Producing device of high-purity selenium and producing process

A kind of production equipment and high-purity selenium technology, applied in the direction of element selenium/tellurium, etc., can solve the problems of small production capacity, slow production process, low recovery rate, etc., achieve high yield and product qualification rate, ensure full utilization, Guaranteed high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

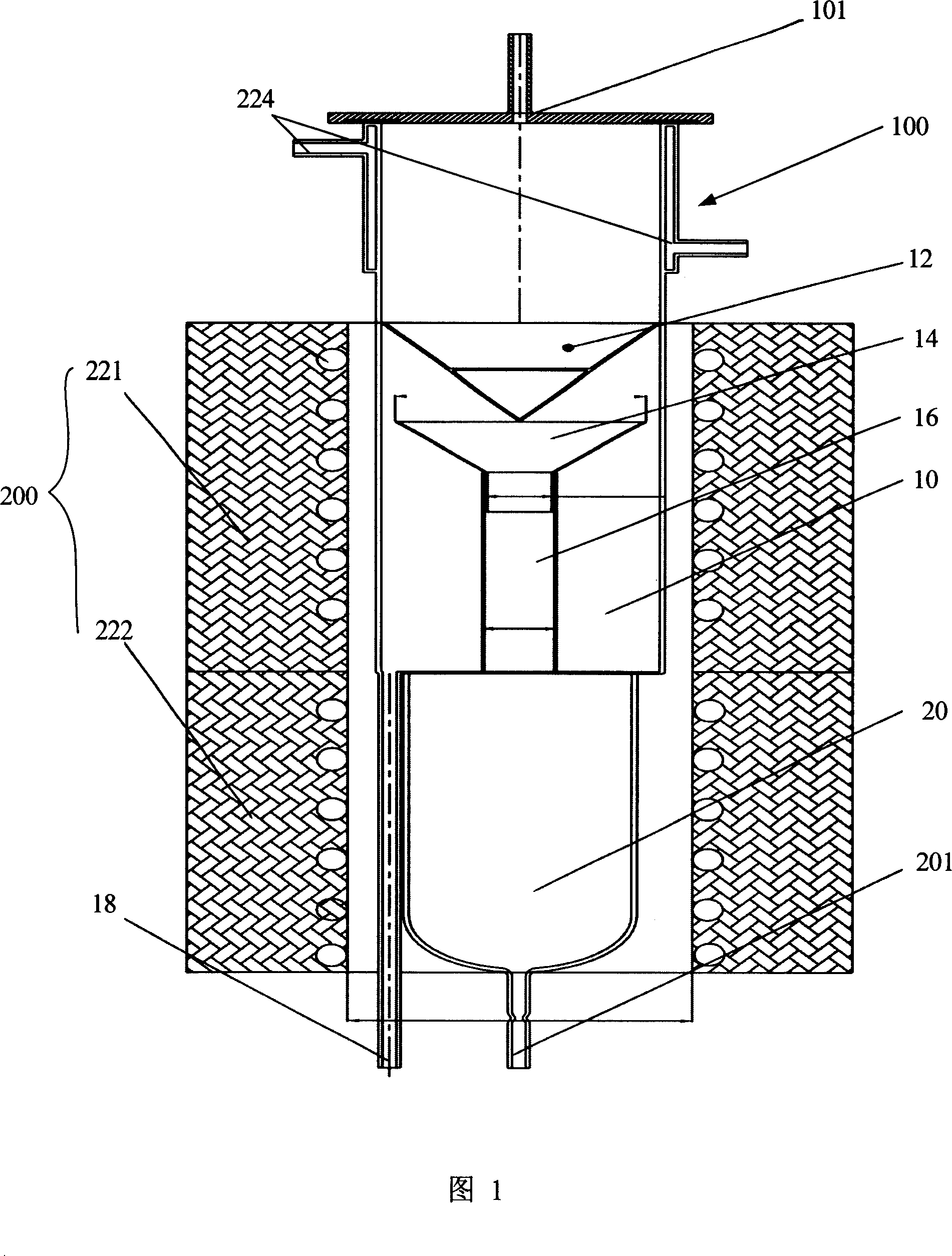

[0037] The present invention provides a kind of high-purity selenium production equipment, as shown in Fig. 1, it comprises rectification equipment 100, temperature control system 200 and vacuum system 300, temperature control system 200 is wrapped outside rectification equipment 100, vacuum system 300 is arranged on the upper layer of the rectification equipment 100, and the temperature in the rectification equipment 100 is kept accurate and constant during the production process through the temperature control system 200.

[0038]The rectification equipment 100 is divided into two stages, the upper layer is used to hold raw materials, and the lower layer is provided with a product kettle 20 for collecting products. Wherein, the upper layer includes a raw material kettle 10 and a built-in condenser 12, a material receiver 14, a connecting pipe 16 and a residual material outlet 18, and the upper opening of the raw material kettle 10 is sealed by a vacuum gland 101 to form a vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com