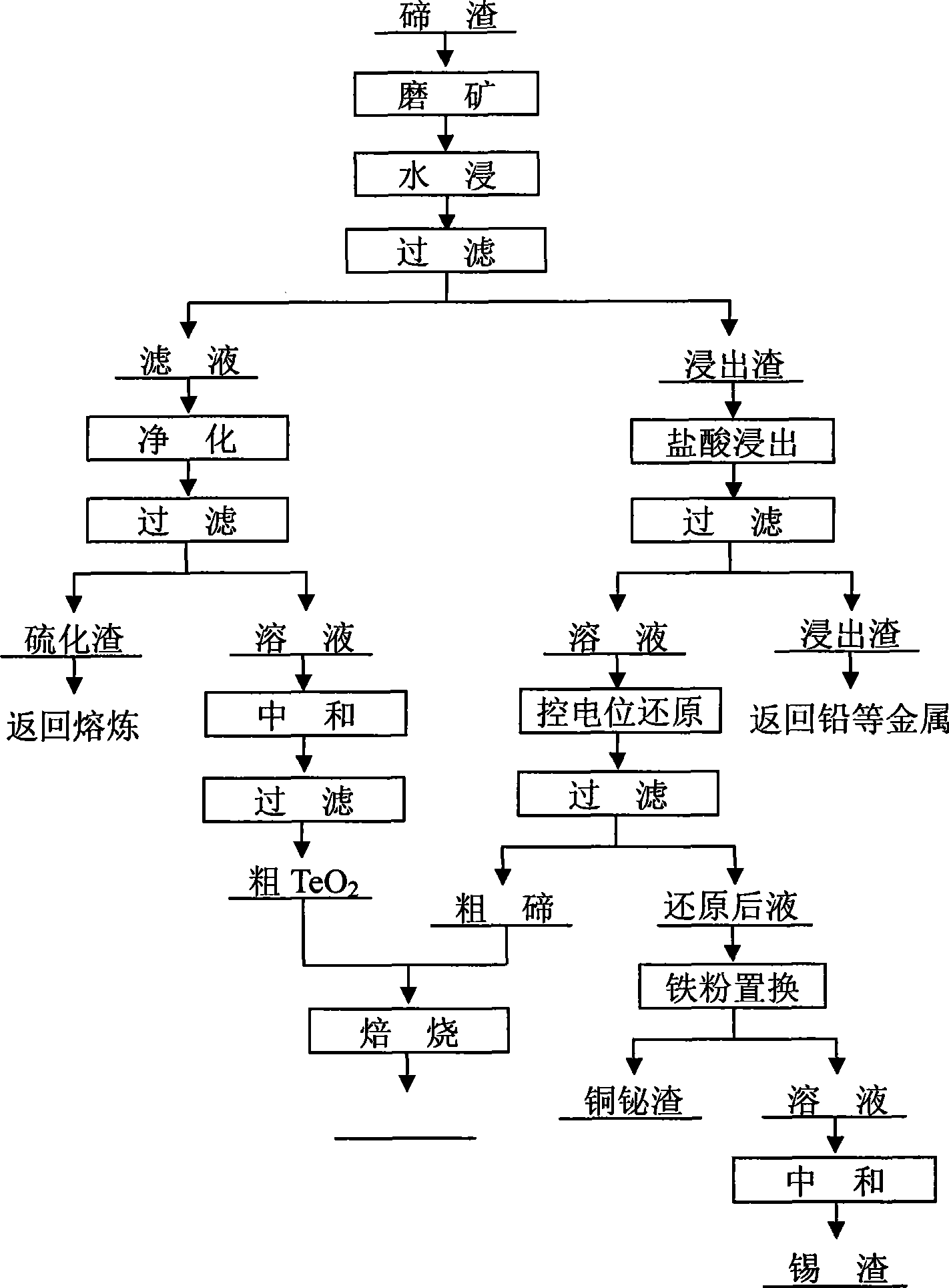

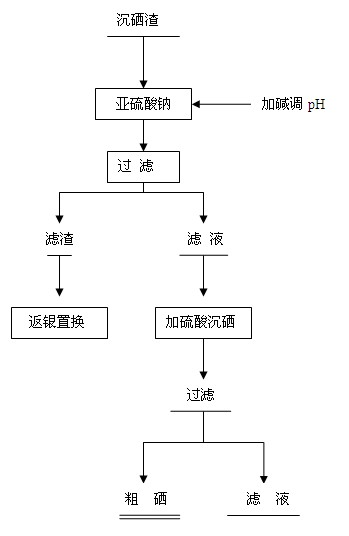

Method for separating tellurium from tellurium slag

InactiveCN101508426APrecisely control the amount addedImprove solubilityElemental selenium/telluriumSludgeSlag

The invention relates to a method for separating tellurium from tellurium slag, which comprises the following steps: firstly, grinding the tellurium slag, leaching out the obtained product in an aqueous solution, purifying and neutralizing a water leaching solution, and producing tellurium dioxide; secondly, performing hydrochloric acid leaching on water leaching residue in a hydrochloric acid system, cooling and filtering an acid leaching solution, and returning acid leaching residue to an anode sludge treatment process; thirdly, performing controlled potential reduction on the acid leaching solution to produce coarse tellurium, and performing roasting and impurity removal on the coarse tellurium and the tellurium dioxide produced by neutralization to obtain pure tellurium dioxide; and fourthly, using the conventional method to reclaim valuable metals such as copper, bismuth, tin, and the like from a reduced solution respectively. The total tellurium leaching rate of the method is as high as more than 98 percent, and the produced coarse tellurium has the advantages of low content of impurity elements, small amount of return slag, small modification amplitude of equipment, short treatment time, and low treatment cost.

Owner:CENT SOUTH UNIV

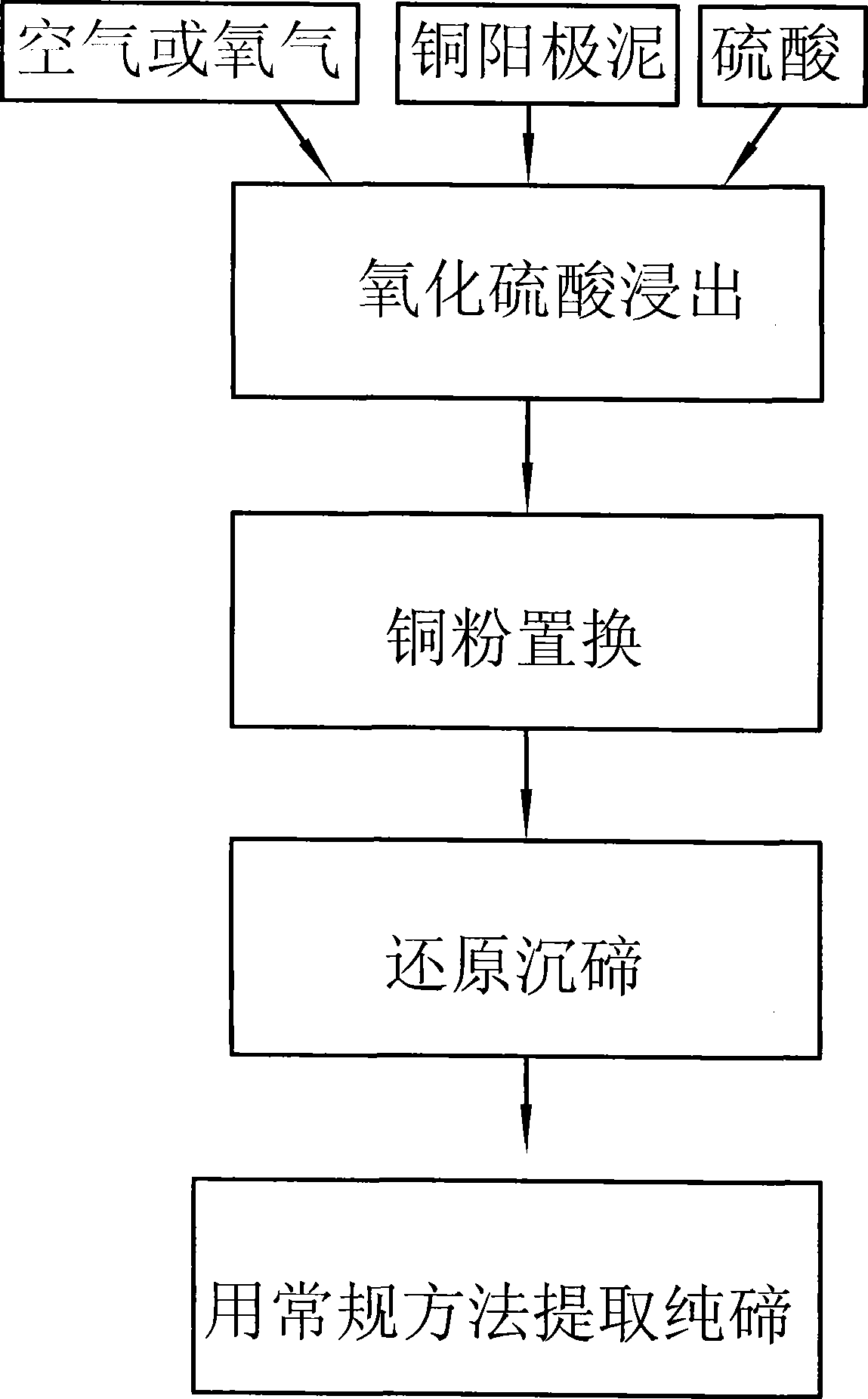

Process for extracting tellurium from copper anode mud

ActiveCN101434385AReduce consumptionEasy to separateProcess efficiency improvementElemental selenium/telluriumTe elementOxygen

The invention discloses a technology for extracting tellurium from copper anode slime, which is characterized by comprising the following steps: (1) the copper anode slime is put into a sulfuric acid solution, oxygen is introduced into the sulfuric acid solution for oxidation sulfuric acid leaching; solid-liquid separation is carried out to obtain leachate containing copper and tellurium; and the leaching process being finished in a closed high-pressure device; (2) copper powder is added into the leachate to remove silver or selenium in the leachate by substitution, and the solid-liquid separation is carried out; (3) sulfur dioxide is introduced into the leachate obtained from the step (2) to precipitate the tellurium by reduction, and the solid-liquid separation is carried out to obtain crude tellurium; and (4) the crude tellurium is processed according to a conventional method to extract pure tellurium. The technology adopts one-section oxidation acid leaching to leach the copper and tellurium out, copper powder to remove the impurities of silver, selenium and the like by substitution, and sulfur dioxide to precipitate the tellurium by reduction (obtaining tellurium dioxide), and the tellurium dioxide precipitation is alkali-dissolved and then electrolyzed to obtain the tellurium, therefore, the flow is simple, the consumption of the copper powder is remarkably reduced, and the simplification of the technology is beneficial to improve the recovery ratio of the tellurium, which can achieve more than 90 percent.

Owner:YANGGU XIANGGUANG COPPER

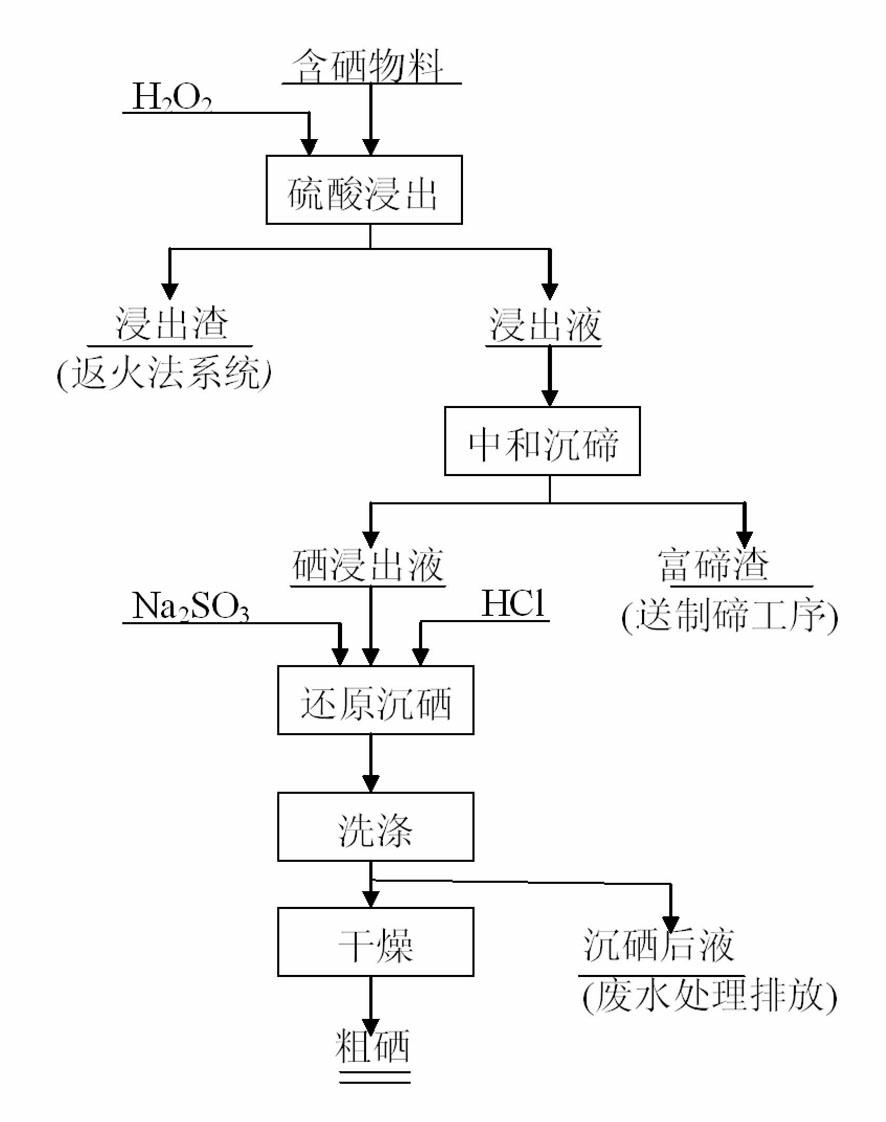

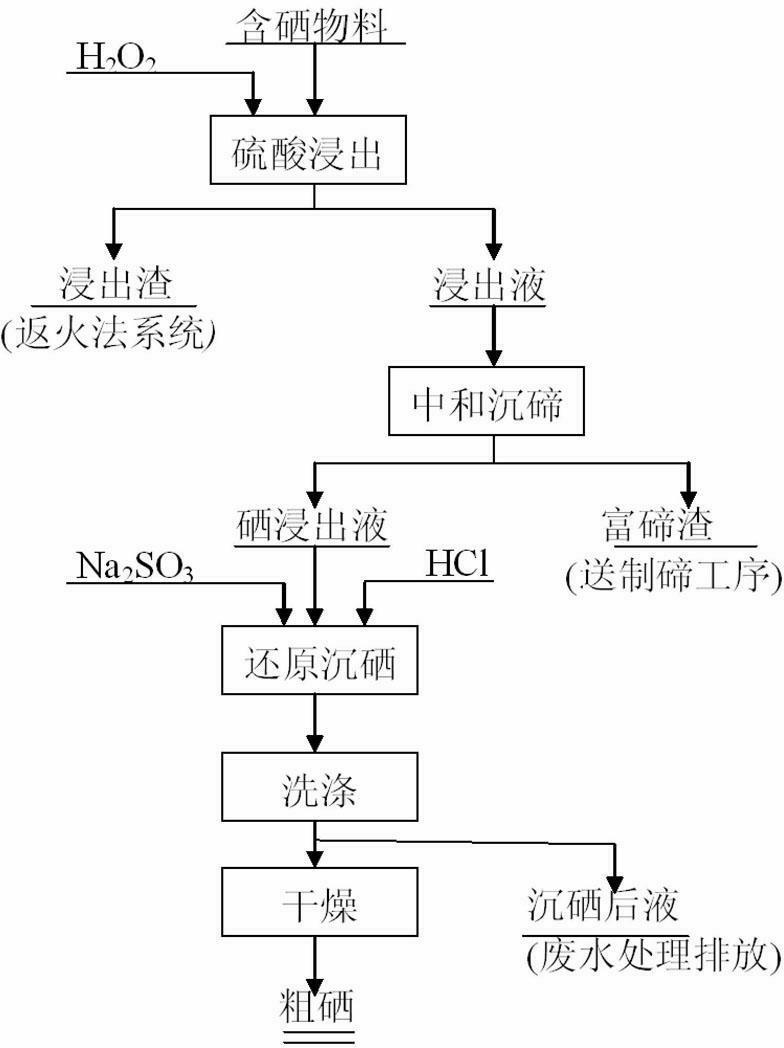

Process for separating and recovering selenium from selenium-containing material

The invention relates to a process for separating and recovering selenium from a selenium-containing material. The process comprises the following steps: dissolving the selenium-containing material into a sulfuric acid solution, adding 10% H2O2 into the mixture, filtering and separating to get leachate and residue containing silver, lead, copper and other valuable metals; separating the selenium from tellurium in the oxidation leachate by using sodium hydroxide; and acidifying the selenium leachate with hydrochloric acid, adding sodium sulfite to reduce the settled selenium, washing and drying to get crude selenium with the grade of not lower than 90%. The crude selenium which is separated by the process is higher in purity and can be directly refined, so that the process flow of recovering selenium is shortened, the recovery rate of selenium is improved, the production cost is reduced and the energy is saved; and the sodium sulfite is used for substituting sulfur dioxide to perform reduction, the control is easy and the environmental pollution is further reduced. The process has very important significance in both aspects of recovering resources and protecting an environment.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for extracting refined tellurium from tellurium-contained smelting slag

InactiveCN101565174AImprove leaching rateReduce invalid consumptionElemental selenium/telluriumSlagTe element

The invention relates to a method for extracting refined tellurium from tellurium-contained smelting slag, which is characterized in that the method comprises the following steps of: oxidizing and leaching inorganic acid, replacing noble metal with a copper plate, depositing the copper by sodium sulfide, counteracting and depositing tellurium, alkaline leaching coarse TeO2, removing impurities by Na2S, concentrating and electrowinning. The method has the advantages of high recovery rate for tellurium, comprehensive and effective recovery of other useful metals, and suitably treating the tellurium-contained waste slag with high water content and small granularity generated in the metallurgy process by a wet-method.

