Patents

Literature

99 results about "Sodium tellurite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium tellurite is an inorganic tellurium compound with formula Na₂TeO₃. It is a water-soluble white solid and a weak reducing agent. Sodium tellurite is an intermediate in the extraction of the element, tellurium; it is a product obtained from anode slimes and is a precursor to tellurium.

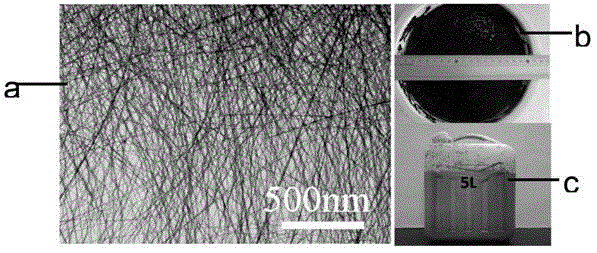

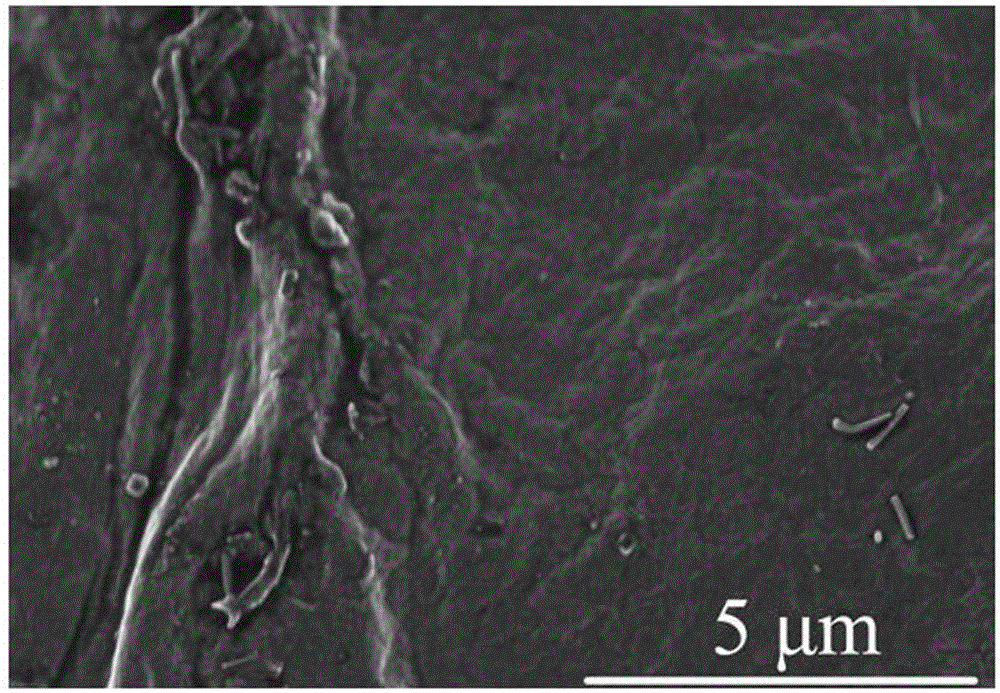

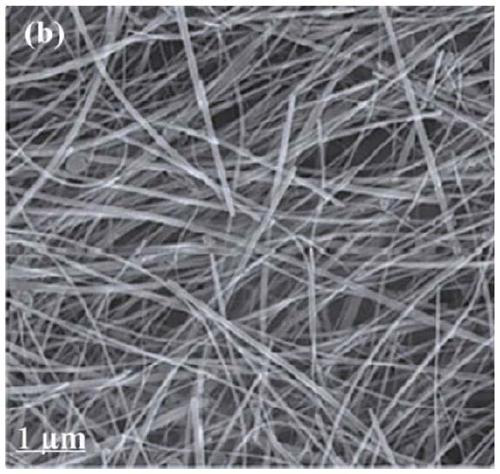

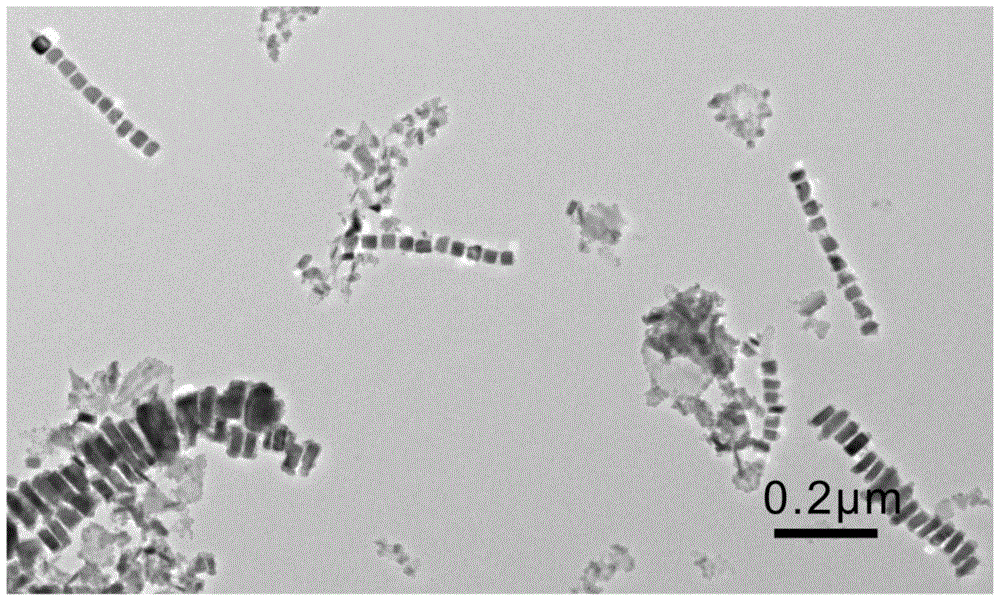

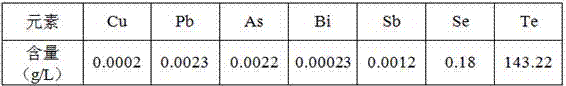

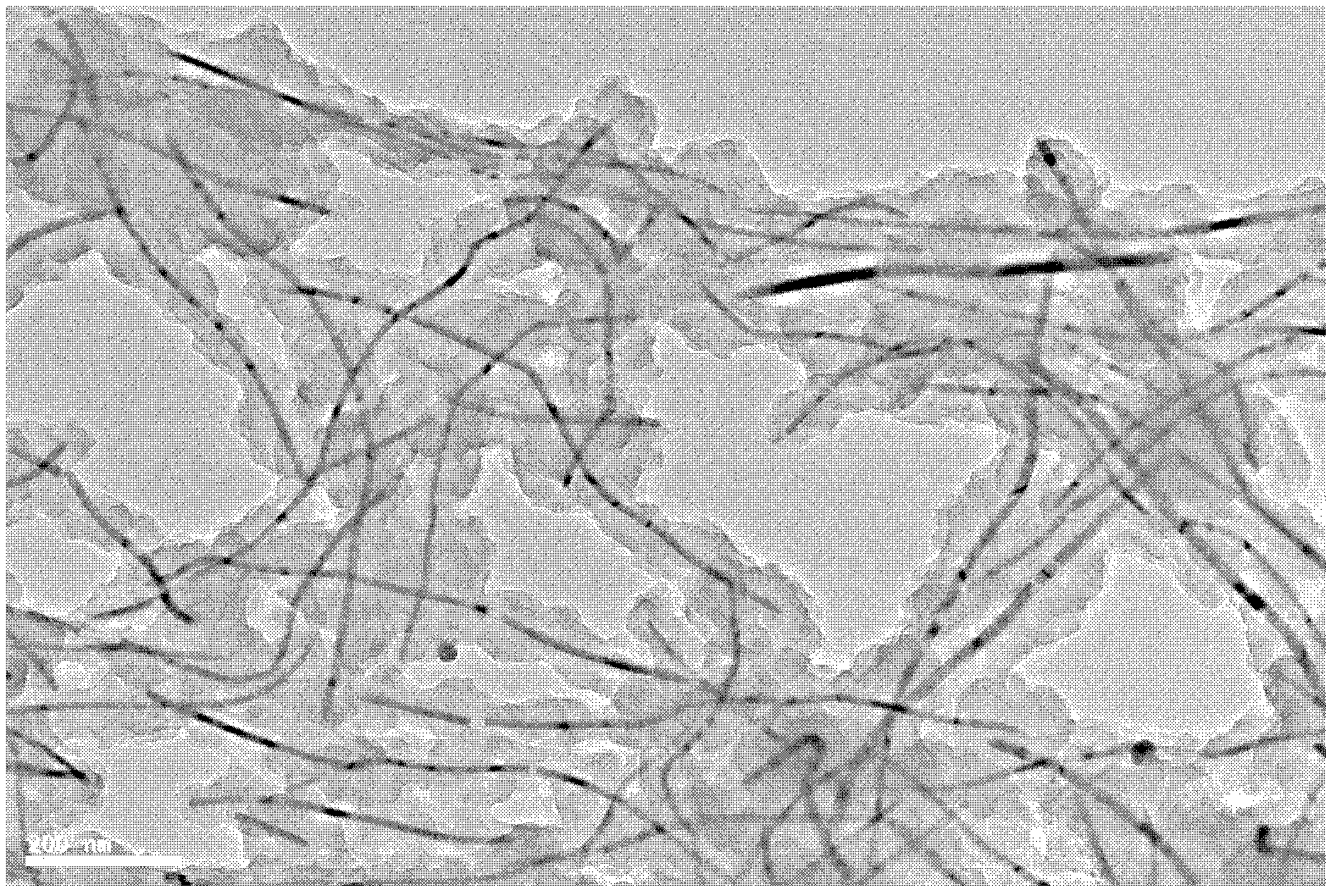

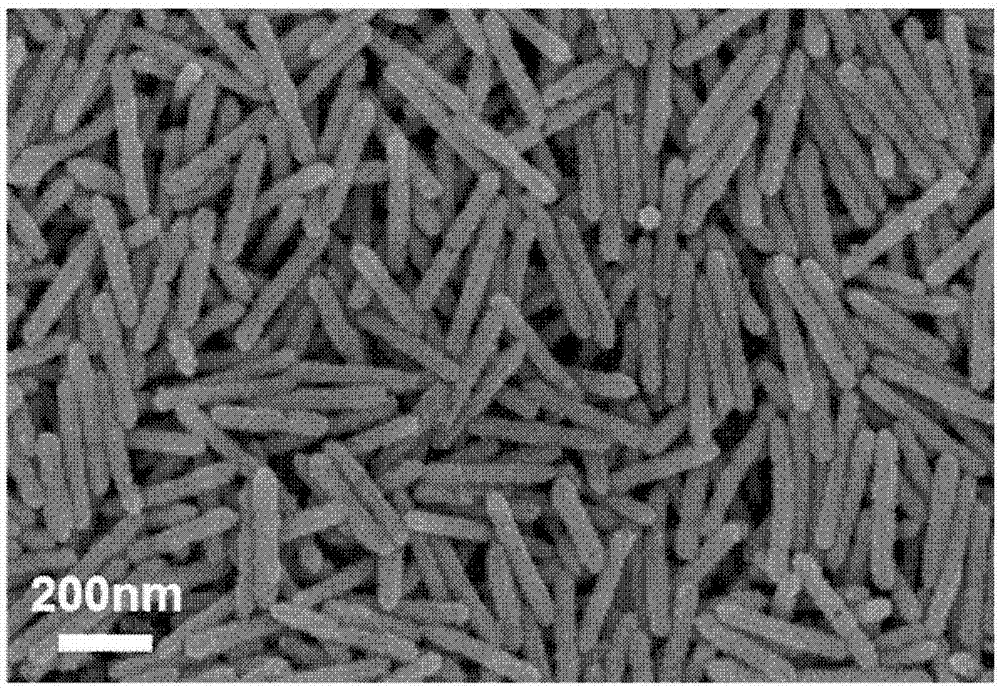

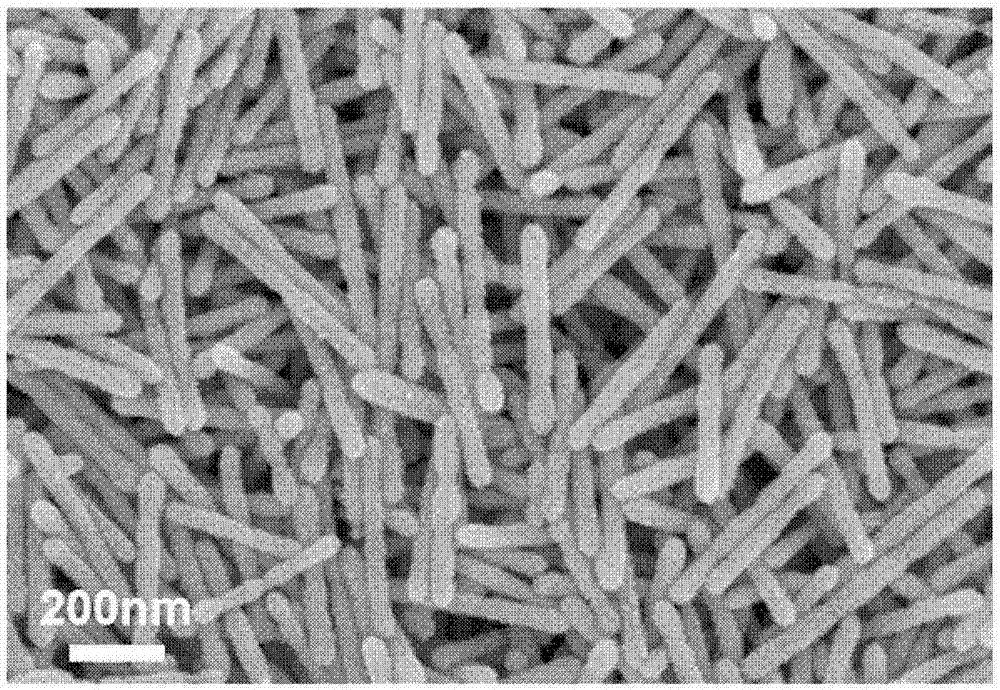

Macro preparation method for superfine tellurium nanowires

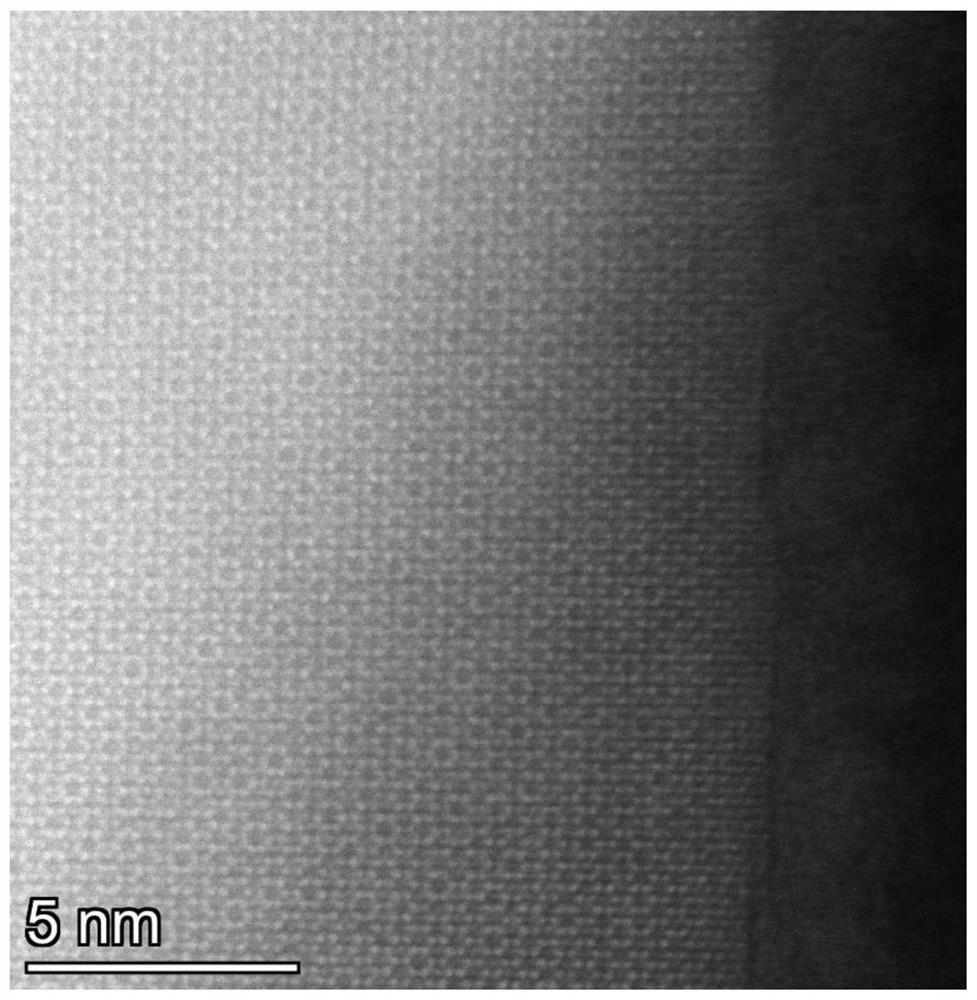

InactiveCN102910595AThin diameterUniform qualityMaterial nanotechnologyElemental selenium/telluriumNanowireTe element

The invention provides a macro preparation method for superfine tellurium nanowires, which comprises the following steps that sodium telluride reacts with a reducer by the action of a polyvinylpyrrolidone pH modifier to obtain a reaction mixture, the reaction mixture is rapidly cooled by cold water to obtain tellurium nanowire mother liquid, and a solvent is added to the tellurium nanowire mother liquid for extraction to obtain the tellurium nanowires. According to the macro preparation method, as the obtained reaction mixture is rapidly cooled by the cold water to prepare the tellurium nanowires, the quality of the tellurium nanowires is more uniform, and the diameters of the tellurium nanowires are smaller. Further, as preparation conditions are optimized, the preparation method facilitates synthesis in large quantity, and is easy to promote and apply.

Owner:UNIV OF SCI & TECH OF CHINA

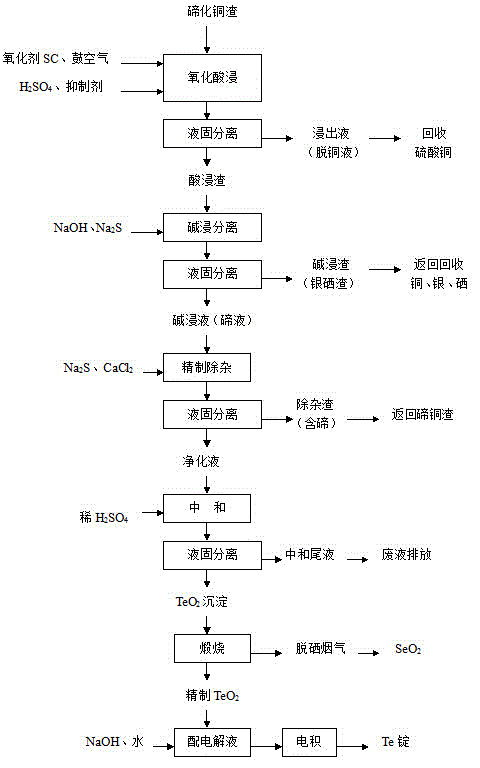

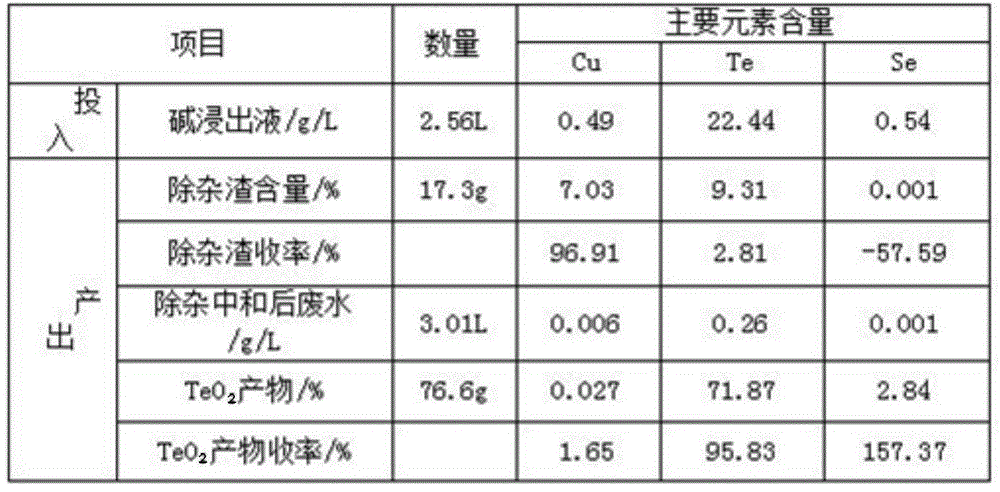

Method for comprehensively recycling silver, selenium, tellurium and copper from telluride copper slag

The invention discloses a method for comprehensively recycling silver, selenium, tellurium and copper from telluride copper slag. The method comprises the following steps of (1), oxidizing acid leaching, wherein the telluride copper slag is added into a sulfuric acid solution containing an oxidizing agent to be heated and stirred so as to be leached, after filtering, copper sulfate leaching liquid and acidic leaching residues are obtained, and the leaching liquid is conveyed to a furnace for copper recycling; and (2) alkali leaching separation, wherein the acidic leaching residues are added into sodium hydroxide solutions to be leached, sodium tellurite solutions and basic leached residues are obtained, the basic leached residues are sent to the KALDO furnace for smelting, so that the silver and the selenium are recycled, and after purification, tellurium deposition, forging and electrolysis of the alkali leaching liquid, refined tellurium is obtained. According to the method, the recycling rate of the silver, the selenium, the tellurium and the copper is high, the silver, the selenium, the tellurium and the copper are not lost, the concentration ratio is high, the silver, the selenium, the tellurium and the copper can be separated from other impurities well, the pollution to the environment is small, the technology is simple, and needed equipment cost is low.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

