Preparation method for nano-selenium

A technology of nano-selenium and selenite, which is applied in the field of preparation of nano-materials, can solve the problems of no water solubility and biocompatibility, large size of nano-selenium, cumbersome preparation process, etc., and achieve good water solubility and biocompatibility, The effect of uniform particle size and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take by weighing the sodium selenite crystal of 0.0233g, join in the mixed solution of 2ml deionized water, 18ml glycerol and 2ml ethanol, stir and make it fully dissolve, obtain sodium selenite solution; Take by weighing 1.0076g glucose powder in addition, make It was dissolved in 2ml deionized water;

[0020] Add the prepared glucose solution to the prepared sodium selenite solution at 60°C, then add 1ml of MPA, stir and heat to 80°C, and keep it warm for 15 minutes to obtain a brick-red nano-selenium solution. Centrifuge at rpm for 30 minutes to obtain water-soluble and biocompatible nano-selenium powder.

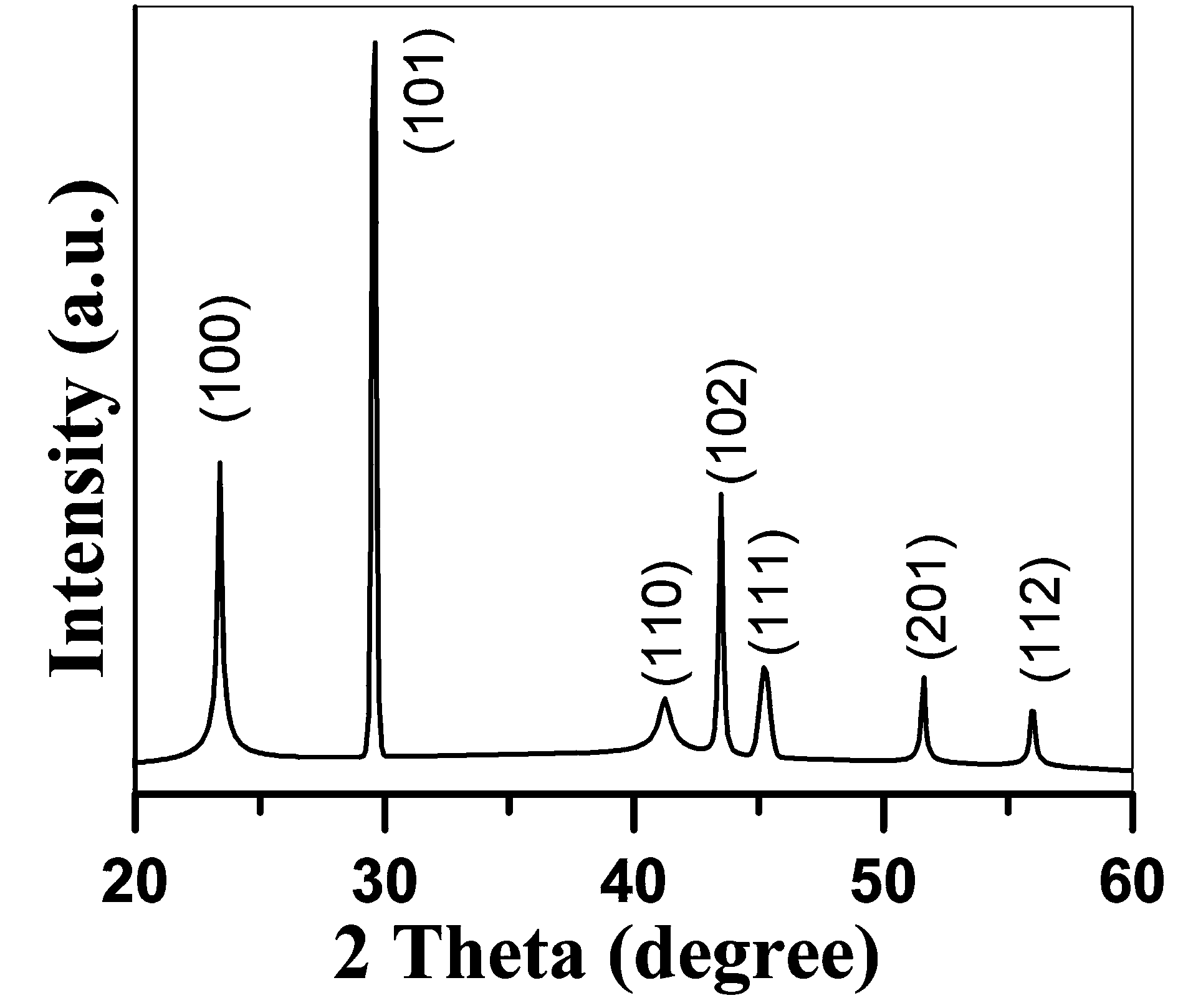

[0021] as attached figure 1 As shown, in the X-ray diffraction pattern diagram of the generated nano-selenium powder, it can be determined that the powder is a pure-phase nano-selenium crystal powder with a hexagonal structure. Among them, when the diffraction angle is 23.5°, 29.7°, 41.4°, 43.6°, 45.4°, 51.7° and 56.0°, the corresponding (1 0 0), (0 1 1), (1 1 ...

Embodiment 2

[0025] Take by weighing the sodium selenite crystal of 0.4156g, join in the mixed solution of 2ml deionized water, 20ml glycerol and 2ml ethanol, stir and make it fully dissolve, obtain sodium selenite solution; Take by weighing 2.5046g glucose powder in addition, make It was dissolved in 3ml deionized water;

[0026] Add the prepared glucose solution to the prepared sodium selenite solution at 60°C, then add 1ml of MPA, stir and heat to 80°C, and keep it warm for 15 minutes to obtain a brick-red nano-selenium solution. Centrifuge at rpm for 30 minutes to obtain water-soluble and biocompatible nano-selenium powder.

