Preparation of nano element tellurium and method for vulcanizing rubber by using nano element tellurium

A technology of element tellurium and nanometer, which is applied in the preparation of nanometer element tellurium and its vulcanized rubber, can solve the problems of limited tellurium and low vulcanization activity, and achieve the effect of simple extraction process, high mechanical properties and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

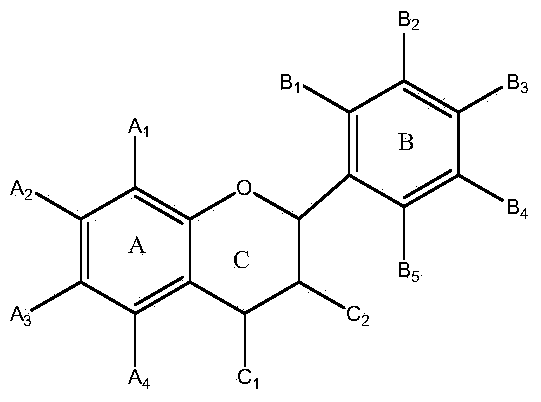

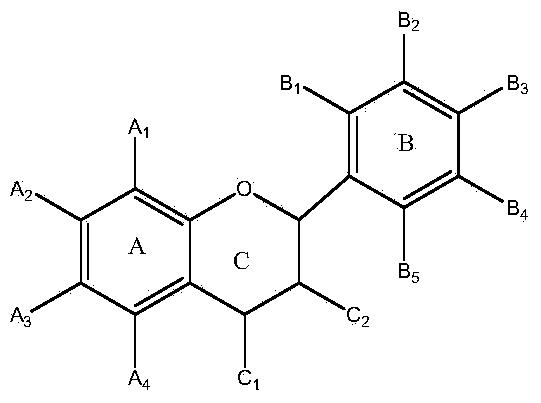

[0034] (1) Disperse sodium tellurite (for example, 100 g) into water in a measured proportion to prepare a 1 mg / ml dispersion. Dissolve epicatechin gallate in water (3wt%), mix the above two solutions in proportion (the amount of epicatechin gallate is 300wt% of sodium tellurite), and after fully stirring, Heated to 50°C and reacted for 24h. The dispersion liquid is suction-filtered, washed repeatedly, and then the obtained modified nano-element tellurium is suction-filtered. The form of the nanometer element tellurium is a nanorod with a diameter of 20-100 nanometers and a length of 0.2-1 micron. The obtained nano element tellurium has excellent solubility and dispersion stability in water.

Embodiment 2

[0036] (2) Disperse sodium tellurite (for example, 100 g) into water in a measured proportion to prepare a 2 mg / ml dispersion. Dissolve tannic acid in water (5wt%), mix the above two solutions in proportion (the amount of tannic acid is 400wt% of sodium tellurite), mix well, stir well, heat to 80°C, and react for 48h. The dispersion liquid is suction-filtered, washed repeatedly, and then the obtained modified nano-element tellurium is suction-filtered. The shape of the nano-element tellurium is a nano-rod with a diameter of 40-80 nanometers and a length of 0.3-2 microns. The obtained nano element tellurium has excellent solubility and dispersion stability in water.

Embodiment 3

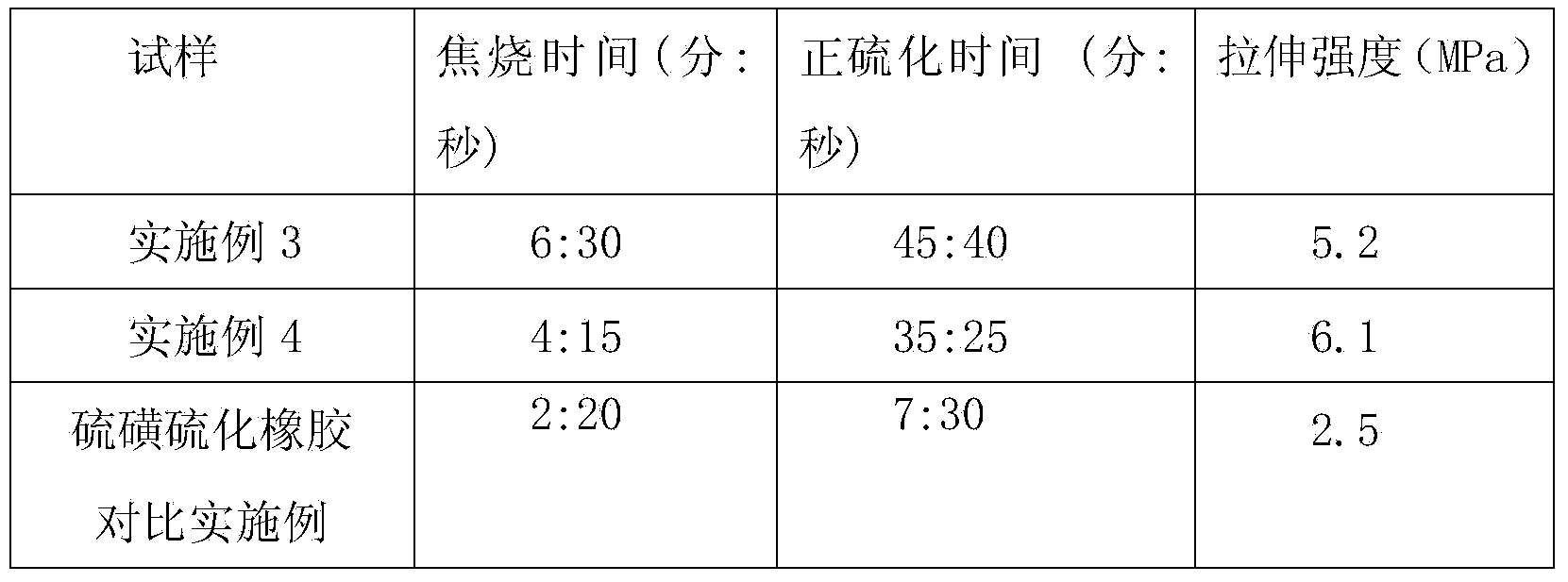

[0038] The modified nano-element tellurium prepared in Example 1 was ultrasonically dispersed in water at a concentration of 2 mg / ml. It is mixed with styrene-butadiene rubber latex (solid content 30%) in the proportion of 100 parts of styrene-butadiene rubber (such as 100 g) and 2 parts of tellurium under stirring, and then co-coagulated with calcium chloride to obtain coprecipitated rubber. The coprecipitated rubber was repeatedly washed with distilled water and dried to obtain styrene-butadiene rubber containing 2 parts of elemental tellurium. In the open mill, sequentially add tellurium-containing styrene-butadiene rubber, 5 parts of ZDC (zinc diethyldithiocarbamate), 5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of anti-aging agent (N-isopropyl -N'-phenyl-p-phenylenediamine), vulcanized at 150 degrees, and its vulcanization time and tensile strength are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com