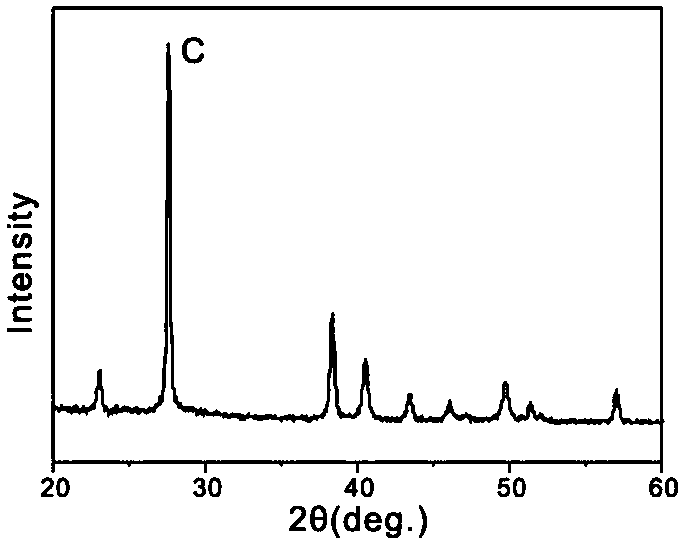

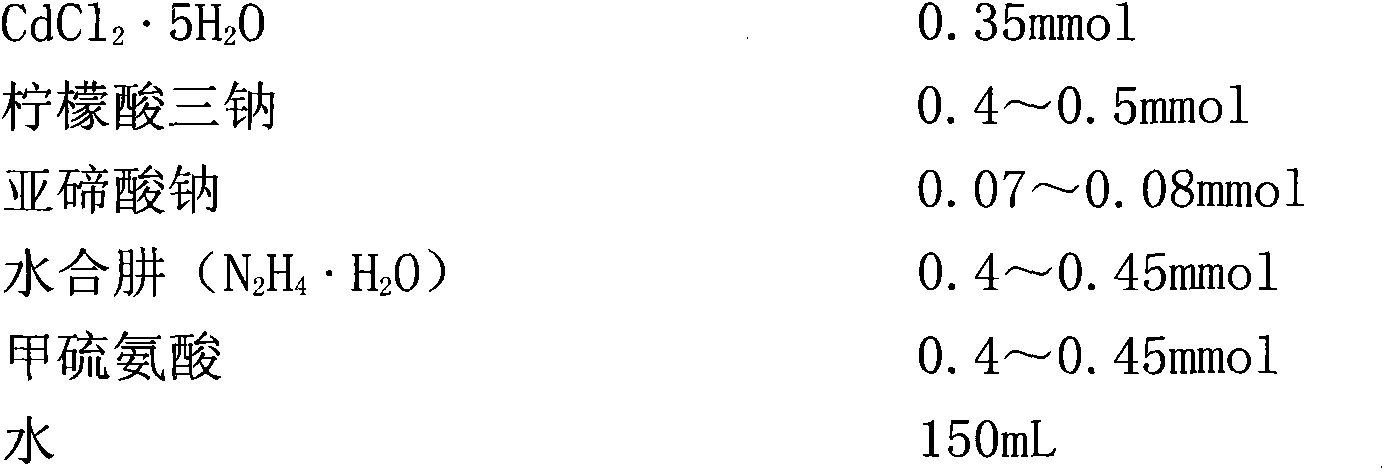

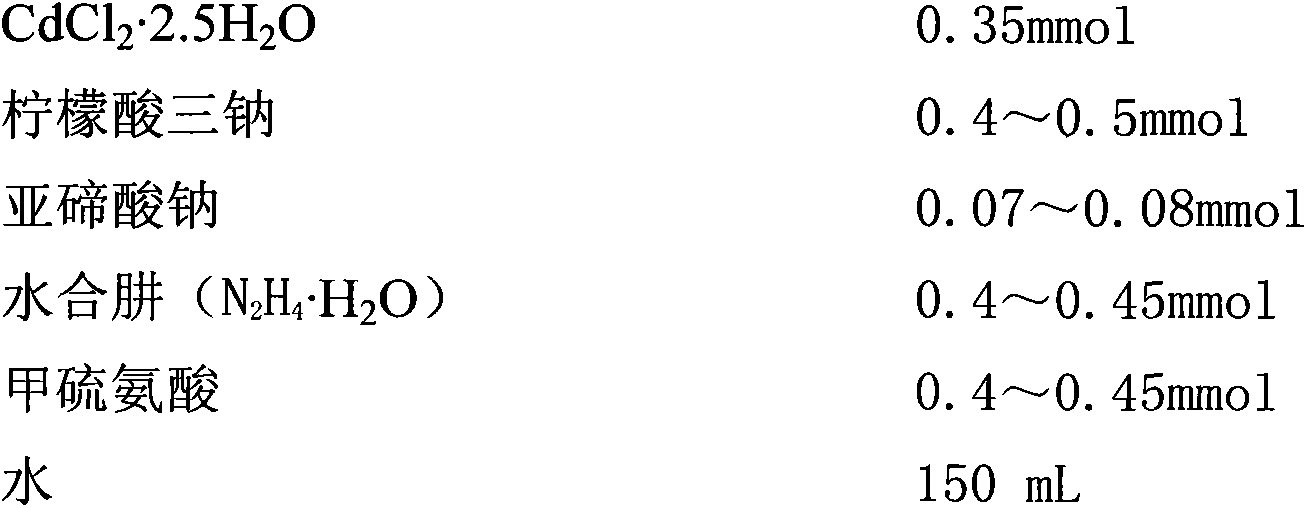

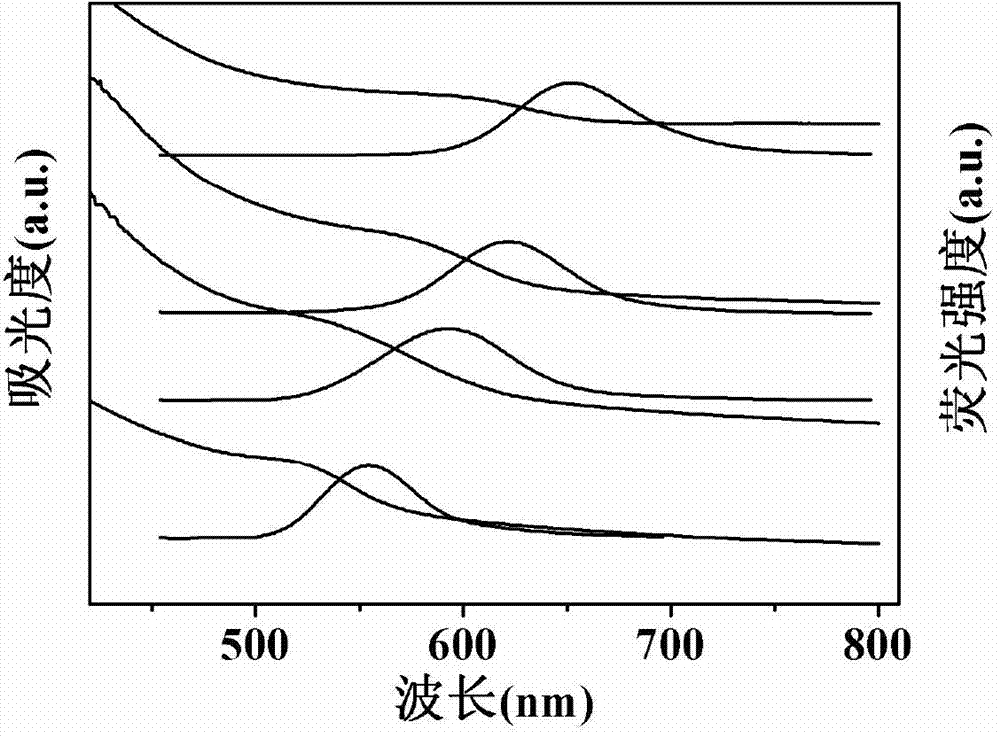

Method for preparing water-soluble CdTe quantum dots

ActiveCN101870459AGood water solubilityImprove stabilityLuminescent compositionsBinary selenium/tellurium compoundsTe elementCadmium Cation

The invention discloses a method for preparing water-soluble cadmium telluride (CdTe) quantum dots, and belongs to the field of nano-technology preparation. In the method, sodium tellurite serves as a tellurium source; cadmium chloride serves as a cadmium source; mercaptopropionic acid serves as a coordination agent; sodium hexametaphosphate serves as an auxiliary stabilizing agent; and the water-soluble CdTe quantum dots are prepared by only one step of reducing the sodium tellurite by using hydrazine hydrate in an aqueous phase system. The method has the characteristics of simple and practical operation, mild condition and low toxicity; and quantum dots with different sizes and emission wavelengths can be obtained by a method for controlling a reaction time.

Owner:SHANDONG UNIV

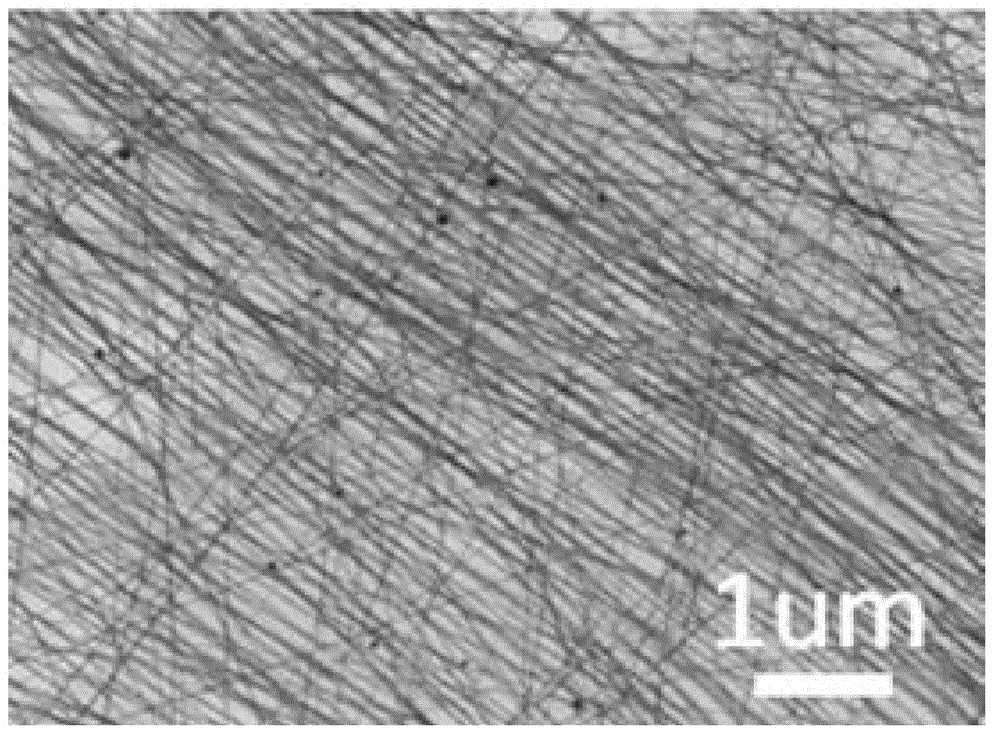

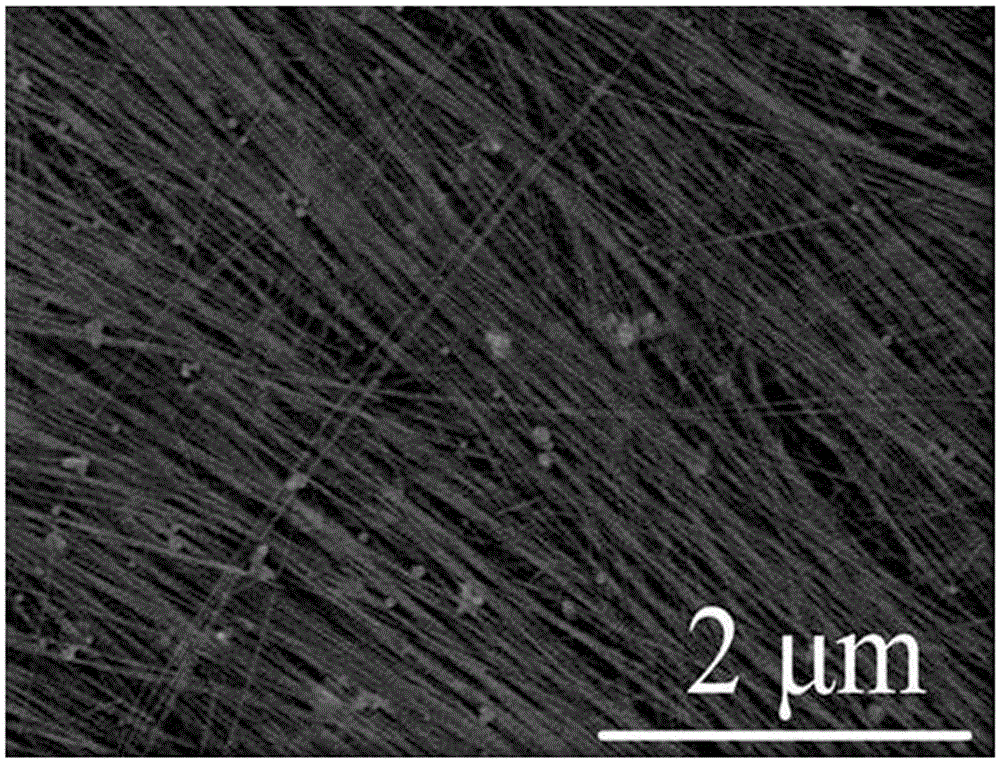

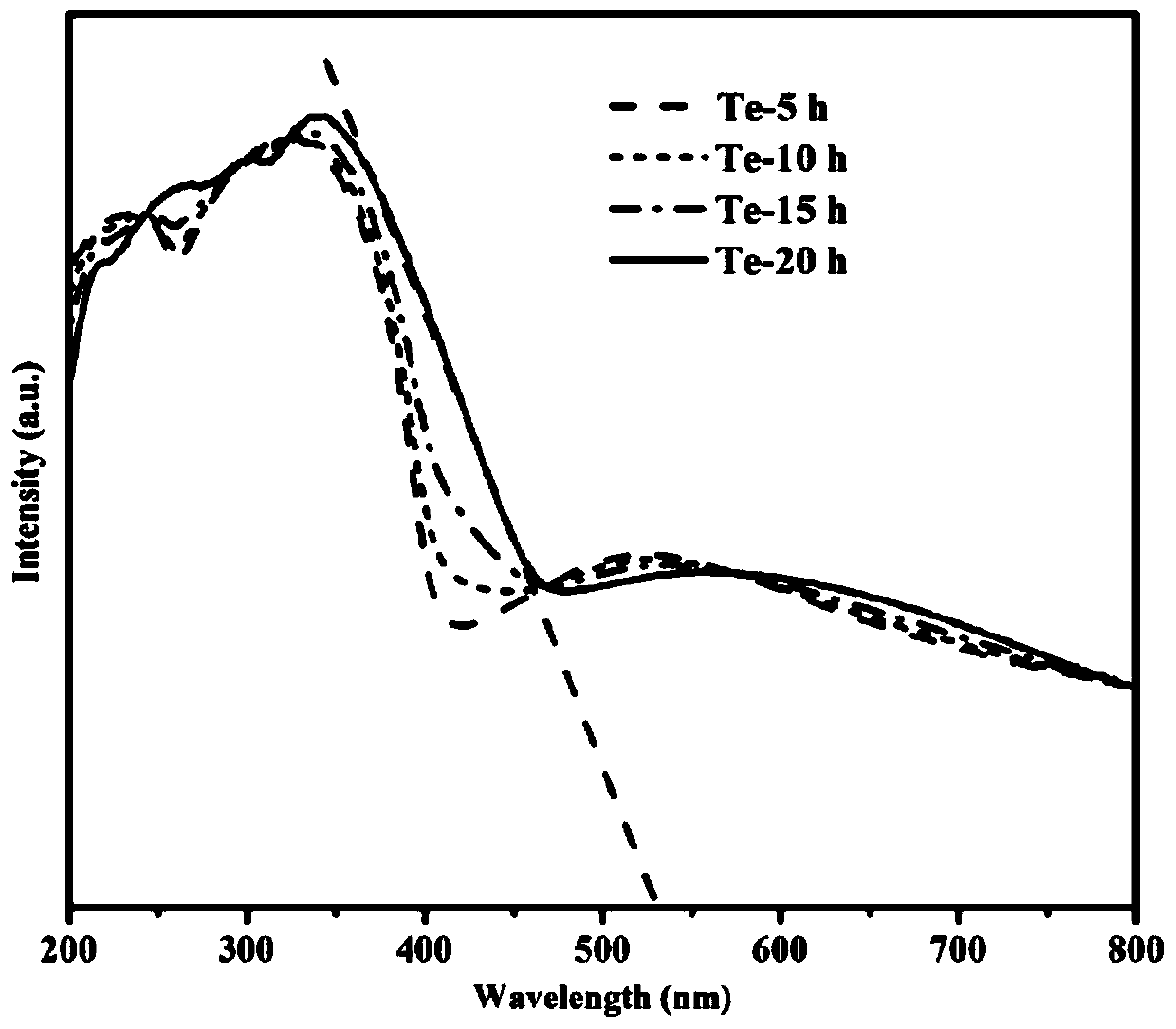

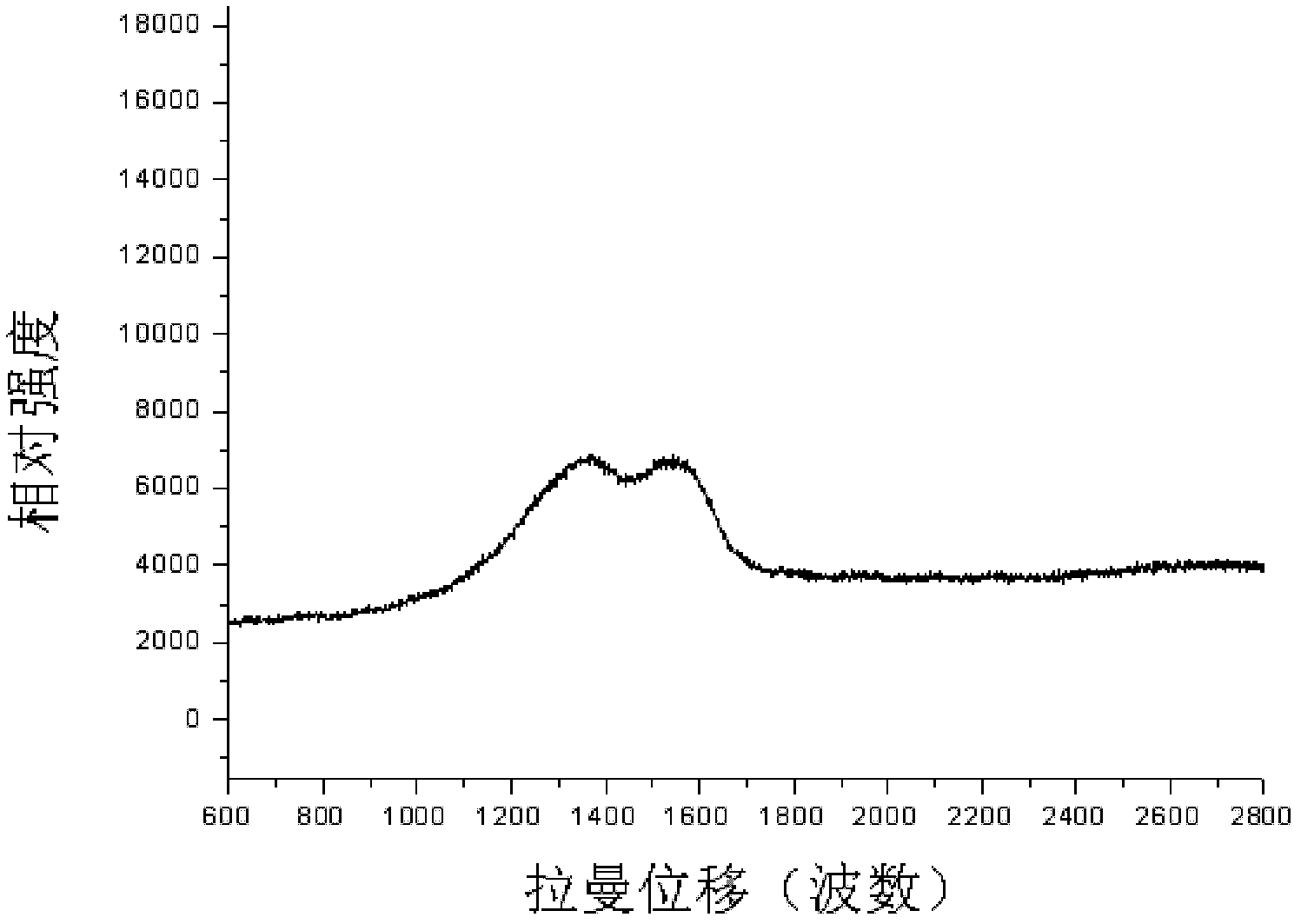

Preparation method for composite thermoelectric film with flexible reduced graphene oxide and tellurium nano wires

InactiveCN105633266AImprove conductivityOptimizing the Seebeck coefficientThermoelectric device manufacture/treatmentComposite filmFiltration

The invention relates to a preparation method for a composite thermoelectric film with flexible reduced graphene oxide (RGO)and tellurium nano wires (Te NWs). The preparation method comprises: reducing preparation is carried out by using oxidized graphene (GO) powder and sodium polystyrene sulfonate (NaPSS) as raw materials according to a hydrothermal method to obtain RGO that can be dispersed in water; reducing preparation is carried out by using sodium tellurite (Na2TeO3) as a raw material and hydrazine hydrate (N2H4.H2O) as a reducing agent according to a hydrothermal method to obtain TeNWs that can be dispersed in watewr; after a certain number of RGO and Na2TeO3 materials are dispersed in water ultrasonically, RGO dispersion liquid and Te NWs dispersion liquid drip on a flexible glass fiber film successively with assistance of vacuum filtration and the glass fiber film is dried in a vacuum environment; annealing is carried out on the glass fiber covered with a composite film at a mixed atmosphere of Ar and H2 under the temperature of 200 DEG C for some time to obtain a composite thermoelectric film with the RGO and Te NWs. The provided preparation method has characteristics of simple and easily controlled process, short reaction time, low energy consumption, high security, good pollution-free performance, and excellent flexible film thermoelectric property and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

