Simple preparation method for synthesizing CdTe quantum dot fluorescence probe at normal temperature and application of CdTe quantum dot fluorescence probe

A technology of fluorescent probes and quantum dots, which can be used in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., and can solve the problems of complex synthesis methods of quantum dots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

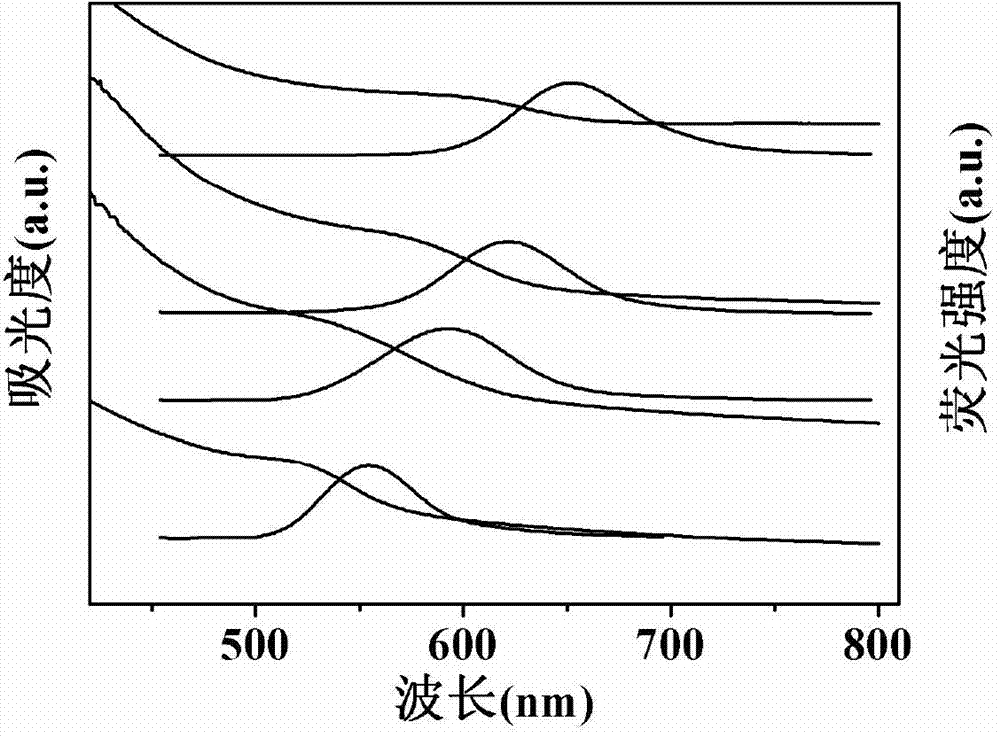

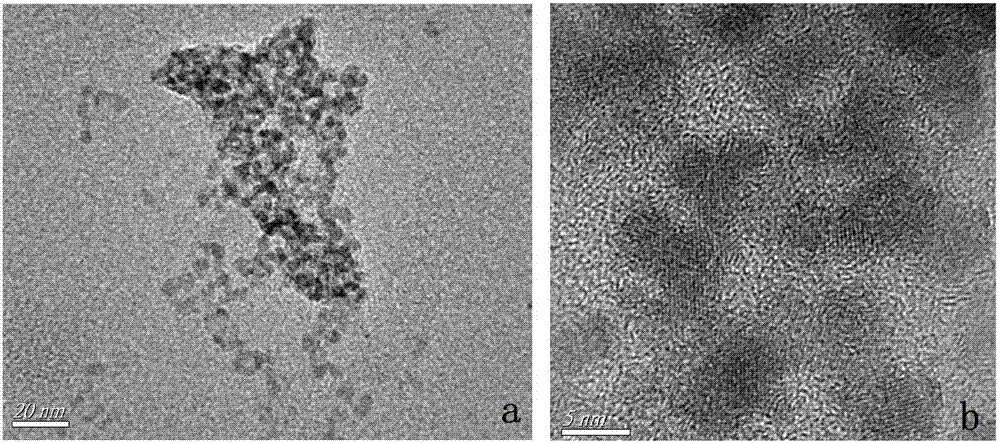

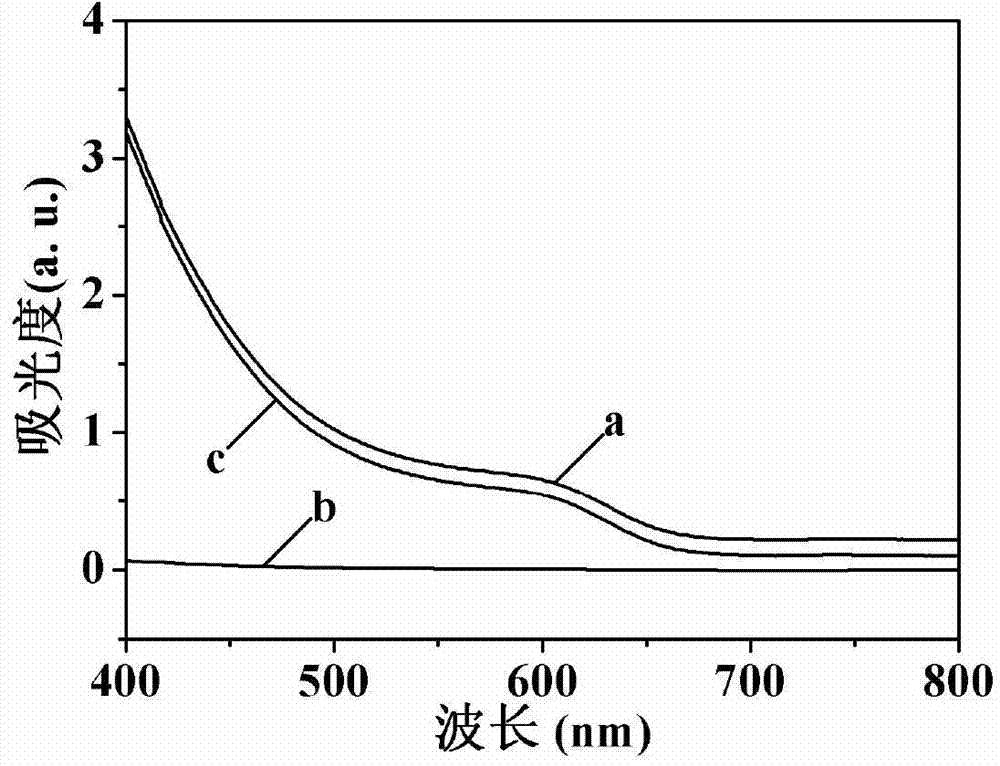

Embodiment 1

[0024] 1.1415g CdCl 2 2.5H 2 O is dissolved in 50mL water to obtain 0.1mol / L CdCl 2 solution; 0.139mL pure TGA was dissolved in 50mL water to obtain a 0.04mol / L TGA solution; 0.0445gNa 2 TeO 3 Dissolve in 50mL water to get 0.004mol / L Na 2 TeO 3 solution, set aside.

[0025] 0.2mL CdCl 2 solution, 20mL water, 1.0mL TGA solution, 1.0mL Na 2 TeO 3 solution, 37.83 mg NaBH 4 , 9.7mL hydrazine hydrate was added to the conical flask one by one, and after standing at room temperature for 3h, an aqueous solution of CdTe QDs was obtained. Wherein, the CdCl described in step (2) 2 , TGA, Na 2 TeO 3 , NaBH 4 and N 2 h 4 ·H 2 The molar ratio of O and five is 1:(2.0):(0.2):(50):(8000).

Embodiment 2