Owner:YONGXING XINTAI SILVER IND

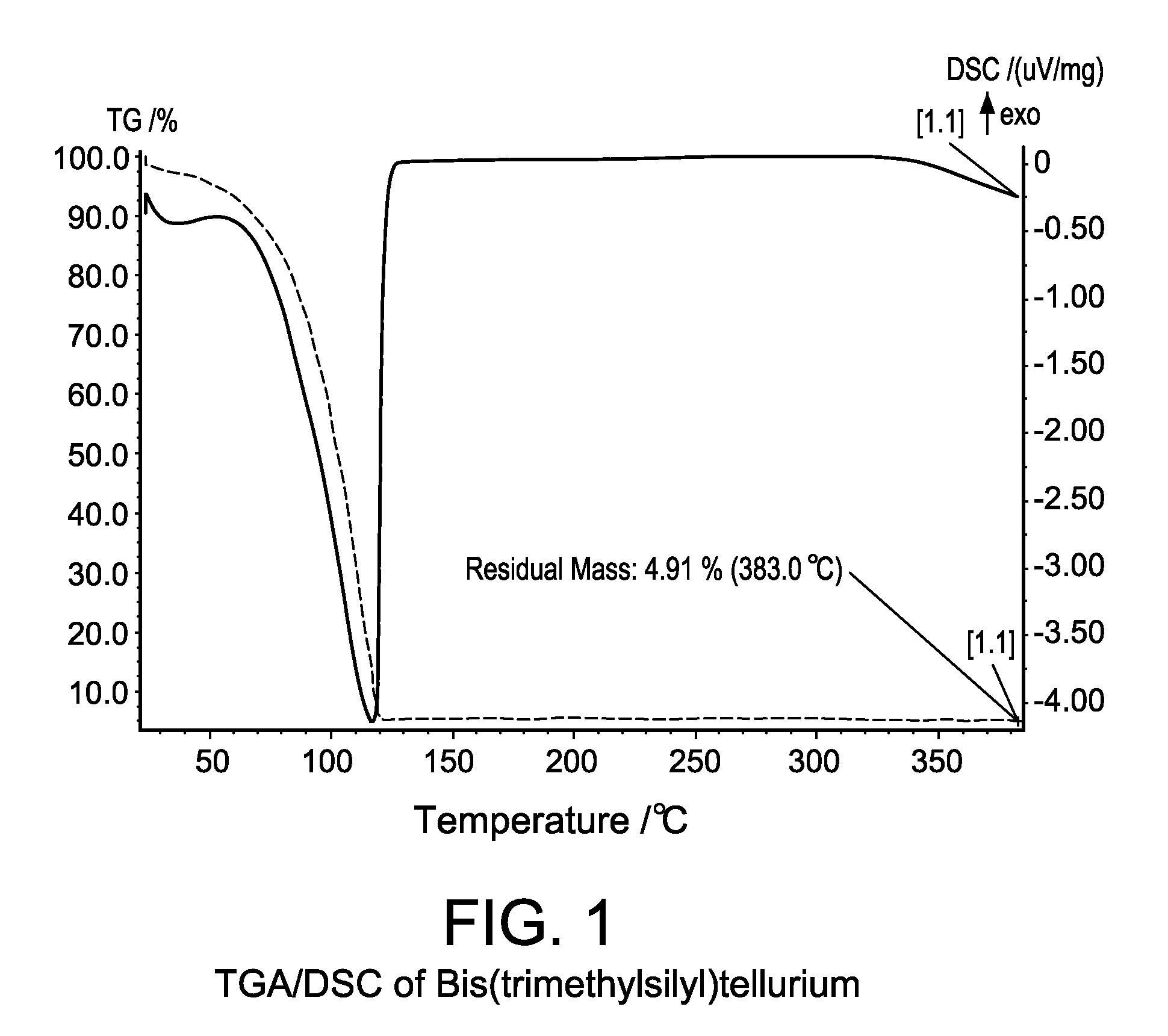

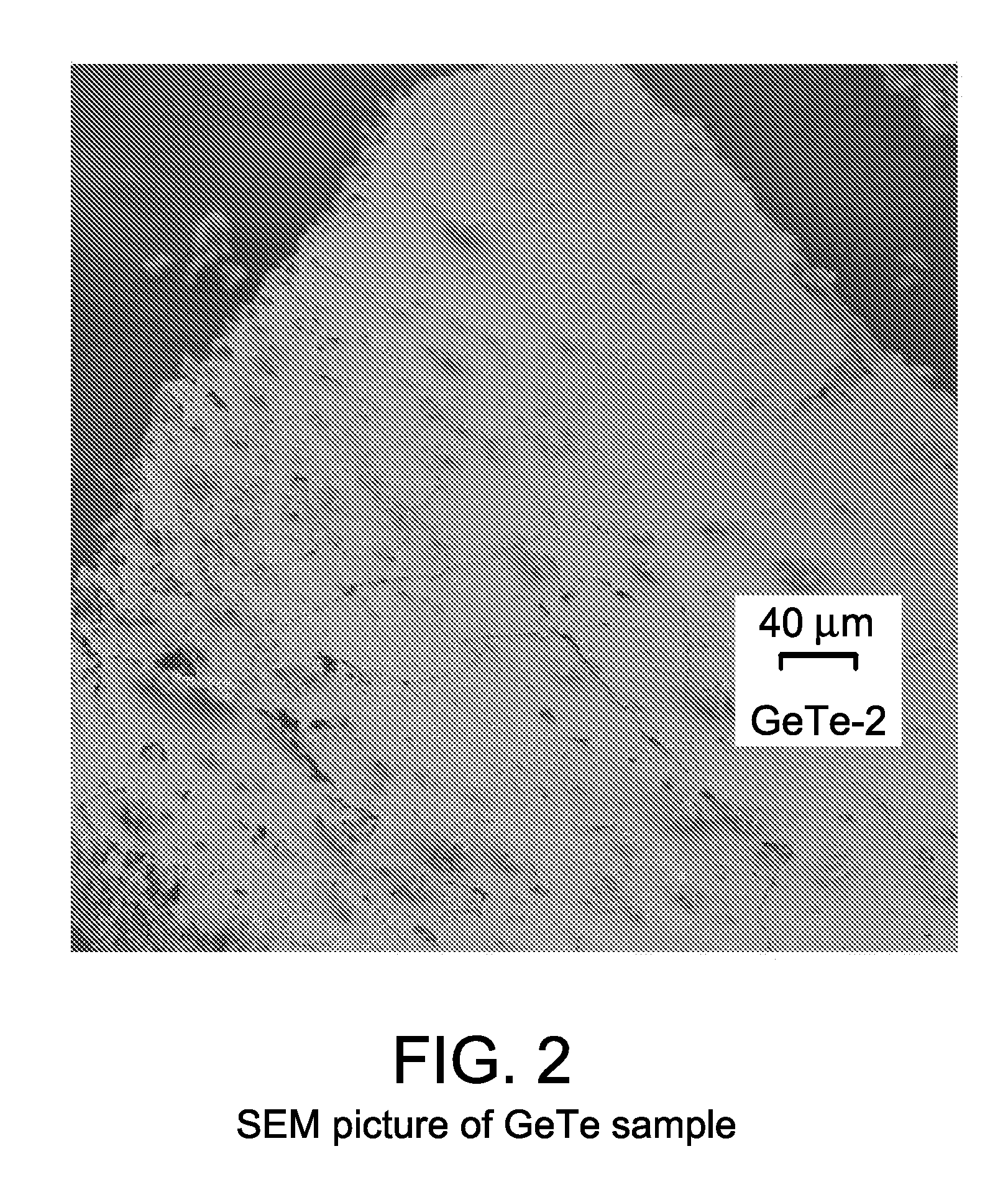

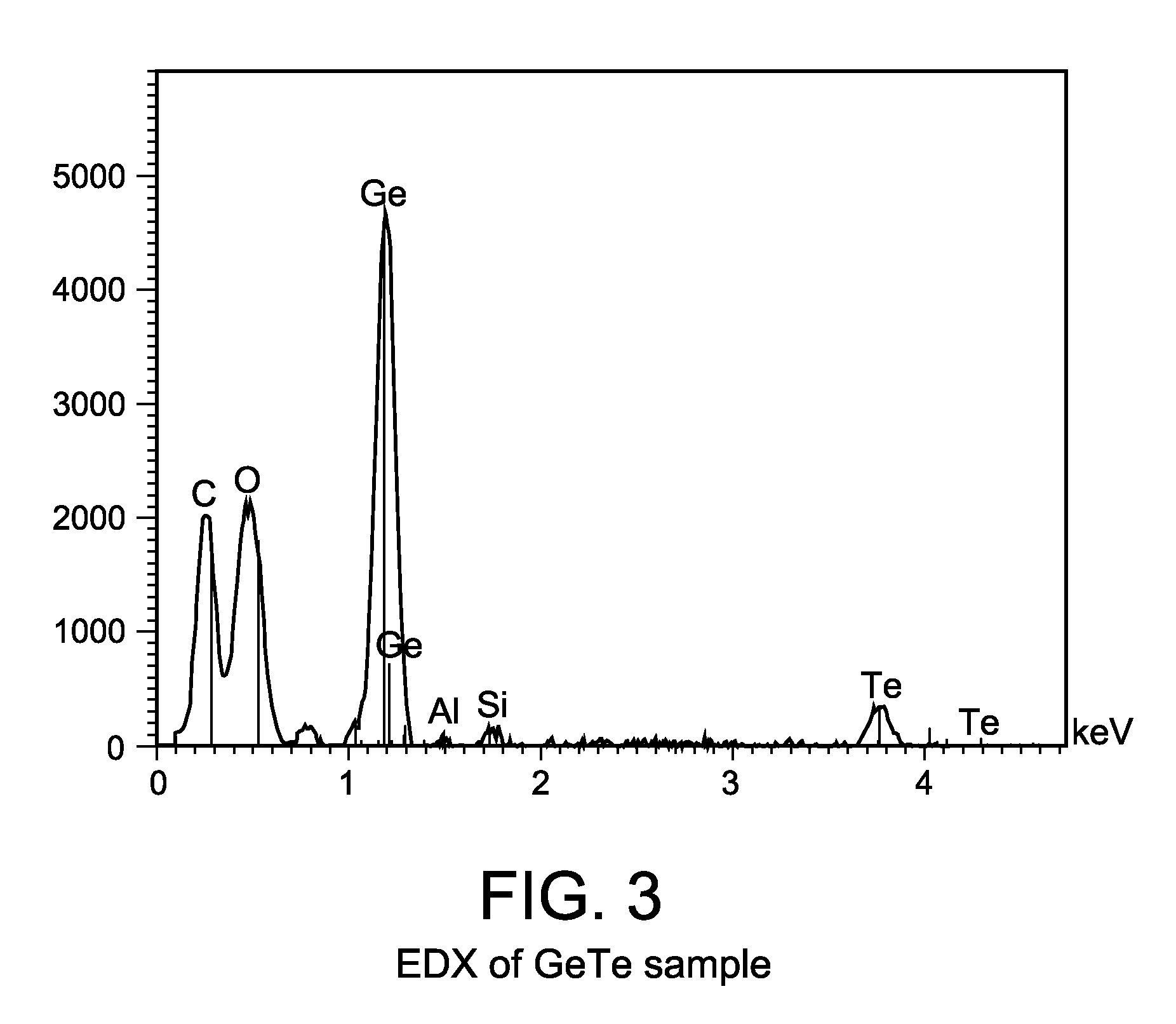

Binary and Ternary Metal Chalcogenide Materials and Method of Making and Using Same

ActiveUS20090280052A1Silicon organic compoundsPhosphorus sulfur/selenium/tellurium compoundsPhase-change memoryMetal chalcogenides

This invention discloses the synthesis of metal chalcogenides using chemical vapor deposition (CVD) process, atomic layer deposition (ALD) process, or wet solution process. Ligand exchange reactions of organosilyltellurium or organosilylselenium with a series of metal compounds having neucleophilic substituents generate metal chalcogenides. This chemistry is used to deposit germanium-antimony-tellurium (GeSbTe) and germanium-antimony-selenium (GeSbSe) films or other tellurium and selenium based metal compounds for phase change memory and photovoltaic devices.

Owner:VERSUM MATERIALS US LLC

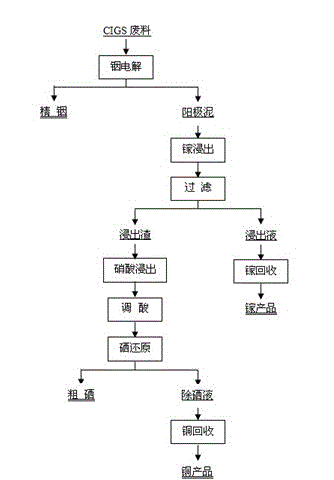

Recovery method of copper indium gallium selenide thin-film solar panel

ActiveCN103184338ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementRecovery methodElectrolysis

The invention provides a recovery method of a copper indium gallium selenide thin-film solar panel. The method comprises the steps that: the copper indium gallium selenide thin-film solar panel is crushed into pieces; the pieces are soaked by using a H2SO4+H2O2 system, such that a soaking liquid is obtained; the soaking liquid is filtered, such that a first leachate is obtained; with a first phase ratio of 1, the first leachate is extracted by using an extraction agent; separation is carried out, such that a first extraction liquid and a first raffinate are obtained; the extraction agent is composed of 30% of P2O4 and 70% of kerosene by volume percentage, the extraction and balance time is 5-20min; an HCl solution is adopted as a stripping agent, and the first extraction liquid is striped by using a second phase ratio, such that In and stripping residual liquid are obtained; a reducing agent is added into the first raffinate; when a reduction reaction is finished, crude Se and a second leachate are obtained by filtering; alkali is added into the second leachate, and a pH value is regulated such that the pH value is constantly higher than 14; when a reaction is finished, filtering is carried out, such that a filtering slag comprising a hydroxide of Cu and a water solution comprising Ga are obtained; the alkali is NaOH, the pH value adjustment process is to add the NaOH in the reaction process after pH=14 so that the pH is always kept more than 14 during the reaction process, and the reaction time is kept for 0.5-2h; and the water solution is electrolyzed.

Owner:FIRST SEMICON MATERIALS

Method for recycling copper, indium, gallium and selenium from indium gallium selenium wastes containing copper

ActiveCN104017995AEfficient recyclingReduce recycling costsProcess efficiency improvementElemental selenium/telluriumIndiumCopper

The invention provides a method for recycling copper, indium, gallium and selenium from indium gallium selenium wastes containing copper. The method comprises the following steps: smashing indium gallium selenium to form powder; leaching the powder in a nitric acid so as to obtain a nitric acid leaching liquid; adding a reducing agent into the nitric acid leaching liquid so as to obtain crude selenium and a reducing liquid in a reducing manner; adding alkali into the reducing liquid and regulating pH to reach 10 to 14 so as to obtain an alkali leaching liquid and alkali leaching residues; neutralizing or electrolyzing the alkali leaching liquid with an acid so as to obtain gallium hydroxide or pure gallium; leaching the alkali leaching residues with a leaching agent so as to obtain ammonia leaching residues and an ammonia leaching liquid; reducing the ammonia leaching liquid with the reducing agent so as to obtain copper powder; and leaching the ammonia leaching residues with the acid and adding the reducing agent for replacement so as to obtain crude indium. When the recycling is carried out by utilizing the method, the indium can be simply and efficiently recycled while the copper, the gallium and the selenium can be efficiently recycled at the same time. Thus, the process procedures are simplified. The method is simple and convenient to operate, has no special requirement on equipment and realizes effective reduction in process production cost.

