Preparation method of silver-doped nano tin dioxide powder

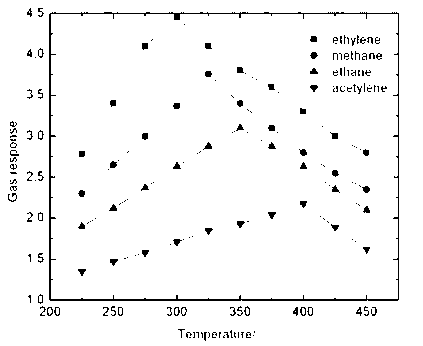

A technology of nano-tin dioxide and powder materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as complex production process, harsh reaction conditions, and complicated operation, and achieve improved Gas sensitivity performance, narrow distribution range, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

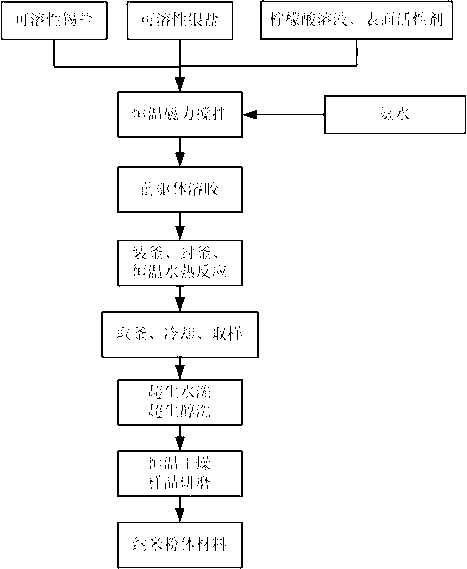

Method used

Image

Examples

Embodiment 1

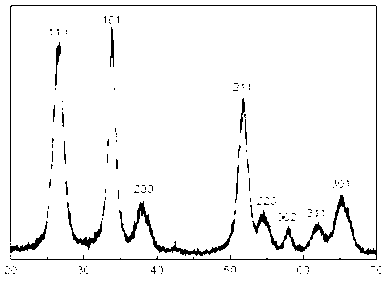

[0024] Weigh 3.506g of tin tetrachloride pentahydrate and 0.0085g of silver nitrate (so that the doping amount of silver is 0.5%), add deionized water to prepare 100ml of a mixed solution of 0.1mol / L, add 10ml of 0.1 mol / L citric acid solution and 2 g polyethylene glycol 4000, configure 500ml 0.1mol / L ammonia solution, and slowly add the configured ammonia solution into the mixed solution with a basic burette to adjust the pH value of the reaction system To 8.5, react under constant temperature magnetic stirring at 80°C for 120min to generate a precursor sol; put the precursor sol into a hydrothermal reaction kettle, place it in an oven, and react under the condition of 150°C for 10h, and take out the The hydrothermal reaction kettle was cooled to room temperature and sampled; the sample was ultrasonically washed 10 times with deionized water and 10 times with absolute ethanol, dried at 80°C for 12 hours, and ground to make nano-tin dioxide powder Body finished product, the pa...

Embodiment 2

[0026] Weigh 2.256g of stannous chloride dihydrate and 0.017g of silver nitrate (so that the doping amount of silver is 1%), add deionized water to prepare 100ml of a mixed solution of 0.1mol / L, add 10ml of 0.1 mol / L citric acid solution and 2 g polyethylene glycol 4000, configure 500ml 0.2mol / L ammonia solution, slowly add the configured ammonia solution into the mixed solution with a basic burette, and adjust the pH value of the reaction system To 9, react for 120 minutes under constant temperature magnetic stirring at 80°C to generate a precursor sol; put the precursor sol into a hydrothermal reaction kettle, place it in an oven, and perform a hydrothermal reaction at 160°C for 12 hours, then take out the The hydrothermal reaction kettle was cooled to room temperature and sampled; the sample was ultrasonically washed 10 times with deionized water and 10 times with absolute ethanol, dried at 90°C for 12 hours, and ground to make nano-tin dioxide powder finished product. Its...

Embodiment 3

[0028] Weigh 7.012g of tin tetrachloride pentahydrate and 0.068g of silver nitrate (so that the doping amount of silver is 2%), add deionized water to prepare 100ml of a mixed solution of 0.2mol / L, add 10ml of 0.1 mol / L citric acid solution and 2 g polyethylene glycol 4000, configure 500ml 0.3mol / L ammonia solution, slowly add the configured ammonia solution into the mixed solution with a basic burette, and adjust the pH value of the reaction system To 9.5, react under constant temperature magnetic stirring at 80°C for 120min to generate a precursor sol; put the precursor sol into a hydrothermal reaction kettle, place it in an oven, and conduct a hydrothermal reaction at 170°C for 14h, then take out the Hydrothermal reaction kettle, cooled to room temperature, sampling; the sample was ultrasonically washed 10 times with deionized water and 10 times with absolute ethanol, dried at 100°C for 12 hours, and ground to make nano-tin dioxide powder Body finished product, the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com