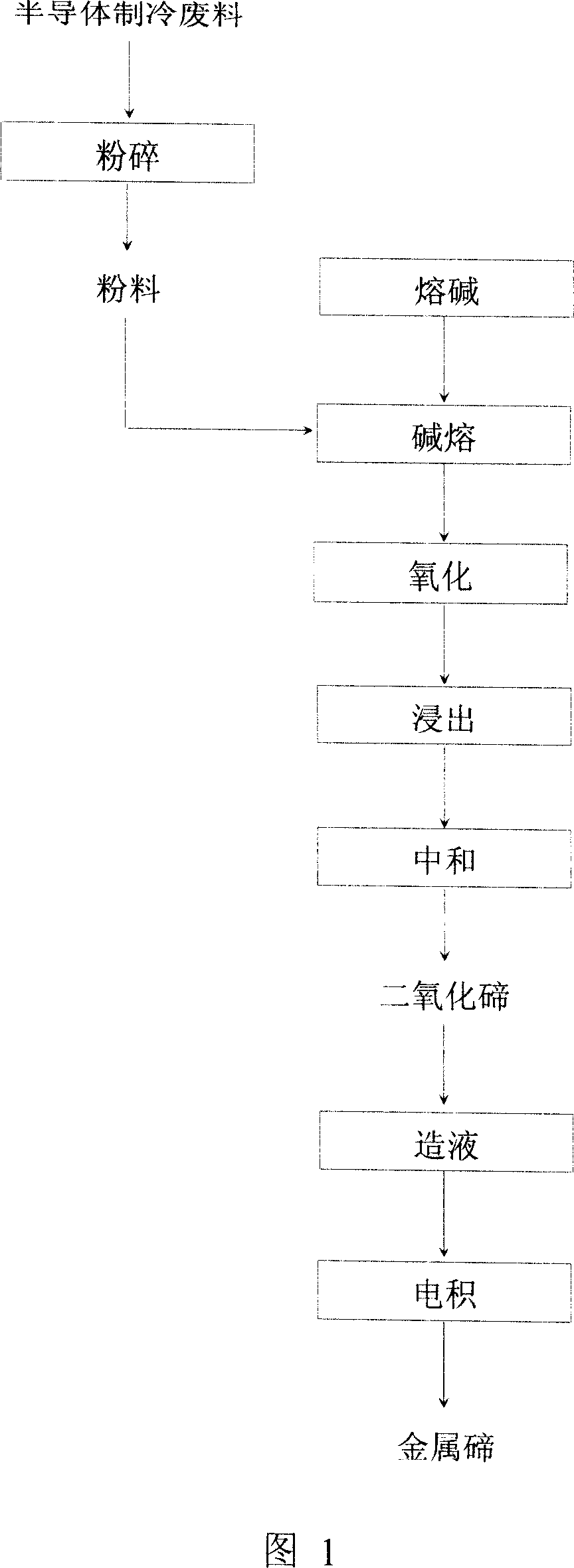

Method for recovering tellurium from bismuth telluride base semiconductor refrigeration material

InactiveCN1994869AImprove applicabilityReduce loadSelenium/tellurium compundsBismuth tellurideTe element

The invention discloses a recycling method of tellurium in the refrigeration material of bismuth telluride based semiconductor, which comprises the following steps: adding broken and grinded material into fused alkali metal hydroxide or compound of other alkali metal carbonate; proceeding alkali fusing at 640-720 deg. c; adding oxidant; leaching molten substance through water once or twice; neutralizing the leached solution through acid until the pH value is 5-6; obtaining tellurium dioxide; dissolving tellurium dioxide through alkali; obtaining sodium tellurate solution; electrodepositing to obtain the metal tellurium.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

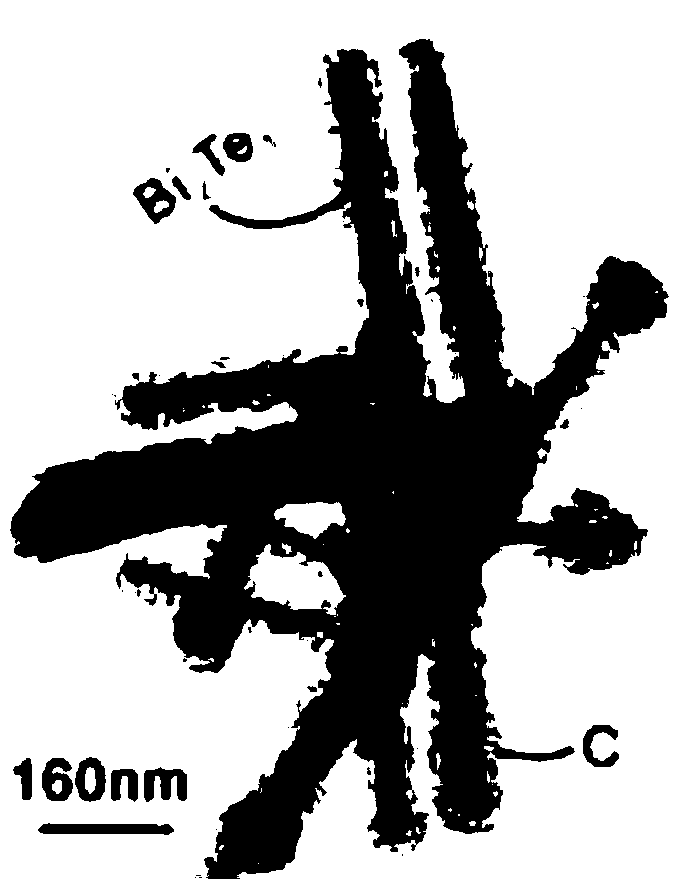

Bismuth base hydrogen storage material and preparation method thereof

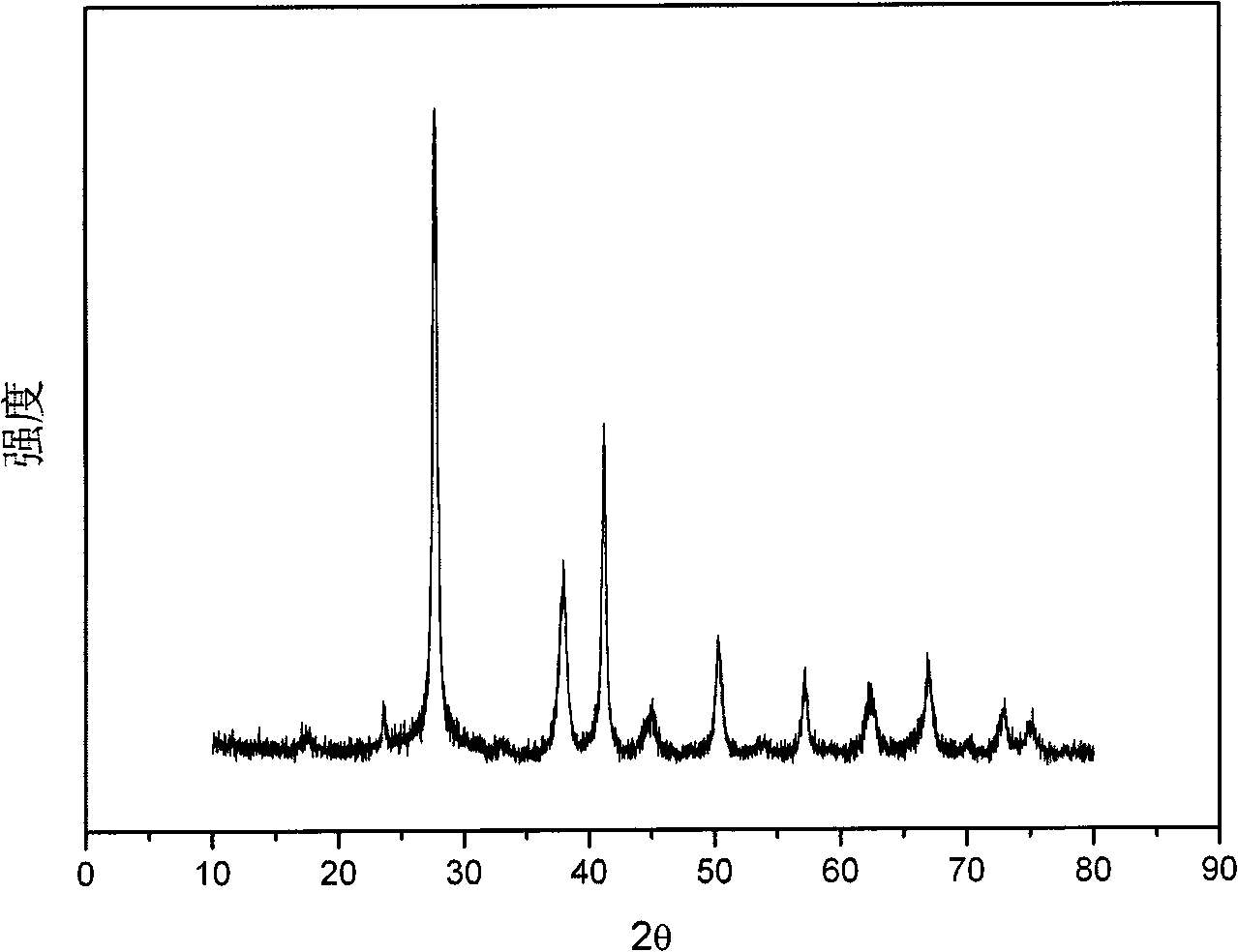

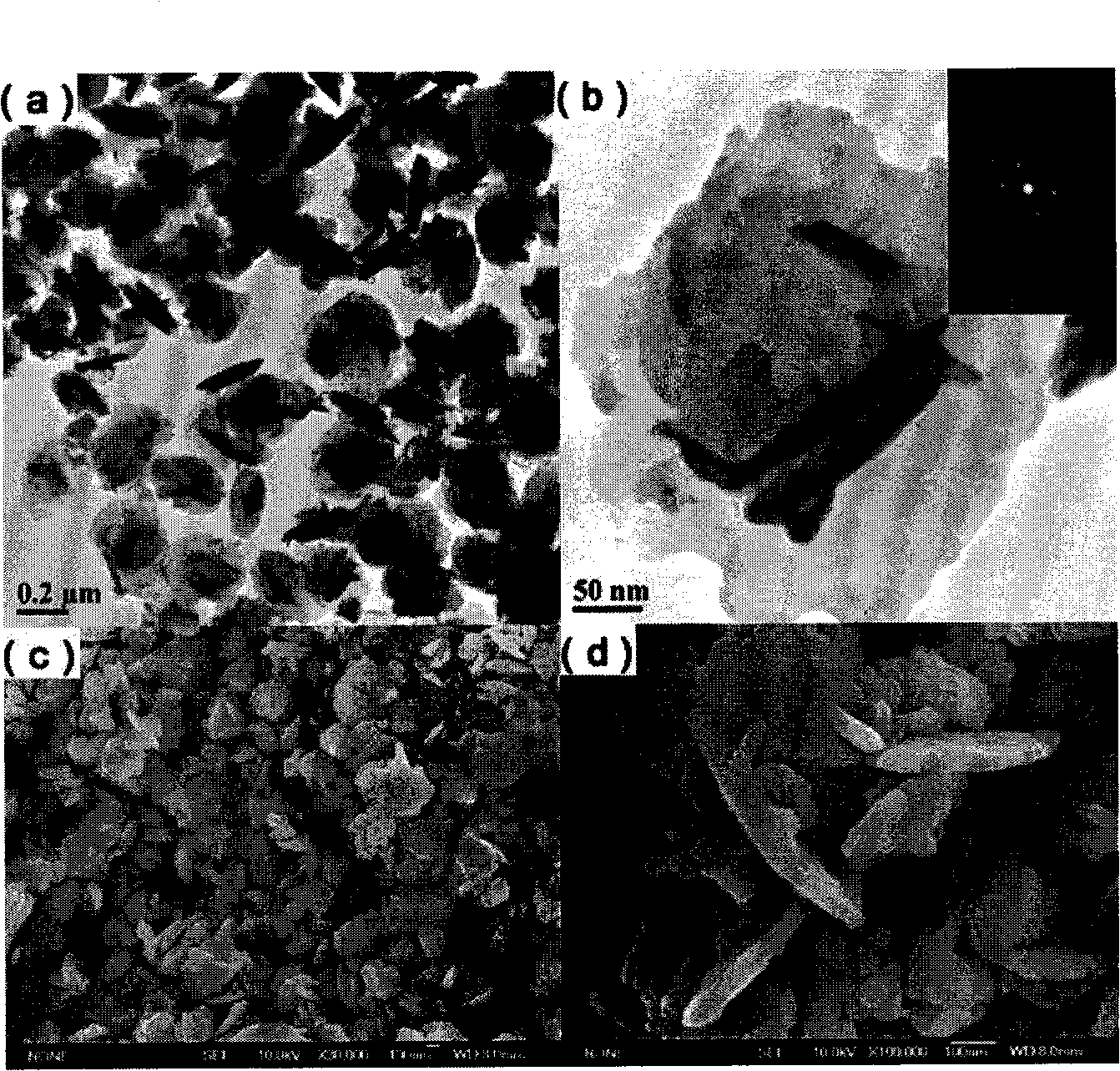

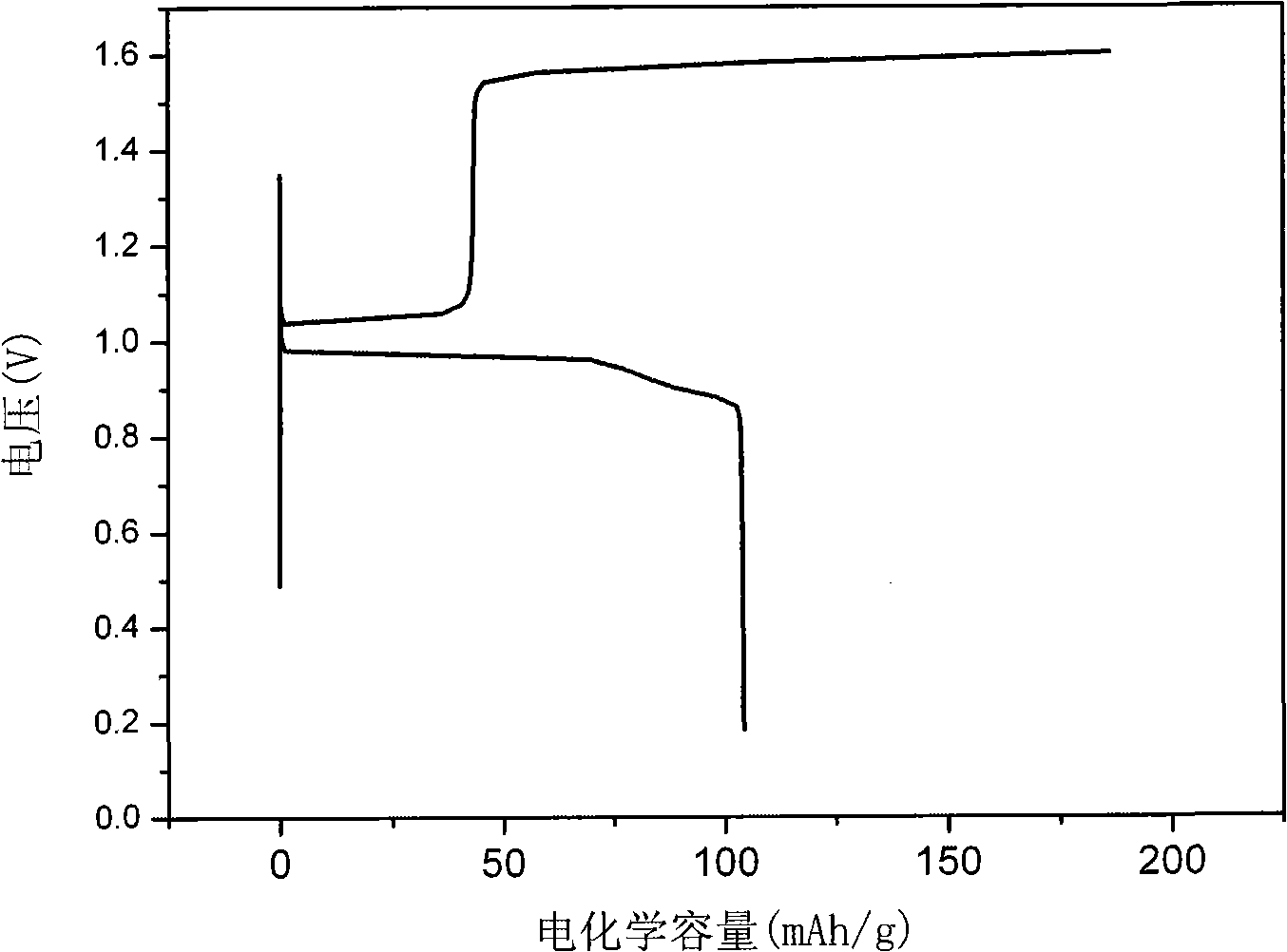

ActiveCN101513994AUniform sizeSingle formCell electrodesBinary selenium/tellurium compoundsTe elementSolvent

The invention relates to a bismuth base (bismuth selenide, bismuth telluride) hydrogen storage material and a preparation method thereof, relating to low temperature liquid phase synthesis of bismuth base material and the application thereof on hydrogen storage, lithium storage and electrode material. The invention is characterized in that water is taken as solvent, bismuth salts such as bismuth nitrate, bismuth chloride and the like as a bismuth source, and water-soluble tellurium (selenium) acid salts (such as sodium tellurite, selenium substituted sodium sulfate, sodium selenite) or tellurium (selenium) acids (such as orthotelluric acid, tellurous acid and selenous acid) as a tellurium source (selenium) source; proper coordination agents (such as nitrilotriacetic acid, hexamethylene diamine tetraacethyl and the like) and reducing agents (such as vitamin C, sodium borohydride and the like) are added for liquid phase reaction synthesis at the low temperature of 60-80 DEG C. The bismuth selenide crystal grains prepared by the invention take on flower shapes with the sphere diameter of 1-6mum, and the bismuth telluride crystal grains take on sheet shapes with nanometer diameter; the hydrogen storage performance reaches over 100mAh.g. The method has the advantages of cheap raw material, simple technique, convenient operation, easy mass production, etc.

Owner:中国科学院上海硅酸盐研究所苏州研究院

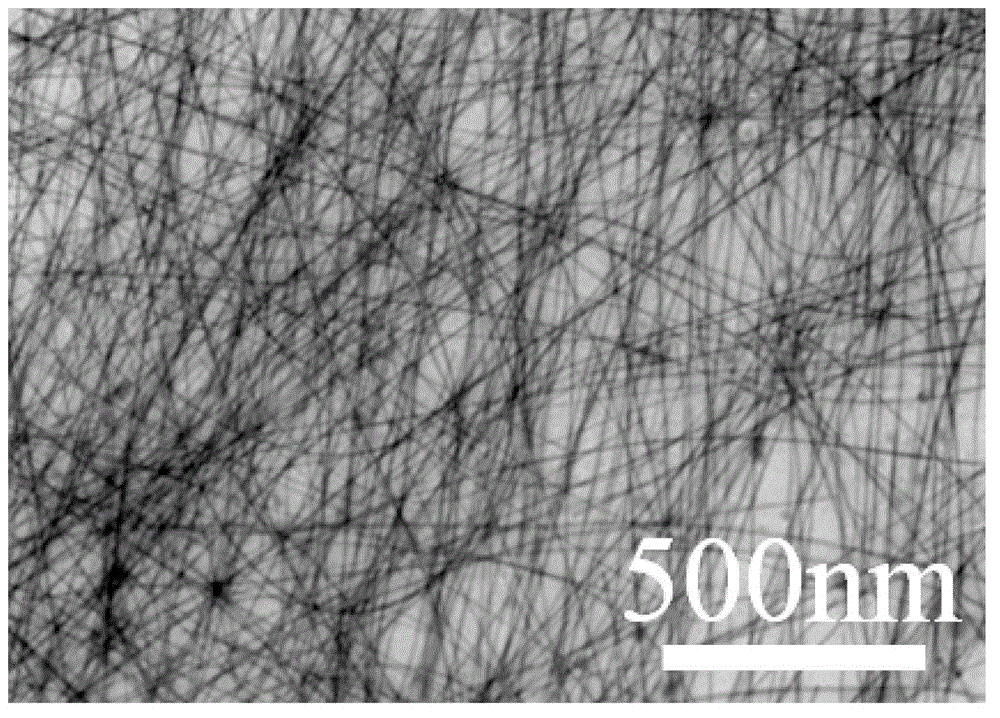

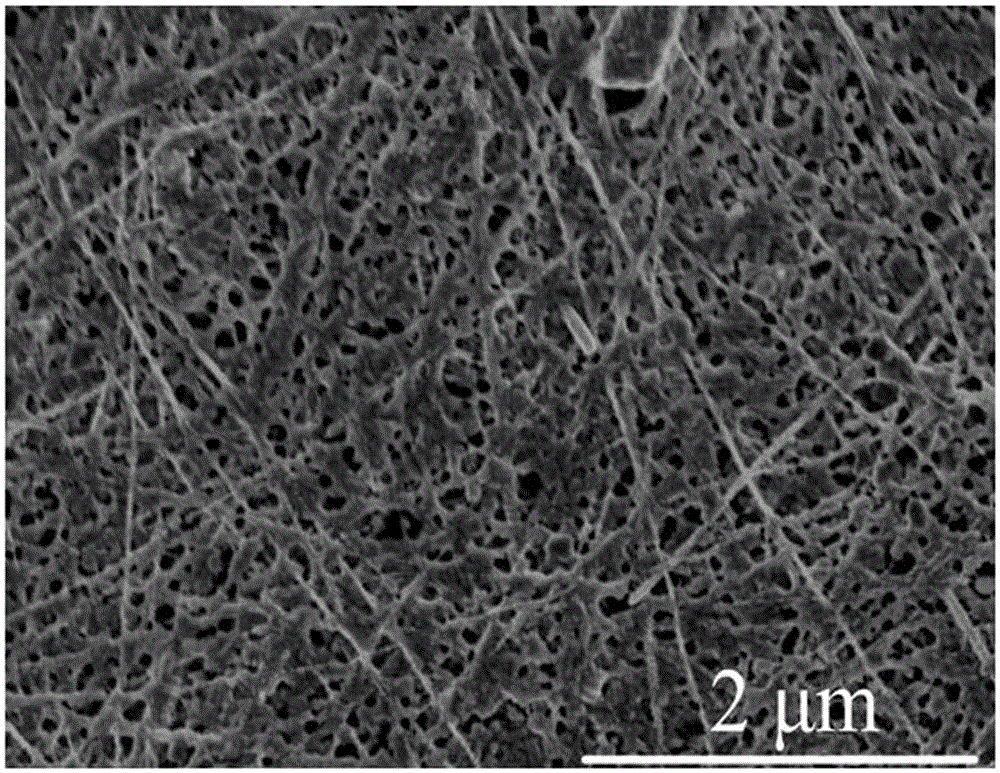

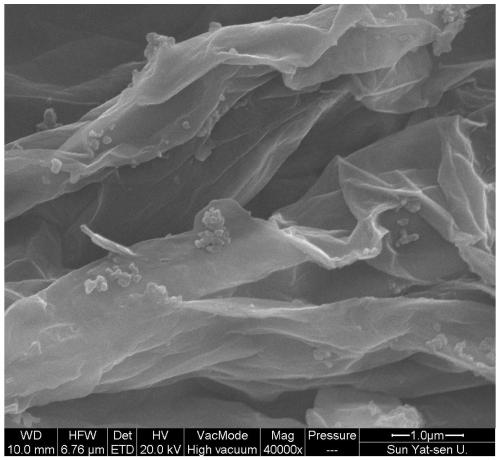

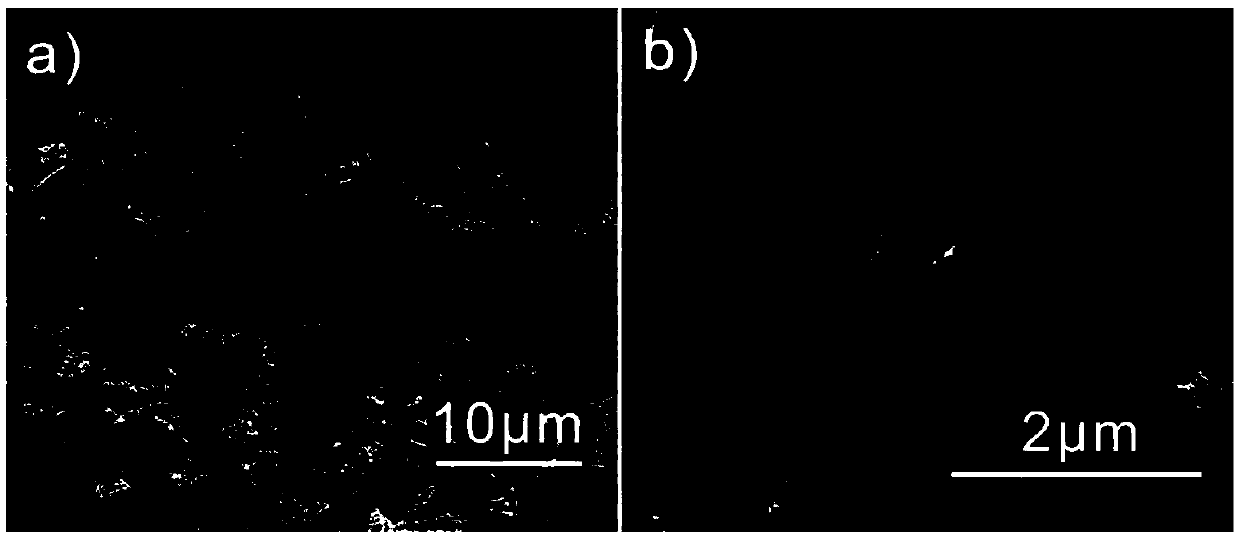

Semi-metal material Te nanowire/graphene hydrogel composite material as well as preparation method and application thereof