Owner:ZHUZHOU SMELTER GRP

Method for recovery of copper, indium, gallium, and selenium

InactiveUS20100329970A1Simple processShorten operation timePhotography auxillary processesGallium/indium/thallium compoundsProduction lineIndium

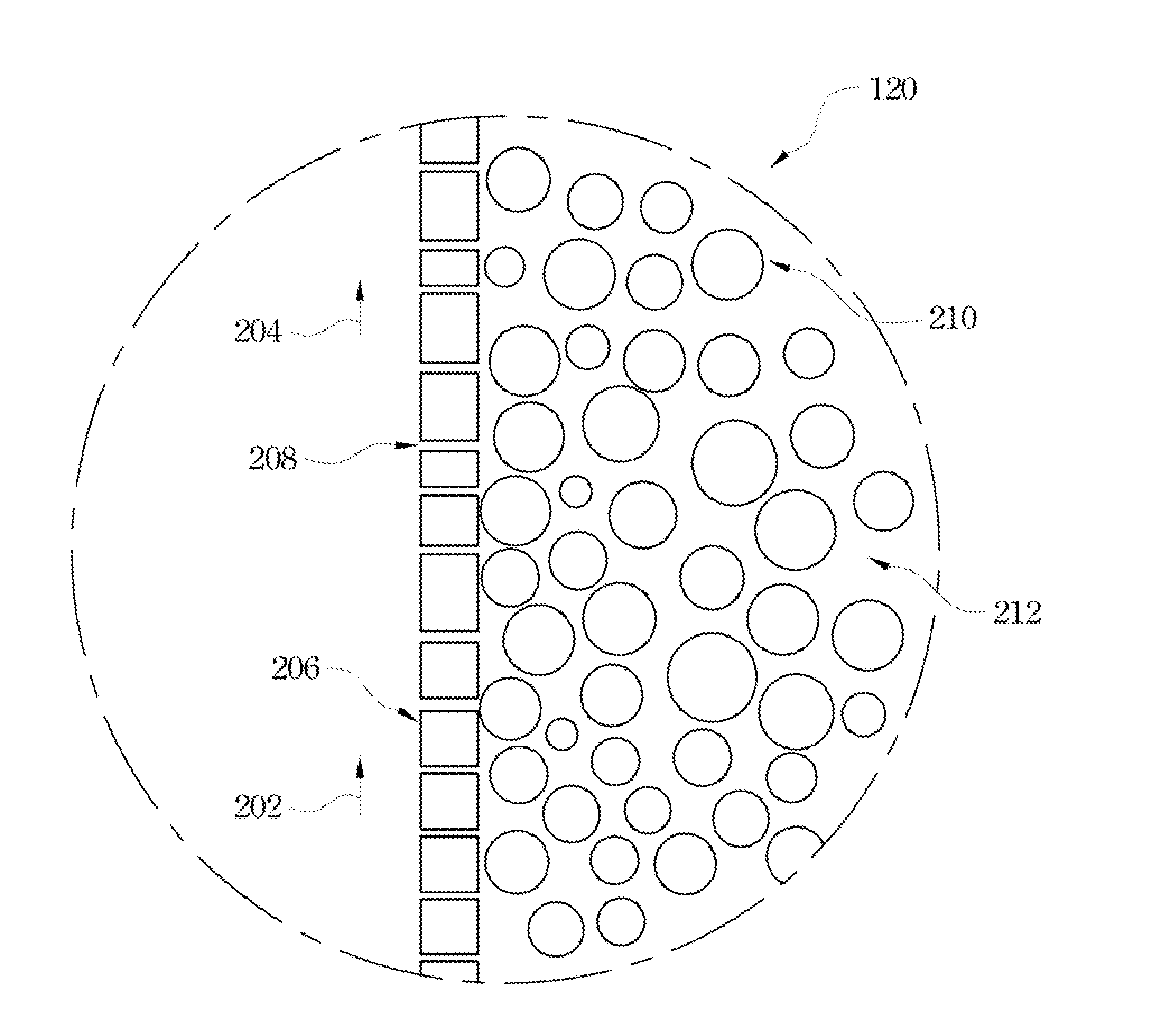

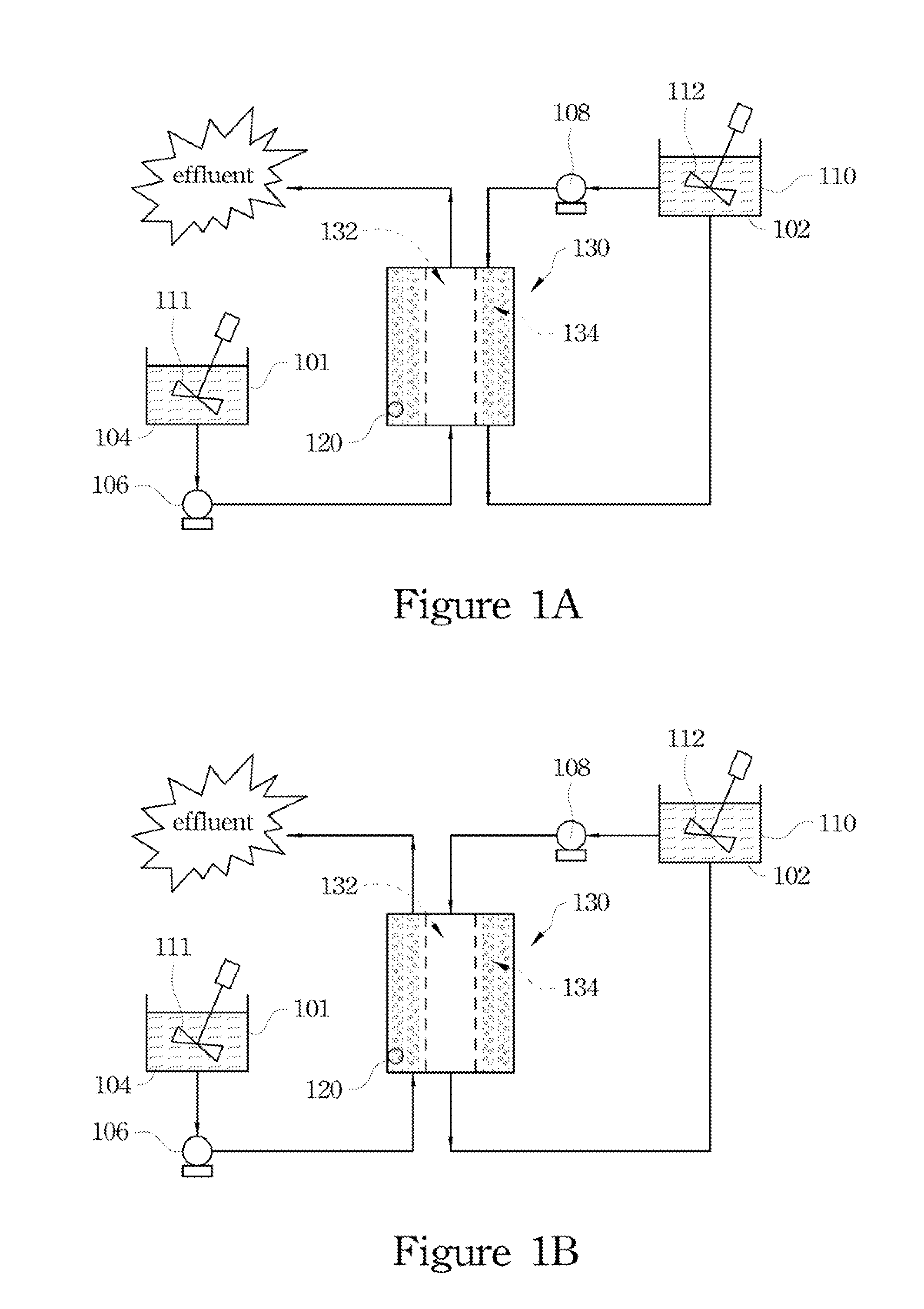

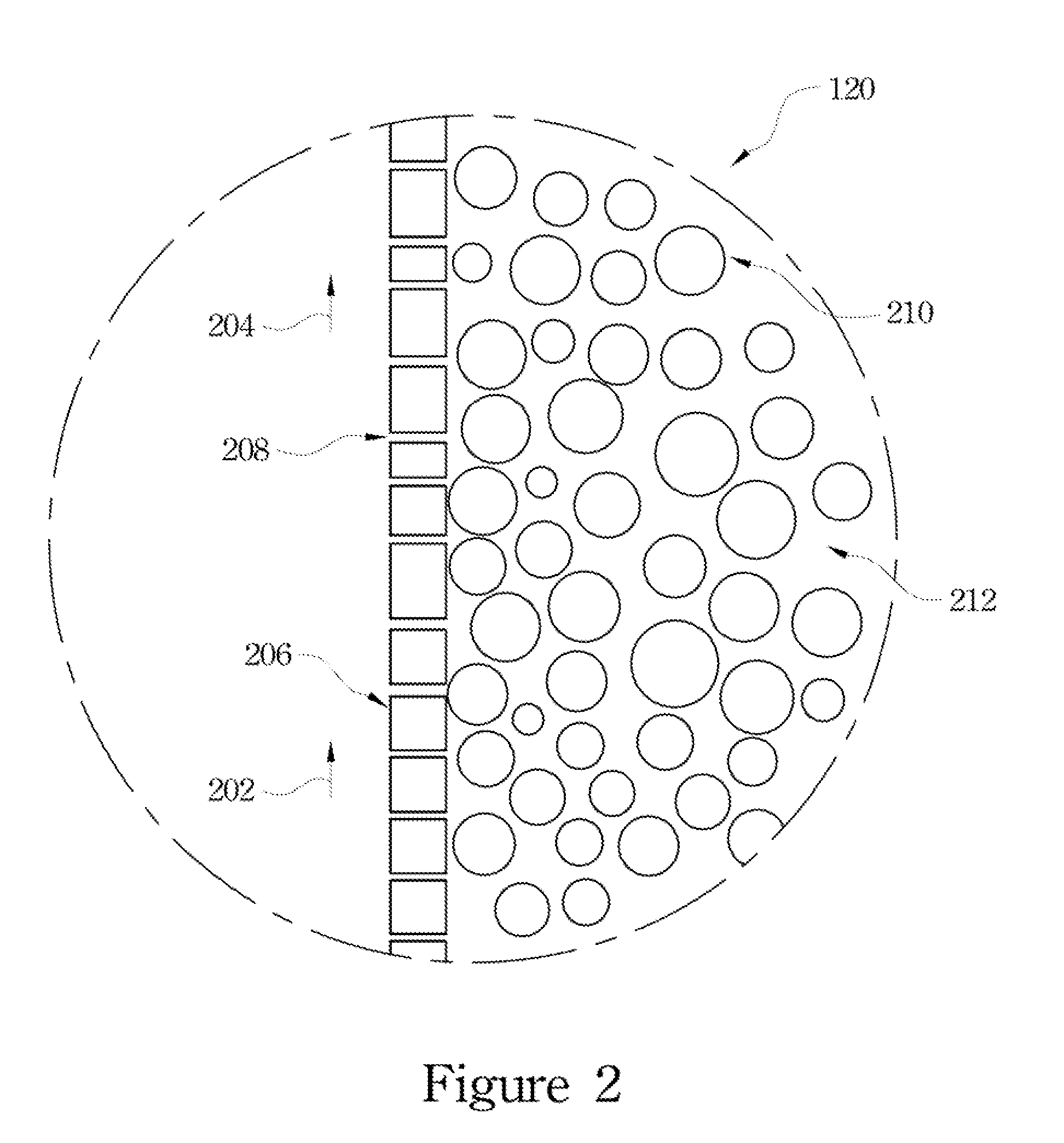

A method for the recovery of copper, indium, gallium, and selenium is provided. The method includes steps of using a mixed solution containing a hydrochloric acid and hydrogen peroxide to dissolve the copper, indium, gallium, and selenium. After using the hydrazine to separate the selenium out, the copper is reduced by indium metal. Later, a combination of a supported liquid membrane (SLM) and a strip dispersion solution separates the gallium from the indium. The acid performed in all the steps of the method is hydrochloric acid. Therefore, the copper, indium, gallium, and selenium can be separated one by one in a single production line without changing the solution during the operation process, thereby simplifying the process, shortening the operation time and lowering the manufacture cost.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

Method for extracting selenium from selenium-contained material

ActiveCN102086029AHigh purityImprove pass rateElemental selenium/telluriumSulfite saltSodium sulfites

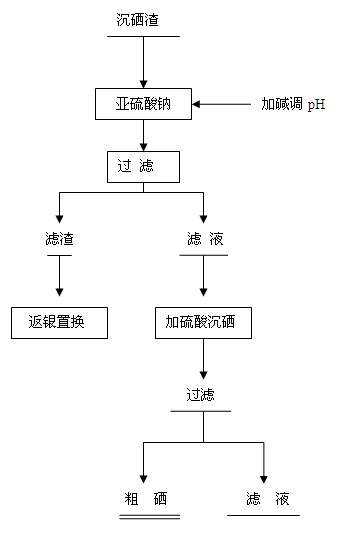

The invention relates to a method for extracting selenium from selenium-deposited residue. The method comprises the following steps of: dissolving selenium-deposited residue to an alkaline sodium sulfite solution, generating water-soluble seleno sodium sulfate through a reaction between elemental selenium and the sodium sulfite solution; fully reacting the seleno sodium sulfate under the acidification of sulfuric acid to obtain a selenium elemental precipitate; and washing and drying to obtain coarse selenium with the purity of about 90 percent. The invention realizes separation of copper, silver and selenium in the selenium residue, and the separated selenium can be directly refined due to higher purity, therefore, the process flow of selenium recovery is shortened, the recovery rate is increased, and the production cost is decreased; the trouble of high copper content of an anode plate in silver electrolysis in the gold and silver refining process is solved and the pass rate of primary silver powder electrolysis is increased. The invention can be applied to recovering and extracting selenium from materials, such as selenium-contained residue generated in the technical process by using a wet method for treatment or selenium-contained acid mud generated in the production process of the copper anode slime by using a pyrogenic method for treatment and can also be applied to the production of high-purity selenium products by directly purifying a coarse selenium raw material.

Owner:JINCHUAN GROUP LIMITED

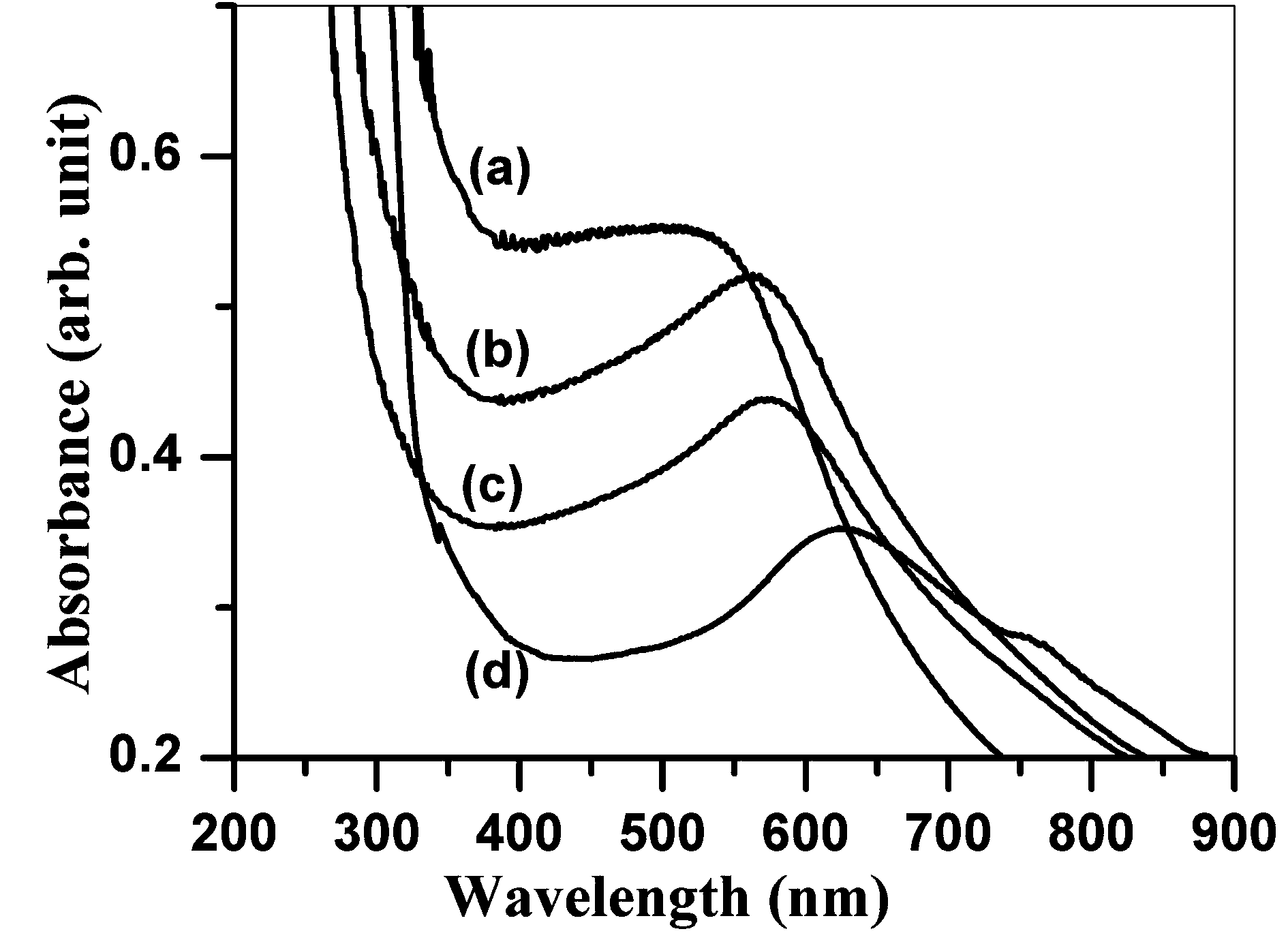

Preparation method for nano-selenium

InactiveCN103420344AAvoid coalescent growthUniform particle sizeNanotechnologyElemental selenium/telluriumSolubilityBrick

The invention relates to a preparation method for nano-selenium. The preparation method comprises the following steps: 1) weighing a selenite crystal, adding into a mixed liquid of deionized water, a stabilizing agent A and a stabilizing agent B, dissolving to obtain a selenite solution; weighing a reducing agent powder, dissolving in deionized water to obtain a reducing agent solution; 2)adding the prepared reducing agent solution into the prepared selenite solution, then adding a stabilizing agent C, stirring and heating, keeping warm to obtain a brick-red nano-selenium solution; and 3) centrifuging the prepared nano-selenium solution to obtain the nano-selenium powder. The preparation method has the advantages of normal-pressure preparation conditions, lower reaction temperature (60-80 DEG C), short reaction time, whole safe and stable preparation process, easy controllability, low cost of the raw materials, no toxicity and no harm; and the product prepared by the preparation method has uniform product particle size, smaller particles (2-6 nm), good crystallization perpformance, good water-solubility and biocompatibility.

