Controllable preparation method for petaliform tin oxide nano powder

A technology of nano-powder and tin oxide, which is applied in the field of preparation of flake-shaped SnO2 nano-powder, can solve the problems of high cost, complex process technology, and large one-time investment, and achieve low cost, simple process, and simple raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] a. Weigh 1.3539g of anhydrous SnCl 2 Dissolve in 20ml of water, then magnetically stir for 10 minutes until a 0.3mol / L white suspension is formed. Weigh 0.8 g of NaOH and dissolve it in 20 ml of deionized water, and then magnetically stir until a transparent NaOH solution of 1.0 mol / L is formed.

[0027]b. Under strong magnetic stirring, evenly drop the transparent NaOH solution into the above white suspension until the pH value is 11, and then magnetically stir for 3 hours to form a precursor suspension with black precipitates.

[0028] c. The above precursor suspension was transferred to a 100ml reaction kettle, hydrothermally treated at 200°C for 24h, and then naturally cooled to room temperature.

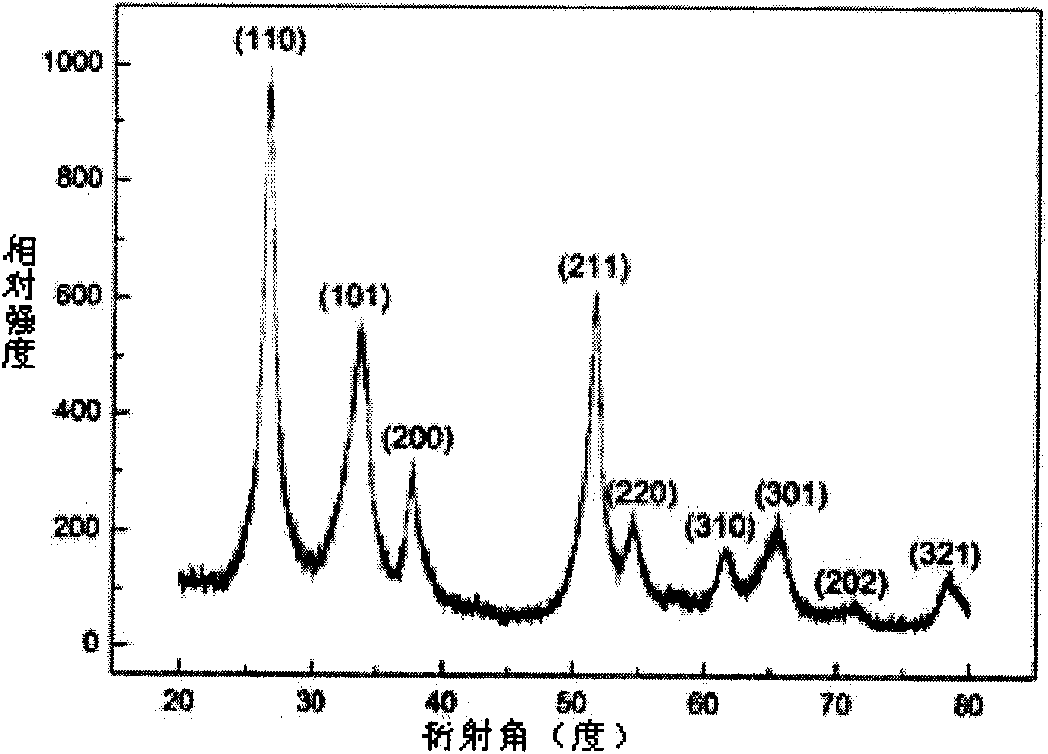

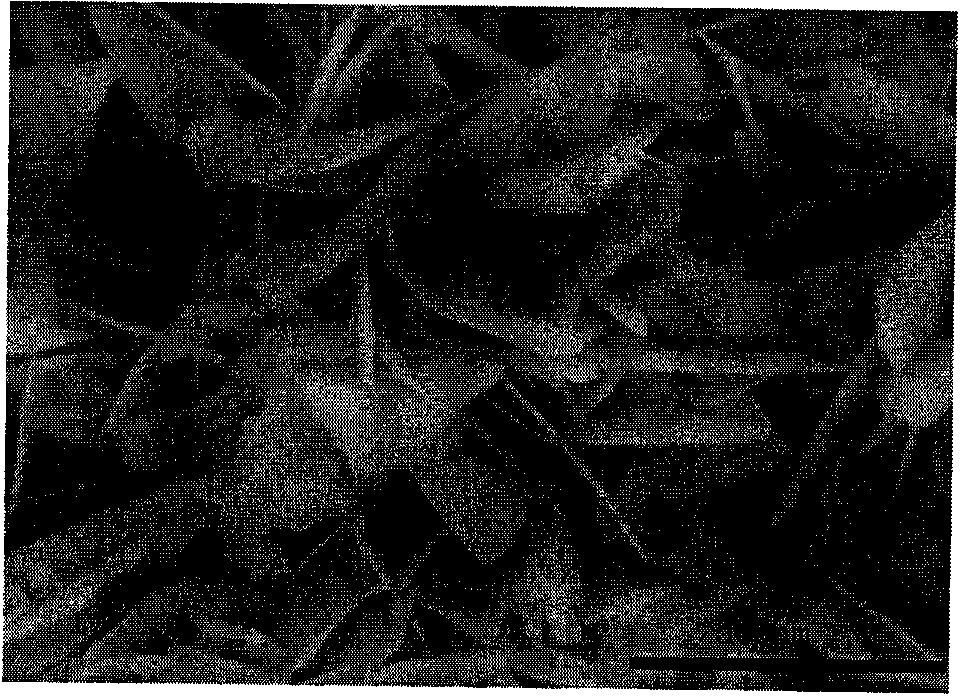

[0029] d. Wash the hydrothermal product several times with deionized water and ethanol in sequence until the Cl - Completely removed, dried at 70°C for 1 hour under vacuum conditions to obtain khaki SnO 2 Nano powder, its specific surface area is 51.6m 2 / g. SnO 2 T...

specific Embodiment 2

[0031] a. Weigh 1.3539g of anhydrous SnCl 2 Dissolve in the mixed solution of 5ml ethanol and 15ml water (volume ratio is 1:3), then magnetically stir for 10 minutes until forming 0.3mol / L white suspension. Weigh 0.8g NaOH and dissolve it in 50ml deionized water, then magnetically stir to form a 0.4mol / L transparent NaOH solution.

[0032] b. Under strong magnetic stirring, evenly drop the transparent NaOH solution into the above white suspension until the pH value is 13, and then magnetically stir for 2 hours to form a precursor suspension with black precipitate.

[0033] c. The above precursor suspension was transferred to a 100ml reaction kettle, hydrothermally treated at 180°C for 12h, and then naturally cooled to room temperature.

[0034] d. Wash the hydrothermal product several times with deionized water and ethanol in sequence until the Cl - Completely removed, dried at 70°C for 1 hour under vacuum conditions to obtain khaki SnO 2 Nano powder, its specific surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com