Preparation methods of tin telluride nanorods and tin telluride based binary metal telluride nanorods

A binary metal, tin telluride-based technology, used in selenium/tellurium compounds, chemical instruments and methods, binary selenium/tellurium compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the preparation method of the present invention, the target product is directly synthesized through a simple chemical conversion method in a system using ethylene glycol as a solvent.

[0038] The basic process of the method of the present invention is as follows: firstly, in a suitable environment system, add a tellurium source and a surfactant to form a first mixture, and heat the first mixture to react to prepare the first mixture containing uniform tellurium nanorods. Two mixtures. Then, adding the tin source as a precursor and an optional second metal source to the second mixture, and raising the reaction temperature above 170° C. to react for a period of time, the corresponding metal telluride nanorod structure can be obtained.

[0039] The overall reaction mechanism of the method of the present invention is: the tellurium source is reduced to elemental tellurium under the action of hydrazine hydrate, and at this time the synthesis of nanorod morphology is cont...

Embodiment 1

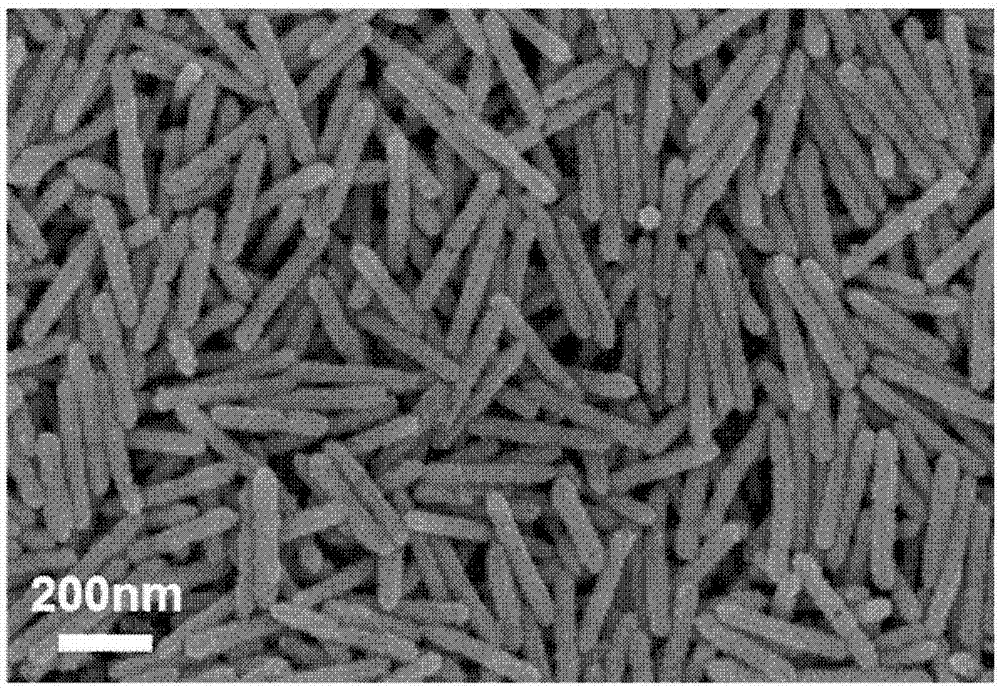

[0053] Take a 50mL three-neck flask, add 0.2216g (1mmol) sodium tellurite, 1g polyvinylpyrrolidone and 30mL ethylene glycol into it, pass through argon protection and heat to 120°C under magnetic stirring, then immediately add 2mL of 98% hydrated Hydrazine, reaction 2h. Then add 0.2257 g (1 mmol) of stannous chloride dihydrate pre-dissolved in a small amount of ethylene glycol, heat up to 180 ° C, react for 2 h, wash once with water and twice with ethanol after cooling, and dry in vacuum at 60 ° C for 12 h.

[0054] The scanning electron microscope image of this nanorod is shown in figure 1 , XRD data see Figure 4 . At this time, the length of the nanorod is about 280 to 300 nm, and the diameter is about 50 nm.

Embodiment 2

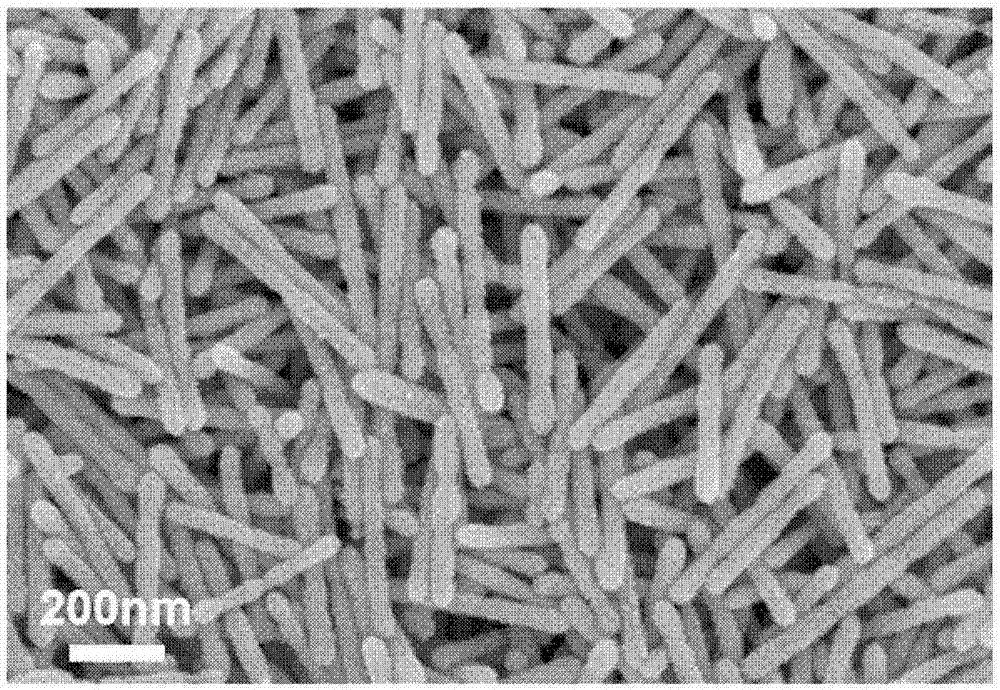

[0056] Take a 50mL three-neck flask, add 0.2216g (1mmol) sodium tellurite, 1g polyvinylpyrrolidone and 30mL ethylene glycol into it, pass through argon protection and heat to 140°C under magnetic stirring, then immediately add 2mL of 98% hydrated Hydrazine, reaction 2h. Then add 0.2257 g (1 mmol) of stannous chloride dihydrate pre-dissolved in a small amount of ethylene glycol, heat up to 180 ° C, react for 2 h, wash once with water and twice with ethanol after cooling, and dry in vacuum at 60 ° C for 12 h.

[0057] The scanning electron microscope image of this nanorod is shown in figure 2 , XRD data see Figure 4 . At this time, the length of the nanorod is about 360 to 420 nm, and the diameter is about 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com