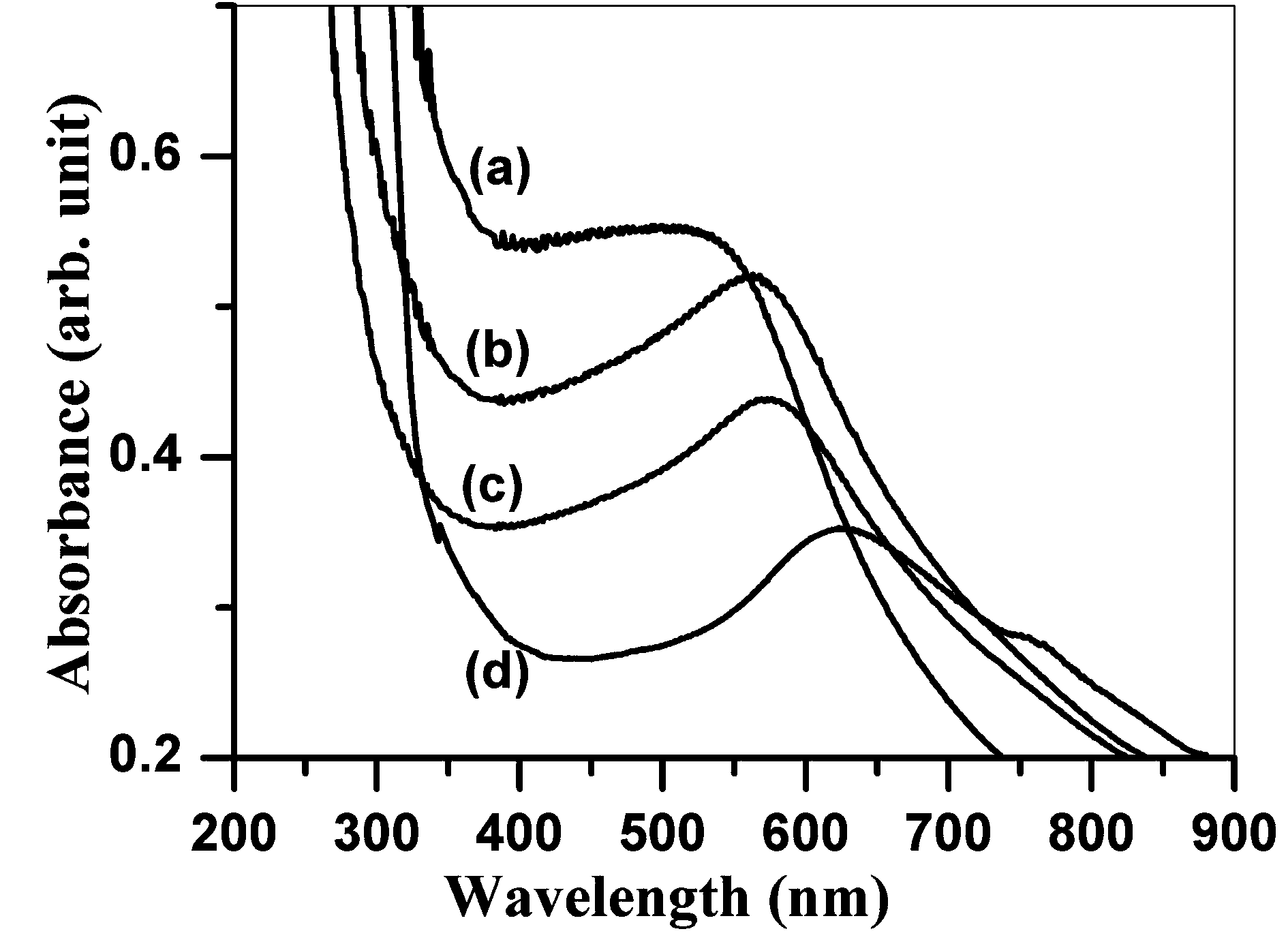

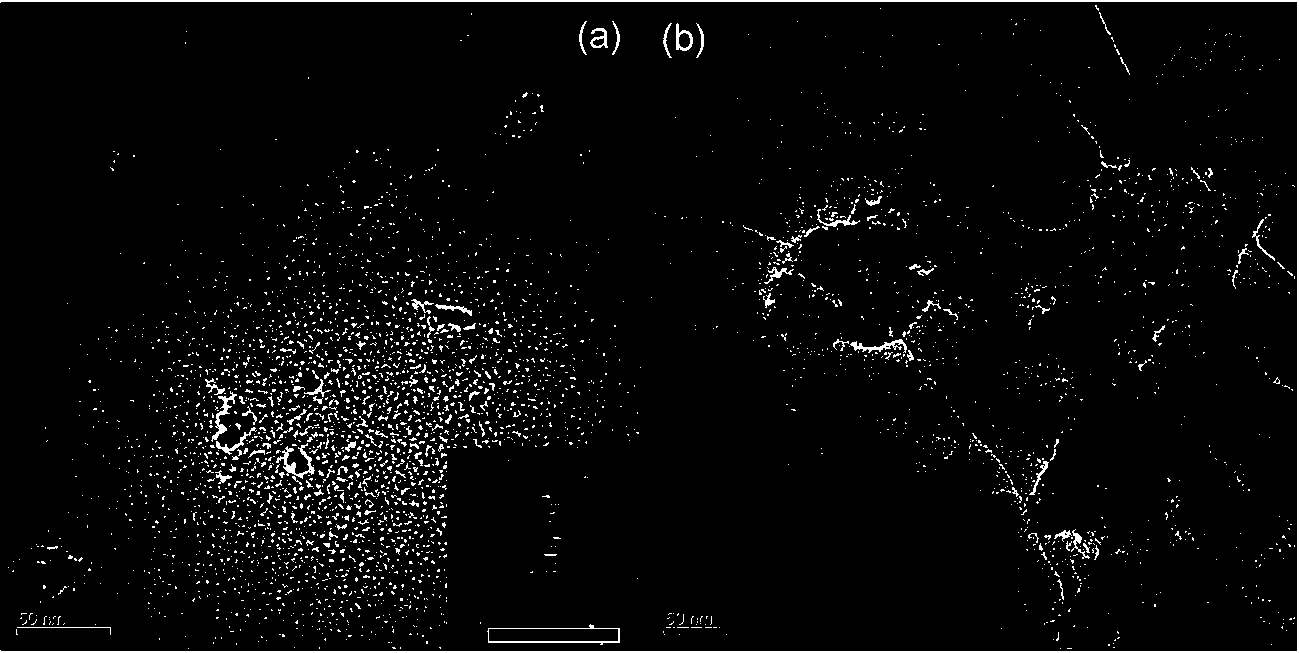

[0027]

Embodiment 3

[0029] Weigh 0.0254g of sodium selenite crystal, add it to the mixed solution of 2ml deionized water, 2g polyethylene glycol and 2ml ethanol, stir to make it fully dissolved, and obtain sodium selenite solution; in addition, weigh 2.5046g glucose powder , so that it was dissolved in 3ml deionized water;

[0030] Add the prepared glucose solution to the prepared sodium selenite solution at 60°C, then add 1ml of MPA, stir and heat to 80°C, and keep it warm for 15 minutes to obtain a brick-red nano-selenium solution. Centrifuge at rpm for 30 minutes to obtain water-soluble and biocompatible nano-selenium powder.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com