Owner:WUHAN UNIV OF TECH

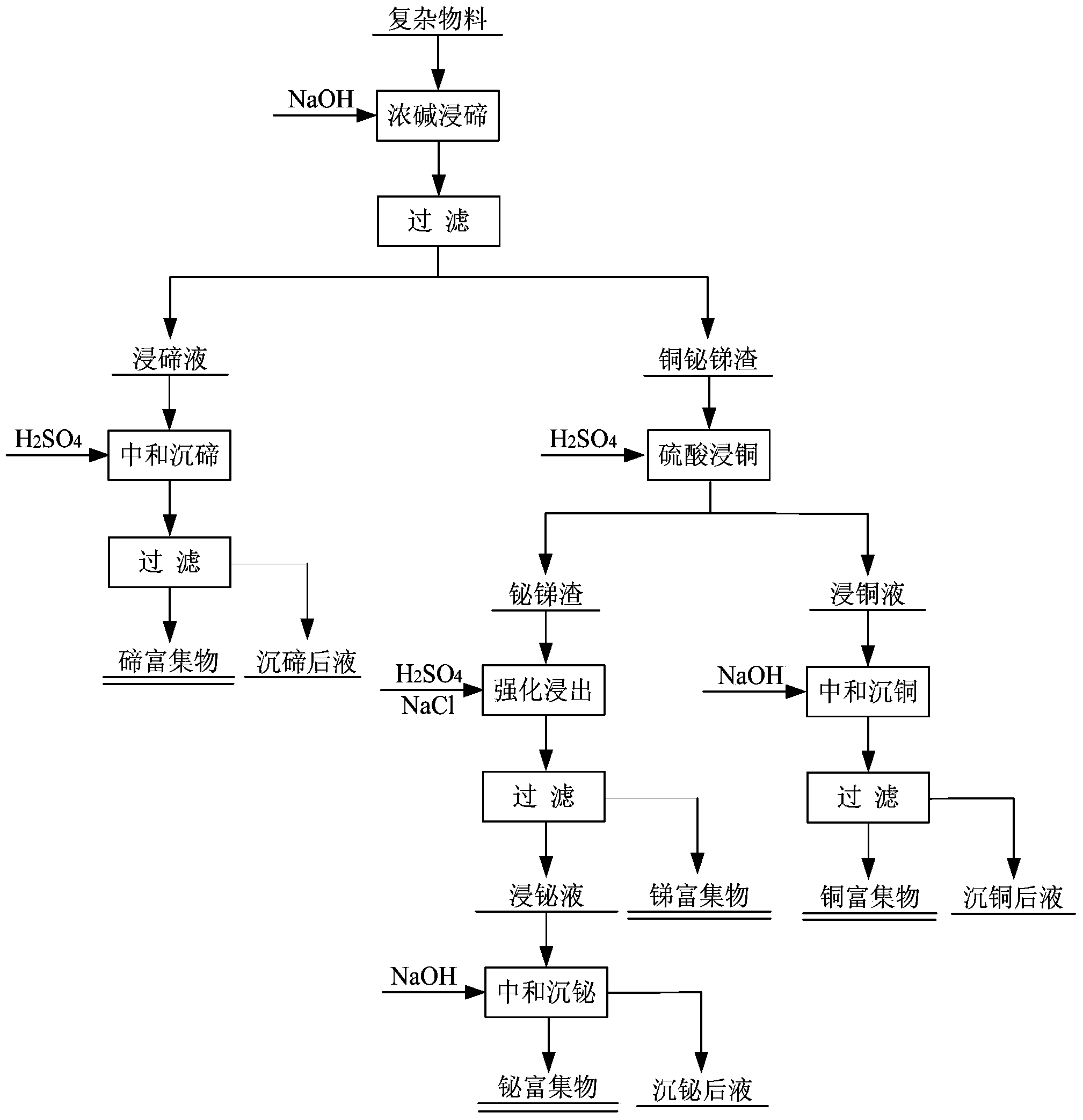

Method for recovering tellurium, bismuth, antimony, and copper from complex material

The invention aims at providing a method for recovering tellurium, bismuth, antimony, and copper from a complex material. The method comprises the steps that: the complex material is added into a sodium hydroxide solution according to a solid-liquid ratio; a temperature and a stirring time are controlled; when a reaction is finished, bismuth, antimony and copper slag and tellurium leaching liquid are obtained; the pH of the tellurium leaching liquid is regulated by adding dilute sulfuric acid; the mixture is settled and is subjected to solid-liquid separation, such that tellurium enrichment is obtained; the bismuth, antimony and copper slag is added into a dilute sulfuric acid solution according to a solid-liquid ratio; a reaction is sufficiently carried out, such that bismuth and antimony slag and copper leaching liquid are obtained; the solution temperature of the copper leaching liquid is controlled, and NaOH is added for precipitating copper; according to a solid-liquid ratio, the bismuth and antimony slag is added into a mixed solution of sulfuric acid and sodium chloride; the mixture is violently stirred, such that bismuth-antimony separation is realized; NaOH is used for regulating solution pH value and for precipitating bismuth; when the reaction is completed, bismuth enrichment and bismuth-precipitated liquid are obtained. With the technical scheme provided by the invention, tellurium, bismuth, antimony, and copper valuable metals can be comprehensively recovered from the complex material, such that waste is turned into valuable matters.

Owner:JIANGXI COPPER

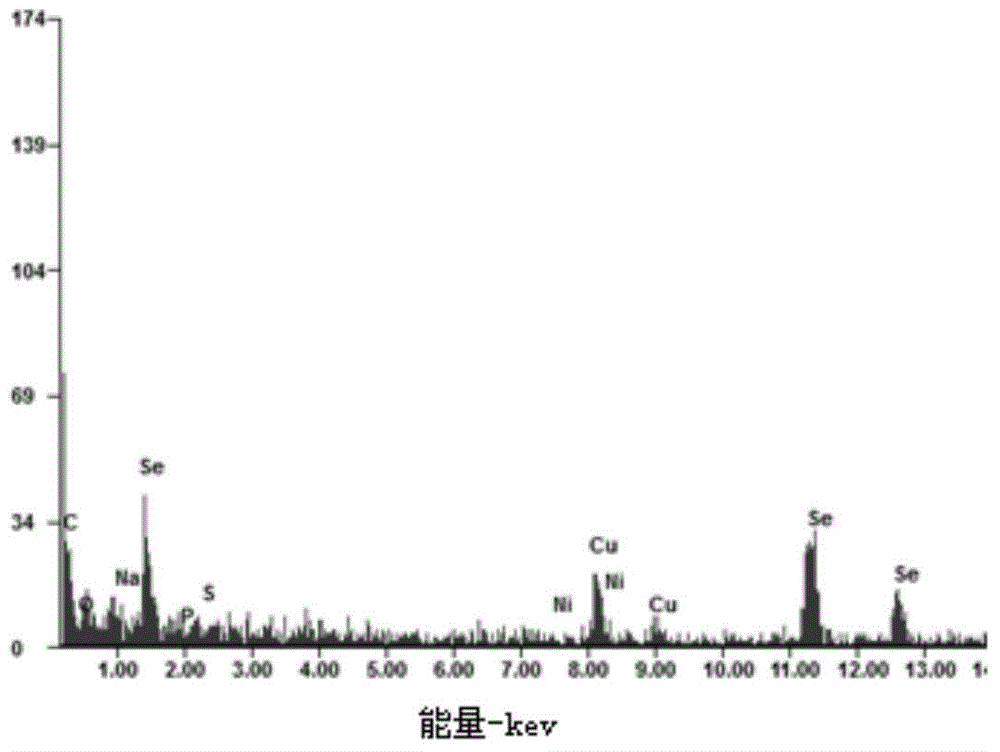

Load type nano selenium and preparation method

InactiveCN1686789ASolve reunionFix stability issuesAnimal feeding stuffAccessory food factorsNanoreactorAquatic product

The present invention discloses a load-type nano selenium and its preparation method. It is a nano-elementary selenium loaded no the porous mineral material, the average particle size of said elementary selenium is less than 100 nano. By weight percentage, selenium content in the porous mineral material is 0.1-1%. It is made up by using porous mineral material as miniature nano reactor and adding reductant into selenium salt to make reduction reaction to obtain the nano elementary selenium, drying-grinding or spray-drying so as to obtain the invented product.

Owner:BEIJING BOAI XIKANG NITRITION TECH

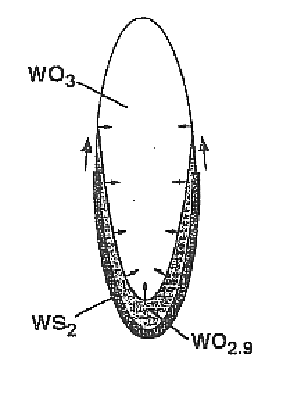

Bulk synthesis of long nanotubes of transition metal chalcogenides

Nanotubes of transition metal chalcogenides as long as 0.2-20 microns or more, perfect in shape and of high crystallinity, are synthesized from a transition metal material, e.g. the transition metal itself or a substance comprising a transition metal such as an oxide, water vapor and a H2X gas or H2 gas and X vapor, wherein X is S, Se or Te, by a two-step or three-step method including first producing nanoparticles of the transition metal as long as 0.3 microns, and then annealing in a mild reducing atmosphere of the aforementioned gas or gas mixture. The transition metal chalcogenide is preferably WS2 or WSe2. Tips for scanning probe microscopy can be prepared from said long transition metal chalcogenide nanotubes.

Owner:YEDA RES & DEV CO LTD

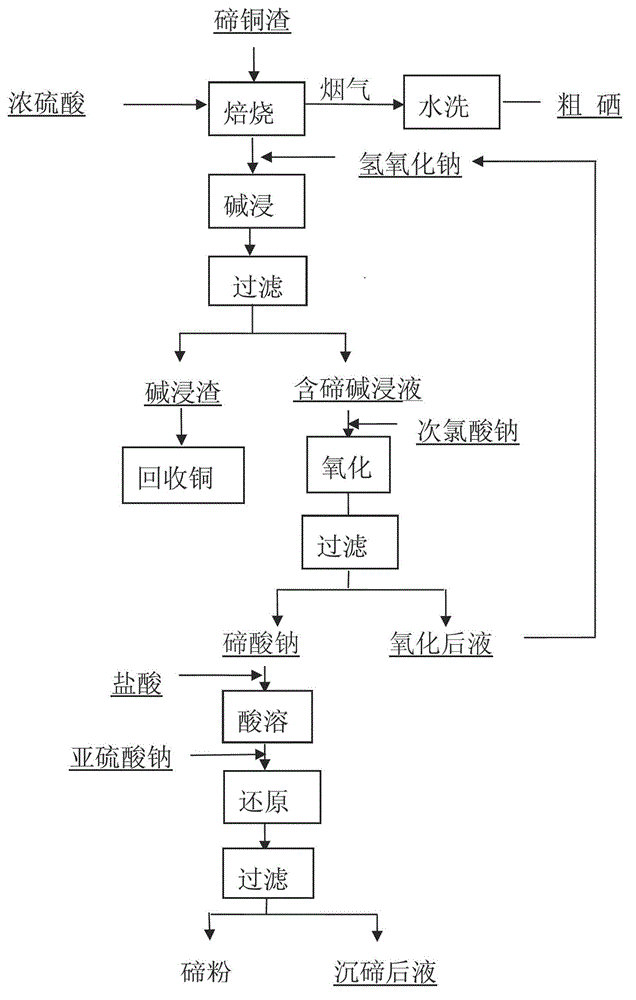

Method for extracting tellurium from tellurium copper slags

ActiveCN102745657AEasy to separateAchieve separationProcess efficiency improvementElemental selenium/telluriumAcid dissolutionCalcination

The invention provides a method for extracting tellurium from tellurium copper slags. The method includes the following steps of (1) sulfating calcination at a high temperature, grinding the tellurium copper slags, mixing ground tellurium copper slags with a concentrated sulfuric acid to calcine, enabling the mass ratio between the concentrated sulfuric acid and the tellurium copper slags to be (1.2-1.5):1, maintaining the calcination temperature in a range from 450 DEG C to 600 DEG C and maintaining the calcination time in a range from 3 hours to 5 hours; (2) alkaline leaching to separate the tellurium, leaching obtained calcination slags by a sodium hydroxide alkaline liquor, and then filtering to obtain a tellurium containing alkali leaching liquid and alkali leaching slags; (3) oxidizing the alkali leaching liquid, oxidizing the tellurium containing alkali leaching liquid by sodium hypochlorite of an oxidant and then filtering to obtain sodium tellurate filtered slags; and (4) acid dissolution reduction, dissolving the sodium tellurate filtered slags by a chloridion containing acidic system, adding a reducing agent to achieve reduction and then filtering to obtain tellurium powders. According to the method for extracting the tellurium from the tellurium copper slags, a complete separation of copper, selenium and tellurium can be fully achieved, a comprehensive recovery of the copper, selenium and tellurium can be achieved, the technological process is simple, tellurium dioxide of an intermediate product is not required, the tellurium powders with a high purity can be directly produced, and the tellurium powders can serve as raw materials of 6N high purity tellurium.