ActiveCN110449169AEasy to operateHas photocatalytic bactericidal propertiesBiocidePhysical/chemical process catalystsNanowireTellurate

The invention discloses a semi-metal material, namely a Te nanowire / graphene hydrogel composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: adding ammonium hydroxide and a reducing agent, namely a hydrazine hydrate solution, into a water solution of sodium tellurate and polyvinylpyrrolidone, performing uniform mixing, performing a hydrothermal synthesis reaction, performing cooling to room temperature, separating a reaction product so as to obtain precipitate, washing the precipitate to be neutral, performing drying and grinding so as to obtain Te nanowires, adding a graphene oxide suspension, performing uniform mixing, performing a hydrothermal synthesis reaction, removing excessive graphene oxide and Te nanowireswhich are not tightly compounded, and performing freeze drying, so as to obtain the composite material. The Te nanowire / graphene hydrogel composite material disclosed by the invention is simple in preparation method, has photocatalysis sterilization and photo-thermal conversion performance, thermocatalytic sterilization can be promoted through a photo-thermal synergetic function, the inactivationratio is 70-100%, no chemical reagent is additionally used, and the problem of secondary pollution of a byproduct of a conventional sterilization technique can be effectively solved.

Owner:SUN YAT SEN UNIV

Method for microwave-assisted preparation of CdTeSeS/ZnTe core-shell quantum dot in water

InactiveCN104974742ARich sourcesLower synthesis costLuminescent compositionsQuantum yieldPotassium borohydride

The invention relates to a method for microwave-assisted preparation of a CdTeSeS / ZnTe core-shell quantum dot in water. The method comprises the following steps: 1) preparing a sodium elenosulfate solution; 2) preparing a cadmium chloride solution; 3) adding mercaptopropionic acid into the cadmium chloride solution; 4) adjusting the pH value of the solution; 5) dissolving a sodium tellurite crystal in the solution and simultaneously adding potassium borohydride and the sodium elenosulfate solution; 6) subjecting a mixture obtained in the step 6) to heating reaction in a microwave digestion furnace; 7) carrying out cooling to room temperature and adding isopropanol for purification so as to obtain CdTeSeS quantum dot gel; and 8) preparing a mixed solution of the cadmium chloride solution, the mercaptopropionic acid and the sodium tellurite crystal, dissolving the CdTeSeS quantum dot gel in the mixed solution anew, adding potassium borohydride and successively carrying out heating reaction in the microwave digestion furnace, cooling to room temperature, addition of isopropanol for purification and drying with a lyophilizer so as to obtain solid powder of the CdTeSeS / ZnTe core-shell quantum dot. The method is fast and simple and has easily controllable technological parameters and a low price; and the synthesized quantum dot has uniform particle size distribution, high stability, high fluorescence quantum yield and wide emission spectrum.

Owner:天门市天宝化工科技有限公司

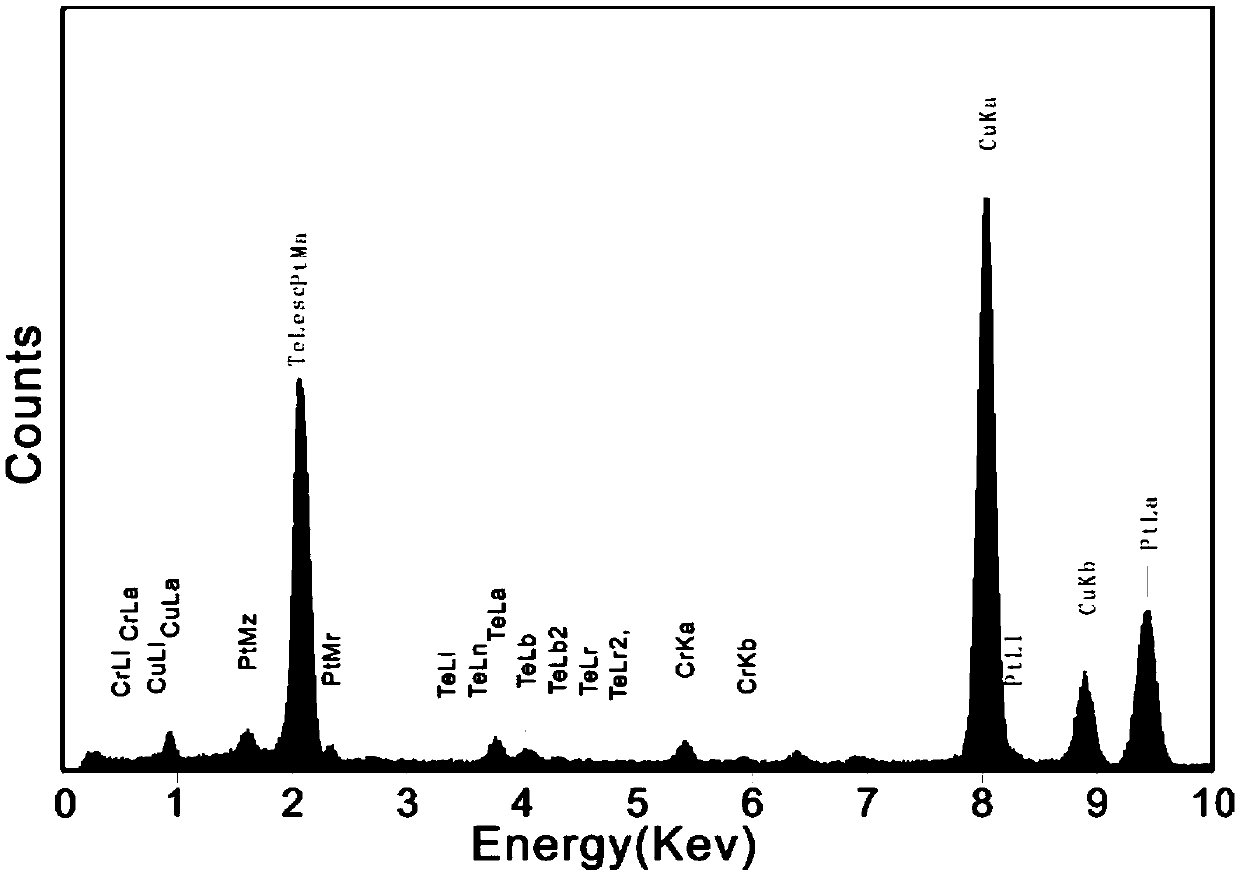

Hollow spindle-shaped nanometer telluride platinum and preparation method thereof

InactiveCN105502312ASimple post-processingImprove uniformityMetal selenides/telluridesBinary selenium/tellurium compoundsFuel cellsDissolution

The invention discloses a preparation method of hollow spindle-shaped nanometer telluride platinum. The method includes the following steps of adding sodium tellurite and polyvinylpyrrolidone to deionized water to be dissolved, and sequentially adding hydrazine hydrate and ammonium hydroxide to be evenly stirred to obtain a material a; conducting the hydrothermal reaction on the material a, conducting filtering to obtain a first filter cake, and conducting centrifugal cleaning on the first filter cake to obtain a material b; adding the material b to deionized water, conducting ultrasonic dissolution, adding chloroplatinic acid for oscillation, conducting filtering to obtain a second filter cake, conducting centrifugal cleaning on the second filter cake, and conducting drying to obtain the hollow spindle-shaped nanometer telluride platinum. The preparation process is simple, production cost is low, the preparation process is easy to control, sample postprocessing is simple, the hollow spindle-shaped nanometer telluride platinum is quite suitable for industrial production, the obtained hollow spindle-shaped nanometer telluride platinum has the advantages of being regular in shape and appearance, high in uniformity and the like, and a novel nanometer material is provided for biological sensors, electrochemical sensors, fuel batteries and the like.

Owner:HEFEI NORMAL UNIV

Method for extracting high-purity tellurium oxides from copper anode mud

ActiveCN102502532AEasy to separateHigh purityBinary selenium/tellurium compoundsFiltrationSodium hydroxide

The invention discloses a method for extracting high-purity tellurium oxides from copper anode mud. The method comprises the steps as follows: firstly, sulfuric acid is added in the copper anode mud at first, sodium chlorate is then added in the copper anode mud, the mixture is heated, silver and lead are precipitated in residues and are separated out, and gold, copper, bismuth, tellurium and selenium enter leach liquor; secondly, common salt is added in leach liquor that is processed in the first step, the mixture is mixed and resolved, then gaseous SO2 is pumped in mixed liquor for 1 hour, and gold, tellurium and selenium are reduced and deposited and then are processed through pressure filtration; thirdly, in step A, sulfuric acid is added in deposited residues of the gold, tellurium and selenium, then catalytic agents are added in the mixture, then sodium chlorate is added in the mixture until the color of the deposited residues is transformed into the color of tellurium oxides, and pressure filtration is carried out; in step B, sodium hydroxide is added in the deposited residues that are processed in the step A, the mixture is processed through pressure filtration, and then sodium tellurite and sodium selenite solution are obtained; and fourthly, sulfuric acid is added in sodium tellurite and sodium selenite solution which are obtained in the third step, sodium selenite remains in liquid, and tellurium dioxide is precipitated and separated out.

Owner:湖南省金润碲业有限公司

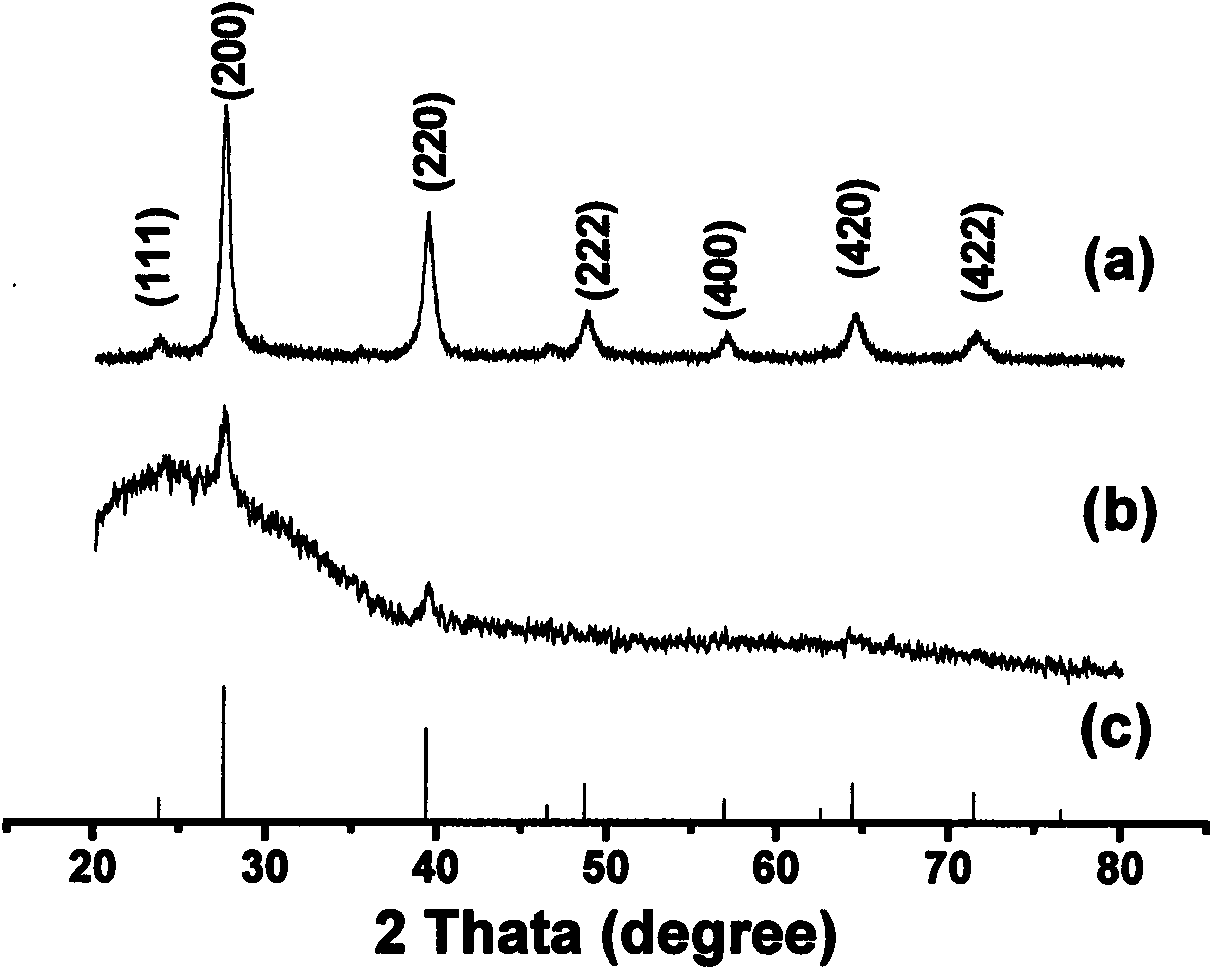

Synchronic preparation method of lead telluride thin film and nano powder

InactiveCN101602496ARaw materials are cheap and easy to getSimple processPolycrystalline material growthSingle crystal growth detailsPotassium borohydrideFluorescence

The invention belongs to the lead telluride (PbTe) thin film and nano powder preparation method field. In a low temperature aqueous solution synchronic synthesis method of PbTe thin film and nano powder, inorganic salt containing lead and tellurium dioxide or sodium tellurite are taken as raw materials, potassium borohydride or sodium borohydride is taken as reducing agent, and PbTe thin film and nano powder are simultaneously synthesized in alkaline aqueous solution at room temperature to 50 DEG C. The invention initially synthesizes PbTe thin film and nano powder at normal atmosphere and below 100 DEG C, the prepared thin film is flat, compact and uniform; and powder product is small in grain diameter uniform in grain fineness distribution, and grain diameter size can be controlled by controlling reaction temperature. The raw materials used in the whole technology are available, the technology is simple, scale production is easy to realize, and organic solvent is not used in the reaction process, thus being beneficial to environmental protection. The synthesized PbTe thin film and nano powder can be widely applied to thermoelectric device, solar battery, fluorescence device, infrared optical element, infrared thin film device, semiconductor detector and the like and has a wide application prospect.

Owner:TONGJI UNIV

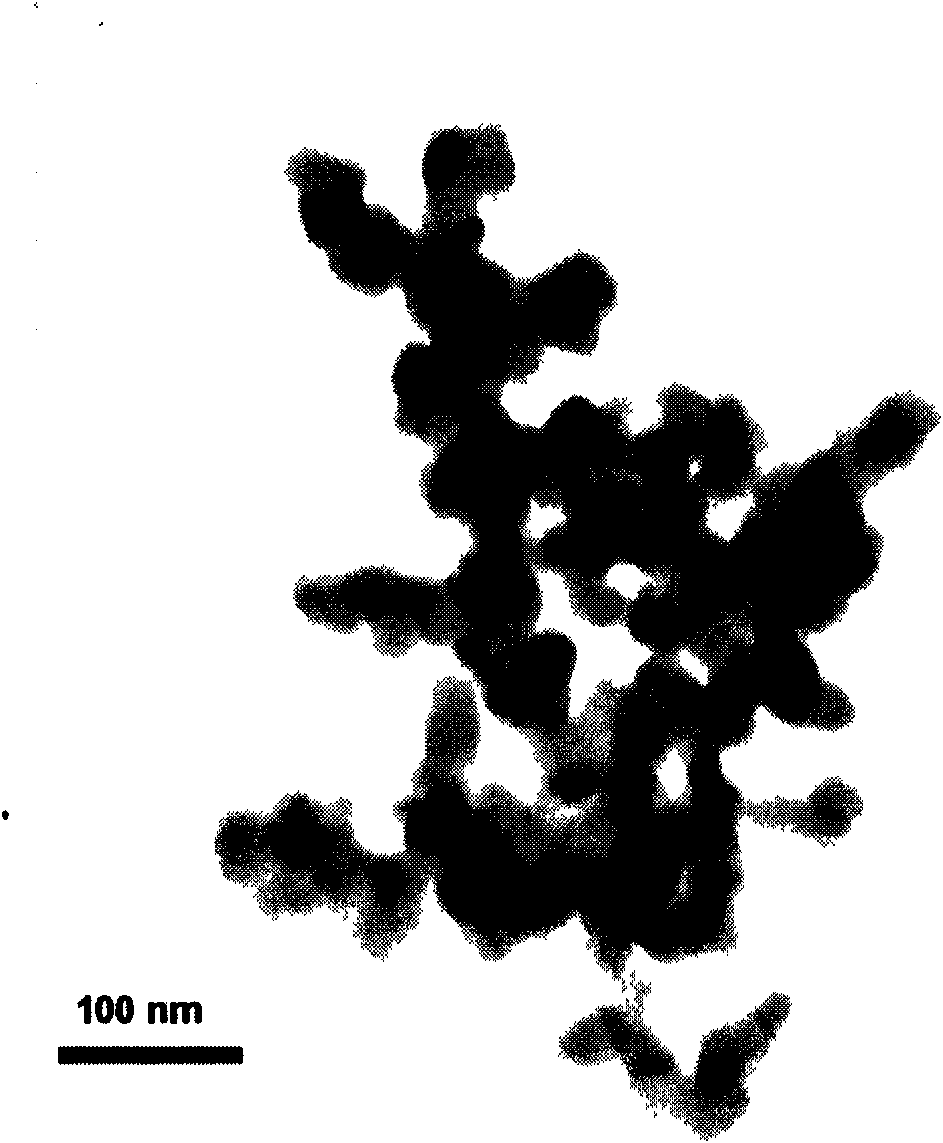

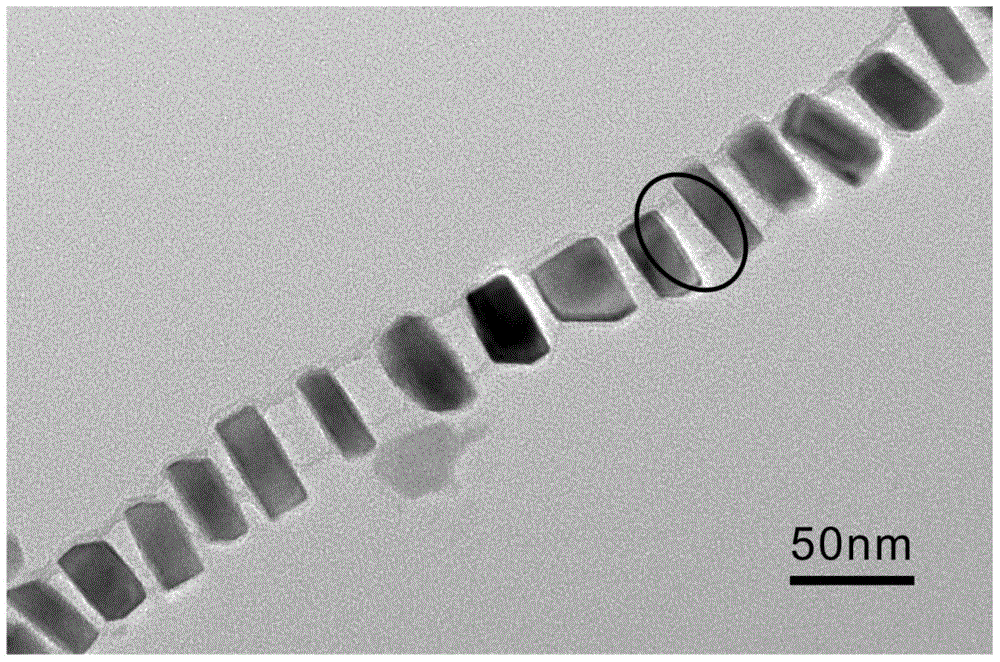

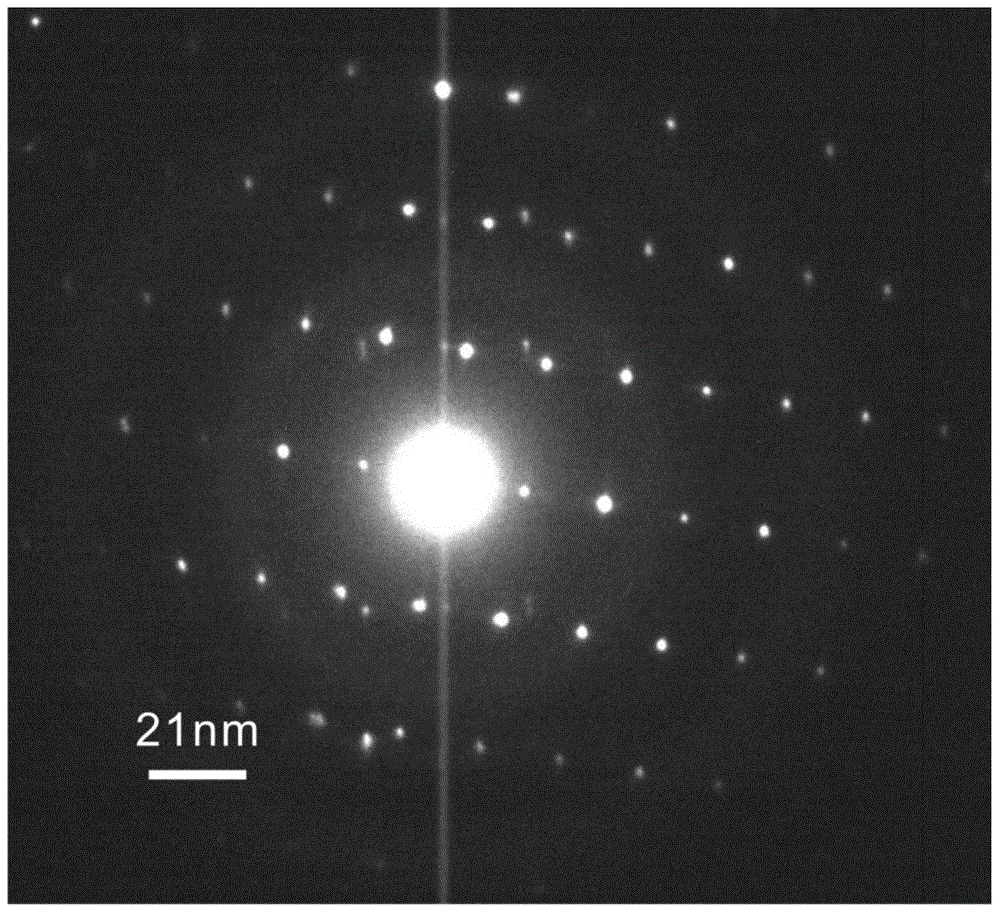

Carbon-containing necklace-like nano nickel telluride as well as preparation and application thereof

InactiveCN105731396ASimple post-processingHave shape rulesMaterial nanotechnologyMetal selenides/telluridesNickel saltSodium tellurite

The invention discloses a preparation method of carbon-containing necklace-like nano nickel telluride. The preparation method comprises the following steps: adding a nickel salt into the deionized water, and dissolving the nickel salt to obtain a nickel ion solution; adding sodium tellurite into the nickel ion solution, and stirring to obtain a turbid solution; adding ascorbic acid into the turbid solution, and stirring to obtain a mixed solution a; dropwise adding a hydrazine hydrate solution into the mixed solution a until the pH is greater than 7, and then stirring until the solution turns brown or dark brown to obtain a mixed solution b; and performing the hydrothermal reaction for the mixed solution b to obtain the carbon-containing necklace-like nano nickel telluride. The invention also discloses carbon-containing necklace-like nickel telluride. The invention also discloses an application of the carbon-containing necklace nano nickel telluride. The preparation process is simple, the production cost is low, no dispersion agent and no surfactant are used, the preparation process is easy to control, a product is simple in post-treatment, and the preparation method is very suitable for the industrialized production; and moreover, the prepared carbon-containing necklace-like nano nickel telluride has the characteristics of regular appearance, good homogeneity and the like.

