Preparation method for composite thermoelectric film with flexible reduced graphene oxide and tellurium nano wires

A technology of tellurium nanowires and thermoelectric thin films, applied in the field of new energy materials, can solve the problems of no effective matching of composite components, narrow applicable temperature range, low Seebeck coefficient, etc., achieve broad industrial application prospects, optimize electrical conductivity and Effect of Seebeck coefficient and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

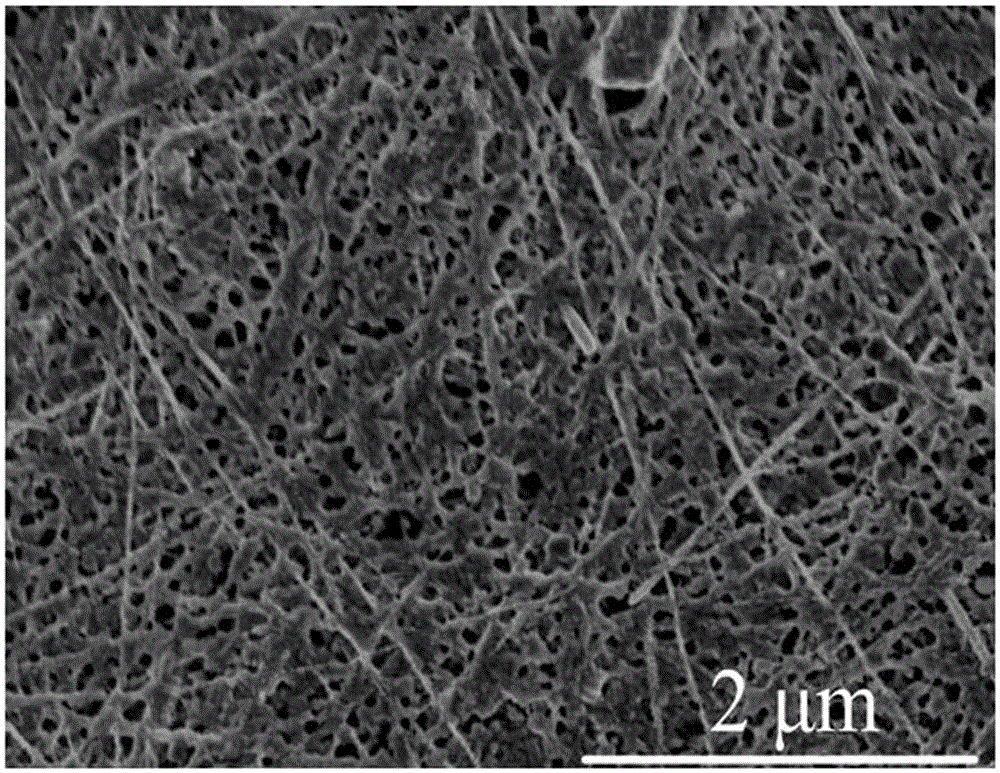

[0031] like figure 1 As shown, a preparation method of a flexible reduced graphene / tellurium nanowire composite thermoelectric film, which comprises the following steps:

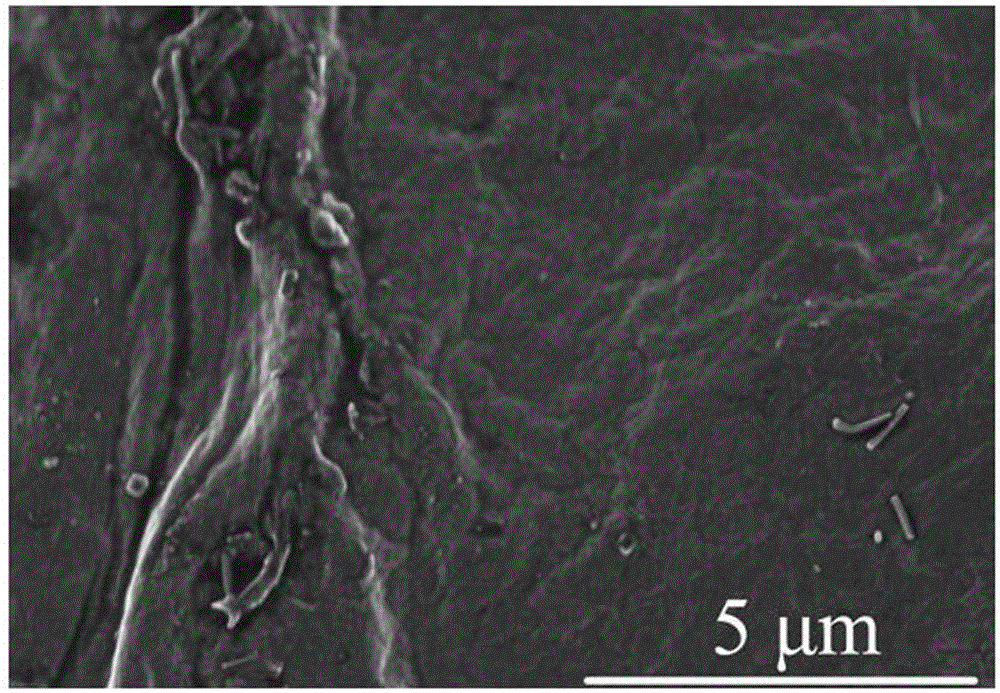

[0032] (1) ultrasonically disperse 25 mg of graphene oxide (GO) and 12.5 mg of sodium polystyrene sulfonate (NaPSS) in 12.5 mL of deionized water, then add 25 mL of saturated hydrobromic acid solution to the dispersion, and transfer the mixture In a 50mL reactor, hydrothermally react at 120°C for 2 hours and then naturally cool to obtain a precipitate; after washing the precipitate with deionized water for 3-5 times, vacuum-dry the precipitate at 60°C for 3 hours to obtain dispersible reduced graphene. Scanning electron microscope pictures of dispersible reduced graphene such as figure 2 shown;