Owner:YANGGU XIANGGUANG COPPER

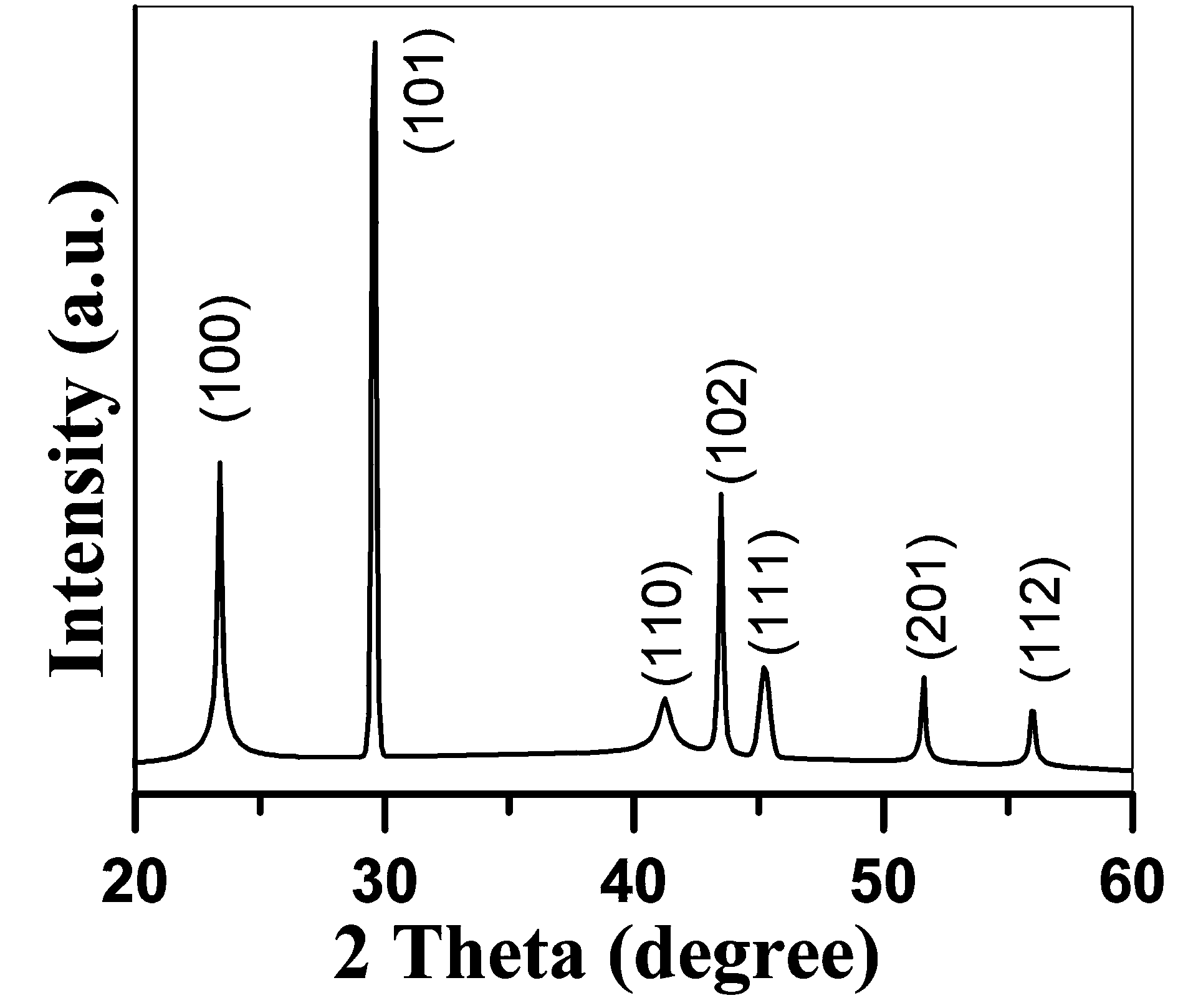

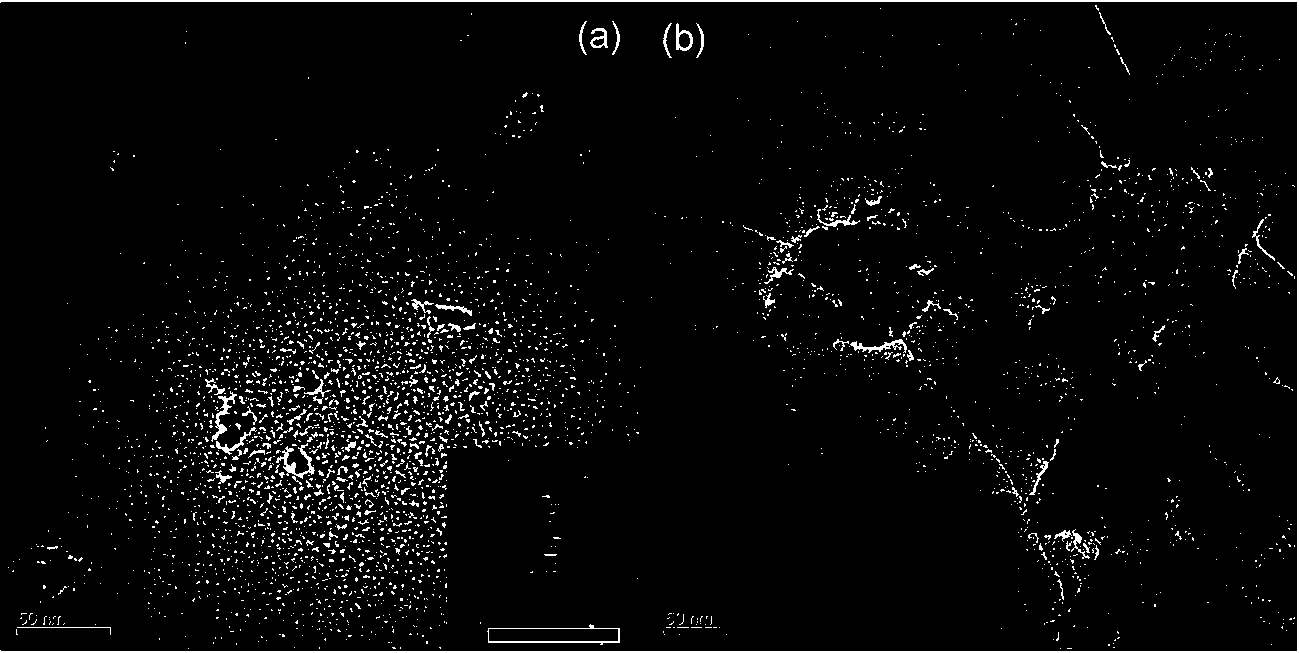

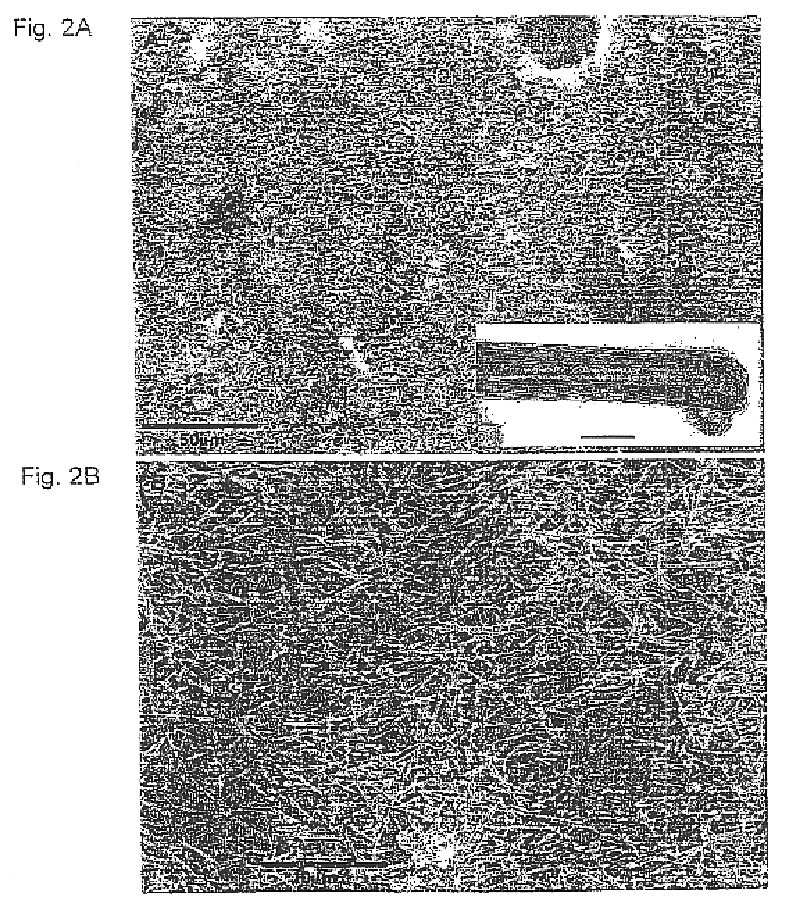

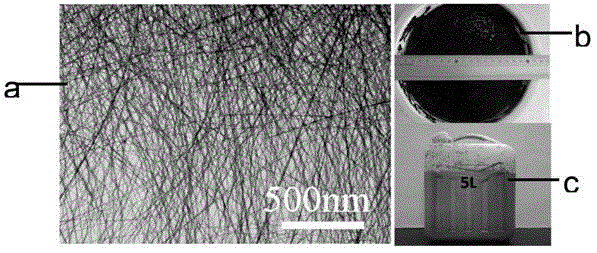

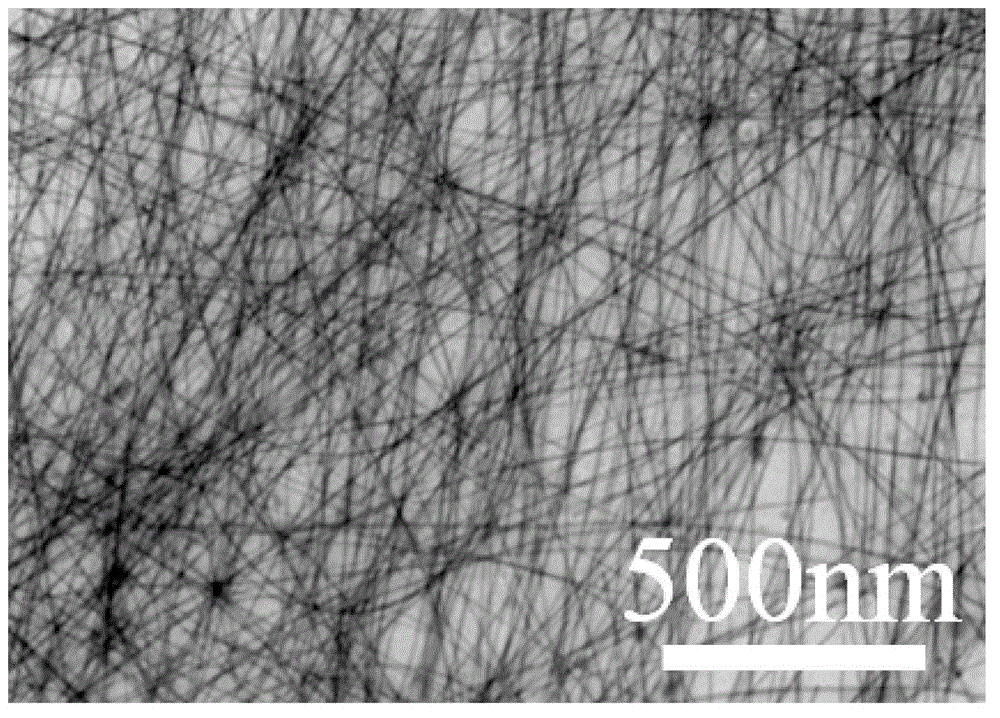

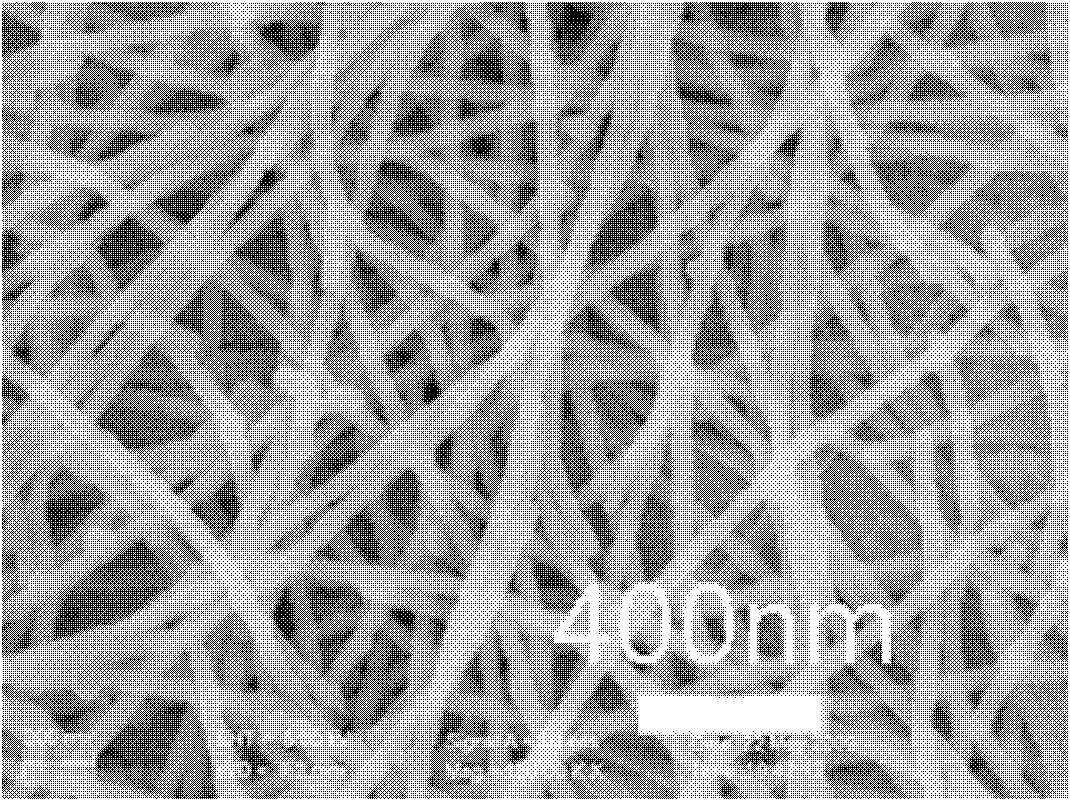

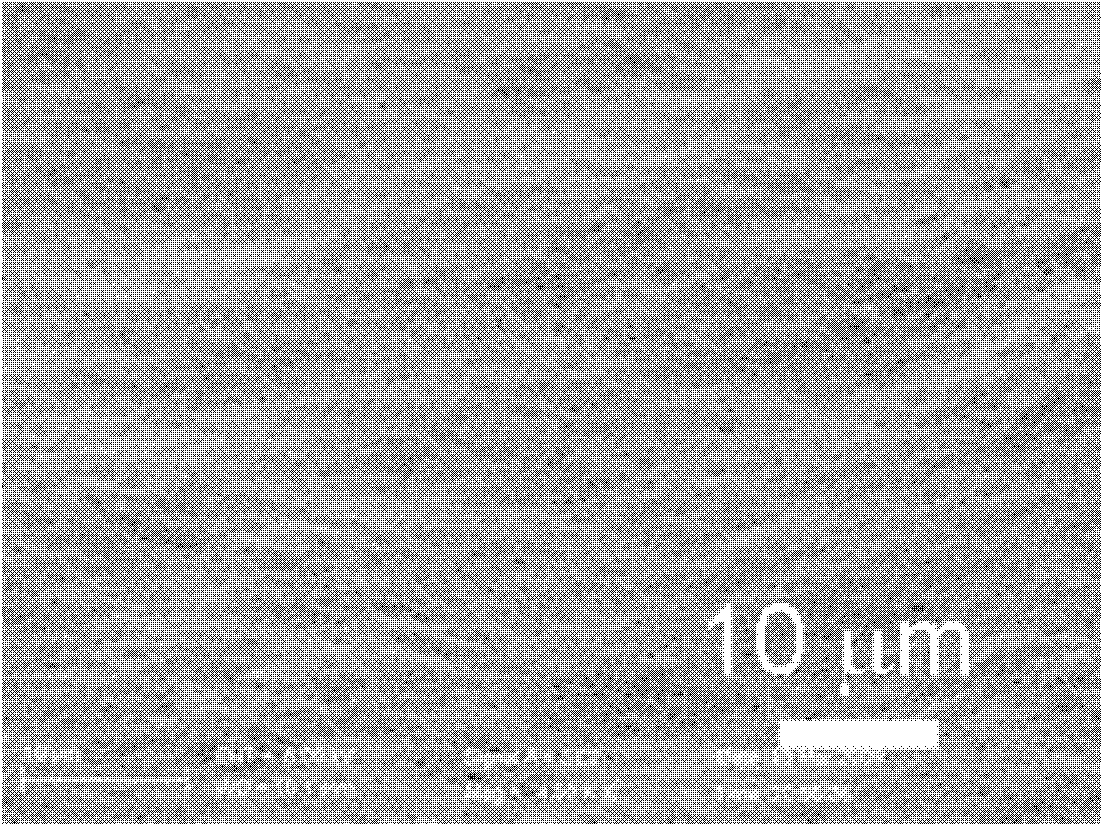

Macro preparation method for superfine tellurium nanowires

InactiveCN102910595AThin diameterUniform qualityMaterial nanotechnologyElemental selenium/telluriumNanowireTe element

The invention provides a macro preparation method for superfine tellurium nanowires, which comprises the following steps that sodium telluride reacts with a reducer by the action of a polyvinylpyrrolidone pH modifier to obtain a reaction mixture, the reaction mixture is rapidly cooled by cold water to obtain tellurium nanowire mother liquid, and a solvent is added to the tellurium nanowire mother liquid for extraction to obtain the tellurium nanowires. According to the macro preparation method, as the obtained reaction mixture is rapidly cooled by the cold water to prepare the tellurium nanowires, the quality of the tellurium nanowires is more uniform, and the diameters of the tellurium nanowires are smaller. Further, as preparation conditions are optimized, the preparation method facilitates synthesis in large quantity, and is easy to promote and apply.

Owner:UNIV OF SCI & TECH OF CHINA

Method for recovering copper, indium, gallium and selenium

ActiveCN104018186ASimple methodEasy to recyclePhotography auxillary processesProcess efficiency improvementMaterials preparationIndium

The invention provides a method for recovering copper, indium, gallium and selenium. The method comprises the following steps of: recovering the indium by carrying out electrolysis by taking a CIGS (Copper Indium Gallium Selenium) waste material as an anode; recovering the gallium by leaching precipitates, namely anode mud and the like, and electrodepositing leach liquor; respectively recovering the selenium and the copper by pickling leached residues, regulating alkali into acid and then respectively adding reducing agents. The method provided by the invention is simple. According to the method, the recovered indium, copper and gallium can be recycled in CIGS target material preparation. The method provided by the invention can be used for respectively separating and recovering gallium, copper and selenium by carrying out the electrolysis by using the CIGS waste material as the anode, directly electrodepositing indium and then using a conventional chemical separation method, thereby being an excellent method capable of extremely easily and efficiently recovering the high-purity indium and gallium. In industrial production, the recovery rate of indium is more than 99%, the grade of refined indium achieves 99.995%, the recovery rate of copper achieves 98.8%, the recovery rate of gallium is more than 98.5%, and the recovery rate of selenium achieves 98%.

Owner:ZHUZHOU SMELTER GRP

Controllable preparation method for petaliform tin oxide nano powder

InactiveCN101823703ASimple processRaw materials are easy to obtainElemental selenium/telluriumSingle crystalSalt solution

The invention discloses a controllable preparation method for petaliform tin oxide nano powder, which is mainly characterized in that SnCl2 and NaOH serve as raw materials. The method comprises the following detailed steps: dissolving the SnCl2 and NaOH in deionized water respectively to prepare a tin salt suspension of which the concentration is 0.2 to 0.4mol / L and NaOH solution of which the concentration is 0.3 to 1mol / L; under magnetic stirring, uniformly dripping the NaOH solution into the tin salt solution until the pH value is between 11 and 13, and stirring the solution for 2 to 3 hours to obtain SnO2 precursor; pouring the precursor into a water heating reaction kettle for water heating treatment for 12 to 24 hours at the temperature of 160 to 200 DEG C; and washing and drying the obtained product, and obtaining the petaliform SnO2 powder consisting of single crystal nano sheets of which the thickness is about 3 to 10nm. No any surfactant is added. The method has the characteristics of high quality and yield of the product, low cost, massive production and the like, and is an environment-friendly synthetic method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for processing copper anode slime in total wet manner

ActiveCN102965501ABig investmentHigh separation recovery rateProcess efficiency improvementElemental selenium/telluriumRaffinateTin

The invention discloses a method for processing copper anode slime in a total wet manner, relating to a total wet production process for recycling rare and precious metals from the copper anode slime in nonferrous metallurgy. The method comprises the steps of pressurizing the copper anode slime by a chloride medium at a high temperature and leaching to directly separate out valuable metals such as copper, stibium, bismuth, tellurium, and tin; and recycling tellurium, stibium, tin, bismuth, copper and the like from a pressurized lixivium in stages. The method is further characterized in that a selective extraction method is adopted to separate gold in a gold selenium chloride solution and the selenium is recycled from a gold raffinate. According to the method, the sulfating roasting with serious pollution and huge investment is avoided, but the sulfating roasting is carried out firstly for the copper anode slime in the conventional wet method or (pyrometallurgical process); the separation recovery rate of the metals is high, but the separation effect of tellurium, stibium, tin and bismuth in the conventional process is far from ideal; by adopting the method, the leaching problems of above metals can be solved in a single process and above metals can be recycled respectively from the lixivium; the recovery rate of the metals is 90-99% respectively; the copper separation and the tellurium separation can be simplified; and the operation flow is optimized in a better manner.