Owner:HEFEI NORMAL UNIV

Method for preparing high-purity tellurium by using tellurium dioxide

InactiveCN102874772ASimple production processReduce dosageElemental selenium/telluriumTellurateEthylic acid

The invention relates to a method for preparing high-purity tellurium by using tellurium dioxide. According to the technical scheme, the method comprises the following steps of: dissolving the tellurium dioxide by using NaOH, regulating the pH value of the dissolved tellurium dioxide to 13, stirring for 3h, filtering, adding a Na2S solution into a filtrate, detecting an end point by using lead acetate test paper, stirring for 2h to remove foreign ions, and filtering; adding a hydrogen dioxide solution into a sodium tellurite solution, stirring for 4h in an ice-water bath to generate a sodium tellurate precipitate, filtering, washing by using absolute ethanol, and drying to obtain sodium tellurate; dissolving the sodium tellurate in 6 mol / L hydrochloric acid, heating to 75 DEG C, introducing sulfur dioxide gas to generate tellurium, and filtering; and stirring at the temperature of 60 DEG C for 1h in the 2 mol / L hydrochloric acid, filtering, washing by using second boiling water until the acidity is not acid, and drying to obtain high-purity tellurium. By the method, the yield of the tellurium can reach 70.12 percent, and the product purity of the tellurium is more than 99.99 percent.

Owner:LIAONING UNIVERSITY

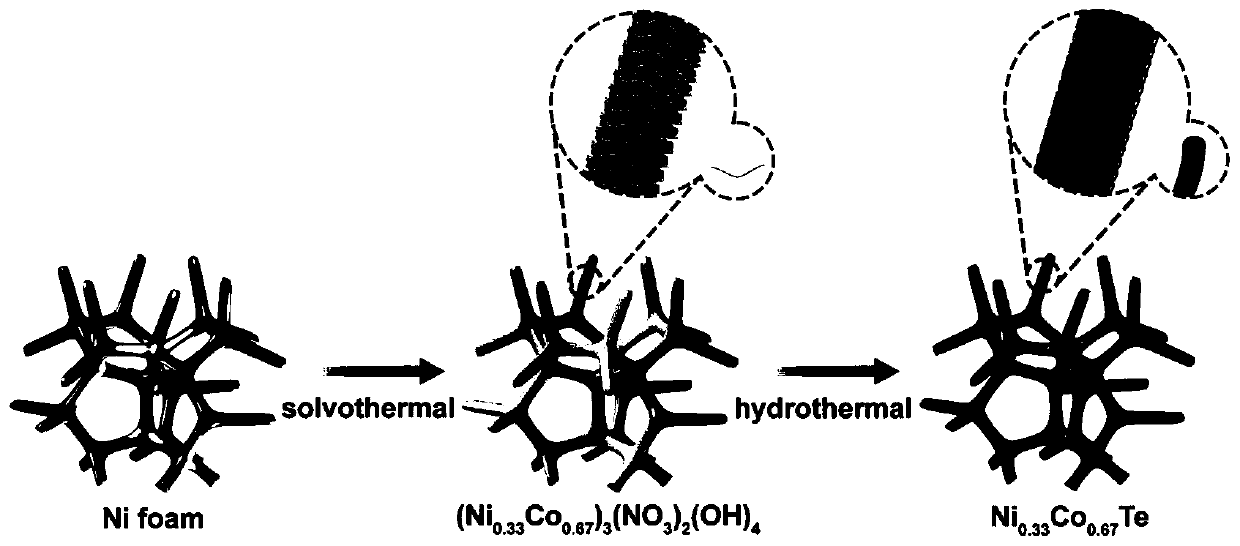

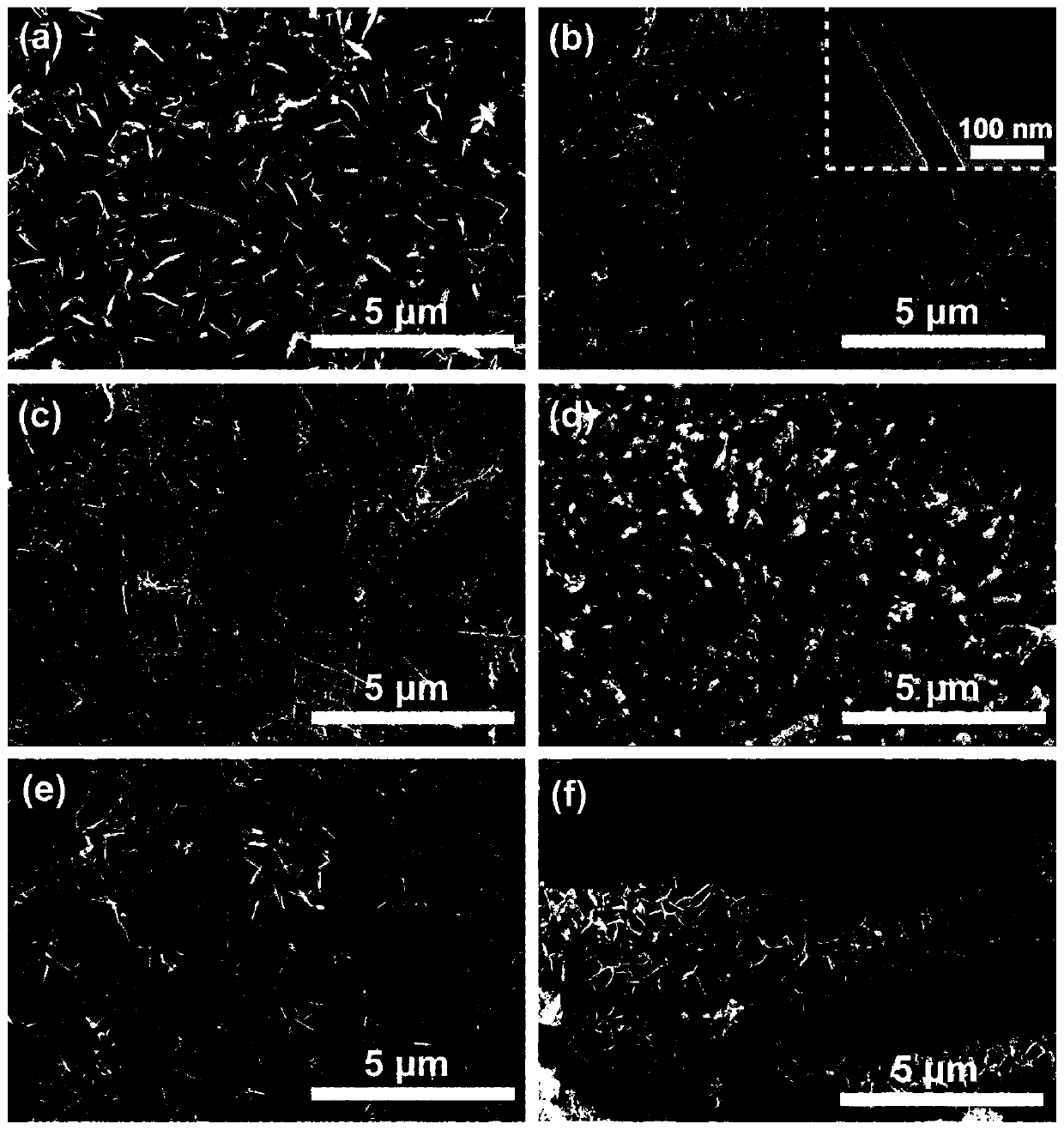

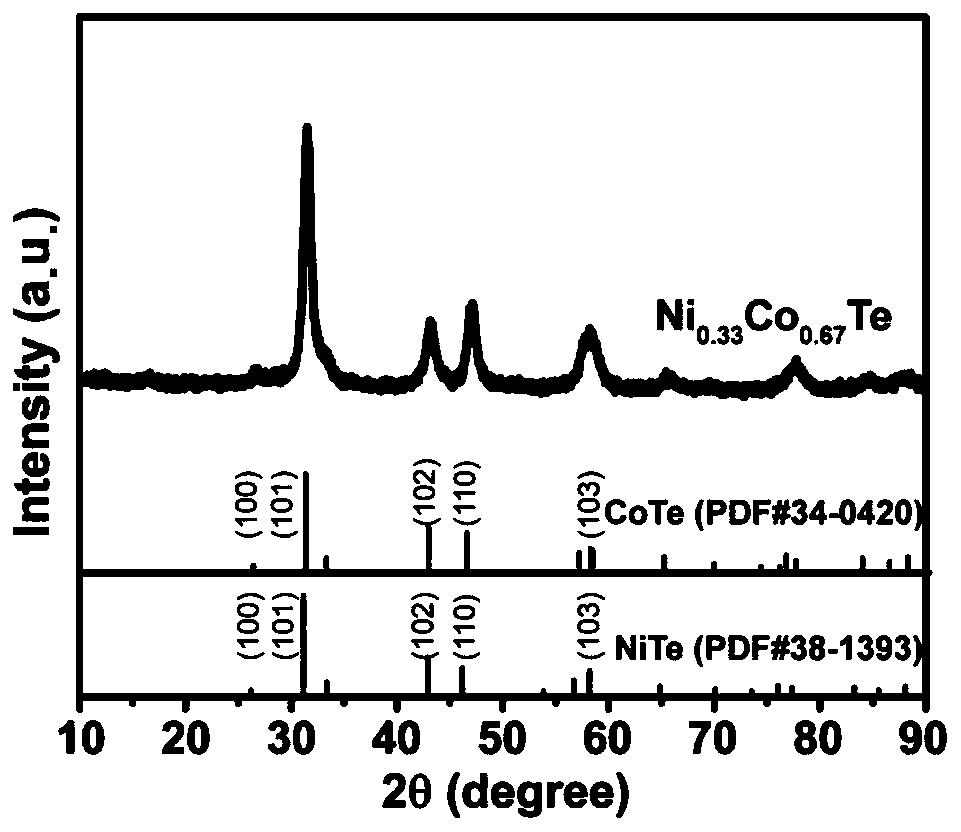

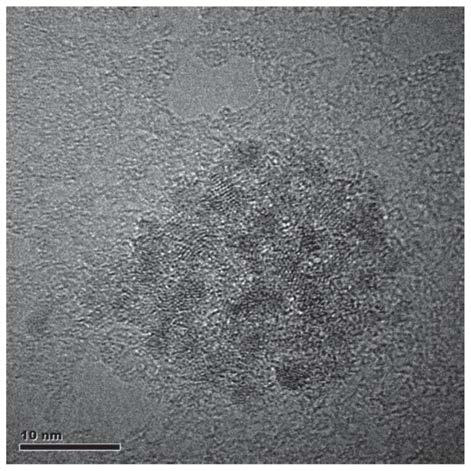

Bimetallic nickel-cobalt telluride supercapacitor electrode material and preparation method thereof

InactiveCN110767462ALarge specific surface areaFully contactedHybrid capacitor electrodesHybrid/EDL manufactureIon exchangeCobalt

The invention discloses a bimetallic nickel-cobalt telluride supercapacitor electrode material and a preparation method thereof, and belongs to the technical field of energy storage materials. The method comprises the steps of: taking urea as a precipitant, growing free Ni2+ and Co2+ in a Ni2+ and Co2+ mixed solution on a conductive substrate to form a nickel-cobalt precursor; then, allowing the conductive substrate with the nickel-cobalt precursor to enter a reductive aqueous solution containing sodium tellurite and hydrazine hydrate, and after Te4+ is reduced by hydrazine hydrate, forming abimetallic nickel-cobalt telluride through an ion exchange reaction; and obtaining nickel-cobalt precursors with different morphologies by adjusting a solvent of a Ni2+ and Co2+ mixed solution, and regulating and controlling the morphology of the bimetallic nickel-cobalt telluride by adjusting the concentration of sodium tellurite in a reductive aqueous solution and adjusting the reaction time. The morphology of the final product bimetallic nickel-cobalt telluride on the conductive substrate is one or more of a nanosheet, a nanoneedle, a nanotube and a nanorod. The electrochemical performanceis improved.

Owner:BEIJING UNIV OF CHEM TECH

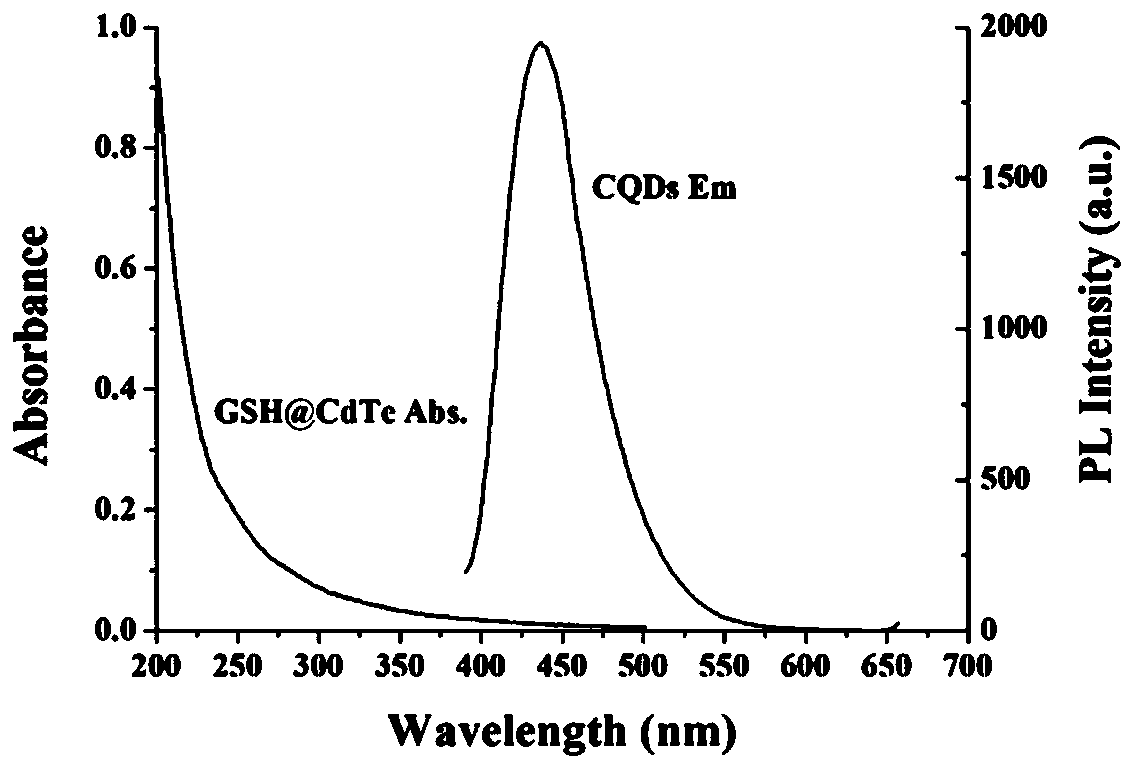

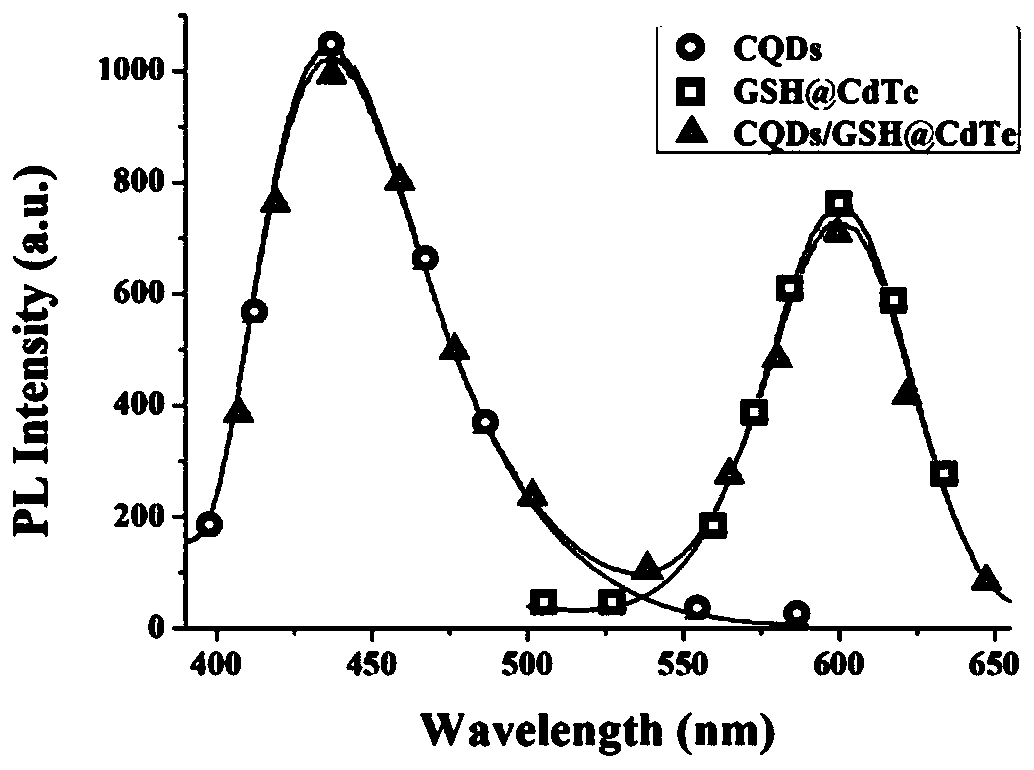

Preparation method and application of ratiometric fluorescent probe for detecting copper ions

PendingCN111040757ASelf-calibratingEliminate Light Source FluctuationsFluorescence/phosphorescenceLuminescent compositionsFluorophoreFluorescent quenching

The invention discloses a preparation method and application of a ratiometric fluorescent probe for detecting copper ions. The method specifically comprises the following steps: firstly, preparing water-soluble CQDs from ethylenediamine and citric acid by virtue of a one-step hydrothermal method, and taking the water-soluble CQDs as reference fluorophores; then, through a reflux method, synthesizing GSH@CdTe QDs adopted as detection fluorophores of the ratiometric fluorescent probe, with the molar ratio of cadmium chloride hydrate, sodium tellurite, glutathione, trisodium citrate dihydrate tosodium borohydride in the reaction being controlled to be 1:0.06:1.02:2.13:8.28; finally, directly mixing the CQDs and the GSH@CdTe QDs to prepare the CQDs / GSH@CdTe QDs ratiometric fluorescent probe.Under the optimal condition, the prepared ratiometric fluorescent probe is used for quantitatively detecting copper ions based on a fluorescence quenching method. The detection limit of the ratiometric fluorescent probe to copper ions is as low as 0.35 nM, and the ratiometric fluorescent probe has great application potential in copper ion detection and analysis.