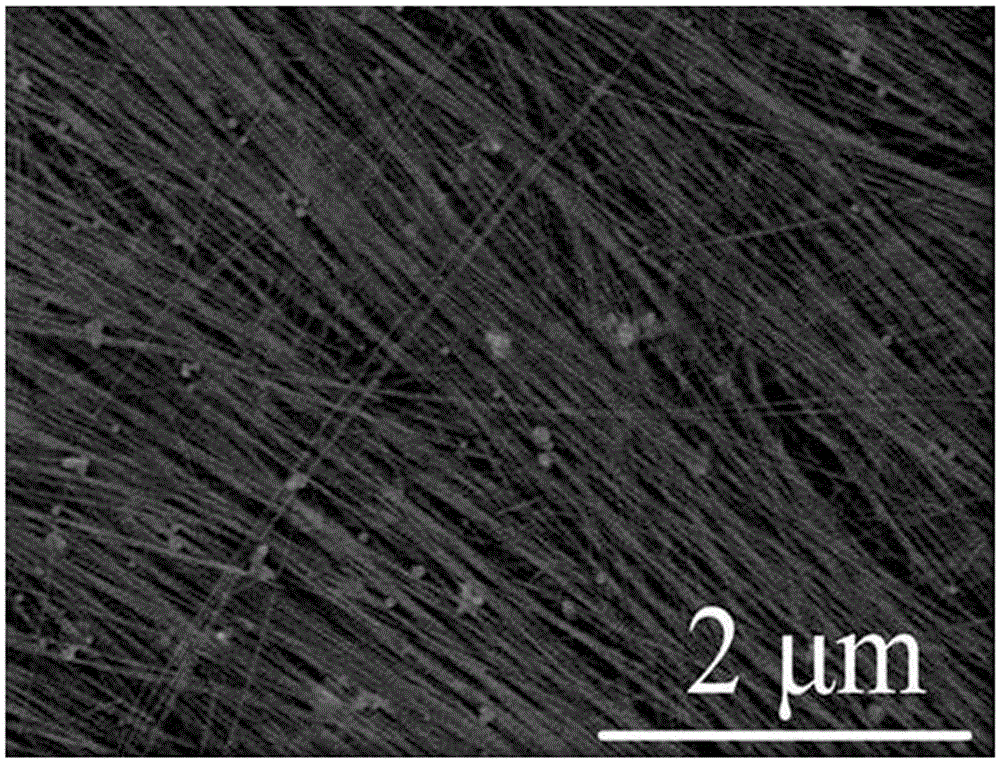

[0033] (2) 0.369g of sodium tellurite and 2g of polyvinylpyrrolidone were stirred and dissolved in 70mL of deionized water, then 6.6mL of 25% ammonia water and 3.4mL of 98% hydrazine hydrate were added to the sol...

Embodiment 2

[0037] (1) Disperse 25mg graphene oxide (GO) and 50mg sodium polystyrene sulfonate (NaPSS) ultrasonically in 12.5mL deionized water, then add 50mL saturated hydrobromic acid solution to the dispersion, and transfer the mixture to In a 100mL reactor, hydrothermally react at 150°C for 2 hours and then naturally cool to obtain a precipitate; after washing the precipitate with deionized water for 3-5 times, vacuum-dry the precipitate at 60°C for 3 hours to obtain dispersible reduced graphene;

[0038] (2) 0.369g of sodium tellurite and 2g of polyvinylpyrrolidone were stirred and dissolved in 70mL of deionized water, then 6.6mL of 25% ammonia water and 3.4mL of 98% hydrazine hydrate were added to the solution, and the mixed solution was transferred to a 100mL reactor After the hydrothermal reaction was carried out at 180°C for 1.5 hours, the reactor was cooled with flowing tap water; after adding 320 mL of acetone to the cooled mixture, the mixture was centrifuged and the supernatan...

Embodiment 3

[0042](1) ultrasonically disperse 25 mg of graphene oxide (GO) and 25 mg of sodium polystyrene sulfonate (NaPSS) in 12.5 mL of deionized water, then add 25 mL of saturated hydrobromic acid solution to the dispersion, and transfer the mixture to In a 50mL reactor, hydrothermally react at 120°C for 2 hours and then naturally cool to obtain a precipitate; after washing the precipitate with deionized water for 3-5 times, vacuum-dry the precipitate at 60°C for 3 hours to obtain dispersible reduced graphene;

[0043] (2) 0.369g of sodium tellurite and 2g of polyvinylpyrrolidone were stirred and dissolved in 70mL of deionized water, then 6.6mL of 25% ammonia water and 3.4mL of 98% hydrazine hydrate were added to the solution, and the mixed solution was transferred to a 100mL reactor After the hydrothermal reaction was carried out at 180 °C for 3 hours, the reaction kettle was cooled with flowing tap water; after adding 160 mL of acetone to the cooled mixture, the mixture was centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com