Macro preparation method for superfine tellurium nanowires

A tellurium nanowire and macro-quantity technology, applied in the field of nanomaterial preparation, can solve the problems of difficulty in ensuring product quality and uniformity, thick tellurium nanowire diameter, low yield of tellurium nanowire, etc., so as to facilitate mass synthesis and achieve uniform quality. , the effect of thin diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a macro-preparation method of ultrafine tellurium nanowires, comprising the following steps:

[0026] A) Sodium tellurite and the reducing agent react under the action of polyvinylpyrrolidone pH regulator to obtain a reaction mixture;

[0027] B) rapidly cooling the reaction mixture with cold water to obtain a tellurium nanowire mother liquor, and extracting with a solvent to obtain a tellurium nanowire.

[0028] In the present invention, the sodium tellurite and the reducing agent react under the action of the polyvinylpyrrolidone pH regulator to obtain a reaction mixture. In the present invention, the surfactant polyvinylpyrrolidone and the tellurium source sodium tellurite are preferably stirred and then dissolved Into the water, quickly add the pH adjuster and the reducing agent, transfer the solution to the reaction kettle, and heat the reaction to obtain the reaction mixture. Wherein, the stirring is preferably mechanical stirring; the wate...

Embodiment 1

[0033] Add 1.0g polyvinylpyrrolidone (PVP) (Shanghai Reagent Company, molecular weight ≈40,000) into the inner lining of a 50mL polytetrafluoroethylene reactor filled with 32mL deionized water, and mix 1.0g sodium tellurite ( Na 2 TeO 3 ) Add the above solution and stir evenly, quickly add 3.35mL ammonia water with a mass percentage of 25% and 1.65mL hydrazine hydrate with a mass percentage of 85%; put the polytetrafluoroethylene reactor into the cylinder liner, place it in an oven and heat The reaction was carried out for 3 hours, and after the reaction was completed, cold water at 4° C. was added and cooled to room temperature within 5 minutes to obtain a mother liquor of tellurium nanowires. After extraction with 50 mL of acetone, put it into a vacuum drying oven and dry overnight to obtain 0.5 g of tellurium nanowire product.

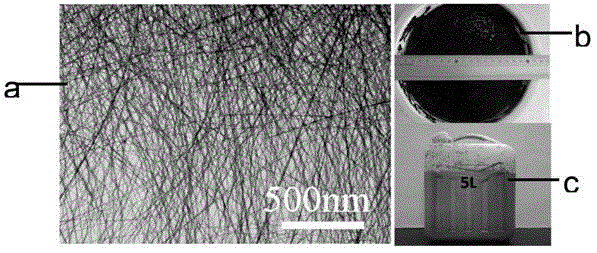

[0034] Observing the tellurium nanowire product prepared in Example 1 of the present invention with a transmission electron microscope, the resul...

Embodiment 2

[0036] Add 2.0g of polyvinylpyrrolidone (PVP) (Shanghai Reagent Company, molecular weight ≈40,000) into the lining of a 100mL polytetrafluoroethylene reactor filled with 64mL of deionized water, and mix 2.0g of sodium tellurite ( Na 2 TeO 3 ) Add the above solution and stir evenly, quickly add 6.70mL of 27% by mass ammonia water and 3.30mL of 86% by mass hydrazine hydrate; put the polytetrafluoroethylene reactor into the cylinder jacket, and react at 183°C for 3 hours, After the reaction, cold water at 4° C. was added and cooled to room temperature within 5 minutes to obtain a mother liquor of tellurium nanowires. After extraction with 100 mL of acetone, put it into a vacuum oven and dry overnight to obtain 1 g of tellurium nanowire product.

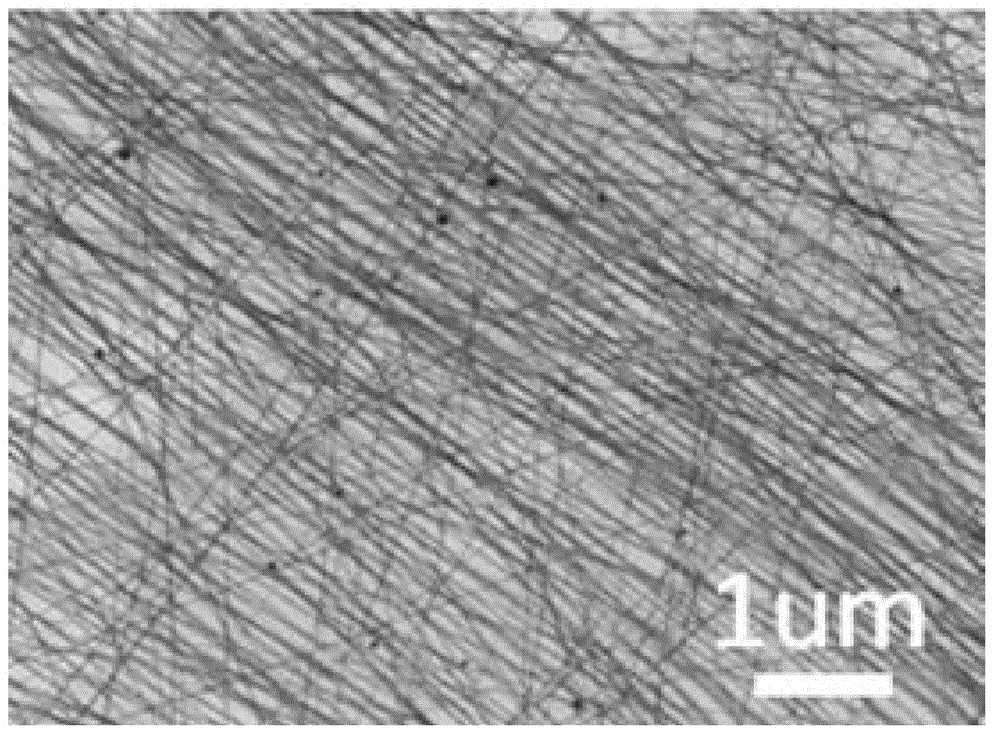

[0037] Observing the tellurium nanowire product prepared by the embodiment of the present invention 2 with a transmission electron microscope, the results are shown in figure 2 , figure 2 The transmission electron micrograph of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com