Owner:ZHEJIANG UNIV OF TECH

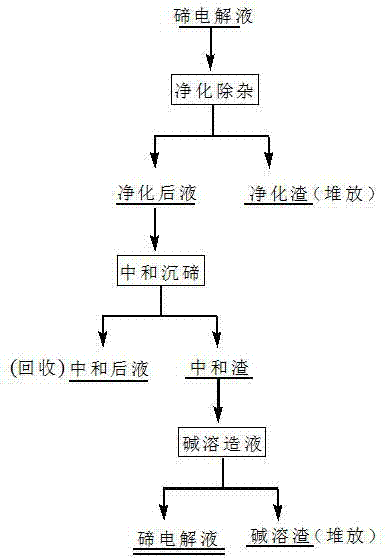

New method for removing impurities in tellurium electrolyte

InactiveCN105441970AAchieve purification effectRealize impurity removalElectrolysis componentsSolubilityFiltration

The invention relates to the technical field of metallurgy and discloses a new method for removing impurities in tellurium electrolyte. According to the method, the wet process for preparing qualified tellurium electrolyte by removing lead through purification, depositing tellurium through hydrolysis and dissolving tellurium dioxide through sodium hydroxide is adopted; after the lead is removed through sodium sulfide, a solution is subjected to neutralizing treatment through hydrochloric acid, and the pH is adjusted to 5-5.5; sodium tellurite (Na2TeO3) and sodium selenite (Na2SeO3) are hydrolyzed to generate tellurium dioxide (TeO2) and selenium dioxide (SeO2) respectively; the selenium dioxide has good solubility and can be dissolved into water and inorganic acid easily, and the tellurium dioxide has poor solubility within the pH range of 5-5.5; selenium and the tellurium are separated preliminarily; finally, tellurium dioxide is subjected to alkali dissolution and filtration to obtain the qualified tellurium electrolyte. By means of the method, purification and impurity removal of the tellurium electrolyte with high lead and selenium contents are effectively realized; the technological process is simple, the quantity and varieties of adopted raw materials are fewer, and the production cost is effectively lowered; energy consumption is less, and the recovery rate of the tellurium is high.

Owner:JINCHUAN GROUP LIMITED

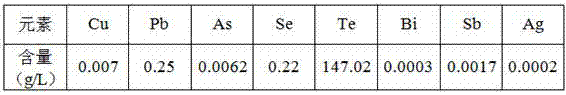

Method for extracting tellurium dioxide from anode slime produced through tellurium electro-deposition

ActiveCN105399062AImprove conversion rateLess residual tellurium in slagSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsIron powderTe element

The invention discloses a method for extracting tellurium dioxide from anode slime produced through tellurium electro-deposition. The method comprises the following steps that 1, the anode slime is put into a reaction kettle, water and sodium hydroxide are added, heating and mixing are performed for two hours, and filter pressing is performed to obtain filter residues, namely the tellurium dioxide; 2, the filter residues are put into the reaction kettle, water is added, a PH value is regulated to be 1.0-1.5 by using sulfuric acid, heating is performed to reach 85 DEG C, stirring is performed for two hours, and filter pressing is performed to obtain filtrate; 3, the filtrate is added into the reaction kettle, and iron powder is added and stirred for three hours; 4, sodium hydroxide is added after the solution is clarified and transparent, the PH value is regulated to be 7.0, then sodium hydroxide with the tellurium metal content 70% is added and stirred for an hour, filter pressing is performed to obtain a sodium tellurite solution, the PH value is regulated to be 5-5.5 by using sulfuric acid, and filter pressing is performed to obtain tellurium dioxide. In the step 3, the amount of the iron powder is determined according to the tellurium content in the filtrate and meets the requirements of a reaction equation: Te<6+> + Fe<0>= Te<4+> + Fe<2+>.

Owner:湖南省金润碲业有限公司

Method for preparing novel carbon material at low temperature for processing dye waste water

InactiveCN102430387AAvoid formingAchieve carbonizationOther chemical processesNanotechnologyFiberDistilled water

The invention relates to a method for preparing novel carbon material at low temperature for processing dye waste water, comprising the following steps: firstly preparing water liquor with sugar, which is to add 12.5-312.5 g of carbohydrate, 7-100 g of amine compounds, 2-48 g of polyvinylpyrrolidone and 1.0-6.6 g of sodium tellurite to each L of water liquid; sealing the reaction container in which the prepared carbohydrate water liquid; heating the reaction container to 120-140 DEG C, and reacting for 10-24 hours; naturally cooling, and centrifuging to separate and obtain the product; washing the product with distilled water and anhydrous alcohol for three times; and drying to obtain the carbon nanometer fiber, wherein the carbon nanometer fiber is the novel carbon material for processing the dye waste water. The invention adopts the carbohydrates of sugars as the raw material, and the reaction is implemented at low temperature (120-140 DEG C), so the carbonization of the carbohydrates is realized. The operation is simple, and the technology requirements are simple, so the method is suitable for the industrial production.

Owner:ZHEJIANG NORMAL UNIVERSITY

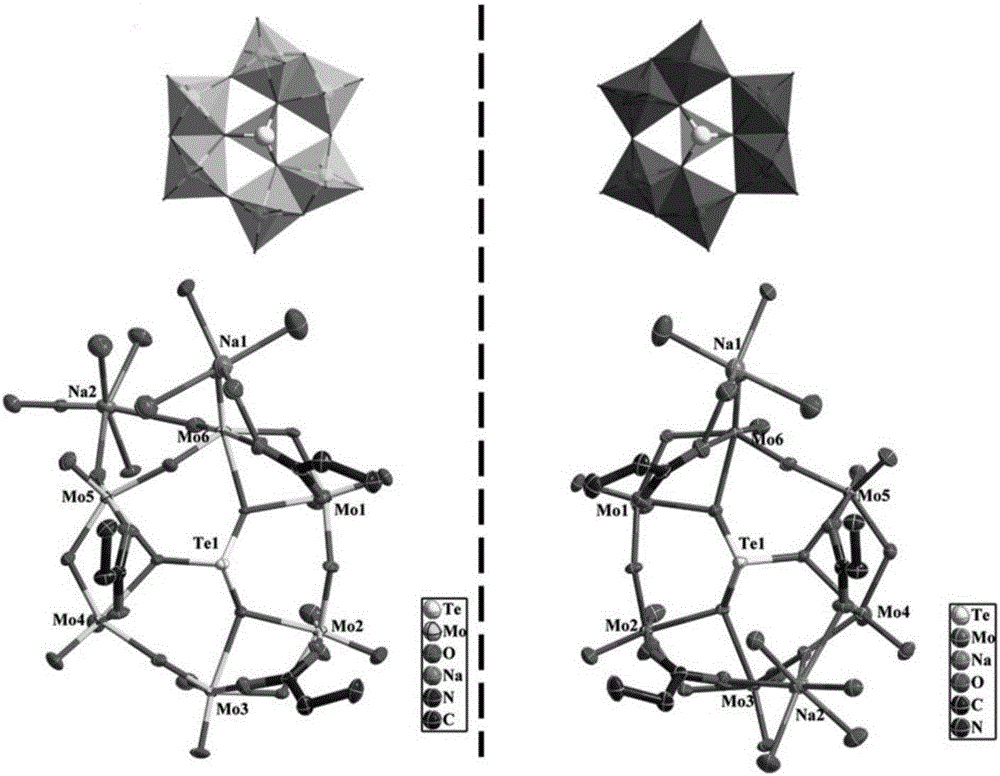

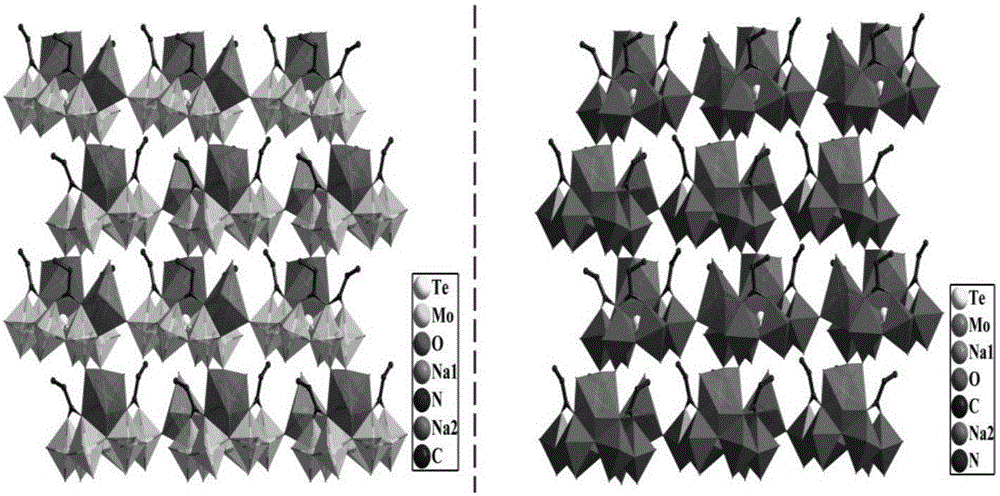

Chiral heteropolymolybdate, preparation method and non-linear optical applications thereof

ActiveCN106544736AClear structureStrong second-order nonlinear optical effectPolycrystalline material growthFrom normal temperature solutionsSodium molybdateGlycine

The present invention belongs to the technical field of new polyacid chemical materials, and relates to a chiral heteropolymolybdate, a preparation method and non-linear optical applications thereof, wherein the chiral heteropolymolybdate belongs to the monoclinic system, the space group is P21, the crystal cell parameters comprise that a is 11.6485(9)angstrom, b is 13.9161(10) angstrom, c is 11.8748(8)angstrom and beta is 113.074(2)DEG when X is Te, and the crystal cell parameters comprise that a is 11.6276(5)angstrom, b is 13.9826(7)angstrom, c is 11.8503(7)angstrom and beta is 113.215(2)DEG when X is Se. According to the present invention, sodium molybdate, sodium tellurite or selenium dioxide and glycine are adopted as the raw materials, the synthesis yield is high, the obtained chiral heteropolymolybdate has the good second-order nonlinear optical properties, the powder frequency multiplication signal is 3.5 and 3.7 times of K2HPO4, the preparation process is simple, the product has high purity, and the obtained chiral heteropolymolybdate has potential non-linear optical application prospect.

Owner:DALIAN UNIV OF TECH

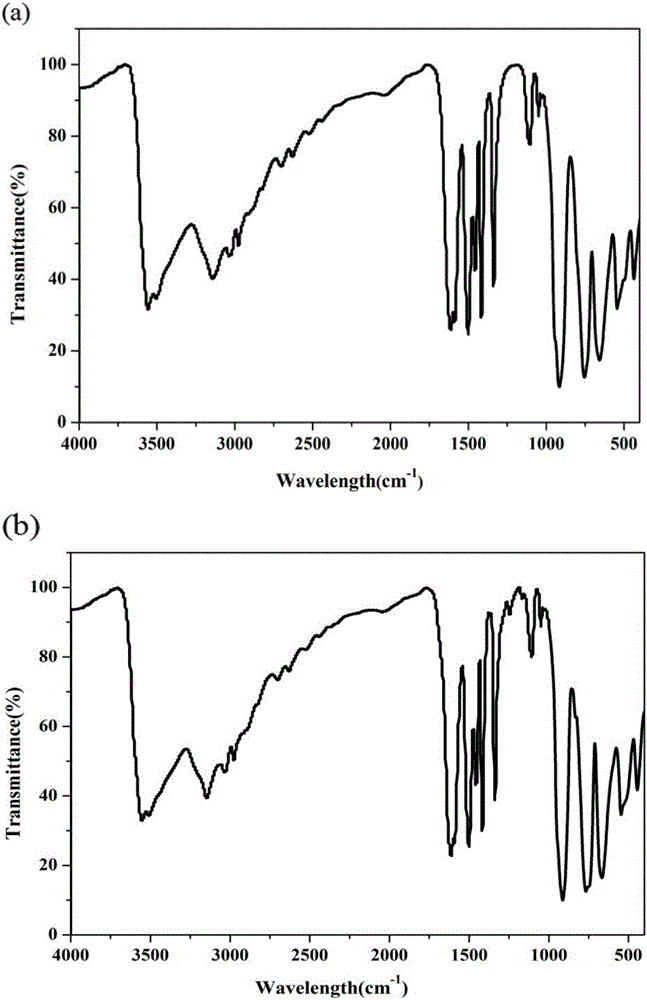

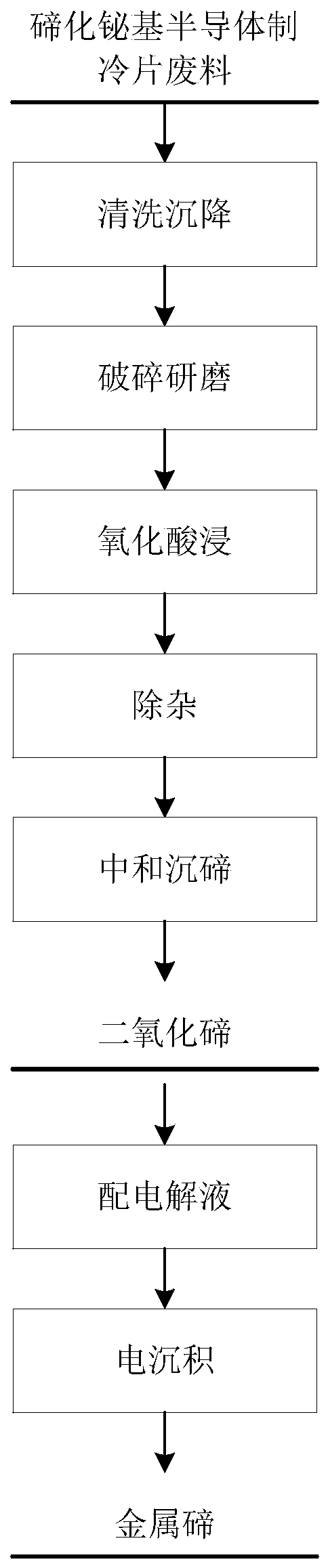

Method for recovering tellurium from bismuth telluride-based thermoelectric cooler wastes

ActiveCN110127632AReduce the impactReduce energy consumptionProcess efficiency improvementElemental selenium/telluriumRecovery methodBismuth telluride

The invention relates to the technical field of nonferrous metal recovery, and discloses a method for recovering tellurium from bismuth telluride-based thermoelectric cooler wastes. The method comprises the following steps: washing, settling, crushing and grinding the bismuth telluride-based thermoelectric cooler wastes to obtain a tellurium-containing material powder, performing acid leaching onthe material powder by using hydrochloric acid, adding an oxidant to perform oxidization, adding a reducing agent to remove selenium impurities, and performing neutralizing precipitation to obtain tellurium dioxide filter residues; and mixing the tellurium dioxide filter residues, water and sodium hydroxide to prepare a sodium tellurite electrolyte, filtering the electrolyte to remove bismuth andantimony impurities, and performing electrodeposition to finally obtain metal tellurium. The bismuth telluride-based thermoelectric cooler wastes are treated through oxidation and acid-leaching processes to recover the metal tellurium. The recovery method does not require high-temperature calcining, so the energy consumption, the cost and the environmental impact are reduced; and the method can beused to treat P-type and N-type coolers without classification, so the method has high applicability. The method has the advantages of high yield and stable quality of tellurium, and easiness in industrialization.

Owner:SICHUAN UNIV

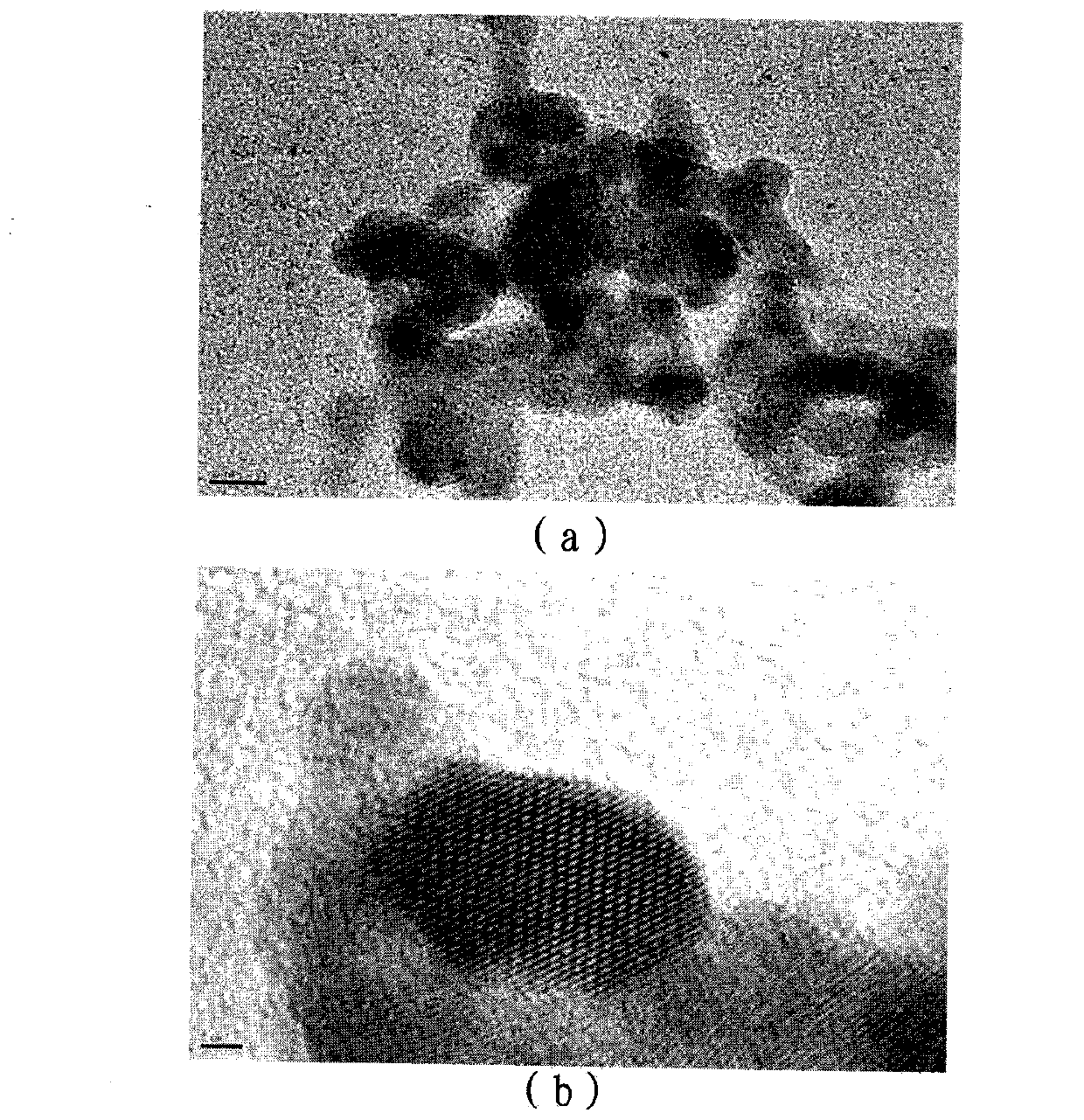

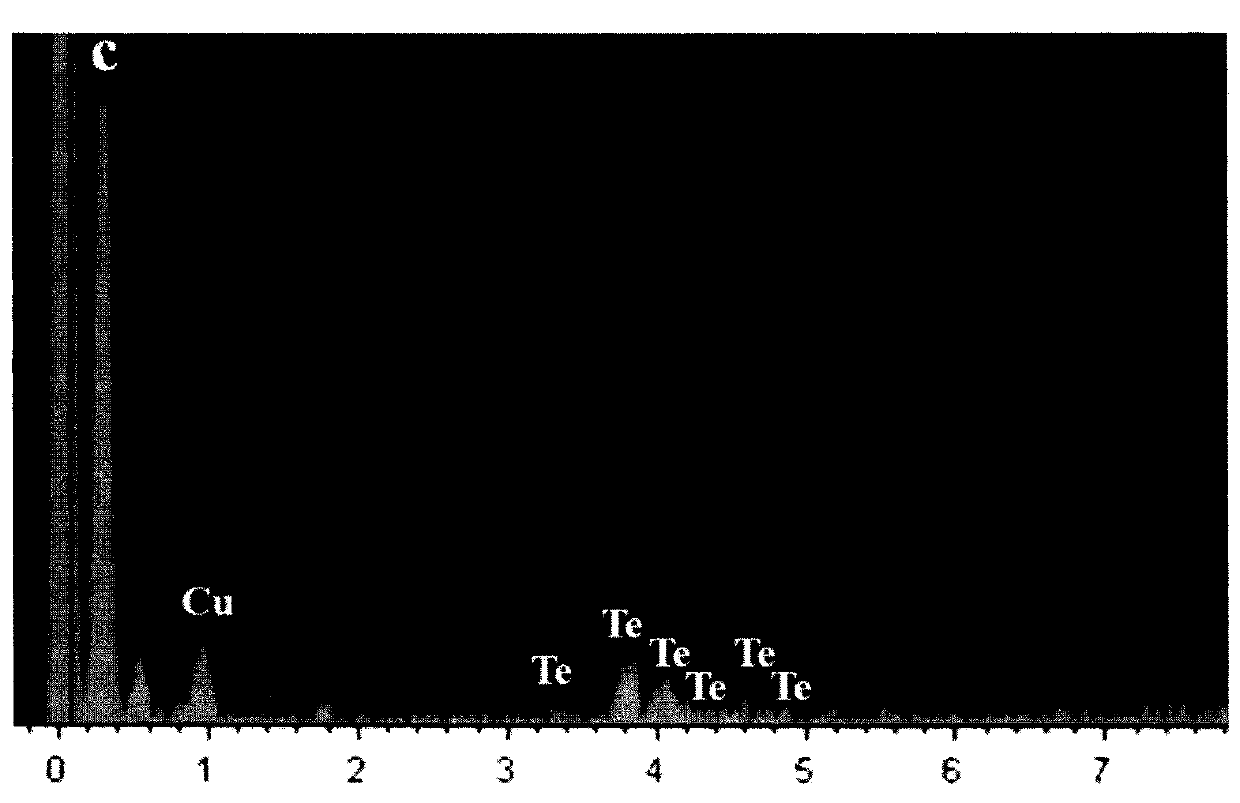

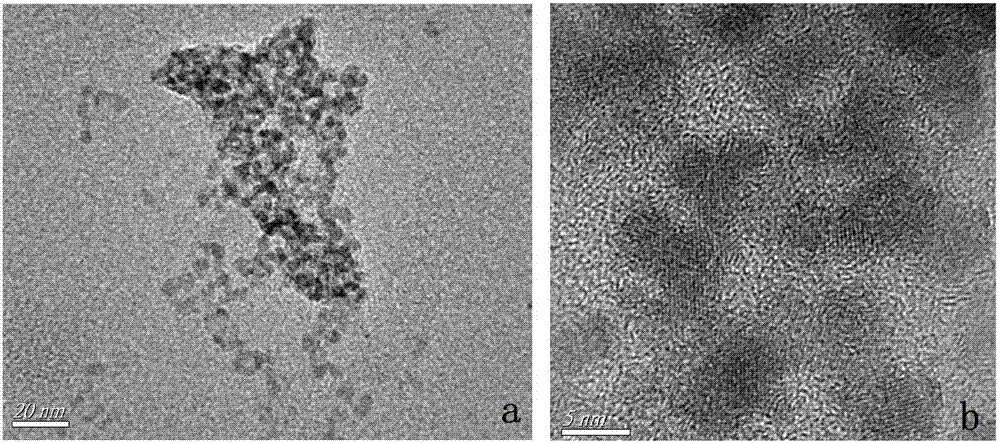

Tellurium nano-particles and preparation method for same

InactiveCN103373713AGood dispersionLarge specific surface areaNanotechnologyElemental selenium/telluriumTe elementInfrared detector