[0027] 1.1415g CdCl 2 2.5H 2 O is dissolved in 50mL water to obtain 0.1mol / L CdCl 2 solution; 0.139mL pure TGA was dissolved in 50mL water to obtain a 0.04mol / L TGA solution; 0.0445gNa 2 TeO 3 Dissolve in 50mL water to get 0.004mol / L Na 2 TeO 3 solution, set aside.

[0028] 0.2mL CdCl 2 solution, 20mL water, 1.25mL TGA solution, 2.0mL Na 2 TeO 3 solution, 75.66 mg NaBH 4, 36.375mL hydrazine hydrate was added to the conical flask one by one, and after standing at room temperature for 6h, an aqueous solution of CdTe QDs was obtained. Wherein, the CdCl described in step (2) 2 , TGA, Na 2 TeO 3 , NaBH 4 and N 2 h 4 ·H 2 The molar ratio of O and five is 1: (2.5): (0.4): (100): (30000).

Embodiment 3

[0030] 1.1415g CdCl 2 2.5H 2 O is dissolved in 50mL water to obtain 0.1mol / L CdCl 2 solution; 0.139mL pure TGA was dissolved in 50mL water to obtain a 0.04mol / L TGA solution; 0.0445gNa 2 TeO 3 Dissolve in 50mL water to get 0.004mol / L Na 2 TeO 3 solution, set aside.

[0031] 0.2mL CdCl 2 solution, 20mL water, 1.15mL TGA solution, 1.5mL Na 2 TeO 3 solution, 60mg NaBH 4 , 20mL of hydrazine hydrate was added to the conical flask one by one, and after standing at room temperature for 5h, an aqueous solution of CdTe QDs was obtained. Wherein, the CdCl described in step (2) 2 , TGA, Na 2 TeO 3 , NaBH 4 and N 2 h 4 ·H 2 The molar ratio of O and five is 1: (2.3): (0.3): (79.3): (16494.8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com