Owner:JIANGXI COPPER

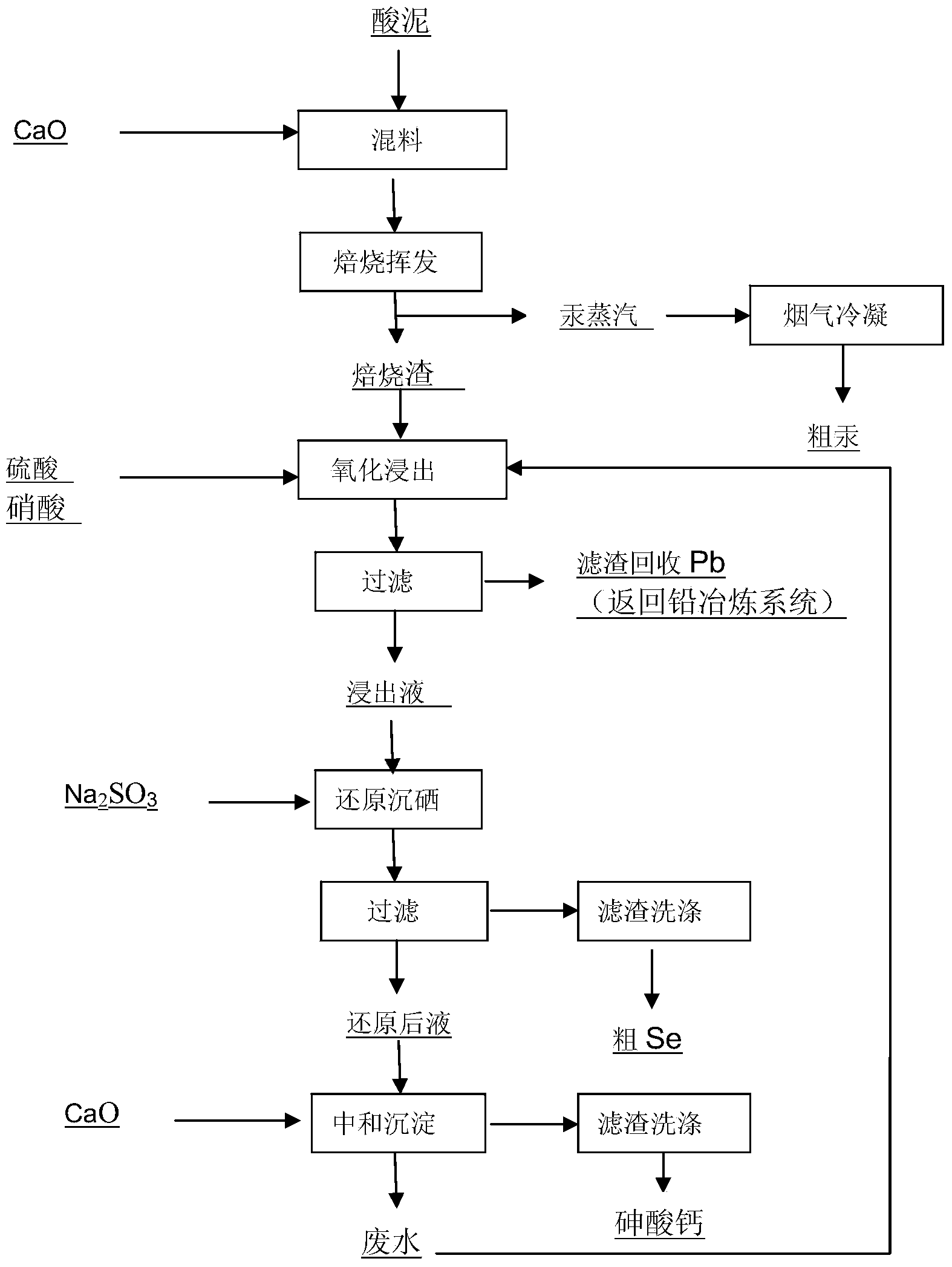

Extraction method of valuable elements from acid mud produced in sulfuric acid production by copper smelting flue gas

InactiveCN103526017AEfficient separationNo pollutionProcess efficiency improvementElemental selenium/telluriumResource utilizationPollution

The invention discloses an extraction method of valuable elements from acid mud produced in sulfuric acid production by copper smelting flue gas. Selenium-containing acid mud is treated by a process combining a fire method and a wet method. The technology process includes temperature-control solid selenium reconstruction, oxidation leaching, and reduction to precipitate selenium. The extraction method has a reasonable technology design, and fully utilizes properties of elements and chemical compounds in specific conditions, and achieves efficient separation and recovery of Hg, Se, As, Pb and other elements in the selenium-containing acid mud. The extraction method has high economic benefit. No "three waste discharge" is existed in the process. The extraction method is an environmental-friendly treating method with high resource utilization rate and low energy consumption. The extraction method solves a problem of recovery difficulty of the mercury and the selenium from the acid mud, a problem of environment pollution by arsenic due to easy dispersion, and the like. The extraction method improves the comprehensive metal recovery rate, and reduces environment pollution. The extraction method is suitable for treatment of high-mercury high-selenium and high-lead materials, and is a new technology process. In addition, the method is suitable for treatment of other materials containing selenium, mercury and arsenic. The extraction method is environmental friendly and has industrialized application value.

Owner:HUNAN RES INST FOR NONFERROUS METALS

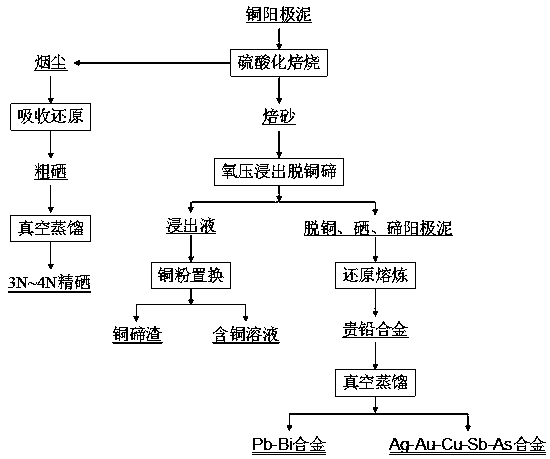

Method for recovering selenium, tellurium, copper and precious metal from copper anode slime

InactiveCN109371228AHigh purityEasy to separateProcess efficiency improvementElemental selenium/telluriumBismuthSelenium

The invention discloses a method for recovering selenium, tellurium, copper and precious metal from copper anode slime. The copper anode slime is subjected to segment treatment, the copper anode slimeis subjected to sulfation roasting at first, mixed gas of SeO2, SO2, SO3 and other gases and a roasted product are obtained, the obtained mixed gas is subjected to absorption reduction and dried, crude selenium is obtained, then the crude selenium is put in a vacuum distillation furnace, and refined selenium is obtained through purification; the roasted product obtained through sulfation roastingis subjected to oxygen pressure acid leaching, and leachate containing copper and tellurium and lead anode slime without selenium, copper and tellurium are obtained; the leachate containing copper and tellurium is subjected to copper powder reduction treatment, and copper-tellurium slag and a copper sulfate solution are obtained after reaction, so that copper and tellurium are convenient to recover; and the lead anode slime without selenium and copper is subjected to reduction smelting, noble lead alloy is obtained and put in a continuous vacuum distillation furnace, volatile lead and volatile bismuth are changed into volatile phases, thus, high-grade lead is recovered, non-volatile metal such as gold, silver, copper, antimony and arsenic remains in residues, and alloy is formed, so thatrecovery of subsequent precious metal is facilitated. Through the method provided by the invention, the refined selenium with the purity being 99.9%-99.99%, the copper sulfate solution, the copper-tellurium slag, the lead bismuth alloy and silver antimony gold copper arsenic alloy can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

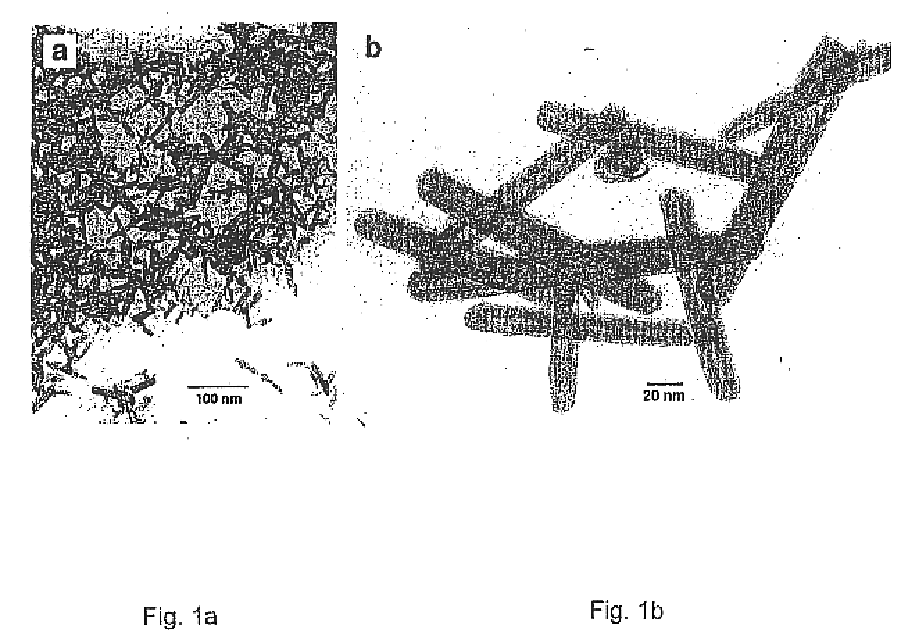

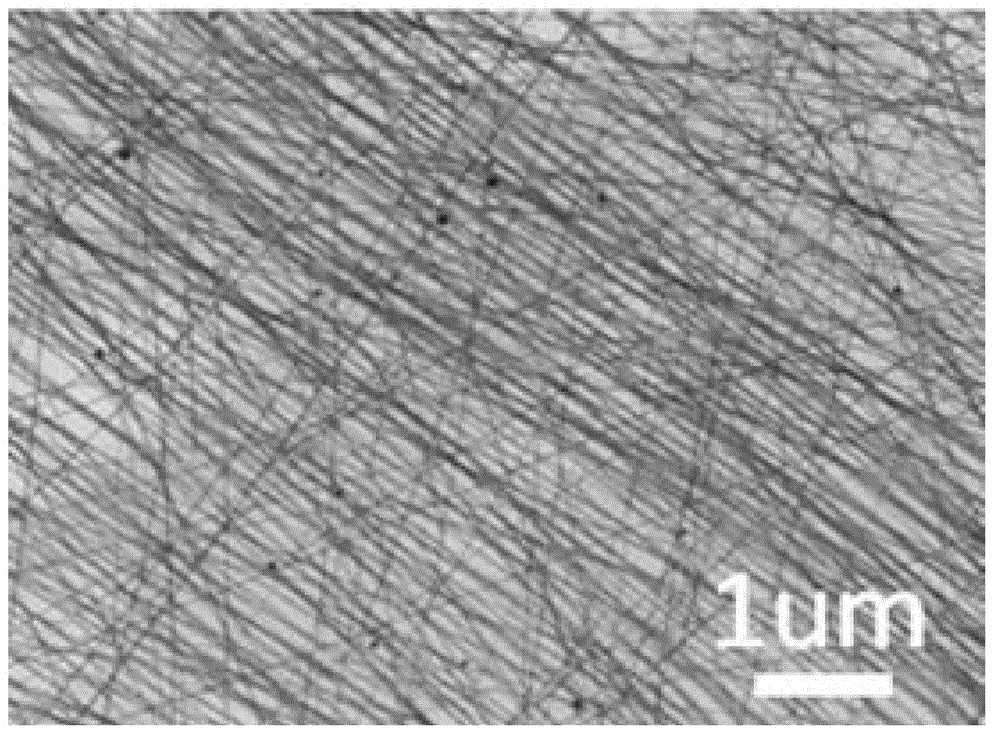

Method for preparing carbon nanofiber membrane

InactiveCN102179182AUniform diameterHigh water flowSemi-permeable membranesNanotechnologyFiberNanowire

The invention provides a method for preparing a carbon nanofiber membrane, which comprises the following steps of: a) mixing tellurium nanowires and glucose in aqueous solution, and performing carbonation reaction to obtain a carbon-coated tellurium nano cable; b) adding hydrochloric acid and hydrogen peroxide into the carbon-coated tellurium nano cable, and performing oxidation reaction to obtain carbon nanofibers; and c) dispersing the carbon nanofibers in a solvent o obtain slurry, coating the slurry on a support material, and drying to obtain the carbon nanofiber membrane. The prepared carbon nanofibers are uniform in diameter, so tht the obtained carbon nanofiber membrane has narrow pore diameter distribution; by controlling synthetic conditions of the nanofibers, carbon nanofibers with different diameters can be obtained, so that the pore diameter of the carbon nanofiber membrane is controllable, and the carbon nanofiber membrane is better applied to a membrane separation technology. In addition, the surface of the carbon nanofiber membrane is rich in hydrophilic groups, the water circulation quantity of the membrane is large, and the efficiency is high during membrane separation.

Owner:UNIV OF SCI & TECH OF CHINA

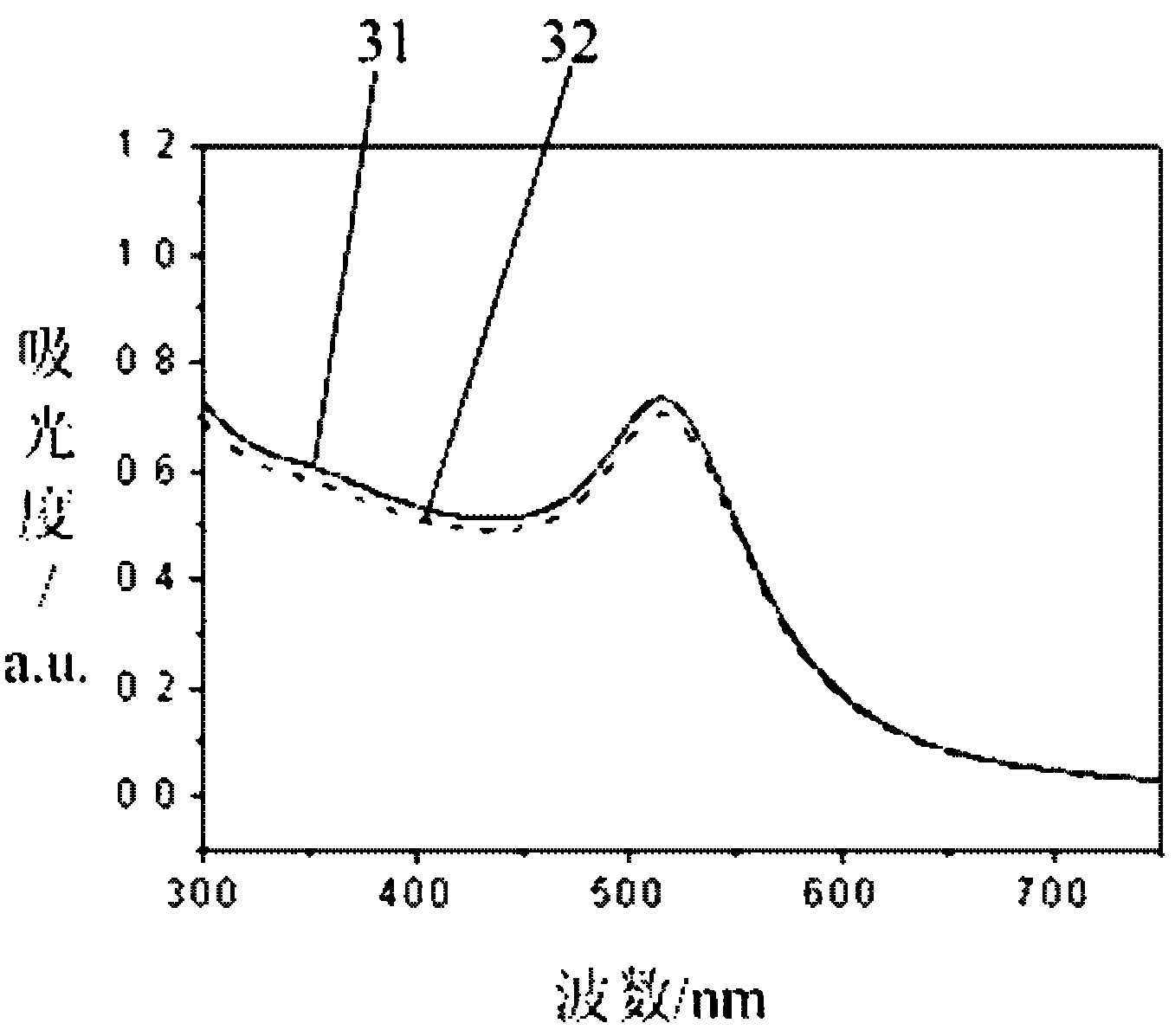

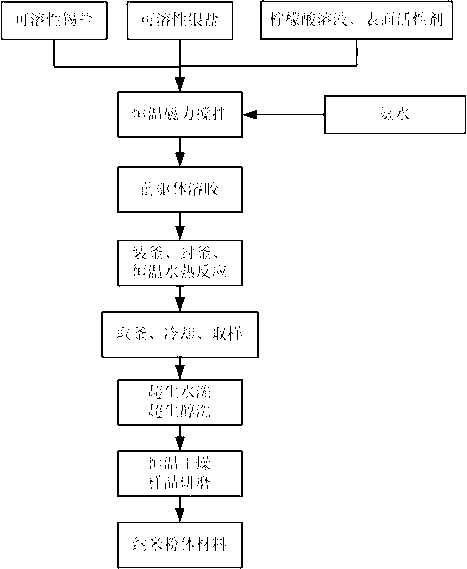

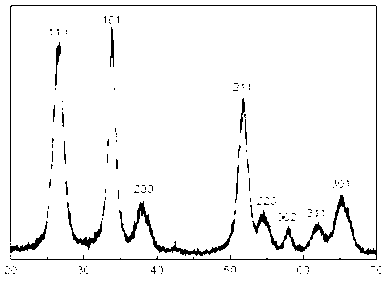

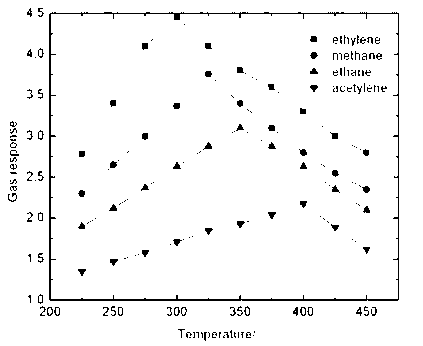

Preparation method of silver-doped nano tin dioxide powder

ActiveCN102838094ASmall granularityNarrow distributionMaterial nanotechnologyElemental selenium/telluriumDispersitySurface-active agents