The invention discloses a tellurium nano-particles and a preparation method for the same. The particles are composed of tellurium and have particle sizes ranging from 7 to 13 nm, and the tellurium particles are spherical or ellipsoidal or multi-prismatic. The method comprises the following steps of: firstly, adding sodium tellurite in water, and stirring to completely dissolve, so as to obtain sodium tellurite aqueous solution, then adding glutathione in the sodium tellurite aqueous solution, stirring for at least 1 day, so as to obtain reaction solution, wherein the weight ratio of sodium tellurite to glutathione to water in the reaction solution is (7 to 11): (3 to 5): 2000; and secondly, performing solid-solution separation treatment on the reaction solution, then performing cleaning treatment on a solid-state object obtained after separation, so as to prepare a target product, wherein the solid-solution separation treatment is centrifugal separation, during centrifugal separation, the centrifugal rotation speed is 5000-9000 r / min and the time is 7-10 minutes, and the cleaning treatment is sequentially performing washing and centrifugal separation on the solid-state object for 1-3 times. The tellurium nano-particles can be widely used for producing quantum dot laser devices, quantum dot infrared detectors, single-electron devices and the like, and used for the fields of catalysis and medicine development.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

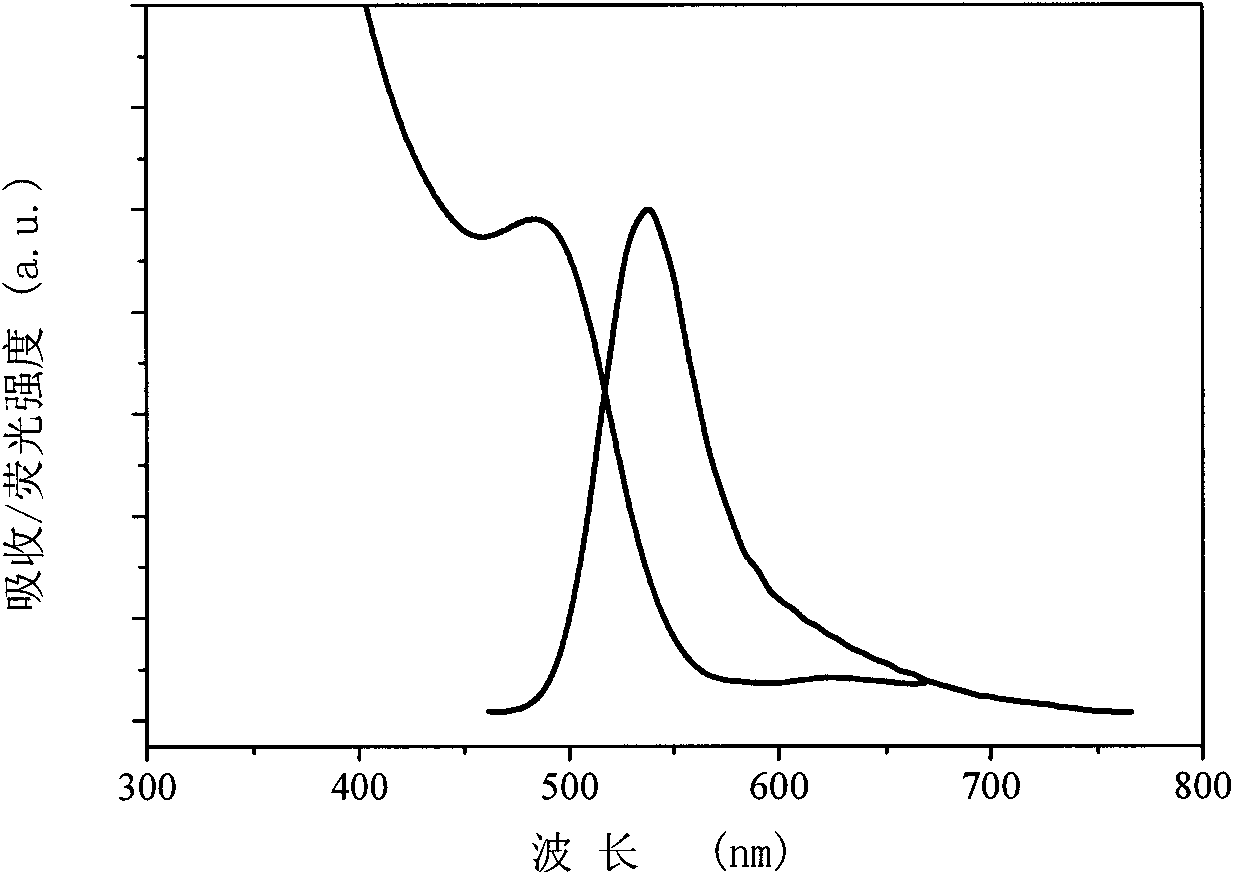

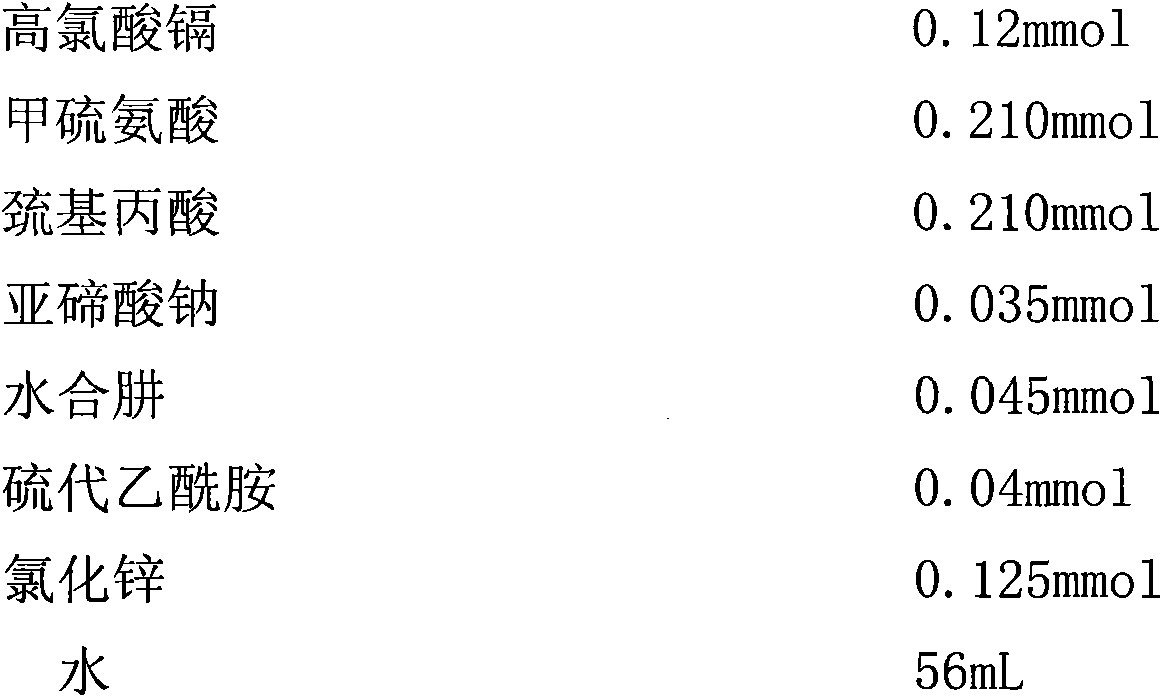

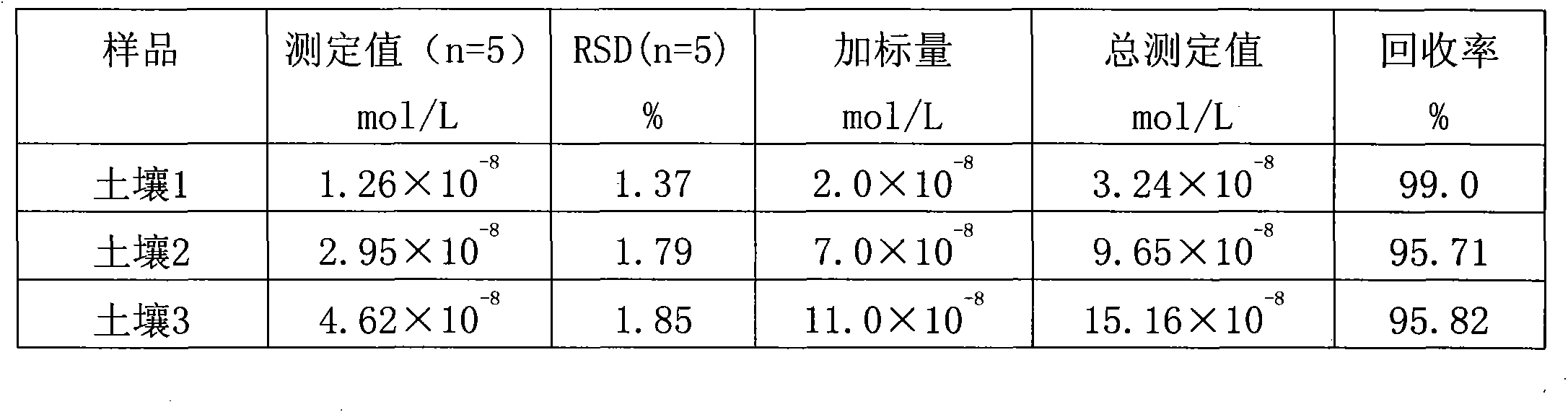

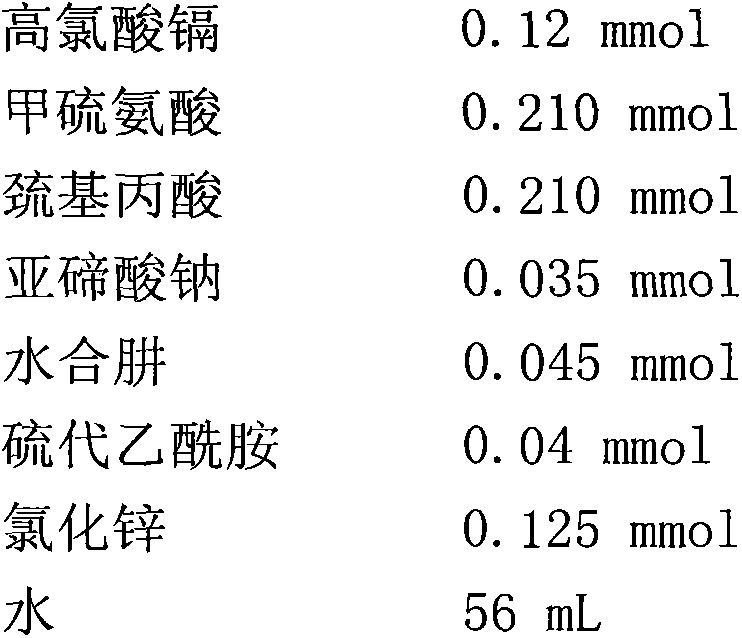

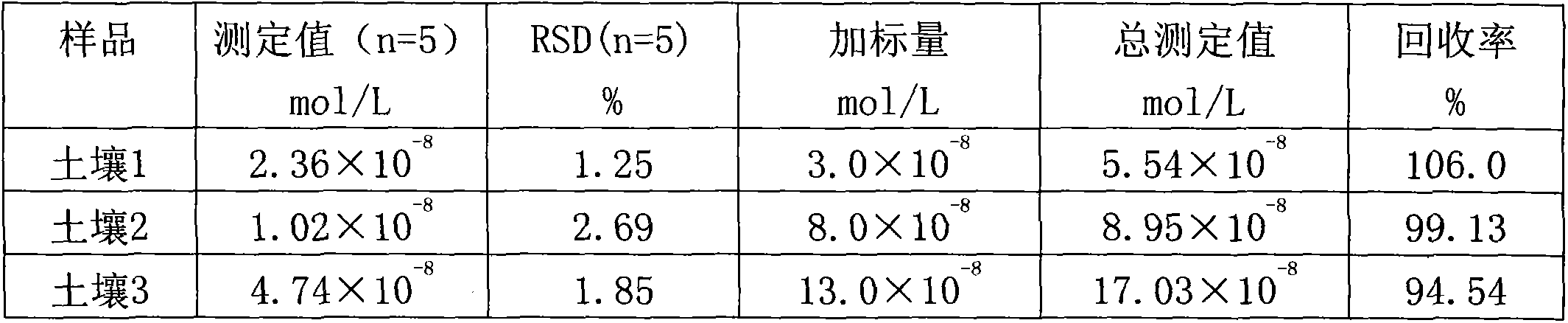

Preparation method and application of CdTe/ZnS core-shell quantum dots

InactiveCN103555334AGood dispersionImprove stabilityZinc sulfidesLuminescent compositionsNitrobenzeneExplosive material

The invention discloses a CdTe / ZnS core-shell quantum dot, a preparation method of the CdTe / ZnS core-shell quantum dots and an application of the CdTe / ZnS core-shell quantum dots in detecting trace explosive, and belongs to the technical fields of analytic chemistry and nanometer. The CdTe / ZnS core-shell quantum dots are produced from cadmium perchlorate, methionine, thiohydracrylic acid, sodium tellurite, hydrazine hydrate, thioacetamide and zinc chloride; and the quantum dots are used for detecting the explosive nitrobenzene. The method is capable of detecting the nitrobenzene low to 1.2*10<-9>mol / L.

Owner:SHANDONG JIAOTONG UNIV

Preparation methods of tin telluride nanorods and tin telluride based binary metal telluride nanorods

InactiveCN107539961AFriendly and easy to manufactureHigh aspect ratioMaterial nanotechnologyBinary selenium/tellurium compoundsTelluric acidHydrazine compound

The invention provides a preparation method of tin telluride nanorods. The method comprises the following steps: a tellurium source and a surfactant are added into glycol in order to obtain a first mixture, wherein a tellurium source is sodium tellurite or telluric acid; the first mixture is heated to a first temperature which is higher than 110 DEG C, hydrazine hydrate is added, and after reaction, a second mixture containing the tellurium nanorods is obtained; a tin source is added into the second mixture, the second mixture is heated to a second temperature which is higher than 170 DEG C, and after reaction, the tin telluride nanorods are obtained, wherein the tin source is chloride or nitrate of tin. The invention also provides a method for preparing tin telluride based binary metal telluride nanorods, and a second metal source and the tin source are added at the same time in the method.

Owner:UNIV OF SCI & TECH OF CHINA

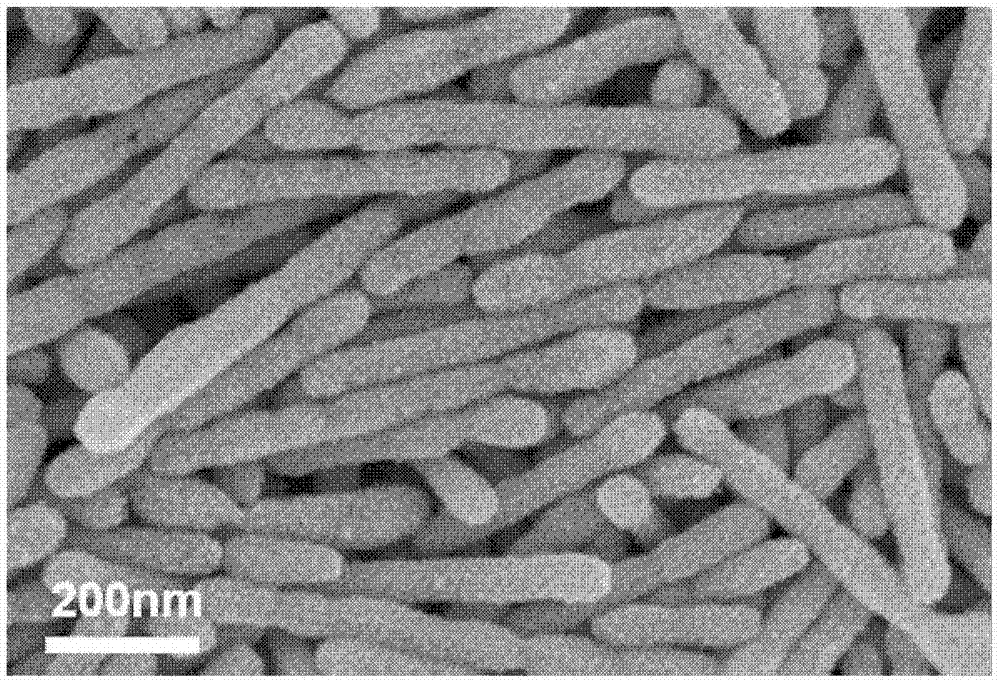

Preparation method of carbon-coated core-shell structure bismuth telluride nanorod, prepared carbon-coated core-shell structure bismuth telluride nanorod and application

ActiveCN107697891ASimple post-processingImprove uniformityMaterial nanotechnologyCarbon preparation/purificationBismuth tellurideCarbon coated

The invention discloses a preparation method of a carbon-coated core-shell structure bismuth telluride nanorod, a prepared carbon-coated core-shell structure bismuth telluride nanorod and application.The method includes the steps of: S1. adding a bismuth salt into deionized water for dissolving to obtain a bismuth ion solution; S2. adding sodium tellurite into the bismuth ion solution, and performing stirring to obtain a turbid solution; S3. adding ascorbic acid into the turbid solution, and conducting stirring to obtain a mixed solution a; S4. adding polyvinylpyrrolidone into the mixed solution a, and performing stirring to obtain a mixed solution b; S5. adding an ethylene glycol solution dropwise into the mixed solution b, and performing stirring to obtain a mixed solution c; and S6. transferring the mixed solution c into a reaction kettle and carrying out hydrothermal reaction so as to obtain the carbon-coated core-shell structure bismuth telluride nanorod. The method provided by the invention has the advantages of easy preparation control, simple process and low cost, and is suitable for industrial batch production. Moreover, the carbon-coated core-shell structure bismuth telluride nanorod obtained by the method provided by the invention has the characteristics of regular morphology, good uniformity and the like.

Owner:HEFEI NORMAL UNIV

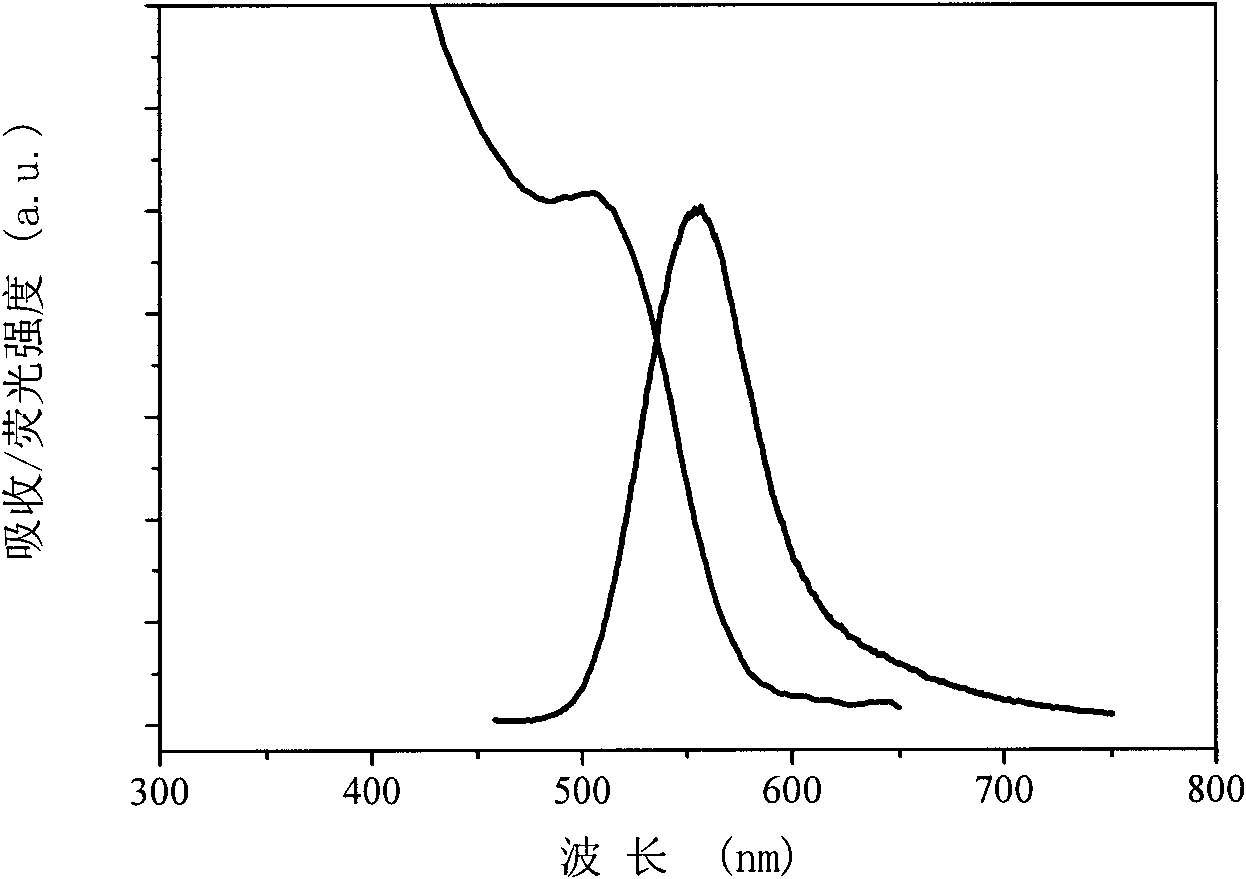

CdTe quantum dots, preparation method therefor and applications in detection of trace explosives

InactiveCN103525424ALow costSimple processFluorescence/phosphorescenceLuminescent compositionsHydrazine compoundQuantum dot

The invention discloses CdTe quantum dots, a preparation method therefor and applications in detection of trace explosives, and belongs to the analytical chemistry and nanotechnology fields. The CdTe quantum dots are prepared from cadmium chloride, trisodium citrate, sodium tellurite, hydrazine hydrate and methionine. The quantum dots can be applied in detection of dinitrotoluene explosive. The method has high sensitivity, and dinitrotoluene with a concentration of 1.5*10<-9> mol / L can be detected.

Owner:SHANDONG JIAOTONG UNIV

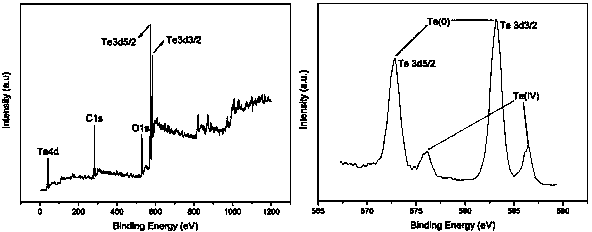

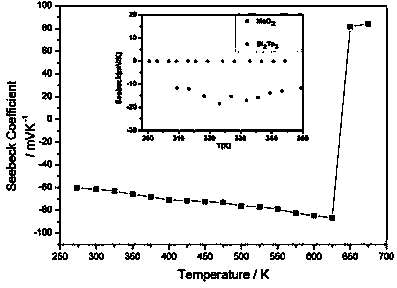

Method for preparing high-seebeck-coefficient tellurium/tellurium oxide nanocomposite with solvothermal

InactiveCN104362248ASimple processLow equipment requirementsThermoelectric device manufacture/treatmentNanotechnologySodium acetateNanowire

The invention discloses a method for preparing a high-seebeck-coefficient tellurium / tellurium oxide nanocomposite with solvothermal. The method includes: adopting a solvothermal method, weighing sodium tellurite, sodium acetate and PVP (polyvinyl pyrrolidone), sequentially adding ethylene glycol as solvent and reductant with uniform mixing at normal temperature, then pouring the obtained mixed solution into a reaction kettle, putting the reaction kettle into a contact-temperature box for reaction, and naturally cooling the reaction kettle to the room temperature after reaction to obtain products, namely tellurium nanowires; putting the tellurium nanowires in a culture dish prior to placing the culture dish in the constant-temperature box for several days so as to obtain a product, namely Te / TeO2 nanocomposite. The seebeck coefficient of one single nanowire is up to 81mVK-1 which is the maximum value so far. The method is simple in technique, low in equipment requirement, high in controllable degree, low in cost and high in product purity, and is a good way for preparing the Te / TeO2 nanocomposite.

Owner:ZHEJIANG SCI-TECH UNIV

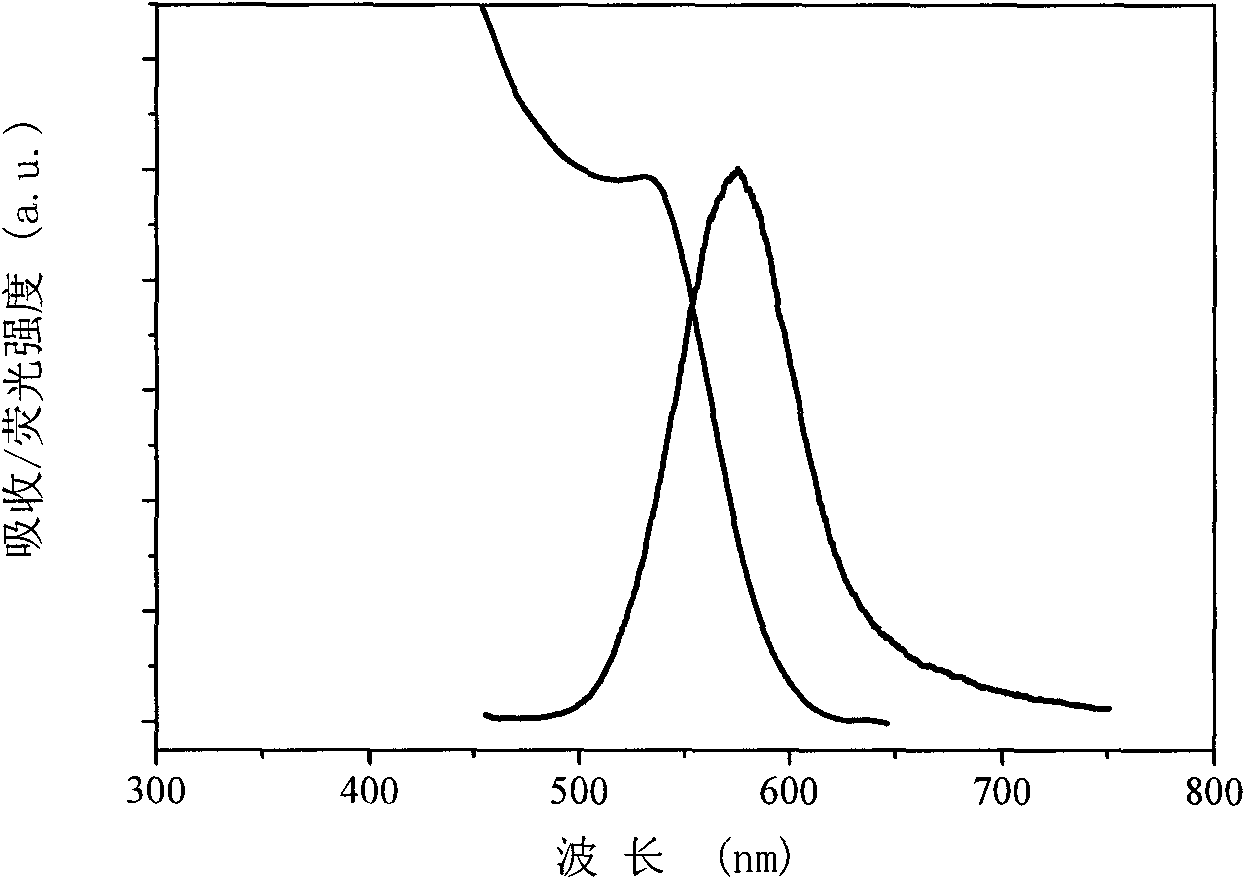

Simple preparation method for synthesizing CdTe quantum dot fluorescence probe at normal temperature and application of CdTe quantum dot fluorescence probe

InactiveCN103937503AEasy to synthesizeShortcut synthesisFluorescence/phosphorescenceLuminescent compositionsMaterials preparationOptical property

The invention relates to a simple preparation method for synthesizing a CdTe quantum dot fluorescence probe at a normal temperature and an application of the CdTe quantum dot fluorescence probe, and belongs to the technical field of material preparation and medicine content detection. The method comprises the following steps: firstly, respectively preparing cadmium chloride (CdCl2), sodium tellurite (Na2TeO3) and thioglycollic acid (TGA) into aqueous solutions with certain concentrations; then, sequentially adding the CdCl2, water, the TGA, the Na2TeO3, sodium borohydride (NaBH4) and hydrazine hydrate (N2H4.H2O) into a conical flask one by one; and standing for certain time at the normal temperature so as to obtain a CdTeQDs aqueous solution which is used for optical detection of norfloxacin lactate. The TGA-modified CdTeQDs prepared by utilizing the method has the good optical property and has the ability of detecting the norfloxacin lactate content.

Owner:JIANGSU UNIV

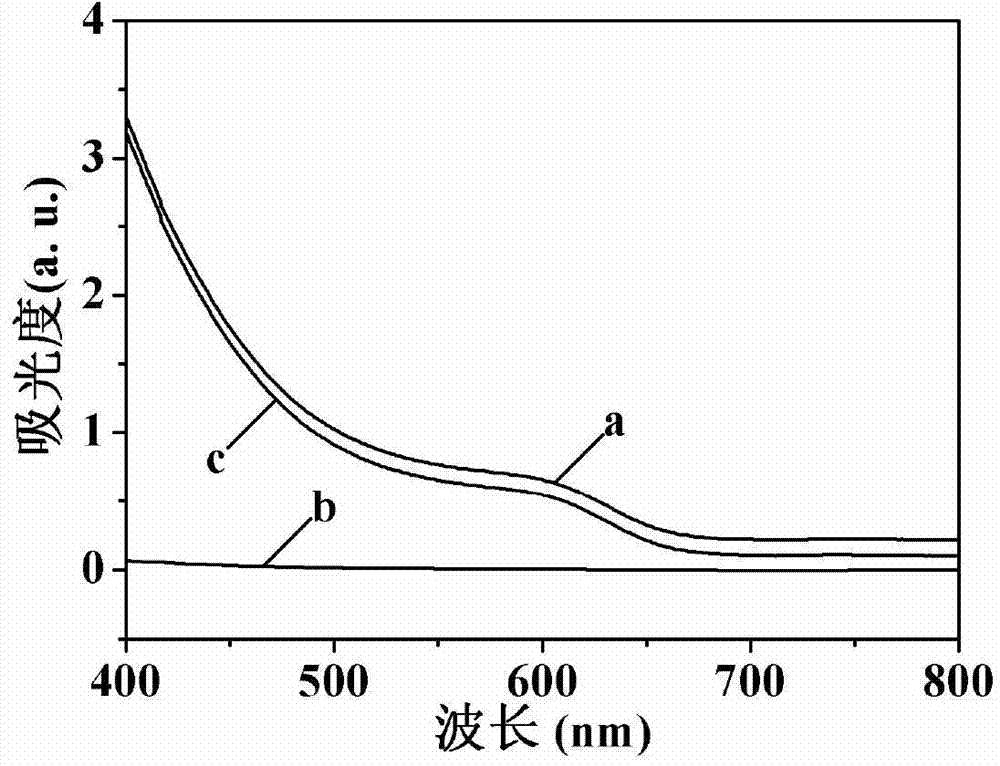

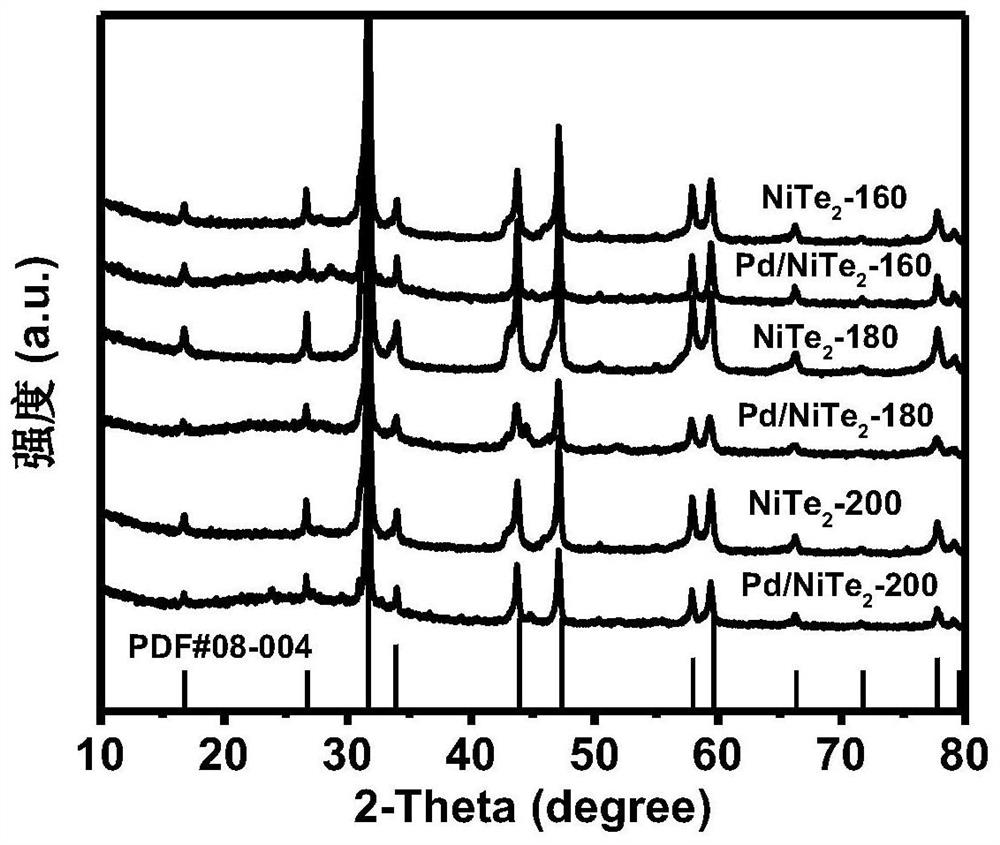

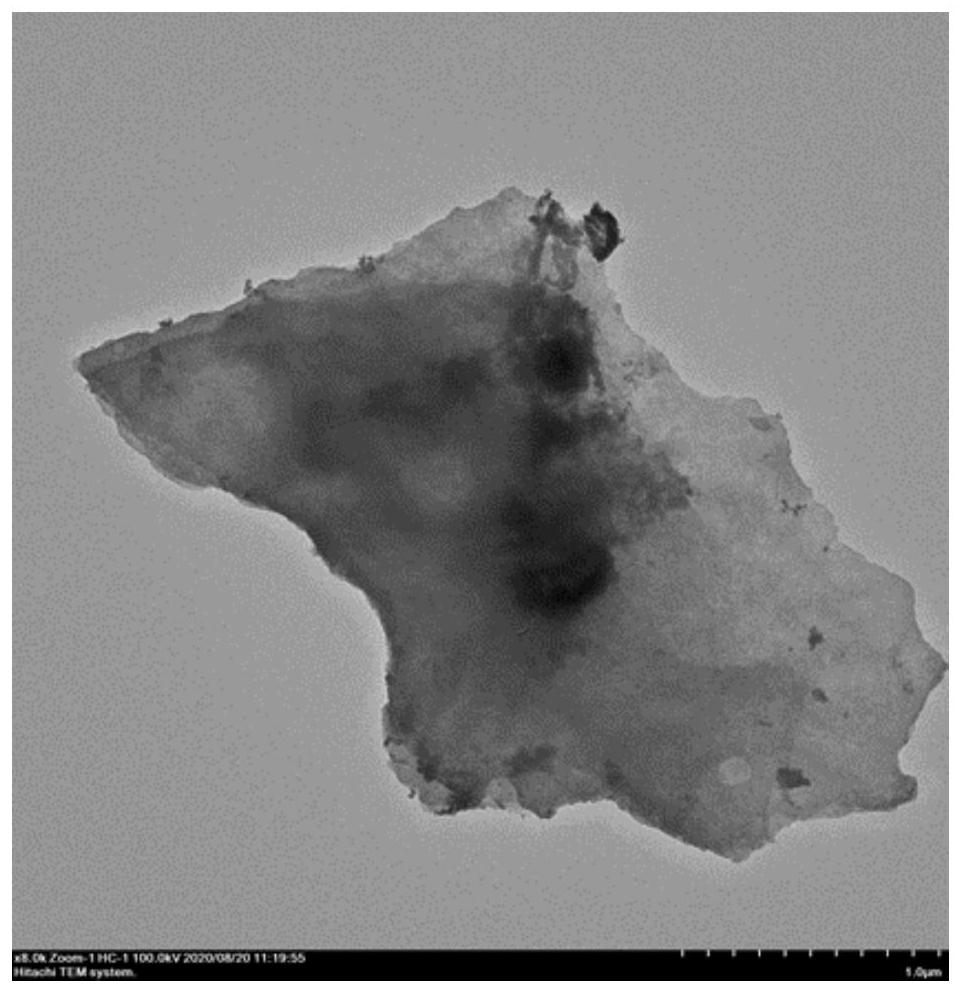

Two-dimensional nickel telluride supported palladium monatomic catalyst as well as preparation method and application thereof

The invention relates to the technical field of nano catalytic materials, and discloses a two-dimensional nickel telluride supported palladium monatomic catalyst and a preparation method and application thereof.The catalyst takes a two-dimensional nickel telluride nanosheet as a carrier and loads palladium monatomic; wherein the thickness n of the two-dimensional nickel telluride nanosheet is greater than 0 nm and less than or equal to 5 nm, and the loading capacity of palladium single atoms is 0.1-0.5 wt%. The preparation method comprises the following steps: by taking nickel nitrate, urea and ammonium fluoride as raw materials, preparing Ni(OH)2 by a hydrothermal method; carrying out telluridation reaction on the two-dimensional nickel telluride nanosheet, sodium tellurite and hydrazinehydrate in a solvent to obtain a two-dimensional nickel telluride nanosheet; impregnating the two-dimensional nickel telluride nanosheet in a palladium salt solution, and then carrying out annealing and acid pickling to produce the catalyst. The catalyst not only can prevent Pd monogen from being agglomerated and falling off, but also can further improve the oxygen adsorption and product dissociation capacity of the catalyst, so that the electrocatalytic activity is improved.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

Manufacturing method for CoTe nanowire for supercapacitor electrode

InactiveCN110676064AHigh mechanical strengthExcellent rate performanceHybrid capacitor electrodesNanotechnologyCapacitanceHigh current density

The invention relates to a manufacturing method for a CoTe nanowire for a supercapacitor electrode. The CoTe nanowire electrode material with the diameter of 20 nm to 40 nm and the length of 1 mum to1.5 mum is prepared by adopting a thermal solvent method, taking cobalt nitrate hexahydrate and sodium tellurite as main raw materials and taking ethylene glycol as a solvent. The specific capacitanceof the electrode reaches up to 643.6 F / g under the current density of 1 A / g, 90.2% of specific capacitance can still be kept under the large current density of 20 A / g, the rate capability is excellent, a traditional soft package supercapacitor manufacturing method can be combined to manufacture a high-performance supercapacitor, and rapid charging and discharging are carried out under the high current density. And the manufactured capacitors can also form a supercapacitor bank for situations with high-power output such as starting and stopping of cranes and automobile engines. Benefited fromthe advantage of high mechanical strength of the nanowires, the cobalt telluride nanowire pseudocapacitance type supercapacitor electrode also has a certain application prospect in the field of flexible wearable energy storage equipment.

Owner:TIANJIN UNIV

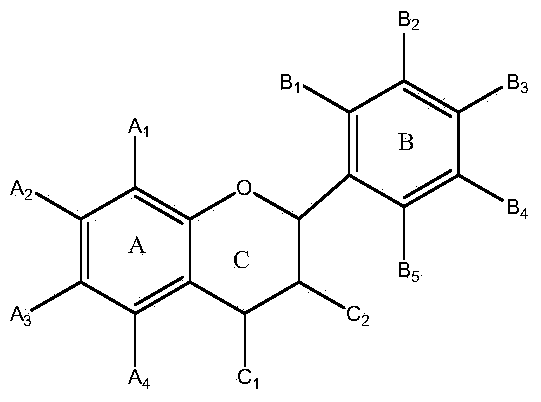

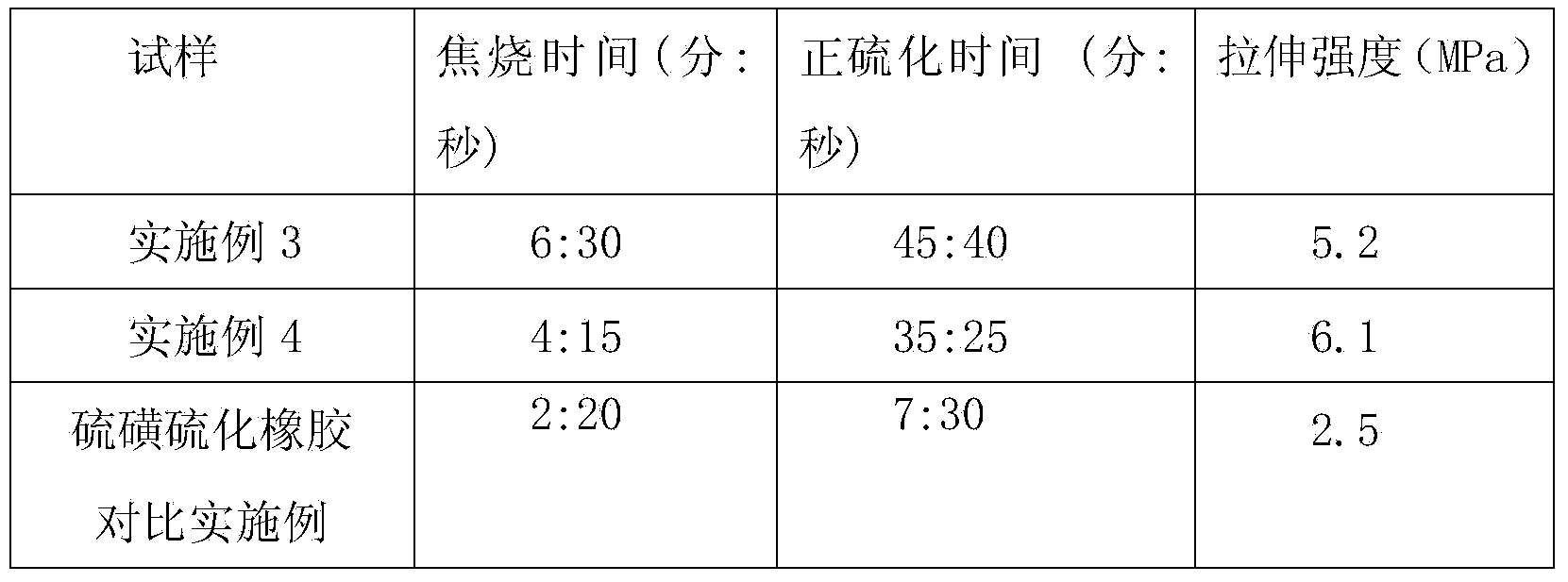

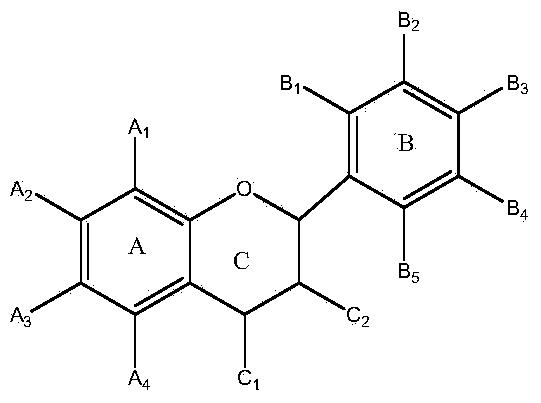

Preparation of nano element tellurium and method for vulcanizing rubber by using nano element tellurium

ActiveCN104292505AWide variety of sourcesSimple extraction processEnvironmental resistanceVulcanization

The invention discloses preparation of a nano element tellurium and a method for vulcanizing rubber by using the nano element tellurium. The polyphenol modified nano element tellurium is prepared by taking cheap sodium tellurite as a tellurium source and plant polyphenol as a reducing agent and a modifier of the nano element tellurium. The rubber which is vulcanized by using tellurium is prepared by taking the prepared nano element tellurium as a vulcanization agent and an over-speed accelerant as an accelerant. The preparation method of the nano element tellurium, which is disclosed by the invention has the advantages of environment friendliness, simple process and the like, and the reducing agent and the modifier used in the preparation method are natural compounds, have the characteristics of being rich in resource, low in price, environment-friendly and non-toxic and are applicable to high-efficiency and on-scale preparation of the nano element tellurium. By adopting the method that the nano element tellurium is taken as the vulcanization agent and the over-speed accelerant is taken as the accelerant, the tellurium vulcanized rubber can be prepared by using a universal rubber machining process. Compared with sulfur vulcanized rubber, the tellurium vulcanized rubber prepared by using the method is relatively good in mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com