The invention belongs to the technical field of preparation of tin dioxide powder, and relates to a preparation method of silver-doped nano tin dioxide powder. The preparation method comprises the following steps of: firstly adding citric acid solution, a surface active agent and ammonia water sequentially into mixed solution of soluble tin salt and soluble silver salt, and adjusting the pH value of a reaction system to 2.5-11, and under the action of constant-temperature magnetic stirring, generating precursor sol; then, adding the precursor sol into a hydrothermal reaction kettle, putting the hydrothermal reaction kettle in a drying oven, carrying out hydrothermal reaction, taking out the hydrothermal reaction kettle after hydrothermal reaction, cooling, and sampling; and finally, cleaning, drying and grinding to prepare a finished nano tin dioxide powder product. The tin dioxide powder prepared by the method has the advantages of fewer granularity, narrow distribution range and good dispersity; and a gas sensor based on the tin dioxide powder material has good detection performance for fault gas in transformer oil.

Owner:PONOVO POWER

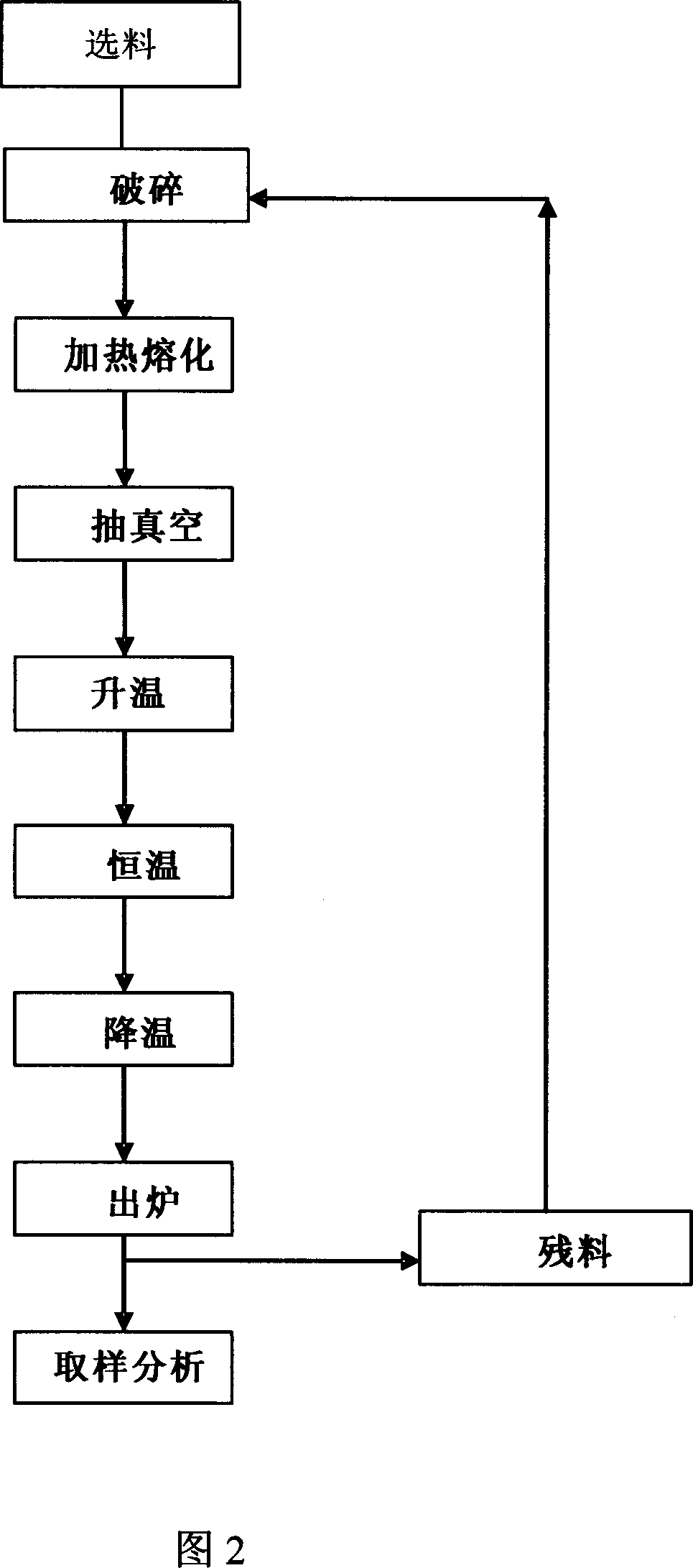

Preparation method of high purity tellurium

InactiveCN102153054AReduce manufacturing costElemental selenium/telluriumSemiconductor materialsPurification methods

The invention discloses a preparation method of high purity tellurium. In the method, industrial tellurium of which purity is 99% is used as a raw material and the chemical and physical methods are combined to prepare high purity tellurium. The method comprises the following steps: dissolving the raw material in nitric acid, stirring, heating, filtering, adding the obtained tellurium dioxide in hydrochloric acid, introducing hydrogen peroxide, filtering after dissolving; adding sodium sulfite solution in the filtrate to reduce and obtain 3N-4N of fine tellurium; and dissolving at 400-450 DEG C in hydrogen atmosphere, and adopting the Czochralski purification method to treat fine tellurium and obtain 5N-6N of high purity tellurium. The method has low preparation cost; and the high purity tellurium can be used in the semiconductor material fields such as solar cell, light-emitting diode (LED), thermoelectricity and infrared field.

Owner:JIAXING DAZE PHOTOELECTRIC TECH

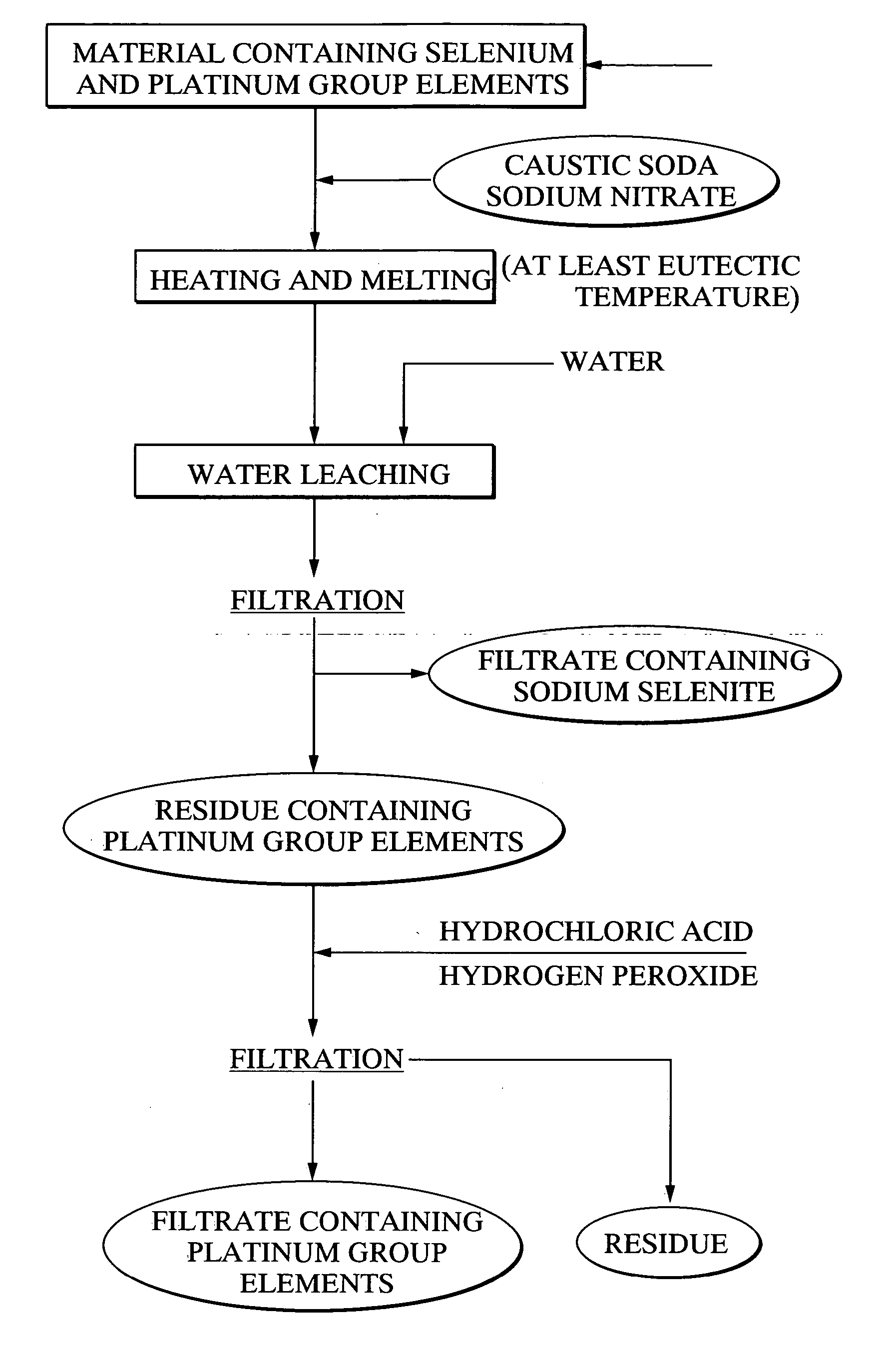

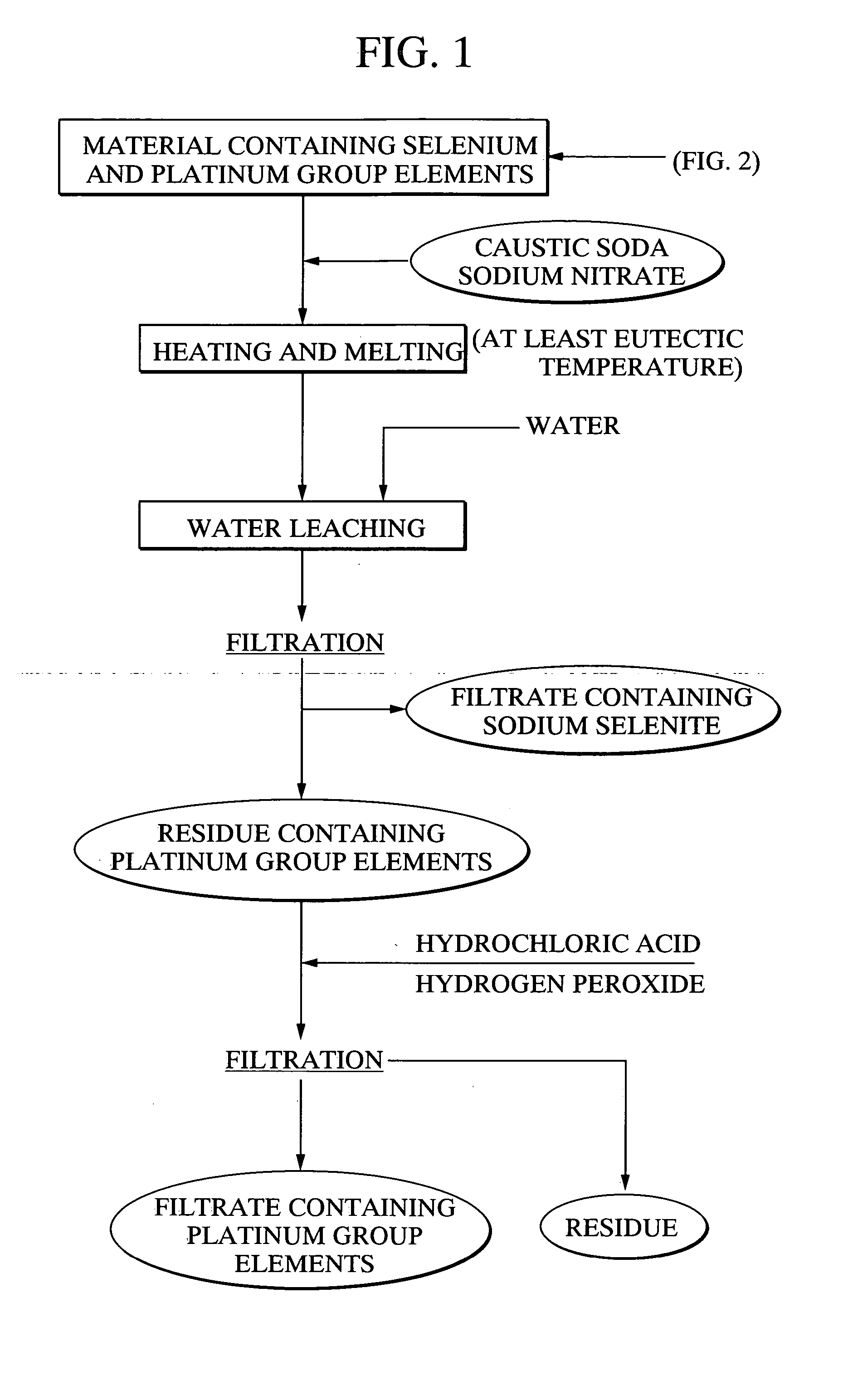

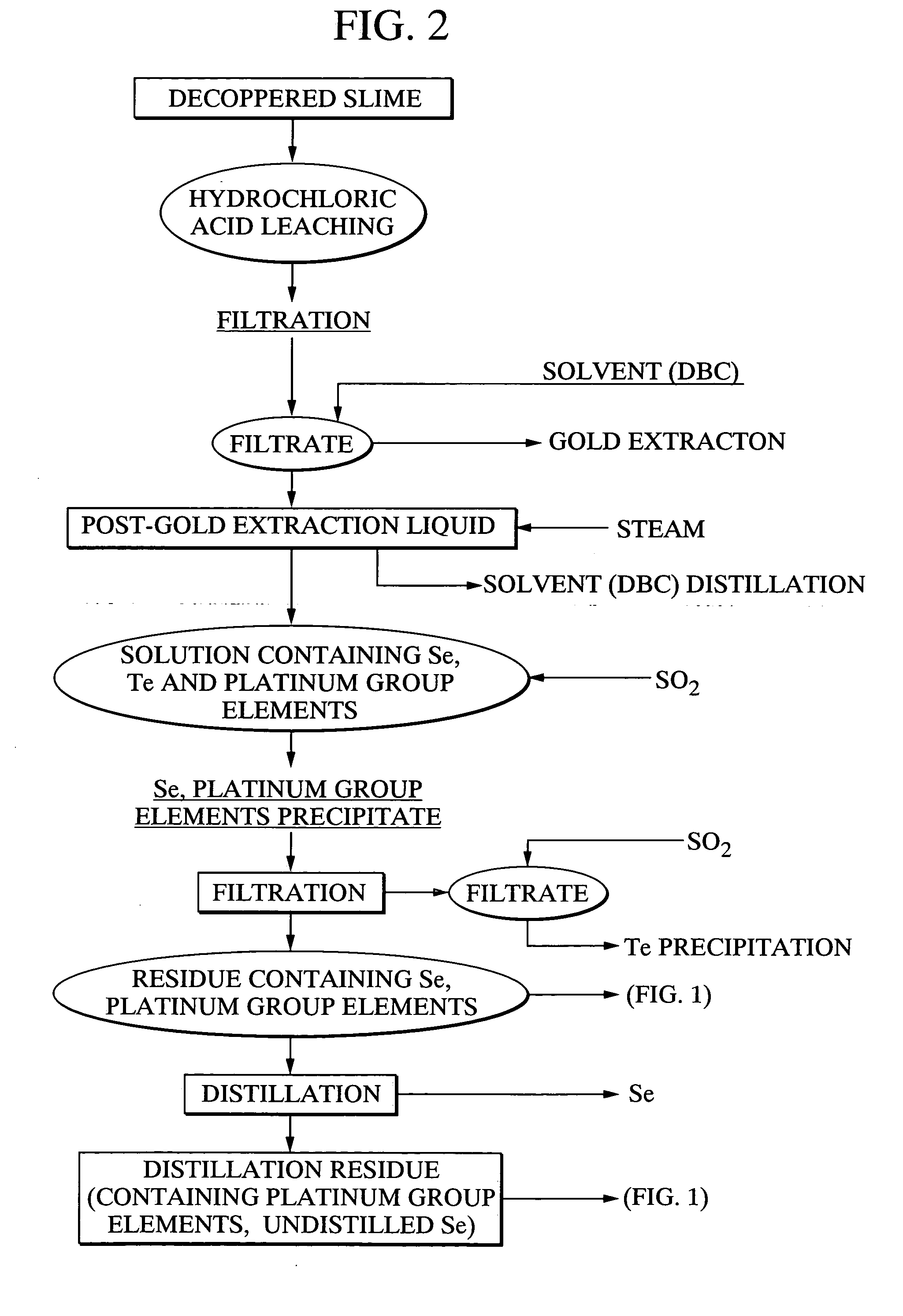

Method for separating platinum group element

InactiveUS20050255017A1Separated and recoveredLow costPhotography auxillary processesPhosphorus sulfur/selenium/tellurium compoundsPhysical chemistryPlatinum group

One object of the present invention is to provide a separation process that enables the efficient separation of selenium, tellurium, and platinum group elements from a material containing selenium / tellurium and platinum group elements. In order to achieve this object, the invention provides a separation process for platinum group elements comprising: a step (A) for treating a material containing selenium / tellurium and platinum group elements with alkali, a step (B) for leaching selenium / tellurium, and a step (C) for separating the platinum group element-containing leaching residue and the selenium / tellurium leachate.

Owner:MITSUBISHI MATERIALS CORP

Method for comprehensively recovering mercury and selenium from metallurgical slag

InactiveCN104498722ALow costNo emissionsProcess efficiency improvementElemental selenium/telluriumMetallurgical slagHydroxylamine

The invention discloses a method for comprehensively recovering mercury and selenium from metallurgical slag and belongs to the field of metallurgy. The method comprises following steps: grinding the metallurgical slag to the range of 130-150 microns, blending the metallurgical slag with quick lime accounting for 10-30% of the metallurgical slag and roasting at a temperature ranging from 750 to 900 DEG C for 6-8 hours; collecting dust from mercury-containing vapor firstly by use of a cloth bag and then by virtue of cyclone, condensing the mercury vapor by use of a two-stage condensation apparatus to recovery the mercury, and returning mercurial soot and a tail gas adsorption filler to the metallurgical slag for reutilization, wherein no pollutant is emitted in the process; next, leaching selenium-containing slag by use of an oxidation solution prepared from hydrochloric acid and sodium chlorate in the ratio of 2:1, analyzing the contents of Hg<2+>, Fe<2+>, Ca<2+> and Mg<2+> in the leachate in the liquid-solid ratio of 2:1, respectively, precipitating the ions by use of sodium sulfide in the ratio of 1:1 to the total content of the ions and then filtering to remove the irons, and reducing for 2 hours by use of hydroxylamine hydrochloride, thereby obtaining the elemental selenium after washing the precipitate. The method for comprehensively recovering mercury and selenium from the metallurgical slag is high in extraction rate and prone to industrial production.

Owner:贵州重力科技环保股份有限公司

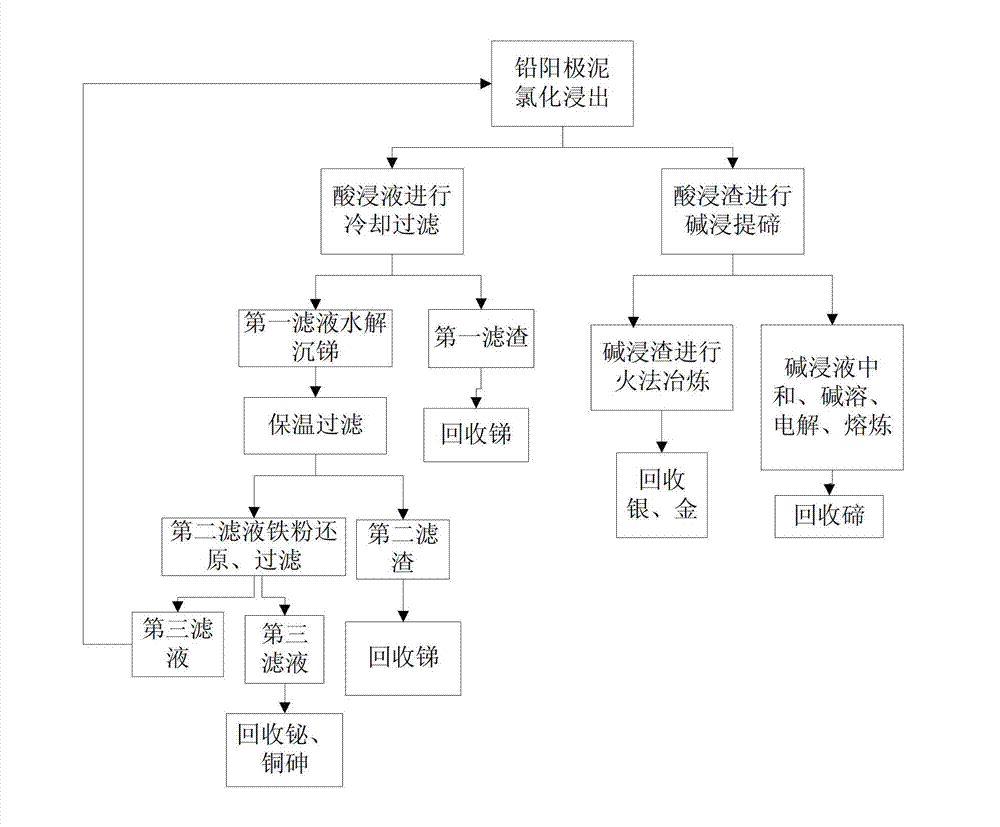

Method for recycling valuable metals from lead anode slime

ActiveCN102925703AHigh recovery rateSimple process routeProcess efficiency improvementElemental selenium/telluriumMaterials scienceAntimony

The invention provides a method for recycling valuable metals from lead anode slime, which comprises the following steps: preprocessing anode slime to obtain oxide anode slime, and performing chloration and leaching on 65-78 wt% of oxide anode slime, 15-20 wt% of sodium chloride and 5-20 wt% of sodium chlorate to obtain an acid leaching liquor and acid leaching residue; performing cooling crystallization on the acid leaching liquor and filtering to obtain first filter residue and a first filter liquor; hydrolyzing, insulating and filtering the first filter liquor to obtain second filter residue and a second filter liquor; recycling antimony from the second filter residue; adding iron powder into the second filter liquor and reducing and filtering to obtain a third filter liquor and third filter residue; recycling bismuth, copper and arsenic from the third residue; taking 70-95 wt% of the acid leaching residue and 5-30 wt% of a reducing agent and performing alkaline leaching to obtain alkaline leaching liquor and alkaline leaching residue; recycling tellurium from the alkaline leaching liquor; and performing pyrogenic process smelting on the alkaline leaching residue to recycle gold and silver. The method solves the technical problems that in the prior art, antimony is difficult to leach, and the recovery rate of valuable metals such as copper, bismuth, antimony, tellurium and the like is low.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

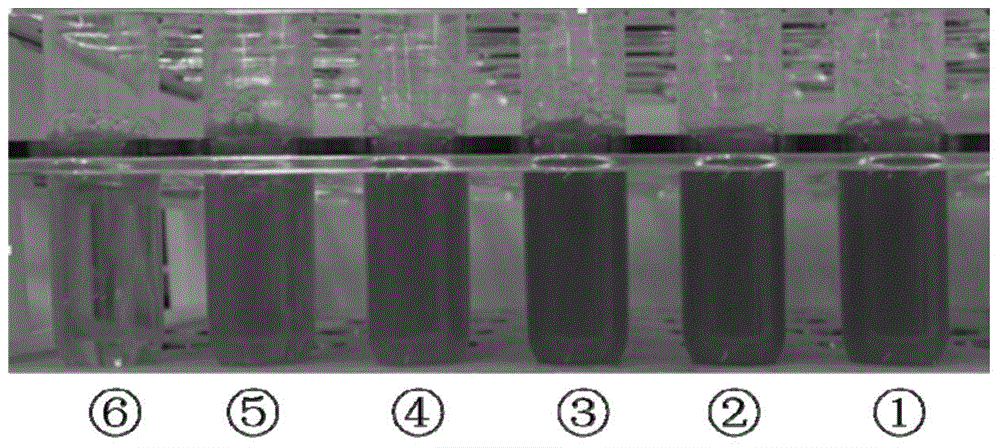

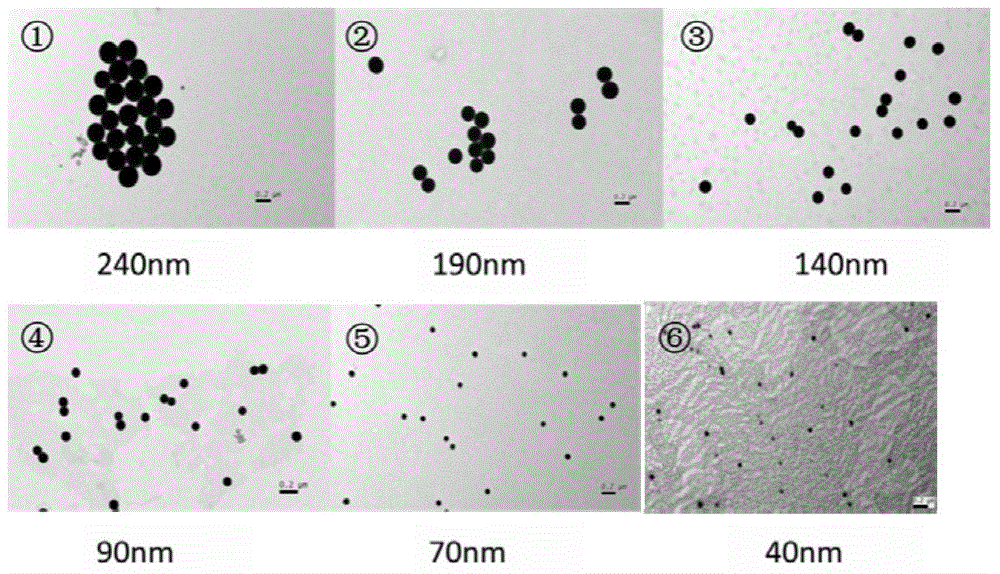

Preparation method for nano-selenium

ActiveCN104310319ASmall particle sizeUniform particle sizeMaterial nanotechnologyElemental selenium/telluriumMass ratioFreeze-drying

The invention relates to a preparation method for nano-selenium. The preparation method comprises the steps of (1) carrying out reduction reaction on a selenite solution and a reducing agent solution when acid liquor and a stabilizer are available so as to obtain a nano-selenium suspension, wherein the mass ratio of the selenite solution to the reducing agent solution is 1:(2-30); and (2) centrifuging the nano-selenium suspension, removing the supernate so as to obtain the finished product-colloid nano-selenium, adding deionized water to re-suspend, freeze drying so as to obtain the finished product solid nano-selenium. The finished product nano-selenium can be preserved at 2-6DEG C. According to the measurement of the recovery rate of the nano-selenium of all diameters, the generation proportion of the nano-selenium is gradually increased along with the decrease of the diameter of the nano-selenium. The preparation method is simple to operate, is safe and stable, is short in time, can prepare uniform nano-selenium of different diameters, and provides good material base for expanding the application field of the nano-selenium and improving the application value of the nano-selenium.

Owner:CHINA AGRI UNIV

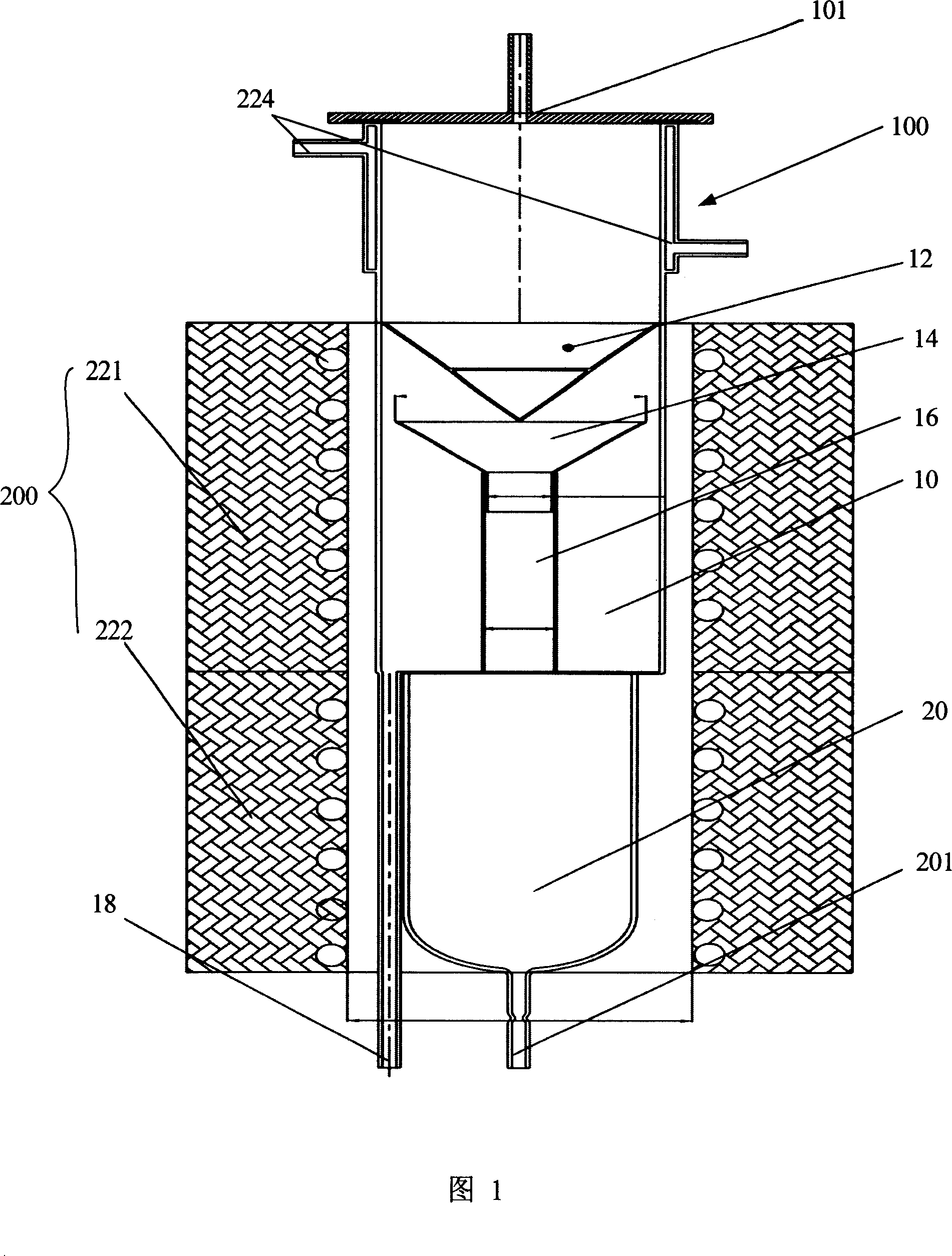

Producing device of high-purity selenium and producing process

ActiveCN1927701AEasy to collectHelp to separateElemental selenium/telluriumTemperature controlBoiling point

High purity selenium producing apparatus and process are disclosed. The producing apparatus includes one rectifying unit coated with heat insulating layer, one temperature controlling system and one vacuum system comprising one mechanical pump and one diffusion pump. The rectifying unit with vacuum gland in the upper part is divided into one material layer and one product layer communicated mutually. The material layer includes one conical condenser, one umbrella shaped material accepter and one connecting pipe vertically distributed successively; and the product layer is provided with one product kettle connected through the connecting pipe to the material accepter. The rectifying unit in inside multilayer structure is favorable to the separation of selenium from other impurity elements, and has high yield and high product purity.

Owner:广东先导稀贵金属材料有限公司

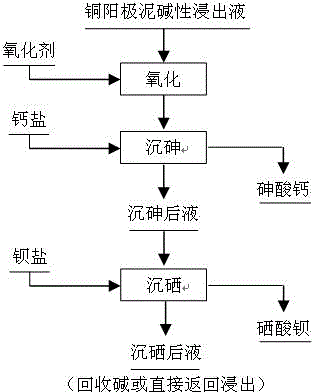

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com